Patents

Literature

1080results about How to "Good reversibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

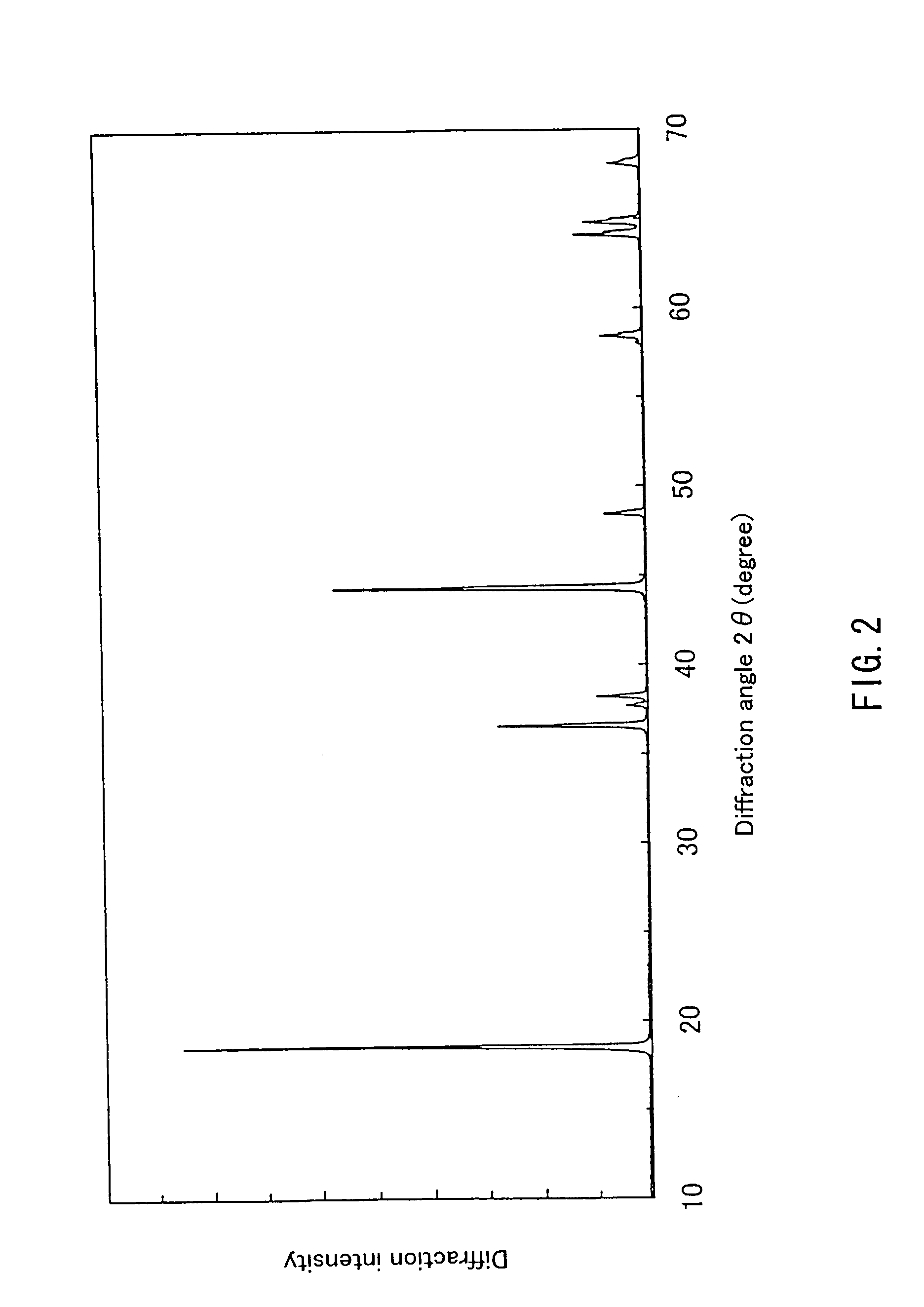

Positive electrode active material for lithium secondary cell and lithium secondary cell

ActiveUS7393476B2Improve cycle performanceIncrease energy densityMaterial nanotechnologyCell temperature controlCrystallographyComposite oxide

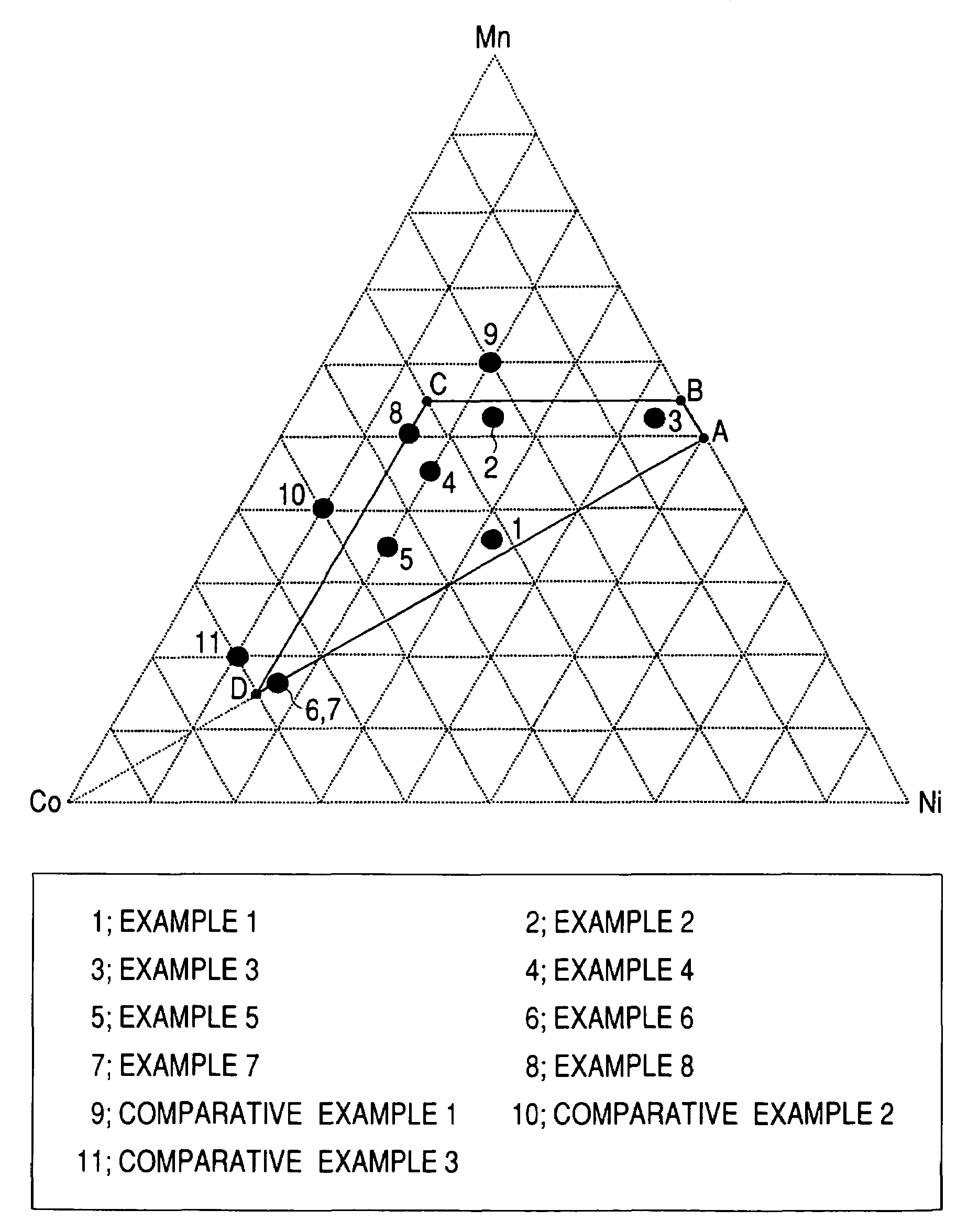

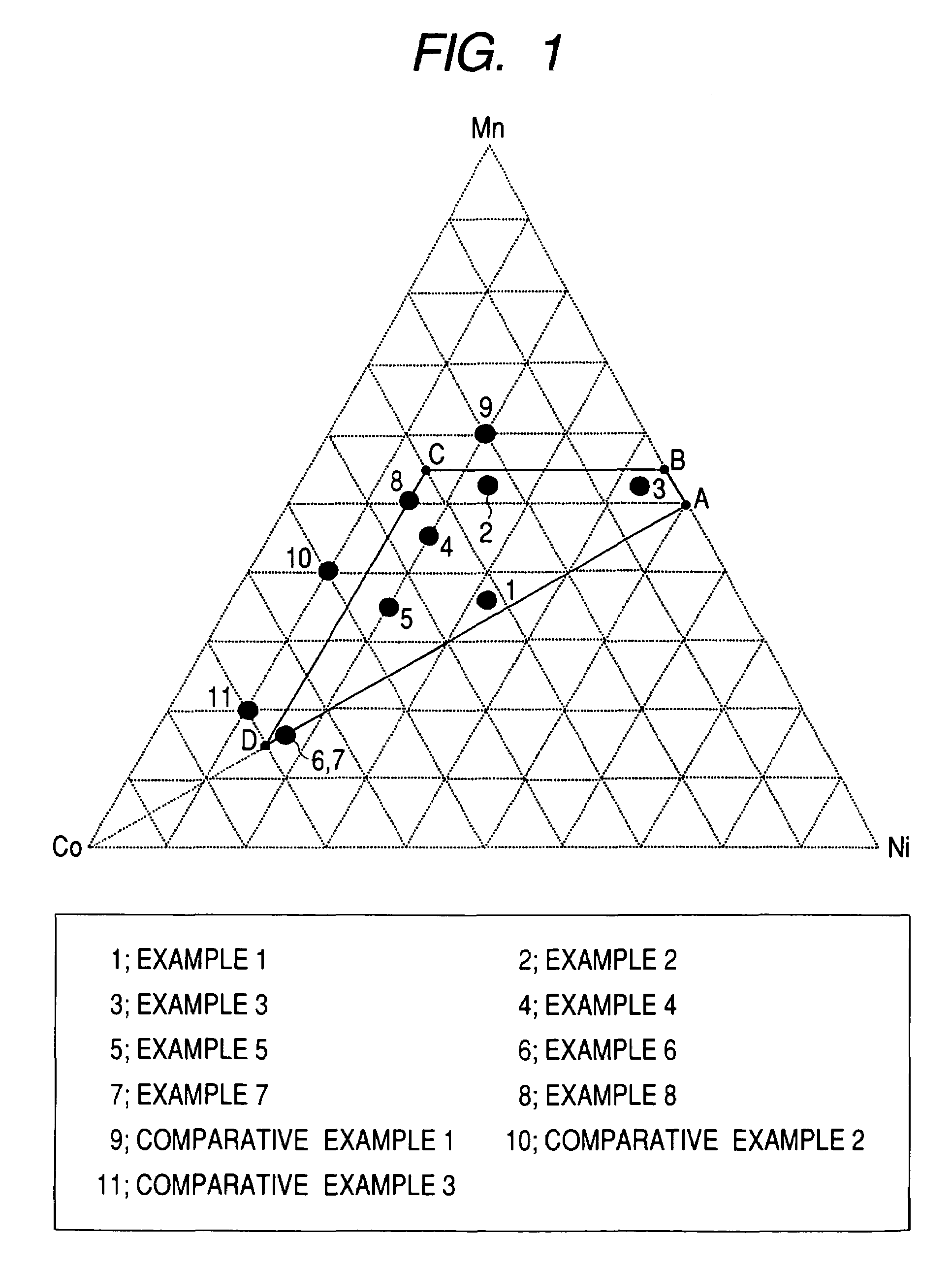

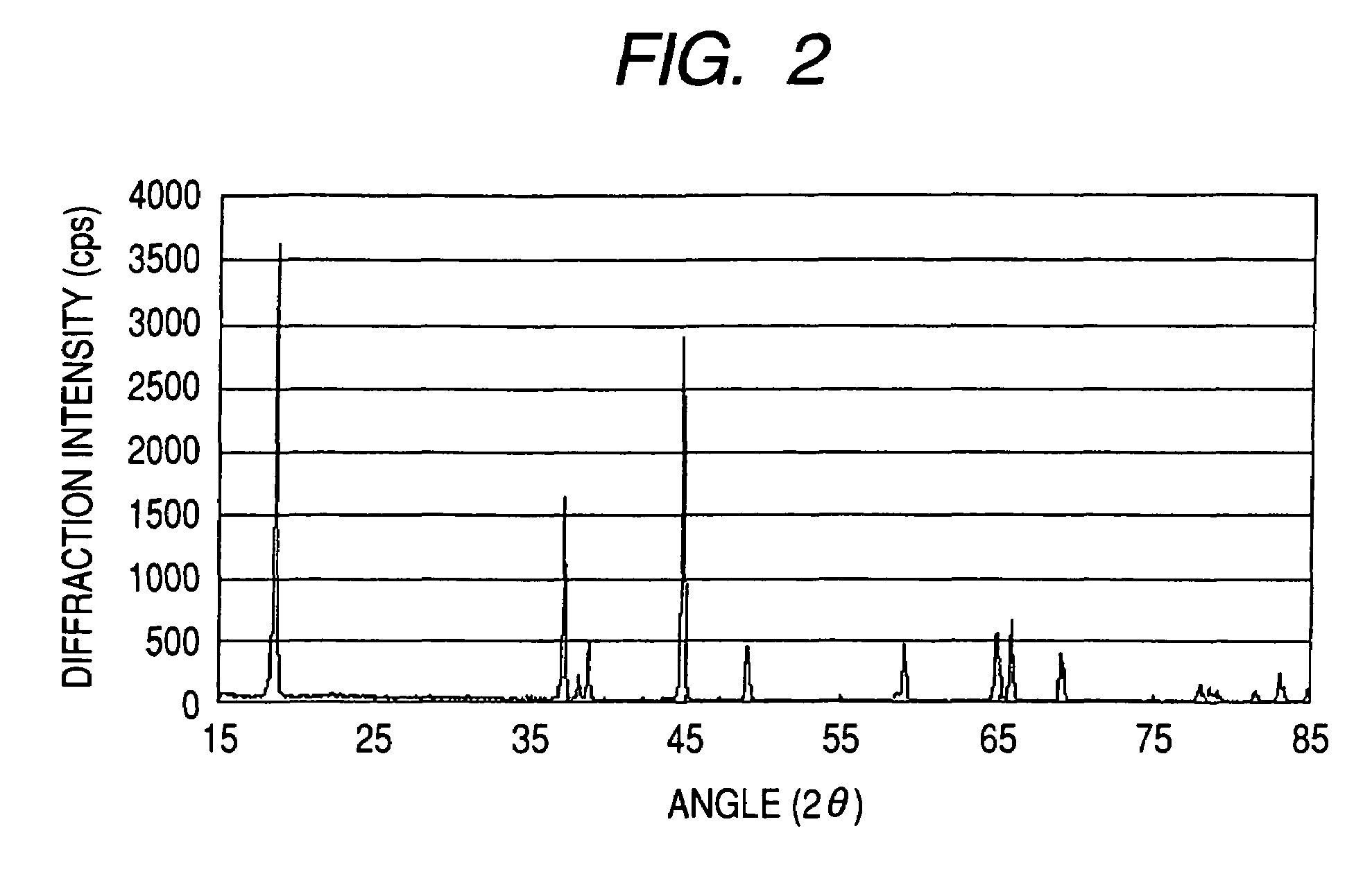

A positive active material for lithium secondary batteries, includes a composite oxide including an oxide which is represented by the composite formula LixMnaNibCocO2 and has an α-NaFeO2 structure, and an impurity phase including Li2MnO3. The values a, b, and c are within such a range that in a ternary phase diagram showing the relationship among these, (a, b, c) is present on the perimeter of or inside the quadrilateral ABCD defined by point A (0.5, 0.5, 0), point B (0.55, 0.45, 0), point C (0.55, 0.15, 0.30), and point D (0.15, 0.15, 0.7) as vertexes, and 0.95<x / (a+b+c)<1.35.

Owner:GS YUASA INT LTD

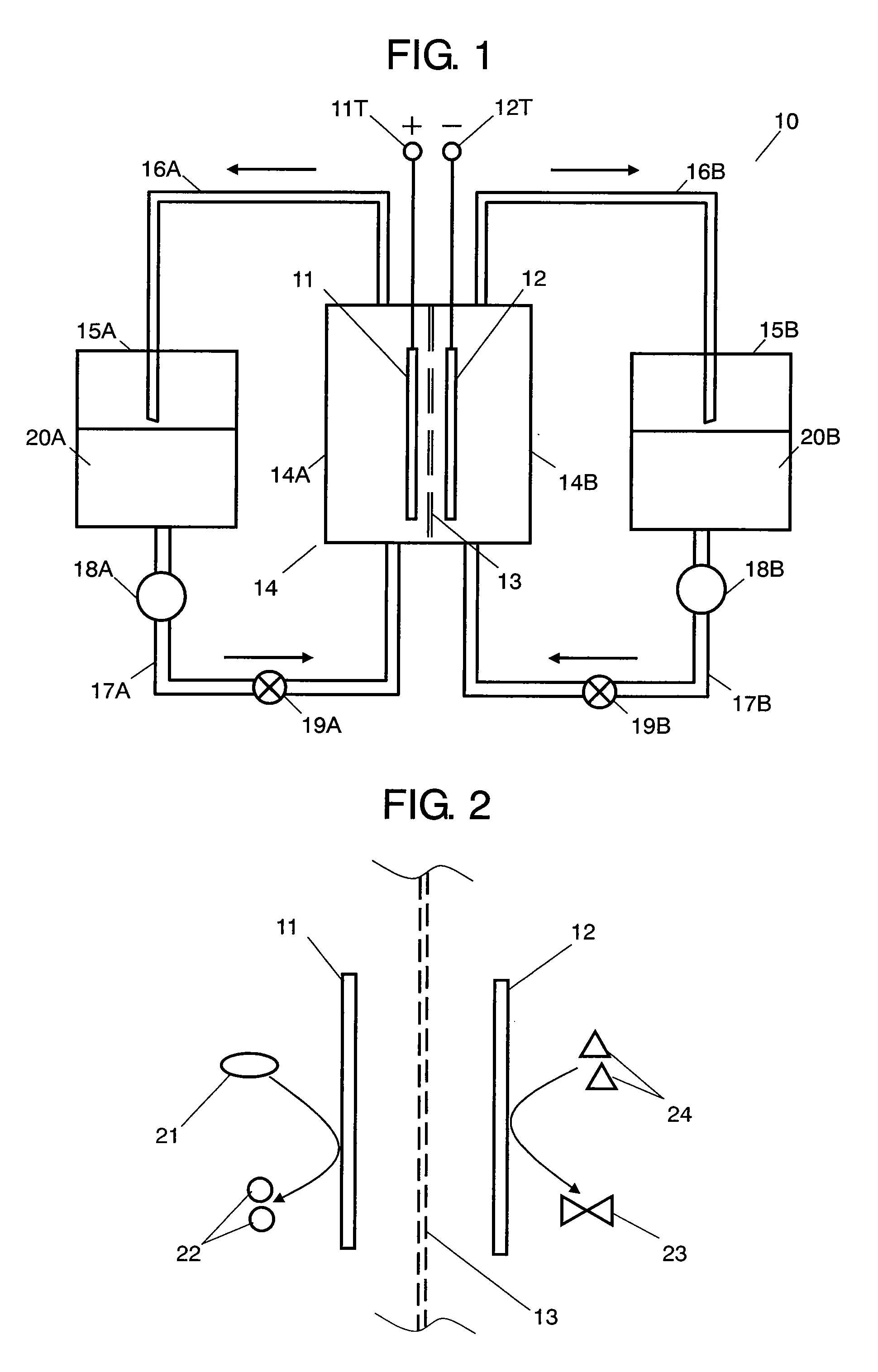

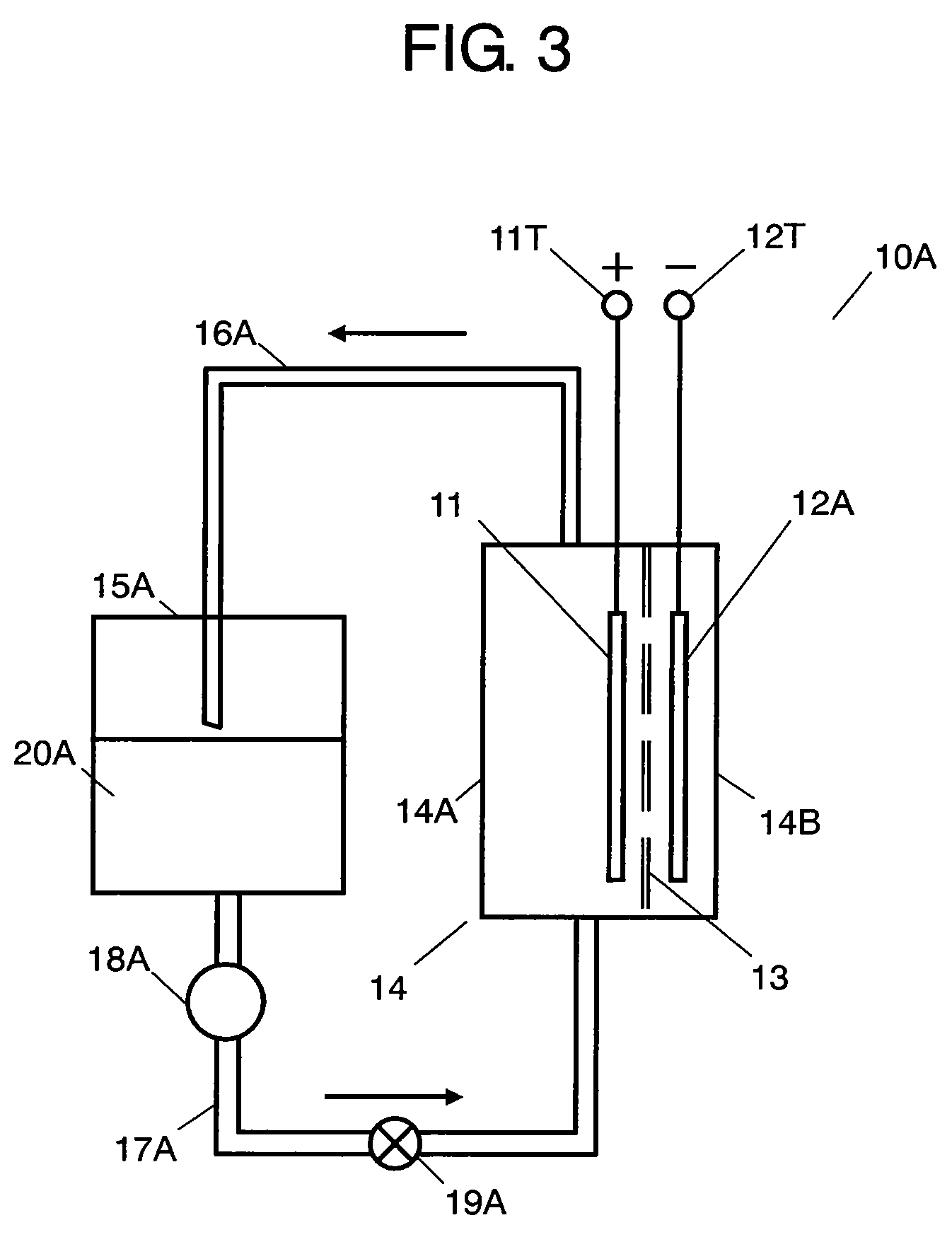

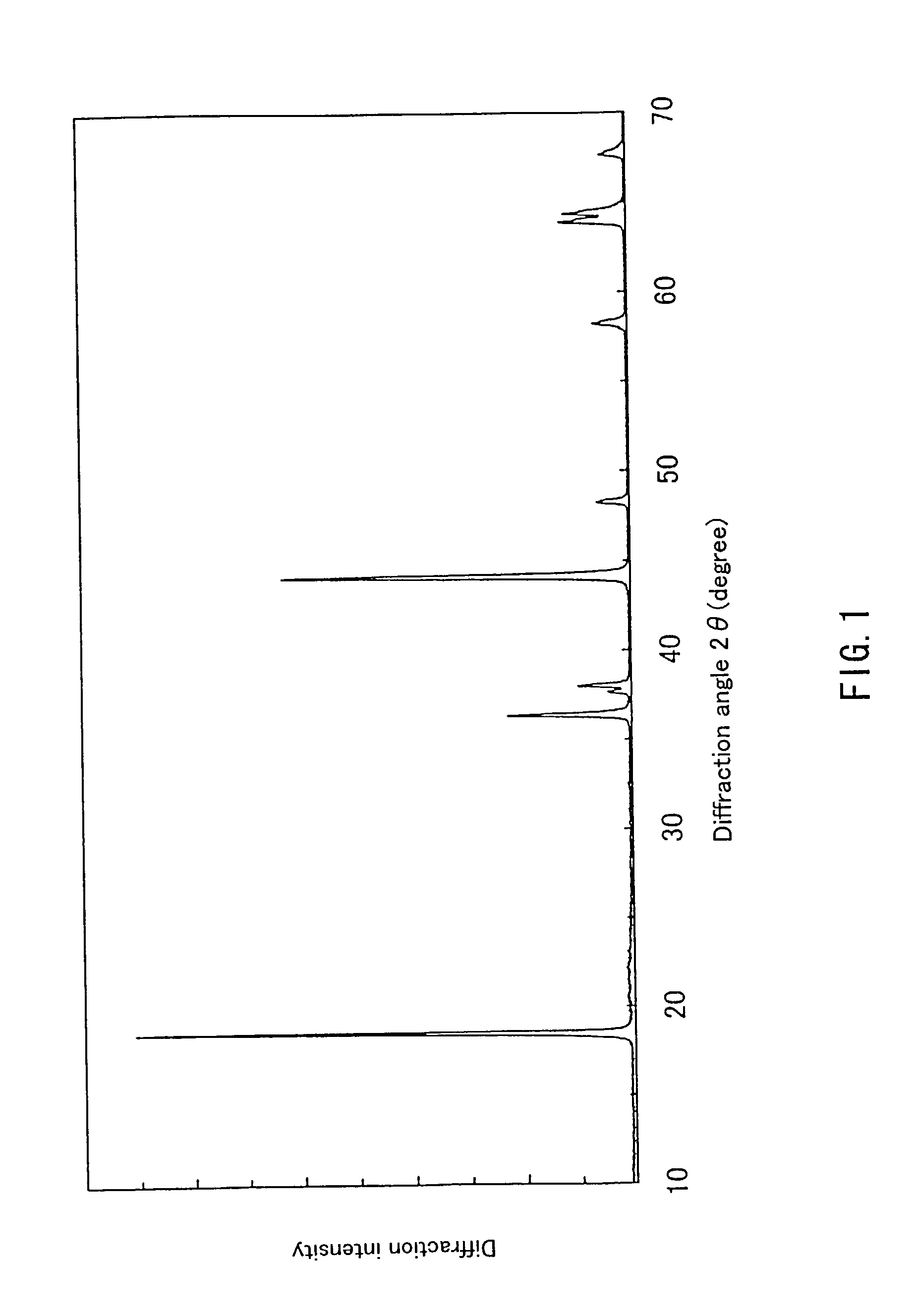

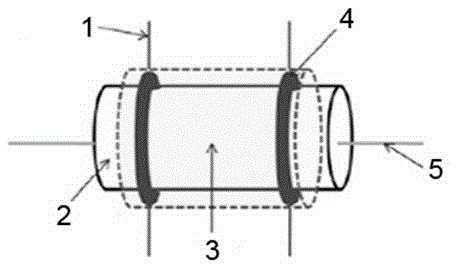

Secondary battery, power supply system using same and usage of power supply system

InactiveUS20090017379A1Good reversibilityEfficient useBatteries circuit arrangementsRegenerative fuel cellsIonCharge and discharge

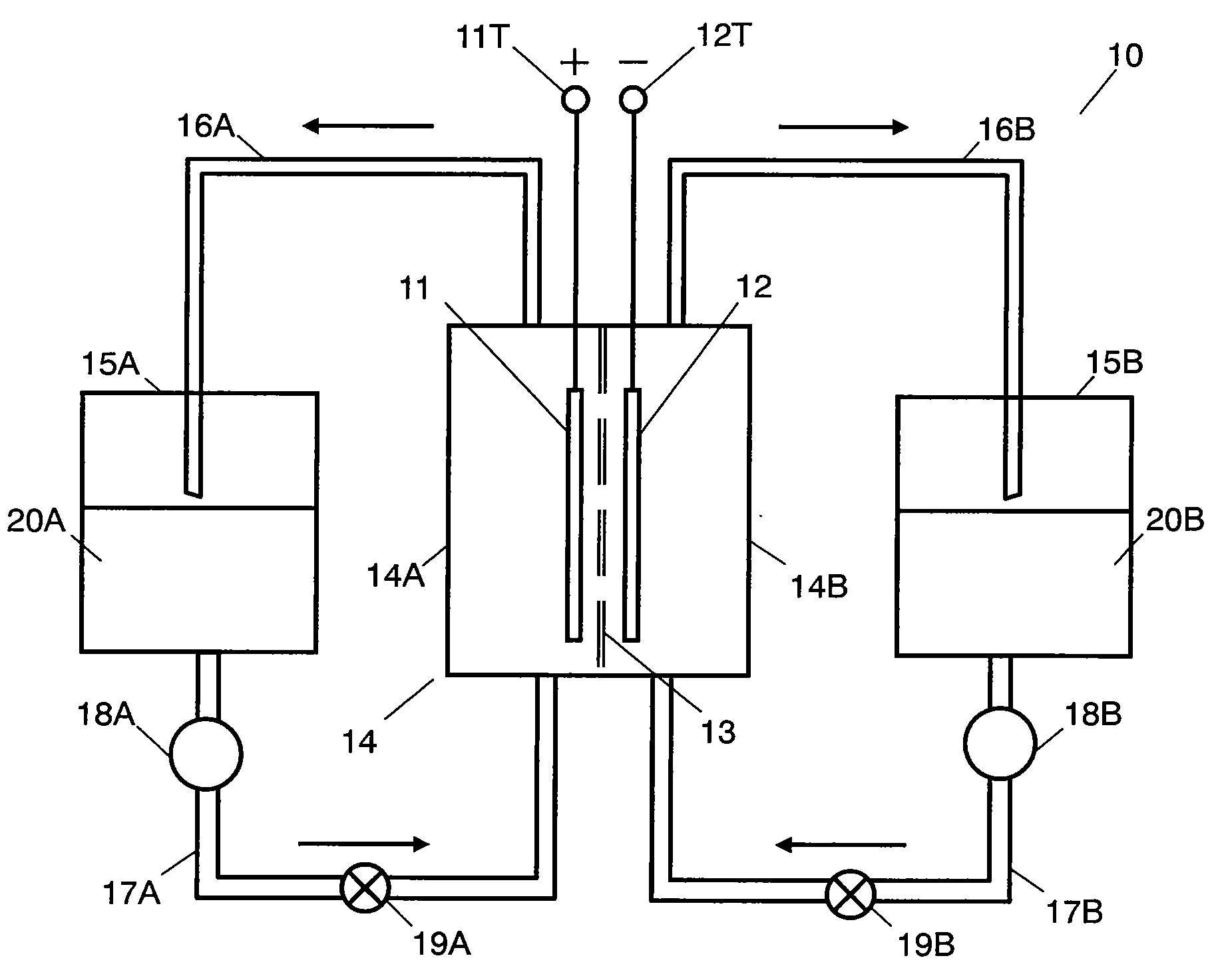

A secondary battery is equipped with a reaction container and a current collector that is built in at least one of a positive electrode side and a negative electrode side. The positive electrode side and the negative electrode side are separated from each other by an ion conductive separator. In the reaction container, an organic matter excluding a metal complex and a radical and capable of reversibly being electrochemically oxidized and reduced is used as an active material together with a supporting salt. The active material and the supporting salt form a liquid. On the surface of the current collector, the active material contained in the liquid is charged and discharged.

Owner:PANASONIC CORP

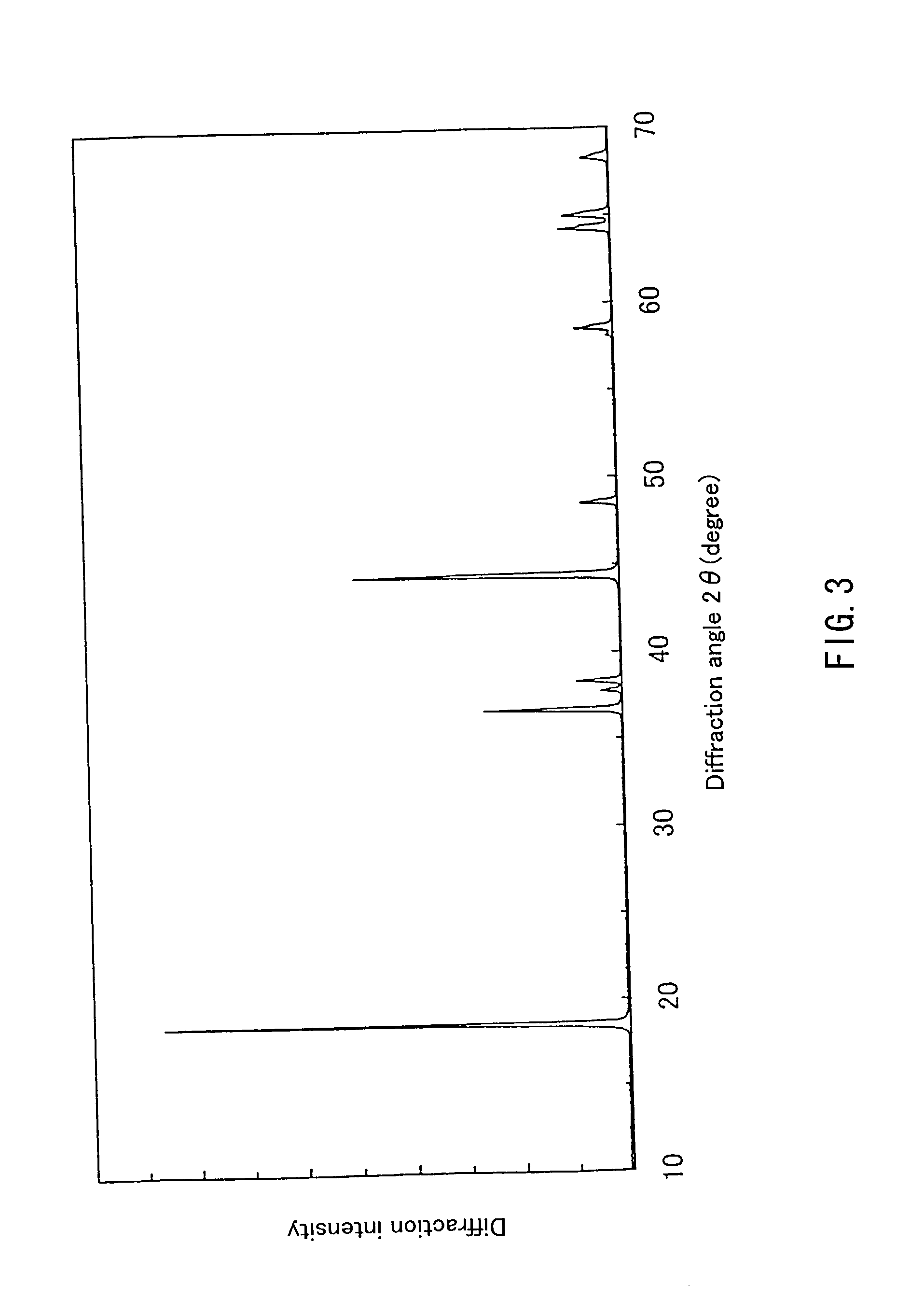

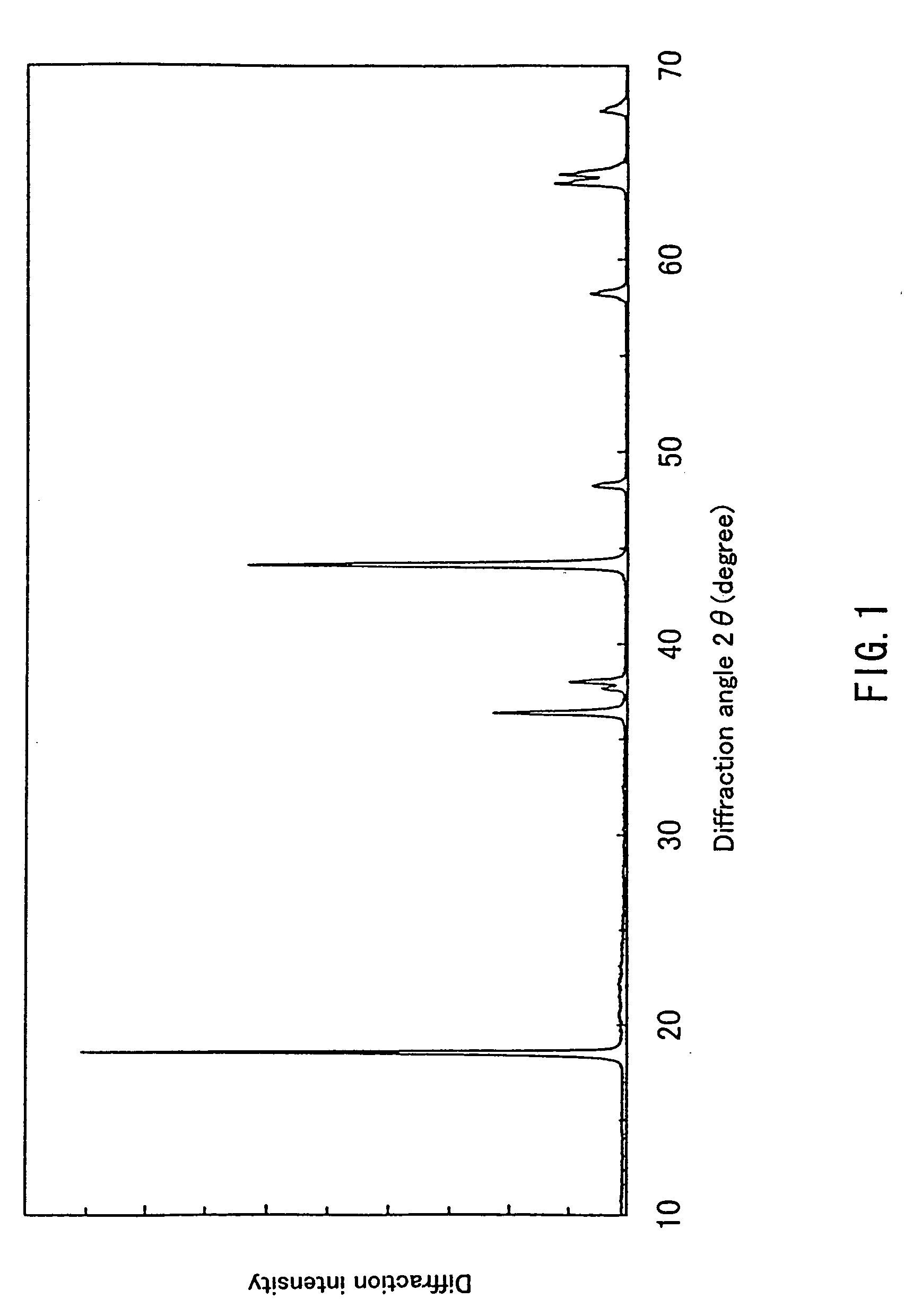

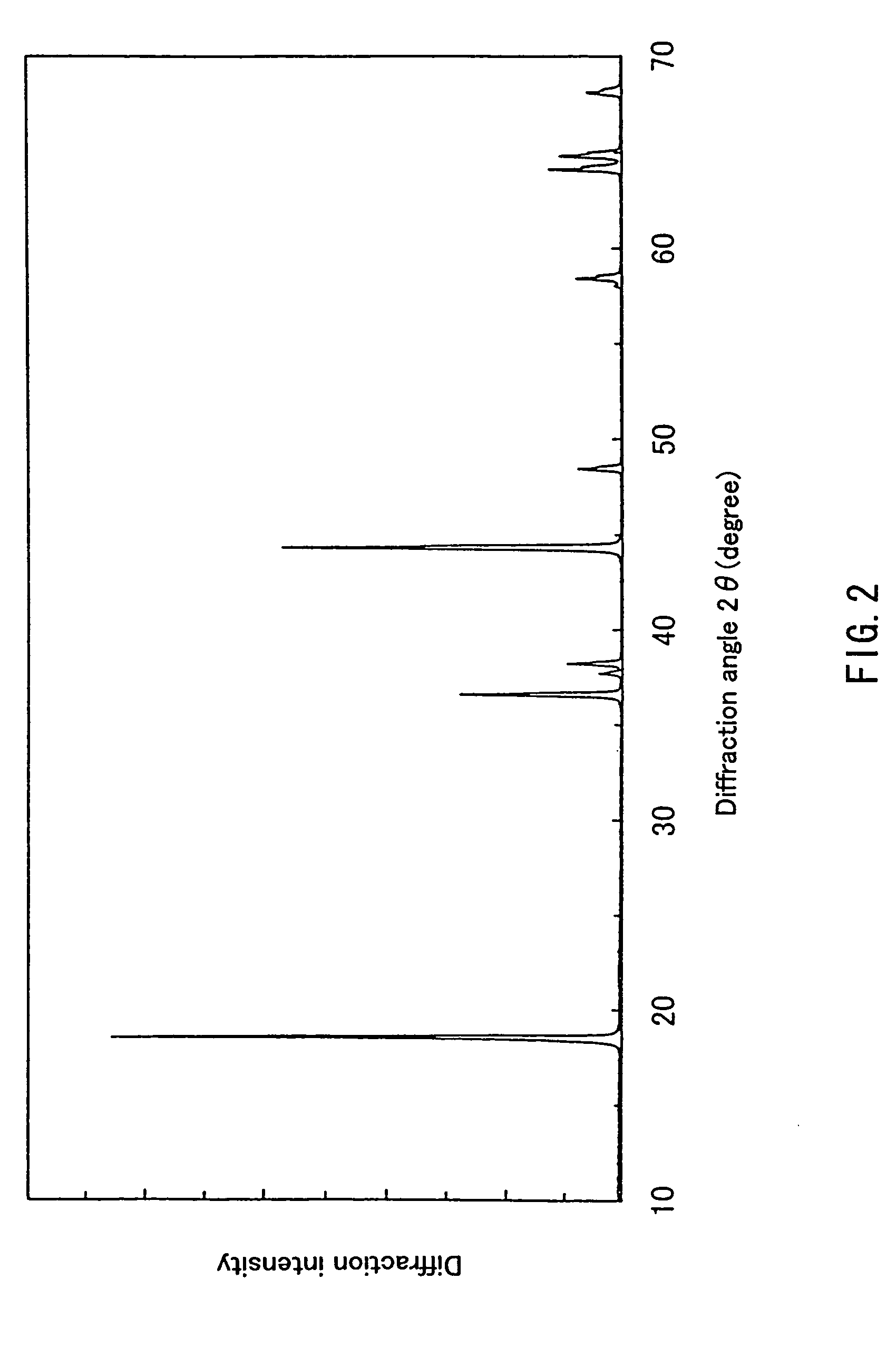

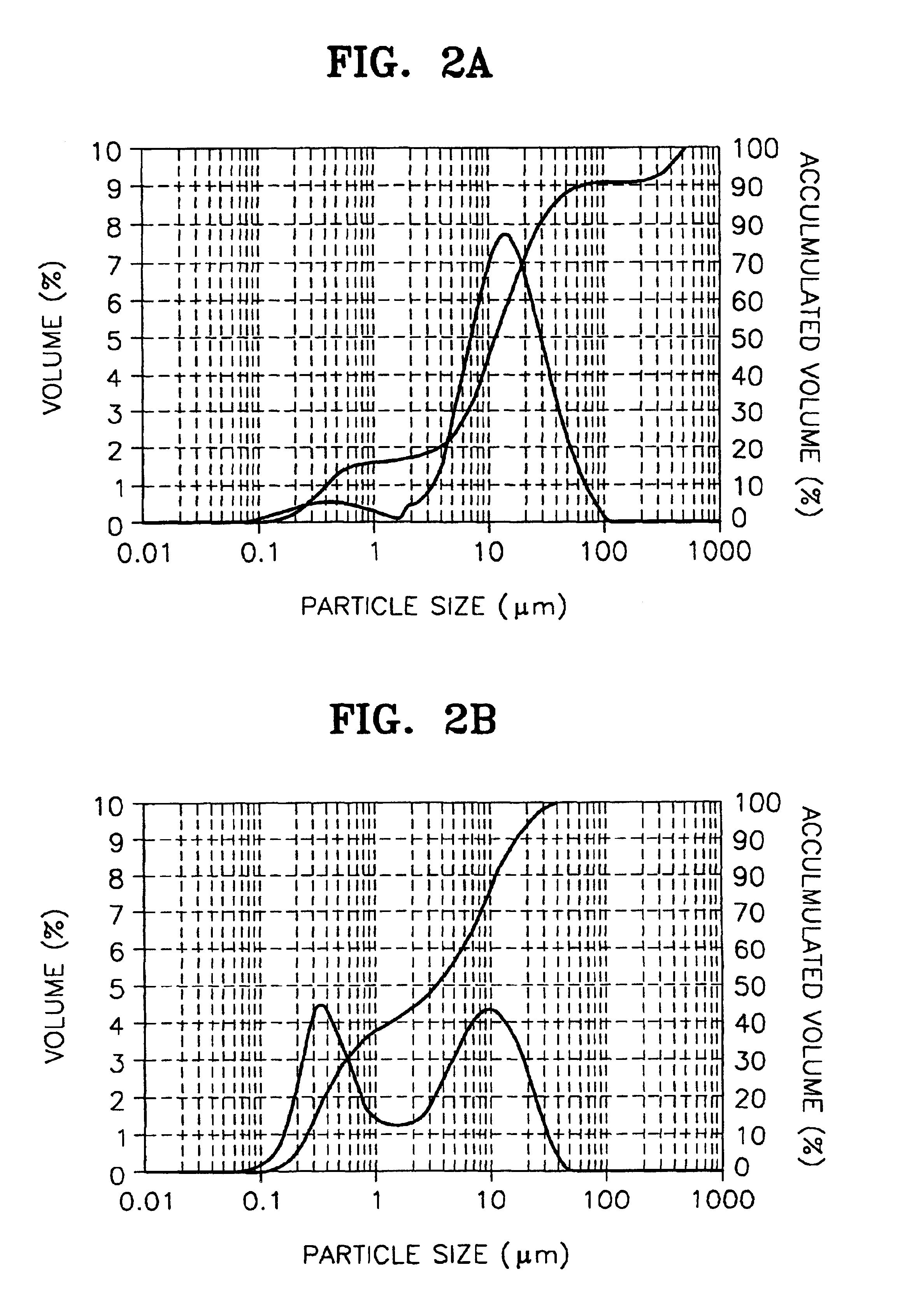

Lithium-containing composite oxide and nonaqueous secondary cell using the same, and method for manufacturing the same

InactiveUS20030082452A1Stable structureHigh energy density per volumeElectrode thermal treatmentOrganic electrolyte cellsLithiumHigh density

Because of the composition represented by General Formula: Li1+x+alphaNi(1-x-y+delta) / 2Mn(1-x-y-delta) / 2MyO2 (where 0<=x<=0.05, -0.05<=x+alpha<=0.05, 0<=y<=0.4; -0.1<=delta<=0.1 (when 0<=y<=0.2) or -0.24<=delta<=0.24 (when 0.2<=y<=0.4); and M is at least one element selected from the group consisting of Ti, Cr, Fe, Co, Cu, Zn, Al, Ge and Sn), a high-density lithium-containing complex oxide with high stability of a layered crystal structure and excellent reversibility of charging / discharging can be provided, and a high-capacity non-aqueous secondary battery excellent in durability is realized by using such an oxide for a positive electrode.

Owner:MAXELL HLDG LTD

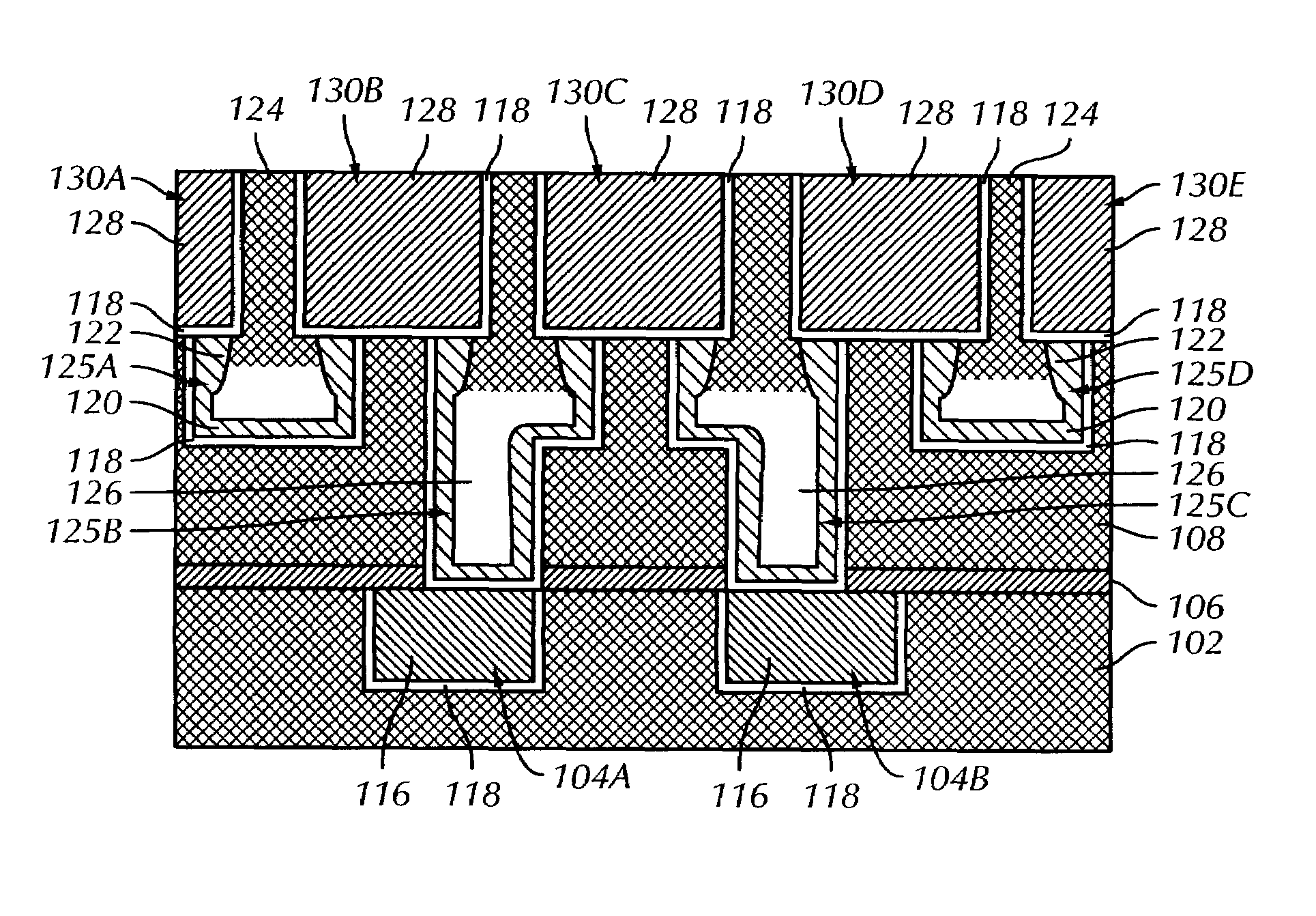

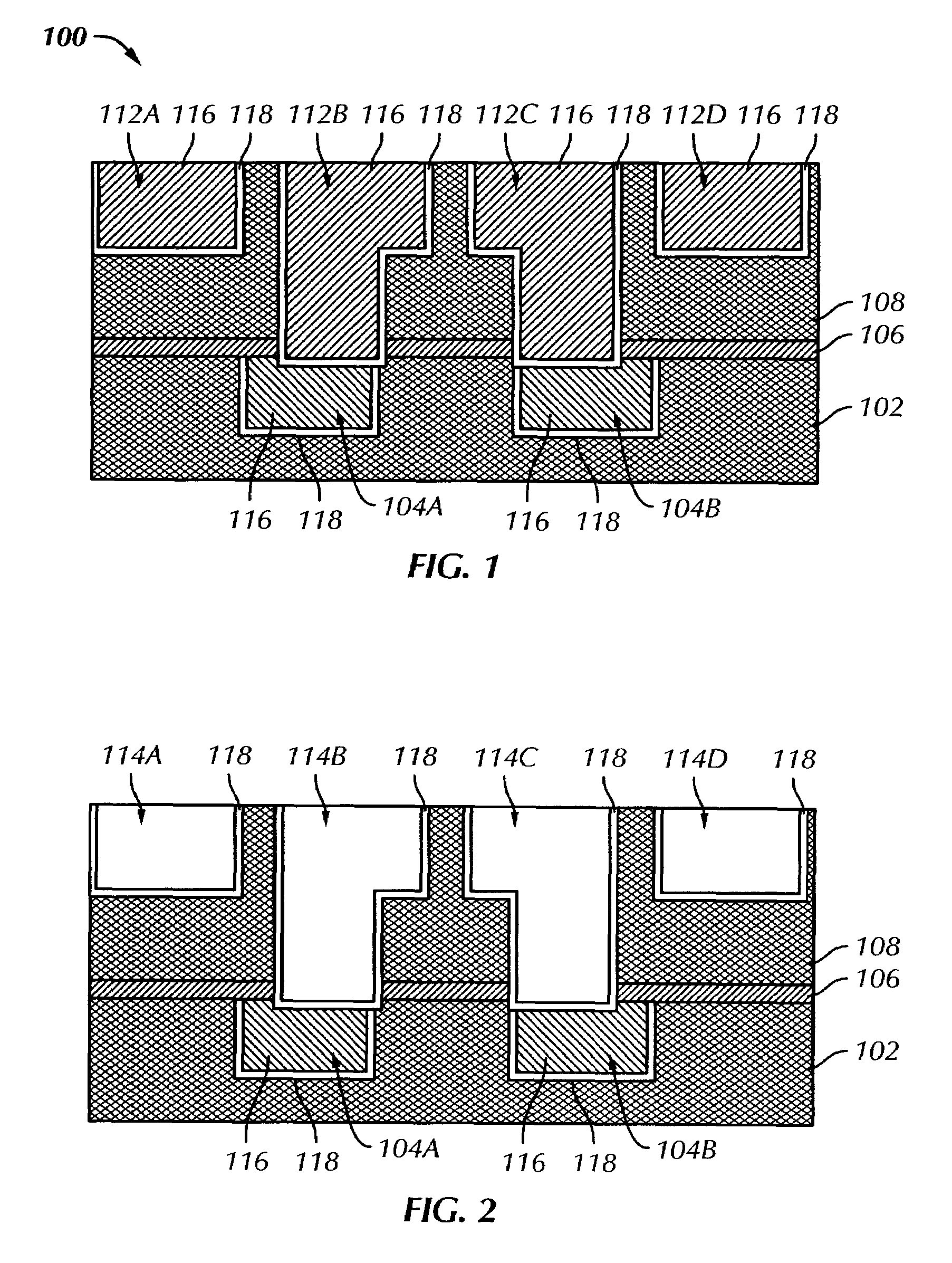

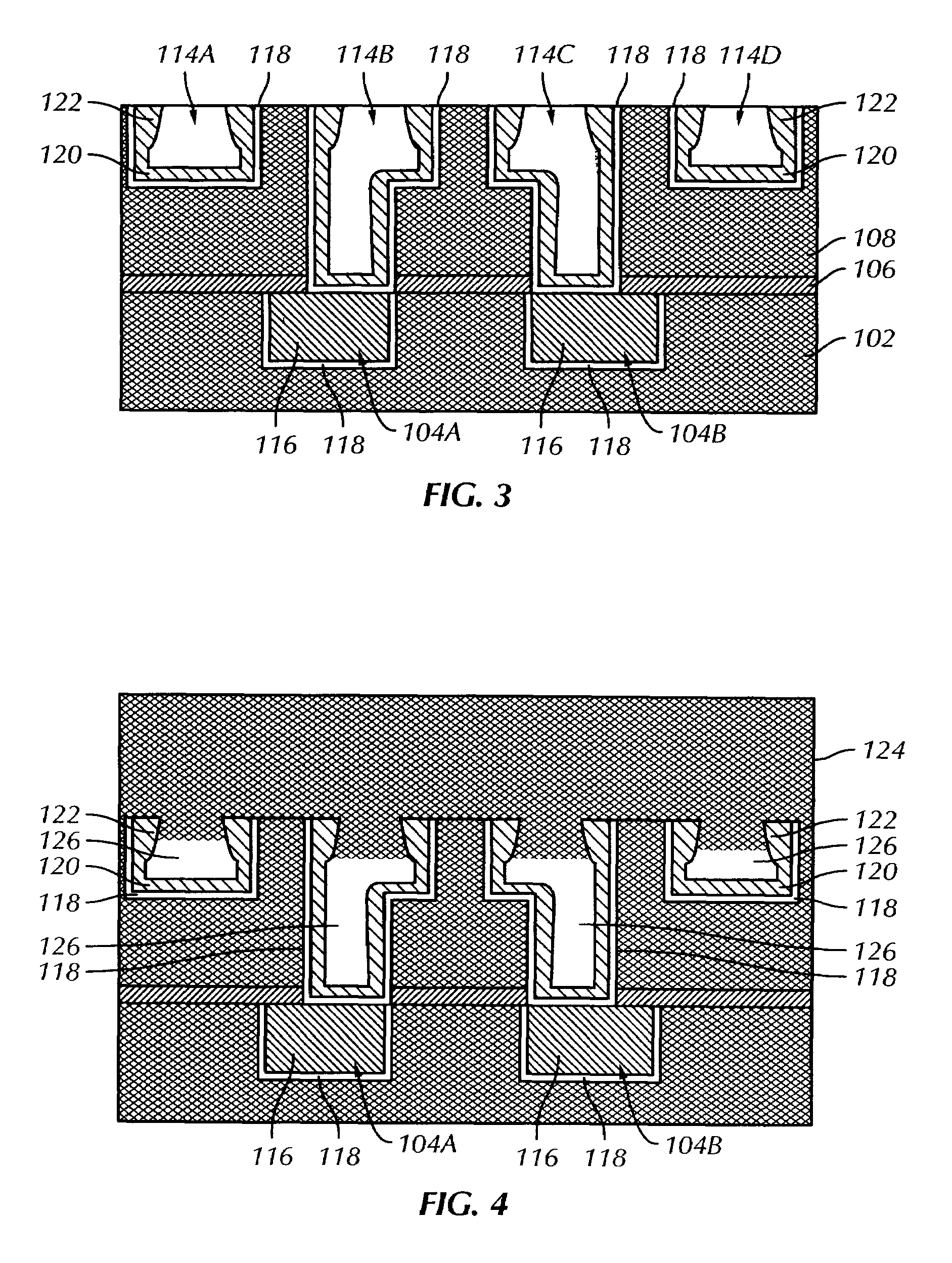

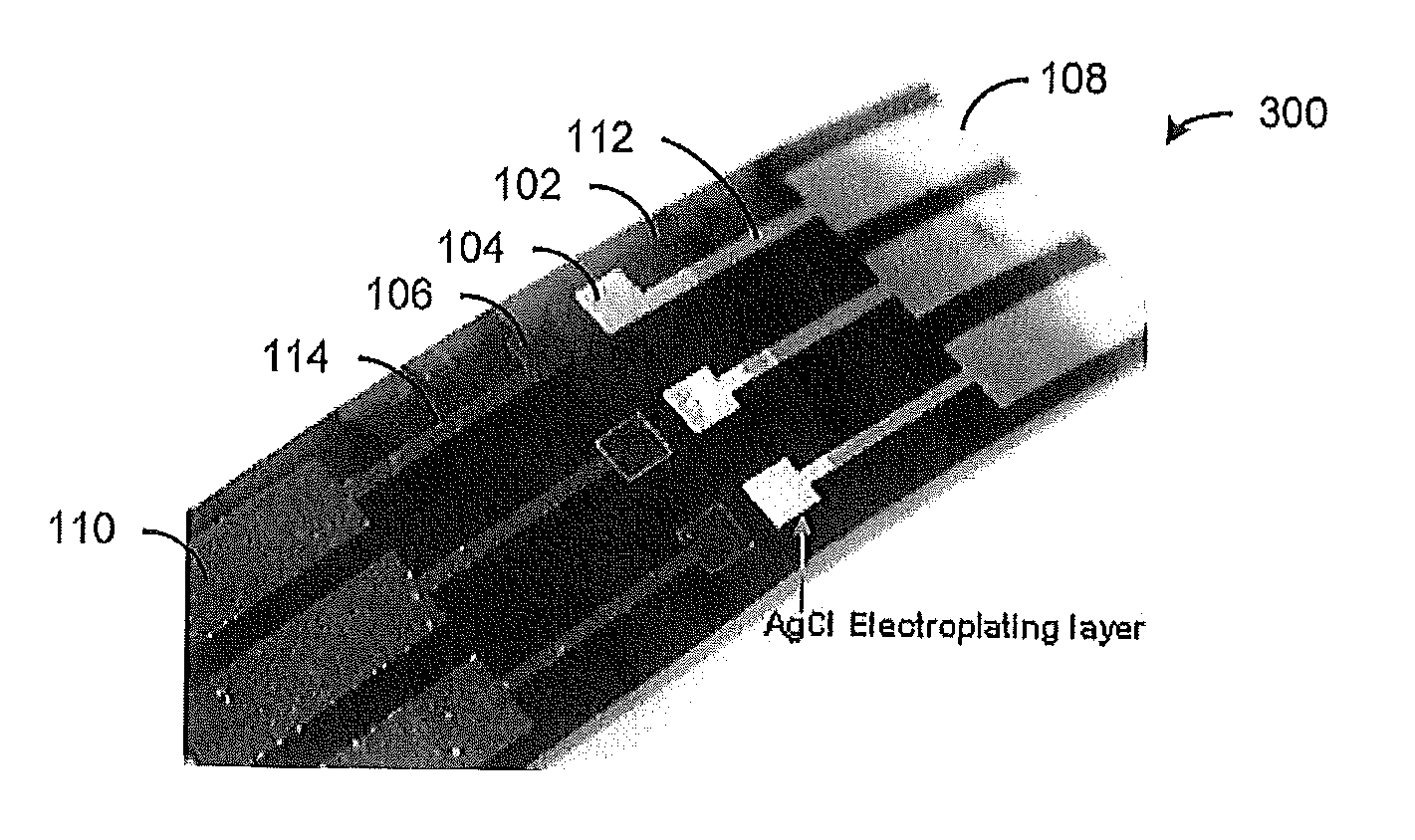

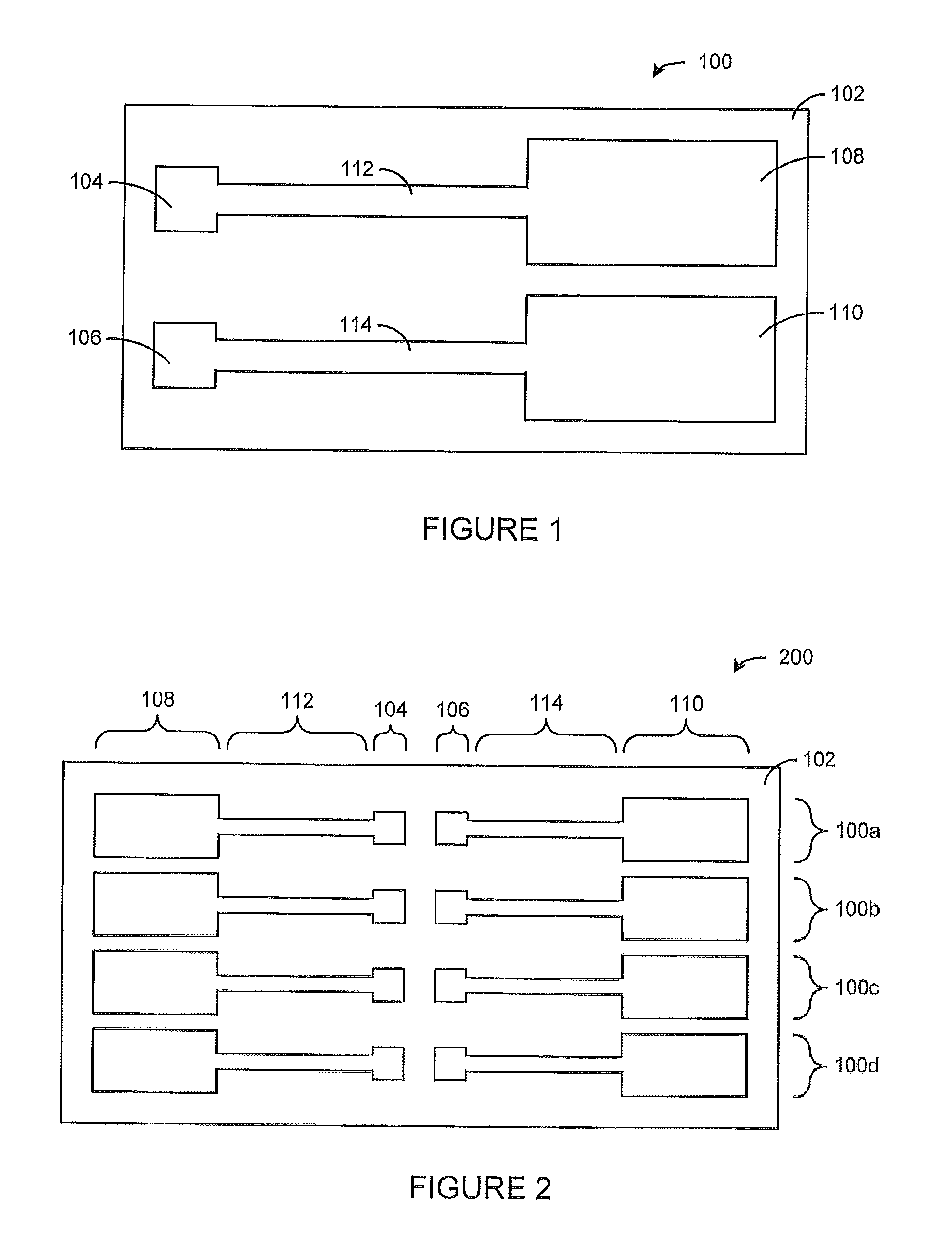

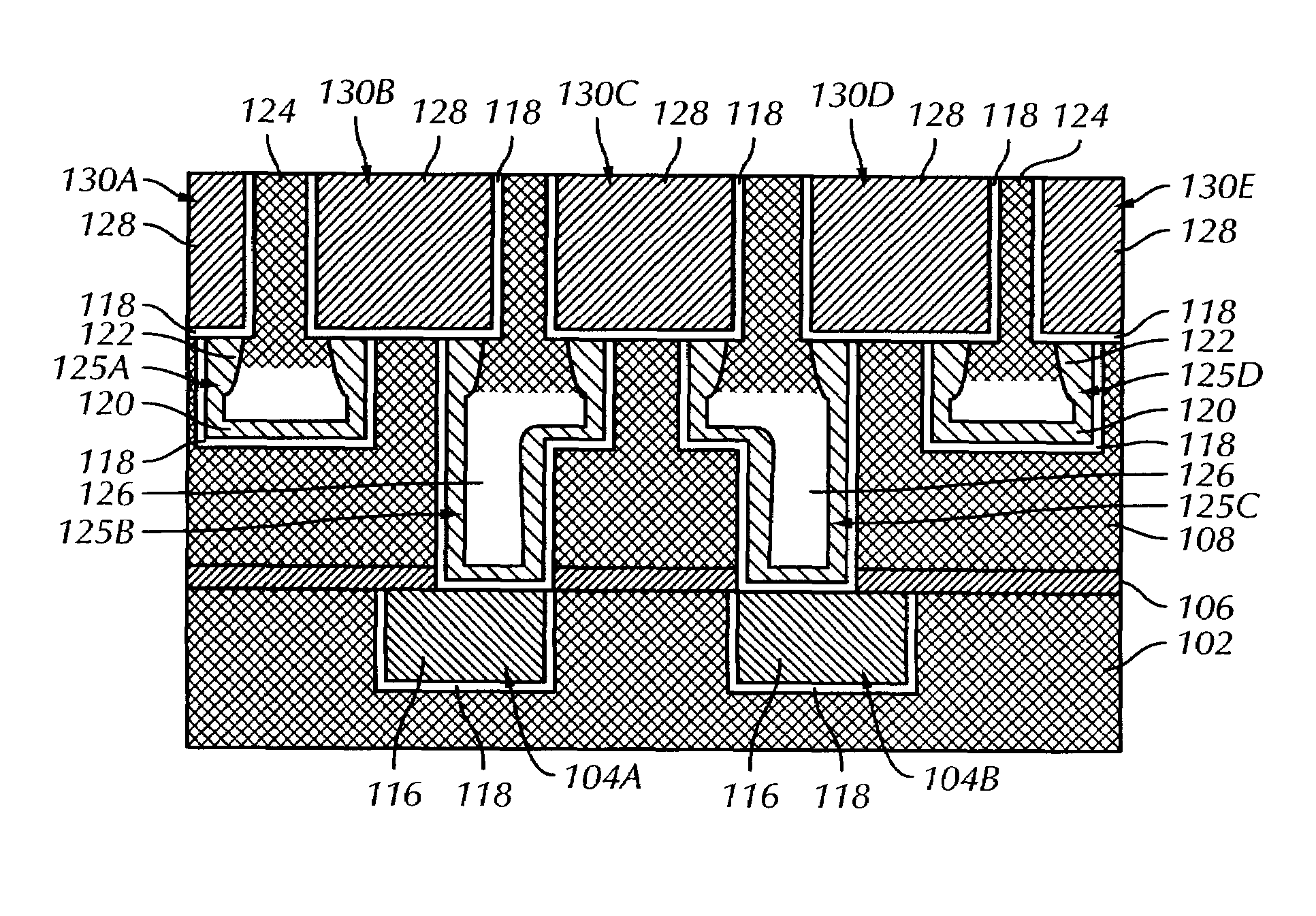

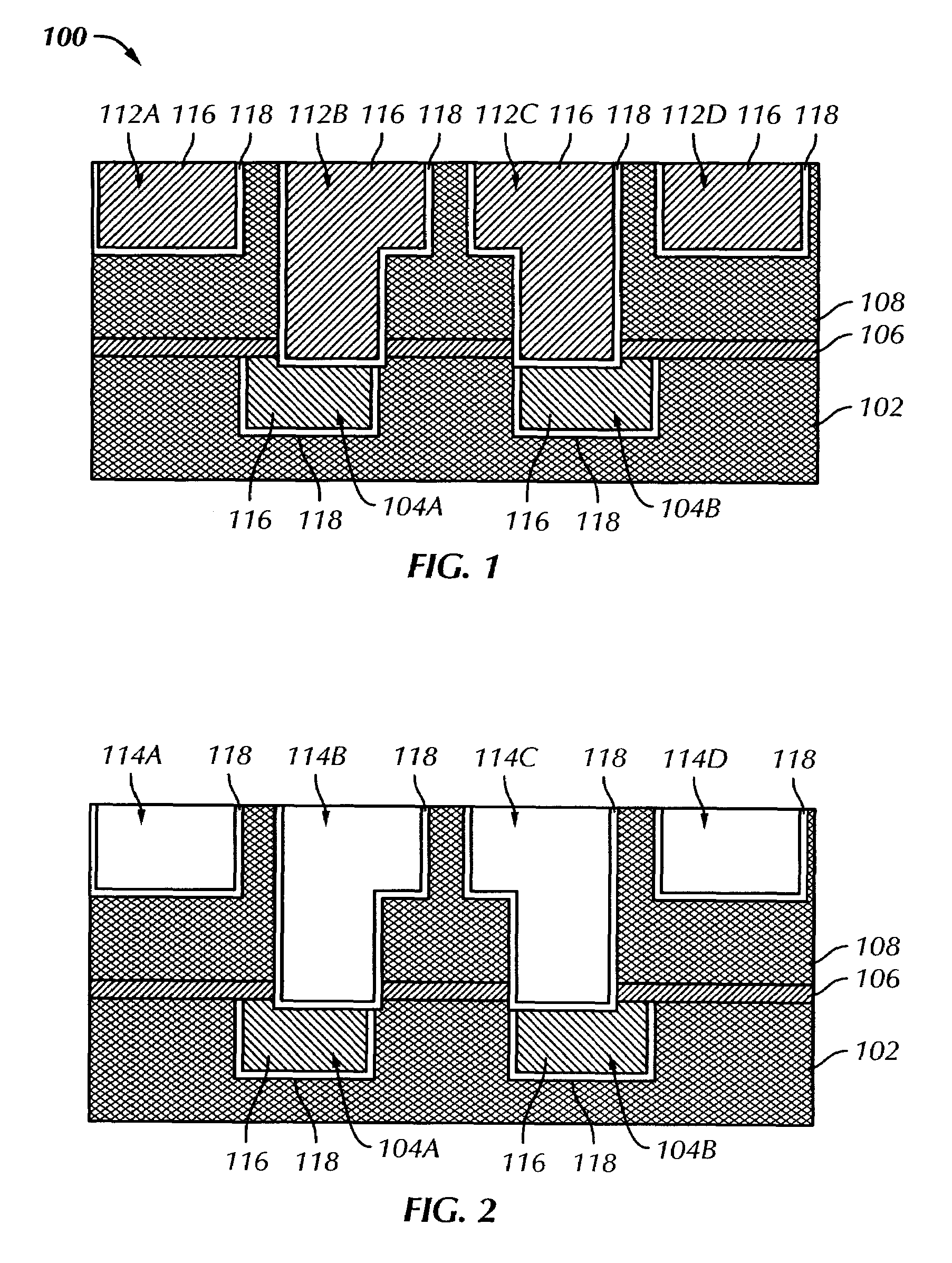

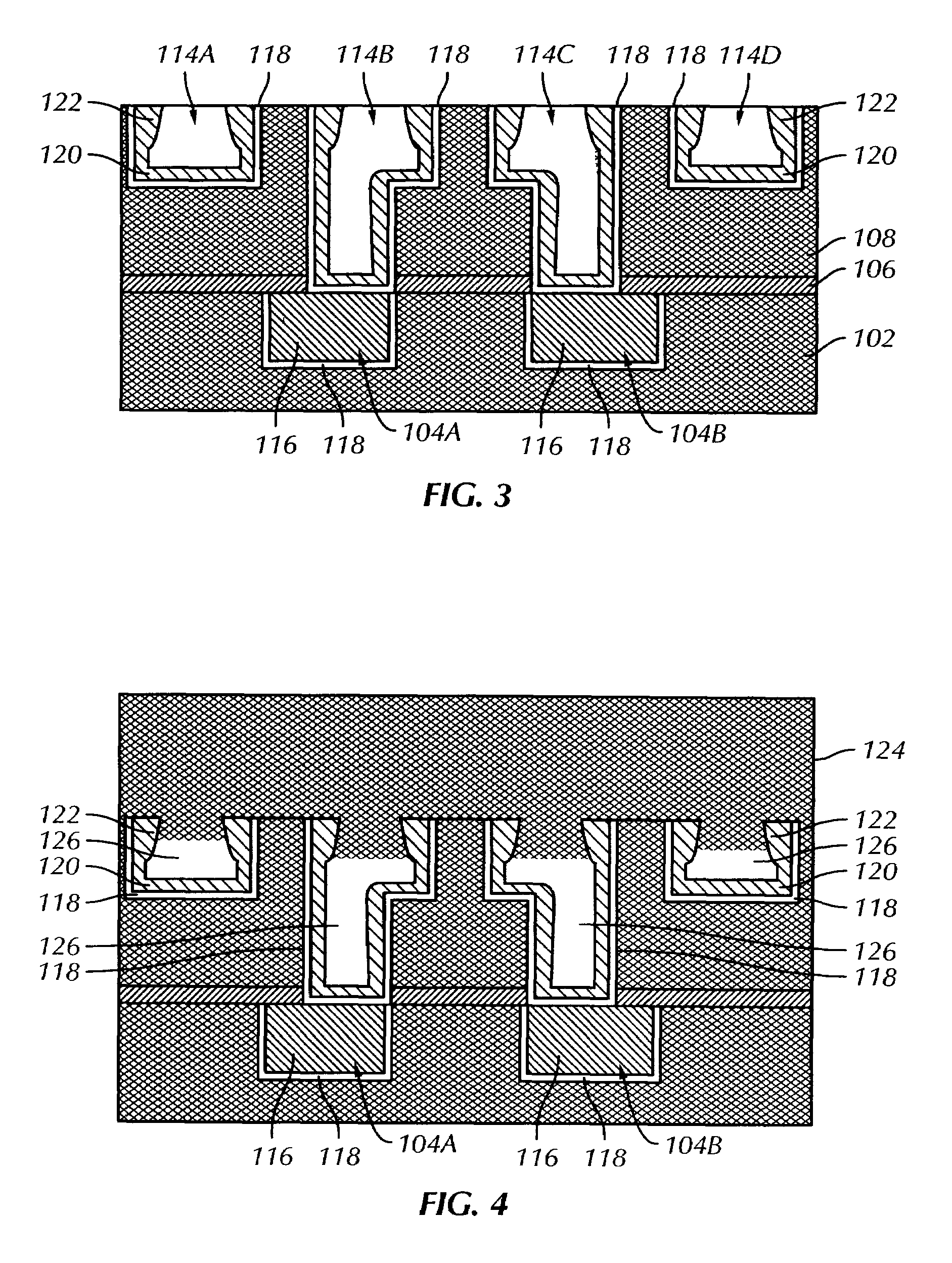

Reversible electric fuse and antifuse structures for semiconductor devices

ActiveUS7557424B2Improve electromigration problemsGood reversibilitySemiconductor/solid-state device detailsSolid-state devicesElectric fusesEngineering

A structure and method of fabricating reversible fuse and antifuse structures for semiconductor devices is provided. In one embodiment, the method includes forming at least one line having a via opening for exposing a portion of a plurality of interconnect features; conformally depositing a first material layer over the via opening; depositing a second material layer over the first material layer, wherein the depositing overhangs a portion of the second material layer on a top portion of the via opening; and depositing a blanket layer of insulating material, where the depositing forms a plurality of fuse elements each having an airgap between the insulating material and the second material layer. The method further includes forming a plurality of electroplates in the insulator material connecting the fuse elements. In another embodiment, the method includes depositing a first and a second material layer on a semiconductor substrate, wherein the second material layer having a higher electrical conductivity than the first material layer; selectively etching the first and second material layer to create at least one constricted region to facilitate electromigration of the second material; wherein the electromigration creates a plurality of micro voids; and forming a plurality of electrical contacts on the second material layer.

Owner:GLOBALFOUNDRIES U S INC

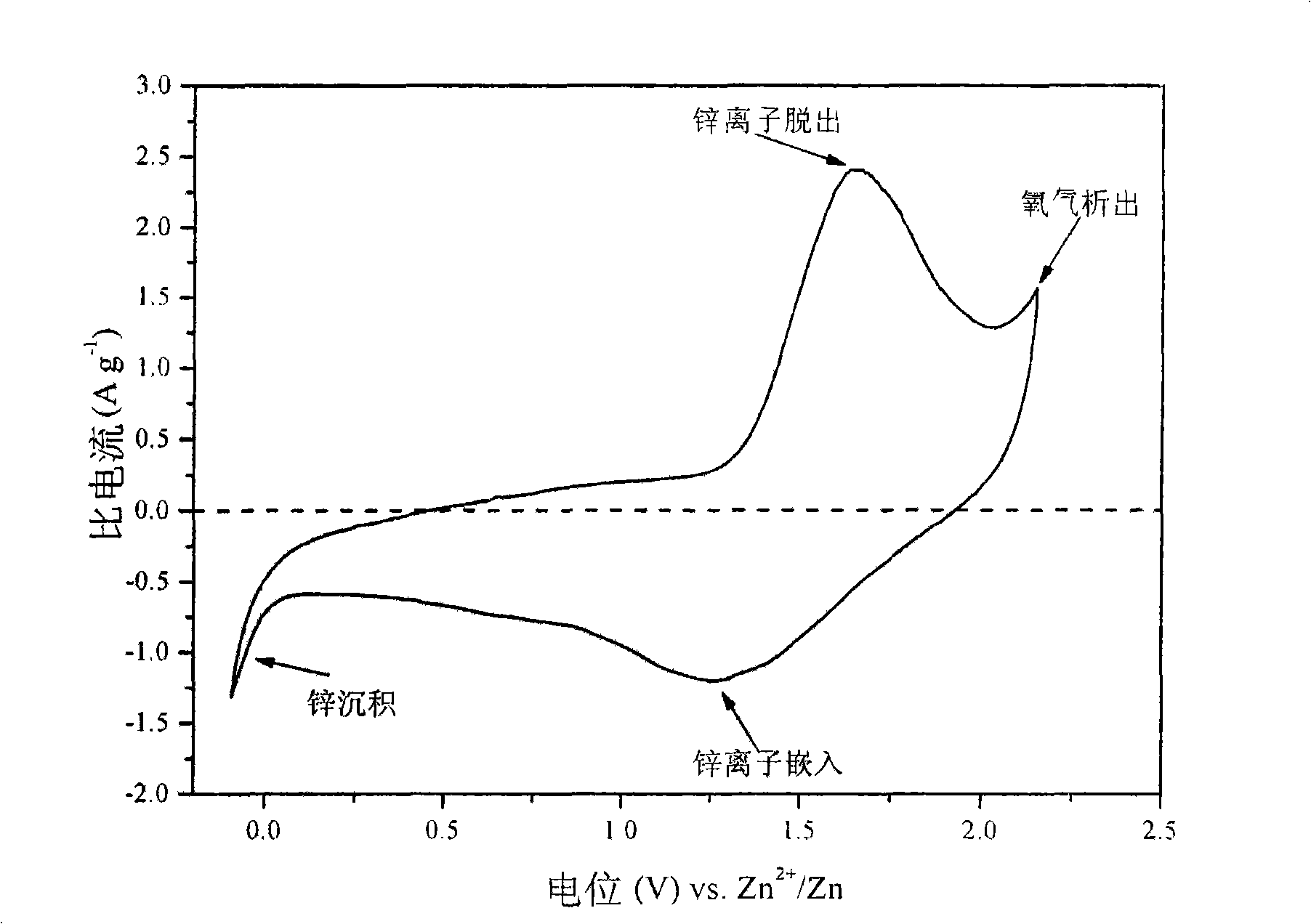

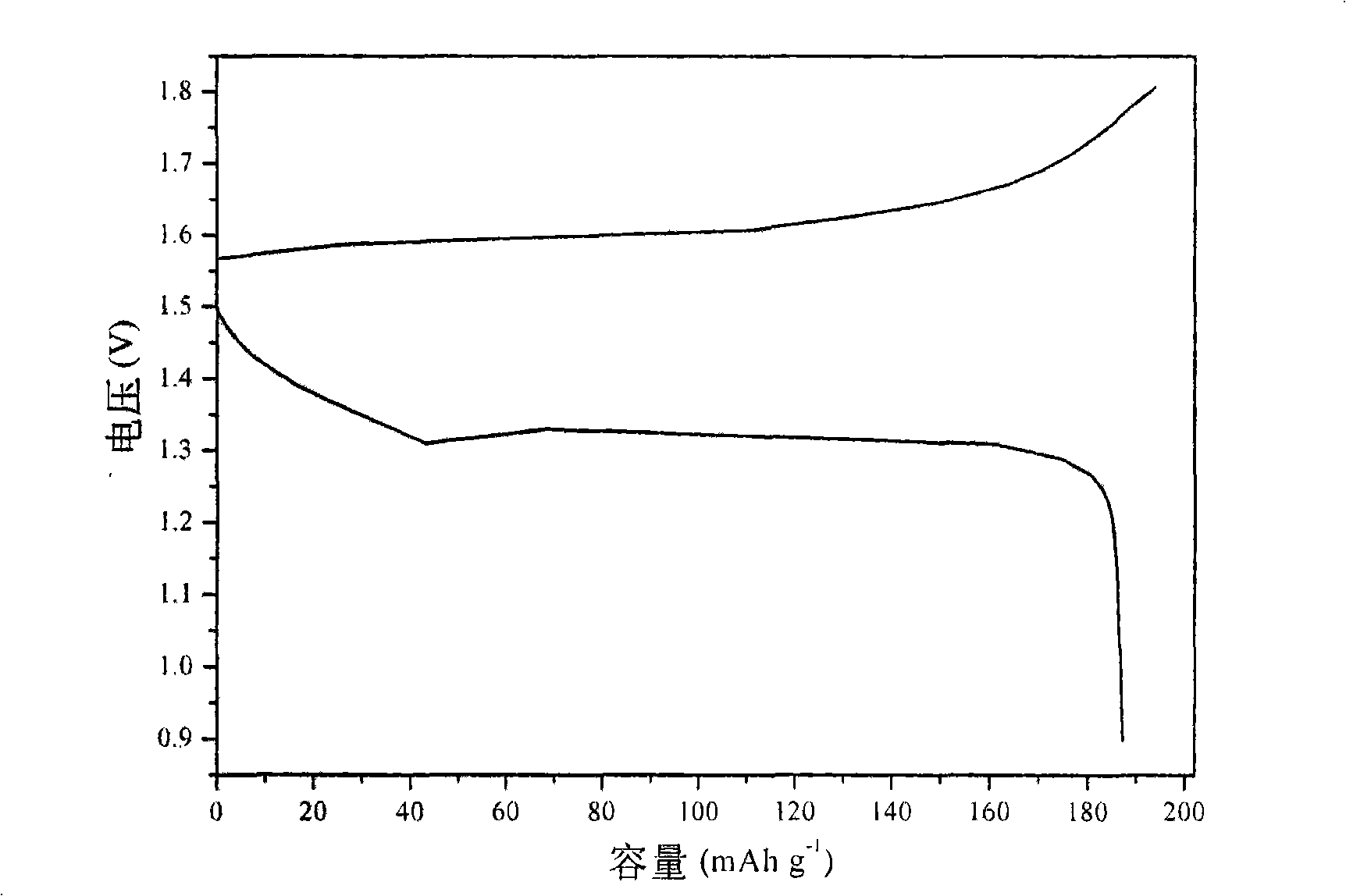

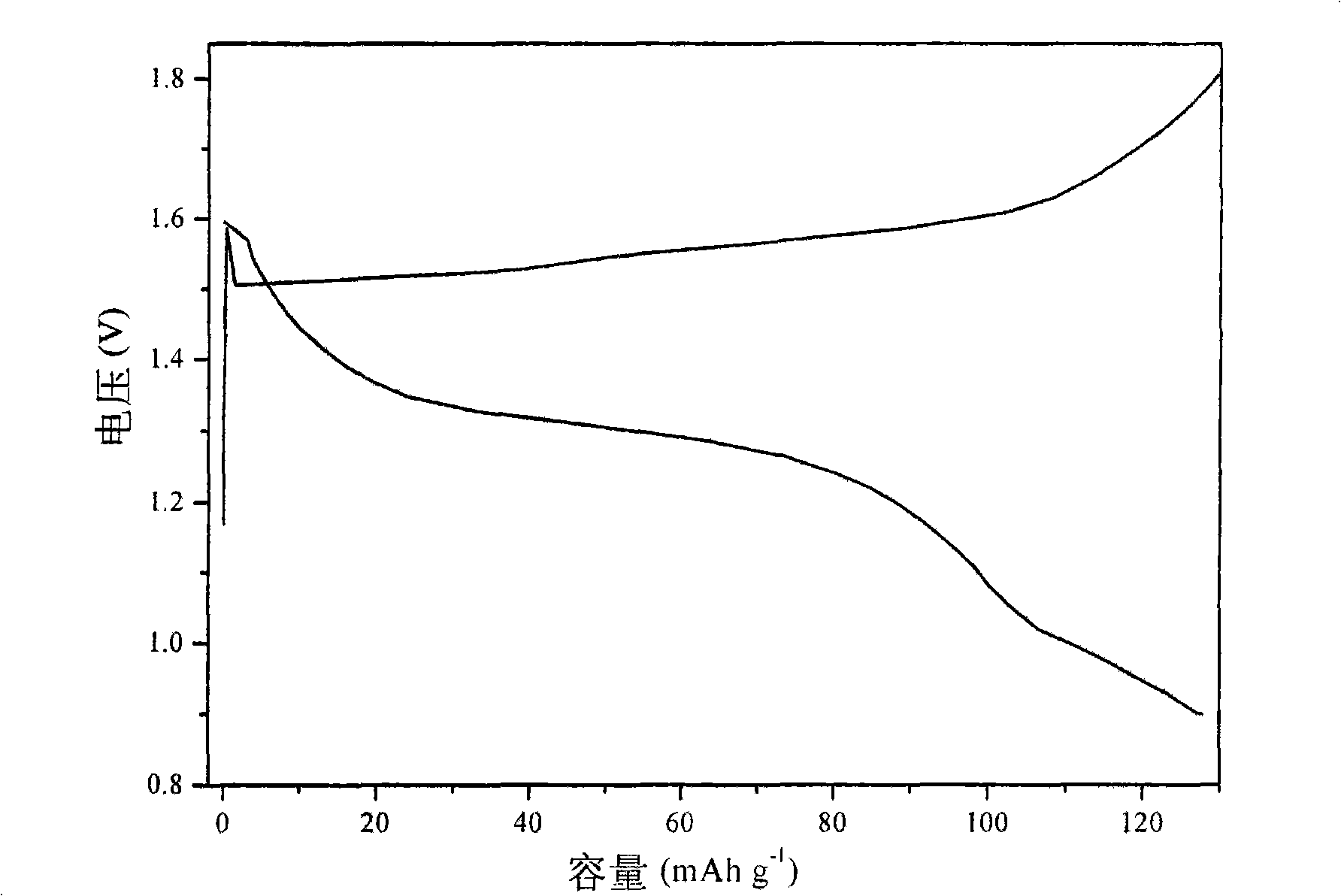

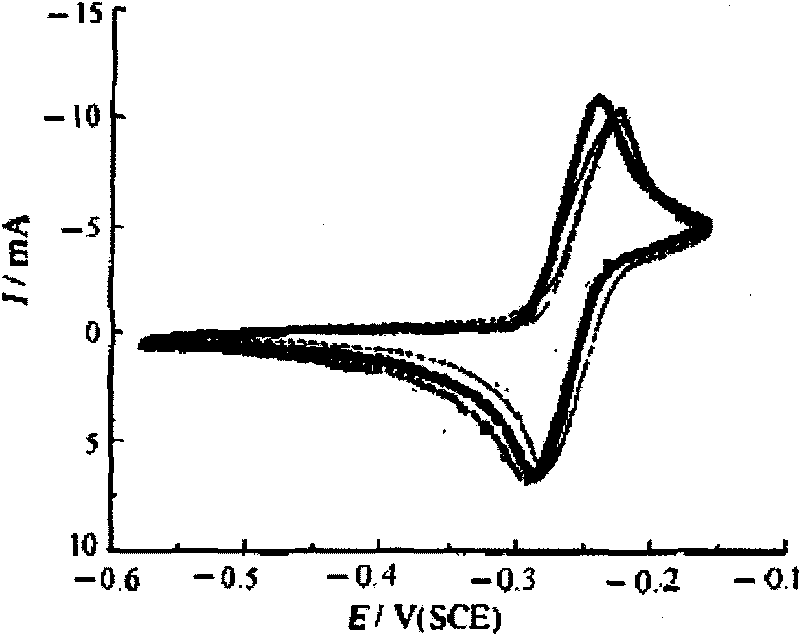

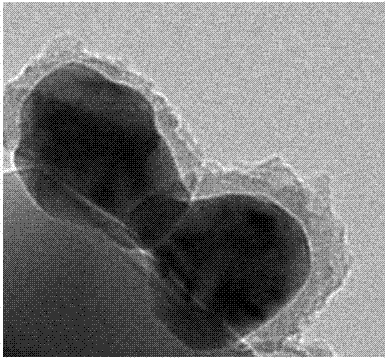

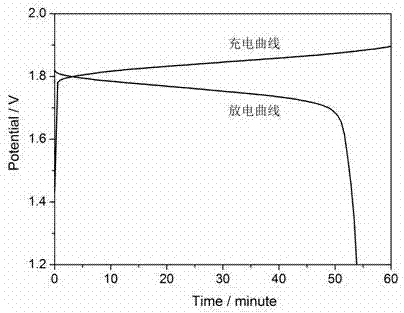

Chargeable zinc ion battery

ActiveCN101540417AImproved magnification performanceGood reversibilityAlkaline accumulatorsActive material electrodesZinc ionManganese

The invention discloses a chargeable zinc ion battery, which comprises an anode, a cathode, isolating membrane arranged between the anode and the cathode, and electrolyte which contains the anion and the cation and has ionicconductivity, wherein the cathode adopts active materials which are mainly zinc elements, the active materials of the anode are oxide materials of manganese which can occlude and release zinc ions, the electrolyte is liquid or gel materials with ionicconductivity which adopts the soluble salt of zinc as solute and water as solvent, and the pH value of the electrolyte lies between 3 and 7. The battery has the characteristics of high capacity, chargeable property, long cycle life and the like. Proven by experiments, the chargeable zinc ion battery has excellent rate performance, reversible performance and cycle performance.

Owner:SHENZHEN CITY THROUGH SCI & TECH OF NEW ENERGY CO LTD

Anode for nonaqueous secondary electrochemical cells

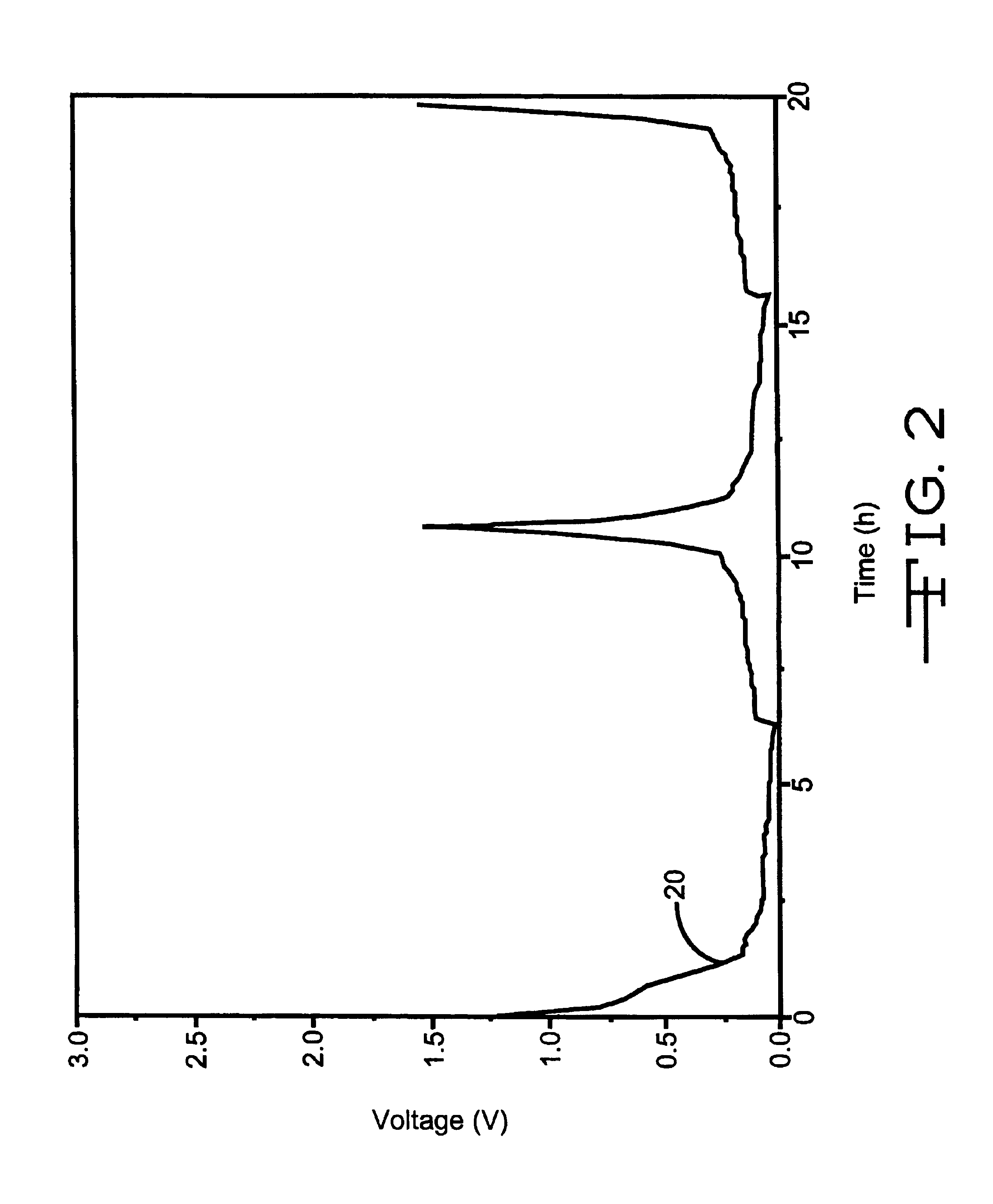

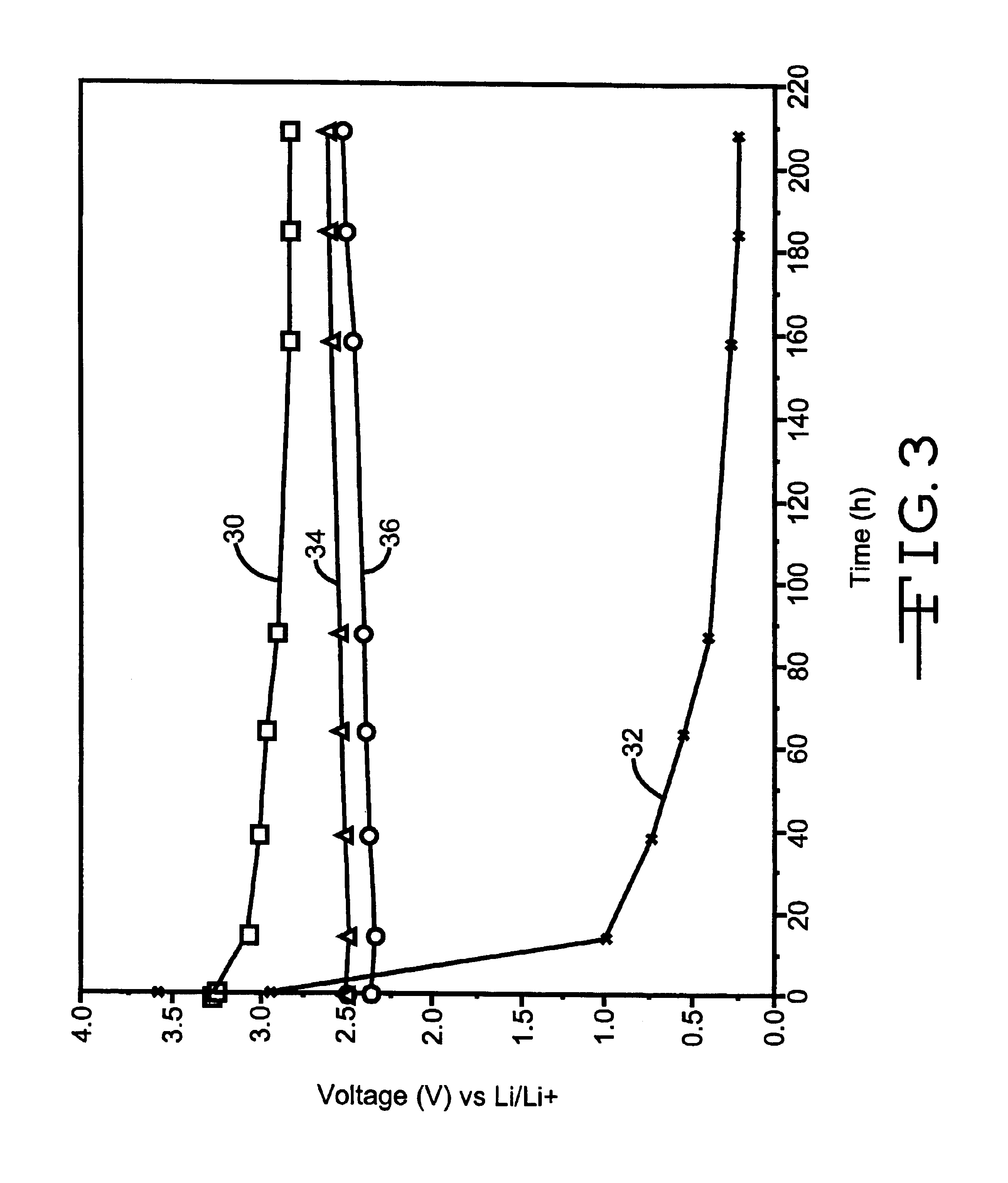

InactiveUS6730437B2Improve performanceAvoid corrosionSilver accumulatorsElectrode carriers/collectorsGraphiteMetallic sulfide

The negative electrode or anode for a secondary electrochemical cell comprising a mixture of graphite or "hairy carbon" and a lithiated metal oxide, a lithiated mixed metal oxide or a lithiated metal sulfide, and preferably a lithiated metal vanadium oxide, is described. A most preferred formulation is graphite mixed with lithiated silver vanadium oxide or lithiated copper silver vanadium oxide.

Owner:WILSON GREATBATCH LTD

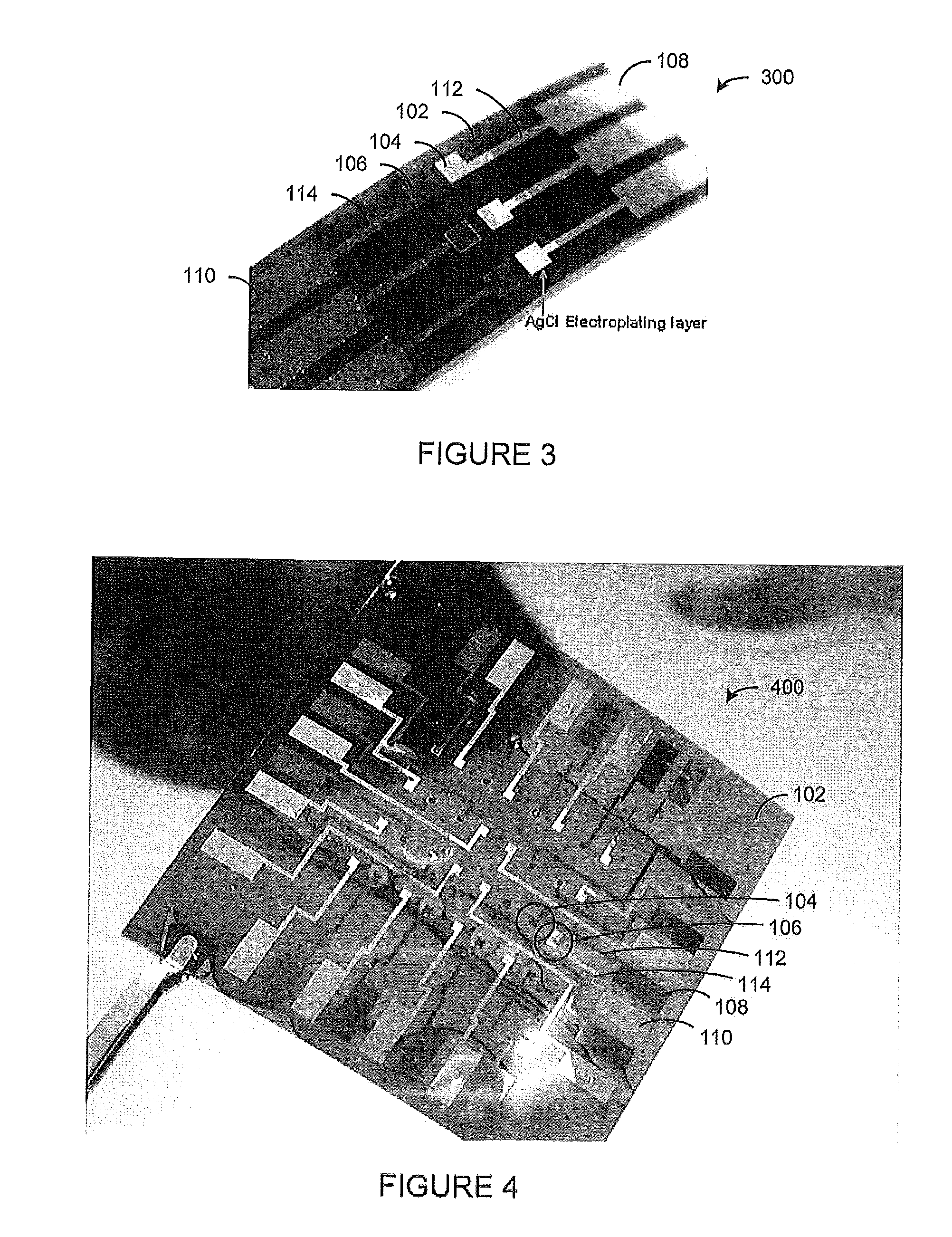

Amorphous irox film ph sensor

ActiveUS20110140703A1Good stabilityLess driftMaterial analysis by electric/magnetic meansSuperimposed coating processPhysicsPolymer substrate

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

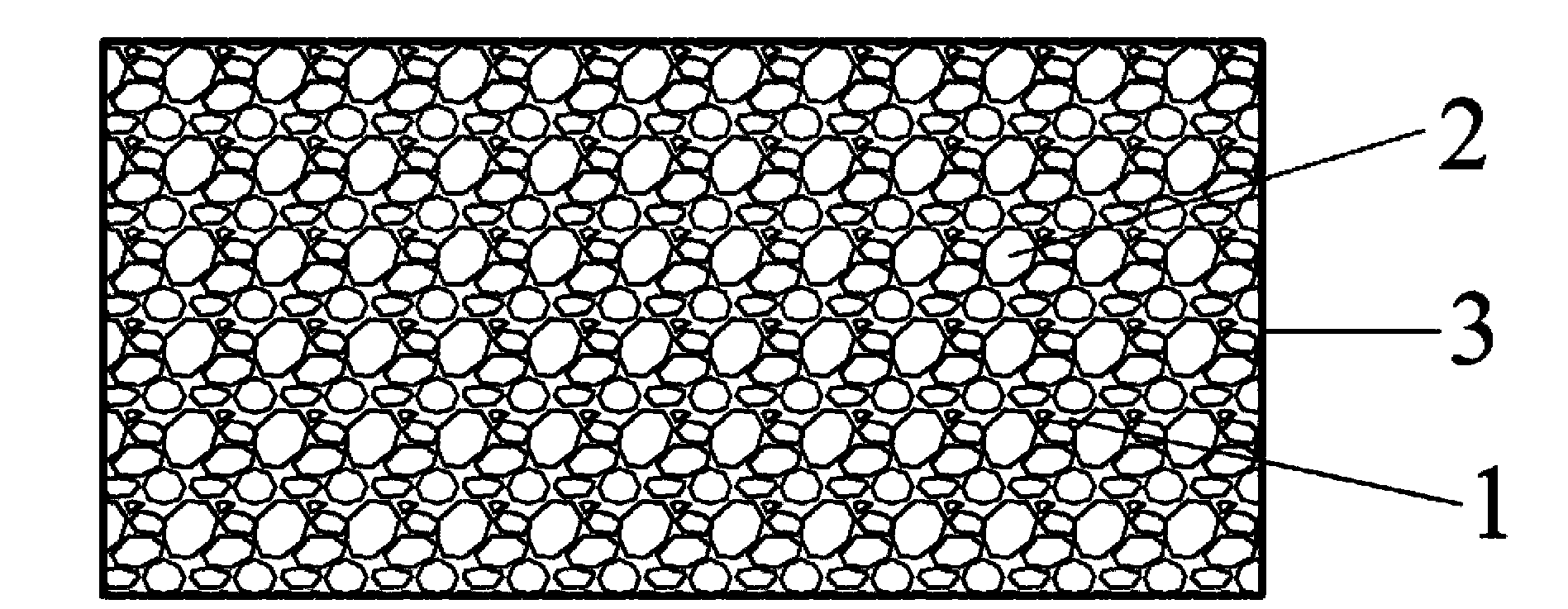

Composite phase-change thermal storage material

ActiveCN104140786AHigh freeze-thaw rateHigh thermal conductivityHeat-exchange elementsLiquid metalVolumetric Mass Density

The invention provides a composite phase-change thermal storage material. A porous material with high thermal conductivity is used as a supporting framework, and low-melting-point metal or low-melting-point metal with nano-particles is distributed in pores of the porous material, wherein melting point or solidus temperature of the low-melting-point metal is less than or equal to 80 DEG C; and thermal conductivity of the porous material is within 40-400 W / (m.K). The material provided by the invention has high equivalent thermal conductivity and high storage energy density; there is a large contact area between the liquid metal and the porous material; and the material has a wide application temperature range, has good fixability, stable physico-chemical property and good reversibility; and the problem of decreasing heat storage efficiency after multiple times of heat adsorption and release cycles is avoided.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Lithium-containing complex oxide, non-aqueous secondary battery using the lithium-containing complex oxide, and method for producing the lithium-containing complex oxide

InactiveUS20050260496A1Stable structureIncreased durabilityElectrode thermal treatmentOrganic electrolyte cellsLithiumHigh density

Because of the composition represented by General Formula: Li1+x+αNi(1−x−y+δ) / 2MyO2 (where 0≦x≦0.05, −0.05≦x+α≦0.05, 0≦y≦0.4; −0.1≦δ≦0.1 (when 0≦y≦0.2) or −0.24≦δ≦0.24 (when 0.2<y≦0.4); and M is at least one element selected from the group consisting of Ti, Cr, Fe, Co, Cu, Zn, Al, Ge and Sn), a high-density lithium-containing complex oxide with high stability of a layered crystal structure and excellent reversibility of charging / discharging can be provided, and a high-capacity non-aqueous secondary battery excellent in durability is realized by using such an oxide for a positive electrode.

Owner:MAXELL HLDG LTD

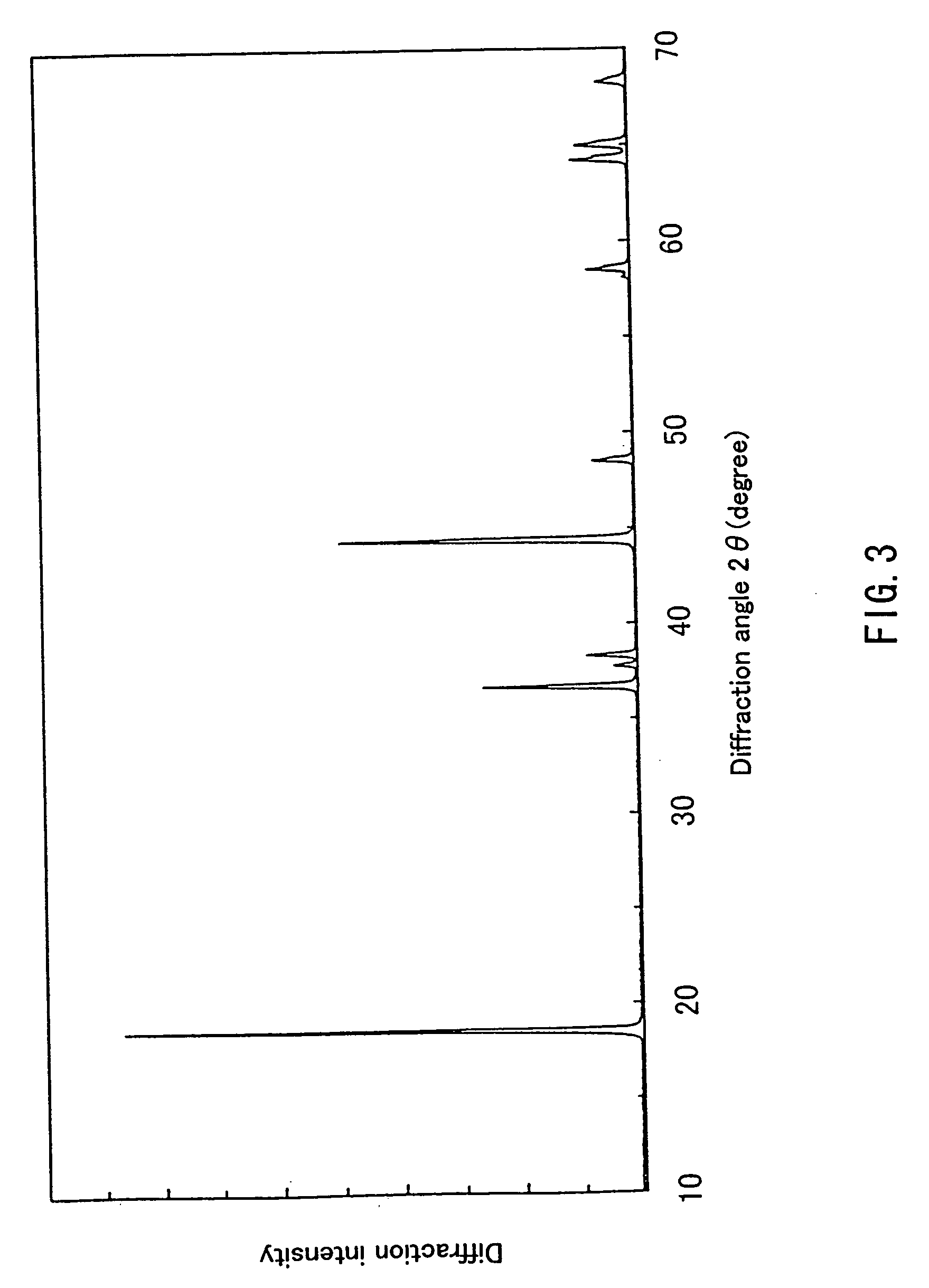

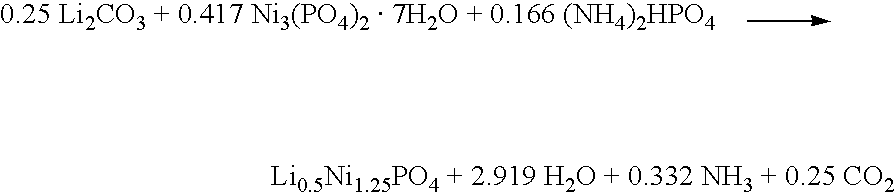

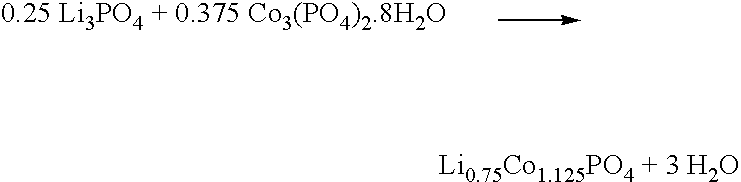

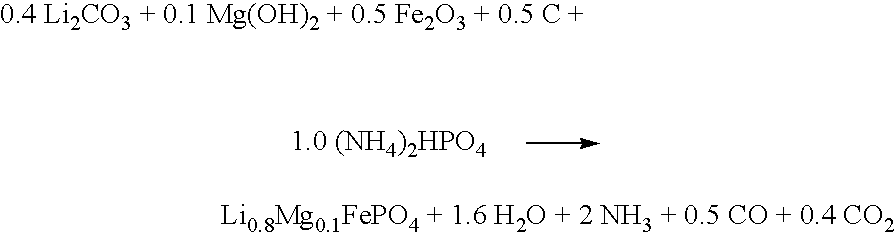

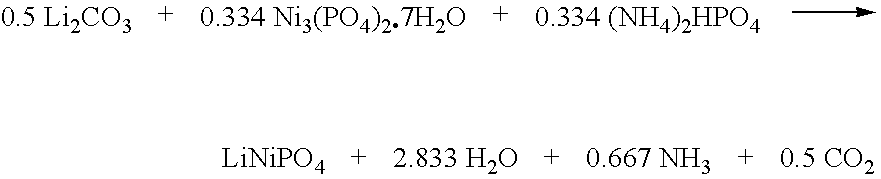

Alkali/transition metal phosphates and related electrode active materials

InactiveUS7087346B2Increase capacityImprove cycle performanceElectrode thermal treatmentOrganic electrolyte cellsLithiumPhosphate

Electrode active materials comprising lithium or other alkali metals, a transition metal, and a phosphate or similar moiety, of the formula:Aa+xMbP1−xSixO4wherein(a) A is selected from the group consisting of Li, Na, K, and mixtures thereof, and 0<a<1.0 and 0≦x≦1;(b) M comprises one or more metals, comprising at least one metal which is capable of undergoing oxidation to a higher valence state, where 0<b≦2; andwherein M, a, b, and x are selected so as to maintain electroneutrality of said compound.

Owner:VALENCE TECH INC

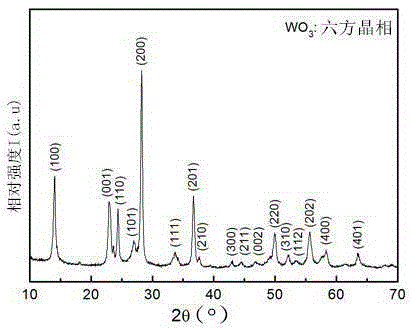

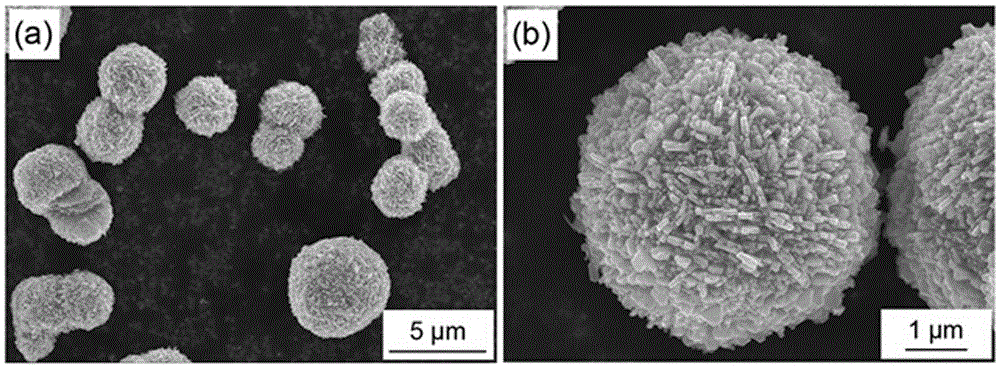

Gas sensor based on graded porous WO3 microspheres and preparation method thereof

ActiveCN105301062AGood reversibilityGood choiceSemi-permeable membranesVolume/mass flow by thermal effectsPorosityDispersity

The invention belongs to the technical field of semiconductor oxide gas sensors, and particularly relates to a gas sensor based on graded porous WO3 microspheres and a preparation method thereof. A gas-sensitive coating in the gas sensor based on the graded porous WO3 microspheres is prepared from the graded porous WO3 microspheres, the graded porous WO3 microspheres have single hexagonal-phase crystal structures and are uniform in body size and good in individual dispersity, the diameter of the graded porous WO3 microspheres is 3-5 micrometers, and each graded porous WO3 microsphere is formed by assembling WO3 nanorods with the diameter being at the nanoscale and has a large specific surface area and high porosity. According to the preparation method, hydro-thermal synthesis is performed in the presence of a mixing assistant, and the graded porous WO3 microspheres are obtained and assembled to form the finished product. The gas sensor based on the graded porous WO3 microspheres has the advantages of being low in working temperature, high in sensitivity, low in energy consumption, high in selectivity and the like.

Owner:NORTHEASTERN UNIV

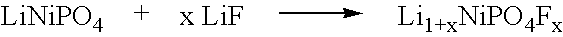

Alkali/transition metal halo-and hydroxy-phosphates and related electrode active materials

InactiveUS20060014078A1Increase capacityImprove cycle performancePositive electrodesLi-accumulatorsHalogenPhosphate

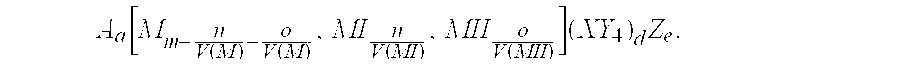

The present invention relates to novel battery having a first electrode comprising an electrode active material represented by the general formula AaMb(XY4)2Zd, a second electrode which is a counter-electrode to the first electrode; and an electrolyte.

Owner:LITHIUM WERKS TECH BV

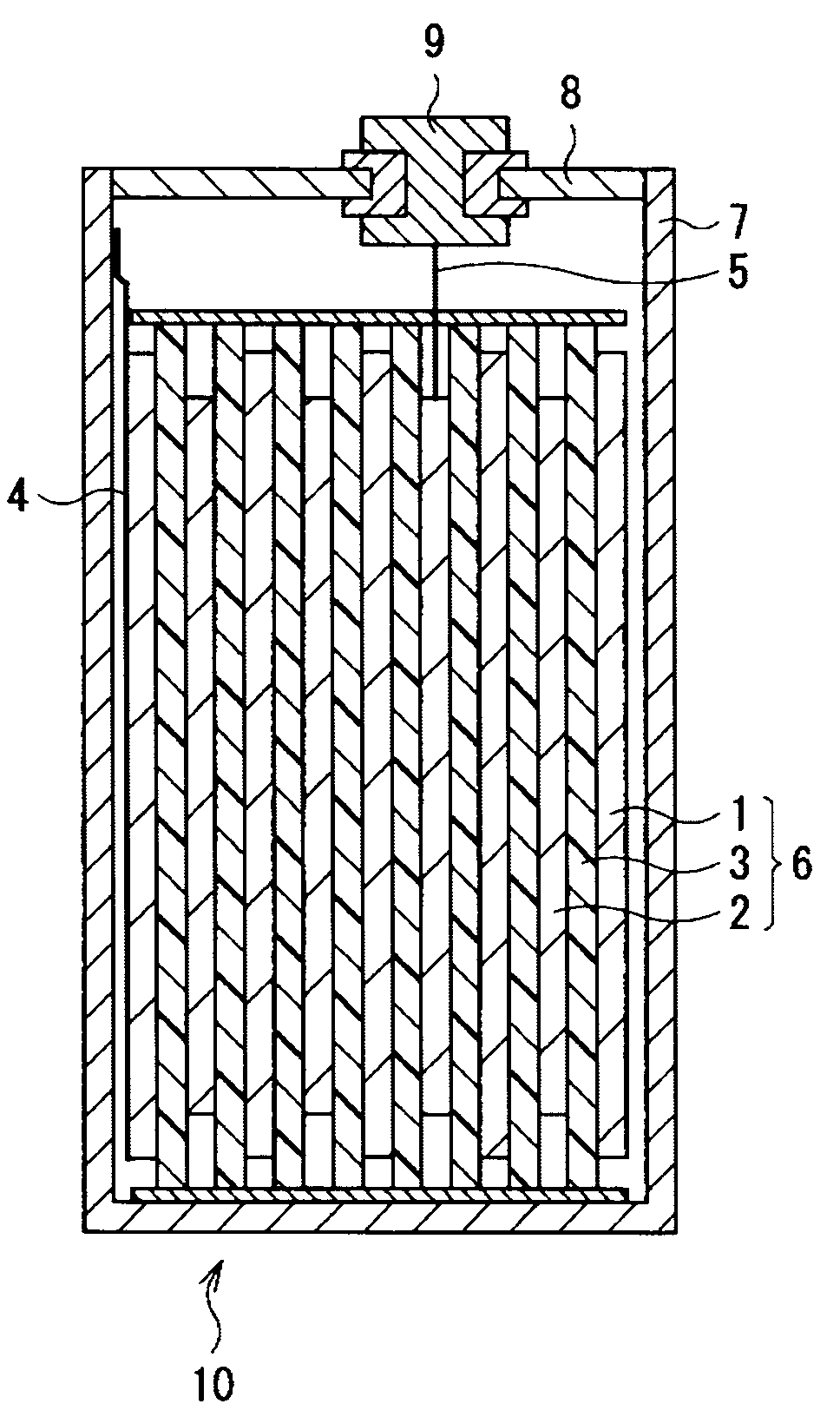

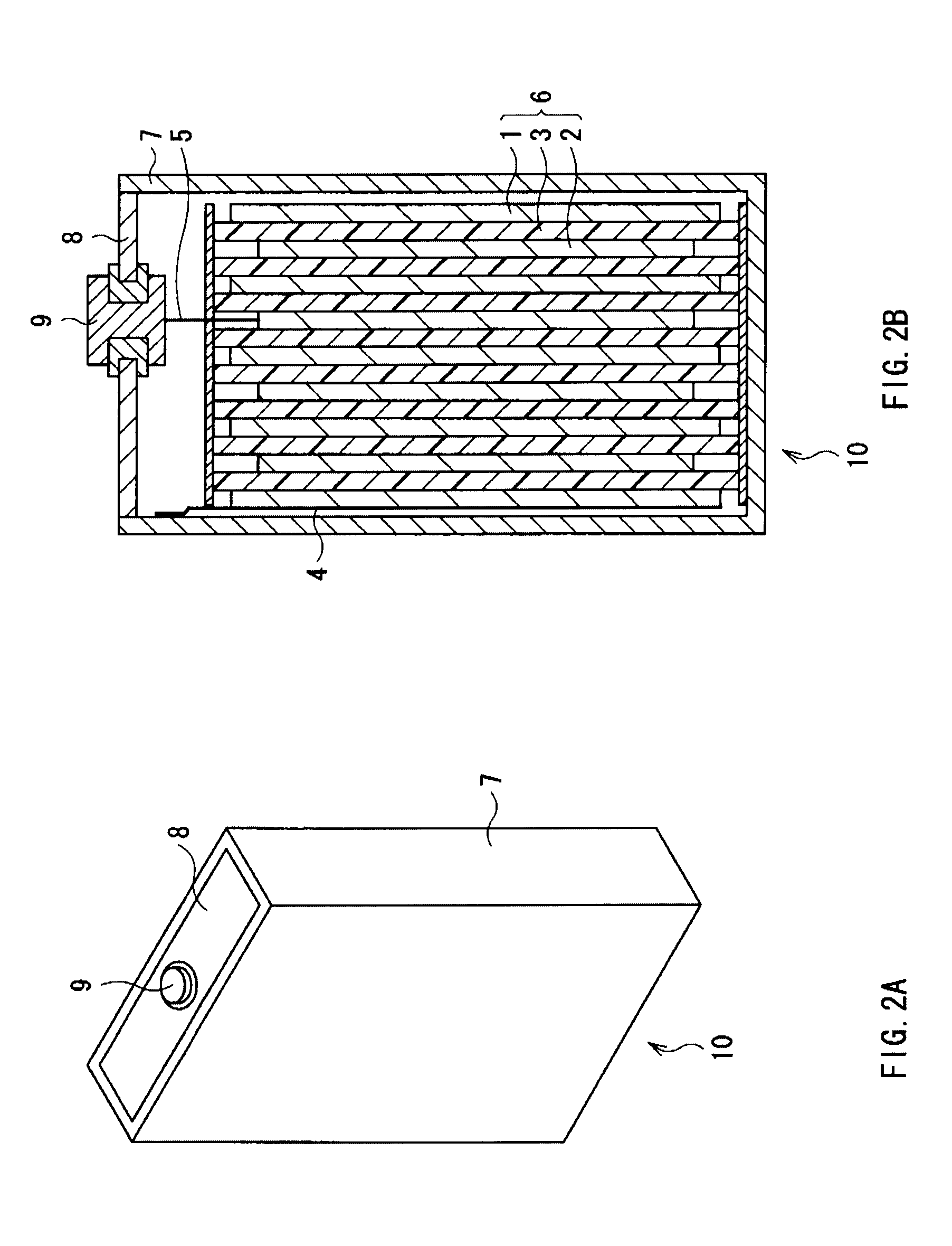

Anode for secondary battery, method of manufacturing it, and secondary battery

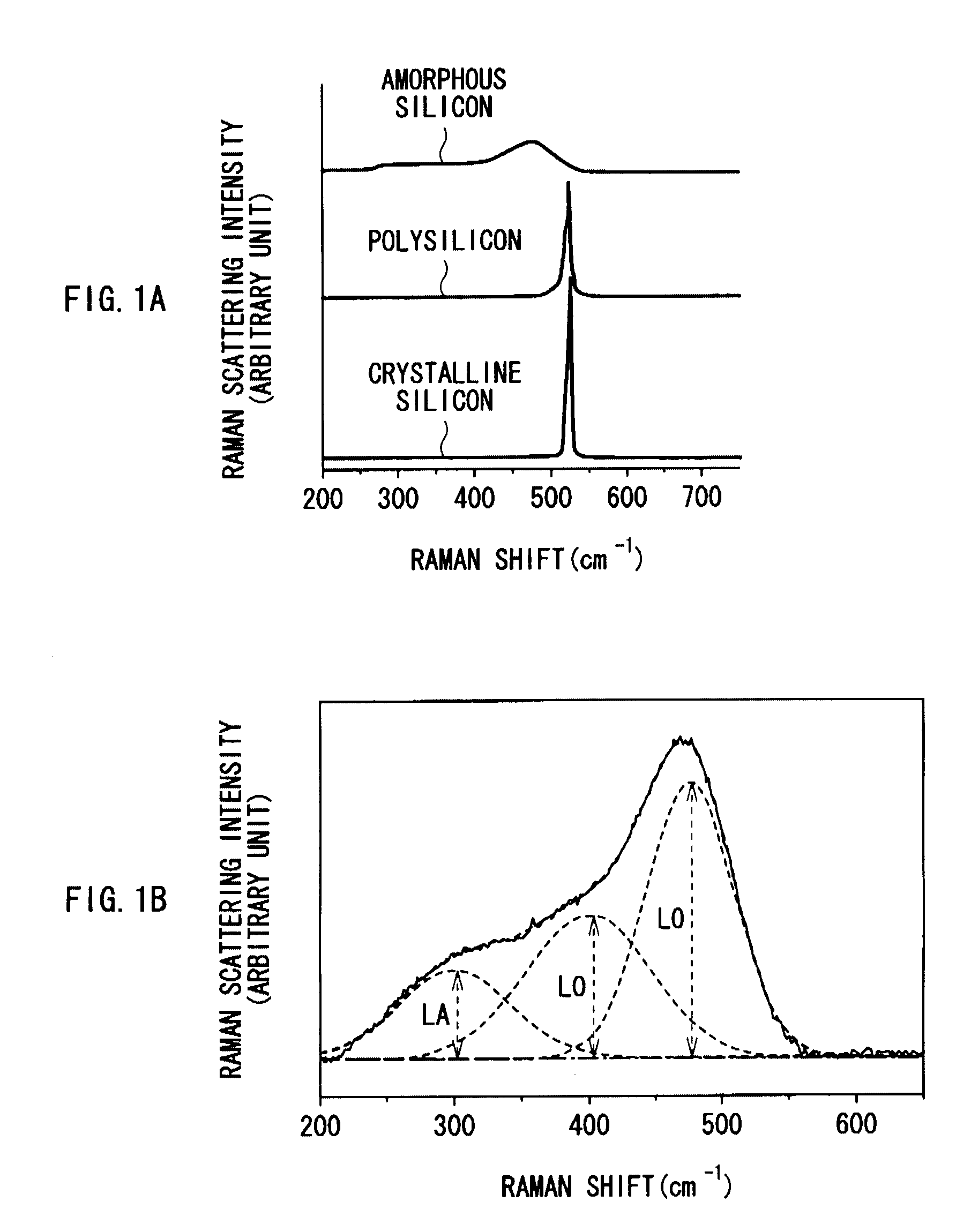

InactiveUS20090068567A1Different degreeLow degreeAlkaline accumulatorsElectrode manufacturing processesAcoustic PhononsSilicon

An anode for secondary battery is provided with an anode active material layer containing silicon on an anode current collector. Silicon in the anode active material has an amorphous structure. In a Raman spectrum of silicon having the amorphous structure after an initial charge and discharge, 0.25≦LA / TO and / or 45≦LO / TO is satisfied, where an intensity of a scattering peak occurred in the vicinity of shift position 480 cm−1 based on scattering due to transverse optical phonon is TO, an intensity of a scattering peak occurred in the vicinity of shift position 300 cm−1 based on scattering due to longitudinal acoustic phonon is LA, and an intensity of a scattering peak occurred in the vicinity of shift position 400 cm−1 based on scattering due to longitudinal optical phonon is LO.

Owner:SONY CORP

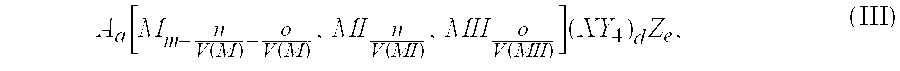

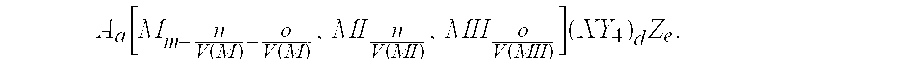

Secondary battery electrode active materials and methods for making the same

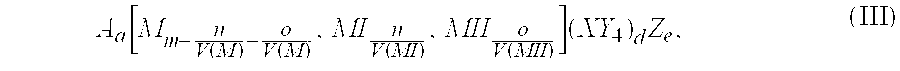

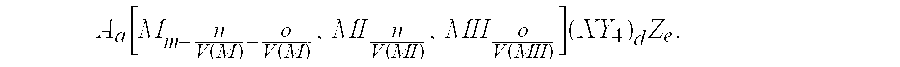

InactiveUS7008726B2Limit scopeIncrease capacitySilver accumulatorsPhosphatesElectrochemical cellBattery electrode

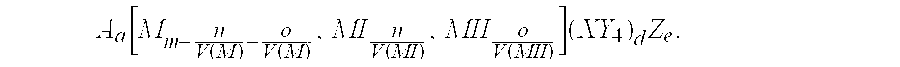

The invention provides an electrochemical cell which includes a first electrode and a second electrode which is a counter electrode to said first electrode, and an electrolyte material interposed there between. The first electrode comprises an electrode active material represented by the general nominal formula Aa[Mm,MIn,MIIo](XY4)dZe, wherein at least one of M, MI and MII is a redox active element, 0<m,n,o≦4, and ½[V(MI)+V(MII)]=V(M), wherein V(M) is the valence state of M, V(MI) is the valence state of MI, and V(MII) is the valence state of MII.

Owner:VALENCE TECH INC

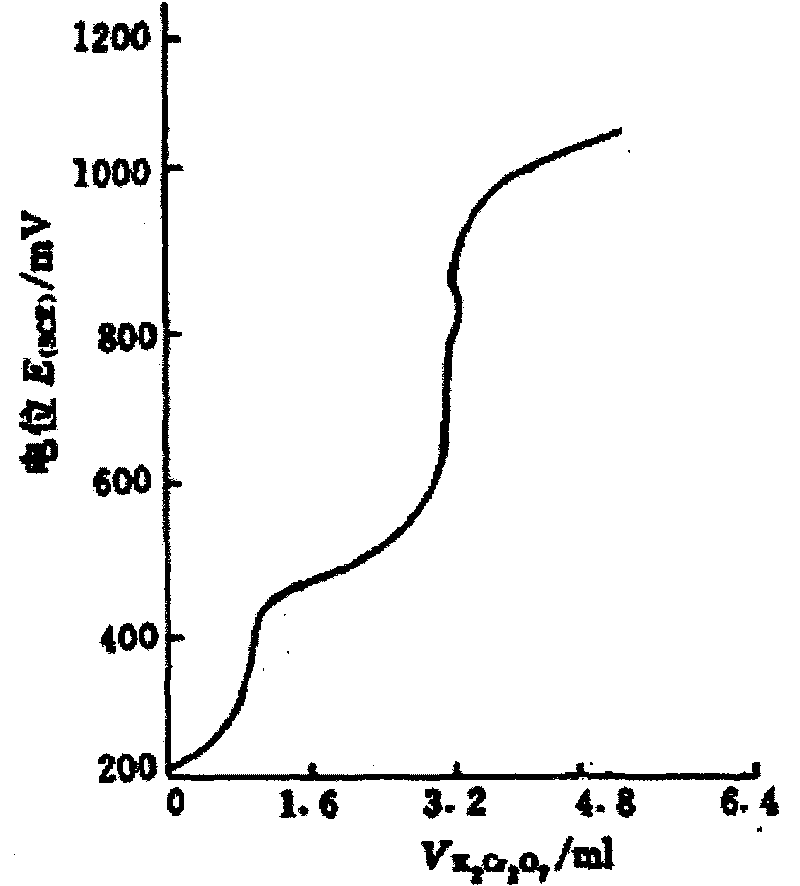

Method for preparing vanadium redox battery negative pole electrolyte

ActiveCN101728560AImproved resistance to low temperature environmentsImprove stabilityFinal product manufactureRegenerative fuel cellsVanadium redox batteryNitrogen

The invention relates to the field of battery manufacturing, in particular to a method for preparing vanadium redox battery negative pole electrolyte, which is characterized in that industrial high purity V2O3 is adopted as raw material, proper additive and reducing agent are added into the raw material, and the vanadium redox battery negative pole electrolyte is directly prepared by a chemical method under the protection of high purity nitrogen. The method has the advantages of easily obtained raw material, low cost, simple reaction condition as well as simple and convenient operation; the prepared electrolyte is high in total vanadium concentration and good in stability, and has the using performance to be obviously improved in the low temperature environment; and the method is suitable for industrialized production.

Owner:承德新新钒钛储能科技有限公司

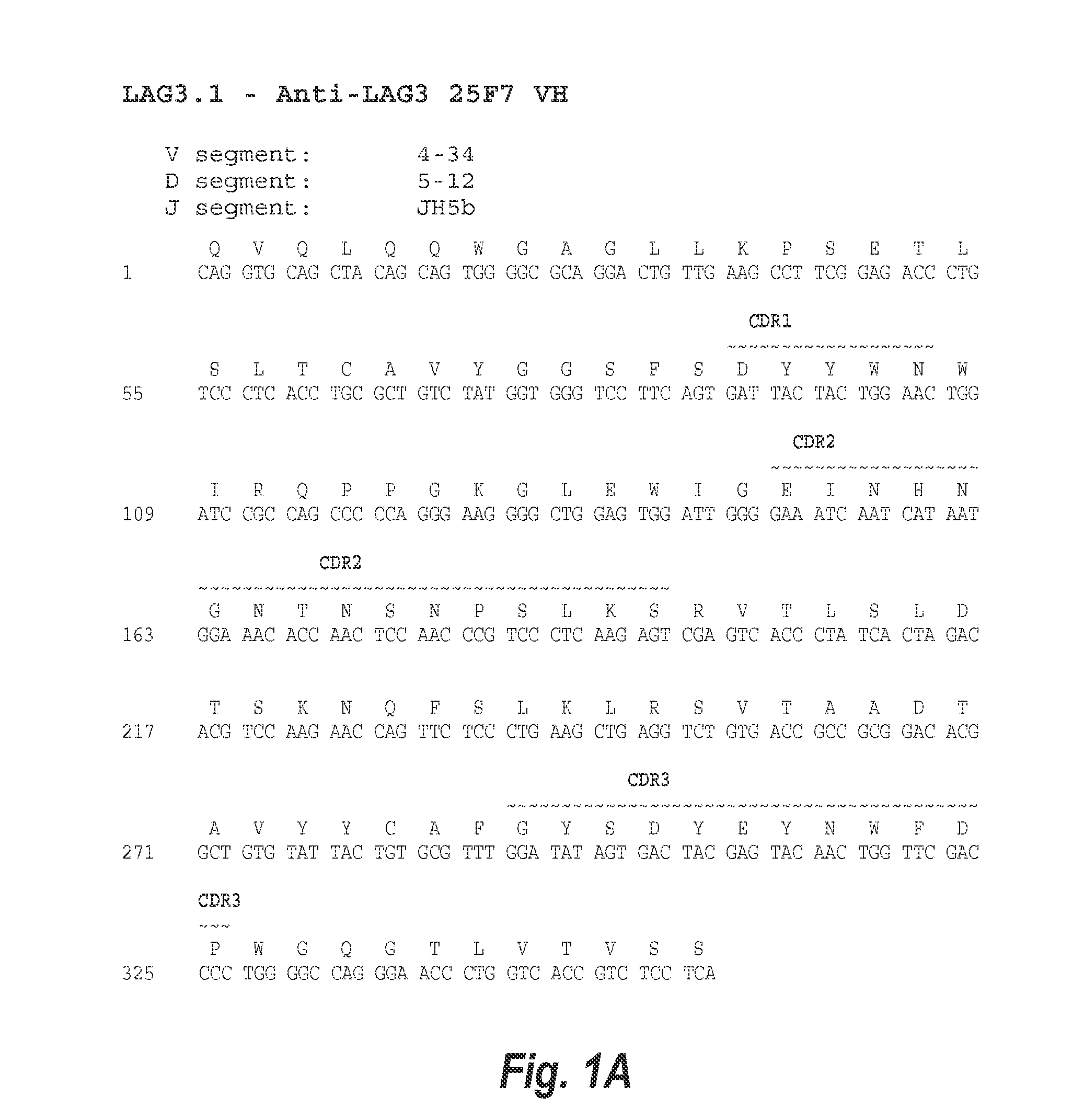

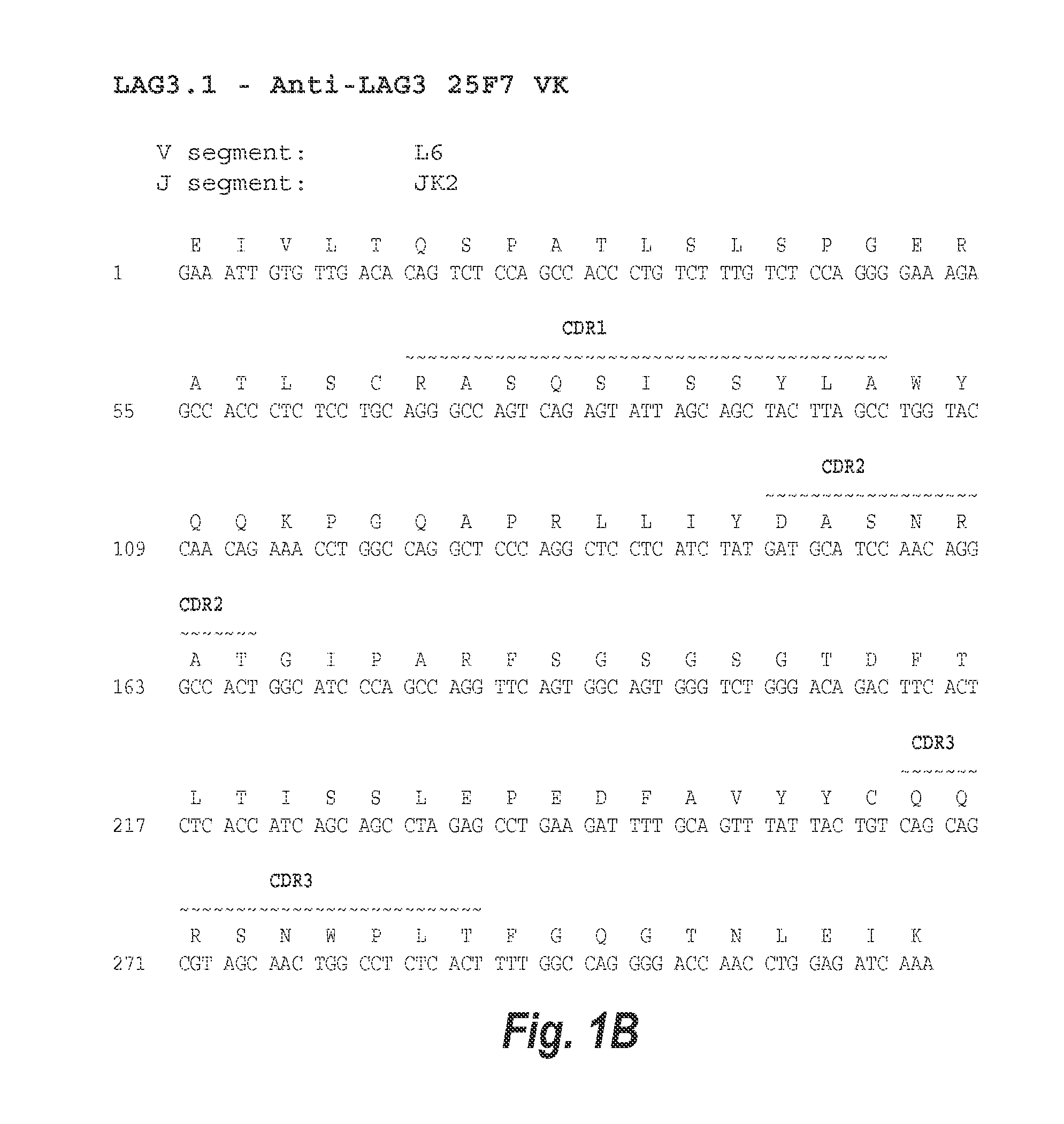

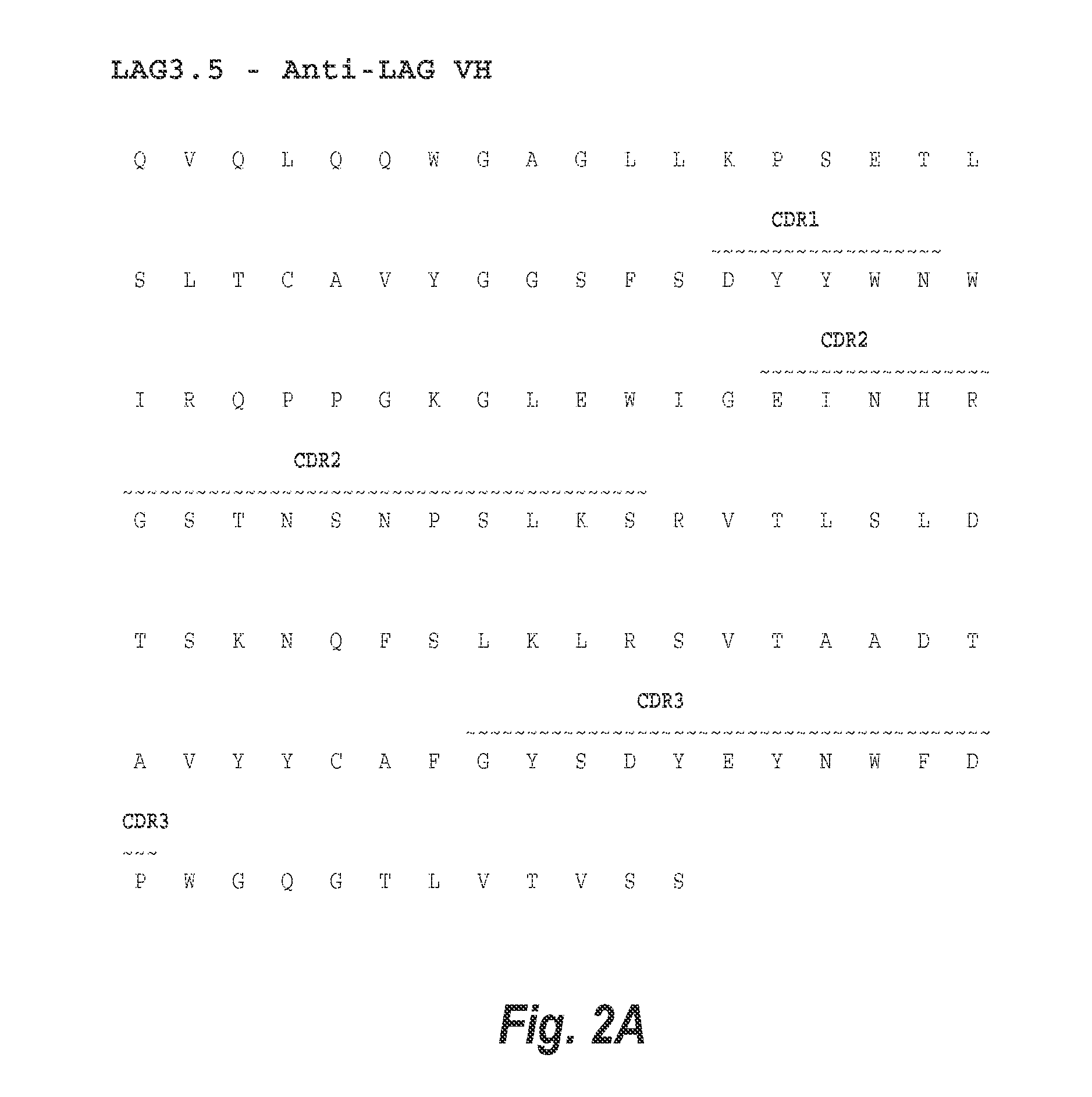

Optimization of antibodies that bind lymphocyte activation gene-3 (lag-3), and uses thereof

InactiveUS20150307609A1Improve stabilityHigh binding affinitySugar derivativesImmunoglobulins against cell receptors/antigens/surface-determinantsLymphocyteLymphocyte activation

The present invention provides isolated monoclonal antibodies that specifically bind LAG-3, and have optimized functional properties compared to previously described anti-LAG-3 antibodies, such as antibody 25F7 (US 2011 / 0150892 A1). These properties include reduced deamidation sites, while still retaining high affinity binding to human LAG-3, and physical (i.e., thermal and chemical) stability. Nucleic acid molecules encoding the antibodies of the invention, expression vectors, host cells and methods for expressing the antibodies of the invention are also provided, as well as immunoconjugates, bispecific molecules and pharmaceutical compositions comprising the antibodies. The present invention also provides methods for detecting LAG-3, as well as methods for treating stimulating immune responses using an anti-LAG-3 antibody of the invention. Combination therapy, in which the antibodies are co-administered with at least one additional immunostimulatory antibody, is also provided.

Owner:MEDAREX INC

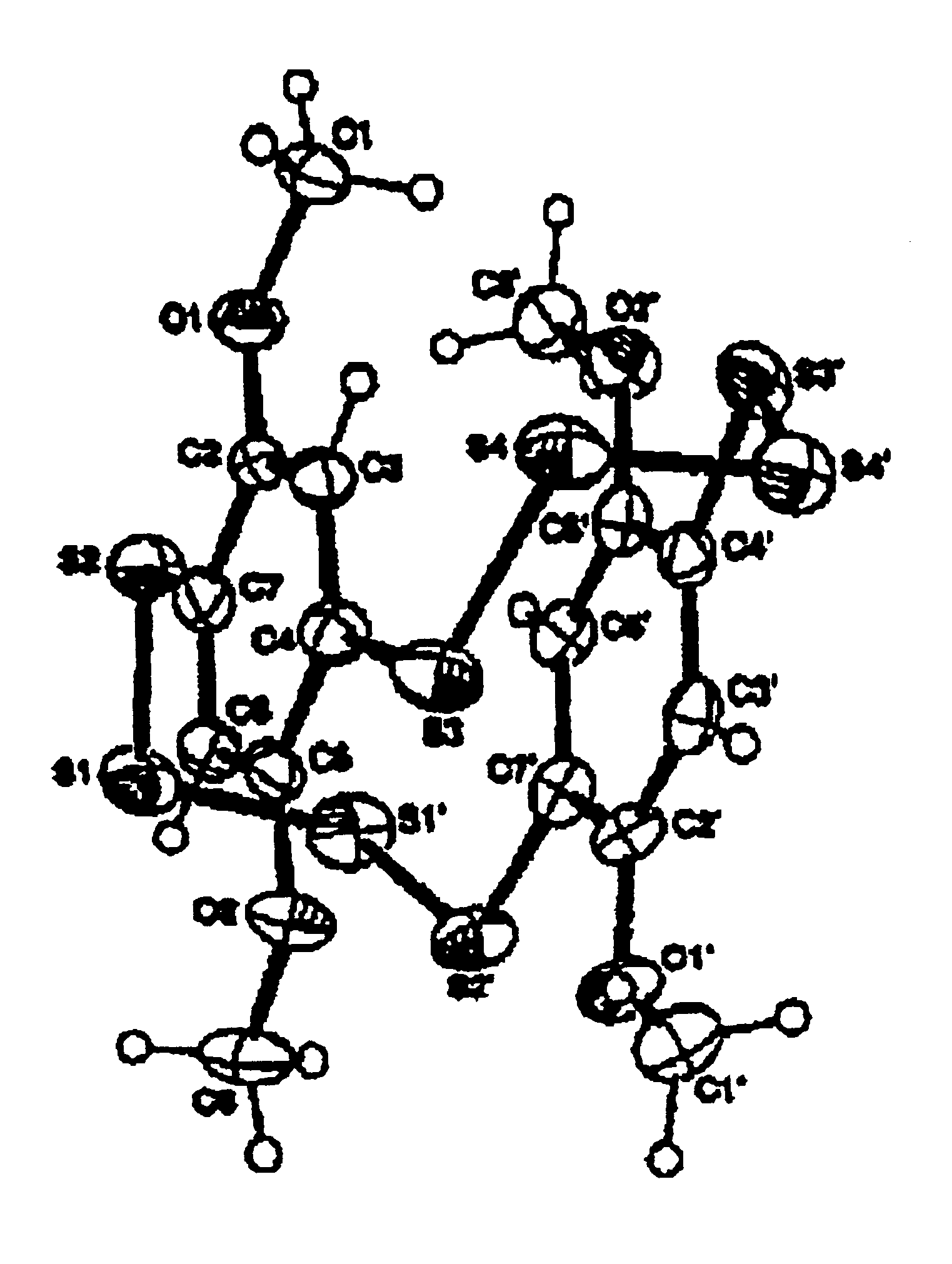

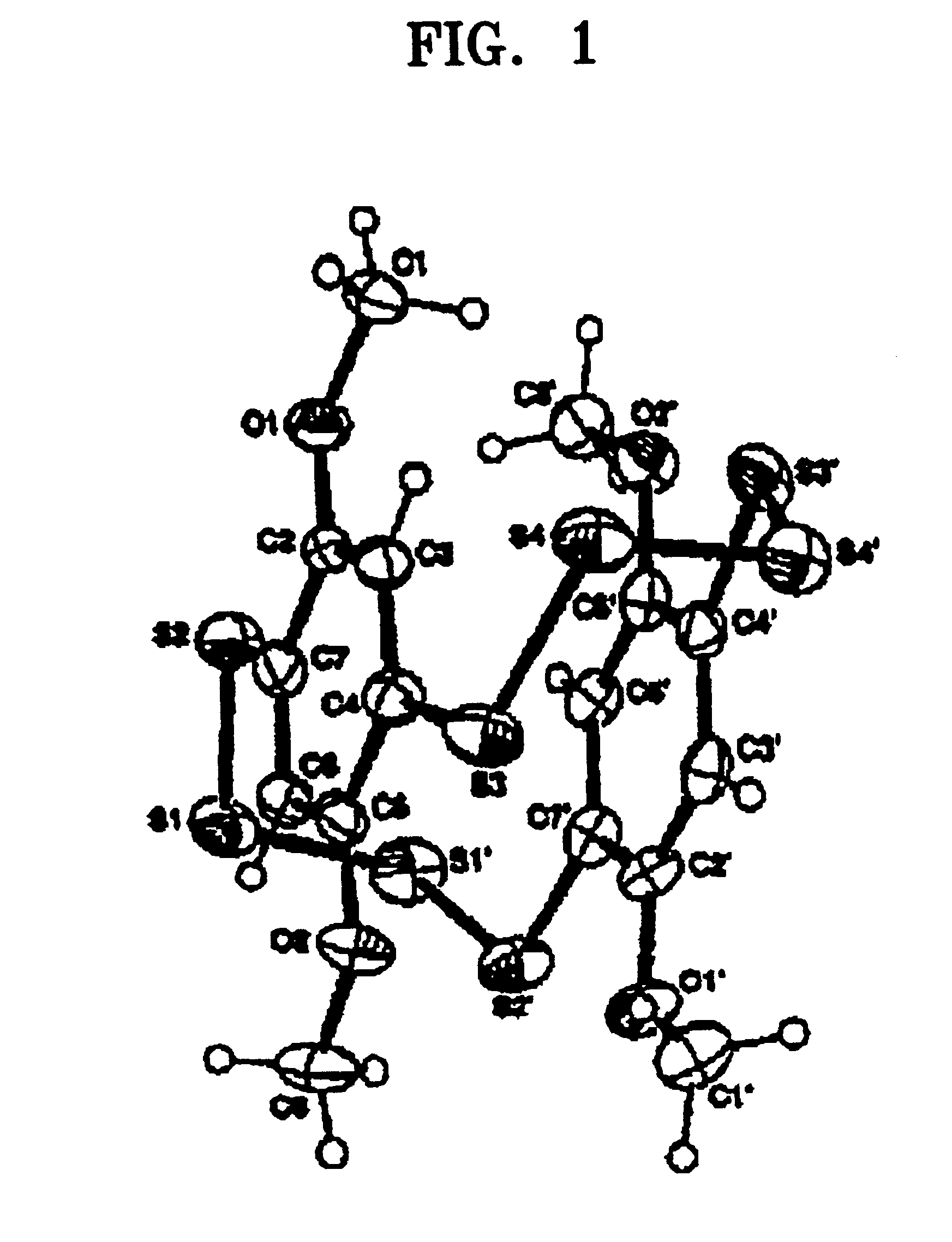

Alkali/transition metal halo- and hydroxy-phosphates and related electrode active materials

InactiveUS6964827B2Increase capacityImprove cycle performancePhosphatesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesHalogenPhosphate

The present invention relates to novel electrode active materials represented by the general formula AaMb(XY4)cZd, wherein:(a) A is one or more alkali metals, and 0<a≦8;(b) M is at least one metal capable of undergoing oxidation to a higher valence state, and 1≦b≦3;(c) XY4 is selected from the group consisting of X′O4−xY′x, X′O4−yY′2y, X″S4, and a mixture thereof, where X′ is P, As, Sb, Si, Ge, S, and mixtures thereof; X″ is P, As, Sb, Si, Ge, and mixtures thereof, Y′ is halogen, 0≦x<3, 0<y<4, and 0<c≦3; and(d) Z is OH, a halogen, mixtures thereof, and 0<d≦6.

Owner:VALENCE TECH INC

Secondary battery electrode active materials and methods for making the same

InactiveUS20050164084A1Limit scopeIncrease capacitySilver accumulatorsPhosphatesPhysical chemistryElectrochemical cell

The invention provides an electrochemical cell which includes a first electrode and a second electrode which is a counter electrode to said first electrode, and an electrolyte material interposed there between. The first electrode comprises an electrode active material represented by the general nominal formula Aa[Mm,MIn,MIIo](XY4)dZe, wherein at least one of M, MI and MII is a redox active element, 0<m,n,o≦4, and ½[V(MI)+V(MII)]=V(M), wherein V(M) is the valence state of M, V(MI) is the valence state of MI, and V(MII) is the valence state of MII.

Owner:VALENCE TECH INC

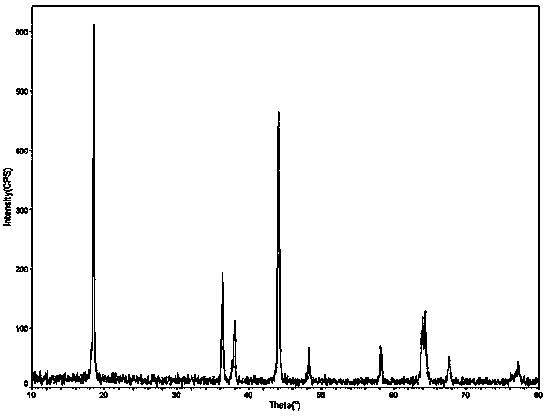

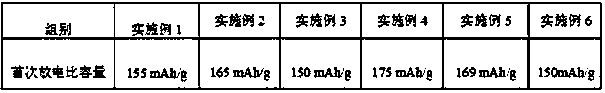

Anode material for lithium ion battery

The invention belongs to the technical field of lithium ion batteries, and particularly relates to an anode material for a lithium ion battery. The anode material is in a laminated structure, and the expression of the anode material is Li1+zNixMnyA1-x-yO2; the anode material further comprises a metal oxide or a metal fluoride coated on the surface of the Li1+zNixMnyA1-x-yO2. Compared with the prior art, according to the Li1+zNixMnyA1-x-yO2 provided by the invention, although x is greater than 0.5, and an appropriate synthetic process is adopted, the structure thereof is extremely stable, and the cycle performance of the anode material for the lithium ion battery containing the anode material is good; moreover, the content of Ni is high, thus the specific capacity of the anode material disclosed by the invention is higher and achieves more than 130 mAh / g; moreover, the material is in the laminated structure, so that the multiplying performance is good, and the lithium ion battery can be quickly charged or discharged.

Owner:HUNAN LIFANG NEW ENERGY SCI & TECH

Reversible electric fuse and antifuse structures for semiconductor devices

ActiveUS20080157269A1Improve electromigration problemsGood reversibilitySemiconductor/solid-state device detailsSolid-state devicesDevice materialElectric fuses

A structure and method of fabricating reversible fuse and antifuse structures for semiconductor devices is provided. In one embodiment, the method includes forming at least one line having a via opening for exposing a portion of a plurality of interconnect features; conformally depositing a first material layer over the via opening; depositing a second material layer over the first material layer, wherein the depositing overhangs a portion of the second material layer on a top portion of the via opening; and depositing a blanket layer of insulating material, where the depositing forms a plurality of fuse elements each having an airgap between the insulating material and the second material layer. The method further includes forming a plurality of electroplates in the insulator material connecting the fuse elements. In another embodiment, the method includes depositing a first and a second material layer on a semiconductor substrate, wherein the second material layer having a higher electrical conductivity than the first material layer; selectively etching the first and second material layer to create at least one constricted region to facilitate electromigration of the second material; wherein the electromigration creates a plurality of micro voids; and forming a plurality of electrical contacts on the second material layer.

Owner:GLOBALFOUNDRIES US INC

Alkali/transition metal halo-and hydroxy-phosphates and related electrode active materials

InactiveUS7214448B2Increase capacityImprove cycle performanceOrganic electrolyte cellsSecondary cellsHalogenPhosphate

The present invention relates to novel electrode active materials represented by the general formula AaMb(XY4)2Zd, wherein:(a) A is one or more alkali metals, and 0<a≦8;(b) M is at least one metal capable of undergoing oxidation to a higher valence state, and 1≦b≦3;(c) XY4 is selected from the group consisting of X′O4−xY′x, X′O4−yY′2−y, X″S4, and a mixture thereof, where X′ is P, As, Sb, Si, Ge, S, and mixtures thereof; X″ is P, As, Sb, Si, Ge, and mixtures thereof, Y′ is halogen, 0≦x<3, 0<y<4, and 0<c≦3; and(d) Z is OH, a halogen, or mixtures thereof, and 0<d≦6.

Owner:VALENCE TECH INC

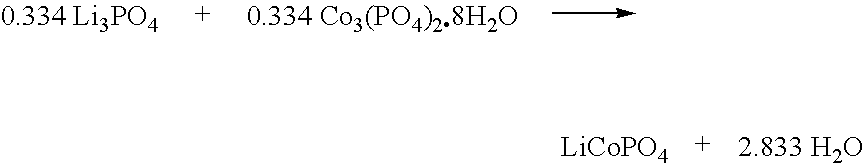

Polypyrrole-clad nano spherical zinc oxide material and preparation method

ActiveCN107275611ASuppress generationLong cycle lifeMaterial nanotechnologyCell electrodesPolypyrroleZno nanoparticles

The invention relates to a polypyrrole-clad nano spherical zinc oxide material with a core-shell structure and a preparation method. The polypyrrole-clad nano spherical zinc oxide material takes nano spherical zinc oxide as a core and polypyrrole as a shell cladding the surface of a zinc oxide particle. The preparation method comprises the steps of adding a precipitant such as hexamine to a zinc source, preparing a nano spherical zinc oxide particle by a hydrothermal reaction, adding nano zinc oxide to a solution containing a surfactant to form zinc oxide sol, adding a pyrrole monomer and an oxidant, performing in-situ oxidation polymerization, and forming a polypyrrole-clad layer on the surface of the zinc oxide particle. The prepared polypyrrole-clad nano zinc oxide material with the core-shell structure has a larger specific surface area; the activity of the nano zinc oxide material is improved; aggregation of the nano zinc oxide particle can be well avoided; existing of the polypyrrole-clad layer effectively alleviates pine-tree crystal forming of the zinc oxide particle in charging and discharging processes; and the cycle life of an electrode is significantly prolonged.

Owner:NANCHANG HANGKONG UNIVERSITY

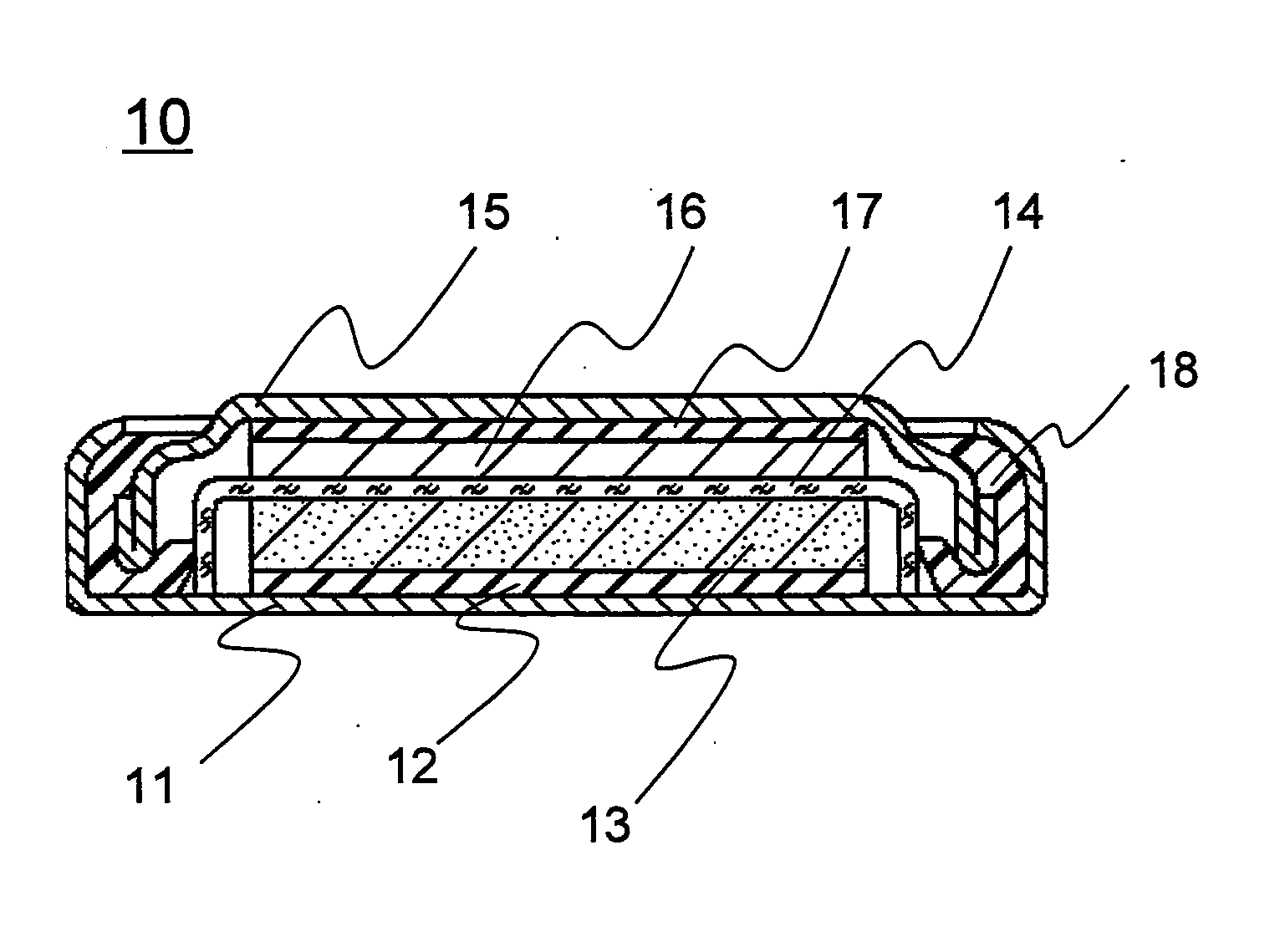

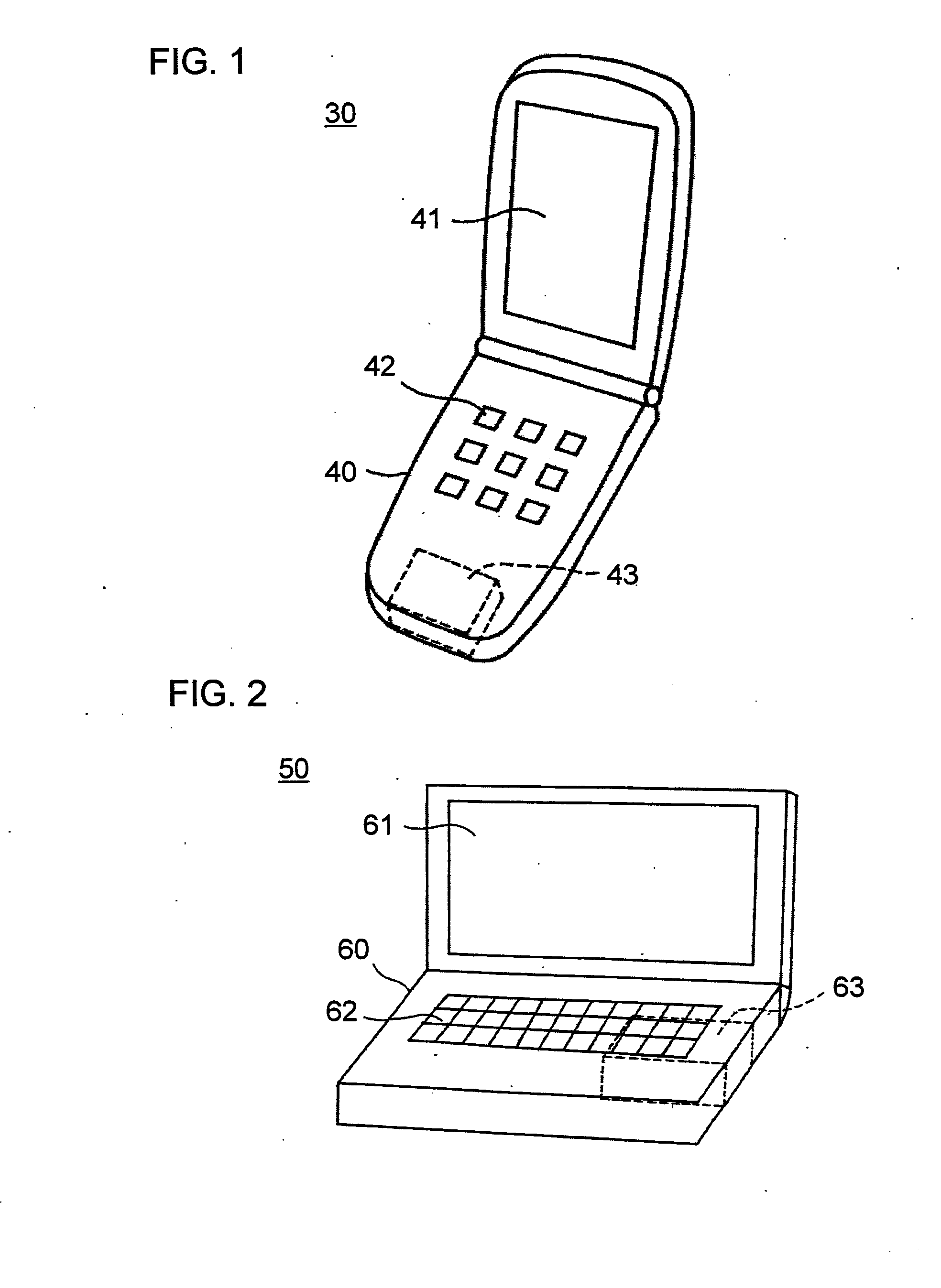

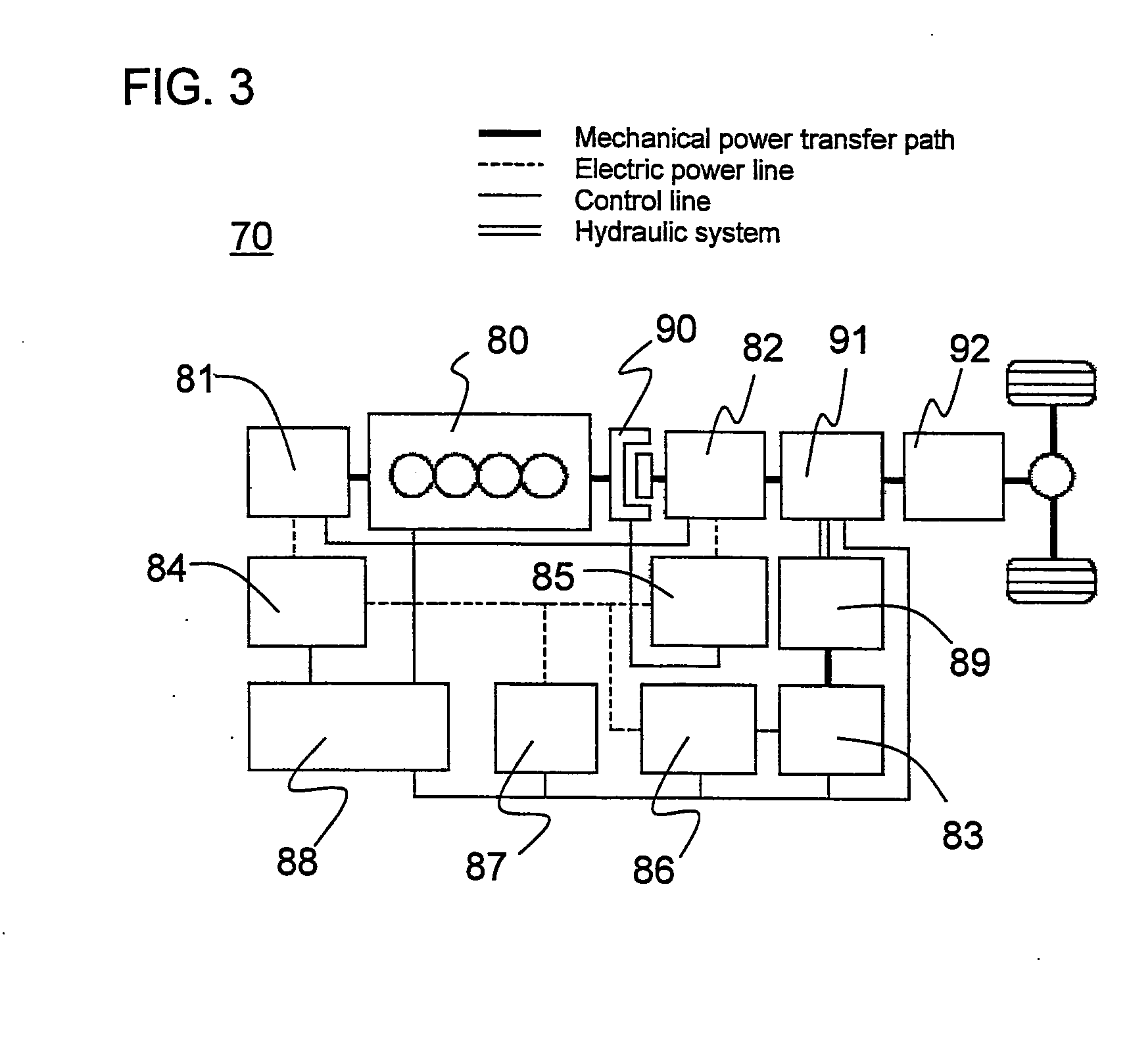

Electrode active material for power storage device, power storage device, and elctronic and transport devices

ActiveUS20100196758A1Increase energy densityGood reversibilityAlkaline accumulatorsOrganic chemistryRedoxEngineering

An electrode active material for a power storage device of the invention includes a ketone compound that includes a ring structure in a molecule, the ring structure being a five-membered or seven-membered ring composed of atoms at least three adjacent ones of which are each bonded to a ketone group. The electrode active material for a power storage device of the invention has a high weight-energy density and good reversibility of oxidation-reduction reaction. The use of the electrode active material for a power storage device of the invention can provide a power storage device having a high capacity, a high voltage, and good charge / discharge cycle characteristics.

Owner:PANASONIC CORP

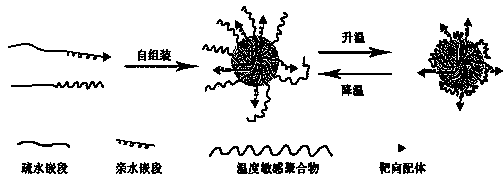

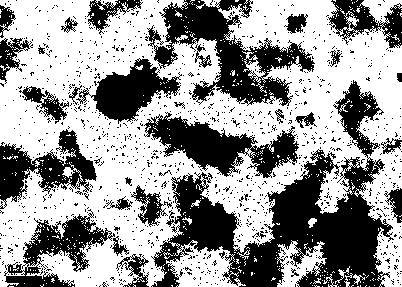

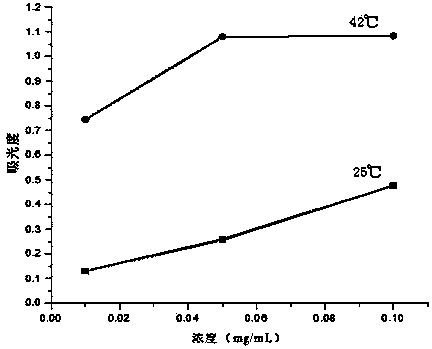

Method for preparing intelligent target medicine carrying composite micelles

InactiveCN104382851ARapid phase transitionOvercome easily clearedOrganic active ingredientsPharmaceutical non-active ingredientsTumor targetTumor targeting

The invention discloses a method for preparing intelligent target medicine carrying composite micelles. The surfaces of the composite micelles are modified by target ligands and pH / temperature synergy sensitive polymers at the same time; and reversible transformation between the shielding state of the target ligands during blood circulation (the temperature is 37 DEG C, and the pH value is 7.4) and the deshielding state of the target ligands in tumor tissues (the thermal therapy temperature ranges from 40 DEG C to 44 DEG C, and the pH value ranges from 6.5 to 6.8) is achieved. The pH and temperature dual sensitivities used in the method have the synergy; and the method is more suitable for the complex physiological environment of the human body. The method has the beneficial effects that targeting of the target ligands and the sensitive phase transformation characters of the pH / temperature synergy sensitive polymers are sufficiently used; and a target reversible shielding nanometer drug delivery system with the tumor targeted specificity and the blood circulation stability is built.

Owner:NANKAI UNIV

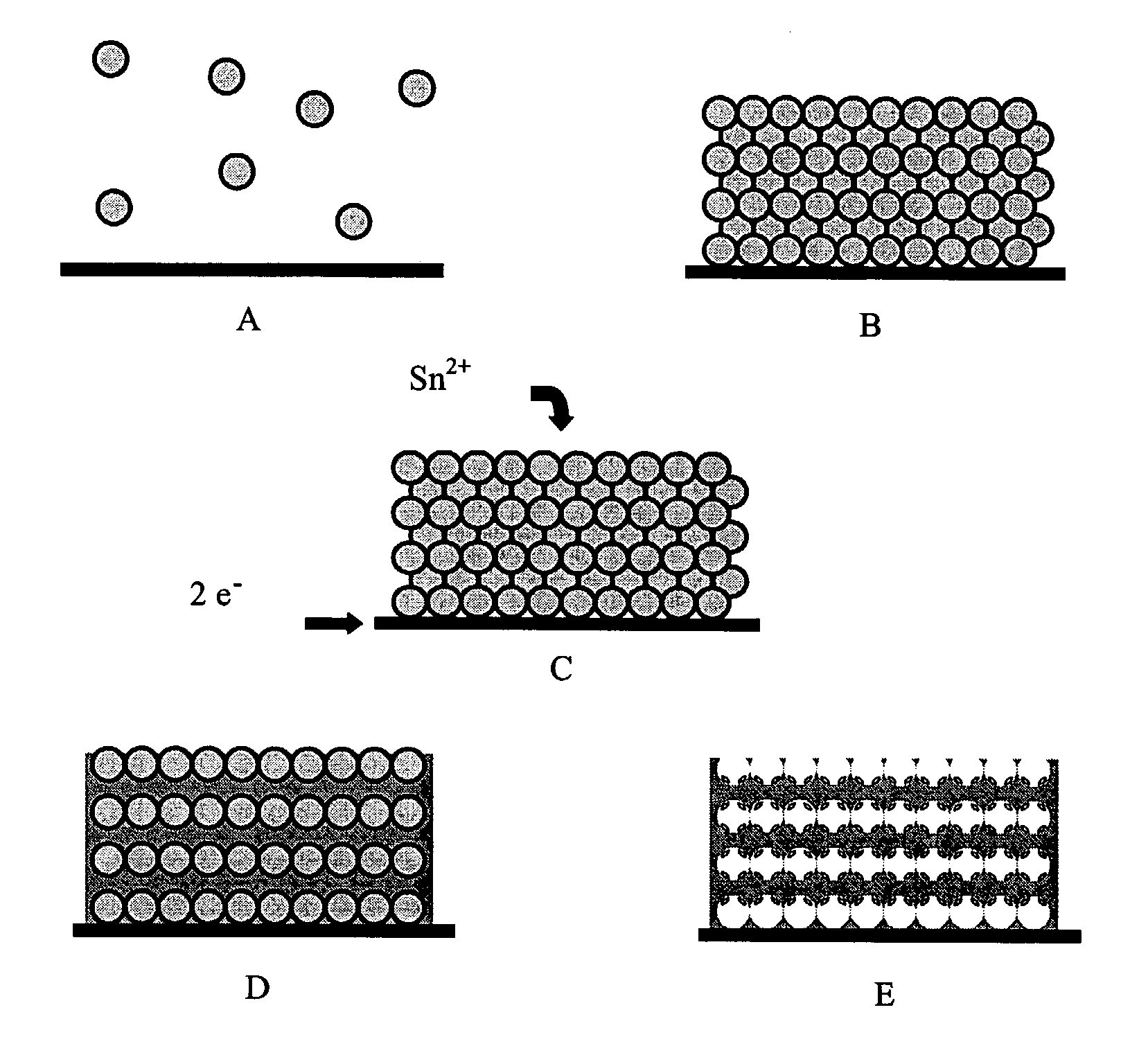

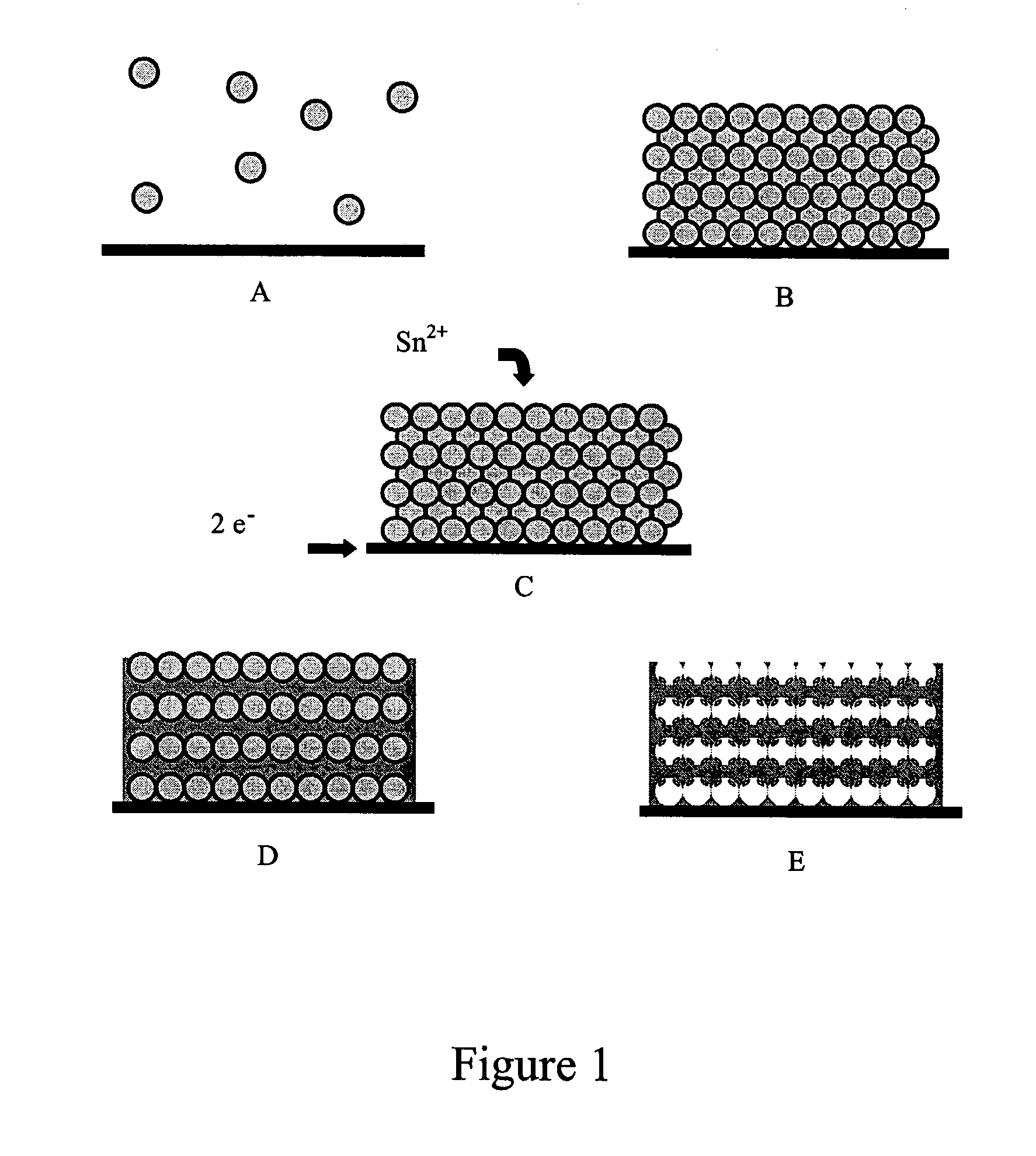

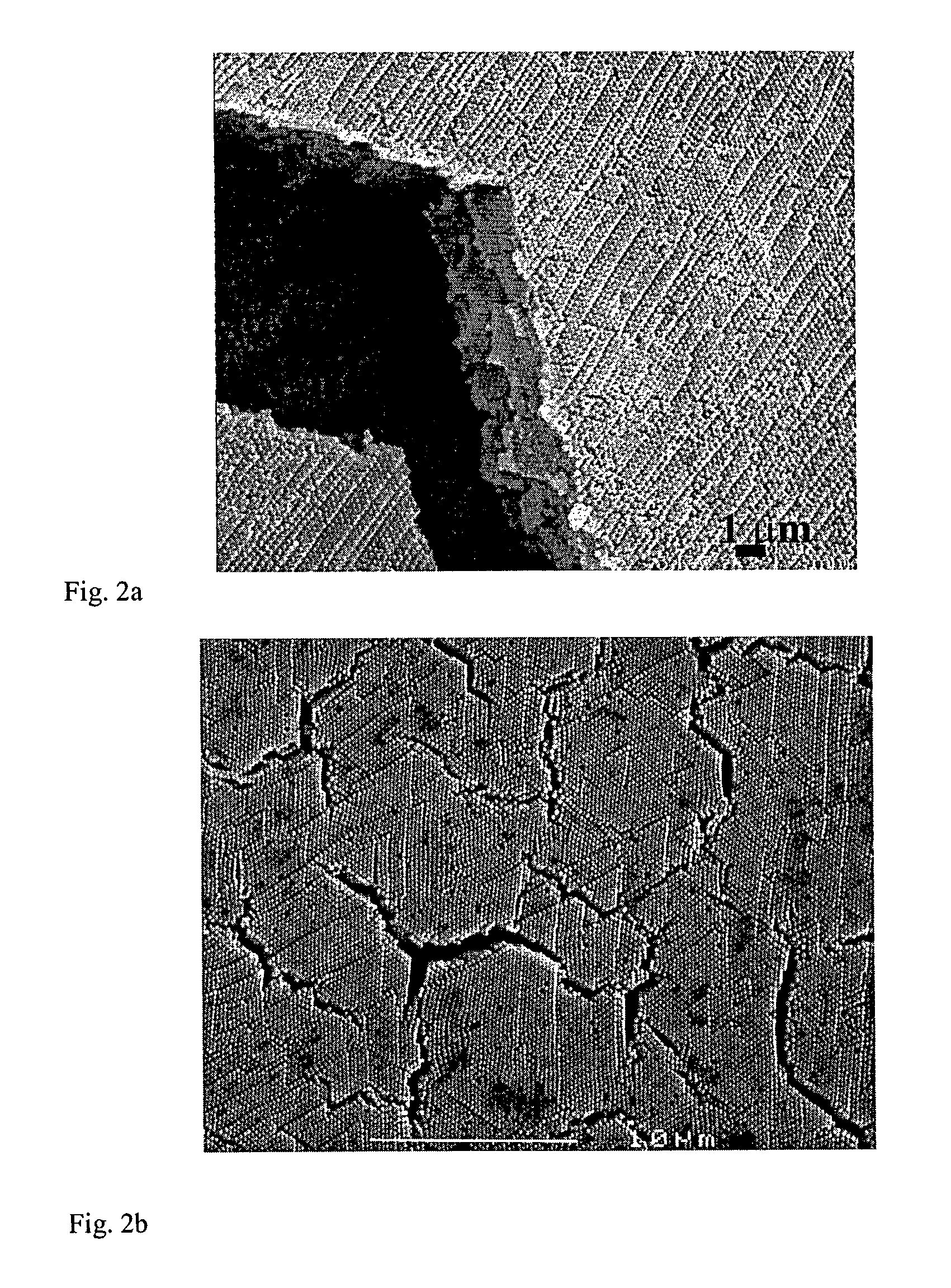

Colloidal sphere templates and sphere-templated porous materials

ActiveUS8137525B1Reduce crackingSpecific charge capacityDuplicating/marking methodsActive material electrodesColloidNanostructured metal

A method of making colloidal sphere templates and the sphere-templated porous materials made from the templates. The templated porous materials or thin films comprise micron and submicron-scaled spheres in ordered, disordered, or partially ordered arrays. The invention is useful in the synthesis of submicron porous, metallic tin-based and other high capacity anode materials with controlled pore structures for application in rechargeable lithium-ion batteries. The expected benefits of the resulting nanostructured metal films include a large increase in lithium storage capacity, rate capability, and improved stability with electrochemical cycling.

Owner:RGT UNIV OF CALIFORNIA

Cathode active material and lithium battery employing the same

InactiveUS6866963B2Excellent electrochemical utilization efficiency and capacity characteristicGood reversibilityOrganic chemistryOther washing machinesLithiumLithium battery

Owner:SAMSUNG SDI CO LTD

Batteries comprising alkali-transition metal phosphates and preferred electrolytes

InactiveCN1650450ALarge capacityImprove cycle performanceElectrode thermal treatmentSecondary cellsHalogenElectrical battery

Lithium batteries comprising: (a) an electrode comprising a material of the formula AaMb(XY4)cZd, wherein (i) A is an alkaline metal and 0 < a <= 9; (ii) M comprises a transition metal, and 1 <= B <= 3; (III) XY4 is X'O4-XY'X, X'O4-y,Y''2y, X'S4, or mixtures thereof, where X' is P, As, Sb, Si, Ge, V, S, or mixtures thereof; X' is P, As, Sb, Si, Ge, V, or mixtures thereof; Y' is halogen, S, N, or mixtures thereof; 0 <= x < 3; and 0 < y <= 2; and 0 < x <= 3; and (iv) Z is OH, halogen, or mixtures thereof, and 0 <= d <= 6; and (b) a counter-electrode; and (c) an electrolyte comprising an alkyl and / or alkylene carbonate and a cyclic ester. Preferably, M additionally comprises at least one non-transition metal. Preferred embodiments include those having an olivine structure, where c = 1, and those having a NASICON structure, where c=3.

Owner:VALENCE TECH INC

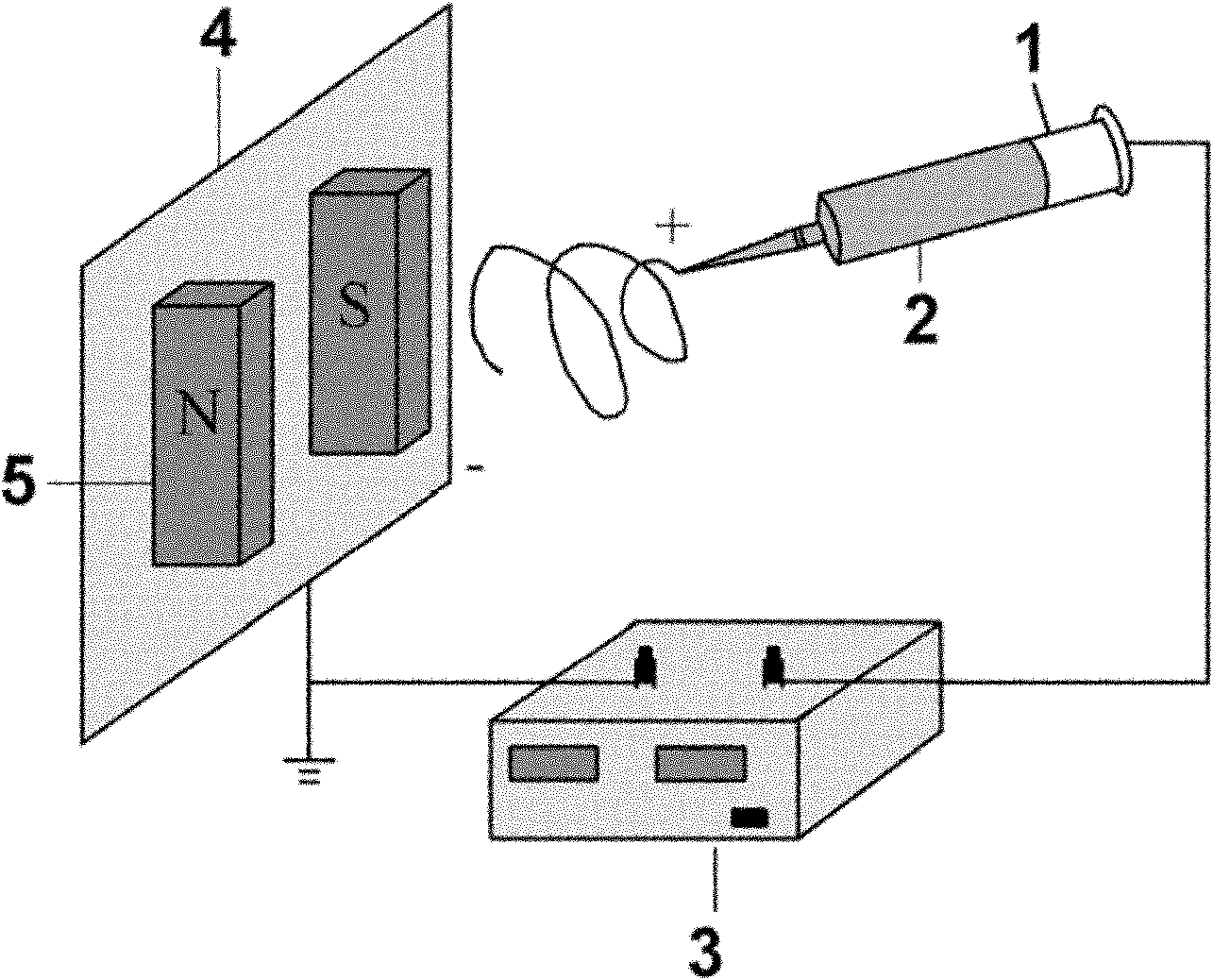

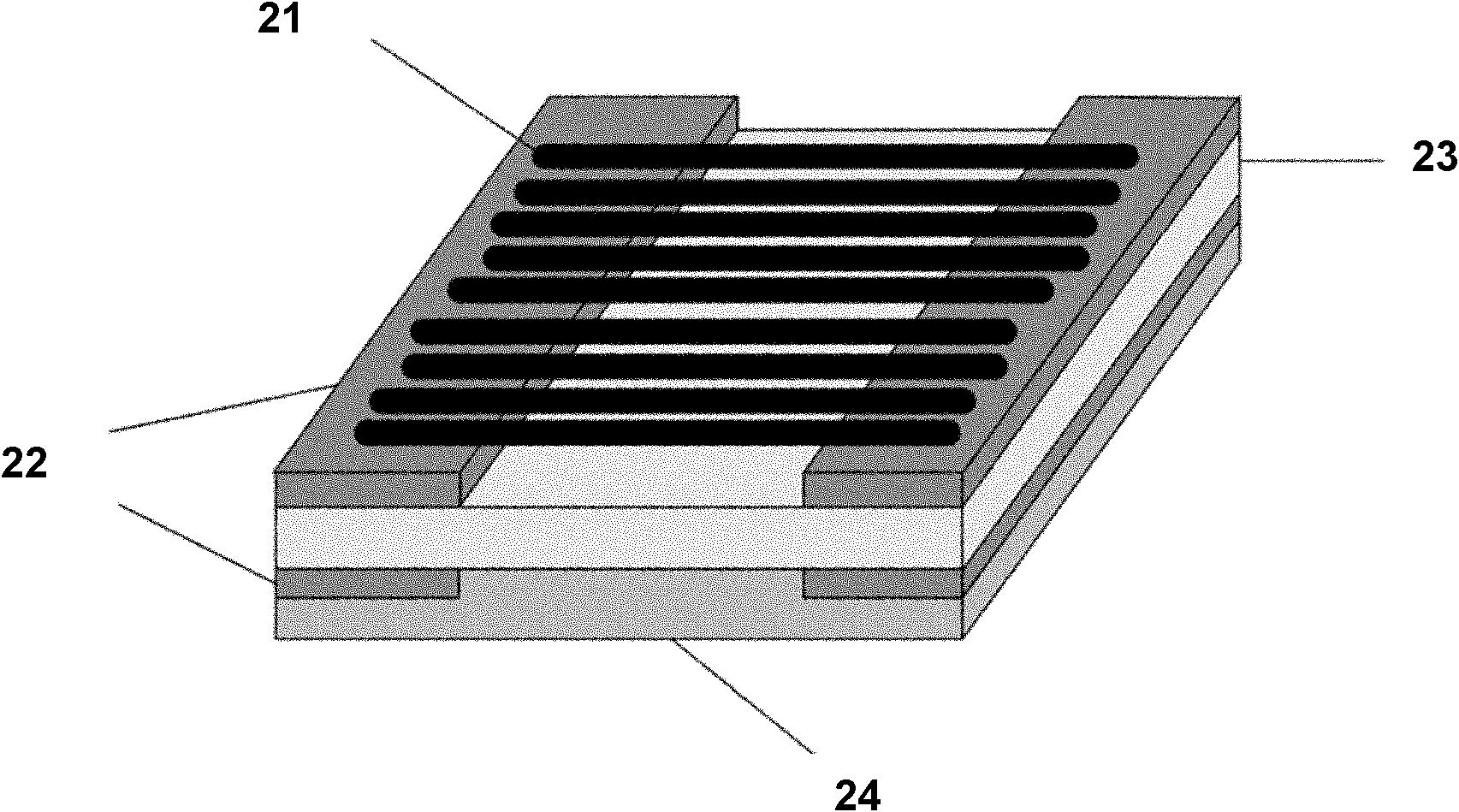

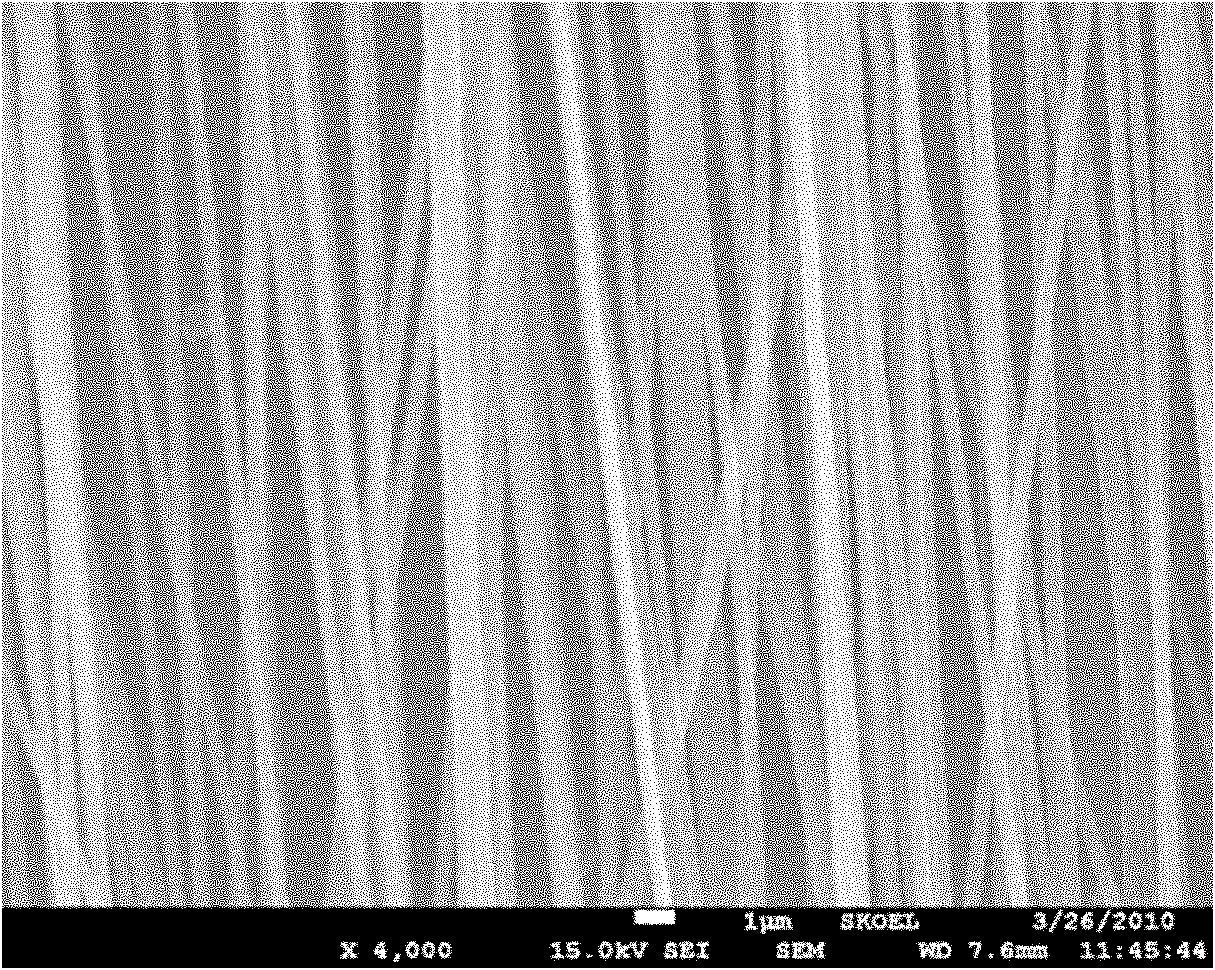

Orderly arranged In2O3 nanofibers and application of same in preparation of ultra-fast response alcohol sensor

InactiveCN102080268AGood reversibilityGood repeatabilityMaterial analysis by electric/magnetic meansFilament/thread formingFiberWorking temperature

The invention belongs to the technical field of preparation of one-dimensional metal oxide nano-materials and semiconductor gas sensors therefrom, in particular relates to orderly arranged In2O3 nanofibers and application of same in preparation of an ultra-fast response alcohol semiconductor sensor. The process for preparing the orderly arranged In2O3 nanofibers comprises the following steps of: preparing a precursor solution from soluble nitrate, high polymer materials and a solvent; preparing orderly arranged composite nanofibers with a magnetic-field-induced electrostatic spinning technology; and performing high-temperature sintering to remove an organic high polymer template and further obtain the orderly arranged In(NO3)3 nanofibers. The alcohol gas sensor prepared from the orderly arranged In(NO3)3 nanofibers and a planar alumina substrate structure has the advantages that: the response time of the alcohol gas sensor to alcohol gas at the working temperature of 275 DEG C is 0.4 s, and the recovery time is 3 s; and the reversibility and repeatability of the sensor are good and far superior to the traditional alcohol sensor made of nano-powder materials of the same type. In the invention, the advantages of simple process, low cost and high yield are achieved.

Owner:JILIN UNIV

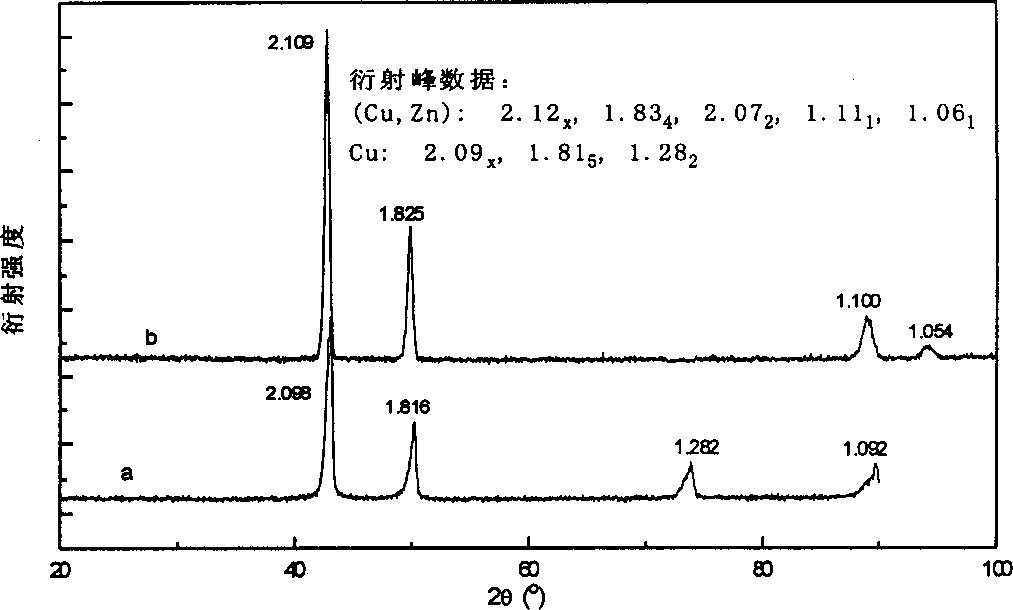

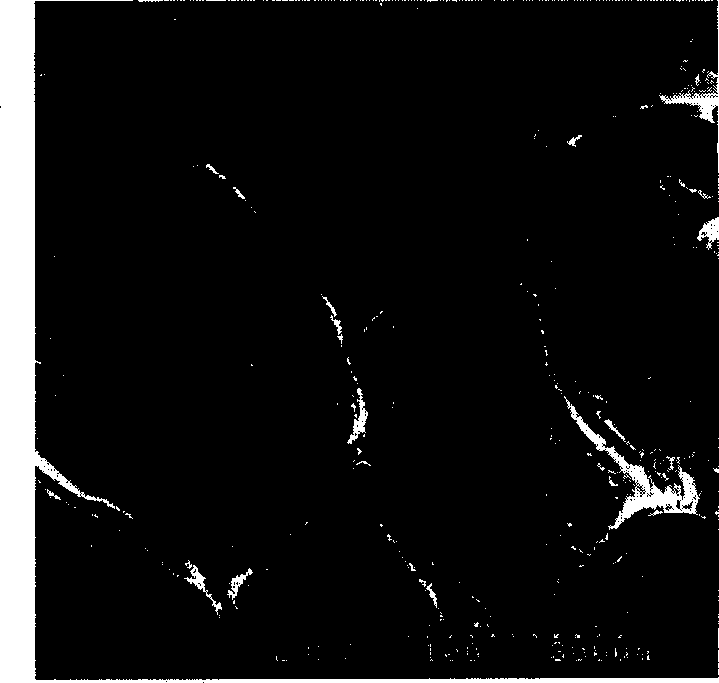

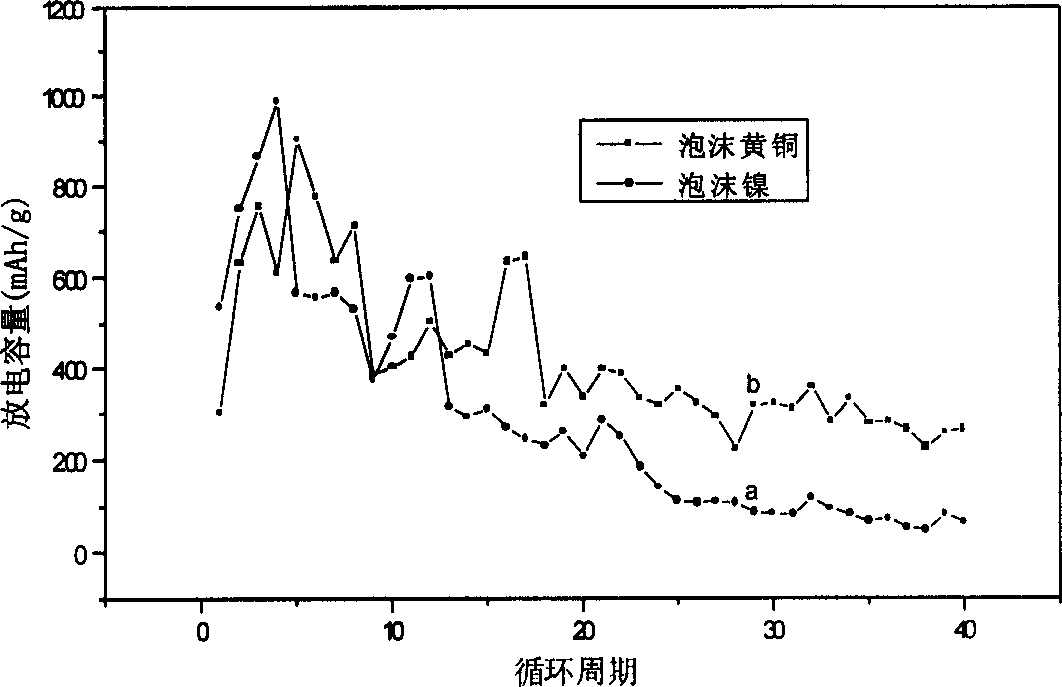

Foam-metal current collector of secondary battery using zinc as negative electrode and its preparing process

InactiveCN1360356ALow costSimple processElectrode manufacturing processesElectrode carriers/collectorsPorosityMetal framework

The invention relates to a method for preparing foam metal current collector (substrate) of new type secondary battery that uses zinc as negative pole. It possesses foamy space structure whose space cellular structure in three dimension is composed of metal framework connected eath other. Its surface ingredient includes copper 68%-75% (Wt), zinc 32-25%, that is copper-zinc alloy or foamy brass. The collector (substrate) being as zinc pole has very good performance in electrochemistry and better circular performance. The invention possesses merits of stable characteristic, low cost, simple technique, lower relative density, good electrical conductivity etc. The invention is particularly suitable for zinc-nickel secondary battery, also other zinc based secondary battery and alkaline secondary battery.

Owner:NANKAI UNIV

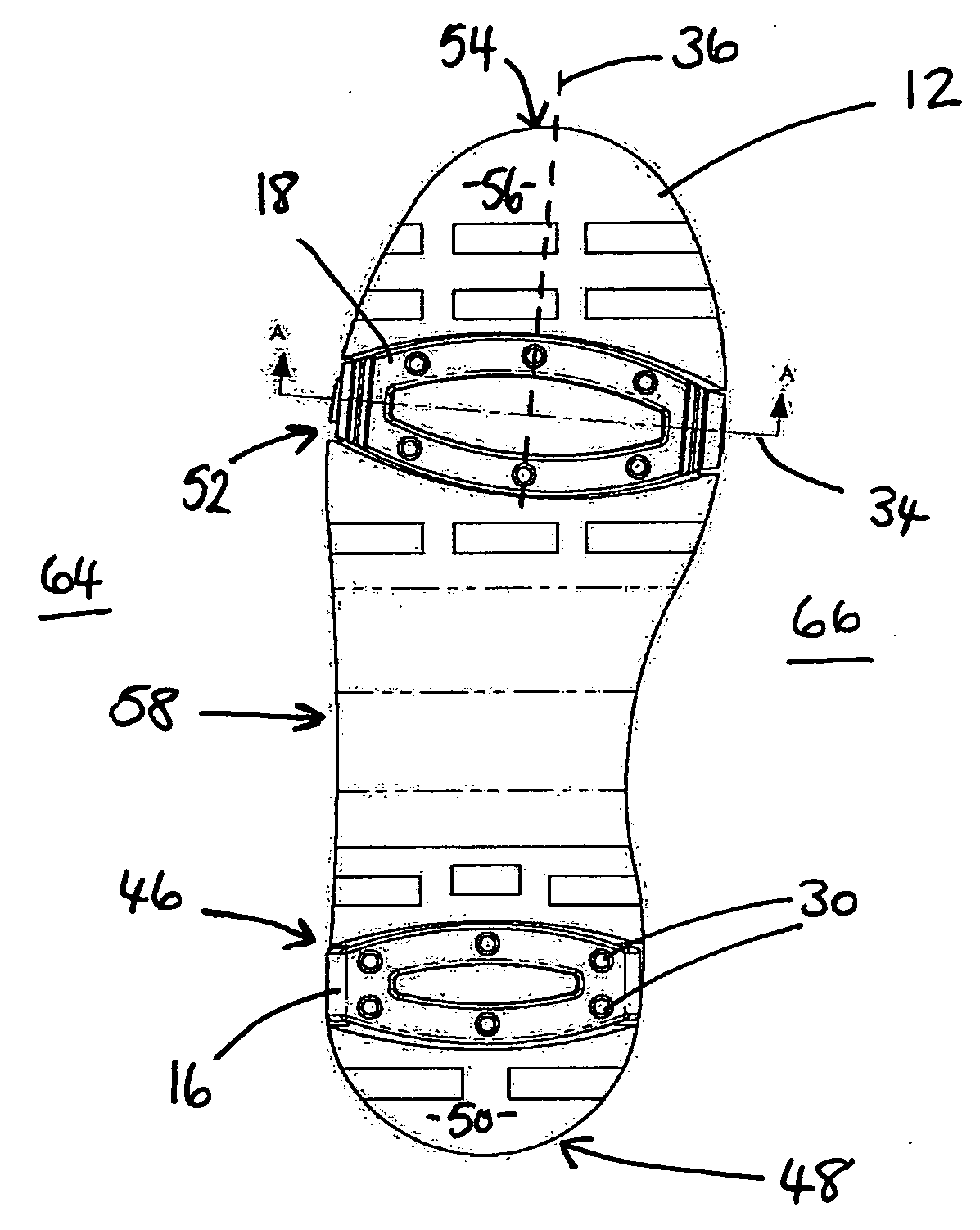

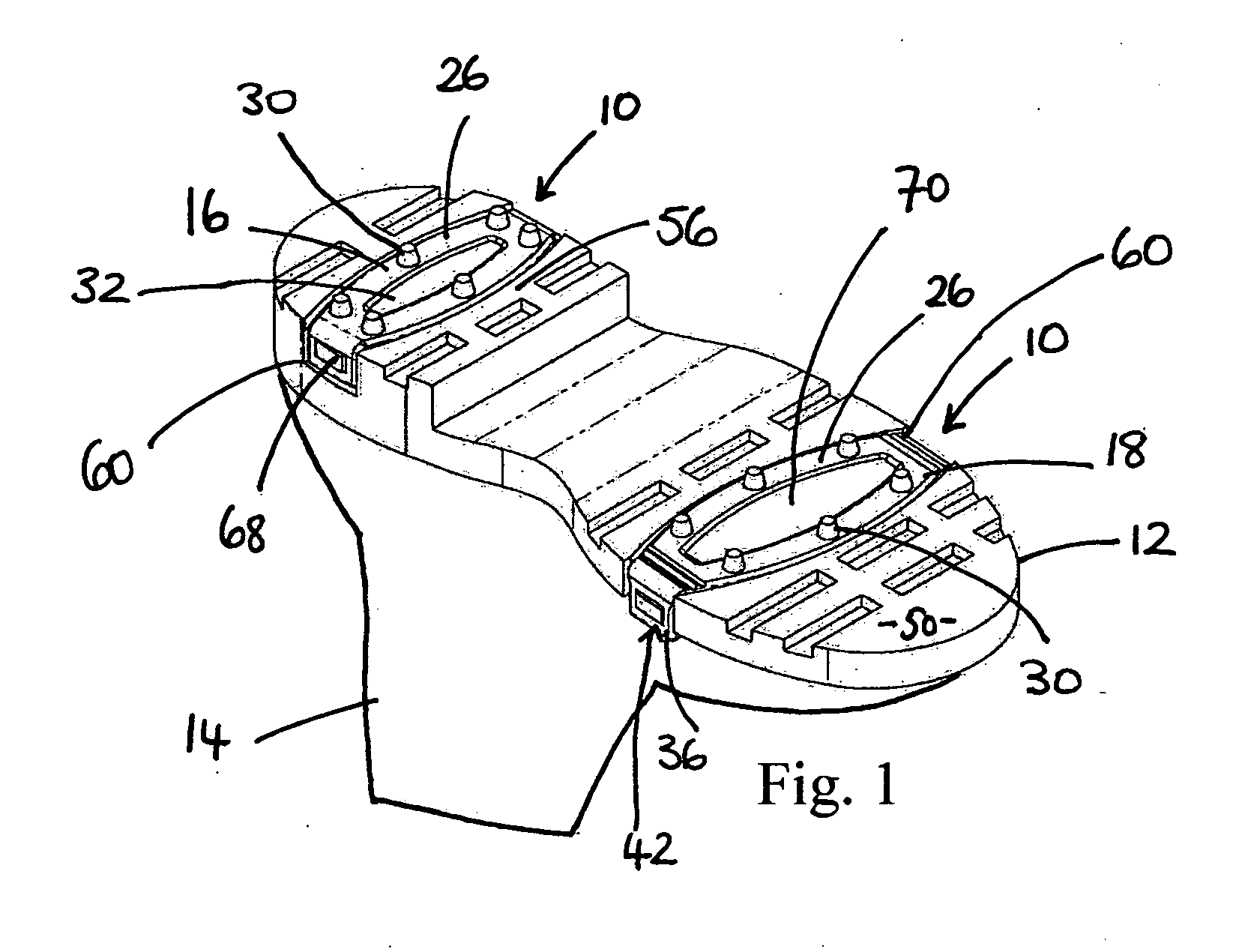

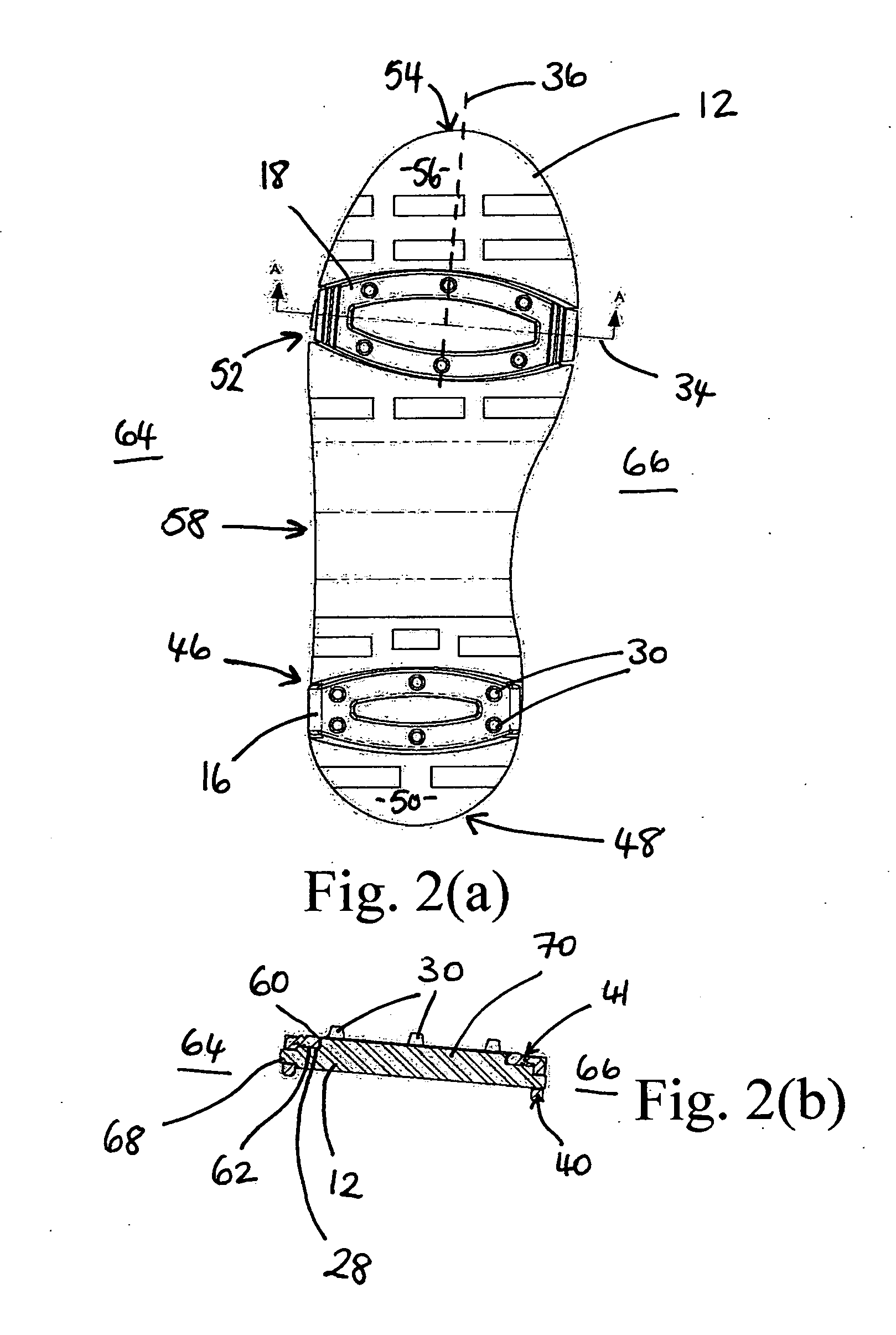

Attachments for an item of footwear

ActiveUS20070163148A1Reduces difficulty and disadvantageEasy constructionFasteningsBiomedical engineeringBody surface

An attachment for an item of footwear having an outsole, the attachment comprising a body having first and second body surfaces, the body being releasably co-operable with the outsole in a first position in which the first body surface is disposable away from the outsole and in a second position in which the second body surface is disposable away from the outsole; an attaching portion which is associated with the body and which includes an inter-engageable formation for releasably attaching the attachment in the first and second positions; and a detaching portion which is associated with the body, the detaching portion having an edge portion moveable with respect to the body to allow the body to be released from the item of footwear. The invention also includes an outsole and an item of footwear to which the attachment can be releasably attached.

Owner:LAPORTE MAXIME

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com