Corrugated connecting pipe device for lowering exhaust emission of automobile

A technology for corrugated connecting pipes and automobile exhaust, which can be used in exhaust devices, noise reduction devices, exhaust treatment, etc., and can solve problems such as short service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

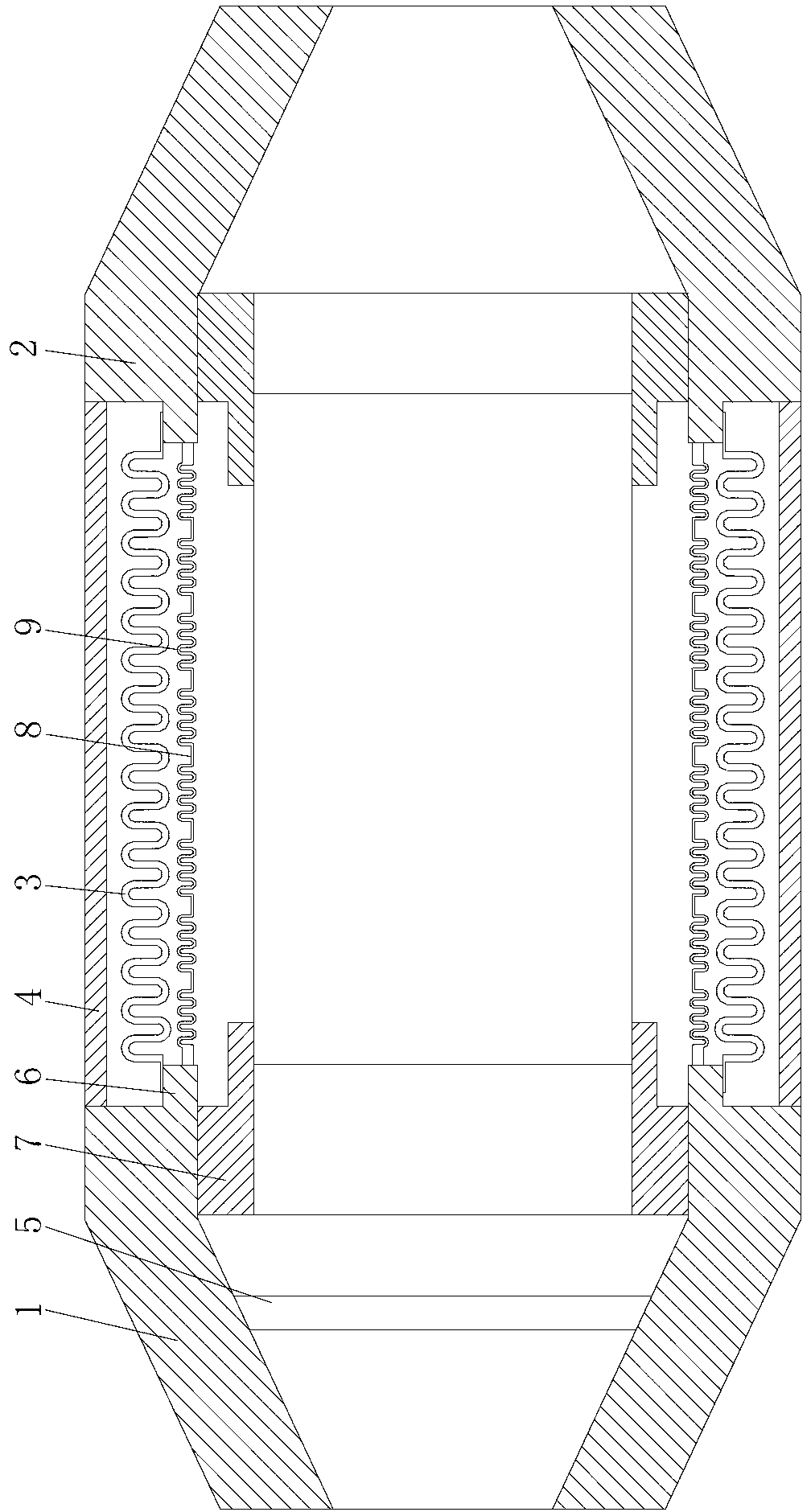

[0013] refer to figure 1 According to the present invention, the corrugated connecting pipe device for reducing automobile exhaust emissions includes a casing, a three-way catalytic converter and an elastic component arranged in the casing. The housing includes an air inlet end cover 1 , an air outlet end cover 2 and a corrugated hose 3 , and the housing also includes a protective body 4 located between the air inlet end cover and the air outlet end cover. A gas buffer combustion disc 5 of porous ceramics is arranged in the air intake end cover, and the gas buffer combustion disc 5 enables exhaust gas to be fully combusted again, reducing exhaust gas emissions and reducing the workload of the three-way catalytic converter. The axial end faces of the air inlet end cover 1 and the air outlet end cover 2 are provided with annular shoulders 6, and the annular shoulders 6 are mainly used for assembling corrugated hoses and elastic parts, so that the corrugated hoses and elastic par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com