Patents

Literature

1915 results about "Gas burner" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A gas burner is a device that produces a controlled flame by mixing a fuel gas such as acetylene, natural gas, or propane with an oxidizer such as the ambient air or supplied oxygen, and allowing for ignition and combustion.

Premix gas burner

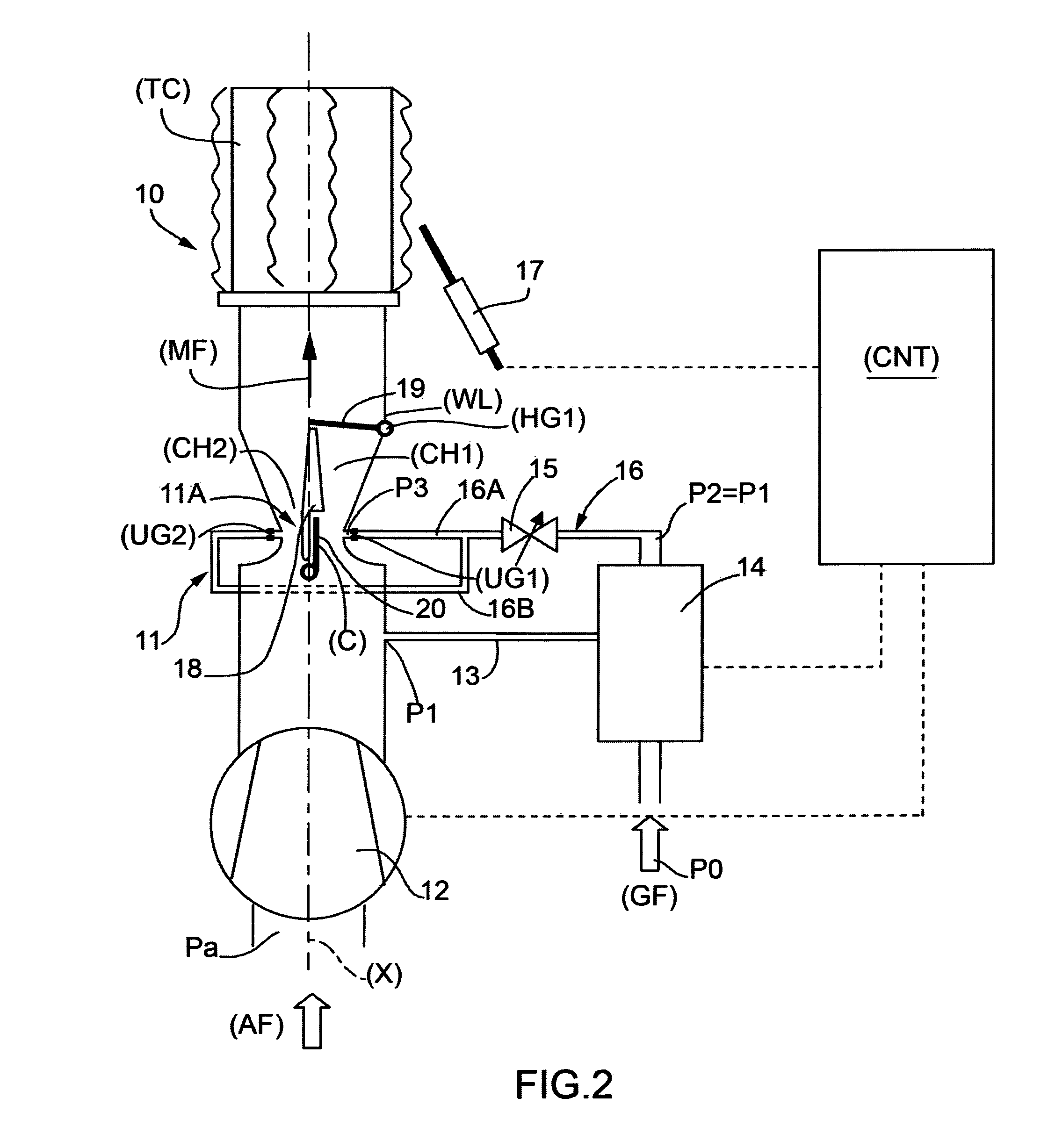

ActiveUS20110139045A1Easy and inexpensive to produceFuel supply regulationGaseous fuel burnerCombustible gasEngineering

An air / gas premix burner, comprising:a fan for sending the air / gas mixture to a combustion head;a gas valve for regulating admission of the combustible gas;an air / gas mixer, which comprises a device for localized loss of pressure; anda combustion head.The premix burner is characterized in that the air / gas mixer comprises at least two channels for mixing the air with the gas; in addition, a channel is provided with an open / close element designed to regulate the flow rate of the mixture.

Owner:GAS POINT

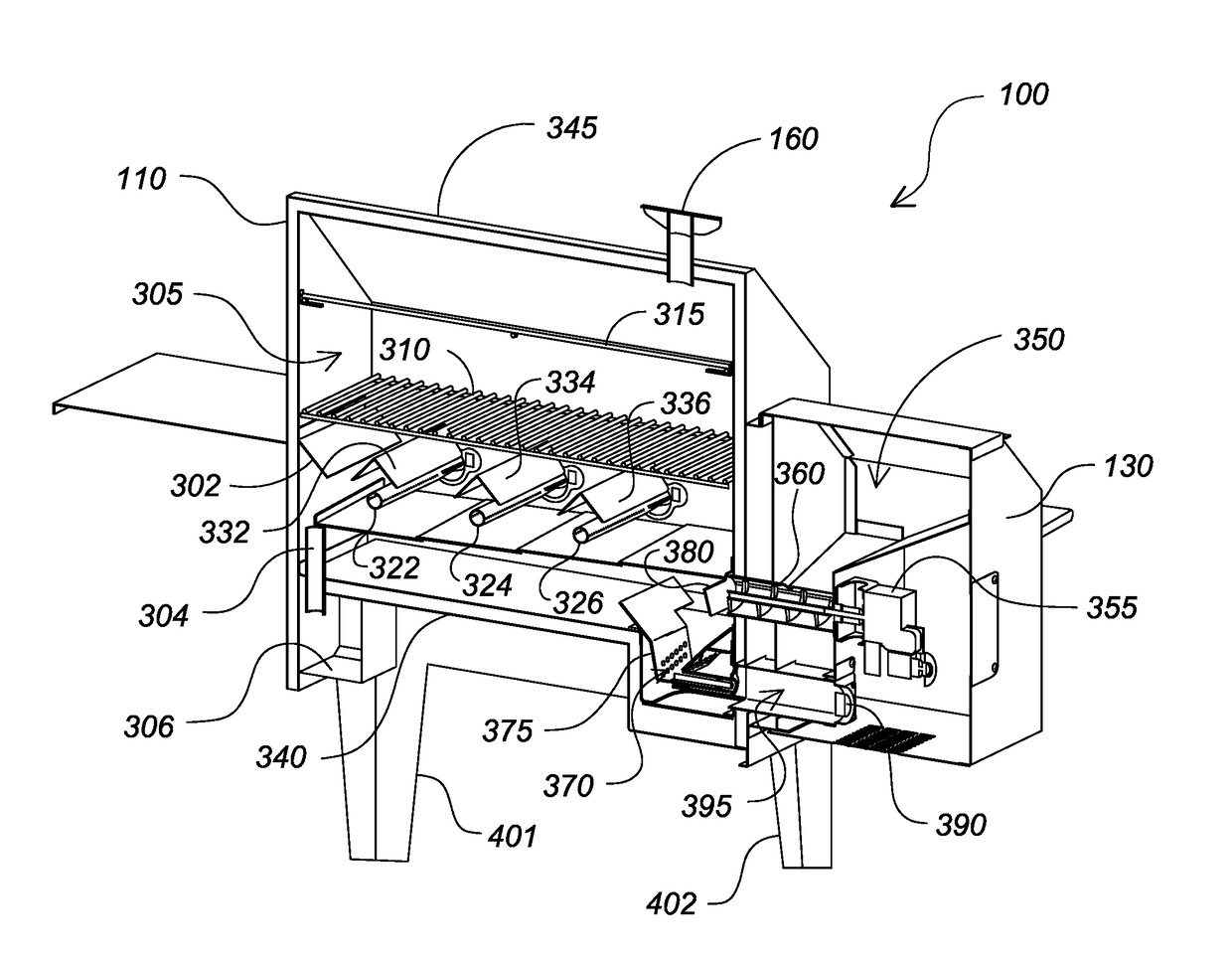

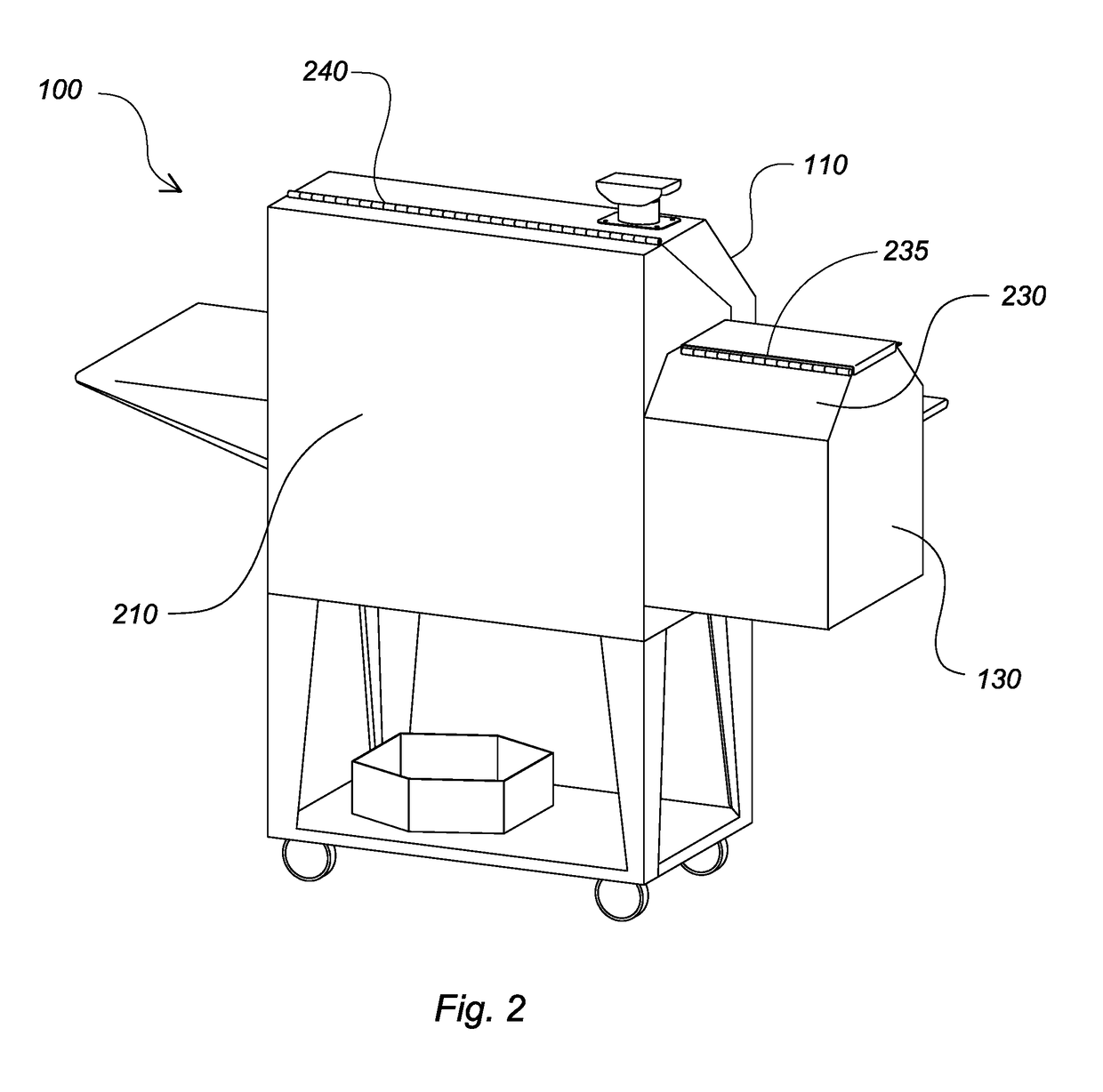

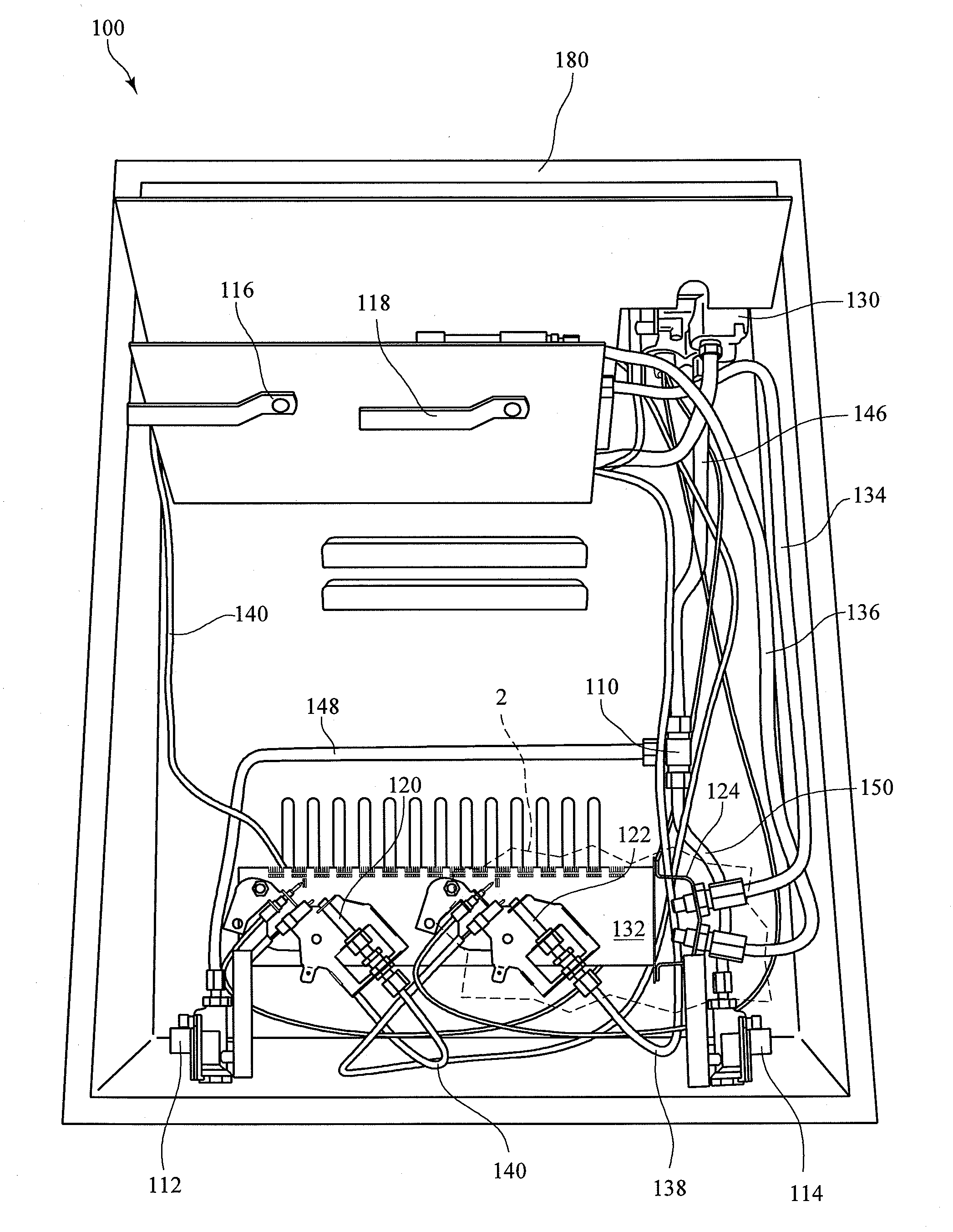

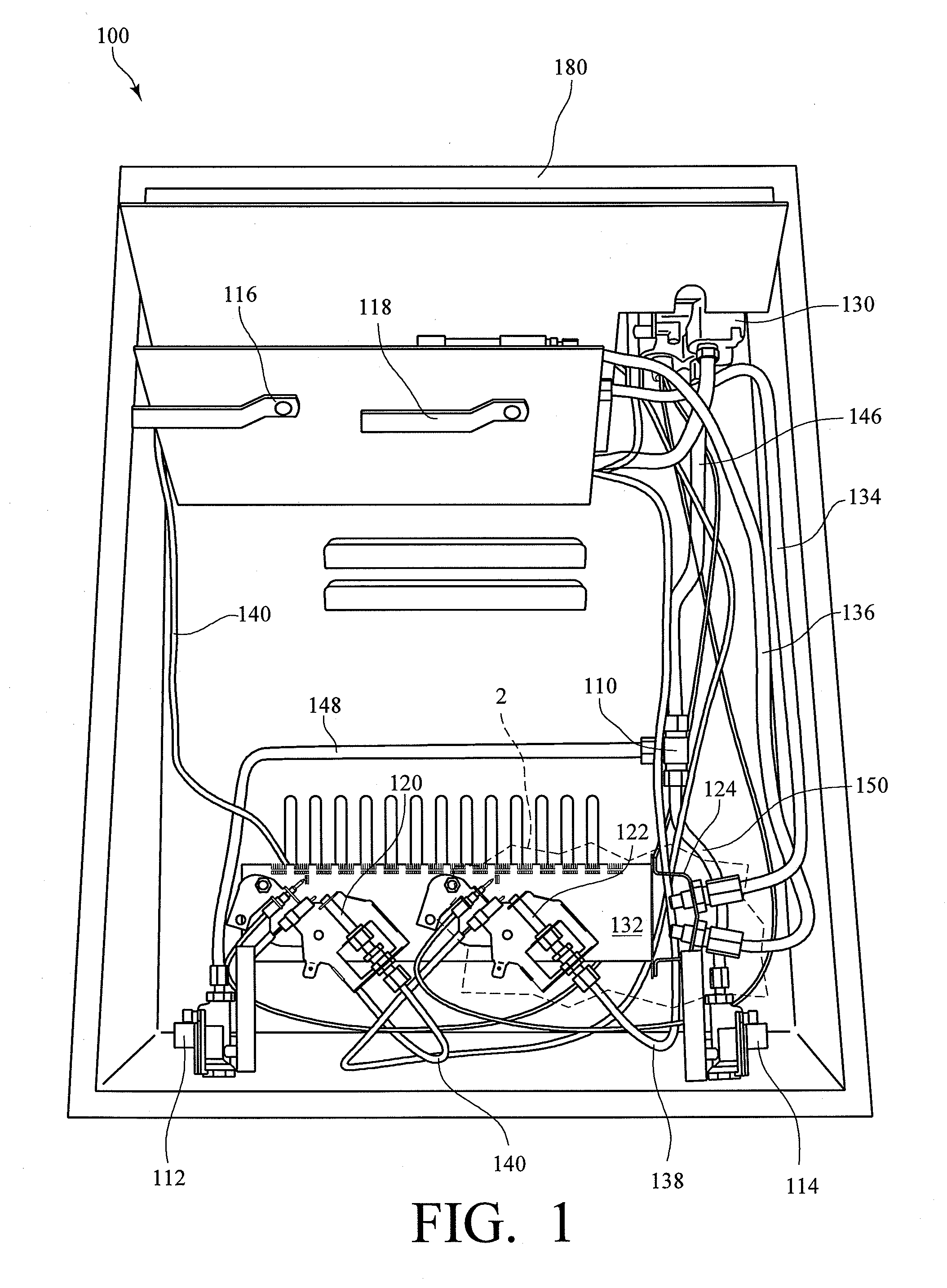

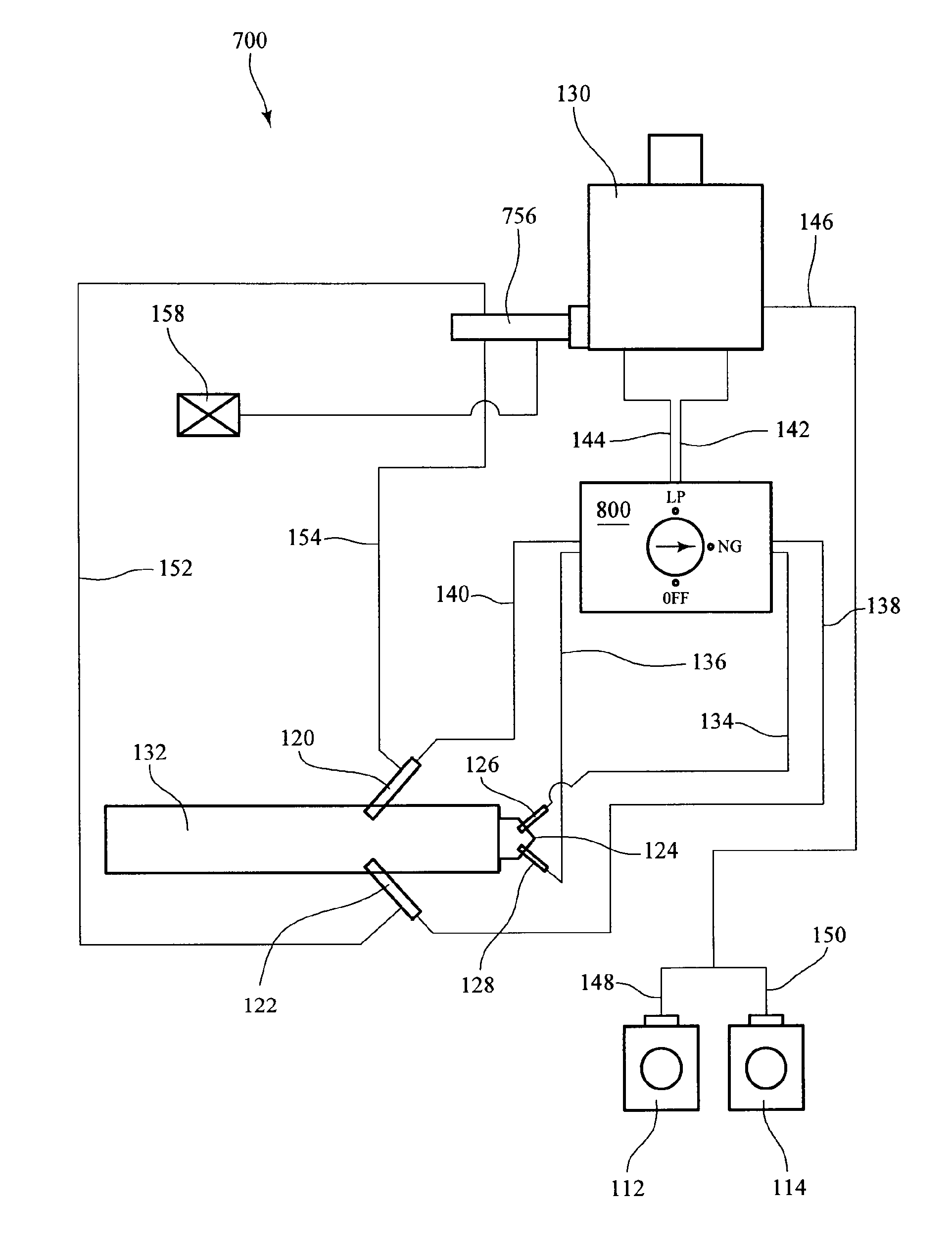

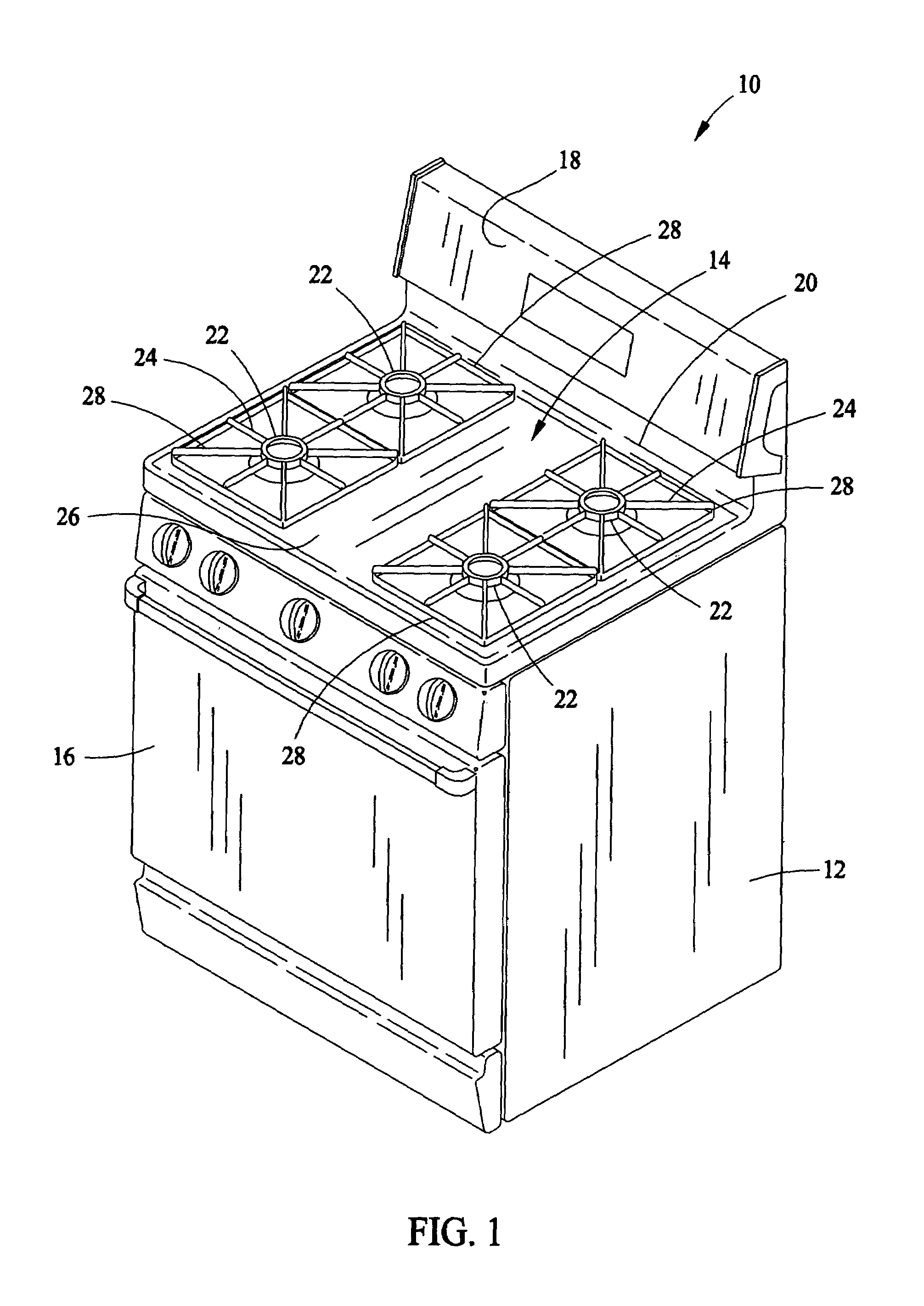

Multiple fuel cooking unit

InactiveUS20170164783A1Maintain sufficiencyWide rangeDomestic stoves or rangesLiquid heating fuelElectrical resistance and conductanceAutomatic control

A cooking unit may operate using multiple types of fuel to cook food. One or more first heat source, such as gas burners, electrical resistive heaters, and / or other heating technology, may provide radiant heat to a cooking chamber. One or more second heat source, such as a firebox, may provide indirect heat to the cooking chamber, for example by producing smoke. User operable controls and / or an automated control unit may alter the rate at which a fuel and / or air is supplied to one or more heat source.

Owner:SMOKESTEAK LLC

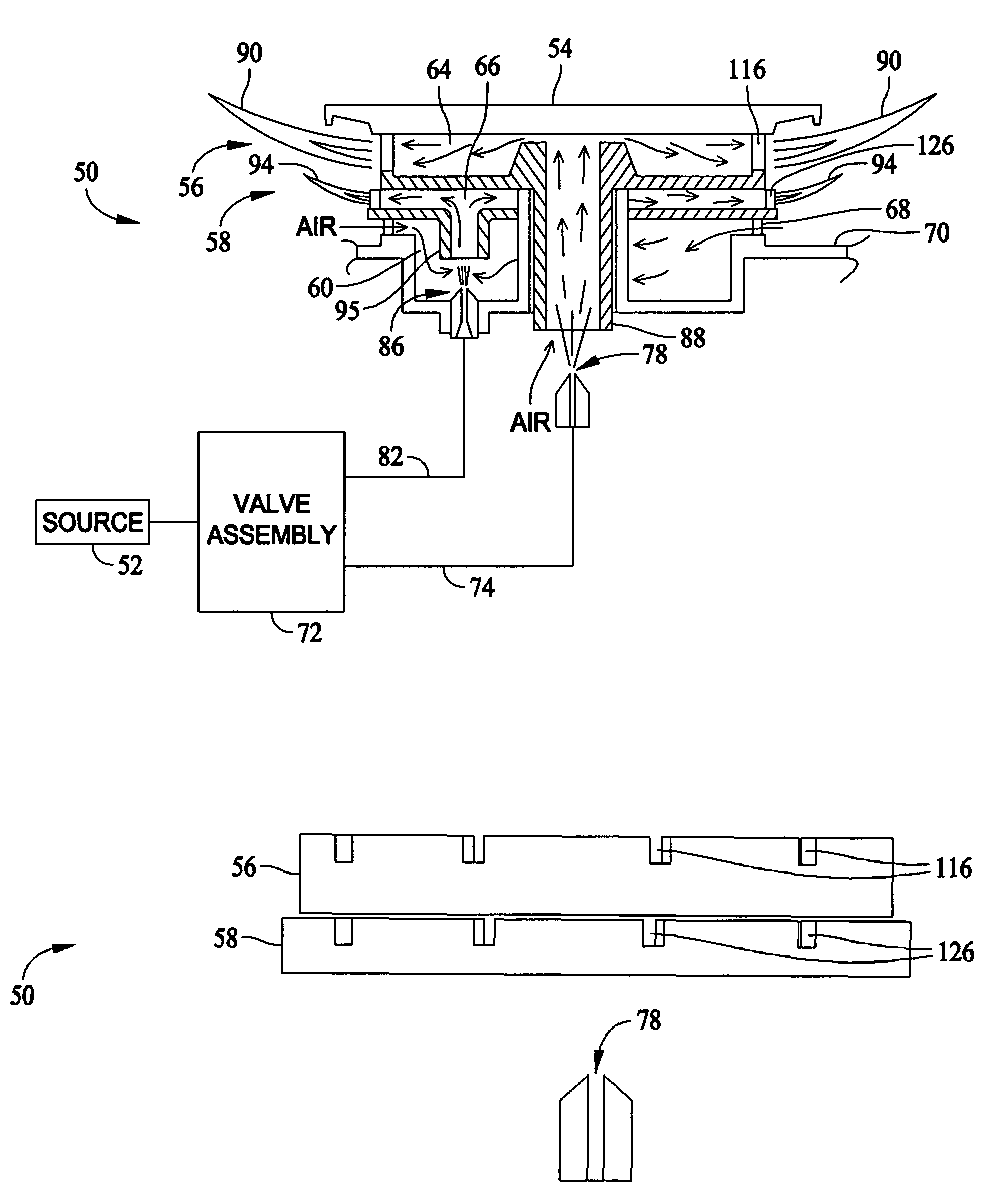

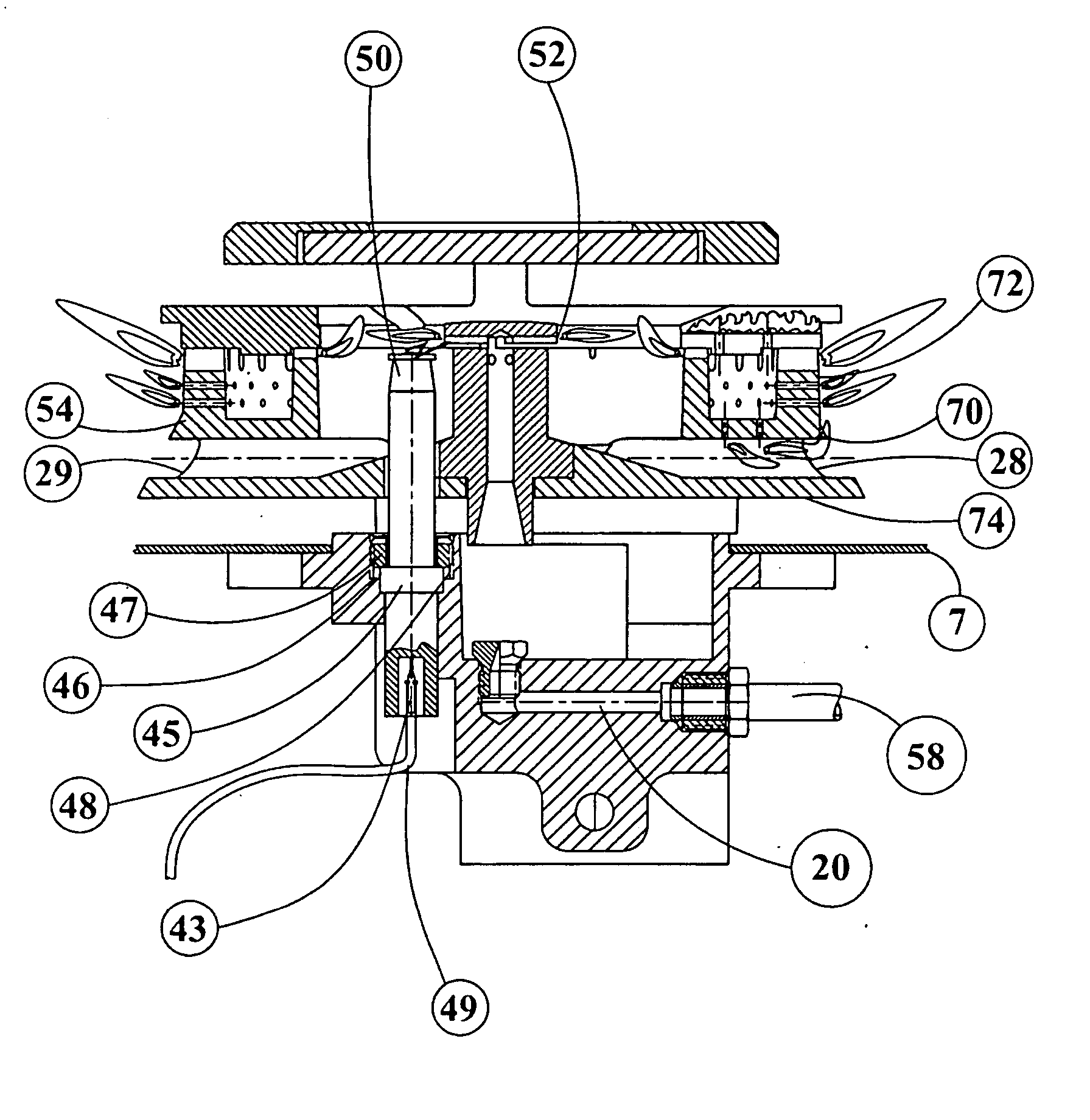

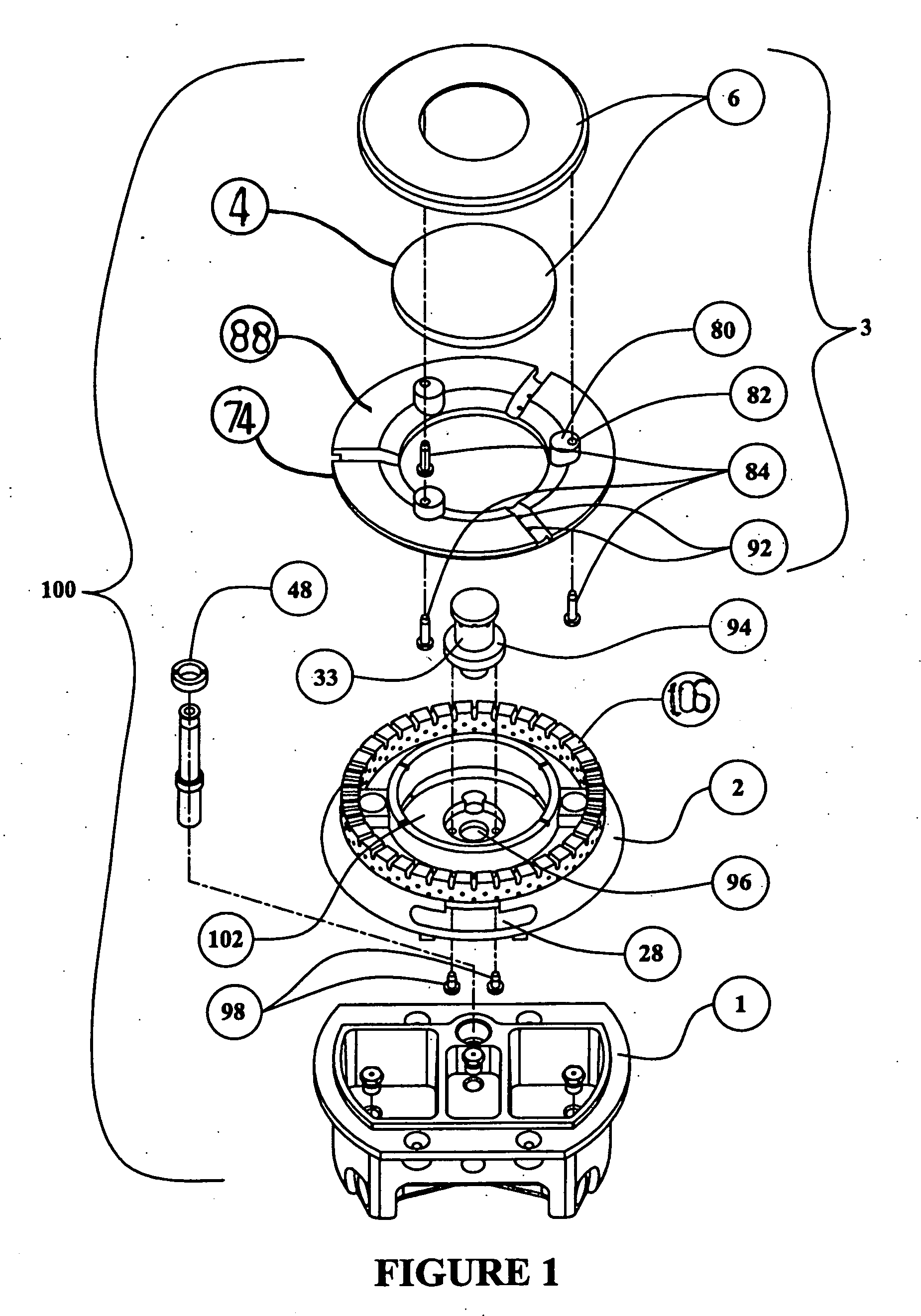

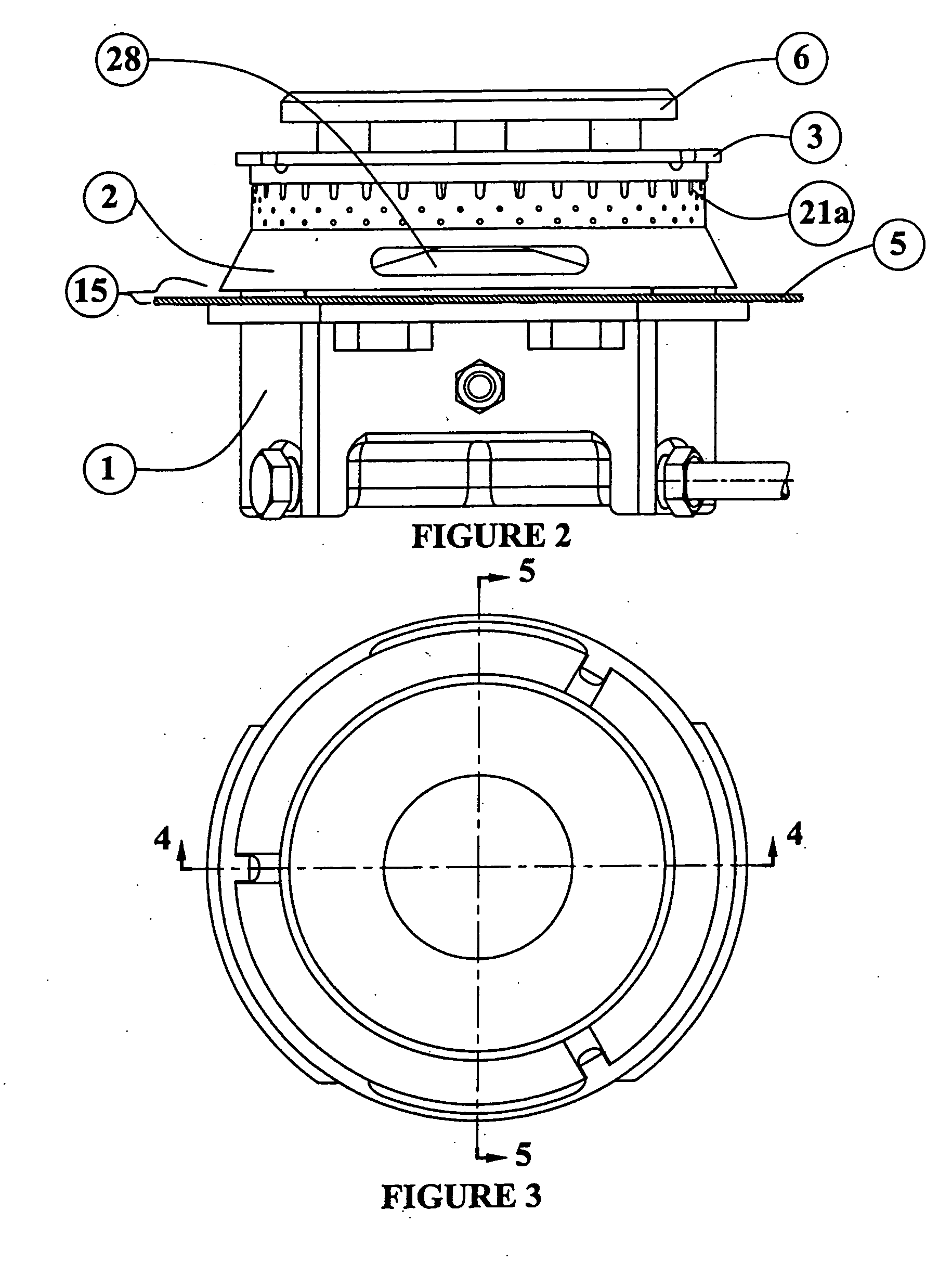

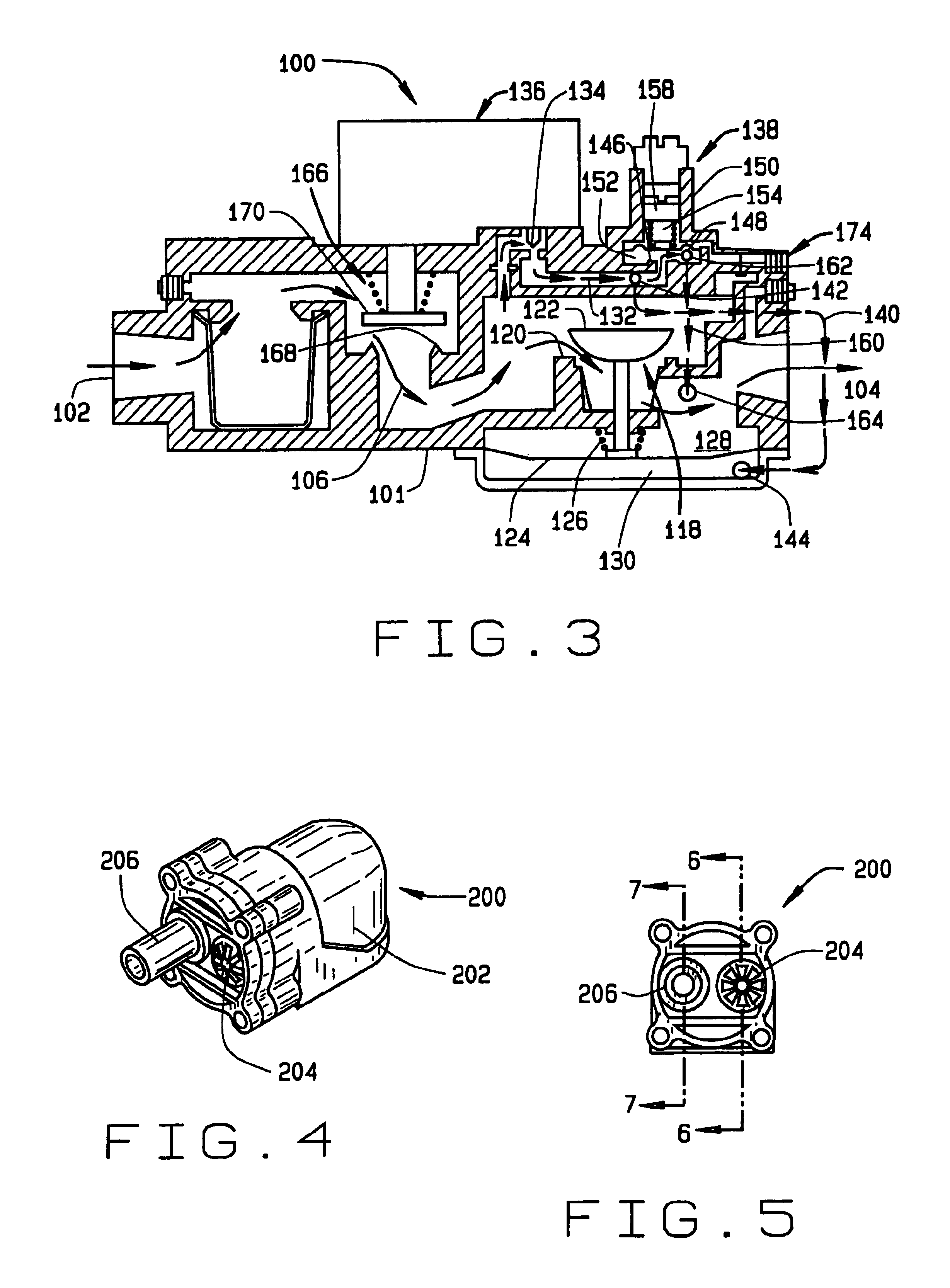

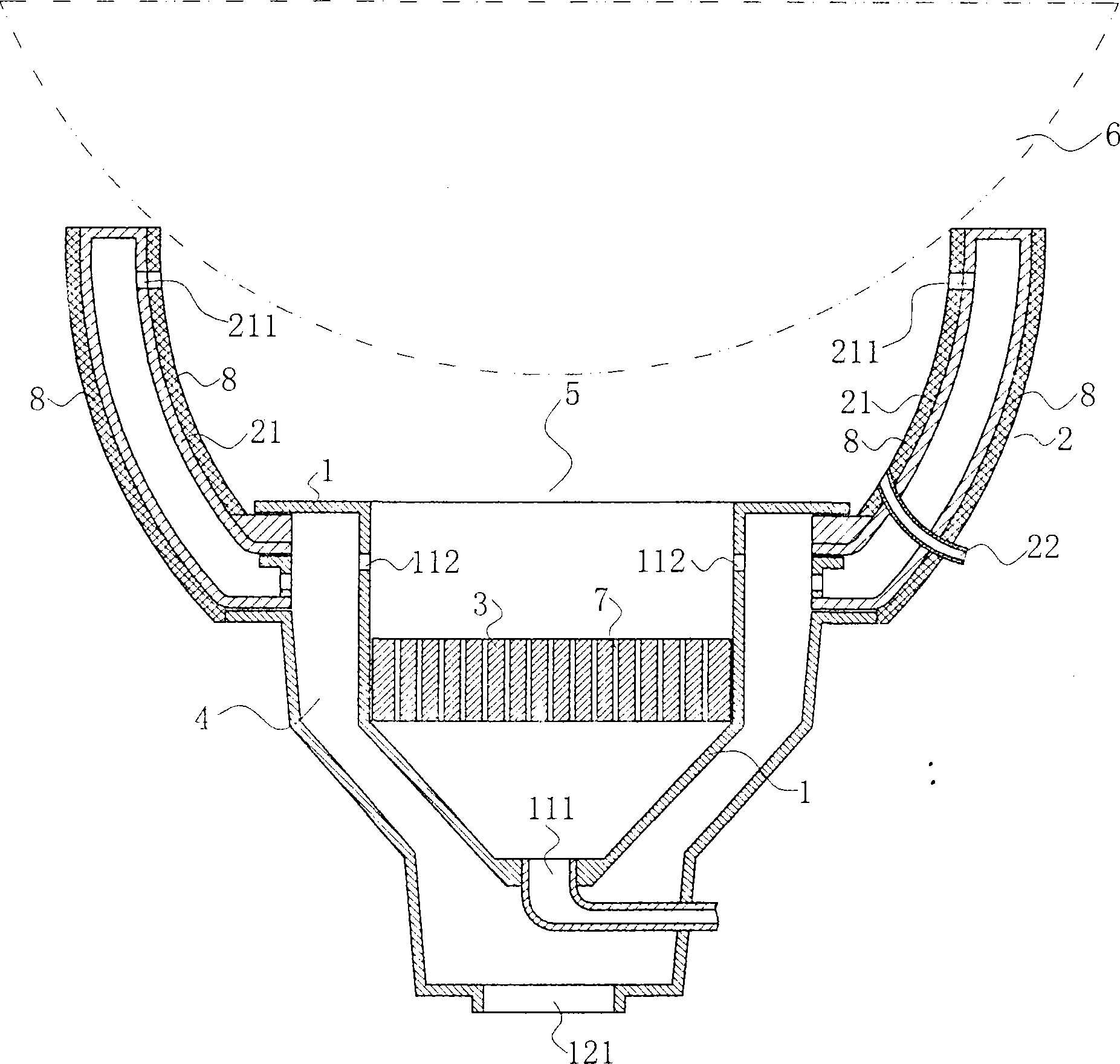

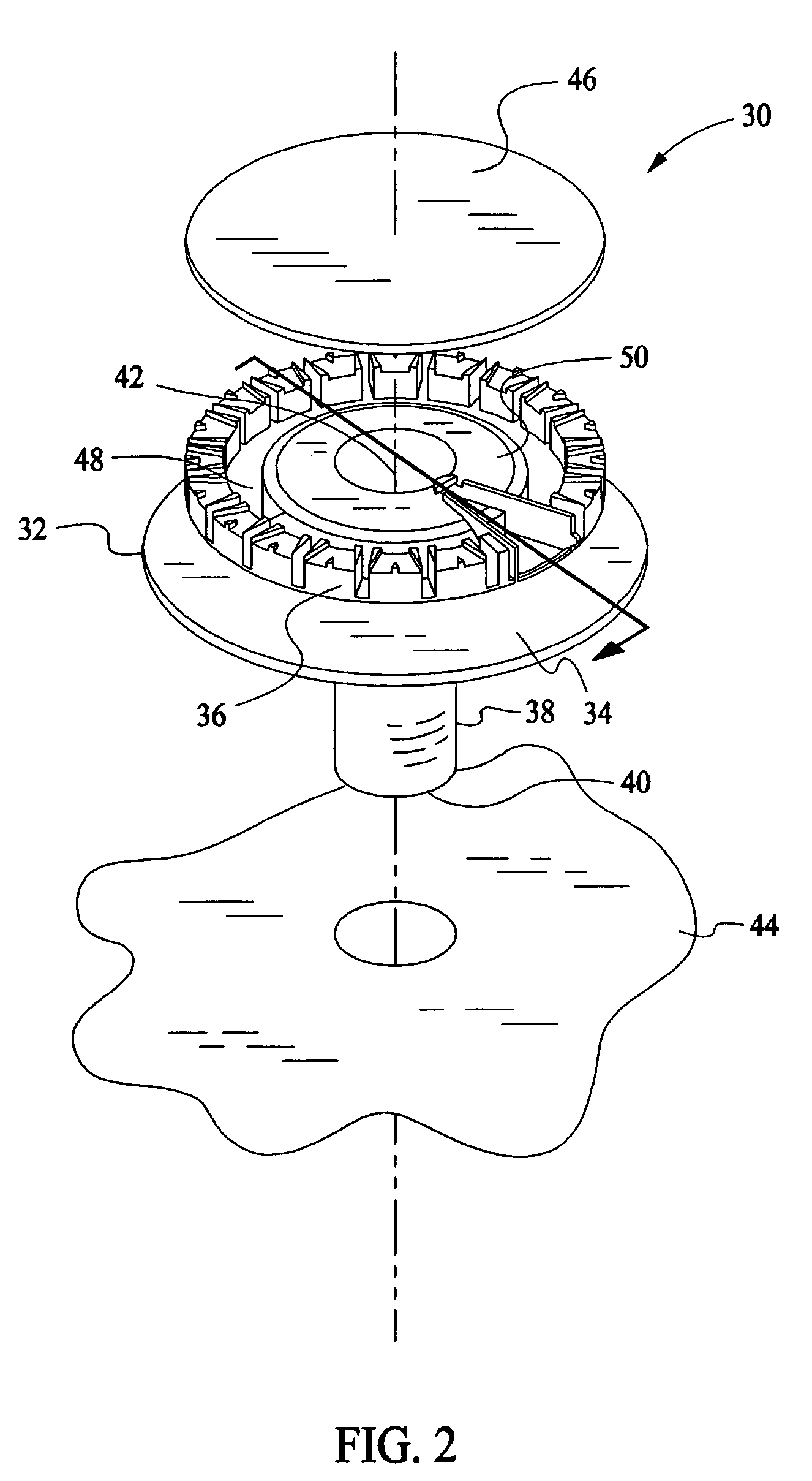

Dual stacked gas burner and a venturi for improving burner operation

ActiveUS7291009B2Amount of timeFacilitates simmeringDomestic stoves or rangesSpray nozzlesEngineeringThermal efficiency

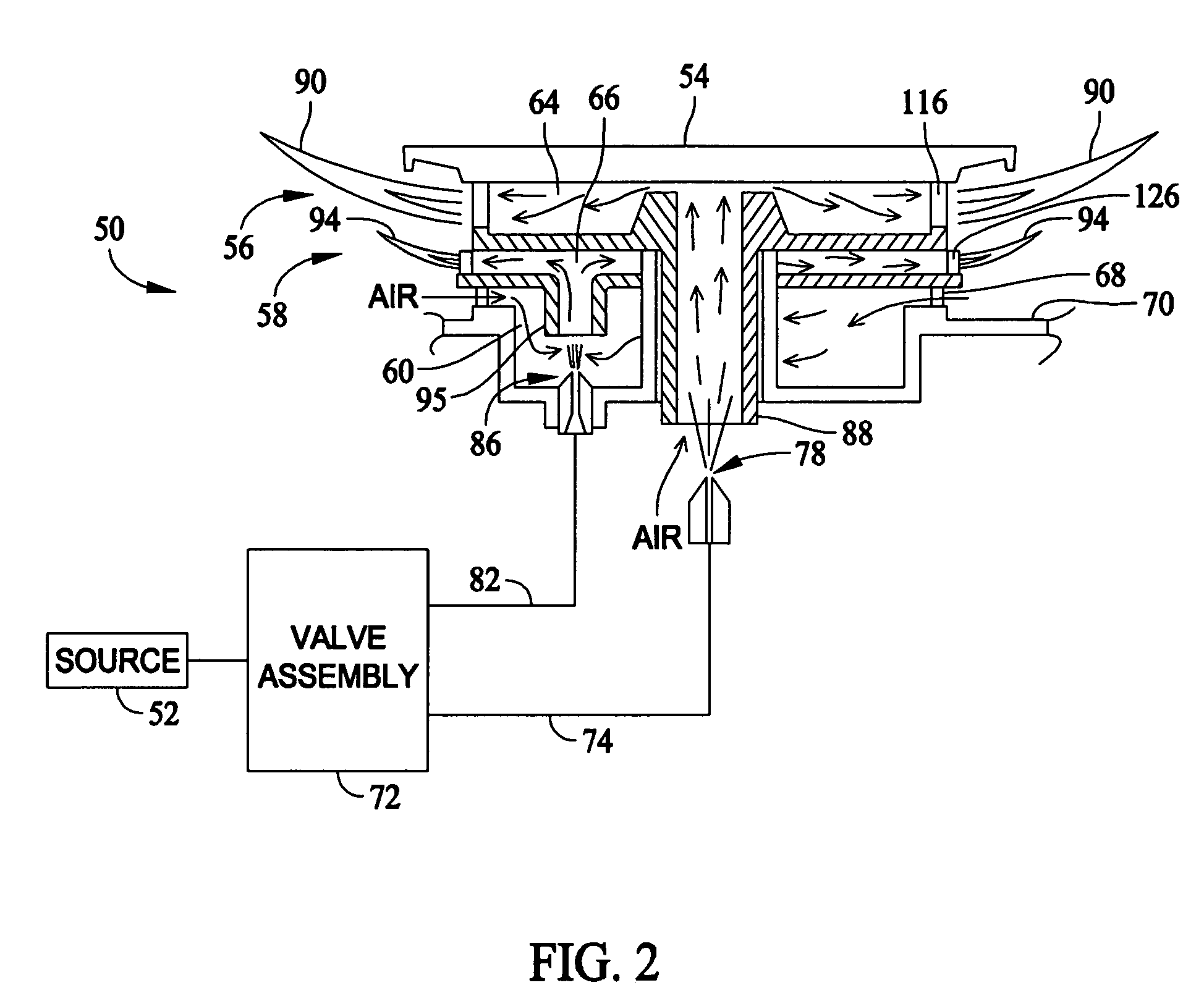

A cooktop burner assembly is described. The cooktop burner assembly includes a main burner, and a simmer burner located below the main burner, where a diameter of the simmer burner is greater than a diameter of the main burner. The closer placement of the main burner to a cooking vessel placed on top of the cooktop burner assembly as compared to the placement of the simmer burner from the cooking vessel increases thermal efficiency. Moreover, the farther placement of the simmer burner from the cooking vessel facilitates simmering of items in the cooking vessel and the larger diameter of the simmer burner reduces a possibility of overheating the main burner and the cooking vessel.

Owner:HAIER US APPLIANCE SOLUTIONS INC

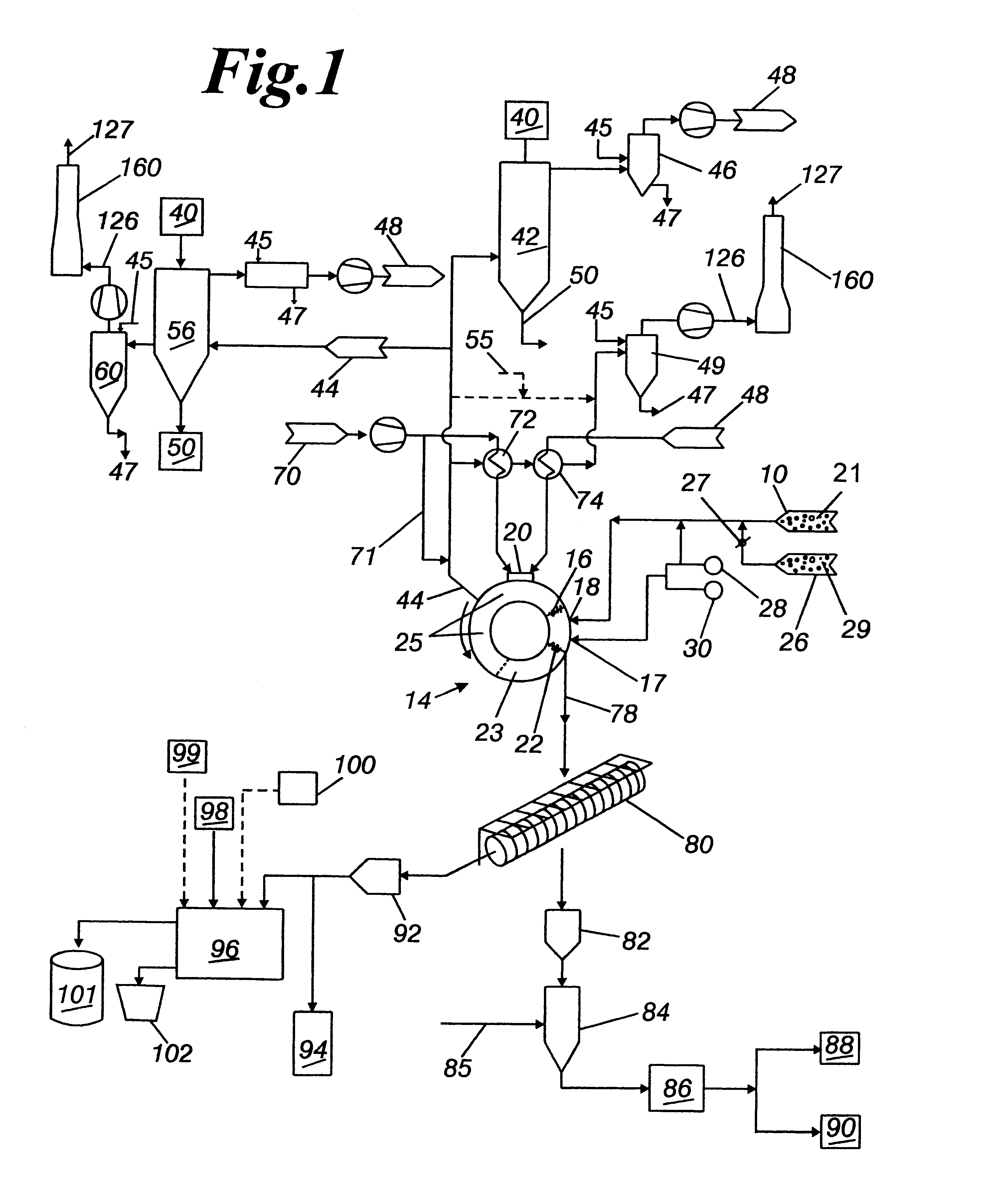

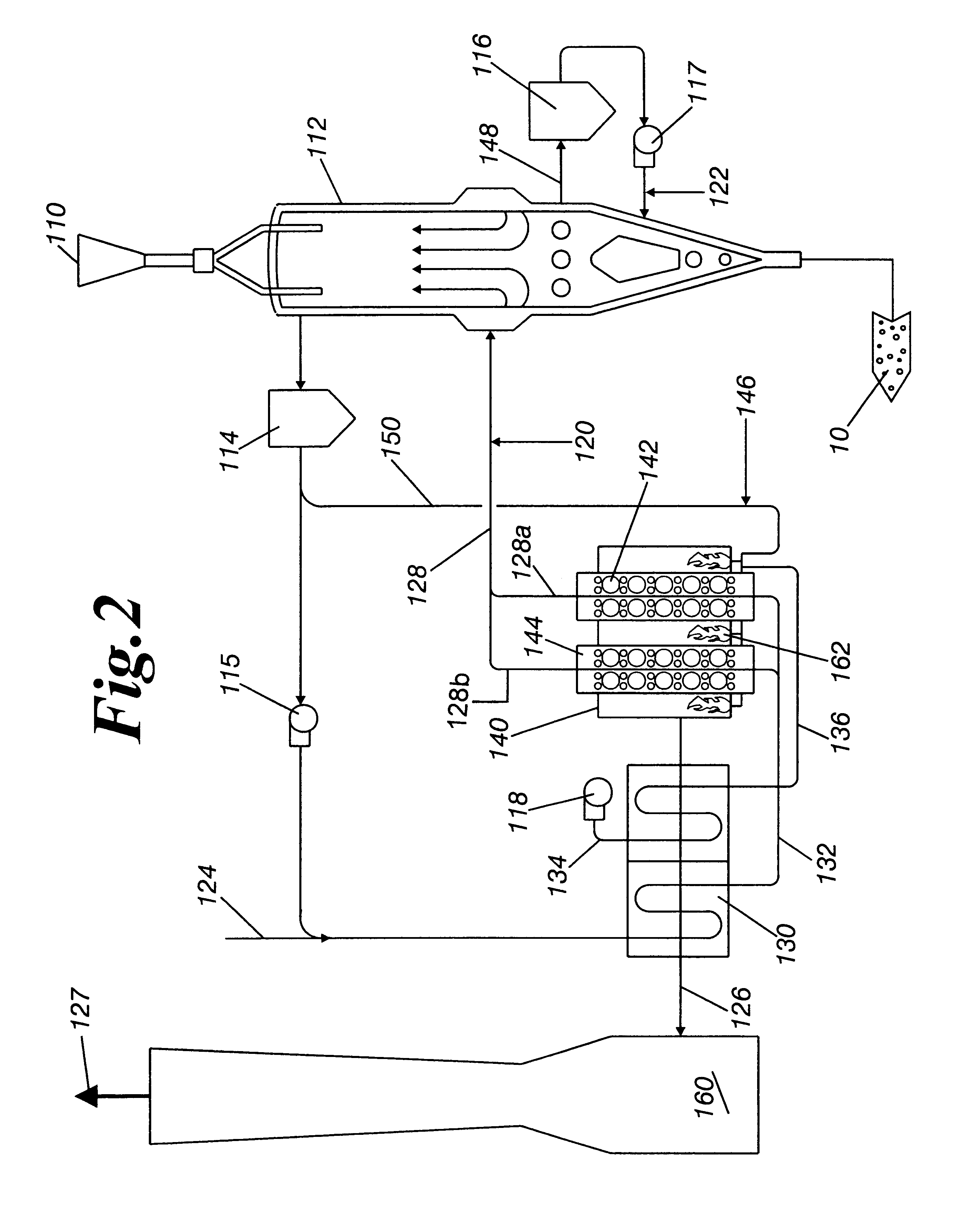

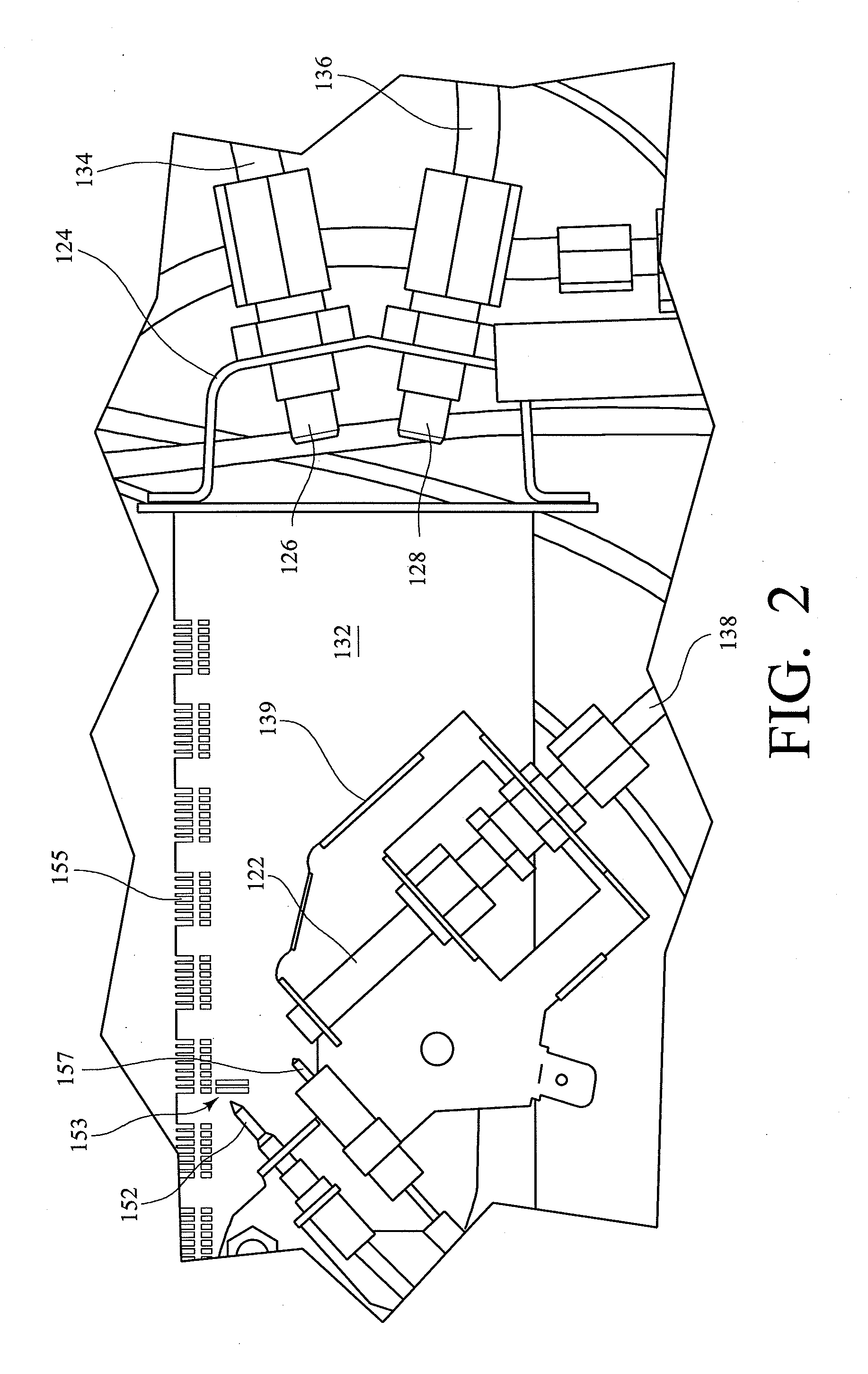

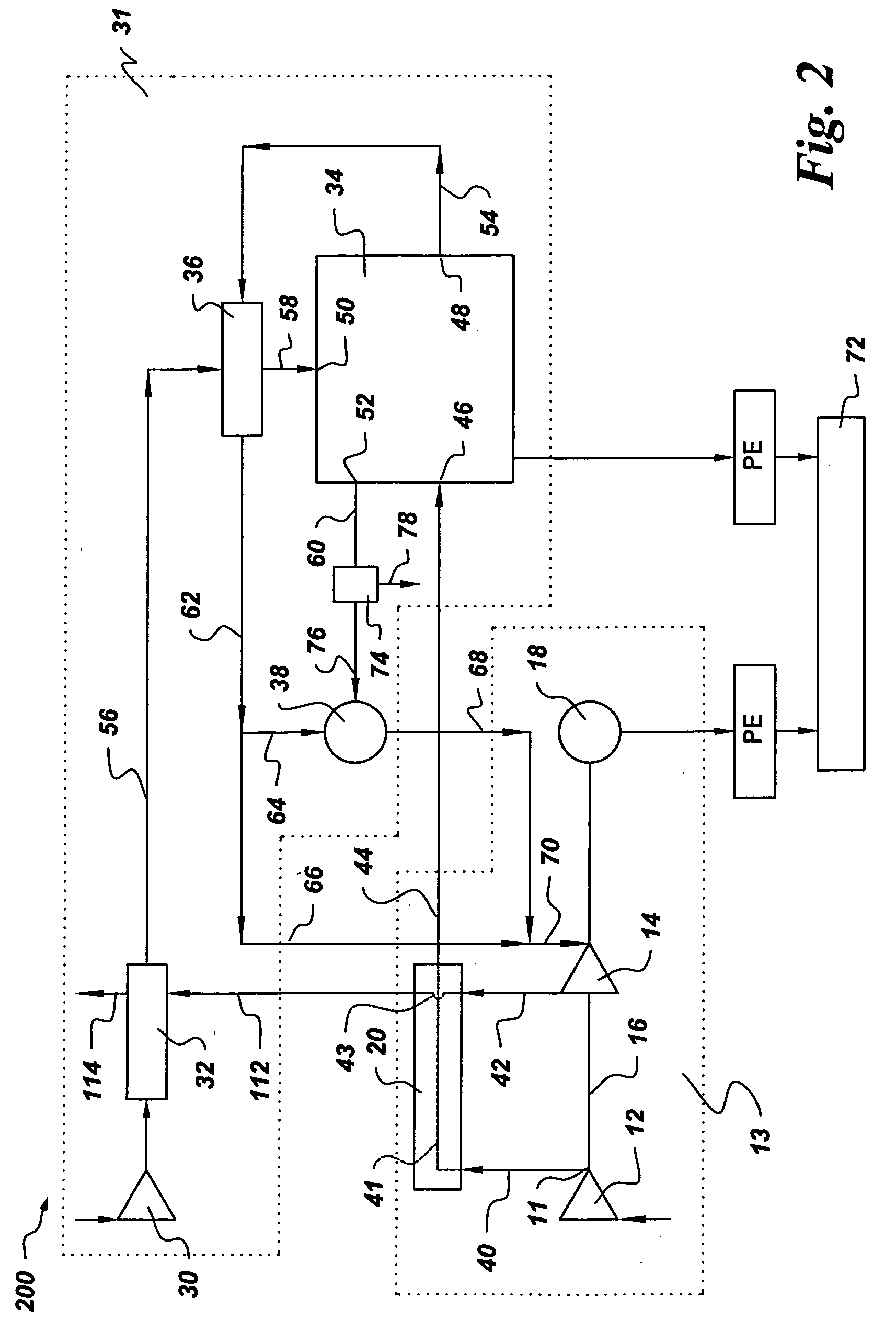

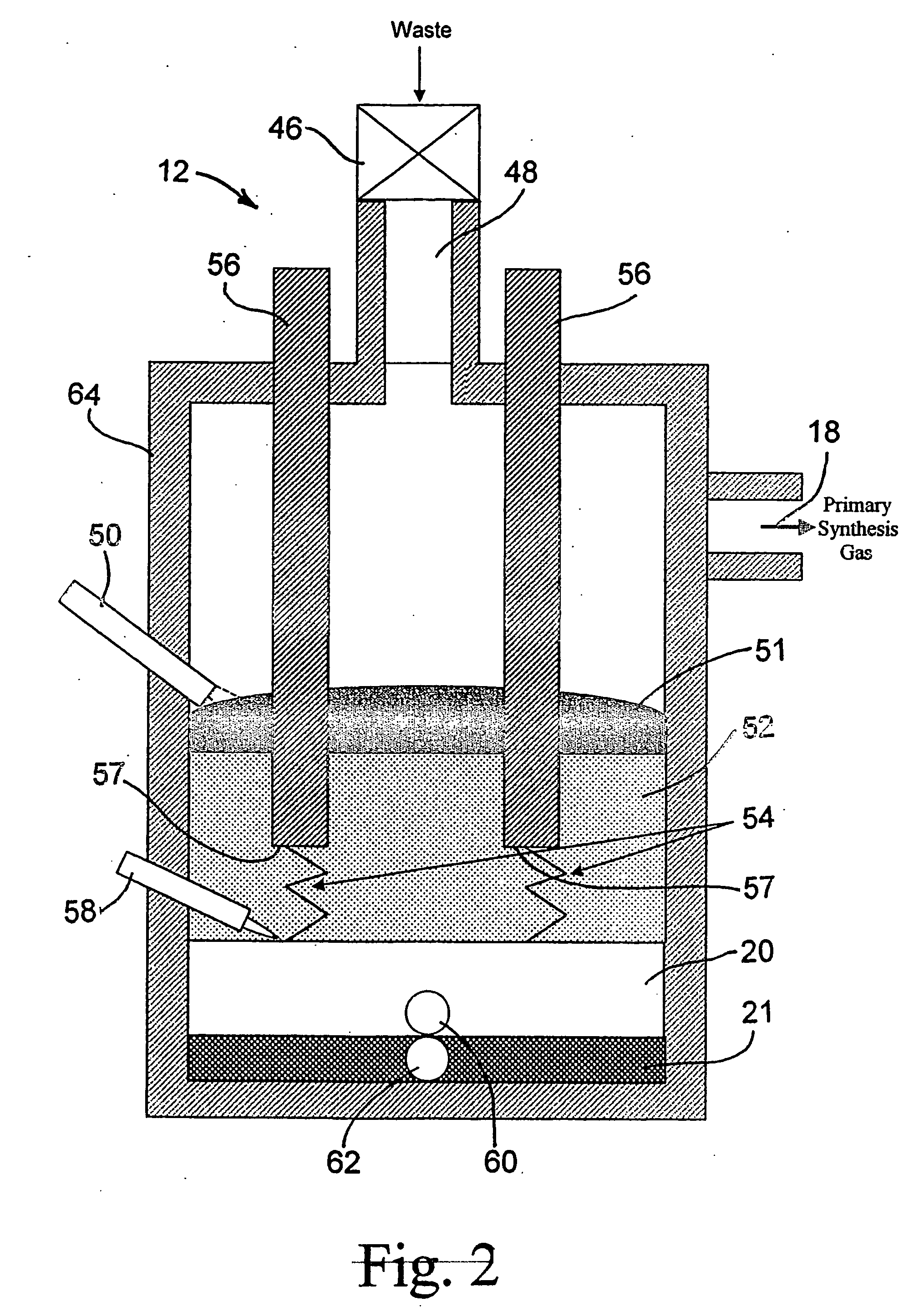

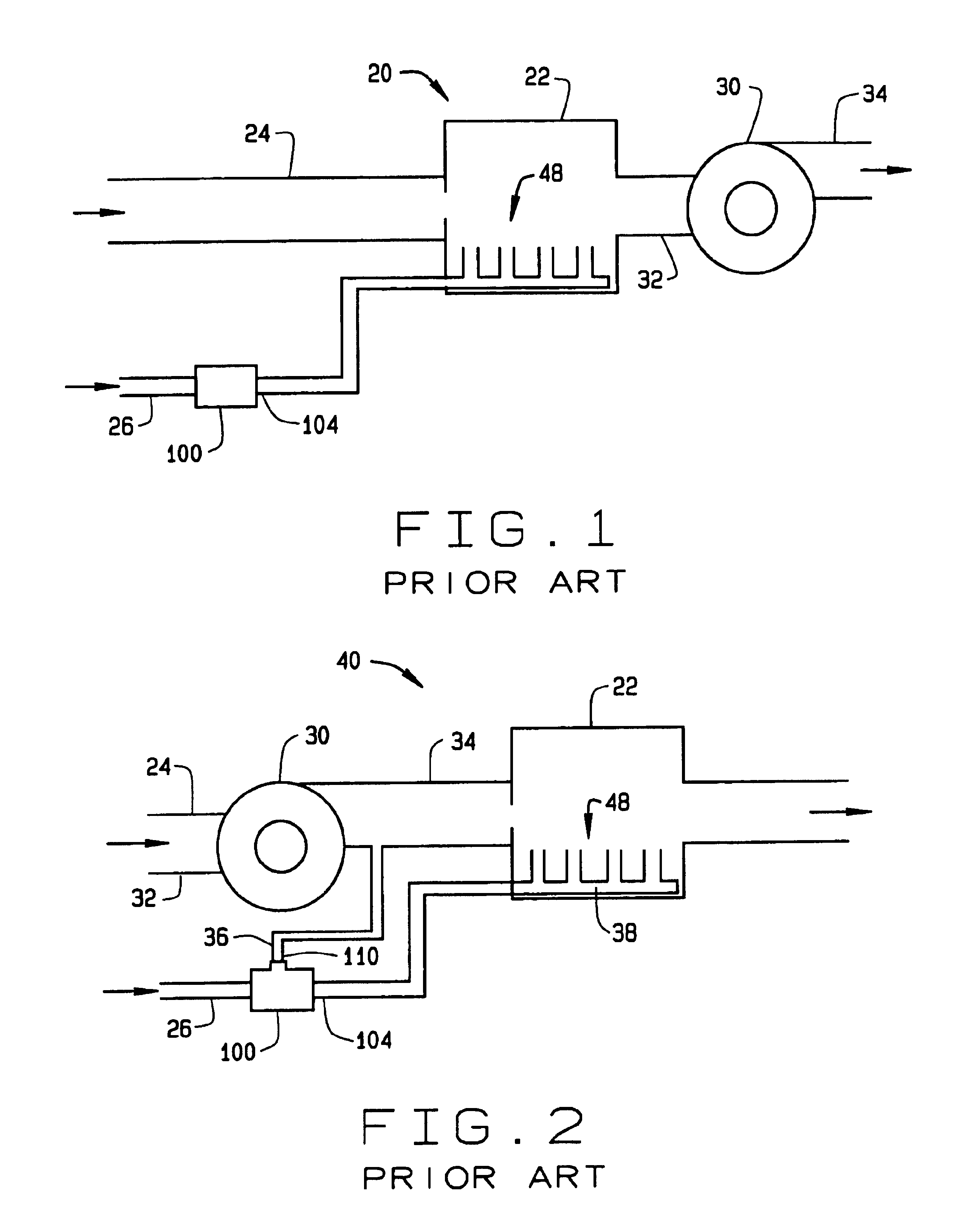

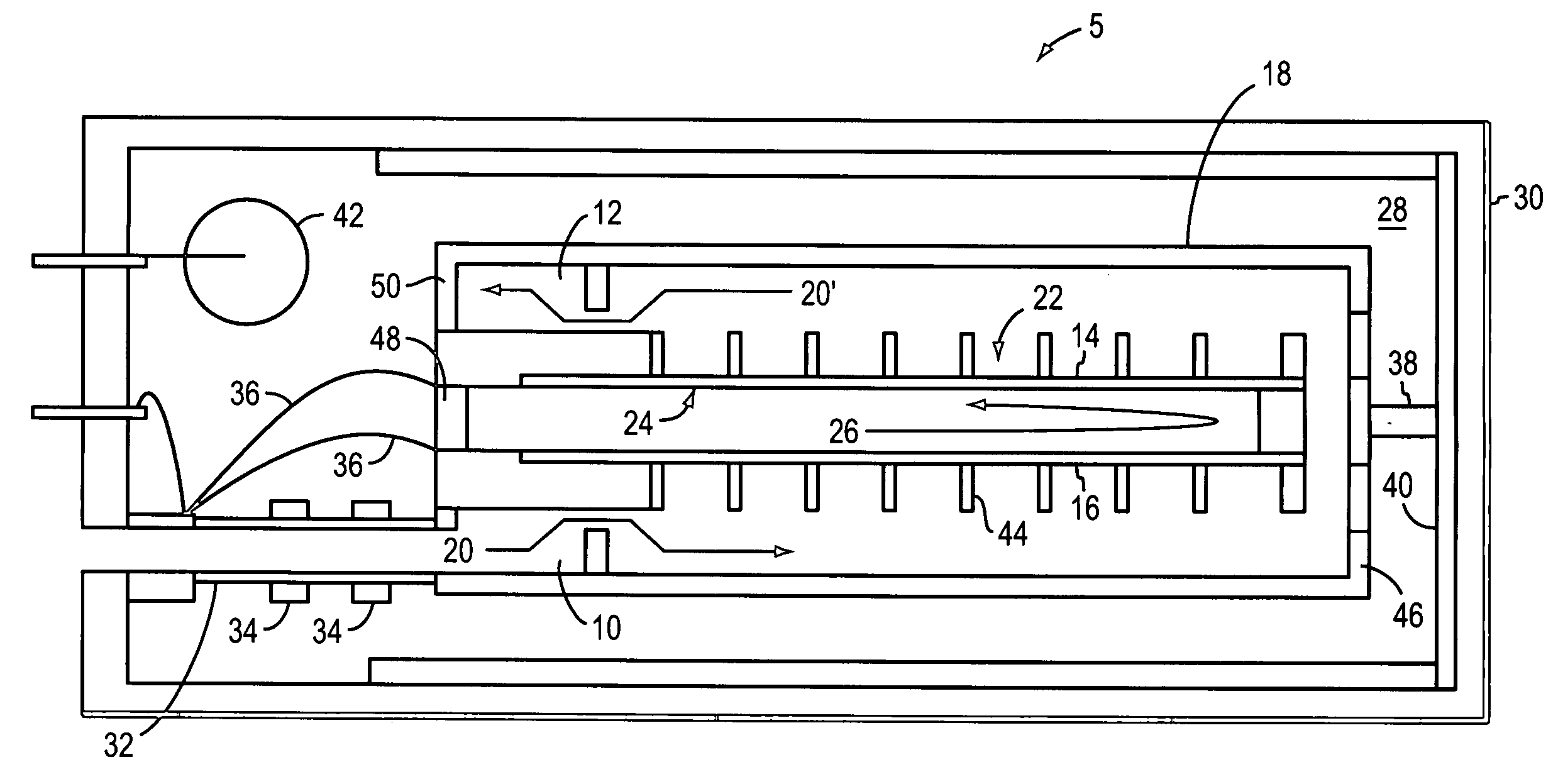

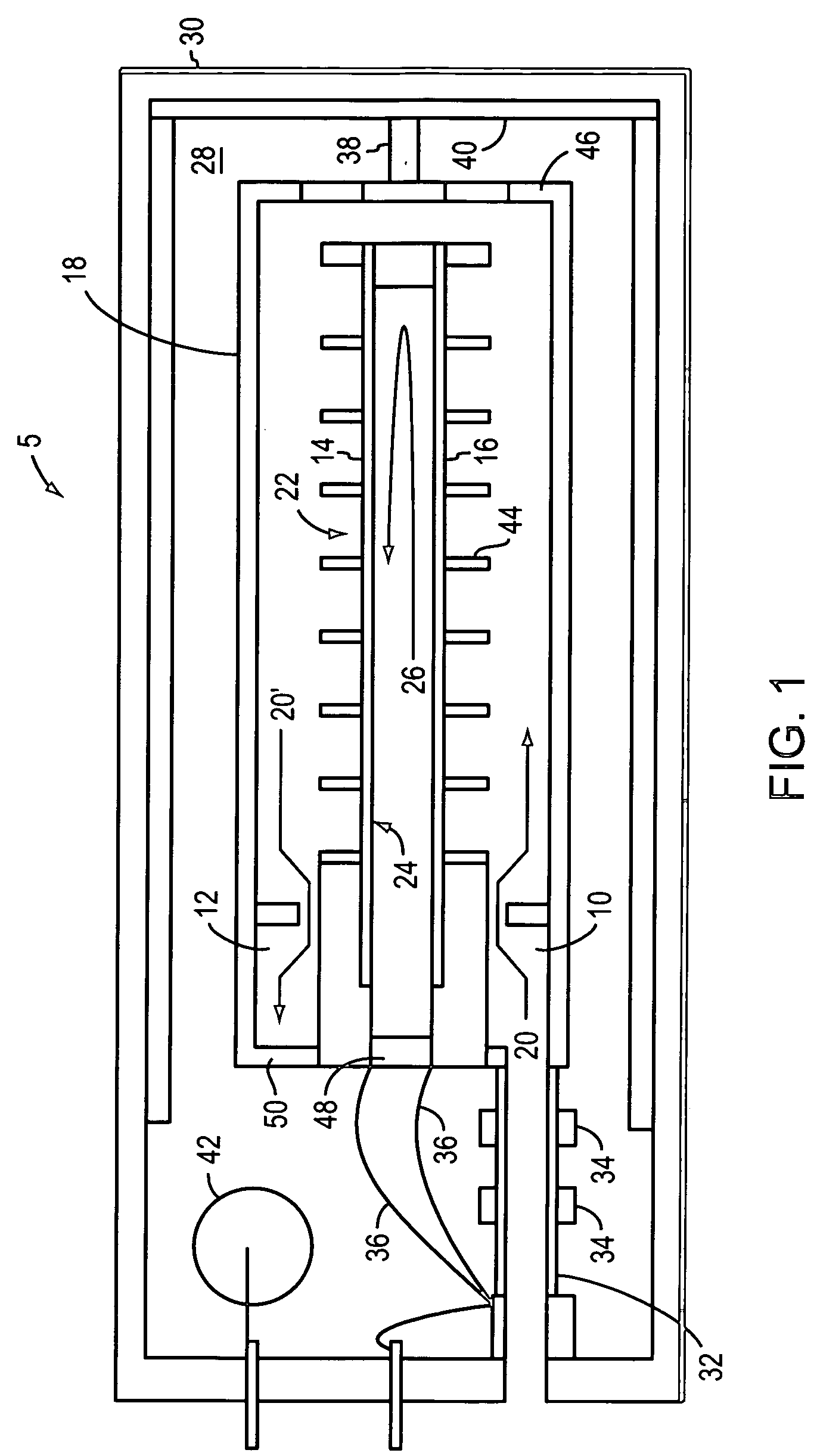

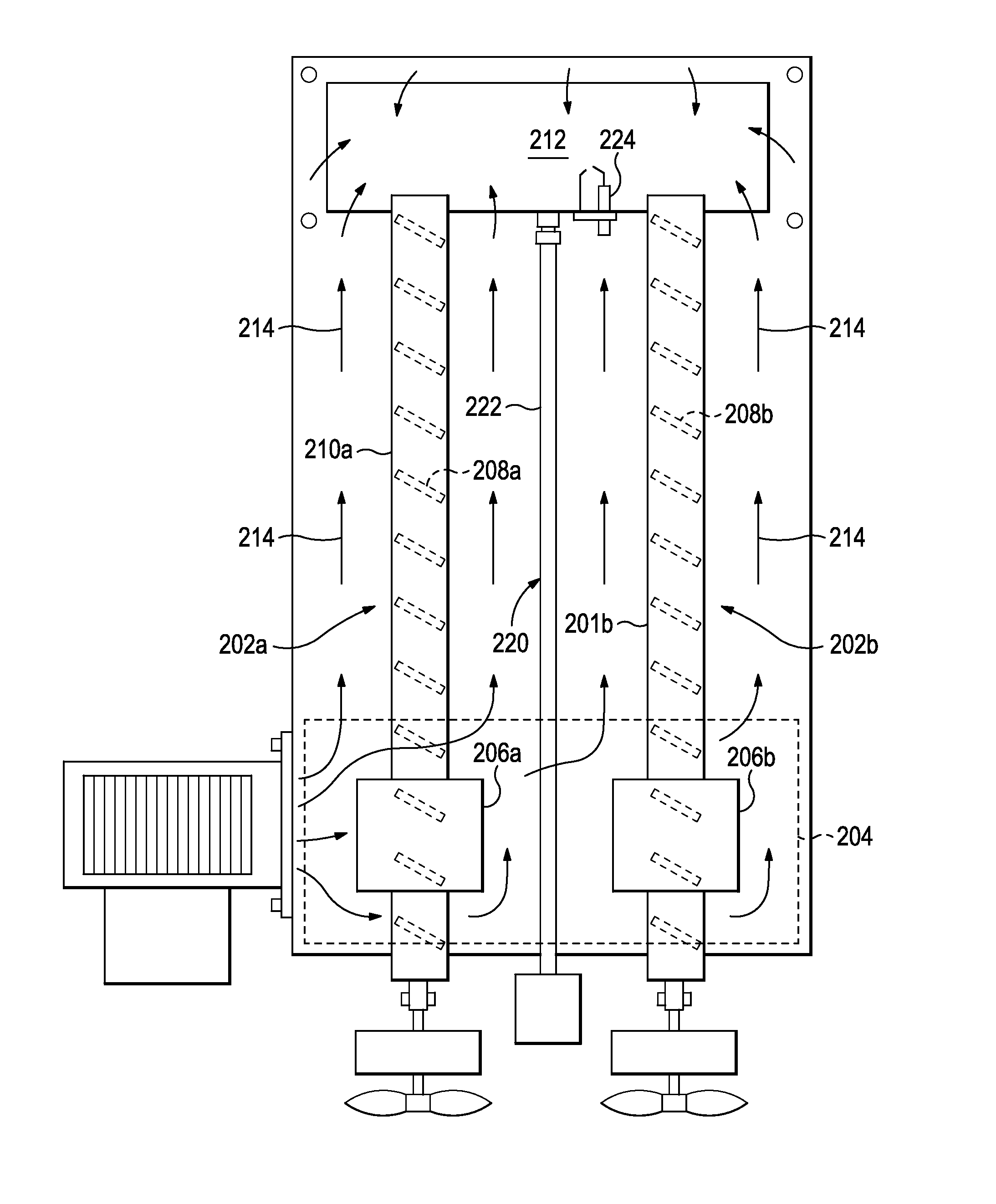

System and method for generation of high pressure air in an integrated gasification combined cycle system

InactiveUS20080115478A1Reduces capital equipment cost and operational costEasy temperature controlMuffle furnacesCombustion enginesAir separationProcess engineering

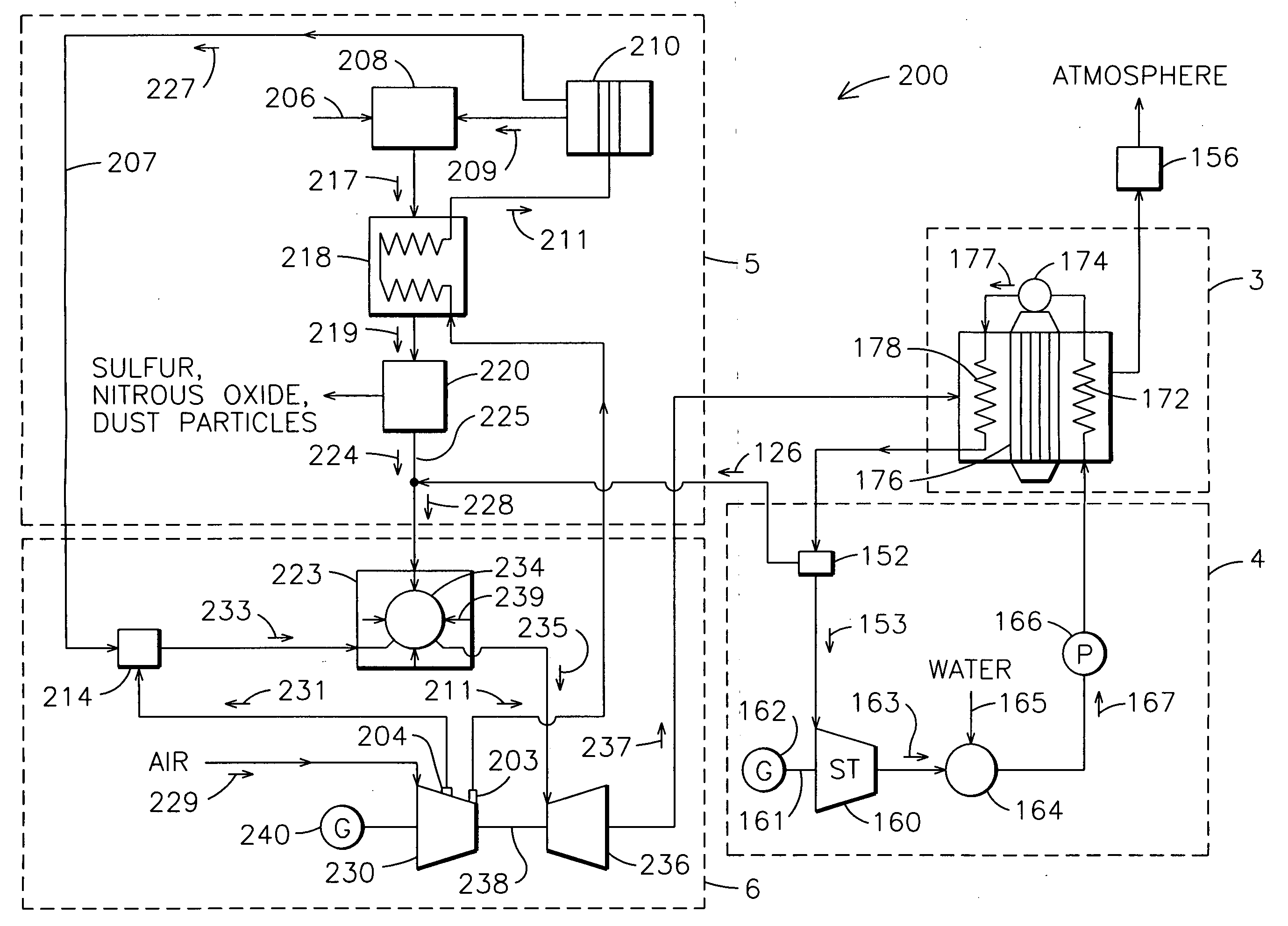

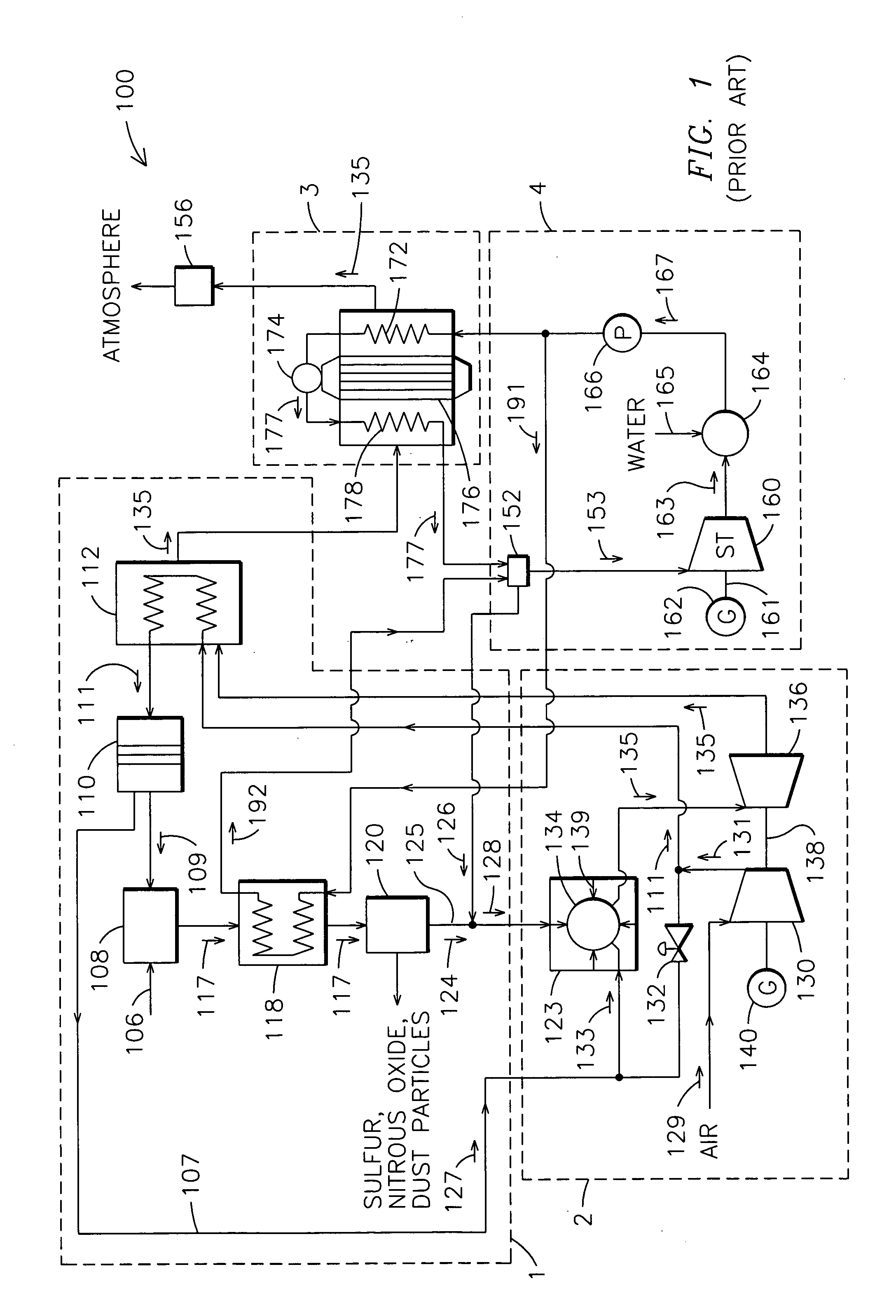

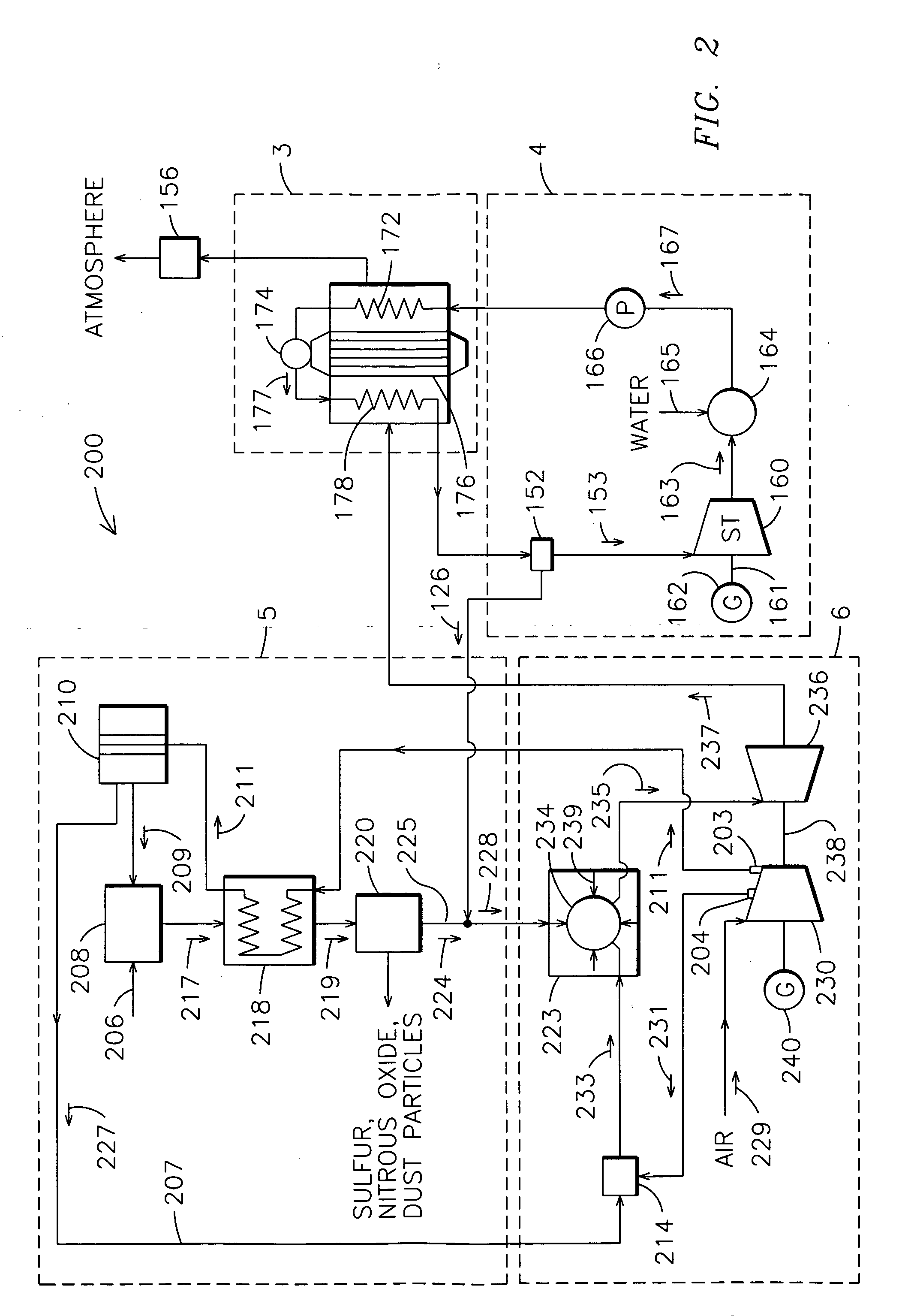

An integrated gasification combined cycle system. In one embodiment (FIG. 2) a system (200) includes an ion transport membrane air separation unit (210) for producing oxygen-enriched gas (209) and oxygen-depleted air (227), a gasification system (5) for generating syngas with the oxygen-enriched gas (209), a gas combustor (234) for reacting the syngas (224), and a subsystem configured to provide a first stream of air to the combustor (234) at a first pressure and to provide a second stream of air to the air separation unit (210) at a second pressure greater than the first pressure. The subsystem includes a compressor (230) having multi-pressure outlets (203, 204).

Owner:SIEMENS ENERGY INC

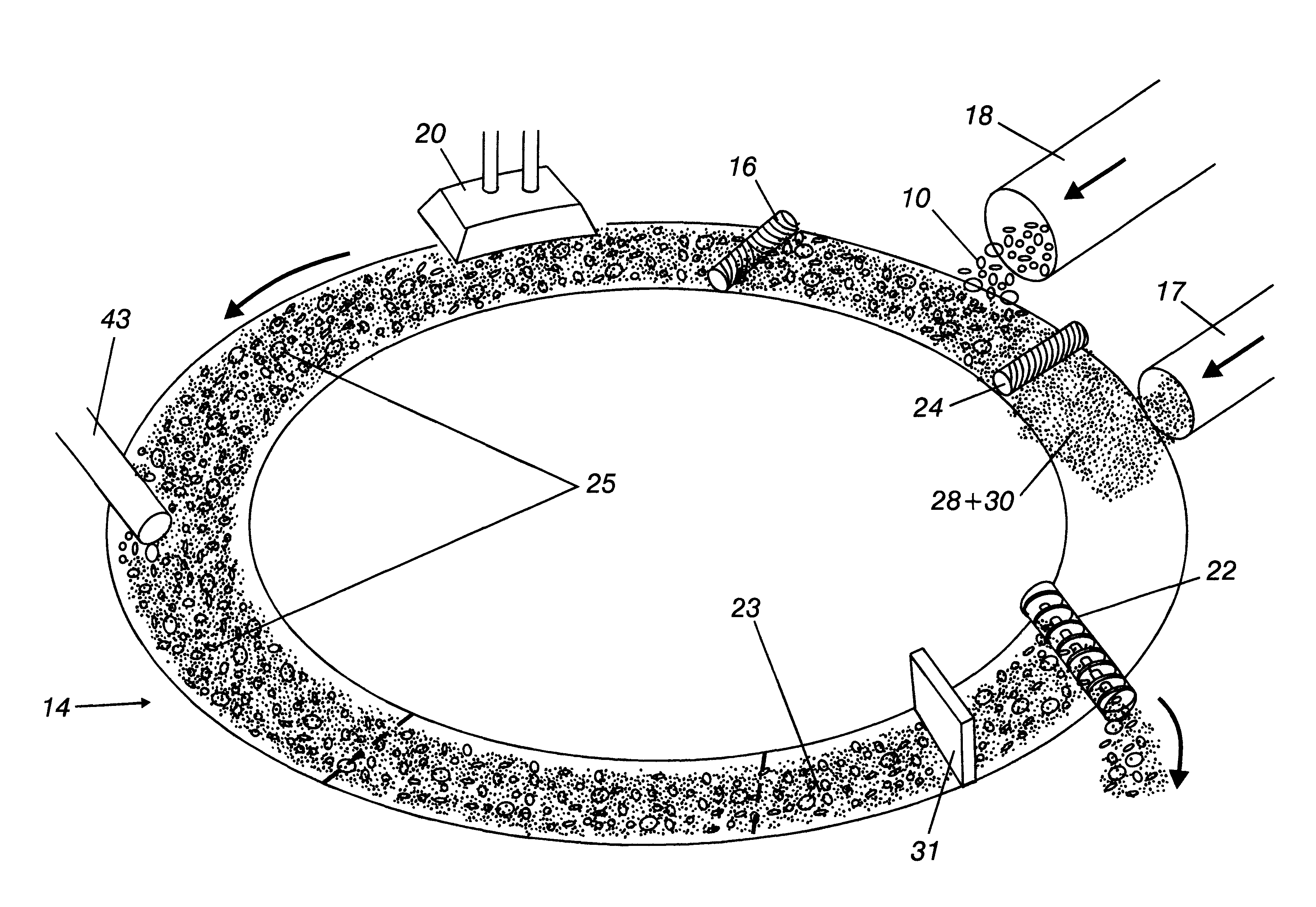

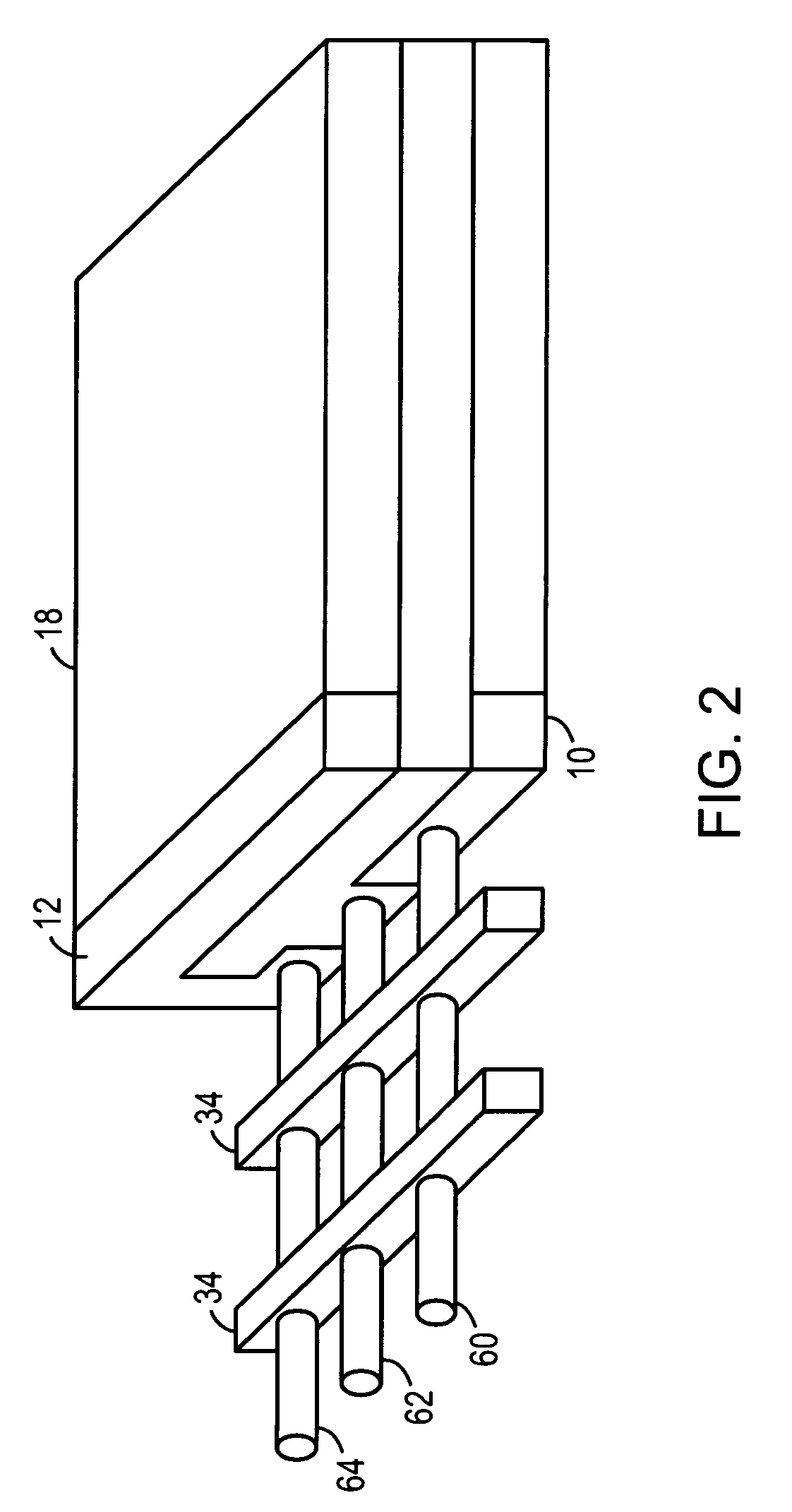

Method of direct iron-making / steel-making via gas or coal-based direct reduction and apparatus

The invention is a method and apparatus for iron-making / steel-making using a modified rotary hearth furnace, that is a finisher-hearth-melter (FHM) furnace. In the method the refractory surface of the hearth is coated with carbonaceous hearth conditioners and refractory compounds, where onto said hearth is charged with pre-reduced metallized iron. The pre-reduced metallized iron is leveled, then heated until molten, and then reacted with the carbon and reducing gas burner gases until any residual iron oxide is converted to iron having a low sulfur content. Nascent slag separates from the molted iron forming carburized iron nuggets. The nuggets are cooled, and then the iron nuggets and the hearth conditioners, including the refractory compounds, are discharged onto a screen, which separate the iron nuggets from the hearth conditioner. The hearth conditioner is recycled, and the iron nuggets are either prepared for sale or for additional treatment, such as alloying, in a final melter, where the final melter is preferably an electric furnace. Exhaust gases from the FHM furnace are recovered for calcining coal into fuel gases and coke.

Owner:KOBE STEEL LTD

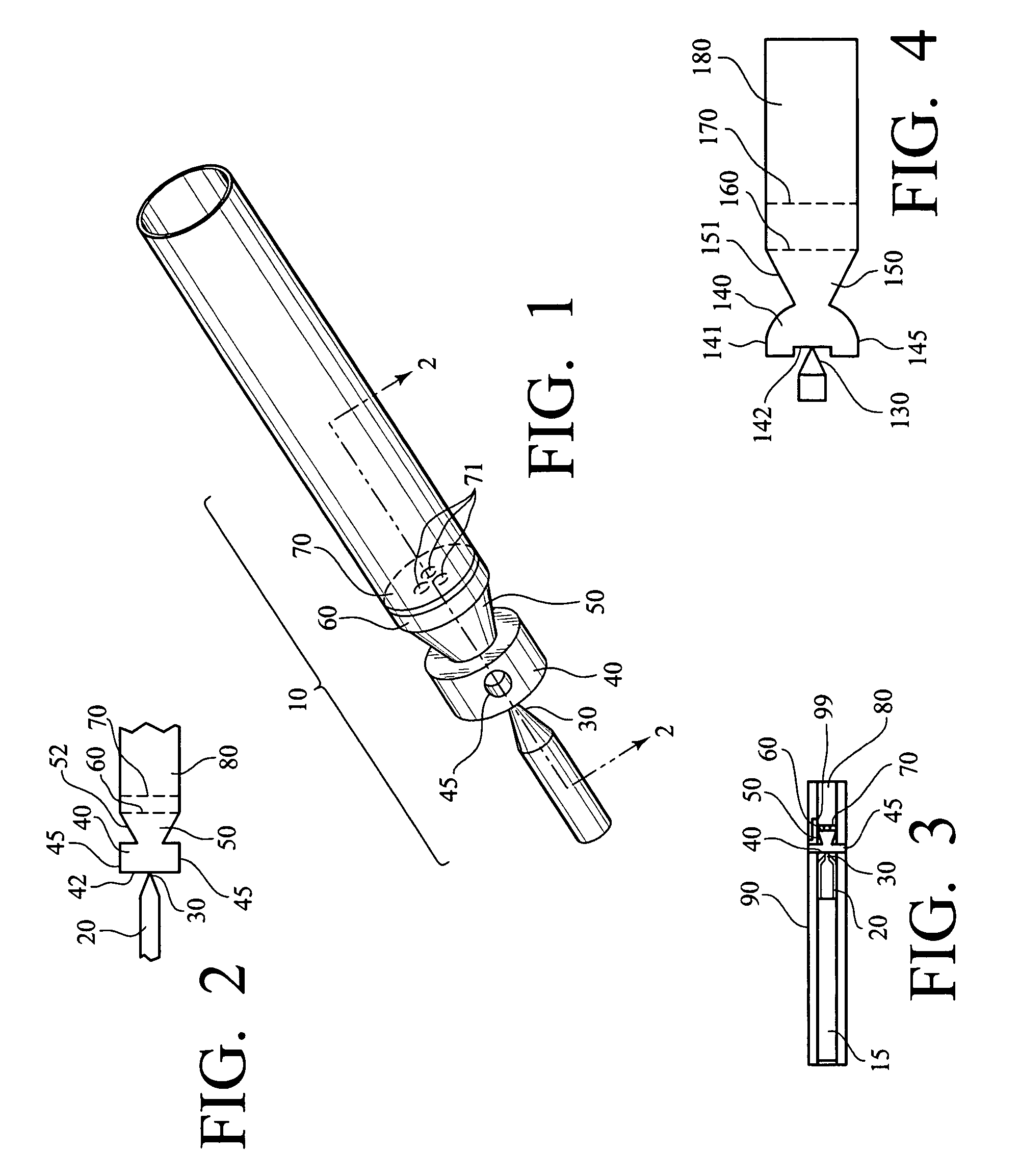

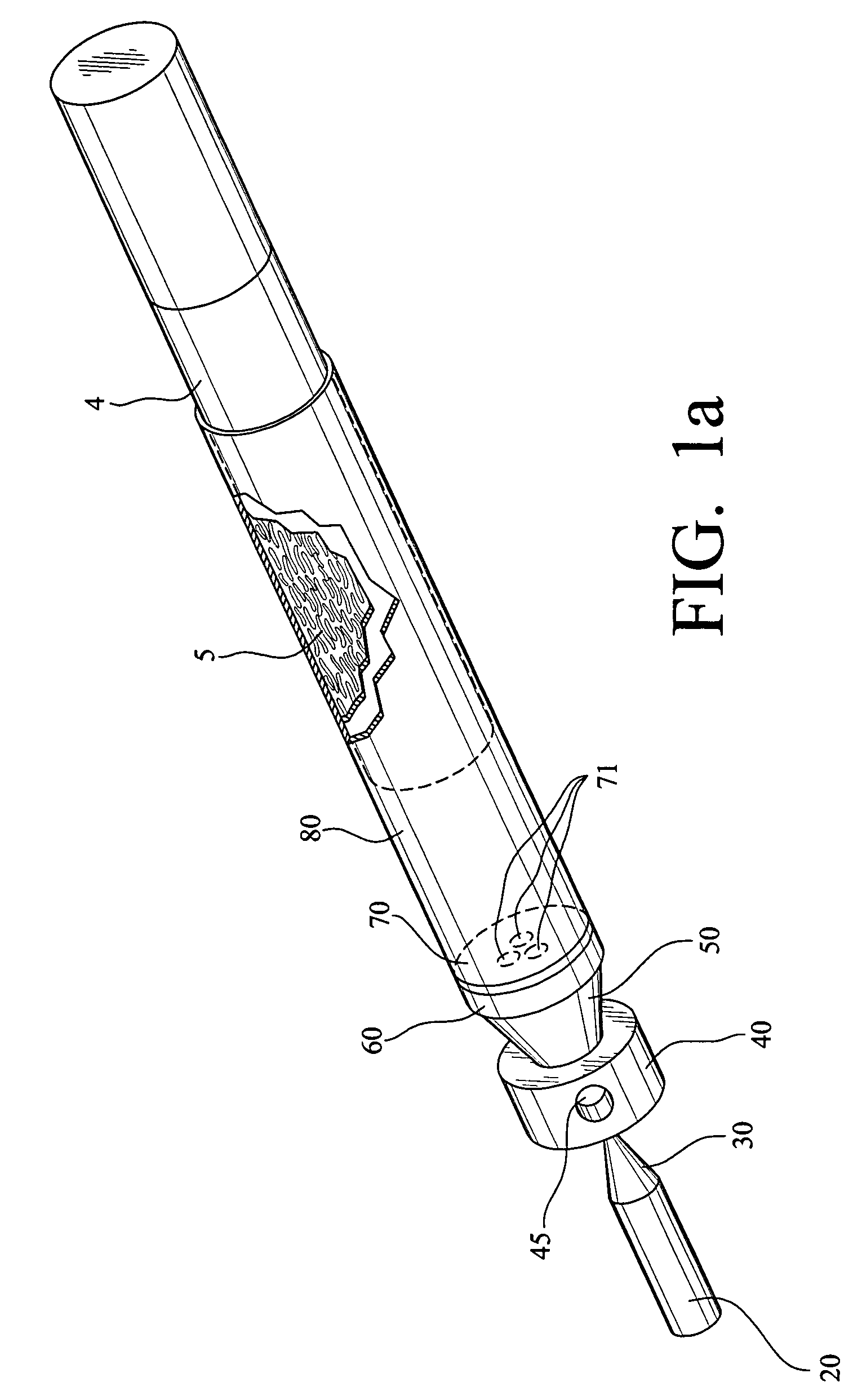

Gas micro burner

InactiveUS7488171B2Low mass flow rateSmall volumeFuel lightersBurner material specificationsProduct gasProcess engineering

A micro gas burner is provided that generates a stable, pre-mixed flame that produces little to no soot or unburned hydrocarbons. The gas burner includes a fuel inlet, nozzle, oxygenation chamber with at least one air inlet, a mixing chamber having a frustoconical inner wall, at least one permeable barrier and a flame holder. The gas burner thoroughly mixes fuel and entrained air to form a nearly stoichiometric mixture prior to combustion. The gas burner mixes the fuel and air so thoroughly that it requires a lower fuel flow rate than would otherwise be necessary to produce a stable, pre-mixed flame. The gas burner may include an optional flame tube with an optional exhaust port in which a flame is contained and sequestered from diffusing air.

Owner:R J REYNOLDS TOBACCO COMPANY

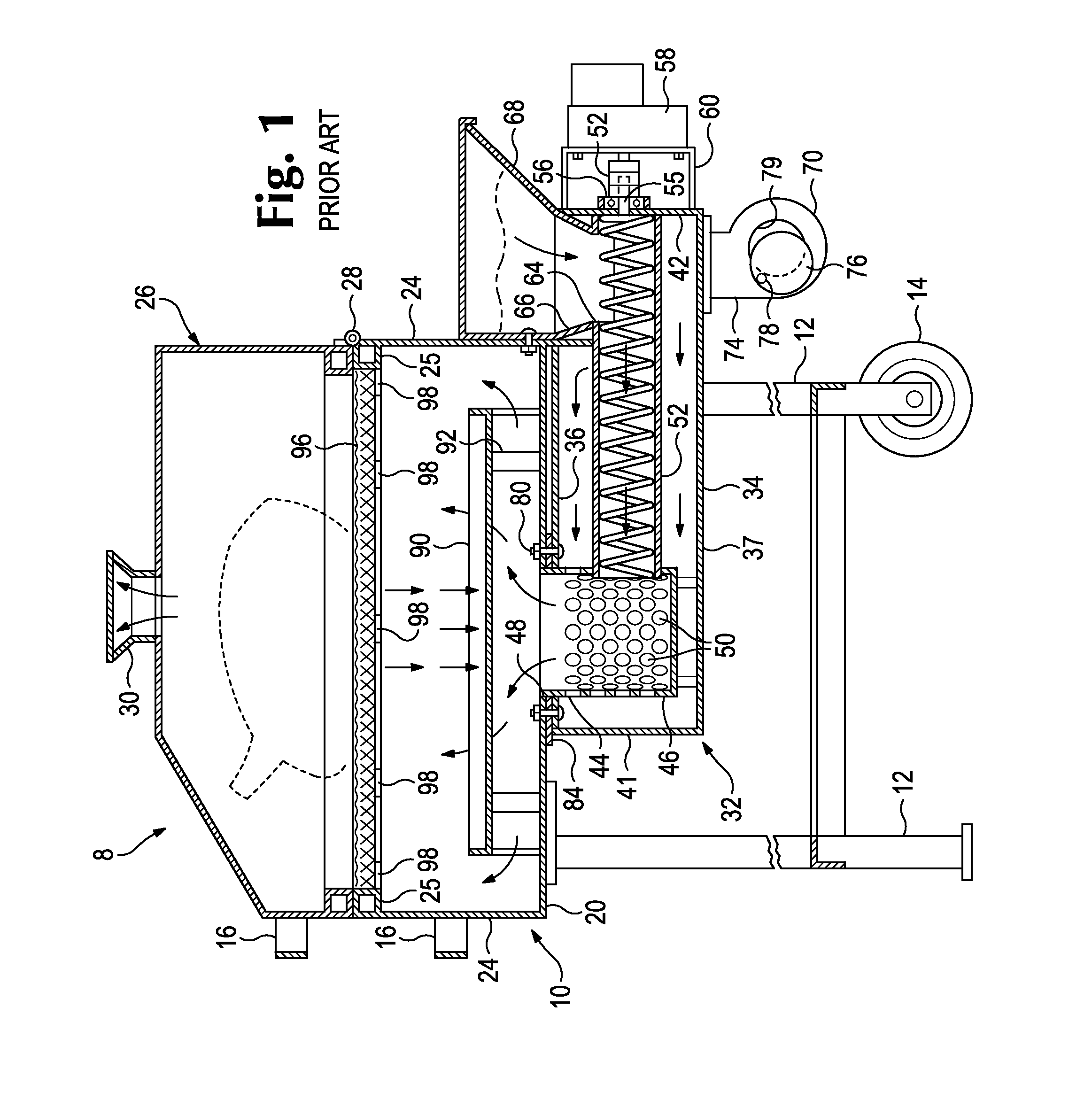

Dual fuel vent free gas heater

ActiveUS20100095945A1Enhanced natural convectionFuel supply regulationAir-treatment apparatus arrangementsControl systemNuclear engineering

A dual fuel vent free gas heater having at least one gas burner with a plurality of gas outlet ports in an upper surface thereof. The gas outlet ports are in flow communication with at least one pilot flame burner. An adjustable fuel injector or at least two fuel injectors feed fuel to the burner providing for introduction of more than one fuel to the burner. Optionally, an oxygen detection system, manual fuel selection control valve, and / or temperature shut off control system may be incorporated into the dual fuel vent free heater.

Owner:COPRECITEC

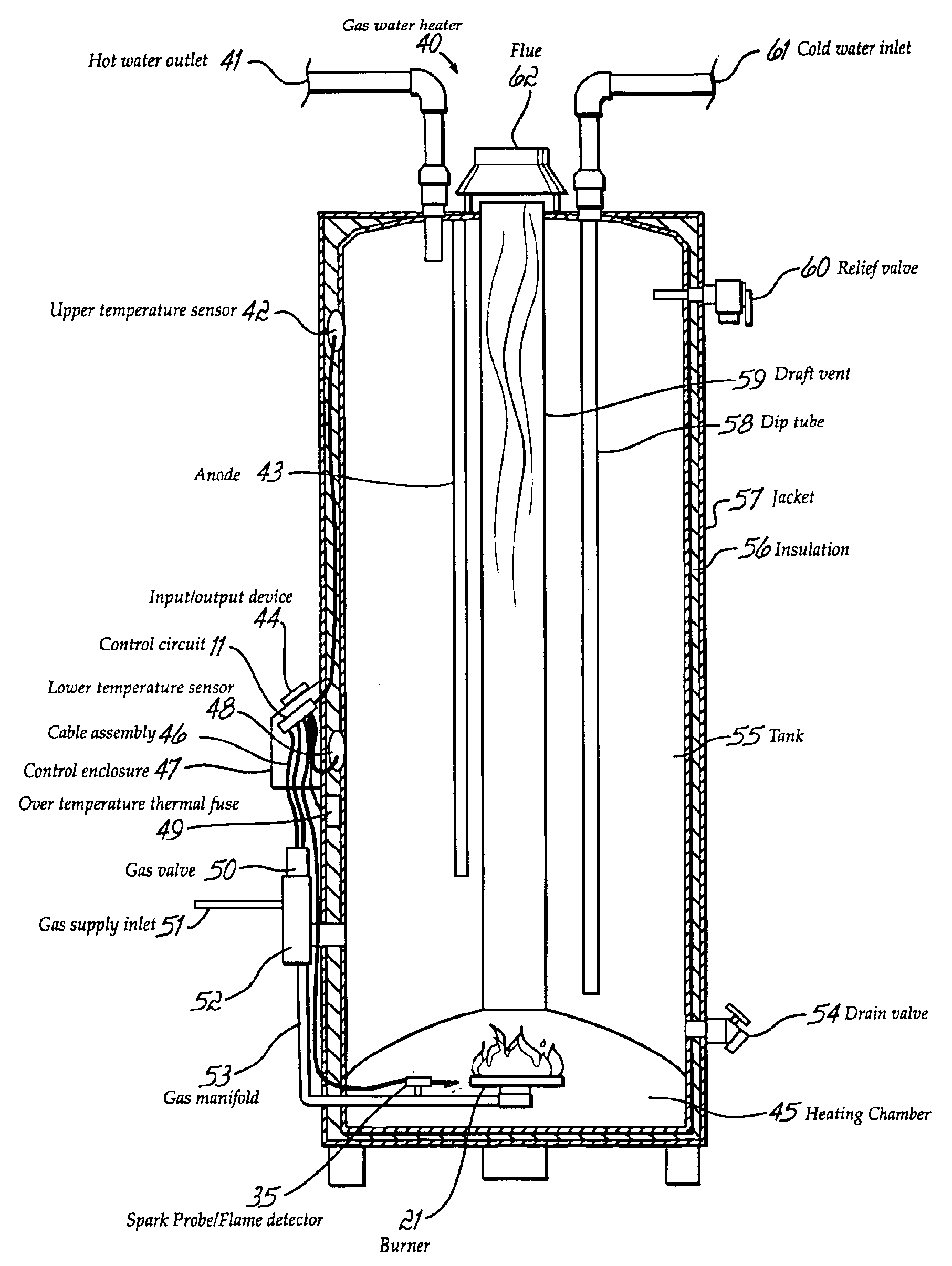

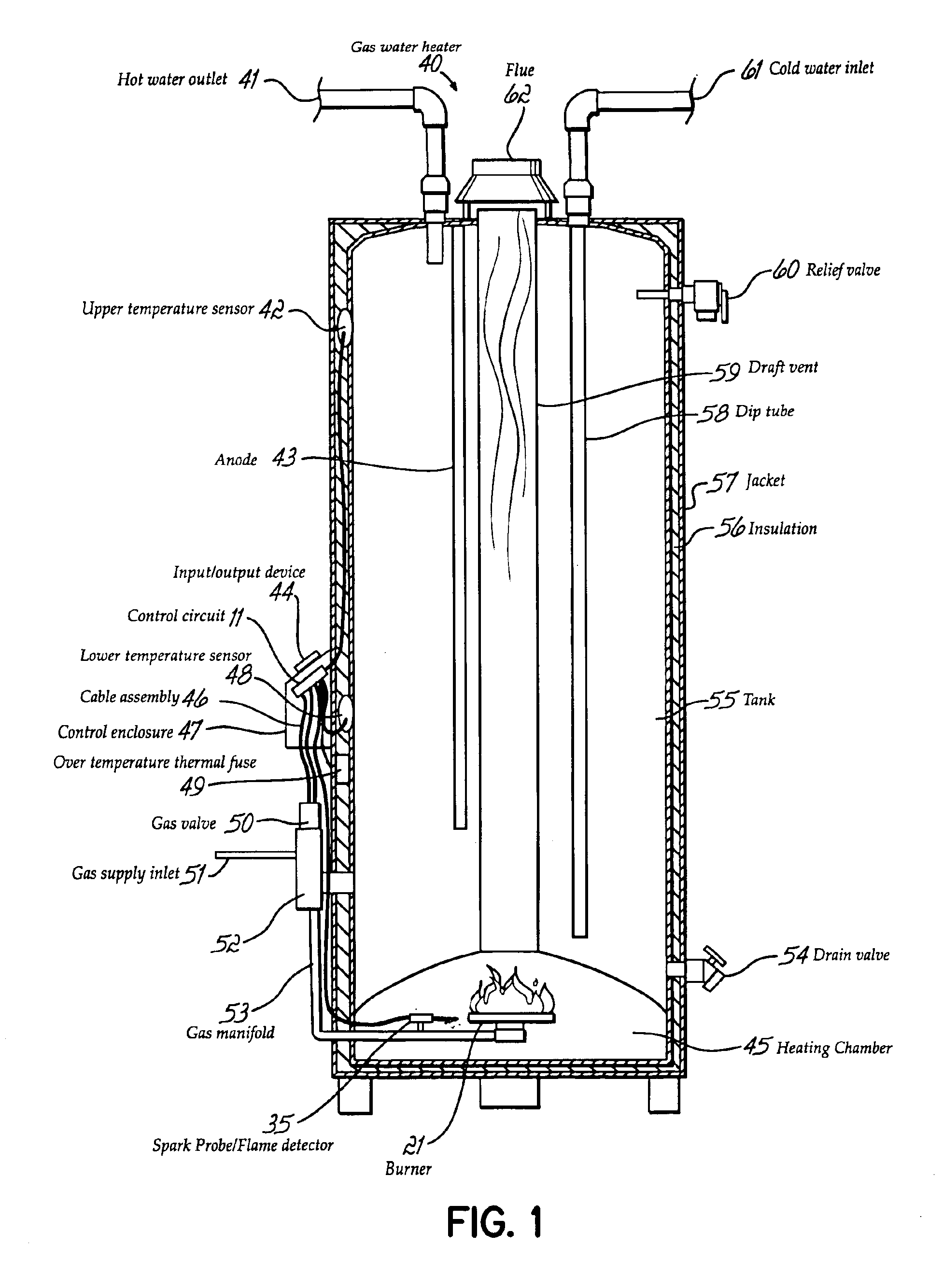

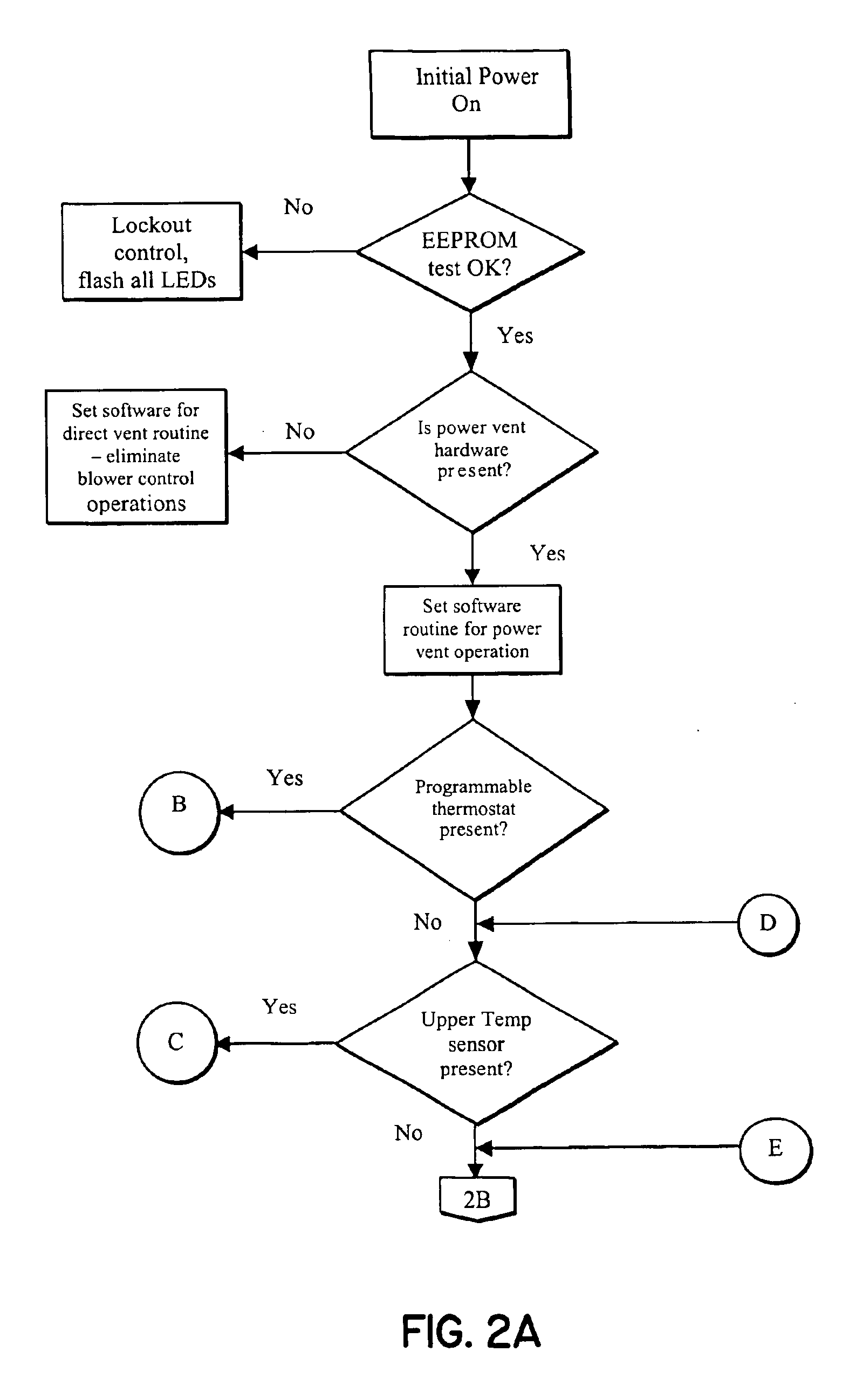

Gas water heater and method of operation

InactiveUS6880493B2Improve performanceStable temperatureFuel supply regulationElectric spark ignitersEngineeringProduct gas

A gas water heater with a tank for holding water including a gas valve mounted below the tank and in fluid communication with a supply of gas. A gas burner is fluidly connected to the gas valve. A first temperature sensor is mounted adjacent a lower portion of the tank and detects a temperature of the water in the lower portion of the tank, and a second temperature sensor is mounted adjacent an upper portion of the tank and detects a temperature of water in the upper portion of the tank. A control has inputs connected to the first and second temperature sensors and outputs connected to the gas valve. The control operates the gas valve in response to reading signals from the first and second temperature sensors such that water in the top and bottom portions of the tank stays within a desired temperature range.

Owner:CLIFFORD TODD W

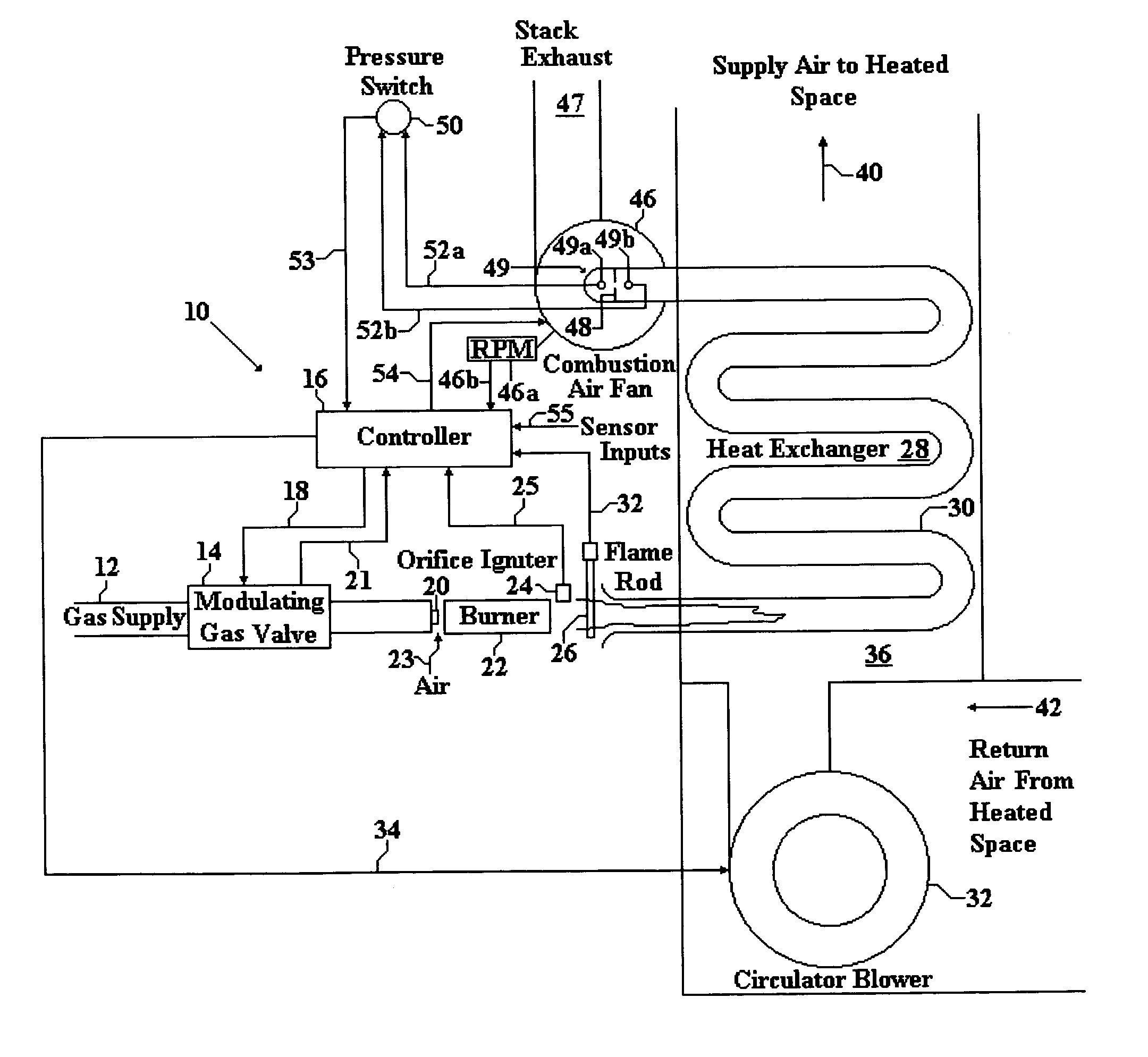

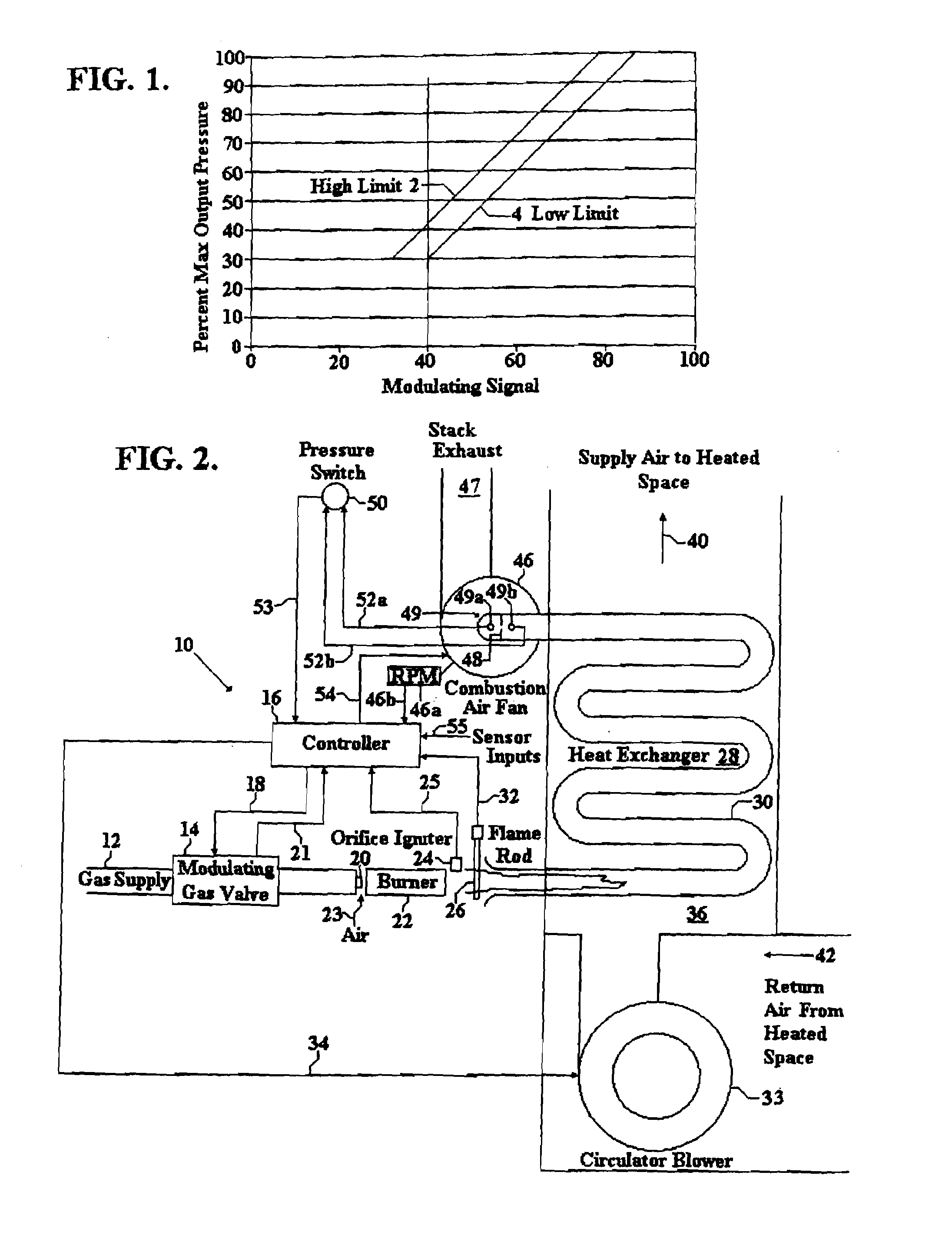

Feedback control for modulating gas burner

Owner:ADEMCO INC +1

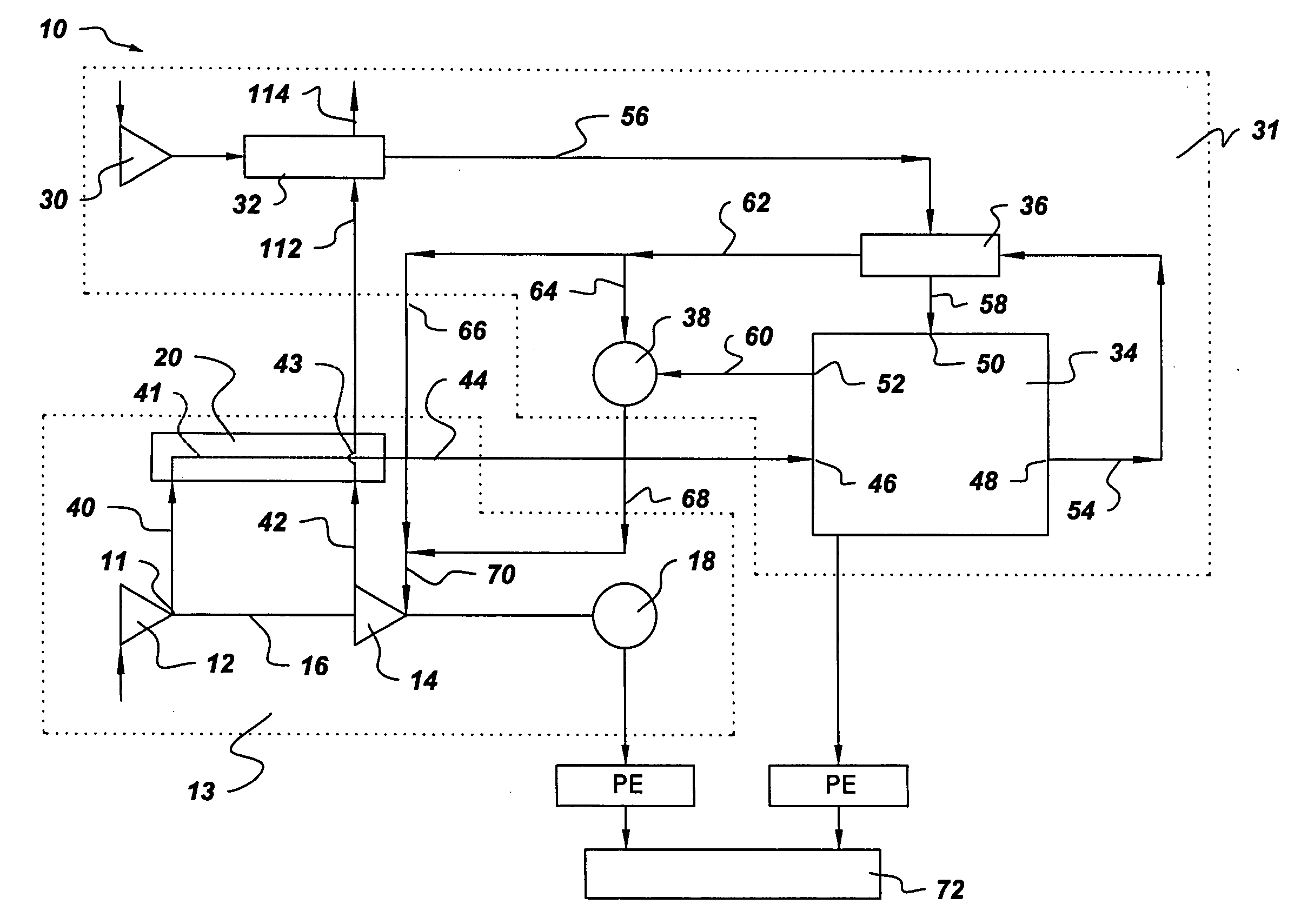

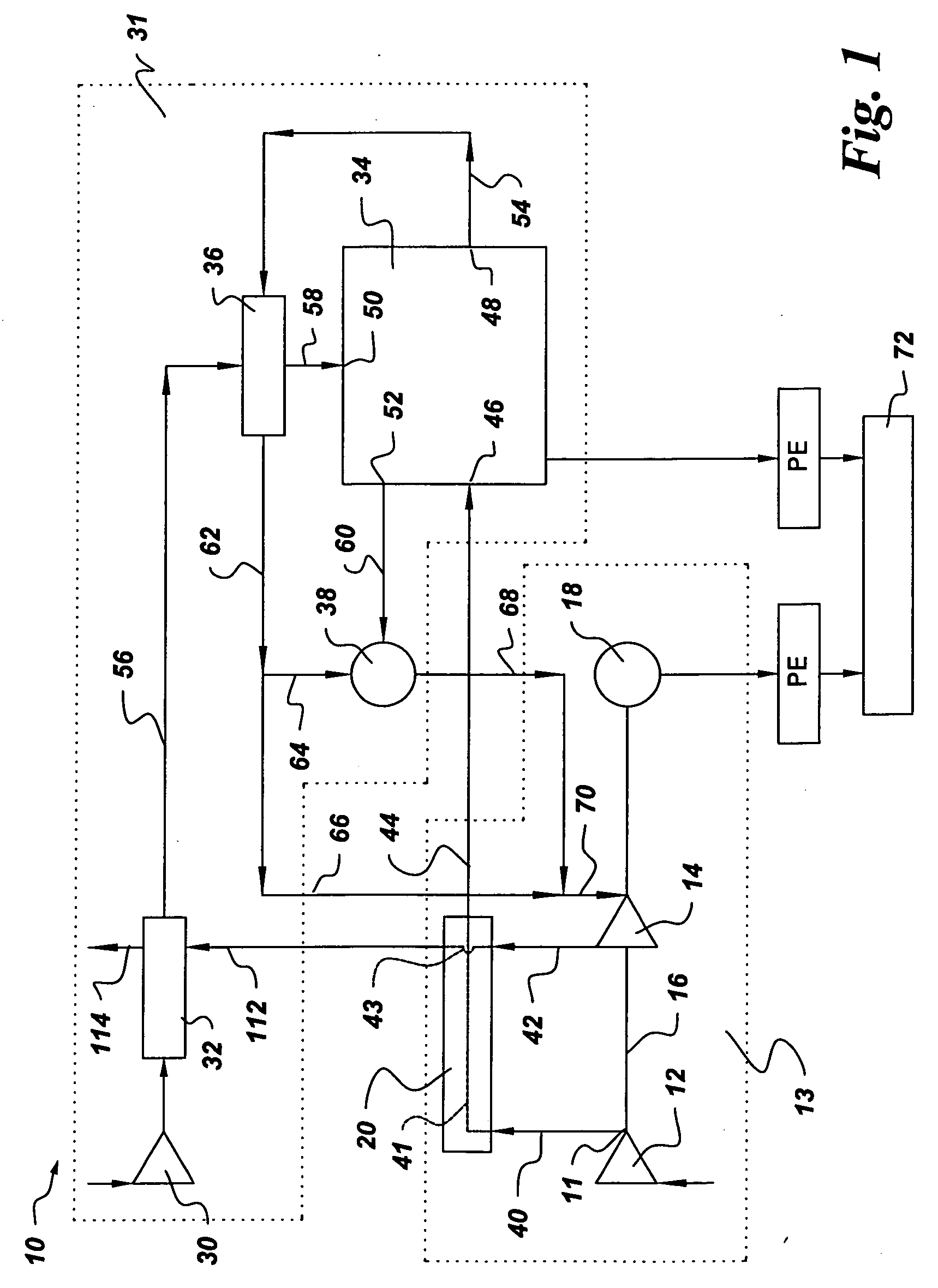

Integrated fuel cell hybrid power plant with controlled oxidant flow for combustion of spent fuel

InactiveUS20050079395A1Reduction of fuelReduction of carbon monoxide emissionFuel cells groupingFuel cell auxillariesElectric forceRecuperator

A hybrid power generation system for generating electrical power comprises a compressor for producing a compressed oxidant and a recuperator in flow communication with the compressor. The hybrid power generation system further comprises a fuel cell assembly comprising a plurality of fuel cells in flow communication with the recuperator to provide the compressed oxidant for the fuel cell assembly. The fuel cell assembly further comprises a cathode inlet for receiving the compressed oxidant, an anode inlet for receiving a fuel stream, an anode outlet in flow communication with an anode exhaust stream and a cathode outlet in flow communication with a cathode exhaust stream, wherein at least a portion of the fuel reacts with the oxidant to produce electrical power. The hybrid power generation system further comprises a tail gas burner in flow communication with the anode outlet and the cathode outlet. The tail gas burner is configured for combusting a mixture of at least a portion of the anode exhaust stream and at least a portion of the cathode exhaust stream and producing a hot compressed gas. A control system is used for controlling the amount of the cathode exhaust stream introduced in the tail gas burner for stable combustion and reduction of fuel and carbon monoxide emission. The hot compressed gas from the tail gas burner is introduced to a turbine, where the hot compressed gas is expanded, thereby producing electrical power and an expanded gas.

Owner:GENERAL ELECTRIC CO

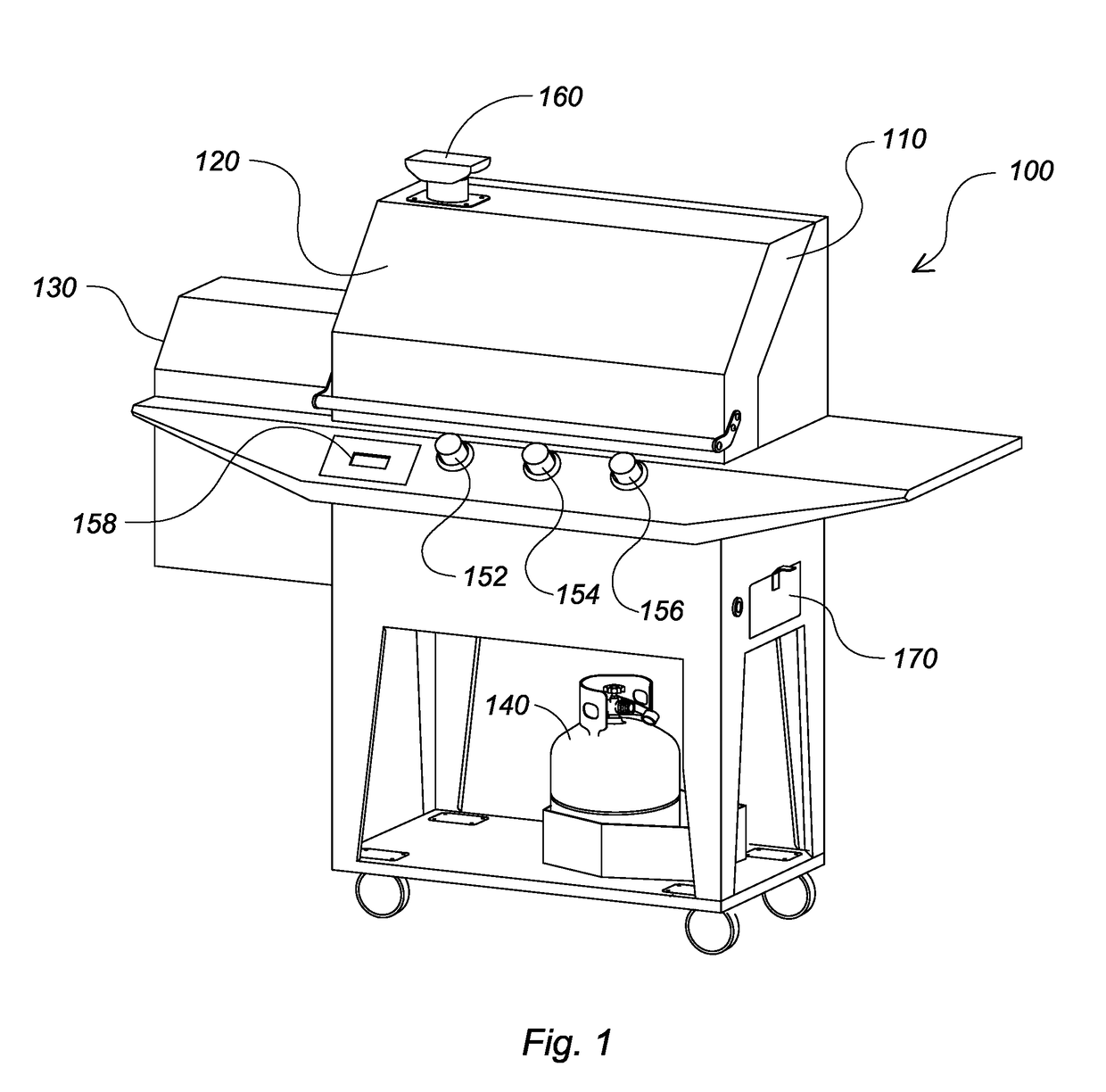

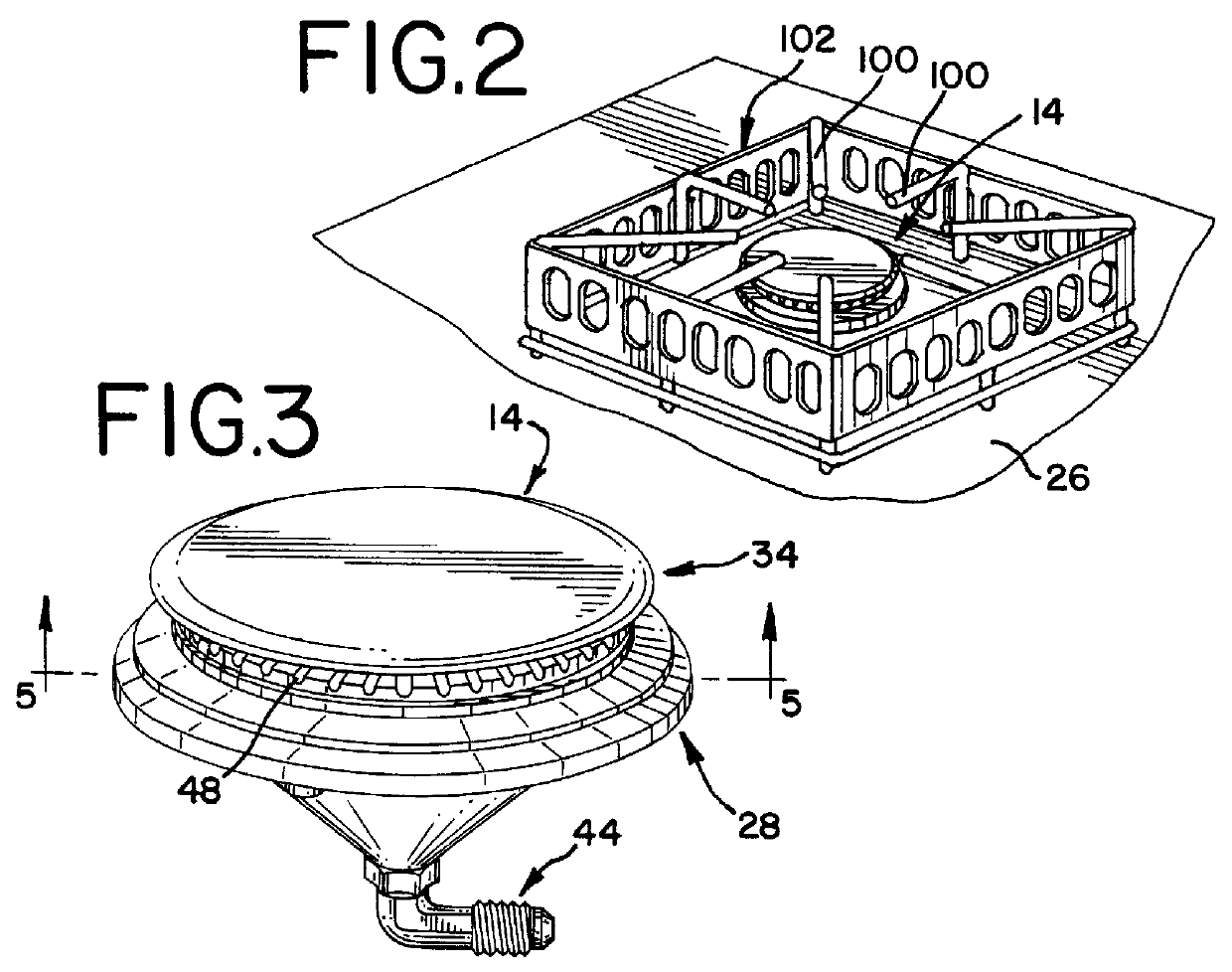

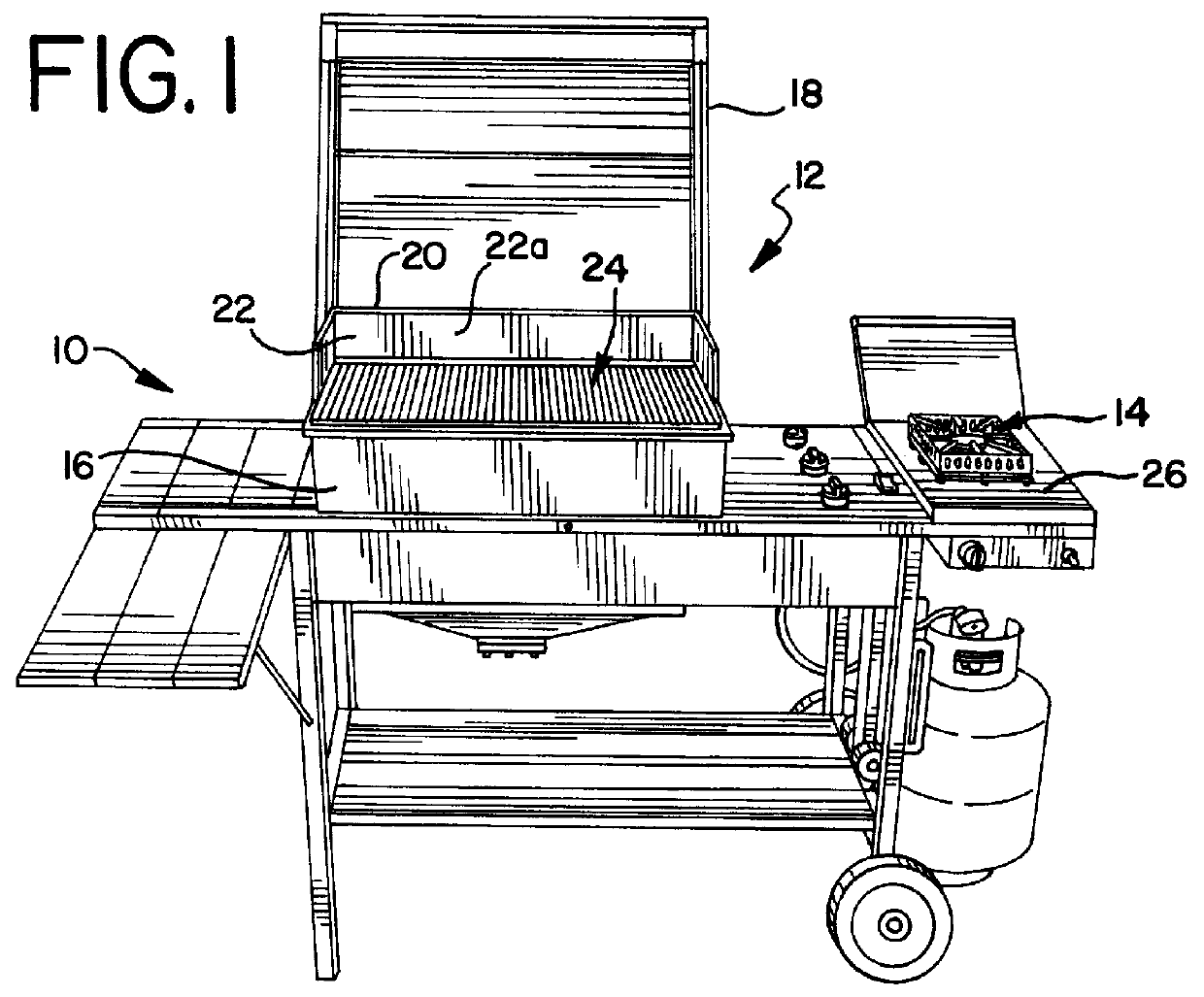

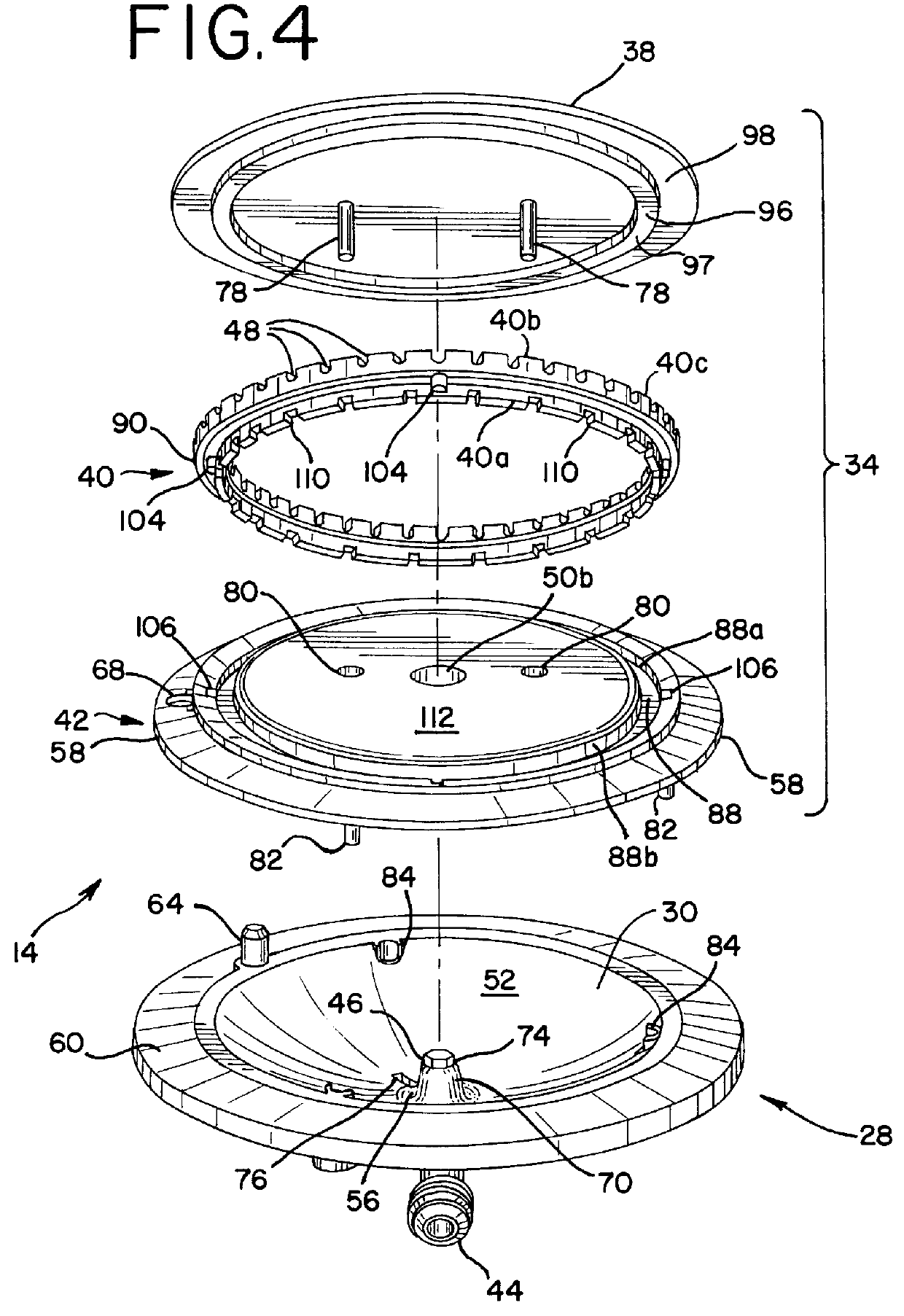

Outdoor cooking apparatus with improved auxiliary gas burner

InactiveUS6067978AEasy to installAvoid mixingDomestic stoves or rangesElectric spark ignitersEngineeringMechanical engineering

A barbecue grill comprising a grilling housing, and a gas burner mounted adjacent the grilling housing. The gas burner includes a burner base having a base chamber, a burner head having at least one air and fuel mixture exit port, and a venturi having opposed relatively open ends, the venturi providing a passage between the burner base and the burner head. The base chamber surrounds one of the opposed relatively open ends of the venturi and the base chamber has an inner wall which reduces from a wider portion to a narrower portion with a fuel inlet providing access for fuel into the base chamber and a combustion air inlet being disposed about at least a portion of a periphery of the wider portion of the base chamber. The burner further including a means for securing the burner head to the burner base such that the burner head may be lifted off the burner base for inspection and cleaning of the burner base.

Owner:HN ENG INC +1

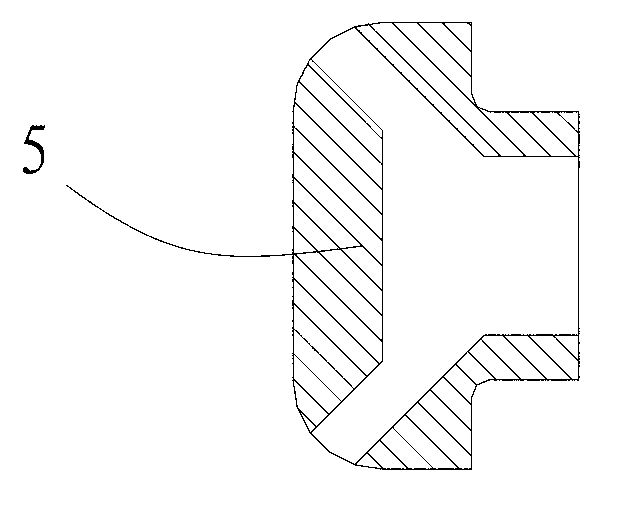

Gas burner

InactiveUS20070218414A1More useable spaceSmall diameterElectric spark ignitersPilot flame ignitersEngineeringHigh intensity

This invention describes an improved gas burner assembly that can be adapted to attach to a range top or cooktop, or the floor of the range and can draw air from either above the range top level by external vents or from below range top level through an open style mixing cup. This invention uses a plurality of different flame rings to provide the user a wide variety of temperature settings starting from a low intensity simmer to high intensity cooking heat. The current invention also utilizes a cover plate of transparent or translucent, heat proof material that allows the user to observe the interior of the burner to see if any of the flame rings have been ignited. The cover plate also transfers heat from the internal flame rings to the cooking utensil which provides a more uniform transfer of heat to the utensil.

Owner:DESIGNGASPARTS

Dual fuel vent free gas heater

A dual fuel vent free gas heater having at least one gas burner with a plurality of gas outlet ports in an upper surface thereof. The gas outlet ports are in flow communication with at least one pilot flame burner. An adjustable fuel injector or at least two fuel injectors feed fuel to the burner providing for introduction of more than one fuel to the burner. Optionally, an oxygen detection system, manual fuel selection control valve, and / or temperature shut off control system may be incorporated into the dual fuel vent free heater.

Owner:COPRECITEC

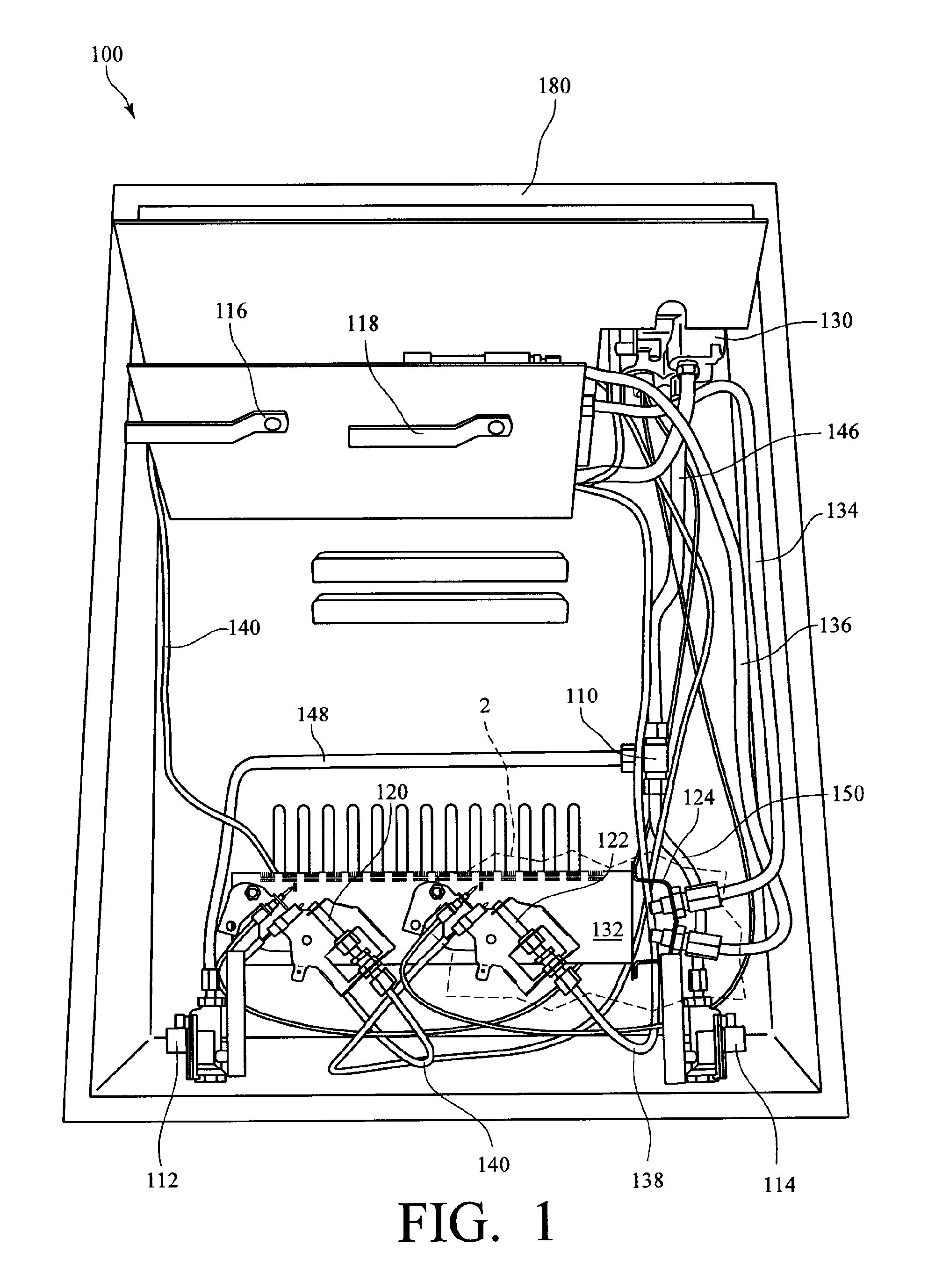

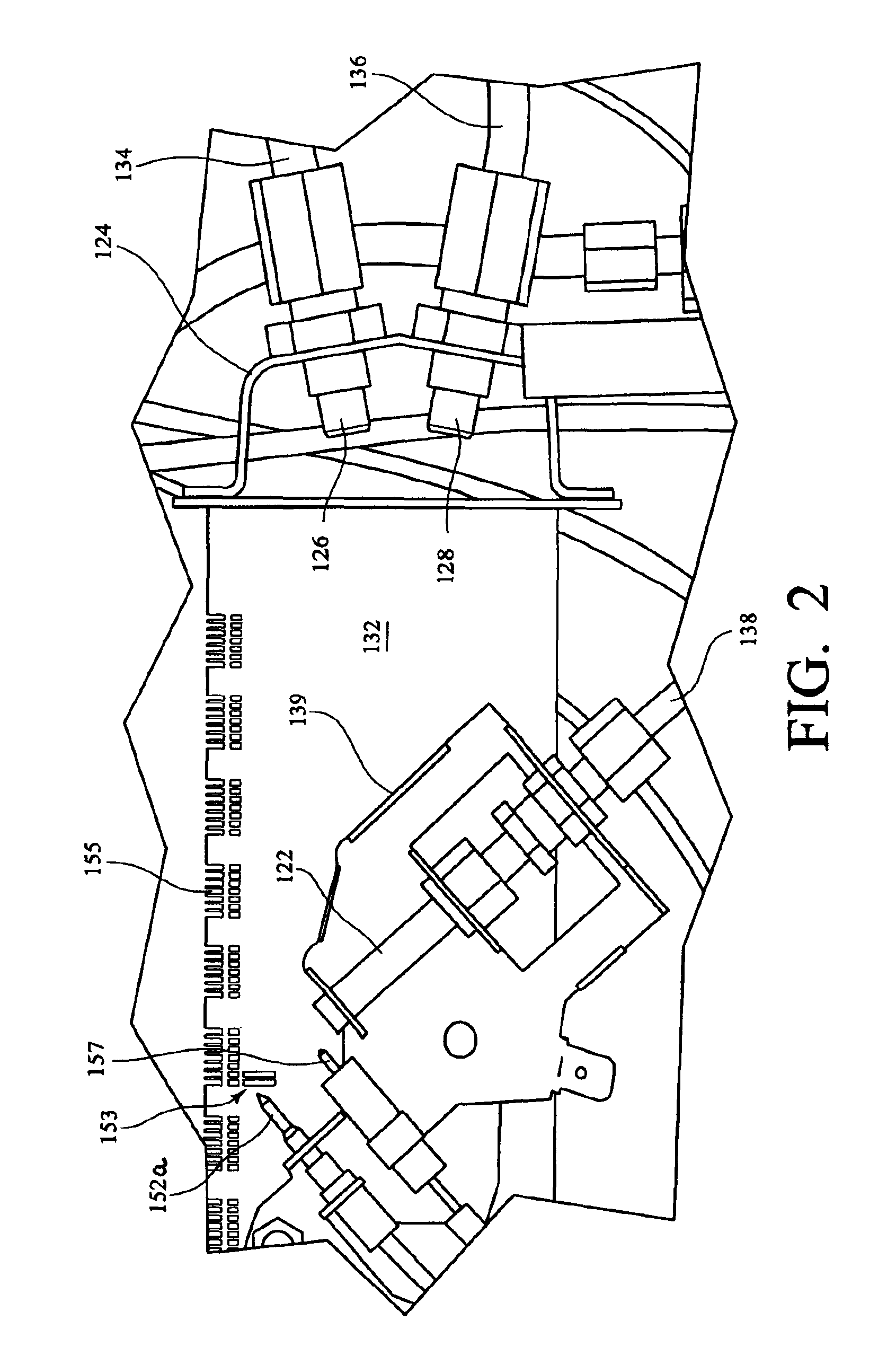

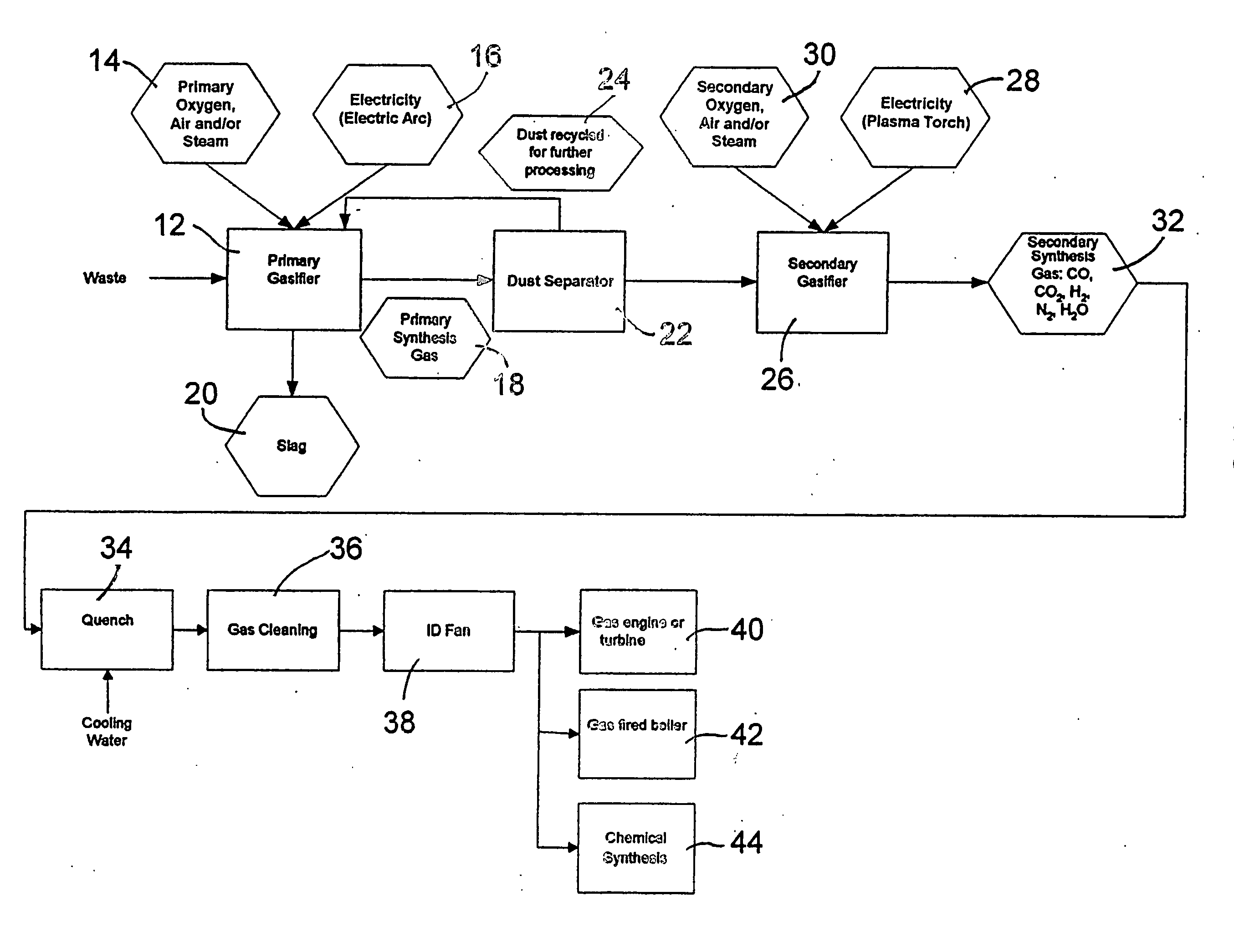

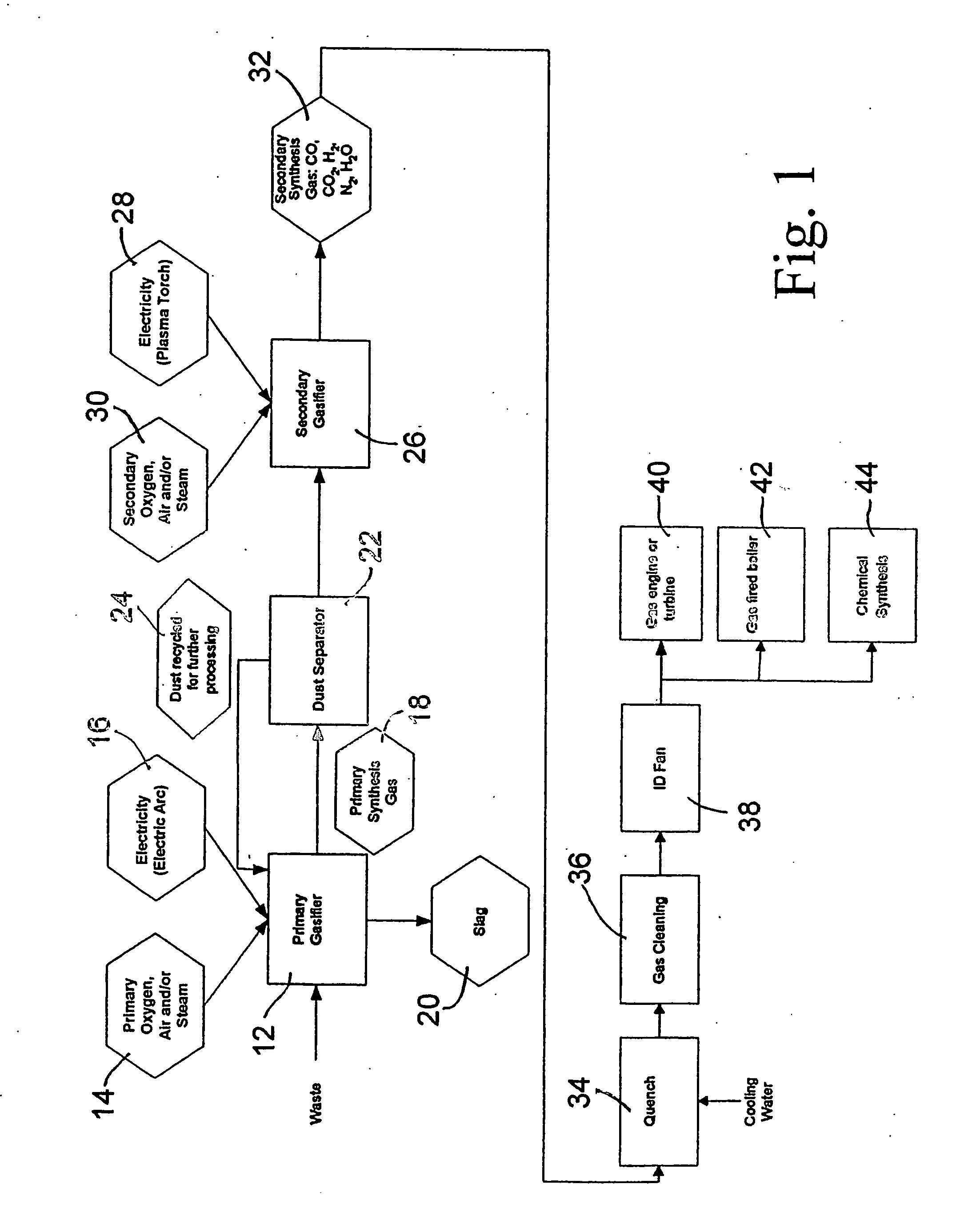

Two-Stage Plasma Process For Converting Waste Into Fuel Gas And Apparatus Therefor

InactiveUS20070272131A1Limited amountImprove energy efficiencyGasifier electrodesGasification processes detailsPlasma jetCyclone

A two-step gasification process and apparatus for the conversion of solid or liquid organic waste into clean fuel, suitable for use in a gas engine or a gas burner, is described. The waste is fed initially into a primary gasifier, which is a graphite arc furnace. Within the primary gasifier, the organic components of the waste are mixed with a predetermined amount of air, oxygen or steam, and converted into volatiles and soot. The volatiles consist mainly of carbon monoxide and hydrogen, and may include a variety of other hydrocarbons and some fly ash. The gas exiting the primary gasifier first passes through a hot cyclone, where some of the soot and most of the fly ash is collected and returned to the primary gasifier. The remaining soot along with the volatile organic compounds is further treated in a secondary gasifier where the soot and the volatile compounds mix with a high temperature plasma jet and a metered amount of air, oxygen or steam, and are converted into a synthesis gas consisting primarily of carbon monoxide and hydrogen. The synthesis gas is then quenched and cleaned to form a clean fuel gas suitable for use in a gas engine or a gas burner. This offers higher thermal efficiency than conventional technology and produces a cleaner fuel than other known alternatives.

Owner:PHOENIX HAUTE TECH

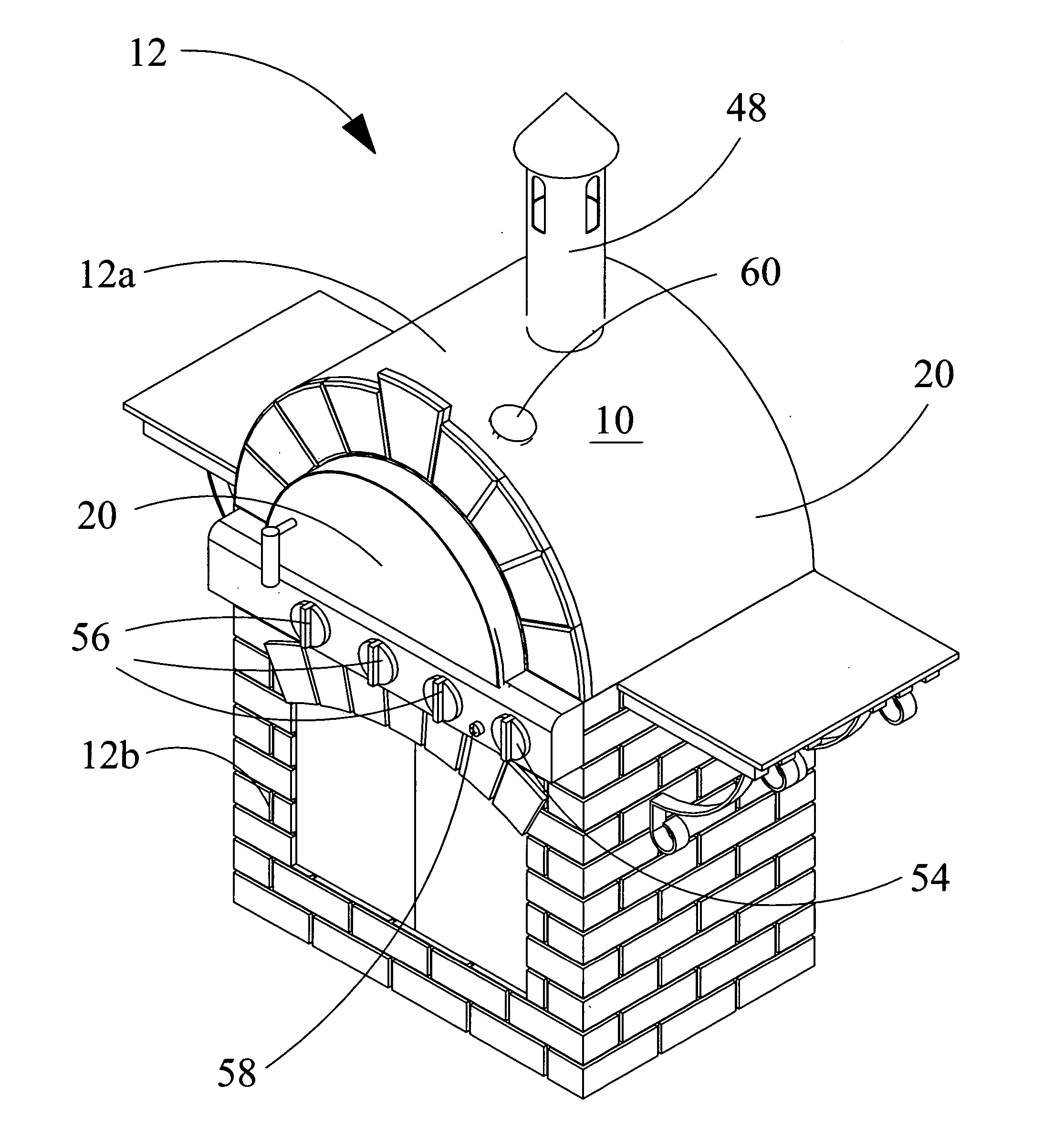

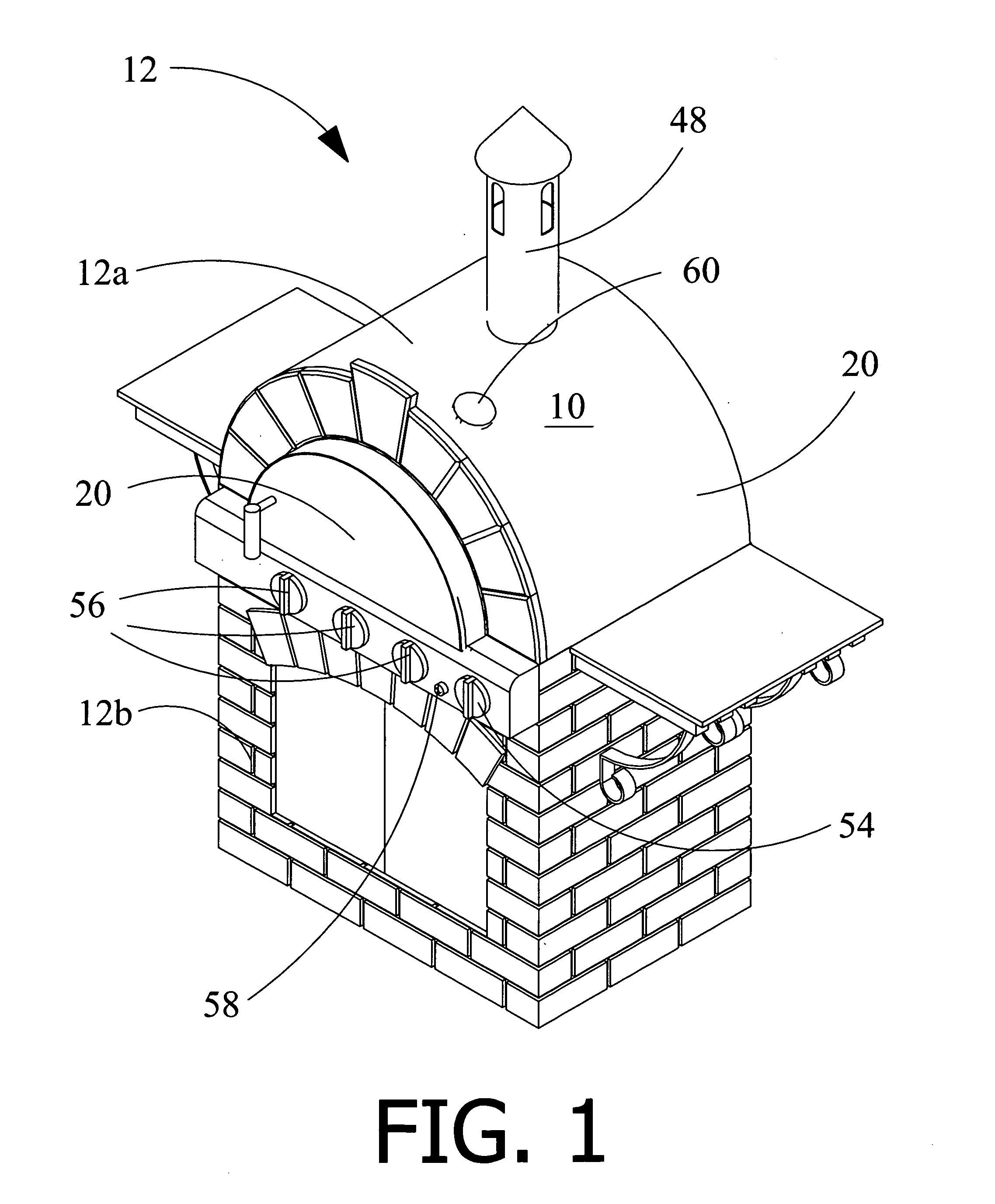

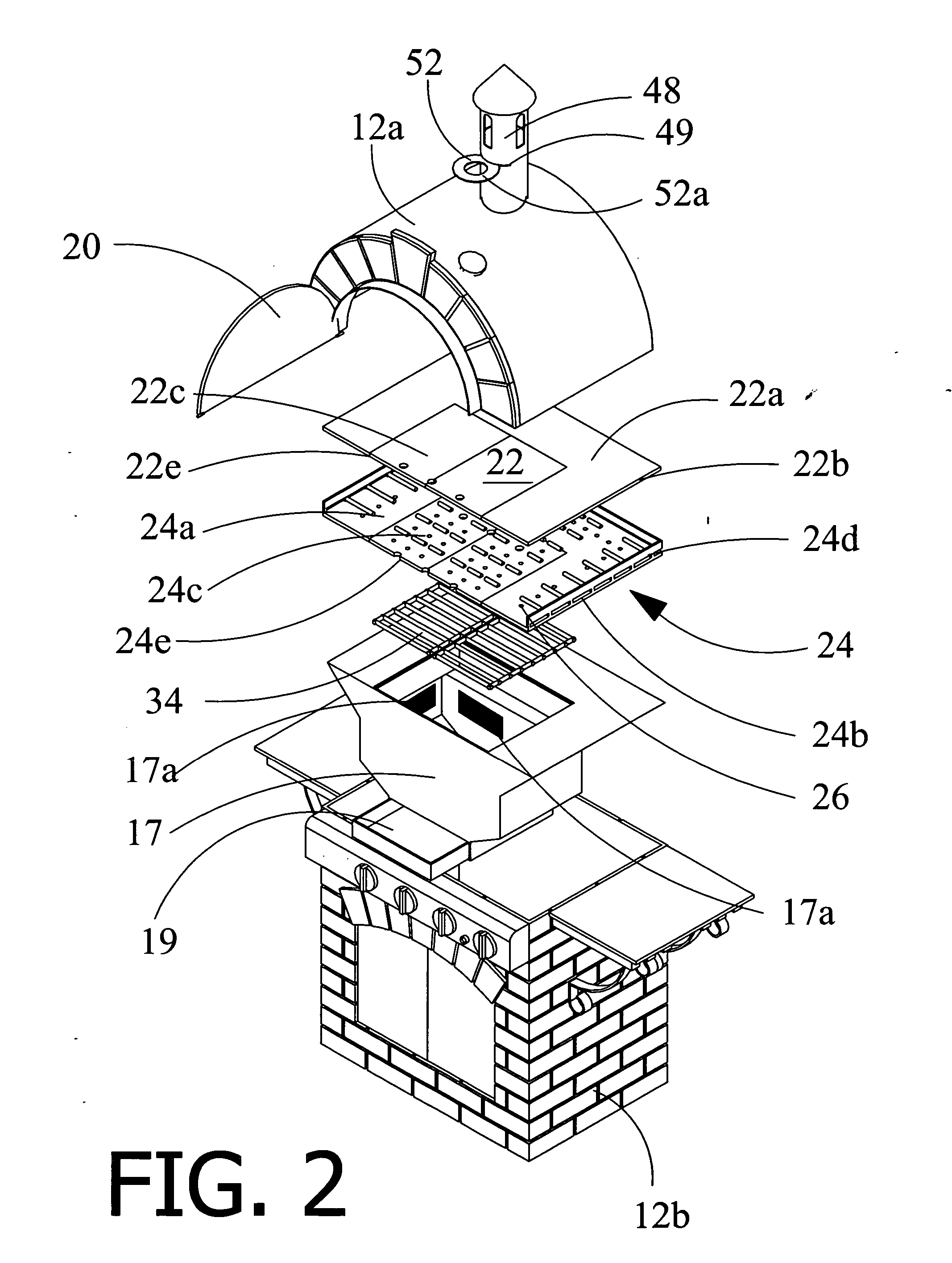

Outdoor oven

InactiveUS20070221191A1Easy to useDomestic stoves or rangesLighting and heating apparatusBrickThermostat

An outdoor oven adapted for use as an old-world style brick oven, a traditional gas grill, or a traditional charcoal grill. The outdoor oven comprises a cooking chamber, at least one gas burner positioned below the cooking chamber, a thermostat operatively connected to the burners for controlling the temperature of the cooking chamber when operated in the oven mode, means for positioning at least one removable cooking tile above the burner, a subfloor mounted to the oven housing between the burner and the cooking chamber. The subfloor has a plurality of openings formed therein through which heated air flows upward toward the bottom surface of the cooking tiles from the burners; and at least one removable insert portion and an outer portion mounted to the oven housing. The oven further provides means for supporting at least one removable grill rack above the burner for use when operated in the grill mode with the cooking tiles and removable insert of the subfloor removed.

Owner:OBRIEN IRIS C +1

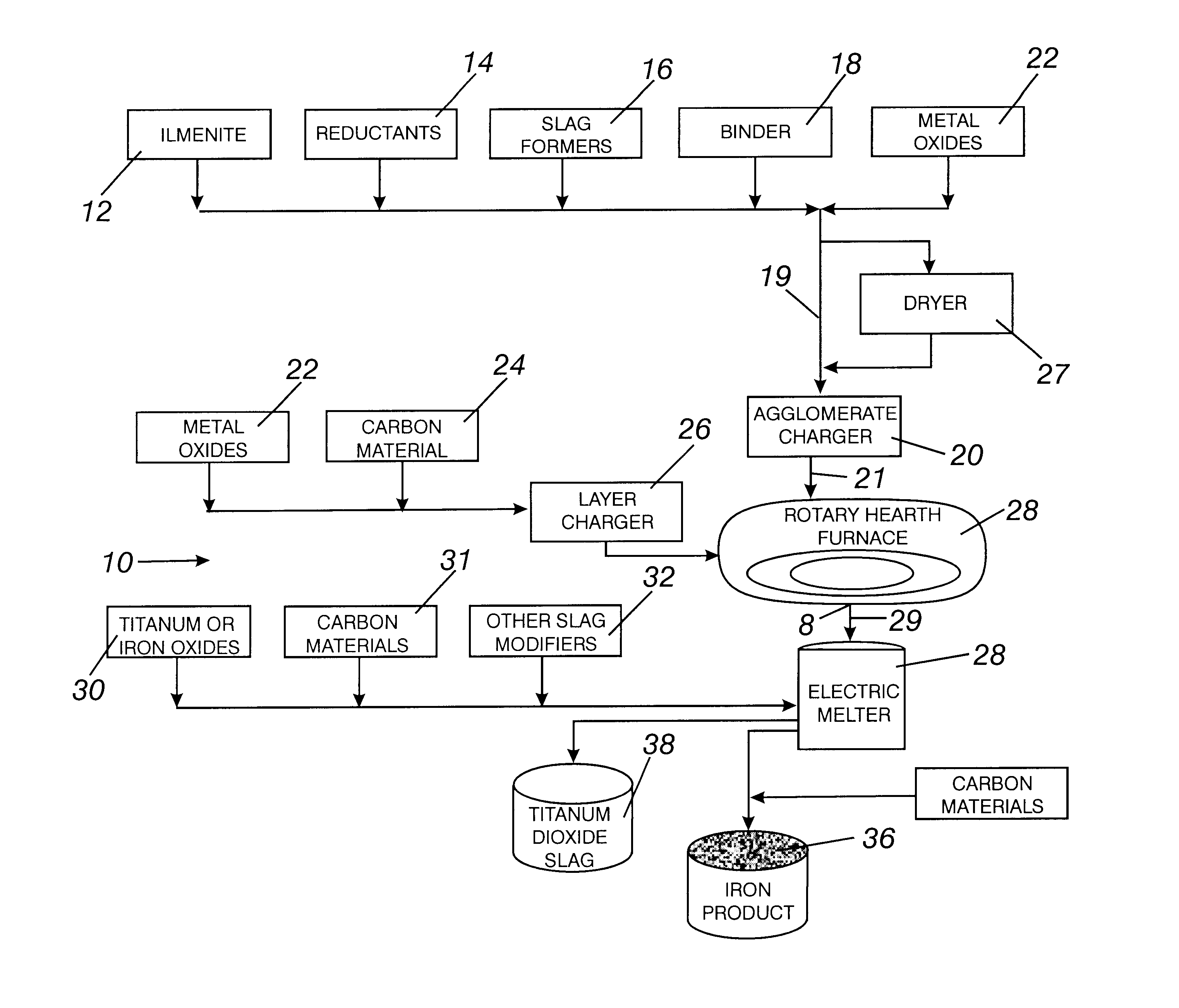

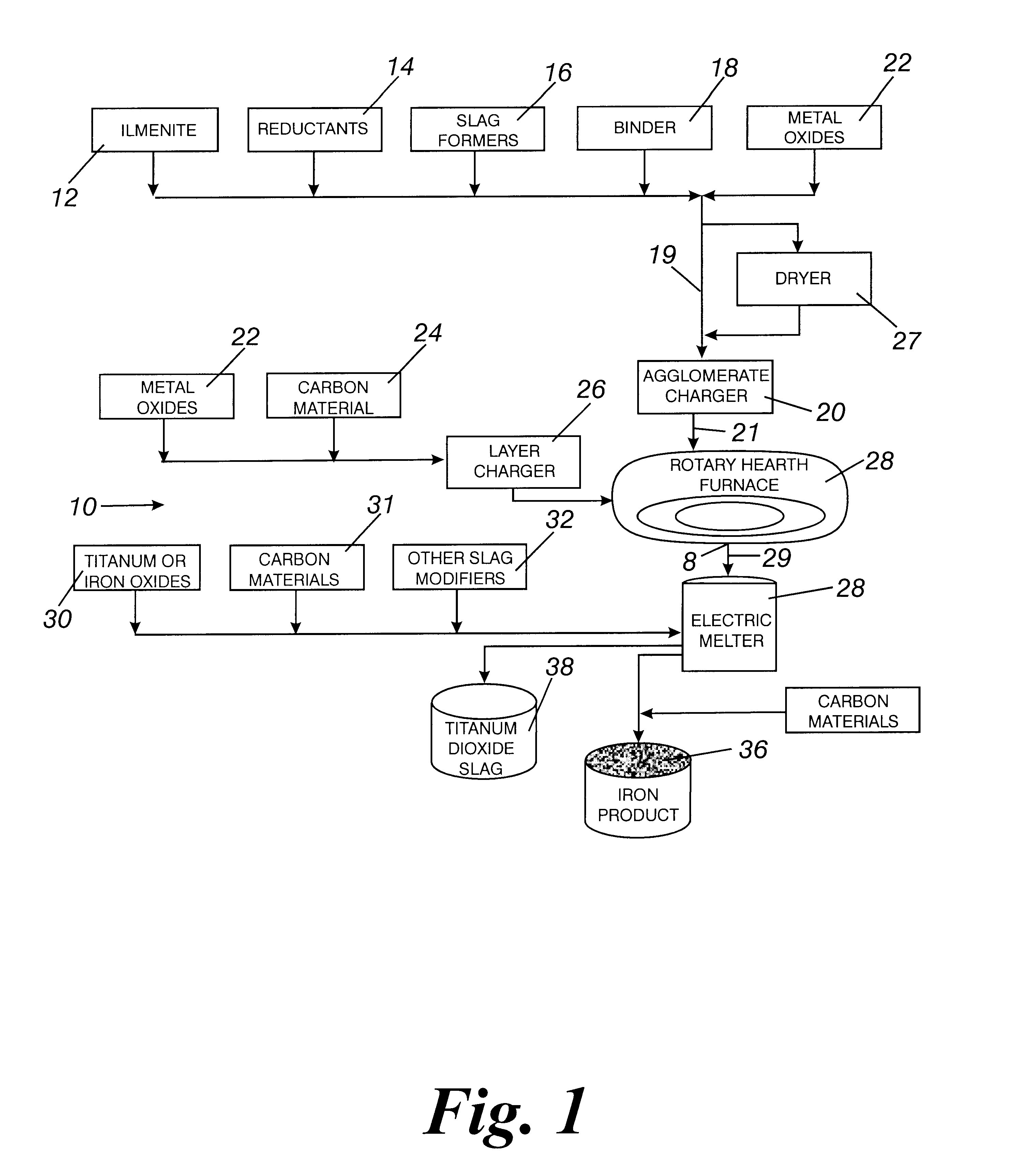

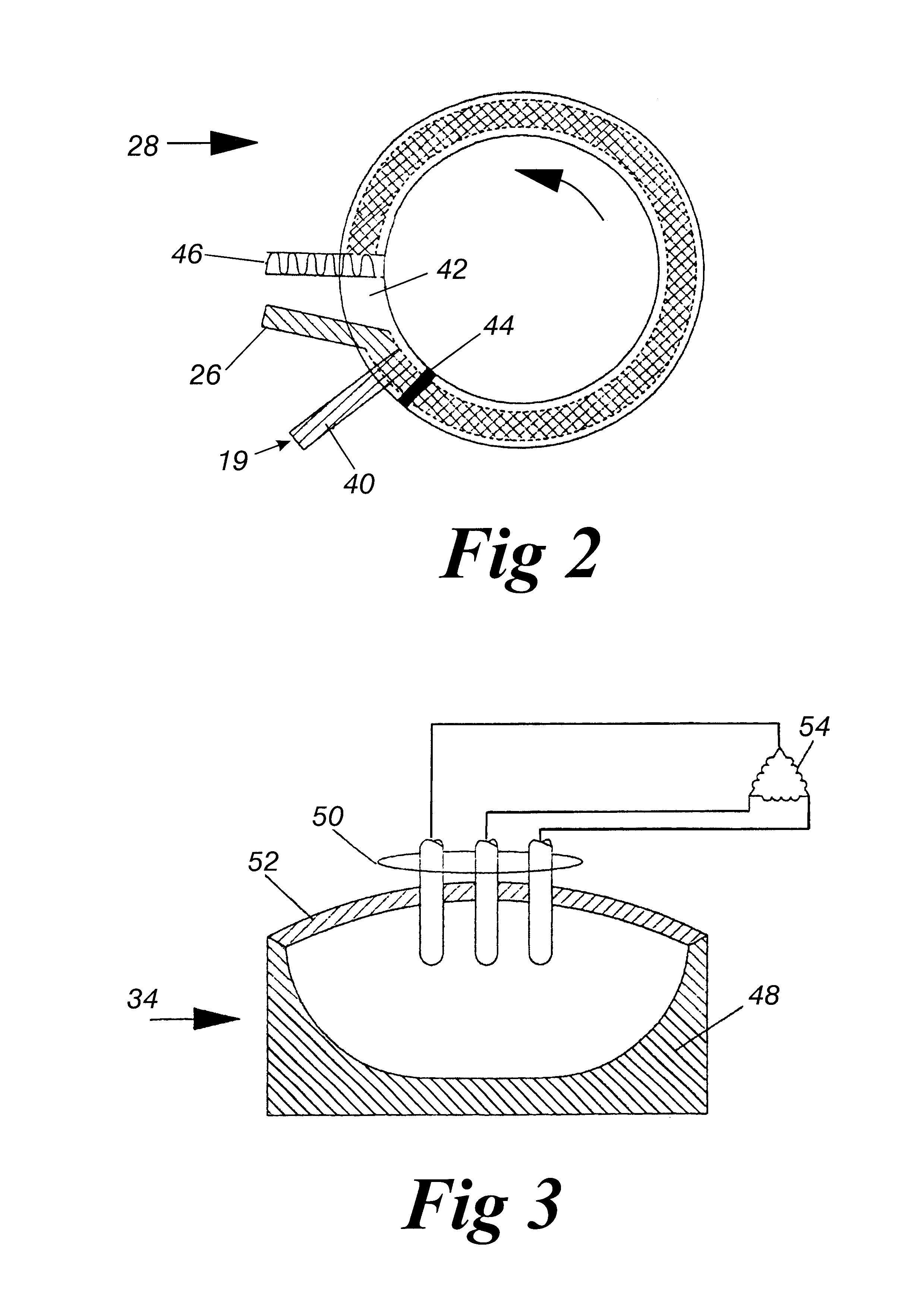

Method for producing beneficiated titanium oxides

The invention is a method and apparatus for producing beneficiated titanium oxides using a modified rotary hearth furnace, that is a finisher-hearth-melter (FHM) furnace. In the method the refractory surface of the hearth is coated with carbonaceous hearth conditioners and refractory compounds, where onto said hearth is charged with pre-reduced agglomerates. The pre-reduced agglomerates is leveled, then heated until molten, and then reacted with the carbon and reducing gas burner gases until any residual iron oxide is converted to iron having a low sulfur content. Fluid slag and molted iron forms melted agglomerates. The fluid slag is rich in titanium. The melted agglomerates are cooled, and then the melted agglomerates and the hearth conditioners, including the refractory compounds, are discharged onto a screen, which separate the melted agglomerates from the hearth conditioner. The hearth conditioner is recycled, and the melted agglomerates are prepared for sale or for additional treatment in a final melter, where the final melter is preferably an electric furnace. Exhaust gases from the FHM furnace are recovered for calcining coal into fuel gases and coke.

Owner:MIDREX TECH INC

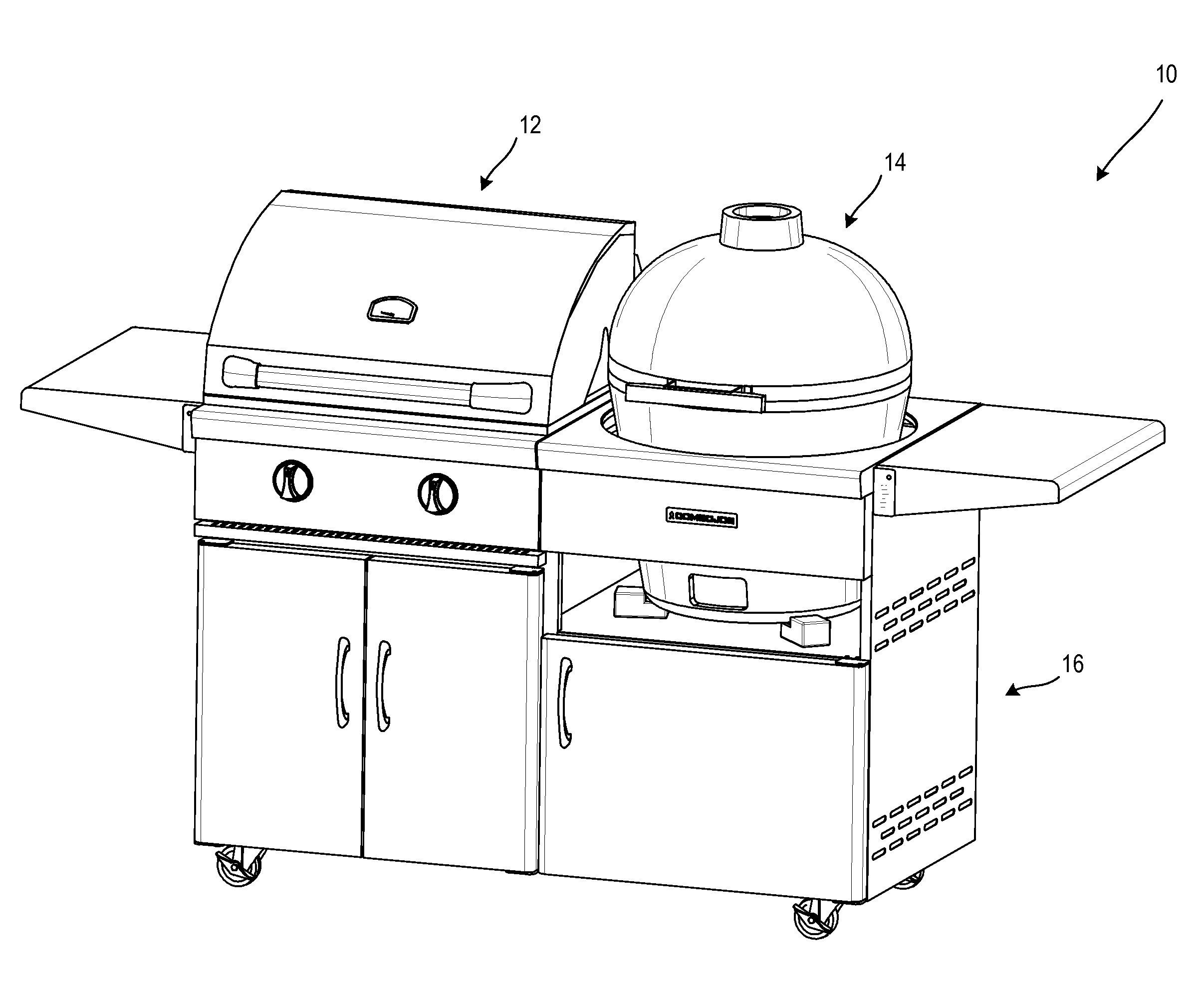

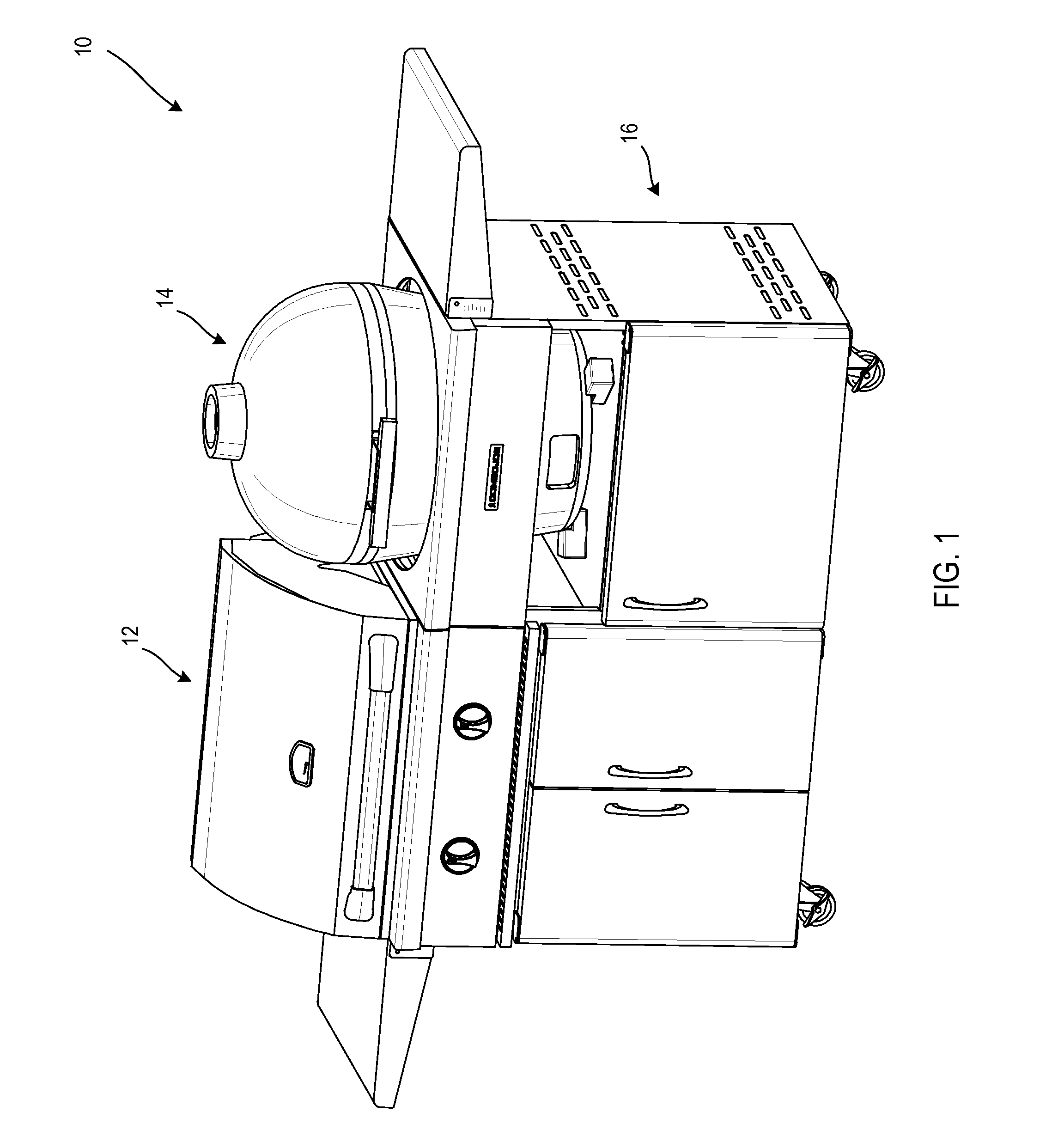

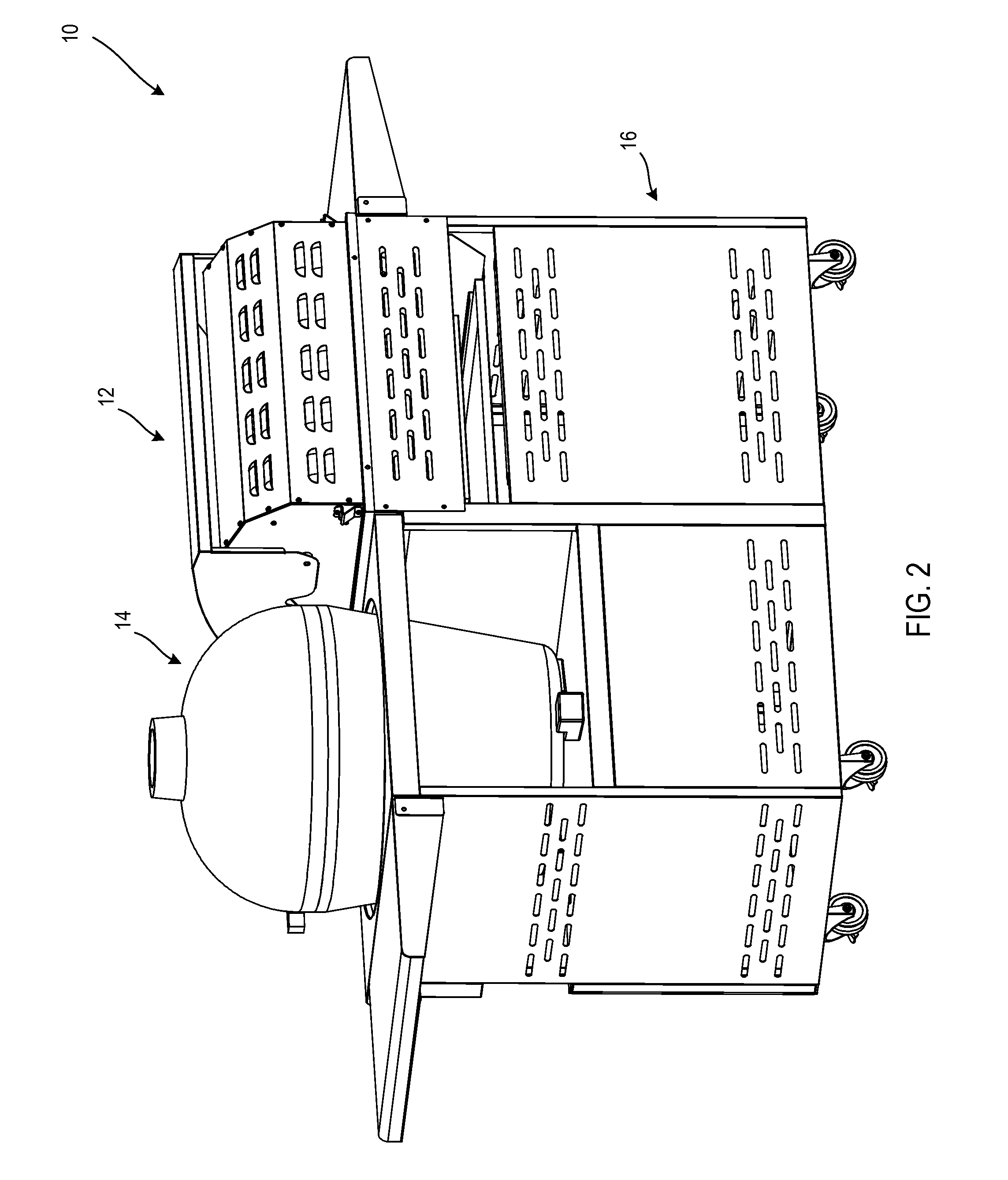

Gas and ceramic grill combination

InactiveUS20130312732A1Great contributionDomestic stoves or rangesLighting and heating apparatusEngineeringGas burner

In various embodiments a gas and ceramic grill combination is provided. The assembly includes a cart adapted to receive a Kamado grill. Additionally the assembly is adapted to provide a gas burner grill, storage, and removable flip-up side shelves. A sear burner is provided for some embodiments. In at least one embodiment the frame structure for the combination may be configured for separation and combining of the gas grill frame and the charcoal grill frame. The combination grill is one integrally formed structure in one embodiment. In an alternative embodiment, the combination grill includes two separate structures that are adapted to be joined one to another.

Owner:PREMIER SPECIALTY BRANDS LLC

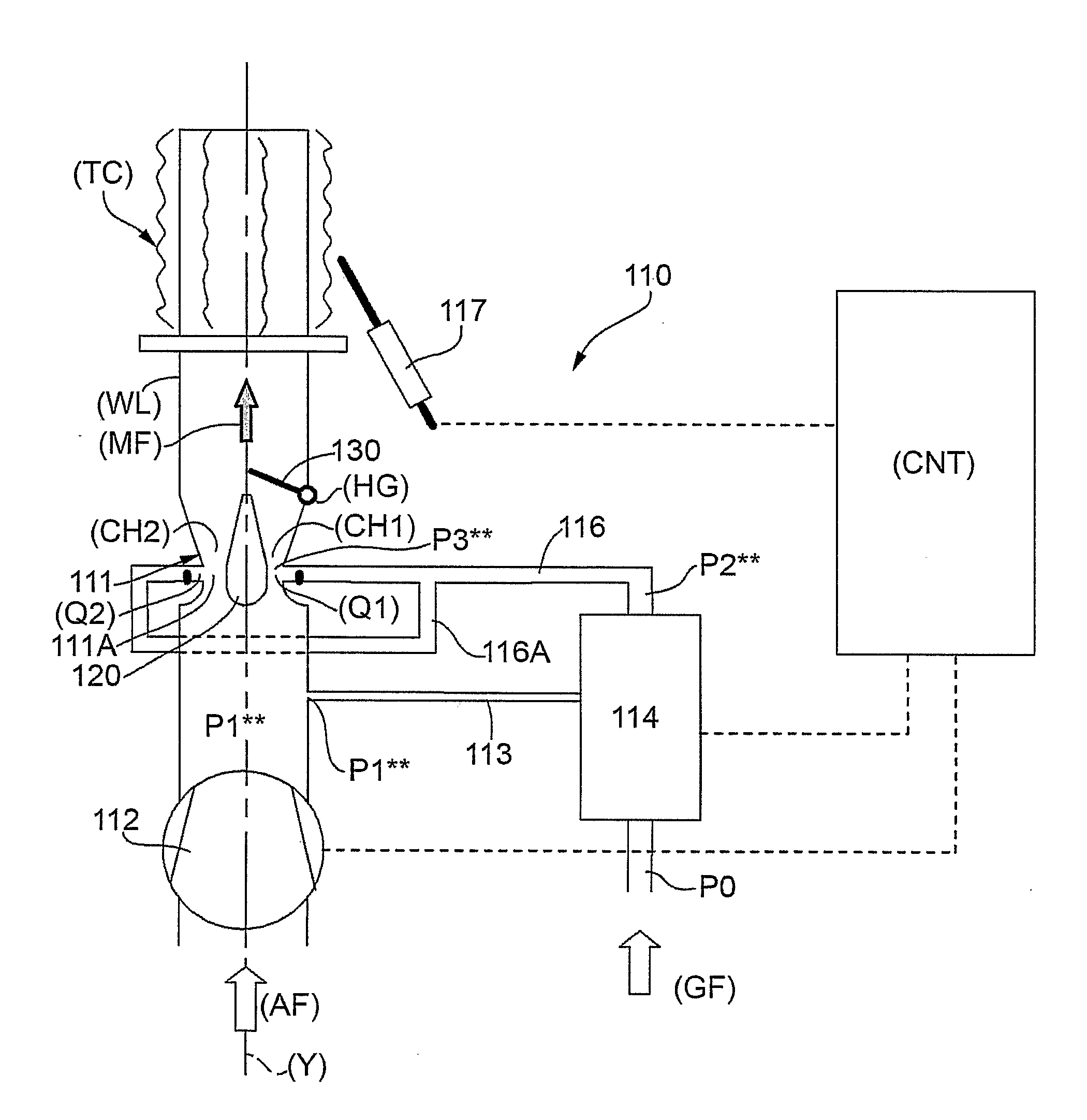

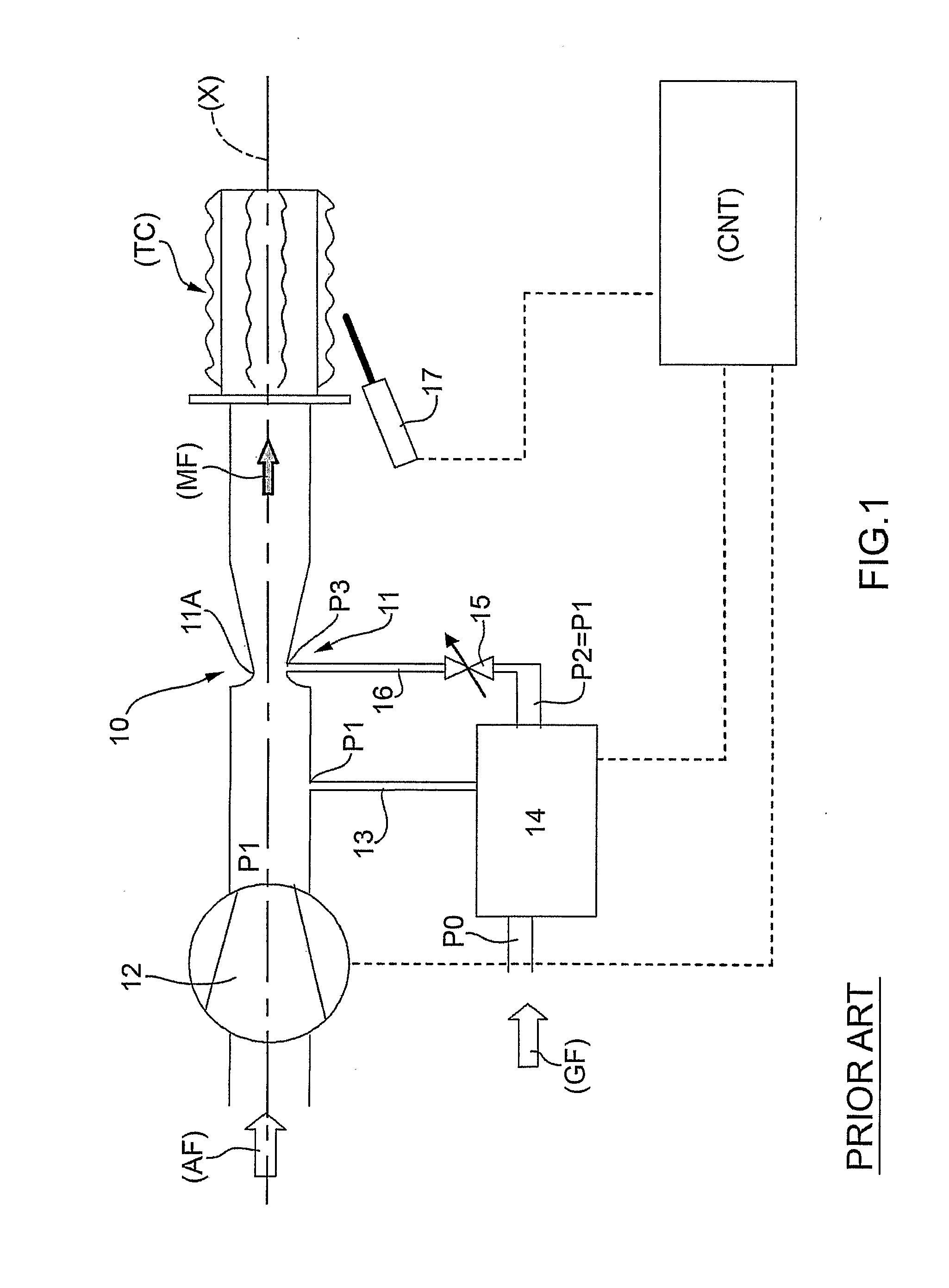

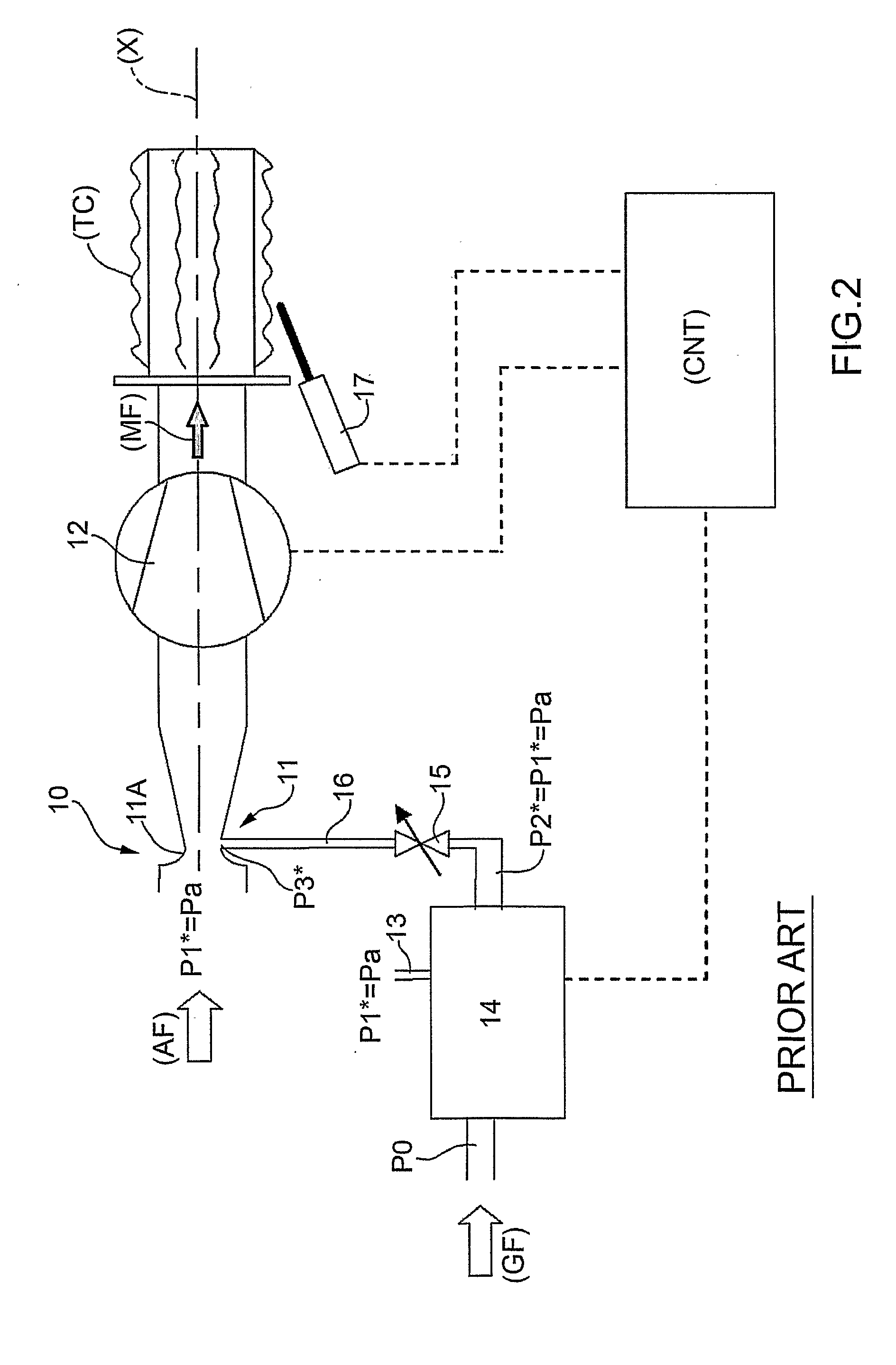

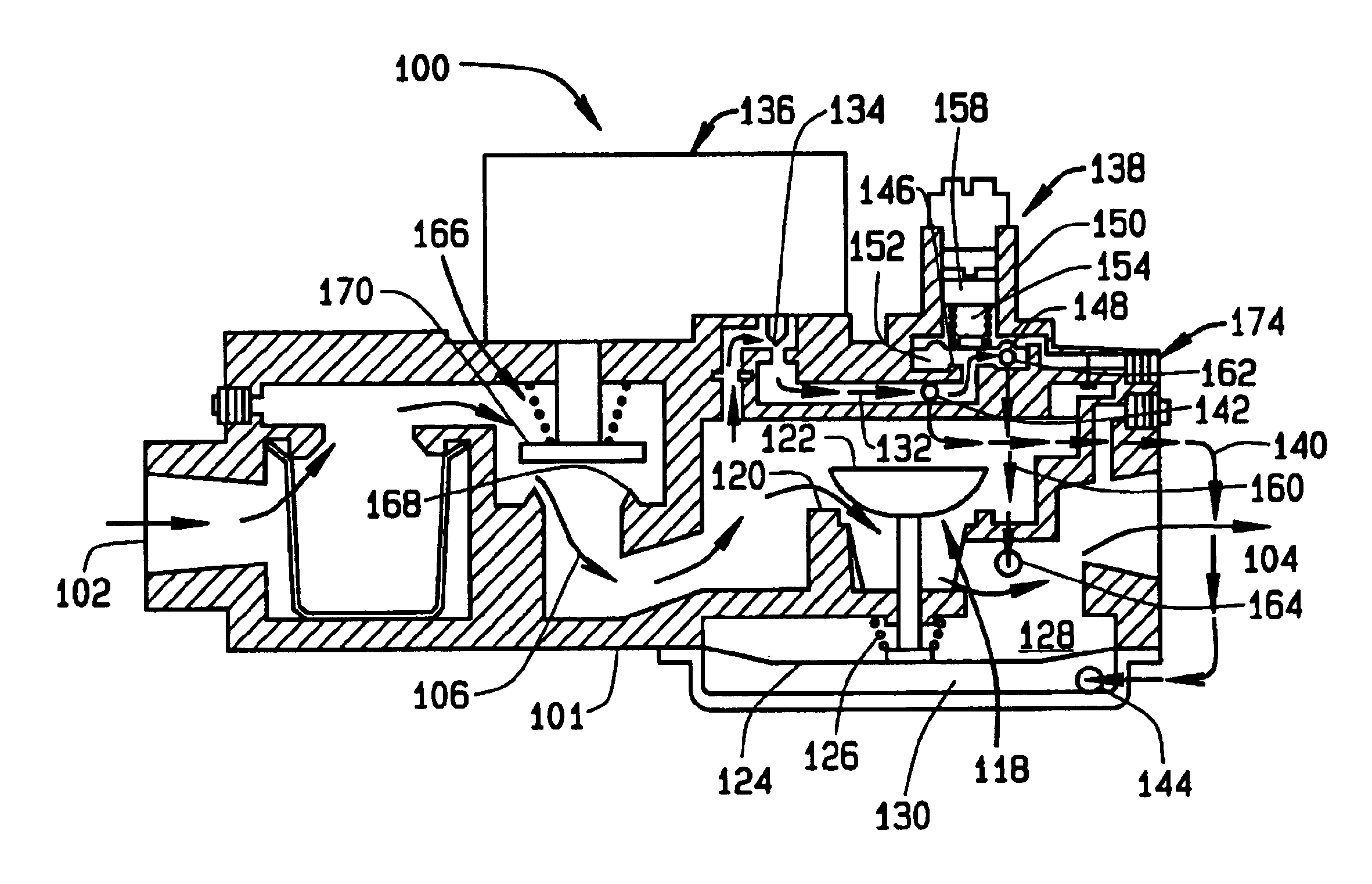

System and methods for modulating gas input to a gas burner

InactiveUS6918756B2Simply and reliably controlledLow costFluidized bed combustionFuel supply regulationMotor driveEngineering

An improved gas appliance having a burner, a gas valve through which the flow of combustion gas to the burner is controlled, and a motor driven blower that supplies combustion air to the burner. The improvement includes means for increasing gas flow through the gas valve as blower speed increases, and decreasing gas flow through the gas valve as blower speed decreases, based on a pressure signal generated independently of combustion air pressure. This improvement allows a constant ratio of gas to air to be maintained in the burner while a combustion flow rate varies dependent on the blower motor revolutions per minute. Thus input pressures of combustion can be controlled at low cost.

Owner:EMERSON ELECTRIC CO

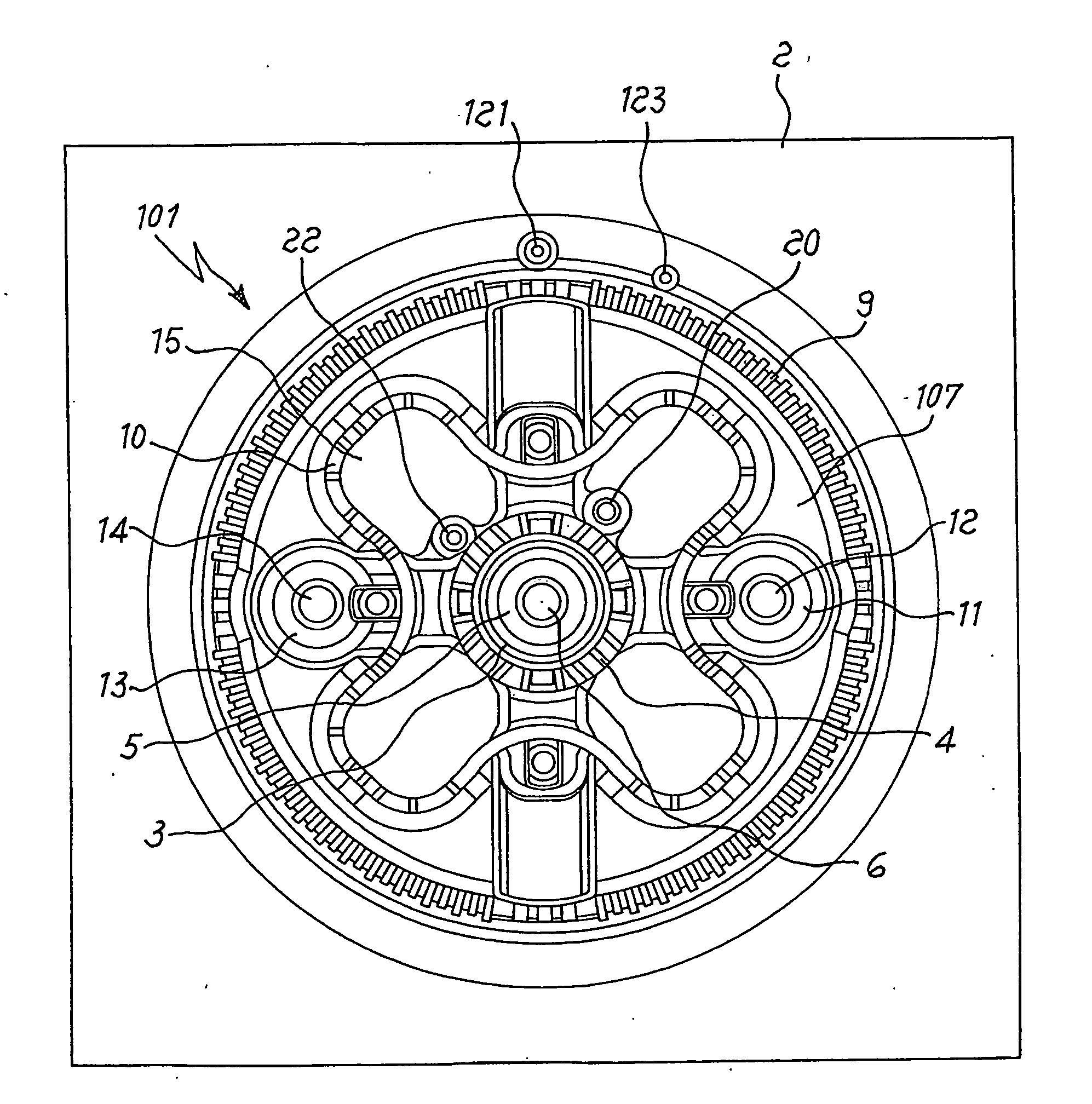

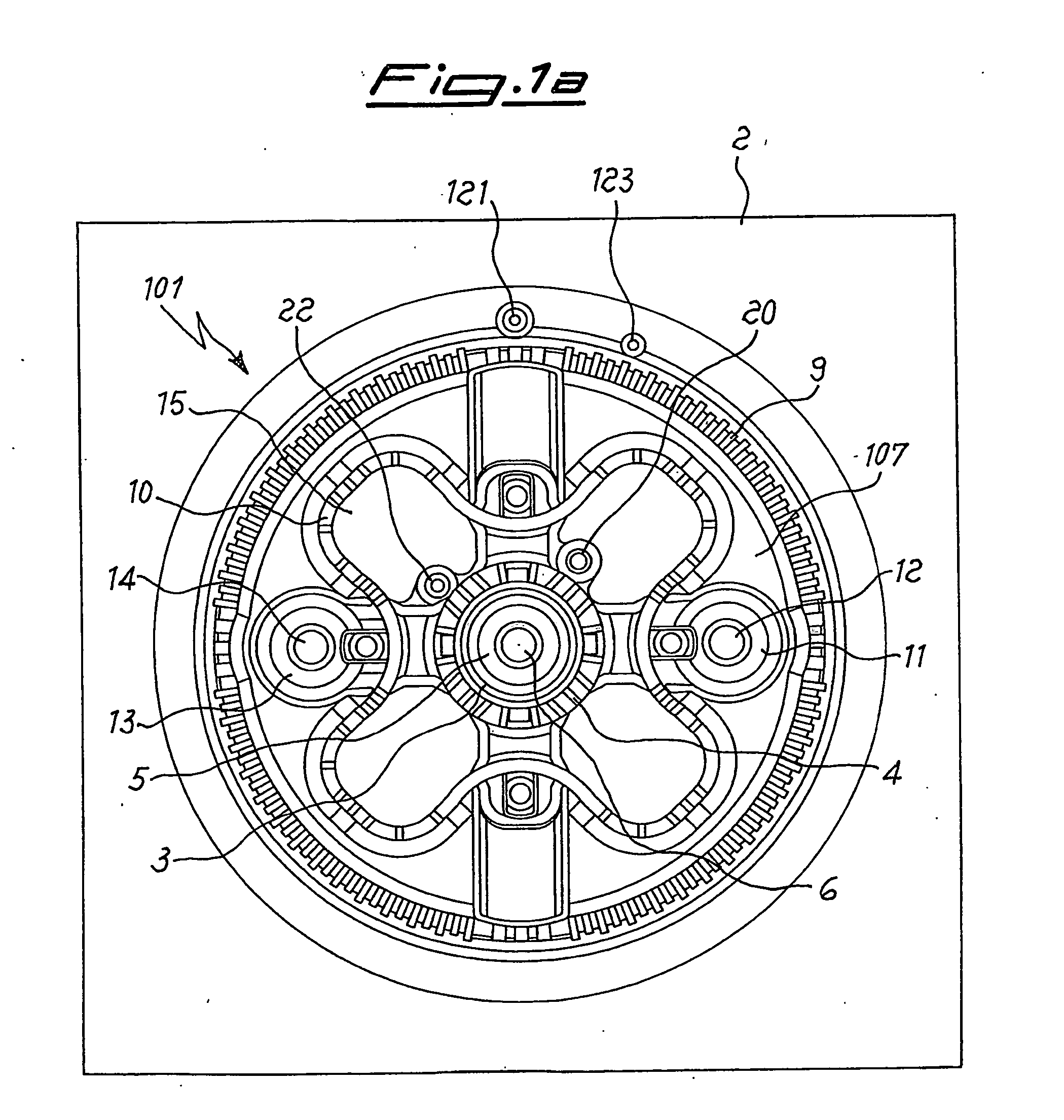

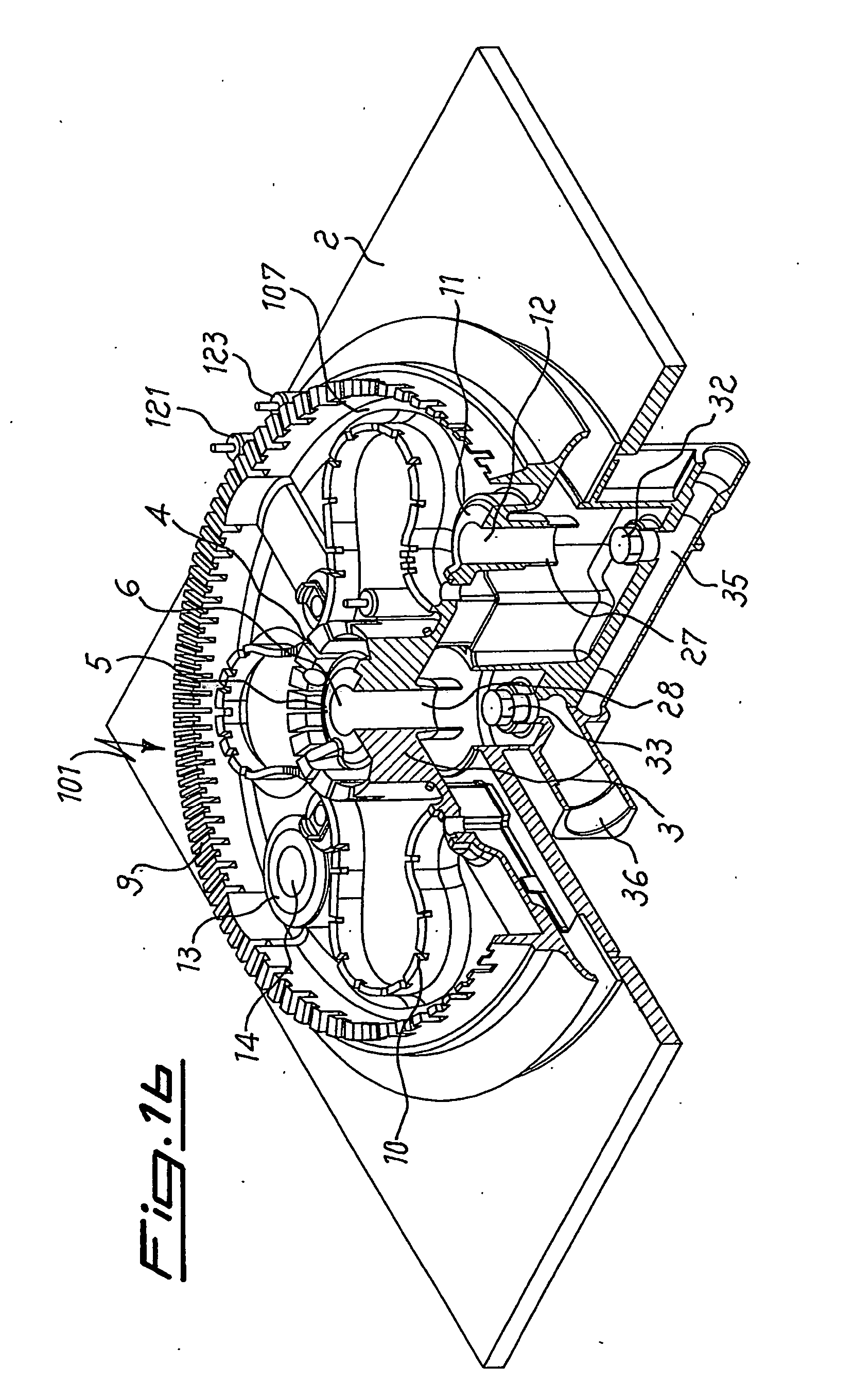

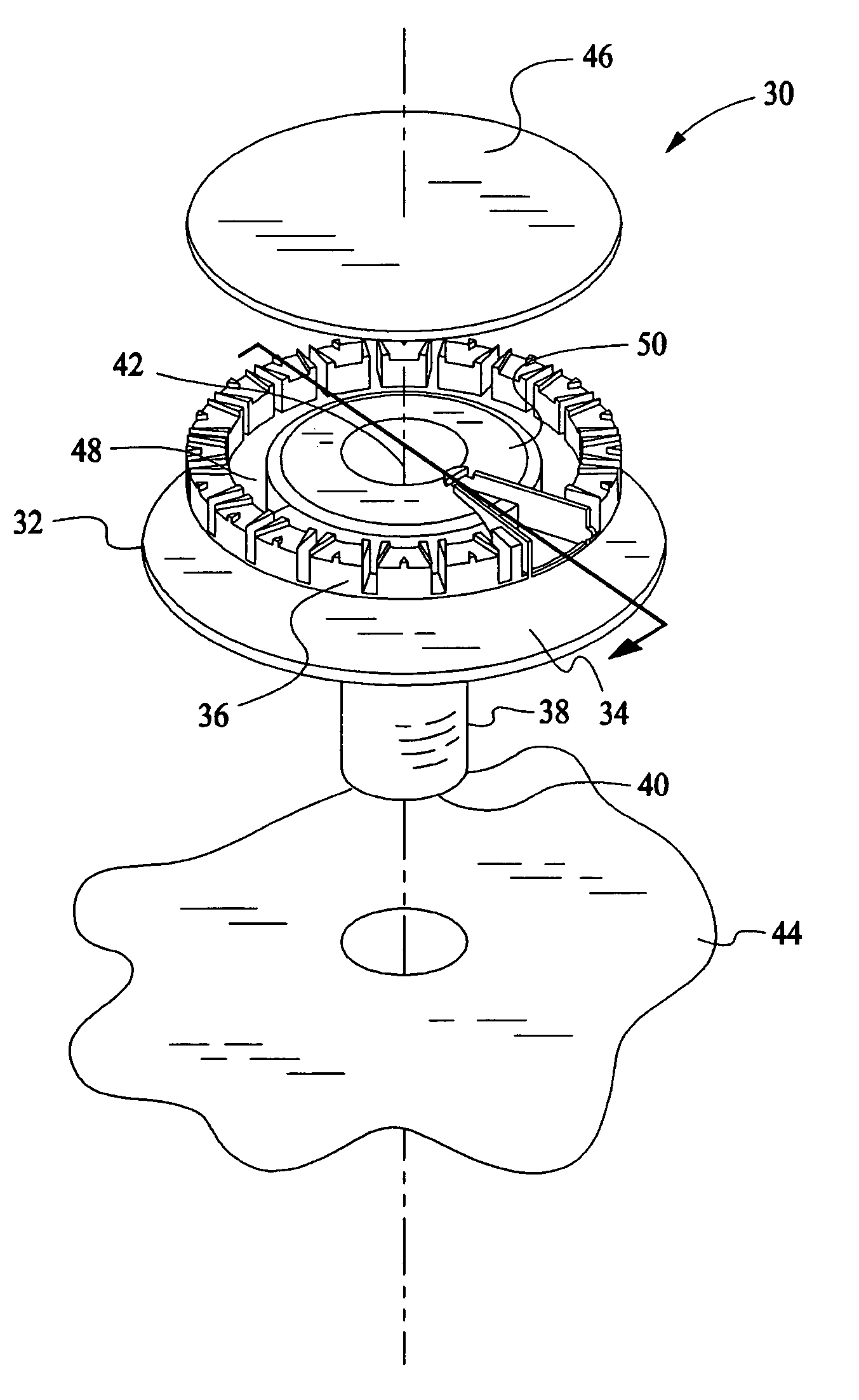

Gas burner with separte feeding of the flame crowns

ActiveUS20060121402A1Reduce burner heightImprove distributionDomestic stoves or rangesElectric spark ignitersGas burnerFuel gas

Gas burner (101) for cookers, of the type fitted to a cooking hob (2), comprising a central body (3) having a first ring of flames (4) and at least one external body (107), fluidly separated from said central body and substantially concentric with it (3), having at least one second (circumferential) ring of flames (9, 10), as well as means for separately feeding the mixture of primary air and gas to the central body and to the external body. These means for feeding the external body comprise at least one horizontal mixing chamber with a radial Venturi effect (11, 12, 13, 14).

Owner:SABAF SPA

Gas stove with thermoelectric generator

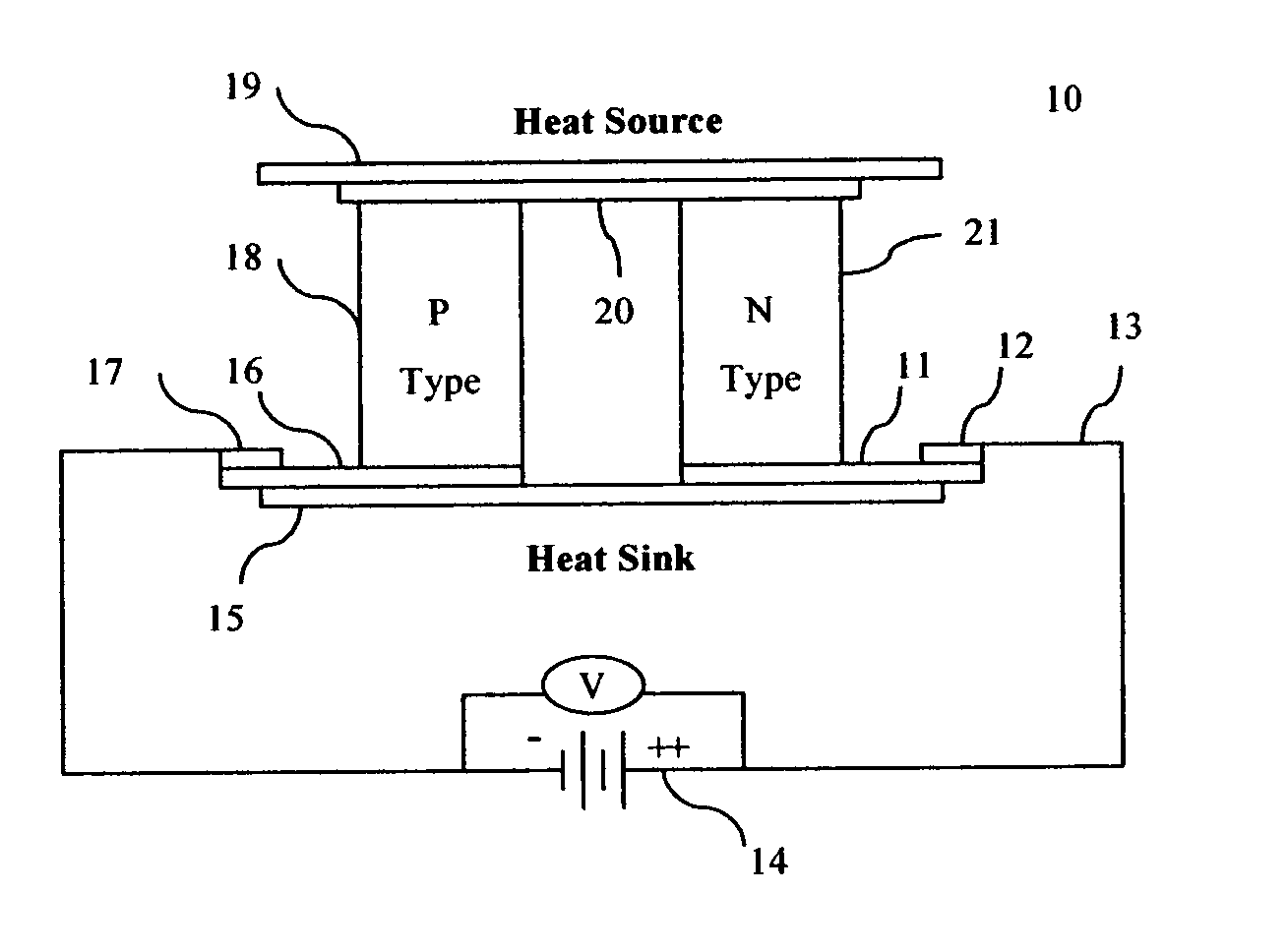

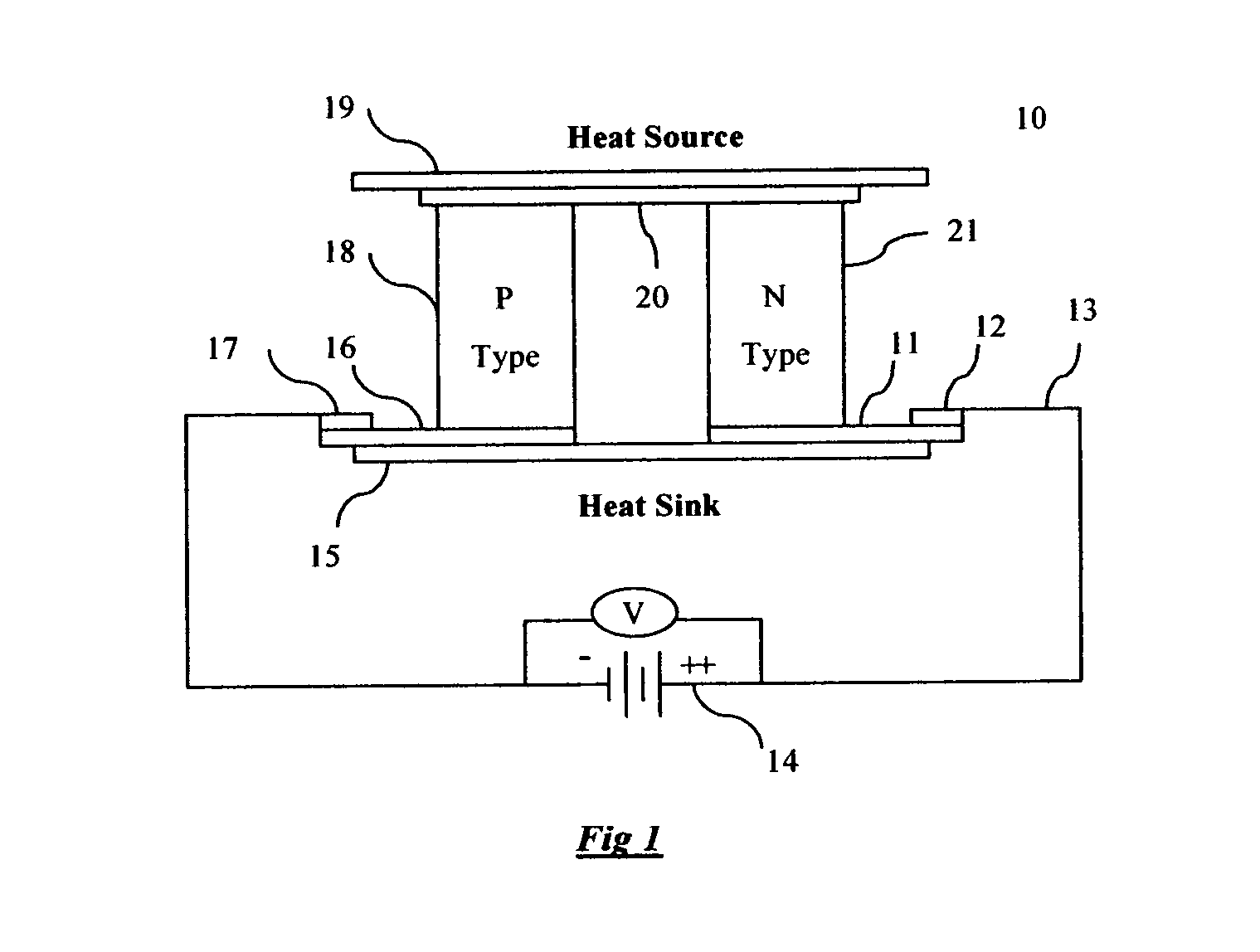

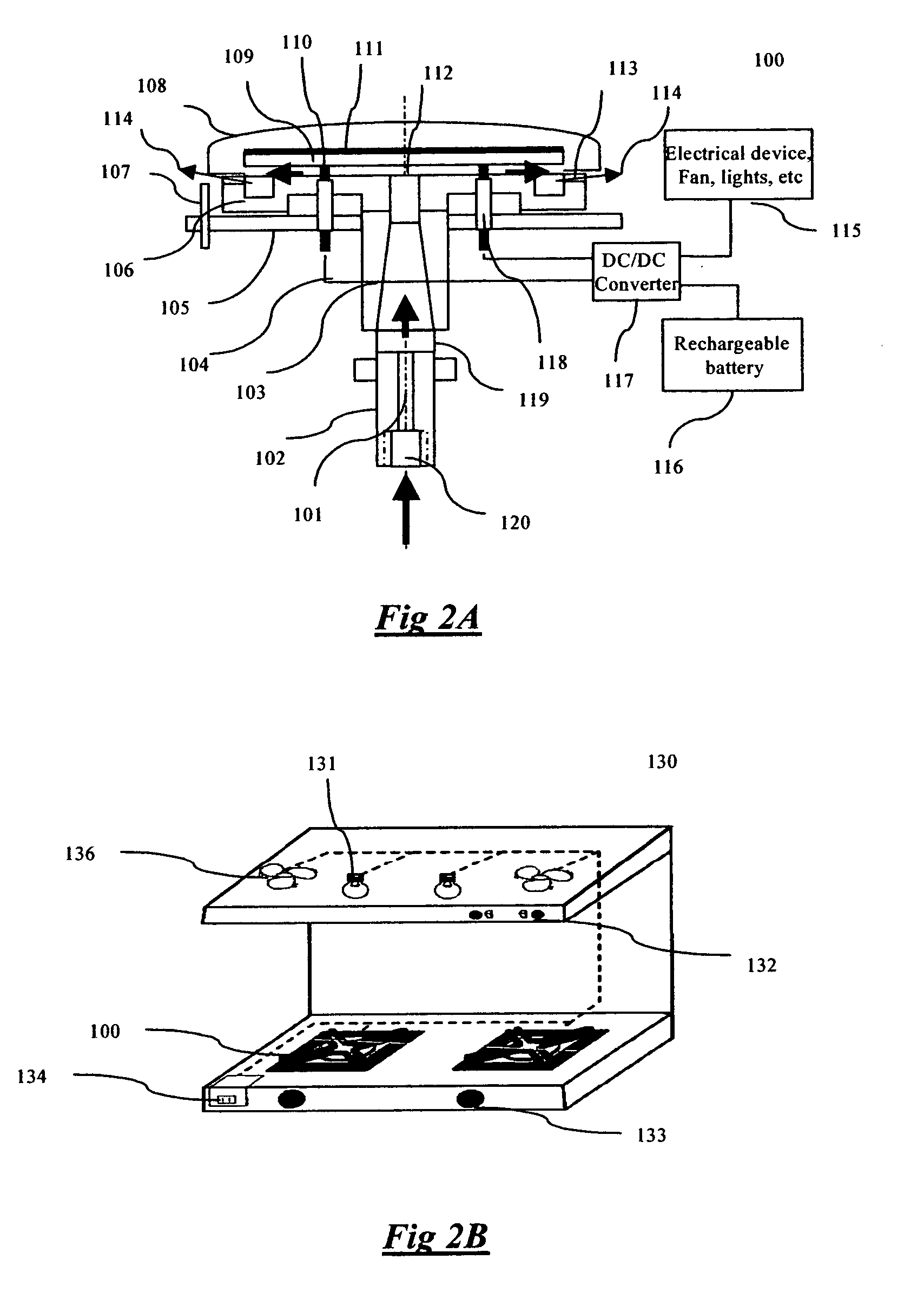

InactiveUS20060016446A1Wasted thermal energyDomestic stoves or rangesGaseous heating fuelElectrical batteryEngineering

A gas burner generates electricity with waste heat energy. At least one thermoelectric unit is installed underneath the burner cap of the gas burner. Gas flame at the edge of the burner cap creates heat sources (hot side) for the thermoelectric unit. A gas-mixing chamber underneath the thermoelectric unit functions as heat sinks (cold side) for the thermoelectric unit. An insulation plate is inserted in between the thermoelectric unit and the burner cap to control the hot side temperature. The thermoelectric unit generates electricity while the gas burner is in use and the flame heats up the burner cap. The thermoelectric unit connects to an electric circuit and provides electricity to power devices such as electric fans, lights, TVs, battery chargers etc.

Owner:HU CAROLINE K +1

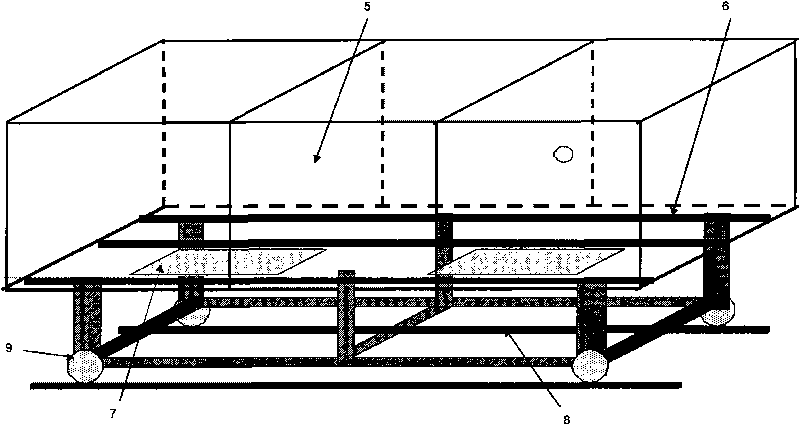

Fire simulation experiment platform for tunnel

InactiveCN101726370AImprove visibilityEasy to observe effectivelySimultaneous control of electric and non-electric variablesAerodynamic testingVisibilityControl system

The invention discloses a fire simulation experiment platform for a tunnel, which comprises a platform main body, a smoke control system, a fire source simulation system and a matched measurement and control system, wherein the platform main body can move horizontally, and at least two of the front surface, the upper surface and the back surface of the platform main body are made of fire-proof transparent materials; the smoke control system can simulate longitudinal wind in the tunnel; the fire source simulation system comprises a porous gas burner capable of controlling fuel flow rate; and the matched measurement and control system comprises a gas component measuring system and a smoke temperature measuring system, wherein the gas component measuring system is used for measuring gas components of burning products, and the smoke temperature measuring system is used for measuring the temperature in the tunnel. In the invention, the fire simulation experiment platform for the tunnel enables the inside of a simulated tunnel to have good visibility, can be used for conveniently and effectively observing the conditions in the tunnel and optically measuring the characteristics of the flow field through laser sheets, and can also realize the purpose of controlling the power of the fire source according to research needs.

Owner:UNIV OF SCI & TECH OF CHINA

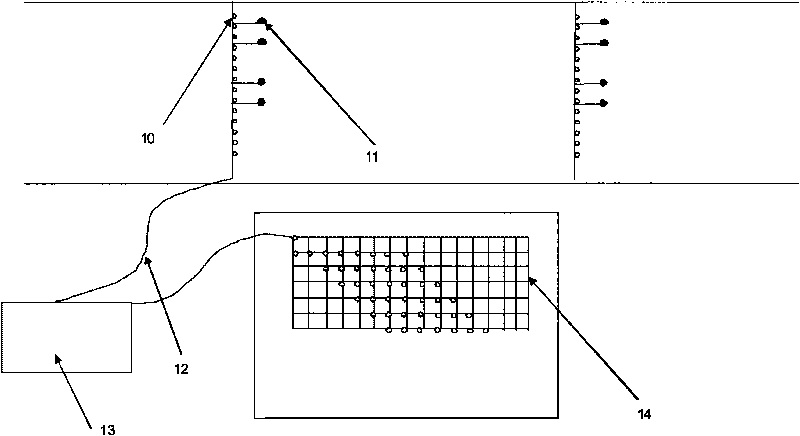

Porous medium combustion apparatus of combustion use liquid fuel

InactiveCN101556040AImproved vaporizationBurn fullyGaseous fuel burnerLiquid wasteCombustion chamber

The invention relates to a porous medium combustion apparatus of combustion use liquid fuel, which comprises a burner shell, a fuel injector, a premixing chamber, a perforated plate, a pulse igniter, porous foam ceramics, and a porous medium pellet and is characterized in that the perforated plate divides the combustion apparatus into a combustion chamber and an upper part and a lower part of the premixing chamber; the combustion chamber is internally provided with the porous medium pellet which is supported by the lower foamed ceramics; the space bond by the foamed ceramics is internally provided with the fuel injector and the pulse igniter; the premixing chamber is connected with an air inlet and a fuel gas inlet; the combustion apparatus preheats the foamed ceramics by the combustion of the gas fuel, and then sprays the liquid fuel on the foamed ceramics to realize the vaporization and combustion of the liquid fuel. The porous medium combustion apparatus of the f combustion use liquid fuel has effects and benefits that the combustion apparatus can burn the liquid fuel such the gas oil difficult to be burned in free space, industrial flammable waste liquor and the like, has the function of a gas burner; the combustion apparatus does not need a vaporizing unit internally and is characterized by high combustion efficiency and low pollutant discharge.

Owner:DALIAN UNIV OF TECH

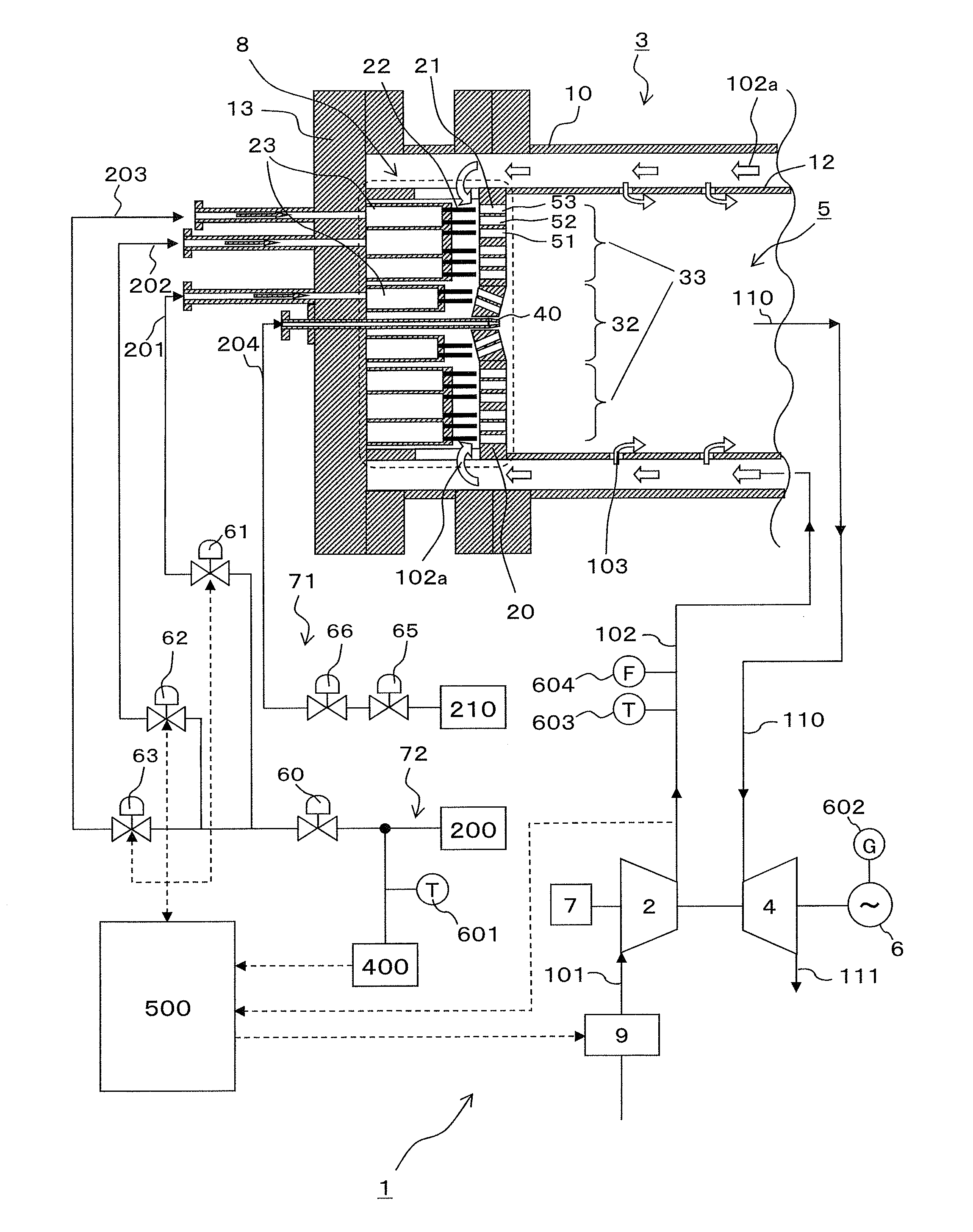

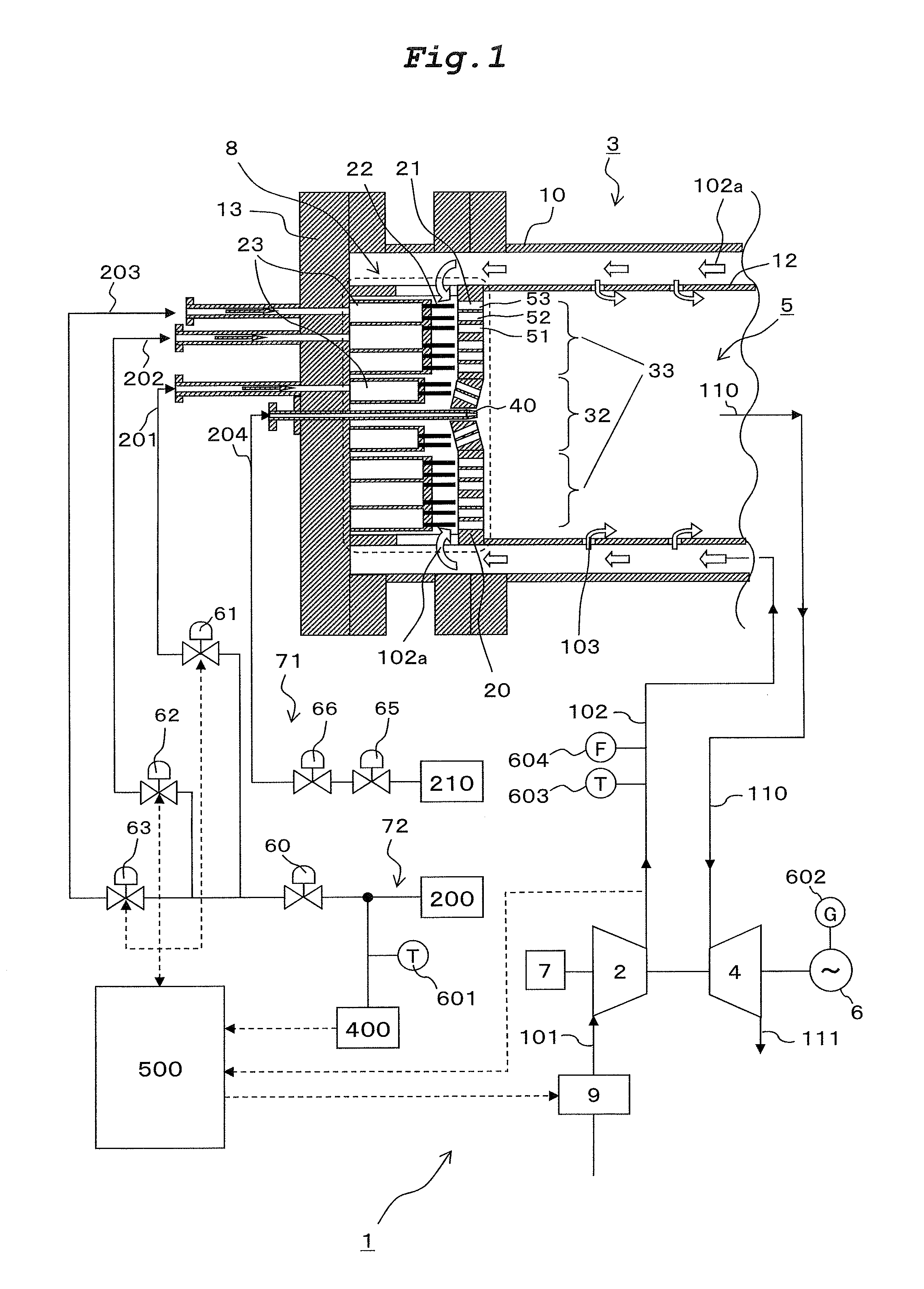

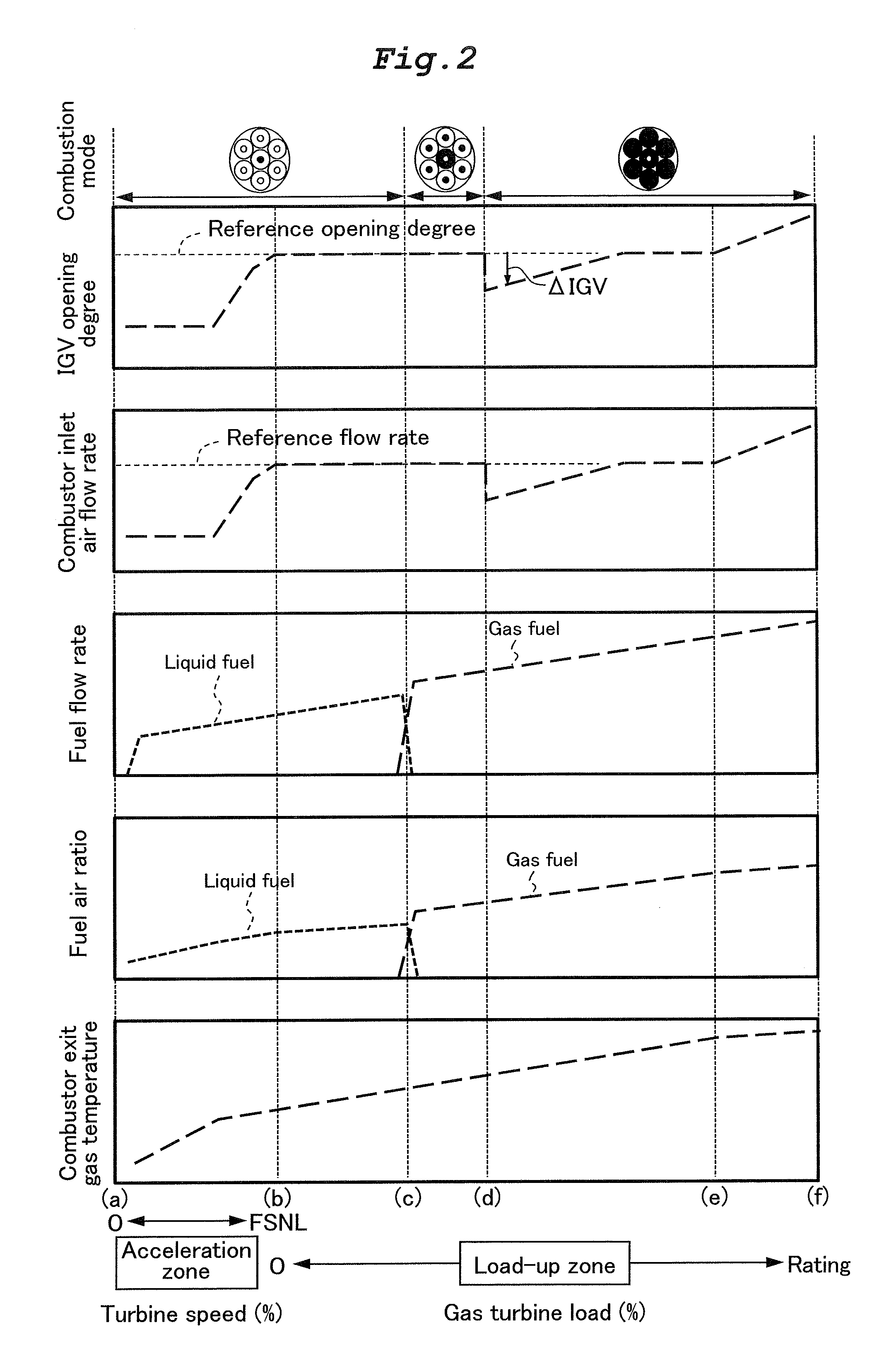

Gas Turbine Combustion System

InactiveUS20150059353A1Minimizing contentReduce the amount requiredFuel supply regulationContinuous combustion chamberCombustion systemControl system

The present invention provides a gas turbine combustion system capable of minimizing unburned content of a gas fuel under all load conditions from partial load to rated load.A gas turbine combustion system includes: a plurality of gas fuel burners 32, 33; an IGV 9 that adjusts a flow rate of air to be mixed with a gas fuel; and a control system 500 that temporarily reduces an air flow rate from a reference flow rate to a set flow rate by outputting a signal to the IGV 9 when a combustion mode is switched from a partial combustion mode in which the gas fuel is burned with part of the gas fuel burners 32, 33 to a full combustion mode in which the gas fuel is burned with all of the gas fuel burners 32, 33.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

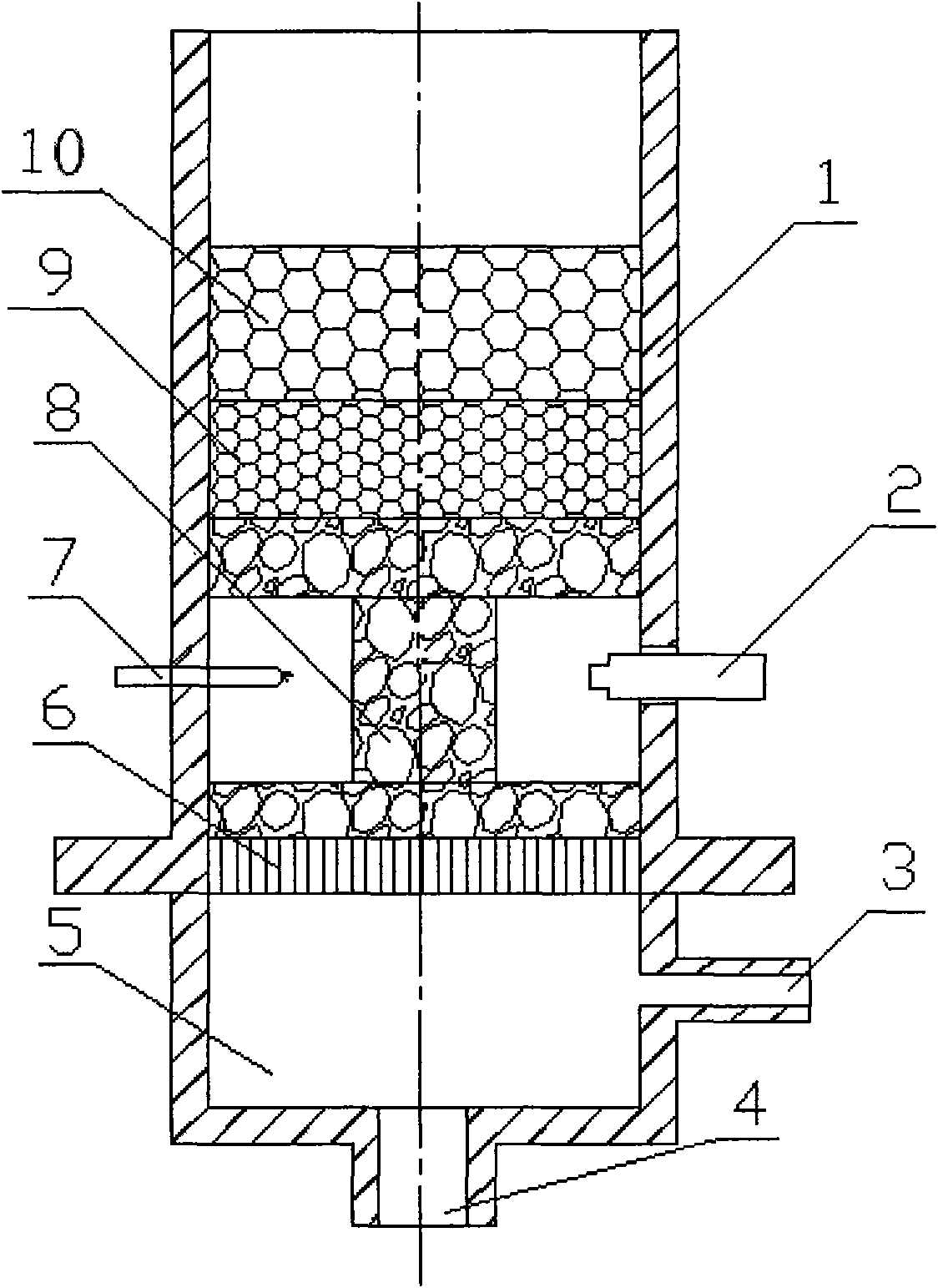

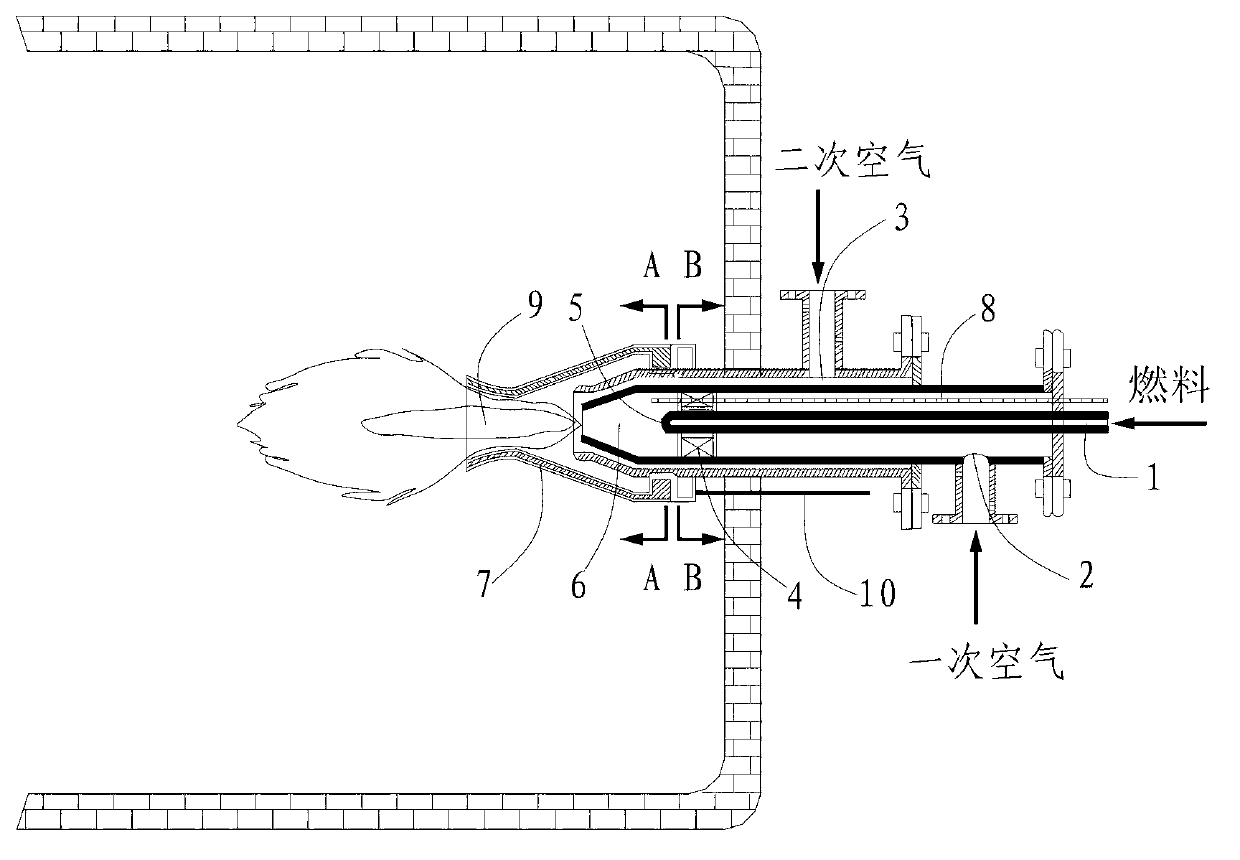

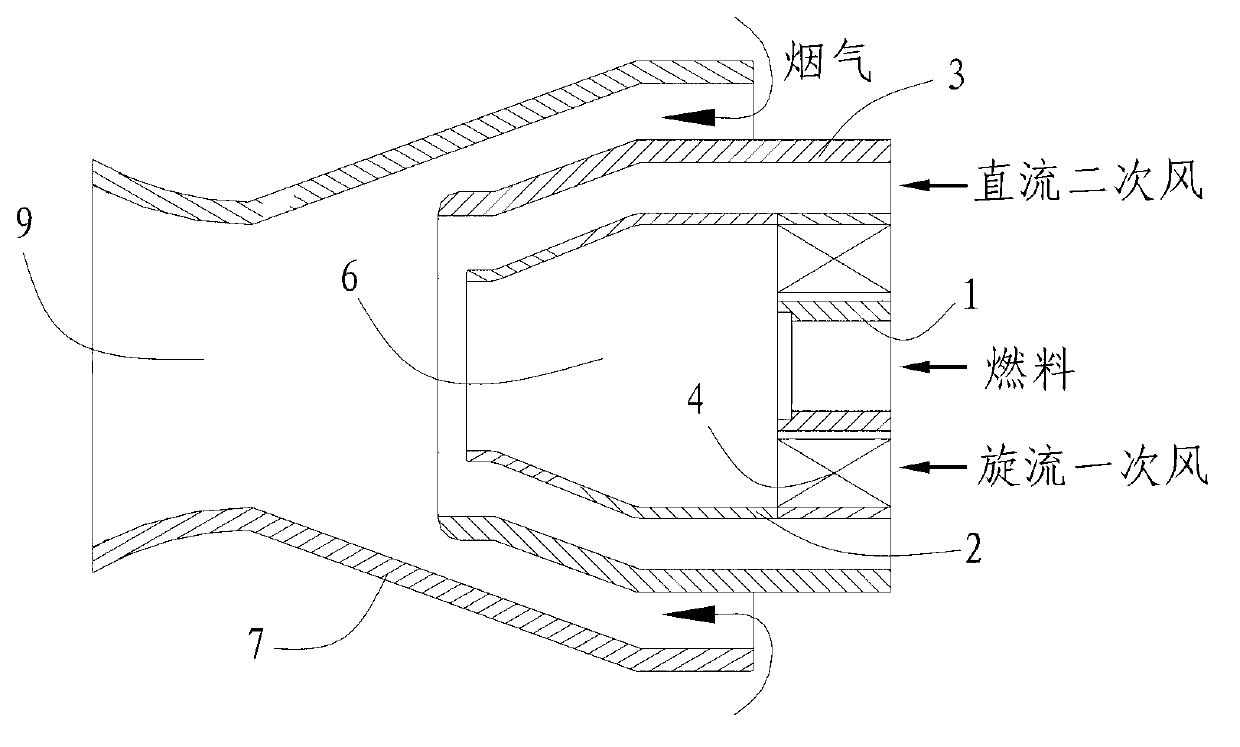

Gas burner capable of adjusting gas to be self-recycling

ActiveCN103277795AWide range of fuelImprove combustion efficiencyGaseous fuel burnerSpray nozzleGas burner

The invention discloses a gas burner capable of adjusting gas to be self-recycling. The gas burner capable of adjusting the gas to be self-recycling comprises a center fuel pipe, a primary rotational-flow air duct, a secondary direct-flow air duct and an ejector, wherein the center fuel pipe, the primary rotational-flow air duct, the secondary direct-flow air duct and the ejector are coaxial from inside to outside and sequentially embedded in a sleeved mode. A fuel nozzle is formed in the outlet segment of the center fuel pipe, an air cyclone and a pre-mixing chamber are arranged inside the primary rotational-flow air duct, the primary rotational-flow air duct and the pre-mixing chamber are communicated with the fuel nozzle, both an outlet of the pre-mixing chamber and the outlet end of the secondary direct flow air duct are arranged at the throat position of the ejector, a main flame burning area is formed at the throat position of the ejector, an electronic igniter is further arranged inside the primary rotational-flow air duct, one end of the electronic igniter penetrates through the air cyclone, the ignition electrode of the electronic igniter is arranged inside the pre-mixing chamber, the end surfaces, being connected with the head of the burner, of the ejector are of a sawtooth disk structure and meshed with each other, and linkage mechanisms are arranged at the positions of the sawtooth disk structures and fixed on the outer pipe wall of the secondary direct-flow air duct. The gas burner capable of adjusting the gas to be self-recycling has the advantages of being easy to manufacture, and capable of achieving the objective that the adapting range of fuel is wide, burning efficiency is high, burning is stable, and pollution is low.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Air thermalization gas burner

InactiveCN101196308AReduce dosageHarm reductionDomestic stoves or rangesStoves/ranges topsCombustion chamberProduct gas

The invention discloses an air thermalization gas burner, which comprises a burner base, a furnace ring and a burning head. The burner base is provided with an air supply port and a plurality of air nozzles as well as an air supply channel communicated with the air nozzles at external side; the air supply channel is positioned with a blower air inlet; the furnace ring, a popper and a burner base form a firebox; wherein, the furnace ring is a hollow interlayer, which is provided with a plurality of back-wind ports on the internal layer interning wall near to the port; an internal cavum of the furnace ring is communicated with the air supply channel; the blower preaches the air form the air inlet, the air supply channel and the air nozzles into the firebox and the air can burn with the gas entered from the air supply port in the firebox to heat the popper; the high temperature air can pass through the back-wind ports and then return to the firebox for burning after passing through the internal cavum of the furnace ring, the air supply channel and the air nozzles; the heat of the high temperature air can be recovered and utilized as well as sufficiently burned, thereby reducing the usage of gas and restraining the generation of gas harmful to human's health as well as deducing the pollution for environment.

Owner:姜亦迎

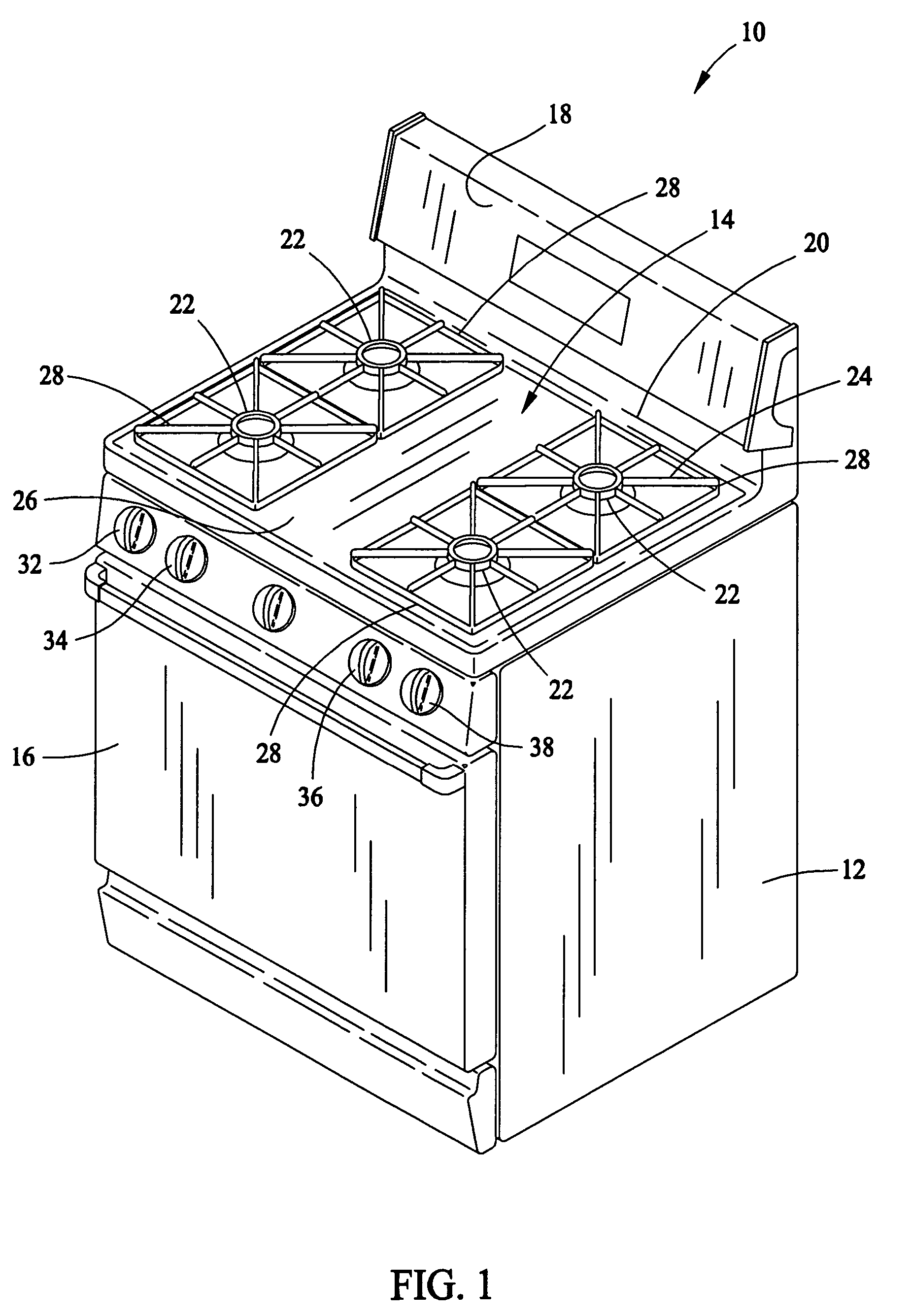

Method and apparatus for gas ranges

A gas burner assembly for connection to a source of gas includes a burner body including at least one receptacle, a burner cap positioned on the burner body, at least two isolation walls coupled to the burner body, and at least one projection extending from the burner cap. The projection is configured to allow substantially uniform gas distribution through a plurality of burner ports at a first gas input rate, and configured to limit the gas distribution to at least one burner port at a second input rate greater than the first input rate input rate.

Owner:HAIER US APPLIANCE SOLUTIONS INC

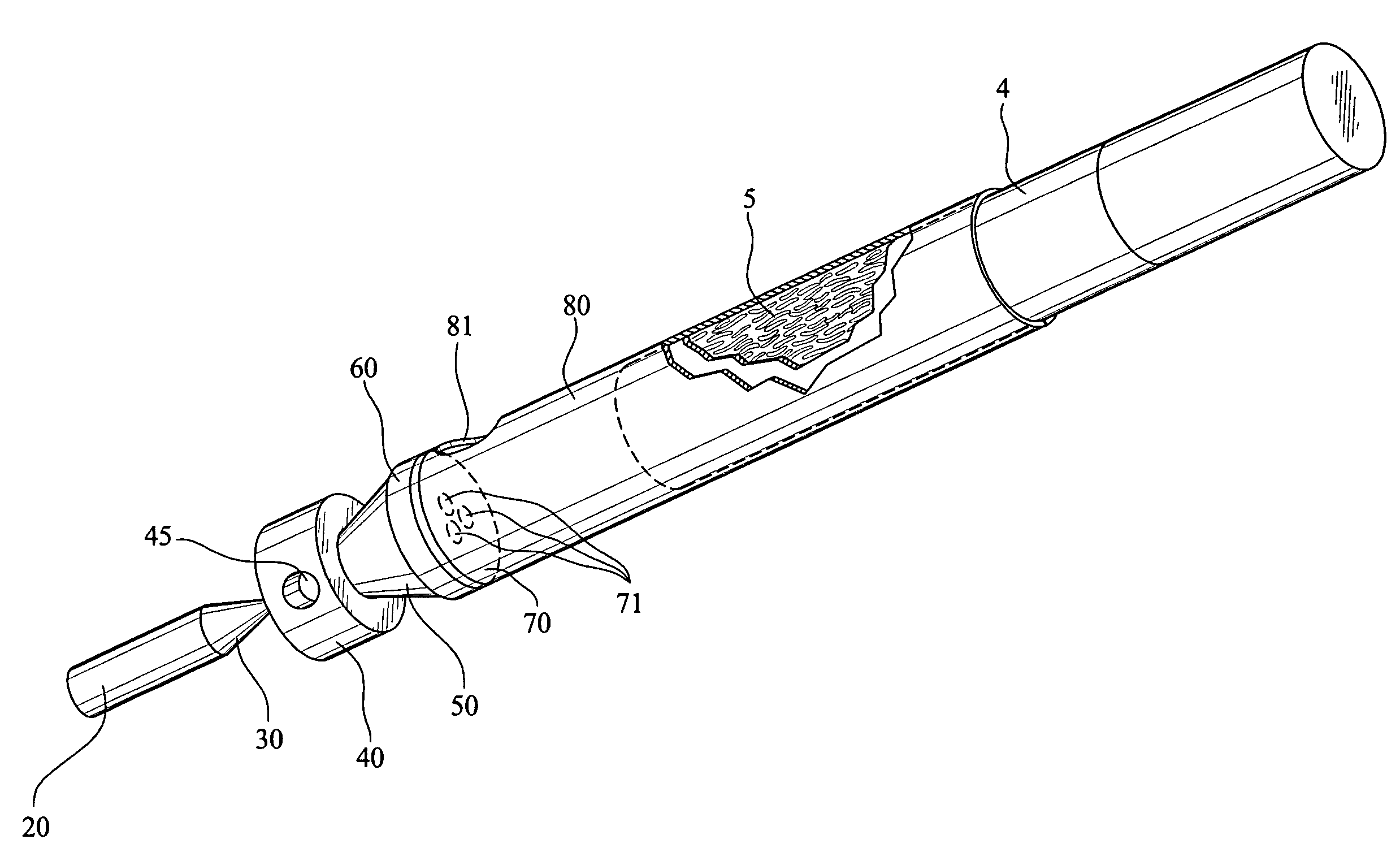

Fuel cell apparatus and methods

InactiveUS20060246333A1Improve thermal efficiencyFuel efficiencyFuel cells groupingCell electrodesFuel cellsGas burner

The invention relates to a fuel cell apparatus that includes a housing. The housing defines a substantially isothermal zone which integrates a fuel cell and a tail gas burner with the isothermal zone. The fuel cell and the tail gas burner are in thermal communication and share a common wall. In one embodiment, the housing further integrates a fuel reformer, where the fuel reformer is in thermal communication with the fuel cell. In one embodiment, the fuel cell and the tail gas burner can be arranged to produce a power density greater than or equal to about 2 W / cc. The fuel cell preferably is a solid oxide fuel cell.

Owner:LILLIPUTIAN SYST

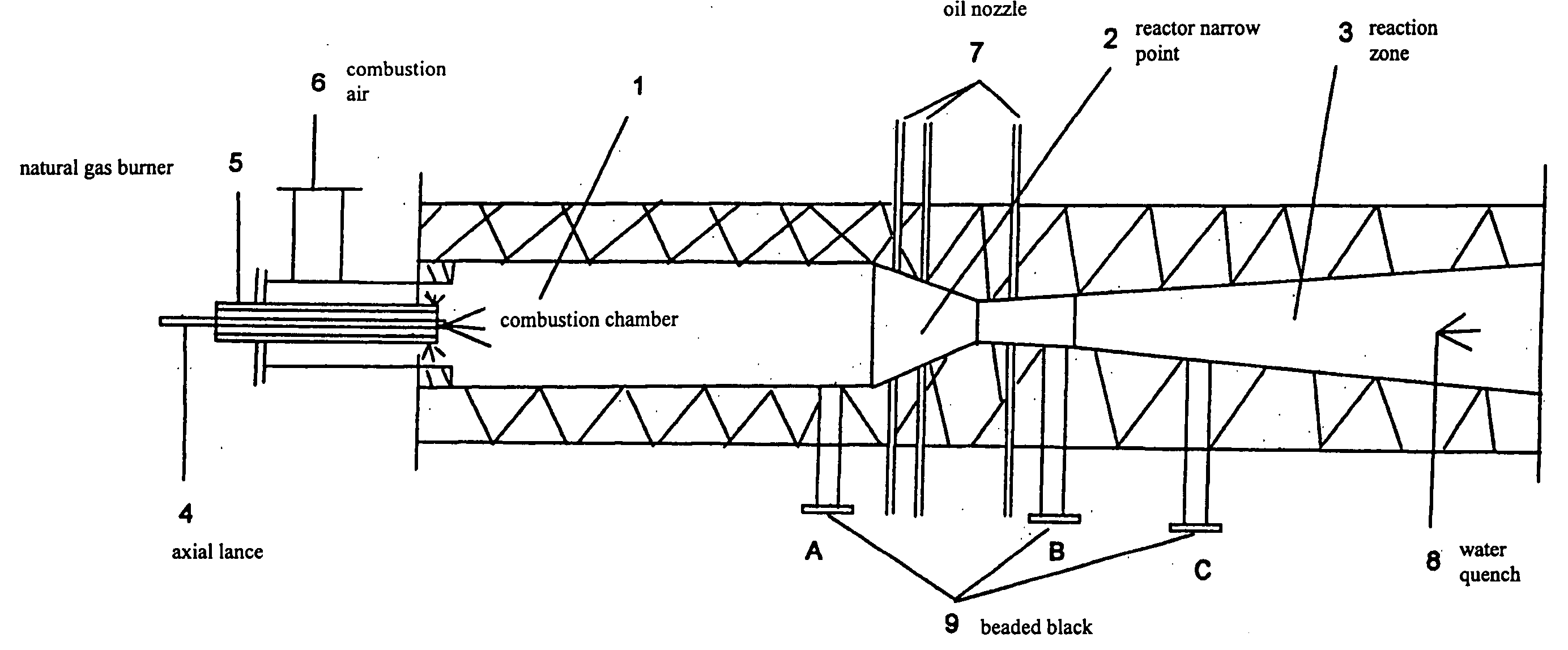

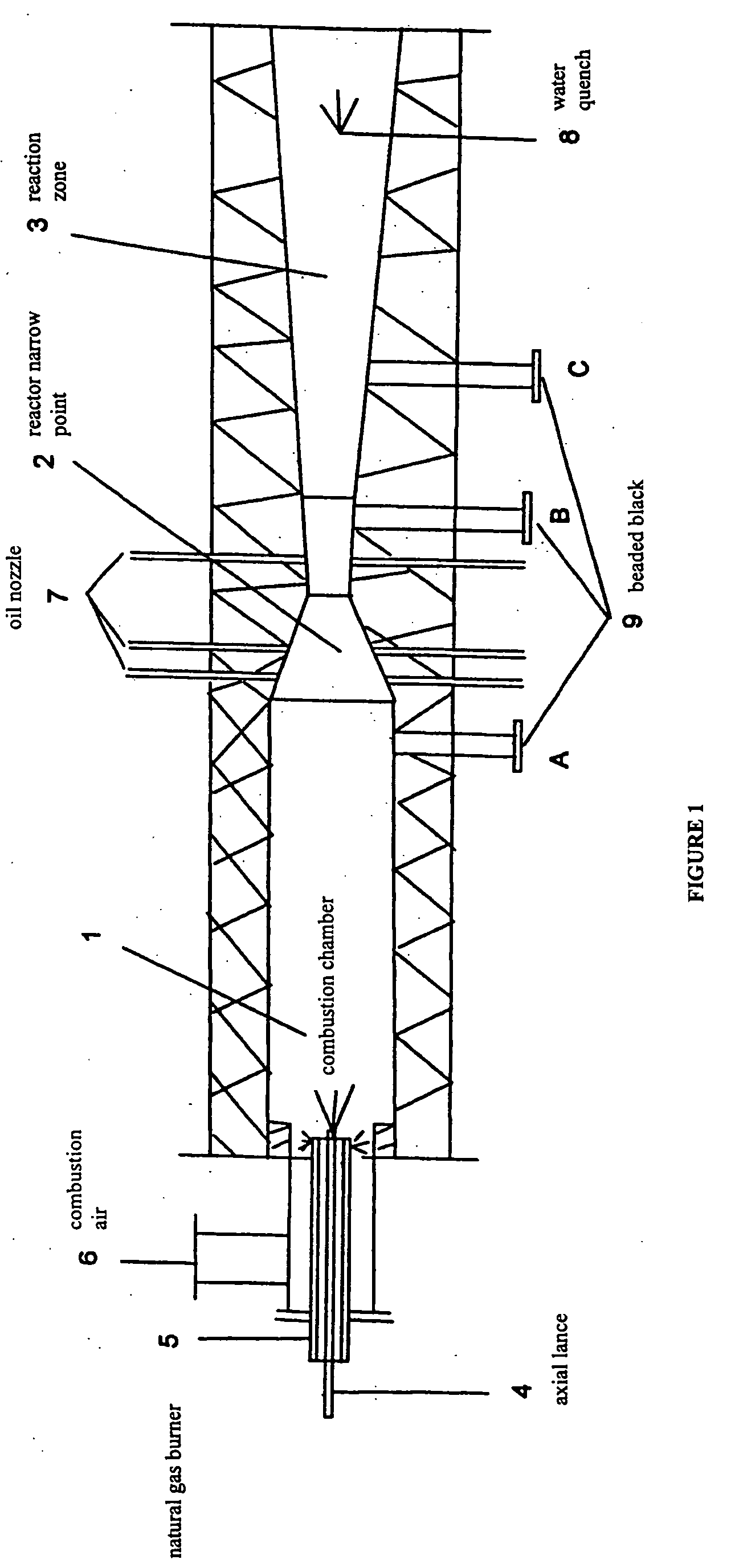

Process for the production of furnace black

Process for the production of furnace black by producing a stream of hot combustion gases in a combustion chamber, feeding the hot combustion gases along a flow axis from the combustion chamber through a reactor narrow point into a reaction zone, mixing carbon black raw material into the flow of the combustion gases in front of, inside or behind the reactor narrow point and stopping carbon black formation downstream in the reaction zone by spraying in water, steam being jetted in axially through the gas burner and optionally at the radial oil nozzles and beaded carbon black being introduced before and / or after the reactor narrow point.

Owner:UBS AG

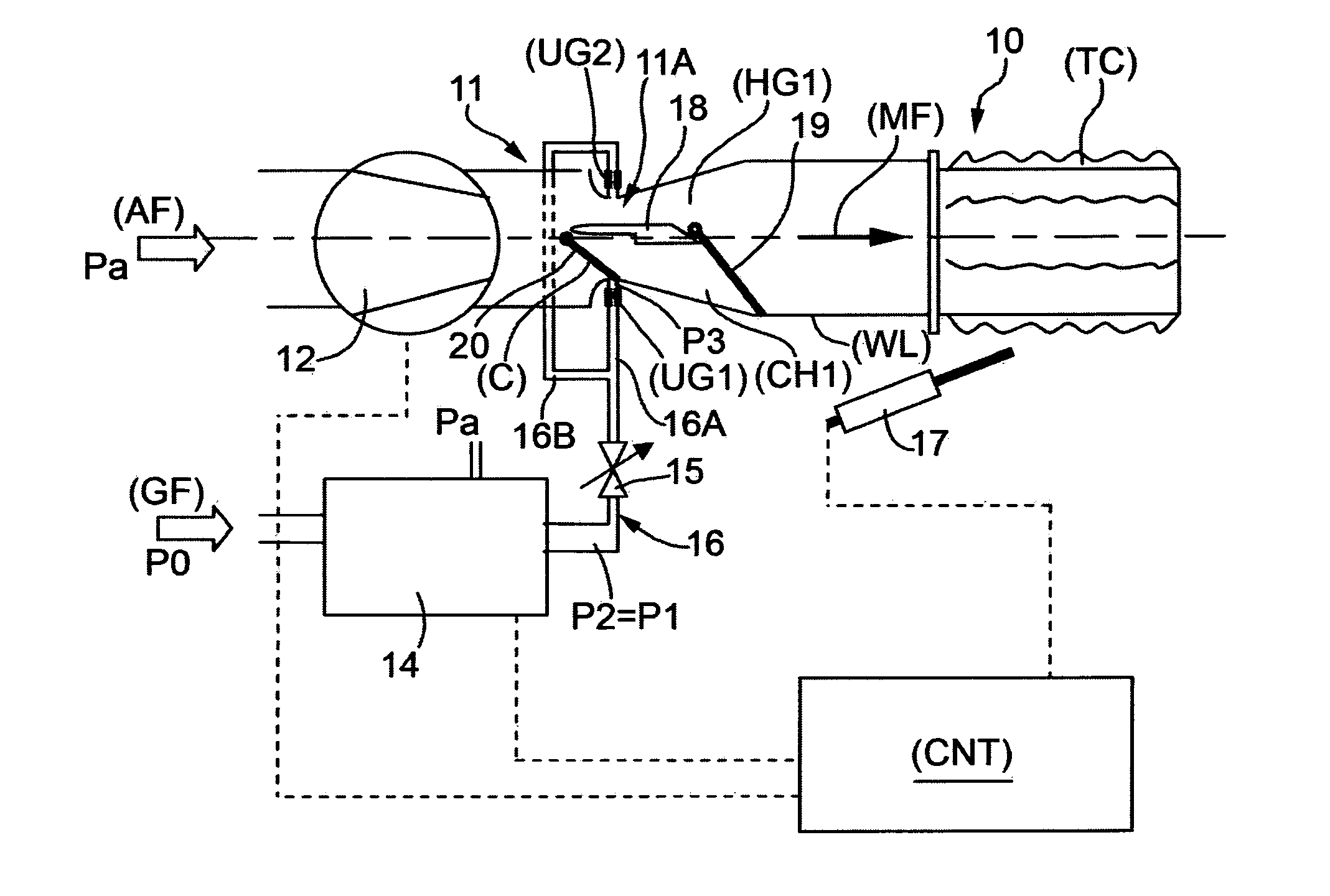

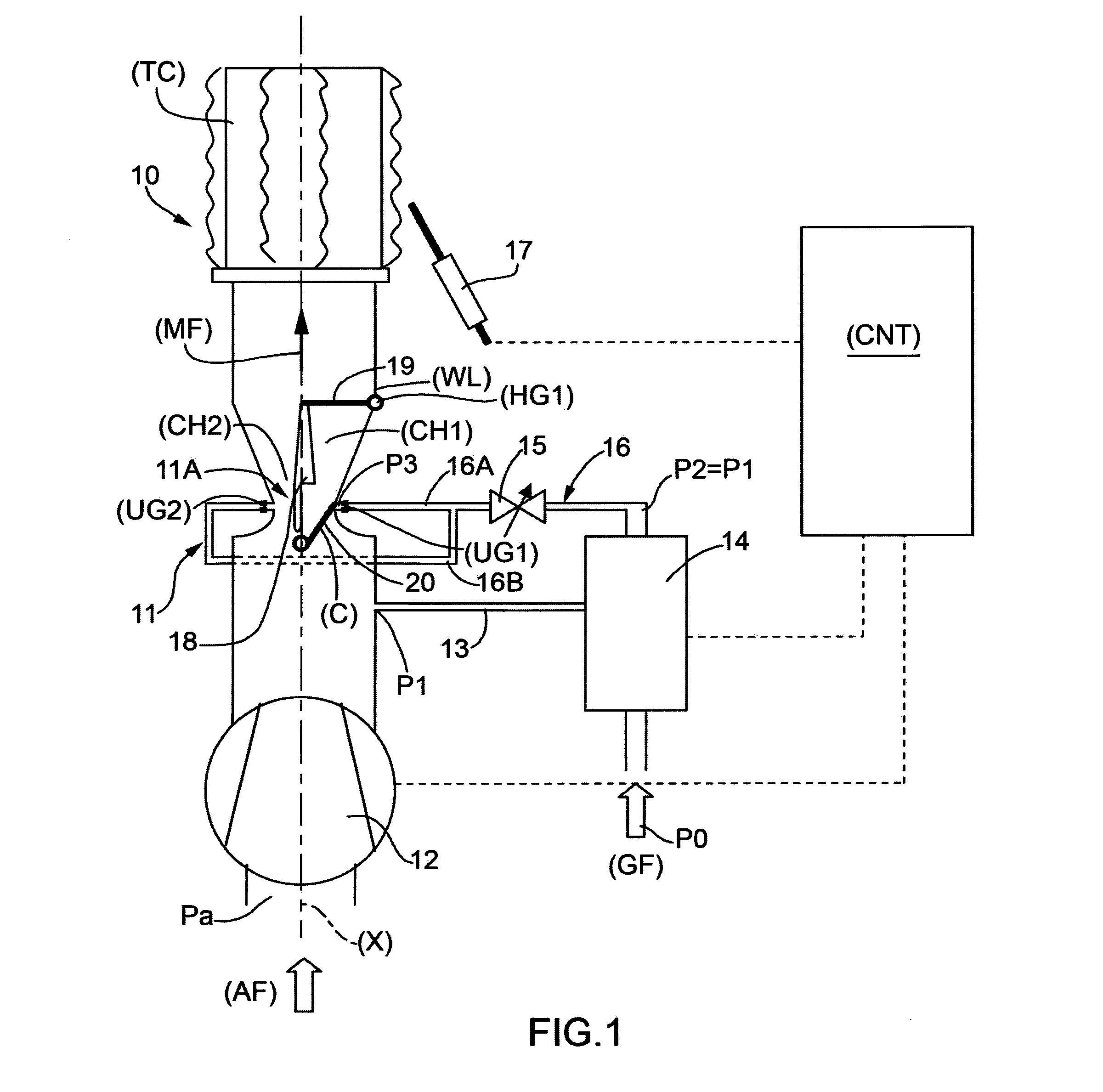

Premix gas burner

InactiveUS20130224670A1Reduce negative impactFuel supply regulationGaseous fuel burnerCombustible gasEngineering

An air / gas premix burner is disclosed. The air / gas premix burner includes a fan for sending an air / gas mixture towards a combustion head and a gas valve for regulating the introduction of combustible gas. The air / gas premix burner also includes an air / gas mixer, which comprises a localized pressure loss device, and a combustion head. The air / gas mixer includes two channels. One of the channels is provided with two hinged flaps that are designed to open and close for regulating the flow rate of the mixture.

Owner:GAS POINT

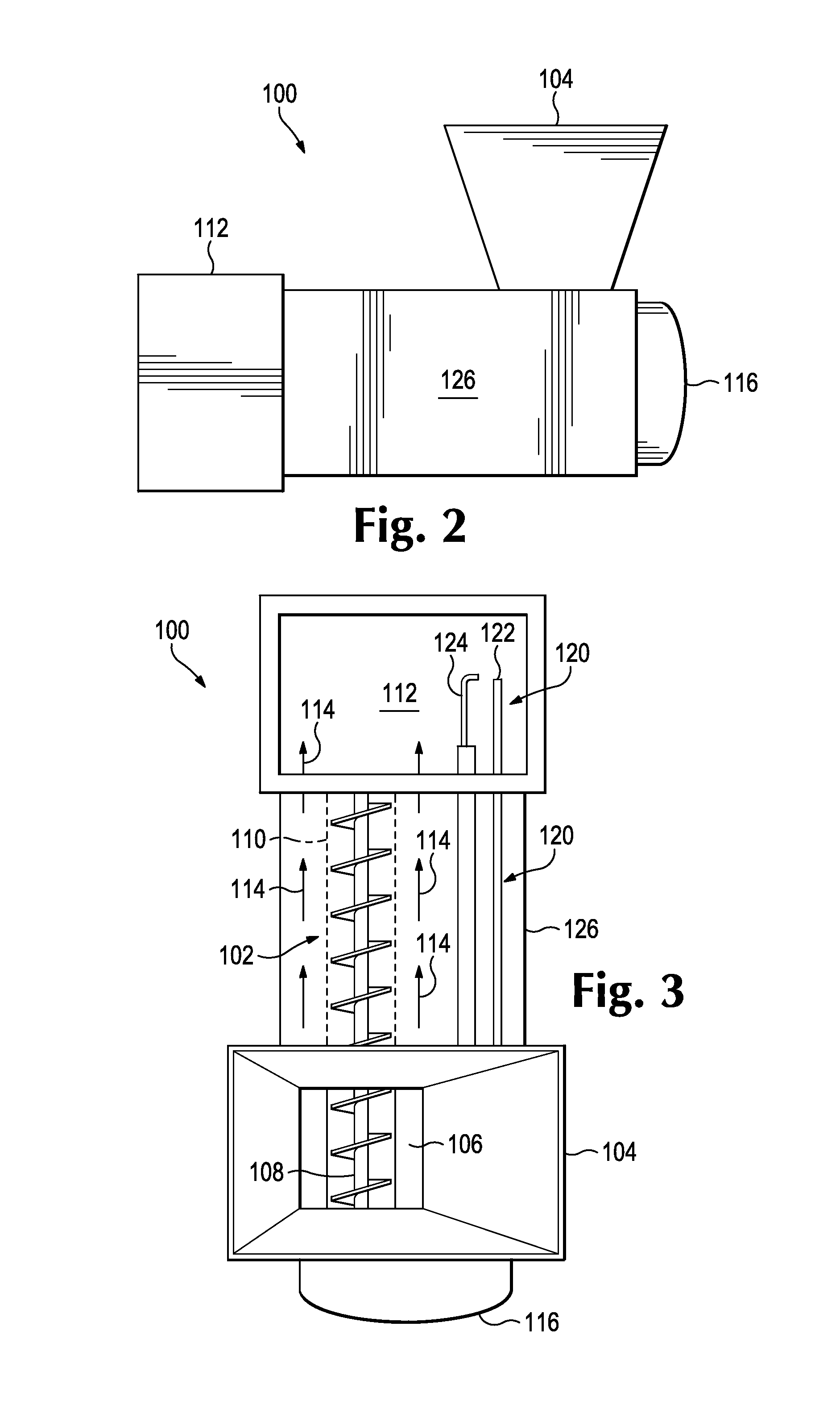

Dual-fuel gas-pellet burner assembly

InactiveUS20140326232A1Domestic stoves or rangesLighting and heating apparatusCombustion chamberEngineering

A dual-fuel gas-pellet barbecue burner assembly includes a combustion chamber, a pellet burner sub-assembly, and a gas burner sub-assembly. The pellet burner sub-assembly includes a motor-driven auger to deliver fuel pellets to the combustion chamber, and the gas burner sub-assembly includes a gas line that extends into the combustion chamber so that either pellets, gas, or both can be burned in the combustion chamber.

Owner:ORIGINAL PELLET GRILL CO LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com