Patents

Literature

568results about "Pilot flame igniters" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Burner apparatus, submerged combustion melters including the burner, and methods of use

Owner:JOHNS MANVILLE CORP

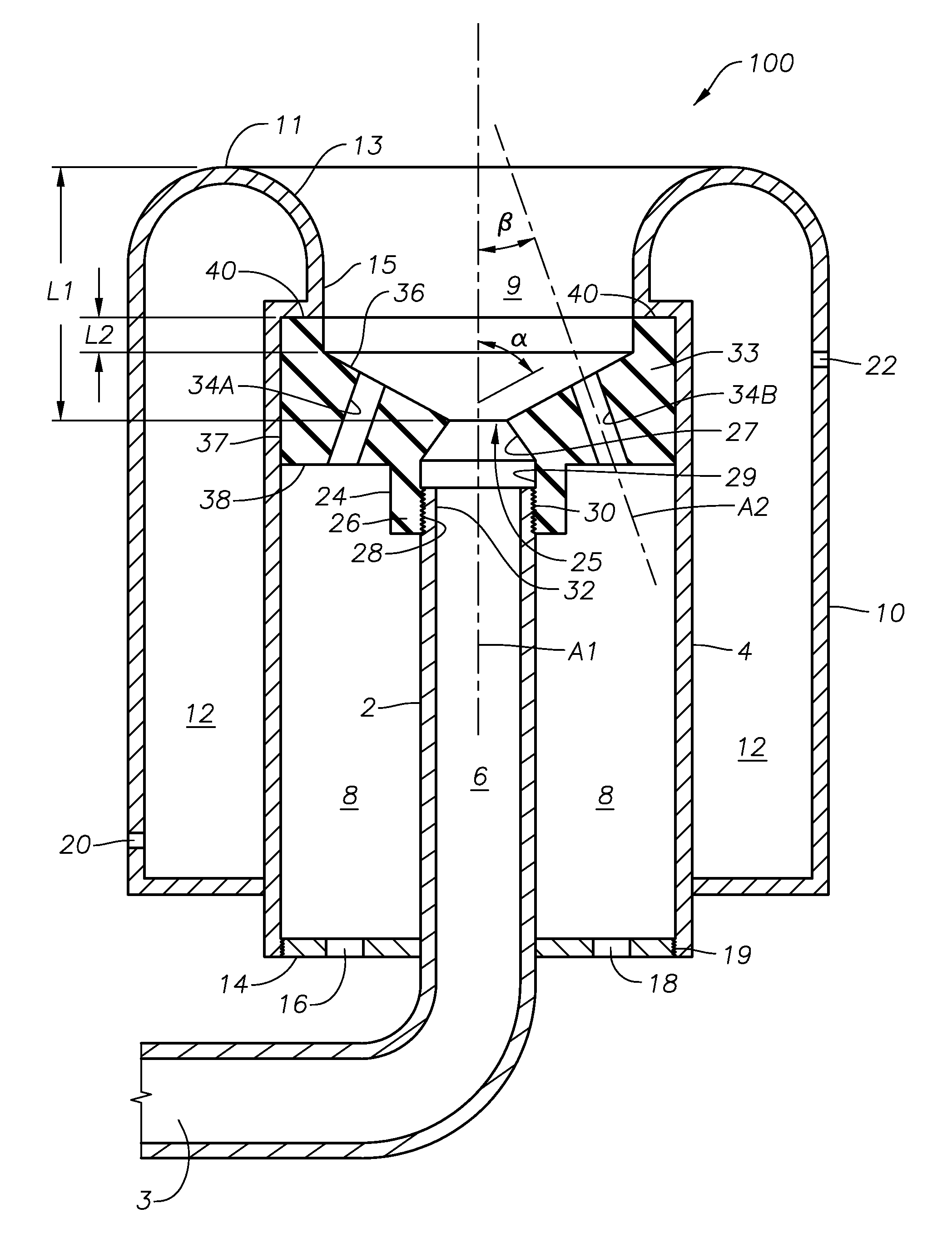

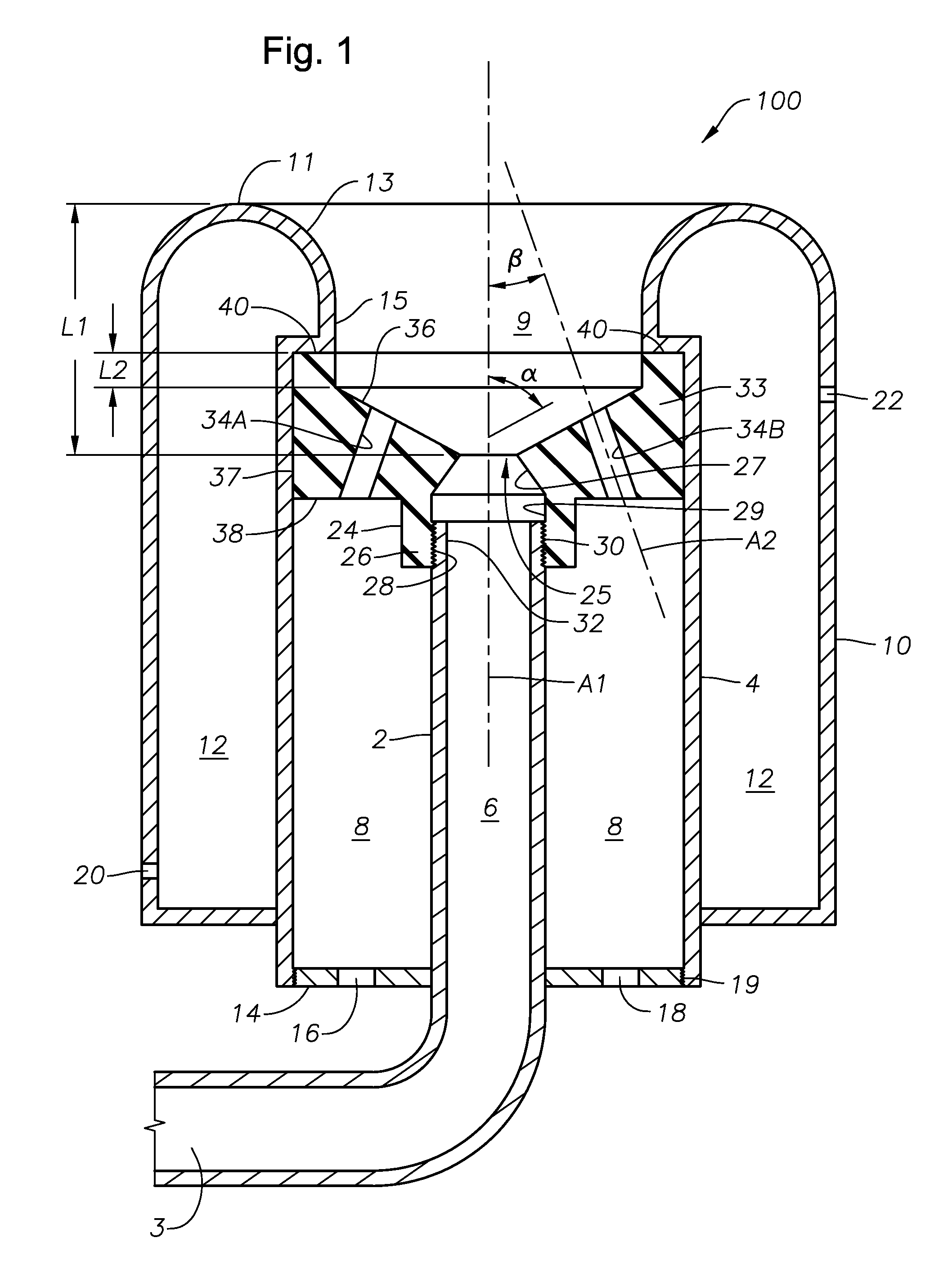

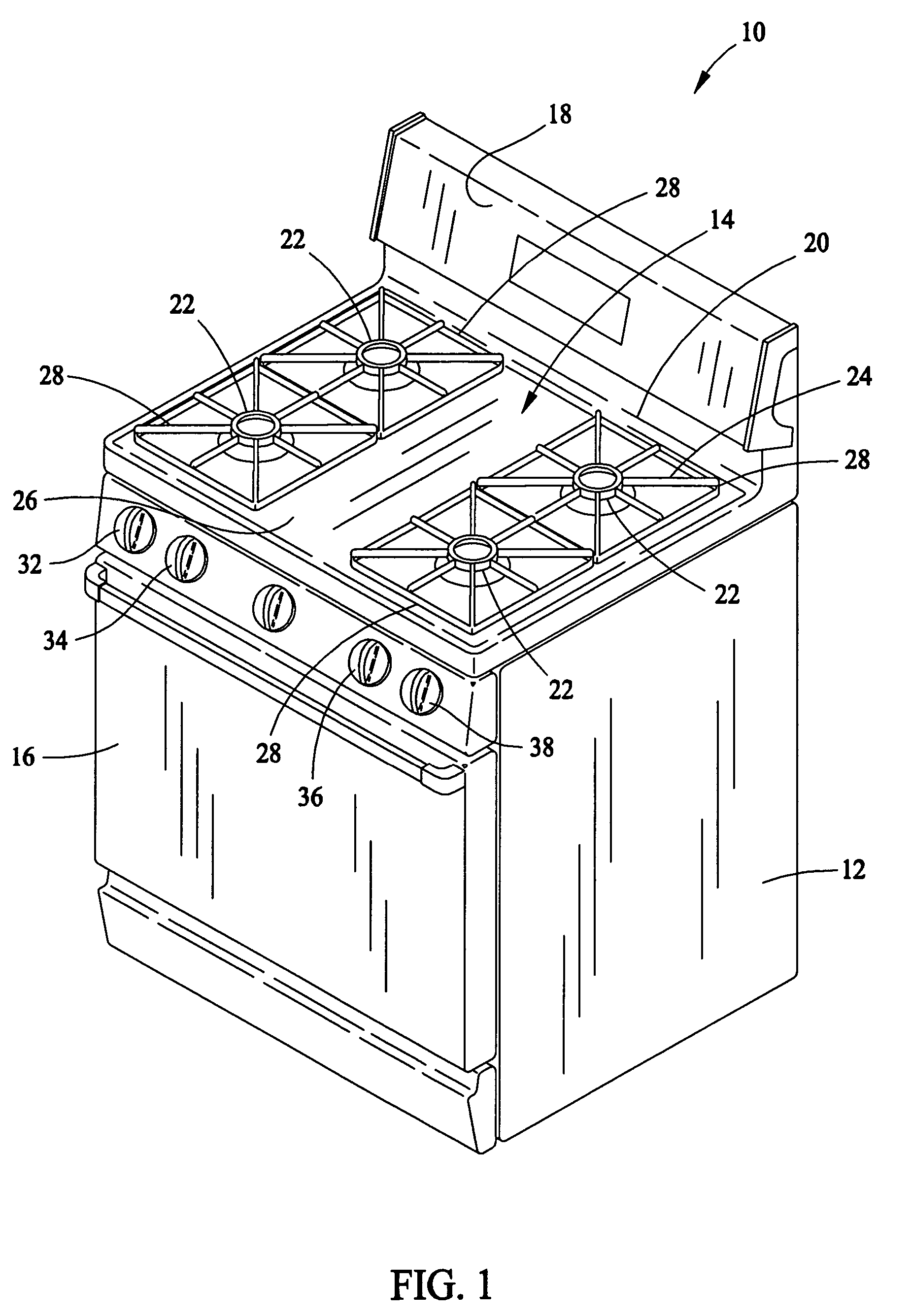

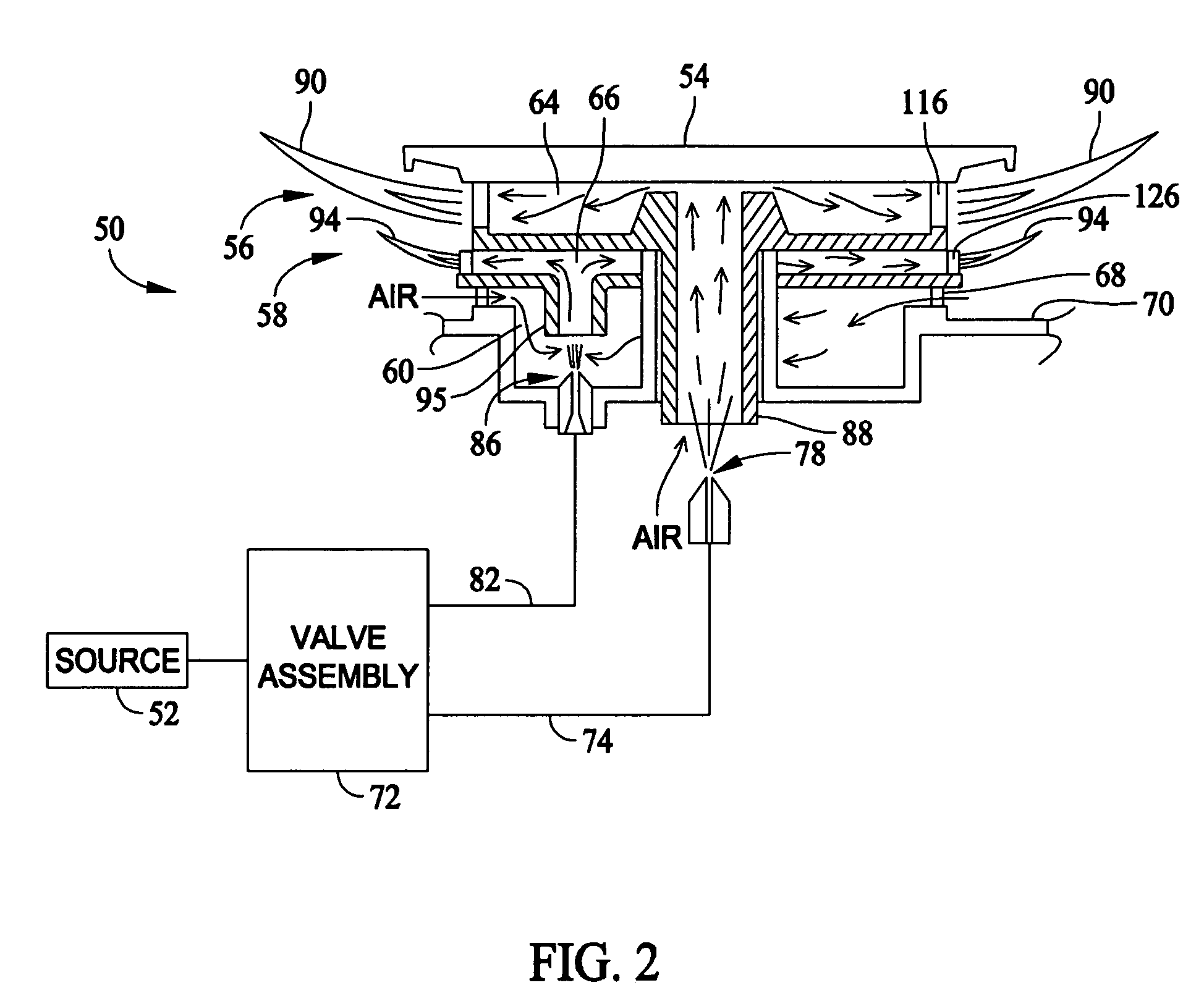

Dual stacked gas burner and a venturi for improving burner operation

ActiveUS7291009B2Amount of timeFacilitates simmeringDomestic stoves or rangesSpray nozzlesEngineeringThermal efficiency

A cooktop burner assembly is described. The cooktop burner assembly includes a main burner, and a simmer burner located below the main burner, where a diameter of the simmer burner is greater than a diameter of the main burner. The closer placement of the main burner to a cooking vessel placed on top of the cooktop burner assembly as compared to the placement of the simmer burner from the cooking vessel increases thermal efficiency. Moreover, the farther placement of the simmer burner from the cooking vessel facilitates simmering of items in the cooking vessel and the larger diameter of the simmer burner reduces a possibility of overheating the main burner and the cooking vessel.

Owner:HAIER US APPLIANCE SOLUTIONS INC

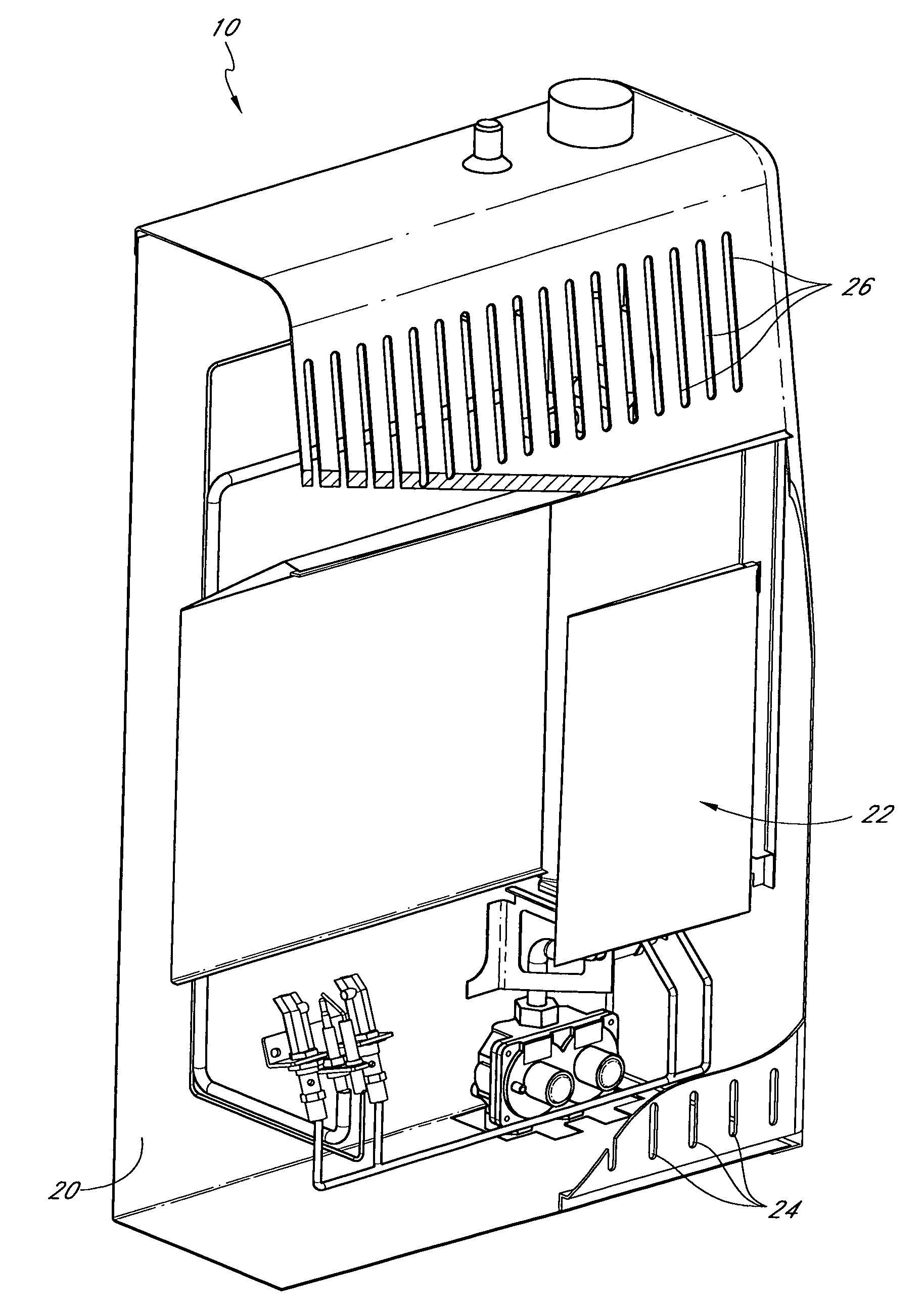

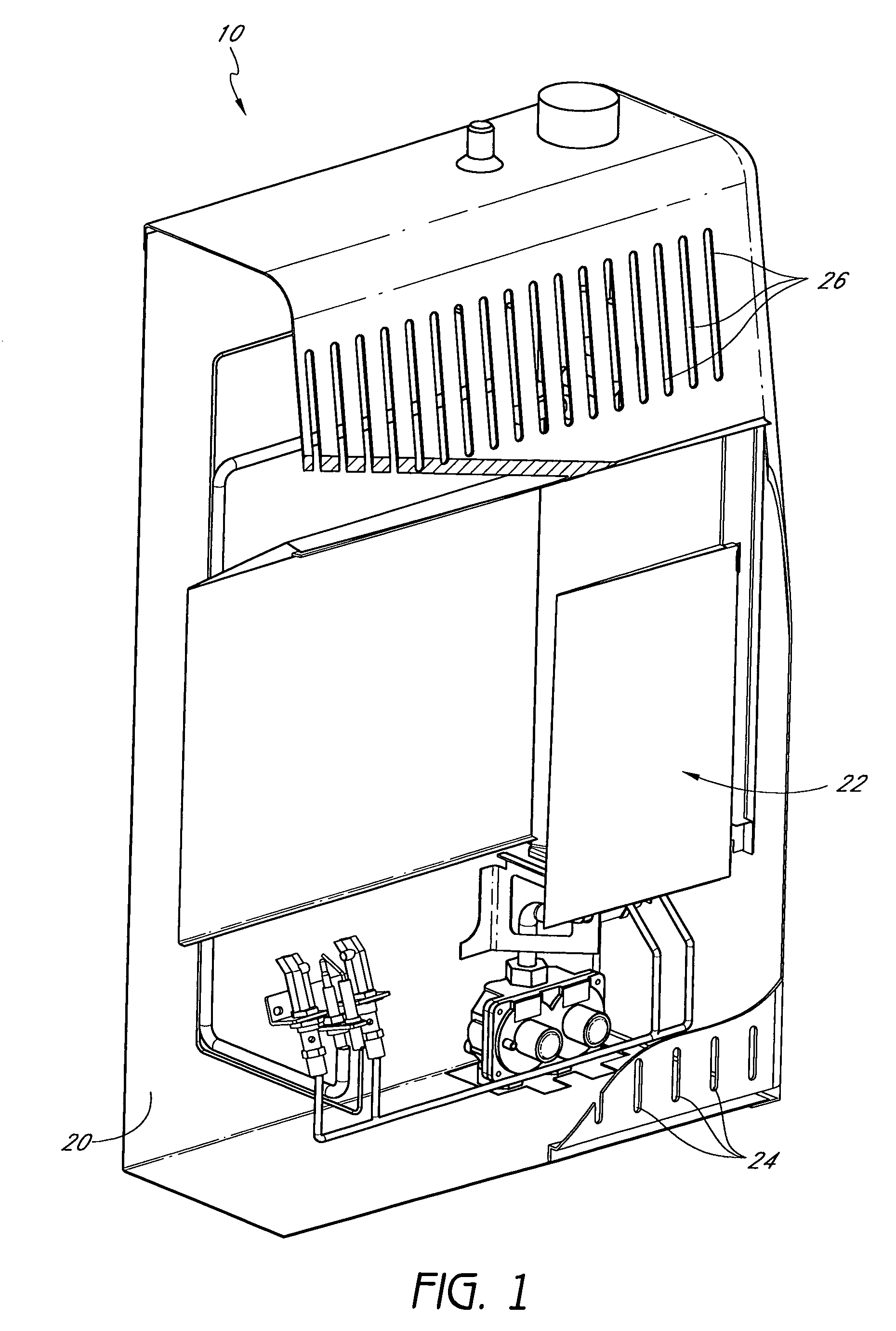

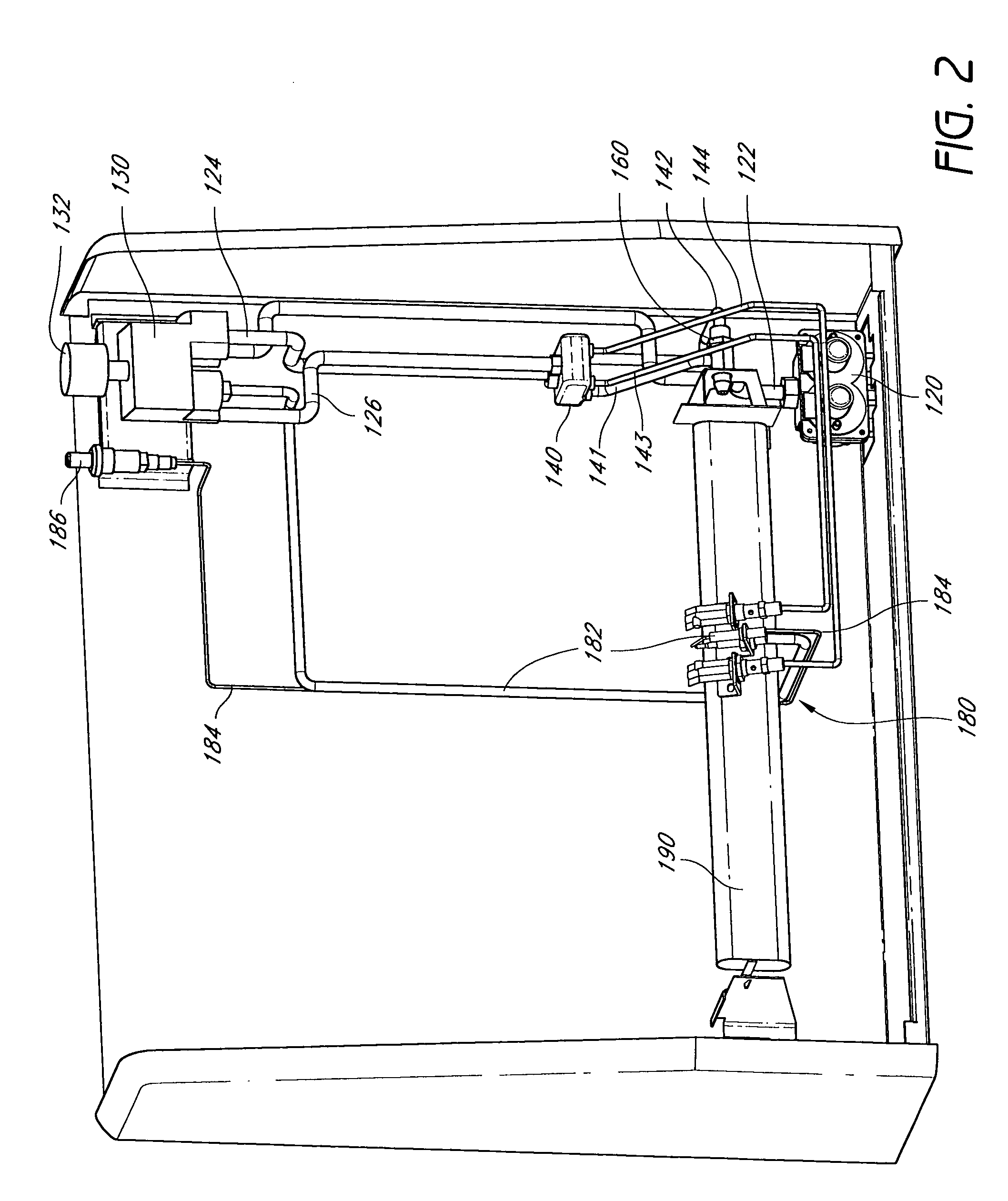

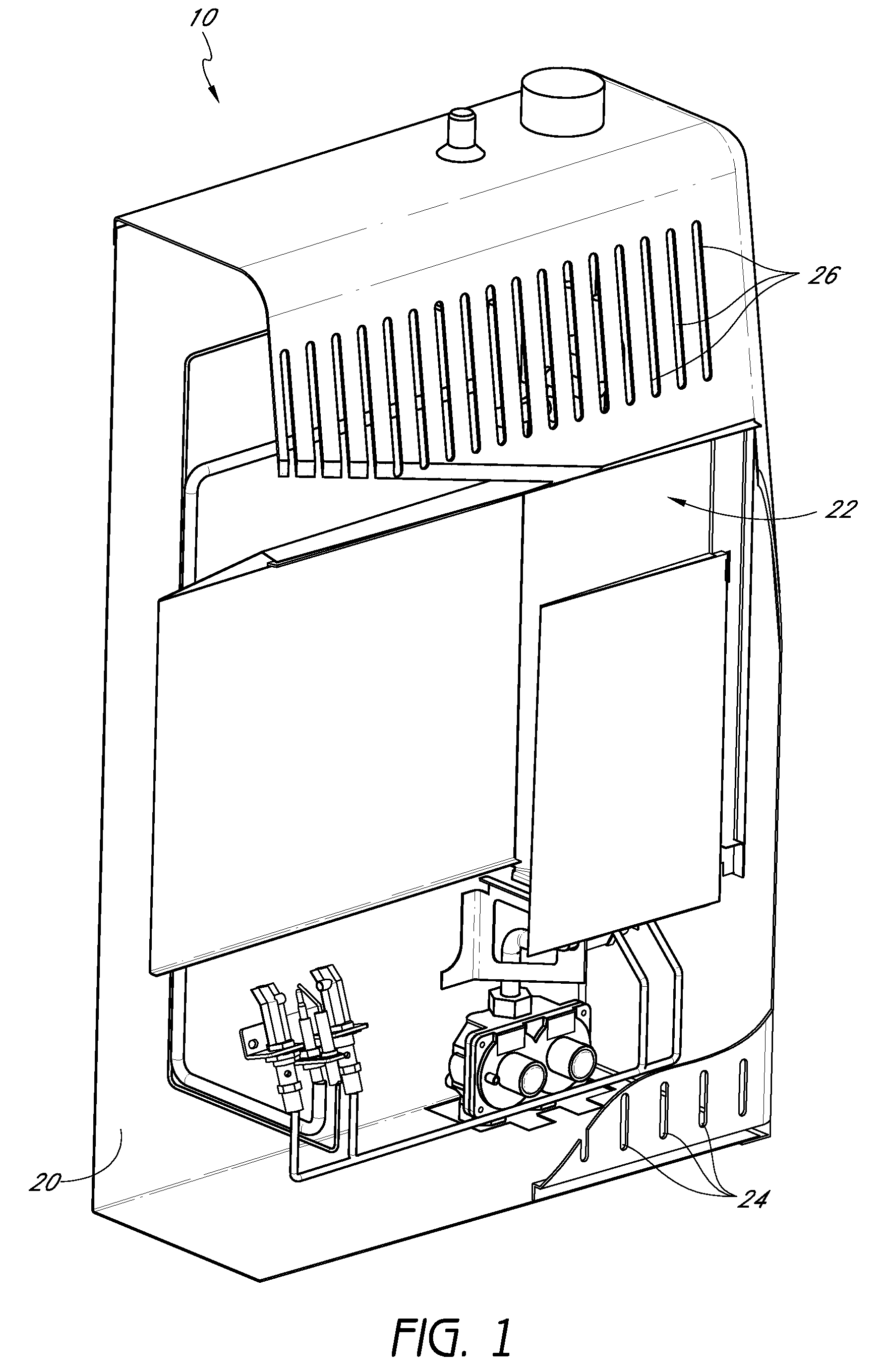

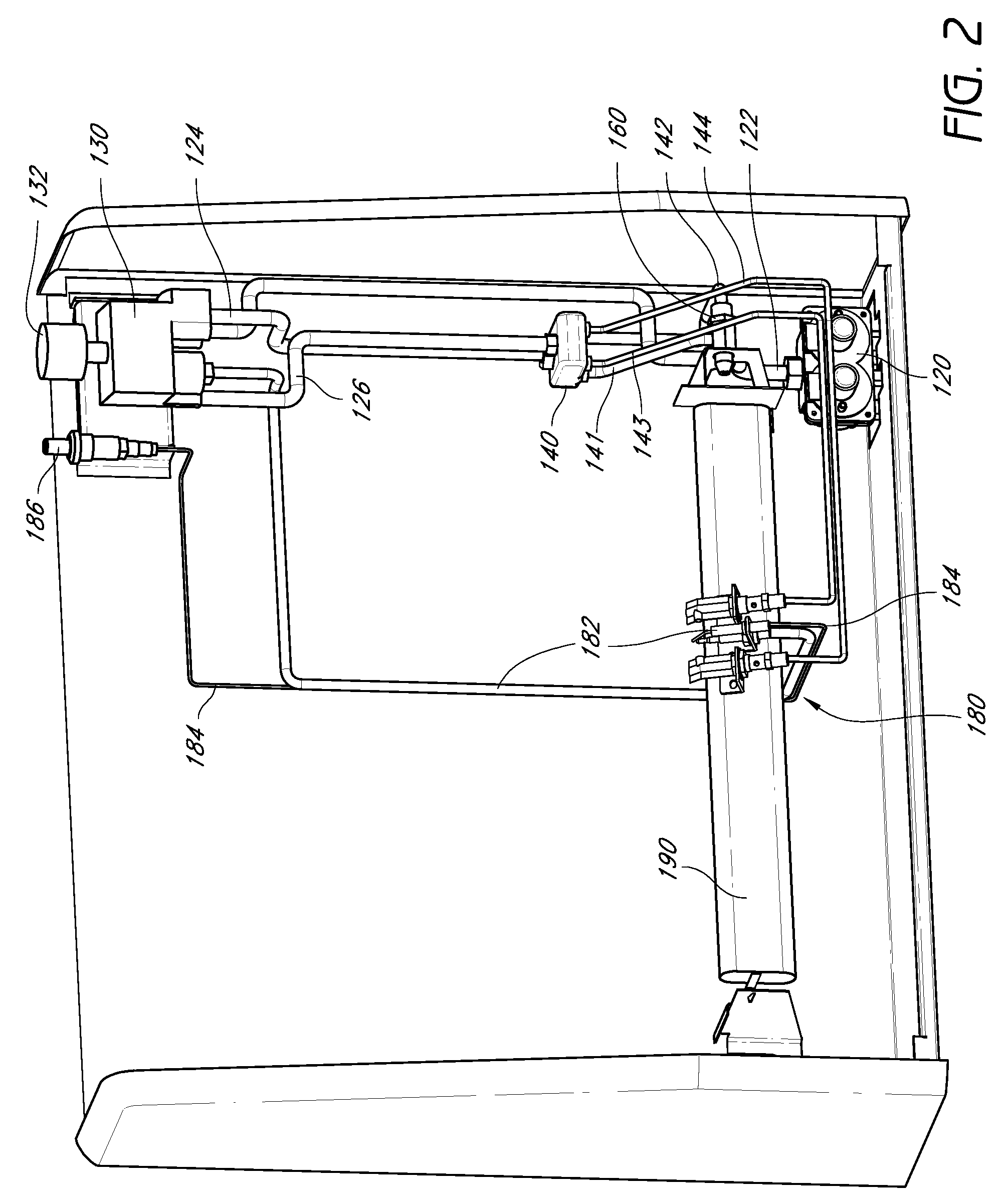

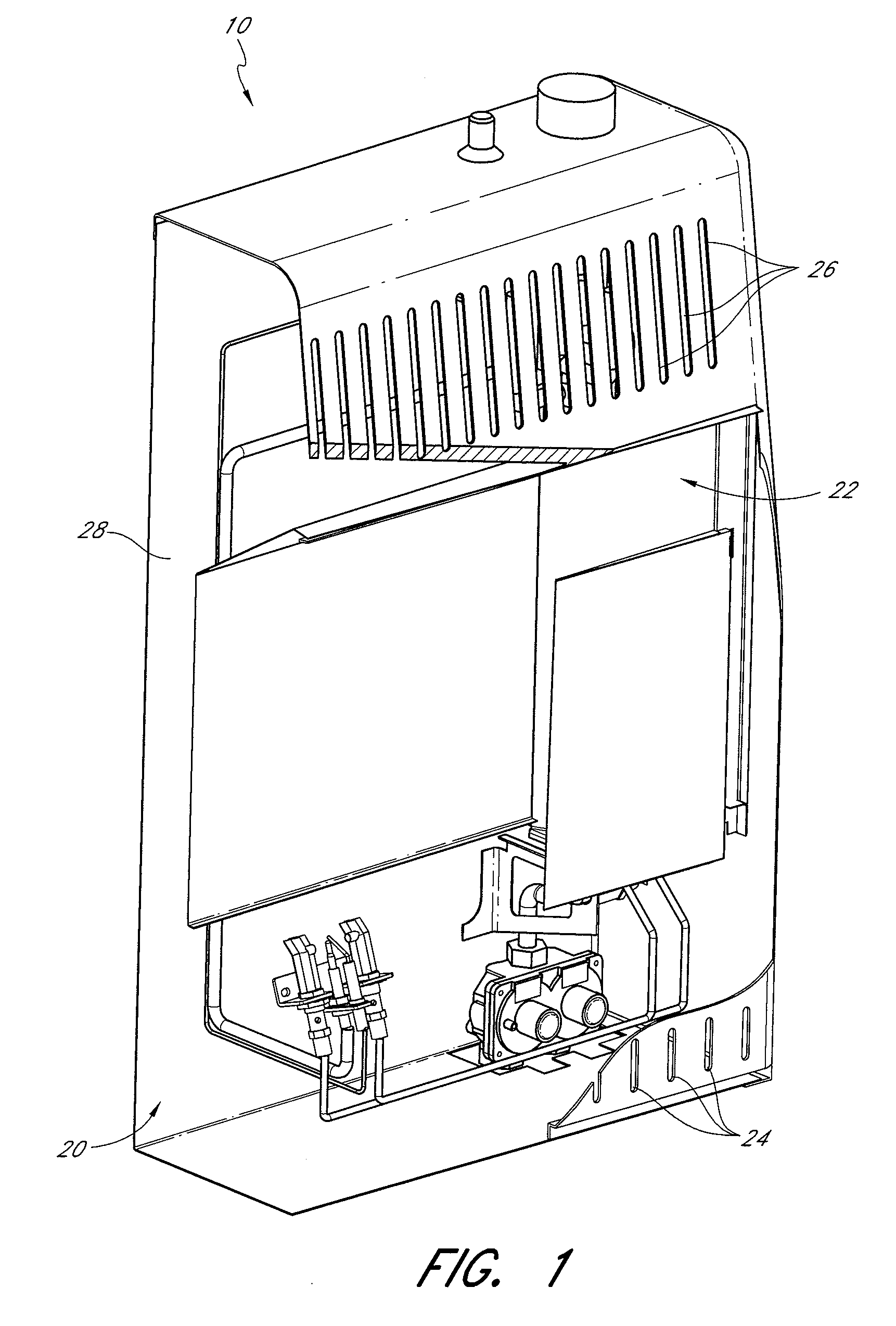

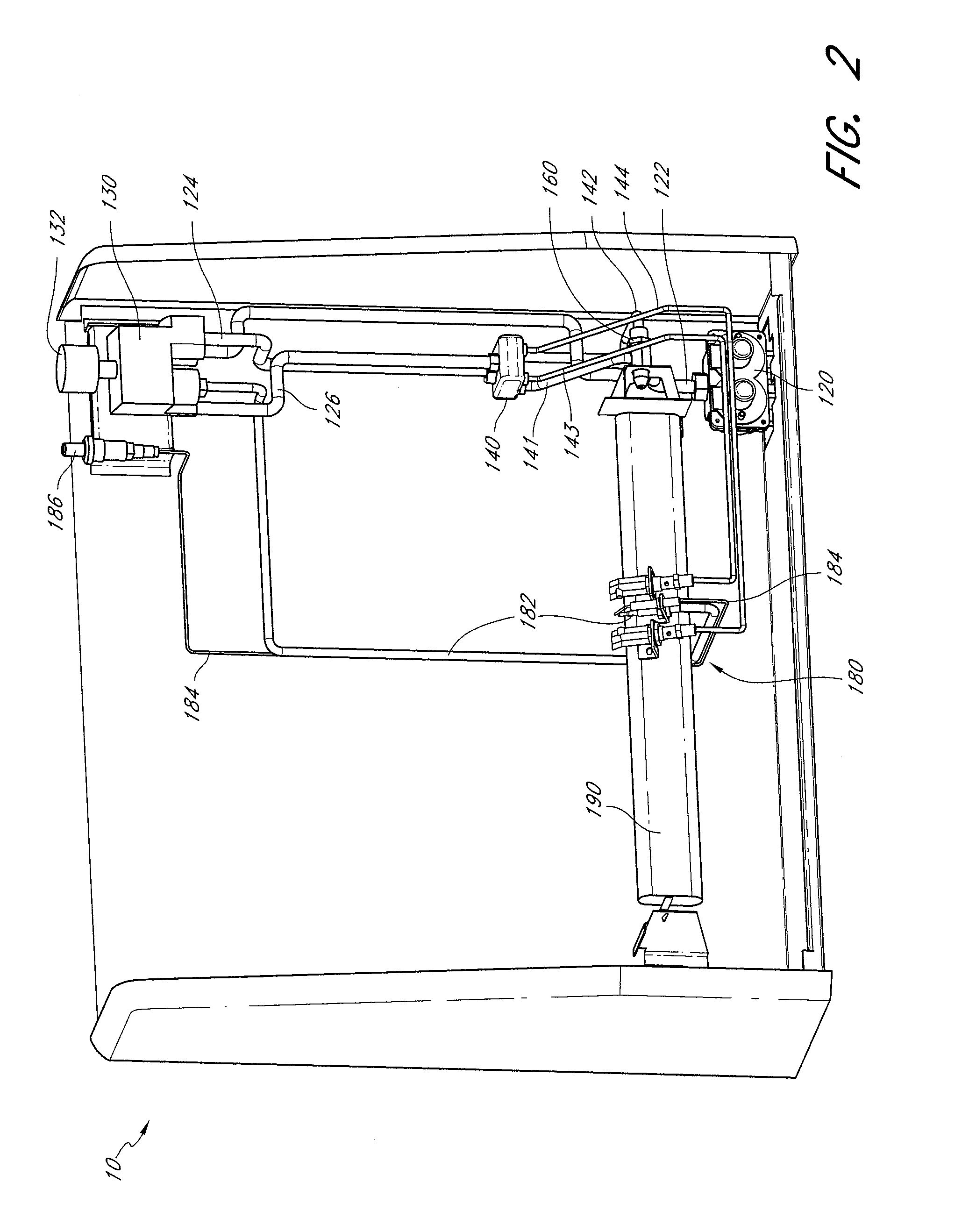

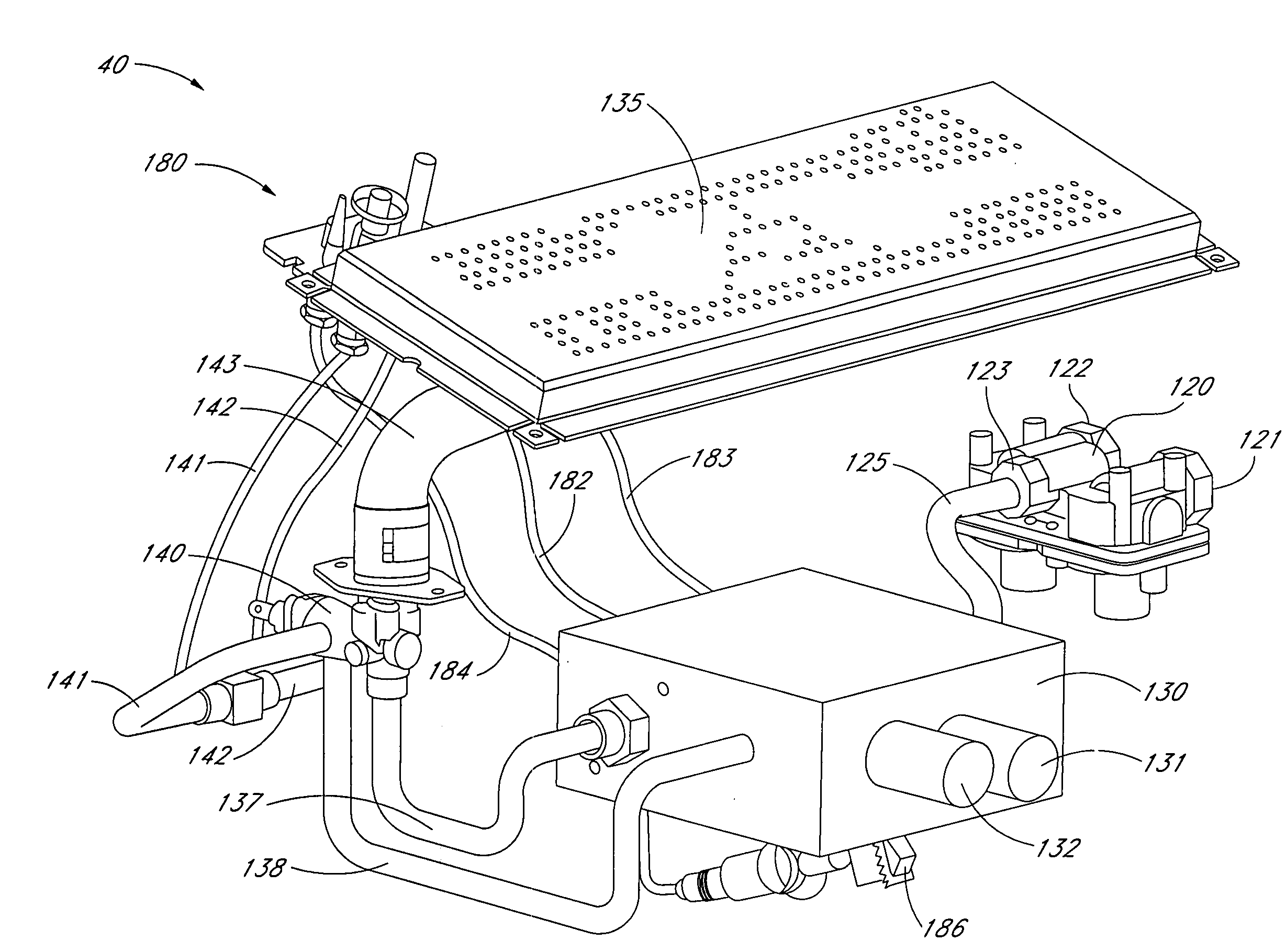

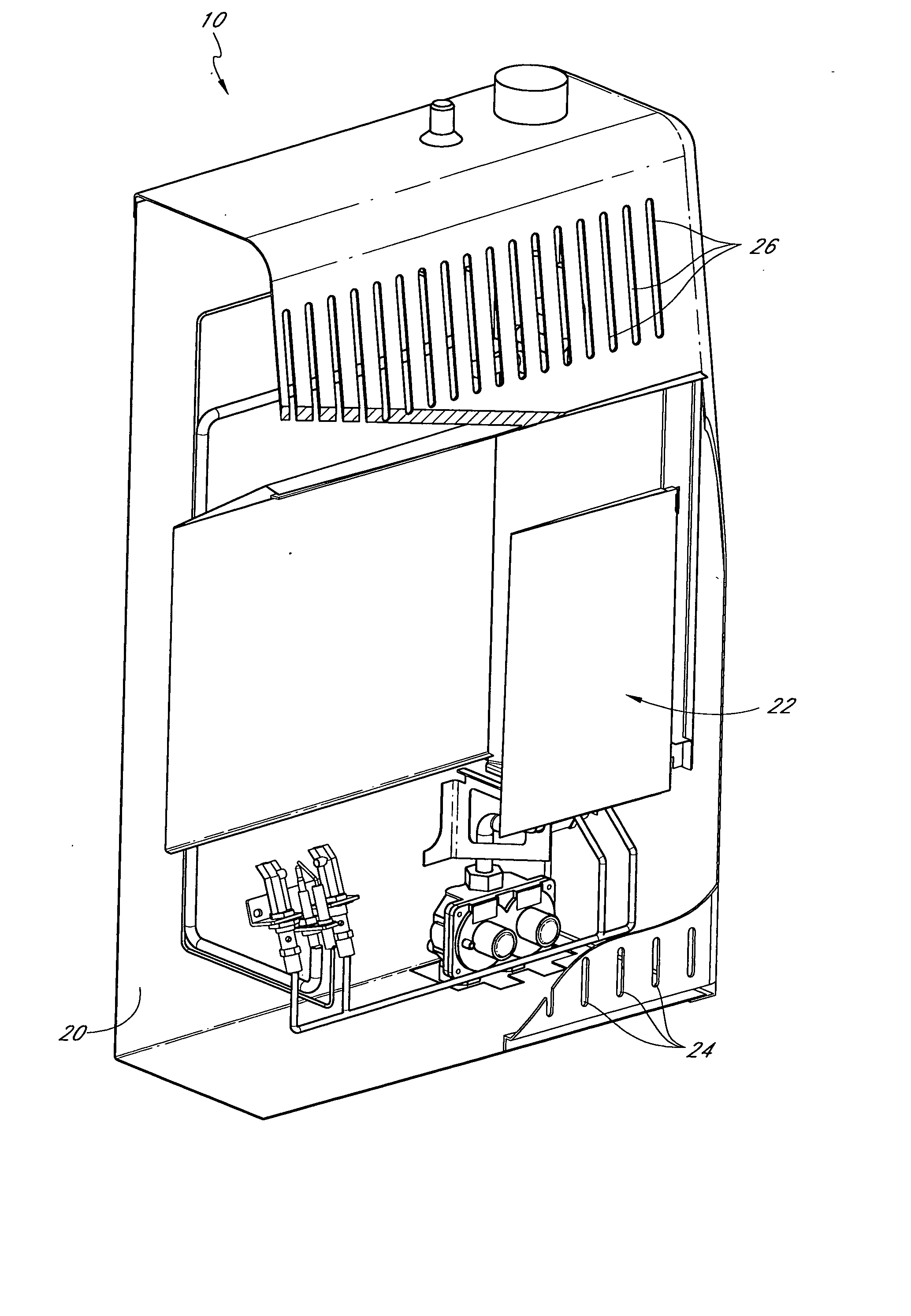

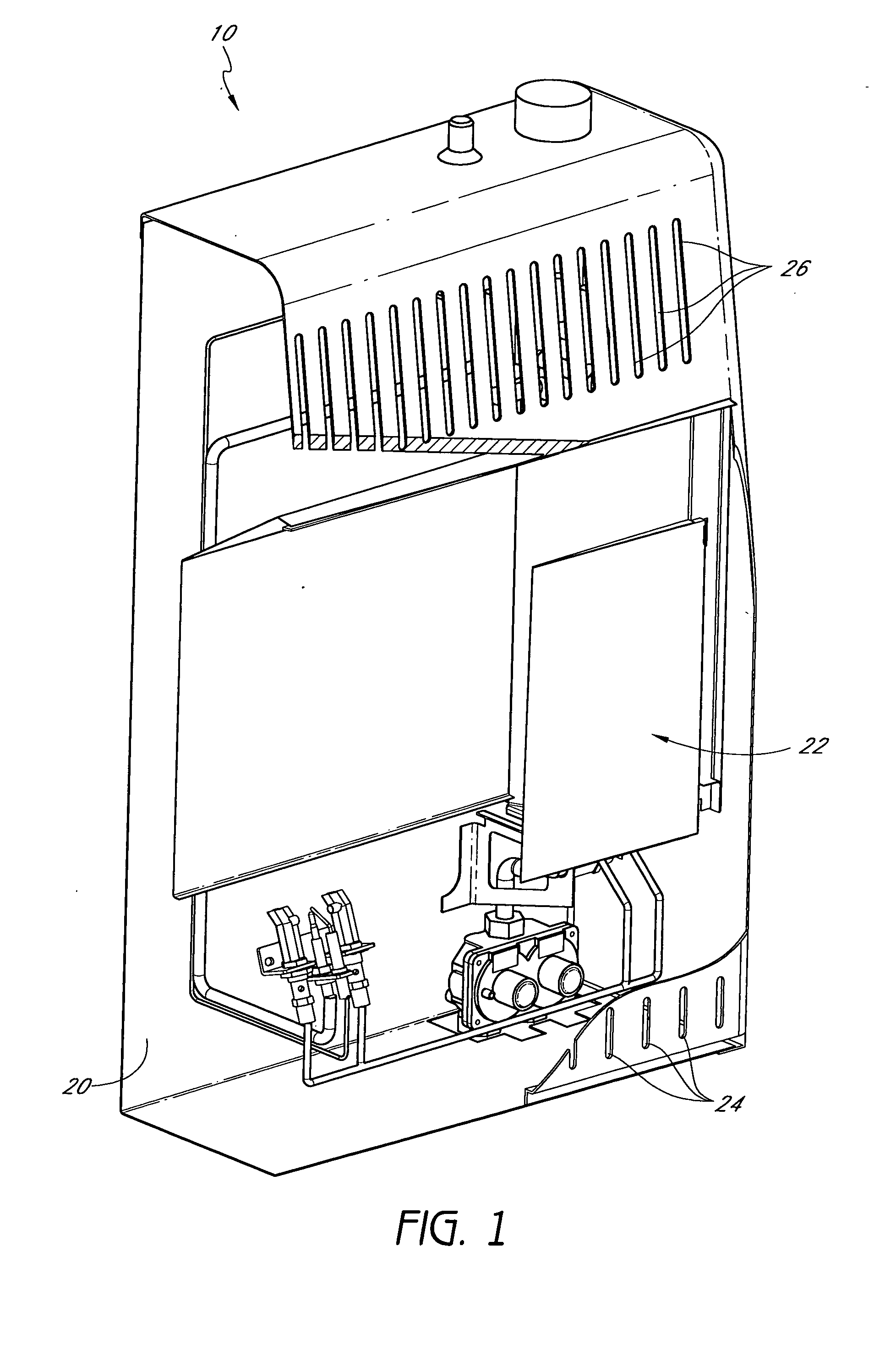

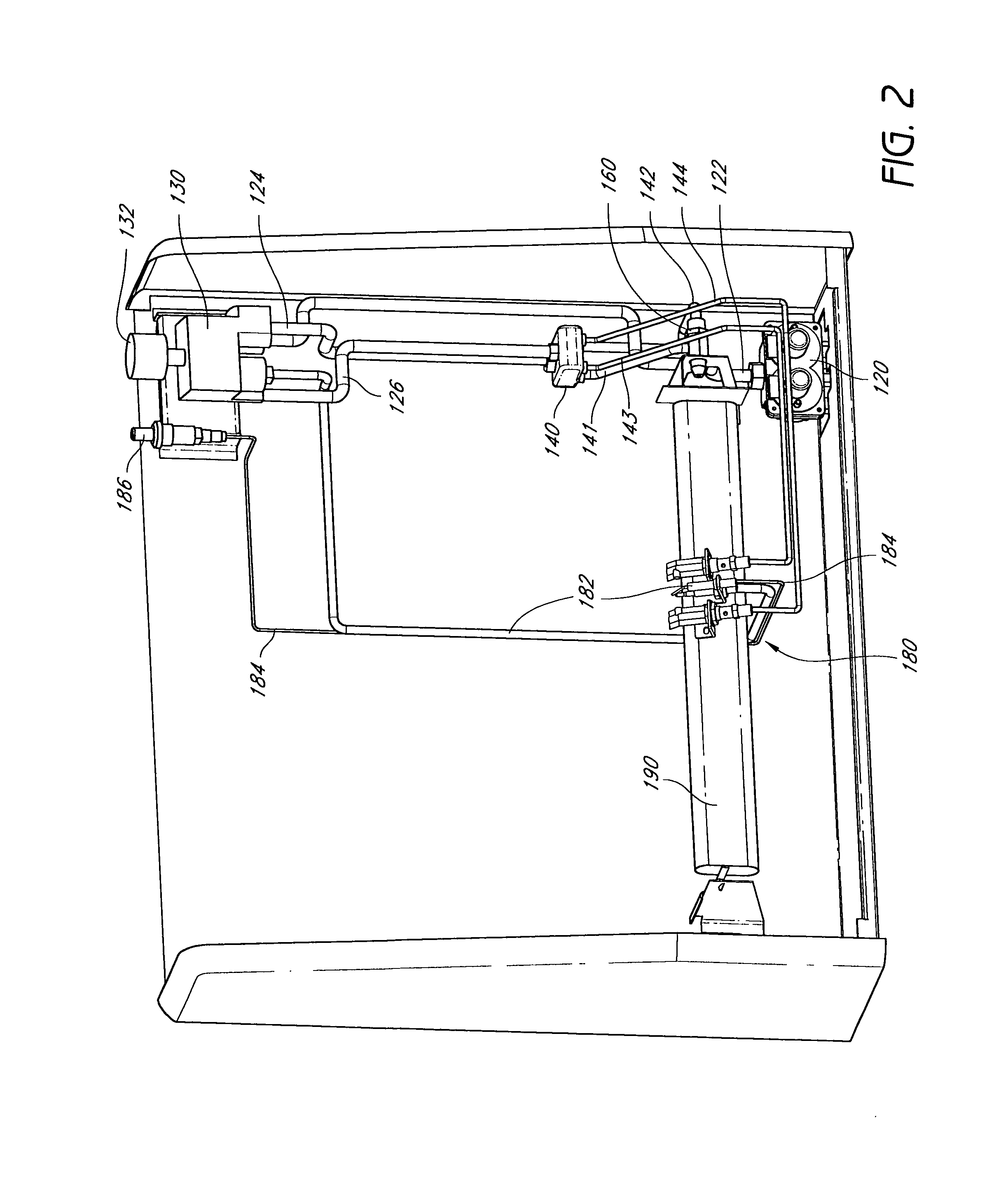

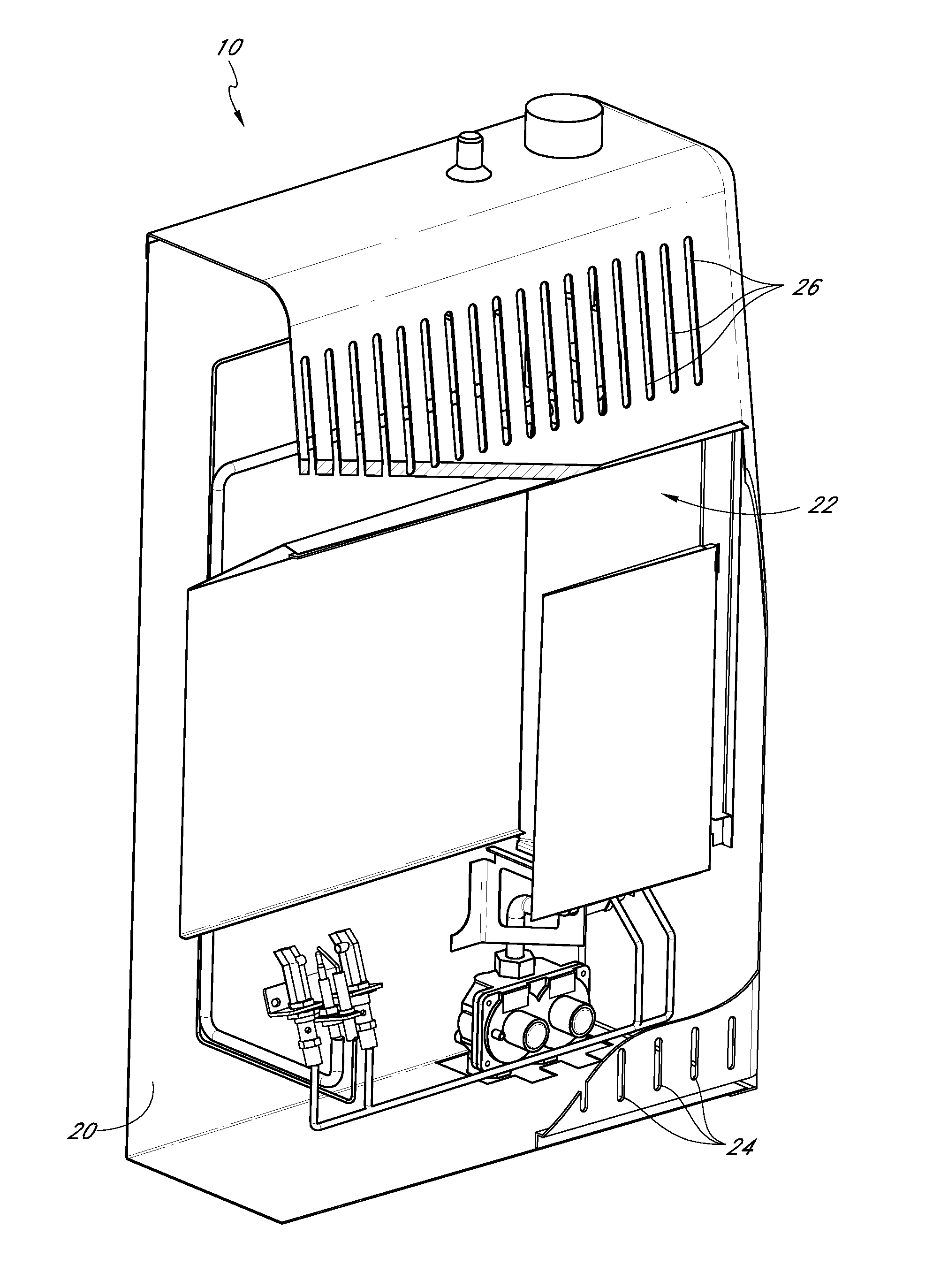

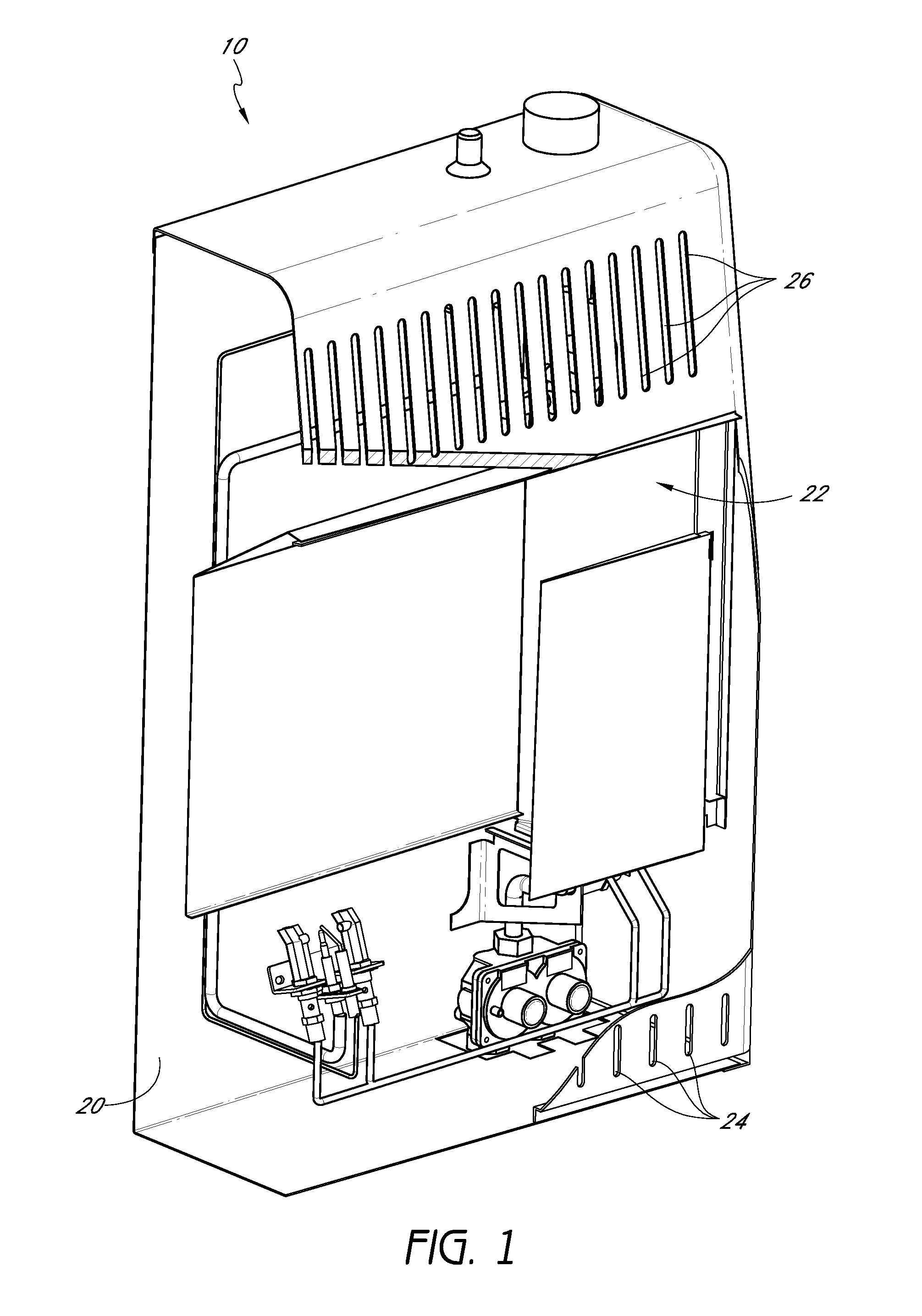

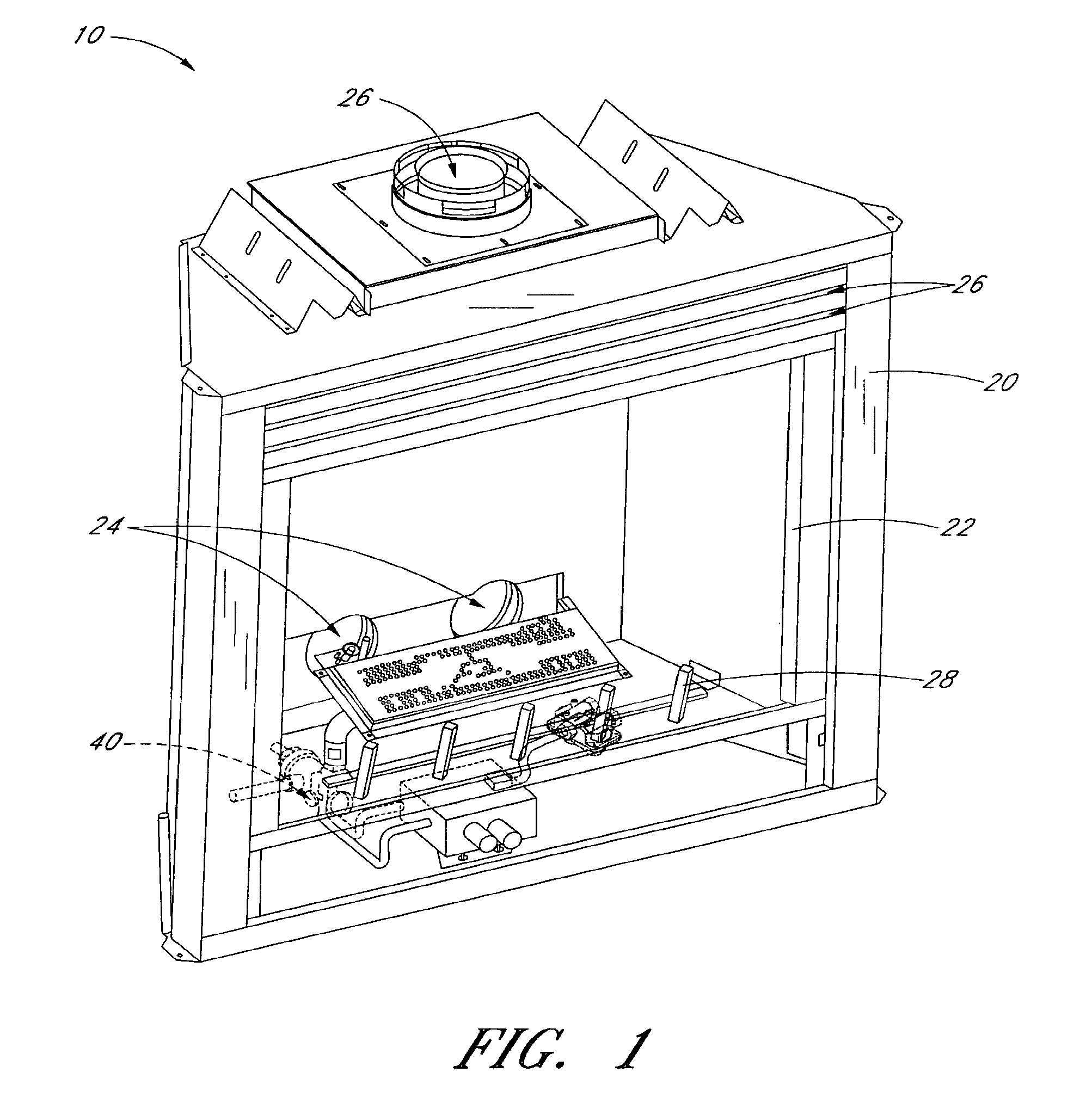

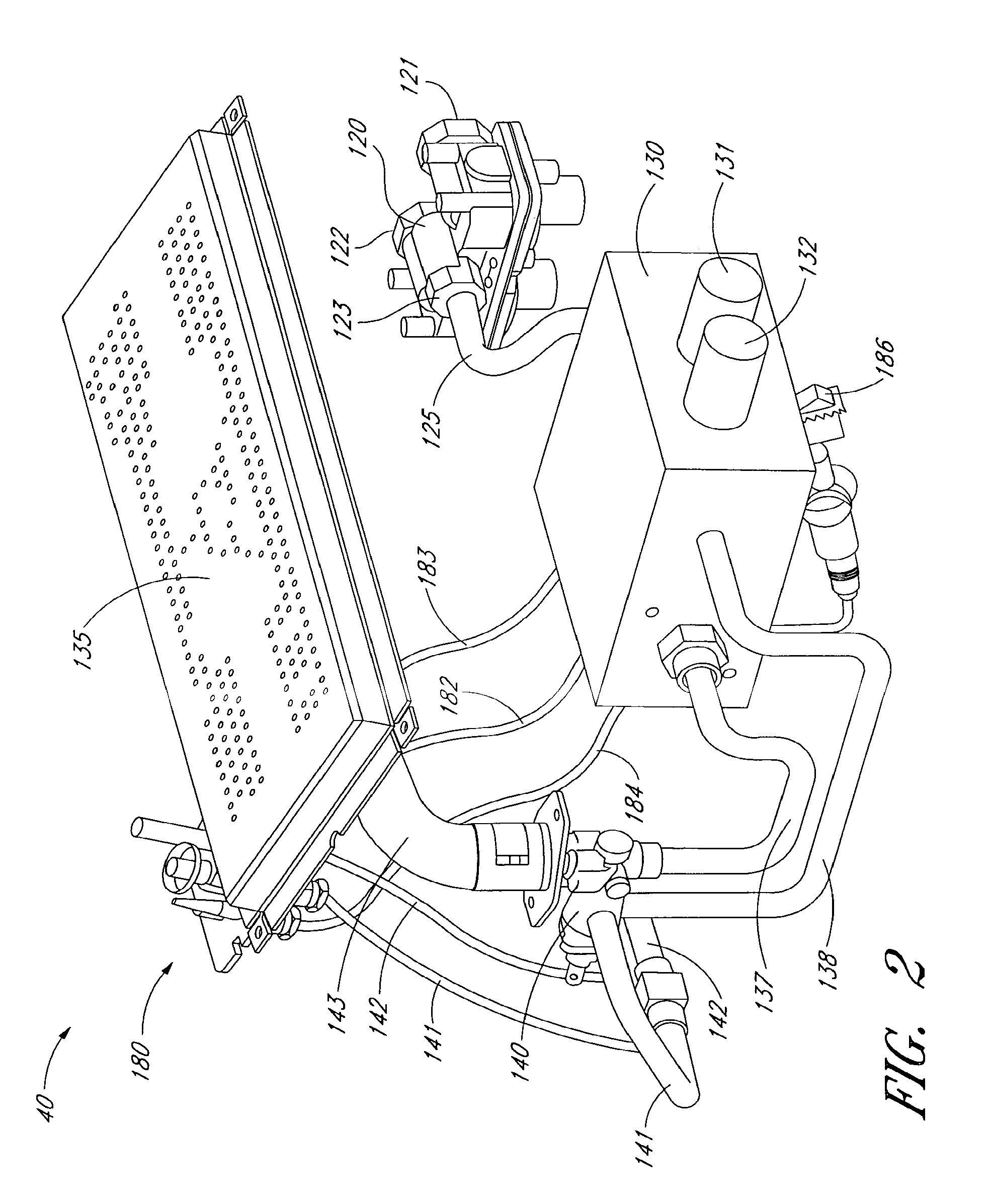

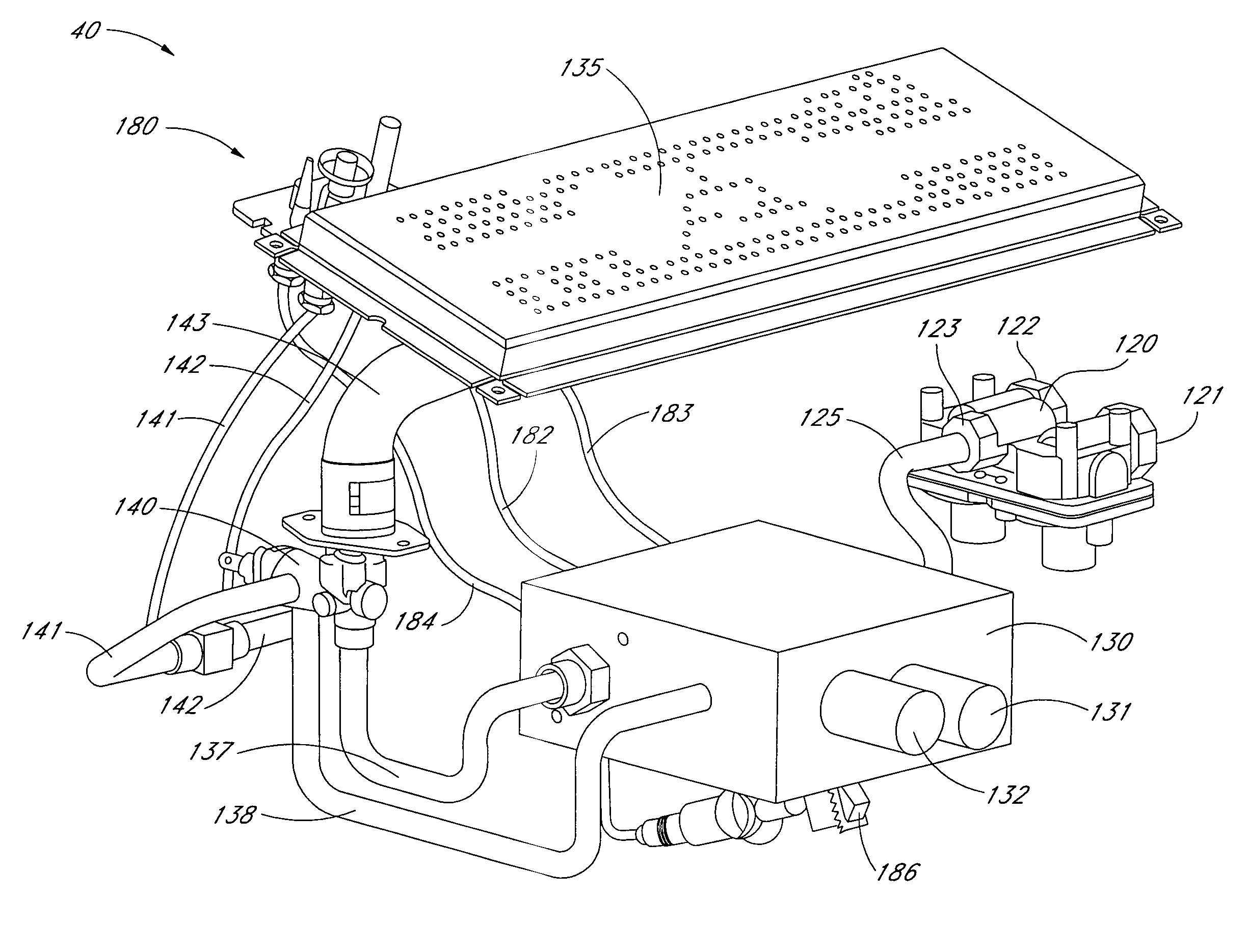

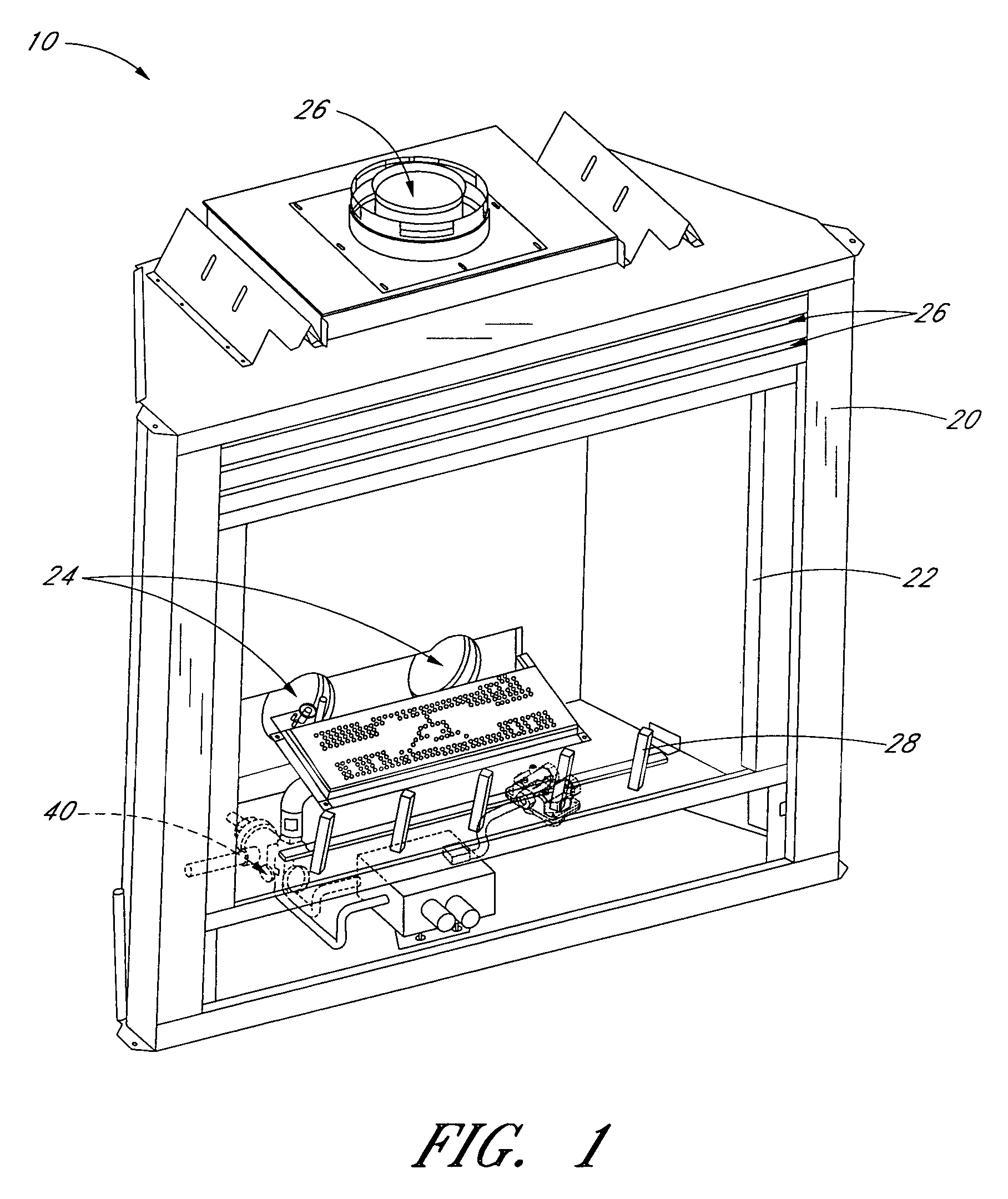

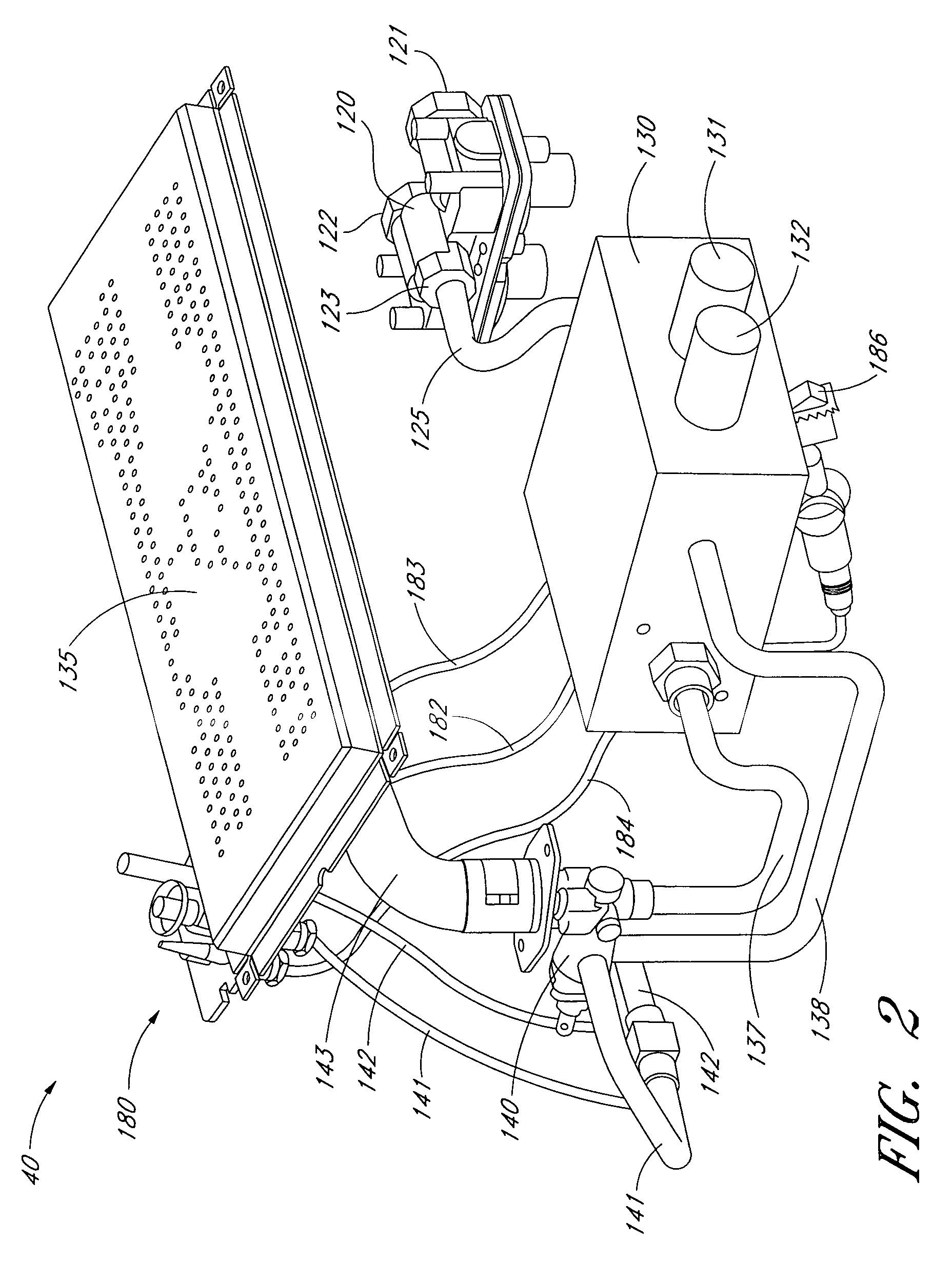

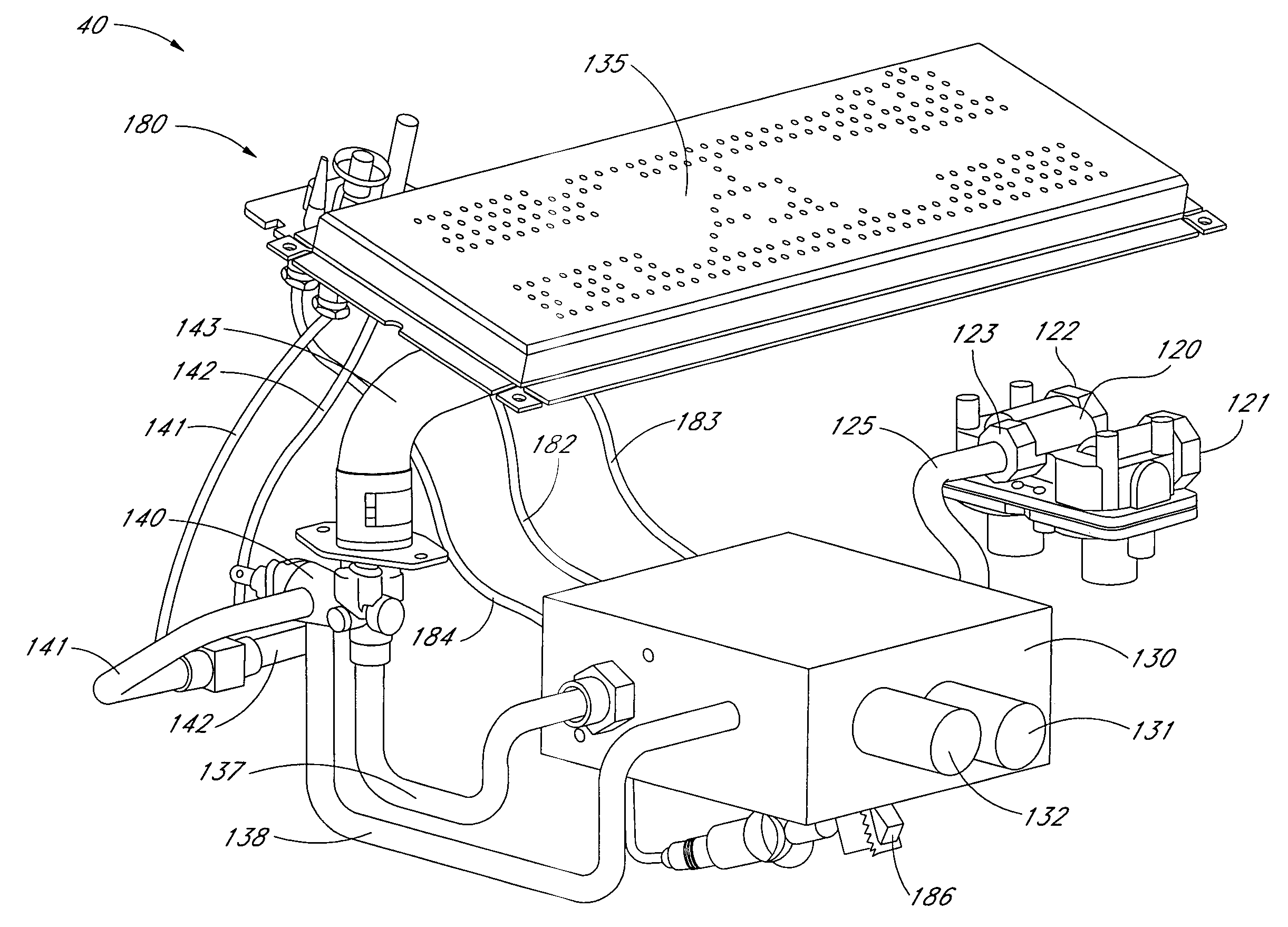

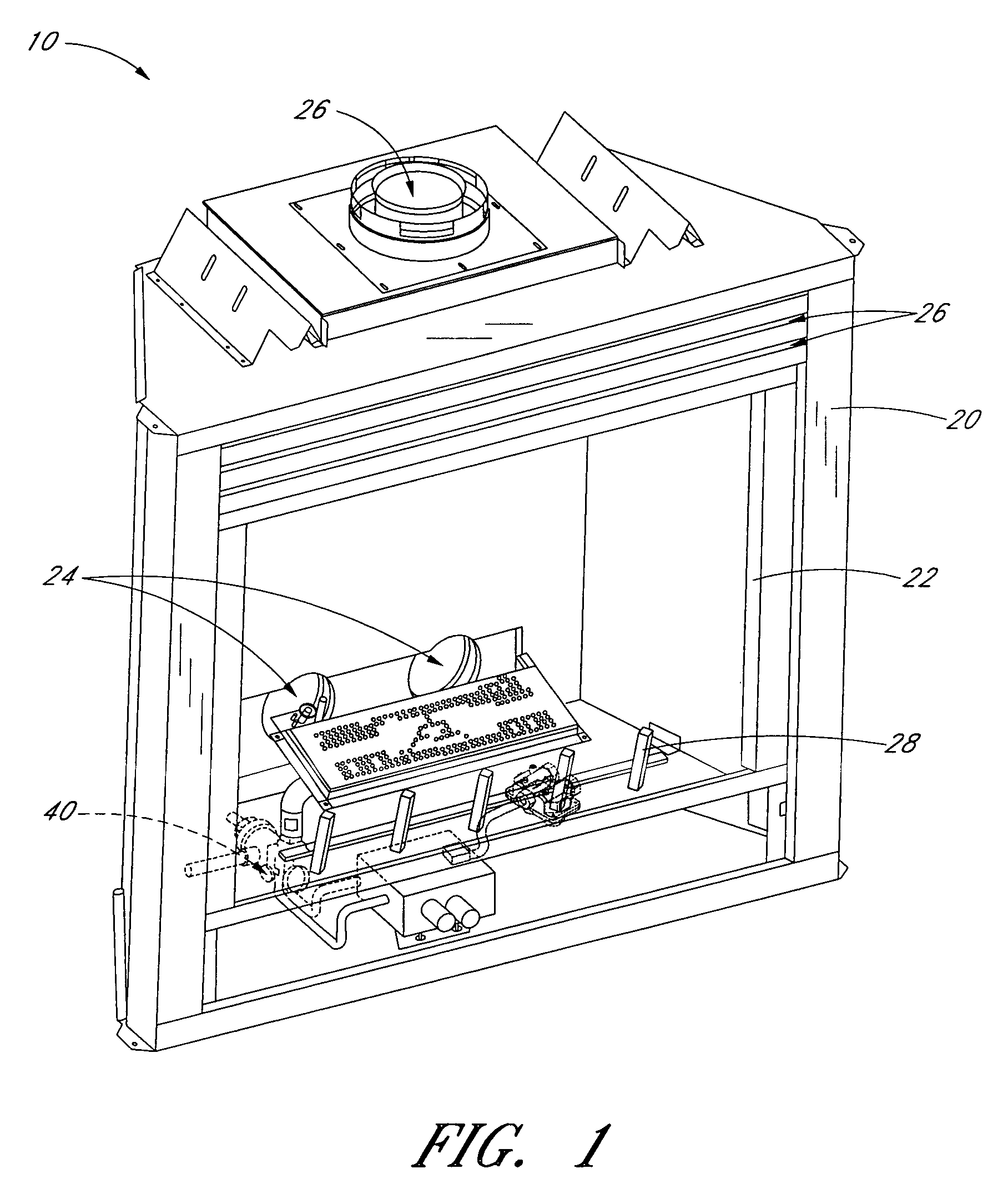

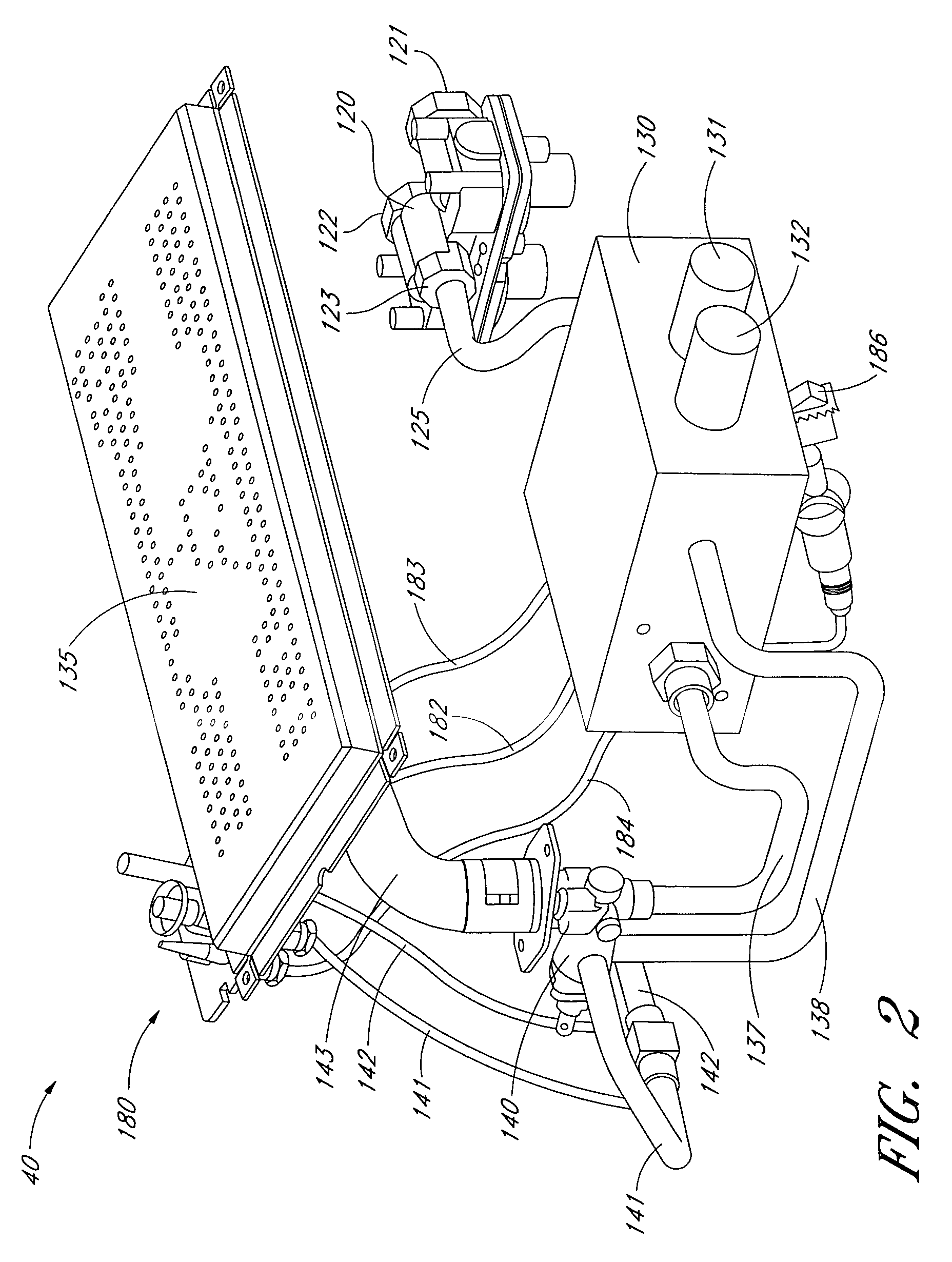

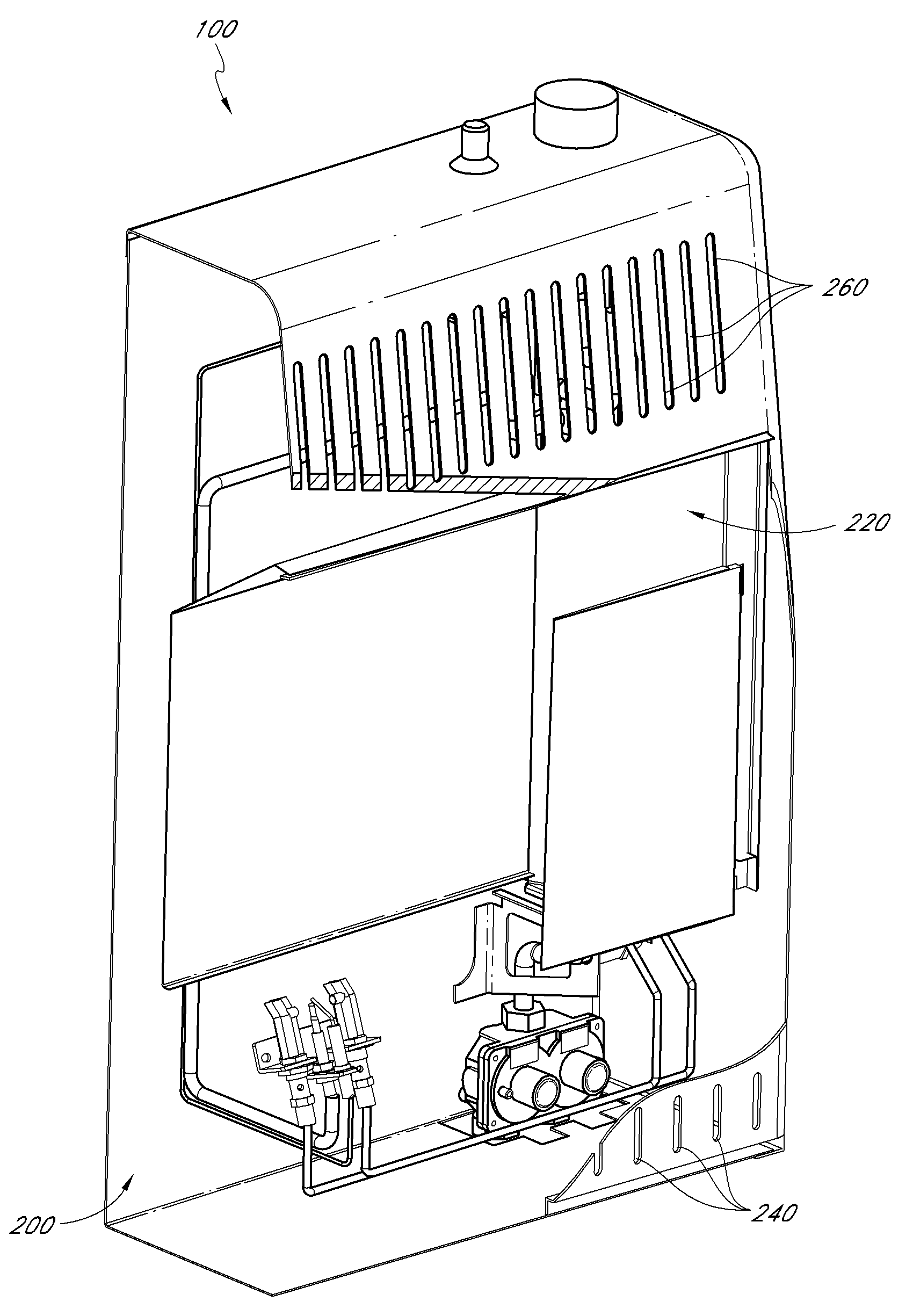

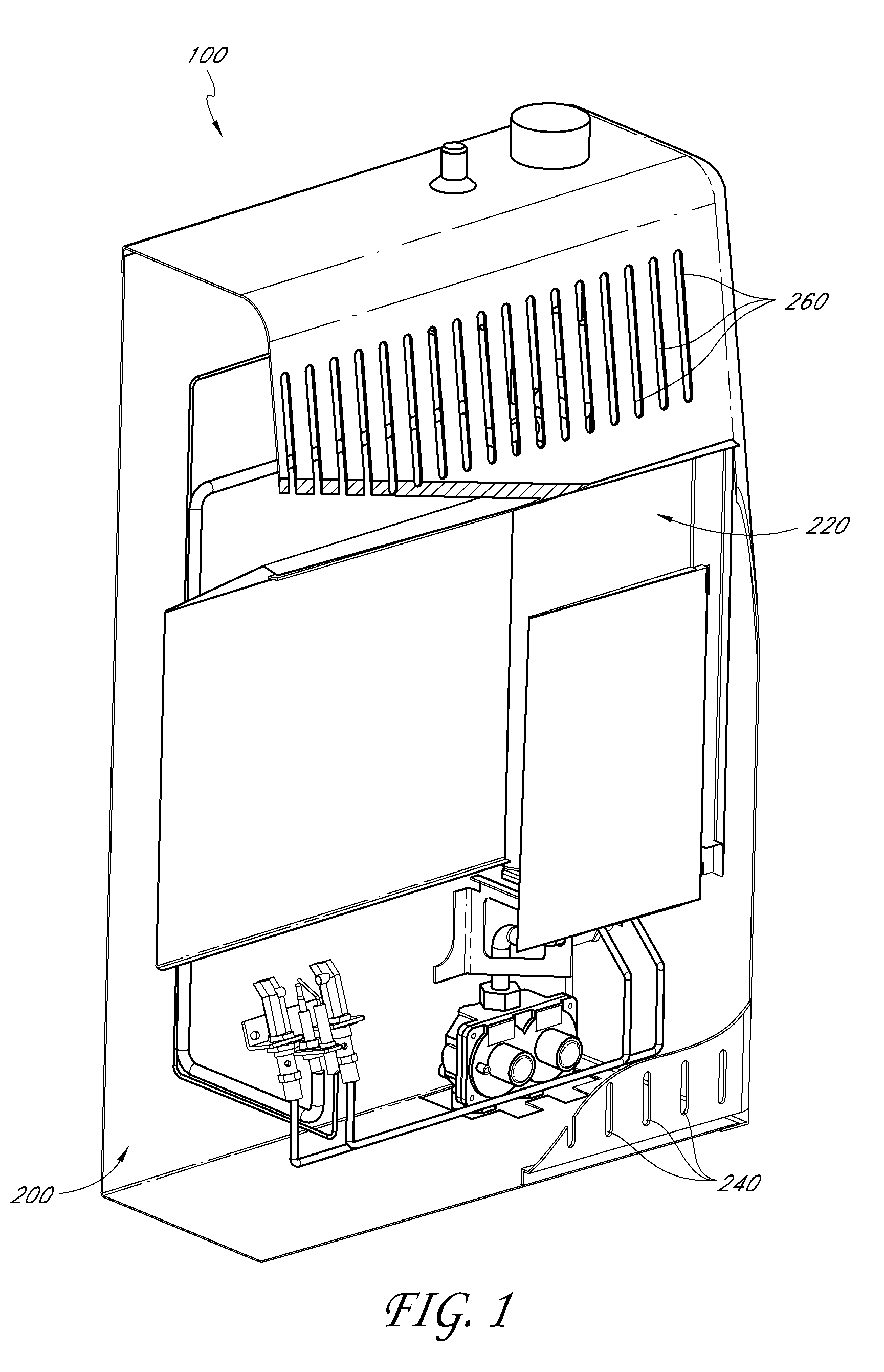

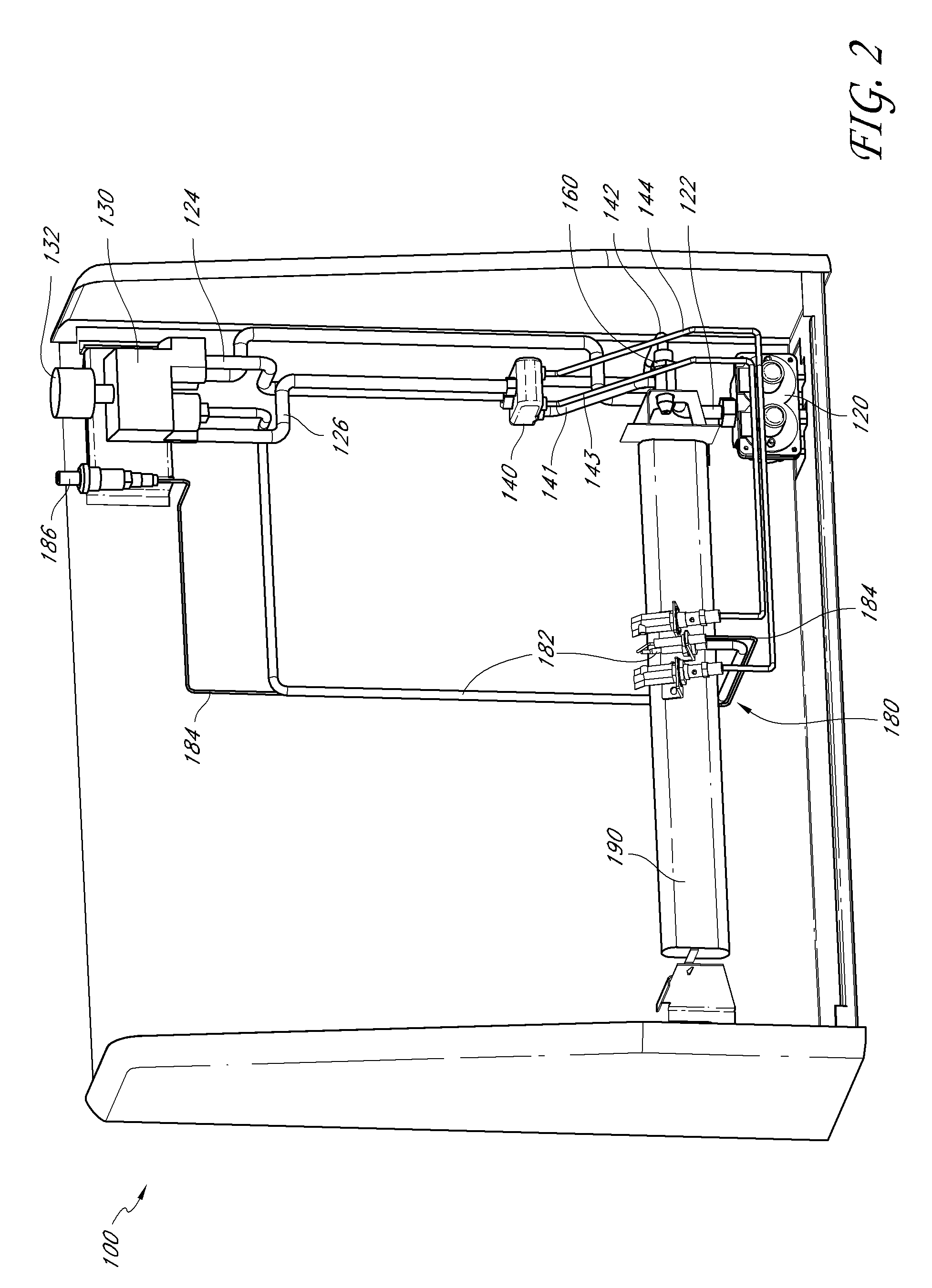

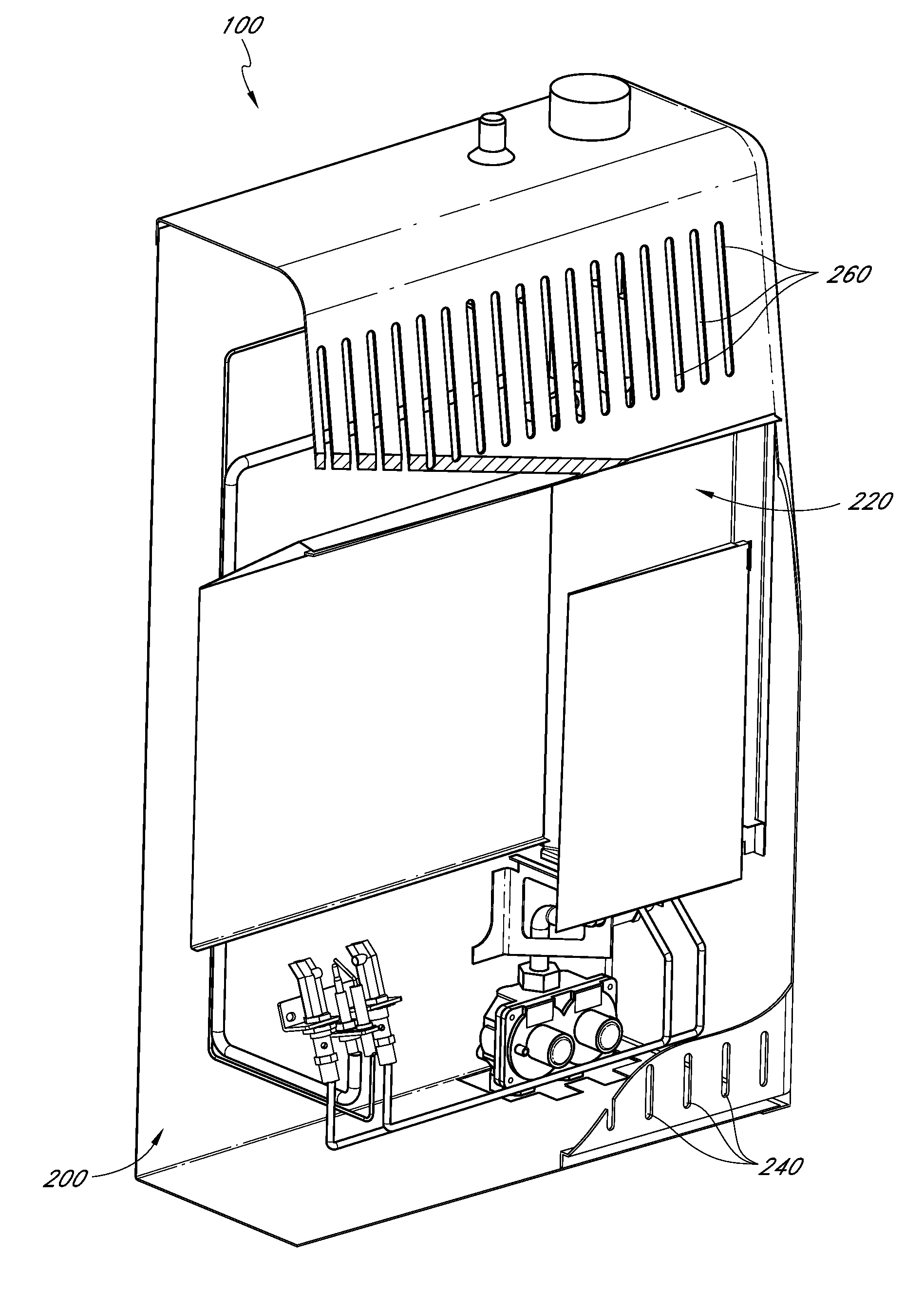

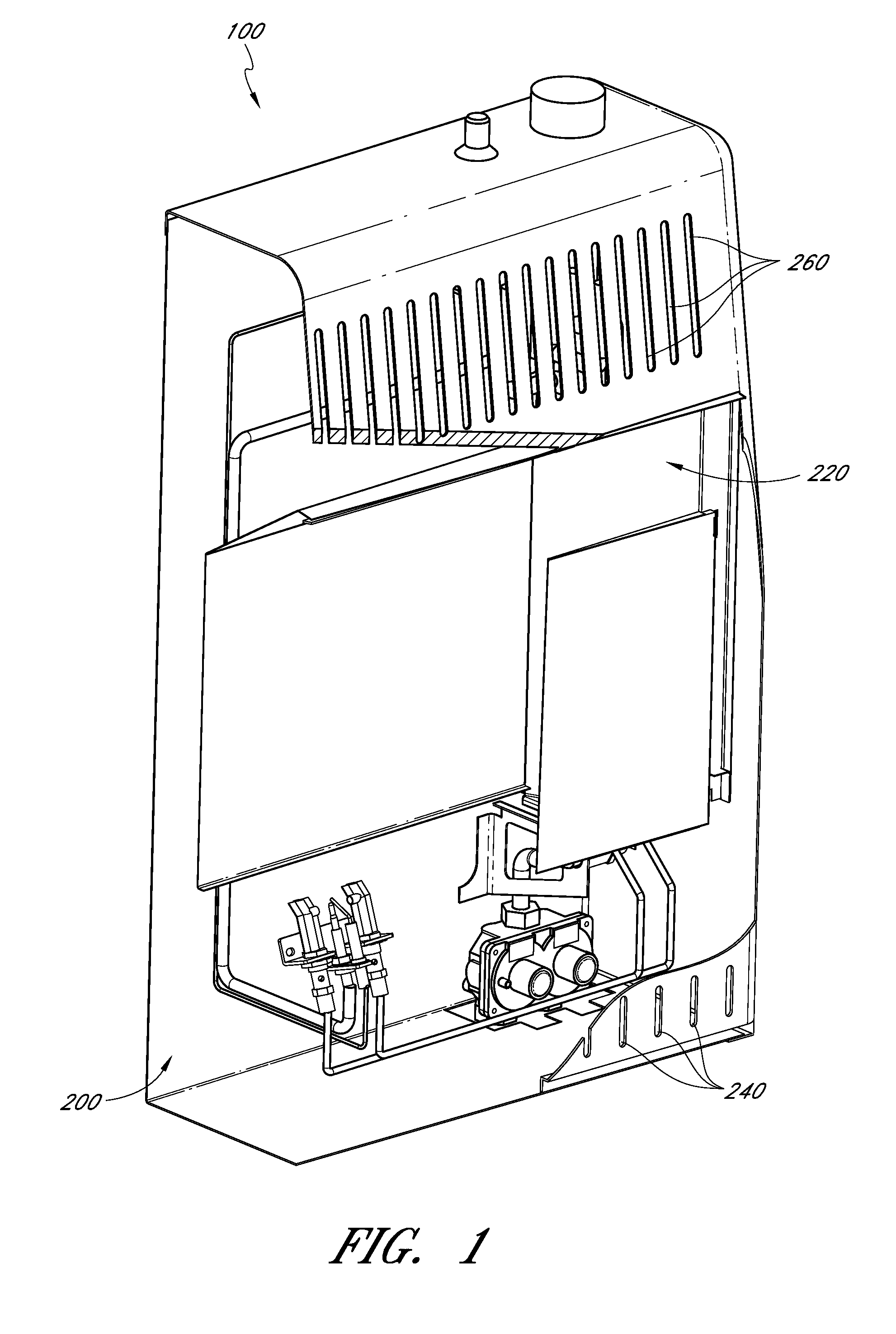

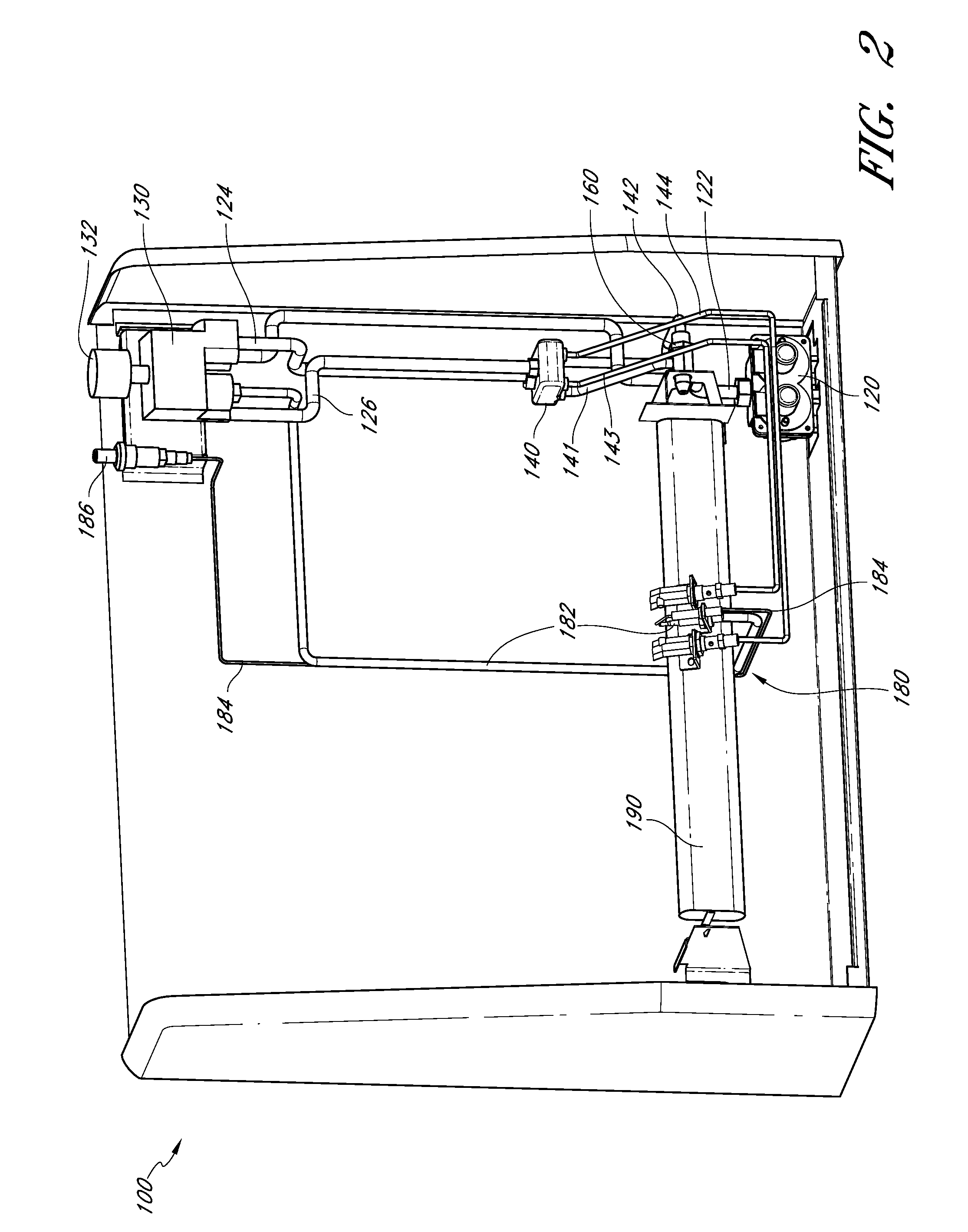

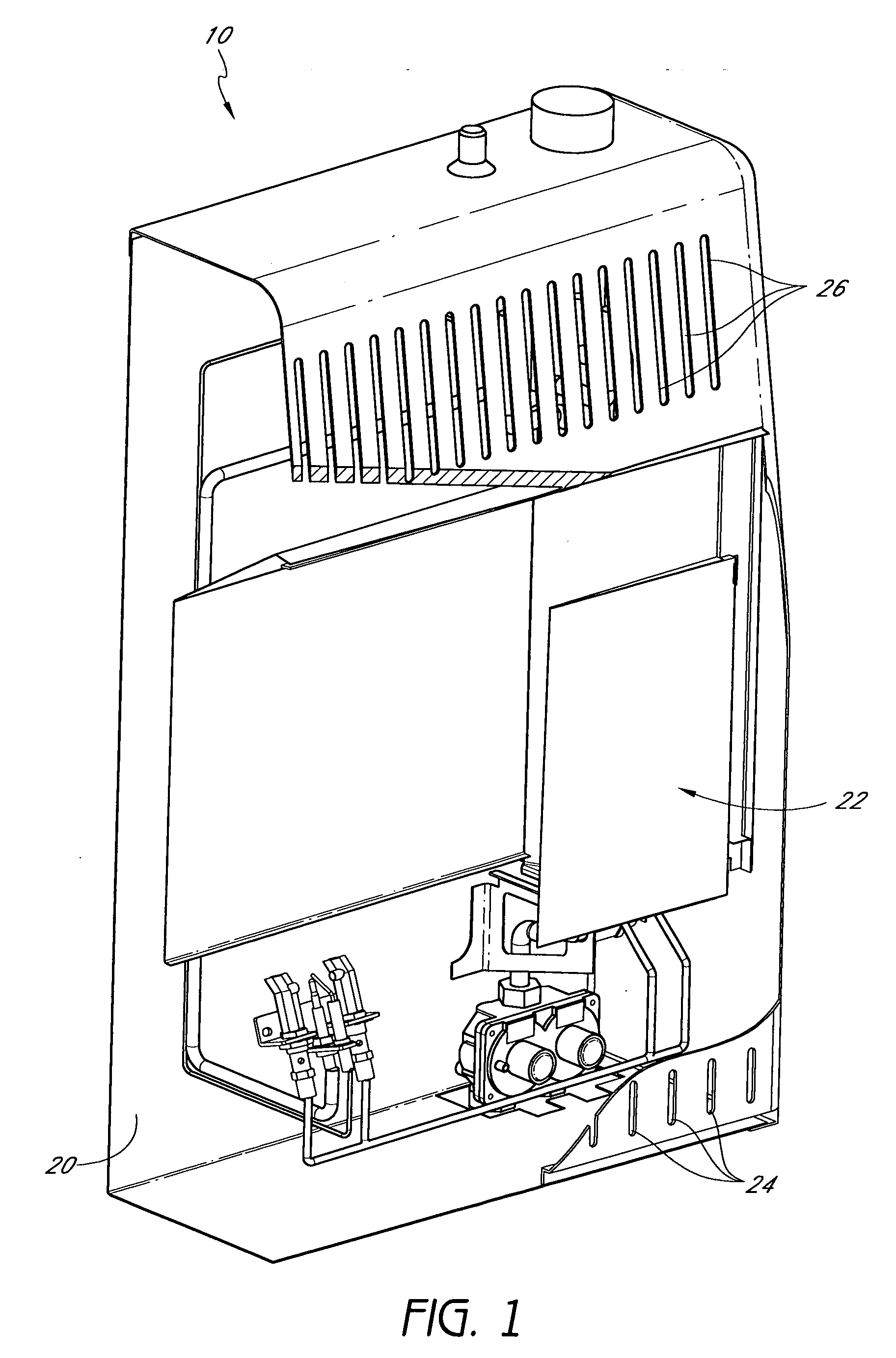

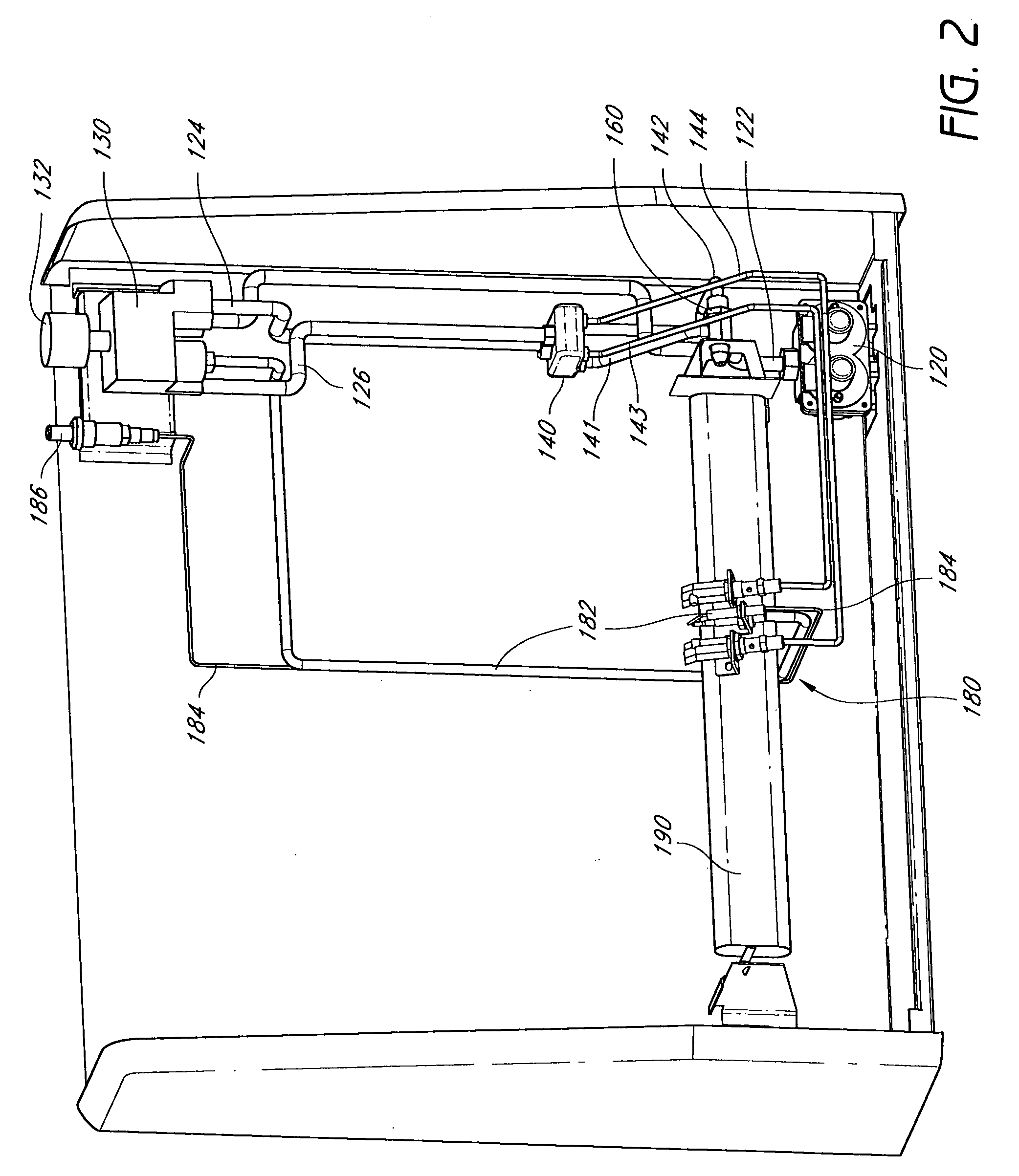

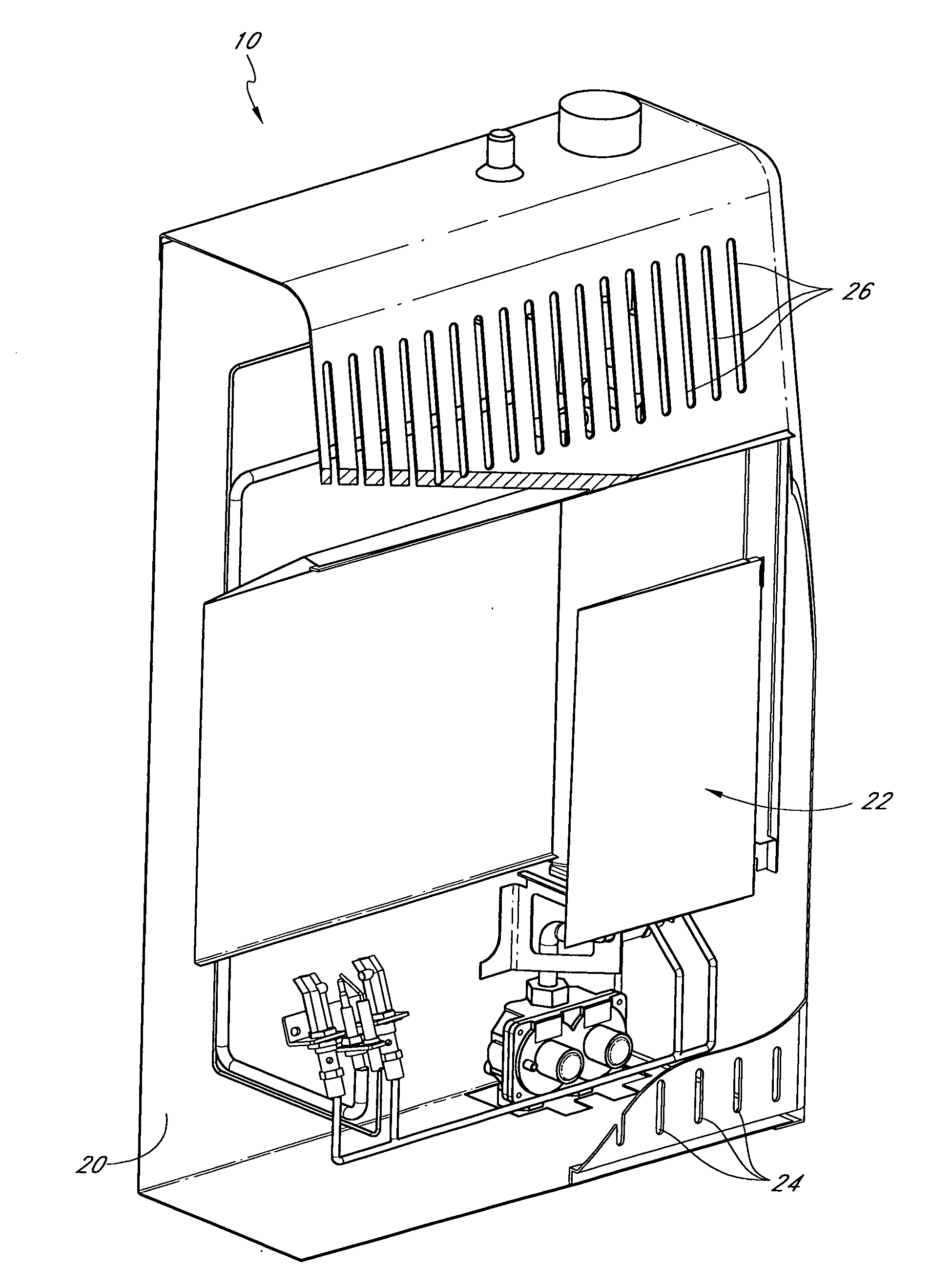

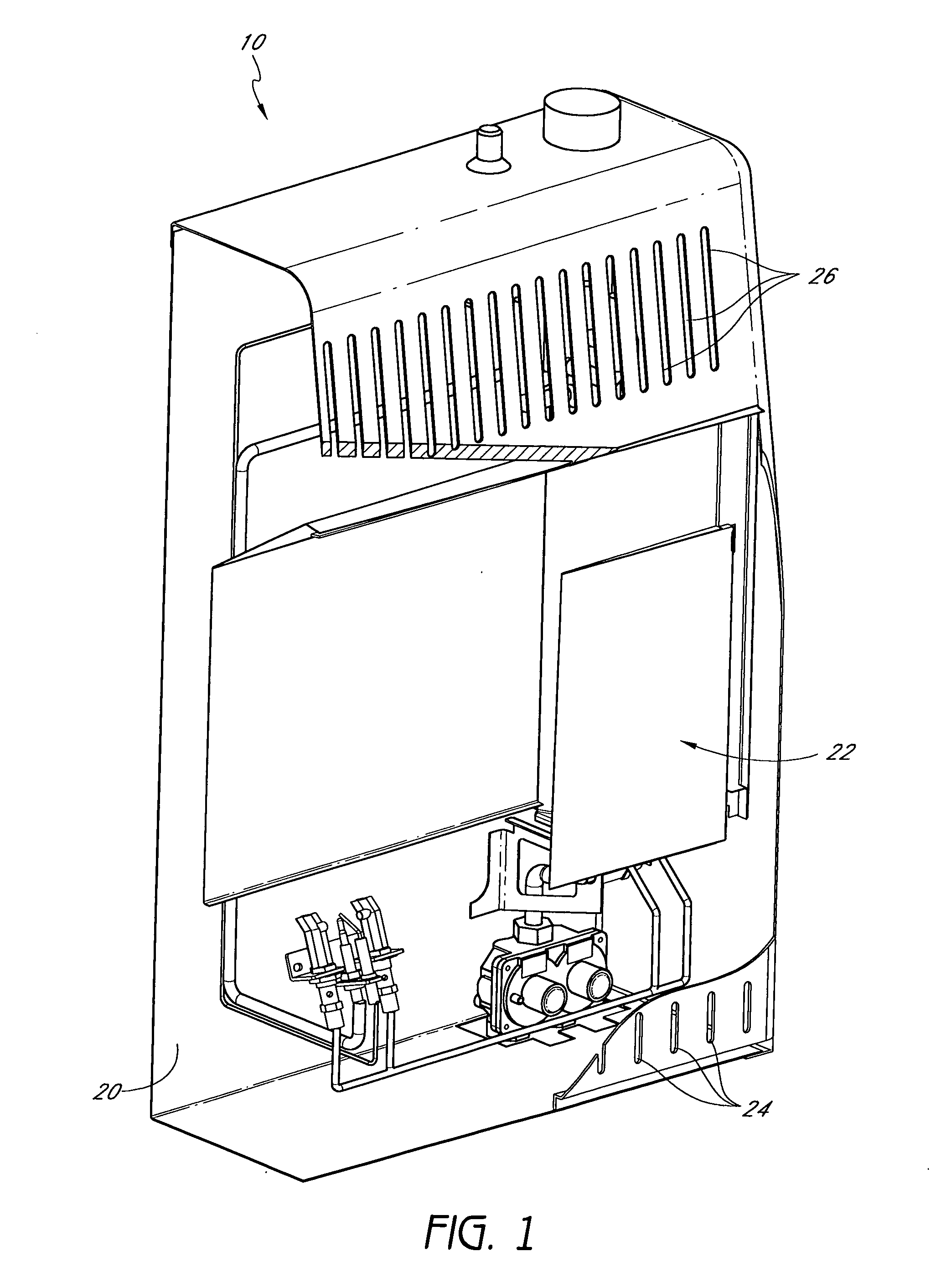

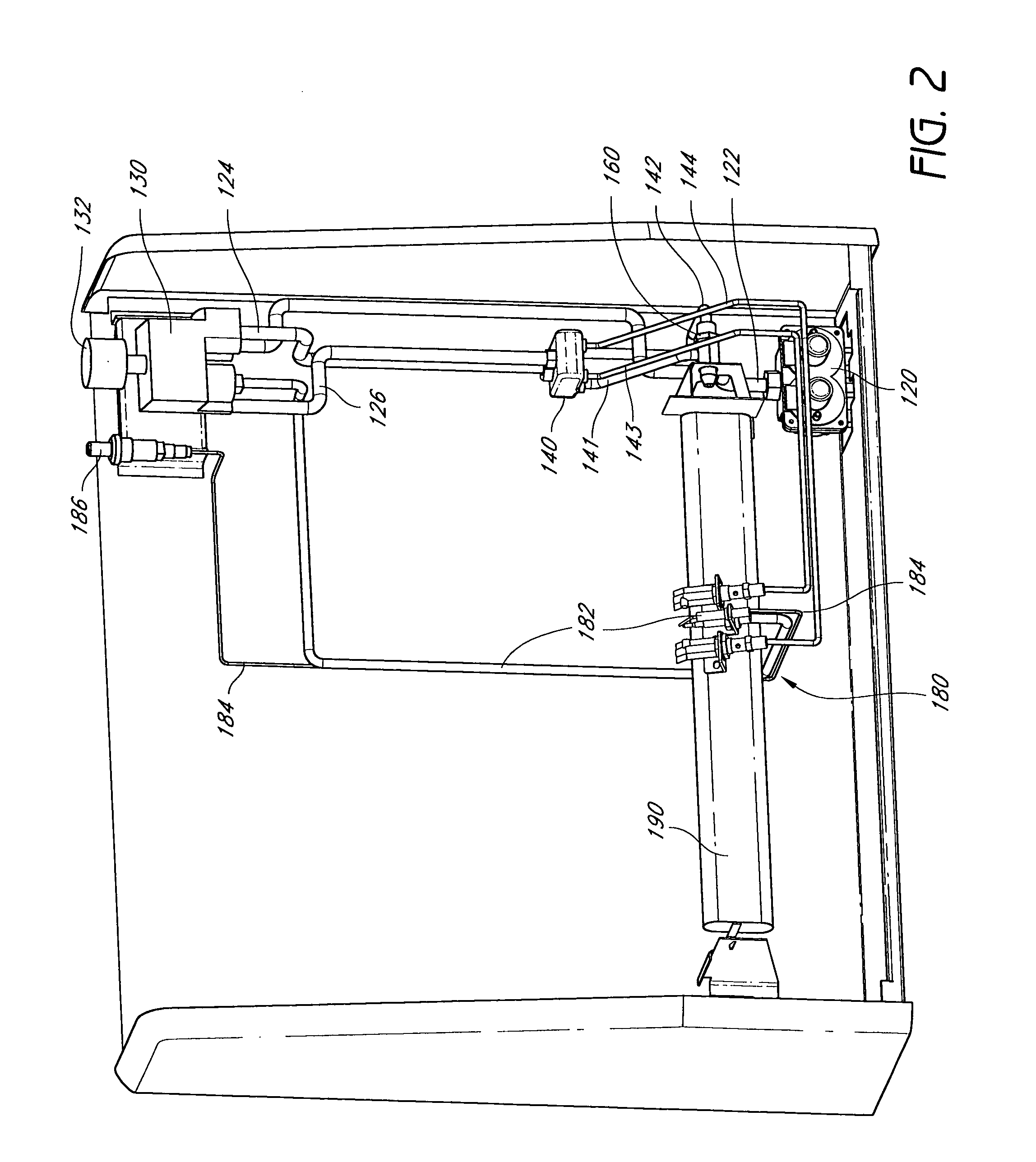

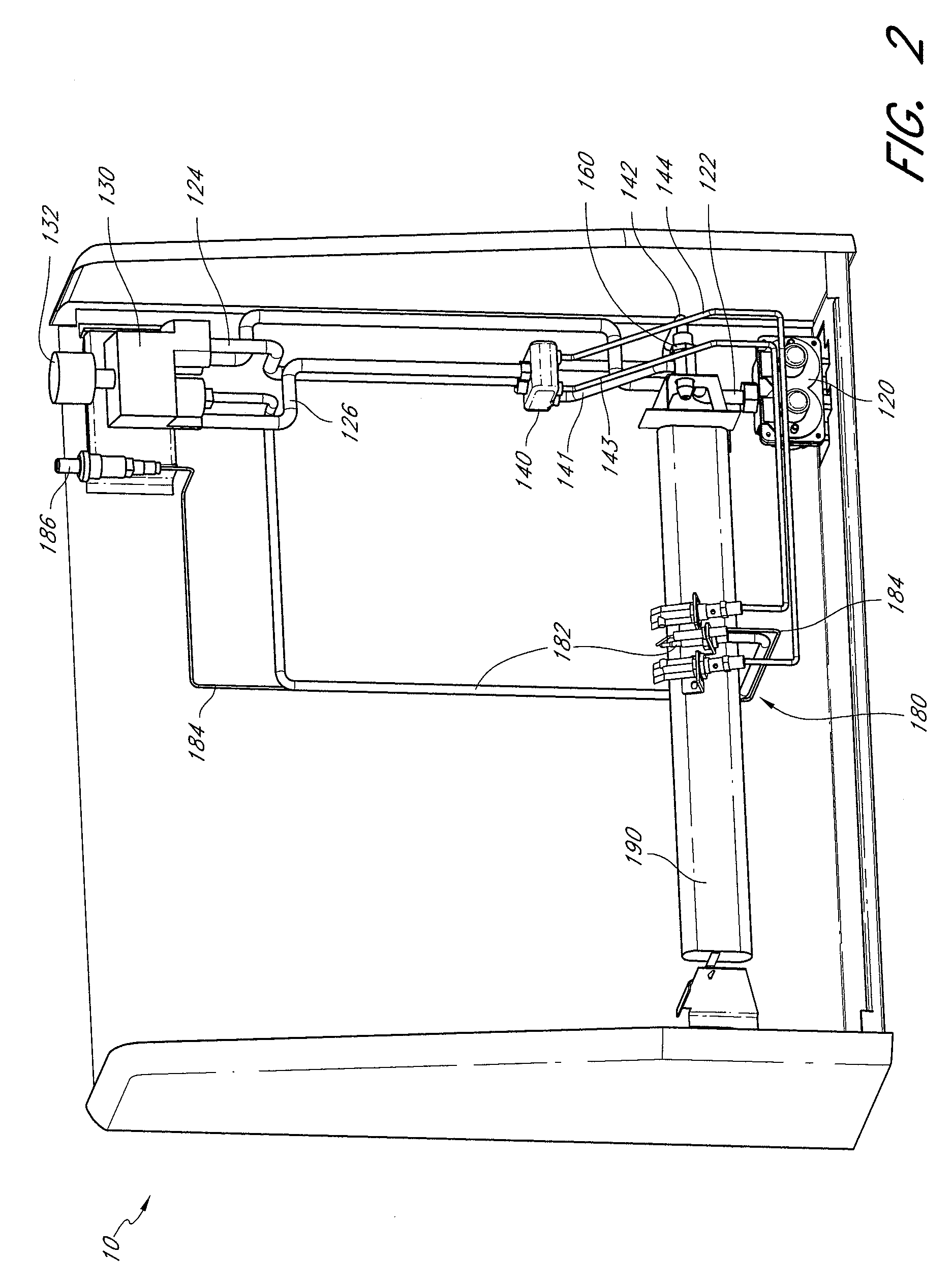

Dual fuel heater

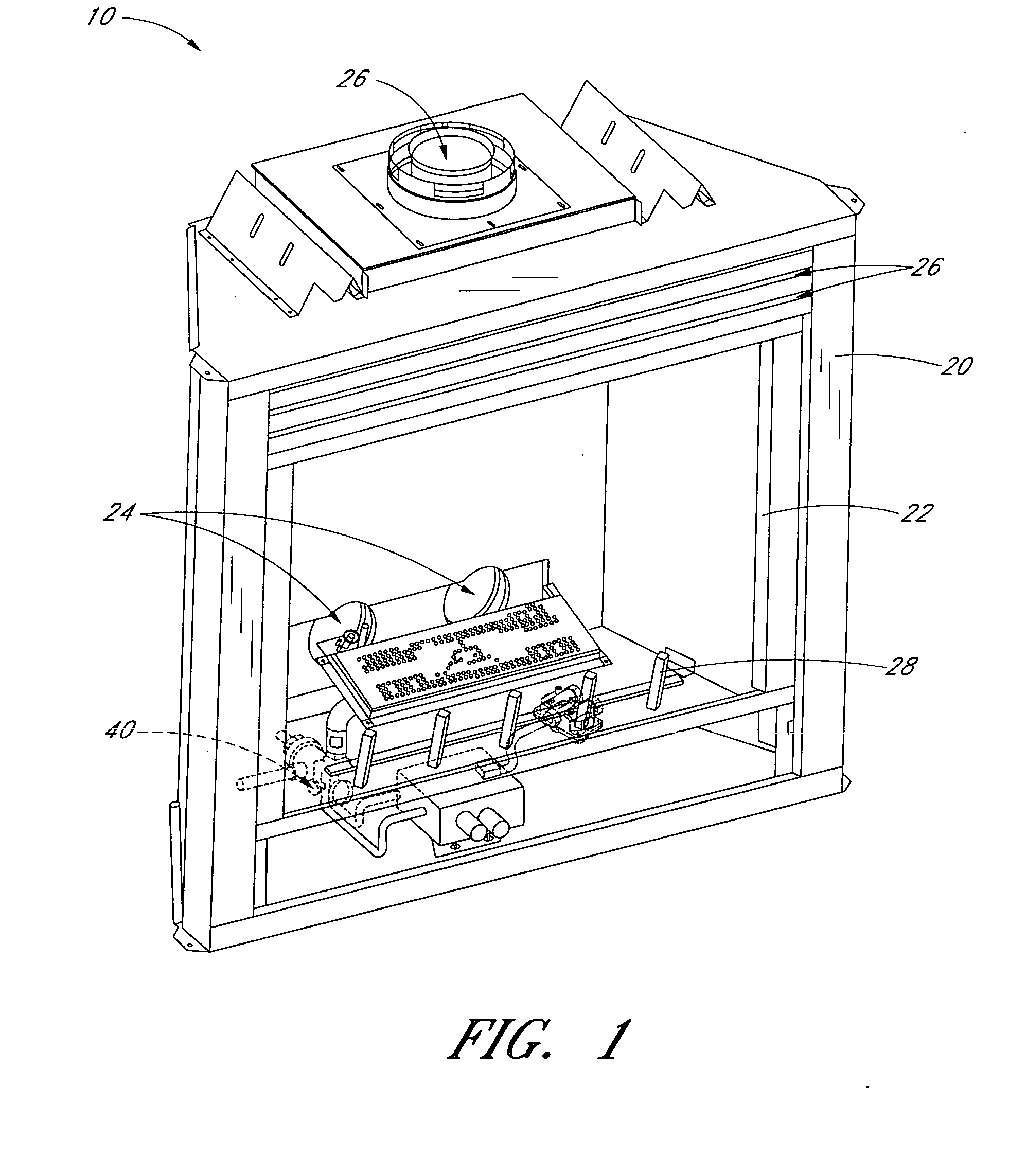

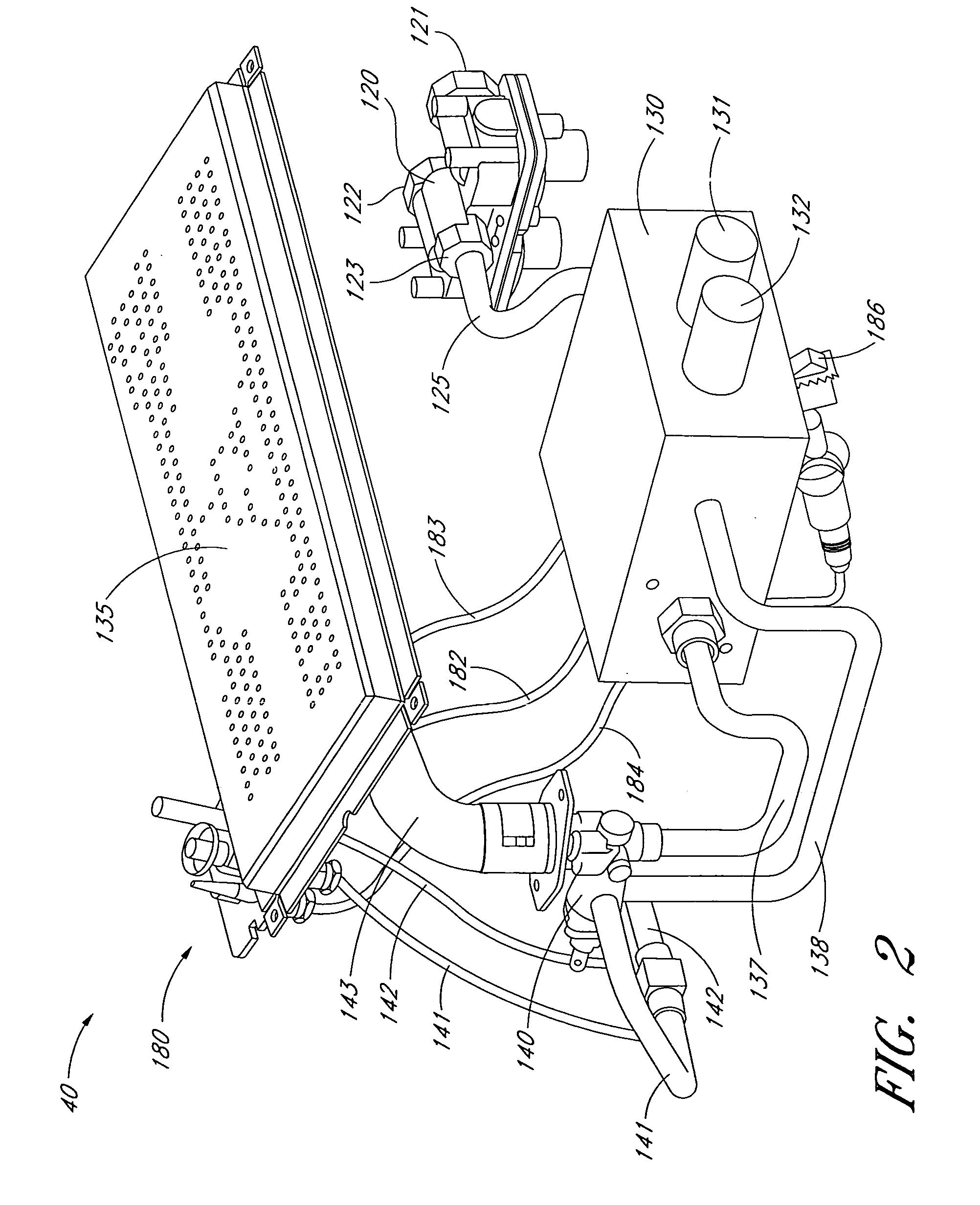

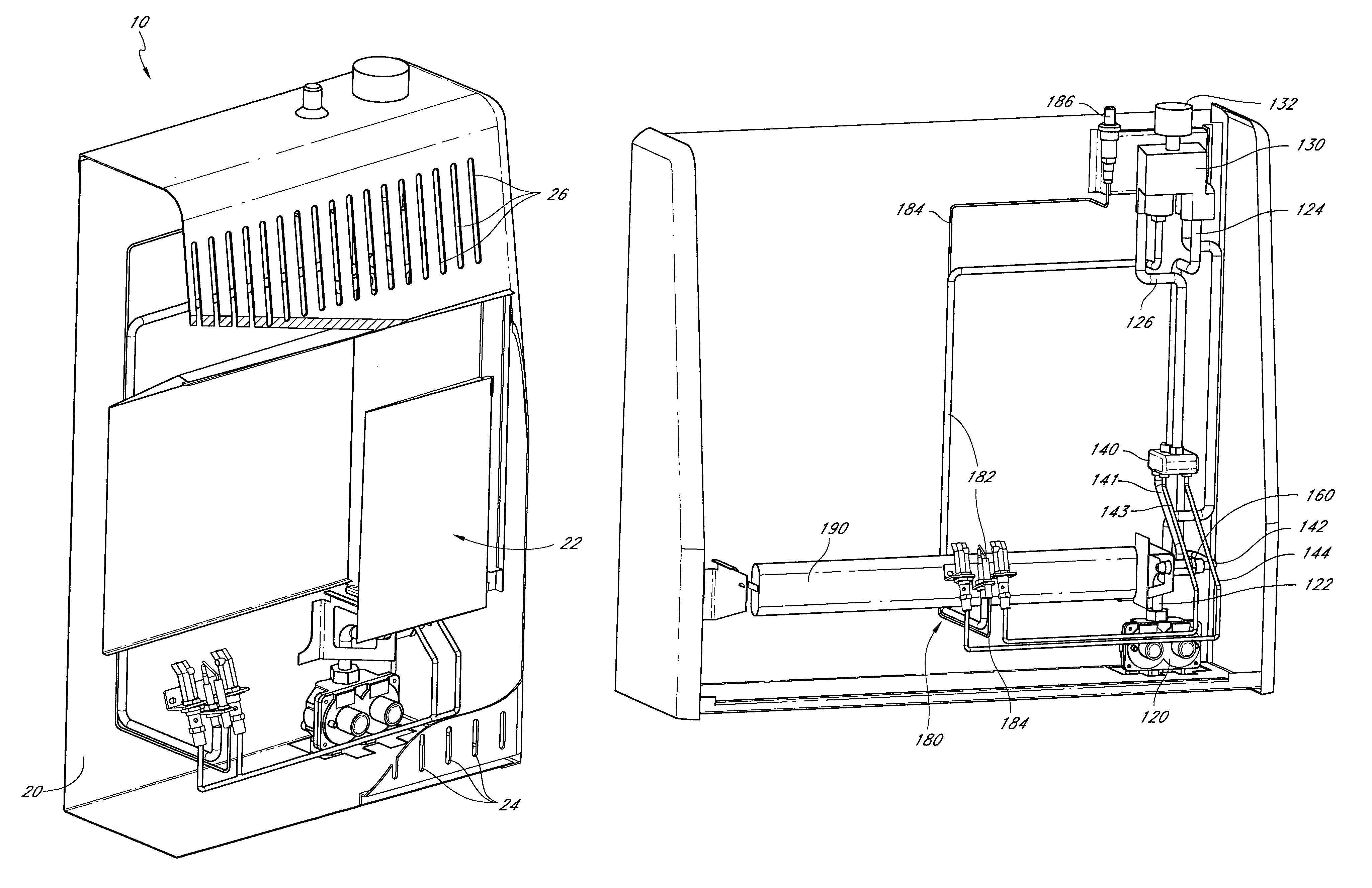

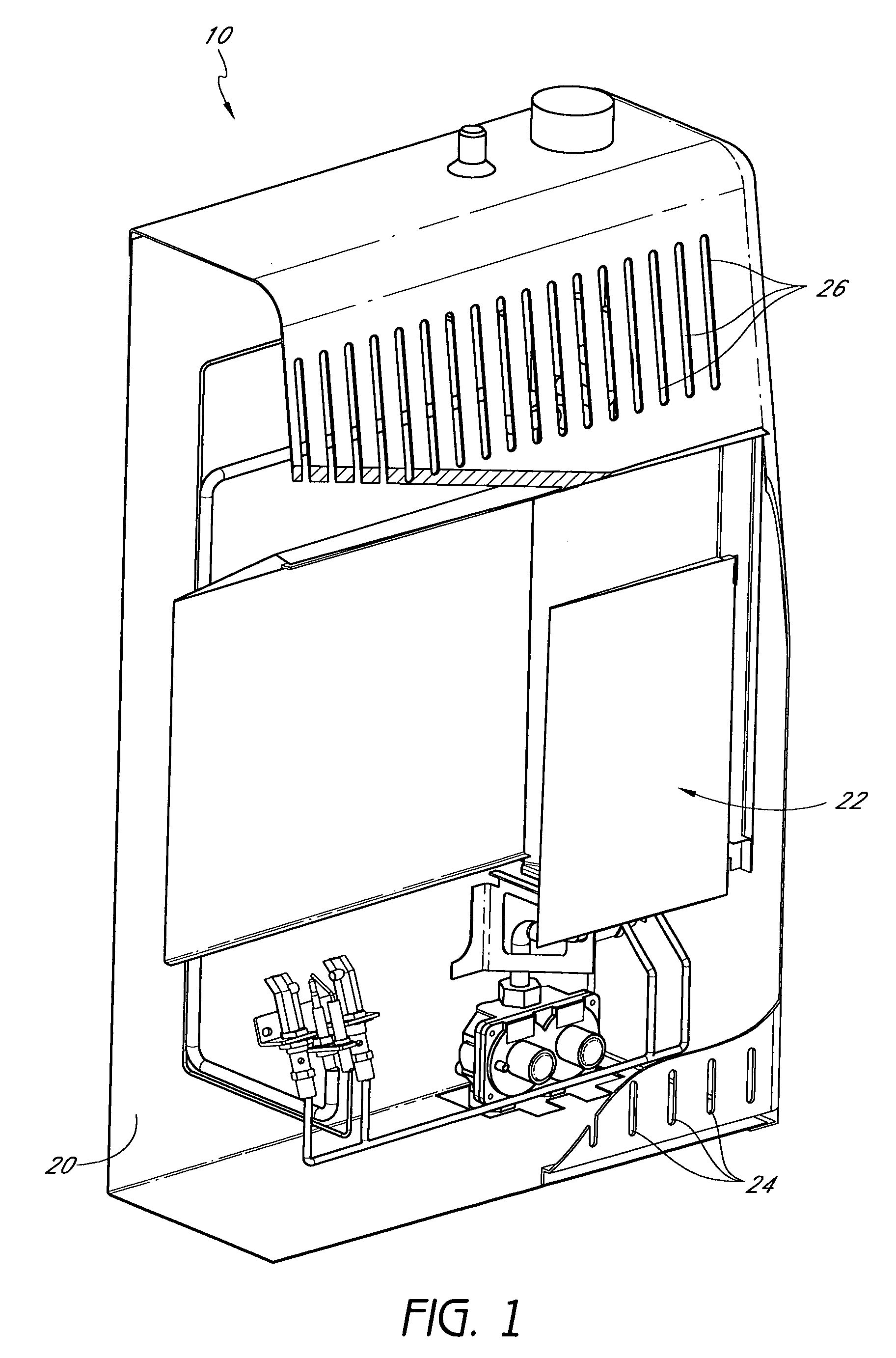

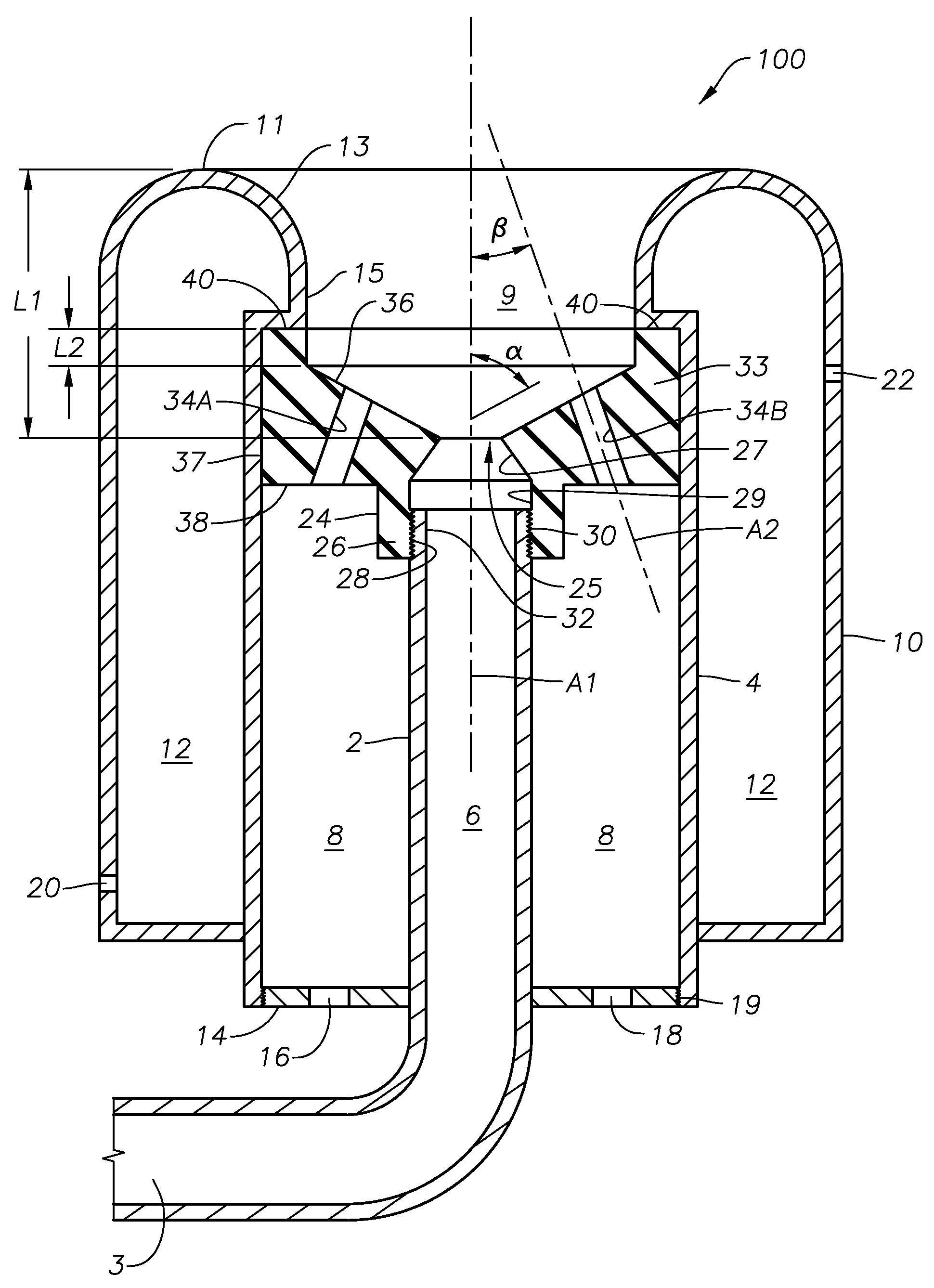

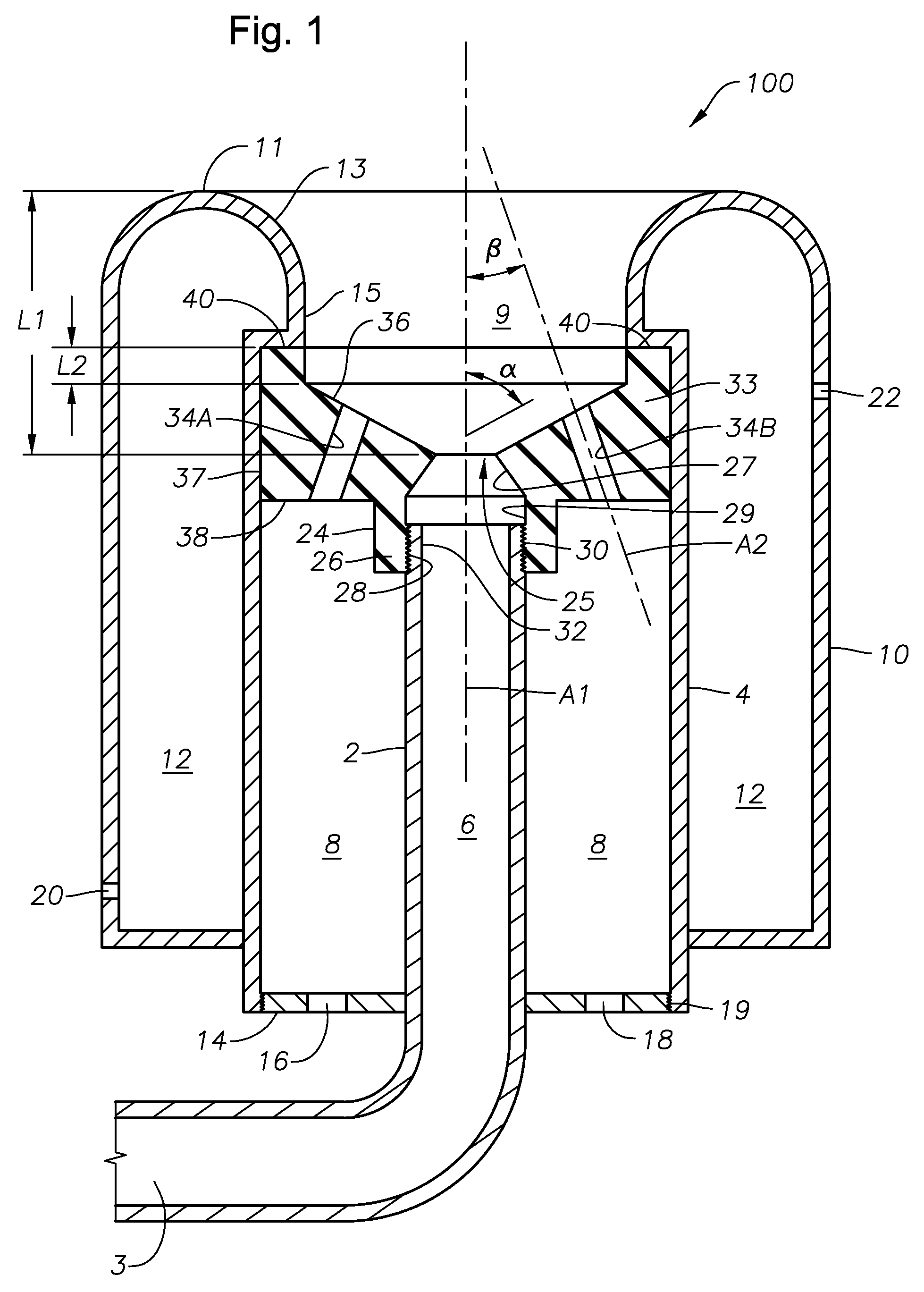

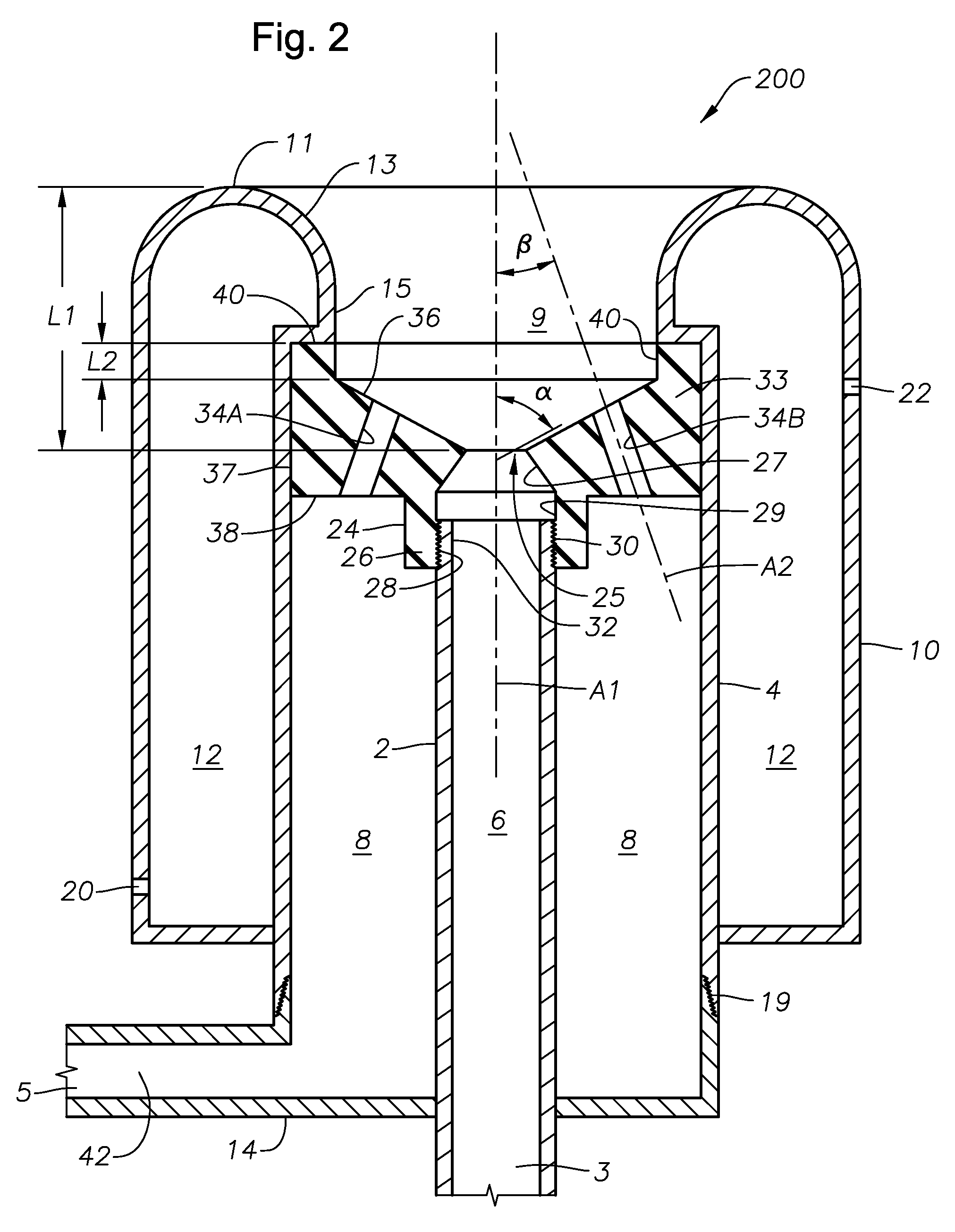

ActiveUS7607426B2Fuel supply regulationDomestic stoves or rangesCombustion chamberNuclear engineering

In certain embodiments, a dual fuel heater has a pressure regulating device for selectively coupling with a first source or a second source operating at different pressures. The dual fuel heater can also include first and second fuel lines, a fluid flow controller, a combustion chamber and first and second oxygen depletion sensor nozzles. The fluid flow controller is configured to selectively permit flow of fuel to either the first fuel line or to the second fuel line. In some embodiments, the first fuel line is connected to the first oxygen depletion sensor nozzle and the second fuel line is connected to the second oxygen depletion nozzle.

Owner:PROCOM HEATING

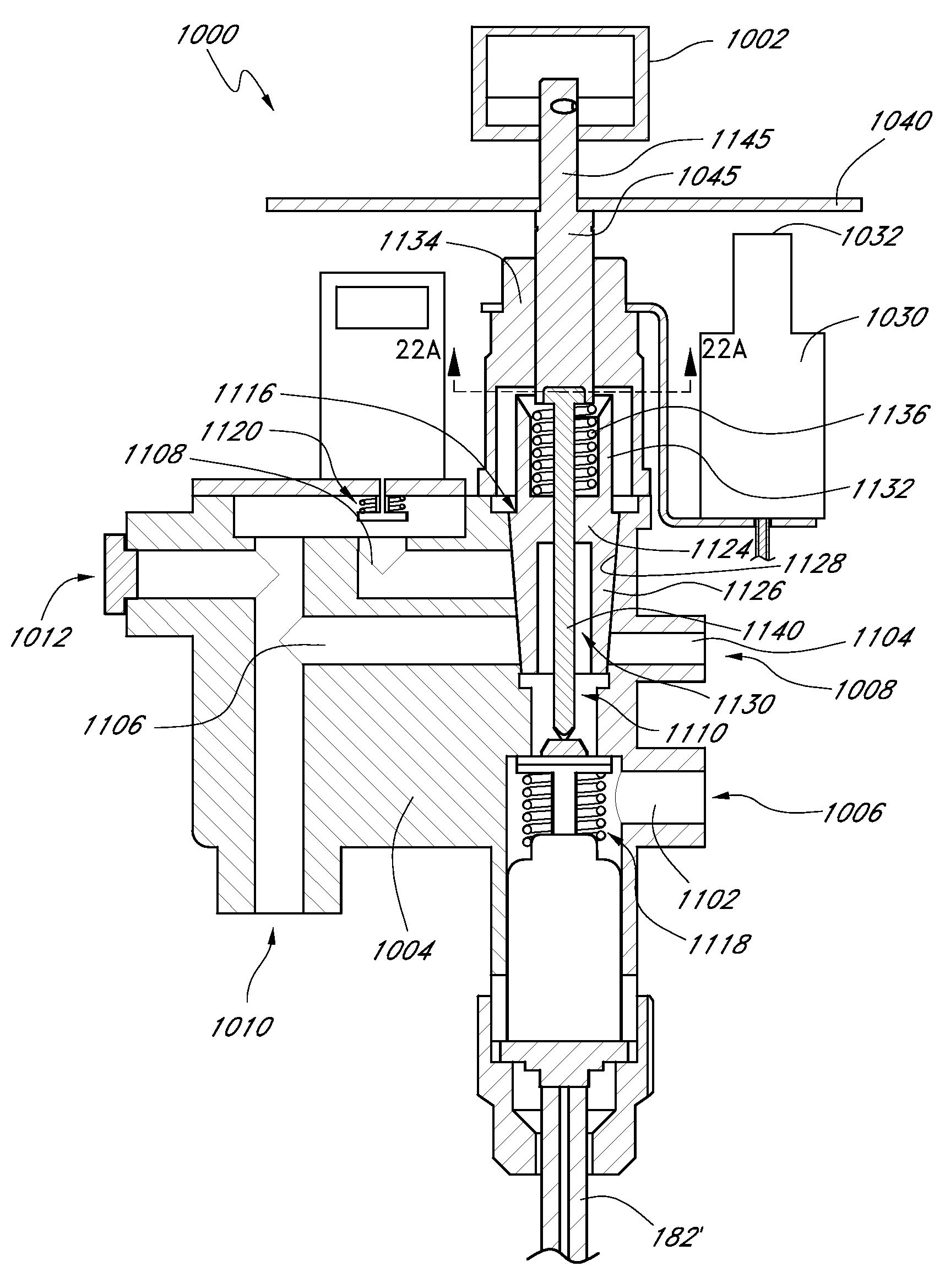

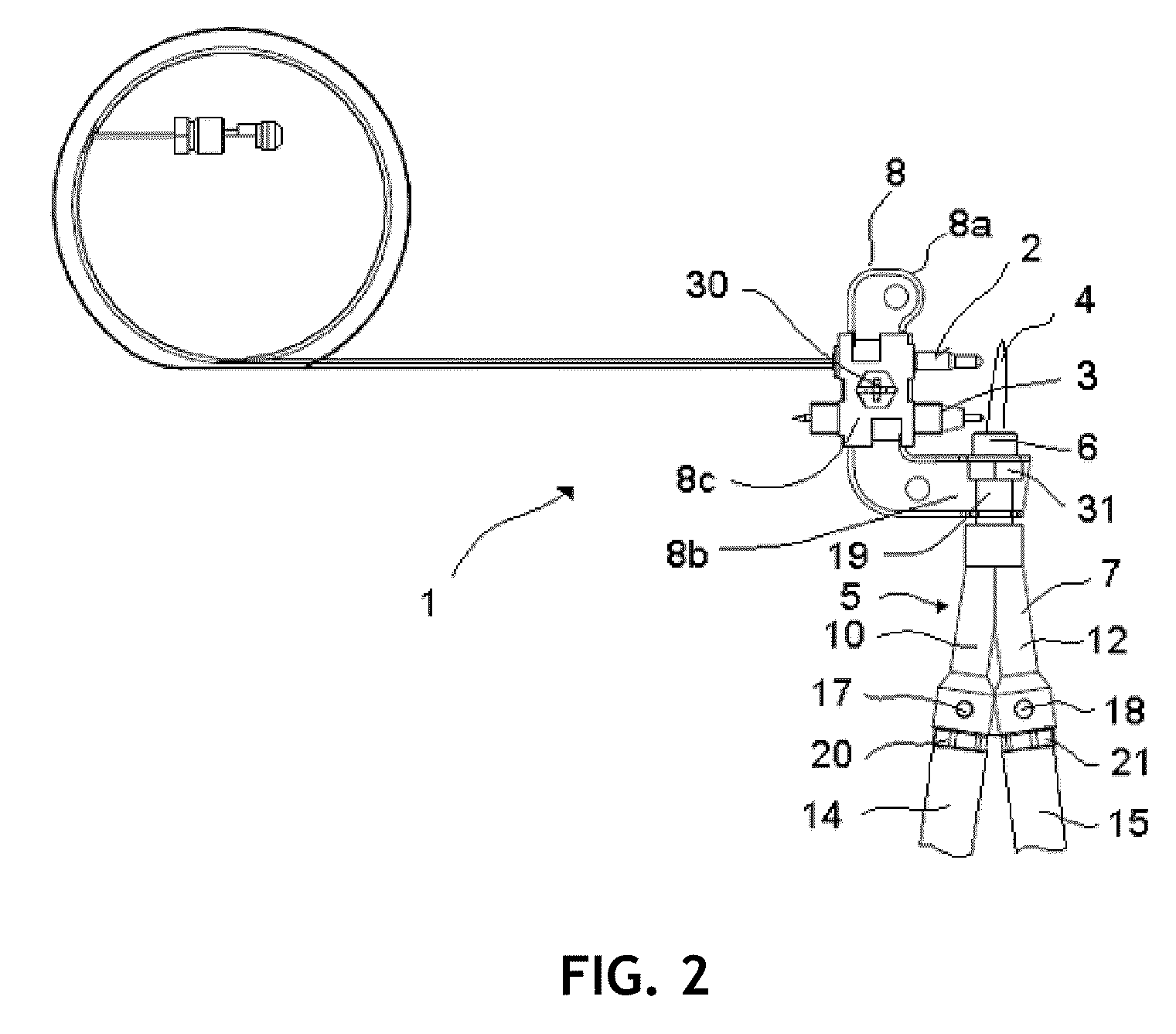

Control valves for heaters and fireplace devices

In certain embodiments, a control valve assembly for gas heaters and gas fireplace devices includes a housing. The housing can define an inlet for accepting fuel from a fuel source, a first outlet for delivering fuel to an oxygen depletion sensor, and a second outlet for delivering fuel to a burner. The assembly can include a valve body configured to selectively provide fluid communication between the inlet and one or more of the first outlet and the second outlet, and can include an actuator configured to move the valve body relative to the housing. The actuator can be configured to transition between a resting state and a displaced state. The assembly can include an igniter that includes a sensor, the igniter electrically coupled with an electrode and configured to repeatedly activate the electrode when the sensor senses that the actuator is in the displaced state. The assembly can include a shutoff valve electrically coupled with the oxygen depletion sensor and configured to operate in response to an electrical quantity communicated by the oxygen depletion sensor.

Owner:PROCOM HEATING

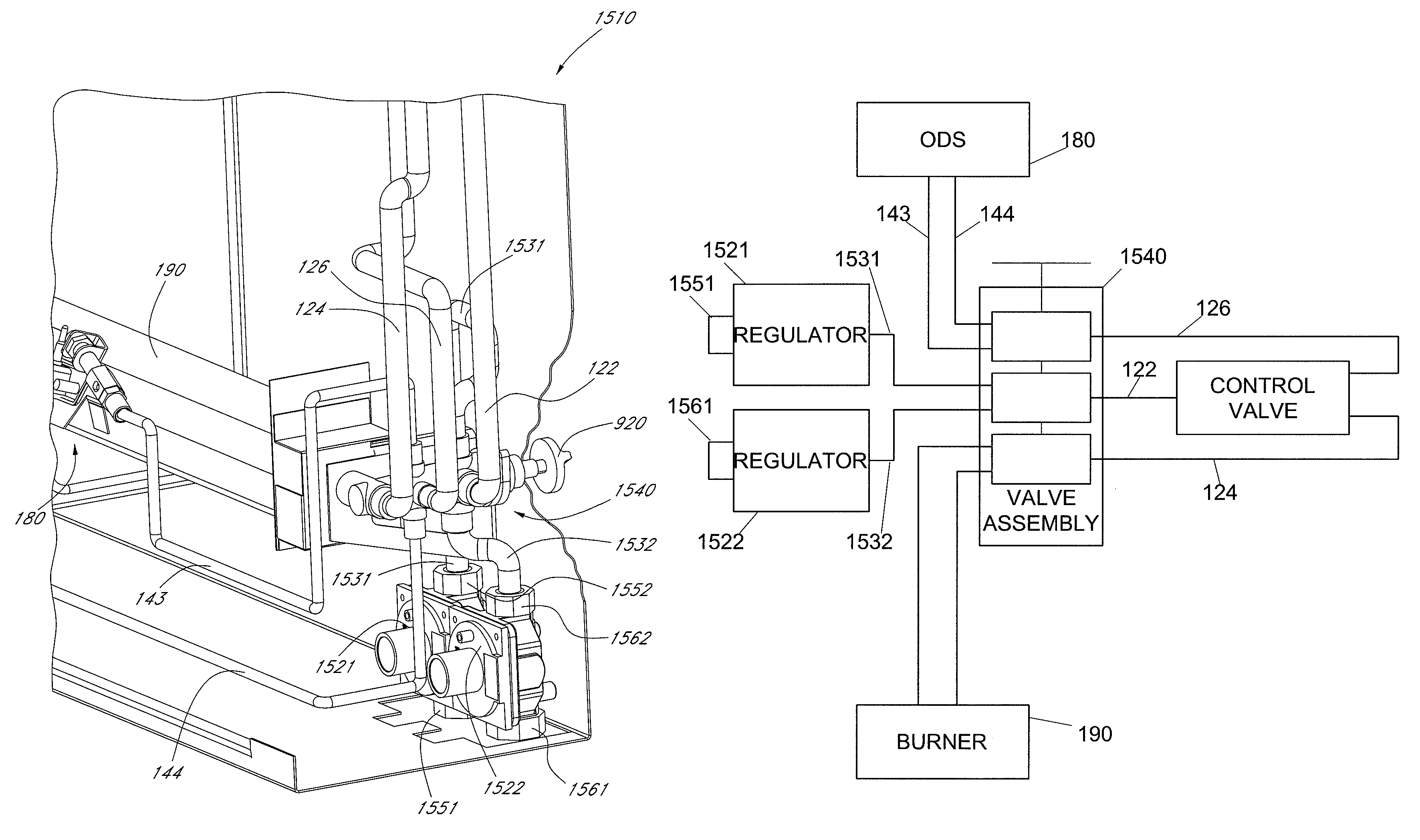

Fuel selection valve assemblies

In certain embodiments, an apparatus includes a control valve for regulating fuel flow. The apparatus can include a burner and a valve assembly. In some embodiments, the valve assembly includes a housing, which can define a first fuel input for receiving a first fuel from a first fuel source and a second fuel input for receiving a second fuel from a second fuel source. The housing can define a first fuel output for directing fuel toward the control valve, and can define a third fuel input for receiving a portion of either the first fuel or the second fuel from the control valve. The housing can define a first egress flow path and a second egress flow path, each for directing fuel to the burner. In certain embodiments, the apparatus includes a valve body configured to selectively permit fluid communication between the first and second inputs and the output and between the third input and the egress flow paths.

Owner:PROCOM HEATING

Valve assemblies for heating devices

In certain embodiments, a valve assembly includes a housing. The housing can define a first fuel intake, a first fuel output, and a second fuel output. The assembly can include a valve member configured to direct fuel from the first fuel intake to either the first fuel output or the second fuel output. The assembly can further include a nozzle having a first portion and a second portion. The first portion of the nozzle can be in communication with the first fuel output, and the second portion of the nozzle can be in communication with the second fuel output. The assembly can include a compartment in communication with the nozzle, and can include one or more air intakes.

Owner:PROCOM HEATING

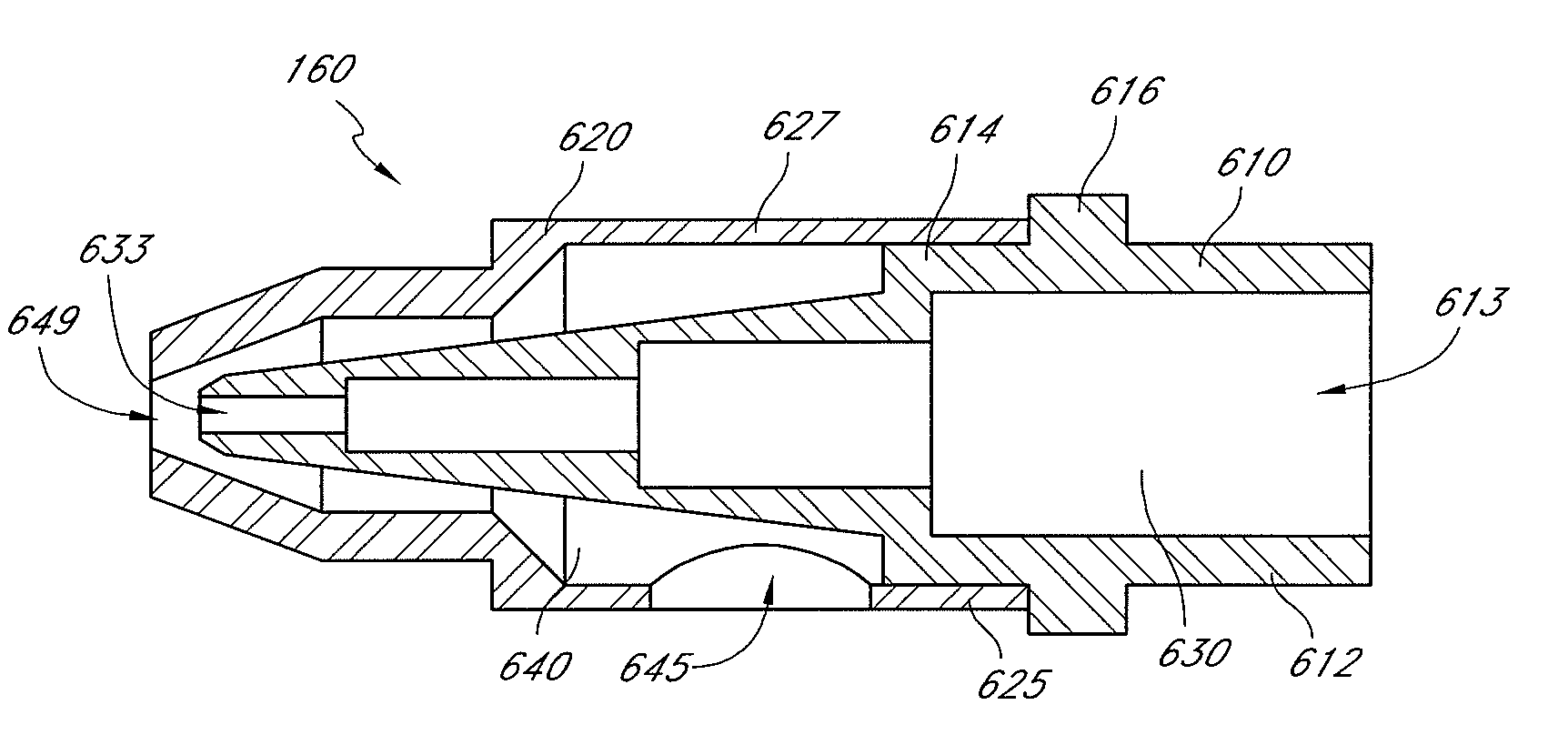

Heater configured to operate with a first or second fuel

Certain embodiments of a nozzle are configured to dispense a first gas, liquid, or combination thereof at a first pressure in a first mode of operation and dispense a second gas, liquid, or combination thereof at a second pressure in a second mode of operation. In some embodiments, the nozzle is integrated in a heat-producing device, such as, for example, a heater, a fireplace, or a stove. In some embodiments, the heat-producing device including the nozzle can operate with a first combustible fuel at a first pressure, or alternatively, can operate with a second combustible fuel at a second pressure. In some embodiments, the nozzle is used in applications other than heat-producing devices.

Owner:PROCOM HEATING

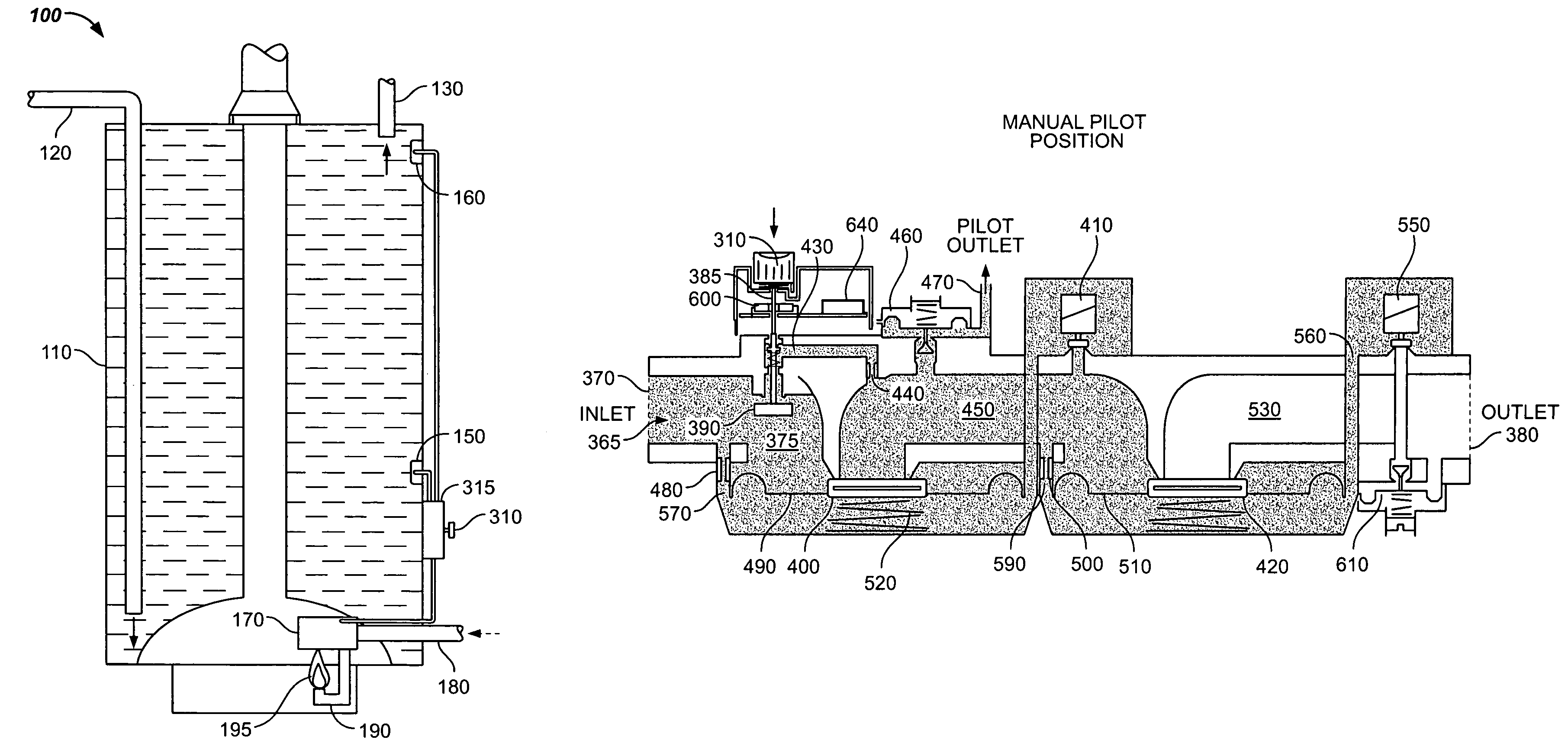

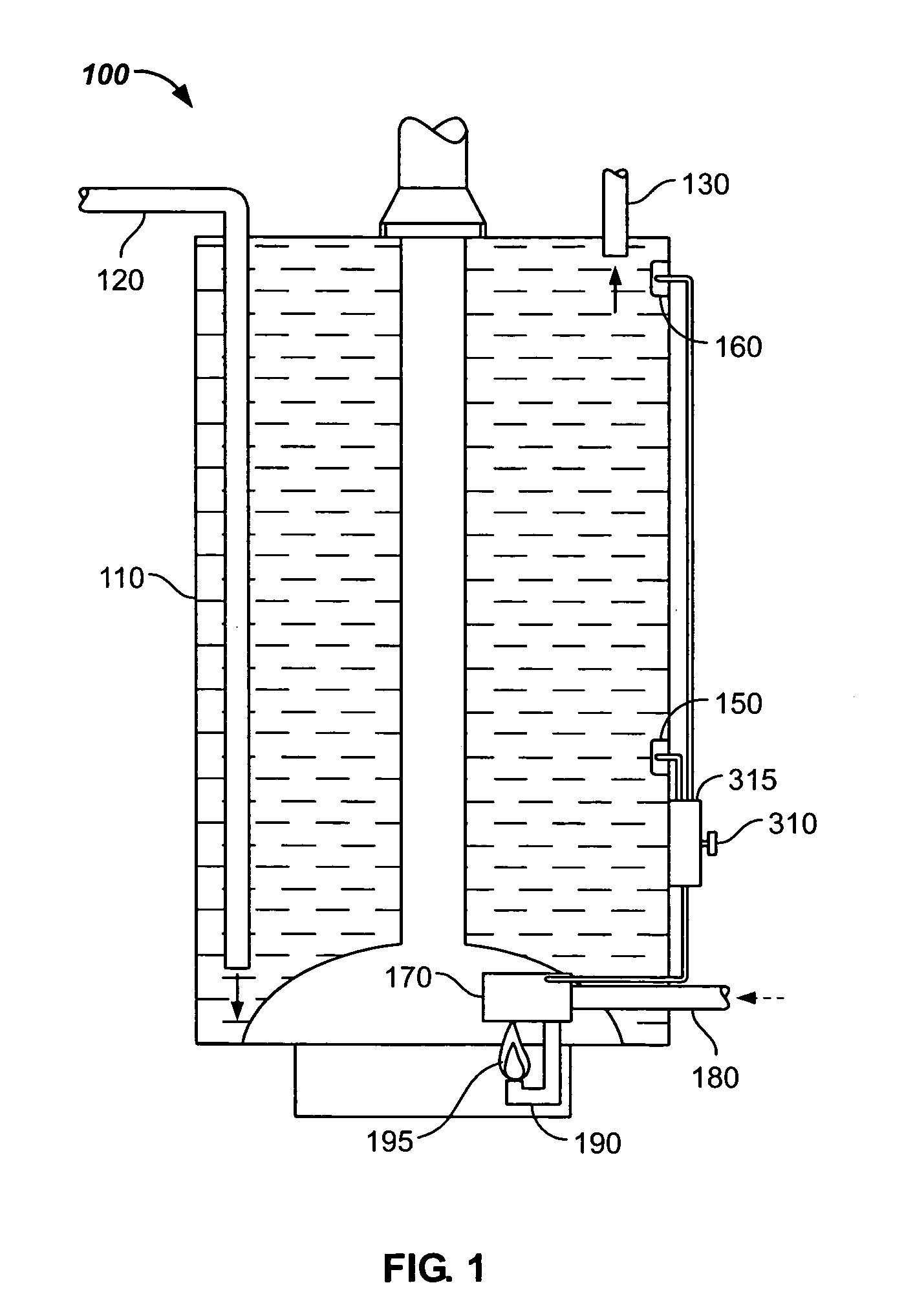

Method and system for combined standing pilot safety and temperature setting

ActiveUS7252502B2Temperature control without auxillary powerFuel supply regulationCombustorElectric potential

The method and apparatus provides a controller (which might comprise a microprocessor) that can control gas flow to a pilot burner in fluid communication with a manual pilot valve and an automatic pilot valve. The exemplary embodiments can comprise a selectable input device that can open the manual pilot valve to allow gas flow to the pilot burner. A pilot flame can then heat one or more thermal detection devices in thermal communication with the pilot burner, wherein the one or more thermal detection devices can output a variable voltage potential to the controller. The controller can then open the automatic pilot valve to maintain gas flow to the pilot burner after the manual pilot valve has been closed. In an exemplary embodiment, the only voltage potential used to power the controller is supplied by the one or more thermal detection devices.

Owner:ADEMCO INC

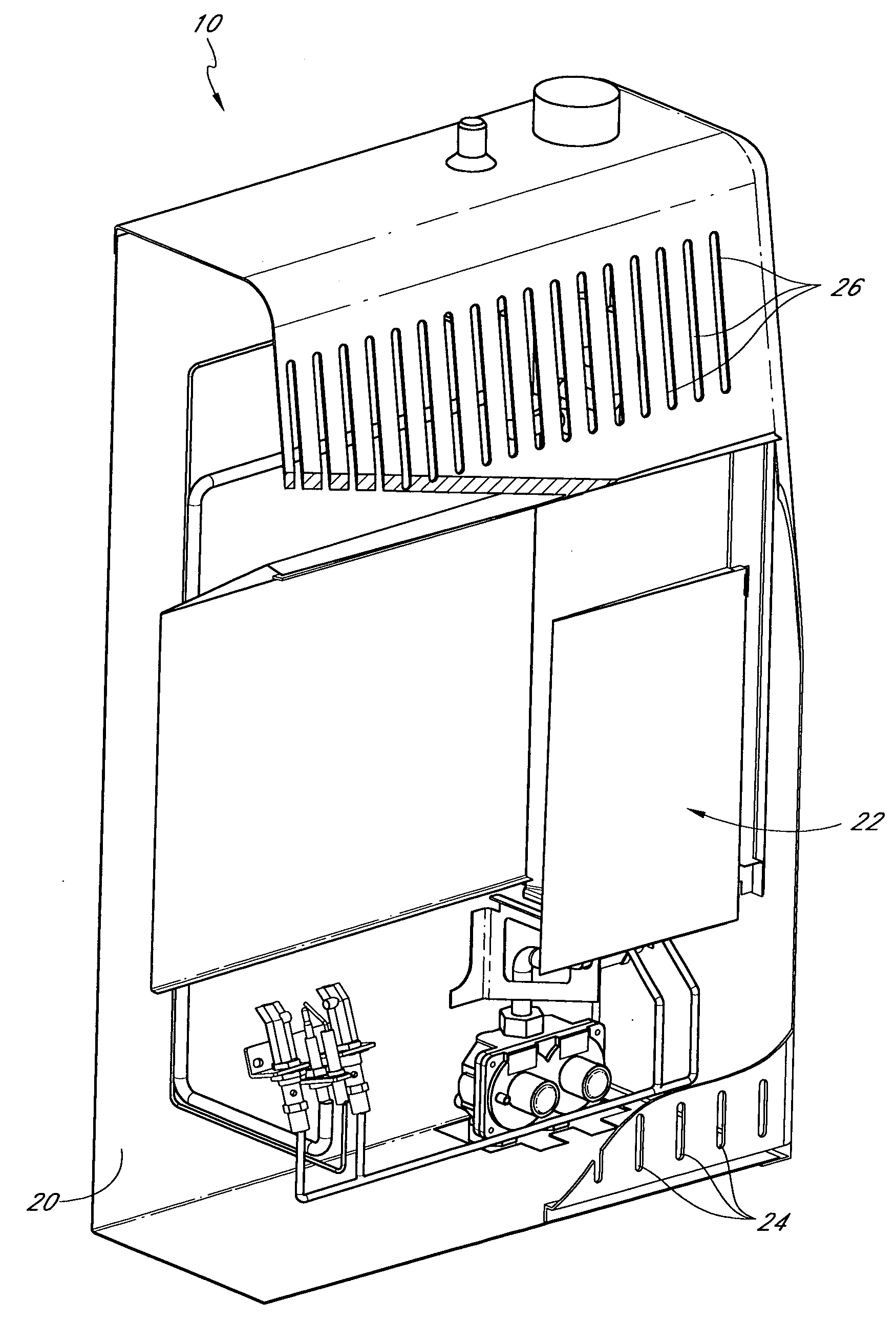

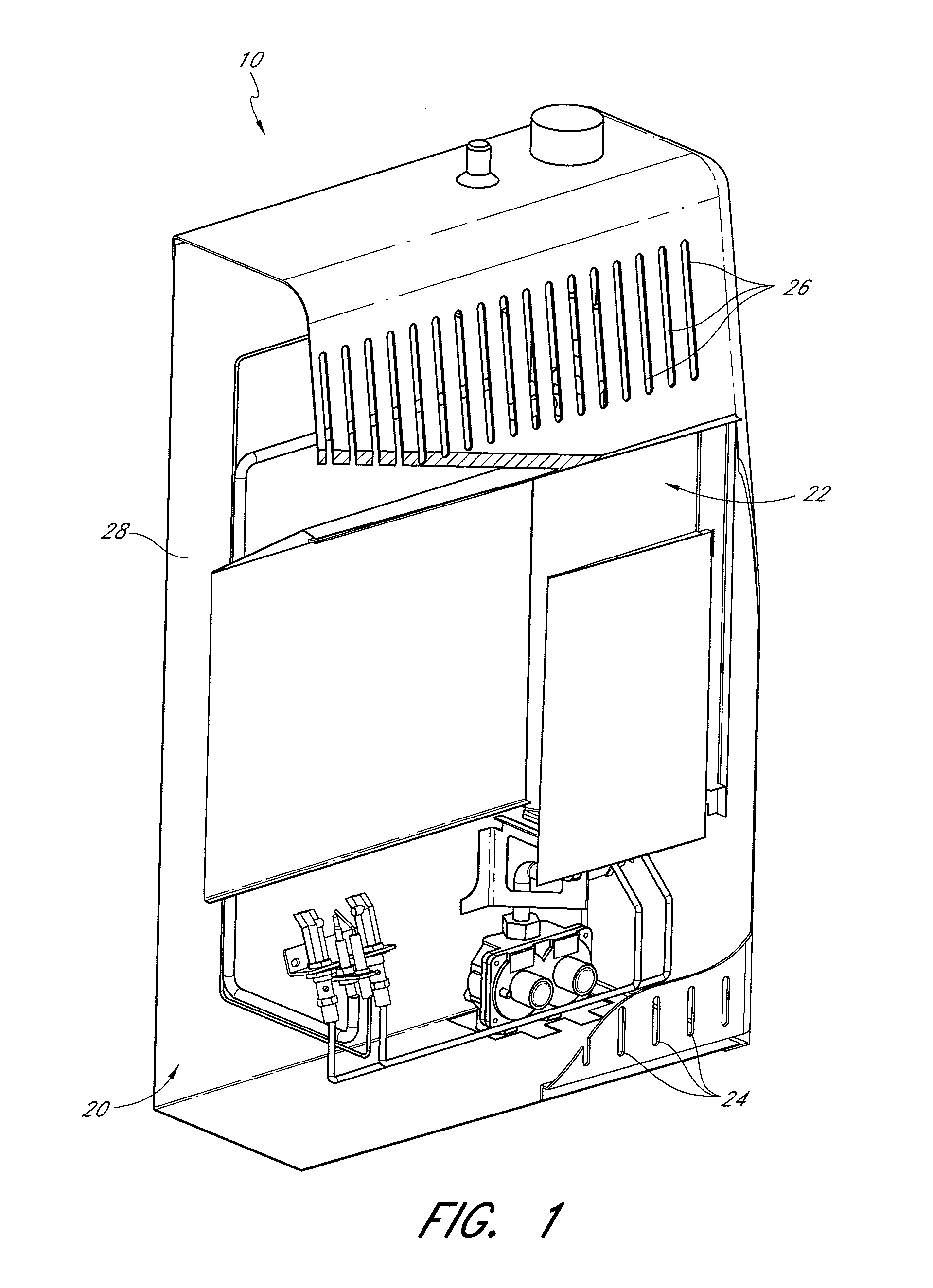

Heater

In certain embodiments, a heater comprises a fluid opening configured to communicate with a source of fuel. In some embodiments, the heater further comprises a first flow channel, a second flow channel, and a fluid flow controller in communication with the fluid opening. In some embodiments, the controller is configured to selectively permit flow of fuel to either the first flow channel or the second flow channel. In some embodiments, the heater further comprises at least one of a nozzle and an oxygen depletion sensor coupled with at least one of the first flow channel and the second flow channel.

Owner:PROCOM HEATING

Combustion process and apparatus therefore containing separate injection of fuel and oxidant streams

InactiveUS6331107B1Reduce nitrogen oxide emissionsAvoid chemical reactionsCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorCombustion chamber

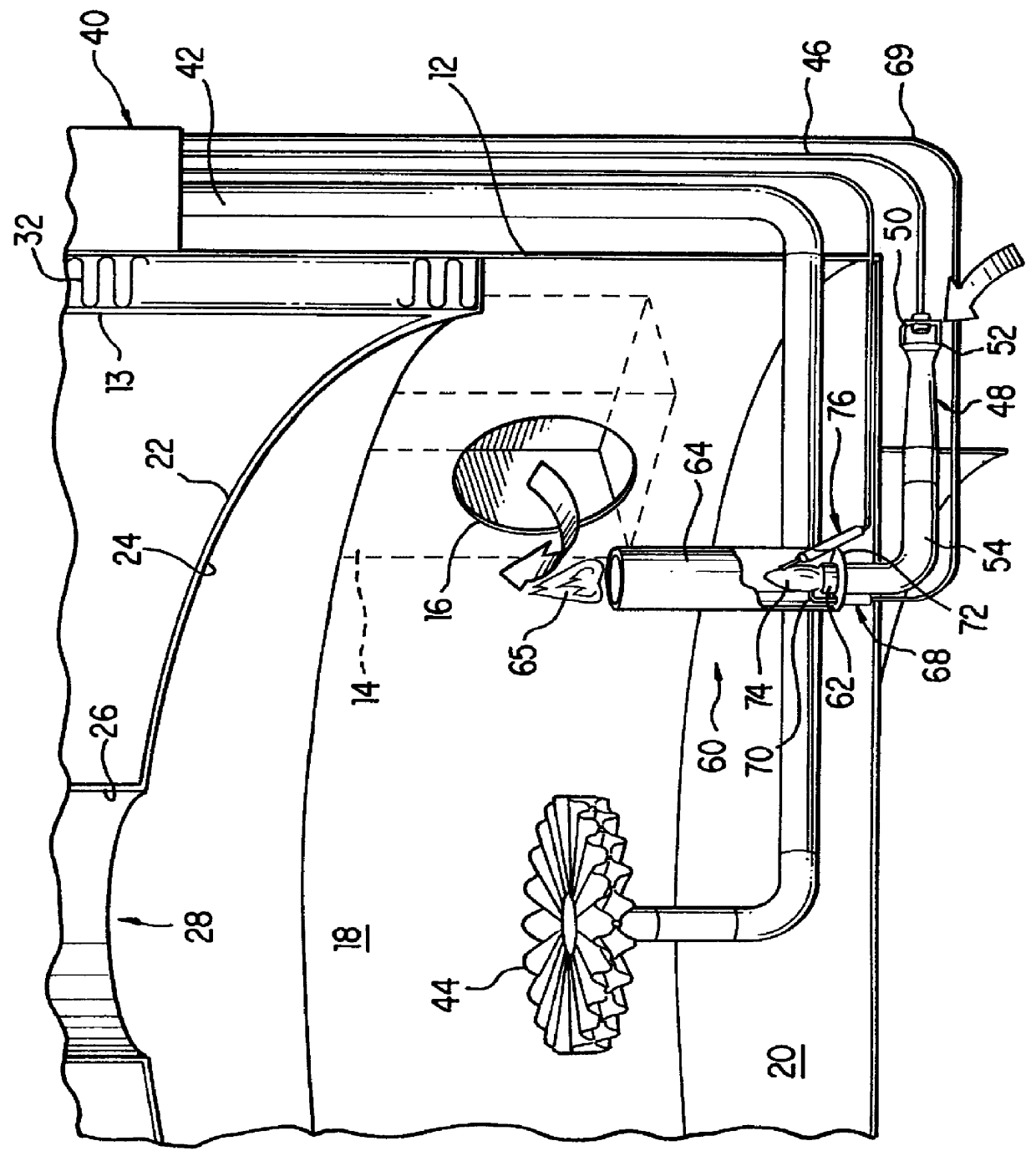

A burner assembly having improved flame length and shape control is presented, which includes in exemplary embodiments at least one fuel fluid inlet and at least one oxidant fluid inlet, means for transporting the fuel fluid from the fuel inlet to a plurality of fuel outlets, the fuel fluid leaving the fuel outlets in fuel streams that are injected into a combustion chamber, means for transporting the oxidant fluid from the oxidant inlets to at least one oxidant outlet, the oxidant fluid leaving the oxidant outlets in oxidant fluid streams that are injected into the combustion chamber, with the fuel and oxidant outlets being physically separated, and geometrically arranged in order to impart to the fuel fluid streams and the oxidant fluid streams angles and velocities that allow combustion of the fuel fluid with the oxidant in a stable, wide, and luminous flame. Alternatively, injectors may be used alone or with the refractory block to inject oxidant and fuel gases. The burner assembly affords improved control over flame size and shape and may be adjusted for use with a particular furnace as required.

Owner:AIR LIQUIDE AMERICA INC

Control valves for heaters and fireplace devices

In certain embodiments, a control valve assembly for gas heaters and gas fireplace devices includes a housing. The housing can define an inlet for accepting fuel from a fuel source, a first outlet for delivering fuel to an oxygen depletion sensor, and a second outlet for delivering fuel to a burner. The assembly can include a valve body configured to selectively provide fluid communication between the inlet and one or more of the first outlet and the second outlet, and can include an actuator configured to move the valve body relative to the housing. The actuator can be configured to transition between a resting state and a displaced state. The assembly can include an igniter that includes a sensor, the igniter electrically coupled with an electrode and configured to repeatedly activate the electrode when the sensor senses that the actuator is in the displaced state. The assembly can include a shutoff valve electrically coupled with the oxygen depletion sensor and configured to operate in response to an electrical quantity communicated by the oxygen depletion sensor.

Owner:PROCOM HEATING

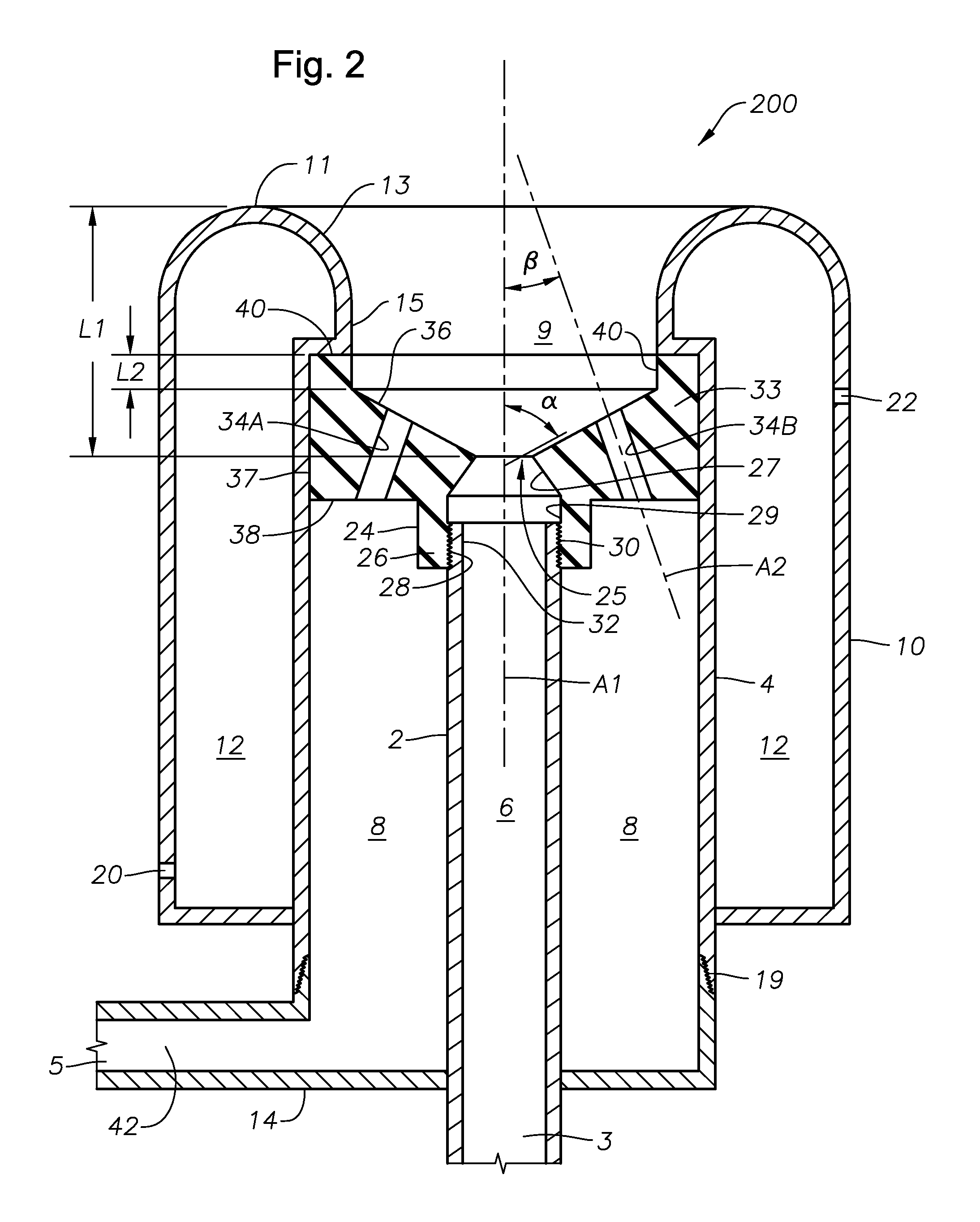

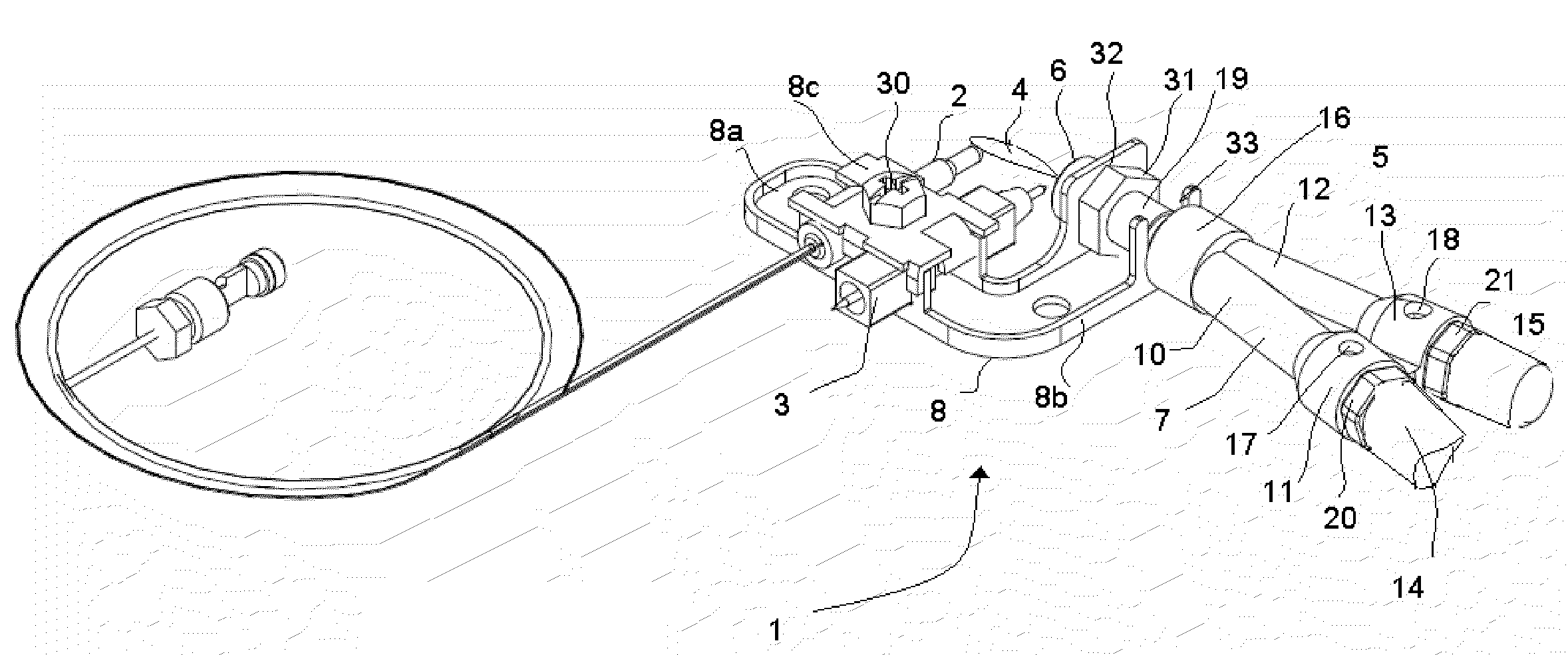

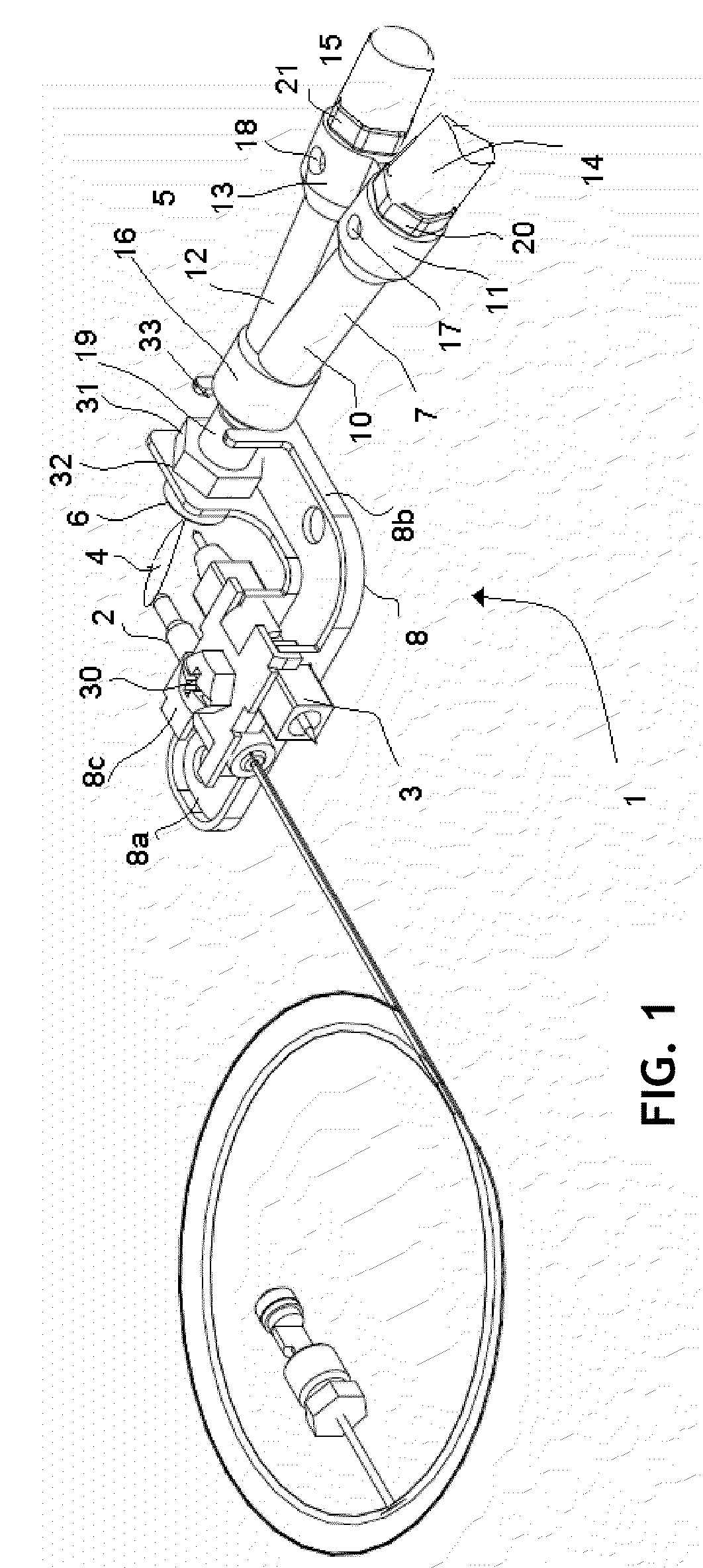

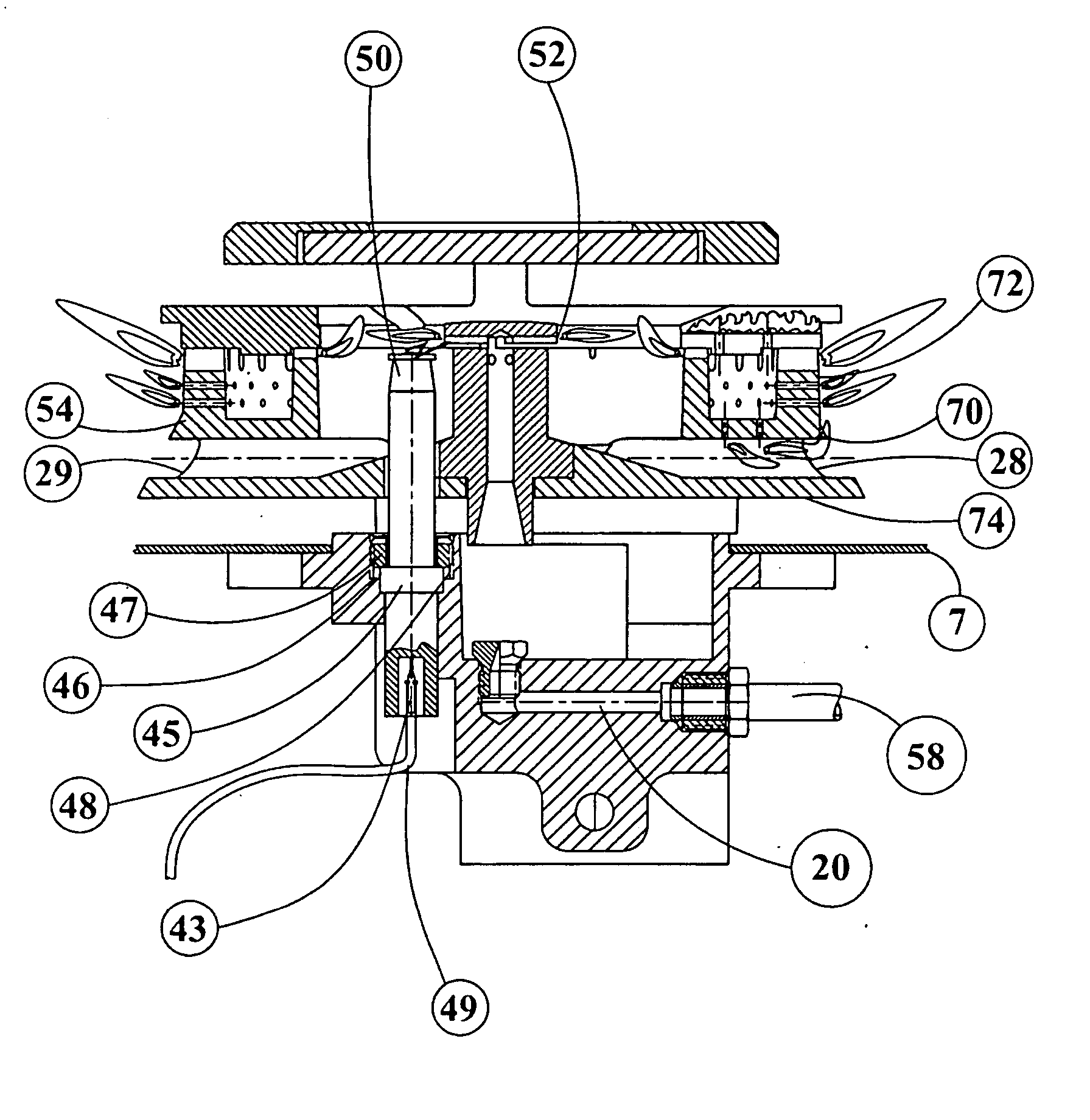

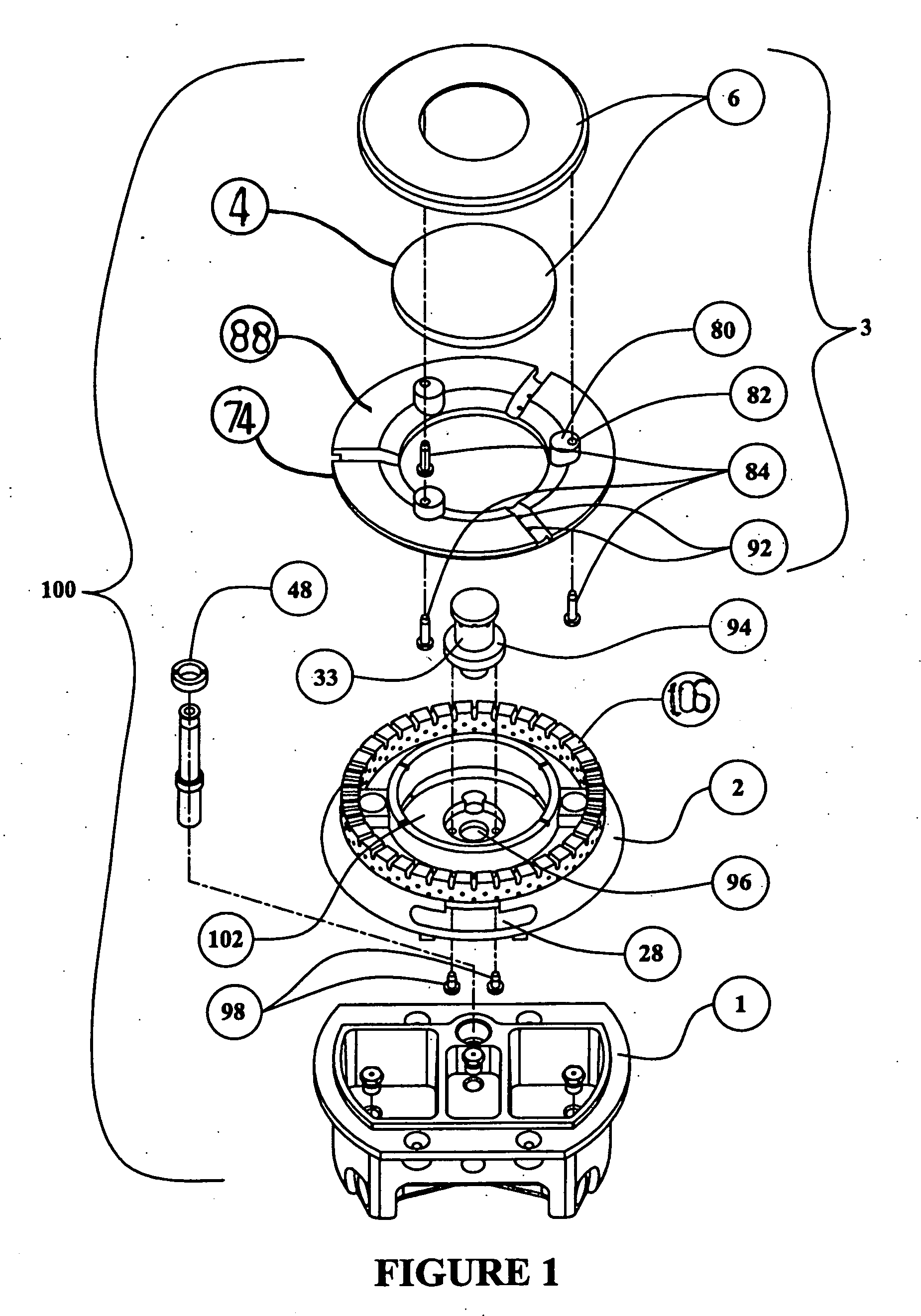

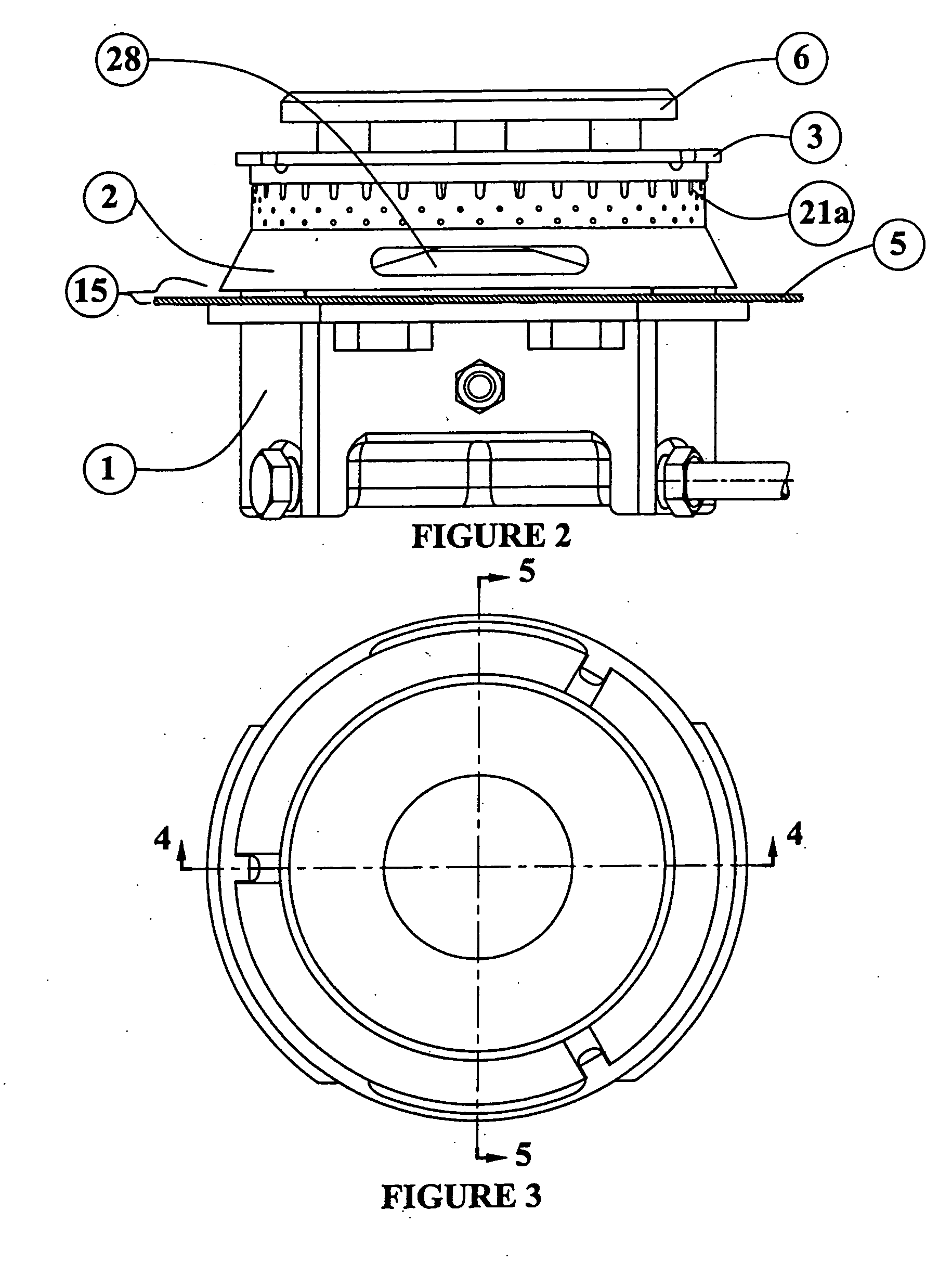

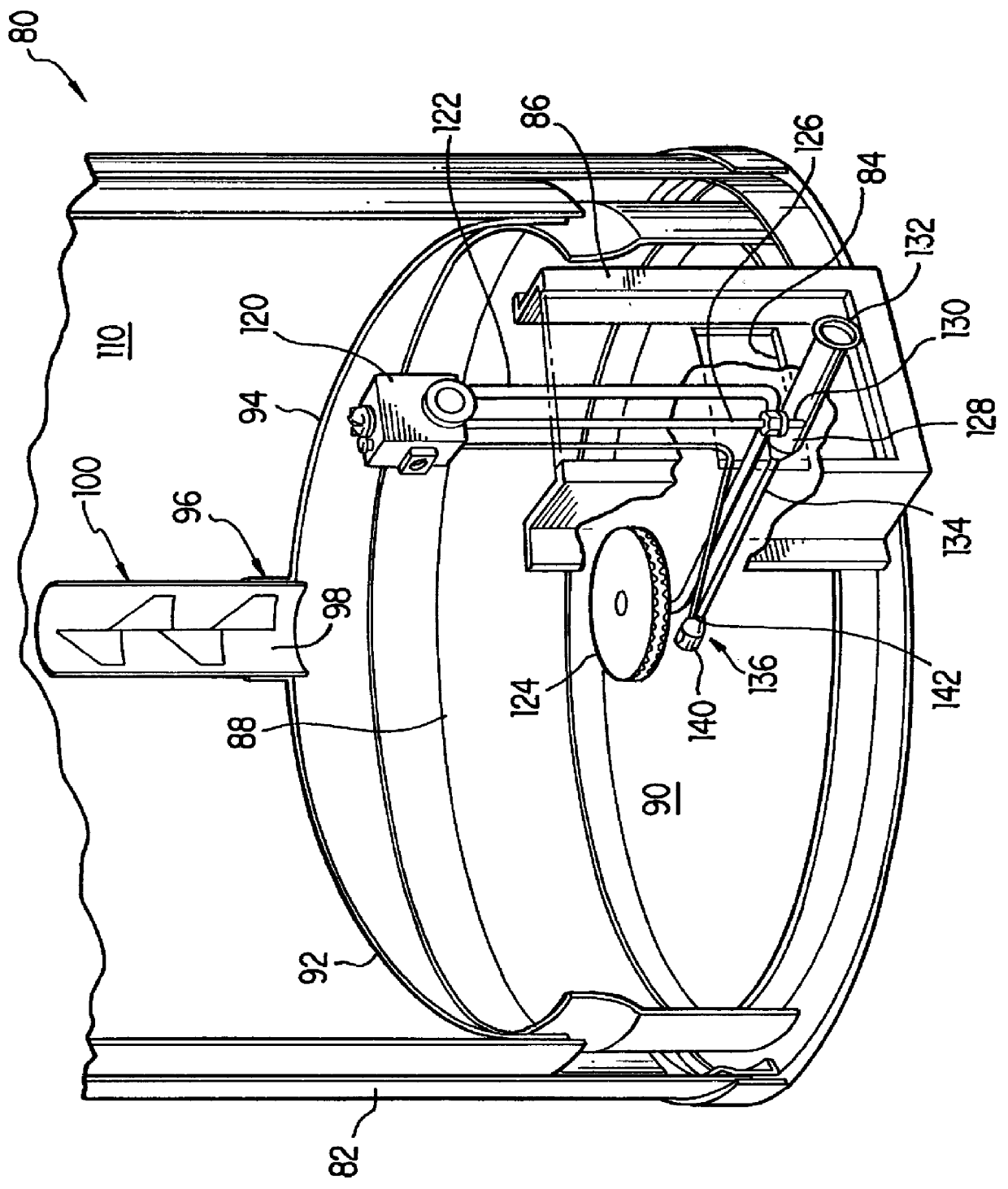

Multiple gas pilot burner

ActiveUS20090280448A1Small sizeLow costIncandescent ignitionPipeline expansion-compensationPower flowThermocouple

A multiple gas pilot burner assembly for a household heating appliance. The pilot burner includes an injector having a first conduit for receiving a flow of a first combustible fluid, a second conduit for receiving a flow of a second combustible fluid and a third conduit connected to and in fluid communication with the first and second conduits which is configured to receive the flow of the first combustible fluid from the first conduit or the flow of the second combustible fluid from the second conduit. A single nozzle at the outlet of the third conduit is provided for supplying a pilot flame. The assembly also includes a single flame igniter positioned to cause an ignition of the pilot flame at the nozzle and also a single thermocouple positioned to be heated by the pilot flame and to generate an electrical current when heated.

Owner:COPRECITEC

Gas burner

InactiveUS20070218414A1More useable spaceSmall diameterElectric spark ignitersPilot flame ignitersEngineeringHigh intensity

This invention describes an improved gas burner assembly that can be adapted to attach to a range top or cooktop, or the floor of the range and can draw air from either above the range top level by external vents or from below range top level through an open style mixing cup. This invention uses a plurality of different flame rings to provide the user a wide variety of temperature settings starting from a low intensity simmer to high intensity cooking heat. The current invention also utilizes a cover plate of transparent or translucent, heat proof material that allows the user to observe the interior of the burner to see if any of the flame rings have been ignited. The cover plate also transfers heat from the internal flame rings to the cooking utensil which provides a more uniform transfer of heat to the utensil.

Owner:DESIGNGASPARTS

Pilot assemblies for heating devices

In certain embodiments, an apparatus can comprise a dual fuel pilot assembly. The pilot assembly can comprise a first fuel dispenser, a second fuel dispenser, an igniter and at least one of a thermocouple, and a thermopile. The pilot assembly can be configured to direct heat from combustion of one of either a first fuel or a second fuel to the at least one of the thermocouple and the thermopile.

Owner:PROCOM HEATING

Valve assemblies for heating devices

In certain embodiments, a valve assembly includes a housing. The housing can define a first fuel input and a second fuel input. The housing can further define a first flow path, a second flow path, a third flow path, and a fourth flow path. The assembly can include a fluid flow controller configured to selectively permit fluid communication between the first fuel input and either the first flow path or the second flow path, and configured to selectively permit fluid communication between the second fuel input and either the third flow path or the fourth flow path. The assembly can further include a first nozzle member defining an inlet and an outlet. The inlet of the first nozzle member can be in fluid communication with the first flow path. The assembly can further include a second nozzle member defining an inlet and an outlet. The inlet of the second nozzle member can be in fluid communication with the second flow path.

Owner:BLUEGRASS LIVING INC

Valve assemblies for heating devices

In certain embodiments, a valve assembly includes a housing. The housing can define a first fuel input and a second fuel input. The housing can further define a first flow path, a second flow path, a third flow path, and a fourth flow path. The assembly can include a fluid flow controller configured to selectively permit fluid communication between the first fuel input and either the first flow path or the second flow path, and configured to selectively permit fluid communication between the second fuel input and either the third flow path or the fourth flow path. The assembly can further include a first nozzle member defining an inlet and an outlet. The inlet of the first nozzle member can be in fluid communication with the first flow path. The assembly can further include a second nozzle member defining an inlet and an outlet. The inlet of the second nozzle member can be in fluid communication with the second flow path.

Owner:PROCOM HEATING

Dual fuel heating source

ActiveUS20100330513A1Avoid flowLiquid fuel feeder/distributionFuel supply regulationEngineeringMechanical engineering

A dual fuel heating source can have a fuel selector valve for selecting between a first fuel and a second fuel different from the first. The dual fuel heating source may selectively have a regulator unit, and an outlet valve. The regulator unit can be configured to regulate the pressure of two different fuels. The outlet valve can be connected to the fuel selector valve such that selecting a fuel can determine the path fuel will flow through the outlet valve and also out of the heating source.

Owner:DENG DAVID

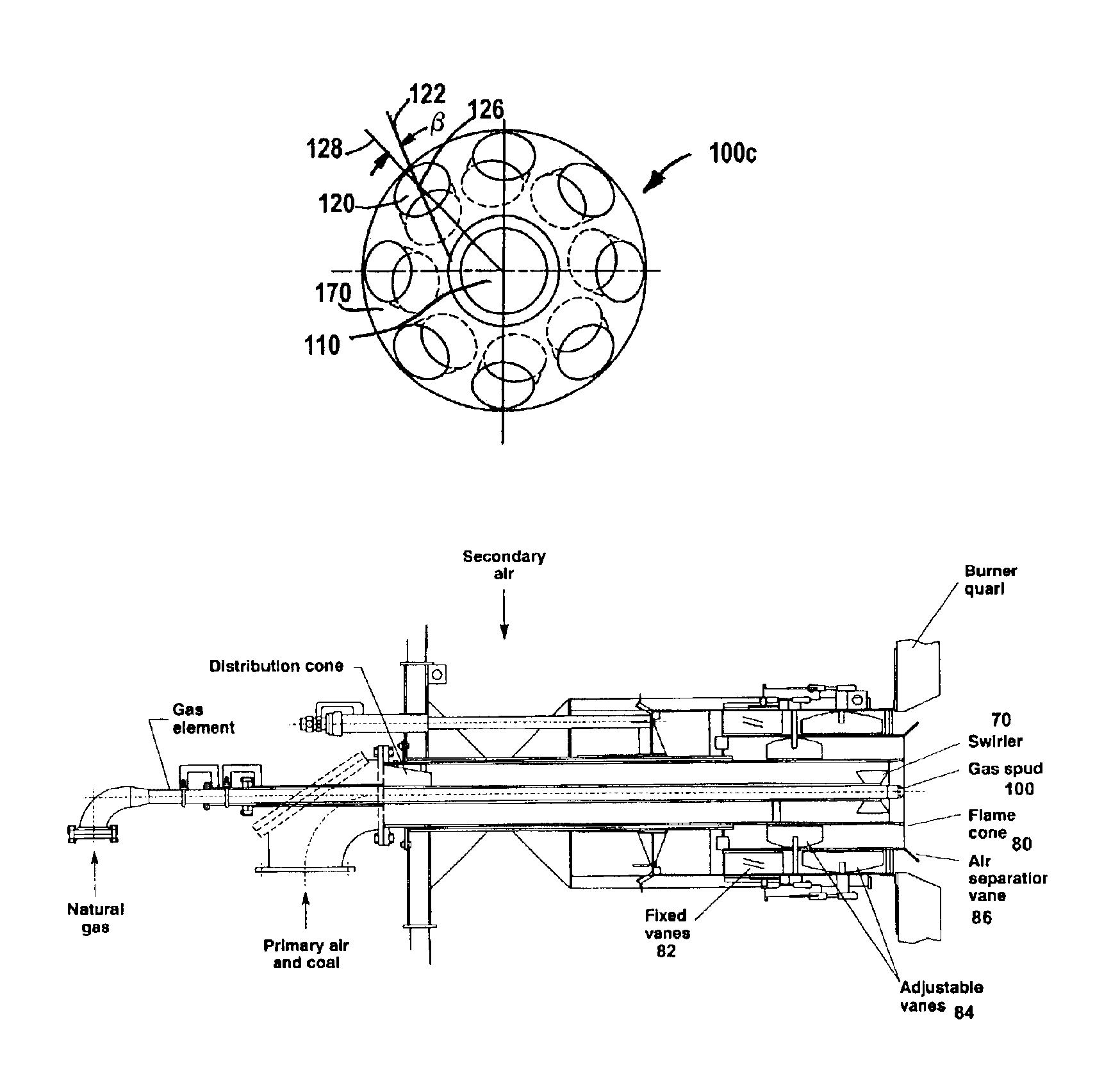

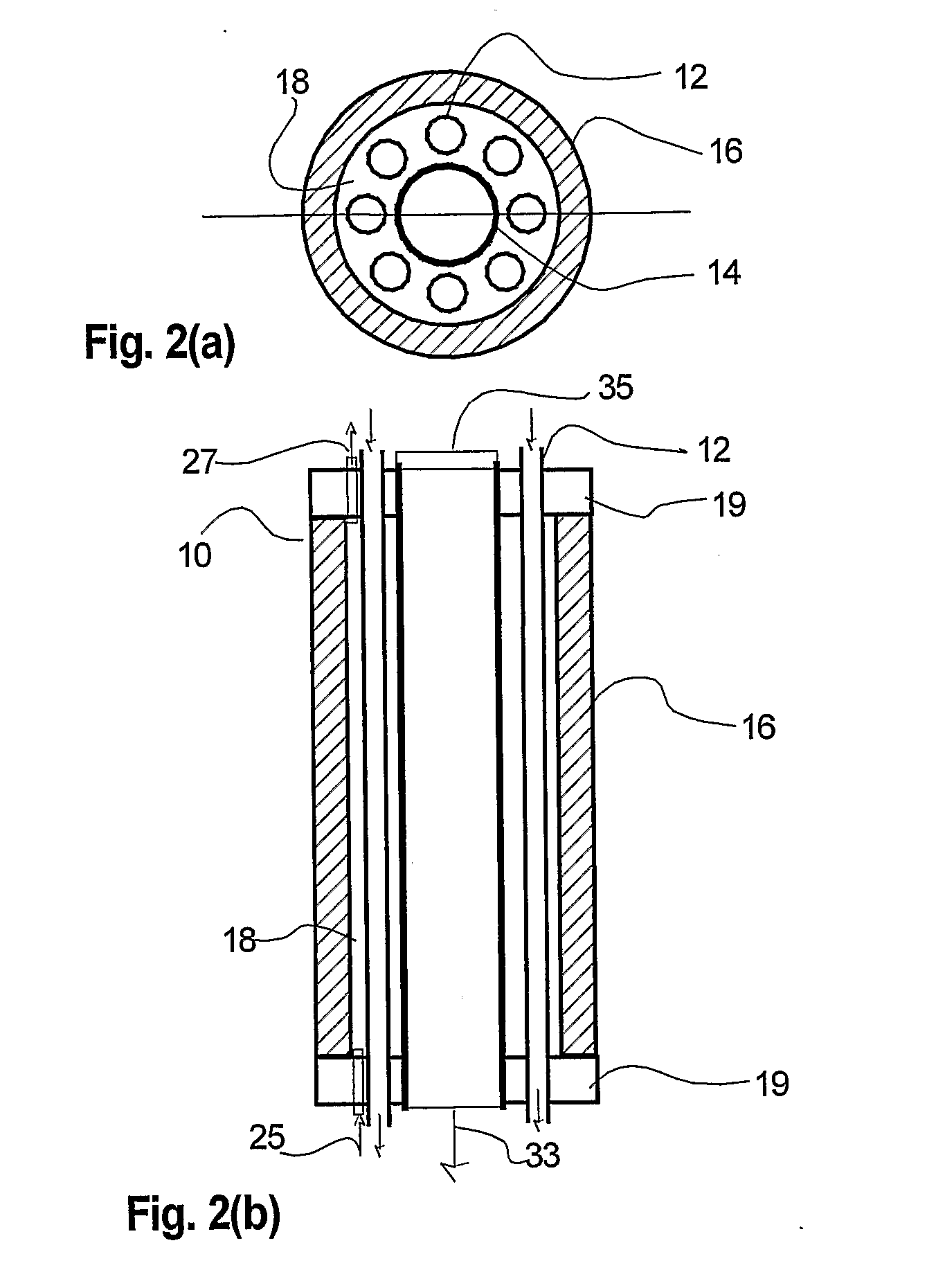

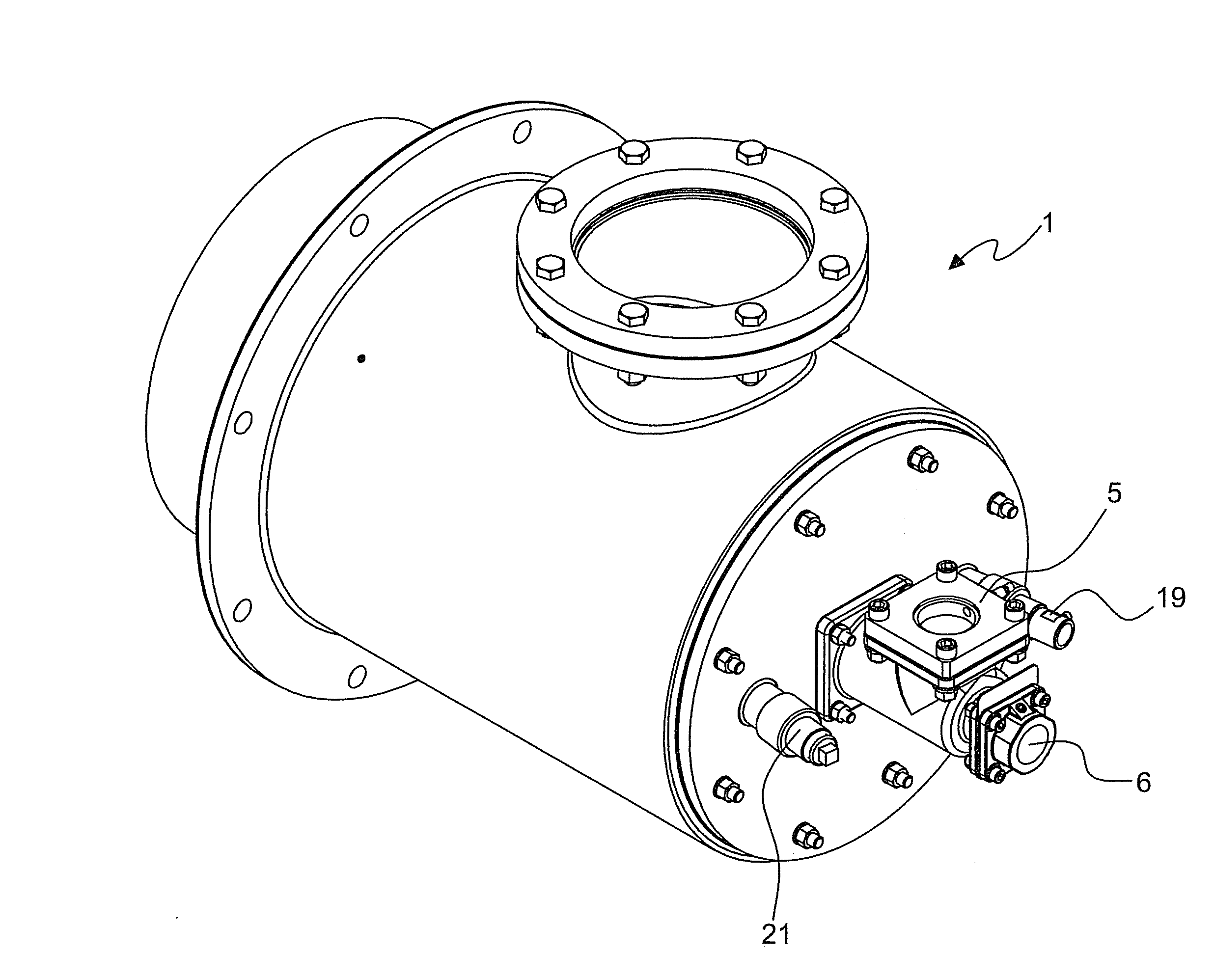

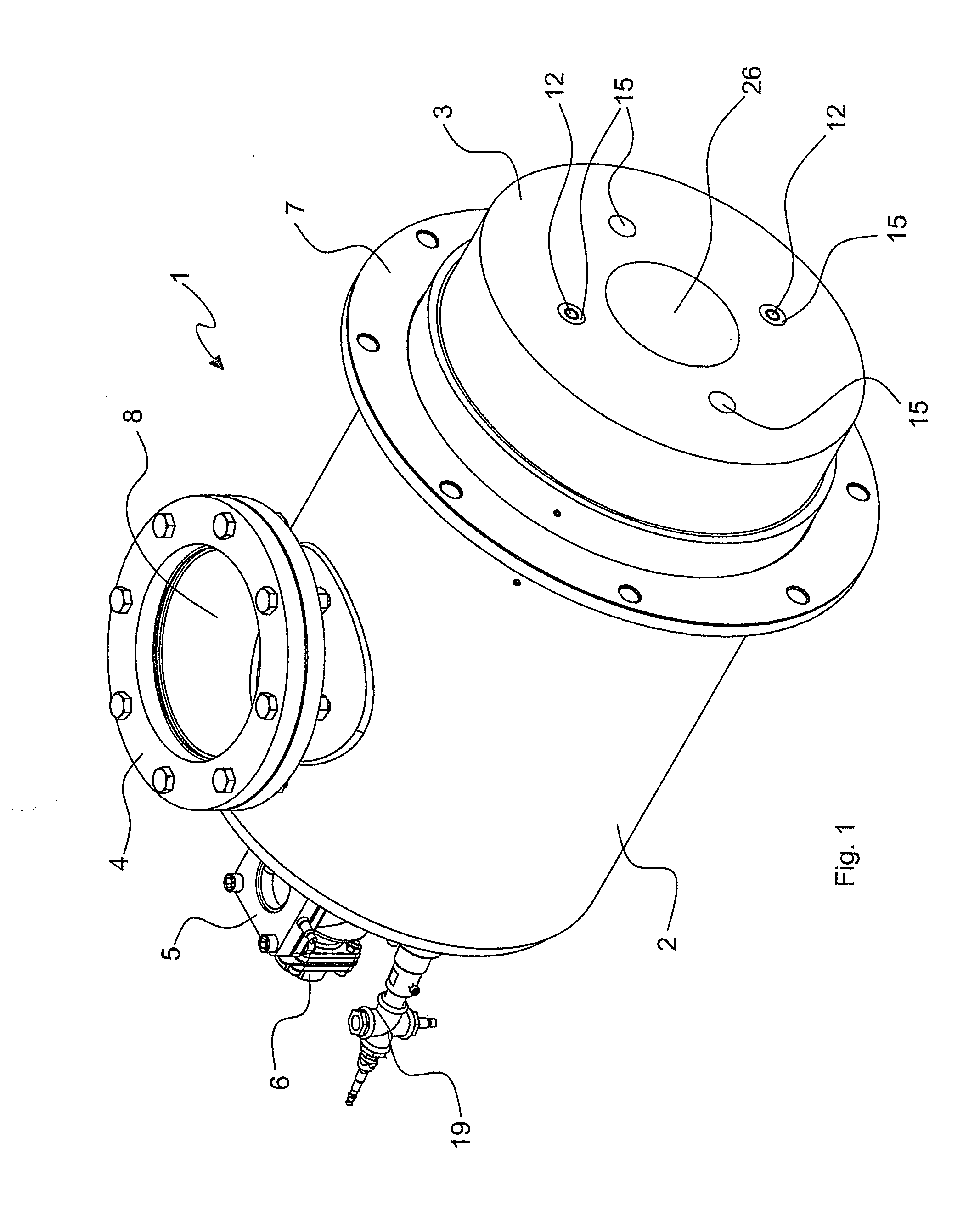

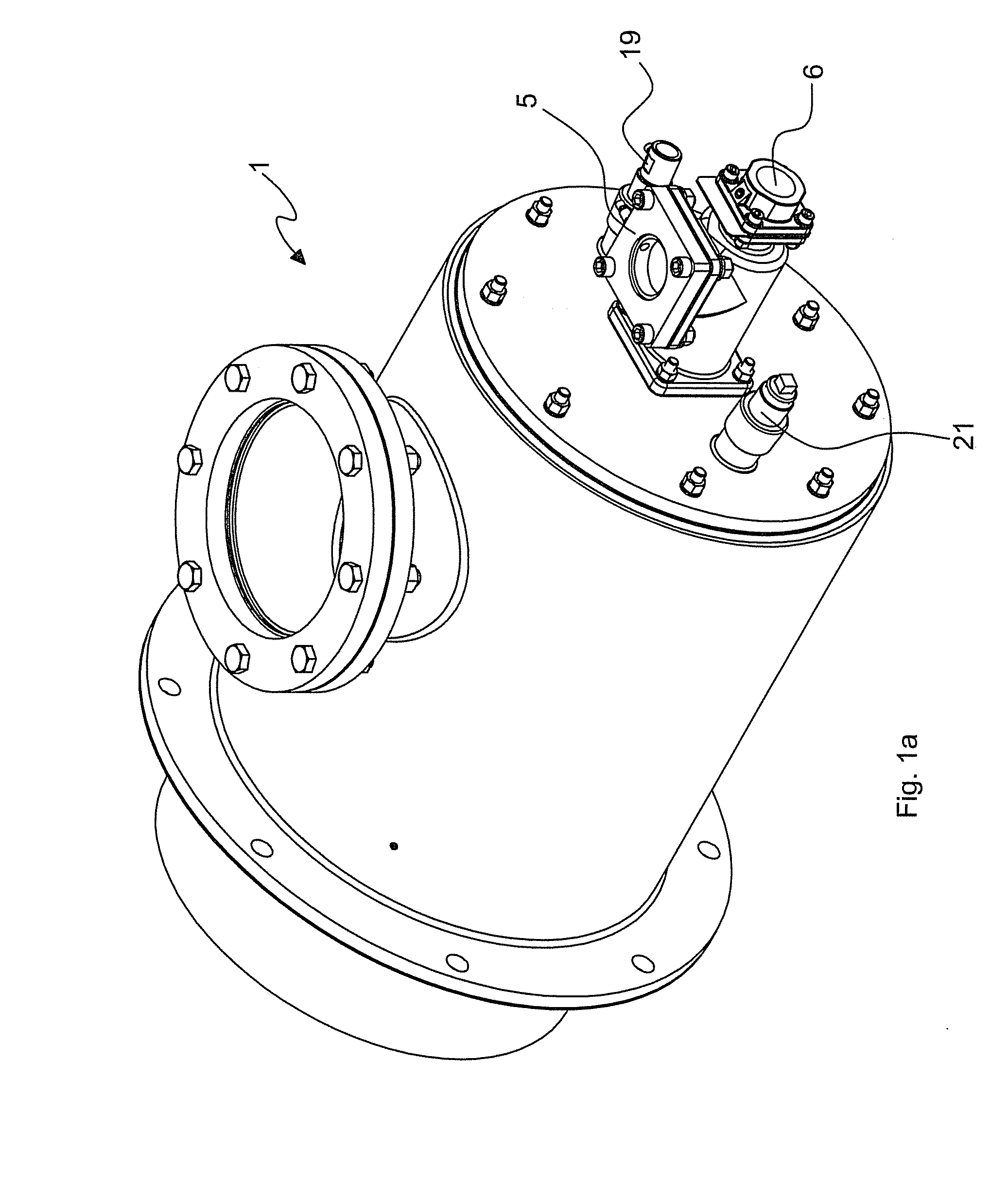

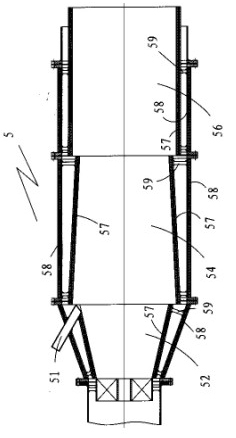

Dual fuel burner for a shortened flame and reduced pollutant emissions

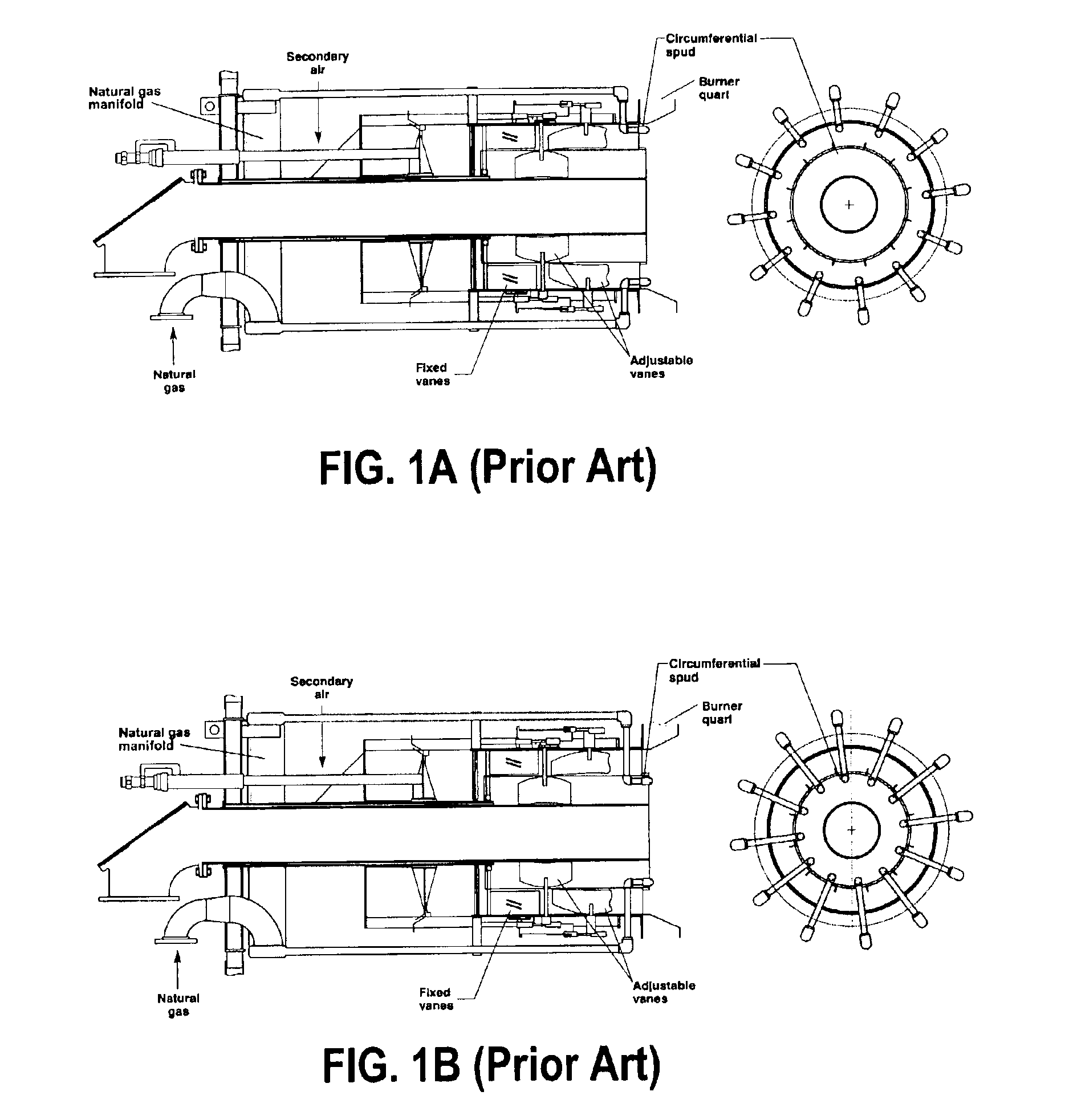

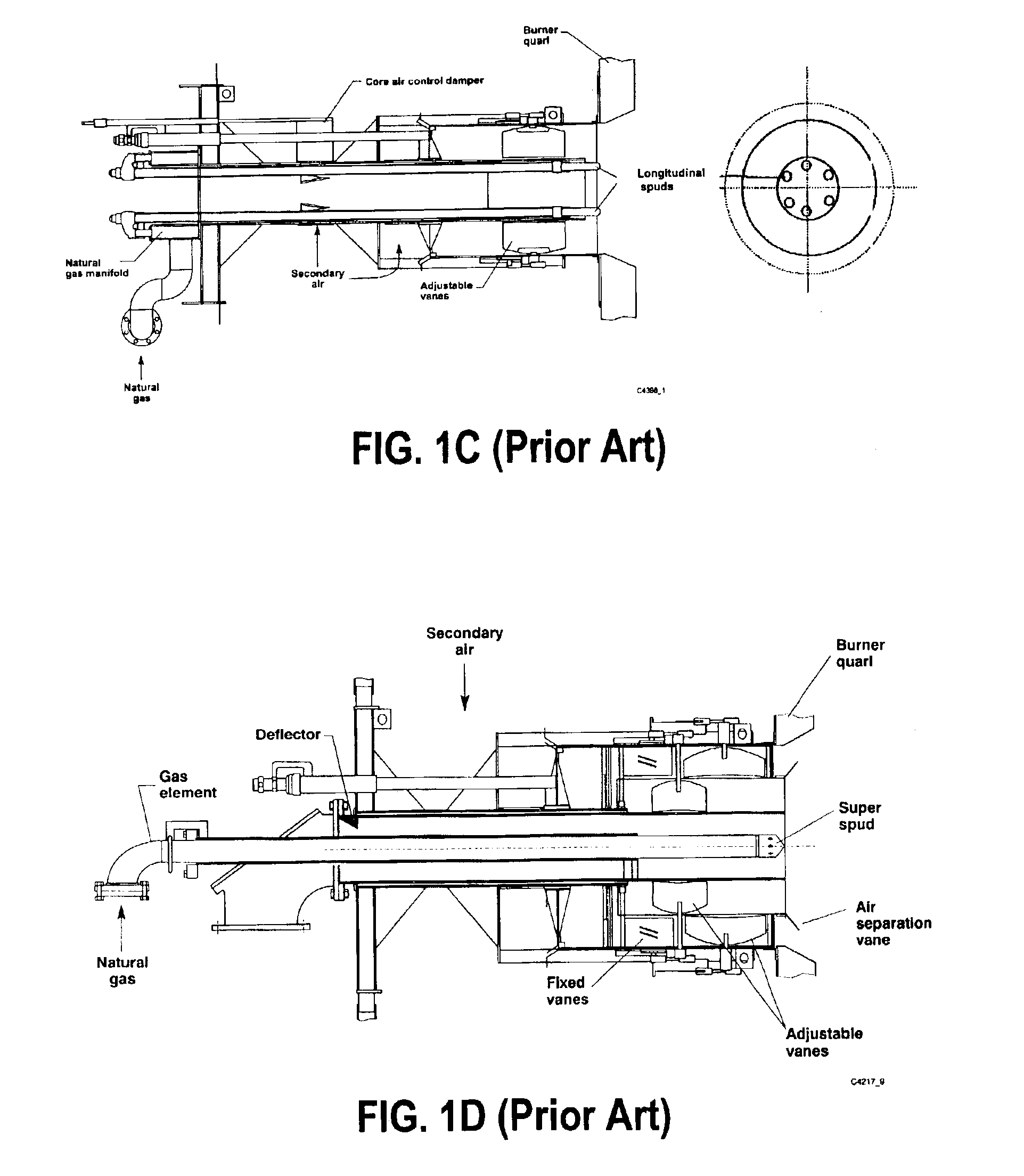

InactiveUS6951454B2Emission reductionShorten the lengthCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelBoiler furnacePollutant emissions

A dual fuel burner including an elongated supply pipe and a gas injector for a boiler furnace having a plurality of peripheral openings around a center opening. The peripheral openings are pitched radially away from the longitudinal axis of the gas injector and also pitched either clockwise or counter-clockwise, to impart a swirling motion to gaseous fuel exiting the injector through the openings. A first sleeve member is concentrically spaced about the supply pipe and the gas injector to form an inner annular passageway for conveying a mixture of primary air and pulverized coal to the furnace combustion zone. A second sleeve member is concentrically spaced about the first sleeve member to form an outer annular passageway for conveying secondary air to the furnace combustion zone, and a plurality of circumferentially spaced vanes mounted within the outer annular passageway for inducing a swirling motion to the secondary air discharging from the outer annular passageway into the furnace combustion zone.

Owner:THE BABCOCK & WILCOX CO

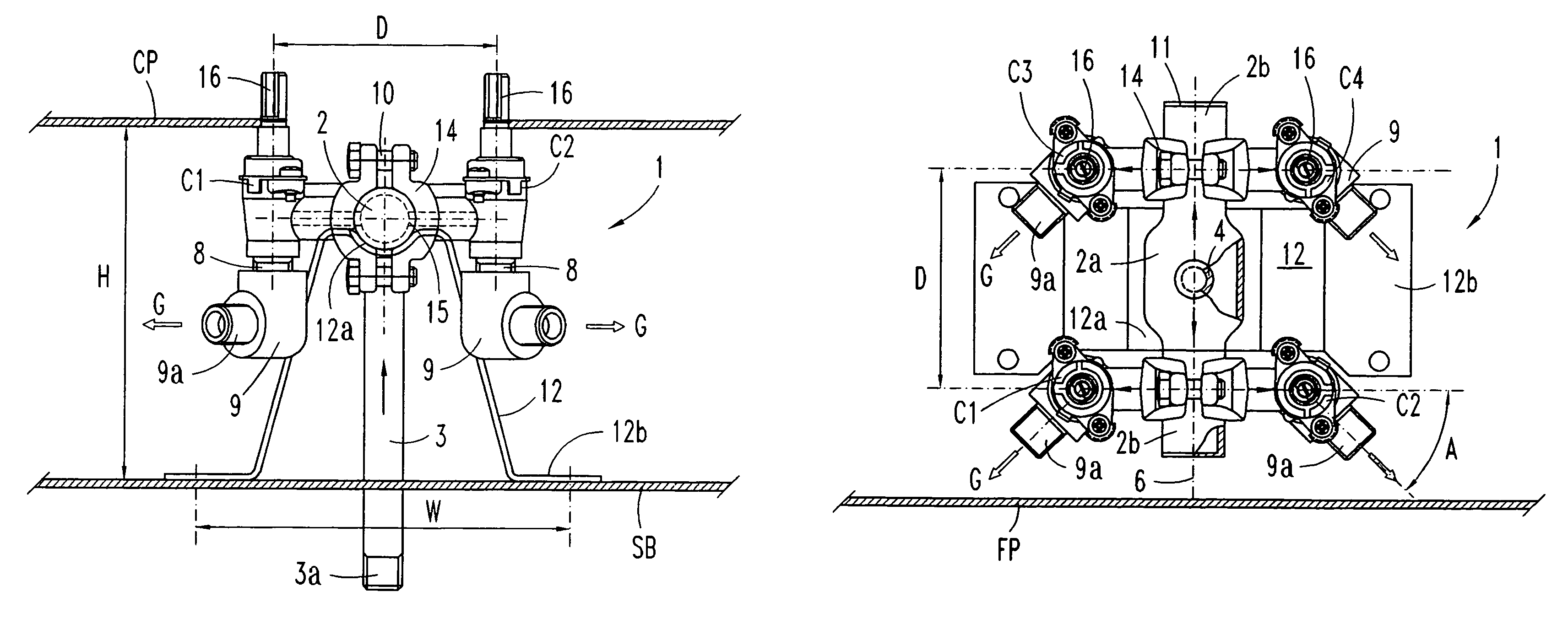

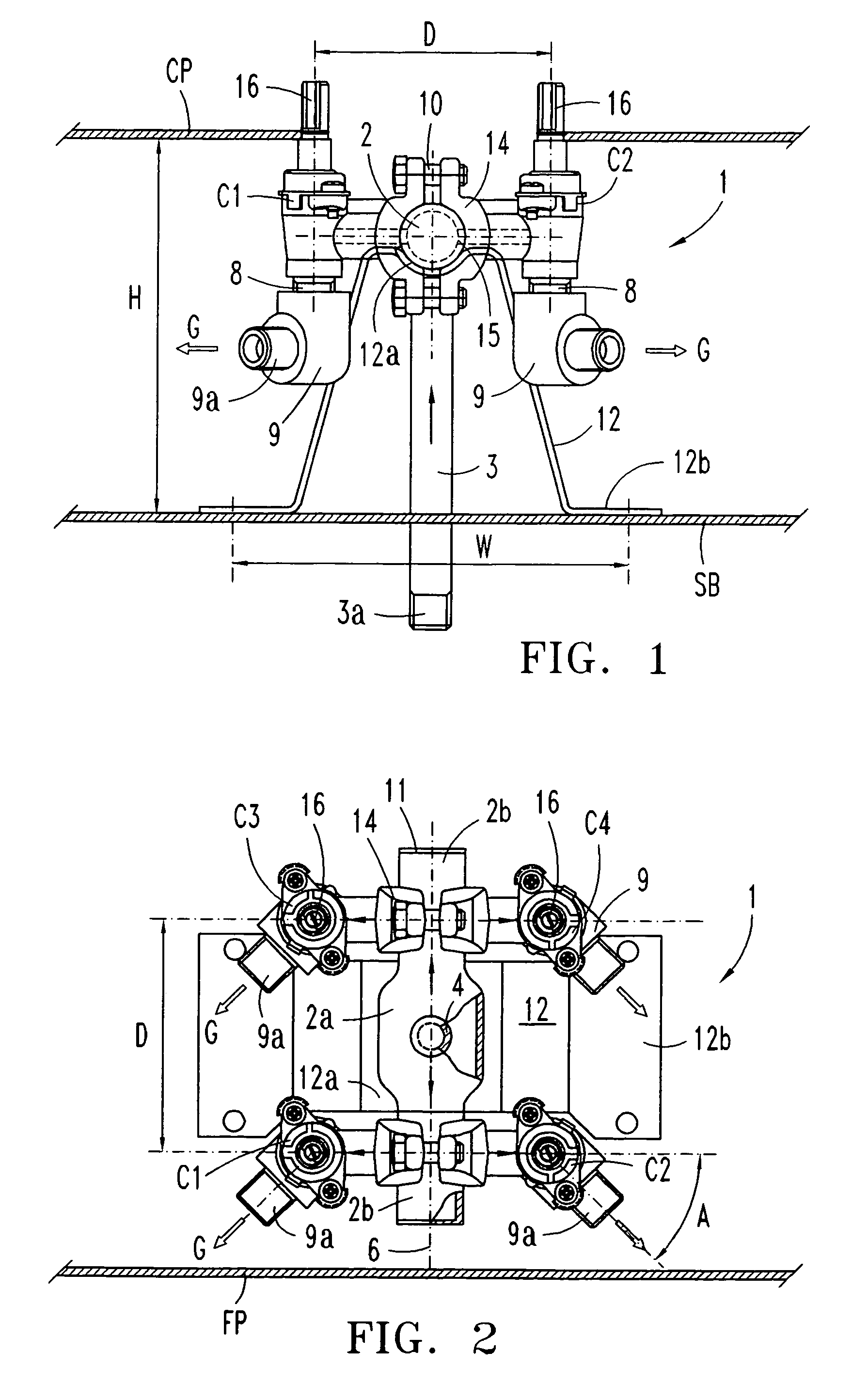

Gas distribution assembly with rotary taps for a cooking appliance

InactiveUS7048538B2Simple configurationCheap constructionDomestic stoves or rangesStoves/ranges topsCombustorDrive shaft

The gas distribution assembly (1) is adapted for the supply of a gas flow (G) to a cooking appliance with top burners, and comprises a straight tubular-shaped manifold conduit. (2) and various rotary taps (C1–C4) provided with an arched mounting base, which are superimposed in twos opposite to each other on a tubular part (2b) of the manifold, and fixed by means of common screws (10). The tap drive shafts (16) stand out from the horizontal cooking plane (CP) occupying a small-sized square geometric area (D×D) . A supporting leg (12) for the distribution assembly (1) is made of a plate folded and fixed on a horizontal structural base (SB), the gas feeder nipple (3) being connected to a central hollow part (2a) of the manifold, extended in a direction opposite to that of the drive shafts (16).

Owner:COPRECITEC

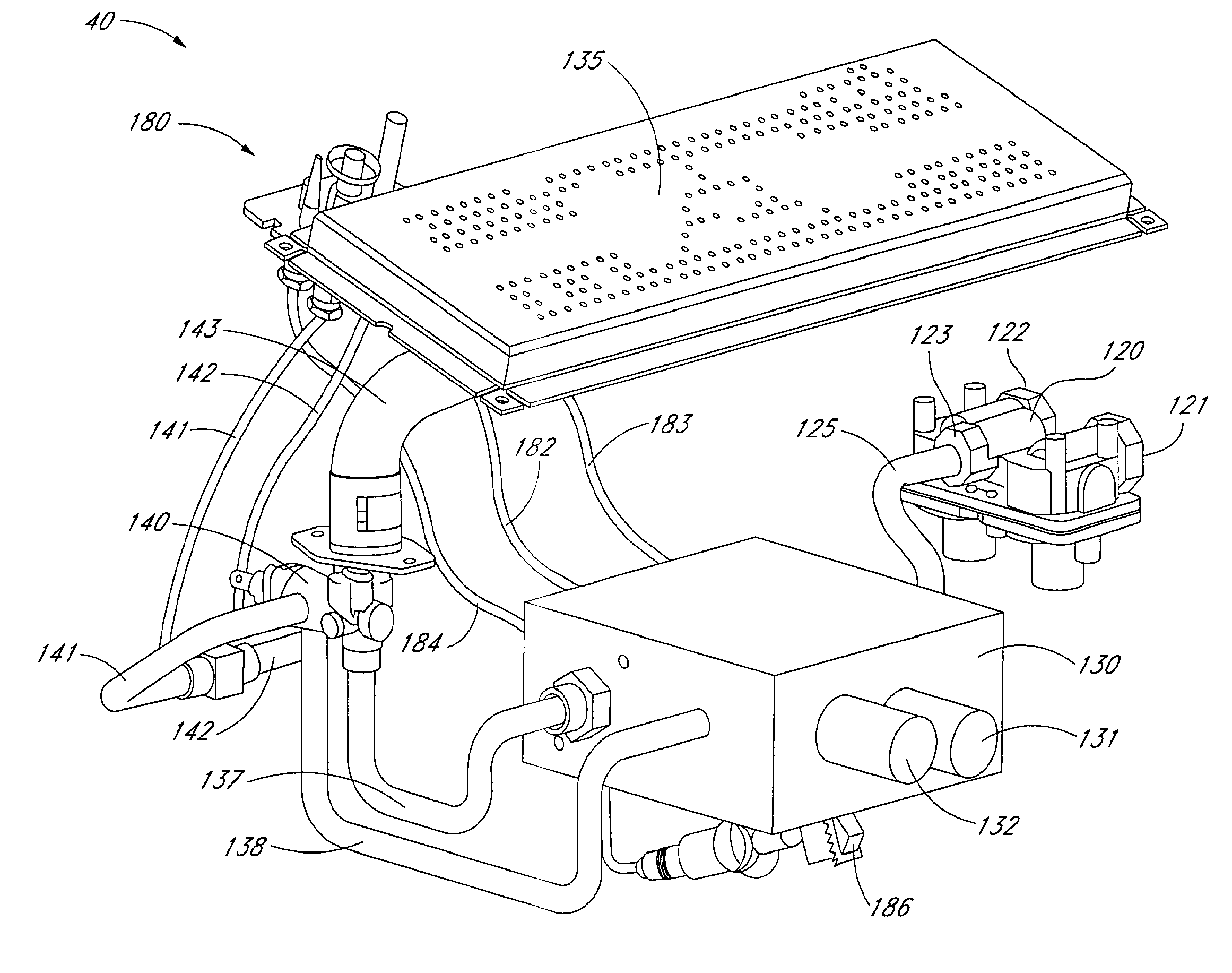

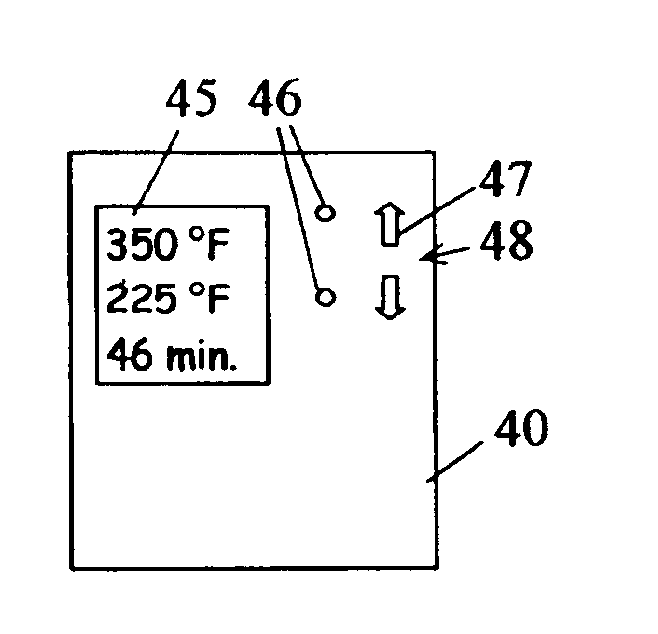

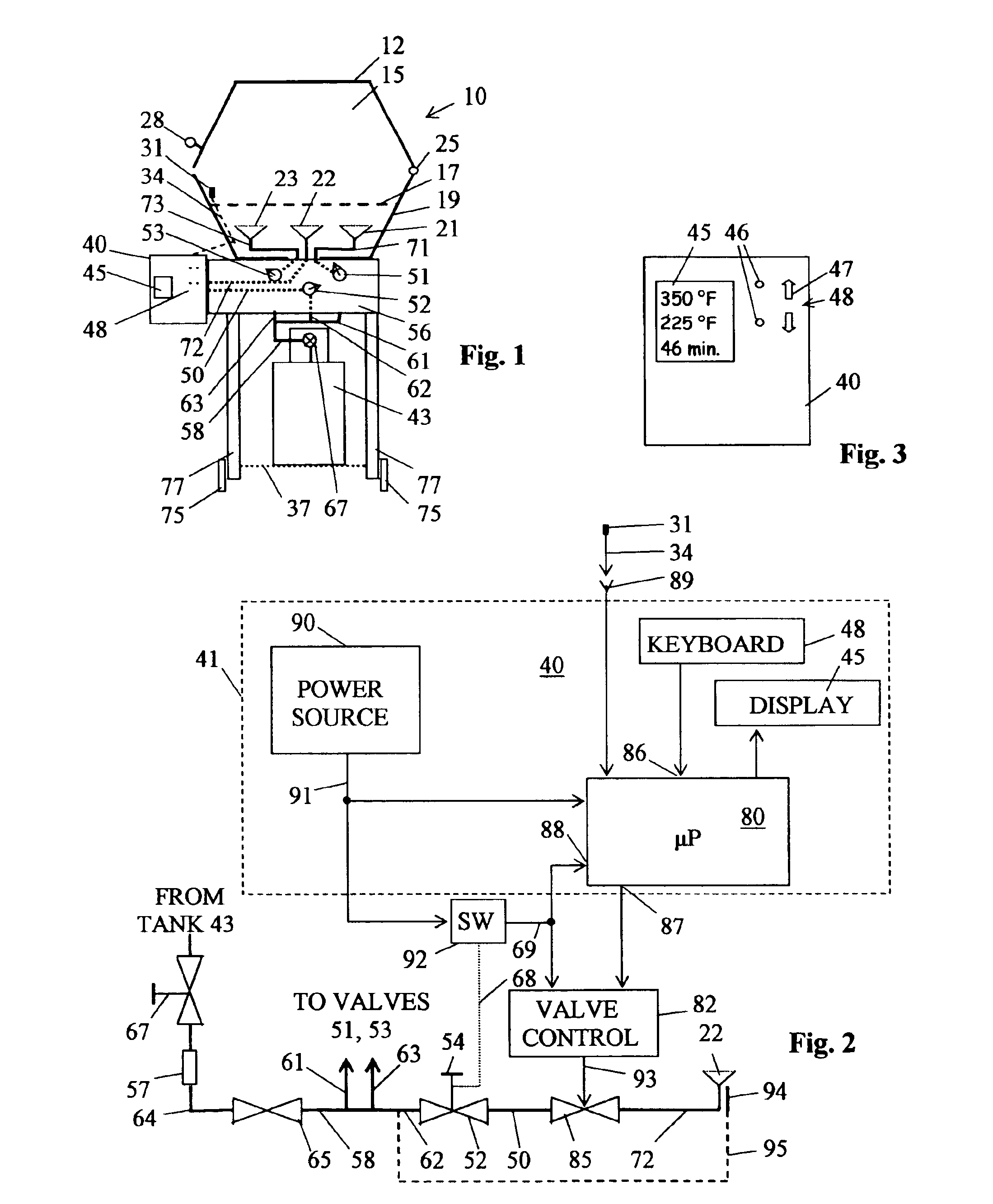

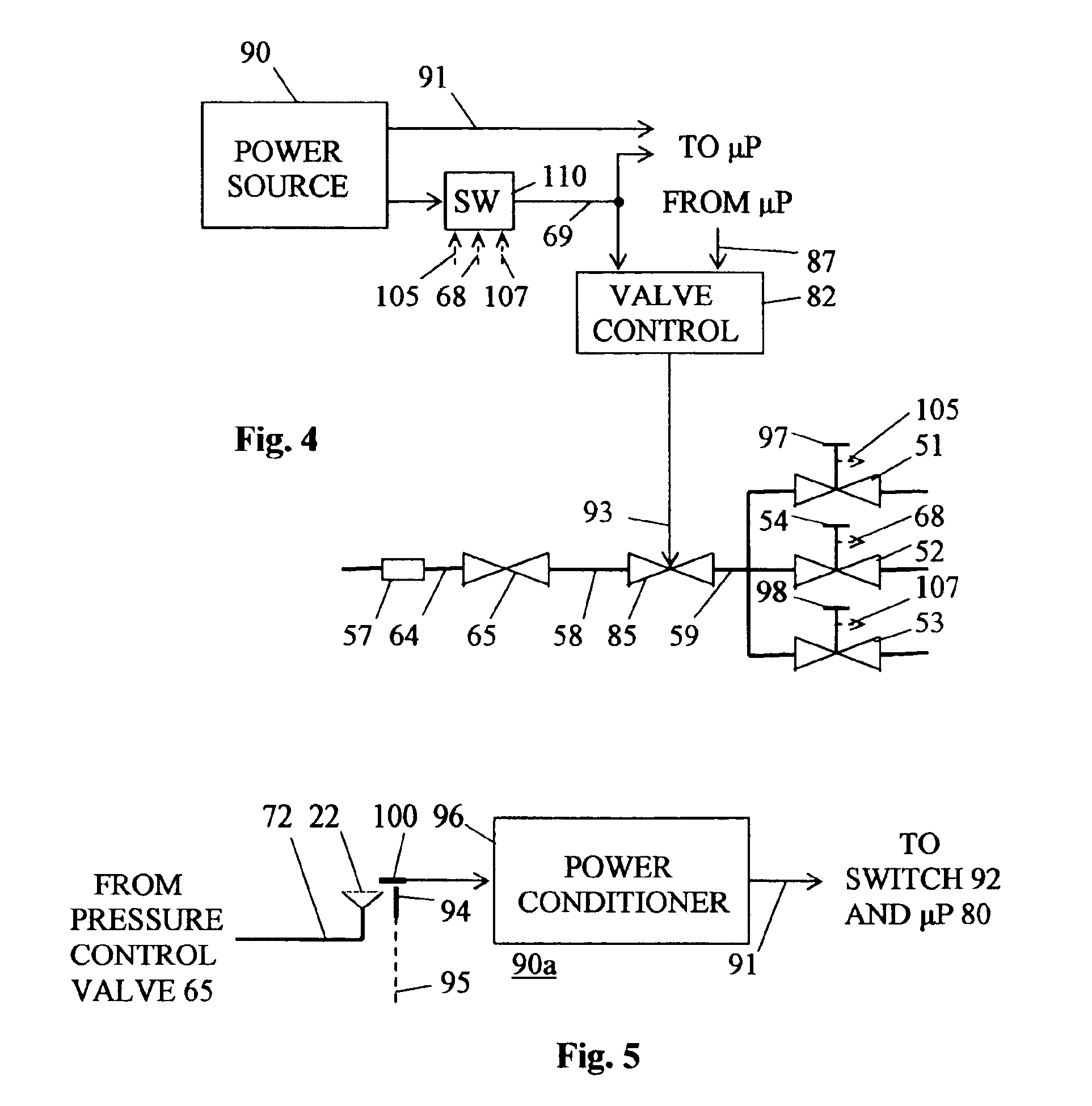

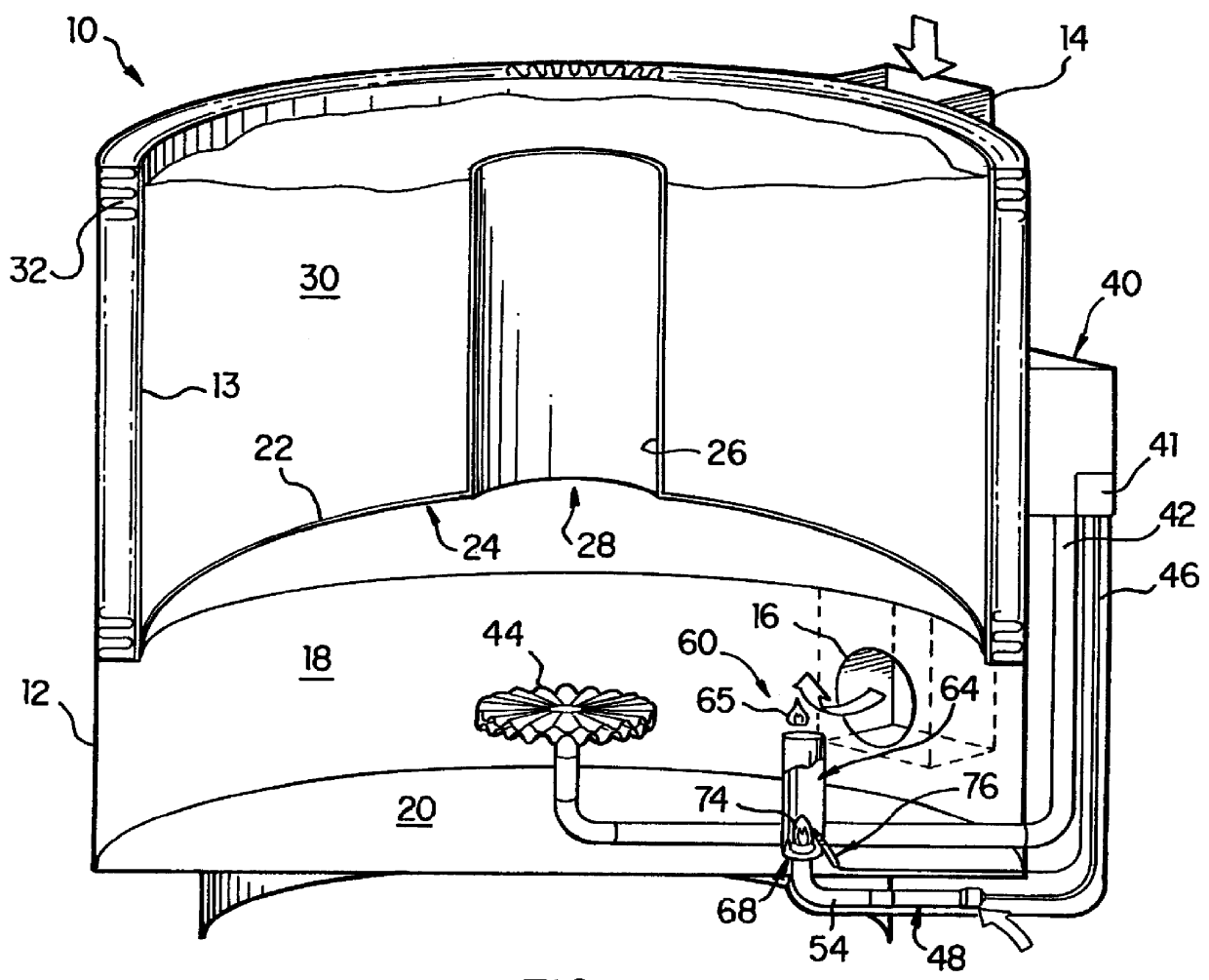

Temperature controlled burner apparatus

InactiveUS6881055B2Easy to controlMore powerTemperature control without auxillary powerSelf-cleaning stoves/rangesTemperature controlCombustor

A system for controlling temperature in an enclosure operates in a low heat or a high heat mode with flame always present. The presently intended use is for providing a cooking grill with a controlled temperature cooking space. An electrically controlled valve having high flow rate and low flow rate settings is interposed in the fuel line for at least one of the burners in the grill. A temperature sensor signals cooking space temperature to a controller that may be a microprocessor. The system includes a keyboard allowing the user to communicate a selected set point to the microprocessor and the microprocessor communicates status to a display. The microprocessor selects the setting of the electrically controlled valve. In a preferred embodiment, the electrically controlled valve is placed in series fuel flow with one of the manually adjustable valves commonly found on cooking grills.

Owner:ADEMCO INC

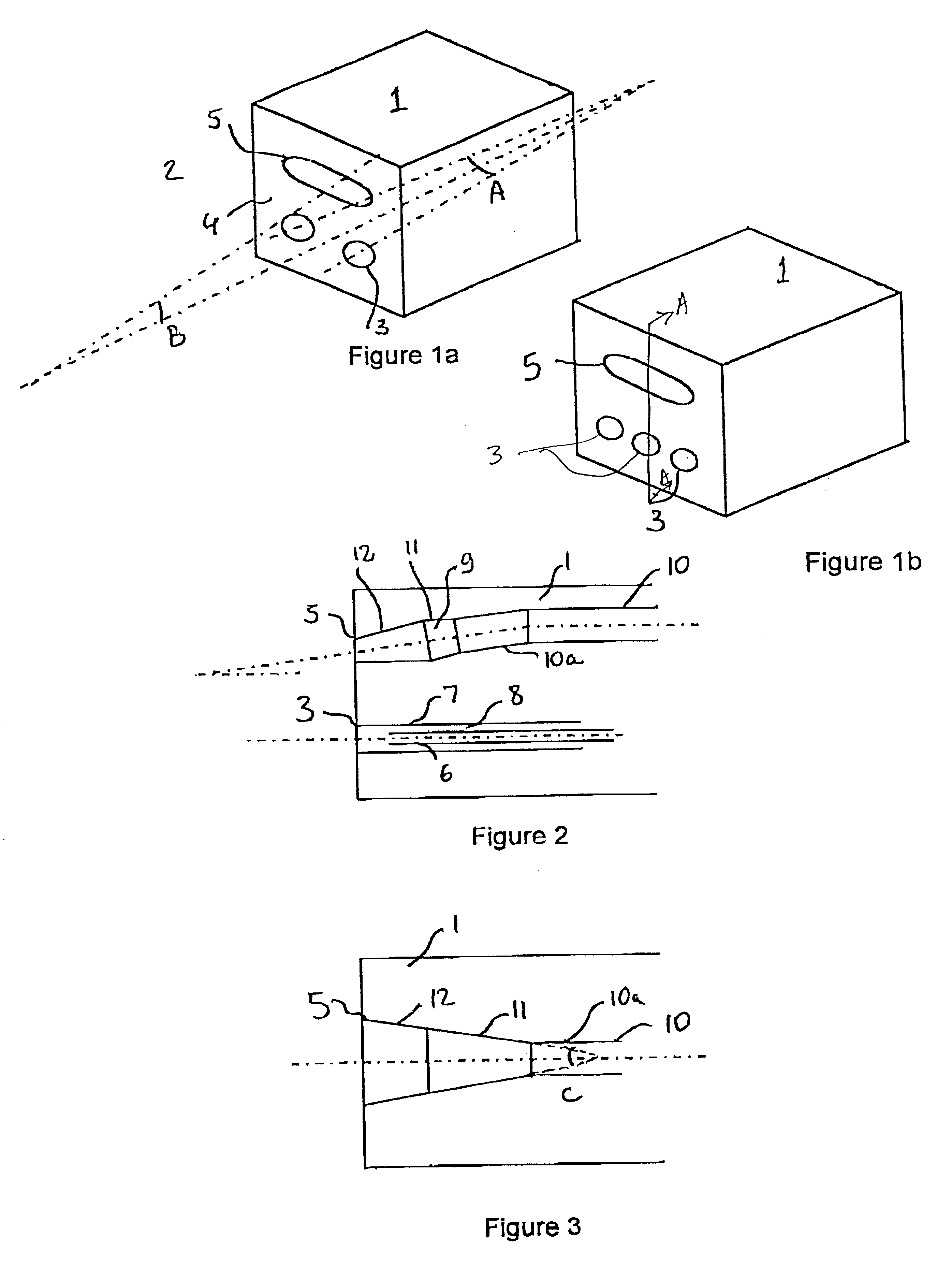

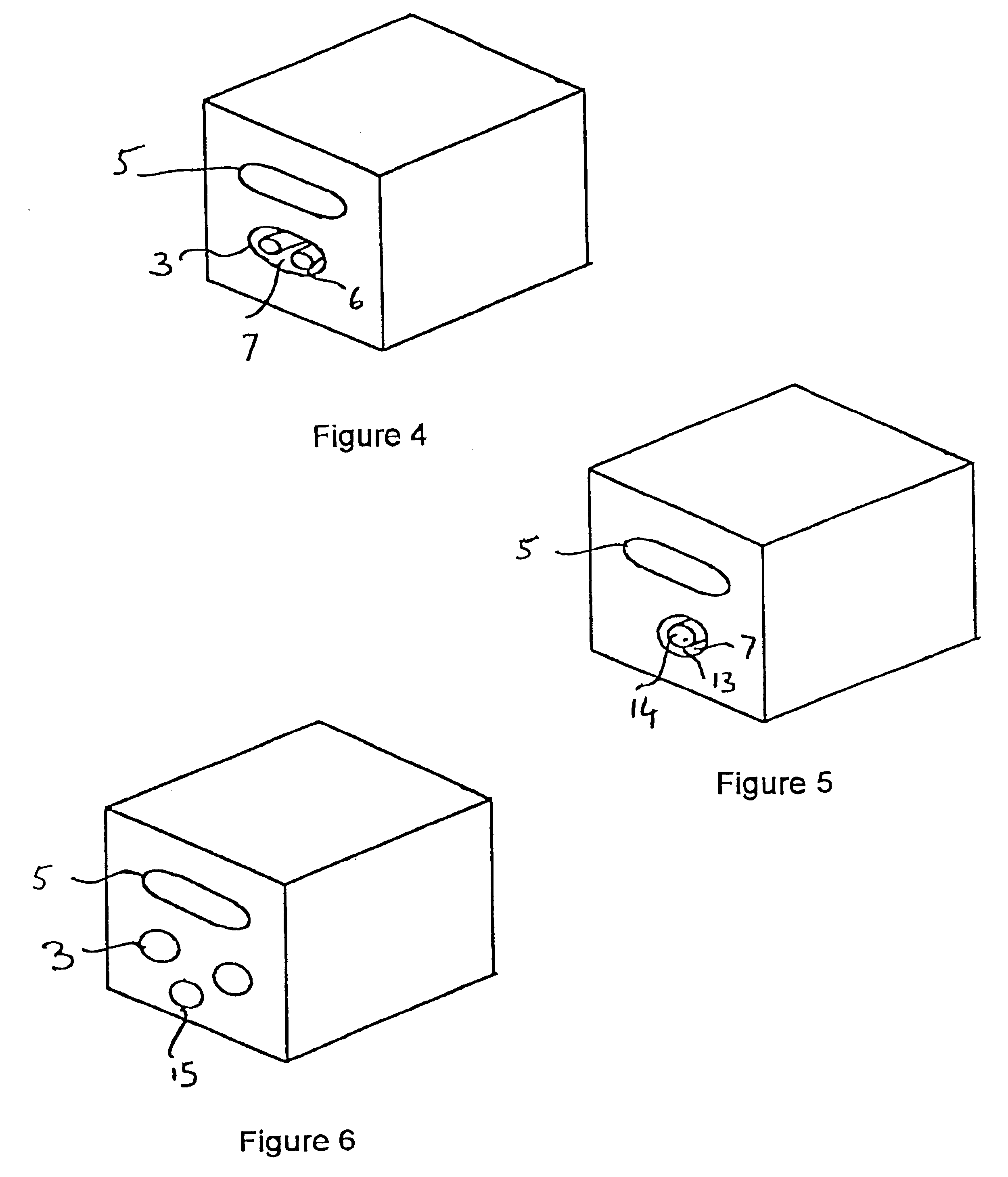

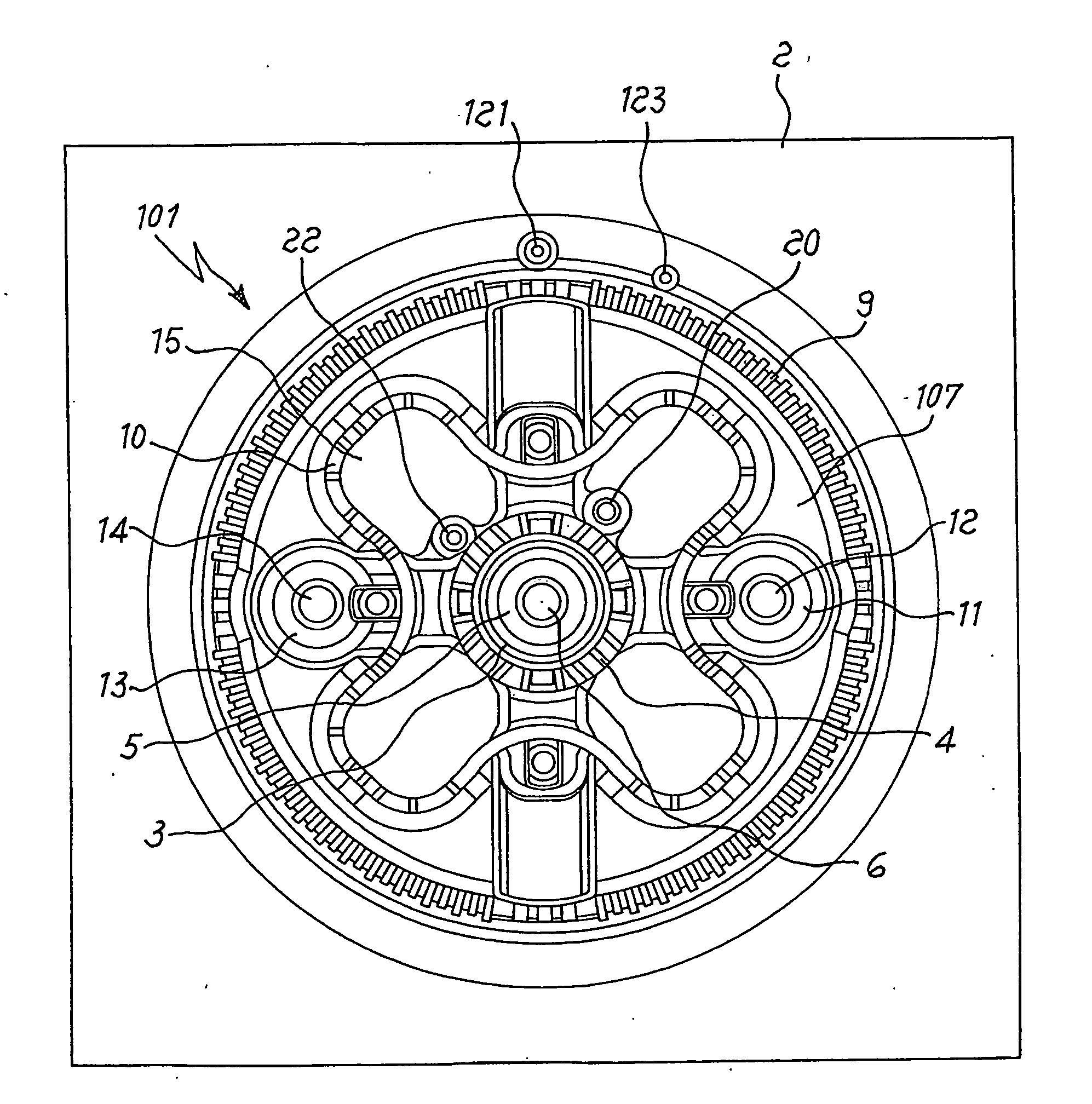

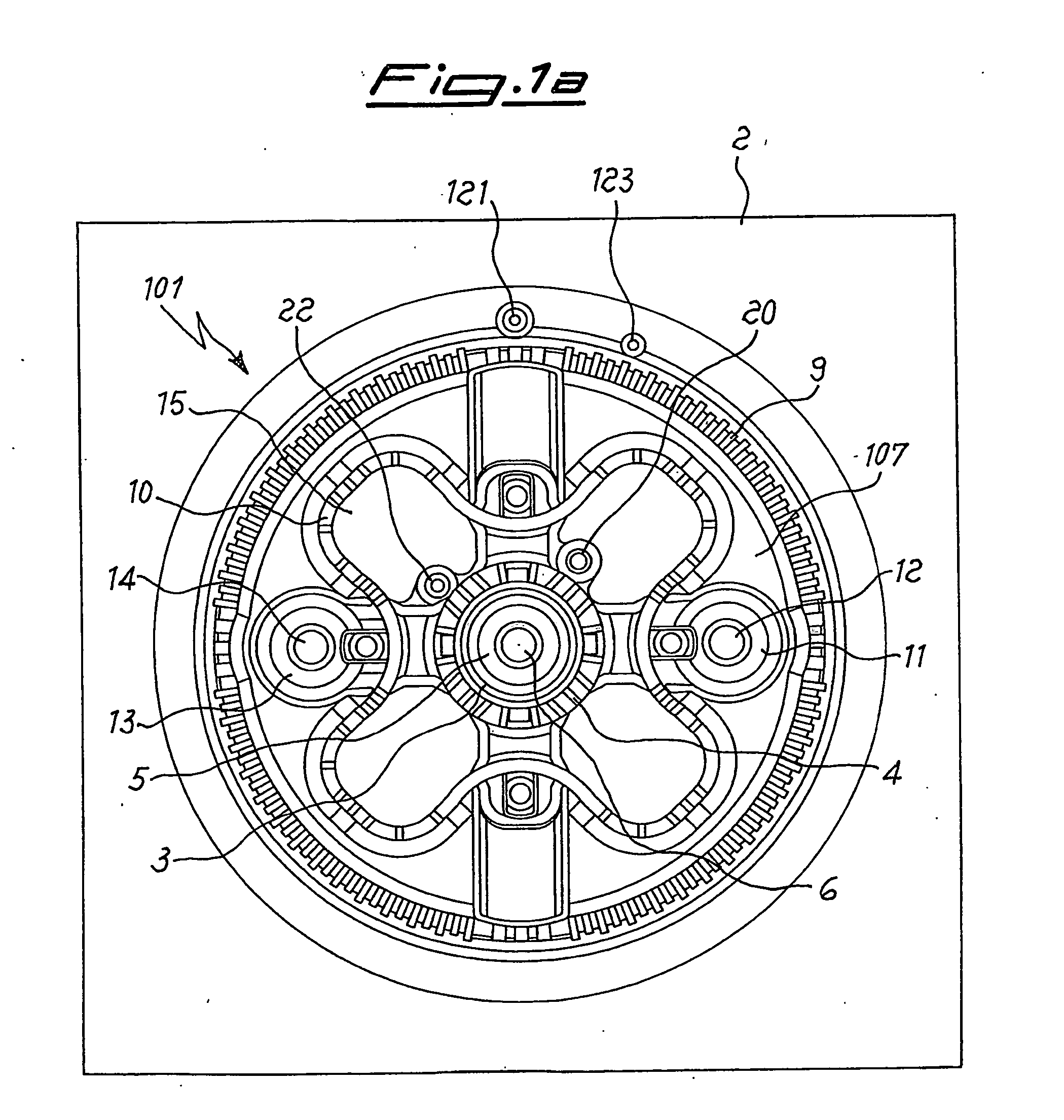

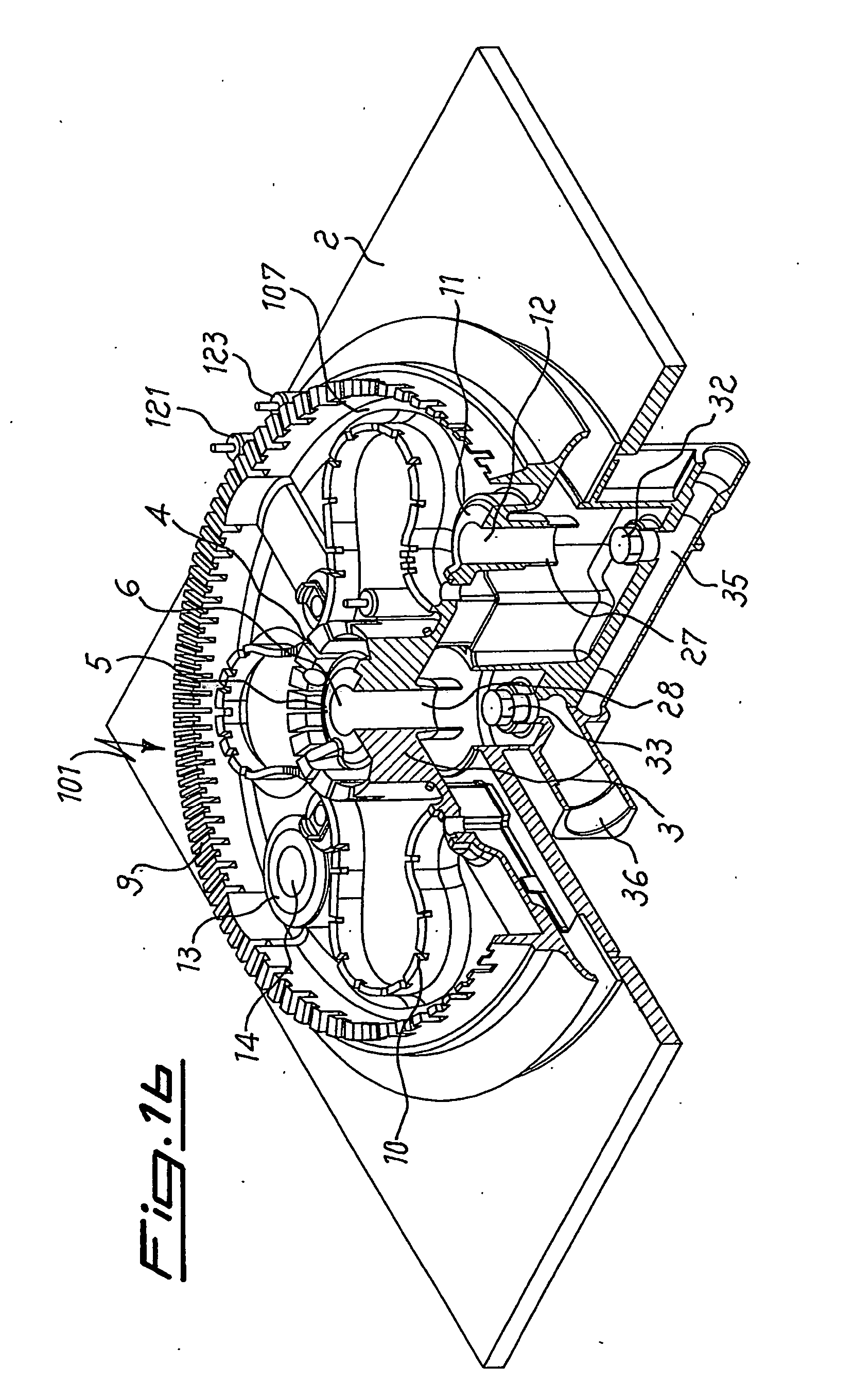

Gas burner with separte feeding of the flame crowns

ActiveUS20060121402A1Reduce burner heightImprove distributionDomestic stoves or rangesElectric spark ignitersGas burnerFuel gas

Gas burner (101) for cookers, of the type fitted to a cooking hob (2), comprising a central body (3) having a first ring of flames (4) and at least one external body (107), fluidly separated from said central body and substantially concentric with it (3), having at least one second (circumferential) ring of flames (9, 10), as well as means for separately feeding the mixture of primary air and gas to the central body and to the external body. These means for feeding the external body comprise at least one horizontal mixing chamber with a radial Venturi effect (11, 12, 13, 14).

Owner:SABAF SPA

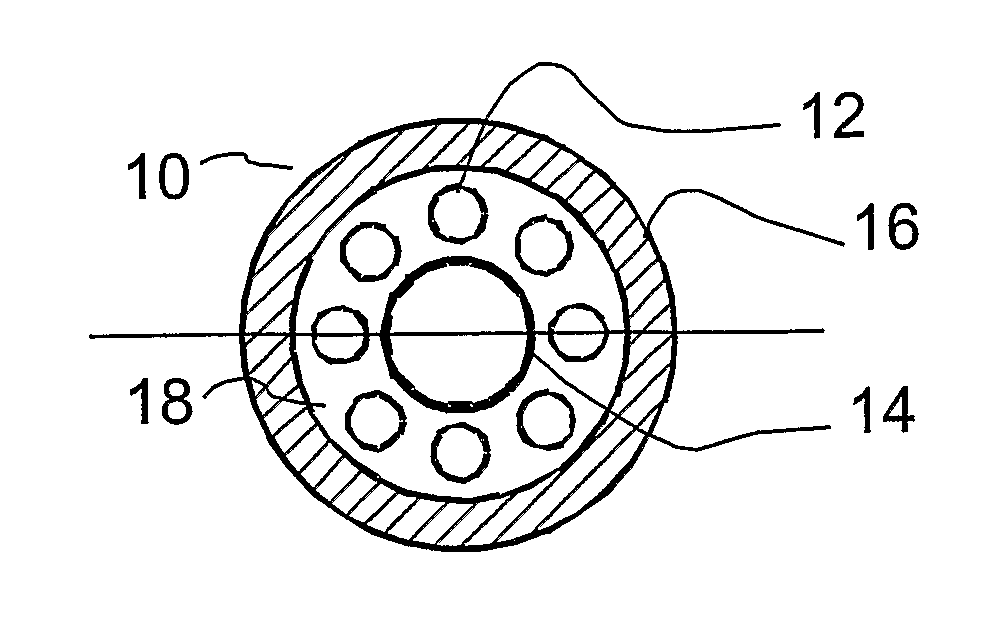

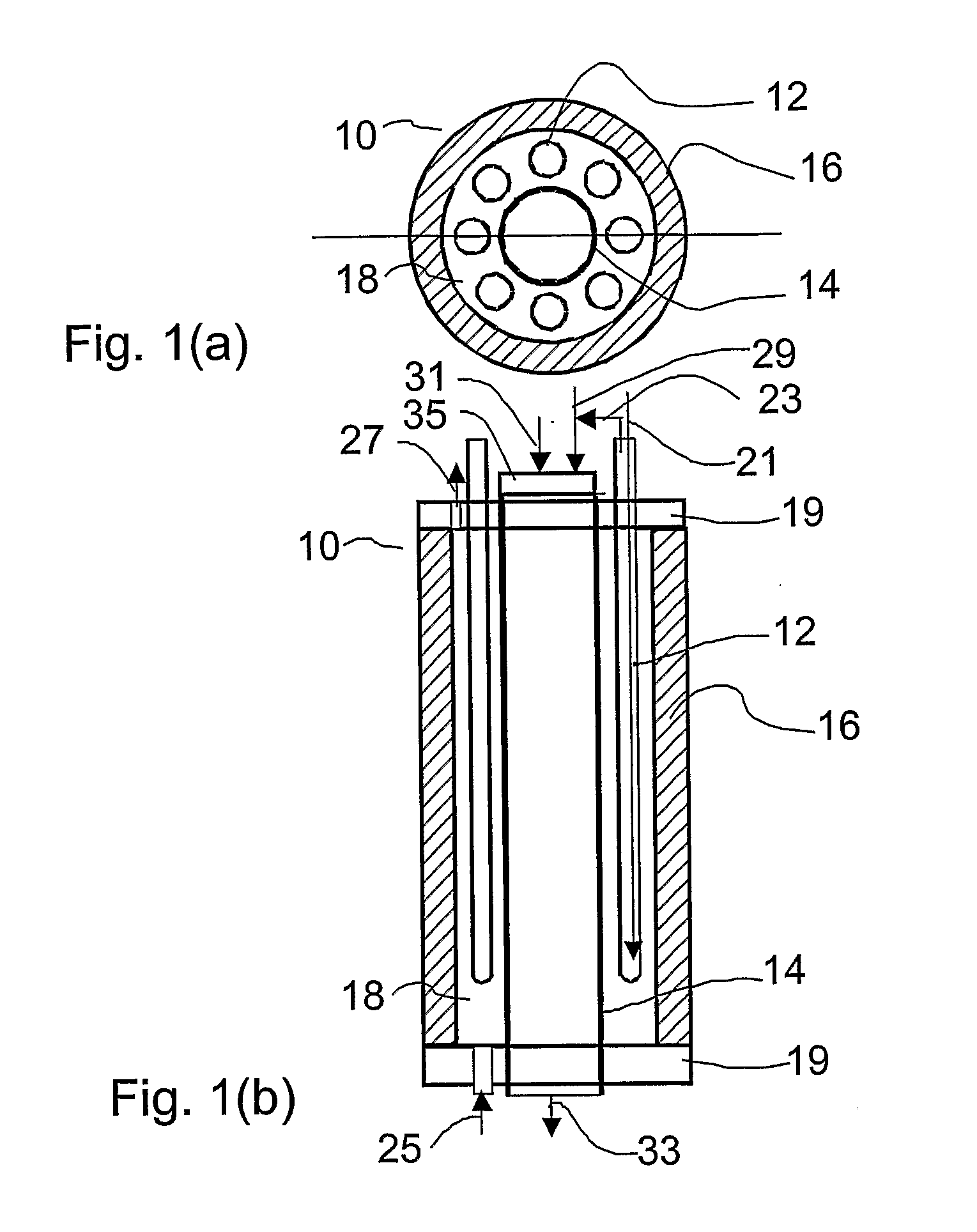

Heating Solid Oxide for Fuel Cell Stack

This invention relates to a solid oxide fuel cell system comprising at least one longitudinally extending tubular solid oxide fuel cell and a longitudinally extending heater mounted in thermal proximity to the fuel cell to provide heat to the fuel cell during start up and during operation as needed. The heater and fuel cell can be encased within a tubular thermal casing; the inside of the casing defines a first reactant chamber for containing a first reactant, such as oxidant. The fuel cell comprises a ceramic solid state electrolyte layer and inner and outer electrode layers concentrically arranged around and sandwiching the electrolyte layer. The outer electrode layer is fluidly communicable with the first reactant, and the inner electrode layer is fluidly isolated from the first reactant and fluidly communicable with a second reactant, such as fuel.

Owner:INNOTECH ALBERTA INC

Dual fuel heating source with nozzle

A dual fuel heating source can have a burner and a nozzle. The heating source can be configured to use one of two different fuels flowing at different pressures. The nozzle can have a body, the body defining an outlet opening, an inlet, and an inner chamber. The nozzle can be configured for the first fuel in a first position of said nozzle, and can be configured for a second fuel in a second position.

Owner:DENG DAVID

Burner apparatus, submerged combustion melters including the burner, and methods of use

Owner:JOHNS MANVILLE CORP

Nozzle

Certain embodiments of a nozzle are configured to dispense a first gas, liquid, or combination thereof at a first pressure in a first mode of operation and dispense a second gas, liquid, or combination thereof at a second pressure in a second mode of operation. In some embodiments, the nozzle is integrated in a heat-producing device, such as, for example, a heater, a fireplace, or a stove. In some embodiments, the heat-producing device including the nozzle can operate with a first combustible fuel at a first pressure, or alternatively, can operate with a second combustible fuel at a second pressure. In some embodiments, the nozzle is used in applications other than heat-producing devices.

Owner:PROCOM HEATING

Pressure regulator

In certain embodiments, a pressure regulating device for selectively coupling with a first source or a second source includes a housing defining at least a portion of a first input channel, a second input channel, and an output channel. In some embodiments, the device further includes a first connector configured to couple with the first source such that the first source is in communication with the first input channel. The device also includes a second connector configured to couple with the second source such that the second source is in communication with the second input channel. The device further includes a first regulator configured to regulate flow from the first input channel to the output channel and a second regulator configured to regulate flow from the second input channel to the output channel.

Owner:PROCOM HEATING

Fuel selection valve assemblies

In certain embodiments, an apparatus includes a control valve for regulating fuel flow. The apparatus can include a burner and a valve assembly. In some embodiments, the valve assembly includes a housing, which can define a first fuel input for receiving a first fuel from a first fuel source and a second fuel input for receiving a second fuel from a second fuel source. The housing can define a first fuel output for directing fuel toward the control valve, and can define a third fuel input for receiving a portion of either the first fuel or the second fuel from the control valve. The housing can define a first egress flow path and a second egress flow path, each for directing fuel to the burner. In certain embodiments, the apparatus includes a valve body configured to selectively permit fluid communication between the first and second inputs and the output and between the third input and the egress flow paths.

Owner:PROCOM HEATING

LOW NOx EMISSION INDUSTRIAL BURNER AND COMBUSTION PROCESS THEREOF

ActiveUS20100233642A1Reduce nitrogen oxide emissionsEmission reductionFuel supply regulationPilot flame ignitersCombustorProcess engineering

Low NOx emission industrial burner, adapted to operate both in a flame or stage mode and in a flameless mode, so that also the heating step of the chamber of a furnace may be made by means of the same burner, without providing a pilot burner, thus ensuring very low NOx emissions for the whole operation range of the burner and for the whole range of temperatures in the chamber. The combustion process, made by means of said burner, provides for the possibility to combine the stage mode operation with the flameless mode operation.

Owner:DANIELI & C OFF MEC SPA +1

Pilot burner apparatus and method for operating

InactiveUS6139311AEasy constructionLow costCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorFuel gas

An apparatus and method for operating a pilot burner apparatus and a main burner apparatus of a gas-fired appliance. The pilot burner apparatus draws combustion air from a first environment. The main combustion apparatus draws air from a second environment. In a shutdown condition, such as when a flammable vapor source is accidentally exposed to the second environment, the pilot burner apparatus draws air containing an undesired flammable vapor which eliminates the pilot flame, triggering a gas valve to close and shut down the fuel gas supply to the main burner apparatus and the pilot burner apparatus.

Owner:GAS TECH INST

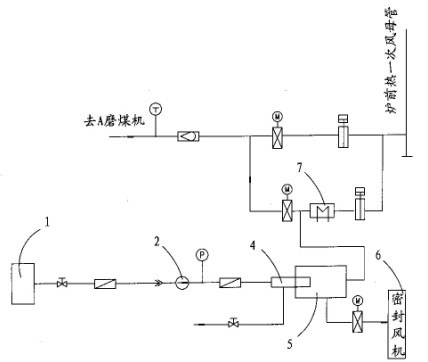

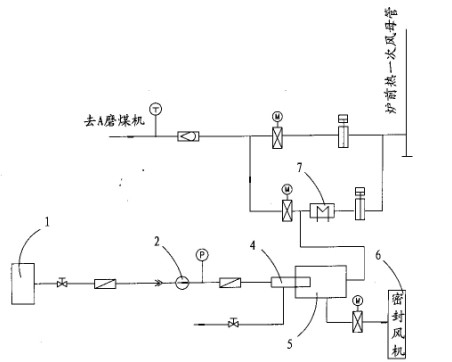

Cold start oil auxiliary heating system of boiler and heat source-less independent starting method of generating set

InactiveCN102506407AAchieving a cold startReduce operating costsPilot flame ignitersBoiler controlAir preheaterEngineering

The invention discloses a cold start oil auxiliary heating system of a boiler and a heat source-less independent starting method of a generating set. The method includes the following steps that: mounting a set of small oil gun igniting system at an inlet air passage of a coal mill for preheating the cold air entering the coal mill and enabling the coal mill to satisfy the working conditions; communicating coal economizer ash conveying gas source of the boiler with a soot blowing steam pipeline of an air preheater through a shutoff valve for supplying soot blowing medium of the air preheater; starting a shaft seal steam valve on a main steam pipeline after the boiler is ignited for supplying steam for shaft seal of a turbine; and supplying steam to an auxiliary steam header of the generating set after the boiler is ignited and the combustion steam reaches a certain parameter, and then supplying steam by the auxiliary steam header for the rolling of a water thermal power deoxidizing and steam-driven feedwater pump. The invention has the advantages that as the cold start of the generating set can be realized through the ignition of the plasma installed in the combustor and the stable combustion technology under the conditions that no starting boiler room is independently established or the external heat source is insufficient, and the operating cost and the labor cost of the power plant are greatly reduced.

Owner:WENERGY HEFEI POWER GENERATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com