Patents

Literature

153results about "Ruthenium/rhodium/palladium/osmium/iridium/platinum oxides/hydroxides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

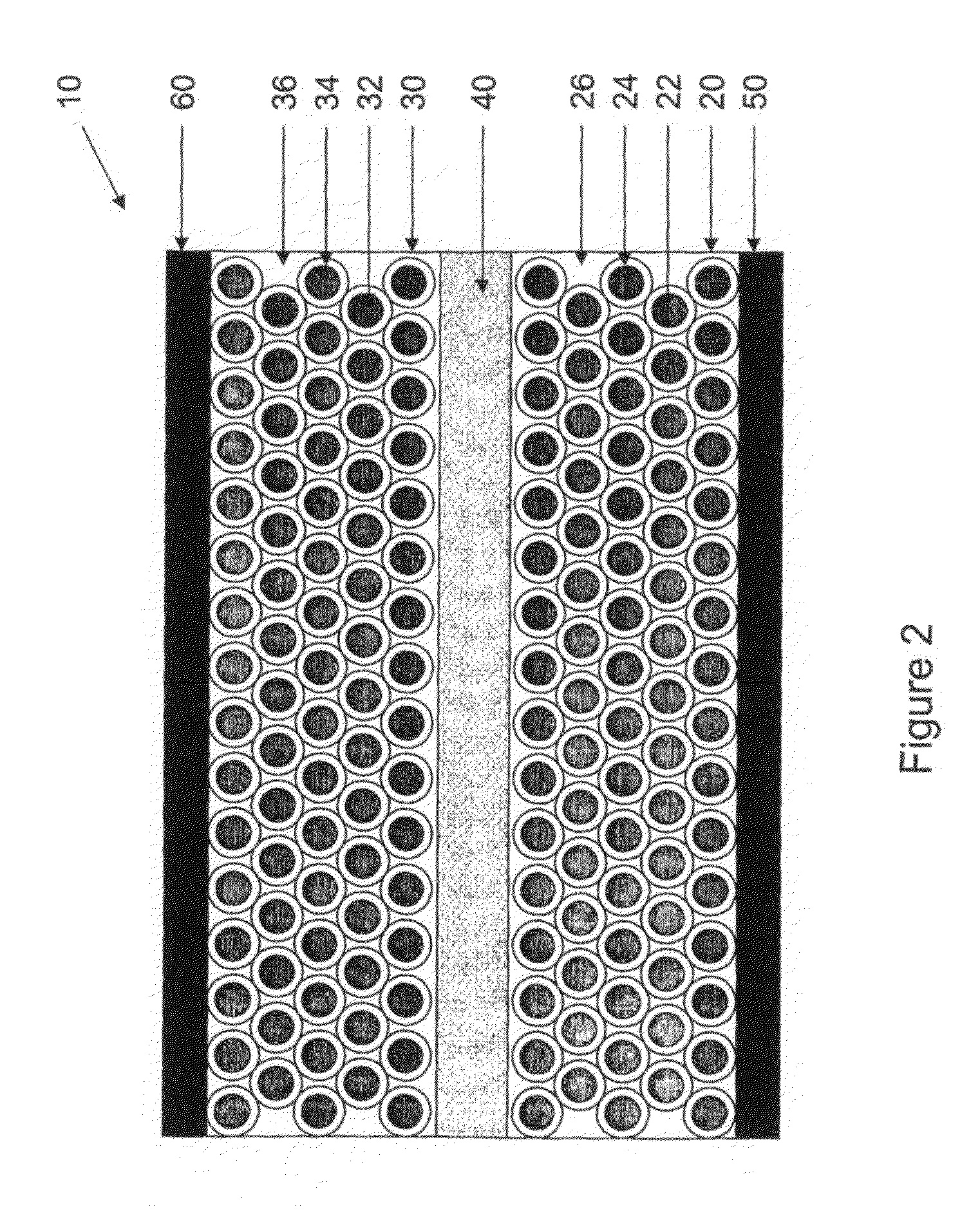

Core-shell nanoparticles in electronic battery applications

InactiveUS20130078510A1Shorten cycle lifeCompromise capacitanceMaterial nanotechnologyRuthenium/rhodium/palladium/osmium/iridium/platinum oxides/hydroxidesCore shell nanoparticlesCore shell

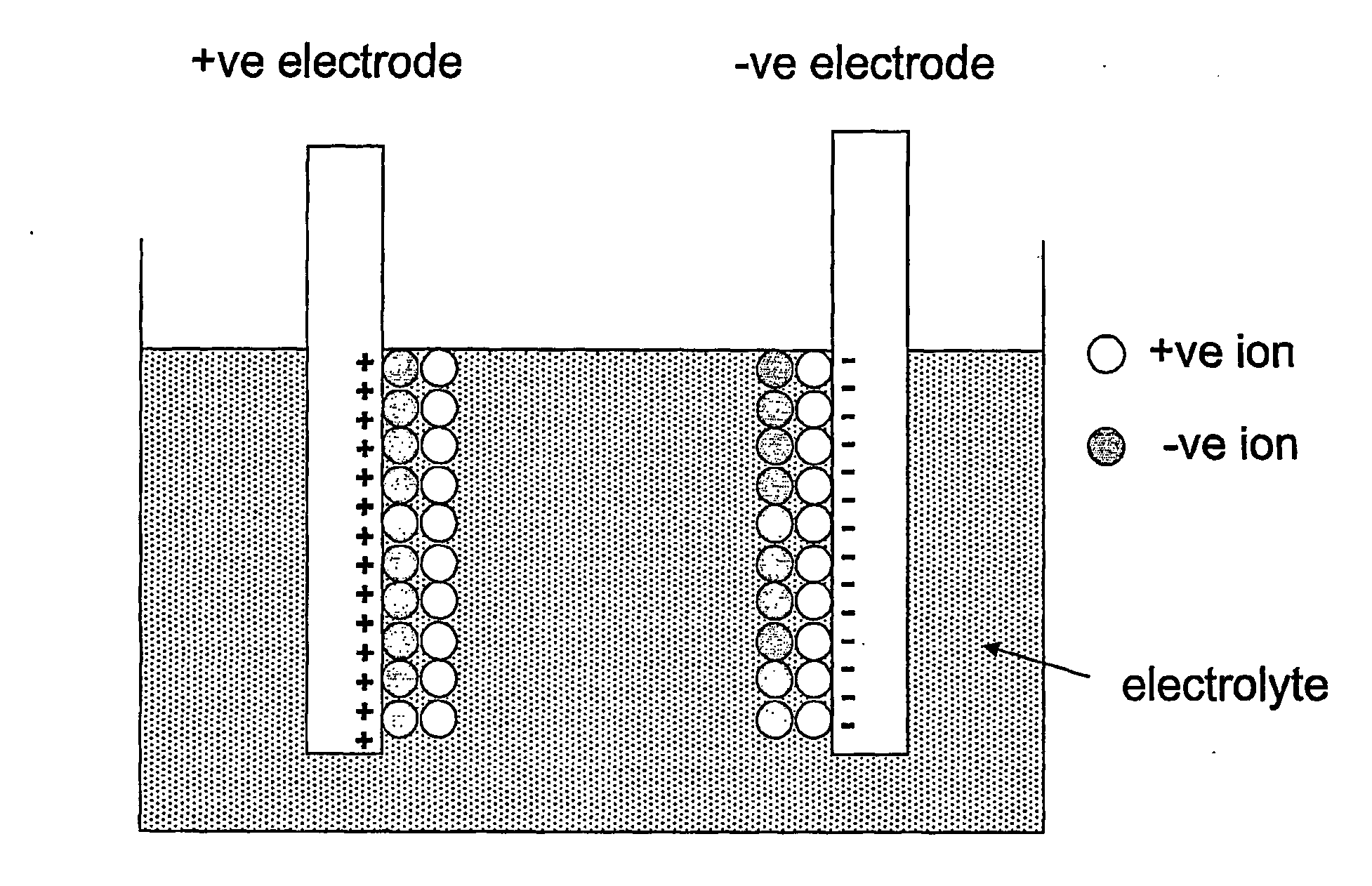

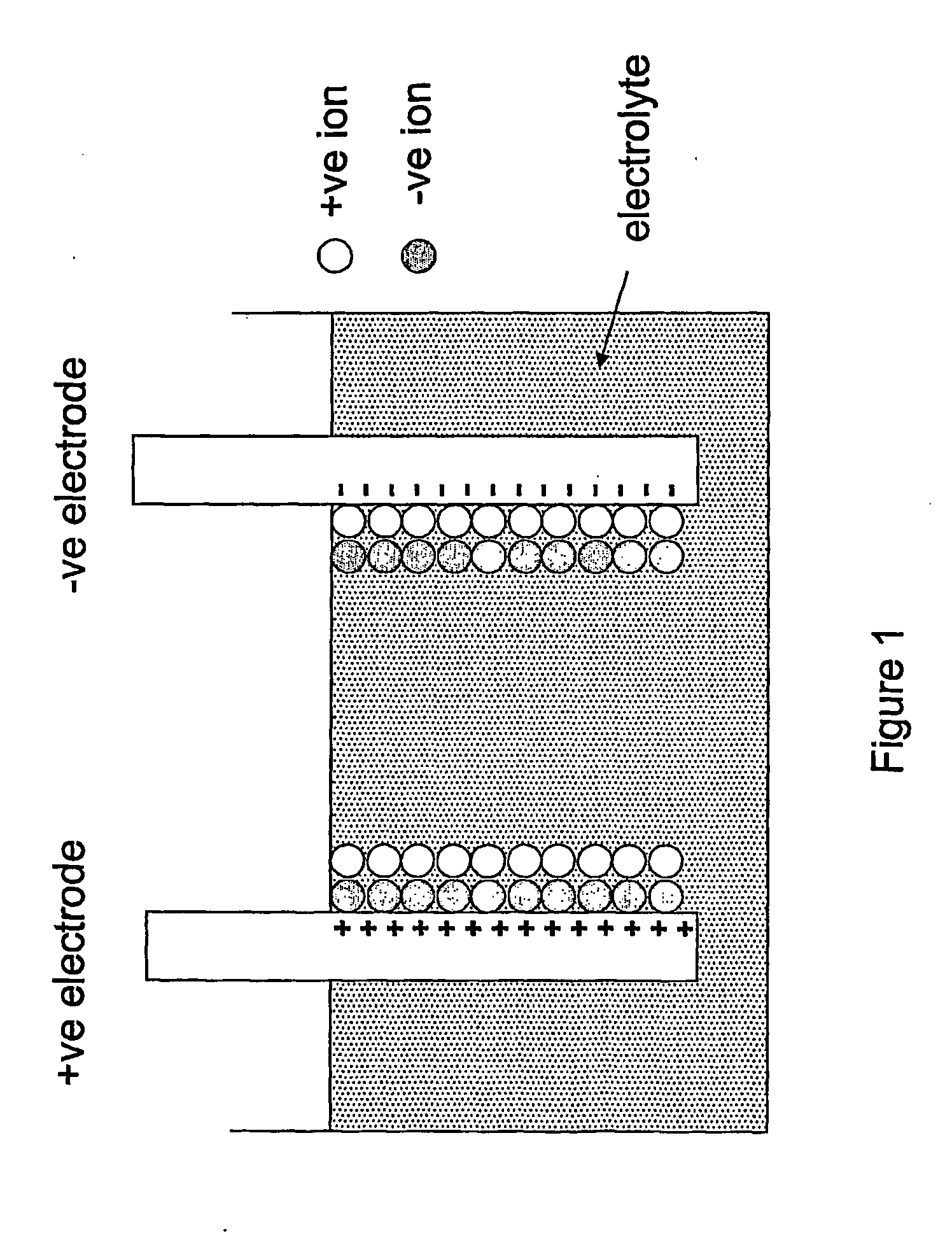

The present invention provides an improved supercapacitor-like electronic battery comprising a conventional electrochemical capacitor structure. A first nanocomposite electrode and a second electrode and an electrolyte are positioned within the conventional electrochemical capacitor structure. The electrolyte separates the nanocomposite electrode and the second electrode. The first nanocomposite electrode has first conductive core-shell nanoparticles in a first electrolyte matrix. A first current collector is in communication with the nanocomposite electrode and a second current collector is in communication with the second electrode. Also provided is an electrostatic capacitor-like electronic battery comprising a high dielectric-strength matrix separating a first electrode from a second electrode and, dispersed in said high-dielectric strength matrix, a plurality of core-shell nanoparticles, each of said core-shell nanoparticles having a conductive core and an insulating shell.

Owner:OERLIKON ADVANCED TECH +1

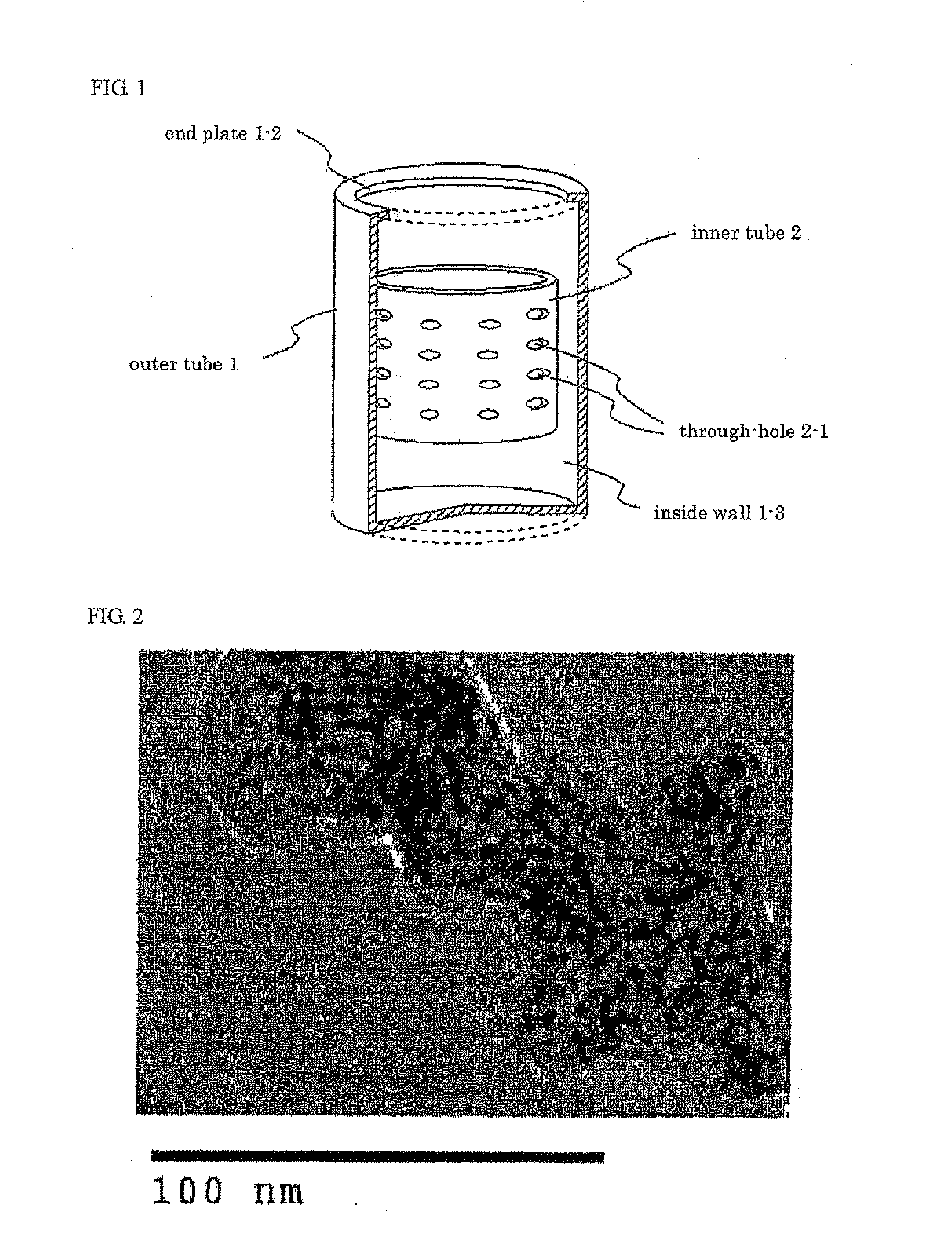

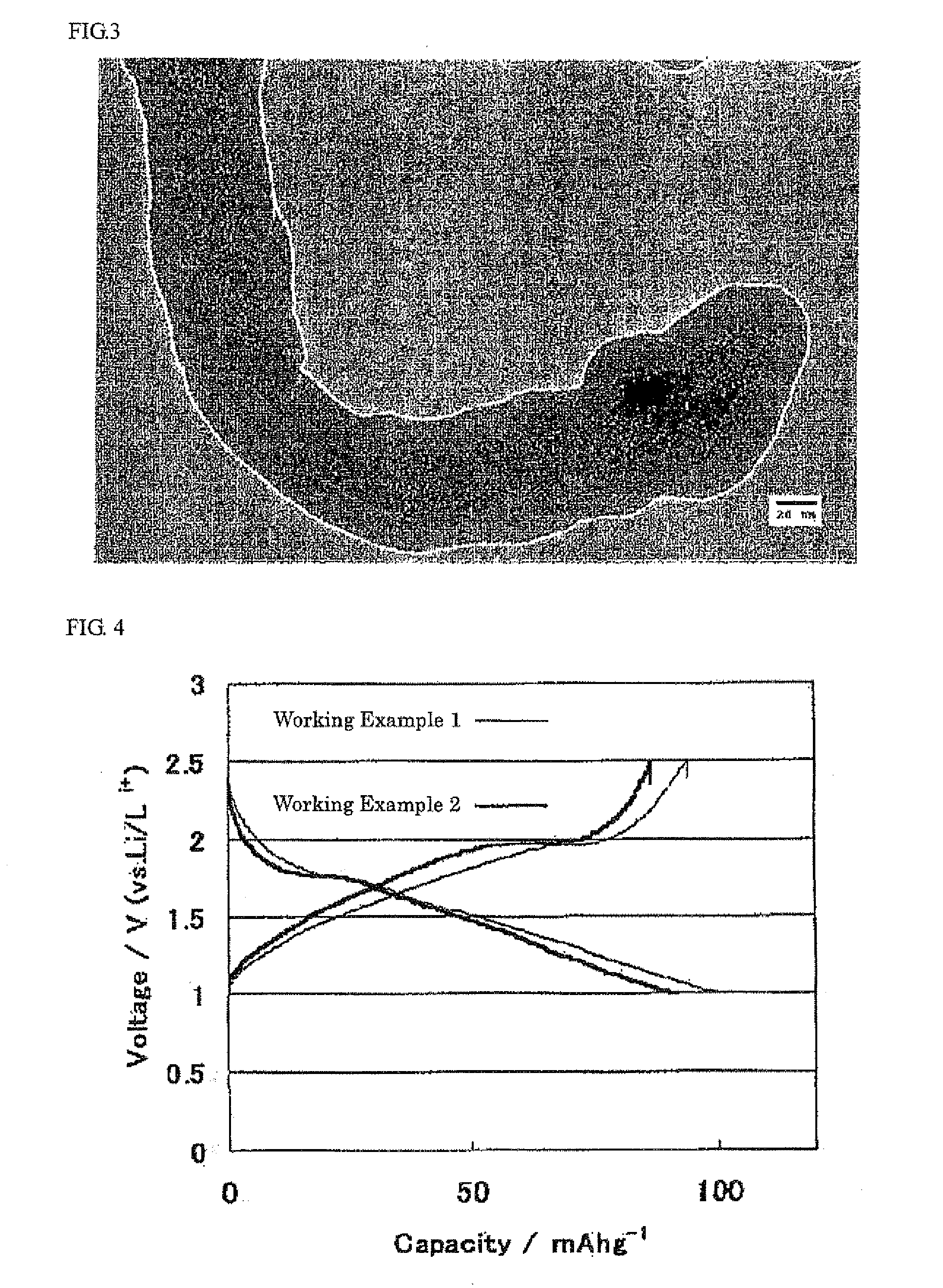

Reaction method, metal oxide nanoparticle or carbon carrying the nanoparticle, obtained by the method, electrode containing the carbon, and electrochemical device with the electrode

InactiveUS20100025627A1Increase surface areaImprove output characteristicsMaterial nanotechnologyPigmenting treatmentChemical reactionMetal oxide nanoparticles

The present invention aims at: providing an accelerated reaction in a liquid-phase reaction; forming, by way of the reaction, a metal oxide nanoparticle and carbon that carries the metal oxide nanoparticle in a highly dispersed state; and providing an electrode containing the carbon and an electrochemical device using the electrode. In order to solve the above-mentioned problem, shear stress and centrifugal force are applied to the reactant in the rotating reactor so that an accelerated chemical reaction is attained in the course of the reaction. Further, the carbon carrying a metal oxide nanoparticle in a highly dispersed state comprises: a metal oxide nanoparticle produced by the accelerated chemical reaction, wherein shear stress and centrifugal force are applied to a reactant in a rotating reactor in the course of the reaction; and carbon dispersed in the rotating reactor by applying shear stress and centrifugal force. An electrochemical device produced by using the carbon carrying the metal oxide nanoparticle as an electrode has high output and high capacity characteristics.

Owner:NIPPON CHIMI CON CORP

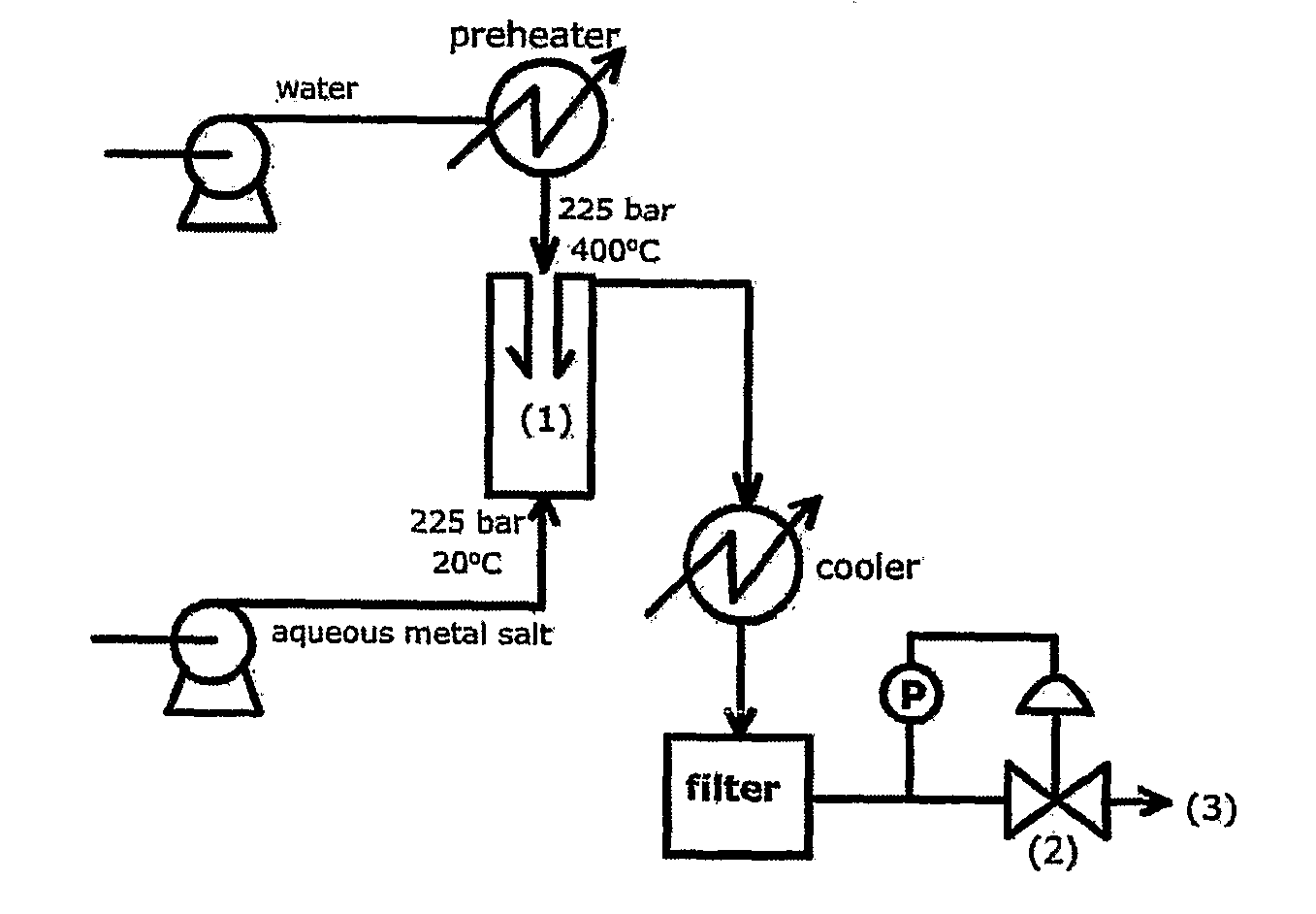

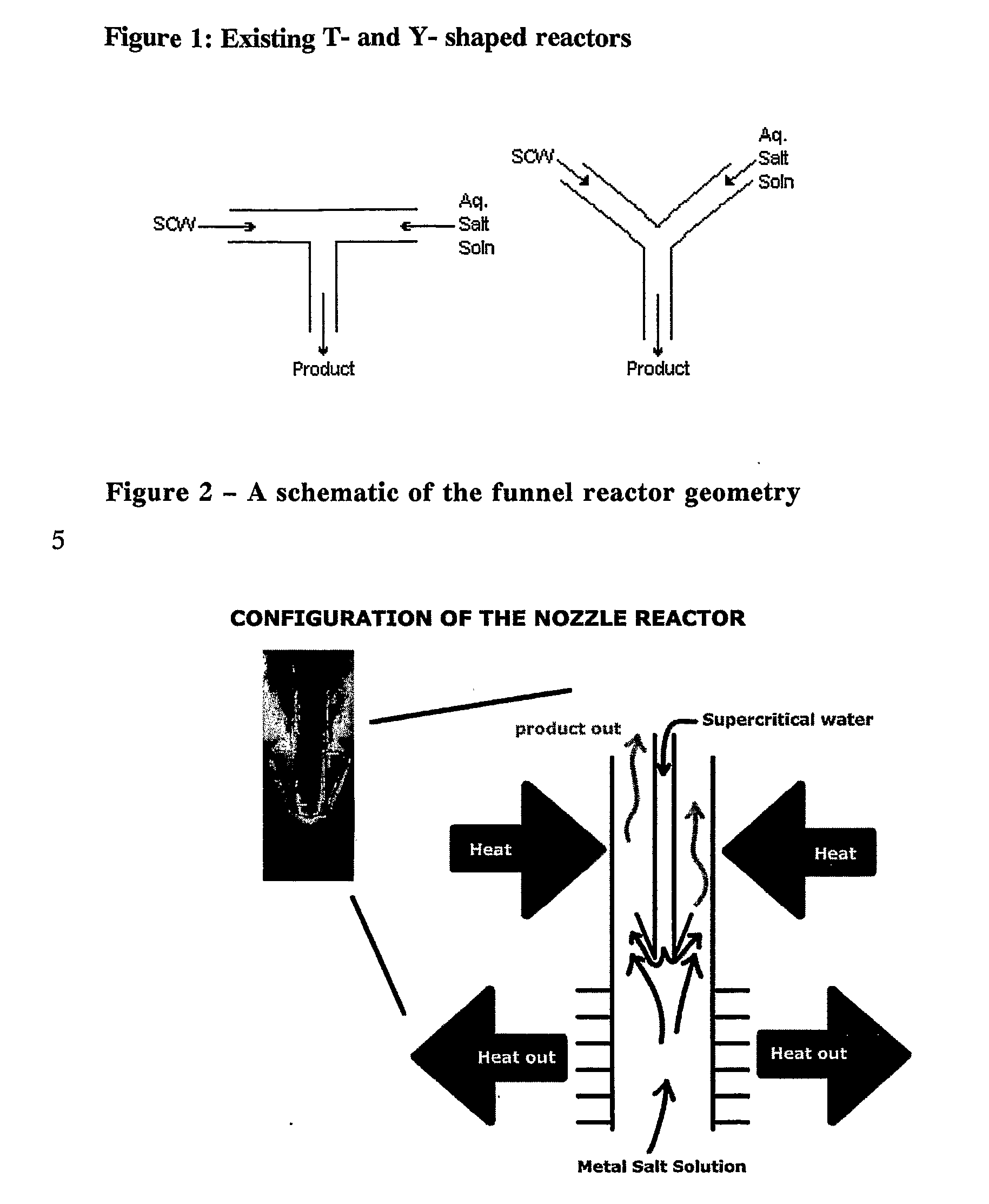

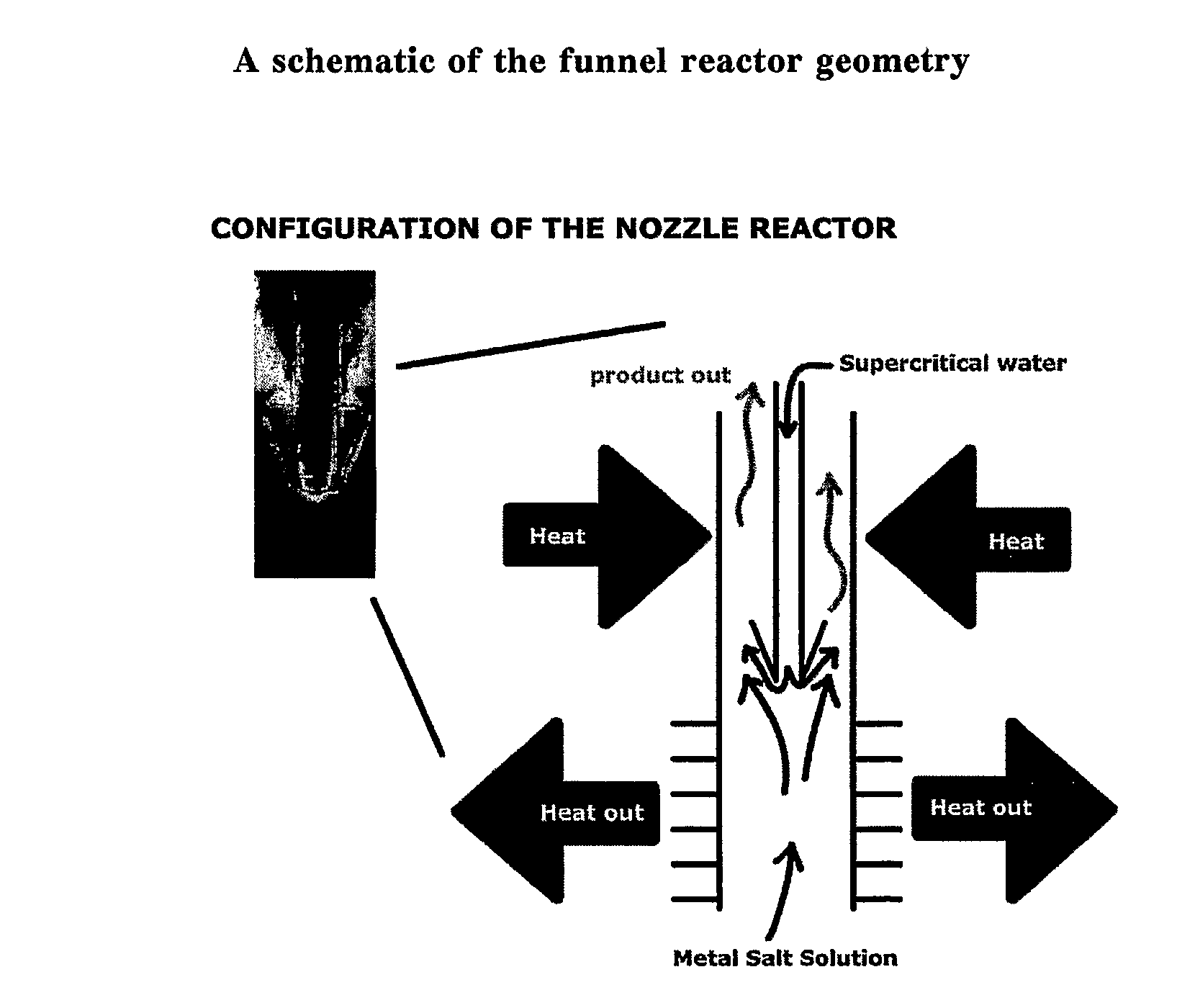

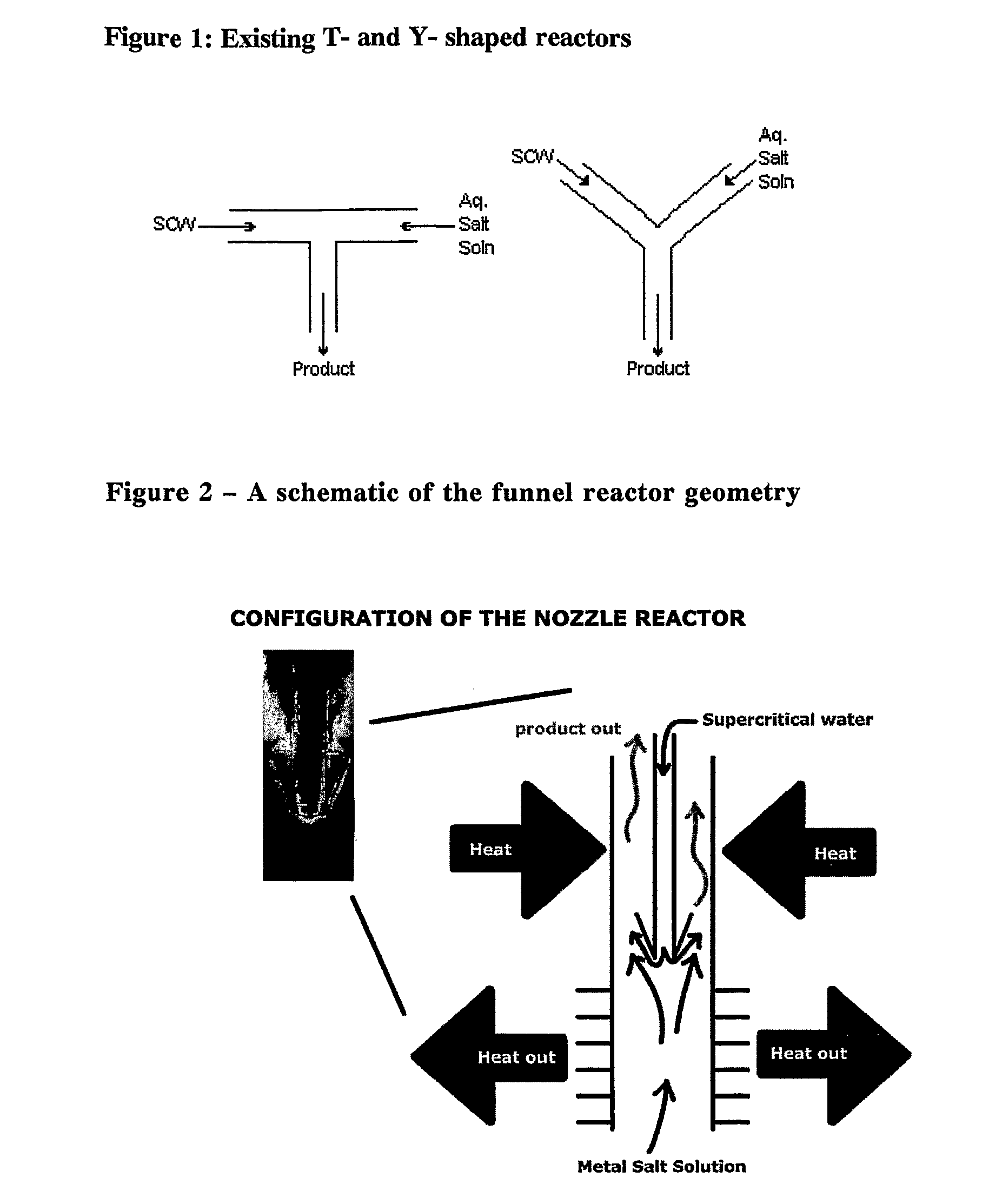

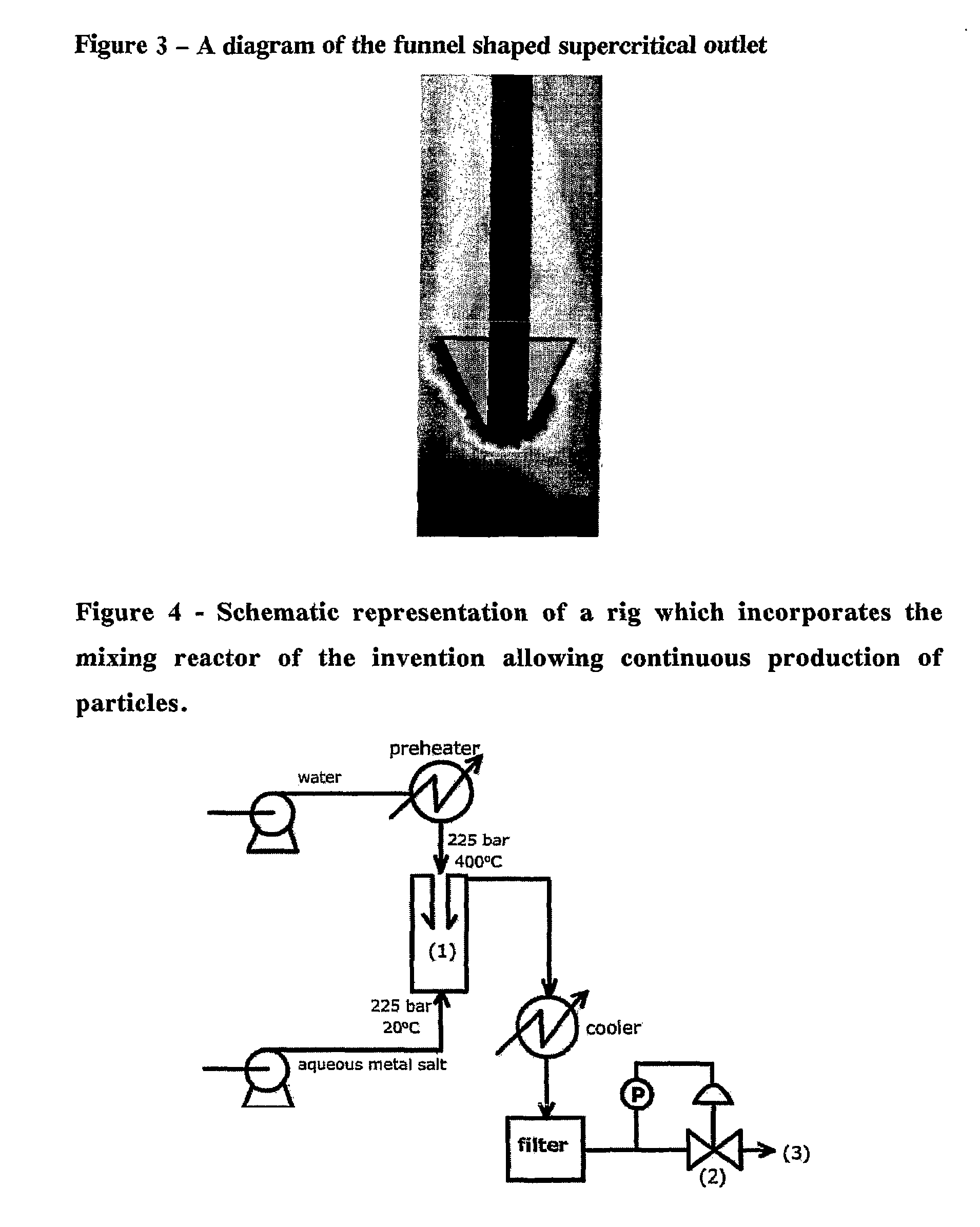

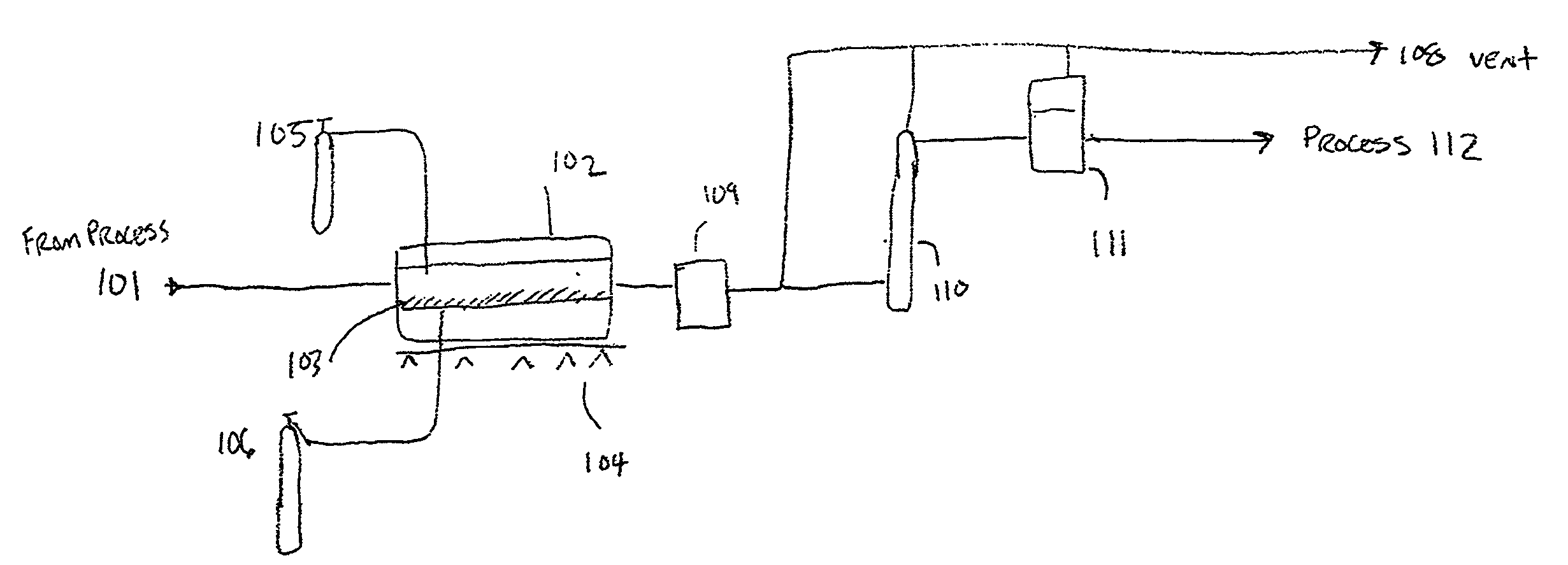

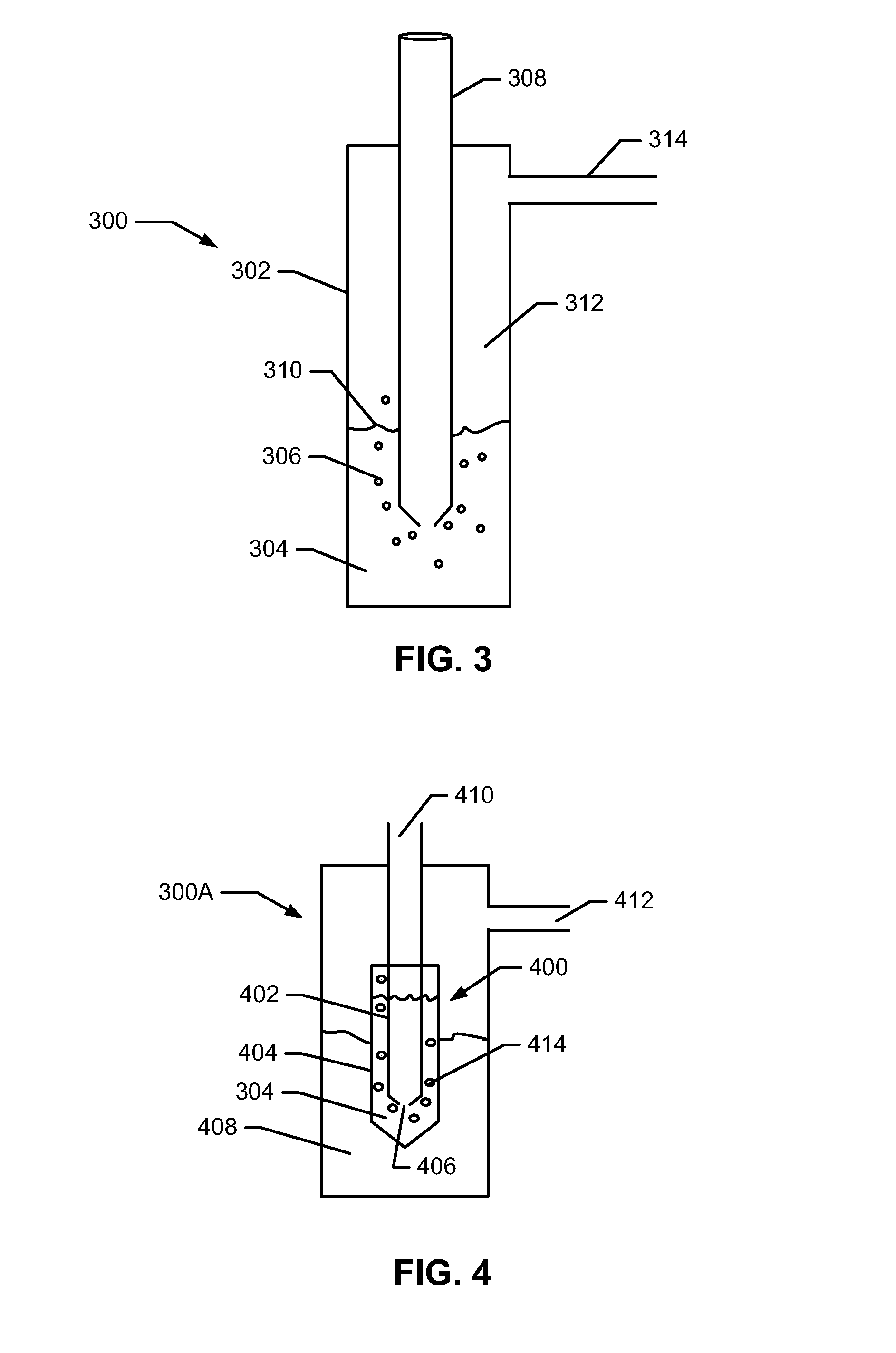

Counter Current Mixing Reactor

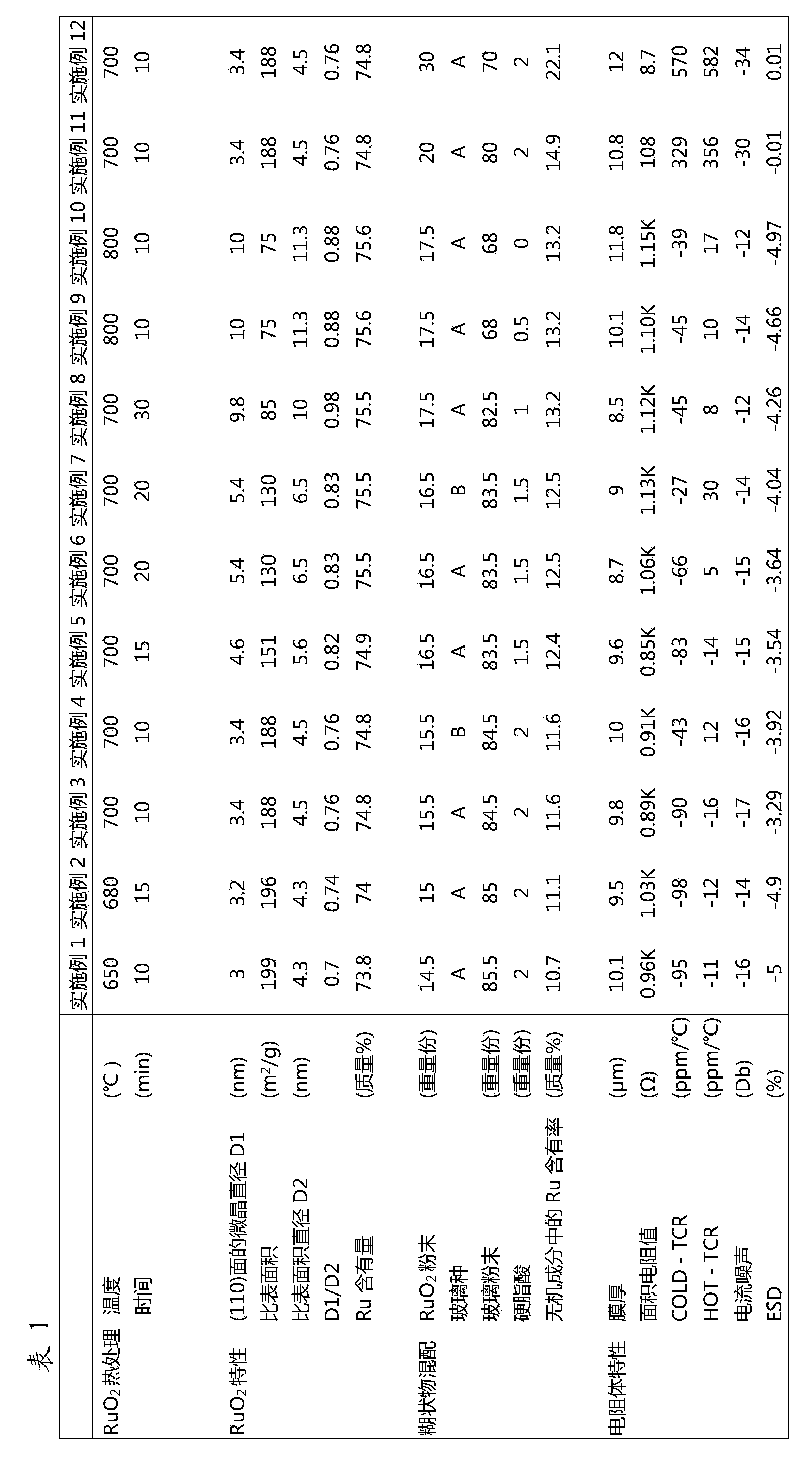

ActiveUS20070206435A1Minimize blockingEliminate mixingRare earth metal oxides/hydroxidesFlow mixersMetal oxide nanoparticlesReactor design

A mixing reactor for mixing efficiently streams of fluids of differing densities. In a preferred embodiment, one of the fluids is supercritical water, and the other is an aqueous salt solution. Thus, the reactor enables the production of metal oxide nanoparticles as a continuous process, without any risk of the reactor blocking due to the inefficient mixing inherent in existing reactor designs.

Owner:PROMETHEAN PARTICLES

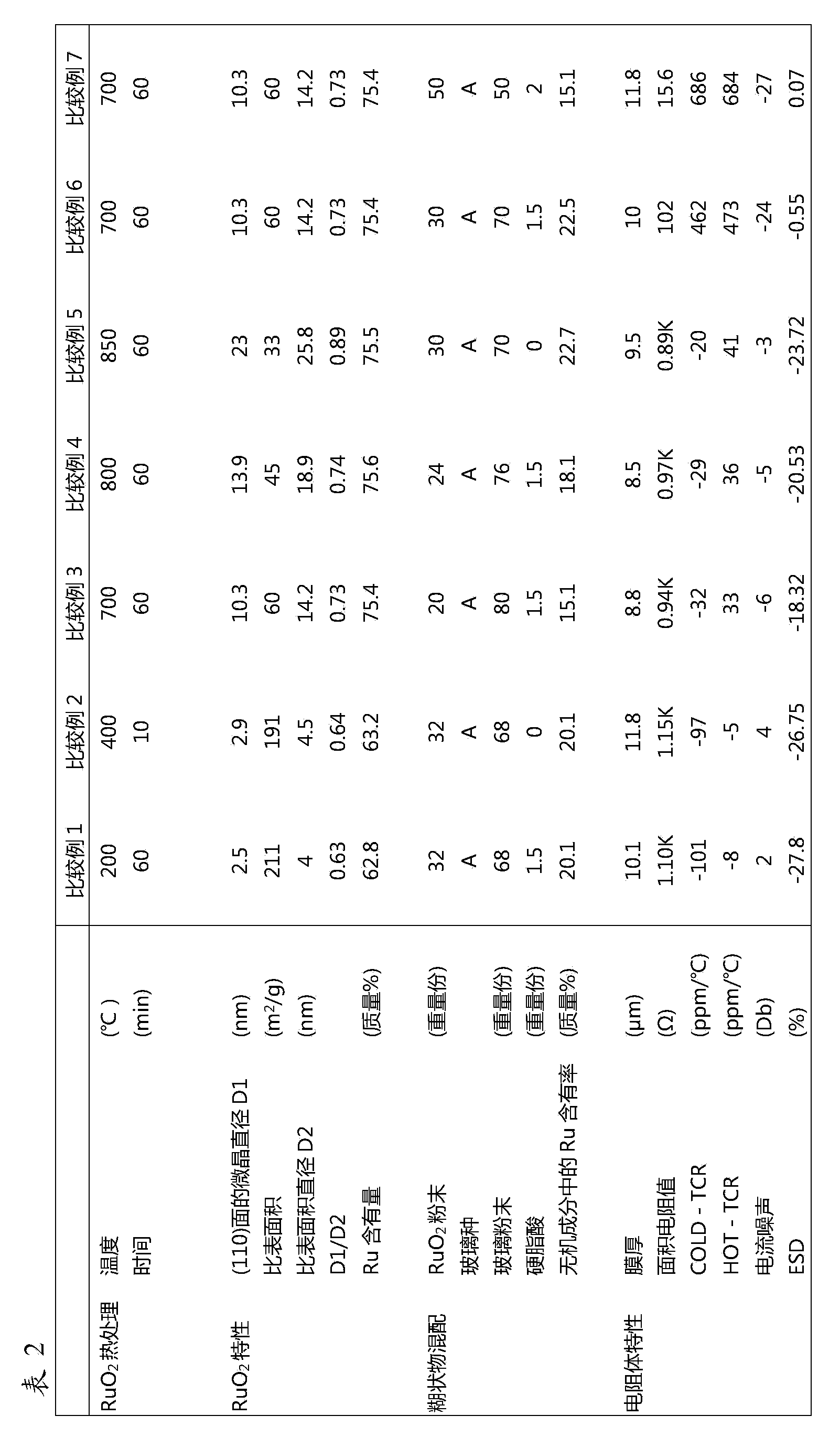

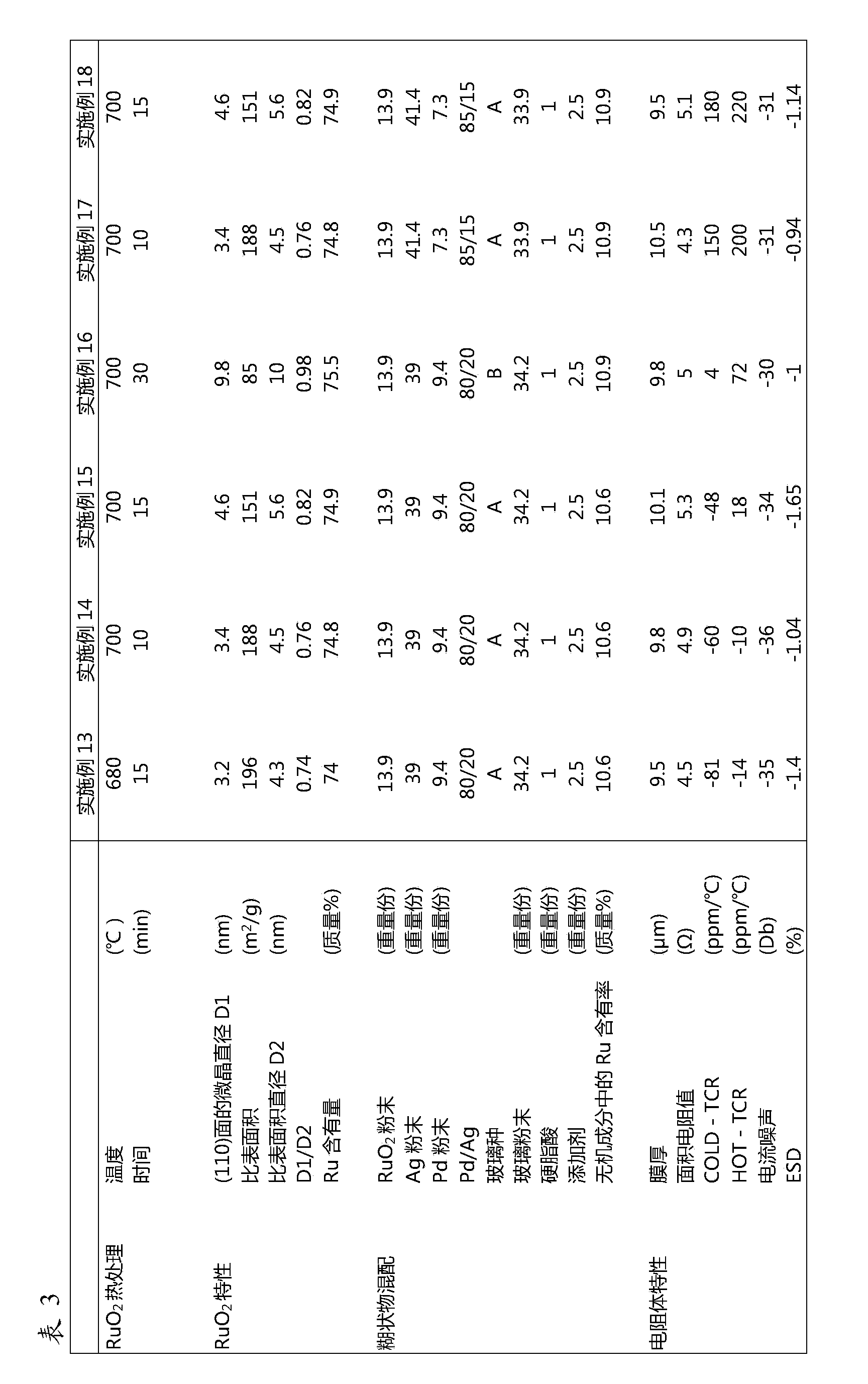

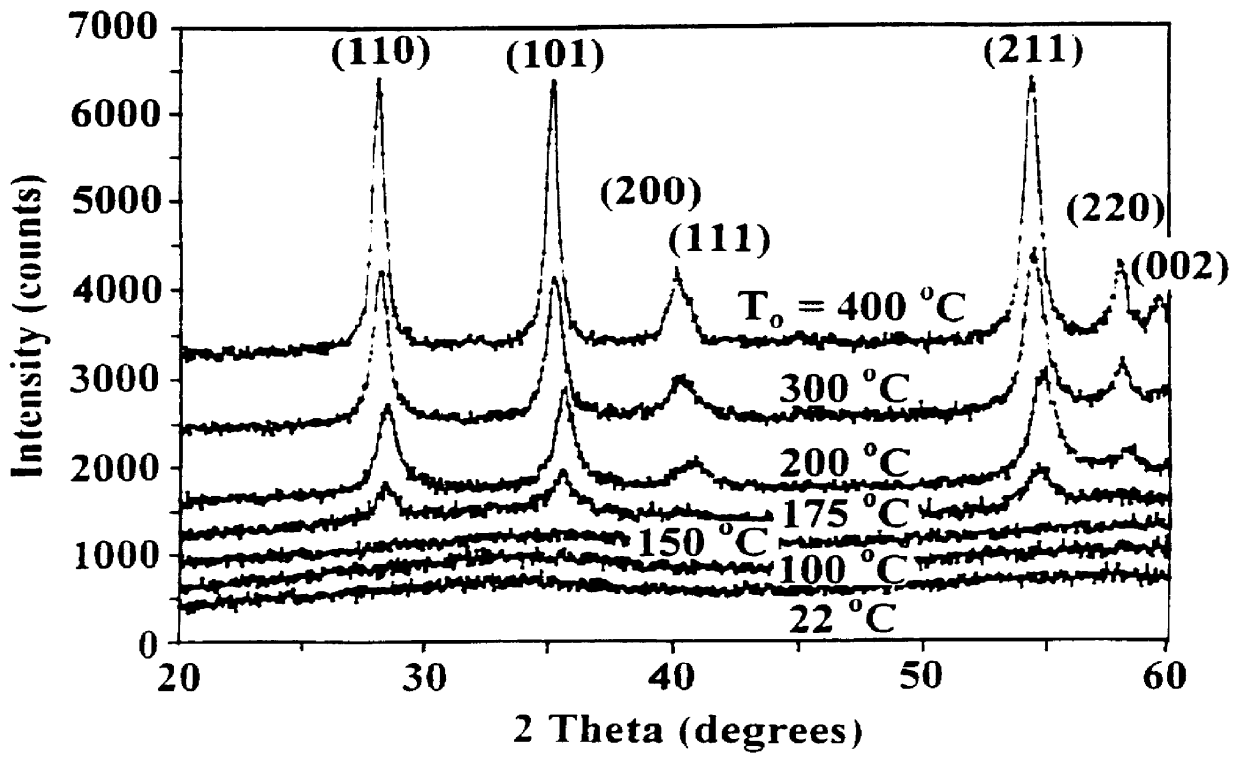

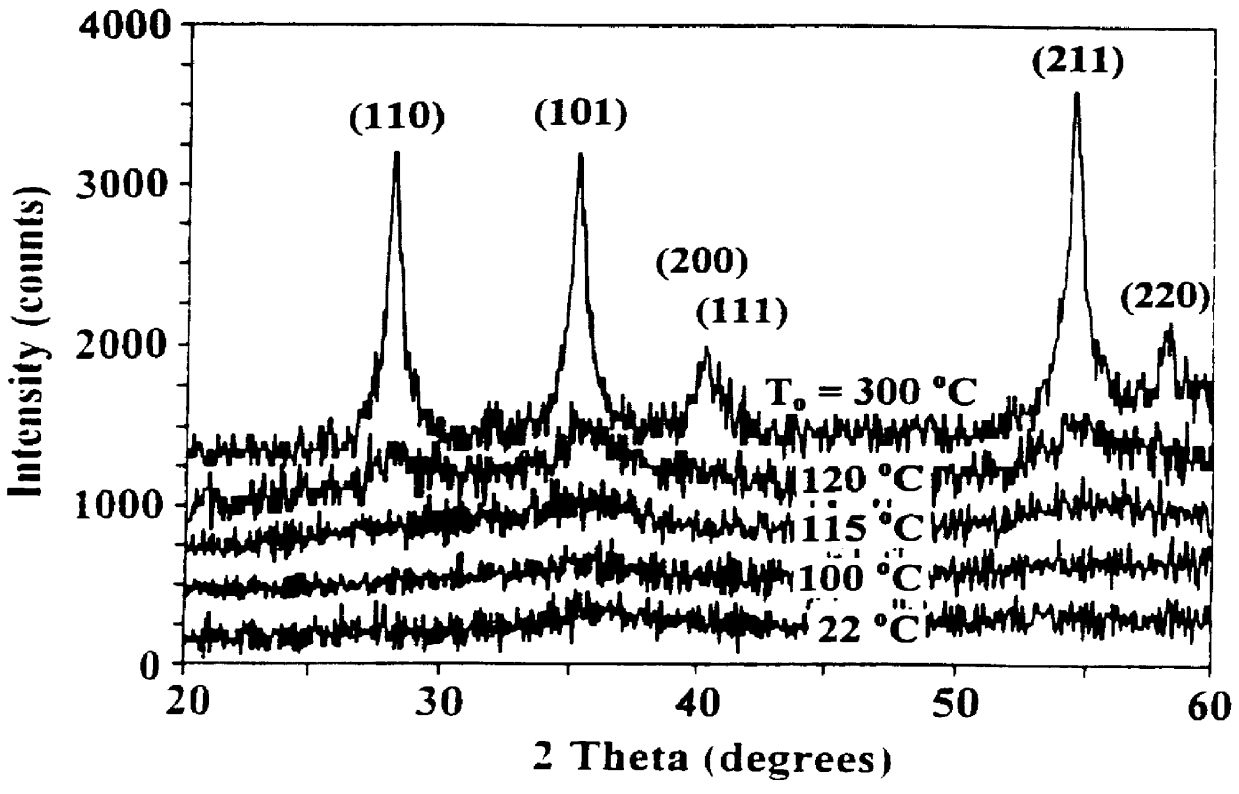

Ruthenium oxide powder, composition for thick film resistor elements using same, and thick film resistor element

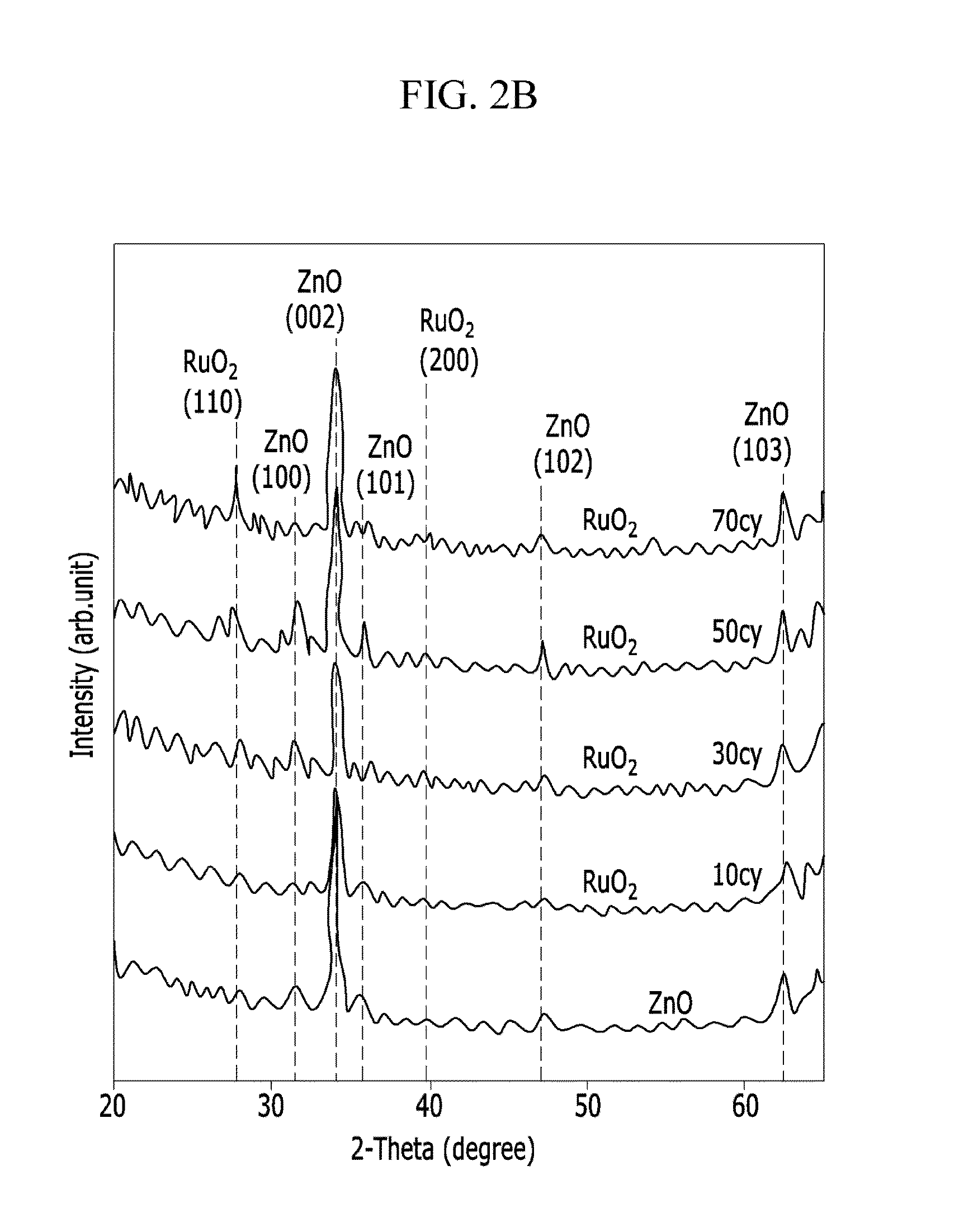

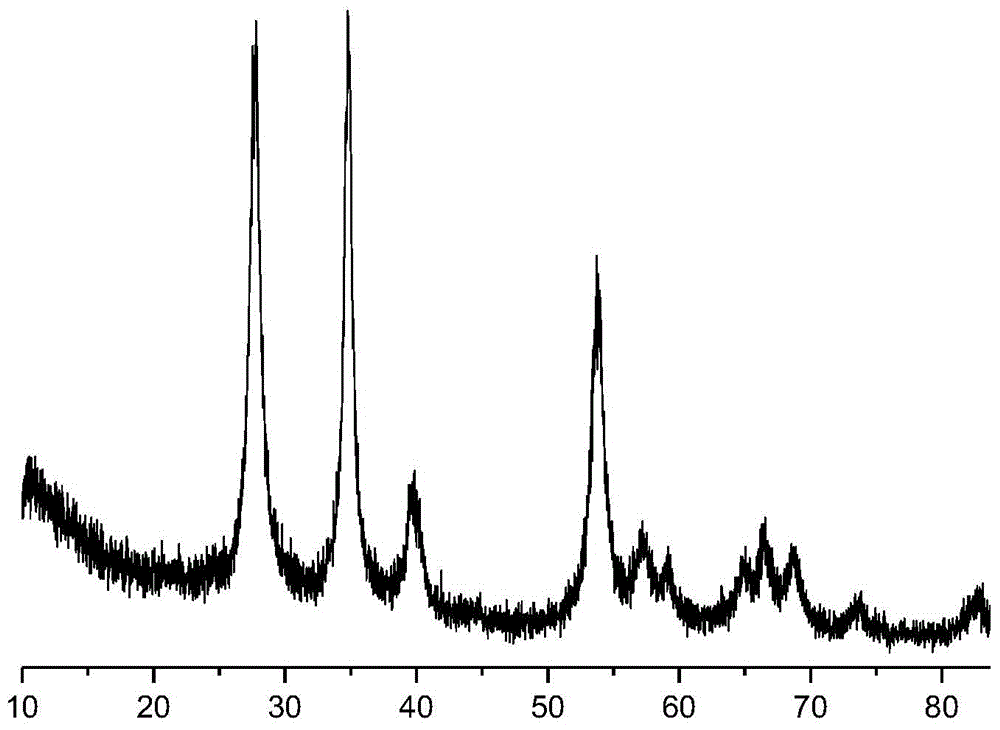

ActiveCN103429537AInhibit growthHigh crystallinityRuthenium/rhodium/palladium/osmium/iridium/platinum oxides/hydroxidesThick film resistorsX-rayEngineering

Provided are: a ruthenium oxide powder which is produced, at low cost, as a material for electronic components such as a chip resistor, a hybrid IC and a resistive network each having a sufficient performance, even if the ruthenium content thereof is low; a composition for thick film resistor elements, which uses the ruthenium oxide powder; and a thick film resistor element. Specifically provided are: a ruthenium oxide (RuO2) powder having a rutile crystal structure, which is characterized in that the crystallite diameter of the (110) plane as determined by an X-ray diffraction method is 3-10 nm and the Ru content is 73% by mass or more; a composition for thick film resistor elements, which is obtained by blending a glass powder and conductive particles that are formed of the ruthenium oxide powder as main constituent elements; and a thick resistor element paste, which is obtained by dispersing the composition for thick film resistor elements in an organic vehicle that contains a fatty acid, and which is characterized in that the content of the fatty acid is 0.1-10 parts by weight per 100 parts by weight of the ruthenium oxide.

Owner:SUMITOMO METAL MINING CO LTD

Oxidatively regenerable adsorbents for sulfur removal

InactiveUS20090065400A1Increase capacityHigh selectivityRare earth metal oxides/hydroxidesGold compoundsSorbentSulfur

Compositions and processes are disclosed for removing sulfur and sulfur compounds from hydrocarbon fuel feedstocks. The feedstock is contacted with a regenerable sorbent such as a compound of the formula TixCeyO2 where 0<x / y≦1 and where 0<x≦1 and 0<y≦1 capable of selectively adsorbing sulfur compounds present in the hydrocarbon feedstock at about 0° C. to about 100° C. such as at about 25° C.

Owner:PENN STATE RES FOUND

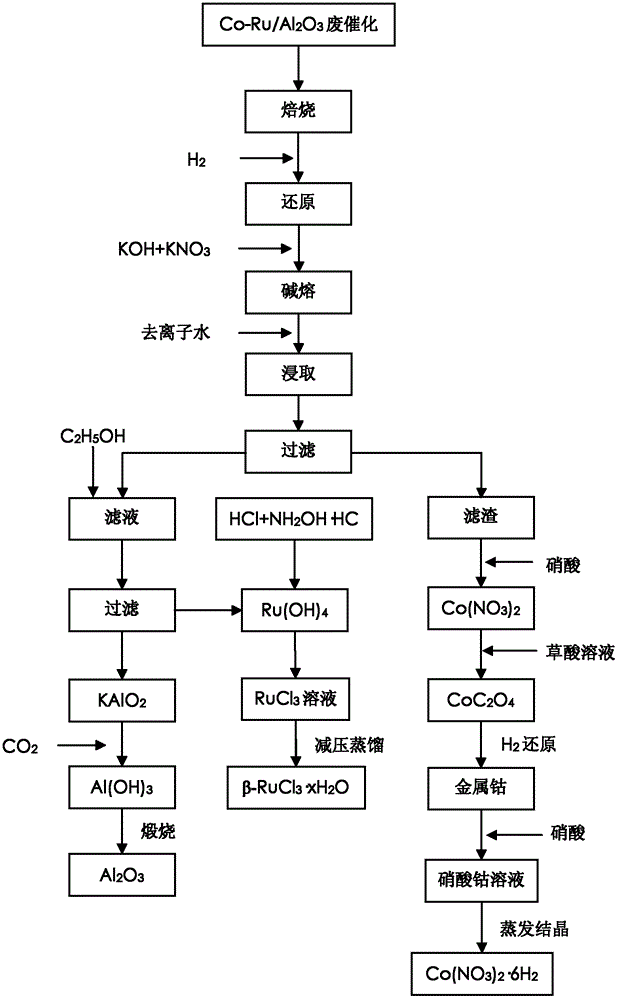

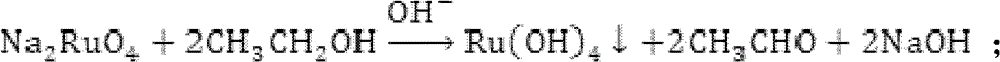

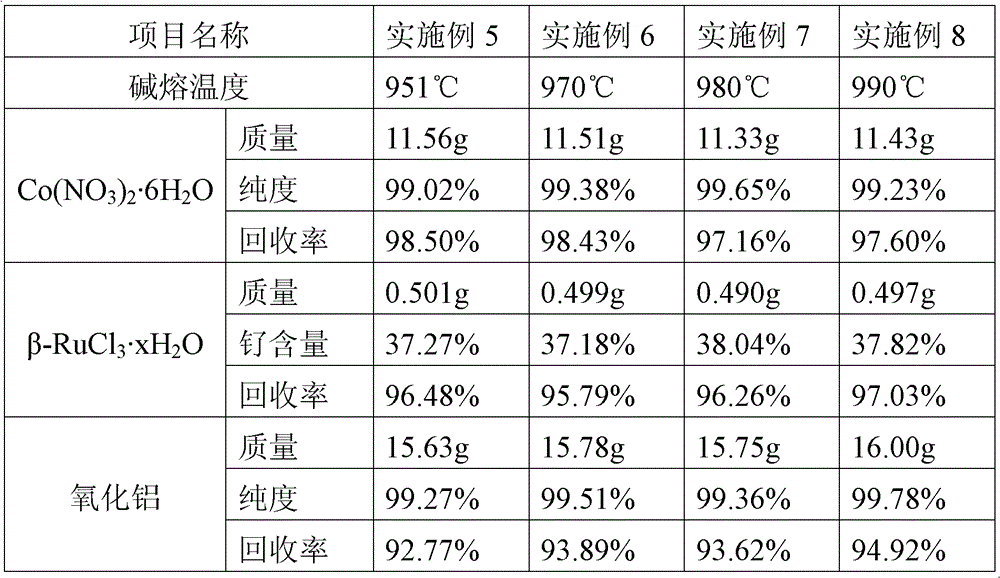

Method for comprehensively recovering metallic cobalt, ruthenium and aluminum from Fischer-Tropsch synthesis dead catalyst Co-Ru/Al2O3

ActiveCN102796873AHigh purityOperational securityProductsAluminium compoundsDistillationAluminium hydroxide

The invention discloses a method for comprehensively recovering metallic cobalt, ruthenium and aluminum from a Fischer-Tropsch synthesis dead catalyst Co-Ru / Al2O3, and the method can be used for effectively separating and comprehensively recovering valuable metallic cobalt, ruthenium and aluminum from the Fischer-Tropsch synthesis dead catalyst Co-Ru / Al2O3. The method comprises the steps of: firstly carrying out hydrocarbon removal and reductive treatment on the dead catalyst; effectively separating cobalt slag in an alkali fusion step; and carrying out acid leaching on the cobalt slag, oxalate or oxalate deposited cobalt, reducing cobalt oxalate, dissolving the metallic cobalt via nitric acid and the like to obtain Co(NO3)2.6H2O. Ruthenate is obtained by the steps of alkali fusion and deionized water leaching; and steps of ethanol reduction, concentrated hydrochloric acid dissolution, reduced pressure distillation and the like are carried out on the ruthenate to obtain a beta-RuCl1.xH2O product which is high in purity. By using a CO2 carbon dioxide decomposition method, the parameters such as reaction temperature, CO2 flow velocity, pH value of reaction destination and the like are controlled and aluminum hydroxide is prepared from meta-aluminate solution; high-temperature calcination is carried out to obtain aluminum oxide; and the product quality meets the quality requirement of first-level aluminum oxide of national standard and the process is economic and environment-friendly. According to the invention, the metallic recovery rate is high, wherein the recovery rate of cobalt is greater than or equal to 97%, the recovery rate of ruthenium is greater than or equal to 95% and the recovery rate of aluminum is greater than or equal to 92%.

Owner:SUNSHINE KAIDI NEW ENERGY GROUP CO LTD

Counter current mixing reactor

ActiveUS7566436B2Minimize blockingRare earth metal oxides/hydroxidesFlow mixersMetal oxide nanoparticlesReactor design

Owner:PROMETHEAN PARTICLES

Electrode materials from hydrous metal and/or hydrous mixed metal oxides

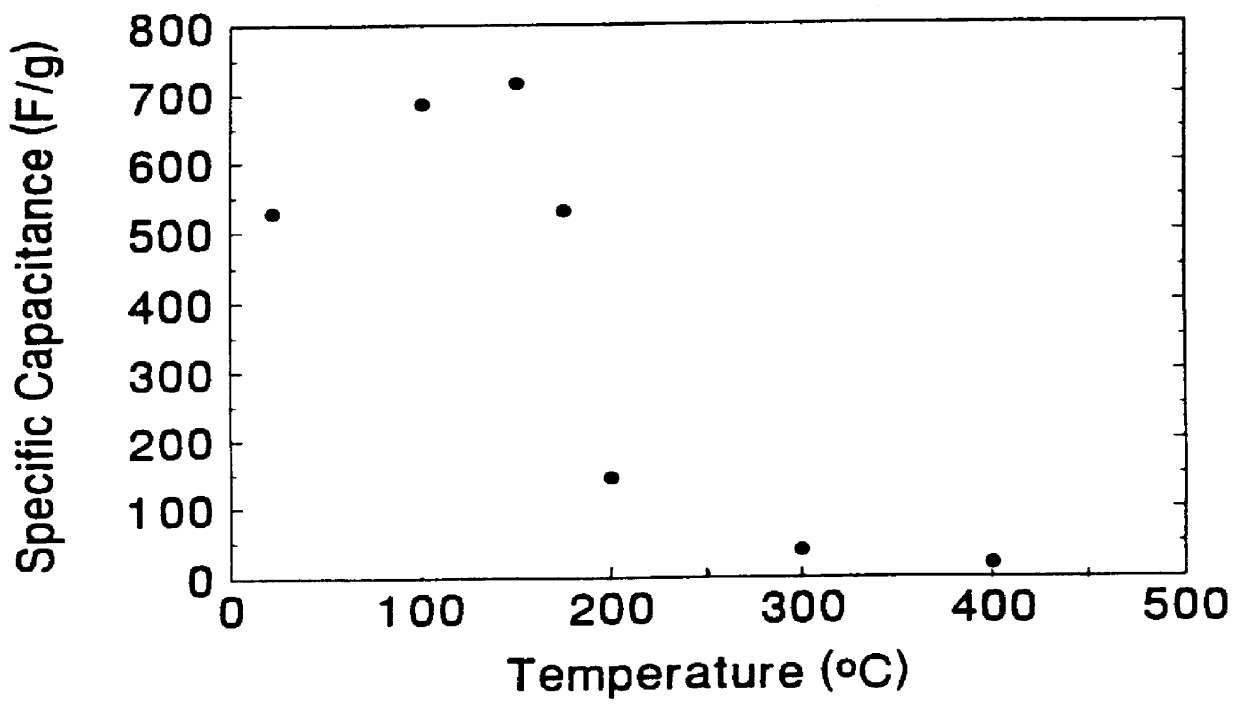

InactiveUS6097588AImprove relationshipGood reversibilityOxide/hydroxide preparationRuthenium/rhodium/palladium/osmium/iridium/platinum oxides/hydroxidesMaterials preparationGram

An electrode material composed of hydrous metal oxide, such as ruthenium oxide, is annealed up to temperature just below the temperature at which the hydrous metal oxide would crystallize. Therefore, the hydrous metal oxide remains amorphous or non-crystalline. A hydrous metal oxide material treated in this manner provides a charge storage capacity and energy density greater than 747 F / g and 92 joules / gram, respectively, over 1 V range in a sulfuric acid electrolyte. This invention also provides a method of material preparation, wherein a sol-gel process is used to fabricate the hydrous metal oxides and wherein commercially available hydrous ruthenium oxide powders are treated and annealed.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

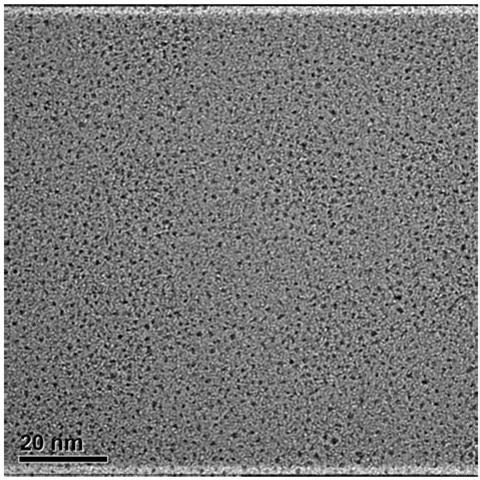

Methods for production of metal oxide nano particles, and nano particles and preparations produced thereby

The invention provides a method for the formation of small-size metal oxide particles, comprising the steps of: a) preparing a starting aqueous solution comprising at least one of metallic ion and complexes thereof, at a concentration of at least 0.1 % w / w of the metal component; b) preparing a modifying aqueous solution having a temperature greater than 5O0C; c) contacting the modifying aqueous solution with the starting aqueous solution in a continuous mode in a mixing chamber to form a modified system; d) removing the modified system from the mixing chamber in a plug-flow mode; wherein the method is characterized in that: i) the residence time in the mixing chamber is less than about 5 minutes; and iii) there are formed particles or aggregates thereof, wherein the majority of the particles formed are between about 2nm and about 500nm in size.

Owner:朱马国际公司

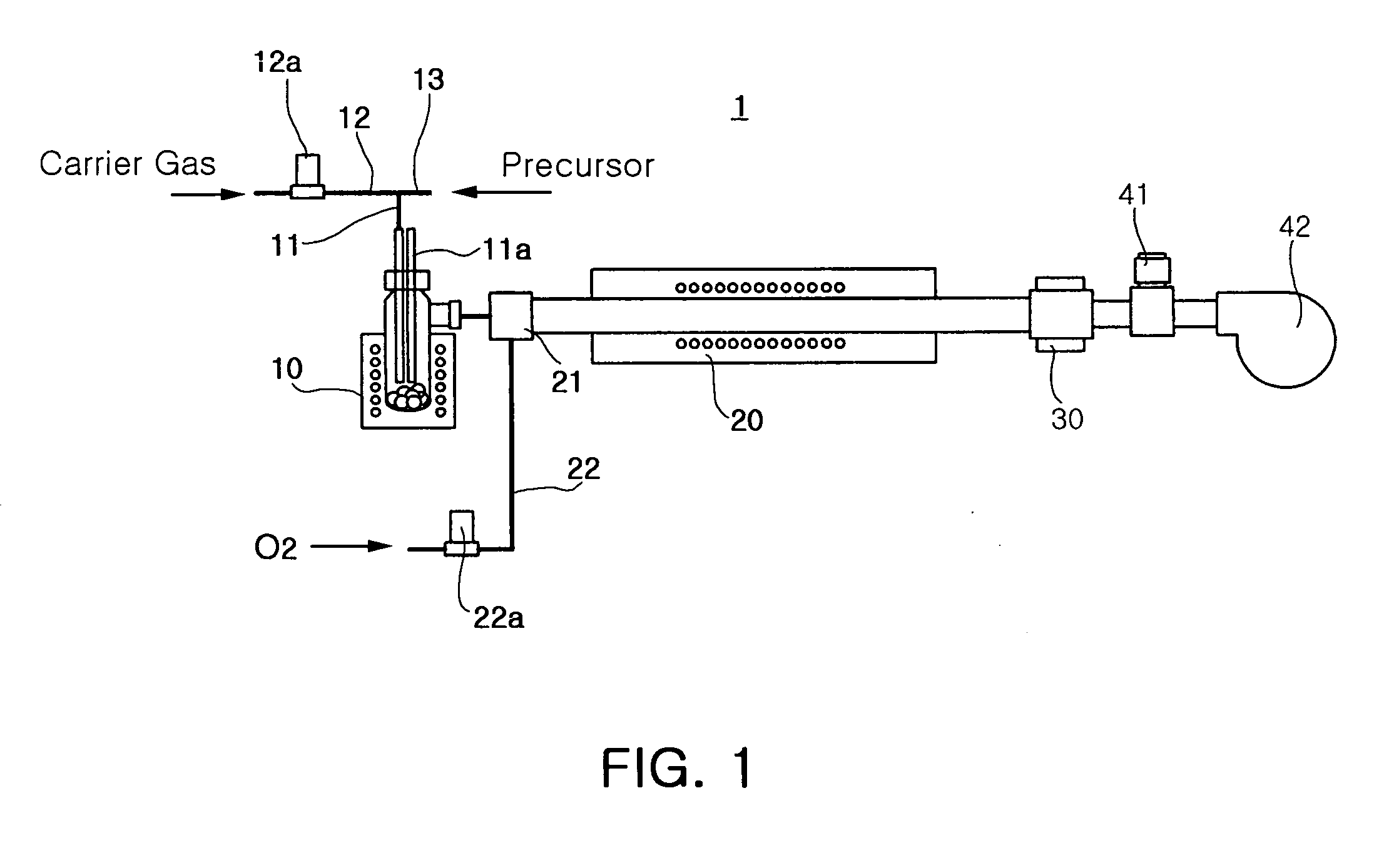

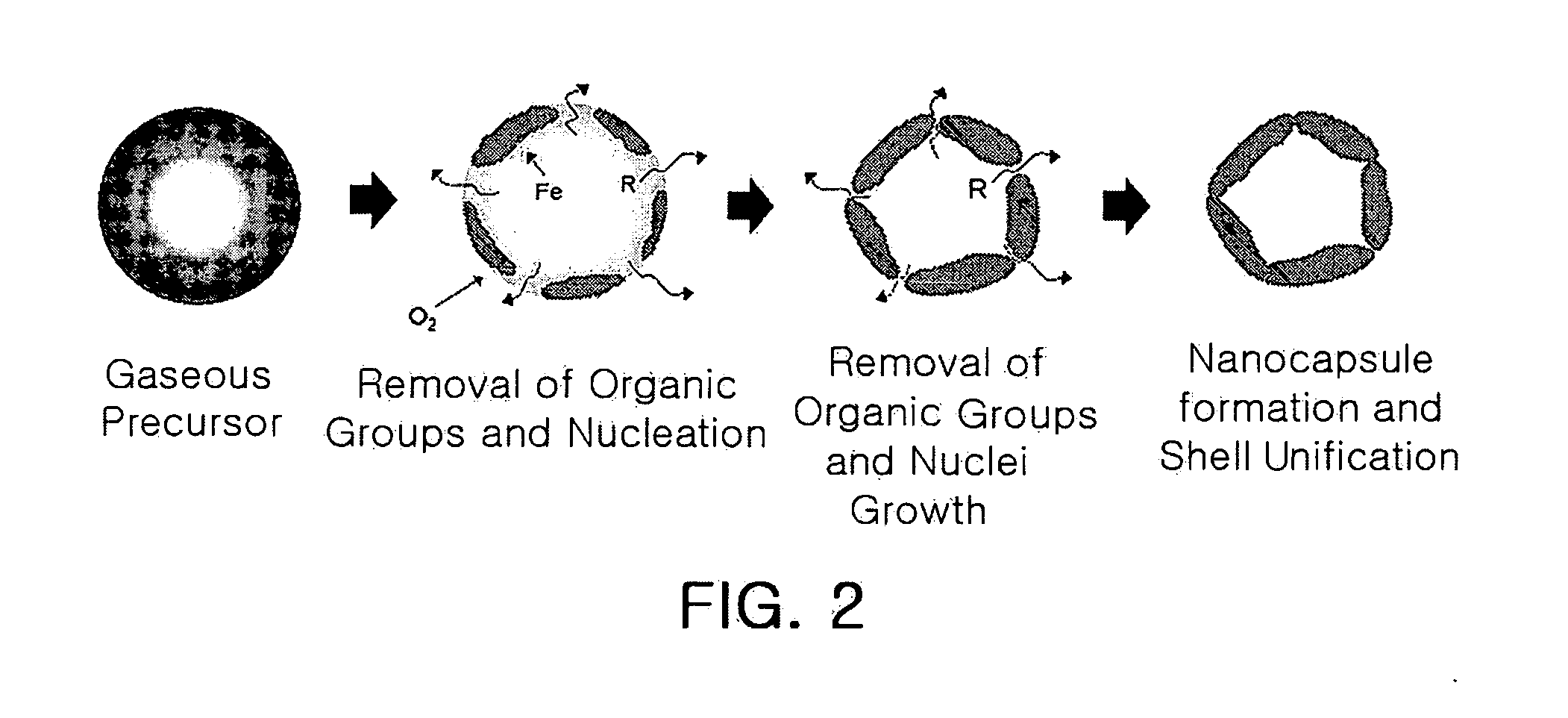

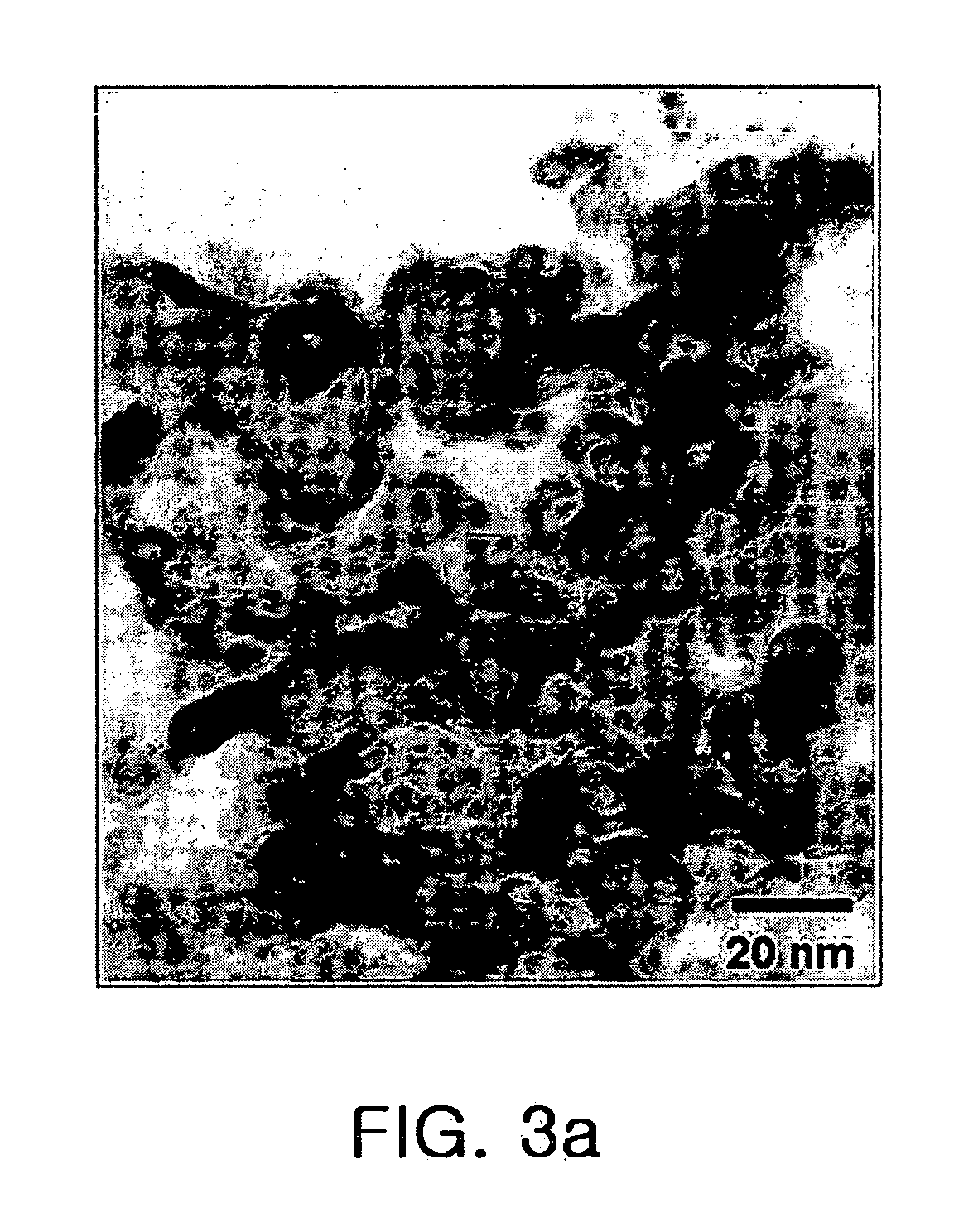

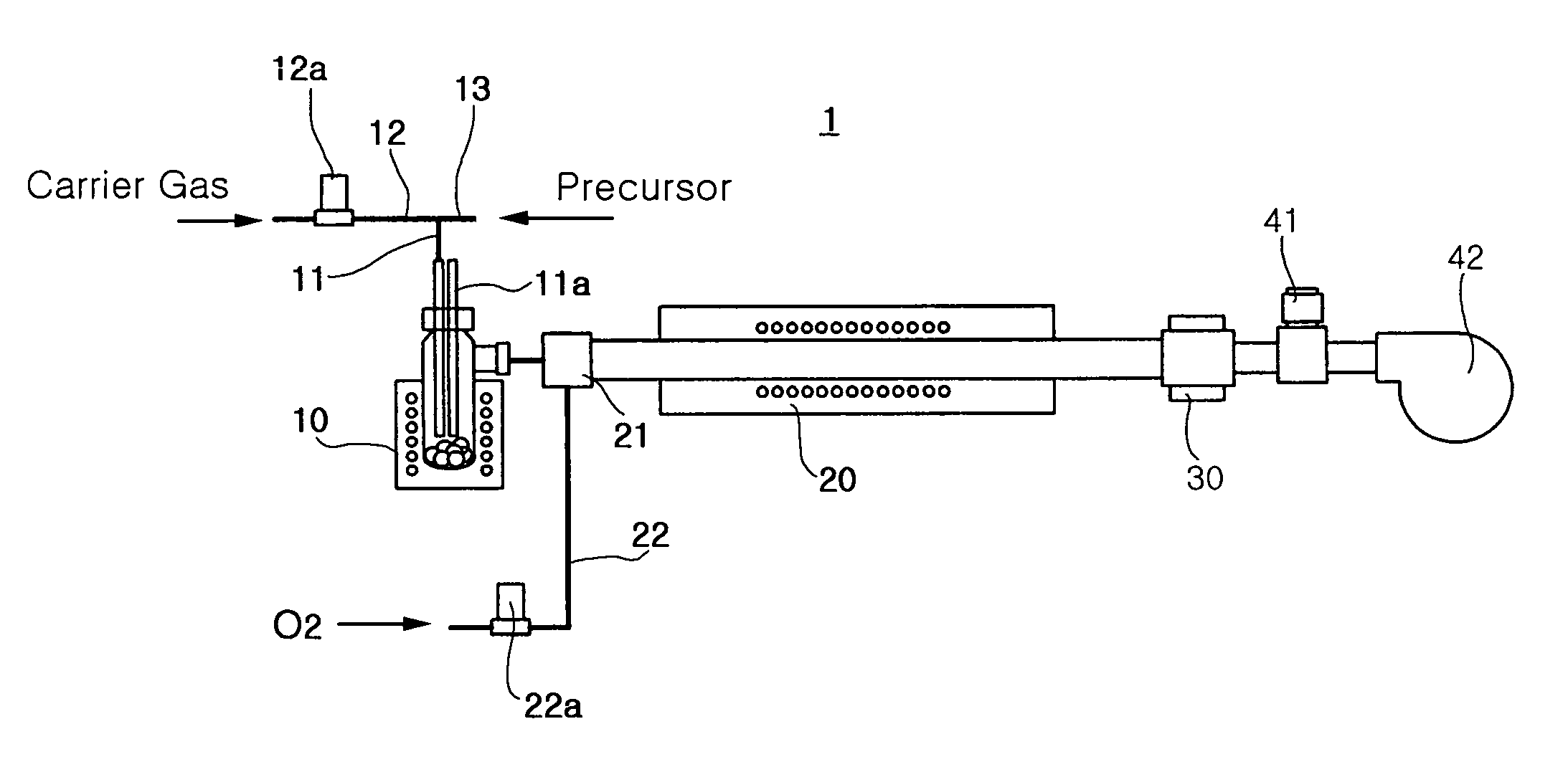

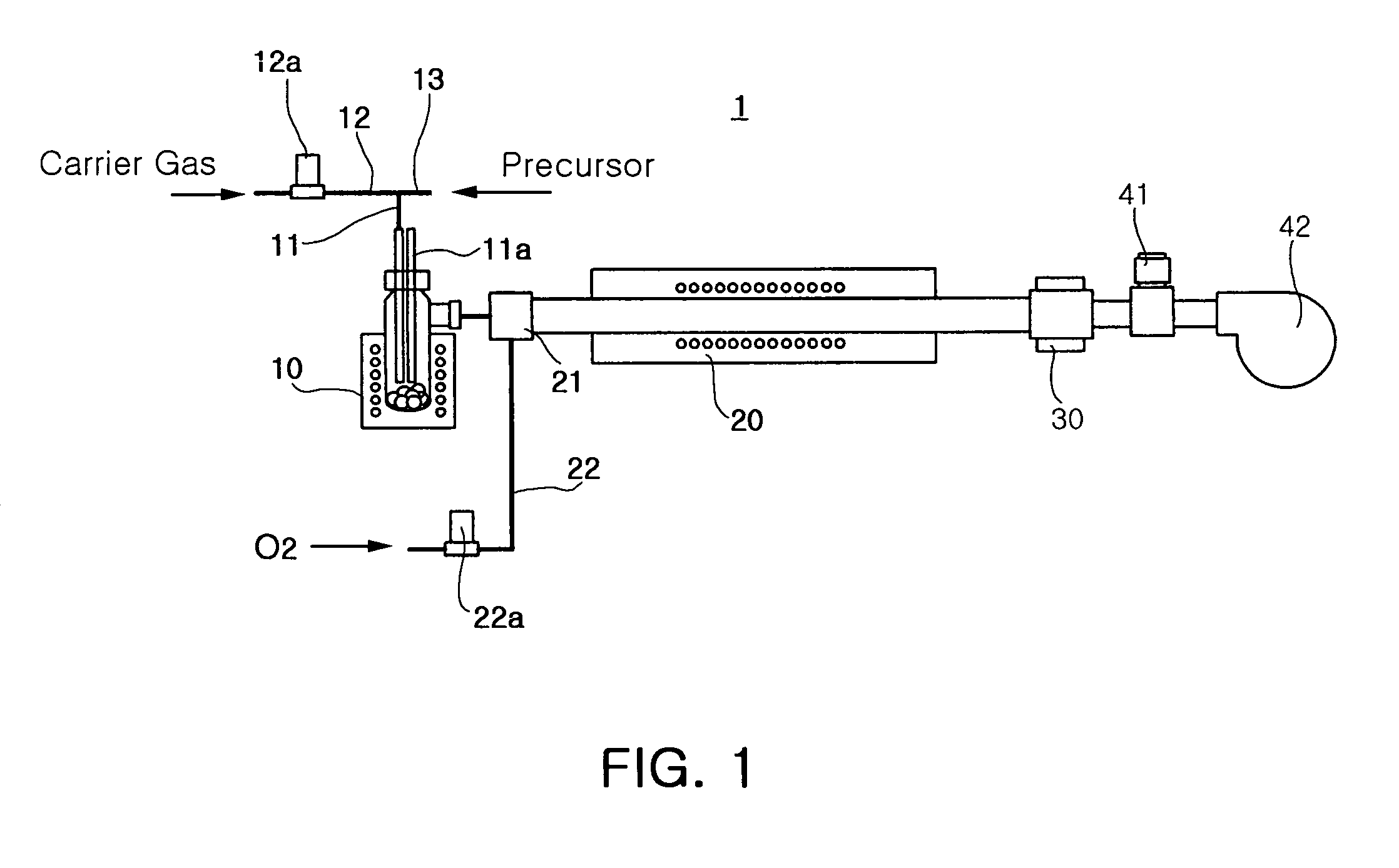

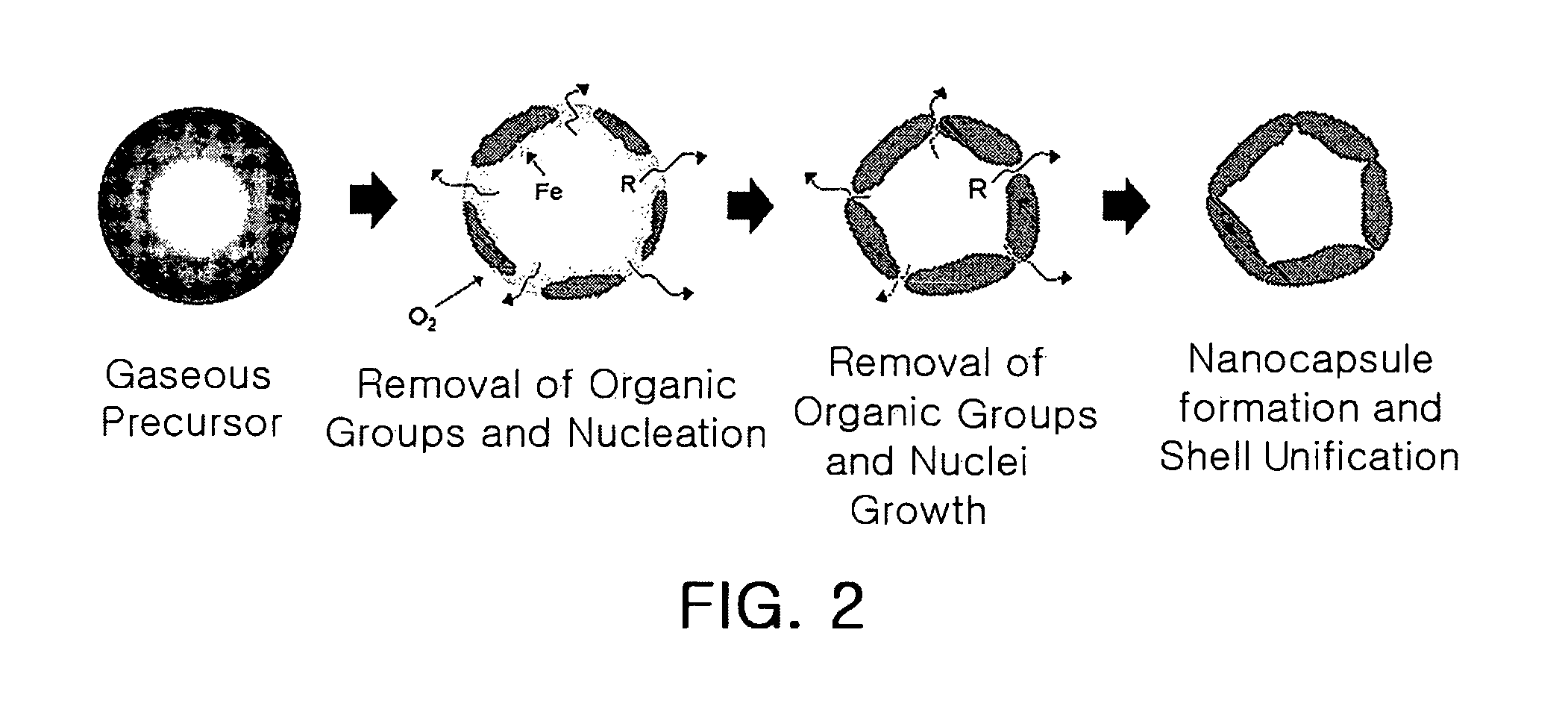

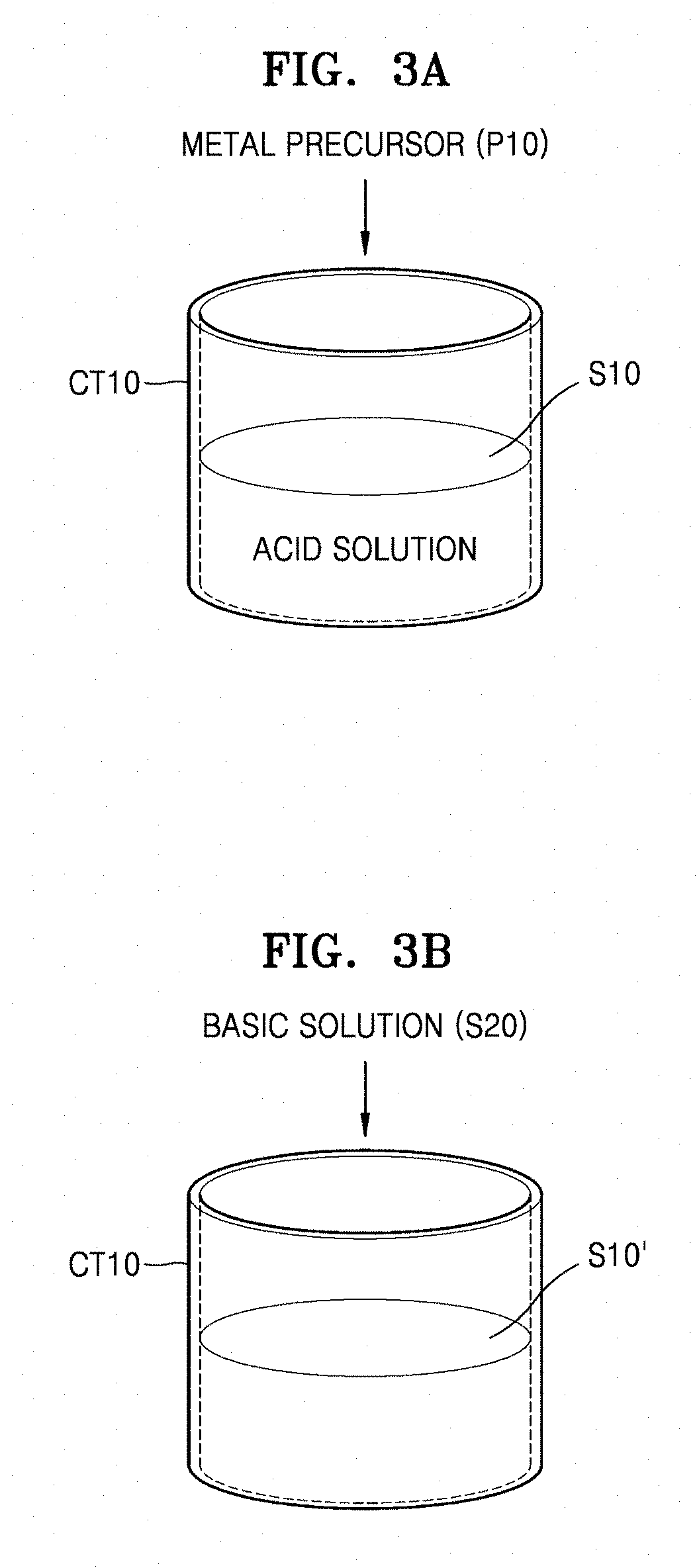

Method for manufacturing metal oxide hollow nanoparticles and metal oxide hollow nanoparticles manufactured by the same

ActiveUS20060269463A1Maintain good propertiesCopper oxides/halidesManganese oxides/hydroxidesNanoparticleOxygen

Provided is a method for manufacturing a metal oxide hollow nanoparticles with excellent properties more easily and simply by a chemical vapor condensation employing metal β-diketonates as precursors, and a metal oxide hollow nanoparticles manufactured by the method. The method includes: preparing metal β-diketonate as a precursor; evaporating the metal β-diketonate at a predetermined temperature higher than a melting point of the metal β-diketonate; transferring the evaporated metal β-diketonate into a reaction region; thermally decomposing the transferred gaseous metal β-diketonate and simultaneously inducing a reaction of the transferred gaseous metal β-diketonate with oxygen to synthesize the metal oxide hollow nanoparticle; and condensing and collecting the synthesized metal oxide hollow nanoparticles.

Owner:IUCF HYU (IND UNIV COOP FOUND HANYANG UNIV)

Oxidatively regenerable adsorbents for sulfur removal

Compositions and processes are disclosed for removing sulfur and sulfur compounds from hydrocarbon fuel feedstocks. The feedstock is contacted with a regenerable sorbent such as a compound of the formula TixCeyO2 where 0<x / y≦1 and where 0<x≦1 and 0<y≦1 capable of selectively adsorbing sulfur compounds present in the hydrocarbon feedstock at about 0° C. to about 100° C. such as at about 25° C.

Owner:PENN STATE RES FOUND

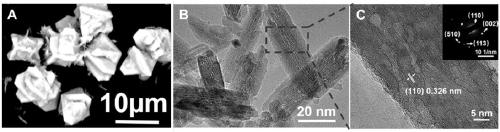

Preparation method of nano ruthenium oxide

ActiveCN107867726ARegulatory TopographySmall sizeMaterial nanotechnologyRuthenium/rhodium/palladium/osmium/iridium/platinum oxides/hydroxidesSpherical formRaw material

The invention discloses a preparation method of nano ruthenium oxide. The preparation method comprises following steps: a ruthenium source solution is mixed with alkali liquor, and a precursor solution with pH being 9-12 is obtained; the precursor solution is subjected to a hydrothermal reaction or calcined, and nano ruthenium oxide is obtained. Prepared nano ruthenium oxide particles are controllable in morphology, that is, the nano ruthenium oxide particles are of a regular spherical structure or rod-like structure. The preparation method is simple, green and environmentally friendly and facilitates industrialization, the raw material cost is relatively low, prepared products have better performance, and the preparation method has good application prospect.

Owner:BEIJING UNIV OF CHEM TECH

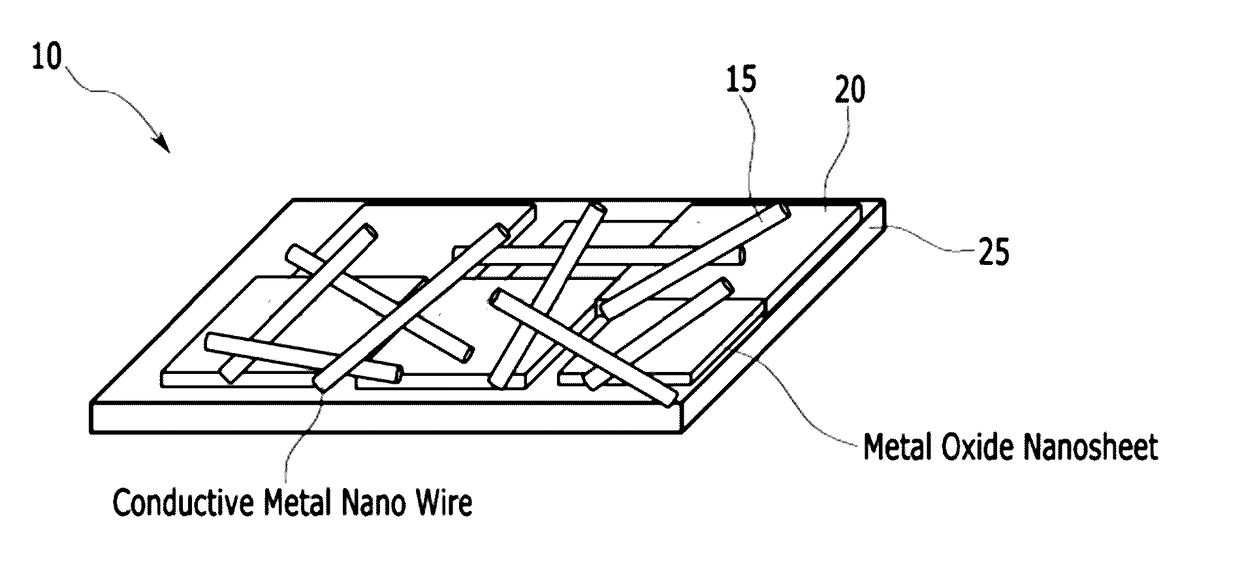

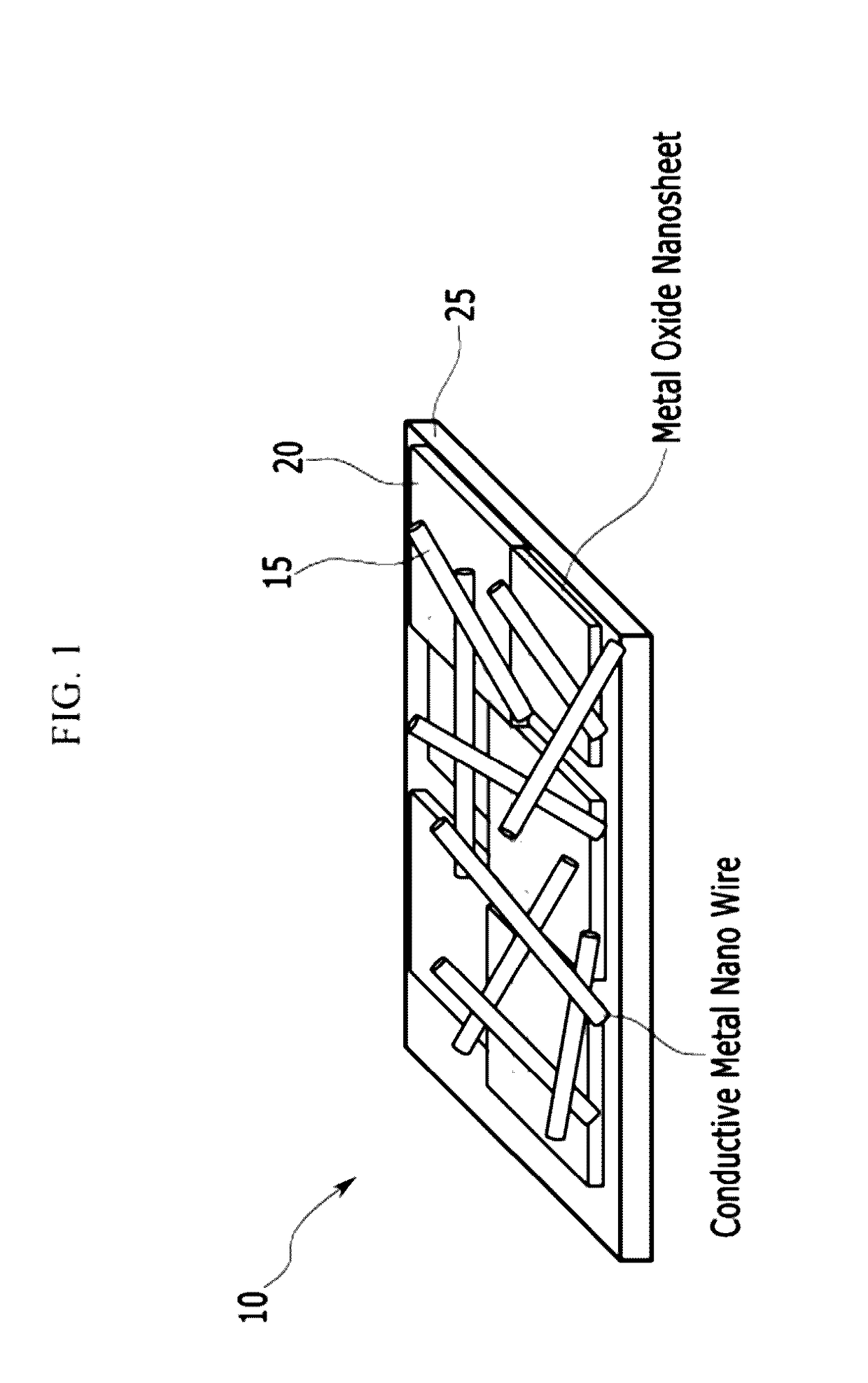

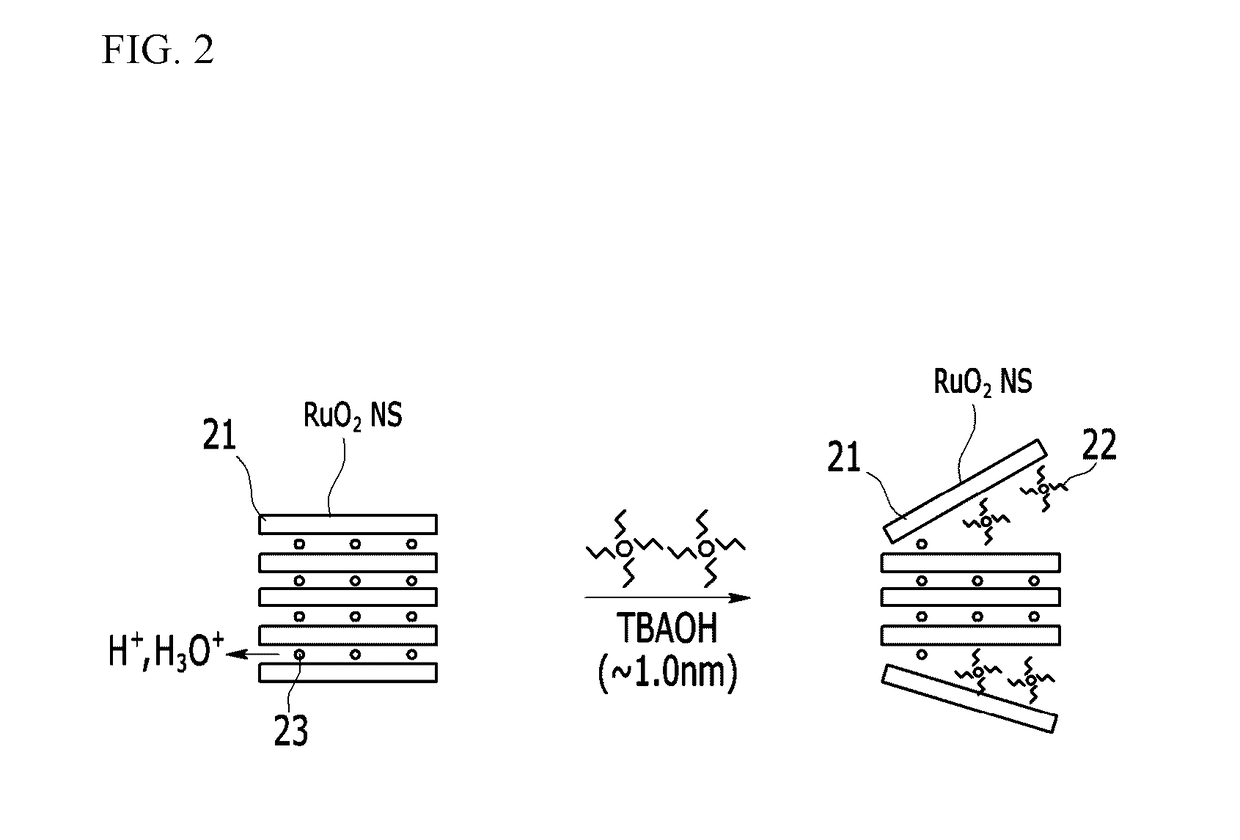

Electrical conductors, electrically conductive structures, and electronic devices including the same

ActiveUS20170094723A1Improve conductivityEasy to optimizeAlkali titanatesConductive layers on insulating-supportsElectrical connectionMaterials science

An electrical conductor including:a first conductive layer including a plurality of metal nanowires; anda second conductive layer disposed on a surface of the first conductive layer, wherein the second conductive layer includes a plurality of metal oxide nanosheets,wherein in the first conductive layer, a metal nanowire of the plurality of metal nanowires contacts at least two metal oxide nanosheets of the plurality of metal oxide nanosheets, andwherein the plurality of metal oxide nanosheets includes an electrical connection between contacting metal oxide nanosheets.

Owner:SAMSUNG ELECTRONICS CO LTD

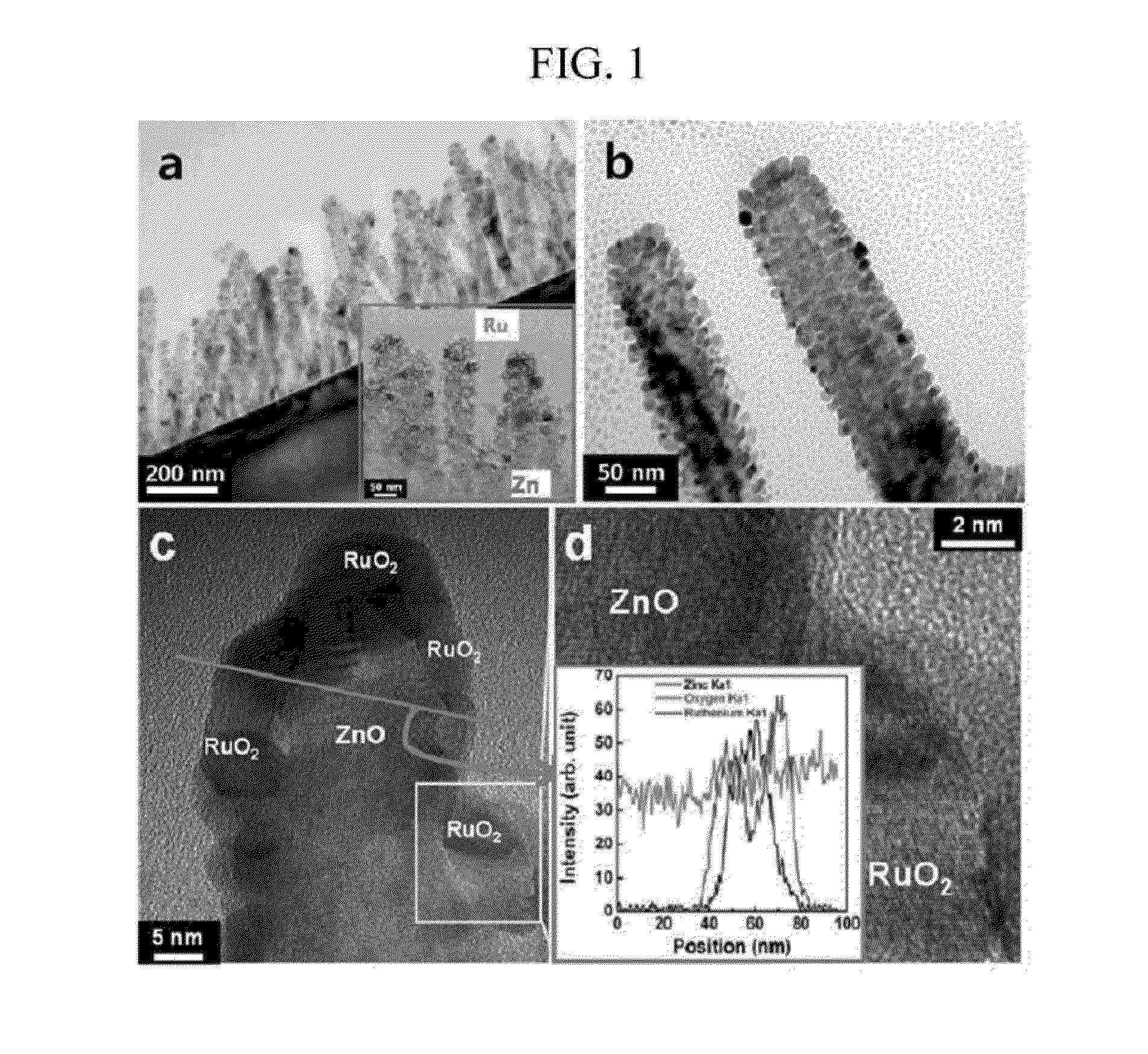

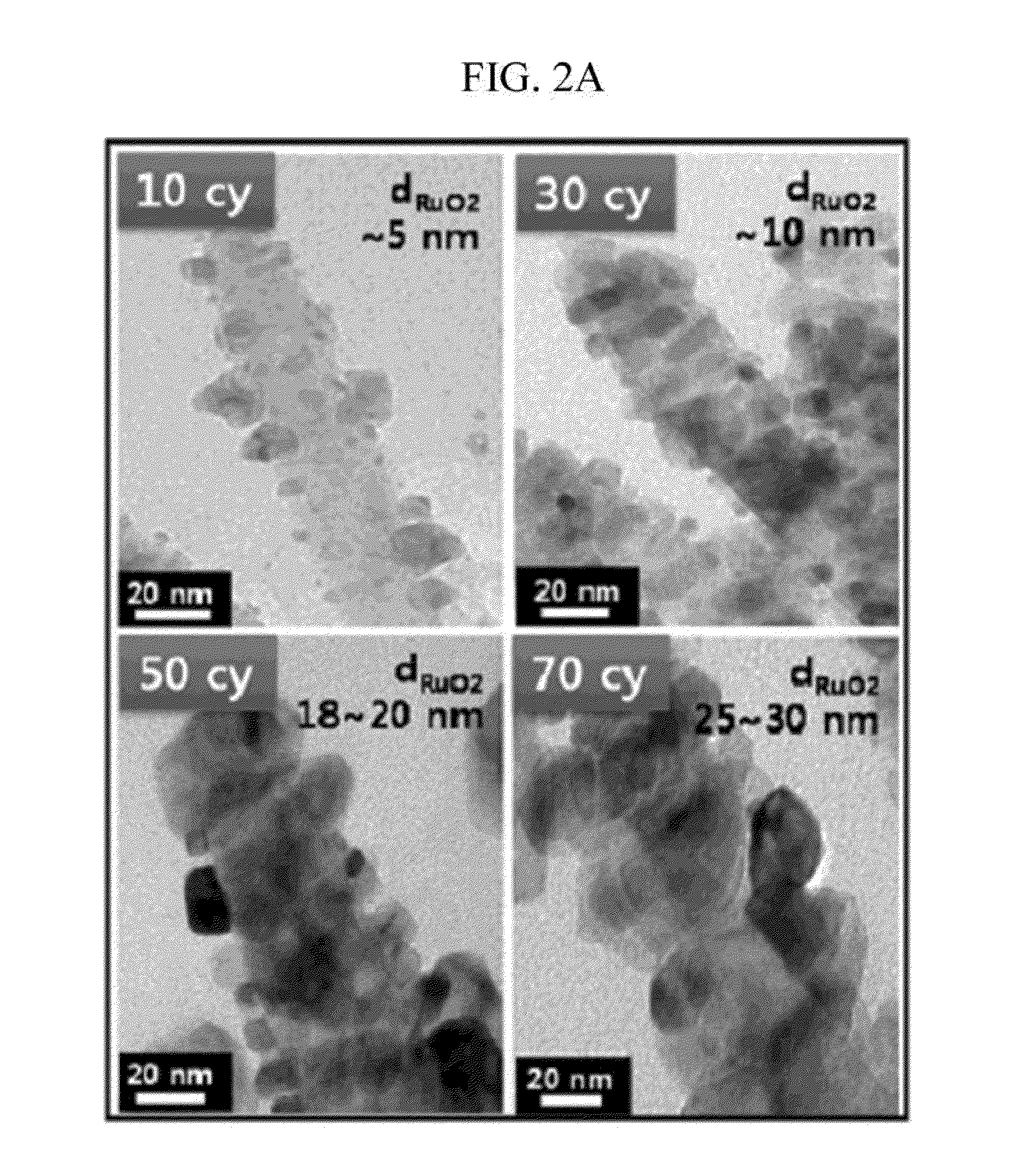

Nanorod and method of manufacturing the same

InactiveUS20140291569A1Improve electricityGood chemical propertiesPigmenting treatmentPiezoelectric/electrostrictive device manufacture/assemblyNanoparticleMaterials science

Owner:INTELLECTUAL DISCOVERY CO LTD

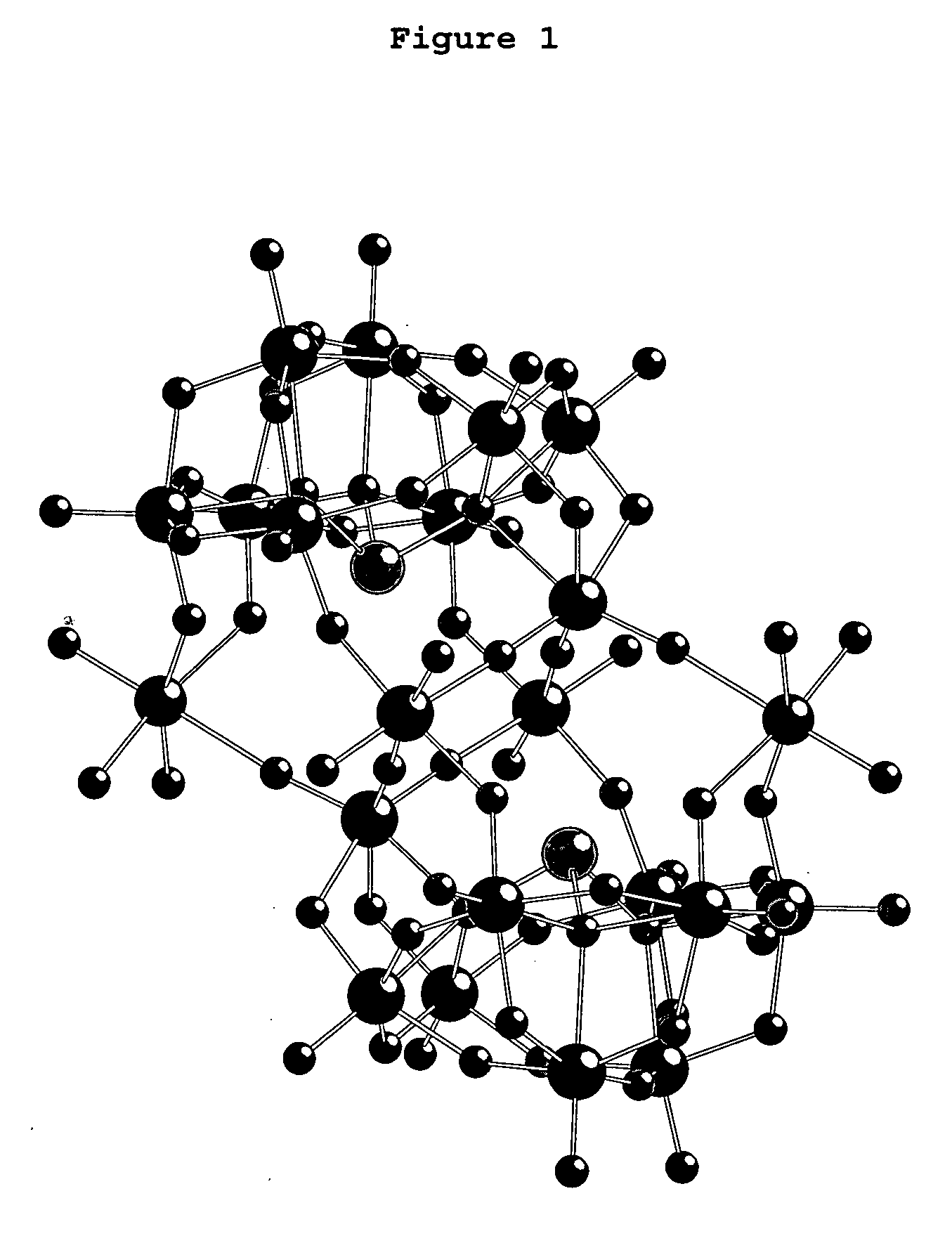

A class of metal oxide materials with special microstructure, and preparation method thereof

ActiveCN110092414ARich varietyMaterial nanotechnologyRuthenium/rhodium/palladium/osmium/iridium/platinum oxides/hydroxidesIndiumNew energy

The invention relates to a class of metal oxide materials with a special microstructure, and a preparation method thereof, and belongs to the field of materials. A purpose of the present invention isto solve the problem of large-scale and low-cost production of high-performance metal oxides for energy storage and catalysis. According to the present invention, a multi-component metal oxide AxMyOz(A represents one or a plurality of elements selected from elements with strong metallicity, M represents one or a plurality of elements selected from transition metal elements or germanium, antimony,indium and other elements with weak metallicity, and O represents oxygen) is used as a raw material, and is subjected to A site element removing through etching with an acidic solution (an aqueous solution or organic solution with a pH value of less than 7) to prepare the metal oxide material, wherein a variety of microstructures such as an amorphous porous material, a mono-dispersed nano-crystalmaterial, a self-assembled nanometer hairball-like material, a porous nano-crystal material, a hollow material, a core-shell structure material and the like can be obtained by controlling experimental conditions. According to the present invention, the method is simple and effective, and does not require complicated post-treatment process, and the product can be widely used in the fields of industrial reaction catalysts or catalyst carriers and new energy.

Owner:PEKING UNIV

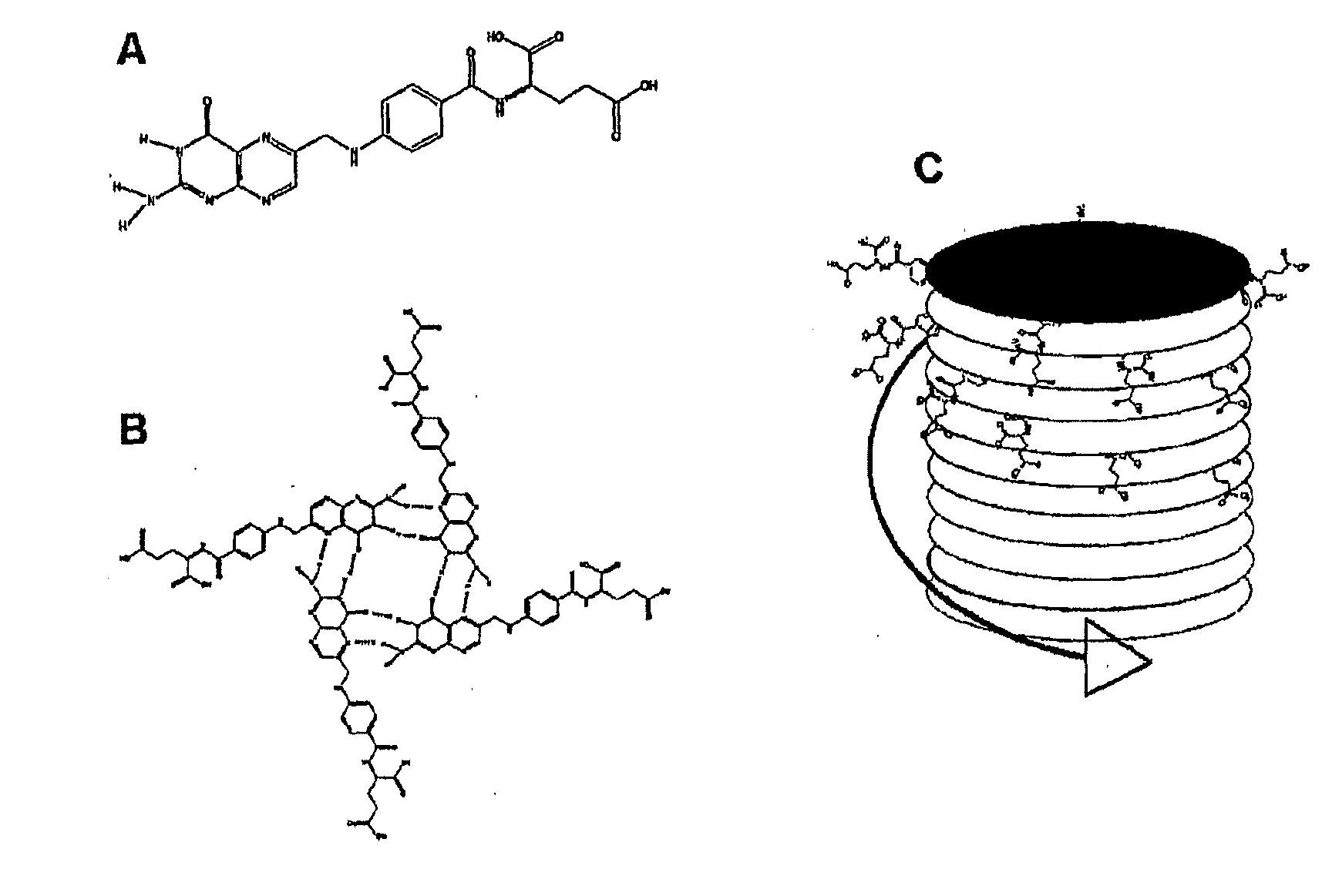

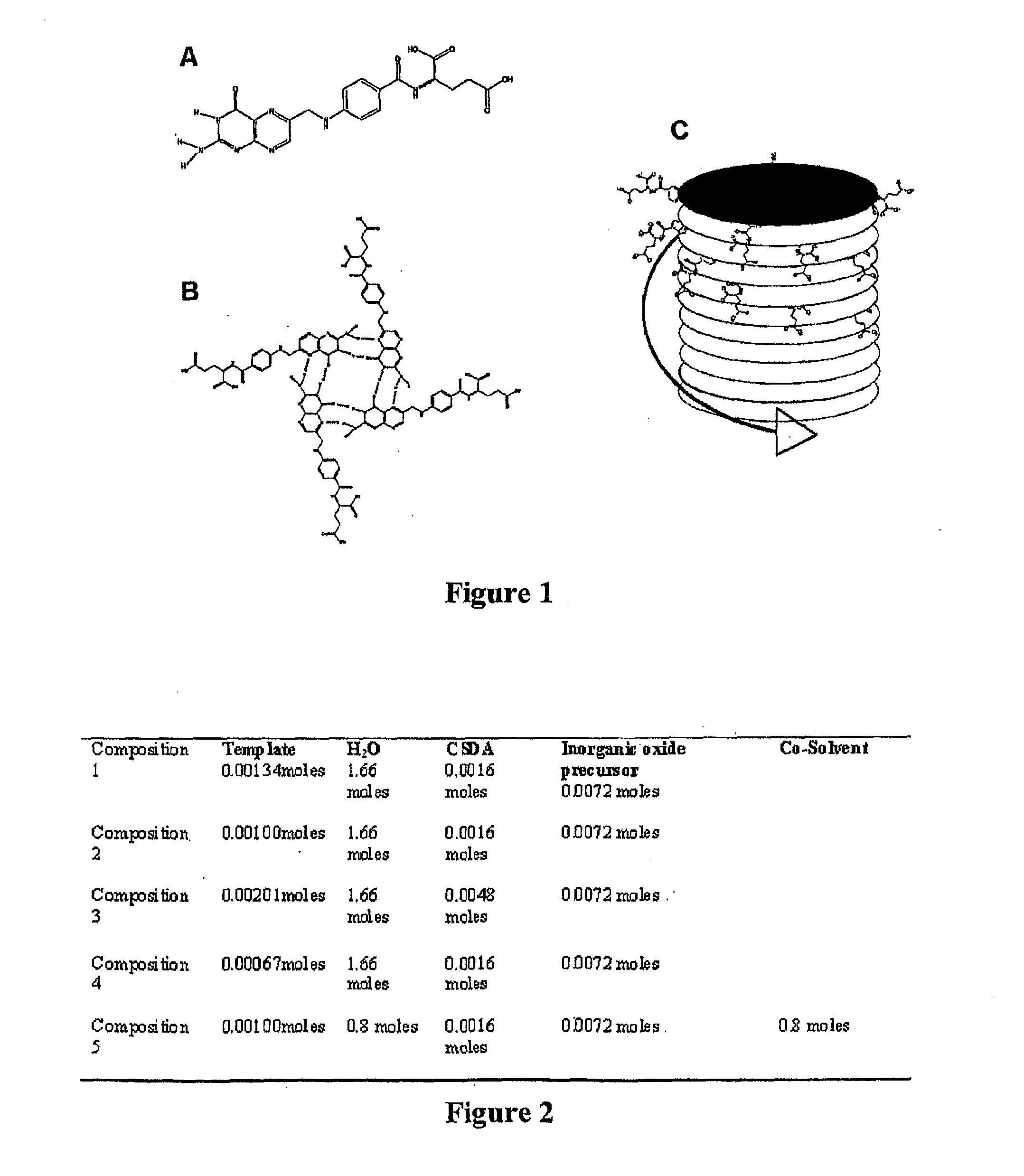

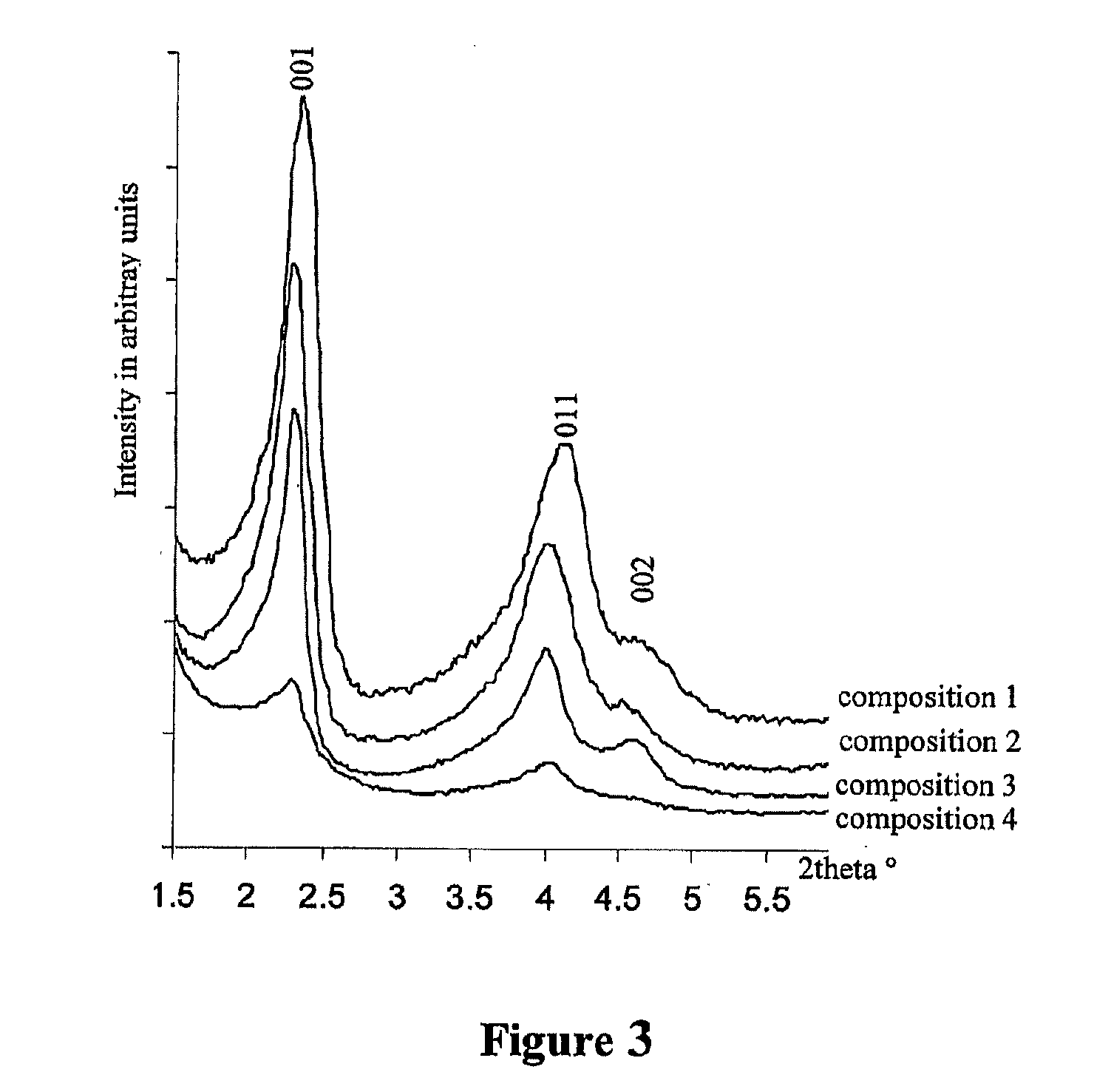

Method for manufacturing mesoporous materials, materials so produced and use of mesoporous materials

InactiveUS20100310539A1Organic active ingredientsPeptide/protein ingredientsMesoporous materialControl drugs

The present invention relates to a new synthetise for the preparation of mesoporous structures including mesoporous materials with chiral morphologies and mesoporous materials with local or surface chirality. The method can be used for manufacturing controlled drug delivery devices, for example for delivery of folic acid, and fluorescent particles.

Owner:NANOLOGICA AB

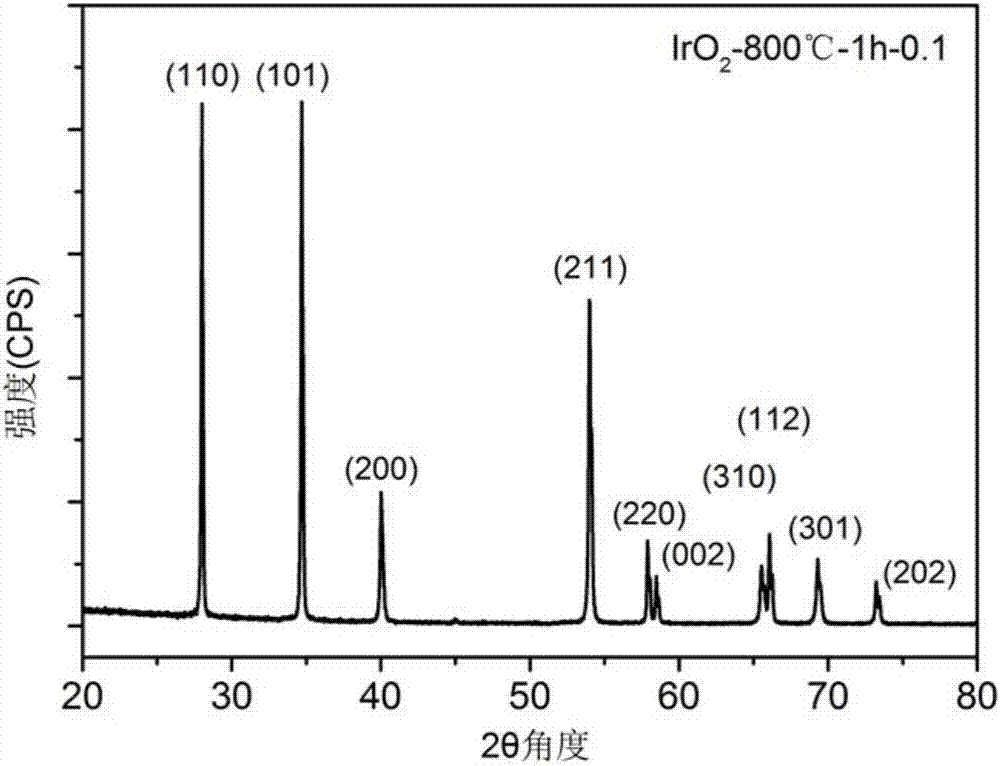

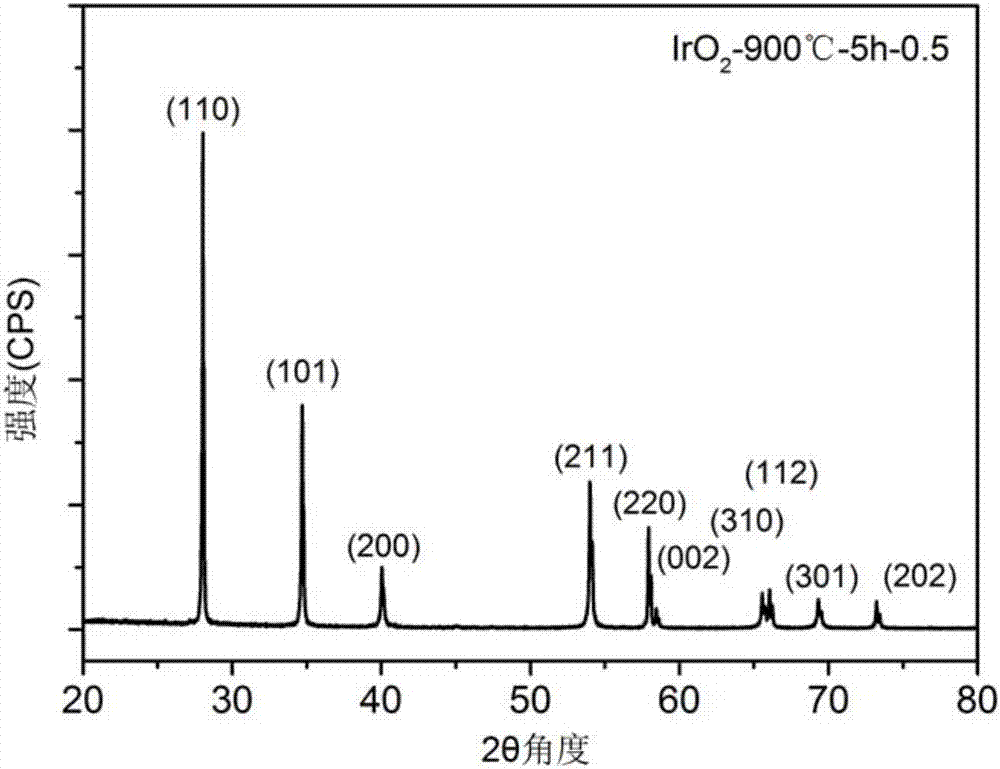

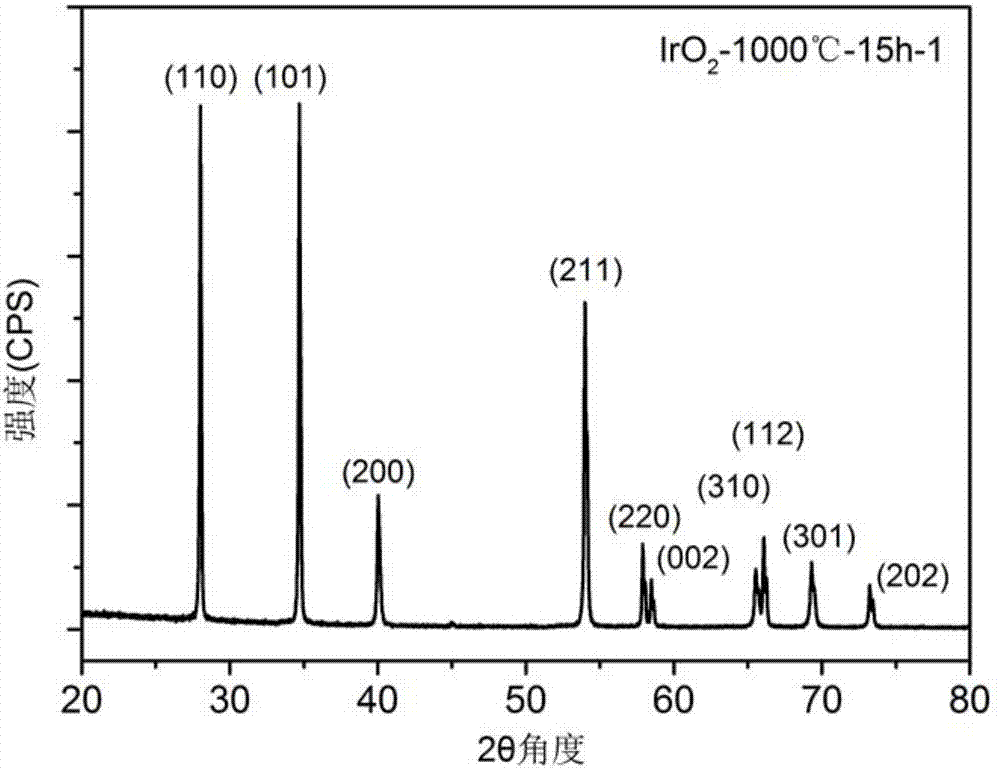

Preparation method of high-purity iridium dioxide

ActiveCN107226488AReduce manufacturing costReduce processing difficultyRuthenium/rhodium/palladium/osmium/iridium/platinum oxides/hydroxidesIridiumSynthesis methods

The invention discloses a preparation method of high-purity iridium dioxide. The method comprises the following steps: (1) mixing elemental iridium powder with copper oxide powder to obtain mixed powder; (2) calcining the mixed powder prepared in the step (1) at 800-1000 DEG C; (3) performing acid washing on the calcined powder in the step (2) to remove the copper oxide, thereby obtaining an IrO2 precipitate; and (4) washing the IrO2 precipitate prepared in the step (3), and performing drying to obtain the target product iridium dioxide. The method disclosed by the invention can eliminate the defects in the existing synthesis method that the IrO2 is difficult to acquire, the preparation process is complicated and complex, the cost is high and the IrO2 purity is low, and greatly lowers energy consumption during synthesis. Besides, the method is simple in process and favorable in repetitiveness; and used chemical reagents are low in price and accessible.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

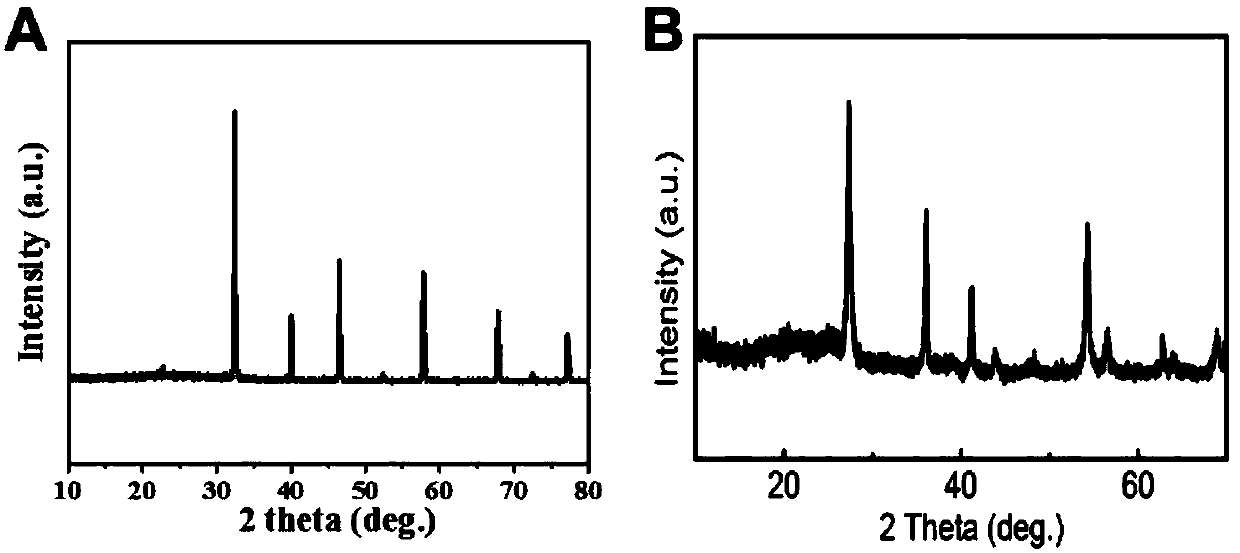

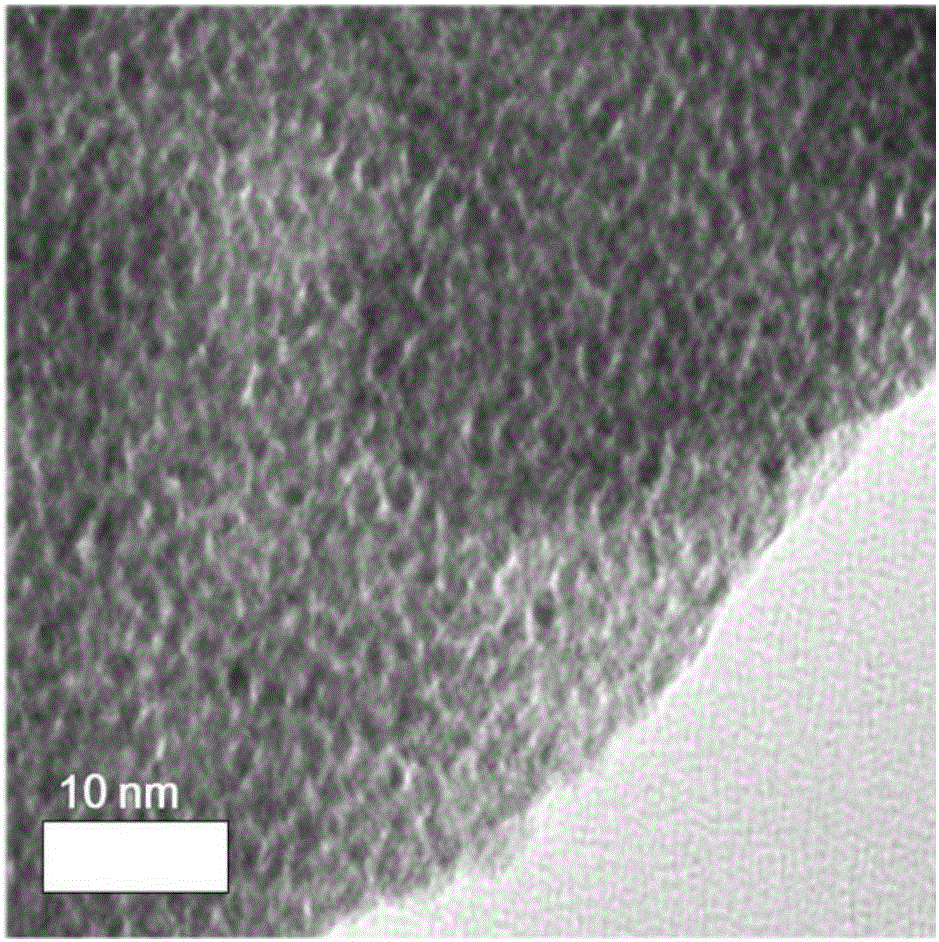

Preparation method of RuO2 material with ordered porous structure

InactiveCN104538204ALarge specific surface areaAperture size adjustableRuthenium/rhodium/palladium/osmium/iridium/platinum oxides/hydroxidesHybrid capacitor electrodesEvaporationSalt solution

The invention relates to a preparation method of a RuO2 material with an ordered porous structure. A SiO2 nanosphere with the length of 10 to 300 nm is placed in water in a static state for evaporation induced self-assembly to form a block body with an ordered and close packing structure; after annealing with the temperature of 600 to 1000 DEG C in air, a hard template is formed; the hard template is placed in a culture dish and a soluble Ru salt solution is added; annealing is carried out with the temperature of 300 to 600 DEG C in air; gaps in the template are filled with RuO2 and multi-times repeated filling is carried out; and the SiO2 template is removed by an HF or NaOH solution and deionized water is used for cleaning and drying, thereby obtaining an ordered porous RuO2 material.

Owner:NANJING UNIV

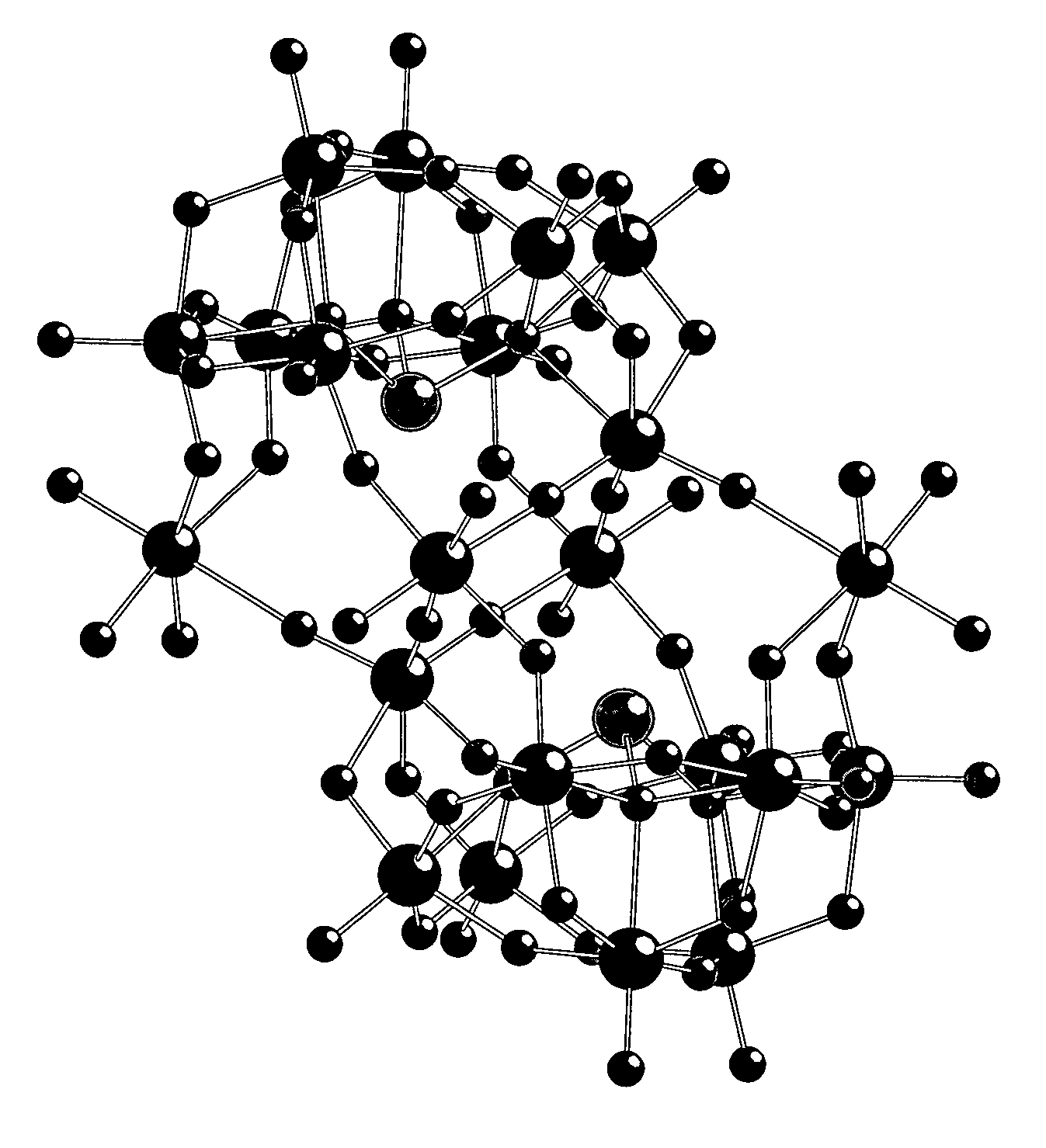

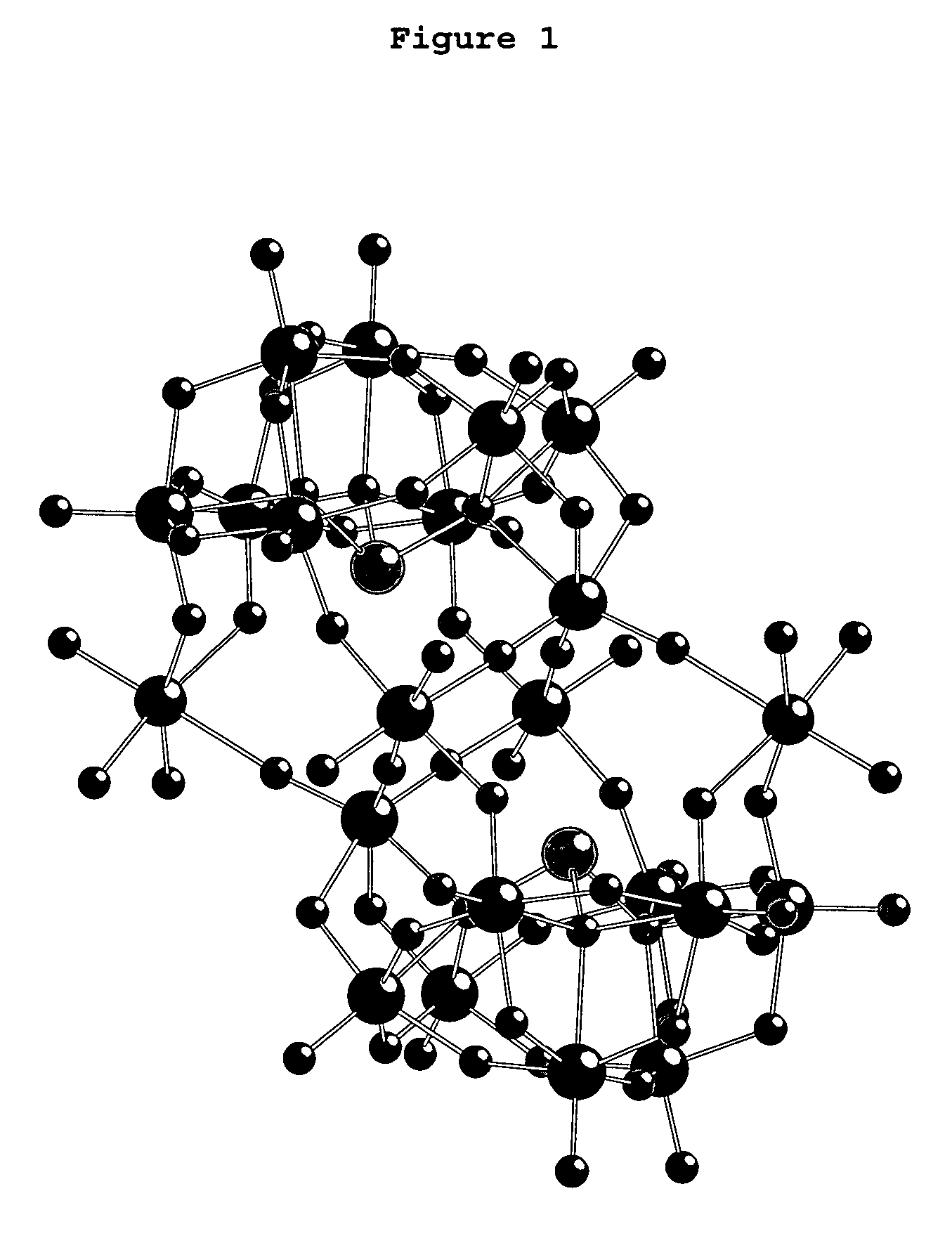

Novel Ru-substituted polyoxometalates and process for their preparation

InactiveUS20070282140A1Group 3/13 element organic compoundsOxygen/ozone/oxide/hydroxideHeteroatomCatalytic oxidation

The invention relates to polyoxometalates represented by the formula (An)m+[R2(H2O)6X2W20O70]m− or solvates thereof, wherein A represents a cation, n is the number of the cations, m is the charge of the polyoxoanion, and X represents a heteroatom selected from SbIII, BiIII, AsIII, SeIV and TeIV, a process for their preparation and their use for the catalytic oxidation of organic molecules.

Owner:EXXONMOBIL CHEM PAT INC

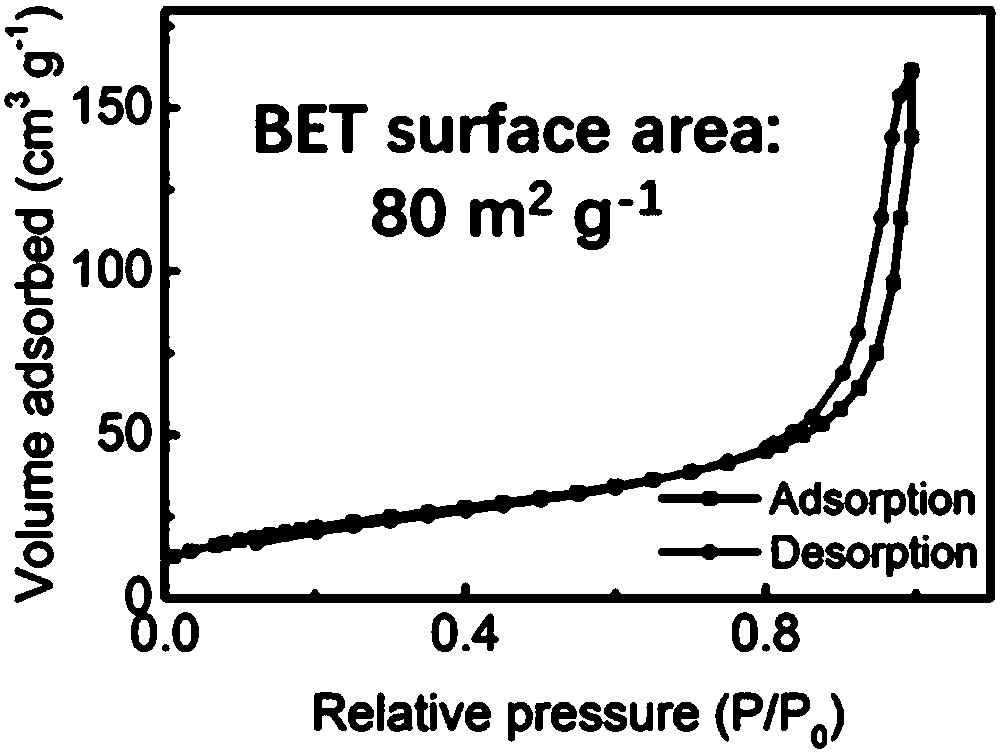

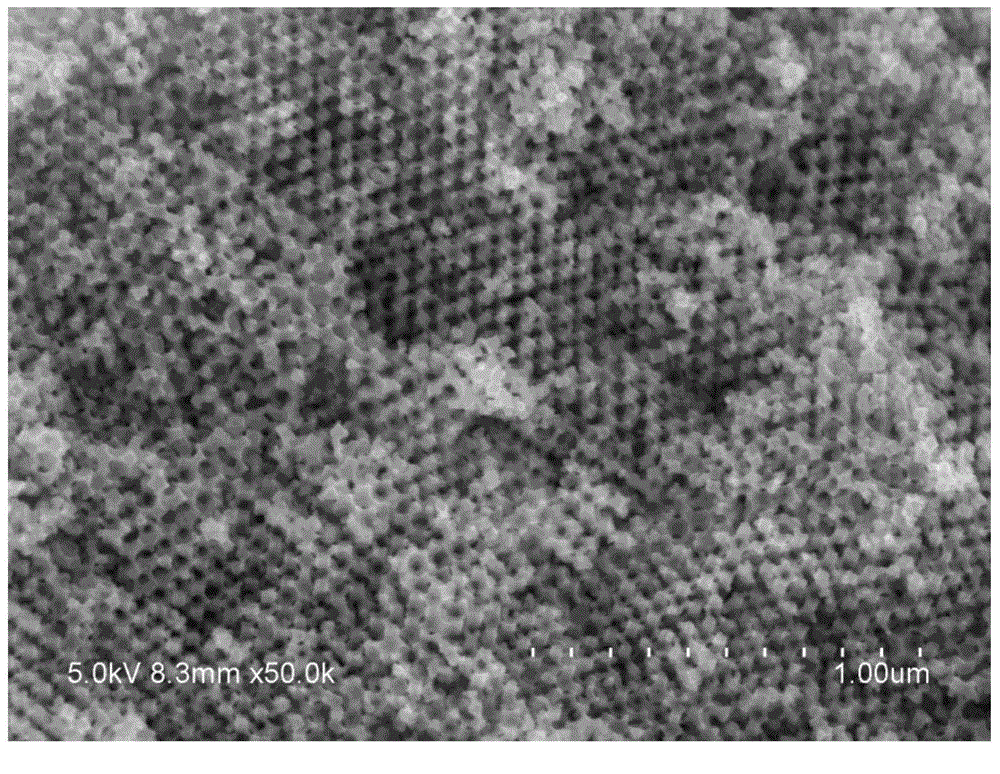

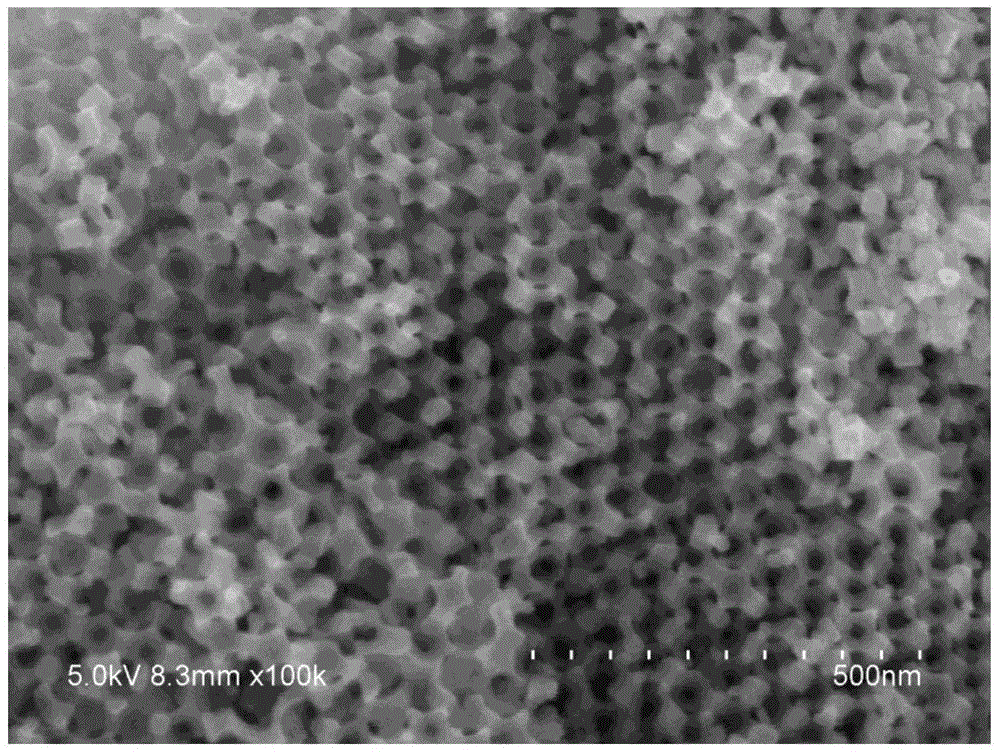

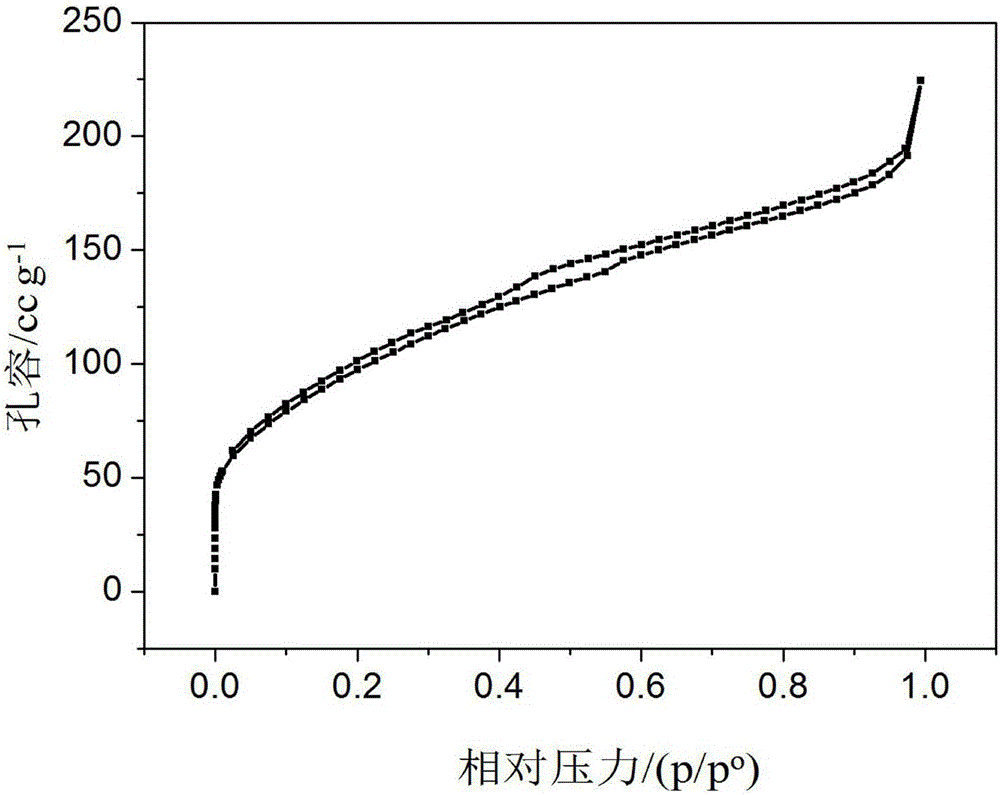

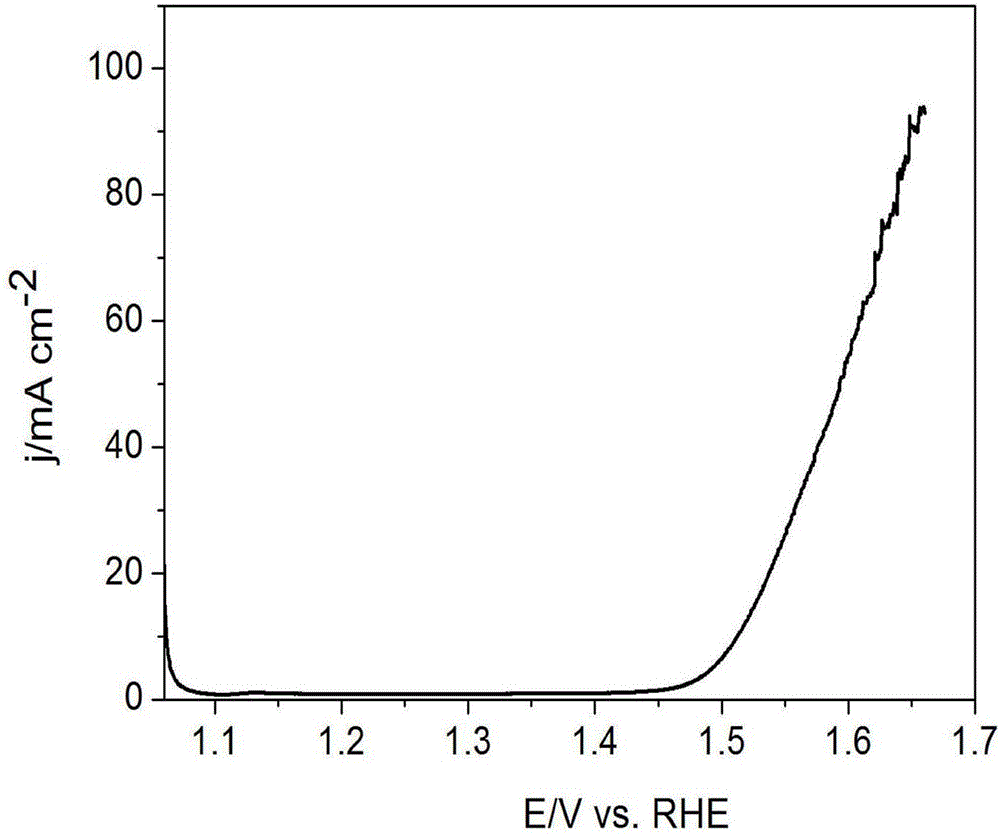

Porous IrO2 oxygen evolution catalyst with super-high specific surface area and preparation method of porous IrO2 oxygen evolution catalyst

ActiveCN106111130ALarge specific surface areaPromote formationElectrolysis componentsRuthenium/rhodium/palladium/osmium/iridium/platinum oxides/hydroxidesOxygenSolvent

The invention provides a porous IrO2 oxygen evolution catalyst with a super-high specific surface area and a preparation method of the porous IrO2 oxygen evolution catalyst, and relates to the field of electrochemistry. The method comprises the following steps: firstly, a H2IrCl6.6H2O precursor is added to deionized water, and a first solution is obtained; then NH3.H2O is added to the first solution for a reaction, and a second solution is obtained; NaNO3 is added to the second solution for a reaction, and a third solution is obtained; finally, a solvent in the third solution is evaporated to dryness, a product is ignited in the air, and the IrO2 oxygen evolution catalyst is obtained. The invention further provides the IrO2 oxygen evolution catalyst prepared with the method. The IrO2 oxygen evolution catalyst has a porous structure and the super-high specific surface area and shows excellent oxygen evolution catalytic performance.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

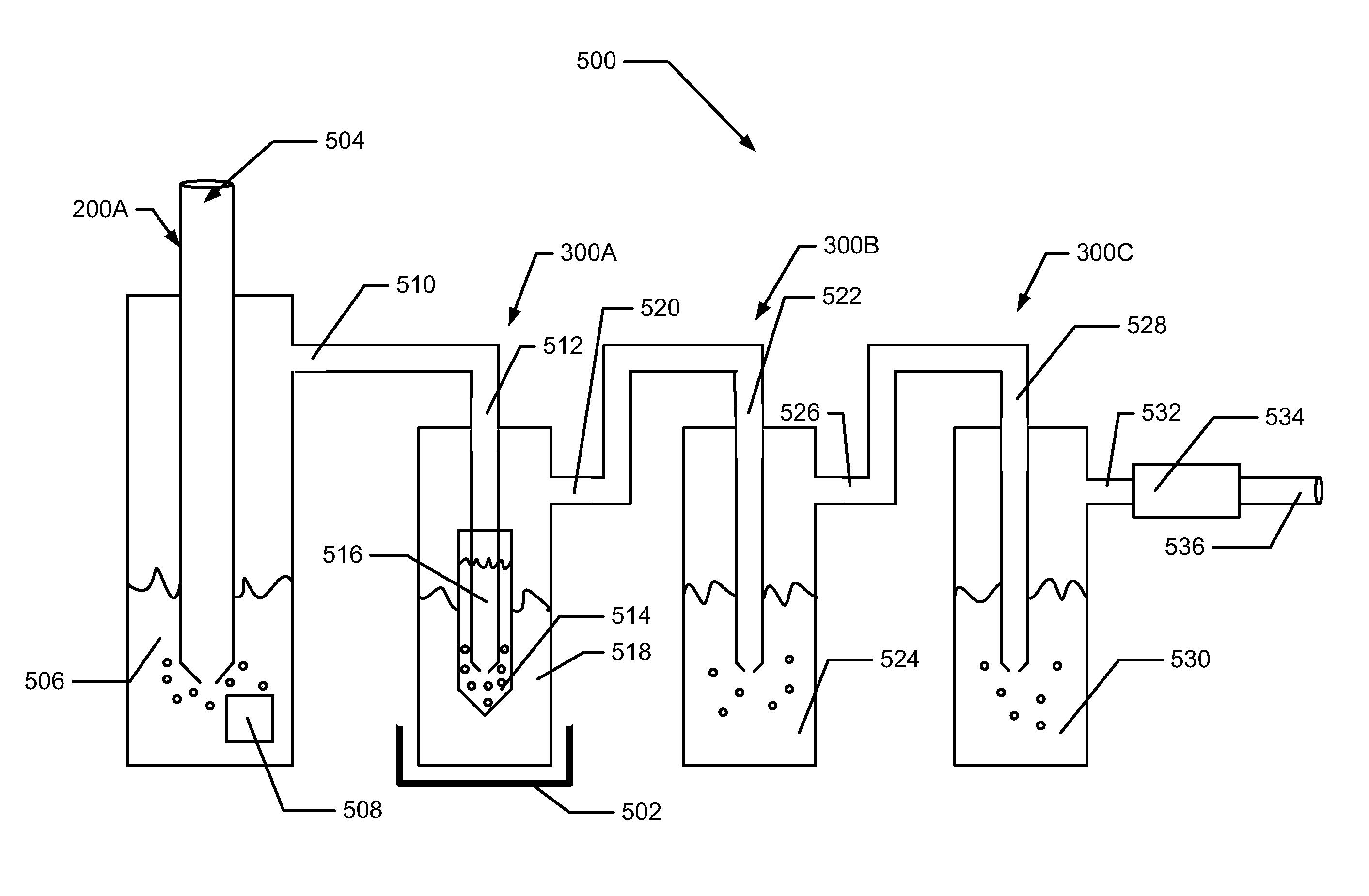

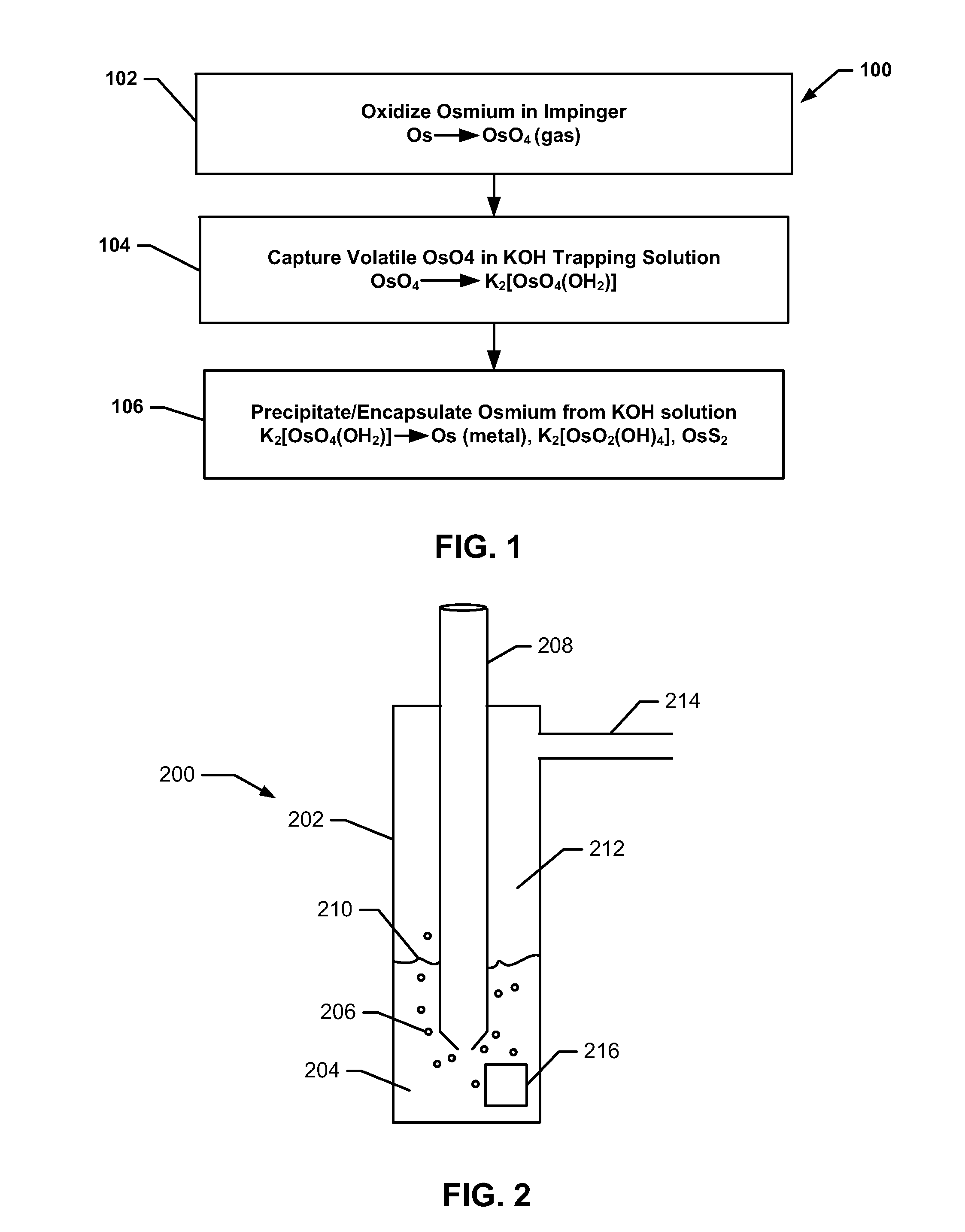

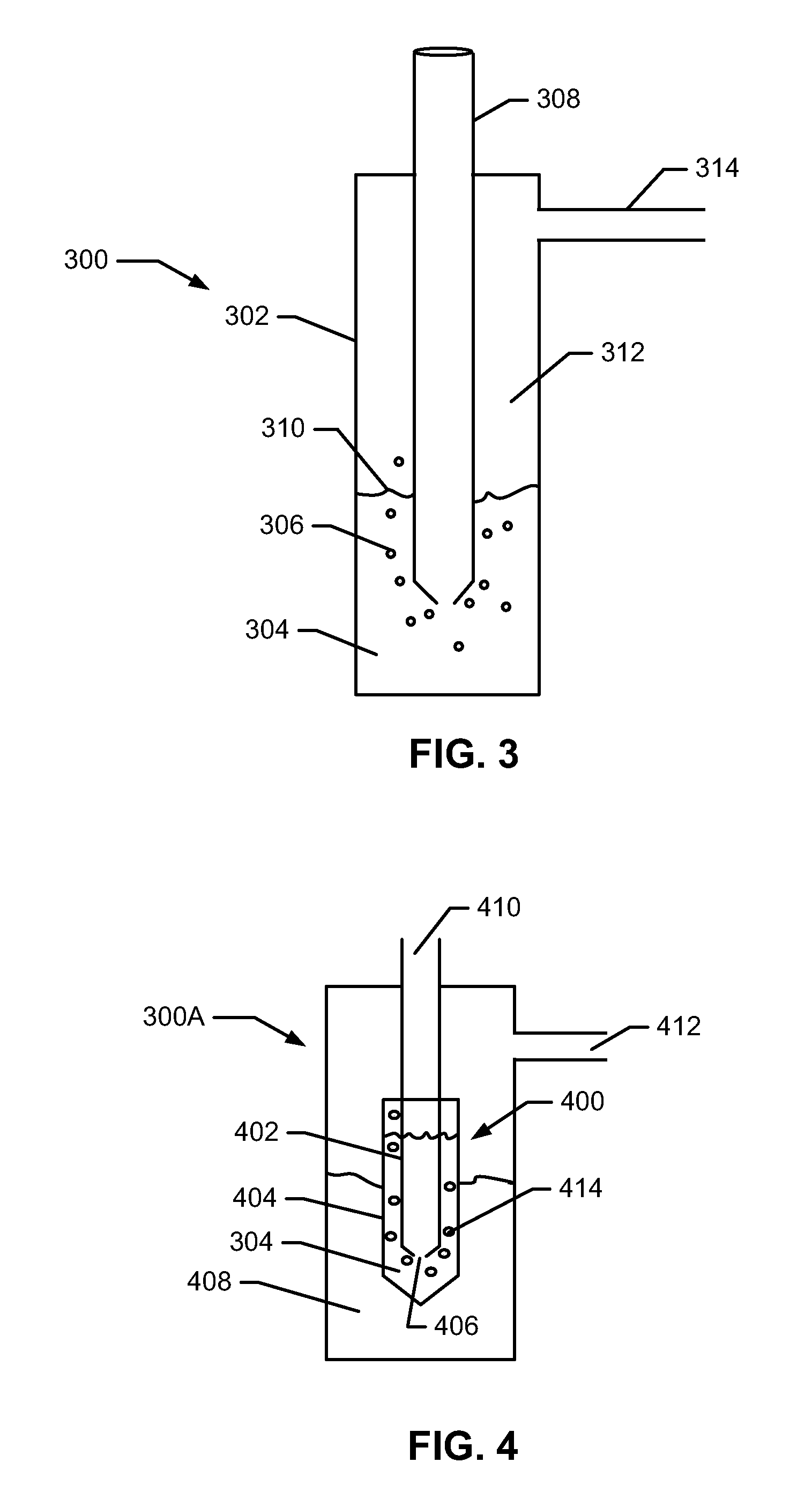

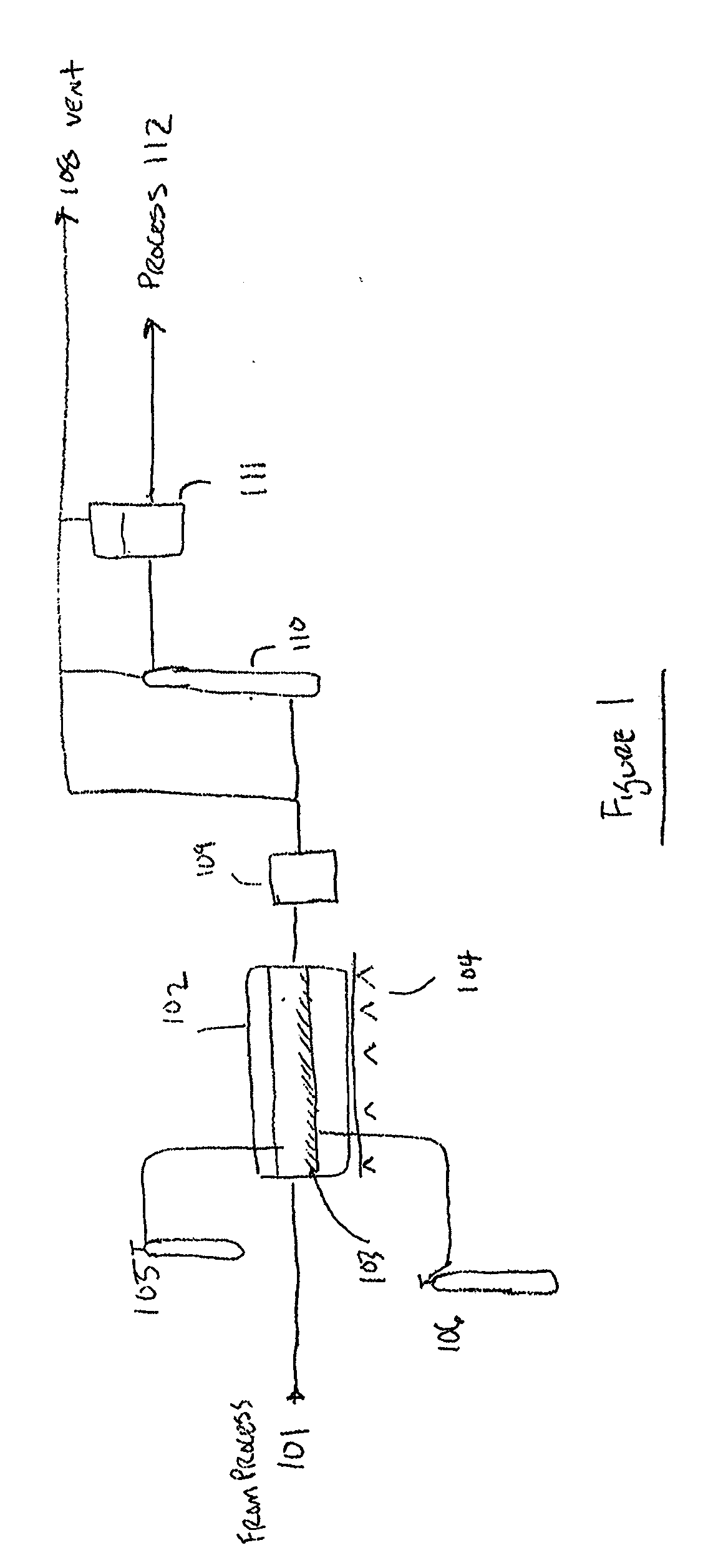

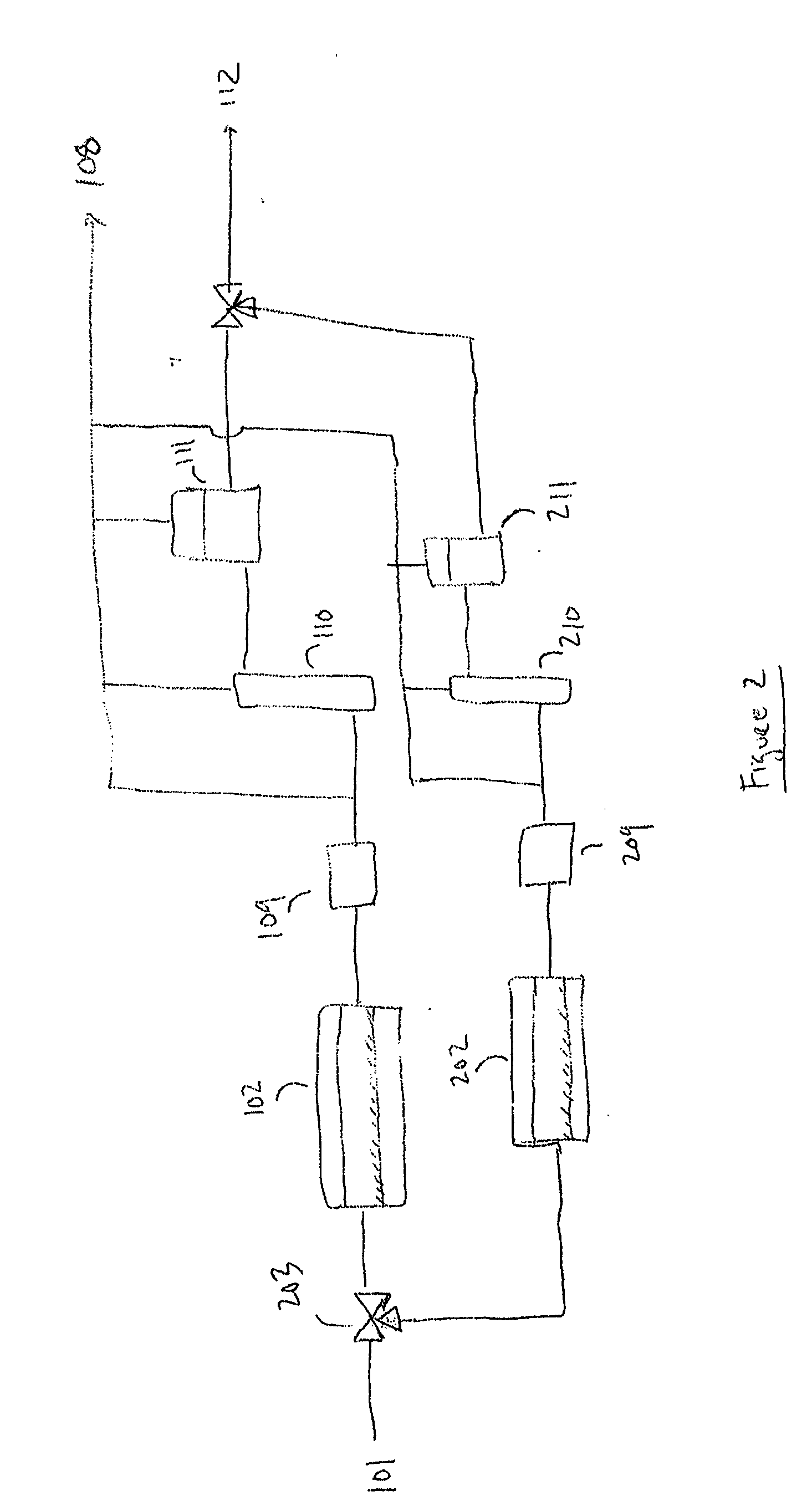

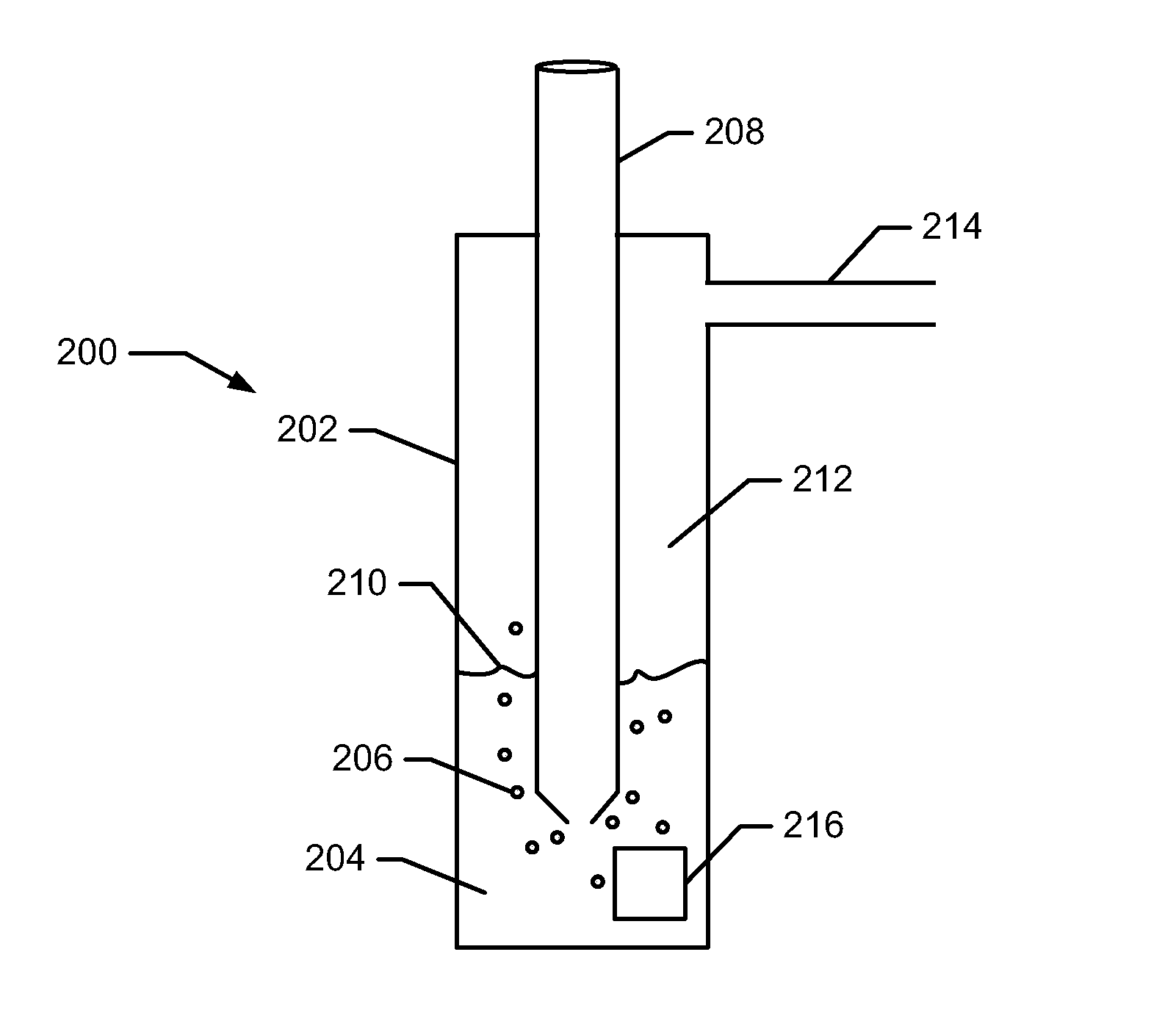

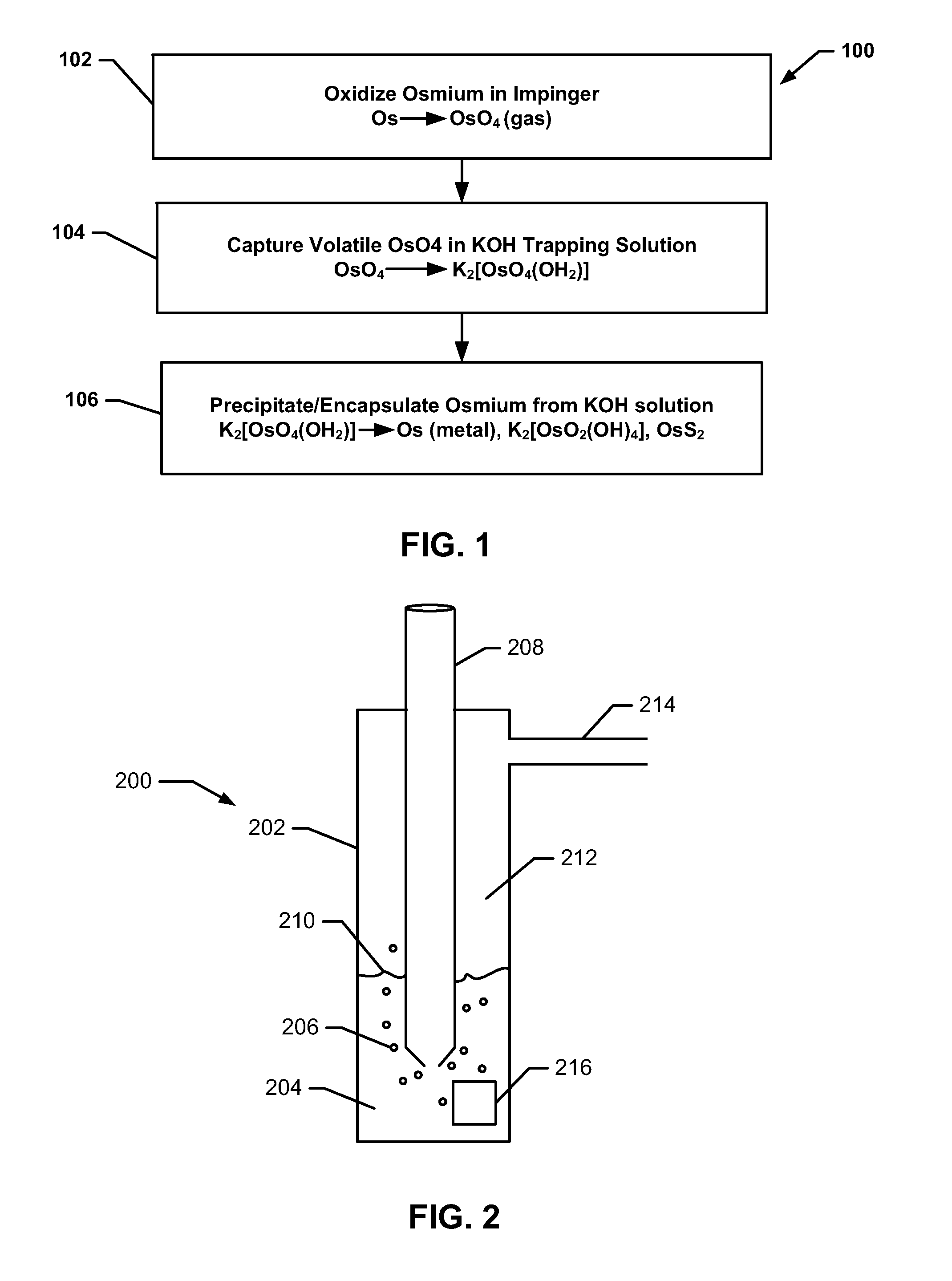

Method for separation of chemically pure os from metal mixtures

InactiveUS20130108525A1Minimize exposurePossibility is limitedSpecific isotope recoveryFrom normal temperature solutionsMetalOsmium

Owner:UNIVERSITY OF MISSOURI

Noble metal oxide nanocomposite material and preparation method and use thereof

ActiveCN109179398AUniform particle sizeStable in natureCarbon compoundsRuthenium/rhodium/palladium/osmium/iridium/platinum oxides/hydroxidesPeroxidaseNanoparticle

The invention provides a noble metal oxide nanocomposite material and a preparation method and use thereof. The preparation method comprises: adding a noble metal into a solvent, carrying out ablationwith pulsed laser to obtain a nano-dispersion liquid containing a noble metal oxide, mixing the nano-dispersion liquid and a carrier dispersion liquid, standing the mixed solution, carrying out solid-liquid separation and then carrying out drying oxidization. The noble metal oxide nanoparticles are prepared through the pulsed laser ablation method. The nanoparticles have even particle sizes and the nanoparticles are compounded to form the nanocomposite material. The preparation method is simple and fast and is environmentally friendly and efficient. The nanocomposite material has peroxide mimic enzyme characters, can replace natural peroxidase and can be used in the fields of biological detection and clinical diagnosis.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Ru-substituted polyoxometalates and process for their preparation

InactiveUS7358380B2Group 3/13 element organic compoundsOxygen/ozone/oxide/hydroxideCatalytic oxidationHeteroatom

The invention relates to polyoxometalates represented by the formula (An)m+[R2(H2O)6X2W20O70]m− or solvates thereof, wherein A represents a cation, n is the number of the cations, m is the charge of the polyoxoanion, and X represents a heteroatom selected from SbIII, BiIII, AsIII, SeIV and TeIV, a process for their preparation and their use for the catalytic oxidation of organic molecules.

Owner:EXXONMOBIL CHEM PAT INC

Method for manufacturing metal oxide hollow nanoparticles and metal oxide hollow nanoparticles manufactured by the same

ActiveUS8052958B2Maintain good propertiesCopper oxides/halidesManganese oxides/hydroxidesNanoparticleGas phase

Owner:IUCF HYU (IND UNIV COOP FOUND HANYANG UNIV)

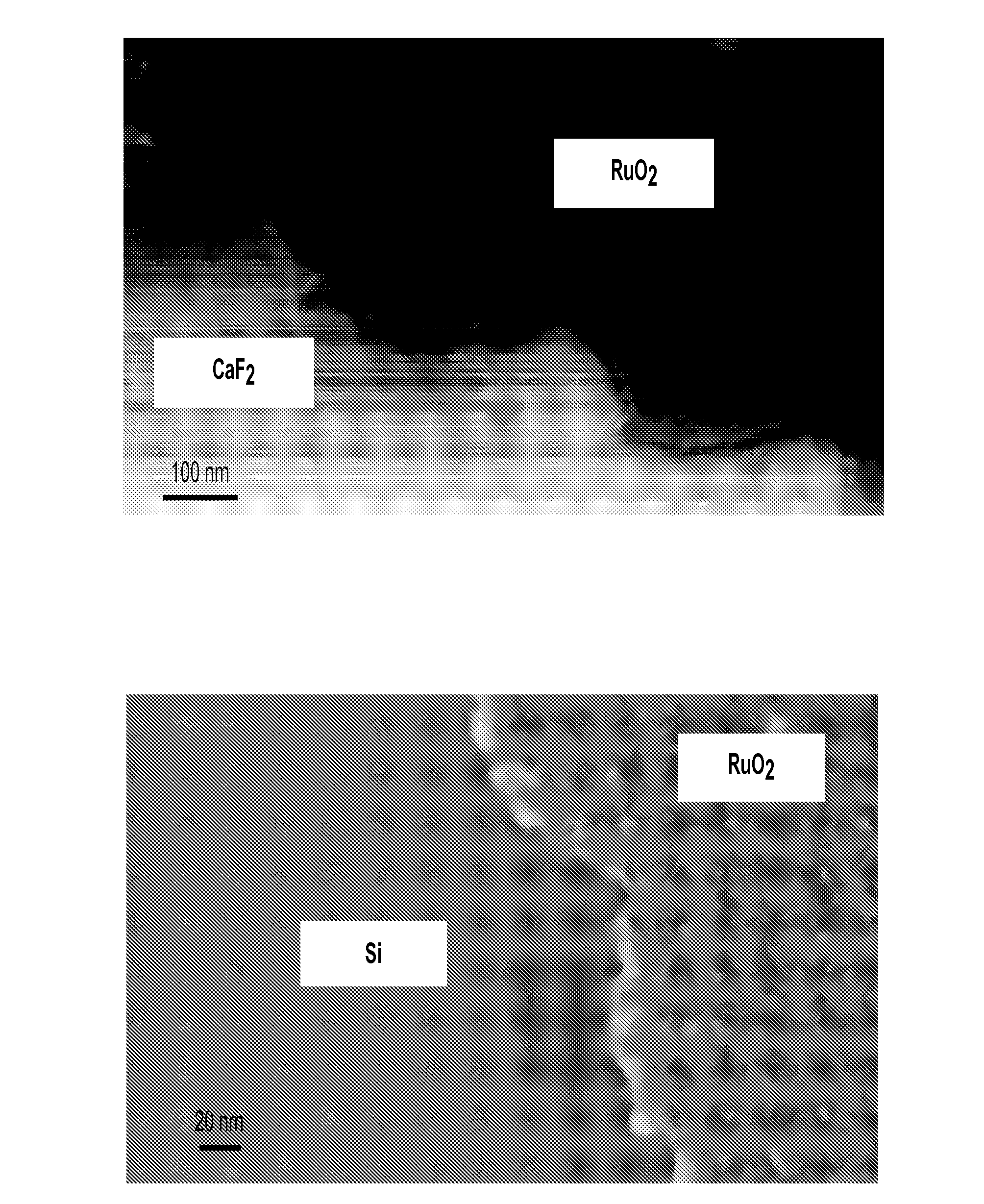

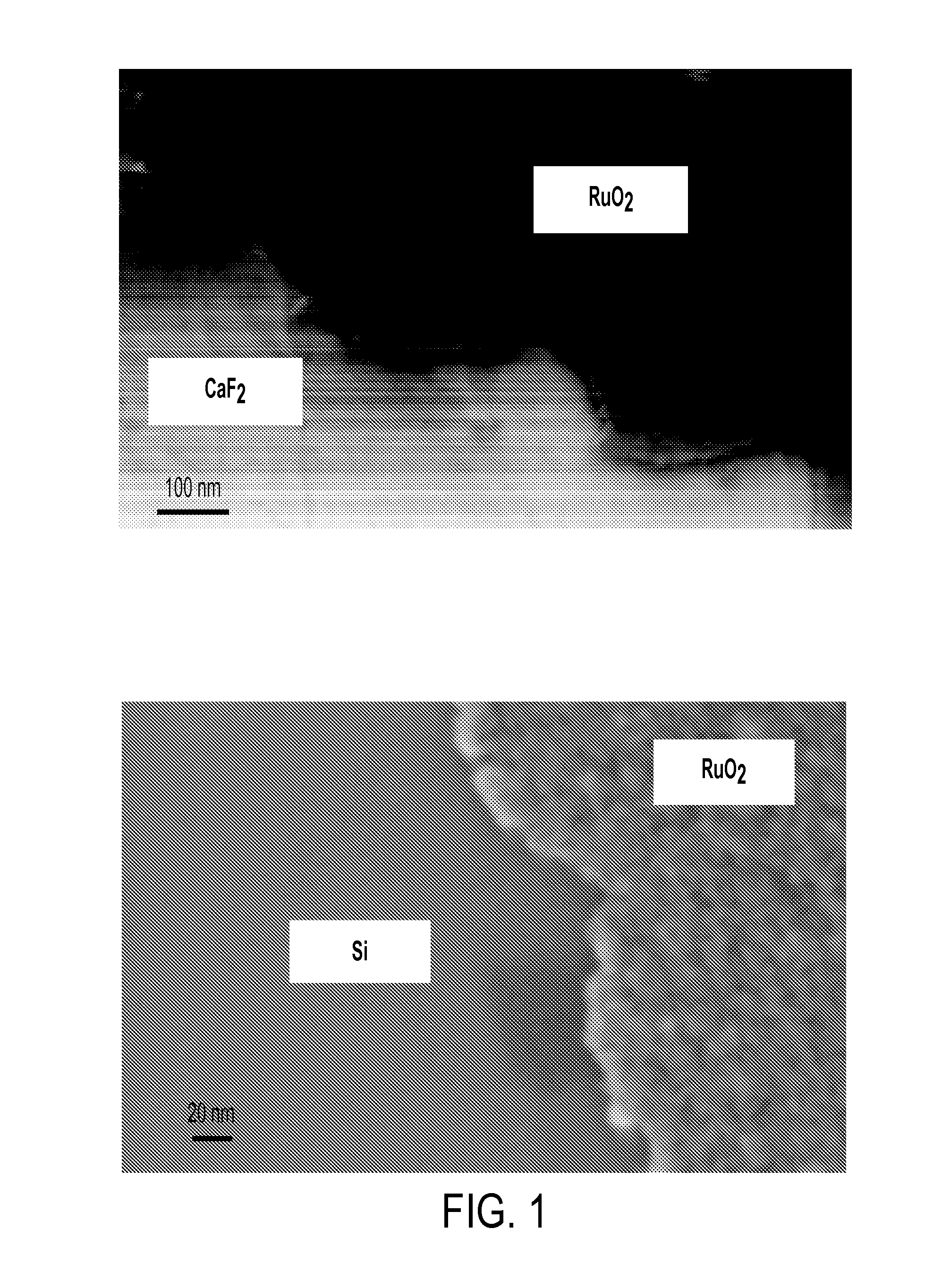

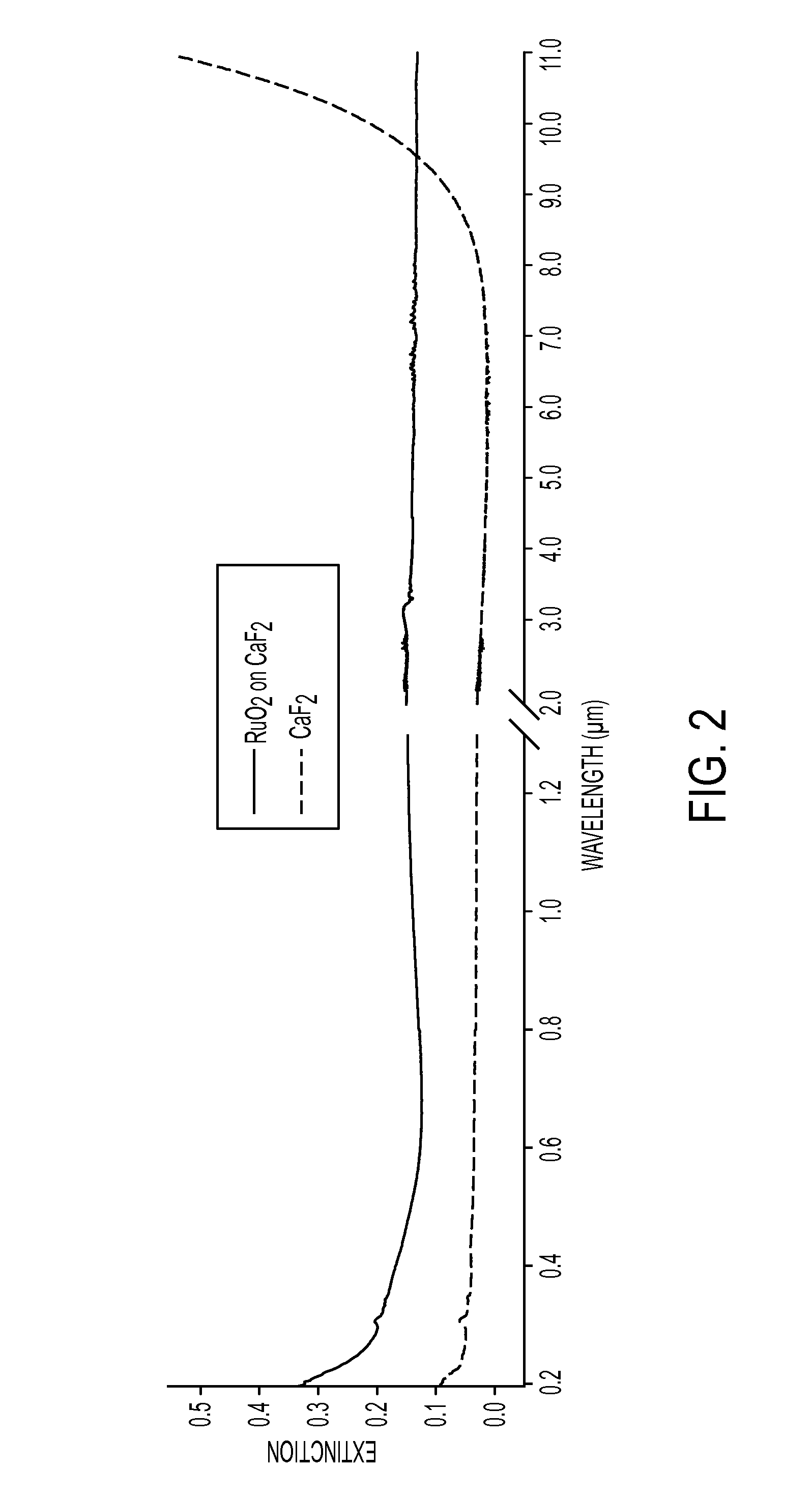

RuO2 Coatings

ActiveUS20110091723A1Material nanotechnologyOxide/hydroxide preparationNanoparticleMaterials science

Disclosed herein is an article having: a substrate and a RuO2 coating having nanoparticles of RuO2. Also disclosed herein is an article having: a substrate and a RuO2 coating. The coating is made by: immersing the substrate in a solution of RuO4 and a nonpolar solvent at a temperature that is below the temperature at which RuO4 decomposes to RuO2 and warming the substrate and solution to ambient temperature under ambient conditions to cause the formation of the coating.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

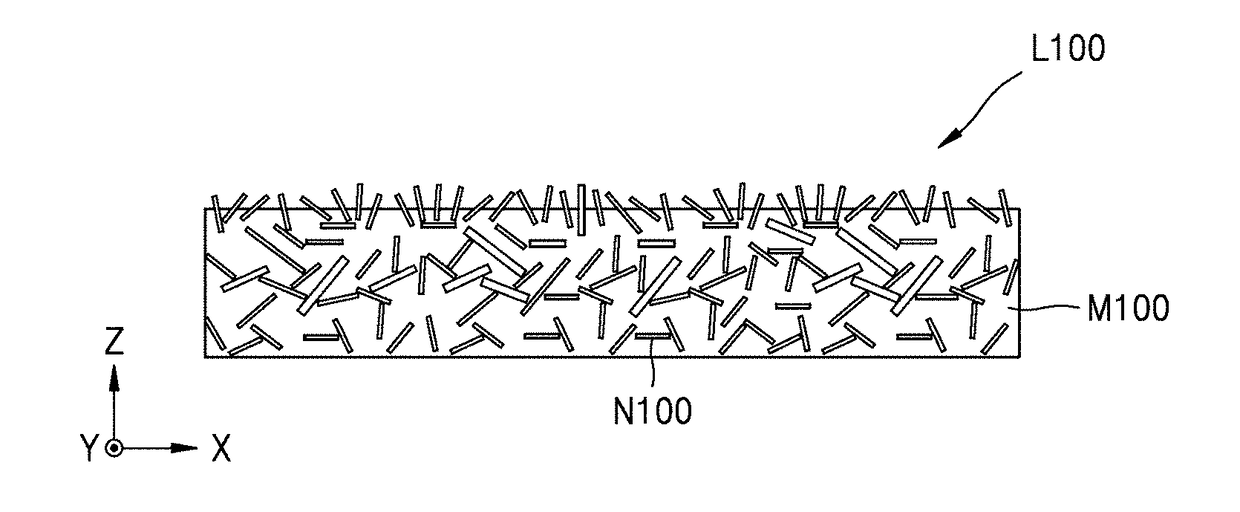

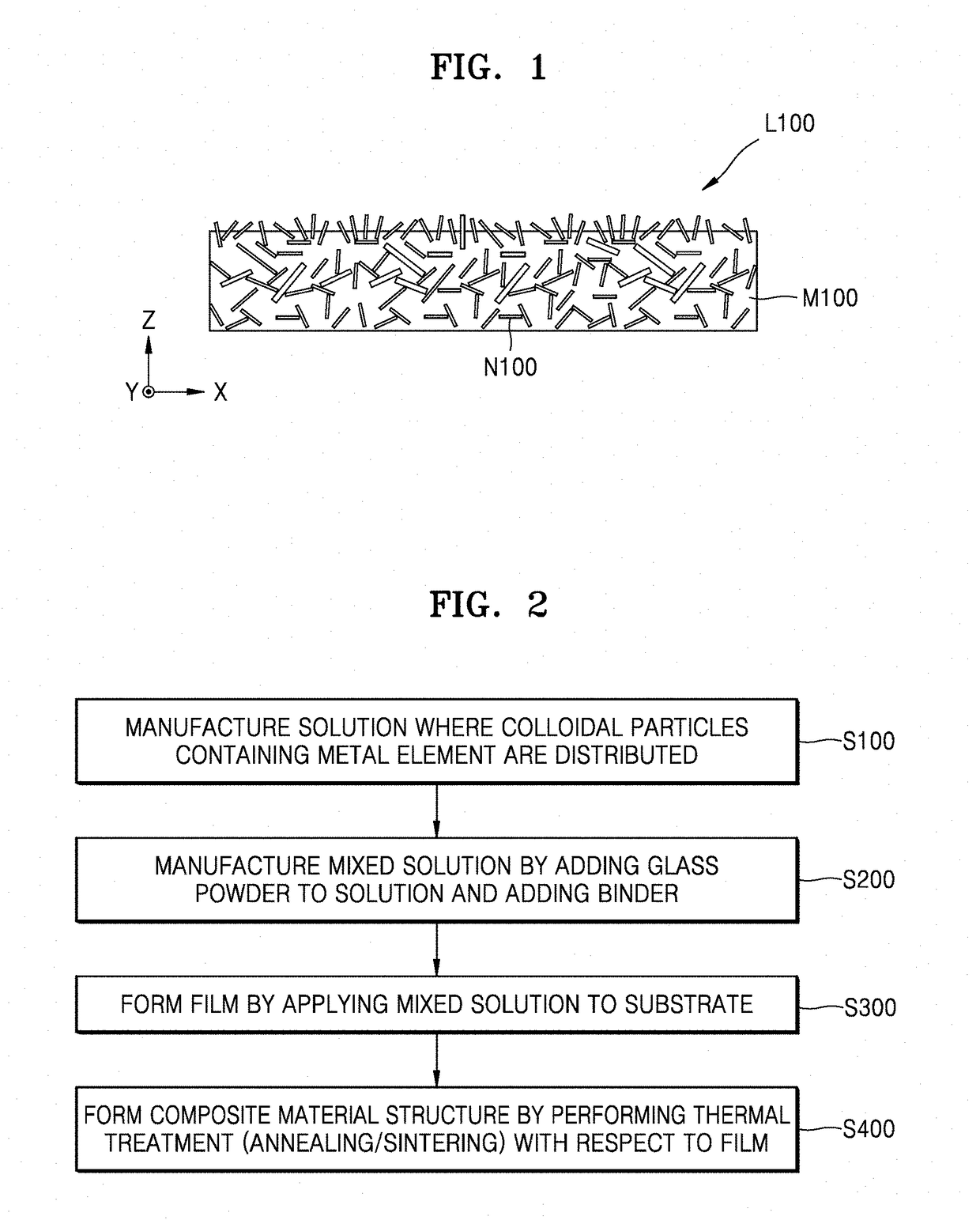

Composite material, method of forming the same, and apparatus including composite material

ActiveUS20180099487A1Good heat dissipationSimple methodMaterial nanotechnologyRuthenium/rhodium/palladium/osmium/iridium/platinum oxides/hydroxidesNanostructureElectrical resistivity and conductivity

A composite material structure including a matrix material layer; and a plurality of one-dimensional nanostructure distributed in the matrix material layer and having an electrical conductivity which is greater than an electrical conductivity of the matrix material layer, wherein the plurality of one-dimensional nanostructures includes a first one-dimensional nanostructure and a second one-dimensional nanostructure in contact with each other.

Owner:SAMSUNG ELECTRONICS CO LTD

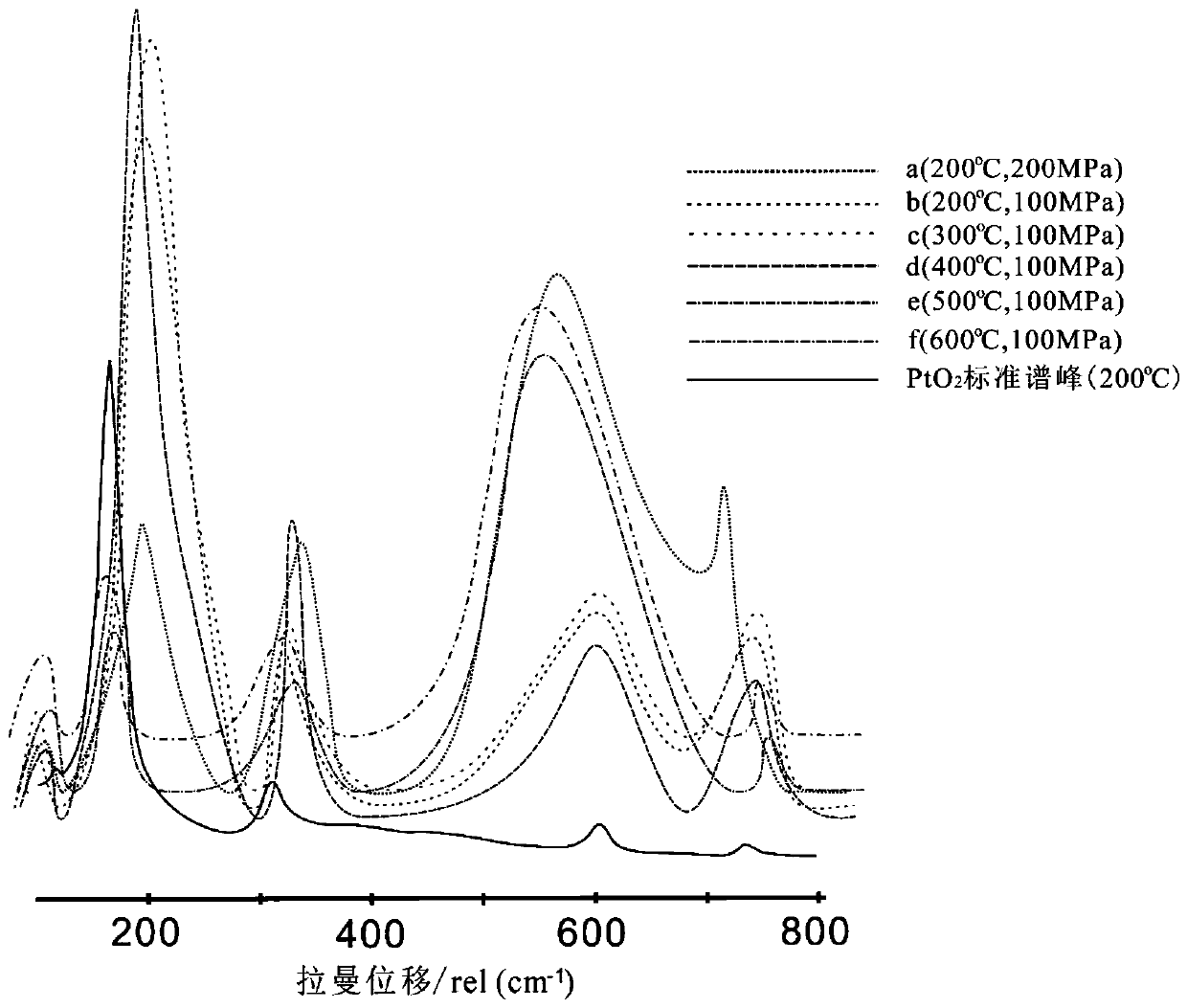

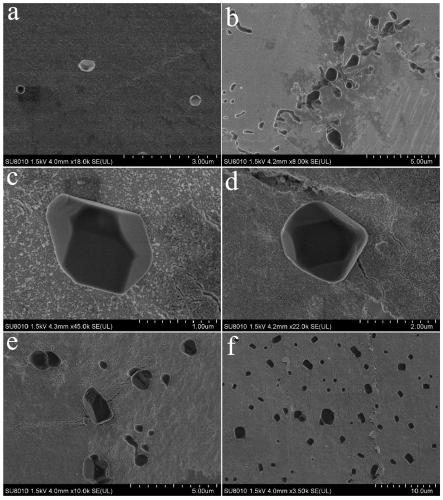

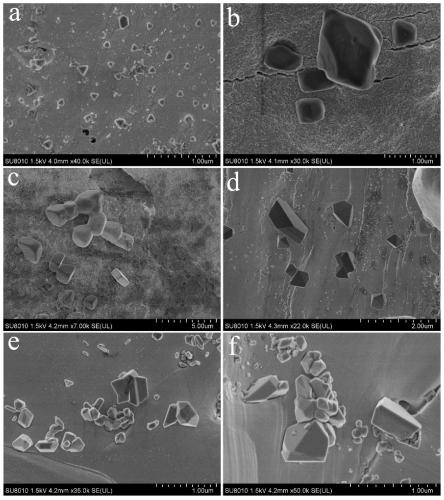

Method for preparing PtO2 conical nano granular material

ActiveCN110217835AEasy to operateGuaranteed tightnessRuthenium/rhodium/palladium/osmium/iridium/platinum oxides/hydroxidesNanotechnologyNanoparticlePotassium

The invention discloses a method for preparing a PtO2 conical nano granular material. The method comprises the following steps: preparing a potassium chloroplatinate diluted solution, putting the potassium chloroplatinate diluted solution into a metallic tube, sealing the metallic tube, putting the metallic tube into a hydrothermal reaction kettle, sealing the hydrothermal reaction kettle, and carrying out a self hydrolysis reaction under conditions of a set temperature and pressure, so as to obtain the PtO2 conical nano granular material, wherein the temperature is 200-600 DEG C, the pressureis 100-200Mpa, and the self hydrolysis reaction time is 1-48 hours. The method is easy in raw material obtaining, low in cost, precise and efficient in experiment process and low in energy consumption, and PtO2 conical nano granules prepared by using the method have particle sizes from tens to hundreds of nanometers, have irregular conical structures, and have complete crystal forms.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

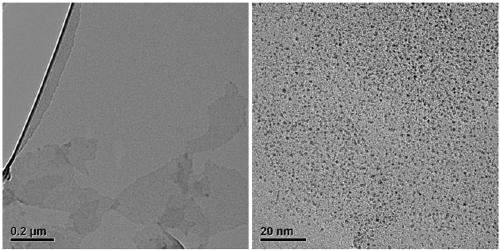

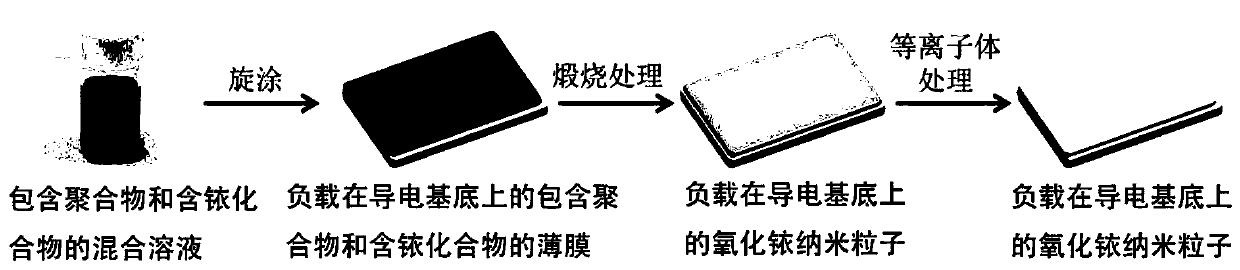

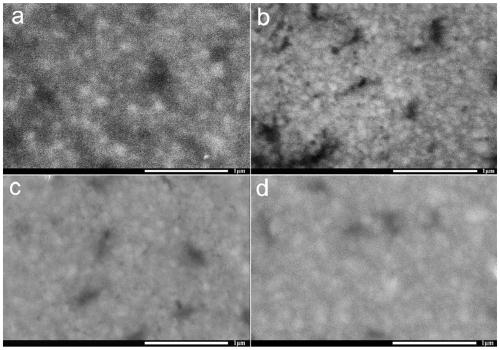

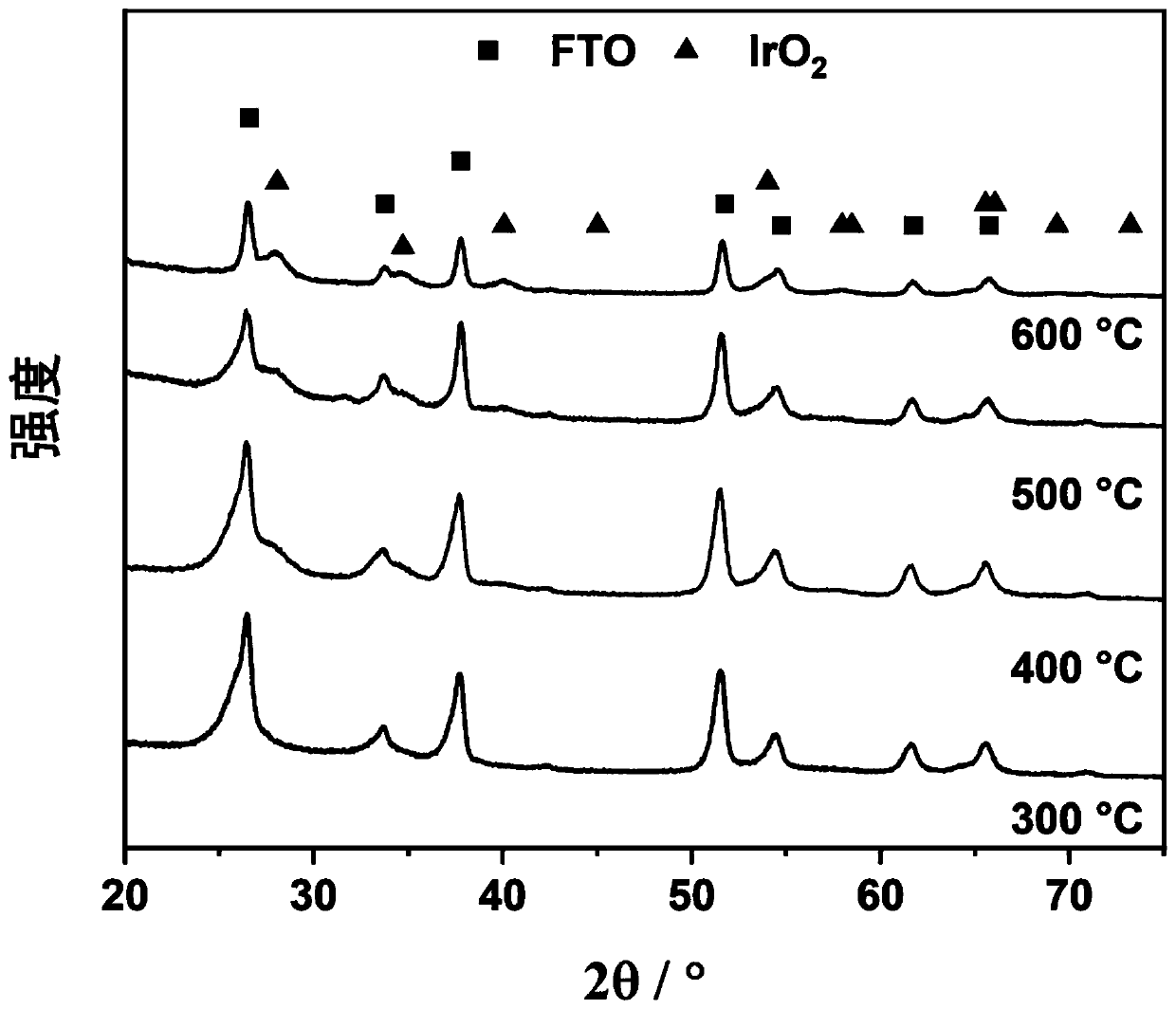

Preparation method and application of iridium oxide nanoparticle catalyst

ActiveCN111375408ASmall particle sizeLarge electrochemical active areaMaterial nanotechnologyRuthenium/rhodium/palladium/osmium/iridium/platinum oxides/hydroxidesPtru catalystPlasma generator

The invention discloses a preparation method and application of an iridium oxide nanoparticle catalyst. A mixed solution containing a polymer and an iridium-containing compound is uniformly applied toa treated conductive substrate; calcining in an air atmosphere is carried out to convert the iridium-containing compound into iridium oxide and the polymer is decomposed at the same time; the iridiumoxide nanoparticle material which is small in particle size, amorphous and of a porous structure is obtained, polymers remaining on the iridium oxide nanoparticle material are removed through a plasma generator, and the surfaces of iridium oxide nanoparticles are rich in hydroxyl. The film formed by the polymer in the mixed solution is utilized to solve the problem that the iridium-containing compound is agglomerated to form large particles when being calcined to generate the iridium oxide nanoparticles, thereby obtaining the small-particle-size iridium oxide nanoparticles. Besides, the plasma generator is used for removing residual polymers in the calcining process, the contact area of the iridium oxide nano particles is increased, and therefore the catalytic efficiency of the iridium oxide nano particles is improved.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Method for the recycling and purification of an inorganic metallic precursor

InactiveUS20080253948A1High purityRuthenium/rhodium/palladium/osmium/iridium/platinum oxides/hydroxidesRuthenium/rhodium/palladium/osmium/iridium/platinum halidesHydrogenDistillation

Methods and apparatus for the recycling and purification of an inorganic metallic precursor. A first gaseous stream containing ruthenium tetroxide is provided, and transformed into a solid phase lower ruthenium oxide. This lower phase ruthenium oxide is reduced with hydrogen to form ruthenium metal. The ruthenium metal is contacted with an oxidizing mixture to produce a stream containing ruthenium tetroxide, and any remaining oxidizing compounds are removed from this stream through a distillation.

Owner:GATINEAU JULIEN +1

Method for separation of chemically pure os from metal mixtures

ActiveUS20140328736A1Minimize exposurePossibility is limitedSpecific isotope recoveryTransuranic element compoundsMetalChemistry

Owner:UNIVERSITY OF MISSOURI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com