Patents

Literature

78results about How to "Avoid Fracture Failure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

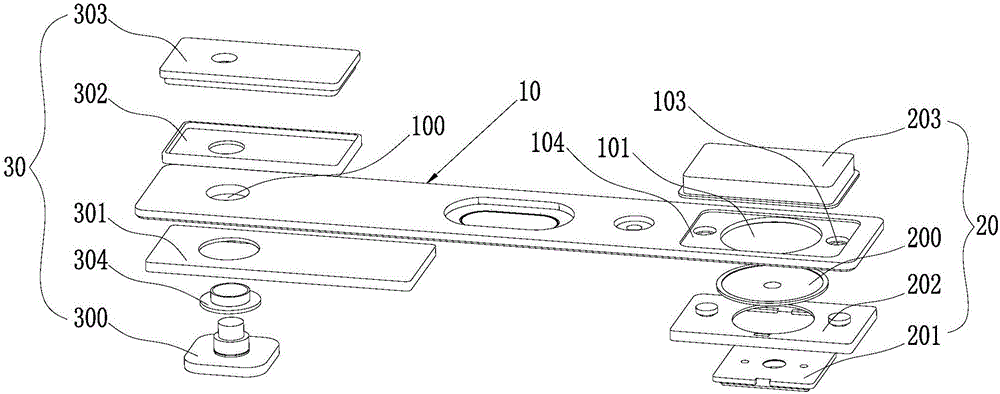

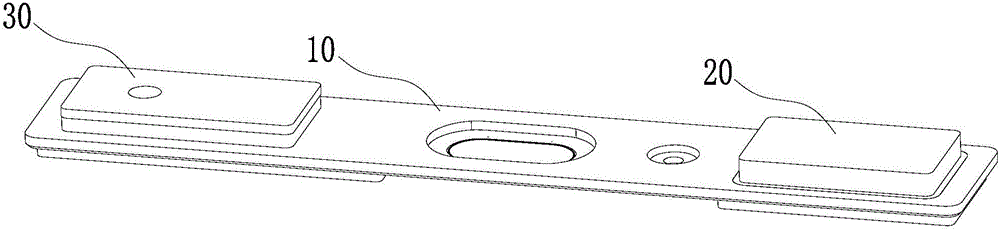

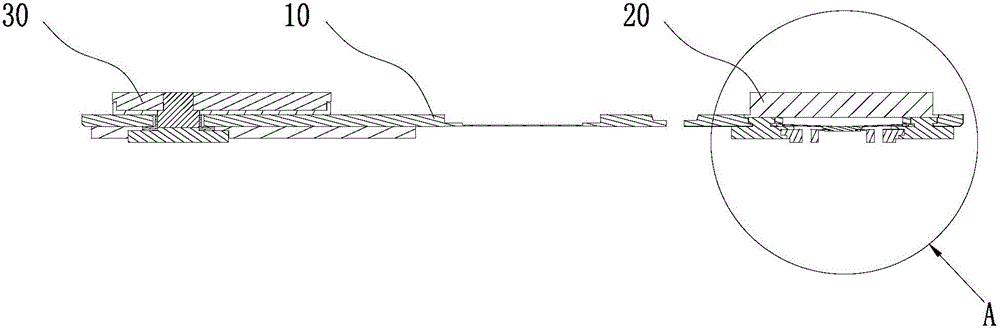

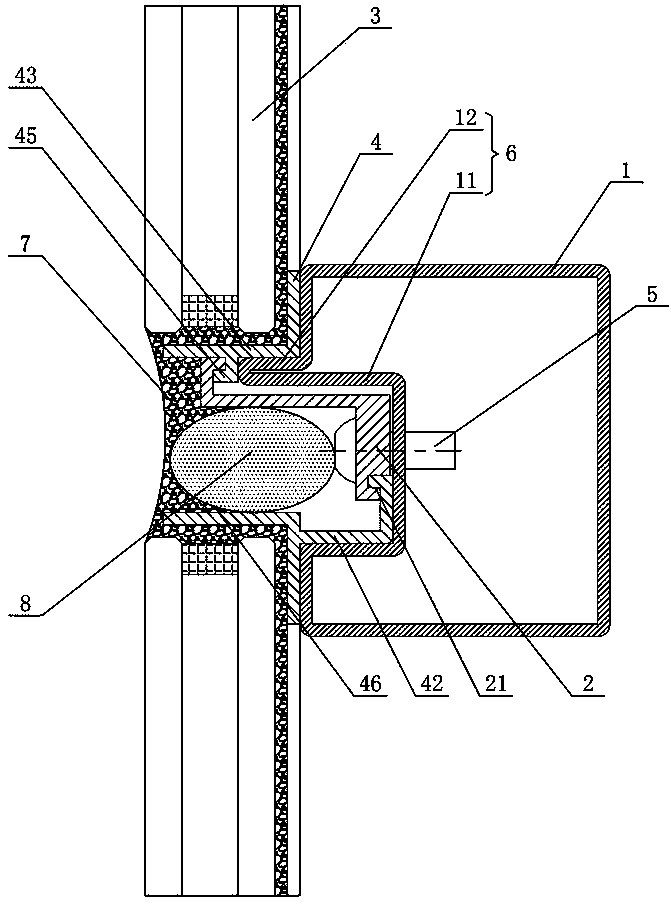

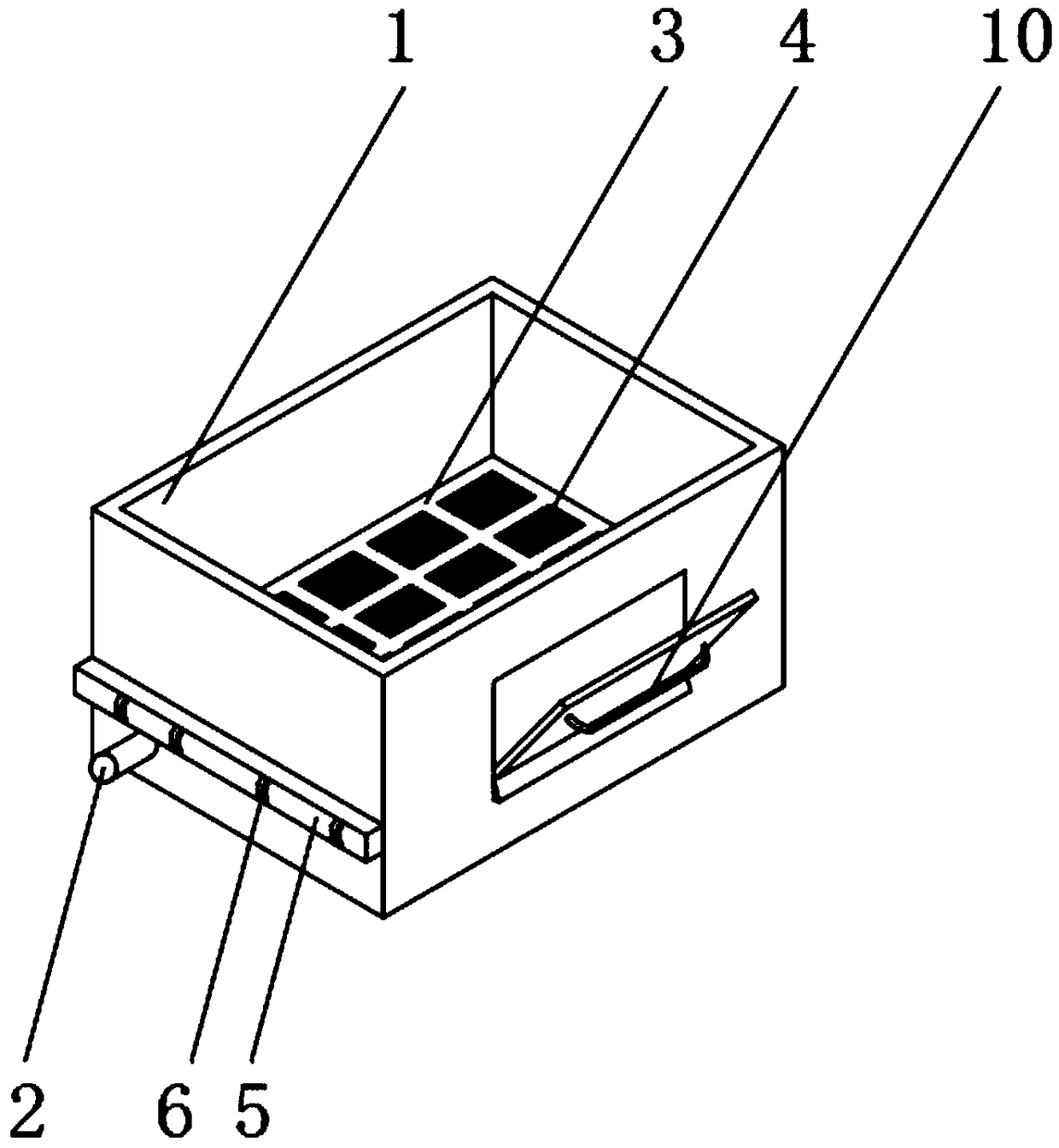

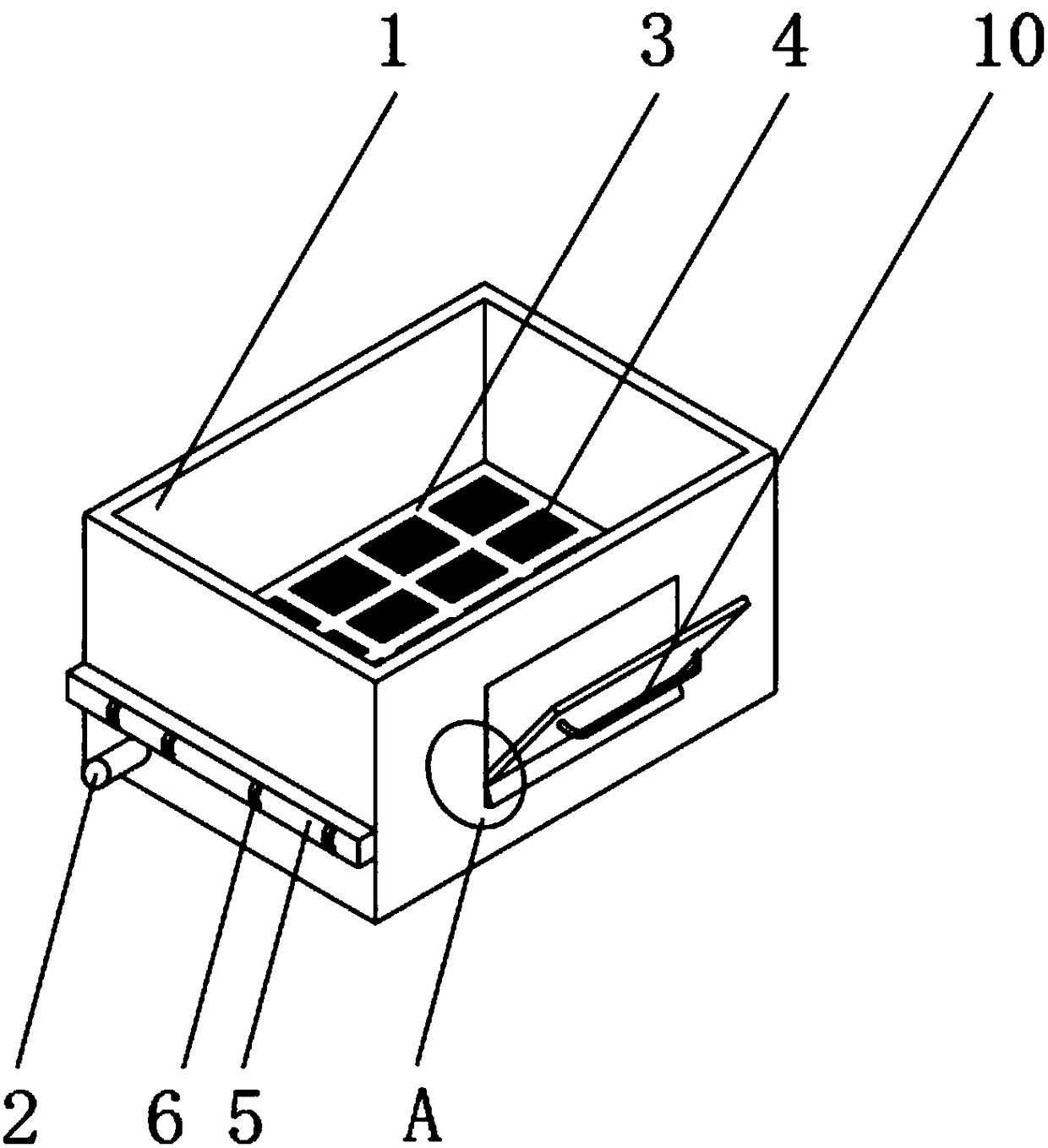

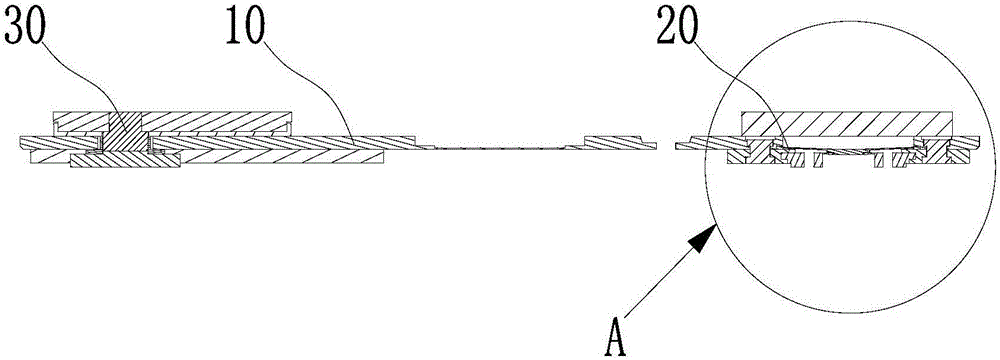

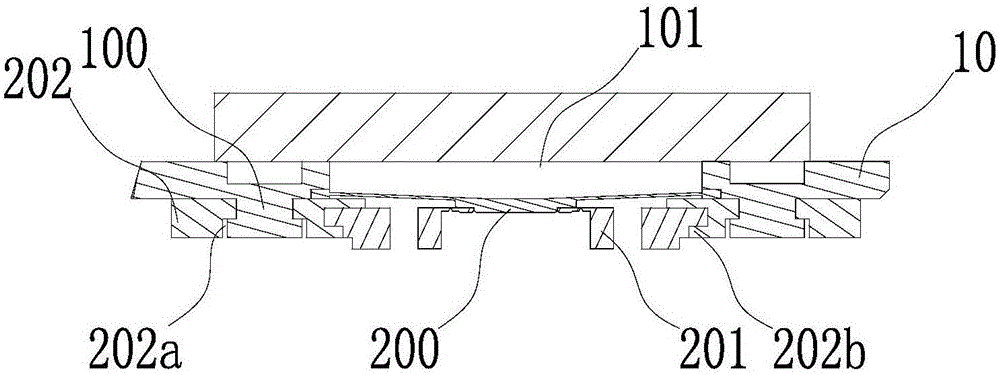

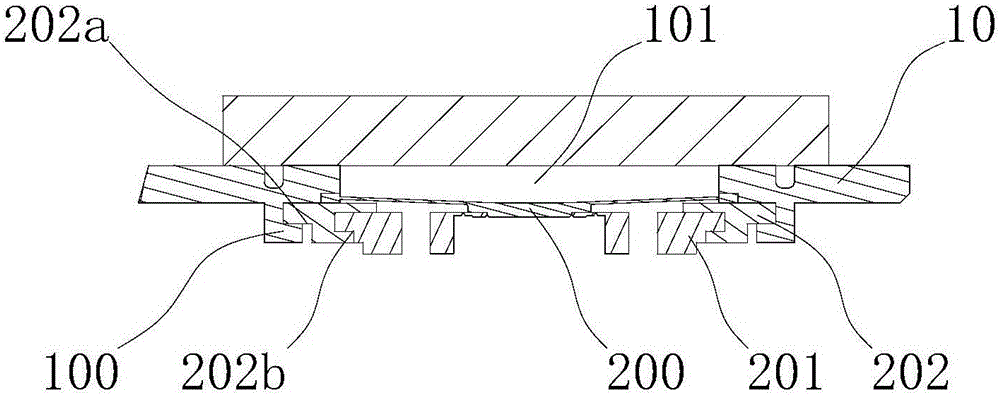

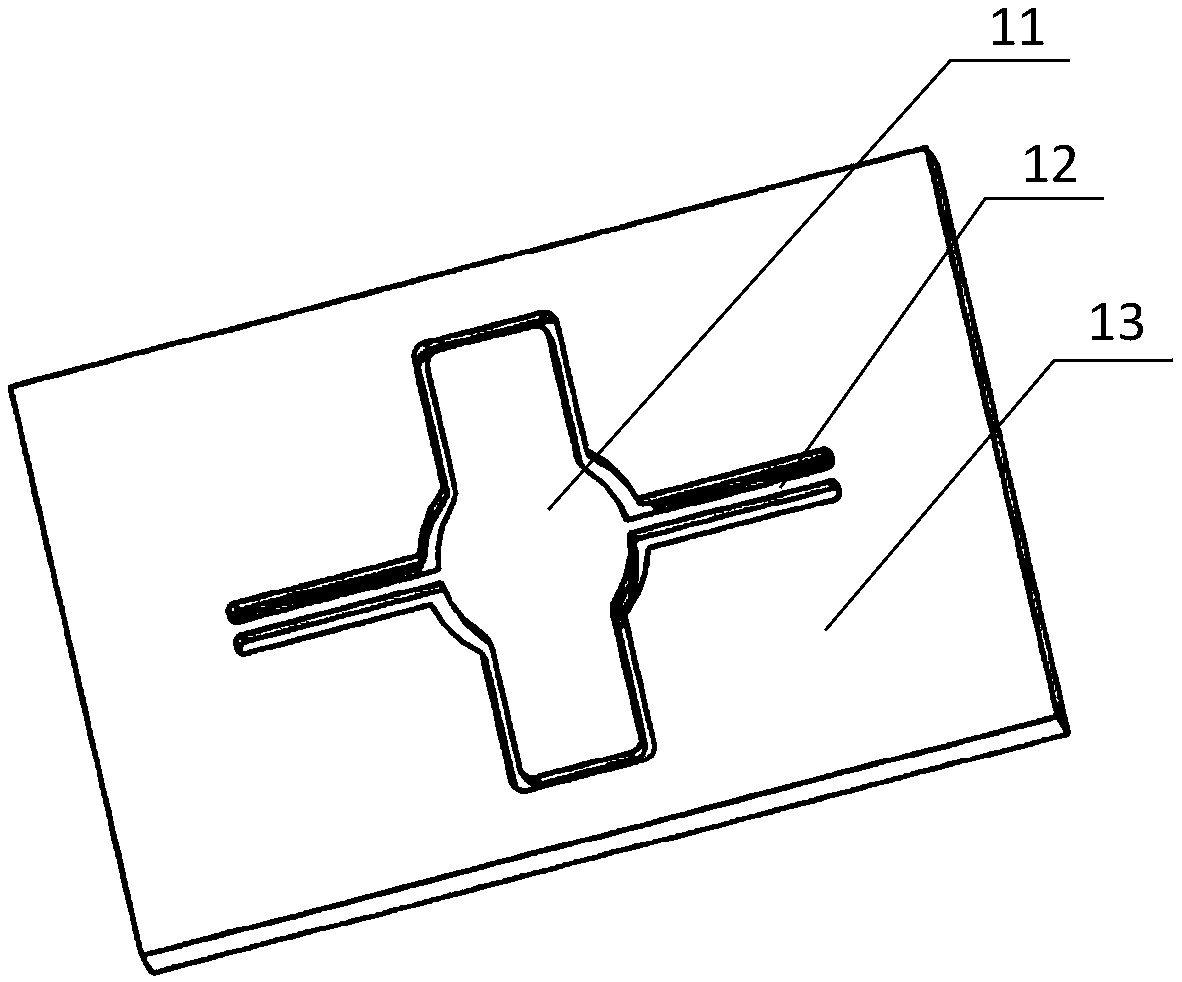

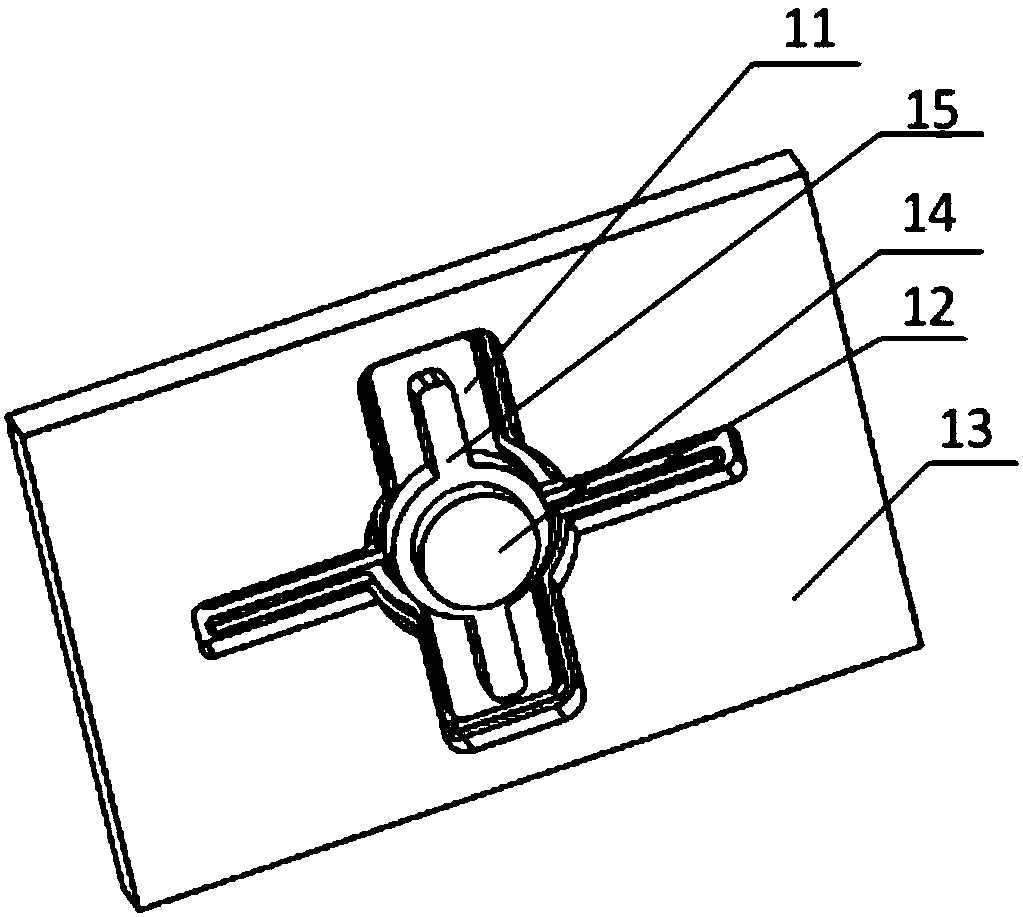

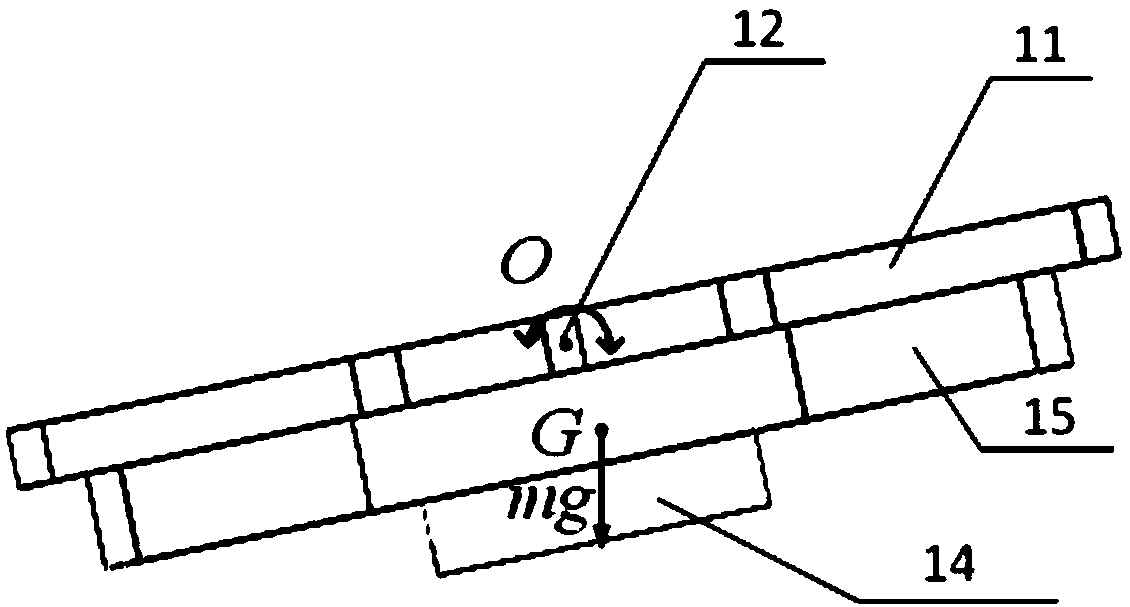

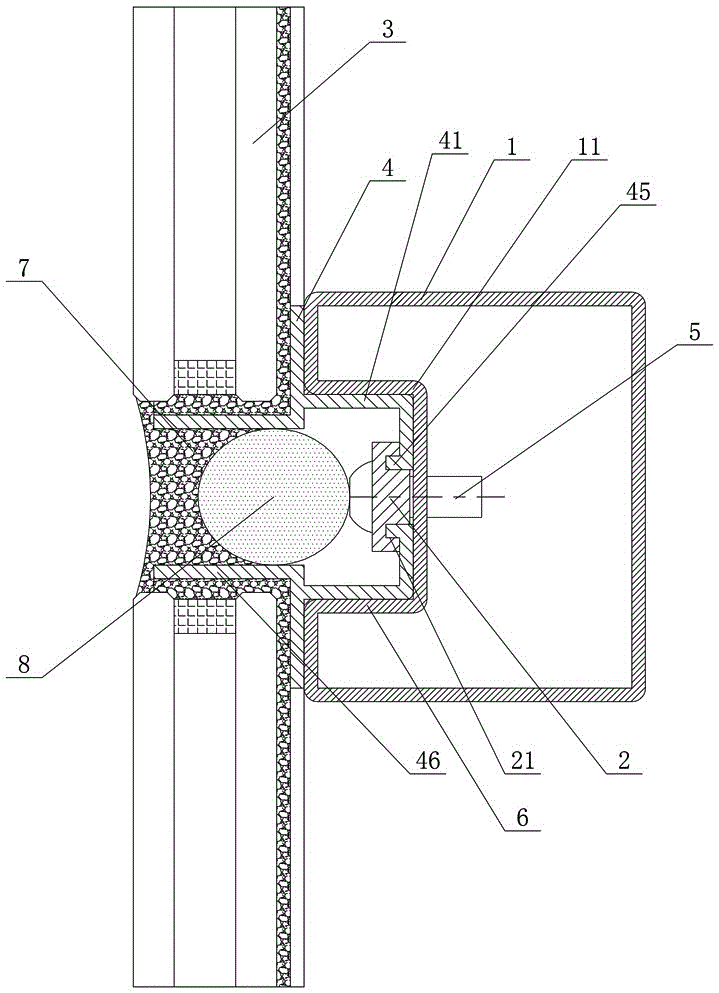

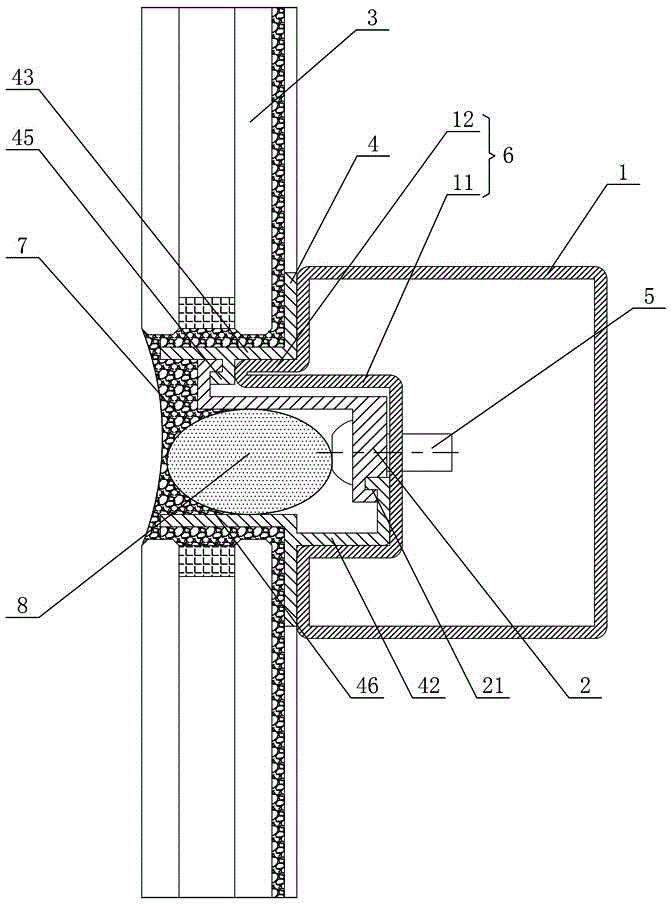

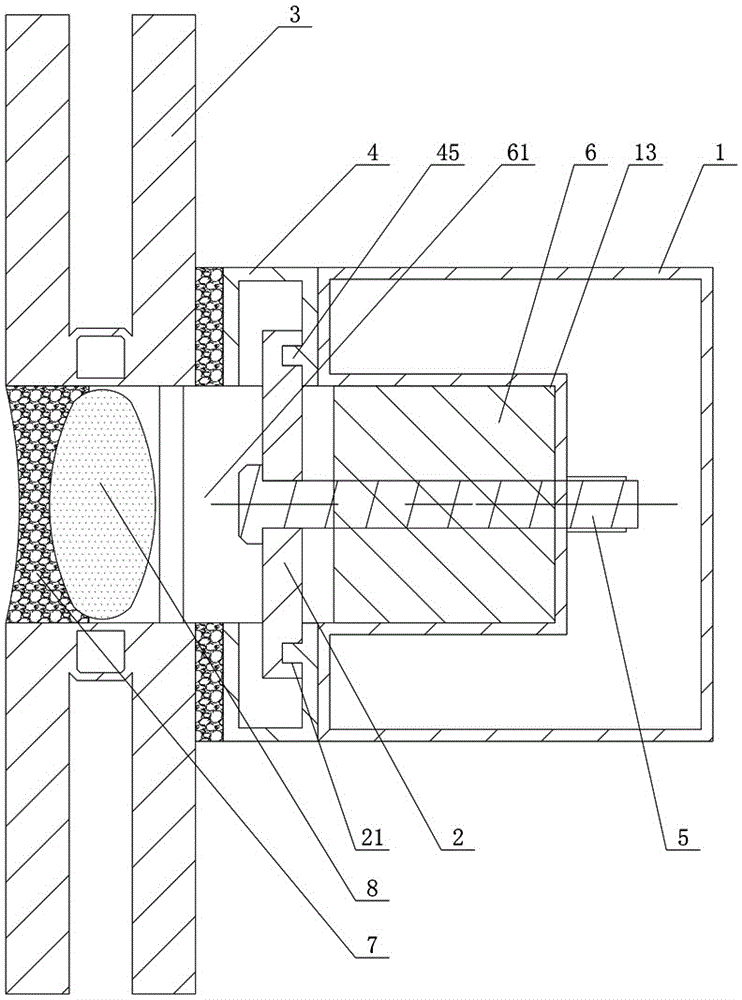

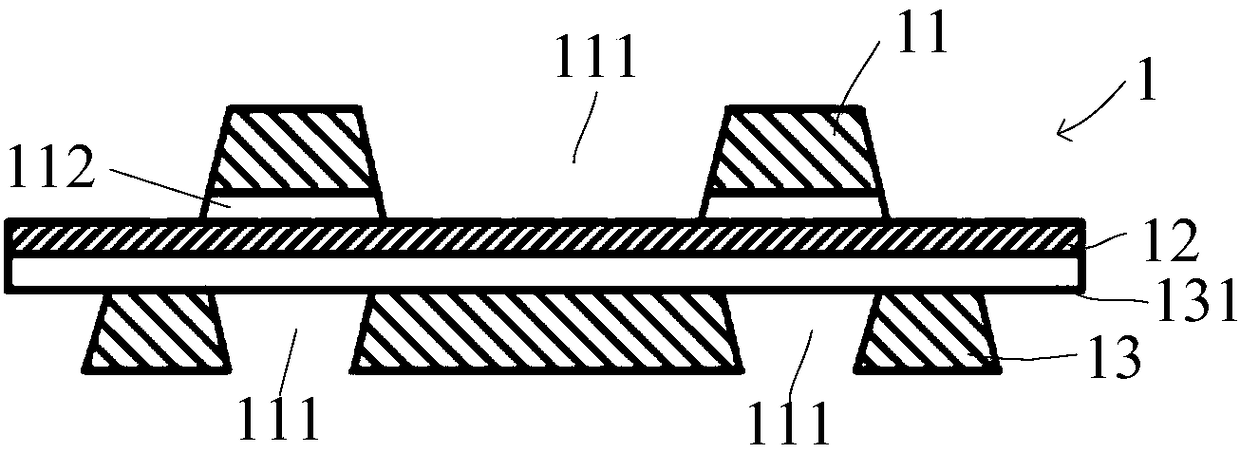

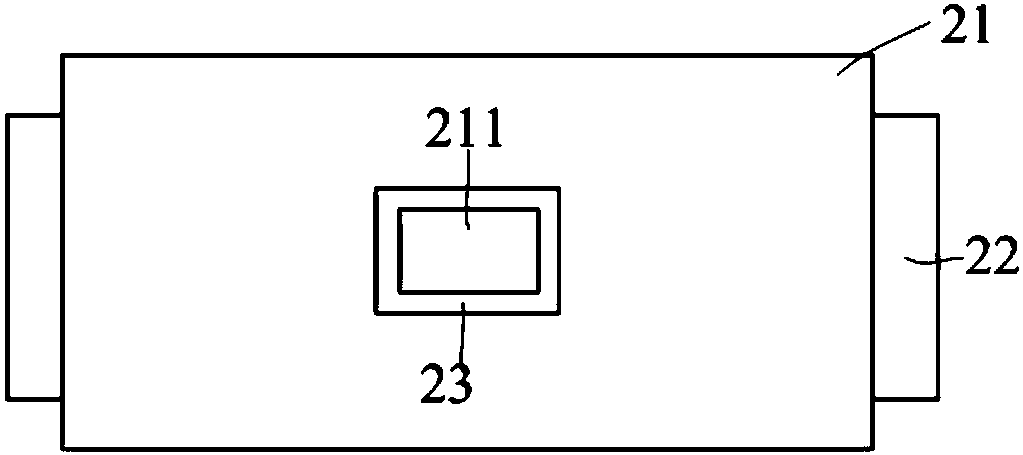

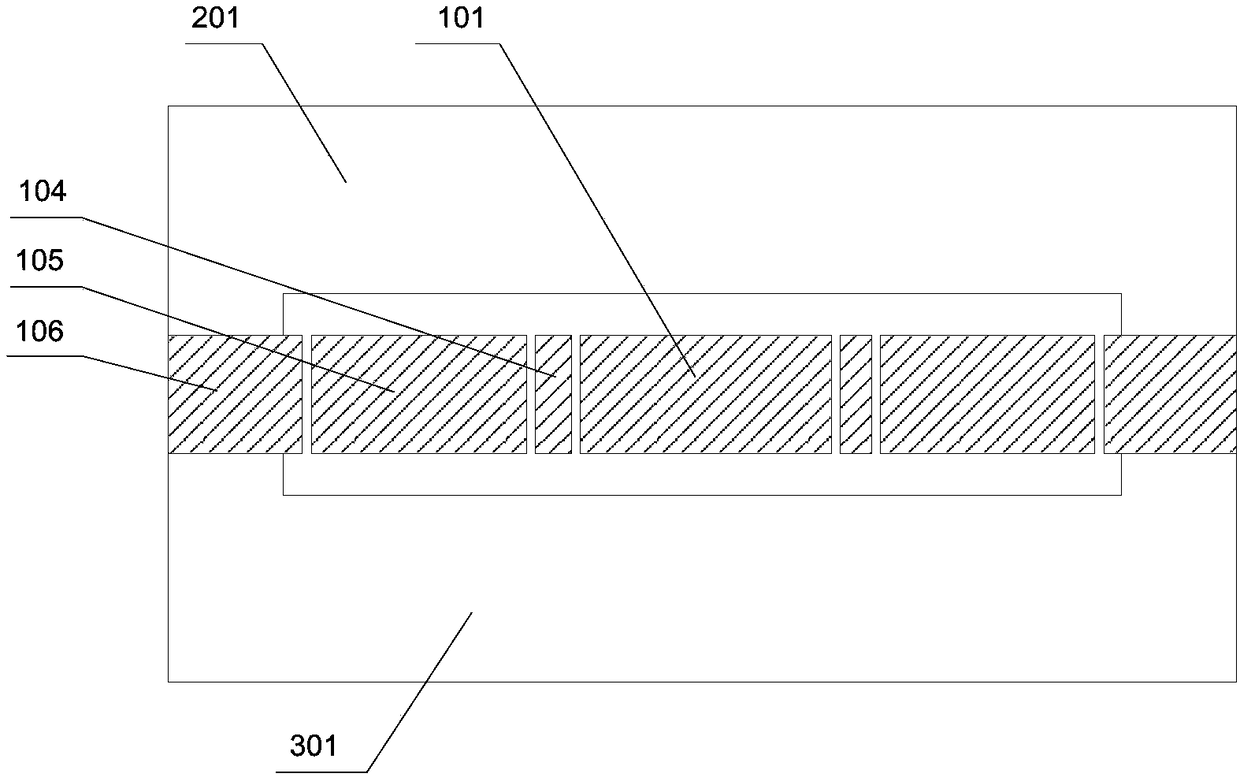

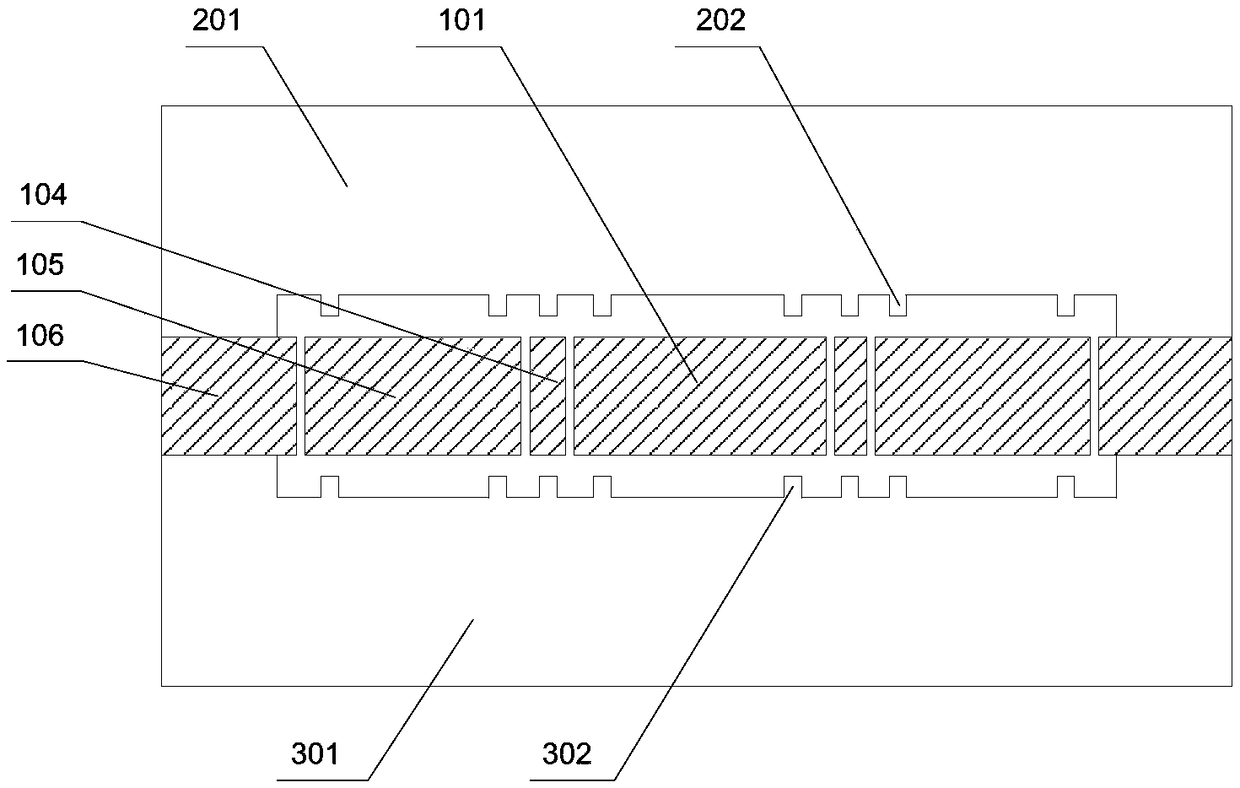

Power battery top cover and power battery

ActiveCN105845851AFirmly connectedAvoid Fracture FailureCurrent conducting connectionsSecondary cellsPower batteryEngineering

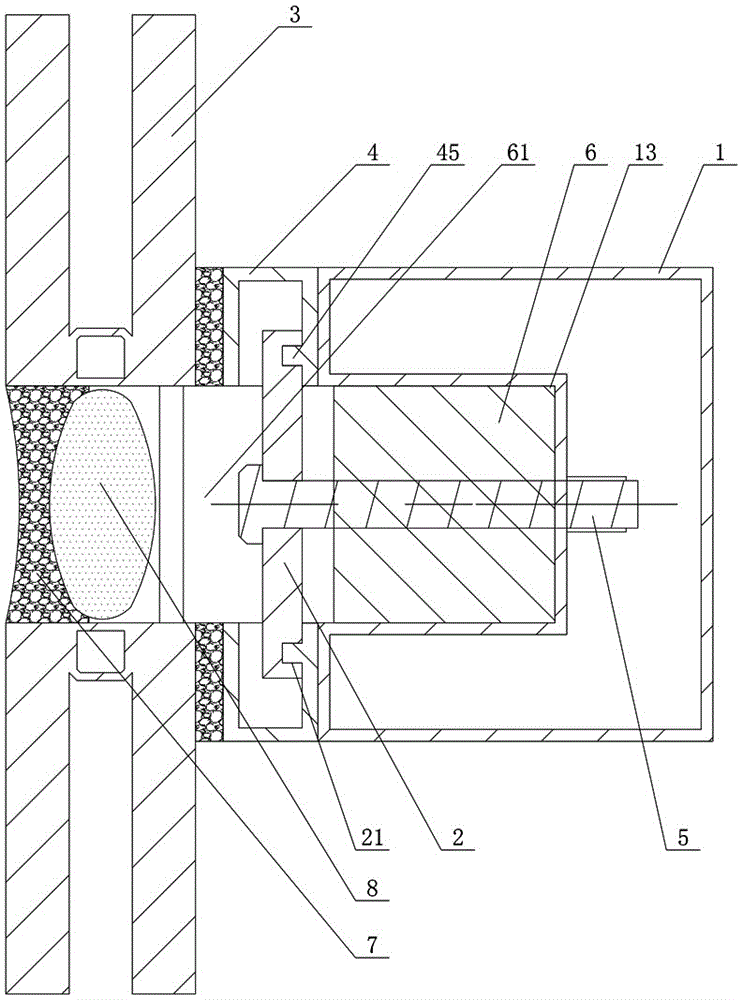

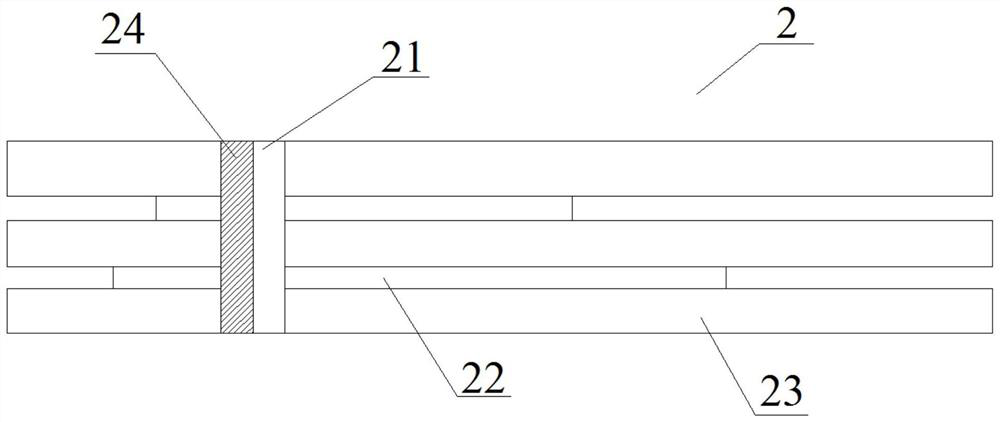

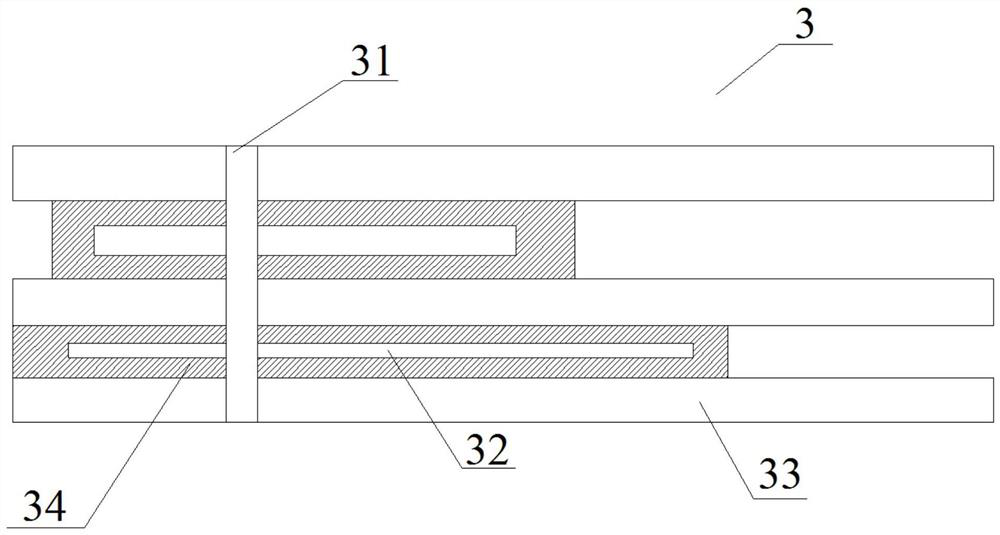

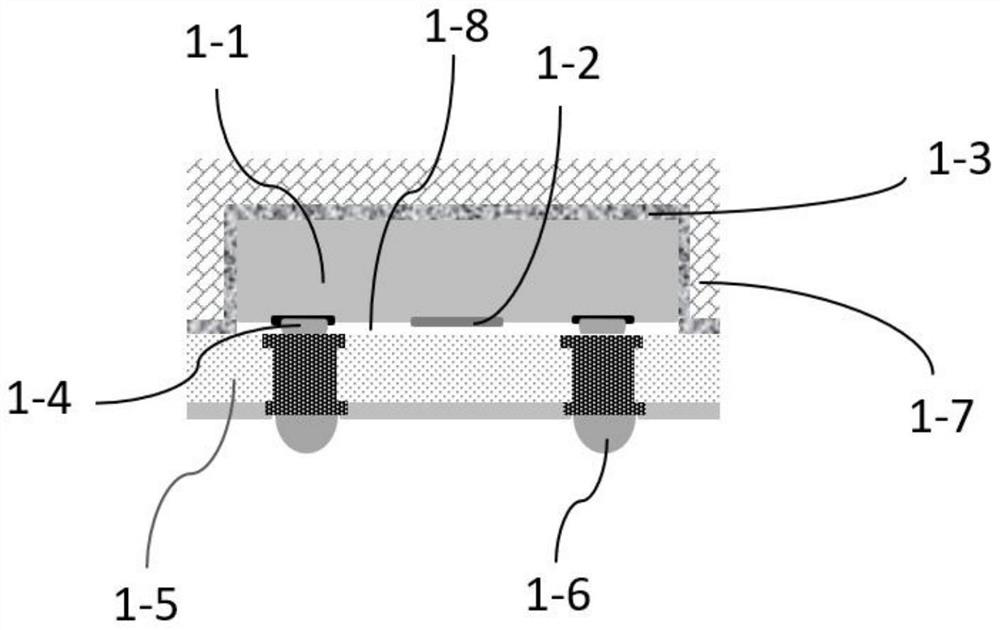

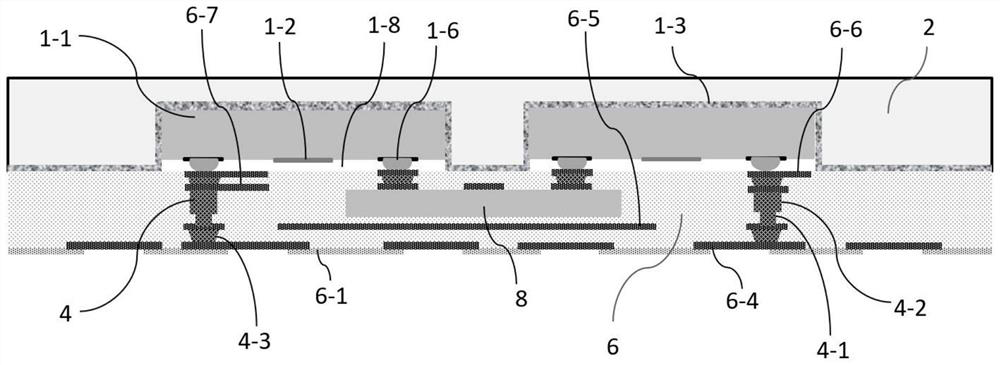

The invention relates to the technical field of lithium ion battery production, and especially relates to a power battery top cover. The power battery top cover comprises a top cover sheet, a first electrode unit and a second electrode unit. An overturning sheet connection hole and an insulation element containing part are arranged on the top cover sheet. The first electrode unit comprises an overturning sheet, a conductive sheet and a first insulation element. The overturning sheet connection hole is sealed by the overturning sheet. The conductive sheet is located under the overturning sheet. The first insulation element comprises a top cover sheet connection part and a conductive sheet connection part. The top cover sheet connection part stretches into the insulation element containing part and is fixed with the insulation element containing part. The conductive sheet is fixed on the top cover sheet by the conductive sheet connection part in an insulated mode. A power battery comprises the power battery top cover. According to the power battery top cover and the power battery provided by the invention, the conductive sheet can be effectively prevented from generating breakage and failure problems due to self displacement in normal assembly and use processes, and the occupied power battery internal space is relatively small.

Owner:CONTEMPORARY AMPEREX TECH CO

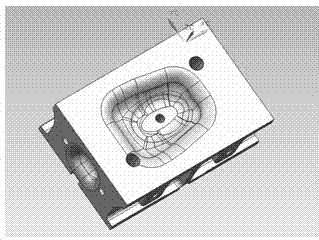

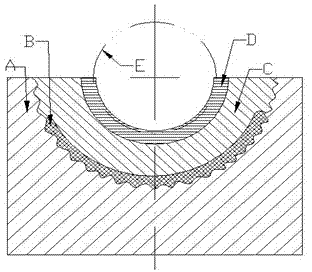

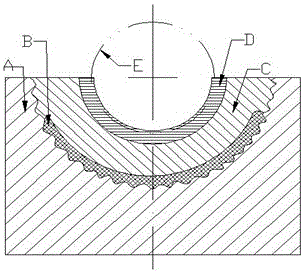

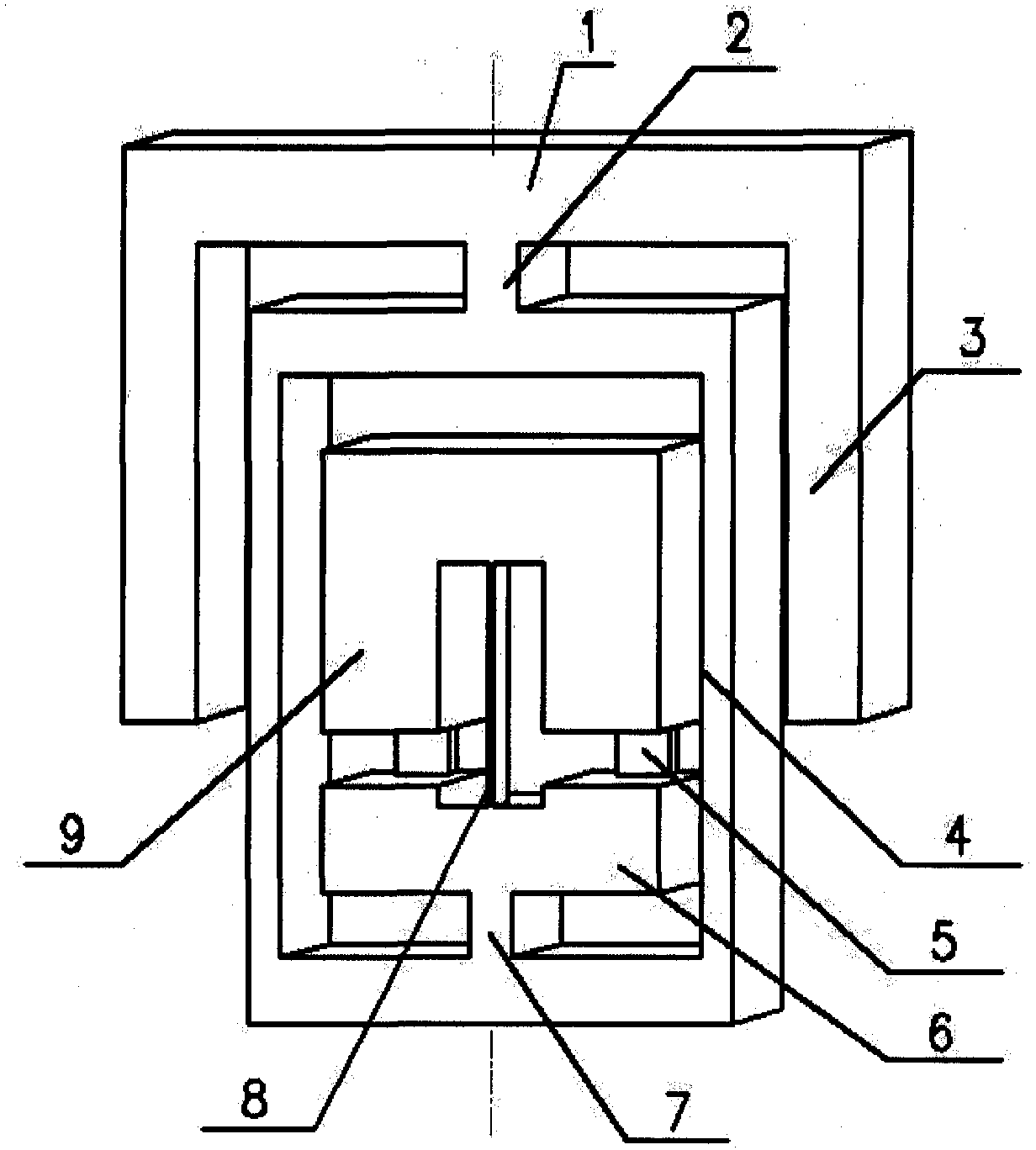

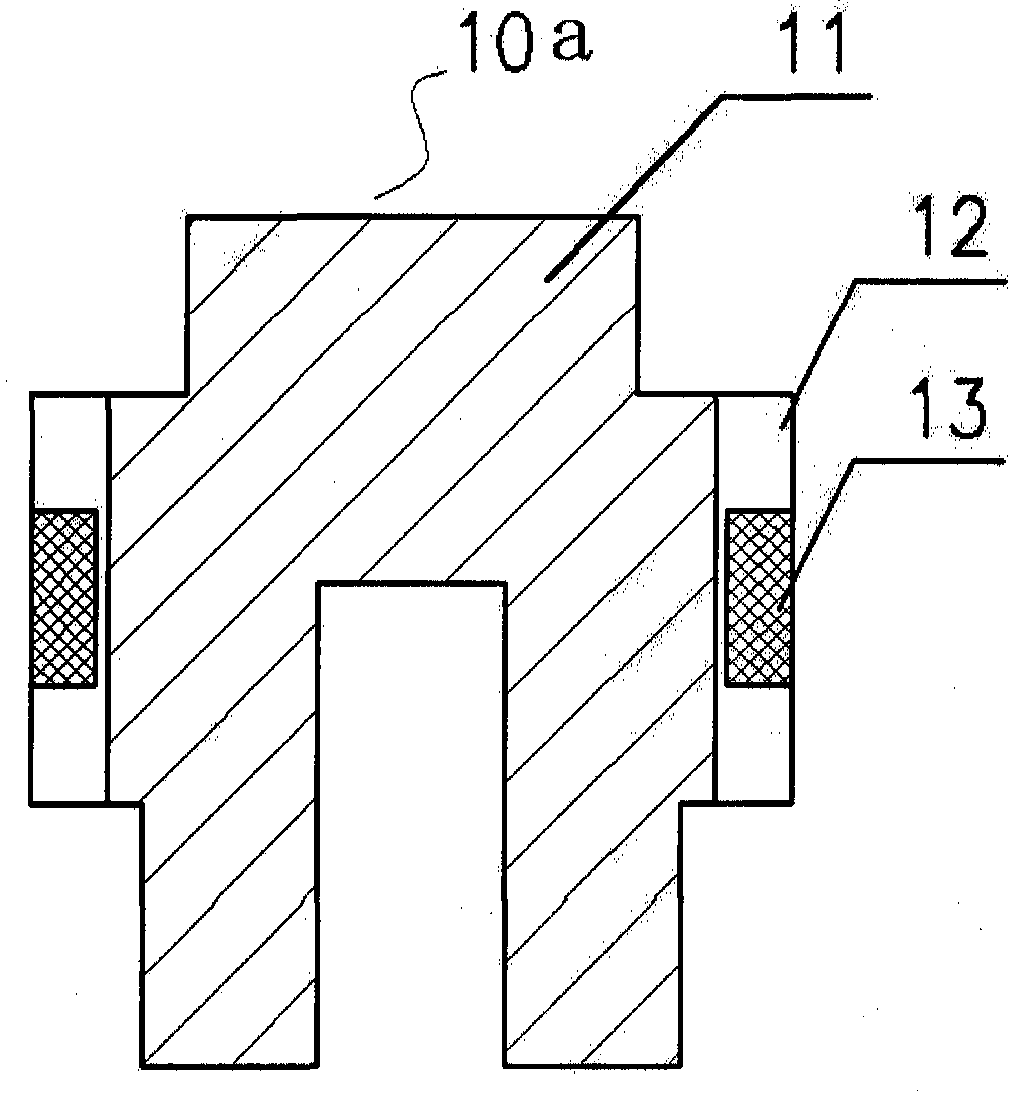

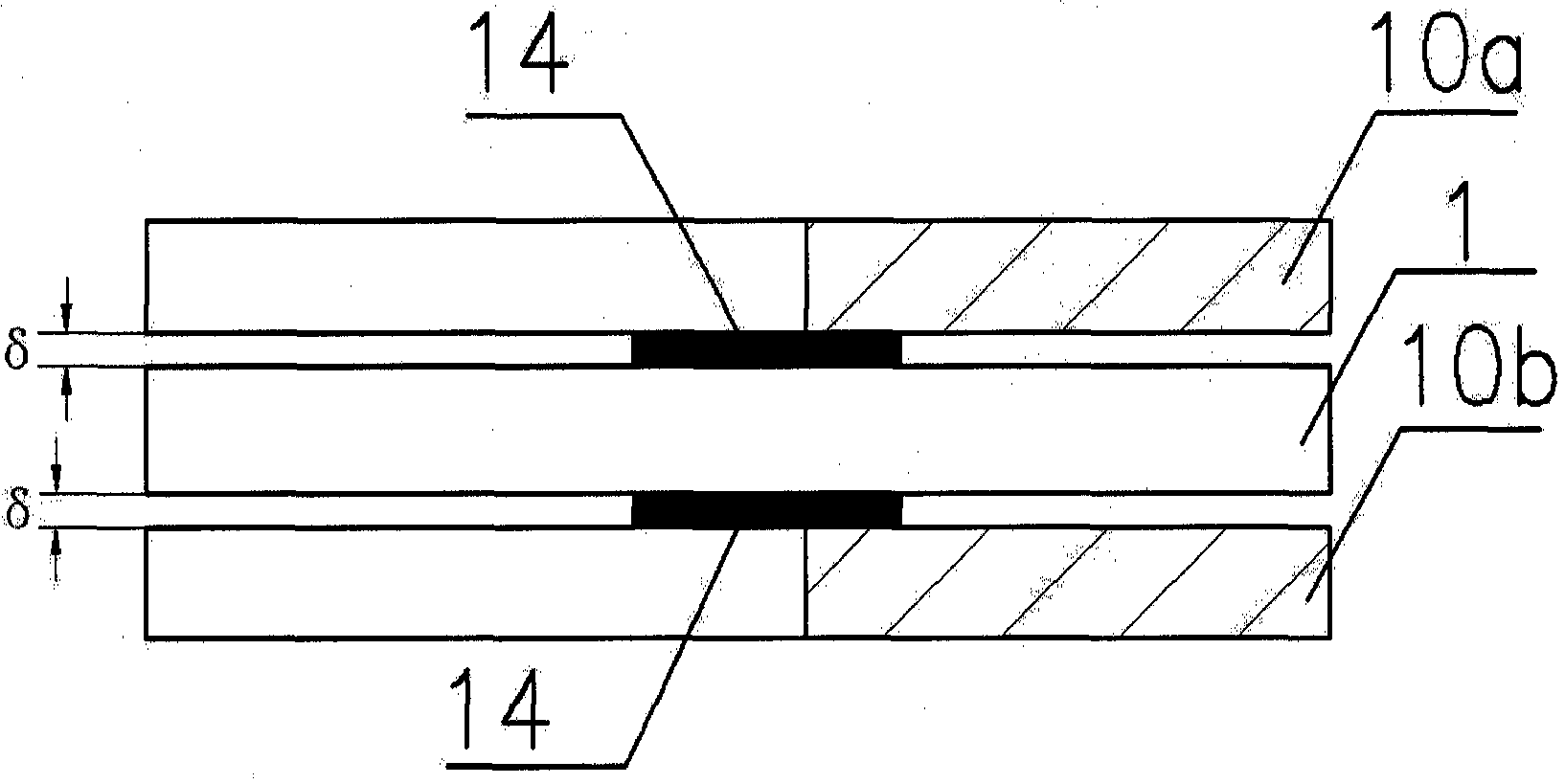

Sandwich layer forging die and preparation method of forging die sandwich layer surfacing

ActiveCN104741499AExtended service lifeImprove performanceArc welding apparatusForging/hammering/pressing machinesSoft materialsHigh pressure

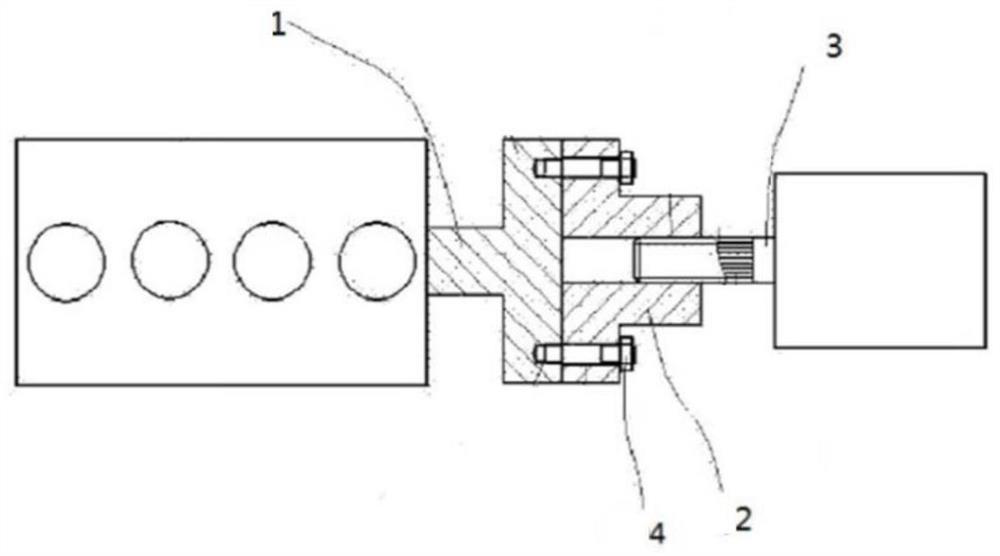

The invention discloses a sandwich layer forging die and a preparation method of forging die sandwich layer surfacing. The sandwich layer forging die is used for surfacing a layer of sandwich layer soft welding material which is better in plasticity and lower in yield strength than a cast steel substrate and a double-metal gradient surfacing material between the cast steel substrate and the double-metal gradient surfacing material; the preparation method of the forging die sandwich layer surfacing comprises the following steps of taking cast steel as the cast steel substrate, and welding a sandwich layer soft material on a substrate layer; surfacing a transition layer material on a substrate of a sandwich layer welded, welding and covering all sandwich materials to form a surfacing transition layer; welding a high-temperature wearing layer material; tempering to distress after the completion of the welding, and then mechanically processing to obtain a mould. The sandwich layer forging die provided by the invention is long service life and high in loading capacity of the cast steel substrate. According to the method provided by the invention, the critical bottleneck problems that the forging die is low in life and the die is high in manufacturing cost can be solved thoroughly, the die forging forming of various materials can be supported at high temperature and high pressure, and a brand new manufacturing method can be provided for forging die manufacturing.

Owner:CHONGQING UNIV +2

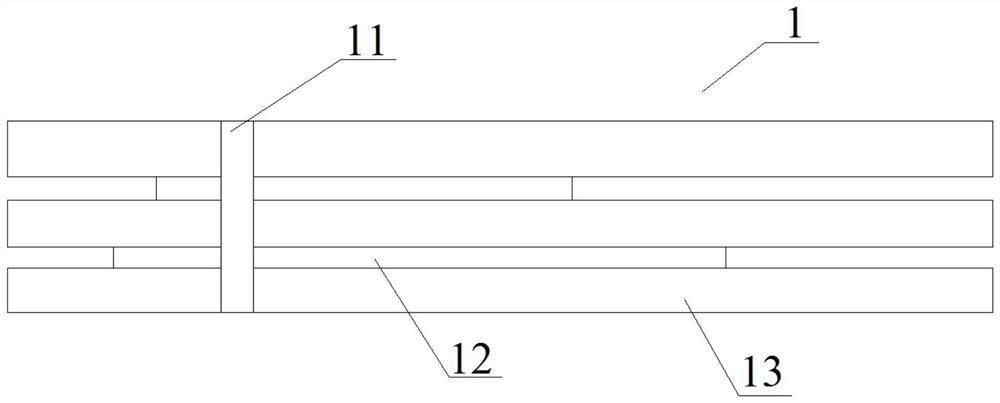

Flexible display module and preparation method thereof

InactiveCN107871453AMeet bending needsAvoid bending requirementsSolid-state devicesSemiconductor/solid-state device manufacturingFlexible displayComputer science

The embodiment of the invention provides a flexible display module and a preparation method thereof. The problem that an existing flexible display module is likely to lose efficacy after being bent issolved. The flexible display module comprises a flexible glass layer and a display panel arranged in the flexible glass layer.

Owner:YUNGU GUAN TECH CO LTD

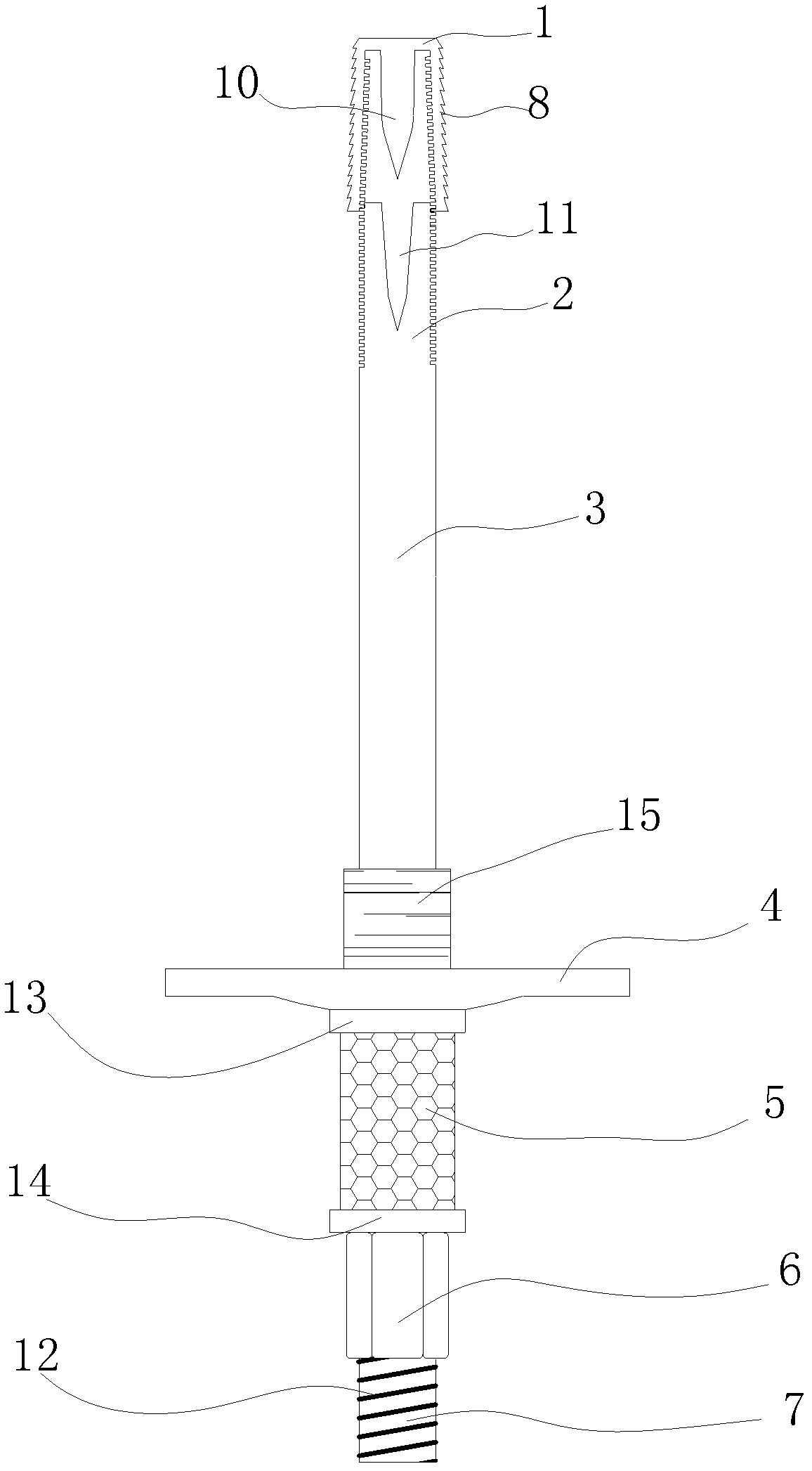

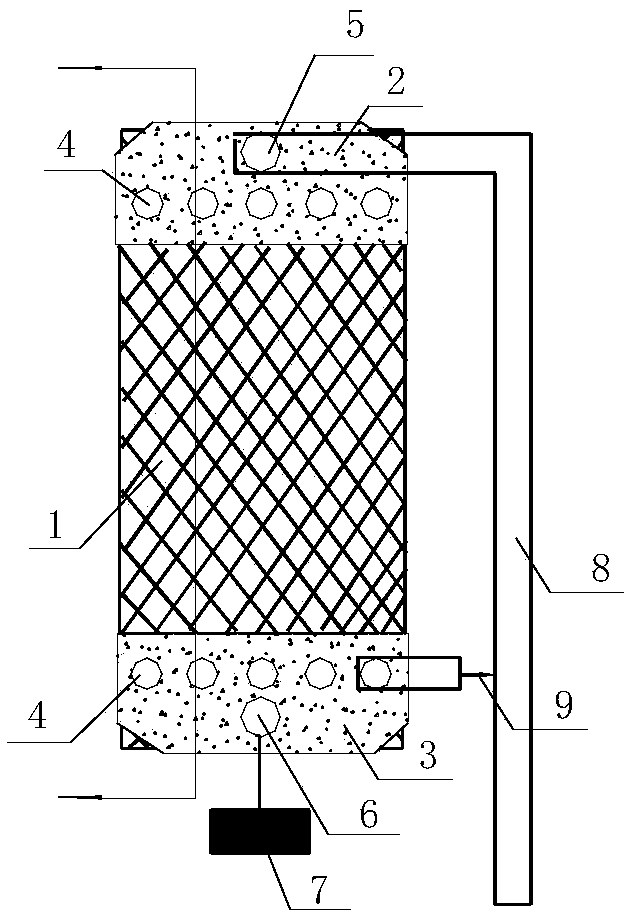

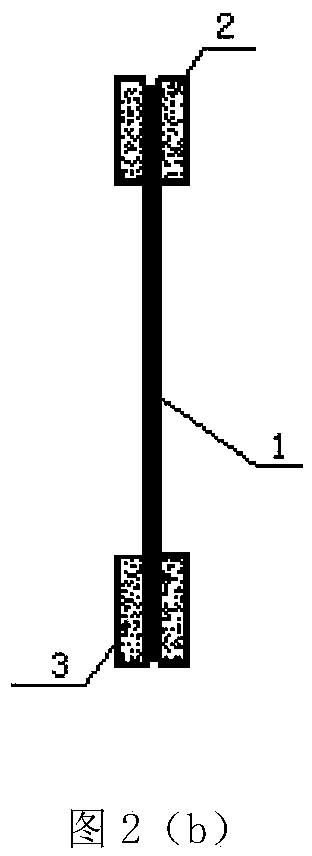

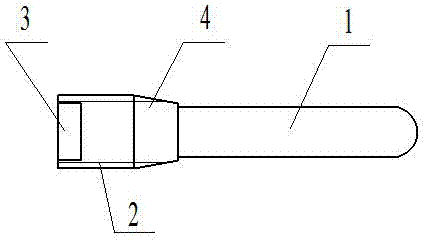

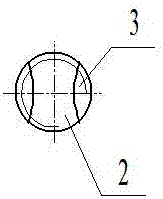

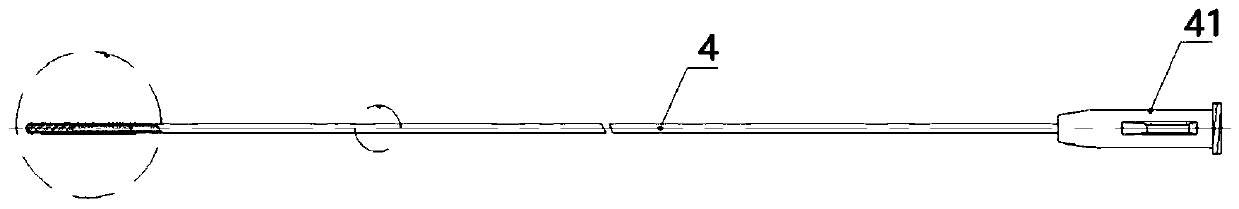

Quickly mounted efficient energy-absorbing mining anchor rod

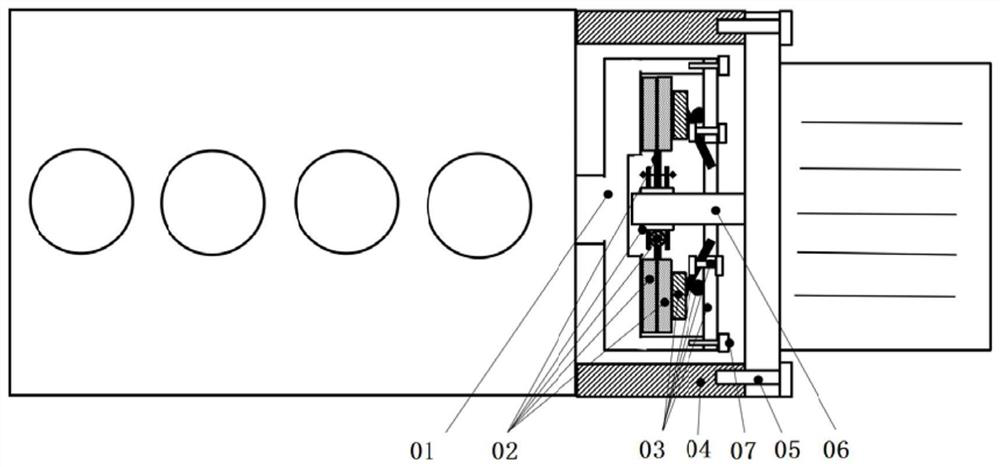

The invention discloses a quickly mounted efficient energy-absorbing mining anchor rod which comprises an expansion shell, a rod head, a rod body, a tray, an anti-seismic buffering material, a nut and a rod tail, wherein a tooth-shaped bulge is arranged on the outer surface of the expansion shell; matched threads are respectively arranged on the inner surface of the expansion shell and the outer surface of the rod head; a tapered bulge is arranged in the expansion shell; a tapered groove is arranged at the top of the rod head; a vertex angle of the tapered bulge is more than the vertex angle of the tapered groove; the thread is arranged on the rod tail; and the tray and the anti-seismic buffering material are respectively sleeved on the rod tail and are positioned and pre-tensioned by the nut. According to the invention, quick loading is realized by the anchor rod; mounting process is simplified; mounting time is shortened; driving speed is increased; the anti-seismic buffering material has a compressing buffering function when rock is burst, so as to effectively resist the dynamic loading effect at rock bursting moment; a certain anchoring force is kept by the anchor rod; and the anchor rod is prevented from being broken and invalid. Besides, the quickly mounted efficient energy-absorbing mining anchor rod has the beneficial effects of simple structure, convenience in mounting, high operability, and the like, and is widely applied to underground supporting for deep well.

Owner:CENT SOUTH UNIV

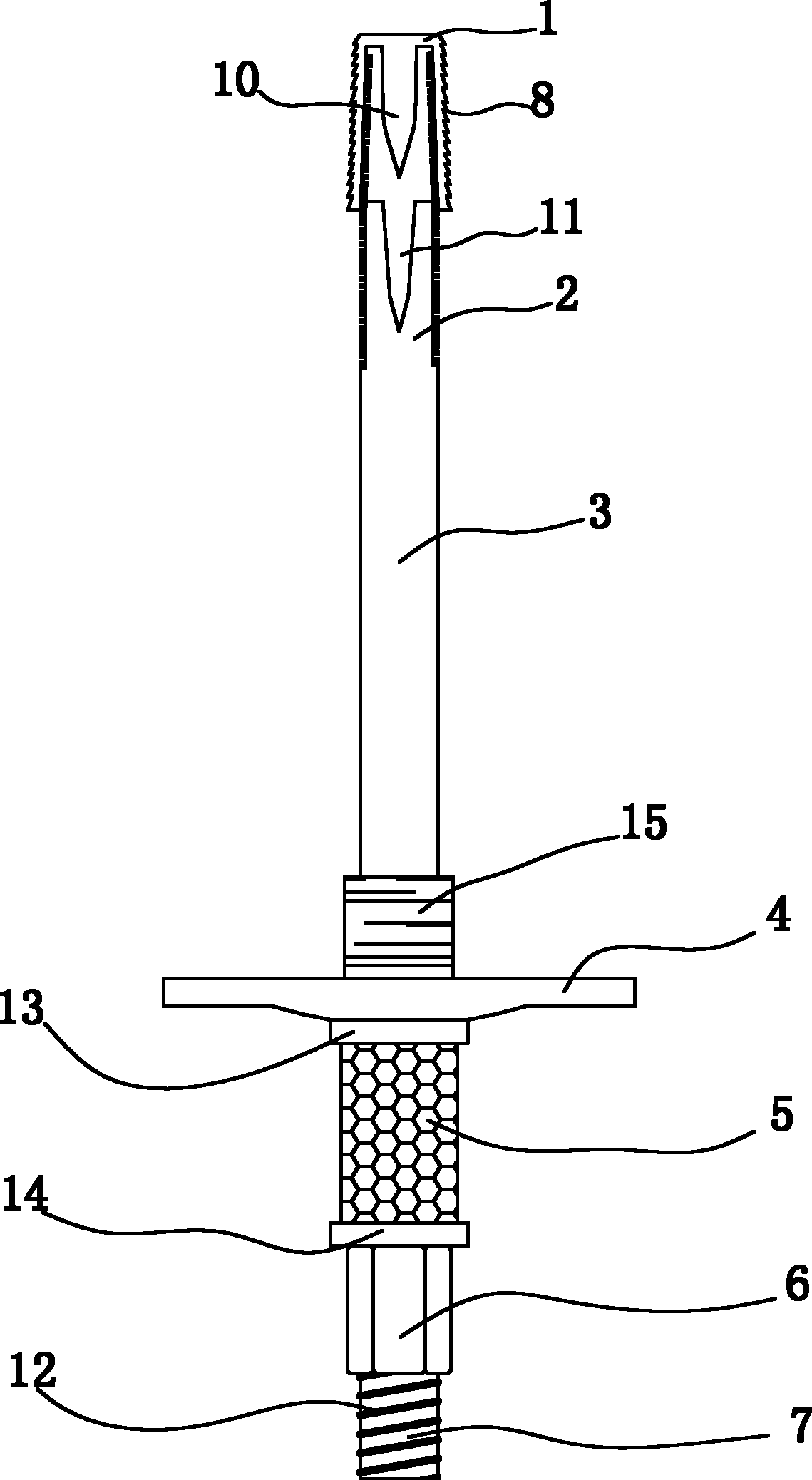

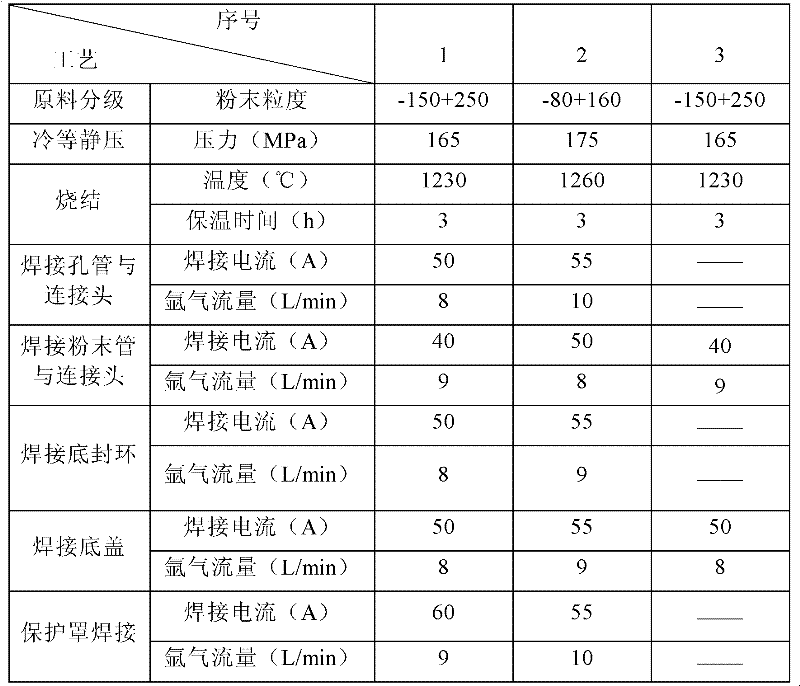

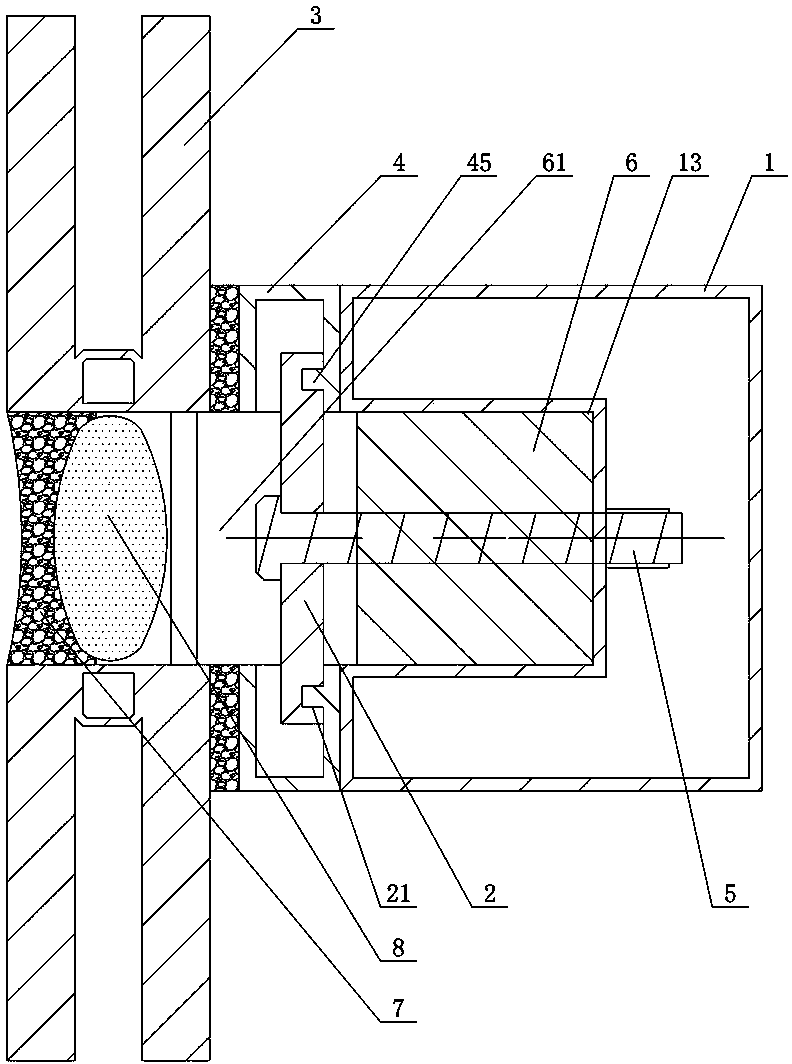

High-strength metal filtering tube and preparation method thereof

ActiveCN102527167AAvoid forceHigh strengthDispersed particle filtrationGravity filtersTransport systemFiltration

The invention relates to a high-strength metal filtering tube and a preparation method of the filtering tube. The high-strength metal filtering tube comprises an inner tube at the internal layer, and an outer tube that is outside and parallel to the inner tube with a certain distance, wherein the inner tube is a perforated tube or a helical tube, and the outer tube is a sintered powder tube with a millipore filtration structure and used for filtering. Compared with the prior art, the metal filtering tube prepared by the invention has substantially increased the bending resistance, and improved the stability and reliability in use. The high-strength metal filtering tube prepared by this invention is mainly used in filtration equipment in a high-temperature and high-pressure (HTHP) working condition, like HTHP pulverized coal transport system and fly ash collecting and disposing system of a coal gasification device.

Owner:AT&M ENVIRONMENTAL ENG TECH CO LTD

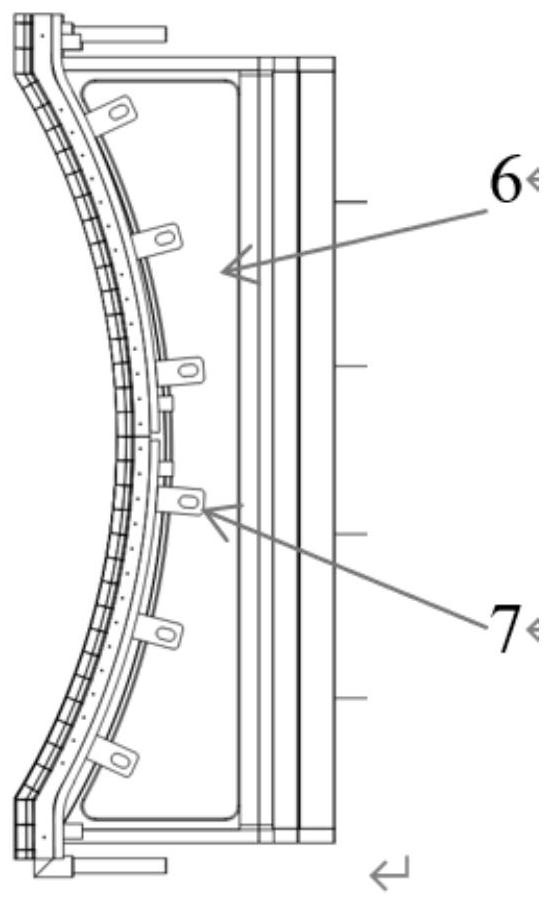

Hidden frame type glass curtain wall

The invention discloses a hidden frame type glass curtain wall. The hidden frame type glass curtain wall comprises a keel, a pressure plate, a glass plate, an aluminum auxiliary frame and a fastening bolt. The glass plate is in glue joint with the outer side of the aluminum auxiliary frame, the fastening bolt penetrates the pressure plate to be fixedly connected with the keel and to drive the pressure plate to tightly press the aluminum auxiliary frame, and a bearing part is arranged between the keel and the glass plate and used for bearing the aluminum auxiliary frame and directly transferring loads of the glass plate and the aluminum auxiliary frame to the keel. The hidden frame type glass curtain wall has the advantages of simple structure and capability of effectively protecting the fastening bolt from damages.

Owner:HUNAN GOLDWELL NEW MATERIALS TECH CO LTD

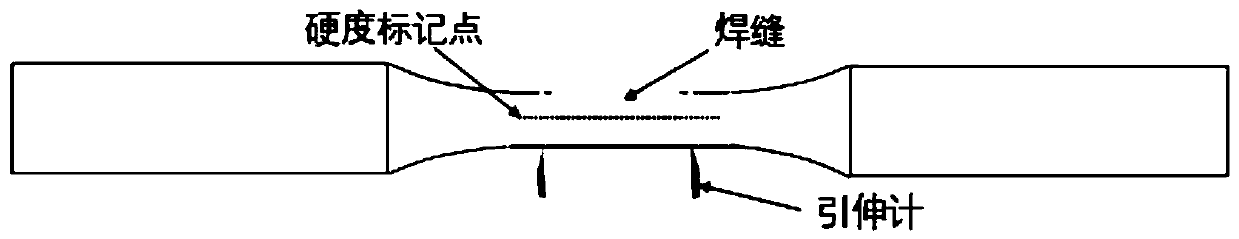

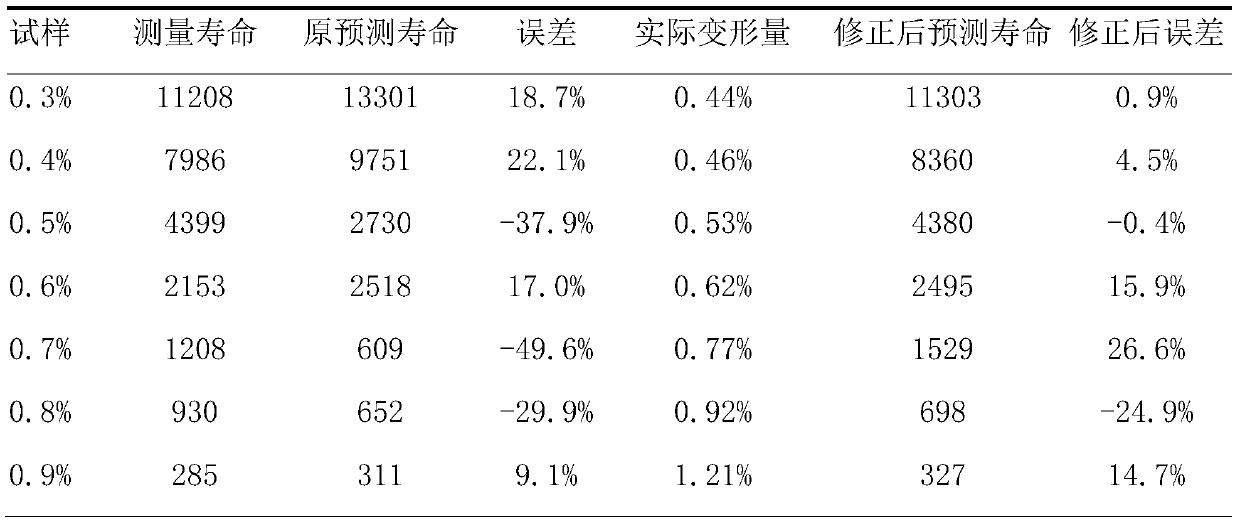

Method for testing subarea strain in low-cycle fatigue process of non-uniform structure welding joint

ActiveCN109883859AAvoid Fracture FailureEffective assessment of low cycle fatigue life of welded jointsMaterial strength using repeated/pulsating forcesSurface corrosionHardness

The invention provides a method for testing subarea strain in the low-cycle fatigue process of a non-uniform structure welding joint. The method comprises the following steps: under the condition of setting strain values, a specimen is subjected to low-cycle fatigue performance testing, corrosion of the fractured specimen is observed, the fracture position is judged, and the strain fatigue life and material properties of the specimen are analyzed; an original position is marked on the same alternative specimen through a microhardness point; the marked specimen is subjected to static stretch testing; the specimen subjected to static stretch testing is subjected to surface corrosion, a subarea corresponding to the hardness mark point is found out, and the plasticity strain capacity generatedby the structure subareas is analyzed; the plasticity strain and total strain which are obtained during low-cycle fatigue testing of all the structure subareas of the specimen are corrected, and theactual strain of all the structure subareas is obtained; according to the actual strain of all the structure subareas and the fracture position of the specimen, the actual strain and the life of the fracture position are calculated; and the different strain values are set, the steps are repeated, and the actual strain-life relation is obtained.

Owner:SHANGHAI JIAO TONG UNIV

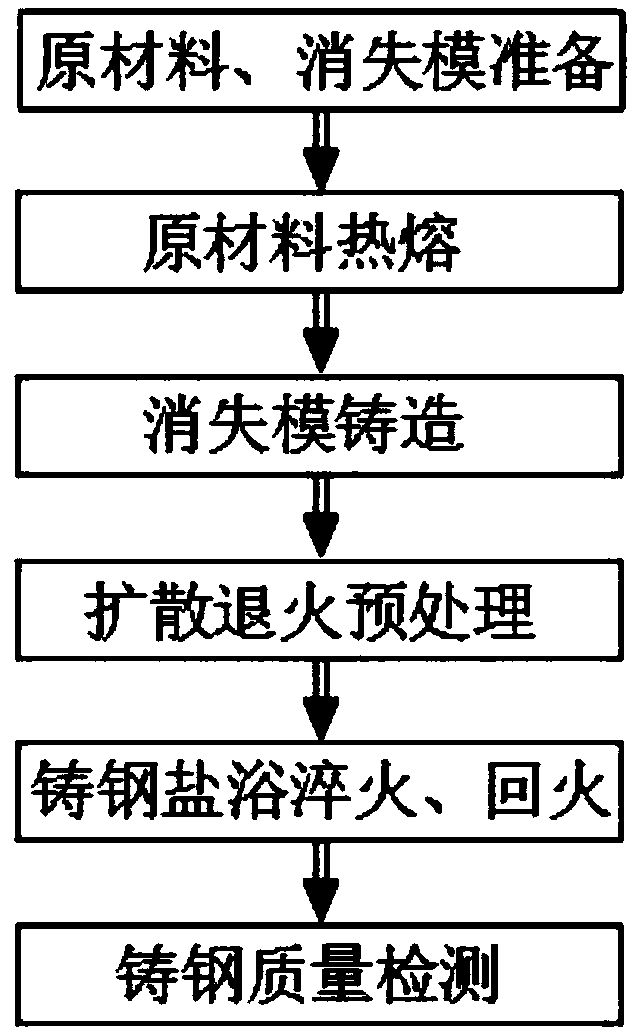

High-strength high-wear-resistant bainite cast steel used for block cast middle groove, and preparation technology thereof

ActiveCN109252098AExtended service lifeHigh strengthFoundry mouldsFoundry coresWear resistantQuenching

The invention discloses high-strength high-wear-resistant bainite cast steel used for a block cast middle groove, and a preparation technology thereof. The preparation technology comprises the following technical steps: preparing raw materials and evanescent modes, carrying out raw material hot melting, casting the evanescent modes, carrying out diffusion annealing preprocessing, carrying out caststeel salt bath quenching and tempering and detecting cast steel quality. The bainite cast steel used for the middle groove has the characteristics of high strength and high wear-resistant performance, the middle groove is subjected to integral casting forming, and the problem that all positions have inconsistent wear resistance is avoided. When a work surface is turned, maintenance is not required, the current work surface is directly turned to a next work surface, and the coal mining efficiency is improved. Meanwhile, since the materials of different positions are different, so that the effect of new goods are traded for old goods is realized, waste middle groove can be recovered and recast, waste is recycled, and the fully mechanized mining cost of users is greatly lowered, thus realizing an important meaning for the energy and material saving, the circular economy and the sustainable development of coal production.

Owner:JIKAI HEBEI MECHATRONICS TECH CO LTD

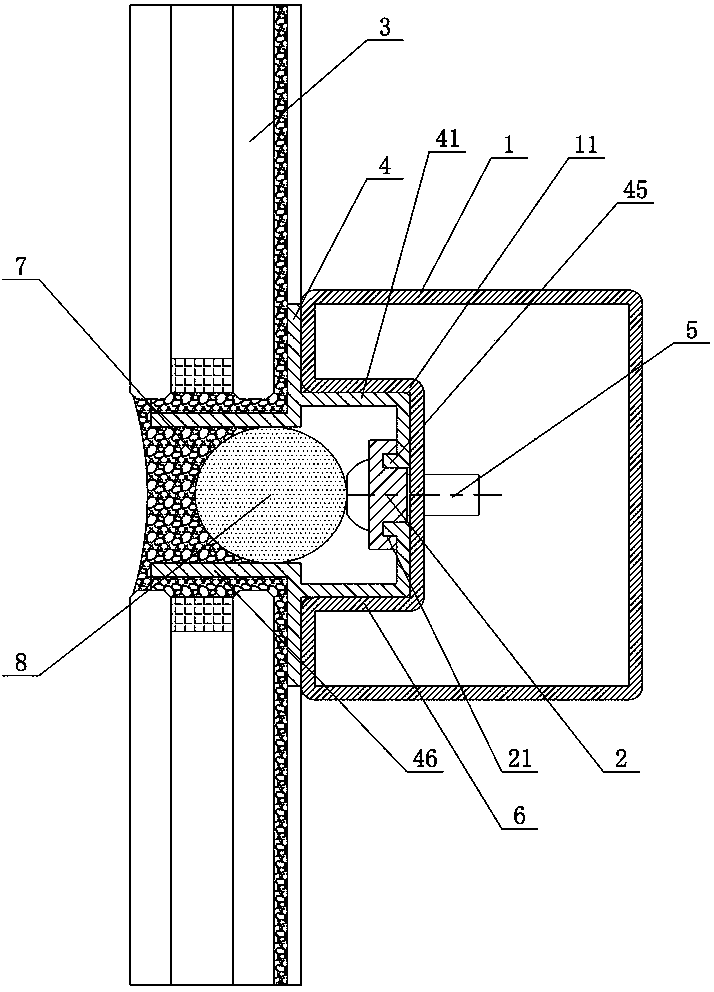

Power battery top cover and power battery

ActiveCN105845850AFirmly connectedAvoid Fracture FailureSecondary cellsCell lids/coversPower batteryEngineering

The invention relates to the technical field of lithium ion battery production, and especially relates to a power battery top cover and a power battery. The power battery top cover comprises a top cover sheet, a first electrode unit and a second electrode unit. An overturning sheet connection hole and an integrally formed first connection part are arranged on the top cover sheet. The first electrode unit comprises an overturning sheet, a conductive sheet and an insulation element. A second connection part and a conductive sheet connection part are arranged on the insulation element. The overturning sheet connection hole is sealed by the overturning sheet. The conductive sheet is located under the overturning sheet and is electrically connected with the overturning sheet. The insulation element is fixed at the lower side of the top cover sheet by matching the first connection part with the second connection part. The conductive sheet is fixed on the top cover sheet by the conductive sheet connection part in an insulated mode. The power battery comprises the power battery top cover. According to the power battery, the conductive sheet can be effectively prevented from breakage, failure or deformation in the using process.

Owner:JIANGSU CONTEMPORARY AMPEREX TECHNOLOGY LIMITED

Tool steel heat treatment process

The invention discloses a tool steel heat treatment process; and a material is W18Cr4V. The process is characterized by comprising the steps of: (1) forging treatment; (2) spheroidizing annealing treatment; (3) thermal refining; (4) quenching treatment; and (5) tempering treatment: the tempering temperature is 150-180 DEG C, and the time is 3-4 hours. The tool steel heat treatment process can improve the toughness of tool steel to prevent fracture failure of the tool steel too early through specifying all step requirements, parameter conditions and notes.

Owner:CHONGQING GUIKUN MACHINERY CO LTD

Drill rod joint wearproof belt and preparation method thereof

ActiveCN110318690AHigh hardnessImprove wear resistanceDrilling rodsDrilling casingsHexagonal boron nitrideHardness

The invention provides a drill rod joint wearproof belt. The drill rod joint wearproof belt comprises a drill rod joint substrate and a coating. The coating is arranged on the surface of the drill rodjoint substrate and is of a multi-layer structure, and the mass contents of hexagonal boron nitride of the coating are different. The coating with the different mass contents of the hexagonal boron nitride is prepared from components including Fe-based amorphous alloy and the hexagonal boron nitride. The mass contents of the hexagonal boron nitride in the multi-layer-structure coating with the different mass contents of the hexagonal boron nitride are gradually increased from the interior to the surface. Compared with the prior art, cold spraying is adopted, and high-temperature phase changeand heat stress generated by a drill rod joint can be avoided; the FeCrMoBYc amorphous alloy has high hardness and has a wearproof effect; and an HBN stratified structure has an antifriction effect, the FeCrMoBYc amorphous alloy and the hexagonal boron nitride are combined to be prepared into the gradient coating, and the comprehensive wearproof performance of the wearproof belt can be greatly enhanced. The invention further provides a preparation method of the drill rod joint wearproof belt.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING) +1

Die steel machining technology

The invention discloses a mold steel processing technology, the material is 3Cr2W8, which is characterized in that the processing method comprises the following steps: (1) forging process; (2) spheroidizing annealing process; (3) rough processing; (4) Quenching and tempering; (5) Semi-finishing; (6) Heat treatment; (7) Finishing; (8) Polishing; (9) Stress relief tempering. The die steel processing technology of the present invention can improve its strength and toughness by standardizing the requirements of each step, parameter conditions and precautions, and prevent premature fracture and failure of the die.

Owner:重庆向阳仪器有限公司

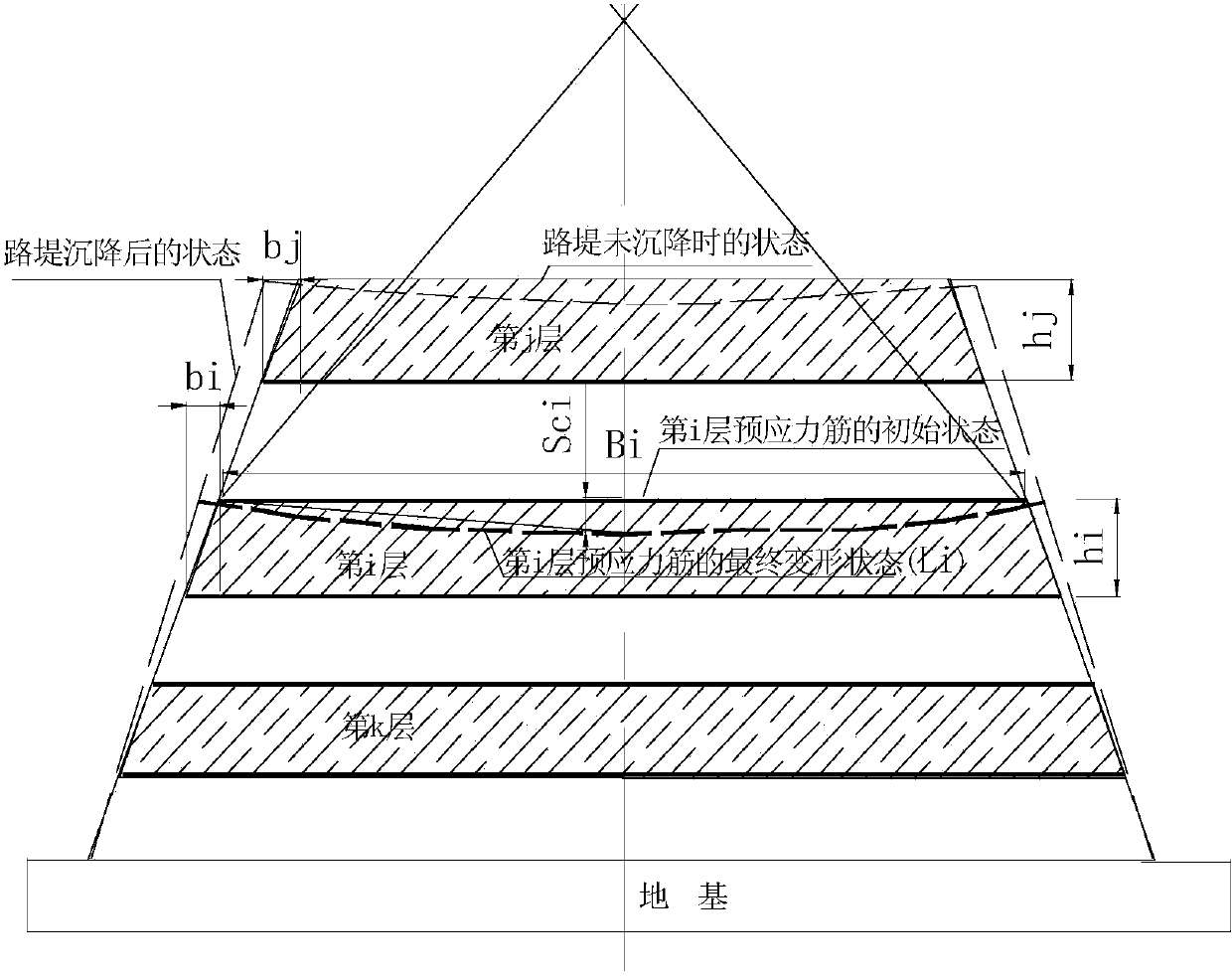

Pre-strain rib total deformation measuring method in pre-strain reinforcement test

InactiveCN103469831AReliable estimateEnsure moderate initial deformationFoundation testingPre strainCreep rate

The invention discloses a pre-strain rib total deformation measuring method in a pre-strain reinforcement test. A calculation formula of the pre-strain rib total deformation epsilon i is Epsilon i=Delta Epsilon'i+Delta Epsilon ci+Delta Epsilon'ri, wherein the Delta Epsilon'i is initial pre-strain of a pre-strain rib, the Delta Epsilon ci is additional strain of the pre-strain rib due to soil body compression, and the Delta Epsilon'ri is rib creep rate. The actual engineering conditions are considered in the formula, the pre-strain rib total deformation can be accurately and reliably estimated, initial deformation degree of the rib during rib tensioning is ensured, overlarge additional rib deformation caused by settlement deformation of an embankment is avoided, accordingly fracture failure caused by the fact that the total rib deformation exceeds allowable strain is prevented effectively, and environmental geological disasters including high and steep slope slippage and the like can be scientifically prevented and decreased.

Owner:CHANGSHA UNIVERSITY

Automobile die steel processing technology

InactiveCN107964578AImprove toughnessPrevent premature fracture failureTemperature treatmentStress relief

The invention discloses a processing technology for automobile mold steel, the material is 3Cr2W8, and it is characterized in that the processing method comprises the following steps: (1) forging process; (2) spheroidizing annealing process; (3) rough processing; (4) ) quenching and tempering; (5) semi-finished car; (6) high temperature treatment; (7) finishing; (8) polishing; (9) stress relief tempering. The automobile mold steel processing technology of the present invention can improve its strength and toughness by standardizing the requirements of each step, parameter conditions and precautions, and prevent premature fracture and failure of the mold.

Owner:重庆华厦新力新能源汽车有限公司

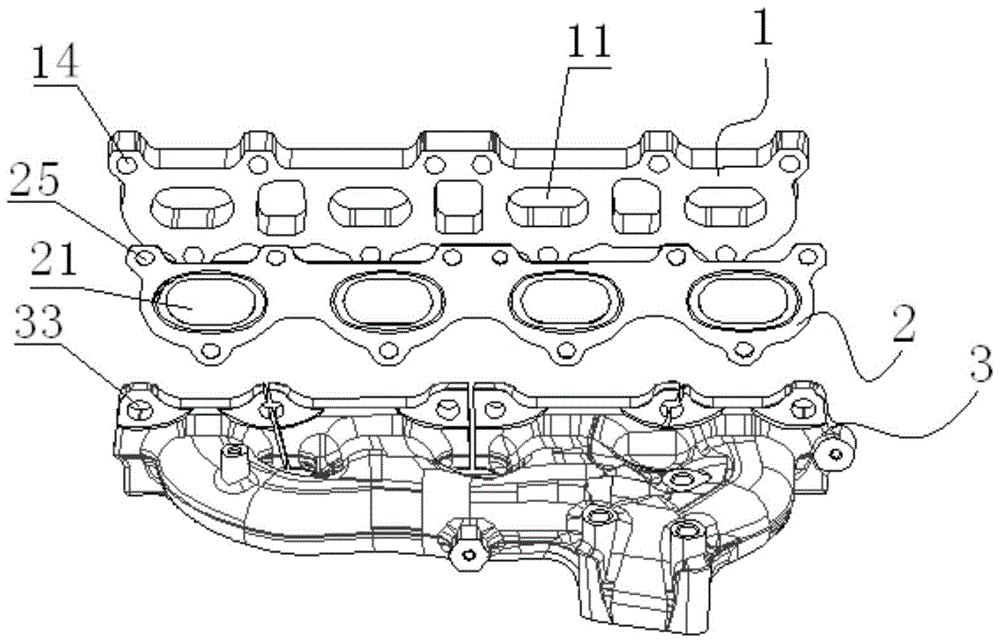

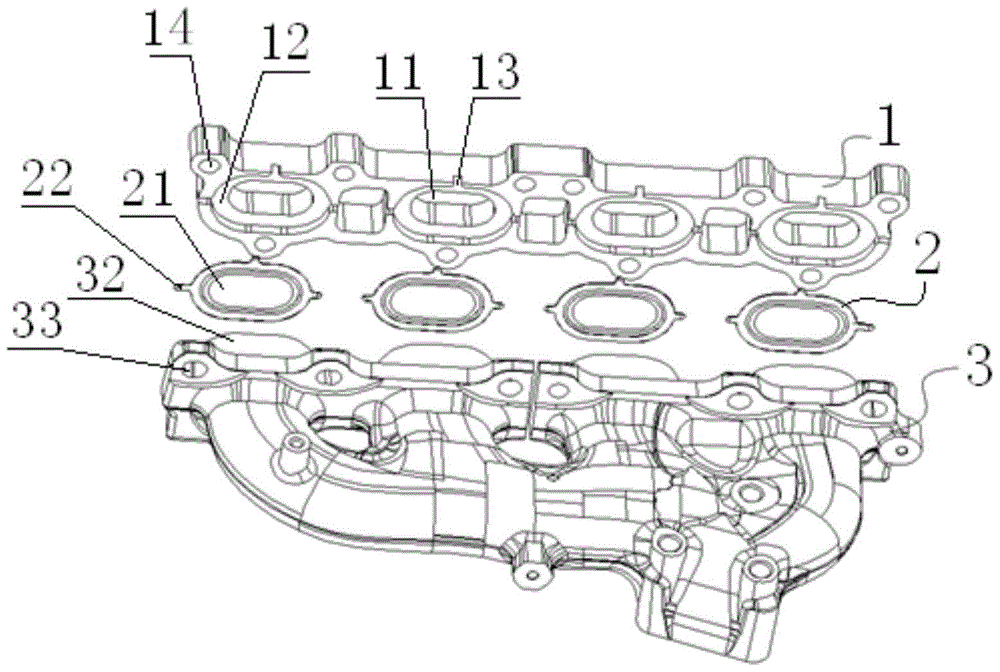

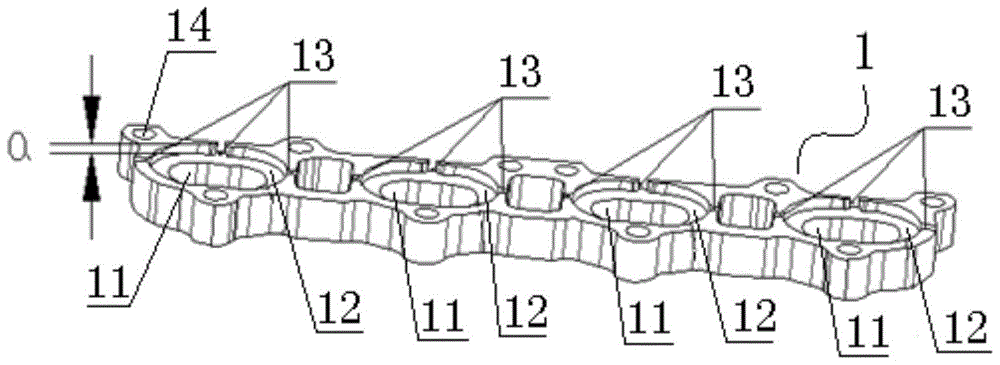

Sealing structure of turbo-charged direct injection engine exhaust system

InactiveCN105697118APrevent slippingPrevent creepEngine sealsExhaust apparatusCylinder headPulp and paper industry

The invention discloses a sealing structure of a turbo-charged direct injection engine exhaust system. The sealing structure comprises a cylinder head flange, sealing gaskets and an exhaust manifold flange. The cylinder head flange is provided with a plurality of exhaust outlets, the sealing gaskets are provided via holes correspondingly, and the exhaust manifold flange is provided with air duct openings as many as the exhaust outlets. Sealing grooves are formed in the edges, corresponding to the exhaust outlets, of the cylinder head flange, and the number of the sealing gaskets is equal to the number of the exhaust outlets. The sealing gaskets are matched with the end faces of the sealing grooves in shape. Exhaust pipes are arranged on the edges, corresponding to the air duct openings, of the exhaust manifold flange, the height of each exhaust pipe is equal to the depth of the corresponding sealing groove, and an inner hole of each exhaust pipe corresponds to the corresponding air duct opening. The sealing gaskets are mounted in the sealing grooves, the exhaust pipes stretch into the sealing grooves, press the sealing gaskets and are in clearance fit with the sealing grooves, the exhaust outlets, the via holes, the inner holes and the air duct openings communicate with one another correspondingly, and the cylinder head flange and the exhaust manifold flange are connected through bolts and nuts. By means of the sealing structure, the bolts can be prevented from being broken, and the sealing gaskets are protected against seal failures.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

A kind of preparation method of sandwich layer forging die and forging die sandwich layer surfacing welding

ActiveCN104741499BExtended service lifeImprove performanceArc welding apparatusForging/hammering/pressing machinesSoft materialsHigh pressure

The invention discloses a sandwich layer forging die and a preparation method of forging die sandwich layer surfacing. The sandwich layer forging die is used for surfacing a layer of sandwich layer soft welding material which is better in plasticity and lower in yield strength than a cast steel substrate and a double-metal gradient surfacing material between the cast steel substrate and the double-metal gradient surfacing material; the preparation method of the forging die sandwich layer surfacing comprises the following steps of taking cast steel as the cast steel substrate, and welding a sandwich layer soft material on a substrate layer; surfacing a transition layer material on a substrate of a sandwich layer welded, welding and covering all sandwich materials to form a surfacing transition layer; welding a high-temperature wearing layer material; tempering to distress after the completion of the welding, and then mechanically processing to obtain a mould. The sandwich layer forging die provided by the invention is long service life and high in loading capacity of the cast steel substrate. According to the method provided by the invention, the critical bottleneck problems that the forging die is low in life and the die is high in manufacturing cost can be solved thoroughly, the die forging forming of various materials can be supported at high temperature and high pressure, and a brand new manufacturing method can be provided for forging die manufacturing.

Owner:CHONGQING UNIV +2

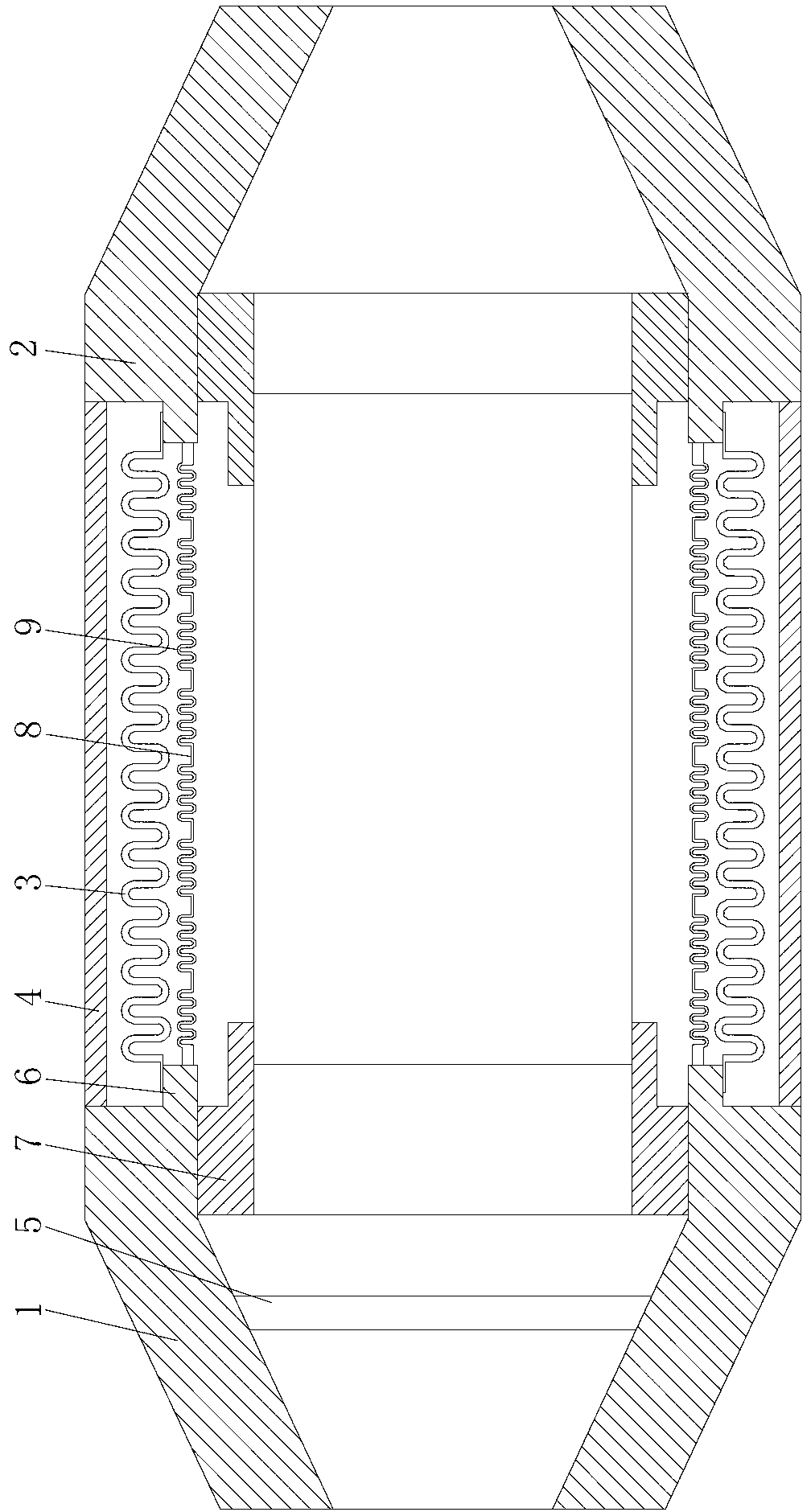

Electromagnetic driving galvanometer for reducing rocking motion

The invention belongs to the field of micro-optoelectronics, and particularly relates to an electromagnetic driving galvanometer for reducing the rocking motion. The galvanometer includes an electromagnetic galvanometer chip, a structure body and a driving magnetic circuit; the structure body is used for fixing the electromagnetic galvanometer chip and the driving magnetic circuit; the electromagnetic galvanometer chip includes a movable structure, a torsion beam and a fixing frame, and the movable structure is fixed on the fixing frame through the torsion beam; the driving magnetic circuit isused for driving the movable structure to move; the movable structure includes a movable mirror and a magnetic material set on the opposite side of the movable mirror; when the movable mirror is located in a horizontal position, the center of the upper surface of the movable mirror is defined as an origin, and the Z axis is perpendicular to the movable mirror; the center of gravity of the movablestructure is on the Z axis, and the Z axis coordinate of the center of gravity of the movable structure is the same as the Z axis coordinate of the center of the torsion beam. By matching the position of the torsion beam of the galvanometer and the gravity center of the galvanometer, the deviation between the torsion beam of the galvanometer and the gravity center of the galvanometer is reduced,and the rocking motion of the galvanometer is reduced.

Owner:XI AN ZHISENSOR TECH CO LTD

Hidden-frame type glass curtain wall

The invention discloses a hidden-frame type glass curtain wall. The hidden-frame type glass curtain wall comprises a keel, a press plate, a glass plate, an aluminum auxiliary frame and a fastening bolt. The glass plate is glued to the outer side of the aluminum auxiliary frame. The fastening bolt penetrates the press plate to be fixedly connected with the keel, and drives the press plate to press the aluminum auxiliary frame. A bearing member is arranged between the keel and the glass plate, and is used for bearing the aluminum auxiliary frame and directly transmitting loads of the glass plate and the aluminum auxiliary frame to the keel. The glass curtain wall has the advantages of simple structure and capability of effectively protecting the fastening bolt from damage.

Owner:HUNAN GOLDWELL NEW MATERIALS TECH CO LTD

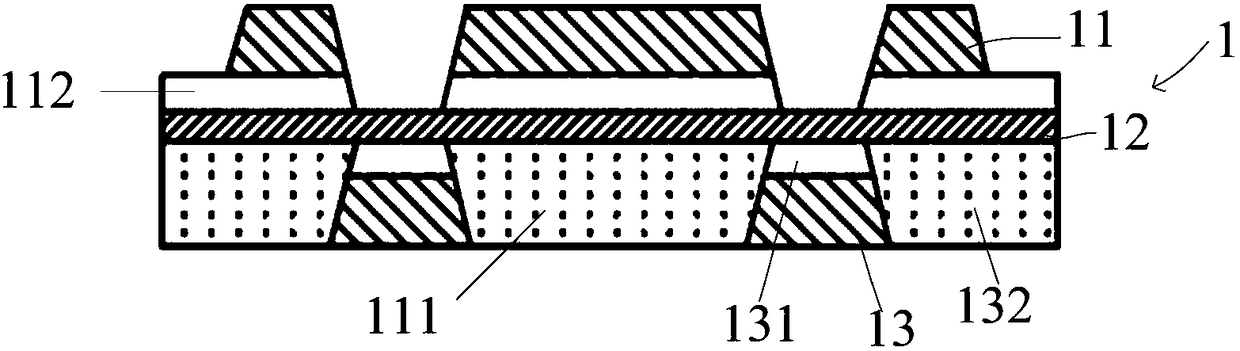

Thin film transistor device and manufacturing method thereof

ActiveCN109427910AImprove bending resistanceAvoid bendingTransistorSemiconductor/solid-state device manufacturingElectrical and Electronics engineeringFailure causes

Embodiments of the invention provide a thin film transistor device and a manufacturing method thereof. A gate electrode of the thin film transistor device comprises a top gate and a bottom gate, wherein the top gate is arranged above a channel layer of the thin film transistor device; the bottom gate is arranged below the channel layer; at least one through hole is formed in the top gate, and theprojection, on a plane parallel to the channel layer, of the through hole in the top gate is covered by the projection, on the plane, of the top gate; and / or at least one through hole is formed in thebottom gate, and the projection, on the plane, of the through hole in the bottom gate is covered by the projection, on the plane, of the top gate. The thin film transistor device provided by the embodiments of the invention is capable of solving the problem of display failure caused by stress concentration when existing thin film transistor devices are bent to deform.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

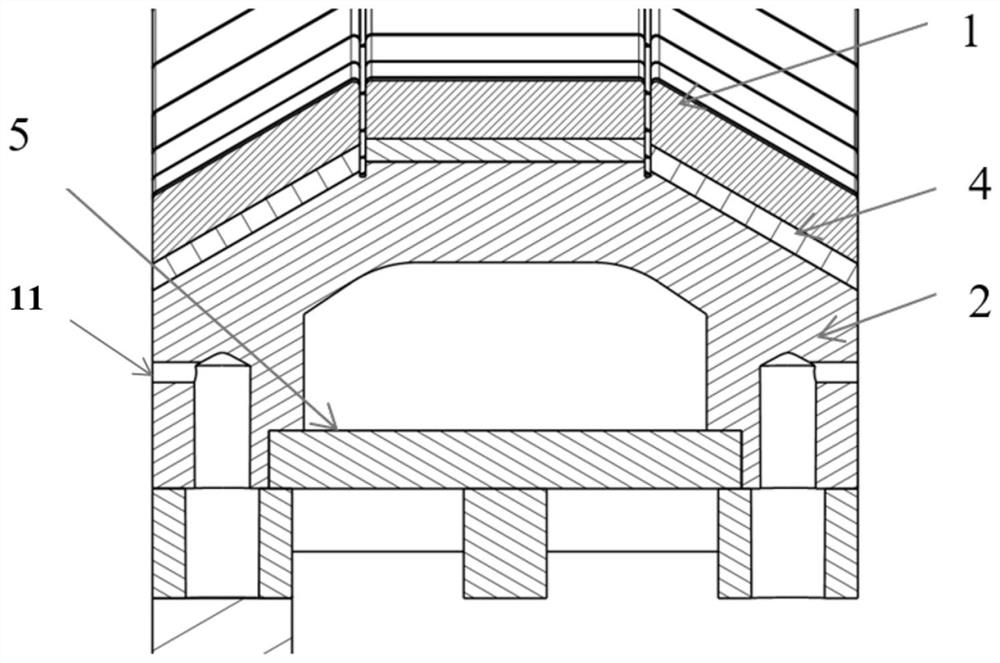

Carbon fiber reinforced composite (CFC) protection limiter

PendingCN112992384AEfficient and stable operationReduce heat transfer resistanceNuclear energy generationThermonuclear fusion reactorPhysicsHeat sink

The invention discloses a carbon fiber reinforced composite (CFC) protection limiter, which mainly comprises CFC modules, an oxygen-free copper metallization layer, a chromium zirconium copper heat sink body and a stainless steel framework. The CFC modules of the limiter are arranged in an annular array along the longitudinal direction of an antenna and are arranged in an isosceles trapezoid in the transverse direction, and the CFC modules are kept at a preset interval. A stress releasing groove is machined in the surface of the heat sink body, the CFC modules and the chromium zirconium copper are sealed in a high-temperature brazing mode, and a heat load on the surface of the CFC takes away heat through an active cooling water channel. The invention provides a high-heat-load-resistant (greater than 2MW / m<2>) limiter structure and a reliable preparation method, and sputtering damage of high-energy particles to the surface of an antenna component during long-pulse high-temperature plasma operation is effectively avoided.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

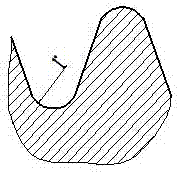

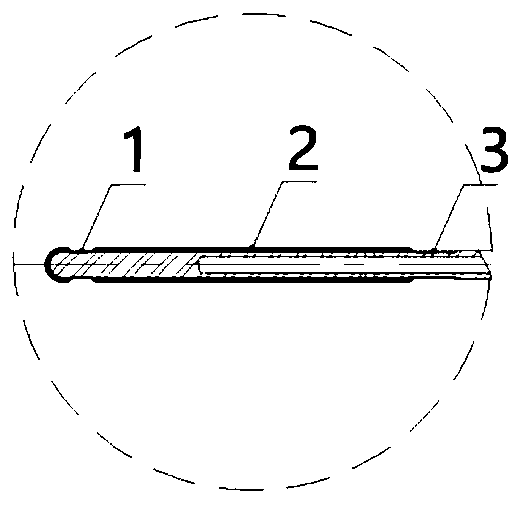

Porous metal rod

ActiveCN107303208AReduce stressAvoid Fracture FailureJoint implantsTissue regenerationTreatment successIntermediate stage

The invention relates to a porous metal rod for medical implanting used for treating early-stage and middle-stage femoral head necrosis. The porous metal rod comprises two parts, wherein one part is a round-rod-shaped part, the other part connected with the round-rod-shaped part is a threaded part, threads are arranged on the outer part of the threaded part, the outer diameter of the threads is greater than that of the round rod shape, a notch is formed in the end face of the threaded part, the outer diameter of one section, close to the round rod shape, of the threaded part is gradually reduced towards the round-rod-shaped part, so that the stress at the joint of the threaded part and the round-rod-shaped part is reduced, thus the fracture failure of the porous metal rod can be avoided, and finally, the treatment success rate is improved.

Owner:CHONGQING RUNZE PHARM CO LTD

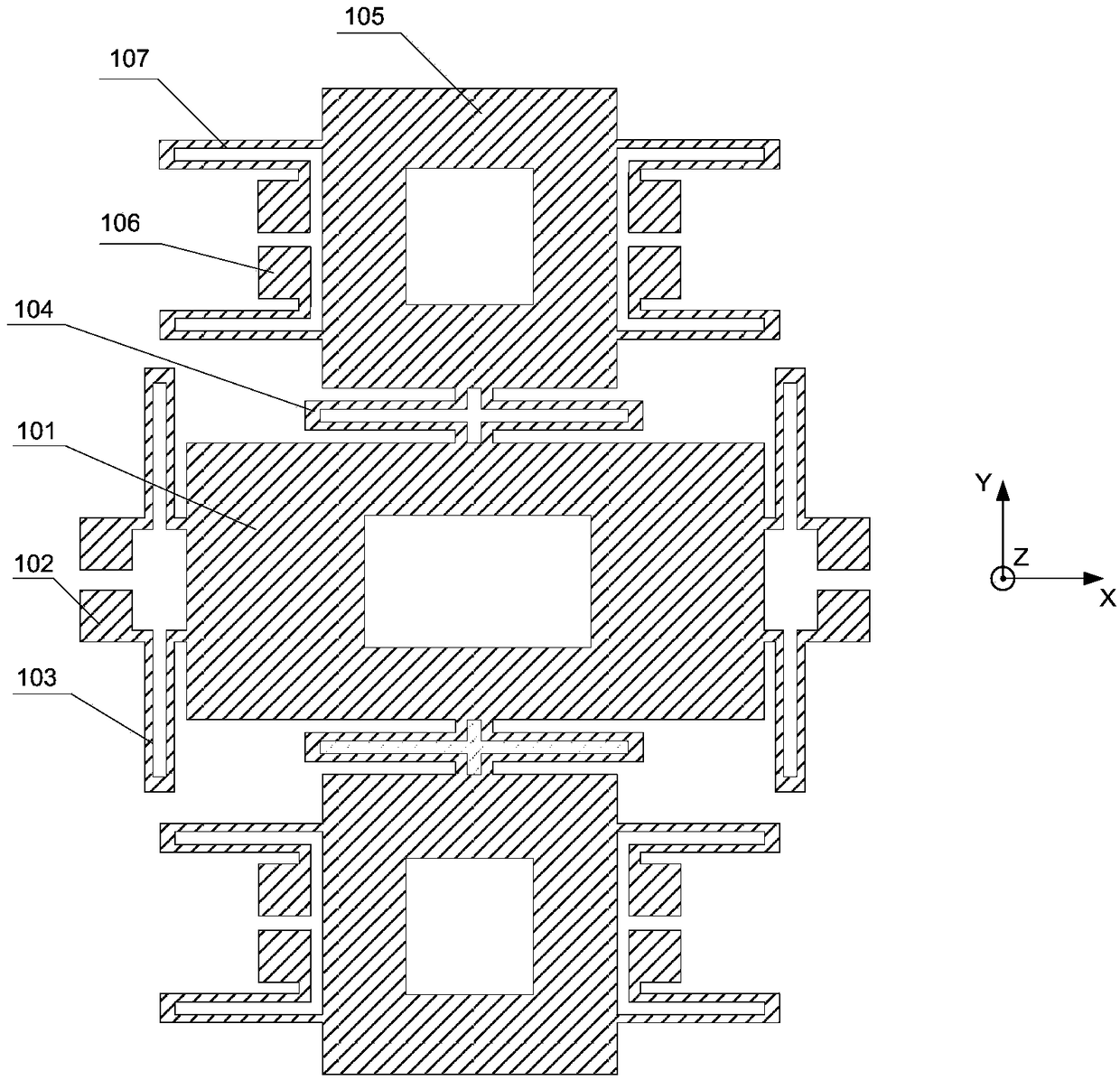

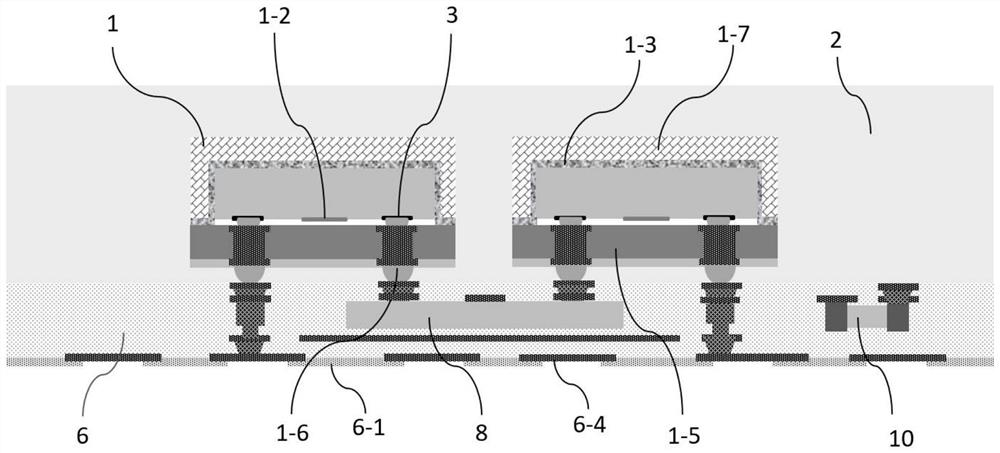

A protection device and processing method for a sensitive structure of a quartz micromachined accelerometer

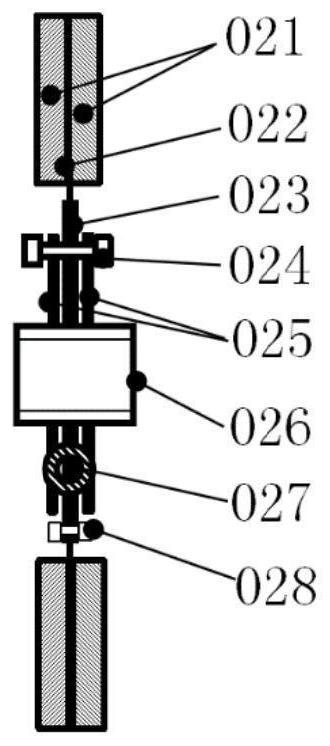

ActiveCN106134431BImprove impact resistanceAvoid Large Displacement DeformationSpeed measurement using gyroscopic effectsGyroscopes/turn-sensitive devicesEtchingAccelerometer

The invention relates to a protection device and a processing method for a sensitive structure of a quartz micromechanical accelerometer. The protection device selects a quartz crystal of the same material and cut shape as the sensitive structure as a base material, adopts a high-precision photolithography process to make patterns, and uses wet etching It is processed by etching process, and the sensitive structure and protective structure are assembled by epoxy adhesive bonding, forming a three-layer assembly structure in which the upper and lower layers are the protective structure and the middle layer is the sensitive structure, and the upper and lower protective structures are sensitive to the middle layer. The mass block on the structure plays the role of limit protection, and at the same time, the groove area is etched to a certain depth on the protection device, providing space for the deformation of the sensitive structural mass block, and at the same time, high alignment accuracy is achieved with the help of an optical microscope system. The protection device of the present invention effectively improves the impact resistance of the sensitive structure, avoids the stress caused by the difference in thermal expansion coefficient, improves the reliability of the sensitive structure, and has high assembly precision, simple process and easy implementation.

Owner:BEIJING RES INST OF TELEMETRY +1

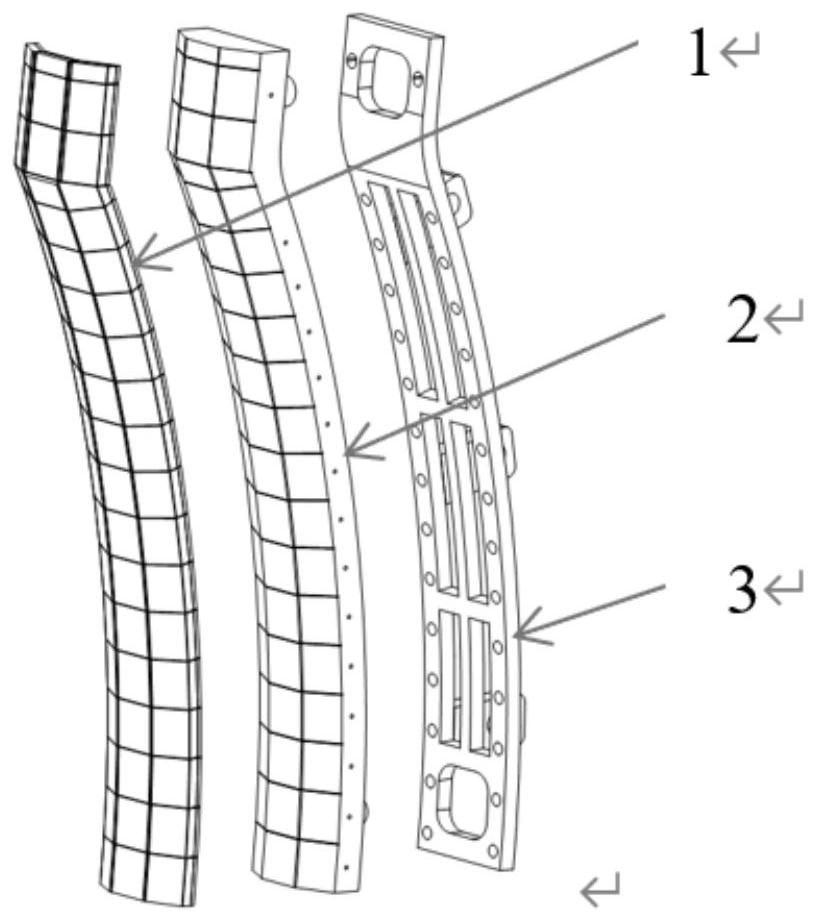

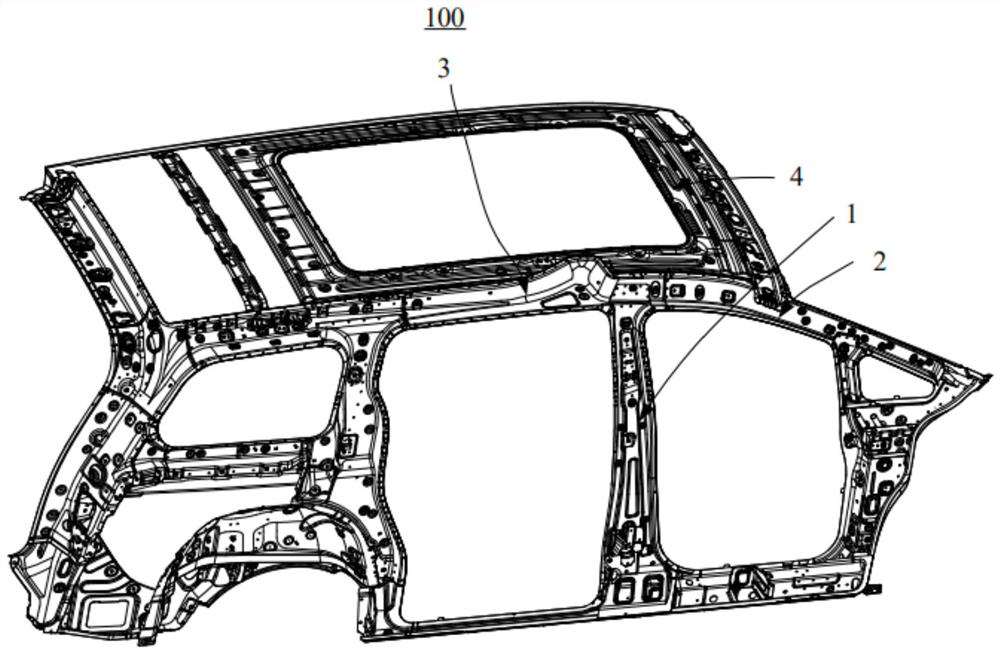

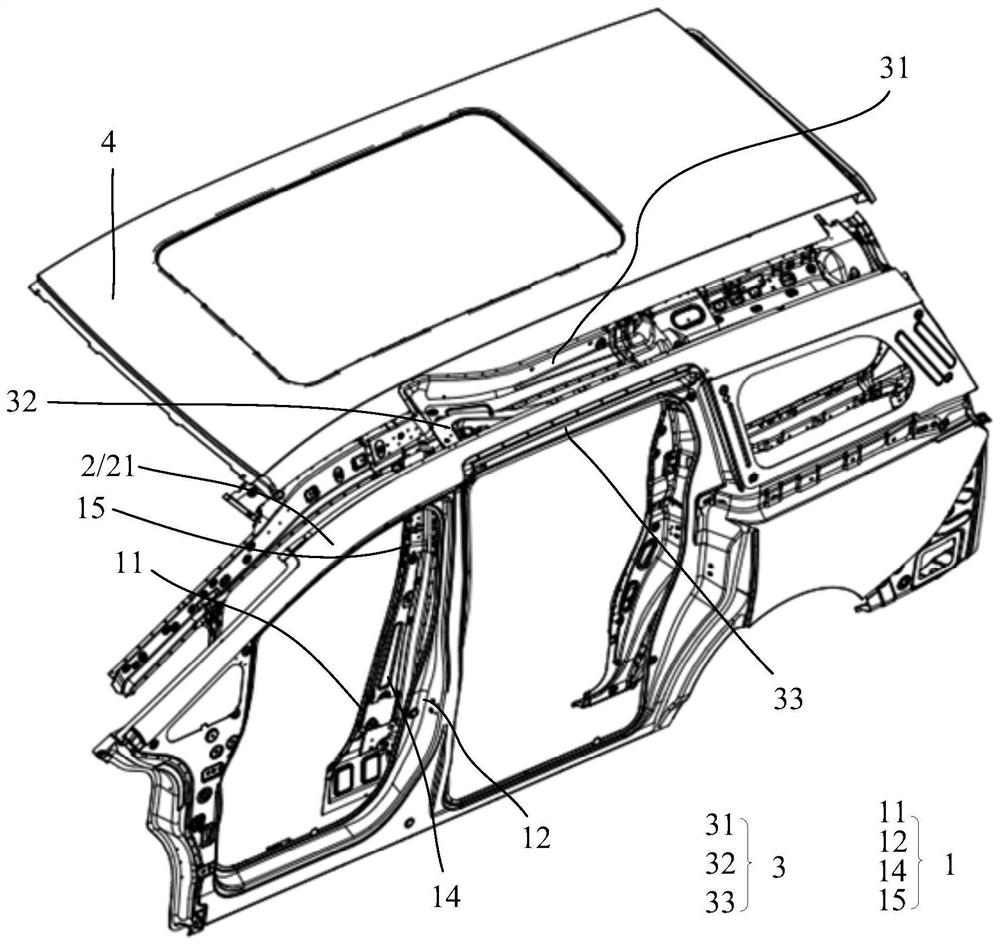

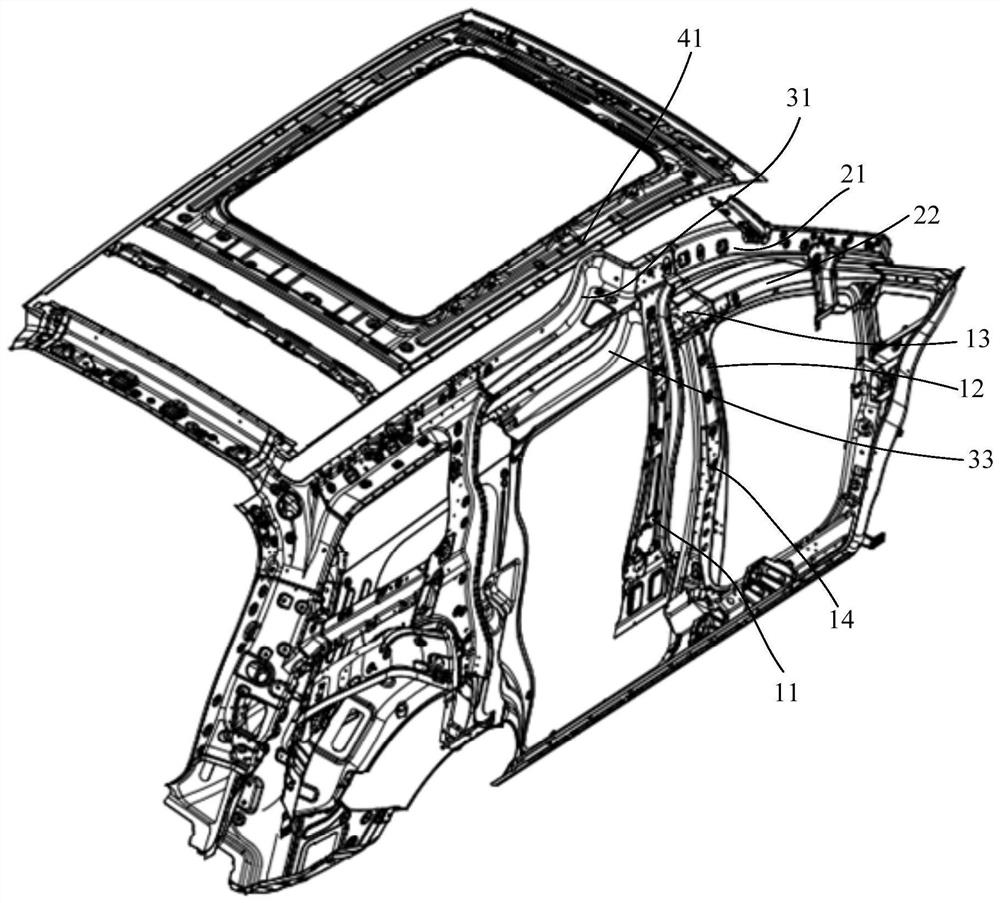

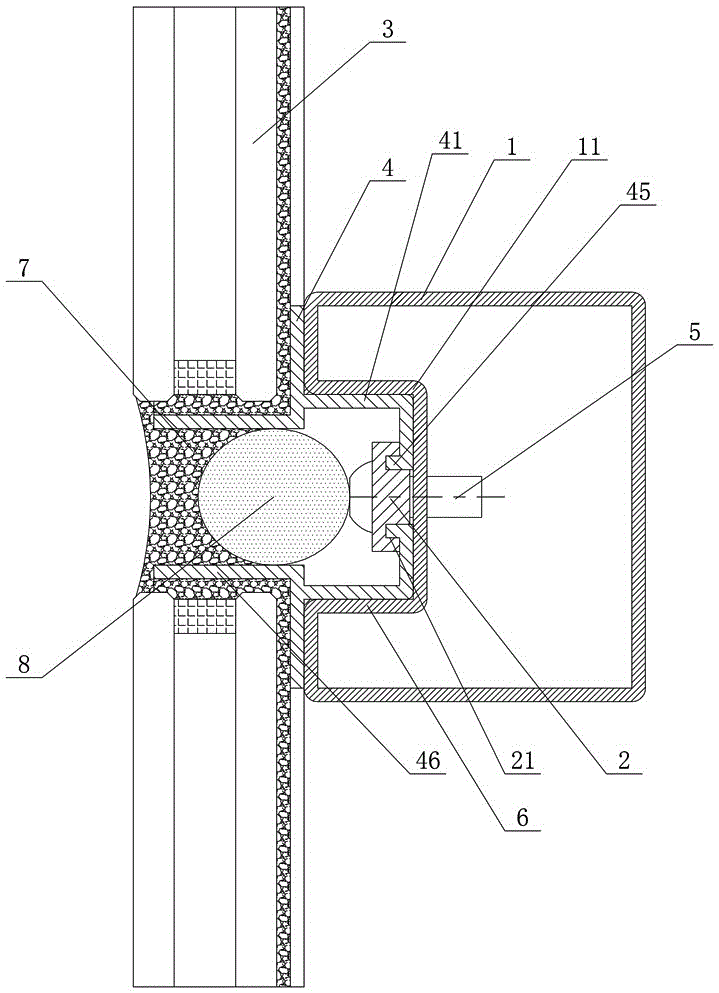

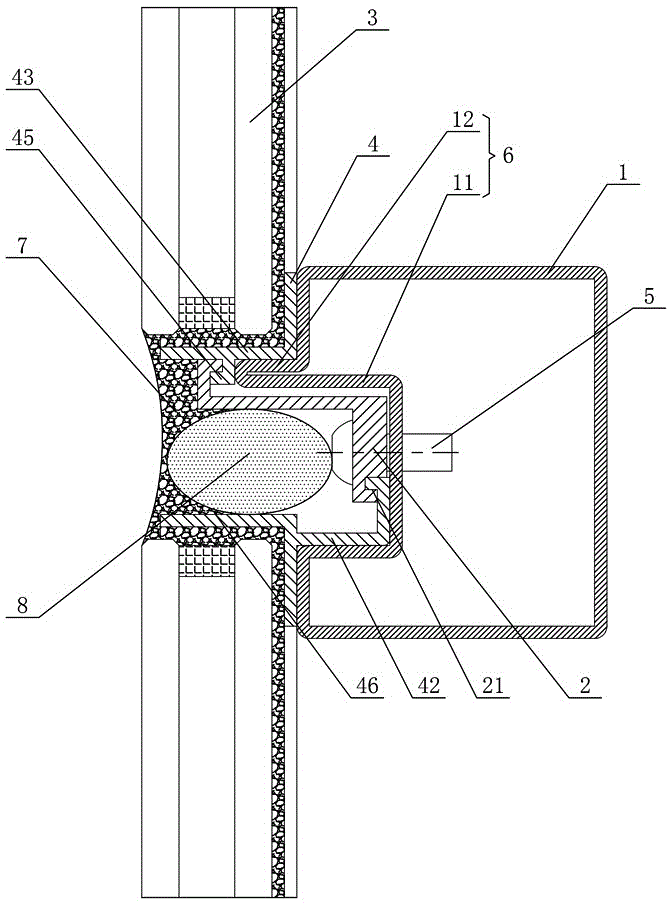

Automobile B column upper connector structure and automobile

PendingCN113428235AStable supportHigh strengthSuperstructure subunitsAutomotive engineeringLap joint

The invention discloses an automobile B column upper connector structure and an automobile. The automobile B column upper connector structure comprises a B column structure, an A column structure and a BC column connecting structure, the B column structure comprises a B column inner plate and a B column outer plate, a lap joint cavity is formed between the B column inner plate and the upper end of the B column outer plate, the A column structure comprises an A column upper inner plate and an A column upper reinforcing plate, the A column upper inner plate and / or the A column upper reinforcing plate are / is partially located in the lap joint cavity, in the BC column connecting structure, the BC column connecting inner plate and / or the sliding door upper guide rail mounting plate and / or the sliding door upper guide rail mounting reinforcing plate are / is partially located in the lap joint cavity, the cavity structure is good in strength and rigidity, the lap joint rigidity of the B column upper connector is improved, the whole sliding door can be effectively supported, and the sliding door mounting frame is prevented from deforming and generating abnormal sound due to insufficient rigidity, can bear load to the maximum extent in side collision, and is prevented from breaking and losing efficacy in the collision.

Owner:DONGFENG LIUZHOU MOTOR

Hidden frame type glass curtain wall

The invention discloses a hidden frame type glass curtain wall. The glass curtain wall comprises a keel, a press plate, a glass plate, an aluminum auxiliary frame and a fastening bolt, wherein the glass plate is glued on the outer side of the aluminum auxiliary frame, the fastening bolt penetrates through the press plate to be in fastening connection with the keel and drives the press plate to press the aluminum auxiliary frame, and a bearing part for bearing the aluminum auxiliary frame and directly transmitting the load of the glass plate and the aluminum auxiliary frame to the keel is also arranged between the keel and the glass plate. The glass curtain wall has the advantages that the structure is simple and the fastening bolt can be effectively protected from damage.

Owner:HUNAN GOLDWELL NEW MATERIALS TECH CO LTD

Electromechanical coupling buffer device of range extender

InactiveCN111853079AAvoid alternationAvoid noiseSlip couplingVibration suppression adjustmentsFlywheelControl theory

The invention discloses an electromechanical coupling buffer device of a range extender. The electromechanical coupling buffer device is used for connecting an engine flywheel and a generator spline shaft; and the device comprises a shell, a friction plate assembly and a pressure plate assembly; the engine flywheel is inserted into the shell; the friction plate assembly is arranged in a gear ringof the engine flywheel in a matched mode; a friction plate is pressed in the middle of the pressing disc assembly in a matched mode, and the edge of the pressing disc assembly is connected with the gear ring; and the generator spline shaft sequentially penetrates through the pressing plate assembly and the friction plate assembly in a matched mode, and the shell is connected with an engine. The electromechanical coupling buffer device of the range extender buffers vibration between the engine flywheel and the generator spline shaft, noise caused by impact generated by an engine and a generatorduring variable-working-condition operation is avoided, and the situation that the service life of an engine crankshaft and the service life of a crankshaft bush are affected due to the fact that theengine crankshaft and the engine crankshaft bush are subjected to large alternating loads is avoided; and meanwhile, fracture failure of bolts and splines caused by impact load is avoided.

Owner:DONGFENG LIUZHOU MOTOR

Anti-shock overload out-of-plane stop structure of micro-inertial silicon sensor

InactiveCN109470229AImproved ability to resist out-of-plane impactLimit Z-axis out-of-plane offsetSpeed measurement using gyroscopic effectsGyroscopes/turn-sensitive devicesClassical mechanicsLarge deformation

The invention discloses an anti-shock overload out-of-plane stop structure of a micro-inertial silicon sensor. A plurality of bump structures are arranged on an upper substrate and a lower substrate of a sensitive structure of the sensor to form the out-of-plane stop structure; and the bump structures on the upper substrate and the lower substrate are located in maximum displacement positions corresponding to a middle mass block and beam structures during out-of-plane shock and symmetrically distributed relative to the mass block and the beam structures. Certain gaps exist between the out-of-plane stop structure and the mass block & the beam structures; normal operation of the mass block and the beam structures is not influenced; large deformation of the mass block in a Z axis under strongout-of-plane shock does not occur; and the anti-shock overload capacity is improved.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

Preparation method of multilayer functional ceramic component

ActiveCN112299859AImprove thermal stabilityReduce the probability of warpingLamination ancillary operationsLaminationSlurryTape casting

The invention provides a preparation method of a multilayer functional ceramic component. The method comprises the following steps: preparing ceramic slurry, and carrying out tape casting to obtain aceramic blank sheet; cutting the ceramic blank sheet, and then punching at a preset position to obtain a plurality of ceramic sheets with through holes; preparing a gel injection molding slurry containing an organic auxiliary agent capable of initiating gelation; stacking the ceramic sheets; arranging a metal circuit structure between the layers of the laminated ceramic sheets and in the through holes or in the through holes of the laminated ceramic sheets, injecting gel injection molding slurry matched with the metal circuit structure, and curing the gel to obtain a green body; and laminatingthe green body, and then sintering to obtain the multilayer functional ceramic component. According to the preparation method, the gel injection molding slurry is introduced and is matched with the metal circuit structure, and the shrinkage stress of the ceramic sheet and the expansion stress of the metal circuit structure are released by shrinkage of the gel layer of the gel injection molding slurry during sintering, so that the close fit between the metal circuit structure and the through hole is ensured; and the problems that the metal circuit structure is not shrunk during sintering to crack the ceramic part and the like are avoided.

Owner:SHANDONG RES & DESIGN ACADEMY OF IND CERAMICS

Corrugated connecting pipe device for lowering exhaust emission of automobile

InactiveCN103075236AImprove protectionAvoid harmInternal combustion piston enginesSilencing apparatusElastic componentExhaust emission

The invention relates to a corrugated connecting pipe device for lowering the exhaust emission of an automobile. The two ends of a protecting body are connected with an air inlet end cover and an air outlet end cover respectively; the axial end faces of the air inlet end cover and the air outlet end cover are provided with annular convex shoulders; connecting pipes are arranged in the air inlet end cover and the air outlet end cover; a corrugated hose is positioned in the protecting body; the two ends of the corrugated hose are connected with the axial end faces of the annular convex shoulder of the air inlet end cover and the annular convex shoulder of the air outlet end cover; an elastic component is positioned in the corrugated hose; the two ends of the elastic component are connected with the outer circumferential walls of the annular convex shoulder of the air inlet end cover and the annular convex shoulder of the air outlet end cover; one end of a three-way catalytic converter is fixedly connected with the inner circumferential wall face of the connecting pipe in the air inlet end cover; and the other end of the three-way catalytic converter is in sliding fit in the connecting pipe in the air outlet end cover. According to the corrugated connecting pipe device, the corrugated hose is prevented from being damaged in a tightened state, and the corrugated hose is prevented from being interfered with other components during working.

Owner:无锡市锡山环宇金属软管有限公司

Embedded structure and manufacturing method of filter module

PendingCN114826180AFree from influencePrevents Electrical Performance DegradationImpedence networksEpoxyMechanical engineering

According to the embedded structure of the filter module, full device packaging in the filter module is changed into partial packaging and partial substrate embedding, so that the conflict problem of full filling of a filter cavity covering film and a copper column gap of a flip switch chip is solved, and the problem of gap filling between two poles of an inductance passive element is solved; the problem of reliability hidden danger caused by extremely reduced size of a filter packaging body is solved, the hidden danger of product deformation and failure caused by unbalanced internal stress of various different materials in full-device packaging is solved, and the problems of dense components, small gaps and insufficient epoxy resin filling are solved. Meanwhile, different packaging schemes of the filter can be selected, so that the cost control of a scheme using a high-cost special film coating material can be effectively reduced.

Owner:SHANGHAI PINGSHENG MICRO CORP

Constant-pressure trigeminal nerve meniscus compression balloon (with additional balloon constant pressure)

PendingCN111481241AAvoid Fracture FailureGood for complete developmentBalloon catheterSurgical needlesBalloon catheterReoperative surgery

The invention discloses a constant-pressure trigeminal nerve meniscus compression balloon, which comprises a compression balloon catheter assembly; the compression balloon catheter assembly comprisesan expansion balloon and a supporting tube, and the expansion balloon is located at the end of the supporting tube; the far end of the support tube is connected with an additional balloon positioned in vitro, and the additional balloon is connected with an input source of a contrast agent. The device has the advantages that the additional balloon can buffer the injection pressure of the contrast developer in vitro, so that when the pressure in the expansion balloon changes, the pressure can be transmitted to the additional balloon outside the body; therefore, an operator can observe the pressure conveniently; meanwhile, the operator is reminded of possible surgical abnormal conditions.

Owner:SHANDONG IND TECH RES INST OF ZHEJIANG UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com