Patents

Literature

4580 results about "Curtain wall" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A curtain wall system is an outer covering of a building in which the outer walls are non-structural, utilized only to keep the weather out and the occupants in. Since the curtain wall is non-structural, it can be made of lightweight materials, thereby reducing construction costs. When glass is used as the curtain wall, an advantage is that natural light can penetrate deeper within the building. The curtain wall façade does not carry any structural load from the building other than its own dead load weight. The wall transfers lateral wind loads that are incident upon it to the main building structure through connections at floors or columns of the building. A curtain wall is designed to resist air and water infiltration, absorb sway induced by wind and seismic forces acting on the building, withstand wind loads, and support its own dead load weight forces.

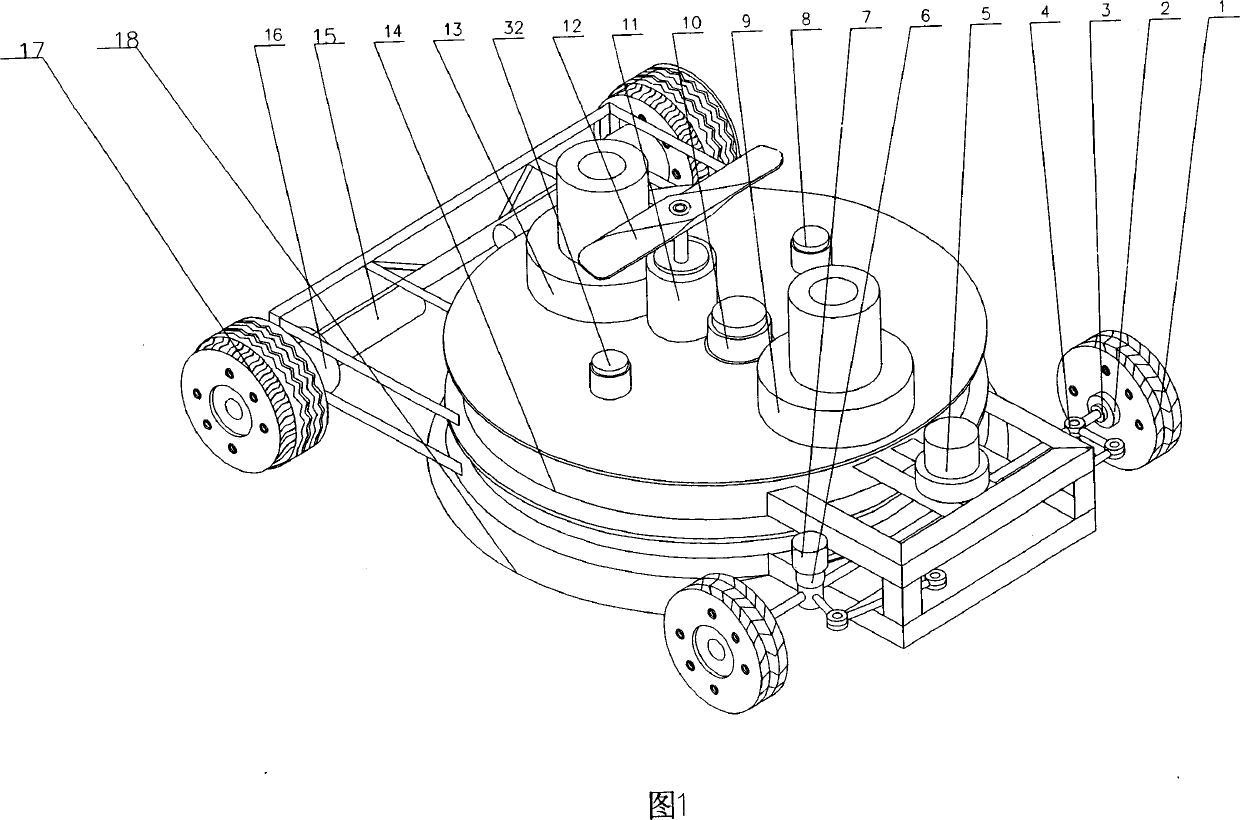

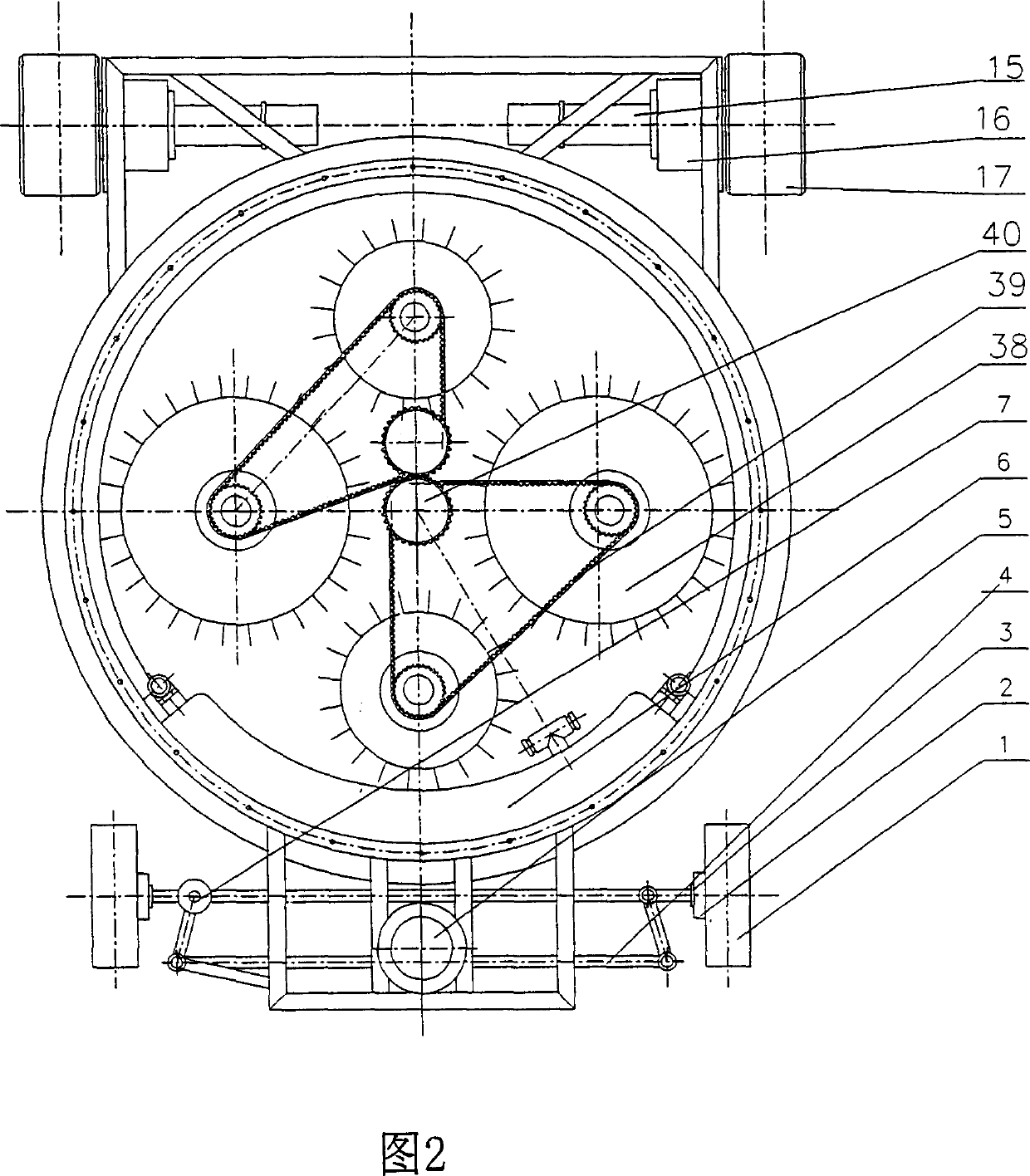

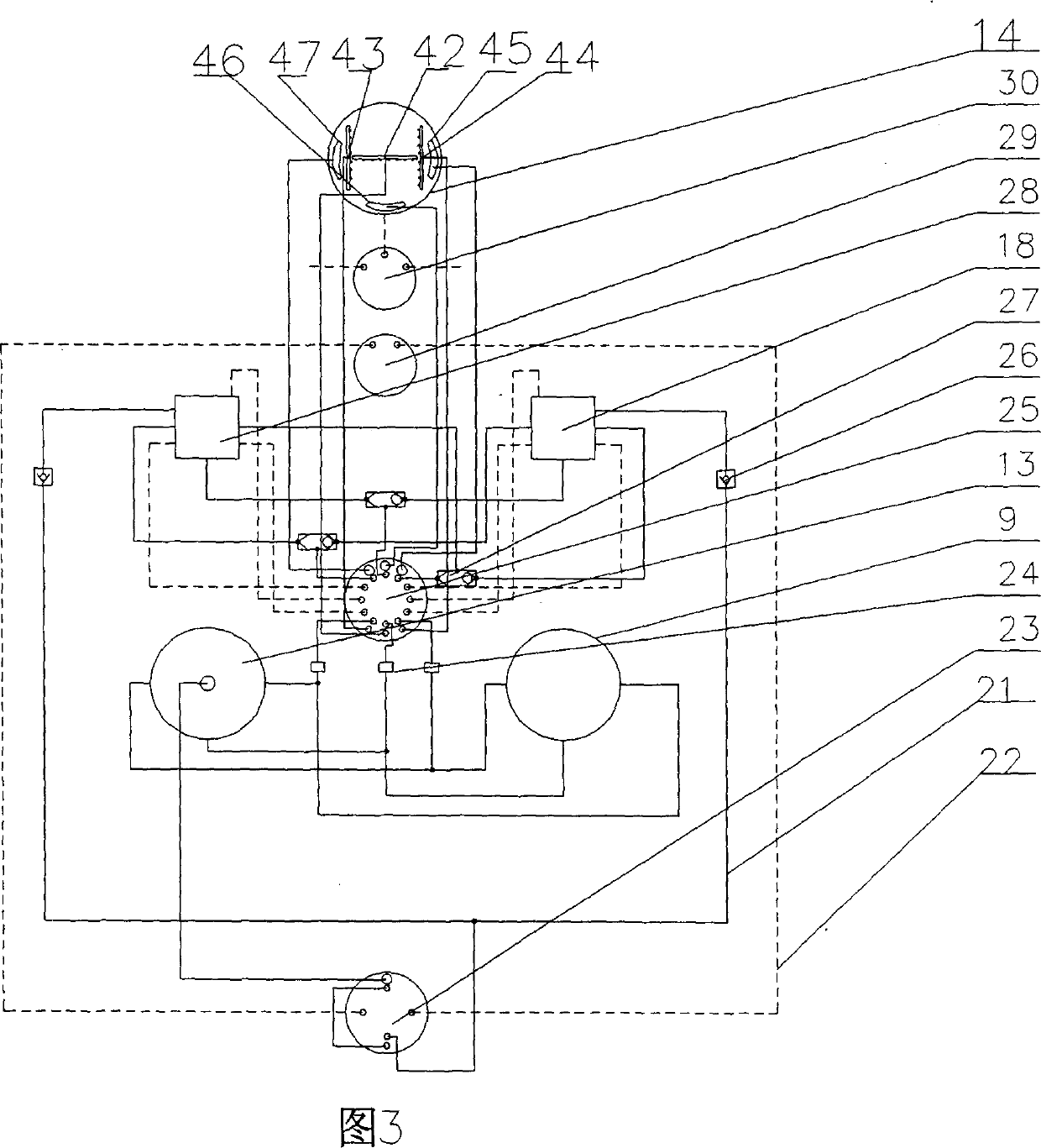

Control method for building environmental protection robot and robot using the method

InactiveCN1413809AIncrease heightReduce frictionCarpet cleanersFloor cleanersControl systemRobot control

A cleaning robot for high bailding is composed of the main body, cleaning unit, control system and safety mechanism, and features that the flexible water-sealing mechanism, drive regulating system, steering regulation and compensation driving system, cleaning unit and control system are combined to reliably stay-on the wall surface and cleaning plane, curved surface, arc surface of curtain wall or ceramic tile wall. Its advantages are high cleaning effect, high recovery rate of water and continuous cleaning.

Owner:吴志明 +1

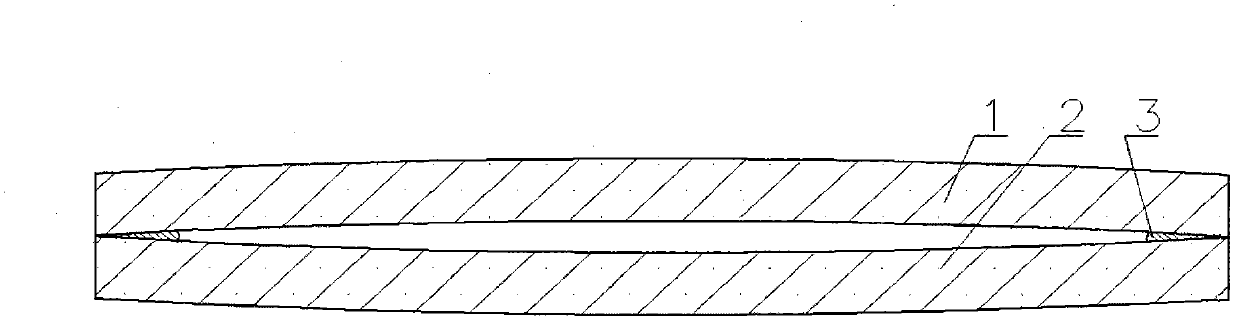

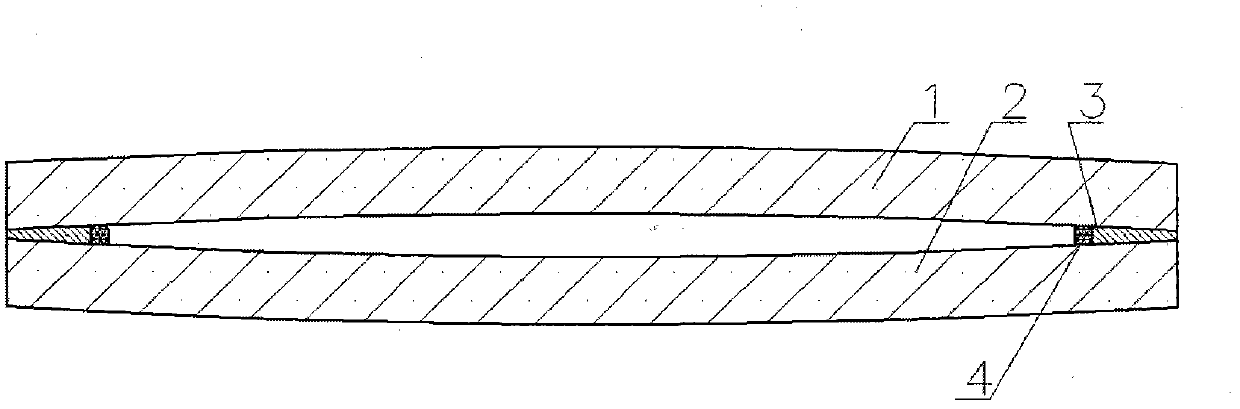

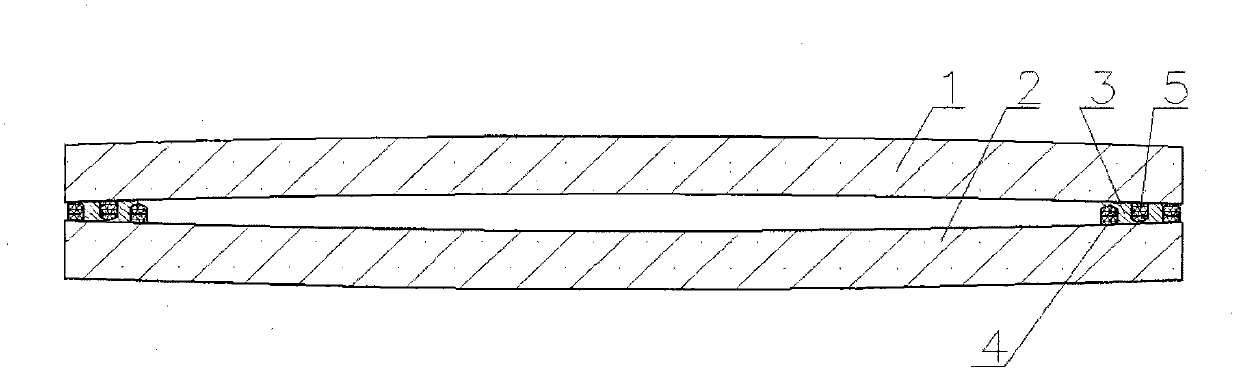

Convex vacuum glass, flat plate vacuum glass and preparation method thereof

ActiveCN102701575ASimple manufacturing processIncrease production costWindows/door improvementGlass reforming apparatusLight pollutionUltimate tensile strength

The invention provides convex vacuum glass, which comprises upper glass and lower glass, wherein peripheries of the upper glass and the lower glass are welded together through low-temperature solder; a sealed vacuum layer is formed between the upper glass and the lower glass; the upper glass and the lower glass are convex glass; and the convex surface is toward the outer side. The manufacture method of the vacuum glass disclosed by the invention is simple in process; and with the adoption of the prepared vacuum glass and toughened vacuum glass, the defects in the prior art can be overcome, the gas tightness of the vacuum glass can be effectively ensured, the transparency, the strength and heat-insulation and sound-insulation performances can be can increased, and light pollution of a glass curtain wall also can be reduced.

Owner:WEIHAI RUNFENG GLASS

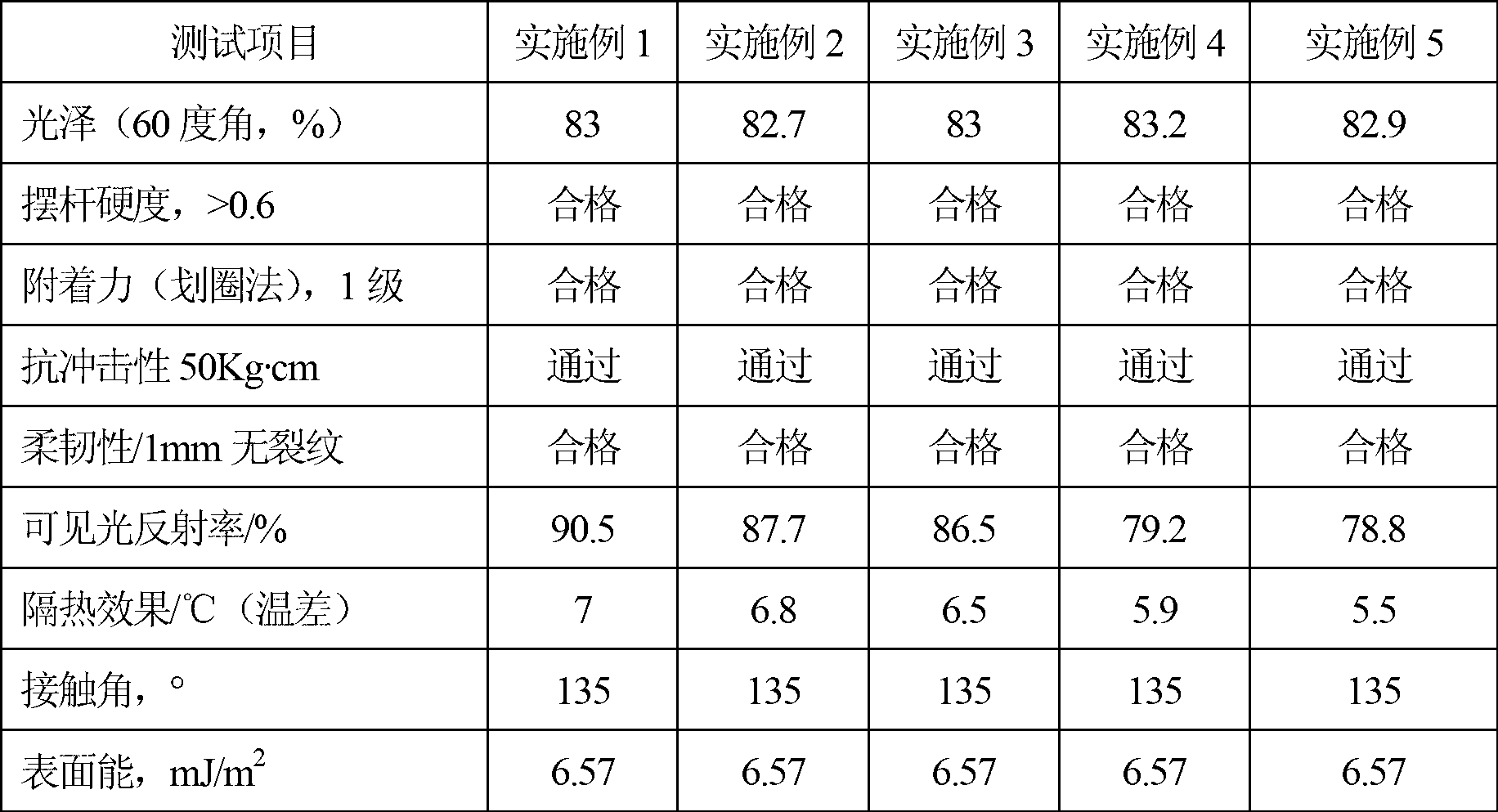

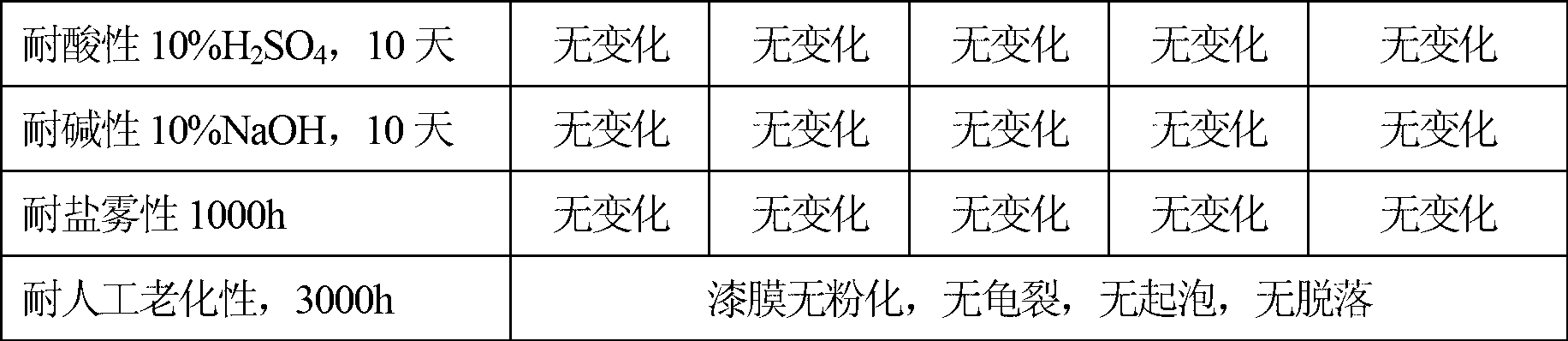

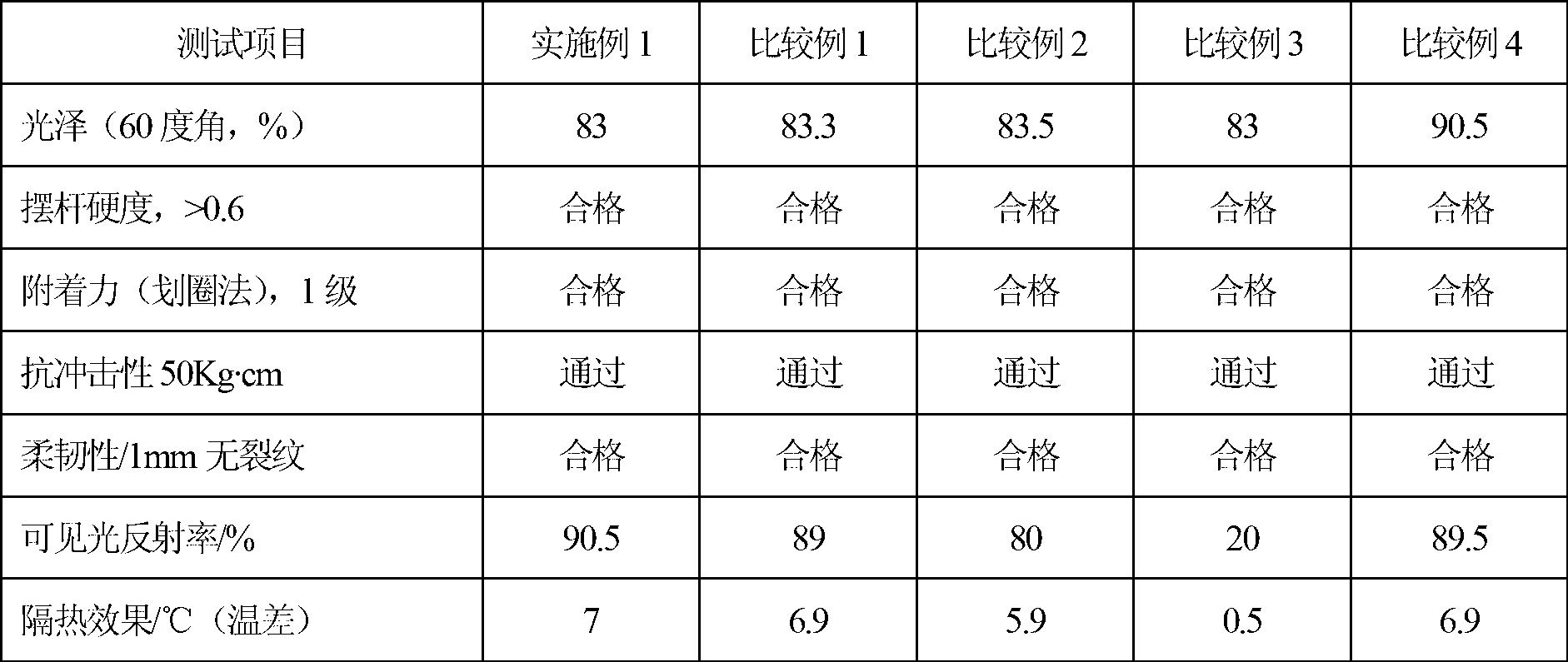

Fluorocarbon nanometer solar heat-insulation reflective paint, preparation method and using method thereof

ActiveCN103013241AImprove reflectivityImprove anti-corrosion performanceReflecting/signal paintsCross-linkInfrared

The invention relates to a fluorocarbon nanometer solar heat-insulation reflective paint, a preparation method thereof and a using method thereof. The paint can be used for roofs and glass curtain walls of the building industry, offshore drilling platforms, oil tanks and petroleum pipelines of the petroleum industry, the surfaces of cars and trains of the transportation industry, hulls and decks of the ship-building industry, and the tanks and warships of the weapon and aerospace industry. The fluorocarbon nanometer solar heat-insulation reflective paint comprises a component A and a component B, wherein the component A comprises the following materials in percentage by weight: 40%-70% of fluorocarbon resin, 1%-10% of nanometer TiO2 concentrated slurry, 10%-30% of infrared-ray reflective pigment, 3%-10% of hollow micro beads, 1%-5% of auxiliaries and 10%-20% of organic solvent; and the component B is cross-linking agent. The preparation method for the fluorocarbon nanometer solar heat-insulation reflective paint comprises the following steps: 1) preparing, dispersing and grinding the materials of the component A in proportion until the fineness is lower than 30 microns; and 2) mixing and curing the component A and the component B to prepare the fluorocarbon nanometer solar heat-insulation reflective paint. The fluorocarbon nanometer solar heat-insulation reflective paint provided by the invention is suitable for normal-temperature drying or low-temperature baking and drying; moreover, a coating film formed by the paint has the characteristics such as high reflectivity, a good heat-insulation effect, high corrosion prevention, high weather resistance, high self-cleanness, low friction and the like.

Owner:大连佳秀百隆新材料股份有限公司

6063 aluminium alloy with high strength and elongation coefficient an dproduction thereof

The invention opened a high strength and high extensibility 6063 Al alloy which contain the Cu, Mn, chrome, Fe, Zn, Ti, Al. The process is: a, founding: adding the material to the furnace melting stir ring and skimming coving refining skimming and refining thermal retardation casting ingot. b extruding and heat processing: isotroping air cooling, heating extruding quenching cutting cooling stretching straightening aging treatment product. The process has improved the mechanics of the alloy, also the elongation percentage (60%) and the intensity (40%). The tensile strength has been improved to 280-300 MPa, the elongation percentage is improved to 13%. So it satisfy the windows and the curtain wall's need.

Owner:CENT SOUTH UNIV +1

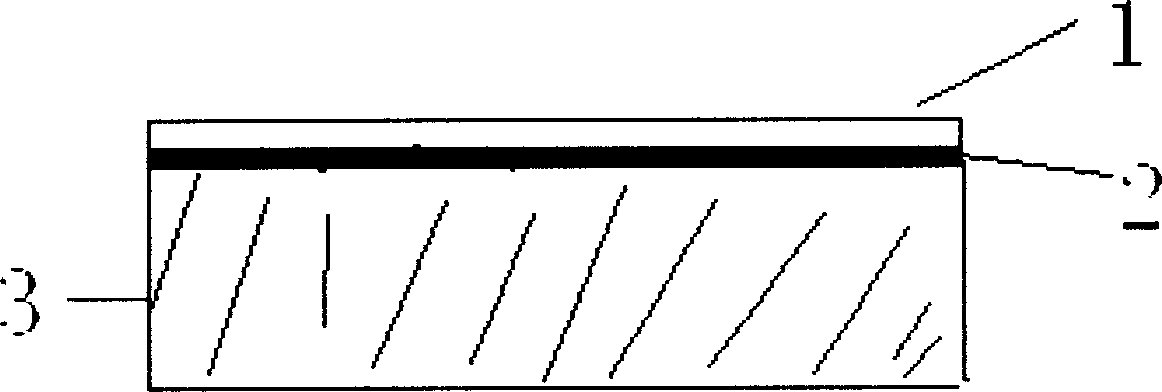

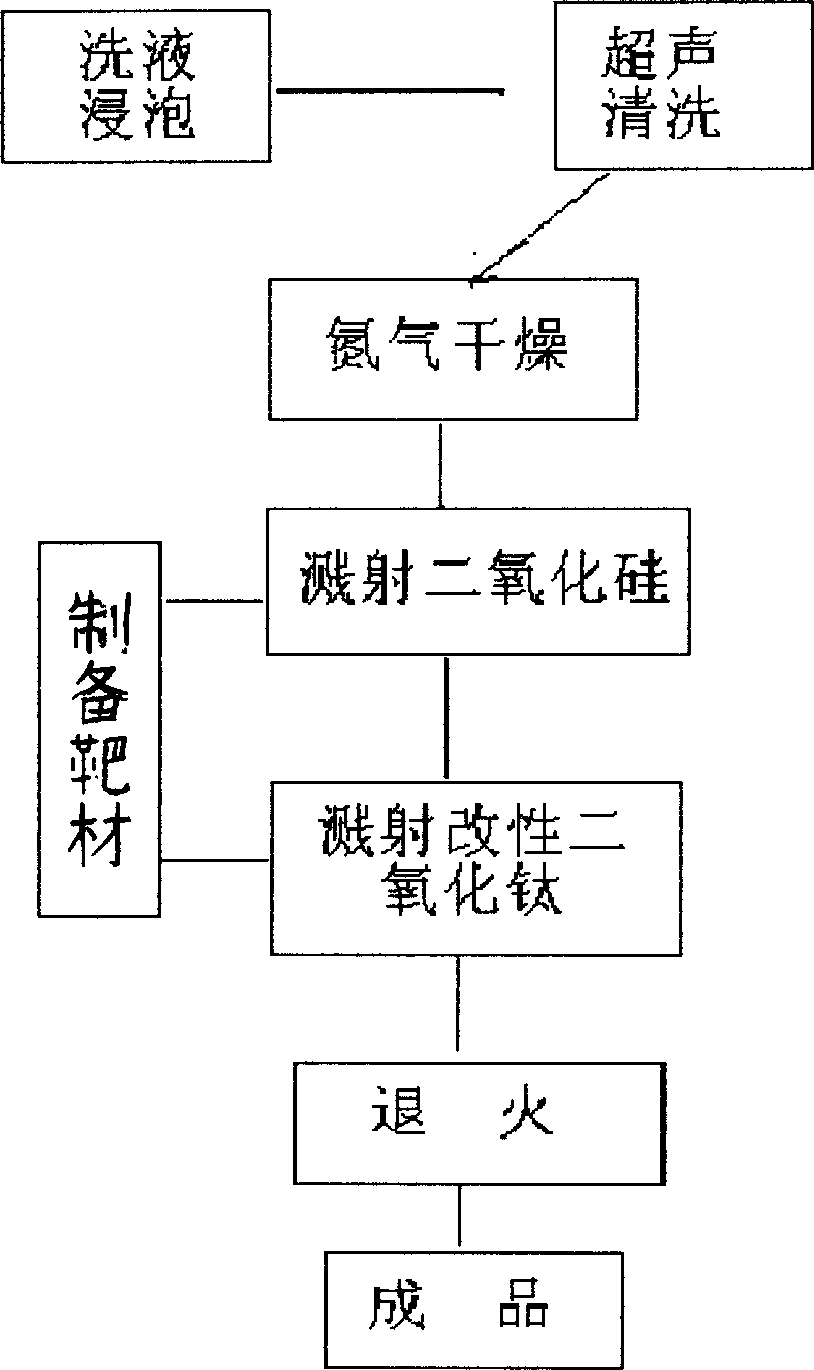

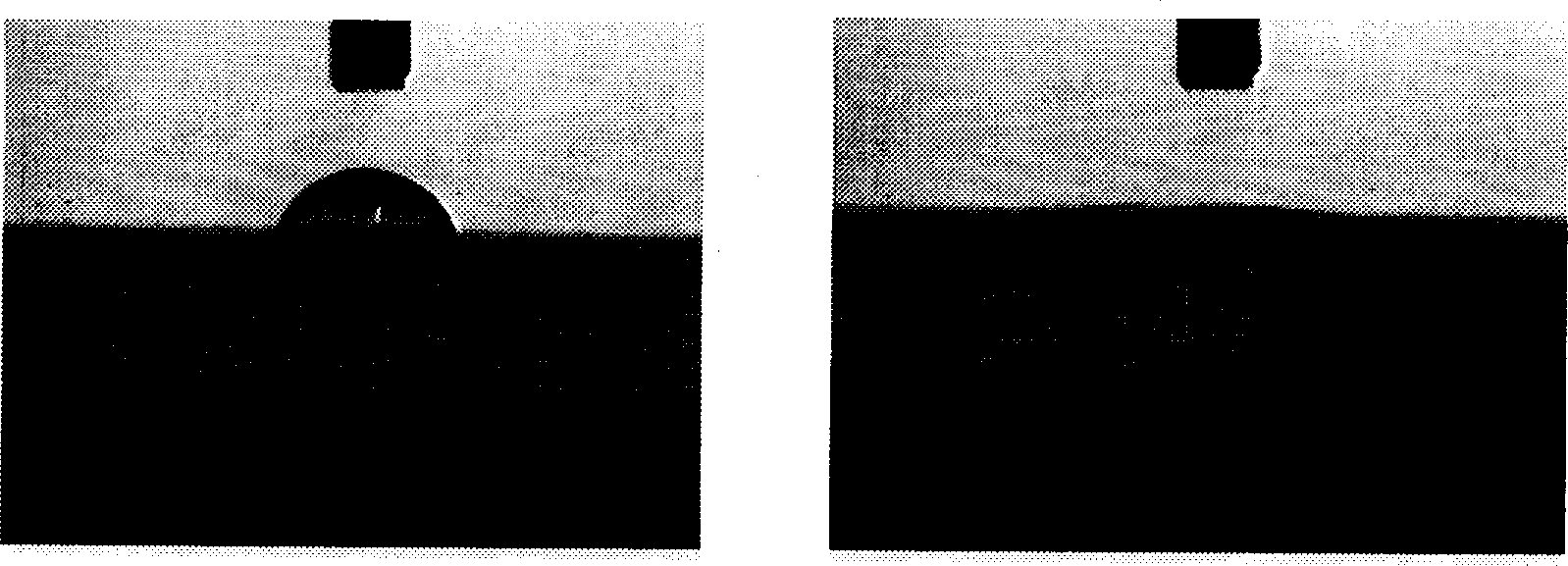

Permanent self-cleaning glass with visible light responsibility and preparation method thereof

The invention belongs to functional material technology and glass processing field, concretely discloses a permanent self-cleaning glass with visible light response and method for making it. Firstly, sputtering silica dioxide film on the surface of glass, sputtering a layer of titanium oxide film with anion and cation codoping on the surface of silica dioxide film, annealing the glass with twin layer films at 500-600 DEG C, cooling by radiation in sintering stove, to get the product. The self-cleaning glass has good photocatalysis property and photo-induced hydrophilicity, stable performance, almost perpetual availability, high light transmittance ratio and transparency. It is widly used in glass curtain wall of skyscrapers, automobile glass, road lamp shade, kitchen galss and antifog glass, avoiding artificial cleaning indoor and outdoor glass of skyscrapers, saving manual power and material, reducing corrosion destruction of cleaning agent to glass and building machinery, embodying environment protection notion.

Owner:JIEYANG HONGGUANG COATED GLASS

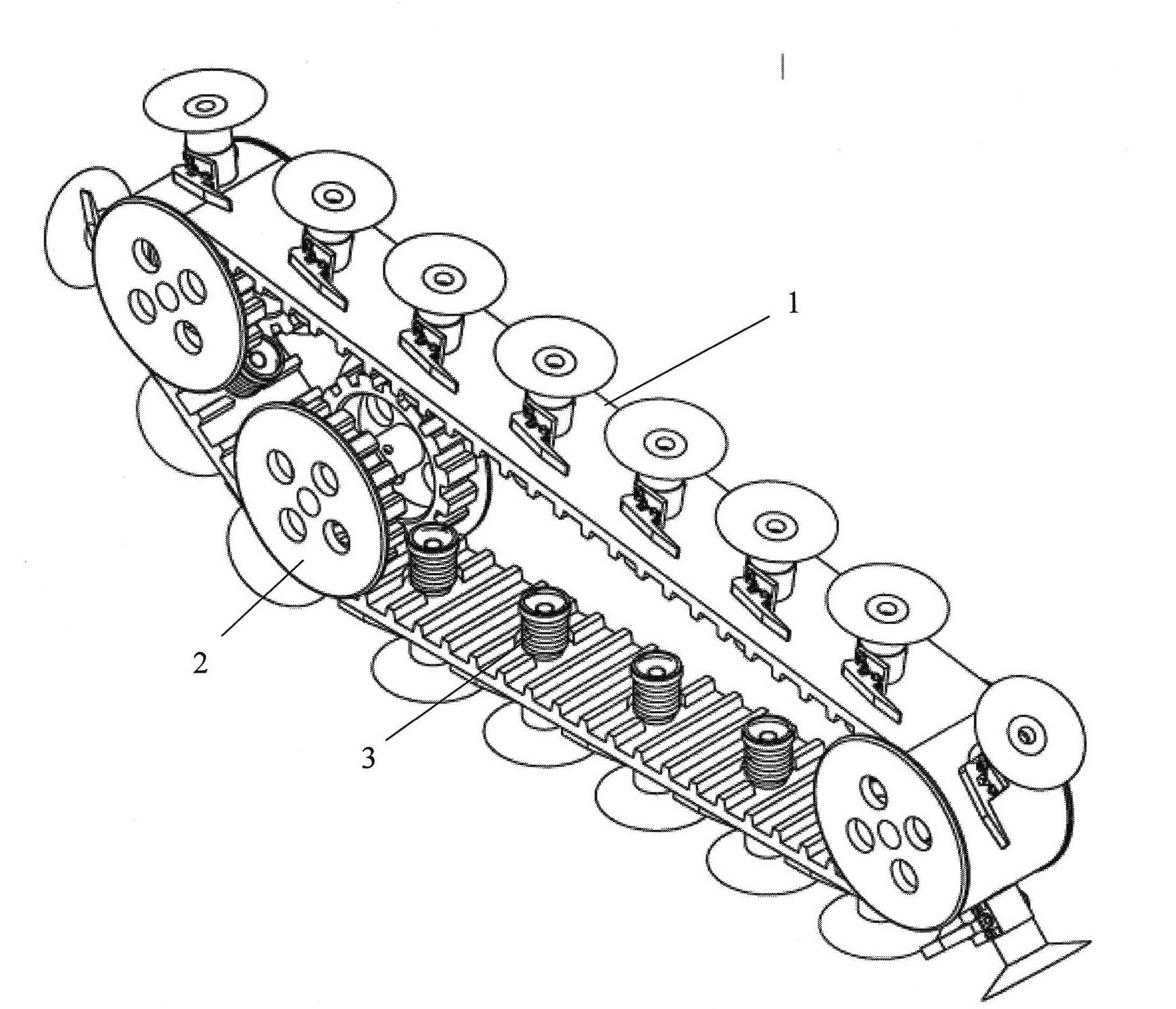

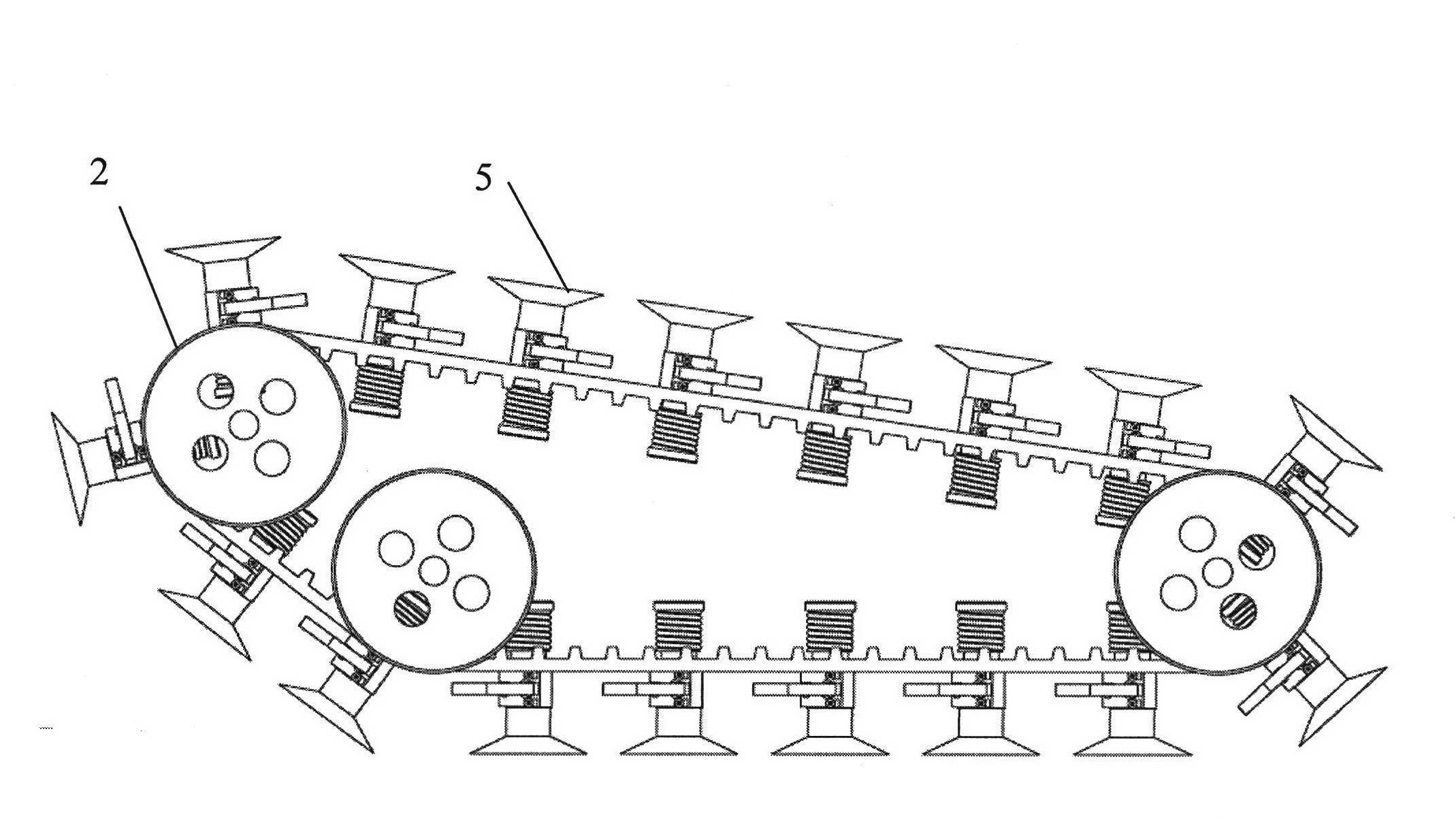

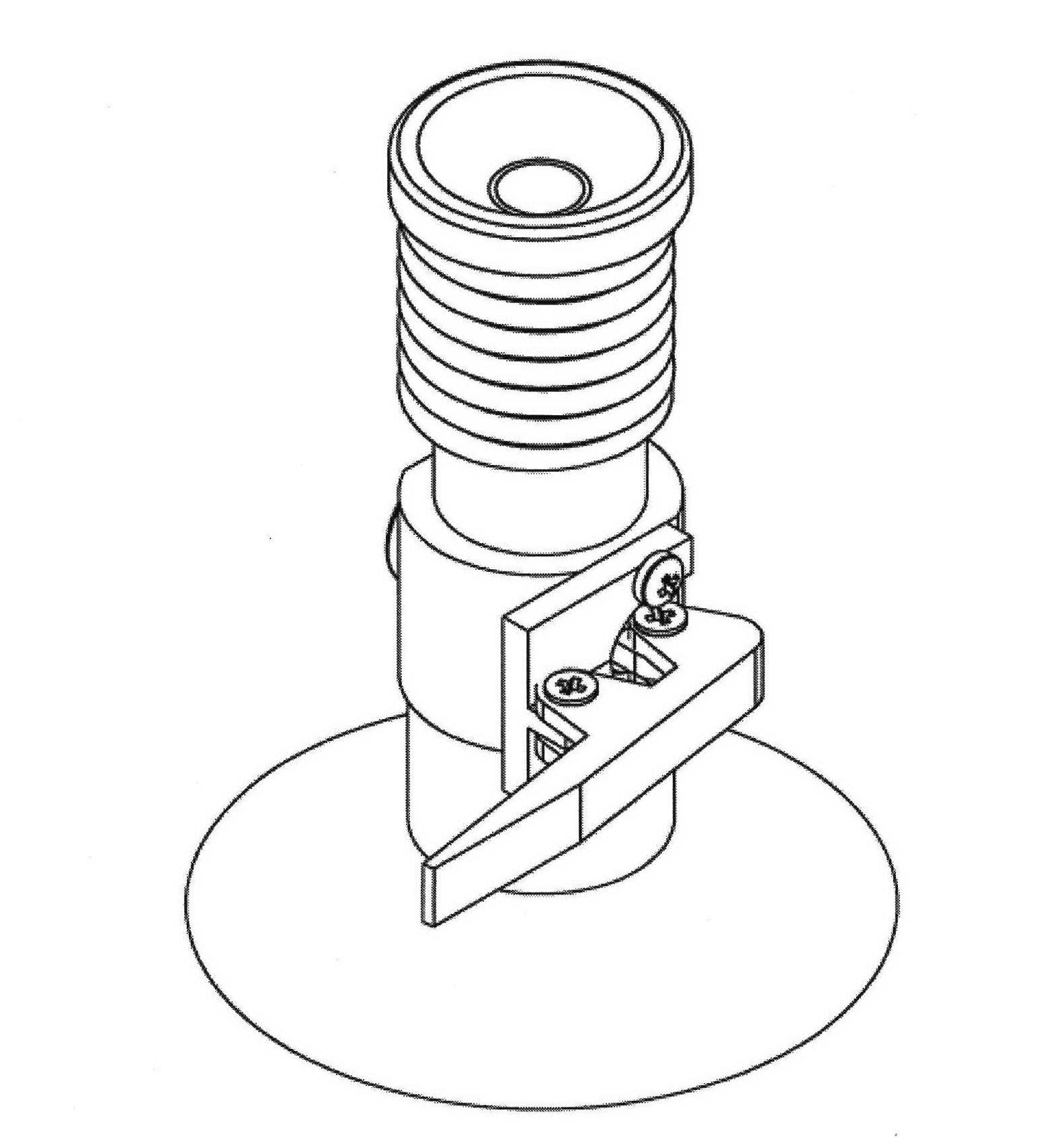

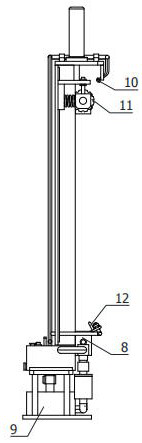

Crawler belt and suction disc combined-type walking device design capable of being used for wall climbing robot

InactiveCN102616294APrevent reverse air leakageEasy to deflateEndless track vehiclesEngineeringPulley

The invention relates to a crawler belt and suction disc combined-type special walking device. The device adopts a combined integral structure with a walking crawler belt which is a synchronous belt and special suction discs which are self-designed. Through the engagement transmission between the synchronous belt and synchronous belt pulleys and the adsorption and desorption effects of the special suction discs, the device is enabled to have the function of reliably walking and flexibly steering on smooth, flat and vertical surfaces such as glass curtain walls, tile exterior walls and the like. Since the walking device adopts the crawler belt and suction disc combined structure, the walking speed is fast, the manipulation performance is good, the volume is small, the steering is flexible and the device can surmount certain obstacles. Since the desorption subsystem of the walking device adopts air-valve-type suction discs, active adsorption or passive adsorption can be realized and the walking device has the characteristics of high adsorption efficiency, high safety factor, simple structure and wide application scope.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

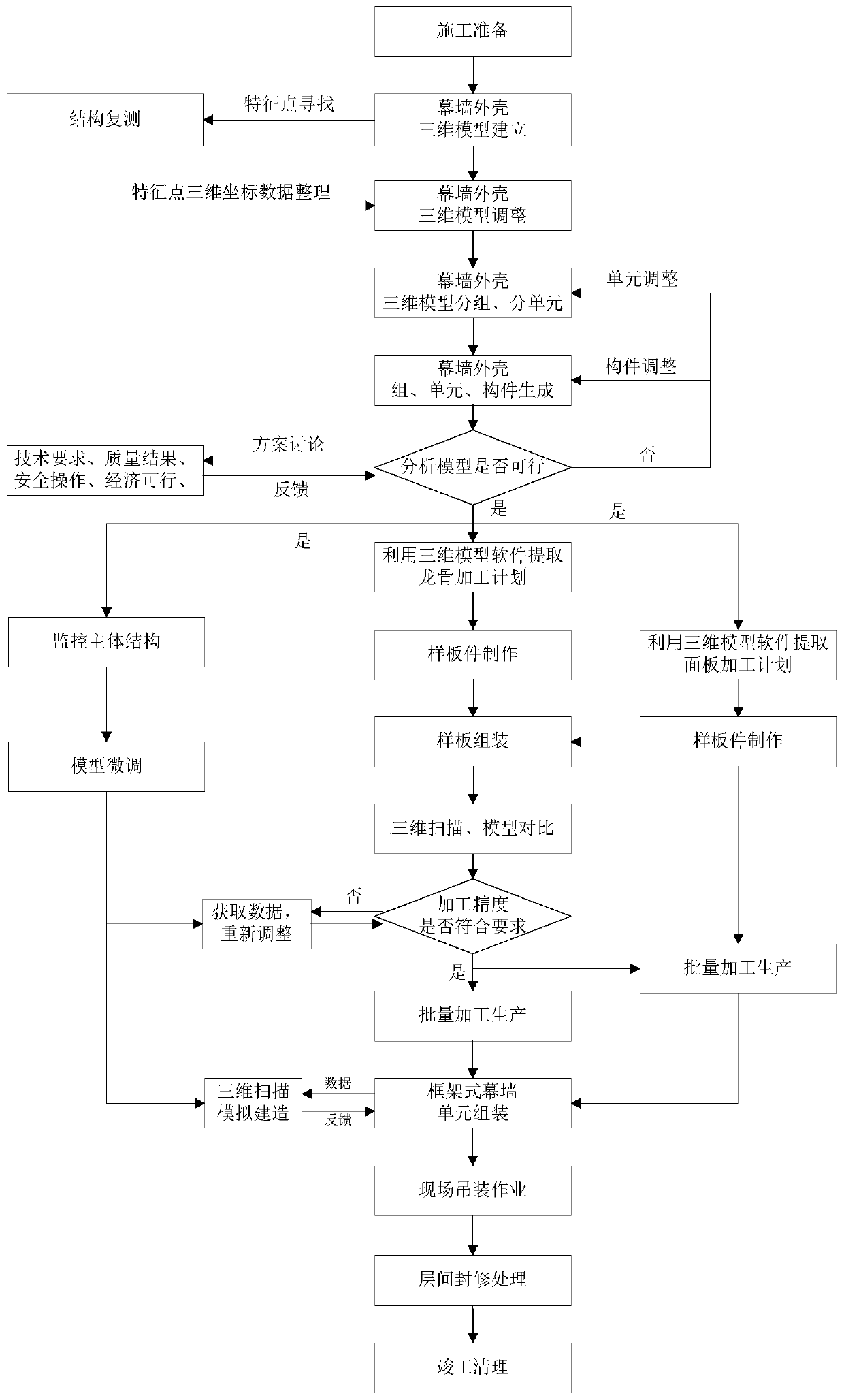

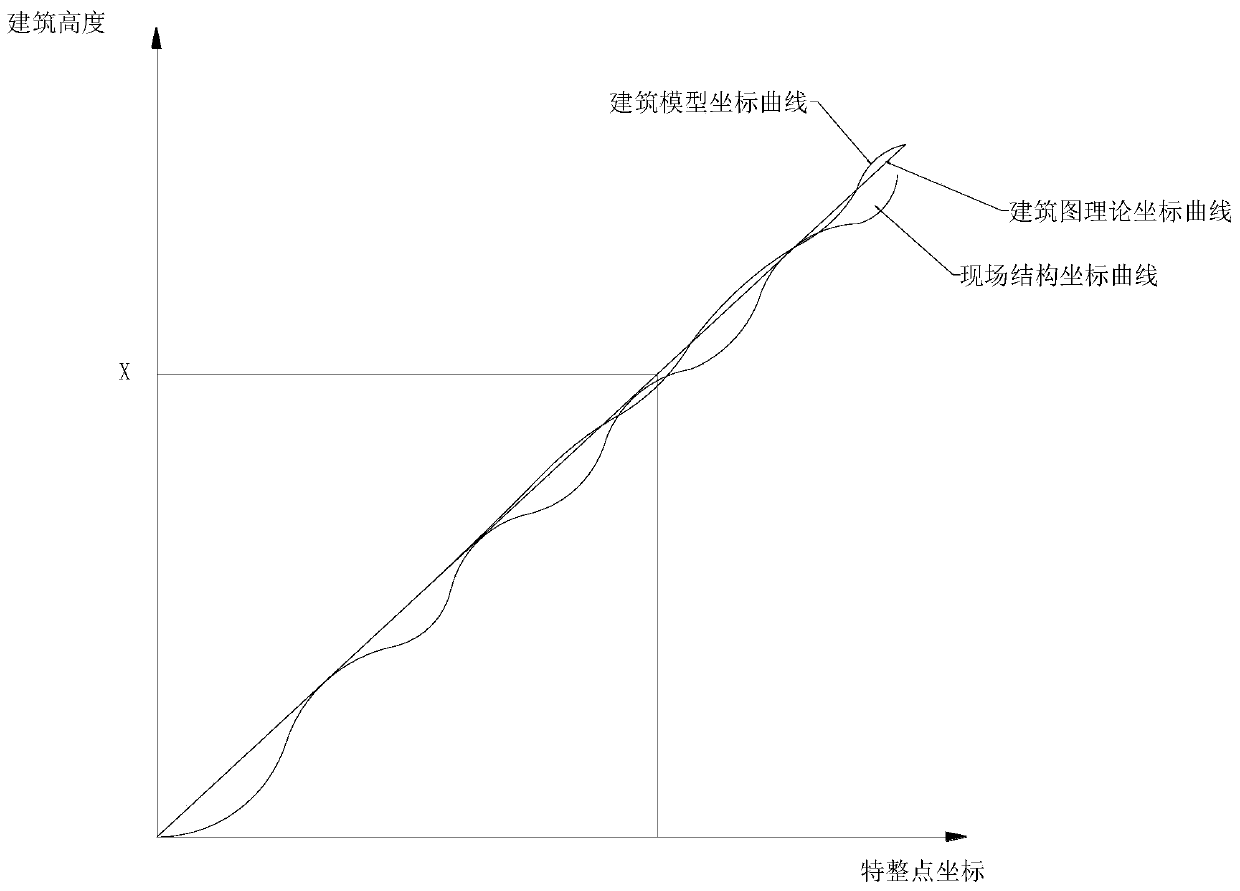

Frame-type curtain wall rapid assembly construction method and system based on BIM

InactiveCN110056106AFast and accurate generationSingle construction workWallsBuilding material handlingThree dimensional measurementHanging basket

The invention discloses a frame-type curtain wall rapid assembly construction method and system based on a BIM, and belongs to the field of curtain wall assembly construction. The to-be-solved technical problems are how to realize rapid assembly construction of a frame-type curtain wall and ensure the installation quality and performance of the curtain wall, according to the technical scheme, theframe-type curtain wall rapid assembly construction method includes the steps that three-dimensional model creation and adjustment of a curtain wall shell, curtain wall unit division, material component splitting and ordering are conducted through a BIM technology and a three-dimensional measurement technology, unit bodies of the frame-type curtain wall are assembled through centralized industrialprocessing, the processing quality of the frame-type curtain wall units is controlled by manufacturing standard parts, standard samples and using a three-dimensional scanning technology, site quick assembly construction of the frame-type curtain wall is completed through an integral hoisting technology, then treatment between layers is completed through a construction hanging basket or an elevating operating vehicle, and finally, rapid assembly construction operation of the frame-type curtain wall is realized. The invention further discloses the frame-type curtain wall rapid assembly construction system based on the BIM.

Owner:CHINA CONSTR EIGHTH ENG DIV

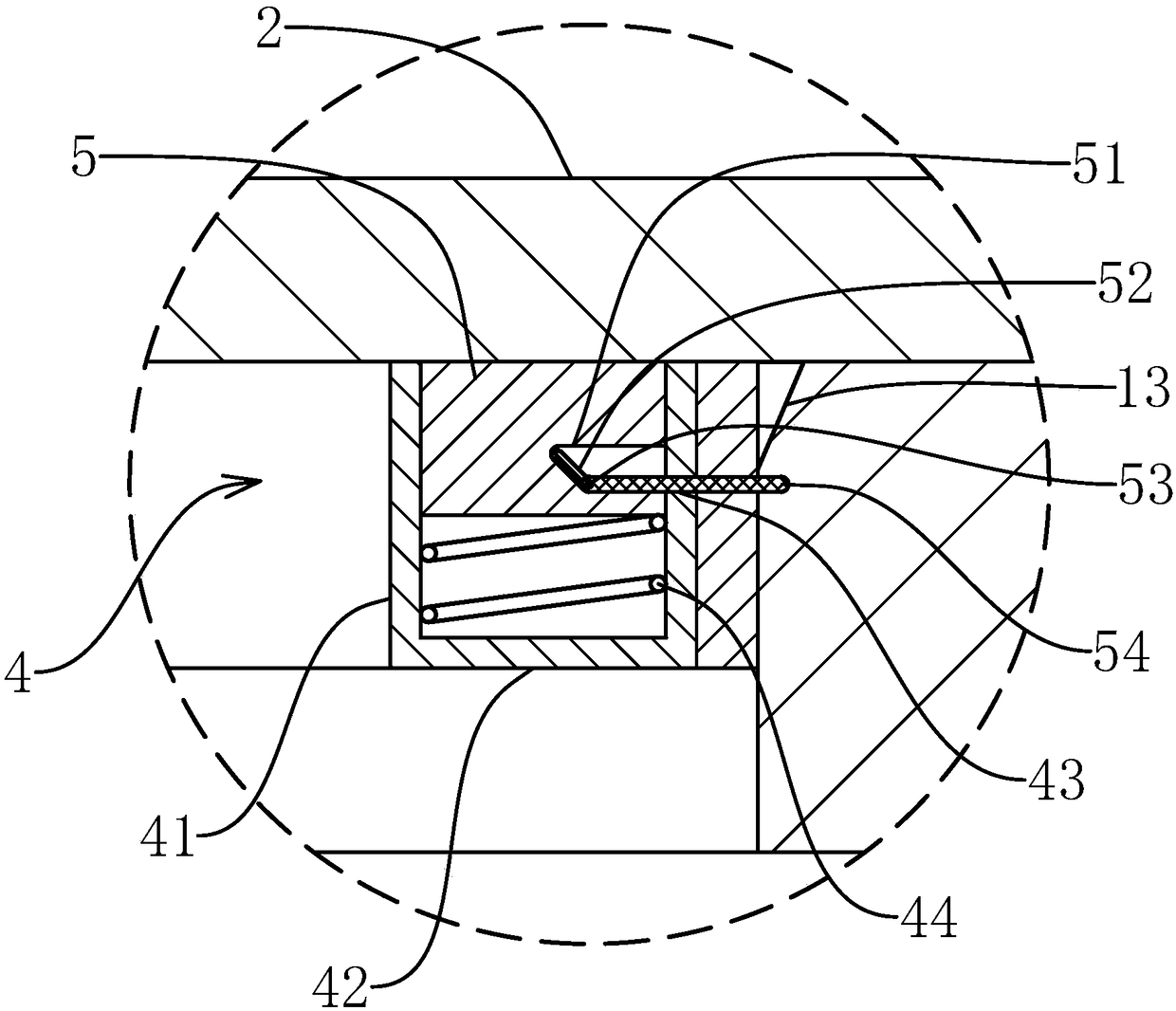

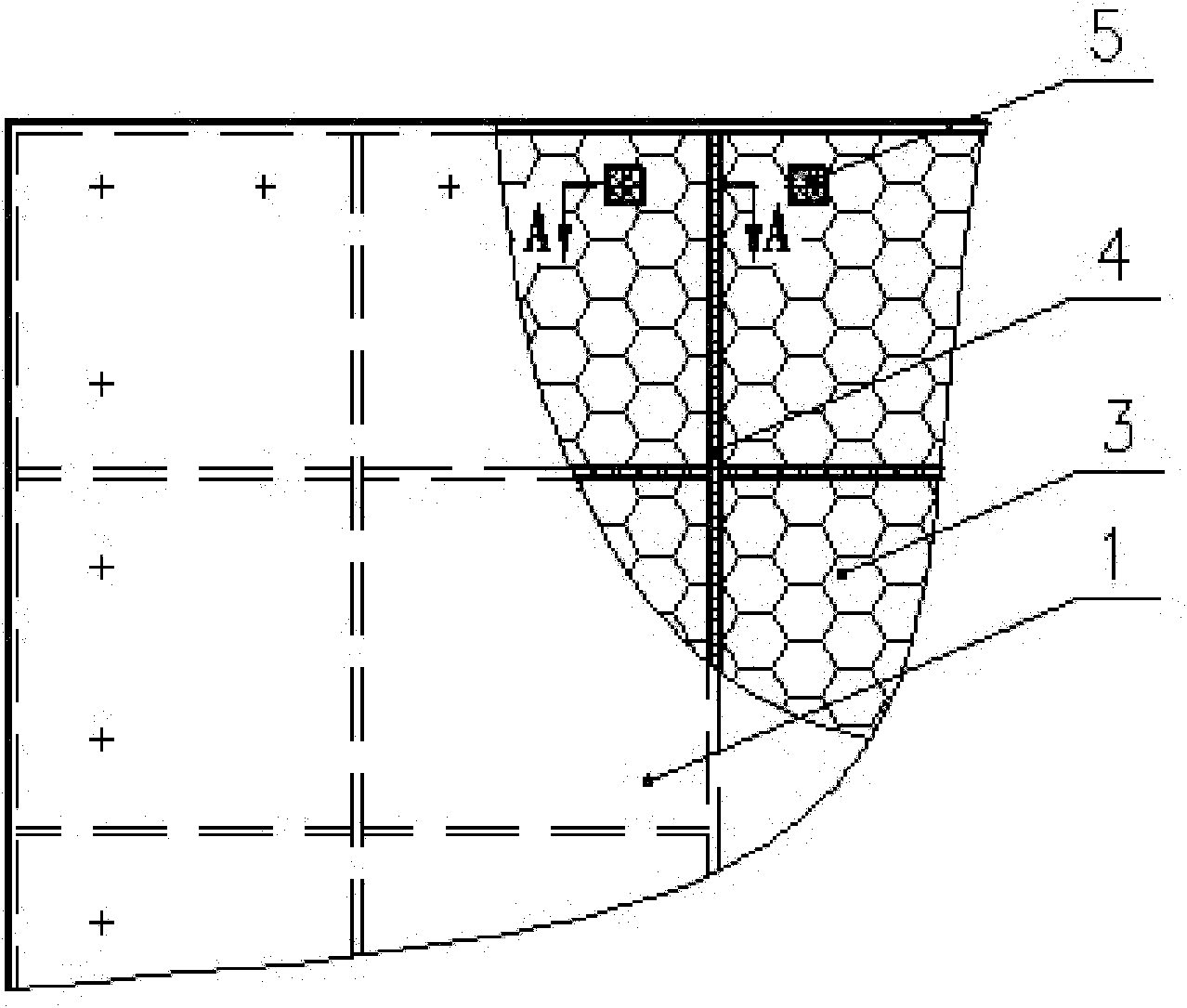

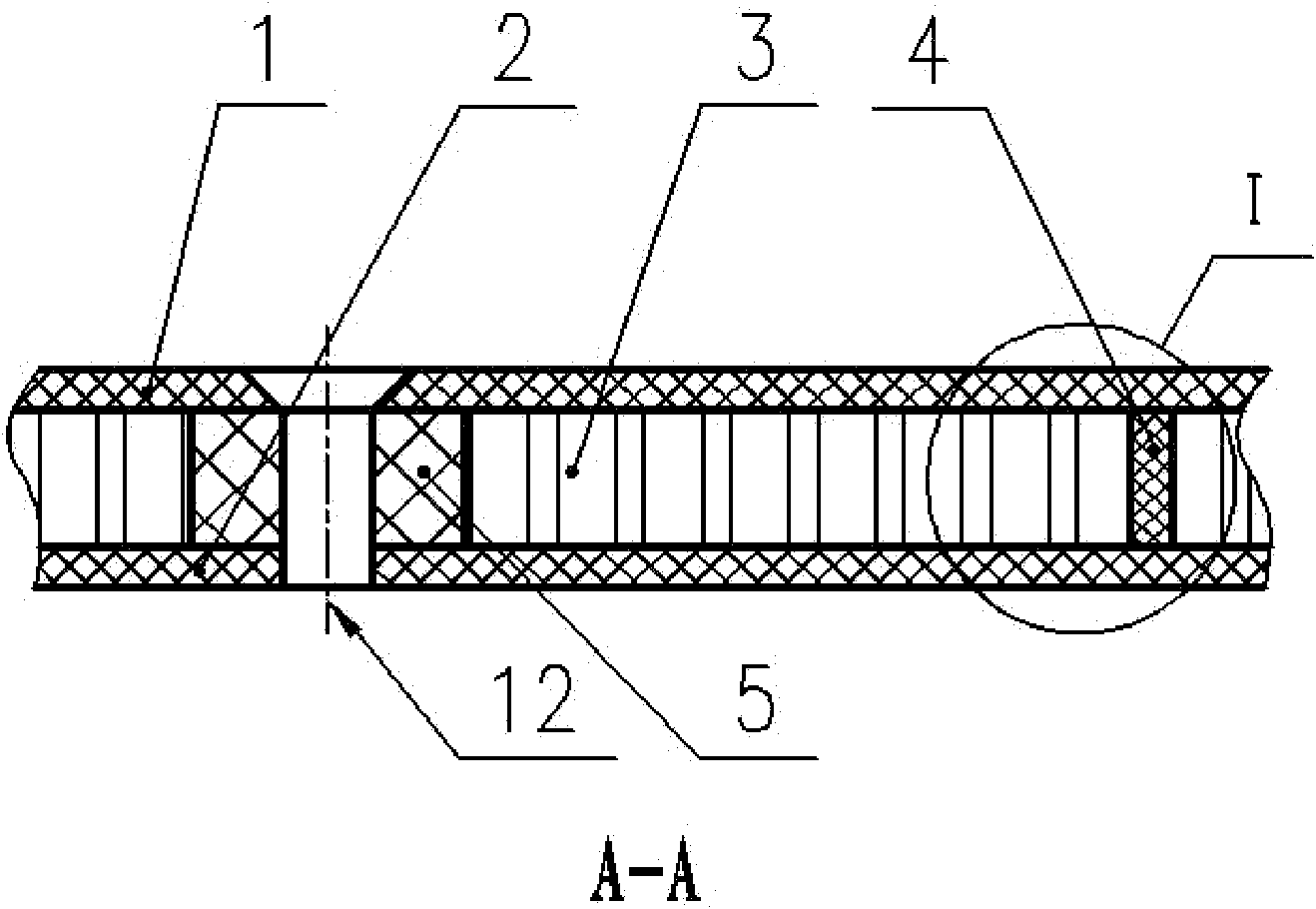

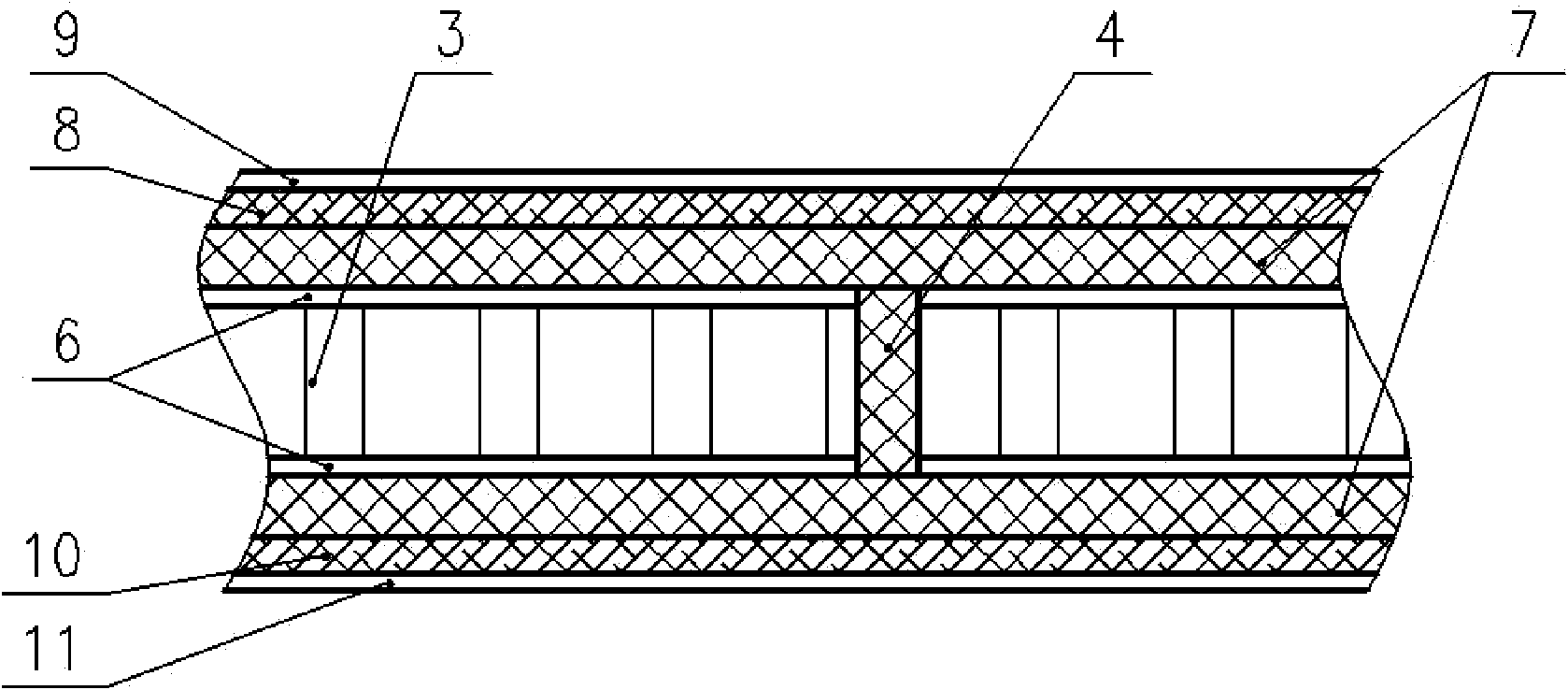

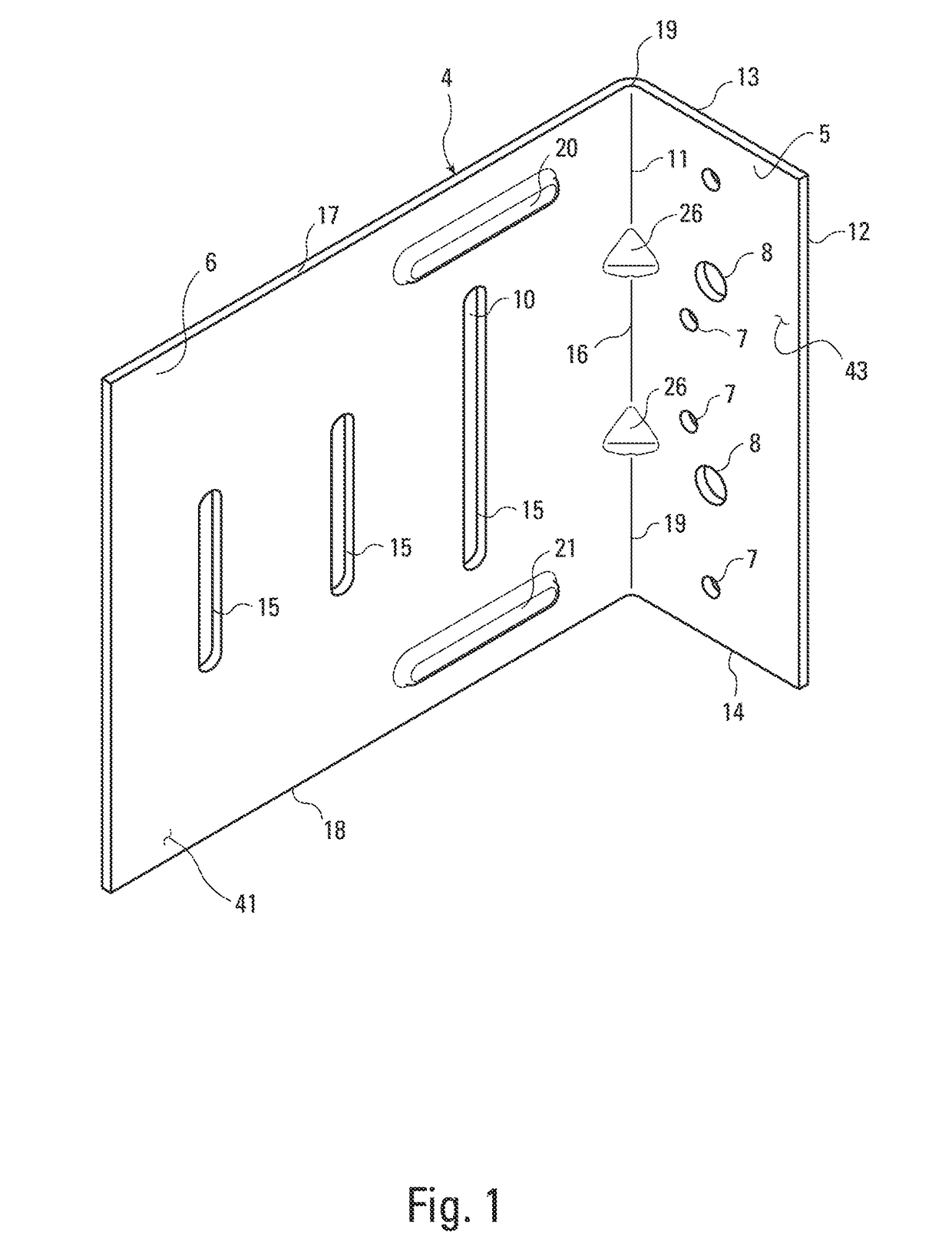

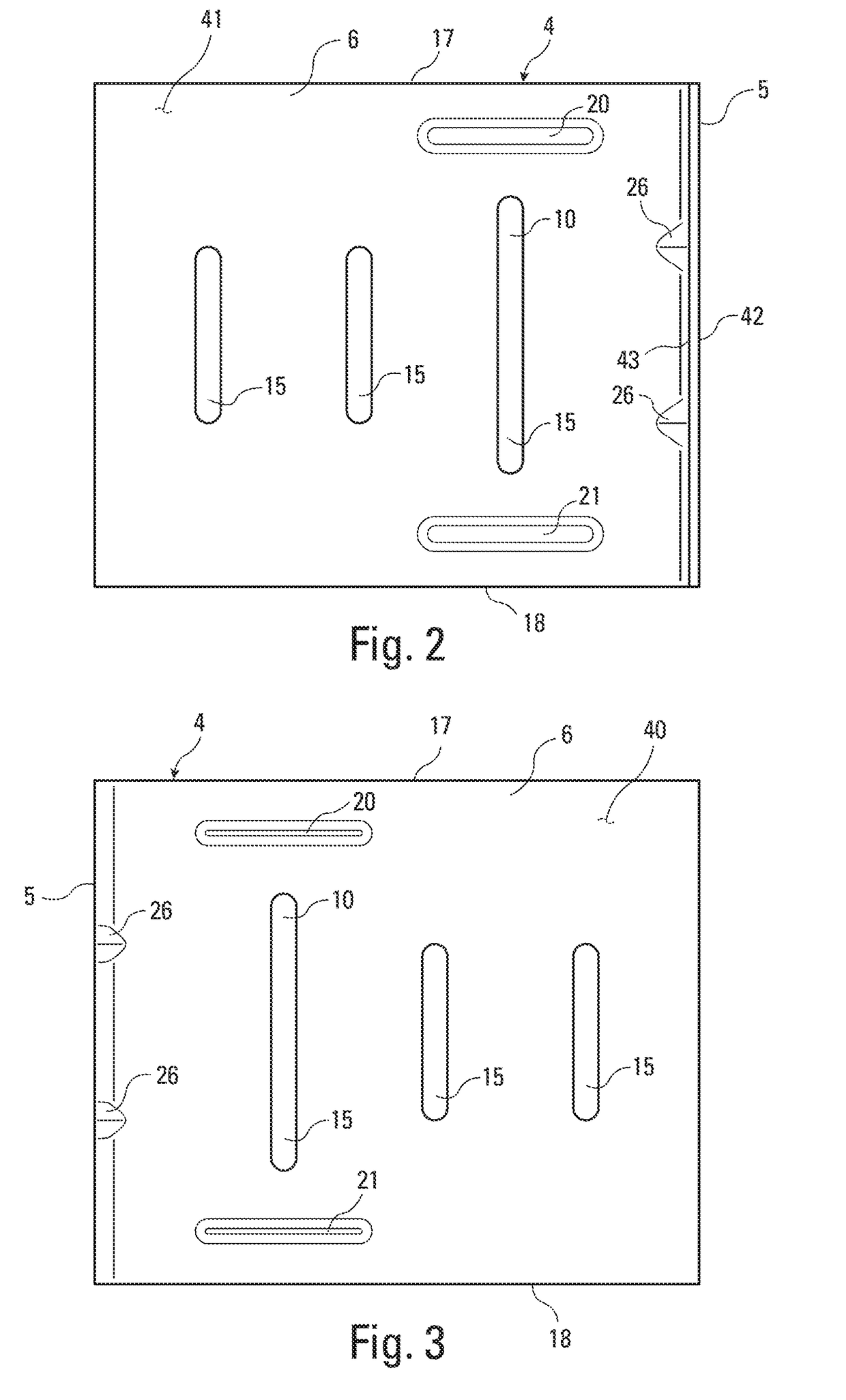

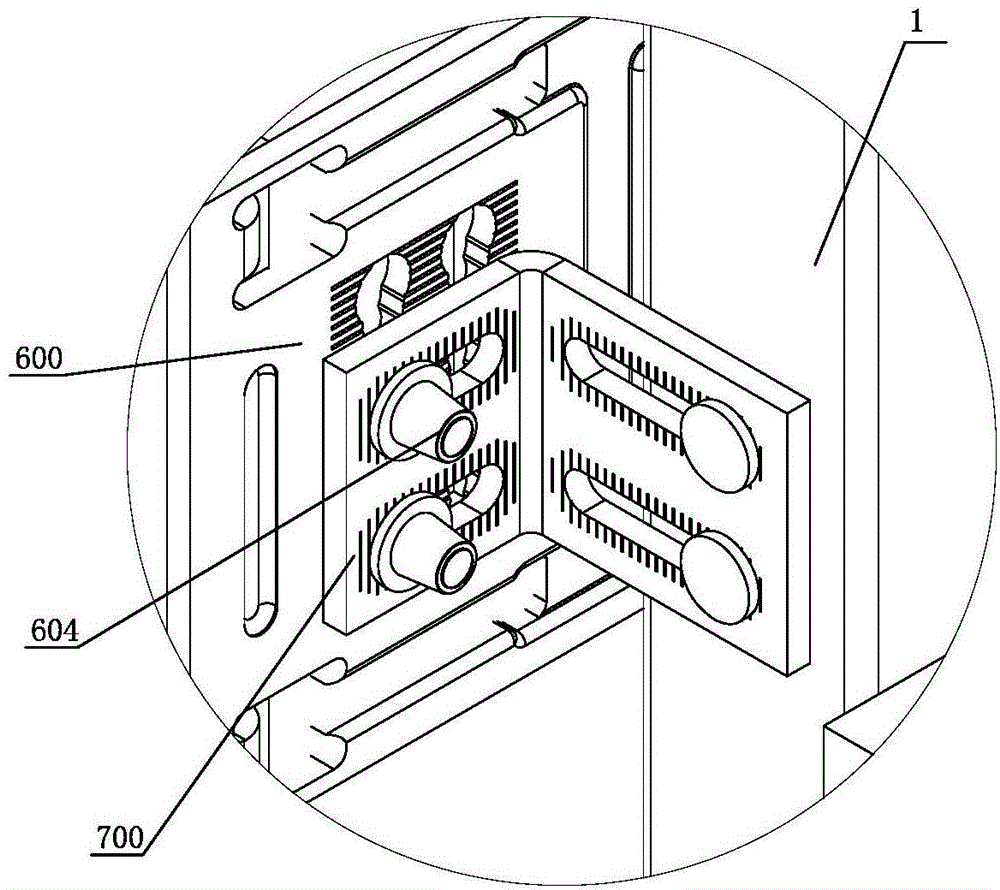

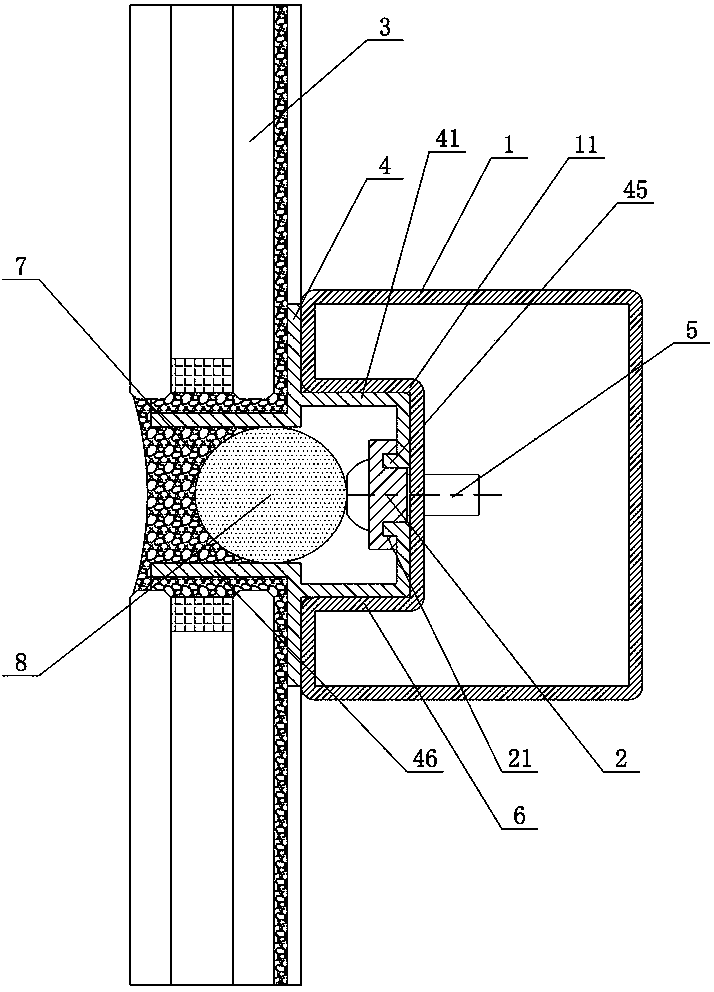

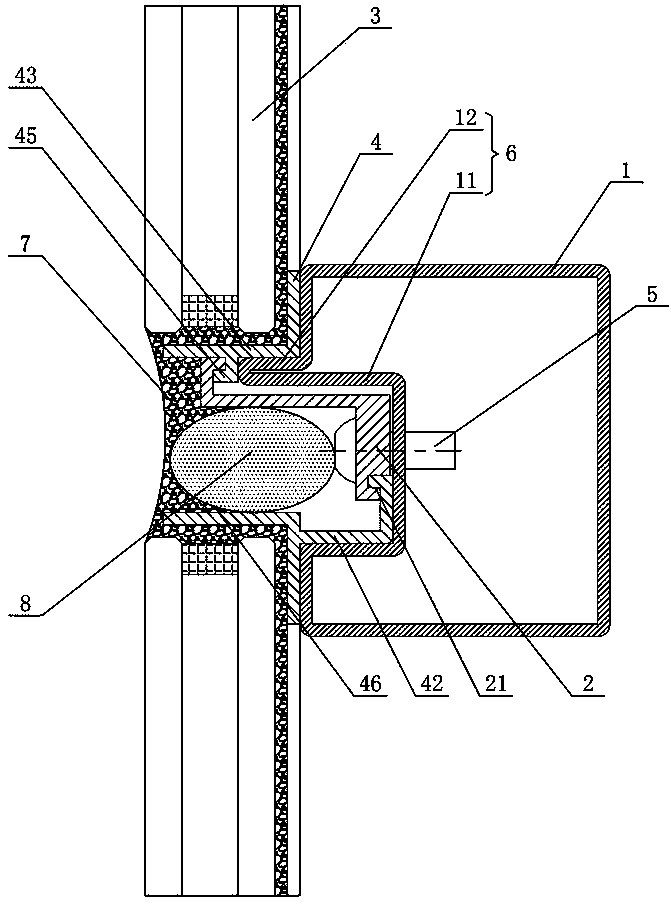

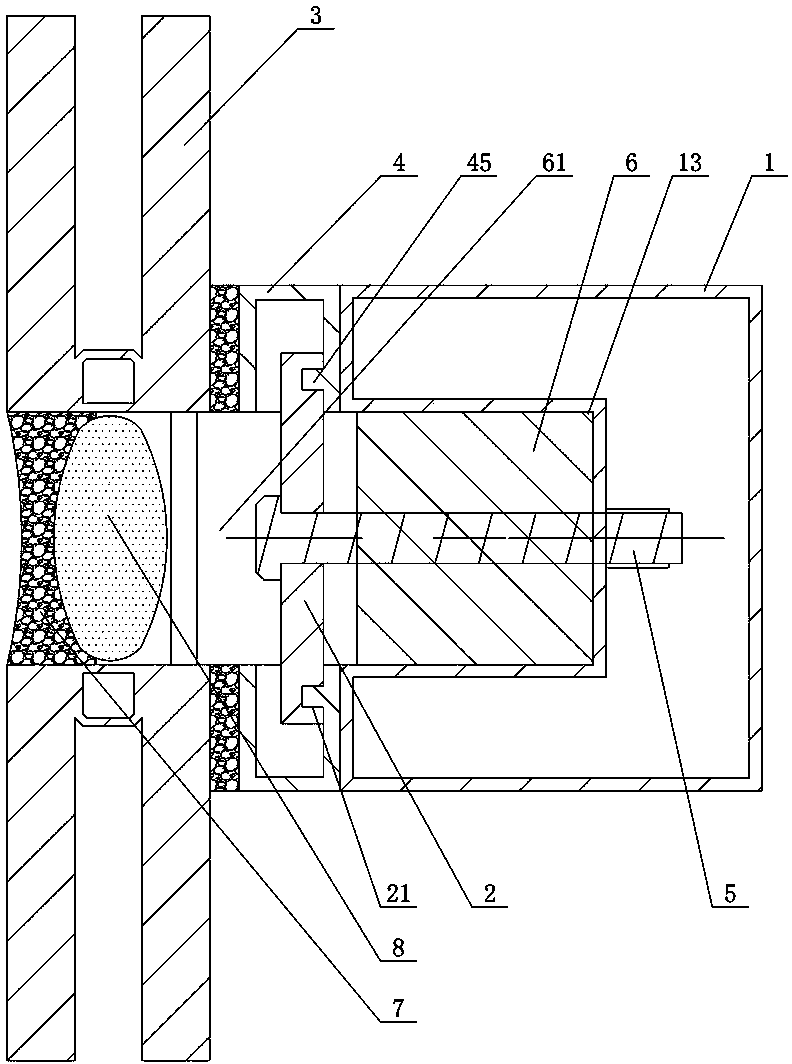

Full frame-hidden glass curtain wall and dismantling tool and method

ActiveCN108951978AEffective installationRealize complete concealed frame installationWallsBuilding repairsLocking mechanismLocking plate

The invention discloses a full frame-hidden glass curtain wall and a dismantling tool and method and belongs to the field of building curtain walls. The curtain wall and the dismantling tool and method solve the problem that the mounting efficiency of existing full frame-hidden glass curtain walls is low. The full frame-hidden glass curtain wall includes a framework and a panel, the framework includes columns and cross girders, a locking frame is fixed to the back side of the panel and provided with four locking mechanisms, and each locking mechanism includes a locking base; each locking basecomprises a locking sleeve fixed to the locking frame, a locking plate is fixed to the rear end of each locking sleeve, a locking block is embedded in each locking sleeve, rod holes are formed in thelocking sleeves and the locking frame, rod grooves are formed in the side walls of the locking blocks, sliding grooves are formed in the rod grooves, and sliding blocks are arranged on the sliding grooves. The curtain wall also includes penetrating rod holes and locking rods with the rear ends fixed with the sliding blocks, and reset springs are also arranged in the locking bases. The junctions between the front side faces of the columns and the left and right side faces of the columns and the junctions between the front side faces of the cross girders and the upper and lower side faces of thecross girders are all sloped guiding surfaces, and locking grooves are formed in the left and right side faces of the columns respectively. The mounting efficiency of the glass curtain wall is high,and a seamless frame-hidden type mounting mode can be achieved.

Owner:东阳市智林科技有限公司

Ultra-large light-transmission-type decorative board

InactiveCN102061790AHigh light transmittanceHigh mechanical strengthCovering/liningsWallsTransmittanceHoneycomb

The invention belongs to building enclosure materials, in particular to a light-transmission-type composite sandwich decorative board with an ultra-large face. In the decorative board, a wholly-reinforced composite sandwich structure of a light-transmission-type FRP (Fiber Reinforced Plastic) panel, a honeycomb core material and latticed FRP reinforcing ribs is adopted, mounting holes are arranged on the periphery and in other specified positions, the product is formed by adopting a die, and the surface is coated with a high-weather-resistant facing layer. The decorative board provided by the invention is suitable for the mass production of boards with ultralarge faces. Compared with hollow glass of a curtain wall, the decorative board provided by the invention has equivalent light transmittance as well as the advantages of great veneer area, light weight, high strength, good impact resistance, sound and heat isolation, good decoration effect, capability of night illumination, easiness for maintenance, long service life, and the like and can meet the demands of curtain walls, enclosures and decoration engineering of buildings and large-scale landscape structures for light-transmission-type decorative boards with ultra-large areas.

Owner:秦皇岛耀华装备集团股份有限公司

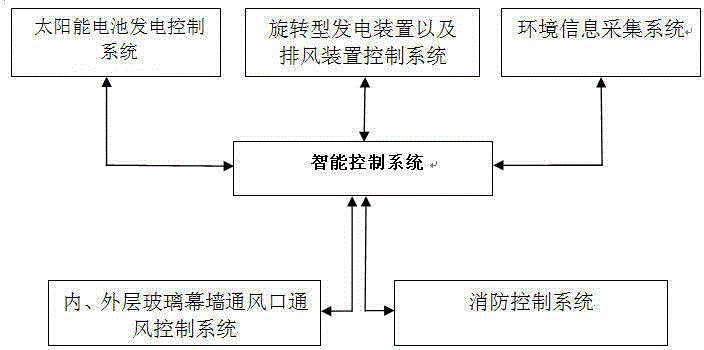

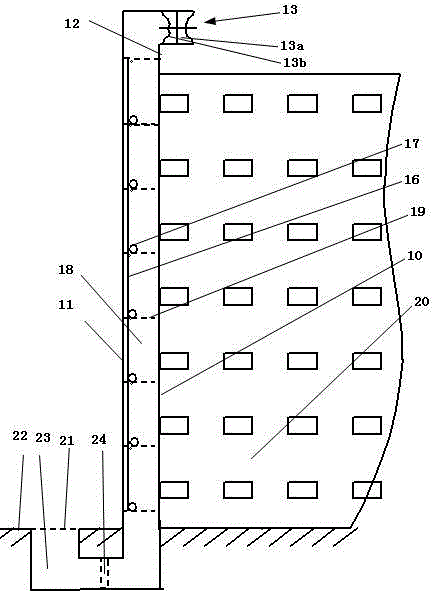

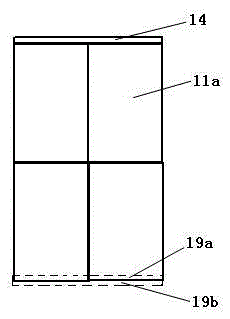

Double-layer glass curtain wall structure and intelligent control method

ActiveCN105649242AReduce consumptionEmission reductionPhotovoltaic supportsRoof covering using slabs/sheetsEngineeringSolar cell

The invention provides a double-layer glass curtain wall structure and an intelligent control method and belongs to the field of construction. An intelligent control system with a plurality of control modes is arranged on a double-layer glass curtain wall. Electric opening degree adjusting devices are arranged at a ventilation opening in an inner glass curtain wall body and at a ventilation opening in an outer glass curtain wall body. Ventilating grill sealing devices are arranged on ventilating grills. A temperature and humidity sensor and smoke probes are arranged in a ventilating channel and in a building correspondingly. Flexible sunshade fabric blinds capable of being rolled are arranged on the inner side of the outer glass curtain wall body. The double-layer glass curtain wall structure is provided with a power generation device. According to the double-layer glass curtain wall structure, indoor temperature adjustment can be conducted automatically through the intelligent control system, natural wind is sufficiently utilized for driving the rotary power generation device to generate power, and flexible solar cells are utilized for generating power, so that green energy resources are generated, carbon emission can be reduced, the greenhouse effect is avoided, and green ecology of the building is achieved.

Owner:宿迁芊森窗业有限公司

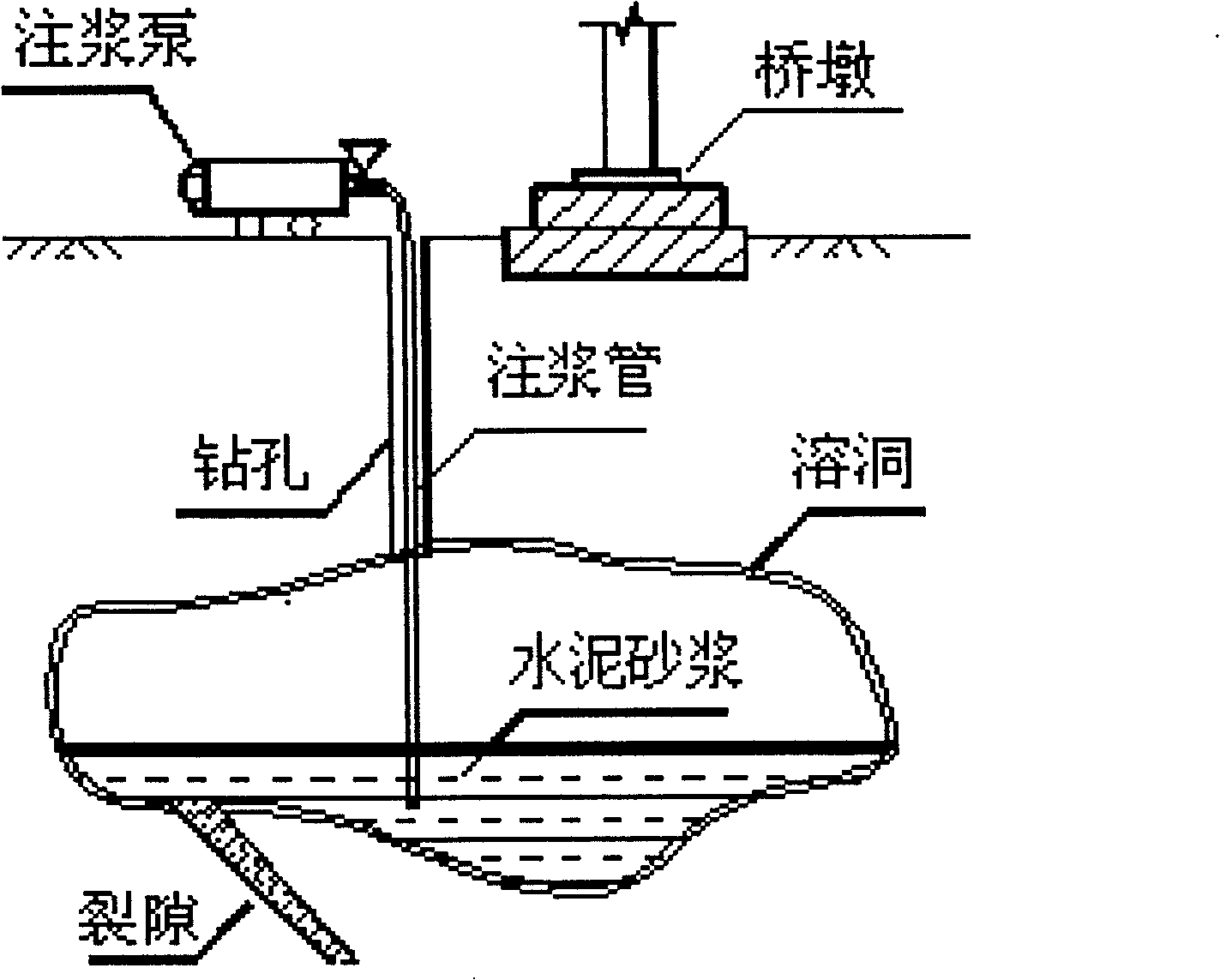

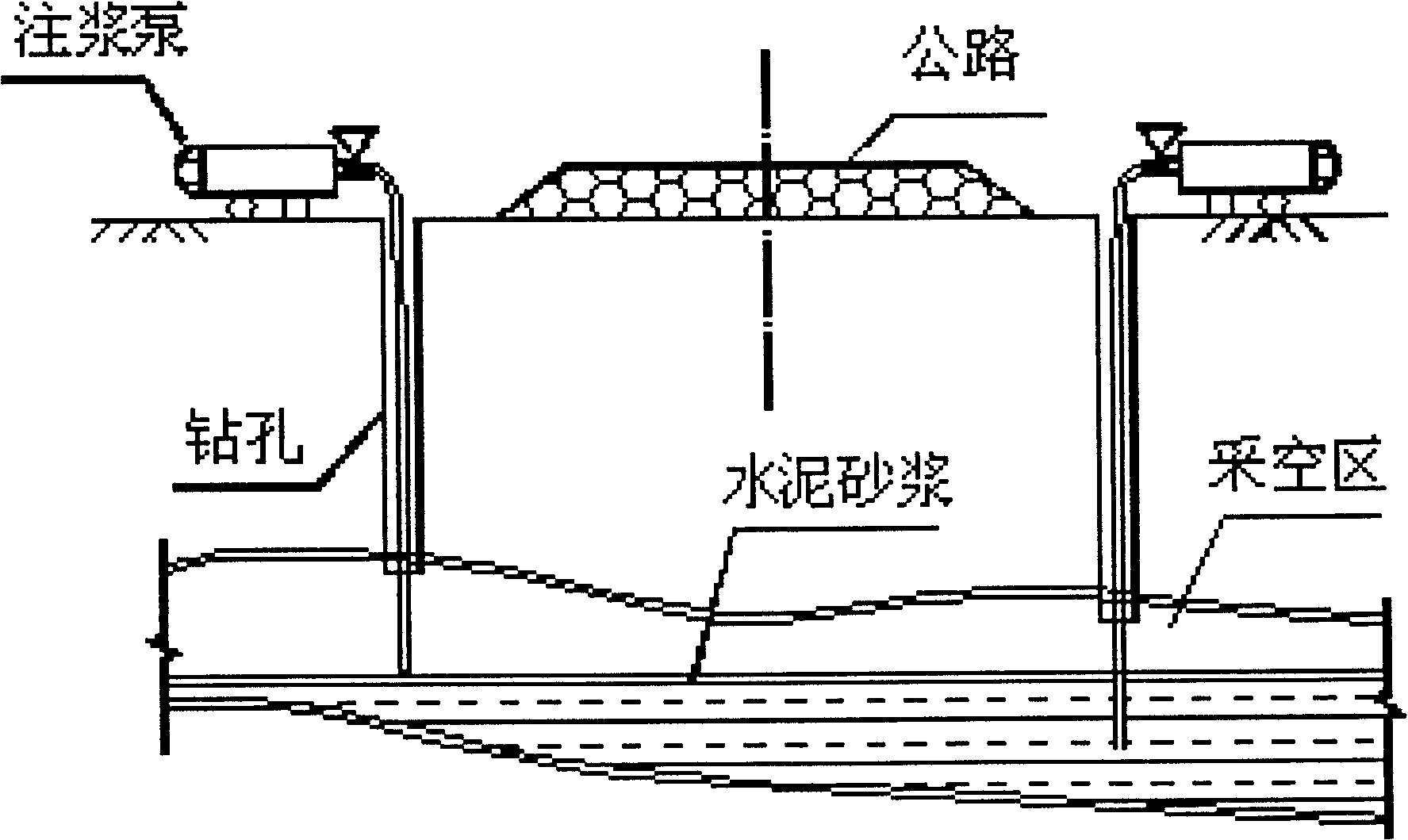

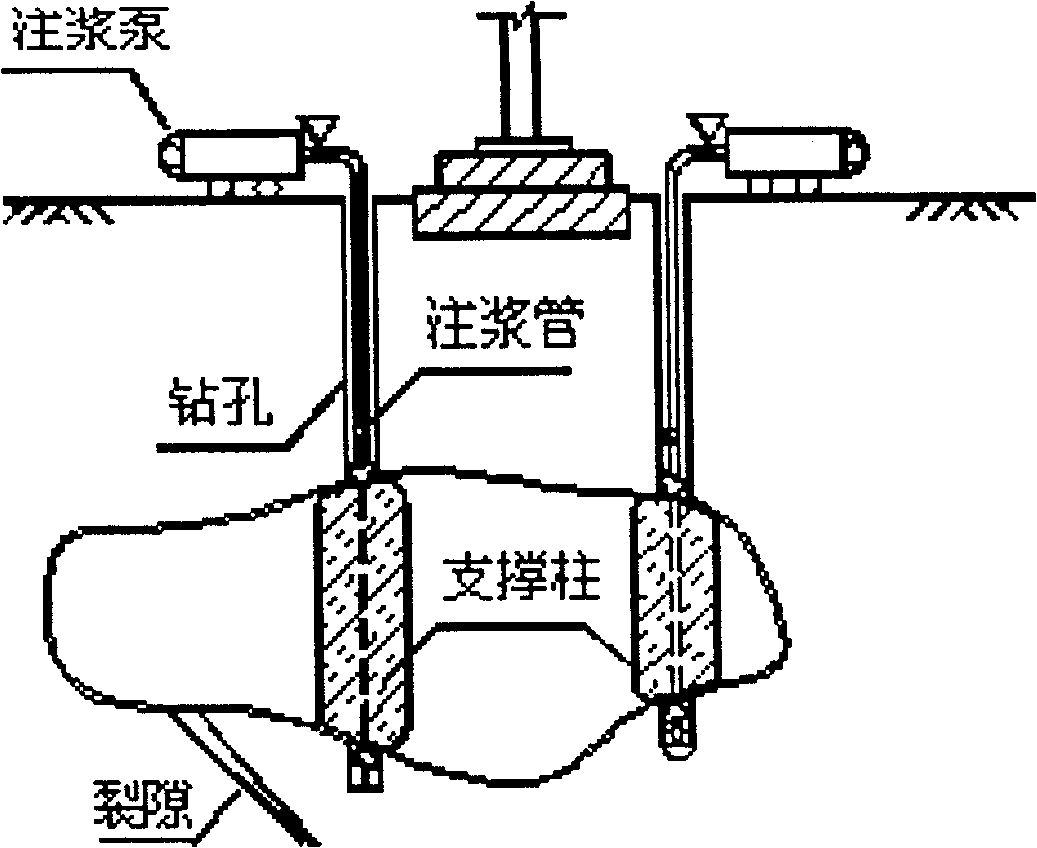

Method for setting bracing column in underground cavity

InactiveCN101270582AAvoid destructionProtect the environmentFoundation engineeringSteel tubeCement slurry

The invention relates to a method for arranging a supporting column used for preventing the ground from collapsing and deforming in an underground cavern (cave, laneway). The invention has broad applications in the constructions of roads, railways, airdromes and water conservancy projects which have underground caves or goaf roadways and can also be applied to the field of environment resuming and governing of a surface collapse area or a mine goaf area. The method of the invention includes: using a drill to drill a bore from the ground to the underground until entering into 40 to 60cm under the bottom surface of the cavern, then inserting a steel pipe the outside of which is coated by a bag into the bottom part of the bore, then inserting a grouting pipe into the bottom part of the steel pipe, pouring cement slurry into the pipe by using a grouting pump through a grouting pipe; a supporting body is formed after the bag is fully filled and solidified. A plurality of supporting columns can also be arranged in the cavern according to the method to form a supporting column group or a curtain wall formed by the supporting columns.

Owner:NORTHWEST RES INST CO LTD OF C R E C

Device and method for testing bonding shearing strength of structural adhesive interface

ActiveCN104132856AEasy to maintain stabilityPrevent twistingPreparing sample for investigationMaterial strength using steady shearing forcesBond interfaceShear stress

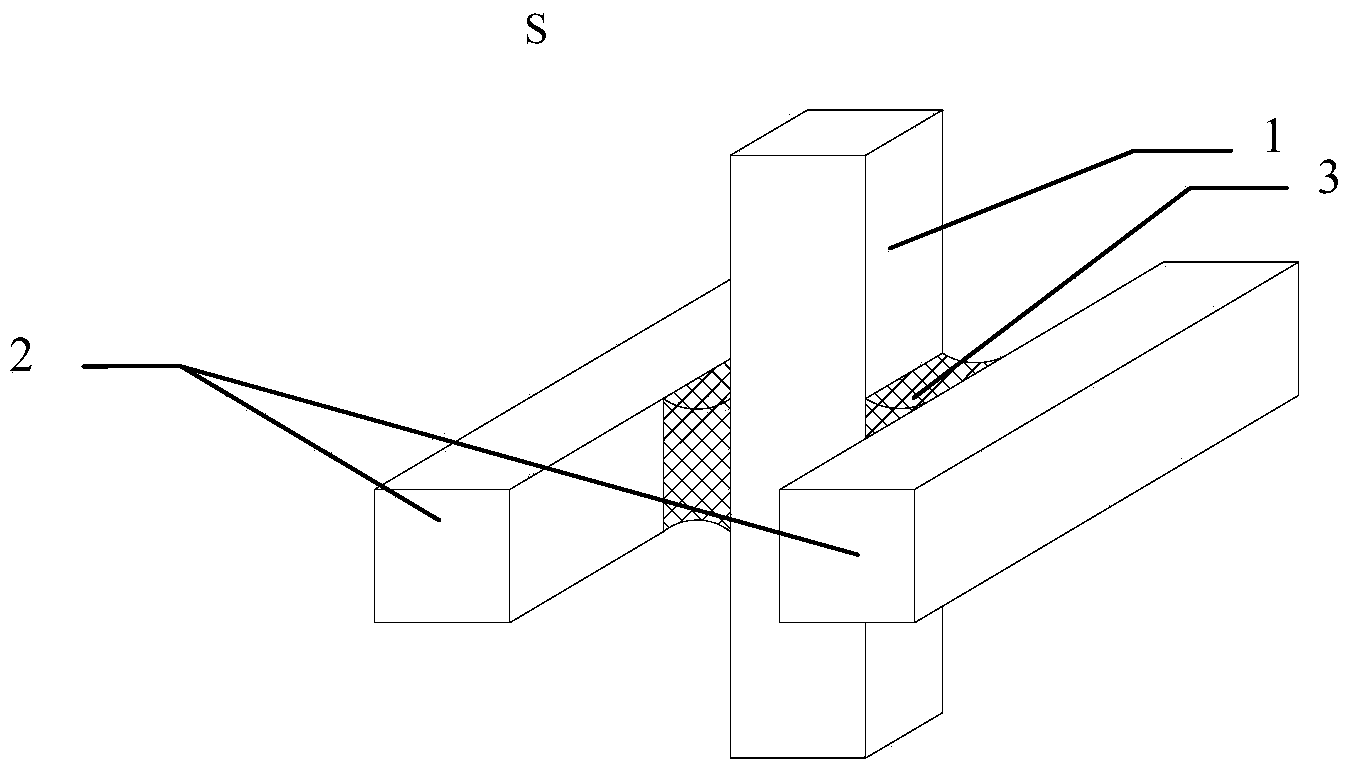

The invention relates to a device and method for testing bonding shearing strength of a structural adhesive interface. The device comprises a bonding base material testing piece and two bonded testing pieces, wherein the bonding base material testing piece and the two bonded testing pieces are bonded in a crisscross manner by using a structural adhesive, the two bonded testing pieces are mutually parallel and are located at two sides of the bonding base material testing piece, the respective centers of the two bonded testing pieces and the bonding base material testing piece are located on the same straight line, a compression load is applied to the bonding base material testing piece to ensure that shear stress can be generated on a bonding interface of two materials, and the bonding shearing strength of the interface is calculated through the shear stress generated during damaging. The device and the method for testing the bonding shearing strength of the structural adhesive interface are suitable for testing the bonding shearing strength of the interface among different materials with certain bonding layer thicknesses, and especially suitable for evaluating the bonding strength of the structural adhesive between glass of a curtain for doors and windows of a building and a metal base material.

Owner:北京玻钢院检测中心有限公司

Slip Clip

Owner:SIMPSON STRONG TIE

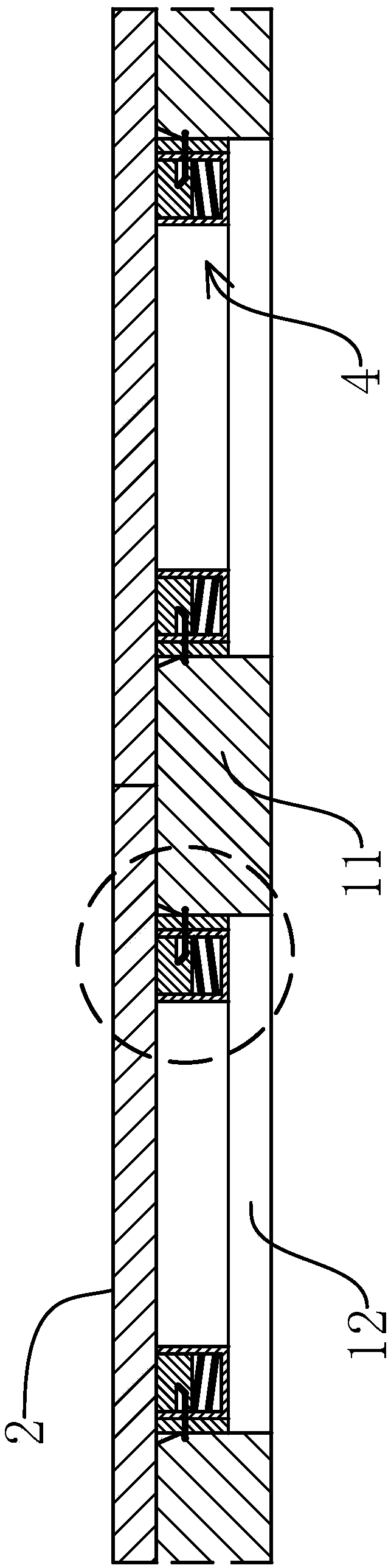

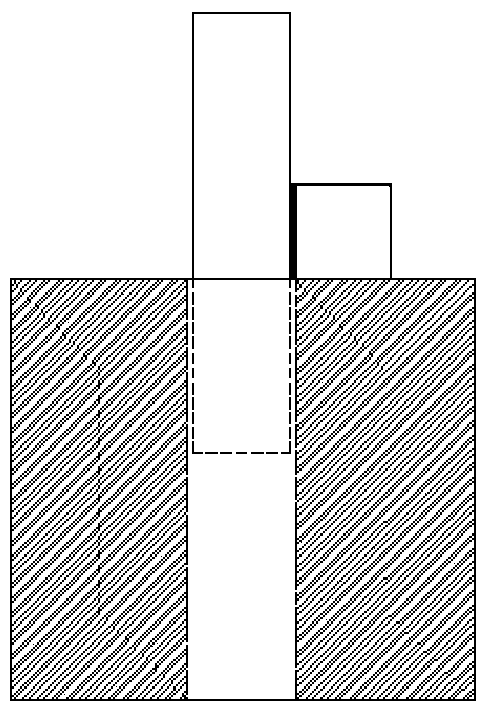

Curtain wall metal structure vertical keel and vertical keel and transverse keel connecting structure

The invention provides a curtain wall metal structure vertical keel. The vertical keel is a square-pipe keel. The vertical keel is characterized in that one end of the vertical keel is extruded into a joint square pipe shape, the surface of the joint square pipe shape is provided with a vertical bulge to form a plugging part of which the upper and lower cross-sectional overall sizes are consistent and which has a heat-expansion and cold-contraction compressive function and is integrated with a square-pipe keel. The plugging part can be matched with the other end of the square-pipe keel in size, so that the plugging part of a vertical keel can be plugged into the other end of a square-pipe keel through interference or transition fit. The end of the plugging part is an anti-cutting plug head. By adopting a connecting structure provided by the invention, during connection of a vertical keel and a transverse keel, the positions can be adjusted quickly and conveniently, the keels can be installed accurately, the transverse keel can adapt to heat-expansion and cold-contraction and does not shift after installation, the keels are installed firmly and never loosen, and no welding is needed.

Owner:HANGZHOU STAN NEW MATERIALS TECH CO LTD

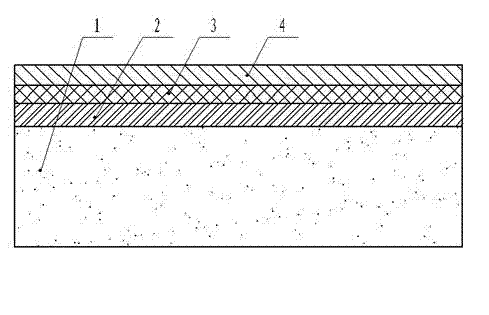

Self-cleaning layer with photocatalysis and anti-static compounding functions and production method thereof

InactiveCN103112231AImprove superhydrophilicityOvercoming the weakness of self-cleaning functionLayered productsSpecial surfacesEngineeringPhoto catalysis

The invention relates to a self-cleaning layer with photocatalysis and anti-static compounding functions and a production method of the self-cleaning layer, and particularly relates to a method of combining photocatalytic materials capable of enabling visible light to respond and anti-static materials on a base material surface in an adhering manner. According to the self-cleaning layer, the anti-fouling, anti-dust and photocatalysis self-cleaning functions can be realized on external decorative material surfaces of different buildings. The self-cleaning layer is formed by a sealing layer, an anti-static layer and a photocatalysis layer, wherein the sealing layer is coated on the base material surface, the anti-static layer is compounded on the sealing layer, and finally, the photocatalysis layer is compounded on the anti-static layer. The self-cleaning layer is a novel self-cleaning layer capable of being automatically cleaned under visible light and preventing dust. The self-cleaning layer is mainly applied on building roofs, building curtain walls, wall decorations and glass surfaces and is also applied in the municipal traffic engineering construction and modification engineering projects.

Owner:NANJING BEILIDA NEW MATERIAL SYST ENG

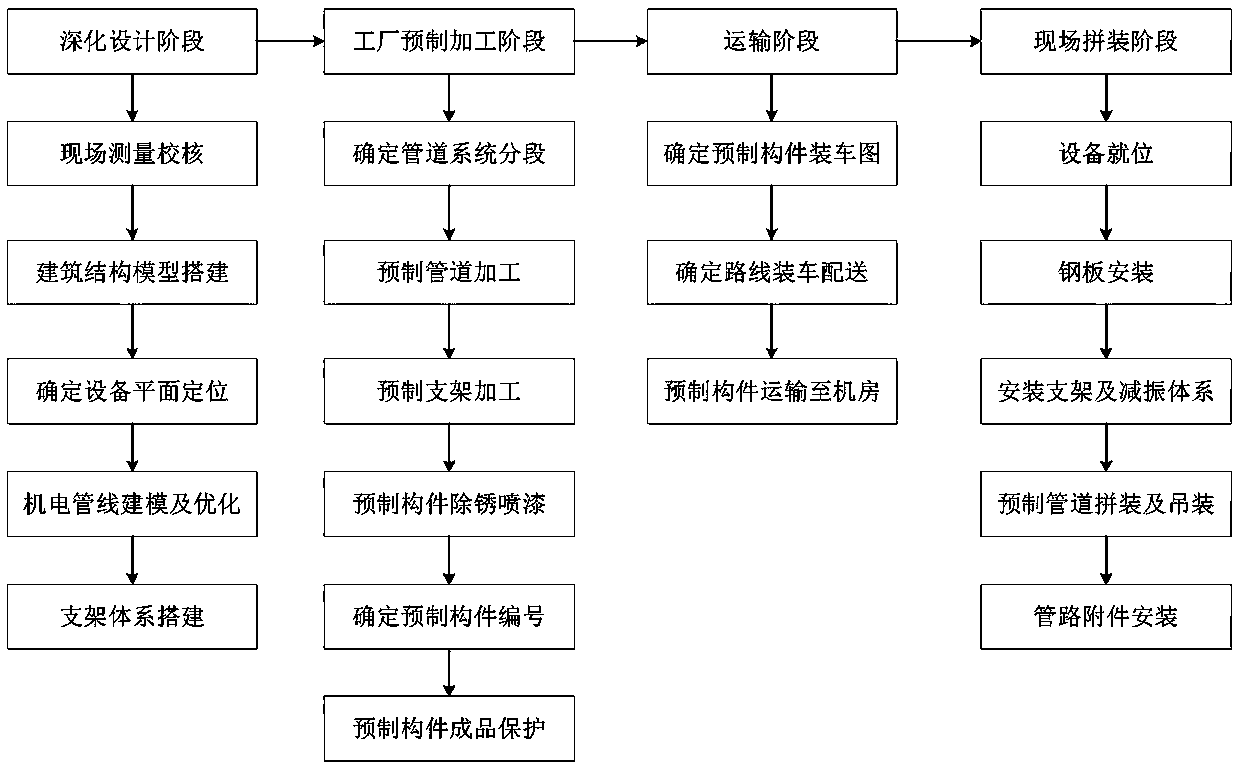

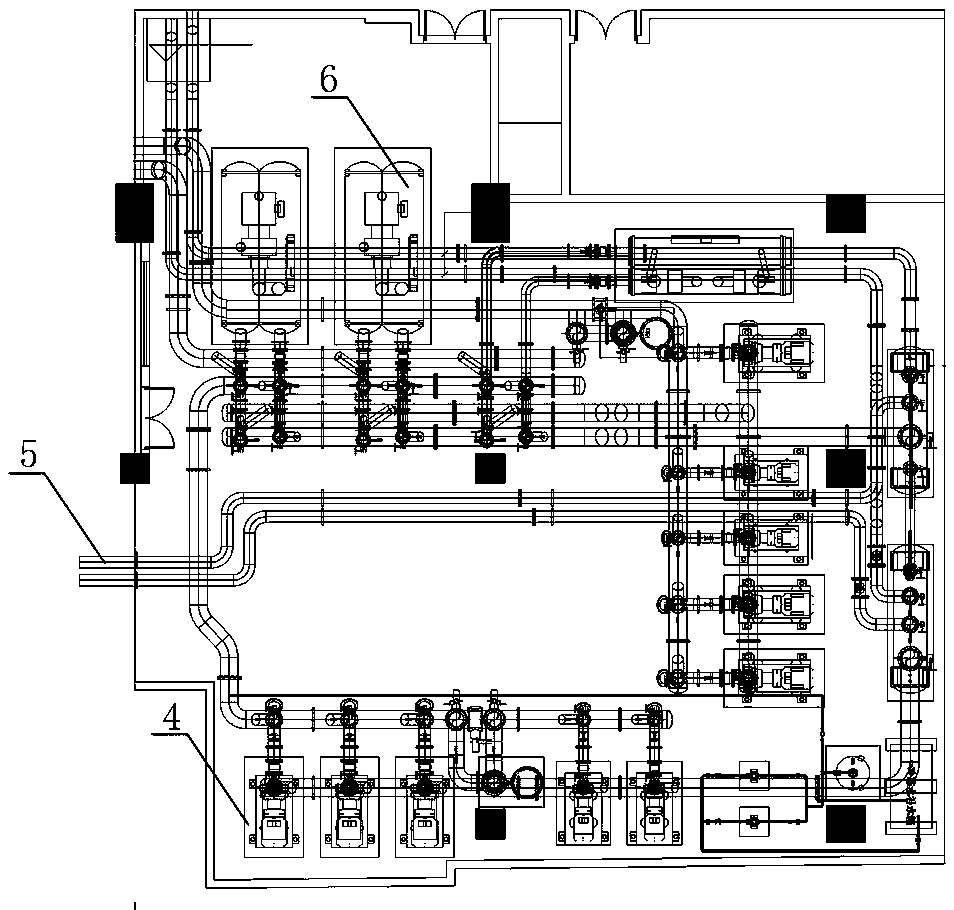

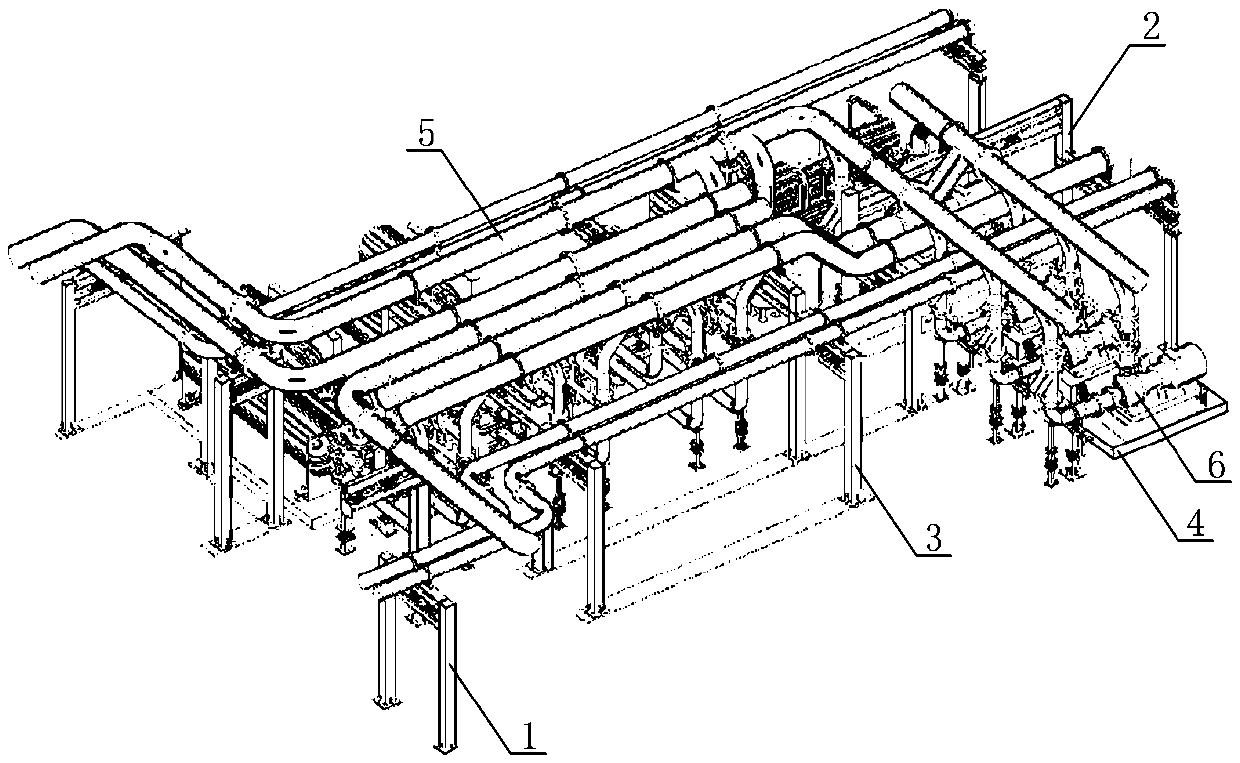

Refrigerating machine room assembly type construction method based on a BIM technology

ActiveCN109614719AEase of industrial productionEasy to transportGeometric CADDesign optimisation/simulationSystem maintenanceMachine

A refrigerating machine room assembly type construction method based on a BIM technology comprises four stages, namely a deepening design stage, a prefabrication machining stage, a transportation stage and a field assembly stage. According to the method, a designed construction drawing is combined with a construction site, electromechanical professions are comprehensively planned, civil engineering, curtain walls, decoration and other acceptance units are connected, and the problem of serious difficulty in construction and key areas are pre-judged. The method has the advantages that on-site construction is guided, engineering quality is improved, guarantee is provided for engineering progress, project cost is saved, completion data is input into the building information model finally, system maintenance and use during project operation are facilitated, and expected functions of buildings are achieved finally and added value is increased. Compared with a traditional refrigerator room construction method, the construction method adopting the prefabricated assembly refrigerator room has remarkable advancement and advantages in the aspects of construction period, quality, safety, manufacturing cost and other technical and economic effects.

Owner:THE FIRST CONSTR ENG COMPANY LTD OF CHINA CONSTR SECOND ENG BUREAU

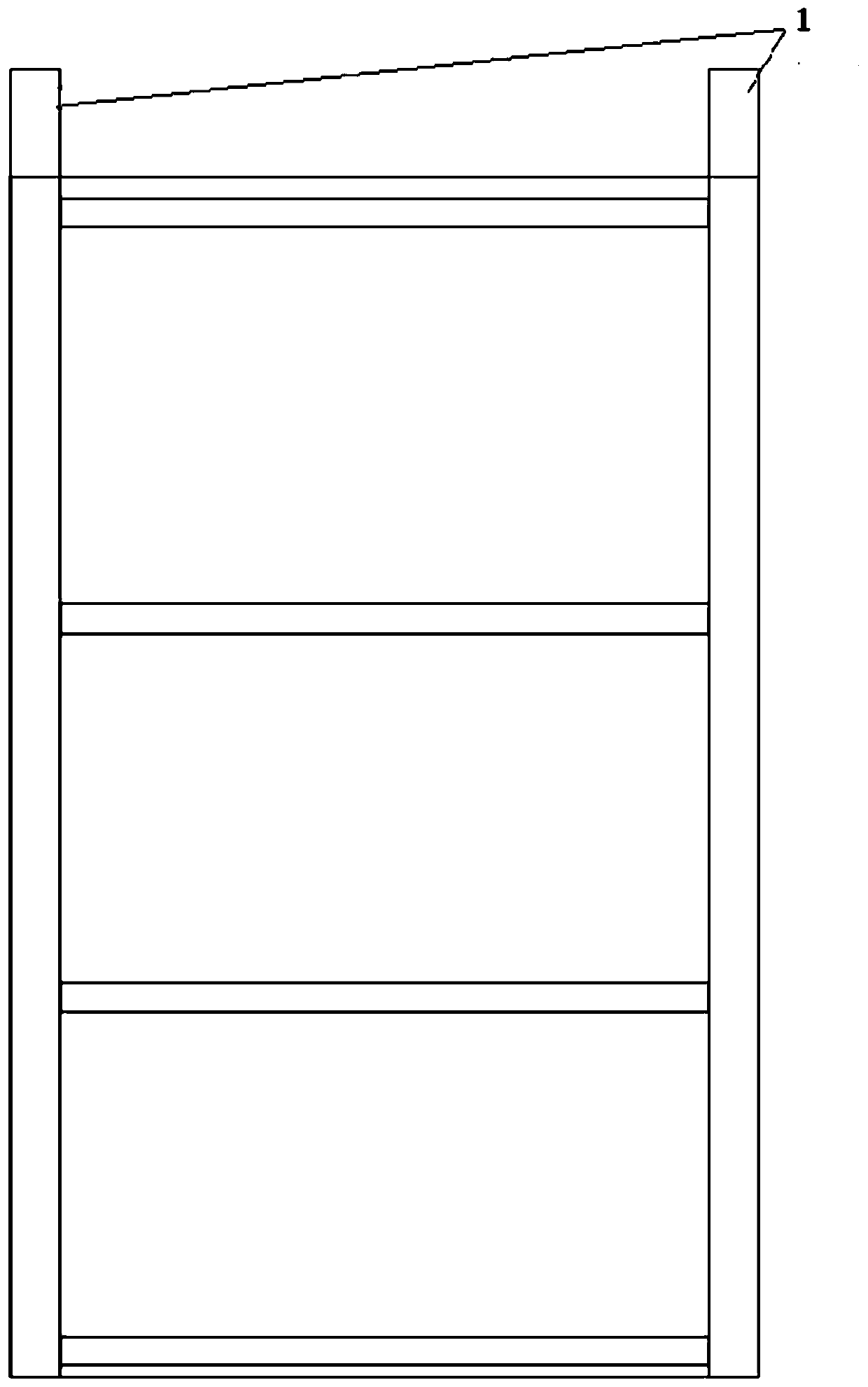

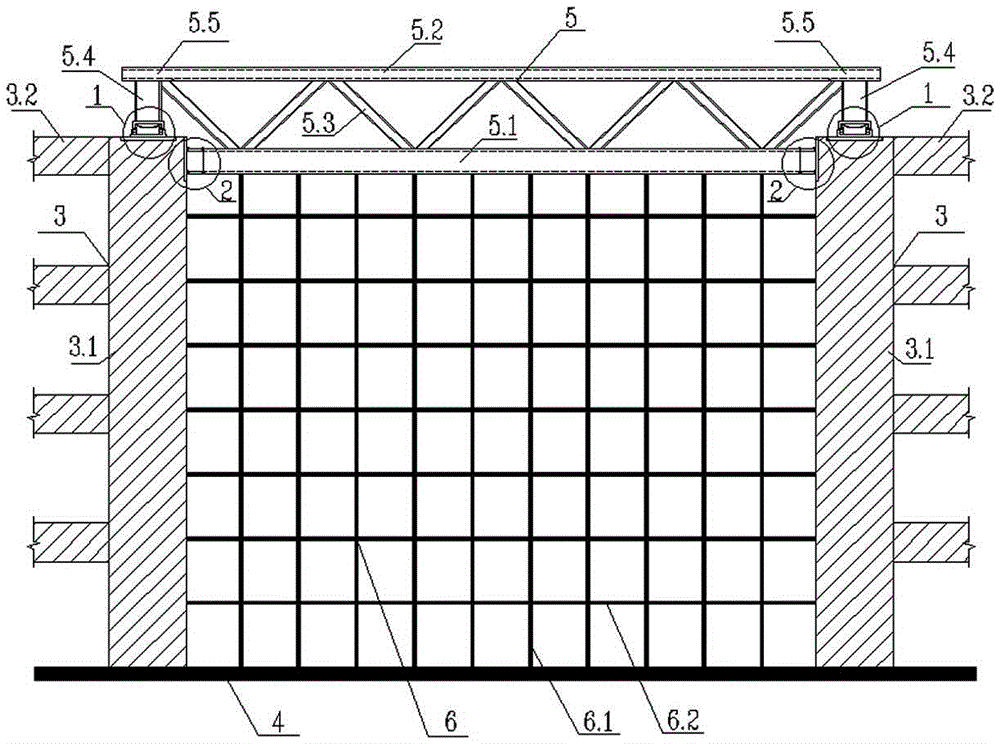

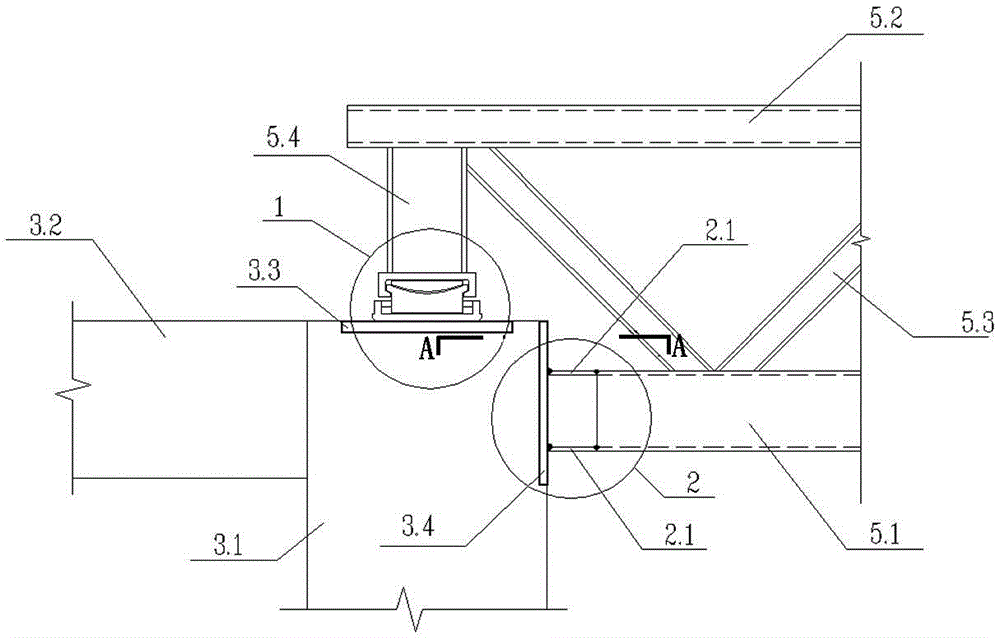

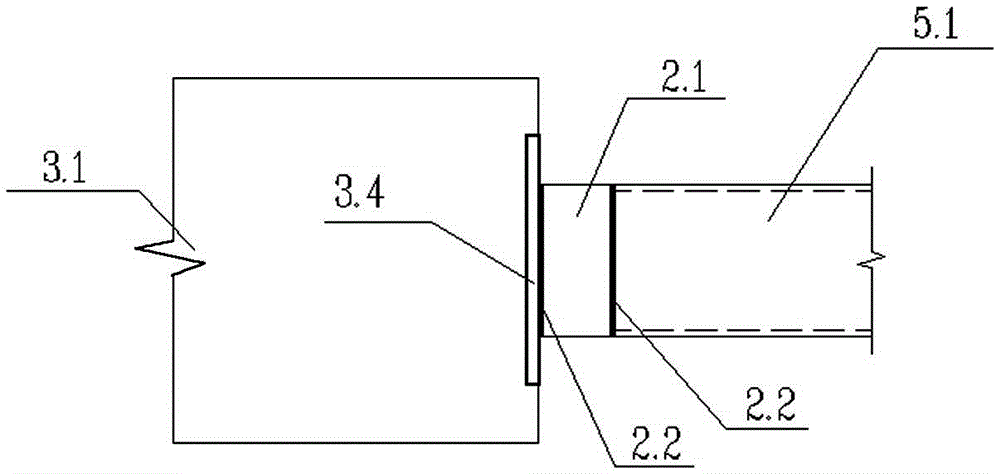

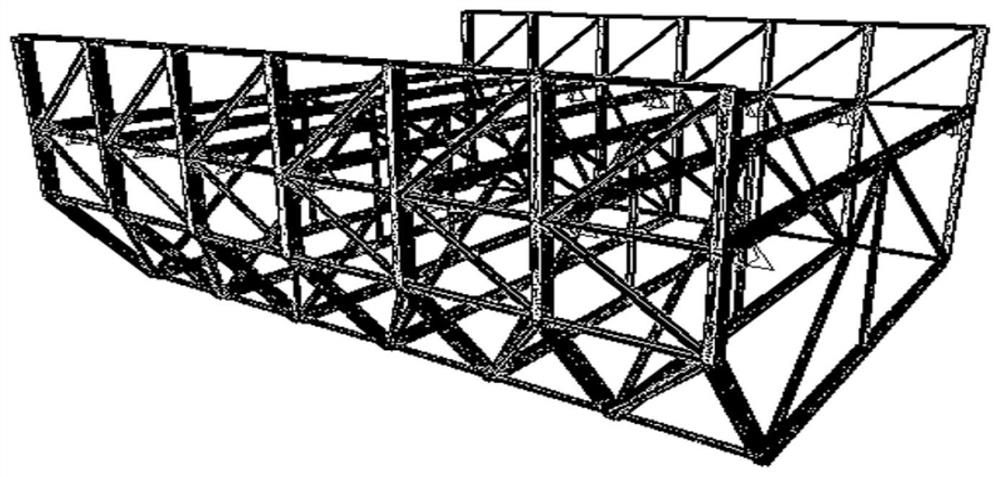

Dragline curtain wall support system with steel truss at top and construction method thereof

ActiveCN105332452ASolve processing problemsImprove structural strengthWallsBuilding material handlingSupporting systemPre stress

The invention provides a dragline curtain wall support system with a steel truss at the top and a construction method thereof. The dragline curtain wall support system comprises main building structures at two sides, a support structure at the lower part, the steel truss at the top and a curtain wall steel cable at the middle, wherein the main building structures provide left and right fixed points of the steel cable, and the steel truss and the support structure at the lower part provide upper and lower fixed points of the curtain wall steel cable; a two-direction fixed mode of horizontal connection and vertical connection is adopted at the two ends of the steel truss and between the main building structures; and the horizontal connection is realized through a horizontal bearing support, and the vertical connection is realized through a vertical bearing support. The dragline curtain wall support system is simple in structure and convenient in construction; by virtue of the two-direction support fixed mode, the structure strength is increased, the node structure is simplified, and the structure safety is greatly increased; The horizontal bearing support is installed after vertical steel cable prestress tension to enable the steel truss to freely rotate under the action of the vertical force, so that the secondary stress of buildings at two sides is reduced; and by transferring force by a horizontal steel plate, the bearing force is large, the stress is reliable, and micro-vertical deformation of the steel truss can also be applicable.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

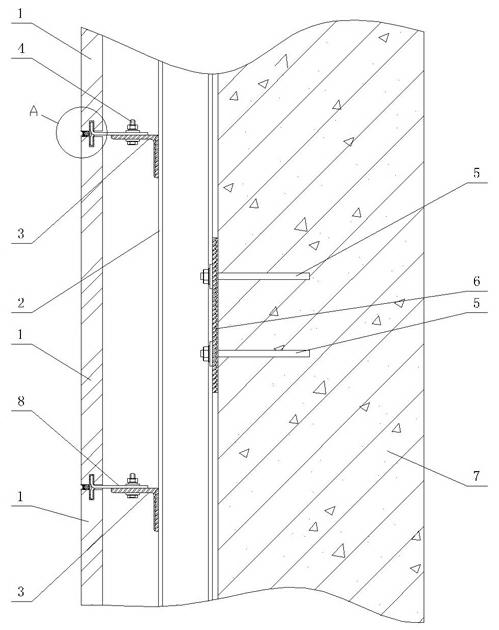

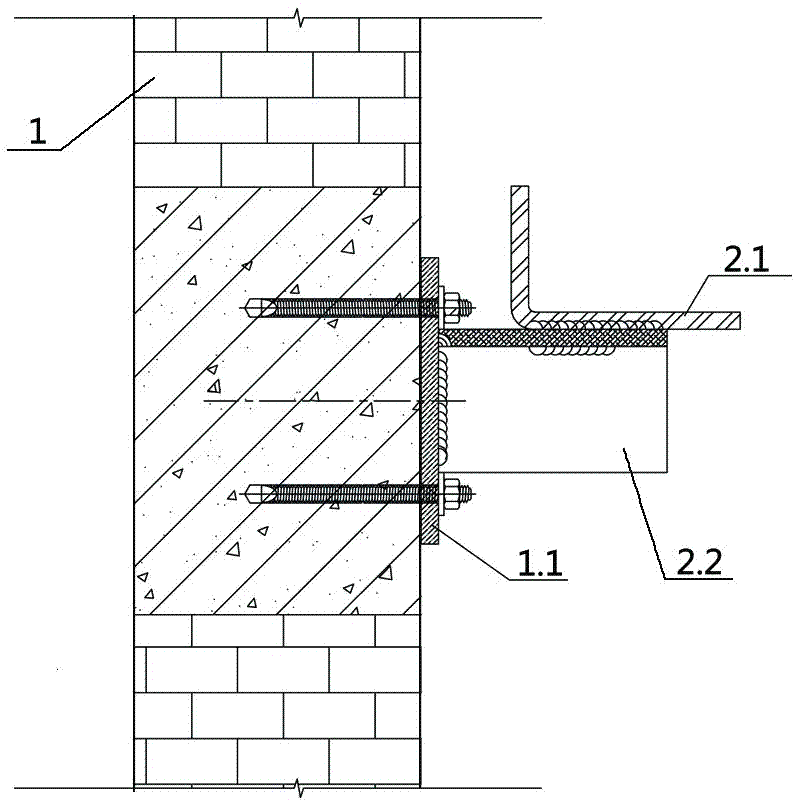

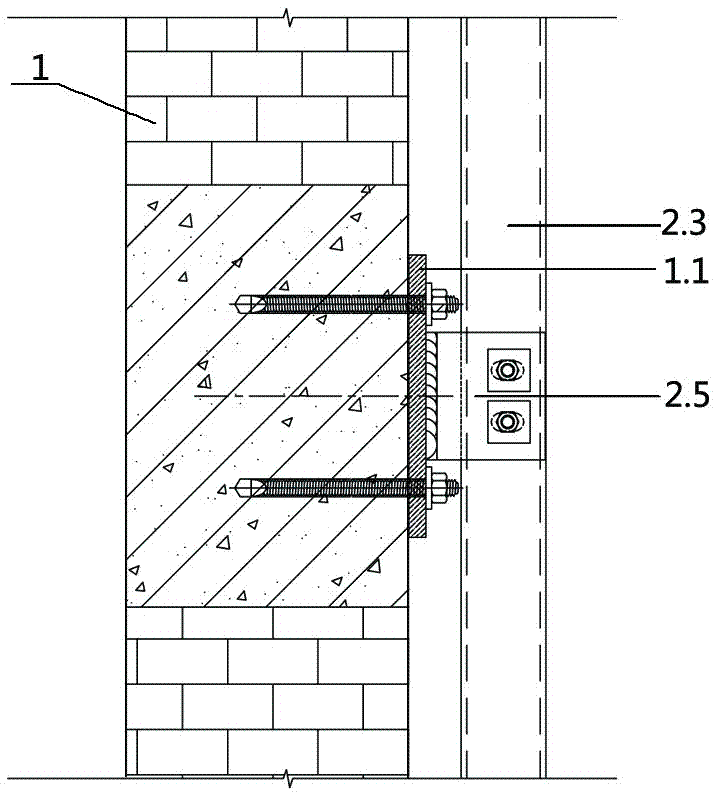

Curtain wall with dry-hanging stone on external wall

InactiveCN102080423AImprove securityNot prone to peelingWallsArchitectural engineeringExternal cladding

The invention discloses a curtain wall with dry-hanging stone on external wall, belonging to the technical field of the curtain wall in building system and comprising stone, a channel steel and a steel plate fixed on the wall body through chemical bolts, wherein the rear end face of the channel steel is fixedly connected with the steel plate, the front end face of the channel steel is fixedly connected with an angle steel which is fixed with a pendant, and the stone is fixed on the channel steel through the pendant. According to the curtain wall with dry-hanging stone on external wall provided by the invention, the stone is fixed on the wall body by means of the effective cooperation of the chemical bolts, the steel plate, the channel steel, the angle steel and the pendant, and the structure of the curtain wall with dry-hanging stone on external wall is not only suitable for the wall of a building with large height, but also has quite small possibility of cracking and flaking off, long service and high safety coefficient.

Owner:浙江环宇建设集团有限公司

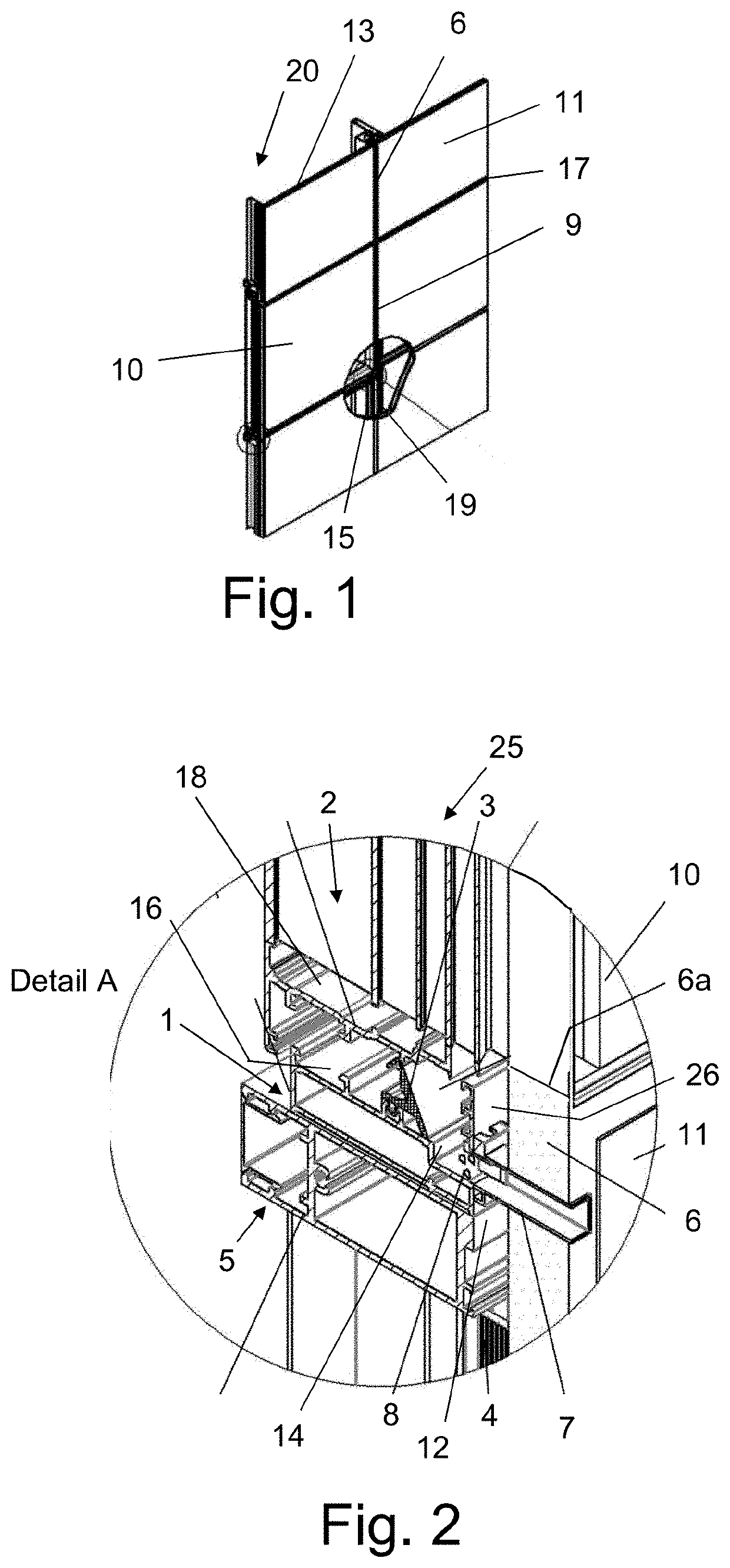

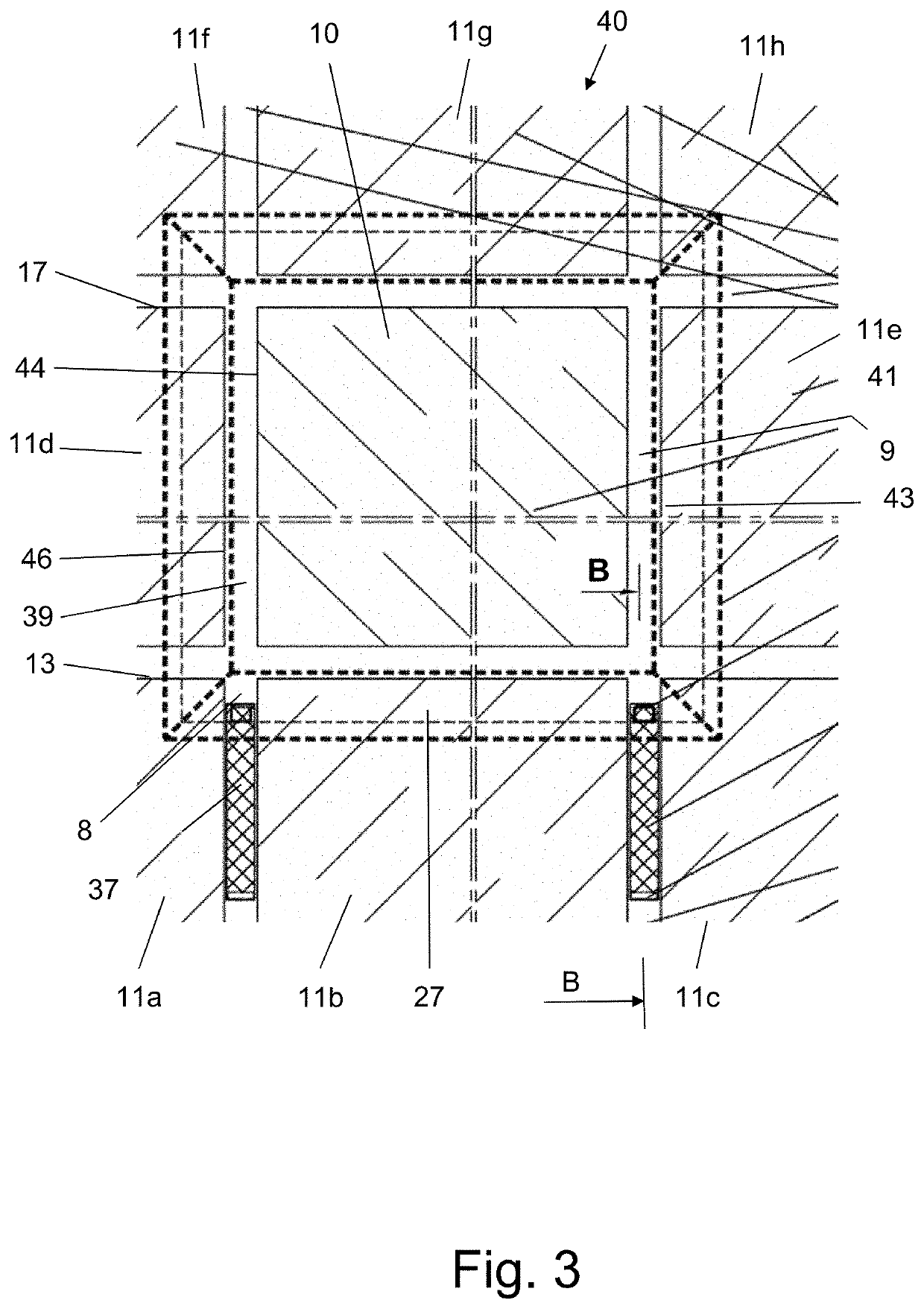

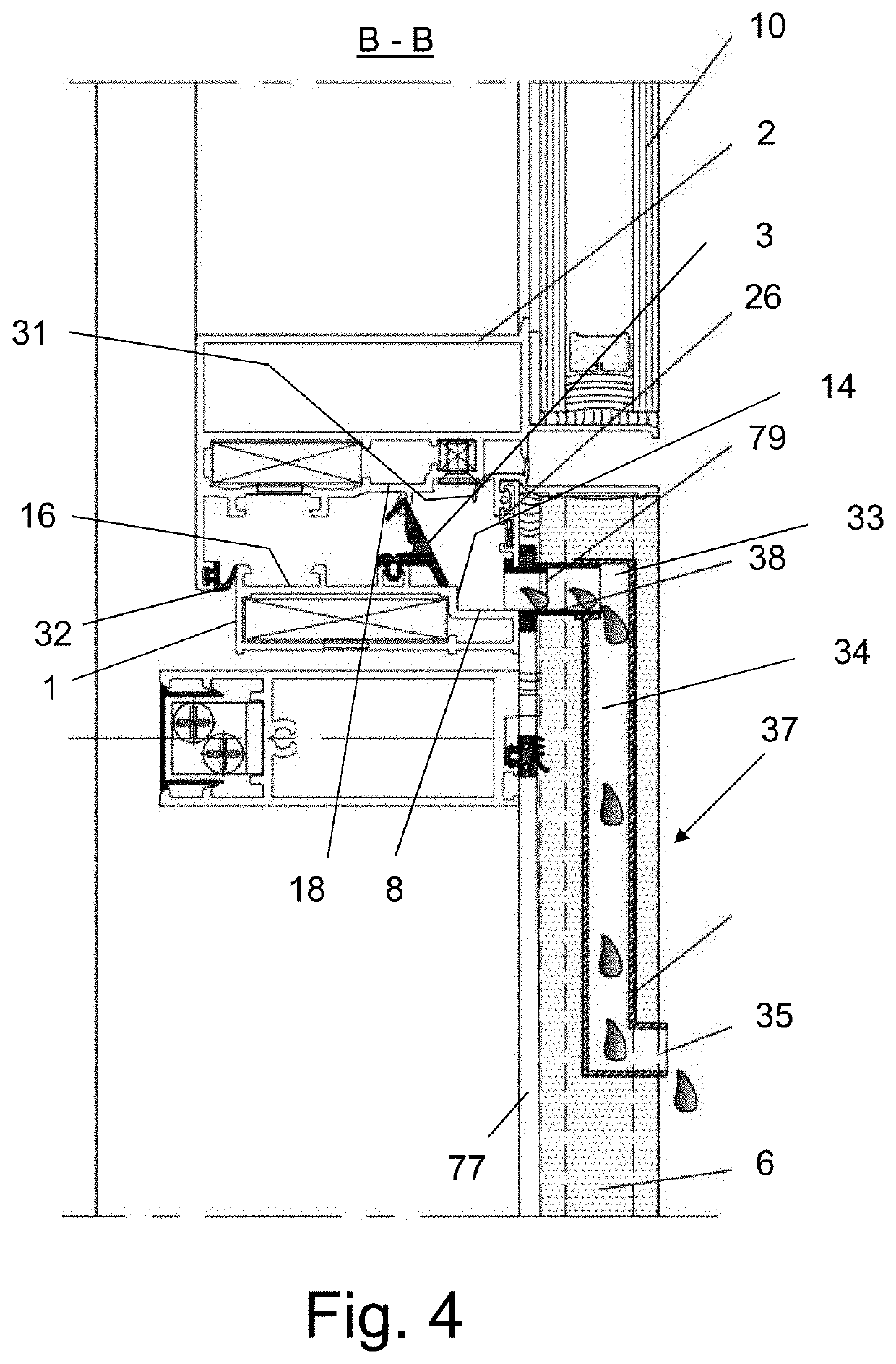

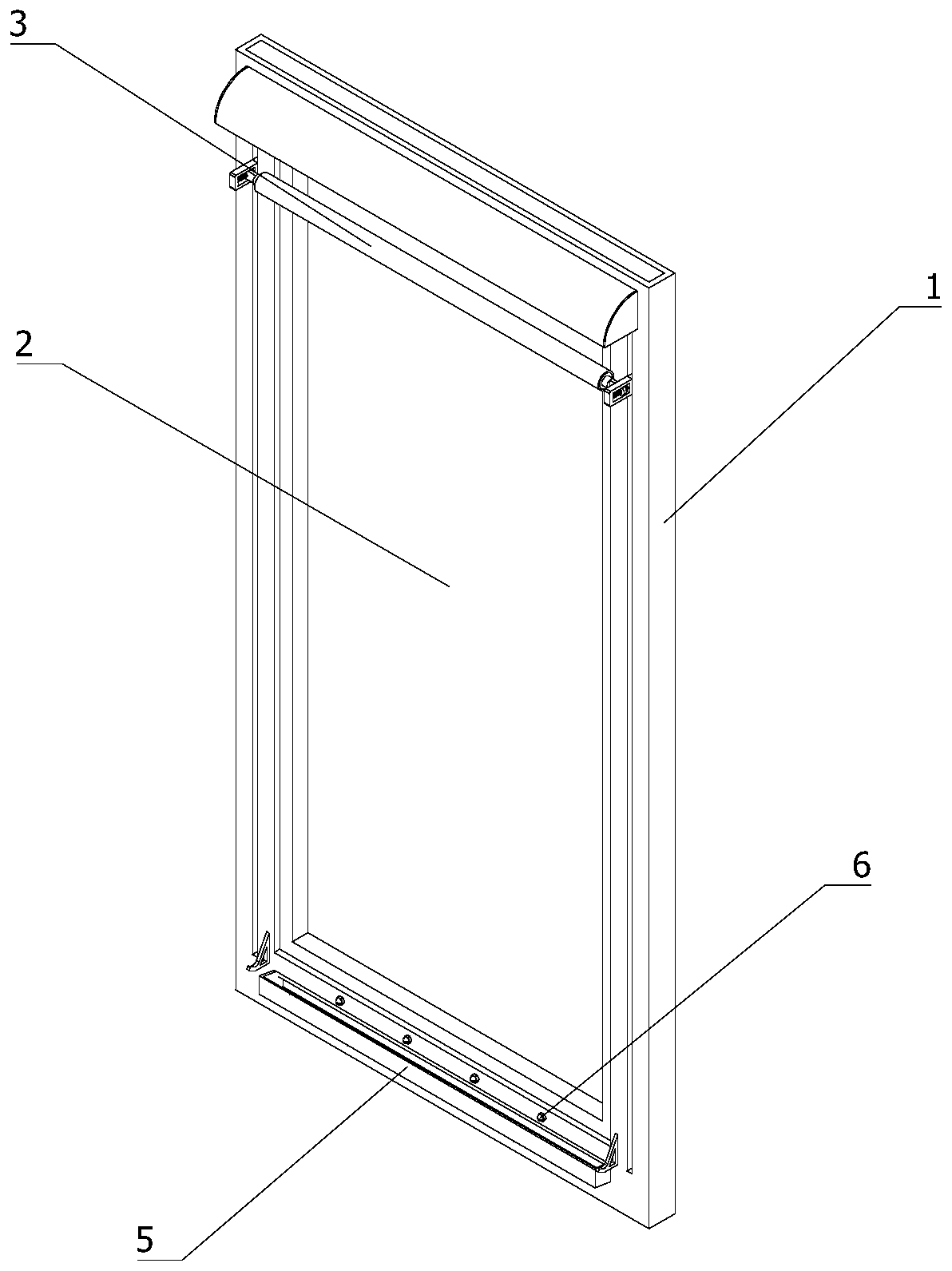

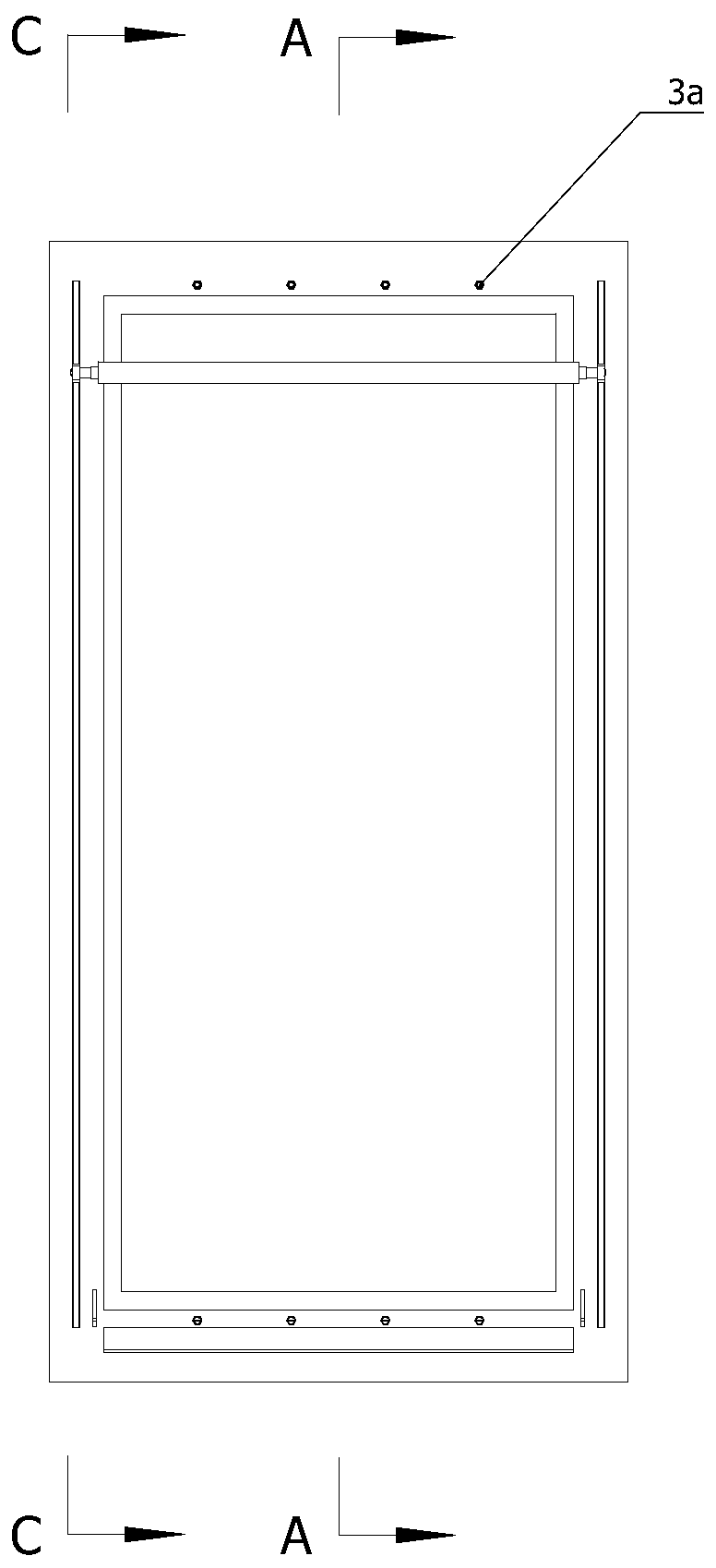

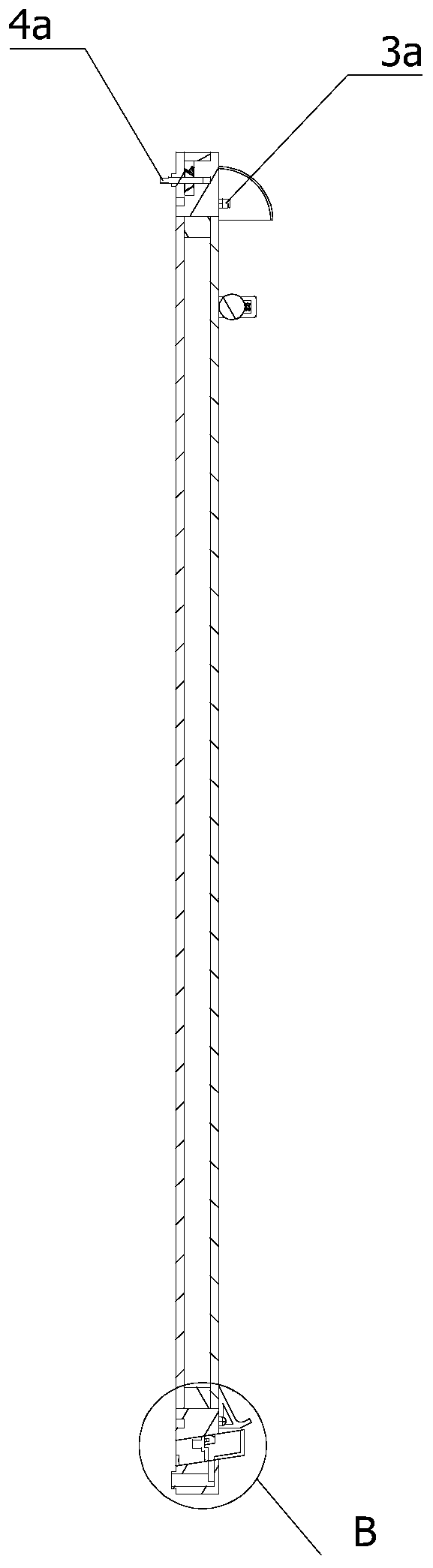

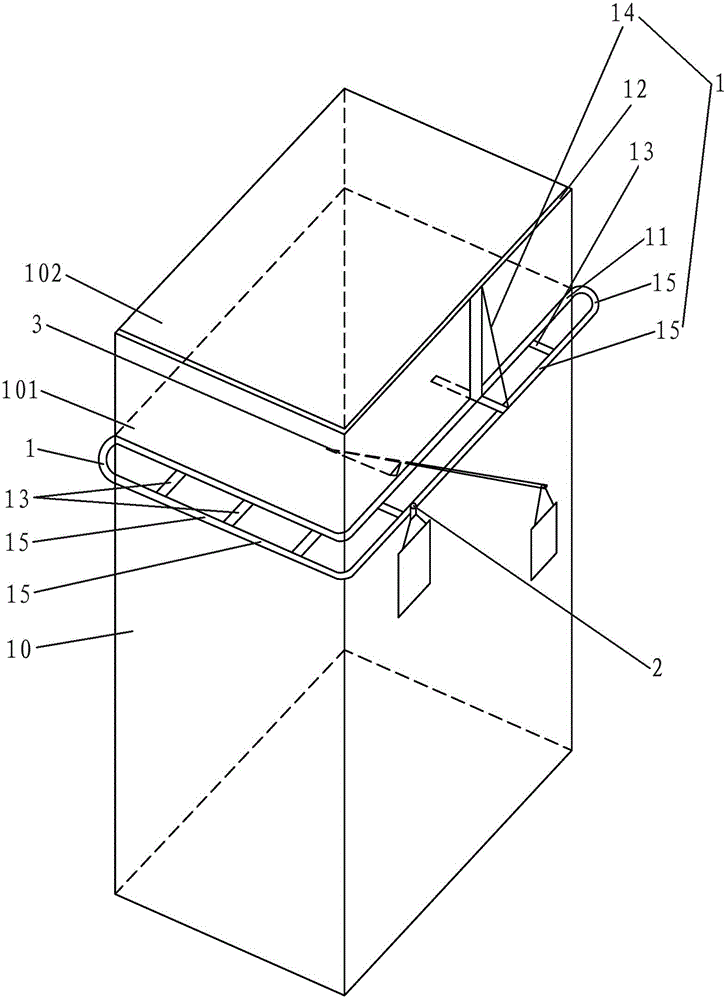

Curtain wall drain opening apparatus

Curtain wall based drain opening apparatus comprises a drainage element extending outwardly from, and in fluid communication with, a concealed horizontal water flow channel associated with a stationary first frame element of an inwardly pivotable window assembly and adapted to receive infiltrated water, wherein the drainage element passes through a second frame element which is laterally spaced from two adjacent fixed panels of a curtain wall and is exposed to atmospheric air.

Owner:EXTAL LTD

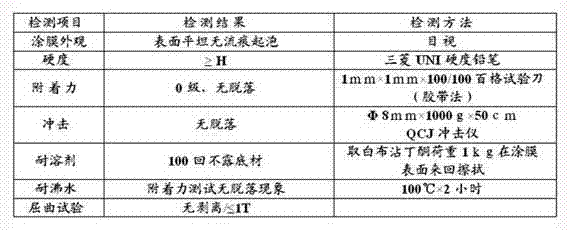

Construction curtain wall ceramic

The invention discloses a nanometer ceramic building curtain wall paint which comprises a nanometer oxide, a coloring pigment, an organosilicon curing agent and an auxiliary agent. The paint is characterized by super weathering resistance, scratch resistance, fireproofness, non-inflammability and self-cleaning, etc. The products of the invention are applicable to the hull painting of an outdoor aluminum curtain wall, and an aluminum veneer and an aluminum honeycomb panel which are used for indoor decoration.

Owner:上海金力泰化工股份有限公司

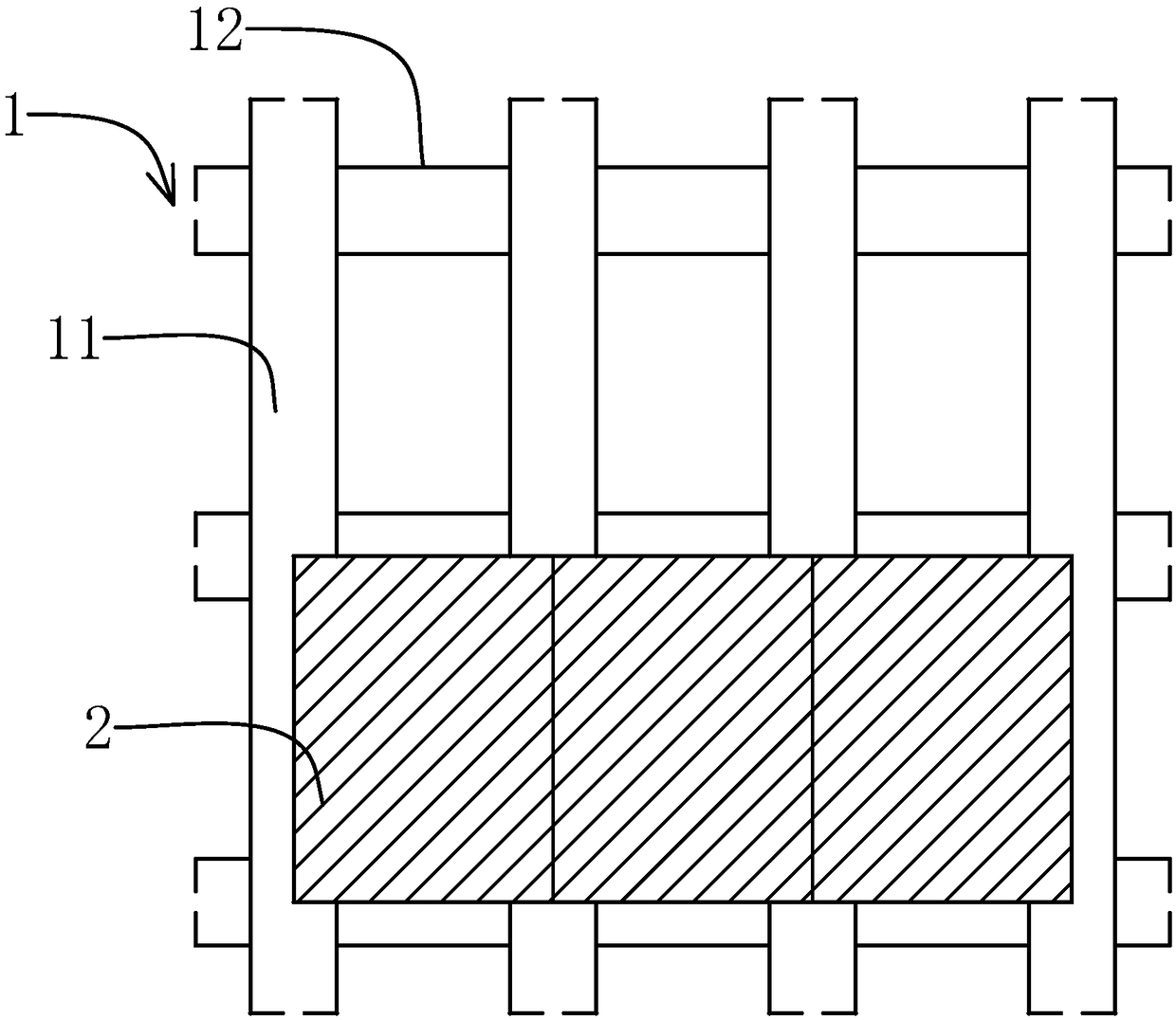

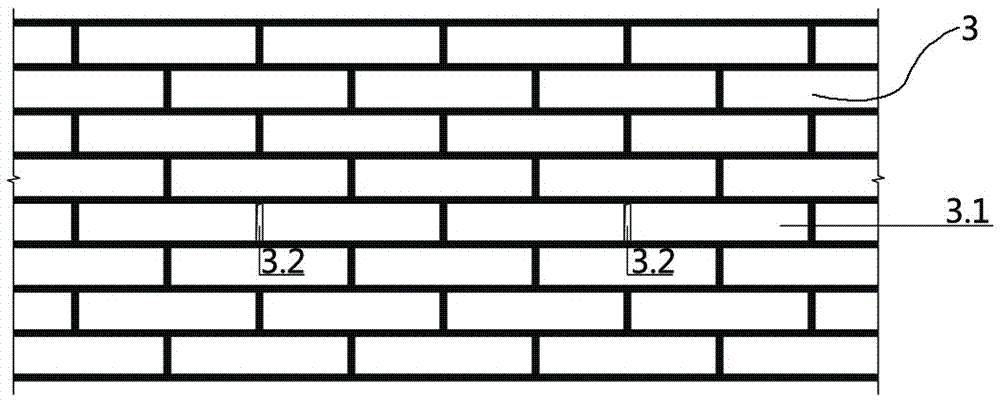

Steel structure keel masonry brick outer curtain wall system and its construction method

ActiveCN107227813ASolve the height-thickness ratioAddressing Structural StabilityWallsBrickBuilding energy

The invention provides a steel structure keel masonry brick outer curtain wall system and its construction method, wherein a curtain wall keel of the curtain wall system comprises a cross supporting angle steel arranged in a full length, and main and secondary keels; the curtain wall is a ganged brick curtain wall, and the part of the wall of which bottom part is located beneath the bottommost cross supporting angle steel is built above a main structure plate or a main structure bracket; the rest part is paved on the cross supporting angle steel; position closing to the bottom part of the curtain wall is provided with an apron flashing board with high inside and low outside; horizontal binding reinforcement meshes are staggered in the curtain wall at intervals; an air interlayer forms between the curtain wall and the main structure outer wall; part of the bottom part of the air interlayer beneath the apron flashing board is grouted by cement mortar. The masonry brick is combined with the curtain wall keel system, thus the ratio of height to thickness and the structure stability are effectively solved; the air interlayer plays the heat insulation and ventilation effects, thus the purpose of building energy-saving is saved; multiple waterproof structures are arranged so that the saltpetering of the ganged brick curtain wall and the water seepage of the main structure outer wall are reduced.

Owner:BEIJING LIUJIAN CONSTR GRP

Technology for painting synthetic resin pseudocurtain series dope on construction surface

ActiveCN1603010ASolve the decorative effectSimple construction processPretreated surfacesSpecial surfacesSurface spreadingWood grain

The invention involves a kind of synthetic resin imitate curtain wall series coating construction craft in building surface.Its characteristic lies in: It is constituted by the following steps, (1) the basic plane processing, (2) shop hangs the glass fiber net, (3) the separate form seam cuts, (4) seeps the special-purpose putty construction, (5) the separate form seam packing, (6)the patches special-purpose putty construction, (7)the polishes special-purpose putty the construction, (8)the Es high attachment strength primer (epoxy anti- alkali primer or other volume primer) construction, (9) spurts spreads spreads, (10) spurts spreads surface spread, (11) separate form seam cuts traces spreads.The invention merit is it may used in the construction craft to construct the superficial painting, achieves the similar installment effect with the stone material, the mirror surface, aluminum sheet and wood grain and so on curtain wall installment effect.

Owner:上海展辰涂料有限公司 +1

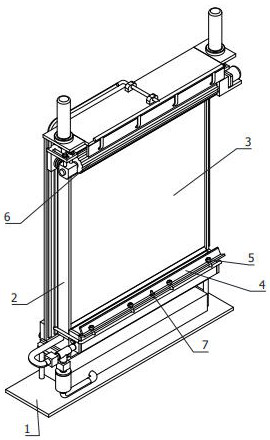

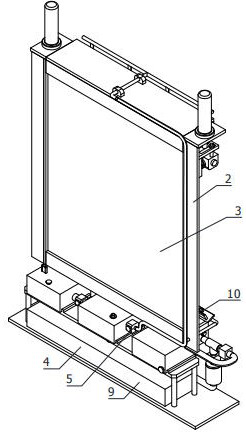

Building outer curtain wall mechanism with self-cleaning device

InactiveCN112022019ARealize self-cleaning functionRealize collection and utilizationCarpet cleanersFloor cleanersWater storage tankWater resources

The invention relates to the technical field of glass curtain wall self-cleaning, in particular to a building outer curtain wall mechanism with a self-cleaning device, which comprises a base, a glassbracket, a glass curtain wall, a water collection assembly, a water spraying assembly, a cleaning assembly and a detection assembly, and is characterized in that the water collection assembly comprises a liquid collection tank, a clear water storage tank and a water purification mechanism; the water spraying assembly comprises a water spraying head capable of spraying water to the outer surface ofthe glass curtain wall, the cleaning assembly comprises a lifting mechanism, a rotary driving mechanism, an attaching mechanism and a cleaning cylinder capable of cleaning the outer surface of the glass curtain wall, and the detection assembly comprises a camera. According to the building outer curtain wall mechanism with the self-cleaning device, glass stains can be automatically detected, the curtain wall can be automatically cleaned, the self-cleaning function is achieved, rainwater and washing water can be collected and utilized, purified water is used for self-cleaning operation of the curtain wall, sewage is collected, the utilization rate of water resources is increased, and the lighting effect of the glass curtain wall is improved.

Owner:汤炬

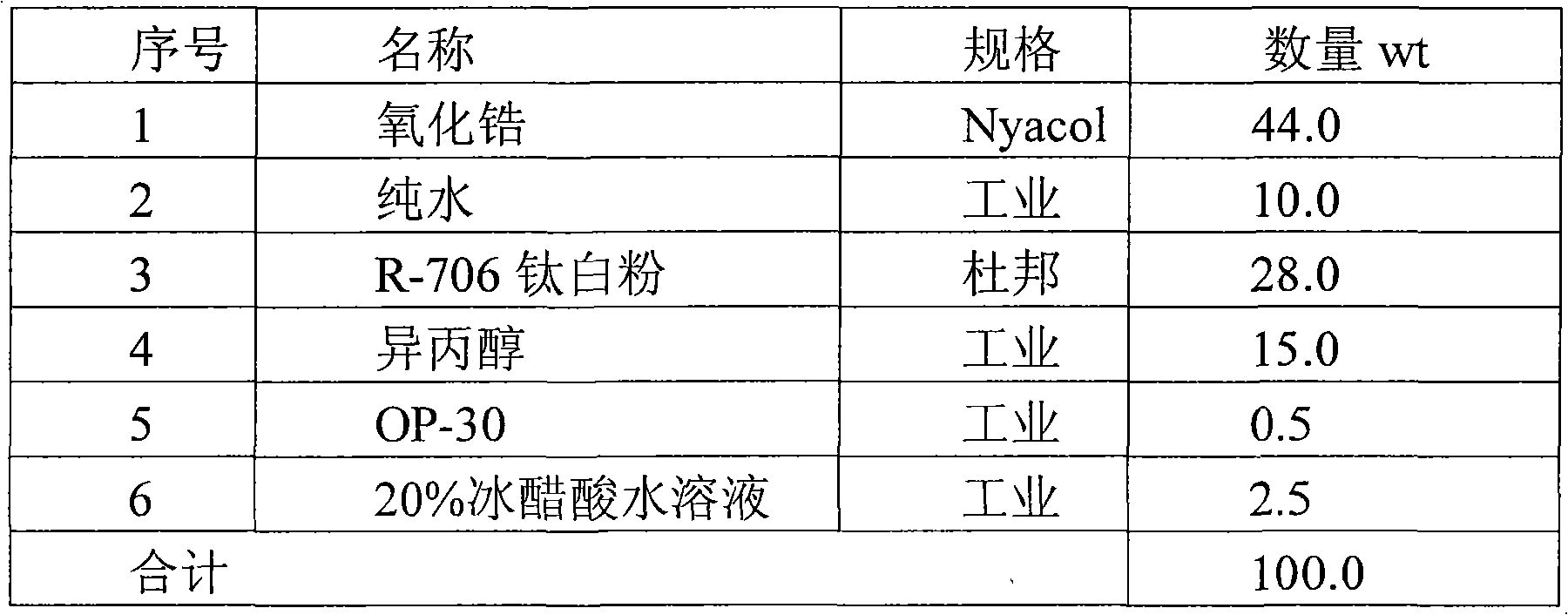

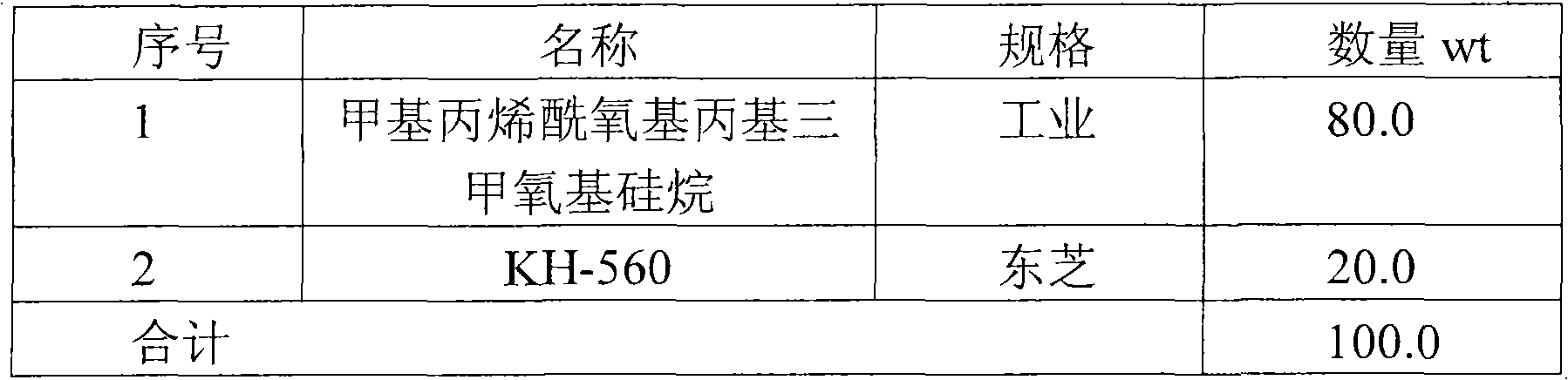

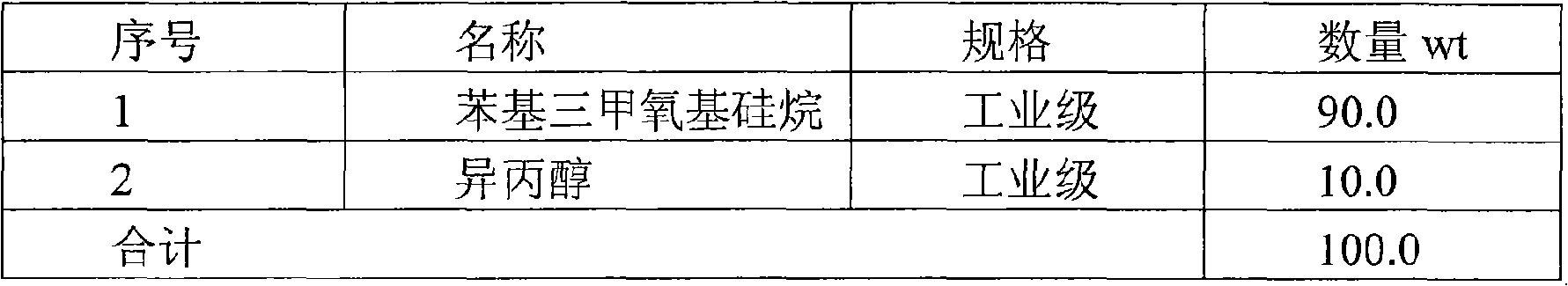

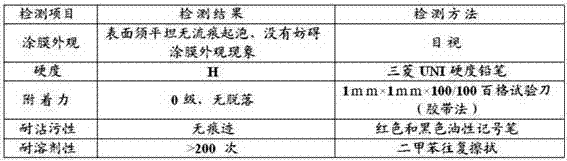

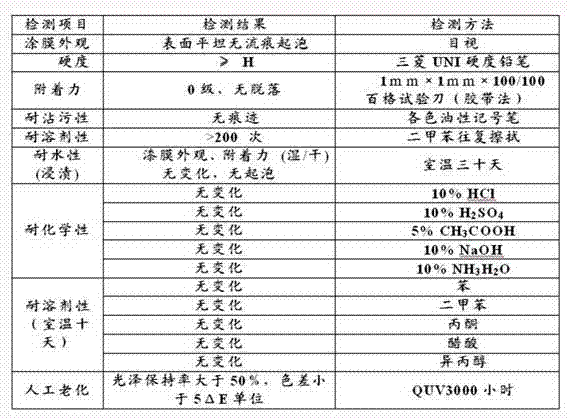

Self-cleaning coating used for building curtain wall aluminum veneer and preparation method thereof

ActiveCN102391736AImprove the protective effectReduce construction costsWallsAnti-corrosive paintsVinyl etherFluorocarbon Resins

The invention relates to self-cleaning coating used for a building curtain wall aluminum veneer and a preparation method thereof. The coating is divided into a first component, a second component and a third component, wherein the first component is coated on the surface of the aluminum veneer for forming a bottom coating; the second component is coated on the surface of the bottom coating to form a middle coating; the third component is coated on the surface of the middle coating to form a top coating; in the first component, polyester resin and amino resin serve as film forming substance, and silicon-titanium or silicon-zirconium coupling agent is used for greatly improving adhesive force on the aluminum veneer by the bottom coating; in the second component, fluoralkene alkyl vinyl ether or ester copolymer (FEVE) fluorocarbon resin serves as the film forming substance, and therefore the coating shows excellent durability, weather fastness and corrosion resistance; and in the third component, the FEVE fluorocarbon resin and organic silicon resin serve as the film forming substance, the coating surface tension is lowered by a fluorine and silicone interpenetrating network, the hydrophobicity and the contamination resistance of the coating surface are improved, and dirt on the coating surface is easy to clean. In addition, the preparation and construction processes of a coatingsystem disclosed by the invention are simple, and the self-cleaning coating is especially suitable for protecting an aluminum sheet curtain wall.

Owner:苏州金近幕墙有限公司

High-rise building glass curtain wall easy to clean

ActiveCN110905109APrevent disengagementFit closelyWallsBuilding repairsArchitectural glassArchitectural engineering

The invention relates to the technical field of building decoration, in particular to a high-rise building glass curtain wall easy to clean. The glass curtain wall comprises a glass frame, a glass plate, a cleaning mechanism, a driving mechanism, a dirty water collecting box and a self-cleaning mechanism, wherein the glass plate and the driving mechanism are arranged on the glass frame, the cleaning mechanism is arranged on the driving mechanism, the working end of the cleaning mechanism abuts against the glass plate, the dirty water collecting box and the self-cleaning mechanism are arrangedat the bottom end of the glass frame, and the self-cleaning mechanism is positioned above the dirty water collecting box. According to the glass curtain wall, the exterior of the curtain wall can be cleaned in the building by a worker without suspending the worker, the cleaning mechanism can be cleaned in the building by the worker, the next cleaning effect is not hindered, the operation is simple, and the cleaning effect is good.

Owner:广东大鹏幕墙科技有限公司

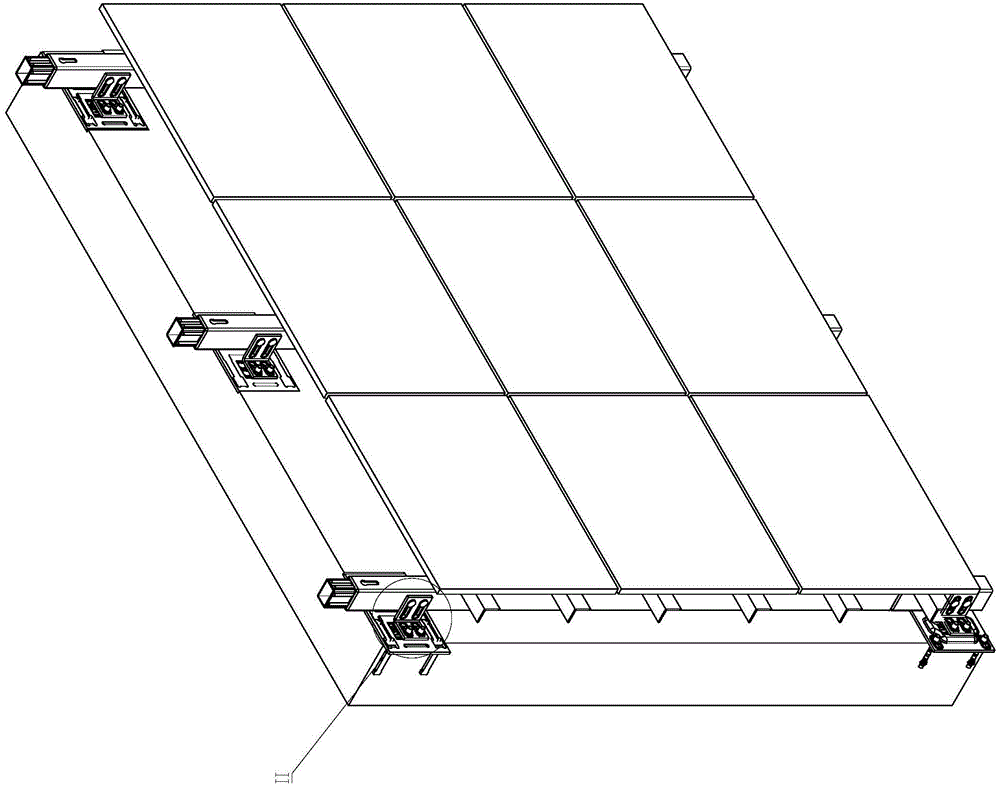

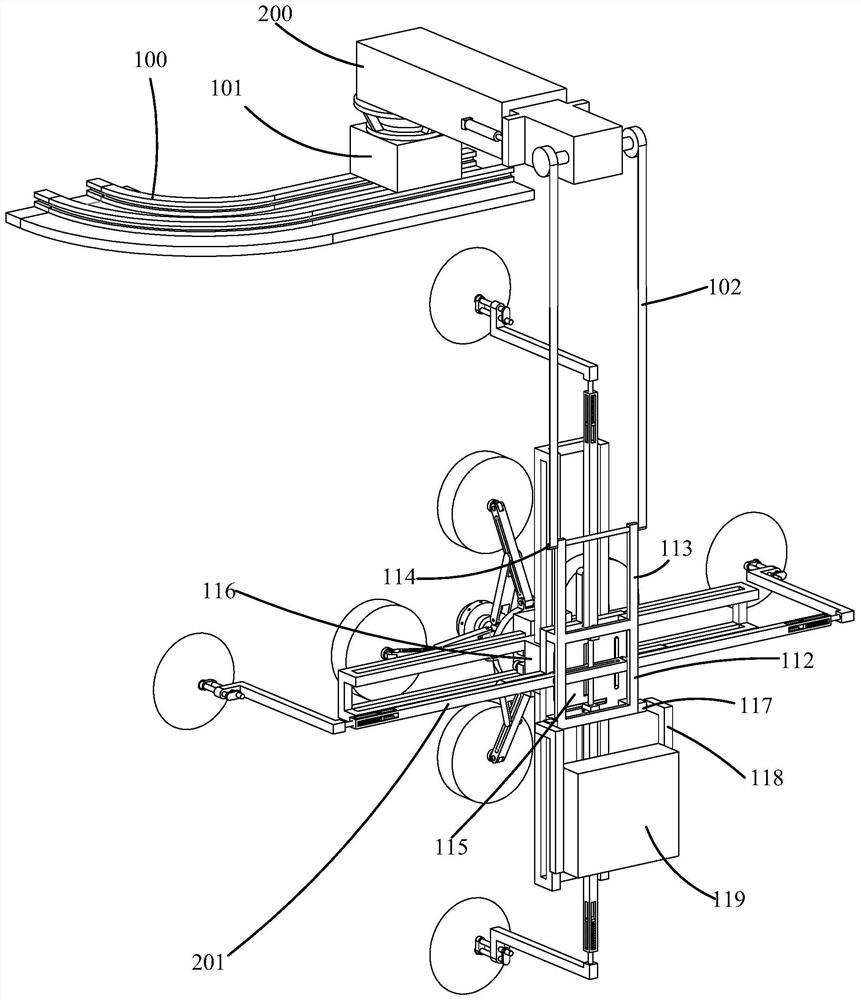

Unit type curtain wall installation system and installation method thereof

InactiveCN104358336ASimple structureStable structureWallsBuilding material handlingFalseworkTower crane

The invention discloses a unit type curtain wall installation system and an installation method thereof. The system comprises an annular track, an electric hoist and a lifting device, wherein the annular track is arranged in a way of surrounding the external circumference of the external frame of a building, and is within the same plane; the upper end of the electric hoist is in sliding connection onto the annular track, and can move along the annular track; the lifting device is installed on one side of the annular track; moreover, the moving path of the lifting end of the lifting device is overlapped with the moving path of the lifting end of the electric hoist. As the system is mainly composed of the annular track, the electric hoist, the lifting device and the like, the structure is quite simple and reliable; for perpendicular transportation, lifting equipment such as a tower crane, a forklift or a cantilever crane is adopted; horizontal transportation is realized through the electric hoist in sliding connection onto the annular track; the time occupied by the lifting equipment is furthest reduced, a curtain wall can be constructed without external scaffolds, so that the measure cost is lowered; meanwhile, with the curtain wall engineering and the main body structure engineering above the track working face constructed at the same time, the schedule is shortened greatly.

Owner:FUJIAN JIULONG CONSTR GRP CO LTD

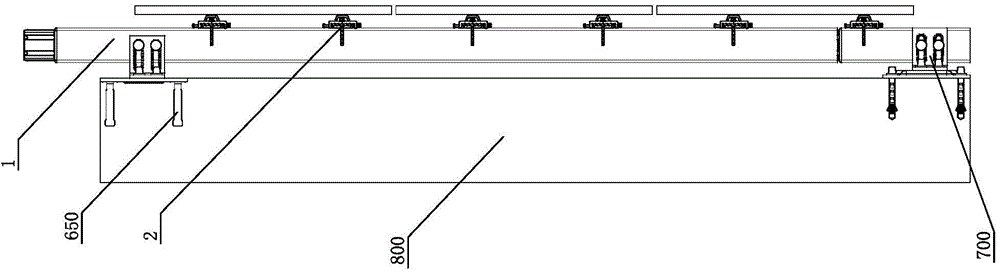

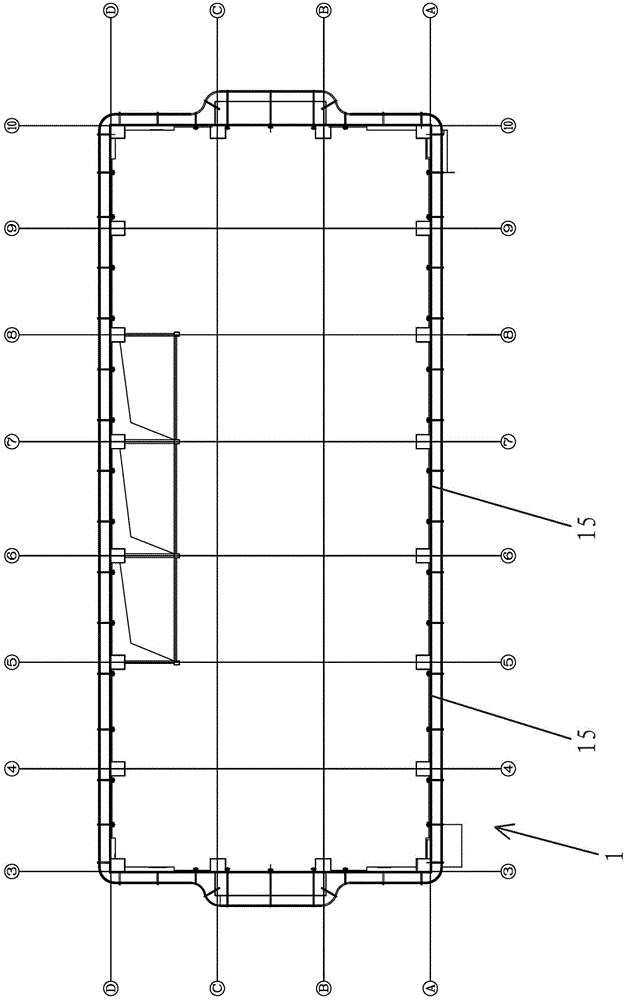

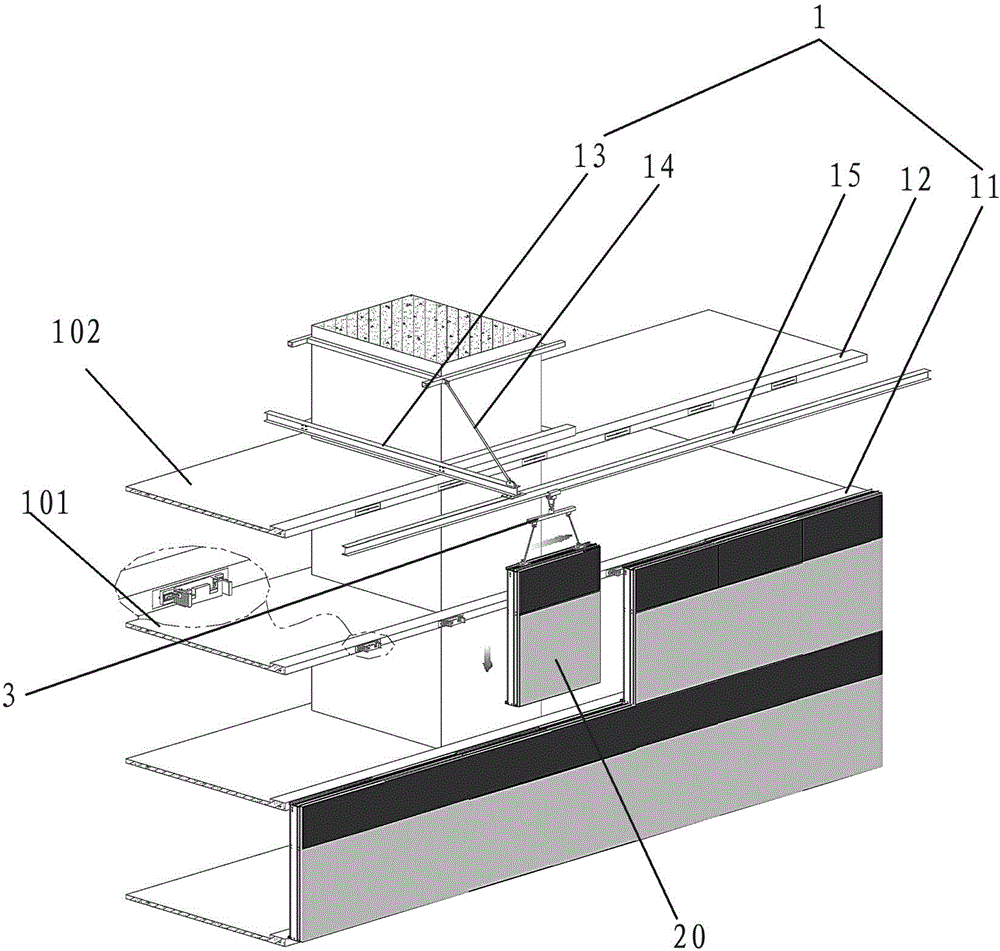

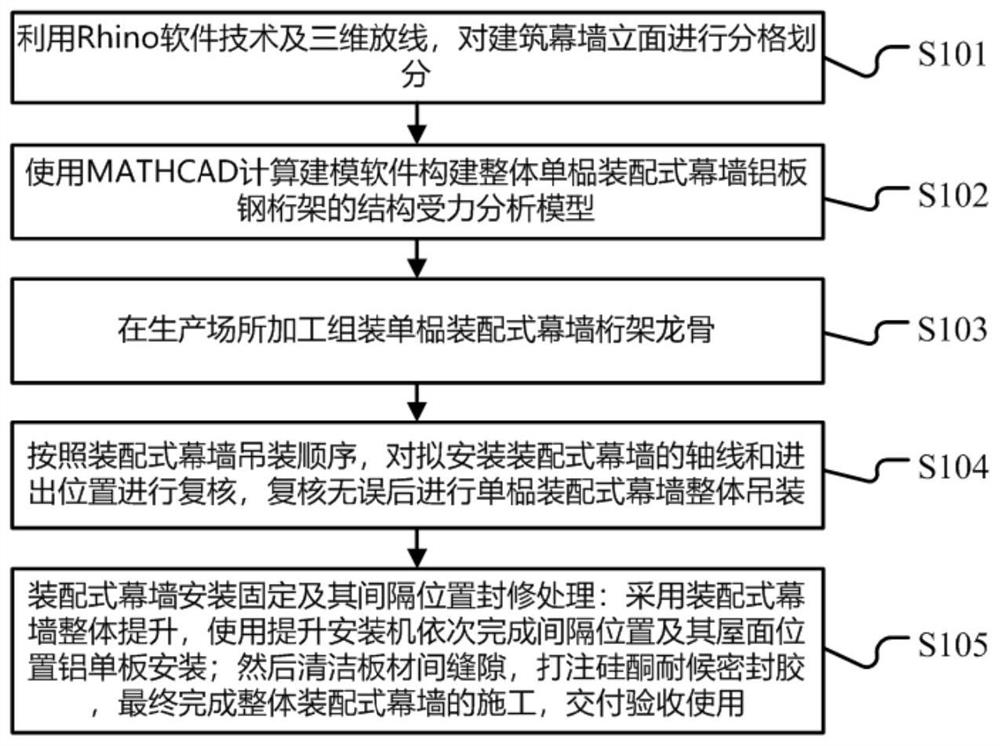

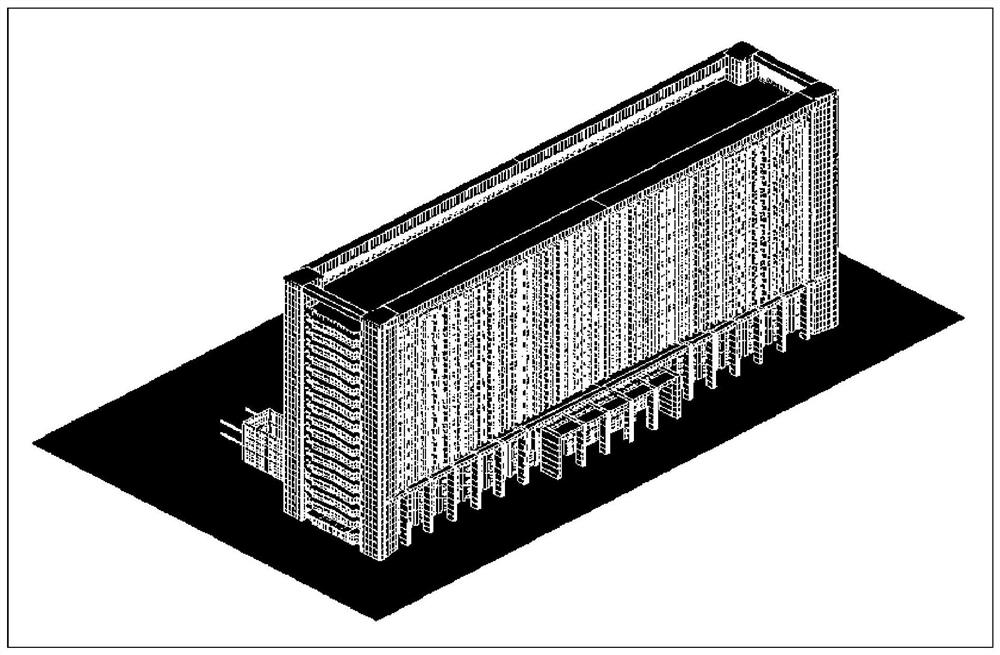

Fabricated curtain wall overall lifting installation construction method based on BIM model construction technical support

PendingCN112347677ARealize the purpose of constructionGuaranteed effectGeometric CADDesign optimisation/simulationModeling softwareArchitectural engineering

The invention provides a fabricated curtain wall overall lifting installation construction method based on BIM model construction technical support. The method comprises the steps: carrying out the grid division of a vertical surface of a building curtain wall through the Rhino software technology and three-dimensional setting-out; using MATHCAD calculation modeling software for constructing a structural stress analysis model of a whole single-truss assembled curtain wall aluminum plate steel truss; processing and assembling a single assembled curtain wall truss keel in a production place; re-checking the position where the assembled curtain wall is to be installed, and integrally hoisting the single assembled curtain wall after the re-checking is errorless; integrally lifting and mountingthe assembled curtain wall; and then cleaning gaps between the plates, injecting silicone weather-proof sealant, and finally completing construction of the integrally-assembled curtain wall, and delivering the integrally-assembled curtain wall to be checked and accepted. The construction method is mainly suitable for building curtain wall places with ultra-high, ultra-difficult, large span and short construction period.

Owner:中铁十四局集团建筑工程有限公司

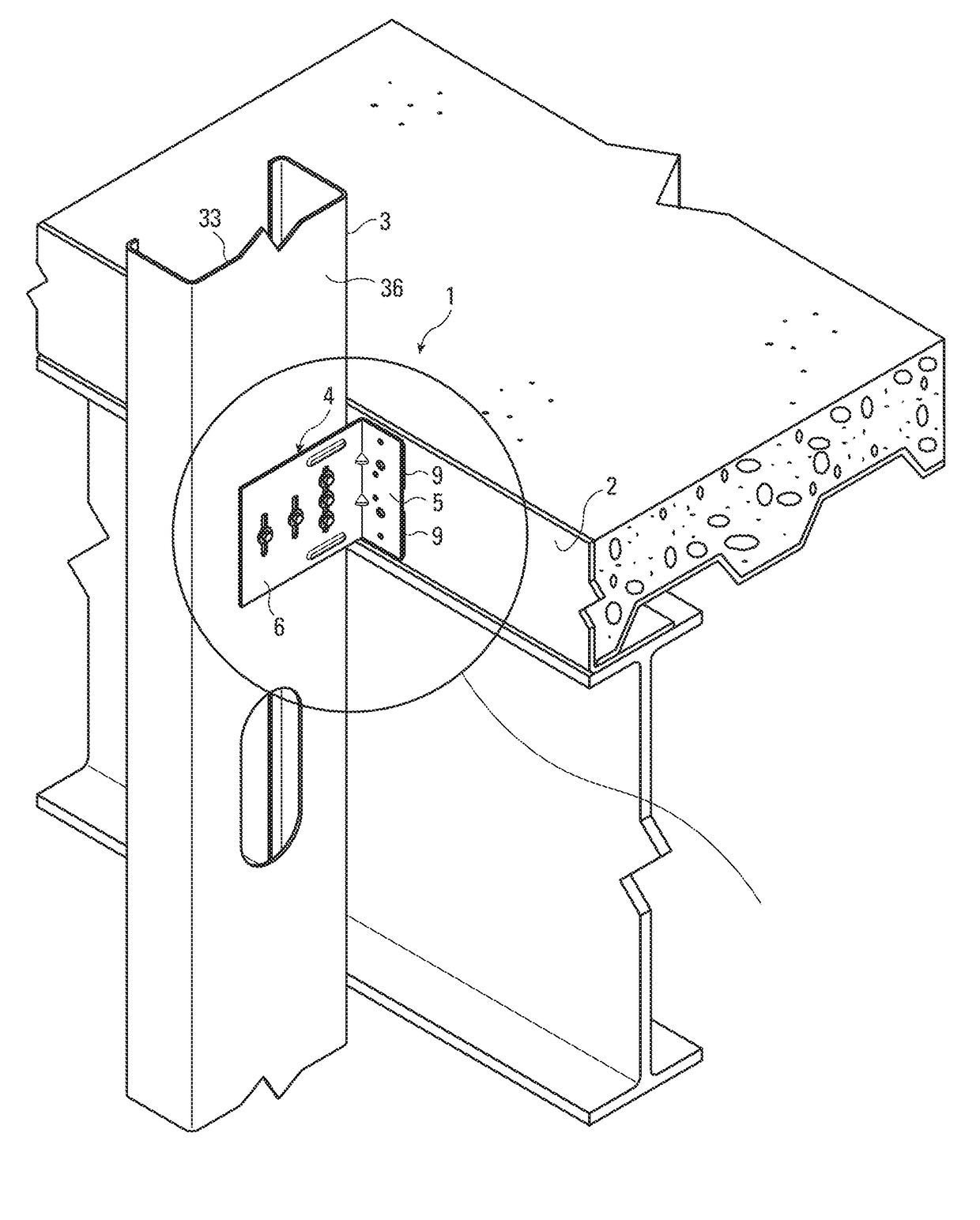

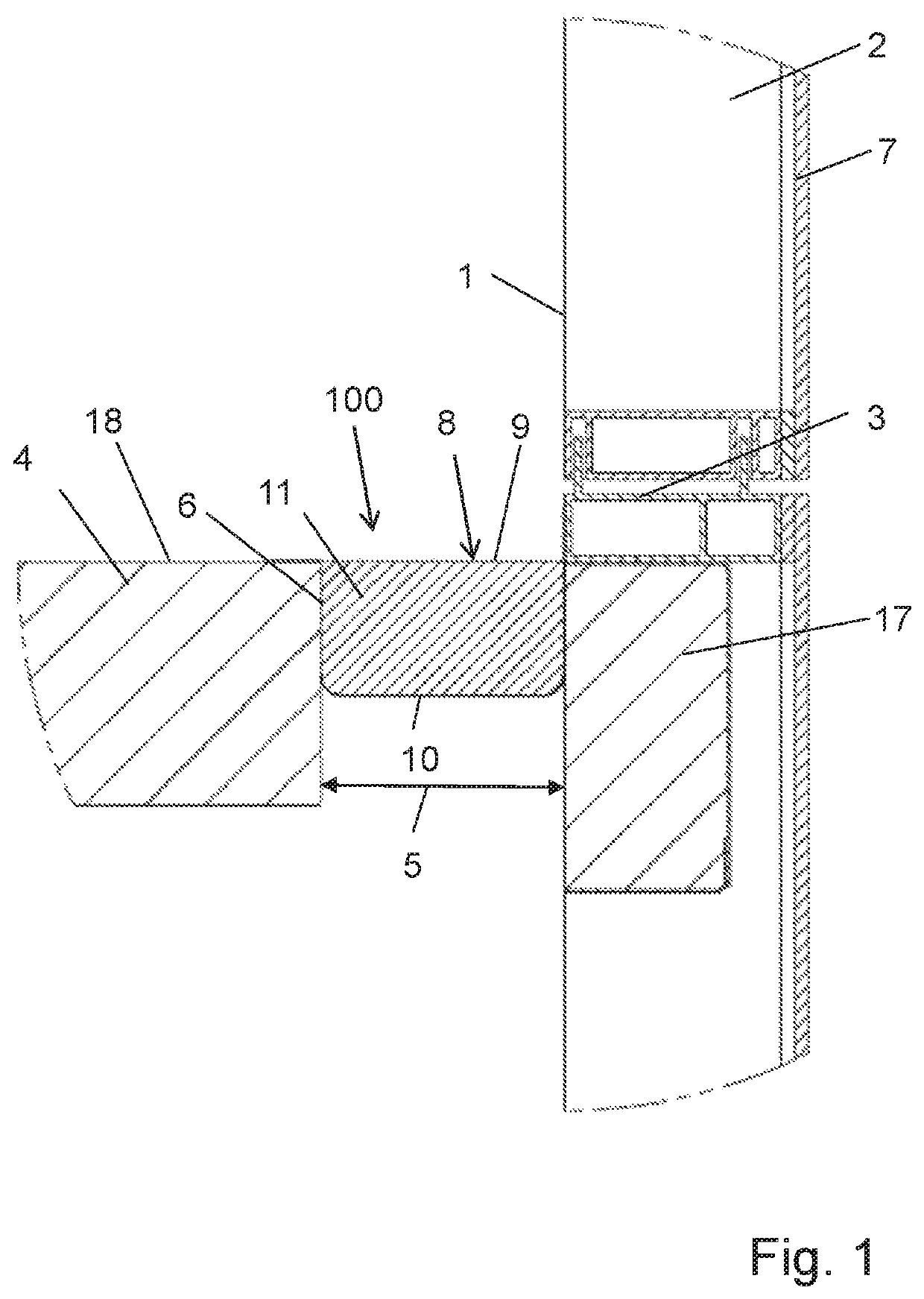

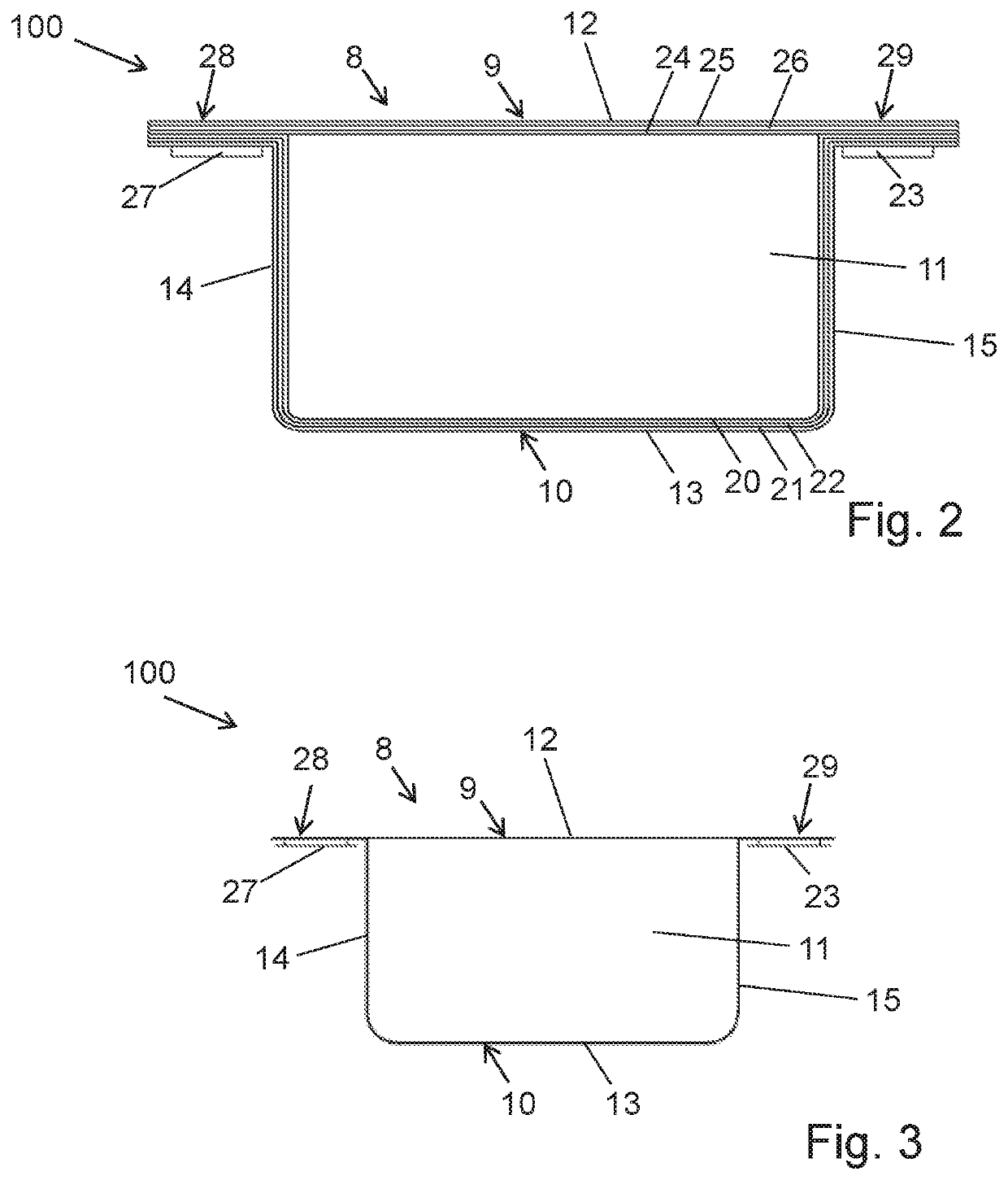

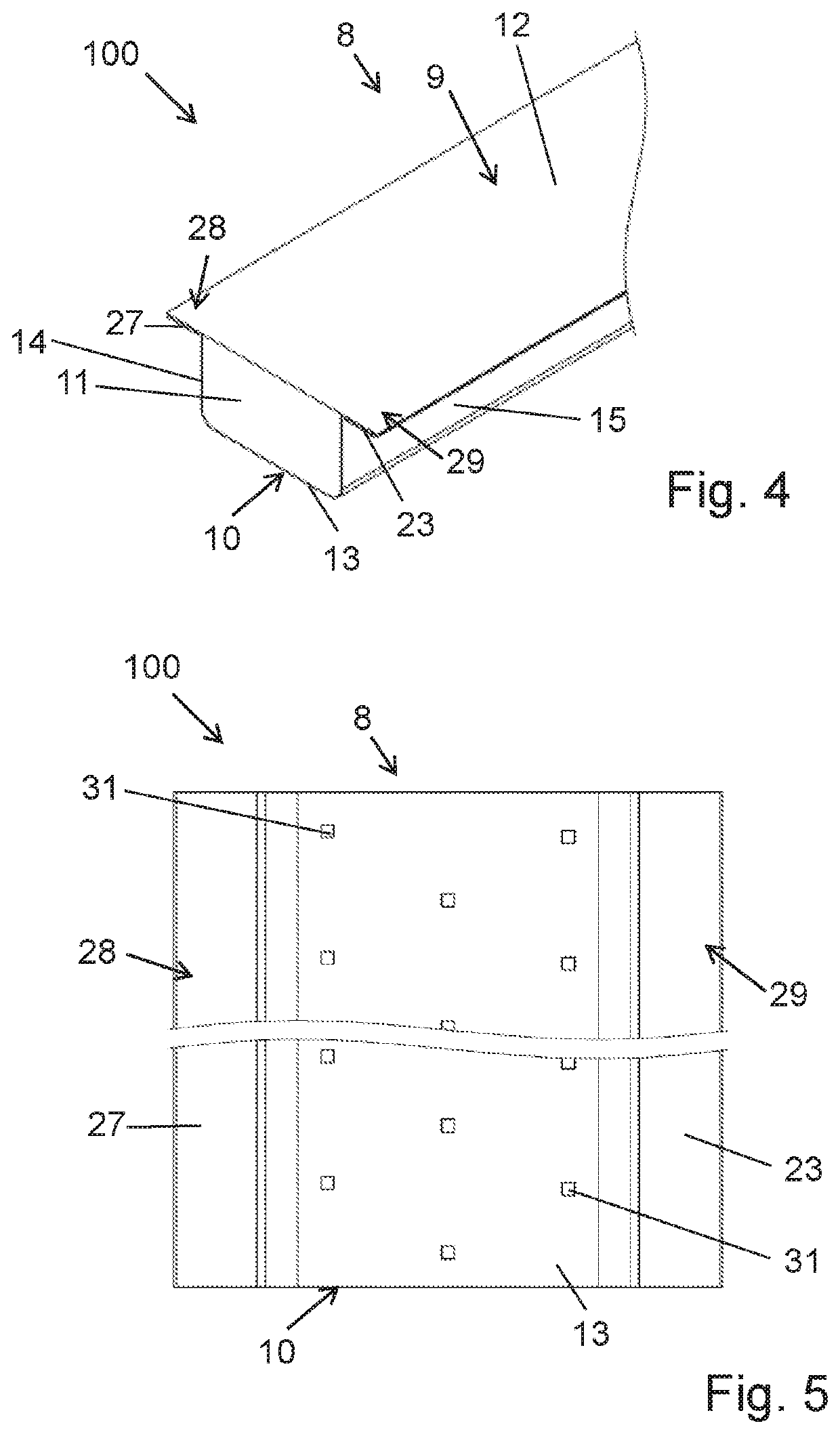

Dynamic, fire-resistance-rated thermally insulating and sealing system having a F-rating of a min. of 120 min for use with curtain wall structures

ActiveUS10731338B1Effectively thermally insulatingImprove sealingCeilingsWallsArchitectural engineeringExternal cladding

An approved dynamic construction is useful for effectively thermally insulating and sealing of a safing slot between a floor of a building and an exterior wall construction wherein the exterior wall construction comprises a curtain wall configuration defined by an interior wall surface. The dynamic, thermally insulating and sealing system contains a tubular sealing element having wing-like connection areas for attaching the tubular sealing element to the curtain wall construction and the floor of a building, to maintain thermally insulating and sealing of the safing slot during exposure to fire and heat as well as movement in order to maintain a complete seal extending across the safing slot and to enhance the water-stopping properties of the insulation and seal within the safing slot.

Owner:HILTI AG

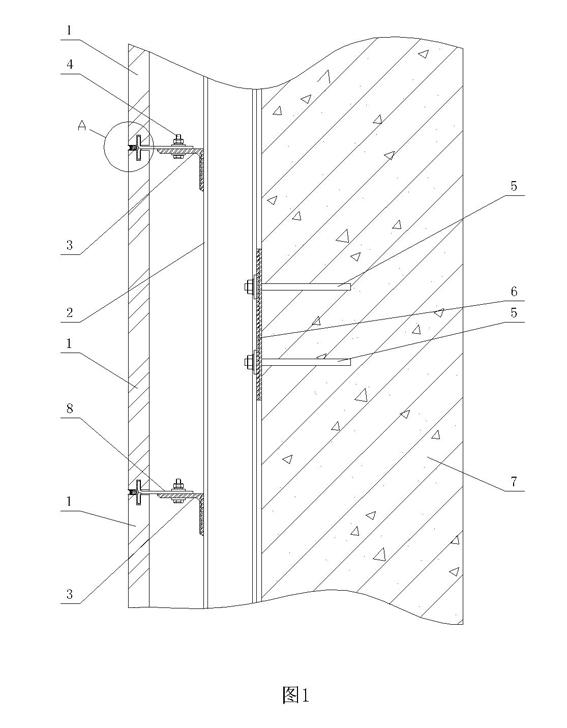

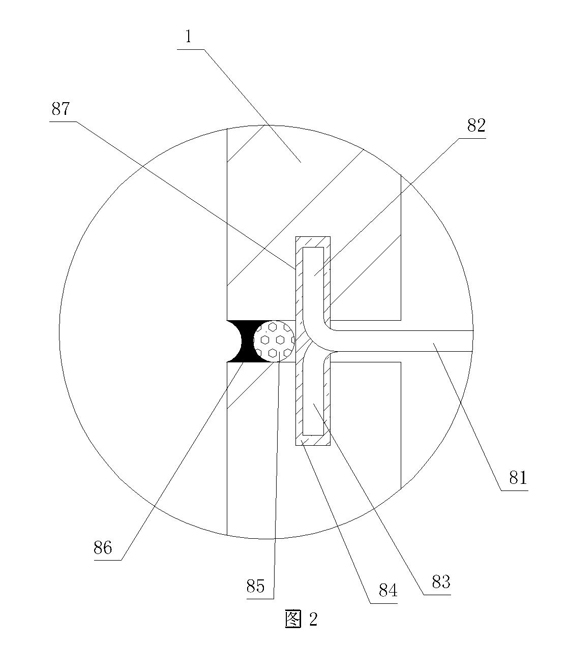

Hidden frame type glass curtain wall

The invention discloses a hidden frame type glass curtain wall. The hidden frame type glass curtain wall comprises a keel, a pressure plate, a glass plate, an aluminum auxiliary frame and a fastening bolt. The glass plate is in glue joint with the outer side of the aluminum auxiliary frame, the fastening bolt penetrates the pressure plate to be fixedly connected with the keel and to drive the pressure plate to tightly press the aluminum auxiliary frame, and a bearing part is arranged between the keel and the glass plate and used for bearing the aluminum auxiliary frame and directly transferring loads of the glass plate and the aluminum auxiliary frame to the keel. The hidden frame type glass curtain wall has the advantages of simple structure and capability of effectively protecting the fastening bolt from damages.

Owner:HUNAN GOLDWELL NEW MATERIALS TECH CO LTD

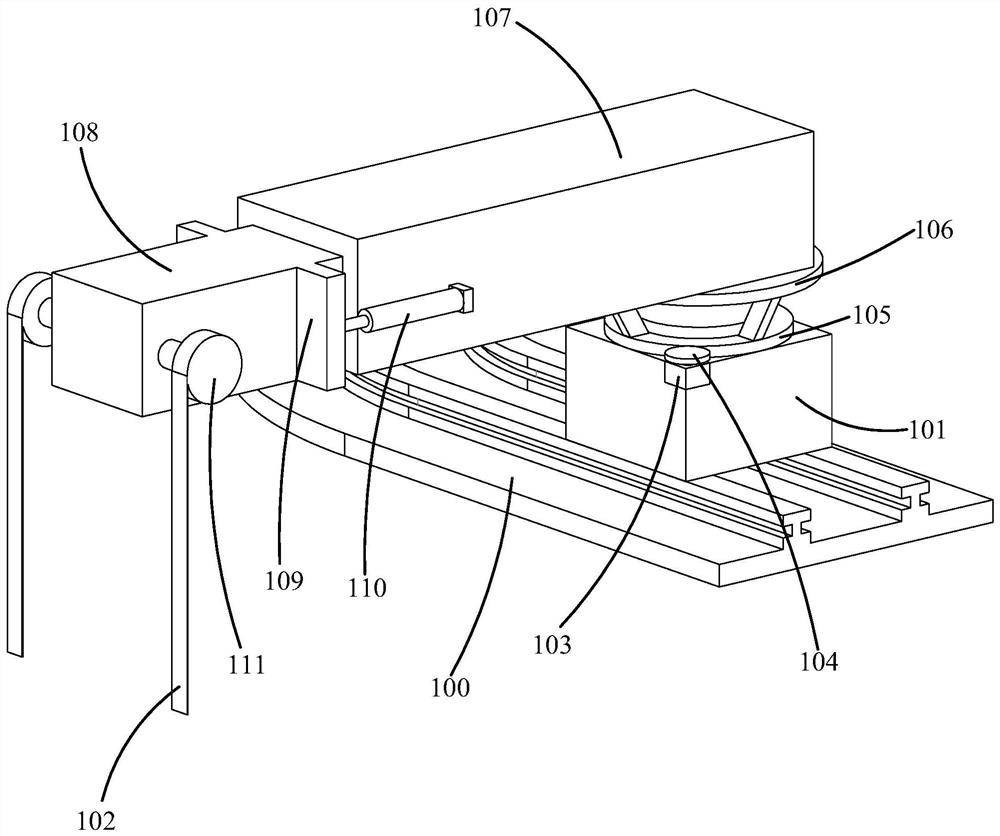

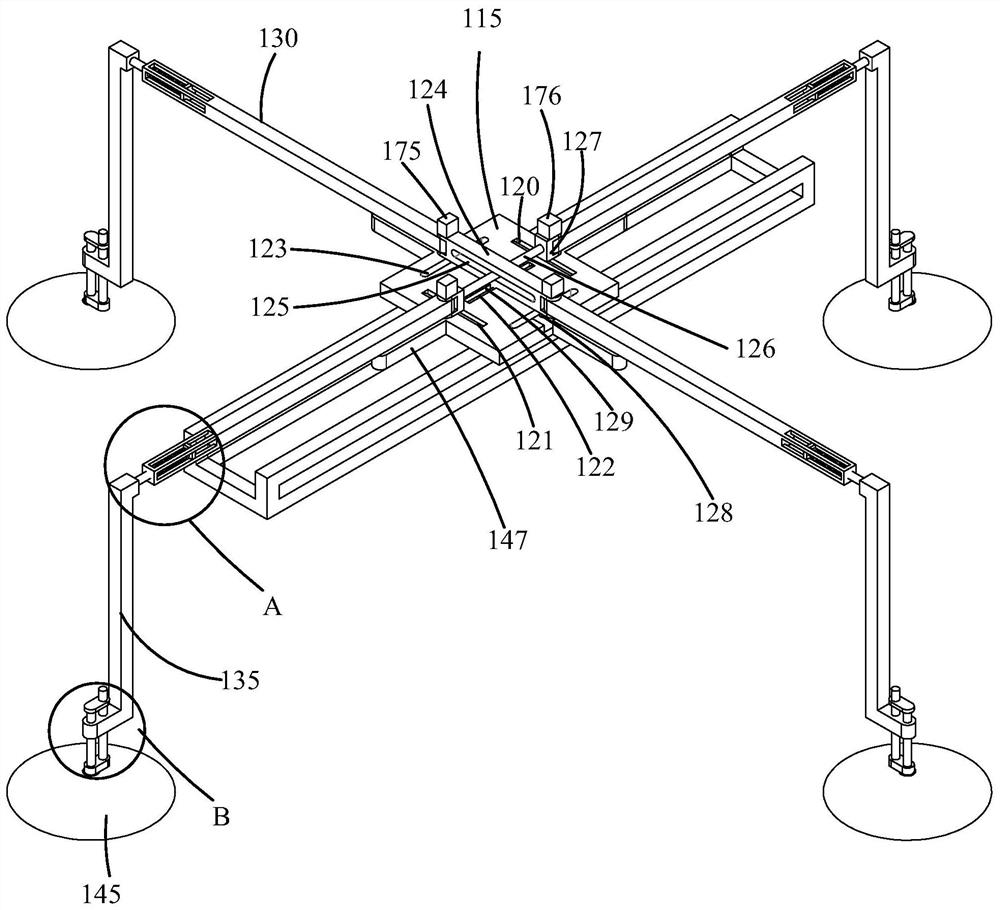

Glass curtain wall cleaning equipment

ActiveCN112120615AImprove securityPrevent fallingCarpet cleanersFloor cleanersEngineeringMechanical engineering

The invention discloses glass curtain wall cleaning equipment which structurally comprises a traction guide rail. The traction guide rail is fixedly arranged on the top layer of a building, a slidingtraction base is arranged on the traction guide rail in a sliding mode, and a traction hoisting assembly used for hoisting the equipment is arranged on the sliding traction base. A wall-climbing cleaning assembly used for cleaning a glass curtain wall is arranged below the traction hoisting assembly, the wall-climbing cleaning assembly is located on the outer side of the glass curtain wall, and the traction hoisting assembly and the wall-climbing cleaning assembly are connected through a traction belt. The glass curtain wall cleaning equipment is used for brushing and cleaning the glass curtain wall, movement in the vertical direction and the horizontal direction can be realized, in match with the hoisting equipment capable of synchronously translating along with the change of the cleaningposition, the safety is enhanced, falling is prevented, the distance between the brush heads and the glass curtain wall can be adjusted, the brush heads can revolve around the axis while rotating, and as agravity center adjusting assembly is arranged, the brush head on the equipment is always vertical to the wall surface of the curtain wall.

Owner:烟台泰特尔机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com