Patents

Literature

118 results about "Unburned hydrocarbon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

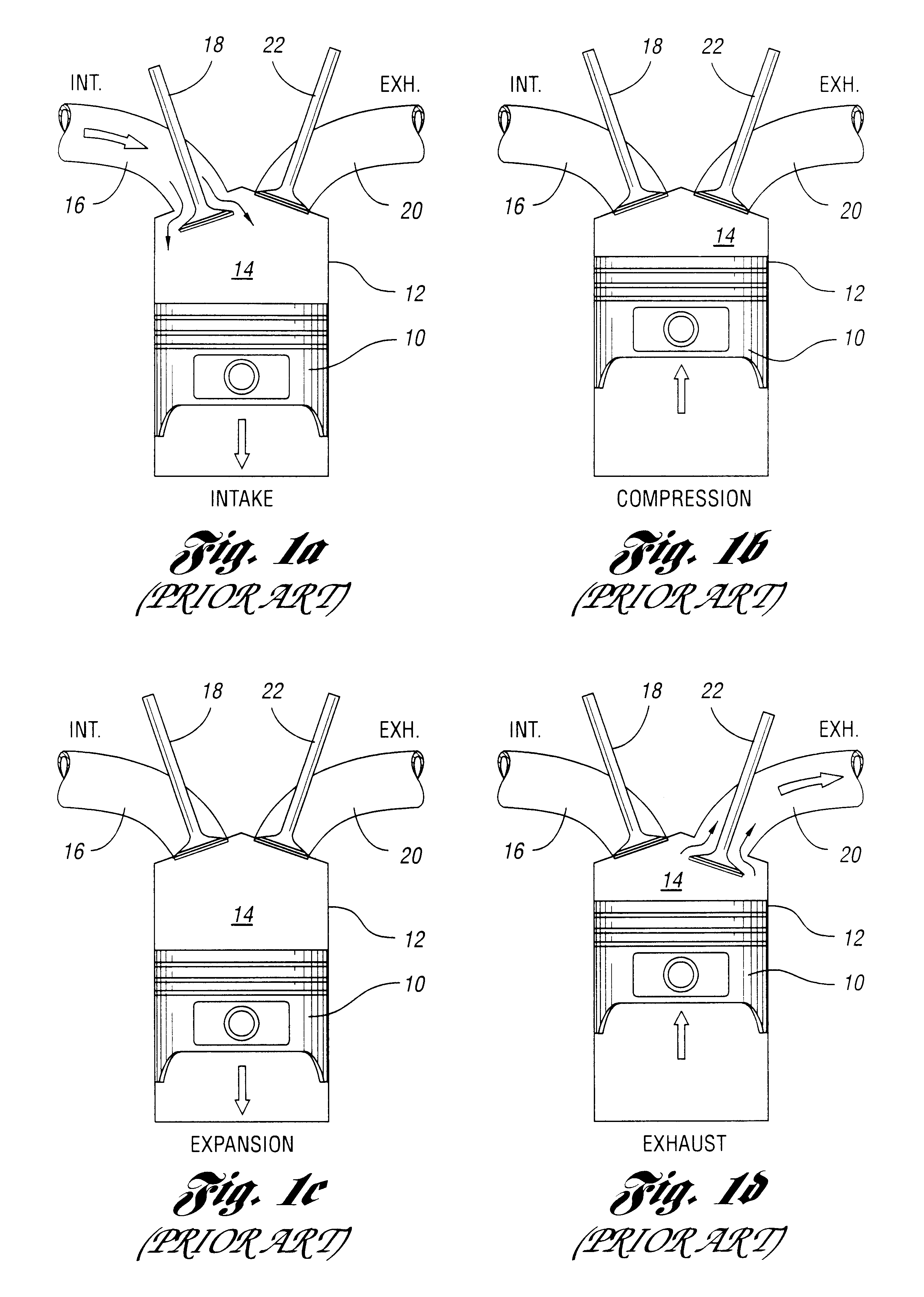

Unburned hydrocarbons (UHCs) are the hydrocarbons emitted after petroleum is burned in an engine. When unburned fuel is emitted from a combustor, the emission is caused by fuel "avoiding" the flame zones. For example, in piston engines, some of the fuel-air mixture "hides" from the flame in the crevices provided by the piston ring grooves. Further, some regions of the combustion chamber may have a very weak flame, that is, they have either very fuel-lean or very fuel-rich conditions and consequently they have a low combustion temperature. These regions will cause intermediate species such as formaldehyde and alkenes to be emitted. Sometimes the term "products of incomplete combustion," or PICs, is used to describe such species.

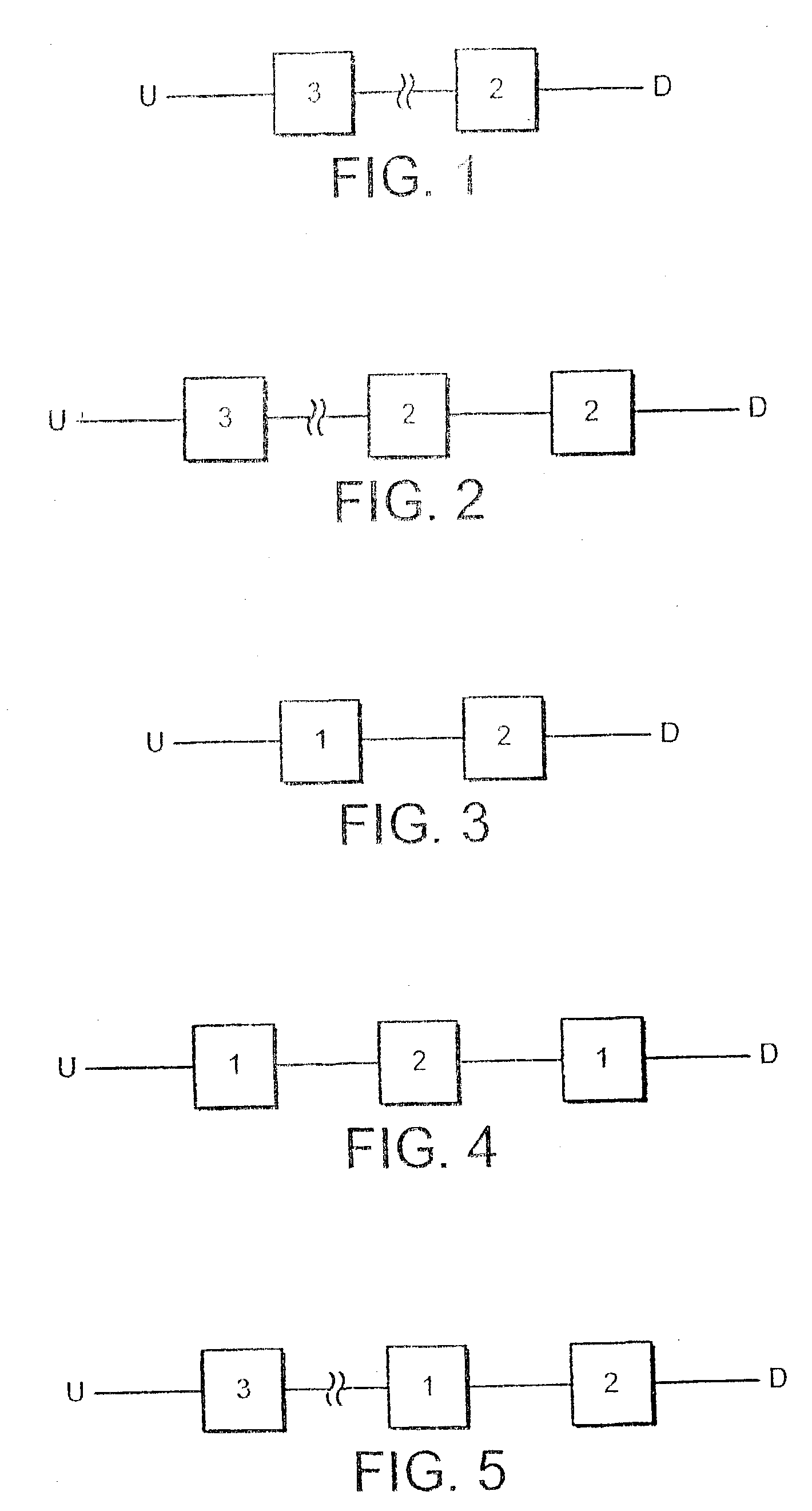

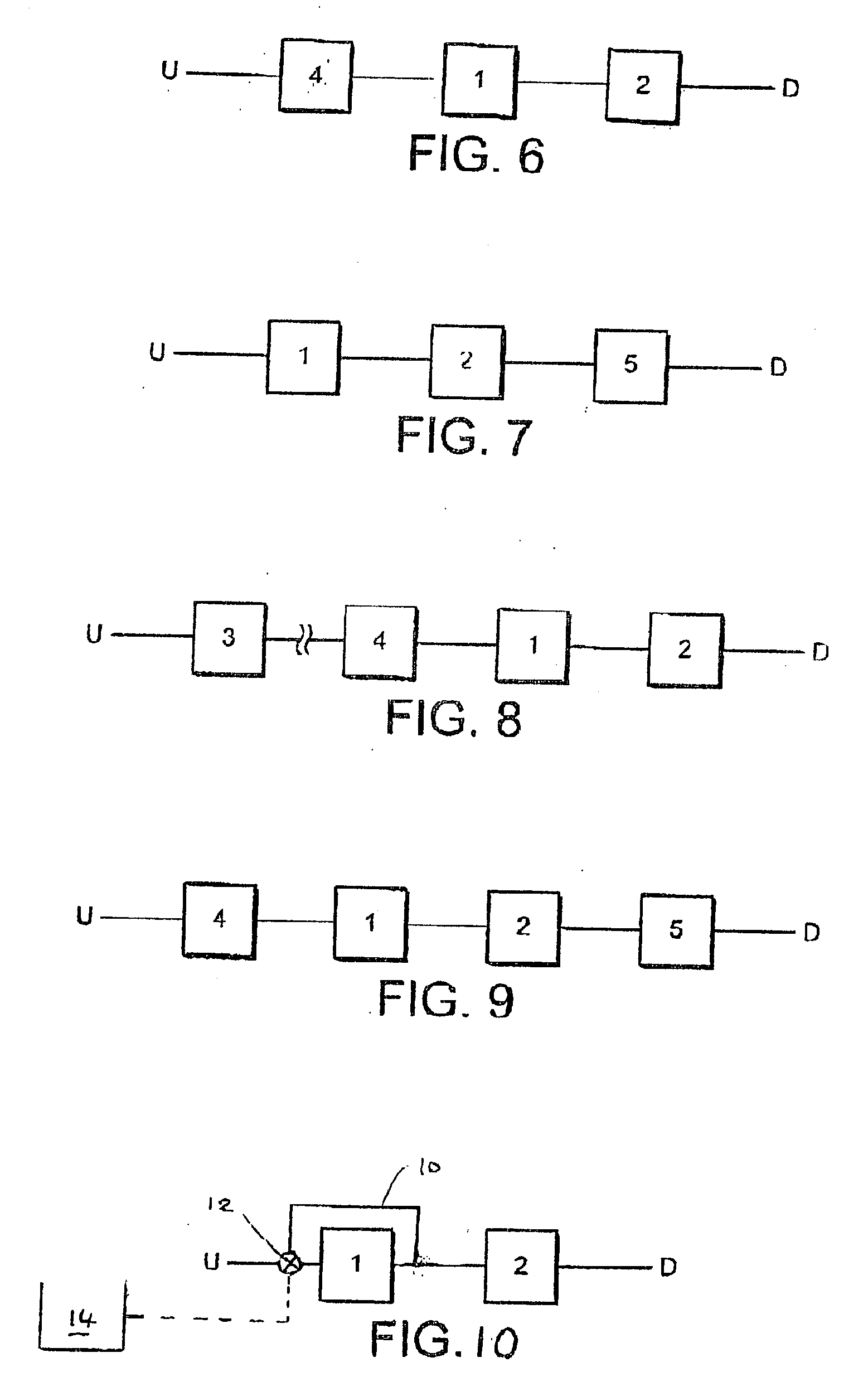

Pt-Pd diesel oxidation catalyst with CO/HC light-off and HC storage function

ActiveUS20080045405A1Nitrous oxide captureMolecular sieve catalystsExhaust gas emissionsNitrogen oxide

The present invention is directed to a diesel oxidation catalyst for the treatment of exhaust gas emissions, such as the oxidation of unburned hydrocarbons (HC), and carbon monoxide (CO) and the reduction of nitrogen oxides (NOx). More particularly, the present invention is directed to a novel washcoat composition comprising two distinct washcoat layers containing two distinctly different ratios of Pt:Pd.

Owner:BASF CATALYSTS LLC

Pt-Pd diesel oxidation catalyst with CO/HC light-off and HC storage function

ActiveUS7576031B2Nitrous oxide captureInternal combustion piston enginesExhaust gas emissionsNitrogen oxide

The present invention is directed to a diesel oxidation catalyst for the treatment of exhaust gas emissions, such as the oxidation of unburned hydrocarbons (HC), and carbon monoxide (CO) and the reduction of nitrogen oxides (NOx). More particularly, the present invention is directed to a novel washcoat composition comprising two distinct washcoat layers containing two distinctly different ratios of Pt:Pd.

Owner:BASF CATALYSTS LLC

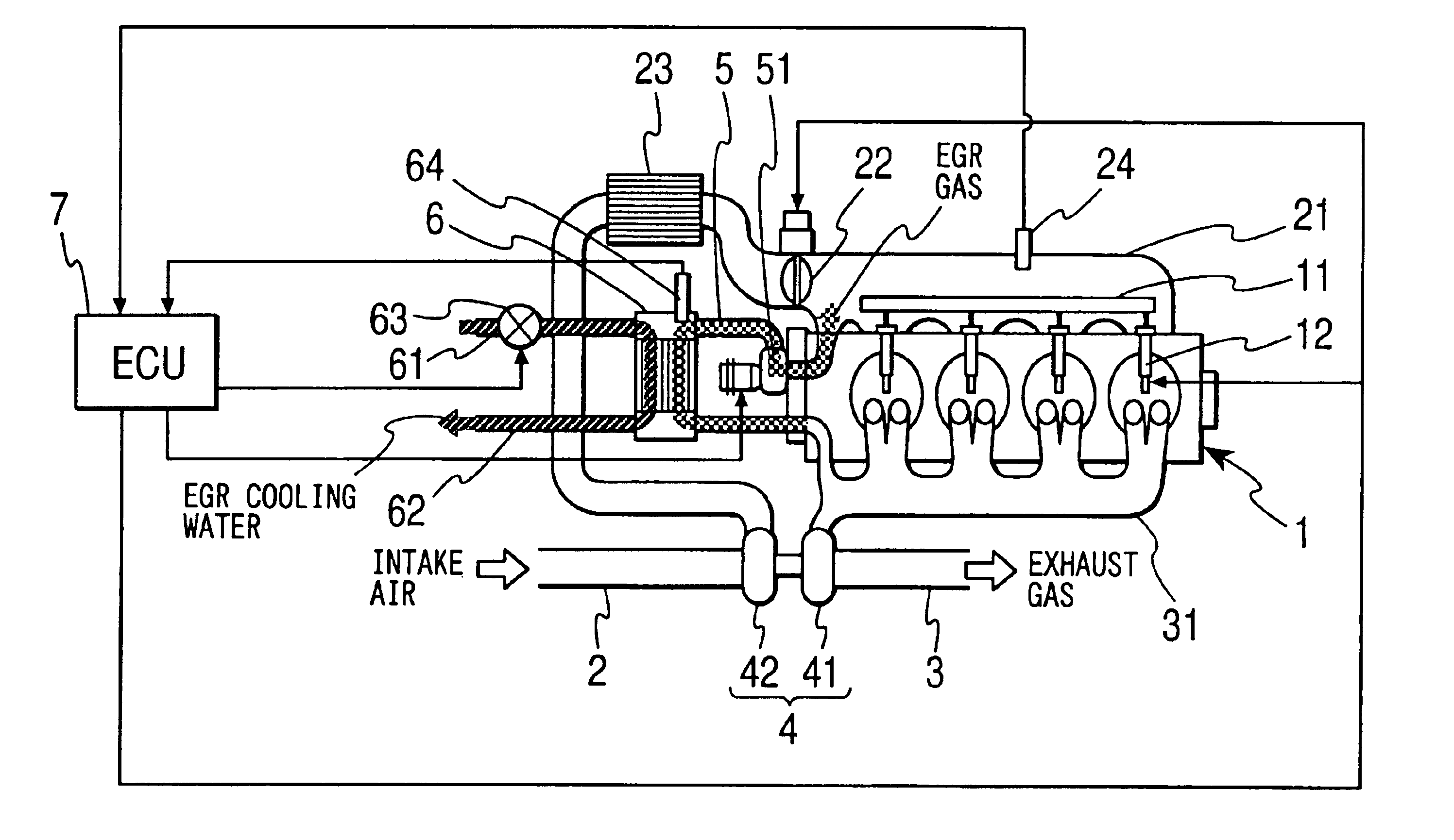

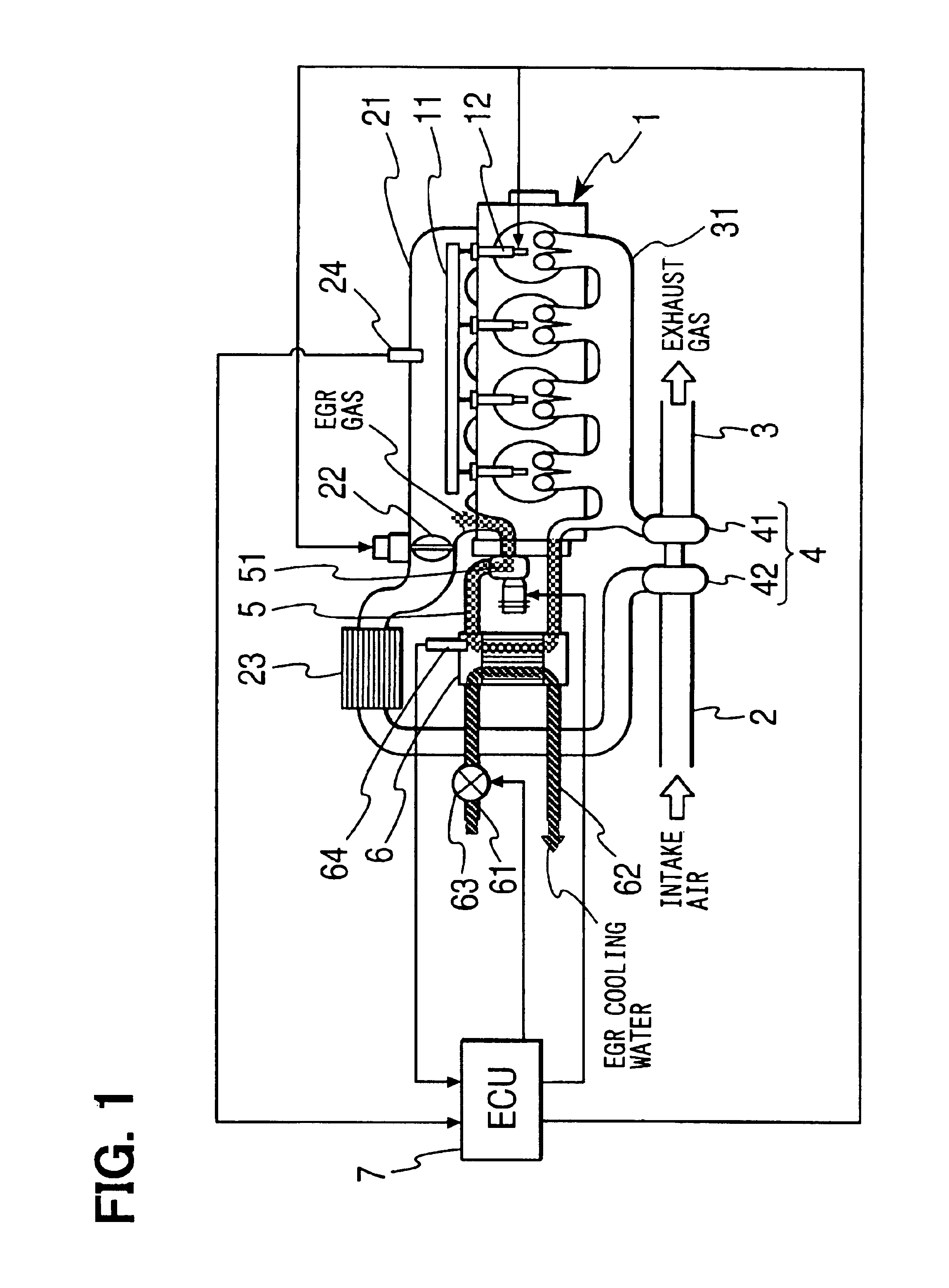

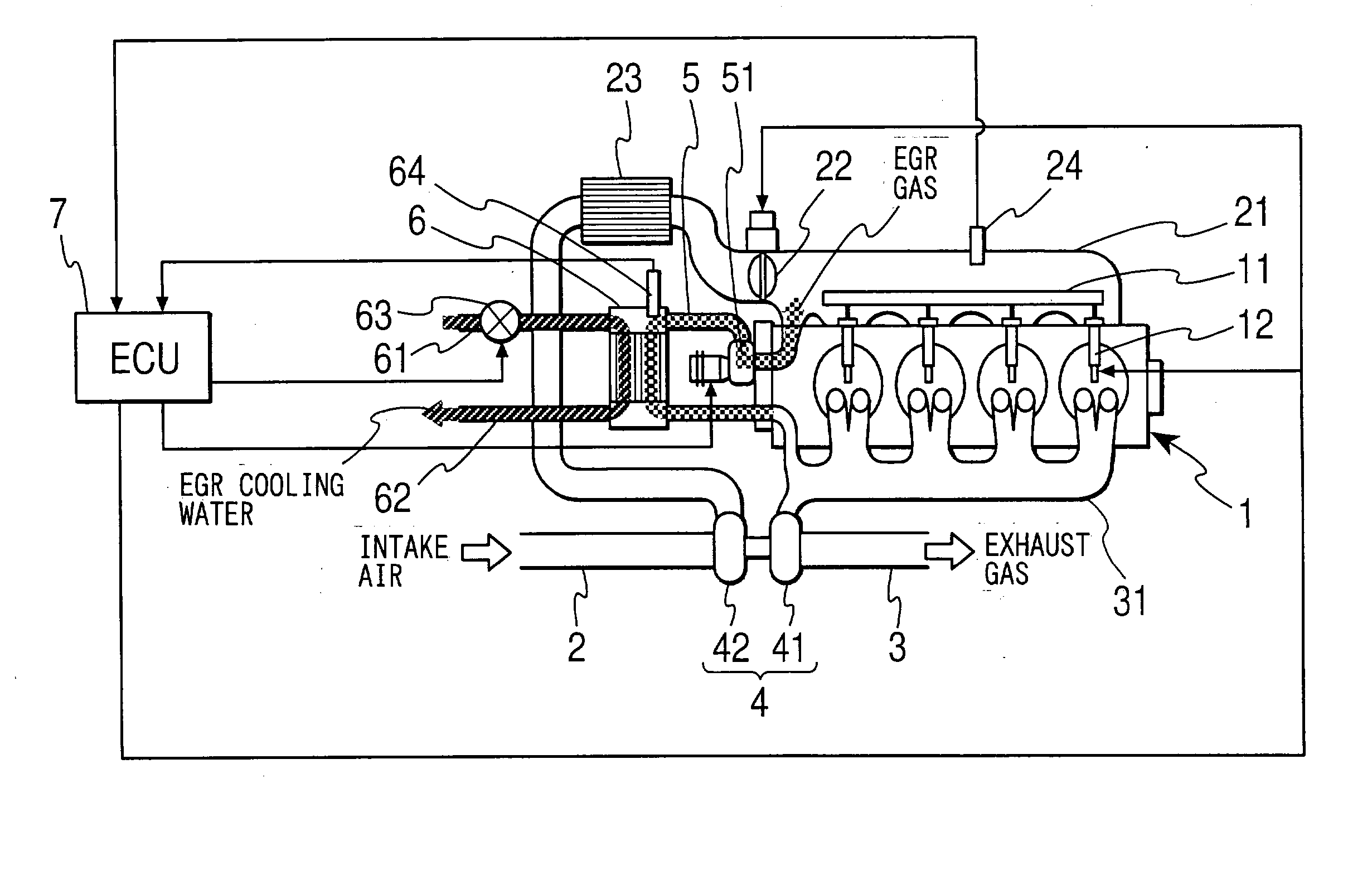

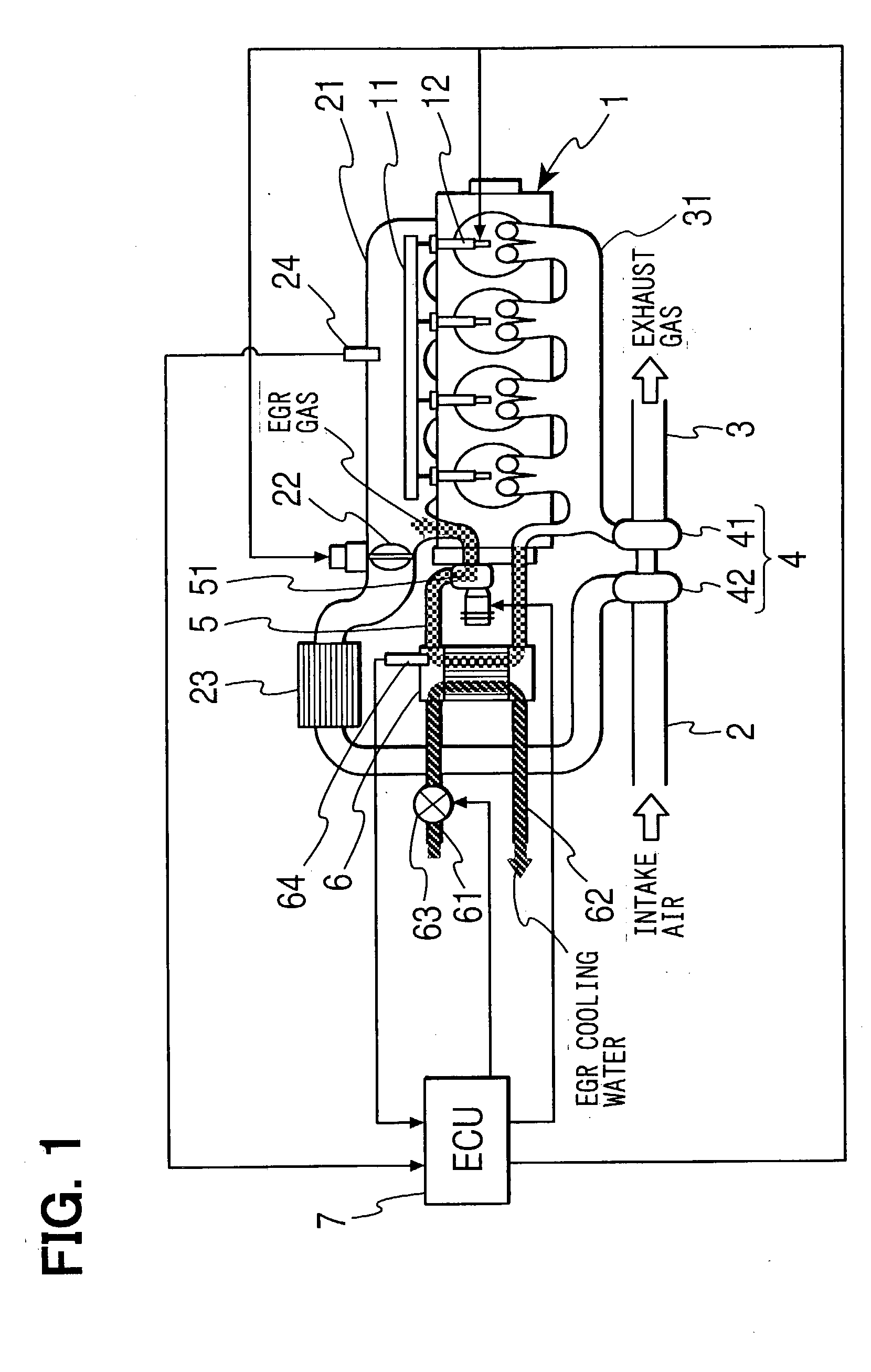

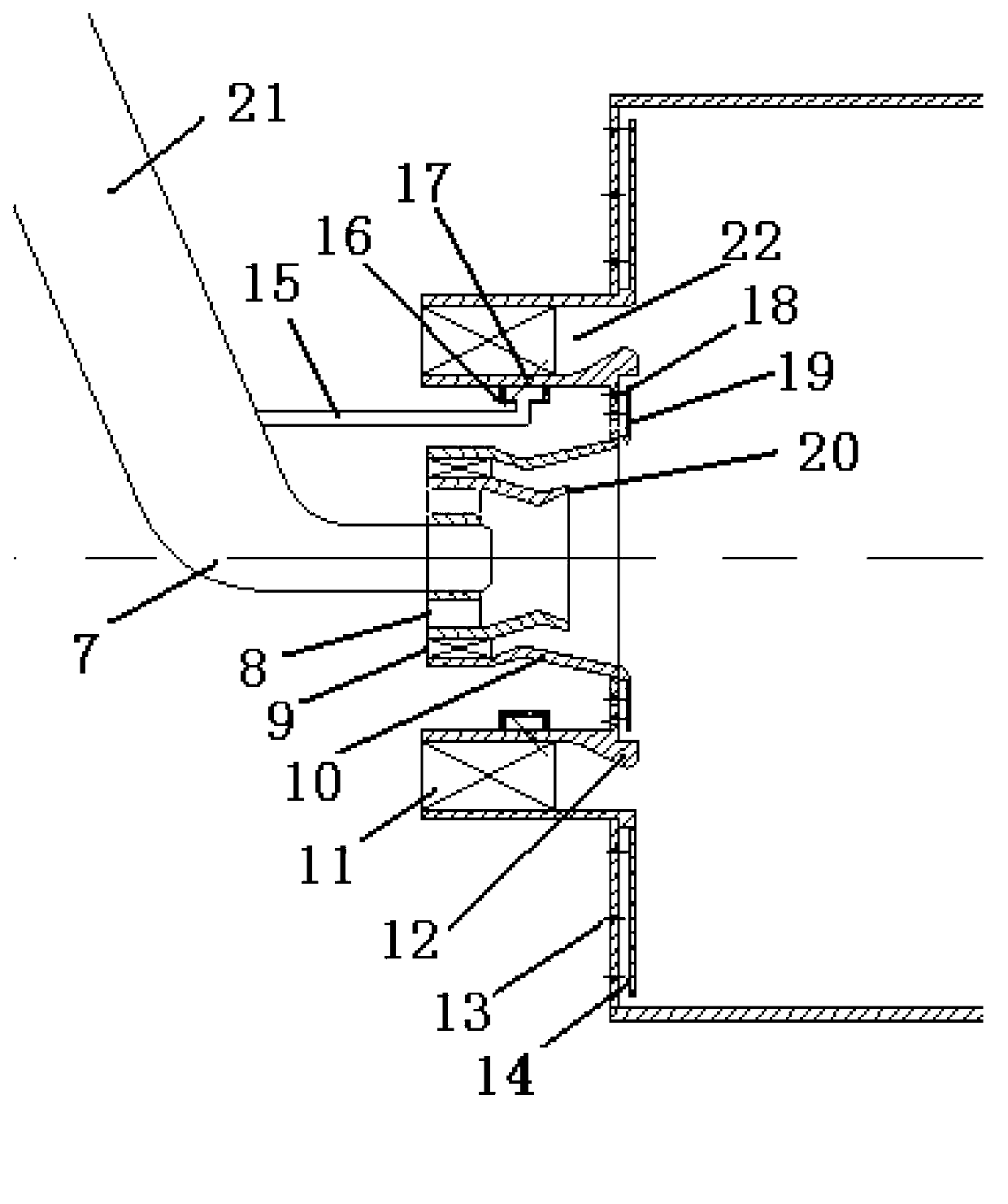

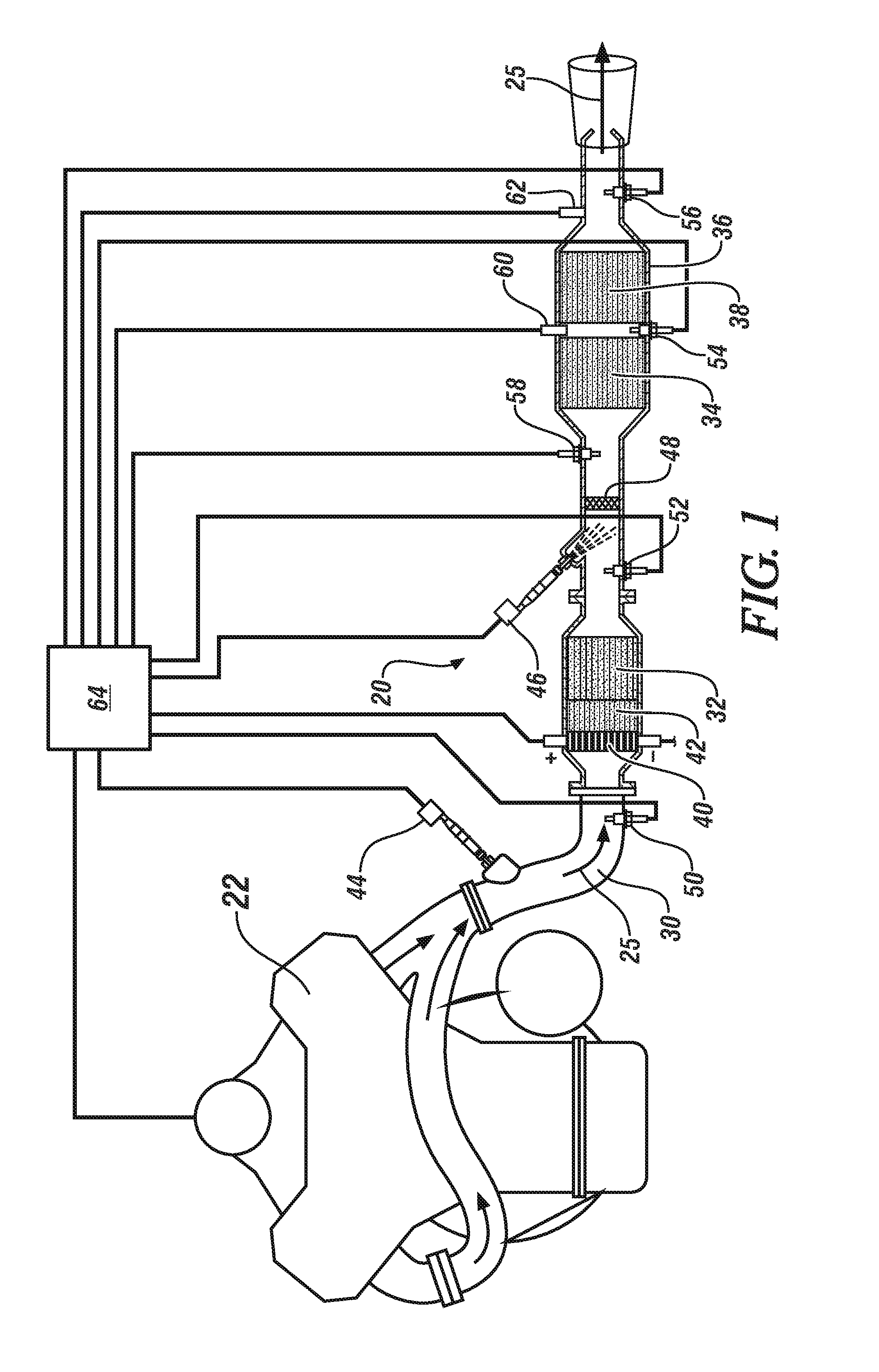

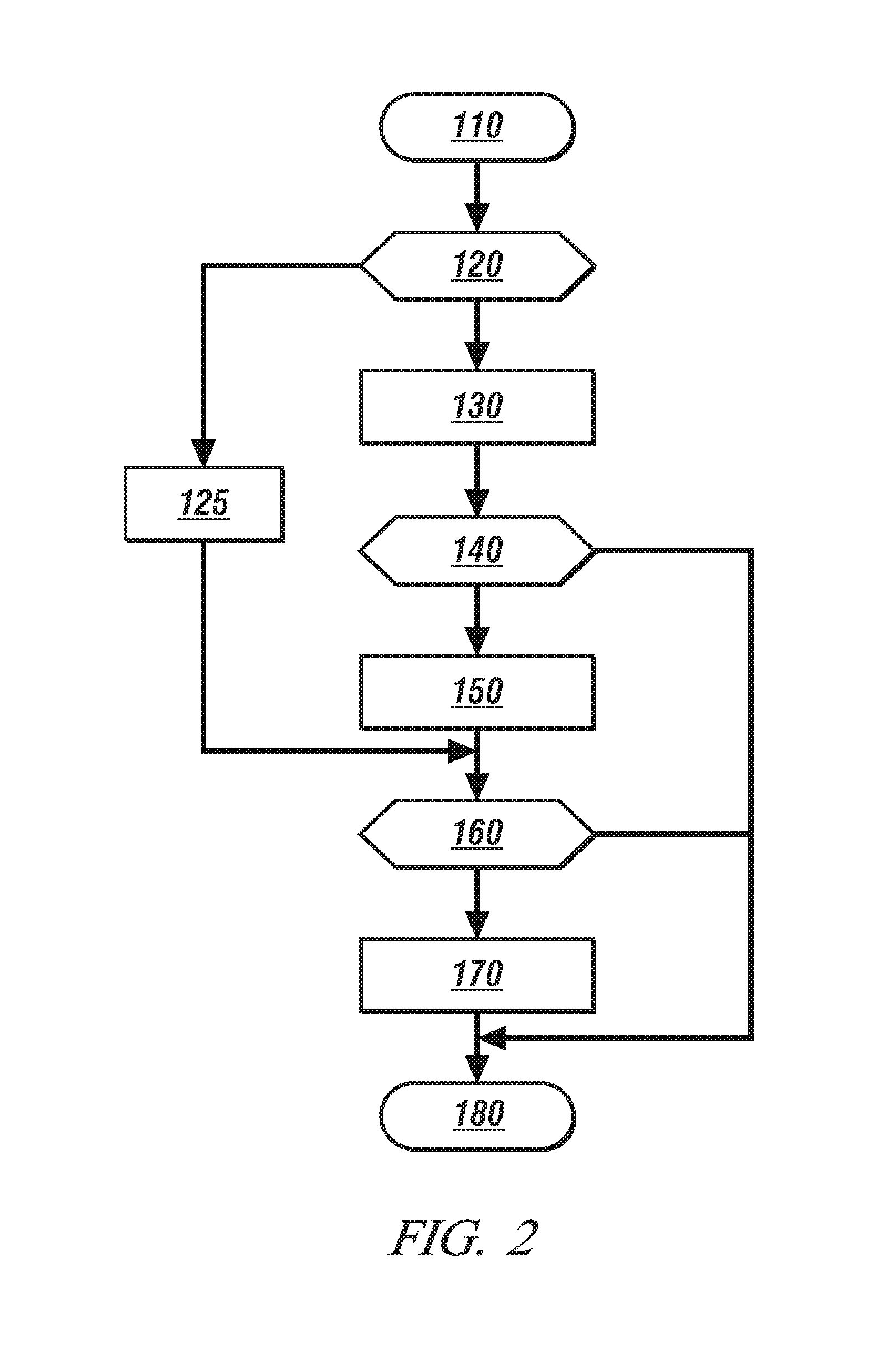

Exhaust gas recirculation system having cooler

InactiveUS6826903B2Improve heat transfer effectElectrical controlNon-fuel substance addition to fuelExhaust fumesExhaust gas recirculation

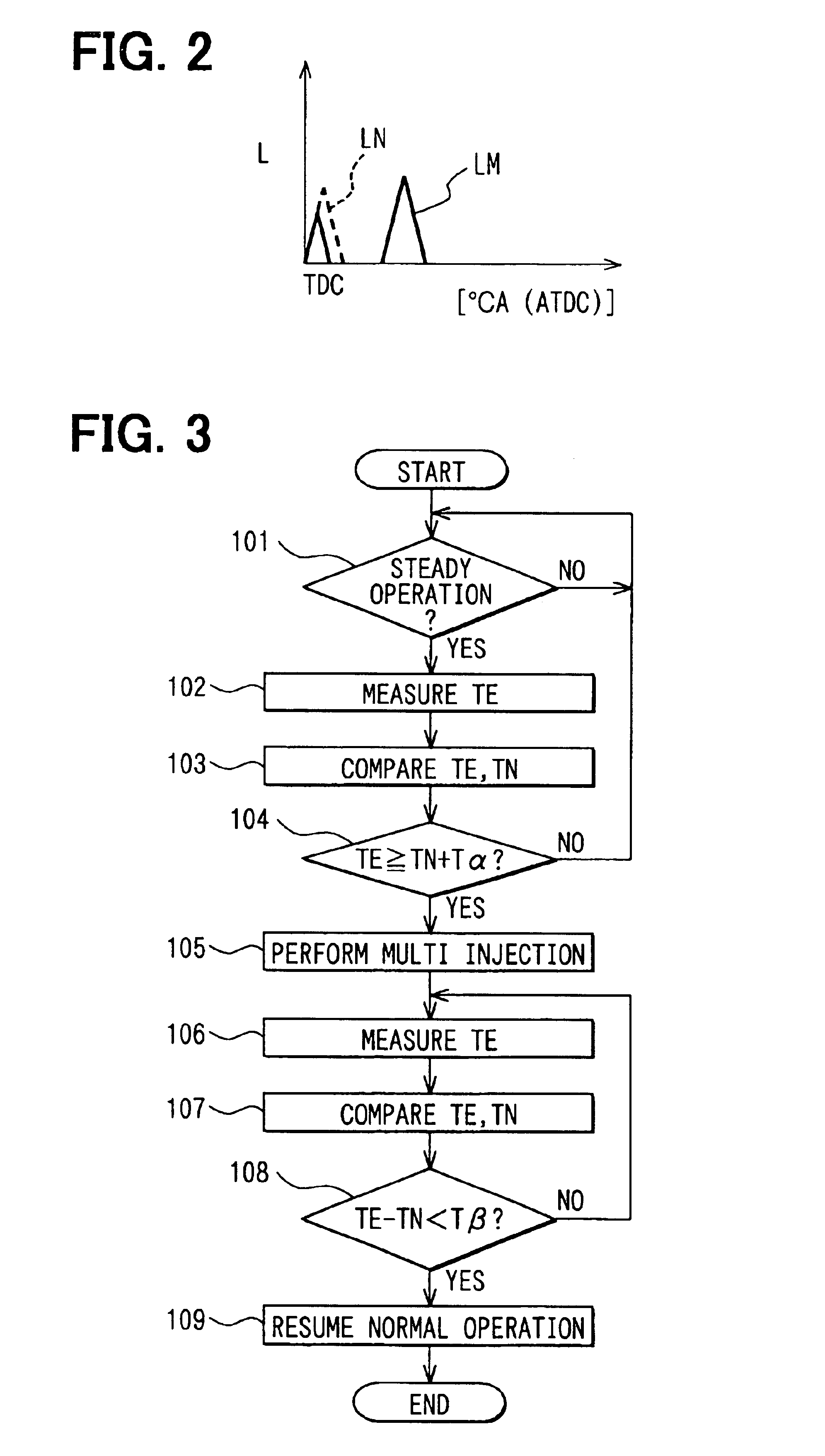

An exhaust gas recirculation (EGR) system of an internal combustion engine has an EGR cooler in an EGR passage connecting an exhaust manifold with an intake manifold. The EGR cooler cools EGR gas recirculated through the EGR passage. Cooling performance detecting means included in an electronic control unit (ECU) determines that cooling performance of the EGR cooler is degraded when intake pressure measured by an intake pressure sensor is lower than a normal intake pressure by at least a predetermined value. When the degradation of the cooling performance is detected, cooling performance regeneration controlling means included in the ECU increases the temperature inside the EGR cooler by heating the exhaust gas to eliminate soot or unburned hydrocarbon by oxidization. Thus, the cooling performance of the EGR cooler is regenerated.

Owner:DENSO CORP

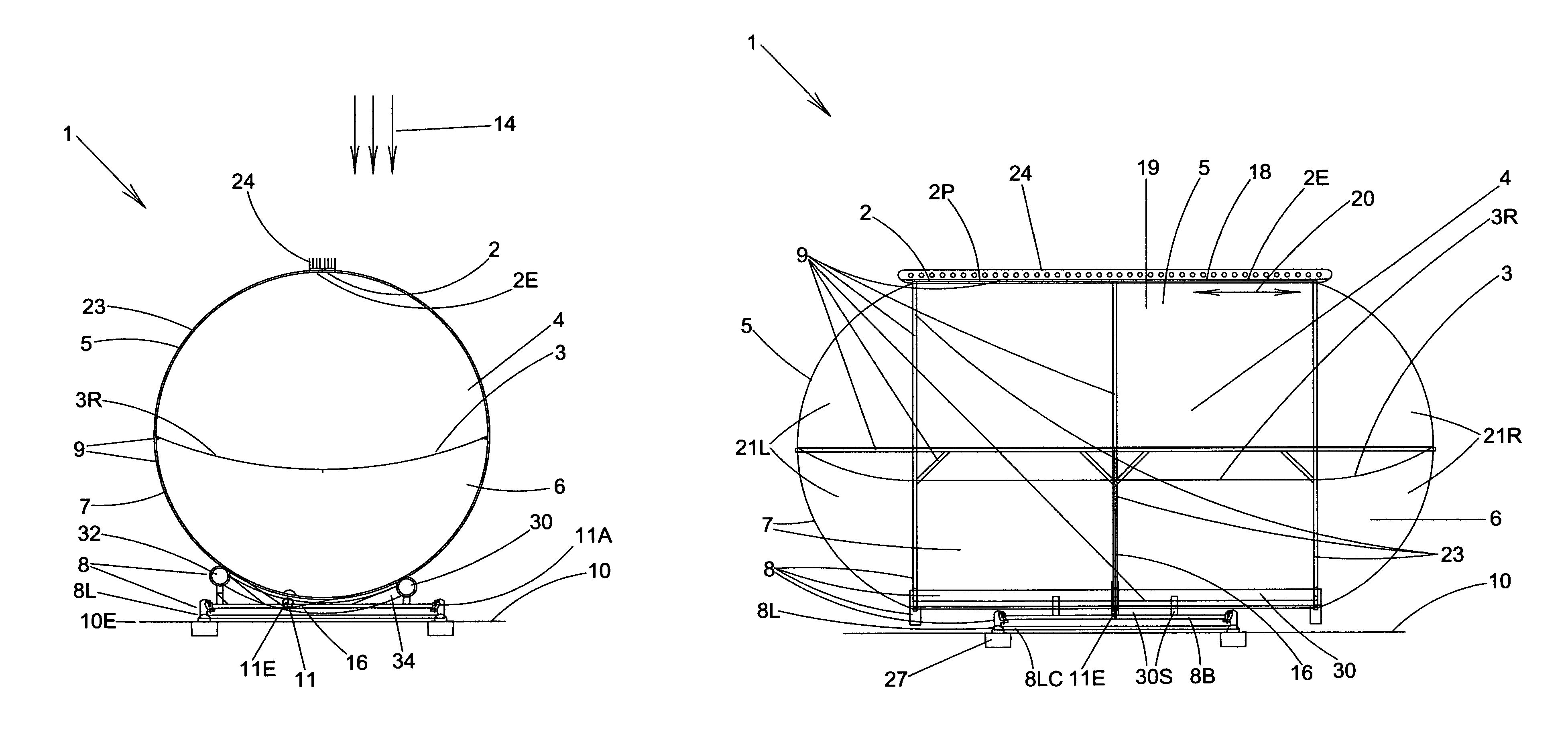

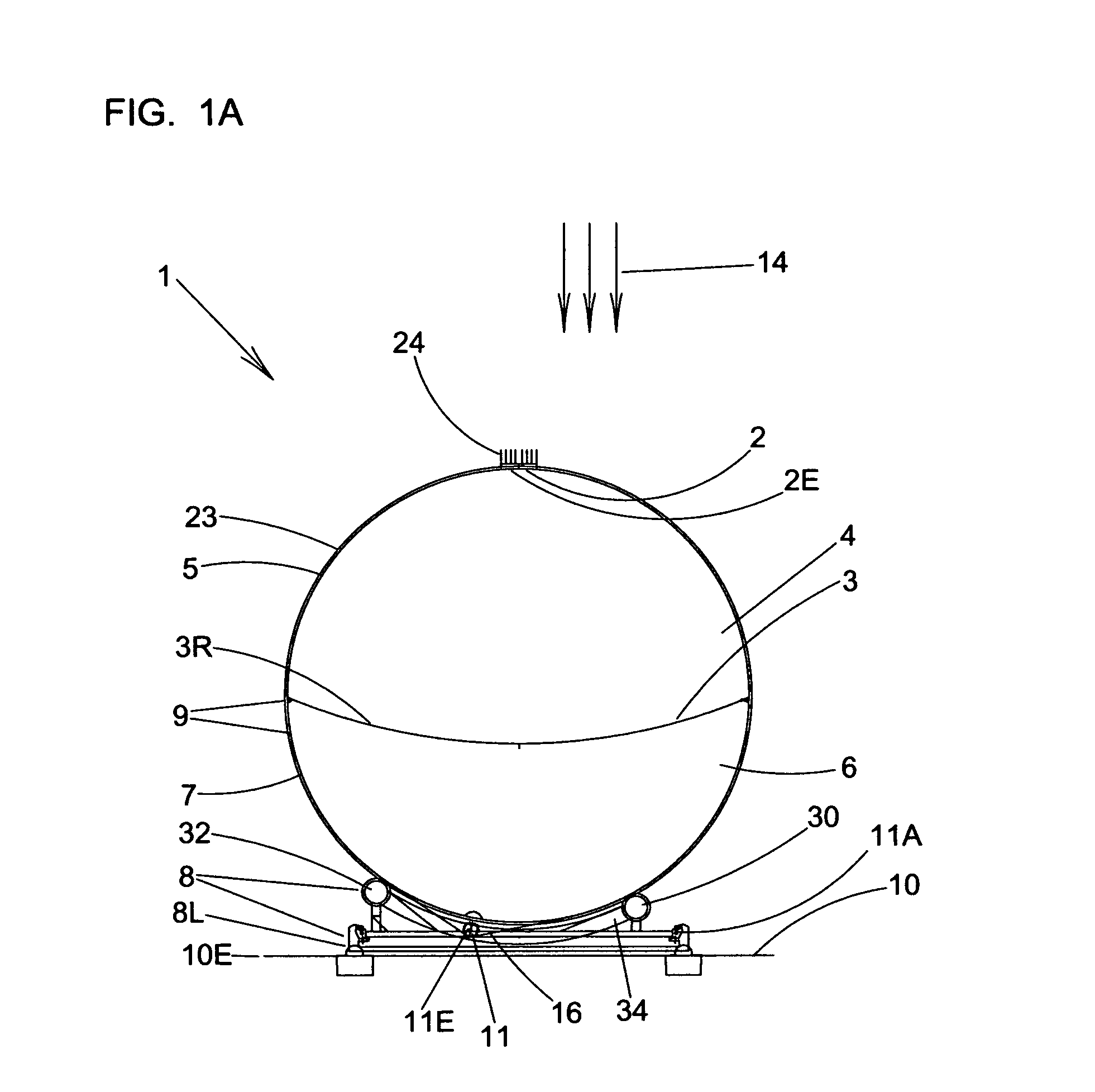

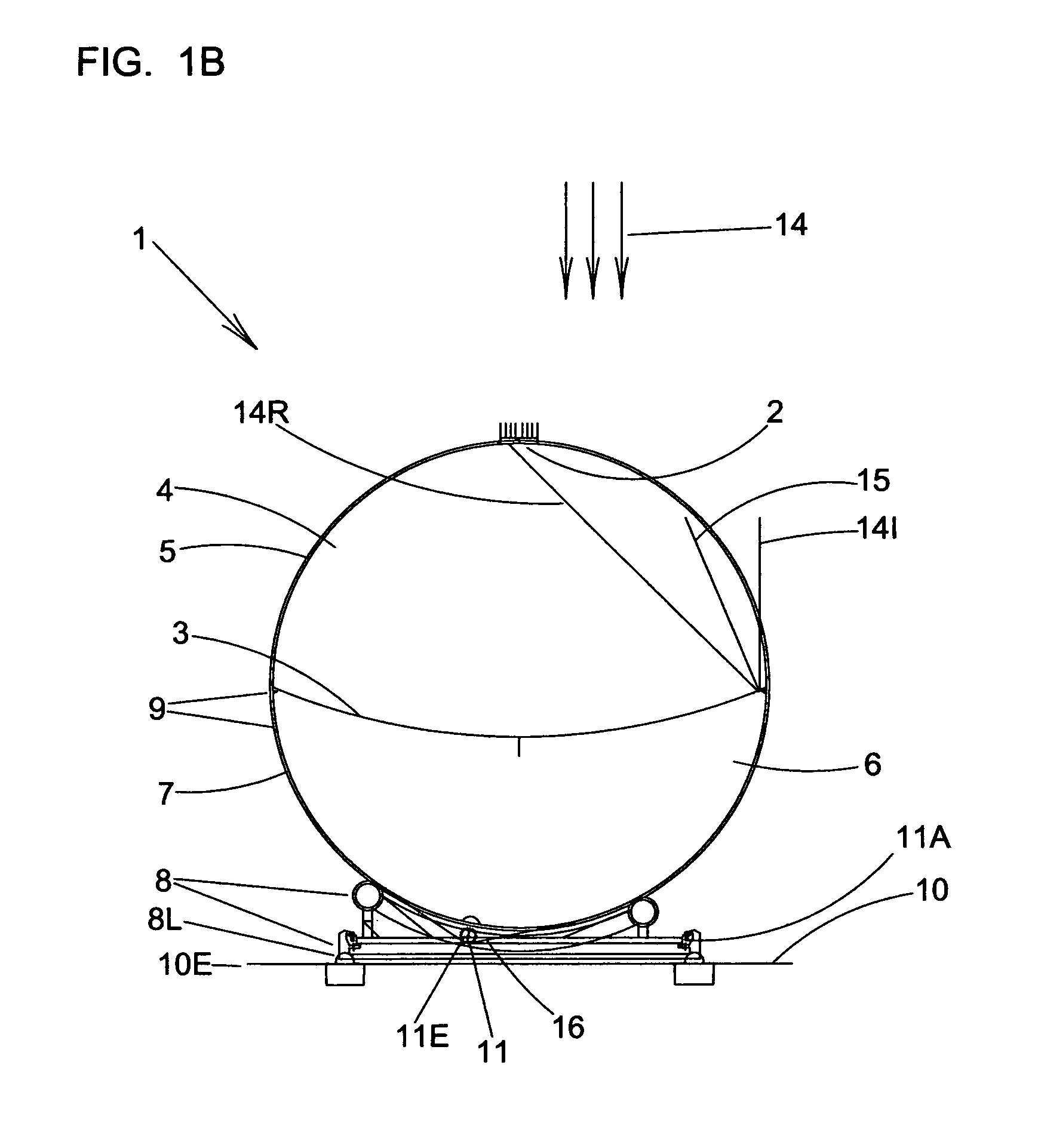

Inflatable heliostatic solar power collector

ActiveUS20100229850A1Low costImprove conversion efficiencyPhotovoltaic supportsSolar heating energyHydrocotyle bowlesioidesCollector device

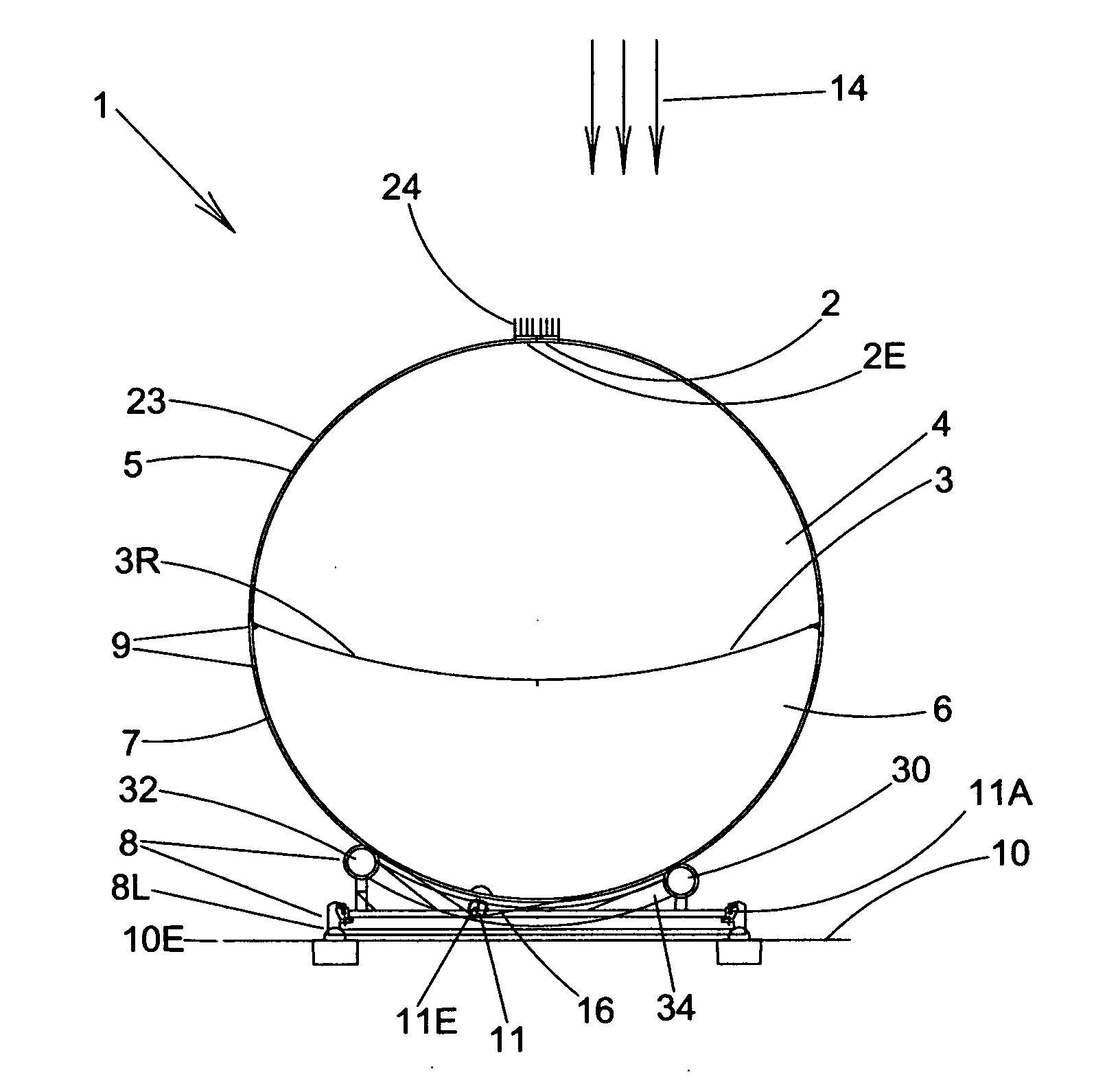

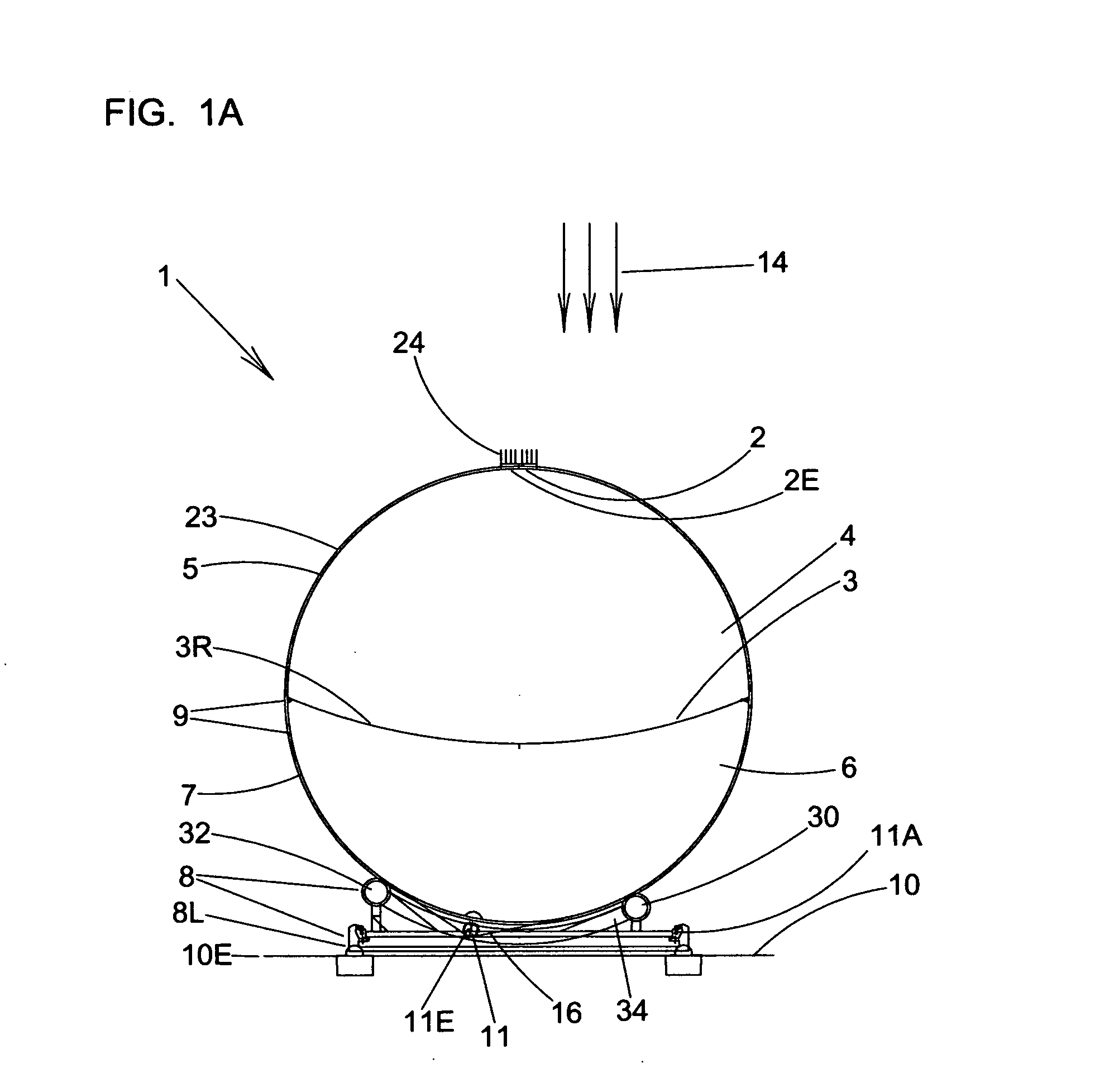

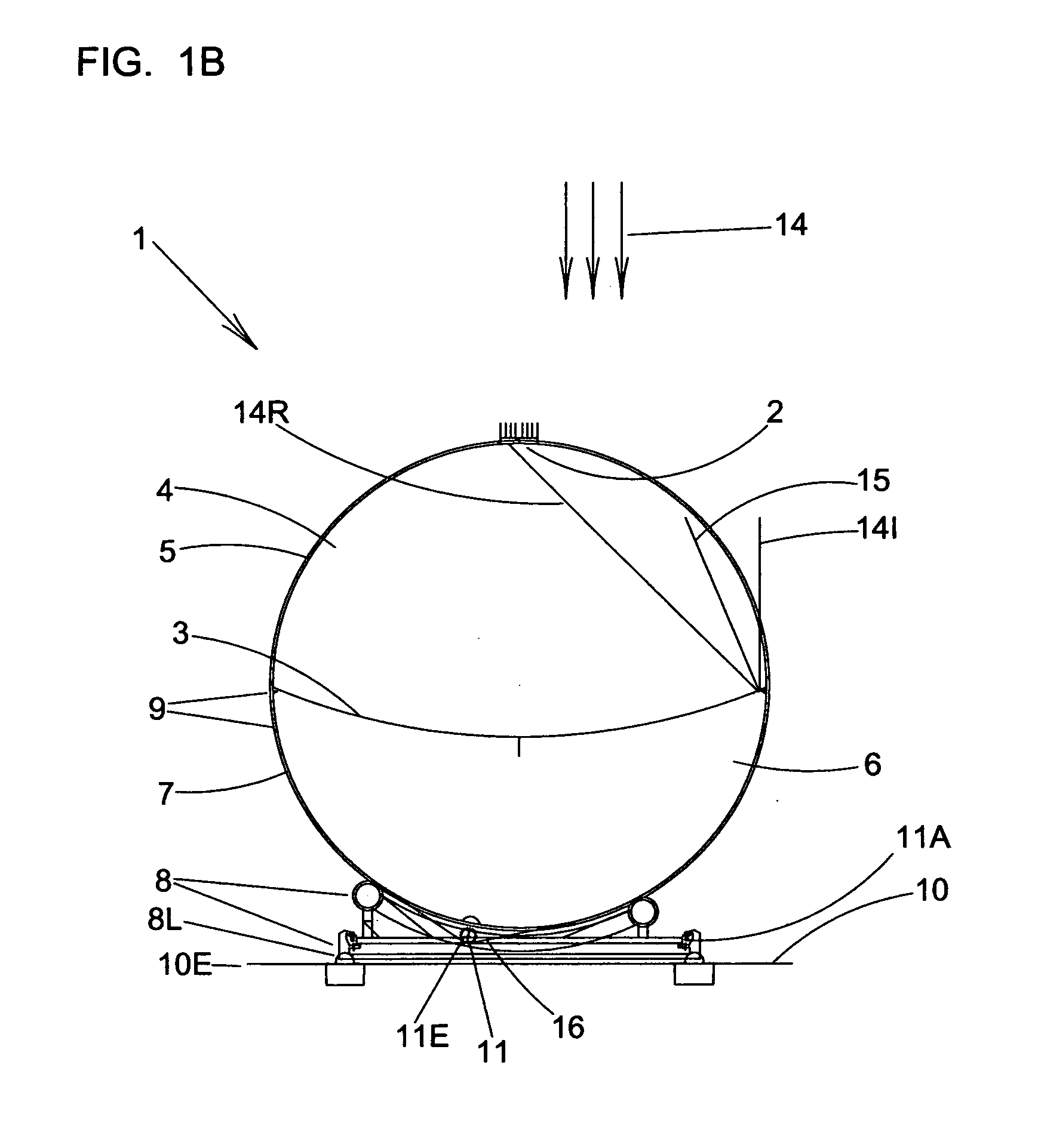

Increased utilization of solar power is highly desirable as solar power is a readily available renewable resource with power potential far exceeding total global needs; and as solar power does not contribute to pollutants associated with fossil fuel power, such as unburned hydrocarbons, NOx and carbon dioxide. The present invention provides low-cost inflatable heliostatic solar power collectors, which can be stand-alone units suitable for flexible utilization in small, medium, or utility scale applications. The inflatable heliostatic power collectors use a reflective surface or membrane “sandwiched” between two inflated chambers, and attached solar power receivers which may be of photovoltaic and / or solar thermal types. Modest concentration ratios enable benefits in both reduced cost and increased conversion efficiency, relative to simple prior-art flat plate solar collectors.

Owner:RIC ENTERPRISES

Gas micro burner

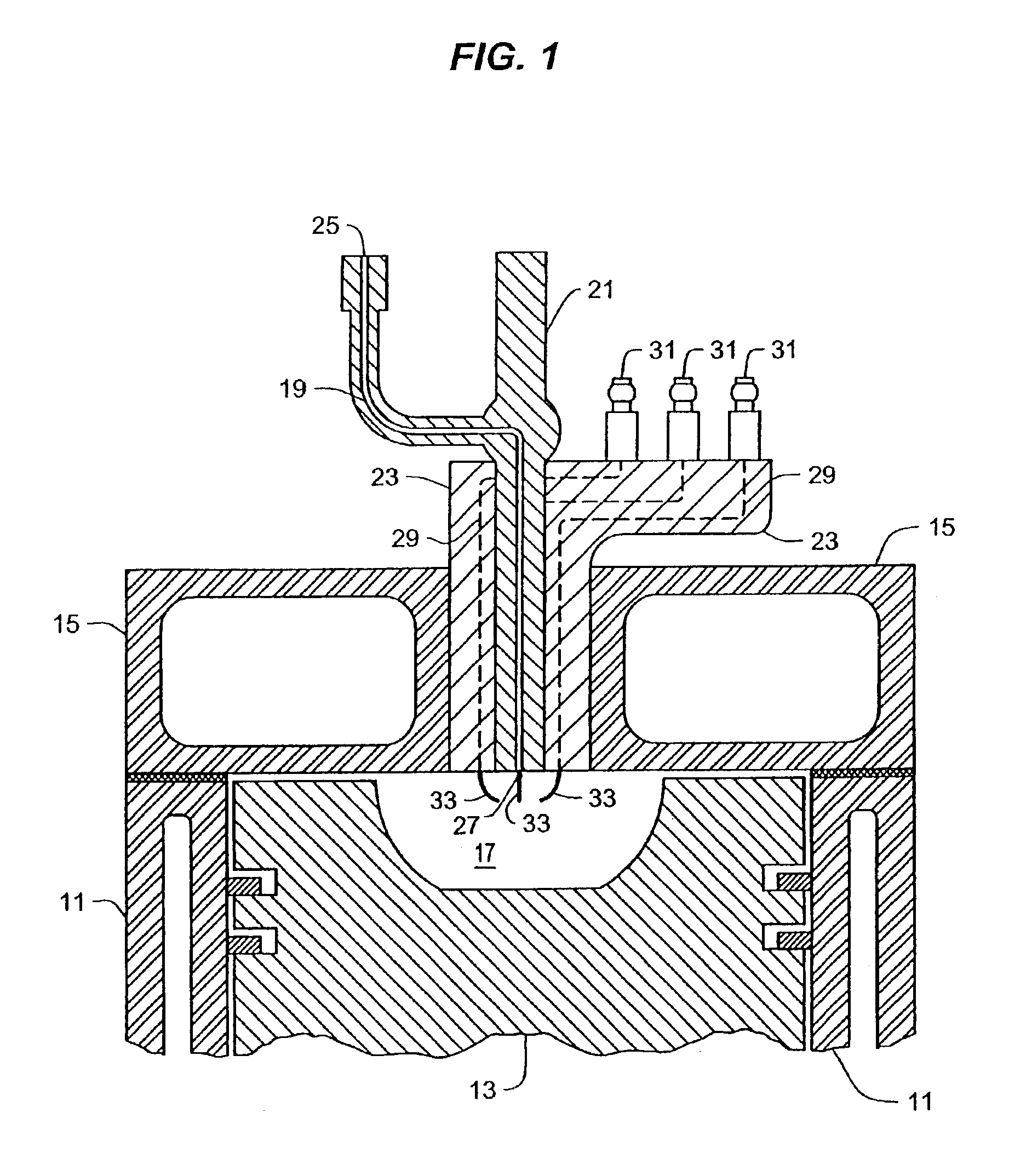

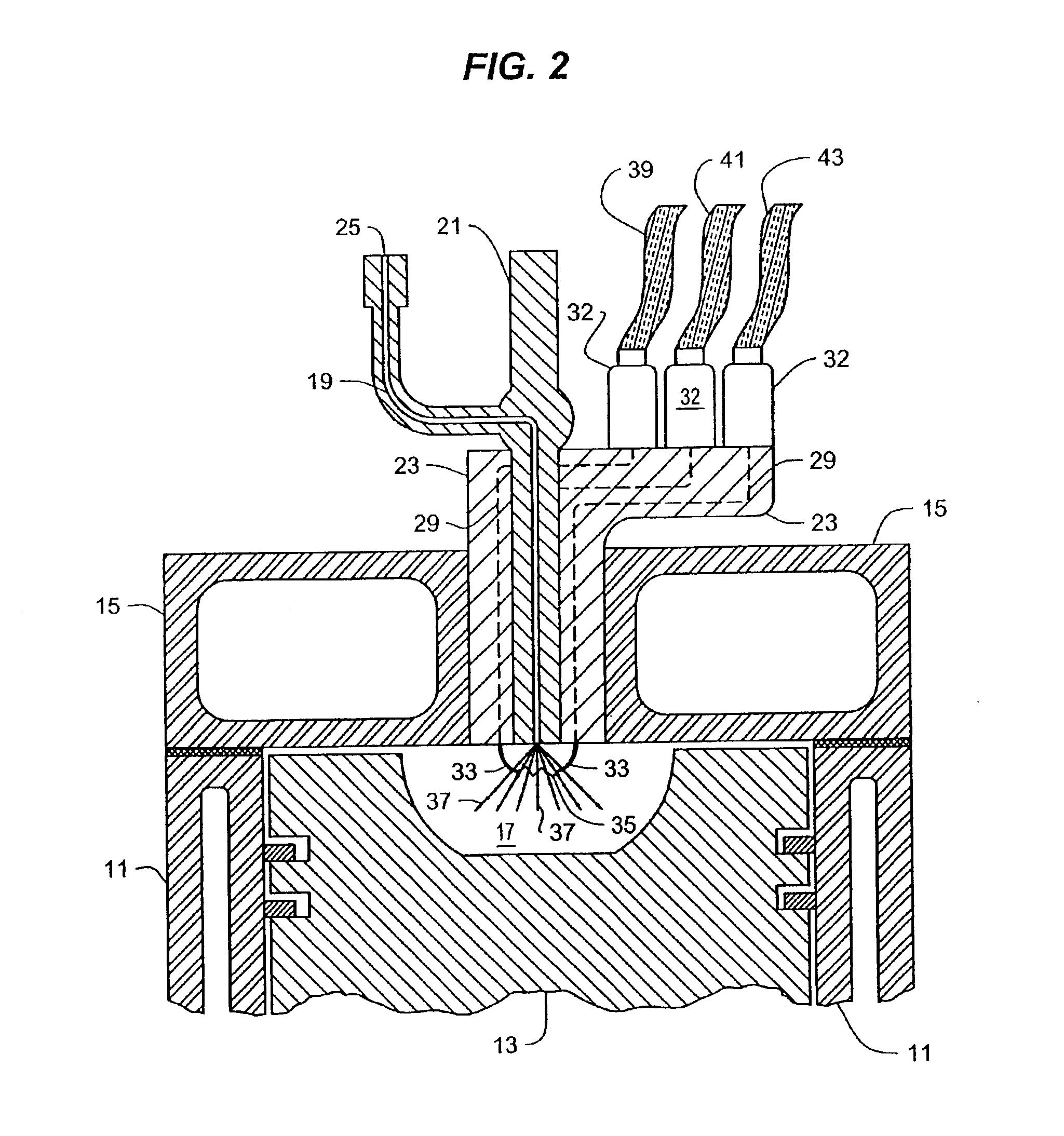

InactiveUS7488171B2Low mass flow rateSmall volumeFuel lightersBurner material specificationsProduct gasProcess engineering

A micro gas burner is provided that generates a stable, pre-mixed flame that produces little to no soot or unburned hydrocarbons. The gas burner includes a fuel inlet, nozzle, oxygenation chamber with at least one air inlet, a mixing chamber having a frustoconical inner wall, at least one permeable barrier and a flame holder. The gas burner thoroughly mixes fuel and entrained air to form a nearly stoichiometric mixture prior to combustion. The gas burner mixes the fuel and air so thoroughly that it requires a lower fuel flow rate than would otherwise be necessary to produce a stable, pre-mixed flame. The gas burner may include an optional flame tube with an optional exhaust port in which a flame is contained and sequestered from diffusing air.

Owner:R J REYNOLDS TOBACCO COMPANY

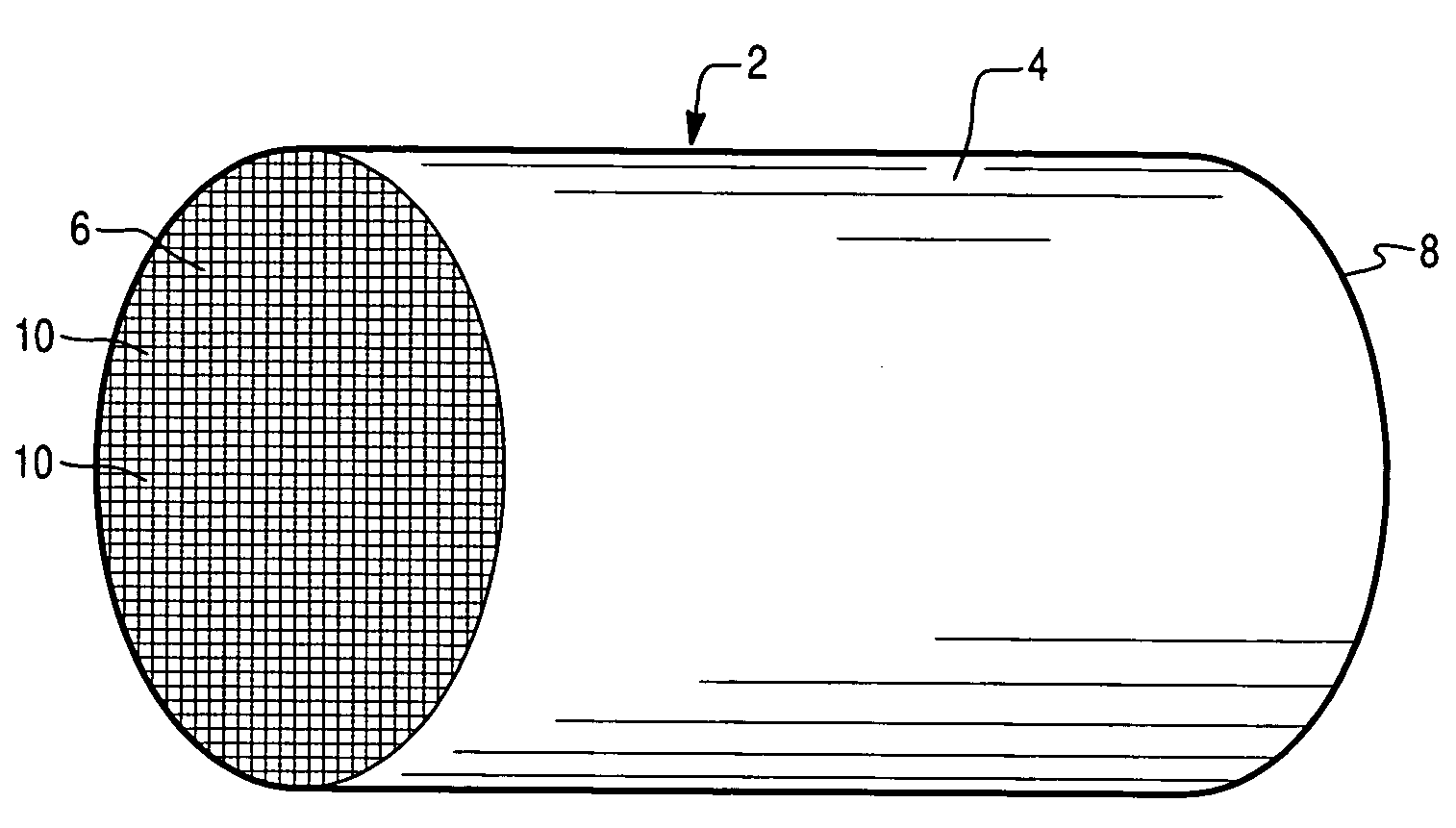

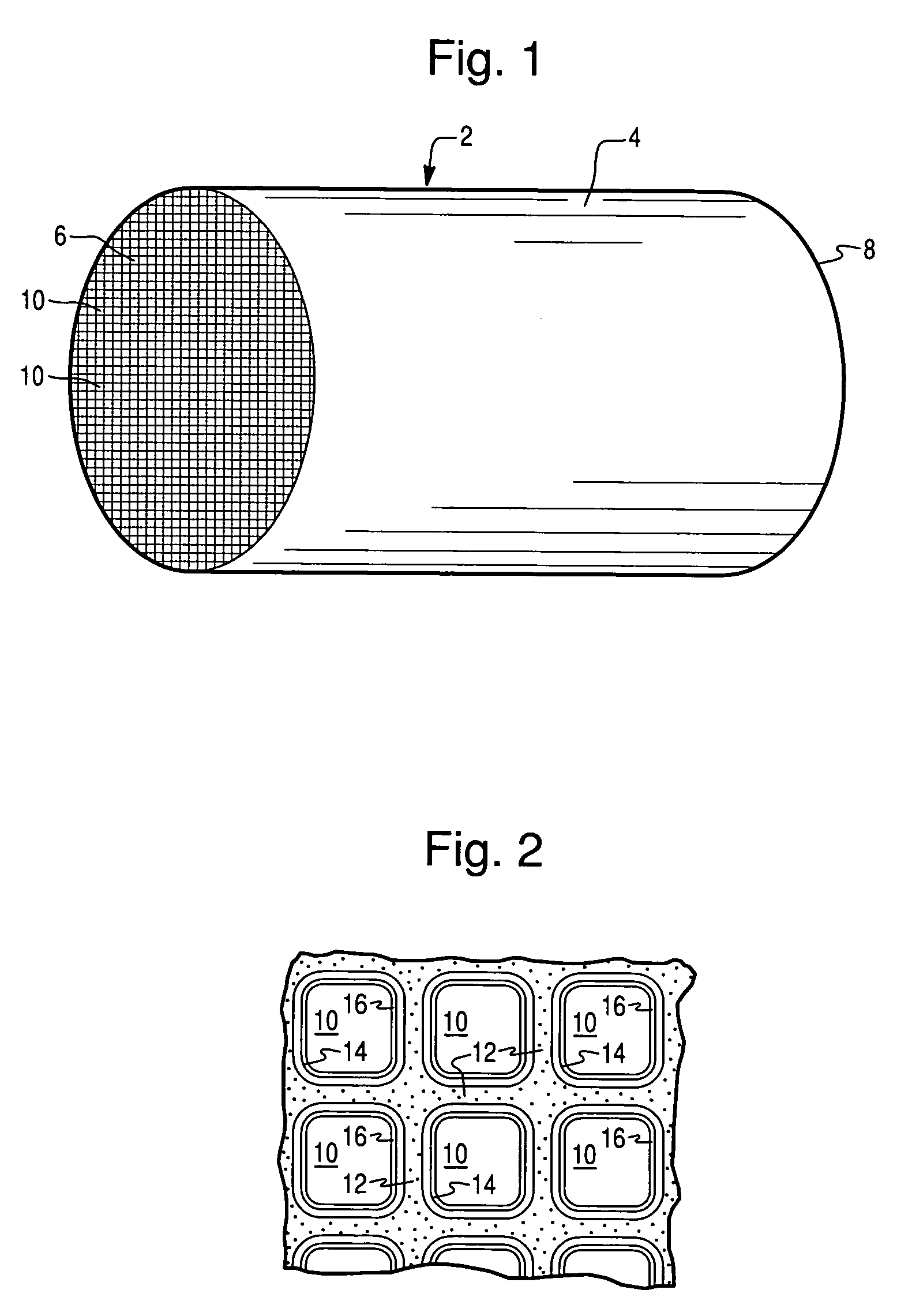

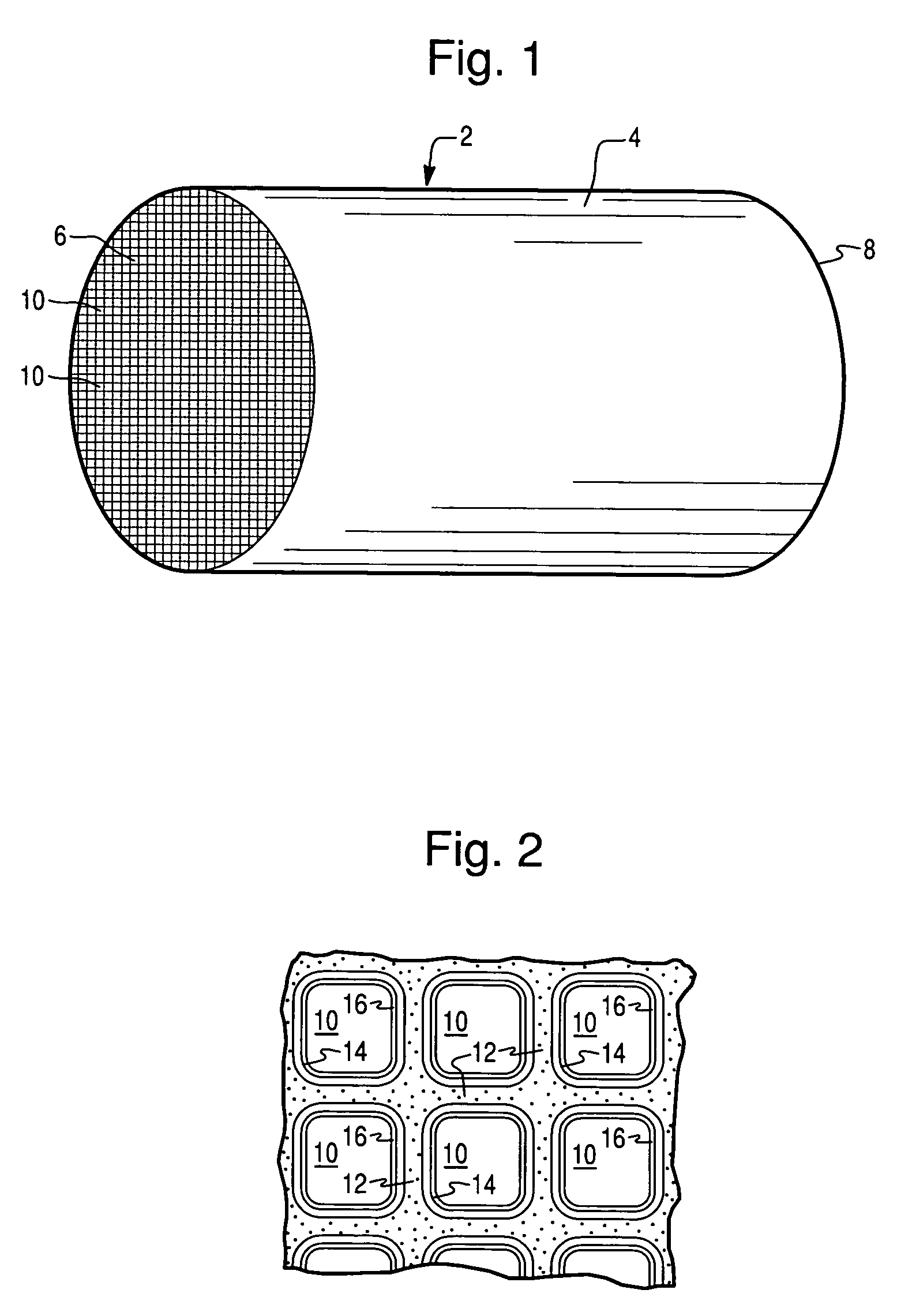

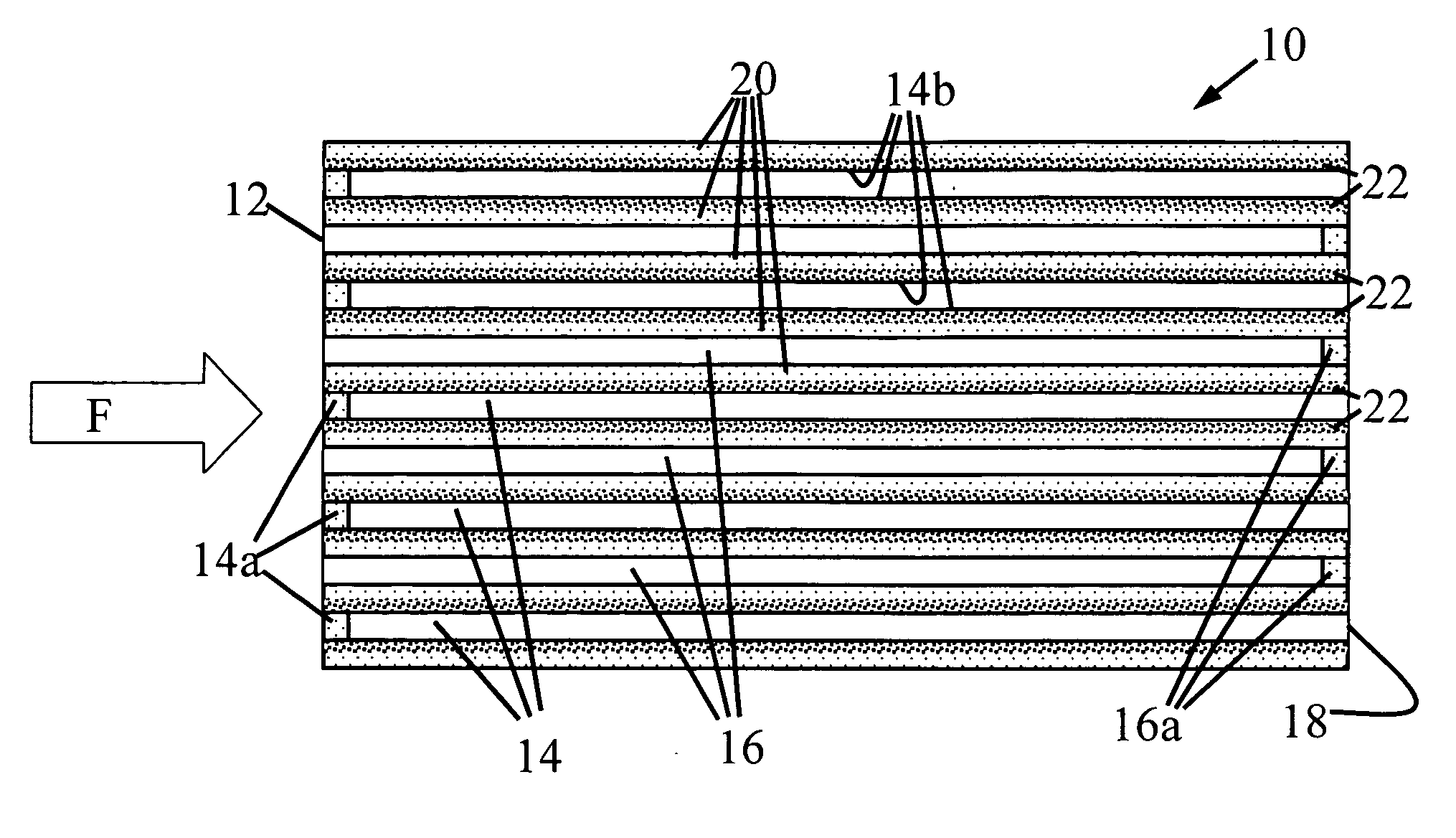

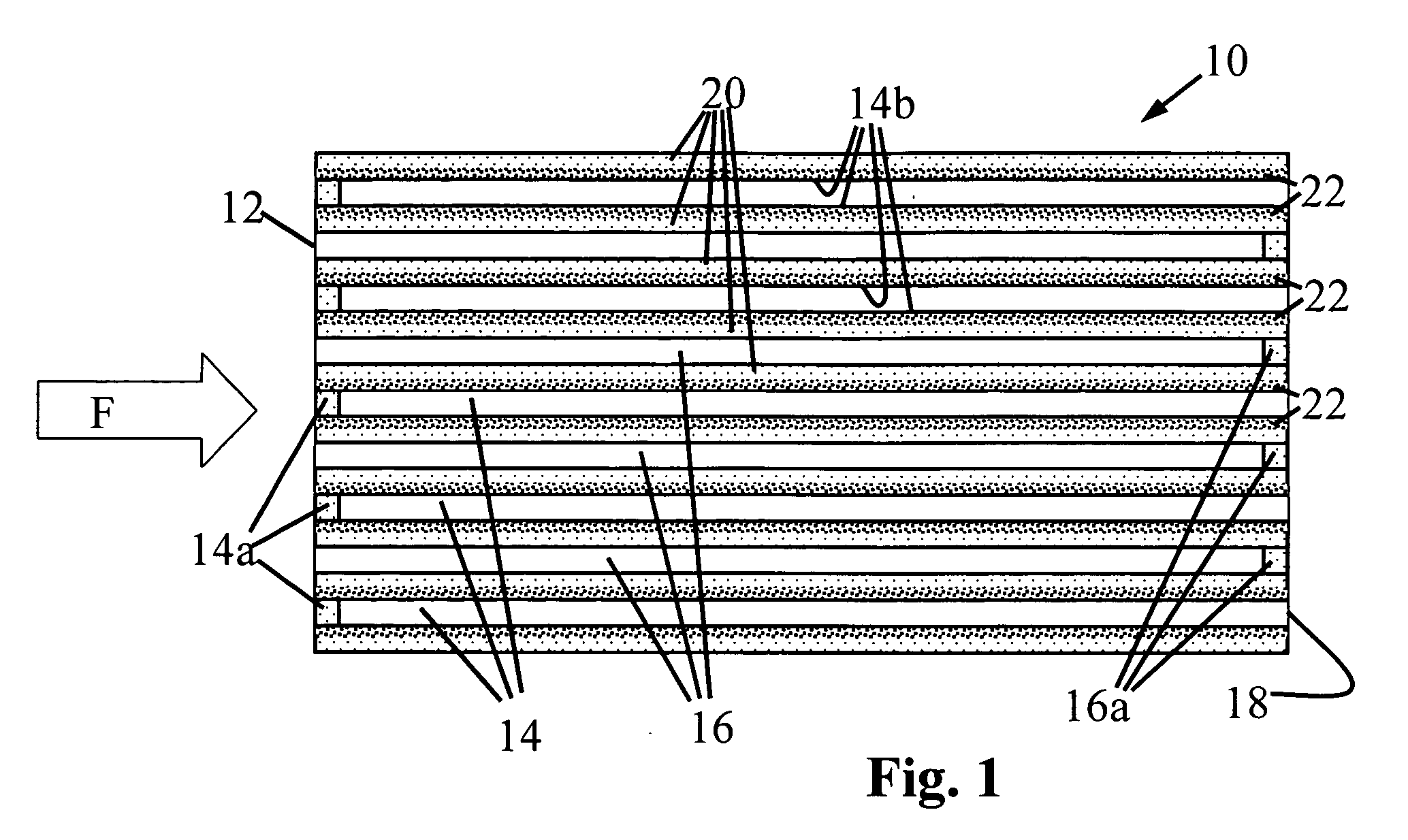

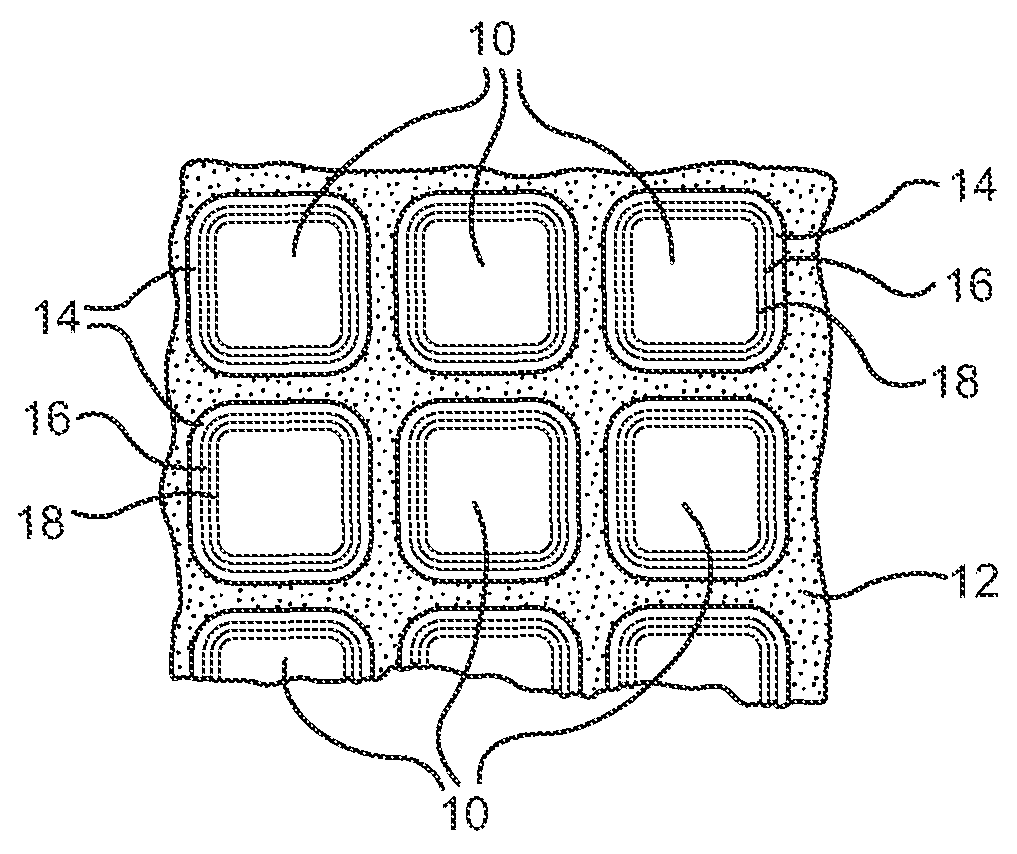

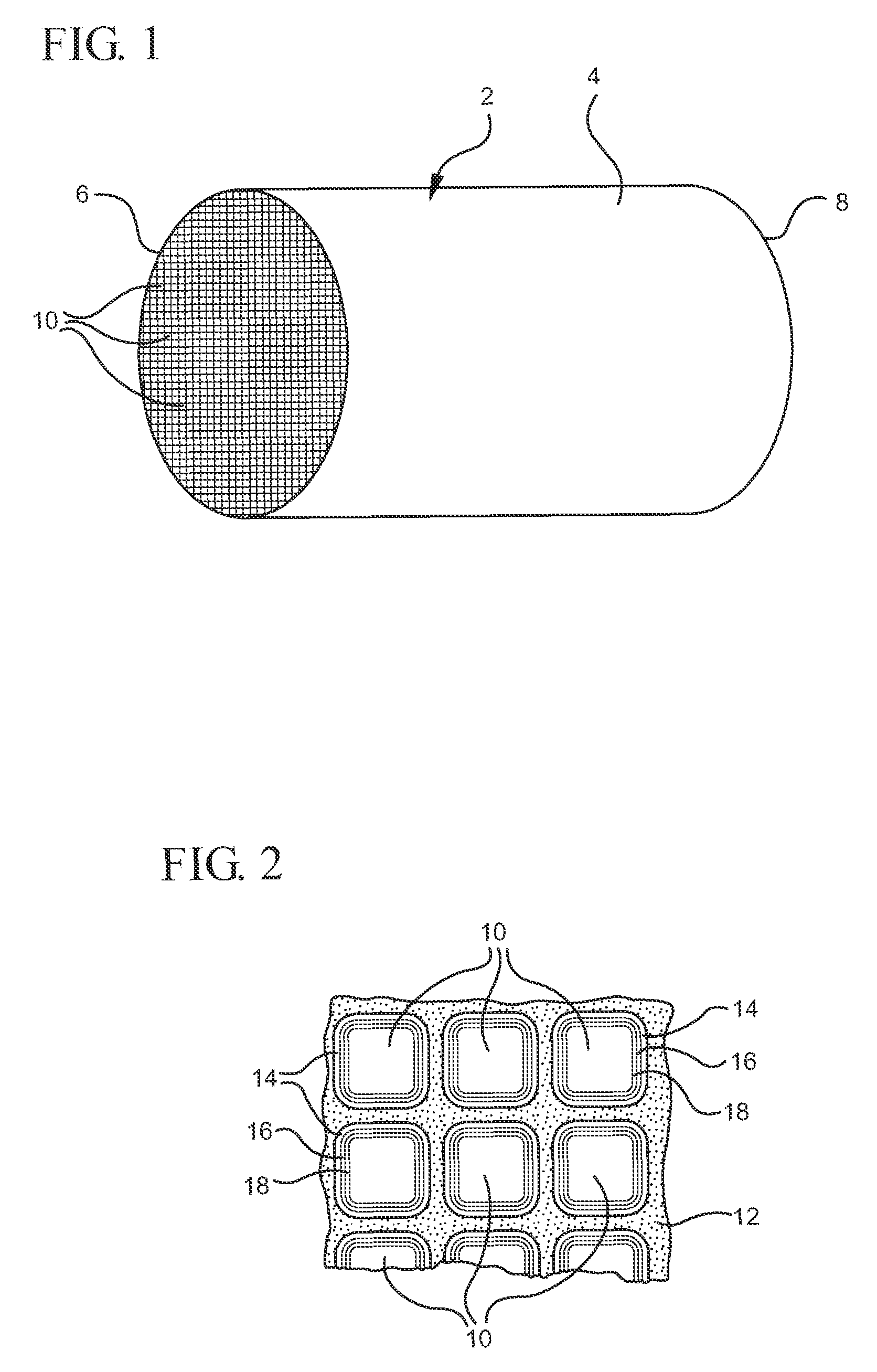

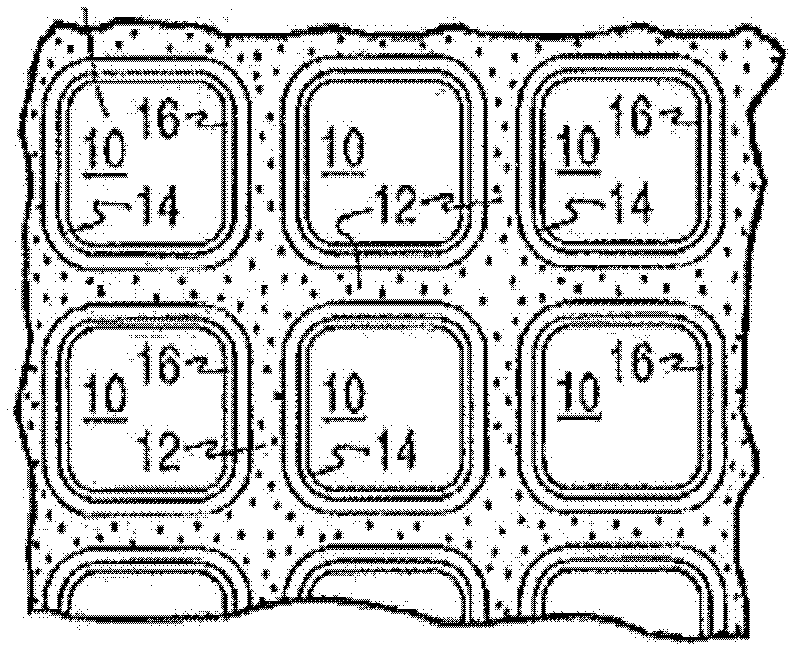

Low pressure drop coated diesel exhaust filter

InactiveUS20070140928A1Promote nitrogen oxide reductionReduce and avoid obstructionCombination devicesSilencing apparatusHigh concentrationNitrogen oxides

A coated diesel exhaust filter is provided that applies a relatively low pressure drop across the exhaust system despite the buildup of soot deposits. The filter includes a porous ceramic structure having an inlet end, an outlet end, and a plurality of gas inlet and gas outlet channels disposed between the inlet and outlet ends, the channels being separated by porous ceramic walls. A catalyst is distributed at least partly within the porous ceramic walls of the structure, and is distributed at a higher concentration within portions of the ceramic walls adjacent to the outlet surfaces than within portions of the ceramic walls adjacent the inlet surfaces. Both the inlet and outlet surfaces are substantially free of the catalyst in order to maintain a gas-conducting porosity in these surfaces. The resulting filter effectively treats nitrogen oxides, carbon monoxide and unburned hydrocarbons present in the exhaust gas stream while advantageously imposing a relatively low pressure drop across the exhaust system even when soot deposits accumulate on the inlet surfaces of the ceramic walls.

Owner:CORNING INC

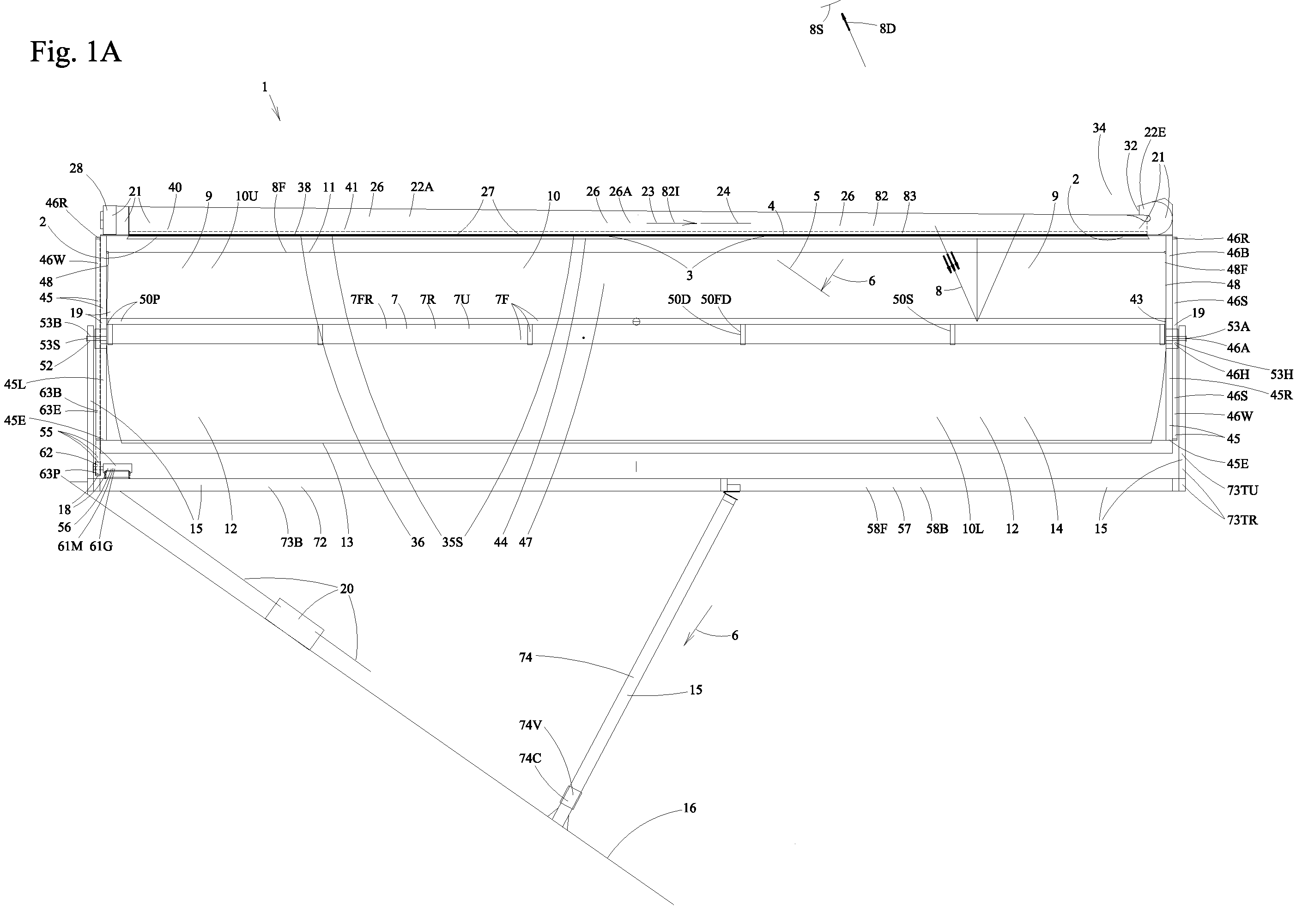

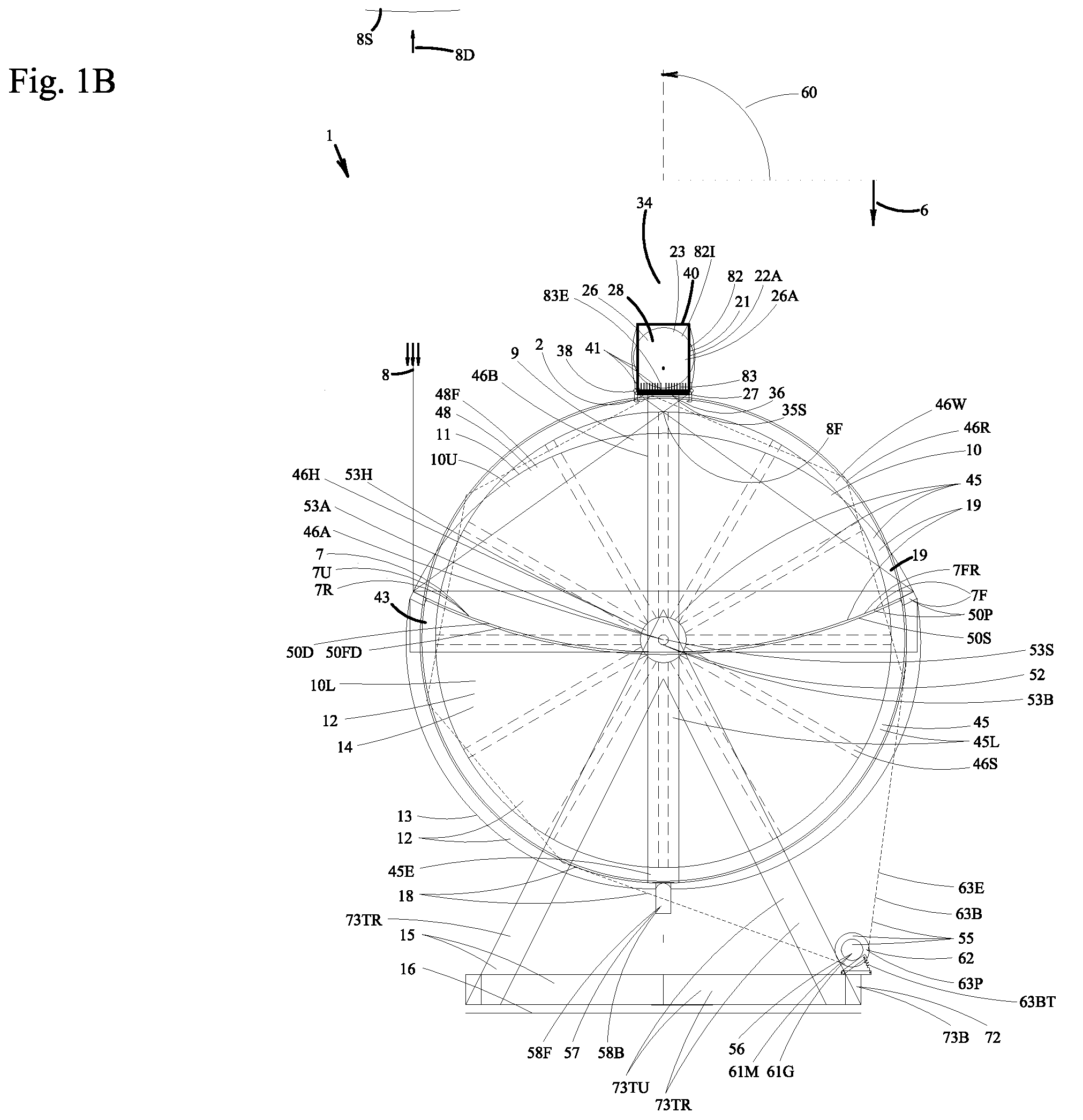

Inflatable Linear Heliostatic Concentrating Solar Module

ActiveUS20110277815A1Low costImprove conversion efficiencySolar heating energySolar heat devicesConcentration ratioEngineering

Increased utilization of solar power is highly desirable as solar power is a readily available renewable resource with power potential far exceeding total global needs; and as solar power does not contribute to pollutants associated with fossil fuel power, such as unburned hydrocarbons, NOx and carbon dioxide. The present invention provides low-cost inflatable heliostatic solar power collectors, which a range of embodiments suitable for flexible utilization in small, medium, or utility scale applications. The inflatable heliostatic power collectors use a reflective surface or membrane “sandwiched” between two inflated chambers, and attached solar power receivers which are of concentrating photovoltaic and optionally also concentrating solar thermal types. Floating embodiments are described for certain beneficial applications on. Modest concentration ratios enable benefits in both reduced cost and increased conversion efficiency, relative to simple prior-art flat plate solar collectors.

Owner:RIC ENTERPRISES

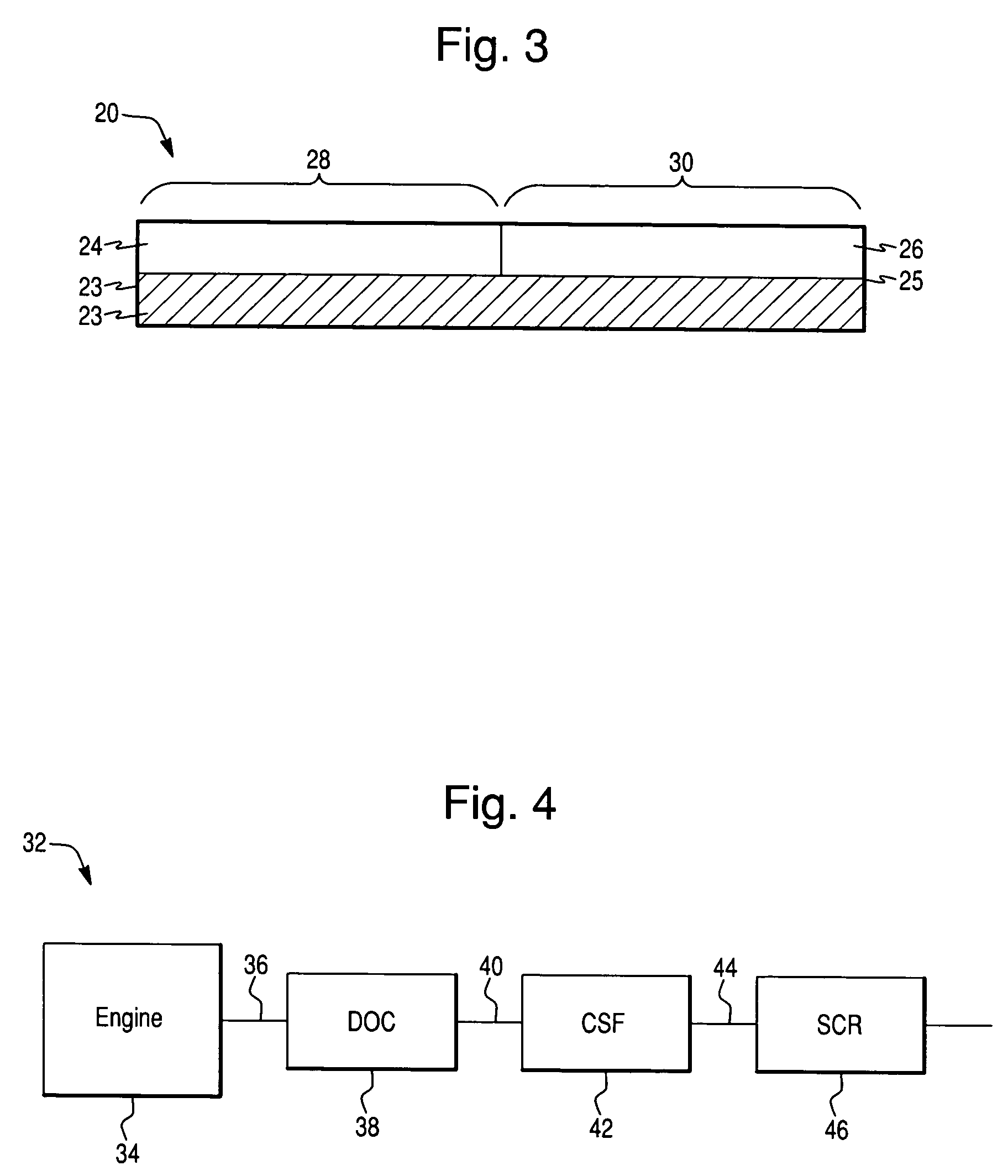

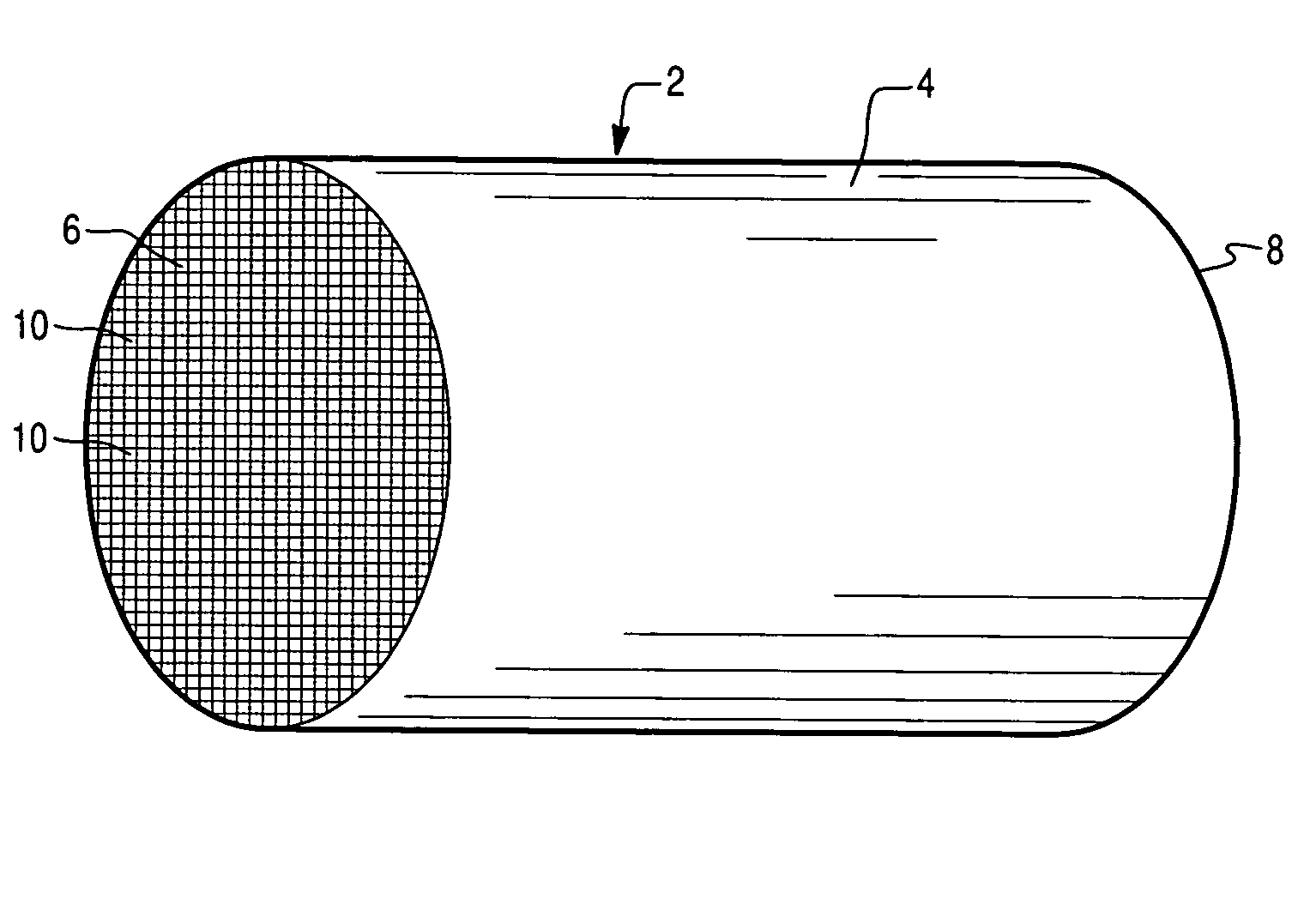

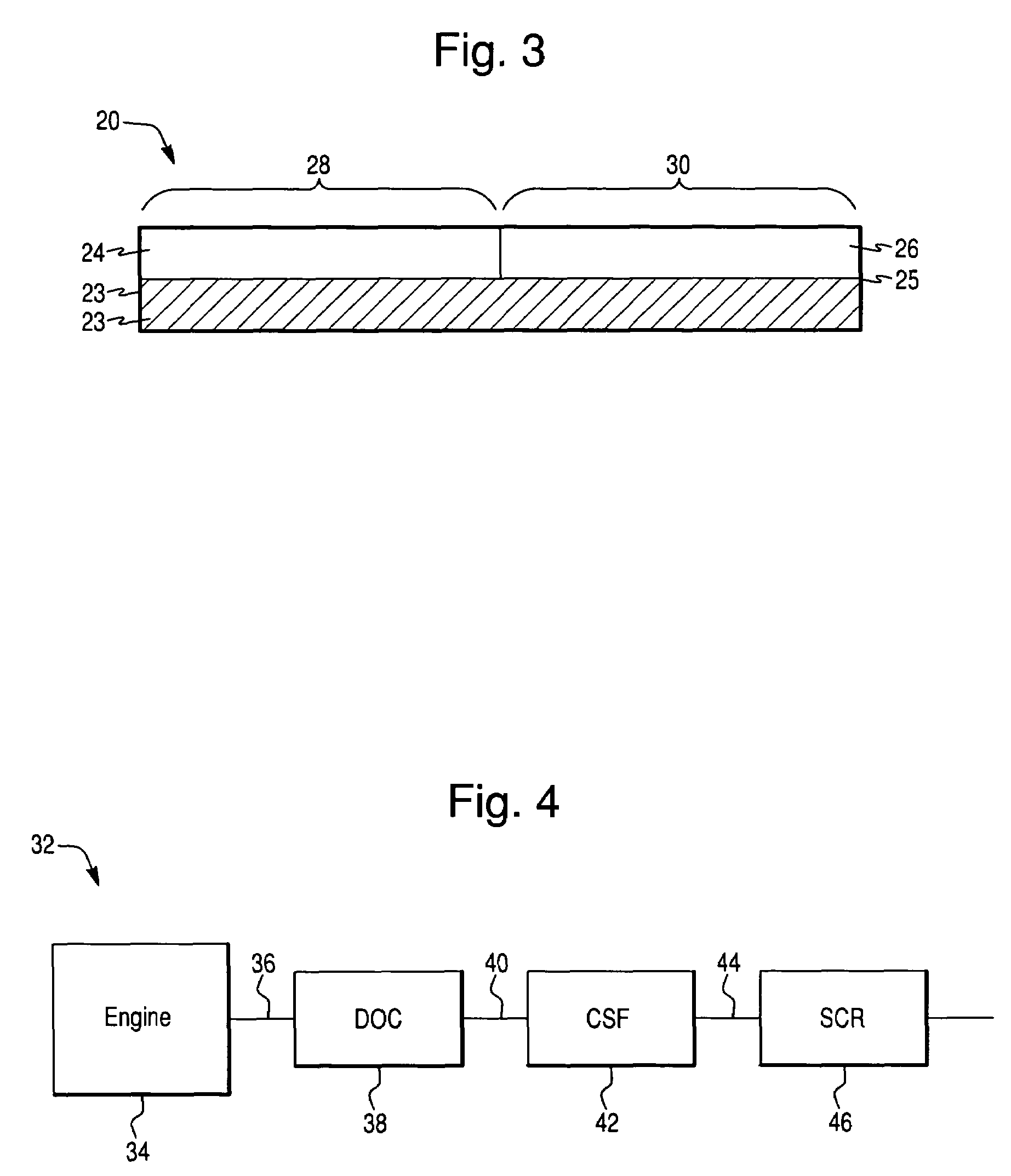

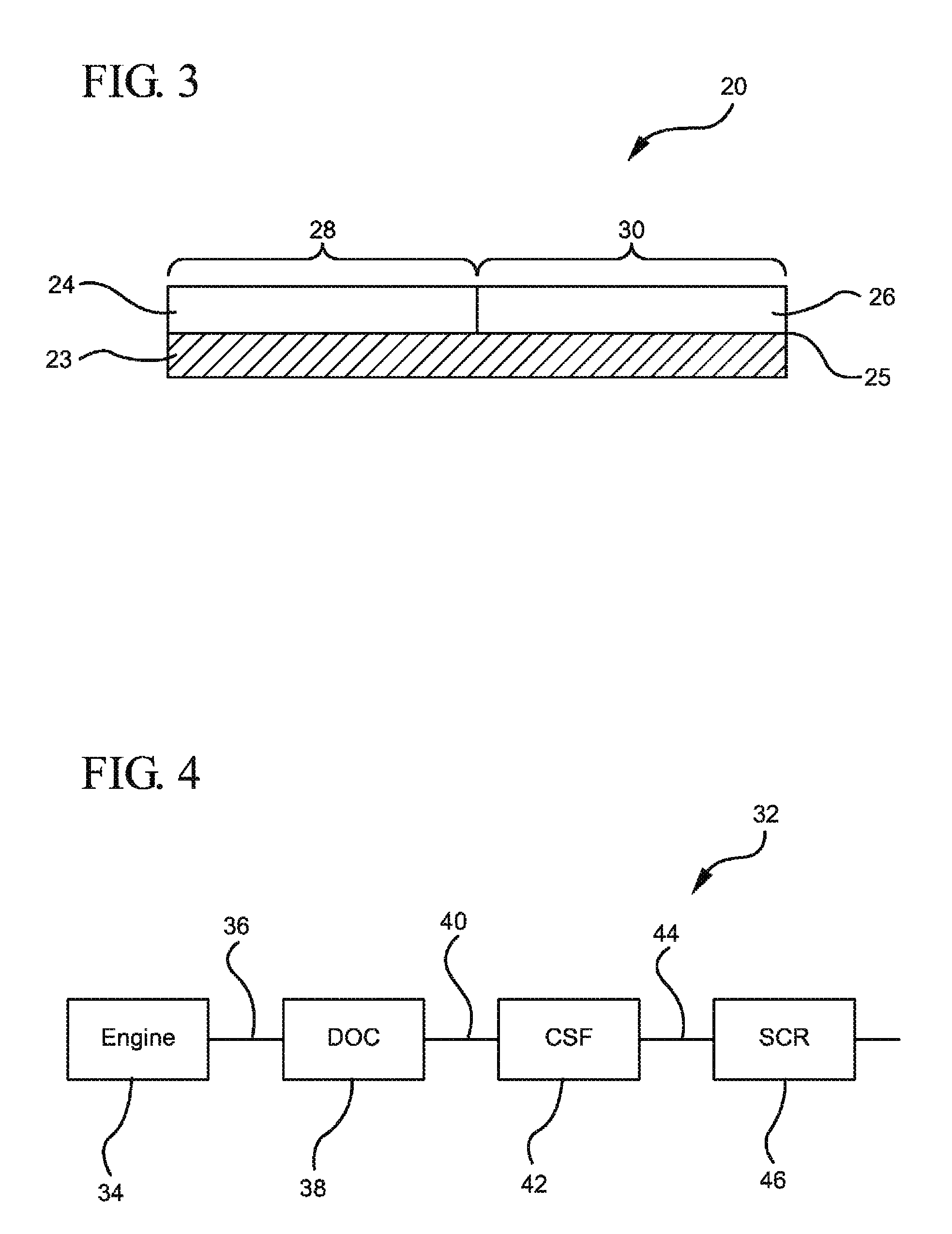

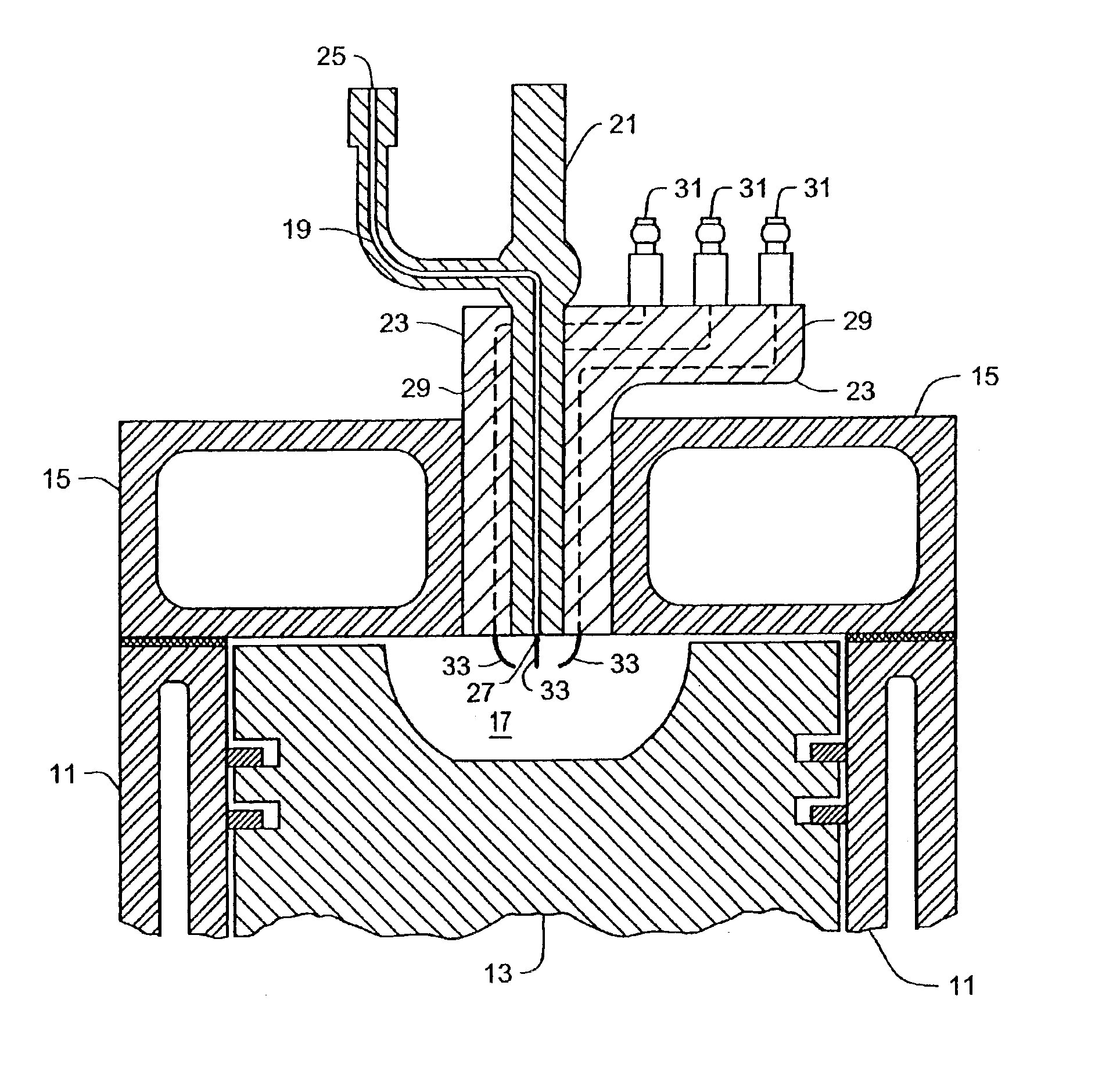

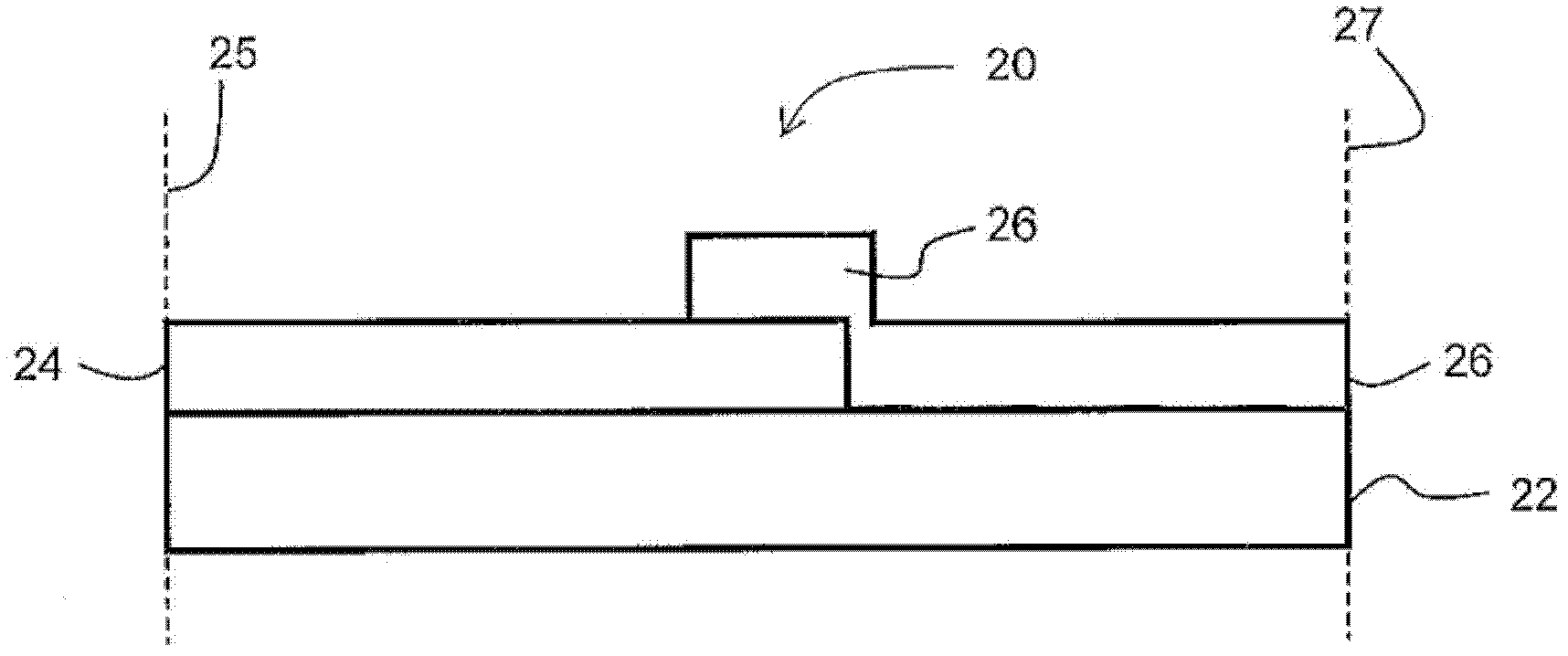

Oxidation catalyst with low CO and HC light-off and systems and methods

An oxidation catalyst for the treatment of exhaust gas emissions, such as the oxidation of unburned hydrocarbons (HC), and carbon monoxide (CO) and the reduction of nitrogen oxides (NOx) from a diesel engine and methods of exhaust gas treatment are disclosed. More particularly, a washcoat composition is disclosed comprising at least two washcoat layers, a first washcoat comprising palladium supported on ceria-zirconia and ceria-zirconia-alumina and a second washcoat containing one or more of platinum and palladium and one or more hydrocarbon storage components. An undercoat may also be included in the catalyst. Also disclosed are method of exhaust gas treatment and diesel exhaust gas treatment systems that include the oxidation catalyst and a downstream soot filter.

Owner:BASF CORP

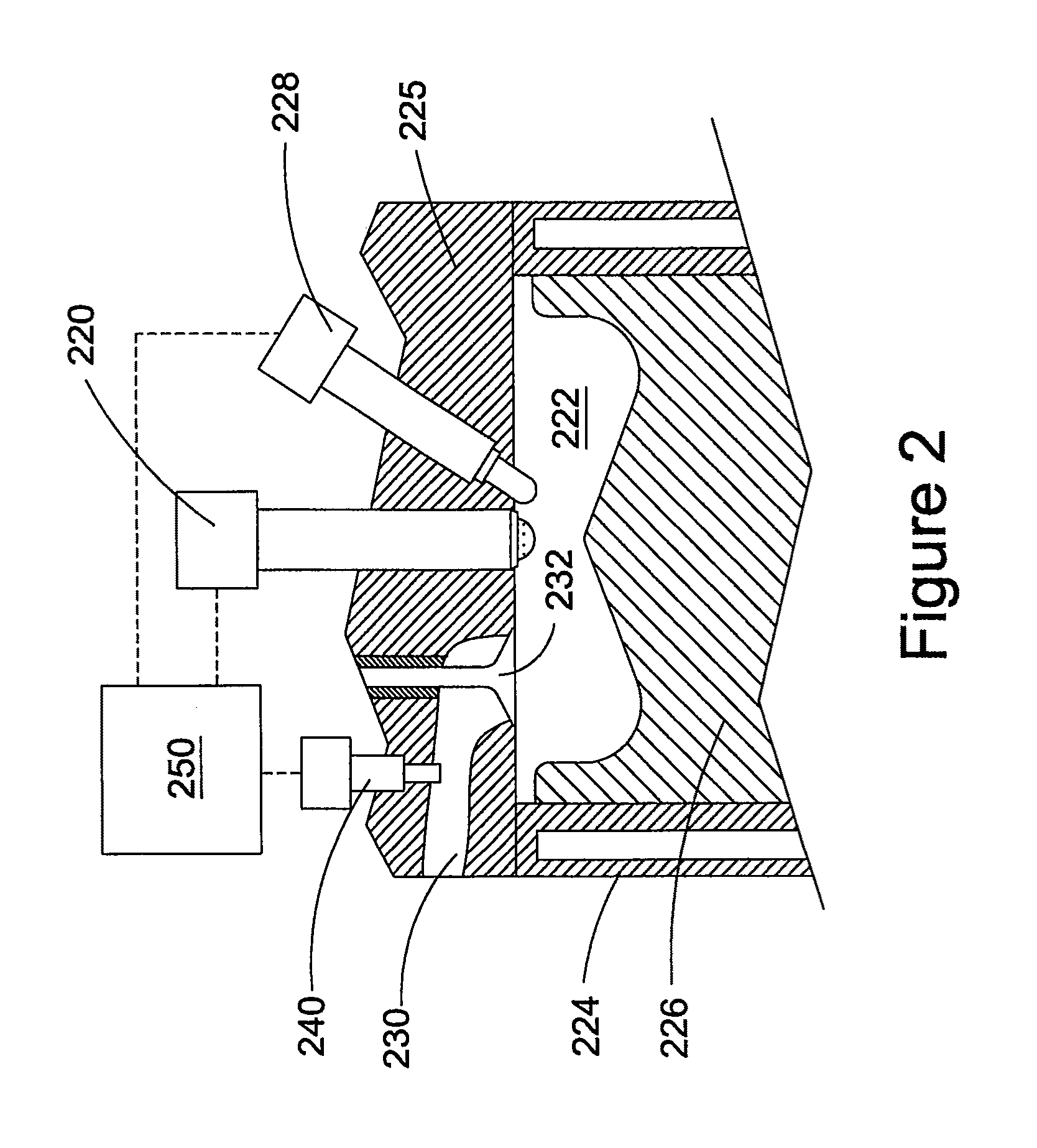

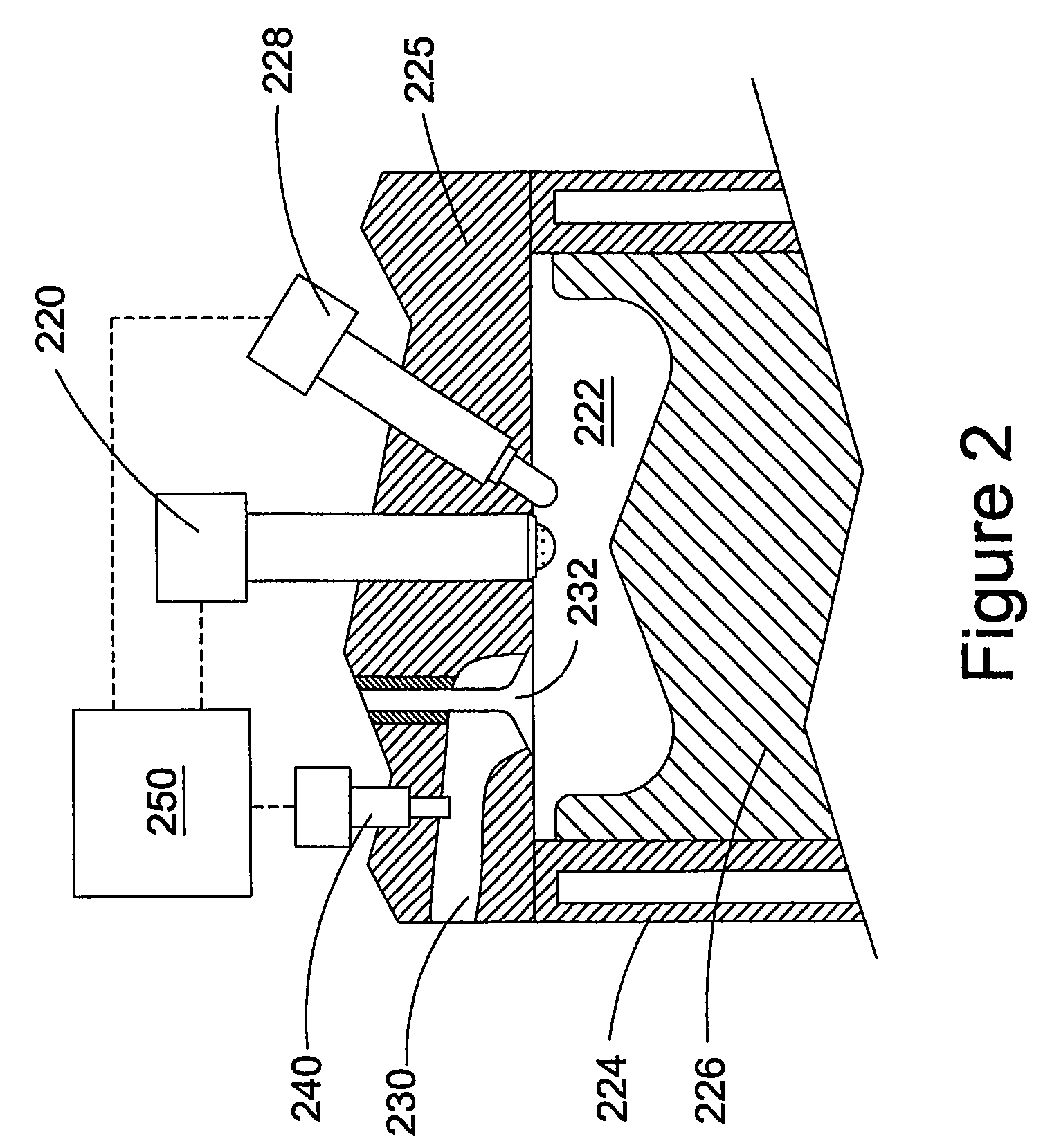

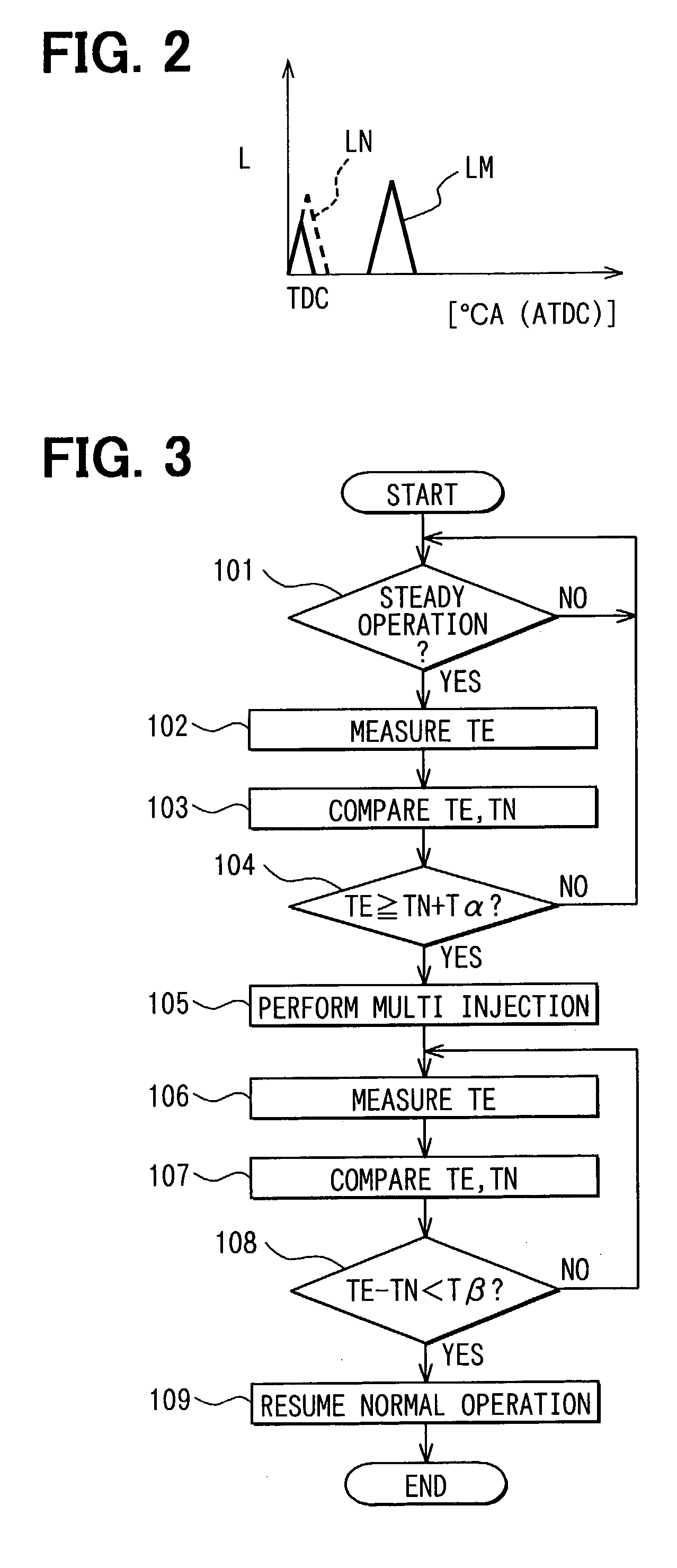

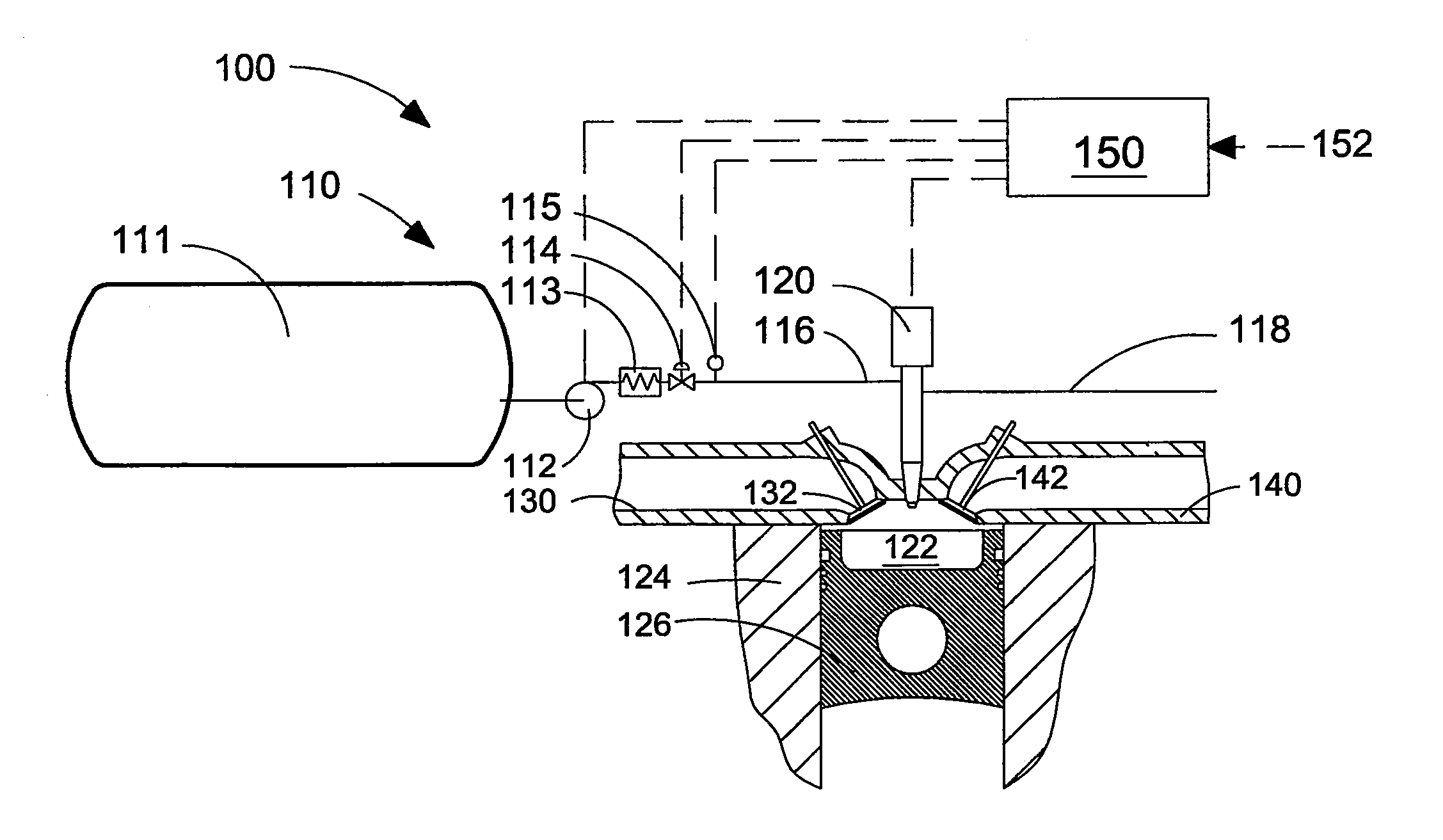

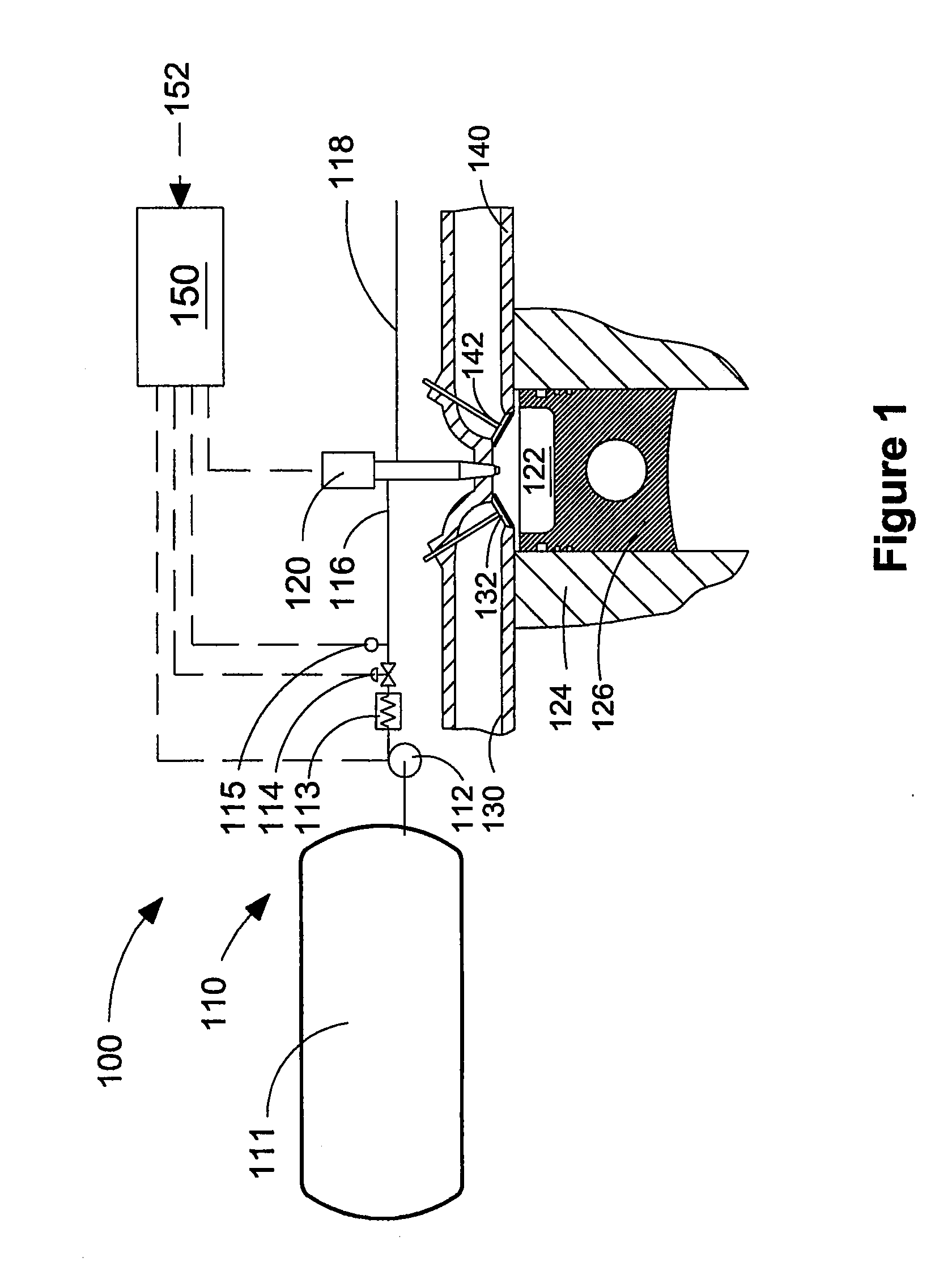

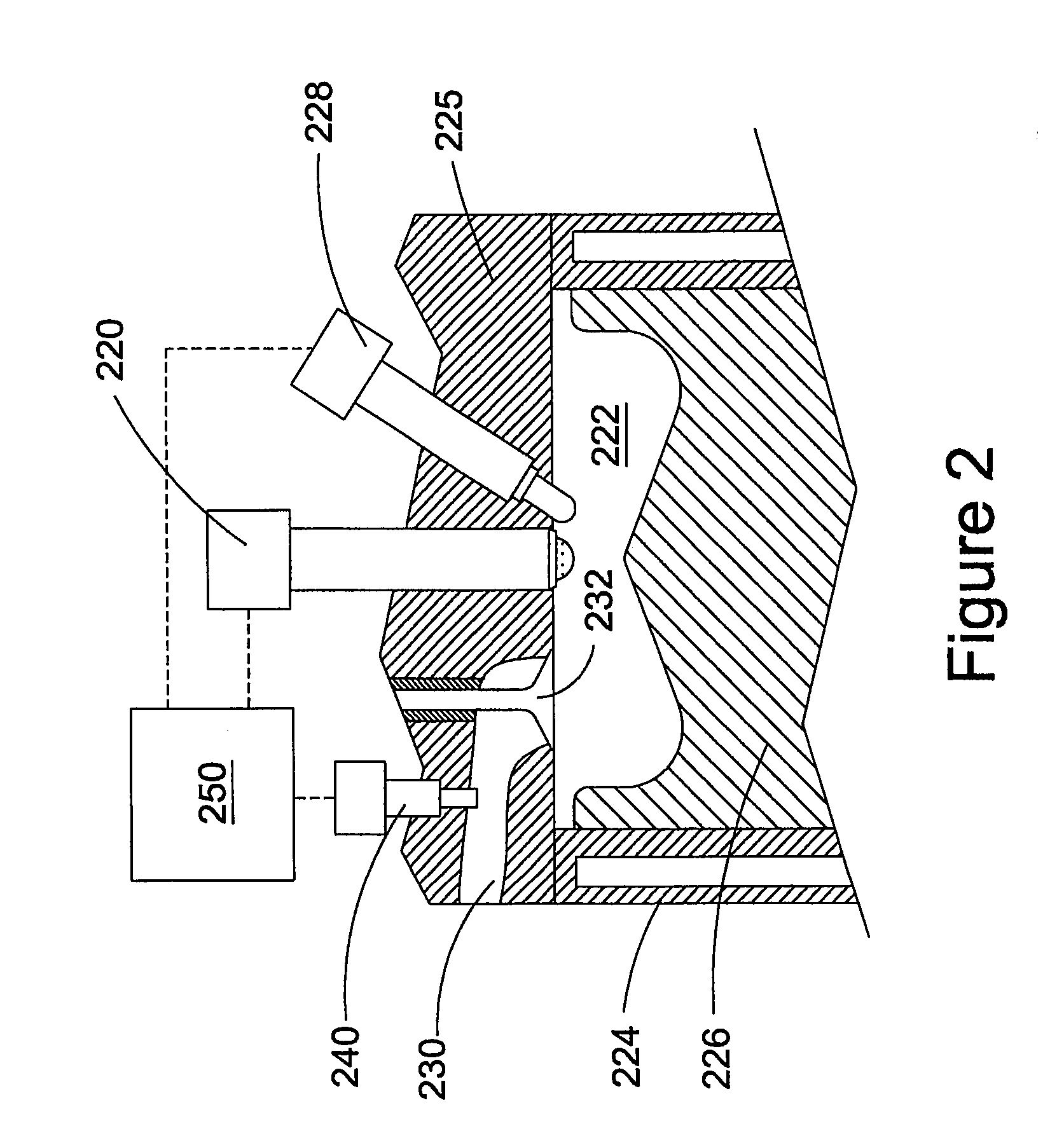

Plasma ignition for direct injected internal combustion engines

InactiveUS6883490B2Extend engine lifeGreater engine durabilitySparking plugsPower operated startersCombustion chamberPollutant emissions

Owner:JAYNE MICHAEL E

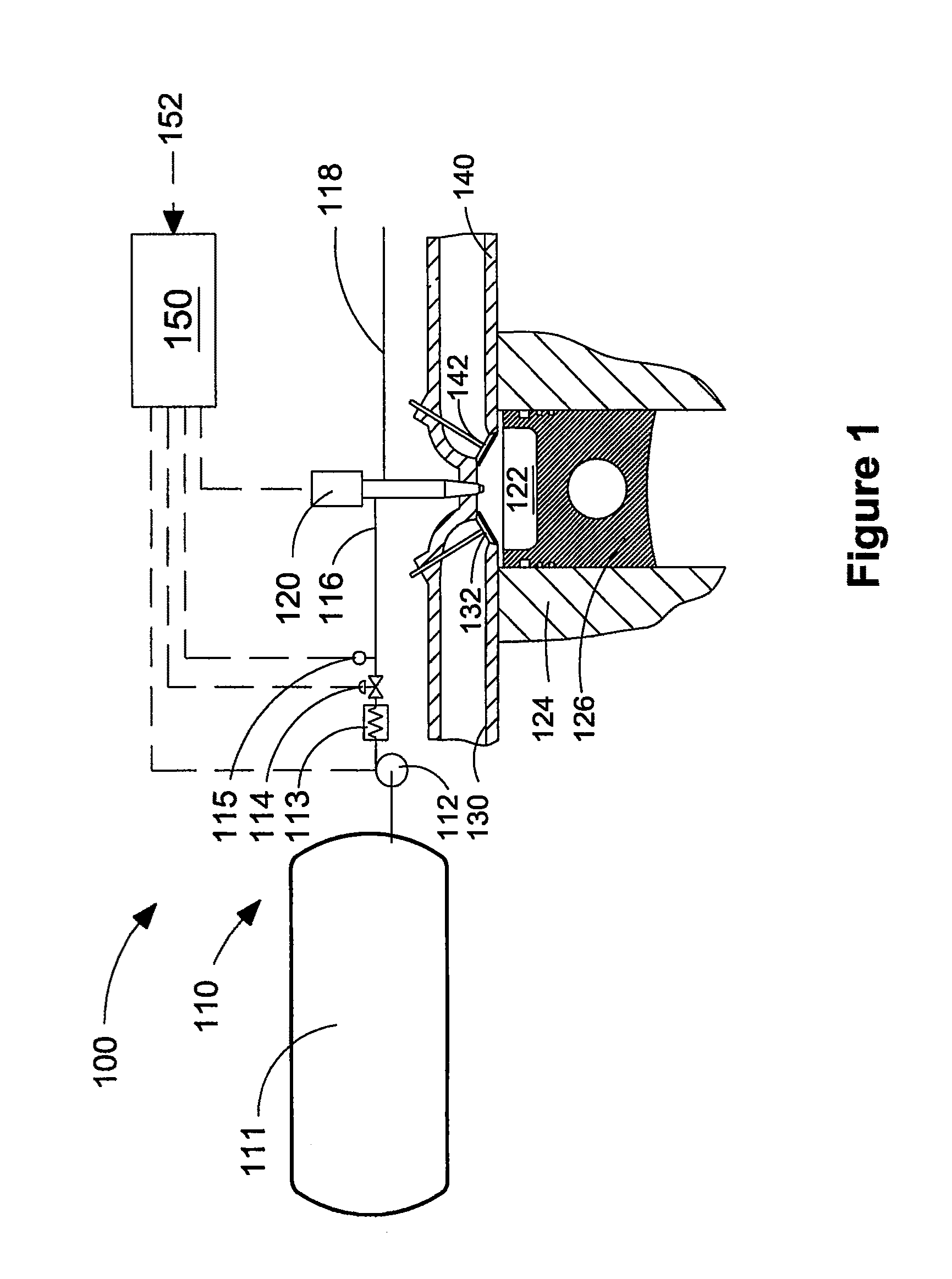

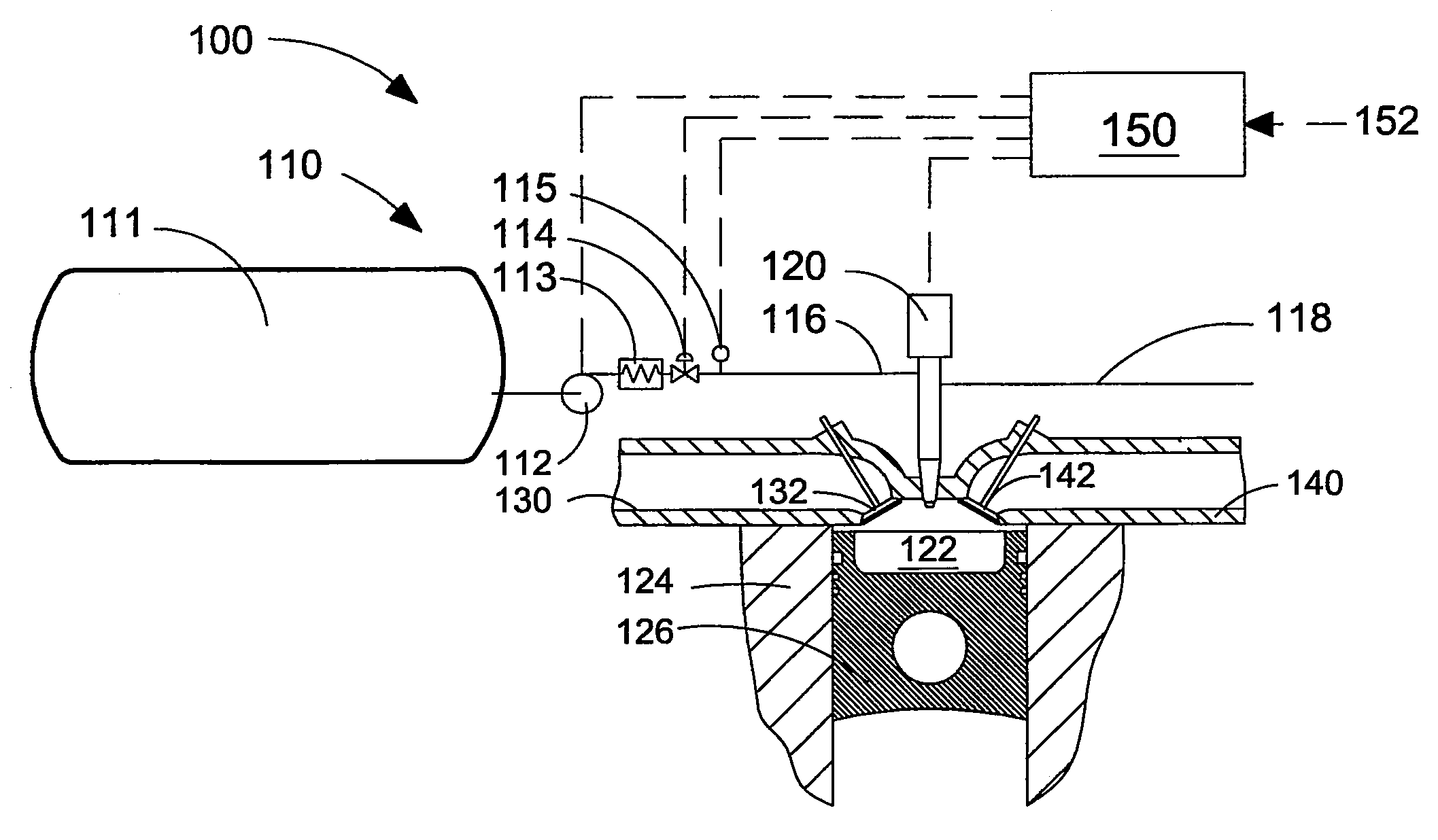

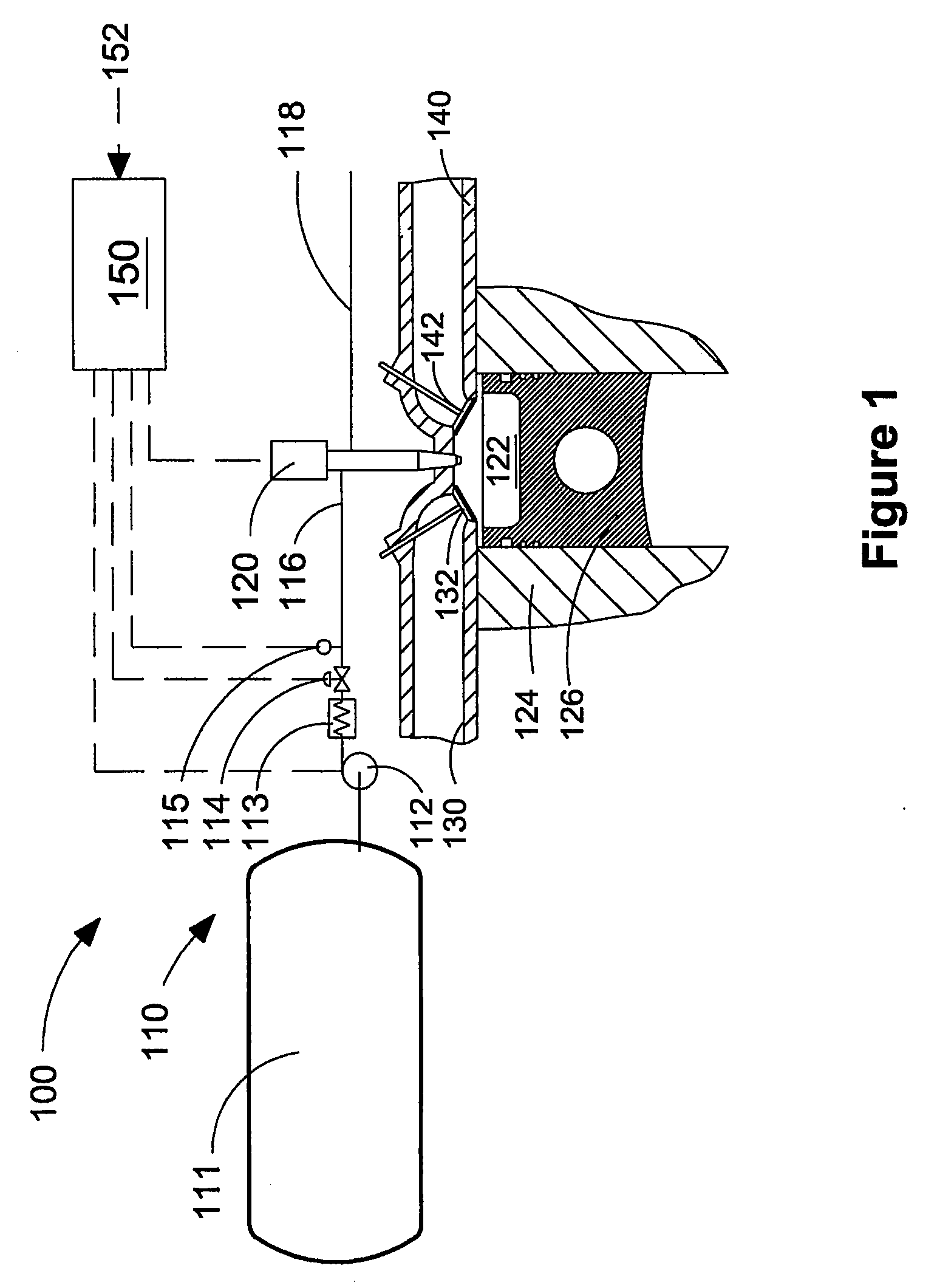

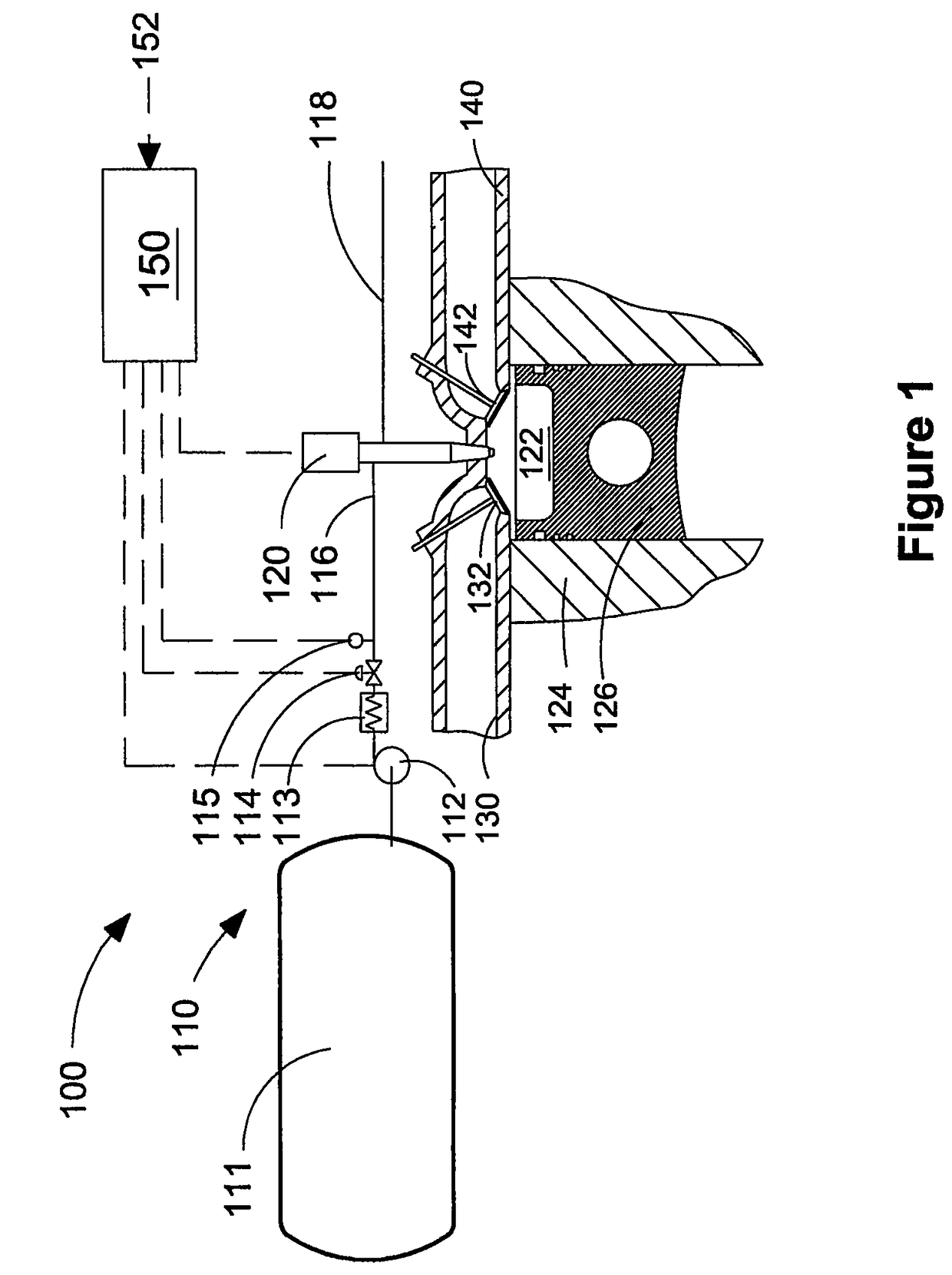

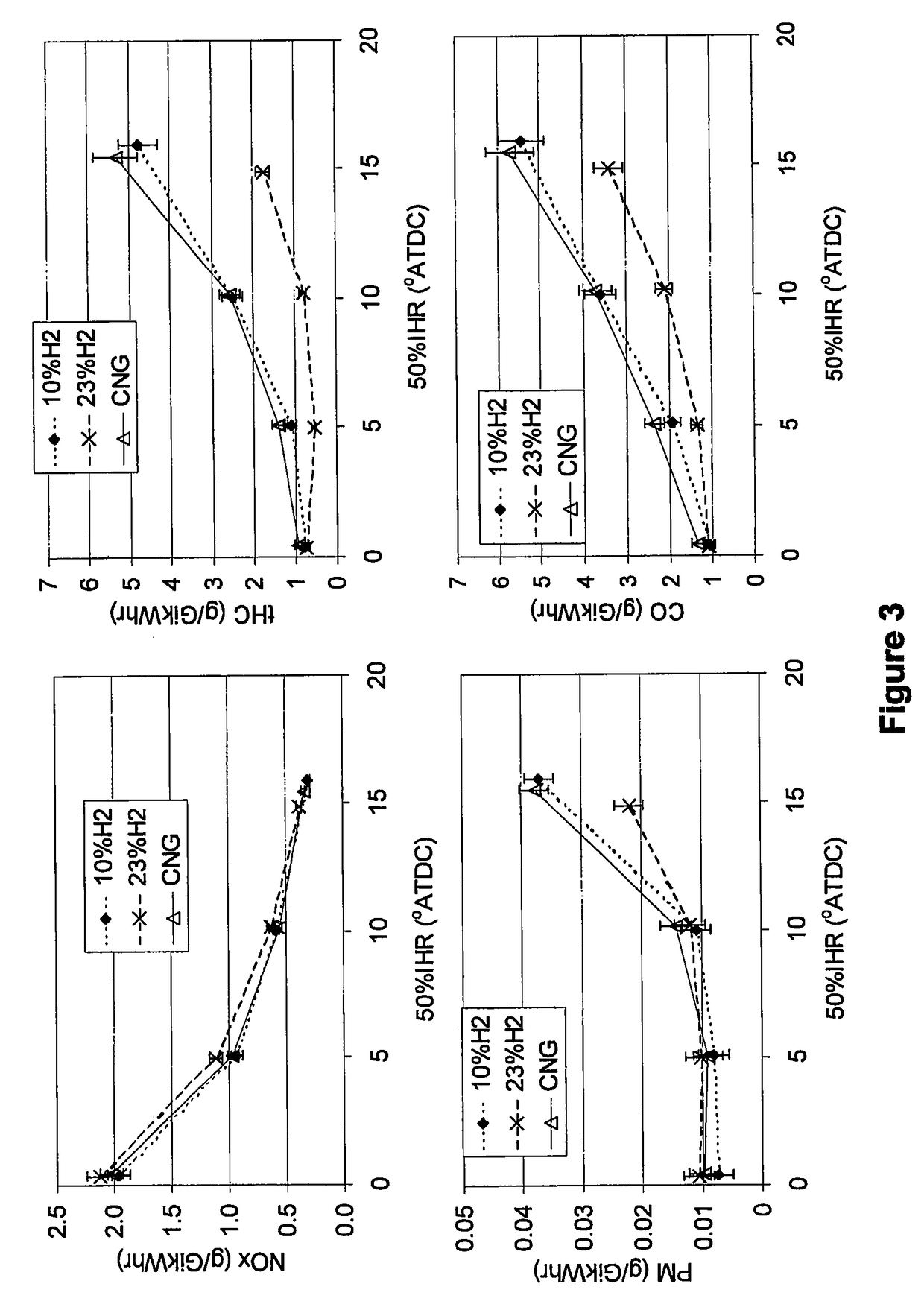

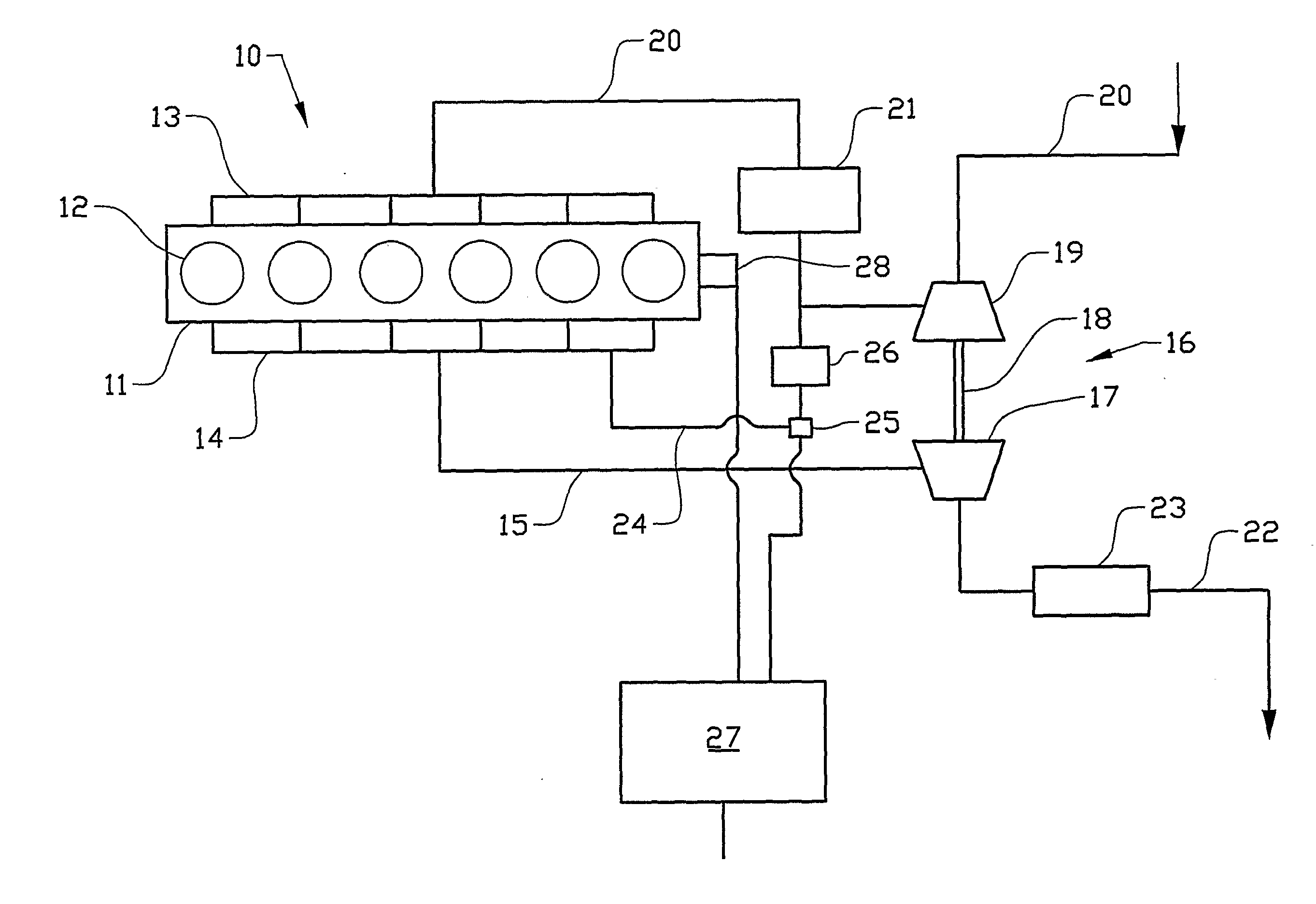

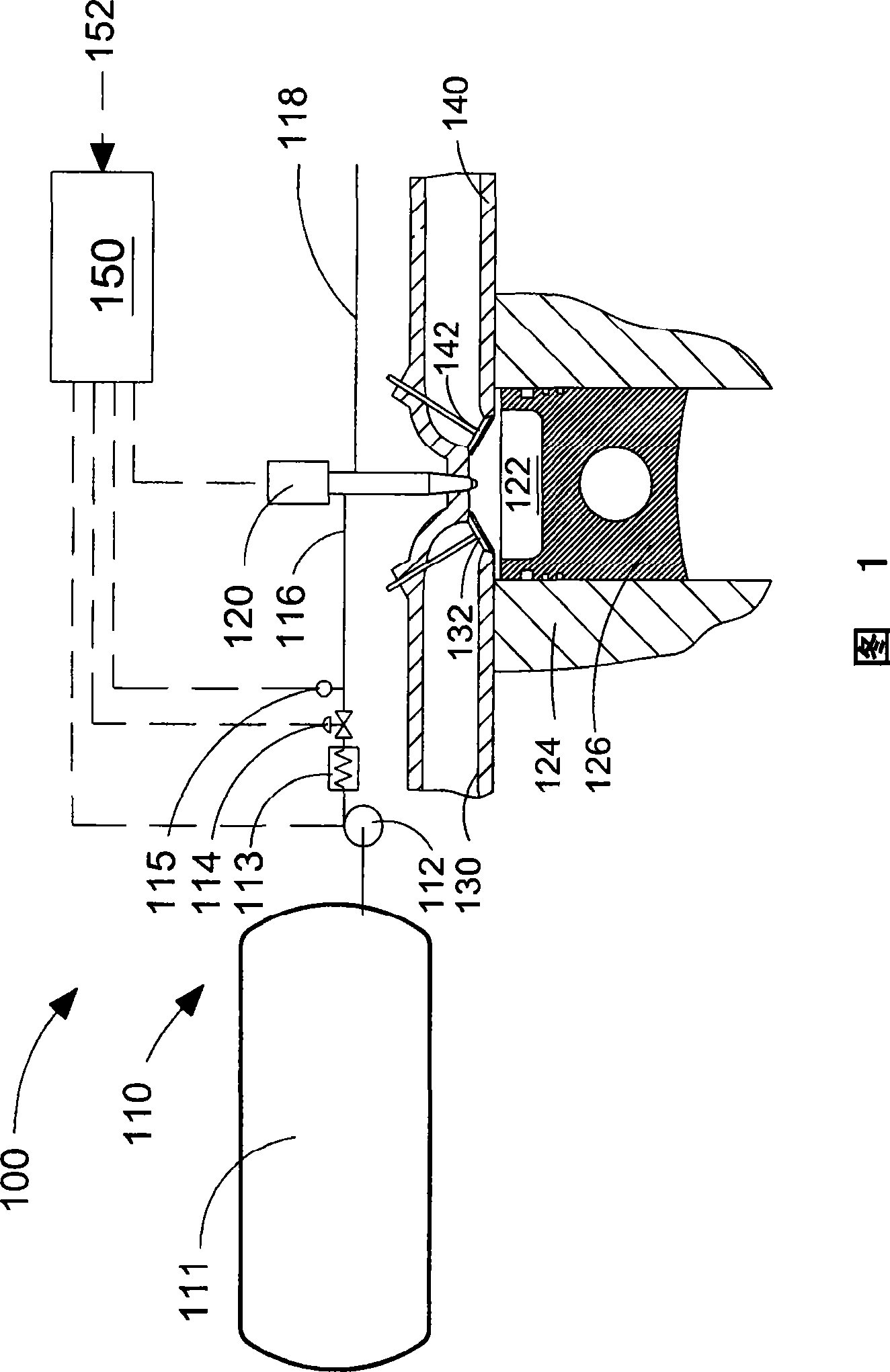

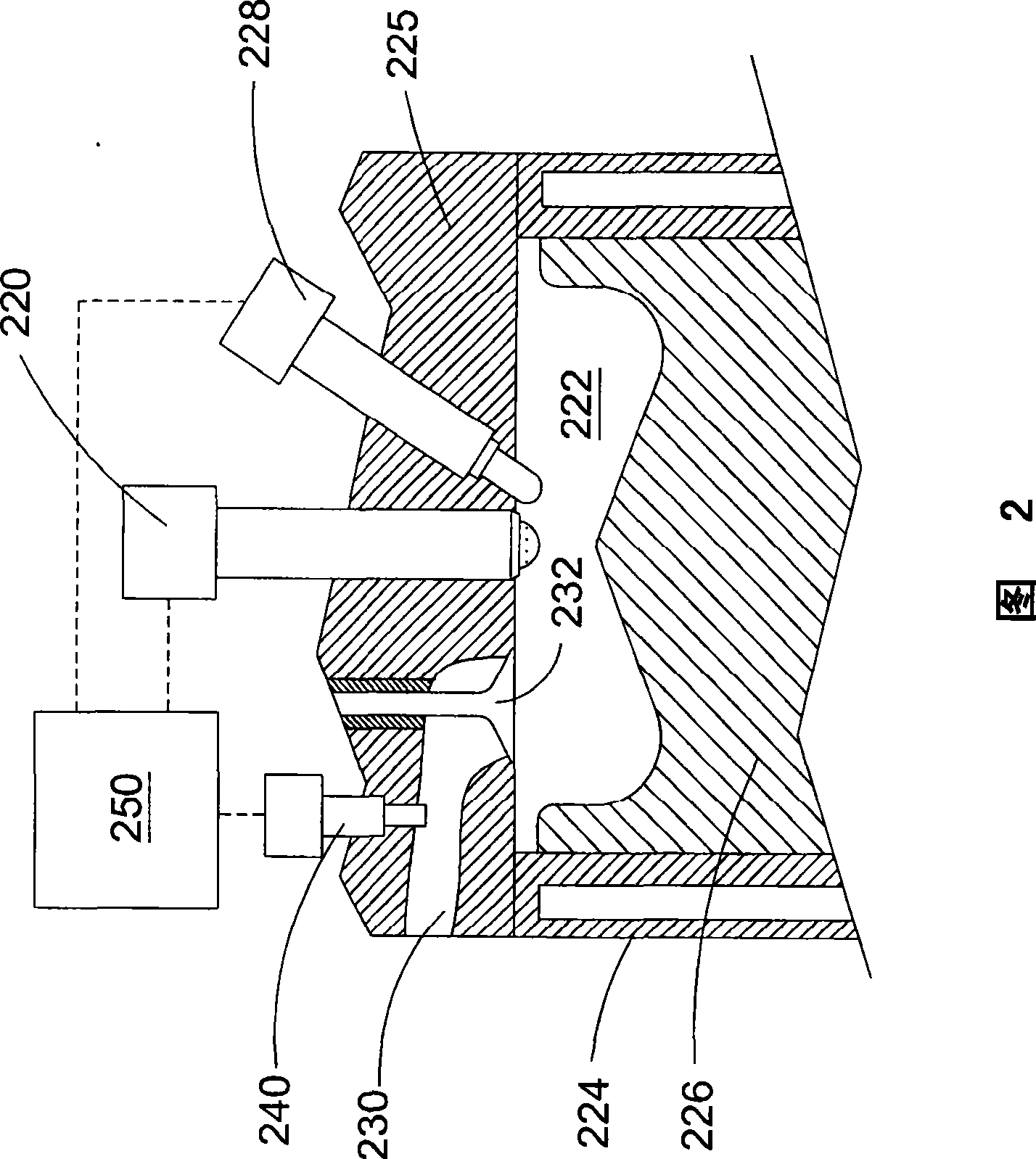

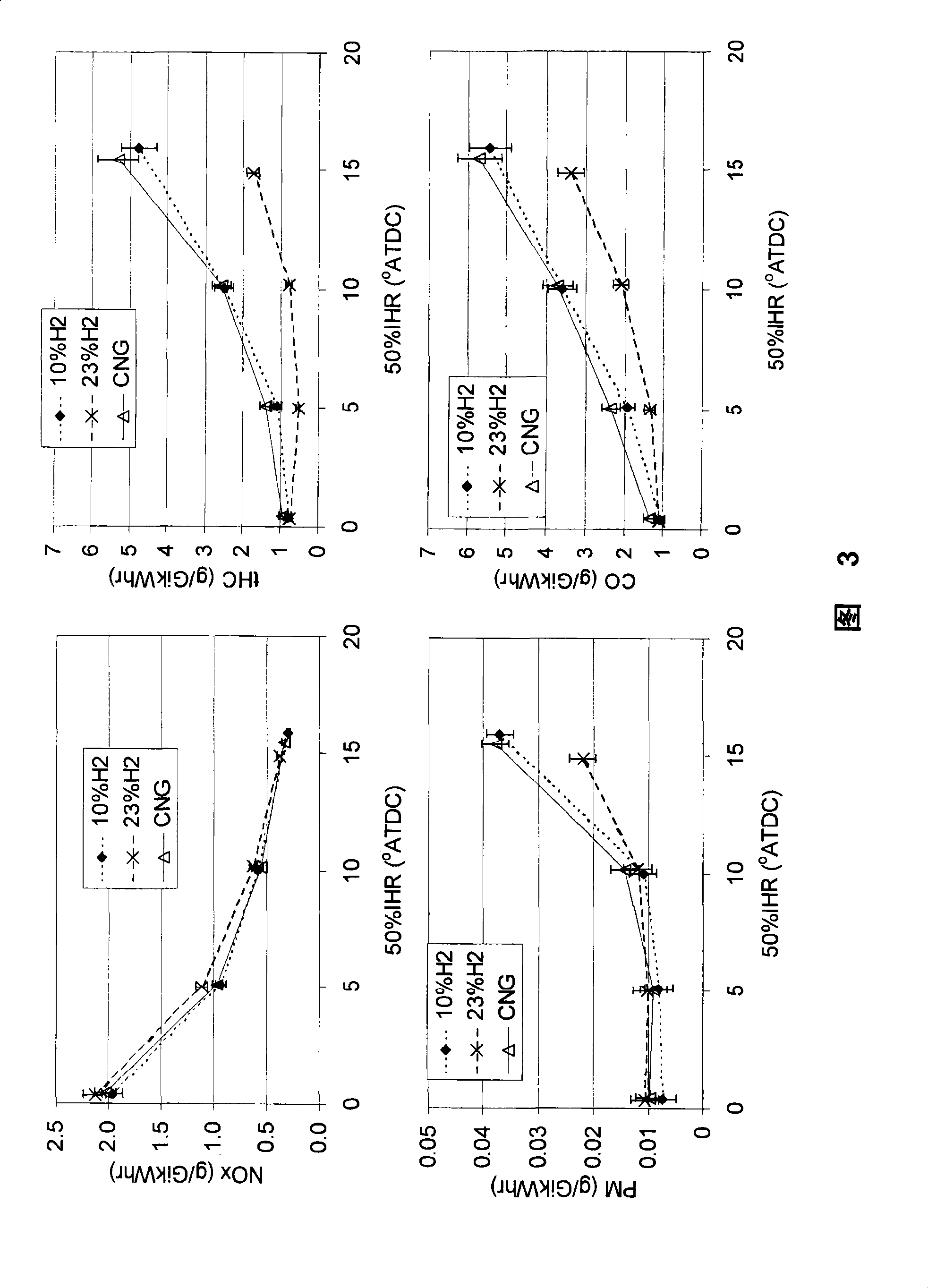

Method and apparatus of fuelling an internal combustion engine with hydrogen and methane

ActiveUS8091536B2Internal combustion piston enginesNon-fuel substance addition to fuelRail pressureElectronic controller

Owner:THE UNIV OF BRITISH COLUMBIA +1

Method And Apparatus Of Fuelling An Internal Combustion Engine With Hydrogen And Methane

ActiveUS20090120385A1Internal combustion piston enginesNon-fuel substance addition to fuelRail pressureElectronic controller

A gaseous-fuelled internal combustion engine and a method of engine operation improve combustion stability and reducing emissions of NOx, PM, and unburned hydrocarbons. The method comprises fuelling an internal combustion engine with hydrogen and natural gas, which can be directly injected into the combustion chamber together or introduced separately. Of the total gaseous fuel delivered to the engine, at least 5% by volume at standard temperature and pressure is hydrogen. For at least one engine operating condition, the ratio of fuel rail pressure to peak in-cylinder pressure is at least 1.5:1. A fuel injection valve introduces the gaseous fuel mixture directly into the combustion chamber. Two separate fuel injection valves could also introduce the methane and hydrogen separately. An electronic controller controls timing for operating the fuel injection valve(s). The engine has a preferred compression ratio of at least 14:1.

Owner:THE UNIV OF BRITISH COLUMBIA +1

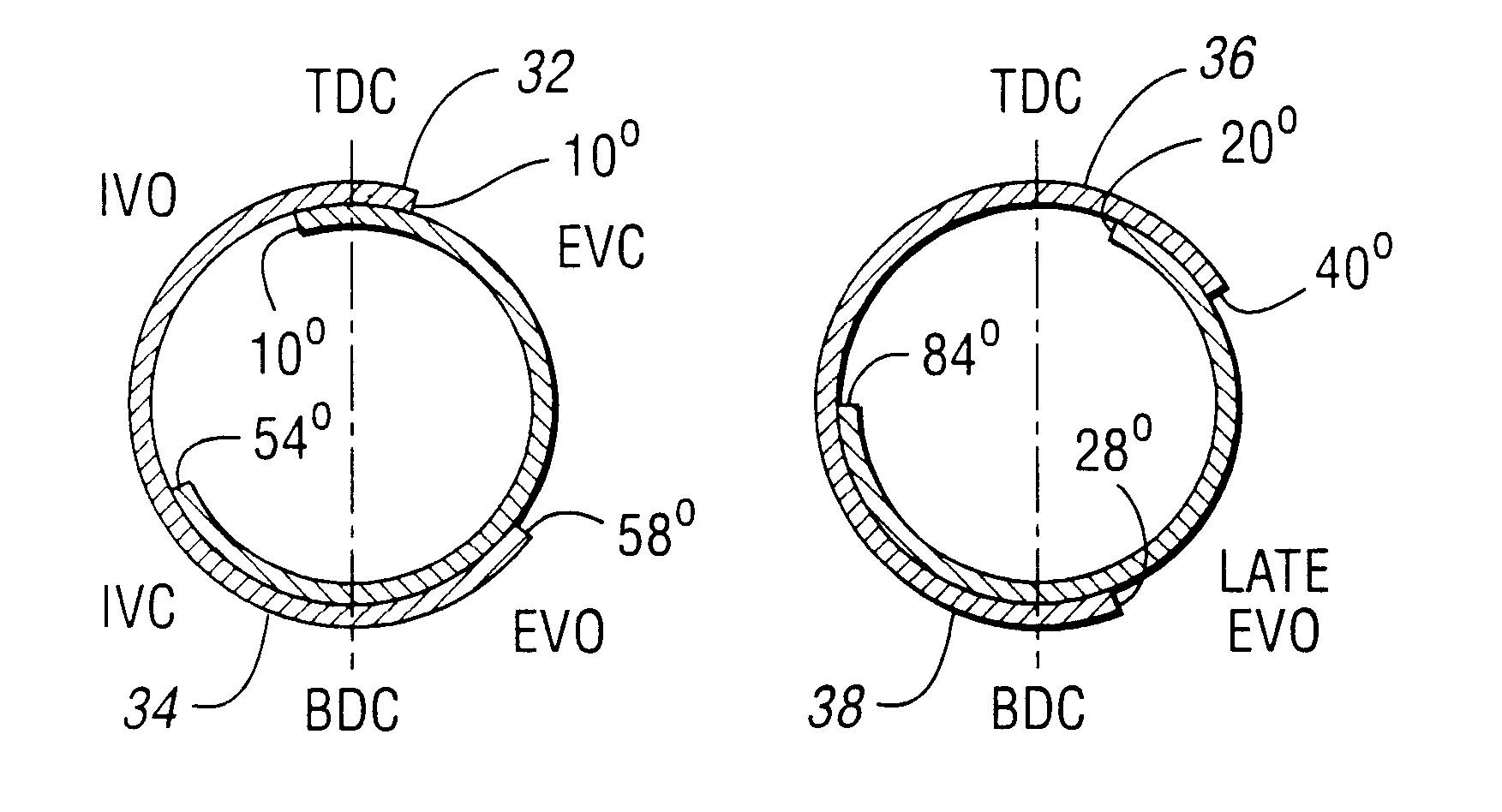

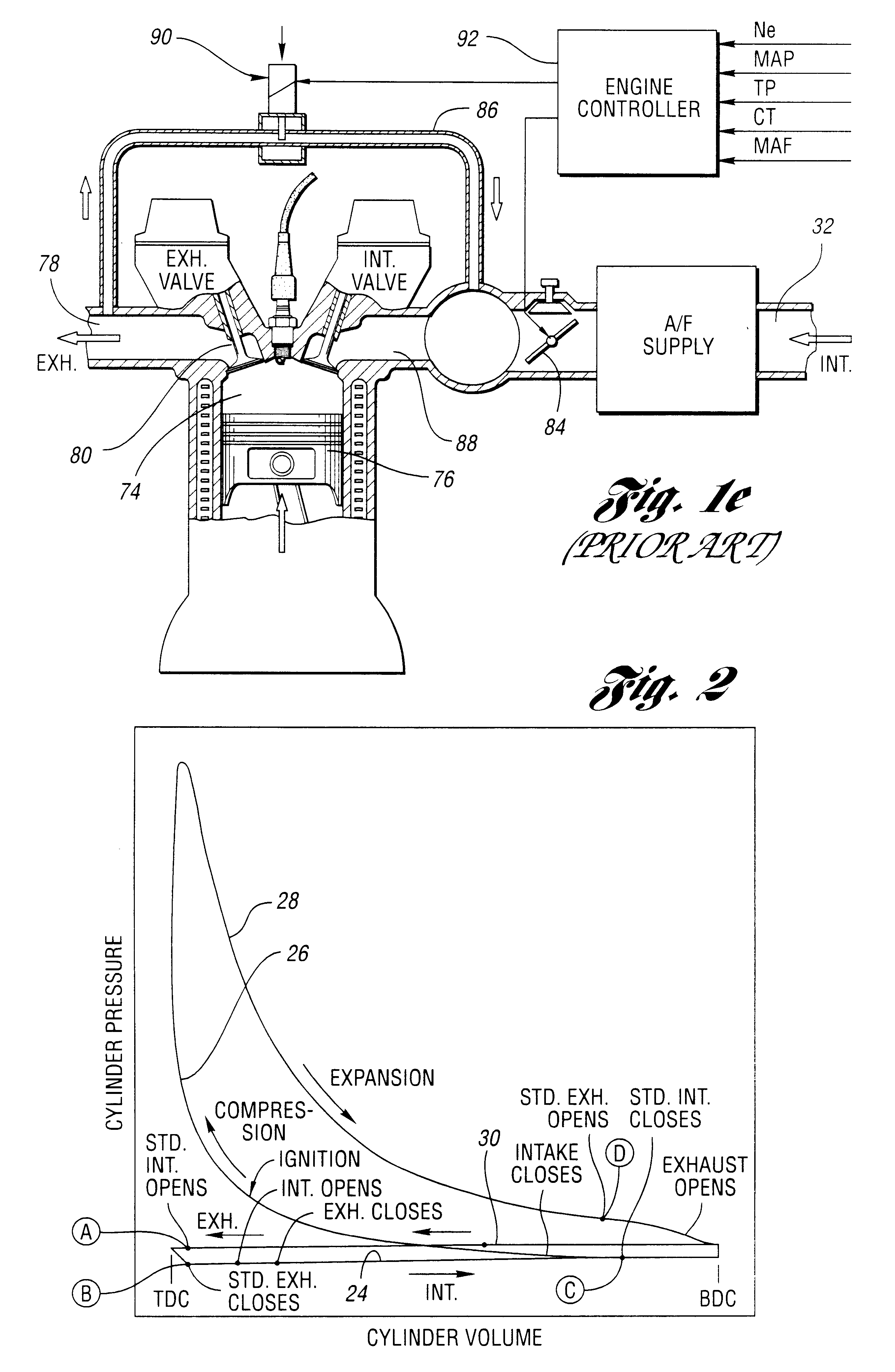

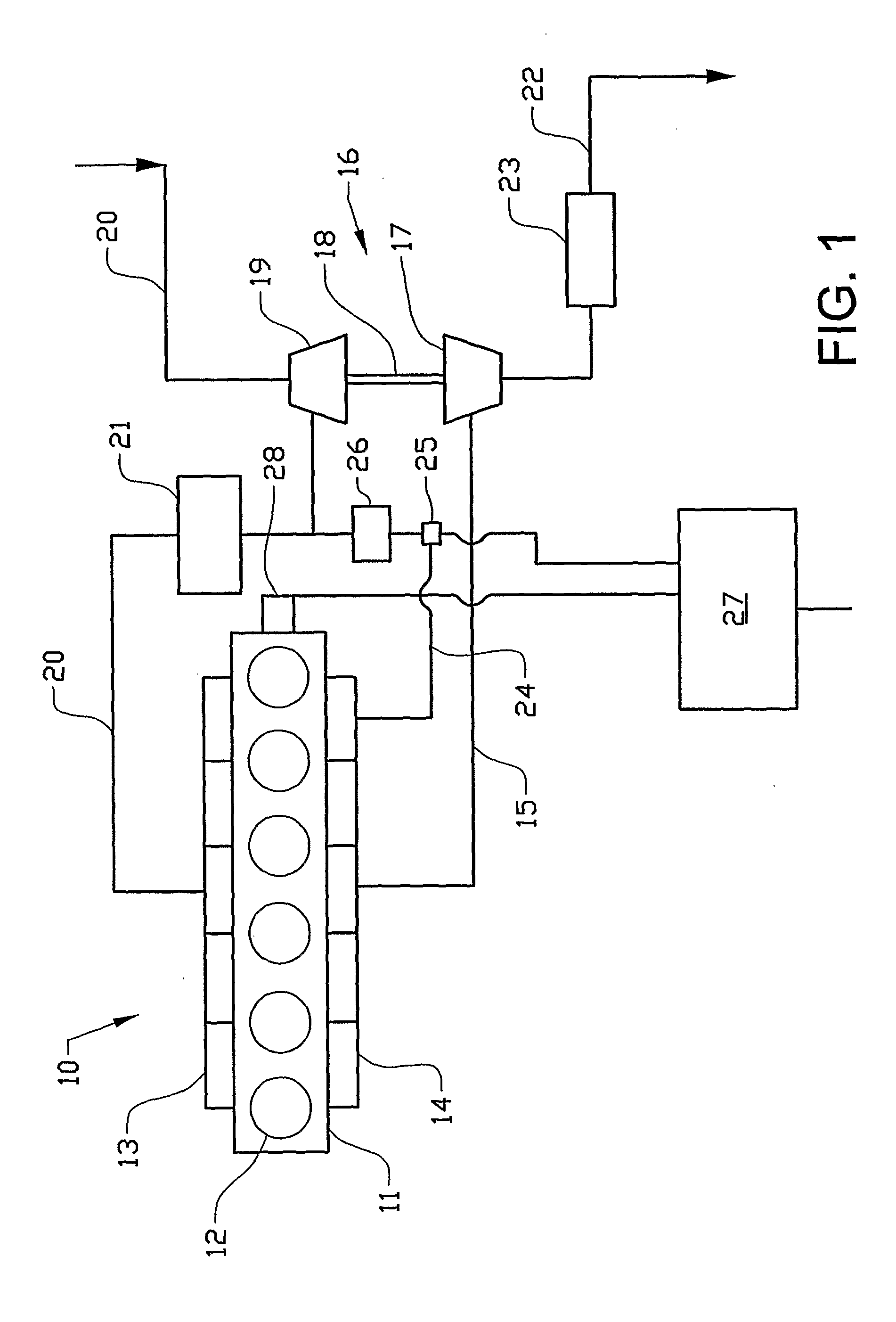

Engine control strategy using dual equal cam phasing combined with exhaust gas recirculation

InactiveUS6321731B1Improve thermal efficiencyReduction nitrous oxide gasInternal combustion piston enginesNon-fuel substance addition to fuelExhaust valveInlet valve

The invention comprises a strategy and method for phase shifting intake and exhaust valve timing relative to crankshaft position as a function of engine operating variables, whereby valve overlap is delayed to obtain improved fuel economy resulting from a late intake valve closing to reduce pumping work during the intake stroke. The exhaust gases are drawn into the combustion cylinder of the engine during the intake stroke, which reduces oxides of nitrogen in the exhaust gas and reduces unburned hydrocarbons. Improved thermal efficiency and reductions in oxides of nitrogen are achieved as the combustion charge is diluted at higher loads by an external exhaust gas recirculation system, thereby combining the effects of exhaust gas recirculation and dual equal variable camshaft timing to obtain fuel economy benefits that cannot be achieved with either a conventional EGR system acting alone or dual equal variable camshaft timing acting alone.

Owner:FORD MOTOR CO

Method and apparatus of fuelling an internal combustion engine with hydrogen and methane

ActiveUS8469009B2Reduce the amount of solutionInternal combustion piston enginesNon-fuel substance addition to fuelElectronic controllerRail pressure

A gaseous-fuelled internal combustion engine and a method of engine operation improve combustion stability and reducing emissions of NOx, PM, and unburned hydrocarbons. The method comprises fuelling an internal combustion engine with hydrogen and natural gas, which can be directly injected into the combustion chamber together or introduced separately. Of the total gaseous fuel delivered to the engine, at least 5% by volume at standard temperature and pressure is hydrogen. For at least one engine operating condition, the ratio of fuel rail pressure to peak in-cylinder pressure is at least 1.5:1. A fuel injection valve introduces the gaseous fuel mixture directly into the combustion chamber. Two separate fuel injection valves could also introduce the methane and hydrogen separately. An electronic controller controls timing for operating the fuel injection valve(s). The engine has a preferred compression ratio of at least 14:1.

Owner:THE UNIV OF BRITISH COLUMBIA +1

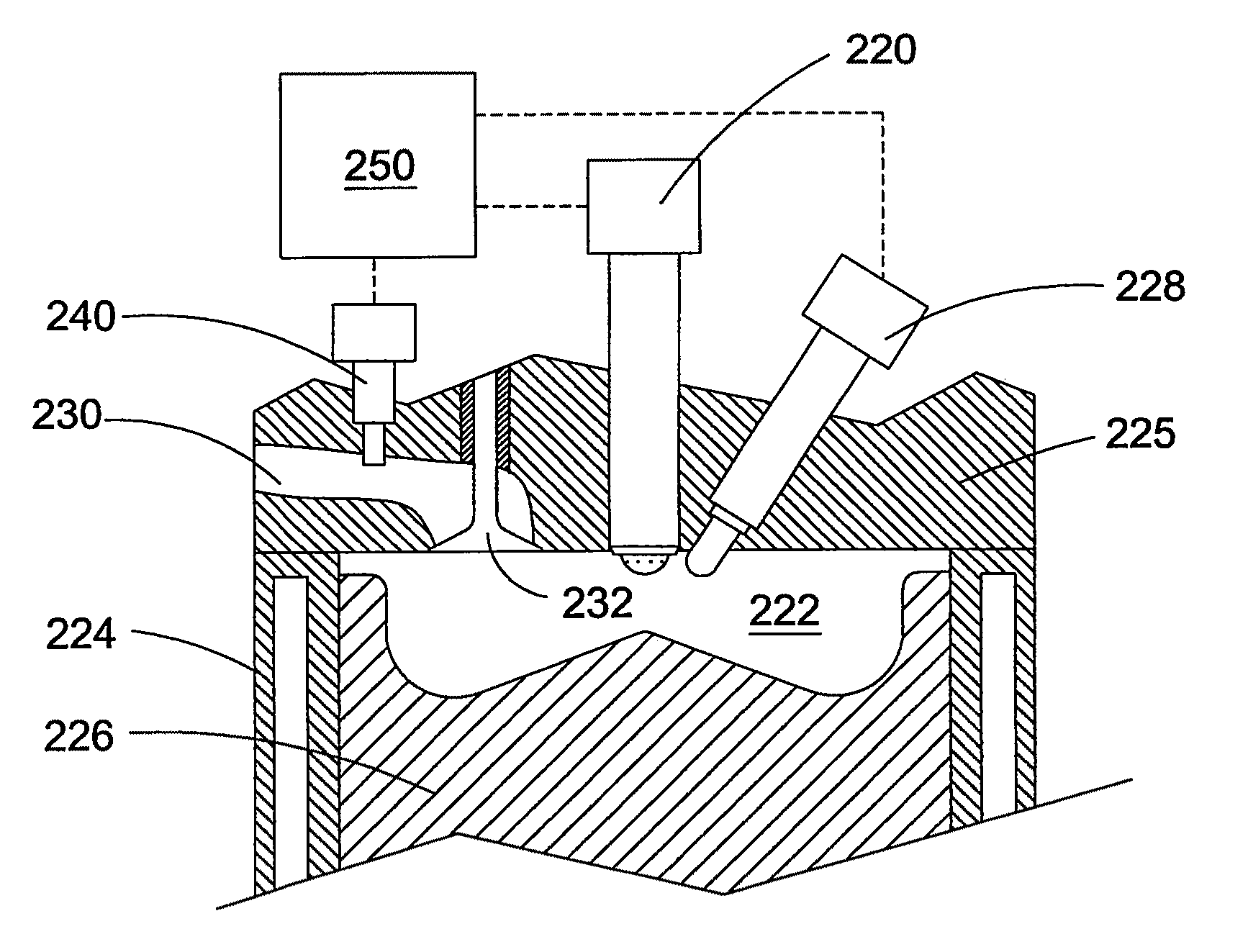

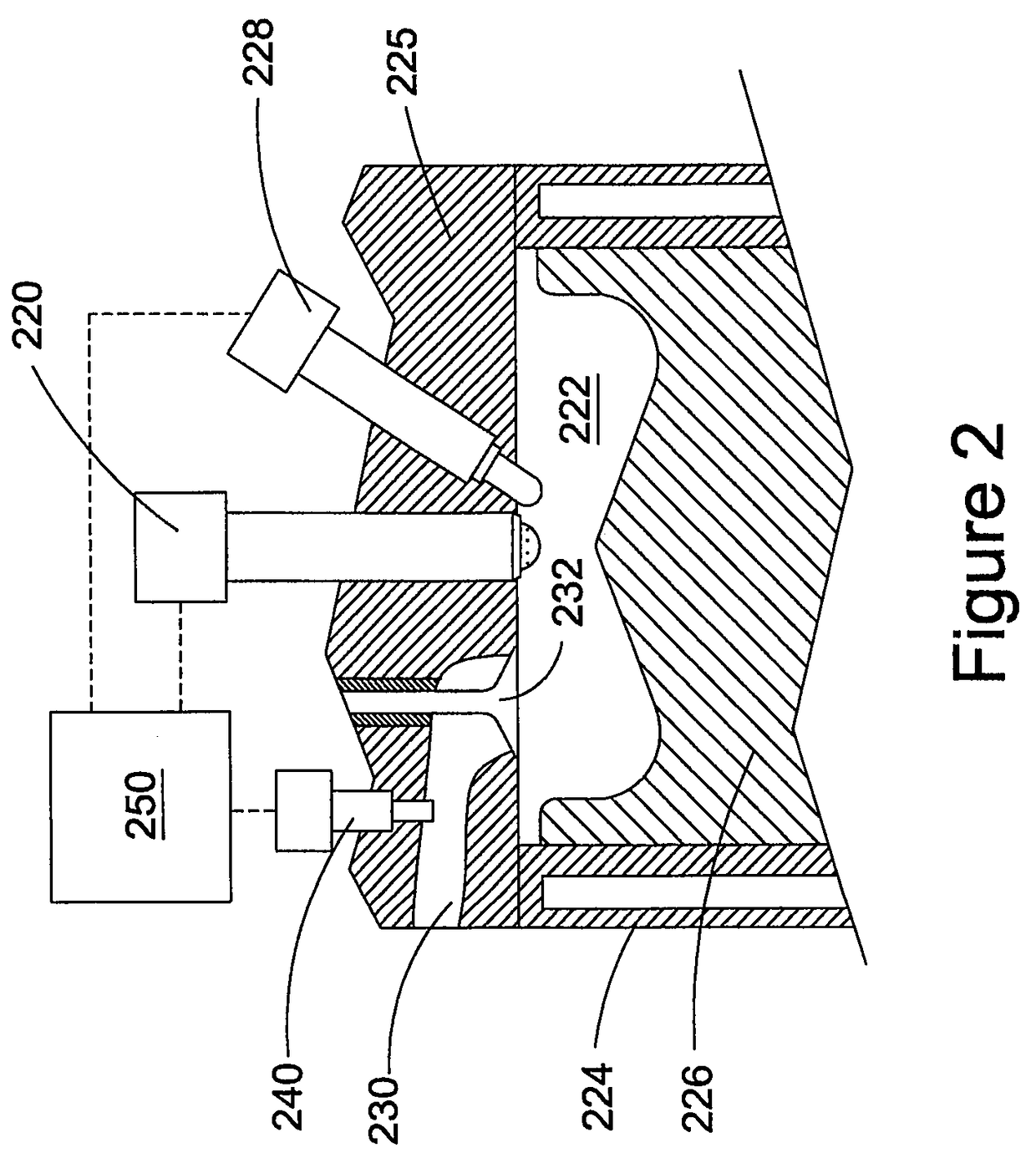

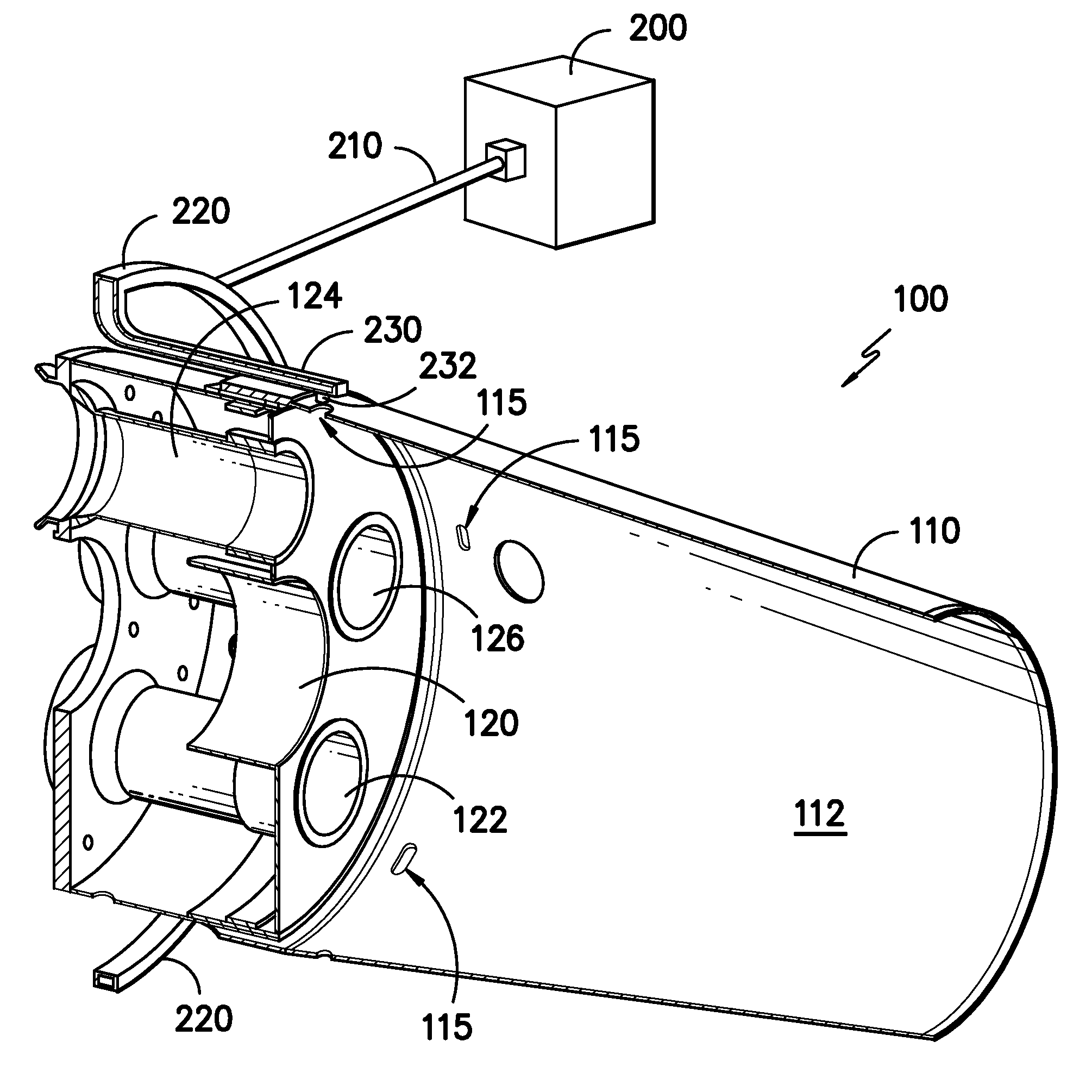

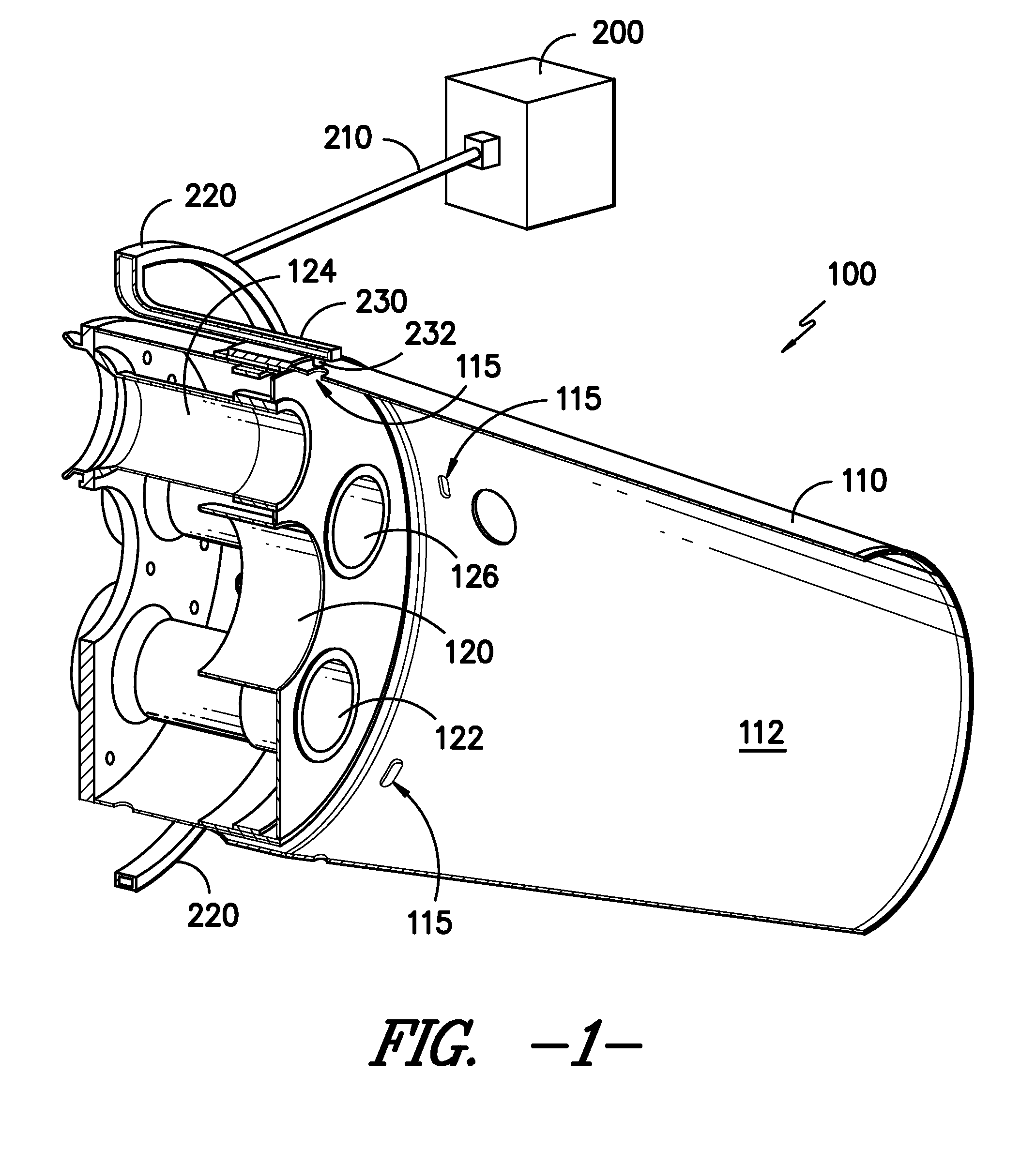

Apparatus for high-frequency electromagnetic initiation of a combustion process

Apparatus for providing electromagnetic radiation to a combustor during a combustion process are disclosed. An electromagnetic radiation source delivers electromagnetic radiation through a first waveguide to a second waveguide that includes an electromagnetic radiation outlet positioned to deliver electromagnetic radiation to the interior of the combustor. Electromagnetic radiation is delivered to low temperature regions of a combustor to reduce carbon monoxide (CO) and unburned hydrocarbon (UHC) emissions. In addition, the electromagnetic radiation stimulates the combustion process so that lean air-fuel mixtures and low BTU gases can be burned at lower combustion temperatures leading to reduced NOx emissions.

Owner:GENERAL ELECTRIC CO

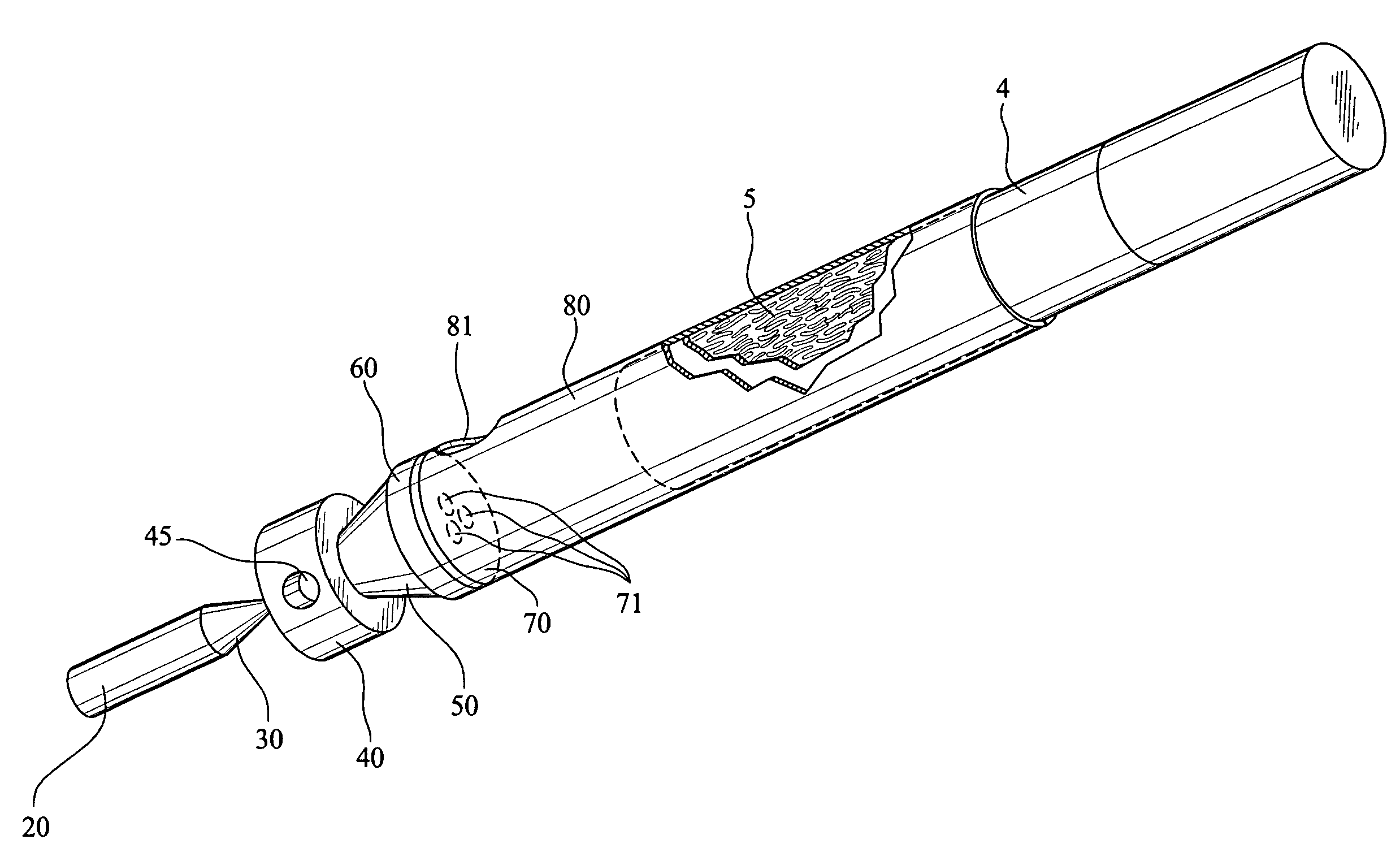

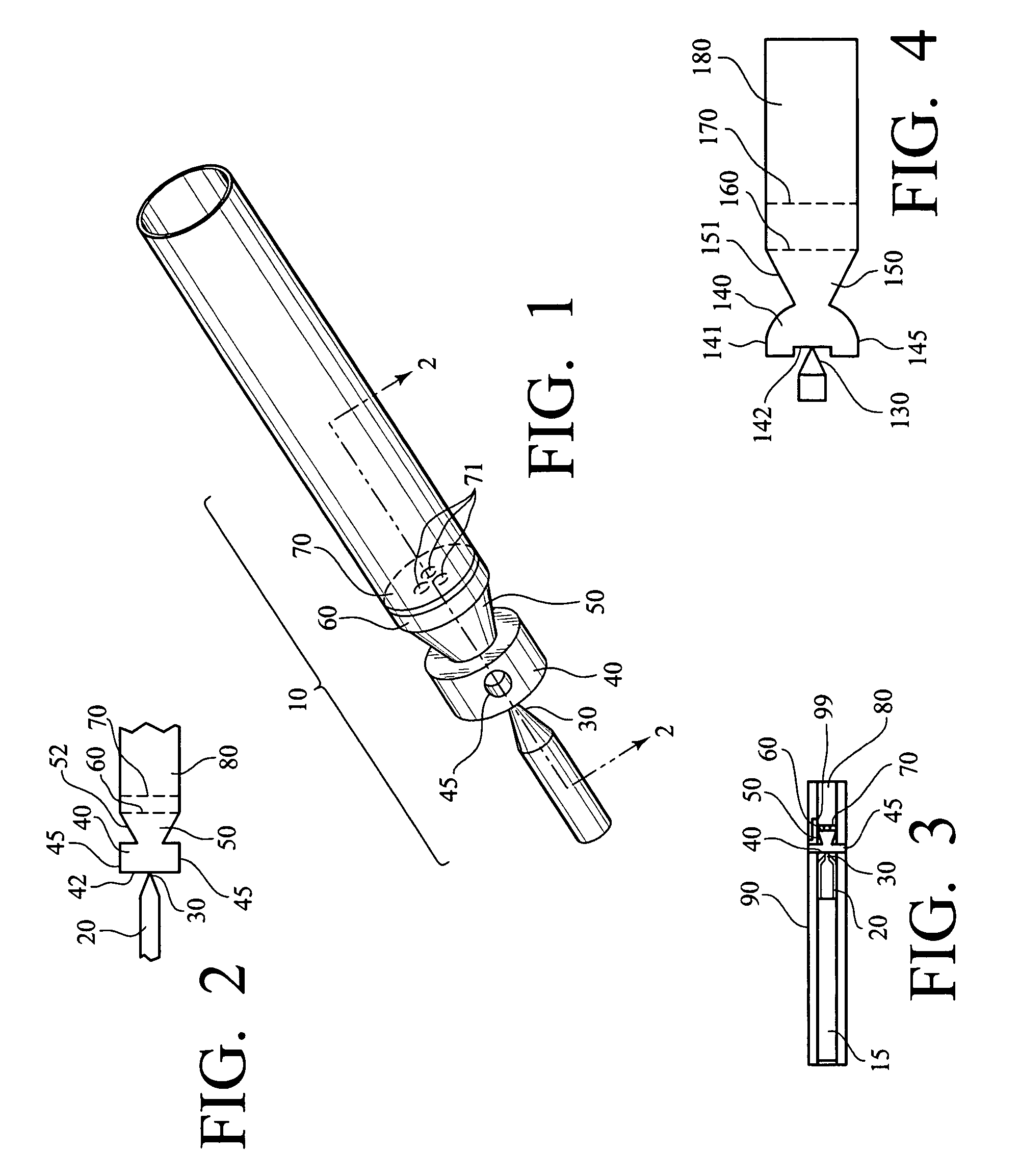

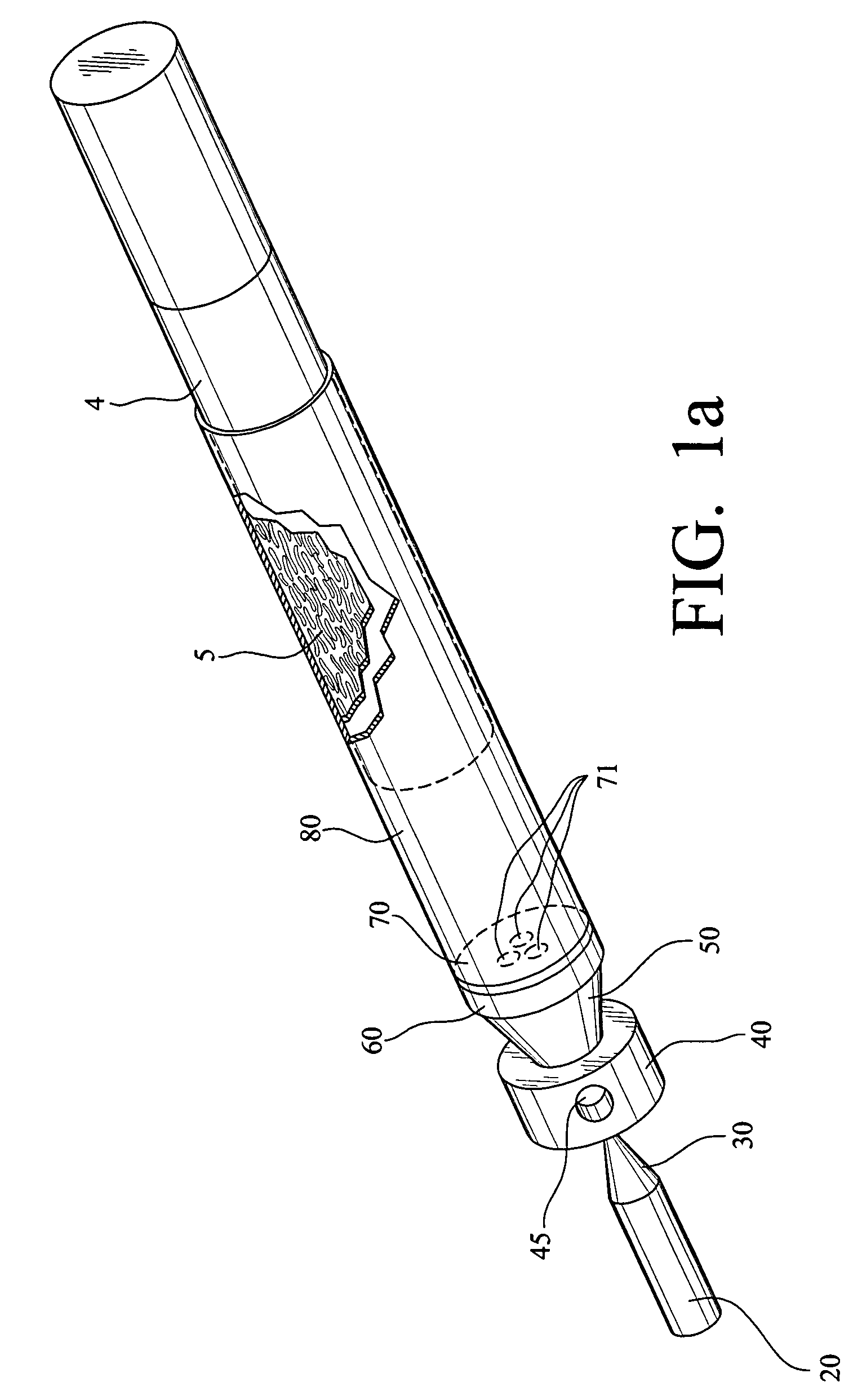

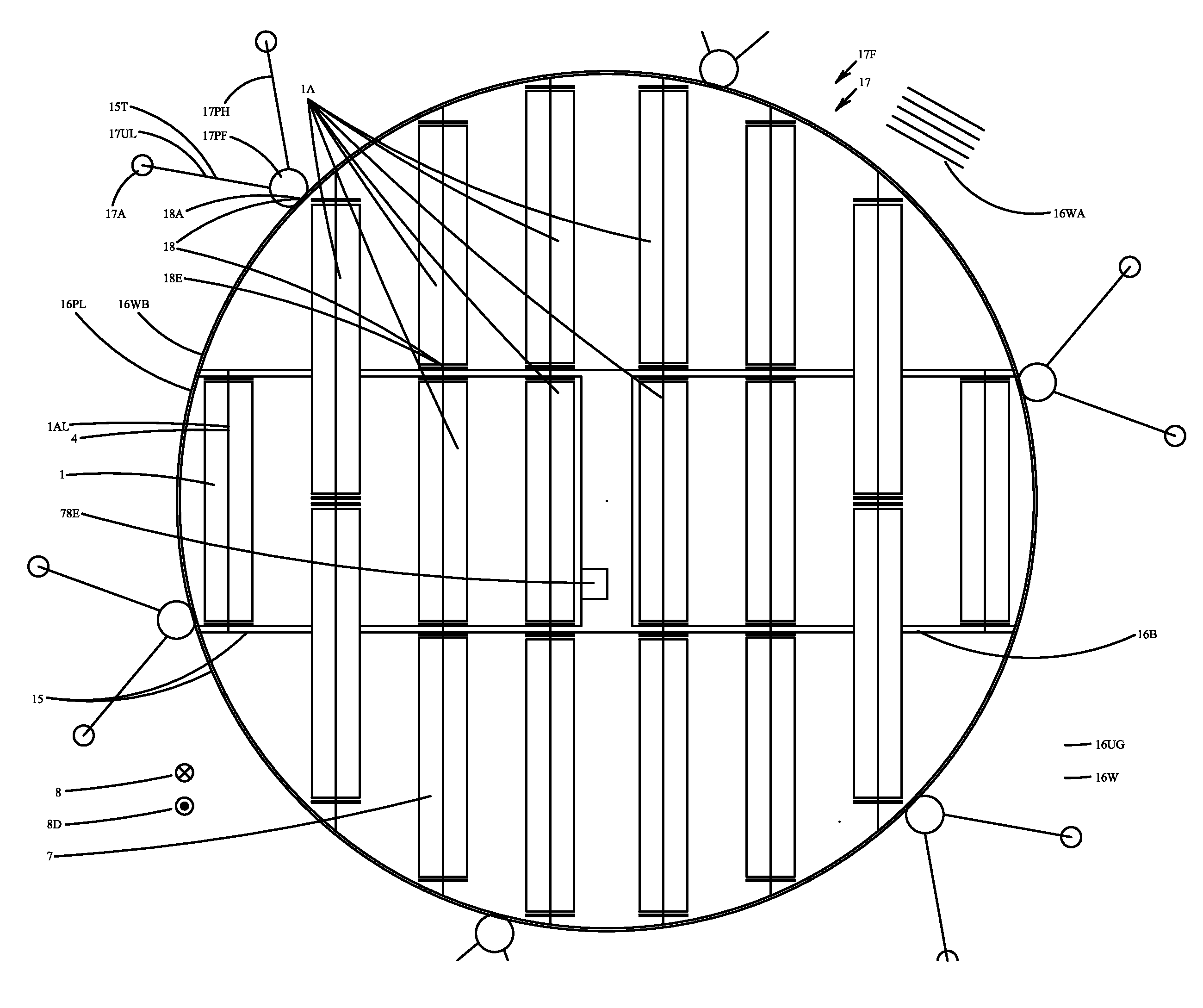

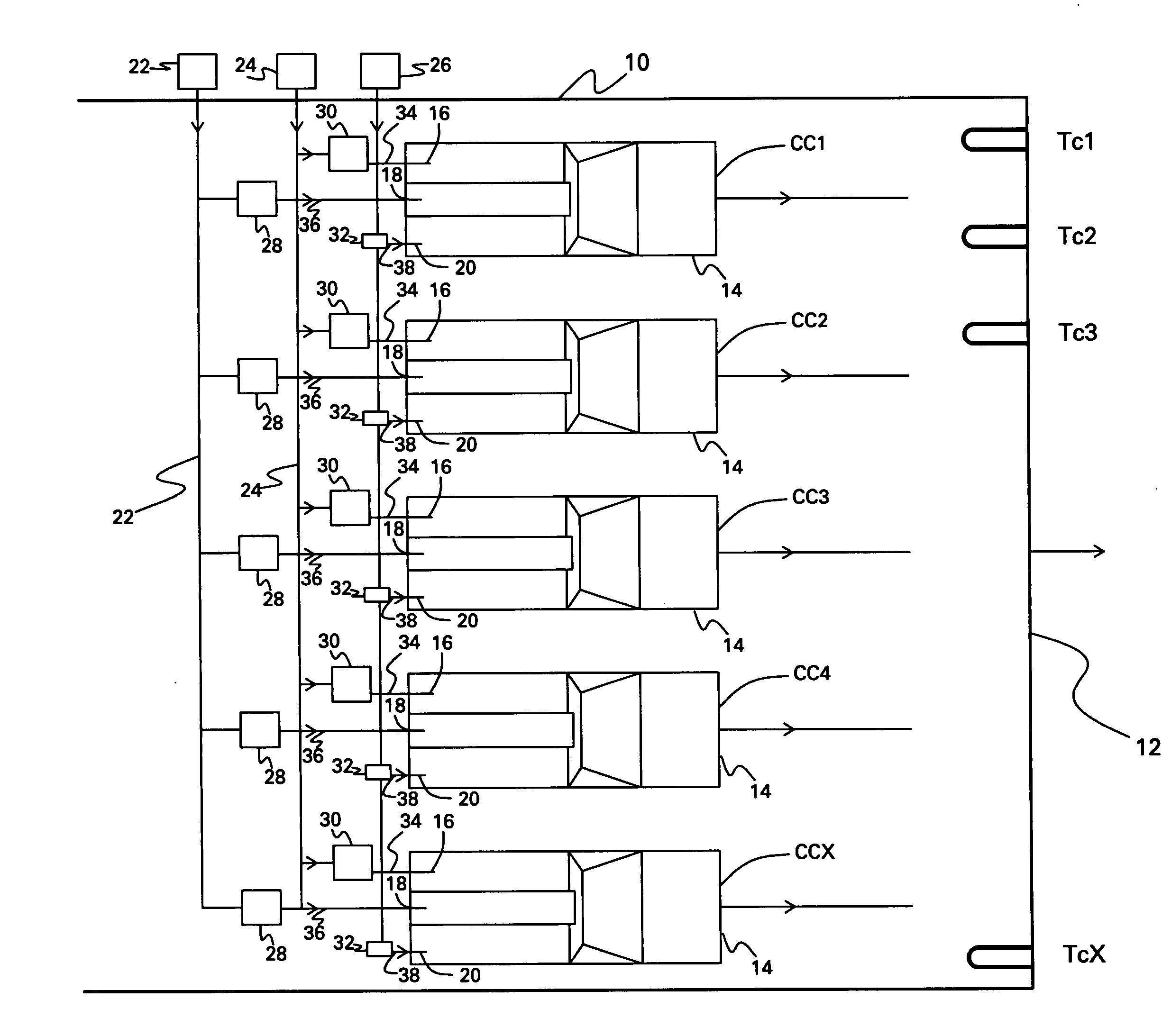

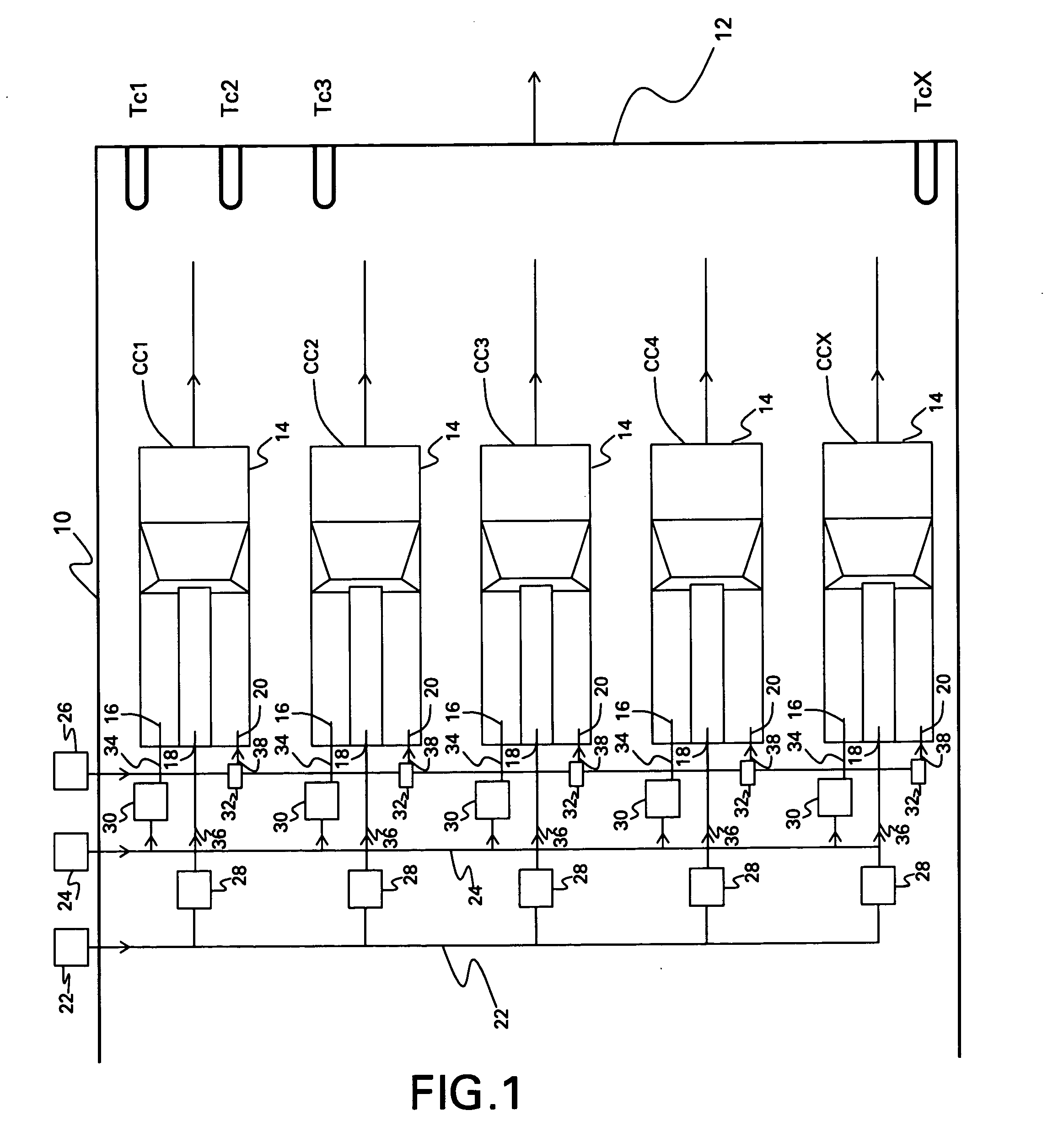

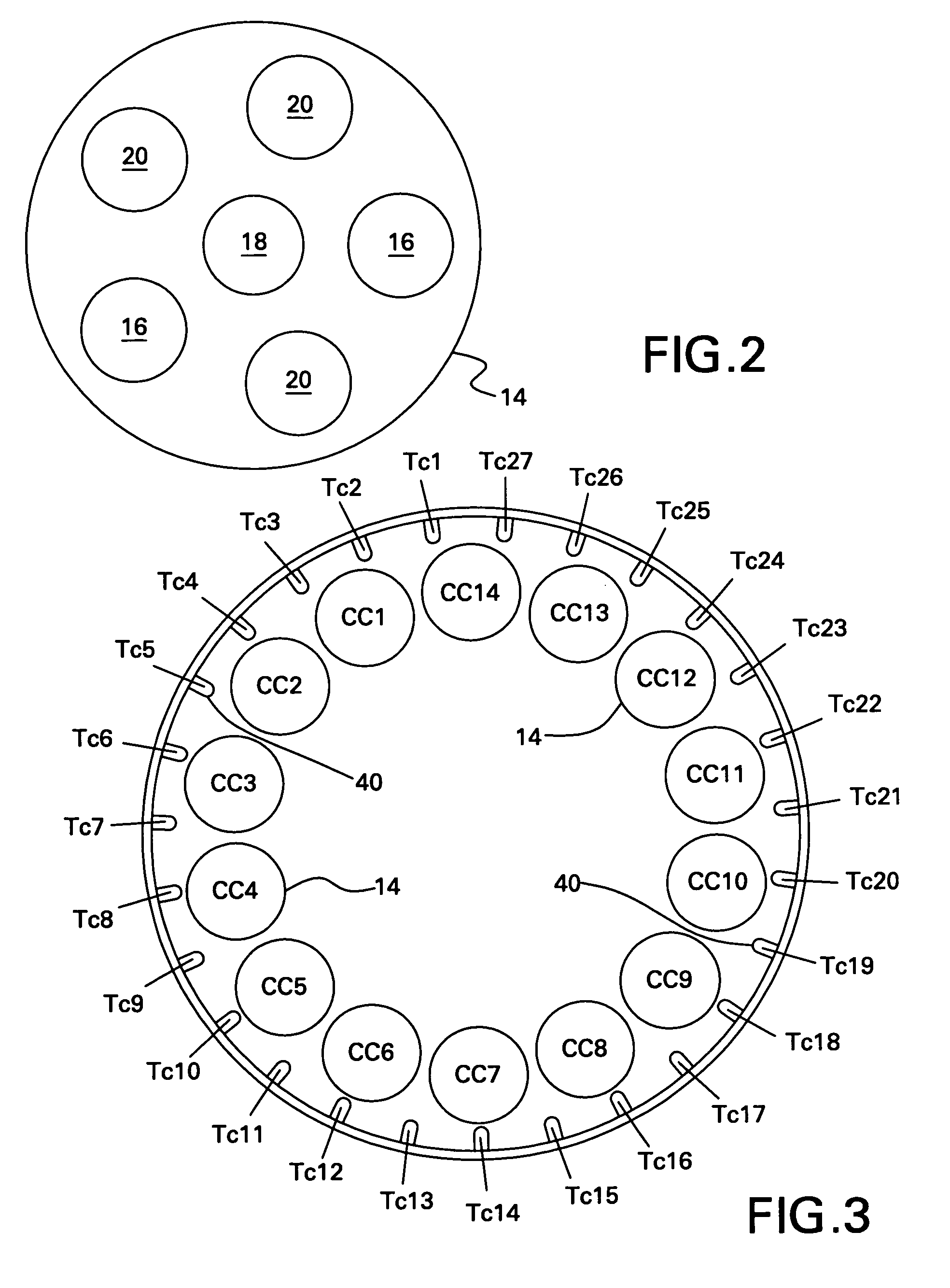

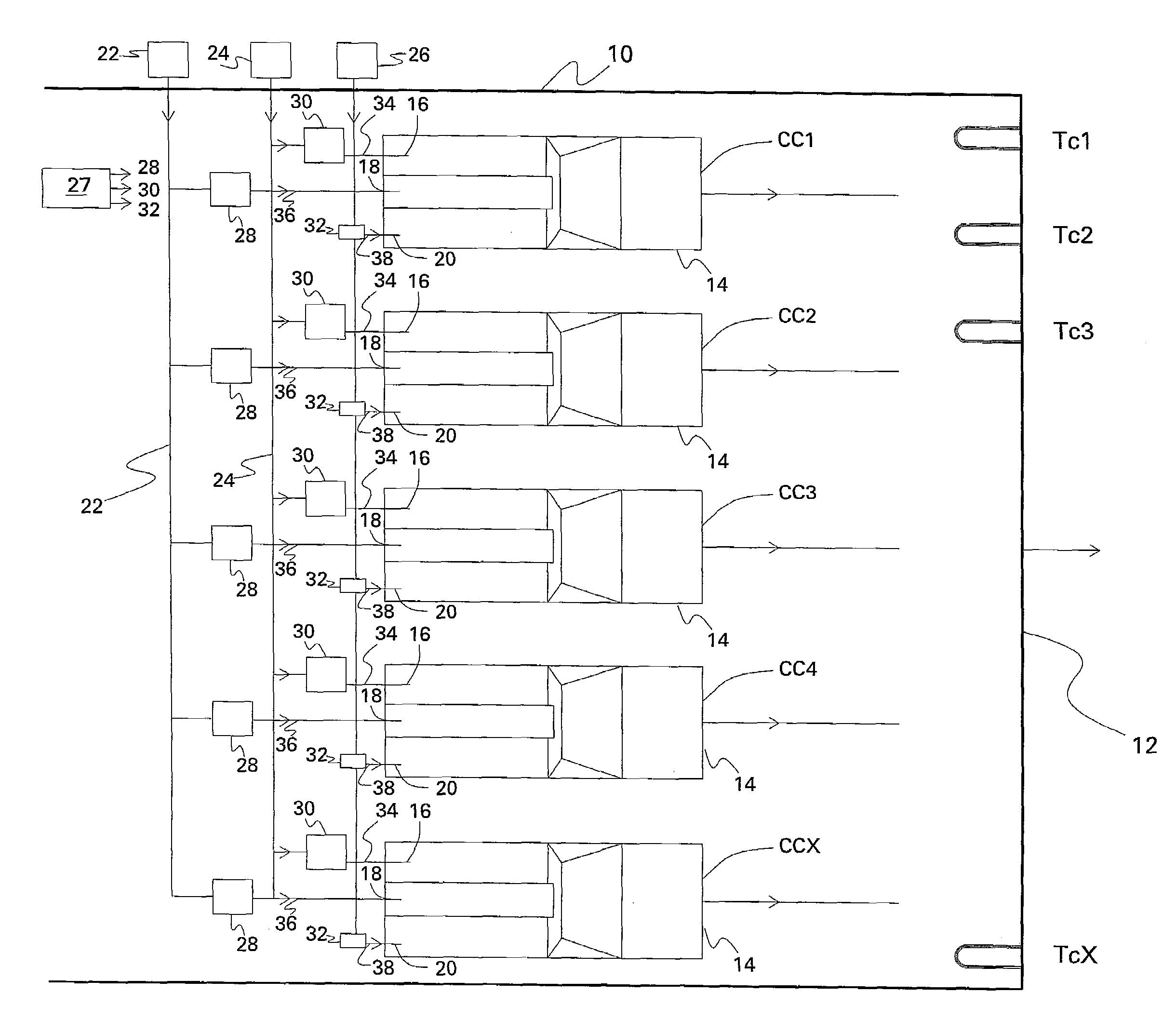

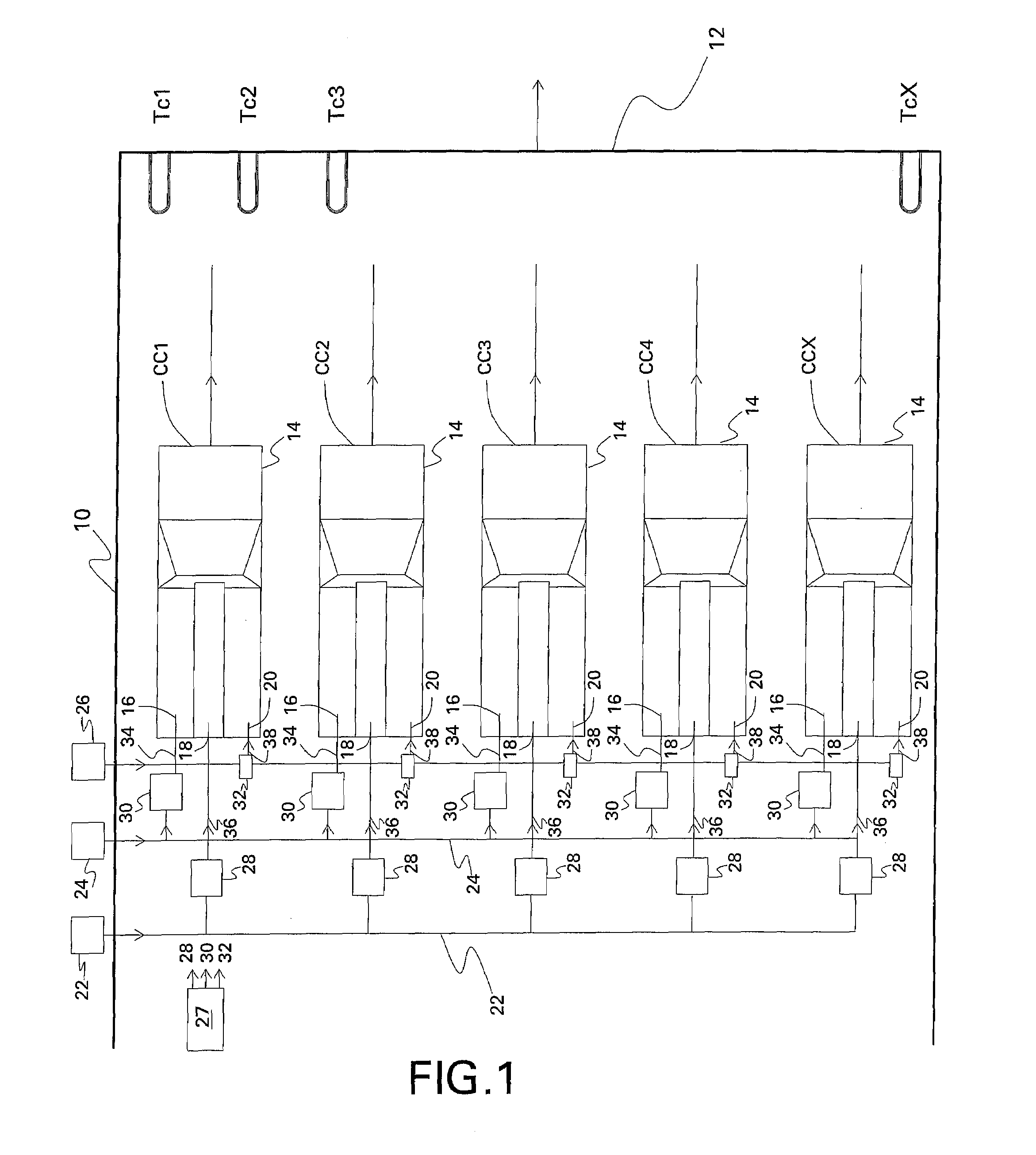

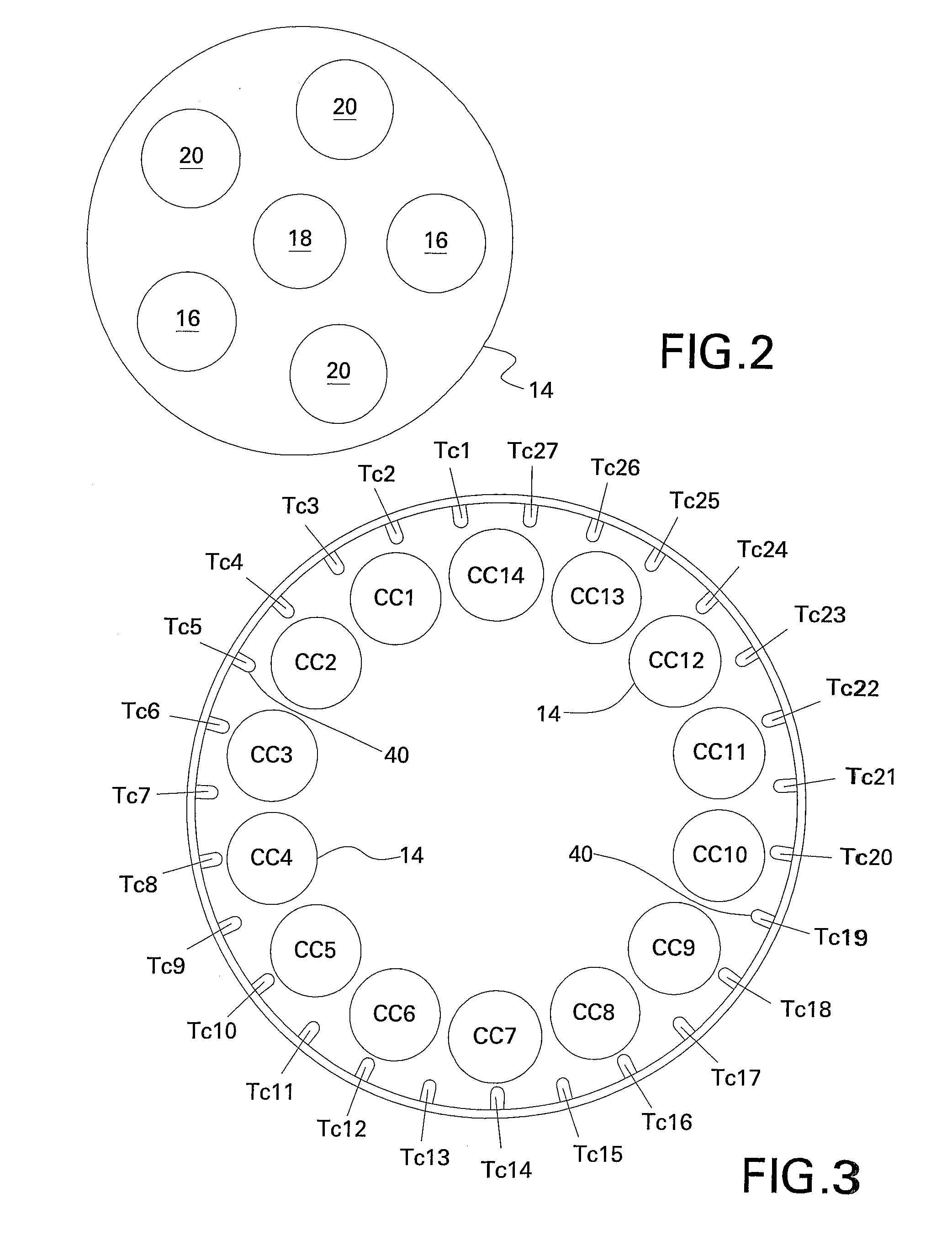

Method and apparatus for actuating fuel trim valves in a gas turbine

ActiveUS20050097895A1Minimized pressure dropOvercomes shortcomingFuel supply regulationContinuous combustion chamberCombustion chamberNitrous oxide

The gas turbines of the present invention have multiple combustion chambers, and within each chamber are multiple fuel nozzles. Each nozzle has its own fuel control valve to control the fuel flowing to the nozzles. To minimize the pressure drop through the fuel control valves, multiple manifolds are employed. Each manifold supplies at least one fuel nozzle in multiple combustion chambers with fuel. The fuel control valves are mounted on the manifolds such that the weight of the fuel control valves and nozzles are carried by the manifolds, not the multiple combustion chambers. A plurality of thermocouples for measuring exhaust gas from said multiple combustion chambers are employed to sense gas exhaust temperature. In carrying out the methods of the present invention for tuning a gas turbine, it is essential to note that the most efficient gas turbine is one which has the least nitrous oxides, the least amount of unburned hydrocarbons, and the least amount of carbon monoxide for a specified energy output. In order to tune the gas turbine to accomplish these objectives, it is desirable that each combustion chamber in the gas turbine be well balanced relative to the remaining combustion chambers. It is an aim of the present invention to tune each of the multiple combustion chambers such that no specific combustion chamber is rich or lean, and all are operating within about 1% of the remaining combustion chambers.

Owner:GENERAL ELECTRIC CO

Inflatable heliostatic solar power collector

ActiveUS7997264B2Low costImprove conversion efficiencyPhotovoltaic supportsSolar heating energyHydrocotyle bowlesioidesCollector device

Increased utilization of solar power is highly desirable as solar power is a readily available renewable resource with power potential far exceeding total global needs; and as solar power does not contribute to pollutants associated with fossil fuel power, such as unburned hydrocarbons, NOx and carbon dioxide. The present invention provides low-cost inflatable heliostatic solar power collectors, which can be stand-alone units suitable for flexible utilization in small, medium, or utility scale applications. The inflatable heliostatic power collectors use a reflective surface or membrane “sandwiched” between two inflated chambers, and attached solar power receivers which may be of photovoltaic and / or solar thermal types. Modest concentration ratios enable benefits in both reduced cost and increased conversion efficiency, relative to simple prior-art flat plate solar collectors.

Owner:RIC ENTERPRISES

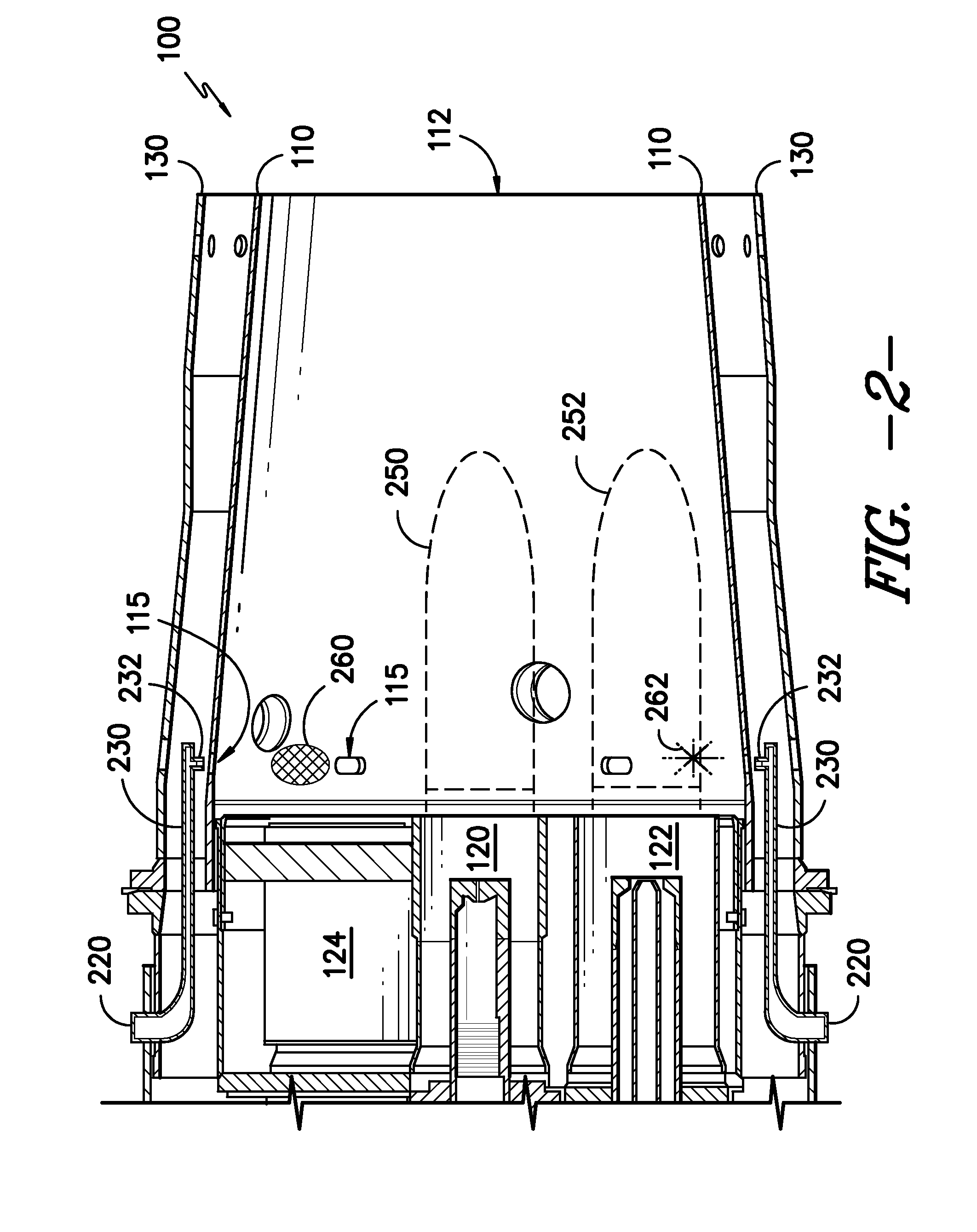

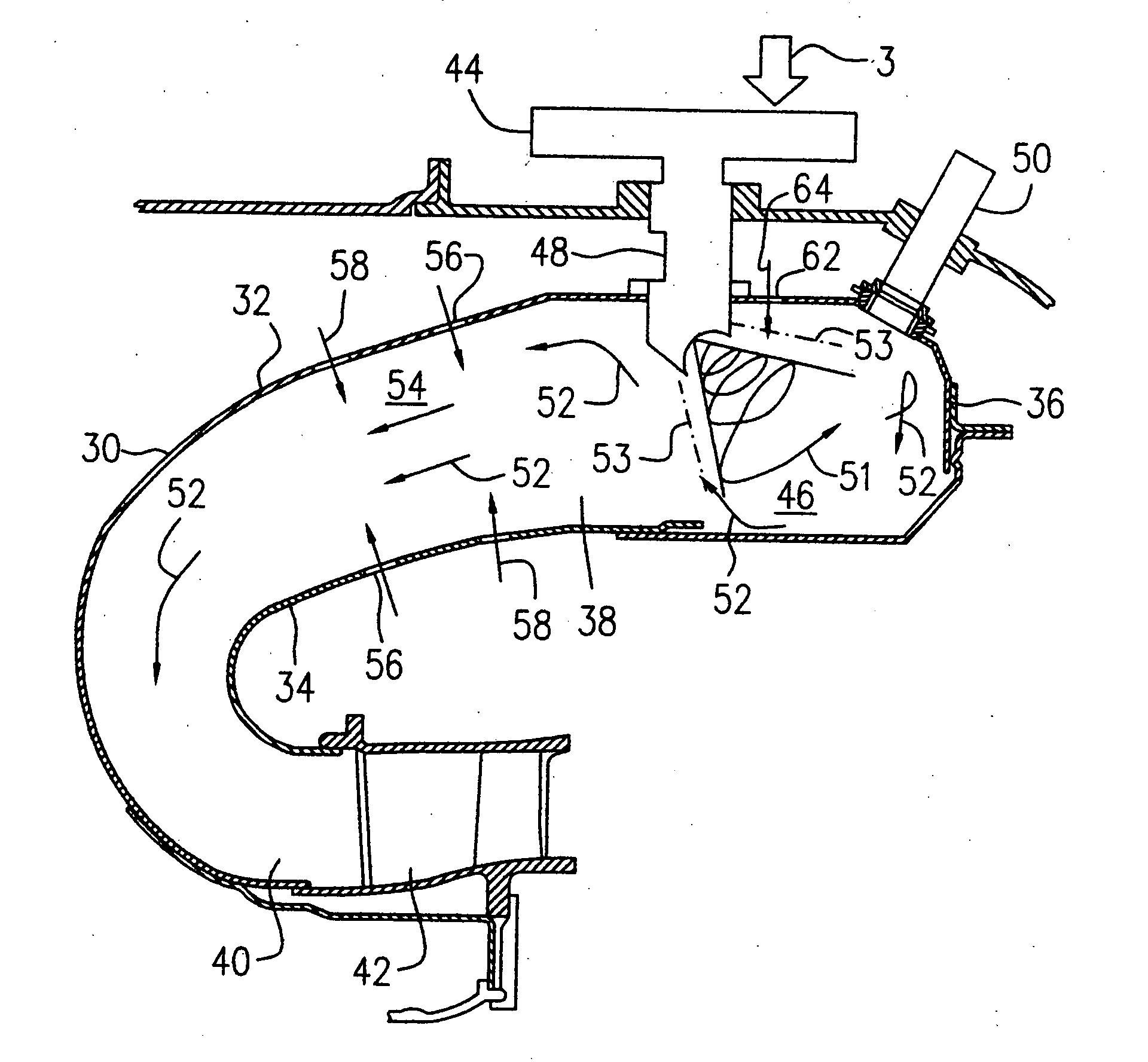

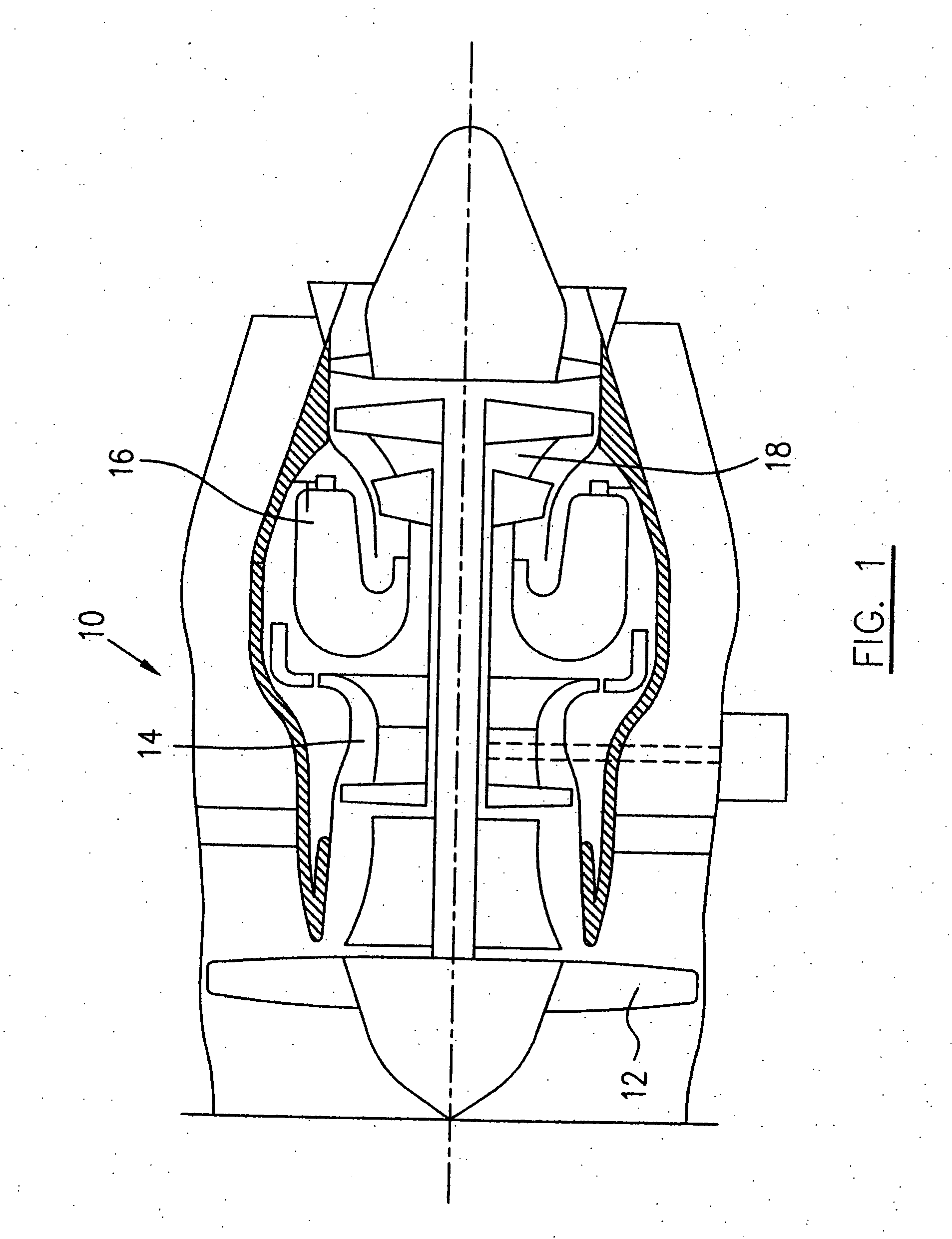

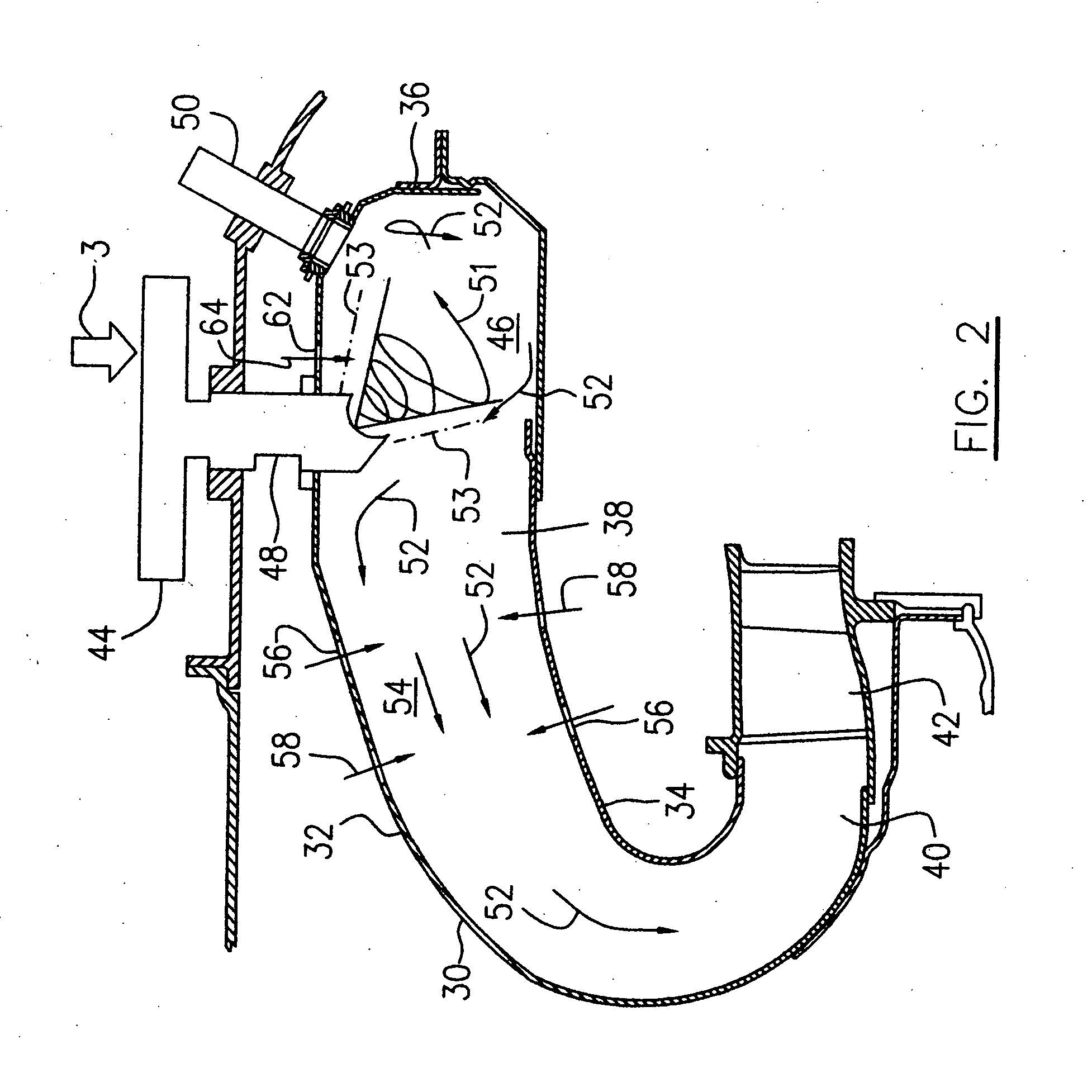

Combustor

ActiveUS20070227150A1Prevent escapeContinuous combustion chamberEfficient propulsion technologiesCombustion systemCombustion chamber

A combustor is provided having one or more apertures adapted to asymmetrically introduce air adjacent the fuel nozzles to reduce smoke resulting from unburned hydrocarbons in a gas turbine engine combustion system by impeding escape of unburned hydrocarbons.

Owner:PRATT & WHITNEY CANADA CORP

Exhaust gas recirculation system having cooler

InactiveUS20030213230A1Improve heat transfer effectElectrical controlNon-fuel substance addition to fuelExhaust fumesExhaust gas recirculation

An exhaust gas recirculation (EGR) system of an internal combustion engine has an EGR cooler in an EGR passage connecting an exhaust manifold with an intake manifold. The EGR cooler cools EGR gas recirculated through the EGR passage. Cooling performance detecting means included in an electronic control unit (ECU) determines that cooling performance of the EGR cooler is degraded when intake pressure measured by an intake pressure sensor is lower than a normal intake pressure by at least a predetermined value. When the degradation of the cooling performance is detected, cooling performance regeneration controlling means included in the ECU increases the temperature inside the EGR cooler by heating the exhaust gas to eliminate soot or unburned hydrocarbon by oxidization. Thus, the cooling performance of the EGR cooler is regenerated.

Owner:DENSO CORP

Method and apparatus for actuating fuel trim valves in a gas turbine

ActiveUS7188465B2Control deteriorationOvercomes shortcomingFuel supply regulationContinuous combustion chamberCombustion chamberNitrous oxide

The gas turbines of the present invention have multiple combustion chambers, and within each chamber are multiple fuel nozzles. Each nozzle has its own fuel control valve to control the fuel flowing to the nozzles. To minimize the pressure drop through the fuel control valves, multiple manifolds are employed. Each manifold supplies at least one fuel nozzle in multiple combustion chambers with fuel. The fuel control valves are mounted on the manifolds such that the weight of the fuel control valves and nozzles are carried by the manifolds, not the multiple combustion chambers. A plurality of thermocouples for measuring exhaust gas from said multiple combustion chambers are employed to sense gas exhaust temperature. In carrying out the methods of the present invention for tuning a gas turbine, it is essential to note that the most efficient gas turbine is one which has the least nitrous oxides, the least amount of unburned hydrocarbons, and the least amount of carbon monoxide for a specified energy output. In order to tune the gas turbine to accomplish these objectives, it is desirable that each combustion chamber in the gas turbine be well balanced relative to the remaining combustion chambers. It is an aim of the present invention to tune each of the multiple combustion chambers such that no specific combustion chamber is rich or lean, and all are operating within about 1% of the remaining combustion chambers.

Owner:GENERAL ELECTRIC CO

Method And Apparatus Of Fuelling An Internal Combustion Engine With Hydrogen And Methane

ActiveUS20120160221A1Reduce the amount of solutionInternal combustion piston enginesNon-fuel substance addition to fuelRail pressureElectronic controller

A gaseous-fuelled internal combustion engine and a method of engine operation improve combustion stability and reducing emissions of NOx, PM, and unburned hydrocarbons. The method comprises fuelling an internal combustion engine with hydrogen and natural gas, which can be directly injected into the combustion chamber together or introduced separately. Of the total gaseous fuel delivered to the engine, at least 5% by volume at standard temperature and pressure is hydrogen. For at least one engine operating condition, the ratio of fuel rail pressure to peak in-cylinder pressure is at least 1.5:1. A fuel injection valve introduces the gaseous fuel mixture directly into the combustion chamber. Two separate fuel injection valves could also introduce the methane and hydrogen separately. An electronic controller controls timing for operating the fuel injection valve(s). The engine has a preferred compression ratio of at least 14:1.

Owner:THE UNIV OF BRITISH COLUMBIA +1

Lean-burn gasoline engine including exhaust system therefor

InactiveUS20030213232A1Avoid contactEmission reductionNitrogen compoundsInternal combustion piston enginesGasolineEnvironmental engineering

A lean-burn gasoline engine including an exhaust system, which system has a first oxidation catalyst for oxidizing engine-derived, unburned hydrocarbons during lambda>1 conditions, and a NOx-trap downstream of the oxidation catalyst. Also included in one embodiment is by-pass means arranged between an upstream end and a downstream end of the oxidation catalyst and means for switching at least some exhaust gas flowing in the exhaust system to flow in the bypass during rich or stoichiometric running conditions, thereby substantially to prevent bypassed exhaust gas from contacting the oxidation catalyst. Included in the invention are methods of treating the exhaust gas streams with the apparati defined above.

Owner:JOHNSON MATTHEY PLC

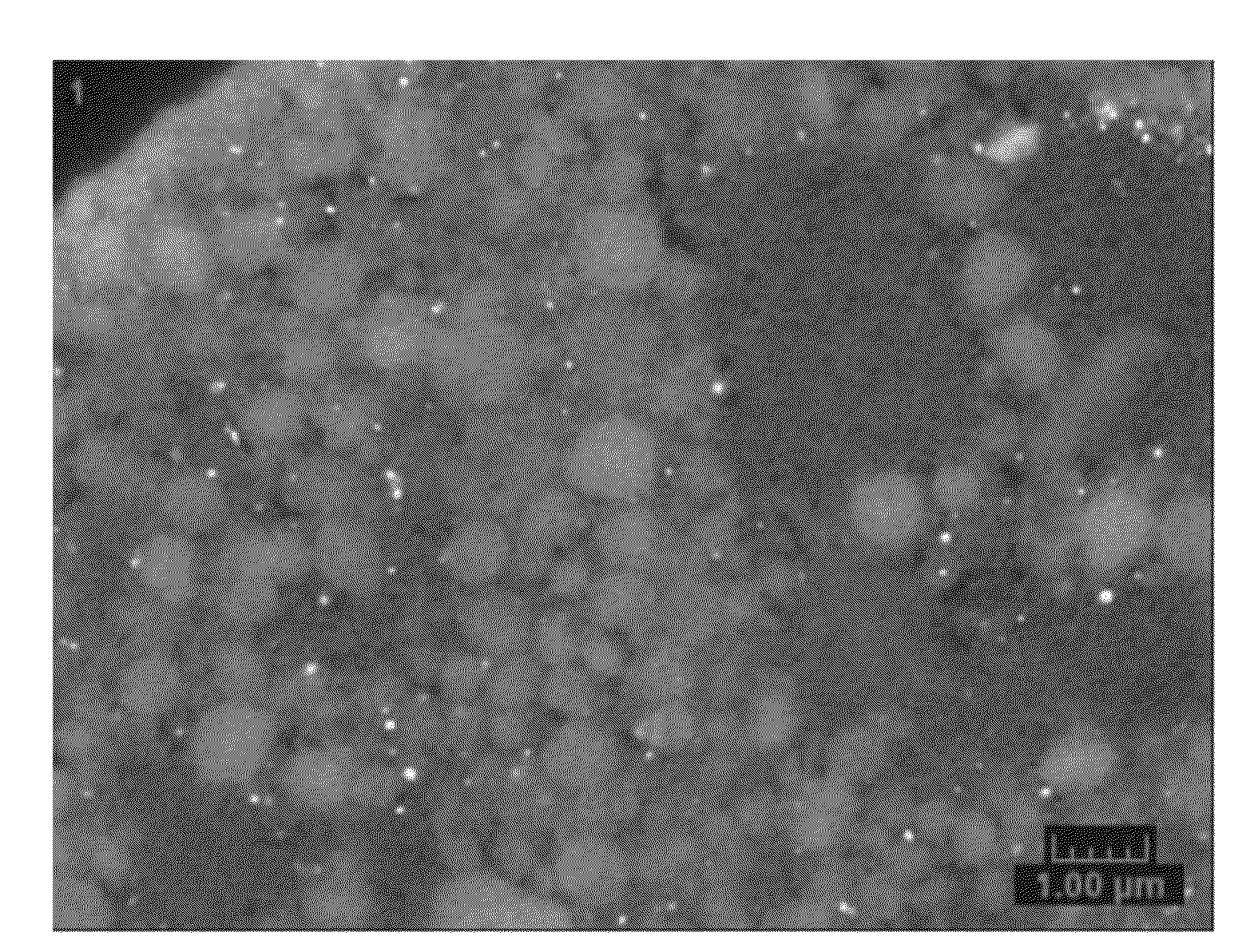

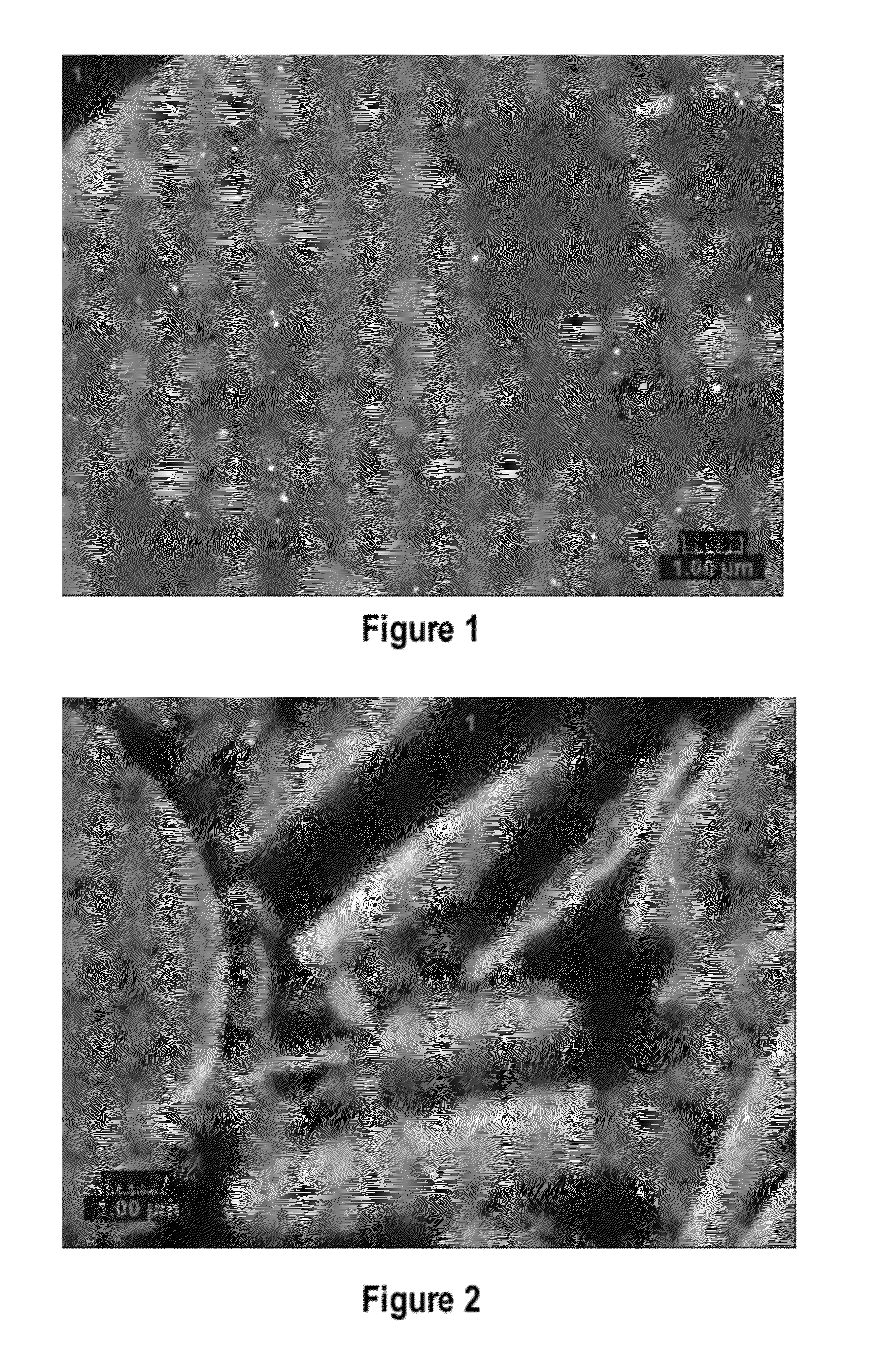

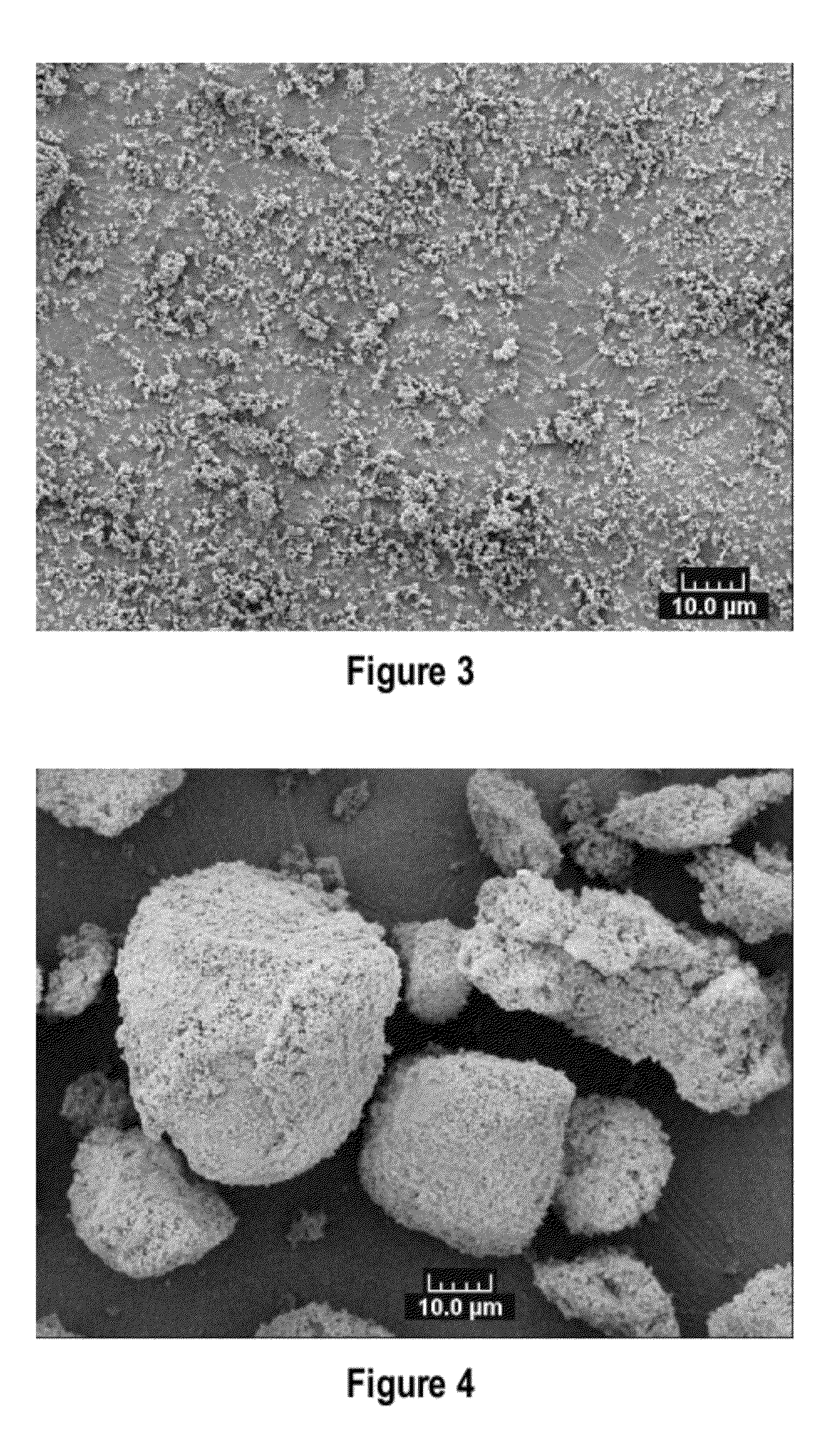

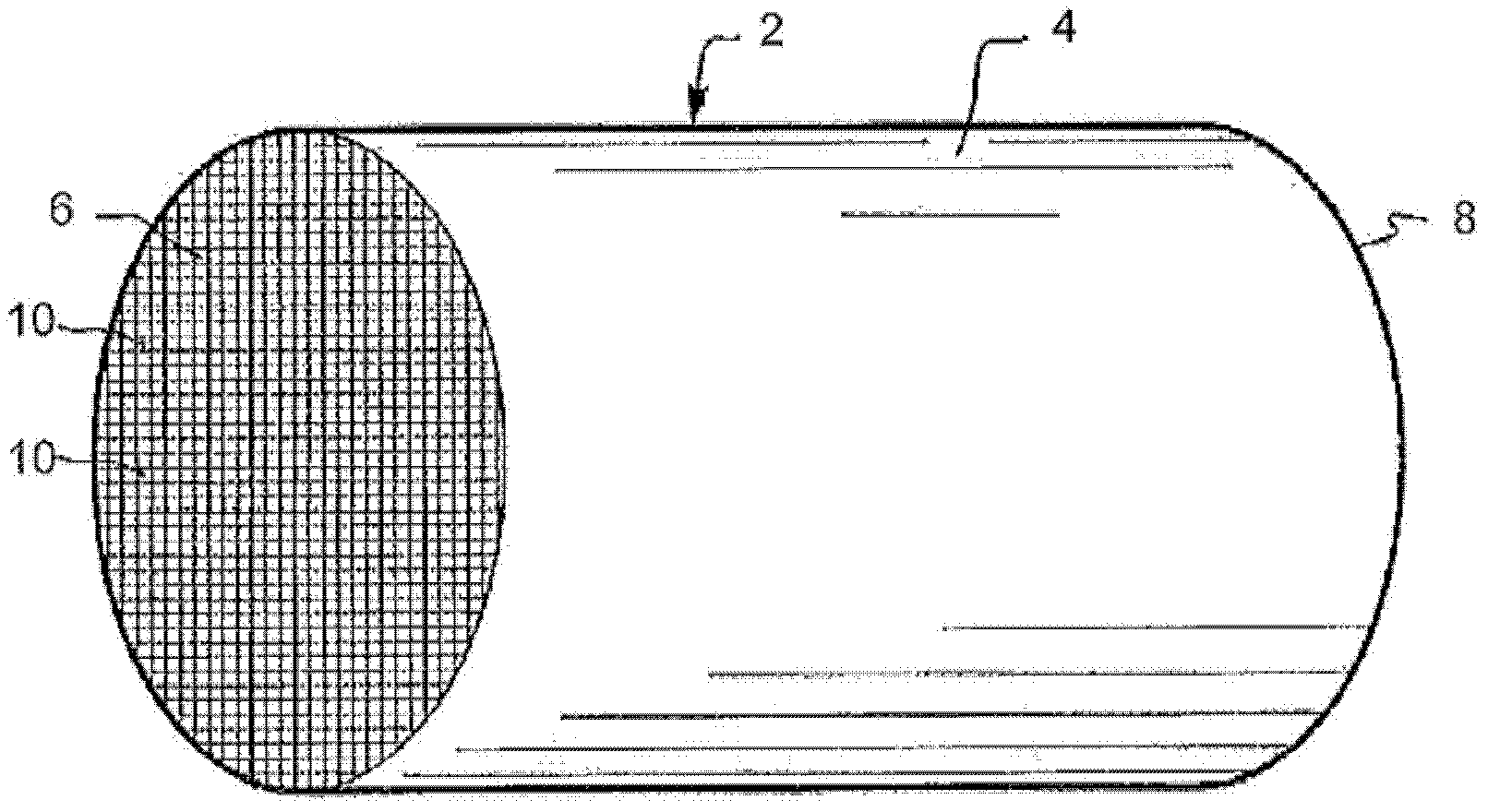

Surface-Coated Zeolite Materials For Diesel Oxidation Applications

A diesel oxidation catalyst for the treatment of exhaust gas emissions, such as the oxidation of unburned hydrocarbons (HC) and carbon monoxide (CO) is described. Also described is a novel washcoat composition including a surface-coated zeolite coated with at least one of zirconia and alumina, and a platinum group metal supported on a high surface area alumina.

Owner:BASF CORP

Zoned catalysts for diesel applications

An oxidation catalyst composite, methods and systems for the treatment of exhaust gas emissions from an advanced combustion engine, such as the oxidation of unburned hydrocarbons (HC), and carbon monoxide (CO) and the reduction of nitrogen oxides (NOx) from a diesel engine and an advanced combustion diesel engine are disclosed. More particularly, washcoat compositions are disclosed comprising at least two washcoat layers, a first washcoat comprising a palladium component and a second washcoat containing platinum and at least about 50% of the total platinum is located in the rear of the catalyst.

Owner:BASF CORP

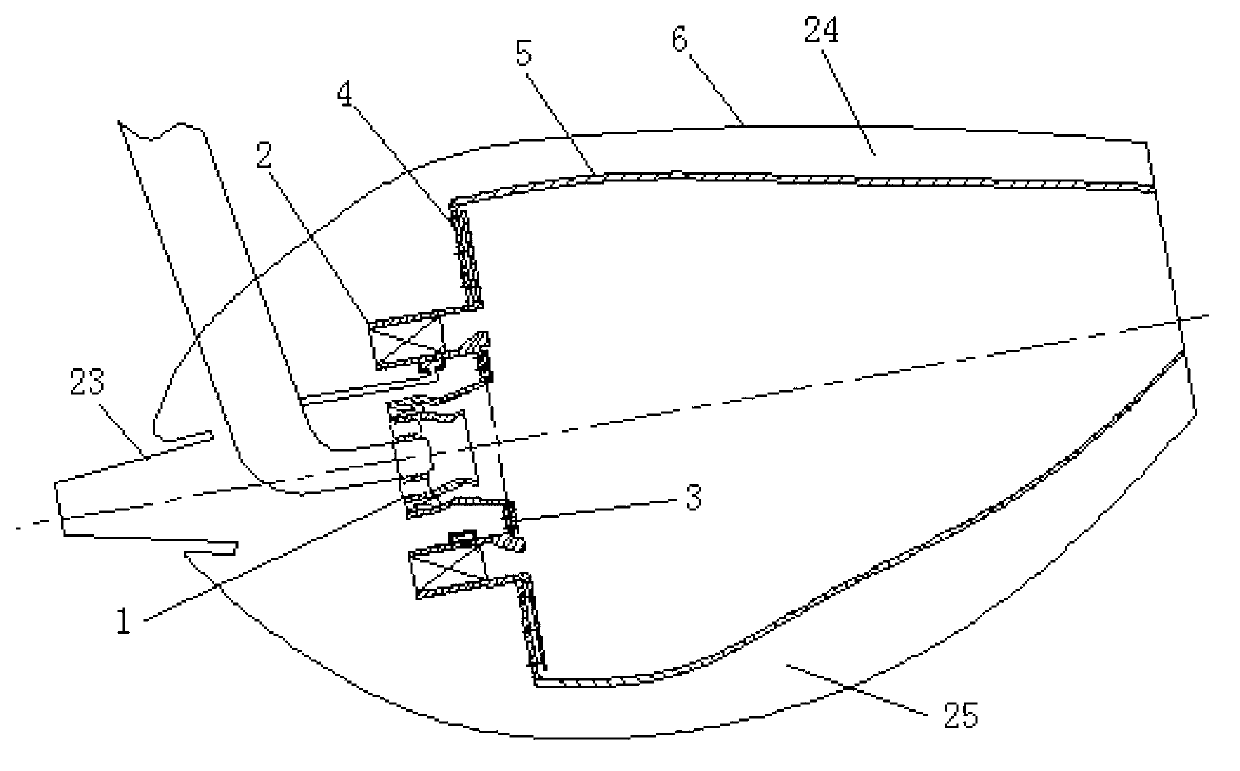

Lean oil pre-mixing and pre-evaporating low-pollution combustion chamber capable of ejecting main-stage fuel oil directly

InactiveCN103123122AStable ignition sourceTaking into account the ignitionContinuous combustion chamberCombustion chamberFuel oil

The invention relates to a lean oil pre-mixing and pre-evaporating low-pollution combustion chamber capable of ejecting main-stage fuel oil directly, and belongs to the field of aero-engines. The core idea of the lean oil pre-mixing and pre-evaporating low-pollution combustion chamber is air classification and fuel oil classification. The lean oil pre-mixing and pre-evaporating low-pollution combustion chamber is composed of an on-duty stage / subsidiary mold and a mainstage / main mold, wherein the on-duty stage is composed of a first-stage axial swirler (8), a second-stage axial swirler (9), a sleeve (10) and an on-duty stage contraction and expansion segment (20), realizes diffusive combustion and provides a stable ignition source; and the main stage comprises a main-stage swirler (11), a main-stage oil supply pipe (15), an oil collection cavity (16), a fuel oil direct-injection type nozzle (17), a main-stage contraction and expansion segment (12) and a main-stage pre-mixing annular cavity (22) and is used for combusting a part of pre-mixed and pre-evaporated lean oil and lowering a high-temperature hotspot so as to reduce the emission of thermal nitric oxide (NOX). The lean oil pre-mixing and pre-evaporating low-pollution combustion chamber is in the mode of lean oil pre-mixing and pre-evaporating combustion with a central classification idea, other properties of the chamber cannot be sacrificed, and the emission of pollutants, including the NOX, smoke, carbon oxide (CO) and unburned hydrocarbon (UHC), of an aero-engine chamber can be effectively lowered at the same time.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

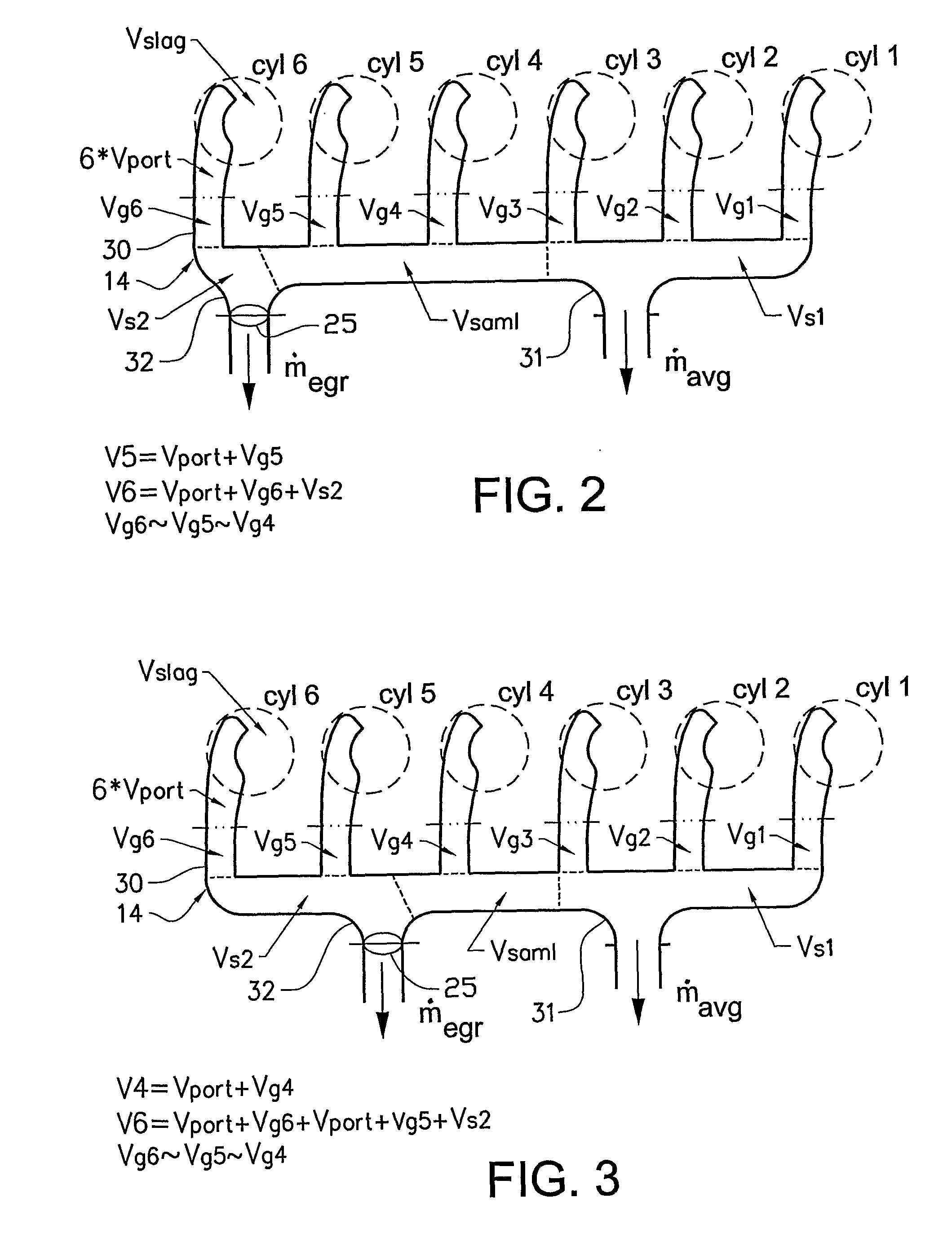

Arrangement For Controlling Exhaust Pressure Pulses At An Internal Combustion Engine

ActiveUS20080110161A1Reduce fuel consumptionAccelerate emissionsElectrical controlNon-fuel substance addition to fuelCombustionExternal combustion engine

An arrangement for controlling exhaust pressure pulsation in a combustion engine including six cylinders. The engine also includes an inlet for supply of air to the cylinders, and an exhaust manifold for delivery of exhaust gases from the cylinders. The manifold is provided with a first outlet to an exhaust system and with a second outlet to a conduit for feeding exhaust gases back, via an EGR circuit, from at least one of the engine's cylinders to the inlet. At least one of the cylinders is adapted to enrich the exhaust gases with unburnt hydrocarbon with a view to regeneration of an exhaust gas post-treatment unit situated in the exhaust system. A special configuration of the exhaust manifold results in separation of regeneration gas from EGR gas in the exhaust manifold.

Owner:VOLVO LASTVAGNAR AB

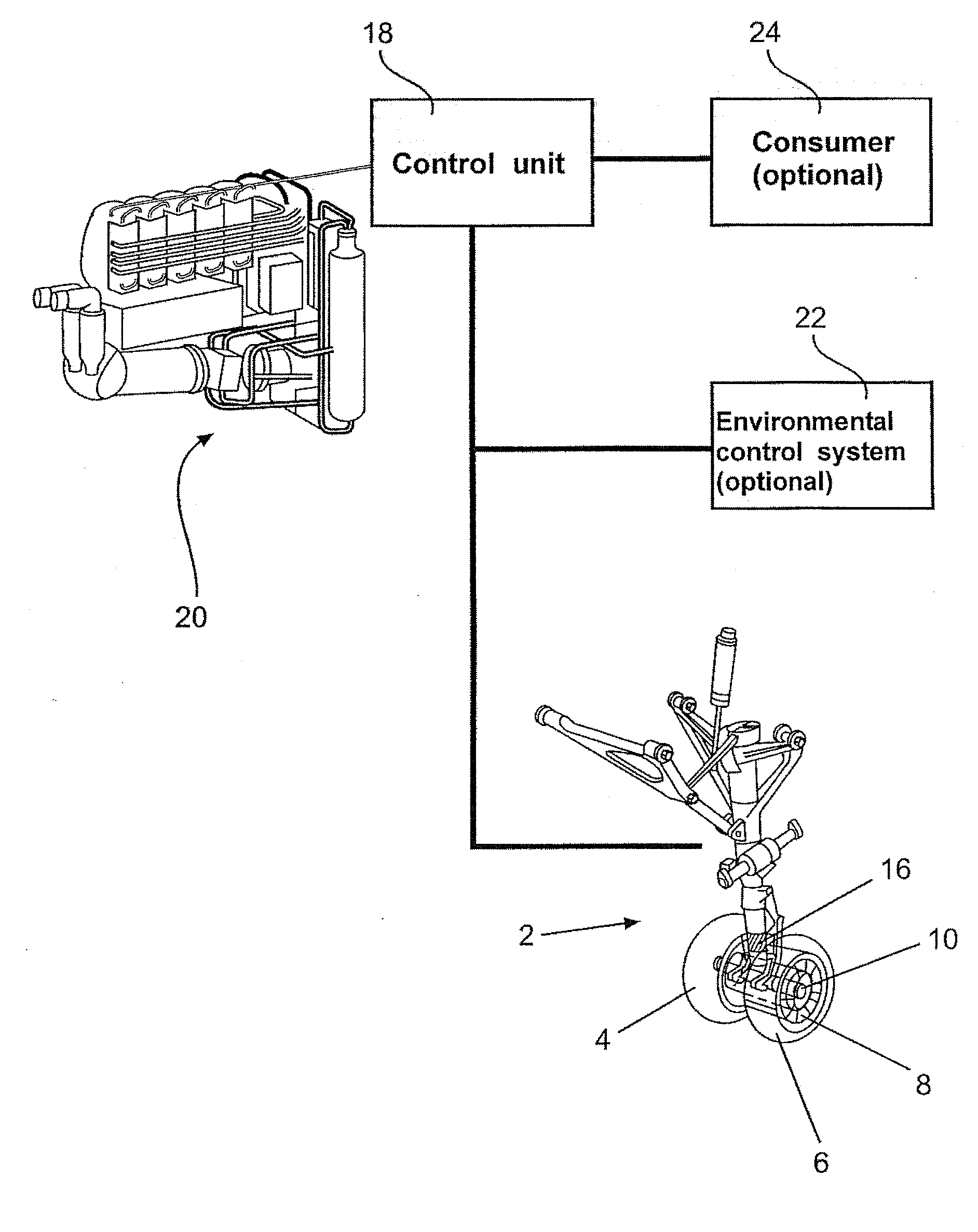

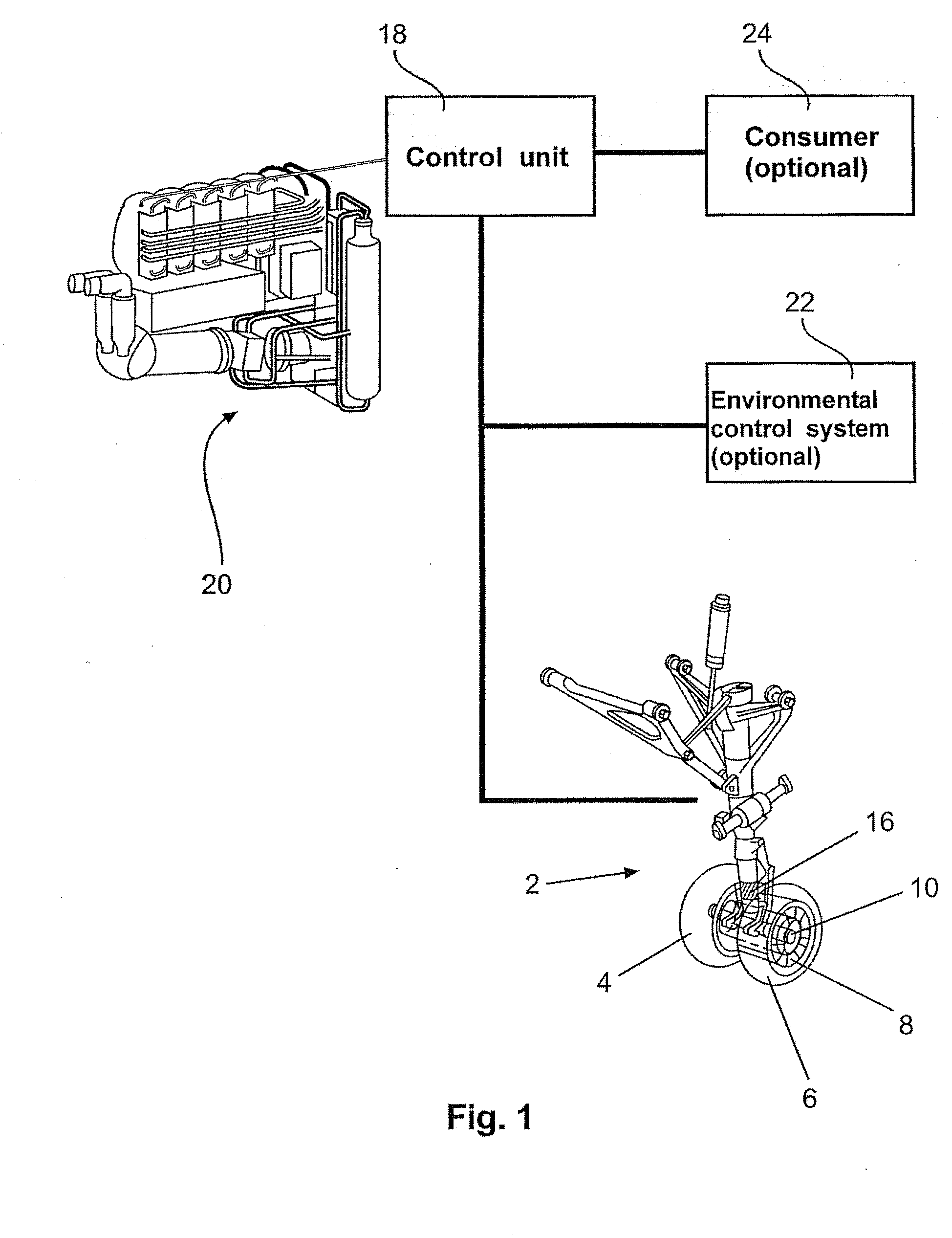

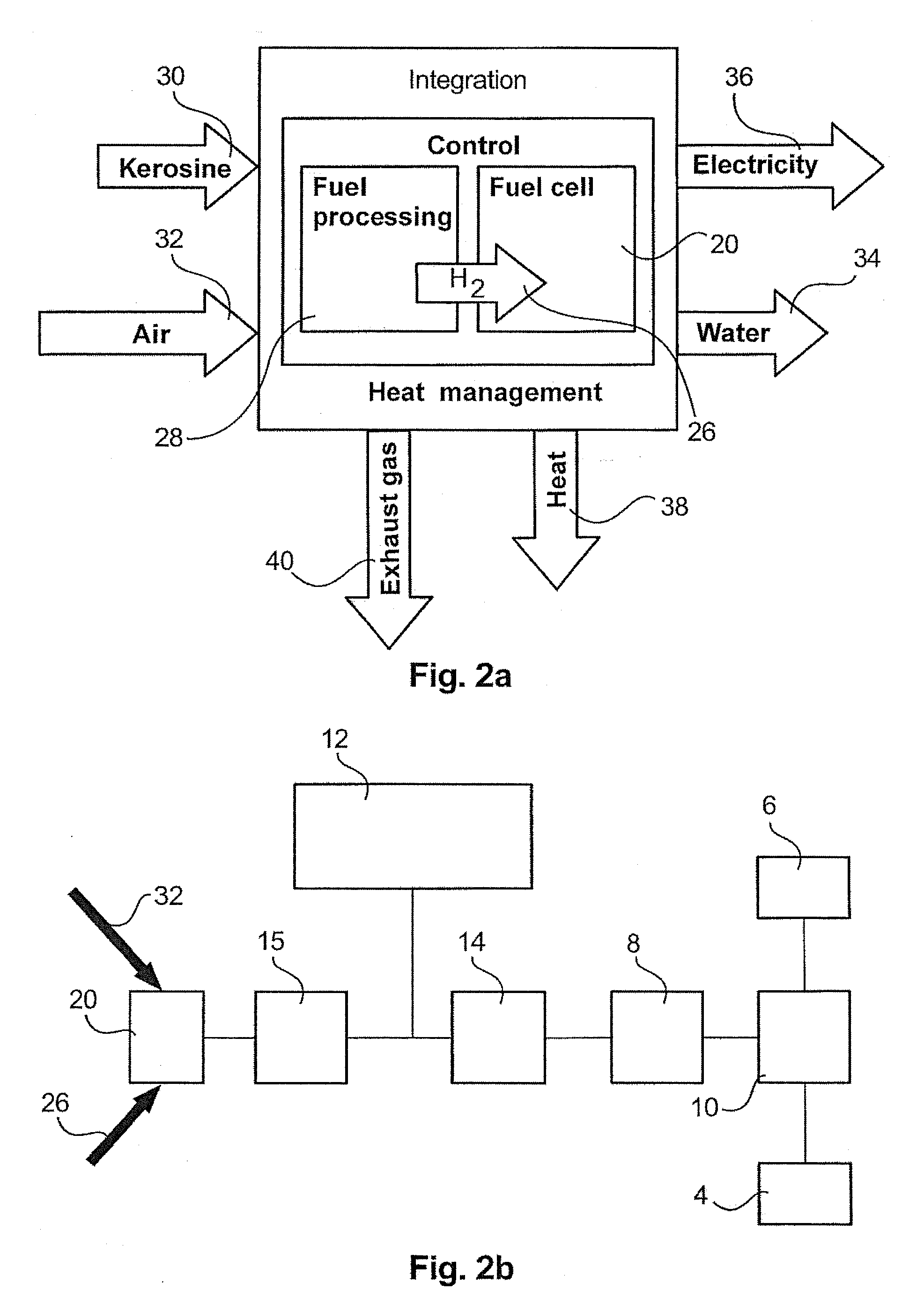

Wheel drive system for an aircraft comprising a fuel cell as an energy source

InactiveUS20110198439A1Convenient power supplyReduce supplyPower installationsEnergy efficient operational measuresFuel cellsFlight vehicle

The invention pertains to a wheel drive system for an aircraft that features at least one electric motor and at least one fuel cell as energy source for the electric motor, wherein the electric motor is coupleable to at least one wheel of at least one landing gear of the aircraft. The inventive wheel drive system reduces the fuel consumption and lowers the emission of CO2 and pollutants—primarily carbon monoxide and unburned hydrocarbons. Persons, vehicles and other aircraft furthermore are not endangered by a jet blast while the aircraft is taxiing because the main engines do not have to be started until the take-off and landing strip is reached. The operation of the inventive wheel drive system furthermore leads to a reduced noise pollution.

Owner:AIRBUS OPERATIONS GMBH

Method and apparatus of fuelling an internal combustion engine with hydrogen and methane

ActiveCN101421500ANon-fuel substance addition to fuelInternal combustion piston enginesElectronic controllerRail pressure

A gaseous-fuelled internal combustion engine and a method of operating same are provided for improving combustion stability and reducing emissions of NOx, PM, and unburned hydrocarbons. The method comprises fuelling an internal combustion engine with hydrogen and natural gas, which can be directly injected into the combustion chamber together or introduced separately. Of the total gaseous fuel delivered to the engine, at least 5% by volume at standard temperature and pressure is hydrogen. For at least one engine operating condition, the ratio of fuel rail pressure to peak in-cylinder pressure is at least 1.5: 1. The engine comprises a combustion chamber defined by a cylinder, a cylinder head, and a piston movable within the cylinder; and a fuel injection valve operable for introducing the gaseous fuel mixture directly into the combustion chamber, or two separate fuel injection valves for introducing the methane and hydrogen separately. An electronic controller is in communication with actuator(s) for the fuel injection valve(s) for controlling timing for operating the fuel injection valve(s). The engine has a compression ratio of at least 14:1.

Owner:WESTPORT POWER +1

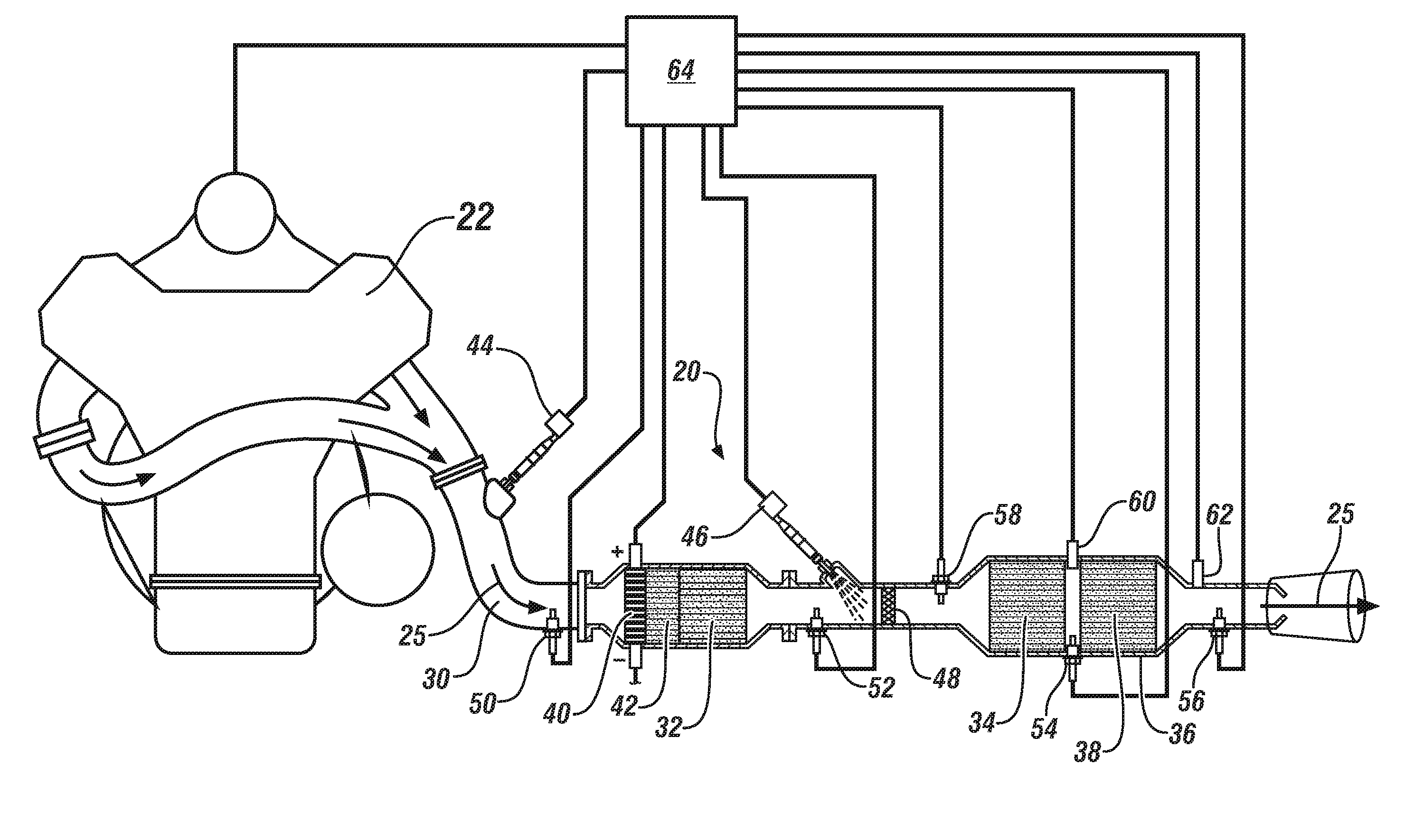

Electrically heated doc using hcscr cold start NOX controls

InactiveUS20140311123A1Reduce NOxInternal combustion piston enginesSilencing apparatusParticulatesProcess engineering

An exhaust gas treatment system for an internal combustion engine is provided. The system includes an exhaust gas conduit extending from the engine configured to receive an exhaust gas stream from the engine, a first injector in fluid communication with the exhaust gas conduit configured to selectively inject fuel containing unburned hydrocarbon (HC) into the exhaust gas conduit and an oxidation catalyst disposed in the exhaust gas conduit downstream from the first injector. The system further includes a hydrocarbon selective catalyst reduction (HCSCR) catalyst applied on the oxidation catalyst, a heating device positioned at an upstream side of the oxidation catalyst configured to heat the oxidation catalyst and HCSCR catalyst, a selective catalyst reduction (SCR) device disposed within the exhaust gas conduit downstream from the oxidation catalyst, and a particulate filter positioned downstream from the selective catalyst reduction device.

Owner:GM GLOBAL TECH OPERATIONS LLC

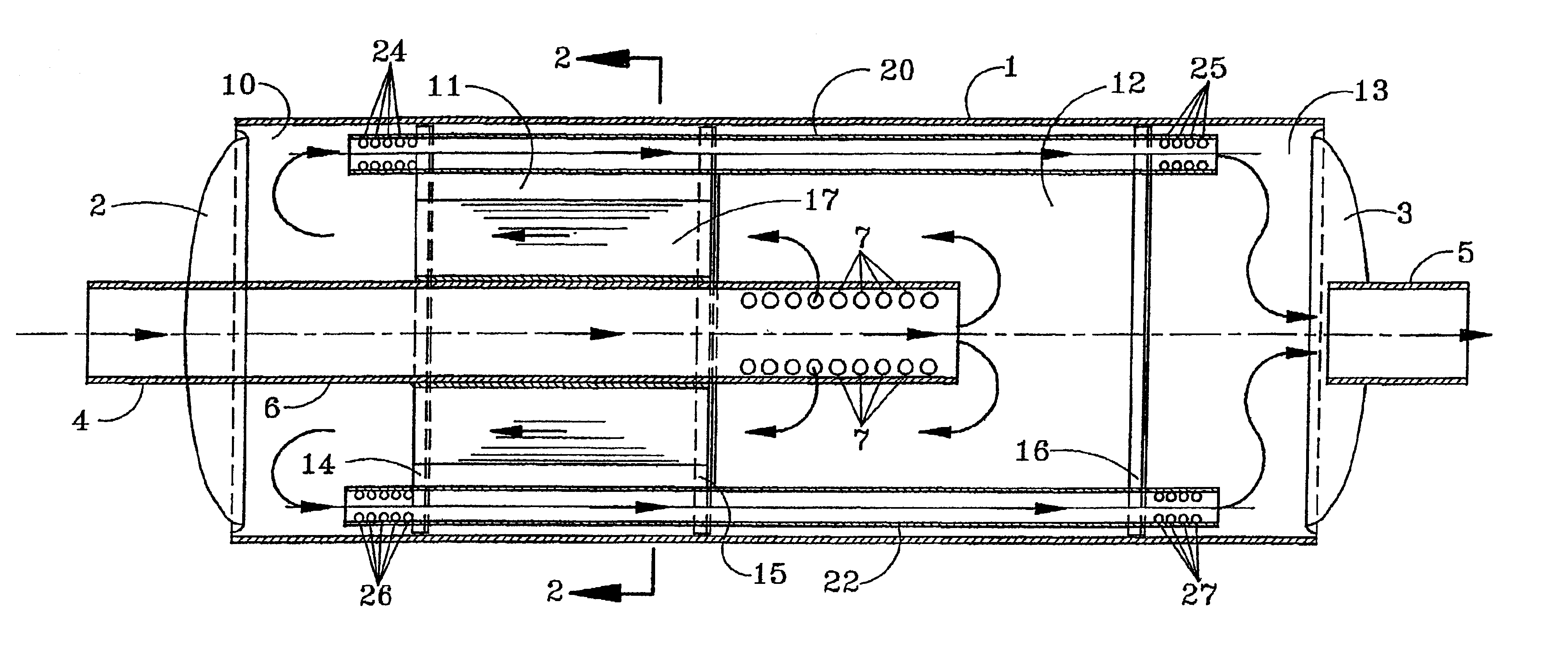

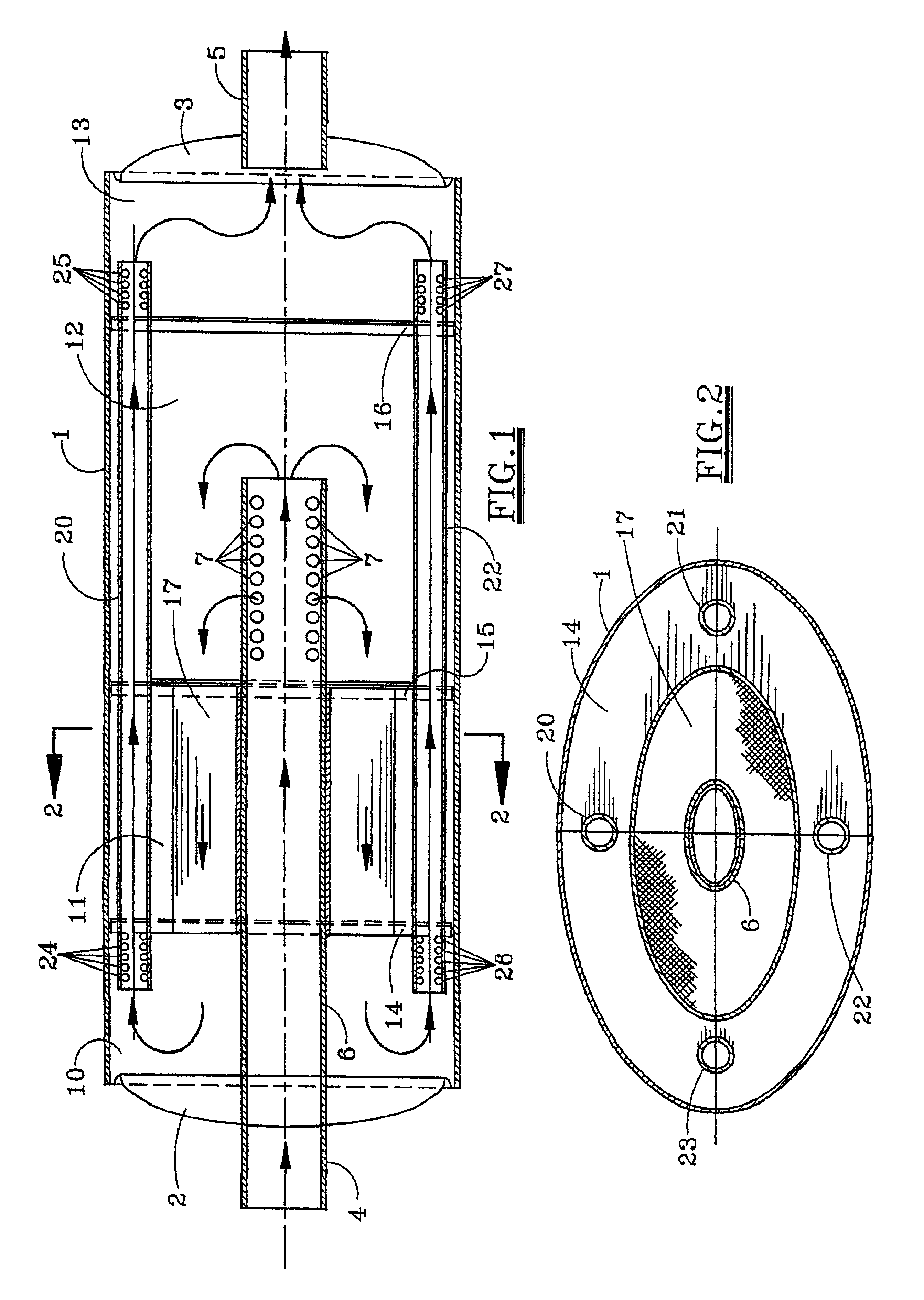

Emission control apparatus

InactiveUS7282185B2Reduce gas emissionsReduce noiseCombination devicesInternal combustion piston enginesNitrogen oxidesEngineering

Apparatus for controlling emissions from an internal combustion engine including an enclosed housing one end of which is provided with an inlet and the other end an outlet. A coaxial tubular member extends from the inlet into the housing. A catalytic cell surrounds the tubular member and separates two chambers, a first surrounding the tubular member near the inlet and the other on the opposite side of the catalytic cell. Exhaust gases from the internal combustion engine flow through the tubular member, expanding into the other chamber, then through the catalytic cell for conversion of nitrogen oxides, carbon monoxide and unburned hydrocarbons to less noxious components, expanding into the first chamber for eventual discharge through the outlet.

Owner:CLEAN AIR POWER

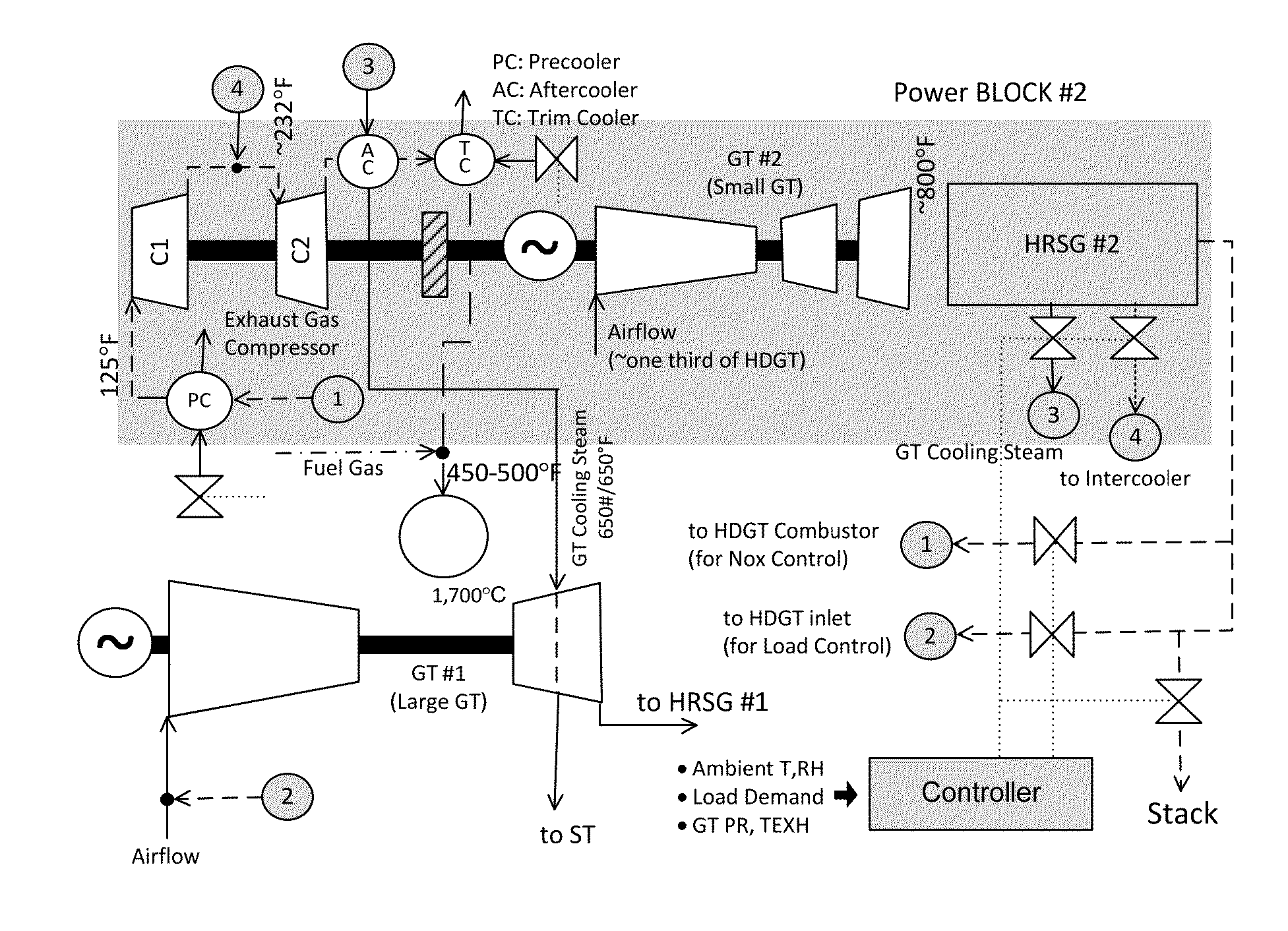

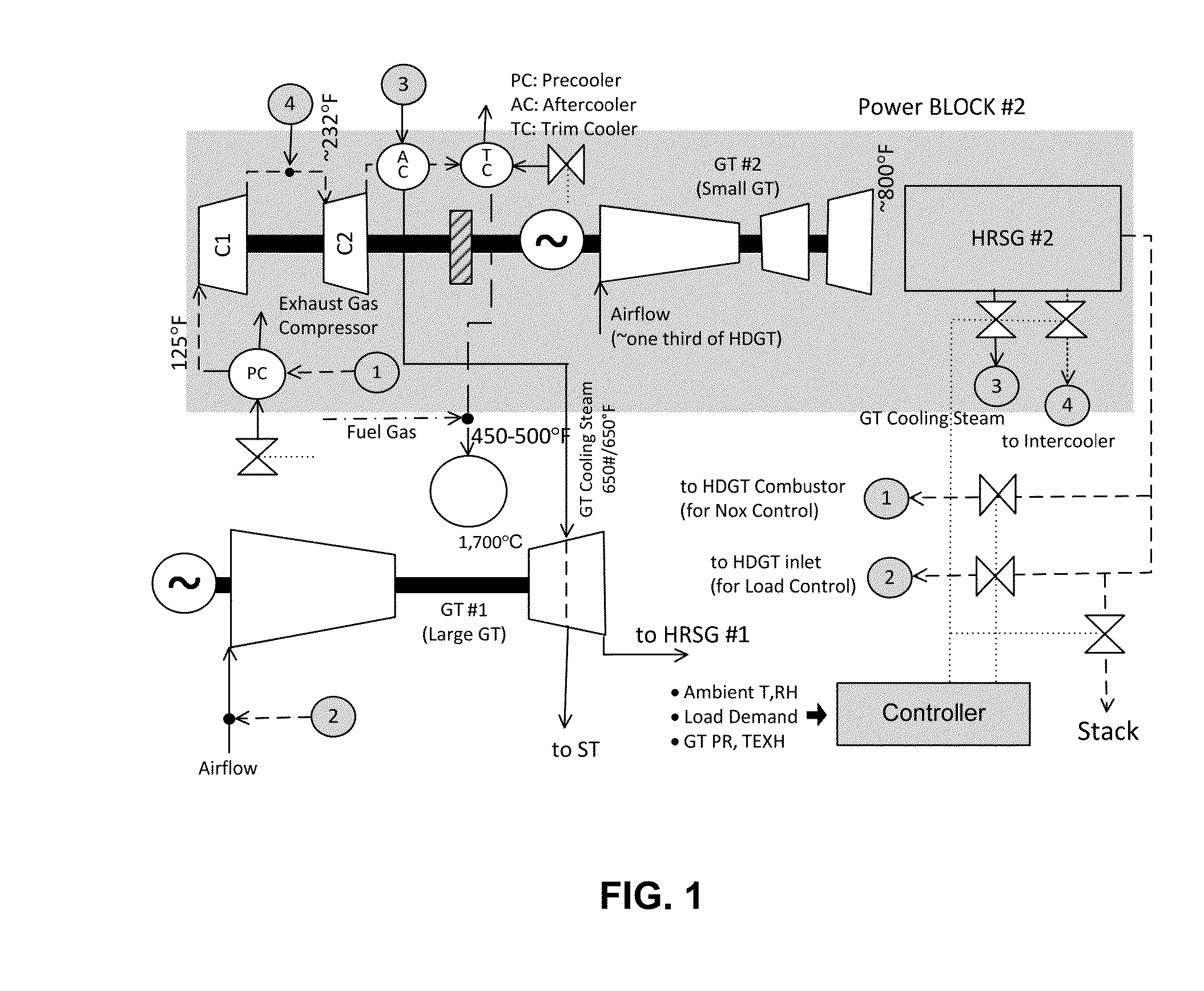

Gas turbine combined cycle system

InactiveUS20140331686A1Efficient power generationReduce nitrogen oxide emissionsGas turbine plantsSteam engine plantsHydrocotyle bowlesioidesHeavy duty

In a combined cycle gas turbine configuration having at least two power blocks, stack emissions (particularly nitrous oxides or NOx but also carbon monoxide CO and unburned hydrocarbons, UHC) are controlled concurrently with part load power output. In one power block a combined cycle power plant has a relatively large heavy-duty industrial gas turbine fired to about 1,700° C. at the turbine inlet leading to a first heat recovery system. A second power block with a smaller gas turbine has a second heat recovery system. A controller adjusts coupling of flue gas and steam paths from the second power block to the first power block to meet load demand in compliance with applicable emissions regulations.

Owner:BECHTEL POWER CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com