Patents

Literature

72 results about "Platinum chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Platinum(II) chloride is the chemical compound PtCl2. It is an important precursor used in the preparation of other platinum compounds. It exists in two crystalline forms, but the main properties are somewhat similar: dark brown, insoluble in water, diamagnetic, and odorless.

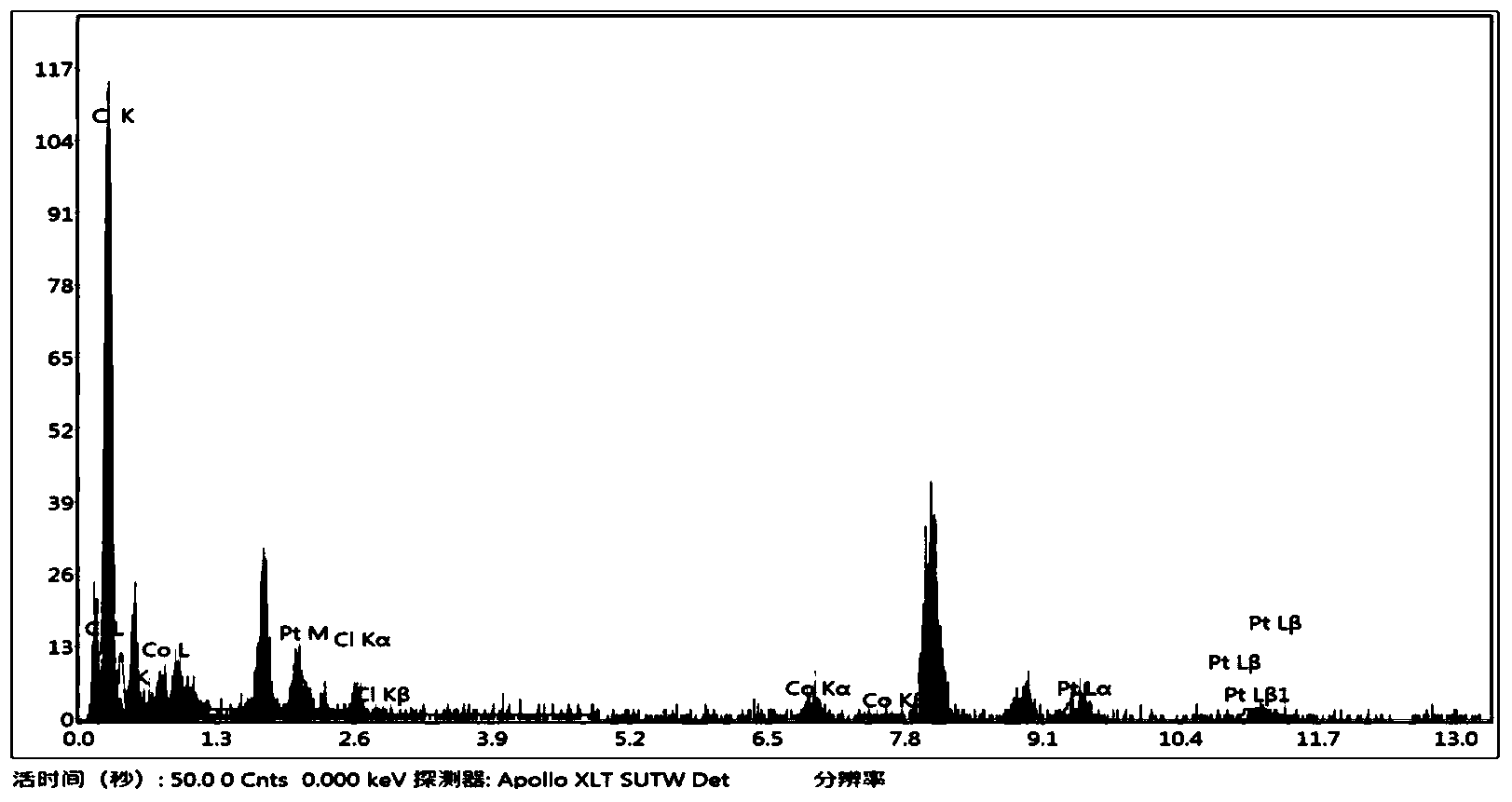

Method for manufacturing strepto-shaped cobalt platinum alloy by using octreotide acetate as template

InactiveCN104014810ASimple molecular structureEasy to analyzeNanotechnologyWater bathsOctreotide acetate

A method for manufacturing strepto-shaped cobalt platinum alloy by using octreotide acetate as a template mainly comprises the steps that the octreotide acetate is dissolved through pH2-3 hydrochloric acid, the octreotide acetate is regulated into an acid solution, a cobalt chloride solution and a platinum chloride solution which are the same in amount are simultaneously added in the regulated solution with the mole ratio of 1:10-20, the solution is then put in a water bath constant temperature oscillator, and hatching is carried out for 20-26 hours under the temperature of 13-25 DEG C at 100-200 rpm.; then, the reducing agent sodium borohydride is added in the hatched solution at a time so that the hatched solution is changed into dark black from light yellow, and the strepto-shaped cobalt platinum alloy is obtained, wherein the mole ratio of the reducing agent sodium borohydride and the octreotide acetate is 1:25-35. The method for manufacturing the strepto-shaped cobalt platinum alloy by using the octreotide acetate as the template has the advantages that the manufacturing technology is simple, conditions are mild, the strepto-shaped cobalt platinum alloy is cheap and easy to obtain, the reaction is easy to control, the productivity is high, and mass production is easy to achieve.

Owner:YANSHAN UNIV

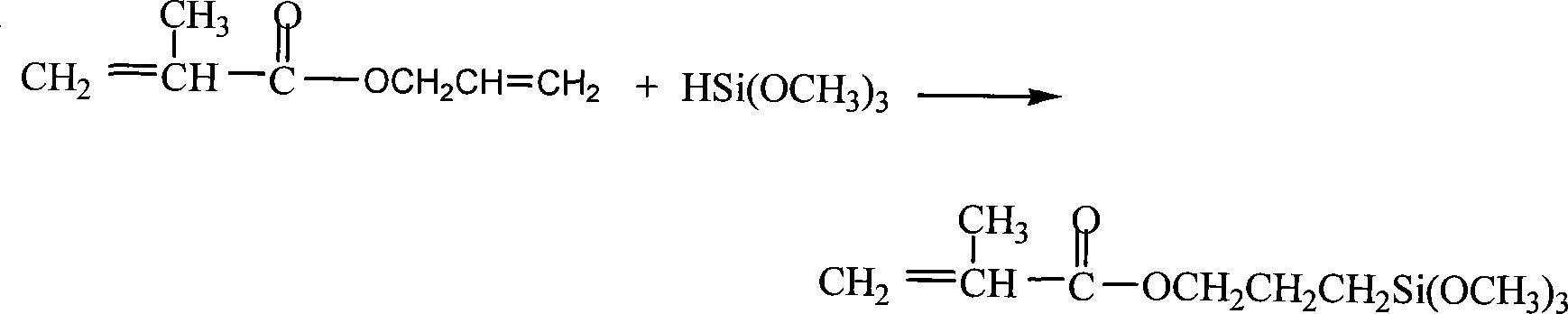

Method for preparing 3-(methacryloxy)propyltrimethoxysilane

ActiveCN101121724AHigh catalytic efficiencyLow costGroup 4/14 element organic compoundsSilanesDissolution

The invention discloses a preparation method of the 3-(methacryloyl oxygen) propyl tri-methoxy silane. The steps are: first the platinum chloride acid, isopropanol and the compound A are used as the raw materials; the platinum chloride acid is added into the isopropyl alcohol; after the dissolution, the compound A is added and then to be heated; secondly, the polymerization-preventing reagent phenothiazine and ZJ-701 are added into the tri-methoxy silane to dissolve the raw material X; thirdly, the polymerization-preventing reagent N, N'-drophenyl-p-phenylenediamine are added in the methacrylate allylic ester to dissolve the raw material Y; fourthly, the polymerization-preventing reagent ZJ-701 and ZJ-101 are added in the reaction materials after the reaction between the raw materials and the catalysts to dissolve to get the 3-(methacryloyl oxygen) propyl tri-methoxy silane. The invention is of the simple preparation, the high efficiency, the little consumption, the strong selectivity, and the high collection rate of the products; the polymerization-preventing effects of the polymerization-preventing technology are good; the polymerization-preventing reagents are not easy to be gelated; the consumption is little; the polymerization-preventing reagents are easily separated from the products; the products are easy to be decolorized, good in quality, and have no harm to the catalyst.

Owner:湖北武大有机硅新材料股份有限公司

Environment-friendly non-mercury catalyst for acetylene-method chloroethylene synthesis and preparation method thereof

InactiveCN103386315AAvoid pollutionImprove conversion ratePhysical/chemical process catalystsPreparation by halogen halide additionCeriumCuprous chloride

The invention discloses an environment-friendly non-mercury catalyst for acetylene-method chloroethylene synthesis and a preparation method thereof. According to the non-mercury catalyst disclosed by the invention, a precious metal chloride, namely any of gold chloride, platinum chloride and palladium chloride, is adopted as a main active substance, wherein the content of the precious metal chloride accounts for 0.5-5% of the weight of the catalyst; an assistant active ingredient is one or more than one of non-precious metal chlorides, namely bismuth chloride, cuprous chloride, cerium chloride and zinc chloride, wherein the content of the non-precious metal chlorides accounts for 1-10% of the weight of the catalyst; and a support is one of coconut shell charcoal, fruit shell charcoal and coal charcoal. The non-mercury catalyst is prepared by a conventional impregnation method. The preparation method of the catalyst is simple and is environmental-friendly, few byproducts are generated, the stability of the prepared catalyst is good, the environmental pollution caused by mercury catalysts is avoided, the service life of the catalyst is prolonged, the acetylene conversion ratio can reach 96-99%, and the selectivity to chloroethylene is not lower than 98%.

Owner:湖北随州双星生物科技有限公司

Method for preparing direct methyl alcohol fuel cell nano electric catalyst

InactiveCN1461069ACell electrodesMetal/metal-oxides/metal-hydroxide catalystsAlcohol fuelNitrogen gas

The present invention respectively uses water soluble platinum chloride, ruthenium chloride or bromide and non-water-soluble platinum ruthenium olefine complex as raw material, in which the mole ratio of platinum and ruthenium is 1:0.5-1, its organit solvent is acetone, ethyl alcohol or dichloromethane, the volume ratio of organic solvent and ion liquid is 0.5-2:1, its adopted ion liquid is water soluble or non-water-soluble, and the content of noble metal in the organic solution is 2-10 g / L, then the active carbon can be added to make adsorption, then the above-mentioned materials are stirred, the pure hydrogen gas or hydrogen gas and nitrogen gas mixed gas is introduced to make reduction, and then the above-mentioned material is centrifugatized, washed with organic solvent and dried.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

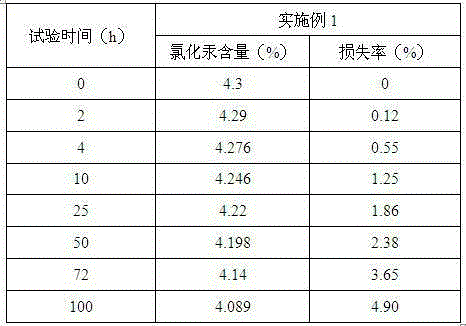

Method for low-mercury catalyst with good heat stability

ActiveCN105195224AImprove thermal stabilityPreparation by halogen halide additionOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystPhenylphosphine

A provided method for low-mercury catalyst with good heat stability comprises preparation of active carbon, preparation of an adsorption solution, and adsorption processing. The adsorption processing steps comprises ultrasonic assisted adsorption, microwave assisted adsorption and vacuum penetration adsorption. The prepared low-mercury catalyst comprises, in percent by weight, 4.3% of mercuric chloride, 8.6% of zinc chloride, 8.6% of palladium chloride, 2.87% of platinum chloride, 2.87% of tetrabutyl ammonium chloride, 2.87% of tripotasium triphenylphosphine-3,3',3''-trisulfonate, and 0.18% of water. The low-mercury catalyst possesses the mechanical strength of 98.6%, the granularity of 3-6 mm (98%), the bulk density of 460 g / L, and the mercuric chloride ignition loss of 0.39%. The prepared low-mercury catalyst is good in heat stability and low in mercuric chloride loss rate. When the low-mercury catalyst is applied to vinyl chloride synthesis reaction, the acetylene conversion rate is 99.93%, the vinyl chloride selectivity is close to 100%, and the vinyl chloride yield is 95.2%.

Owner:NINGXIA JINHAI CHUANGKE CHEM TECH

Method for preparation of highly dispersed supported platinum catalyst

InactiveUS20070135299A1Uniform sizeEvenly distributedOrganic-compounds/hydrides/coordination-complexes catalystsCell electrodesFiltrationDistilled water

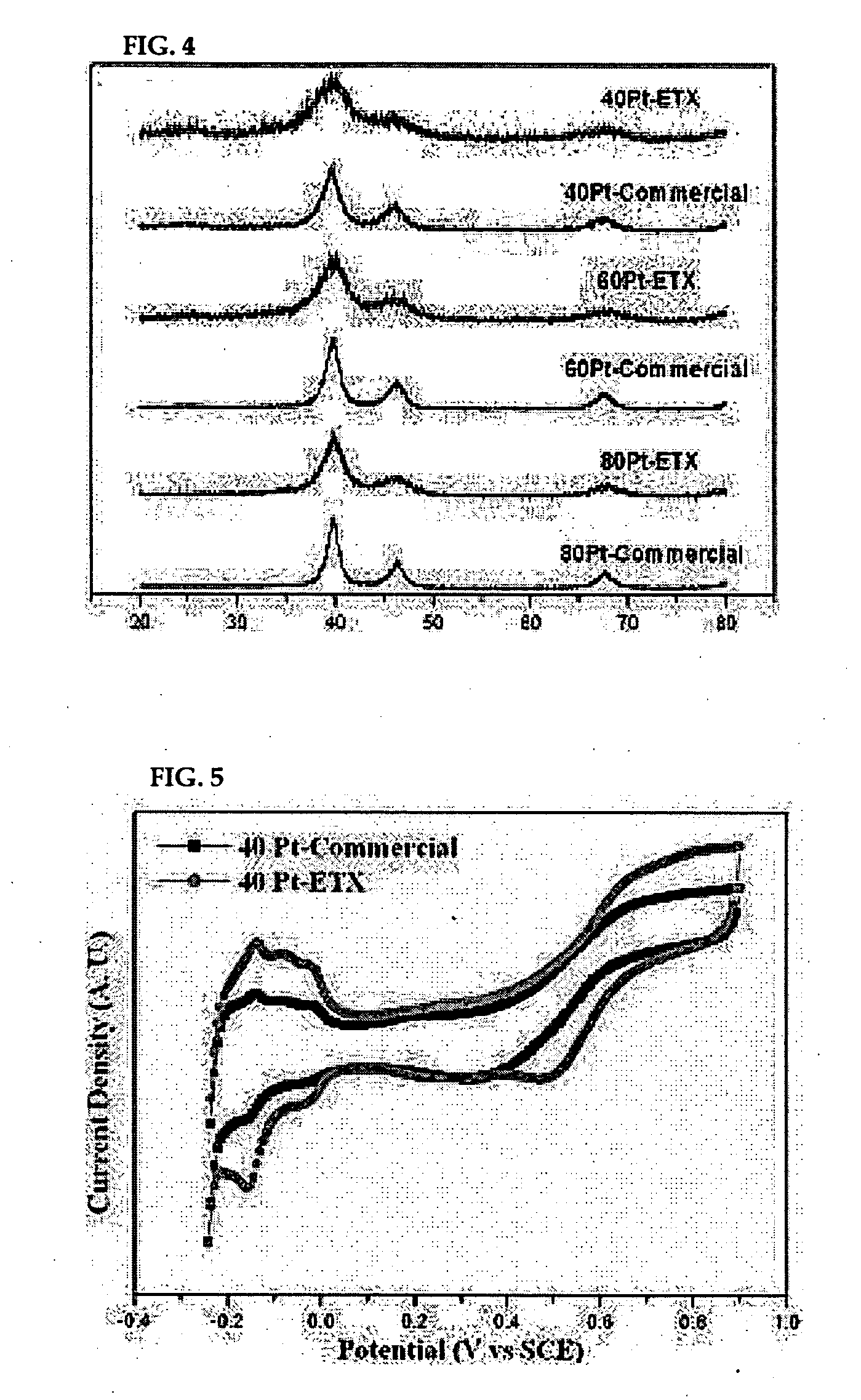

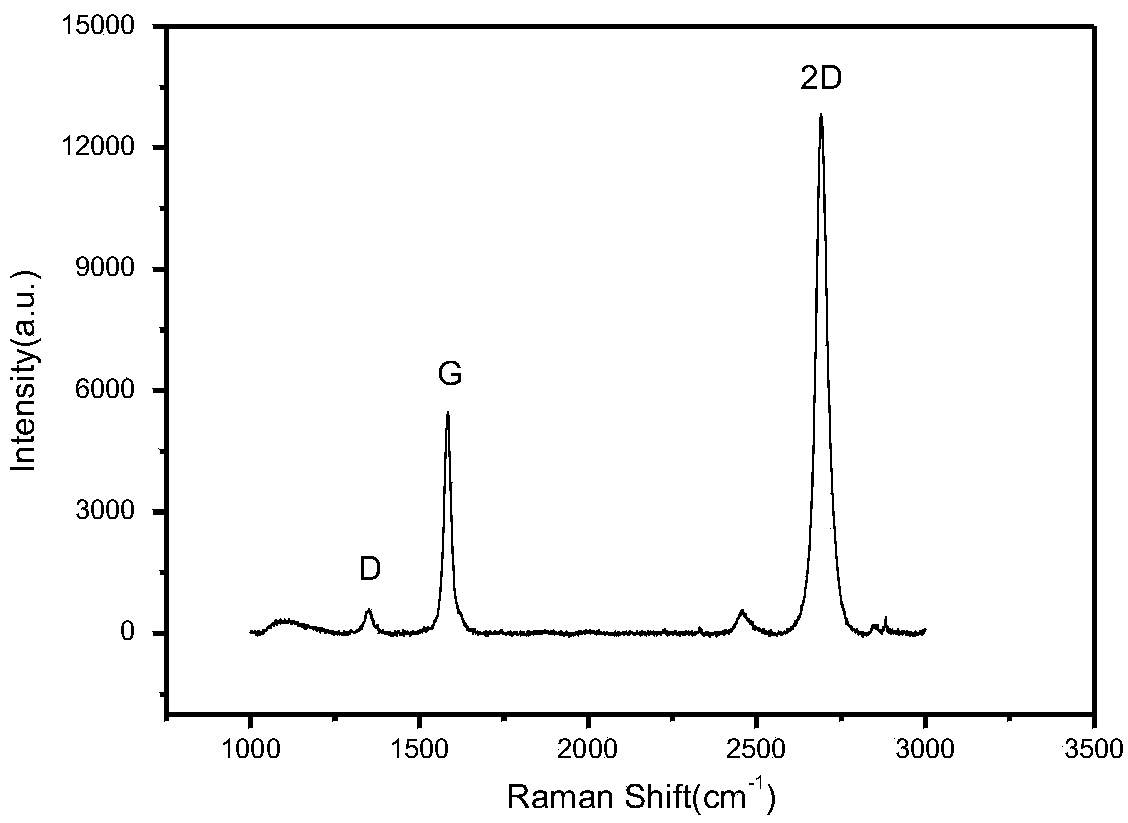

The present invention relates to a method for synthesizing highly dispersed supported platinum catalyst. More particularly, the present invention relates to a method of synthesizing highly dispersed supported platinum catalyst comprising:dissolving a reducing agent in a solvent to produce a solution, dissolving a platinum chloride to the same solvent; adding a carbon support and platinum in a predetermined ratio to the above mixed solution, agitating the mixture, performing ultrasonic treatment, and performing heat treatment; and adding a HCl solution, agitating the mixture, separating the precipitates via filtration to produce a catalyst, and then washing the catalyst with distilled water, thereby obtaining an active highly dispersed supported platinum catalyst which has excellent electric charge activity, uniformly-sized platinum particles and relatively high specific surface area.

Owner:HYUNDAI MOTOR CO LTD

Ammonia gas sensor loaded with platinum particles and preparation method thereof

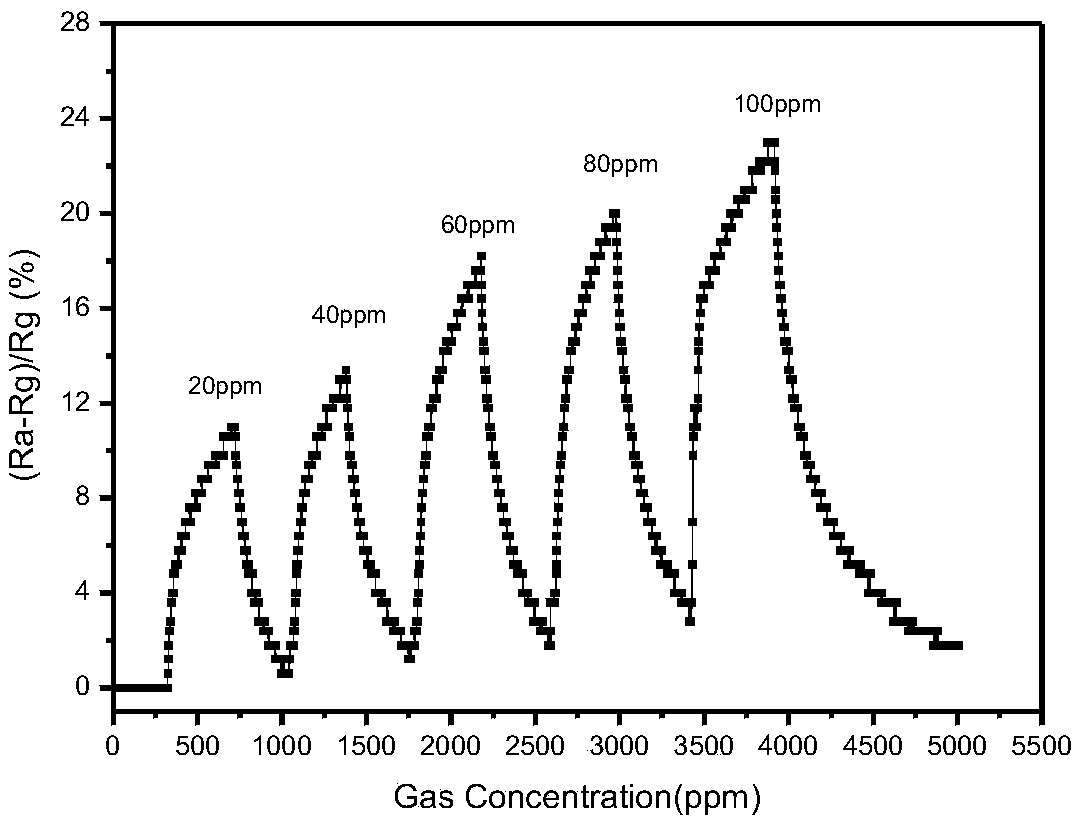

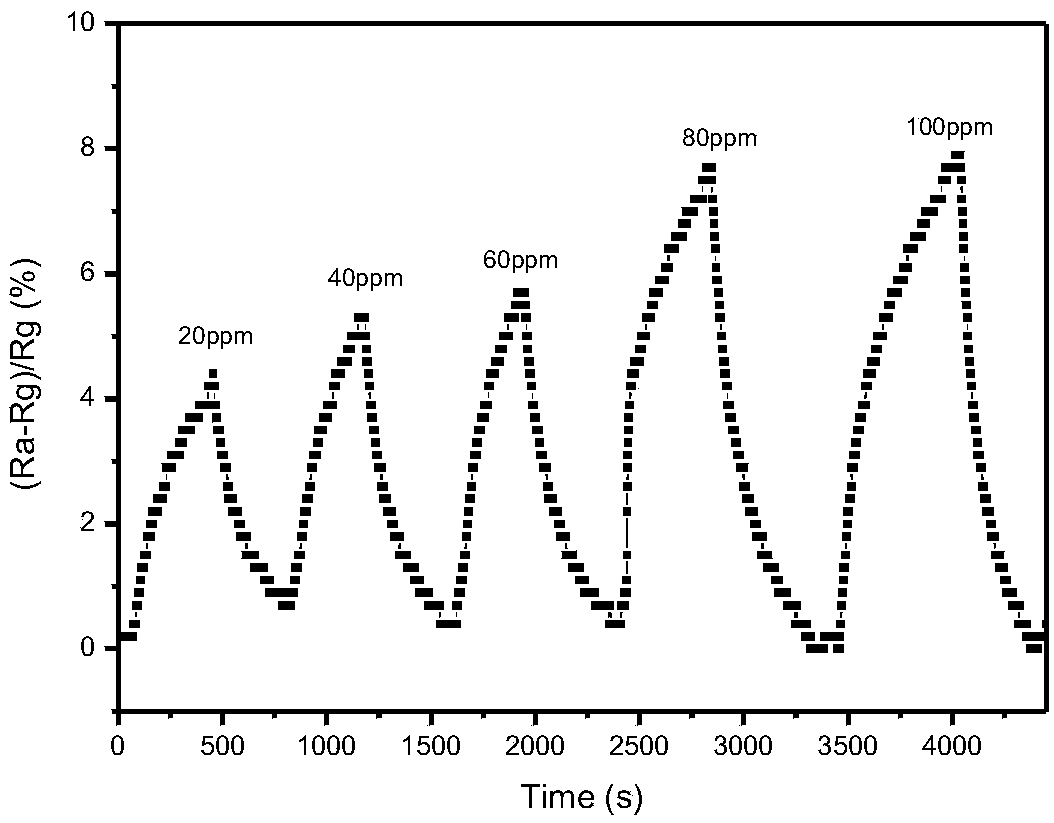

InactiveCN108896621AAdd defect siteImprove responsivenessCarbon compoundsMaterial resistanceElectrical resistance and conductanceGas detector

The invention relates to an ammonia gas sensor loaded with platinum particles and a preparation method thereof, and belongs to the field of gas sensors. A gas sensitive material is composed of the platinum particles and a graphene film. The platinum particles are loaded on the graphene film carrier. The method includes the following steps: (1) preparing the graphene film and keeping for later use;(2) using ultraviolet ozone to modify the graphene film obtained in the step (1) and keeping for later use; and (3) impregnating the modified graphene film in the step (2) in a platinum chloride solution, and heating and insulating the graphene film after the impregnation so as to decompose chloroplatinic acid into the platinum particles to obtain the ammonia gas sensitive material loaded with the platinum particles on the graphene film. According to the preparation method, through the ultraviolet ozone treatment, the graphene film is firstly modified by introducing an oxygen-containing functional group, increasing defect sites and adsorption sites of the film, changing resistance characteristics and wettability of the film and loading the platinum particles onto the graphene film. The gas sensitive sensor prepared according to the method has excellent room temperature response performance to ammonia gas.

Owner:SHANDONG UNIV

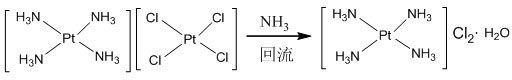

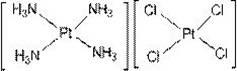

Preparation method of tetramine platinum chloride

InactiveCN102328962AAchieve recyclingImprove protectionRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsPlatinum complexTetramine

The invention relates to a preparation method of a platinum complex, namely tetramine platinum chloride, which belongs to the field of pharmacochemistry. The preparation method comprises the following steps: carrying out a reaction on a Magnus salt and concentrated ammonia solution under the condition of heating reflux till the green Magnus salt disappears completely so as go generate pale yellow or colorless clear liquid, and concentrating to get a solid of the tetramine platinum chloride. According to the preparation method of the tetramine platinum chloride, the higher conversation rate is kept, the cyclic utilization of byproducts can be simultaneously achieved when a target compound is synthesized, the cost is saved, and the preparation method is suitable for large-batch industrial production and conductive to environmental protection.

Owner:KUNMING UNIV OF SCI & TECH

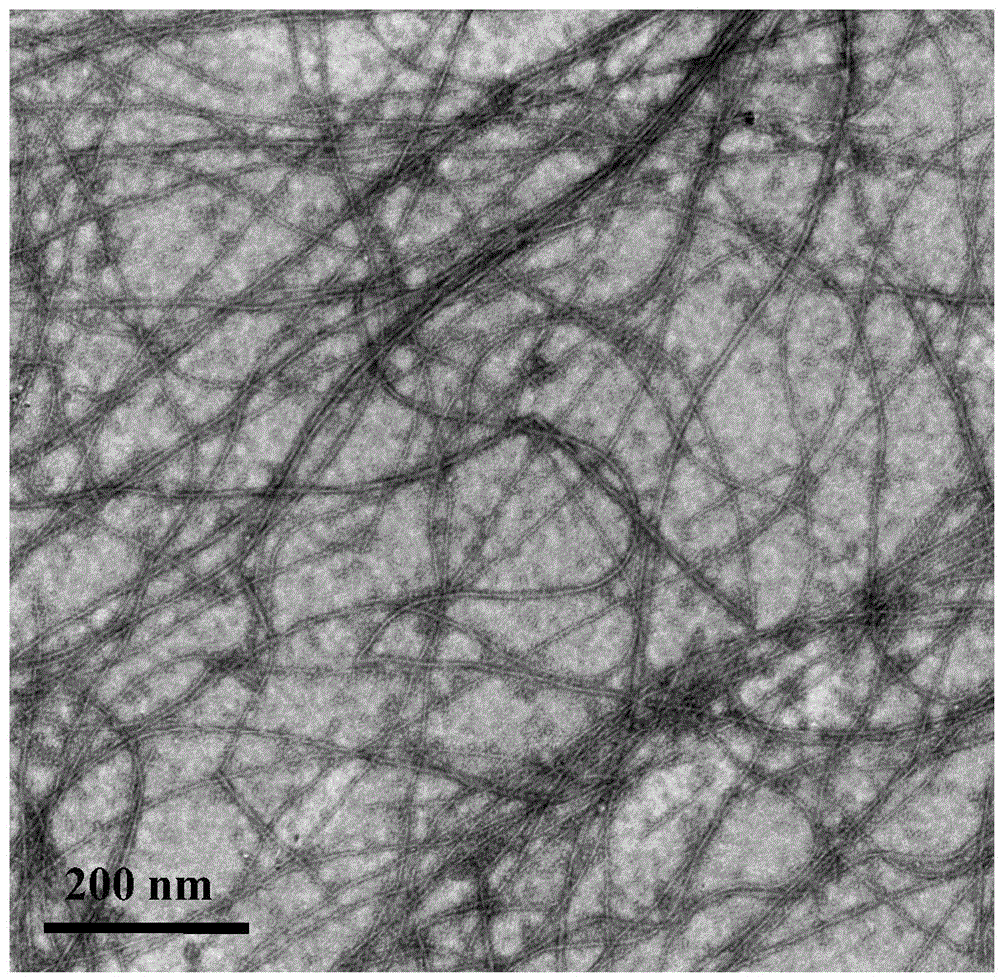

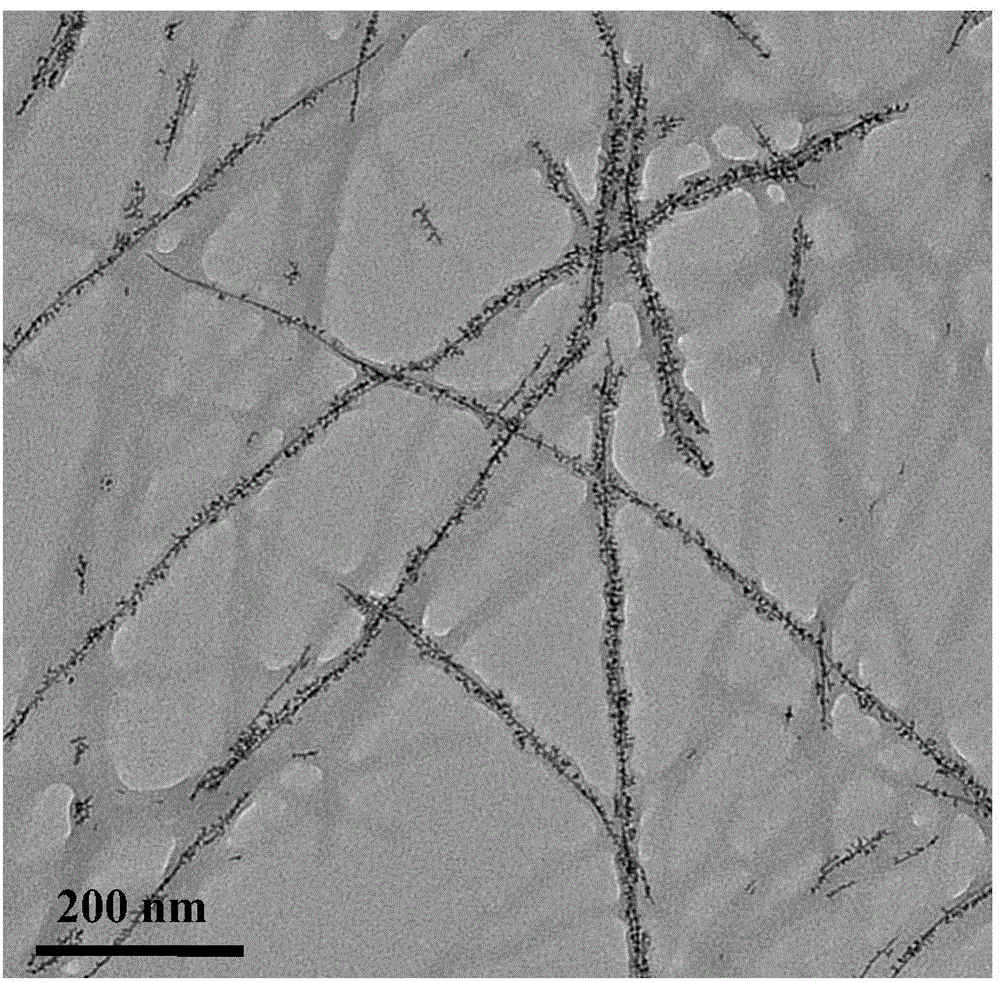

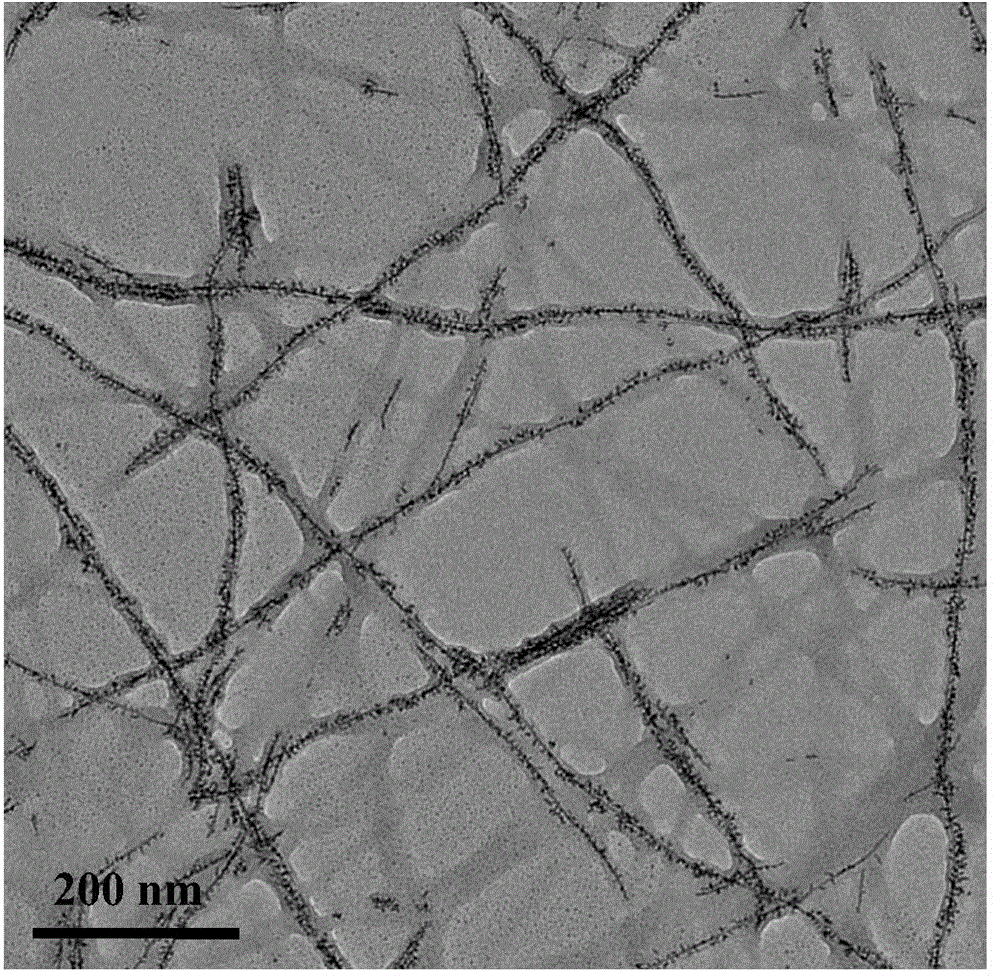

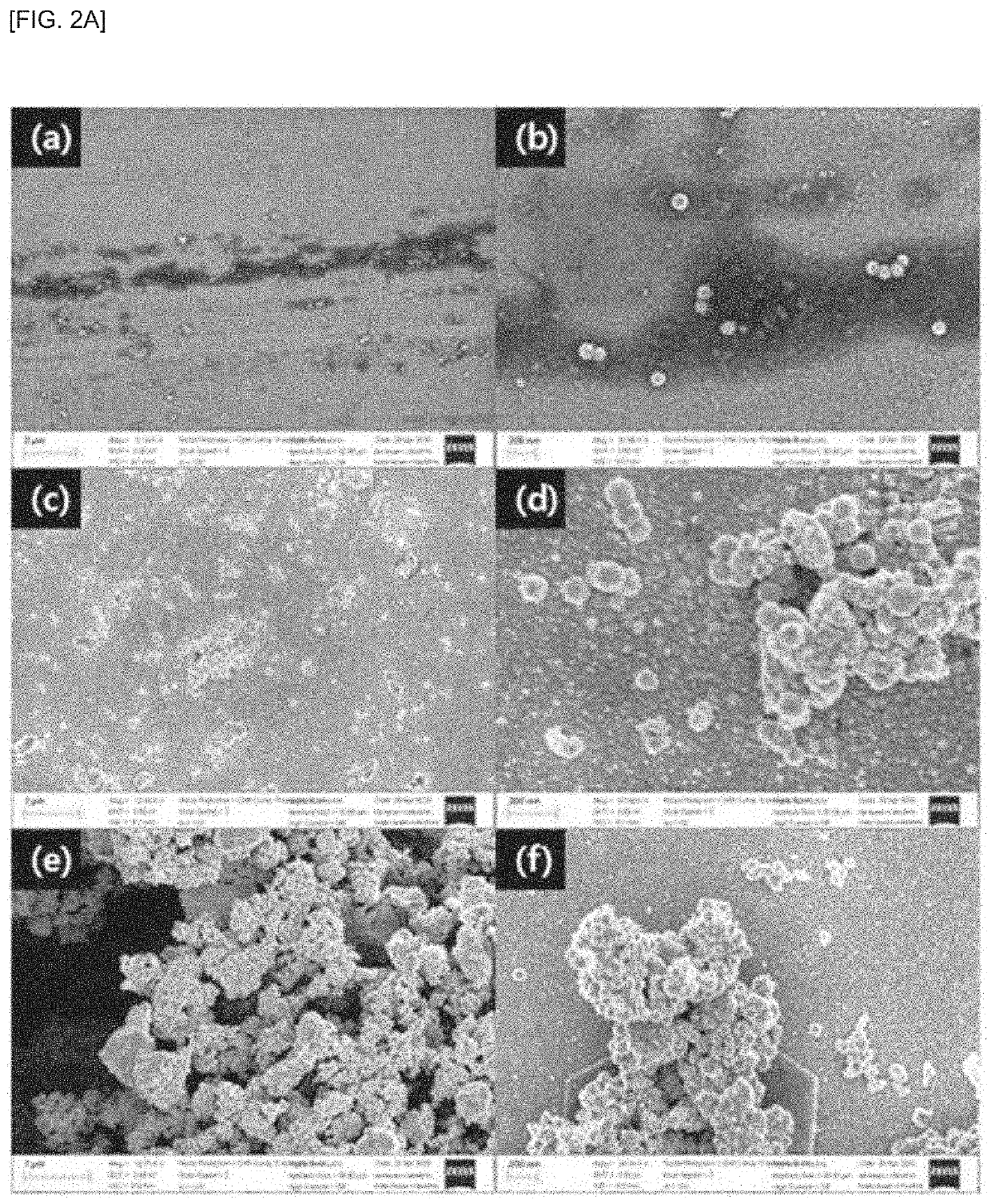

High-activity spiral Pt-Rh alloy nanocatalyst and preparation method thereof

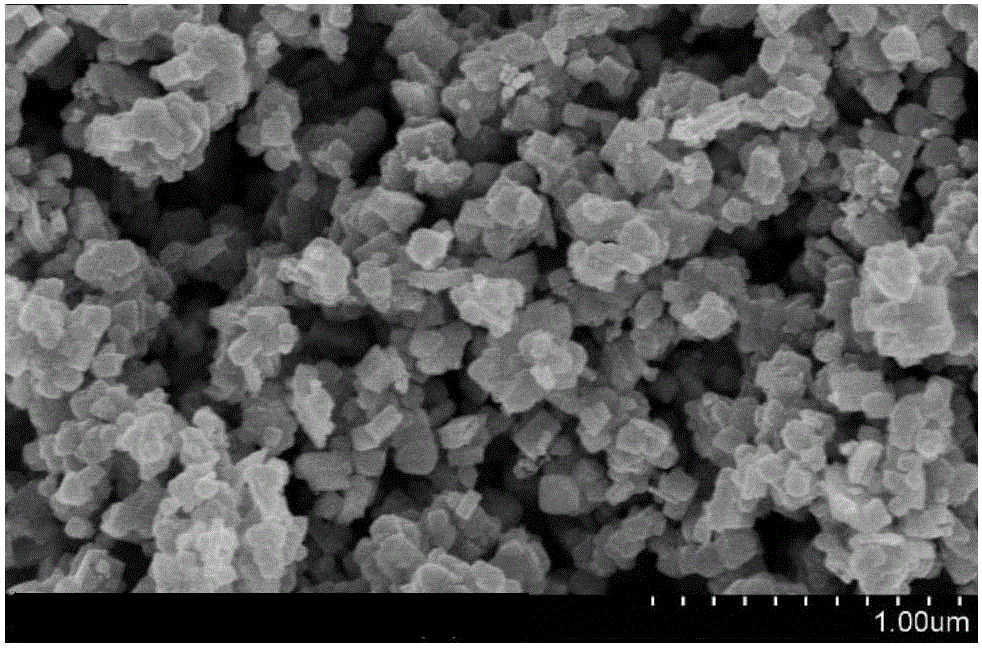

InactiveCN104607184AStable arrangementSmall particle sizeCell electrodesMetal/metal-oxides/metal-hydroxide catalystsFiberEnvironmental resistance

The invention discloses a high-activity spiral Pt-Rh alloy nanocatalyst which is structurally characterized in that a Pt-Rh nanowire forms a framework in the middle, does not have branches, and has the uniform diameter of 1.5-2 nm and the length of a few micrometers; Pt-Rh alloy nanoparticles spirally surround the periphery of the nanowire framework in an axial direction, are distributed orderly and have the uniform sizes of 2-3 nm. A preparation method for the high-activity spiral Pt-Rh alloy nanocatalyst mainly comprises the following steps: taking a hollow spiral insulin fiber obtained after treatment of raw insulin powder as a control template, performing co-hatching on the insulin fiber and a mixed water solution of platinum chloride and rhodium chloride, and performing ultrasonic-assisted co-reduction treatment to prepare the high-activity spiral Pt-Rh alloy nanocatalyst. The nanocatalyst combines the advantages of the nanowire and the nanoparticles and has very high electrocatalytic activity and anti-carbon monoxide poisoning capability; the preparation method is low in preparation cost, environment-friendly, efficient, free of other chemical stabilizers and carriers, simple in preparation process, mild in reaction condition and high in product morphology repeatability.

Owner:YANSHAN UNIV

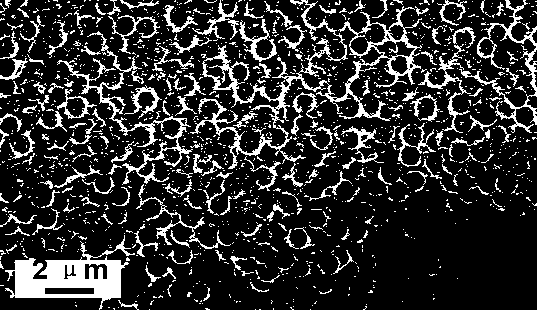

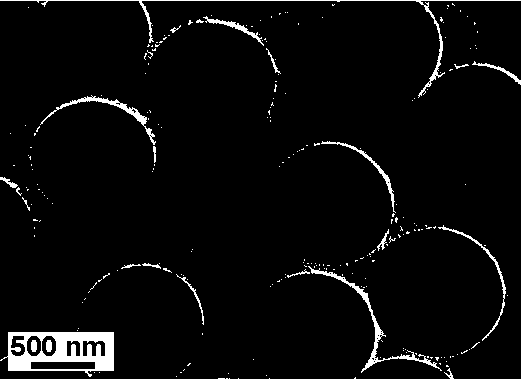

Preparation method of multinuclear platinum-polymer nanometer core-shell material

ActiveCN108421508AUniform shapeThe synthesis process is easy to controlNanotechnologyMicroballoon preparationPorous carbonMicrosphere

The invention discloses a preparation method of a multinuclear platinum-polymer nanometer core-shell microsphere. The preparation method comprises the steps: firstly, synthesizing a resorcinol-formaldehyde resin (RF) nanometer microsphere from resorcinol and formaldehyde serving as precursors, sodium hydroxide or ammonia water serving as a catalyst and an alkalinity regulator as well as surfactants CTAB and F127 serving as co-stabilizers in an alcohol-water solution by using an improved Stuber method; and then, preparing a multinuclear nanometer microsphere with resorcinol-formaldehyde resin (Pt@RF) coated outside platinum from chloroplatinic acid or platinum chloride serving as a platinum source by using a hydrothermal method. The synthesis method can be expanded to prepare other preciousmetal-polymer core-shell microspheres, for example, the synthesis method can be used for preparing composites such as multinuclear Au@RF and Pd@RF. In addition, precious metal-porous carbon materialssuch as Pt@C, Au@C and Pd@C can be prepared by taking the precious metal-polymer core-shell microspheres as precursors and can be applied to the field such as catalysis or lithium ion batteries.

Owner:5ELEM HI TECH CORP

Method for preparing low mercury catalyst by using activated carbon with high carbon tetrachloride adsorption value

ActiveCN105413719AShorten activation timeReduce sublimation speedCatalyst activation/preparationPtru catalystPhenylphosphine

The present invention provides a method for preparing a low mercury catalyst by using activated carbon with a high carbon tetrachloride adsorption value. The method comprises gas phase adsorption, absorption solution preparation and microwave absorption. The microwave absorption comprises first-stage microwave absorption. The first-stage microwave absorption is performed at the temperature of 60 DEG C, the microwave wavelength is 139 mm, the frequency is 2650 MHz, the power is 310 w, and the adsorption treatment lasts for 10 minutes. The method has the beneficial effects that the low mercury catalyst prepared by the method provided by the present invention comprises the following components in percentages by weight: 4.91% of chlorinated mercury, 4% of zinc chloride, 2% of palladium chloride, 2% of platinum chloride, 2% of tetrabutyl ammonium chloride, 2% of triphenylphosphine sulfonic acid potassium and 0.20% of water; the mechanical strength is 99.6%, the particle size is 3-6 mm (99.8%), and the bulk density is 516 g / L; and In the synthesis reaction of vinyl chloride, the conversion rate of acetylene reaches 99.98%, and the yield of the vinyl chloride reaches 97.3%.

Owner:NINGXIA JINHAI CHUANGKE CHEM TECH

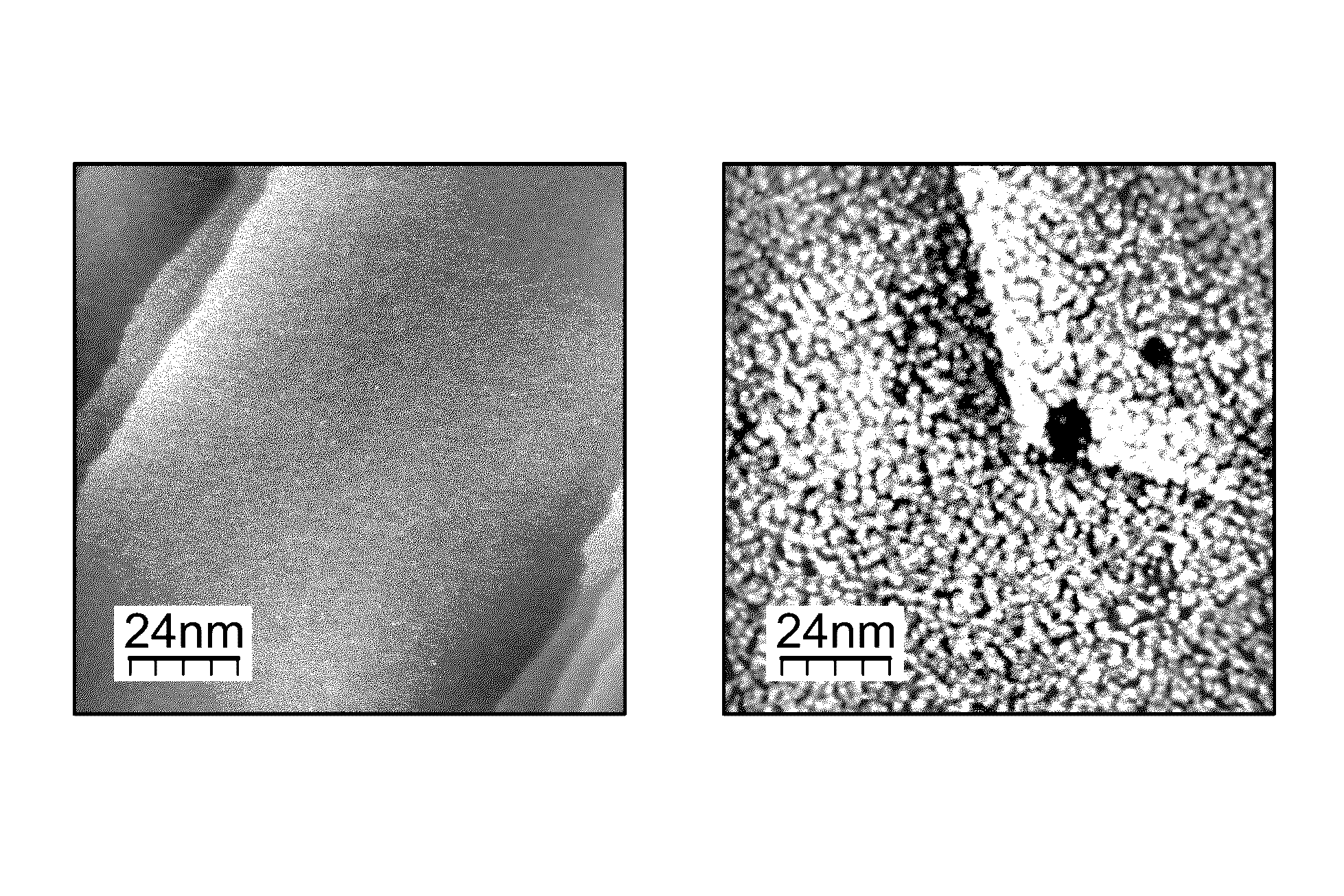

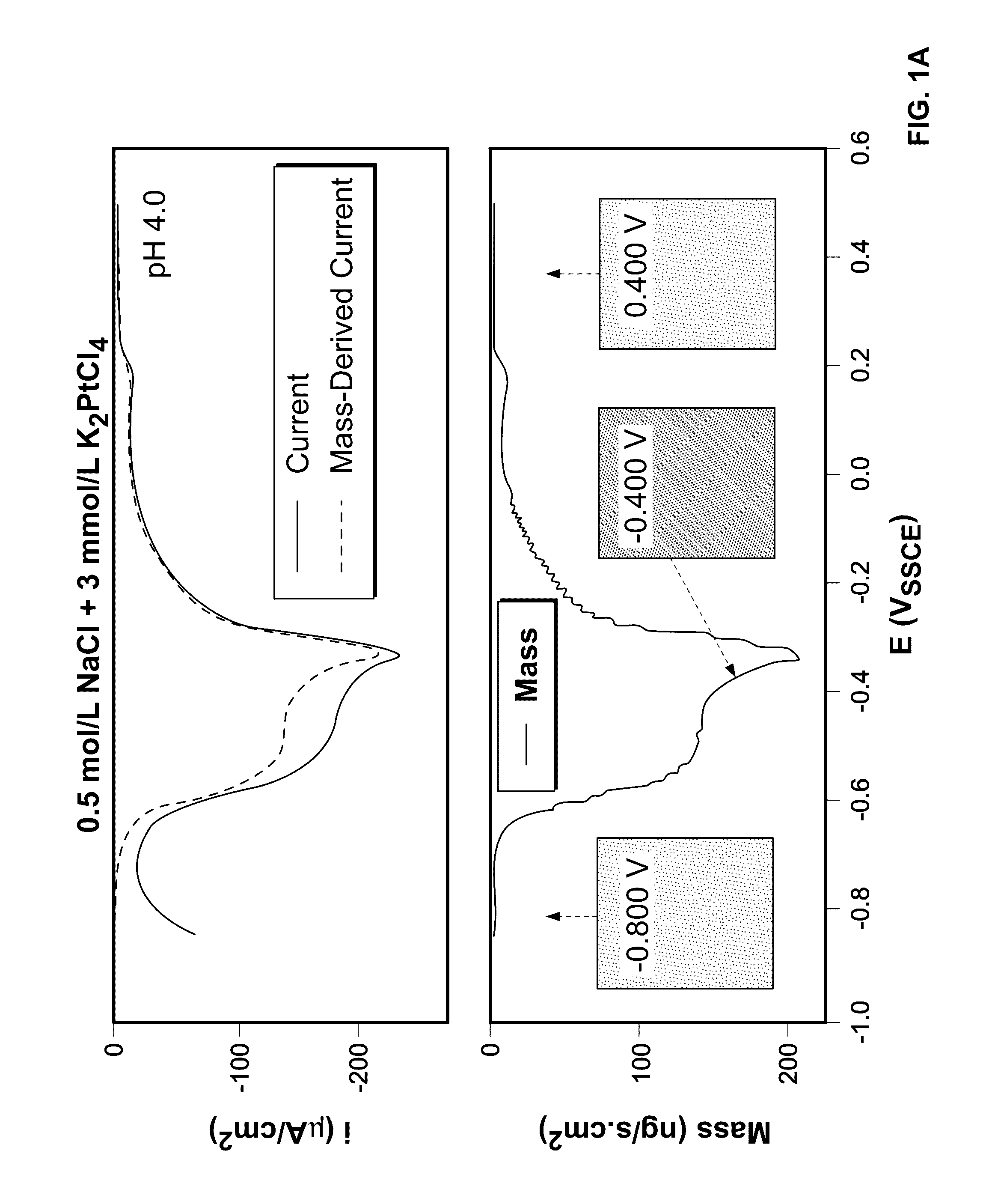

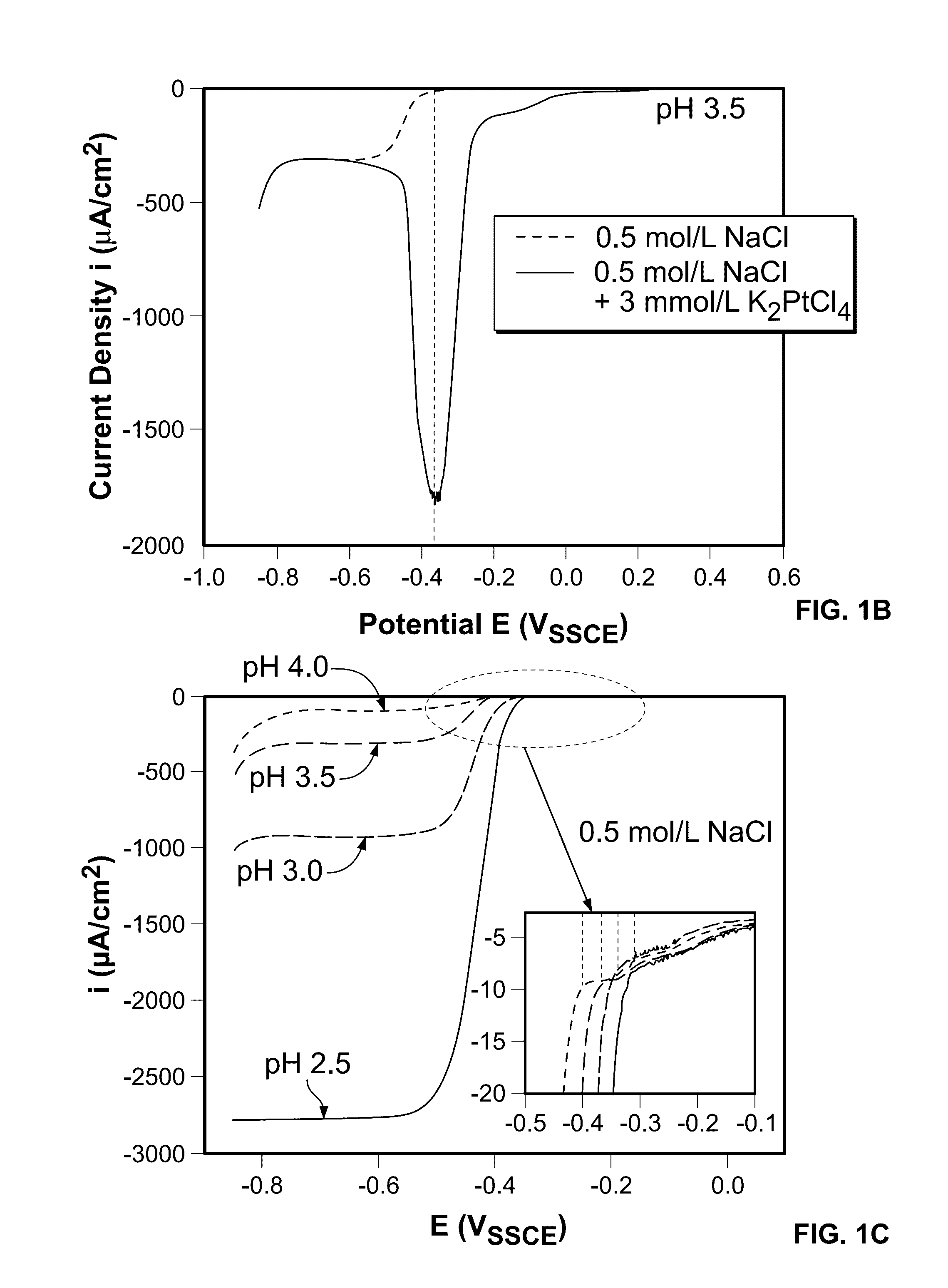

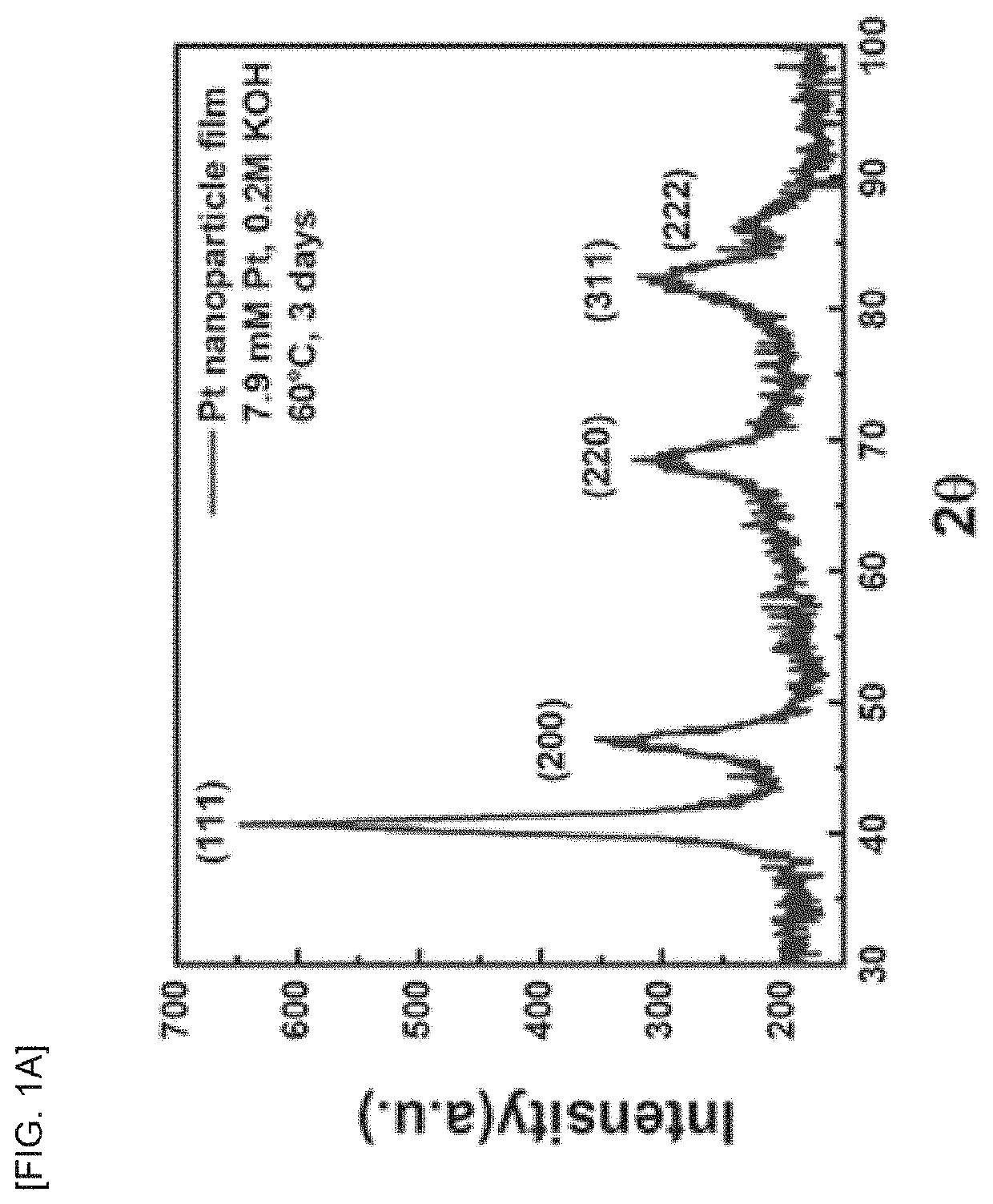

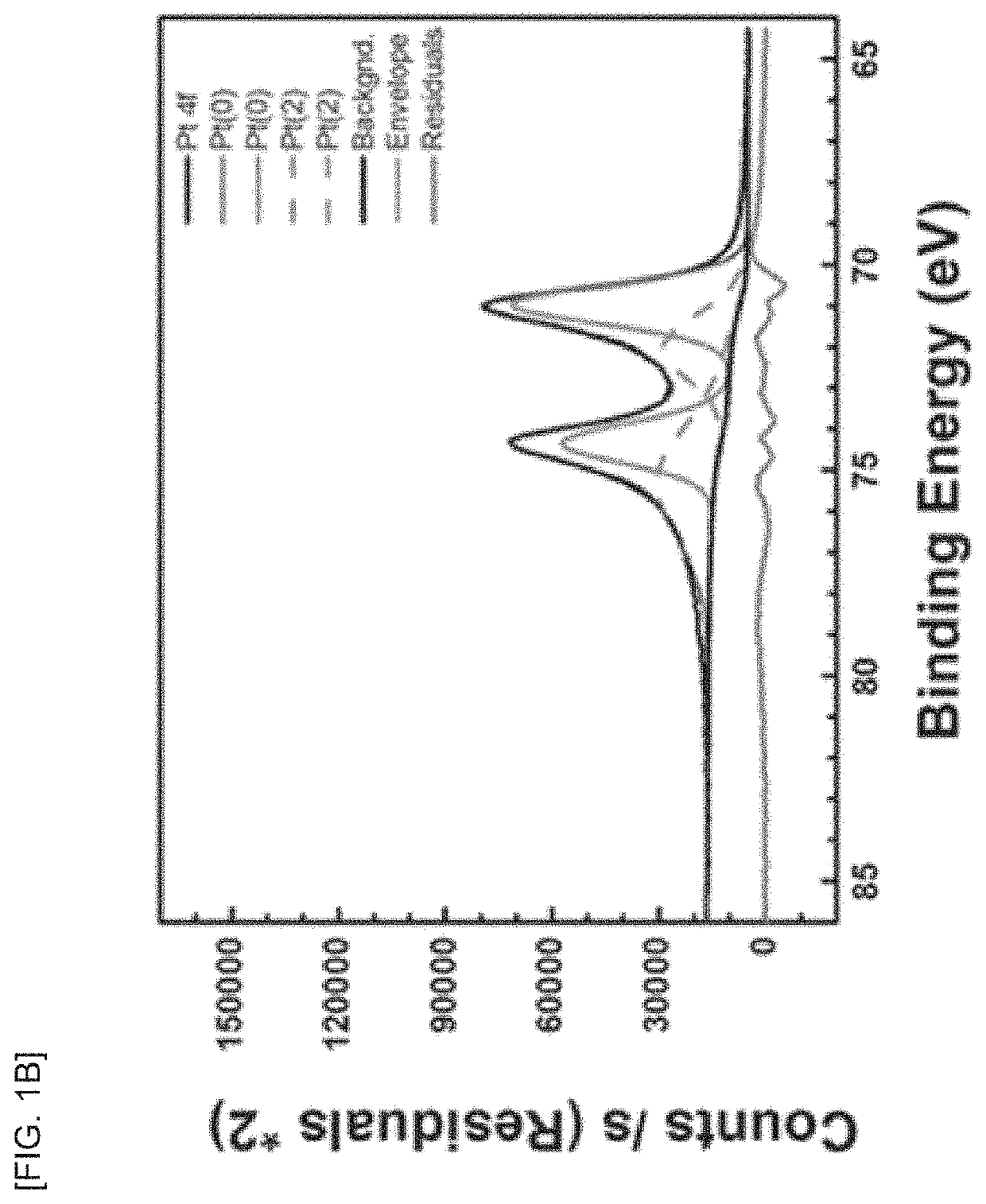

Self-terminating growth of platinum by electrochemical deposition

A self-terminating rapid process for controlled growth of platinum or platinum alloy monolayer films from a K2PtCl4—NaCl—NaBr electrolyte. Using the present process, platinum deposition may be quenched at potentials just negative of proton reduction by an alteration of the double layer structure induced by a saturated surface coverage of underpotential deposited hydrogen. The surface may be reactivated for platinum deposition by stepping the potential to more positive values where underpotential deposited hydrogen is oxidized and fresh sites for absorption of platinum chloride become available. Periodic pulsing of the potential enables sequential deposition of two dimensional platinum layers to fabricate films of desired thickness relevant to a range of advanced technologies, from catalysis to magnetics and electronics.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE COMMERCE

Method for the production of electrodes on a type II or VI semiconductor material or on a compound of said material

InactiveUS20060121716A1Improve adhesionSemiconductor/solid-state device manufacturingPhotovoltaic energy generationSemiconductor materialsPlatinum chloride

A method for manufacturing electrodes on a semiconducting material of type II-VI or on a compound of this material. The electrodes are preferably in gold or platinum and are formed by electrochemical deposition of gold or platinum from a solution of gold or platinum chloride in pure hydrochloric acid.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

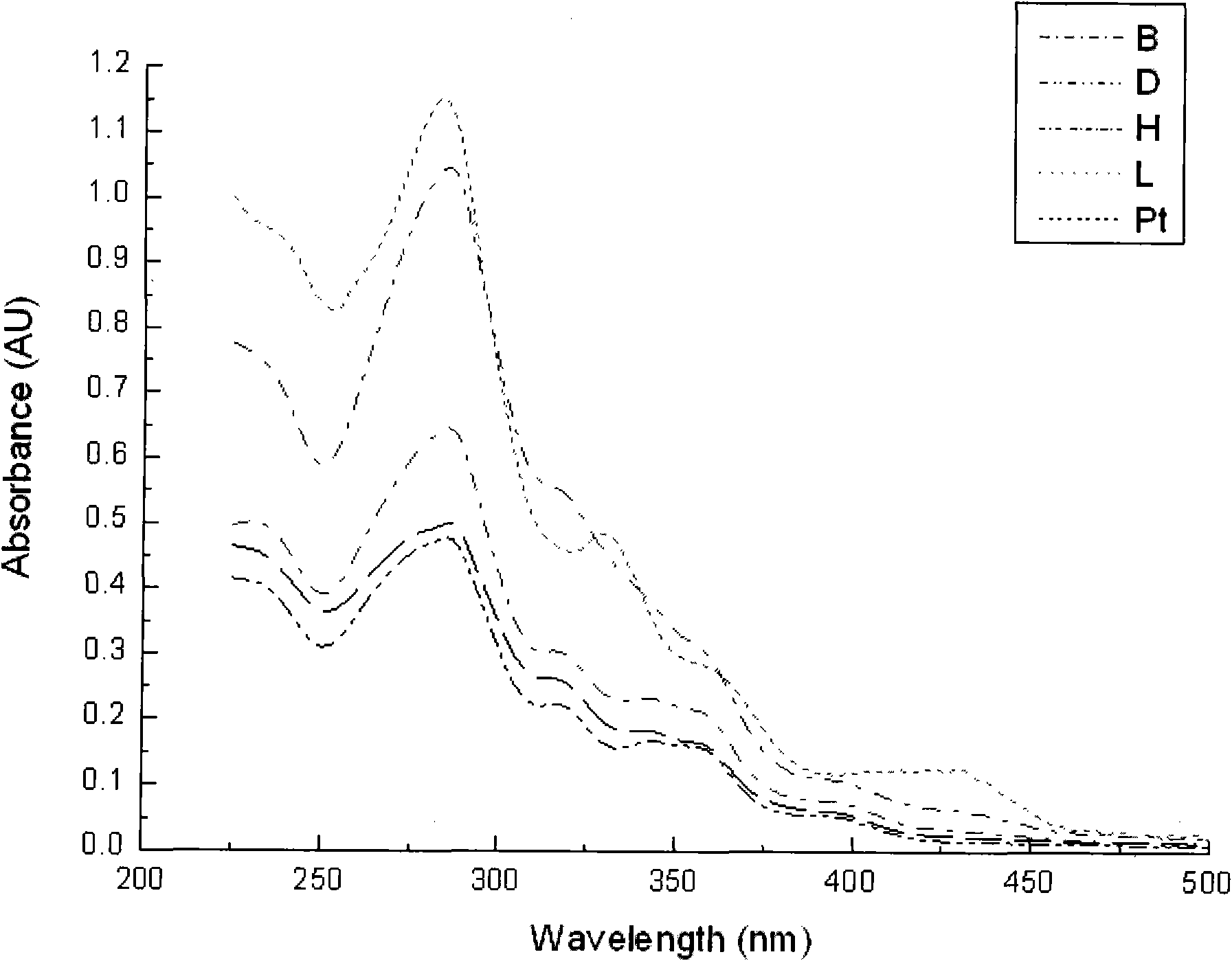

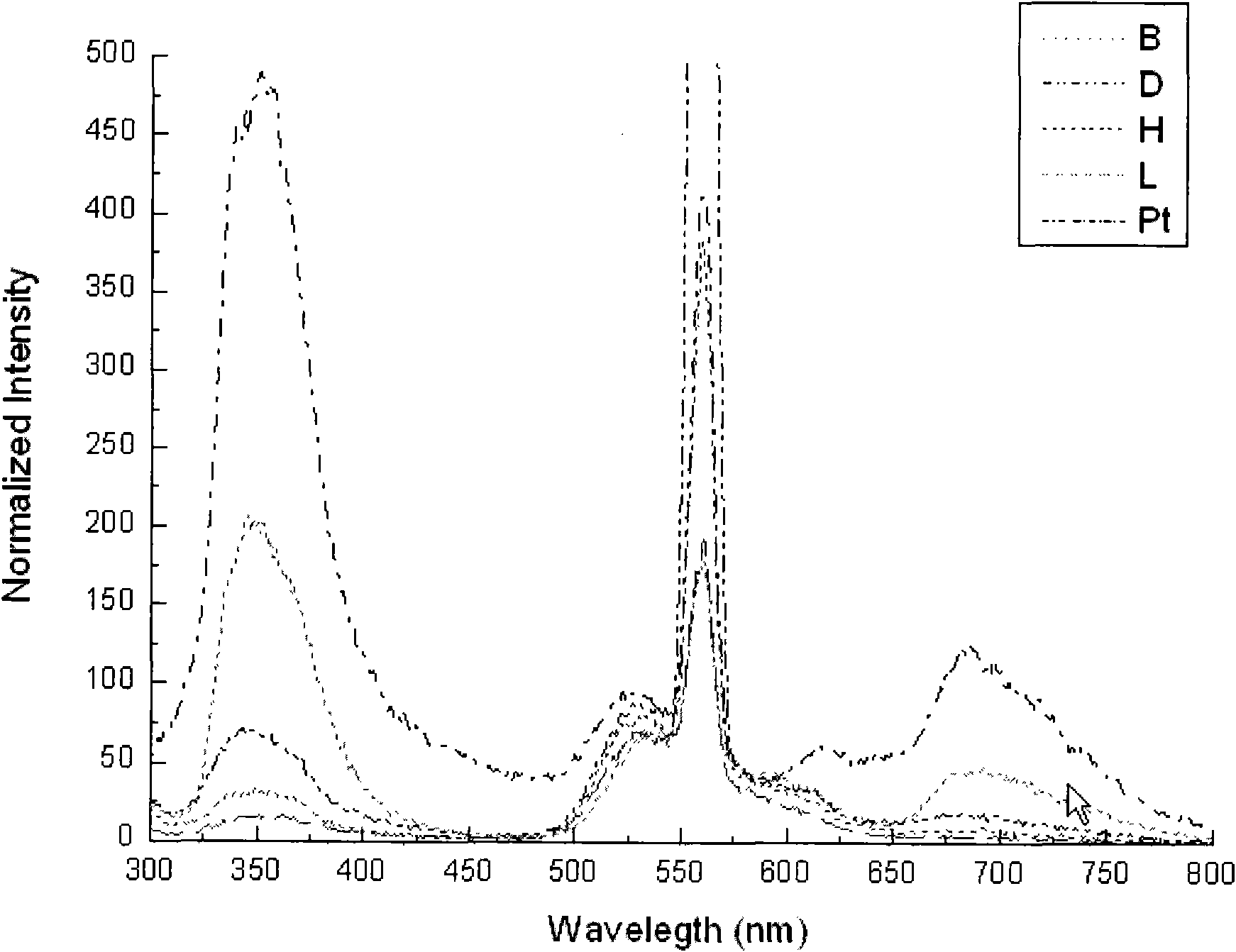

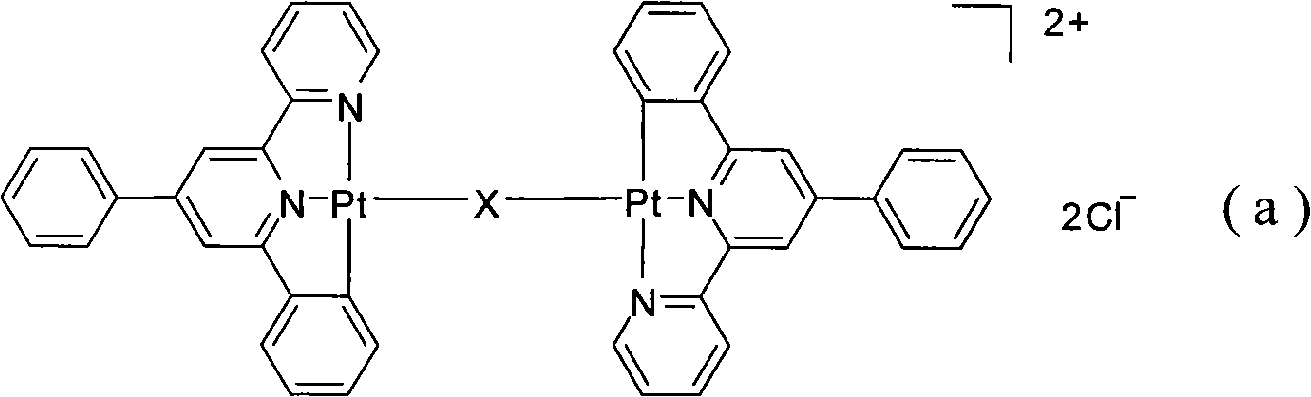

Double platinum (II) pyridine complex of organic photoelectric materials, synthetic method and applications

InactiveCN101550165AGroup 8/9/10/18 element organic compoundsLuminescent compositionsPotassiumBipyridine

The invention provides a double platinum (II) pyridine complex, a synthetic method and applications thereof. In a structural formula (a) of the double platinum (II) pyridine complex, X is bipyridine connected by linking groups. The invention adopts 4, 6-diphenyl 2, 2'-bipyridyl as ligand which reacts with potassium chloroplatinite, so as to synthesize 4, 6-diphenyl 2, 2'-bipyridyl platinum chloride (II), and X is used as bridging ligand to synthesize the double platinum (II) pyridine complex. The compound can be used as the organic photoelectric materials.

Owner:NANJING UNIV OF TECH

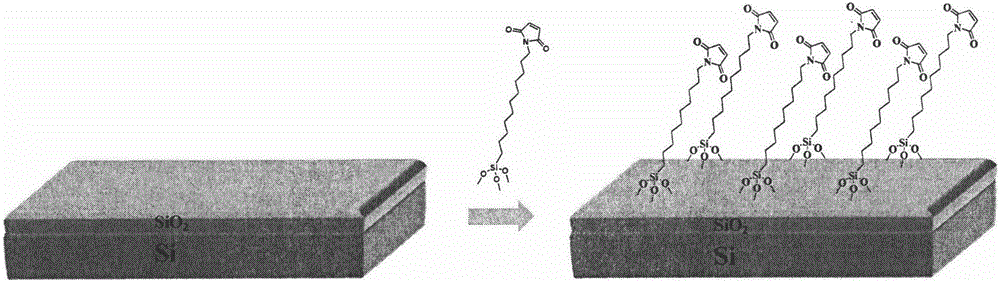

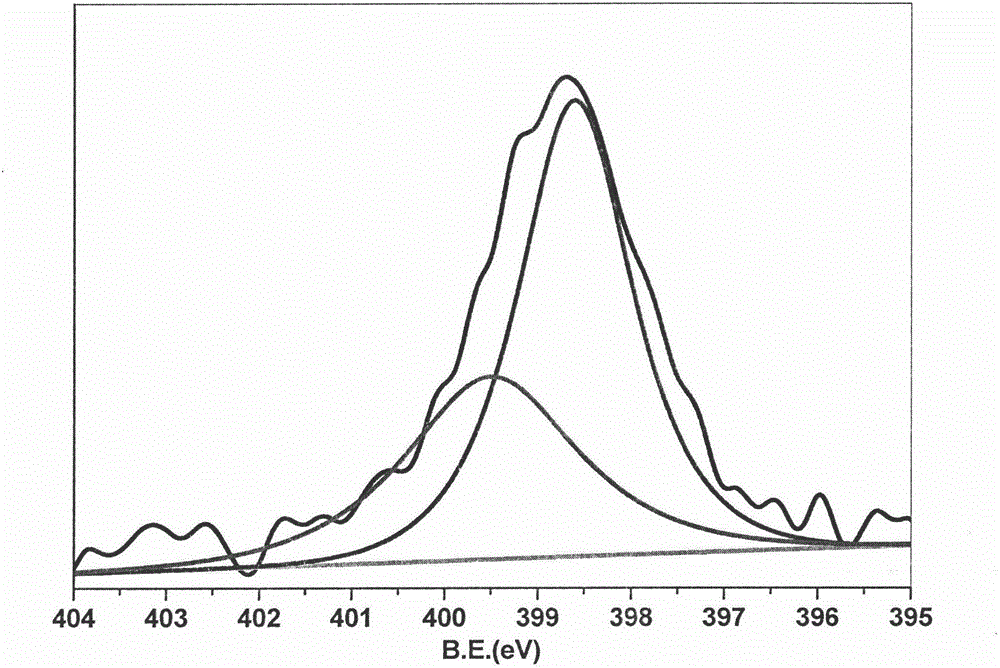

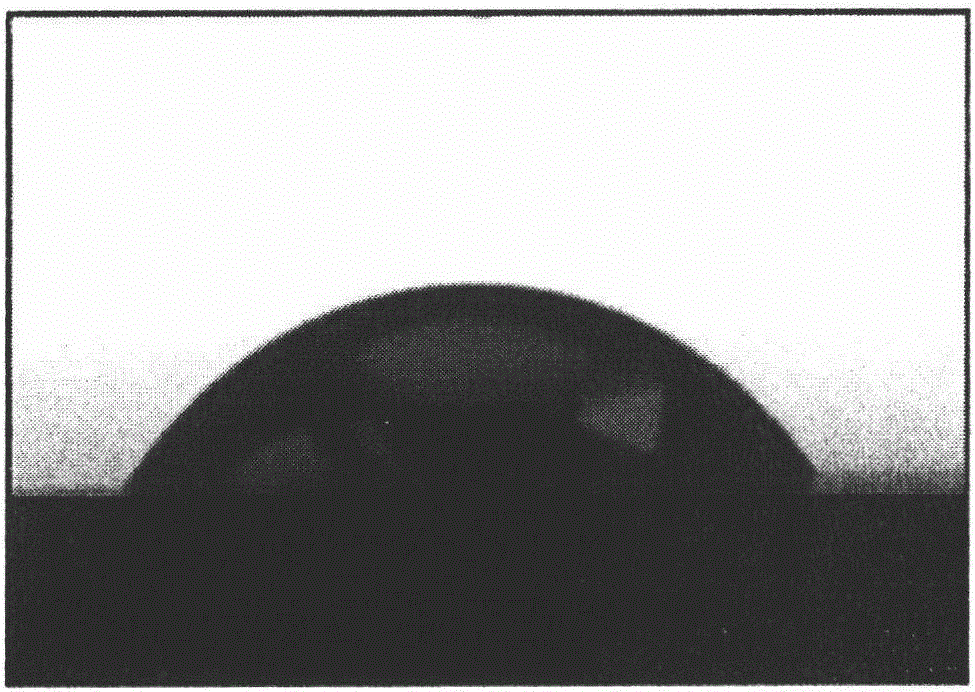

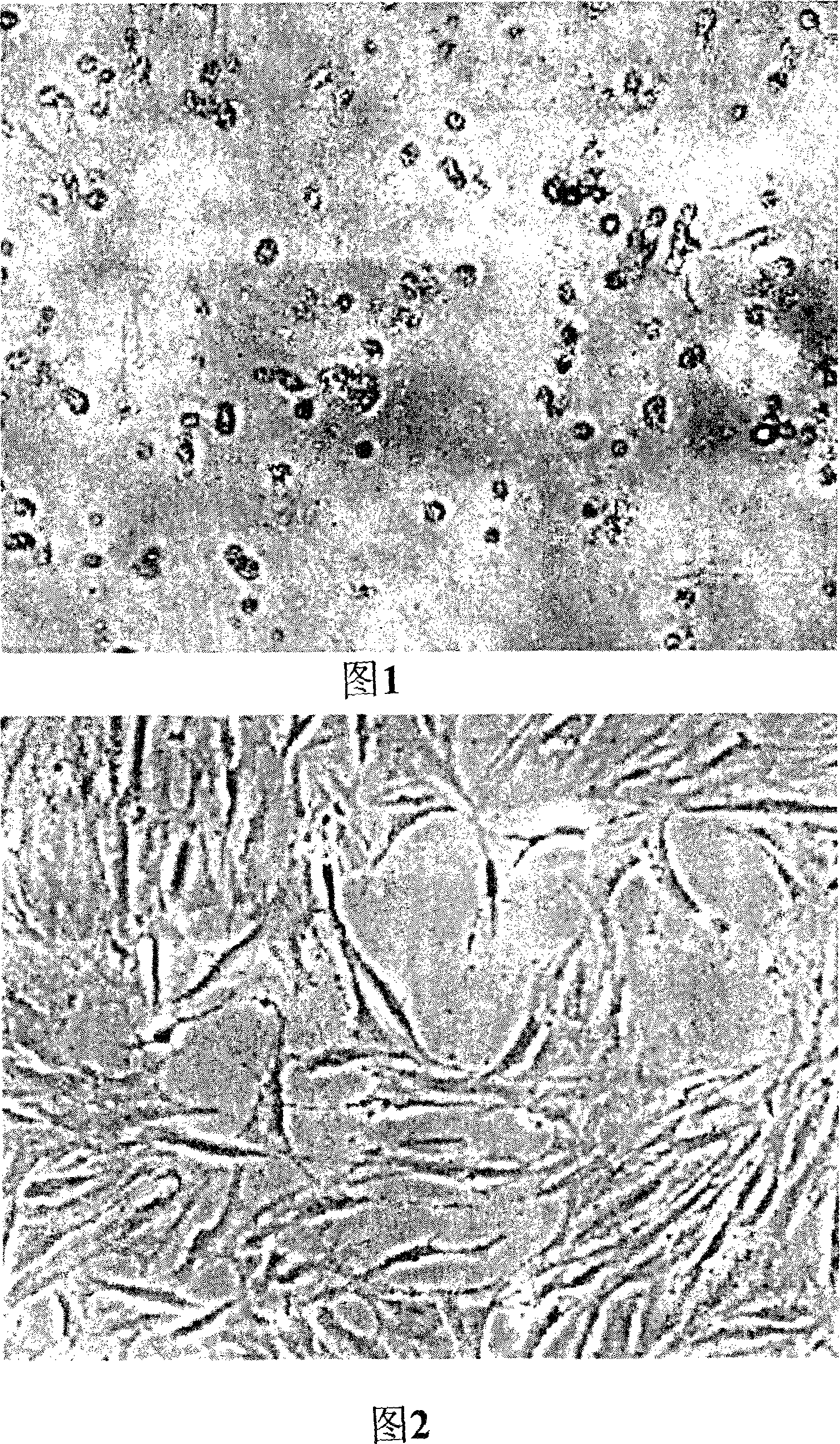

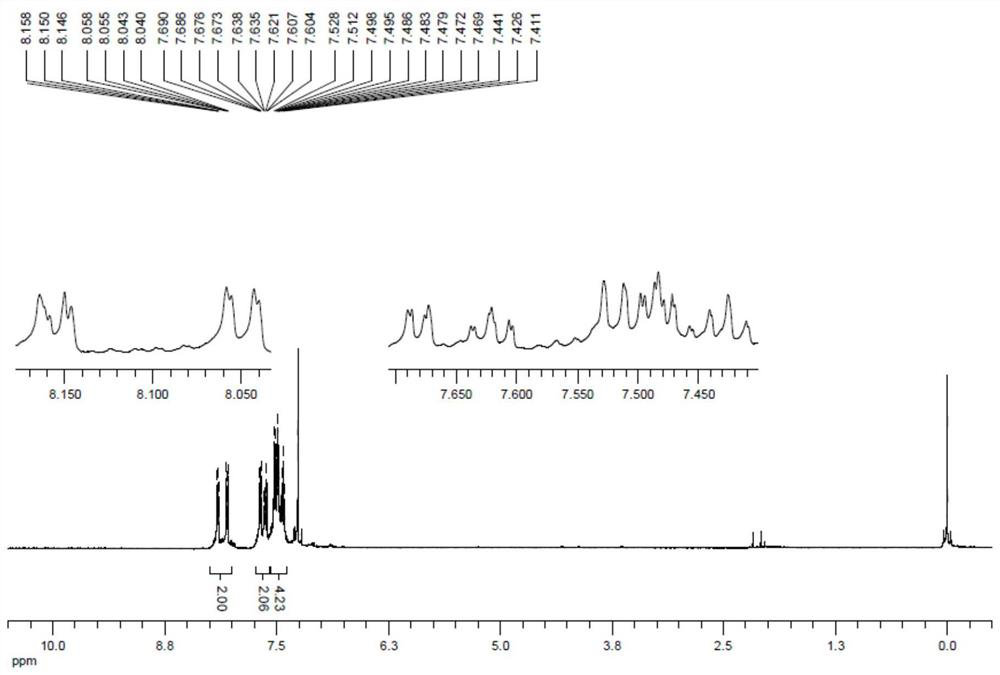

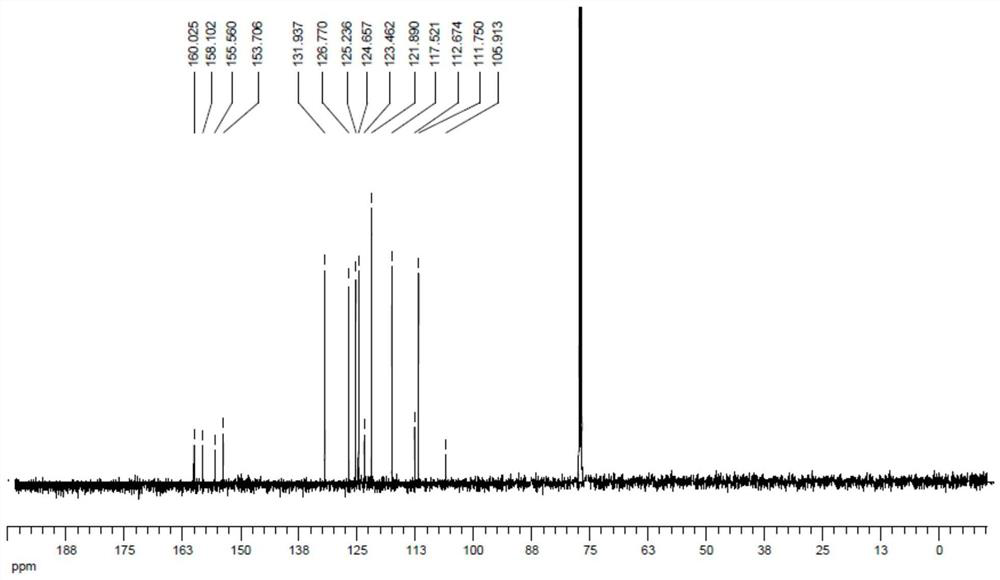

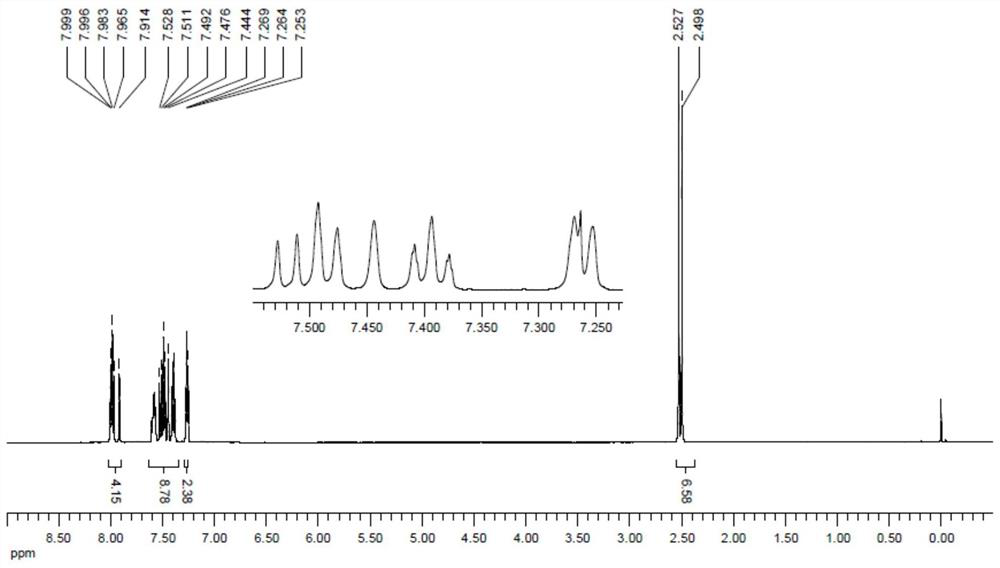

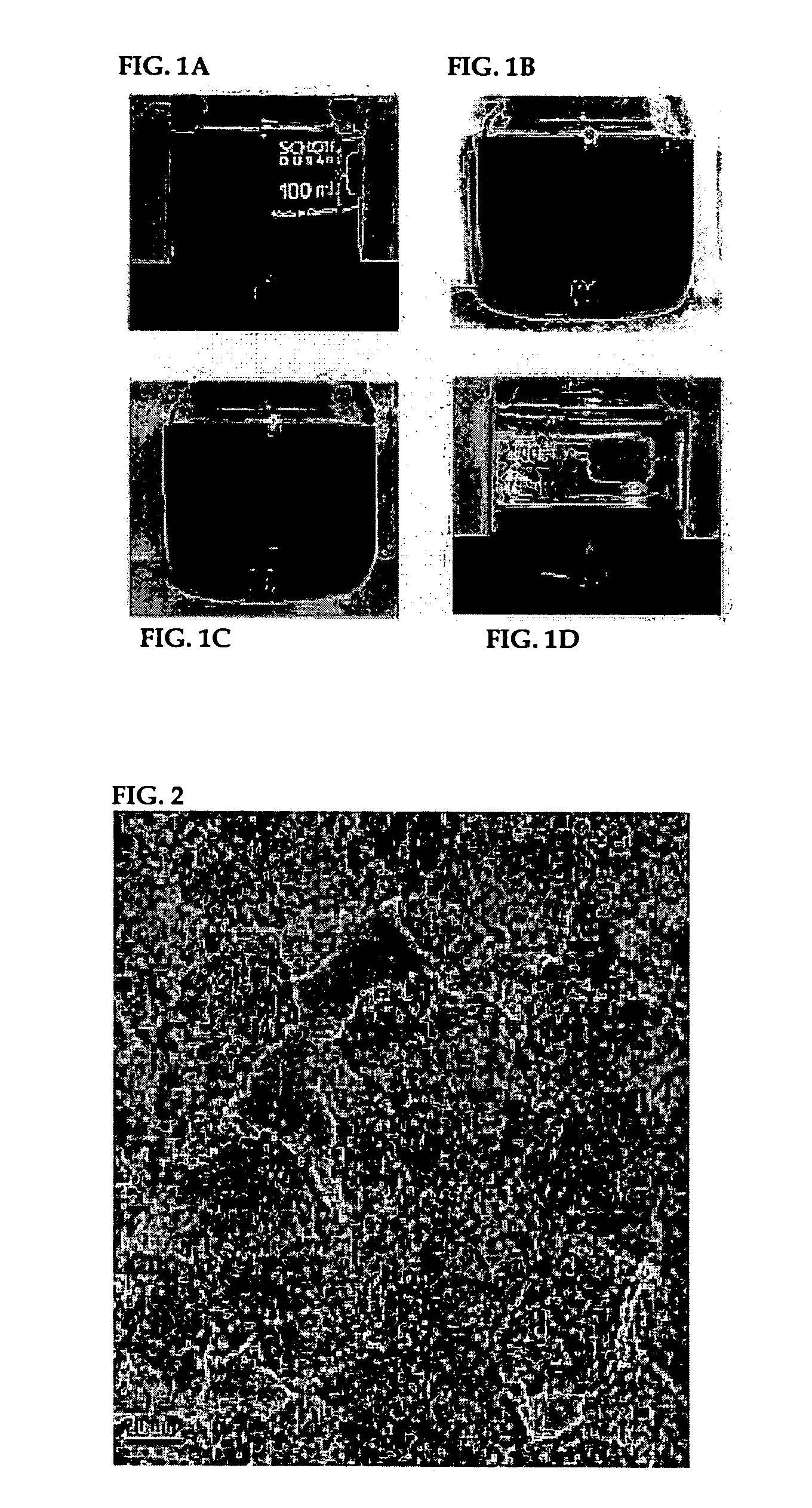

Synthesis of maleimidotriethoxy silane-series compounds, and preparation method of self-assembled film

Among various factors influencing performances of organic electronic components, interfacial property is the most important one influencing the performance of the whole component. In the invention, a series of maleimidotriethoxy silane-series compounds are synthesized, wherein a monomolecular film layer is formed on a surface of an oxide substrate through a self-assembling method, thereby modifying the substrate. Dicyclopentadiene platinum chloride is employed as a catalyst to perform hydrosilylation. Nuclear magnetism is carried out for representation. A test result proves that the catalyst allows catalytic addition to a compound having an amino group to be carried out high-efficiently, and furthermore, silicone on a silanoethoxyl group is connected to a position of a terminal group of a double bond before addition. A self-assembling method is utilized to form the monomolecular film layer on the surface of the oxide substrate. A Young contact angle instrument and XPS is employed for representation, which proves that a flat monomolecular film layer is formed on the surface of the oxide substrate.

Owner:NANJING UNIV OF TECH

Antitumor composition

InactiveCN101027067AHeavy metal active ingredientsPowder deliveryDisodium hexachloroplatinateSide effect

Antitumor agents with high antitumor effect have much side-effect, and its activity decreases when the toxicity decreases. Thus, satisfactory antitumor effects are not always obtained. Therefore, development of an antitumor agent having a high antitumor effect, with less side-effect and low toxicity is awaited. The present invention is to provide an antitumor agent of fine particles, wherein platinum chloride, chloroplatinic acids and hydroxyapatite are blend. Platinum chloride and chloroplatinic acids are platinum tetrachloride, tetrachloroplatinate, hexachloroplatinate, disodium platinum tetrachloride, disodium platinum hexachloride, dipotassium platinum tetrachloride, or dipotassium platinum hexachloride. The maximum particle diameter of hydroxyapatite is 1 [mu]m or less.

Owner:SANGI CO LTD

Photovoltaic device and method of manufacture

InactiveUS20150111336A1Improve throughput potentialEasy to scaleLight-sensitive devicesFinal product manufactureAlcoholDoped oxide

A counter electrode generally shown as 1 is formed of a conductive substrate e.g. a glass substrate 10 on which is deposited doped oxide, e.g. a fluorine doped tin oxide 20. Overlaying the fluorine layer is a layer of a metal halide, e.g. platinum chloride 30 (5 Mm H2PtCl6(H2O6) in isoproply alcohol. Metal is deposited from the solution by treating with NIR. The tin oxide layer renders the glass electrically conductive, absorbs significantly in the NIR and allows for the subsequent heating of the Pt—Cl via a heat transfer process to make the counter electrode in a very efficient manner.

Owner:SWANSEA UNIV

Method for preparing dithiocoumarin benzothiophene compound through platinum catalysis

The invention discloses a method for preparing a dithiocoumarin benzothiophene compound shown as a formula (IV) through platinum catalysis. The preparation method comprises the following steps: preparing a reaction product from a 2-mercaptocinnamic acid compound as shown in a formula (I), carbon disulfide as shown in a formula (II) and a 2-bromophenol compound as shown in a formula (III) by takingplatinum chloride as a catalyst, sodium ethoxide as alkali and acetonitrile as a medium, and carrying out aftertreatment on the reaction product to obtain the dithiocoumarin benzothiophene compound.The method has the advantages of wide raw material source, simple operation, simple treatment after reaction, excellent yield and the like. The method has an important application prospect in the industrial field of synthesis of related medical intermediates.

Owner:JIYANG COLLEGE OF ZHEJIANG A & F UNIV

Method for preparation of highly dispersed supported platinum catalyst

InactiveUS7557057B2Easy to controlEasily reproducibleCell electrodesOrganic-compounds/hydrides/coordination-complexes catalystsFiltrationDistilled water

The present invention relates to a method for synthesizing highly dispersed supported platinum catalyst. More particularly, the present invention relates to a method of synthesizing highly dispersed supported platinum catalyst comprising: dissolving a reducing agent in a solvent to produce a solution, dissolving a platinum chloride to the same solvent; adding a carbon support and platinum in a predetermined ratio to the above mixed solution, agitating the mixture, performing ultrasonic treatment, and performing heat treatment; and adding a HCl solution, agitating the mixture, separating the precipitates via filtration to produce a catalyst, and then washing the catalyst with distilled water, thereby obtaining an active highly dispersed supported platinum catalyst which has excellent electric charge activity, uniformly-sized platinum particles and relatively high specific surface area.

Owner:HYUNDAI MOTOR CO LTD

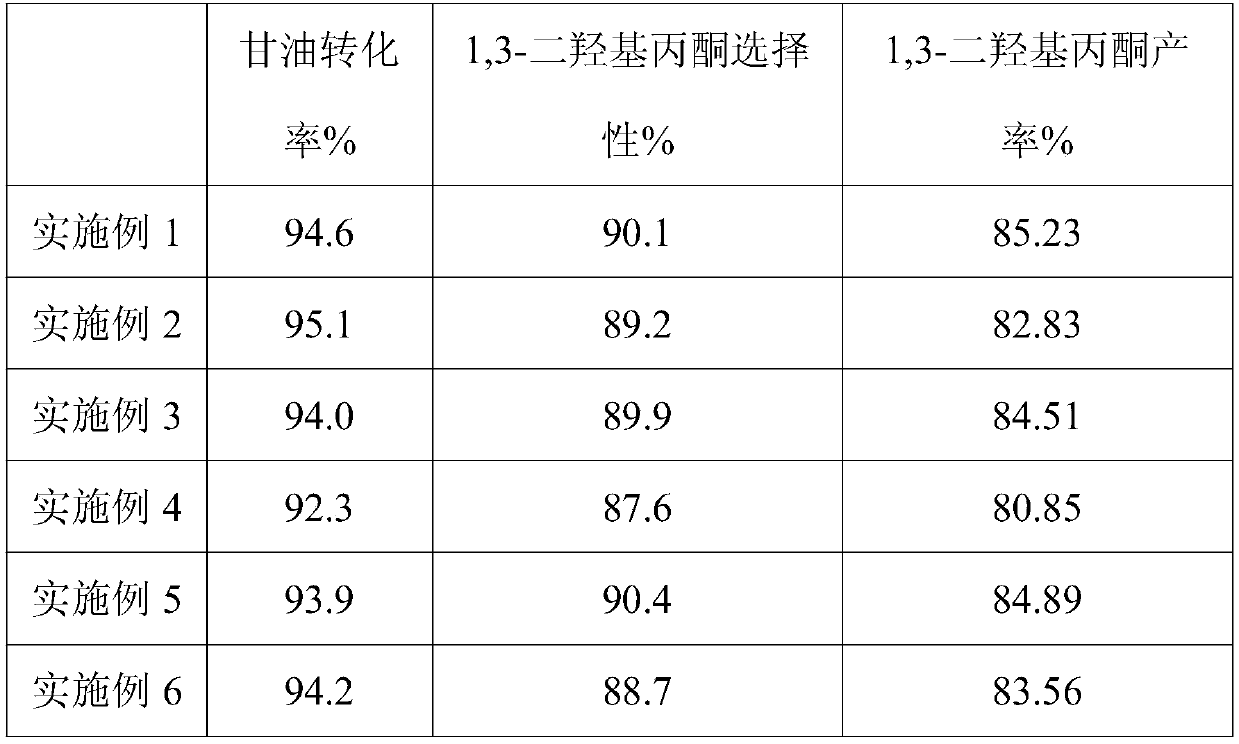

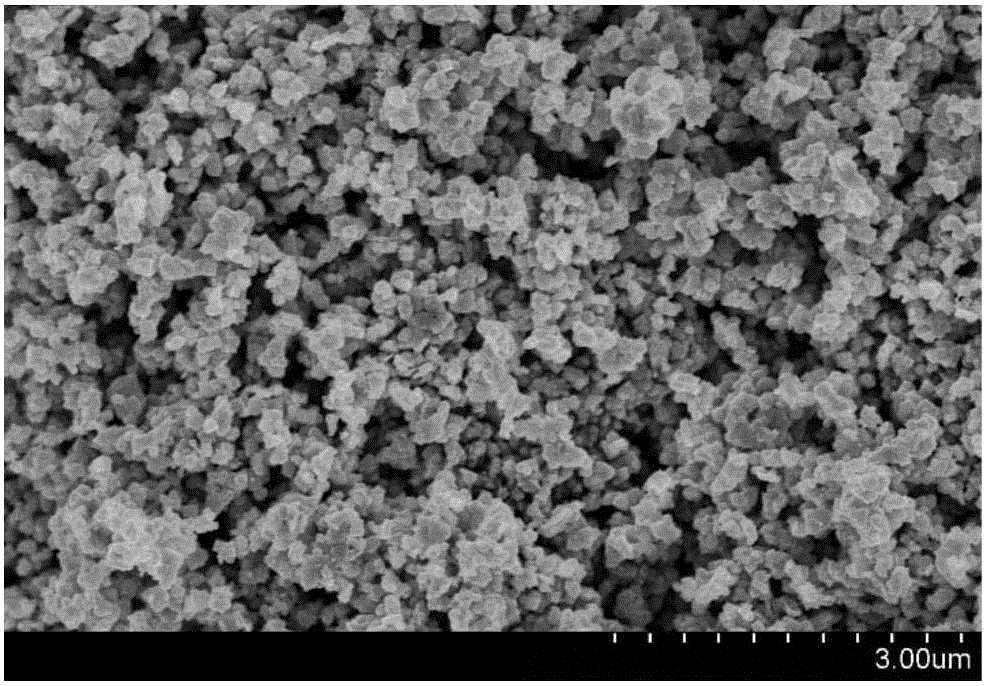

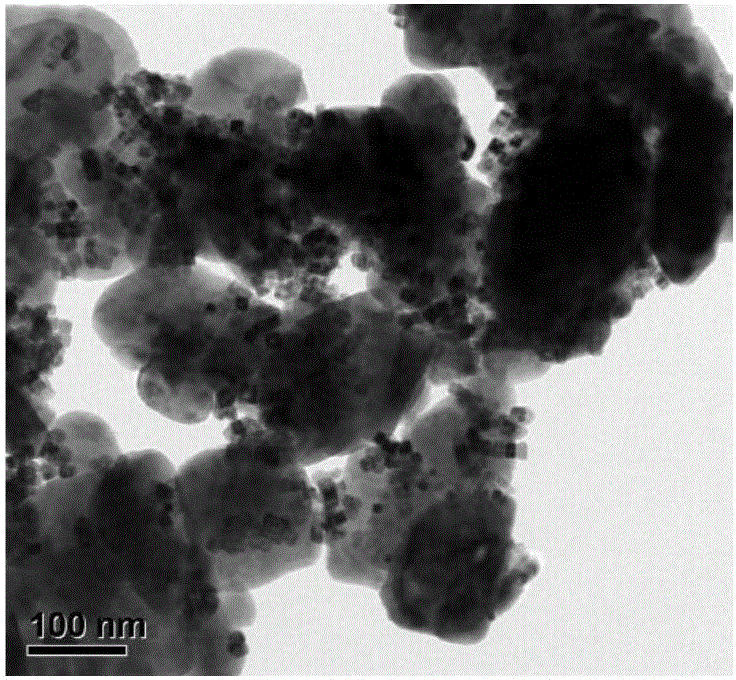

Catalyst to prepare 1,3-dihydroxyacetone and preparation method thereof

ActiveCN109569599ASimple structureStrong adsorptionOrganic compound preparationCatalyst activation/preparationCarbon compositesCerium nitrate

The invention discloses a catalyst to prepare 1,3-dihydroxyacetone and a preparation method thereof. The preparation method includes the steps of (1) preparing ZnAl-HTLc, to be specific, dissolving azinc salt and an aluminum salt in deionized water to obtain solution A, preparing solution B with Na2CO3 and NaOH, quickly mixing the solution A and the solution B, allowing refluxing reaction, centrifugally washing, and drying to obtain ZnAl-HTLc; (2) preparing a composite supporter, to be specific, adding the prepared ZnAl-HTLc into glucose monohydrate solution, mixing well, transferring the mixture to a polytetrafluoroethylene reactor, allowing hydrothermal reaction, cooling, and washing to obtain ZnAl-HTLc / carbon composite supporter; (3) preparing the catalyst, to be specific, preparing asolution with platinum chloride, neodymium nitrate and cerium nitrate, adding the solution to the composite supporter, impregnating, drying, calcining, and activating with hydrogen to obtain the catalyst. The catalyst has good activity, selectivity and stability and has a good application prospect.

Owner:JIANGXI NORMAL UNIV

A kind of preparation method of room temperature hydrogen sensor

InactiveCN103558261BIncrease productivityLow costMaterial resistanceHydrogen sensorUltrasonic dispersion

Owner:XIAMEN UNIV

Preparation method of nano platinum oxide powder

ActiveCN108821352AEasy reunionSecure nanostructureRuthenium/rhodium/palladium/osmium/iridium/platinum oxides/hydroxidesNanotechnologyElectrolysisPlatinum oxide

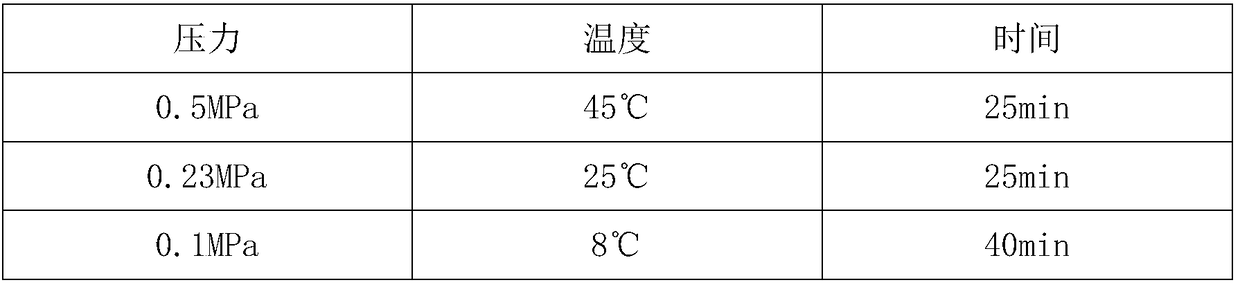

The invention belongs to the technical field of catalysis and particularly relates to a preparation method of nano platinum oxide powder. The preparation method comprises the following steps: step one, adding platinum chloride into distilled water and stirring until platinum chloride is completely dissolved; then slowly dropwise adding an alkali solution until no precipitate is produced, filteringand washing to obtain platinic hydroxide precipitate; step two, adding the platinic hydroxide precipitate into absolute ethyl alcohol for stirring and uniformly dispersing; then adding crown ether and stirring until crown ether is completely dissolved to obtain mixed ethanol liquid; step three, carrying out thermostatic standing on the mixed ethanol liquid for 2 to 5 hours, carrying out gradientdepressurization, standing for 4 to 8 hours and filtering to obtain crystal; step four, putting the crystal into a ball-milling device and carrying out constant temperature ball-milling reaction for 1to 2 hours to obtain crystal fine powder; step five, adding the crystal fine powder into electrolyte, carrying out electrolytic reaction for 2 to 4 hours and filtering to obtain precipitate; step six, putting the precipitate into absolute ethyl alcohol, carrying out ultrasonic washing for 30 to 40 minutes, filtering and drying to obtain the nano platinum oxide powder. According to the preparationmethod disclosed by the invention, a double passivation mode is utilized, so that the nano-structure of platinum oxide is ensured; in addition, the agglomeration is avoided.

Owner:SHAOXING UNIVERSITY

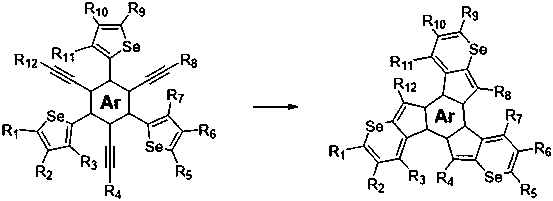

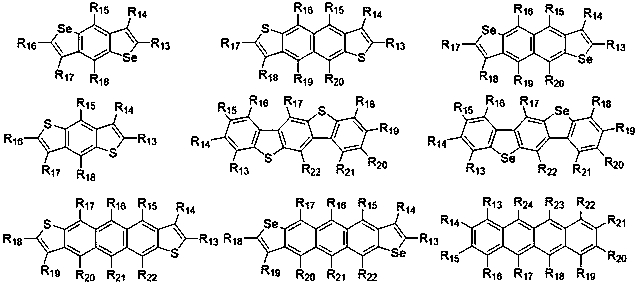

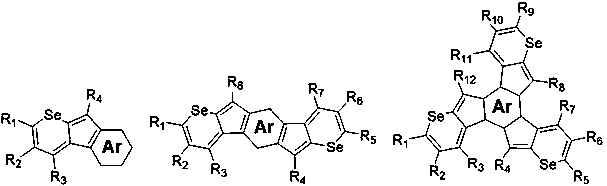

Near infrared organic photoelectric material containing cyclopentadiene selenium furan, and preparation method thereof

The invention belongs to the technical field of organic photoelectric material, and more specifically relates to a near infrared organic dye containing cyclopentadiene selenium furan, and a preparation method thereof. The chemical structure of the near infrared organic dye containing cyclopentadiene selenium furan is simple; the near infrared organic dye containing cyclopentadiene selenium furan is an organic photoelectric material containing cyclopentadiene selenium furan structure, possesses the properties of aromatic and nonalternant hydrocarbons at the same time, is capable of absorbing near infrared light, possesses extremely low oxidation potential and excellent electrochemical stability. The near infrared organic dye containing cyclopentadiene selenium furan is prepared through one-step intramolecular cyclisation reaction of a selenophen derivative precursor under the catalytic effect of platinum chloride. The steps are few; the yield is high; and the cost is low.

Owner:FUDAN UNIV

Preparation method of zirconium dioxide-based platinum oxide catalyst with core-shell structure

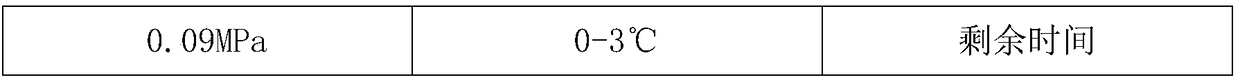

ActiveCN112871155AHigh catalytic efficiencyExtended service lifeCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystDistillation

The invention discloses a preparation method of a zirconium dioxide-based platinum oxide catalyst with a core-shell structure, which specifically comprises the following steps of: firstly, adding zirconium chloride into absolute ethyl alcohol, adding ethyl cellulose, carrying out ultrasonic dispersion and reduced pressure distillation to form viscous slurry, and adding the viscous slurry into a mold to form prefabricated particles; adding ethyl cellulose into absolute ethyl alcohol, and carrying out ultrasonic dispersion; spraying the obtained solution into the prefabricated particles, and carrying out constant-temperature standing reaction to obtain first coated particles; adding platinum chloride into distilled water, spraying the obtained solution on the first coated particles, standing at constant temperature for reaction, and repeating spraying-constant temperature standing for several times to obtain second coated particles; and finally, putting the second coated particles into a reaction kettle for reaction to obtain a prefabricated catalyst, and performing constant-temperature illumination reaction to obtain the zirconium dioxide-based platinum oxide catalyst. The zirconium dioxide-based platinum oxide catalyst with the shell-core structure prepared by the method can reflect external light to the inner surface of the catalyst, so that the catalytic efficiency is effectively improved, and the service life can be greatly prolonged.

Owner:陕西瑞科新材料股份有限公司

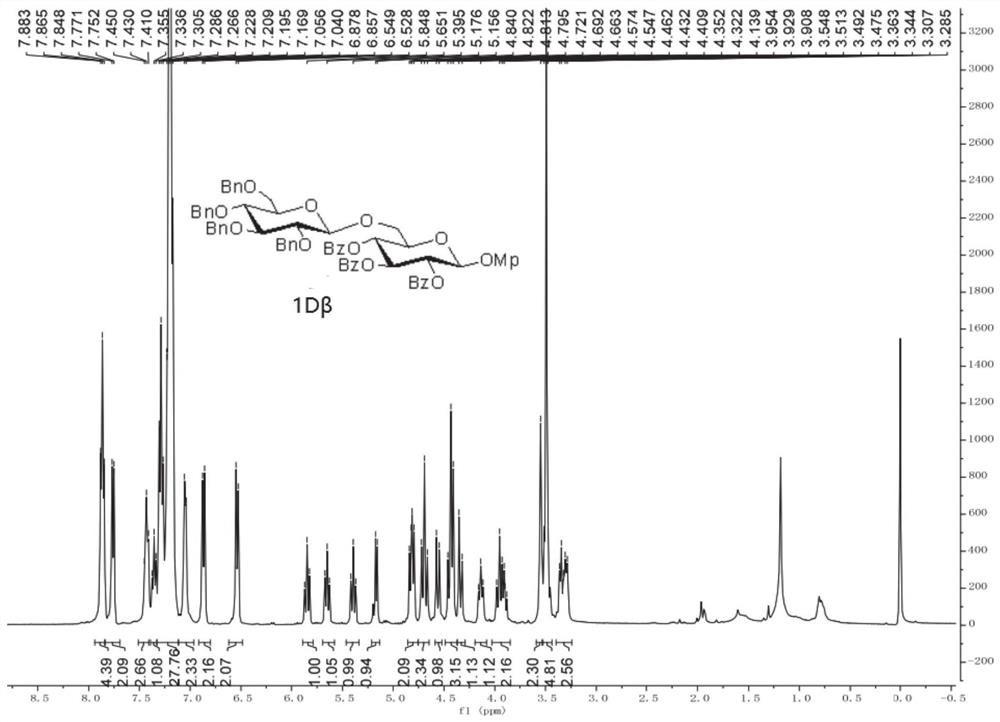

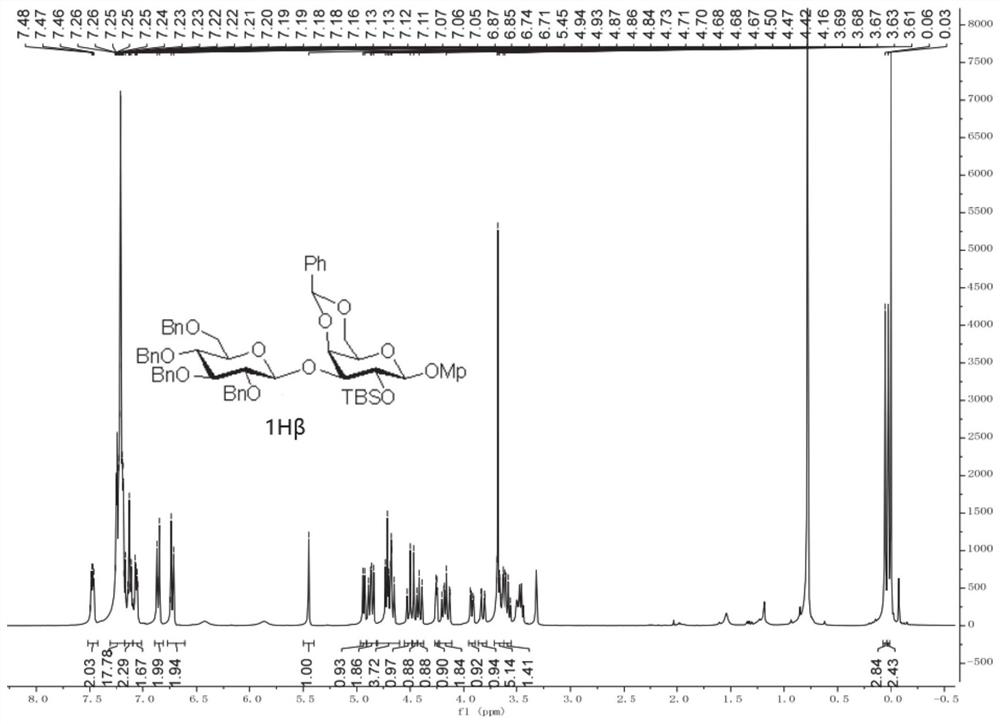

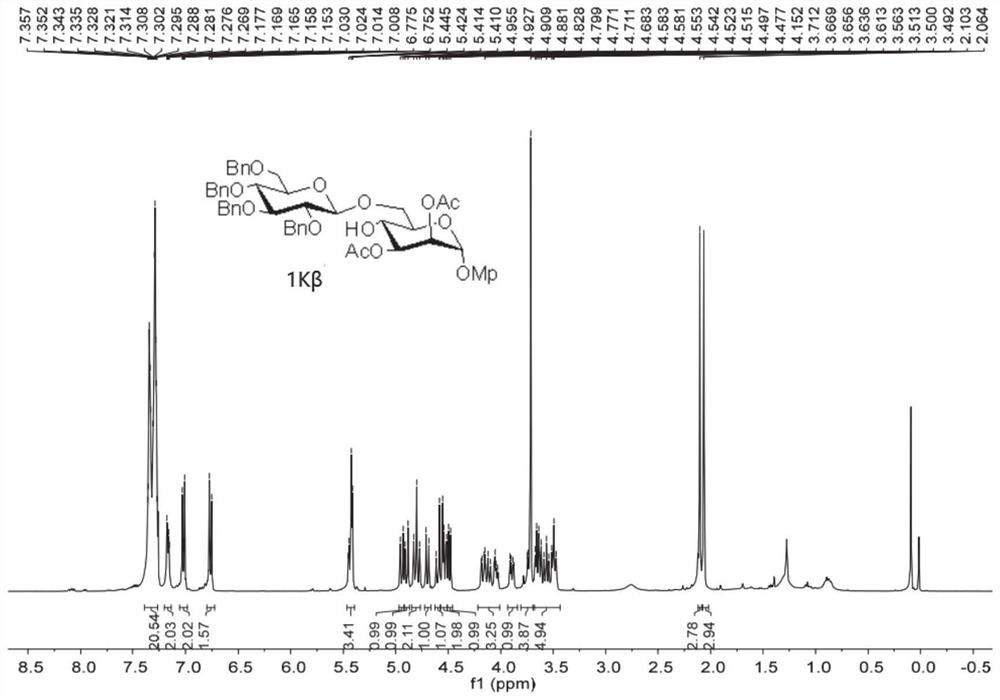

Glycosylation reaction catalyst, glycosylation method and application

ActiveCN113926472AHigh yieldHigh stereoselectivityPhysical/chemical process catalystsSugar derivativesPtru catalystReceptor

The invention belongs to the technical field of sugar chemistry, and relates to a glycosylation reaction catalyst, a glycosylation method and application. The glycosylation method takes platinum chloride (IV) as a catalyst and is simple to operate, wide in substrate application range and high in reaction regioselectivity and stereoselectivity, and application of the method in glycosylation reaction is disclosed. According to the method, alpha-configuration O-glycosyl trichloroacetimidate is used as a donor, platinum (IV) chloride is used as a catalyst of an acid-base catalysis way, and a product mainly having a beta-configuration is obtained. In the method, a catalyst and a glycosyl acceptor are firstly combined to form a catalyst-acceptor adduct, so that proton acidity and oxygen affinity are increased, donor activation is enhanced, and acceptor transfer is carried out. According to the invention, the ligand binding capacity of platinum (IV) chloride and the characteristic that a diol receptor can be used as a bidentate ligand thereof are fully utilized, so that the method is not only suitable for construction of high-stereoselectivity glycosidic bonds of monohydroxyl receptors, but also can realize glycosidic bond construction with high regioselectivity and stereoselectivity of receptors of 1,3-diol, 1,2-cis-diol, 1,2-trans-diol, and 1,2,3-triol structures.

Owner:SHANDONG UNIV

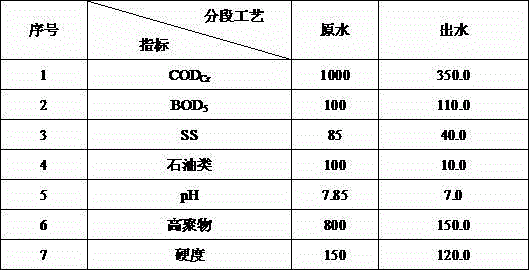

Electrocatalytic oxidation coated electrode for treating oilfield wastewater and preparing method thereof

InactiveCN104370348AImprove structural strengthReduce lossFatty/oily/floating substances removal devicesWater contaminantsTreatment effectIridium chloride

The invention discloses an electrocatalytic oxidation coated electrode for treating oilfield wastewater and a preparing method thereof, wherein the preparing method comprises the following steps: preparing a titanium-based polar plate; mixing arbitrary one or more of iridium trichloride (Cl3Ru), tantalum chloride (Cl5Ta), platinum chloride (Cl4Pt2) and iridium chloride (IrCl3H2O) with ethanol, and after mixing evenly, coating the surface of the titanium-based polar plate with a hair brush; coating the MnO2 surface layer; drying; and sintering at the high temperature to form the titanium-based coated electrode. The electrode having better structural strength can be obtained by the method, and the effective reaction area and the service life of an electrode material are improved. The electrode can effectively remove dispersed oil and emulsified oil in the oily wastewater, can overcome the disadvantage that a common electrode lose efficacy because of being easily polluted by oil stain, can be widely and effectively applied to the fields of oilfield wastewater treatment and reinjection and the like, has the advantages of good treatment effect, good oil pollution resistance performance, small electrode loss, simple preparation method and operation, and good reproducibility, and is suitable for large-scale production and popularization.

Owner:杭州广联新能源科技有限公司

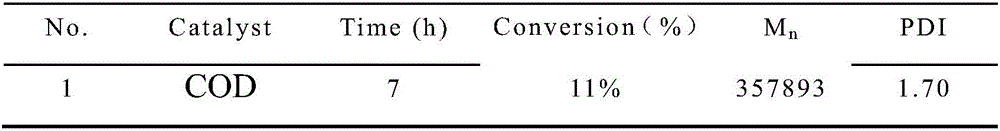

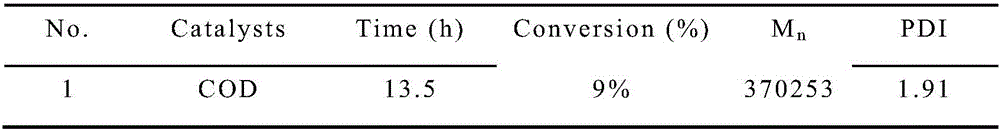

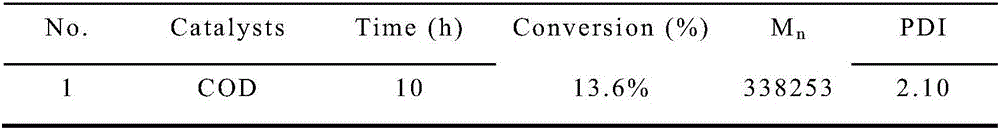

Polyphenylacetylene preparing method initiated by phenylsilane

The invention discloses a polyphenylacetylene preparing method initiated by phenylsilane. The preparing method includes the steps that under catalysis of (1,5-cyclooctadiene) platinum chloride, phenylsilane is used as initiator, phenylacetylene is subjected to polymerization reaction, and polyphenylacetylene is obtained after reaction is finished. As the new catalyst and initiator are adopted in the preparing method, the molecular weight of the product polyphenylacetylene is higher, and the molecular weight distribution range is narrower.

Owner:ZHEJIANG UNIV OF TECH

A kind of preparation method of porous platinum oxide catalyst

ActiveCN108704640BUniform porosityStable structureRuthenium/rhodium/palladium/osmium/iridium/platinum oxides/hydroxidesMetal/metal-oxides/metal-hydroxide catalystsAluminium chloridePtru catalyst

The invention belongs to the technical field of precious metal catalysts, and particularly relates to a preparation method of a porous platinum oxide catalyst. The method comprises the following stepsthat 1, platinum chloride is added into distilled water for even stirring to obtain a platinum ion solution; 2, aluminium chloride is added into the platinum ion solution, stirring is continued untilcomplete dissolution, then high-substituted hydroxypropyl cellulose is slowly added, and even stirring is conducted to obtain aluminium-platinum dispersion liquid; 3, ammonia gas is introduced circularly by means of sealed reflux until no sediment is generated, so that suspended dispersion liquid is obtained; 4, the suspended dispersion liquid is subjected to reduced pressure distillation reaction for 2-4 h, after cooling, viscous liquid is obtained, and then the viscous liquid is added into a mould for constant-temperature pressurizing solidification reaction for 2-4 h to obtain mixed solid;5, the mixed solid is immersed in distilled water for low-temperature stirring reaction for 2-4 h, and then porous solid is obtained after removal; 6, the porous solid is soaked in a hydrochloric acid solution for sealed micro-boiling reaction for 20-50 min, and then through filtering, washing and sintering, the porous platinum oxide catalyst is obtained.

Owner:辽宁精细化工产业技术发展有限公司

Preparation method of porous platinum oxide catalyst

ActiveCN108704640AUniform porosityStable structureRuthenium/rhodium/palladium/osmium/iridium/platinum oxides/hydroxidesMetal/metal-oxides/metal-hydroxide catalystsAluminium chlorideViscous liquid

The invention belongs to the technical field of precious metal catalysts, and particularly relates to a preparation method of a porous platinum oxide catalyst. The method comprises the following stepsthat 1, platinum chloride is added into distilled water for even stirring to obtain a platinum ion solution; 2, aluminium chloride is added into the platinum ion solution, stirring is continued untilcomplete dissolution, then high-substituted hydroxypropyl cellulose is slowly added, and even stirring is conducted to obtain aluminium-platinum dispersion liquid; 3, ammonia gas is introduced circularly by means of sealed reflux until no sediment is generated, so that suspended dispersion liquid is obtained; 4, the suspended dispersion liquid is subjected to reduced pressure distillation reaction for 2-4 h, after cooling, viscous liquid is obtained, and then the viscous liquid is added into a mould for constant-temperature pressurizing solidification reaction for 2-4 h to obtain mixed solid;5, the mixed solid is immersed in distilled water for low-temperature stirring reaction for 2-4 h, and then porous solid is obtained after removal; 6, the porous solid is soaked in a hydrochloric acid solution for sealed micro-boiling reaction for 20-50 min, and then through filtering, washing and sintering, the porous platinum oxide catalyst is obtained.

Owner:绍兴市梓昂新材料有限公司

Composition for electroless platinum plating and electroless platinum plating method using the same

PendingUS20220112604A1Simple and safe mannerUniform and stableLiquid/solution decomposition chemical coatingAlcoholMetallurgy

The present invention relates to a composition for electroless platinum plating and an electroless platinum plating method using the same, wherein it is possible to easily and safely produce a uniformly dispersed platinum thin film without expensive additional equipment by performing electroless platinum plating with a composition for electroless platinum plating containing an alcohol, an aqueous solution of a platinum chloride compound, and an aqueous solution of a basic compound.

Owner:FOUND OF SOONGSIL UNIV IND COOP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com