Patents

Literature

4260 results about "Soot" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Soot /sʊt/ is a mass of impure carbon particles resulting from the incomplete combustion of hydrocarbons. It is more properly restricted to the product of the gas-phase combustion process but is commonly extended to include the residual pyrolysed fuel particles such as coal, cenospheres, charred wood, and petroleum coke that may become airborne during pyrolysis and that are more properly identified as cokes or char.

Catalyzed SCR filter and emission treatment system

ActiveUS7229597B2Reduce the temperaturePromote regenerationCombination devicesLiquid degasification with auxillary substancesNitrogen oxideSoot

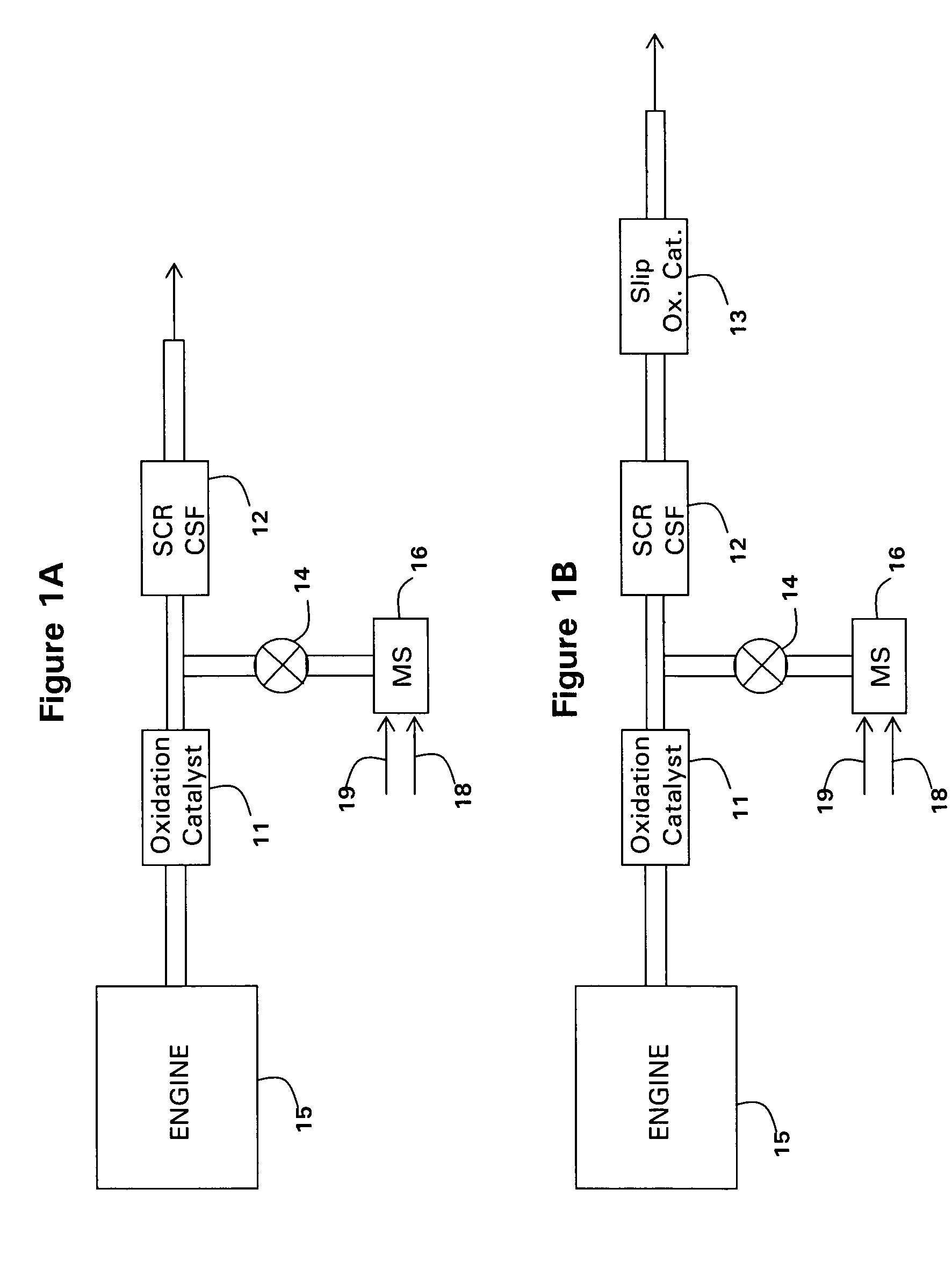

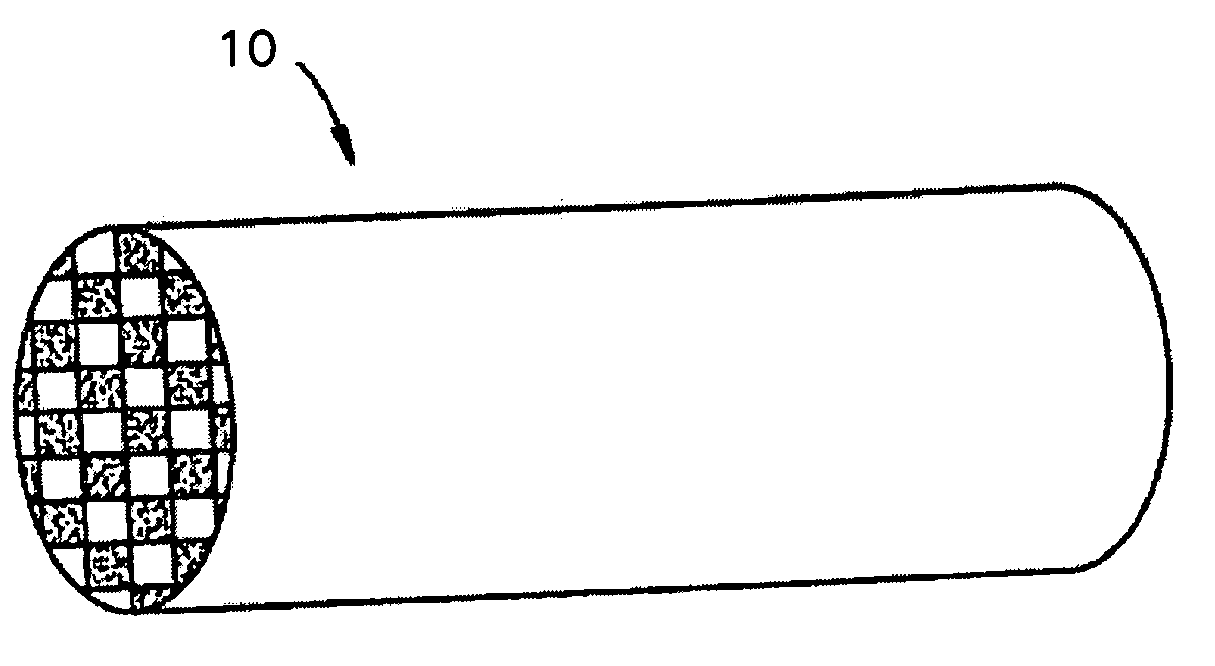

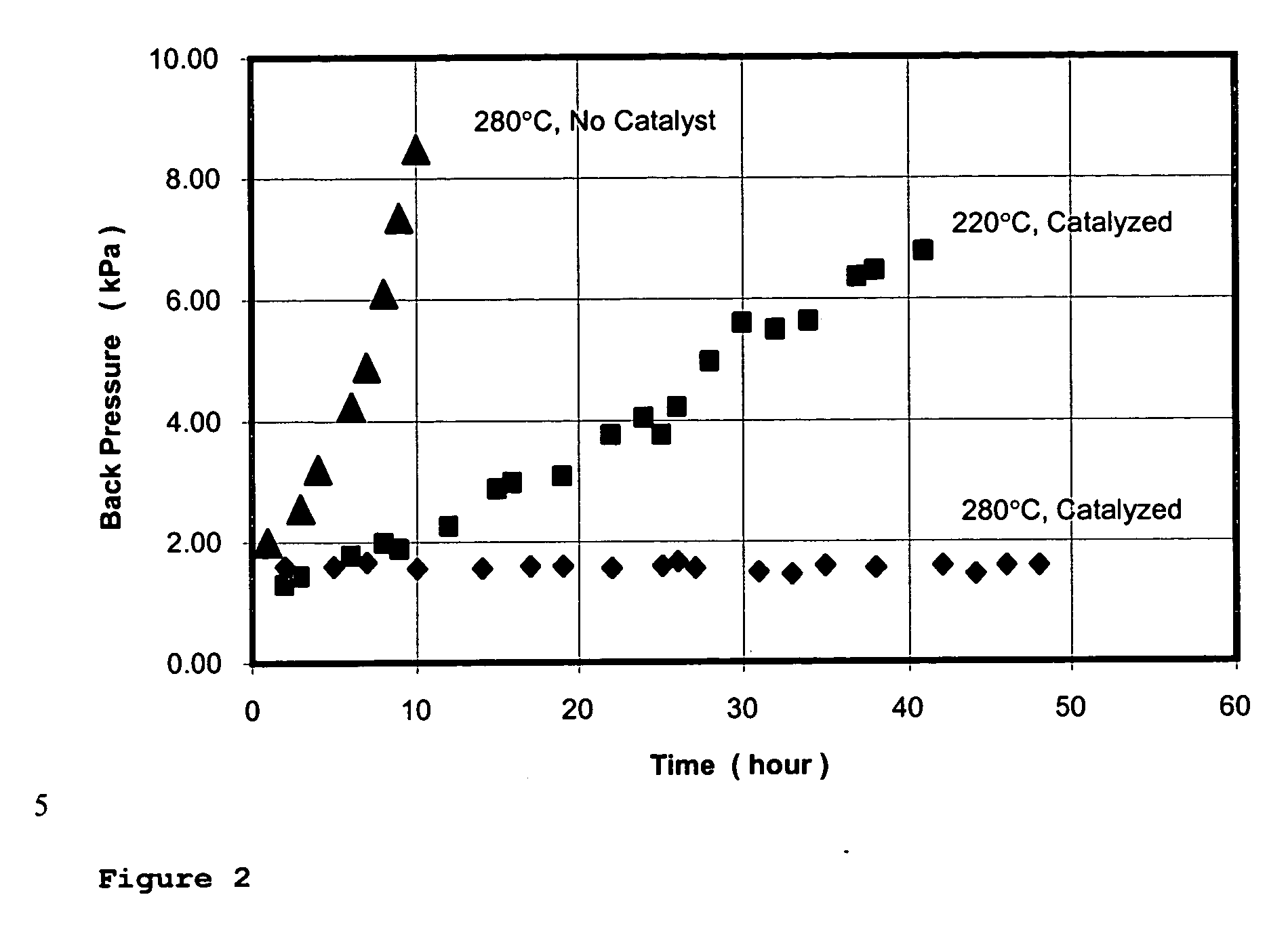

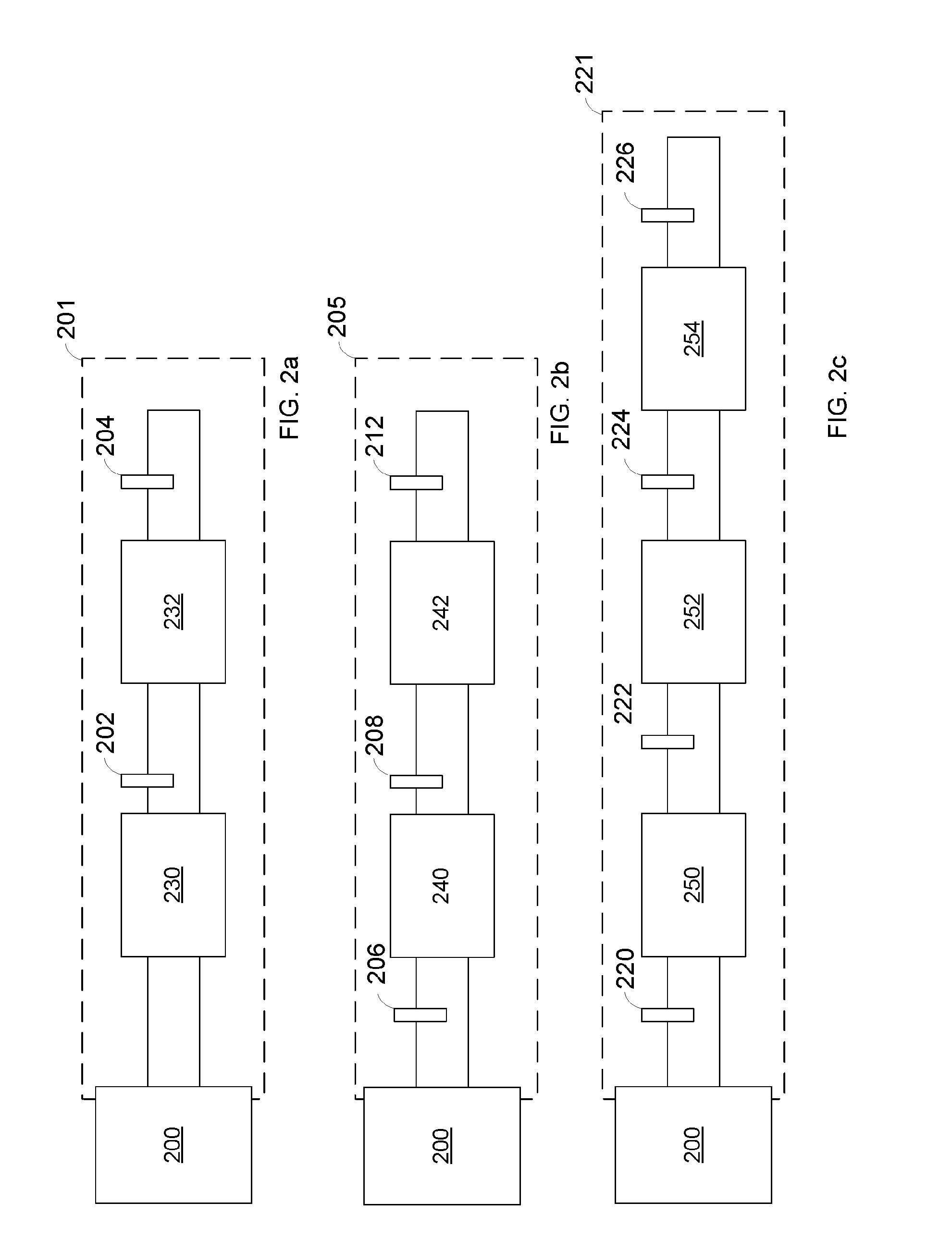

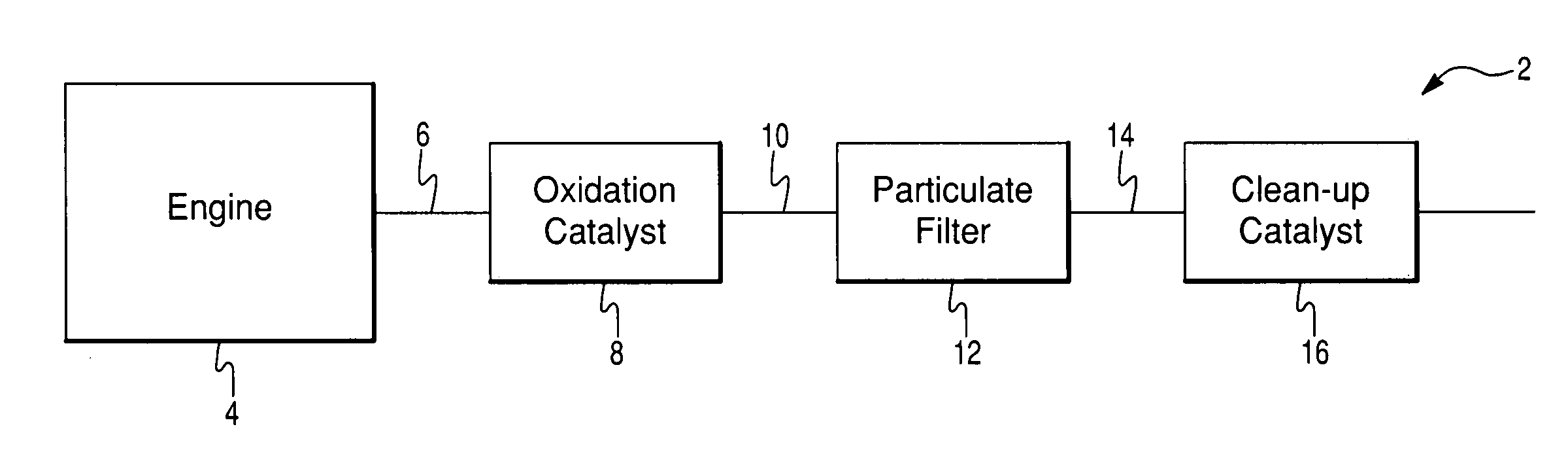

Provided is an emission treatment system and method for simultaneously remediating the nitrogen oxides (NOx), particulate matter, and gaseous hydrocarbons present in diesel engine exhaust streams. The emission treatment system has an oxidation catalyst upstream of a soot filter coated with a material effective in the Selective Catalytic Reduction (SCR) of NOx by a reductant, e.g., ammonia. Also provided is a method for disposing an SCR catalyst composition on a wall flow monolith that provides adequate catalyst loading, but does not result in unsuitable back pressures in the exhaust.

Owner:BASF CORP

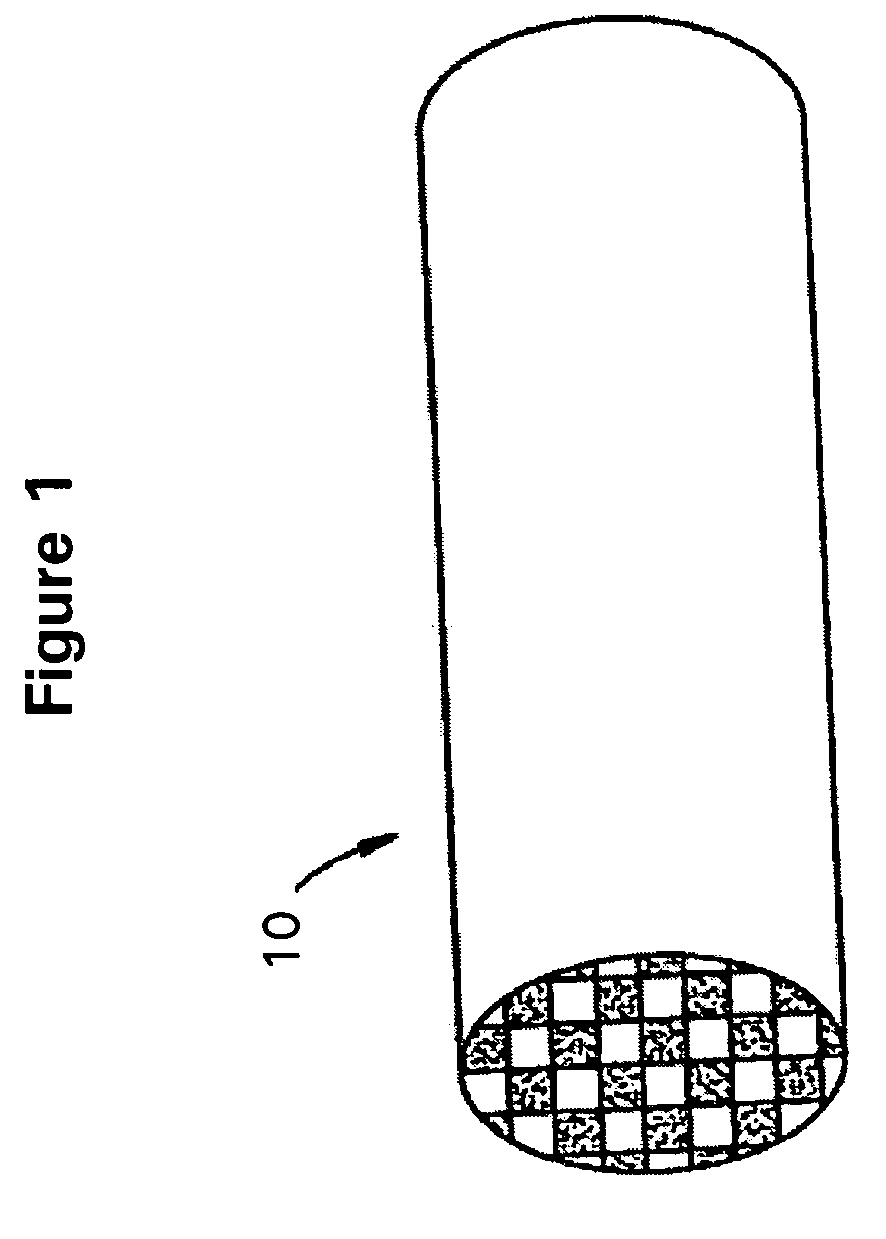

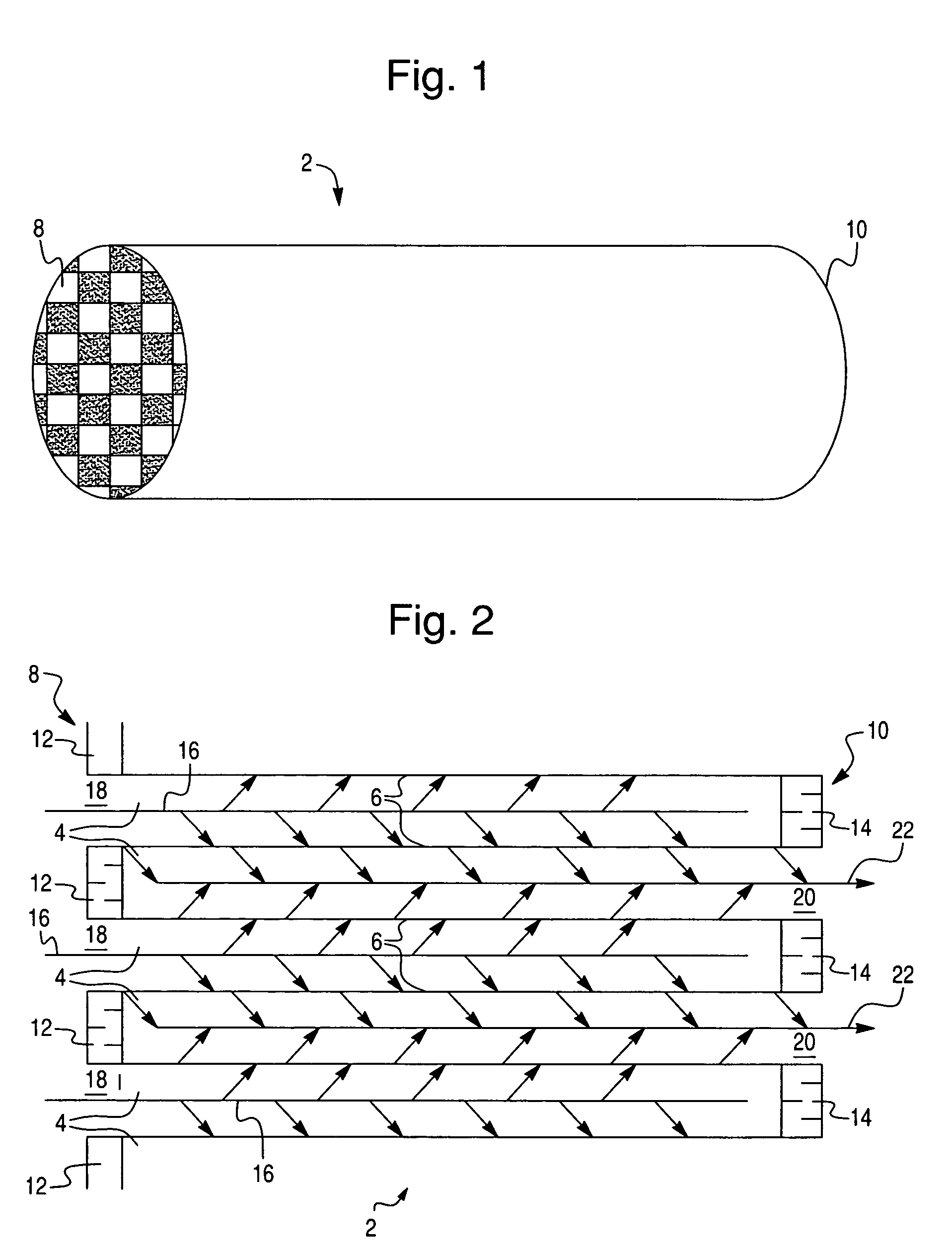

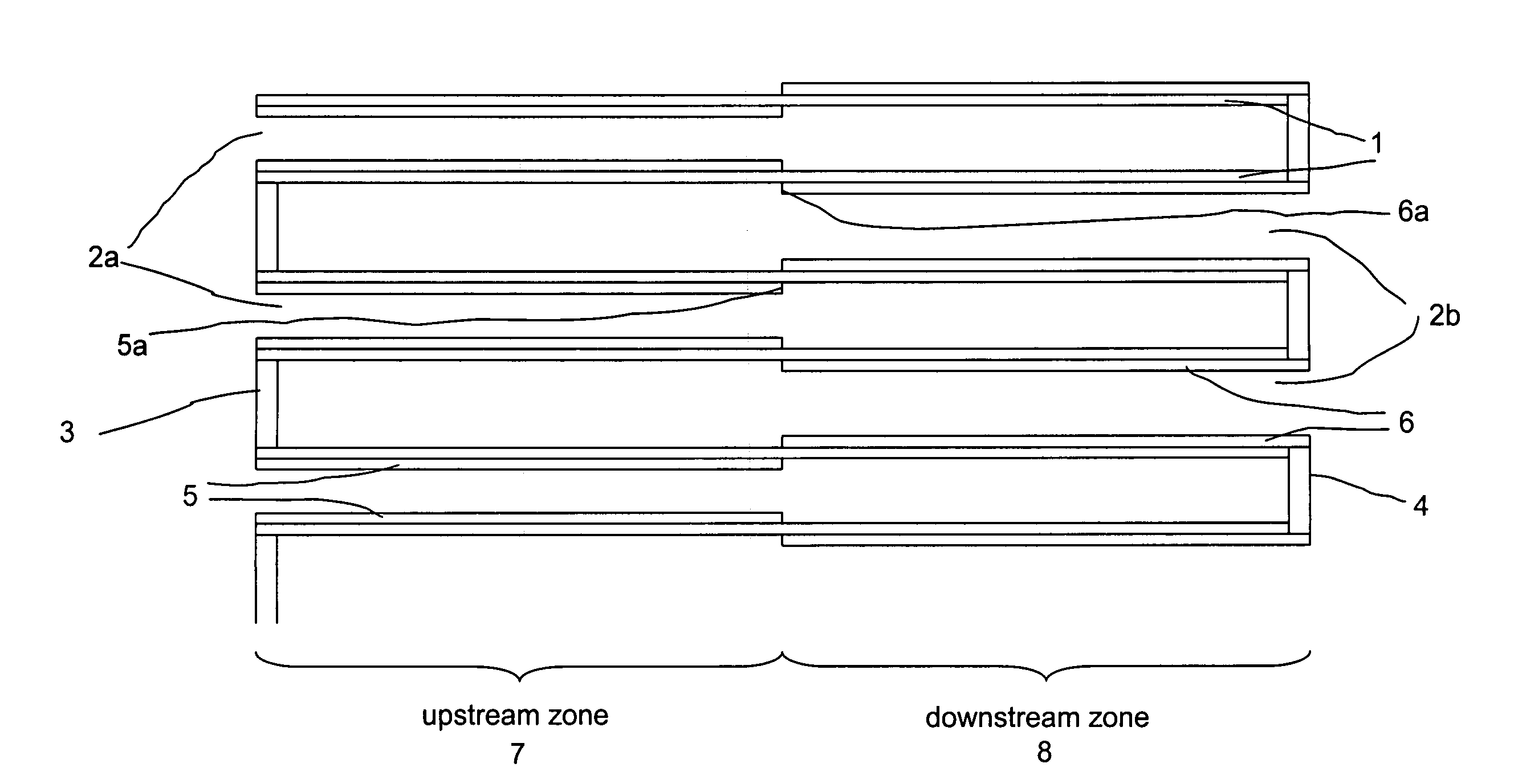

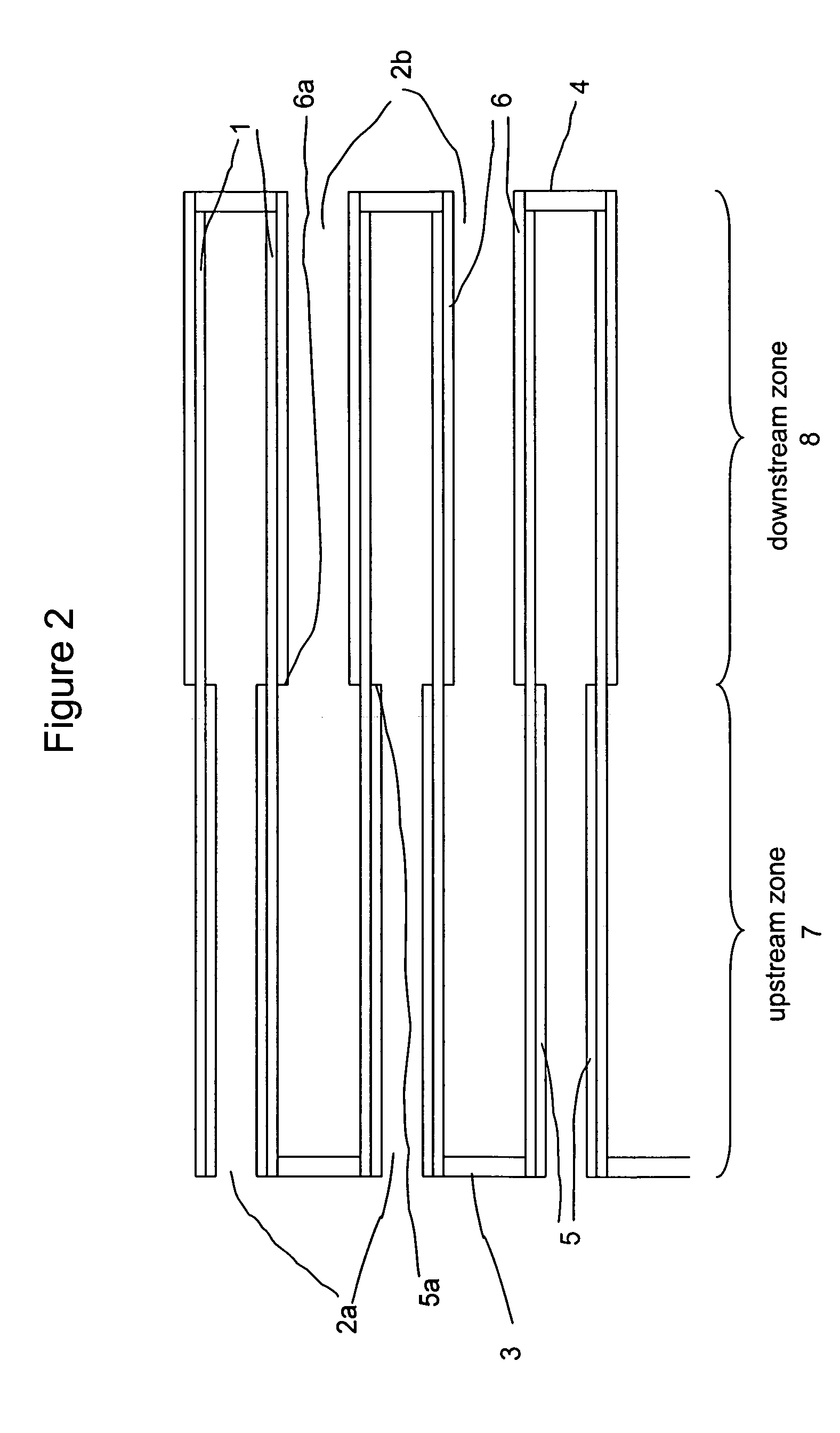

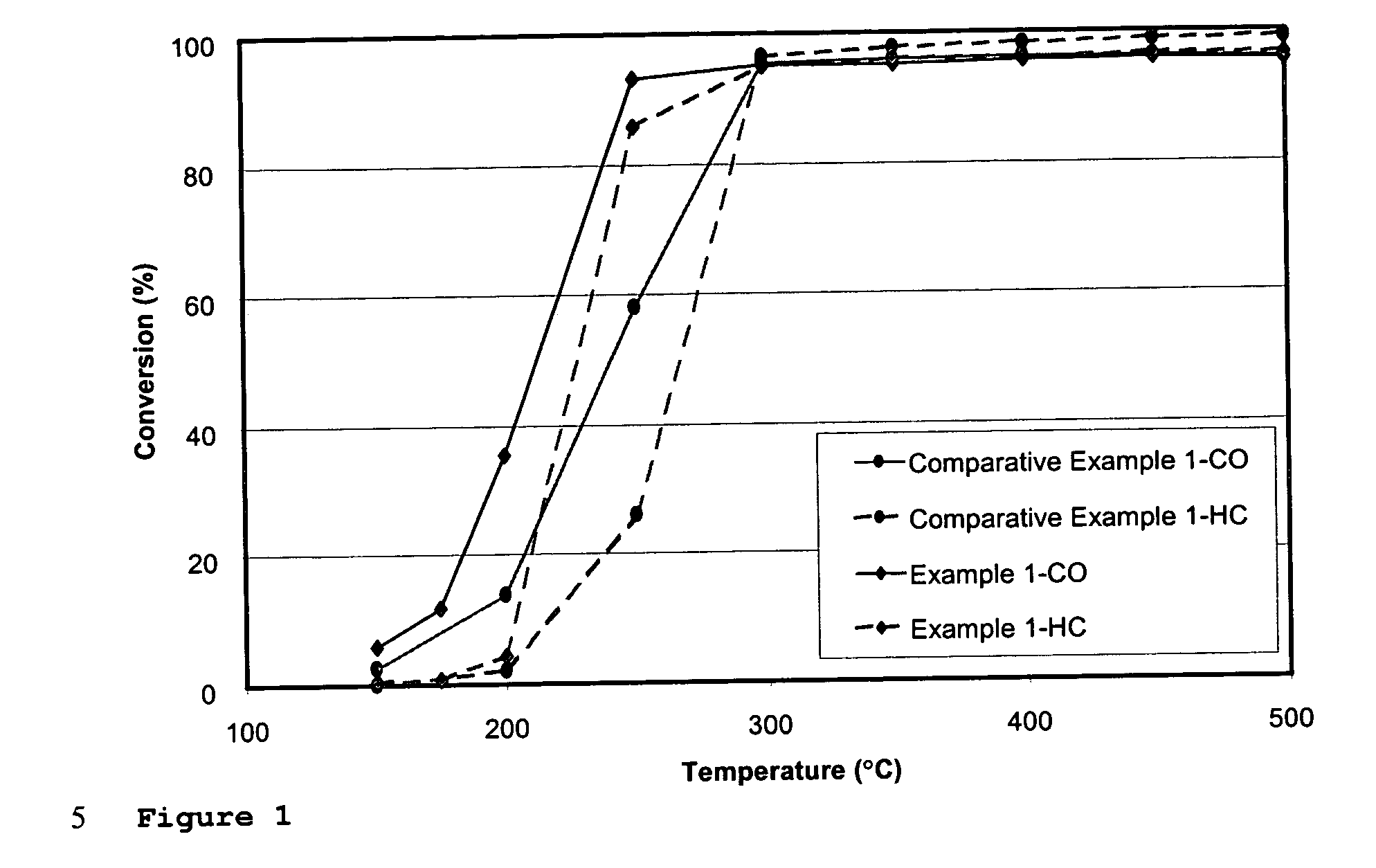

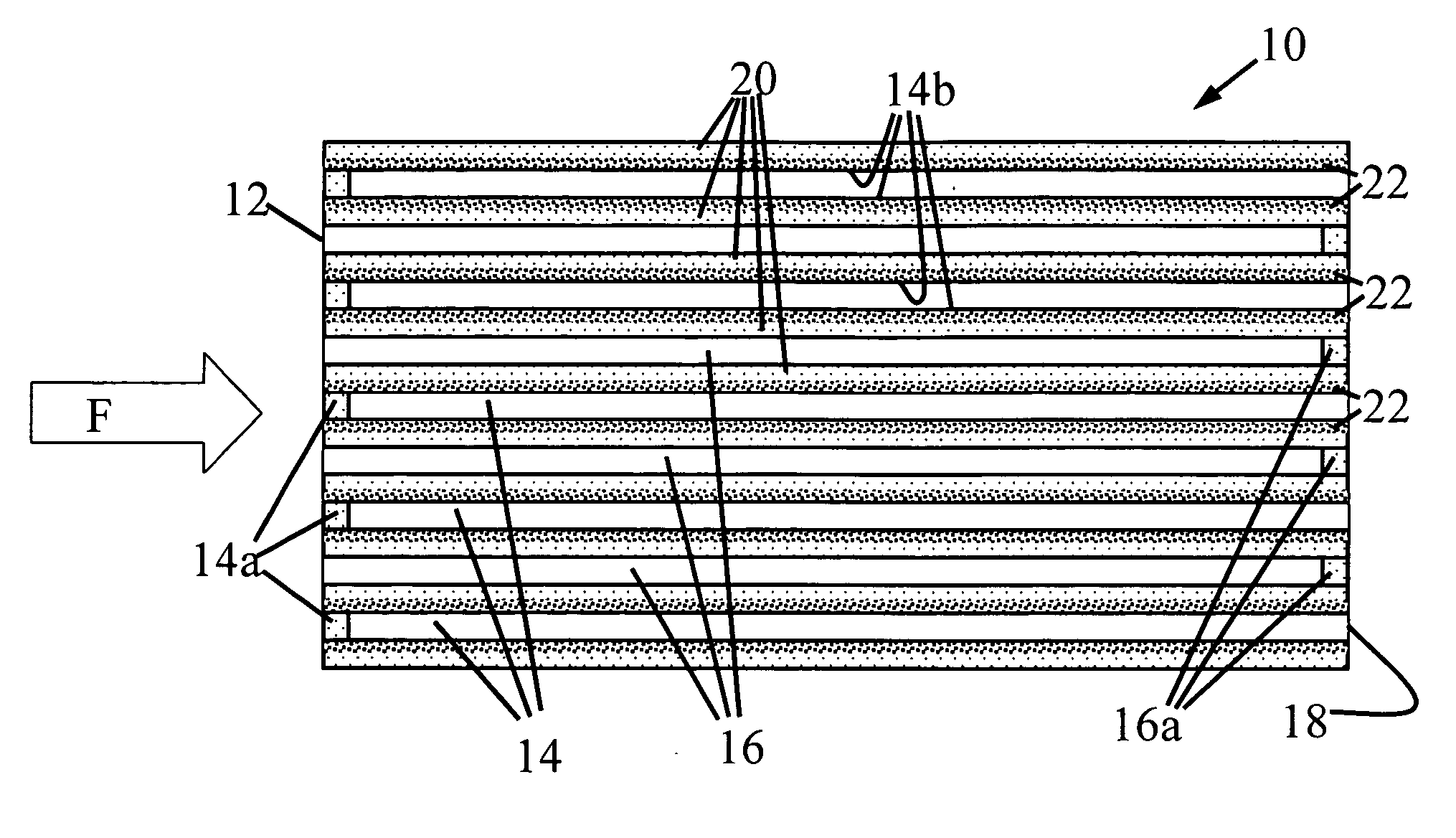

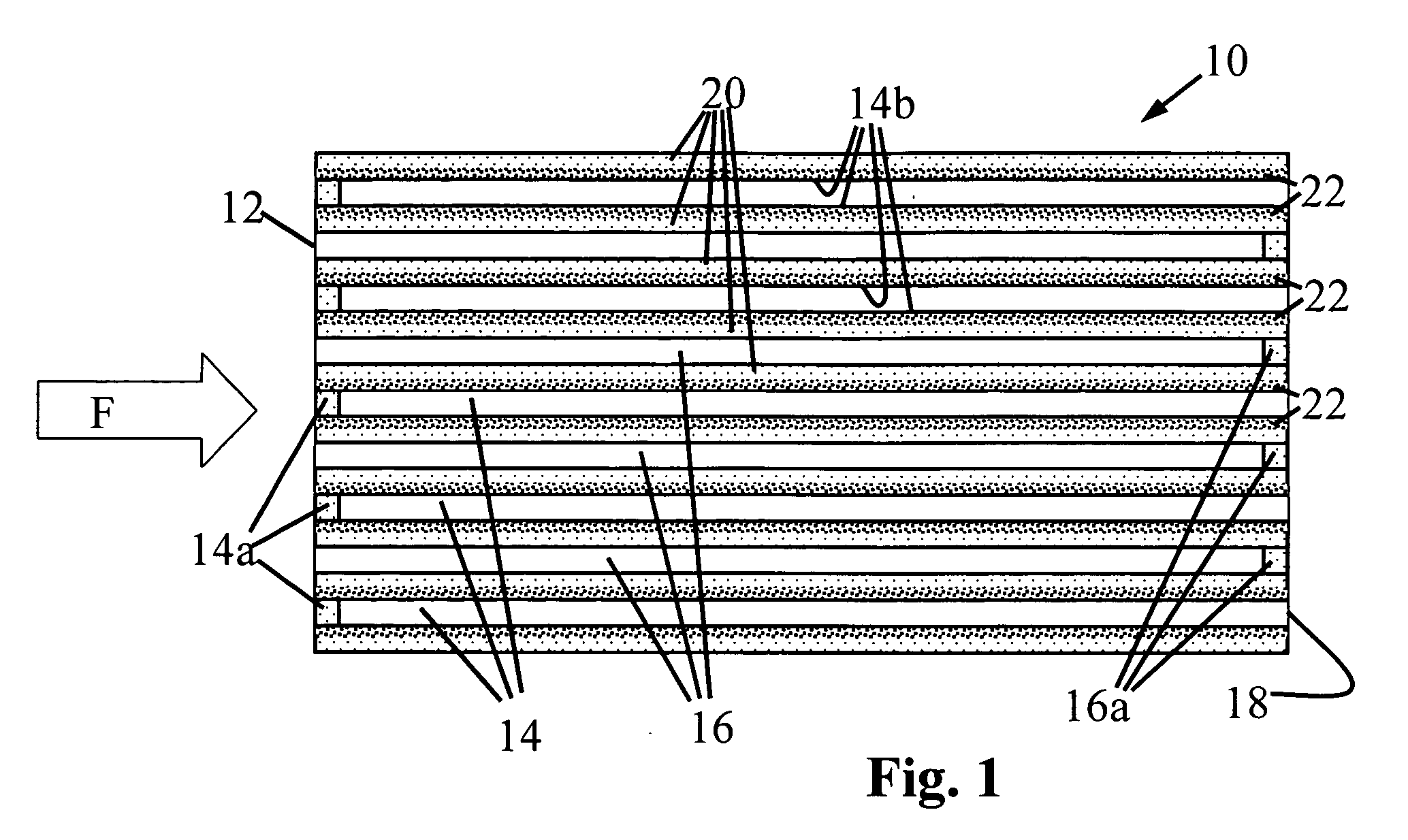

Pressure-balanced, catalyzed soot filter

ActiveUS20060057046A1Minimal overall platinum group metal component material costSpeed up the conversion processCombination devicesMolecular sieve catalystsParticulatesCatalytic function

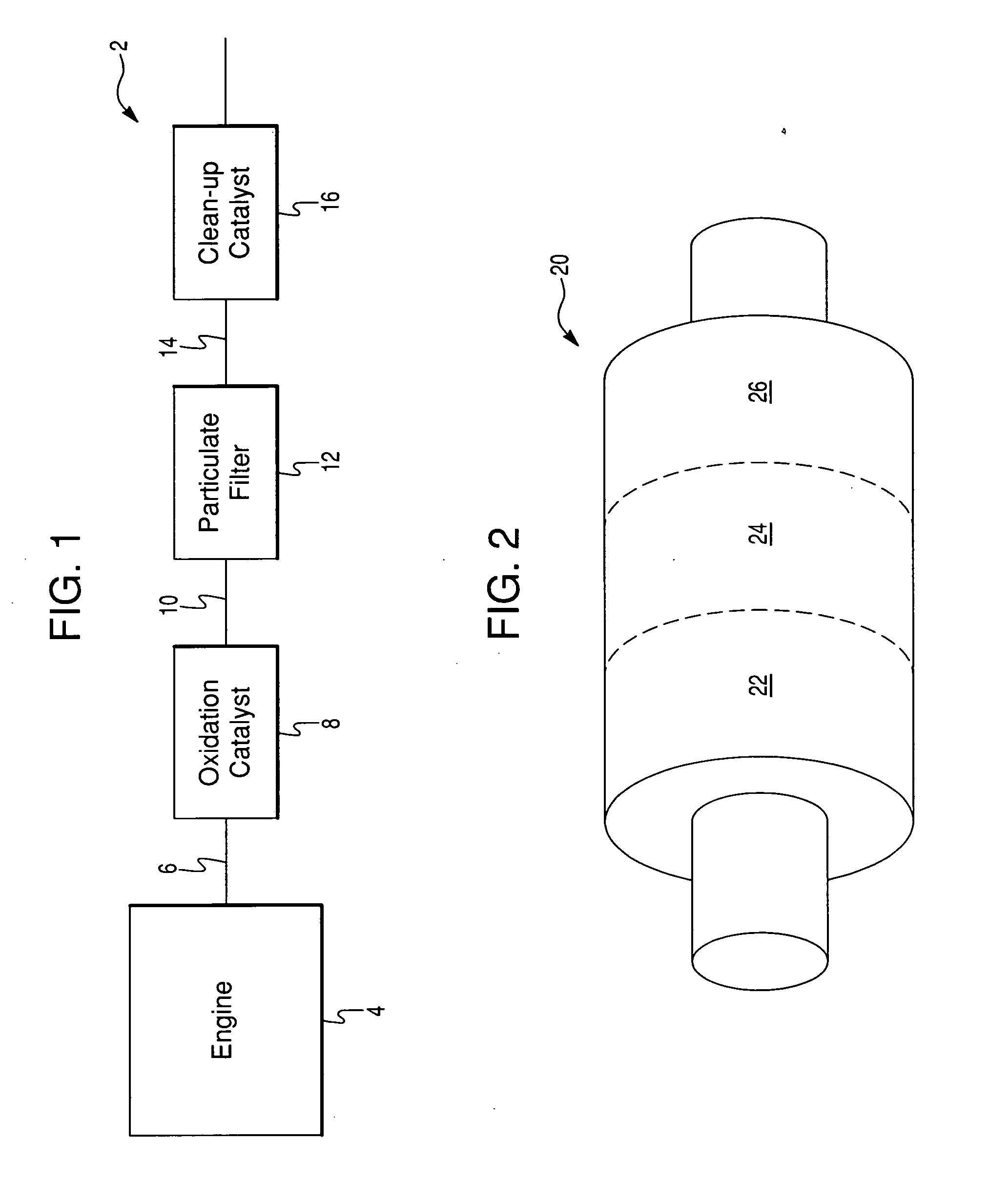

The invention provides a catalyzed soot filter formed on a wall flow substrate having internal walls coated with catalyst compositions. The soot filter maintains a homogeneous flow of the exhaust gases through the internal walls of the substrate along the length of the filter due to the coating design. Both the efficiency and the durability of the catalytic function are increased over conventionally designed catalyzed soot filters. The catalyzed soot filter provides an integrated function for simultaneously treating the gaseous components of the exhaust (e.g., CO and HC) and the particulate matter deposited in the filter.

Owner:BASF CATALYSTS LLC

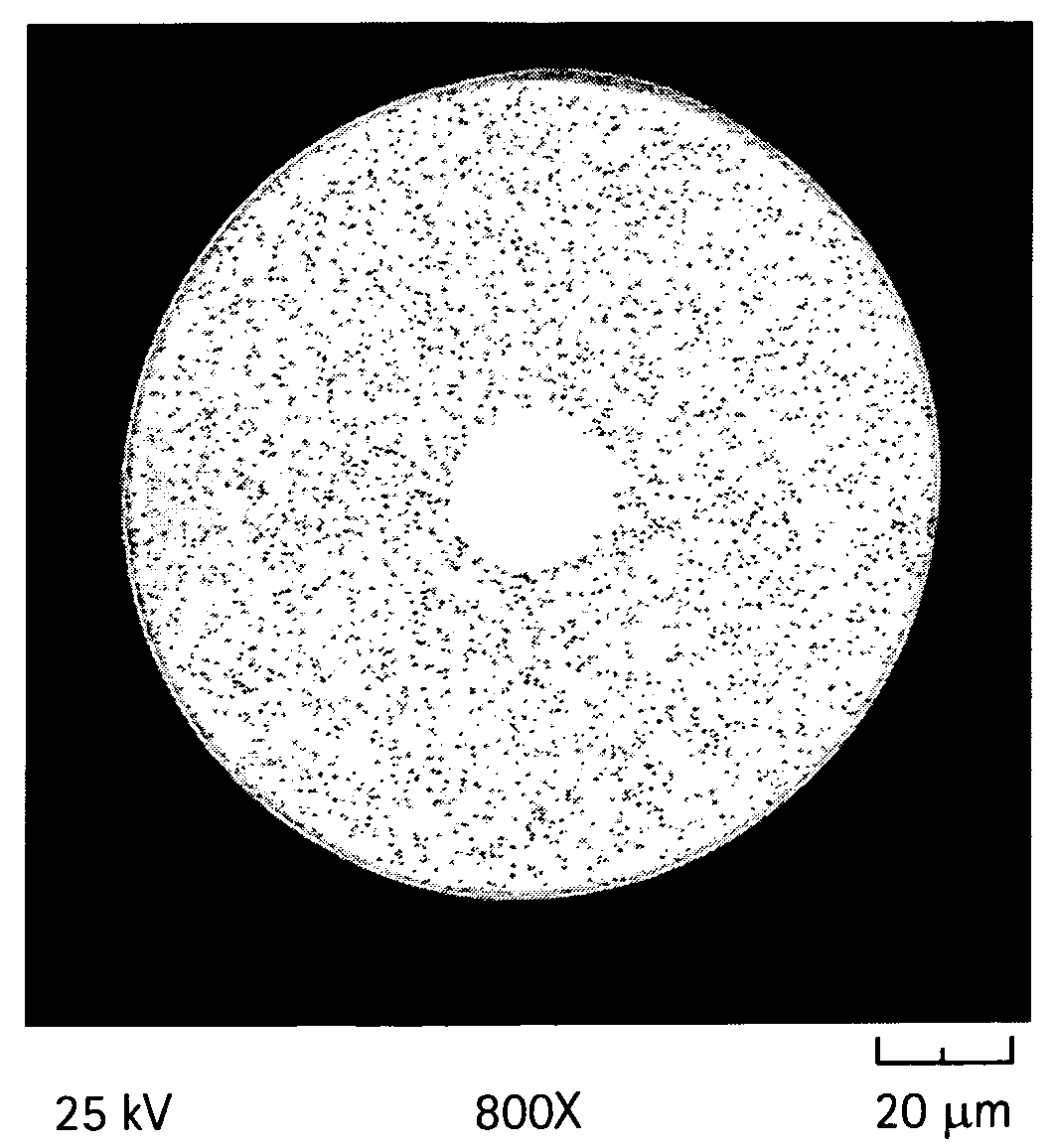

Microstructured optical fibers and methods

InactiveUS7450806B2Improve bending performanceLower refractive indexGlass making apparatusOptical fibre with graded refractive index core/claddingNitrogenNitrogen gas

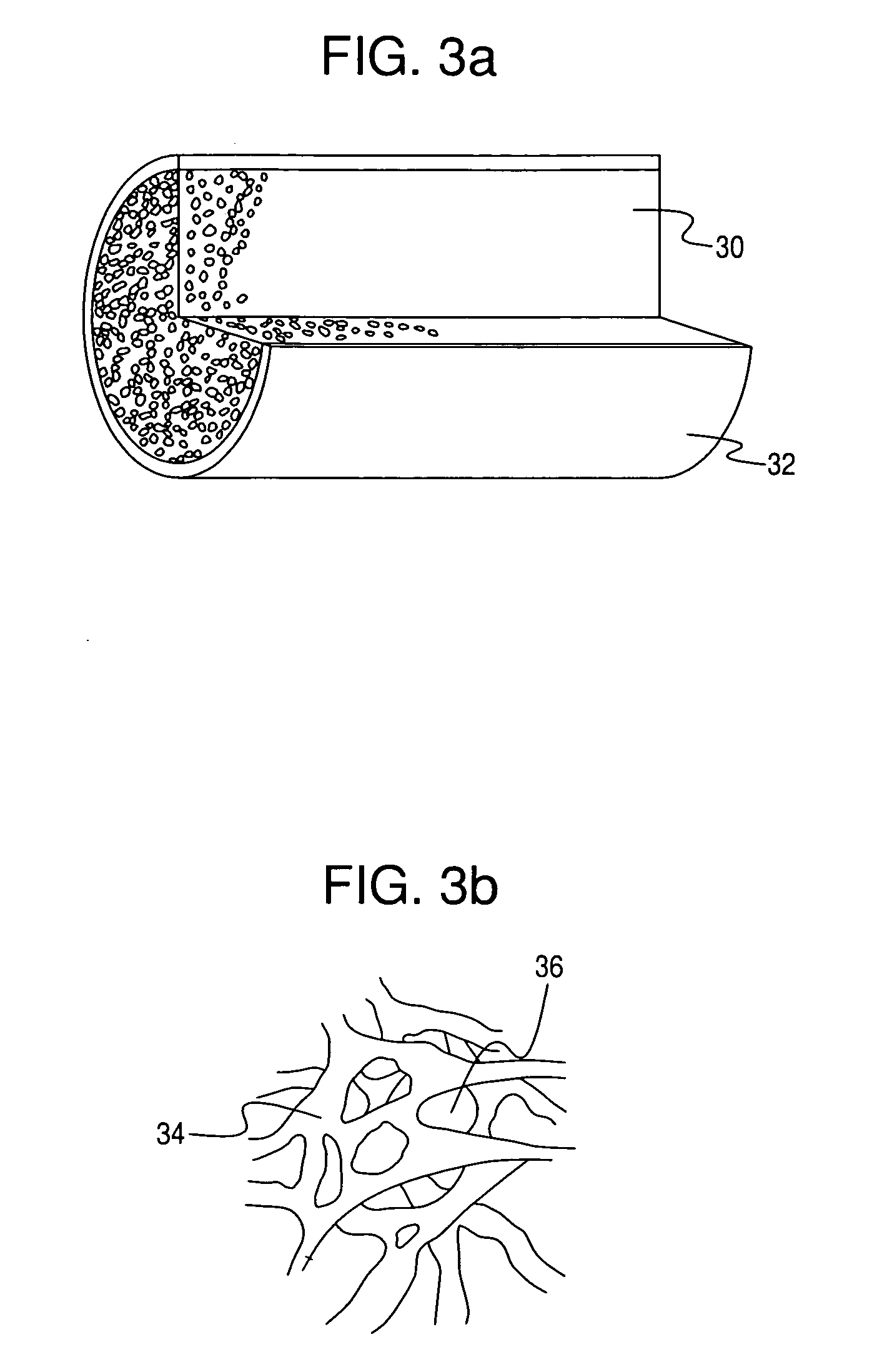

Microstructured optical fiber and method of making. Glass soot is deposited and then consolidated under conditions which are effective to trap a portion of the consolidation gases in the glass to thereby produce a non-periodic array of voids which may then be used to form a void containing cladding region in an optical fiber. Preferred void producing consolidation gases include nitrogen, argon, CO2, oxygen, chlorine, CF4, CO, SO2 and mixtures thereof.

Owner:CORNING INC

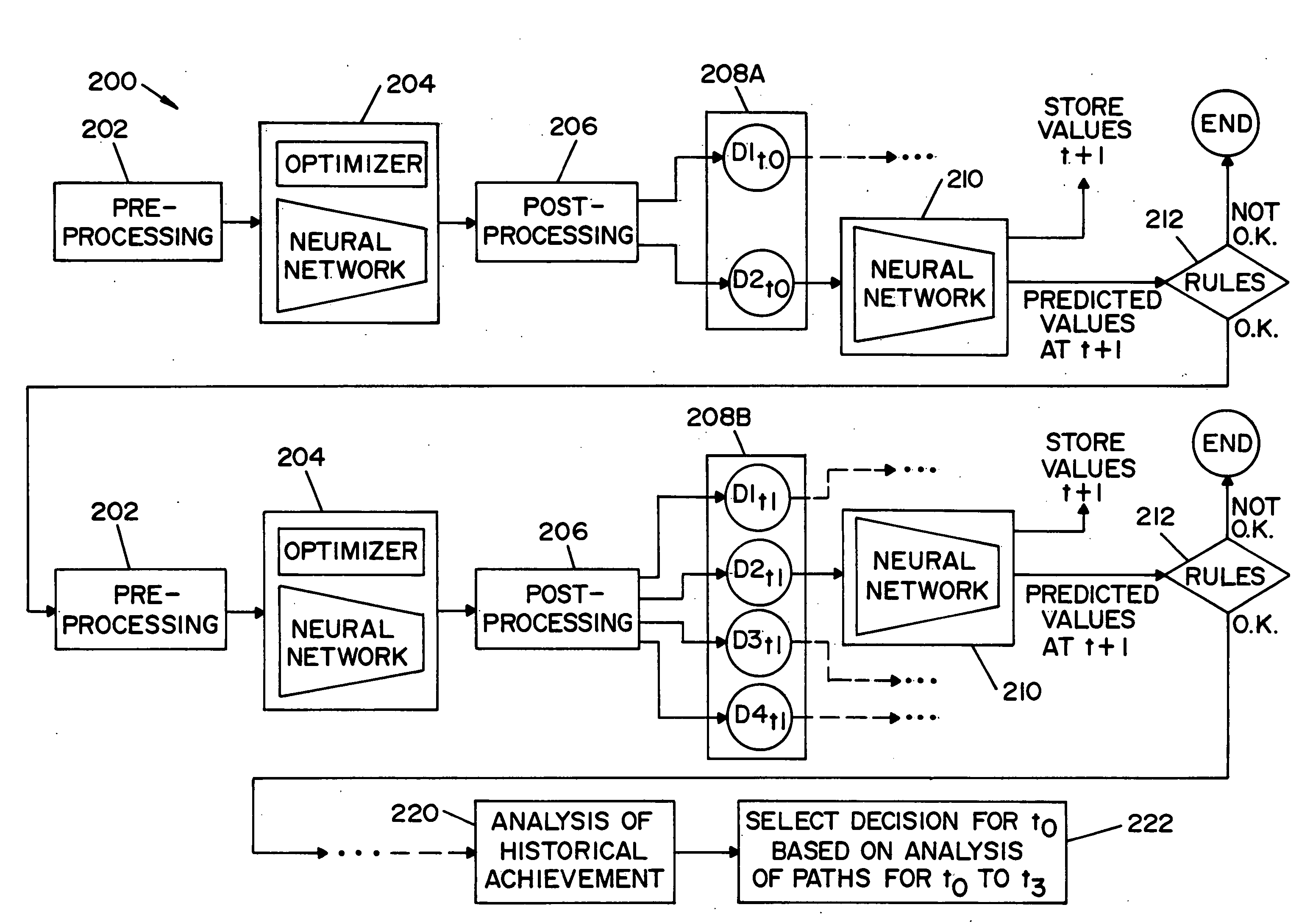

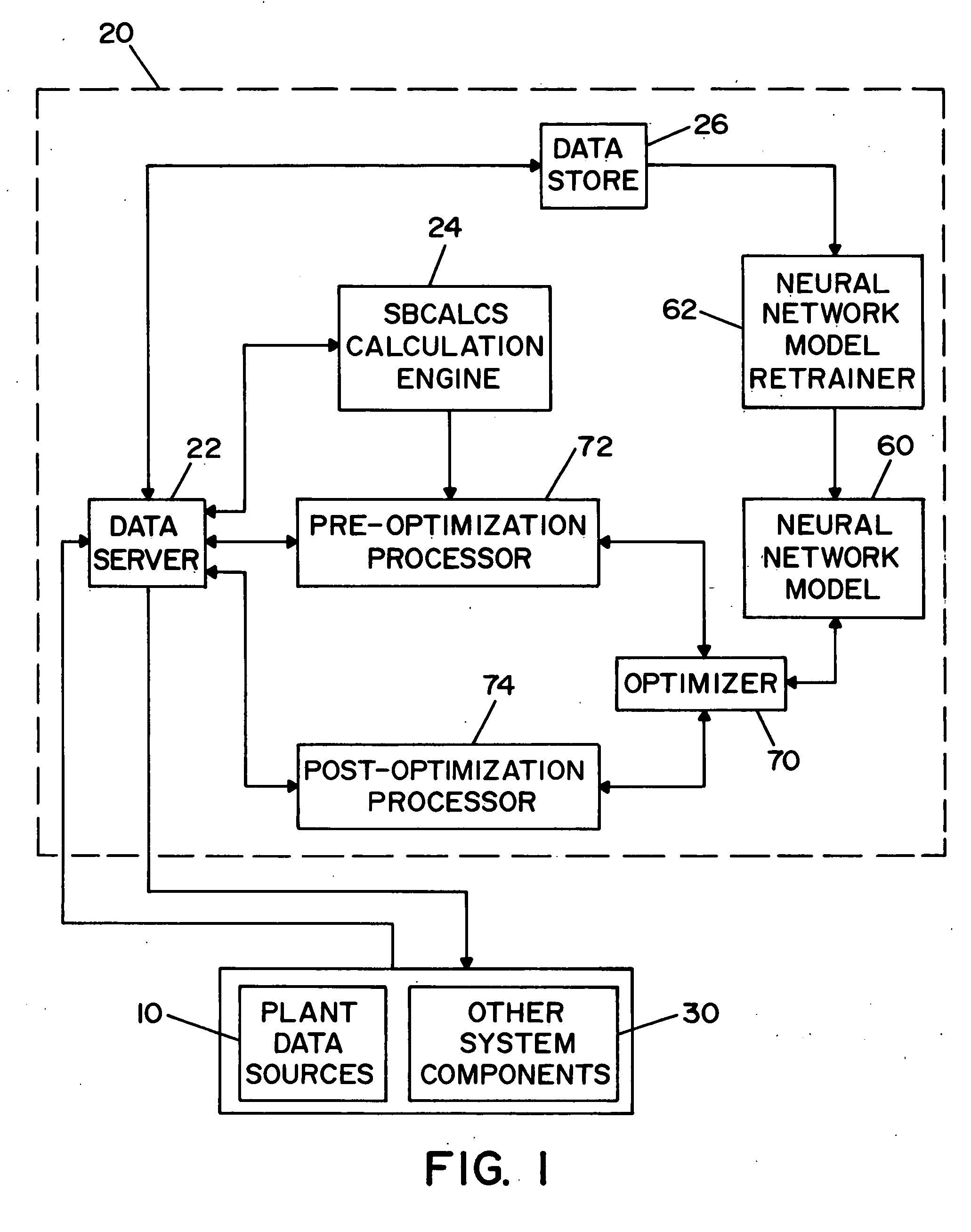

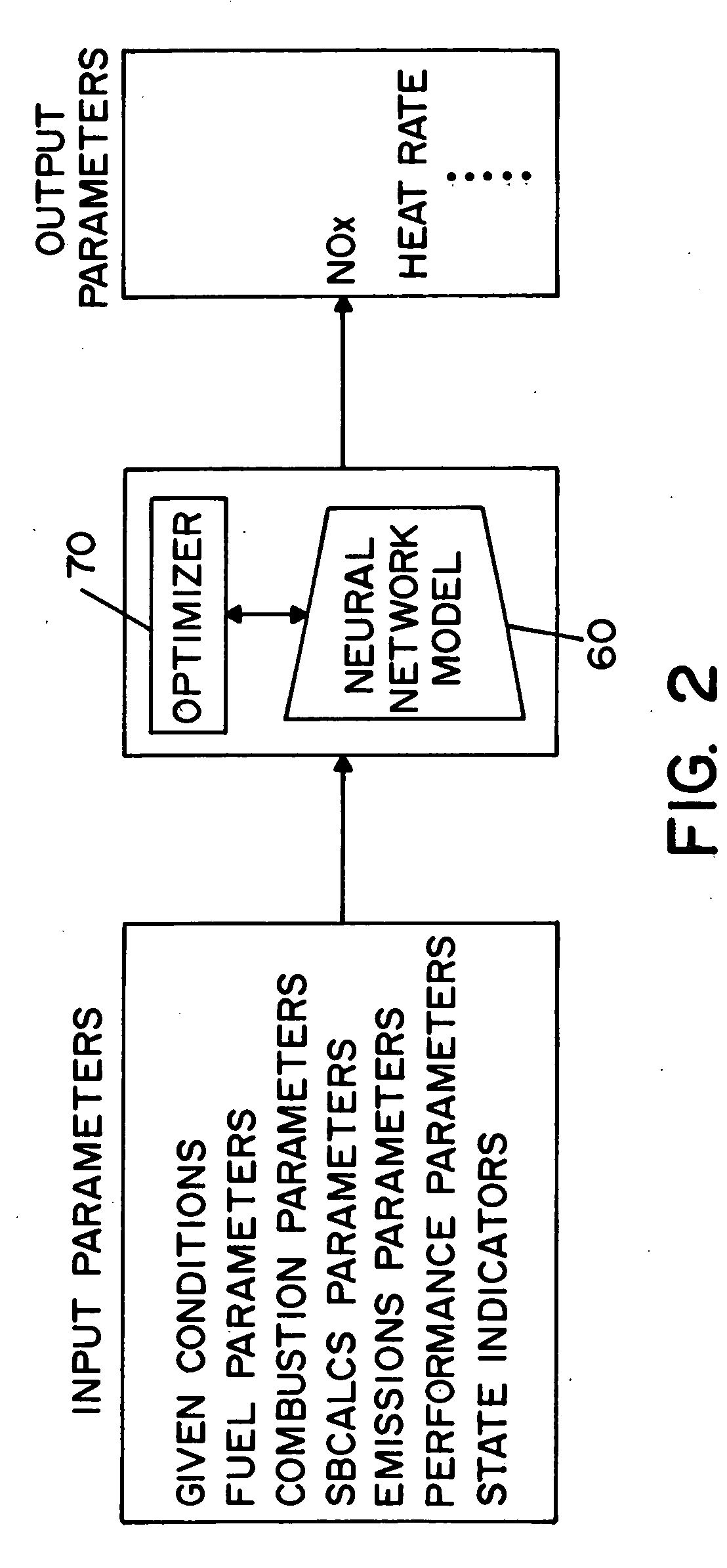

Method and apparatus for optimizing operation of a power generating plant using artificial intelligence techniques

ActiveUS20060178762A1Easy to cleanAccelerate buildingTemperatue controlAdaptive controlPower stationProcess engineering

A method and apparatus for optimizing the operation of a power generating plant using artificial intelligence techniques. One or more decisions D are determined for at least one consecutive time increment, where at least one of the decisions D is associated with a discrete variable for the operation of a power plant device in the power generating plant. In an illustrated embodiment, the power plant device is a soot cleaning device associated with a boiler.

Owner:GENERAL ELECTRIC CO

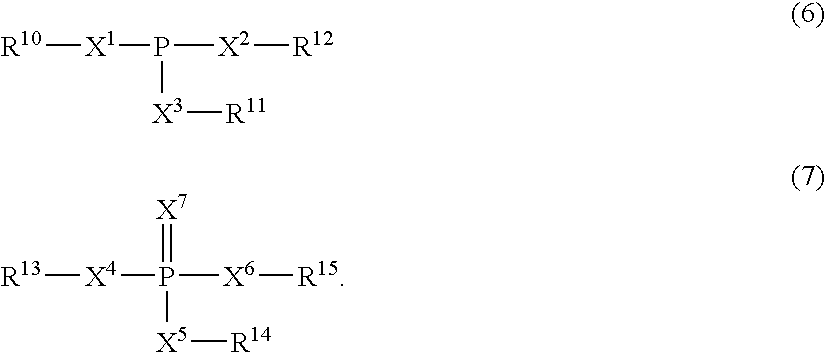

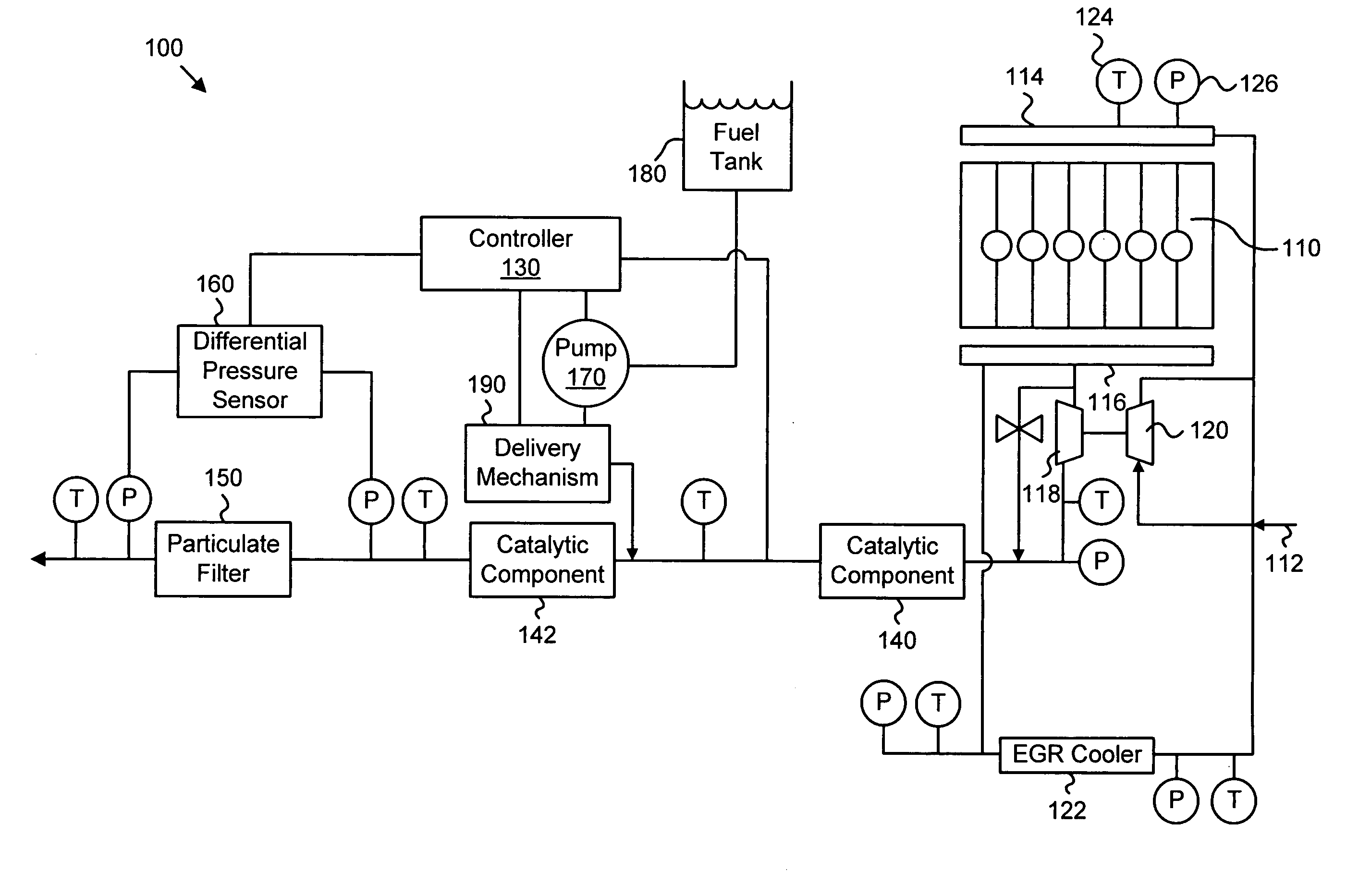

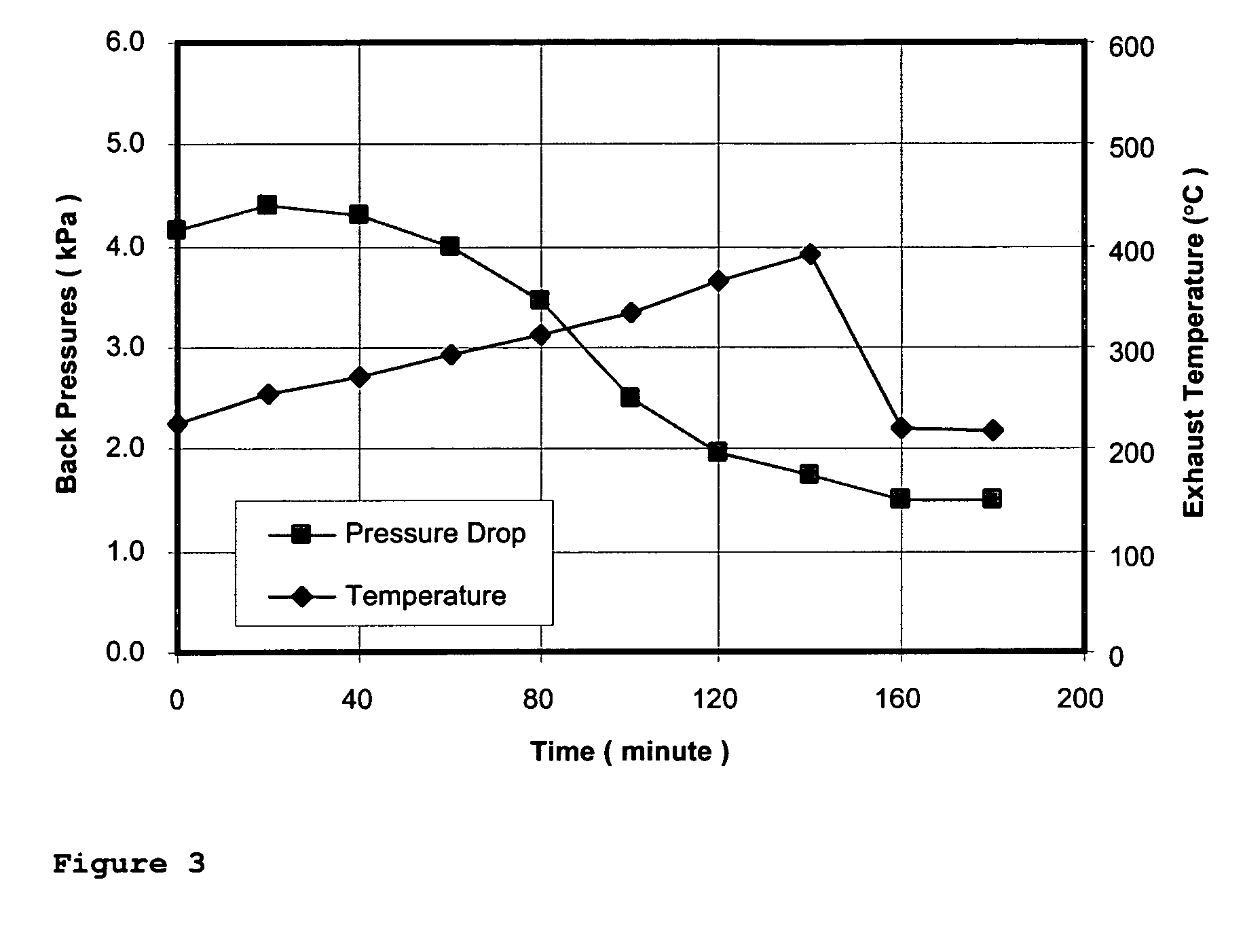

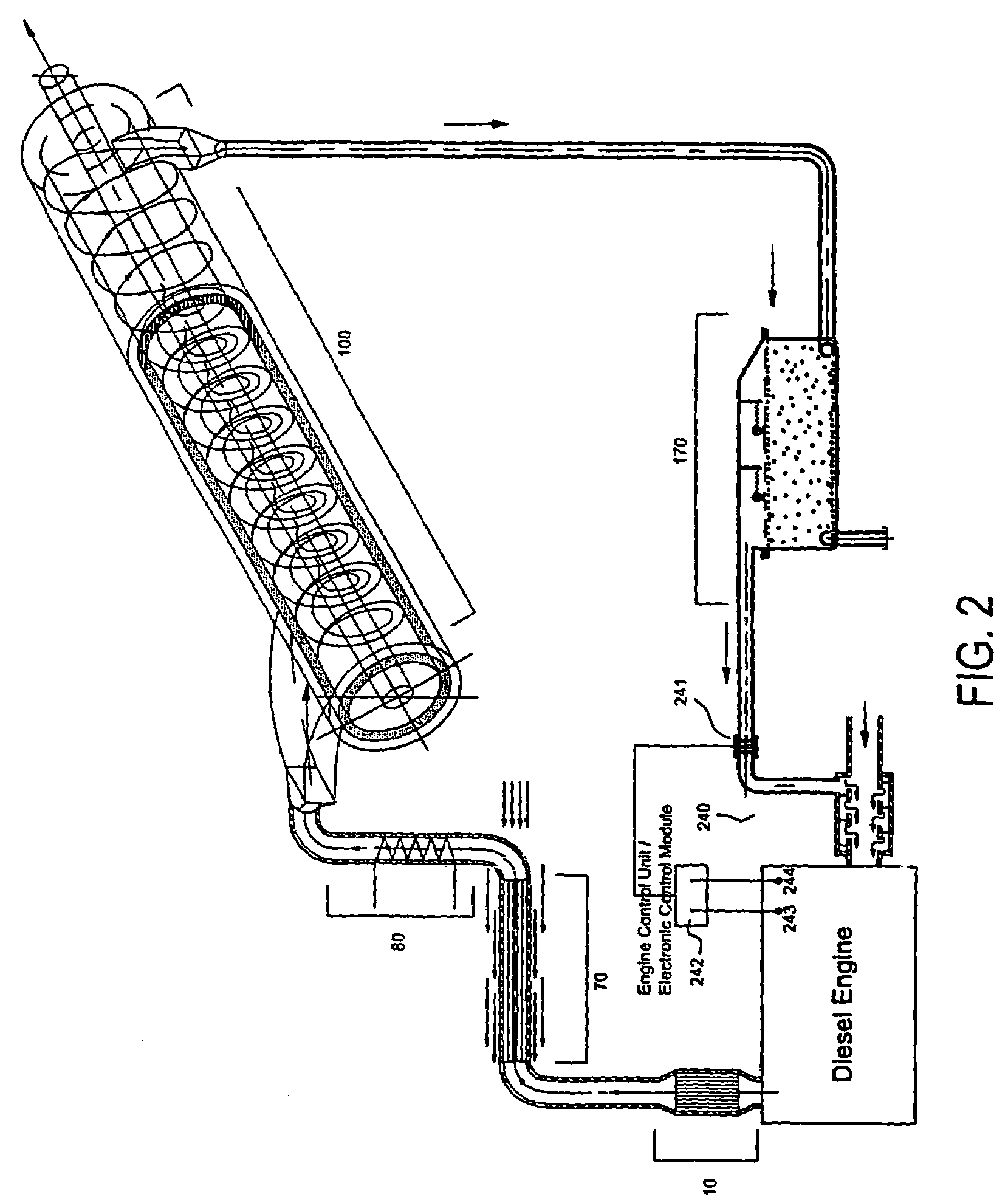

System and method for regenerating exhaust system filtering and catalyst components

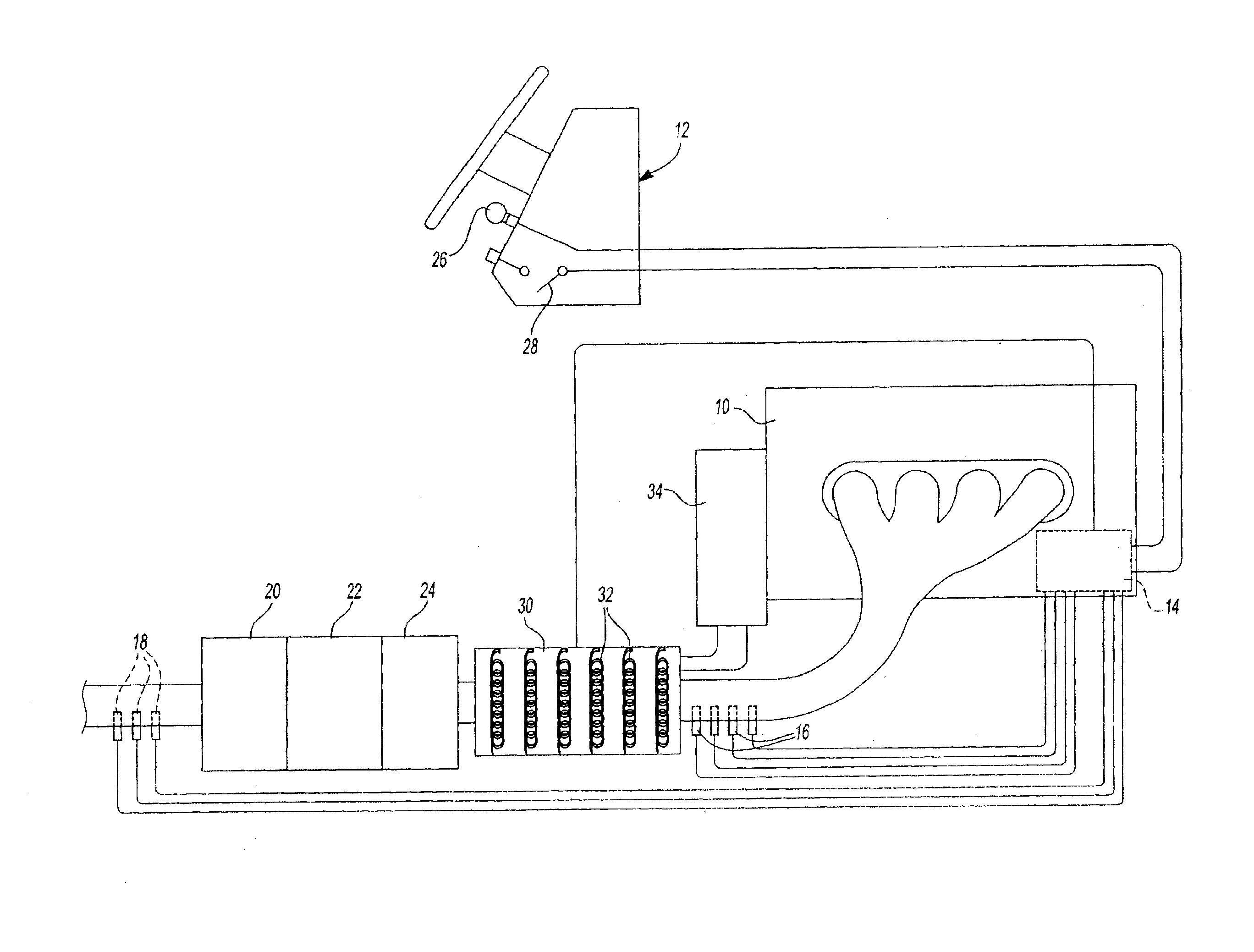

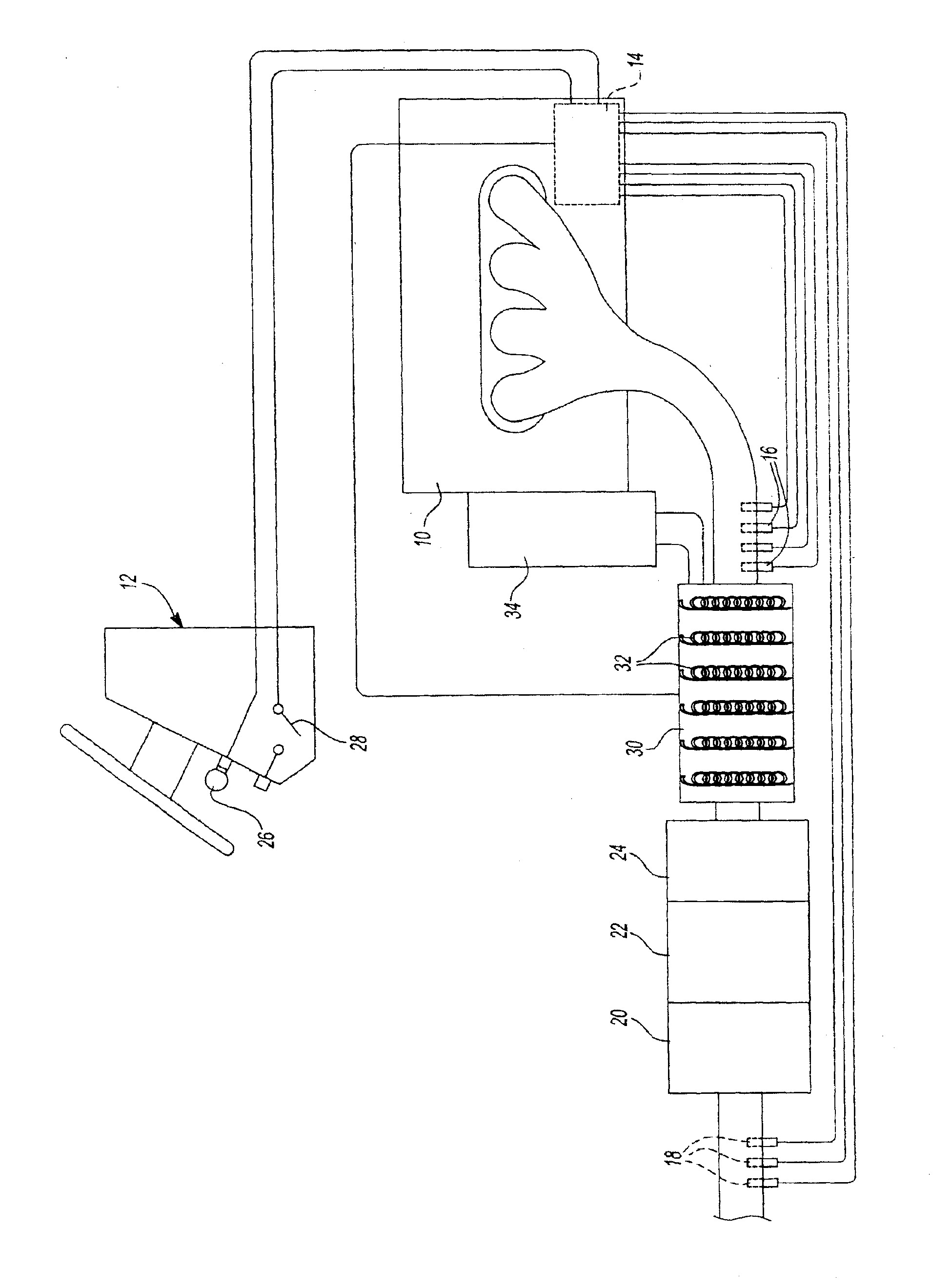

InactiveUS6865883B2Increase exhaust temperatureEasy loadingElectrical controlInternal combustion piston enginesParticulatesAlternator

A system and method for regenerating particulate filters, catalyzed soot filters and NOx catalysts for a vehicle having a compression ignition engine. An engine control module controls engine operation and regeneration functions. The engine preferably includes an integrated starter / alternator / flywheel / retarder assembly. A load bank heater is provided in the exhaust system that is activated to directly heat exhaust gases raising the temperature thereof and approaching the temperatures required for regeneration and desulfation. Activation of the heater applies a load through the integrated starter / alternator / flywheel / retarder assembly that increases the load on the engine and in turn further increases the temperature of the exhaust to levels required for regeneration and desulfation.

Owner:DETROIT DIESEL CORP

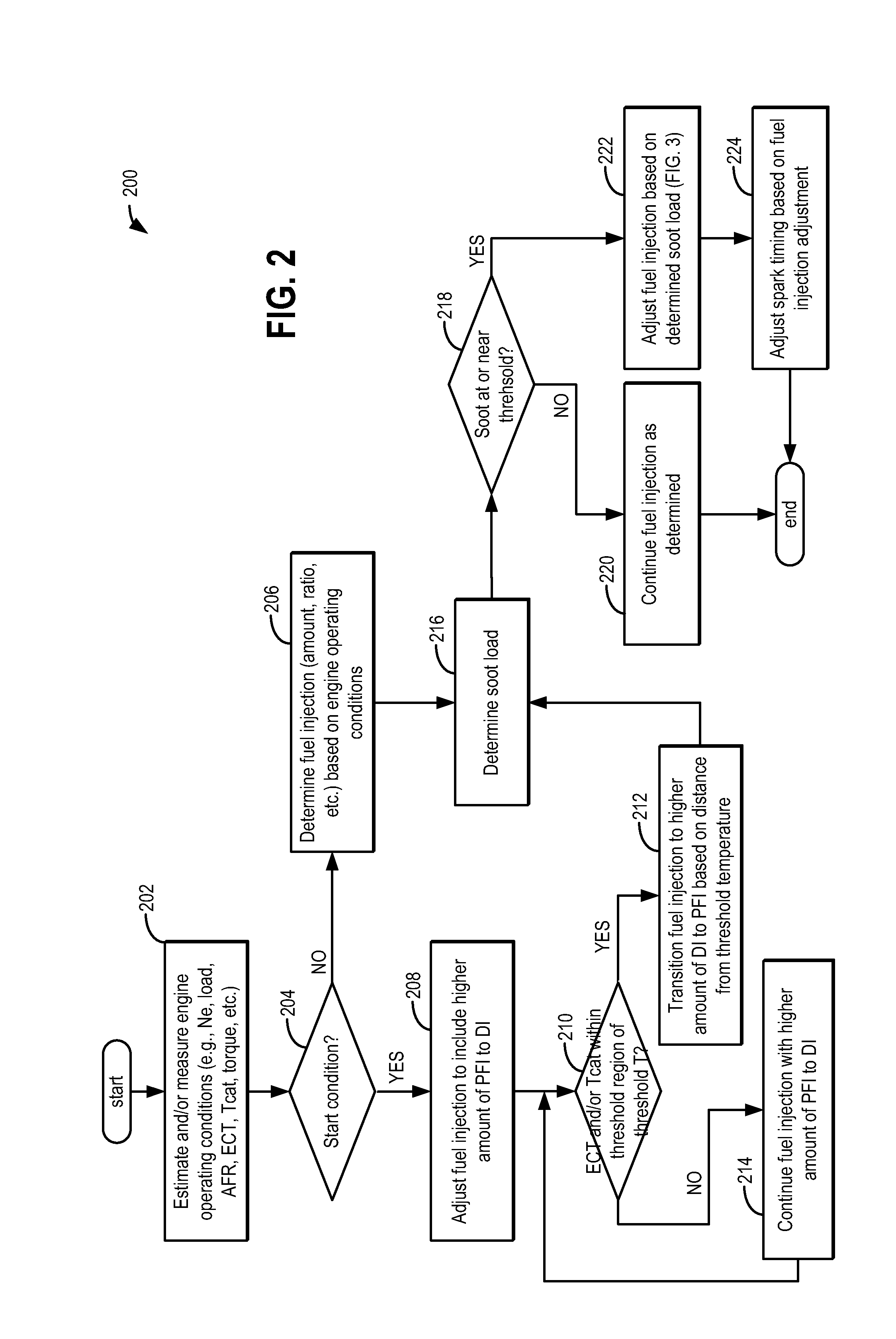

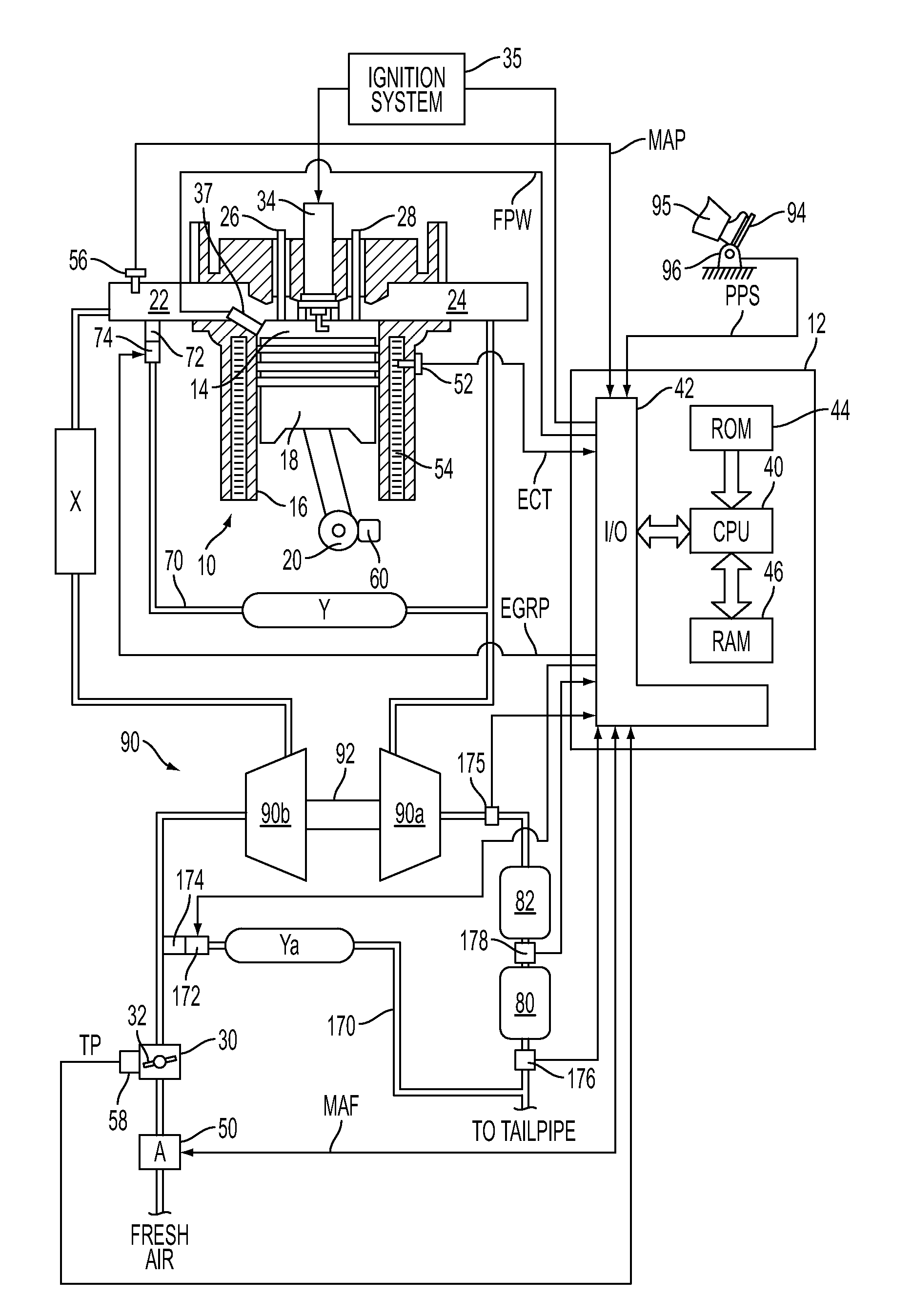

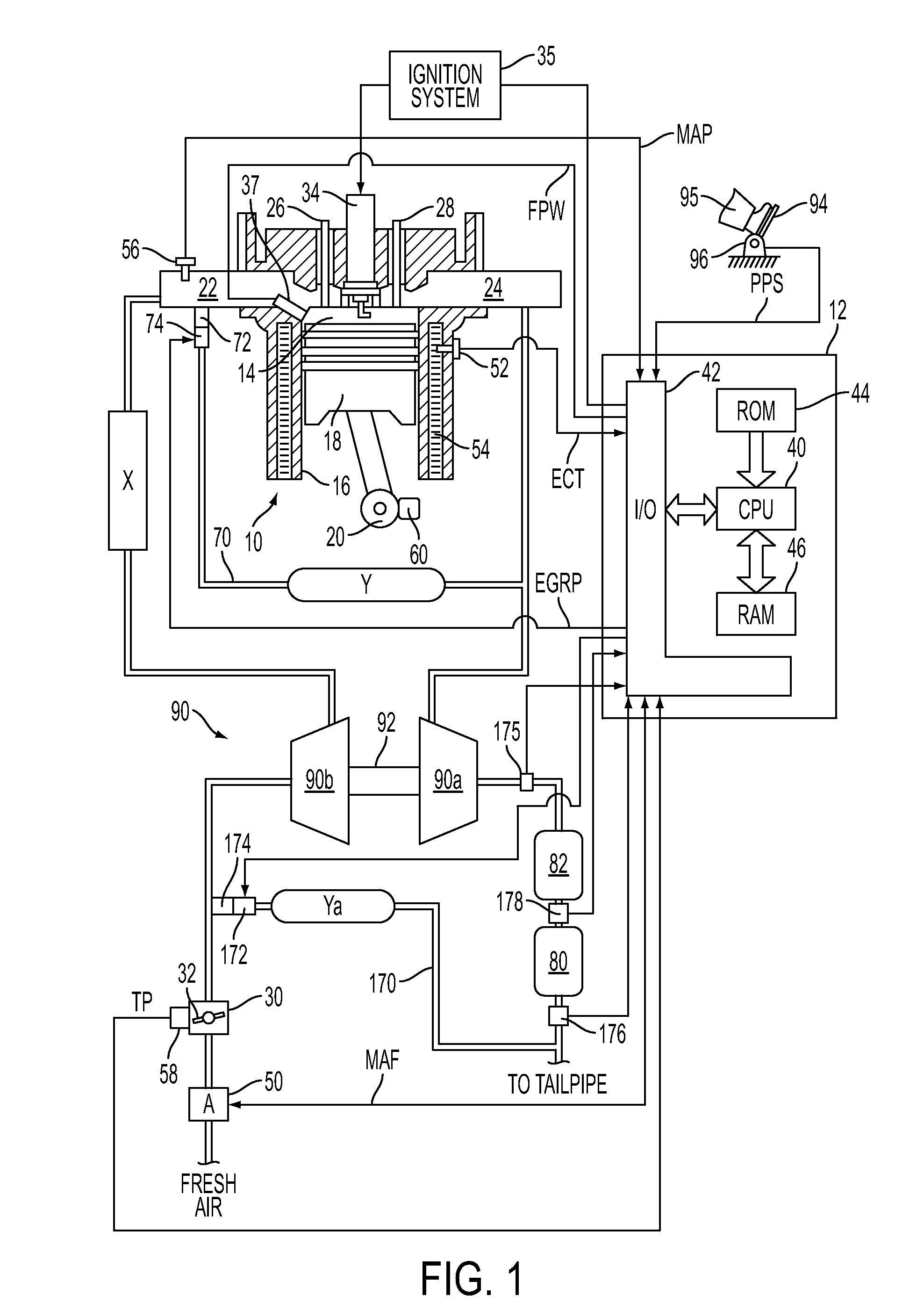

Method and system for engine control

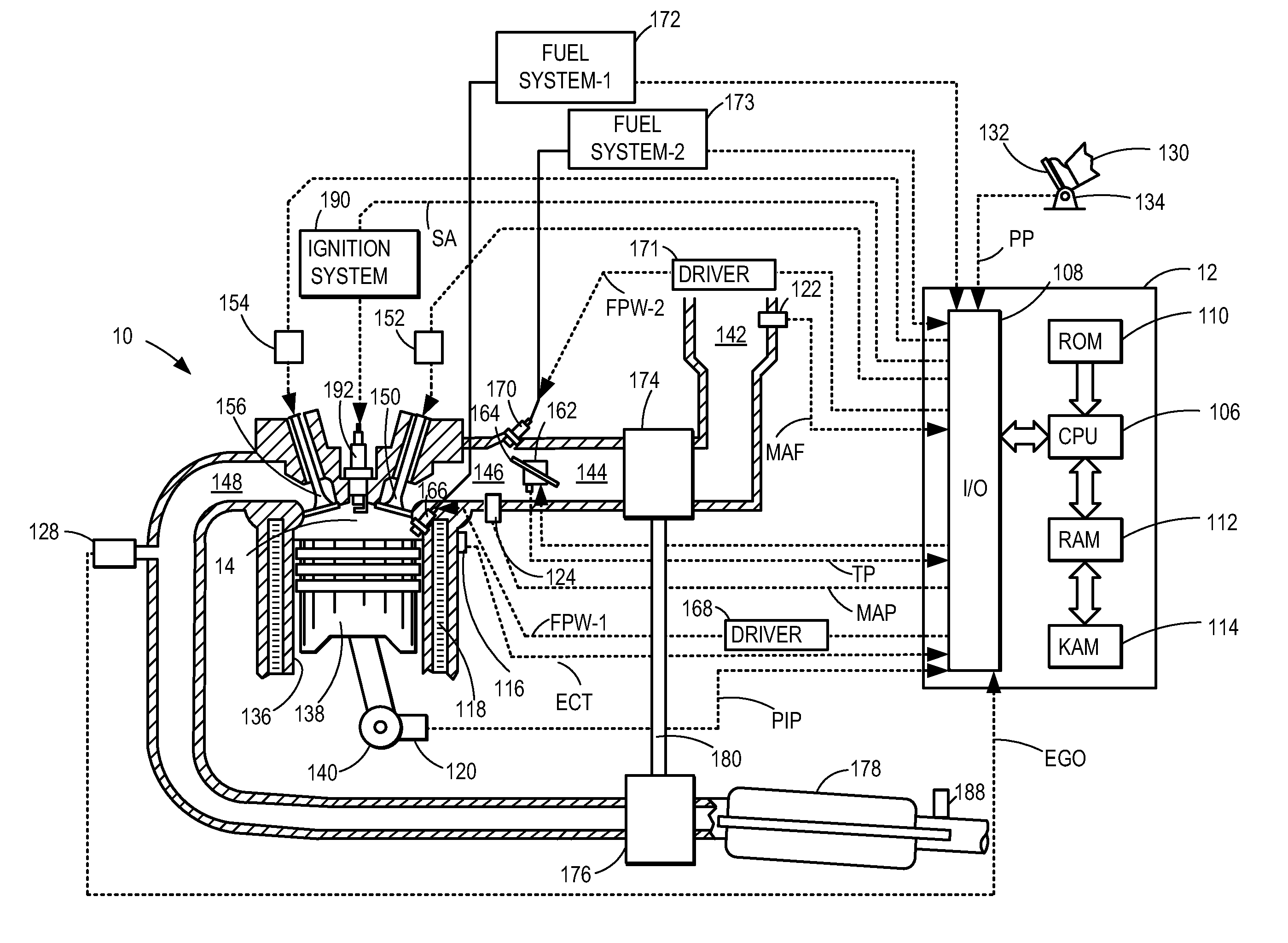

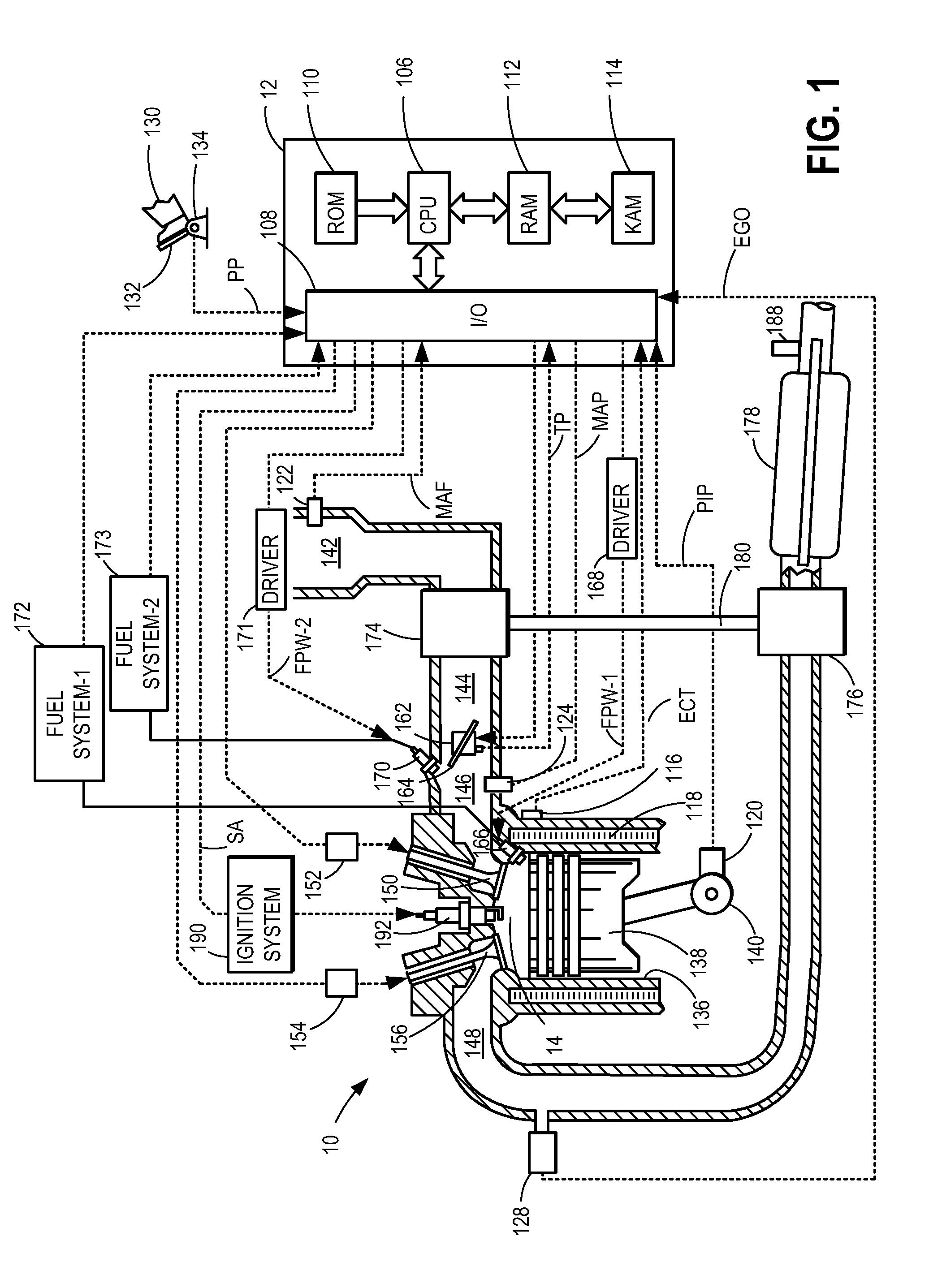

ActiveUS20110162620A1Improve fuel efficiencyImprove cooling effectElectrical controlExhaust apparatusExhaust fumesLoad regulation

Methods and systems are provided for controlling exhaust emissions by adjusting a fuel injection into an engine cylinder from a plurality of fuel injectors based on the fuel type of the injected fuel and further based on the soot load of the engine. Soot generated from direct fuel injection is reduced by decreasing an amount of direct injection into a cylinder as the engine soot load increases.

Owner:FORD GLOBAL TECH LLC

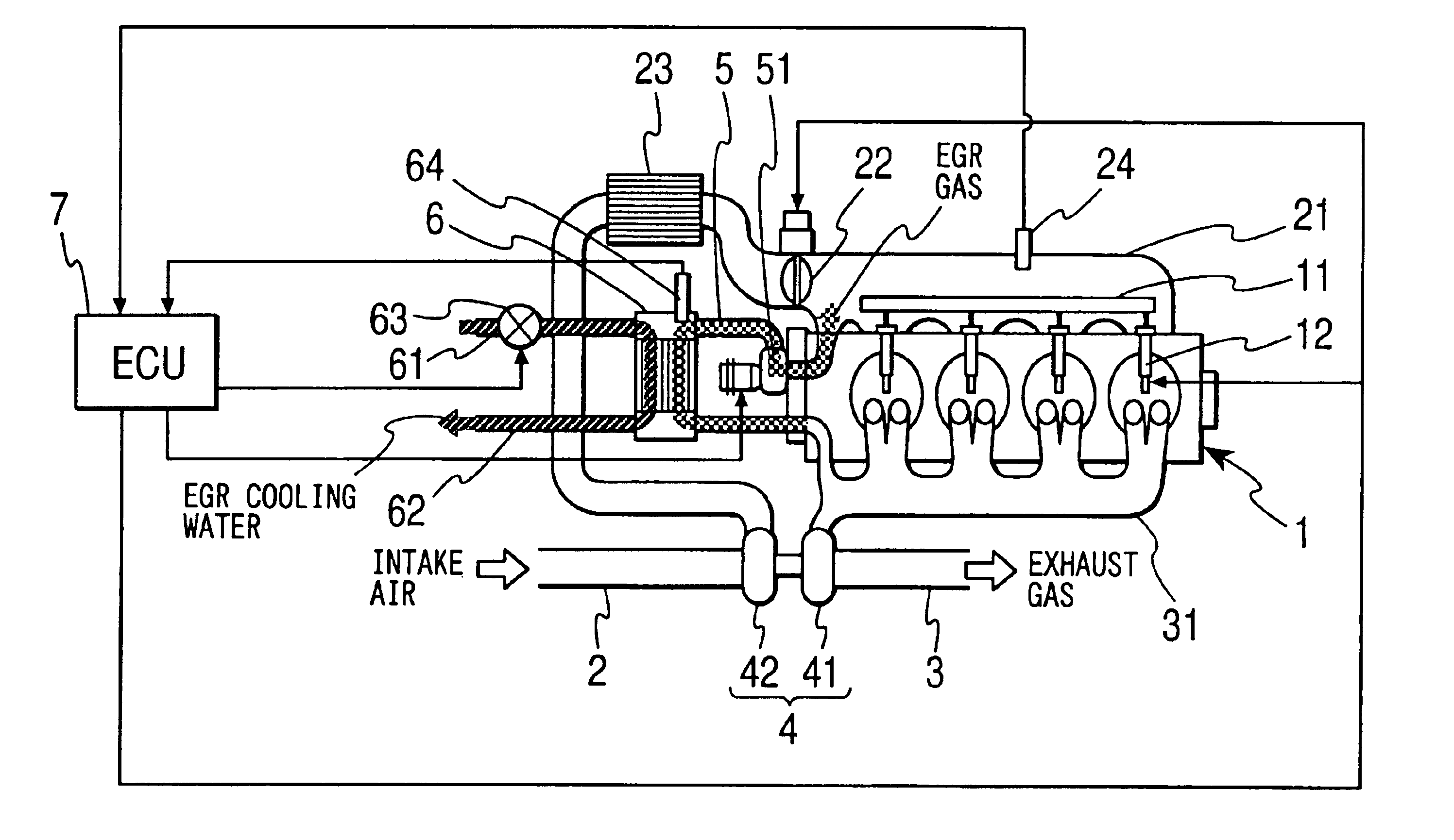

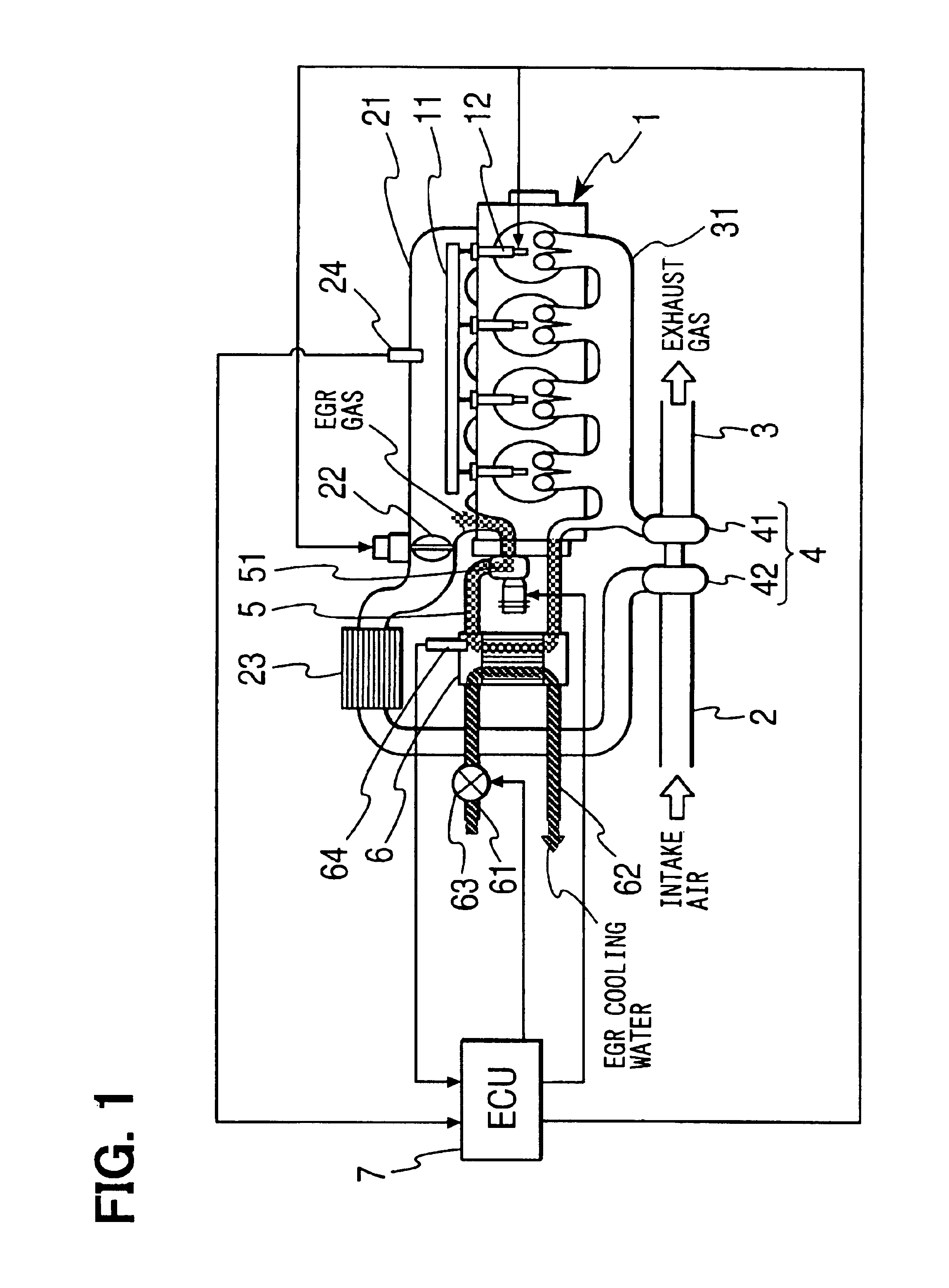

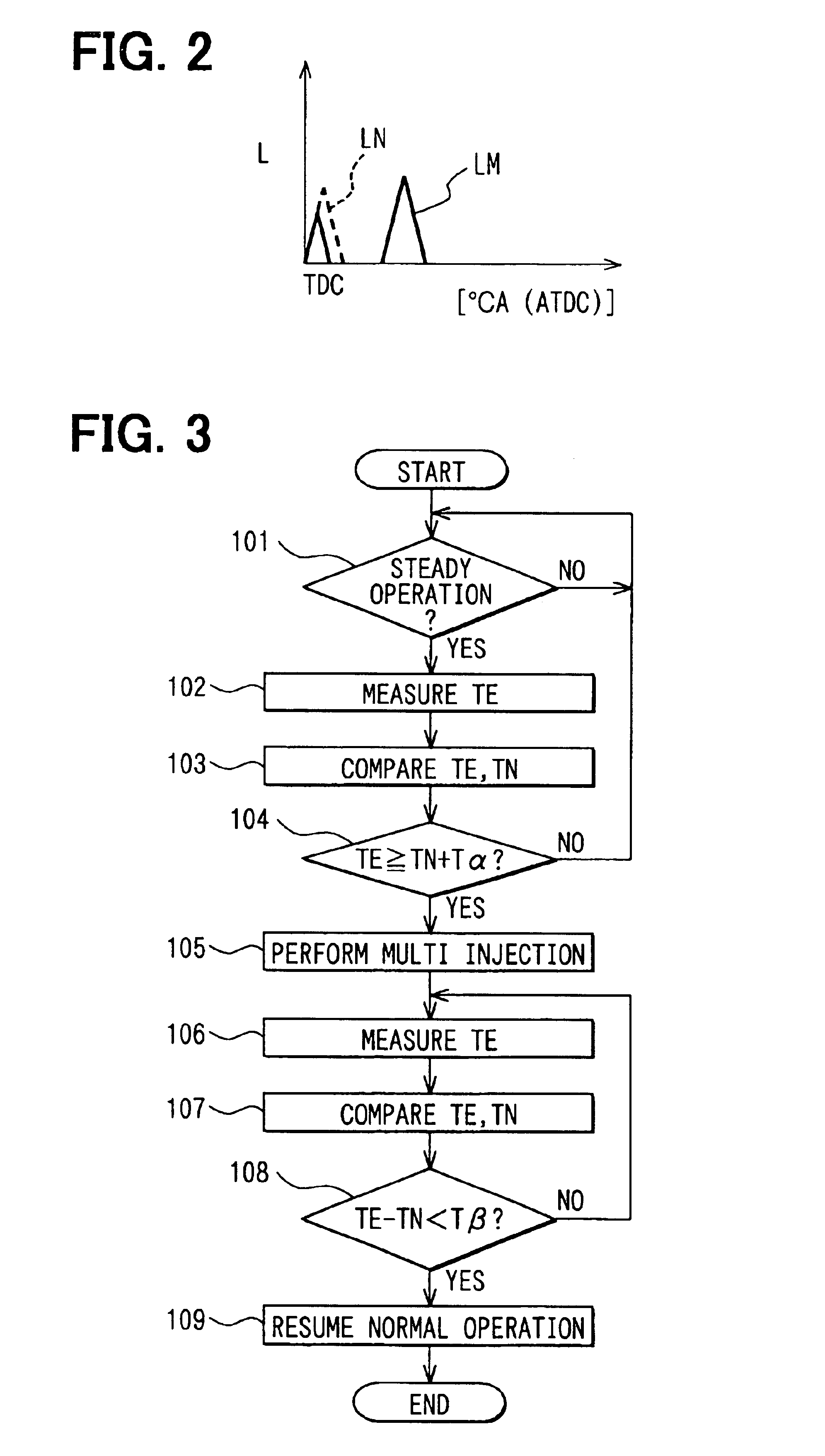

Exhaust gas recirculation system having cooler

InactiveUS6826903B2Improve heat transfer effectElectrical controlNon-fuel substance addition to fuelExhaust fumesExhaust gas recirculation

An exhaust gas recirculation (EGR) system of an internal combustion engine has an EGR cooler in an EGR passage connecting an exhaust manifold with an intake manifold. The EGR cooler cools EGR gas recirculated through the EGR passage. Cooling performance detecting means included in an electronic control unit (ECU) determines that cooling performance of the EGR cooler is degraded when intake pressure measured by an intake pressure sensor is lower than a normal intake pressure by at least a predetermined value. When the degradation of the cooling performance is detected, cooling performance regeneration controlling means included in the ECU increases the temperature inside the EGR cooler by heating the exhaust gas to eliminate soot or unburned hydrocarbon by oxidization. Thus, the cooling performance of the EGR cooler is regenerated.

Owner:DENSO CORP

Upgrading of tar using POX/coker

ActiveUS8083931B2Reduce and eliminate needThermal non-catalytic crackingTreatment with plural serial cracking stages onlyNaphthaPartial oxidation

The invention is directed to a process wherein a feedstock or stream comprising steam cracker tar is passed to a vacuum pipestill. A deasphalted cut of tar is obtained as an overhead (or sidestream) and a heavy tar asphaltenic product is obtained as bottoms. In preferred embodiments, at least a portion of the bottoms product is sent to a partial oxidation unit (POX) wherein syn gas may be obtained as a product, and / or at least a portion of the bottoms product is used to produce a light product stream in a coker unit, such as coker naphtha and / or or coker gas oil. In another preferred embodiment at least a portion of the overheads product is added to refinery fuel oil pools and in yet another preferred embodiment at least a portion of the overheads product is mixed with locally combusted materials to lower soot make. Two or more of the aforementioned preferred embodiments may be combined.

Owner:EXXONMOBIL CHEM PAT INC

Diesel particulate filters having ultra-thin catalyzed oxidation coatings

The present invention is directed to an exhaust gas treatment system and method for removing particulate matter and nitrogen oxides from diesel engine exhaust streams. More specifically, the present invention relates to an emission treatment system that effectively provides simultaneous treatment of the particulate matter, as well as the NOx and other gaseous components of diesel engine exhaust. The emission treatment system uses an integrated soot filter coated with a catalyst washcoat composition comprising sub-micron particles, thereby providing an ultra-thin sub-micron washcoat layer showing improved catalyst performance without causing excessive backpressure.

Owner:ENGELHARD CORP

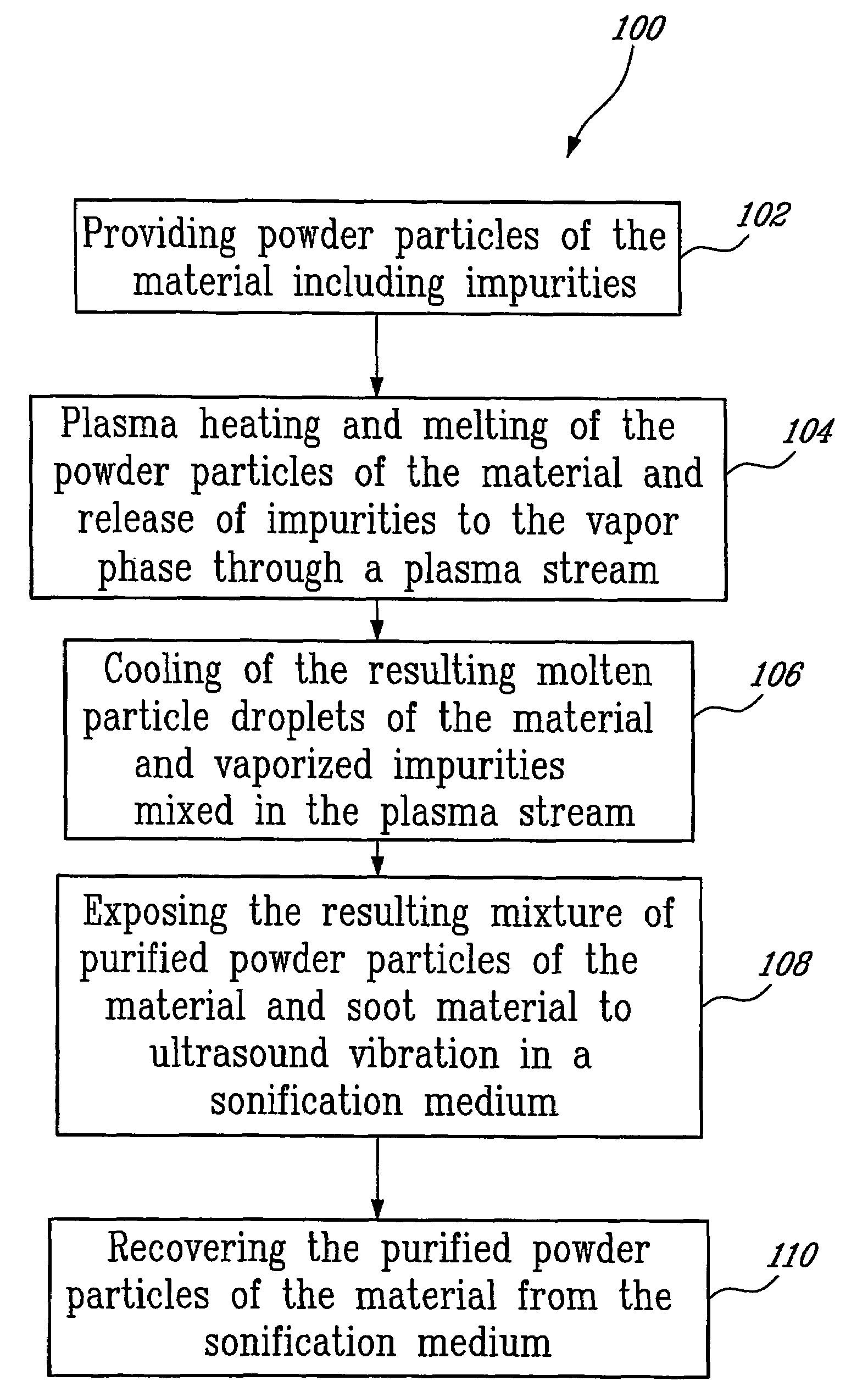

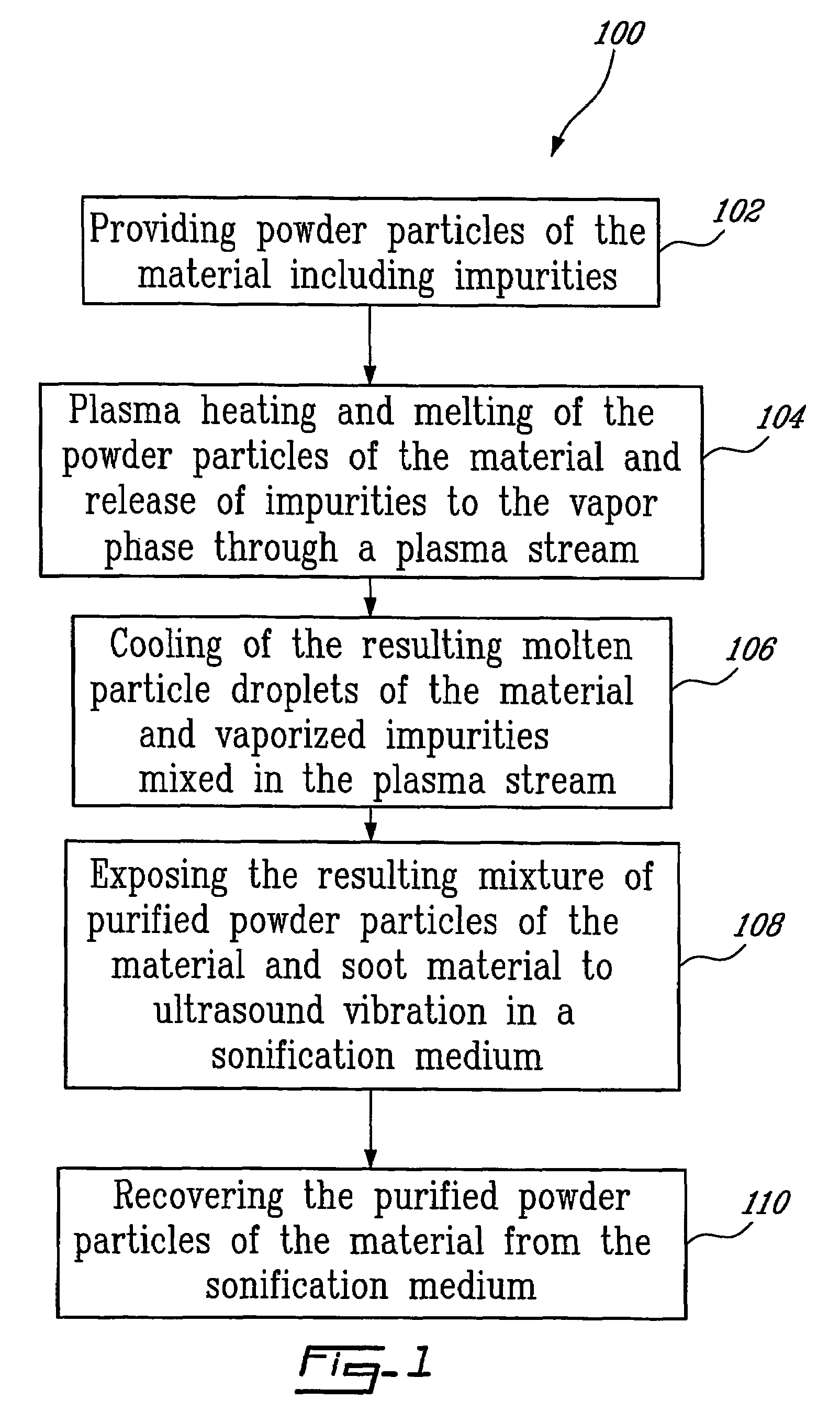

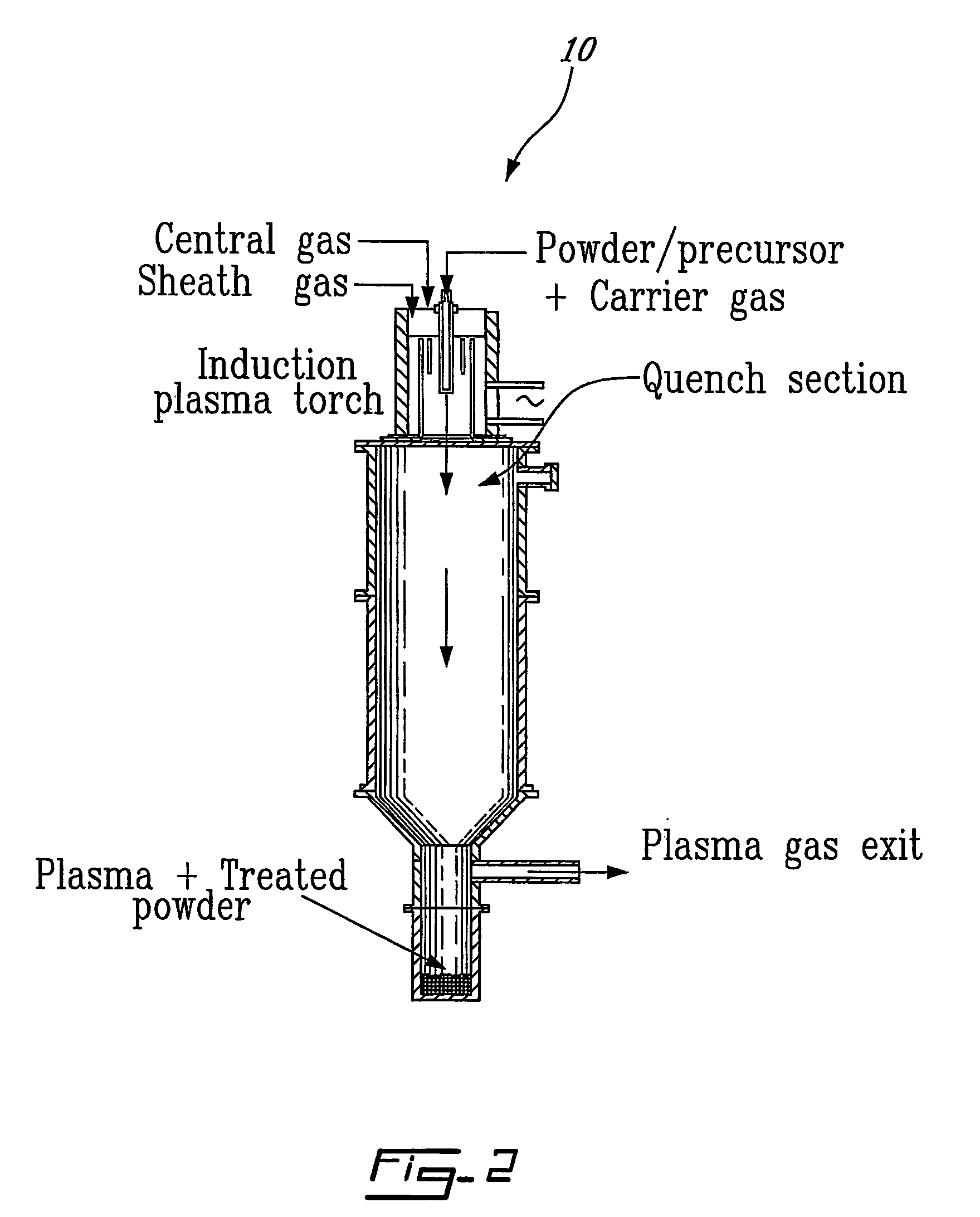

Process for the synthesis, separation and purification of powder materials

ActiveUS7572315B2Speed up the processTransportation and packagingMetal-working apparatusPurification methodsVaporization

Owner:TEKNA PLASMA SYST INC

Diesel engine system comprising a soot filter and low temperature NOx trap

The invention provides low temperature NO2 trap compositions useful for adsorbing NO2 from a gas stream at lower temperatures, and releasing the NO2 at higher temperatures. The low temperature trap compositions are useful for incorporation into a diesel exhaust system equipped with a soot filter. The NO2 from the diesel exhaust can be stored when the exhaust temperature is cool, e.g., during startup and at times of low load, and released when the exhaust is at higher temperatures. The released NO2 serves as an effective oxidant for the combustion of soot deposited on the soot filter. These temperatures are significantly lower than those required for the combustion of soot using O2 as an oxidant. The methods of the invention thereby provide a method for regenerating the soot filter within operating temperature ranges typical of diesel engine exhaust systems.

Owner:BBNT SOLUTIONS LLC +1

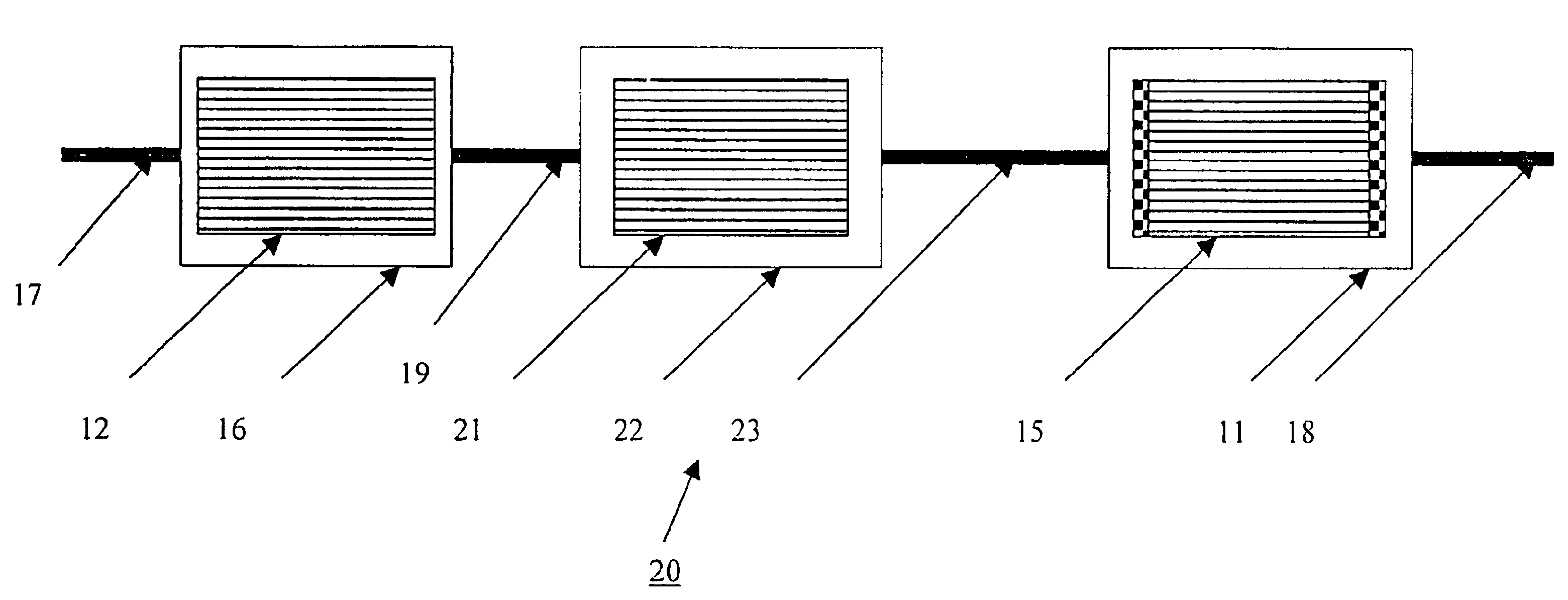

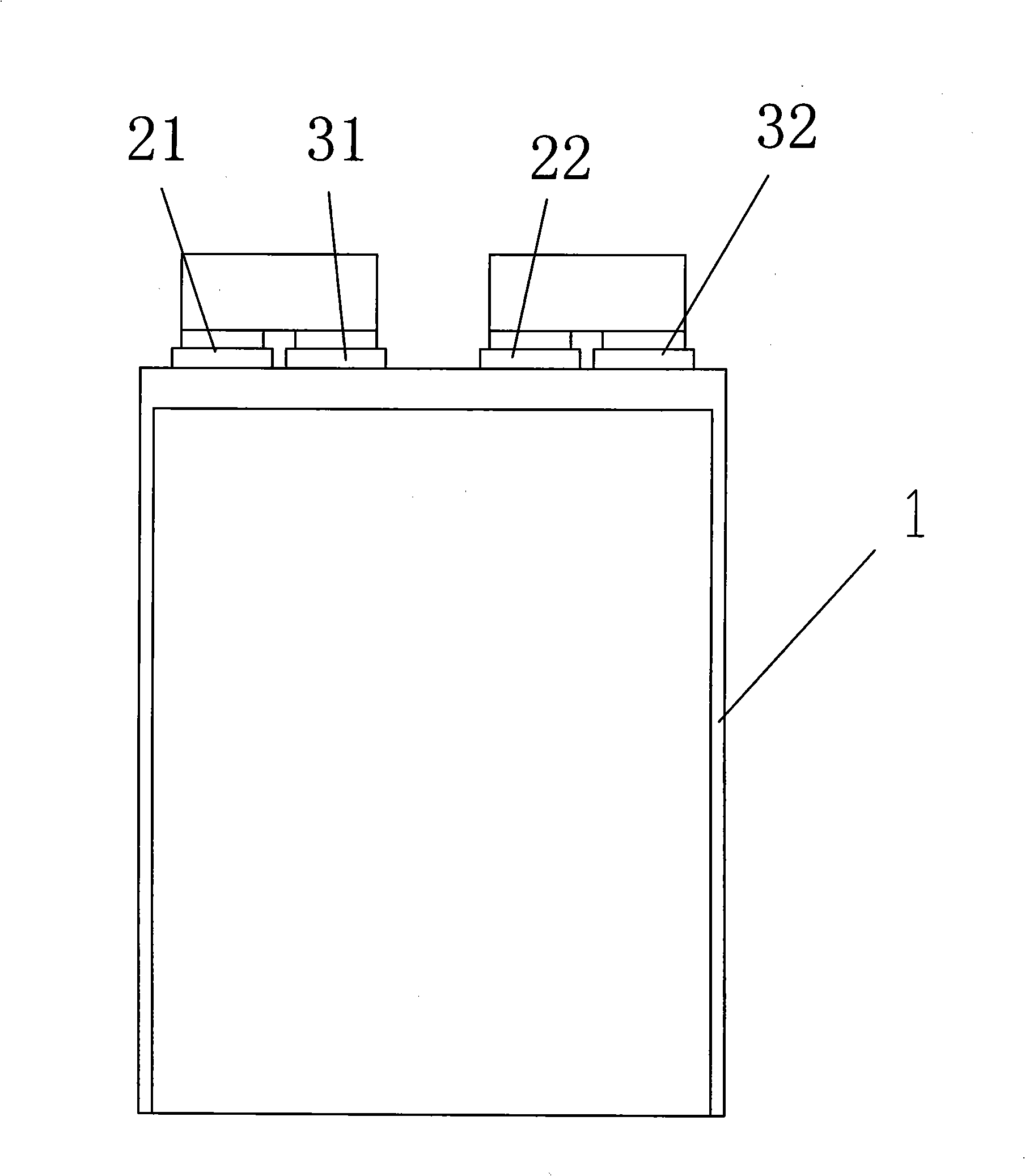

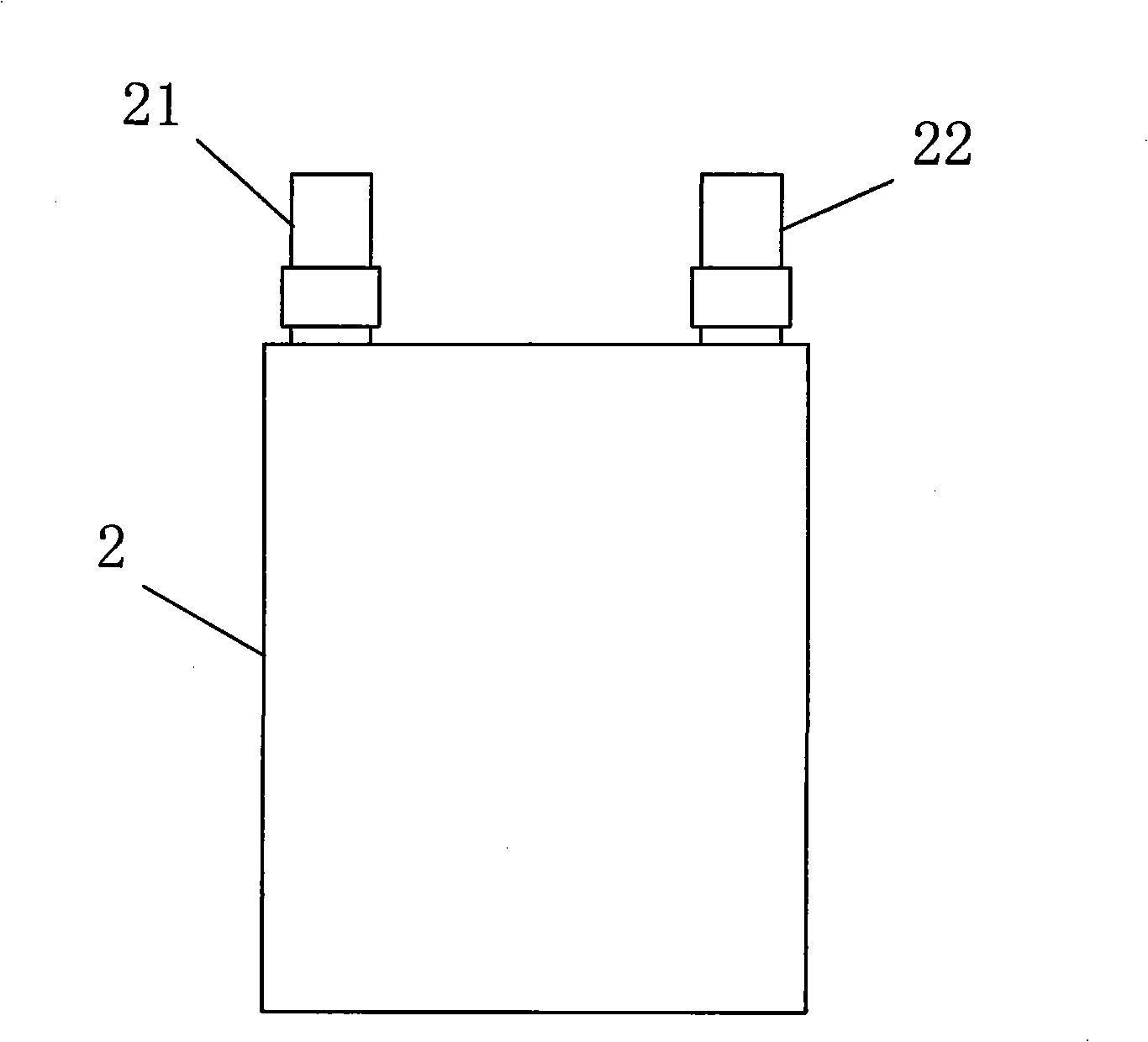

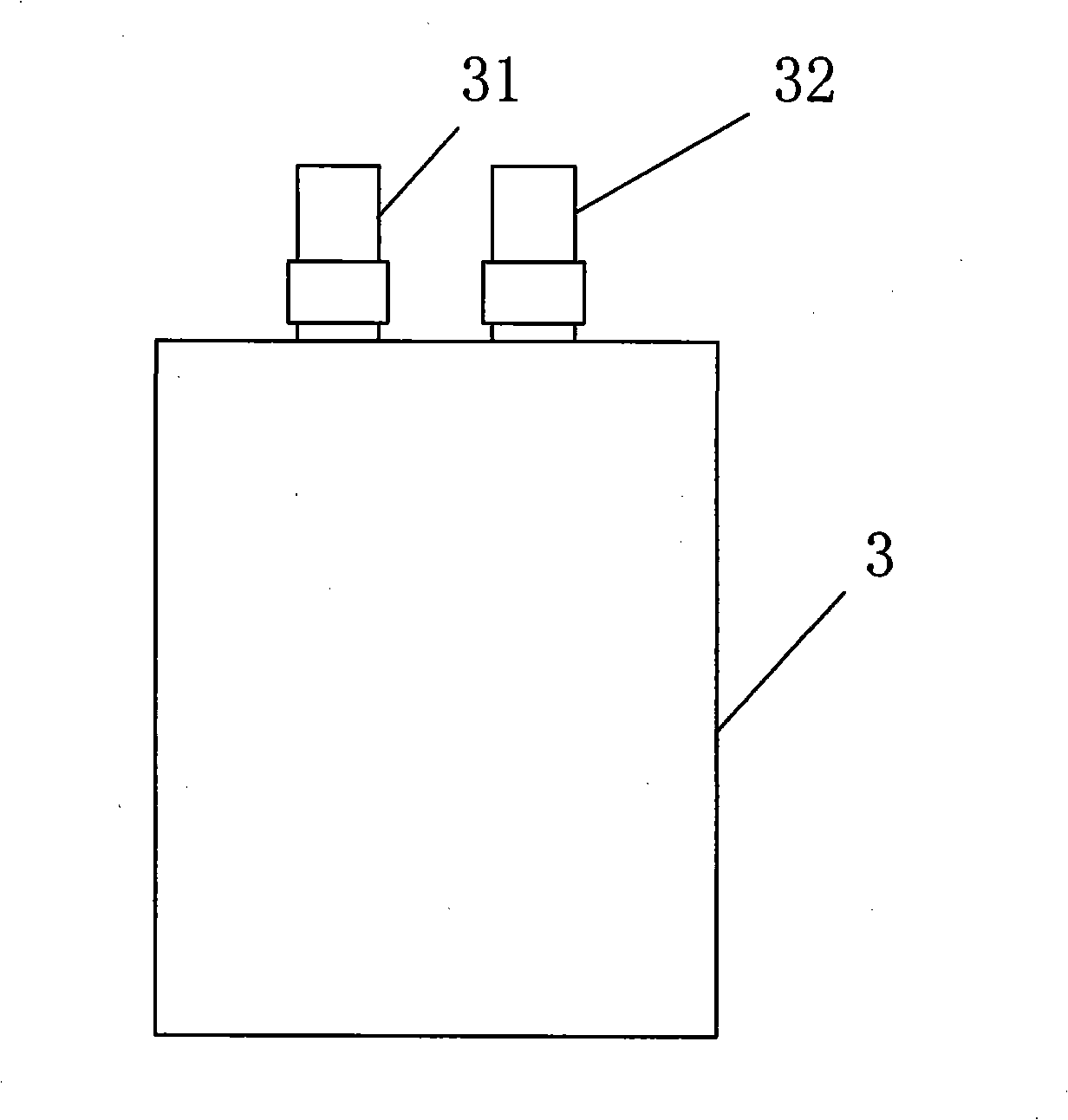

Large-capacity high power polymer ferric lithium phosphate power cell and preparation method thereof

InactiveCN101409369AImprove securityIncrease capacityElectrode manufacturing processesFinal product manufactureSlurryElectric vehicle

The invention discloses a large-capacity high-power polymer lithium iron phosphate power battery. The weight ratio of anode slurry is as follows: 81 to 85 percent of lithium iron phosphate, 1 to 5.5 percent of superconduction carbon, 0 to 2.5 percent of conductive carbon soot, 0 to 4 percent of conductive black lead, 0 to 2.5 percent of crystalline flake graphite, 0 to 2 percent of carbon nanometer tube as well as 6 to 7.5 percent of polyvinylidene fluoride; the weight ratio of cathode slurry is as follows: 89 to 91 percent of cathode material, 1 to 3.5 percent of superconduction carbon, 0 to 2 percent of conductive carbon soot, 0 to 4 percent of conductive black lead, 2.5 to 3.5 percent of styrene-butadiene rubber as well as 1.5 to 2 percent of sodium carboxymethyl cellulose; the steps for preparing the battery are as follows: preparing slurry, coating the anode and the cathode, rolling and pressing a polar plate, transversely and separately cutting the polar plate, baking the polar plate, welding the polar ears of the anode and the cathode, preparing a battery cell, putting the electric core into a shell and sealing, baking the electric core, injecting liquid into the battery as well as forming the battery and dividing the volume of the battery. The invention relates to a lithium-ion secondary battery which can provide drive energies for electric tools, electric bicycles, motor cars and electric vehicles.

Owner:MCNAIR TECH

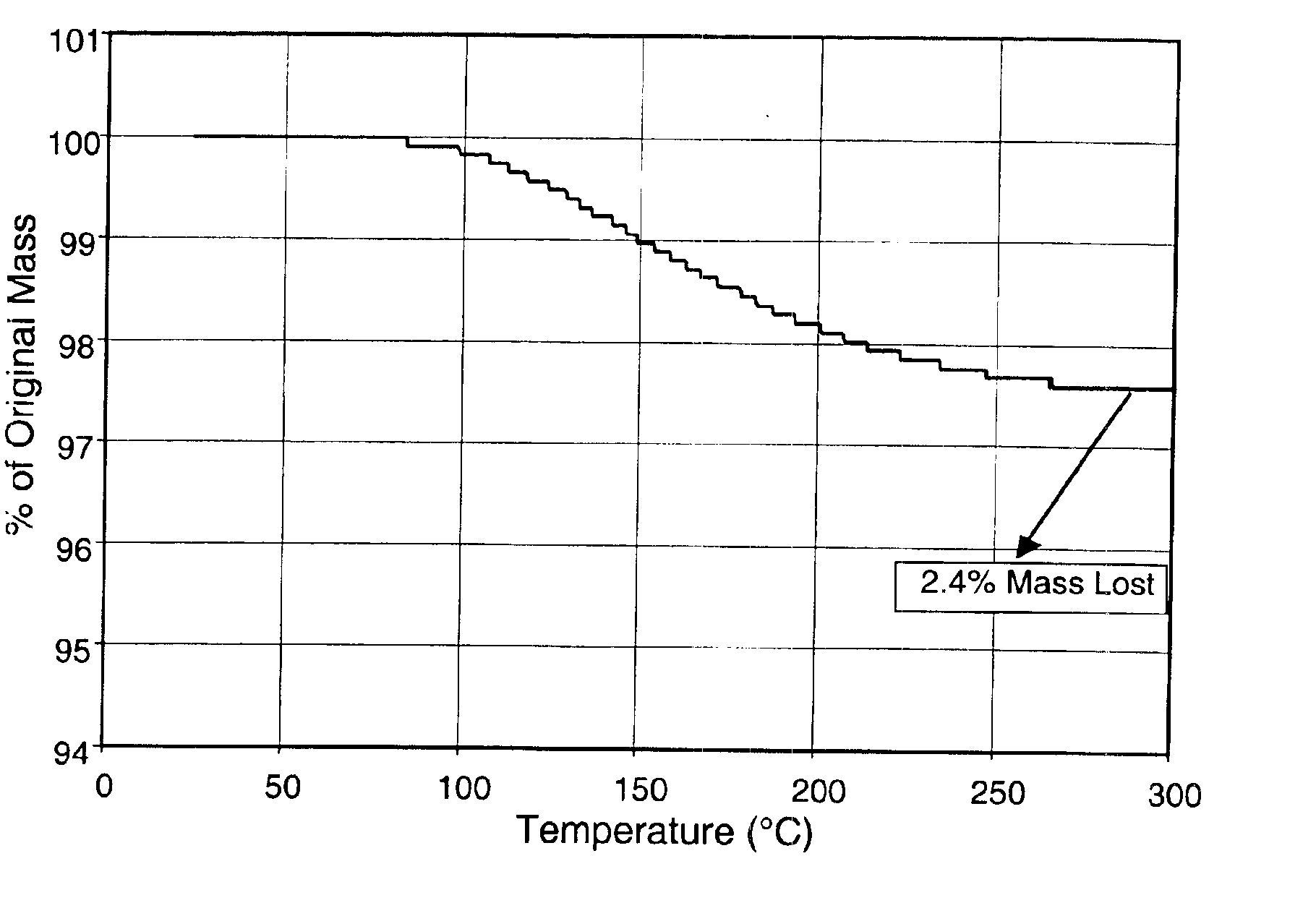

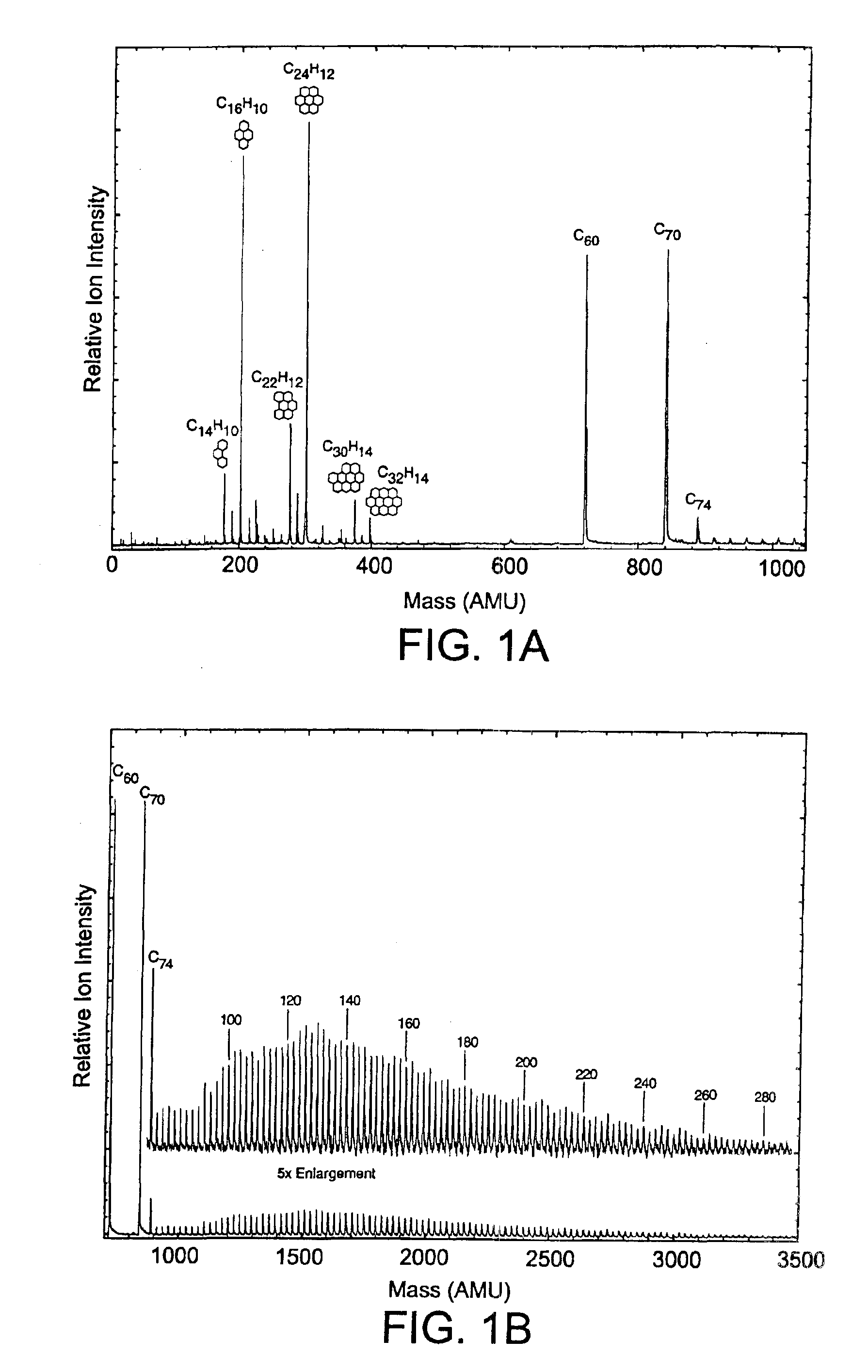

Process for the removal of impurities from combustion fullerenes

InactiveUS6923915B2Without incurring undo costEfficient removalMaterial nanotechnologyFullerenesO-XylenePurification methods

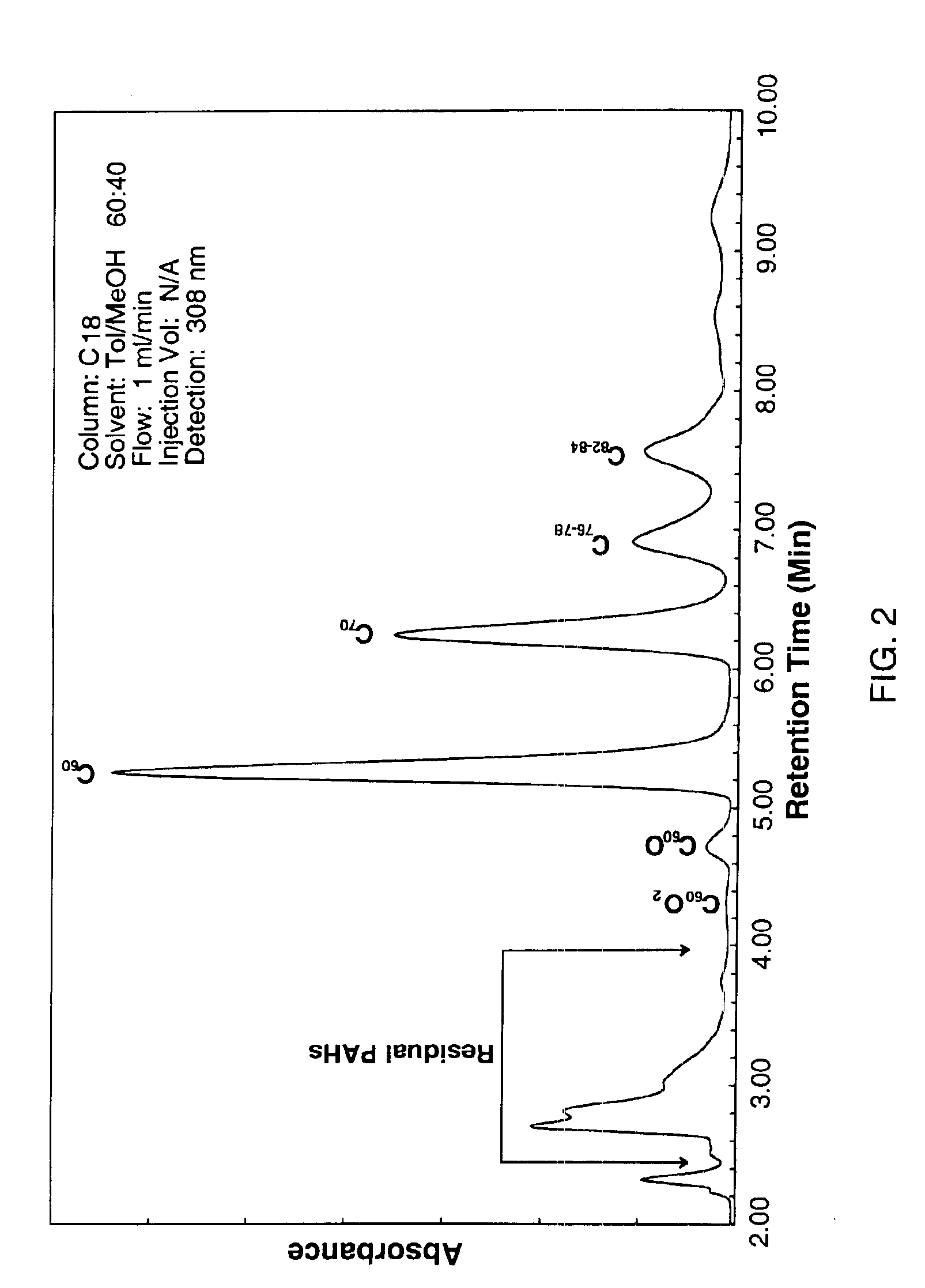

The invention generally relates to purification of carbon nanomaterials, particularly fullerenes, by removal of PAHs and other hydrocarbon impurities. The inventive process involves extracting a sample containing carbon nanomaterials with a solvent in which the PAHs are substantially soluble but in which the carbon nanomaterials are not substantially soluble. The sample can be repeatedly or continuously extracted with one or more solvents to remove a greater amount of impurities. Preferred solvents include ethanol, diethyl ether, and acetone. The invention also provides a process for efficiently separating solvent extractable fullerenes from samples containing fullerenes and PAHs wherein the sample is extracted with a solvent in which both fullerenes and PAHs are substantially soluble and the sample extract then undergoes selective extraction to remove PAHs. Suitable solvents in which both fullerenes and PAHs are soluble include o-xylene, toluene, and o-dichlorobenzene. The purification process is capable of treating quantities of combustion soot in excess of one kilogram and can produce fullerenes or fullerenic soot of suitable purity for many applications.

Owner:FRONTIER CARBON CORP

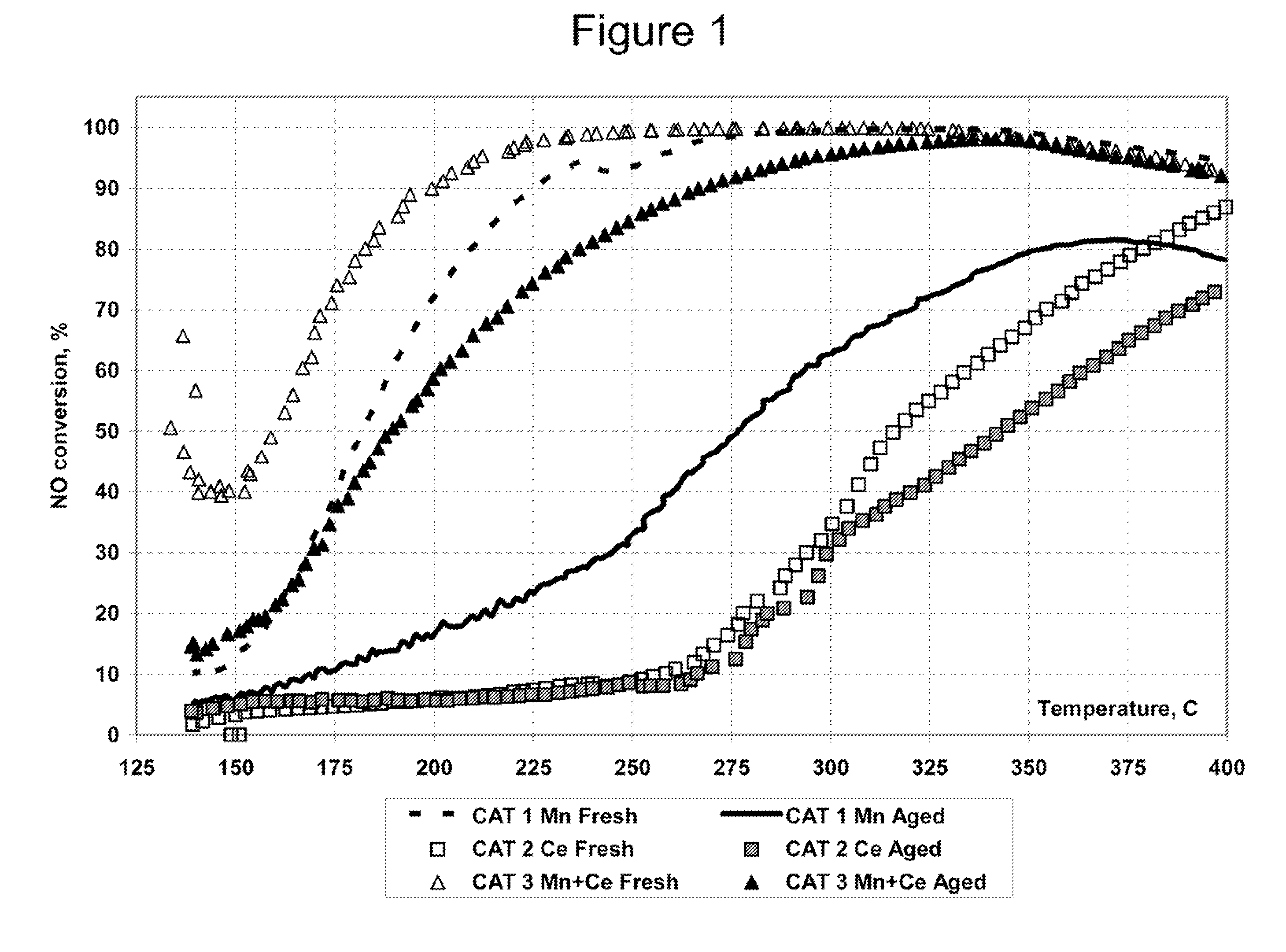

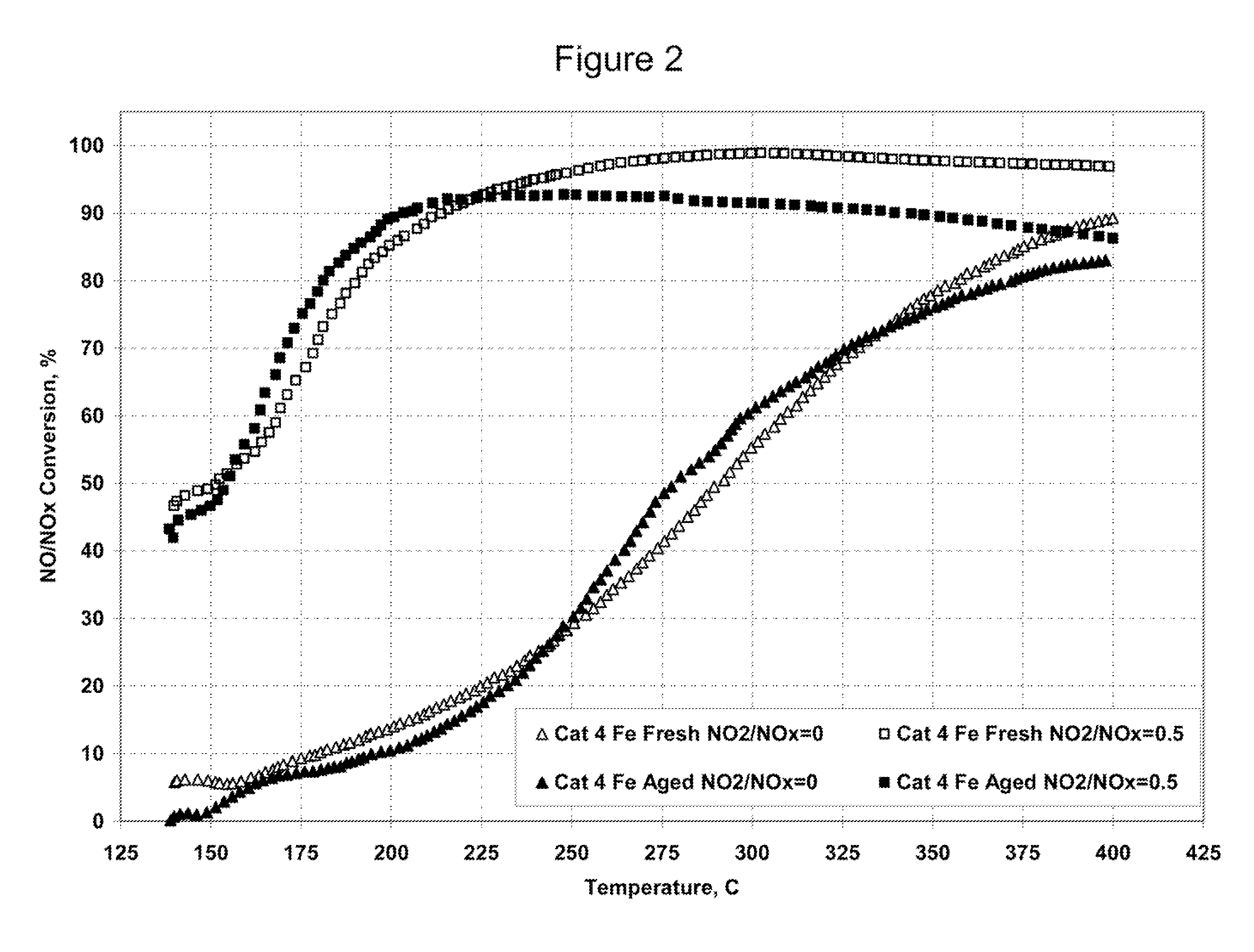

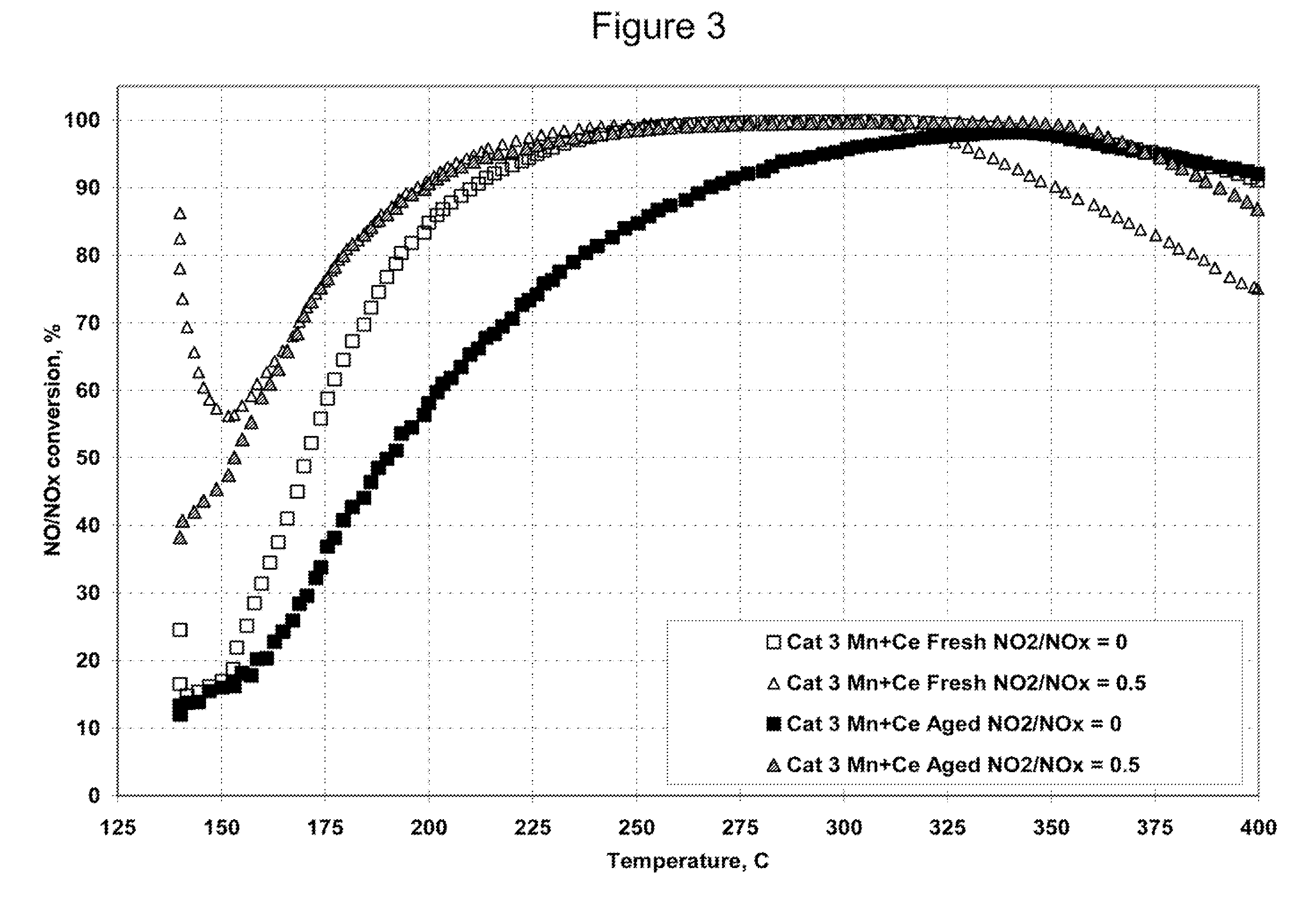

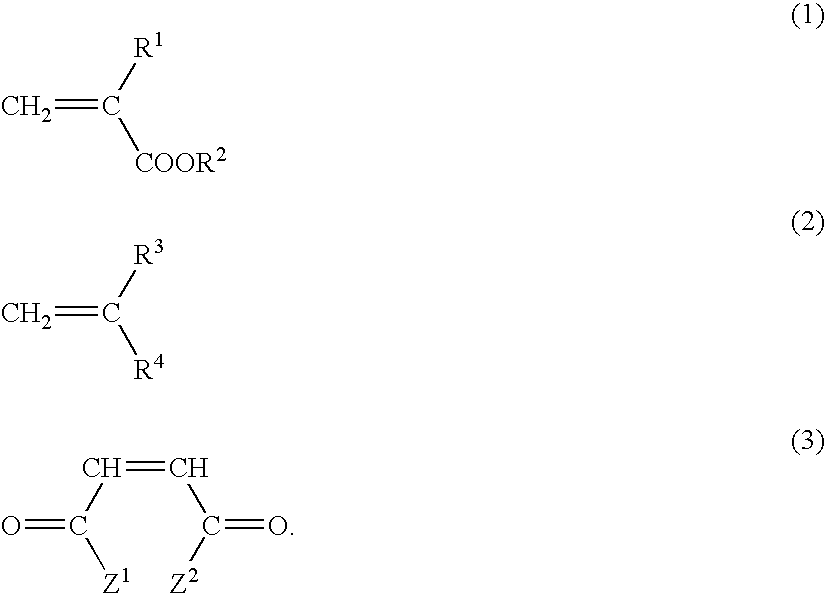

Ammonia scr catalyst and method of using the catalyst

ActiveUS20090304566A1Enhanced Surface AcidityCombination devicesOrganic chemistryParticulatesNiobium

A DPF with an SCR catalyst and a method for selectively reducing nitrogen oxides with ammonia, filtering particulates, and reducing the ignition temperature of soot on a DPF are provided. The catalyst includes a first component of copper, chromium, cobalt, nickel, manganese, iron, niobium, or mixtures thereof, a second component of cerium, a lanthanide, a mixture of lanthanides, or mixtures thereof, and a component characterized by increased surface acidity. The catalyst may also include strontium as an additional second component. The catalyst selectively reduces nitrogen oxides to nitrogen with ammonia and oxidizes soot at low temperatures. The catalyst has high hydrothermal stability.

Owner:CATALYTIC SOLUTIONS INC

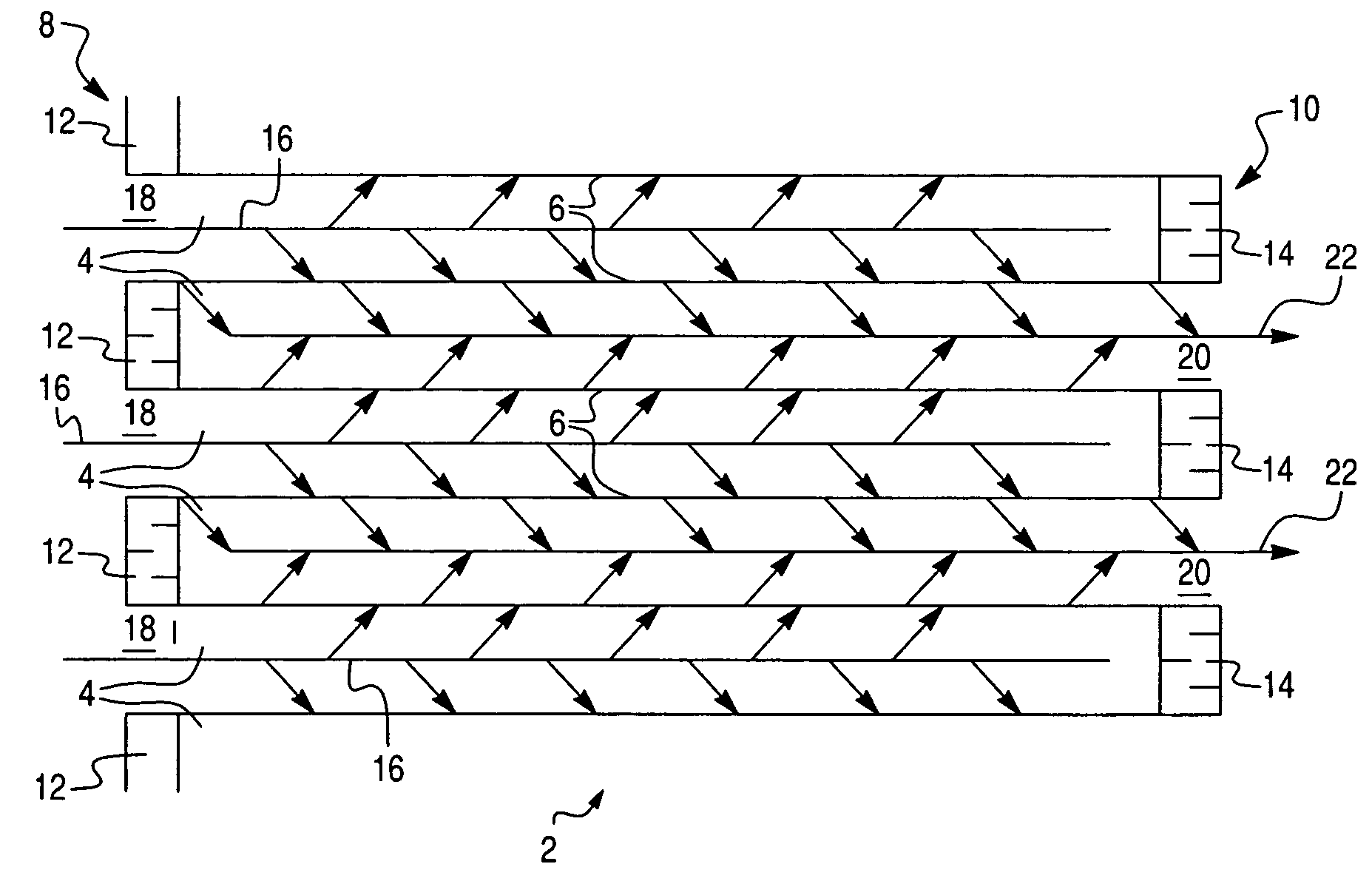

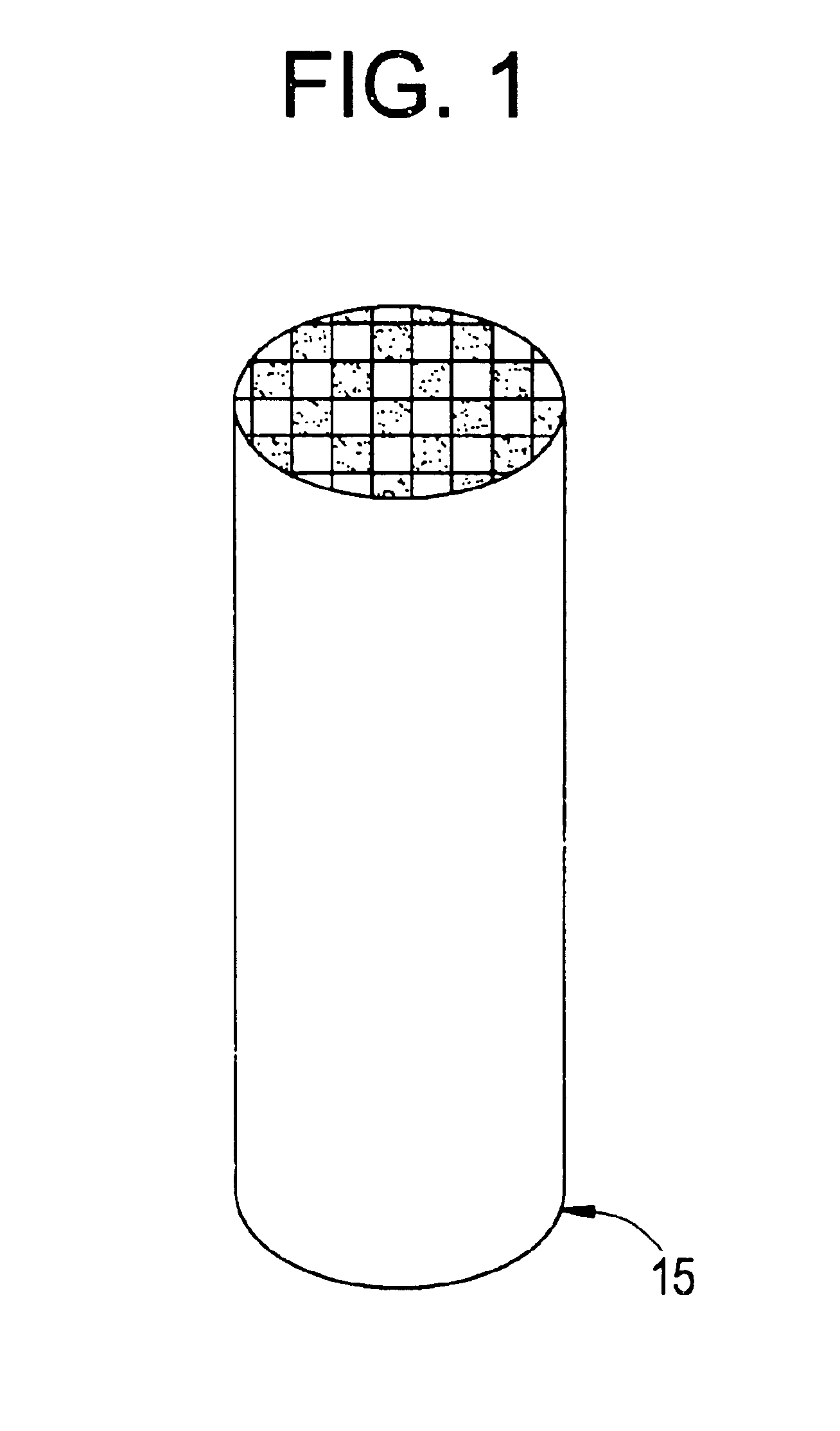

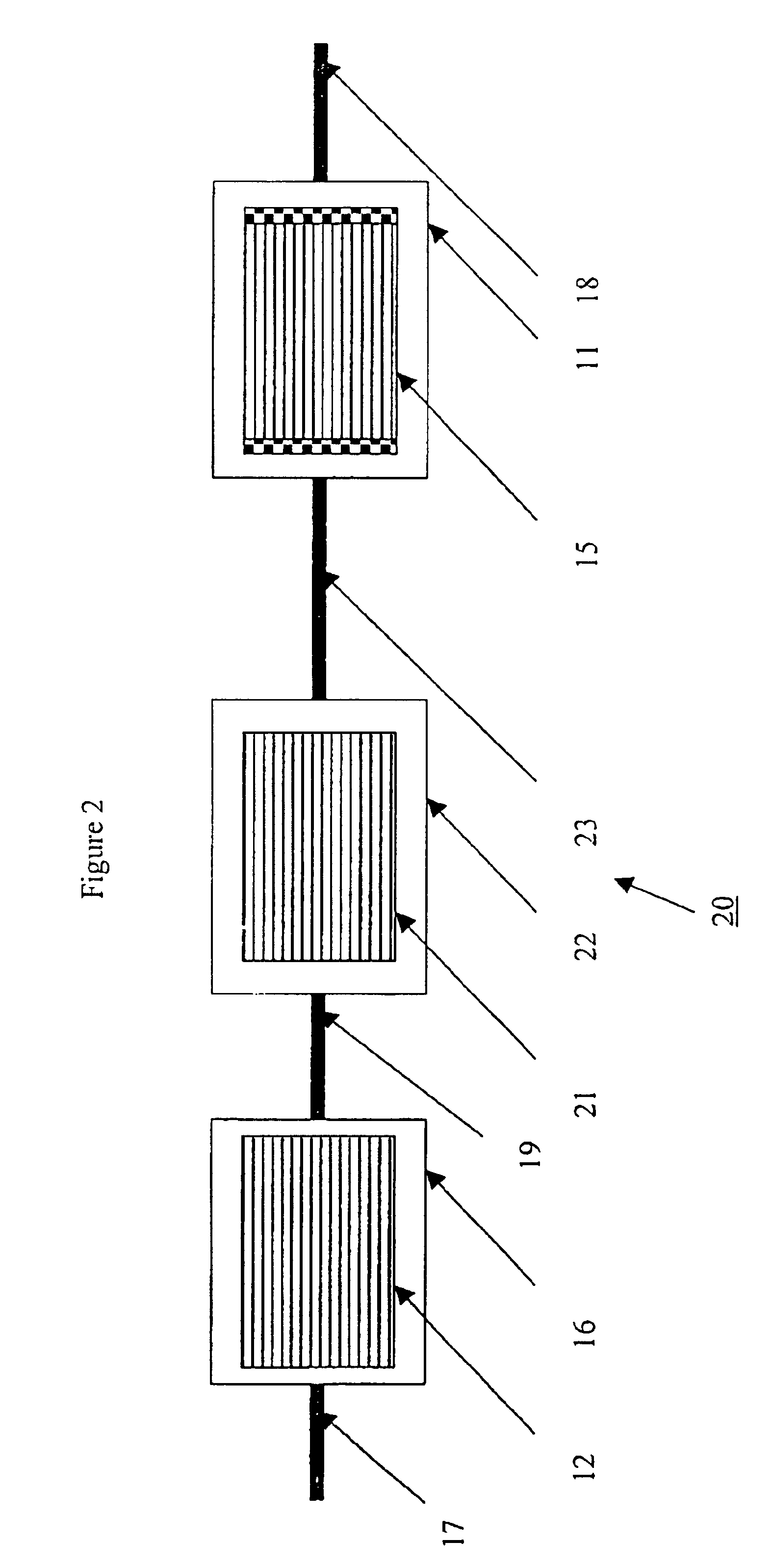

Pressure-balanced, catalyzed soot filter

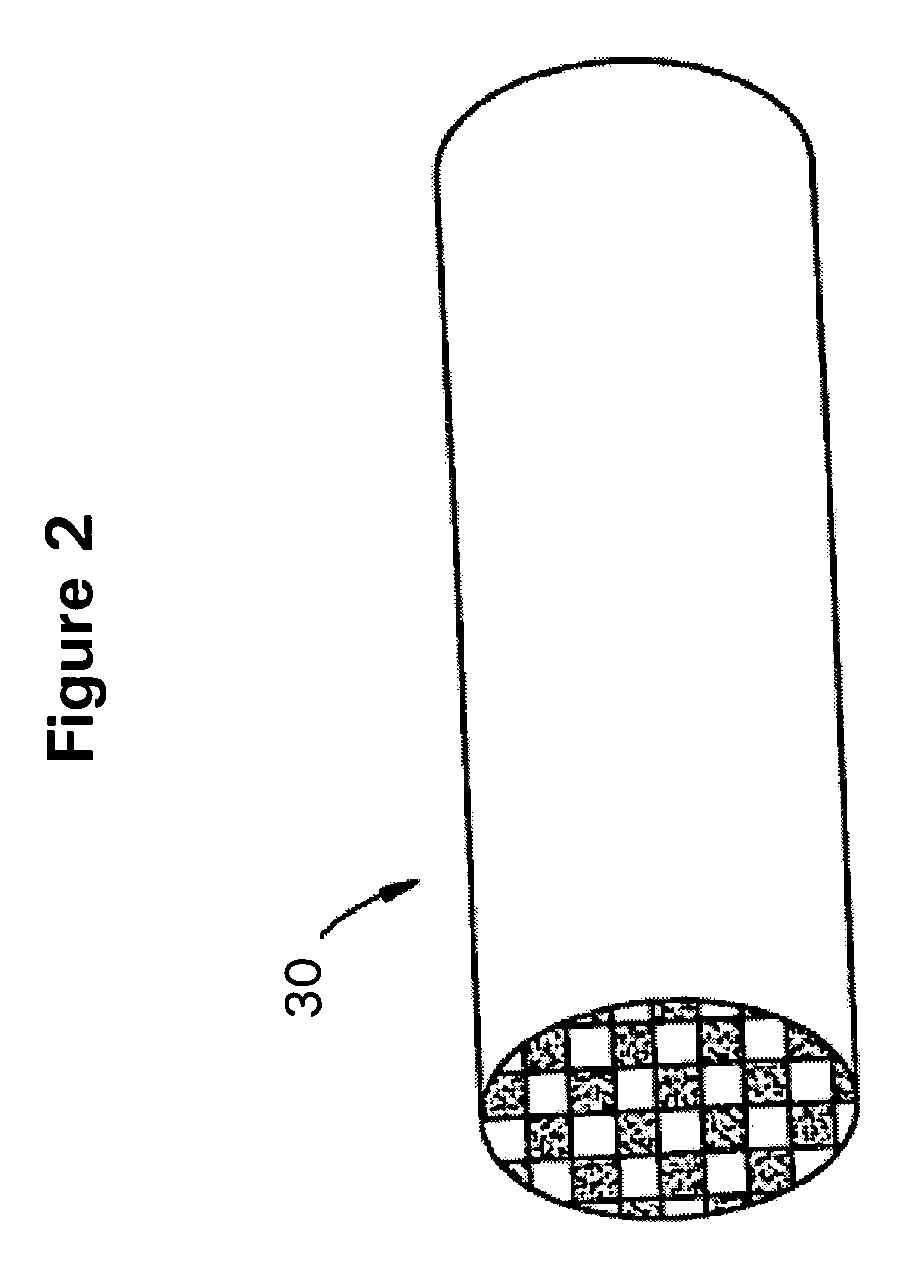

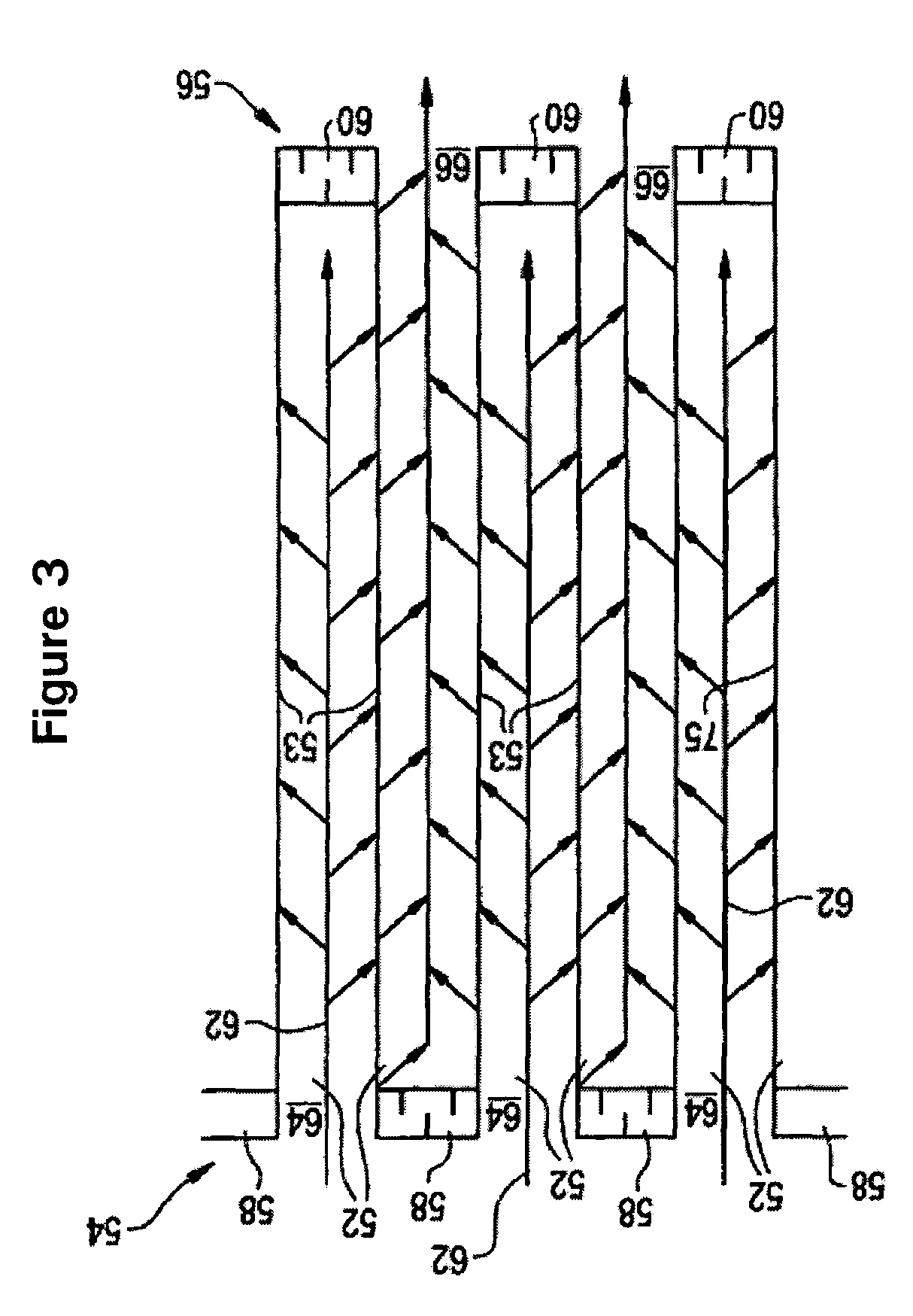

ActiveUS7722829B2High particulate matter reductionPromote combustionCombination devicesMolecular sieve catalystsParticulatesCatalytic function

The invention provides a catalyzed soot filter formed on a wall flow substrate having internal walls coated with catalyst compositions. The soot filter maintains a homogeneous flow of the exhaust gases through the internal walls of the substrate along the length of the filter due to the coating design. Both the efficiency and the durability of the catalytic function are increased over conventionally designed catalyzed soot filters. The catalyzed soot filter provides an integrated function for simultaneously treating the gaseous components of the exhaust (e.g., CO and HC) and the particulate matter deposited in the filter.

Owner:BASF CATALYSTS LLC

Lubricating oil composition

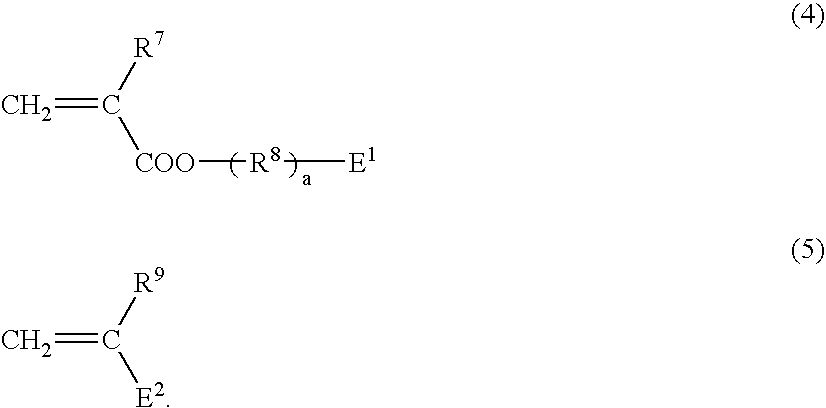

ActiveUS20080110799A1Excellent in thermal/oxidation stabilityInhibit of acid numberLiquid carbonaceous fuelsAdditivesInternal combustion engineSoot

The present invention provide a lubricating oil composition suitable for internal combustion engines, which composition is excellent in thermal / oxidation stability and can inhibit the increases of the viscosity and acid number even in the presence of NOx and can be used for a long period of time or provide a lubricating oil composition particularly suitable for diesel or direct injection engines equipped with an exhaust-gas after-treatment device such as DPF or various catalysts, which composition is excellent in high-temperature detergency and base number retention properties and further can achieve the effect of inhibit wear caused by soot contamination in the oil occurring significantly when the content of phosphorus compounds such as ZnDTP is decreased, at a high level and can inhibit the exhaust-gas after-treatment device from being adversely affected. The lubricating oil composition comprises a lubricating base oil containing, a specific amount of a base oil with specific properties, and two or more types of additives selected from specific additives.

Owner:NIPPON OIL CORP

Apparatus, system, and method for detecting and labeling a filter regeneration event

ActiveUS7263825B1Easily trigger appropriate responseImprove fuel economyAnalogue computers for vehiclesInternal combustion piston enginesParticulatesEngineering

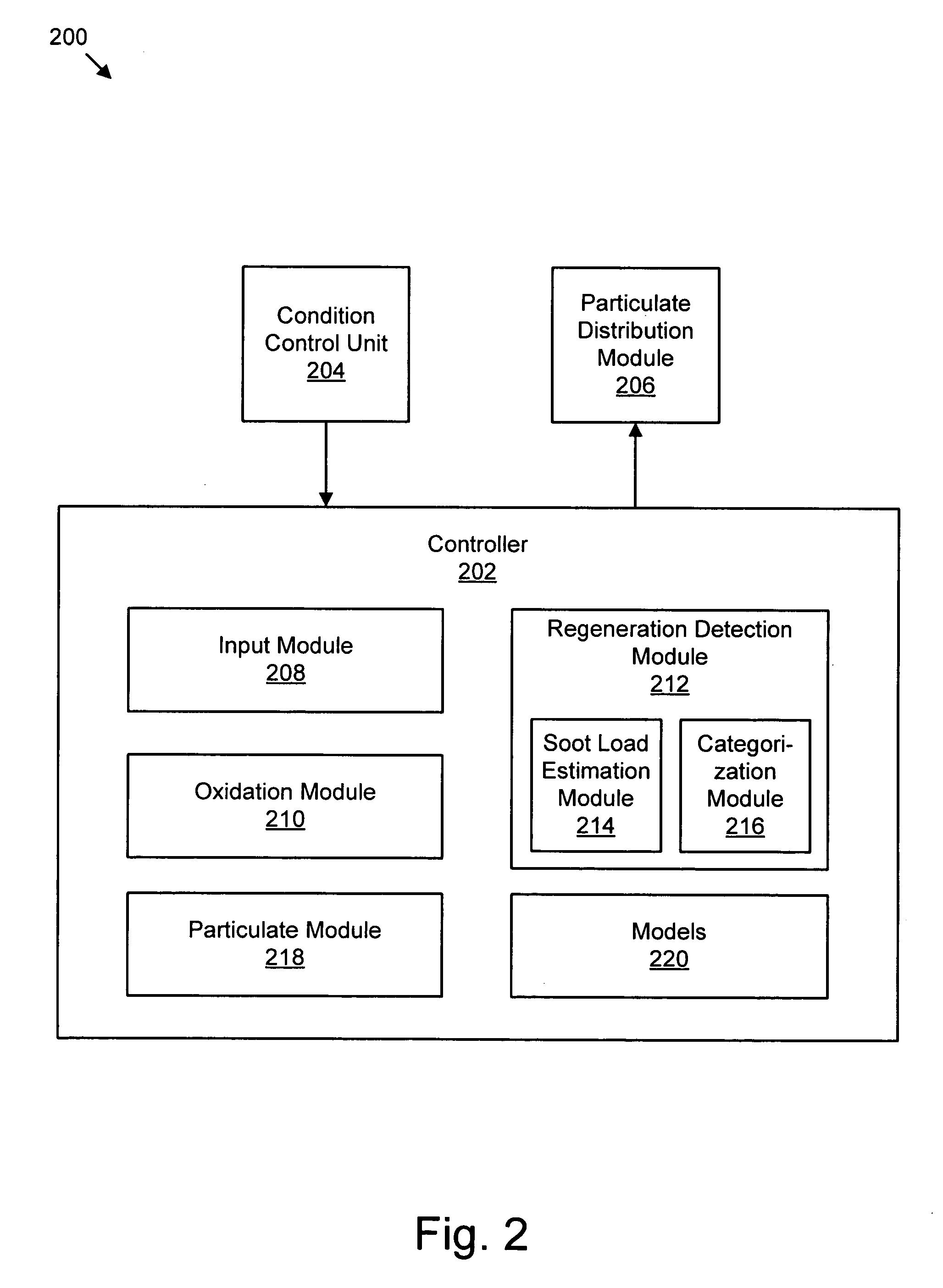

An apparatus, system, and method are disclosed for detecting and evaluating a filter regeneration event. The apparatus, in one embodiment, is configured to determine whether an oxidation rate of soot accumulated on a particulate filter has attained a level sufficient to indicate that a filter regeneration event is occurring. The apparatus may include an input module for receiving input relative to engine operating conditions and exhaust gas produced as a byproduct of engine operation, an oxidation module for communicating with the input module and for determining an oxidation rate of soot accumulated on a particulate filter from the input, and a regeneration detection module to determine whether a filter regeneration event is occurring. The apparatus may further categorize a detected filter regeneration event and to facilitate defining the actual condition of soot on a particulate filter.

Owner:CUMMINS INC

Cordierite body

InactiveUSRE38888E1Improve permeabilityReduce back pressureDispersed particle filtrationSilencing apparatusGramVolumetric Mass Density

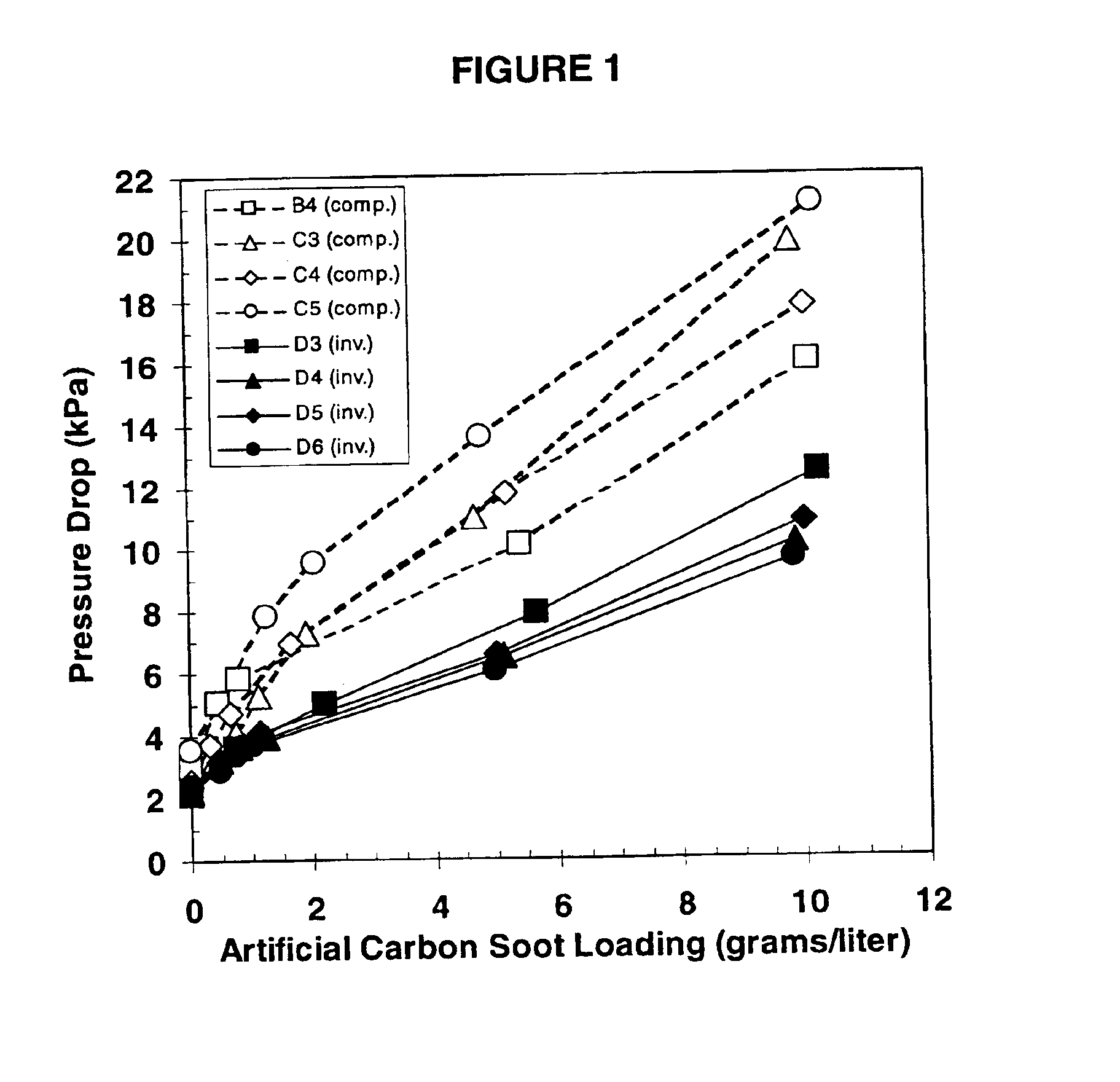

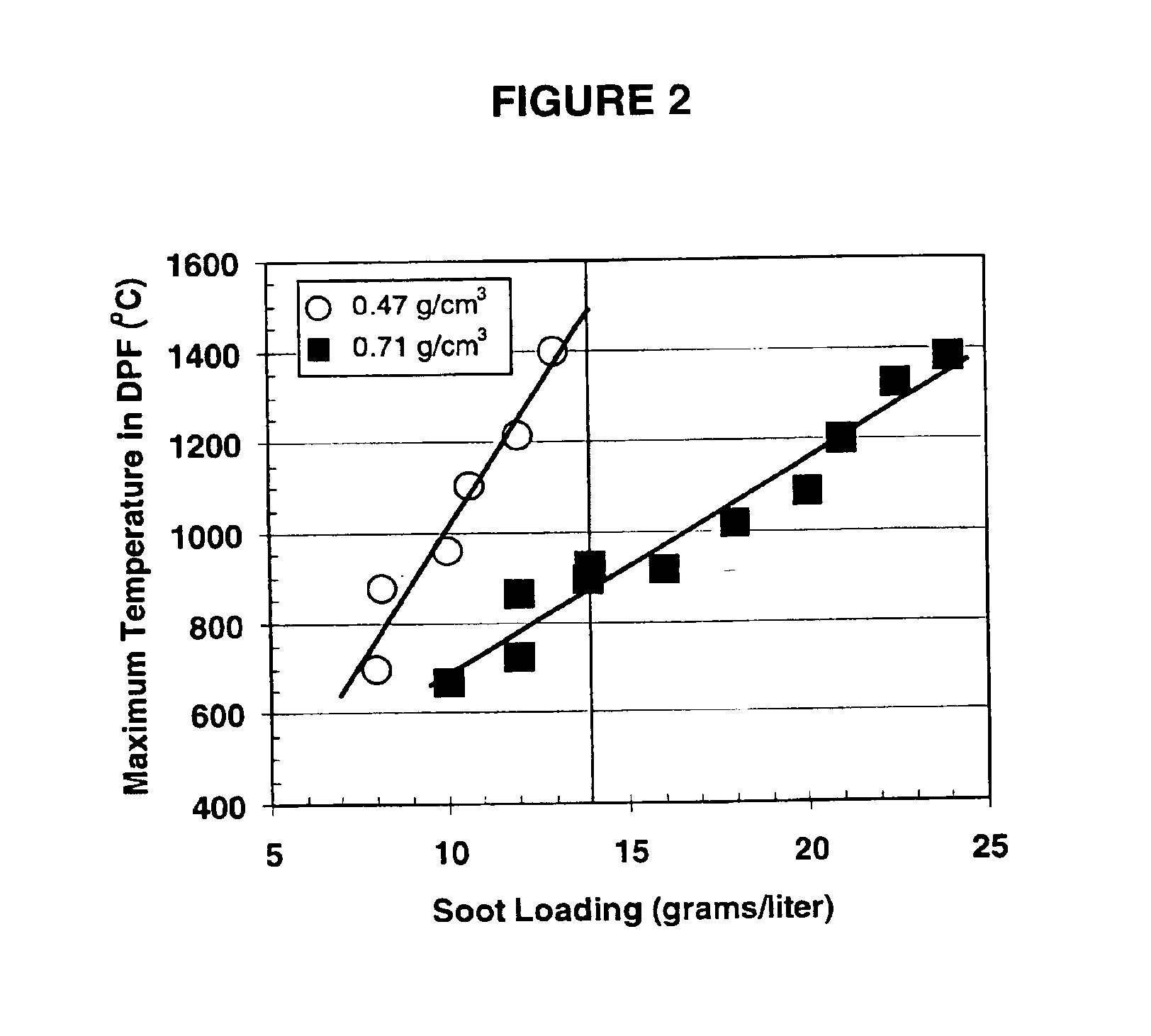

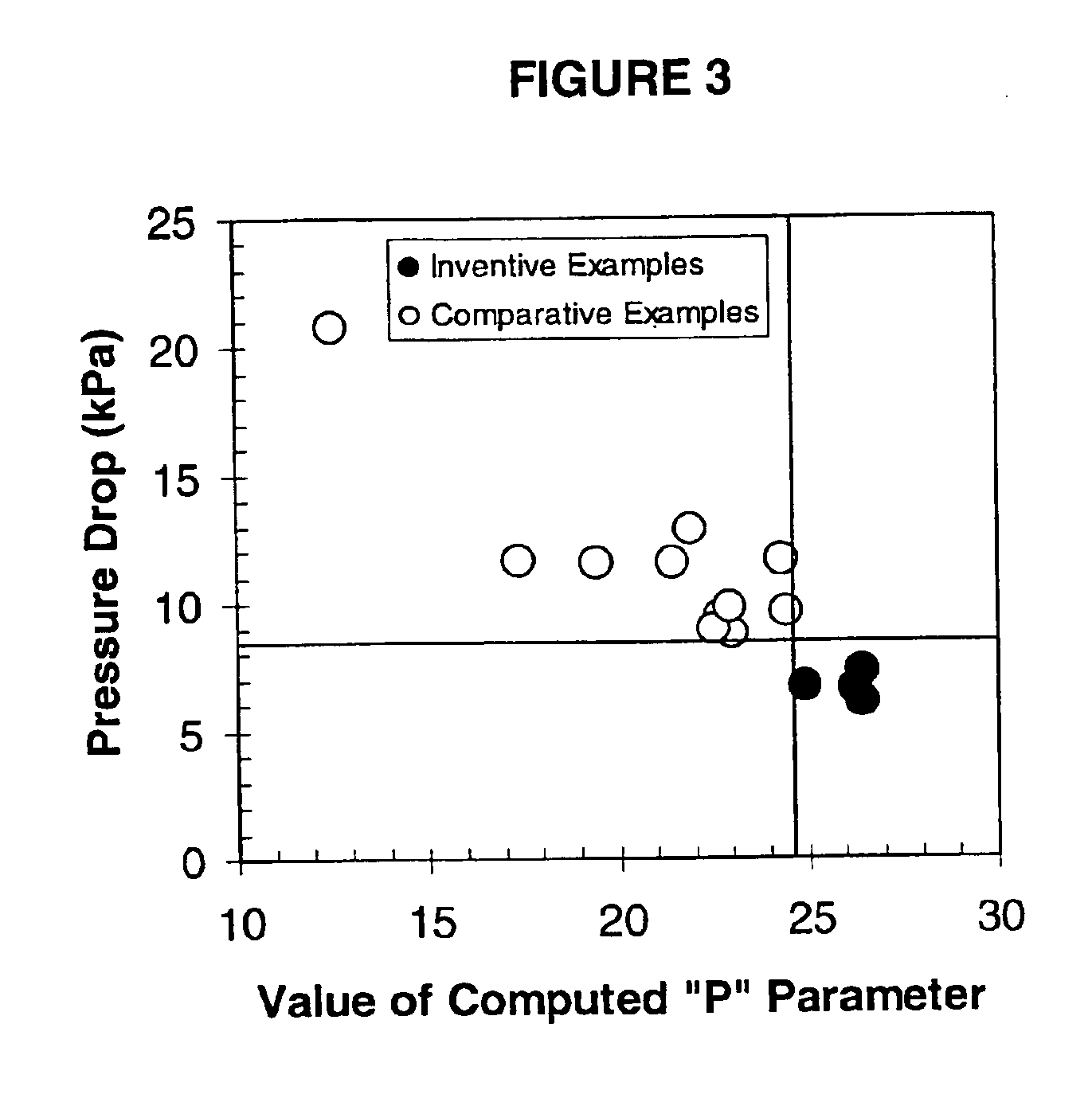

A ceramic comprising predominately a cordierite-type phase approximating the stoichiometry Mg2Al4Si5O18 and having a coefficient of thermal expansion (25-800° C.) of greater than 4×10−7 / ° C. and less than 13×10−7 / ° C. and a permeability and a pore size distribution which satisfy the relation 2.108 (permeability)+18.511 (total pore volume)+0.1863 (percentage of total pore volume comprised of pores between 4 and 40 micrometers)>24.6. The ceramic is suitable in the fabrication of cellular, wall-flow, diesel particulate filters having a pressure drop in kPa that at an artificial carbon soot loading of 5 grams / liter and a flow rate of 26 scfm is less than 8.9-0.035 (number of cells per square inch)+300 (cell wall thickness in inches), a bulk filter density of at least 0.60 g / cm3 and a volumetric heat capacity of at least 0.67 J cm−3 K−1 as measured at 500° C.

Owner:CORNING INC

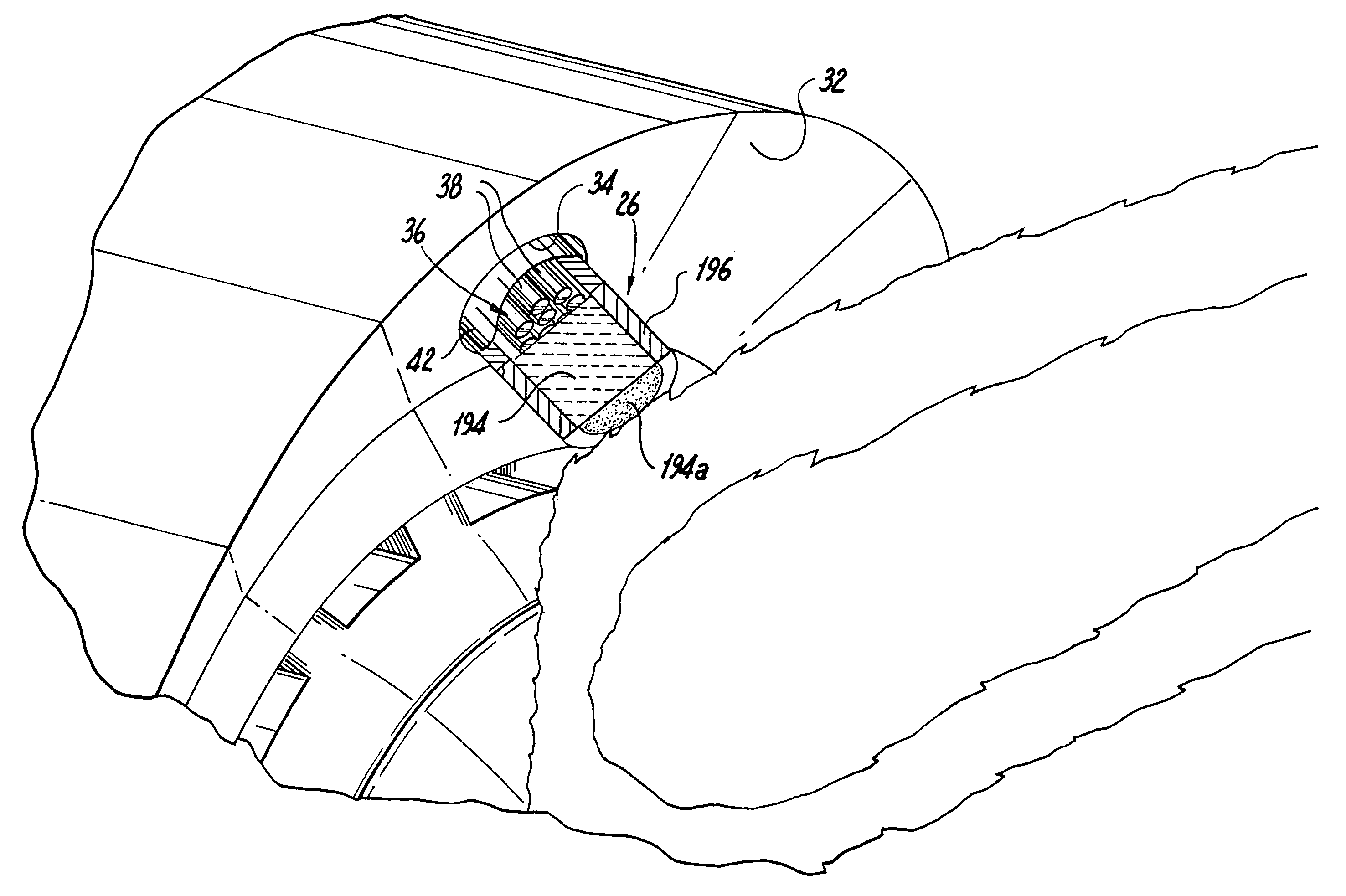

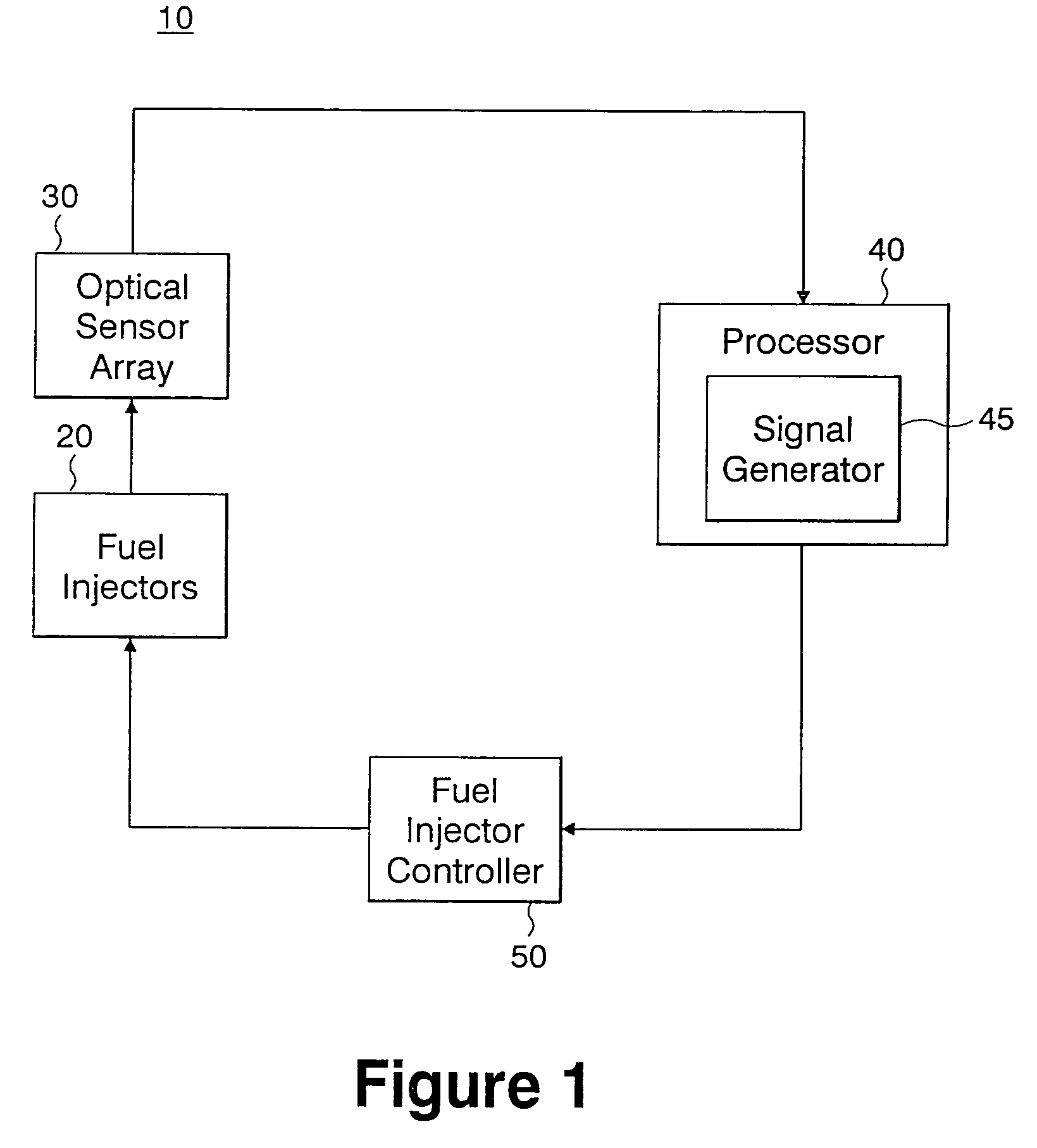

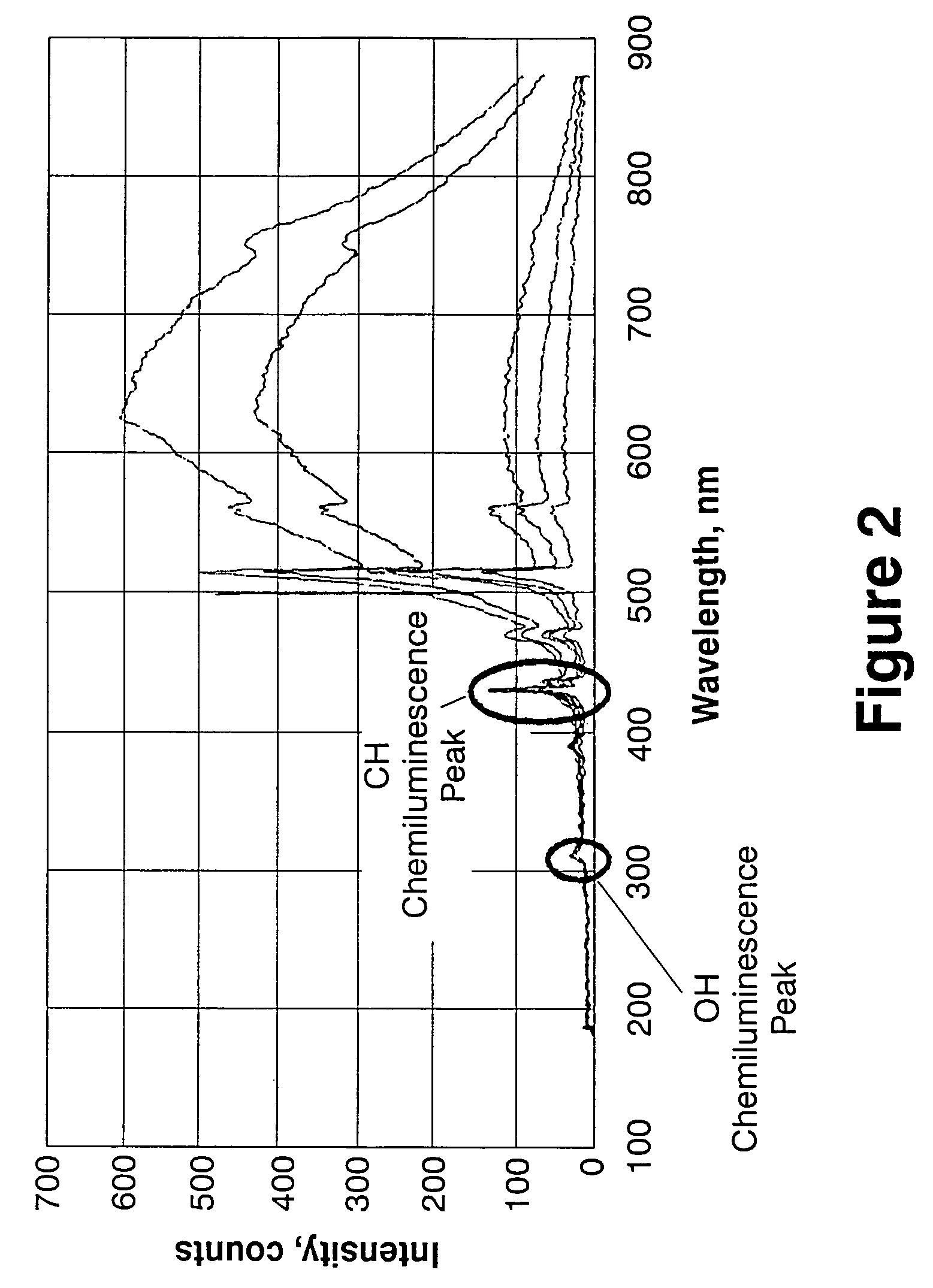

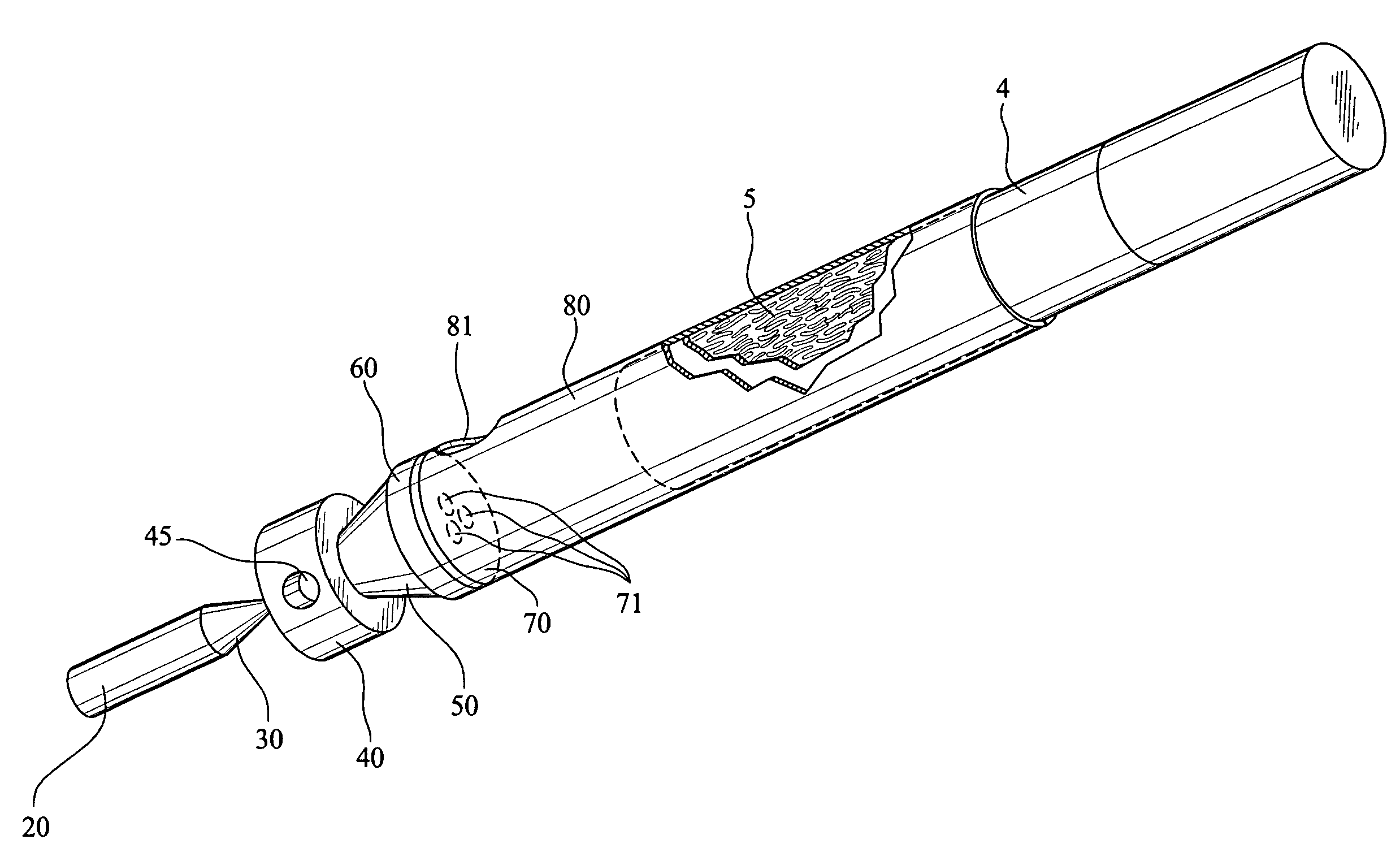

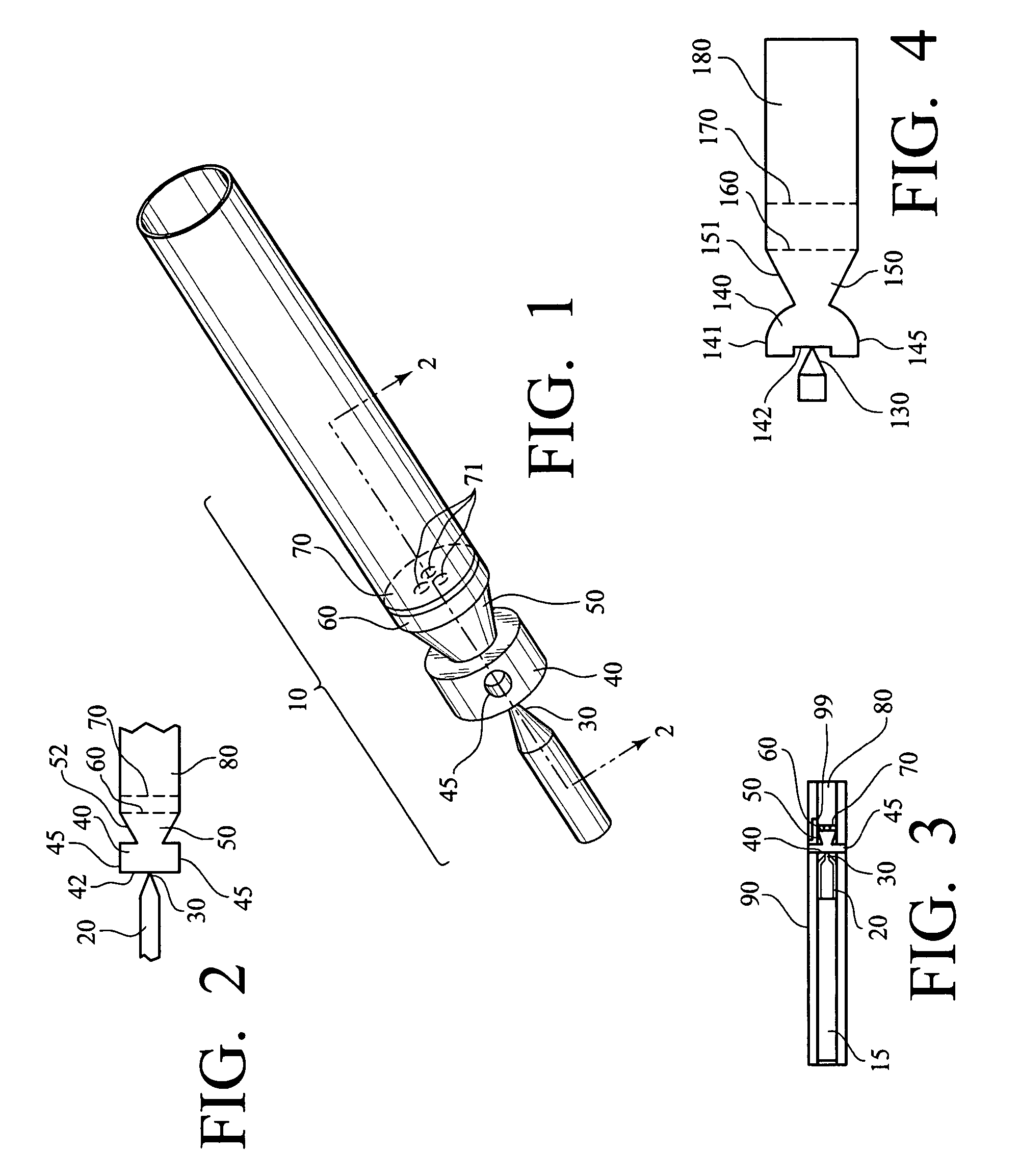

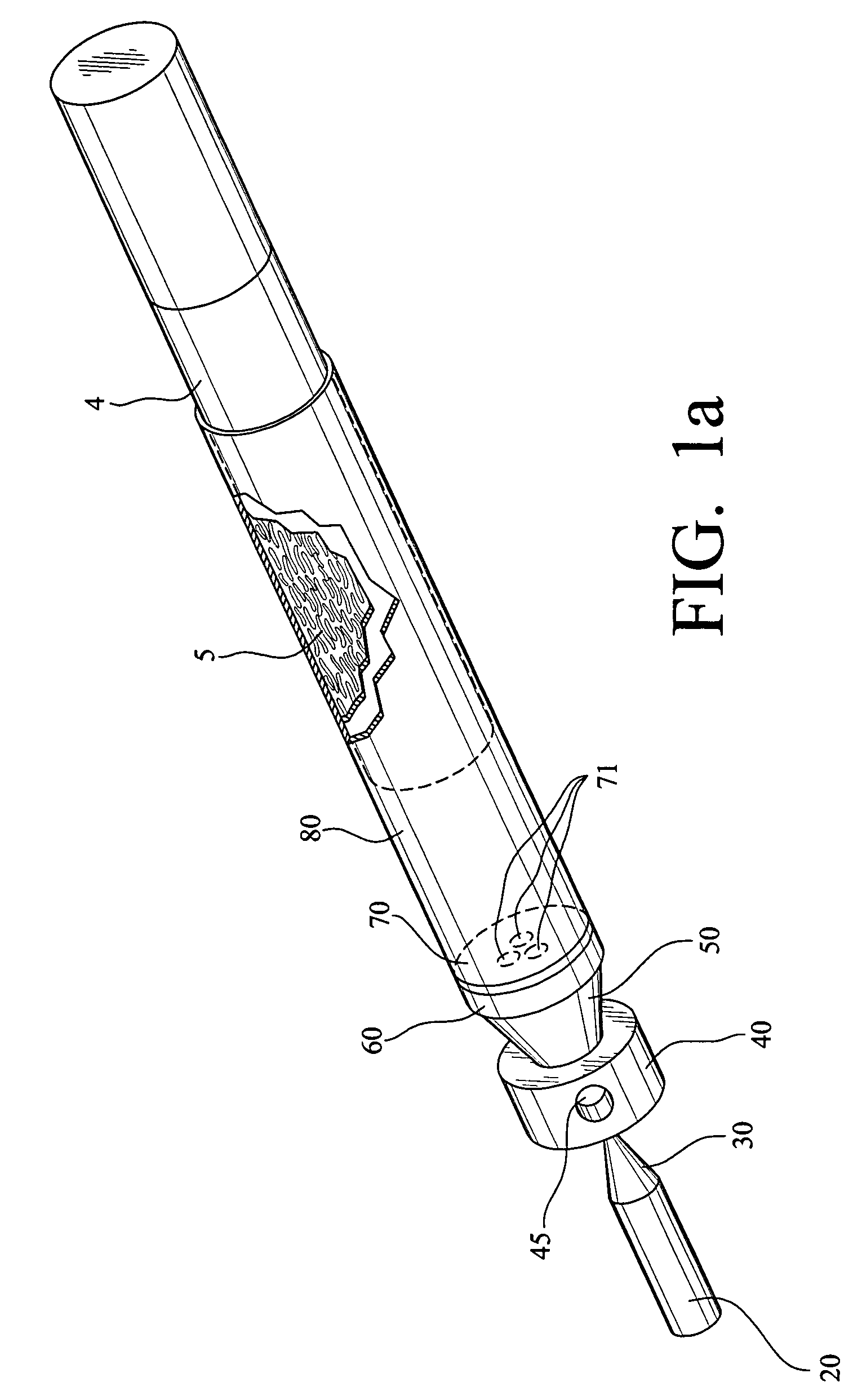

Apparatus for observing combustion conditions in a gas turbine engine

ActiveUS7484369B2Reduce instabilityPromote oxidationContinuous combustion chamberMaterial analysis by optical meansCombustorSoot

A fuel injector for a gas turbine combustor is disclosed which includes a feed arm having a flange for mounting the injector within the combustor and a fuel nozzle depending from the feed arm for injecting fuel into the combustor for combustion. An optical sensor array is operatively associated with the fuel nozzle for observing combustor flame characteristics. The optical sensor array includes a plurality of sapphire rods positioned to be close enough to the combustor flame to oxidize soot deposits thereon.

Owner:ROSEMOUNT AEROSPACE

Oxidation catalyst on a substrate utilized for the purification of exhaust gases

InactiveUS20060211569A1Molecular sieve catalystsDispersed particle separationParticulatesHydrocotyle bowlesioides

Owner:CLARIANT INT LTD

Method for controlling fuel of a spark ignited engine while regenerating a particulate filter

ActiveUS20110073088A1Improve efficiencyLower charging temperatureElectrical controlInternal combustion piston enginesGasoline direct injectionExhaust fumes

A system for filtering and oxidizing particulate matter produced by a gasoline direct injection engine is disclosed. In one embodiment, engine cylinder air-fuel is adjusted to allow soot to oxidize at an upstream particulate filter while exhaust gases are efficiently processed in a downstream catalyst.

Owner:FORD GLOBAL TECH LLC

DOC and particulate control system for diesel engines

The present invention is directed to an emission treatment system for the treatment and / or conversion of engine emissions and particulate matter from diesel engines. The emission treatment system of the present invention comprises an upstream oxidation catalyst, a particulate filter or soot filter section and optionally a downstream catalytic element or clean-up catalyst for the treatment and / or conversion of any remaining emission gas stream contaminants.

Owner:BASF CATALYSTS LLC

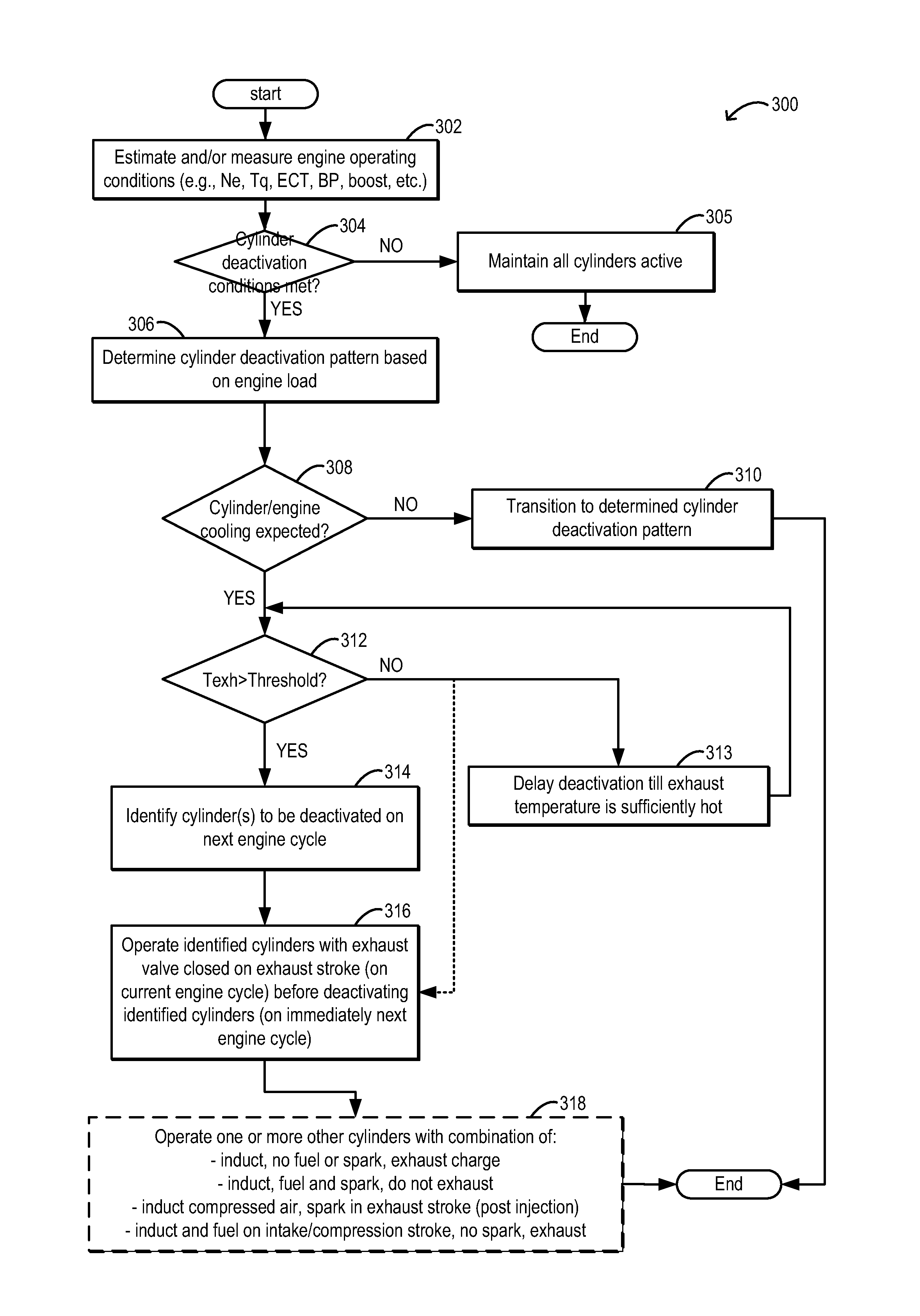

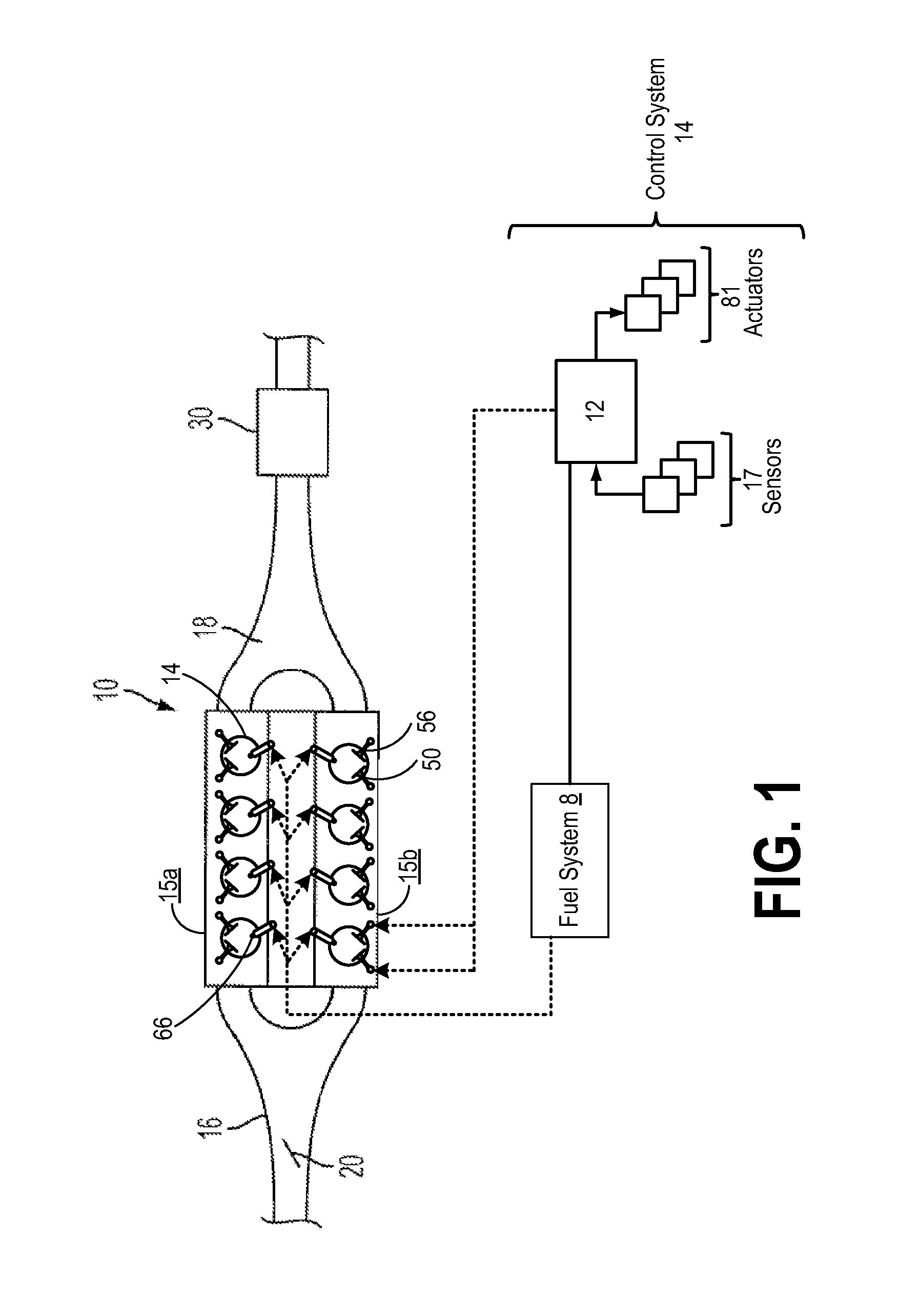

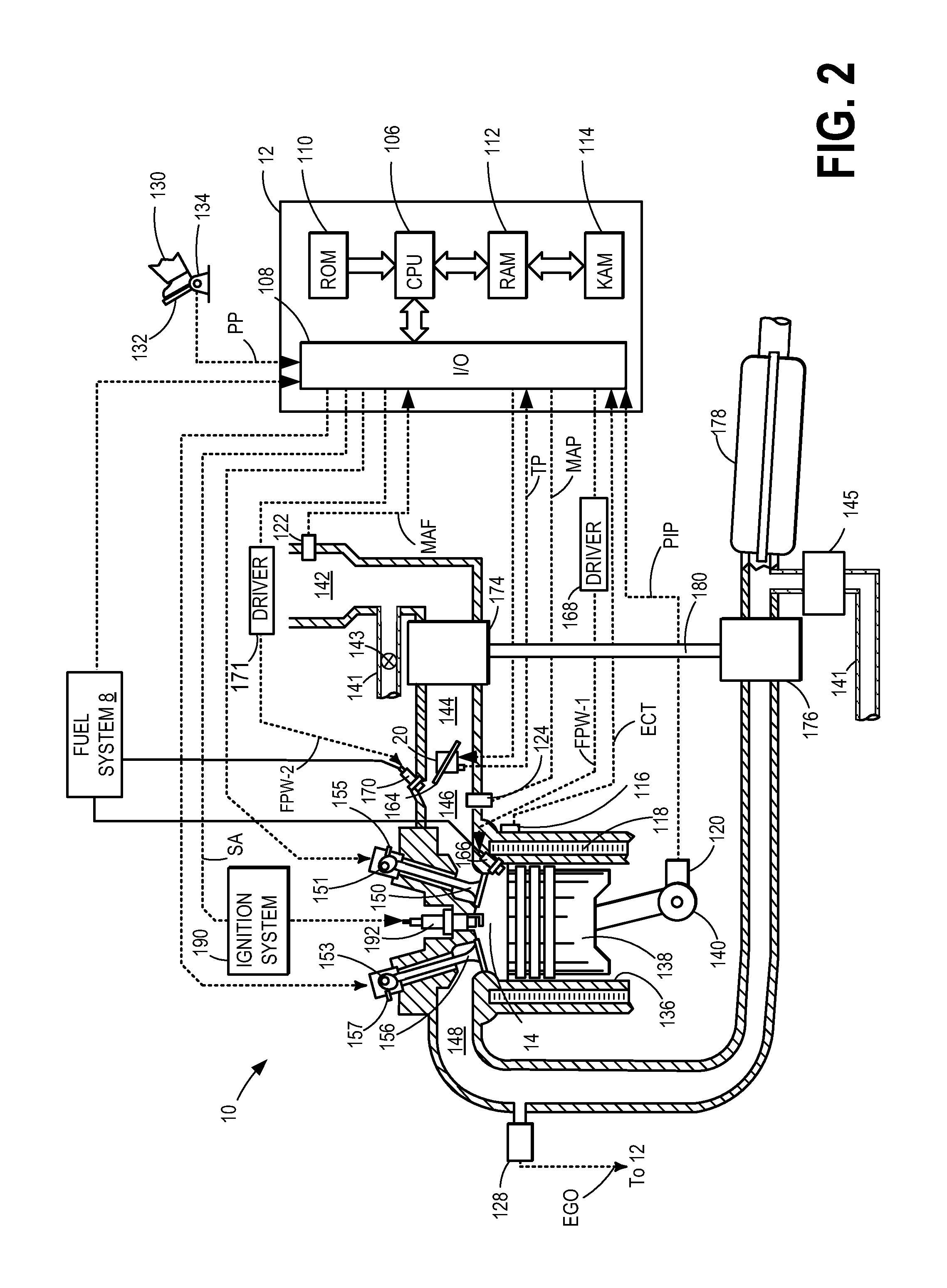

Method and system for engine temperature control

ActiveUS20160115884A1Increased hydrocarbonExhaust emission be highElectrical controlInternal combustion piston enginesTemperature controlExhaust valve

Methods and systems are provided to improve engine temperature control. Cylinders scheduled for deactivation may have their exhaust retained in the cylinder by holding an exhaust valve closed on the preceding firing cycle. In this way soot emissions on reactivation are reduced.

Owner:FORD GLOBAL TECH LLC

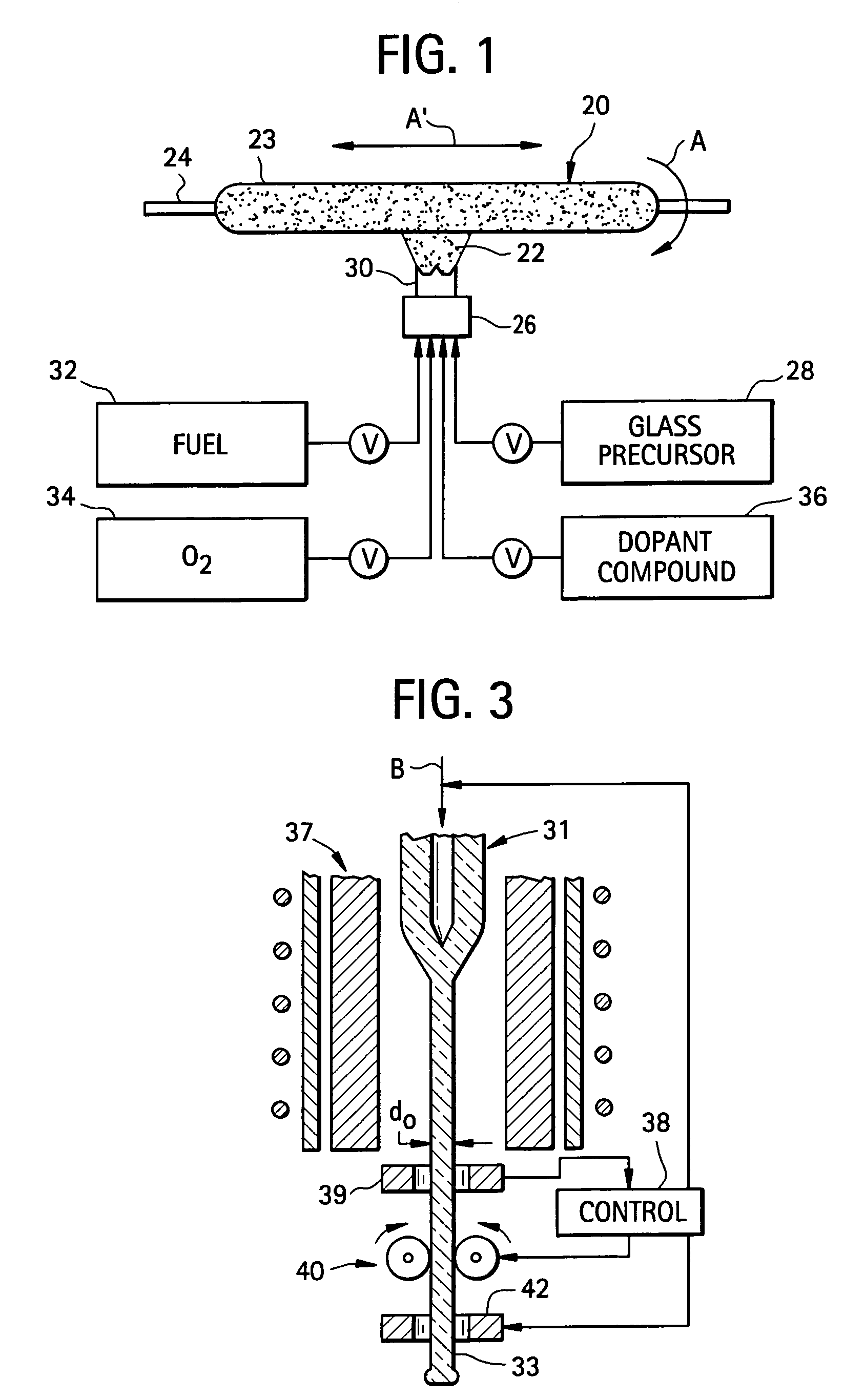

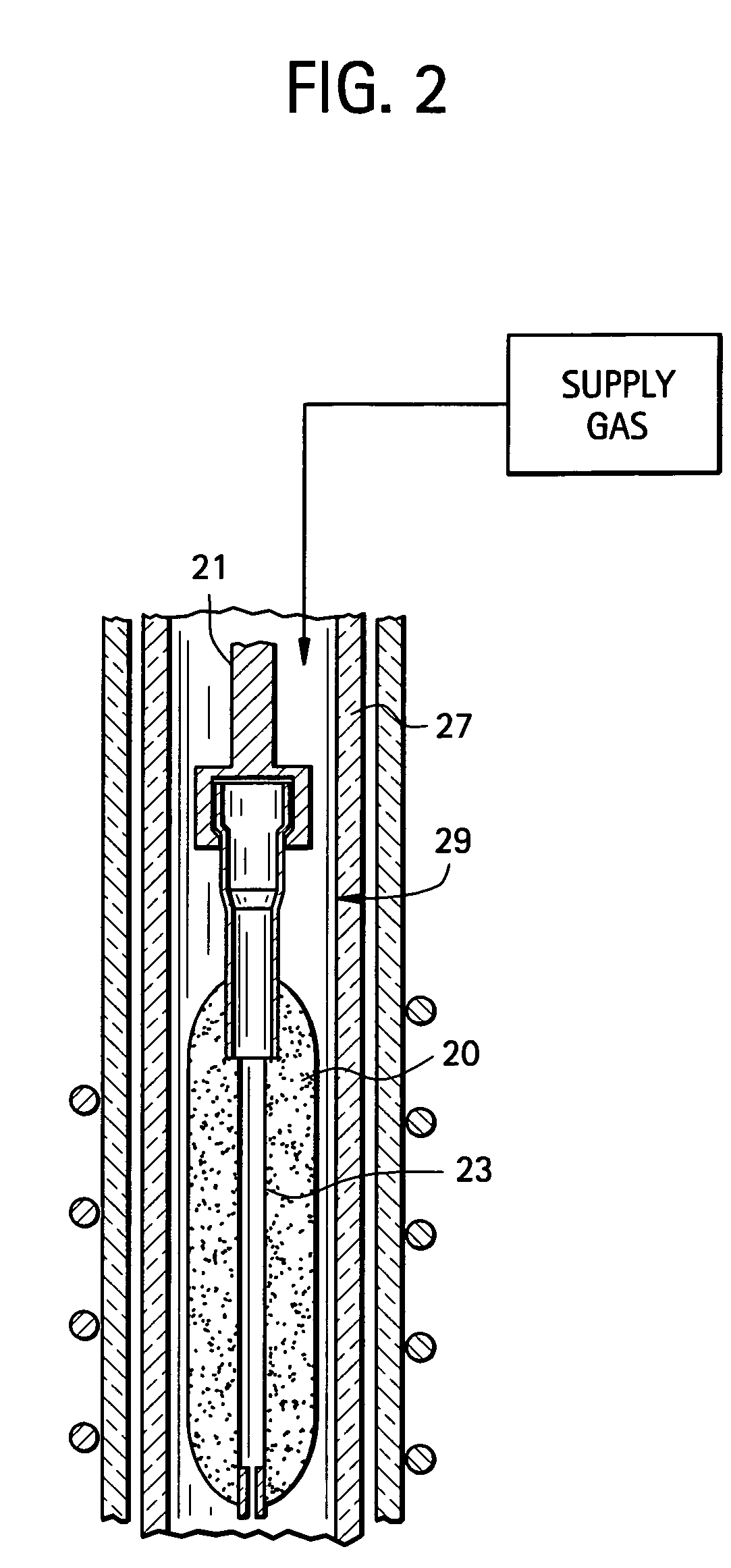

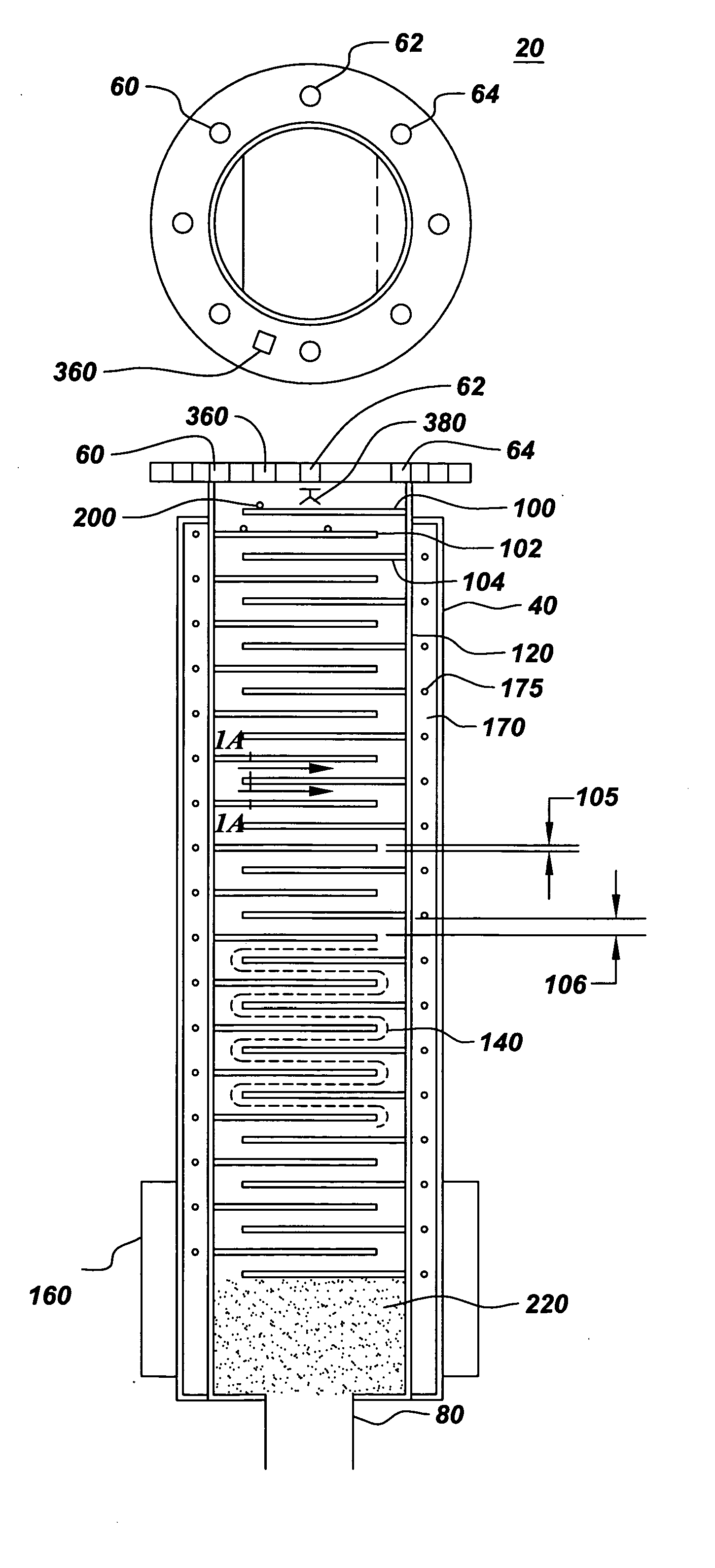

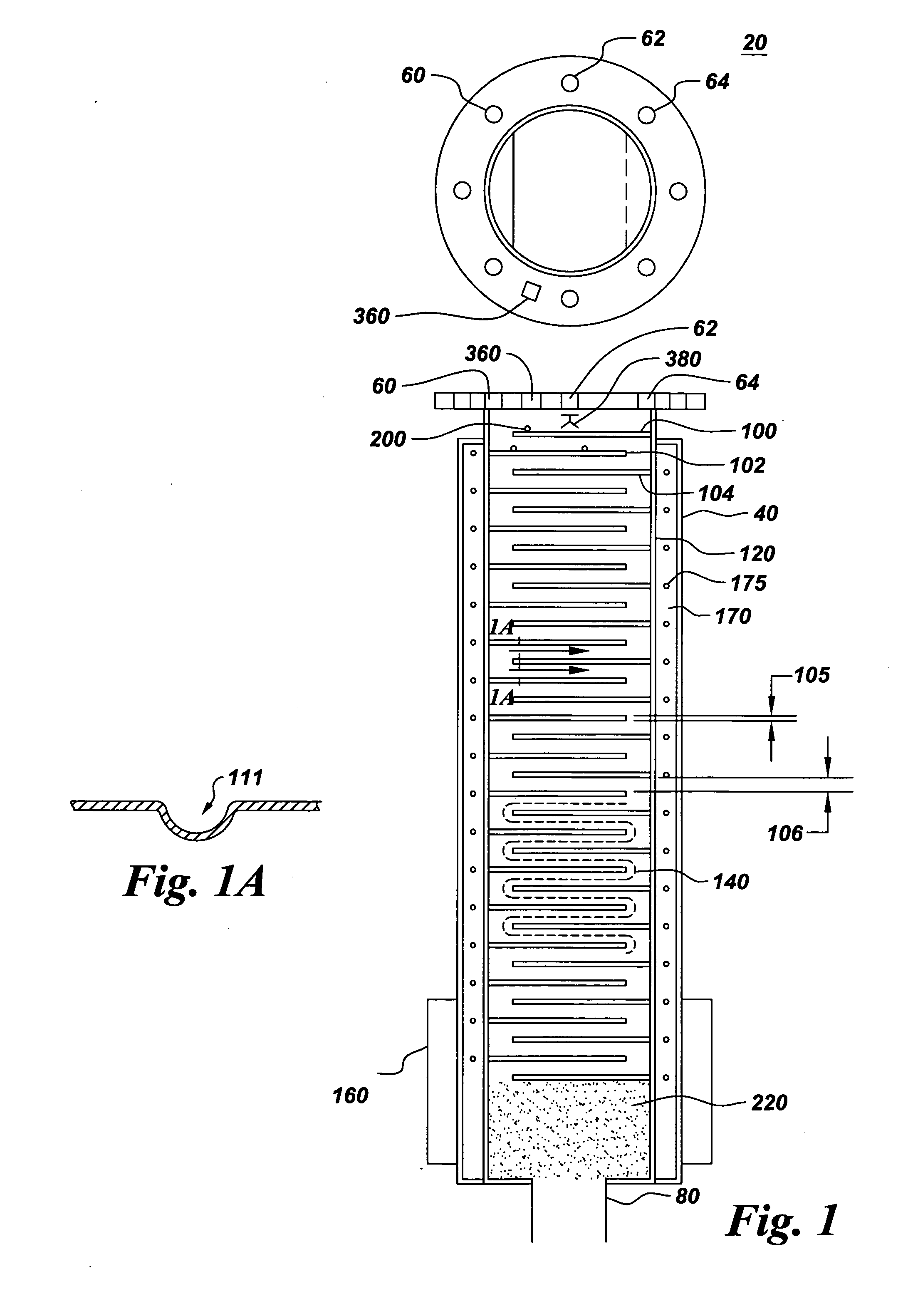

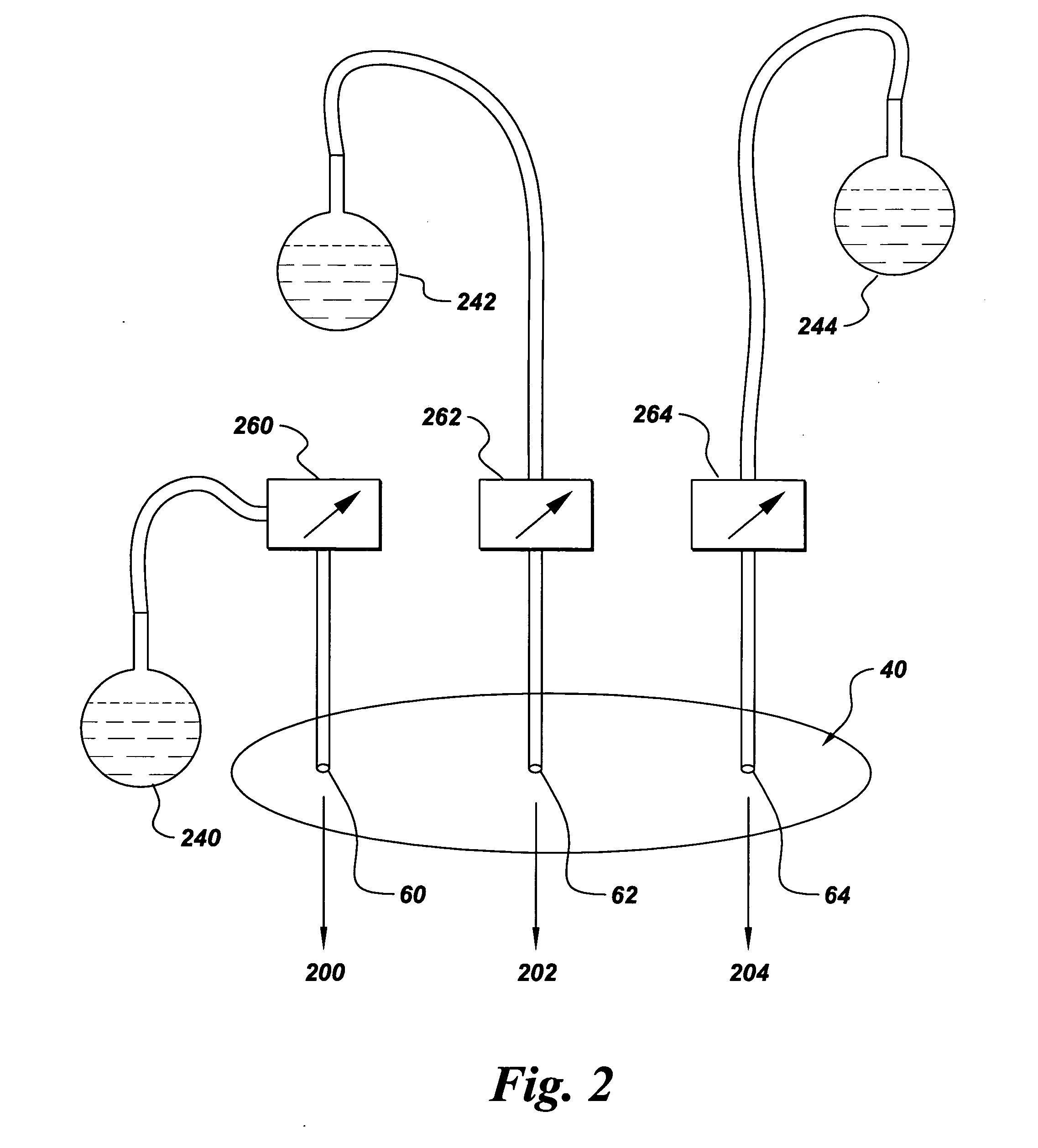

Apparatus for the evaporation of aqueous organic liquids and the production of powder pre-forms in flame hydrolysis processes

InactiveUS20050205215A1Drying using combination processesEvaporator liquid feederOrganic liquidsEvaporation

An organic liquid evaporation system is disclosed. The organic liquid evaporation system comprises a housing having at least one inlet and at least one outlet. At least a first evaporator plate radially extending from a sidewall of the housing, and at least a second evaporator plate radially extending from a sidewall of the housing define a serpentine flow path within the housing. A heating source is in thermal communication with the first evaporator plate and the second evaporator plate, wherein the heating source provides heat to the first and second evaporator plates to evaporate organic liquid introduced within the inlet to produce a vapor through the outlet. A method for preparing powder pre-forms and oxide soot using the organic liquid evaporation system is also disclosed.

Owner:GENERAL ELECTRIC CO

Gas micro burner

InactiveUS7488171B2Low mass flow rateSmall volumeFuel lightersBurner material specificationsProduct gasProcess engineering

A micro gas burner is provided that generates a stable, pre-mixed flame that produces little to no soot or unburned hydrocarbons. The gas burner includes a fuel inlet, nozzle, oxygenation chamber with at least one air inlet, a mixing chamber having a frustoconical inner wall, at least one permeable barrier and a flame holder. The gas burner thoroughly mixes fuel and entrained air to form a nearly stoichiometric mixture prior to combustion. The gas burner mixes the fuel and air so thoroughly that it requires a lower fuel flow rate than would otherwise be necessary to produce a stable, pre-mixed flame. The gas burner may include an optional flame tube with an optional exhaust port in which a flame is contained and sequestered from diffusing air.

Owner:R J REYNOLDS TOBACCO COMPANY

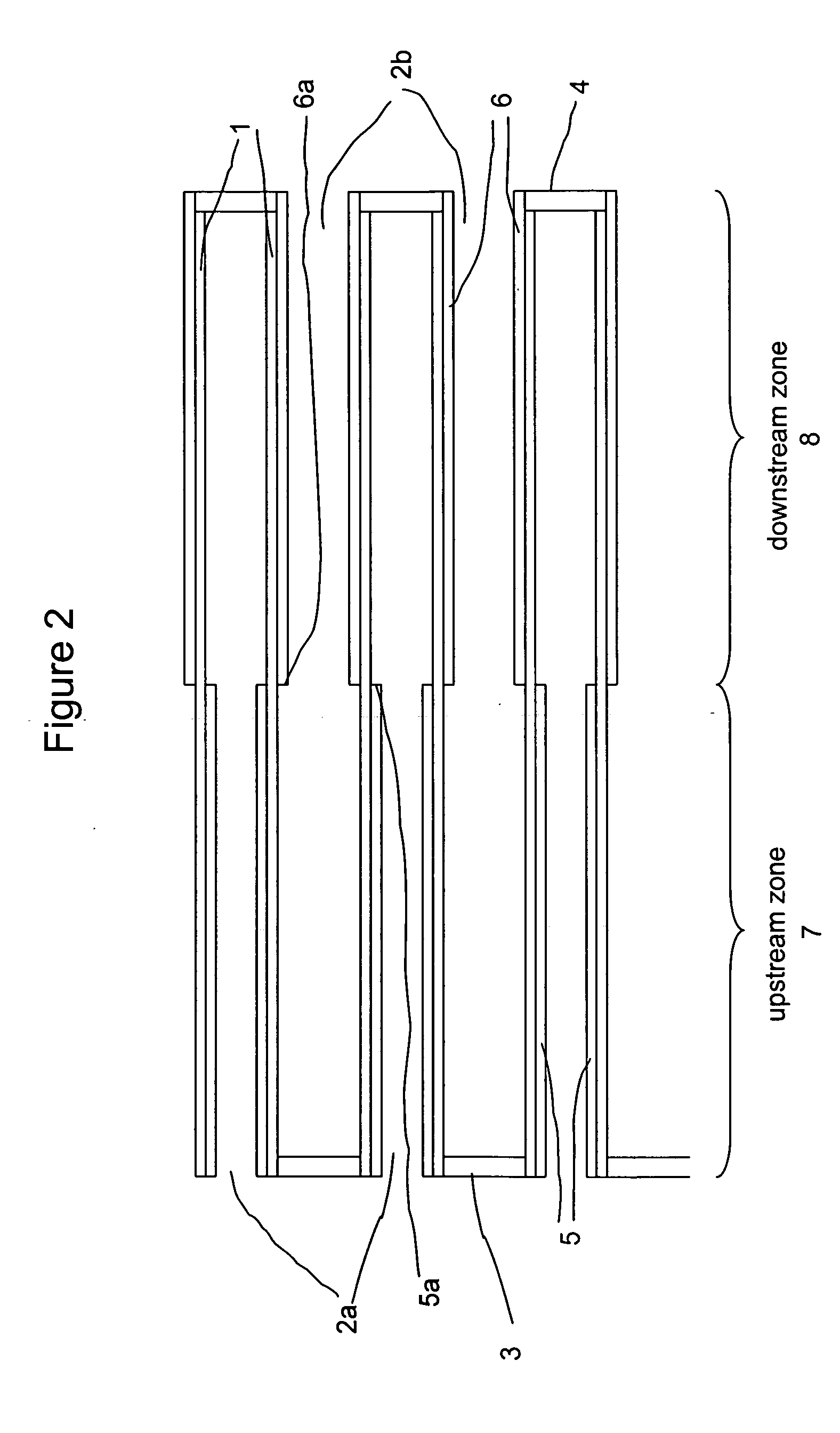

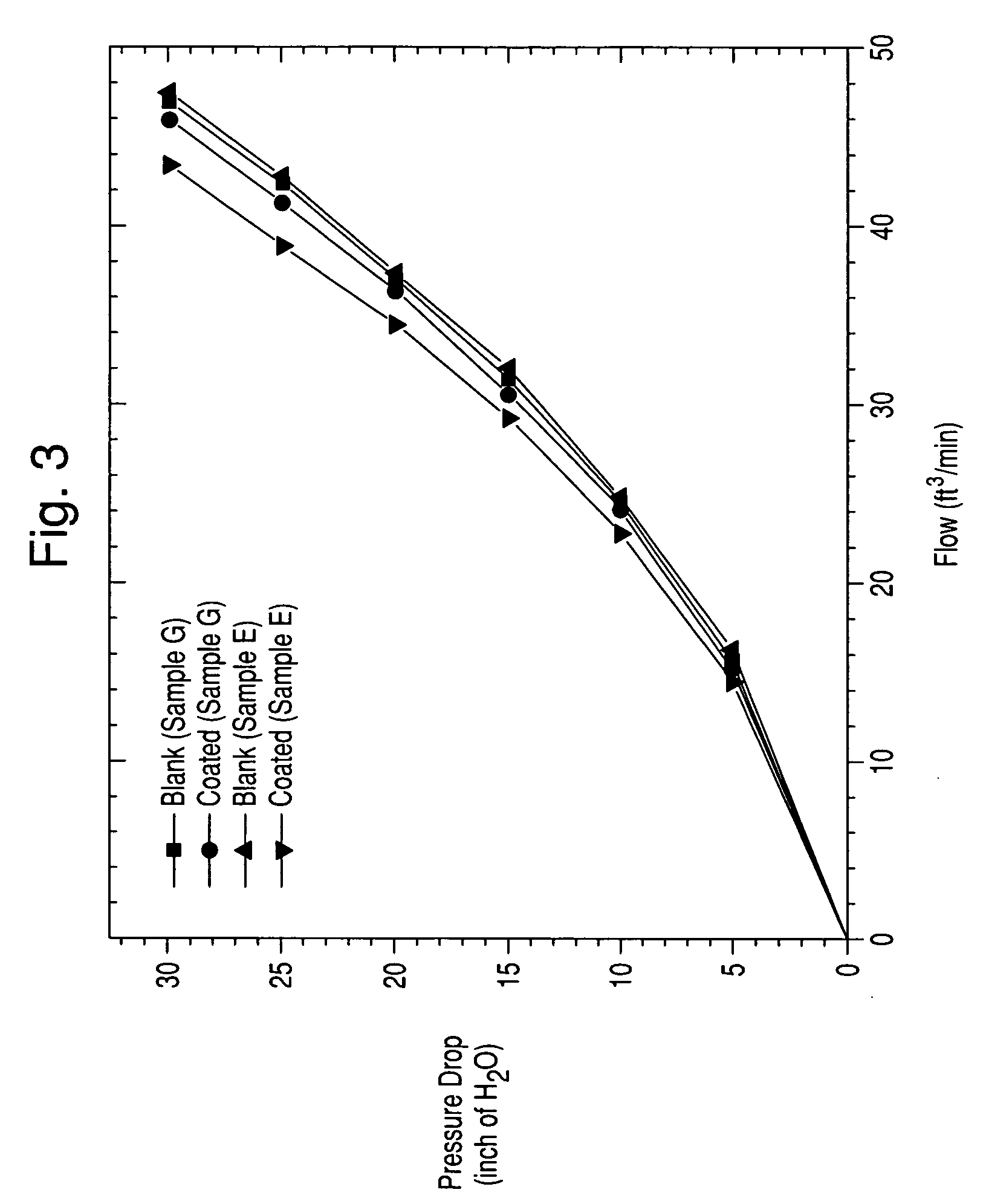

Low pressure drop coated diesel exhaust filter

InactiveUS20070140928A1Promote nitrogen oxide reductionReduce and avoid obstructionCombination devicesSilencing apparatusHigh concentrationNitrogen oxides

A coated diesel exhaust filter is provided that applies a relatively low pressure drop across the exhaust system despite the buildup of soot deposits. The filter includes a porous ceramic structure having an inlet end, an outlet end, and a plurality of gas inlet and gas outlet channels disposed between the inlet and outlet ends, the channels being separated by porous ceramic walls. A catalyst is distributed at least partly within the porous ceramic walls of the structure, and is distributed at a higher concentration within portions of the ceramic walls adjacent to the outlet surfaces than within portions of the ceramic walls adjacent the inlet surfaces. Both the inlet and outlet surfaces are substantially free of the catalyst in order to maintain a gas-conducting porosity in these surfaces. The resulting filter effectively treats nitrogen oxides, carbon monoxide and unburned hydrocarbons present in the exhaust gas stream while advantageously imposing a relatively low pressure drop across the exhaust system even when soot deposits accumulate on the inlet surfaces of the ceramic walls.

Owner:CORNING INC

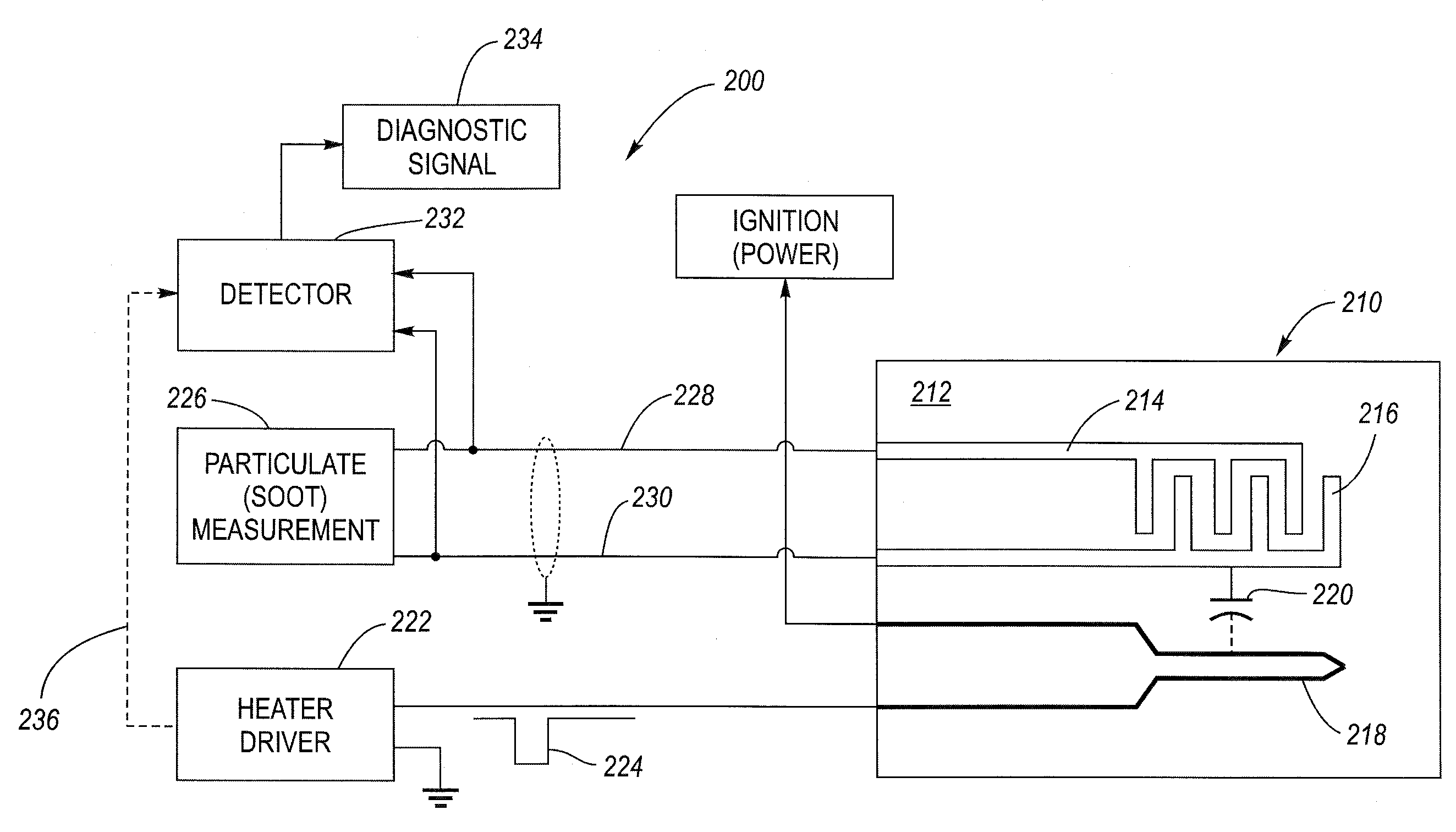

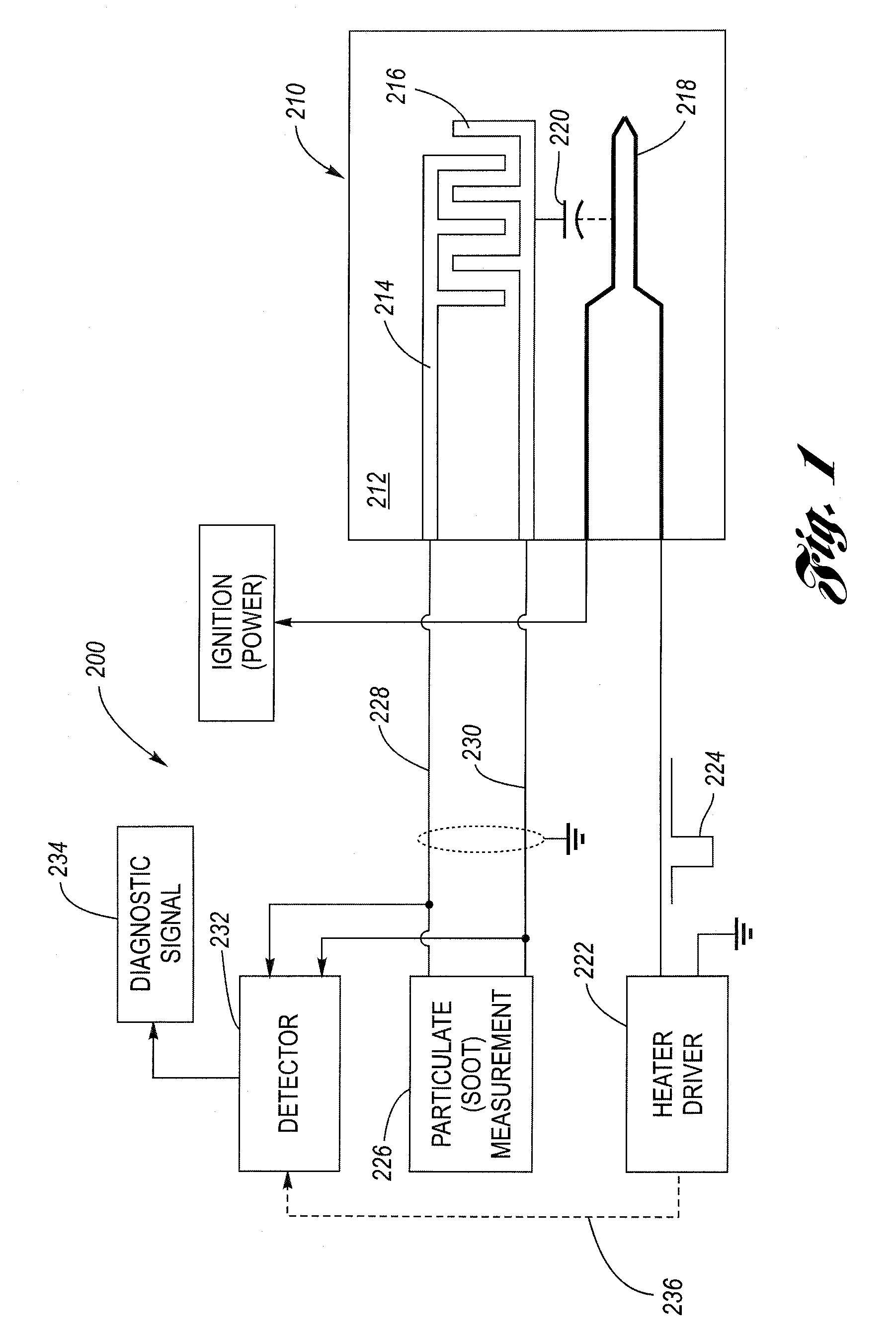

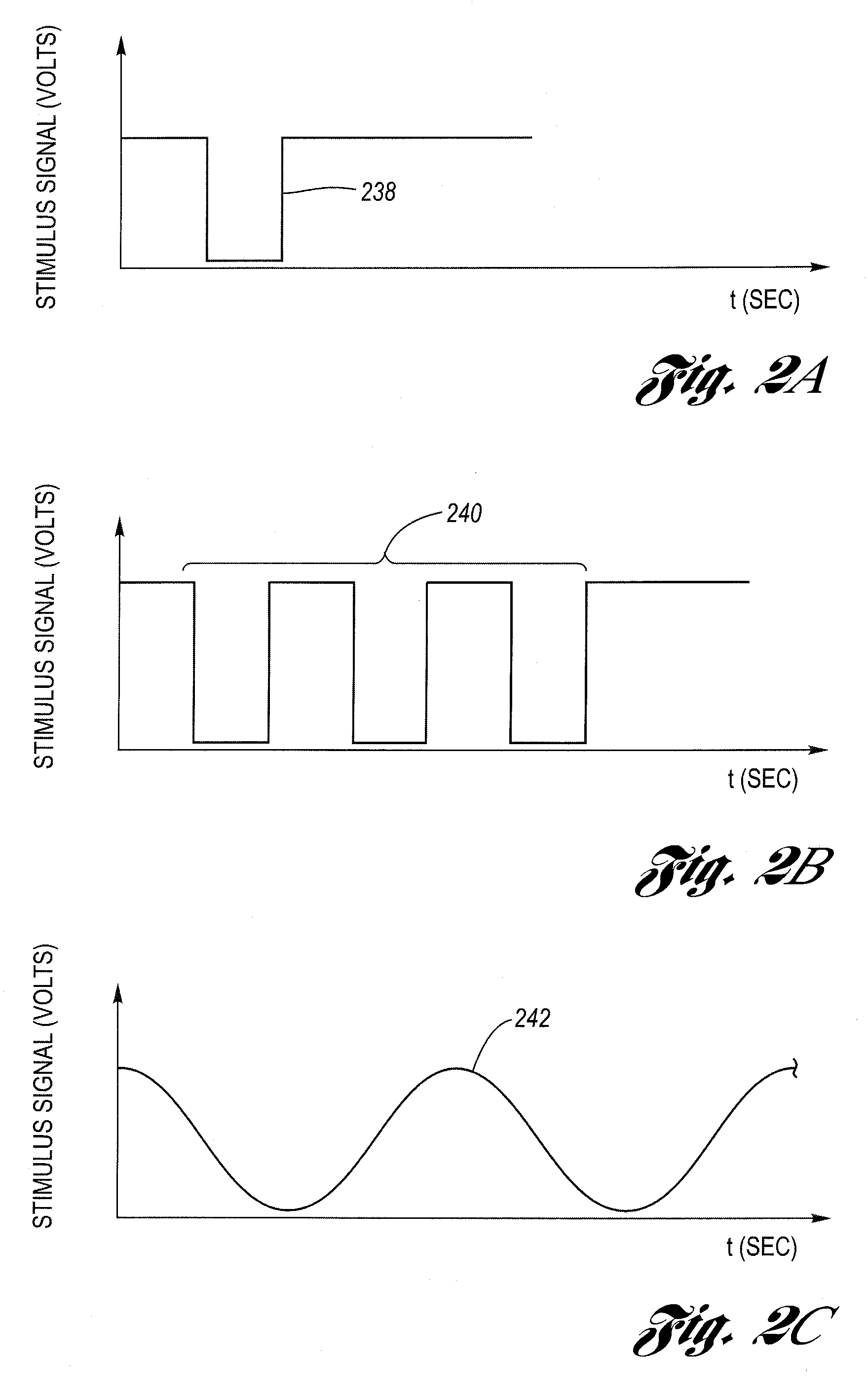

System and method for particulate sensor diagnostic

ActiveUS20090090622A1Fault locationMaterial electrochemical variablesParasitic capacitanceEngineering

A particulate (soot) sensor system has a diagnostic feature for verifying the integrity of the wiring leads. The sensor system includes a sensor and processing circuitry. The sensor has a substrate, first and second sensing electrodes on the substrate and a heater electrode. The heater electrode is electrically isolated from the first and second sensing electrodes, although there is a parasitic capacitance between them. The processing circuitry includes a heater driver, a measurement circuit connected to the sensing electrodes by wire leads, and a detector. The heater driver, in addition to energizing the heater, produces a stimulus signal that is applied to the heating electrode, which is then coupled via the parasitic capacitance to the sensing electrodes. The detector is coupled to the wiring leads and is configured to detect the stimulus signal when there is electrical conductivity over the leads to the sensing electrodes.

Owner:DELPHI TECH IP LTD

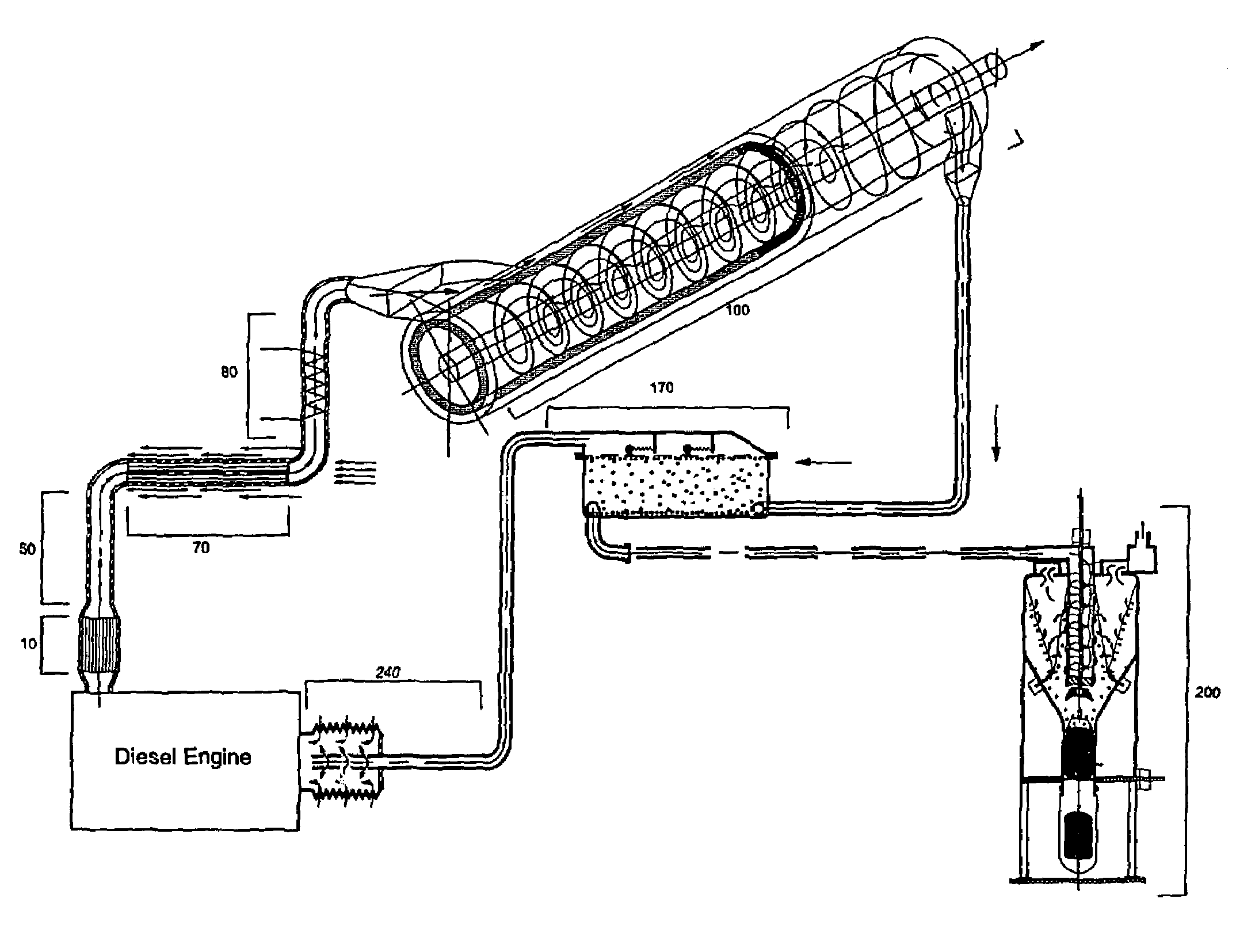

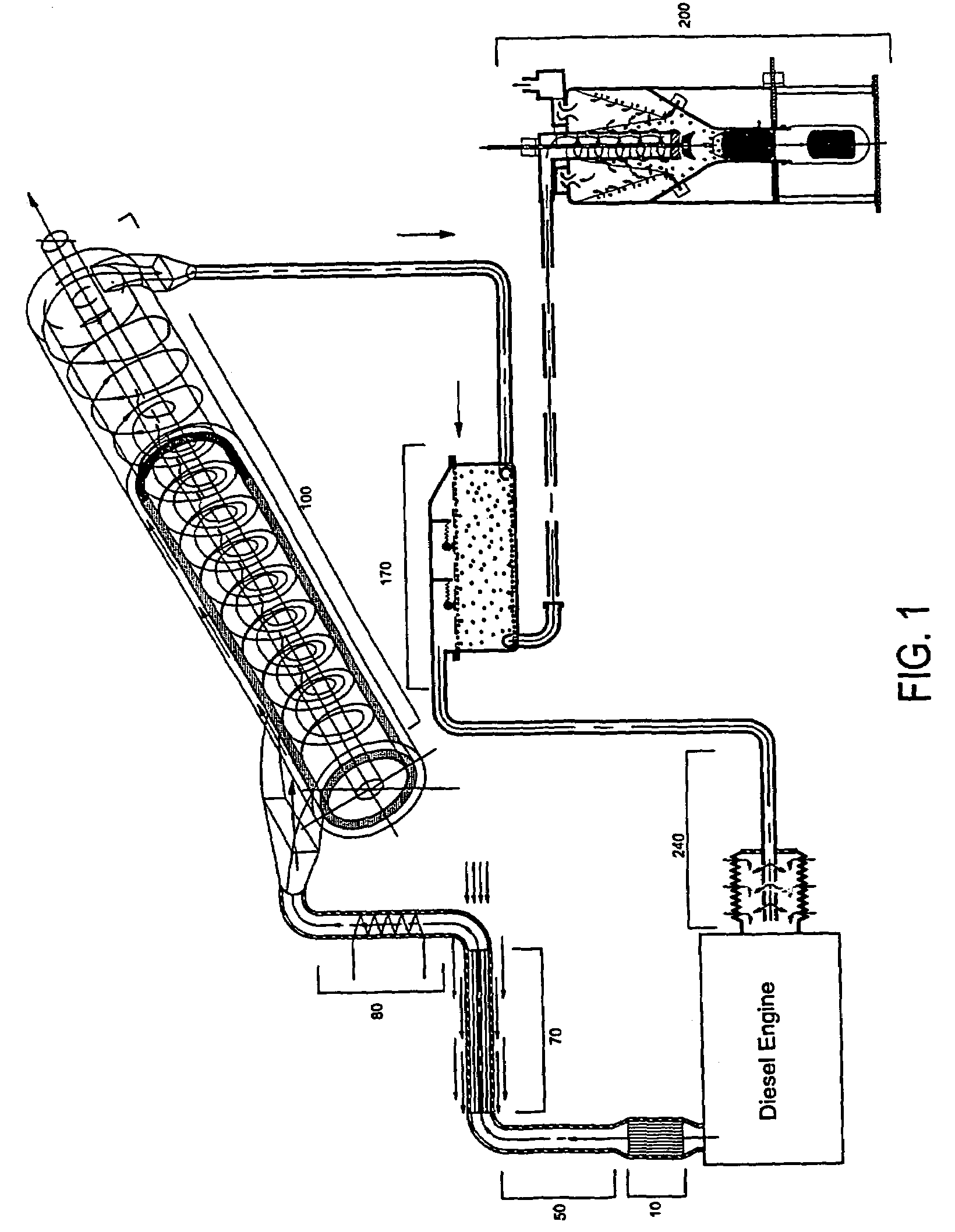

Exhaust after-treatment system for the reduction of pollutants from diesel engine exhaust and related method

InactiveUS7266943B2Easy to separateLower overall pressure dropCombination devicesInternal combustion piston enginesParticulatesAfter treatment

Exhaust after-treatment system for the reduction of particulate, NOx, HC, CO, VOCs, nano-particle count and sulfur dioxide from diesel exhaust. System employs diesel oxidation catalyst, exhaust cooling system, particulate converter, soot collection chamber, soot processing drum, EGR and water scrubber.

Owner:KAMMEL REFAAT

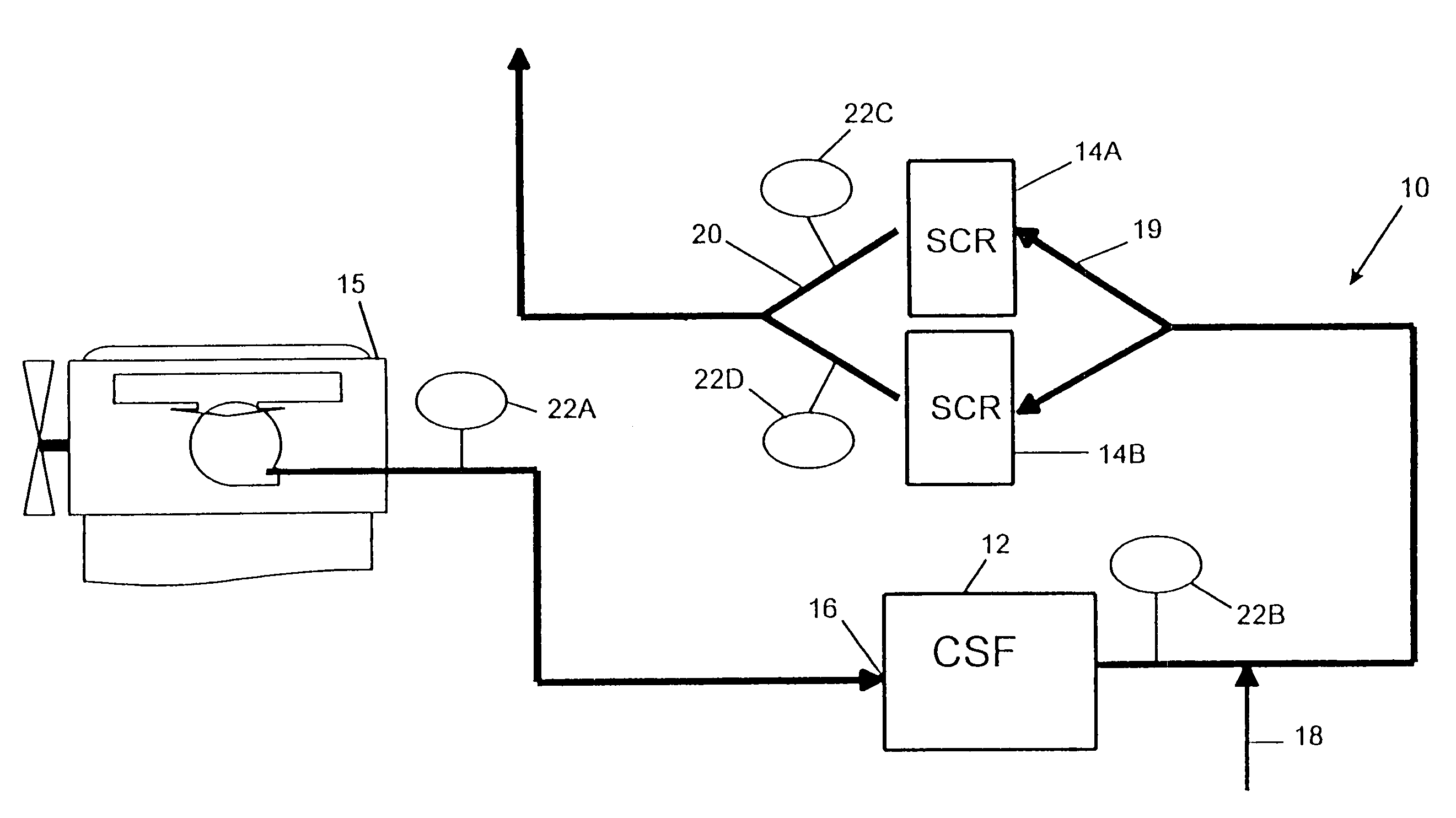

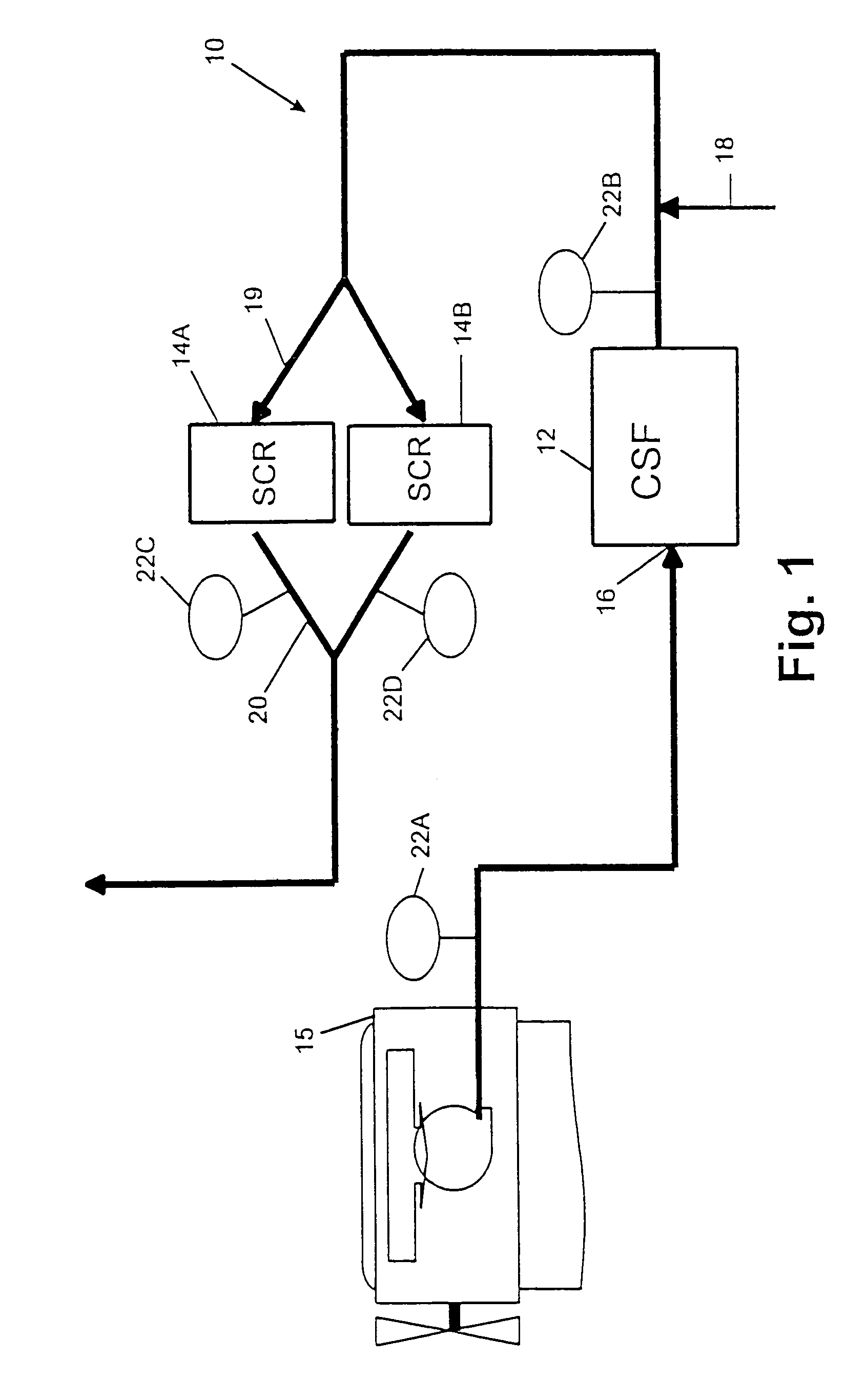

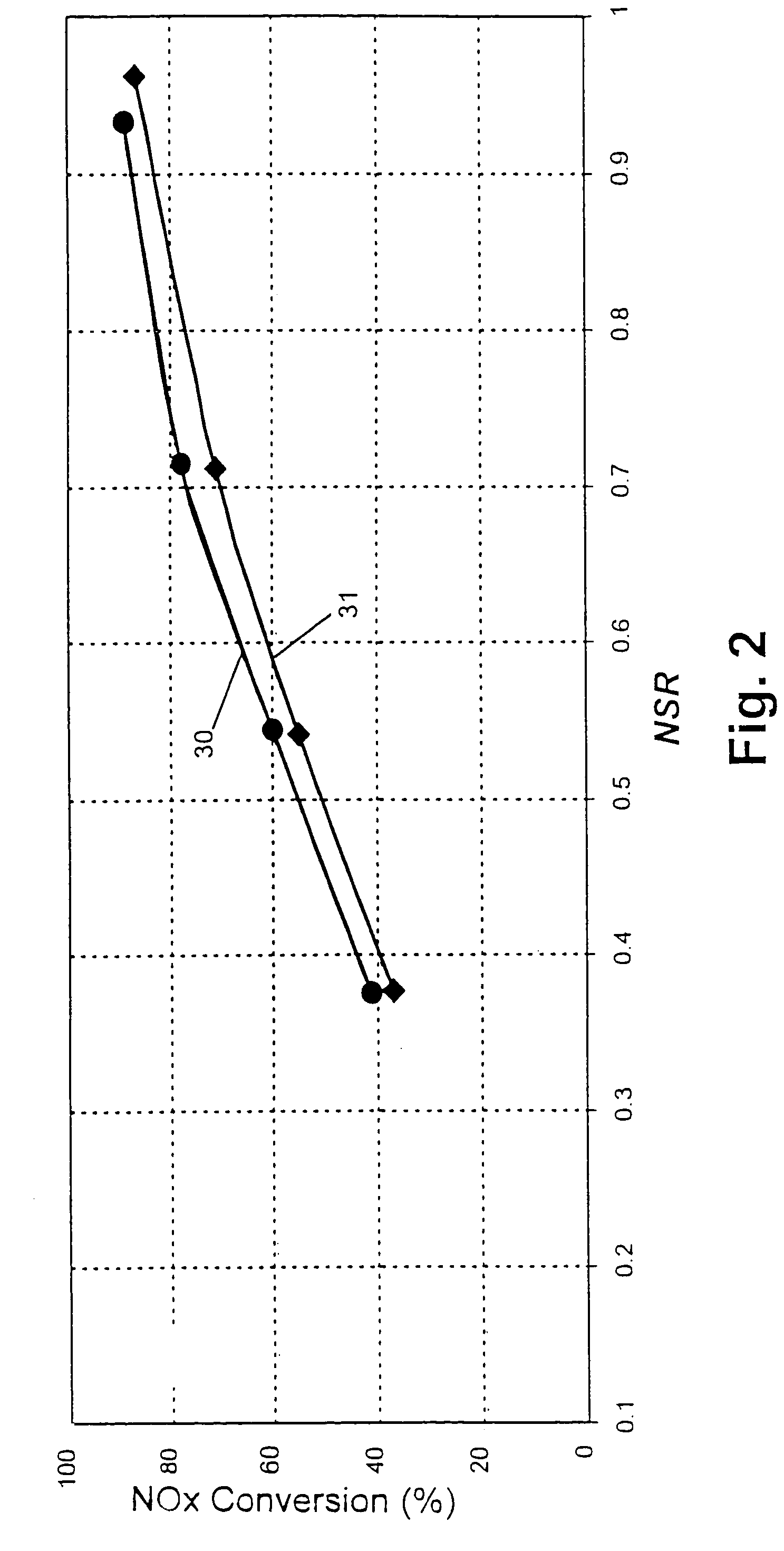

Exhaust system for enhanced reduction of nitrogen oxides and particulates from diesel engines

InactiveUS7143578B2Promote conversionImprove overall utilizationNitrous oxide captureGas treatmentParticulatesNitrogen oxides

A diesel engine aftertreatment exhaust system uses catalyzed soot filters for particulate matter reduction and urea SCR catalysts for NOx reduction on diesel engines in a combined system to lower particulate matter and NOx at the same time. With this integral emission control system, diesel engines are able to meet ultra low emission standards.

Owner:ENGELHARD CORP

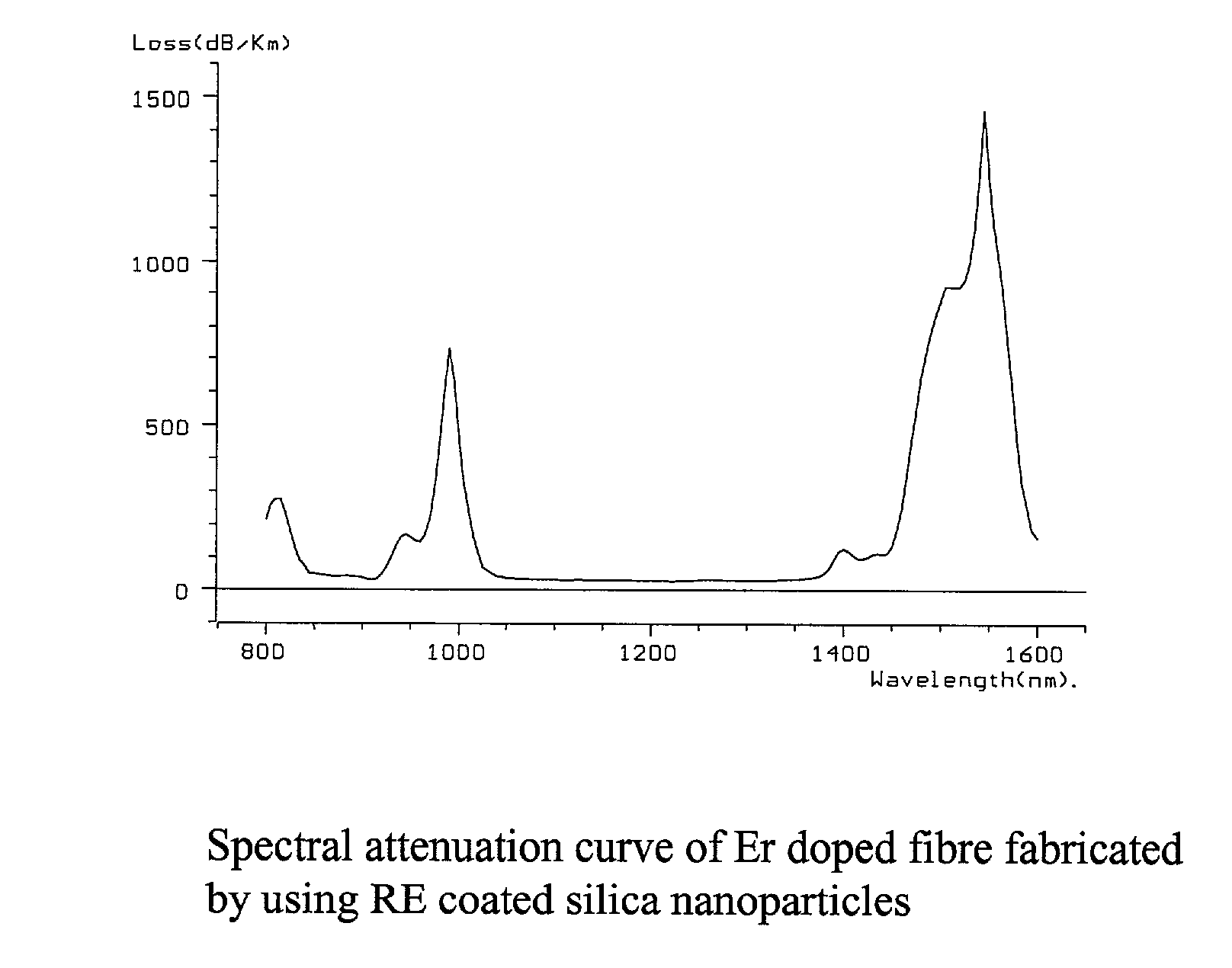

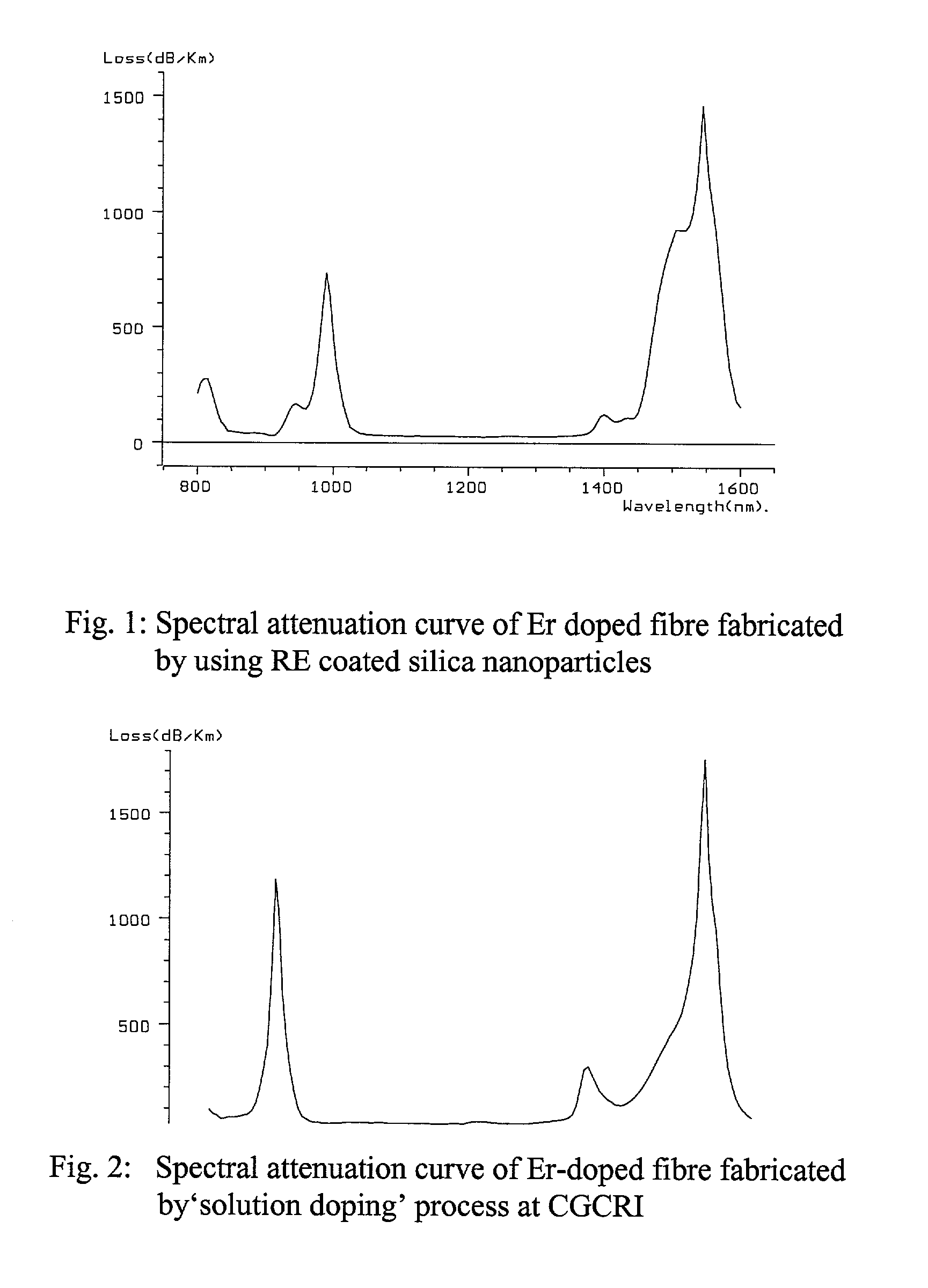

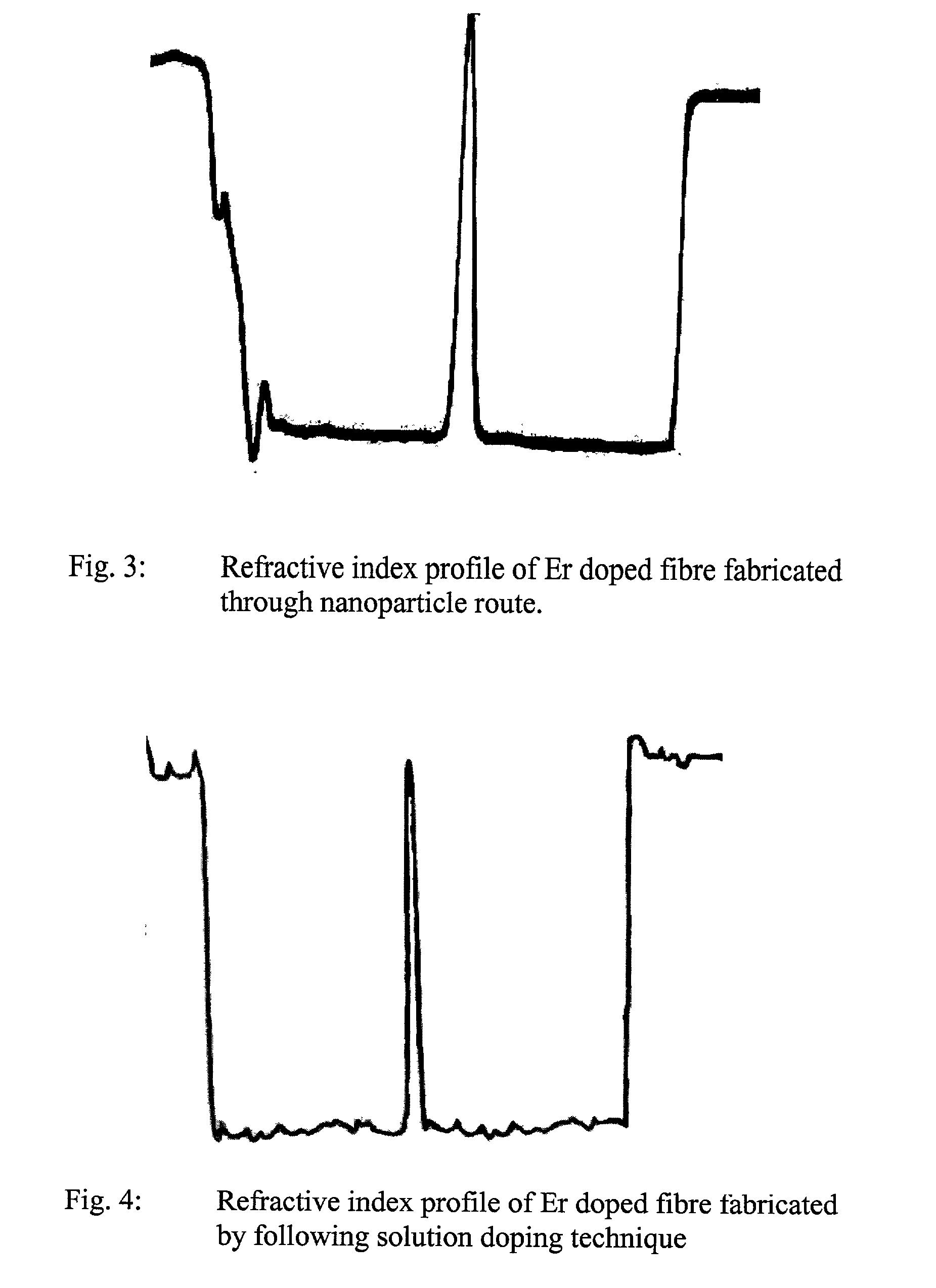

Process of making rare earth doped optical fibre

InactiveUS20040187524A1Reduce in quantityNumber of step involvedMaterial nanotechnologyCladded optical fibreDip-coatingSoot

The present invention discloses a process for making rare earth (RE) doped optical fibre by using RE oxide coated silica nanoparticles as the precursor materia, more particularly the method of the present invention involves preparation of stable dispersions (sol) of RE oxide coated silica nanoparticles at ambient temperature and applying a thin coating on the inner surface of silica glass tube following dip coating technique or any other conventional methods, of the said silica sol containing suitable dopants selected from Ge, Al, P, etc., the coated tubes were further processed into optical preforms by following MCVD technique and fiberised in desired configuration, the novelty lies in eliminating the step of the formation of porous soot layer at high temperature by CVD process inside a fused silica glass tube for formation of the core and also in the elemination of the incorporation of the rare earth ions into the porous soot layer following the solution doping technique or other conventional methods, the direct addition of RE oxides in the sol eliminates the formation of microcrystalites and clusters of rare earth ions and prevents change in composition including variation of RE concentration in the core which results in increase in the reproducibility and reliability of the process to a great extent, further the addition of Ge(OET)4 at ambient temperature in the silica sol reduces the quantity of GeCl4 which is required at high temperature to achieve the desired Numerical Aperture.

Owner:COUNCIL OF SCI & IND RES +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com