Hidden frame type glass curtain wall

A glass curtain wall and hidden frame technology, applied in the direction of walls, building components, buildings, etc., can solve problems such as failure of fastening bolts, and achieve the effects of simple structure, prolonging service life, and improving stability and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

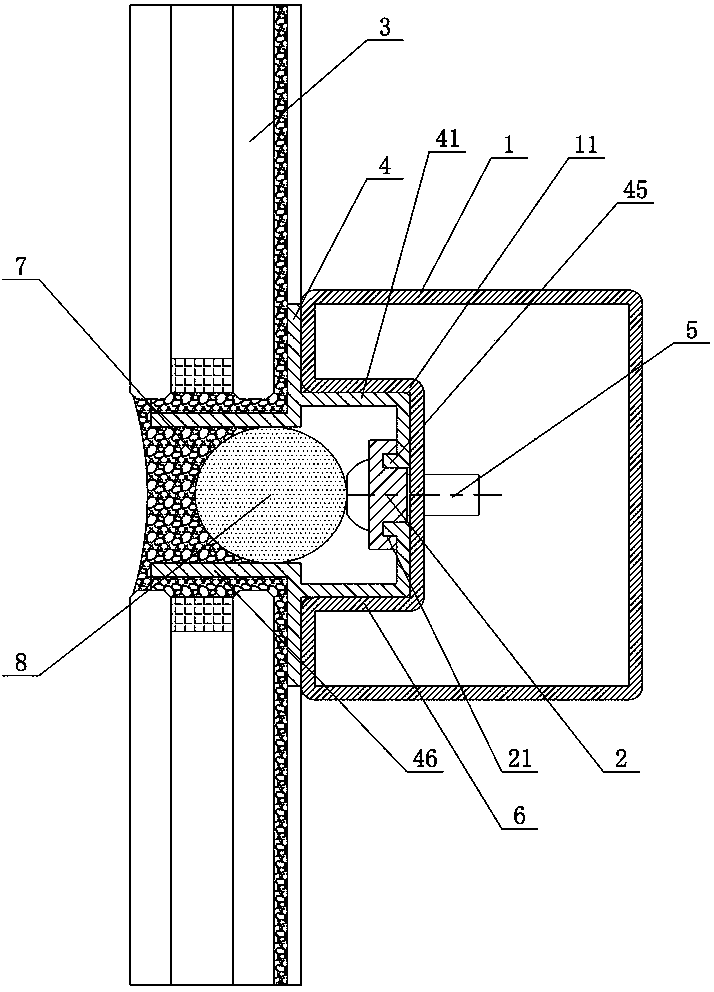

[0028] like figure 1 As shown, the first embodiment of the hidden frame glass curtain wall of the present invention, the glass curtain wall includes a keel 1, a pressure plate 2, a glass plate 3, an aluminum sub-frame 4 and fastening bolts 5, and the glass plate 3 is glued to the aluminum On the outside of the sub-frame 4, the fastening bolts 5 pass through the pressure plate 2 and are fastened to the keel 1, and drive the pressure plate 2 to be pressed against the aluminum sub-frame 4. There is also an aluminum frame between the keel 1 and the glass plate 3. Sub-frame 4, and directly transmit the load of glass plate 3 and aluminum sub-frame 4 to the bearing part 6 of keel 1, the end of glass plate 3 is filled with structural glue 7 and foam 8, and the keel 1, pressure plate 2, Metal parts such as the aluminum sub-frame 4 hide the back of the glass plate 3, and its structure is simple. In this structure, the supporting part 6 is used to carry the glass plate 3 and the aluminum...

Embodiment 2

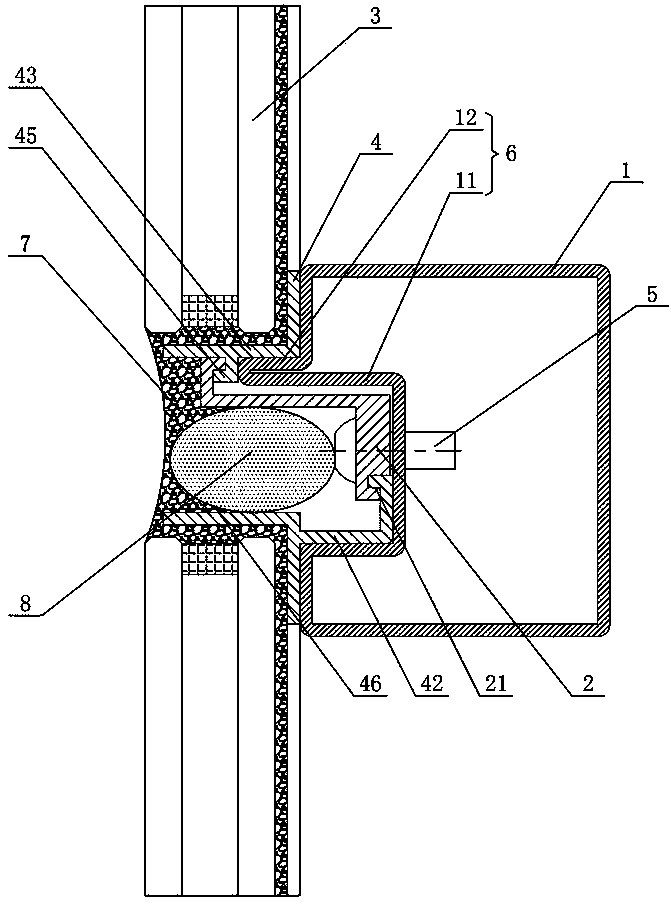

[0034] like figure 2 As shown, the second embodiment of the hidden frame type glass curtain wall of the present invention, the glass curtain wall is basically the same as that of Embodiment 1, the only difference is that the carrier 6 includes a groove 11 arranged on the keel 1 and a groove 11 arranged on the groove 11 The supporting edge 12 on the top, the aluminum sub-frame 4 includes an extended edge 42 carried in the groove 11 and an L-shaped edge 43 carried on the supporting edge 12, and the pressure plate 2 is pressed against the extended edge 42 and the L-shaped edge at the same time. Shaped side 43, the fastening bolt 5 passes through the pressure plate 2 and is firmly connected with the keel 1, and drives the extended side 42 and the L-shaped side 43 to be pressed against the groove 11 and the supporting side 12 respectively. In this structure, when installing, The aluminum sub-frame 4 can be glued to the glass plate 3 first, and then the extended side 42 of the alum...

Embodiment 3

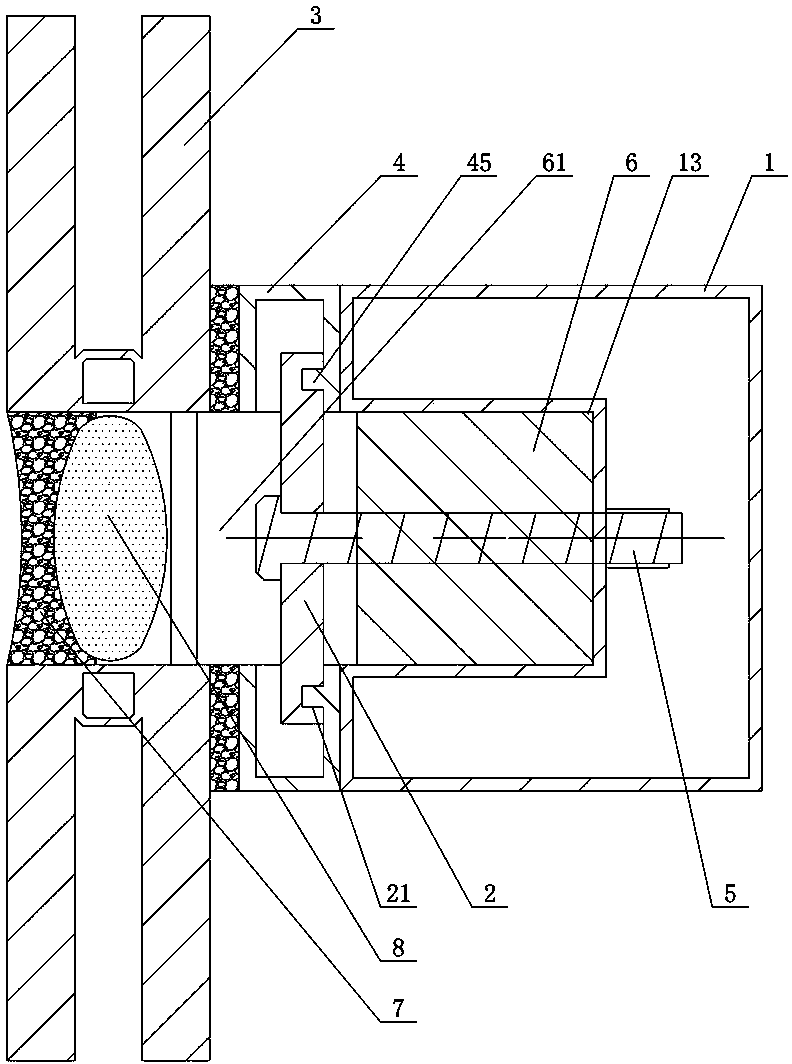

[0036] Figure 3 to Figure 5 Shows the third embodiment of the hidden frame glass curtain wall of the present invention, the glass curtain wall is basically the same as the first embodiment, the only difference is that: the bearing part 6 includes a spacer 61, the keel 1 is provided with an accommodating groove 13, and the spacer 61 is inserted into the accommodating groove 13 and firmly connected with the keel 1, and is supported on the bottom end of the glass plate 3 and the aluminum sub-frame 4. In this structure, when installing, the aluminum sub-frame 4 and the glass plate 3 can be connected first. After gluing, insert the spacer 61 into the accommodating groove 13 and fasten it with the keel 1, then place the glass plate 3 and the aluminum sub-frame 4 on the spacer 61, and finally press the pressure plate 2 tightly on the aluminum The inner side of the sub-frame 4 is fastened to the keel 1 after passing through the pressure plate 2 with the fastening bolt 5. When the fas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com