Zoned catalysts for diesel applications

A technology for oxidation catalysts and diesel oil, which is applied in molecular sieve catalysts, catalyst activation/preparation, physical/chemical process catalysts, etc., and can solve problems such as weak activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

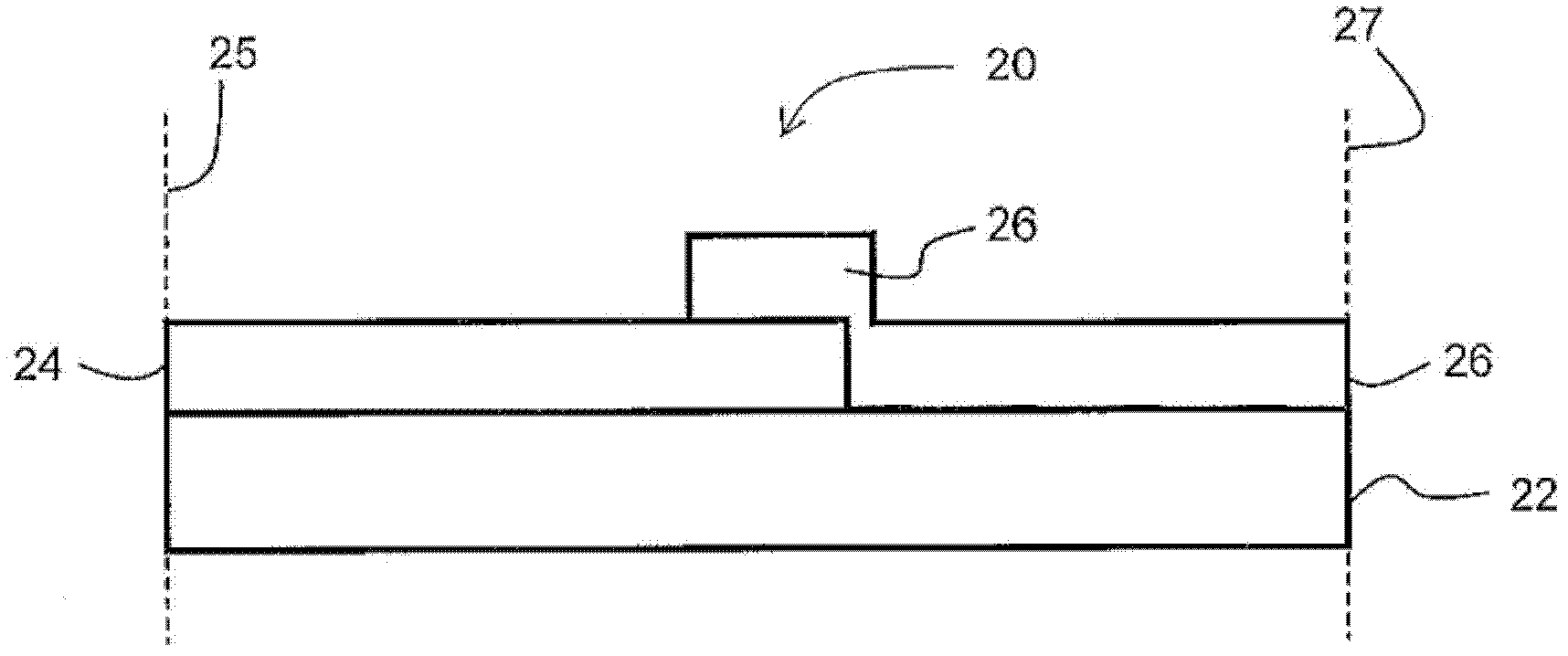

[0051] Preparation of catalyst composite

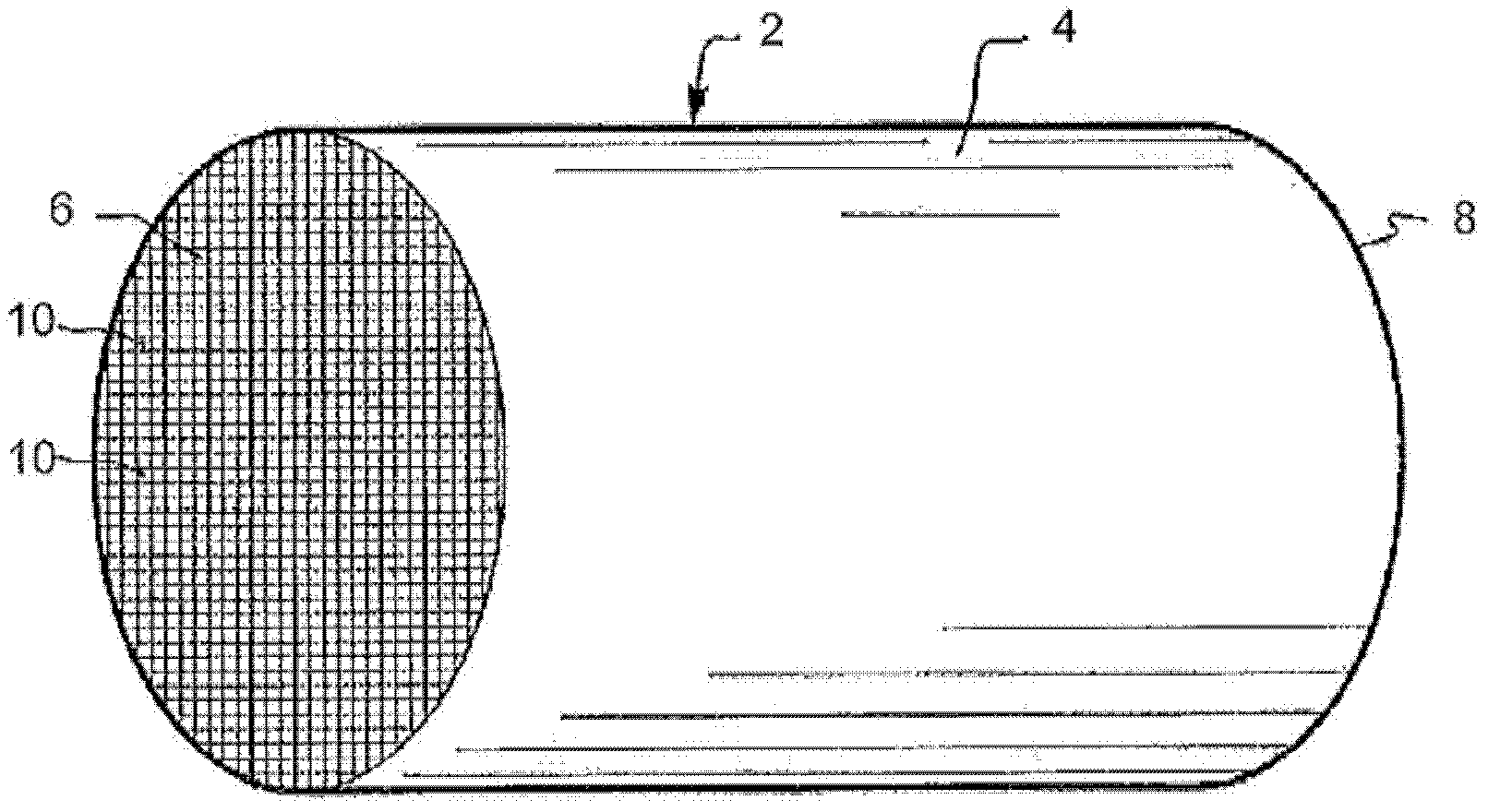

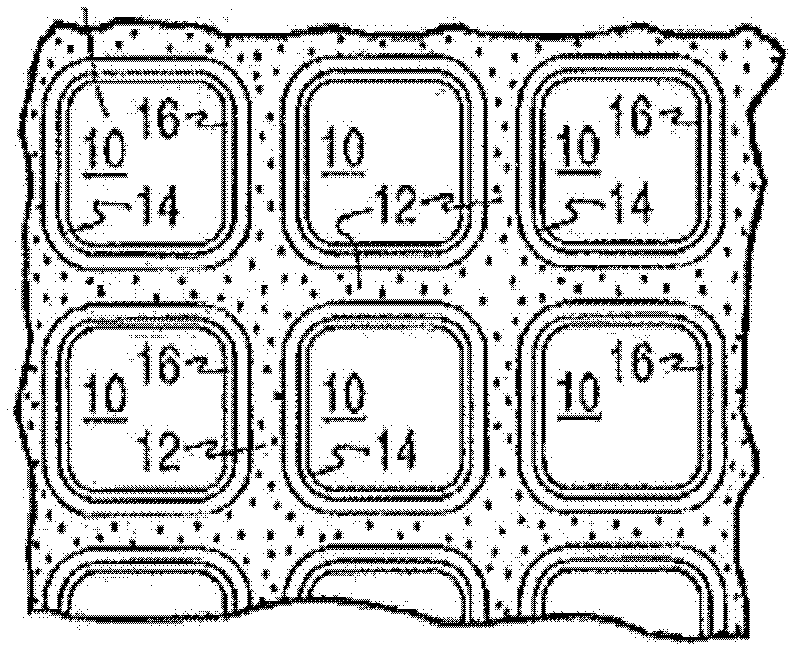

[0052] The catalyst composite of the present invention can be formed into a single layer or multiple layers. In some cases, it is suitable to prepare a slurry of the catalytic material and use the slurry to form multiple layers on the carrier. The complex can be easily prepared by well-known procedures. A representative process is described below. The term "washcoat" as used herein has a general meaning in the art, and refers to a thin adherent washcoat of catalytic material or other materials coated on a substrate carrier material, such as a honeycomb-type carrier An element that is sufficiently porous to allow the air flow to be processed to pass through the channel.

[0053] The catalyst composite layer can be easily prepared on a single support. For the first layer of a specific washcoat layer, ground particles of high specific surface area refractory metal oxide (for example, γ-alumina) are made into a slurry in a suitable medium ...

Embodiment

[0085] Reference sample A

[0086] By applying an aqueous slurry containing Pt and Pd on a cordierite honeycomb monolithic substrate (400cpsi, wall thickness 4mil) of "diameter 4.66" by length 6"", using the Pd on OSC and alumina on A homogeneous mixture of Pt prepares a wash-coated Pt / Pd catalyst composite. The total carrying capacity of precious metals is 110g / ft 3 , The ratio of Pt / Pd is 1:2. The water-based slurry containing Pt and Pd is prepared as follows:

[0087] Use standard incipient wetness impregnation technique to impregnate with water-soluble Pd salt containing 20% ceria, 6% neodymium oxide, 6% lanthanum oxide and 68% zirconium oxide and have a diameter of approximately 90m 2 / g of OSC material with BET surface area. Separately, using standard incipient wetness impregnation technique with water-soluble Pd salt impregnation with a diameter of about 150m 2 / g BET surface area, approximately 0.4cc / g pore volume and approximately The high specific surface area of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com