Patents

Literature

2901 results about "Catalytic converter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

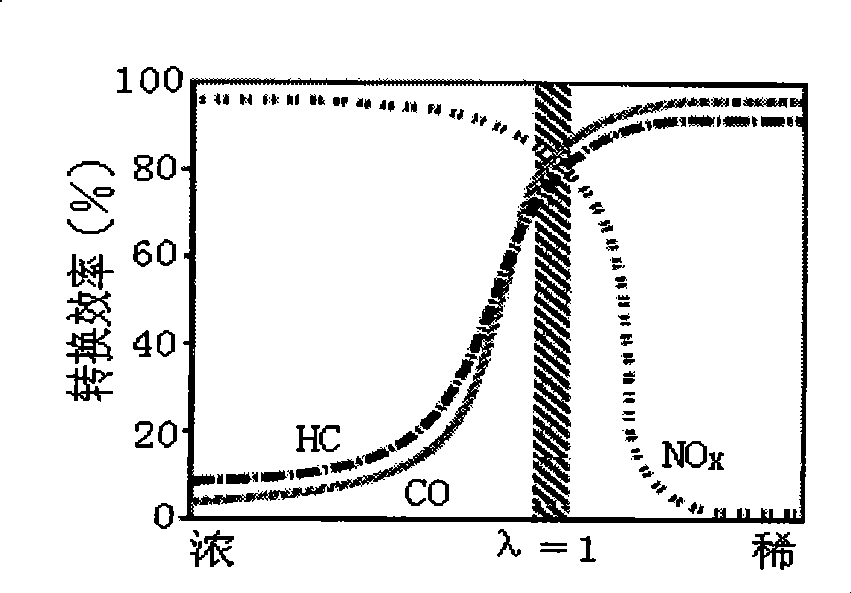

A catalytic converter is an exhaust emission control device that reduces toxic gases and pollutants in exhaust gas from an internal combustion engine into less-toxic pollutants by catalyzing a redox reaction (an oxidation and a reduction reaction). Catalytic converters are usually used with internal combustion engines fueled by either gasoline or diesel—including lean-burn engines as well as kerosene heaters and stoves.

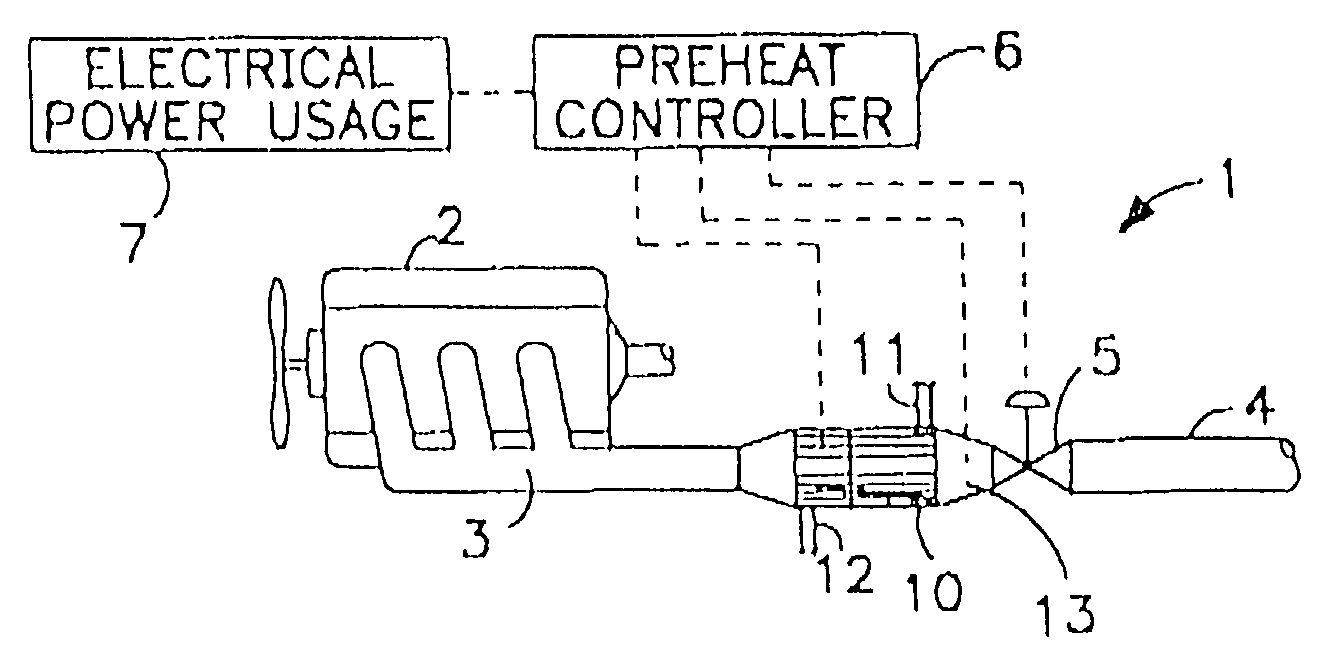

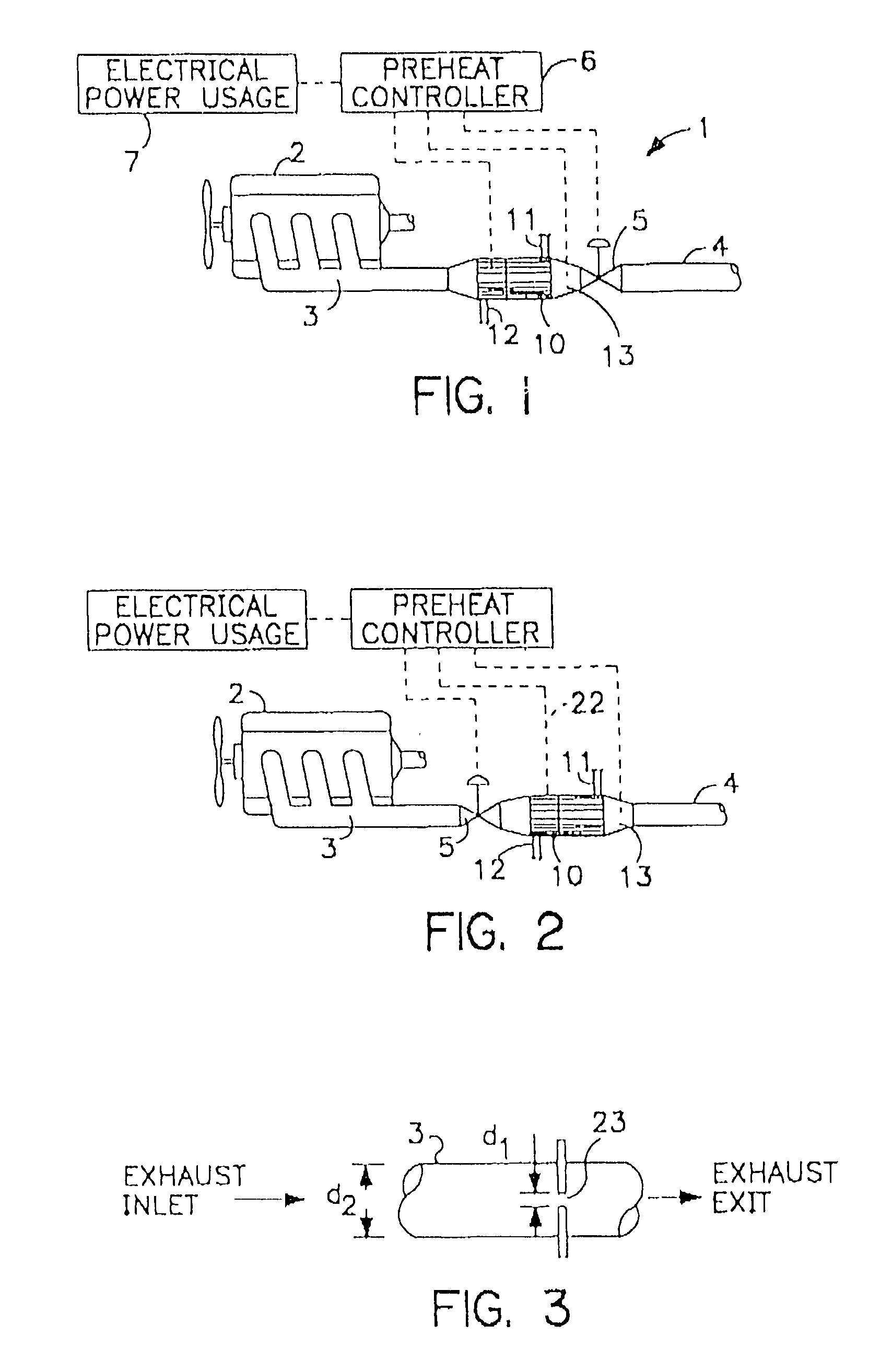

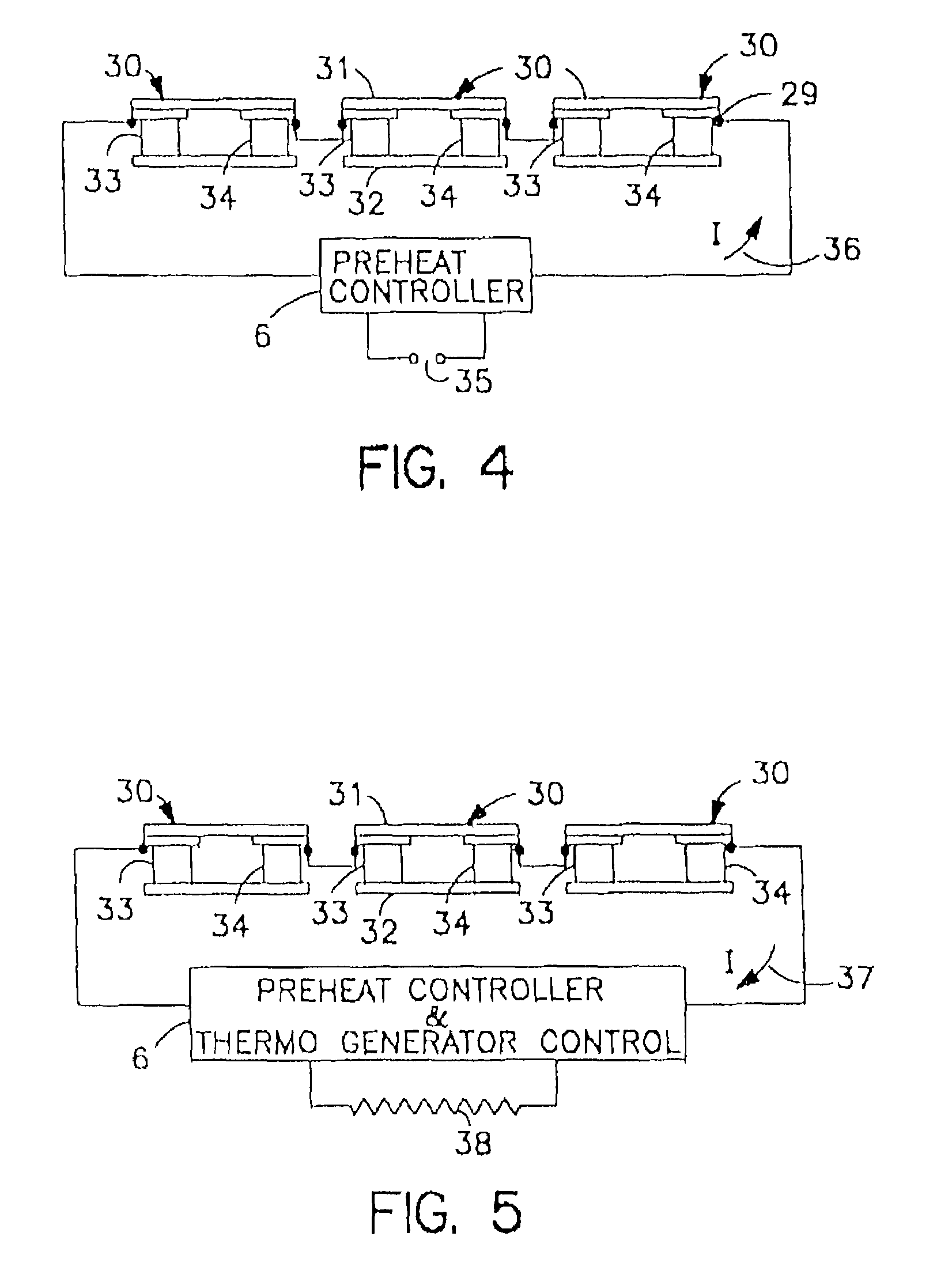

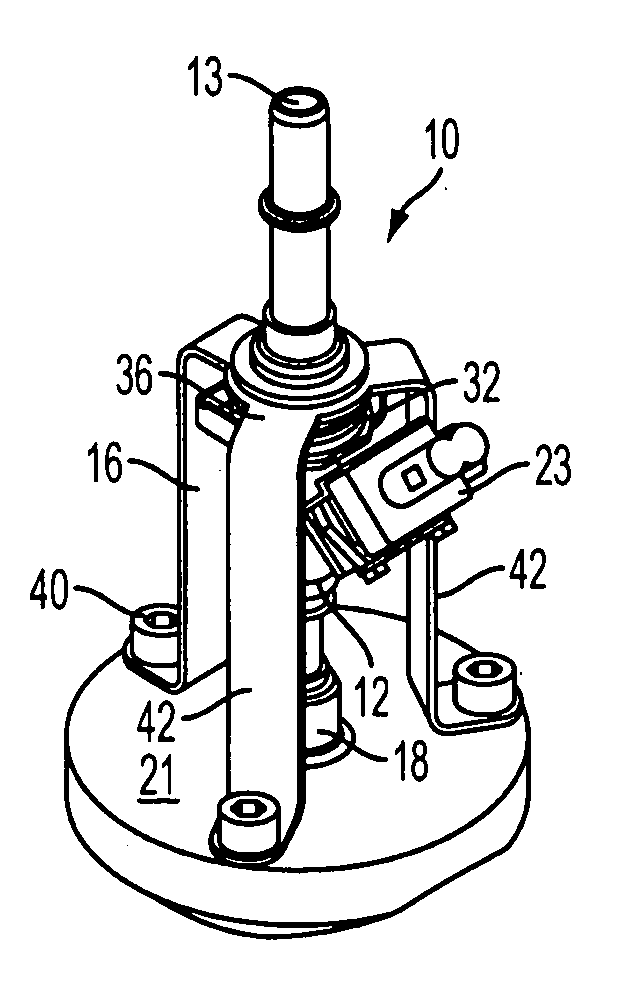

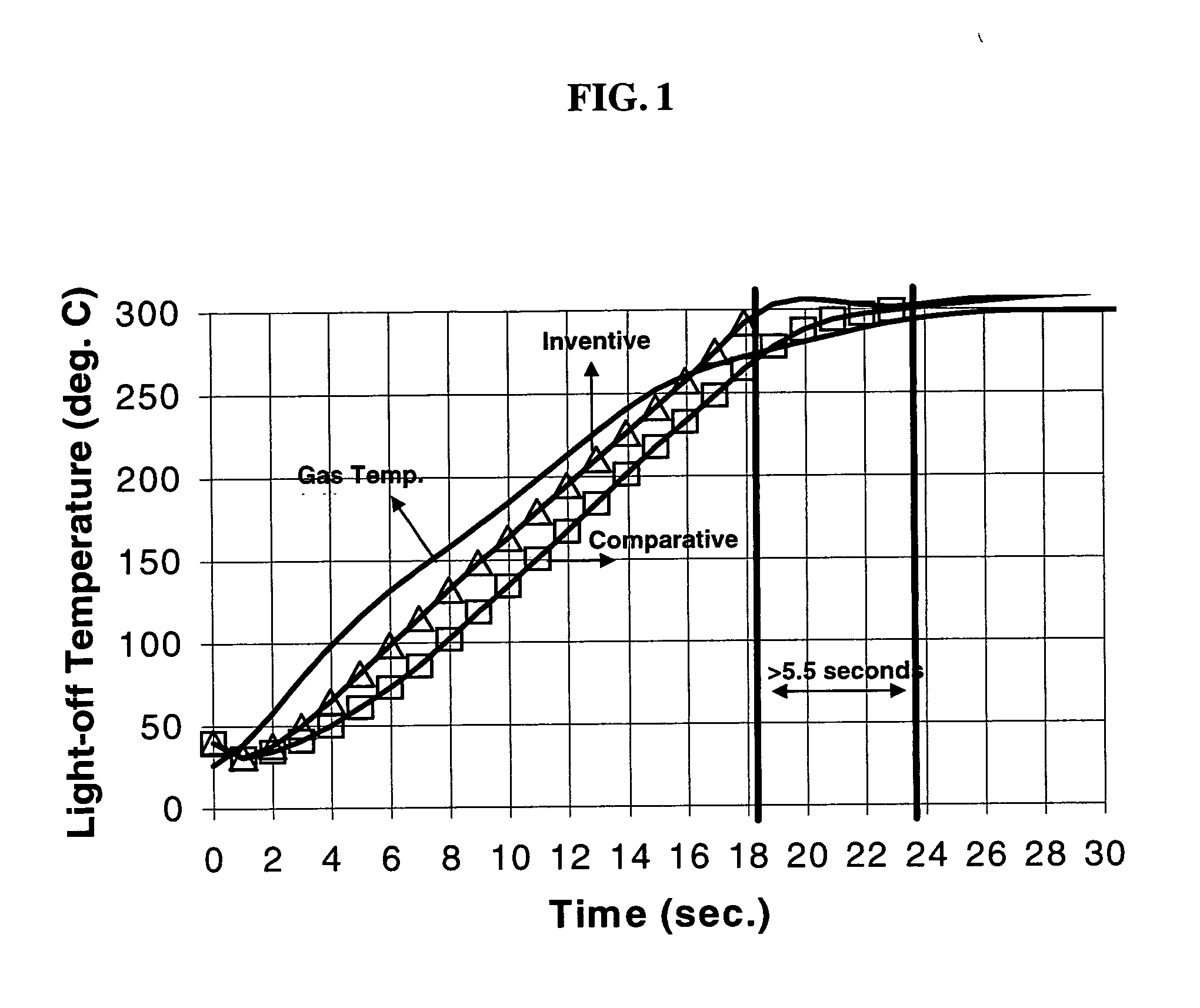

Thermoelectric catalytic power generator with preheat

InactiveUS6986247B1New pollutionMeet the test requirementsBatteries circuit arrangementsFuel cell heat exchangePollutant emissionsEngineering

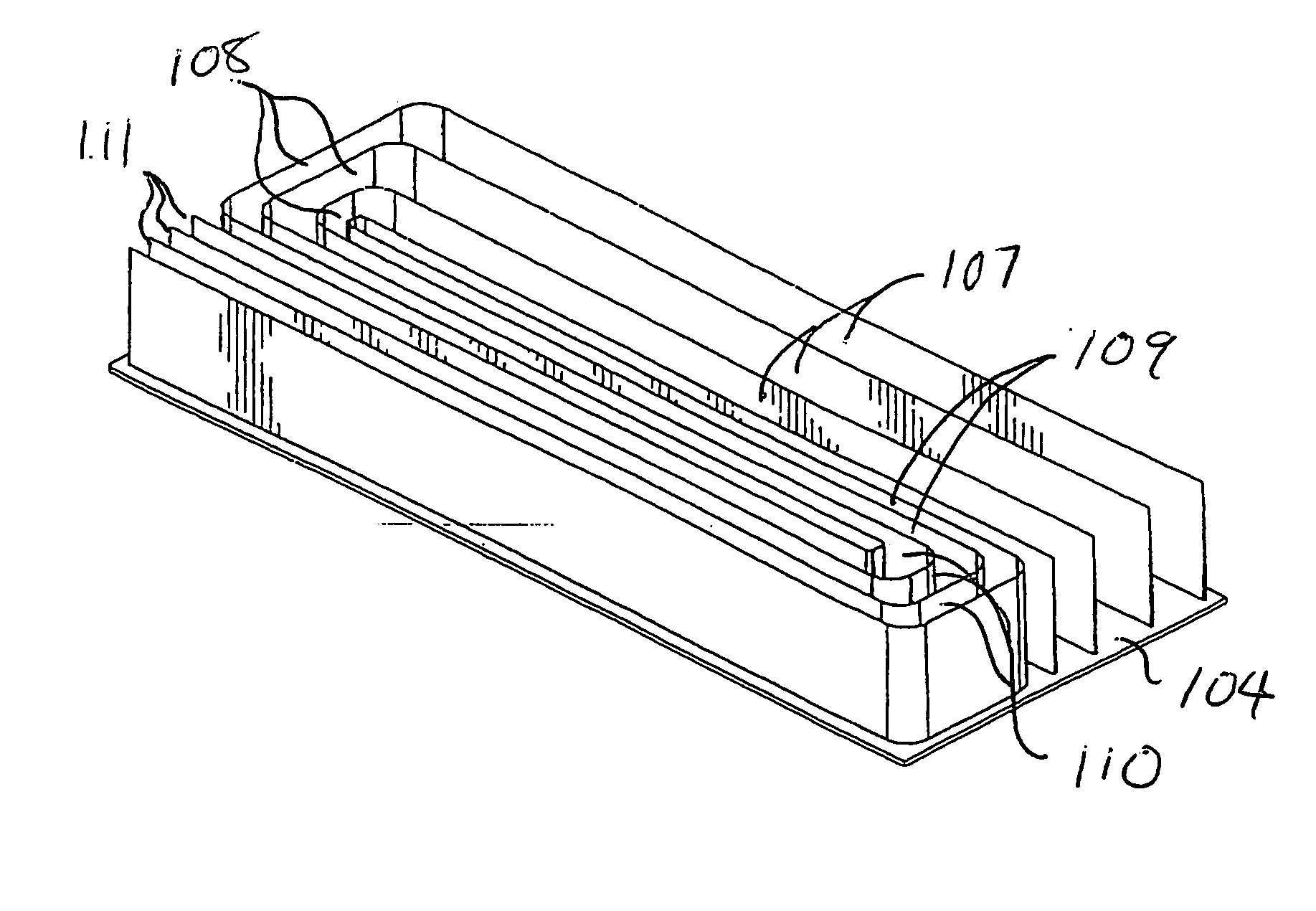

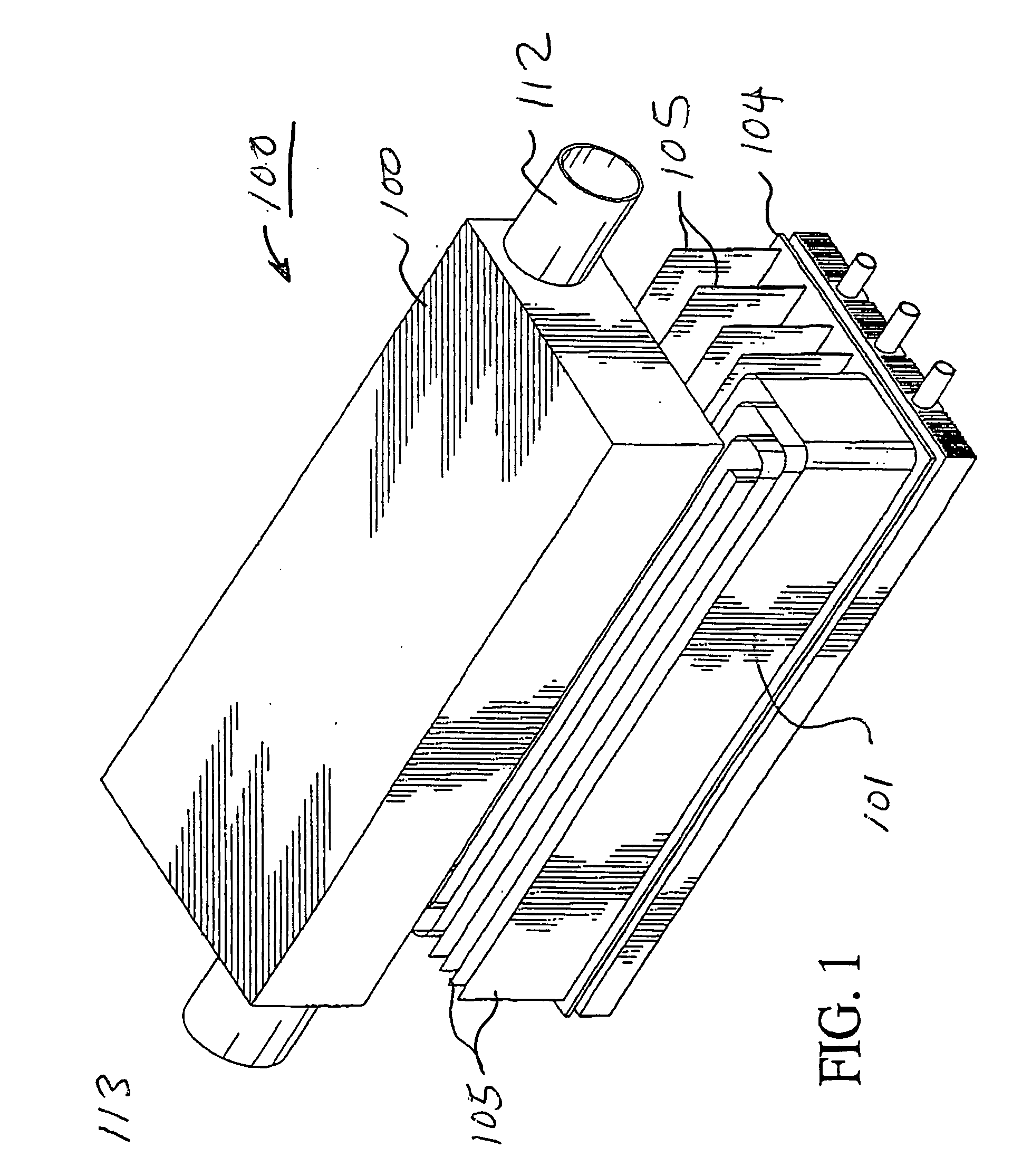

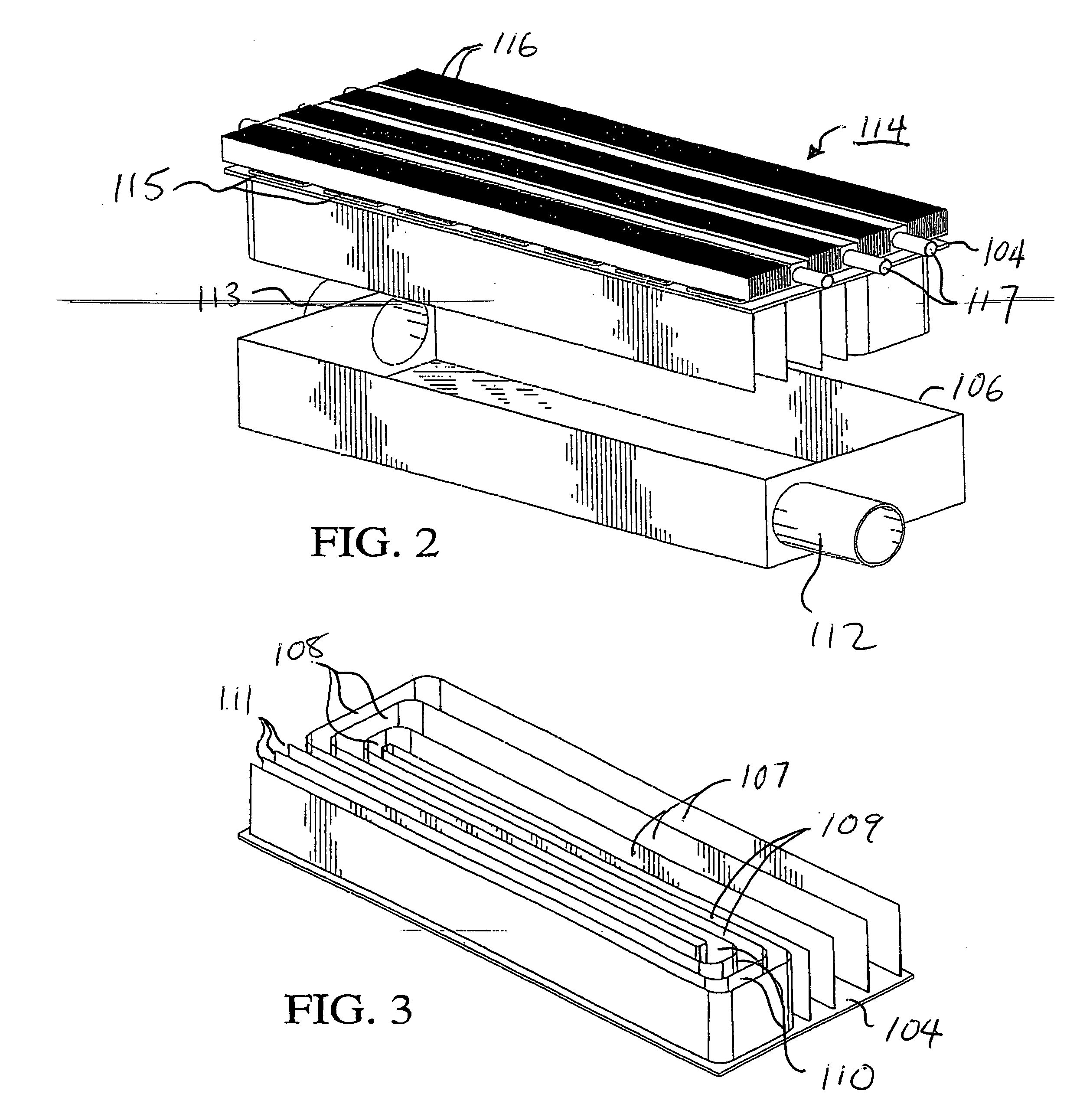

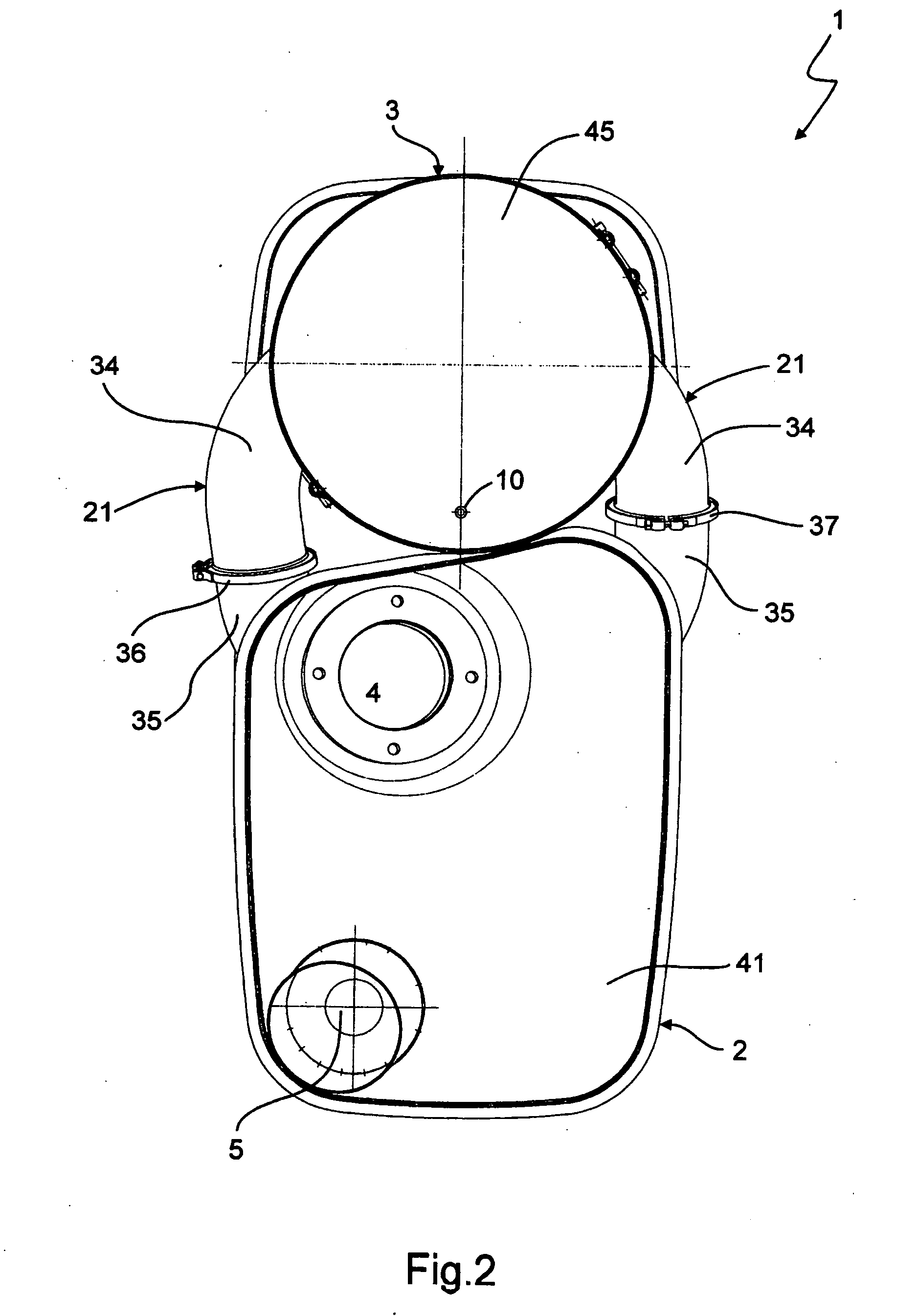

An automobile catalytic converter that utilizes the energy of the exothermic reactions that take place in the catalysis substrate to produce electrical energy with a thermoelectric generator. On vehicle cold start, the thermoelectric generator is used as a heat pump to heat the catalyst substrate to reduce the time to catalyst light-off. In this way, the catalytic converter comes up to operating temperature more rapidly, reducing the amount of pollutant emissions at vehicle start-up.

Owner:PARISE RONALD J

Reductant delivery unit for selective catalytic reduction

ActiveUS20080236147A1Avoid boilingInternal combustion piston enginesExhaust apparatusAfter treatmentExhaust fumes

Owner:CONTINENTAL AUTOMOTIVE SYST INC

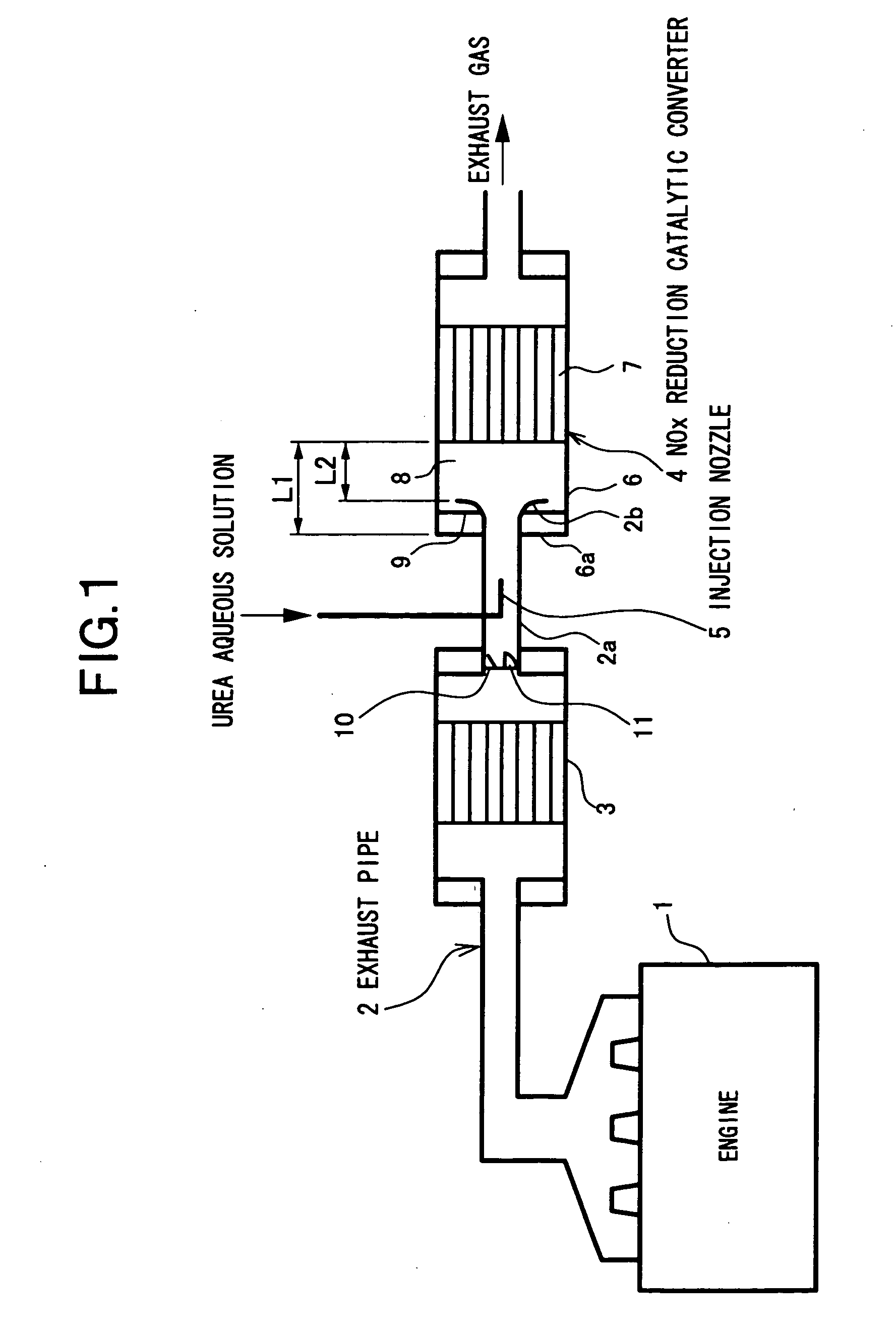

Exhaust emission purifying apparatus for engine

ActiveUS20070101703A1Easy to produceEasily swirling flowInternal combustion piston enginesFlow mixersNitrogen oxidesExhaust fumes

An exhaust emission purifying apparatus has a NOx reduction catalytic converter in an exhaust passage of an engine, for purifying nitrogen oxides in the exhaust gas by reduction with urea aqueous solution; an injection nozzle injecting the urea solution toward an exhaust upstream side of the converter in the exhaust passage; and fins disposed on an exhaust upstream side of an injection position of the urea solution in the injection nozzle, for generating a spiral swirling flow of the gas swirling about a center corresponding to the central axis of an exhaust pipe. The swirling flow generated in the exhaust gas prior to the injection-supply of the urea aqueous solution promotes mixing of the solution with the gas to thereby promote the hydrolysis of the urea solution. And the exhaust gas and ammonia generated from the urea solution are uniformly mixed together.

Owner:TOKYO ROKI +2

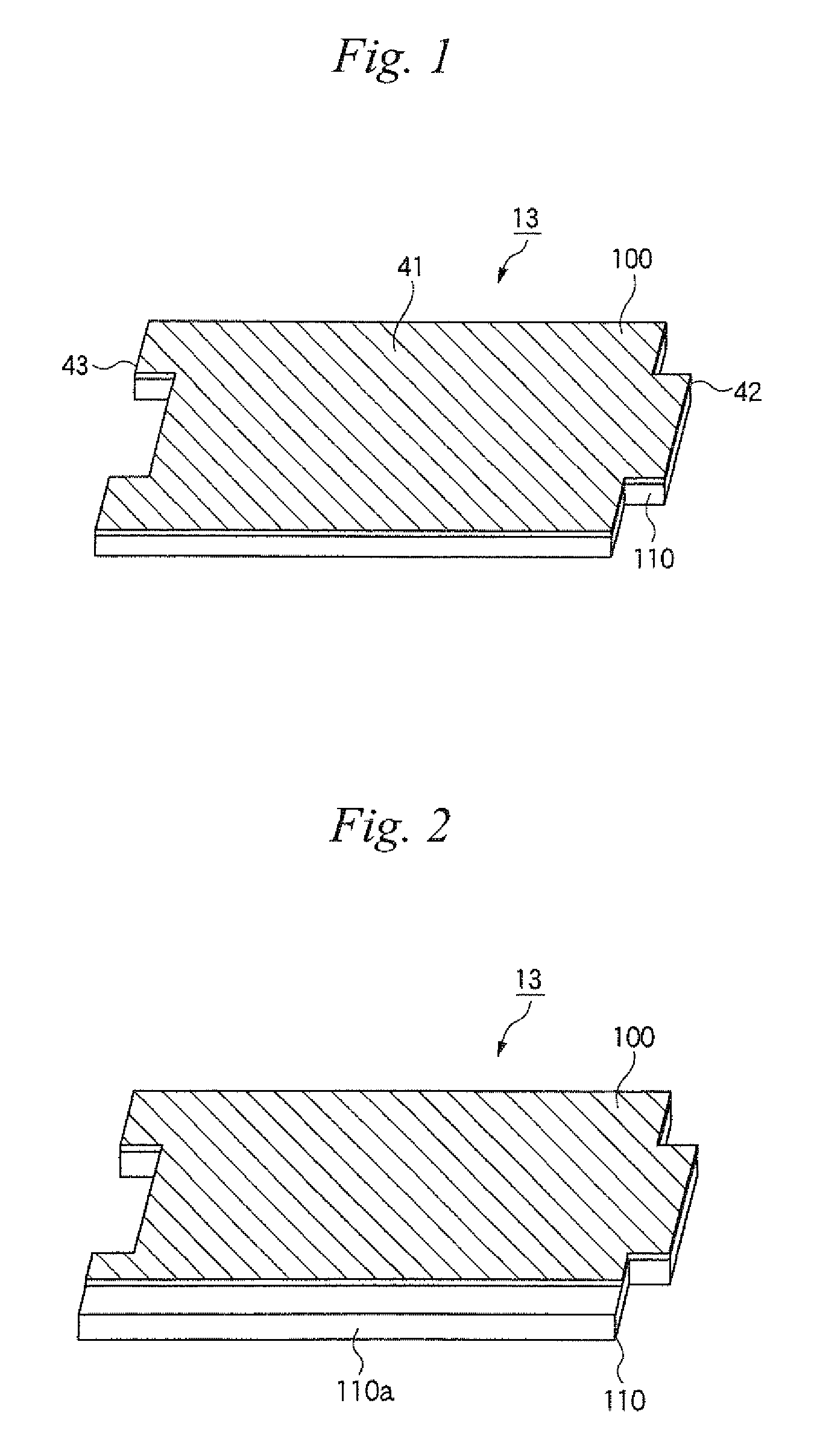

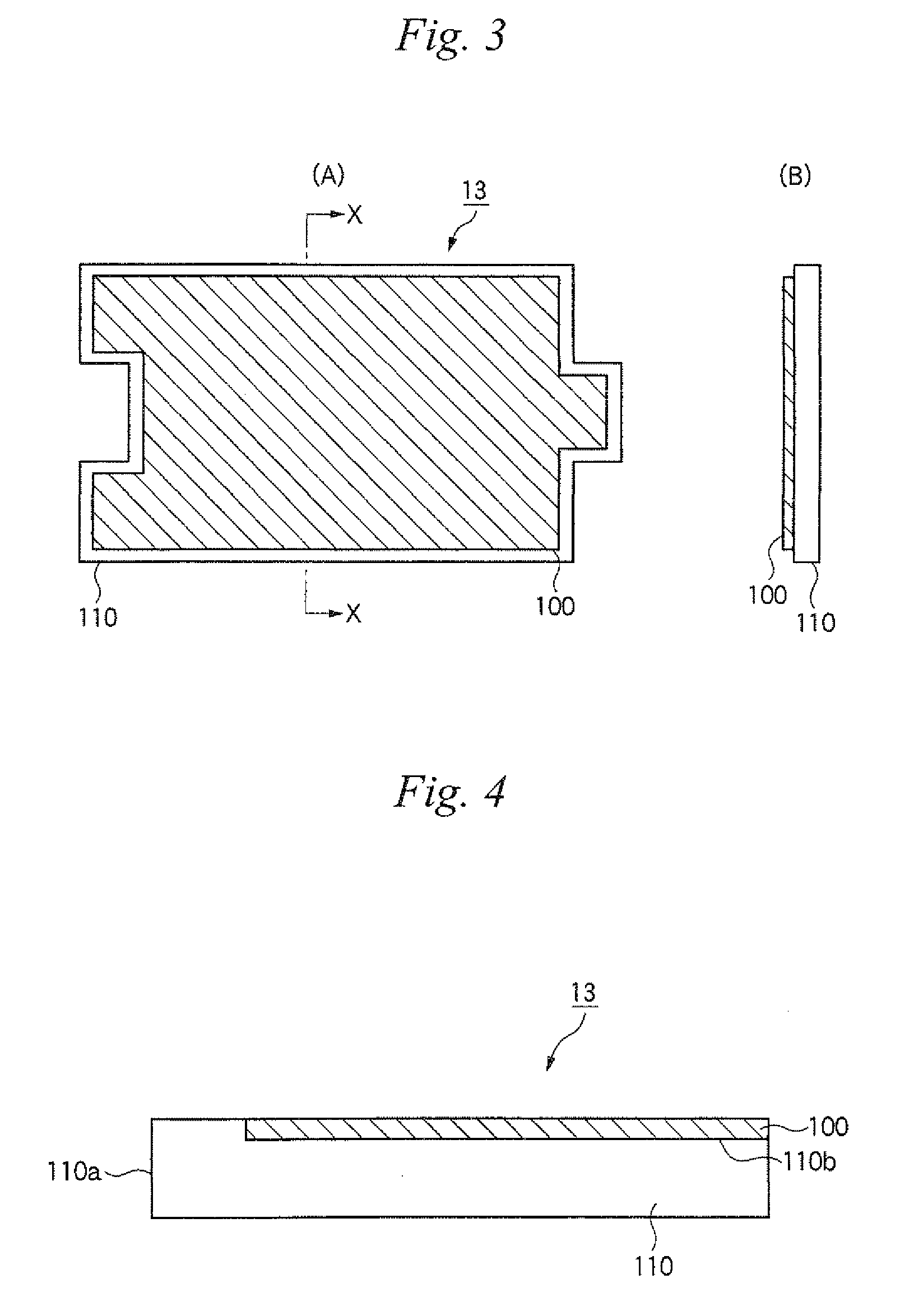

Catalytic converter, holding material for catalytic converter and production method thereof

ActiveUS20090022633A1Improve insulation performanceImprove exhaust gas purification performanceCombination devicesLamination ancillary operationsPorous substrateCatalyst support

The present invention relates to a holding material for a catalytic converter including a catalyst carrier, a metal casing for receiving the catalyst carrier, and the holding material wound around the catalyst carrier and interposed in a gap between the catalyst carrier and the metal casing, the holding material including a low thermal conductivity layer, in which the low thermal conductivity layer includes: a molded material containing an inorganic powder; or a composite material of a porous substrate with an aerogel.

Owner:NICHIAS CORP

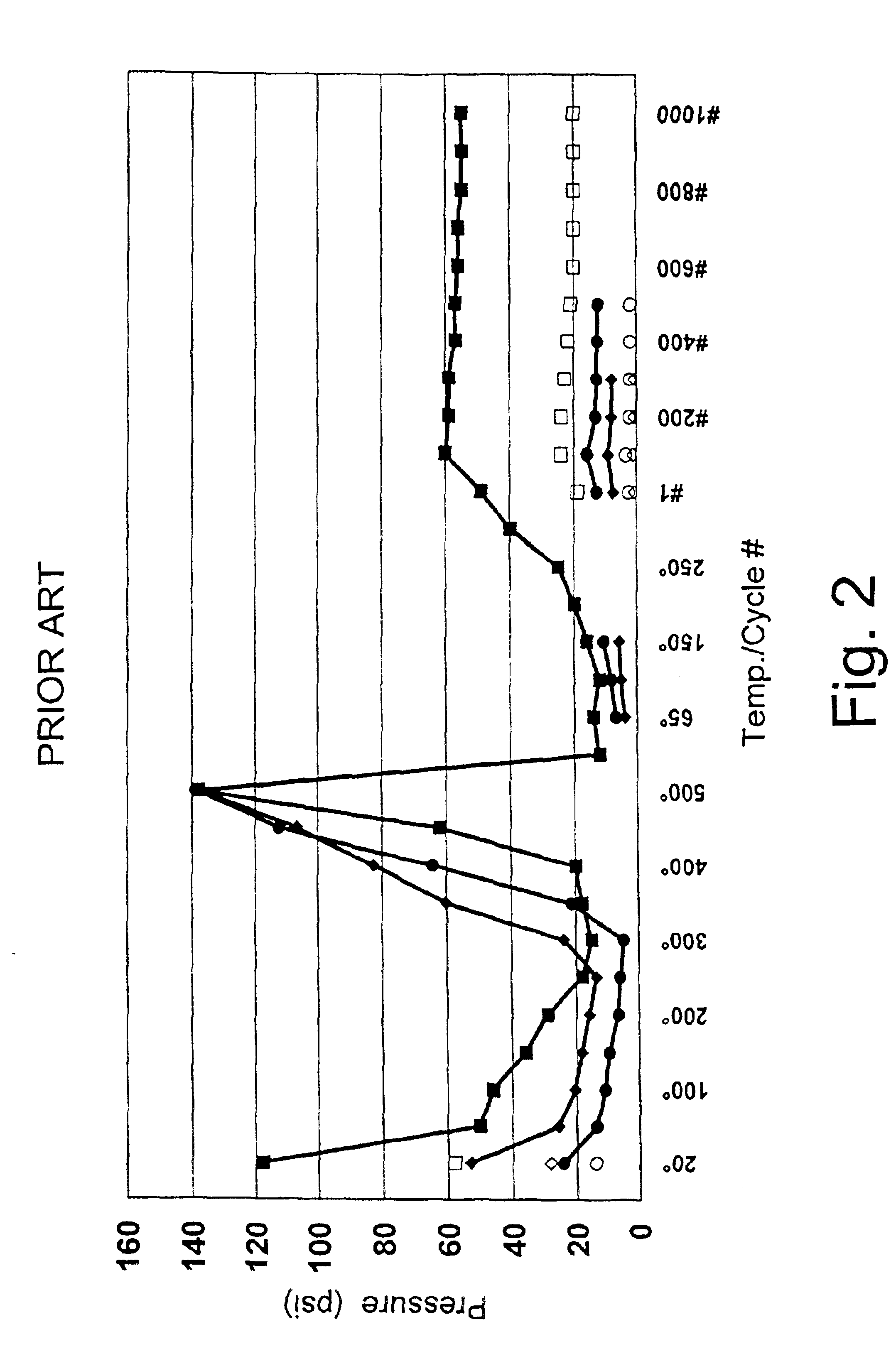

Amorphous non-intumescent inorganic fiber mat for low temperature exhaust gas treatment device

A non-intumescent mat for providing a support structure for low temperature fragile structures in exhaust gas treatment devices, such as catalytic converters, diesel particulate traps, and like, comprising amorphous inorganic fibers. The fibers have Young's Modulus of less than about 20×106 psi and a geometric mean diameter less than about 5 μm. The mat is adapted to provide a holding force of at least 15 psi throughout an average mat temperature range from ambient temperature up to at least about 350° C. The amorphous inorganic fibers are preferably melt formed fibers comprising the fiberization product of a melt comprising alumina / silica.

Owner:UNIFRAX I LLC

High porosity honeycomb and method

ActiveUS20050069469A1Improved light off performanceHigh porosityCombination devicesDispersed particle filtrationPorosityMicrometer

A ceramic honeycomb substrate for use in an automotive catalytic converter system which exhibits improved light-off performance by virtue of a high porosity of 45 to 75% while still maintaining a wall thickness of greater than 2.0 mil (0.0020 inch, 0.0508 mm), preferably 2.5 mil (0.0025 in., 0.0635 mm) to 7 mil (0.0070 in., 0.1778 mm), and more preferably 2.5 mil (0.0025 in., 0.0635 mm) to 3 mil (0.0030 in., 0.0762 mm). The median pore size is in the range of 2-10 micrometers, and a coefficient of thermal expansion (CTE) (25-800° C.) of less than 15×10−7 / ° C.

Owner:CORNING INC

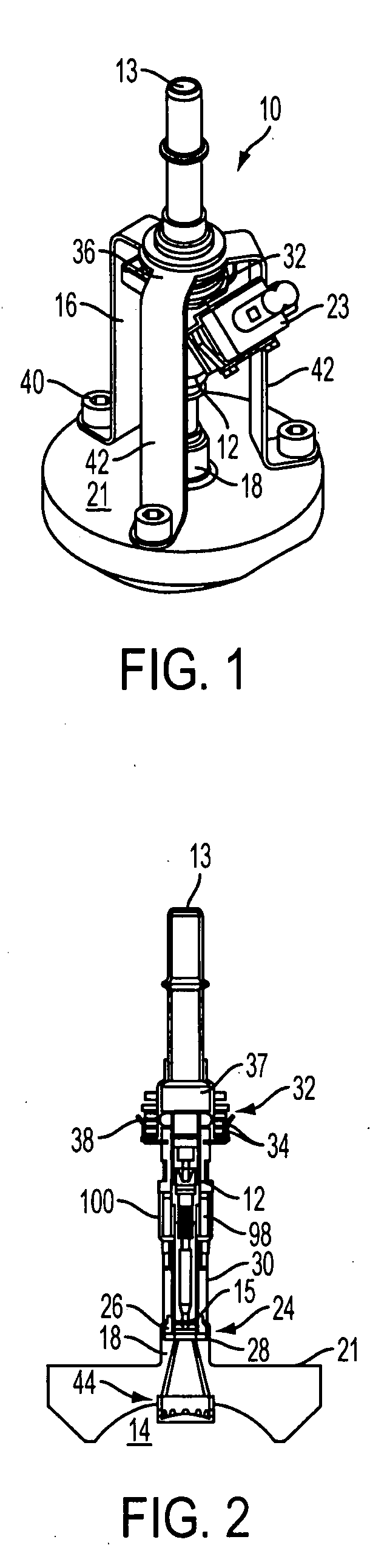

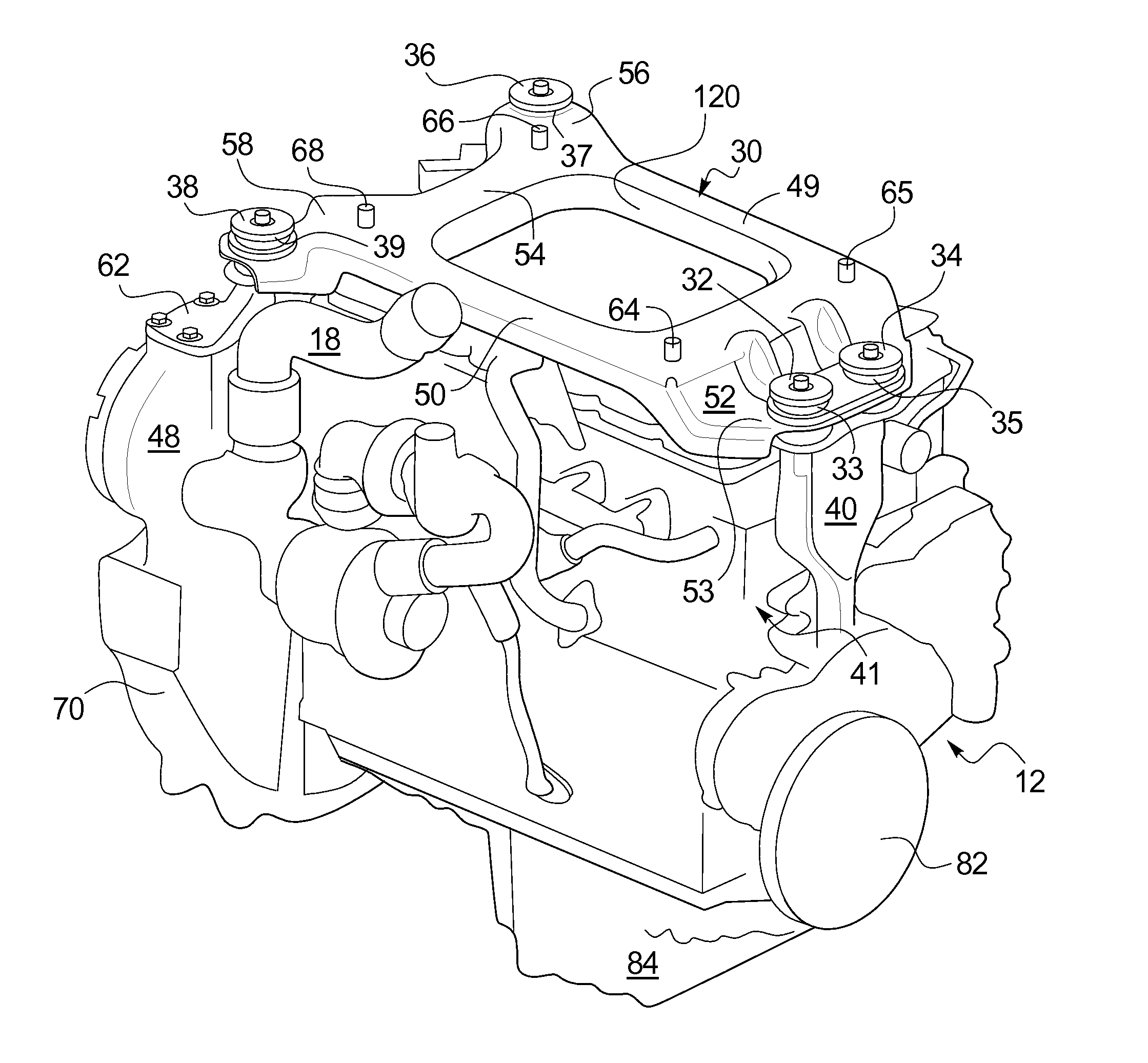

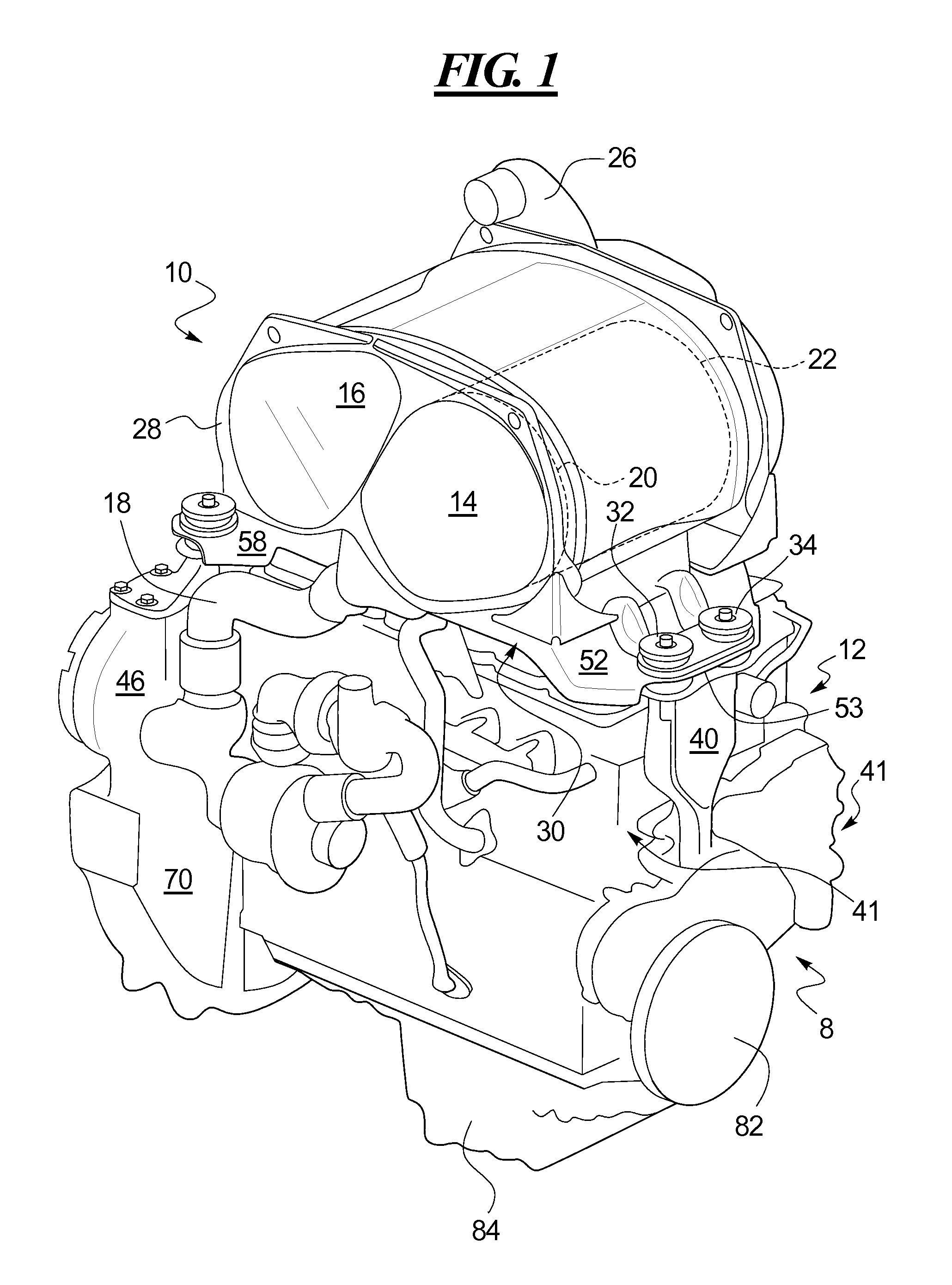

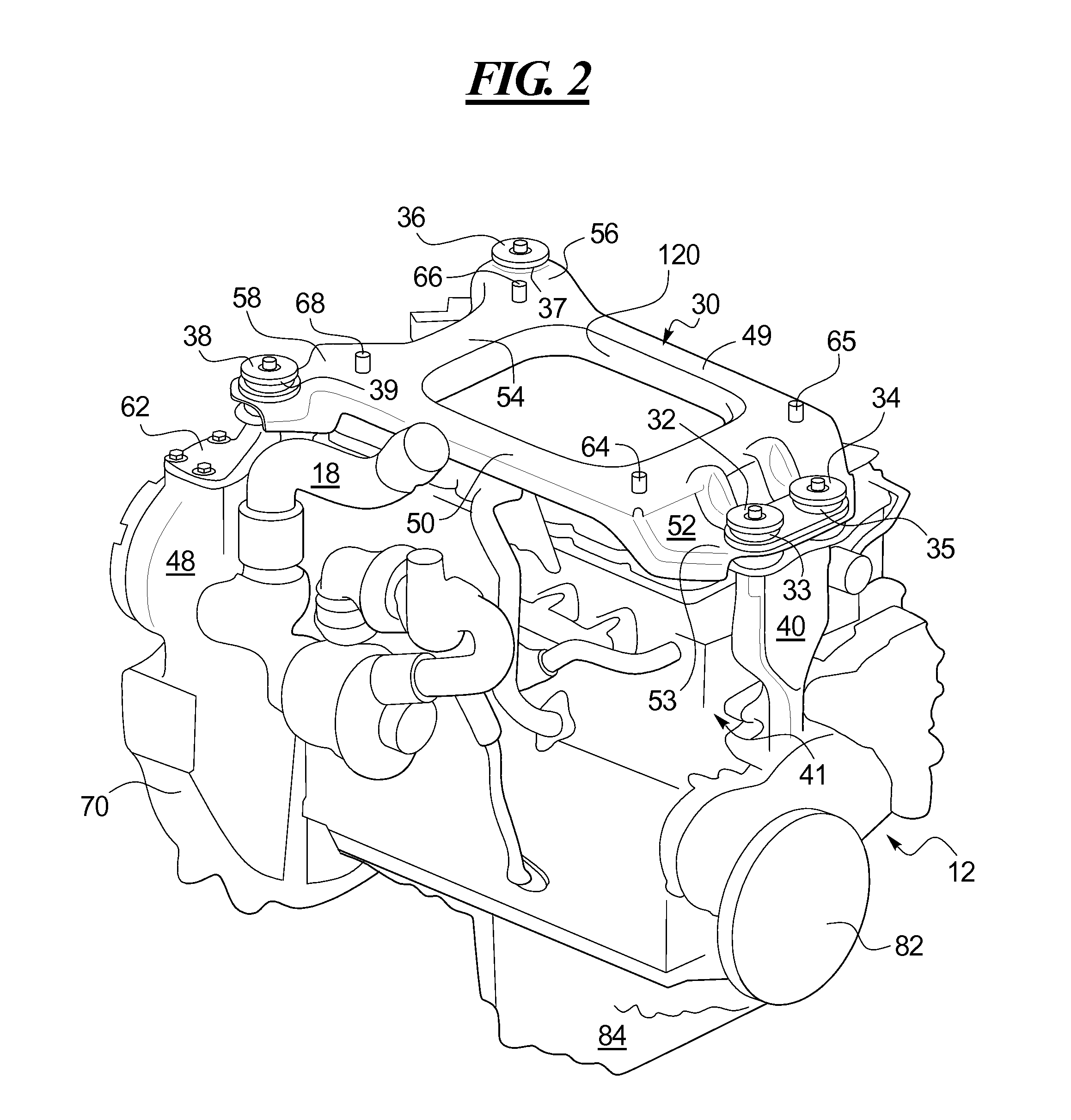

Exhaust Gas Aftertreatment Support Assembly

An improved aftertreatment support assembly is disclosed. The support assembly includes a mounting plate that may be adapted to be affixed above an engine, and may be used to support engine exhaust aftertreatment components, including particulate filters and catalytic converters. The mounting plate may include front and rear isolation mounts, and each mount may incorporate an elastomeric vibration absorbing bushing. The mounting plate may be attached to either or both of an engine block or flywheel housing by means of brackets, each of which may be affixed to one of the mounts. In one disclosed embodiment, the mounting plate and brackets may be formed of stamped metal components, and at least one pair of the mounts may share a common bracket.

Owner:CATERPILLAR INC

Temperature control of exhaust gas catalytic converters in vehicles

InactiveUS6057605AIncreased the braking torqueDecreased the driving torqueElectrical controlInternal combustion piston enginesBrake torqueTemperature control

A vehicle powertrain comprises an internal combustion engine 10 and an electric motor 14 capable of producing driving or braking torque for the vehicle. The exhaust system for the engine 10 includes a catalytic converter 22. A control unit 18 monitors the temperature of the catalytic converter 22 using a sensor 32 and controls the driving or braking torque produced by the electric motor 14 so that the load on the engine produces exhaust gases of a suitable temperature to keep the catalytic converter within its optimum operating temperature range while maintaining the desired total output of torque from the powertrain.

Owner:BAYERISCHE MOTOREN WERKE AG

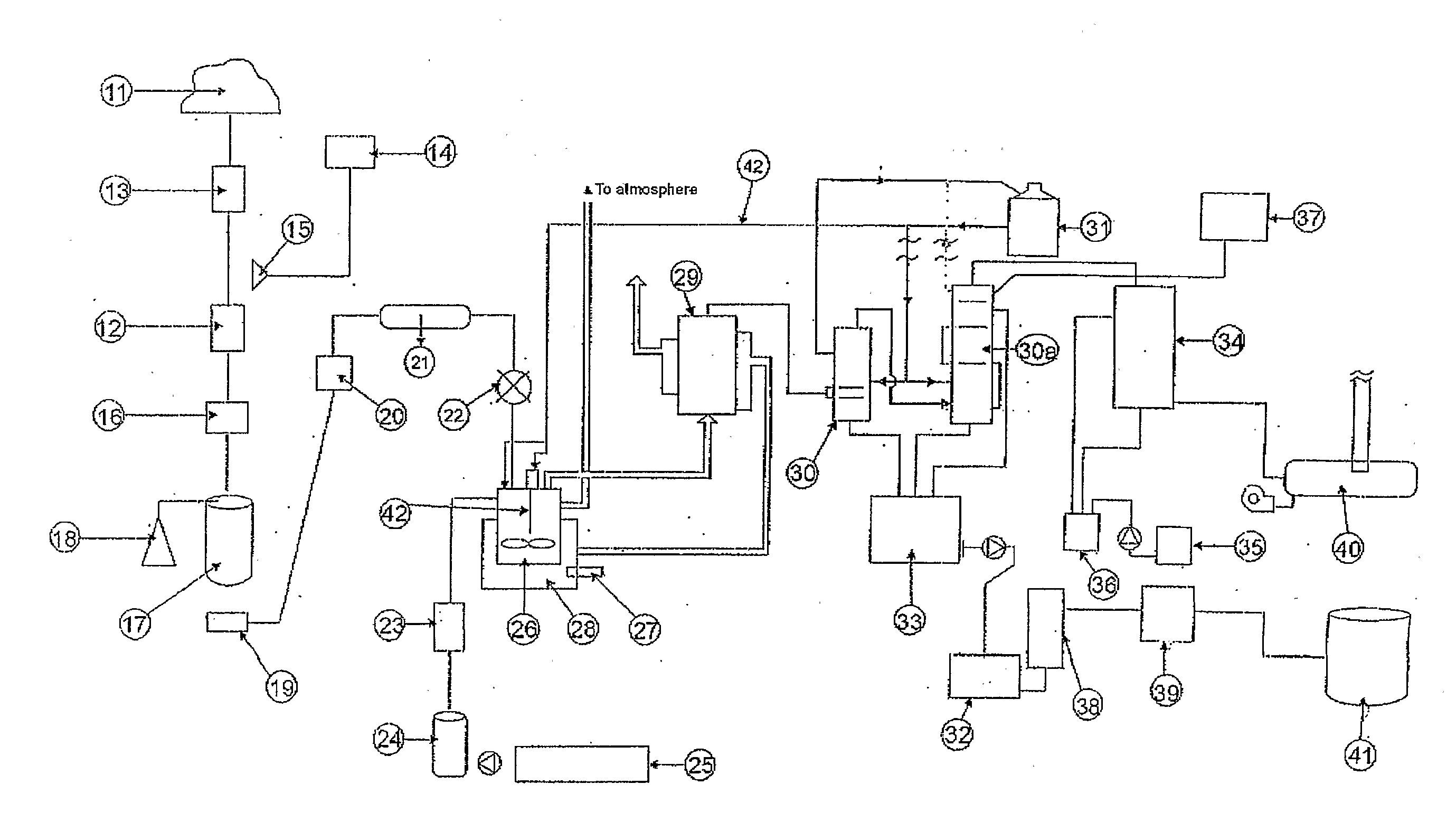

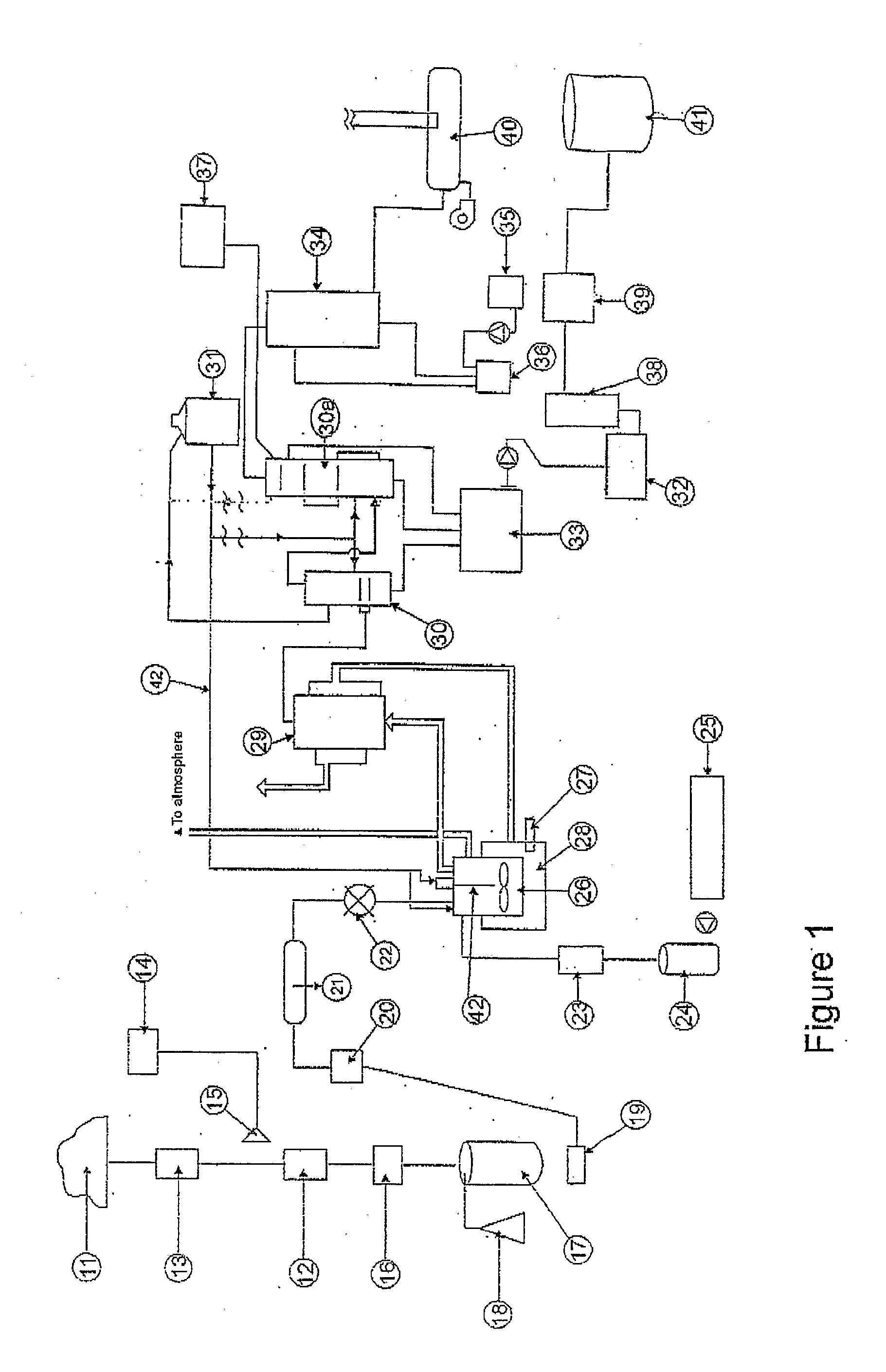

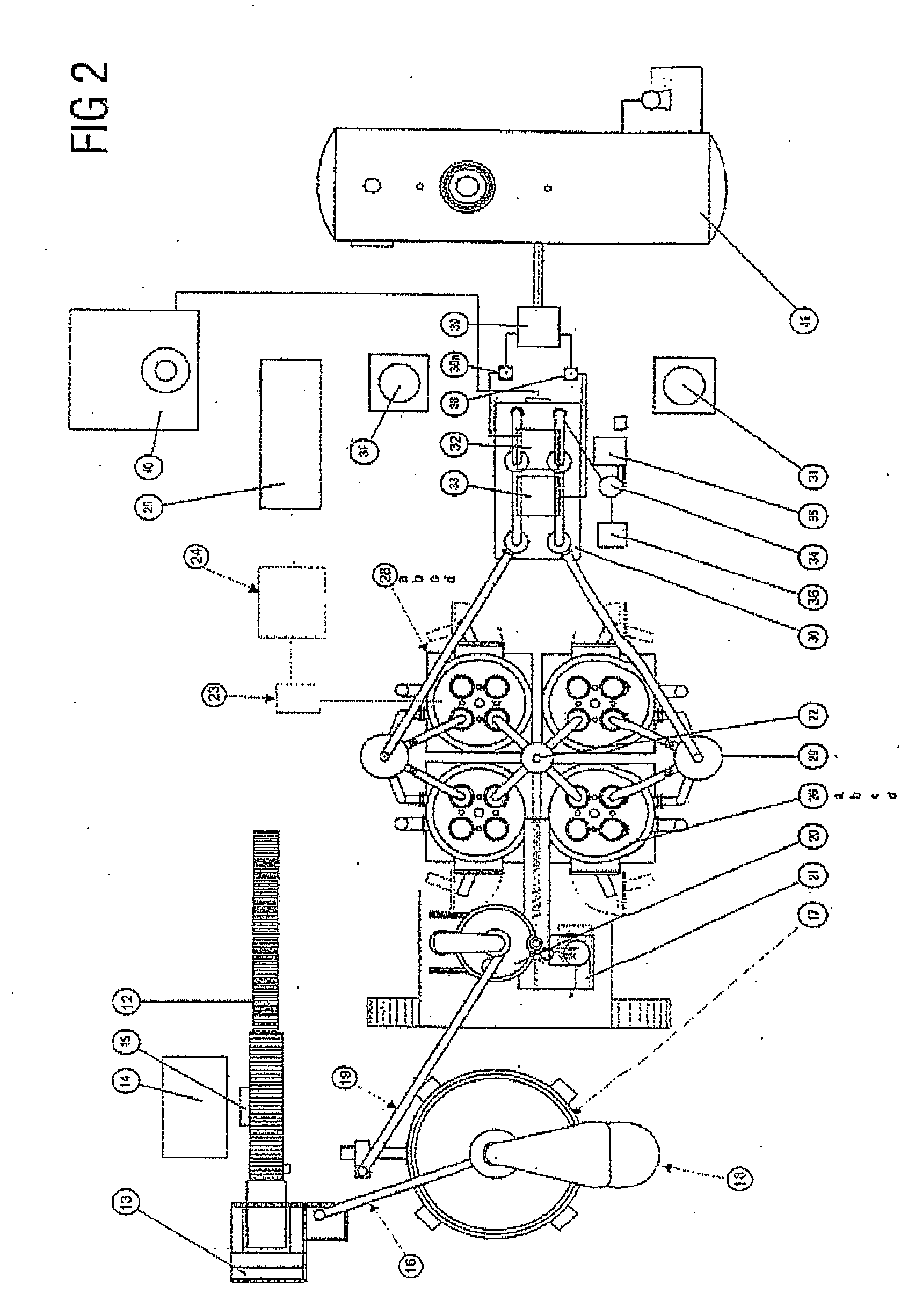

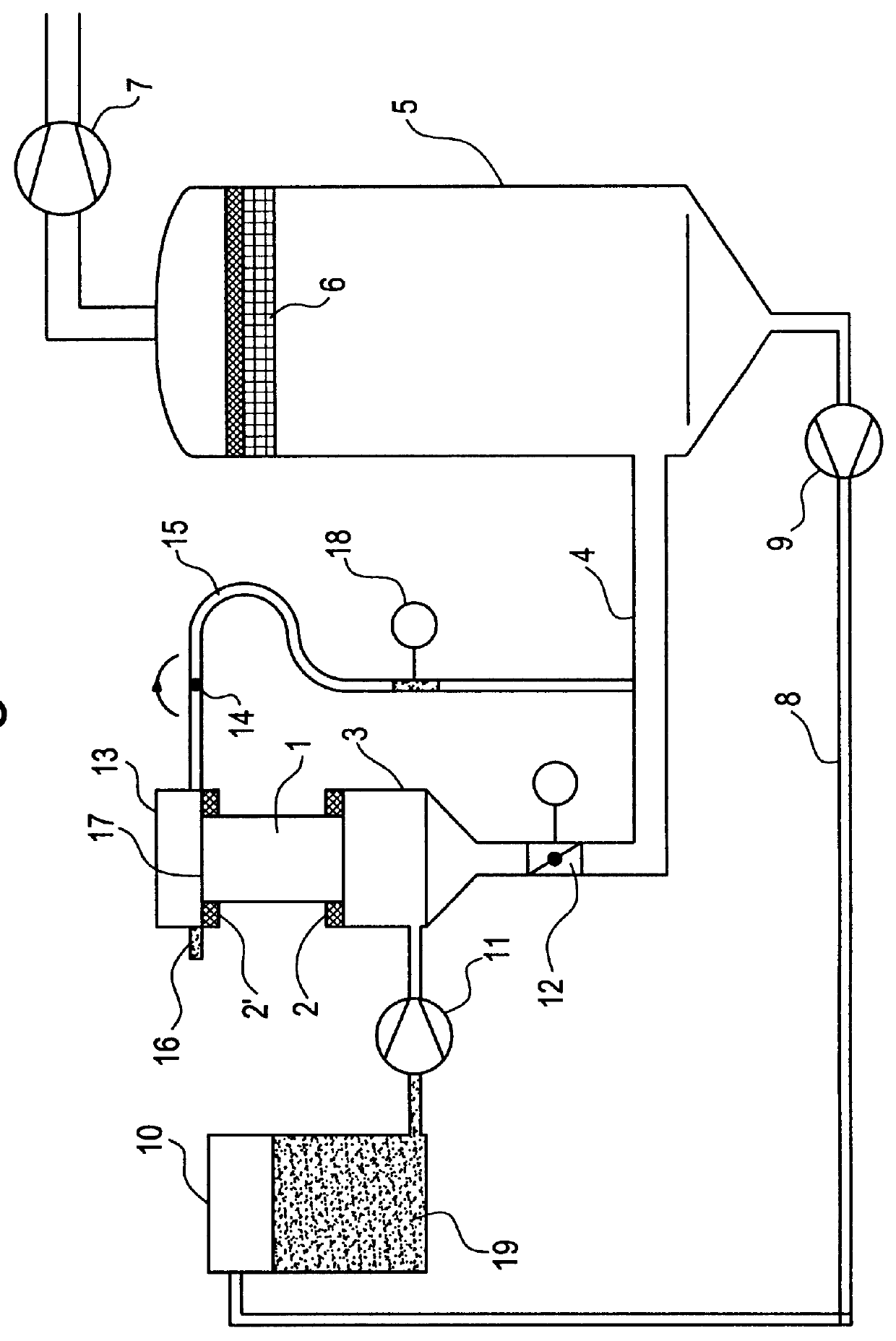

Process and plant for conversion of waste material to liquid fuel

ActiveUS20070179326A1Easy to wasteEasy feedingCatalytic crackingIndirect and direct heating destructive distillationEnvironmental engineeringLiquid fuel

A process and plant for the thermocatalytic conversion of waste materials into reusable fuels and a fuel produced by the process, involving the steps of delivering melted waste material (11) to one or more pyrolysis chambers (26) via heated and valved manifolds (22) and effecting pyrolysis of the waste material into a gascous state in an oxygen purged and pressure controlled environment. Pyrolytic gases are, then transferred to a catalytic converter (29) where the molecular structure of the gaseous material is altered in structure and form, with gases then transferred to one or more condensers (30a) to distil and cool gases in to their respective fractions. After post pyrolysis treatment, fuel fractions thon form a useable fuel. Includes the melting of waste (plastic) material (11) before delivery into any of the pyrolysis chambers (26), making the movement of material into the catalytic tower (29) a semi-continuous operation, directing melted waste material into one or more, but preferably four, pyrolysis chambers (26a, b, c, d), making each chamber capable of independent operation, optionally mechanically removing waste char from the pyrolysis chamber (107) by use of an internet auger (112) or other suitable means.

Owner:FUTURE ENERGY INVESTMENTS PTY LTD

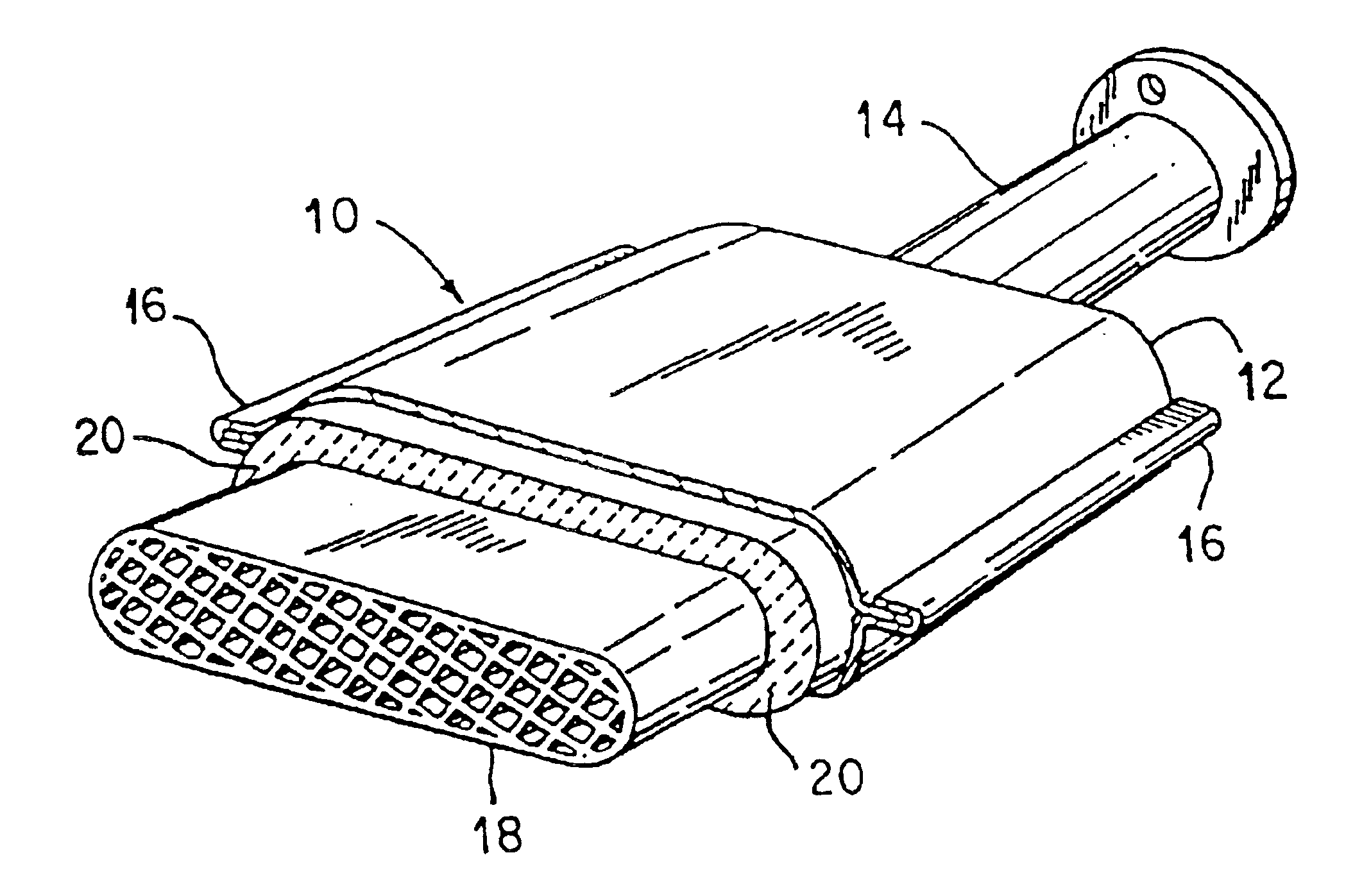

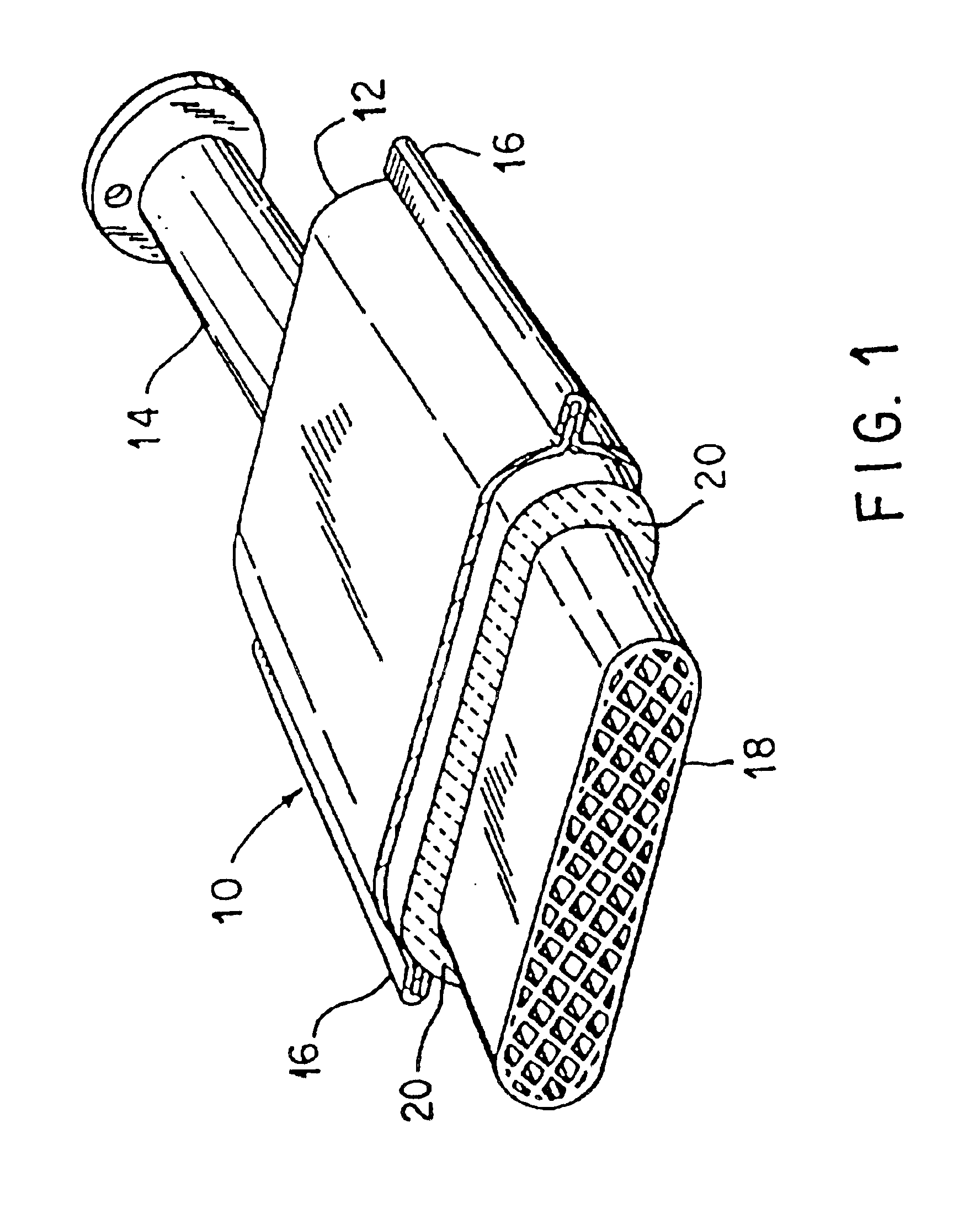

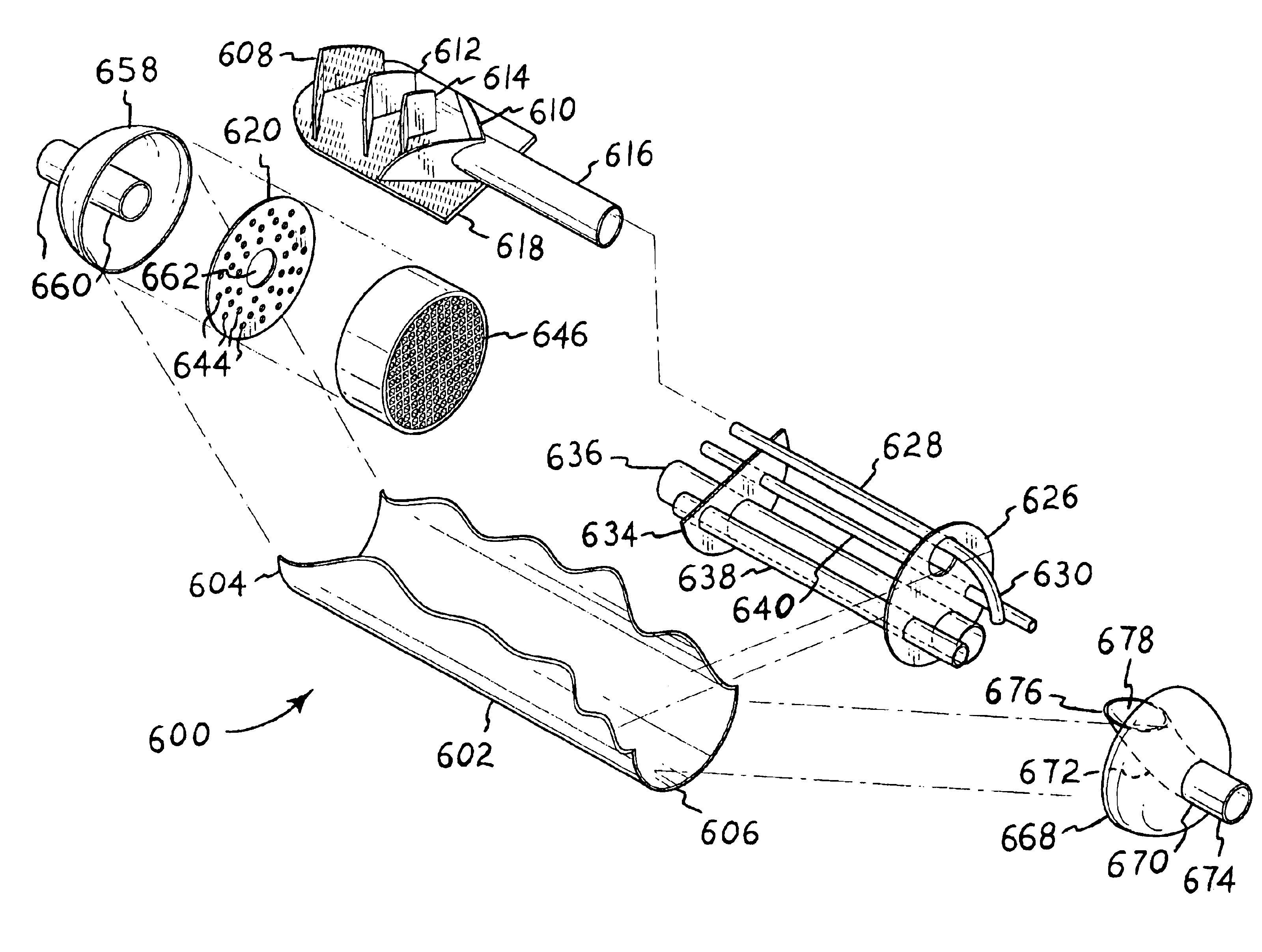

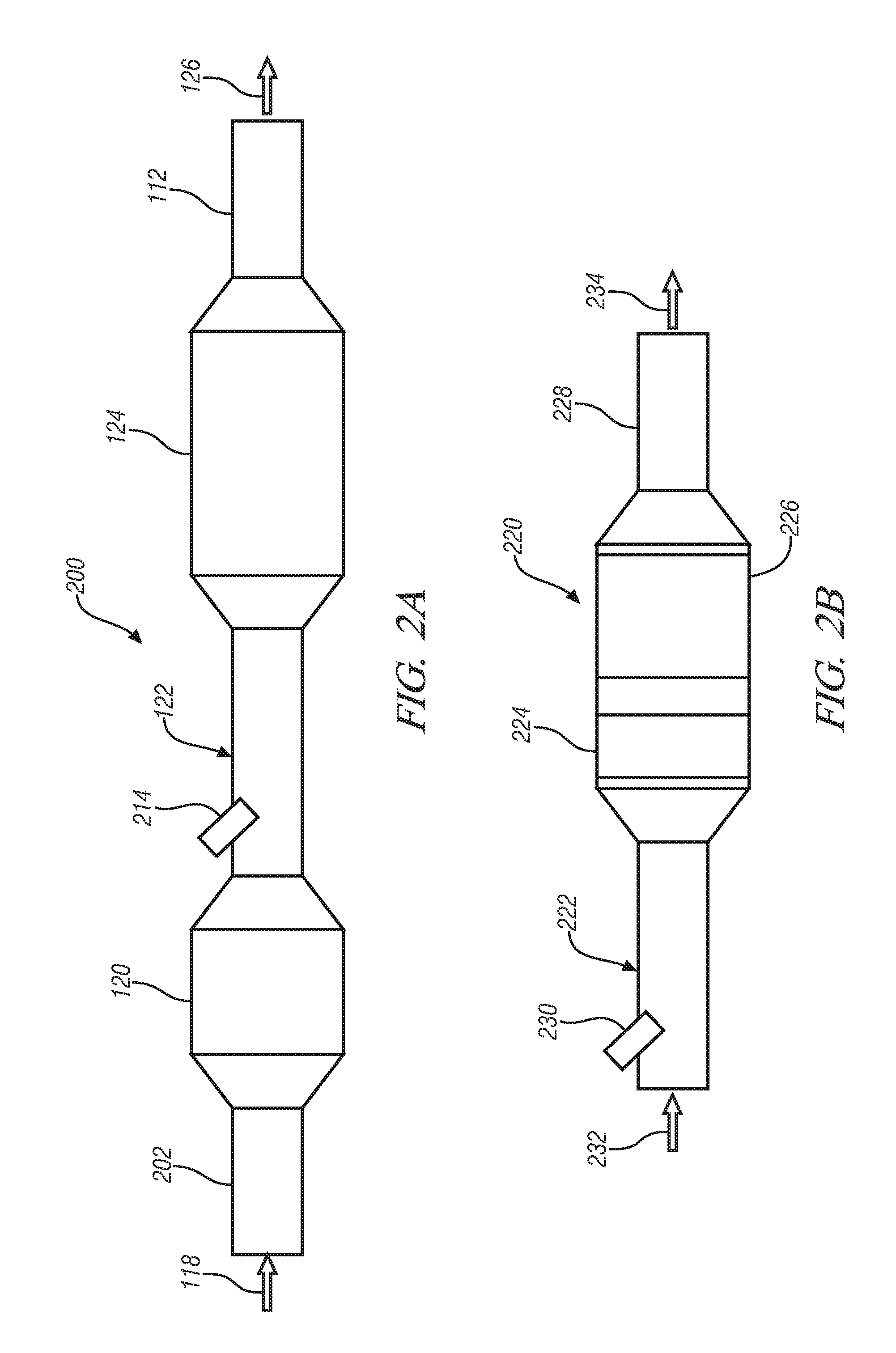

Flow-through mufflers with optional thermo-electric, sound cancellation, and tuning capabilities

InactiveUS20070045044A1Reduce engine fuel consumptionInternal combustion piston enginesThermoelectric device with peltier/seeback effectHeat conductingAcoustic wave

Owner:SULLIVAN JOHN TIMOTHY

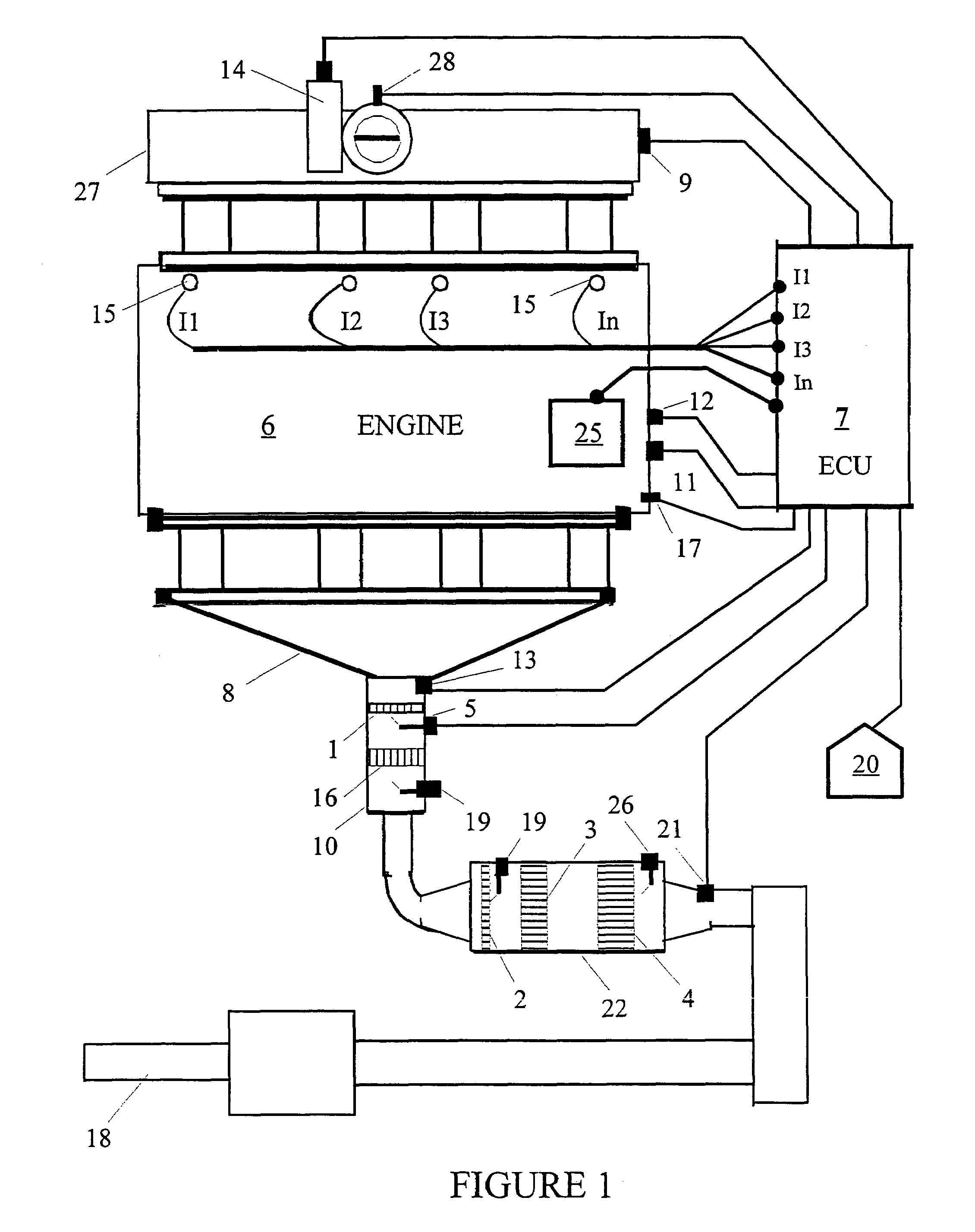

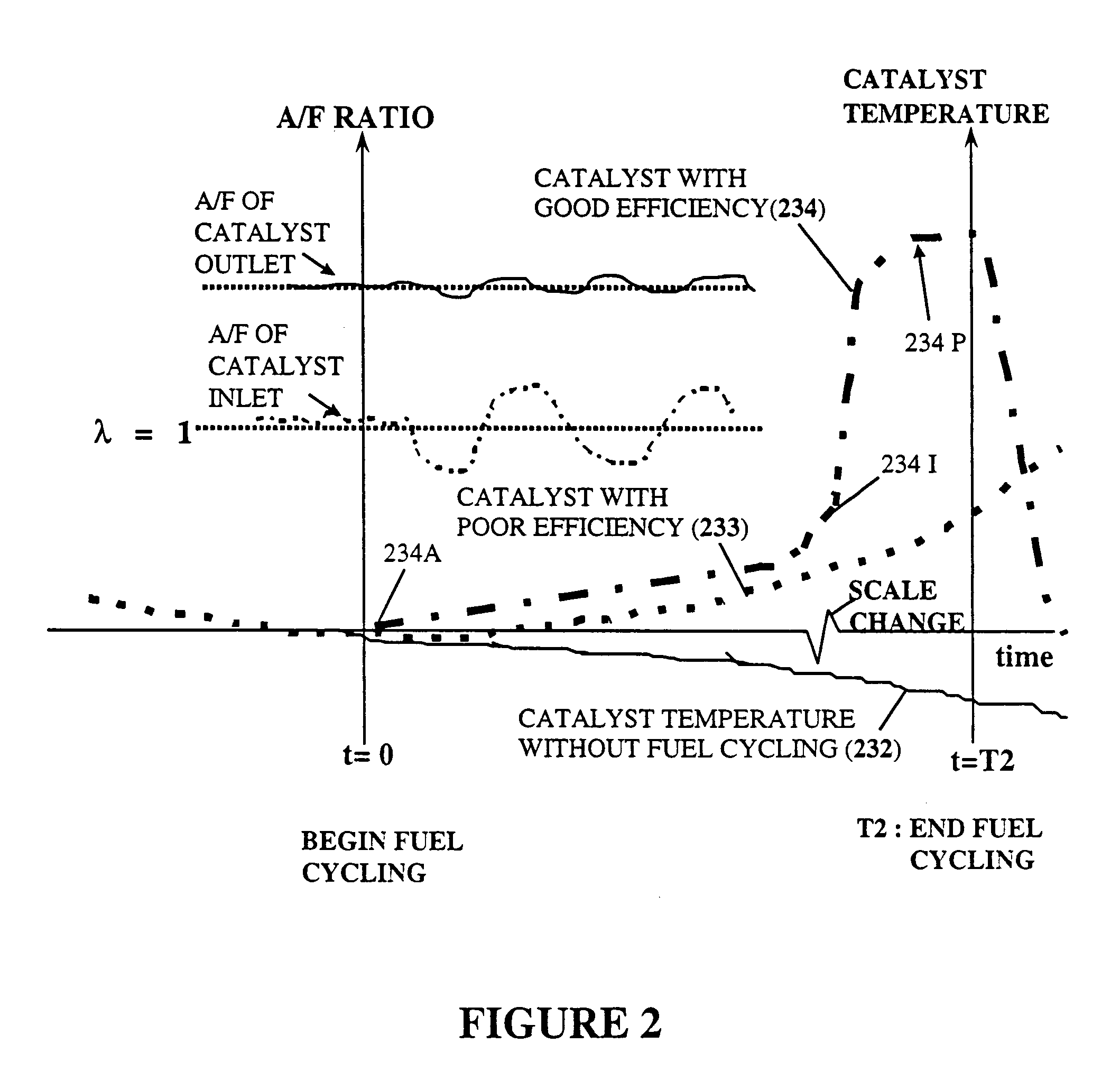

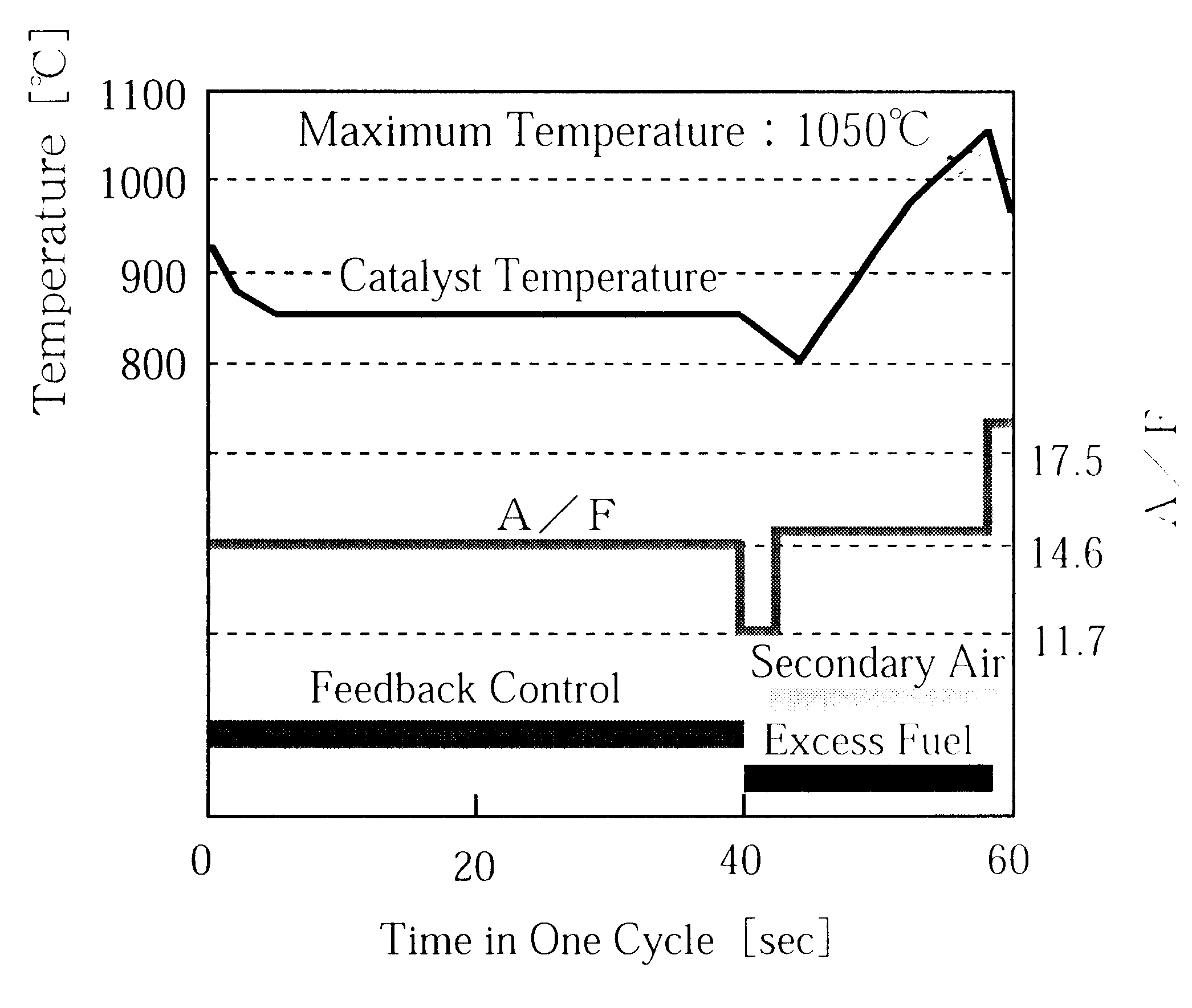

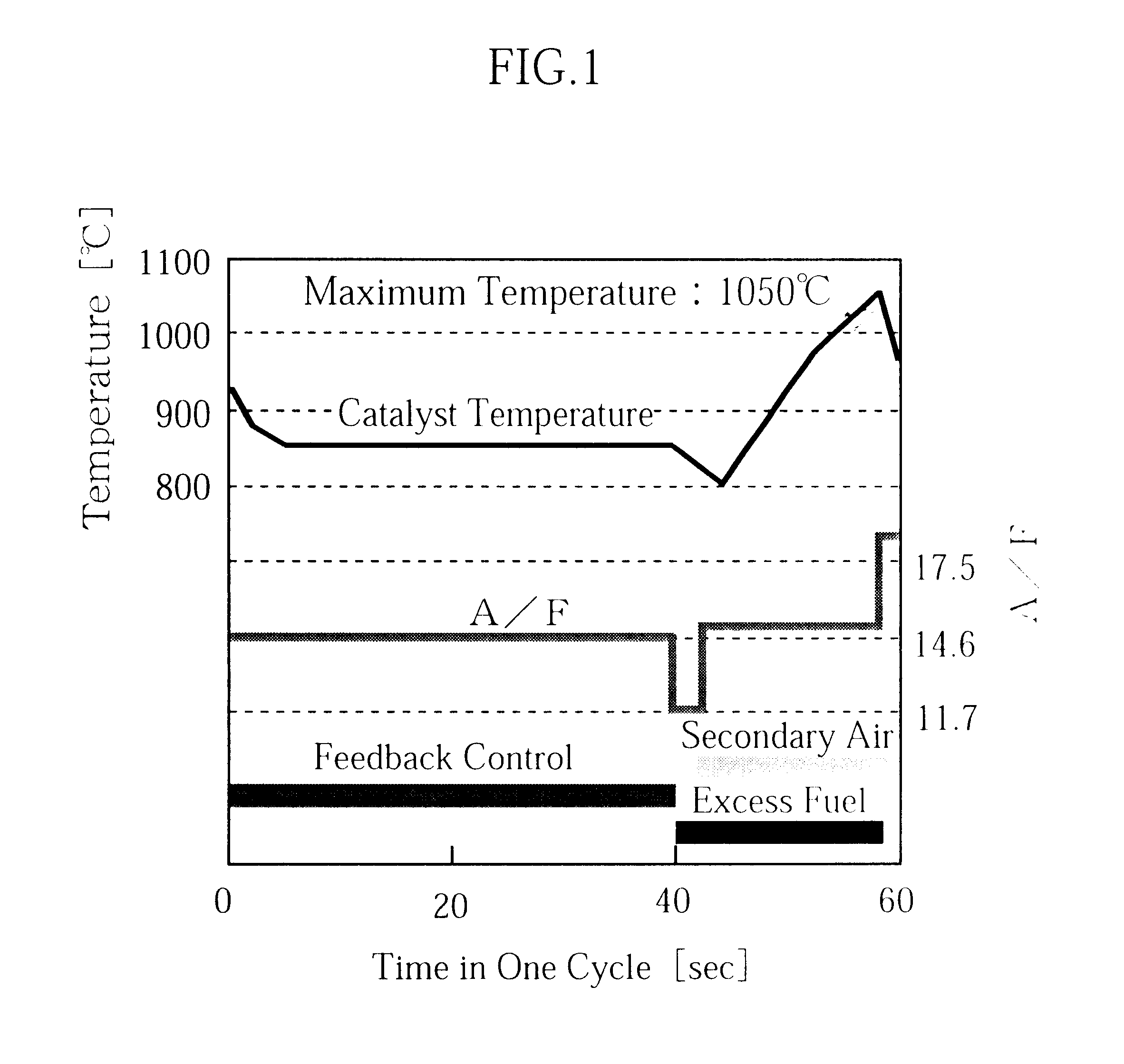

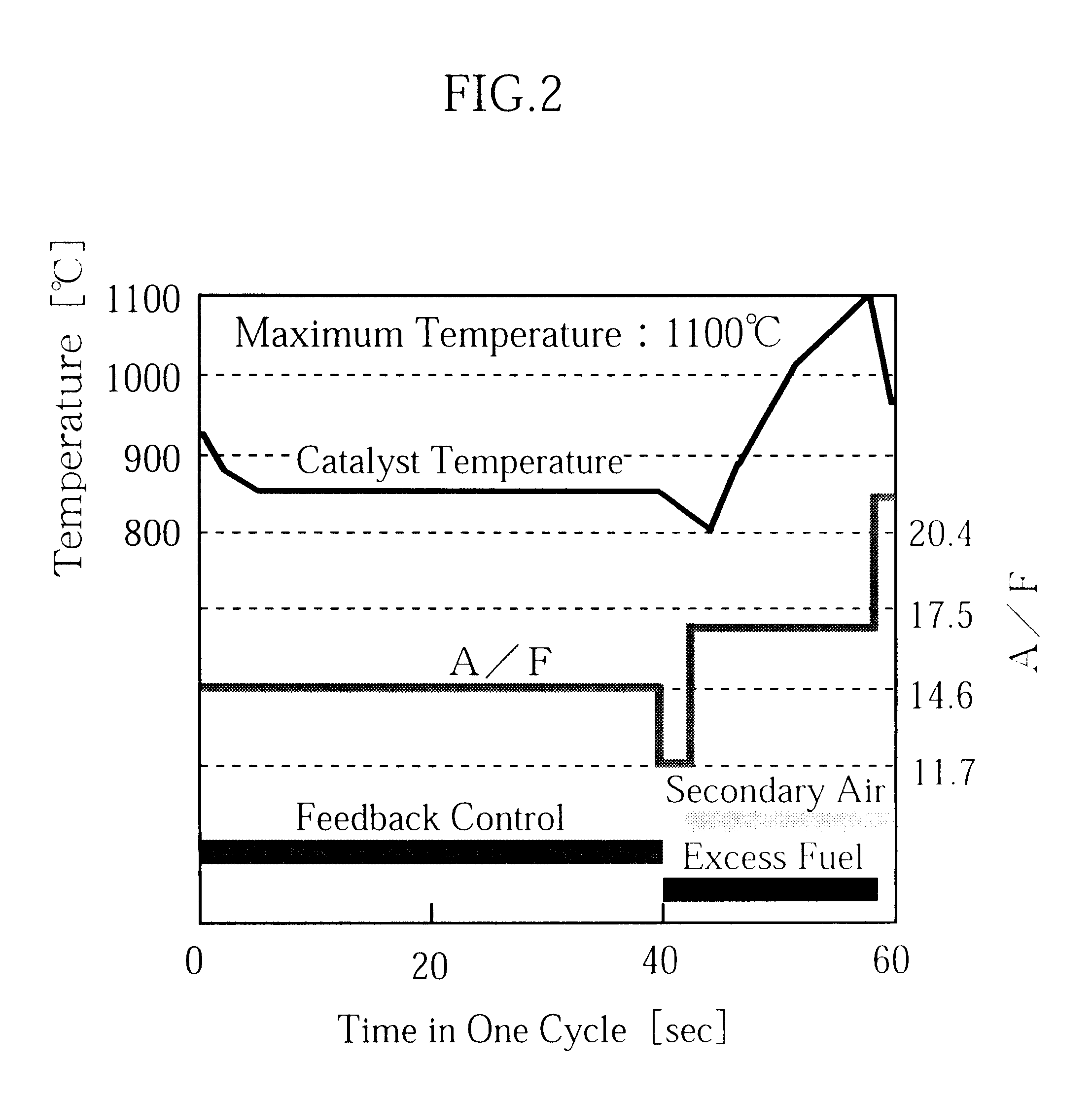

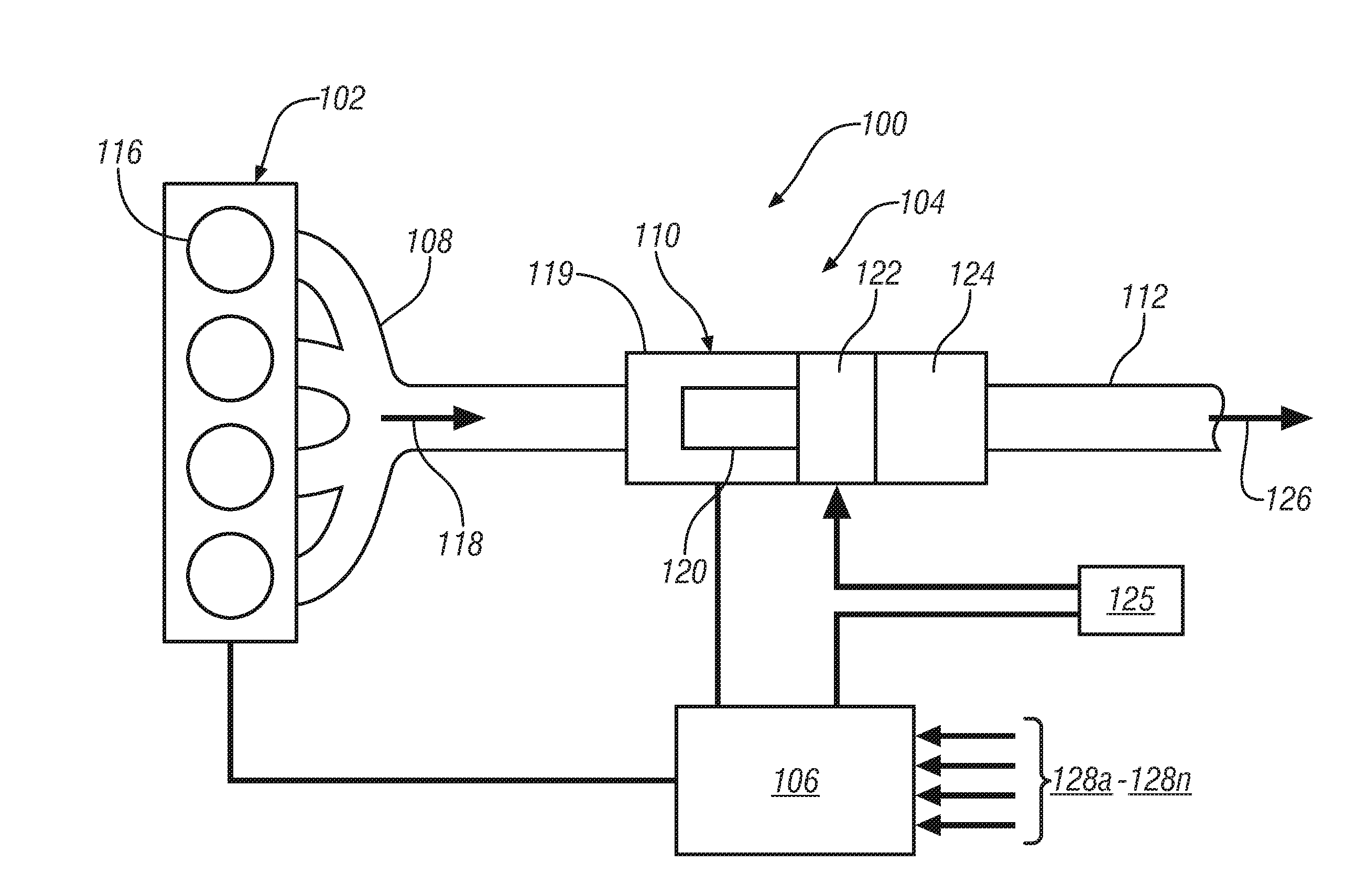

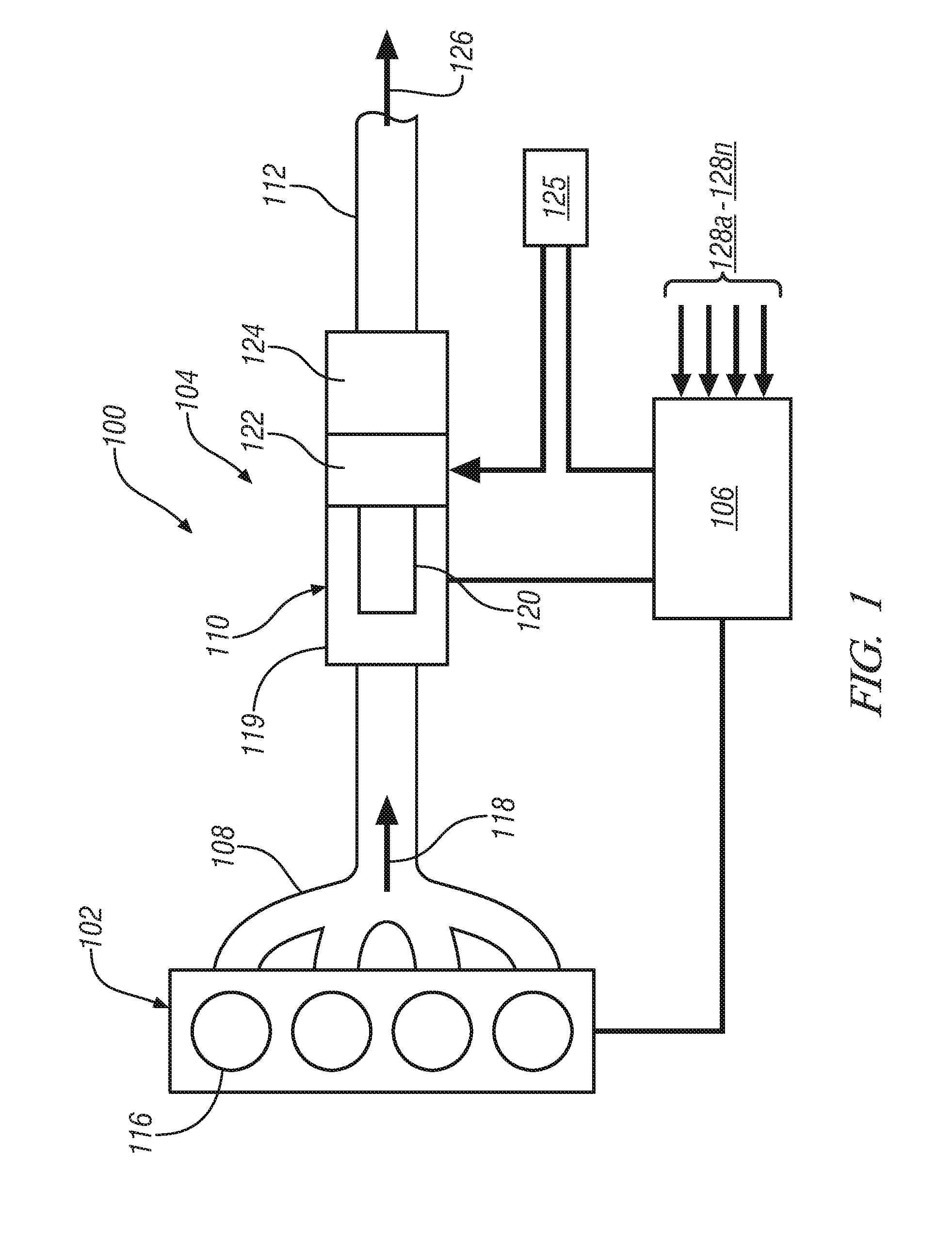

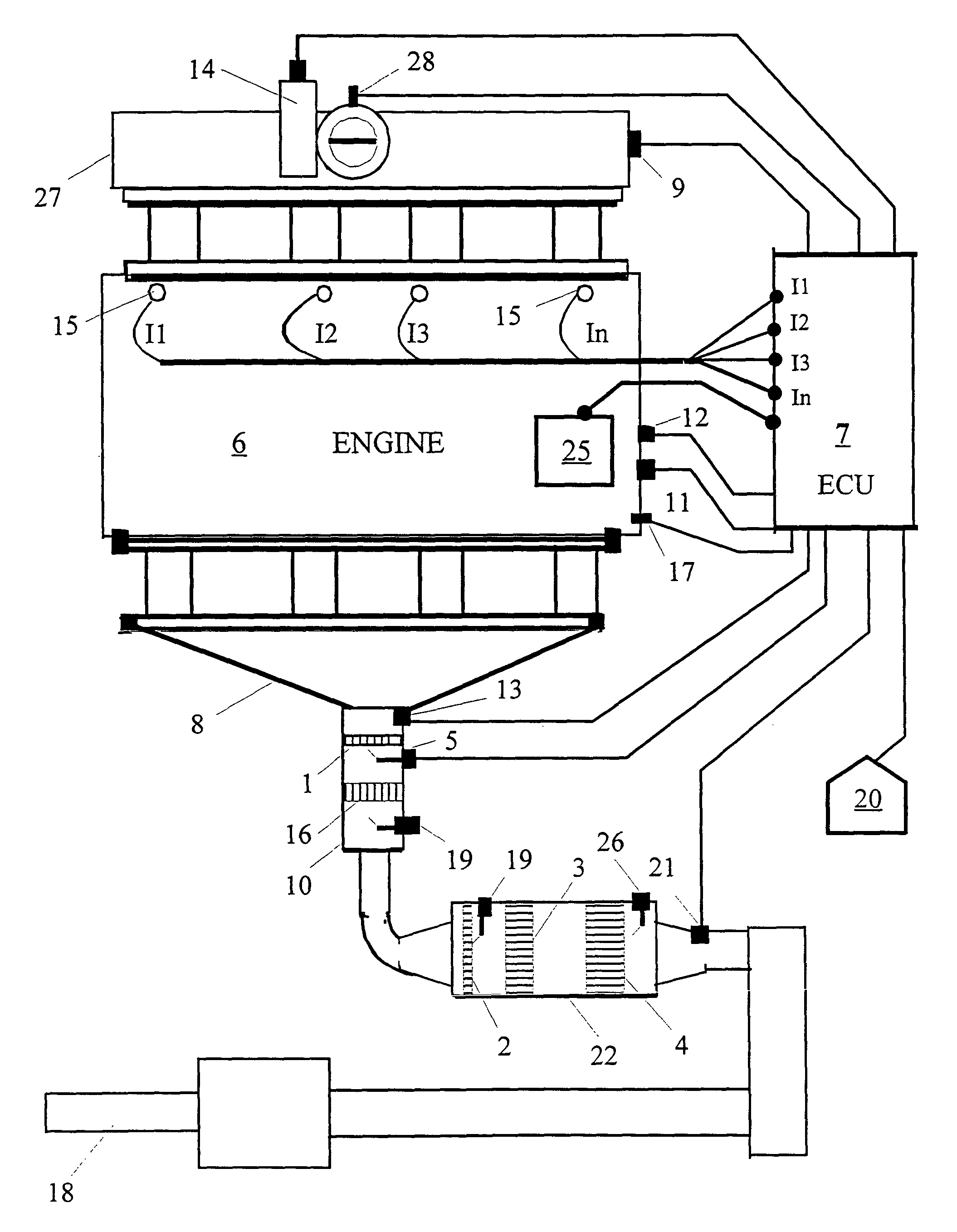

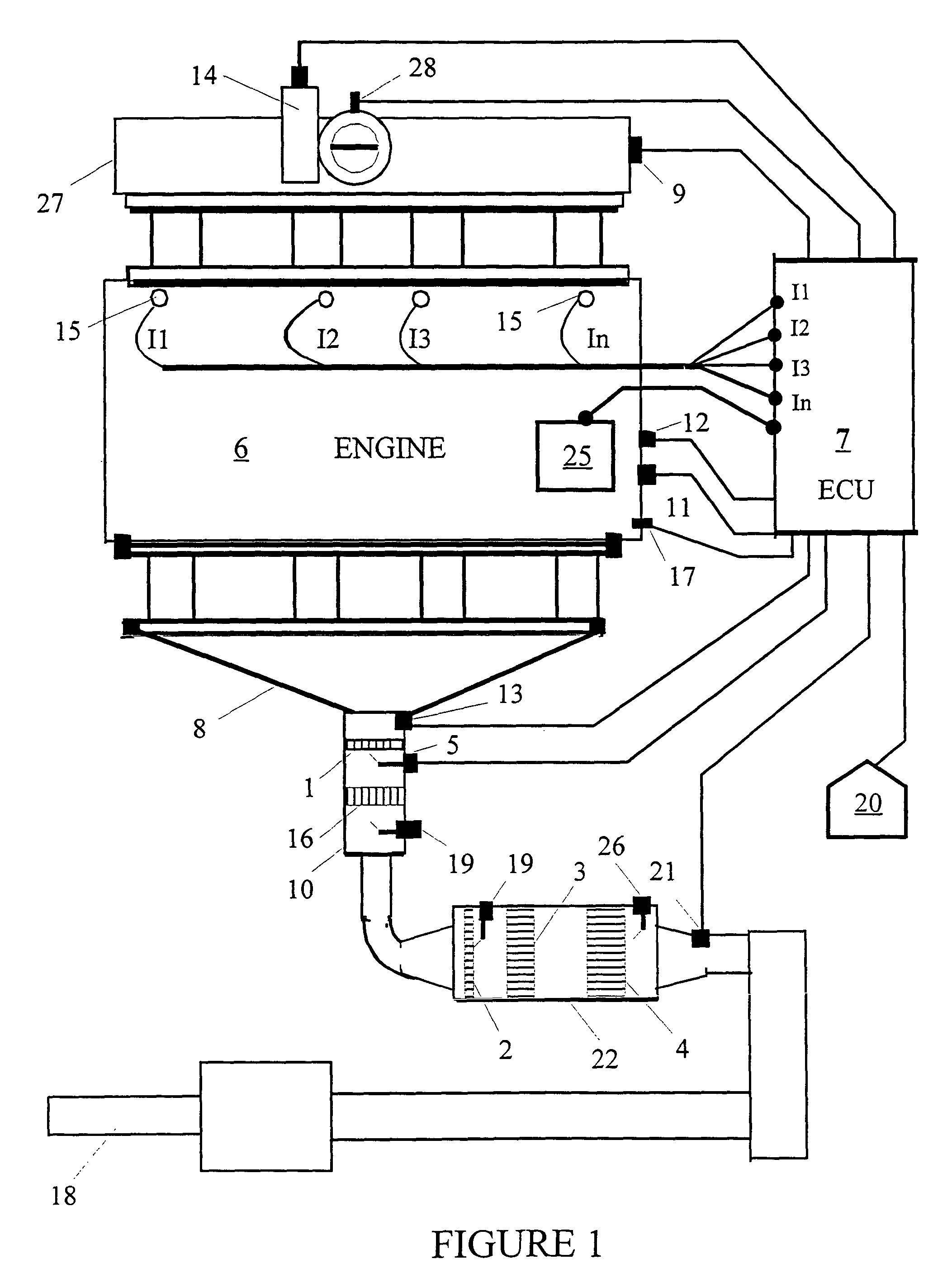

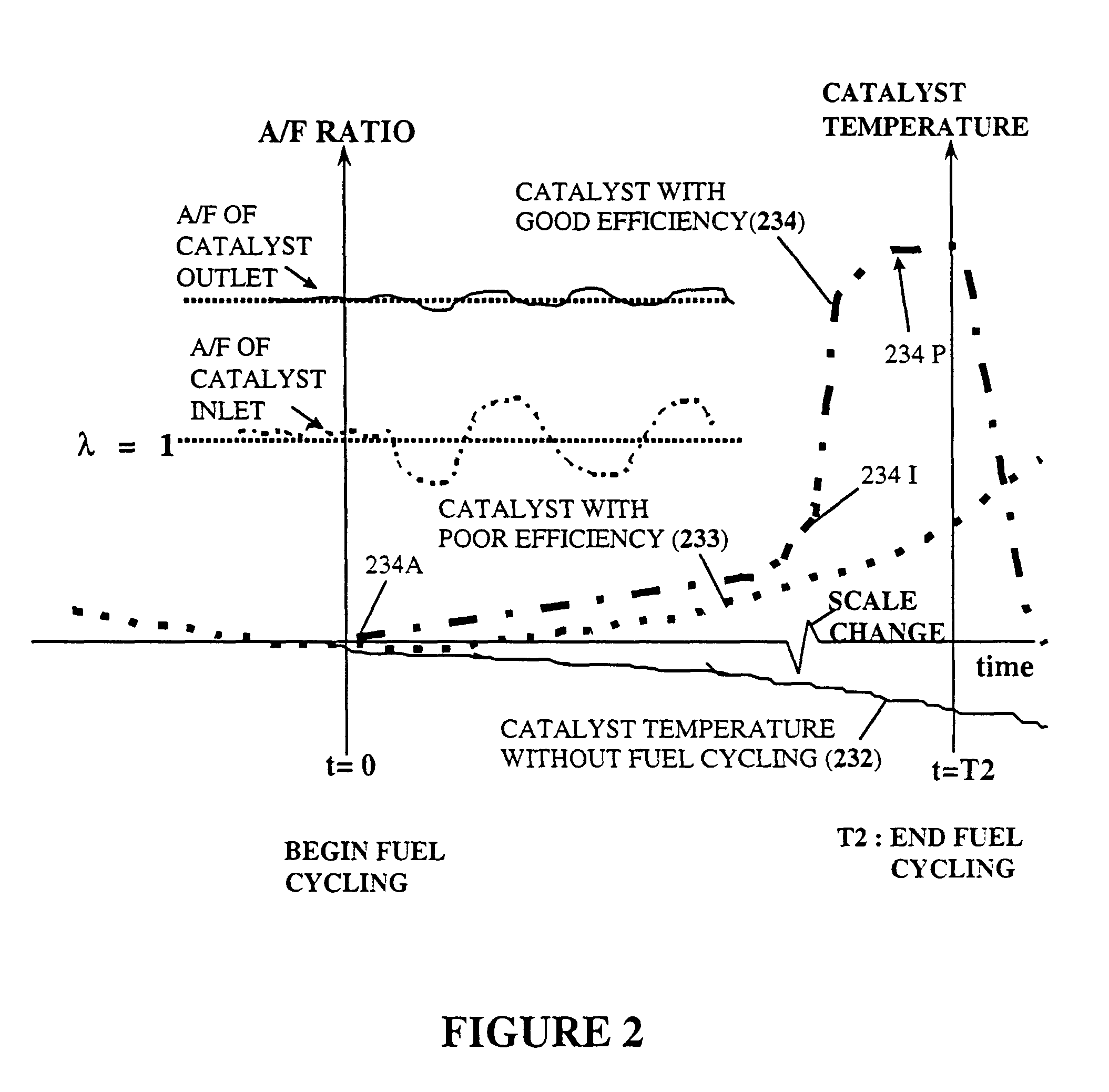

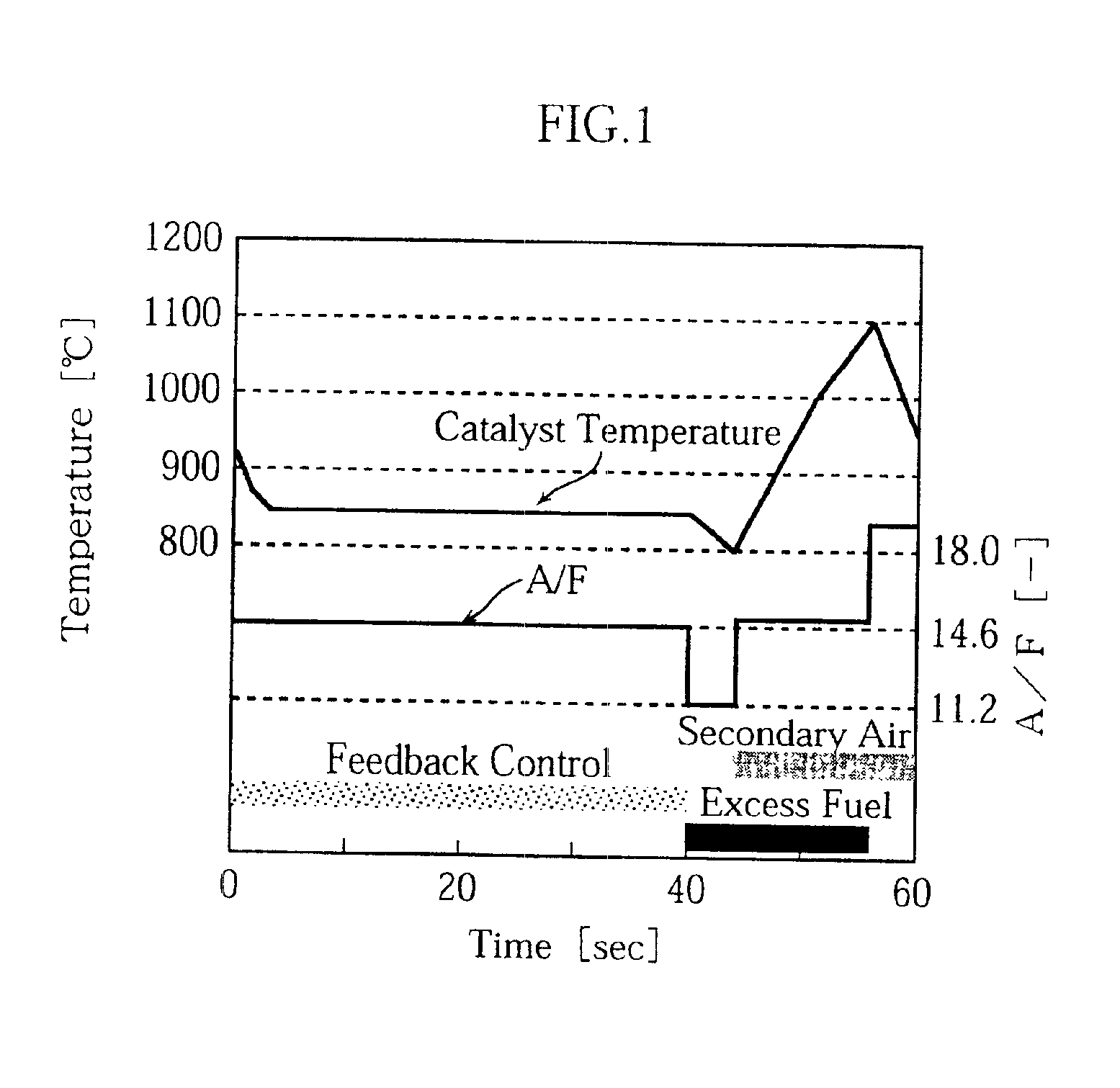

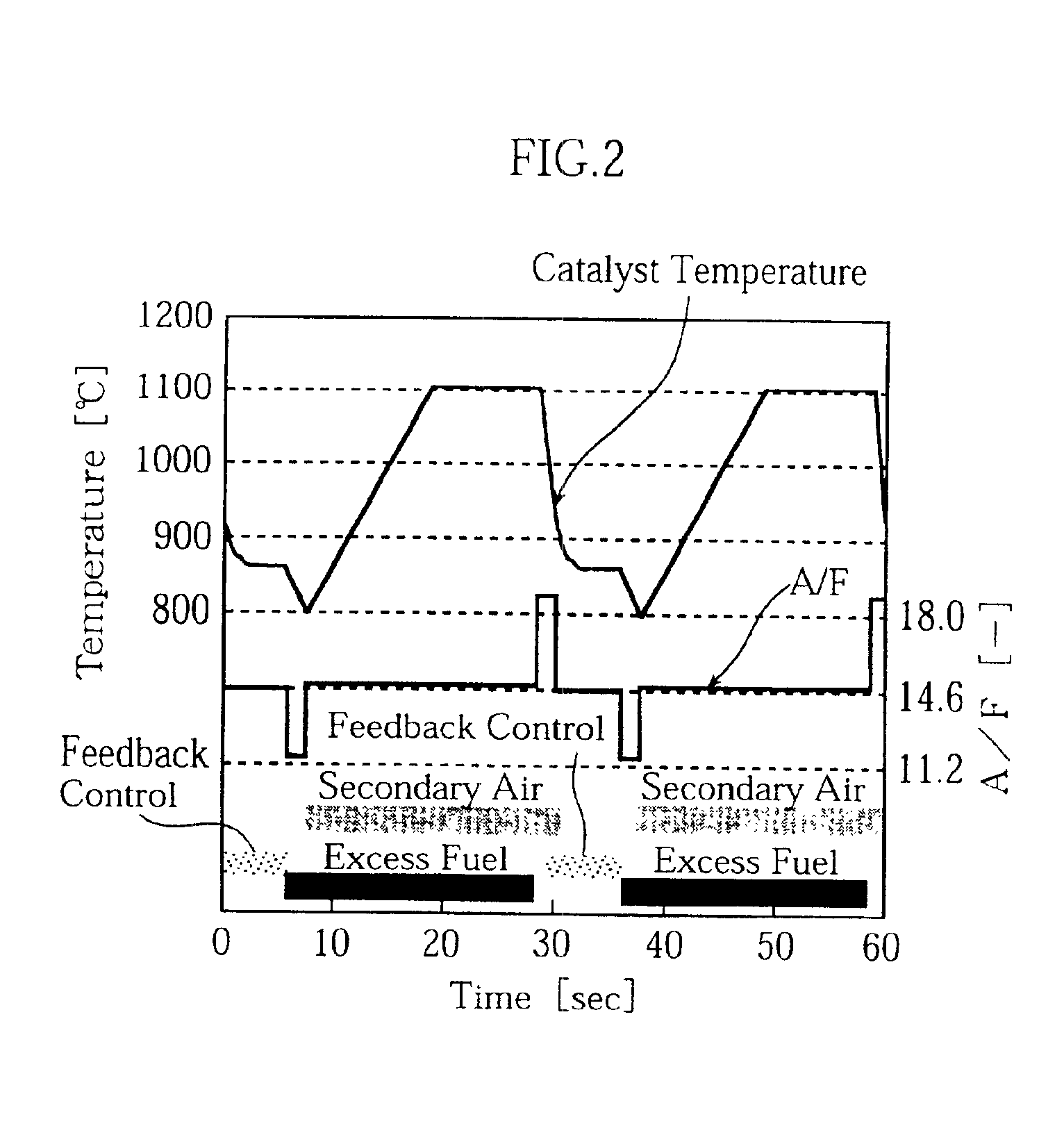

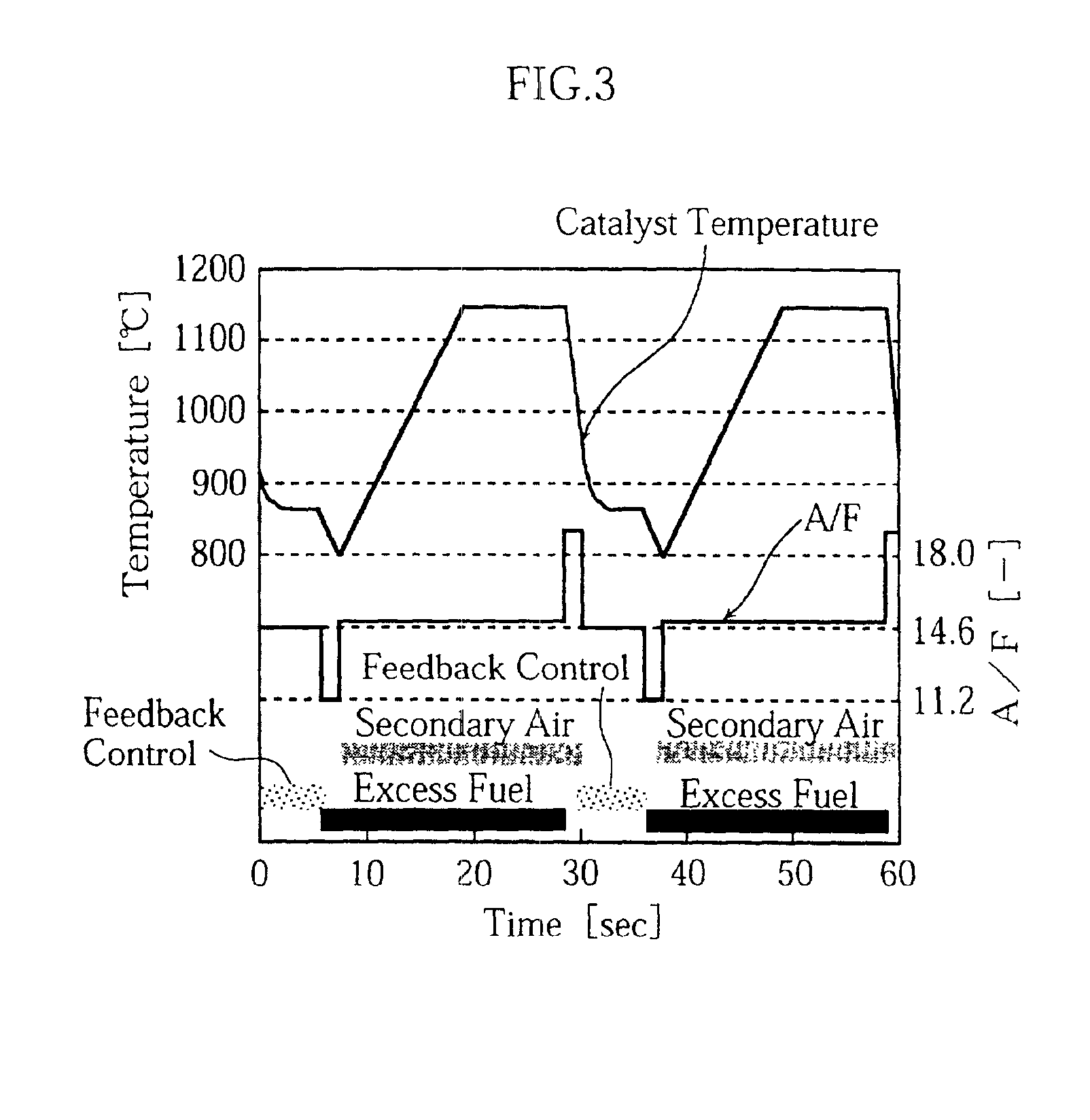

Control methods for improved catalytic converter efficiency and diagnosis

InactiveUS7707821B1Improve efficiencyImprove performanceElectrical controlInternal combustion piston enginesClosed loopProcess engineering

A controlling method for adjusting concentrations of, for example, individual cylinder's exhaust gas constituents to provide engine functions such as catalytic converter diagnosis, increased overall catalytic converter efficiency and rapid catalyst heating, before and / or after initiating closed loop fuel injection control, using a selected temperature sensor location within a low thermal mass catalytic converter design.

Owner:LEGARE JOSEPH E

Catalytic converter for cleaning exhaust gas

InactiveUS6261989B1Reduce and preventEasy to cleanNitrogen compoundsInternal combustion piston enginesCeriumCe element

A catalytic converter for cleaning exhaust gas includes a heat-resistant support, and a catalytic coating formed on the heat-resistant support. The catalytic coating contains Pd-carrying particles of a cerium complex oxide, Pt & Rh-carrying particles of zirconium complex oxide, and particles of a heat-resistant inorganic oxide.

Owner:DAIHATSU MOTOR CO LTD +1

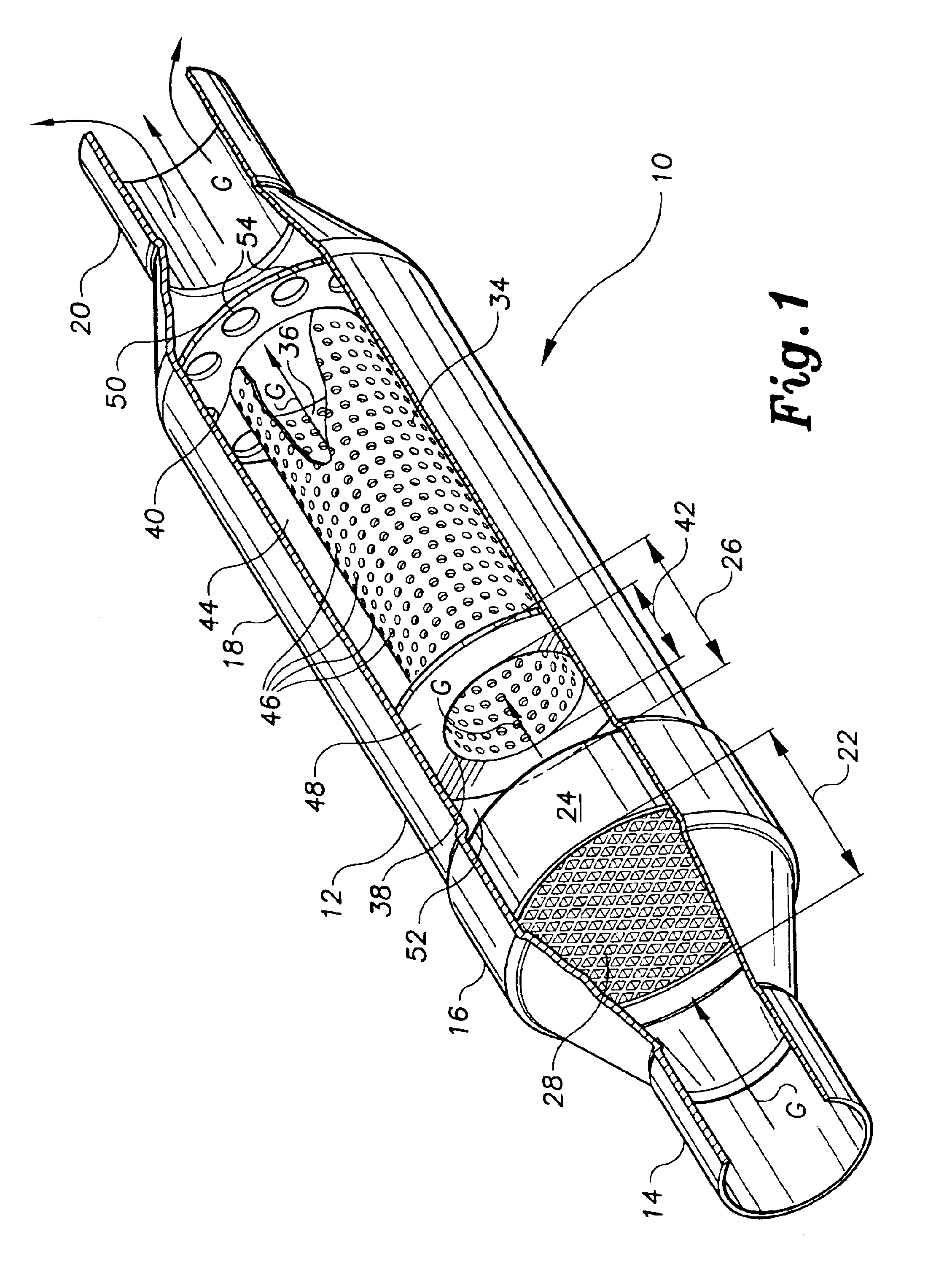

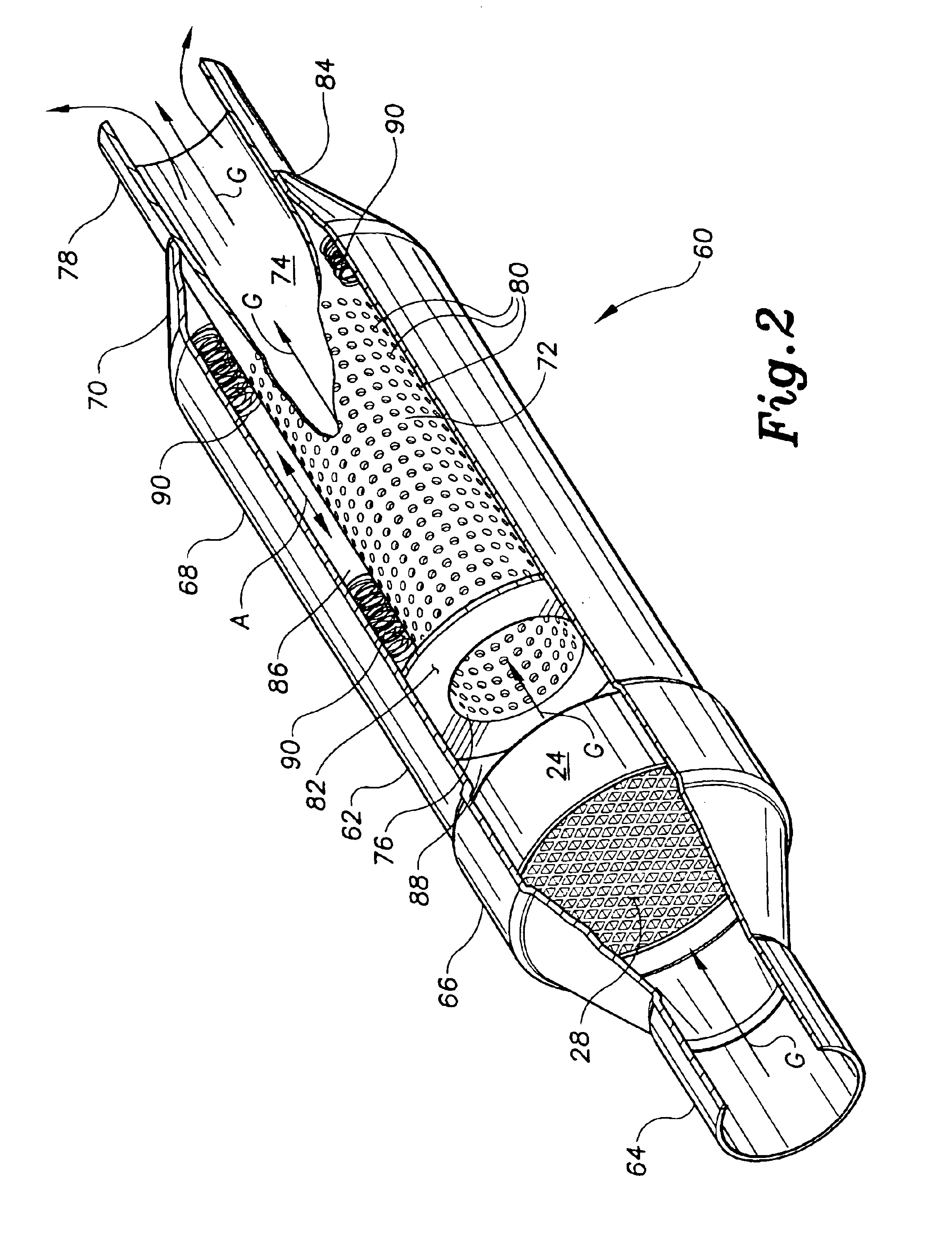

Exhaust sound and emission control systems

InactiveUS6935461B2Enhance emission reductionReduce componentsSilencing apparatusThermometers using physical/chemical changesControl systemDouble wall

The exhaust sound and emission control system is a system for reducing sound and noxious emissions from an automotive exhaust. The system may have an exhaust resonator having one or more catalytic converter elements in combination therewith in a single device. Alternatively, the system may have multiple angularly disposed chambers therein, with a series of V-shaped baffles or guides in one of the chambers, thereby combining resonator and muffler functions in a single device. In another alternative, the system has a series of longitudinal tubes therein, in combination with a series of V-shaped guides or vanes, combining catalytic converter, muffler, and resonator functions in a single device. The various elements of the different embodiments, e.g. catalytic converter element(s), double wall shell, perforated tubes and multiple flow paths, interconnecting crossover tubes, etc., may be combined with one another as practicable.

Owner:MAROCCO GREGORY M

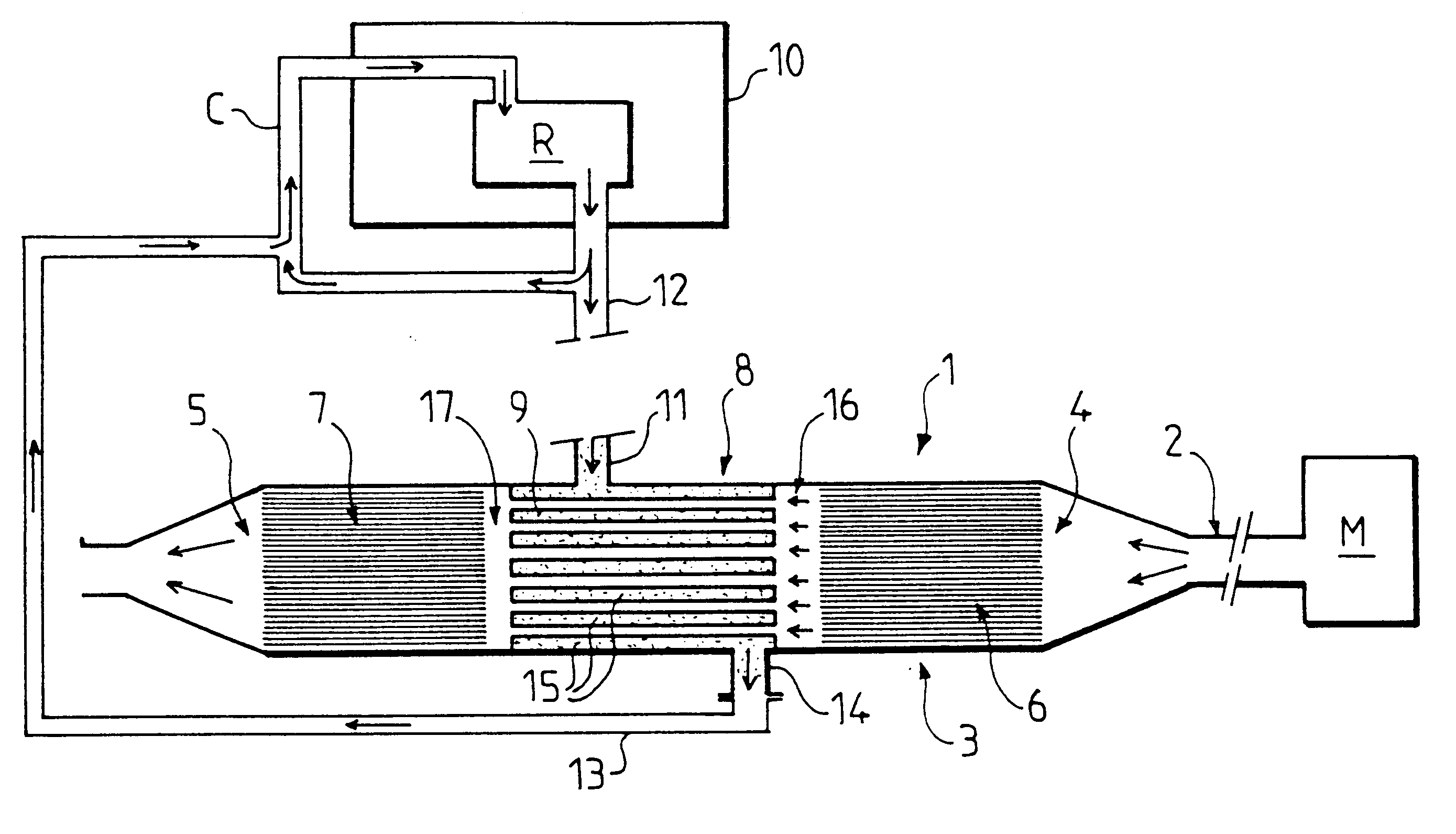

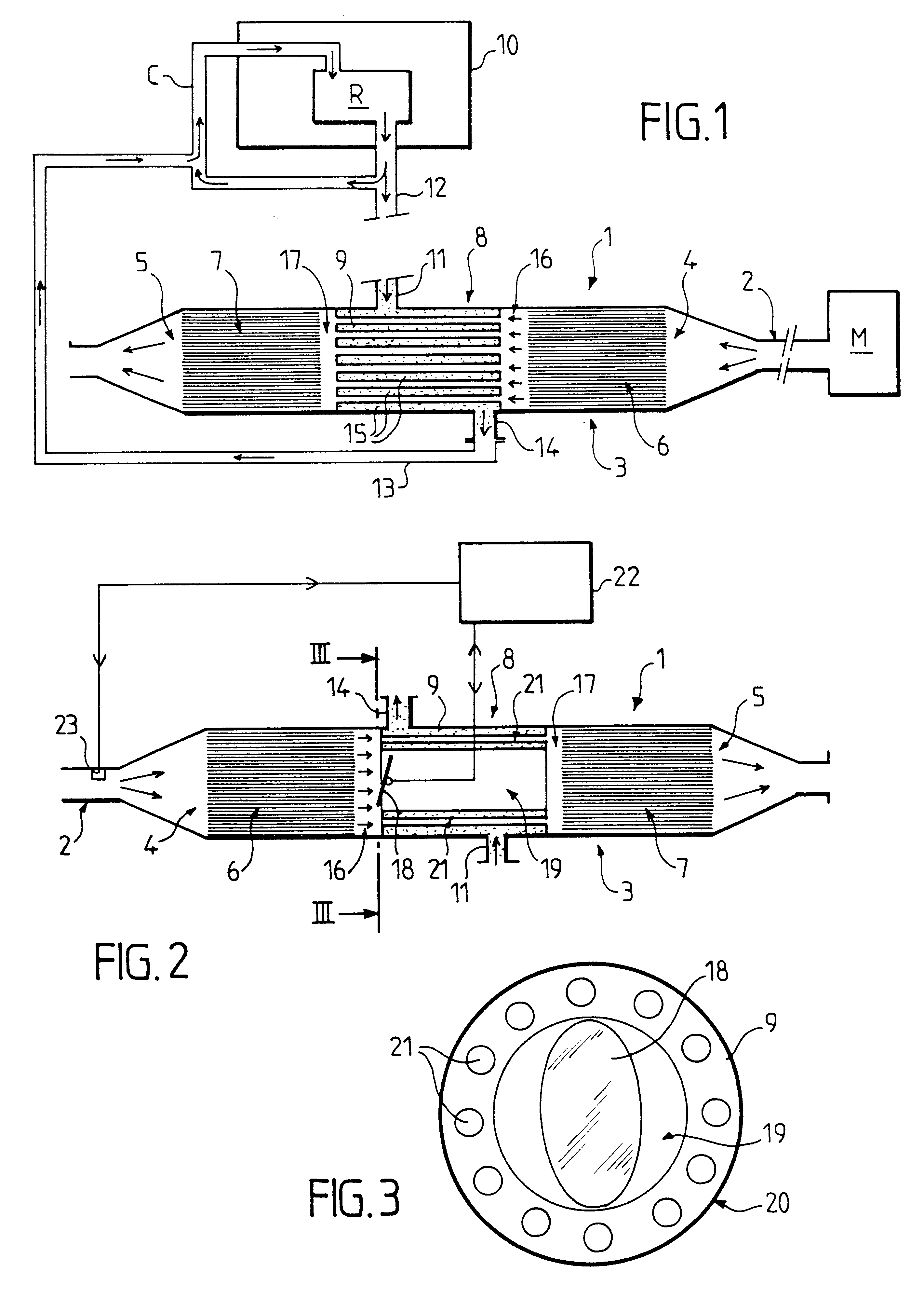

Controlled temperature catalytic converter, in particular for a motor vehicle

InactiveUS6178744B1Uniform temperatureImprove distributionInternal combustion piston enginesExhaust apparatusMobile vehicleExhaust fumes

A catalytic converter includes a casing connected to the output from an exhaust gas and residue manifold of an engine, in particular an engine of a motor vehicle. The casing contains arrangements for oxidizing the exhaust gases and residues and for trapping the oxidized gases and residues. A central part of the casing houses cooling arrangements for reducing the temperature of the gases and residues upstream of the trapping arrangements below a predetermined threshold.

Owner:VALEO THERMIQUE MOTEUR

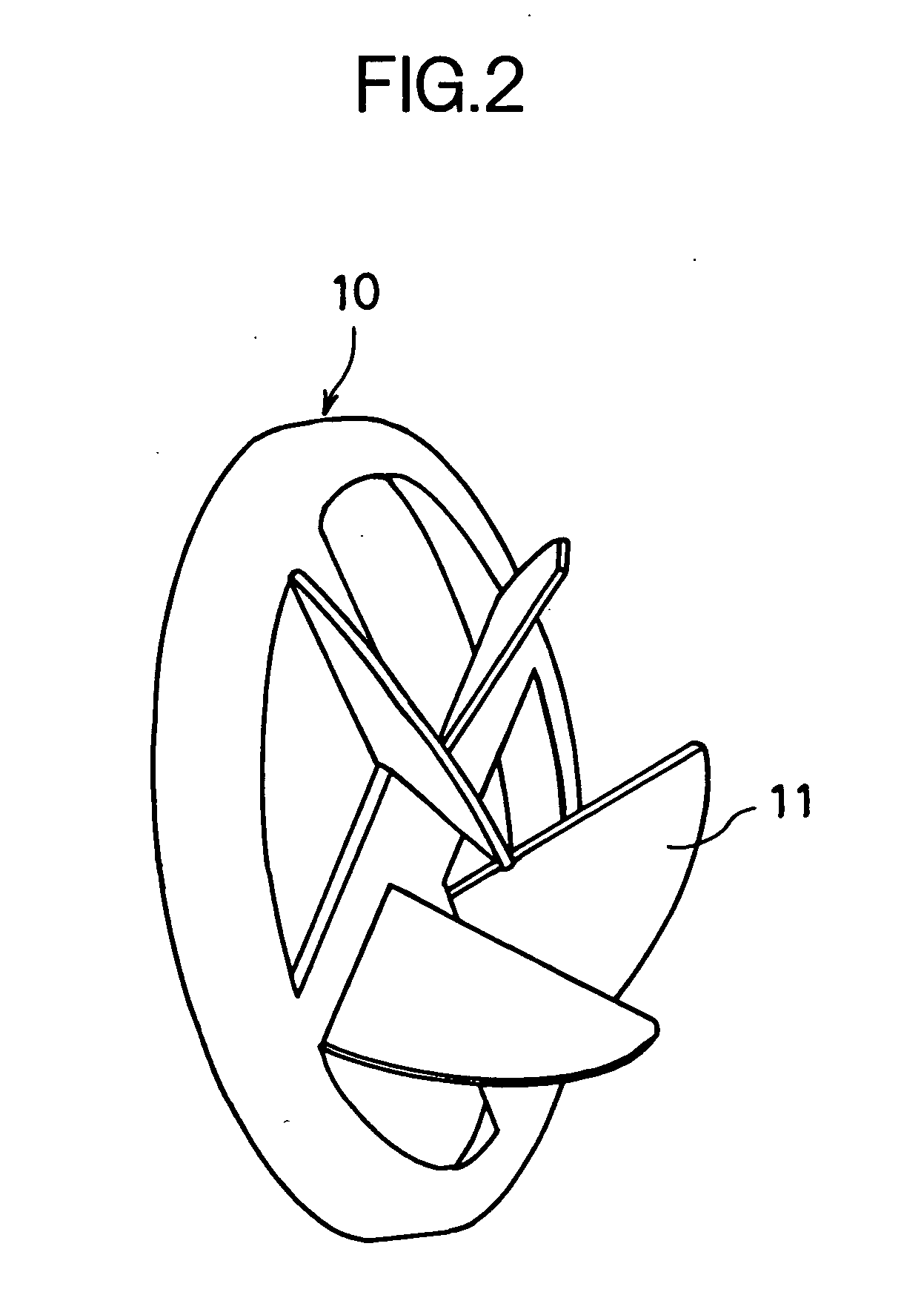

Exhaust mixer element and method for mixing

According to one aspect of the invention, a mixer element to be placed between an internal combustion engine exhaust manifold and catalytic converter is provided. The mixer element includes a tubular conduit that receives an exhaust gas flow from the internal combustion engine, a first mixer configured to induce a first vortex of the exhaust gas flow in a first rotational direction and an injector disposed in the tubular conduit downstream of the first mixer, the injector being configured to inject a diesel emission fluid flow into the exhaust gas flow. The mixer element also includes a second mixer positioned downstream of the injector and a third mixer positioned downstream of the second mixer, the third mixer being configured to induce a second vortex of the exhaust gas flow and the diesel emission fluid mixture in a second rotational direction, opposite of the first rotational direction.

Owner:GM GLOBAL TECH OPERATIONS LLC

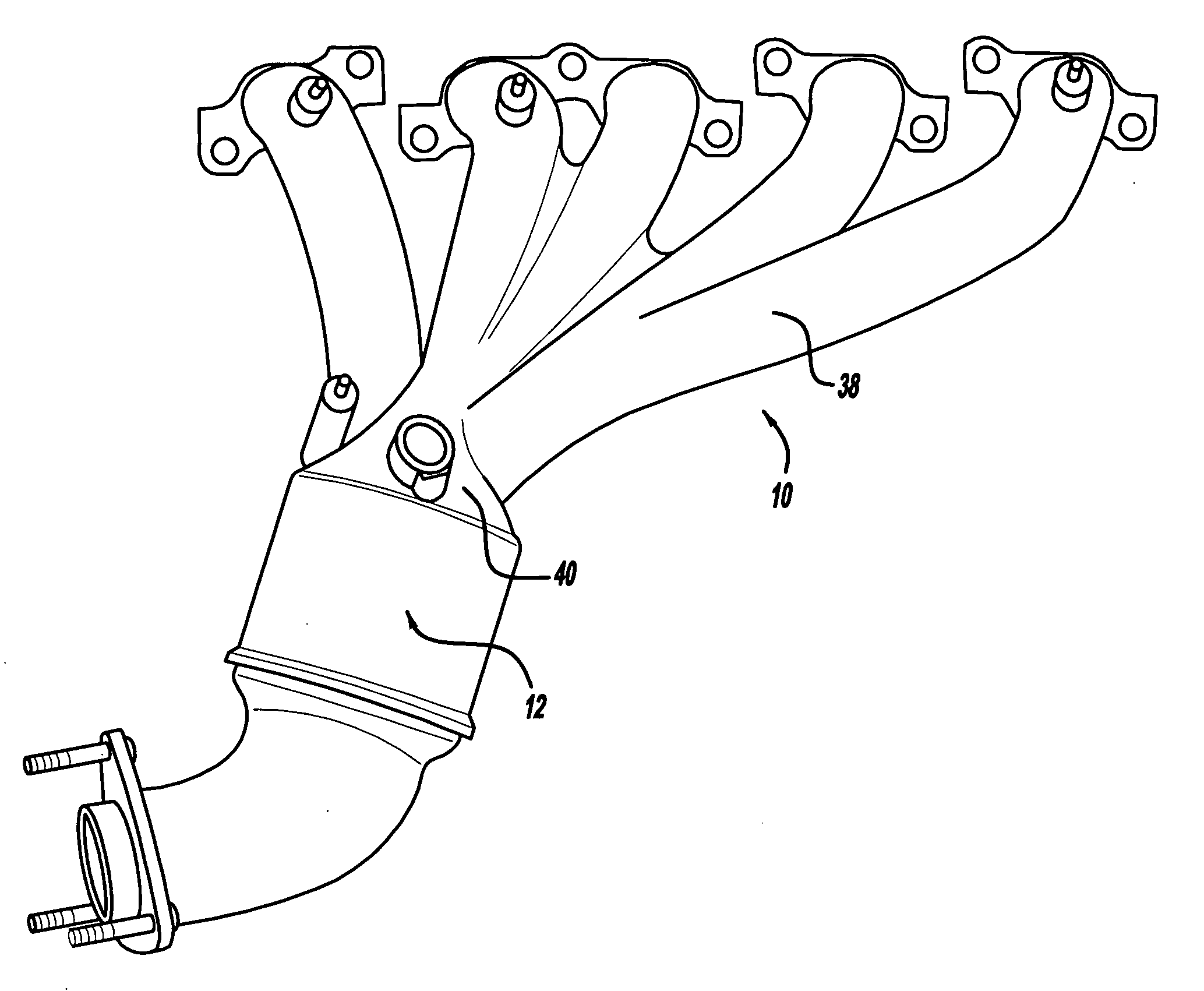

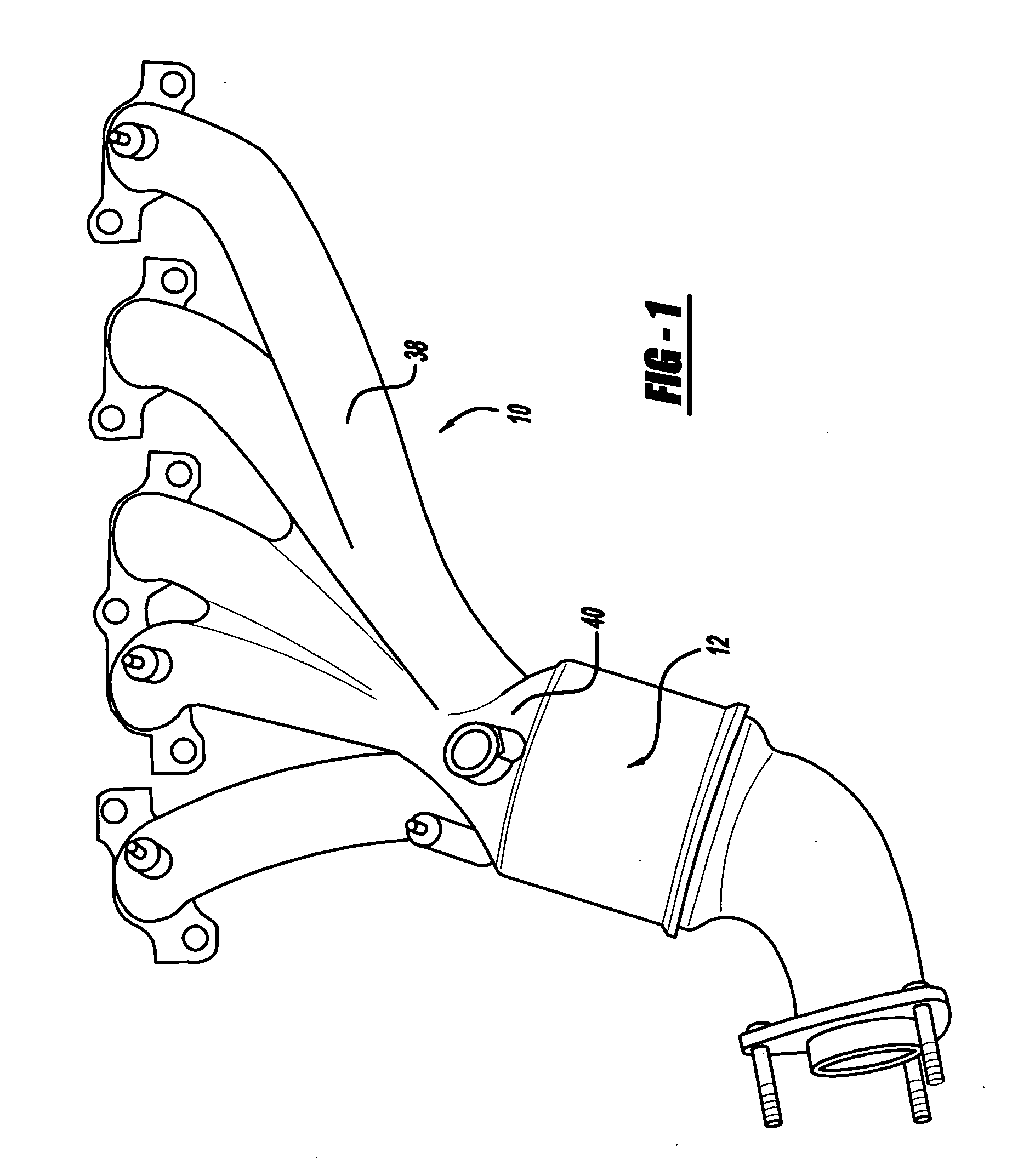

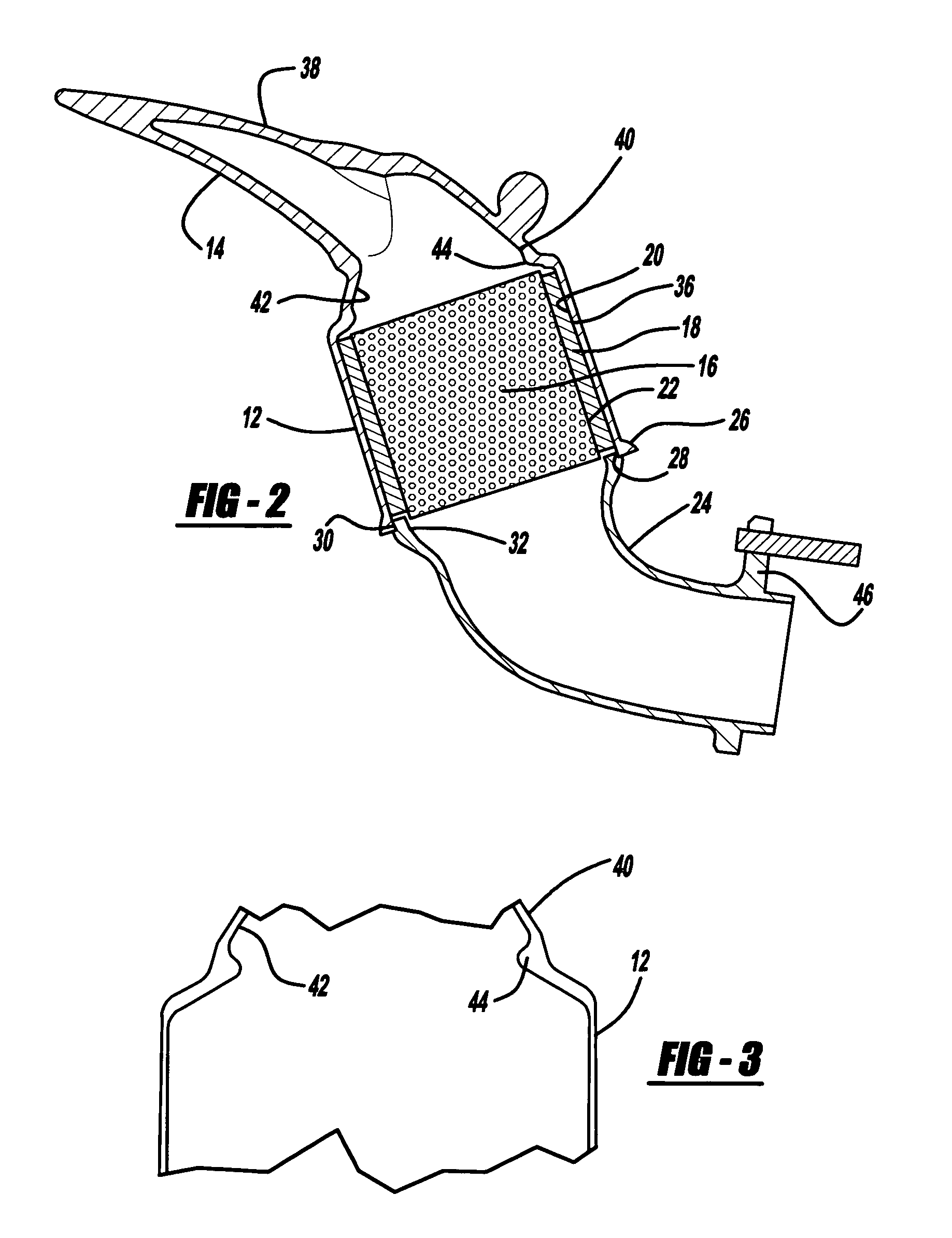

One piece catalytic converter with integral exhaust manifold

InactiveUS20050150222A1Reduce in quantityExhaust apparatusSilencing apparatusEngineeringExhaust manifold

The present invention relates to exhaust system assemblies and, more particularly, to a one piece catalytic converter can with an integral exhaust manifold. Disposed within the catalytic converter can are the catalytic conversion components. Coupled to the one piece converter can and integral exhaust manifold is a second end cone to provide a substantially air tight seal to the assembly.

Owner:WESCAST USA

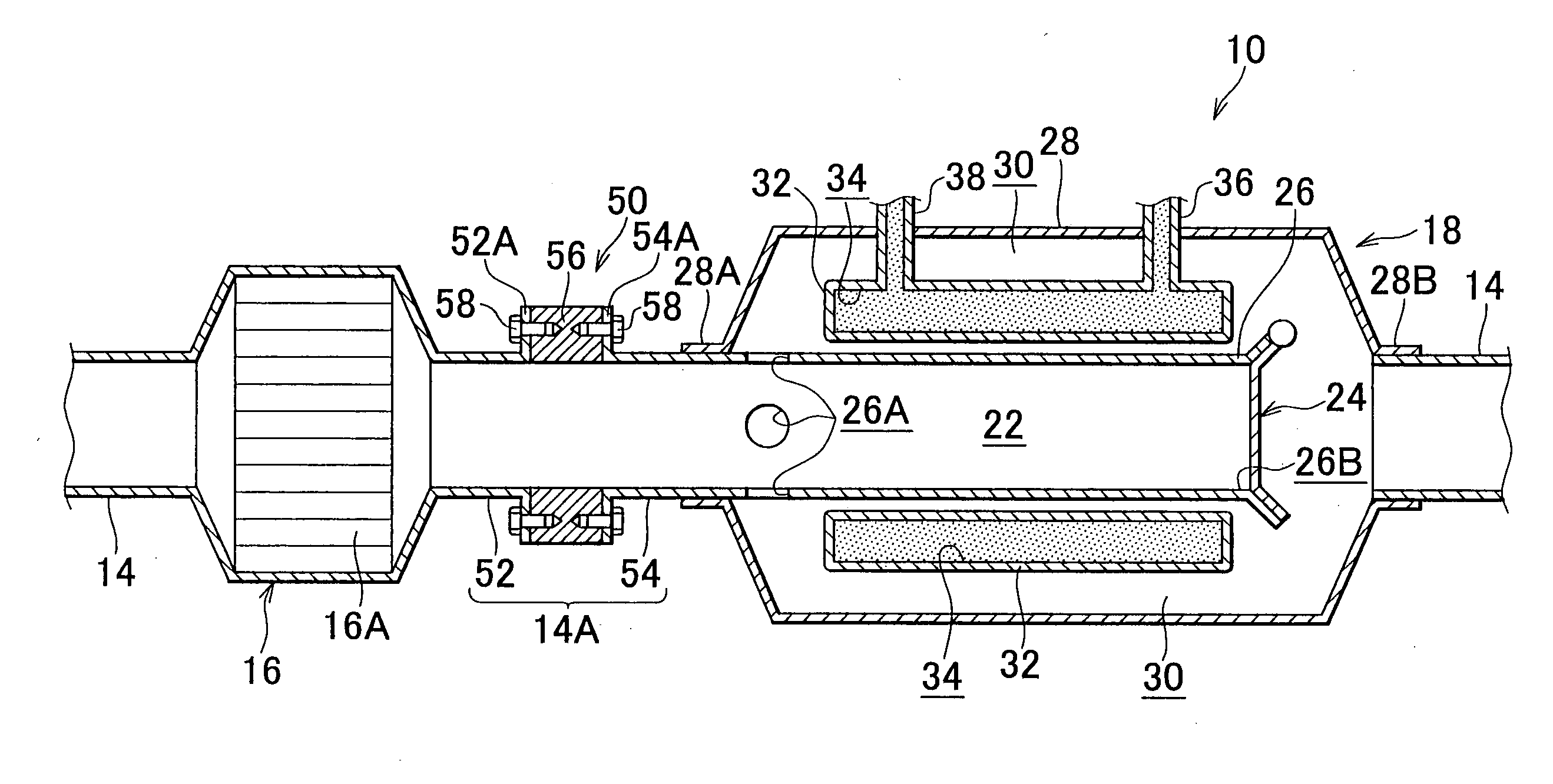

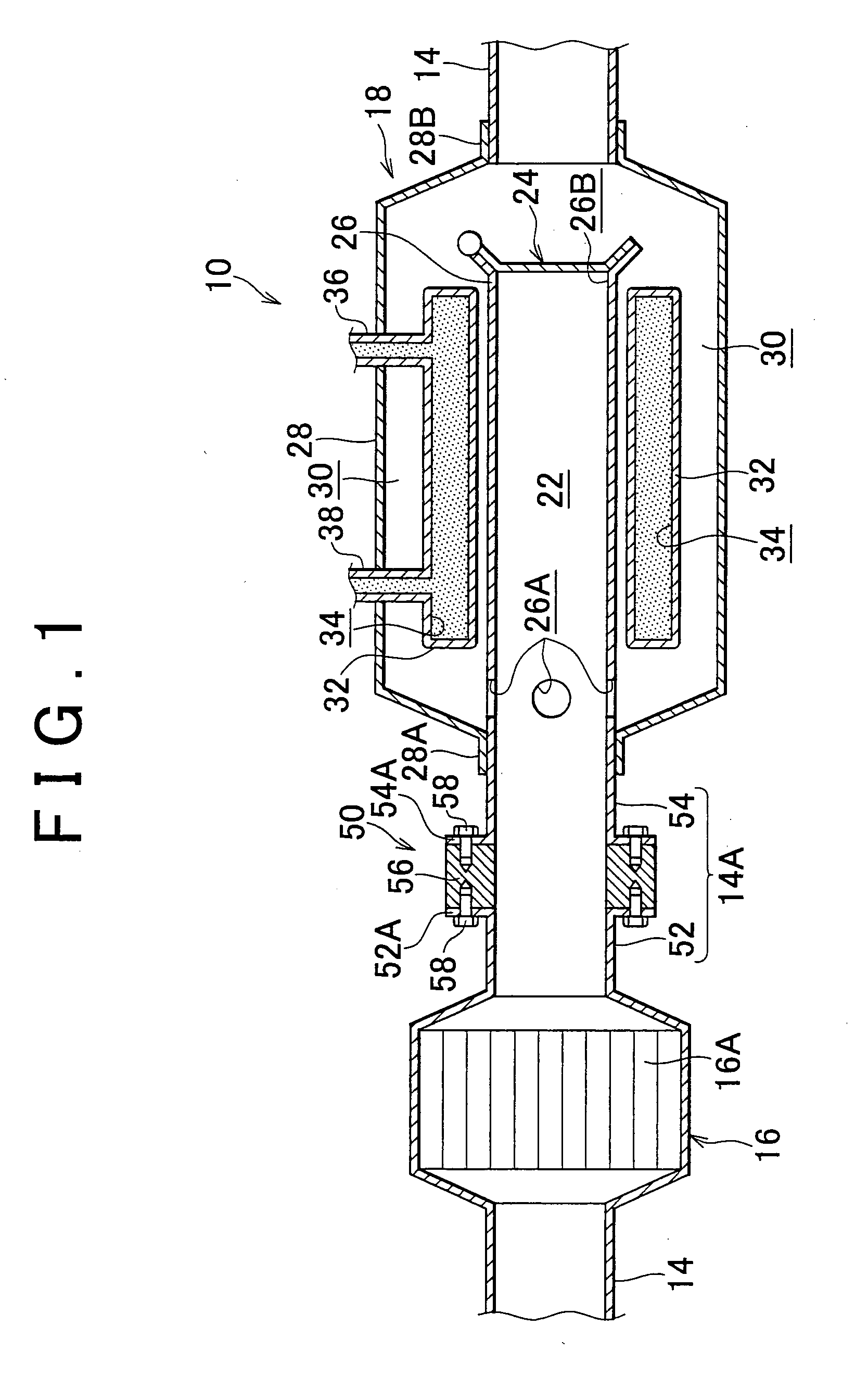

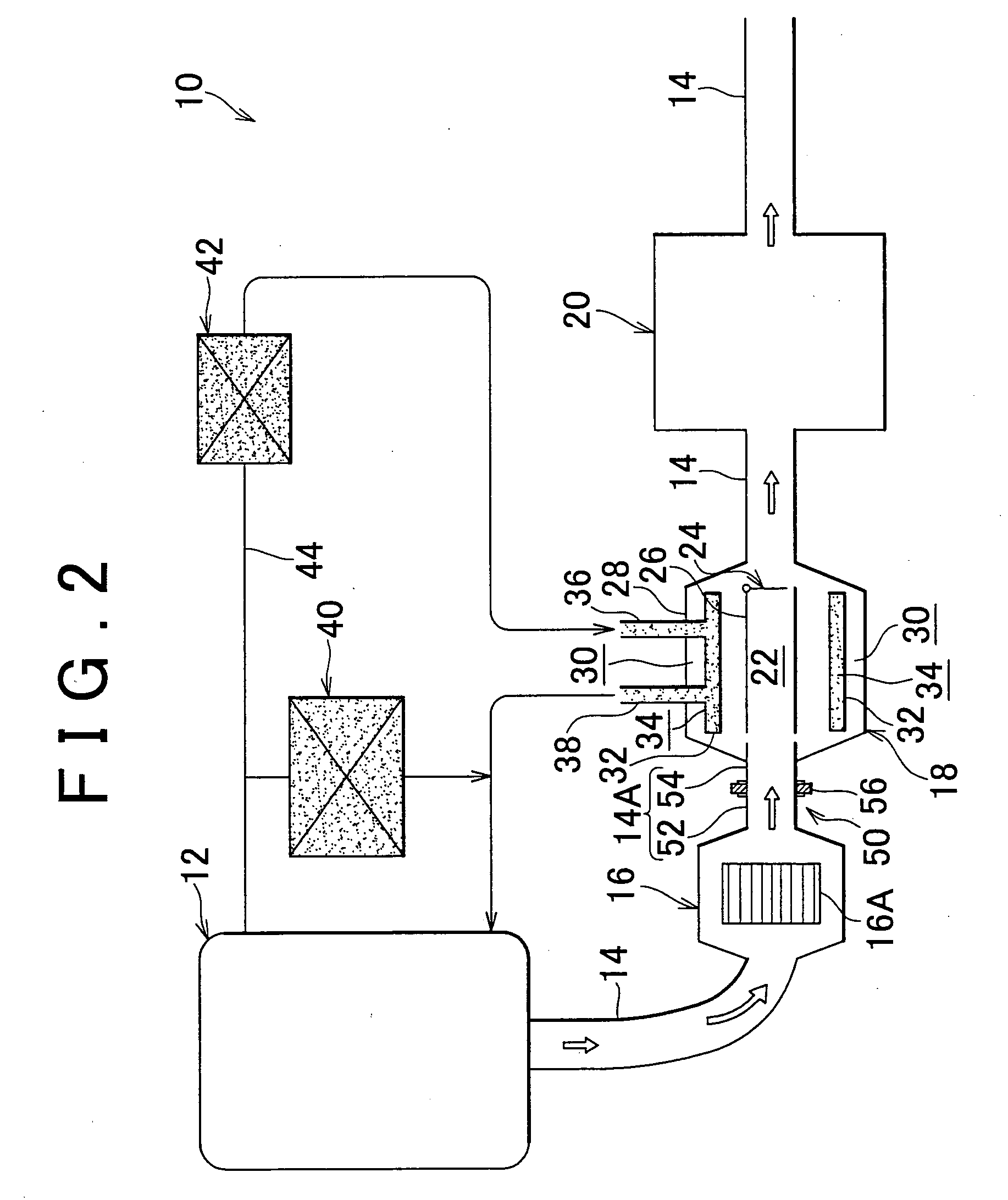

Exhaust heat recovery system

InactiveUS20100043413A1Combination devicesInternal combustion piston enginesEngineeringExhaust heat recovery system

An exhaust heat recovery system (10) includes: an exhaust heat exchanger (18) that is communicated with a catalytic converter (16) through an exhaust gas pipe (14A), and that recovers exhaust heat into a coolant; and heat transfer restriction means (50) provided between the catalytic converter (16) and the exhaust heat exchanger (18). The heat transfer restriction means (50) includes a heat insulator (56) disposed between a first exhaust gas pipe (52) and a second exhaust gas pipe (54) that constitute the exhaust gas pipe (14A), and. restrains a released heat from the catalytic converter (16) from reaching the exhaust heat exchanger (18).

Owner:TOYOTA JIDOSHA KK

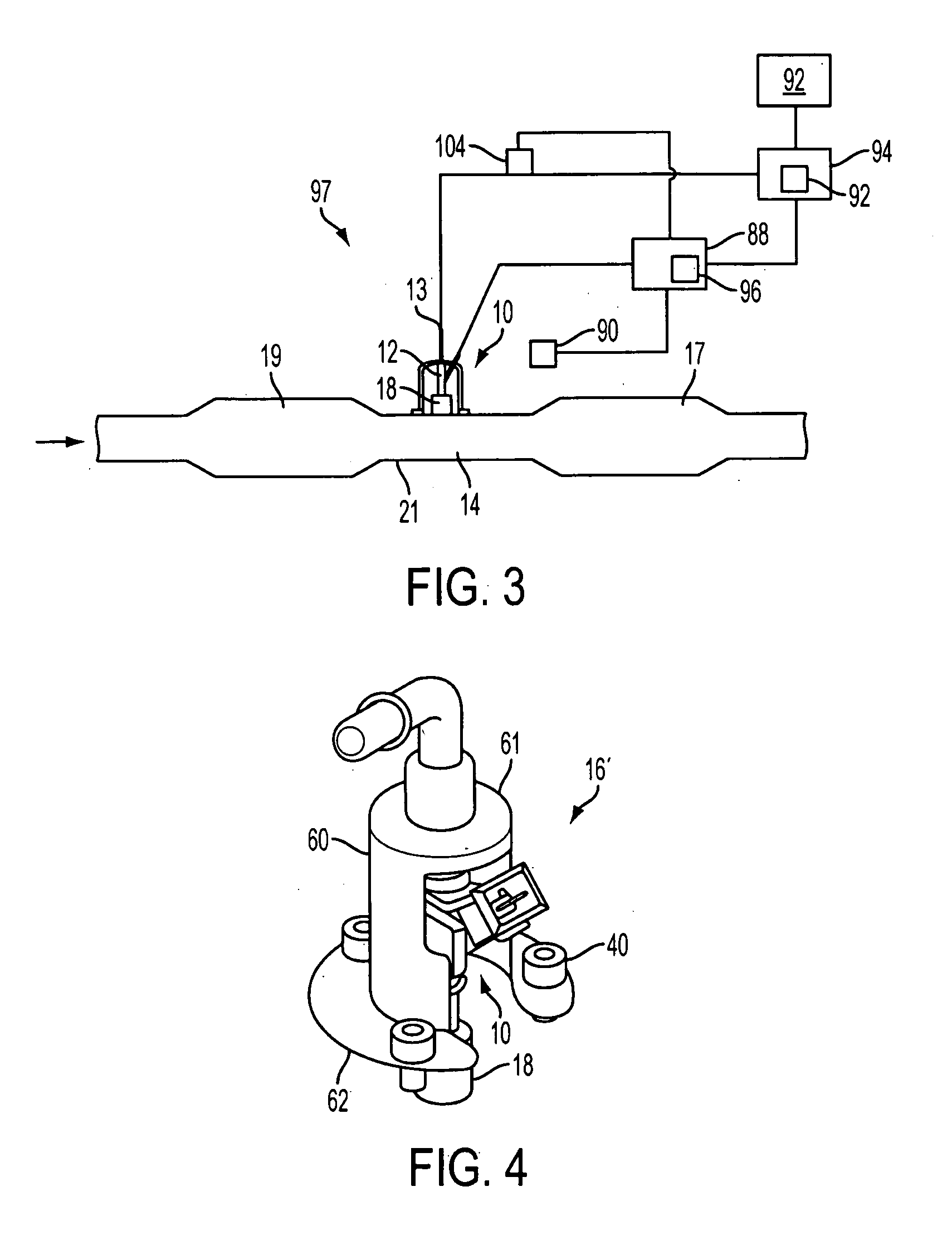

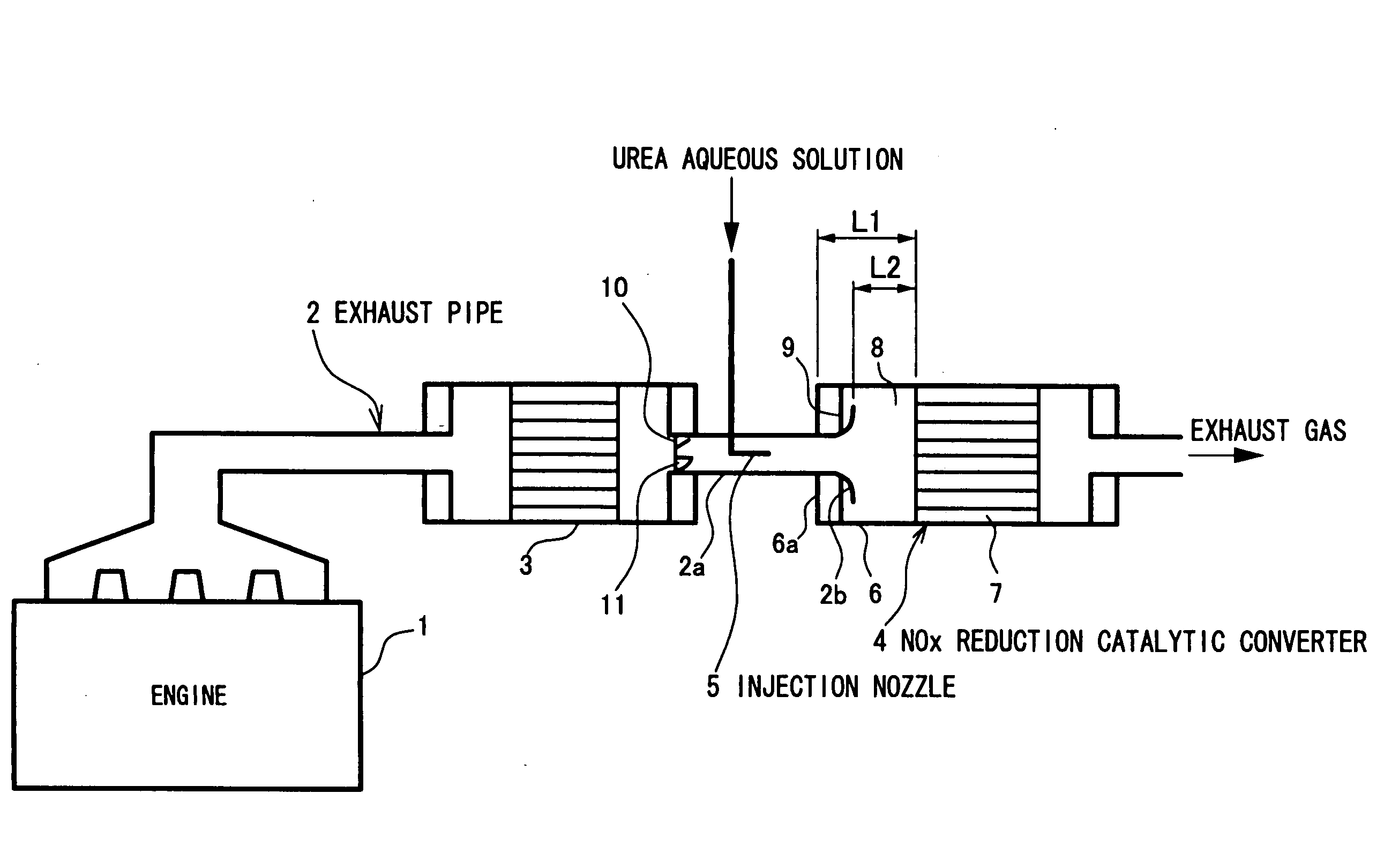

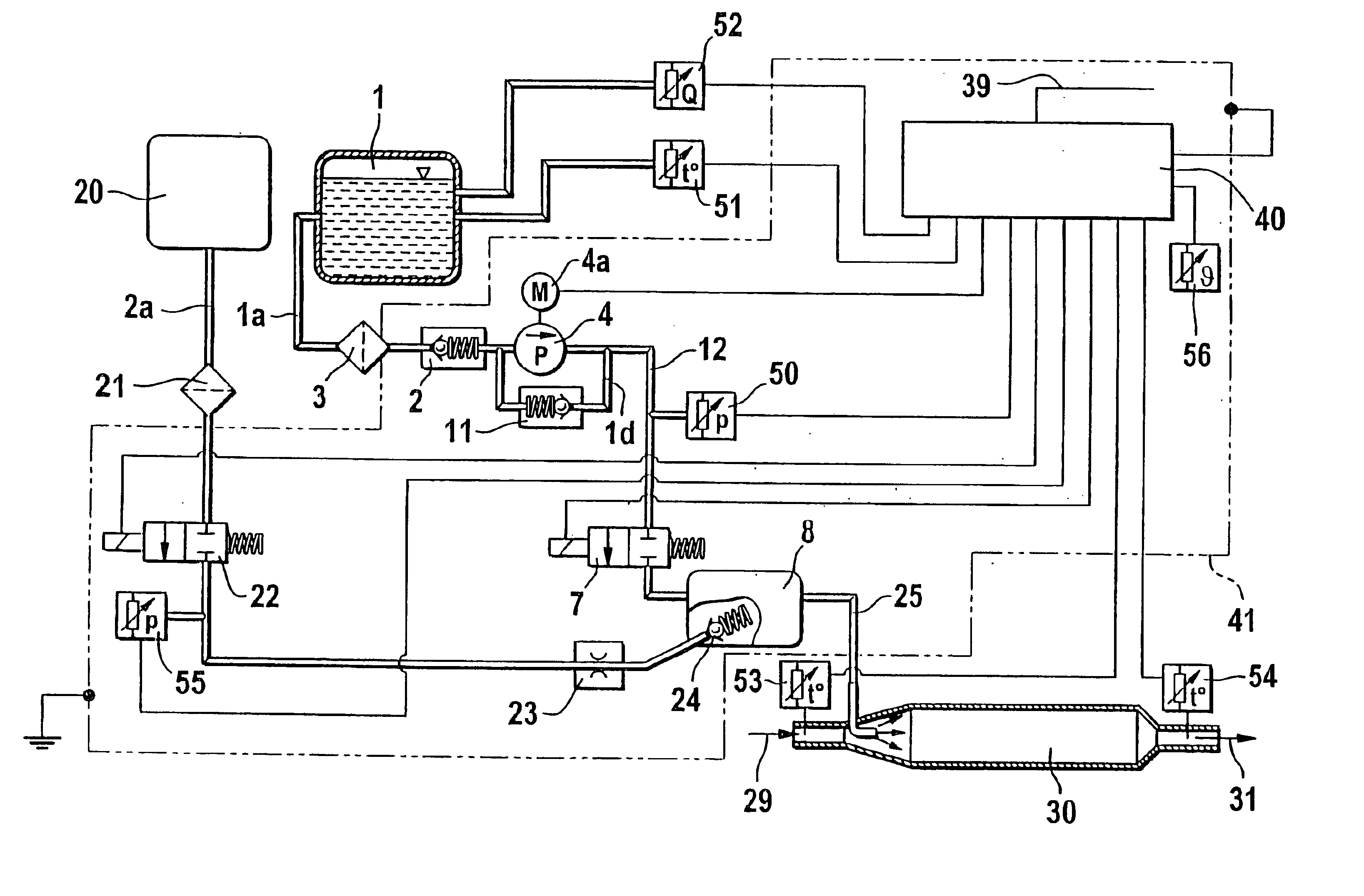

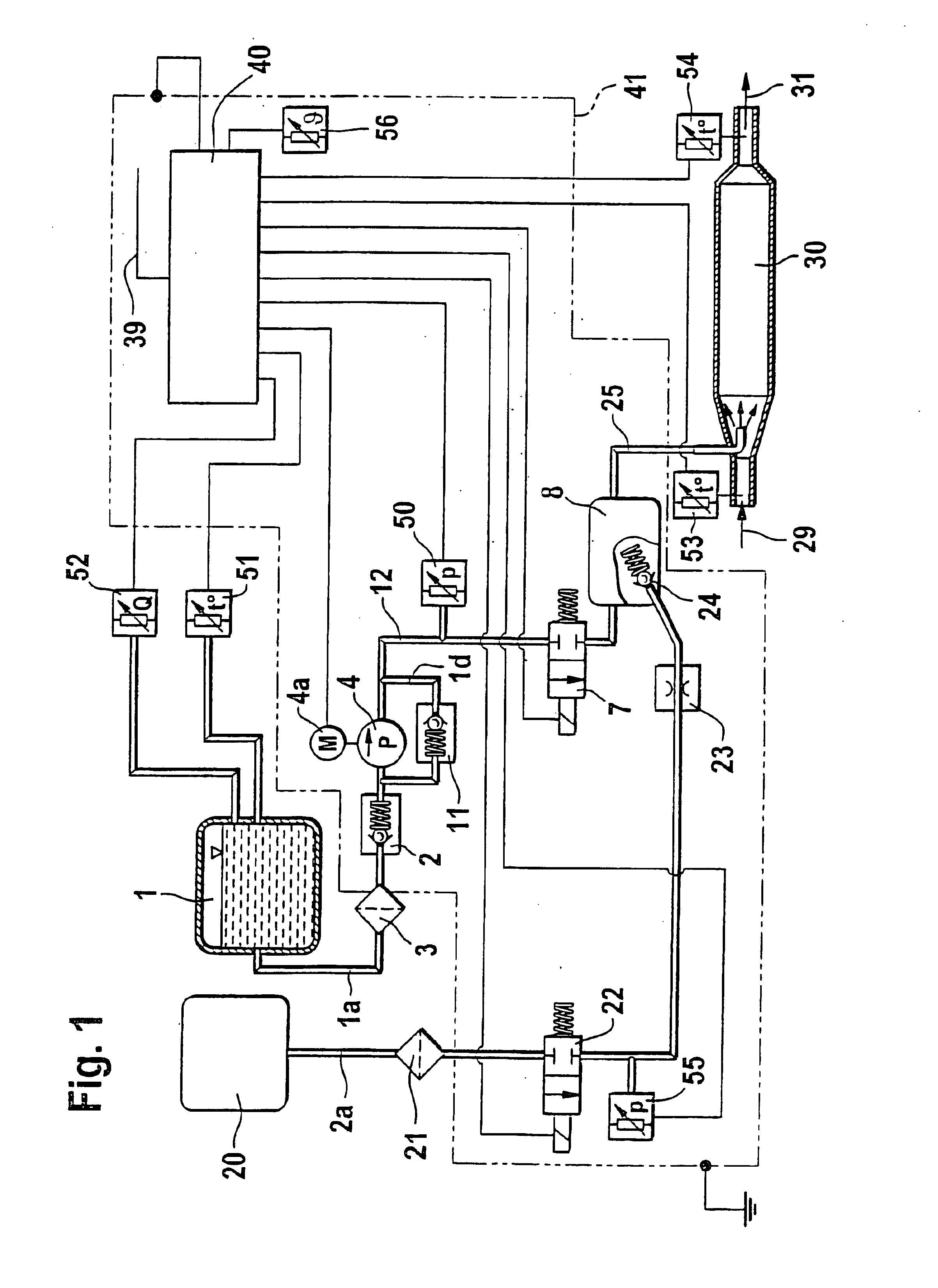

Method and apparatus for metering a reducing agent for removing nitrogen oxides from exhaust gases

InactiveUS6912846B2Reduce in quantityLine course simplerOperating means/releasing devices for valvesInternal combustion piston enginesNitrogen oxidesLine tubing

A method and an apparatus for metering a reducing agent in which the reducing agent is delivered, via a line and a final control element that regulates the metering, in particular a metering valve, to a catalytic converter assembly for removing nitrogen oxides from the exhaust gases, in particular of a Diesel engine; a pressure drop in the line dictated especially by gas inclusions is detected, and the line is ventilated via the final control element.

Owner:ROBERT BOSCH GMBH

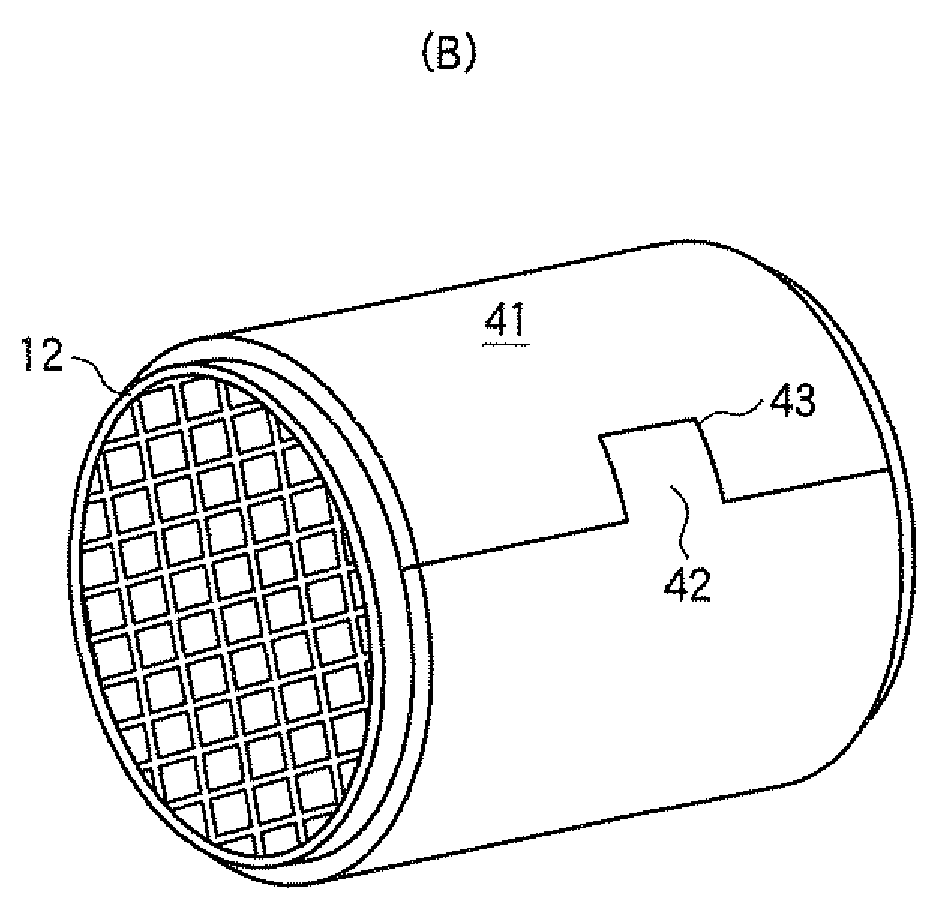

Process for the coating of the flow channels of a honeycomb form catalytic converter carrier with a dispersion coating

A process for the coating of the flow channels of a cylindrical, honeycomb form catalyst carrier with a dispersion coating through filling of the vertically oriented flow channels with a fill quantity of the coating dispersion through the bottom face of the catalyst carrier and subsequent downward emptying and clearance extraction of the flow channels, as well as drying and calcination of the catalyst carrier, by the following steps: a) filling of the flow channels with a fill quantity that is about 10% greater than the empty volume of the flow channels, so that the coating dispersion goes over the upper face of the catalyst carrier after completion of the filling cycle, b) removal of the excess coating dispersion at the top before emptying of the flow channels and c) emptying and clearance extraction of the flow channels through an extraction impulse, which is generated by connection of a vacuum tank with the bottom face of the catalyst carrier, whereby the time between the beginning of the fill cycle and the end of the emptying and clearance extraction amounts to no more than 5 seconds.

Owner:DMC2 DEGUSSA METALS +1

Exhaust gas catalyst

InactiveUS6180075B1Favorable degree of conversionExceptional heat and aging resistanceNitrogen compoundsInternal combustion piston enginesZirconium hydrideCerium(IV) oxide

A single-layered three-way catalytic converter containing palladium as the only catalytically active noble metal, with high activity and heat resistance. The catalyst contains, in addition to finely divided, stabilized aluminum oxide, at least one finely divided cerium / zirconium mixed oxide and optionally finely divided nickel oxide as well as highly dispersed amounts of cerium oxide, zirconium oxide and barium oxide. The palladium is distributed largely uniformly throughout the entire catalyst.

Owner:DMC2 DEGUSSA METALS +1

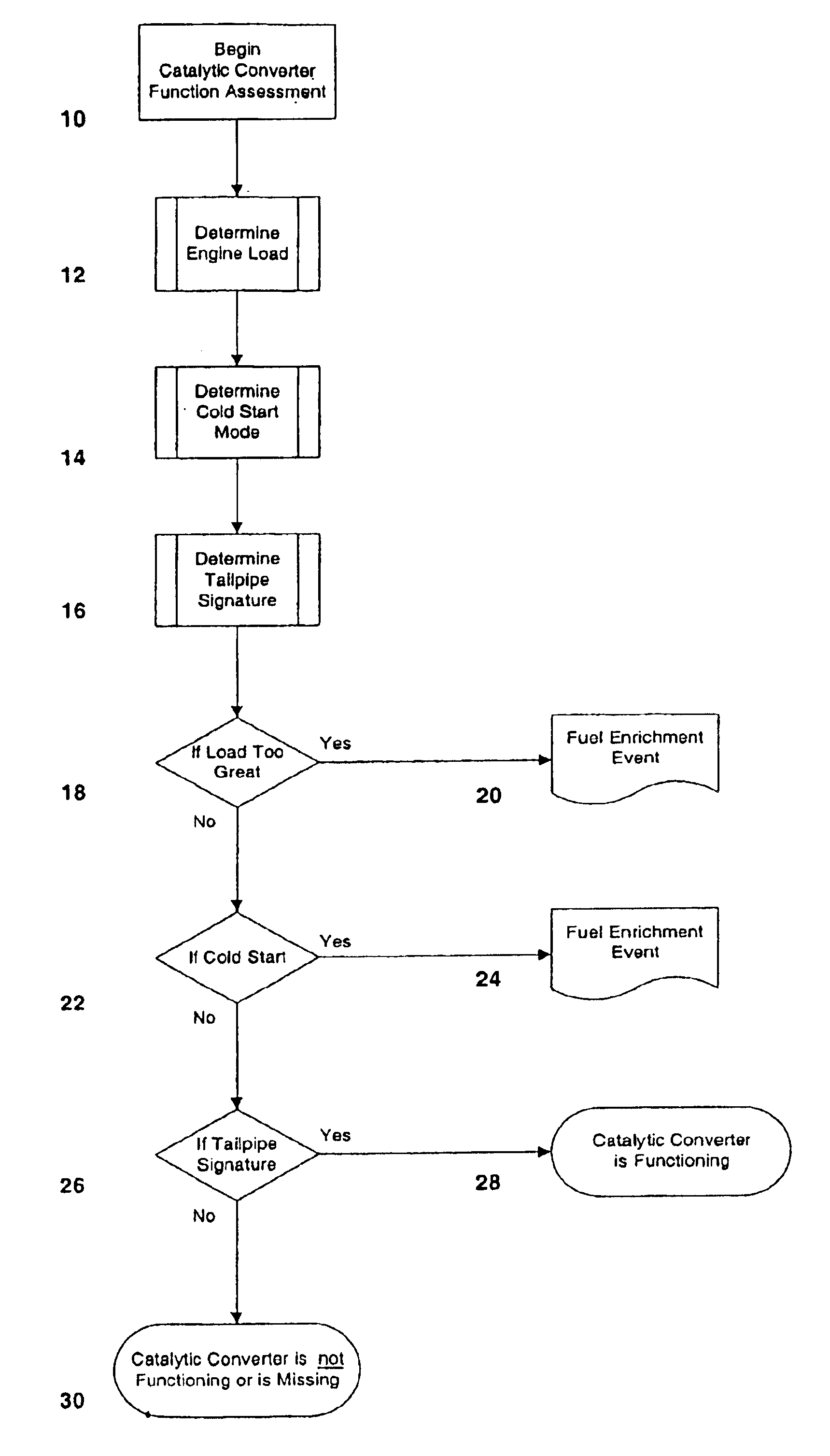

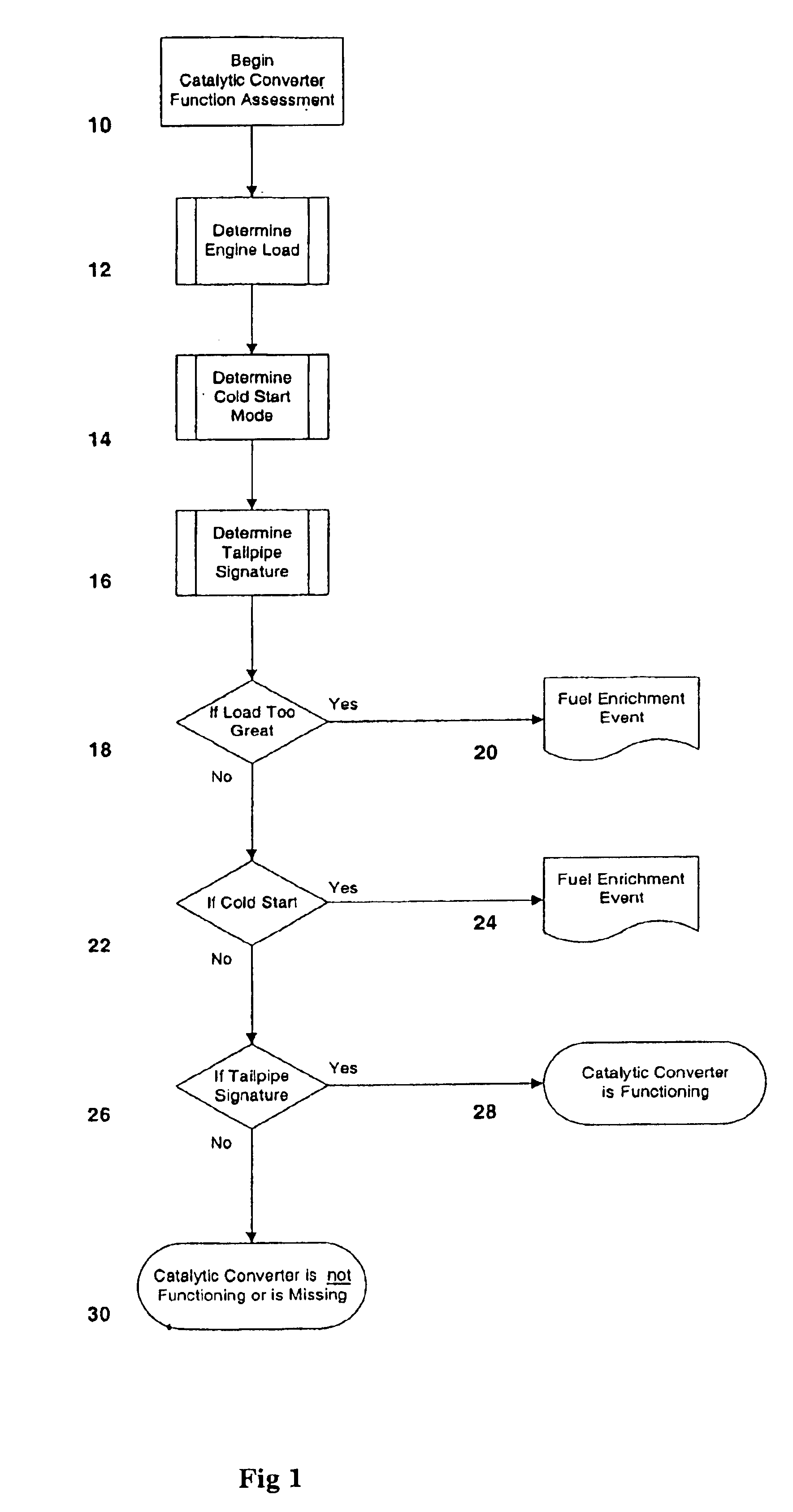

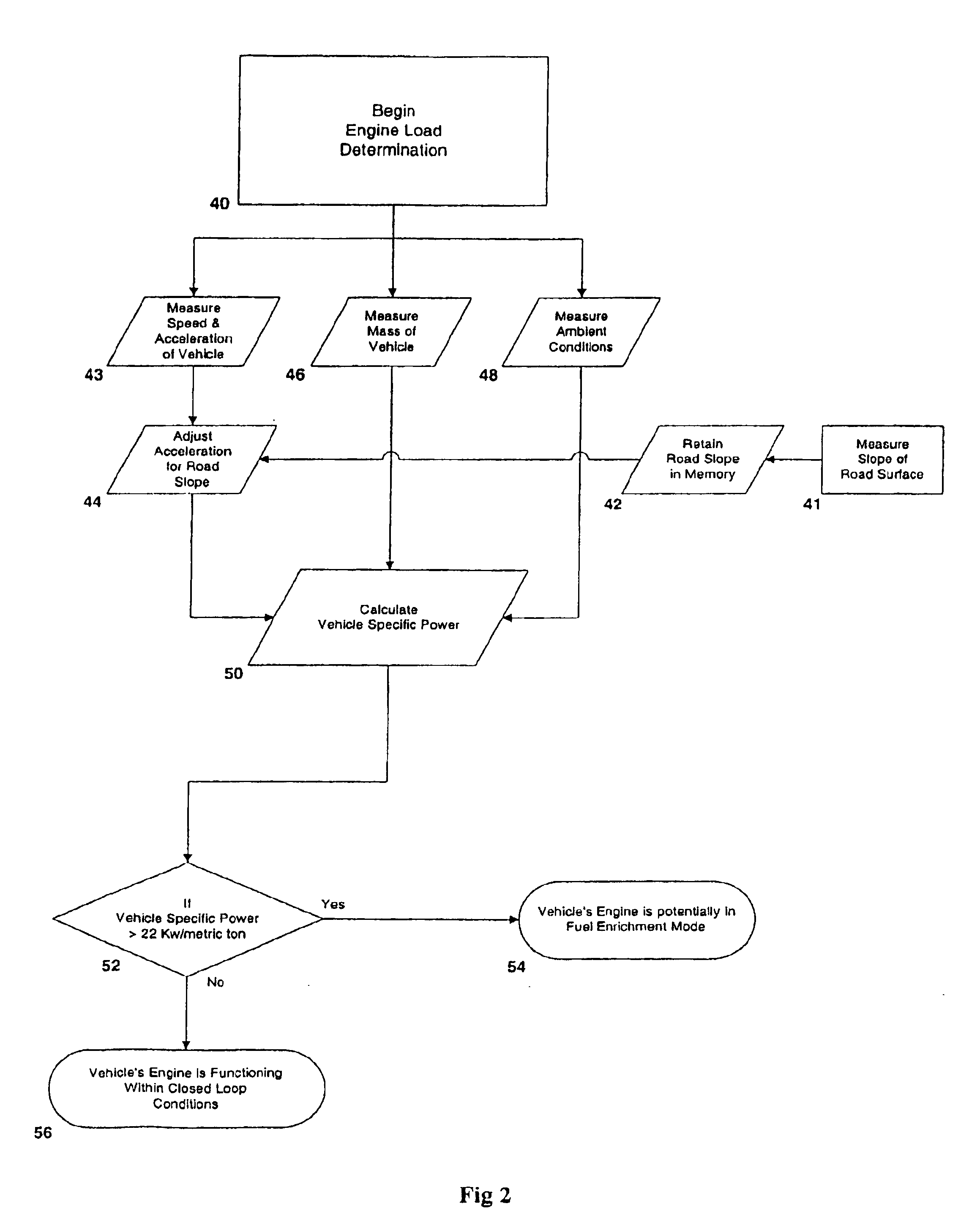

Catalytic converter function detection

InactiveUS6857262B2Great contributionElectrical controlInternal combustion piston enginesClosed loopOpen path

A method and system detects the function of a catalytic converter in a vehicle using data received from an open path emissions sensor. The factors considered include whether the vehicle moving on a road is operating in a closed loop operating condition, whether the vehicle is operating in a cold start mode, and the hydrocarbon and other tailpipe emissions concentrations in an exhaust stream of the vehicle as measured by the open path sensor.

Owner:SPX CORP

Control methods for improved catalytic converter efficiency and diagnosis

ActiveUS7886523B1Improve performance and efficiencyIncrease speedElectrical controlInternal combustion piston enginesClosed loopProcess engineering

A controlling method for adjusting concentrations of, for example, individual cylinder's exhaust gas constituents to provide engine functions such as catalytic converter diagnosis, increased overall catalytic converter efficiency and rapid catalyst heating, before and / or after initiating closed loop fuel injection control, using a selected temperature sensor location within a low thermal mass catalytic converter design.

Owner:LEGARE JOSEPH E

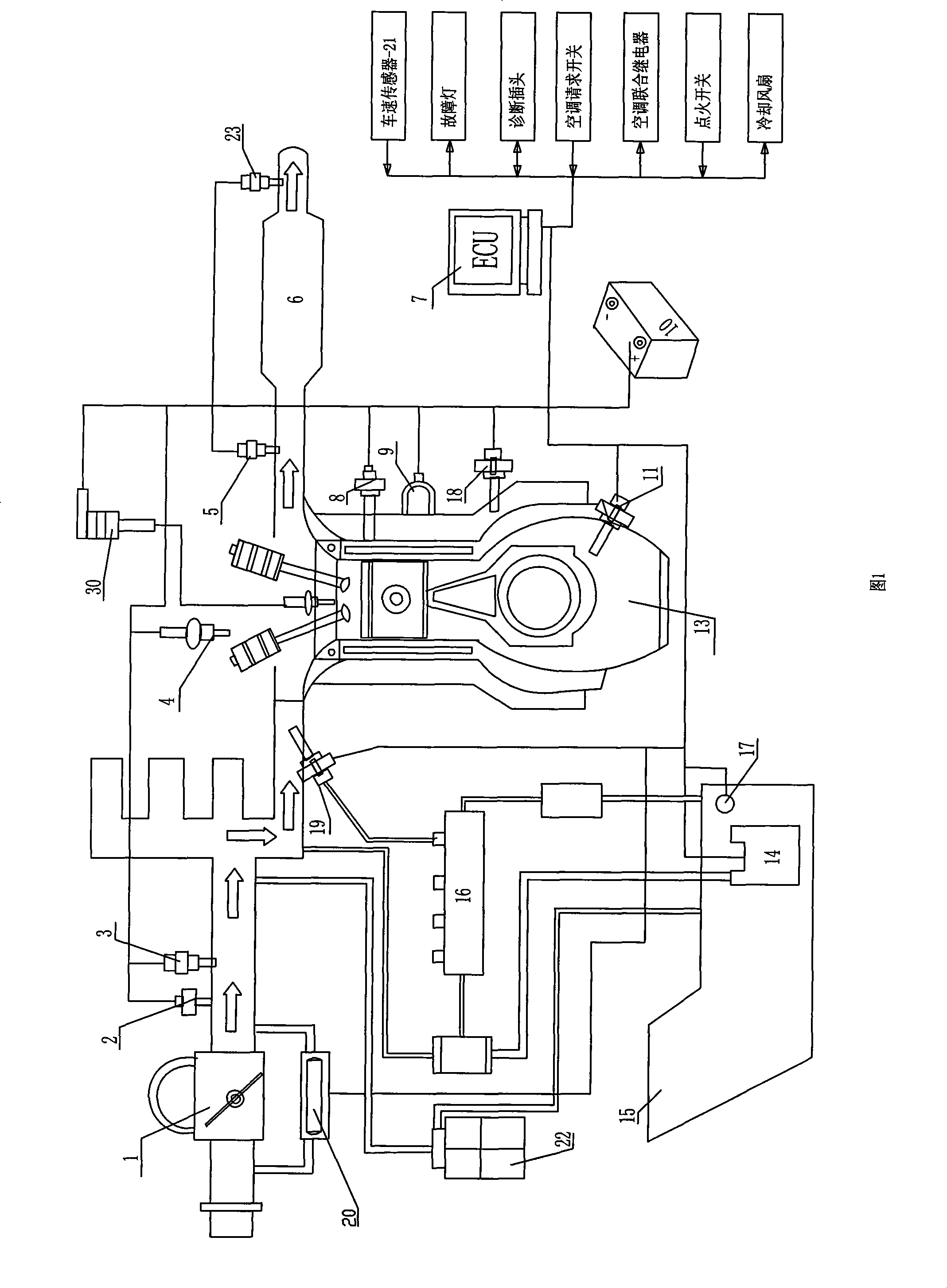

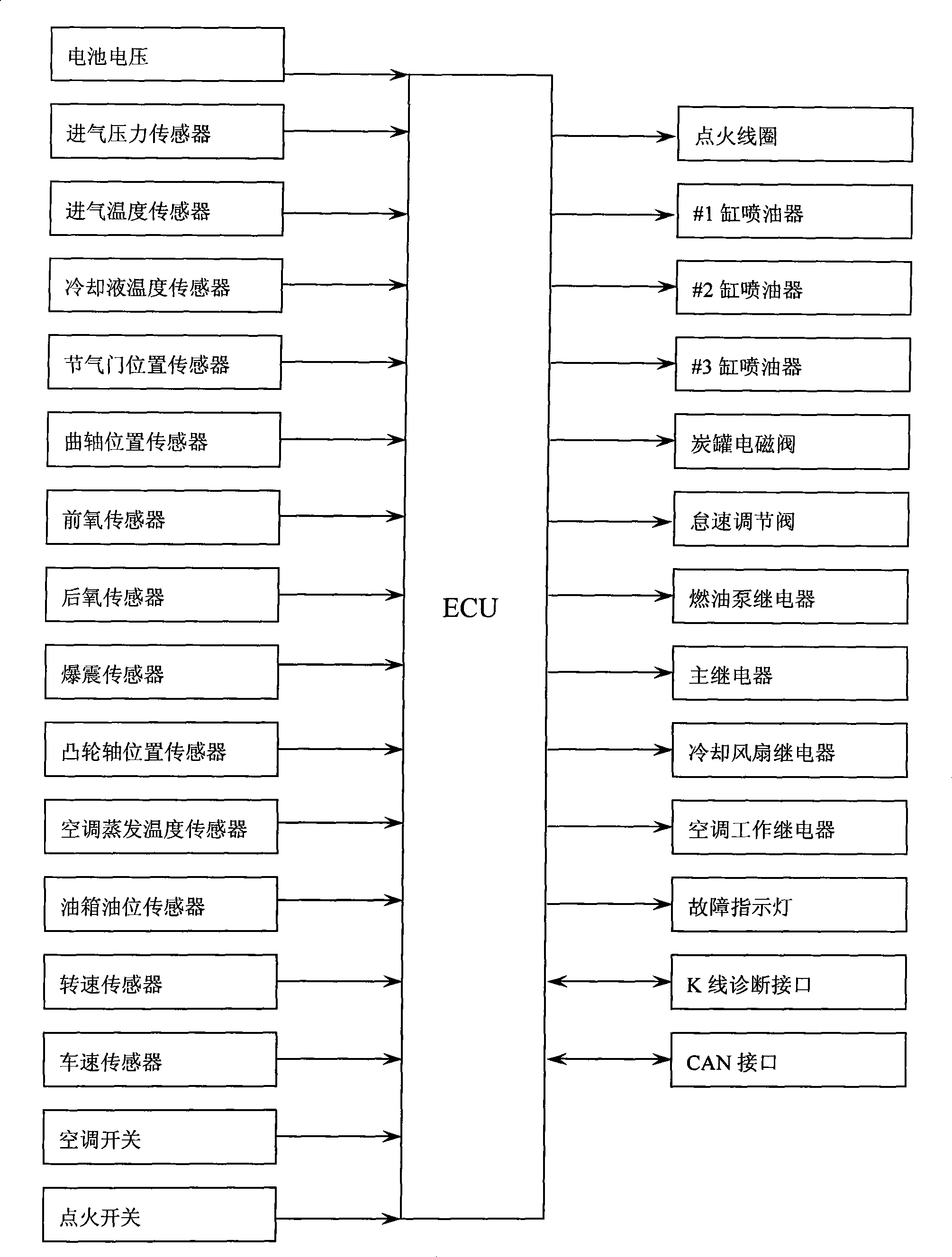

Electric-controlled petrol engine work system

InactiveCN101363380ARich control functionsGood control function integration performanceElectrical controlMachines/enginesIdle speed controlIgnition coil

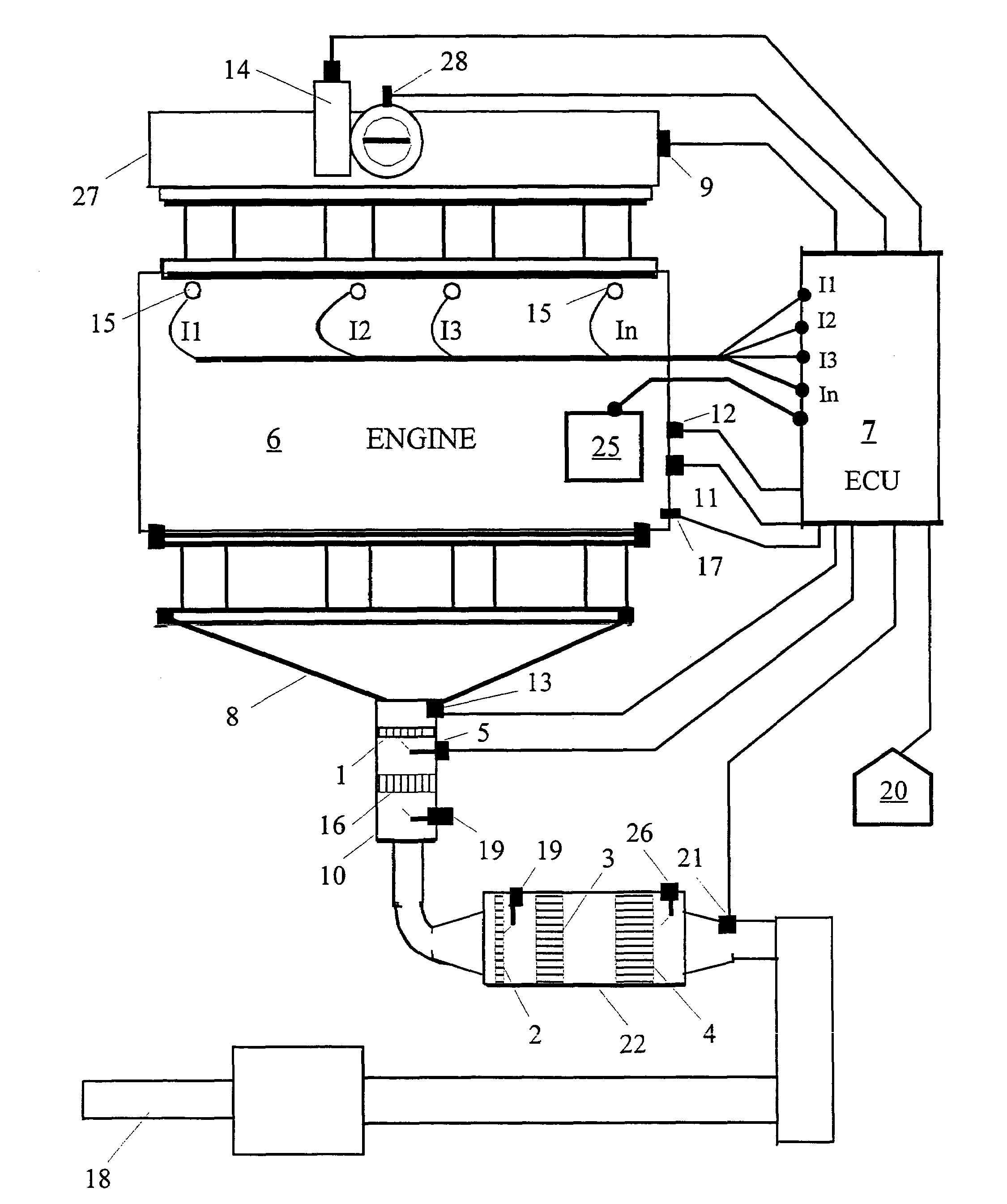

The invention provides a work system of an electronically controlled gasoline engine, comprising an air intake system, a fuel oil supply system, an ignition system as well as an electronic control system; the electronic control system consists of a sensor section, an electronic control unit ECU and an actuator section, wherein, the sensor section includes a throttle position sensor, an intake pressure and temperature sensor and an intake temperature sensor which are arranged on an intake pipe of an intake system, a camshaft position sensor, a coolant temperature sensor and a crankshaft position sensor which are arranged on the engine, a front oxygen sensor arranged in front of a three-way catalyst converter on an exhaust pipe of the engine, and the components of the sensor section are all connected with the ECU, and the actuator section consists of an electric fuel pump, an oil sprayer, an idle speed regulating valve and an ignition coil; the components of the actuator section are all connected with the ECU, and the ECU includes a fuel injection control program, an ignition control program and an idle speed control program; the system adopts reasonable control strategy and has comprehensive control function, good integrated performance of control function and fine system portability.

Owner:张和君 +1

Catalytic converter for cleaning exhaust gas

InactiveUS6881384B1High catalytic activityEffectively its catalytic activityCombination devicesInternal combustion piston enginesCeriumCe element

A catalytic converter for cleaning exhaust gas includes a heat-resistant support, and a catalytic coating formed on the heat-resistant support. The catalytic coating contains zirconium complex oxide on which Pt and Rh are coexistently carried, and cerium complex oxide on which Pt and Rh are coexistently carried. The Pt- and Rh-carrying zirconium complex oxide and the Pt- and Rh-carrying cerium complex oxide are contained in a same layer of the catalytic coating.

Owner:DAIHATSU MOTOR CO LTD

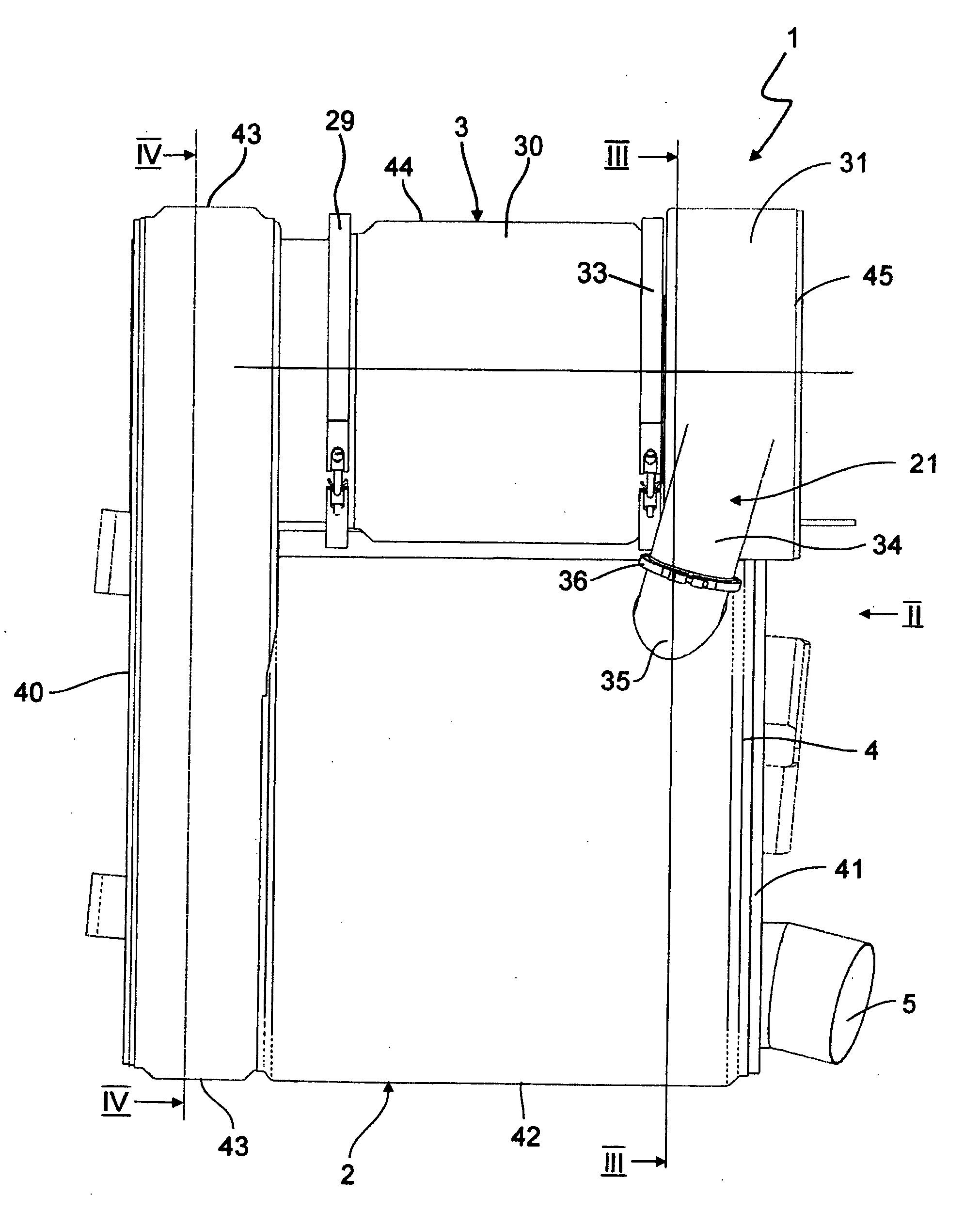

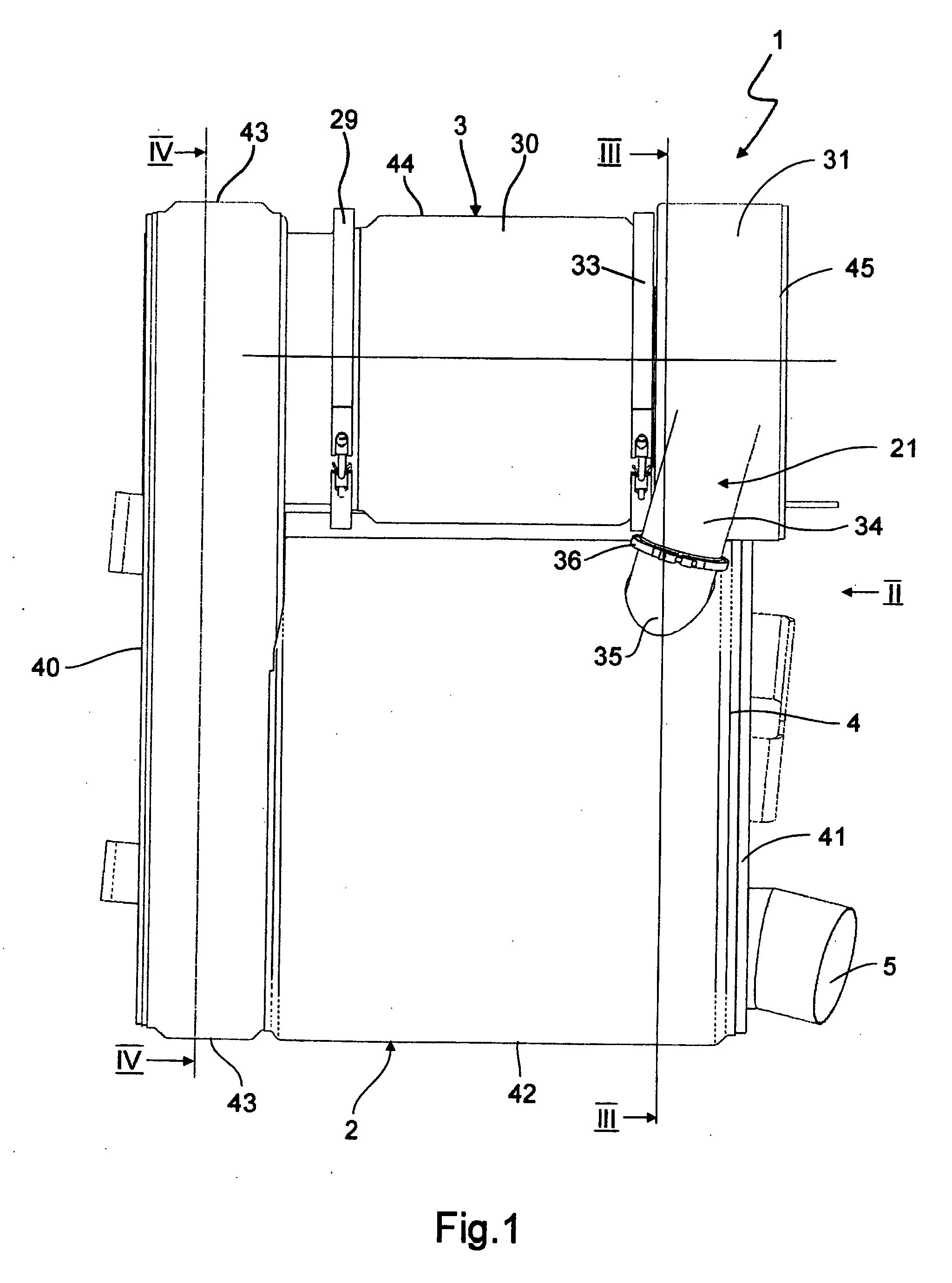

Exhaust gas treatment system

ActiveUS20060156712A1Easy maintenanceCompact designCombination devicesInternal combustion piston enginesExhaust fumesEngineering

The present invention relates to an exhaust gas treatment system for an exhaust system of an internal combustion engine, and comprises a basic housing and an add-on housing mounted thereon so it is at least partially detachable. The basic housing contains at least one inlet pipe which can be connected to the exhaust system and leads into the basic housing, at least one outlet pipe which can be connected to the exhaust system and leads out of the basic housing, at least one SCR catalyst and at least one oxidizing catalytic converter. The add-on housing contains at least one particle separation device and at least one reducing agent feed mechanism.

Owner:PUREM GMBH

Non-classified end cone insulation for catalytic converter

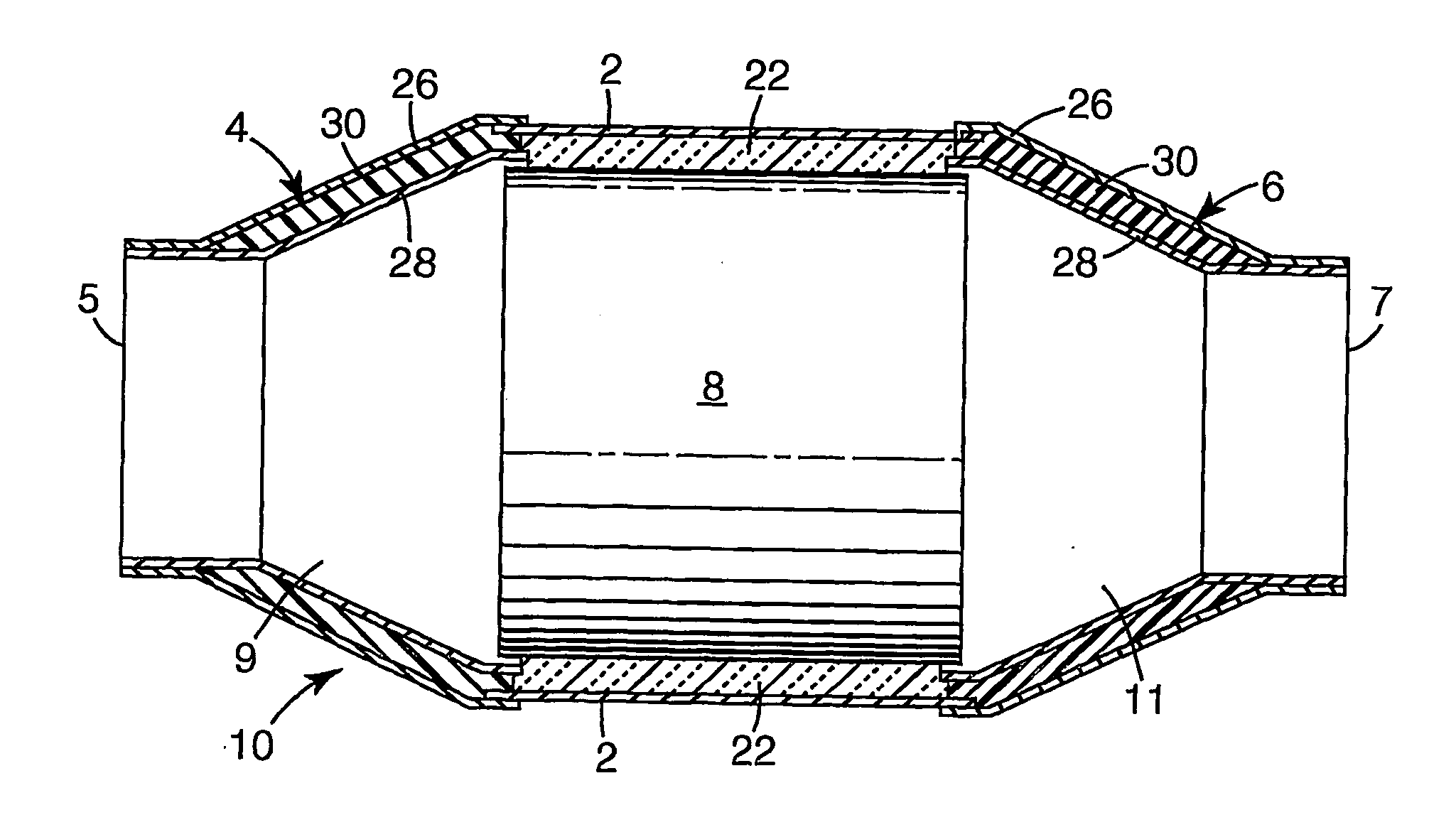

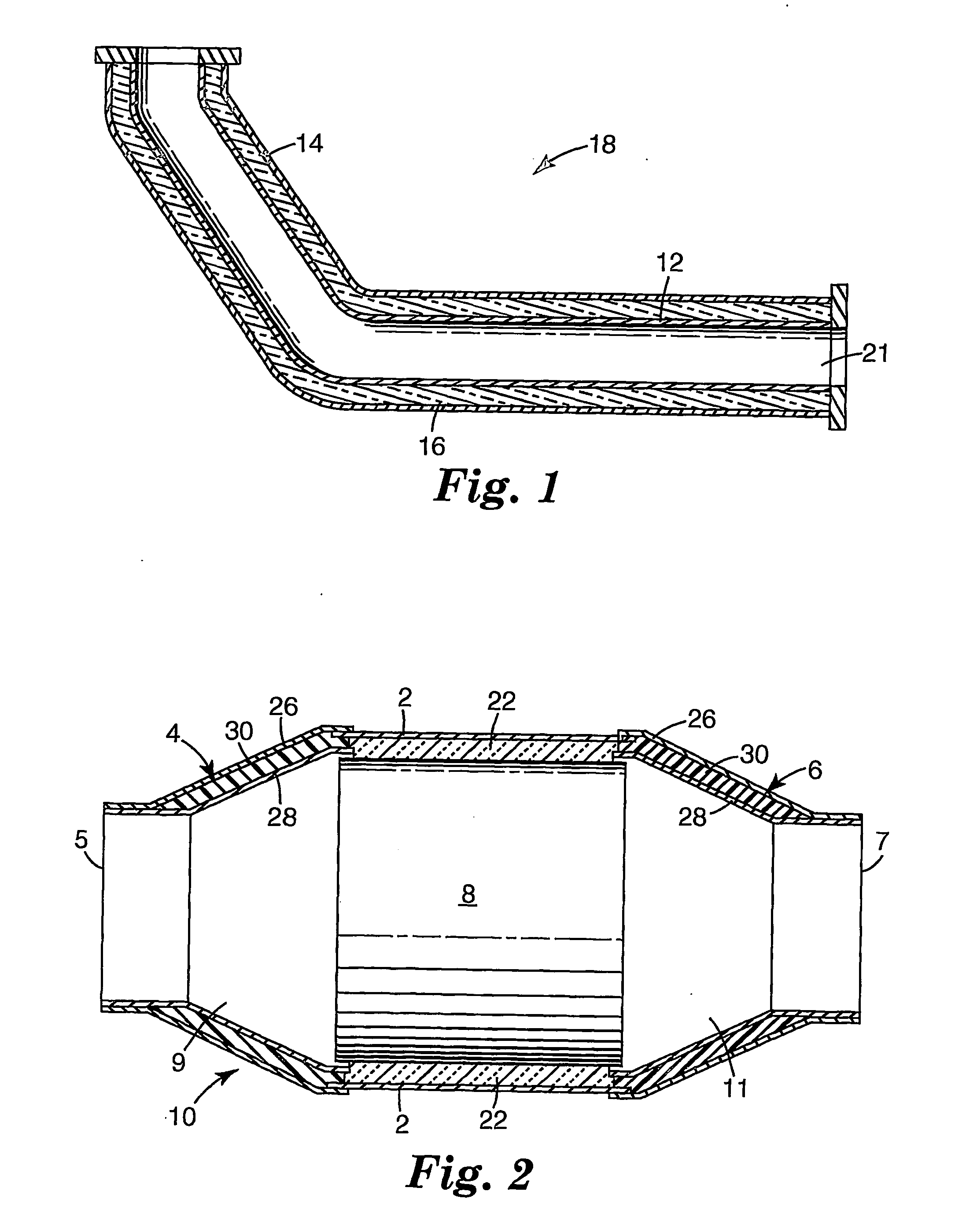

ActiveUS20070065349A1Improve insulation performanceLow costCombination devicesSilencing apparatusGlass fiberSilicate glass

An exhaust system component (18, 10) for use in an exhaust system of a motor vehicle. The exhaust system component comprises a double wall surrounding a space (9, 11; 21) through which exhaust gas may flow when the exhaust system component is in use in an exhaust system. The double wall is comprised of a first and second metal wall (12, 14; 26, 28) that define between them a gap. The gap comprises an insulation material (16) made of chopped aluminium or magnesium aluminium silicate glass fibers. The insulation material can be in the form of, for example, an end cone perform. The exhaust system component can be an exhaust pipe (18).

Owner:3M INNOVATIVE PROPERTIES CO

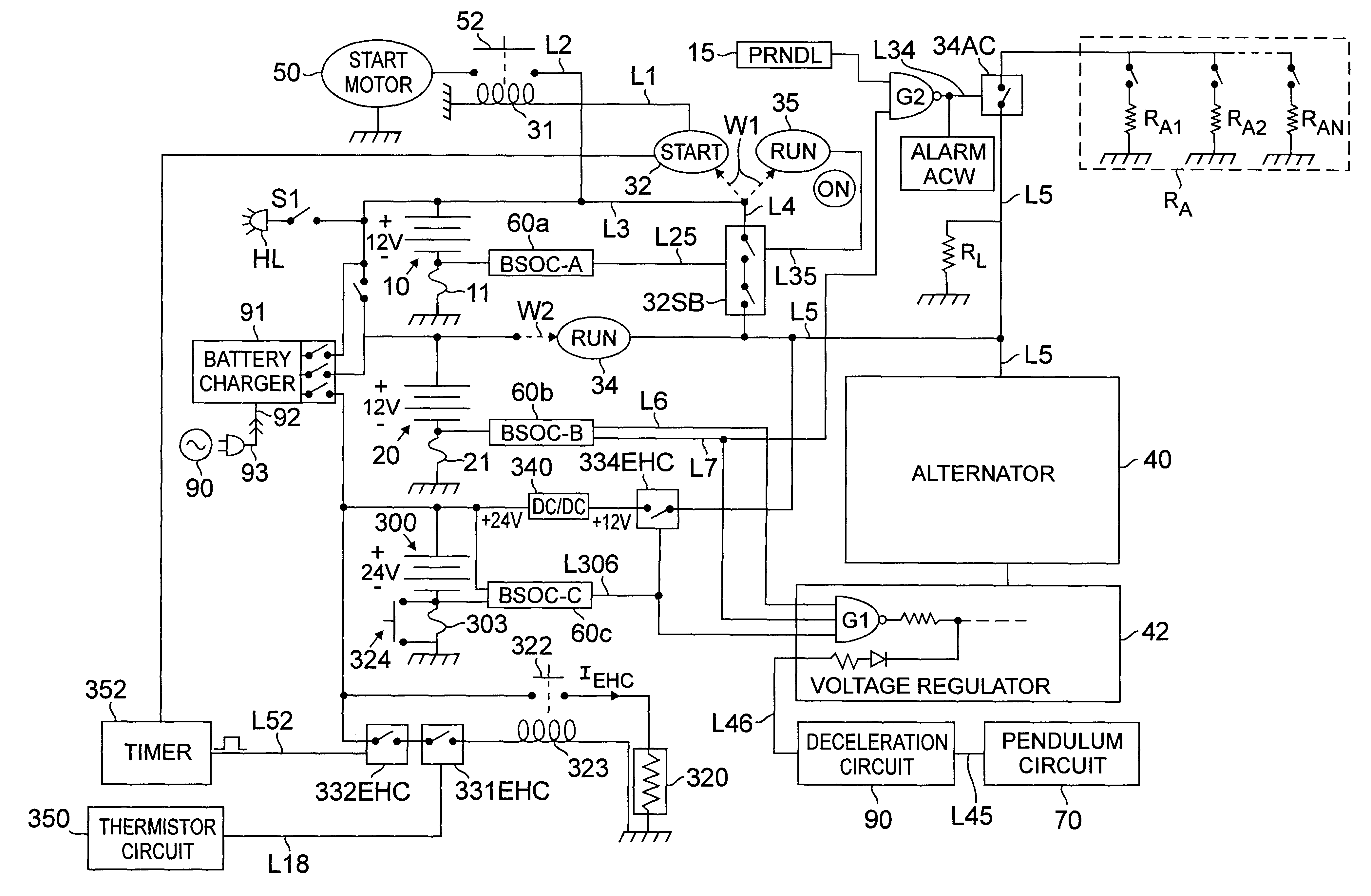

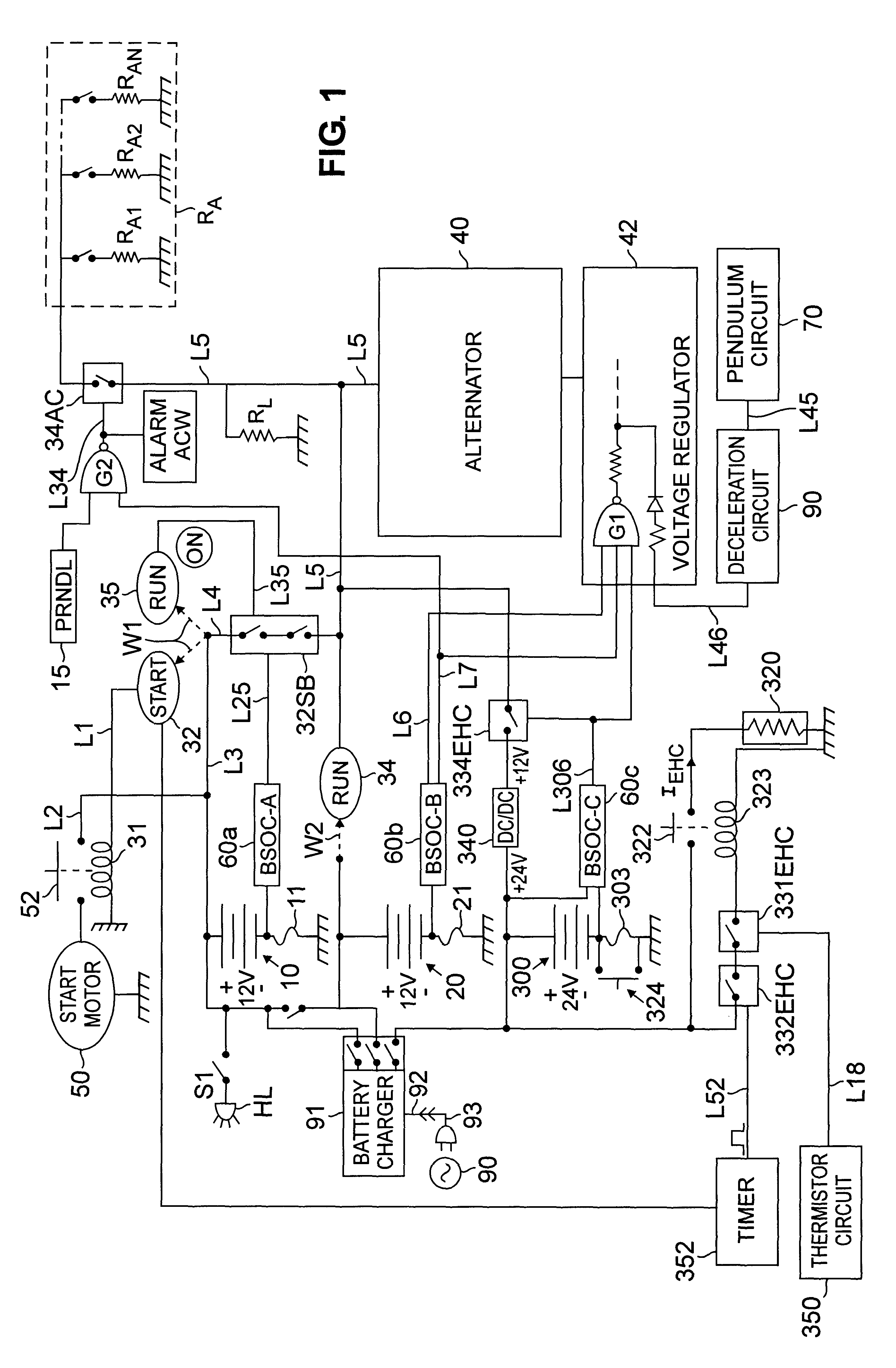

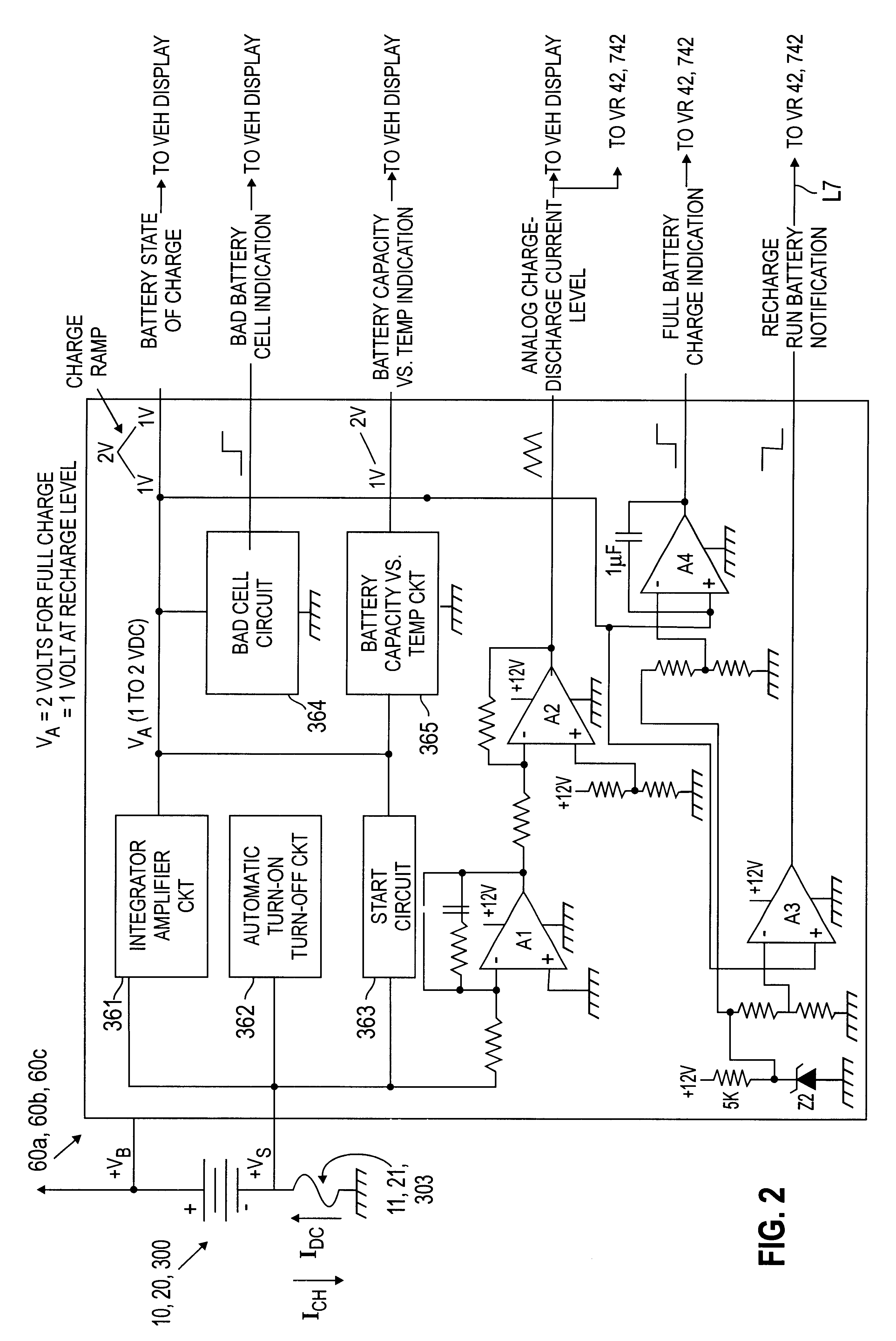

Multi-battery fuel saving and emission reduction system for automotive vehicles

InactiveUS6466024B1Easy to controlImprove the immunityCircuit monitoring/indicationExhaust apparatusAlternatorBattery charge

A multi-battery charging system for reduced fuel consumption and emissions for an automotive vehicle. The system starts the vehicle with a start battery in a fuel savings manner, removing electrical torque from the alternator shaft, and allows a second (run) battery to provide all or some of the current required by the vehicle loads as a fuel savings measure. The system also utilizes an electrically heated catalytic converter (EHC) and a third (EHC or storage) battery to provide a 3 to 15 second preheat and / or a 20 second current, during vehicle start, to the EHC heater coil, e.g., of a small EHC located in series with a standard catalytic converter for emissions reduction to reduce emissions during start. The start battery is recharged after start and switched out of the system fully charged for future vehicle starts. The run battery is recharged when its charge level drops below a predetermined level with an on board battery charging device powered from a 115 volt or 220 volt ac power line source external to the vehicle.

Owner:BRADLEY CHARLES W

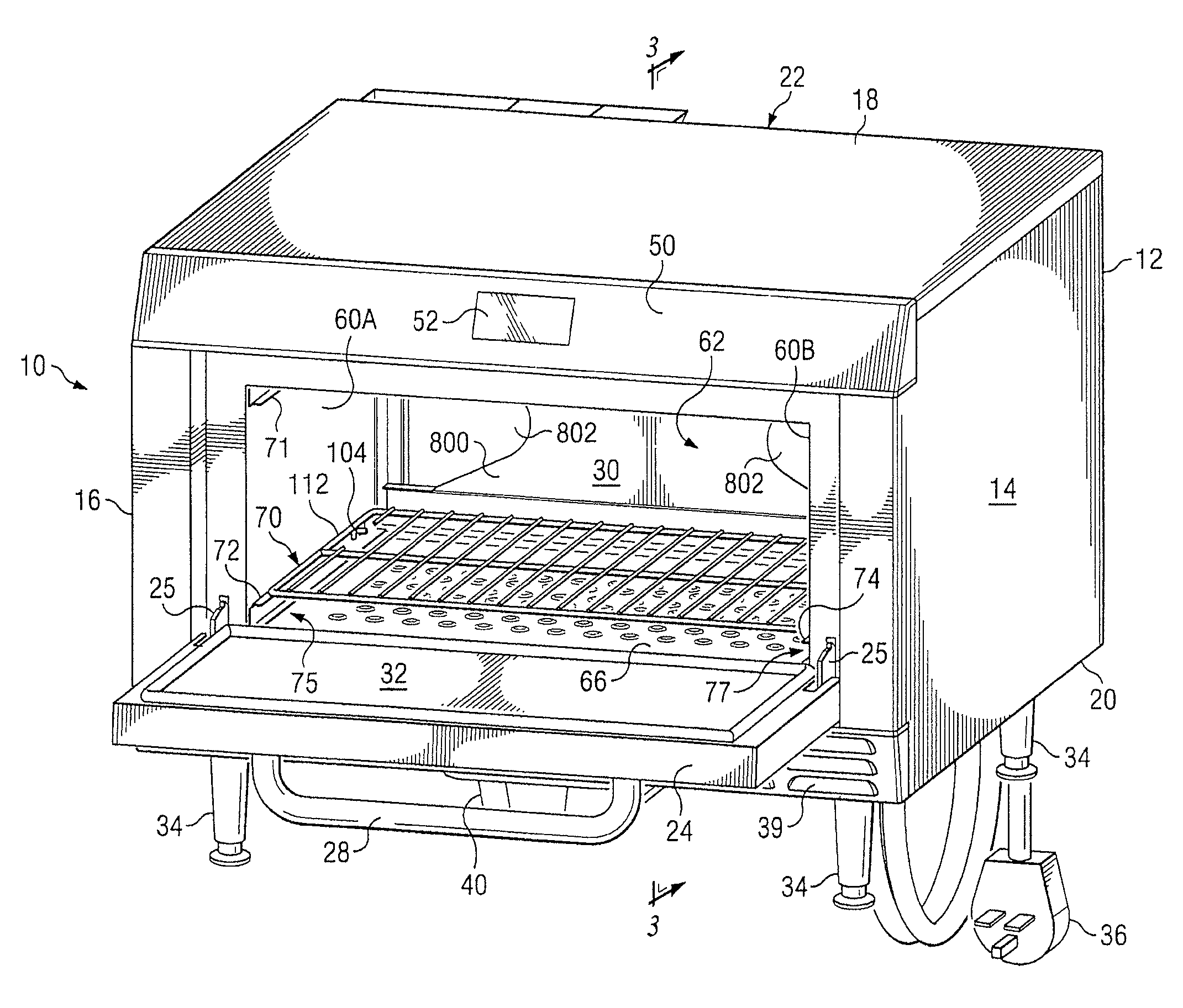

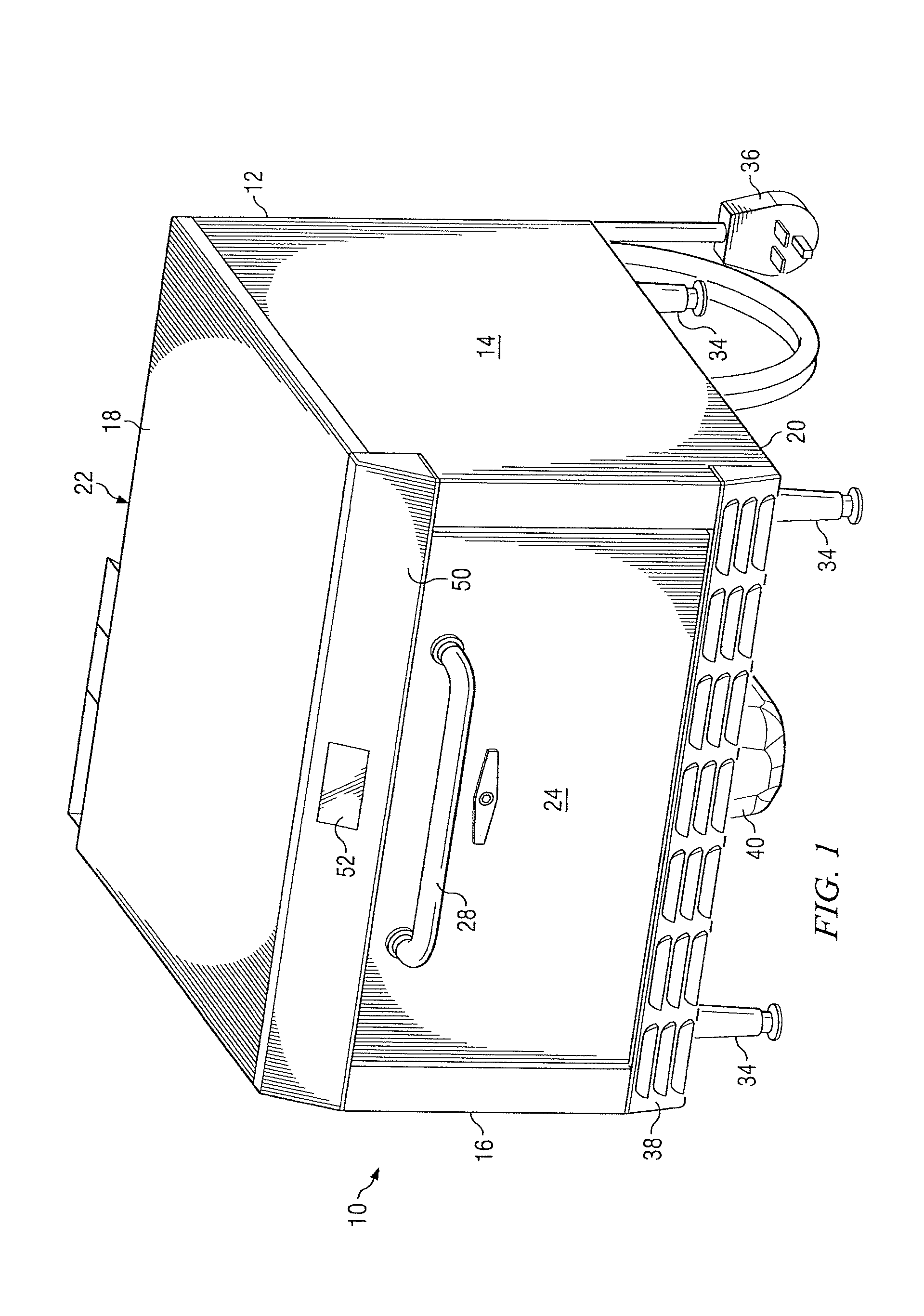

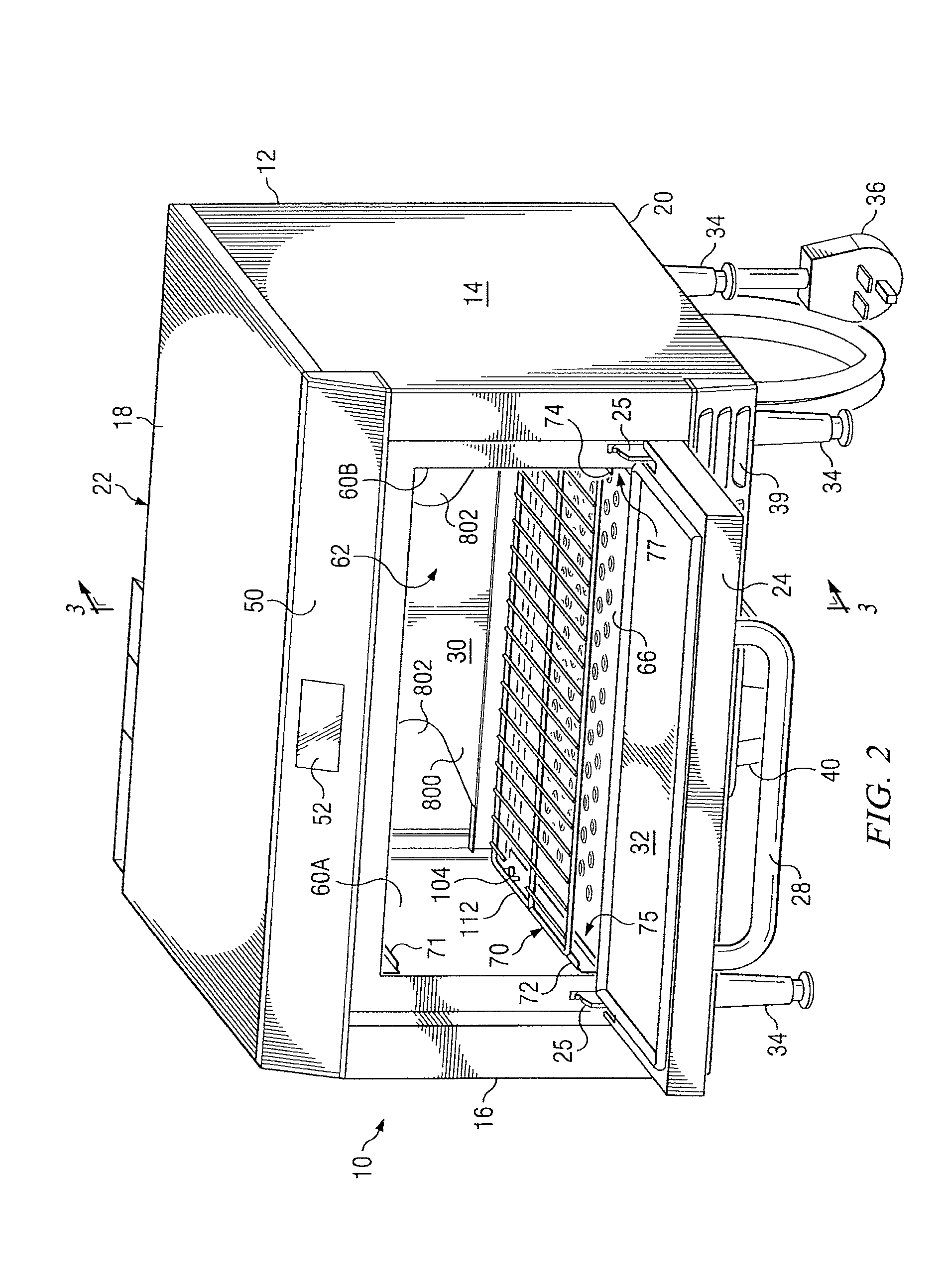

High speed convection oven

A convection heating apparatus capable of providing effective, high speed cooking without the assistance of microwave energy. The oven apparatus includes an exterior cabinet, a door, and a cooking chamber having interior side walls, a back wall, and a lower jet plate. The oven further includes a blower for circulating gas through the lower jet plate into the cooking chamber. In addition, the oven includes a product support disposed within the cooking chamber above said lower jet plate. The product support is disposed on a rail that is positioned to hold the lower jet plate in place when air is circulated therethrough. Optionally, the oven further includes an upper jet plate disposed within the cooking chamber above the product support. Temperature controlled gas is circulated through the upper jet plate toward the product support and any food product disposed on the product support. The oven may also include means for imparting movement to the product support during cooking operations in order to provide a more even cooking of a food product. A catalytic converter material is disposed downstream from the blower and upstream from a return plate which controls the direction of gas flow from the cooking cavity and protects the catalytic converter material.

Owner:TURBOCHEF TECH INC

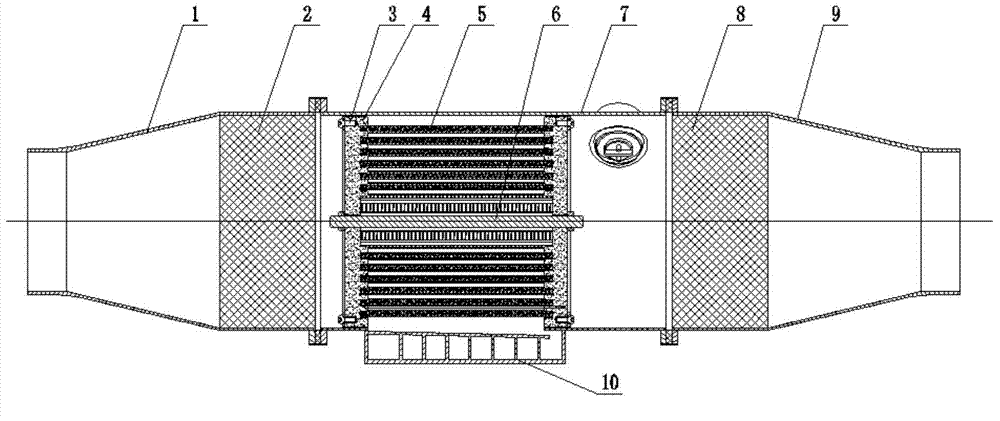

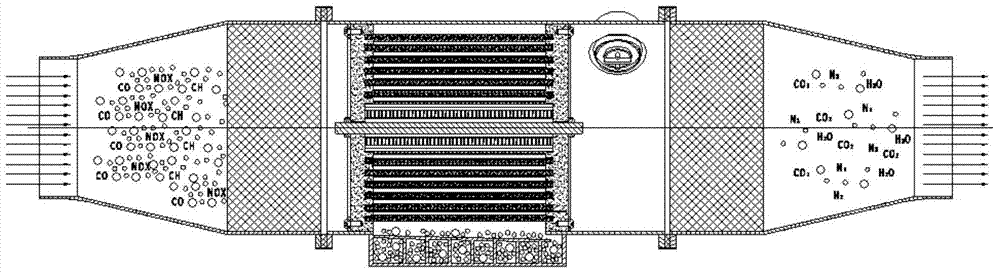

Dielectrophoresis automobile exhaust dust remover

InactiveCN103485864AReduce contentReduce pollutionExhaust apparatusSilencing apparatusEngineeringSolid particle

The invention relates to a dielectrophoresis automobile exhaust dust remover which comprises an air inlet cylinder, an air outlet cylinder, a front-end three-way catalytic converter and a rear-end three-way catalytic converter. The front-end three-way catalytic converter and the rear-end three-way catalytic converter are fixedly arranged in the air inlet cylinder and the air outlet cylinder respectively in a coaxial mode, a processing cylinder is fixedly installed between the air inlet cylinder and the air outlet cylinder in a coaxial and communicated mode, ceramic flange plates are fixedly installed at the two sides inside the processing cylinder in mirror symmetry in a coaxial mode respectively, electrode couples are fixedly distributed between the two ceramic flange plates in the radial direction at intervals, the electrode couple between the lower portion of the processing cylinder and the two ceramic flange plates is fixedly provided with a dust collecting box in a communicated mode, a gap is formed between one ceramic flange plate and the air inlet cylinder arranged at one side, and a gap is formed between the other ceramic flange plate and the air outlet cylinder at the other side. According to the dielectrophoresis automobile exhaust dust remover, the dielectrophoresis technology is adopted and due to the fact that the dielectric polarization capacity of solid particles, the dielectric polarization capacity of heavy metal and the dielectric polarization capacity of suspended gas are different, the solid particles and the heavy metal are pushed out of an electrode or the solid particles are attracted to the electrode through the dielectrophoresis force, so that the content of the solid particles and the content of the heavy metal in automobile exhaust are reduced, and therefore pollution to the atmosphere by the solid particles and the heavy metal is reduced.

Owner:BEIJING SHANGPAI ENVIRONMENTAL TECH CO LTD

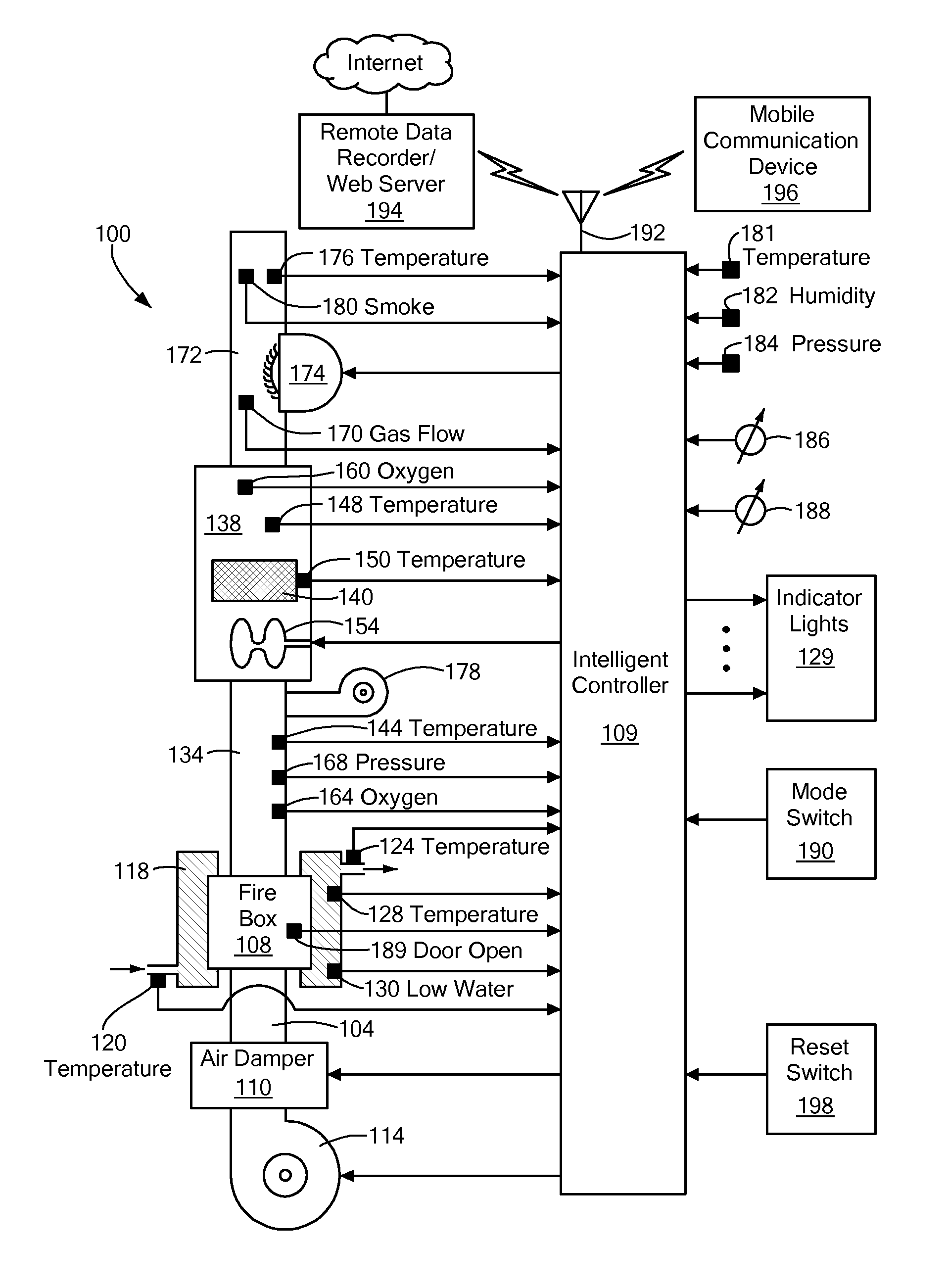

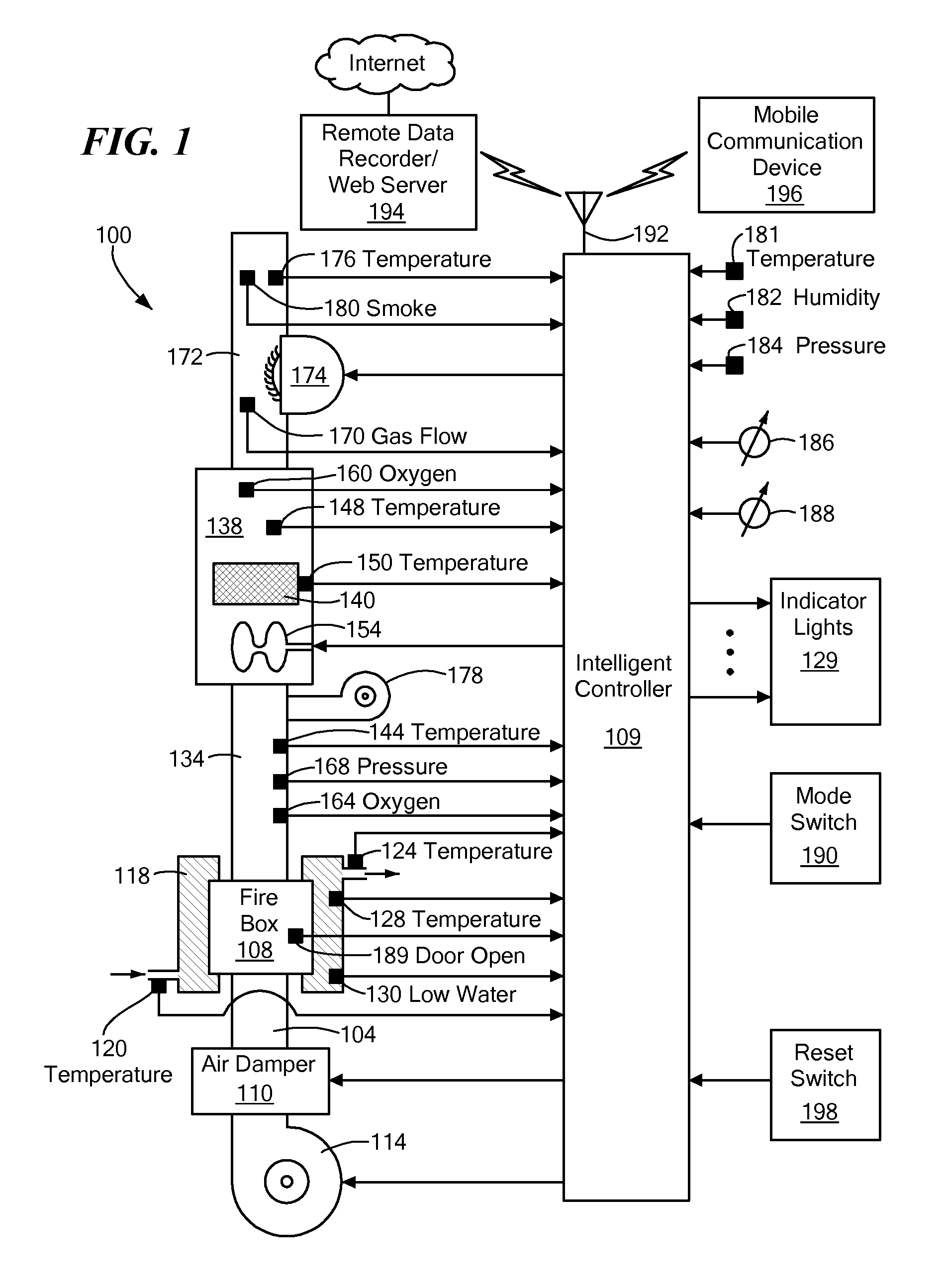

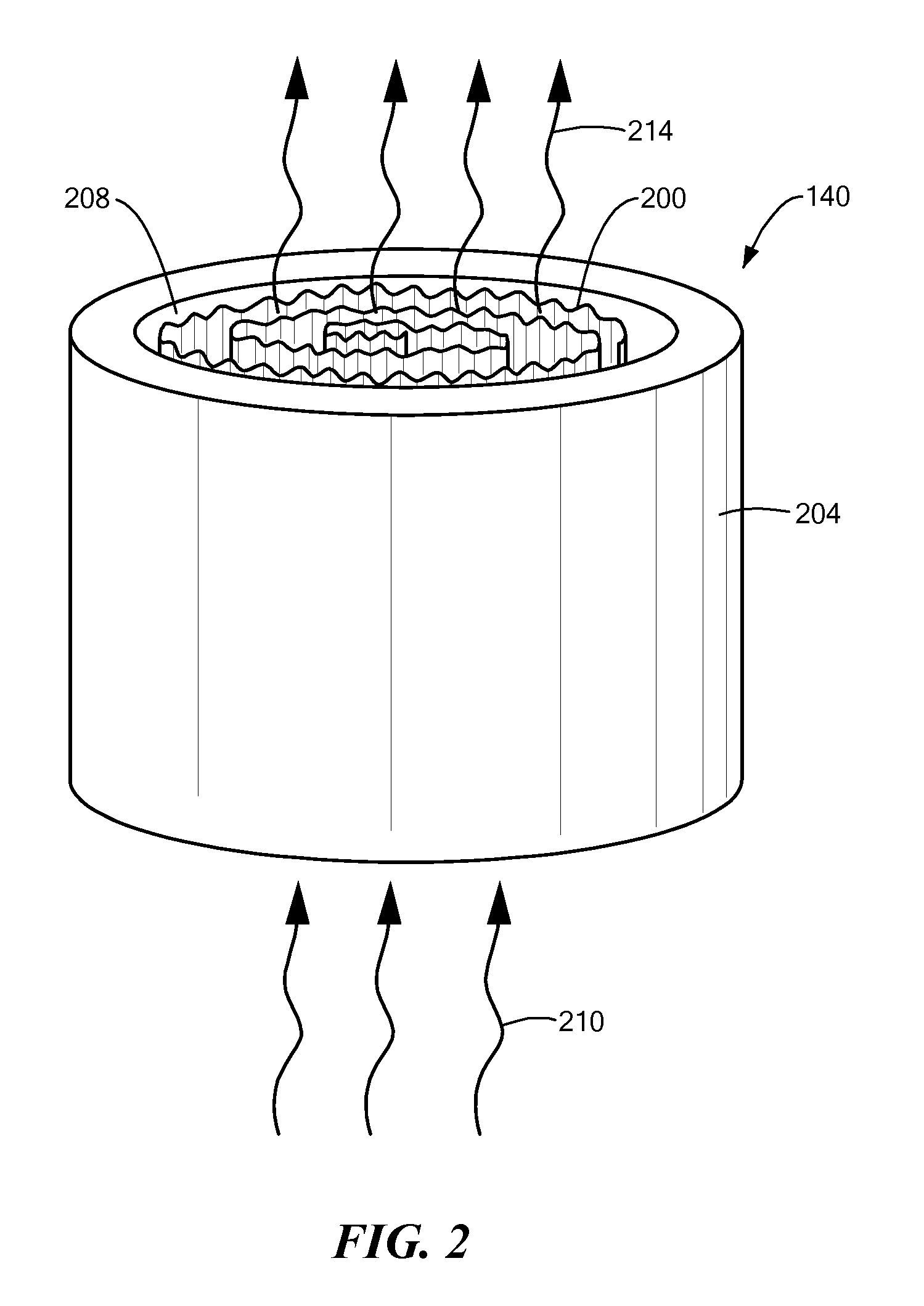

Intelligently-controlled catalytic converter for biofuel-fired boiler

An intelligently controlled catalytic converter automatically monitors various operating parameters, such as water jacket temperature, catalytic input temperature, catalytic converter output temperature, oxygen level, ambient temperature, ambient humidity and / or ambient barometric air pressure, of a biofuel-fired device and automatically controls dampers, blowers and electric heaters in the device.

Owner:BIOMASS CONTROLS PBC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com