Catalyst for complete oxidation of formaldehyde at room temperature

A complete oxidation and catalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve complex raw material preparation methods, regular replacement of adsorbents, and equipment prices Expensive and other issues, to achieve the effect of simple use conditions, no power consumption and heat, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

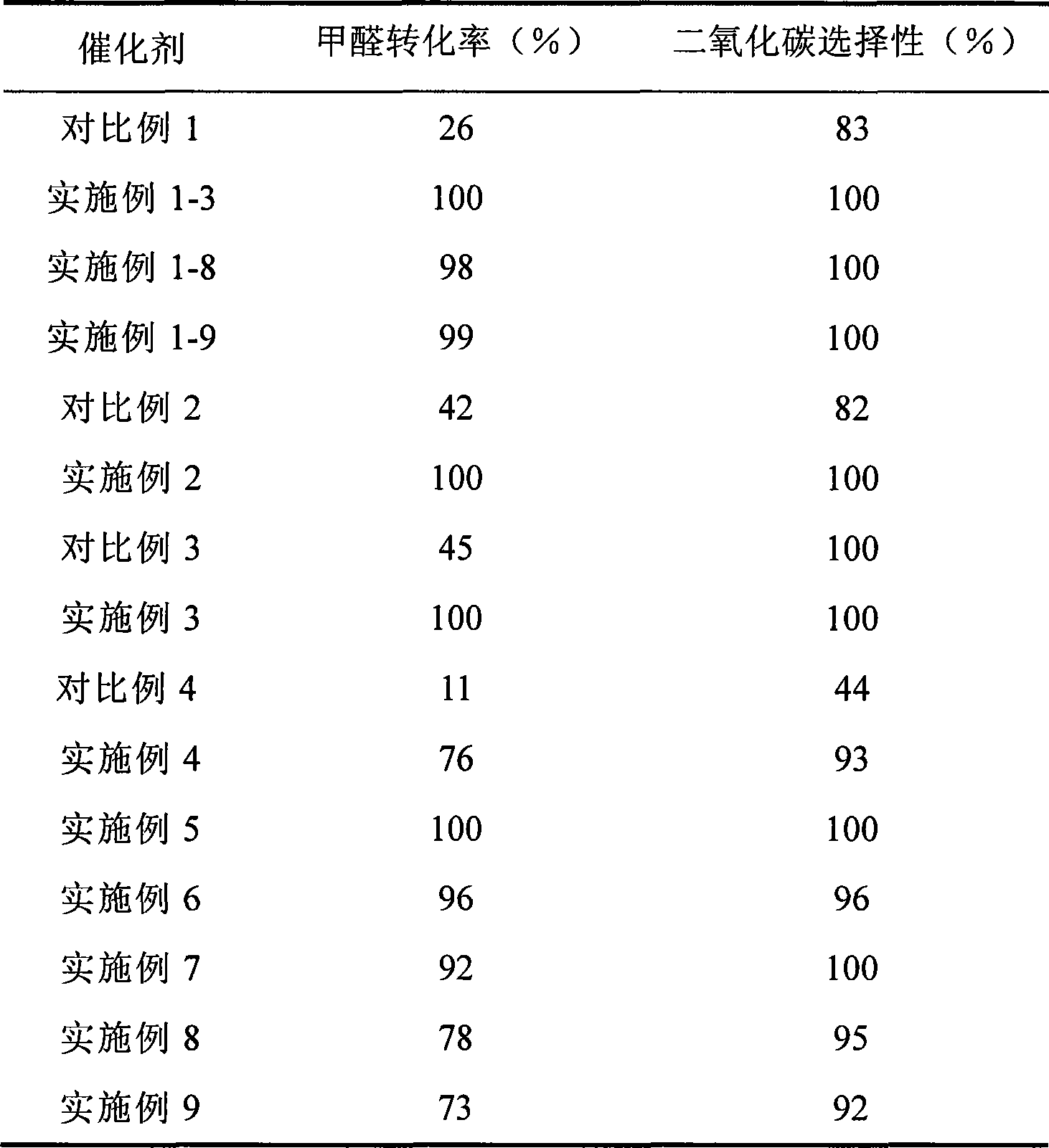

Examples

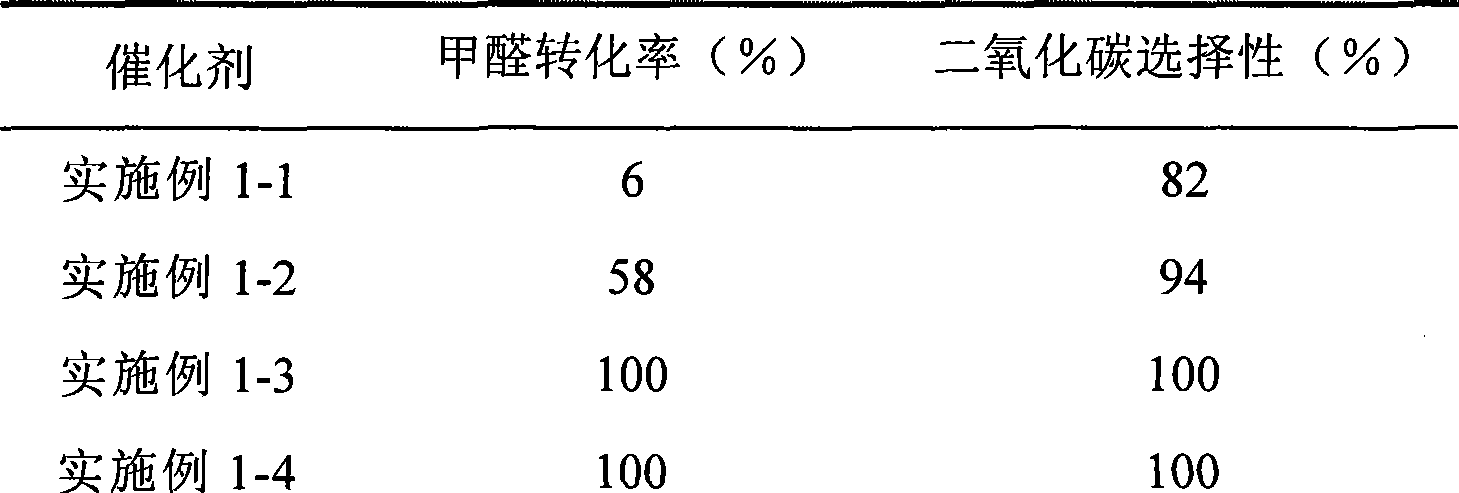

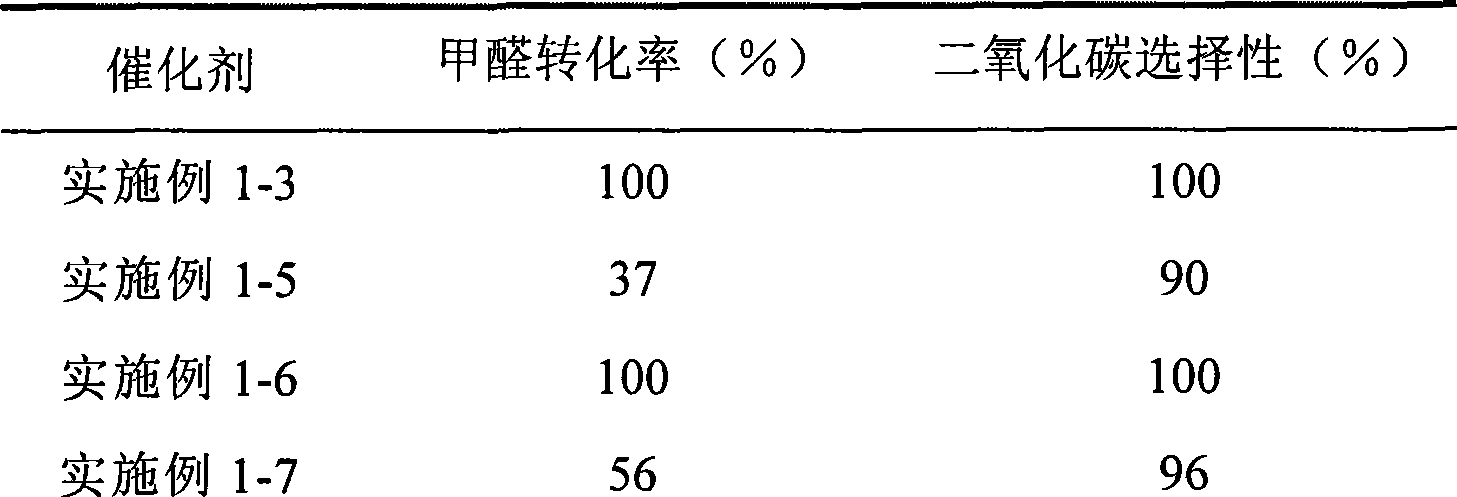

Embodiment 1-1

[0017] Take 10 grams of titanium dioxide powder and immerse it in a mixed aqueous solution of platinum chloride and sodium carbonate at a certain concentration, stir for 2 hours, dry it at 100°C, and roast it in a muffle furnace at 500°C for 2h under air conditions to obtain Example 1 -1 Catalyst. In the prepared catalyst, the loading amount of platinum component is 0.05% in conversion of metal element weight, and the loading amount of sodium component is 4% in conversion of metal element weight.

Embodiment 1-2

[0019] Take 10 grams of titanium dioxide powder and immerse it in a mixed aqueous solution of platinum chloride and sodium carbonate at a certain concentration, stir for 2 hours, dry it at 100°C, and roast it in a muffle furnace at 500°C for 2h under air conditions to obtain Example 1 -2 Catalyst. In the prepared catalyst, the loading amount of platinum component is 0.2% in conversion of metal element weight, and the loading amount of sodium component is 4% in conversion of metal element weight.

Embodiment 1-3

[0021] Take 10 grams of titanium dioxide powder and immerse it in a mixed aqueous solution of platinum chloride and sodium carbonate at a certain concentration, stir for 2 hours, dry it at 100°C, and roast it in a muffle furnace at 500°C for 2h under air conditions to obtain Example 1 -3 Catalyst. In the prepared catalyst, the loading amount of the platinum component is 0.3% in conversion of metal element weight, and the loading amount of sodium component is 4% in conversion of metal element weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com