Embedded structure and manufacturing method of filter module

A filter and module technology, applied in impedance networks, electrical components, etc., can solve problems such as product deformation, hidden dangers of reliability, insufficient epoxy resin filling, etc., to save costs and improve reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0101] The specific embodiments of the present invention will be described in more detail below with reference to the schematic diagrams. The advantages and features of the present invention will become more apparent from the following description and the scope of the patent application. It should be noted that, the accompanying drawings are all in a very simplified form and in an inaccurate scale, and are only used to facilitate and clearly assist the purpose of explaining the embodiments of the present invention.

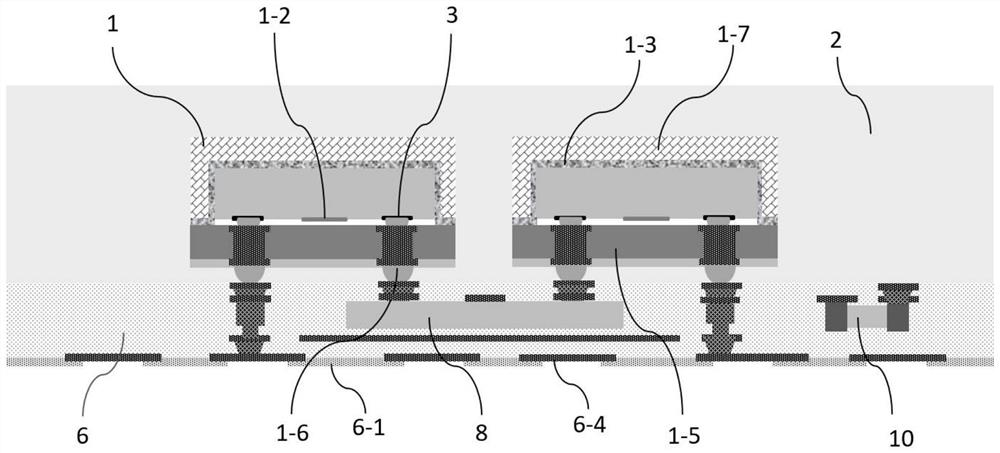

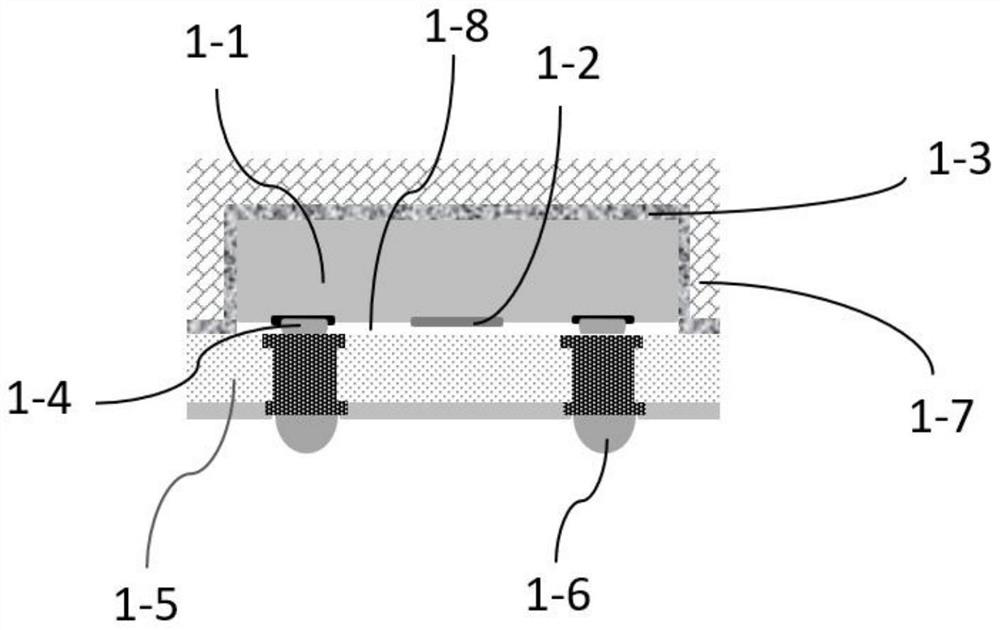

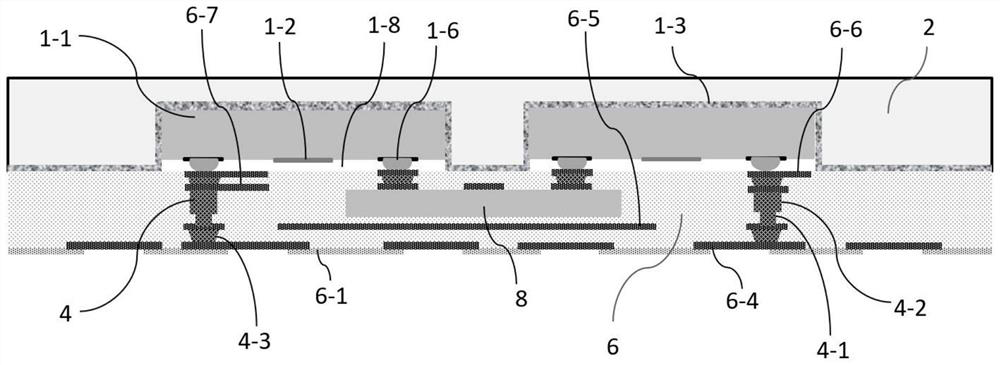

[0102] see figure 1 , A filter module according to the first embodiment of the present invention has a substrate 6, the front surface of the substrate 6 is a PiP structure, and the filter package body 1 is attached to the front surface of the substrate 6 after a plurality of packages and is packaged with a module plastic sealing layer 2, and the switch chip is sealed. 8 and the inductive passive element 10 are placed inside the substrate. The filter package 1 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com