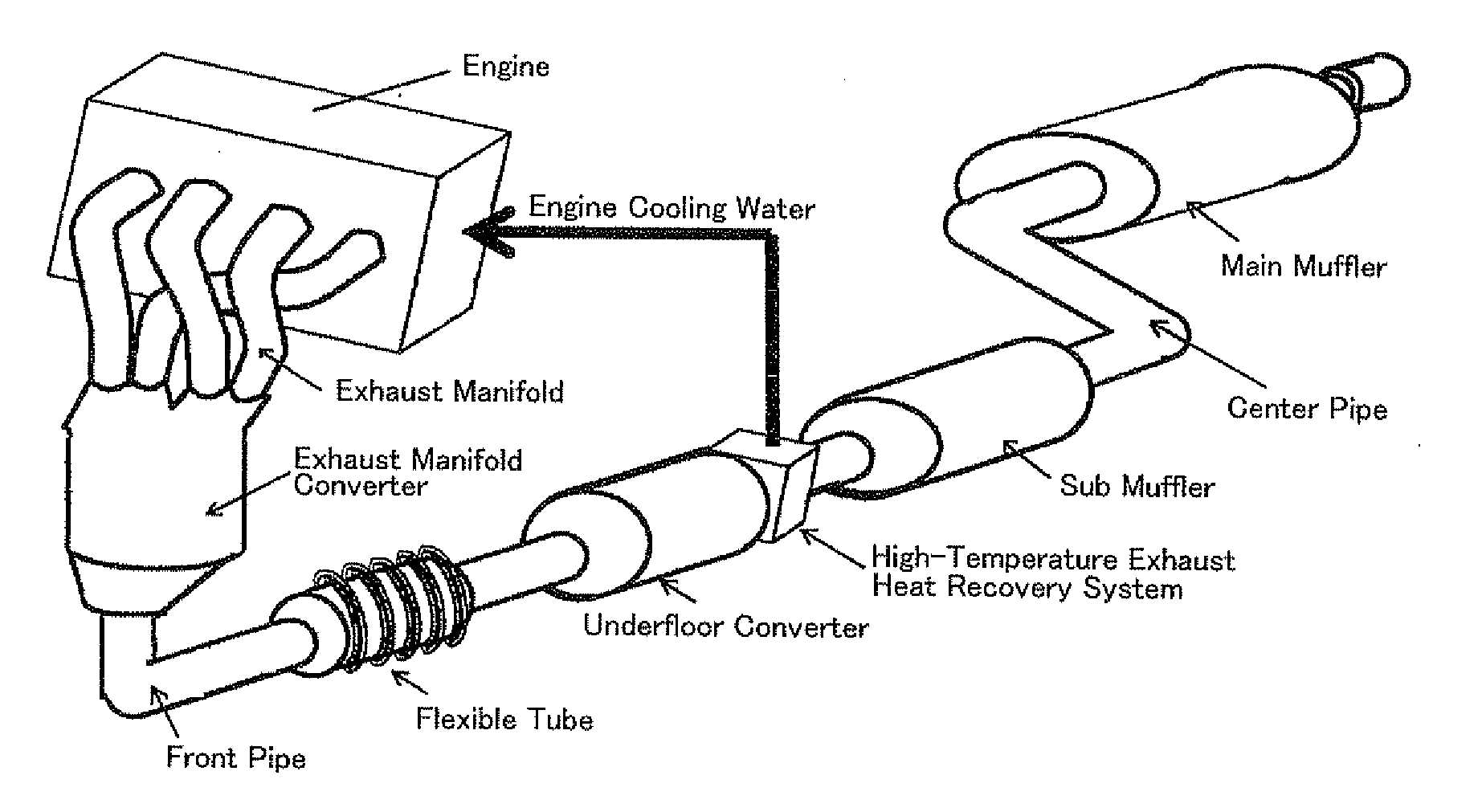

Ferritic stainless steel and steel sheet for heat pipes, and heat pipe and high-temperature exhaust heat recovery system

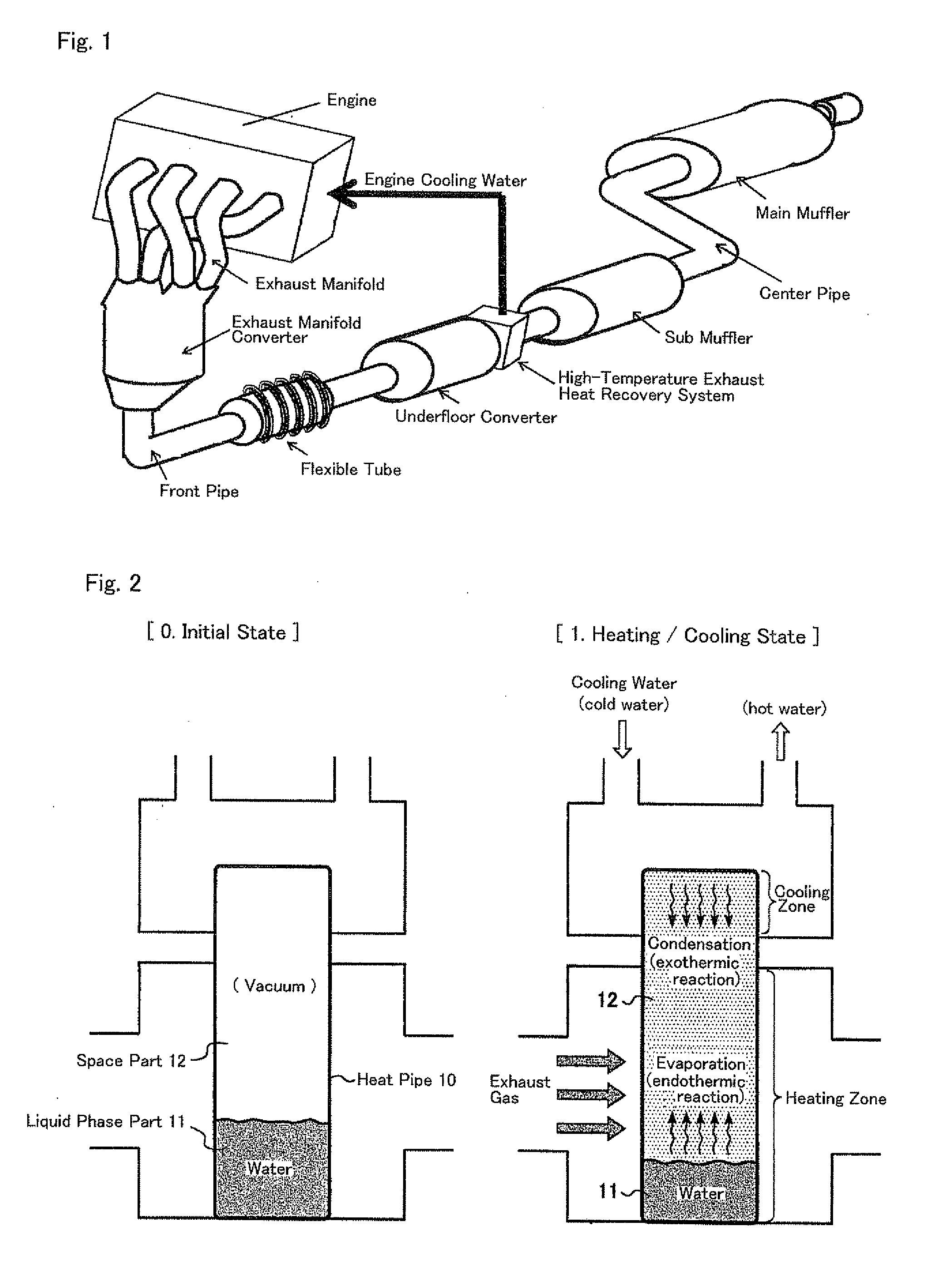

a technology of ferritic stainless steel and heat pipes, which is applied in the direction of indirect heat exchangers, lighting and heating apparatus, etc., can solve the problems of reducing the heat transfer affecting the efficiency of cooling water, etc., and achieves low cost and high popularity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0055]Steels shown in Table 1 (30 kg each) were melt-produced in a vacuum smelting furnace, and hot-rolled, annealed, pickled, cold-rolled and finish-annealed according to an ordinary ferritic stainless steel sheet production method, thereby producing cold-rolled annealed pickled steel materials (sample materials) having a thickness of 1.0 mm, for which the pickling finish was No. 2D as defined in Table 14 in JIS G4305:2005.

TABLE 1Chemical Composition (mas. %)ClassificationNo.CSiMnPSNiCrMoCuNNbTiAlothersSamples ofA10.020.301.000.0250.0020.1118.32.050.180.010.65———the inventionA20.010.190.220.0330.0010.1821.90.980.120.010.270.170.08—A30.010.250.350.0300.0020.1518.21.070.080.010.35———A40.010.220.310.0270.0020.1818.51.010.130.01———Zr: 0.24A50.010.270.420.0310.0010.0818.40.95—0.010.10——V: 0.23A60.010.550.260.0280.0010.0918.5—0.490.020.450.04—Ca: 0.005A70.010.310.220.0210.0030.1120.22.011.520.010.45——W: 1.24A80.020.220.310.0220.0010.0920.50.23—0.010.42——REM: 0.02A90.010.180.250.0290.0010...

example 2

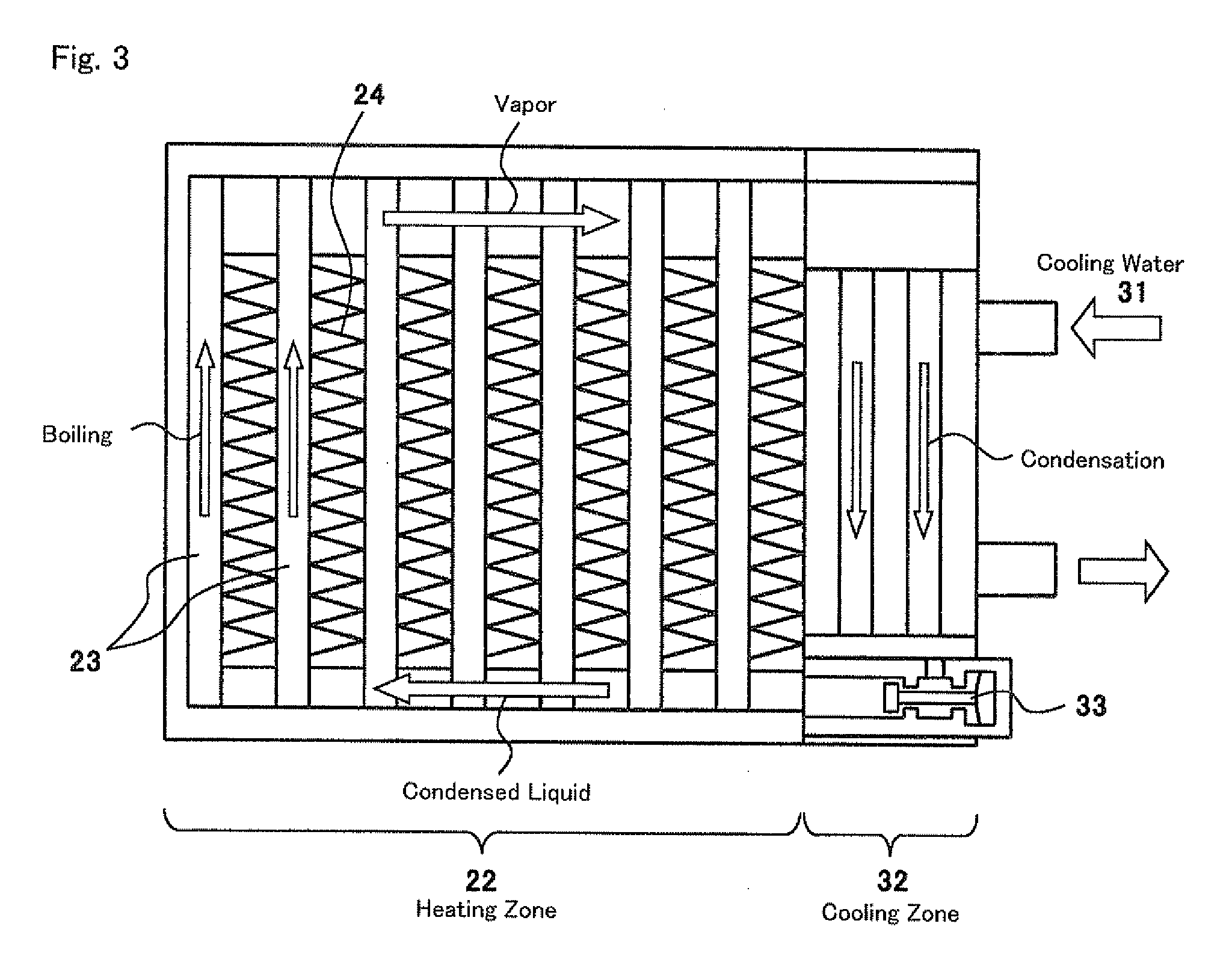

Heating / Cooling Cycle Durability Test

[0070]Using a cold-rolled annealed steel sheet (#400 dry polish-finished steel sheet) having a thickness of 0.8 mm of the samples A1 to A3, B6 and B7 in Table 1, the heat pipe (cup 23) of a high-temperature exhaust heat recovery system as in FIG. 3 was constructed. The heating method employed herein comprises introducing a high-temperature gas into the heat-collecting fin 24 from an external gas burner. The system was exposed to a test of heating / cooling 2000 cycles, in which one cycle comprises “1. heating with coolant (water) circulation for 5 minutes→2. further heating for 5 minutes with coolant circulation stopped→3. coolant circulation and heating stopped for 5 minutes”. The temperature of the heat pipe was about 400° C. in the step 1 of heating with coolant circulation, about 800° C. in the step 2 of heating with coolant circulation stopped, and from 100 to 200° C. in the cooling step 3; and in this cycle, the system is not corroded by dew ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com