Patents

Literature

130 results about "Exhaust heat recovery system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

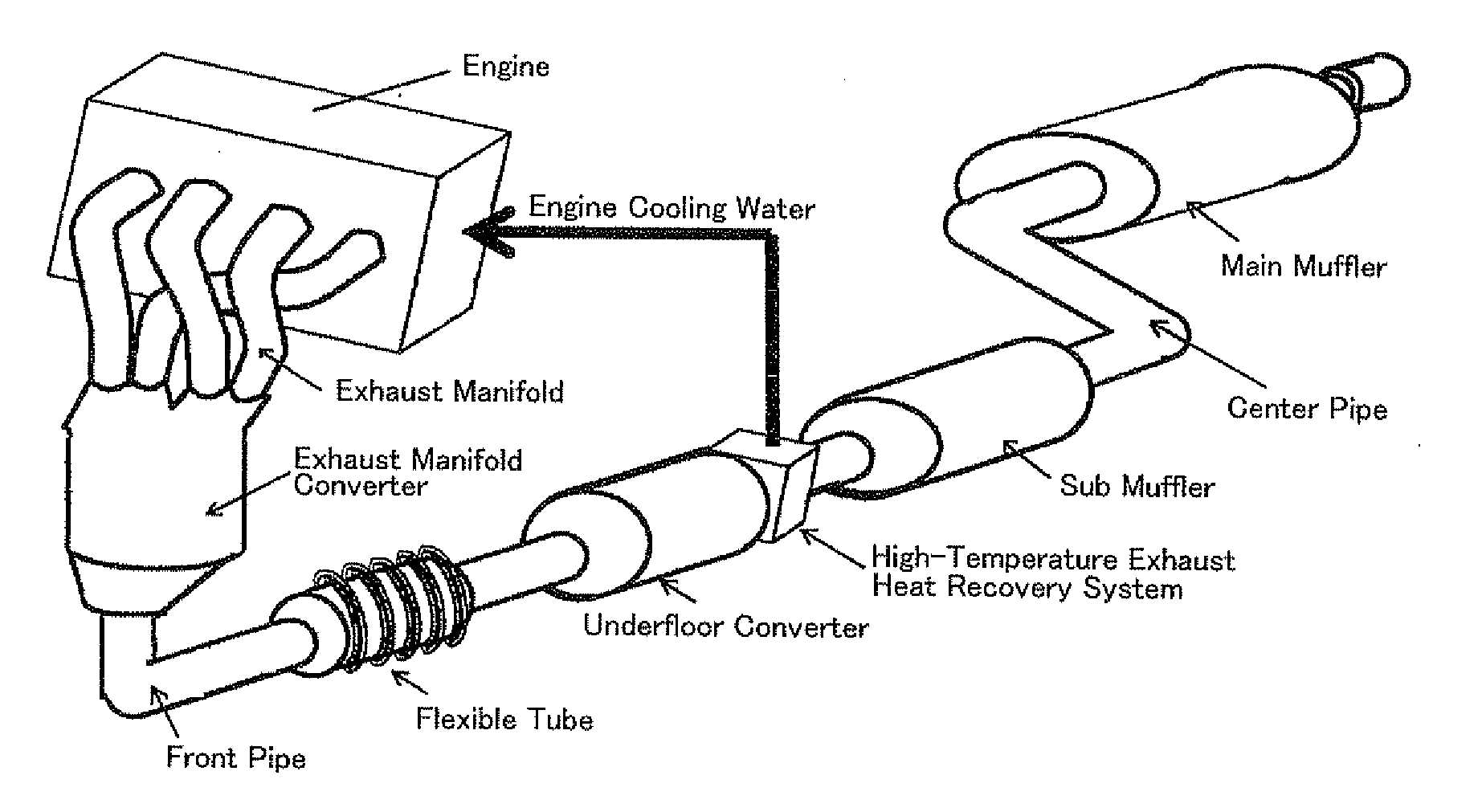

In transportation, an exhaust heat recovery system turns thermal losses in the exhaust pipe into energy. This technology seems to be more and more of interest by car and heavy-duty vehicle manufacturers as an efficient way to save fuel and reduce vehicles’ CO₂ emissions. This technology can be used either on a hybrid vehicle or a conventional one: it produces either electric energy for batteries or mechanical energy reintroduced on the crankshaft.

Exhaust heat recovery system

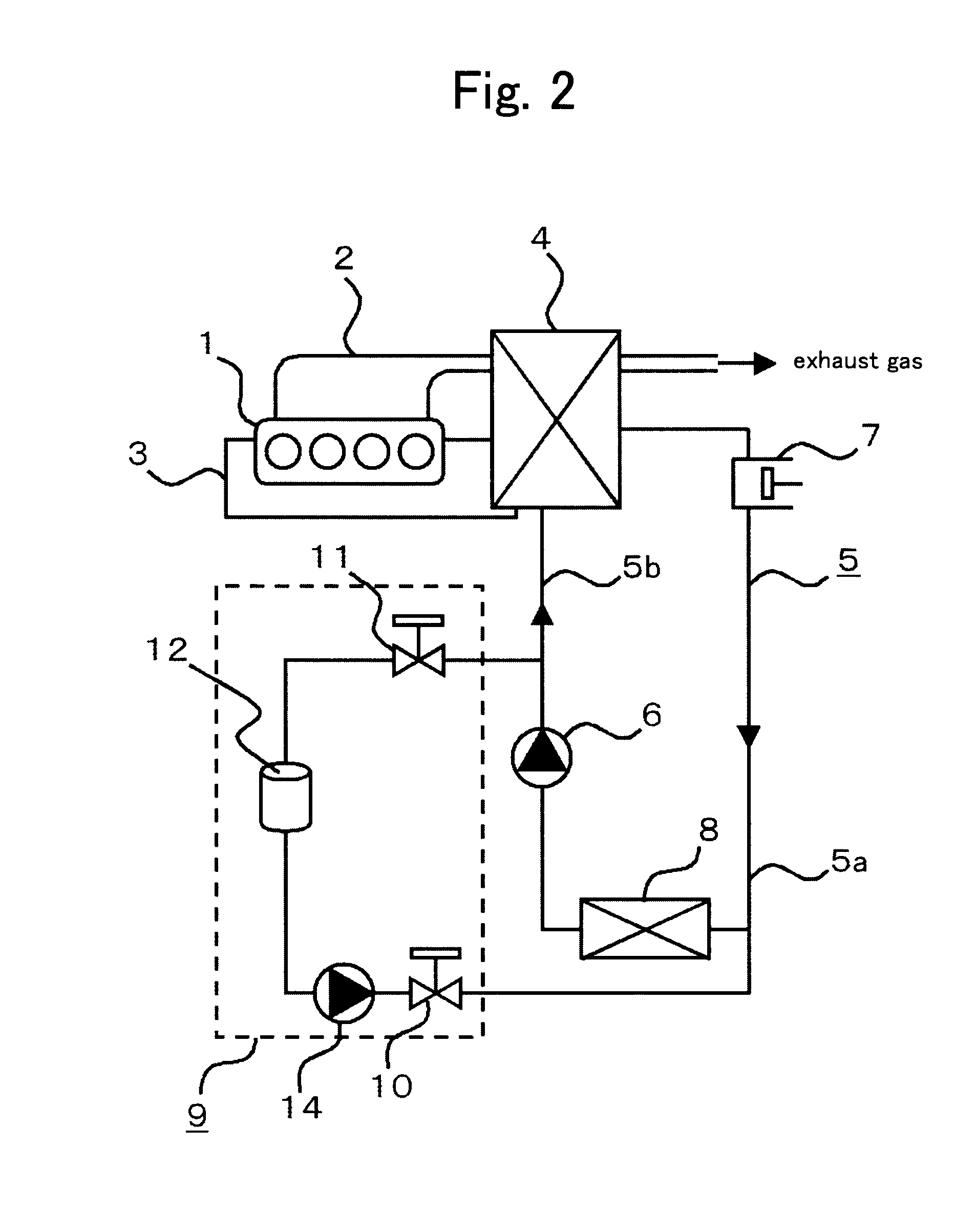

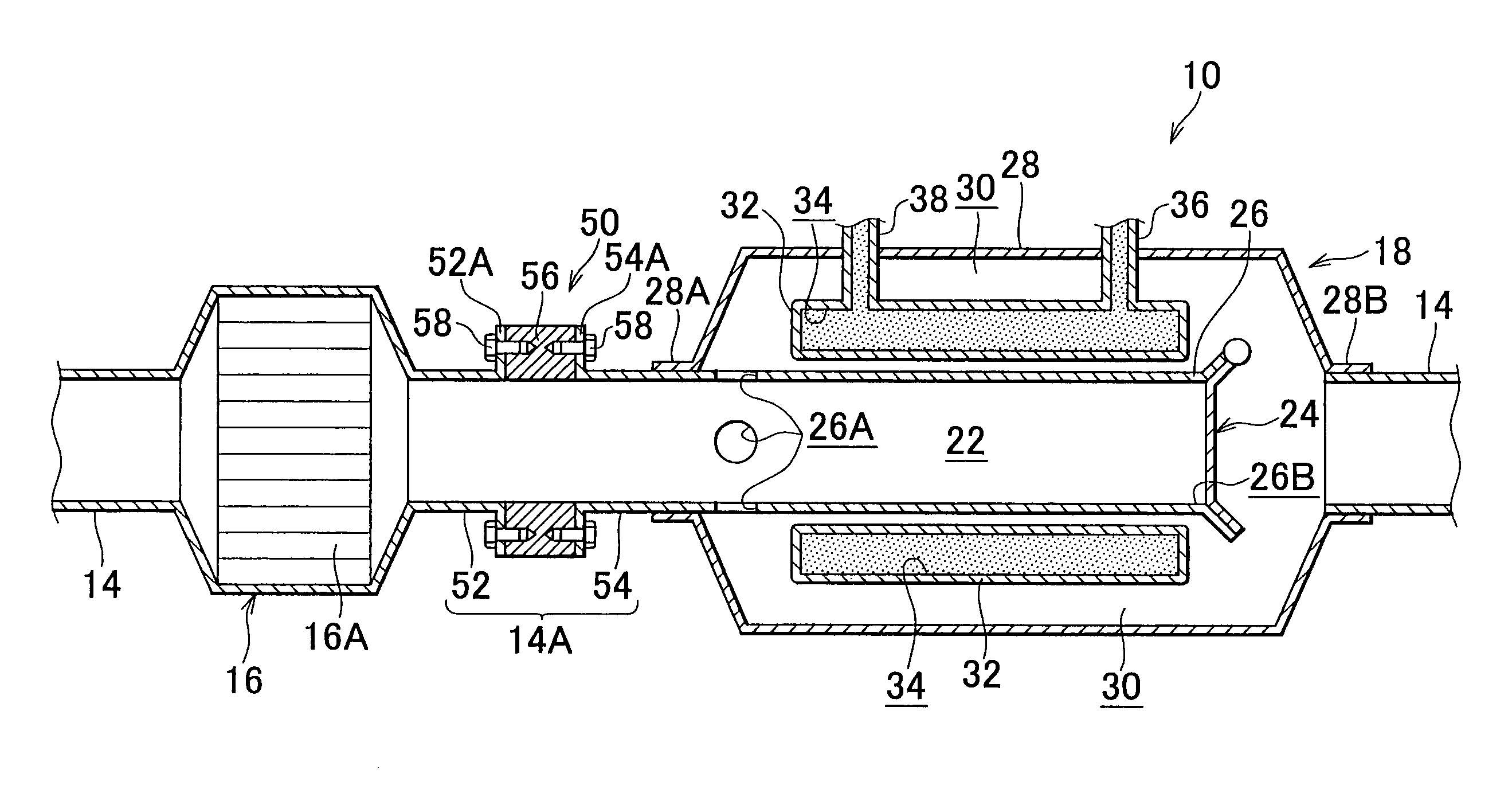

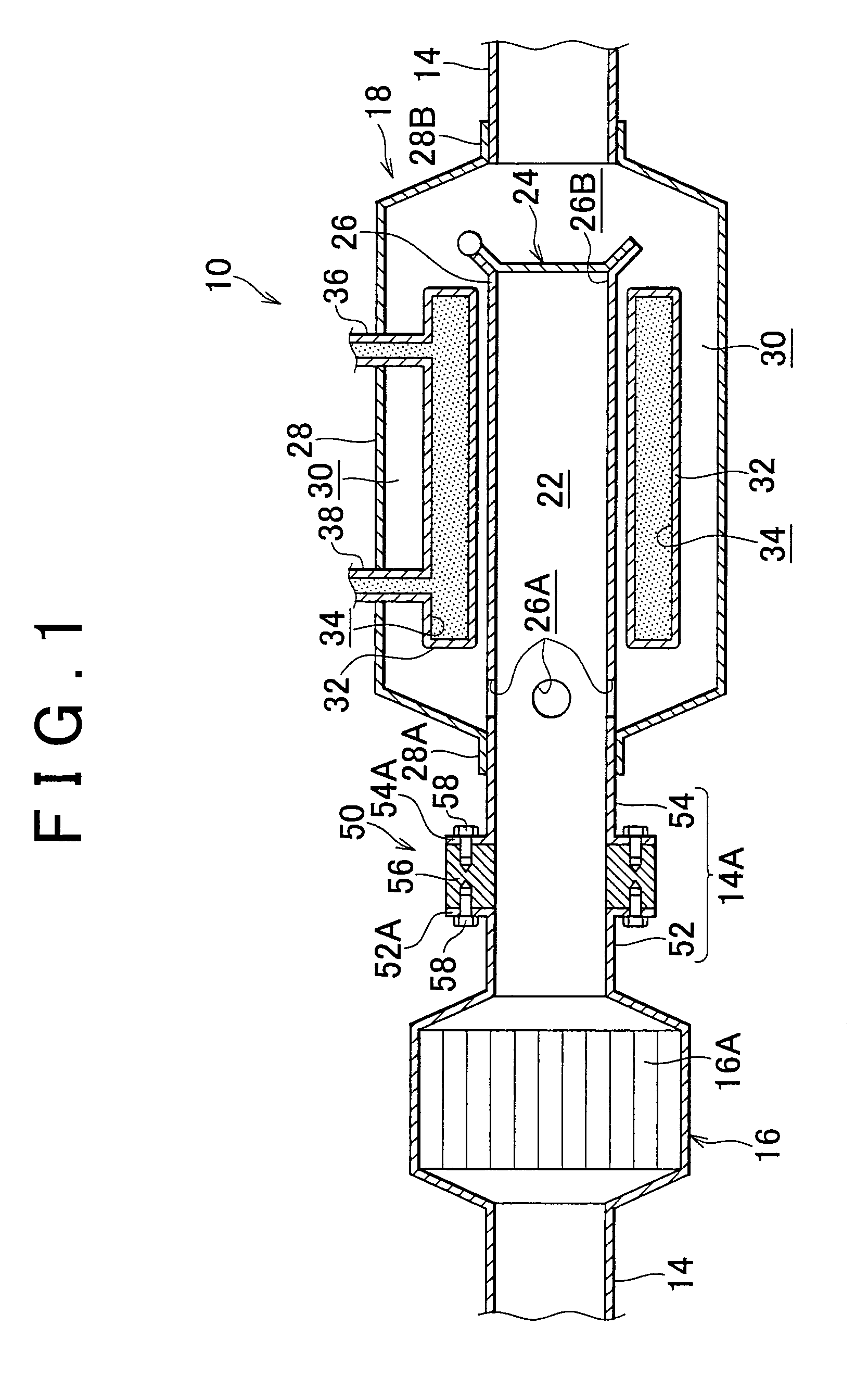

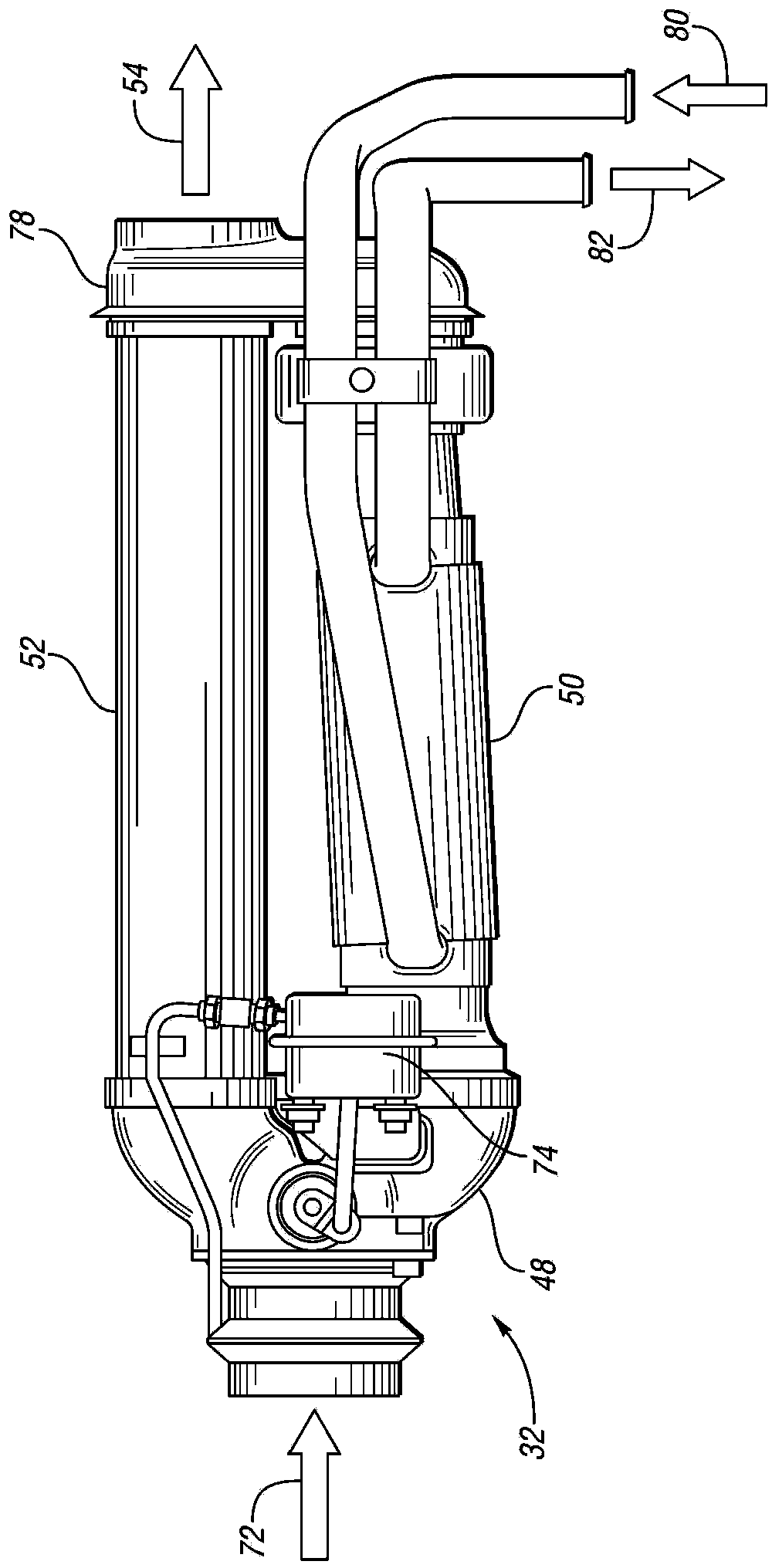

InactiveUS20100043413A1Combination devicesInternal combustion piston enginesEngineeringExhaust heat recovery system

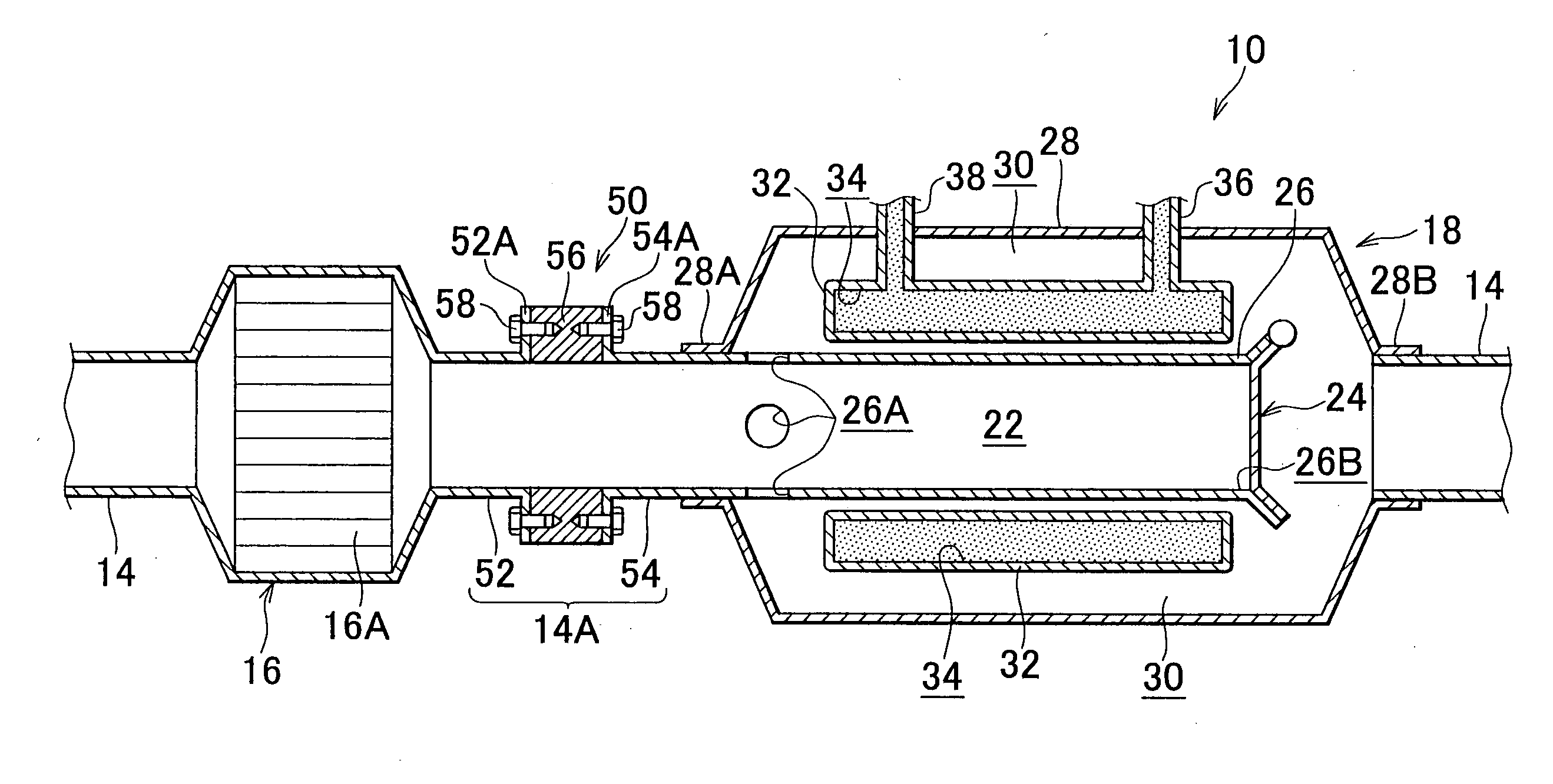

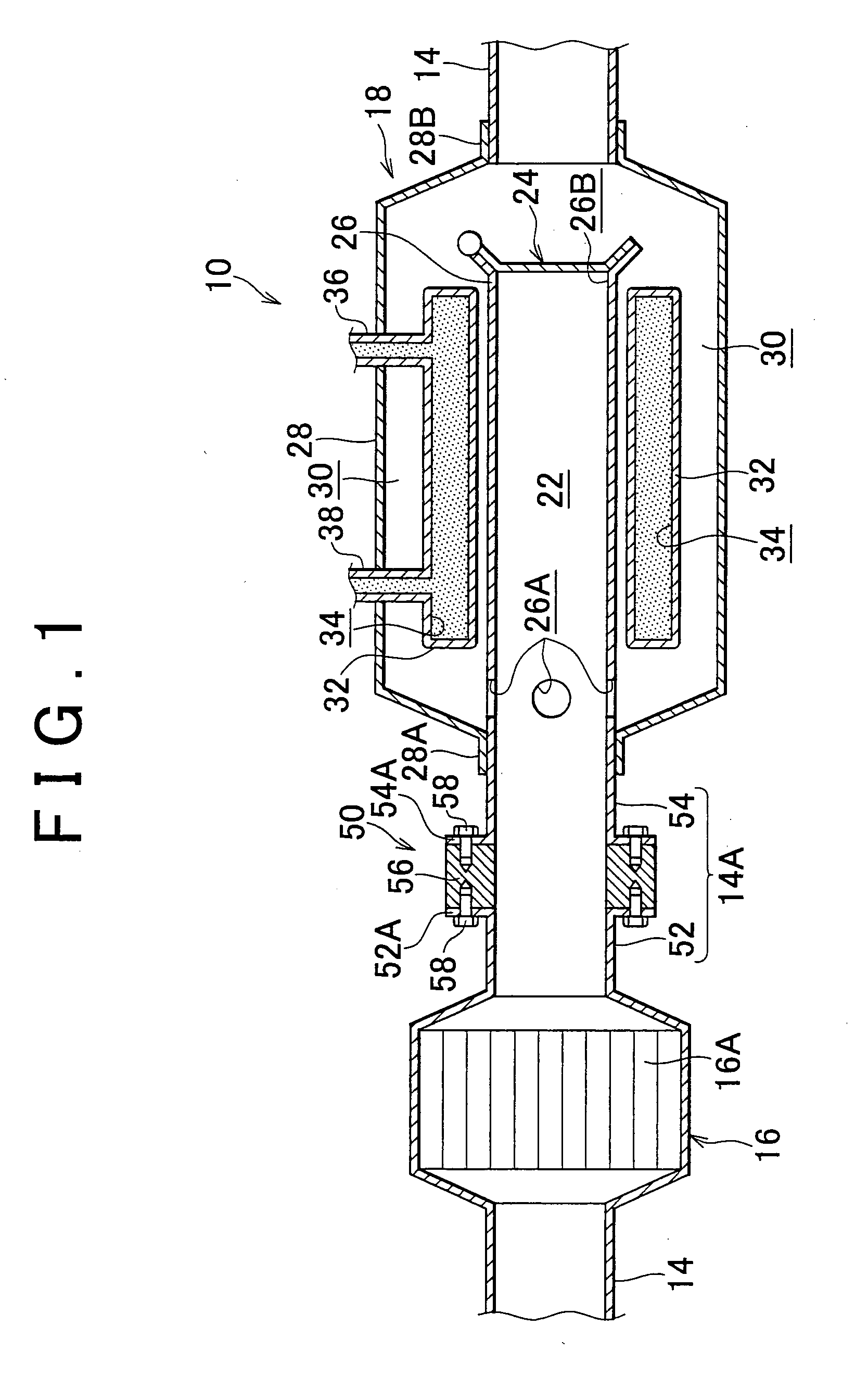

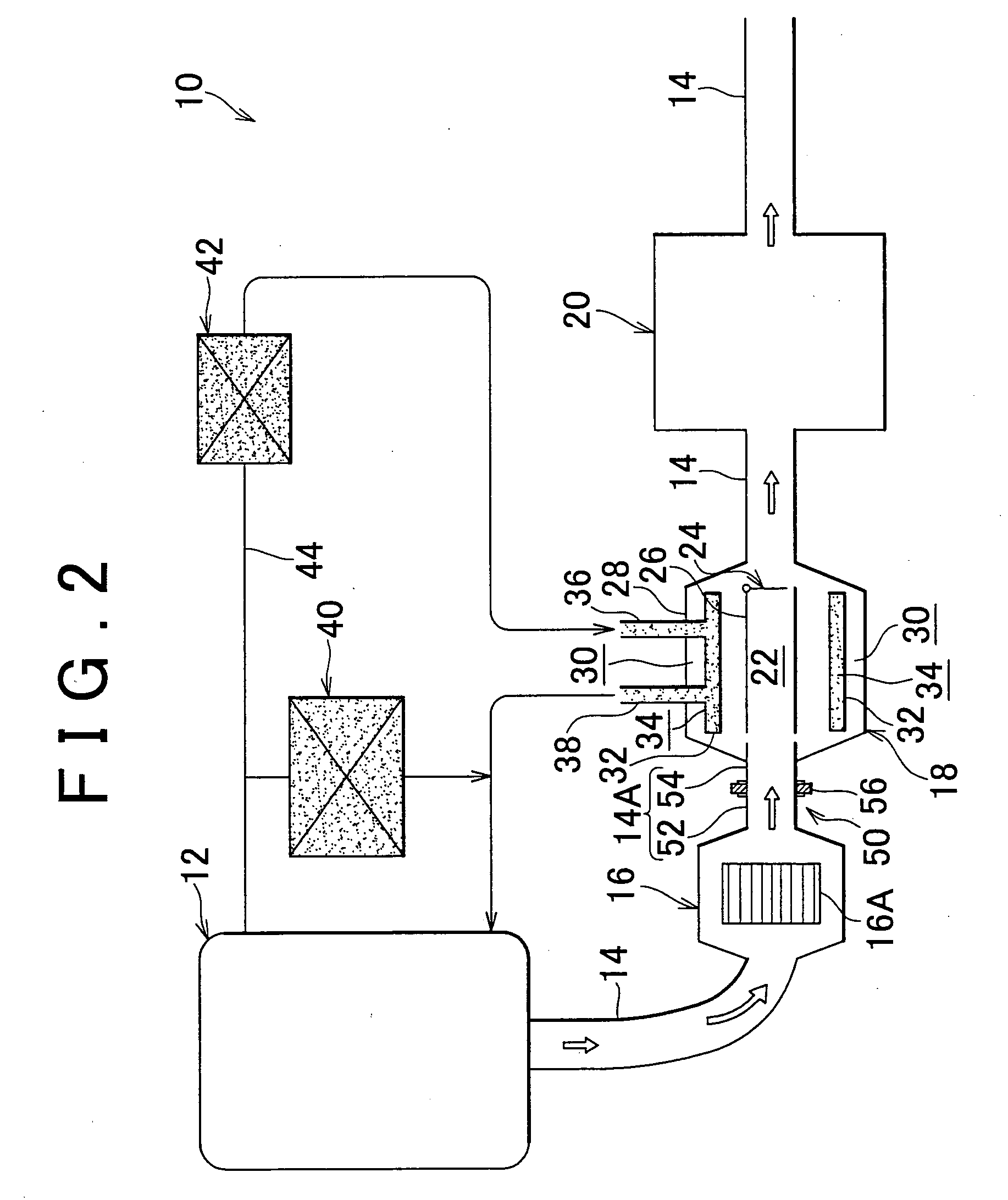

An exhaust heat recovery system (10) includes: an exhaust heat exchanger (18) that is communicated with a catalytic converter (16) through an exhaust gas pipe (14A), and that recovers exhaust heat into a coolant; and heat transfer restriction means (50) provided between the catalytic converter (16) and the exhaust heat exchanger (18). The heat transfer restriction means (50) includes a heat insulator (56) disposed between a first exhaust gas pipe (52) and a second exhaust gas pipe (54) that constitute the exhaust gas pipe (14A), and. restrains a released heat from the catalytic converter (16) from reaching the exhaust heat exchanger (18).

Owner:TOYOTA JIDOSHA KK

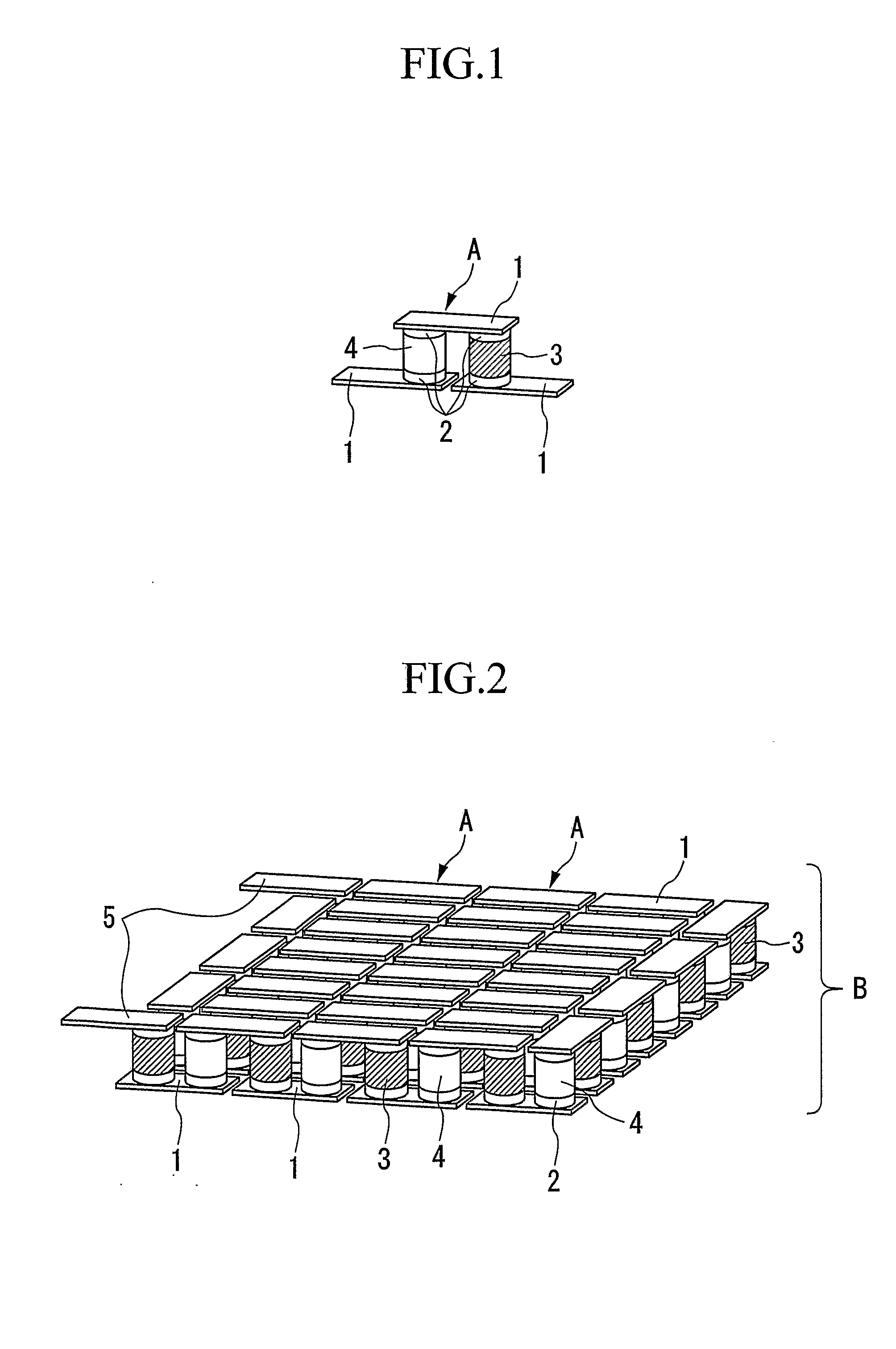

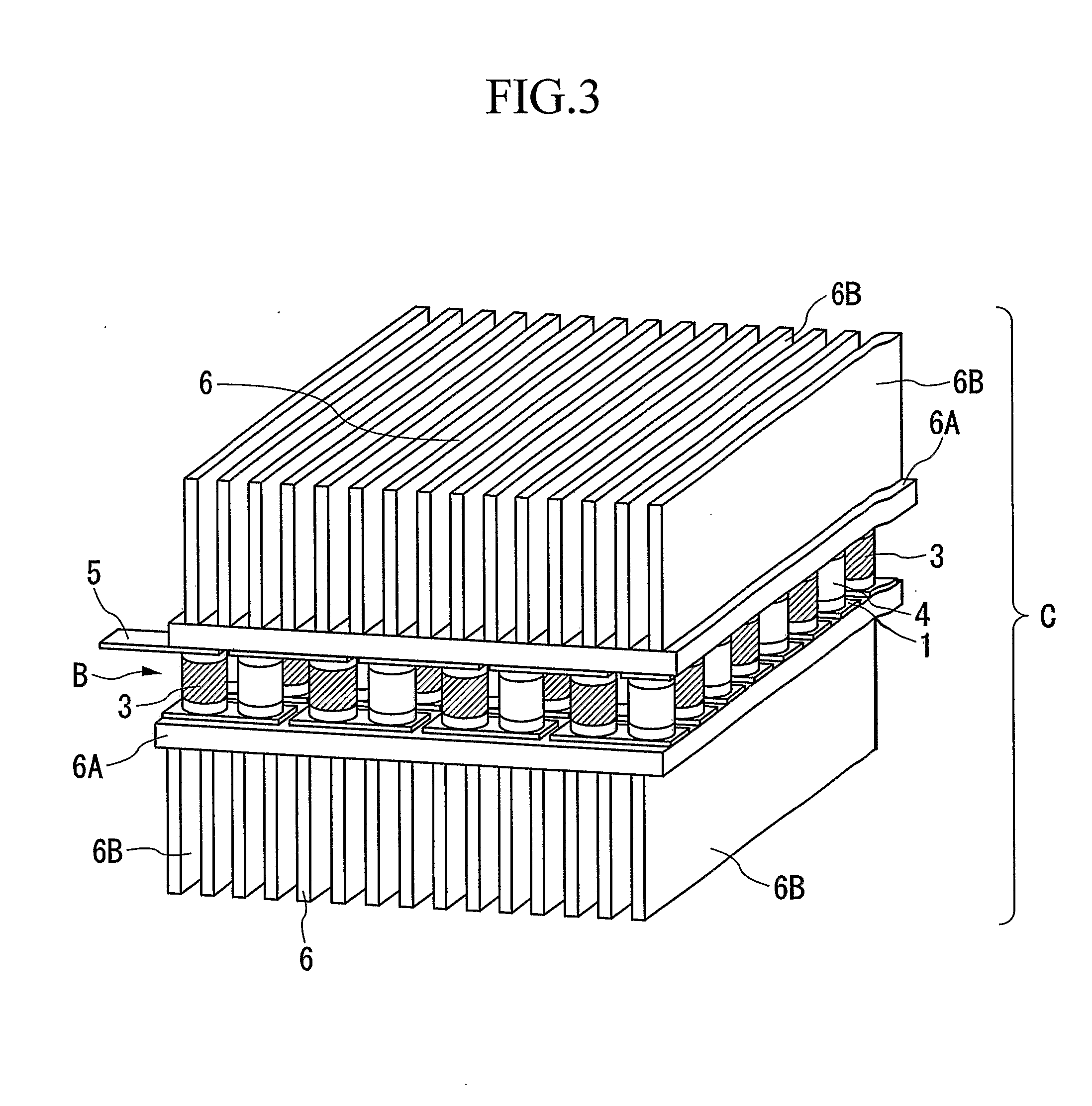

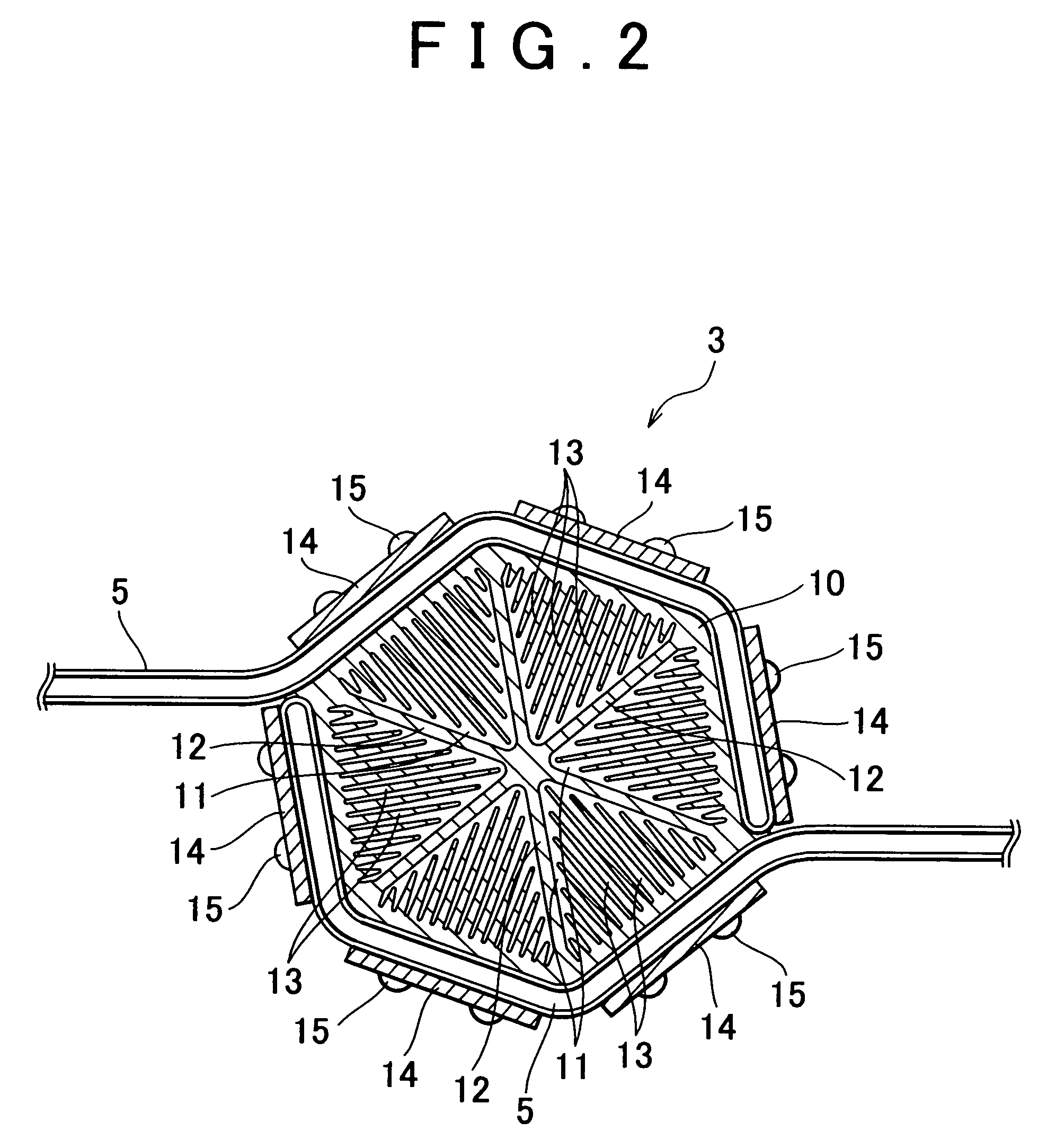

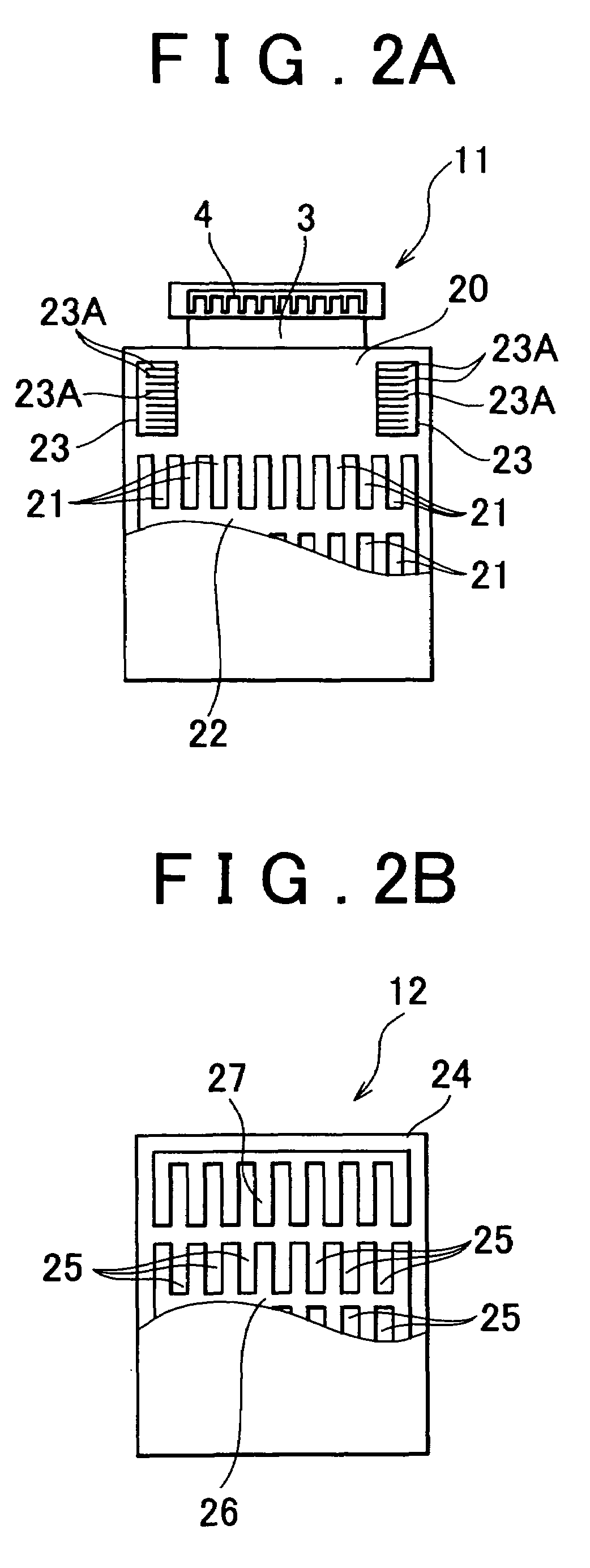

Thermoelectric Conversion Module, and Thermoelectric Power Generating Device and Method, Exhaust Heat Recovery System, Solar Heat Utilization System, and Peltier Cooling and Heating System, Provided Therewith

InactiveUS20080023057A1Promote high performanceHigh reliability high performanceThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentEngineeringThermoelectric element

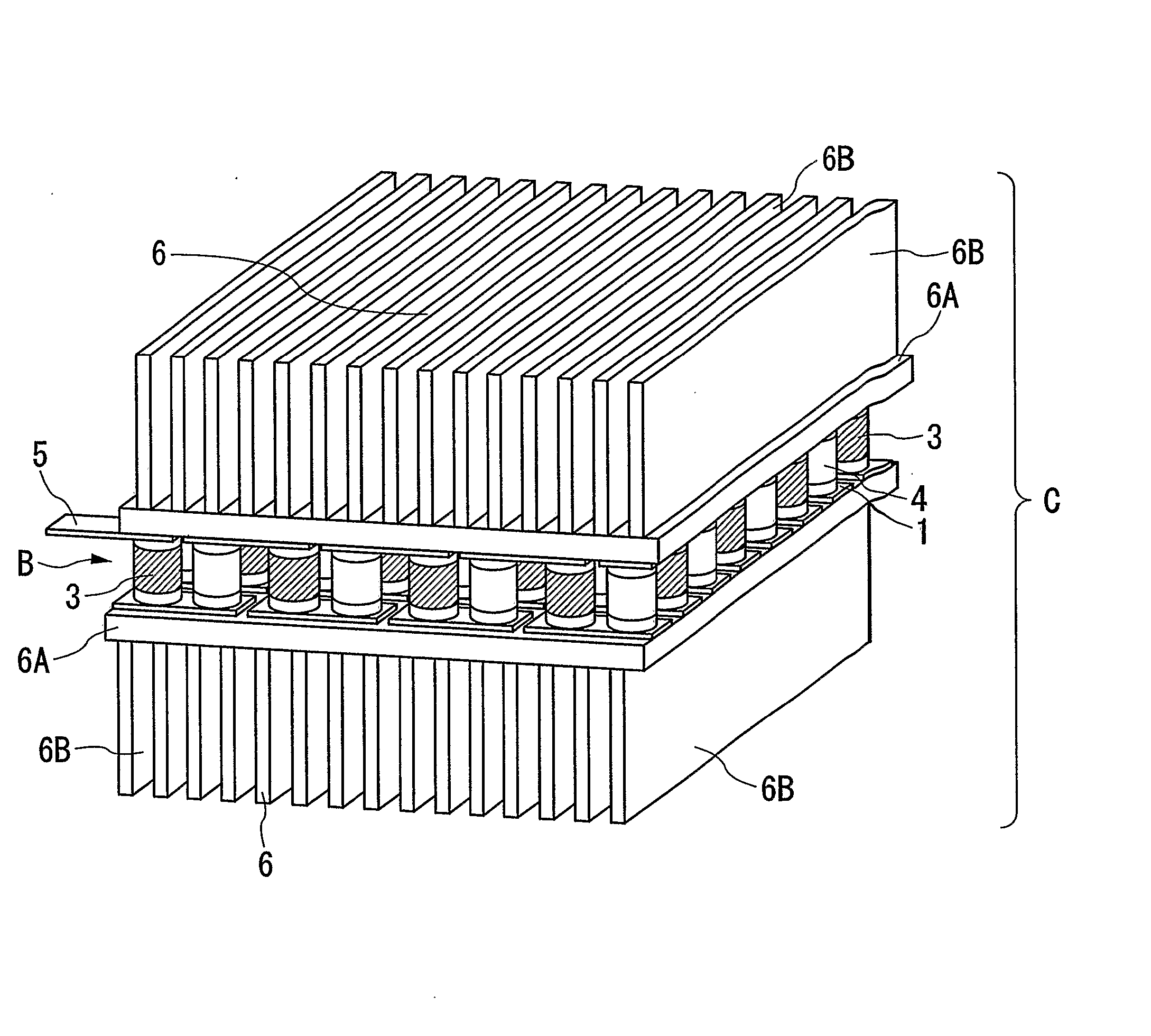

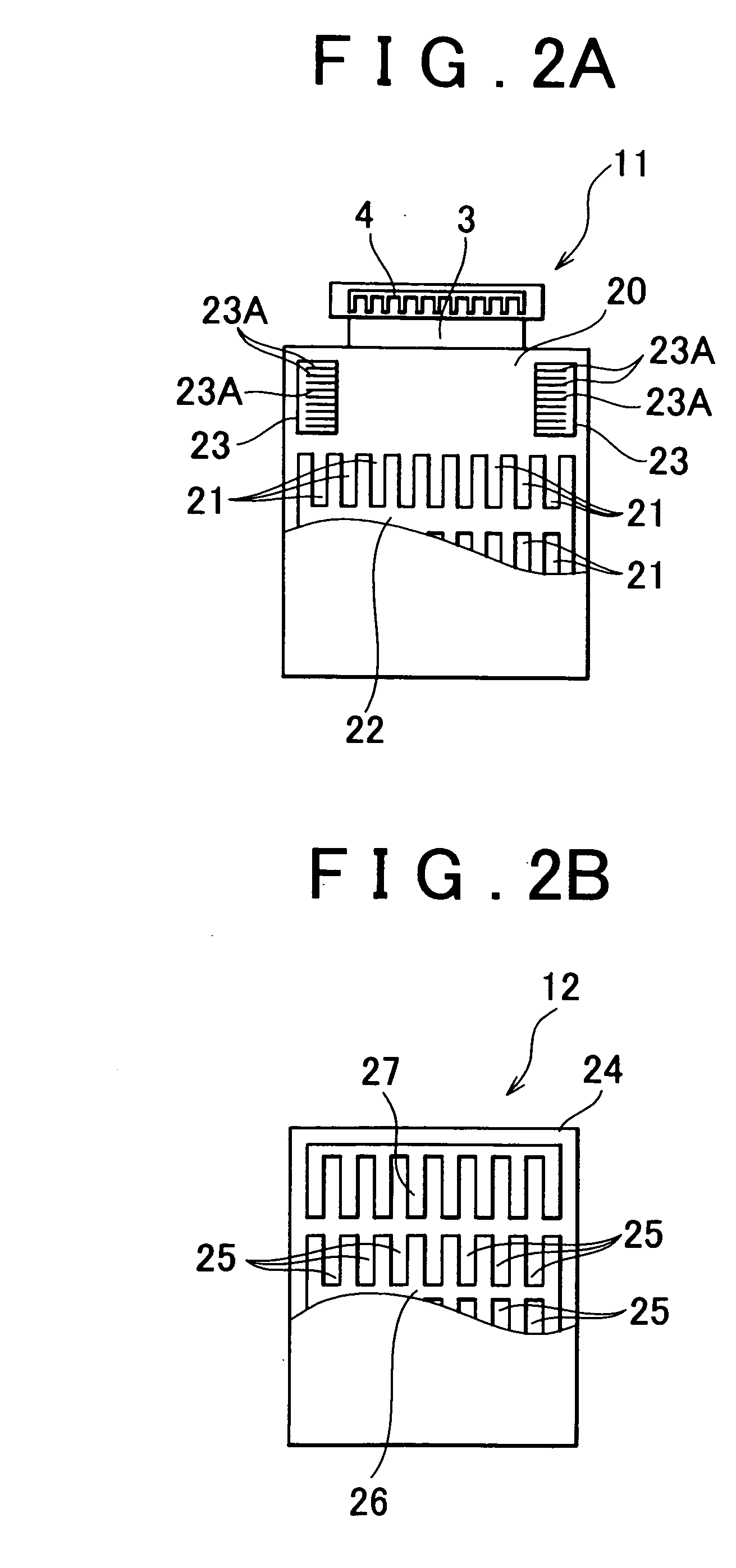

The thermoelectric conversion module is provided, comprising a plurality of thermoelectric elements, and respective thermoelectric elements are electrically connected by metal caps attached to both ends of each thermoelectric element. In addition, the metal cap may be integrally formed with electrodes on both ends of each thermoelectric element.

Owner:SHOWA DENKO KK

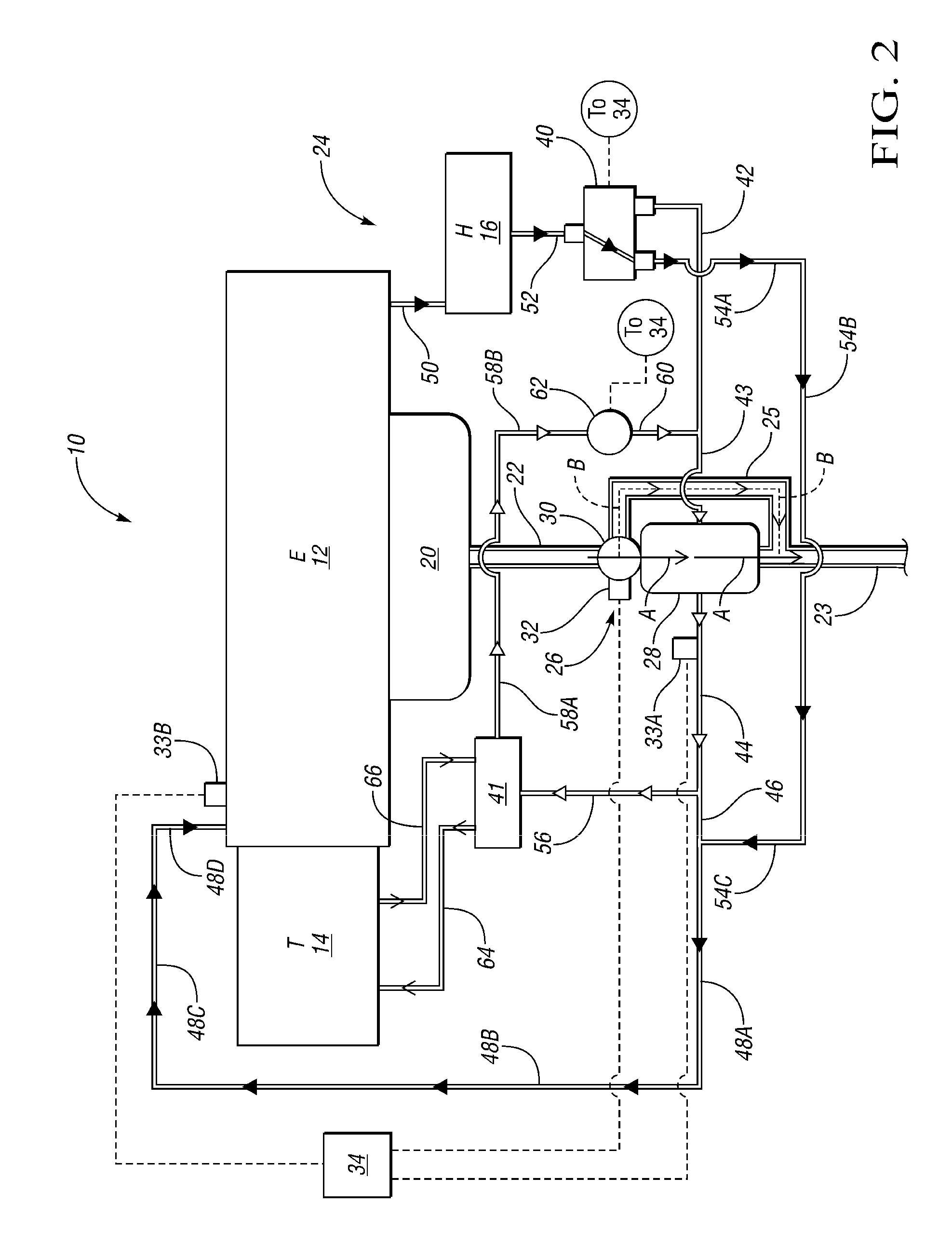

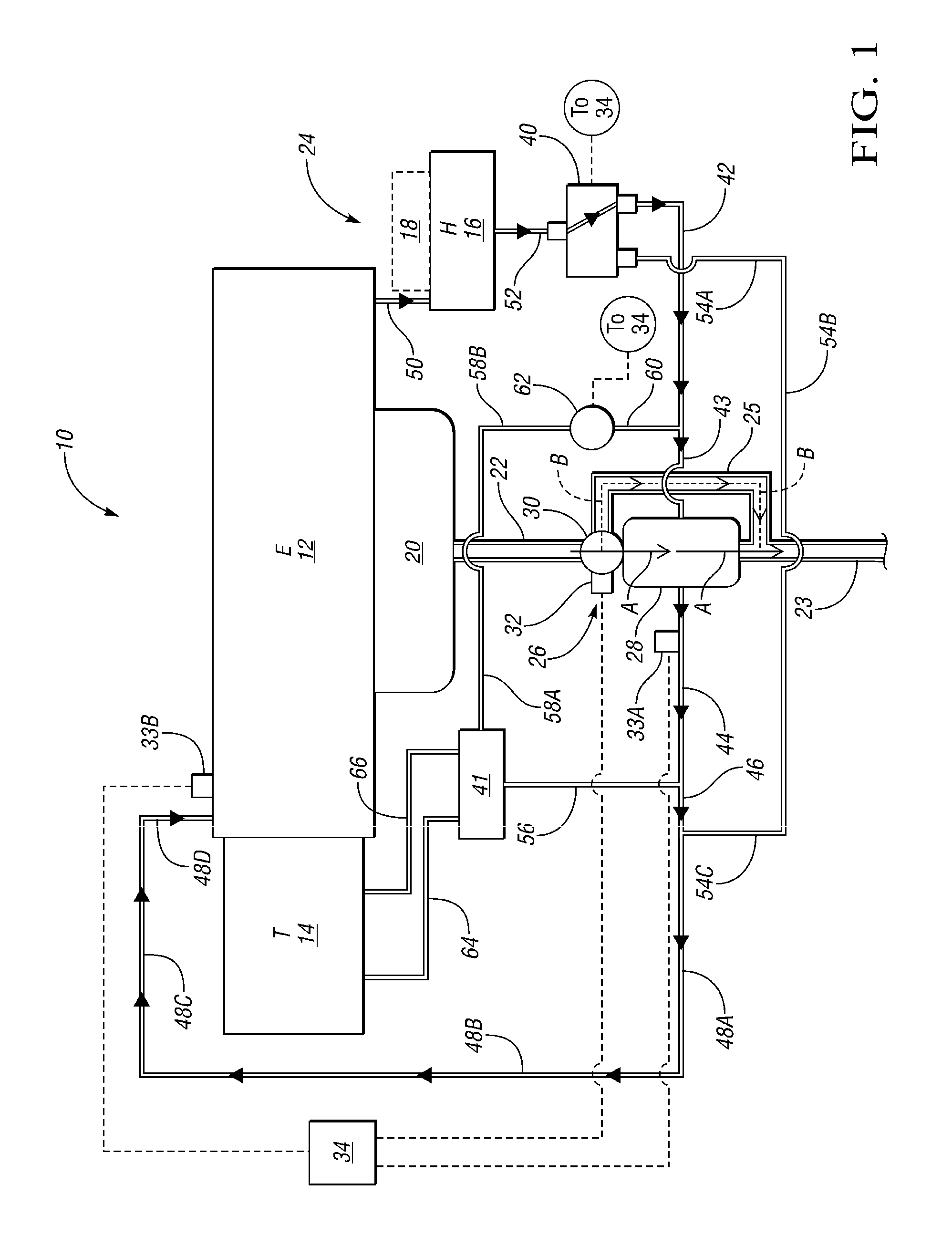

Exhaust heat recovery for transmission warm-up

ActiveUS20110088378A1Waste heat recoveryAvoid insufficient heatingCoolant flow controlInternal combustion piston enginesOperant conditioningOperating temperature

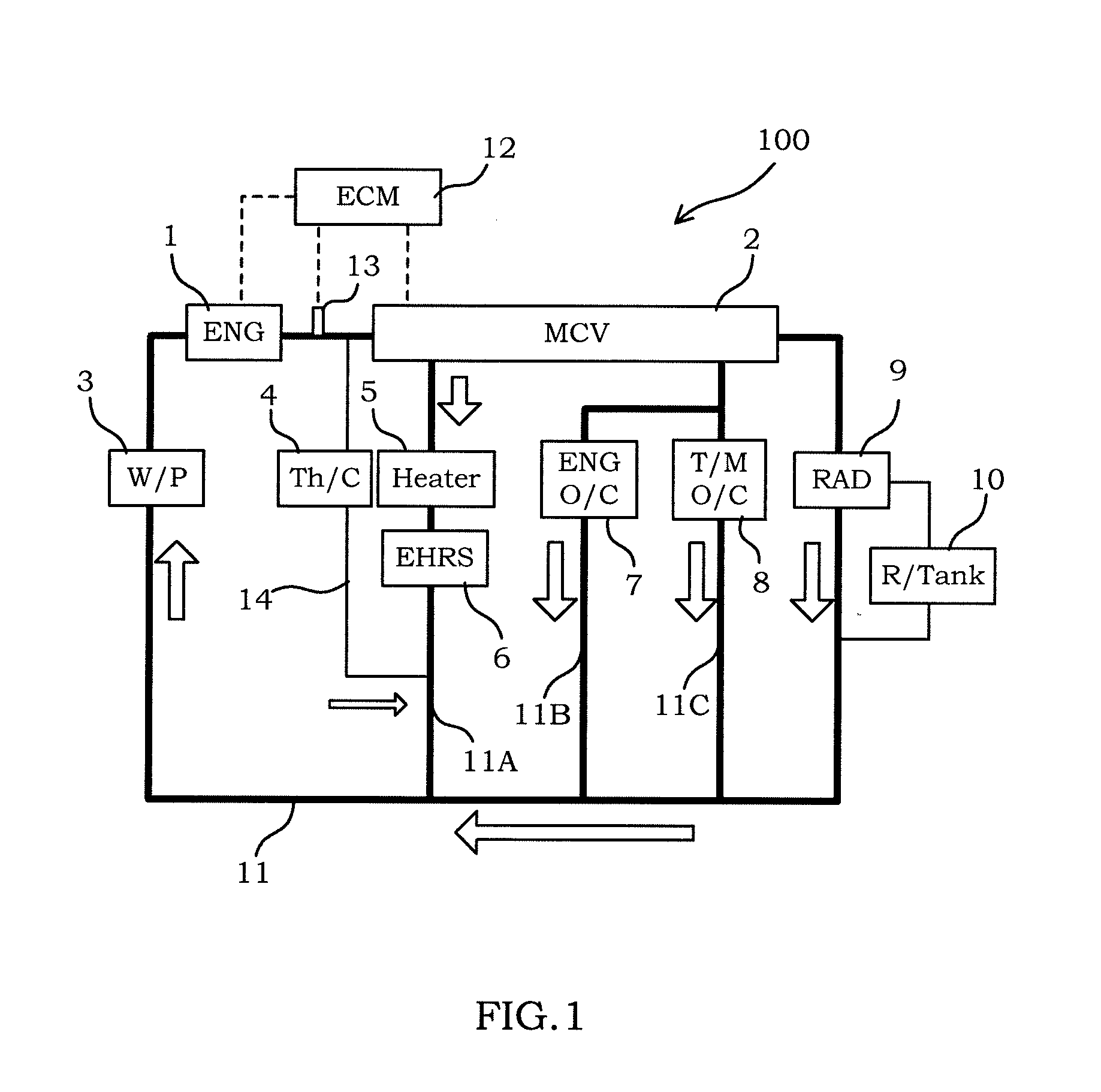

An exhaust heat recovery system (EHRS) for a vehicle is provided that is operable to direct coolant heated by exhaust heat to a vehicle transmission under certain operating conditions after the engine is adequately heated by the exhaust heat and without further heating the engine with the exhaust heat. Thus, recovery of exhaust heat is increased as the transmission is heated to a higher operating temperature than the engine using the heated coolant. The EHRS may also operate in a bypass mode during which exhaust heat is not directed to the engine or the transmission. A method of managing exhaust heat is also provided.

Owner:GM GLOBAL TECH OPERATIONS LLC

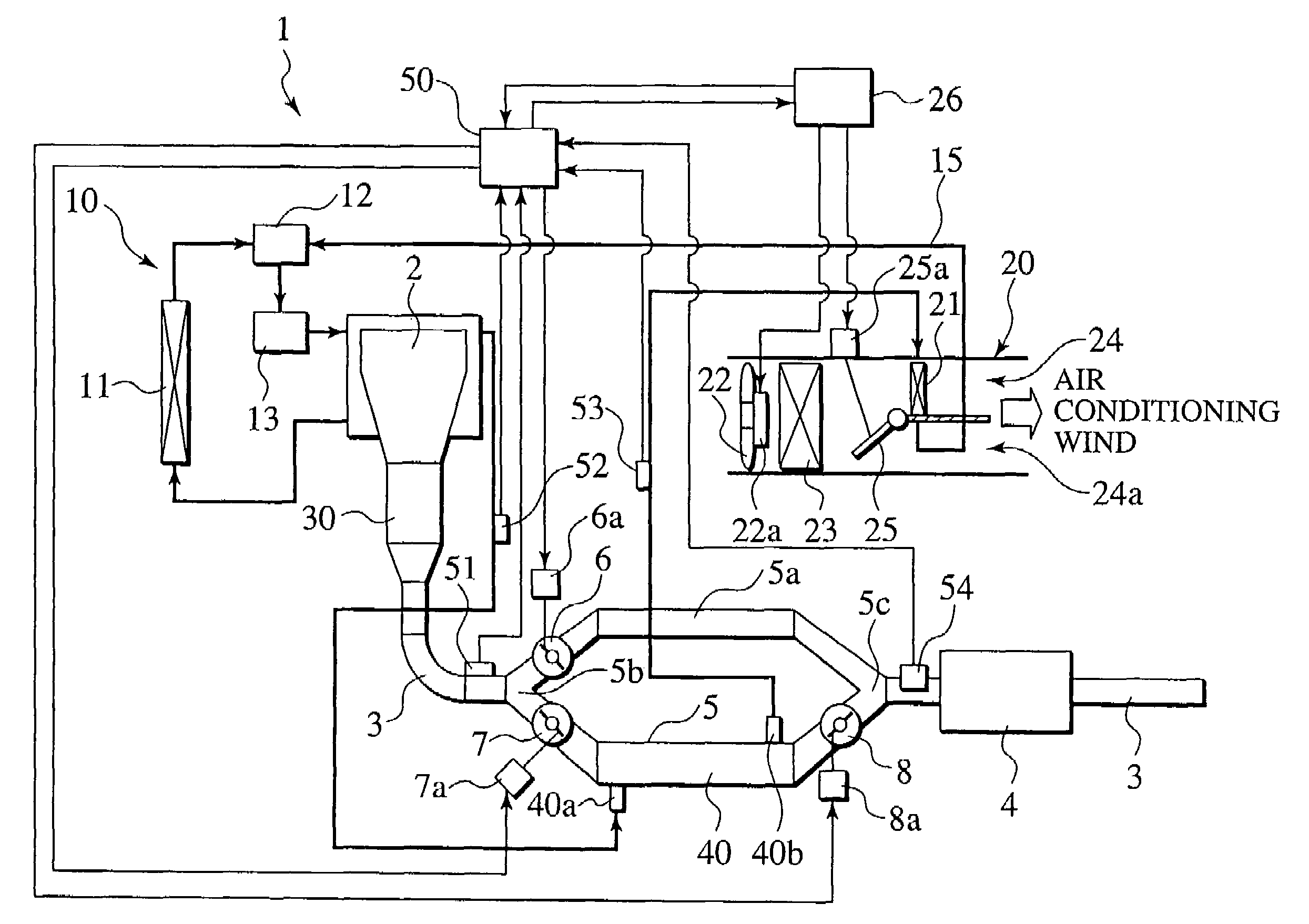

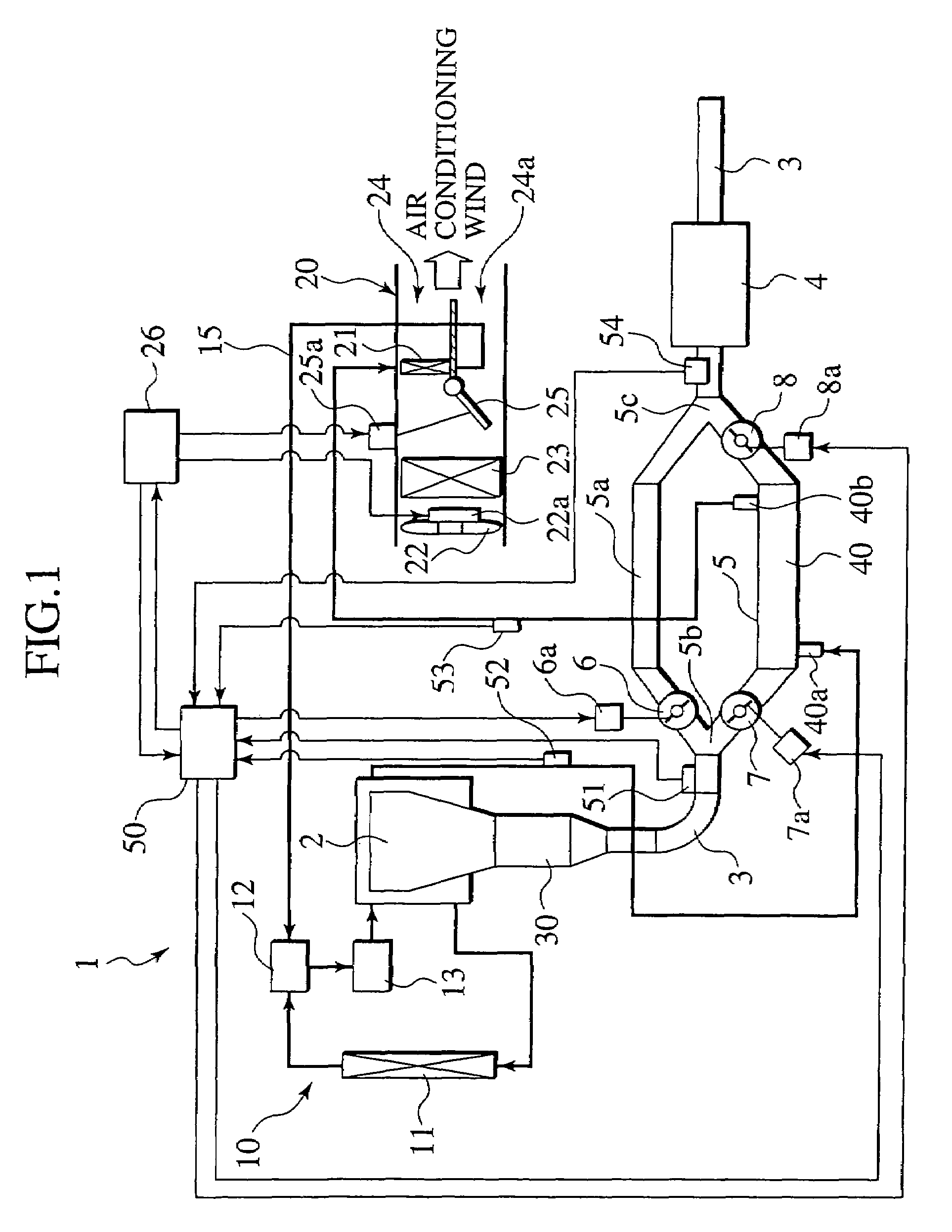

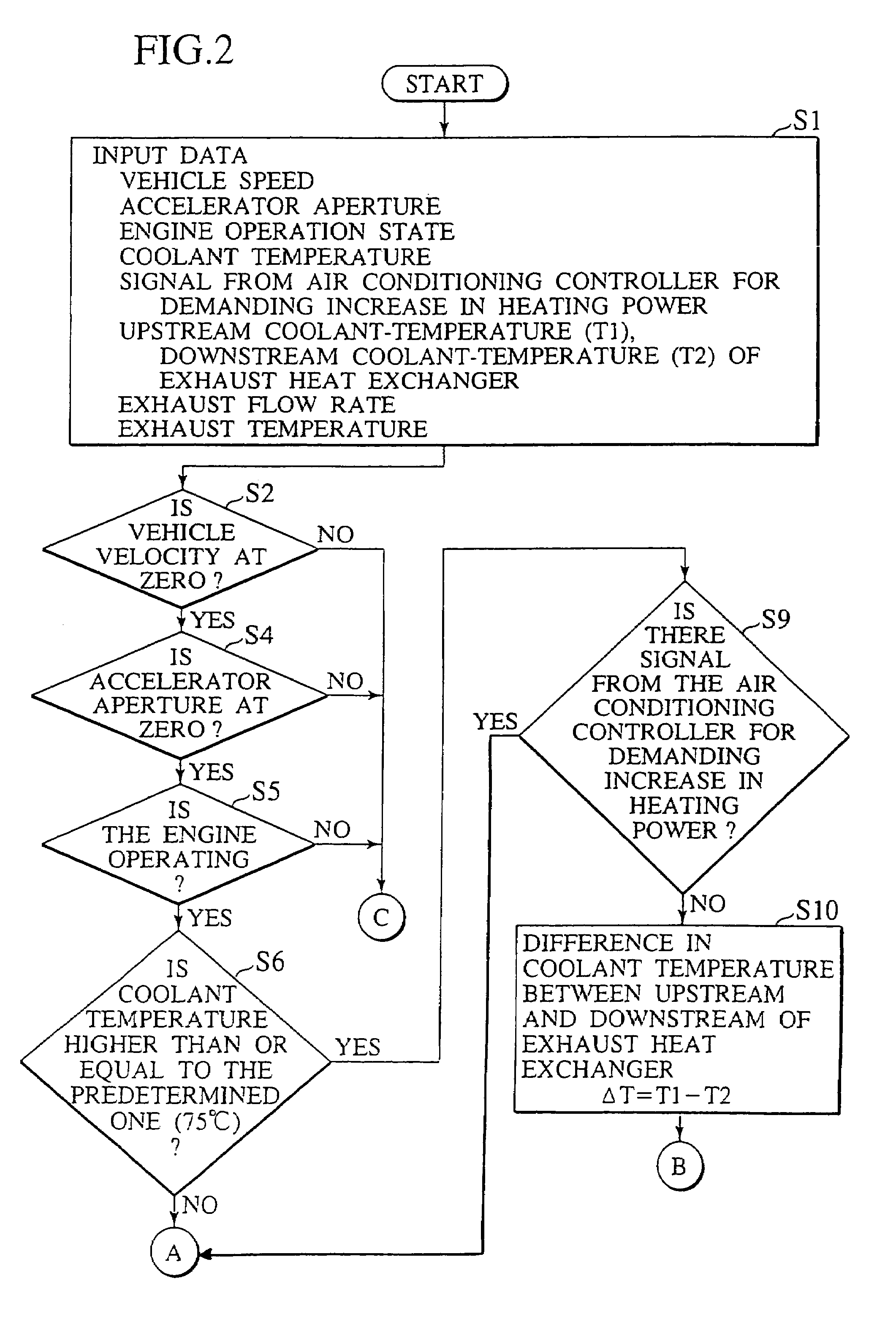

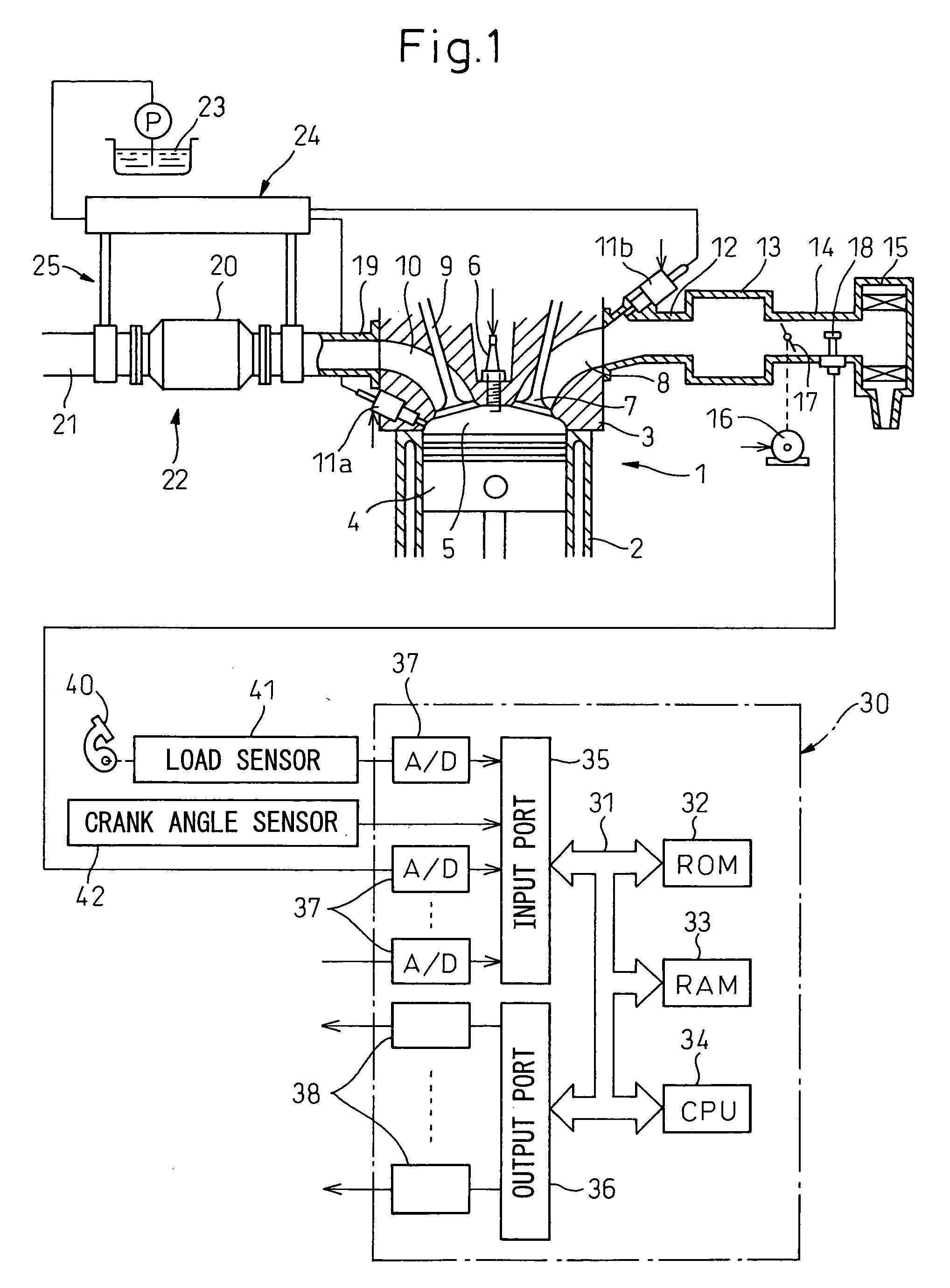

Exhaust-heat recovery system for engine

InactiveUS7246487B2Heat quantity can be increasedEffective temperatureAir-treating devicesElectrical controlExhaust fumesAir conditioning

An exhaust-heat recovery system includes a catalytic converter, an exhaust heat exchanger, an air conditioner and an engine controller. The catalytic converter is such that exhaust discharged from an engine passes therethrough and combustible components in the exhaust are catalytically burned therein. The exhaust heat exchanger induces heat exchange between the exhaust having passed through the catalytic converter and a coolant having passed through the engine. The air conditioner generates a heating wind by means of the heat exchange between the coolant having passed through the exhaust heat exchanger and an air conditioning wind. The engine controller controls incrementally the combustible components in the exhaust to be burned in the catalytic converter when a prescribed heating condition is unsatisfied.

Owner:CALSONIC KANSEI CORP

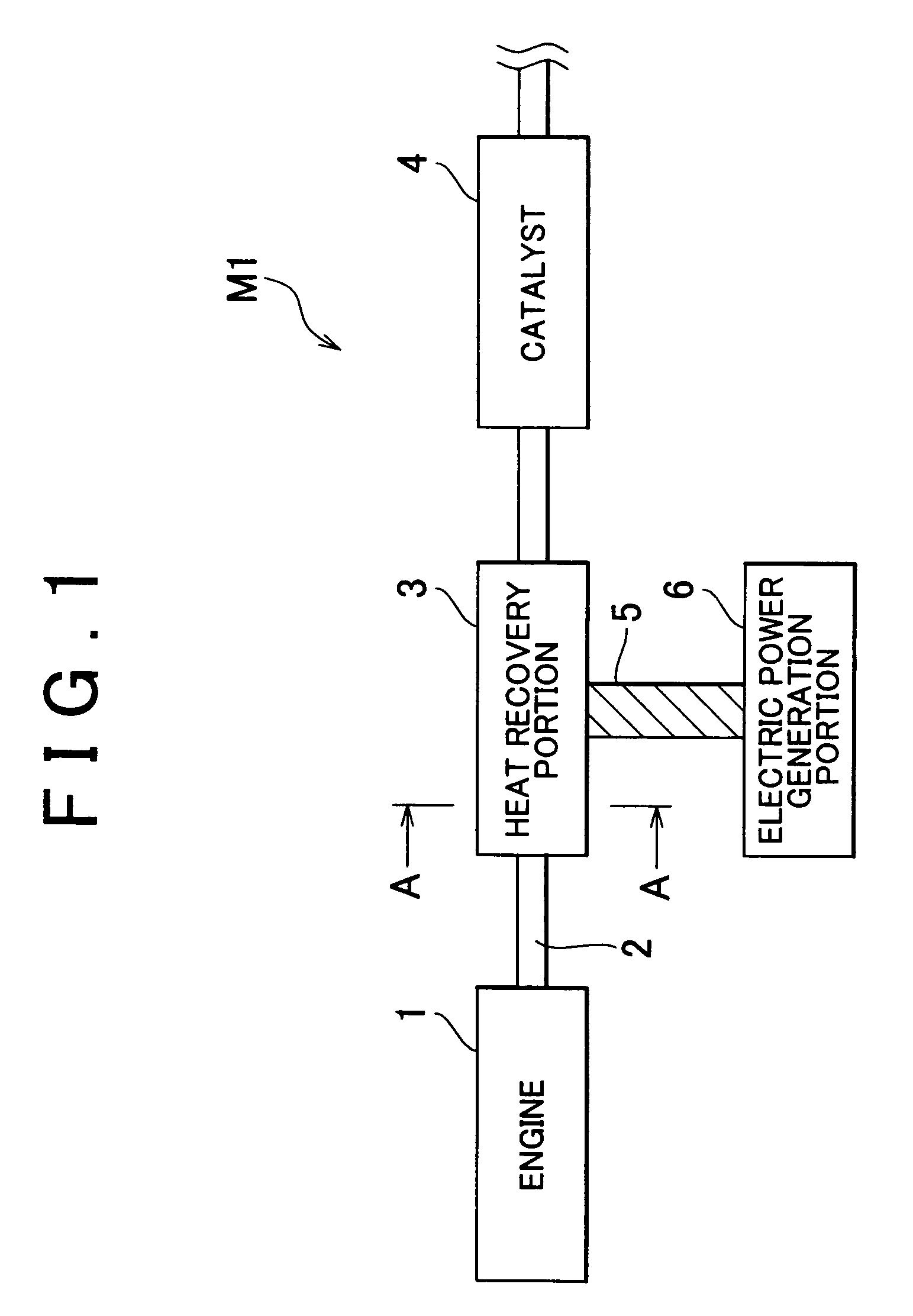

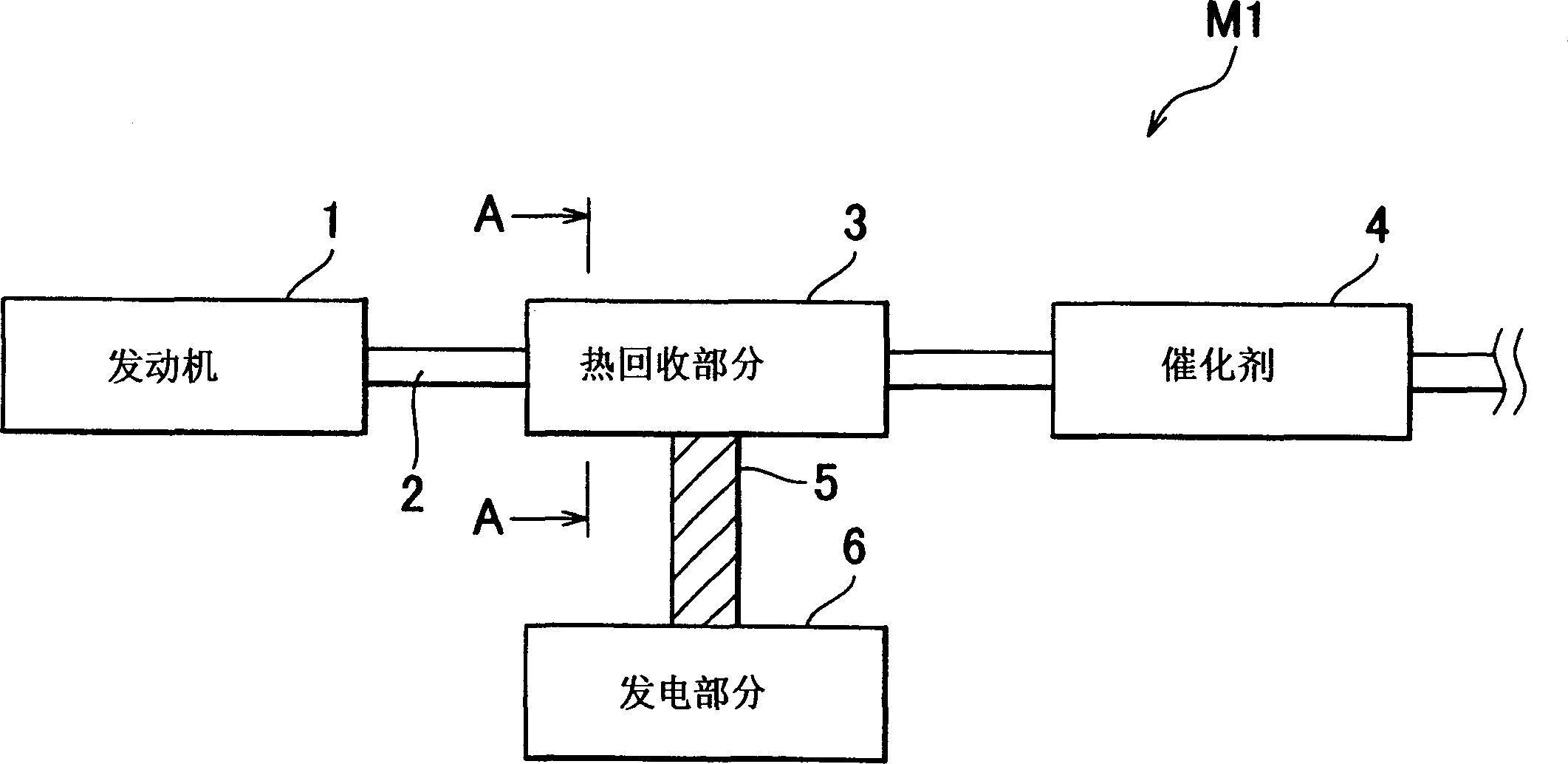

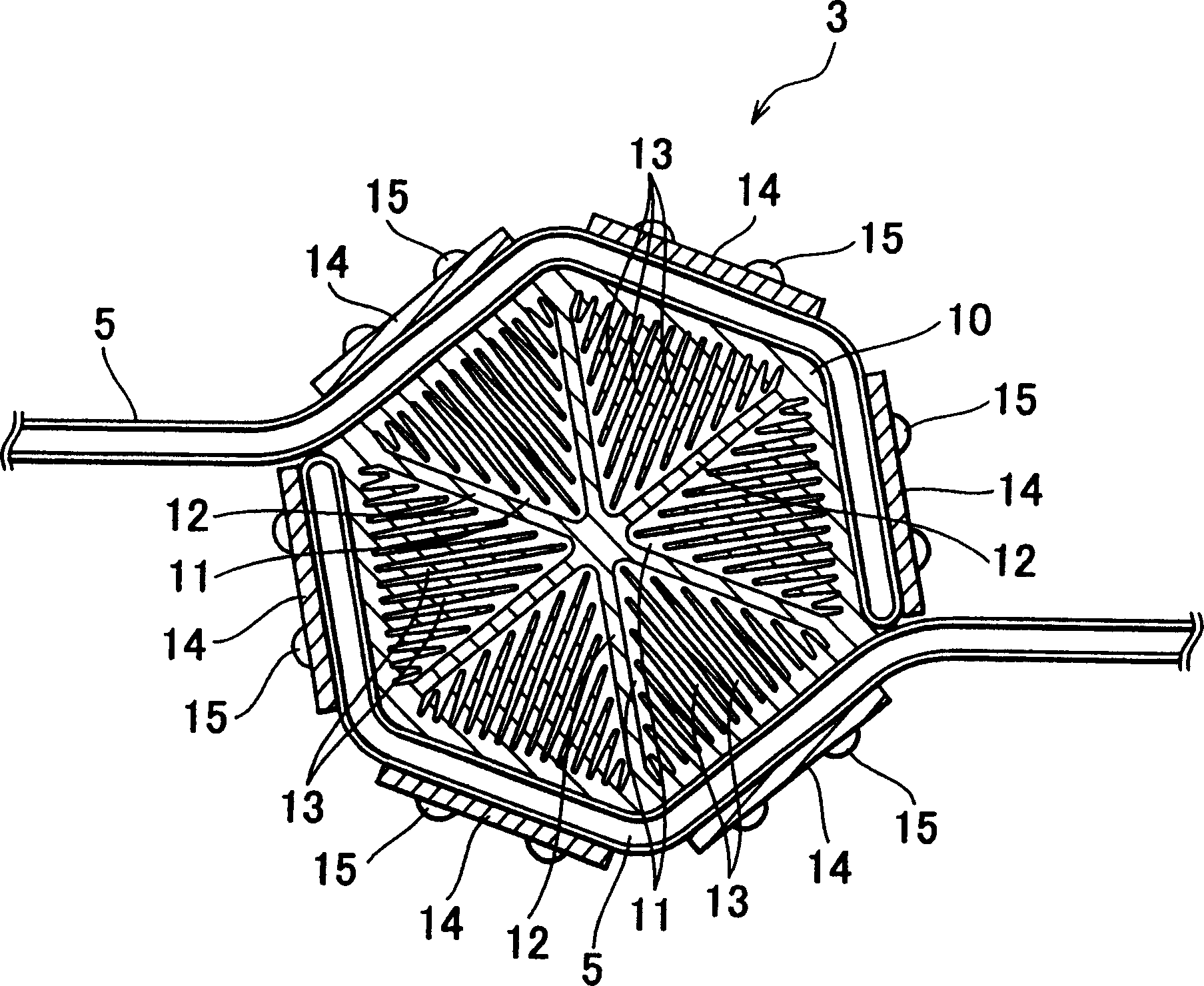

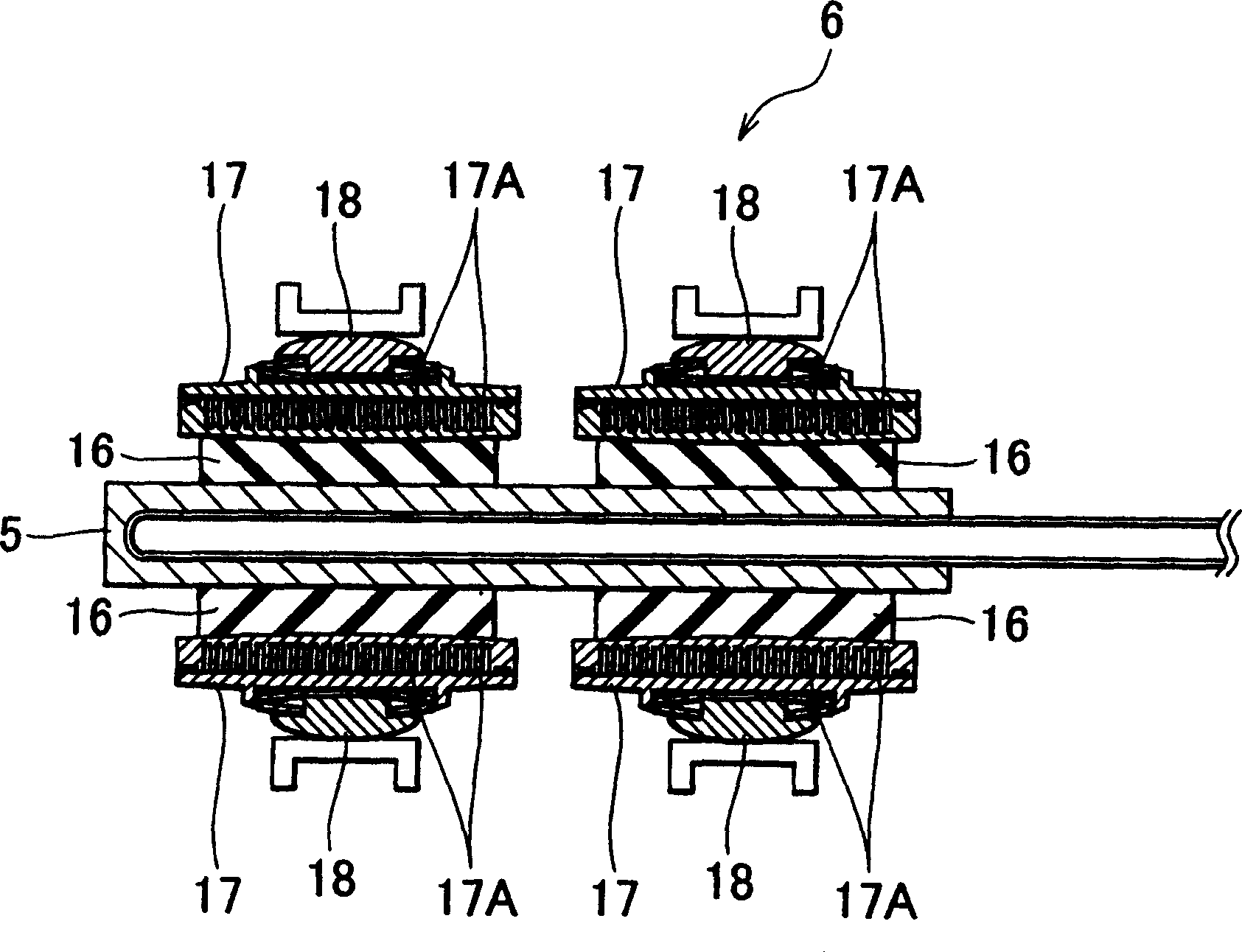

Exhaust heat recovery system

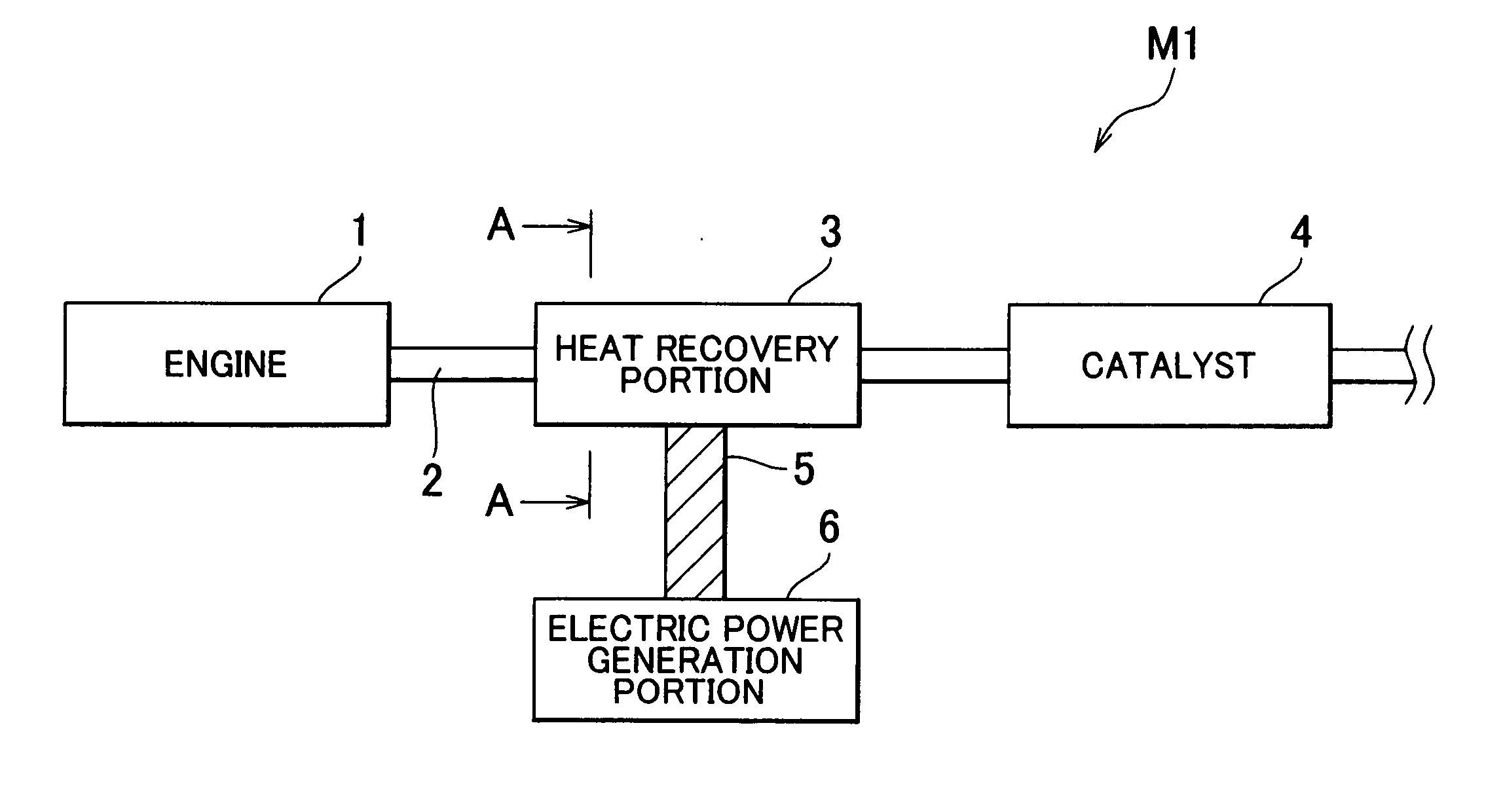

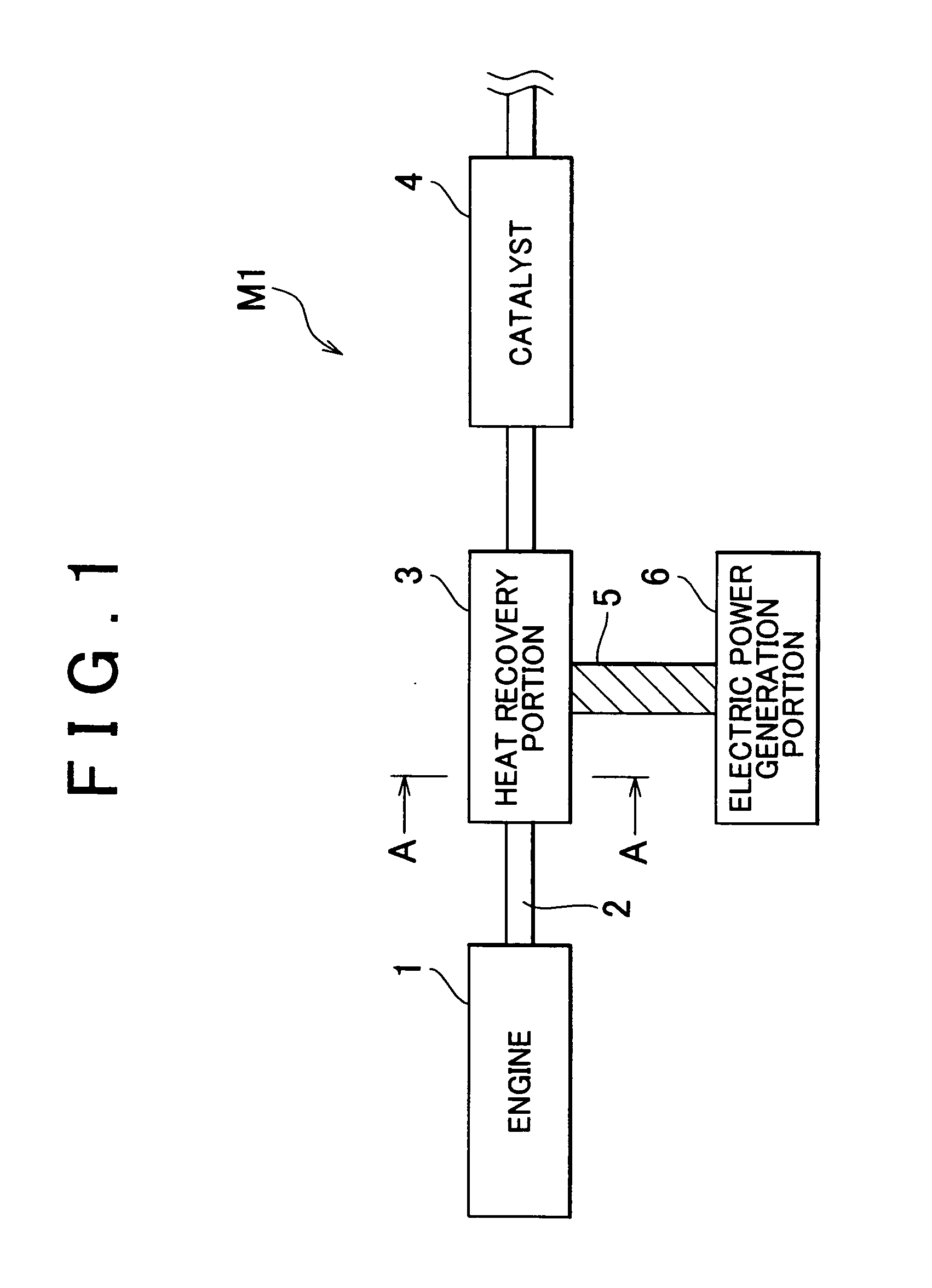

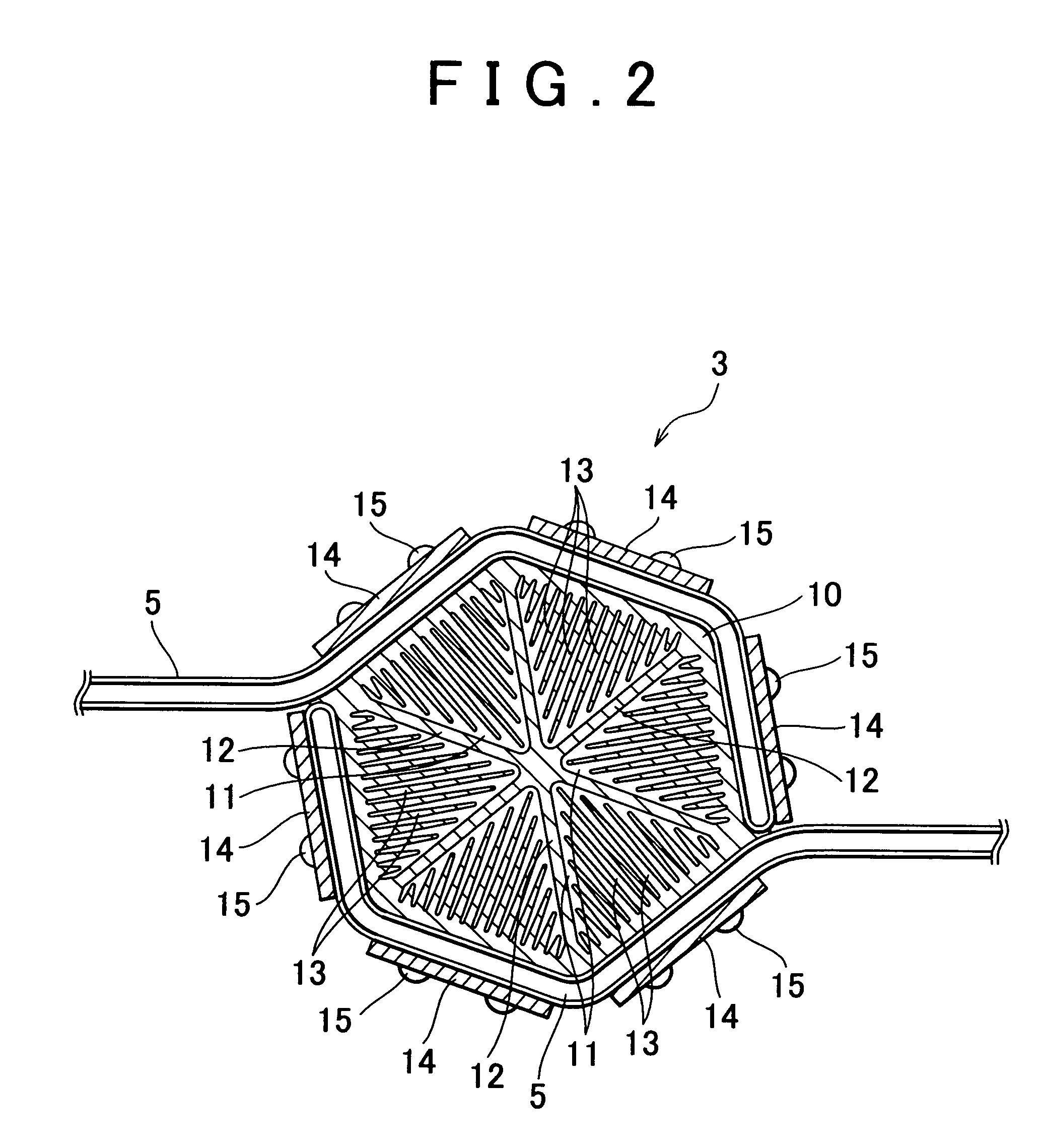

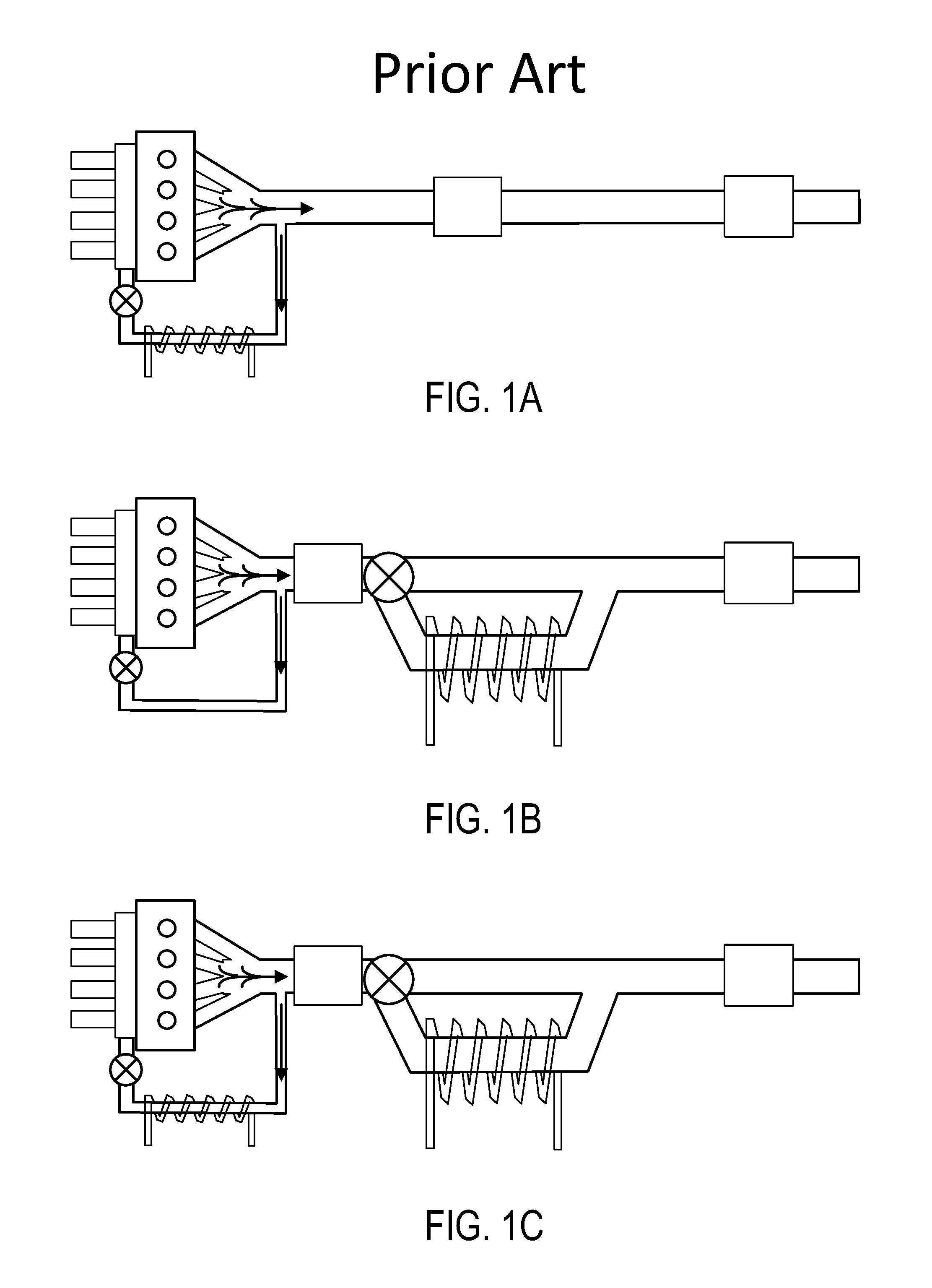

InactiveUS20050204733A1Improve powerSimple configurationInternal combustion piston enginesThermoelectric device with peltier/seeback effectExhaust fumesEngineering

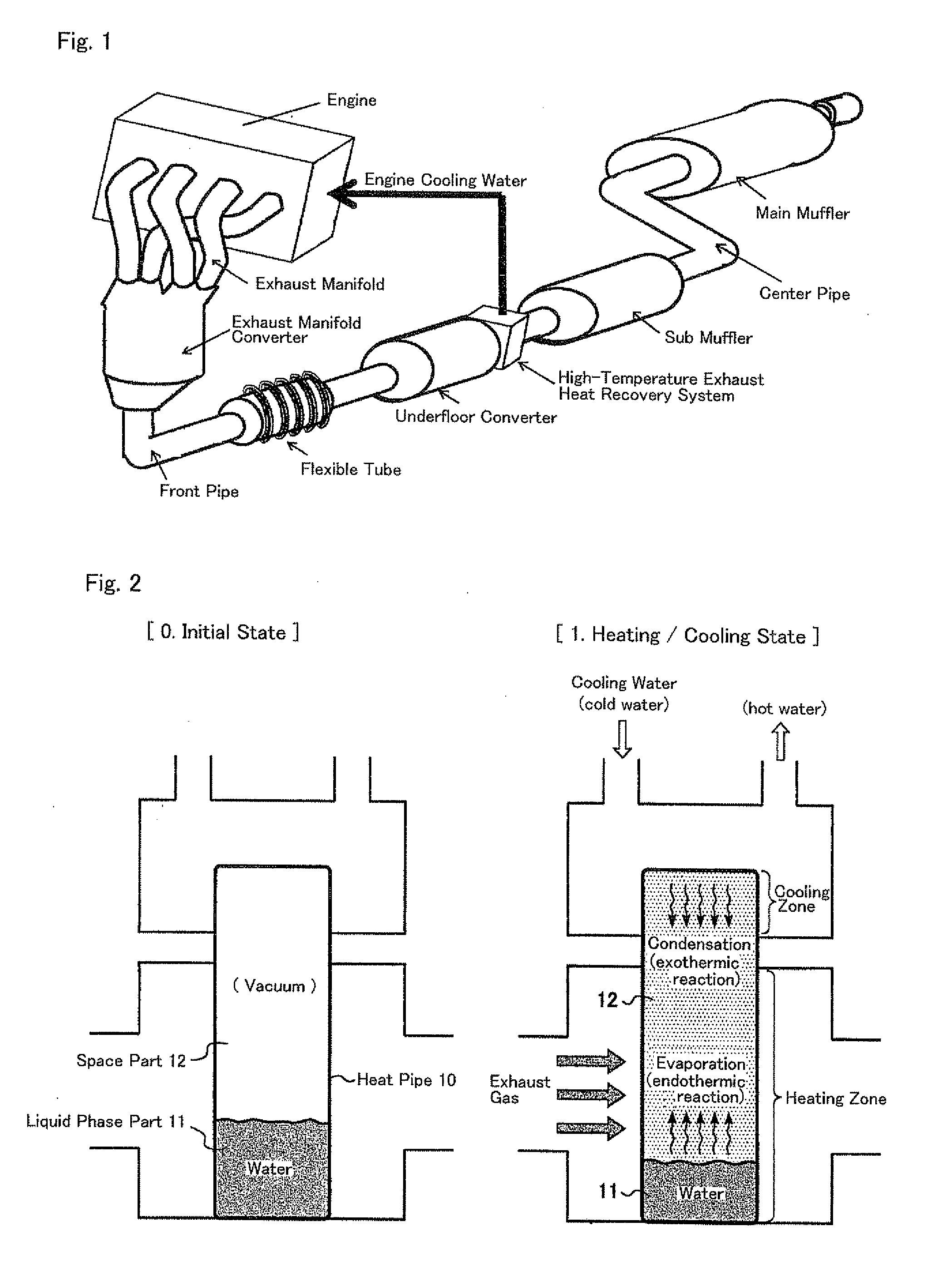

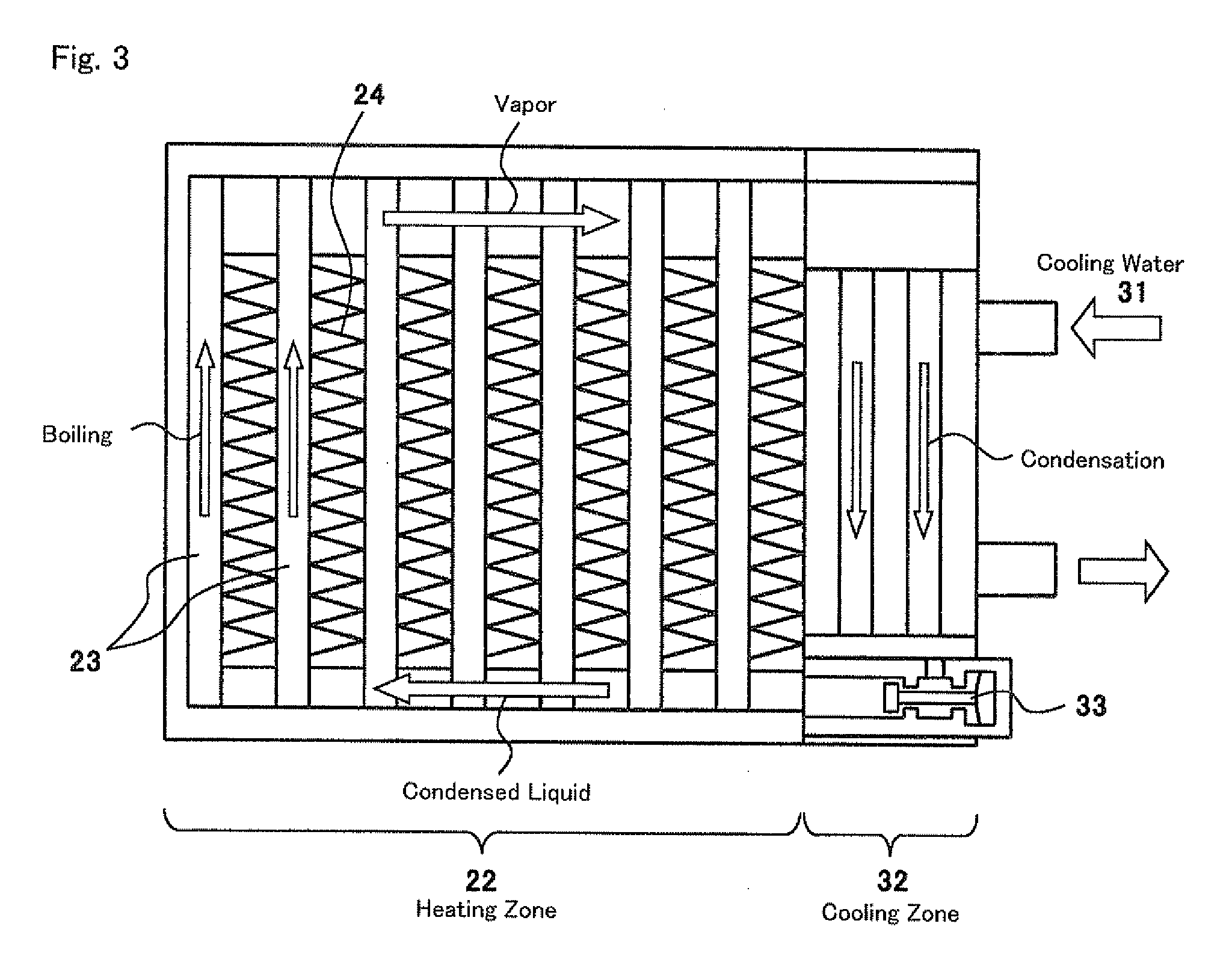

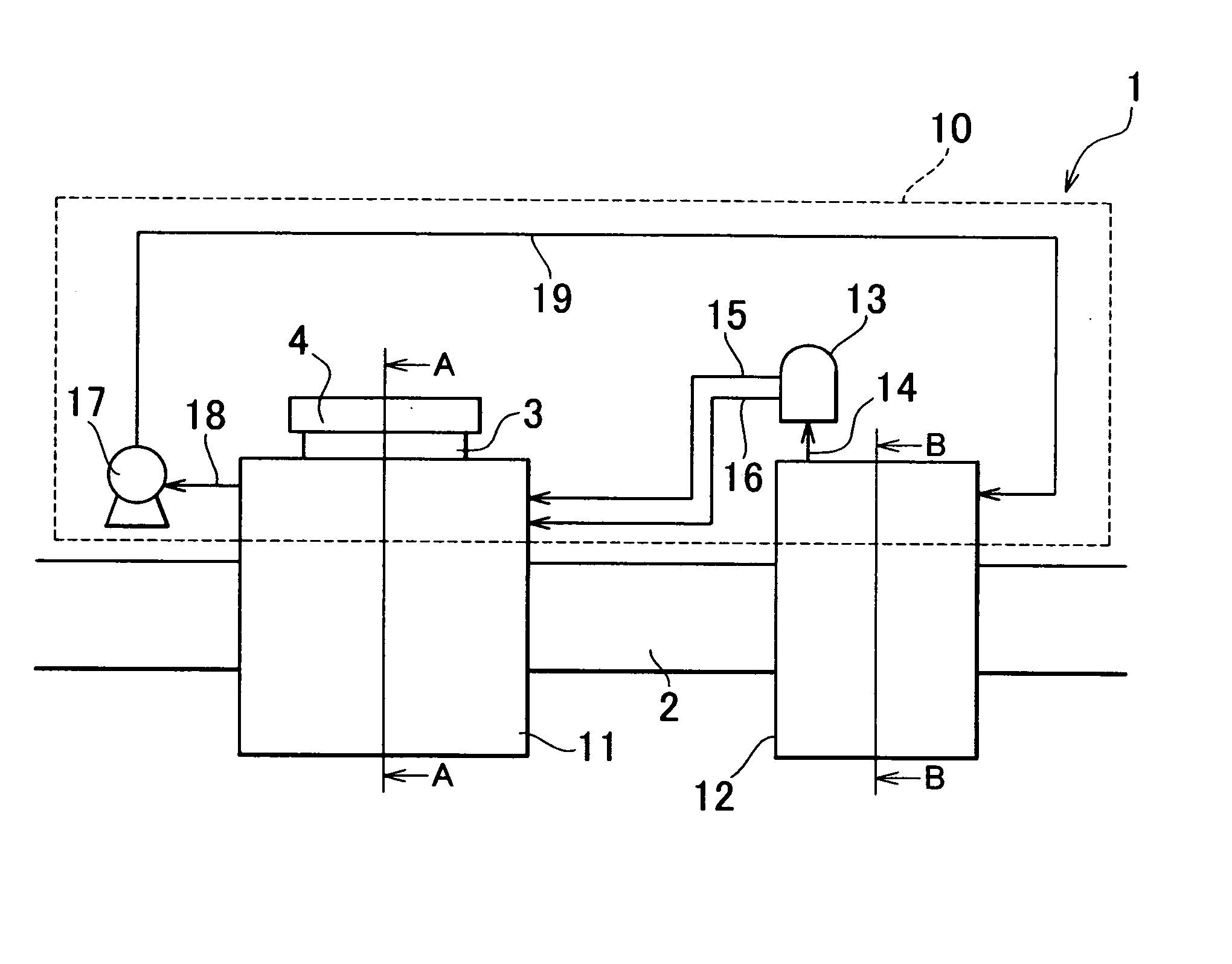

In an exhaust heat recovery system, electric power generation efficiency of a thermoelectric conversion element can be improved, and warming-up of a catalyst can be completed early, without using a complicated device. The exhaust heat recovery system according to the invention includes an exhaust pipe in which exhaust gas discharged from an internal combustion engine flows; a catalyst which purifies the exhaust gas; a heat recovery portion which is fitted to the exhaust pipe, and which recovers heat contained in the exhaust gas; a thermoelectric conversion element which generates electric power using thermoelectric conversion; and a heat pipe which connects the heat recovery portion to the thermoelectric conversion element, and which transfers the heat recovered in the heat recovery portion to the thermoelectric conversion element. An operation starting temperature of the heat pipe is set so as to be higher than an activation temperature of the catalyst.

Owner:TOYOTA JIDOSHA KK

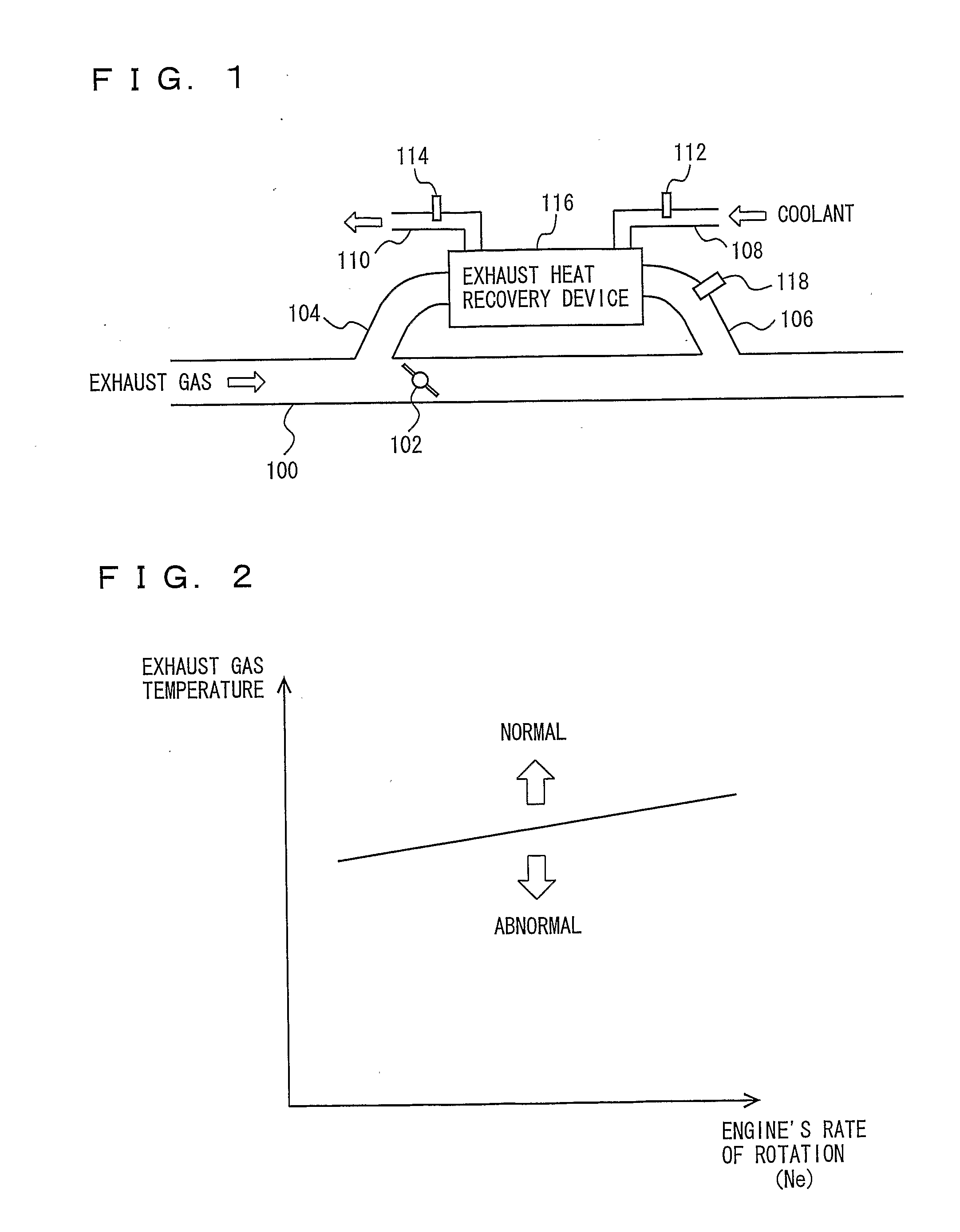

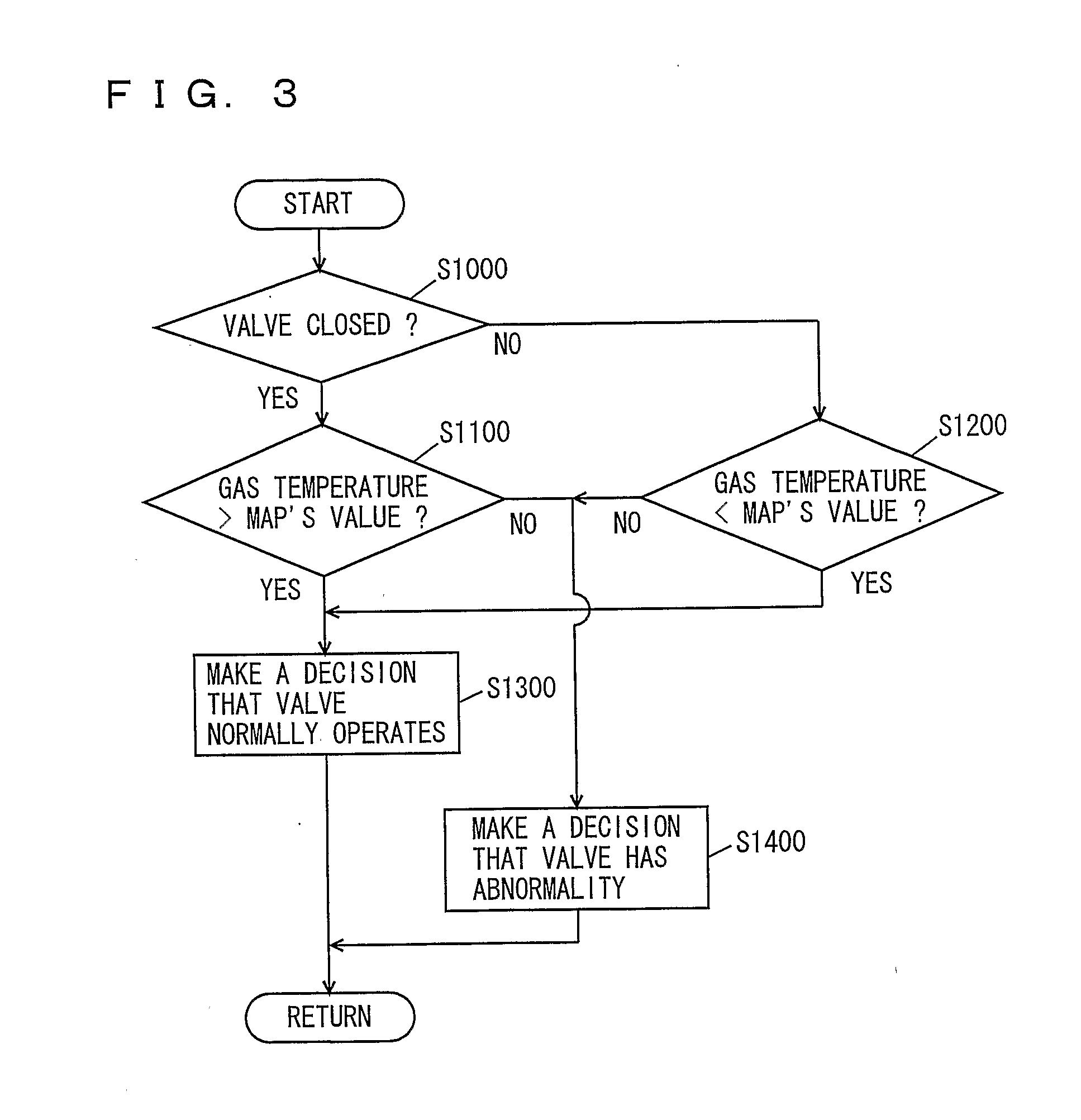

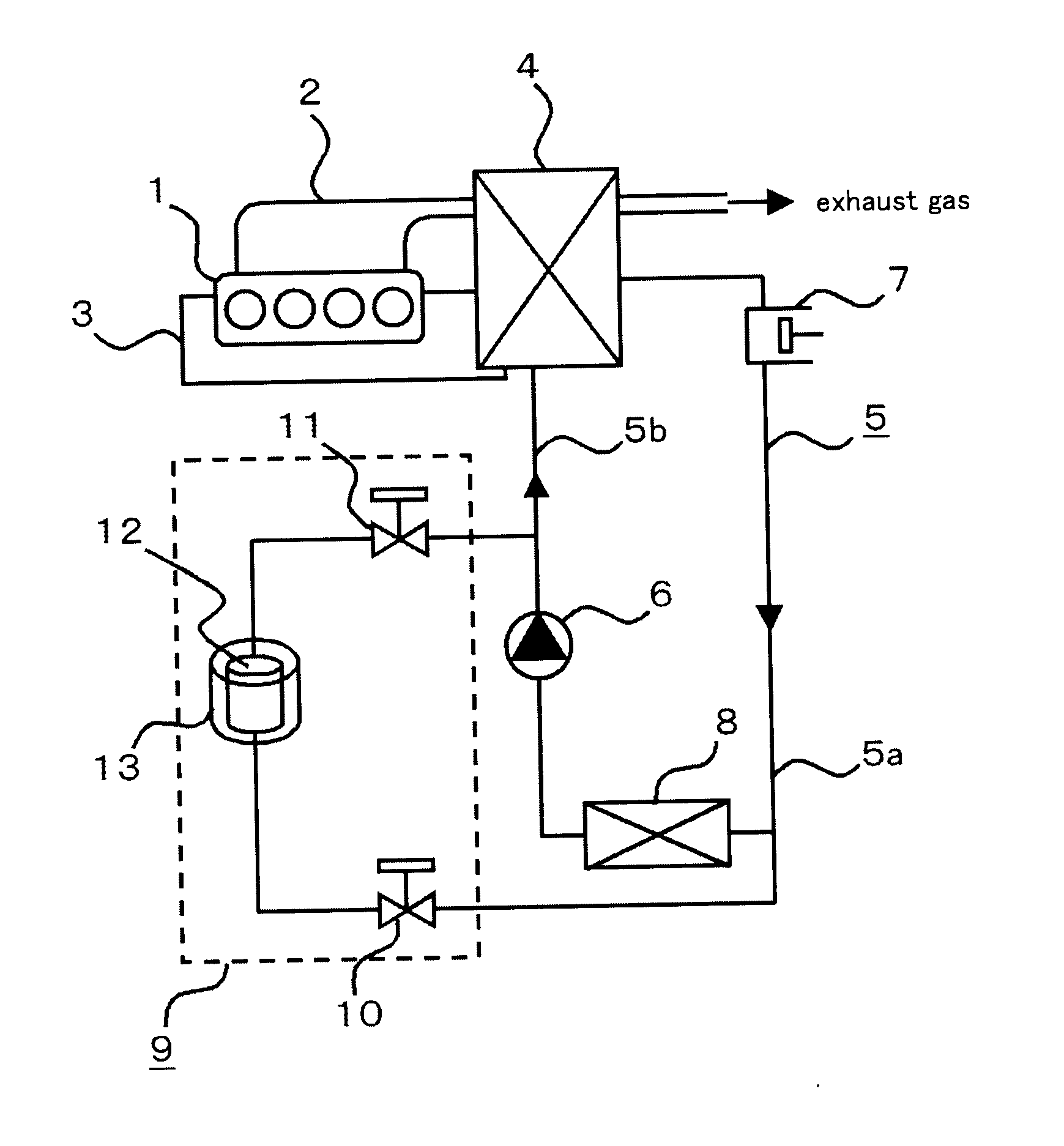

Exhaust Heat Recovery System Abnormality Detection Device

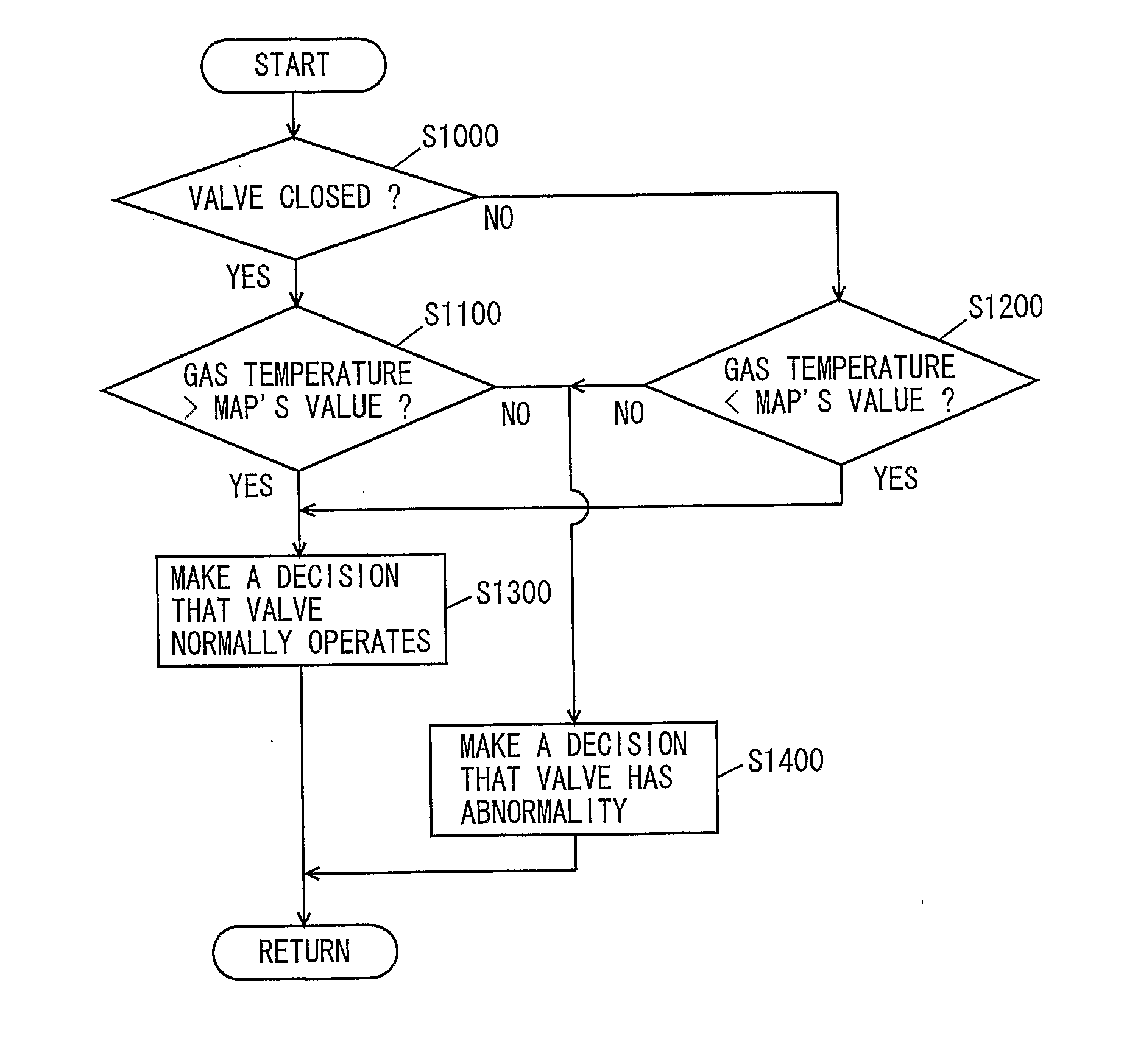

InactiveUS20080115487A1Good decisionImprove accuracyThermometer detailsInternal combustion piston enginesExhaust heat recovery systemElectrical and Electronics engineering

An ECU executes a program including the steps of: when a switching valve is controlled to be closed, comparing exhaust gas's temperature, as detected, with a map value; if the exhaust gas's temperature is larger than the map value, determining that the switching valve normally operates; and if the exhaust gas's temperature is smaller than the map value, determining that the switching valve has abnormality.

Owner:TOYOTA JIDOSHA KK

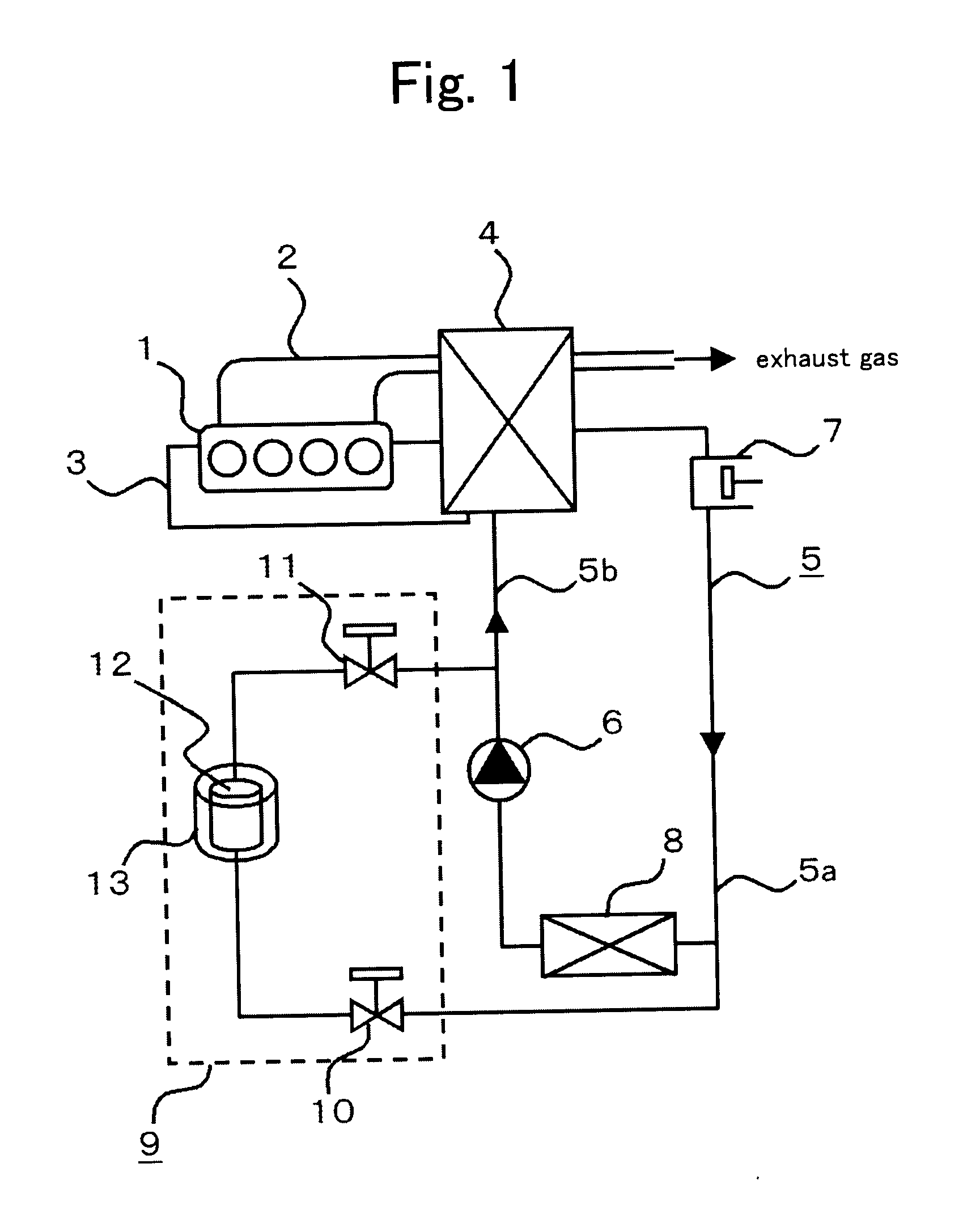

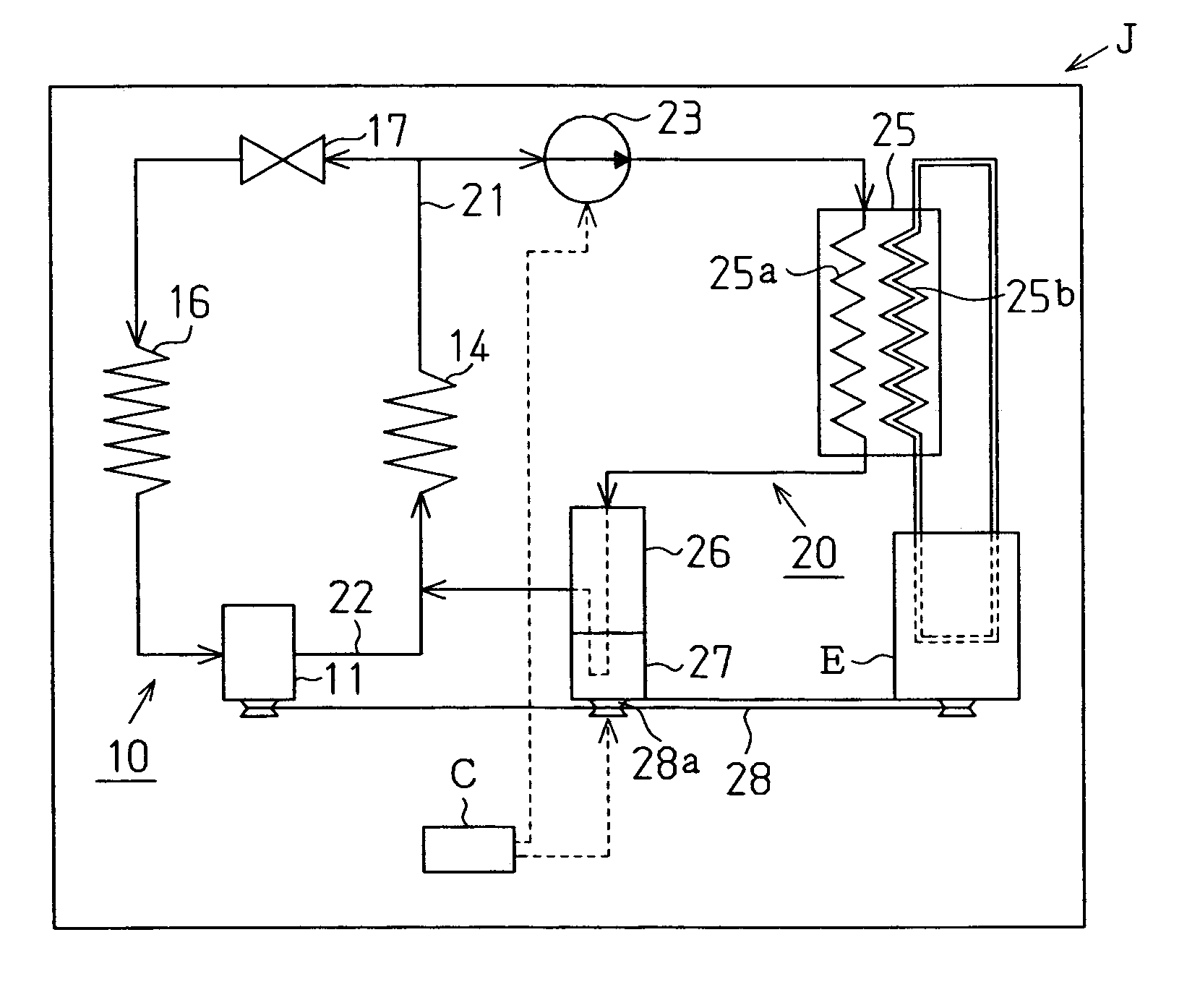

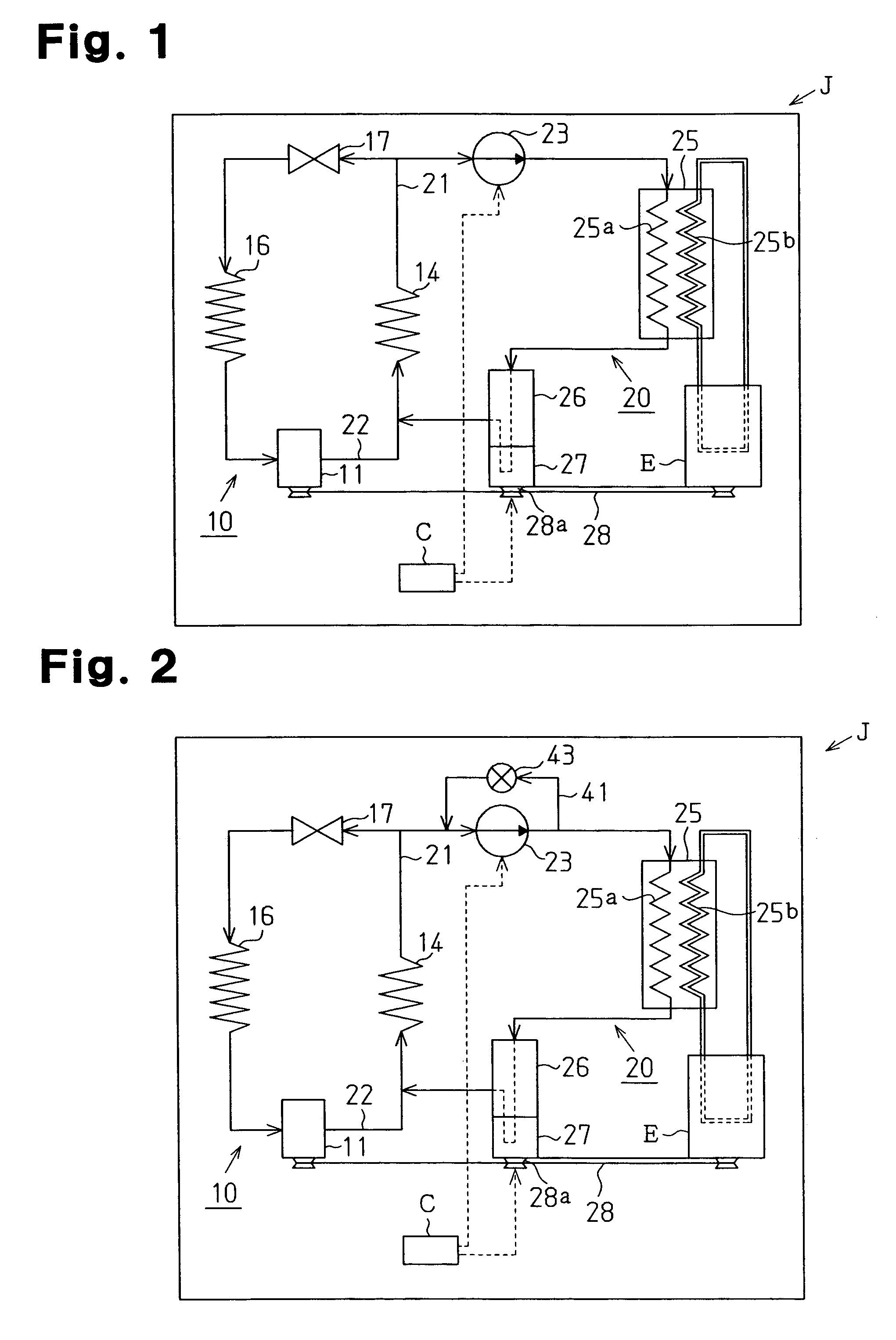

Exhaust heat recovery system

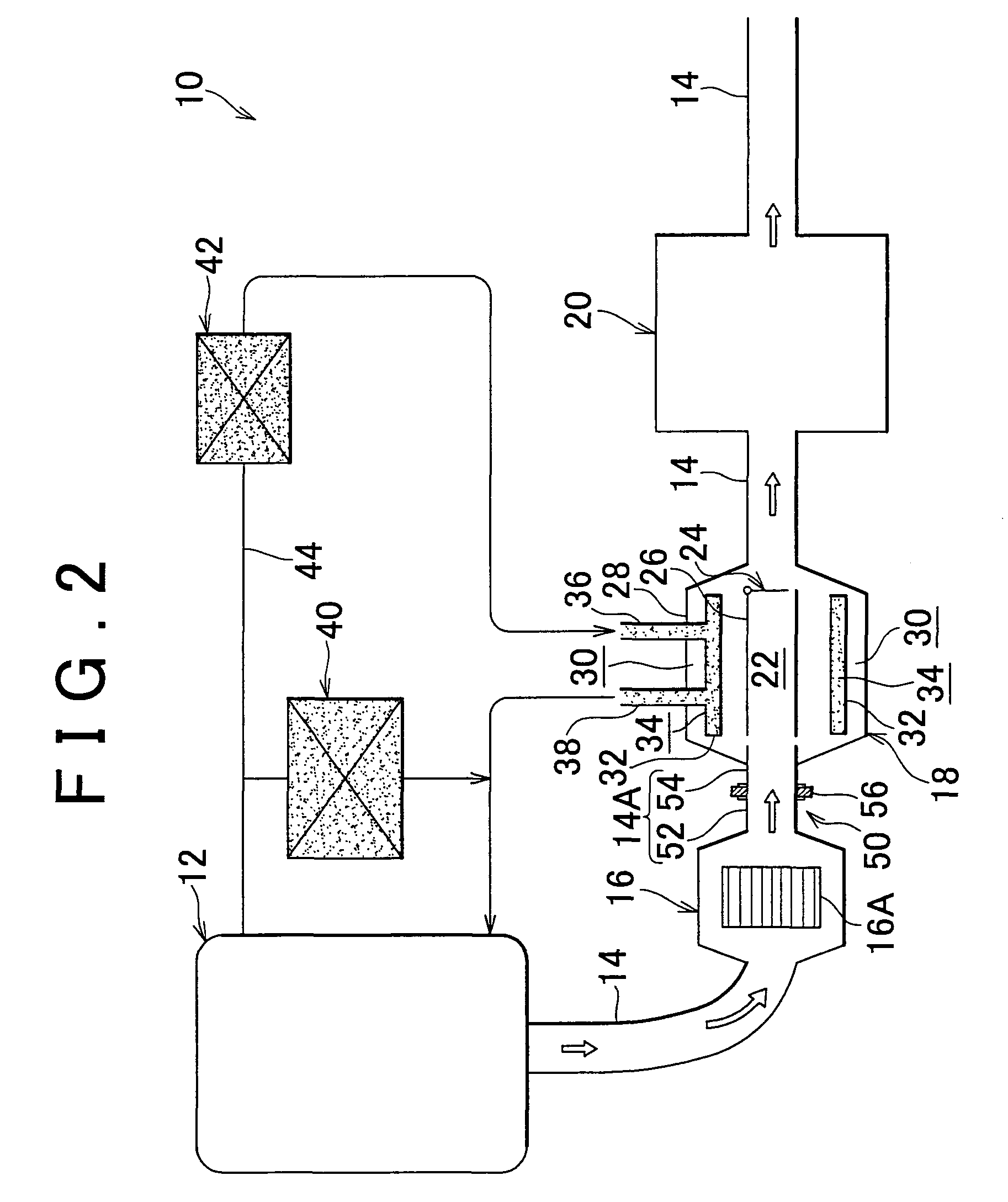

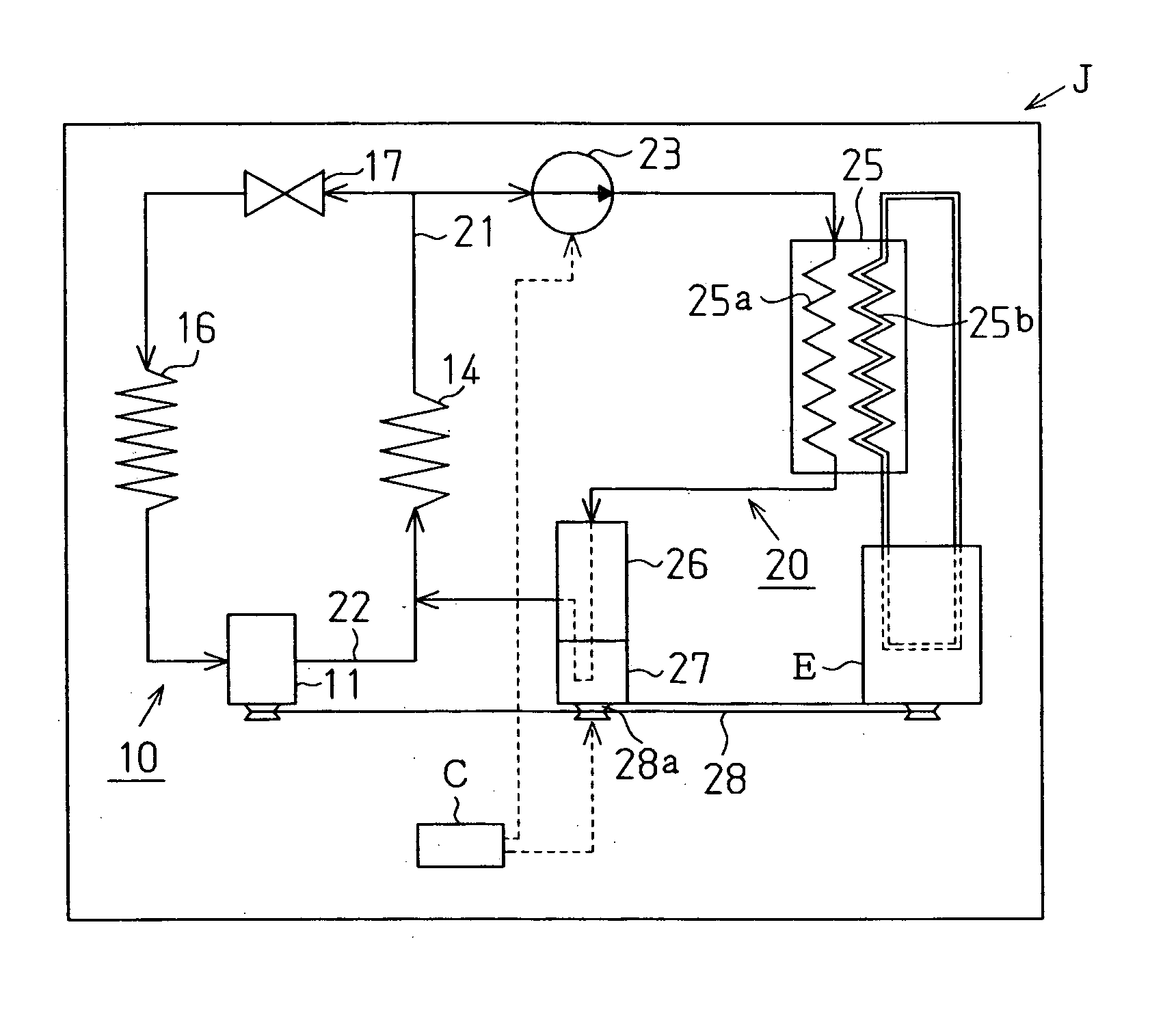

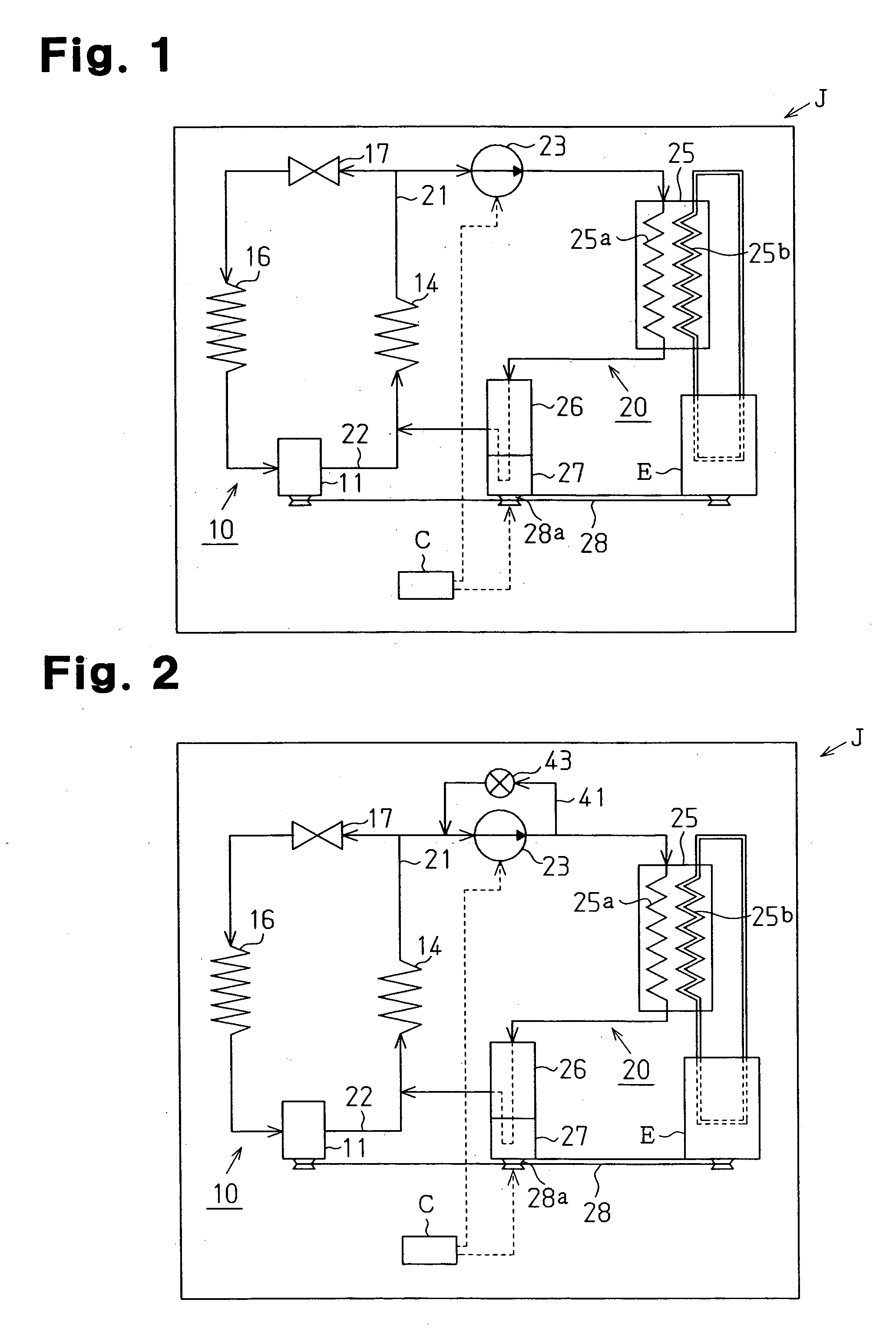

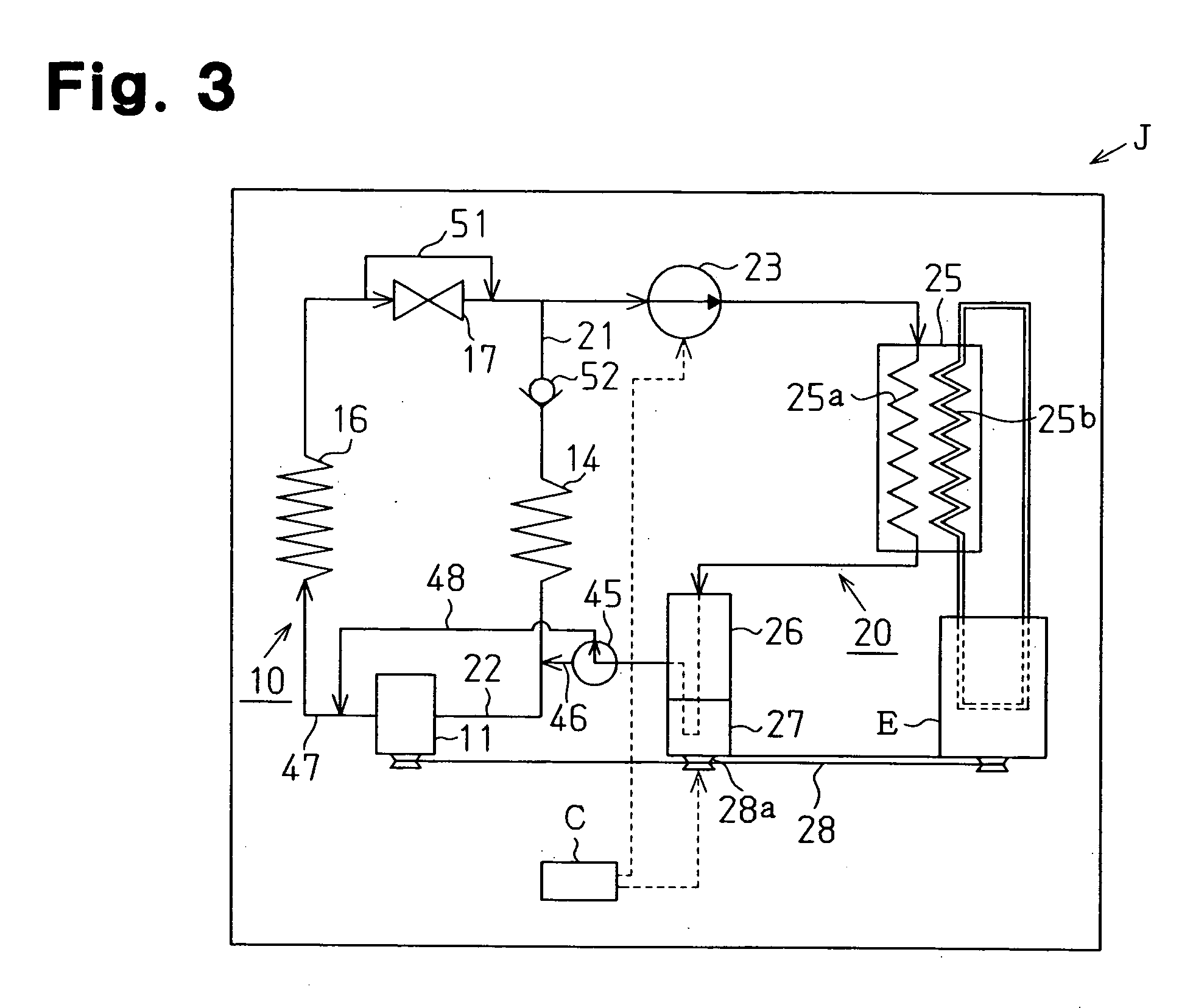

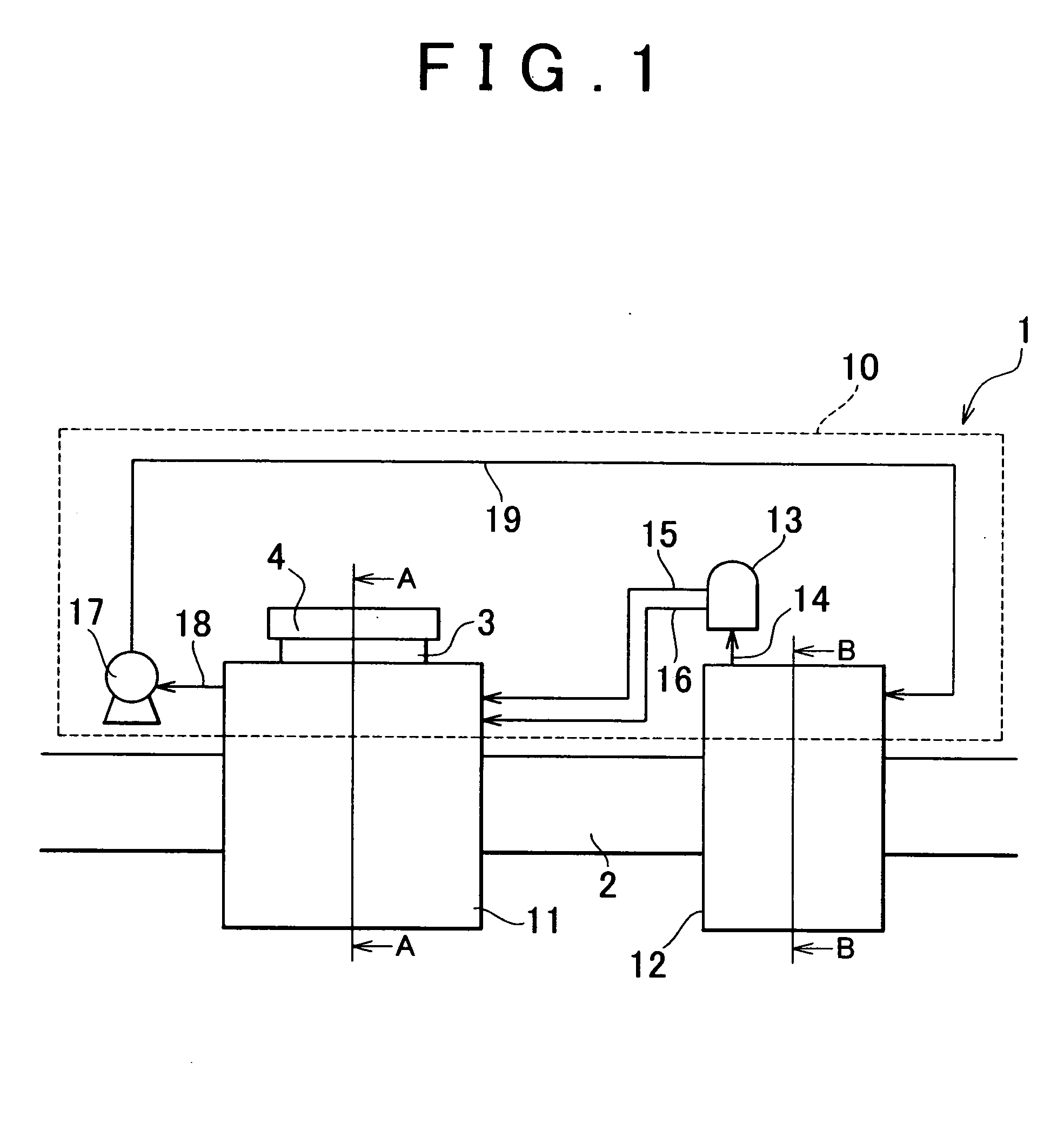

InactiveUS20110167818A1Easy to operateLow efficiencyInternal combustion piston enginesEngine componentsSuper coolingEngineering

In a case of a refrigerant amount being short when a Rankine cycle starts operating, because the pressure difference does not occur across a refrigerant pump, refrigerant cannot be injected from a bypass circuit to the Rankine cycle, and therefore super-cooling degree cannot be controlled. An exhaust heat recovery system is provided that can adjust the super-cooling degree even in the case of the pressure difference not occurring across the refrigerant pump. The system includes a refrigerant tank, for storing refrigerant, which is connected by pipes to the low-pressure circuit side and the high-pressure circuit side of the Rankine cycle through a low-pressure-side valve and a high-pressure-side valve, respectively, and a temperature adjuster for adjusting internal temperature of the refrigerant tank.

Owner:MITSUBISHI ELECTRIC CORP

Exhaust heat recovery system

InactiveUS8327634B2Restrains a coolant from being overheatedCombination devicesInternal combustion piston enginesEngineeringExhaust heat recovery system

An exhaust heat recovery system (10) includes: an exhaust heat exchanger (18) that is communicated with a catalytic converter (16) through an exhaust gas pipe (14A), and that recovers exhaust heat into a coolant; and heat transfer restriction means (50) provided between the catalytic converter (16) and the exhaust heat exchanger (18). The heat transfer restriction means (50) includes a heat insulator (56) disposed between a first exhaust gas pipe (52) and a second exhaust gas pipe (54) that constitute the exhaust gas pipe (14A), and. restrains a released heat from the catalytic converter (16) from reaching the exhaust heat exchanger (18).

Owner:TOYOTA JIDOSHA KK

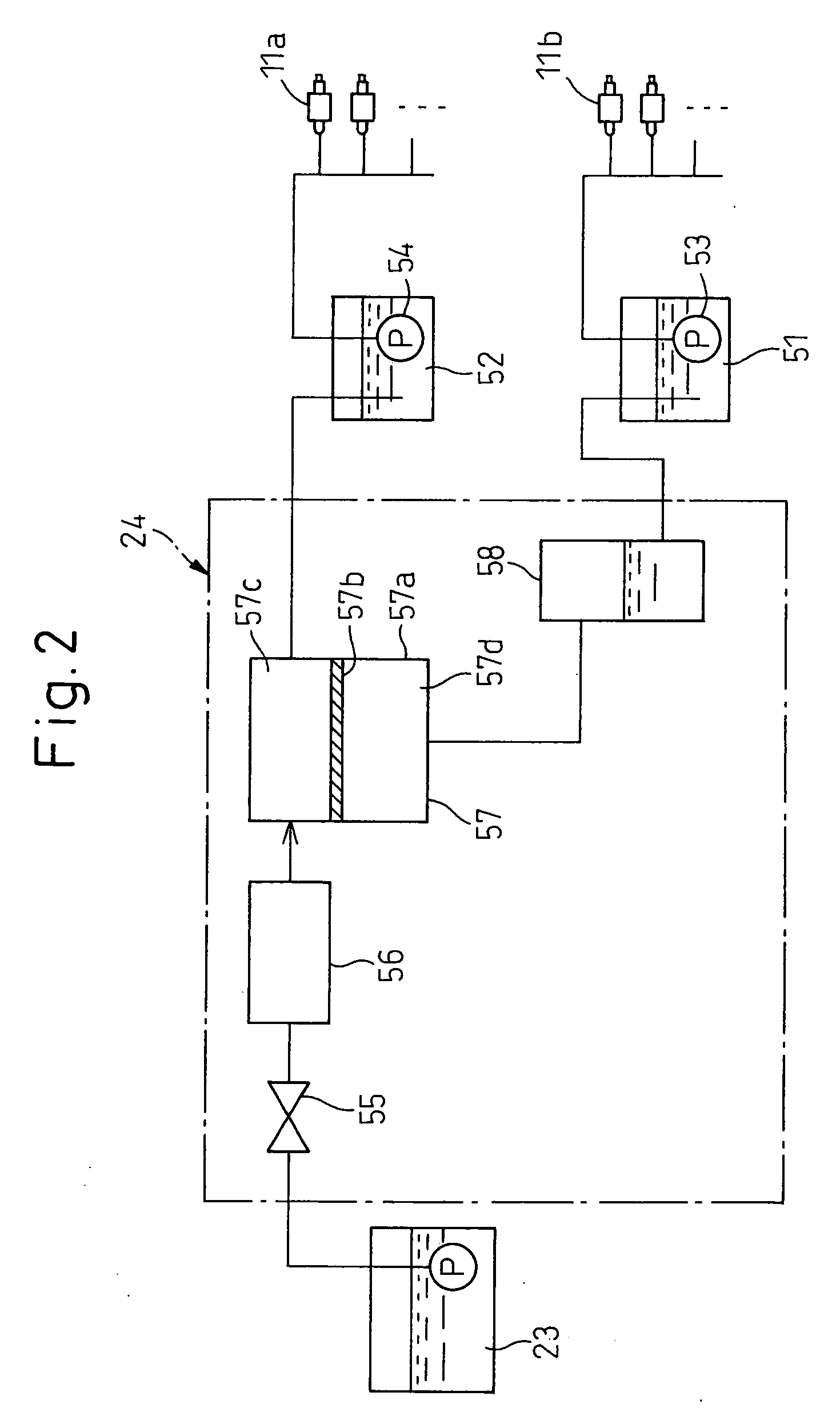

Vehicle exhaust heat recovery system

InactiveUS20050188711A1Small sizeImprove energy conversion efficiencyLiquid coolingAir-treating devicesEngineeringRefrigeration

A vehicle exhaust heat recovery system includes a vapor compression type refrigeration circuit, a boiler to which the refrigerant is introduced from the refrigeration circuit and heated, and an expander for generating motive power by expanding the heated refrigerant. The refrigerant circulates in the refrigeration circuit. The boiler heats the refrigerant introduced therein using exhaust heat generated by the vehicle. The refrigerant that has been subjected to expansion is recycled to the refrigeration circuit.

Owner:TOYOTA IND CORP

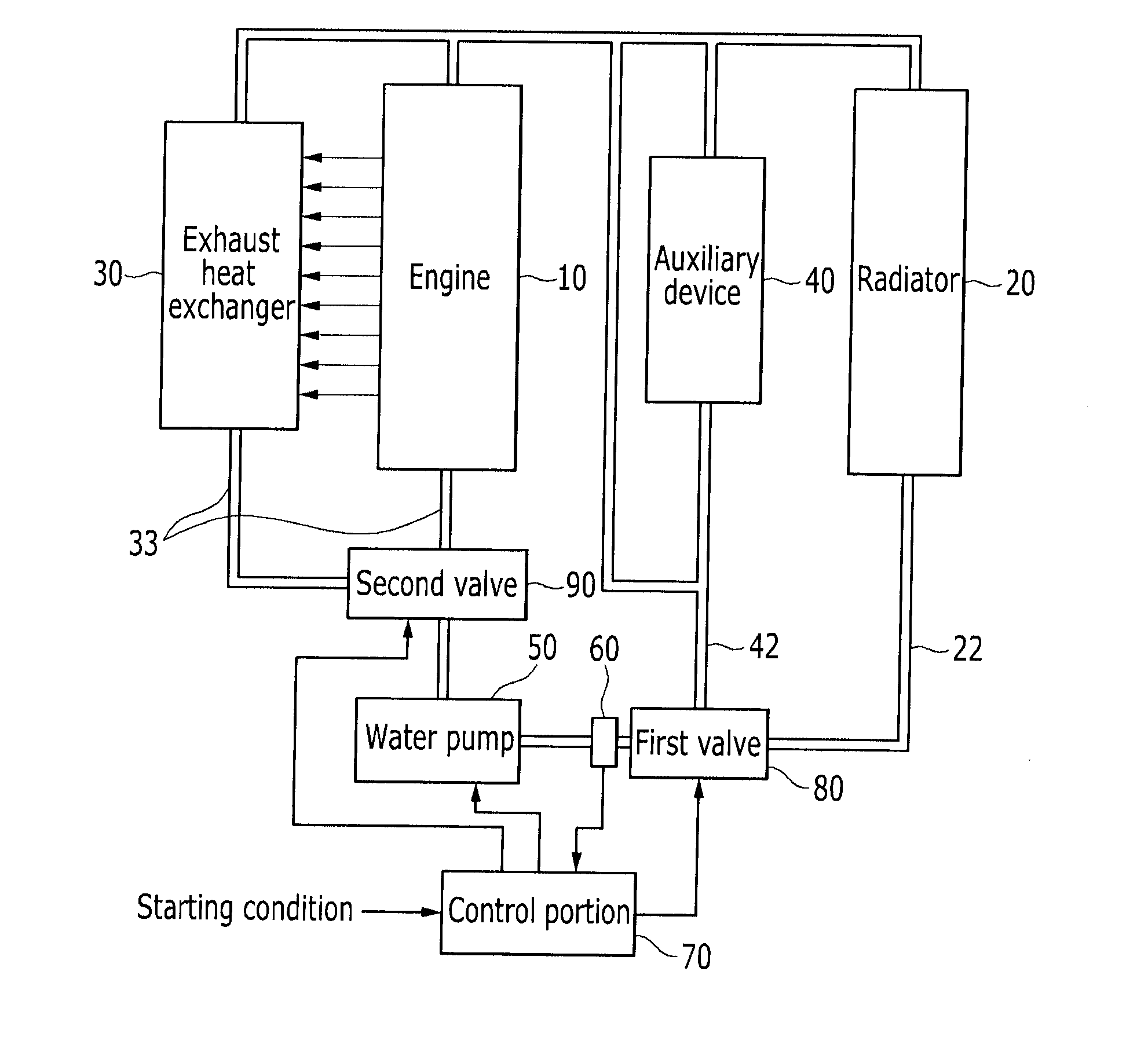

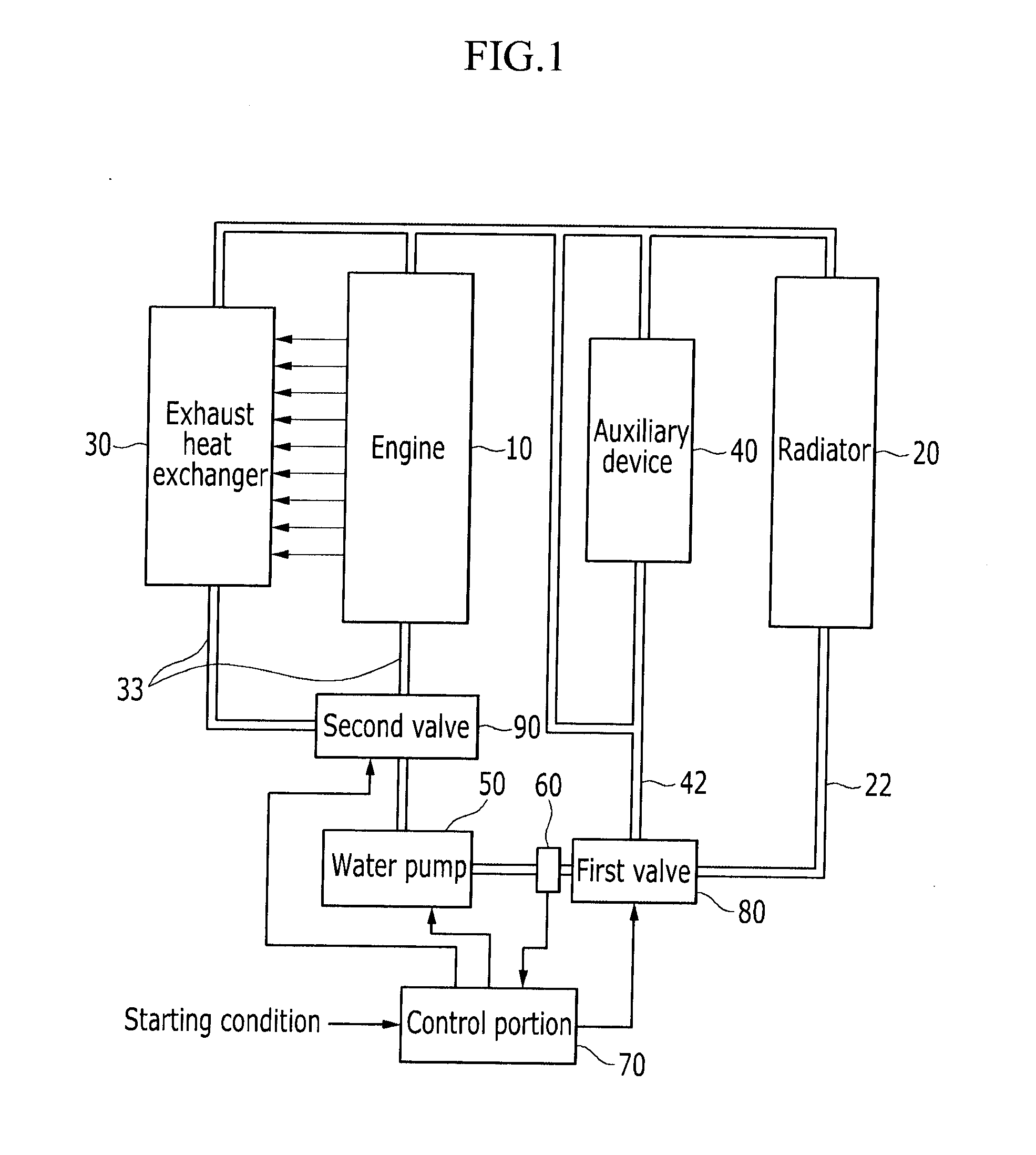

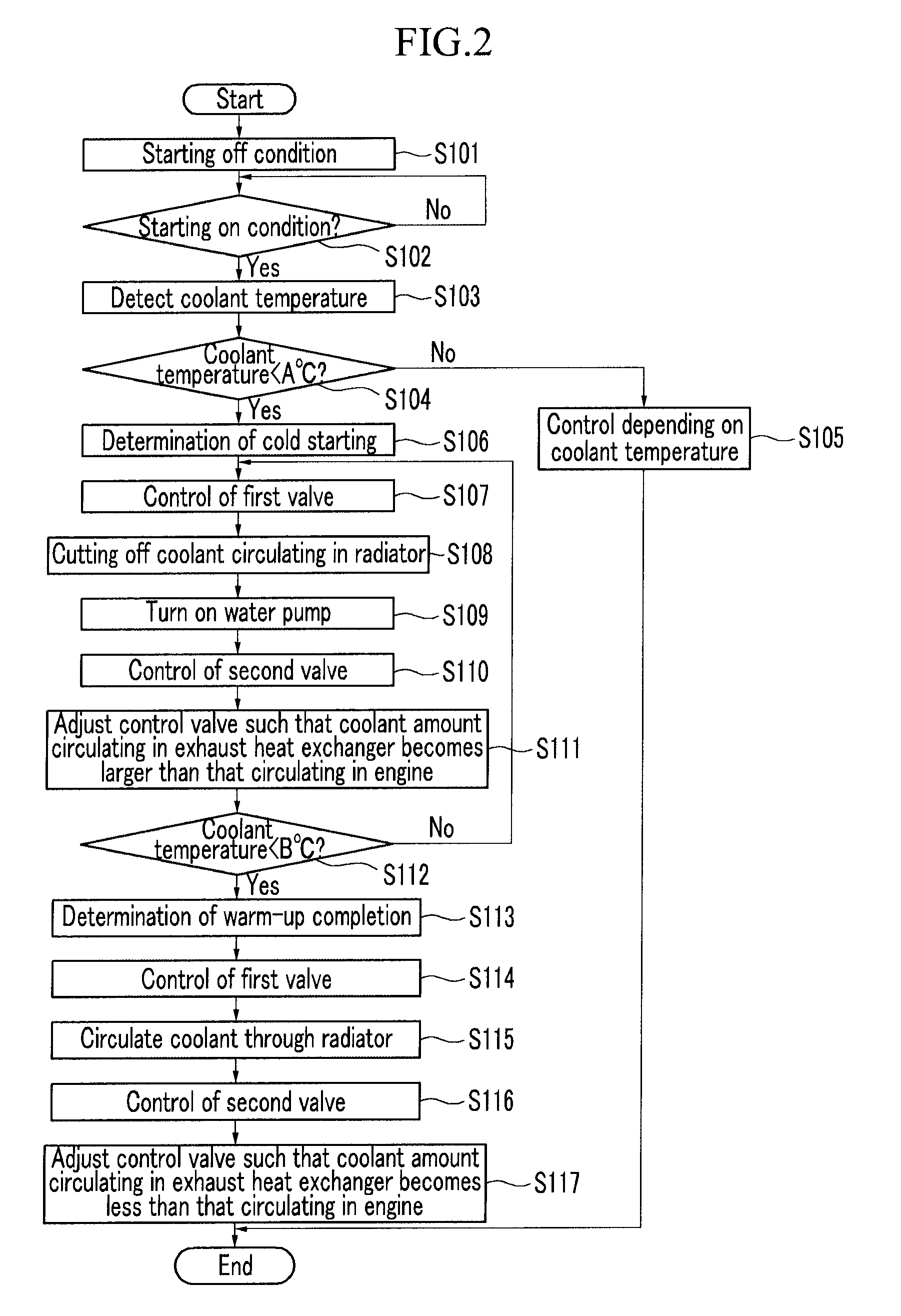

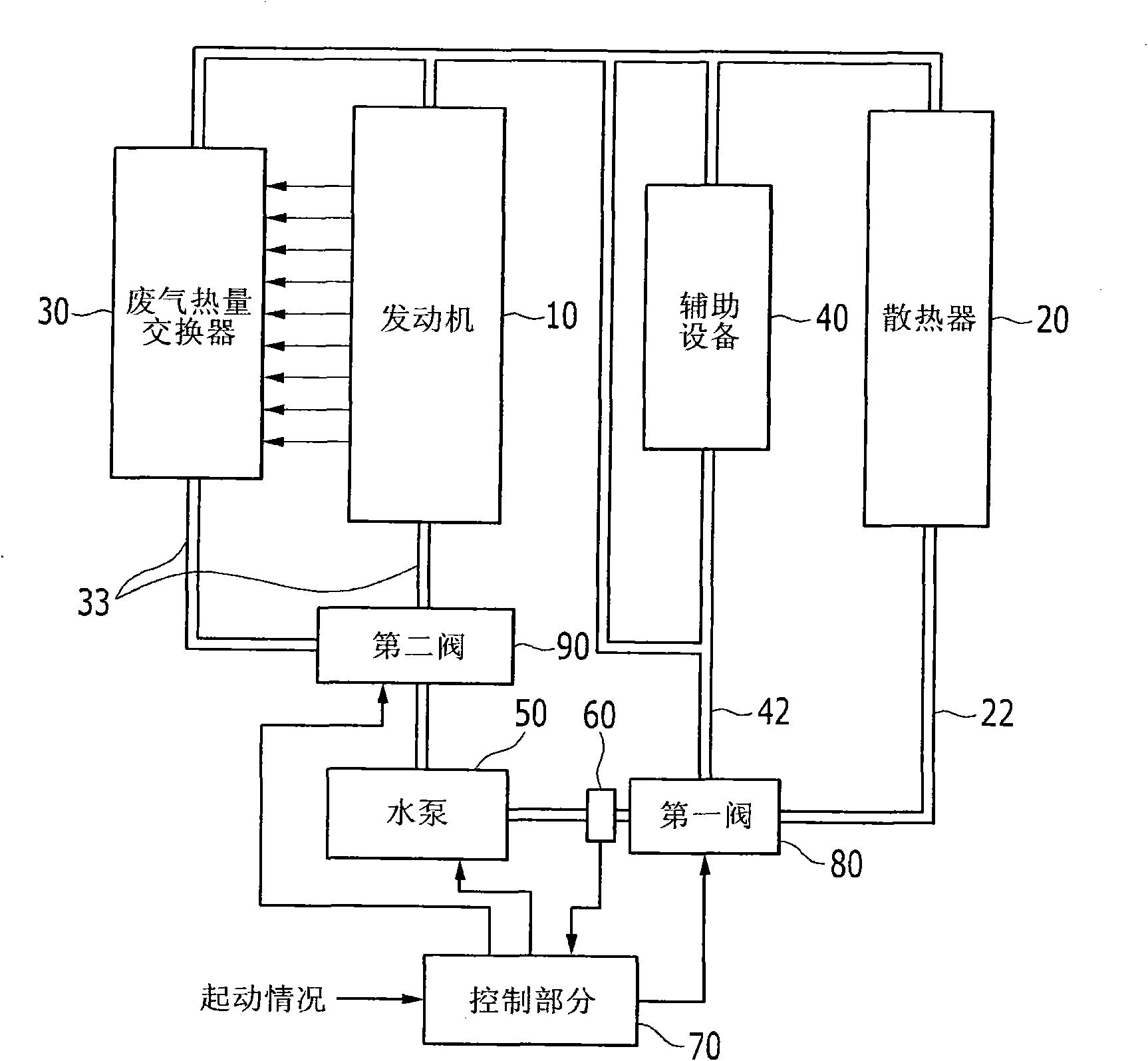

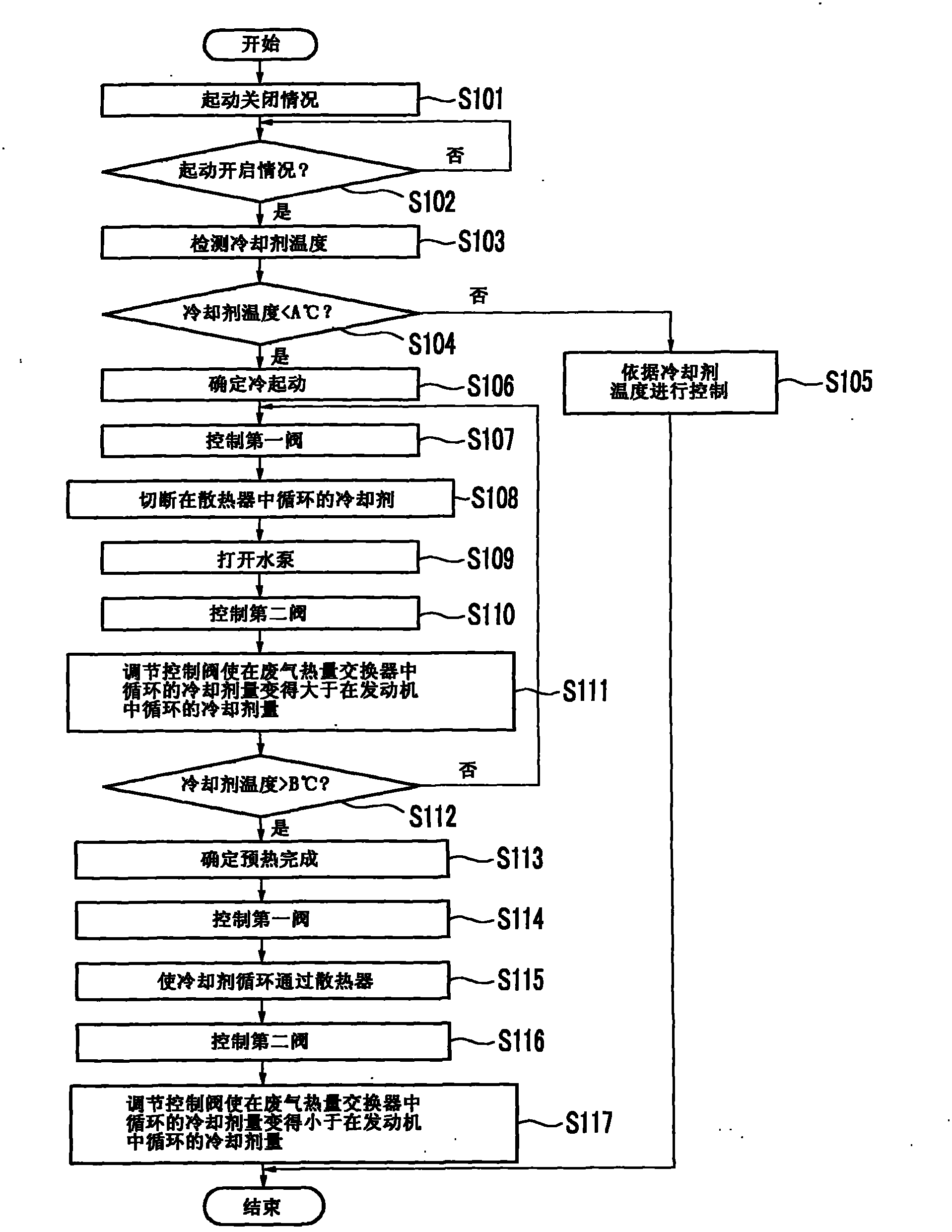

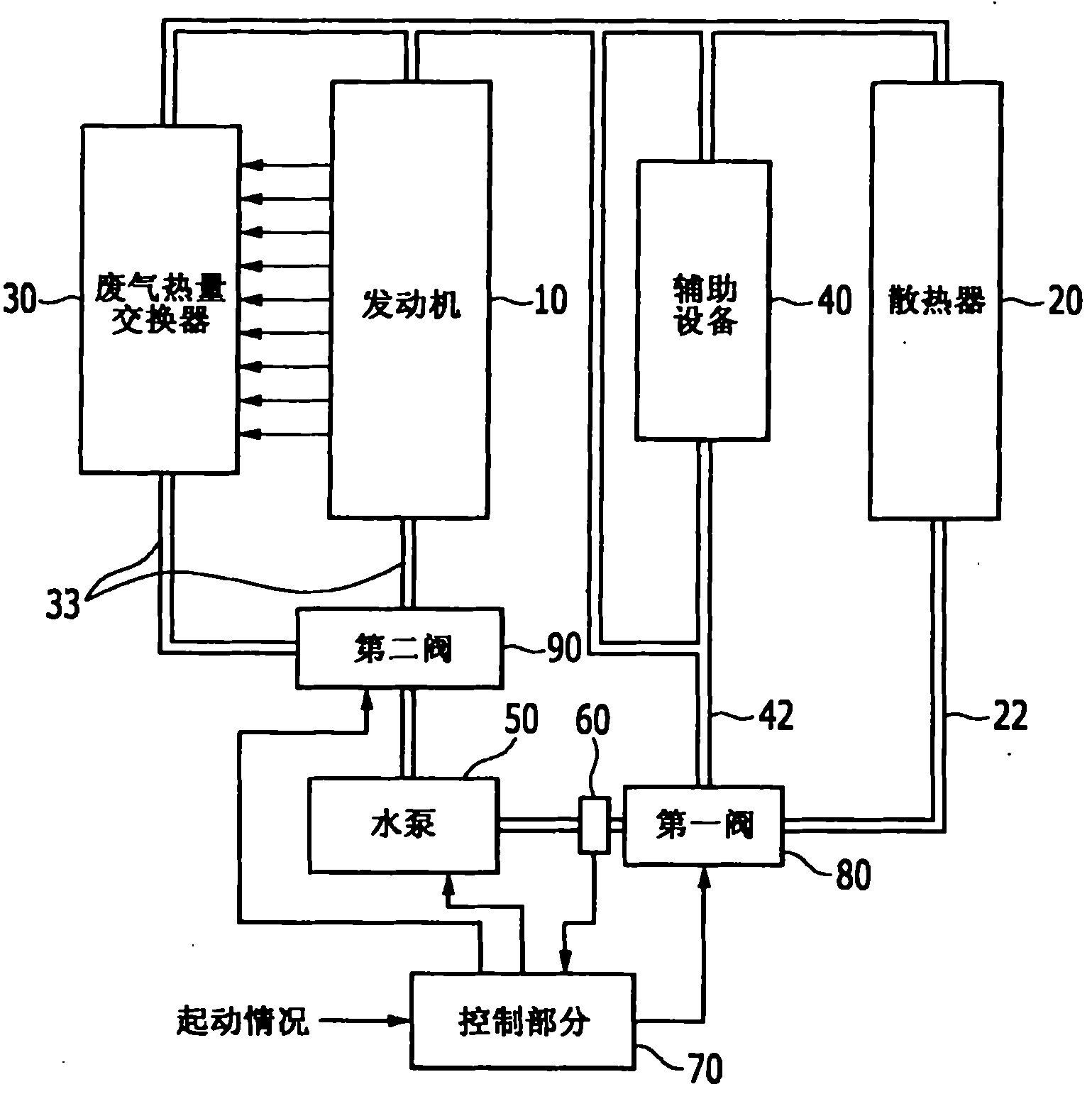

Exhaust Heat Recovery System of Vehicle and Method Thereof

InactiveUS20110126783A1Shorten warm-up timeReduce fuel consumptionCoolant flow controlInternal combustion piston enginesEngineeringCoolant temperature

An exhaust heat recovery device may include a radiator disposed at a main line and through which hot coolant circulates, an exhaust heat exchanger transferring exhaust heat of an engine to coolant, a first valve selectively circulating the coolant to the main line or a bypass line, a water pump connected to the first valve and circulating the coolant, a coolant temperature sensor detecting temperature of the coolant, a second valve connected to the water pump and disposed at a distributing line to distribute the coolant supplied by the water pump to the engine and the exhaust heat exchanger, and a control portion that controls the first and second valves depending on the temperature of the coolant so as to adjust coolant amount circulating in the engine and the exhaust heat exchanger and coolant amount circulating in the radiator and the bypass line.

Owner:HYUNDAI MOTOR CO LTD +1

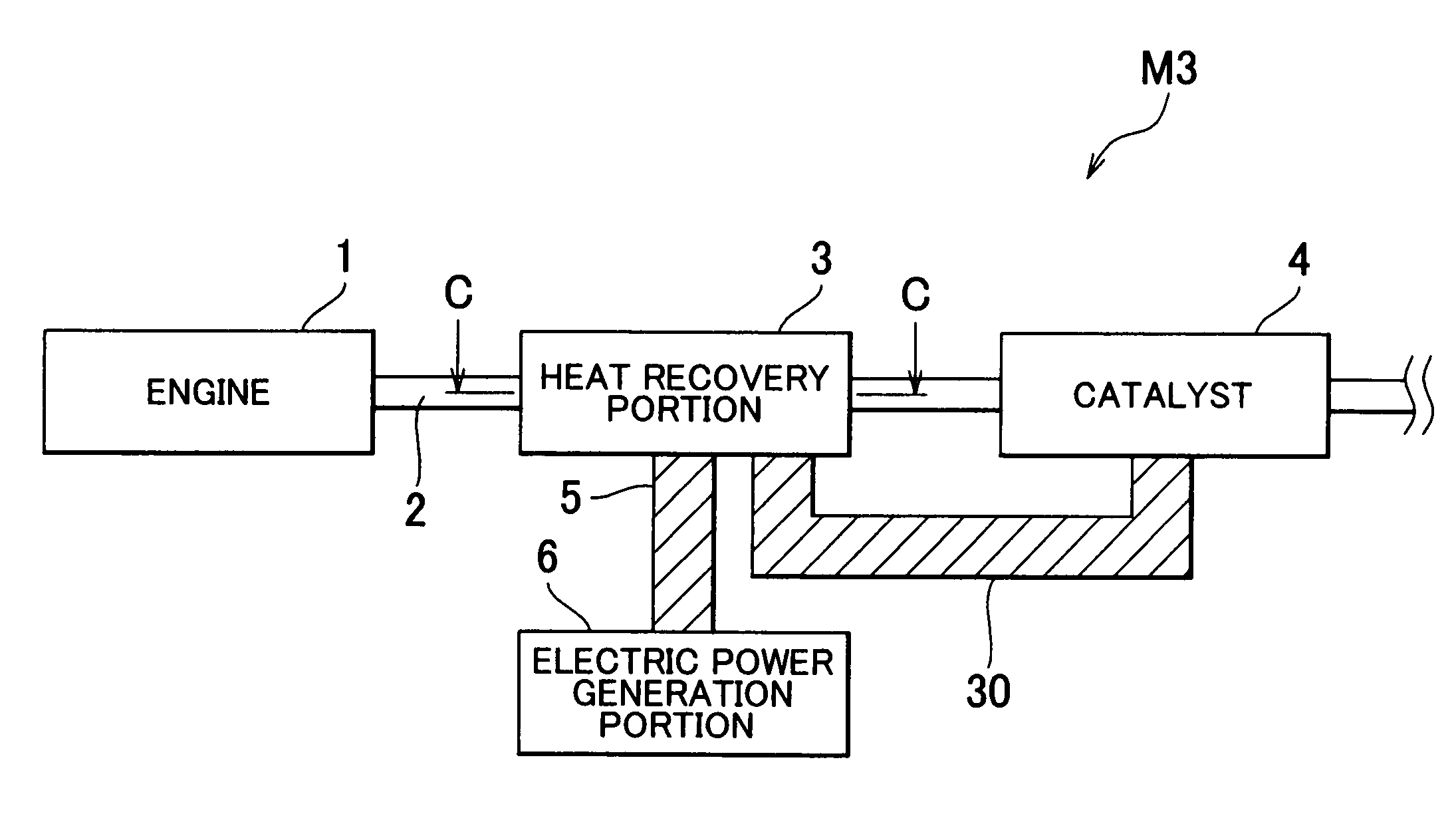

Exhaust heat recovery system

InactiveUS7178332B2Simple configurationImprove power generation efficiencyInternal combustion piston enginesThermoelectric device with peltier/seeback effectExhaust fumesEngineering

Owner:TOYOTA JIDOSHA KK

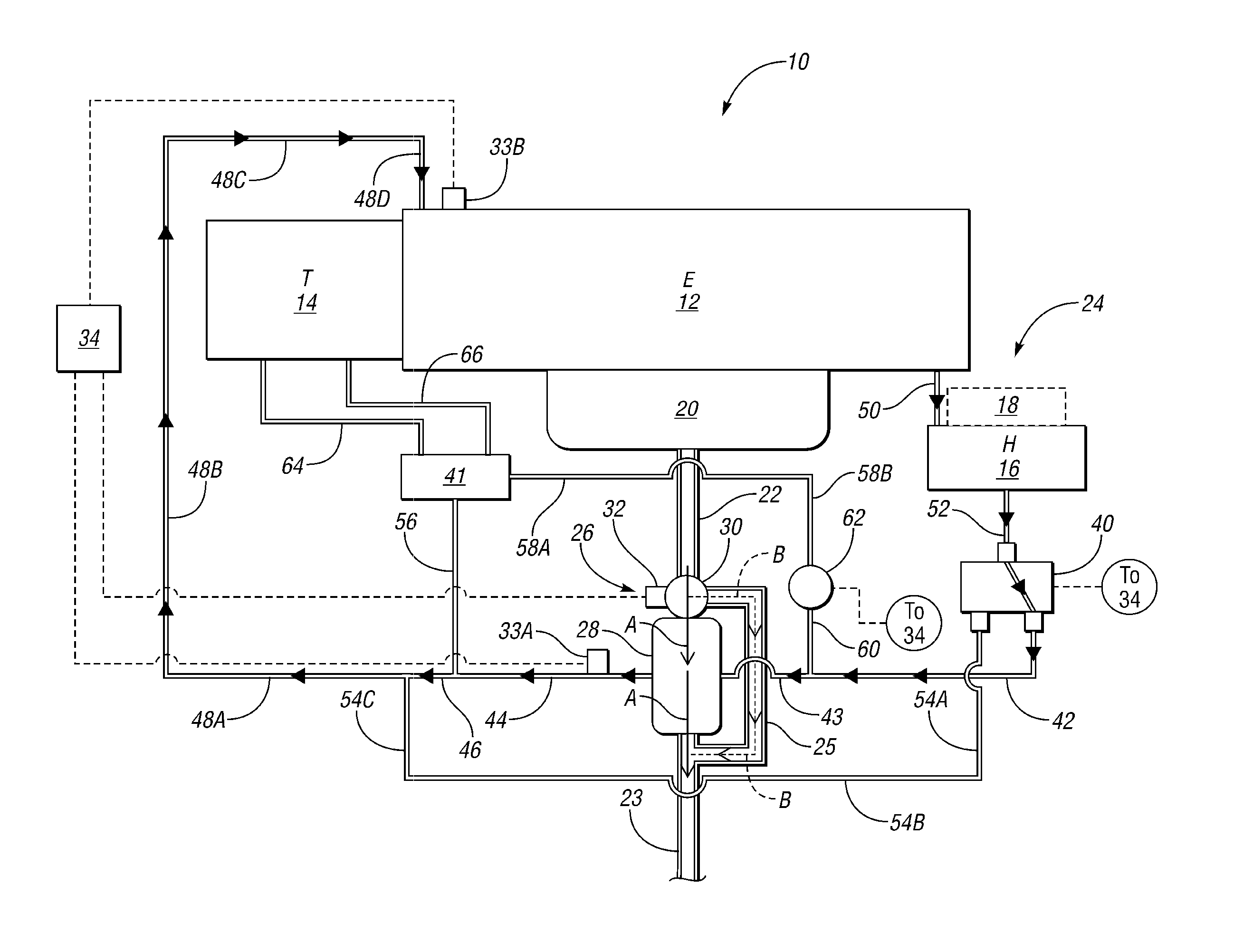

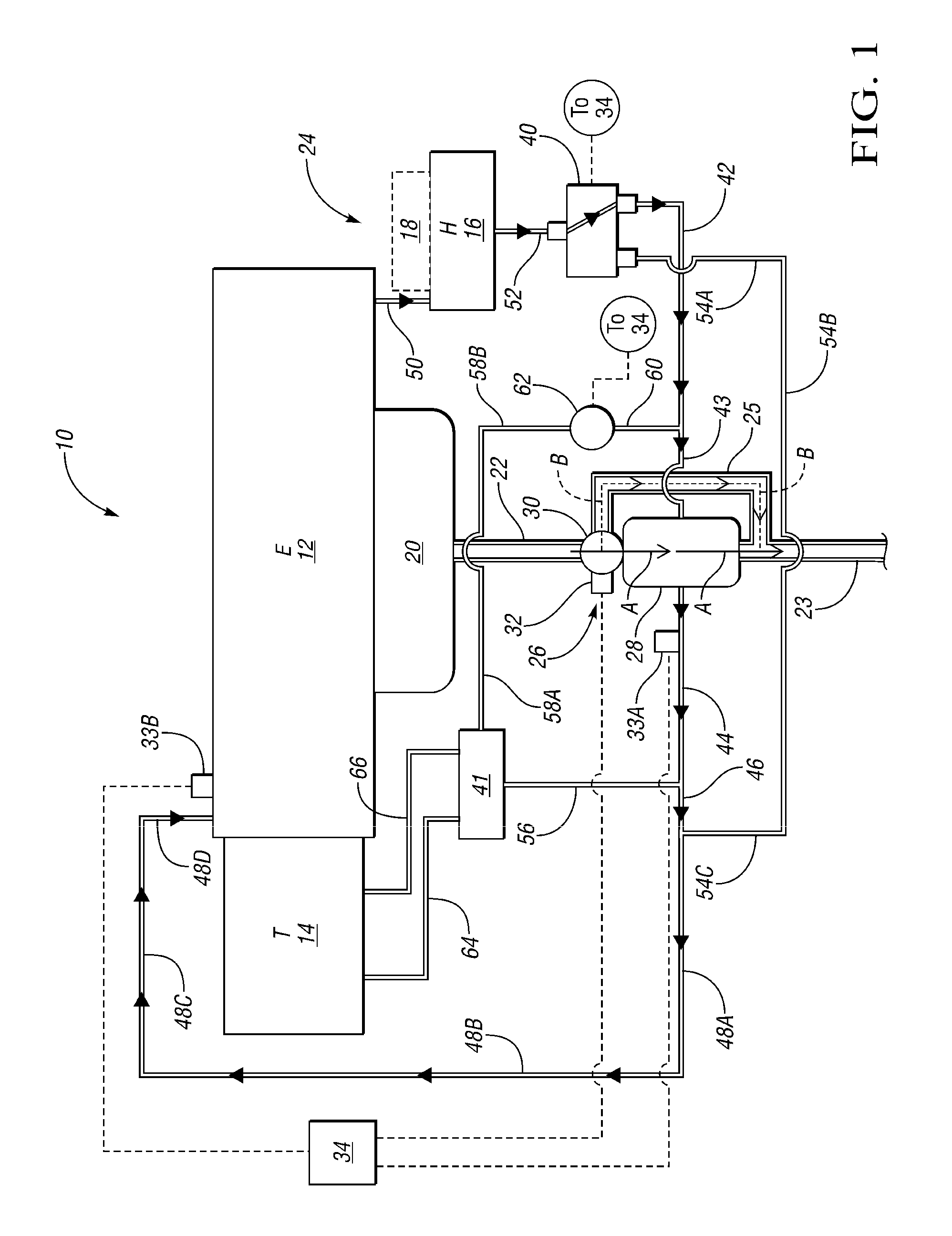

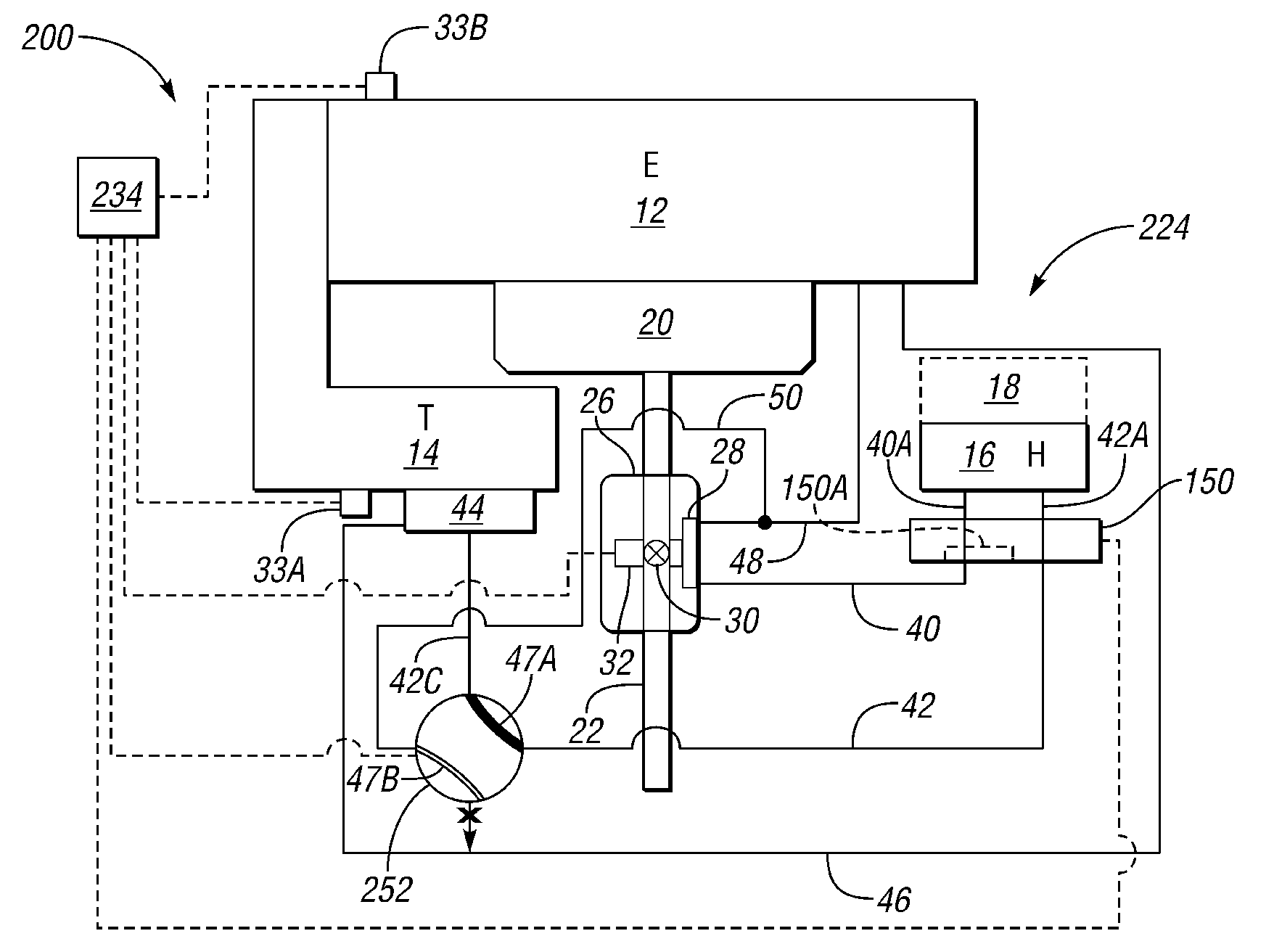

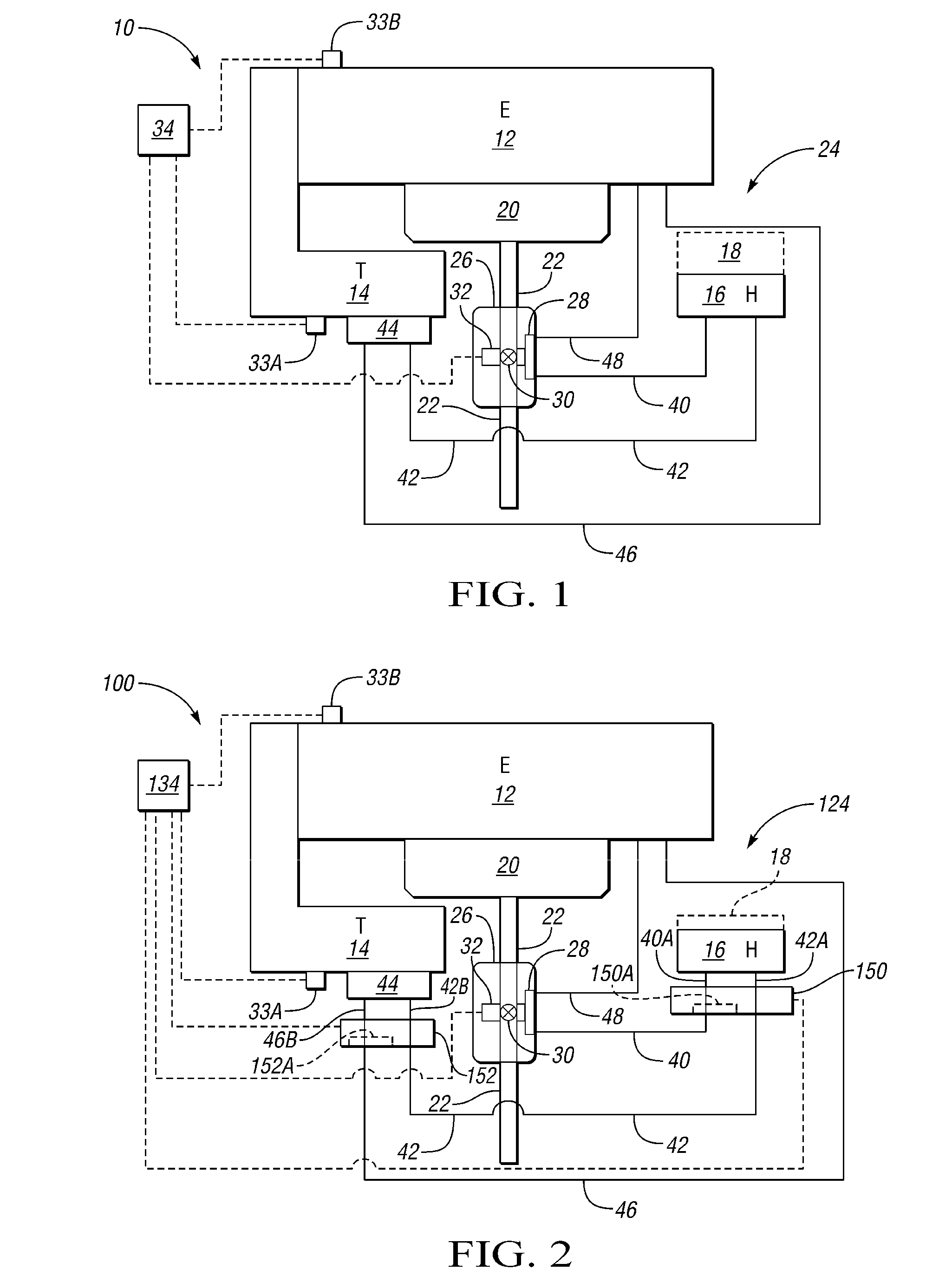

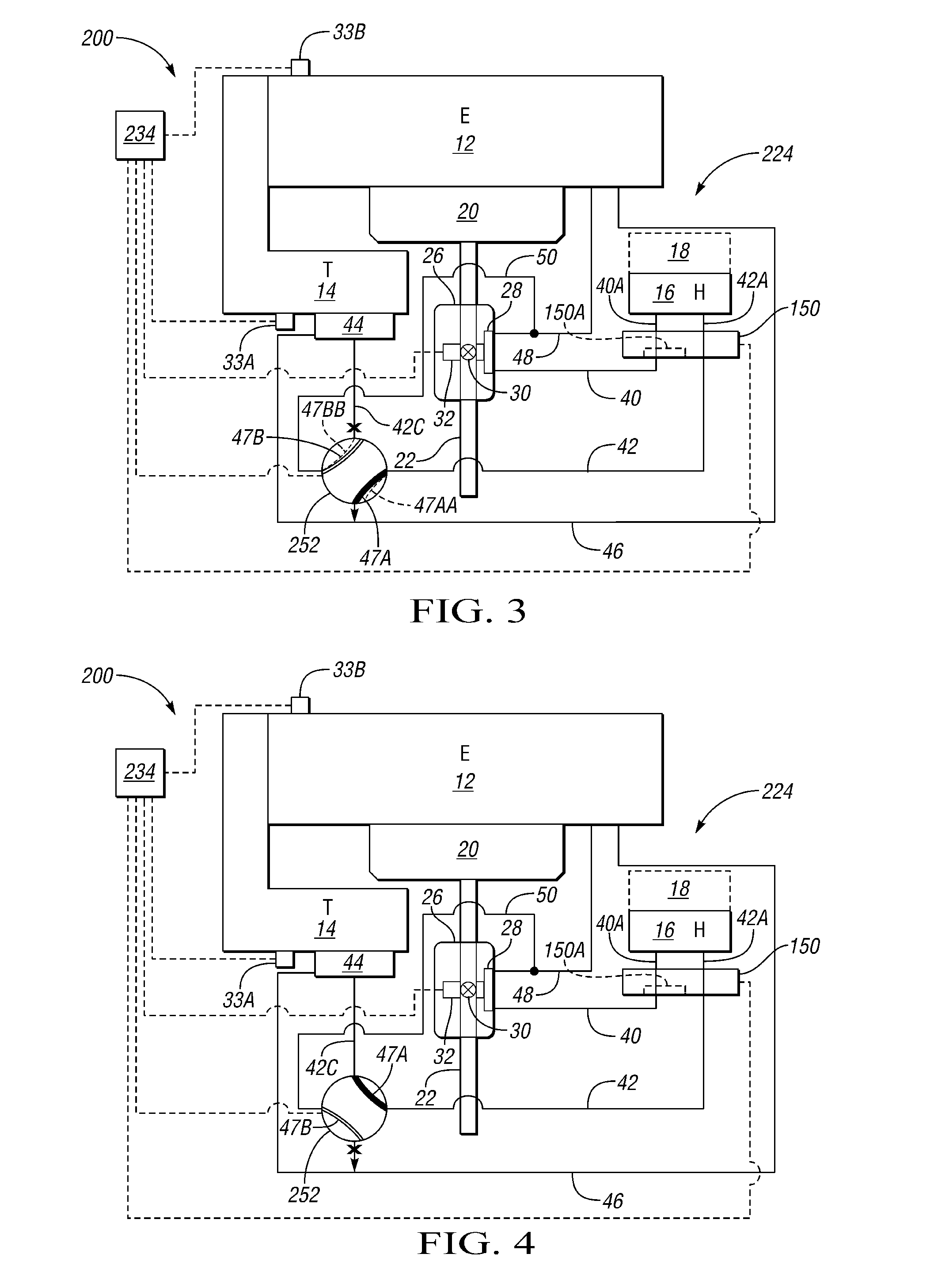

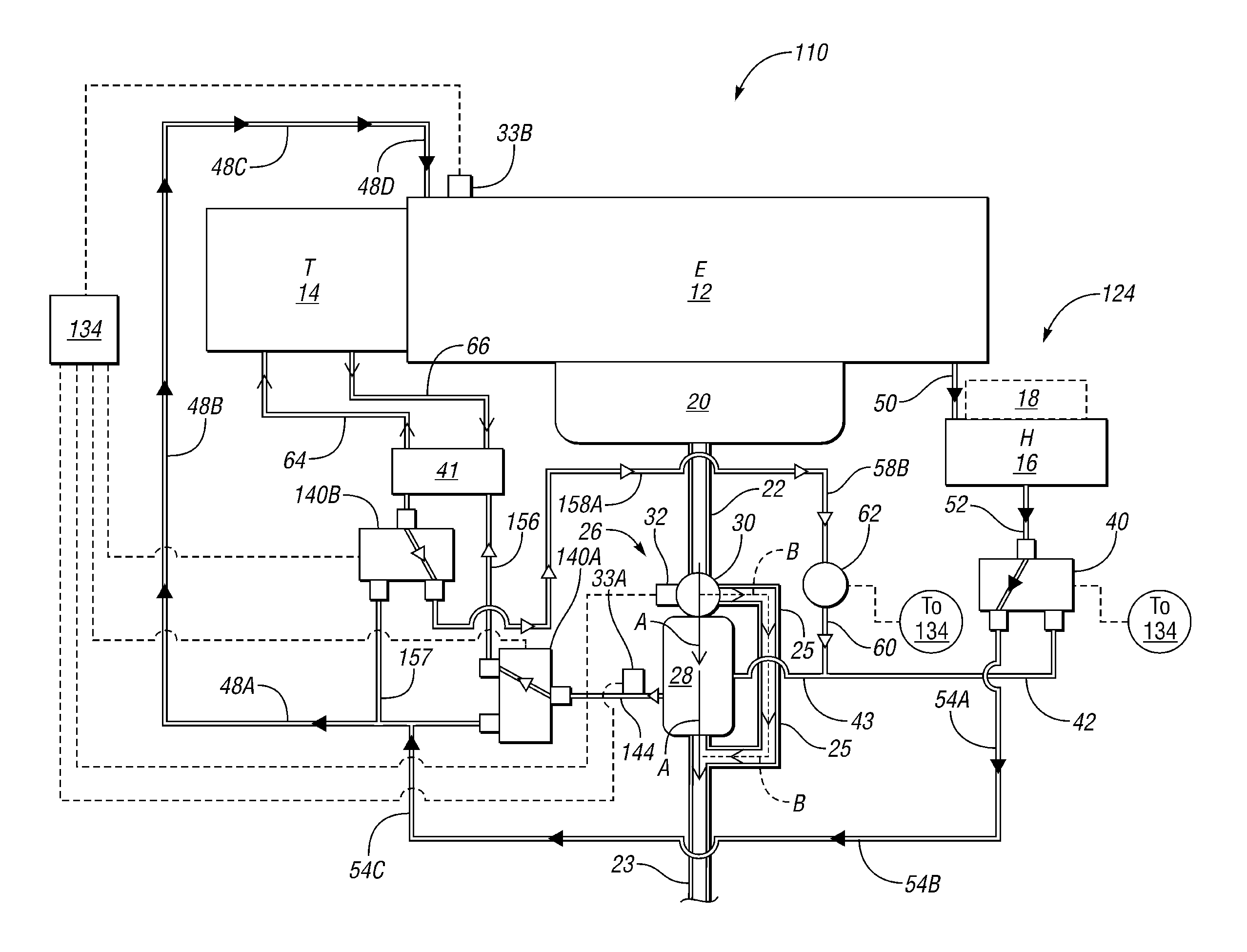

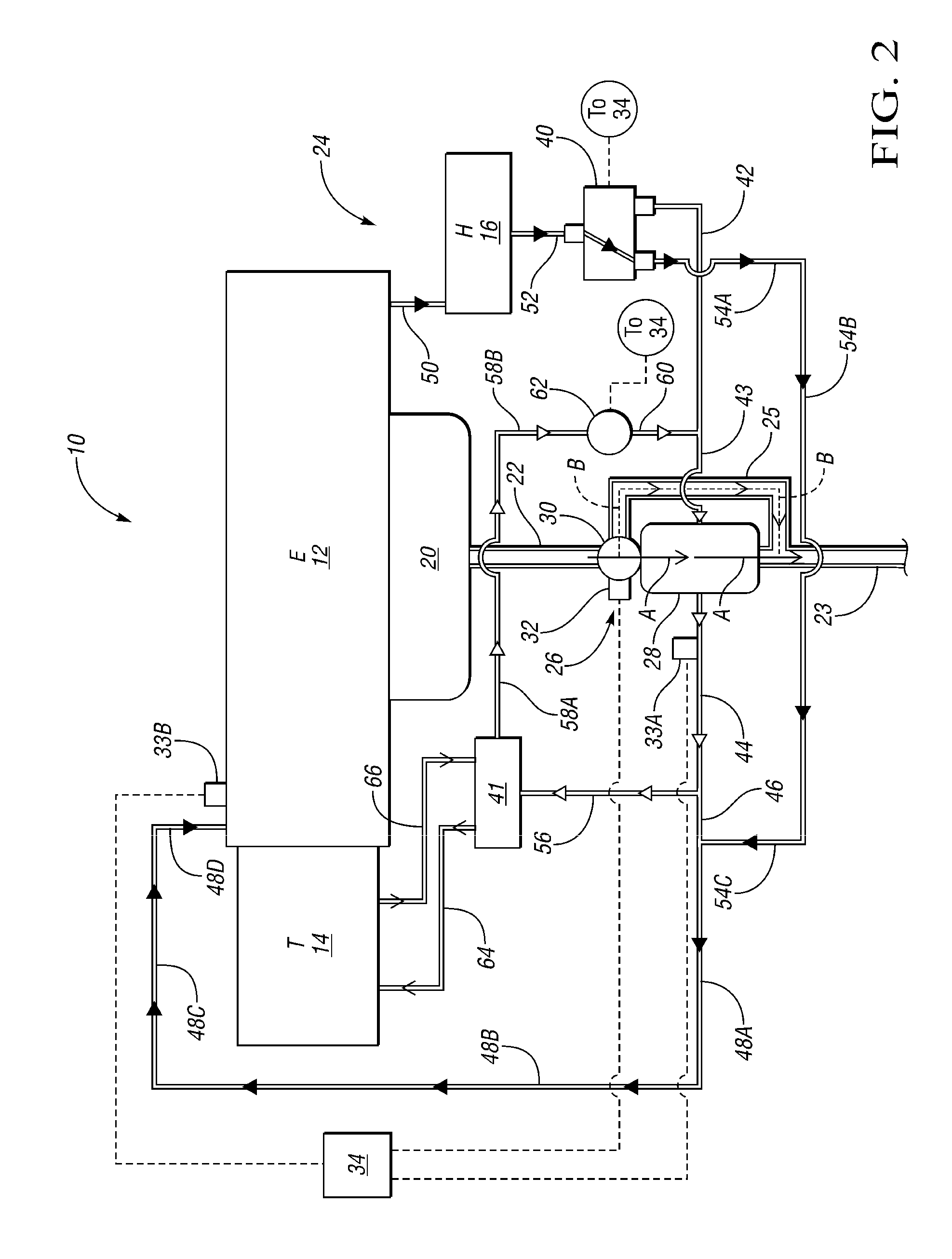

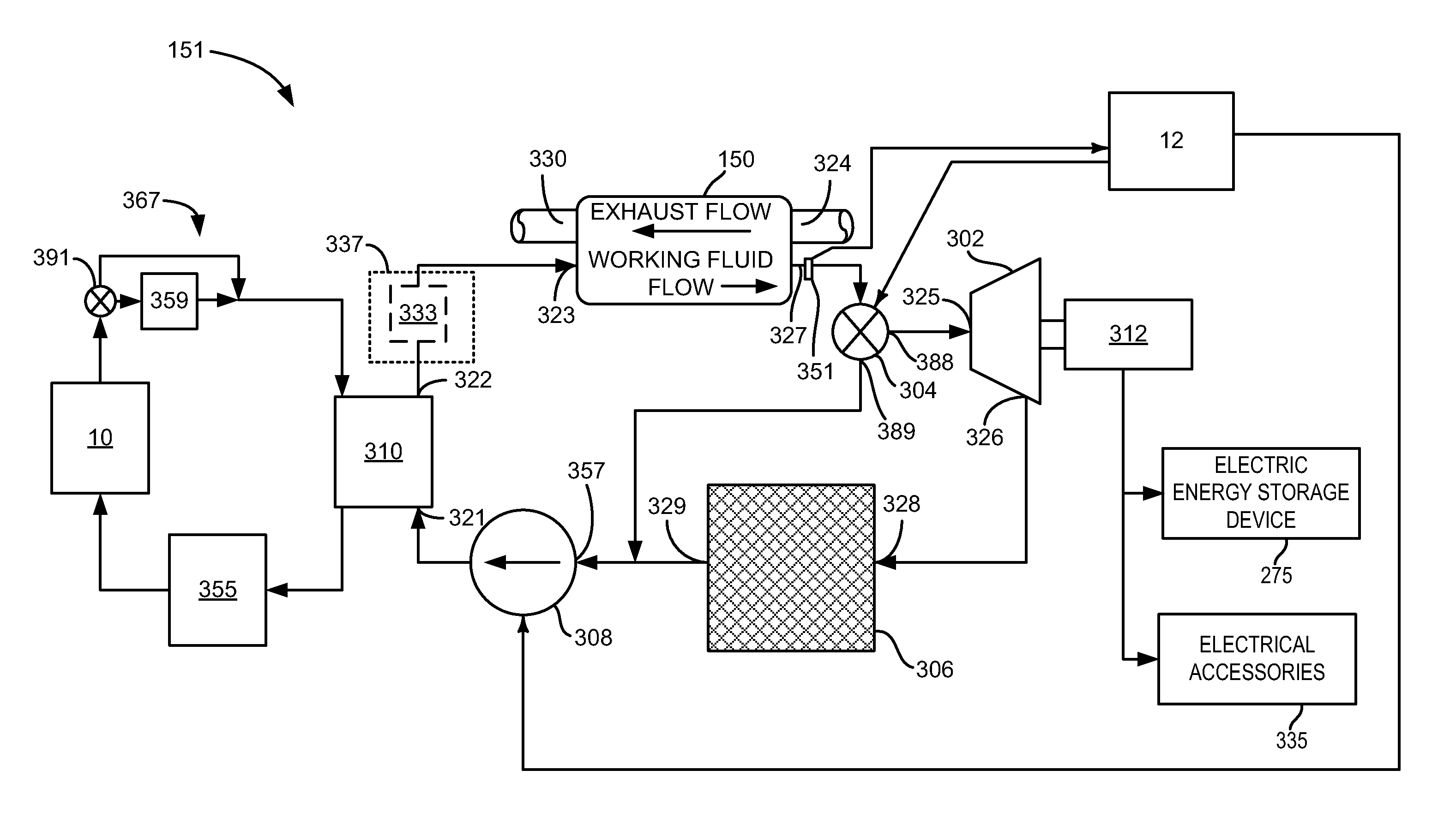

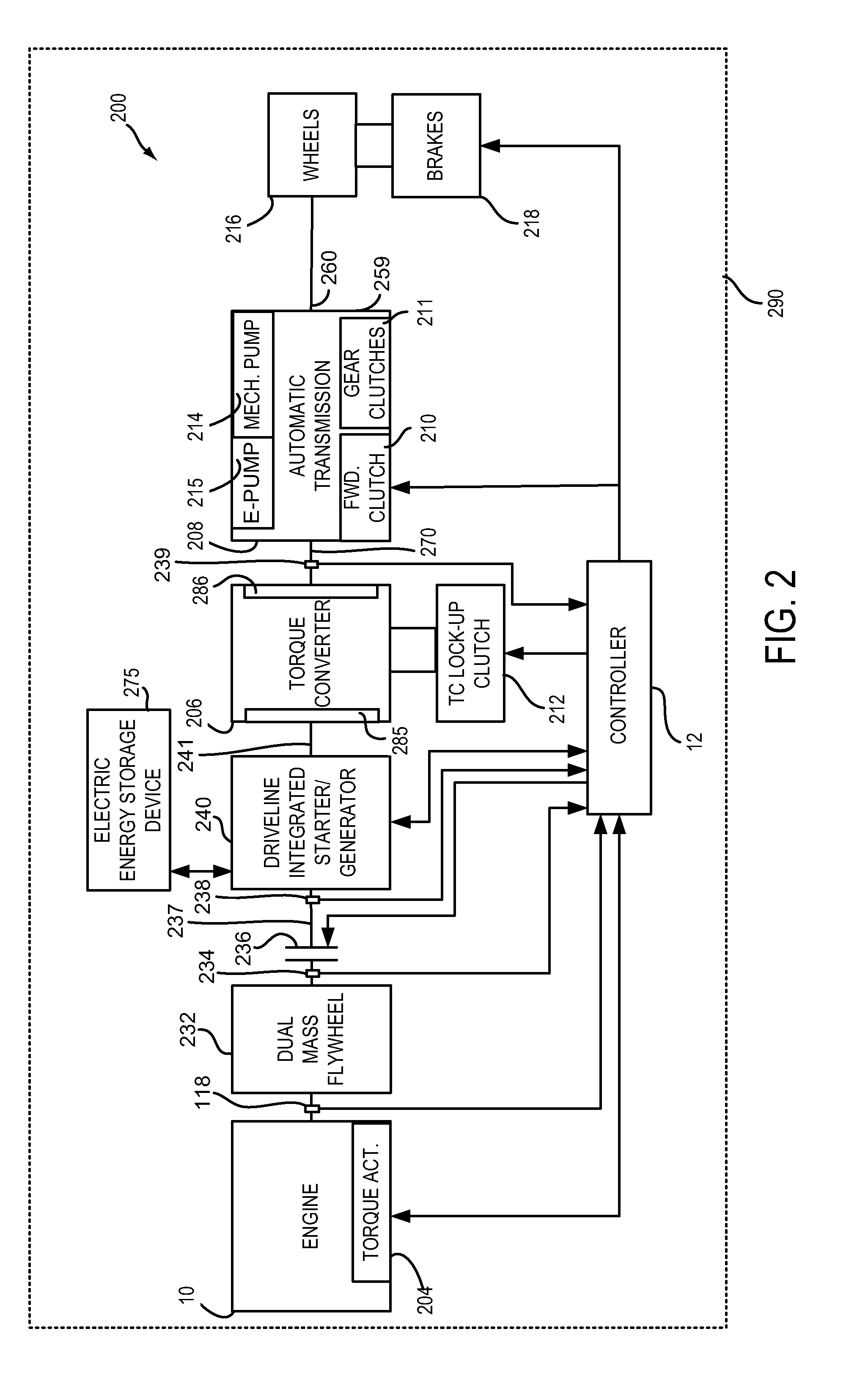

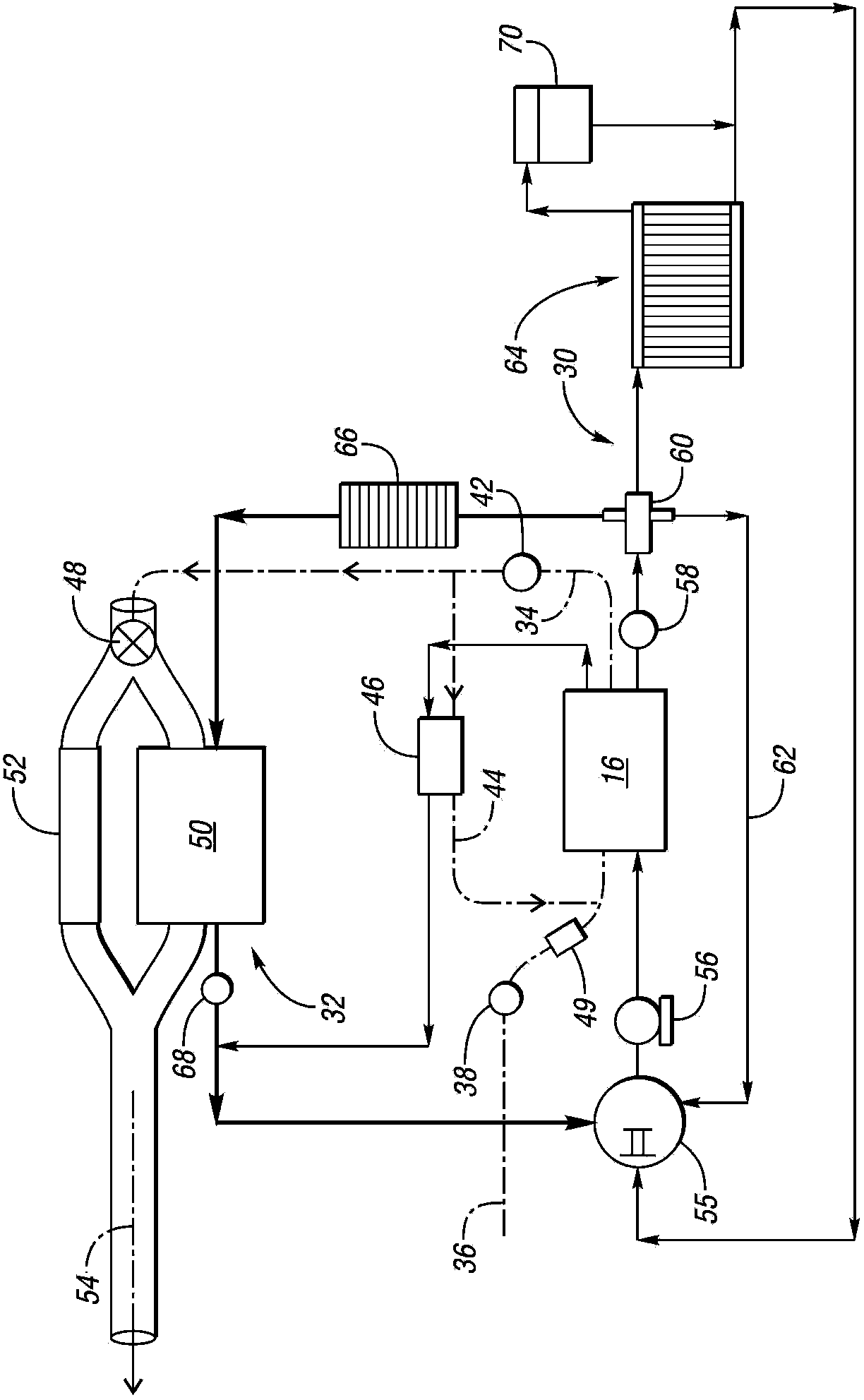

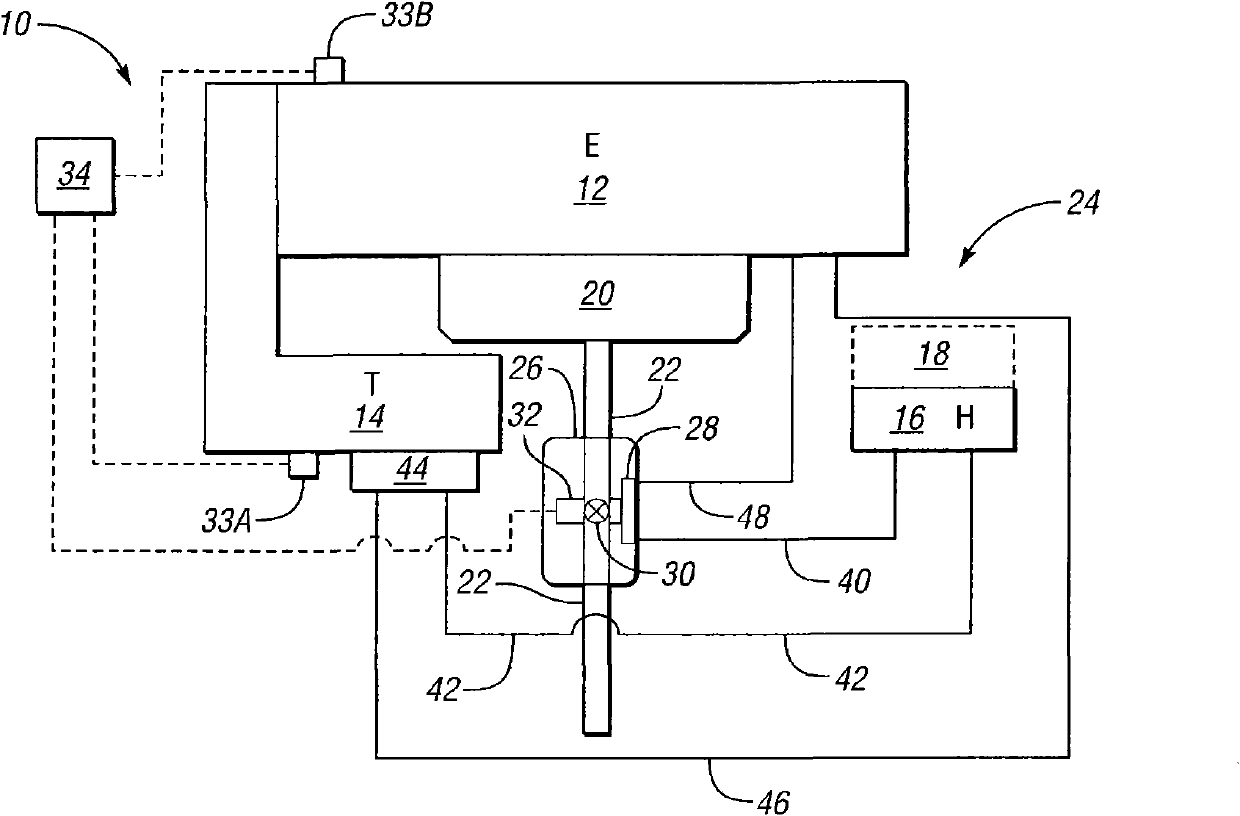

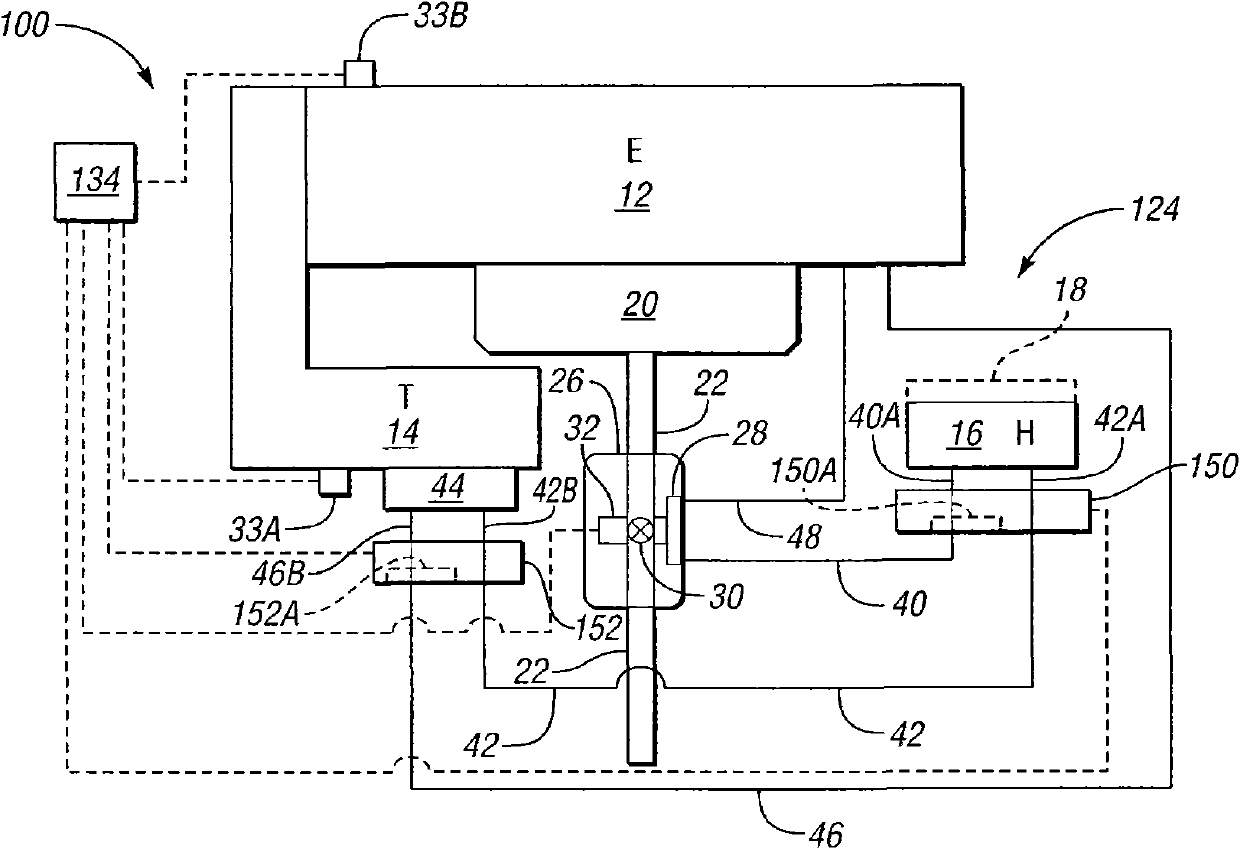

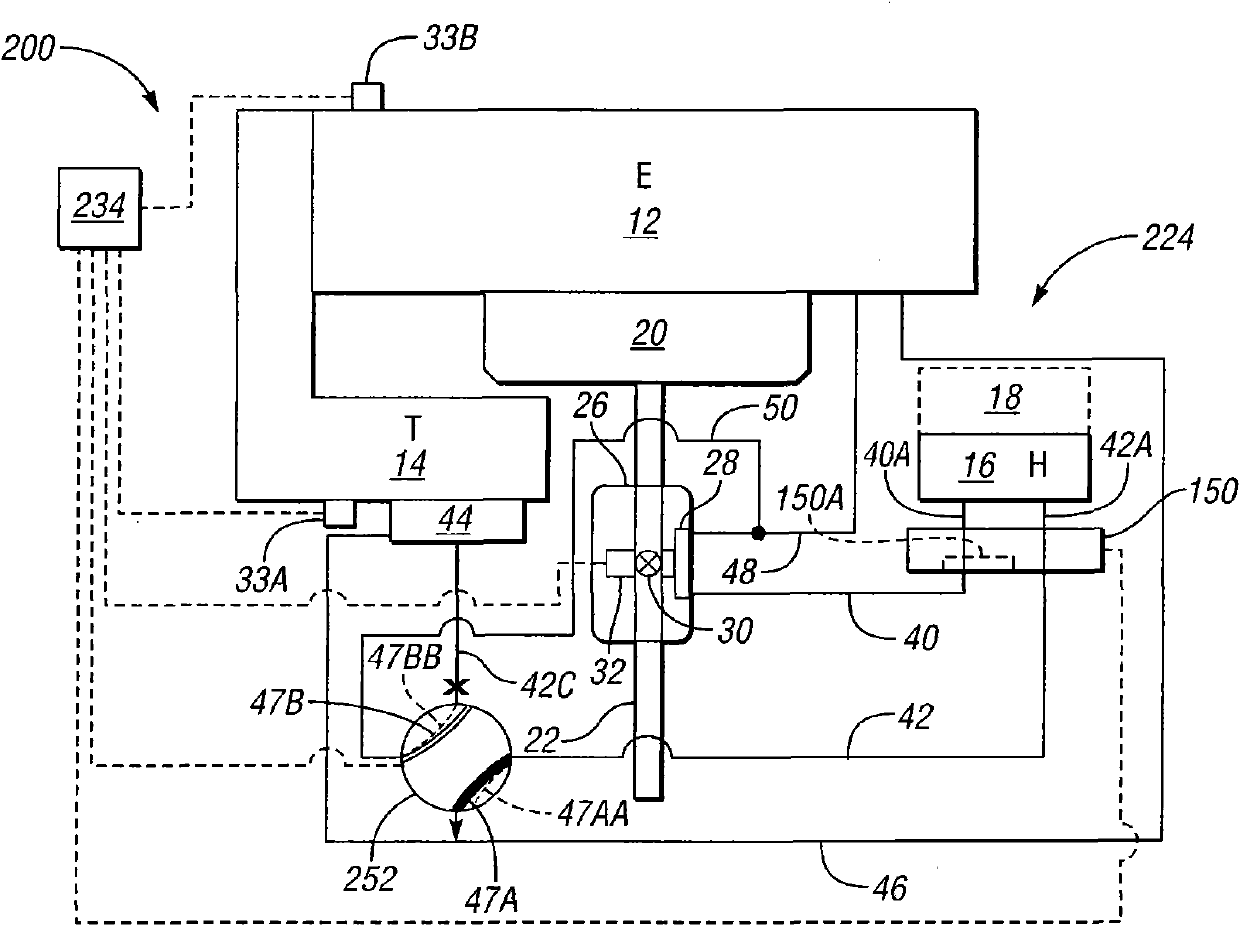

Vehicle exhaust heat recovery system and method of managing exhaust heat

InactiveUS20110067389A1Increased durabilityImprove fuel economyInternal combustion piston enginesExhaust apparatusHeat flowOperant conditioning

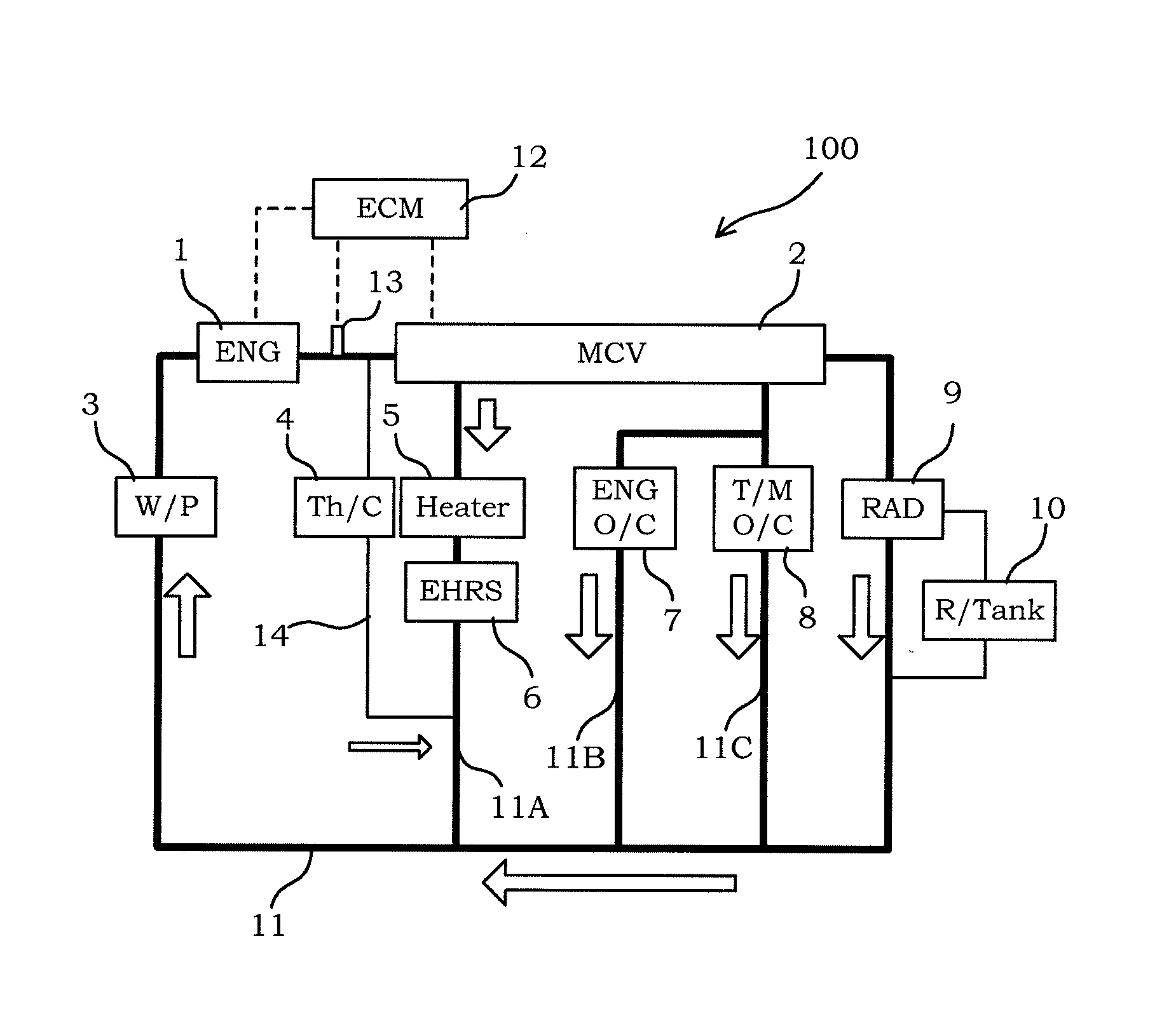

An exhaust heat recovery system (EHRS) for a vehicle is operable to direct exhaust heat to a vehicle transmission under certain operating conditions. In some embodiments, the EHRS may also direct exhaust heat to a heater for vehicle passenger compartment. Preferably, the EHRS is controllable to manage available exhaust heat according to vehicle operating conditions, by prioritizing the heat flow among the engine, the transmission, and the vehicle heater. The EHRS may also operate in a bypass mode during which exhaust heat is not directed to the engine, the transmission or the vehicle heater. A method of managing exhaust heat recovery on a vehicle having an EHRS is also provided.

Owner:GM GLOBAL TECH OPERATIONS LLC

Ferritic stainless steel and steel sheet for heat pipes, and heat pipe and high-temperature exhaust heat recovery system

Provided is a ferritic stainless steel for heat pipes of high-temperature exhaust heat recovery systems, which comprises, in terms of % by mass, from 16 to 32% of Cr, at most 0.03% of C, at most 0.03% of N, at most 3% of Si, at most 2% of Mn, at most 0.008% of S, from 0 to 0.3% of Al, and at least one of at most 0.7% of Nb, at most 0.3% of Ti, at most 0.5% of Zr and at most 1% of V, and optionally at least one of at most 3% of Mo, at most 3% of W, at most 3% of Cu, at most 0.1% of Y, at most 0.1% of REM (rare earth metal) and at most 0.01% of Ca, with a balance of Fe and inevitable impurities, and which satisfies at least the following formula (1), formula (2) and formula (5):Cr+3(Mo+Cu)≧20 (1)Cr+3(Si+Mn+Al−Ti)≧20 (2)0.037{(C+N) / (V+Ti+0.5Nb+0.5Zr)}+0.001≦0.01 (5).

Owner:DENSO CORP +1

Exhaust heat recovery system

InactiveUS20050204762A1High recovery rateAir-treating devicesThermoelectric device with peltier/seeback effectEngineeringThermoelectric conversion

The exhaust heat recovery system of the invention includes: a thermoelectric conversion element that generates electric energy by thermoelectric conversion using heat of exhaust gas discharged from an engine; and a heat pump including a heat recovery unit that absorbs the heat contained in the exhaust gas through an endothermic reaction using a heating medium, and a heat generation unit which generates heat through an exothermic reaction of the heating medium and which supplies the heat to the thermoelectric conversion element. With this configuration, the thermoelectric conversion element and the heat generation unit are movably attached to each other such that they can be placed in contact with and separated from each other, and the heat recovery unit is positioned in an exhaust gas passage in an exhaust gas downstream flow direction from the heat generation unit.

Owner:TOYOTA JIDOSHA KK

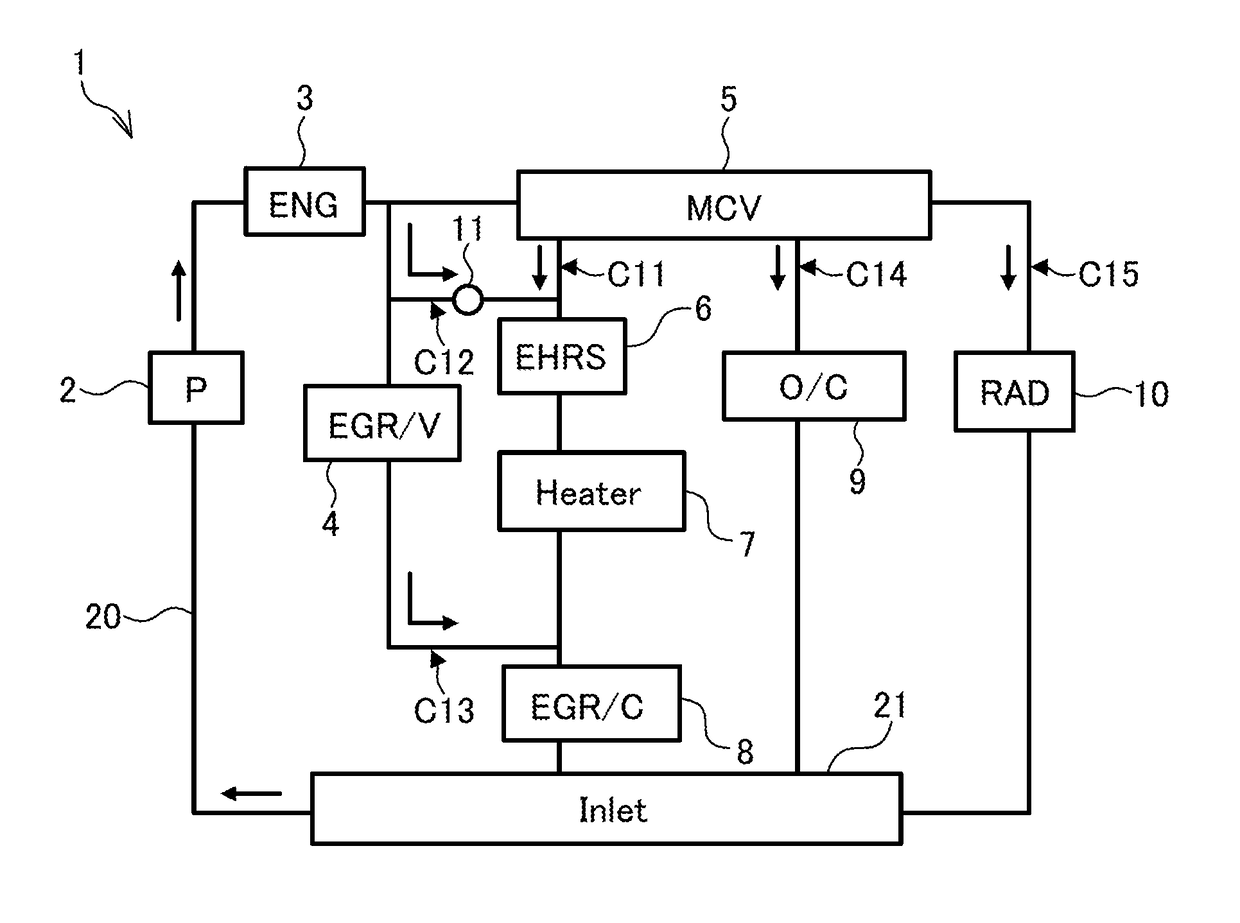

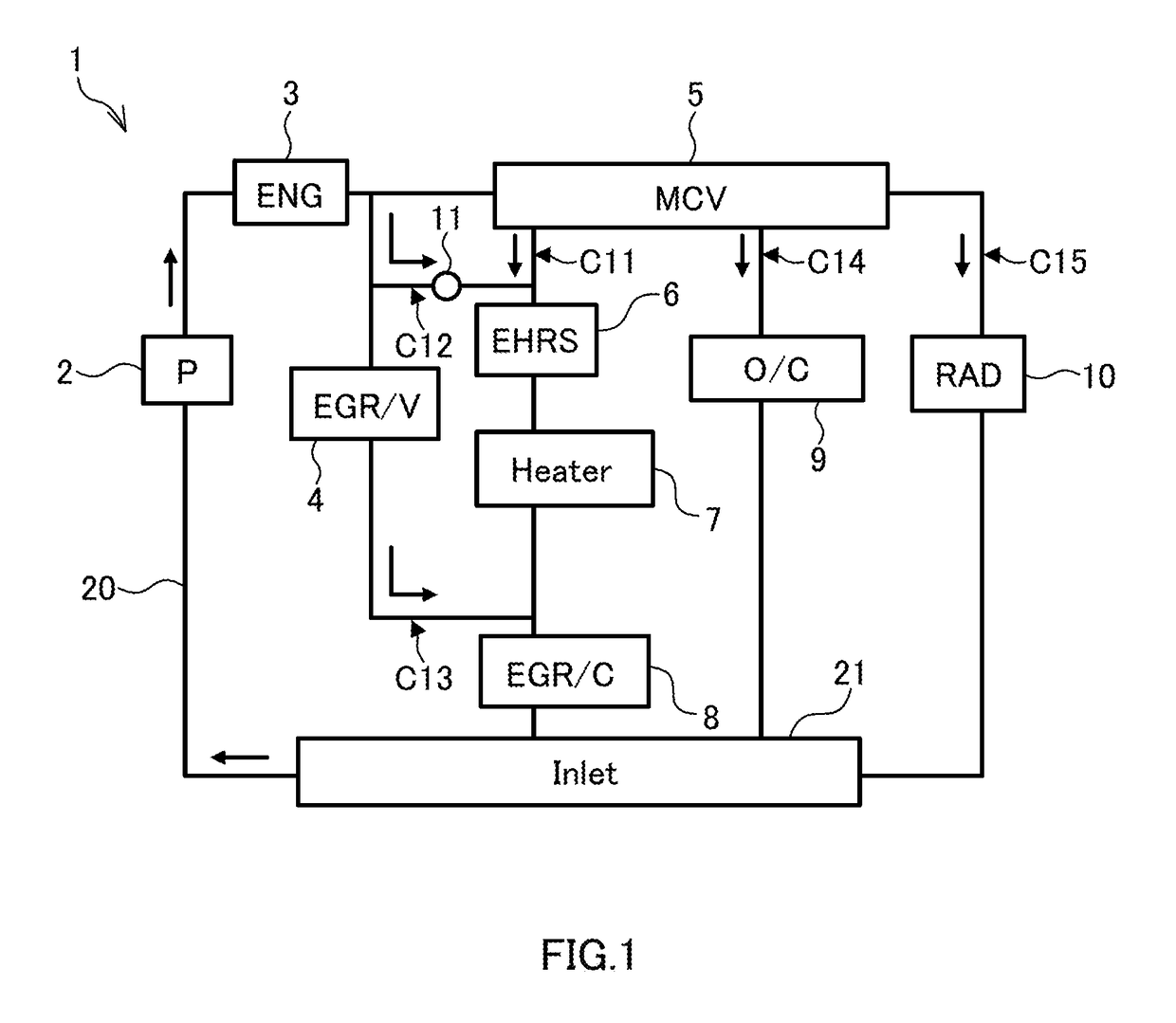

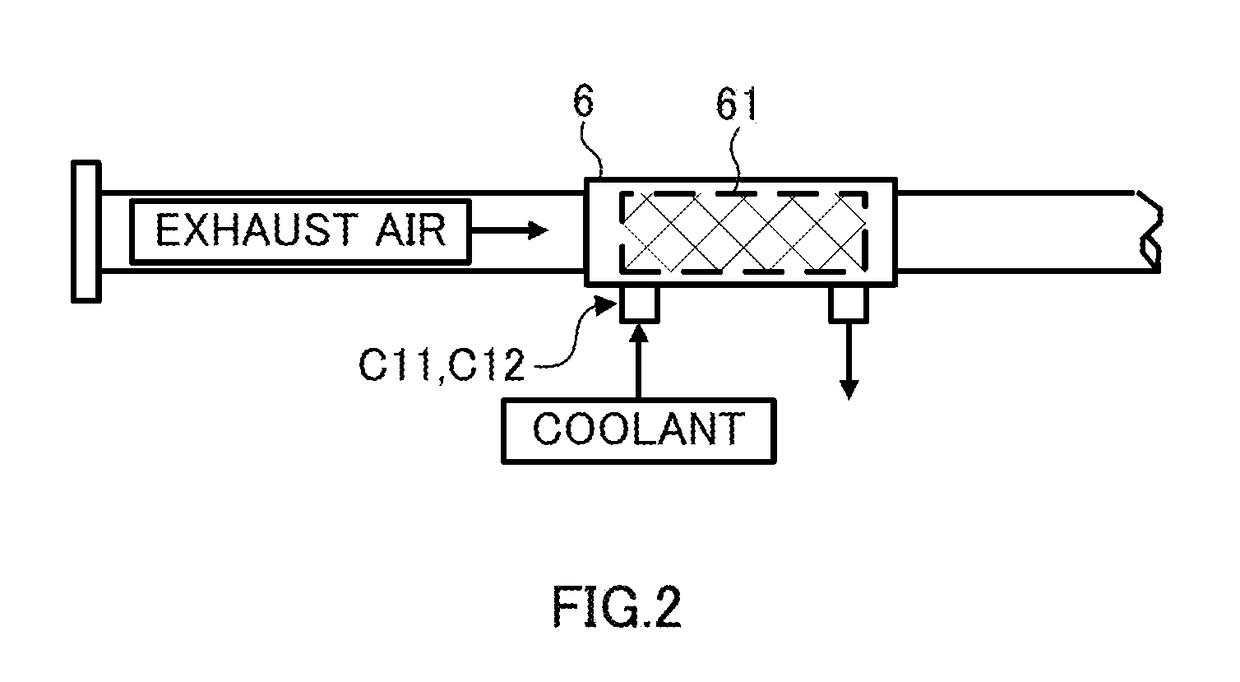

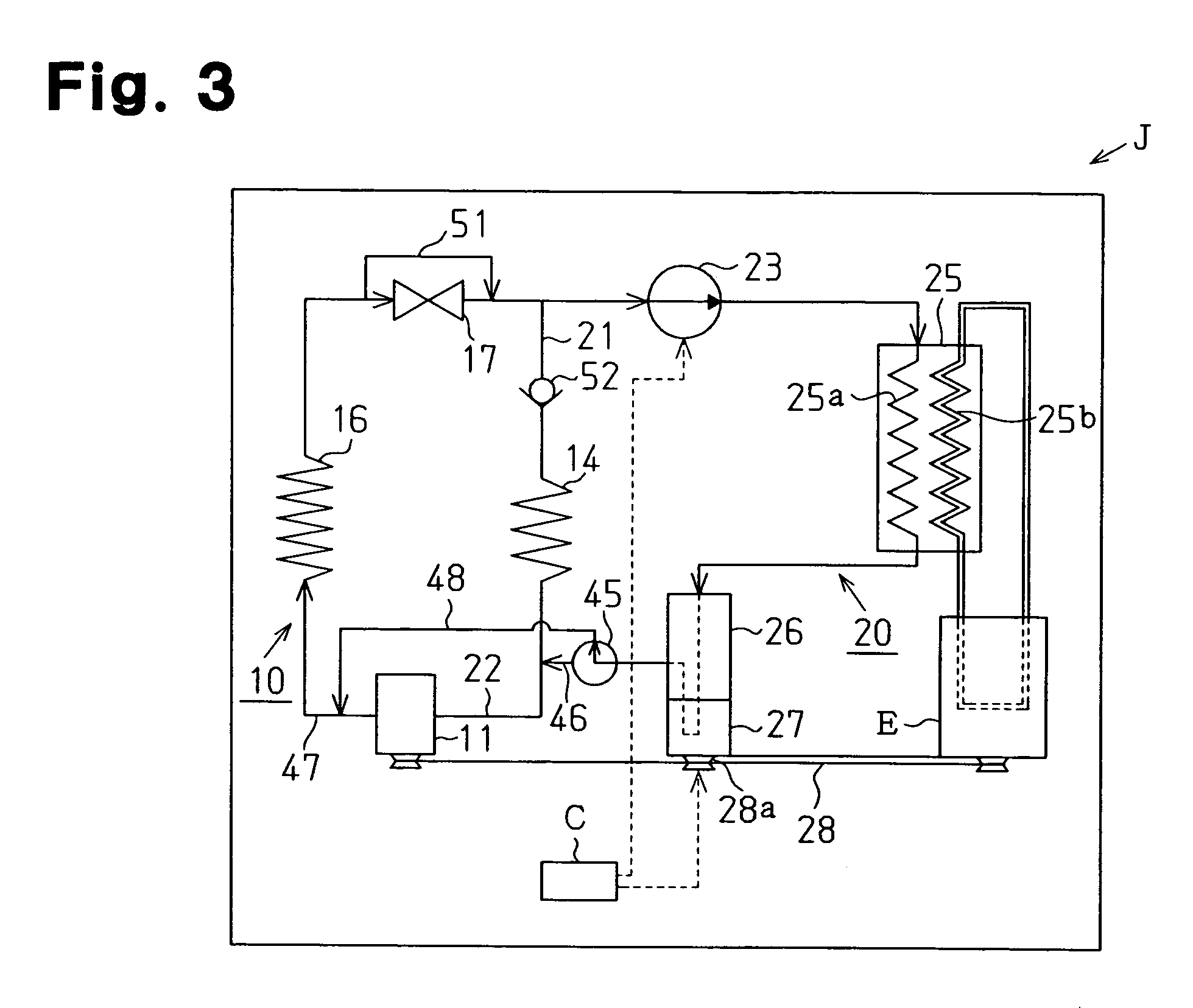

Cooling system controller and method of controlling cooling system

ActiveUS20160341100A1Shorten warm-up timeAvoid boilingLiquid coolingCoolant flow controlNuclear engineeringInternal combustion engine

A cooling system controller controls a cooling system at least having a coolant pump (3) configured to supply a coolant to an internal combustion engine, a heat radiator (9) configured to cool the coolant, and an exhaust heat recovery system (6) configured to perform in heat exchange between the exhaust gas and the coolant. In addition, the cooling system controller (12) has a unit configured to control the coolant flow rate, a unit (13) configured to obtain a coolant temperature or pressure of the internal coolant passage of the engine, and a unit configured to obtain an internal coolant temperature or pressure of the exhaust heat recovery system. Furthermore, the coolant flow rate is restricted at a cold start of the internal combustion engine, and the restriction of the coolant flow rate is released on the basis of the coolant temperature or pressure of the engine coolant passage and the internal coolant temperature or pressure of the exhaust heat recovery system.

Owner:NISSAN MOTOR CO LTD

Exhaust heat recovery system

InactiveCN1673497AImprove power generation efficiencyInternal combustion piston enginesThermoelectric device with peltier/seeback effectExhaust fumesProcess engineering

Owner:TOYOTA JIDOSHA KK

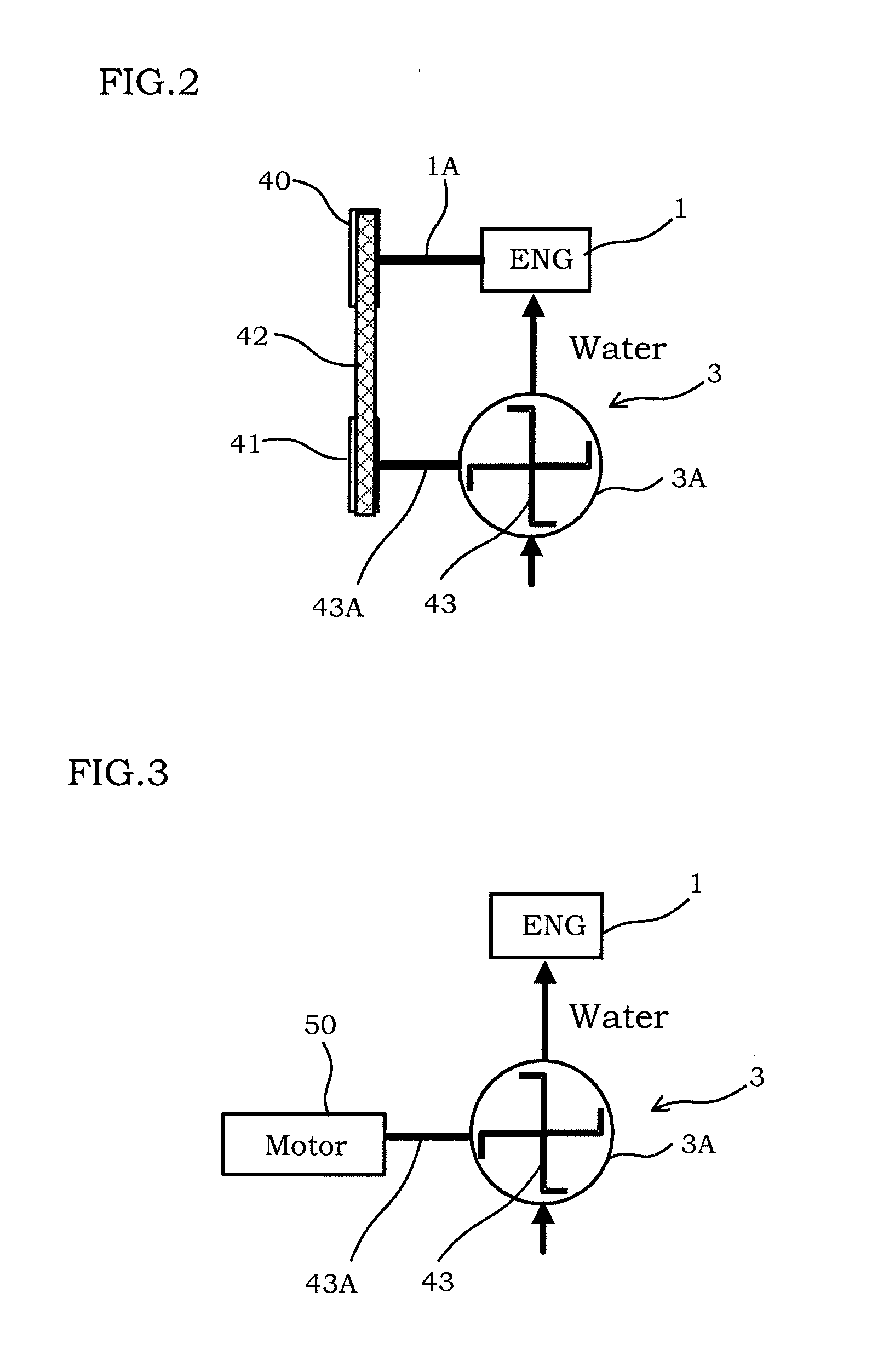

Flywheel Mechanical Energy Derived from Engine Exhaust Heat

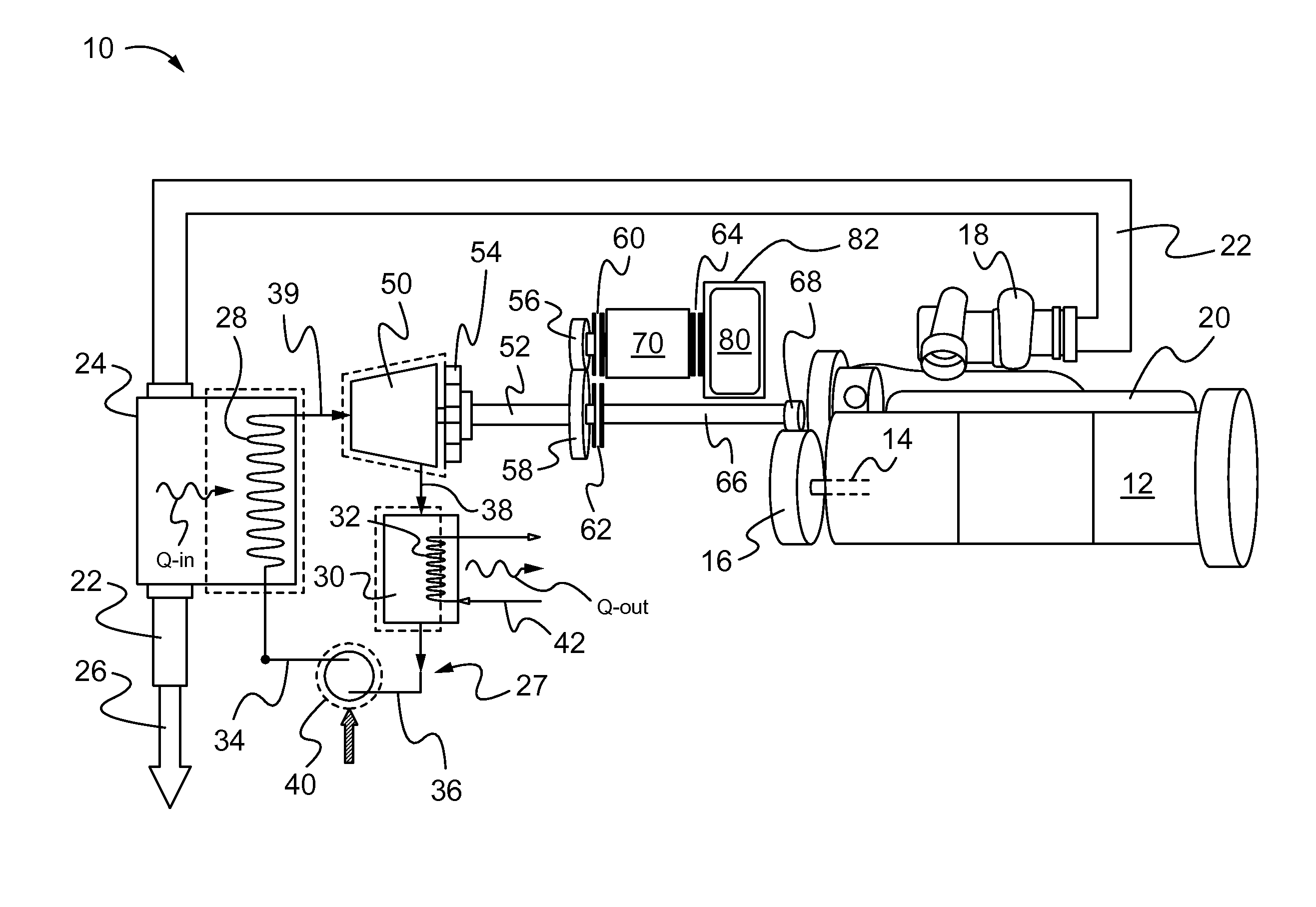

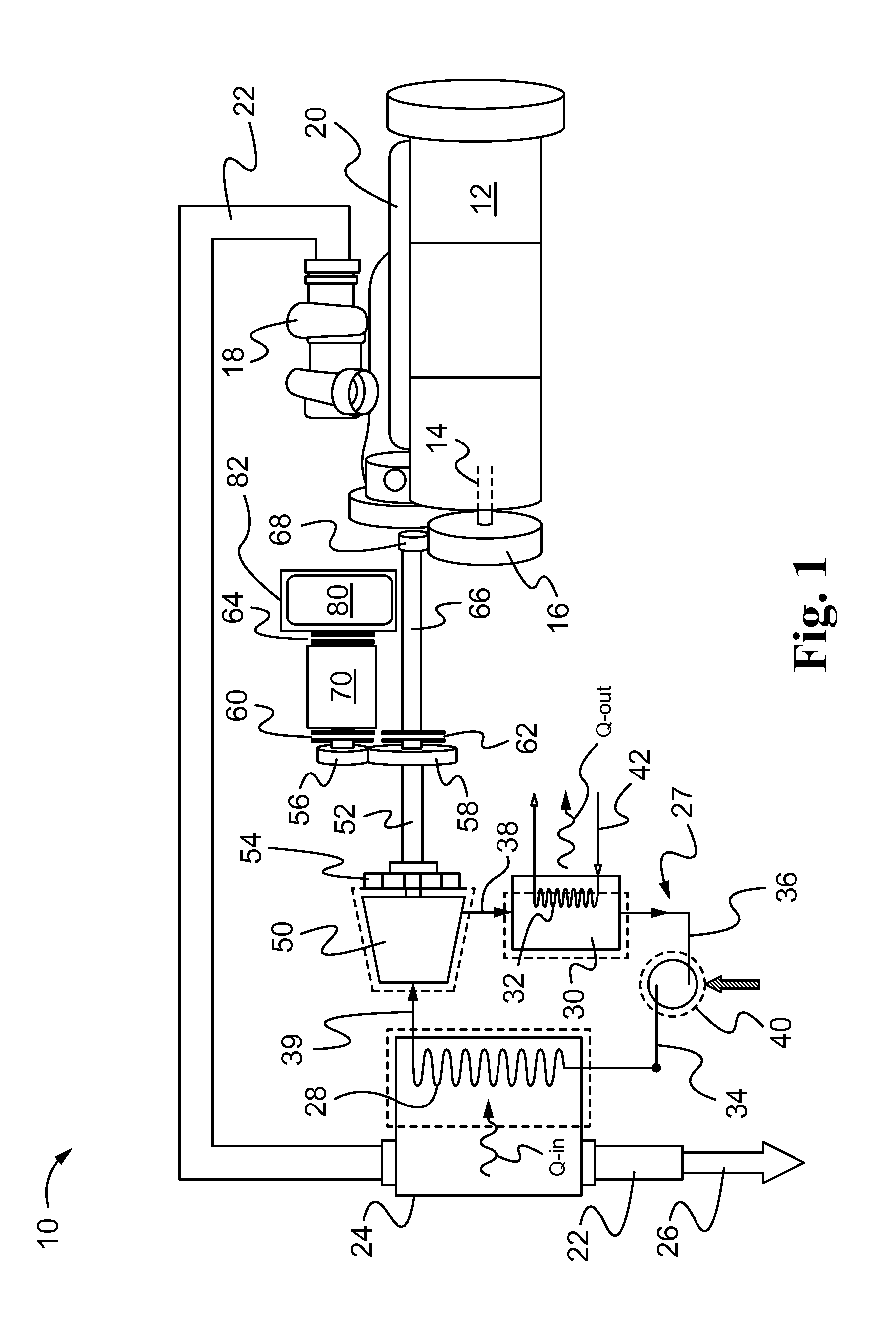

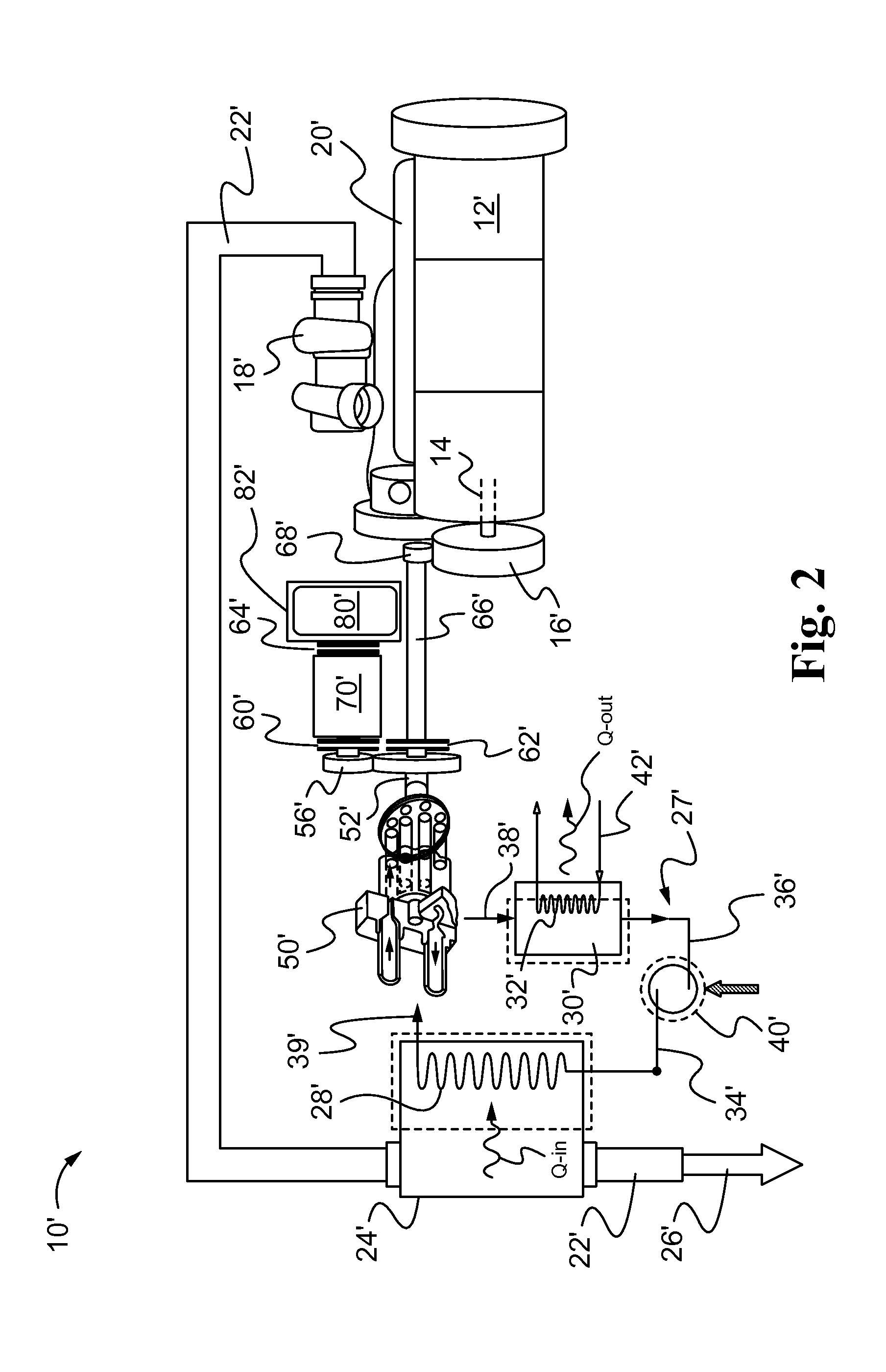

ActiveUS20130219882A1Internal combustion piston enginesExhaust apparatusLiquid stateMechanical energy

An engine exhaust heat recovery system includes an engine exhaust heat conduit that interacts with a two-phase fluid that exists in liquid and gaseous states within a single closed loop. A first heat exchanger, which may be a boiler, interfaces with and receives heat from the engine exhaust conduit. Exhaust heat energy converts the fluid from the liquid state into the gaseous state for transfer into a heat expander situated downstream of the first heat exchanger. The heat expander utilizes the gaseous heat energy to rotate a flywheel, and a system of clutches is situated and adapted to permit the flywheel to transfer mechanical energy for subsequent, selective production of work upon demand. In one disclosed embodiment, the heat expander may be a high-speed turbine with a rotary power shaft coupled to a transmission and a plurality of clutches adapted to engage and actuate the flywheel.

Owner:CATERPILLAR INC

Exhaust system and methods for efficient exhaust heat recovery

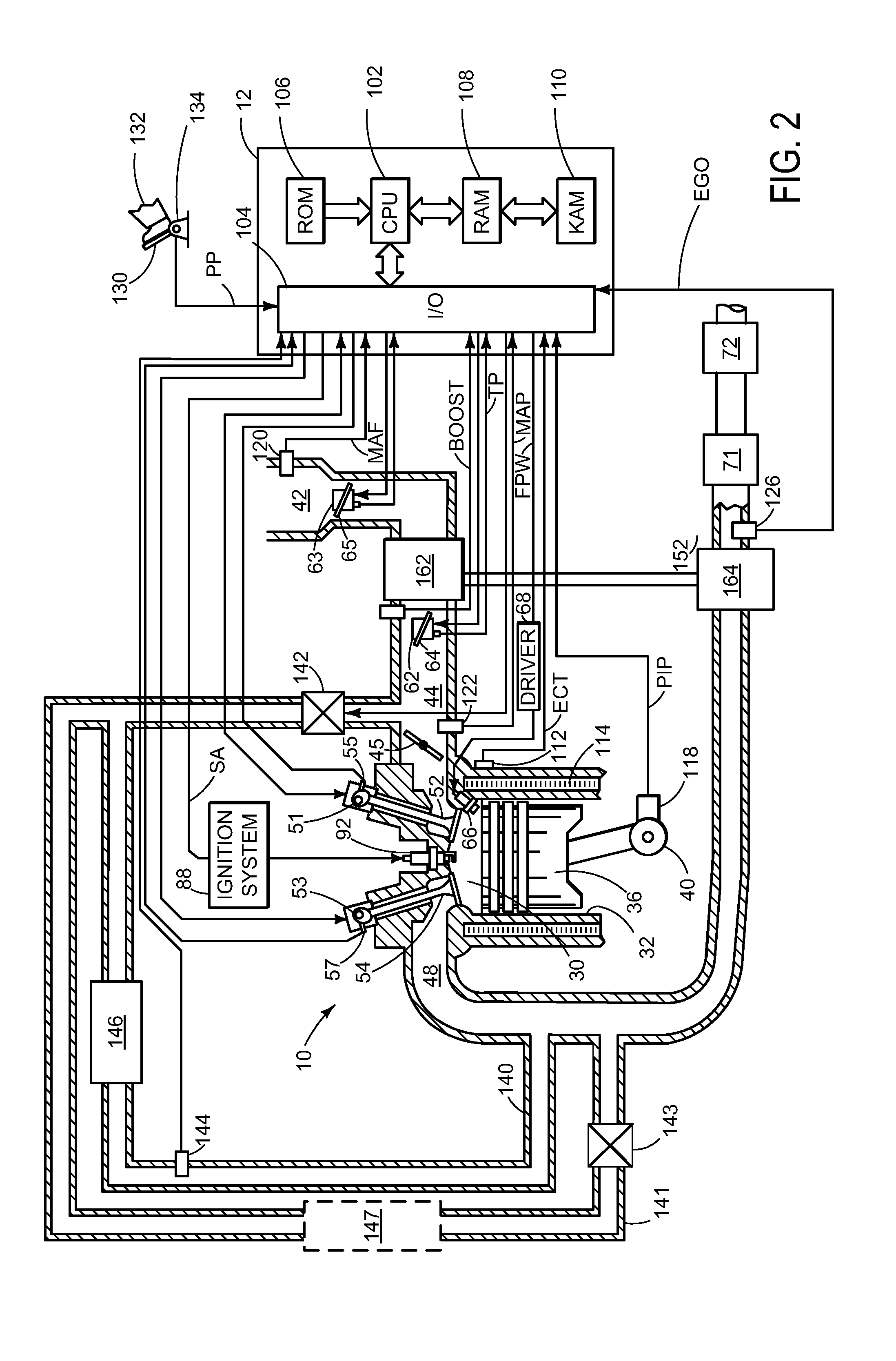

ActiveUS20160115910A1Facilitates heat recoveryEfficiently and expeditiously warmedElectrical controlNon-fuel substance addition to fuelExhaust fumesExhaust gas recirculation

Systems and methods are described for heating engine coolant by transferring heat from an exhaust flow to the engine coolant via a heat exchanger positioned in an exhaust gas heat recovery line coupled to the EGR cooler responsive to an EGR valve position. In one particular example, a branching pathway of the EGR cooler is positioned downstream of the EGR cooler and allows exhaust gas to be routed to the EGR cooler and / or exhaust gas heat exchanger based on the EGR valve position, which allows for control of the amount of heat transferred to the engine coolant as well as exhaust gas recirculation into the engine. With this arrangement, a cabin temperature of a hybrid vehicle may be increased as quickly as possible under cold start conditions to allow the engine to be quickly turned off after heating the vehicle cabin.

Owner:FORD GLOBAL TECH LLC

Exhaust heat recovery for transmission warm-up

ActiveUS8413434B2Coolant flow controlInternal combustion piston enginesOperant conditioningOperating temperature

Owner:GM GLOBAL TECH OPERATIONS LLC

Cooling circuit for internal combustion engines

ActiveUS20170184008A1Avoid failureLiquid coolingCoolant flow controlCombustionExternal combustion engine

A cooling circuit for internal combustion engines includes an internal combustion engine, a pressure-feeding unit for feeding coolant, which cools the internal combustion engine under pressure, a valve unit having a plurality of heat exchangers connected in parallel thereto, an exhaust heat recovery system for recovering heat from exhaust air of the internal combustion engine by the coolant, a first circulation circuit including the pressure-feeding unit, the valve unit and the exhaust heat recovery system, and a second circulation circuit including the pressure-feeding unit and the exhaust heat recovery system.

Owner:NISSAN MOTOR CO LTD

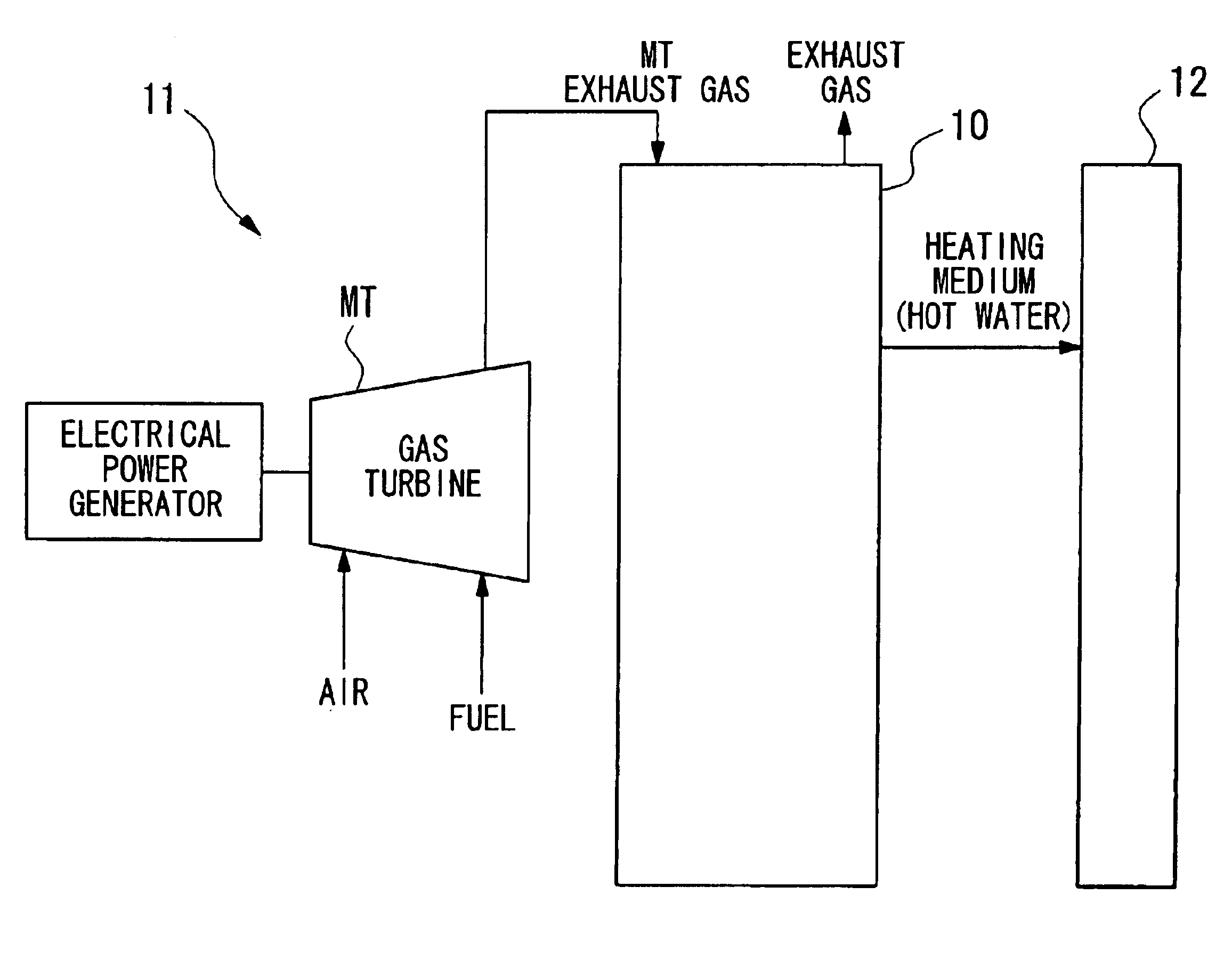

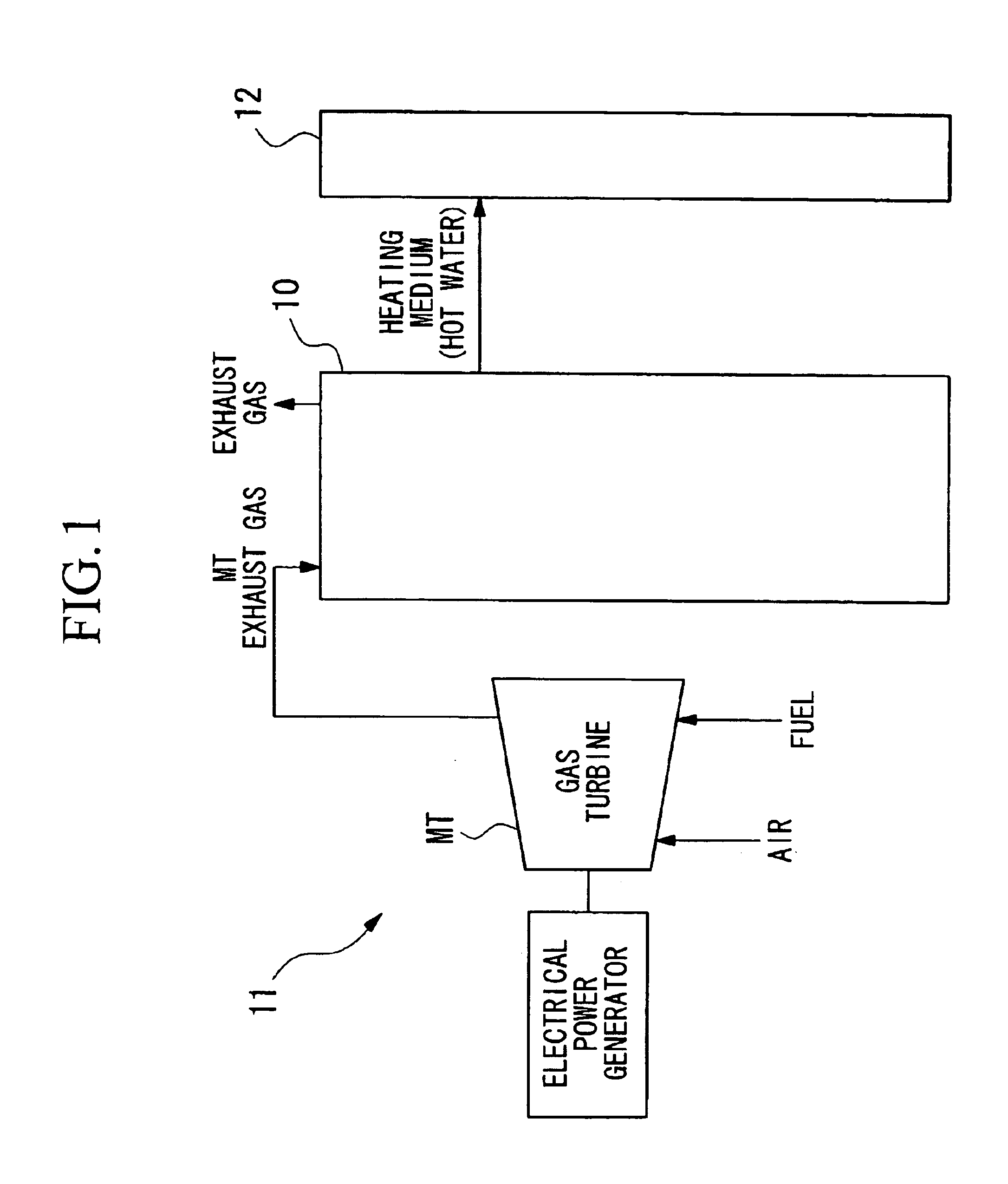

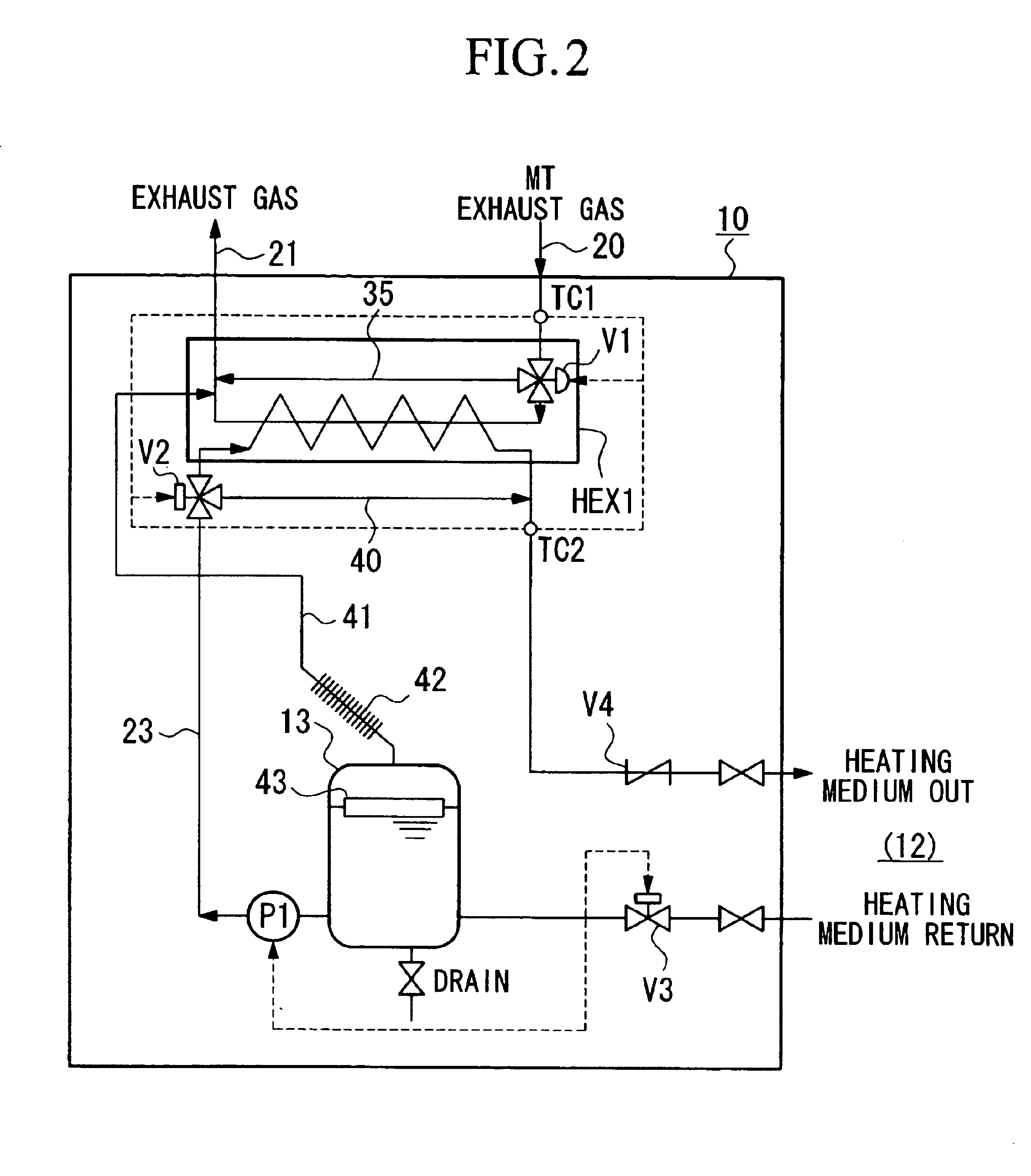

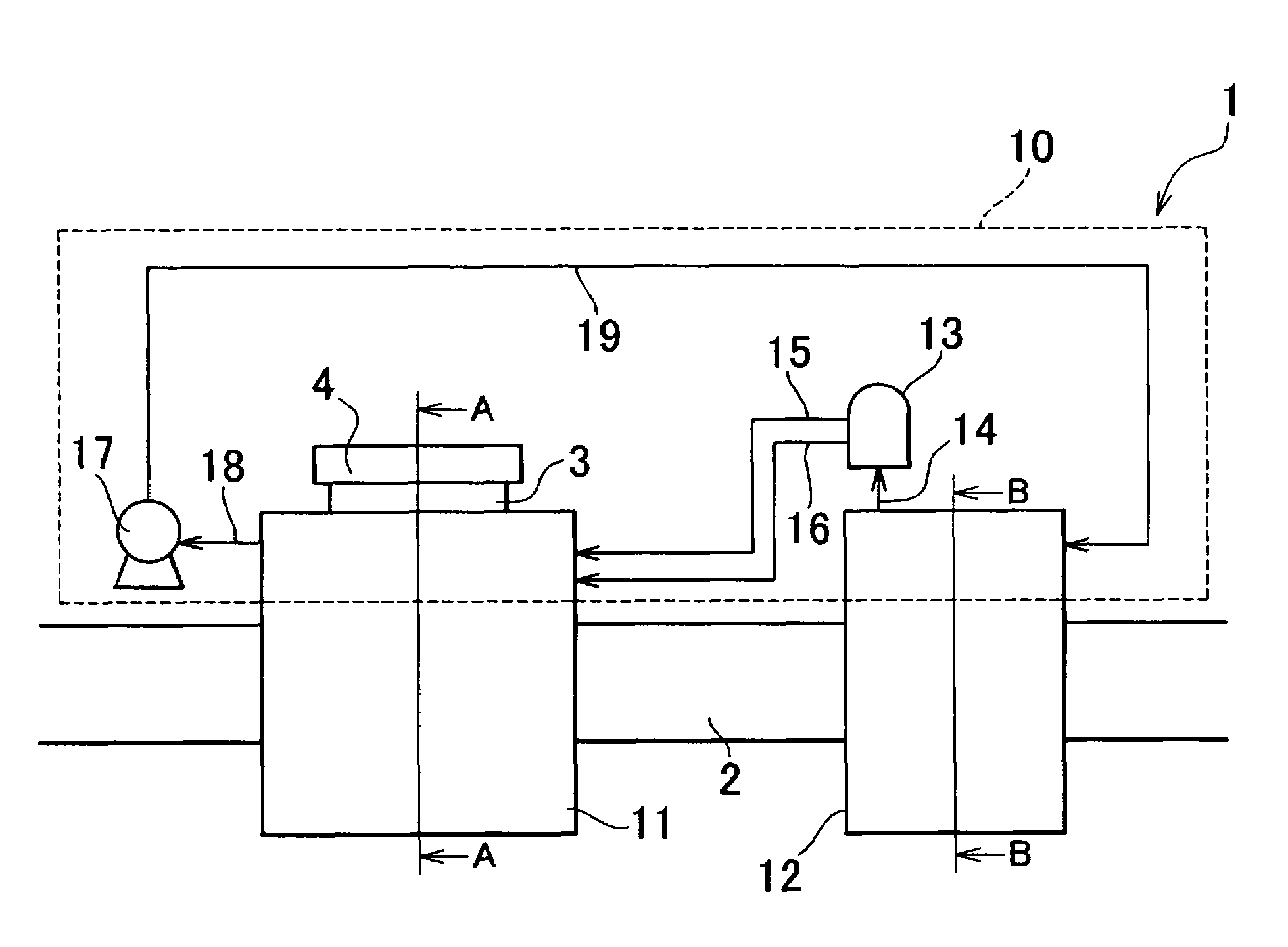

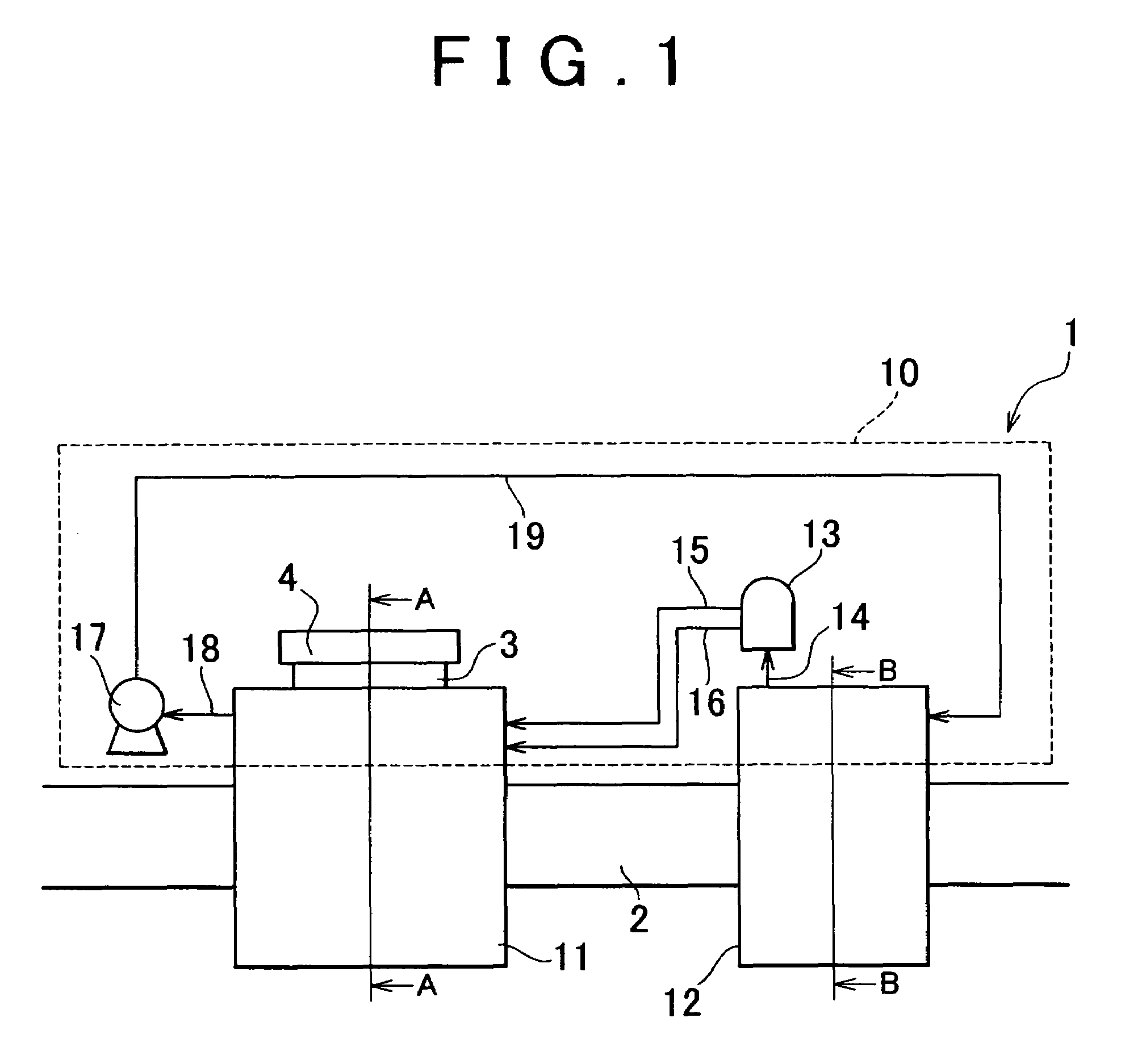

Exhaust heat recovery system

InactiveUS6938417B2Low costImprove energy efficiencyInternal combustion piston enginesRecuperative heat exchangersHigh energyEngineering

The present invention relates to an exhaust heat recovery system that recovers exhaust that is generated by an electrical power generator for use in supplying hot water and air conditioning, and has an object providing an exhaust heat recovery system that realizes reduced costs and has a high energy efficiency. The exhaust heat recovery system provides a heat exchanger HEX1 for exhaust heat recovery that uses the heat of the exhaust gas generated by an electrical power generator to heat a heating medium that is circulated and used in a predetermined facility, and heats the heating medium by carrying out heat exchange between the exhaust gas and the heating medium, a temperature detecting device TC2 that detects the temperature of the heating medium heated by the heat exchanger HEX1 for exhaust heat recovery, and a control valve V1 that controls the amount of exhaust gas fed to the heat exchanger HEX1 for exhaust heat recovery based on the detected results of the temperature detecting device TC2.

Owner:THE TOKYO ELECTRIC POWER CO INC

Vehicle exhaust heat recovery system

InactiveUS7353661B2Small sizeImprove energy conversion efficiencyLiquid coolingAir-treating devicesEngineeringRefrigeration

A vehicle exhaust heat recovery system includes a vapor compression type refrigeration circuit, a boiler to which the refrigerant is introduced from the refrigeration circuit and heated, and an expander for generating motive power by expanding the heated refrigerant. The refrigerant circulates in the refrigeration circuit. The boiler heats the refrigerant introduced therein using exhaust heat generated by the vehicle. The refrigerant that has been subjected to expansion is recycled to the refrigeration circuit.

Owner:TOYOTA IND CORP

Exhaust heat recovery system

InactiveUS7430875B2High recovery rateAir-treating devicesDomestic cooling apparatusWaste heat recovery unitEngineering

The exhaust heat recovery system of the invention includes: a thermoelectric conversion element that generates electric energy by thermoelectric conversion using heat of exhaust gas discharged from an engine; and a heat pump including a heat recovery unit that absorbs the heat contained in the exhaust gas through an endothermic reaction using a heating medium, and a heat generation unit which generates heat through an exothermic reaction of the heating medium and which supplies the heat to the thermoelectric conversion element. With this configuration, the thermoelectric conversion element and the heat generation unit are movably attached to each other such that they can be placed in contact with and separated from each other, and the heat recovery unit is positioned in an exhaust gas passage in an exhaust gas downstream flow direction from the heat generation unit.

Owner:TOYOTA JIDOSHA KK

Exhaust heat recovery system of vehicle and method thereof

InactiveCN102086797AQuality improvementReduce consumptionCoolant flow controlInternal combustion piston enginesRecovery methodTemperature control

Owner:HYUNDAI MOTOR CO LTD +1

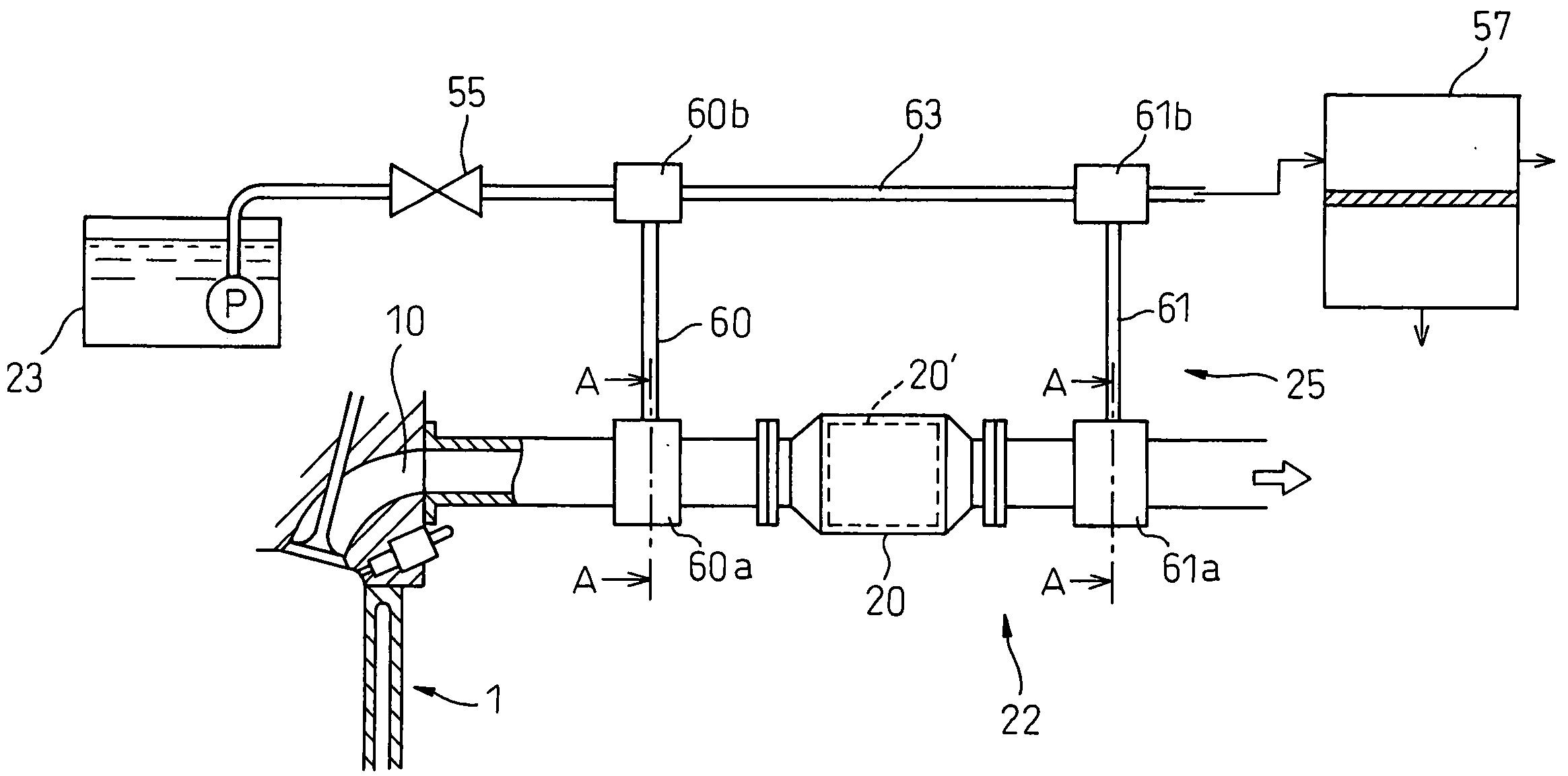

Exhaust heat recovery system

InactiveUS20100154394A1Maintain warm-up performanceHeat recoveryInternal combustion piston enginesRecuperative heat exchangersEngineeringInternal combustion engine

An exhaust heat recovery system 25 provided with a plurality of heat pipes 60, 61 provided with heat recovery parts 60a, 61a and heat exchange parts 60b, 61b. The heat pipes recover heat from exhaust gas exhausted from an internal combustion engine at the heat recovery parts and transfer this recovered heat to an object to be heated at the heat exchange parts. The heat recovery part 60a of the first heat pipe 60 recovers heat from the exhaust gas at an exhaust purification catalyst 20′ provided in an engine exhaust passage or its upstream side. The heat recovery part 61b of the second heat pipe 61 recovers heat from the exhaust gas at the downstream side of the exhaust purification catalyst. Due to this, there is provided an exhaust heat recovery system which can recover at least a fixed amount of exhaust heat at all times while maintaining a warm-up performance of the exhaust purification catalyst.

Owner:EXXON RES & ENG CO +1

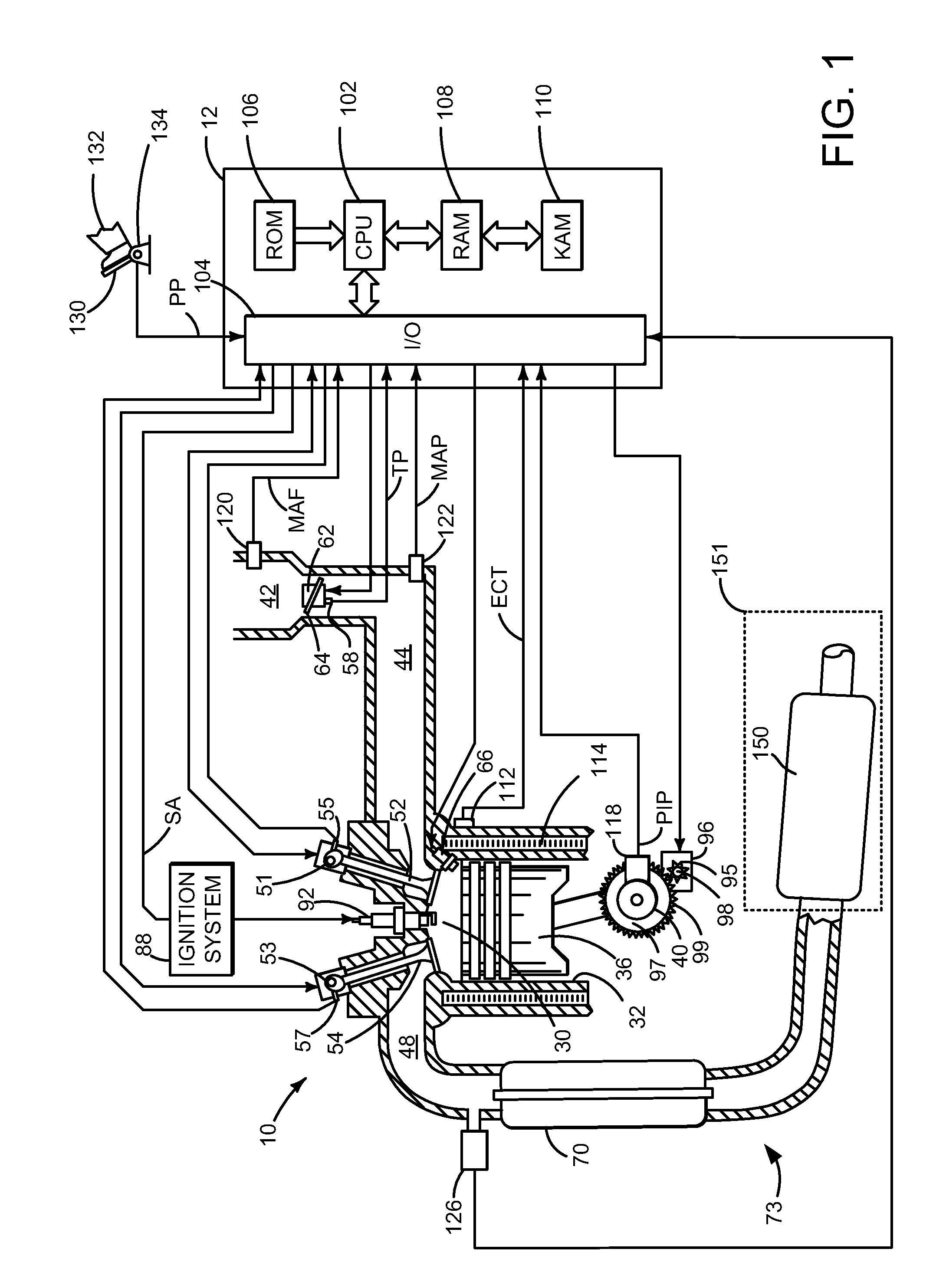

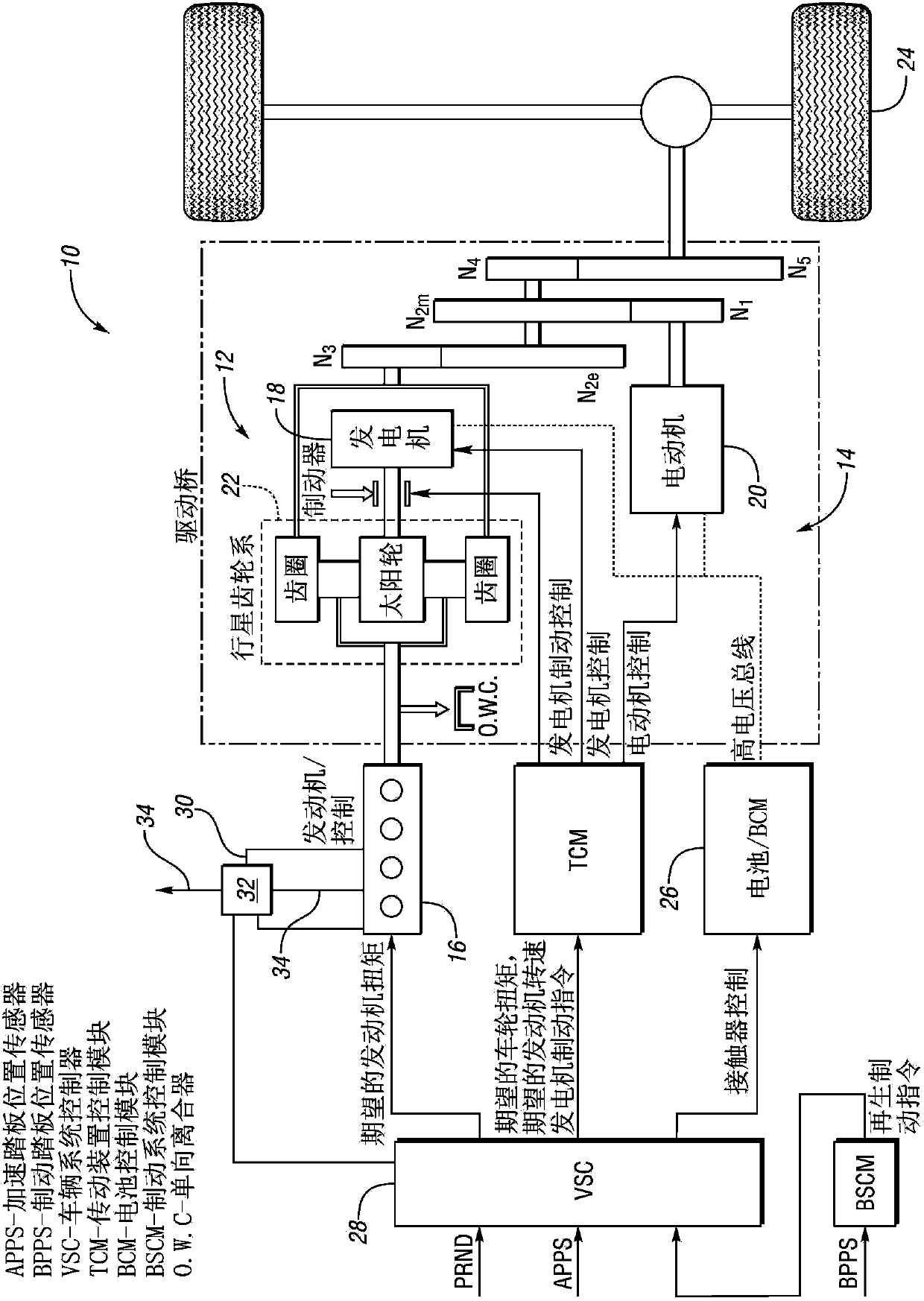

Methods and systems for hybrid vehicle waste heat recovery

InactiveUS9587546B2Function increaseImprove engine warm-upHybrid vehiclesInternal combustion piston enginesElectricityEngineering

Systems and methods for operating an engine that includes an exhaust gas heat recovery system are described. The system may selectively or contemporaneously supply energy from engine exhaust gas to generate electricity or warm the engine. In one example, exhaust gas energy raises a temperature of a heat transfer medium and the heat transfer medium is routed to an engine coolant heat exchanger or an expander via a bypass valve.

Owner:FORD GLOBAL TECH LLC

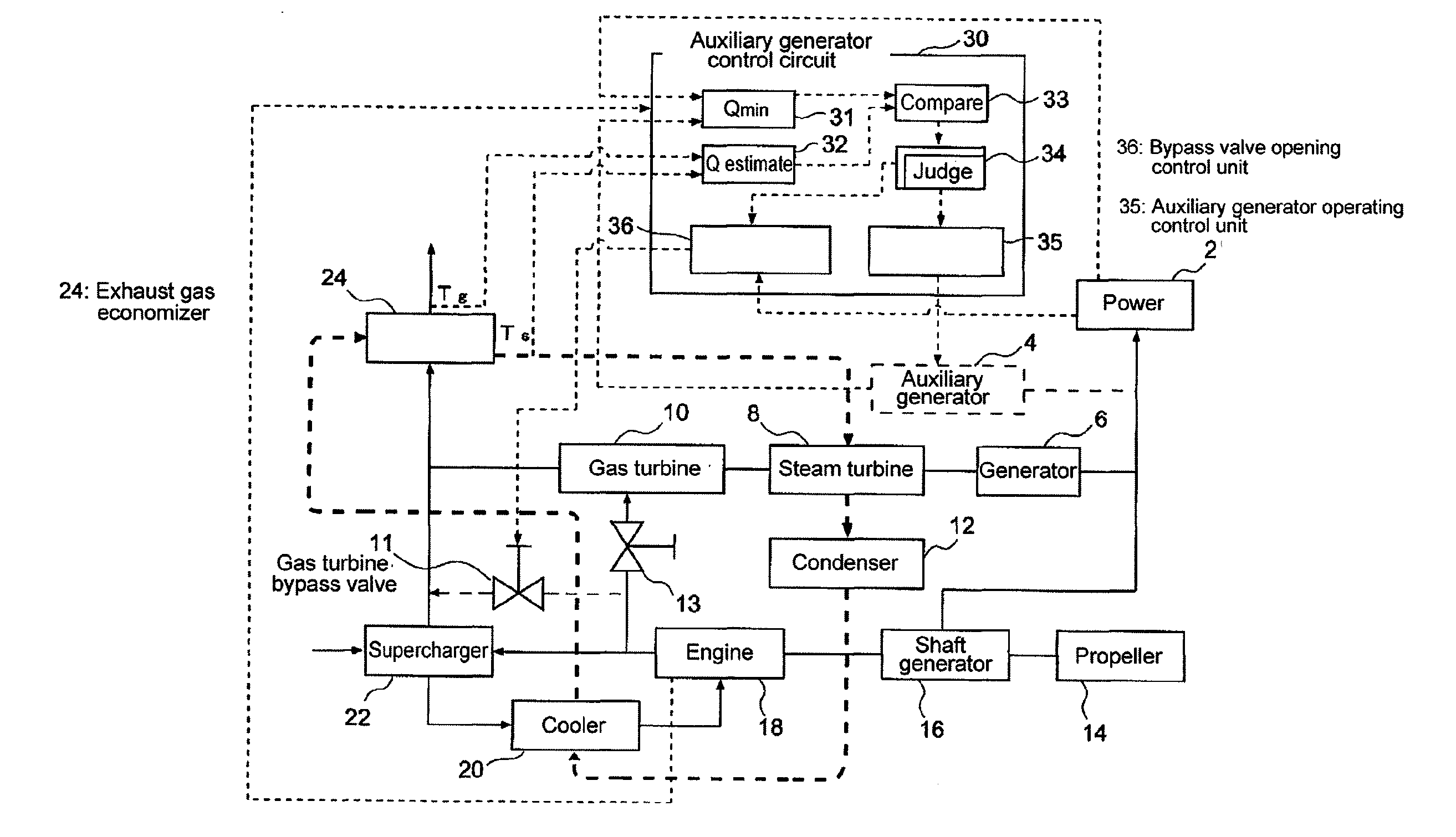

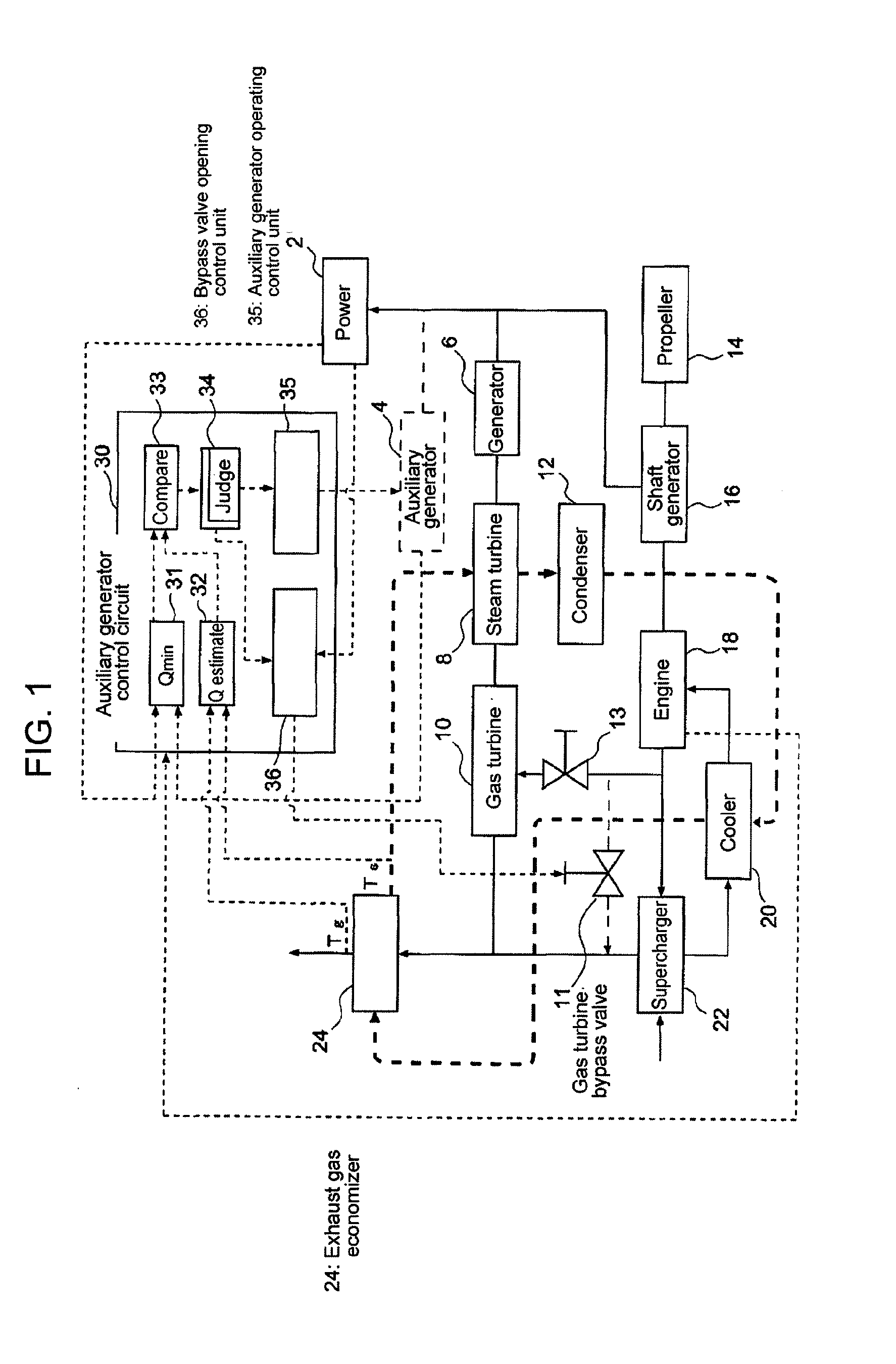

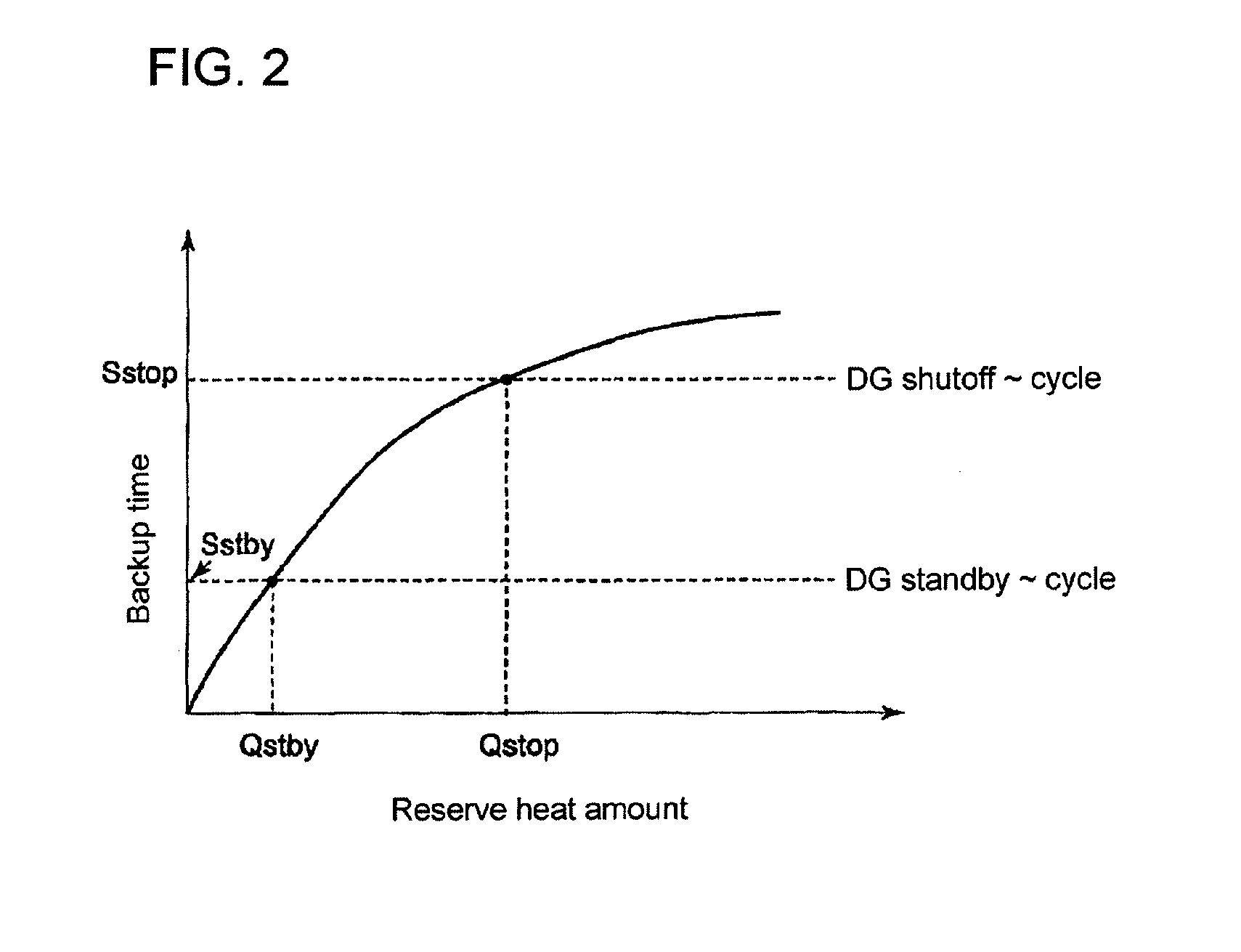

Control method and control device for exhaust heat recovery system for marine vessel

InactiveUS20110203290A1Avoid power outagesPropulsion based emission reductionInternal combustion piston enginesDynamoElectric power

Disclosed are a control method and a control device for an exhaust heat recovery system which are capable of preventing an onboard supply power outage in response to a sharp change in the load of the main drive machine. For an exhaust heat recovery system for which a portion of the exhaust gas generated by the ship's main drive machine is supplied to a gas turbine and the amount of heat of the exhaust gas exhausted by the gas turbine is conducted to an exhaust gas economizer, this control method and control device: obtain an estimated or calculated current reserve amount of heat (Q), which is based on the heat energy detection signal of the exhaust gas economizer; obtain, based on the operation state of an auxiliary electrical generator and on the onboard power demand, a reference amount of heat (Qmin), which is required to maintain the requisite power until the auxiliary electrical generator starts up; compare the current reserve amount of heat (Q) and the reference amount of heat (Qmin); and, based on the result of the comparison, select the operating state of the auxiliary electrical generator from either stop, idle or driving operation.

Owner:MITSUBISHI HEAVY IND LTD

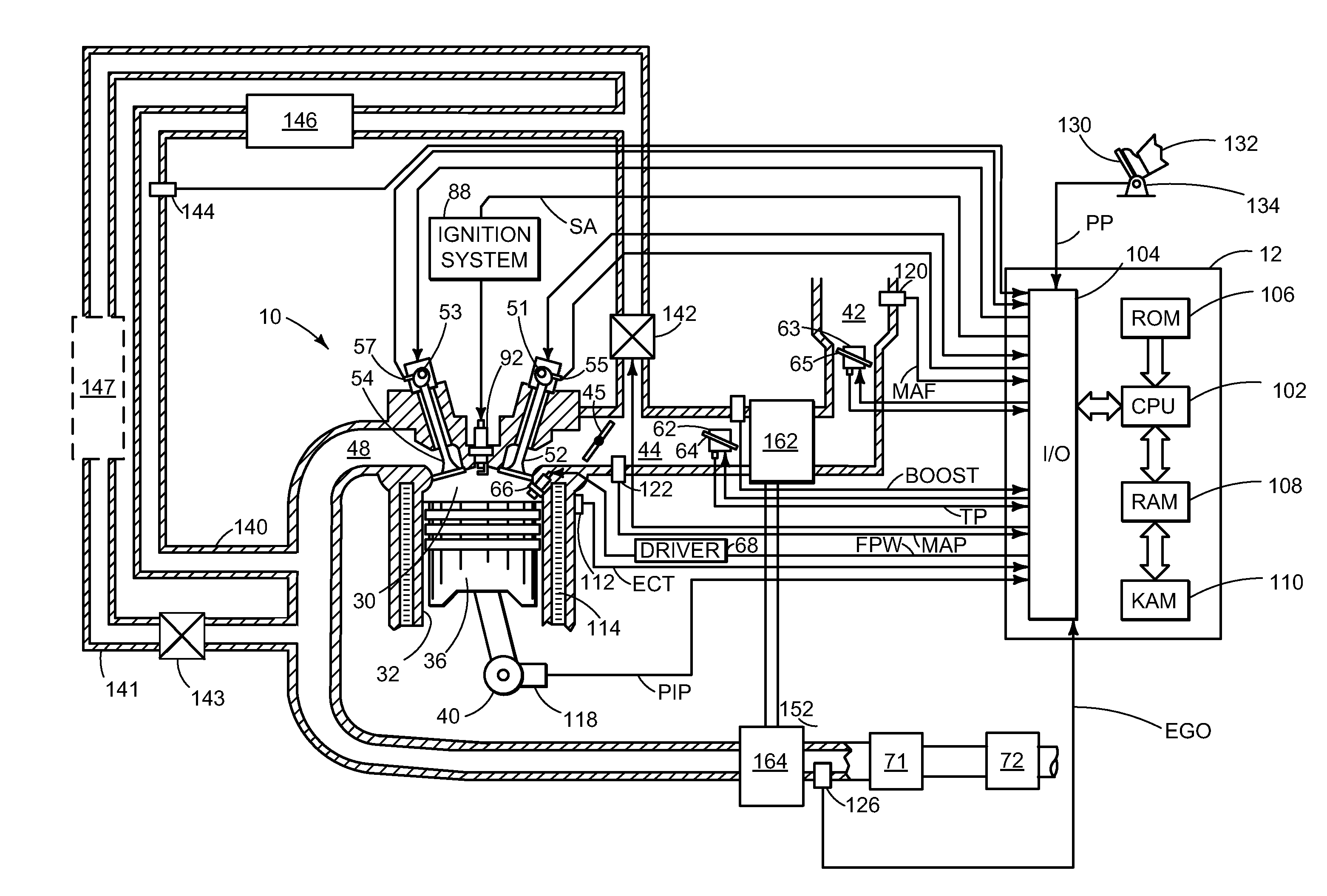

Method to control and diagnose an exhaust gas heat exchanger

ActiveCN103423005AQuick closeTemperature controlElectrical controlCoolant flow controlExhaust fumesCoolant temperature

Provided is a method for controlling and diagnose an exhaust gas heat exchanger. The method includes measuring air mass flow, engine coolant temperature (ECT), exhaust gas temperature (EGT), heat exchanger coolant temperature (HECT), and engine speed; and operating a valve to selectively provide exhaust gas flow through the exhaust gas heat exchanger based on air mass flow, ECT, EGT, HECT, and engine speed. A vehicle has an engine and an exhaust heat recovery system with an exhaust gas heat exchanger and a valve configured to control exhaust gas flow. A controller for the vehicle is configured to (i) measure air mass flow, ECT, EGT, HECT, and engine speed, and (ii) operate the valve to selectively provide exhaust gas flow through the exhaust gas heat exchanger based on air mass flow, ECT, EGT, HECT, and engine speed.

Owner:FORD GLOBAL TECH LLC

Vehicle exhaust heat recovery system and method of managing exhaust heat

An exhaust heat recovery system (EHRS) for a vehicle is operable to direct exhaust heat to a vehicle transmission under certain operating conditions. In some embodiments, the EHRS may also direct exhaust heat to a heater for vehicle passenger compartment. Preferably, the EHRS is controllable to manage available exhaust heat according to vehicle operating conditions, by prioritizing the heat flow among the engine, the transmission, and the vehicle heater. The EHRS may also operate in a bypass mode during which exhaust heat is not directed to the engine, the transmission or the vehicle heater. A method of managing exhaust heat recovery on a vehicle having an EHRS is also provided.

Owner:GM GLOBAL TECH OPERATIONS LLC

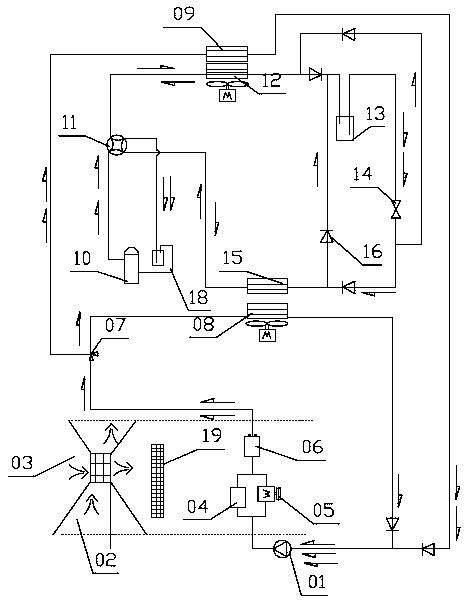

Heat recovery super heat pump system for electric vehicle

InactiveCN104121723AReduce wasteHeat pumpsAir conditioning systemsWaste heat recovery unitFour-way valve

The invention provides a heat recovery super heat pump system for an electric vehicle. The heat recovery super heat pump system comprises the components of a power pump, a motor driver, a driving motor, a storage battery, a three-way stop valve, a first electric vehicle external heat exchanger, a second electric vehicle external heat exchanger, a compressor, a four-way valve, a first electric vehicle internal heat exchanger, a second electric vehicle internal heat exchanger, a throttling element, a control valve and an electric heater. The heat recovery super heat pump system for the electric vehicle comprises an electric heating system, a new air exhausting heat recovery system, a waste heat recovery system and a super heat pump system. The electric heating system, the new air exhausting heat recovery system, the waste heat recovery system and the super heat pump system are respectively formed by connecting parts of the components in sequence to form an integrated circulation system. According to the heat recovery super heat pump system for the electric vehicle, heat emitted by an electric vehicle air conditioner internal radiating system and waste gas exhausted by an air conditioner can be sufficiently recycled and reused, and resource waste is reduced.

Owner:SUZHOU QUTU THERMAL CONTROL SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com