Patents

Literature

118results about "Combustion ventilators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

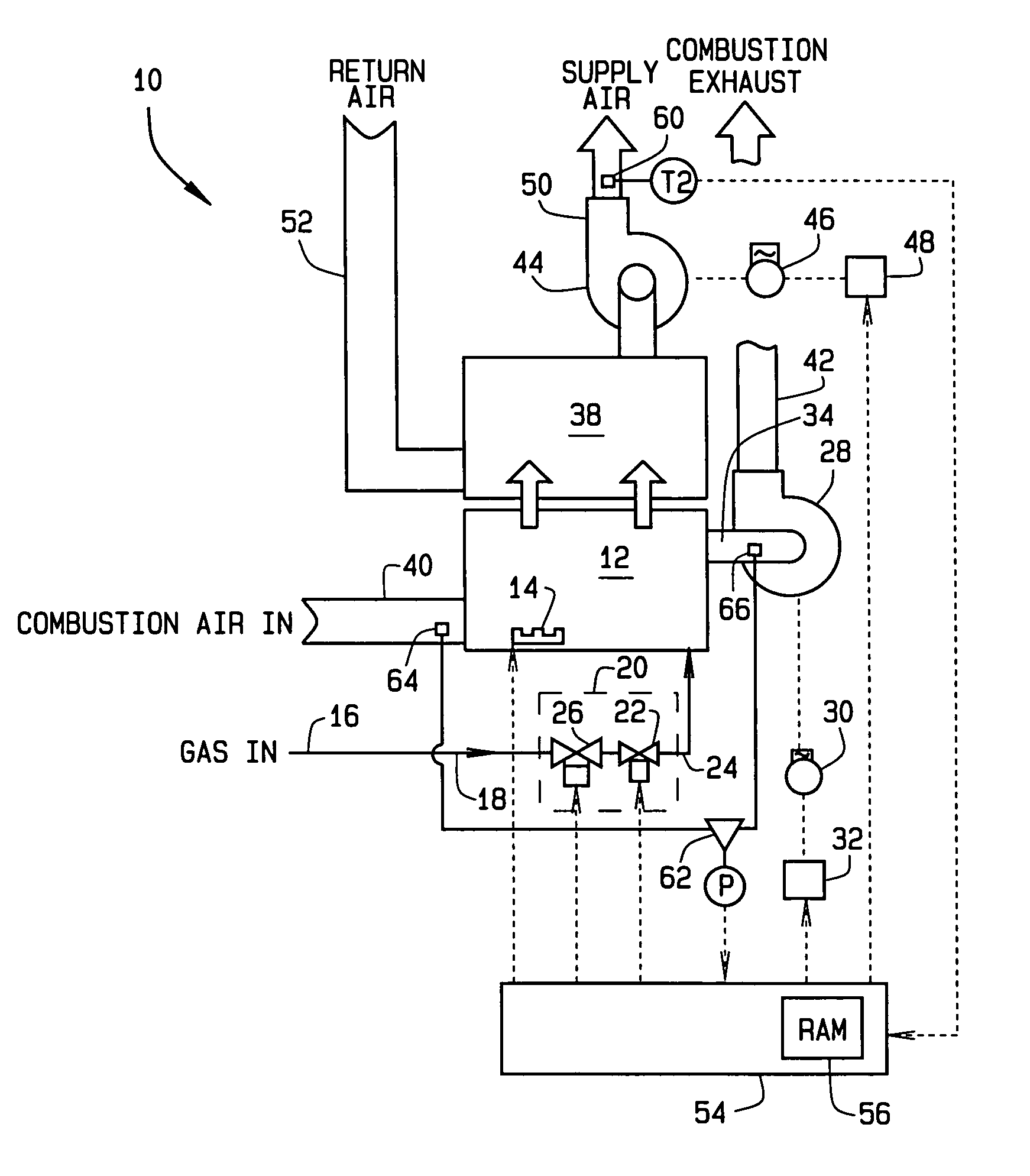

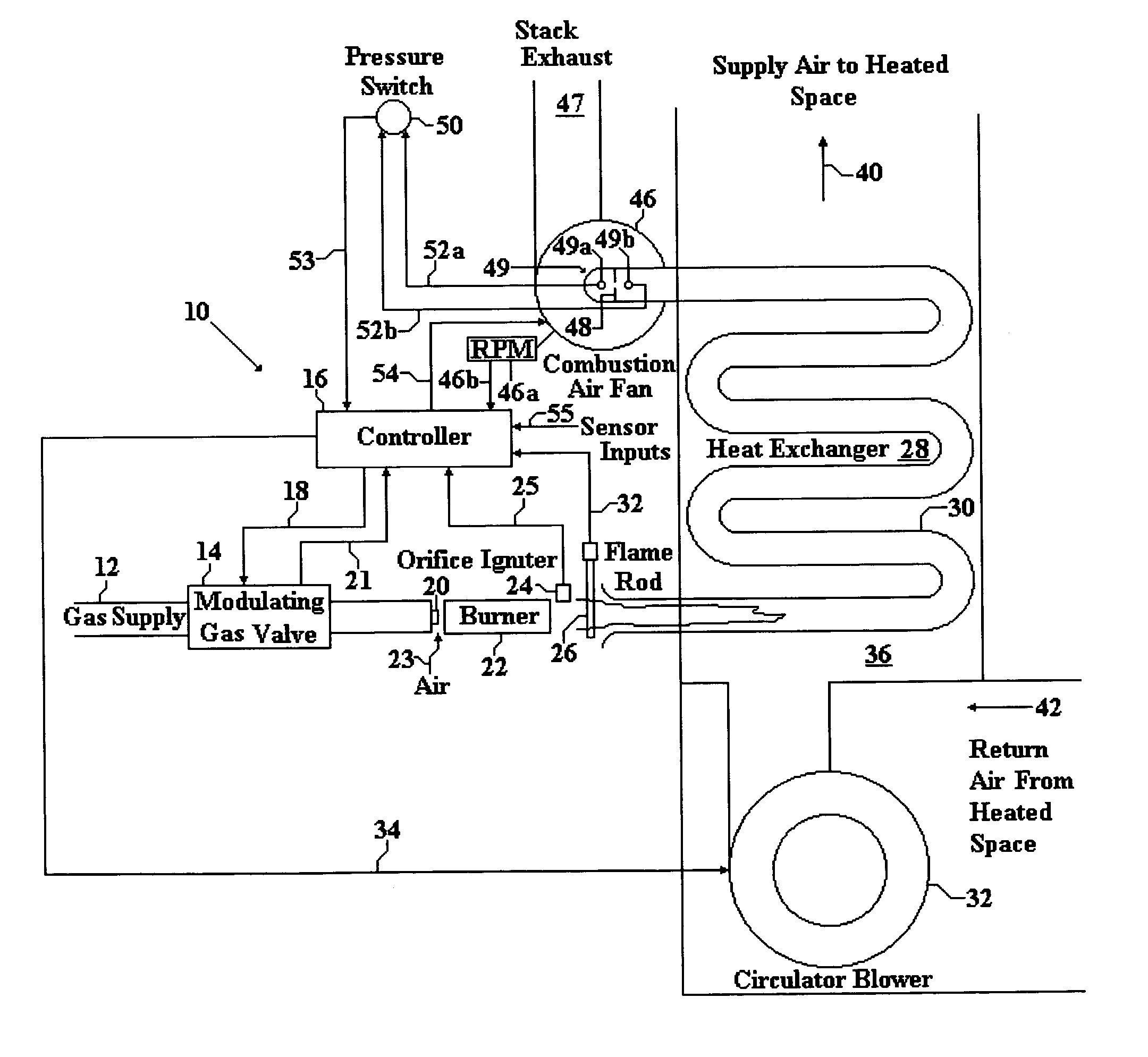

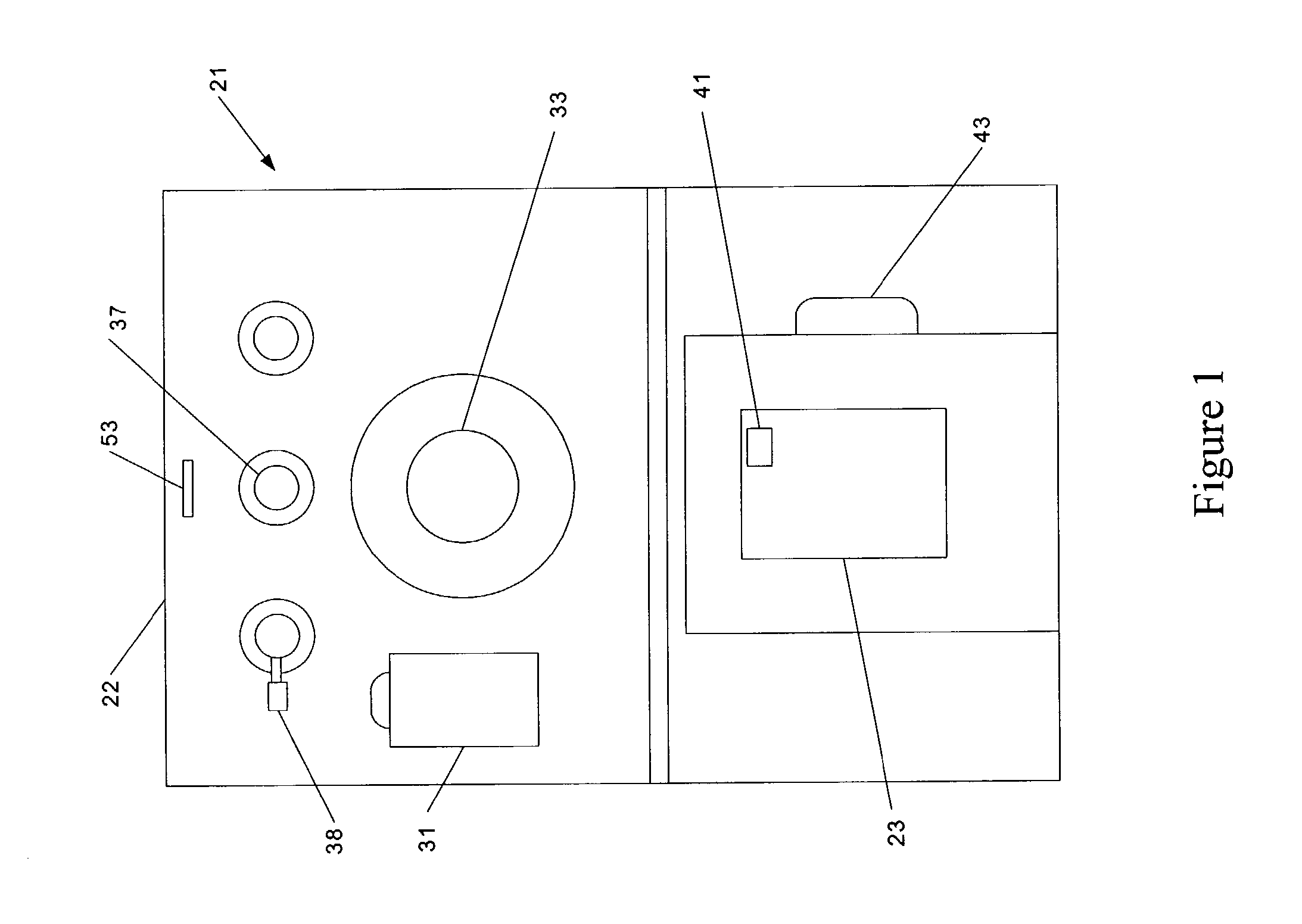

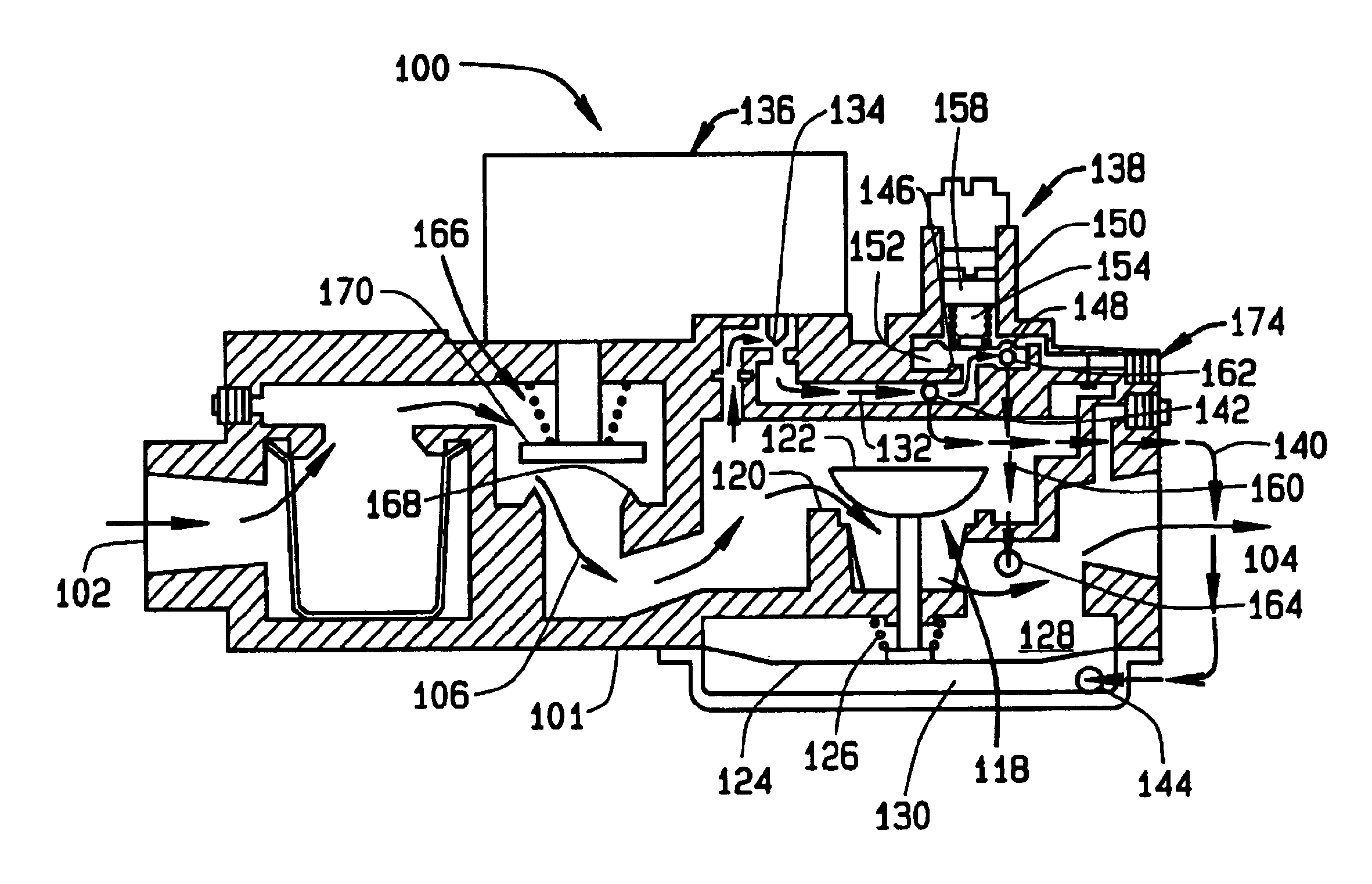

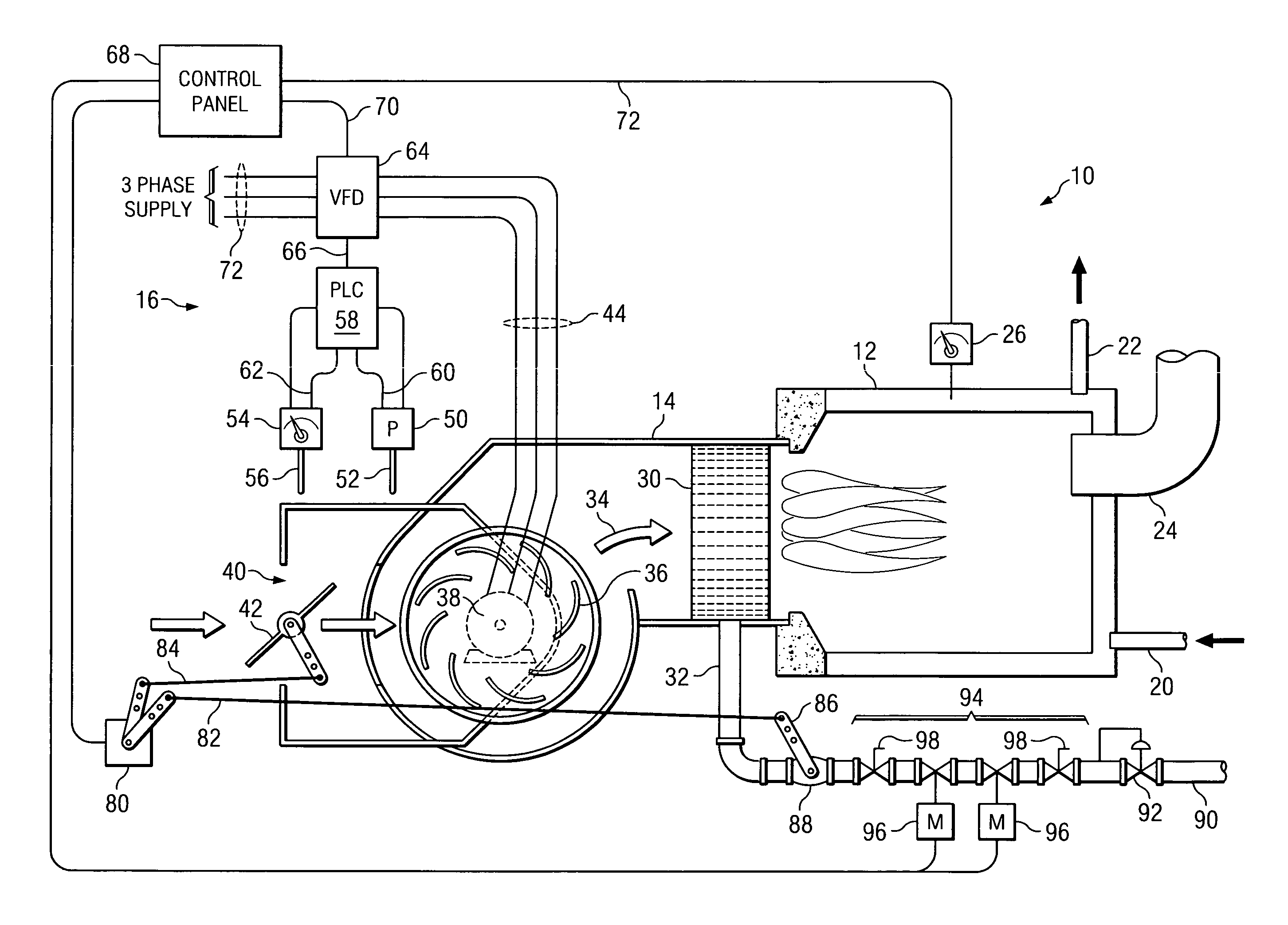

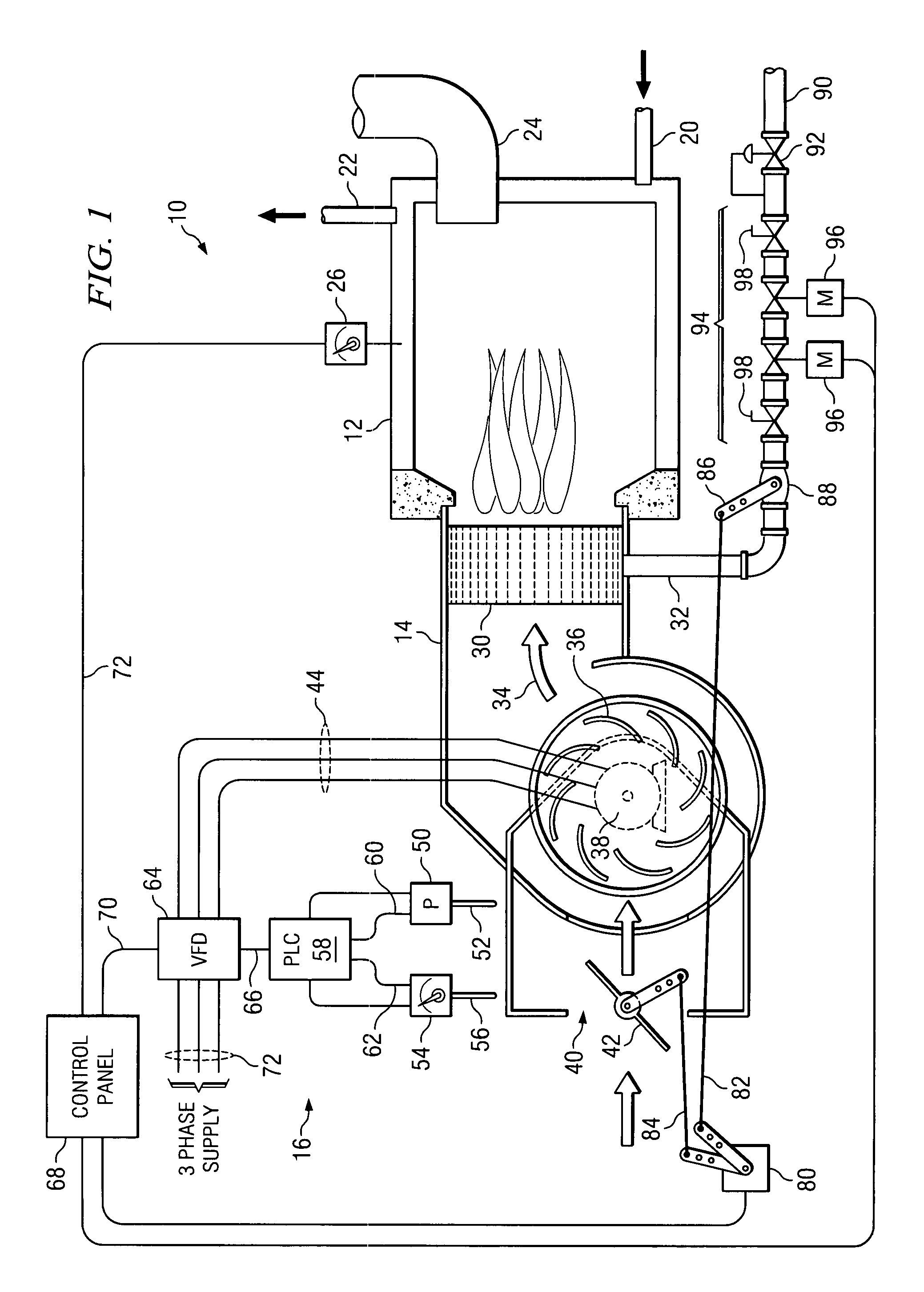

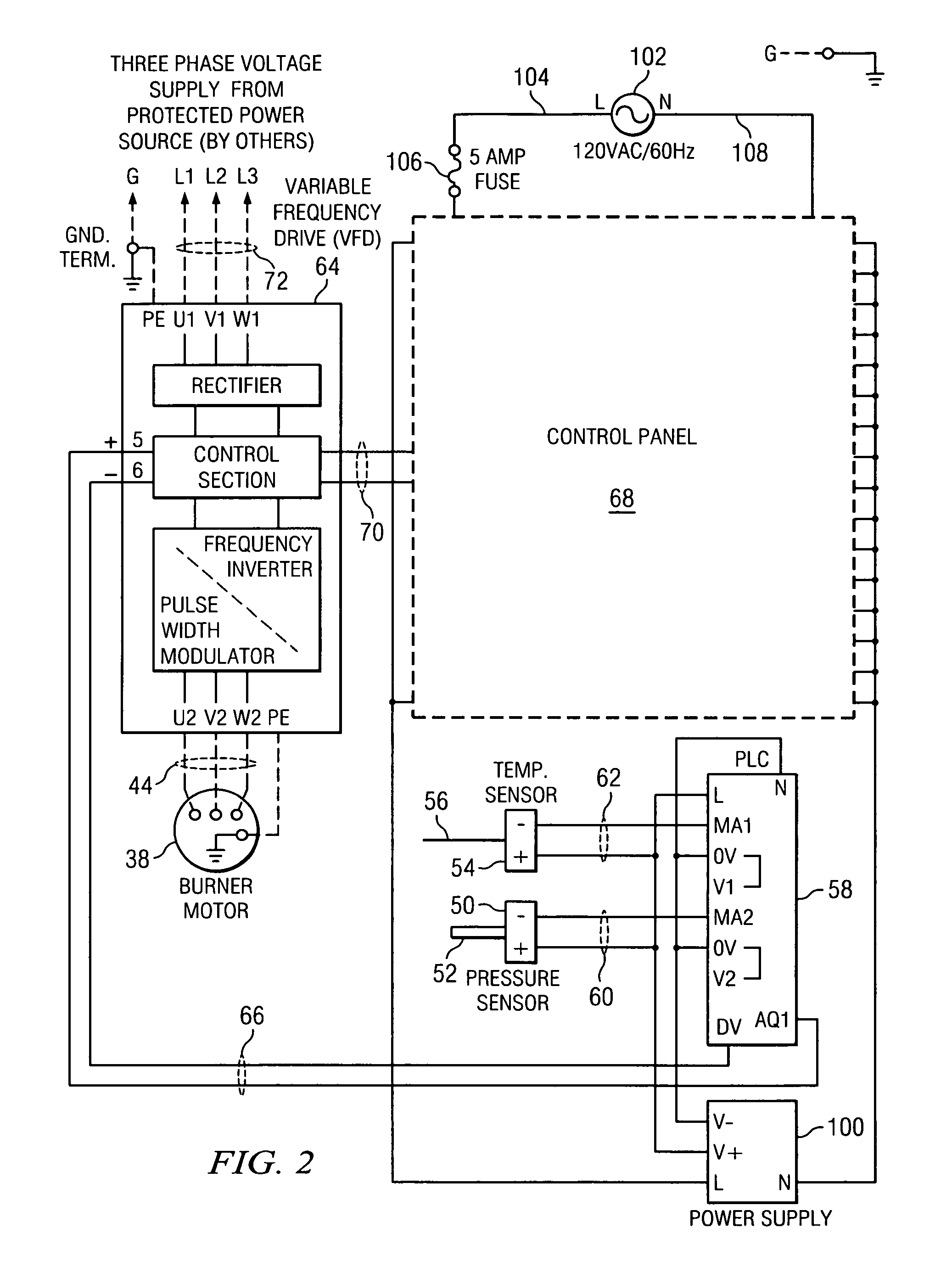

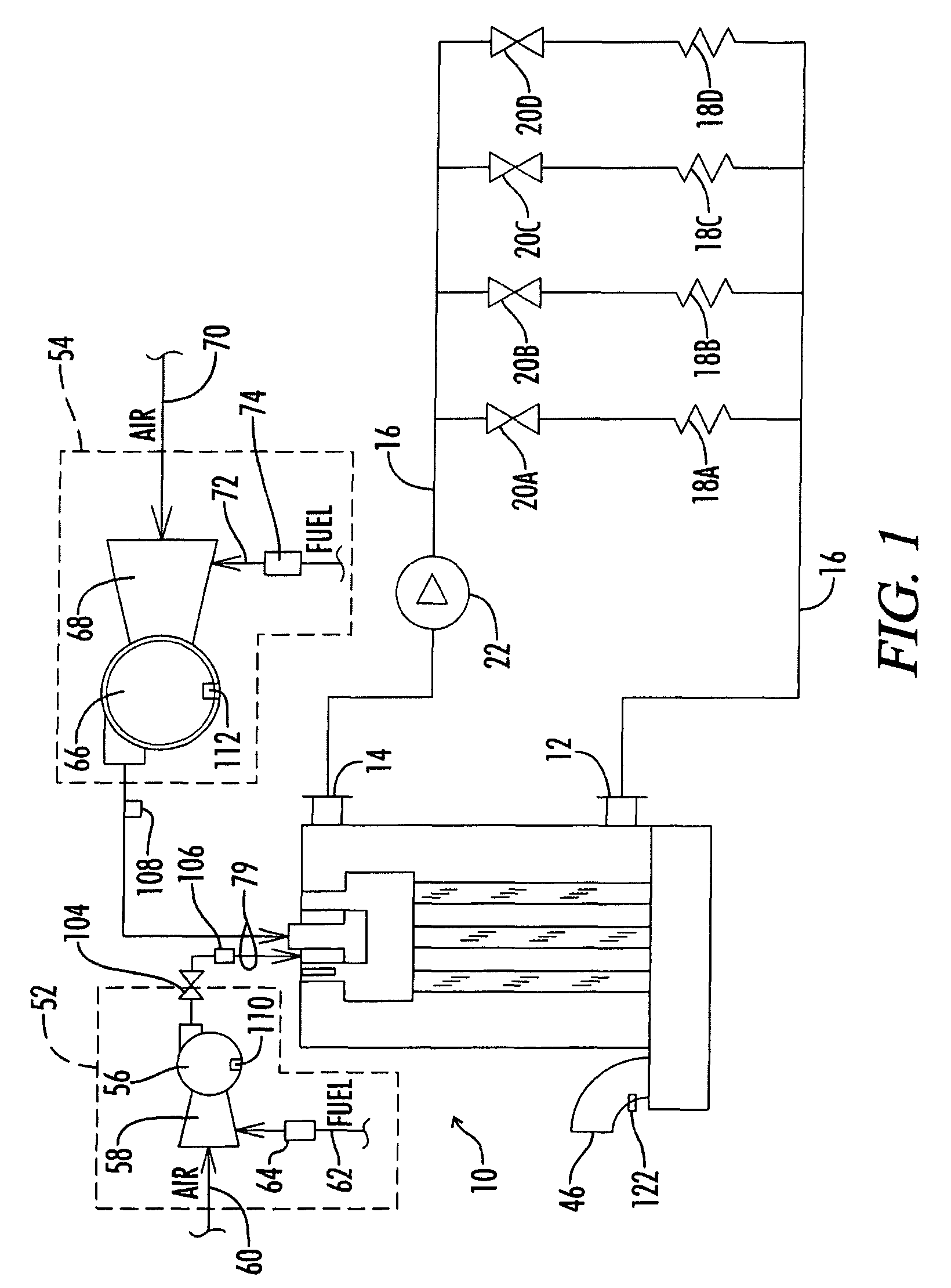

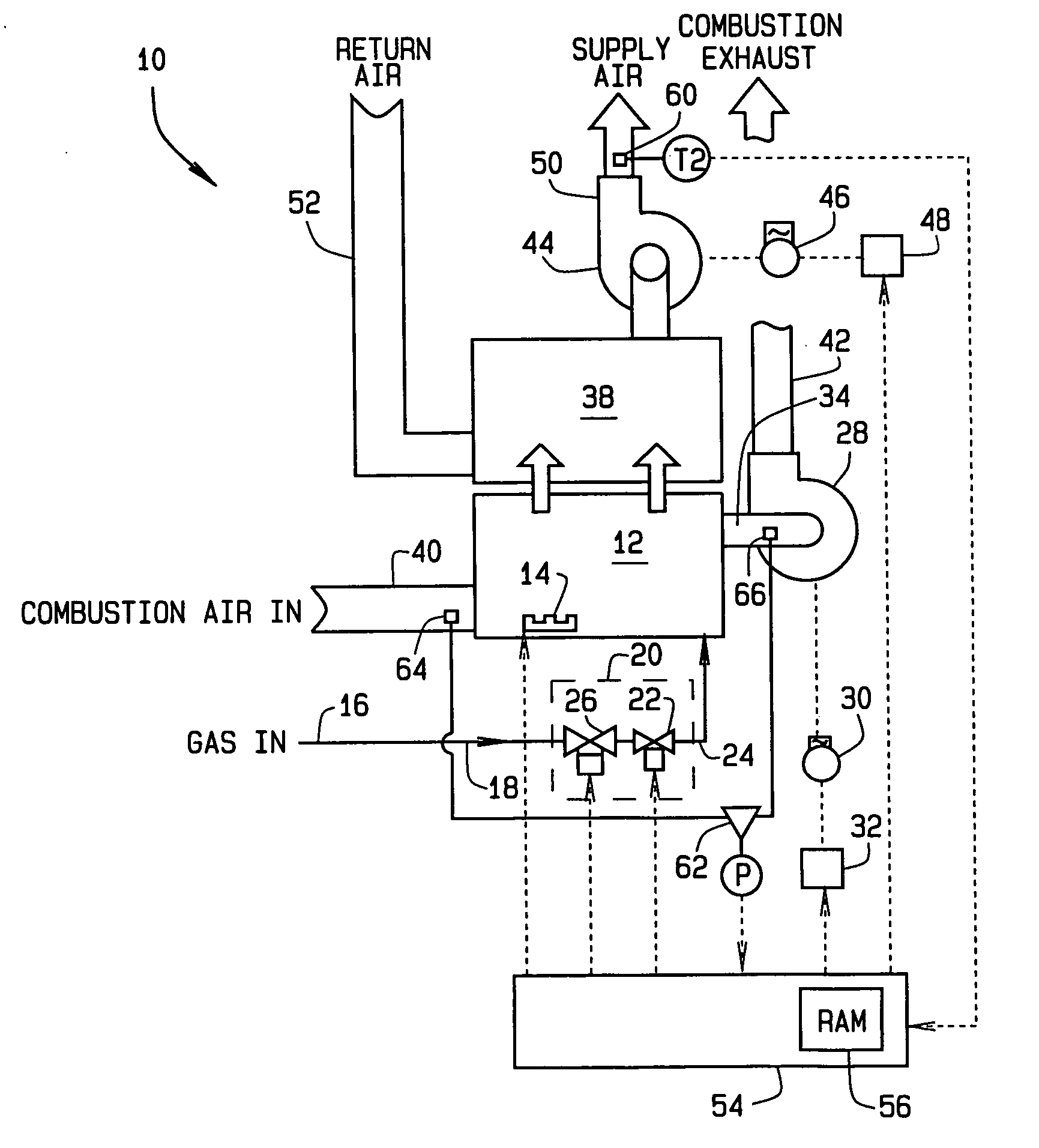

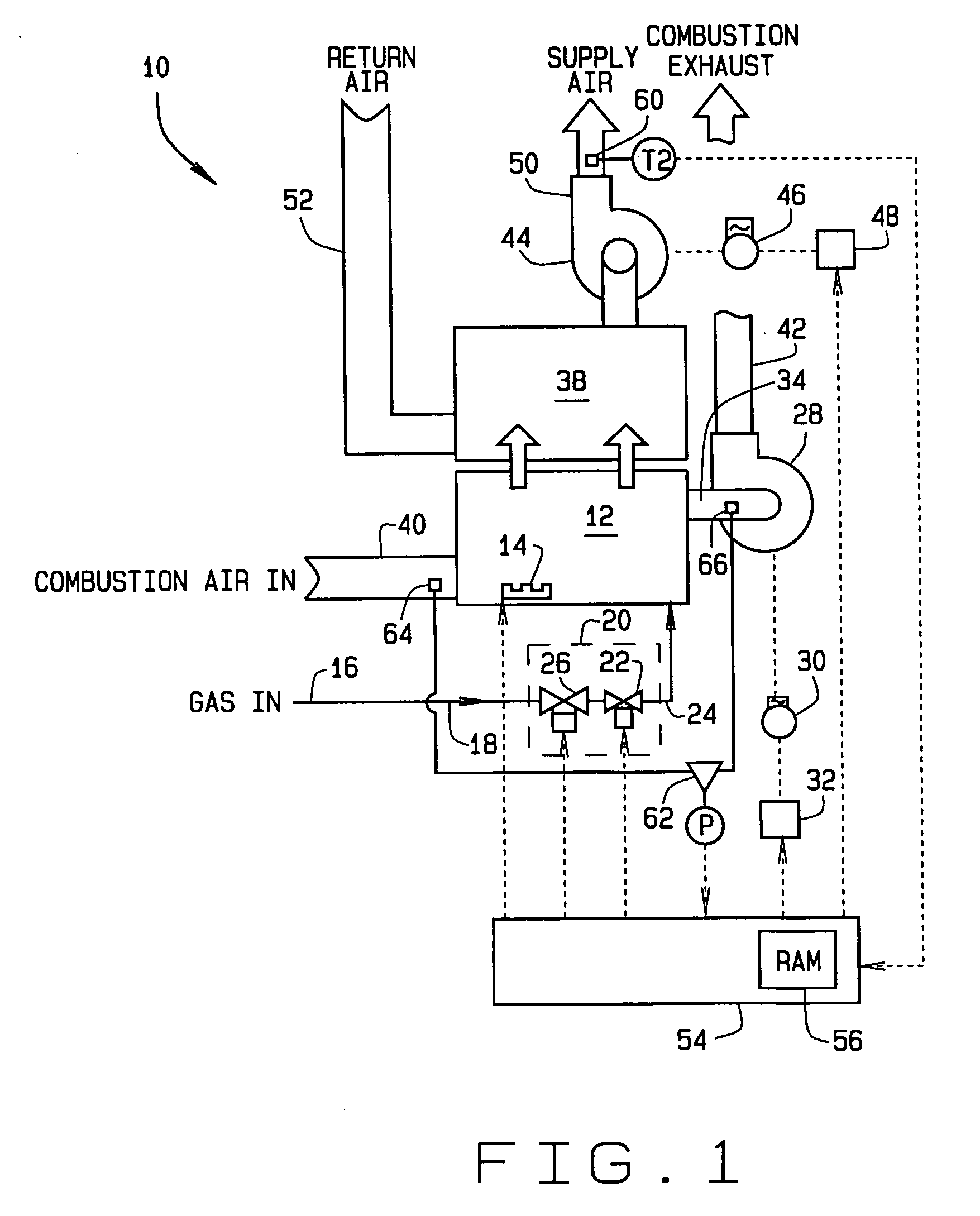

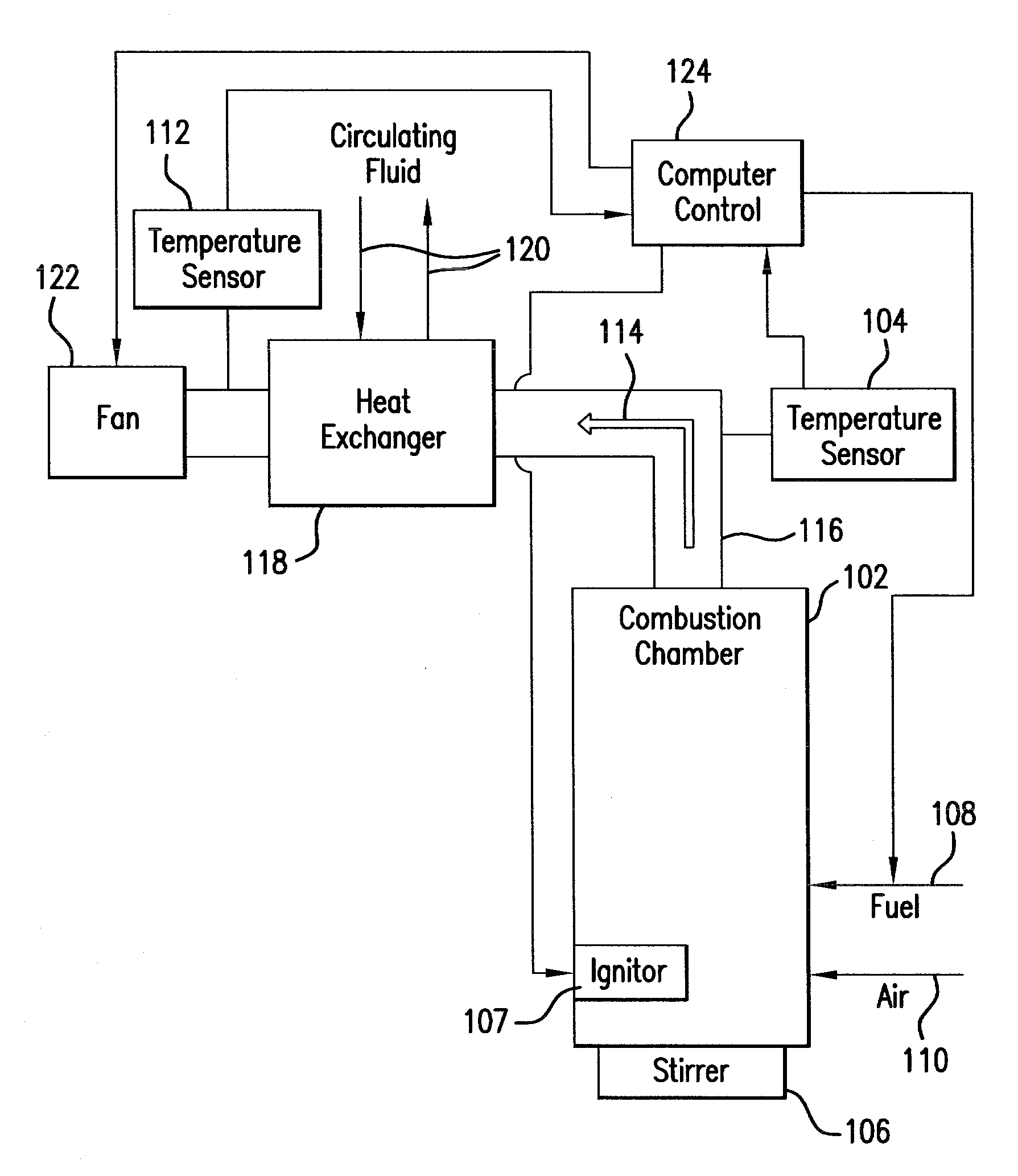

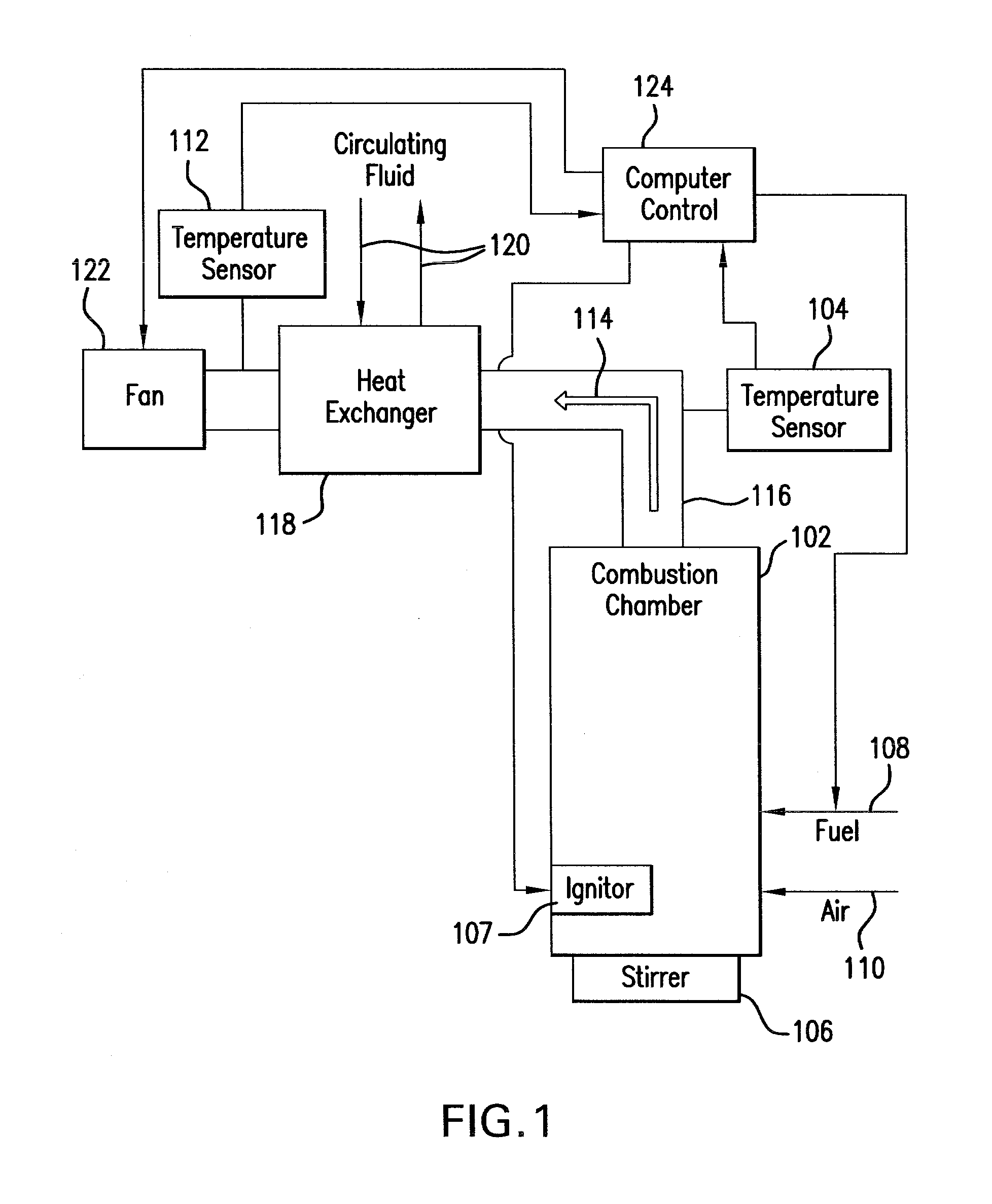

Apparatus and methods for variable furnace control

InactiveUS7101172B2Speed of can varyGreat pressure dropFuel supply regulationAir supply regulationMotor speedCombustion chamber

A furnace control system for controlling a gas-fired induced-draft furnace having a variable speed inducer blower. A control apparatus, responsive to a signal corresponding to the magnitude of a pressure difference between an inlet and outlet of the combustion chamber, controls blower motor speed to maintain the pressure difference at a predetermined magnitude corresponding to a selected gas flow rate. Inducer blower motor speed is varied directly and precisely to maintain an optimal pressure drop across the combustion chamber. The control system can be used in multi-stage and modulating furnace systems and in furnace systems utilizing pressure-assist modulating gas valves.

Owner:COPELAND COMFORT CONTROL LP

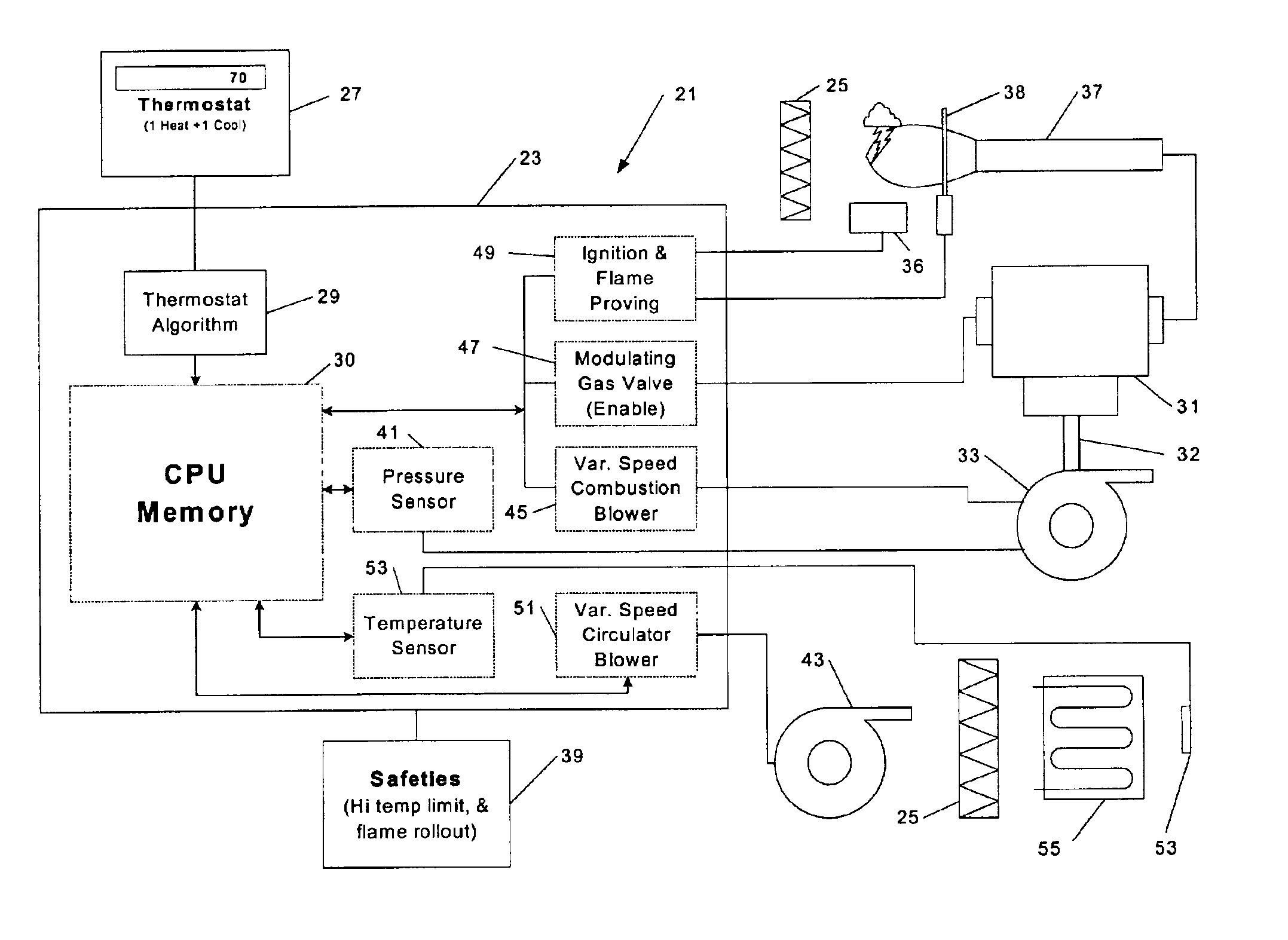

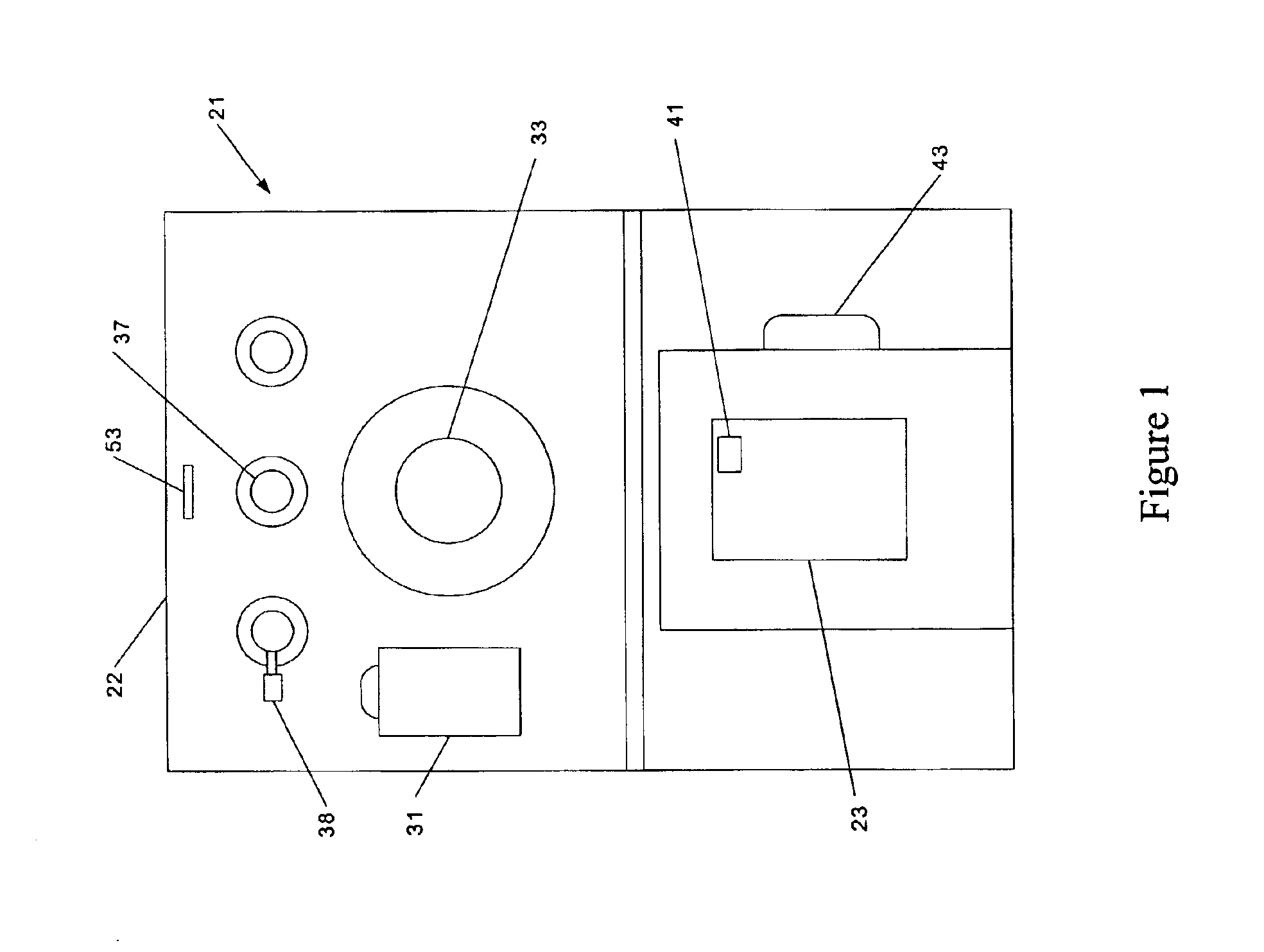

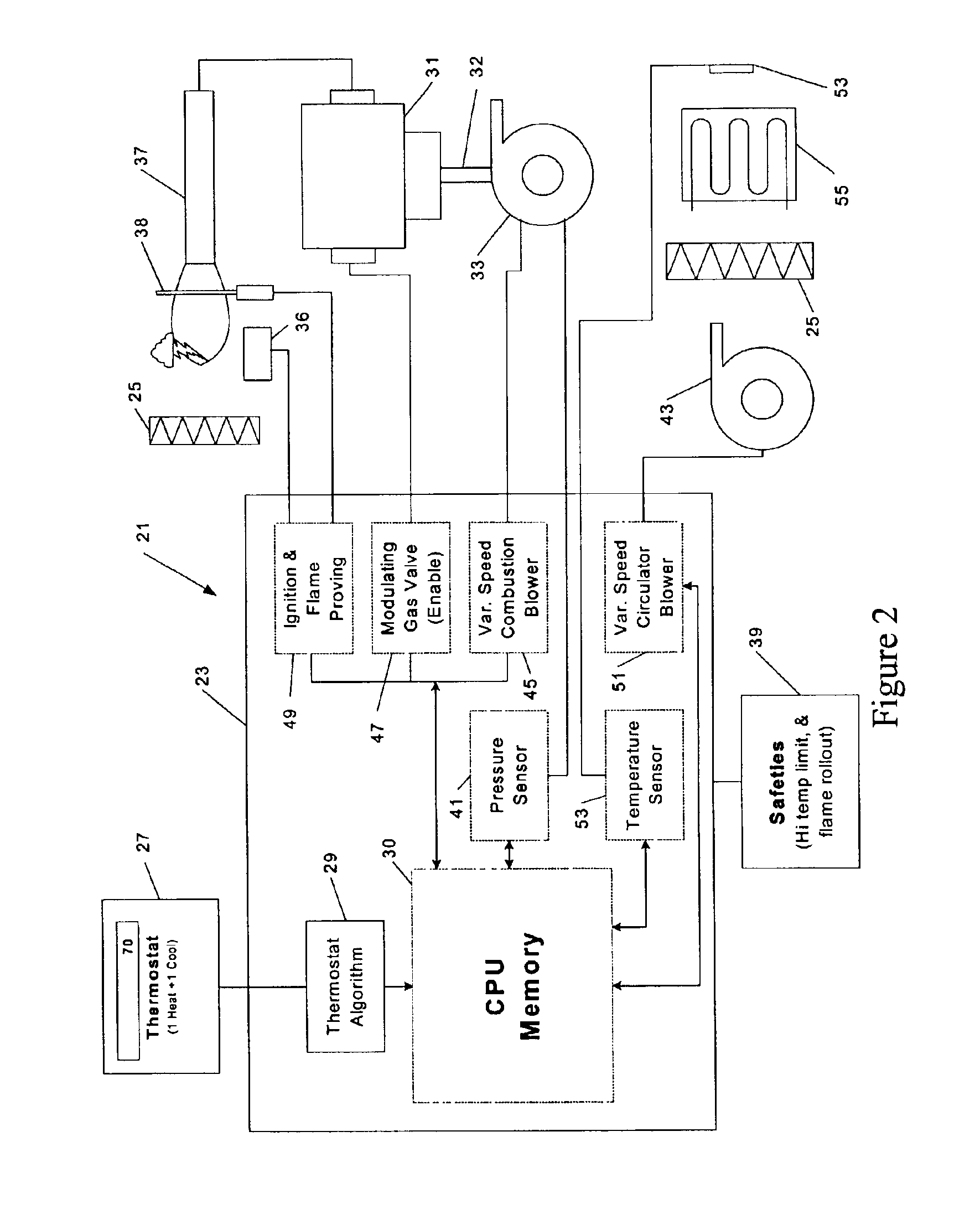

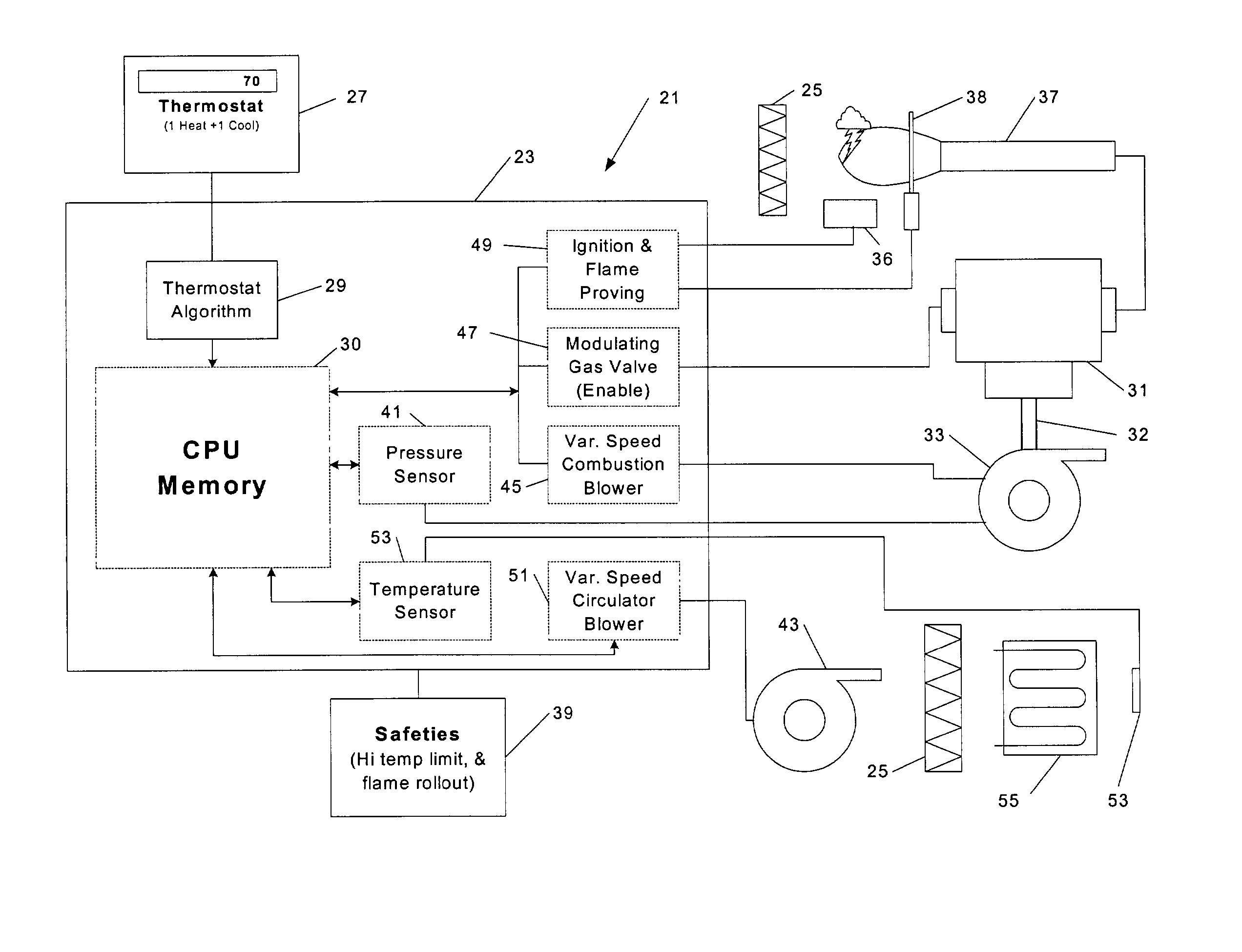

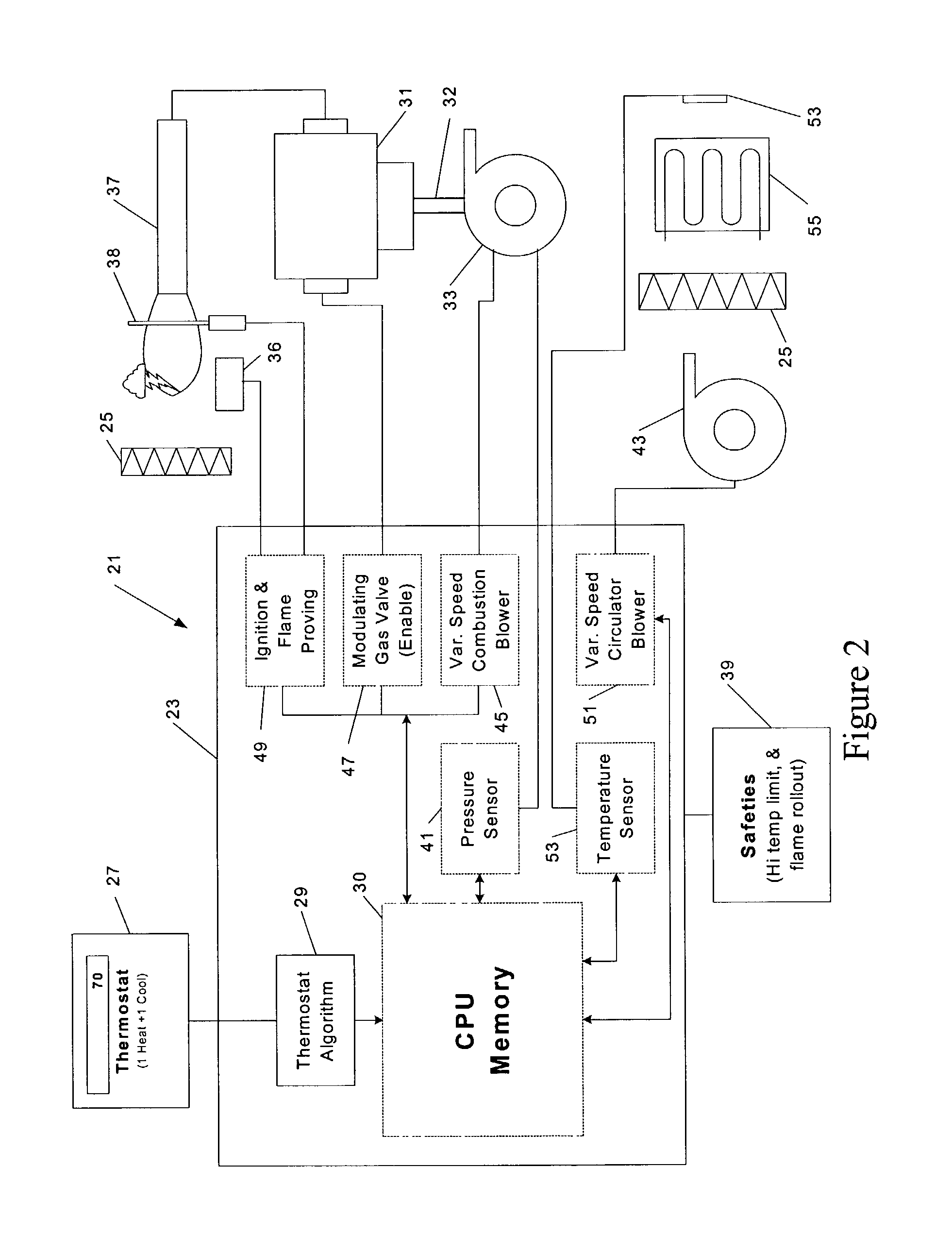

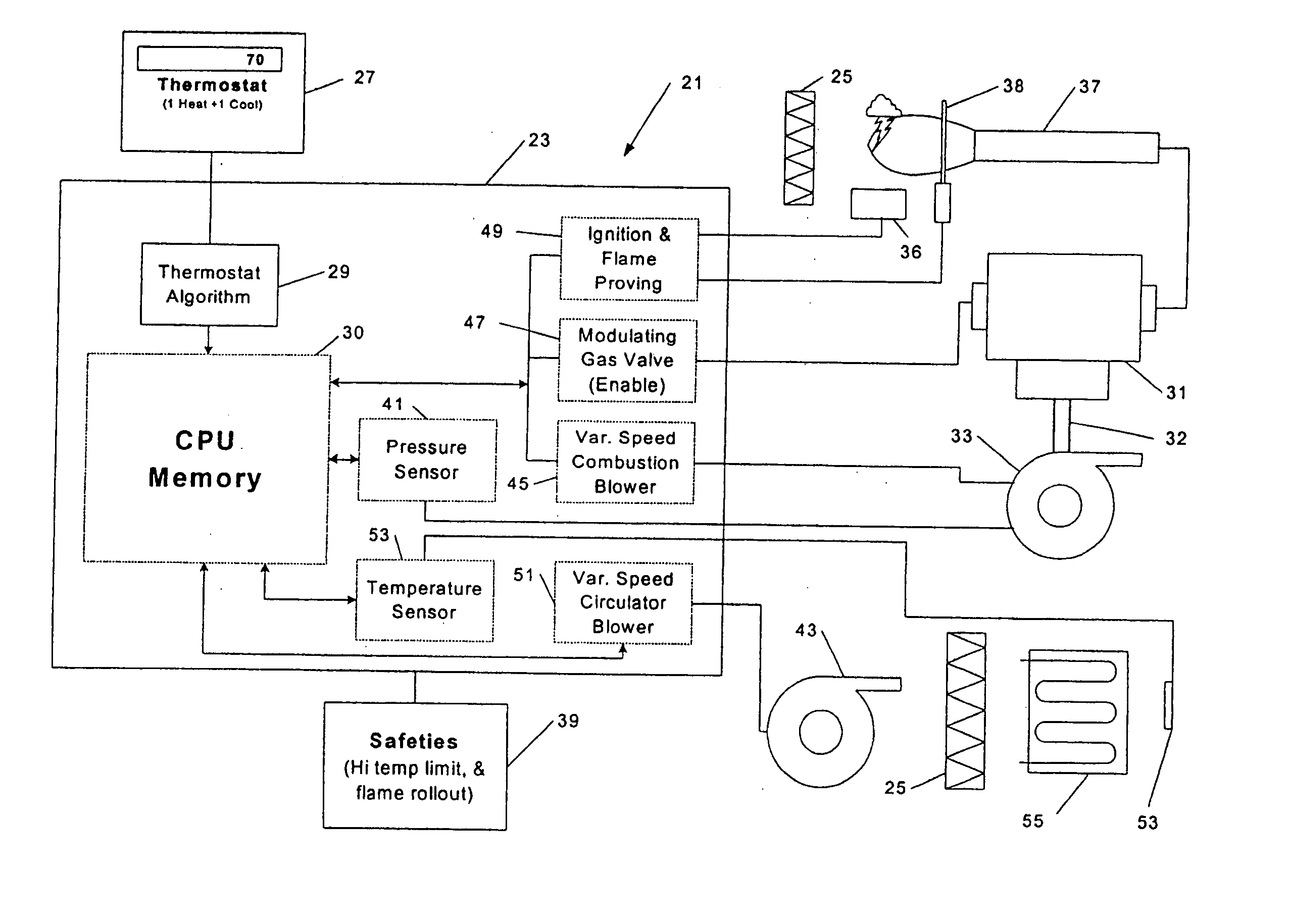

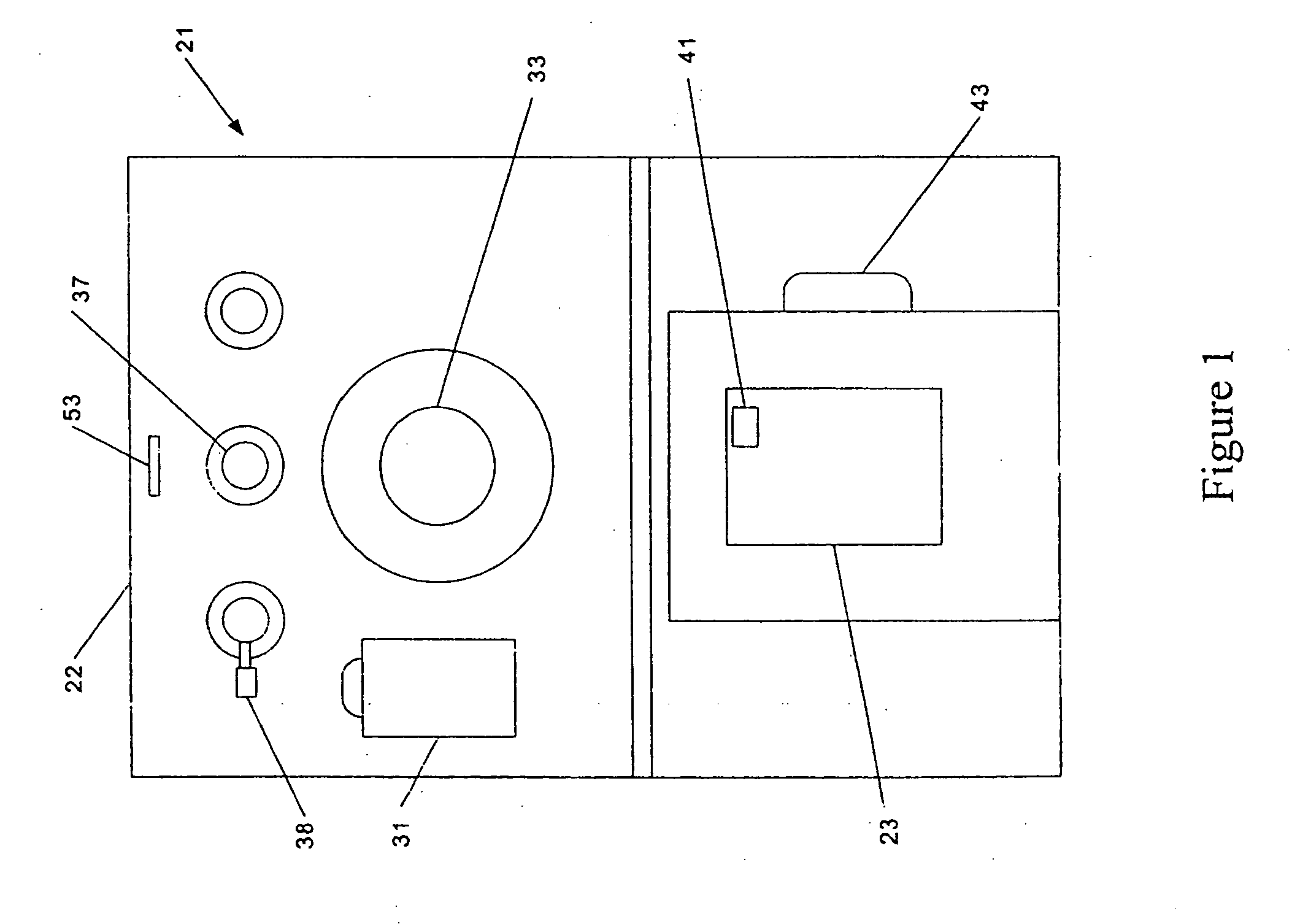

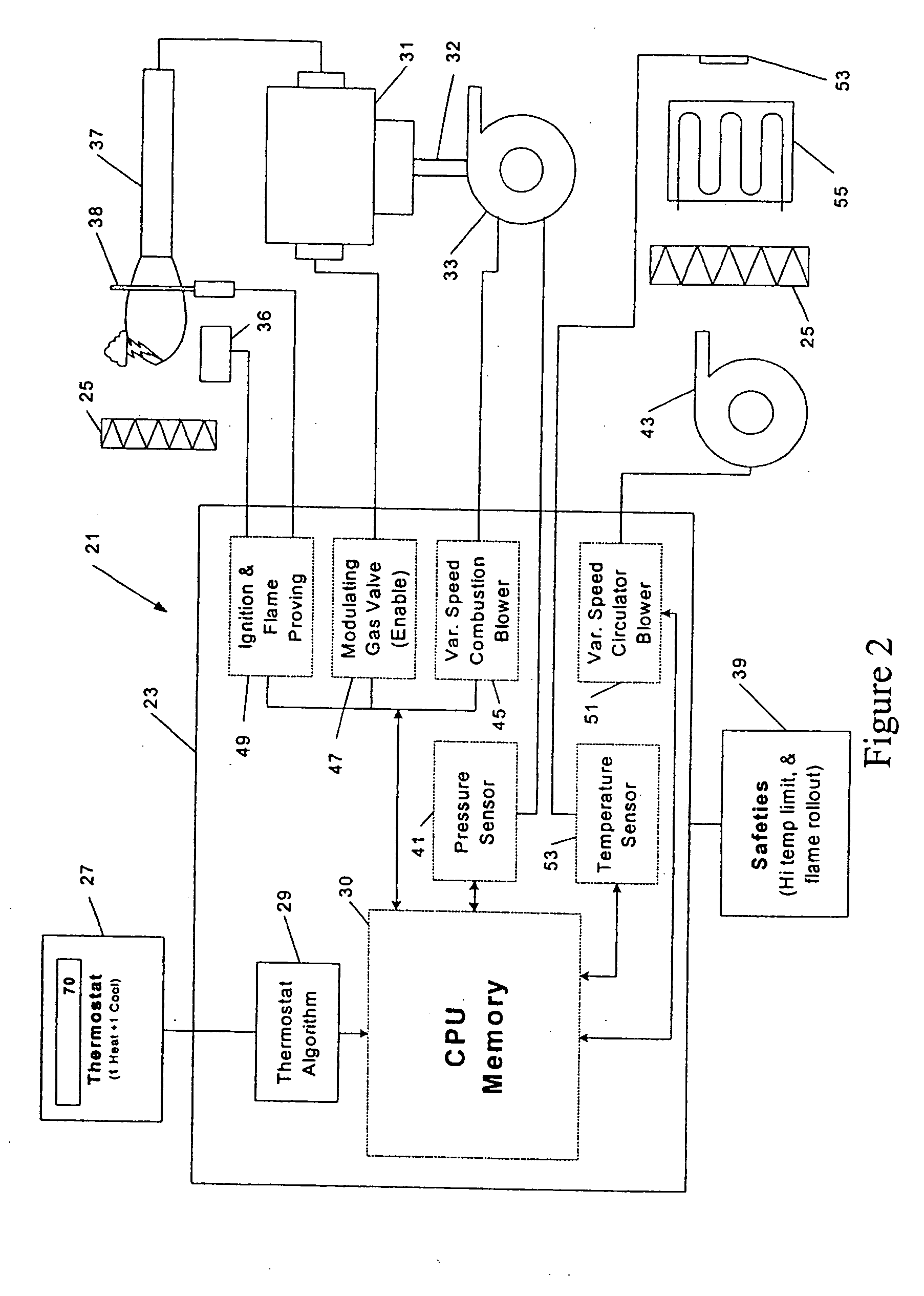

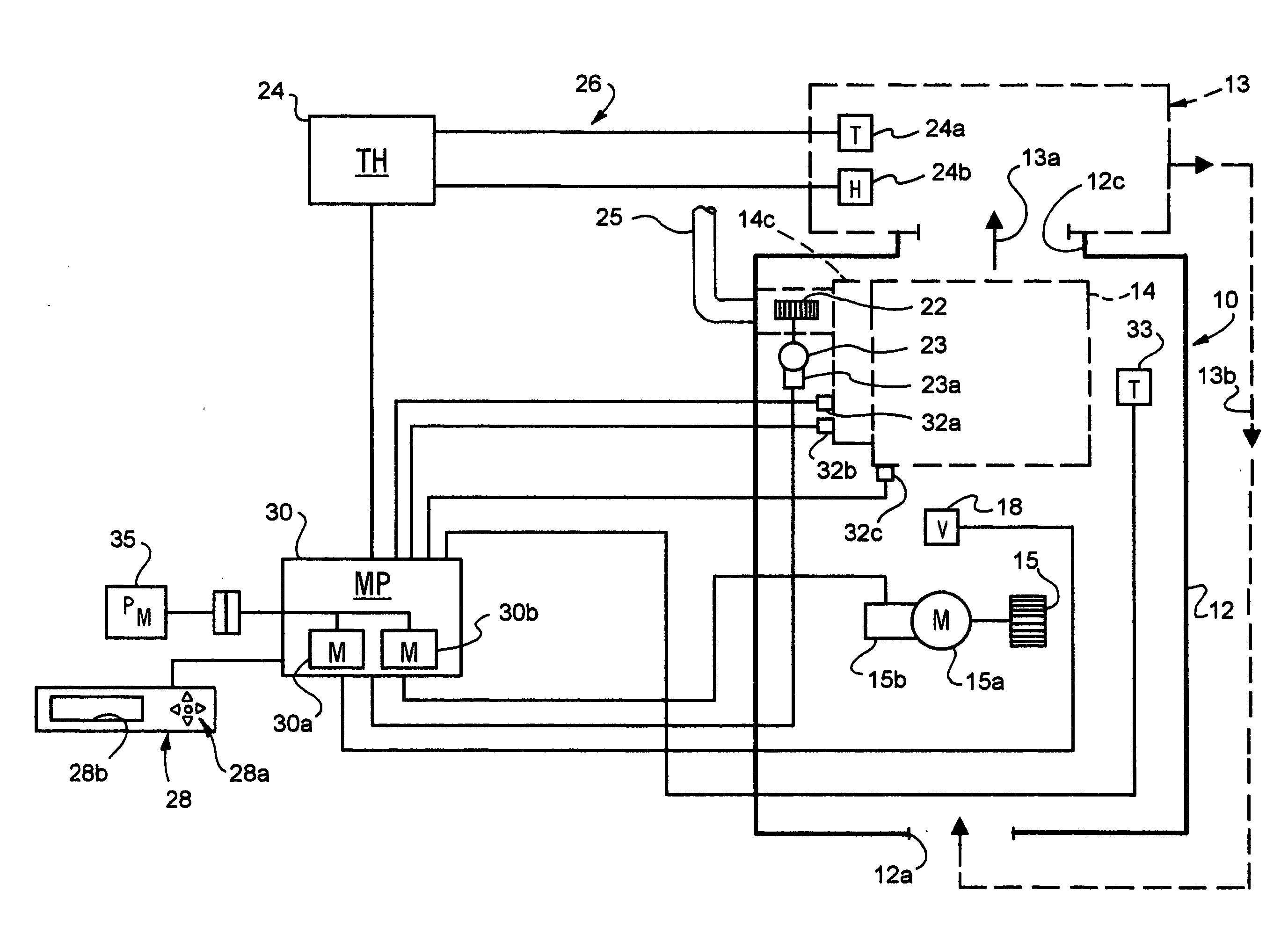

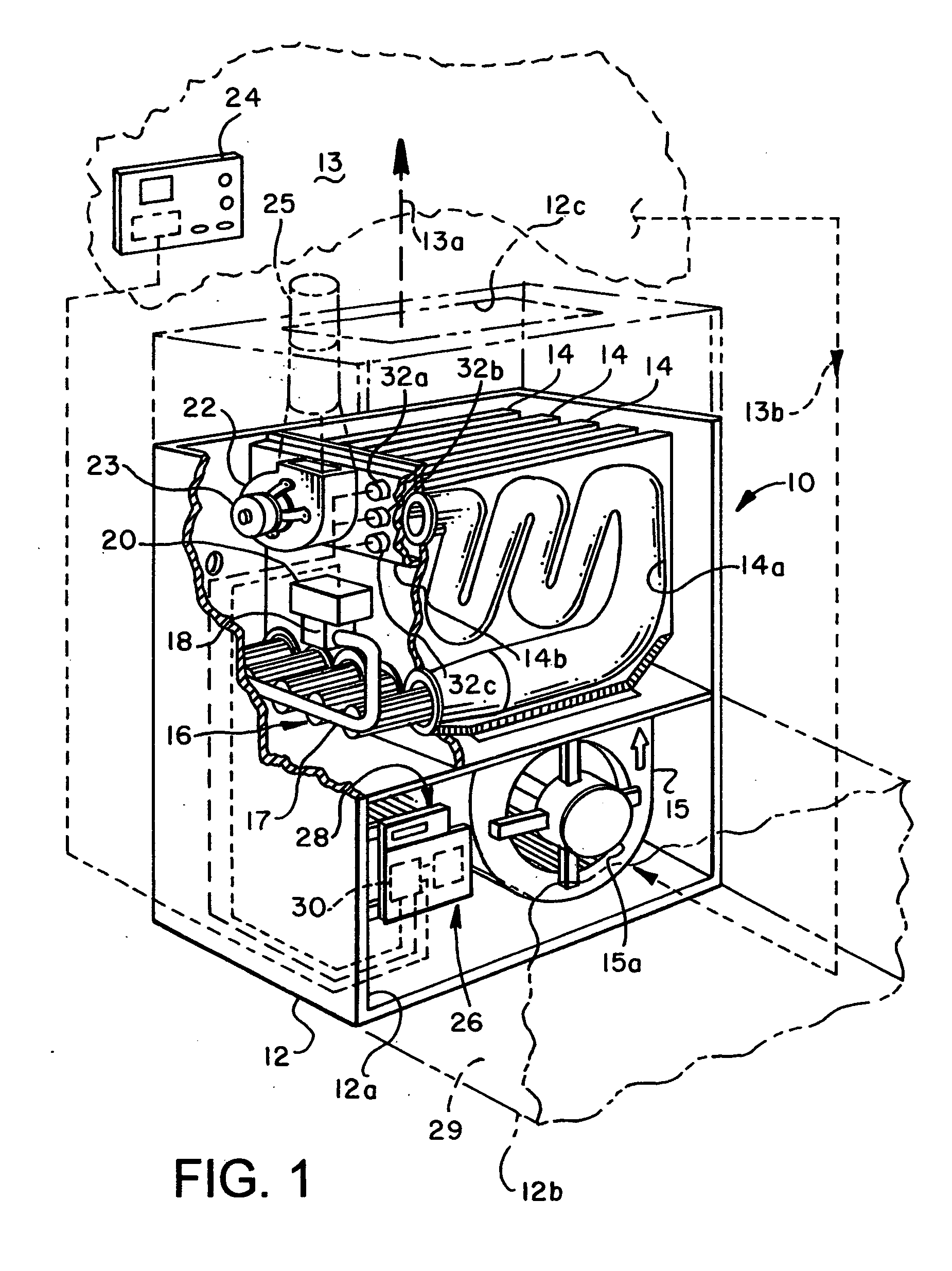

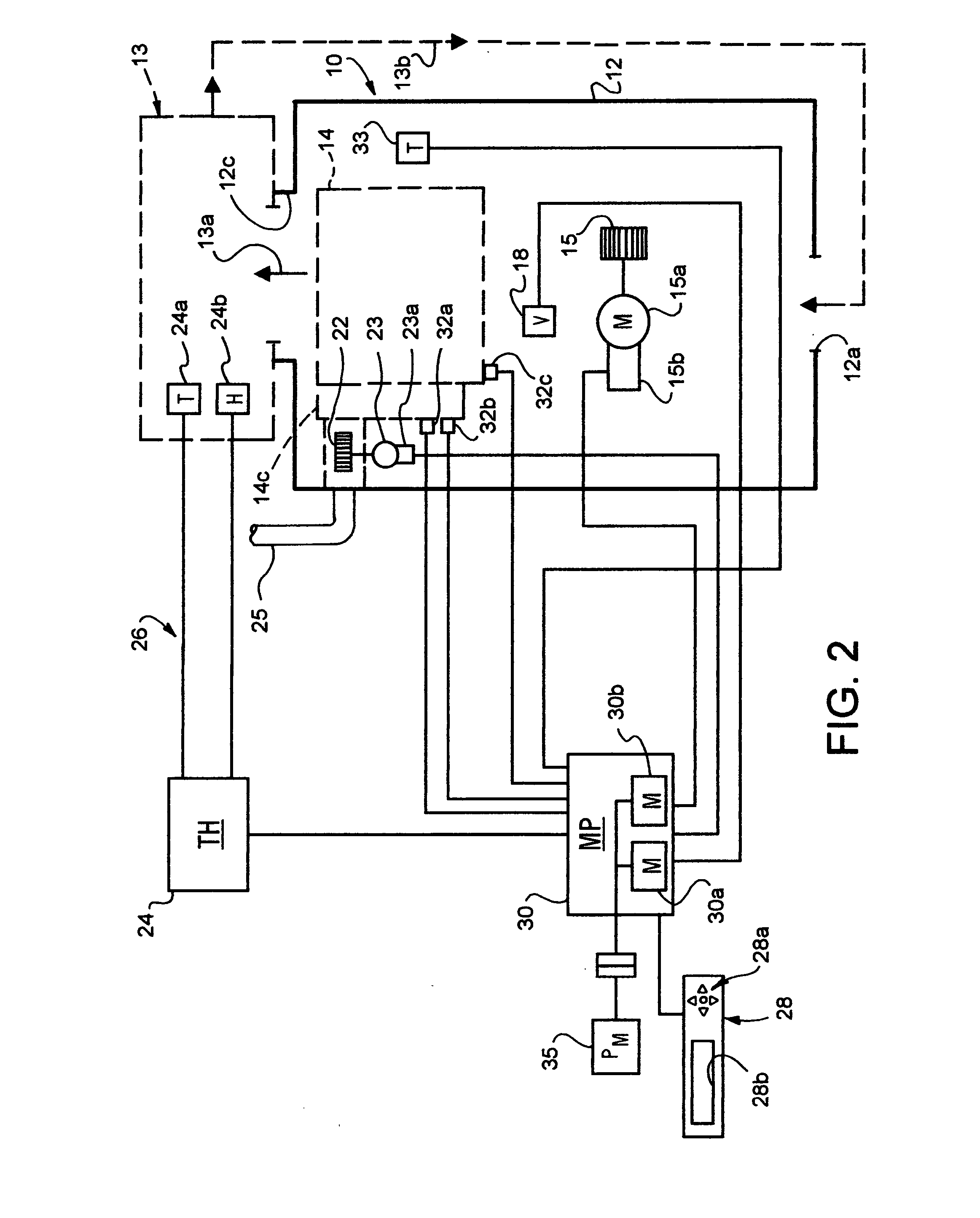

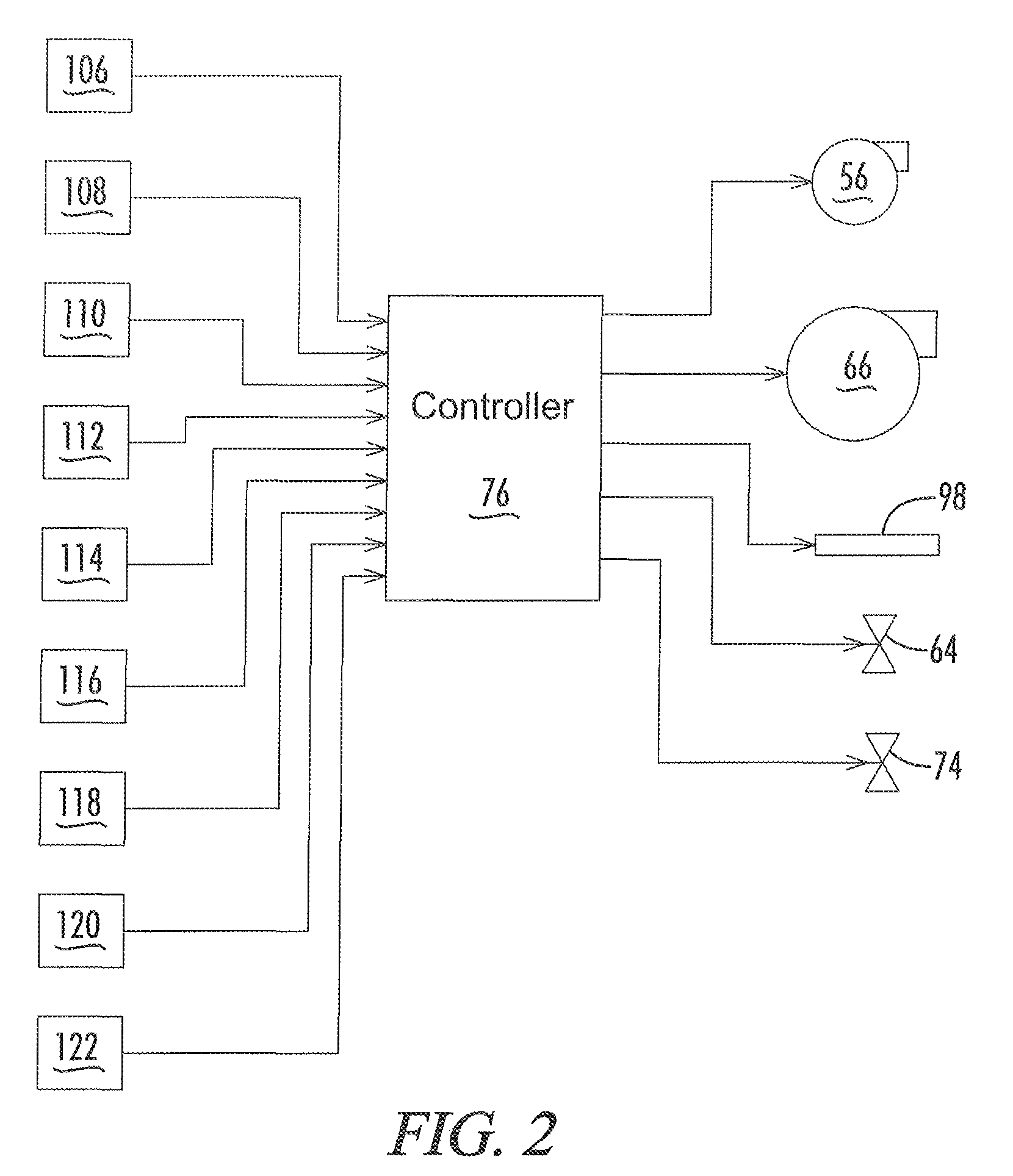

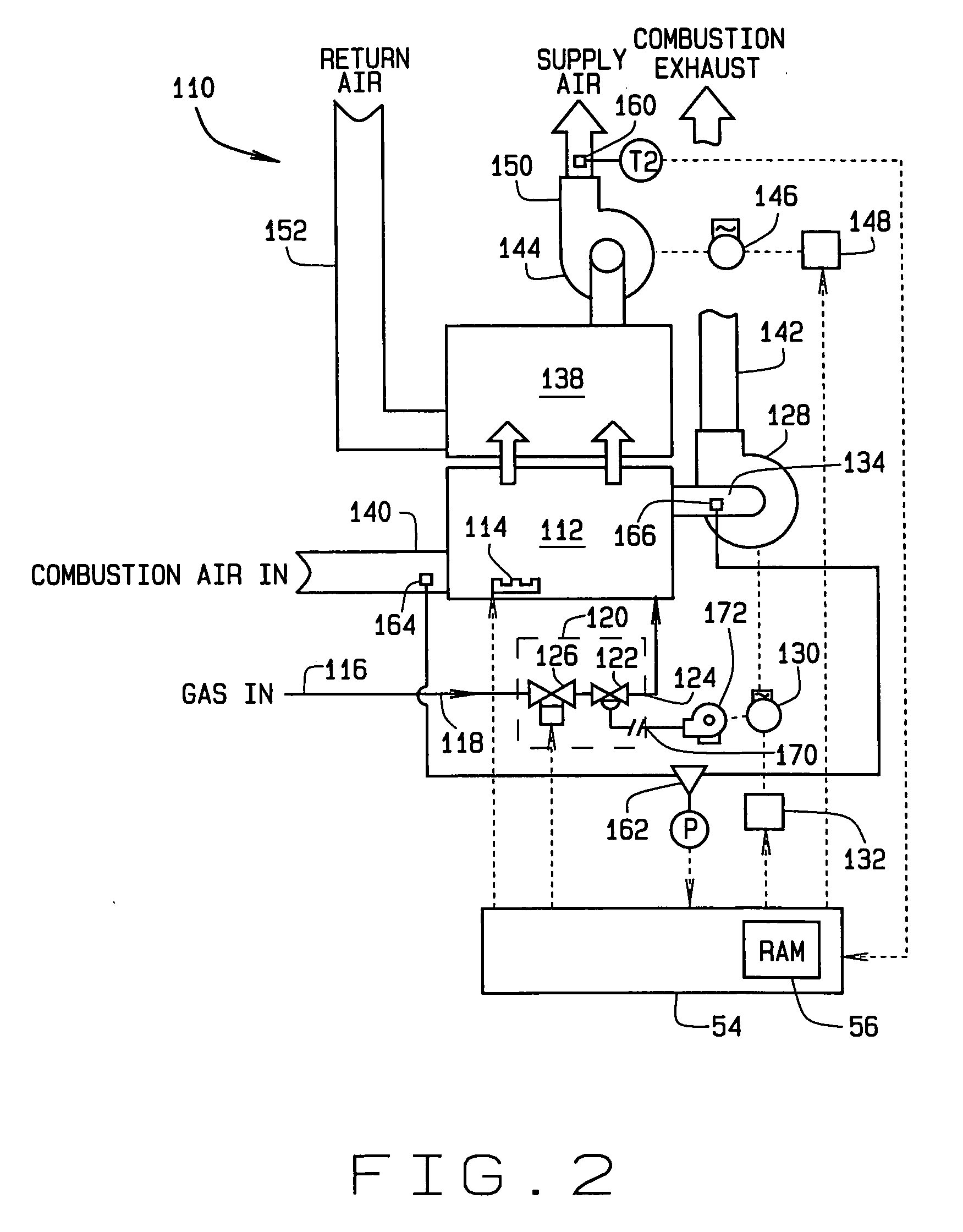

Variable output heating and cooling control

A heating or cooling system, such as an HVAC system, of variable output has a number of control elements and may include a variable speed compressor, a variable speed combustion (induced or forced draft) blower motor; a variable speed circulator blower motor; a variable output gas valve or gas / air premix unit; and a controller specifically developed for variable output applications. The system may utilize a pressure sensor to determine the actual flow of combustion airflow in response to actual space conditions, vary the speed of the inducer blower, and subsequently vary the gas valve output to supply the correct amount of gas to the burner system. A temperature sensor may be located in the discharge air stream of the conditioned air to provide an input signal for the circulator blower.

Owner:HVAC MODULATION TECH

Gaseous fuel burner

ActiveUS7934926B2Address is challengeEliminate needFuel supply regulationAir supply regulationAir velocityAutomatic control

Owner:NEW POWER CONCEPTS

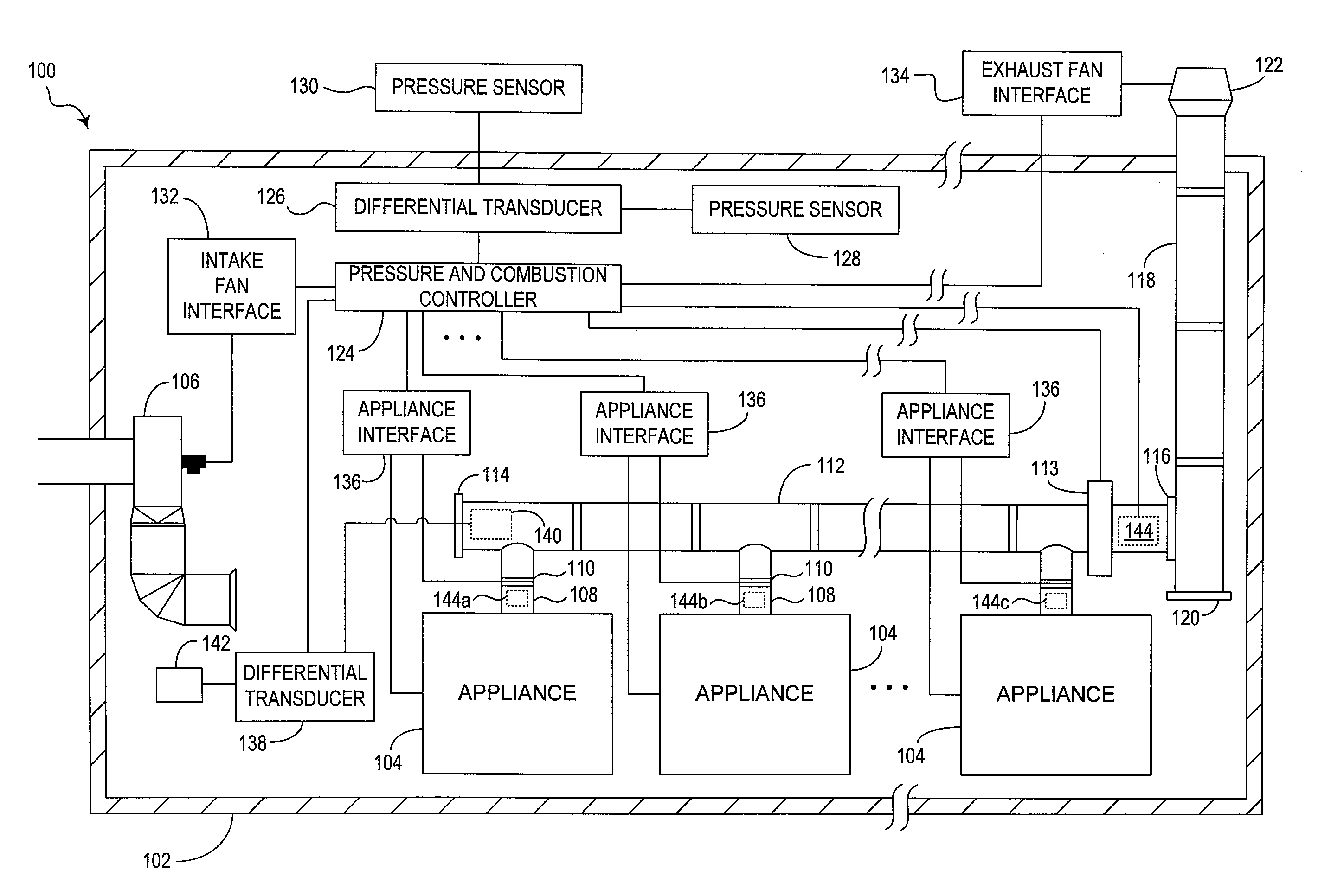

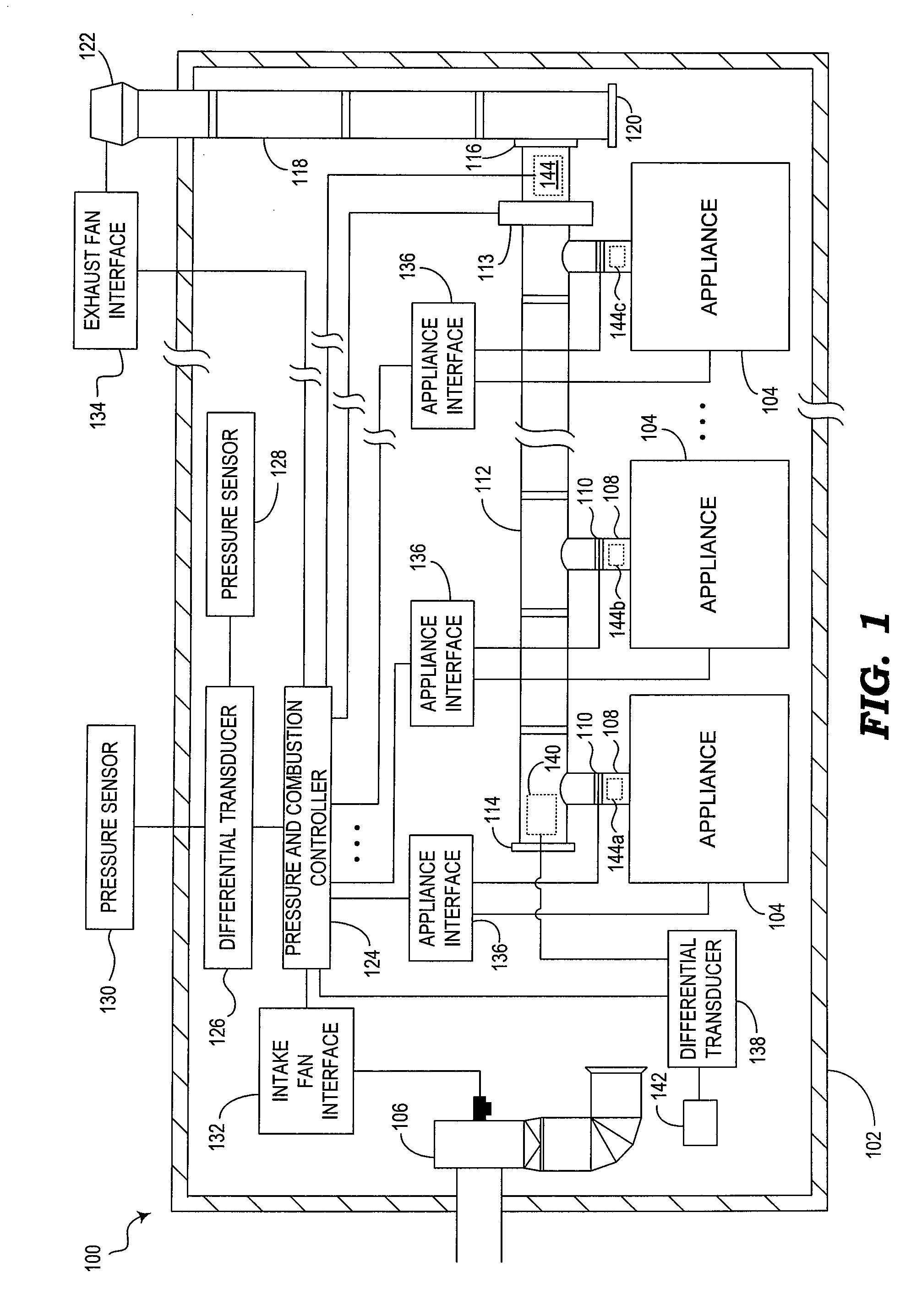

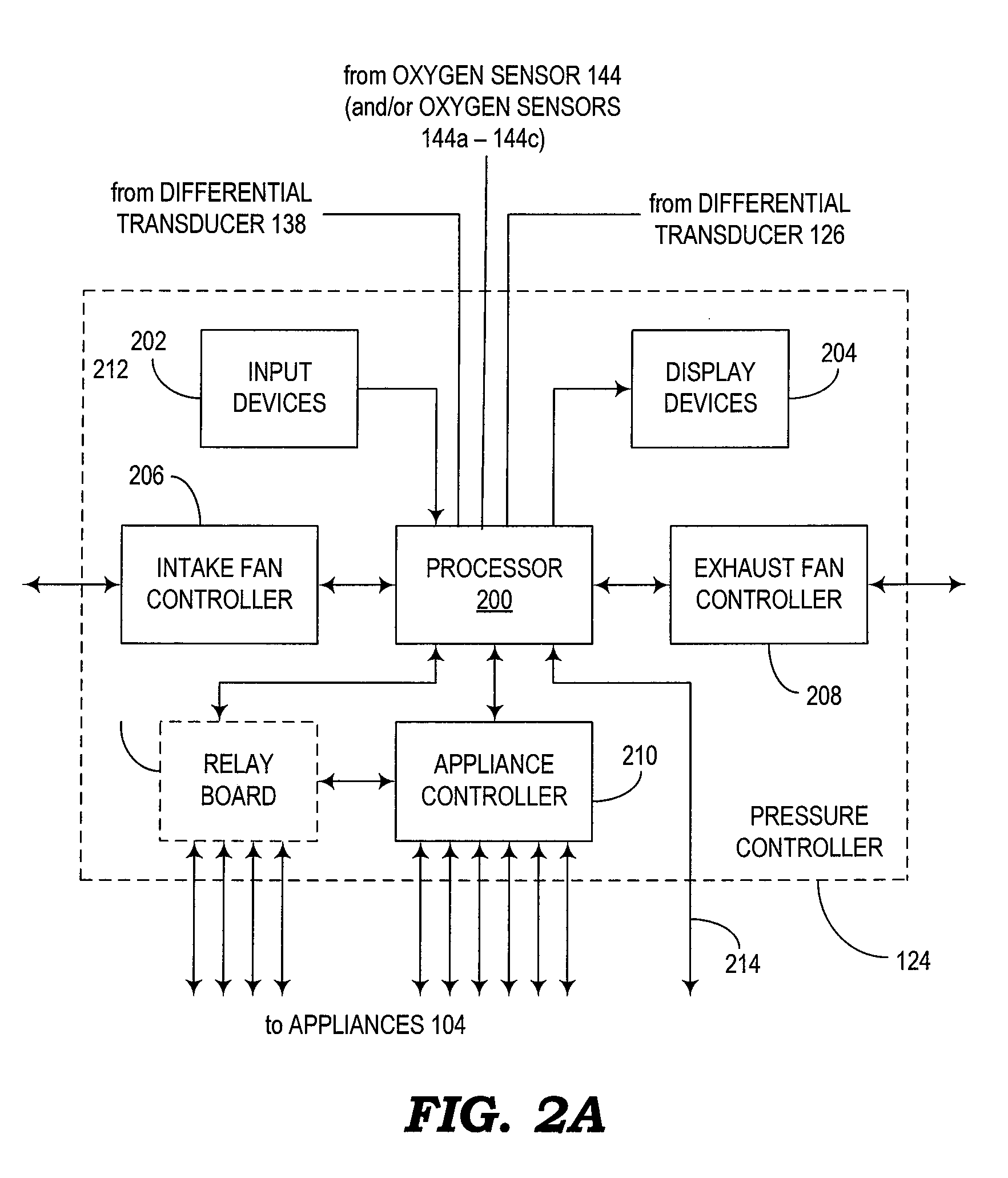

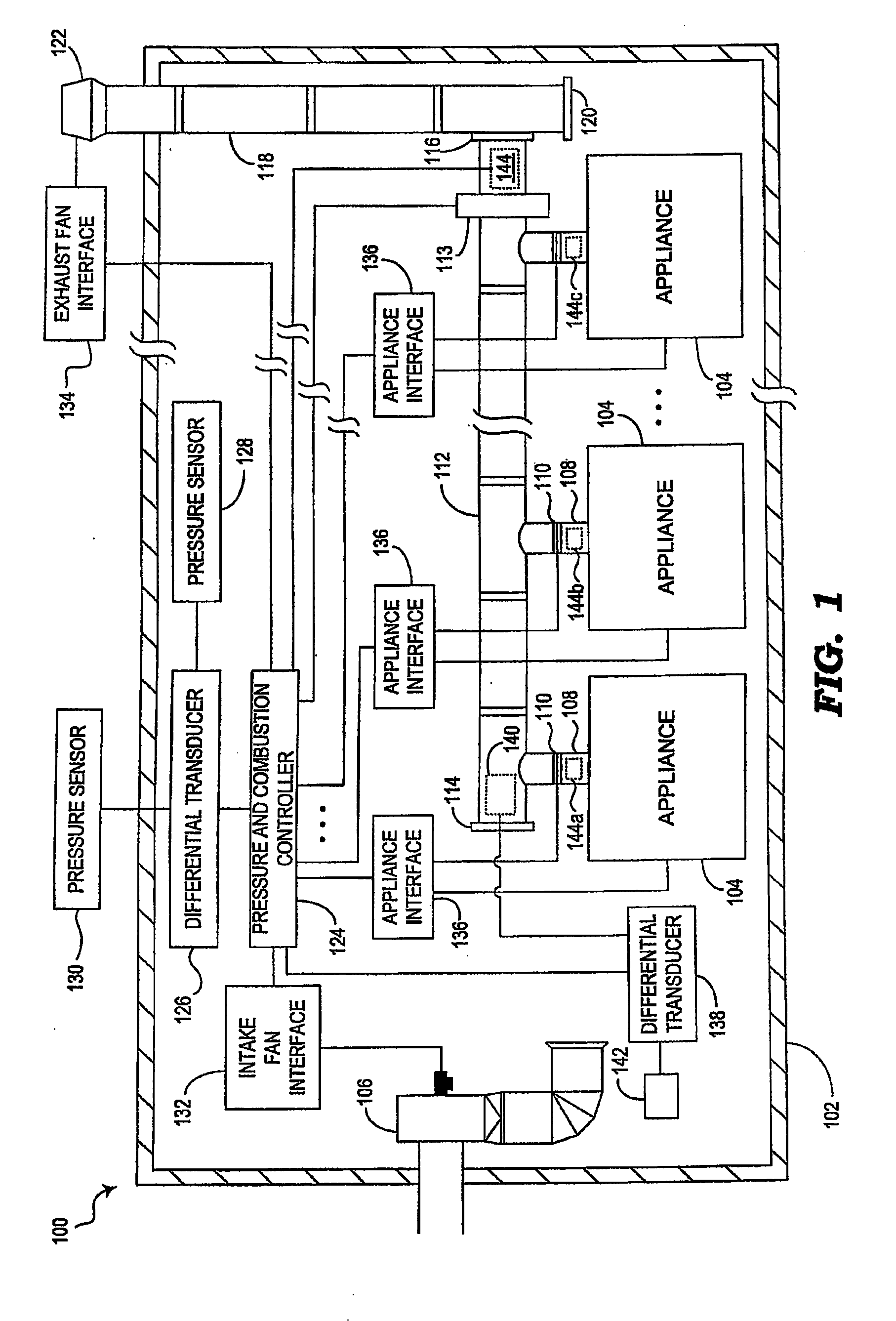

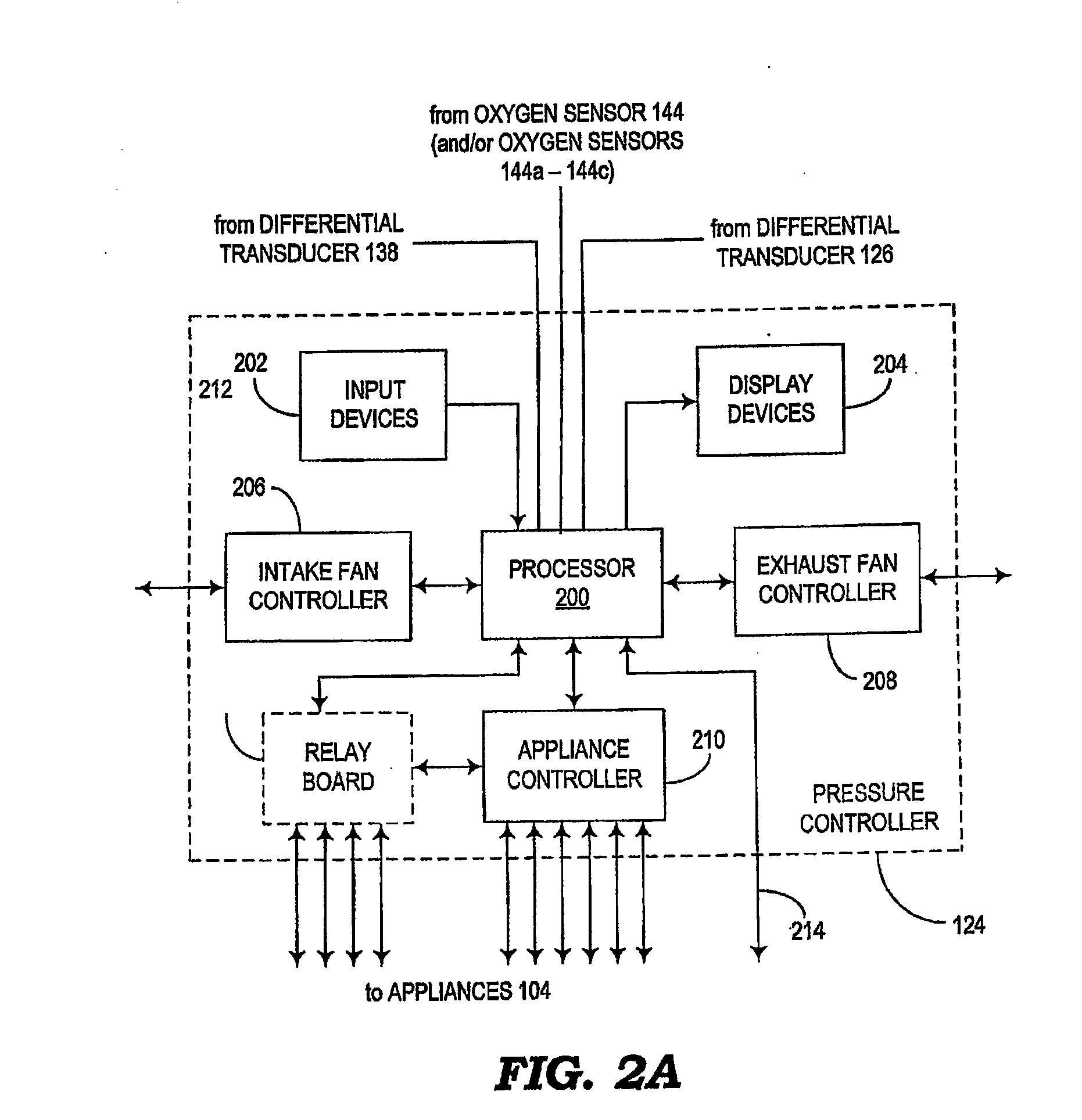

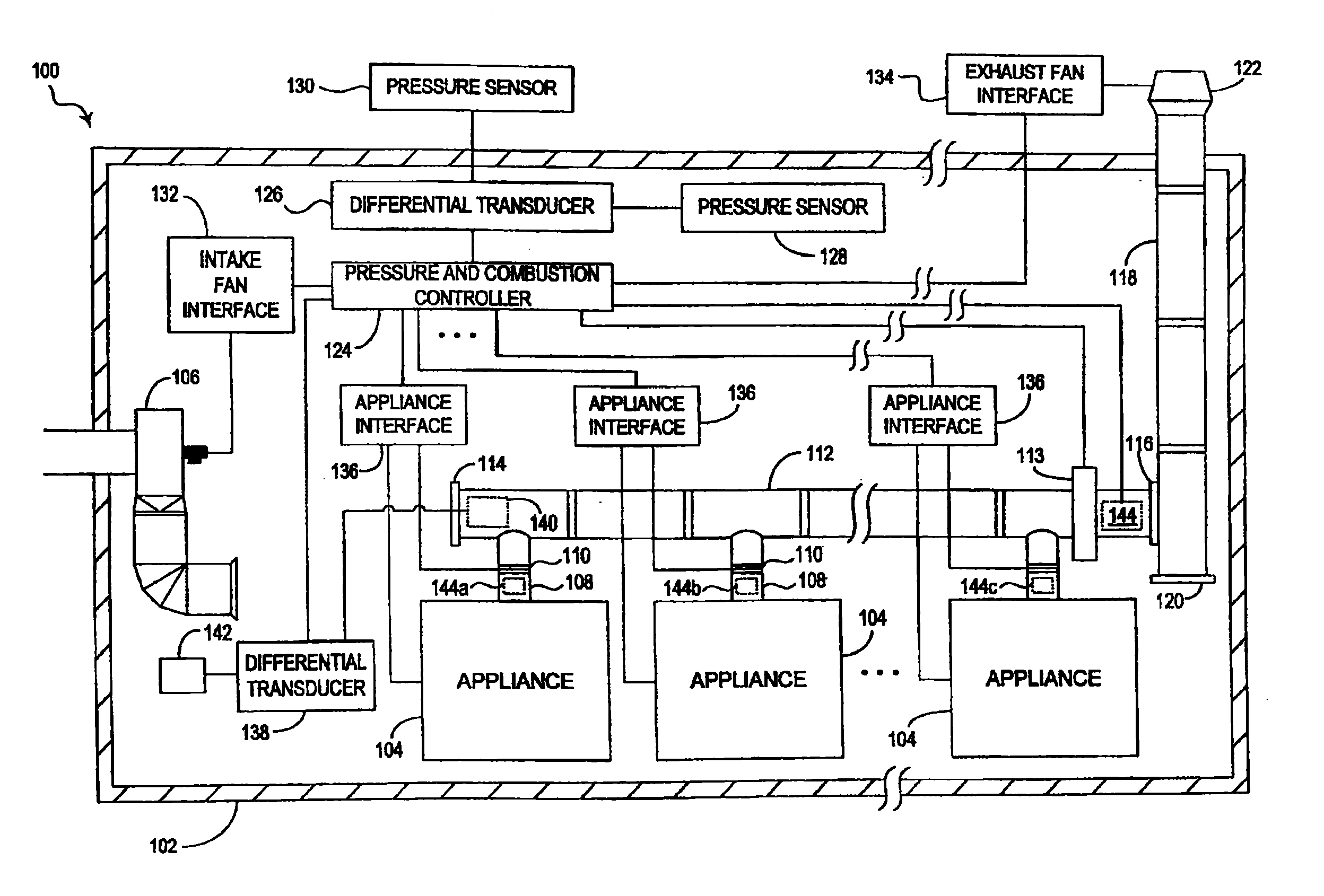

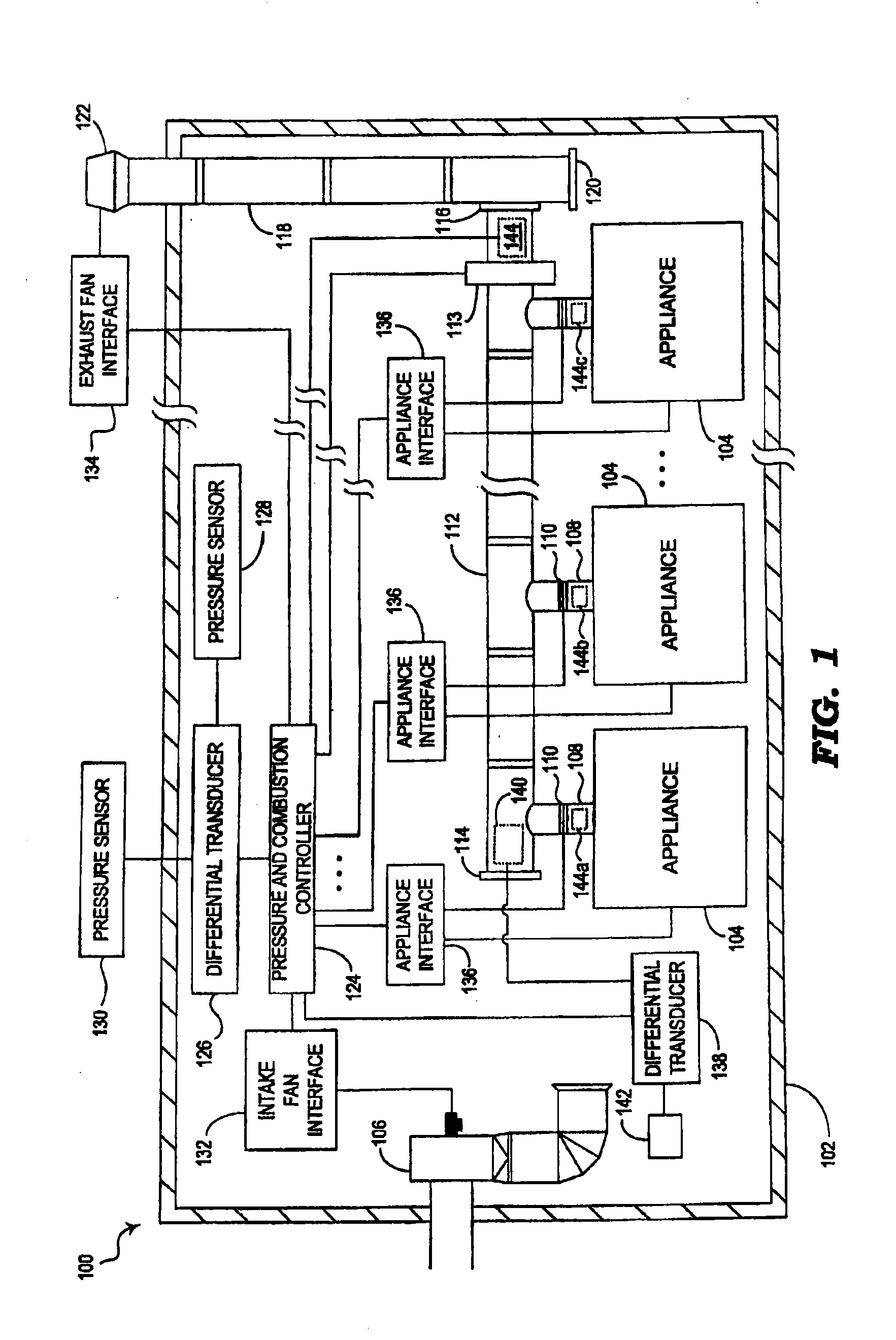

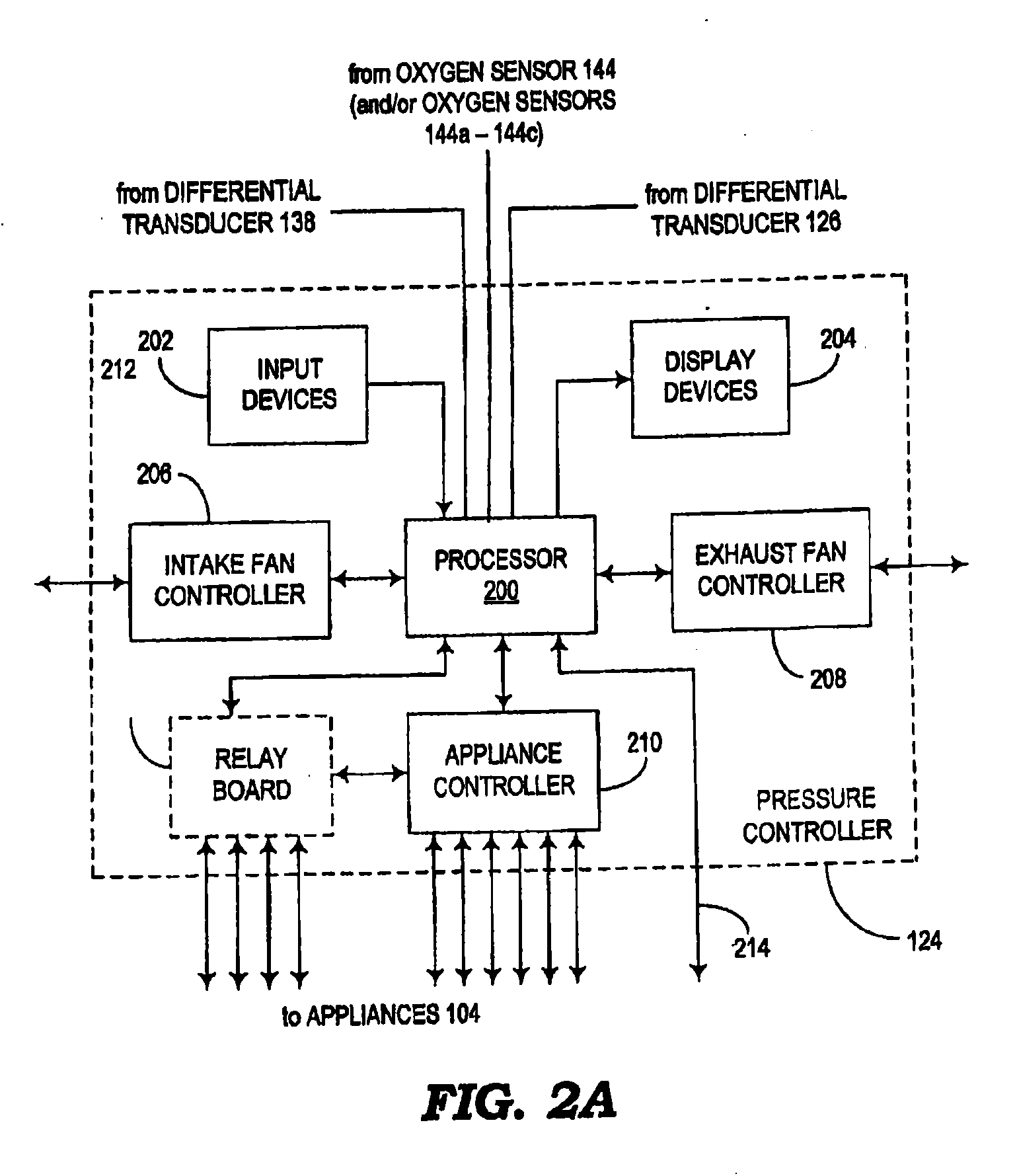

Pressure Controller for a Mechanical Draft System

InactiveUS20070209653A1Mechanical apparatusAir supply regulationDifferential pressureAtmospheric pressure

Systems and method for controlling the flow of air through a mechanical draft system are disclosed herein. A pressure controller for controlling air pressure comprises an appliance controller configured to control the operation of a plurality of appliances, an intake fan controller configured to control the speed of an intake fan, and an exhaust fan controller configured to control the speed of an exhaust fan. The pressure controller also includes a processor configured to receive a differential pressure signal and to control the operation of the appliances, the speed of the intake fan, and the speed of the exhaust fan in response to the differential pressure signal.

Owner:ENERVEX

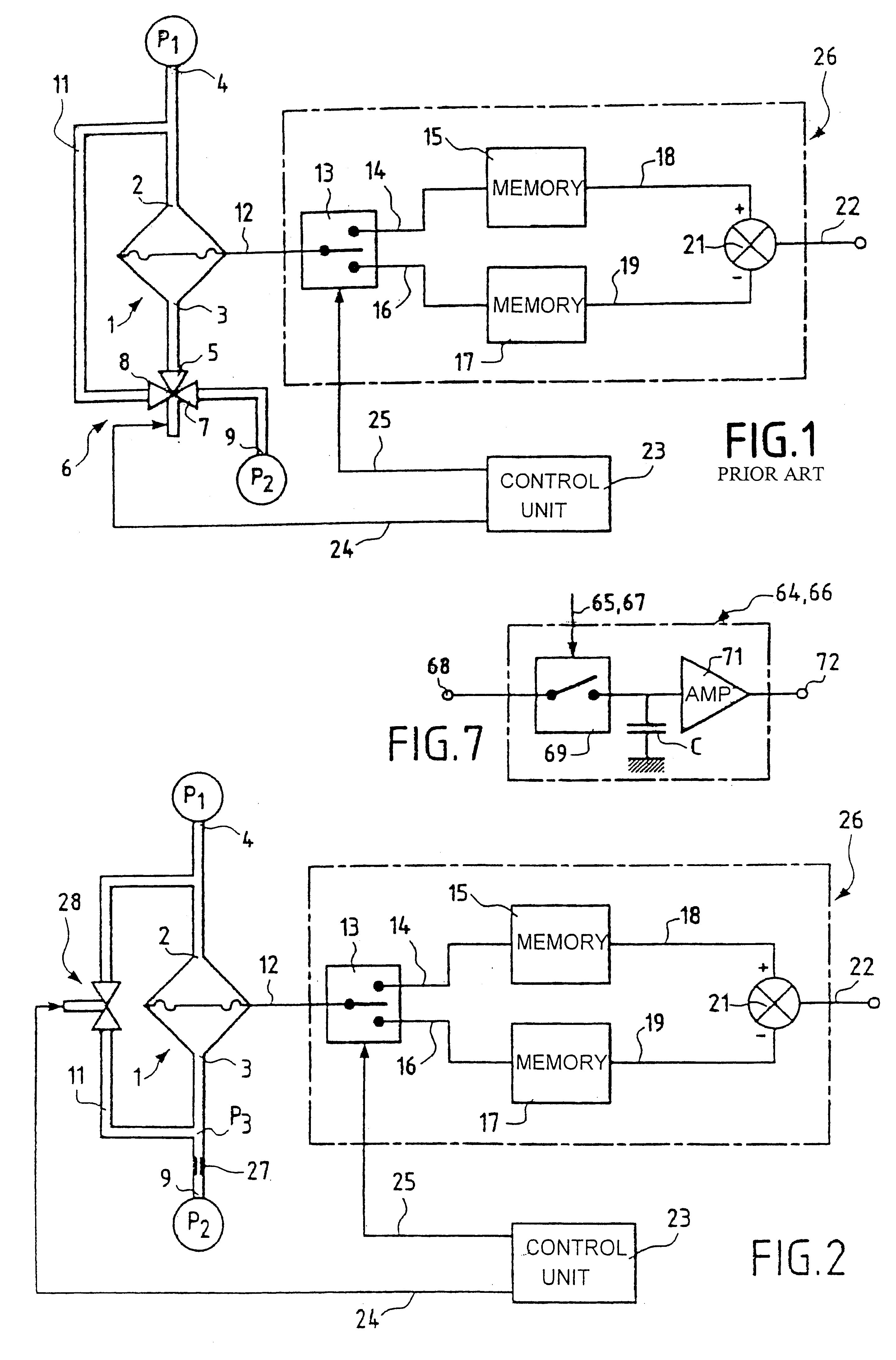

System for active regulation of the air/gas ratio of a burner including a differential pressure measuring system

InactiveUS6533574B1Simpler and less-costlyLess costlyFuel supply regulationCombustion ventilatorsCombustorDifferential pressure

The system for active regulation of the air / gas ratio of a burner comprises one or two differential pressure measuring systems each of which has a differential pressure sensor with two inlet orifices. The orifices are respectively connected to pressure ports in one of which there is a calibrated throttling orifice. The regulator system comprises a 2-channel valve which, when closed, isolates the two inlet orifices from each other, and, when open, connects them to each other. A measurement circuit is provided and has memory means for storing at least two values of the output signal of the sensors, a control unit for switching the valve and controlling the storage of a first value of an output signal of the sensor in the memory means when the valve is closed and the storage of a second value of the output signal of the sensor when the valve is open, and subtractor means for calculating the difference between the two stored values of the output signal of the sensor and thereby eliminating any drift. In a preferred variant, the regulator system includes only one differential pressure measuring system.

Owner:A THEOBALD

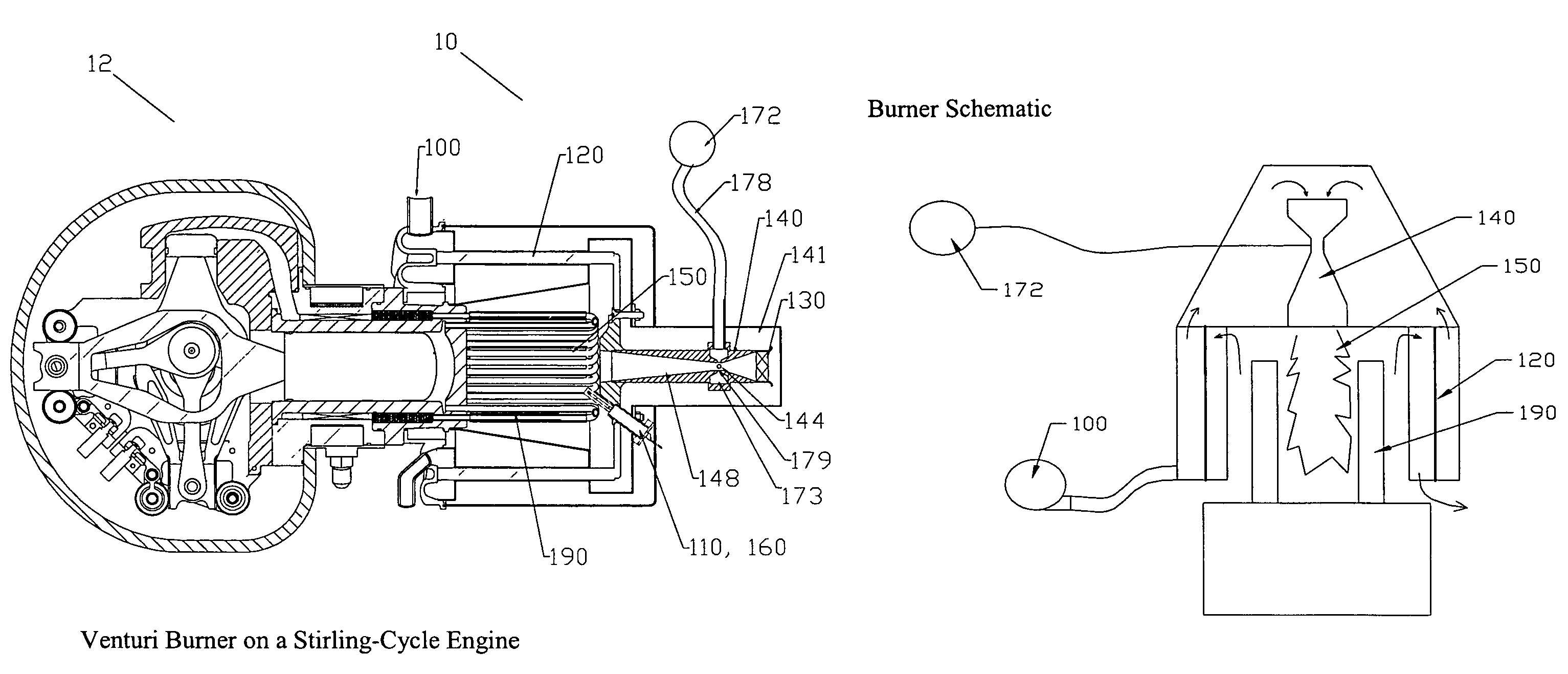

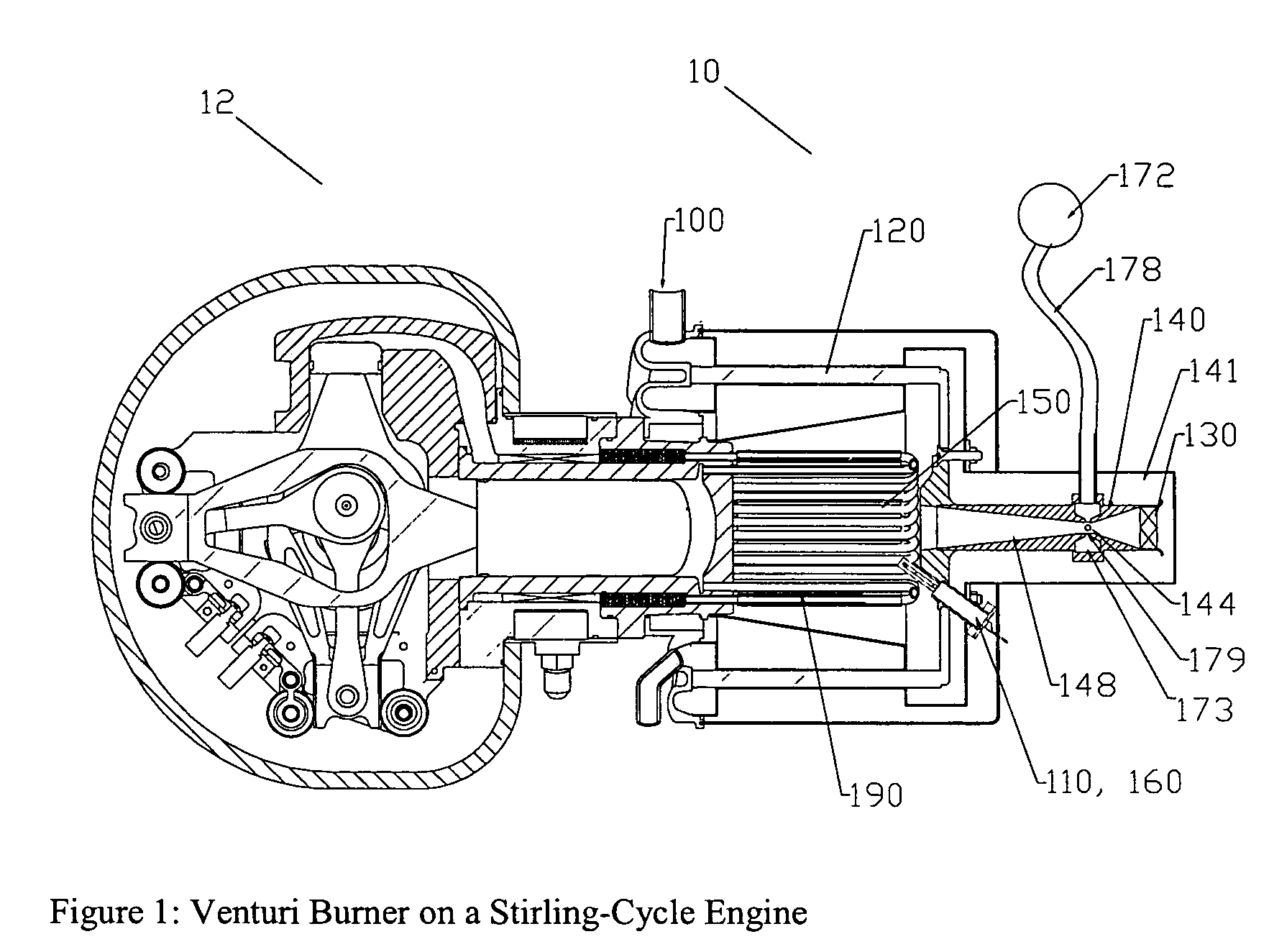

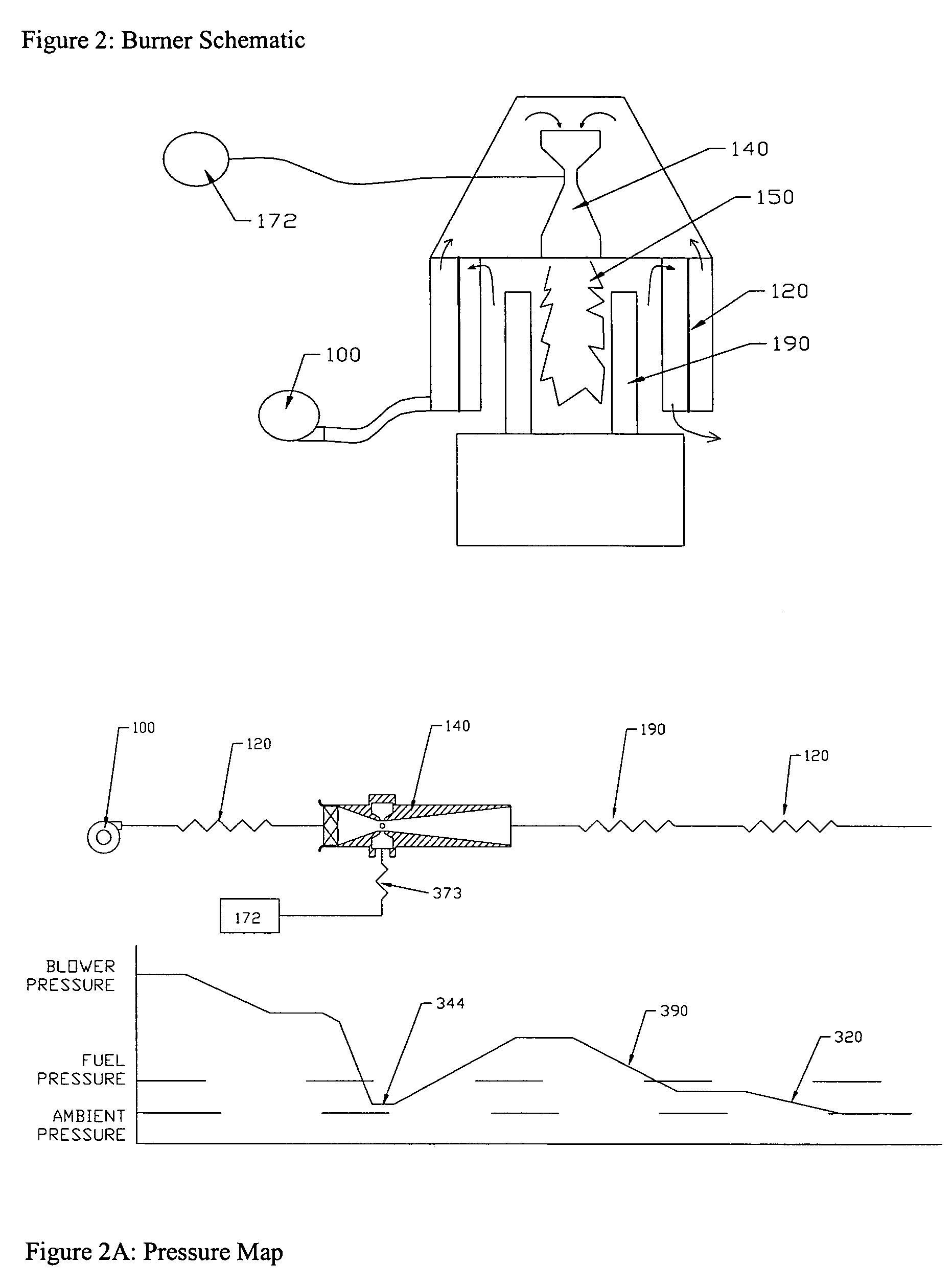

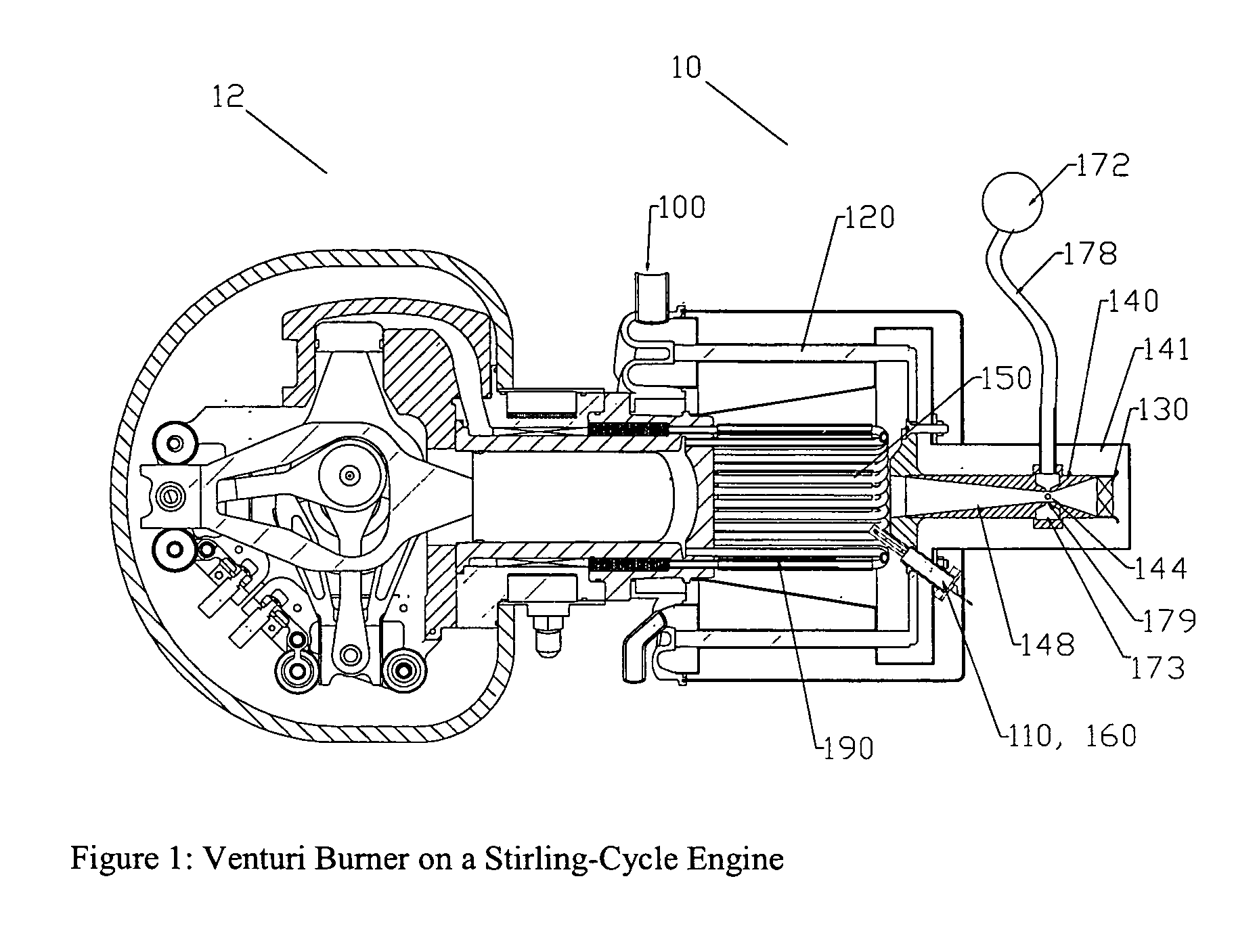

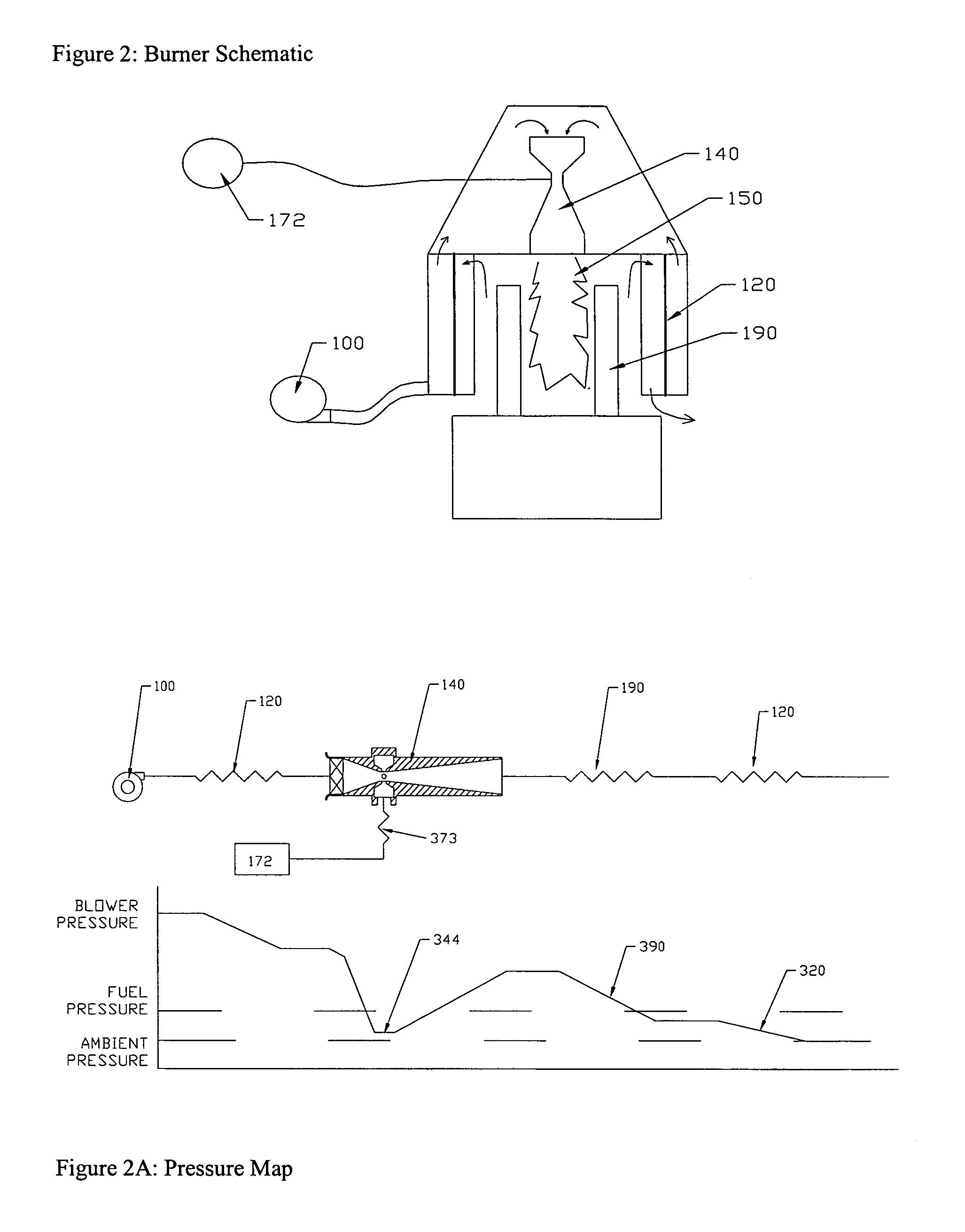

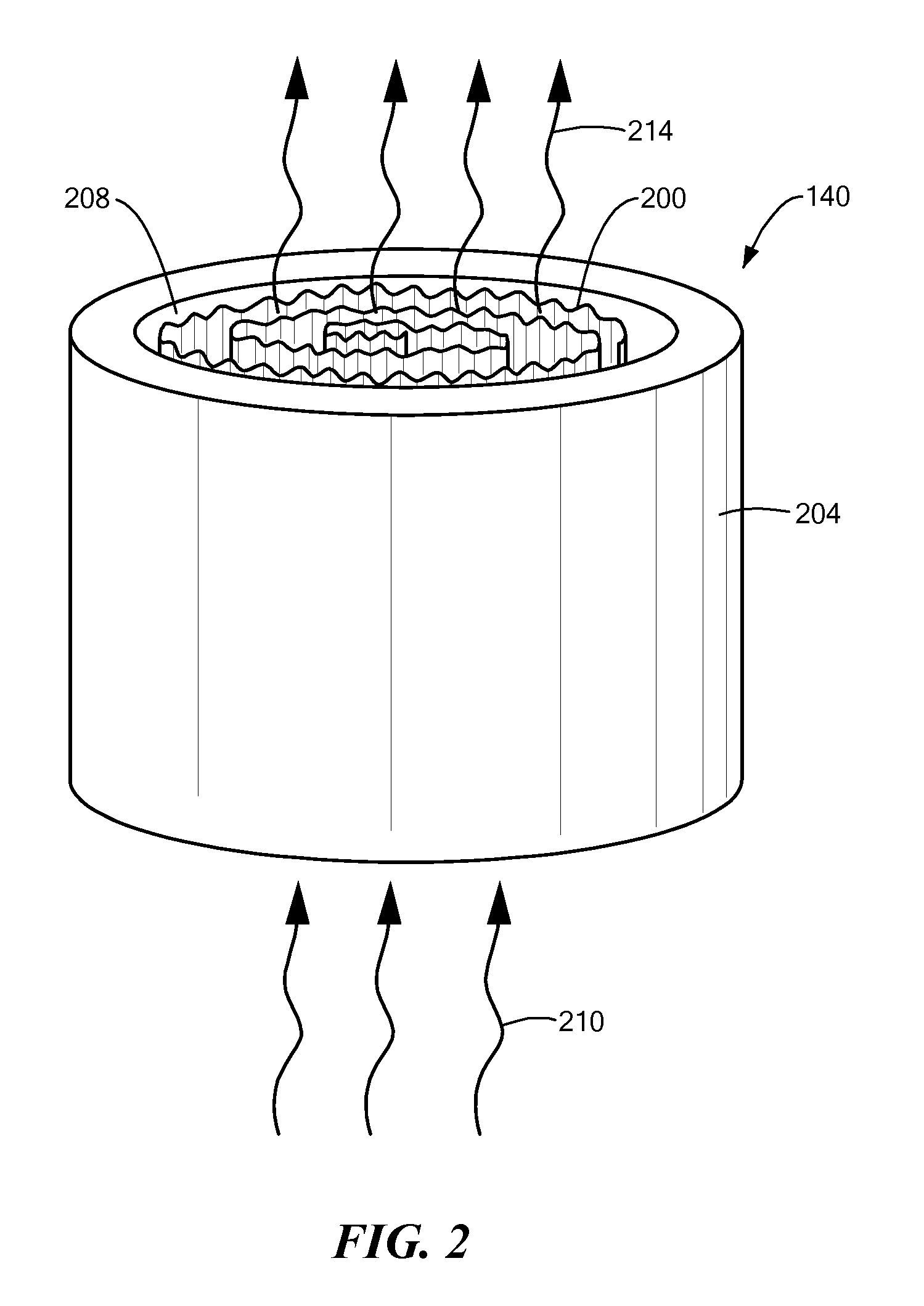

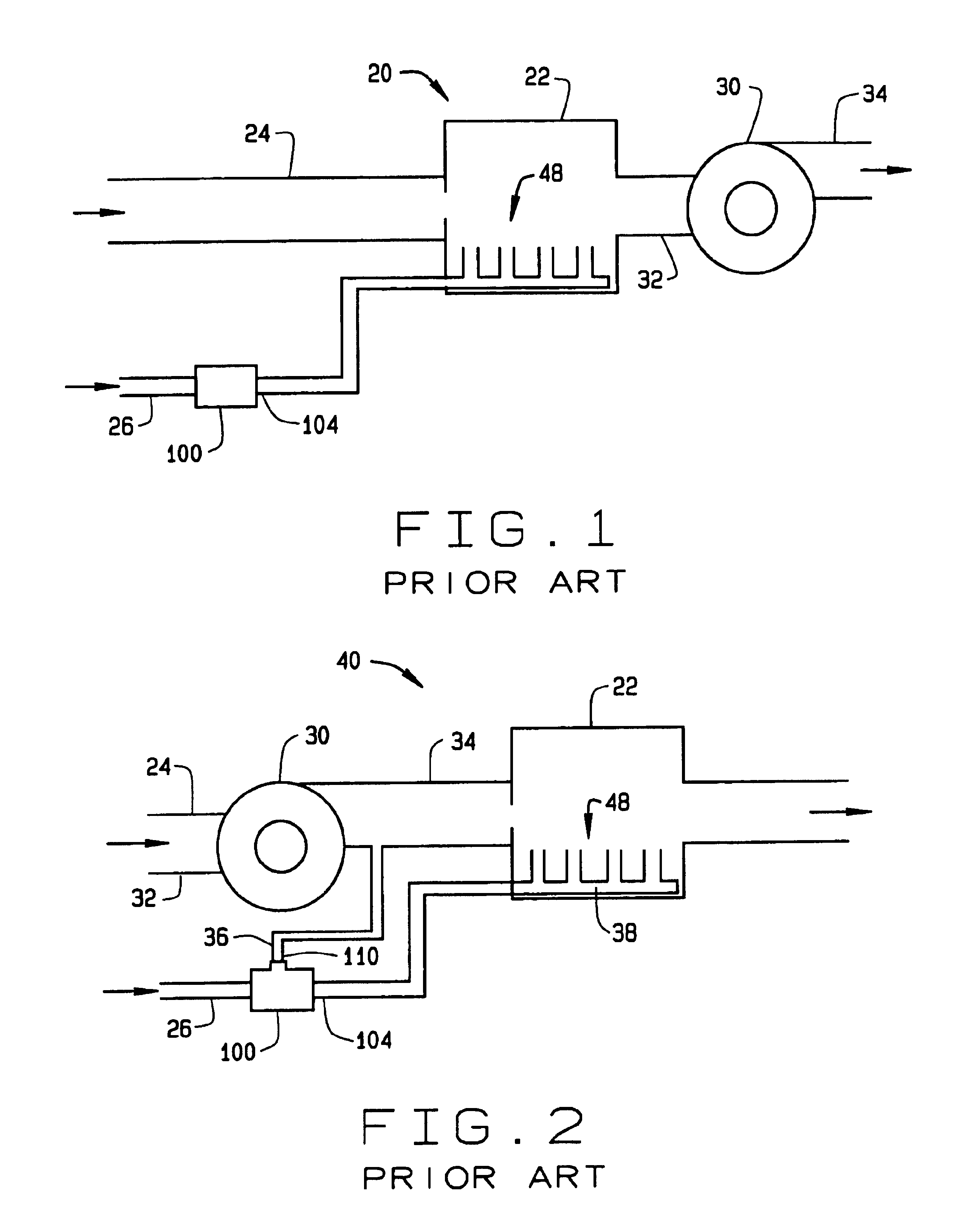

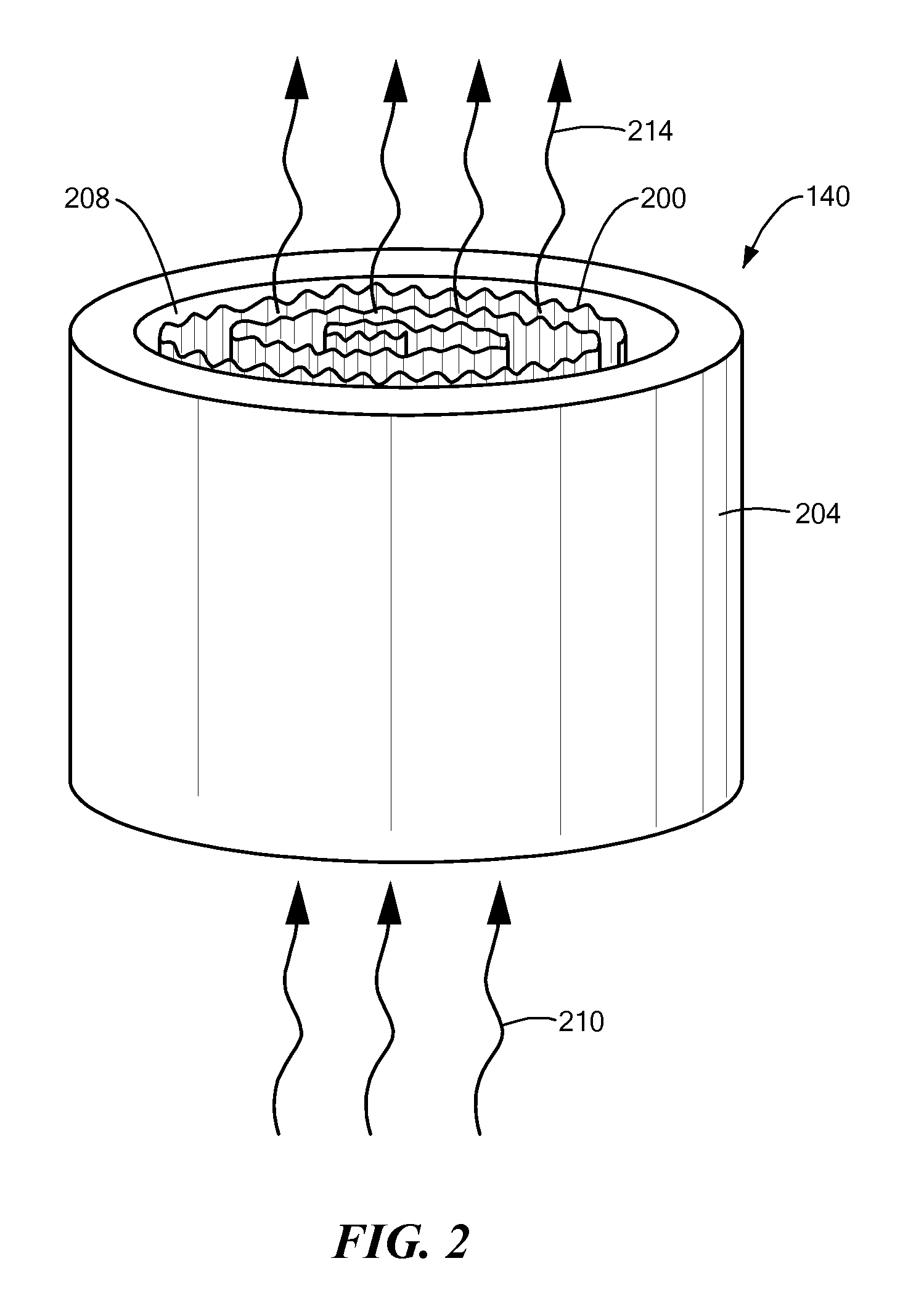

Gaseous fuel burner

ActiveUS20050250062A1Address is challengeEliminate needFuel supply regulationAir supply regulationAir velocityAutomatic control

An ejector, such as a venturi, facilitates the delivery of gaseous fuel to the combustion chamber of a burner. A blower forces air through the ejector, and the air flow produces a suction that draws fuel from a fuel inlet to produce a fuel-air mixture. The amount of fuel drawn from the fuel inlet is a function of the air flow such that a substantially constant fuel-air ratio is obtained over a range of air flow rates and temperatures without the need for a separate high-pressure fuel pump. The fuel-air mixture may be provided to a combustion chamber for combustion. Air from the blower may be pre-heated prior to entering the ejector, for example, using a heat exchanger that recovers some of the heat from the combusted fuel-air mixture. Air flow through the ejector may be conditioned, for example, by a swirler, to produce a tangential air flow that can increase fuel flow by increasing air velocity across the fuel inlet and / or produce a swirl-stabilized flame in the combustion chamber. The combusted fuel-air mixture may be provided to a thermal load, such as an external combustion engine. Blower speed may be controlled manually or automatically to control power output. Fuel flow to the ejector can be controlled manually or automatically to control fuel-air ratio. The burner can be configured to operate with multiple fuel types, for example, using a fuel selector with fixed or variable restrictors.

Owner:NEW POWER CONCEPTS

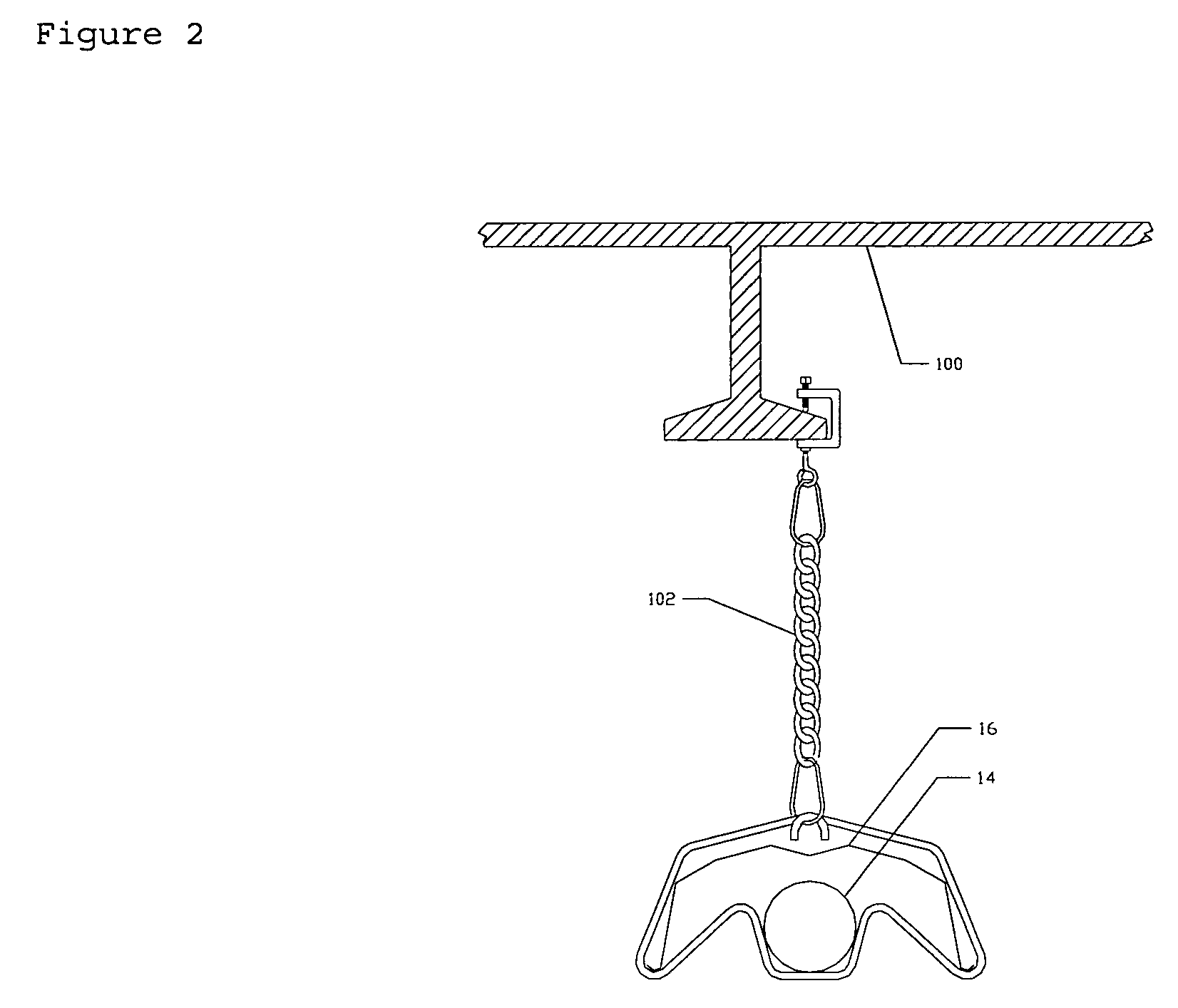

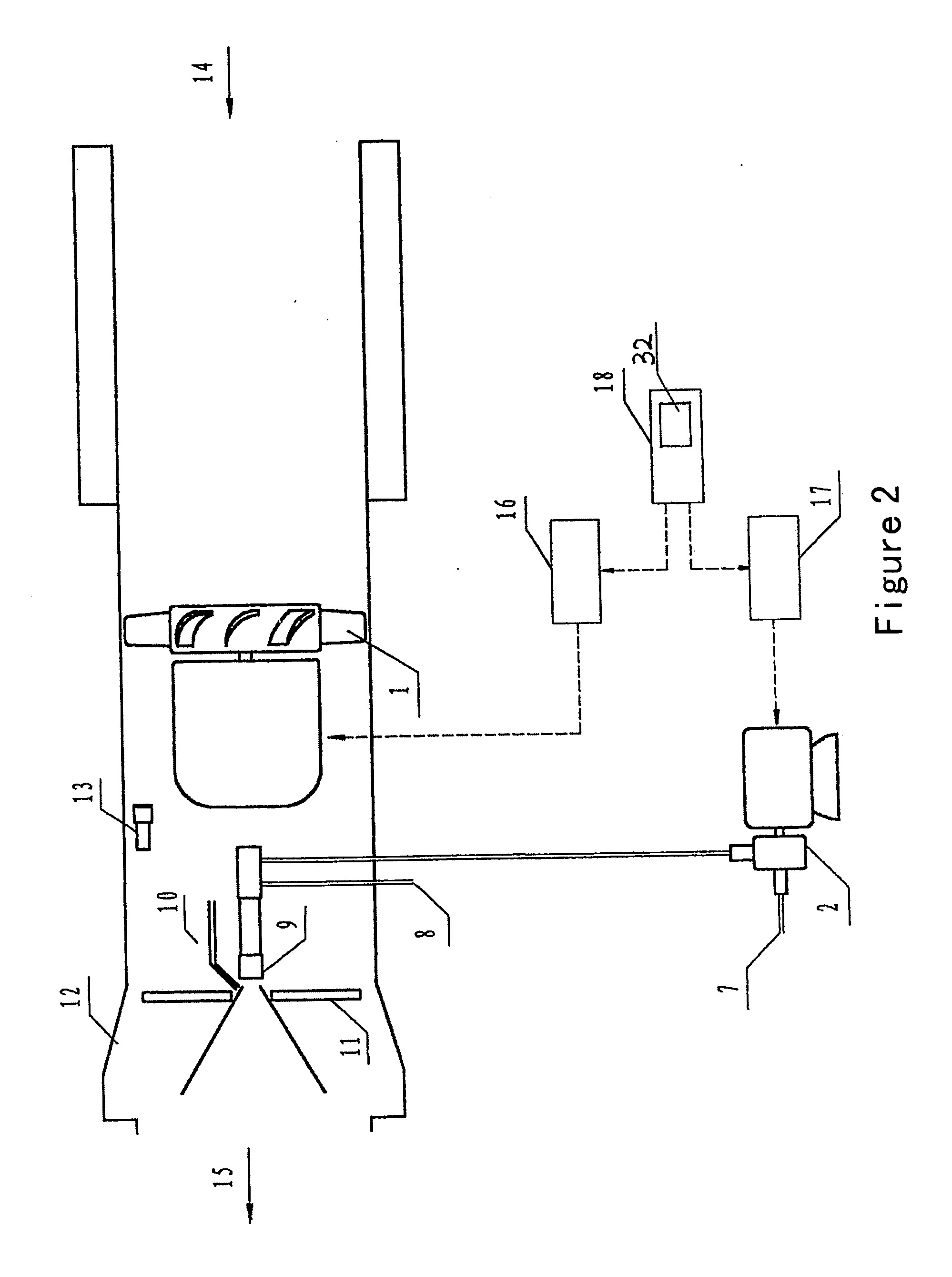

Fan Assemblies, Mechanical Draft Systems and Methods

InactiveUS20090215375A1Facilitate independentFacilitate locally controlled ignitionDomestic stoves or rangesLiquid heating fuelDirect combustionControl theory

Fan assemblies, mechanical draft systems and methods are provided. In this regard, a representative mechanical draft system for use with multiple appliances includes: a chimney operative to direct combustion products from multiple appliances; a chimney fan operative to draw combustion products from the chimney; and a controller operative to adjust an operating speed of the chimney fan such that, responsive to a change in pressure in the chimney, the controller adjusts the operating speed of the chimney fan to maintain a desired pressure in the chimney.

Owner:GREENVEX

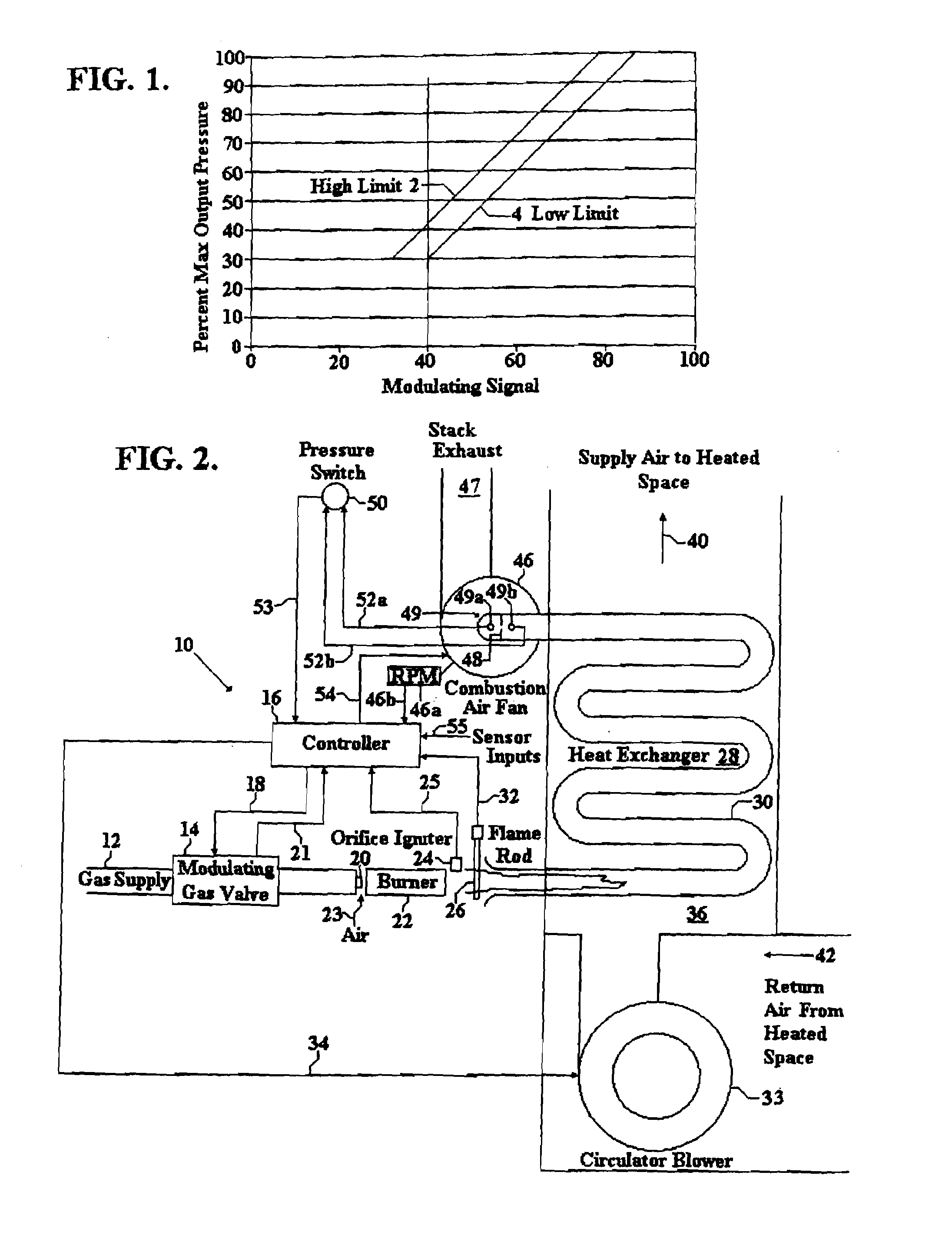

Feedback control for modulating gas burner

Owner:ADEMCO INC +1

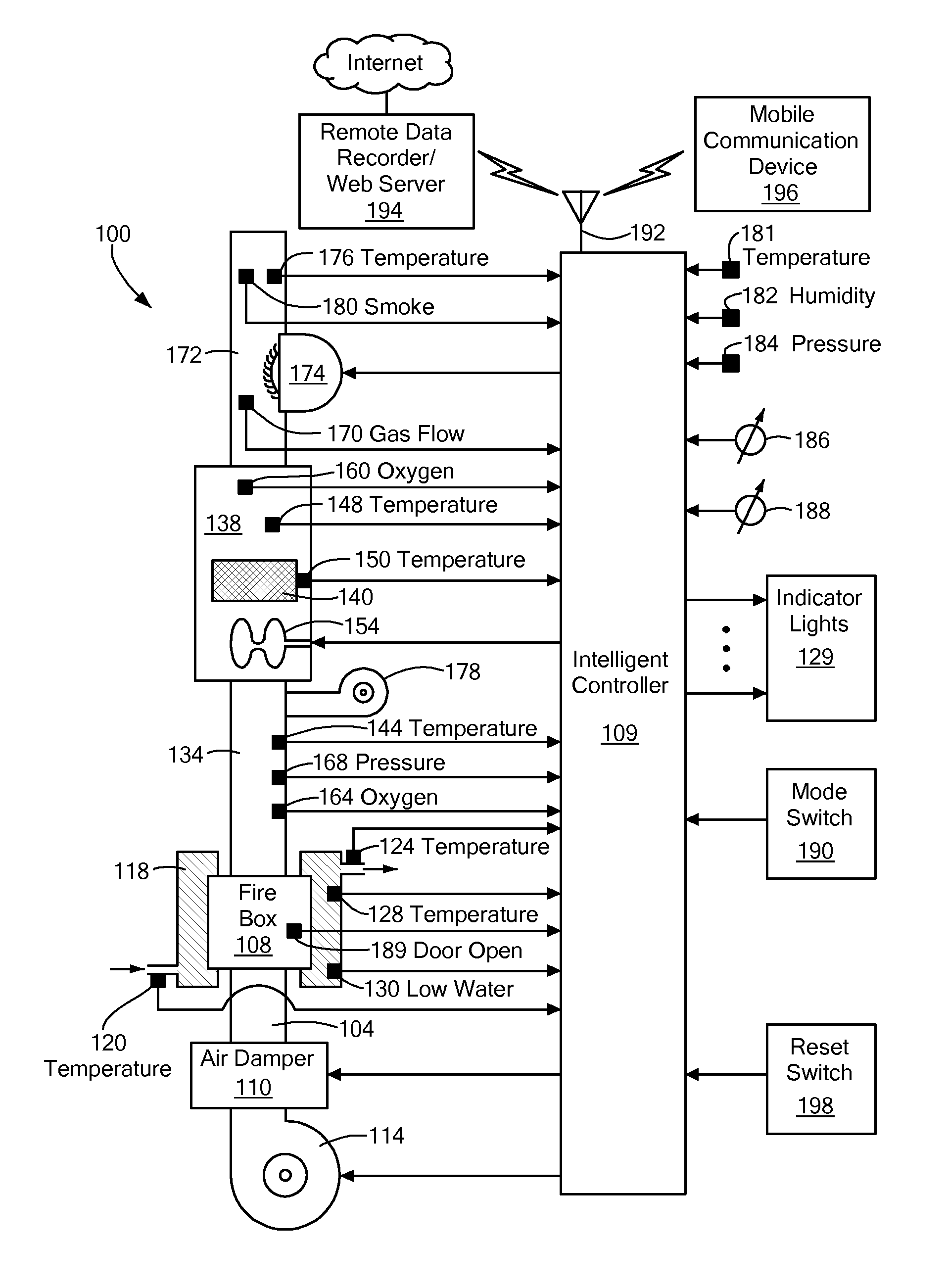

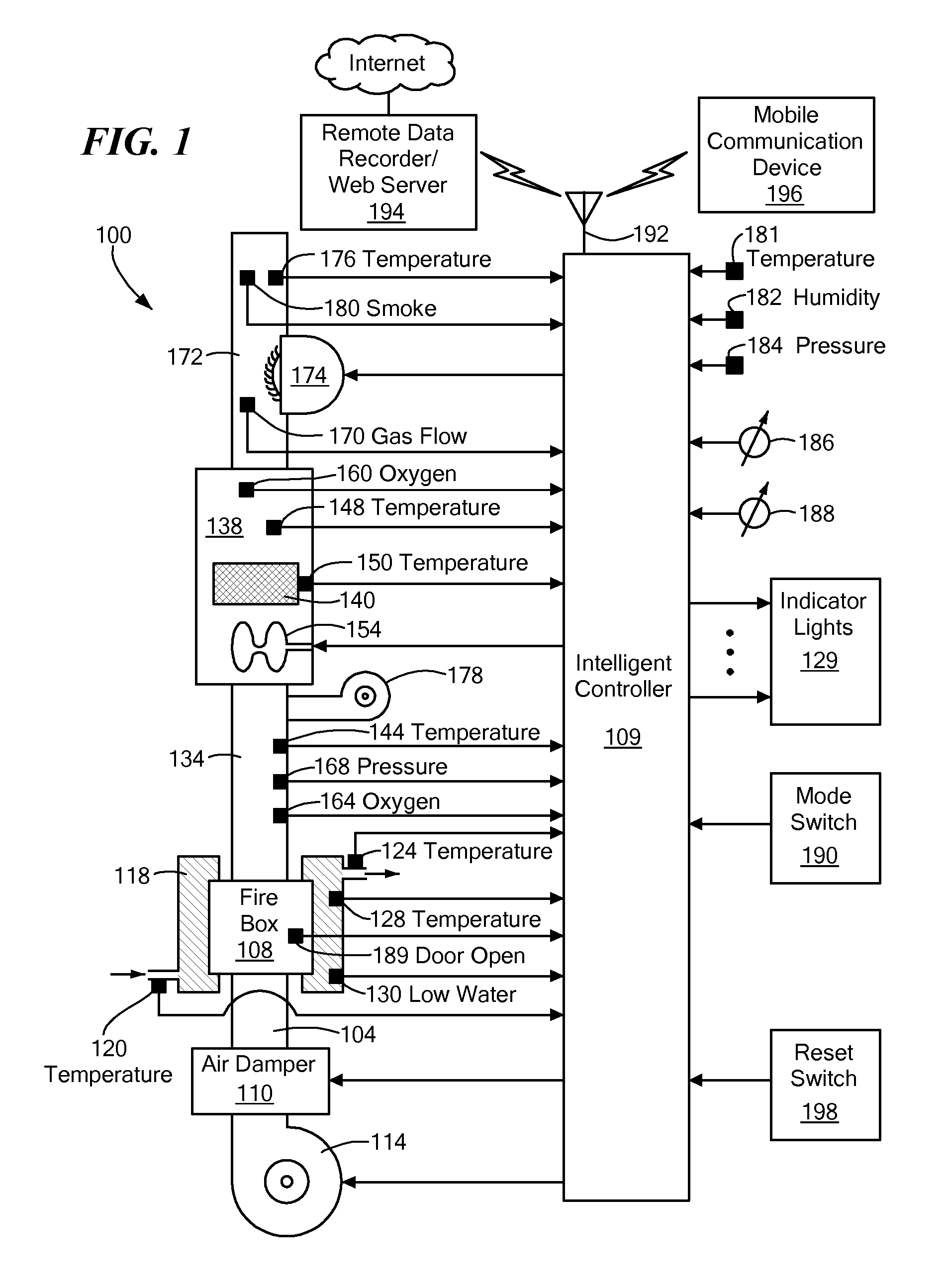

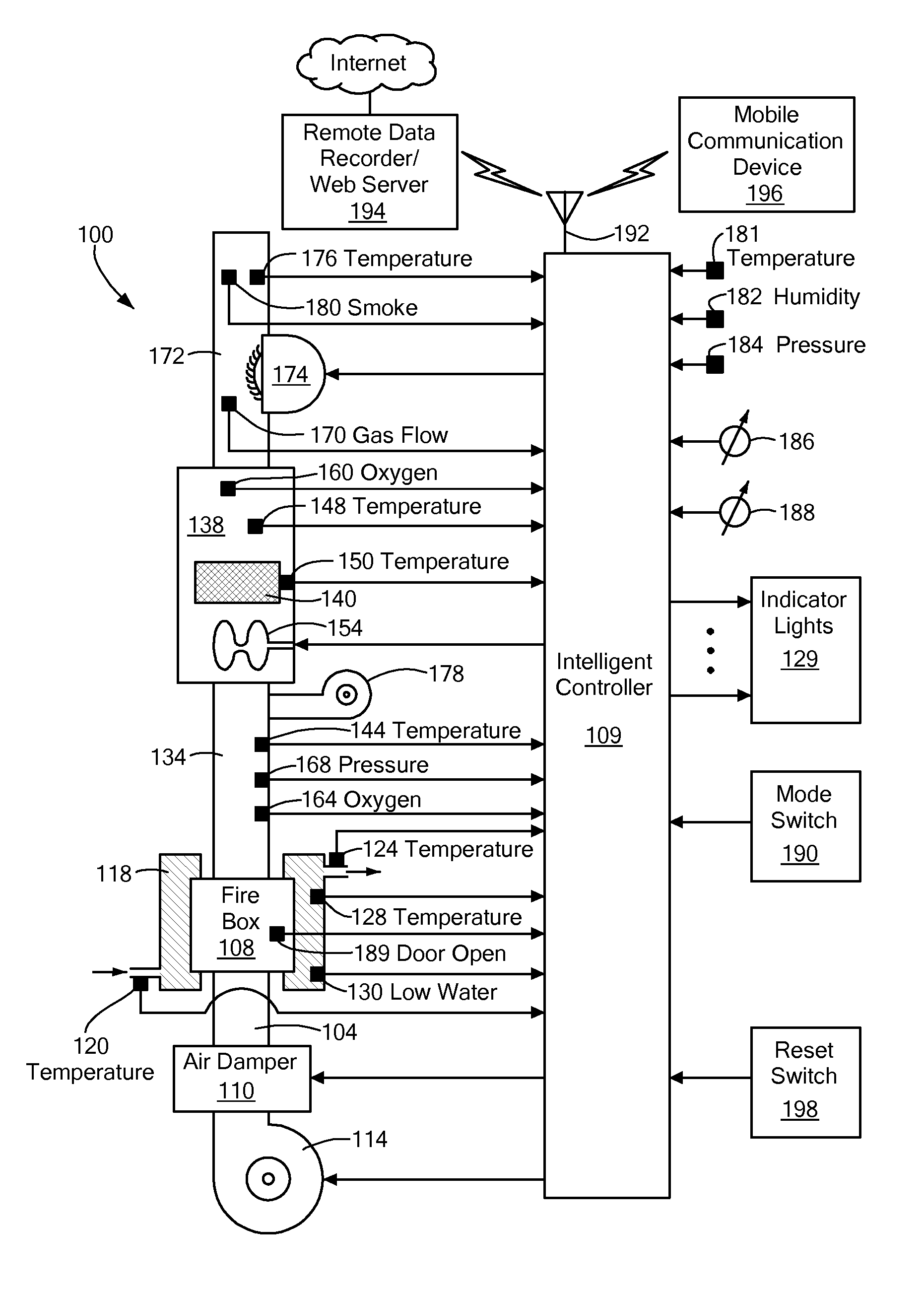

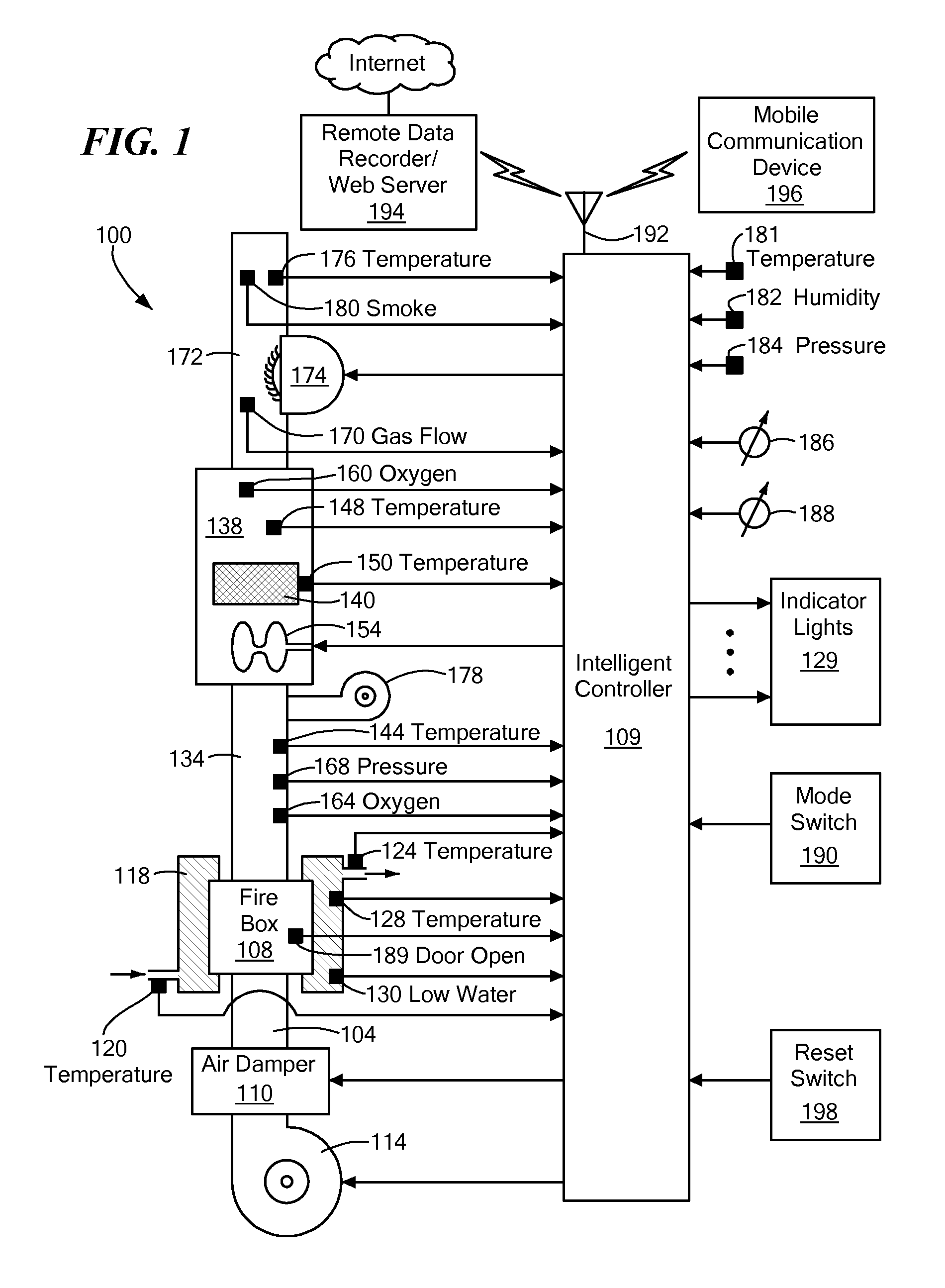

Intelligently-controlled catalytic converter for biofuel-fired boiler

An intelligently controlled catalytic converter automatically monitors various operating parameters, such as water jacket temperature, catalytic input temperature, catalytic converter output temperature, oxygen level, ambient temperature, ambient humidity and / or ambient barometric air pressure, of a biofuel-fired device and automatically controls dampers, blowers and electric heaters in the device.

Owner:BIOMASS CONTROLS PBC

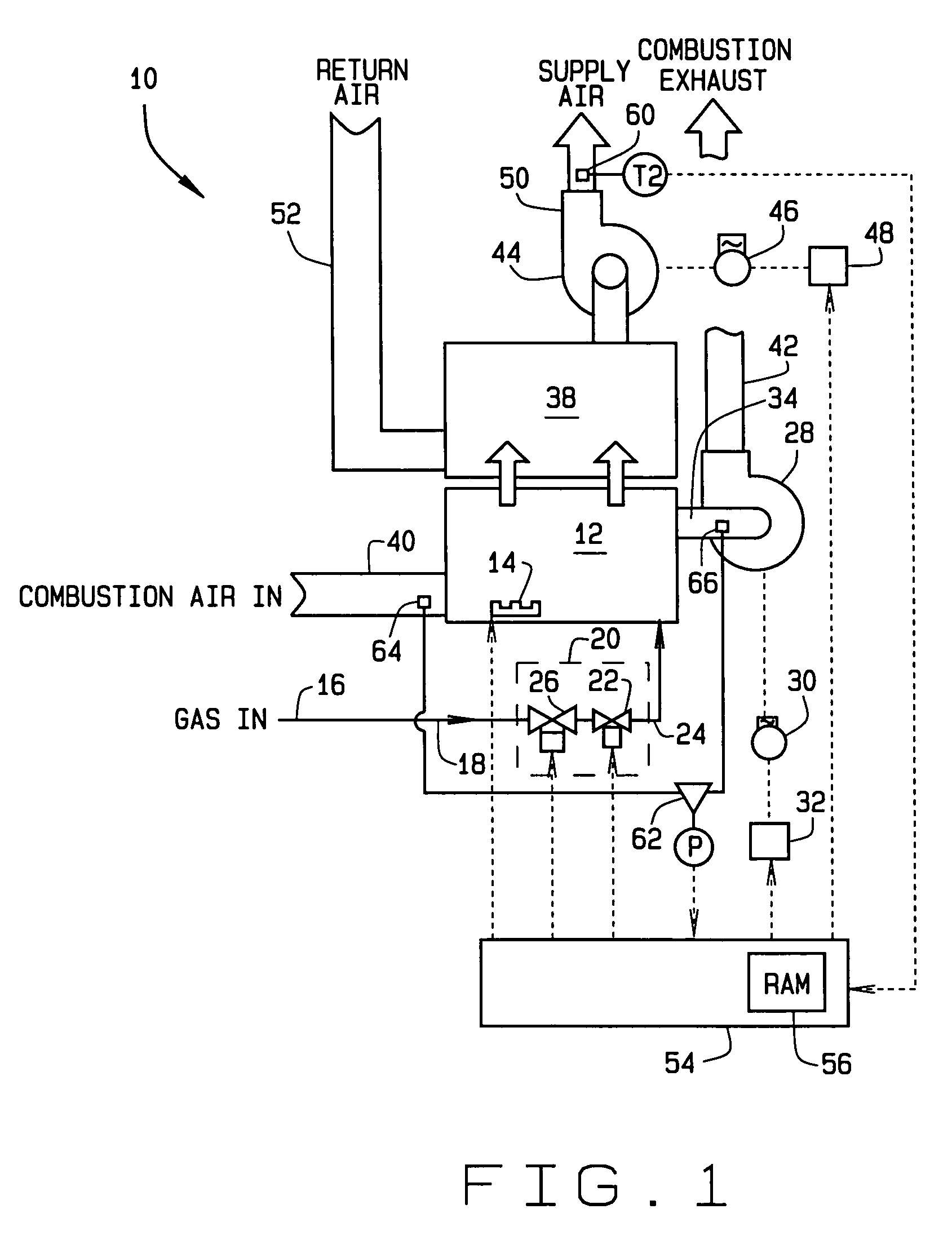

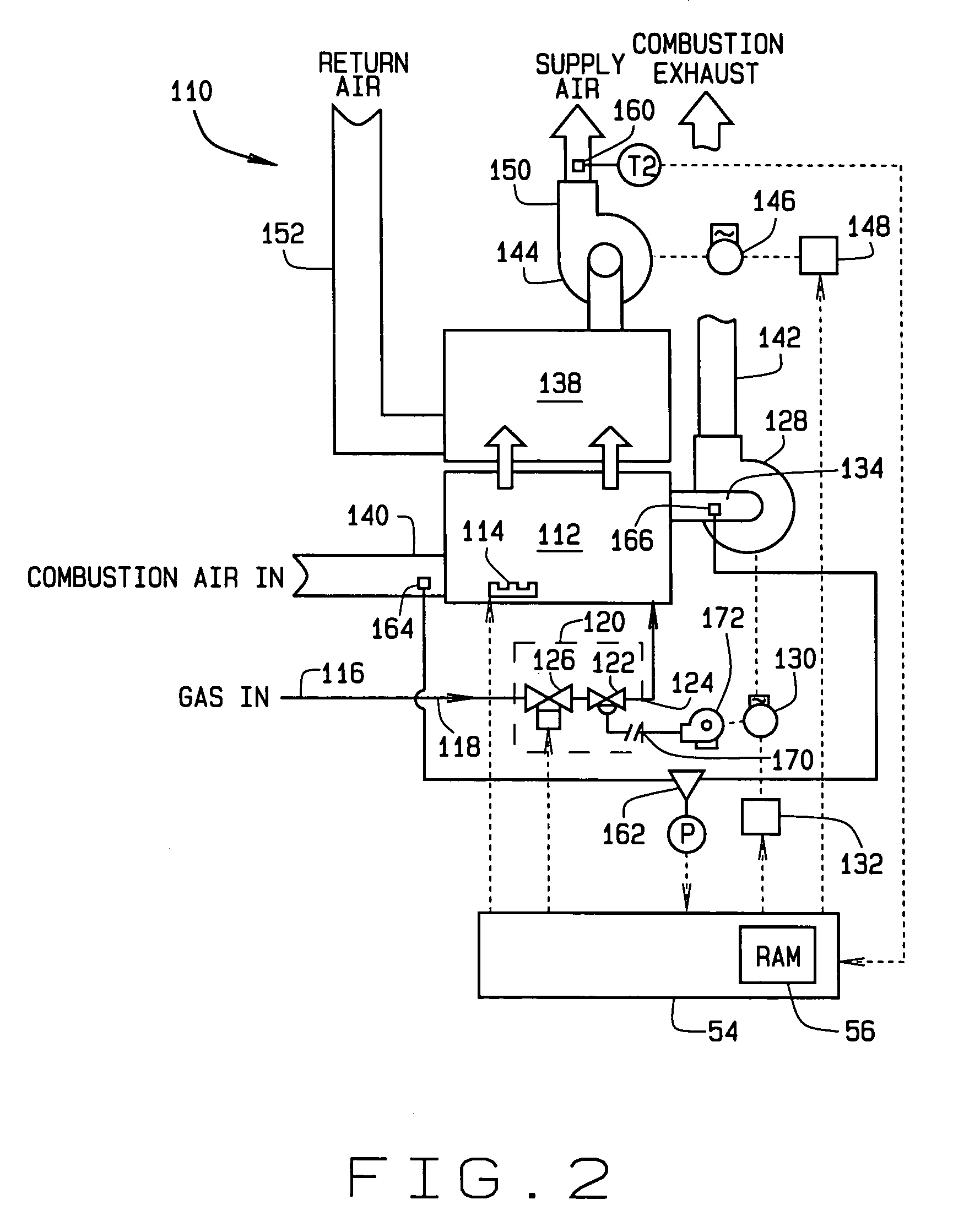

Variable output heating and cooling control

A heating or cooling system, such as an HVAC system, of variable output has a number of control elements and may include a variable speed compressor, a variable speed combustion (induced or forced draft) blower motor; a variable speed circulator blower motor; a variable output gas valve or gas / air premix unit; and a controller specifically developed for variable output applications. The system may utilize a pressure sensor to determine the actual flow of combustion airflow in response to actual space conditions, vary the speed of the inducer blower, and subsequently vary the gas valve output to supply the correct amount of gas to the burner system. A temperature sensor may be located in the discharge air stream of the conditioned air to provide an input signal for the circulator blower.

Owner:HVAC MODULATION TECH

System and methods for modulating gas input to a gas burner

InactiveUS6918756B2Simply and reliably controlledLow costFluidized bed combustionFuel supply regulationMotor driveEngineering

An improved gas appliance having a burner, a gas valve through which the flow of combustion gas to the burner is controlled, and a motor driven blower that supplies combustion air to the burner. The improvement includes means for increasing gas flow through the gas valve as blower speed increases, and decreasing gas flow through the gas valve as blower speed decreases, based on a pressure signal generated independently of combustion air pressure. This improvement allows a constant ratio of gas to air to be maintained in the burner while a combustion flow rate varies dependent on the blower motor revolutions per minute. Thus input pressures of combustion can be controlled at low cost.

Owner:EMERSON ELECTRIC CO

Variable output heating and cooling control

A heating or cooling system, such as an HVAC system, of variable output has a number of control elements and may include a variable speed compressor, a variable speed combustion (induced or forced draft) blower motor; a variable speed circulator blower motor; a variable output gas valve or gas / air premix unit; and a controller specifically developed for variable output applications. The system may utilize a pressure sensor to determine the actual flow of combustion airflow in response to actual space conditions, vary the speed of the inducer blower, and subsequently vary the gas valve output to supply the correct amount of gas to the burner system. A temperature sensor may be located in the discharge air stream of the conditioned air to provide an input signal for the circulator blower.

Owner:HVAC MODULATION TECH

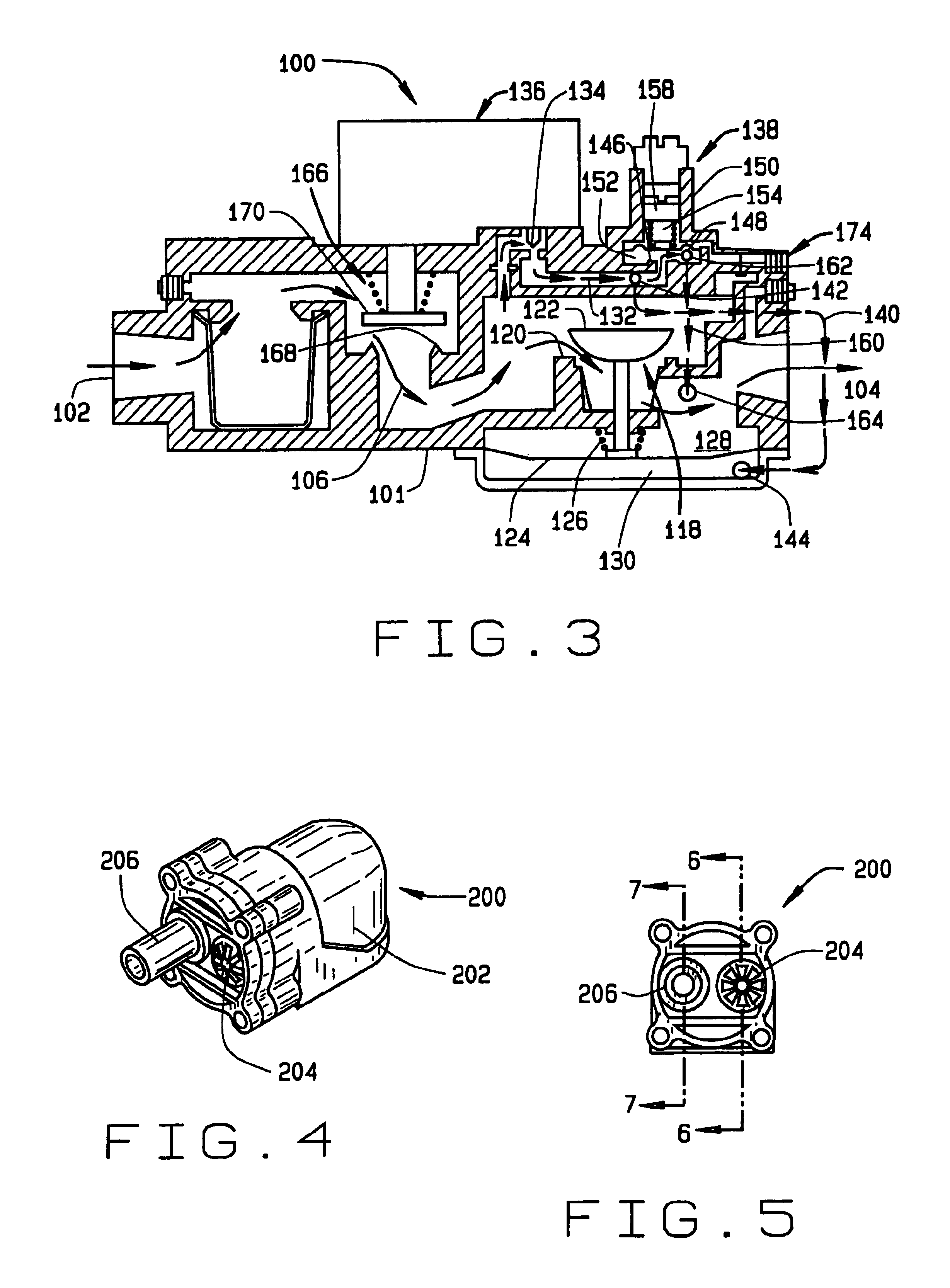

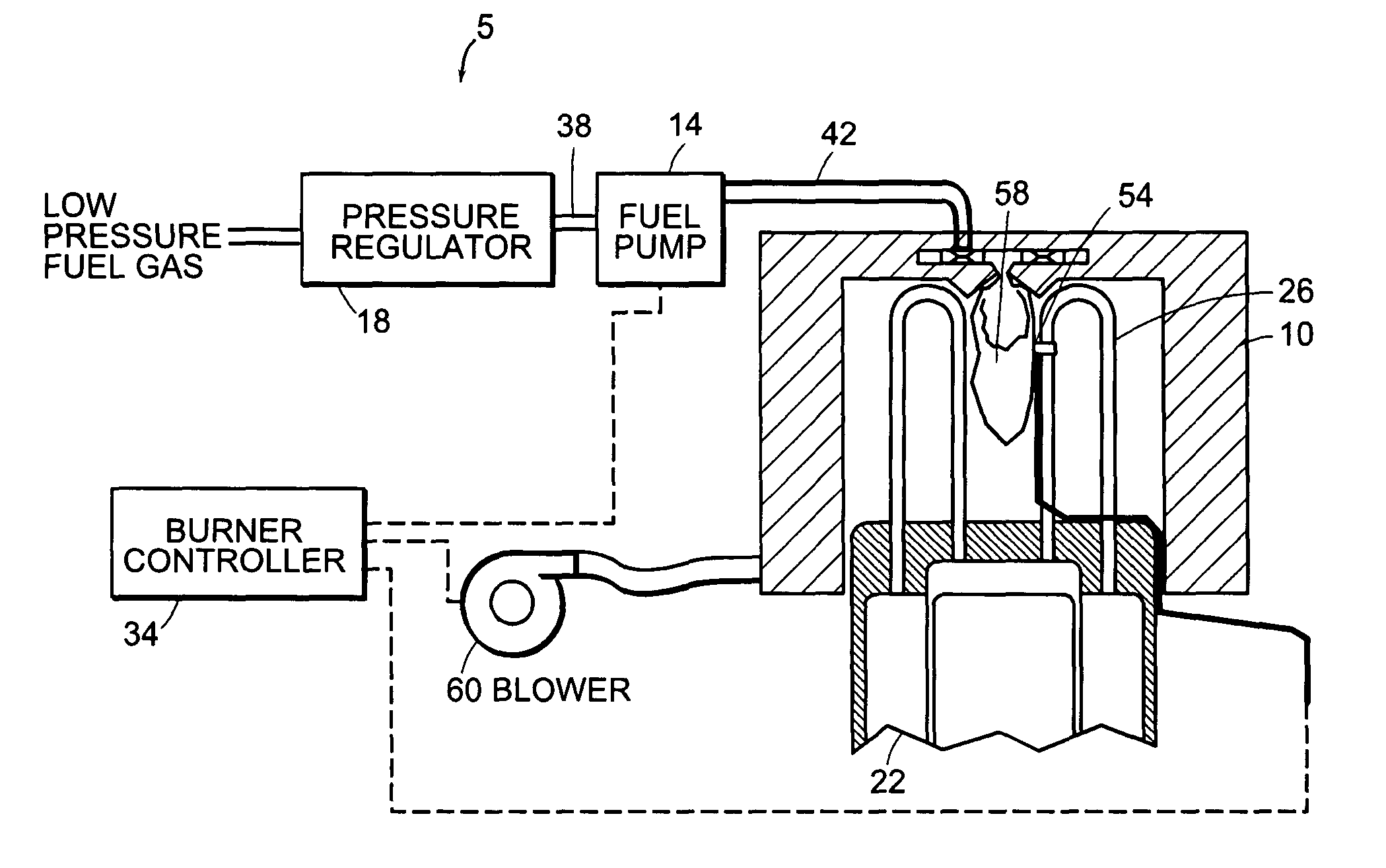

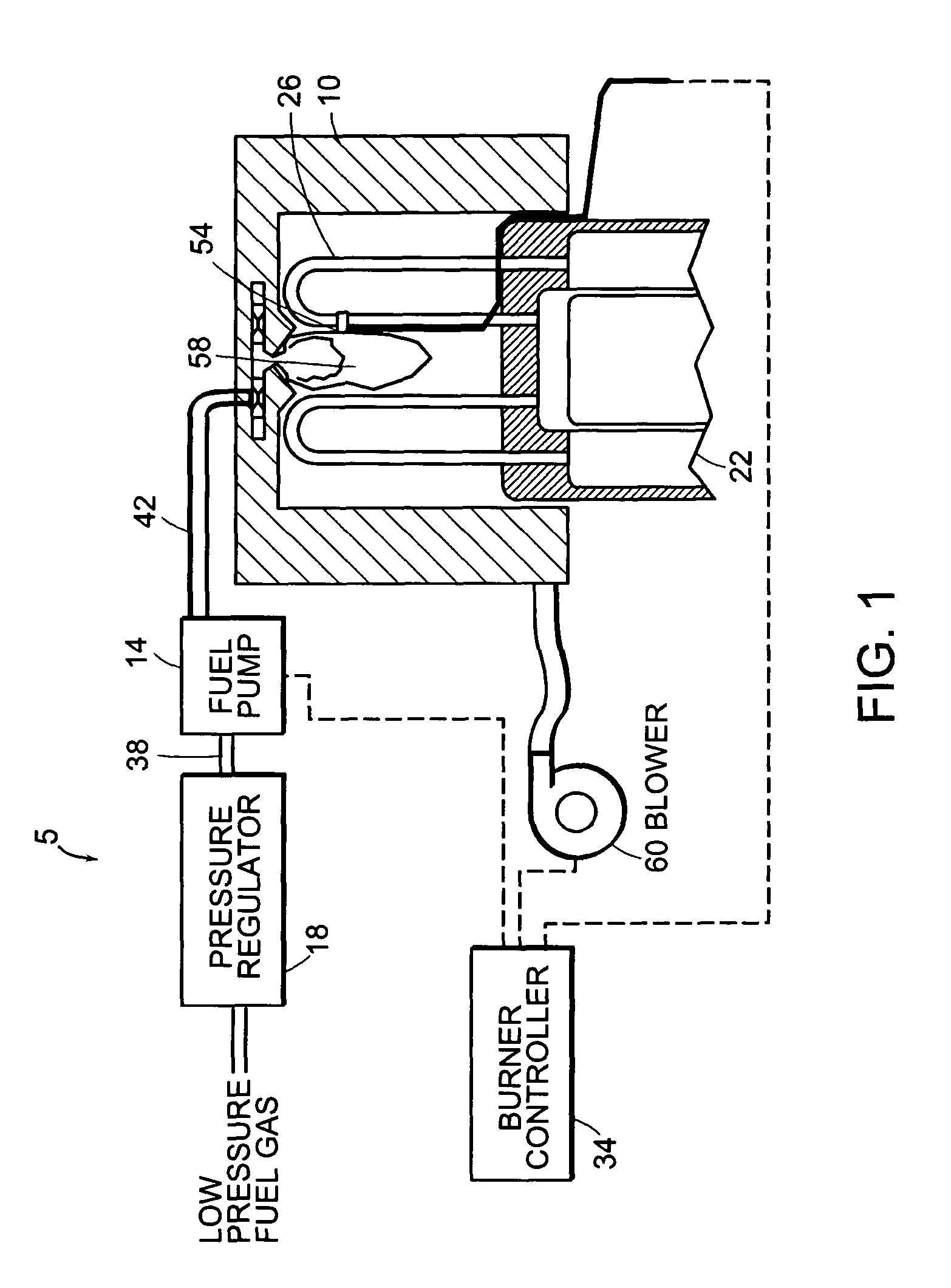

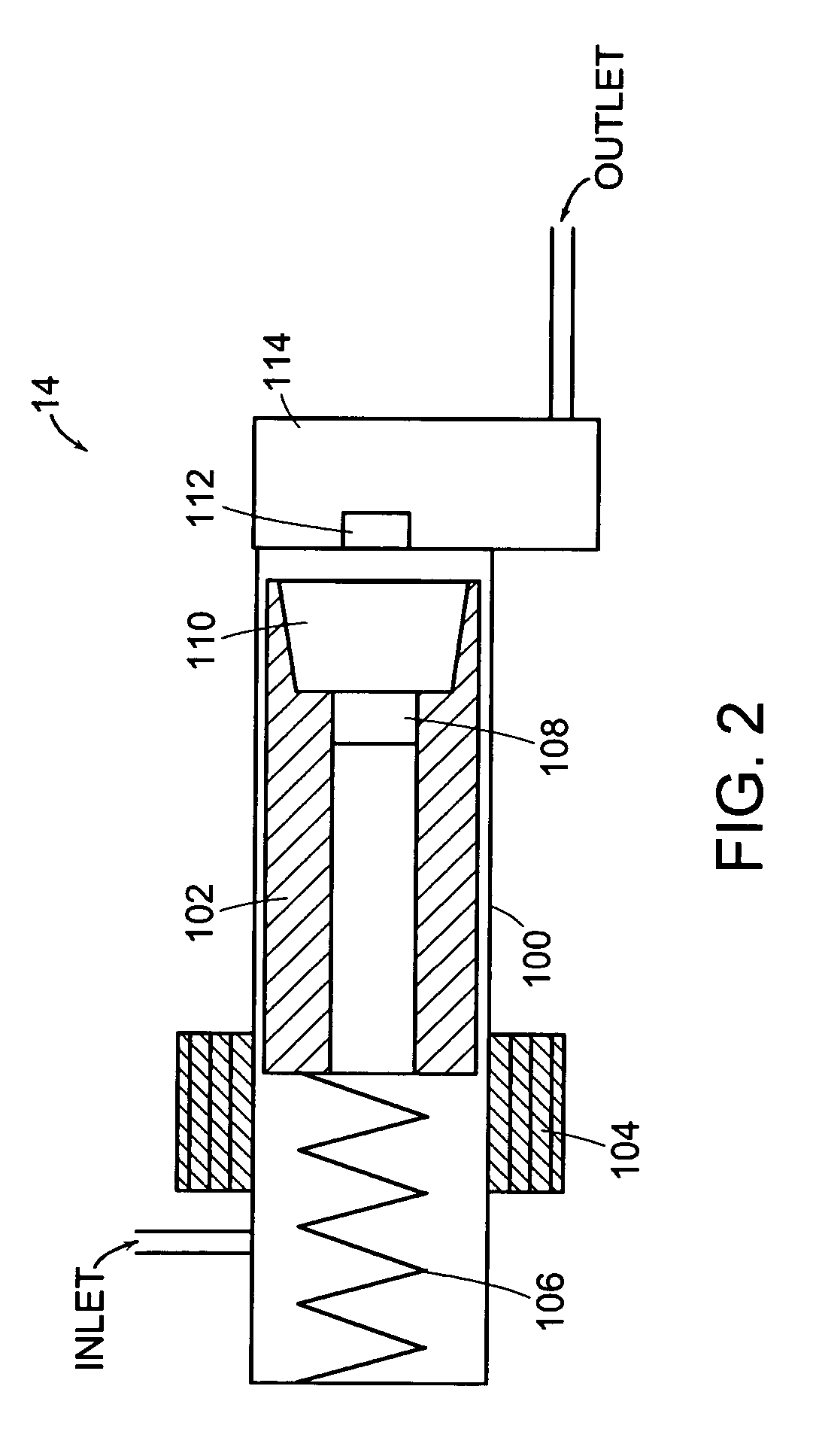

Metering fuel pump

InactiveUS7111460B2Eliminates the throttle plateGaseous fuel feeder/distributionInternal combustion piston enginesDiaphragm pumpCombustion chamber

A device and method for controlling the flow of a gaseous fuel from a fuel supply to a pressurized combustion chamber. A fuel pump is included in the gas train from supply to chamber. The fuel pump increases the pressure of the gas to allow efficient injection into the chamber. The pump is modulated to control the fuel flow. Both alternating current and pulse-width-modulated direct current signals may be used to control the flow. The pump may be a piston pump or a diaphragm pump. Feedback may be provided from sensors that determine operating parameters of the engine and such sensor signals may be used by the controller to maintain a parameter, such as temperature, at a specified value. An acoustic filter can be included in the gas train to significantly reduce gas flow pulsations generated by the pump. This filter improves the uniformity of the combustion process.

Owner:NEW POWER CONCEPTS

Inducer speed control method for combustion furnace

ActiveUS20090044794A1High fire ratingAccurate operationMechanical apparatusDC motor speed/torque controlMotor speedCombustion

In a multistage combustion furnace having a motor driven inducer blower and a pressure sensing device or set of switches for sensing pressure in the combustion gas flowpath through the furnace, a high firing rate blower speed and low firing rate blower speed are set based on the blower speed setting required for a medium firing rate. Each particular furnace, having its own pressures and combustion gas resistance to flow characteristics, may be provided with a database of inducer blower motor speeds required to achieve predetermined pressures in the combustion gas flowpath for a variety of combustion gas venting systems generating such resistance.

Owner:TRANE INT INC

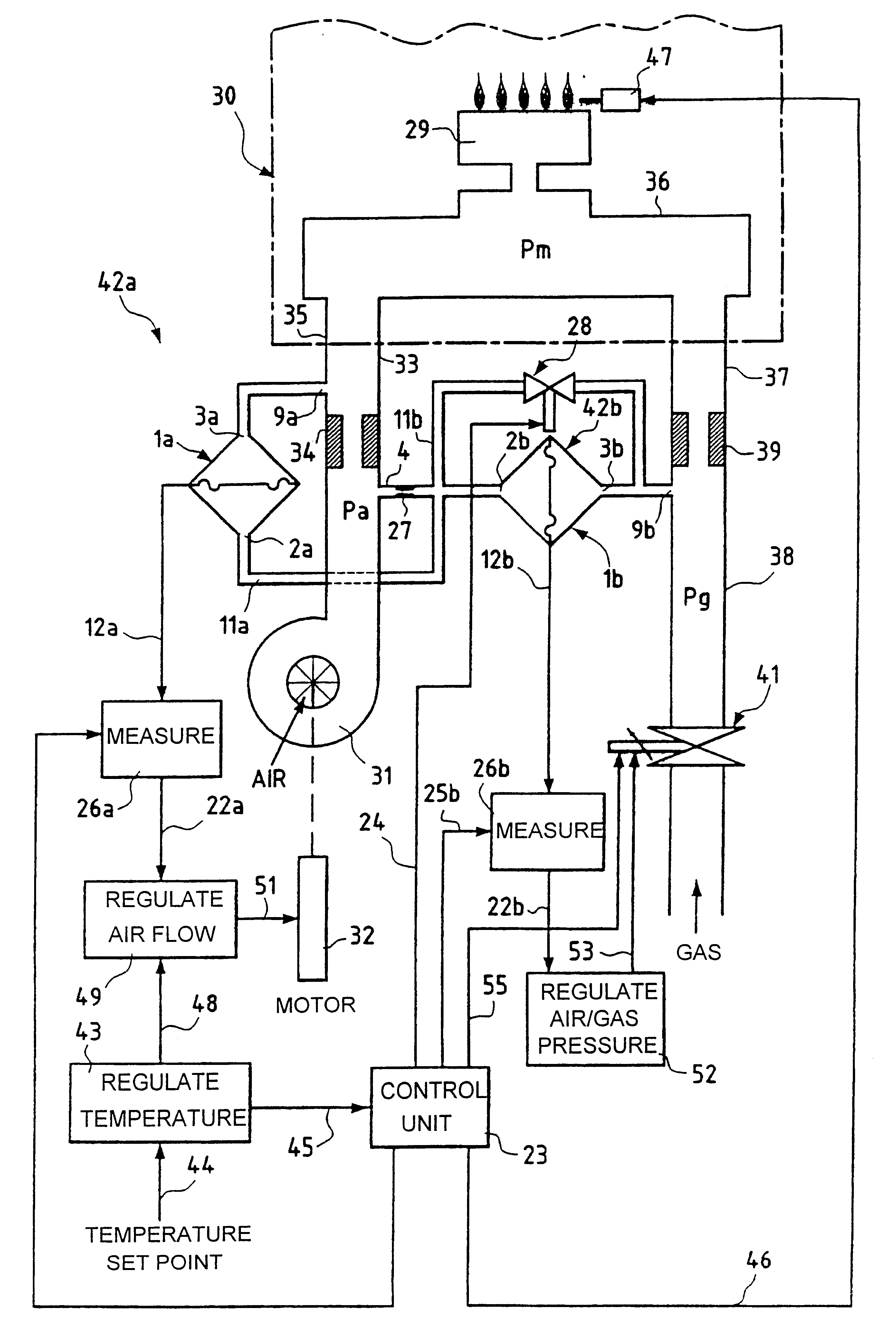

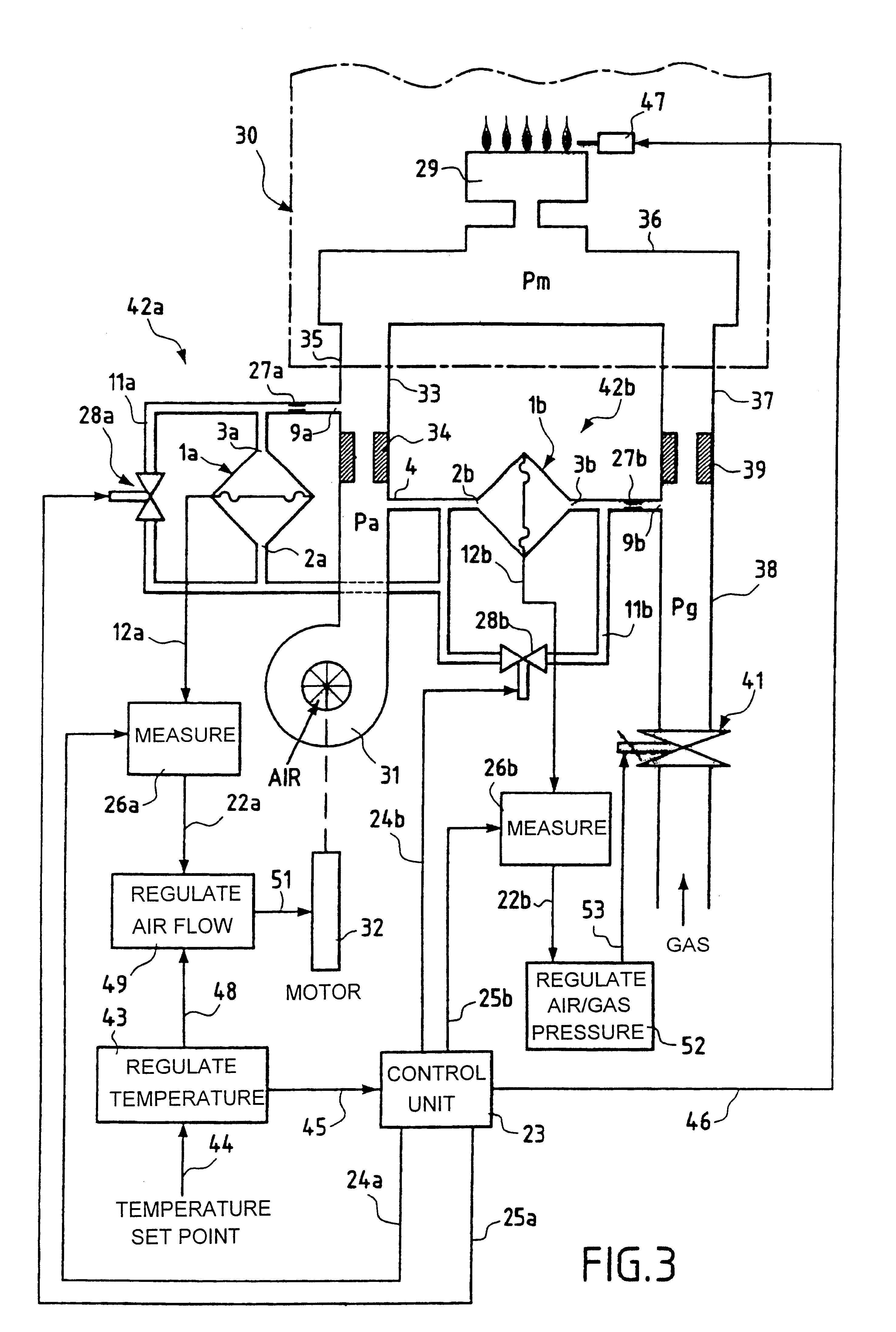

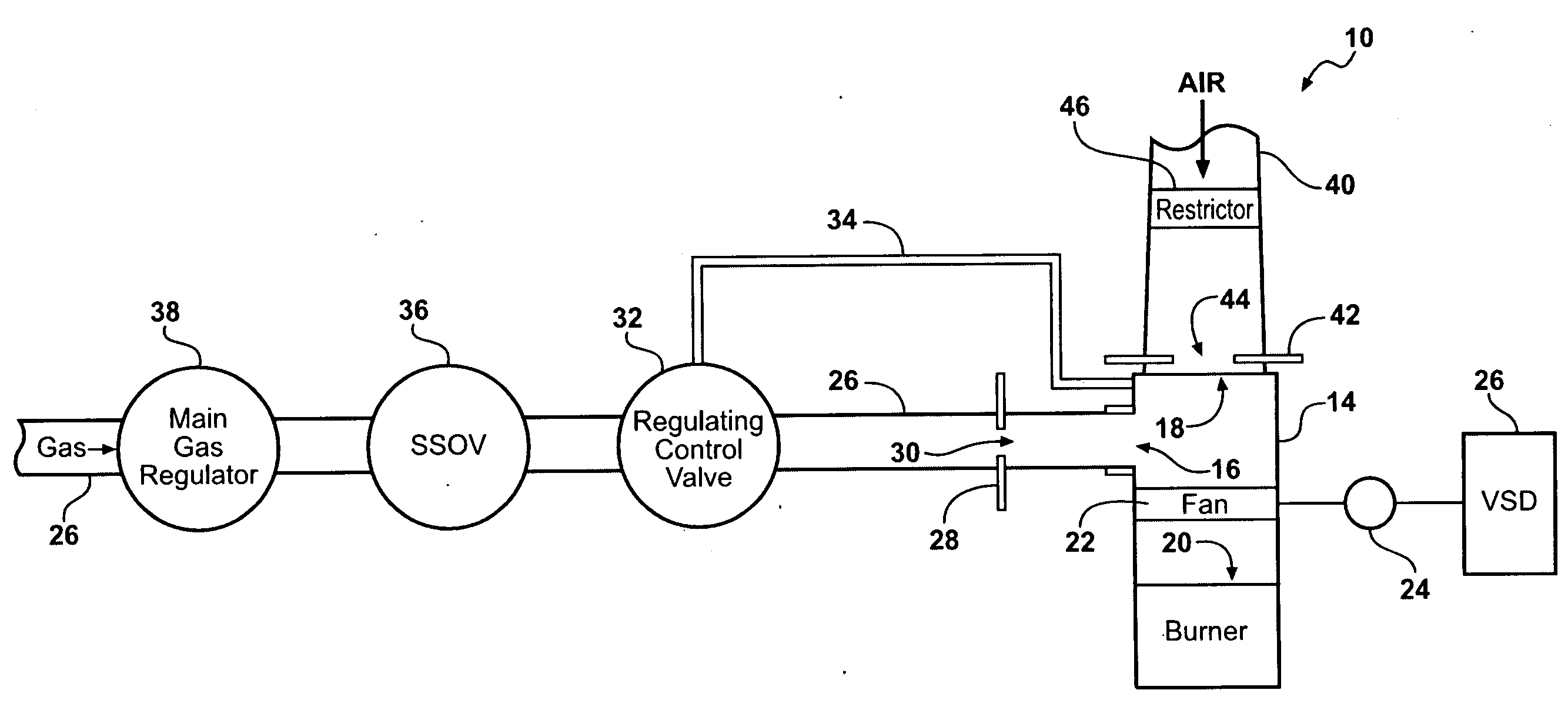

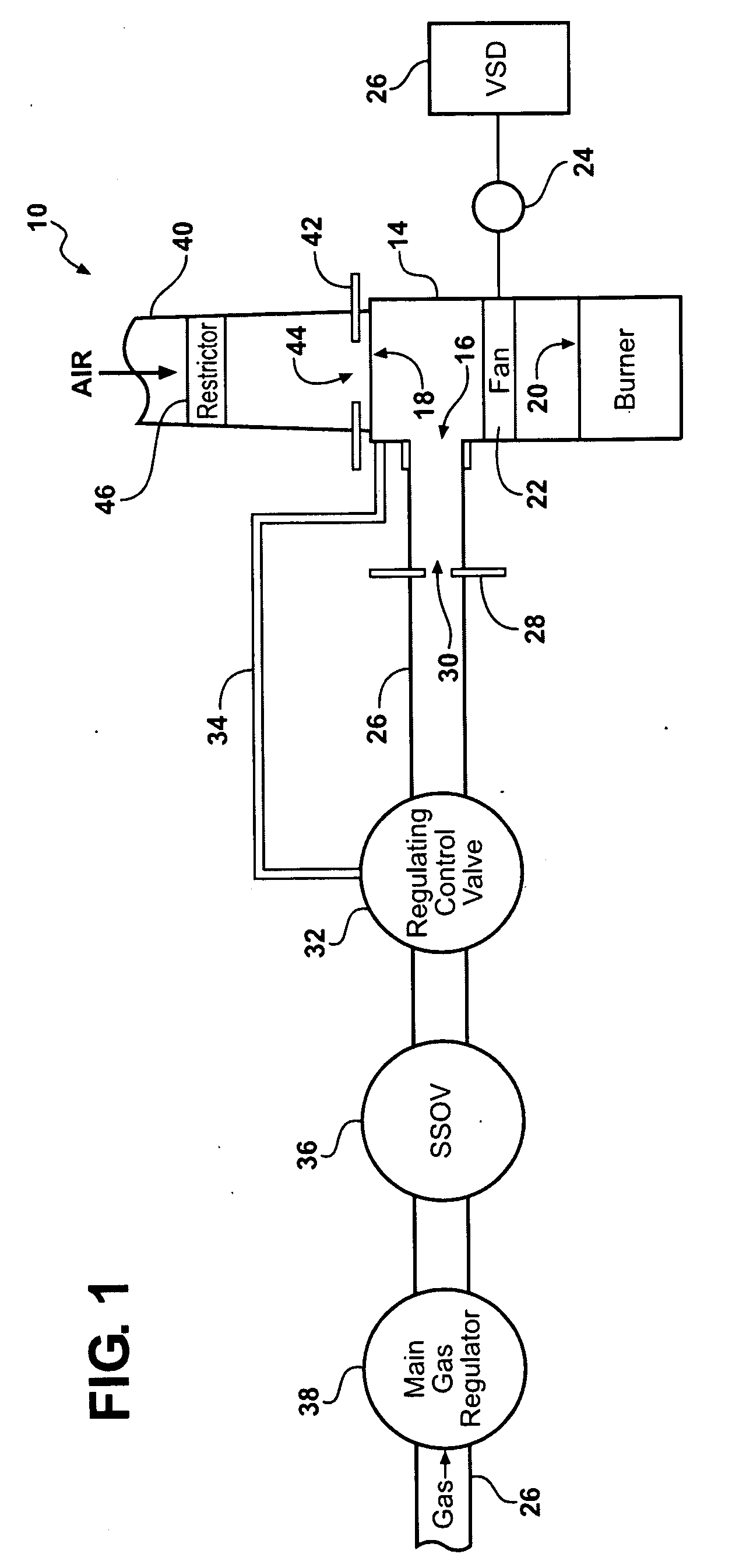

Premix Burner Control System and Method

InactiveUS20090197212A1Reduce flow rateReduce air pressureFuel supply regulationCombustion ventilatorsCombustorControl system

A fan modulated premix burner control system includes a regulating control valve for regulating the pressure of gas fed to a premix chamber. The pressure of the gas is based on the pressure of air also fed into the chamber to produce a constant air / fuel ratio. The system also includes an air restrictor for reducing the pressure of the air to permit operation of the burner at low fan speeds.

Owner:MAXITROL

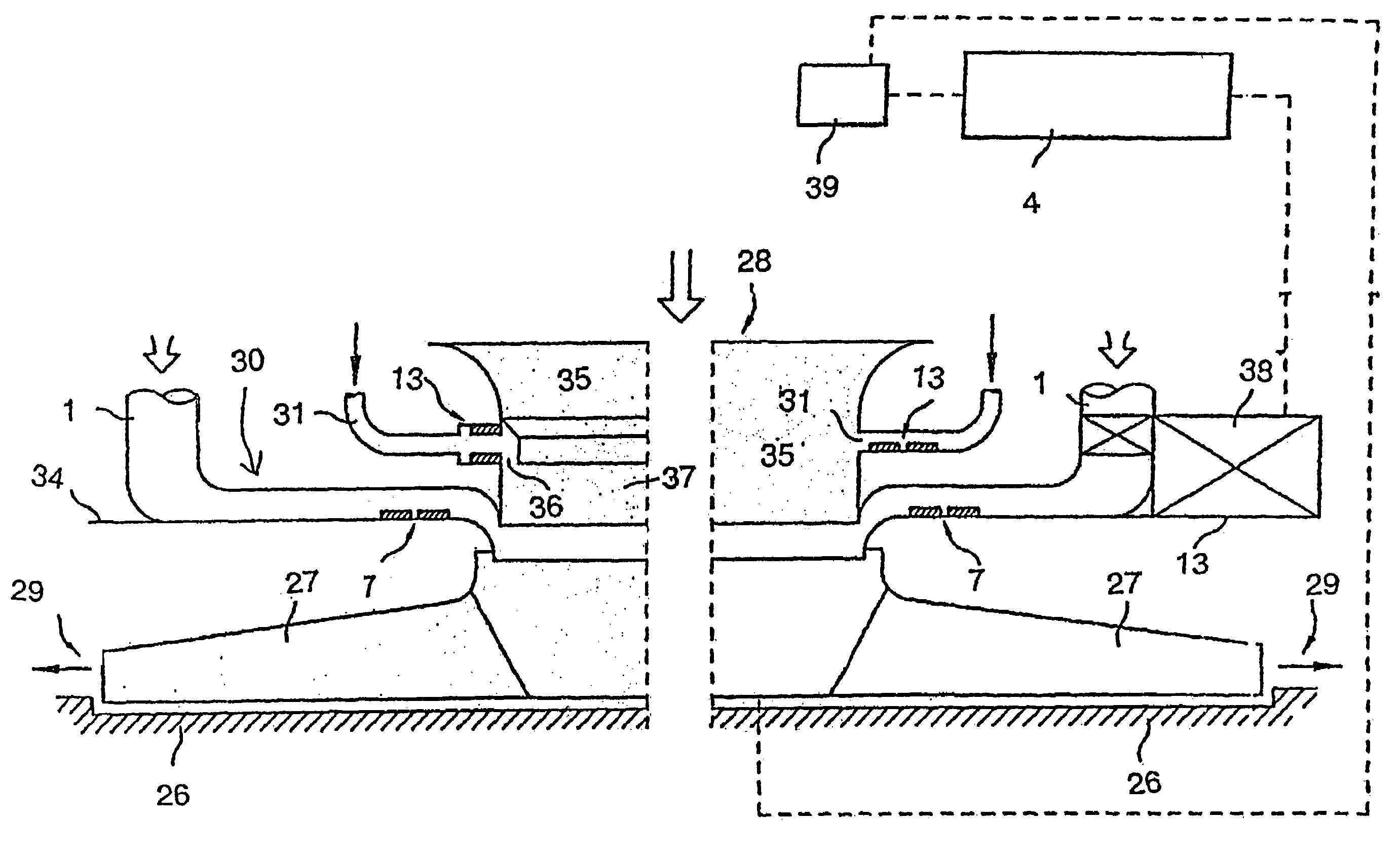

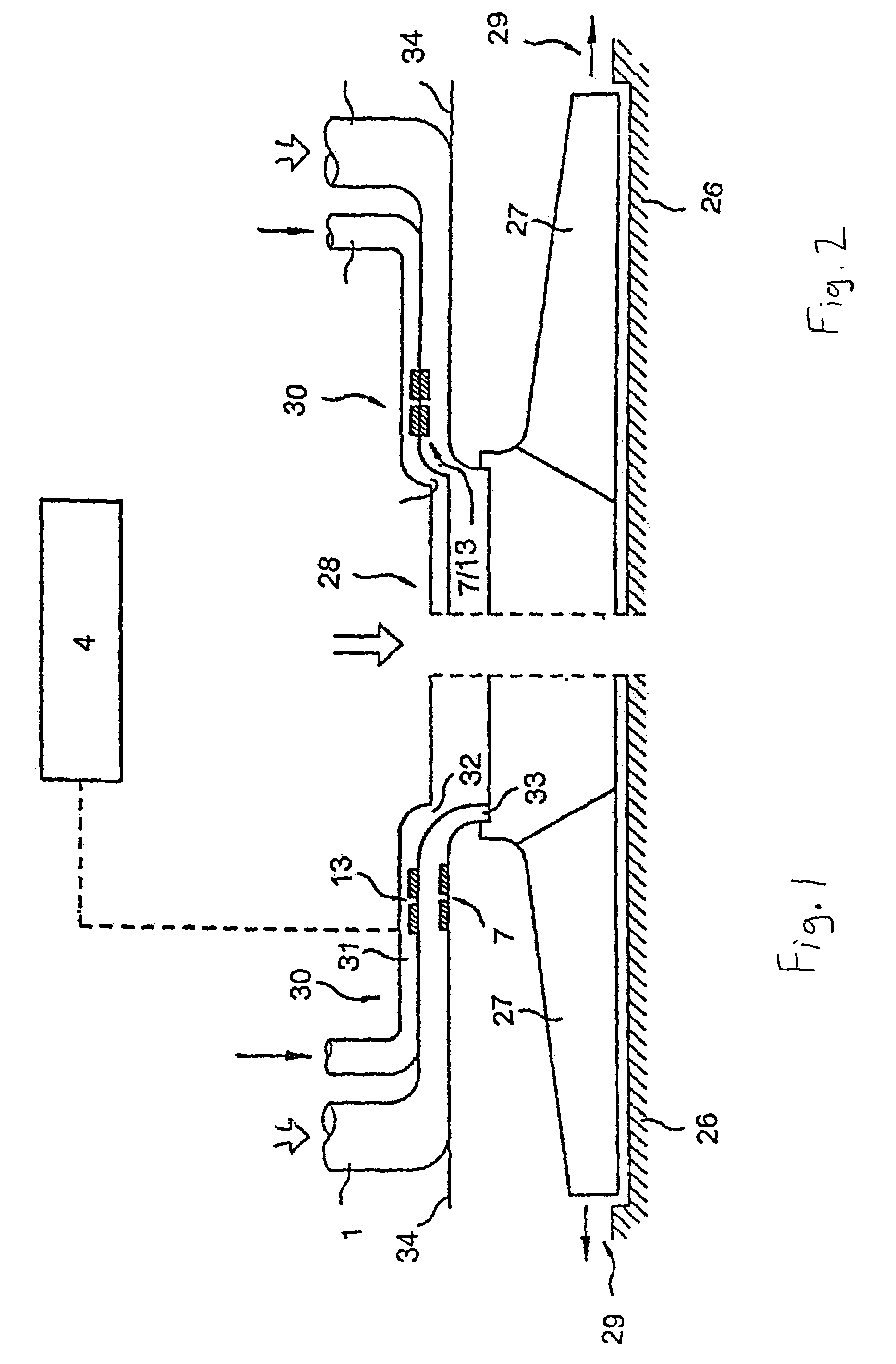

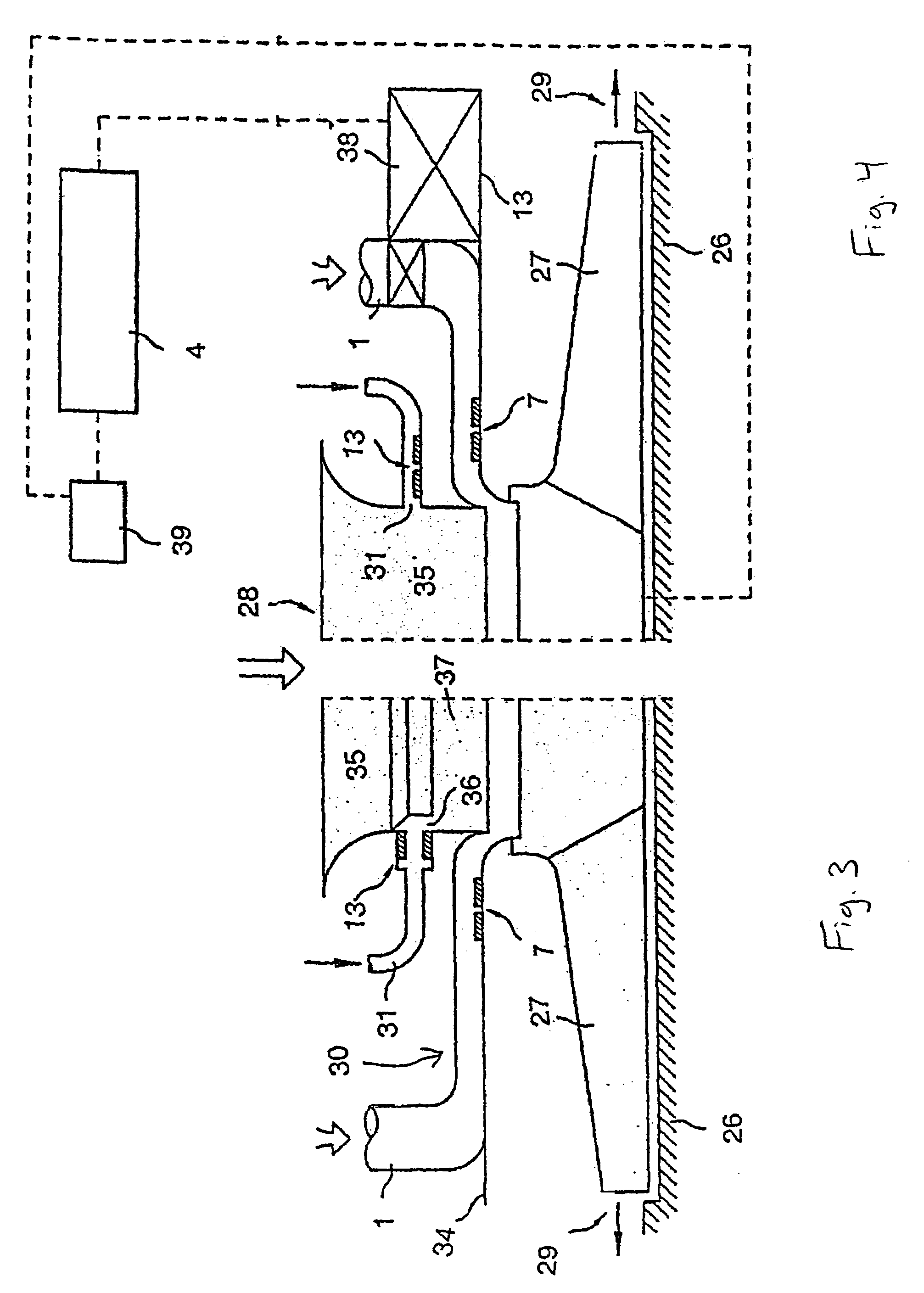

Blower for combustion air

InactiveUS7223094B2Work lessContinuous suctionFuel supply regulationAir supply regulationImpellerCombustion

A blower for combustion air in a wall / floor furnace is provided that includes a blower housing (26), and blower wheel (27), with an air inlet (28) and an air outlet (29), and with a fuel feeder line (1) for fuel, wherein a mass current sensor (13) for determining the air mass current is located on the air inlet (28), which is functionally connected with a data processing device (4) and sends signals to the data processing device for calculation of a ratio of combustion medium to combustion air in dependence on a desired heating capacity.

Owner:EBM PAPST LANDSHUT

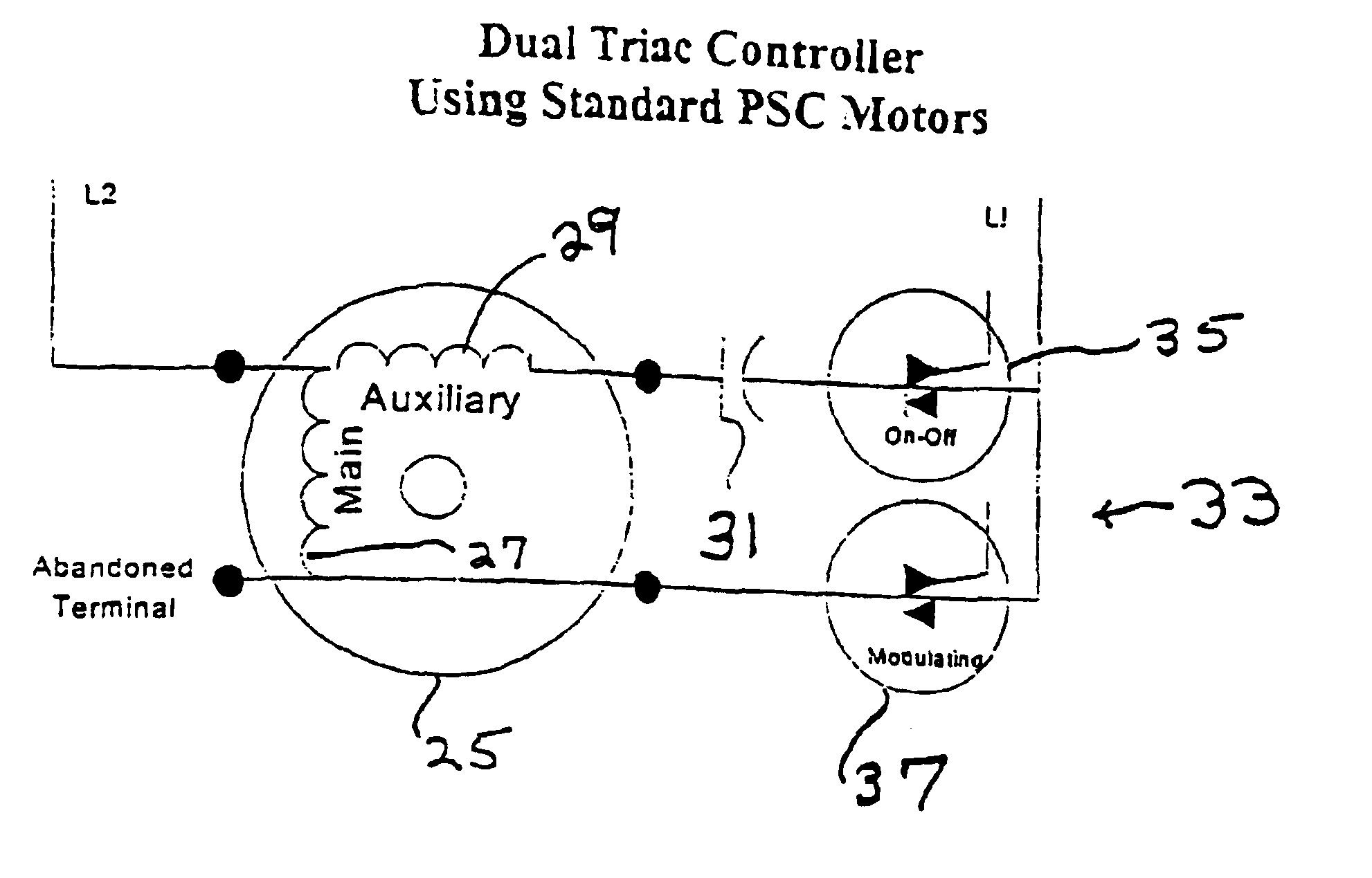

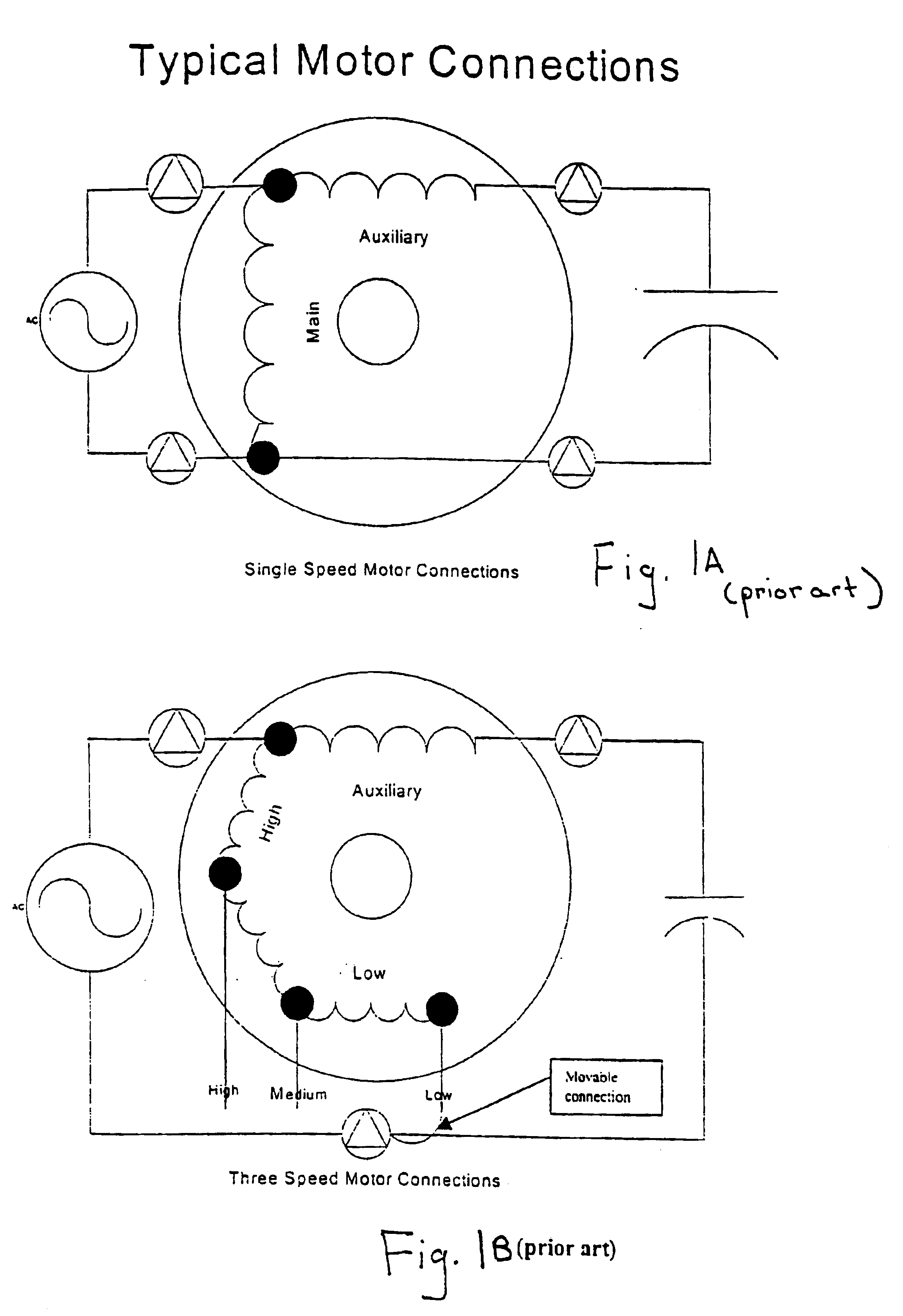

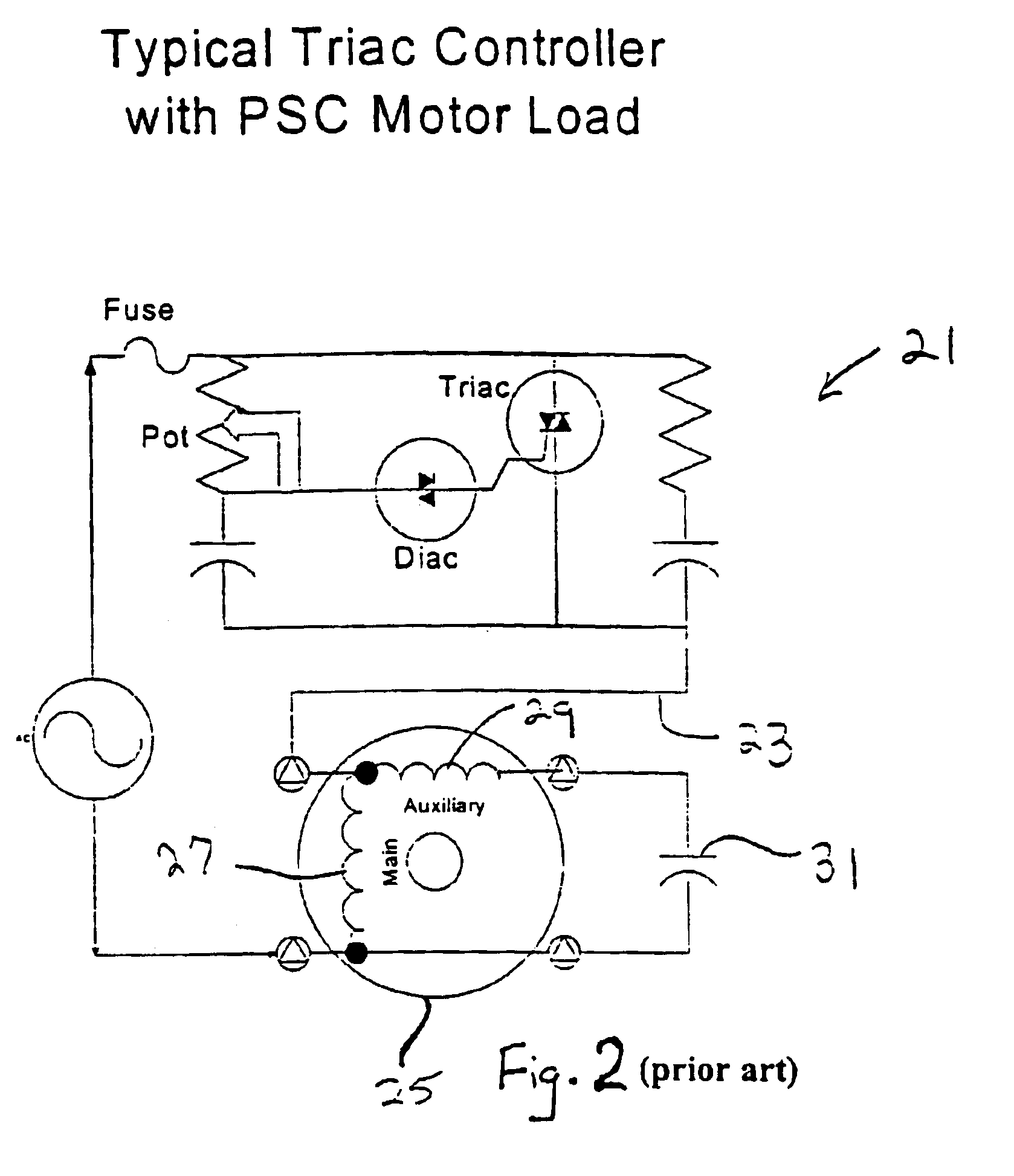

Variable speed controller for air moving applications using an AC induction motor

InactiveUS6864659B2Easy to modifySophisticated control systemSingle-phase induction motor startersFuel supply regulationMotor speedDIAC

An HVAC system has at least one variable speed controller for an AC induction motor, especially of the Permanent Split Capacitor (PSC) type. The variable speed controller provides switched power via a modulating triac to the main coils of the motor and constant power via an on / off triac to the auxiliary coils during operation. A large value capacitor is placed in line with the auxiliary coils to reduce power consumption and current draw over that of known systems. Power to the motor can be turned off to provide for motor speed sensing through monitoring the frequency of a generated voltage when the power is turned off. Frequency-based motor speed sensing is accomplished by shutting off all current to the motor and measuring zero crossings on the generated voltage of the decaying magnetic field. The controller can be easily retrofitted onto existing motors. An optional controller bypass is provided to run the motor at rated speed in case of controller failure.

Owner:HVAC MODULATION TECH

Method and apparatus for controlling combustion in a burner

A method and apparatus that applies corrections to the mass flow rate of combustion air into a gas or oil-fired, forced-draft burner, and thus provides for correcting the air-fuel ratio, by directly measuring the combustion air temperature and / or the barometric pressure of the combustion air, and using these measurements to develop a fan speed drive signal that corrects the volume of air inlet to the burner system without the use of the complex and expensive fully metered control systems, or elaborate feedback systems, or systems that require real-time combustion analysis, and the like.

Owner:WEBSTER COMBUSTION TECH LLC

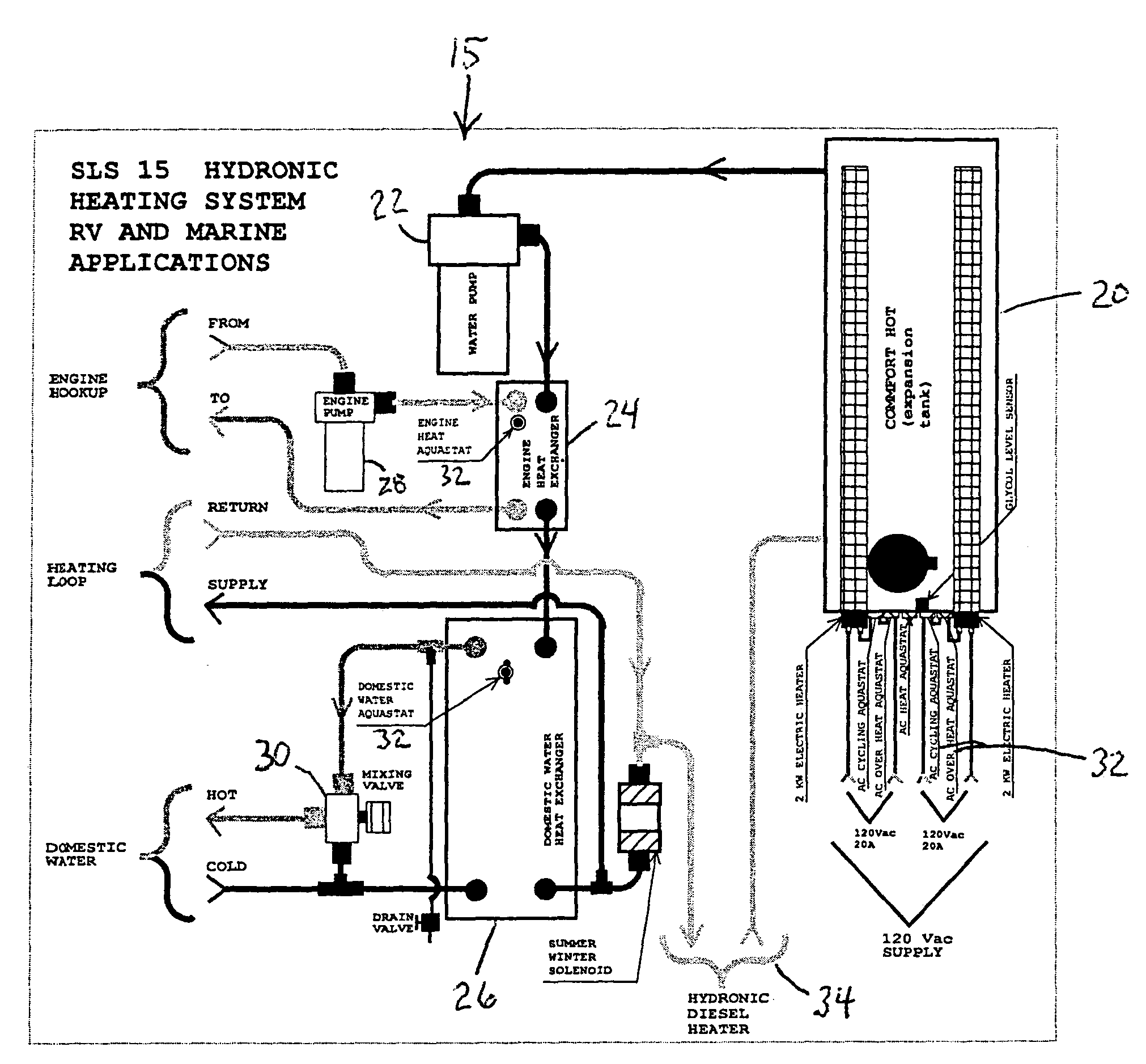

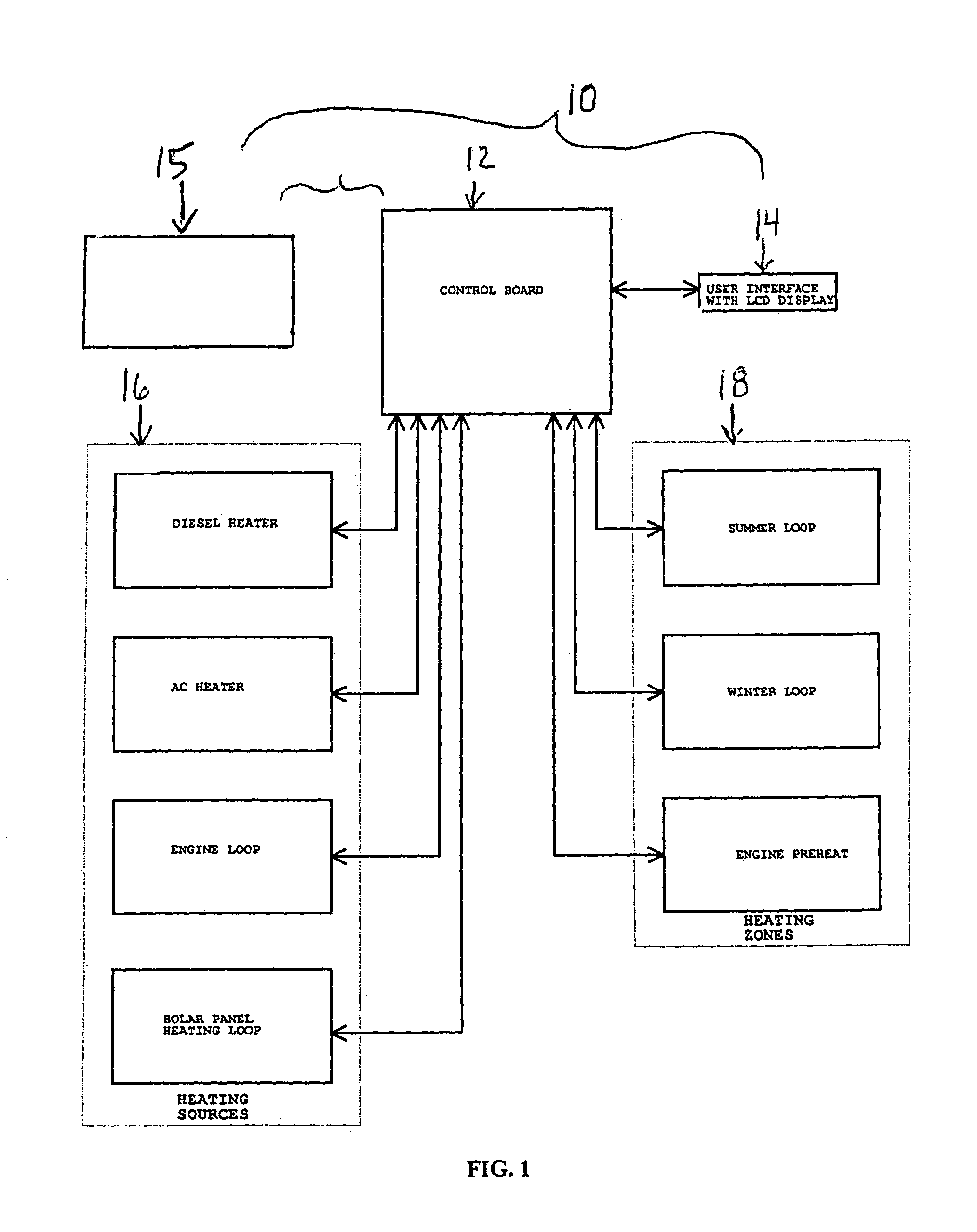

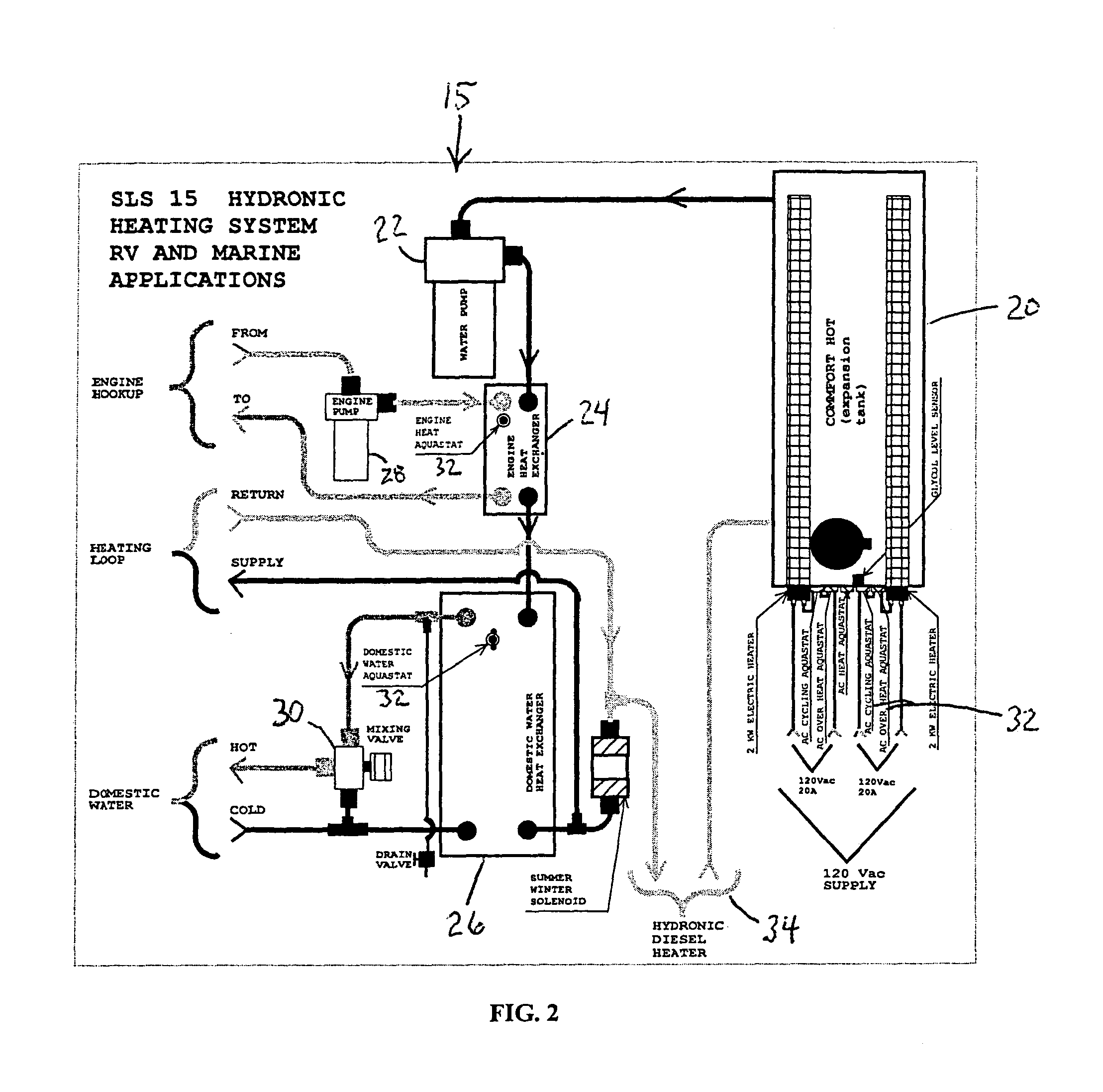

Heating system

InactiveUS7284710B2Rule out the possibilityMaximizes capability and efficiencySolar heating energyWaste gas energyHeat managementEngineering

A heat management system is capable of managing unlimited hydronic heat sources and unlimited heating zones, each located within a desired area and each controlled by temperature sensors. The system uses plural system heating sources to heat a heating solution (preferable glycol-based) that is either heated directly or through a liquid-to-liquid heat exchanger. The heating solution is passed through various plumbing configurations to heat domestic water for users and to heat zones or areas in which user will live. The heat management system of the invention may be used for several applications including RV, marine and home hot water and heating applications.

Owner:NORTH WEST RES & DEV

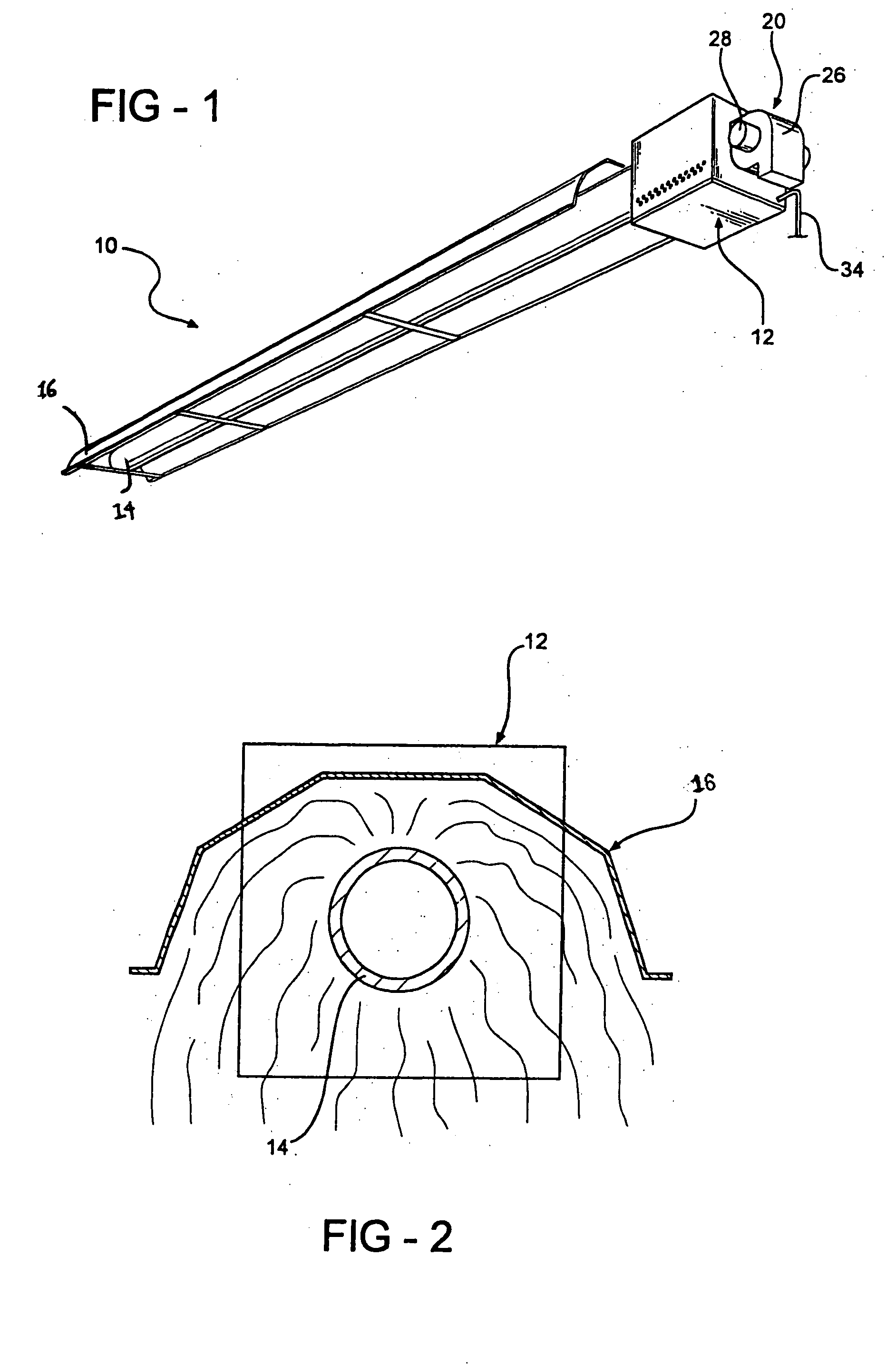

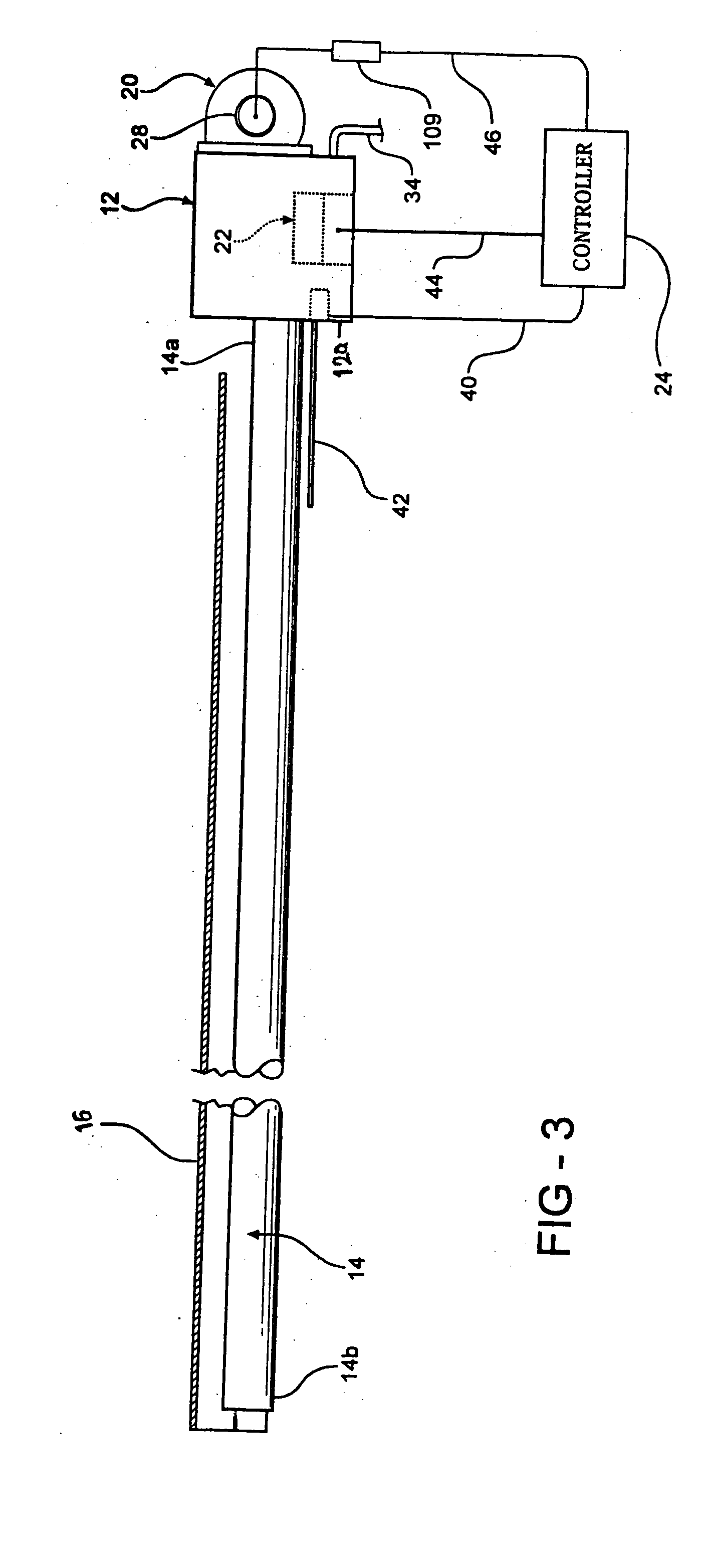

Variable low intensity infrared heater

ActiveUS20050175944A1Improve liquidityEasy to controlDomestic stoves or rangesPilot flame ignitersRadiant heaterCombustor

A radiant heater including a burner having an inlet for receiving an air and gas mixture and an exhaust for emitting exhaust gases generated by combustion of the air and gas mixture within the burner, an elongated radiant heating tube having an inlet for receiving the exhaust gases emitted by the burner, a gas flow control assembly for controlling the flow of gas to the burner, and a blower for controlling the flow of air to the burner. The blower comprises a two-stage blower including a motor having a low winding corresponding to a low blower speed and a high winding corresponding to a high blower speed. The gas flow control assembly comprises a two-stage regulator or two stage two-stage valve having a low setting for delivering a low gas flow to the burner and a high setting for delivering a high gas flow to the burner.

Owner:SOLARONICS

Variable input radiant heater

A variable demand radiant heating system applies variable burner control technology to singular or mulit-burner radiant heating systems. A radiant heater consists of a burner connected to an elongated heat exchanger tube. The combustion air is supplied to the burner via blower or draft inducer. Fuel is supplied to the burner via fuel regulator. Fuel and air are mixed in burner and communicated to the inlet end of the heat exchanger tube. Spent products of combustion are expelled from the heat exchanger at the outlet end. The burner controls continuously vary gas supply pressure (volume), via a modulating gas regulator, and combustion air pressure (volume), via a variable speed blower, communicated to the burner mixing chamber, which in turn, varies the burner input on a continuous curve (not stepped or staged) within a pre-determined input range as heat demand varies.

Owner:ROBERTS GORDON INC

Intelligently-controlled catalytic converter for biofuel-fired boiler

An intelligently controlled catalytic converter automatically monitors various operating parameters, such as water jacket temperature, catalytic input temperature, catalytic converter output temperature, oxygen level, ambient temperature, ambient humidity and / or ambient barometric air pressure, of a biofuel-fired device and automatically controls dampers, blowers and electric heaters in the device.

Owner:BIOMASS CONTROLS PBC

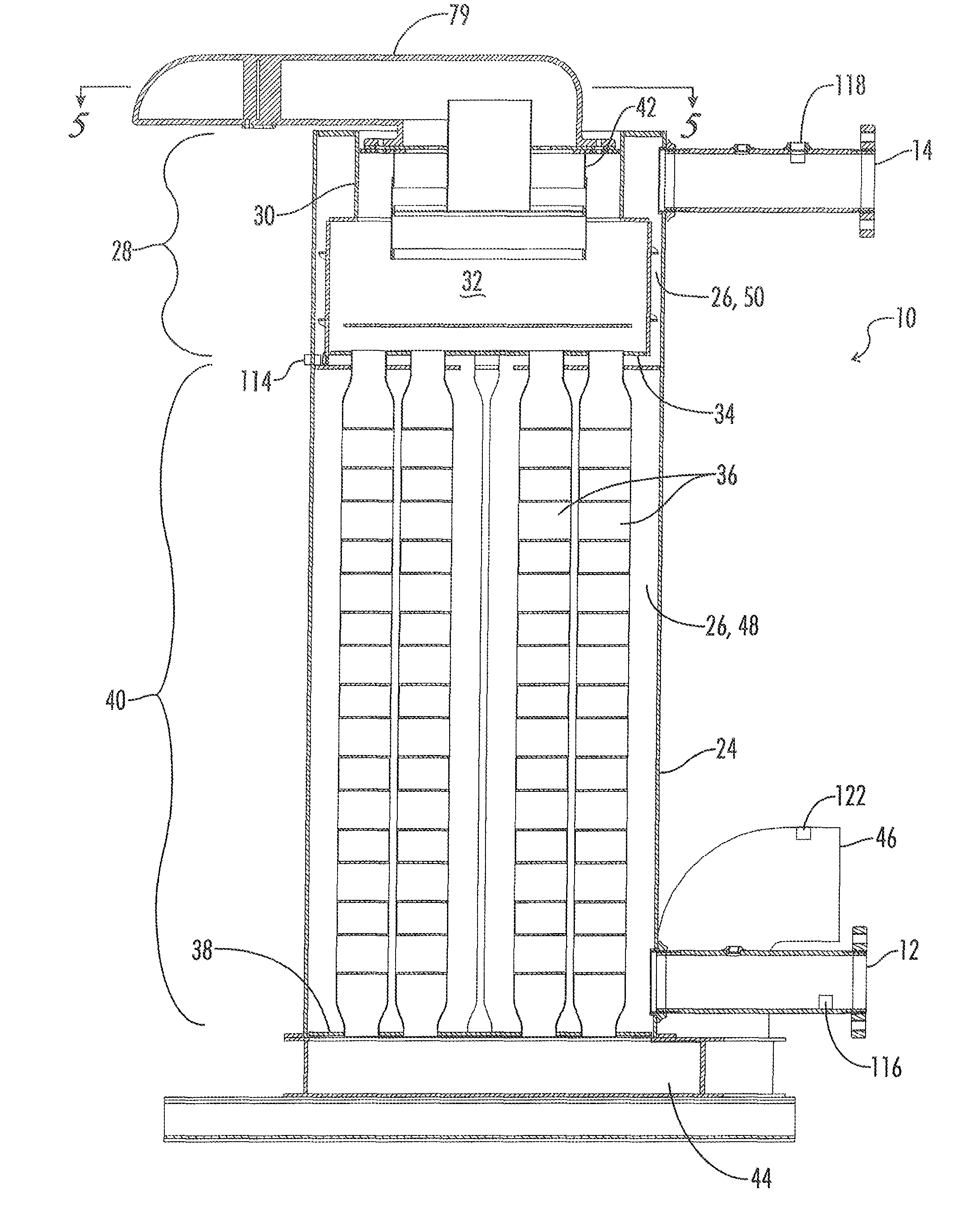

Gas fired modulating water heating appliance with dual combustion air premix blowers

ActiveUS8286594B2Avoid condensationIncrease the turndown ratioWater circulationEnergy efficient heating/coolingCombustorEngineering

A water heating apparatus uses a low range blower assembly and a high range blower assembly, each providing a variable flow of premixed fuel and air to a burner assembly. Appropriate choice of the operating ranges of the blower assemblies can provide a high turndown ratio approximately equal to the product of the turndown ratios of each of the individual blower assemblies. Turndown ratios as high as 25:1 are achievable.

Owner:LOCHINVAR

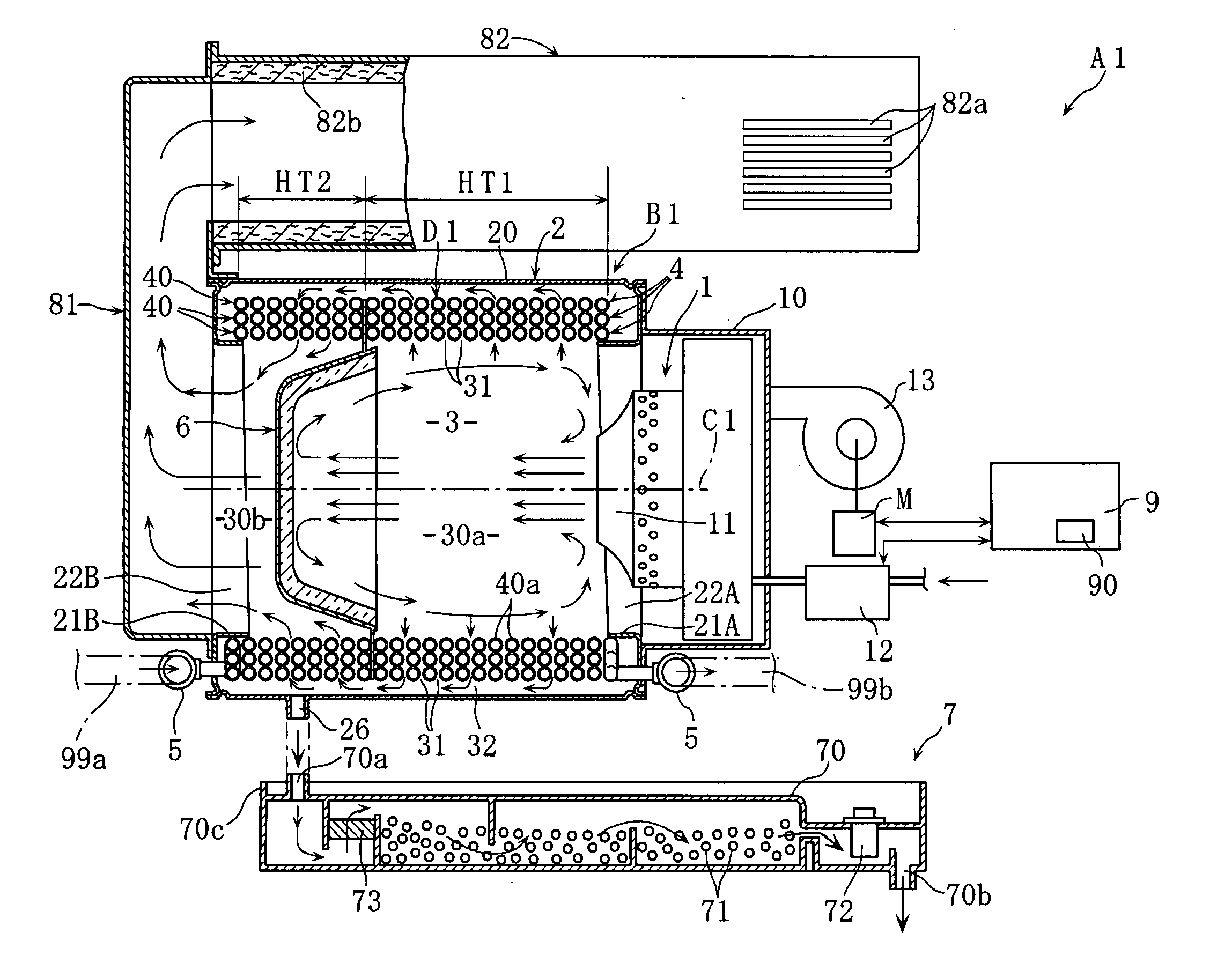

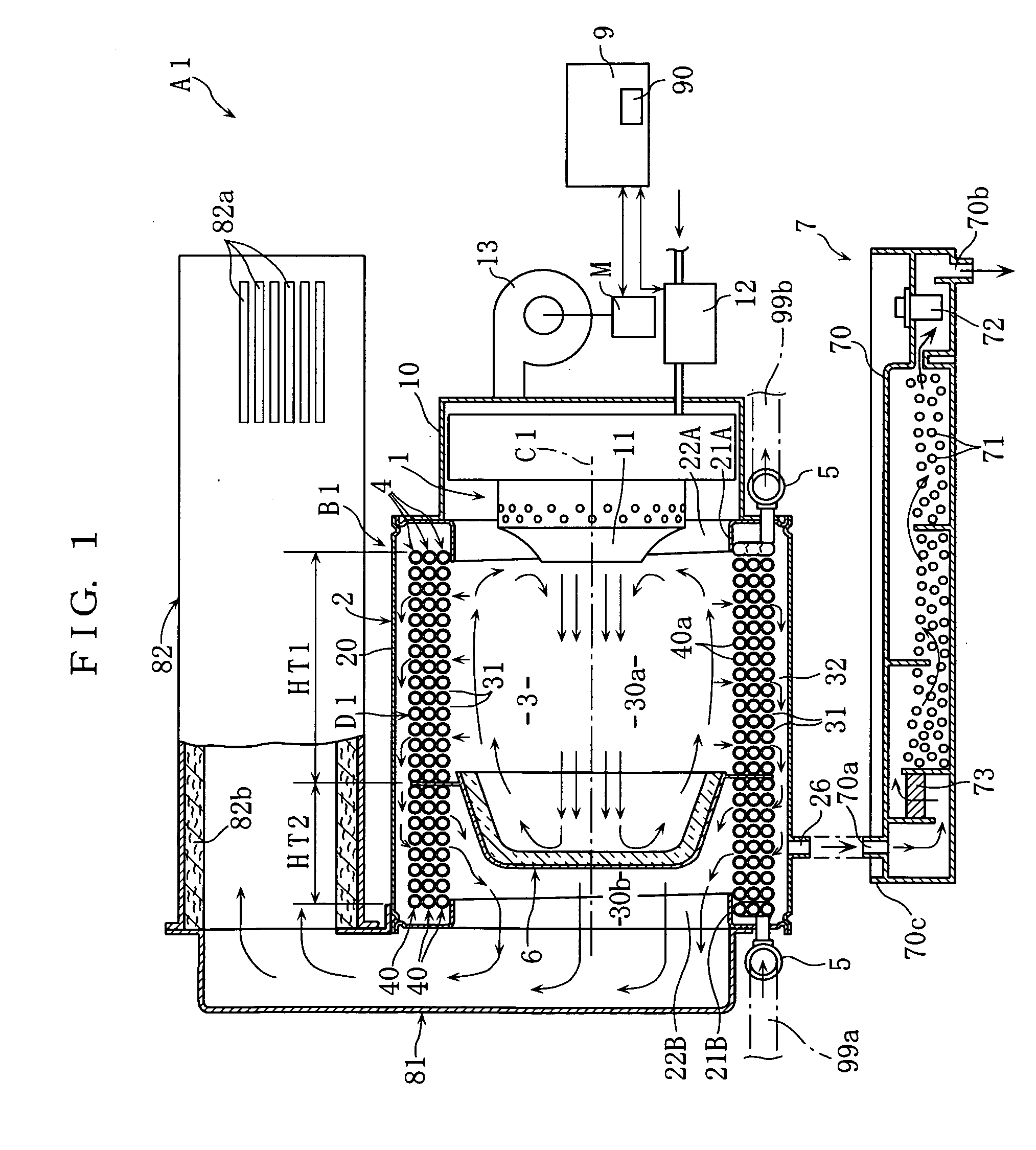

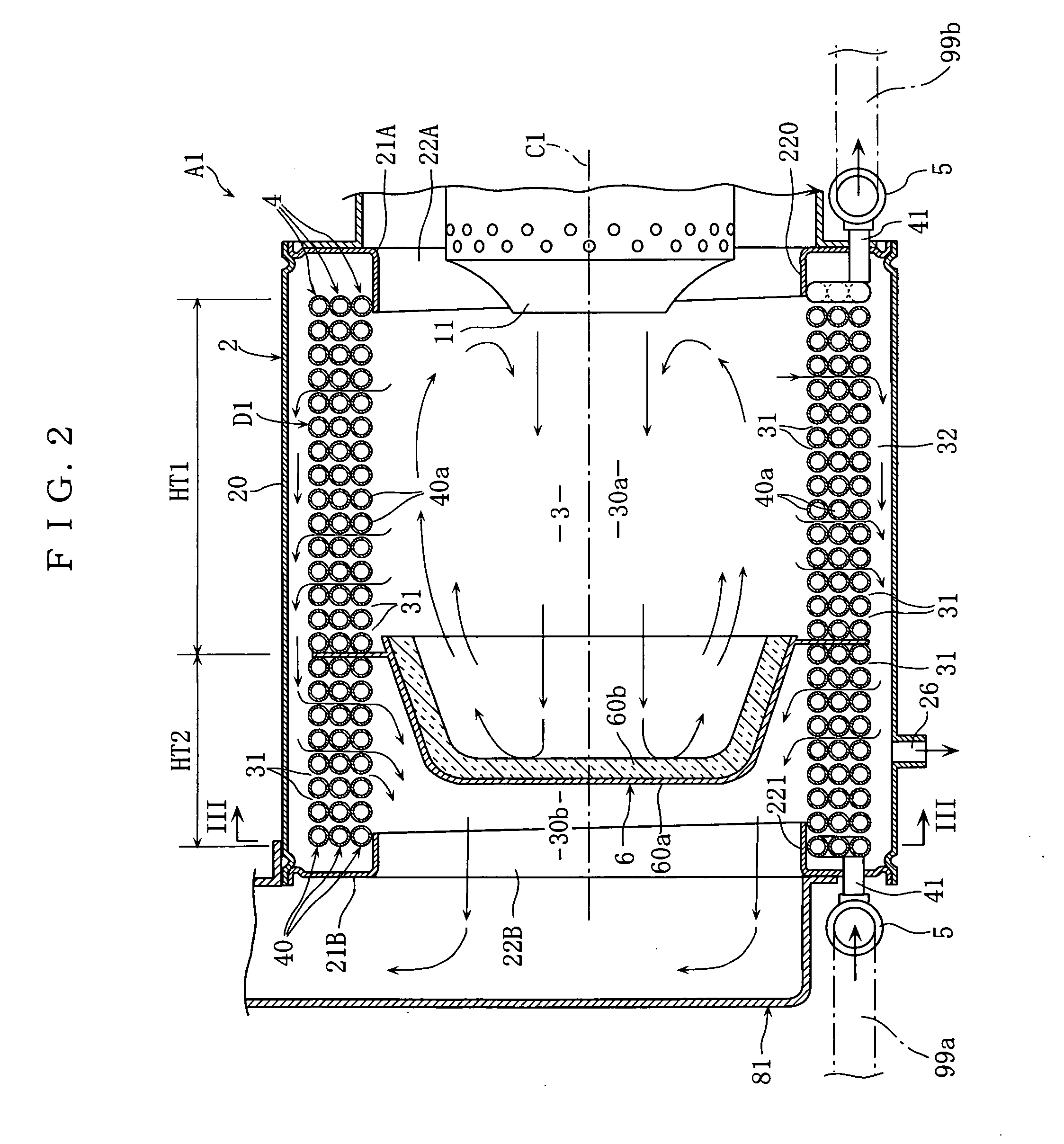

Water heater

A first period during which drain is not substantially generated on a surface of a water tube (4) of a heat exchanger (B1), and a second period as a transition during which an amount of drain on the surface of the water tube (4) is increased are provided. There are a plurality of kinds of fan-controlling data in which operation control contents of the fan (13) in the first and second periods in correspondence with change of conditions of entering water temperature or combustion level of the burner (1). The fan-controlling data are stored in a data table (90) of a controller (9). The controller (9) controls the fan (13) in accordance with the data, and an initial air-fuel ratio of combustion driving of the burner (1) is stabilized.

Owner:NORITZ CORP

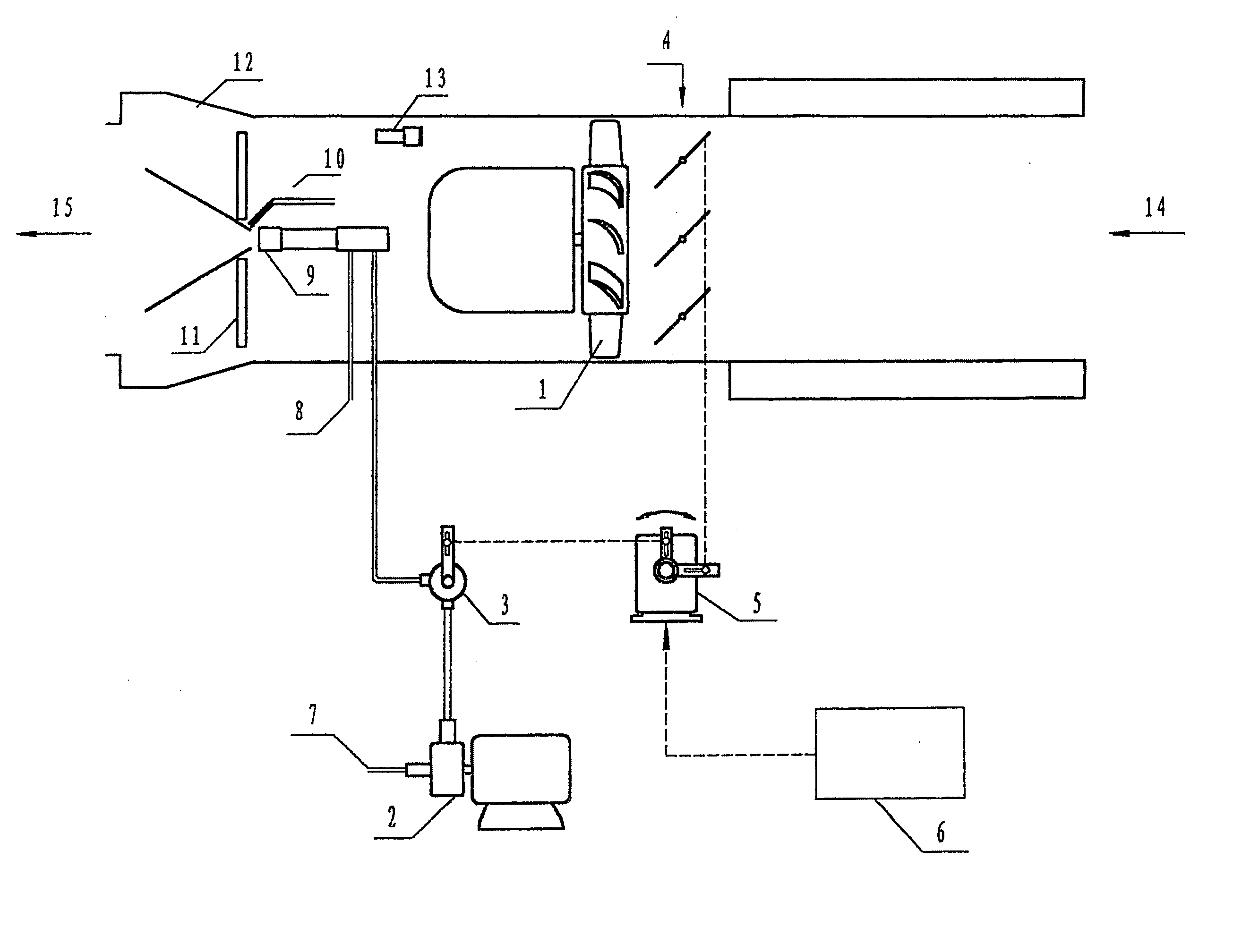

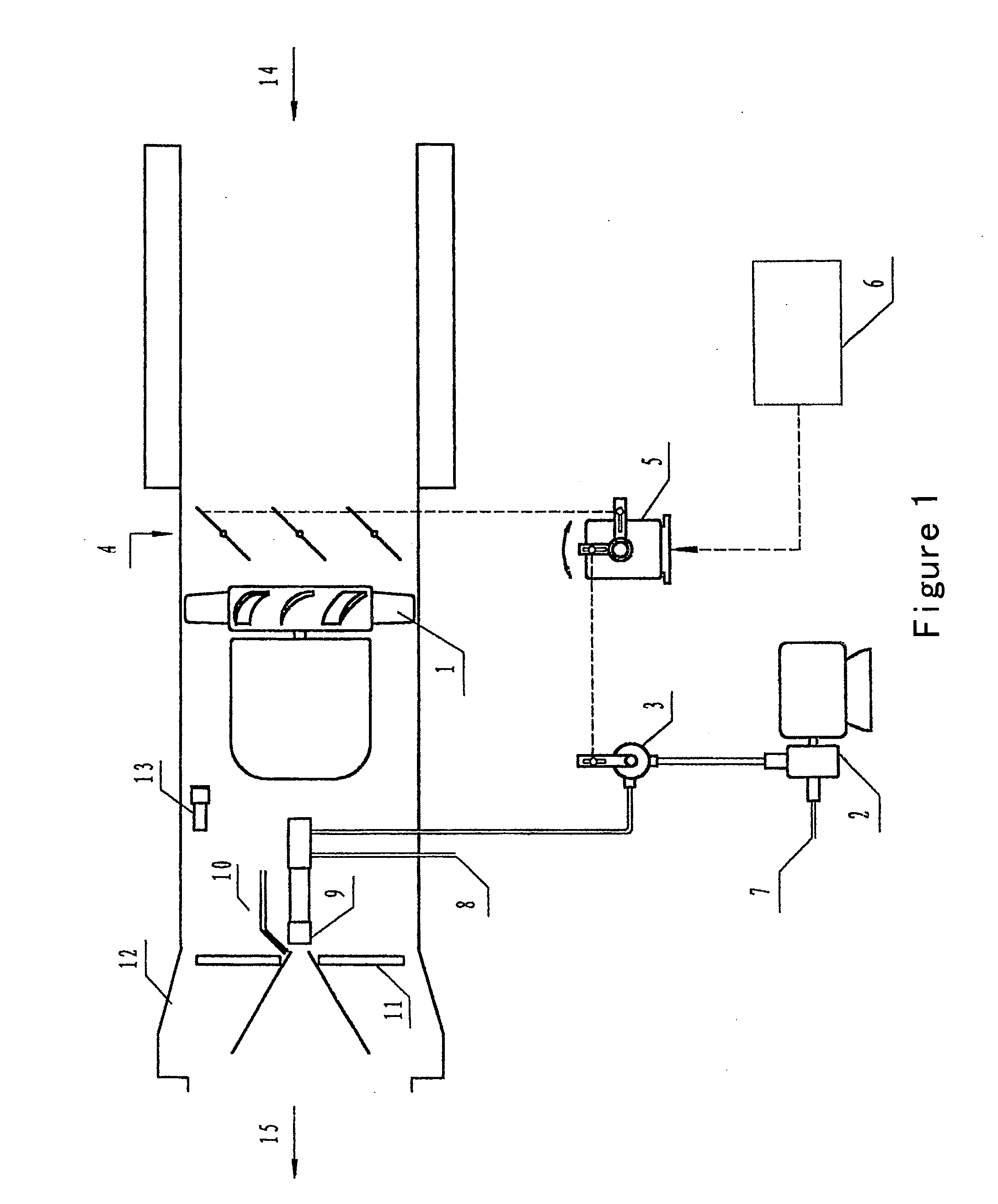

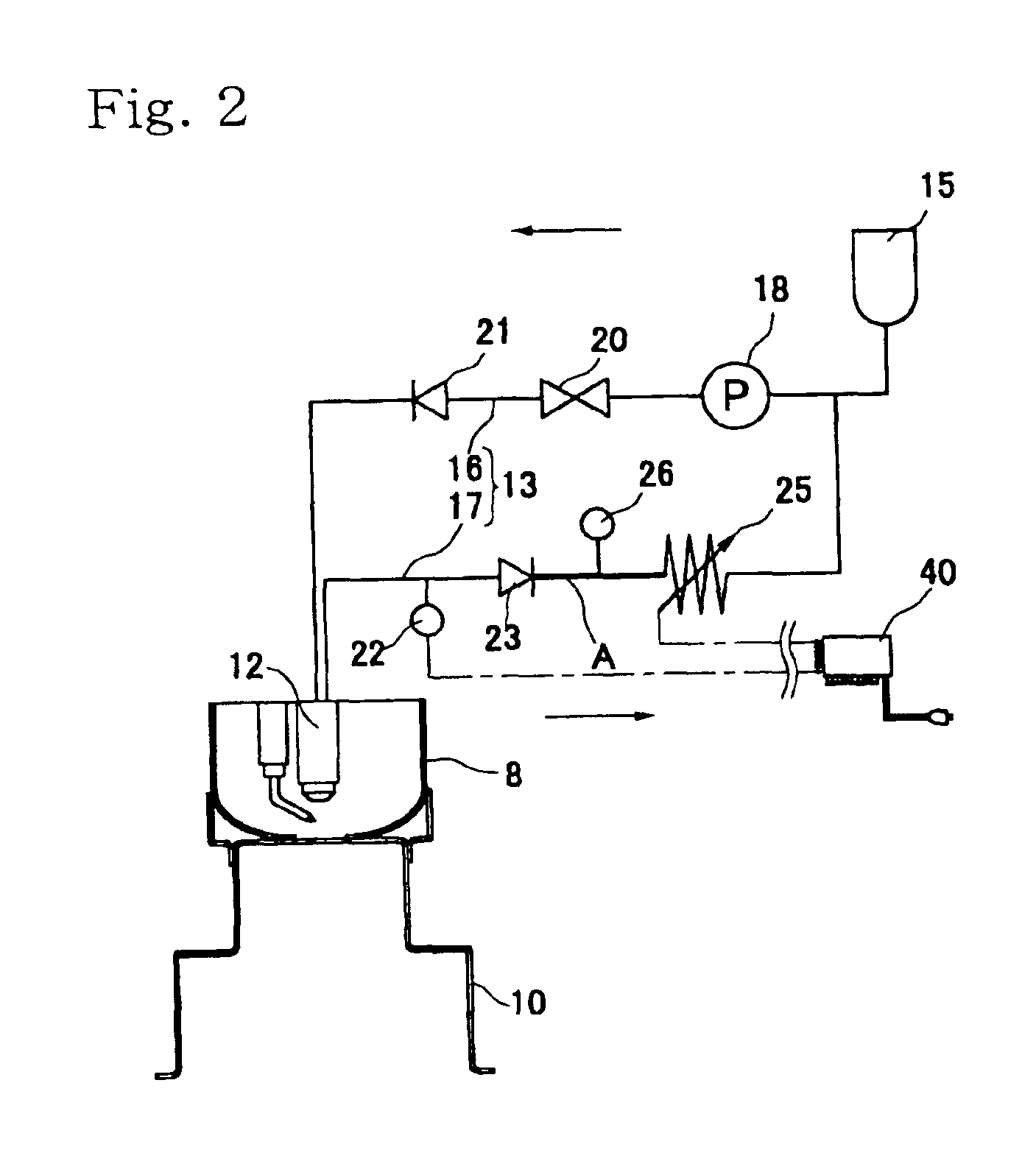

Autocontrol burner and a combustion control method

InactiveUS20060068347A1Improve efficiencyReduce energy consumptionBurnersFuel supply regulationMotor speedCombustor

A combustion control method for a burner comprises: the fuel supplying means outputs a given amount of fuel oil to the fuel oil atomizing means; the fuel atomizing means sprays fuel atomized gas; said gas is ignited by the igniter; the amount of air is sent to facilitate burning by the air blowing means; the outputting flow rate of fuel oil and the flow rate of air are adjusted automatically, simultaneously and proportionally by controlling the rotating speed of the electric motors of the fuel supplying means and the air blowing means. An autocontrol burner comprises a main body, an oil pump (2), a blower fan (1), a spray gun (9) and an ignition gun (10), and further comprises a programmable control unit (18), motor speed controller (16,17) and a signal acquisition assembly. The output port of the signal acquisition assembly is connected with the input port of the programmable control unit (18). The oil pump (2) and the blower fan (1) are connected with the programmable control unit (18) by the motor speed controller (16, 17).

Owner:LI YANXIN

Apparatus and methods for variable furnace control

Owner:COPELAND COMFORT CONTROL LP +1

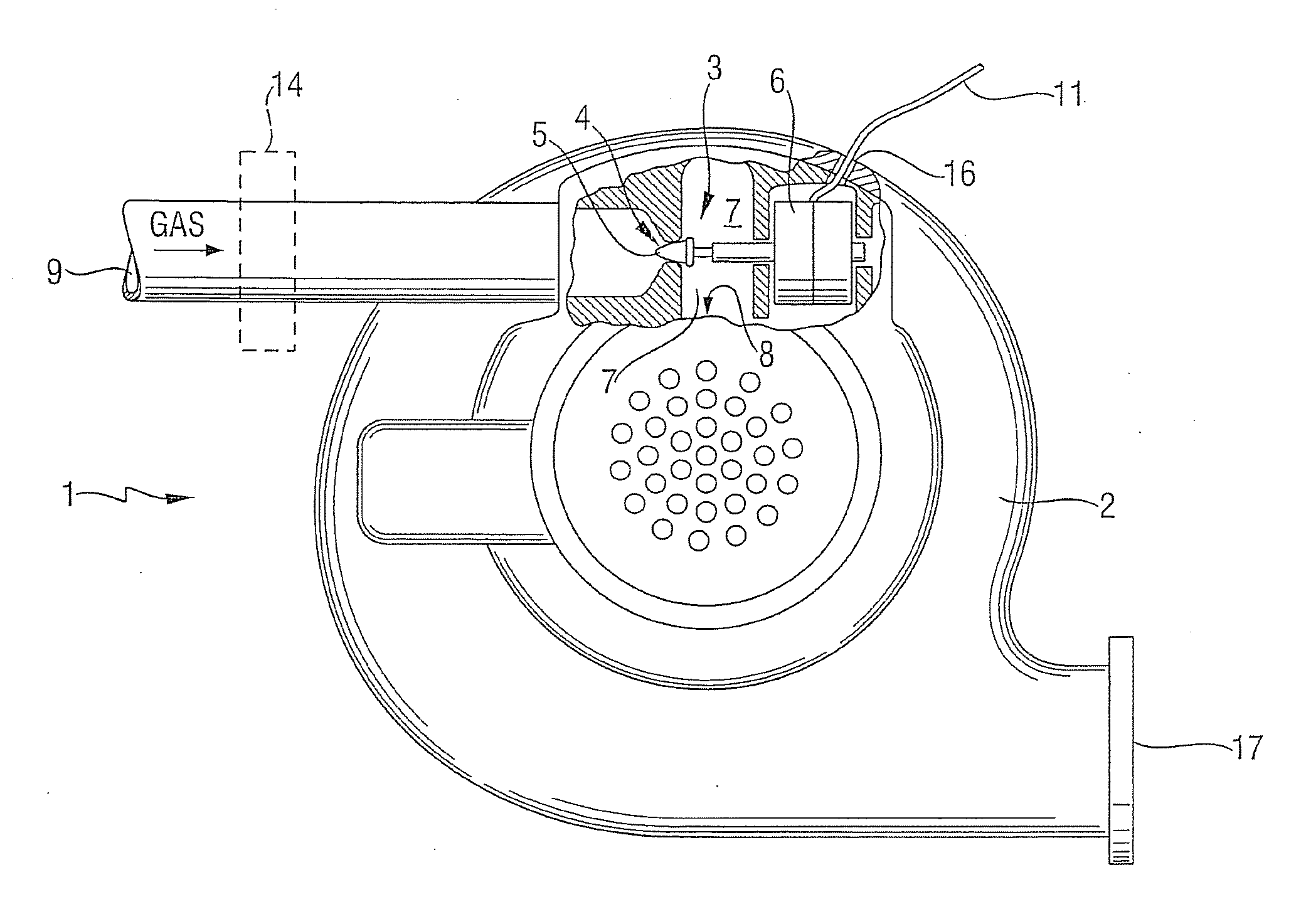

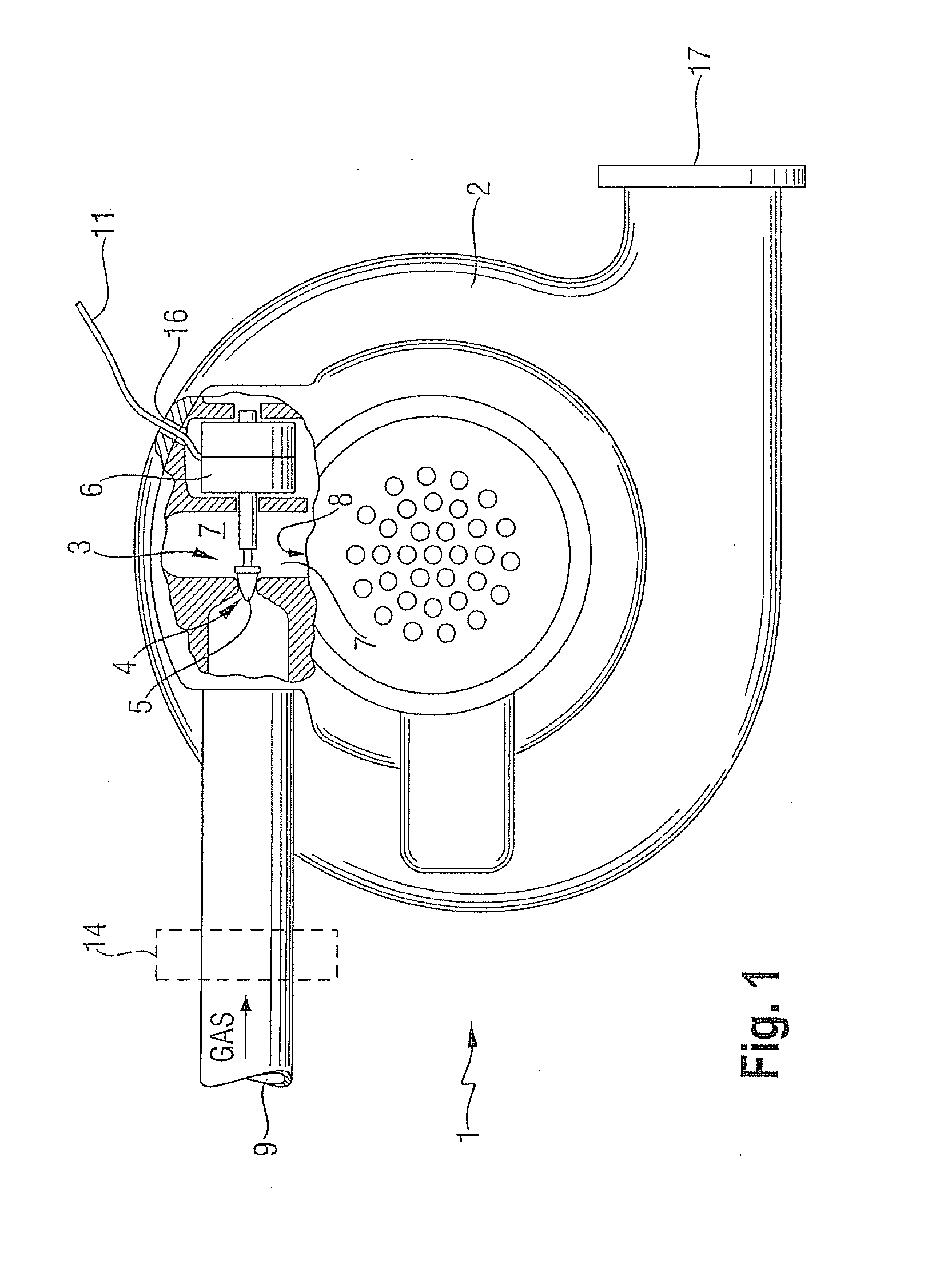

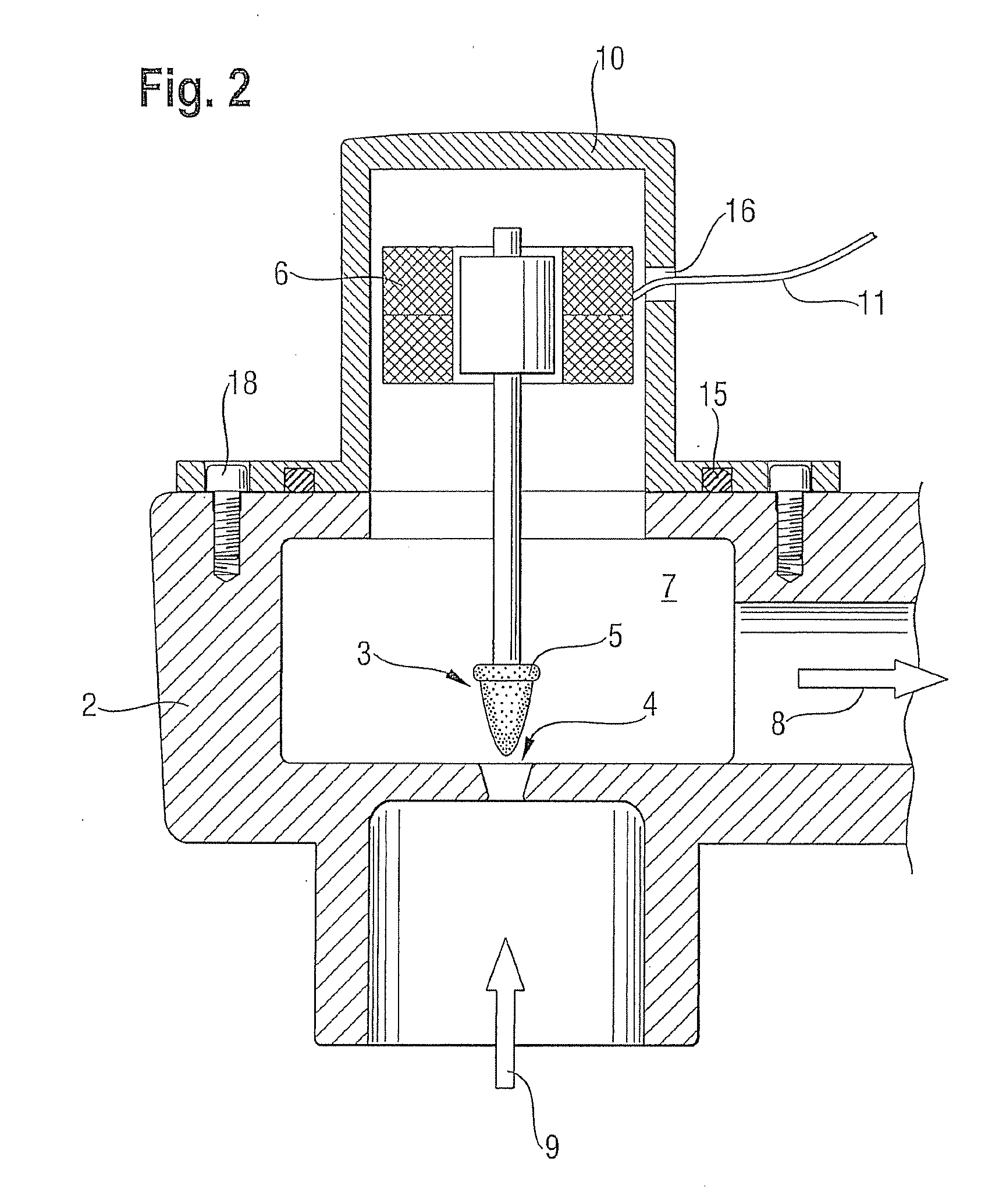

Fan with integrated regulation valve

InactiveUS20100269931A1Produced cost-effectivelyLow production costPump componentsWind motor controlImpellerEngineering

A radial fan, in particular for a gas burner, for premixing air and gas, comprising a housing with a radial fan wheel disposed therein, and a regulation valve for regulating a gas volume, which comprises a valve seat, wherein the valve seat of the regulation valve is formed by a portion of the housing.

Owner:EBM PAPST LANDSHUT

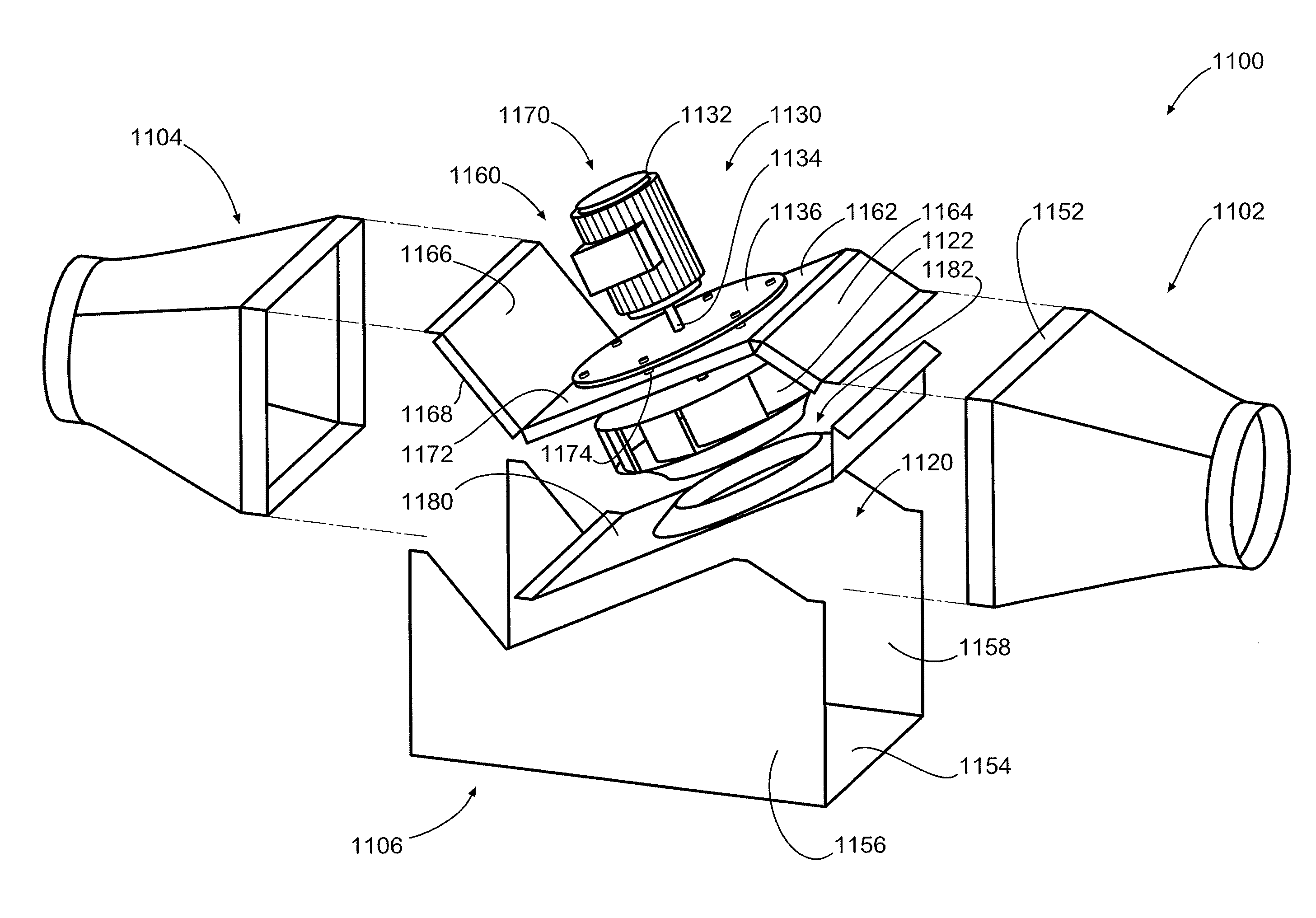

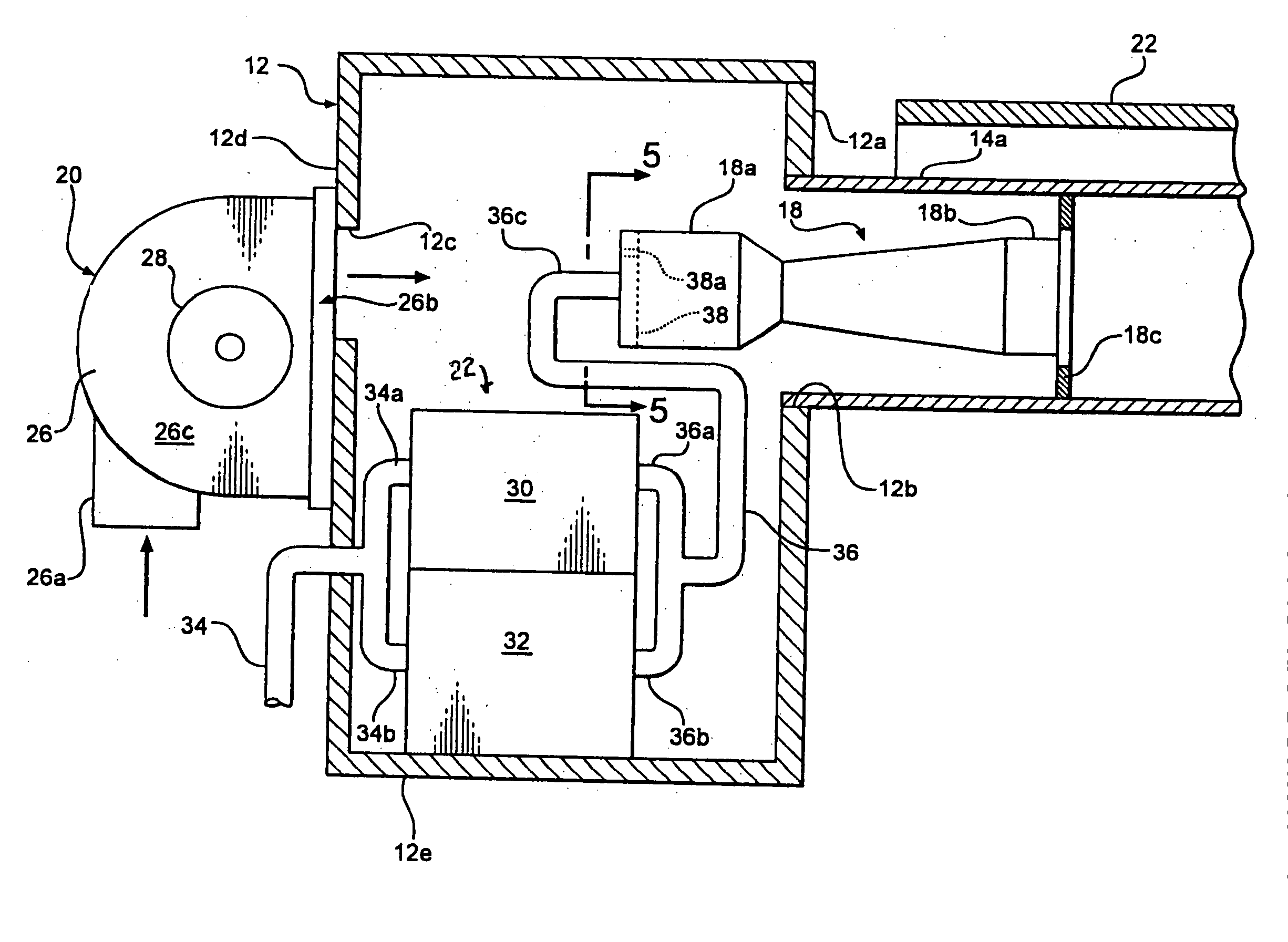

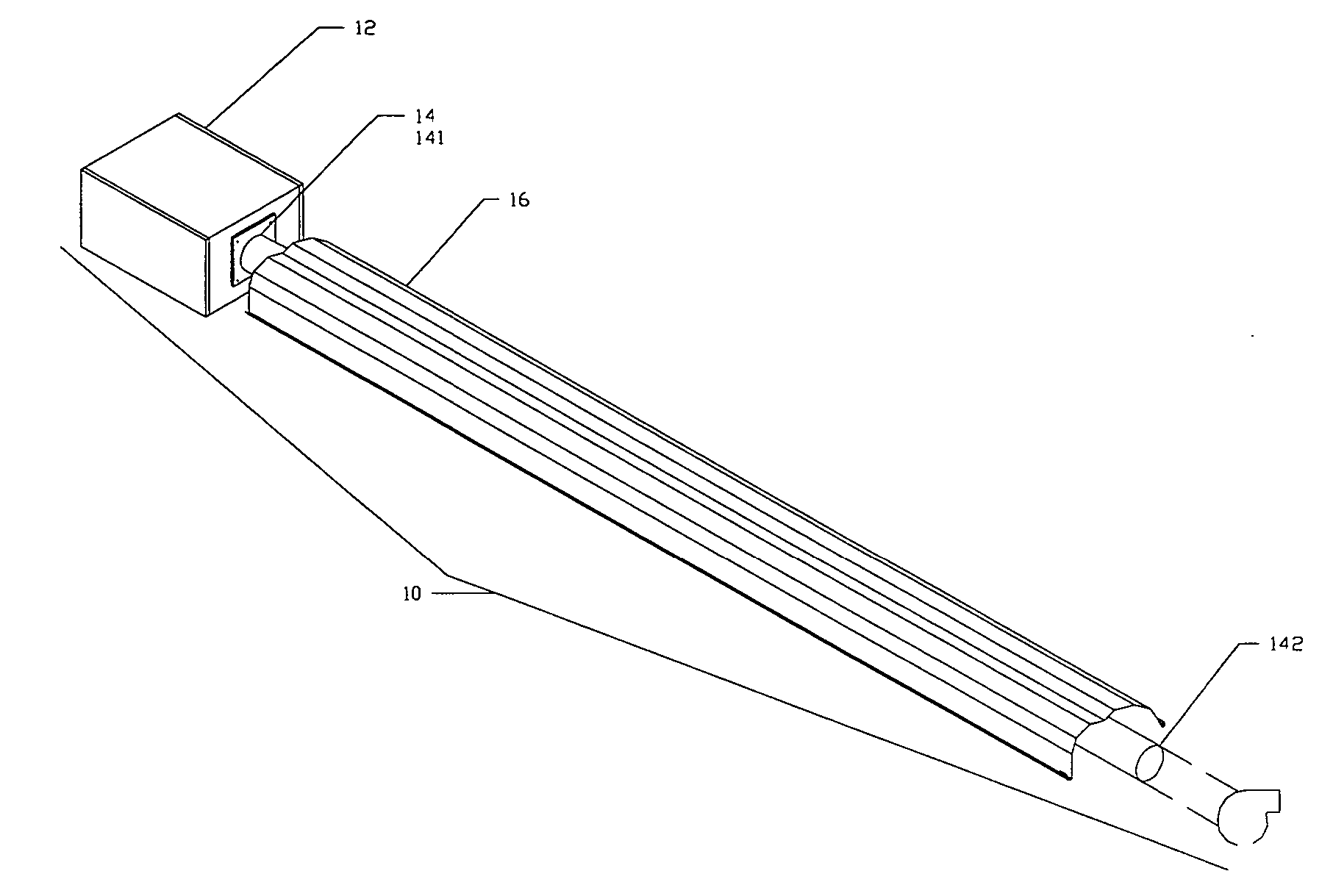

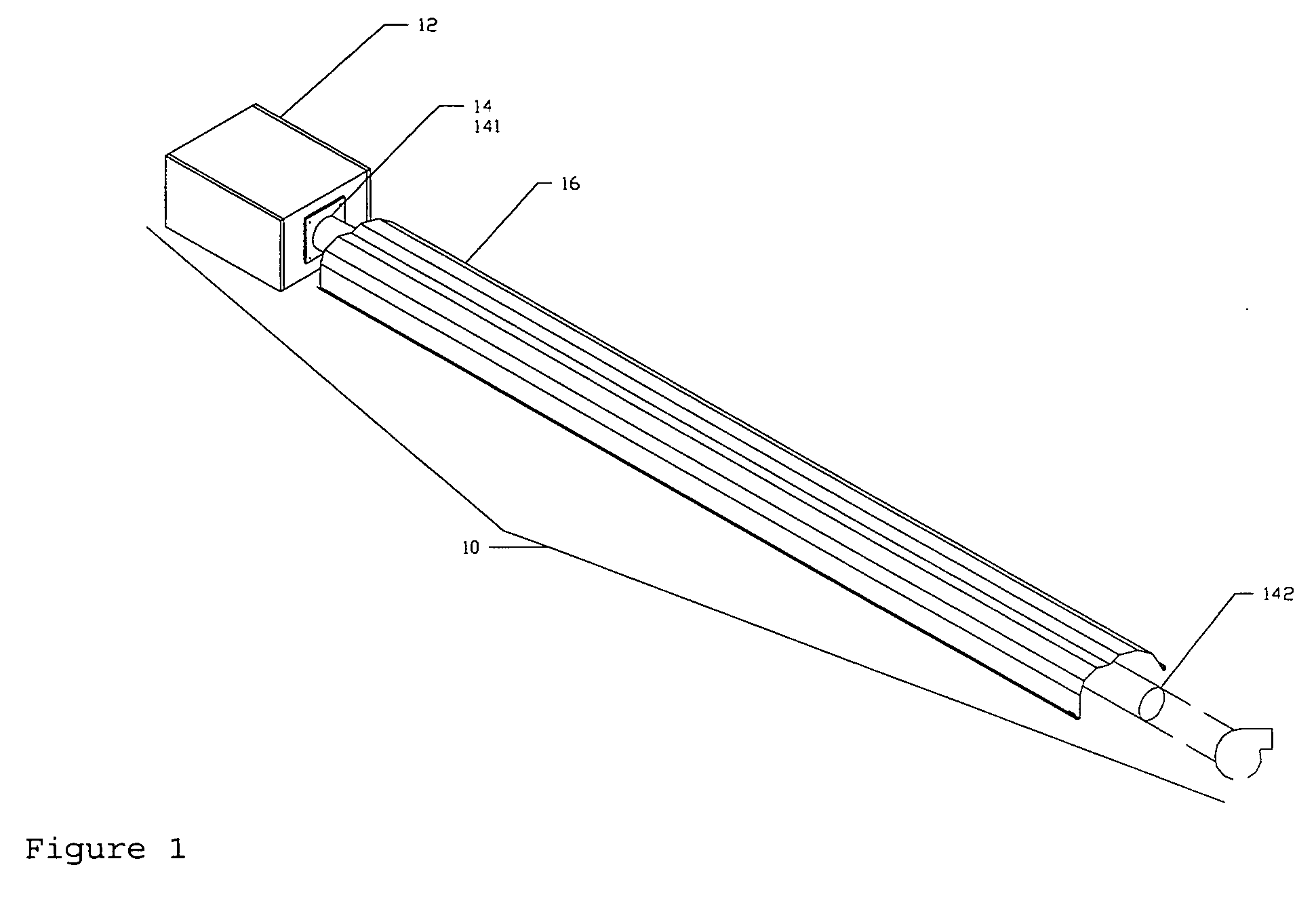

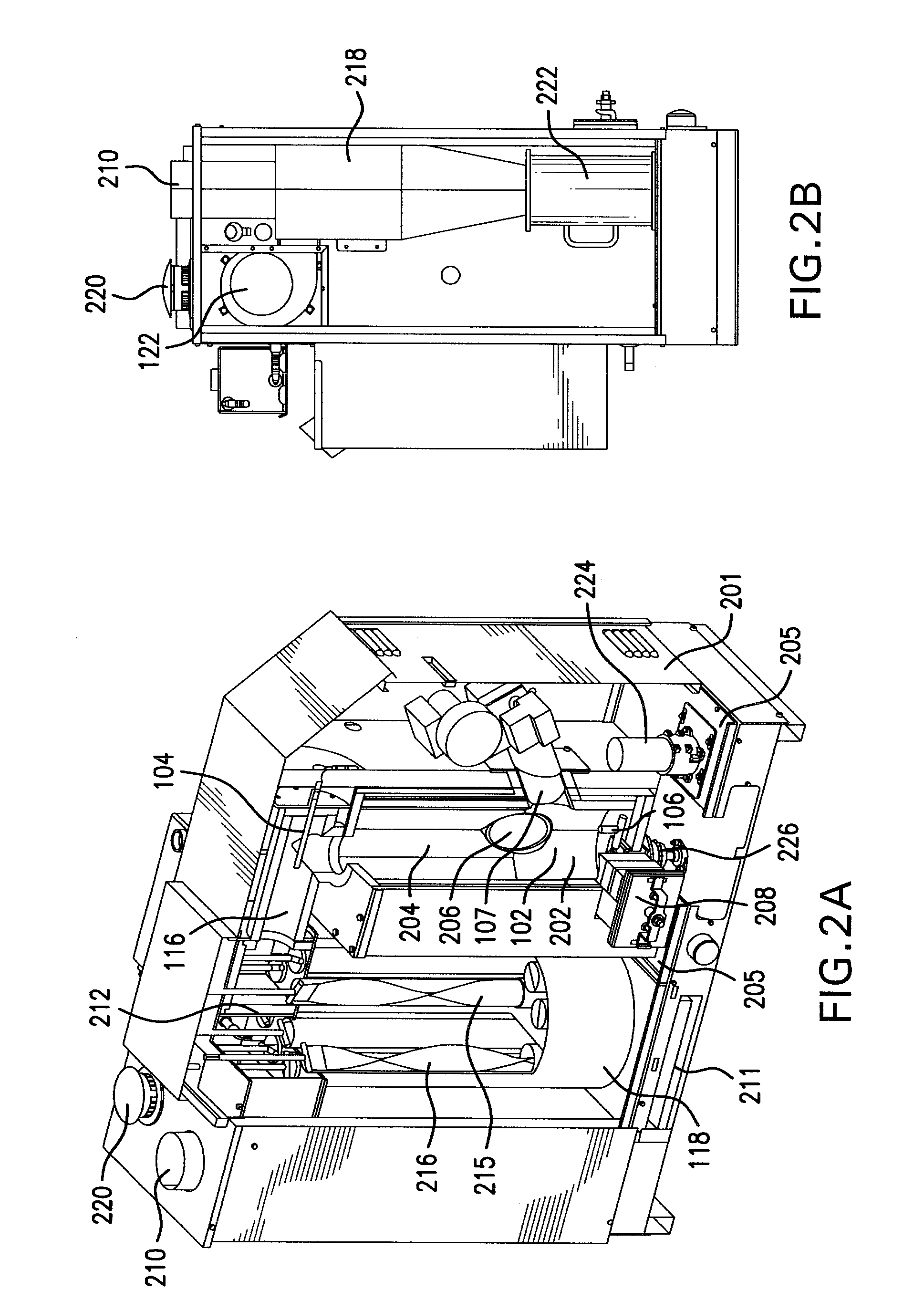

Mechanical draft systems

A representative mechanical draft system for drawing exhaust gasses from a chimney includes: an exhaust fan assembly having: a housing defining a chamber and having opposing openings, the opposing openings having a centerline extending therebetween, a first of the openings being operative to intake a flow of gasses, a second of the openings being operative to exhaust the flow of gasses from the chamber; and a centrifugal fan having a motor and an impeller, the motor being mounted external to the housing, the impeller being positioned within the chamber, a rotational axis of the impeller being inclined with respect to the centerline extending between the openings of the housing.

Owner:ENERVEX

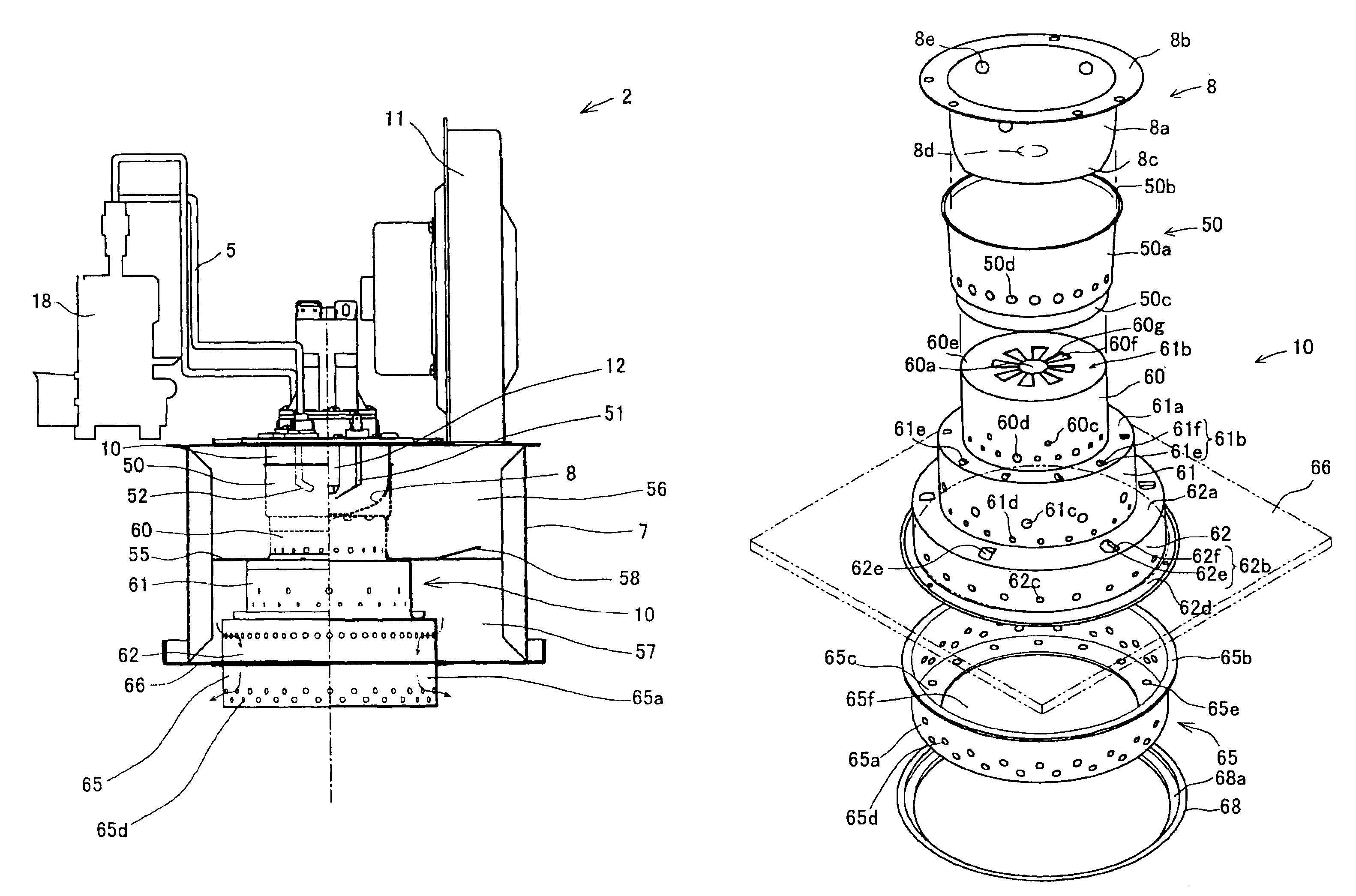

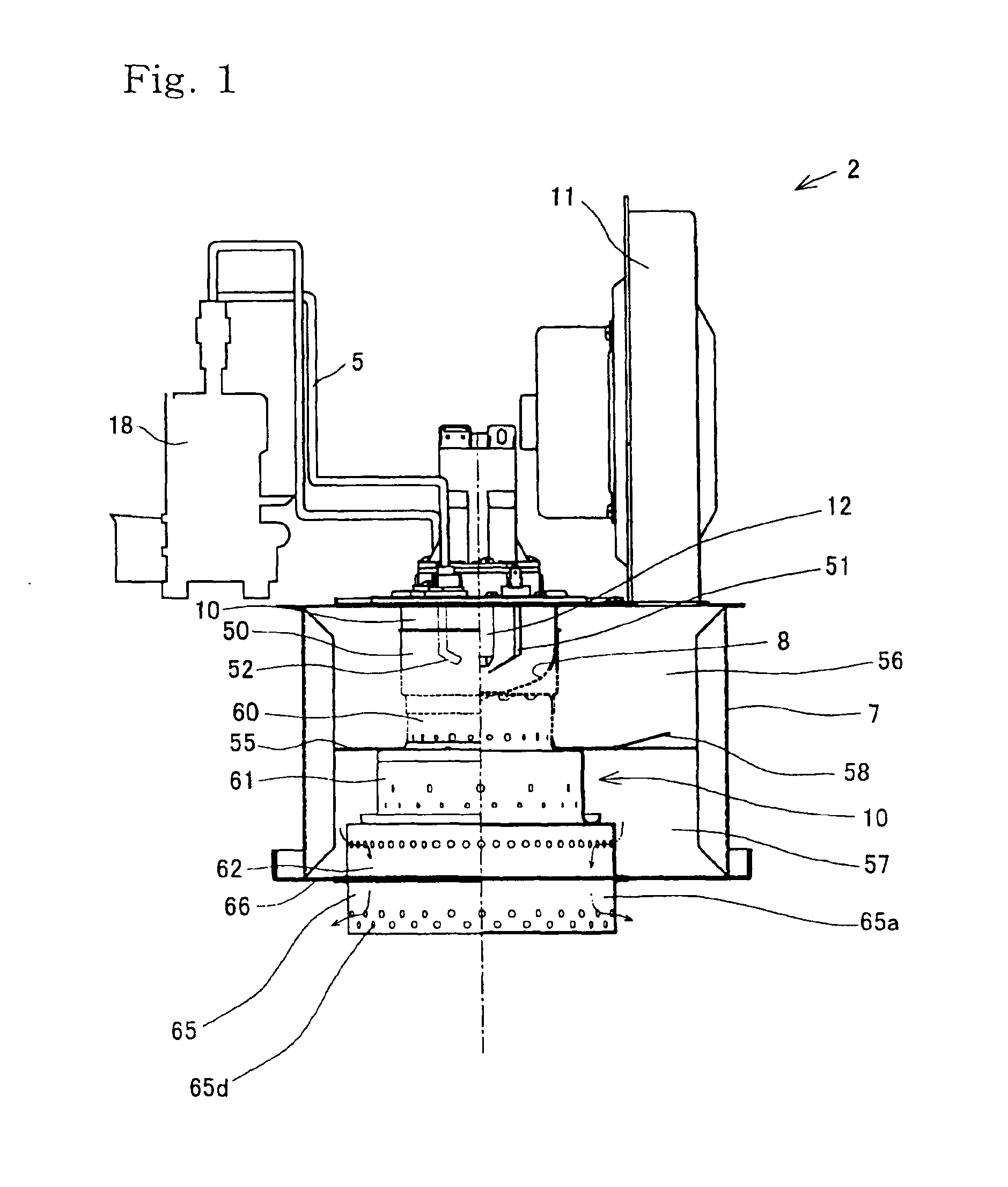

Combustion apparatus

InactiveUS6918757B2Simple structureAccurate supervisionFuel supply regulationCombustion ventilatorsCombustion chamberEngineering

A combustion apparatus 2 has an anti-spreading member 65 disposed below a combustion chamber 10. This anti-spreading member 65 is composed of a generally cylindrical main body 65a, an outer flange 65b and an inner flange 65c, these flanges being formed at and integral with the opposite ends of the main body 65a, respectively. A controller 40 for regulating the operation of this apparatus 2 is designed to preheat the anti-spreading member 65 at a heat generation rate ‘q’ lower than the required heat generation rate ‘Q’, before the apparatus starts its normal operation to burn a fuel.

Owner:NORITZ CORP

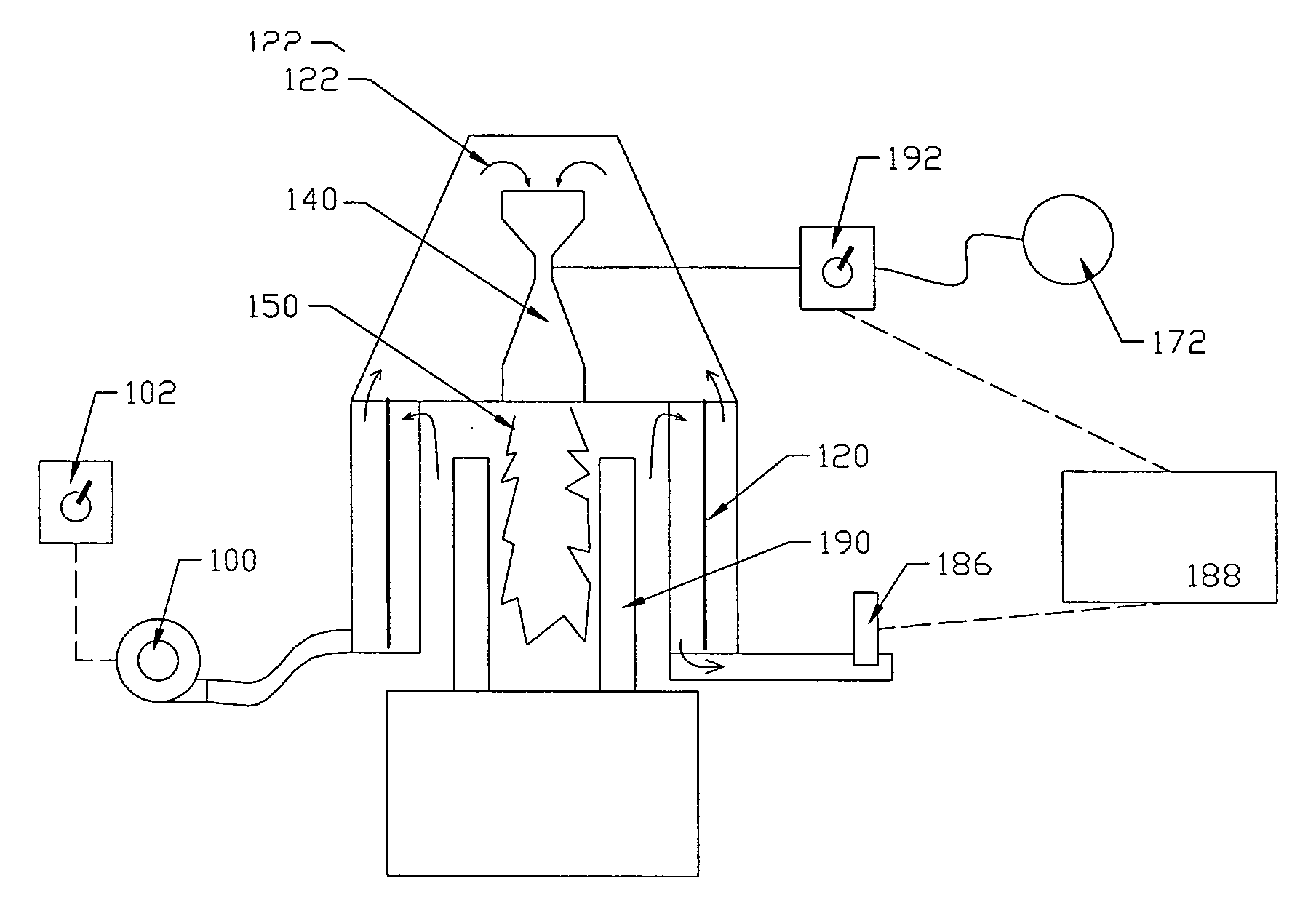

Non-catalytic biomass fuel burner and method

The present invention relates to a non-catalytic biomass burner that may be used to burn a variety of fuel types at high efficiencies. The burner may include a cylindrical combustion chamber with an auxiliary igniter to heat the fuel in the combustion chamber until desirable combustion temperatures are reached. Fuel may be added to the chamber via a fuel feed assembly, and the rate of fuel addition to the chamber by the fuel feed assembly may be controlled by a computer. A fan located on the distal side of a flue pipe from the chamber may also be provided that pulls air into the chamber through one or more air inlets that are designed to encourage cyclonic air and exhaust flow in the chamber. Methods are further provided for controlling the manner of operation of the burner by a computer that may be instructed by a computer program code.

Owner:LASKOWSKI SCOTT +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com