Patents

Literature

115 results about "Solidus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In chemistry, materials science, and physics, the solidus is the locus of temperatures (a curve on a phase diagram) below which a given substance is completely solid (crystallized). The solidus is applied, among other materials, to metal alloys, ceramics, and natural rocks and minerals.

Method of making coated stamped parts and parts made therefrom

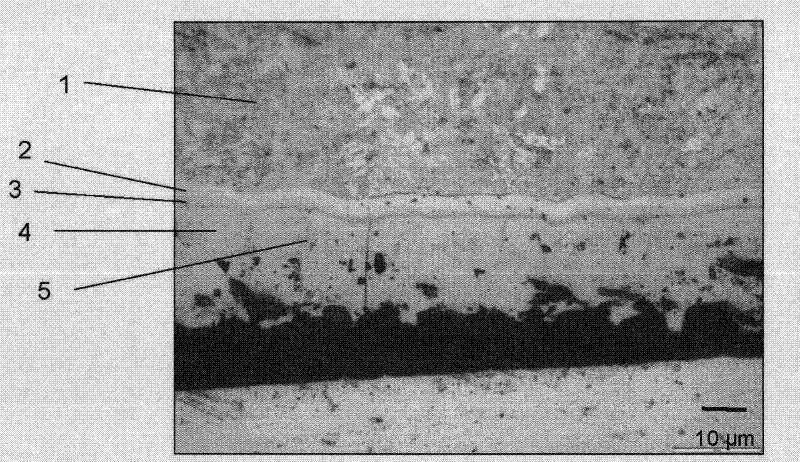

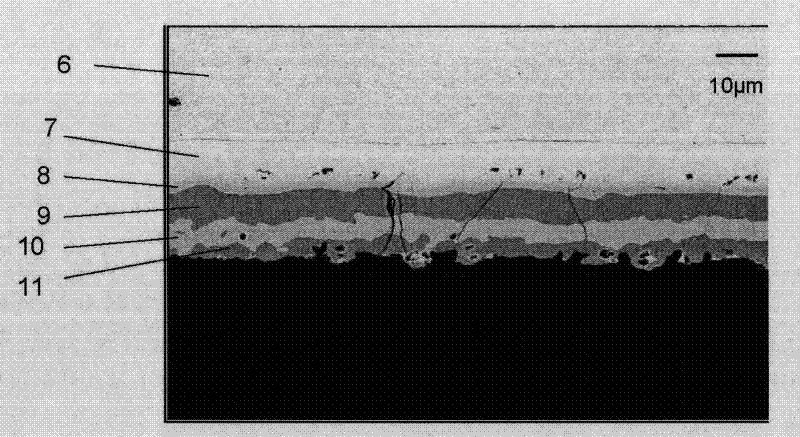

The present invention relates to a method for manufacturing hot stamped coated parts, which method includes the following consecutive steps, in order: providing a hot-rolled or cold-rolled steel plate including a steel substrate and an aluminum-silicon alloy precoat, the precoat containing Greater than 50% free aluminum and with a thickness of 15 to 50 microns; the steel plate is then cut to obtain a pre-coated steel blank; the blank is then heated in a non-protective atmosphere to a temperature Ti of Te-10°C to Te, Te is the eutectic or solidus temperature of the precoat; the billet at temperature Ti is then heated to 840 to 950°C in a non-protective atmosphere at a heating rate V of 30°C / s to 90°C / s The temperature Tm of the coated heated blank is obtained, and V is the heating rate from the temperature Ti to the temperature Tm; then the coated heated blank is soaked at the temperature Tm for a time tm of 20s to 90s; and then hot stamped. The blank is obtained to obtain a hot stamped coated part; the stamped part is then cooled at a cooling rate to form a microstructure including at least one component selected from martensite or bainite in the steel substrate.

Owner:安赛乐米塔尔研究发展有限公司 +2

Method for preparing semisolid blank

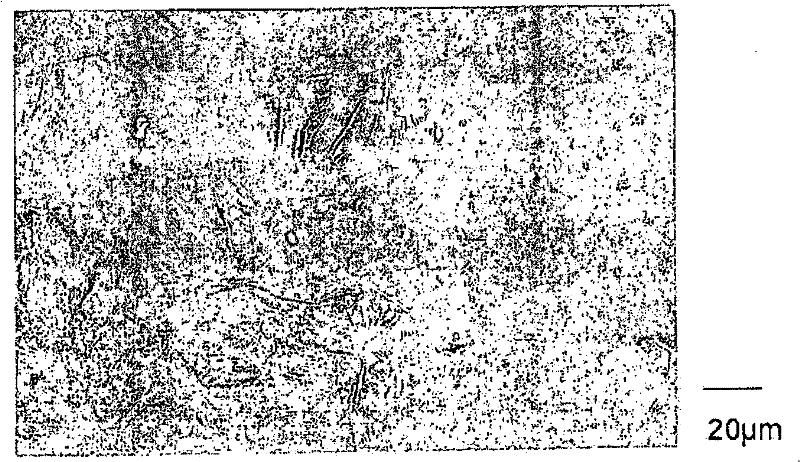

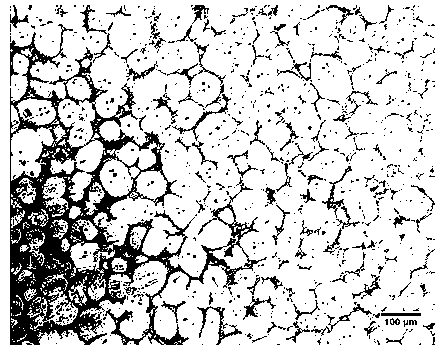

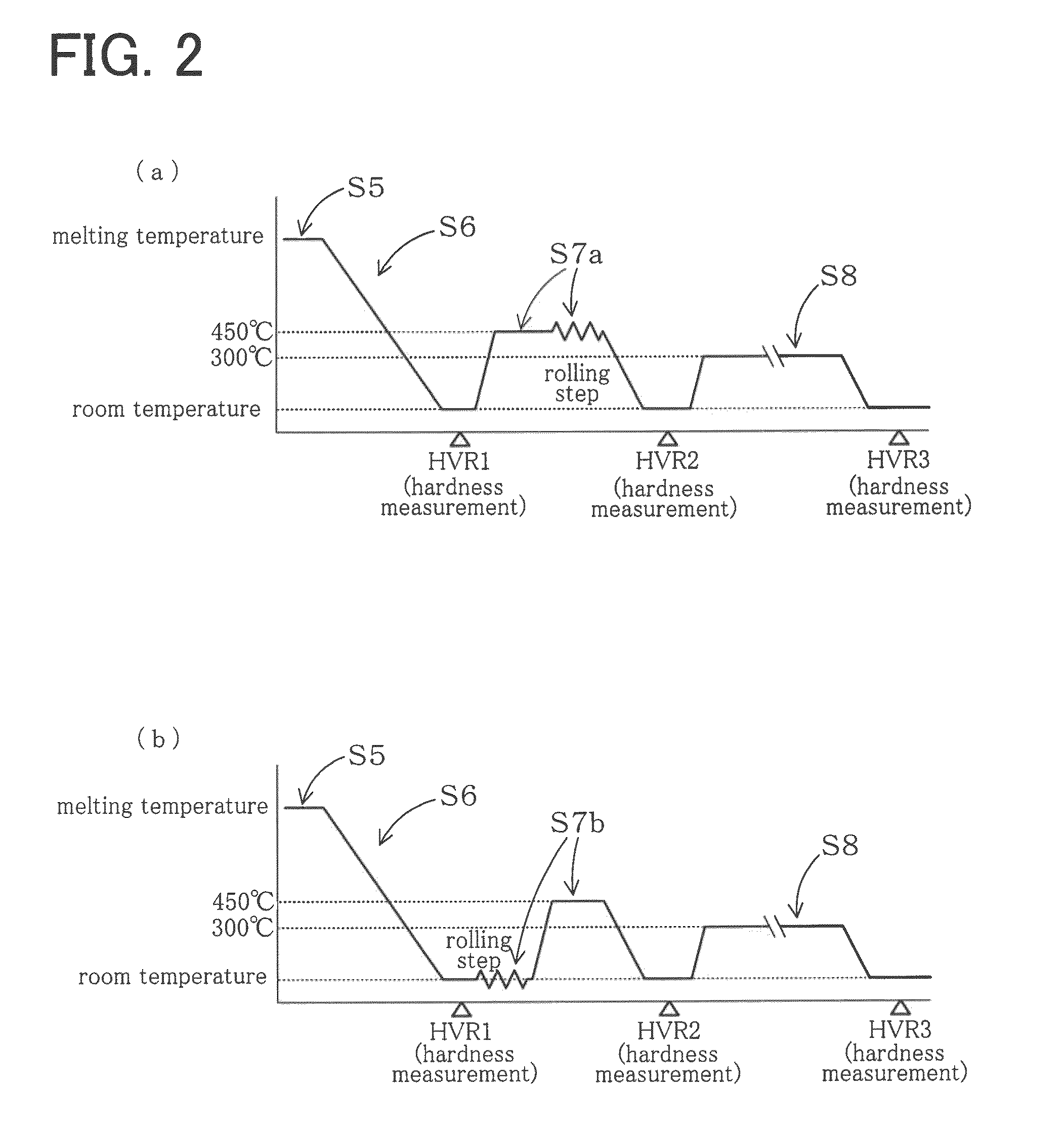

The invention relates to a method for preparing a semisolid blank, utilizes an improved SIMA (strain induced melt activation) method to prepare the semisolid blank, and belongs to the technical field of metal semisolid blank. The method comprises the following steps of: firstly, measuring a liquid solid phase line point of the semisolid alloy to be prepared, then, heating an alloy blank so as to carry out asynchronization multitrack rolling or pillar squeezing transformation, finally, remelting, and carrying out heat preservation for a long time so as to obtain the required semisolid blank. The asynchronization rolling or pillar squeezing transformation is capable of generating large deformation amount, group bough crystal formed in the blank is destroyed, the asynchronization rolling is utilized to replace pre-deformation processes such as the existing upset, compression, equal diameter angle compression, and the semisolid blank is prepared and has the advantages of uniform formation, high nodularity, and accurate control solid phase rate.

Owner:KUNMING UNIV OF SCI & TECH

Low-melting-point and high-intensity aluminum alloy powder brazing filler metal and preparing method of low-melting-point and high-intensity aluminum alloy powder brazing filler metal

ActiveCN104227263APrevent corrosionImprove performanceWelding/cutting media/materialsSoldering mediaSiluminSolidus

The invention discloses a high-intensity aluminum alloy powder brazing filler metal with the melting point being lower than 490 DEG C and a preparing method of the high-intensity aluminum alloy powder brazing filler metal with the melting point being lower than 490 DEG C, and belongs to the technical field of aluminum alloy brazing. The brazing filler metal comprises the following ingredients in parts by weight: 8.6 to 9.5 percent of Si, 16.5 to 17.5 percent of Cu, 8.5 to 9.5 percent of Ge, 4.5 to 5.0 percent of Ni, 4.0 to 5.0 percent of Zn, 0.70 to 0.75 percent of Sr, 0.35 to 0.40 percent of Bi, 0.40 to 0.45 percent of La, 0.40 to 0.55 percent of Ce, 0.10 to 0.20 percent of Yb and the balance Al. The brazing filler metal is prepared by adopting a flux rapid cooling-ball milling technology, the melting point is lower than 490 DEG C, the brazing temperature is 500 to 520 DEG C, and the brazing filler metal is applicable to aluminum alloy brazing with the solid phase line temperature higher than 500 DEG C, such as in-furnace brazing, vacuum brazing, induction brazing and flame brazing. The brazing filler metal is matched with QJ201 for brazing 3003 aluminum alloy, and the shearing intensity of a brazing joint is greater than 74MPa.

Owner:ZHEJIANG UNIV

Solder alloys

InactiveUS20140361070A1Improve thermal conductivityLow thermal conductivityWelding/cutting media/materialsSoldering mediaCopperZinc

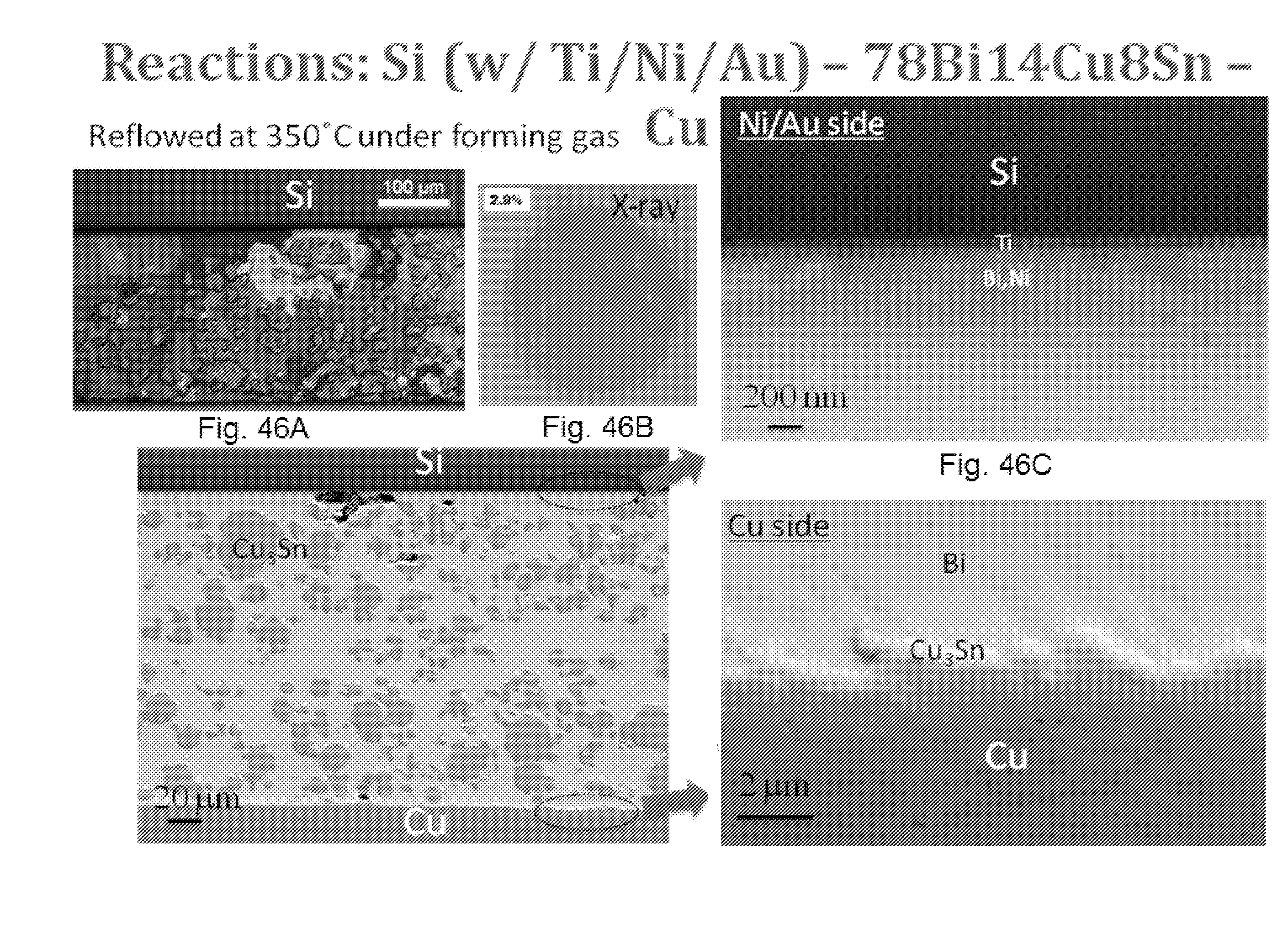

A solder comprising a bismuth matrix, between about 5-24% copper; and about 0.5-36% tin or antimony or zinc; having a solidus temperature of ≧271° C., a reflow temperature of ≦375° C., and at least one intermetallic composition precipitate comprising copper and at least one of tin, antimony and zinc substantially excluding bismuth formed within the solidus phase.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

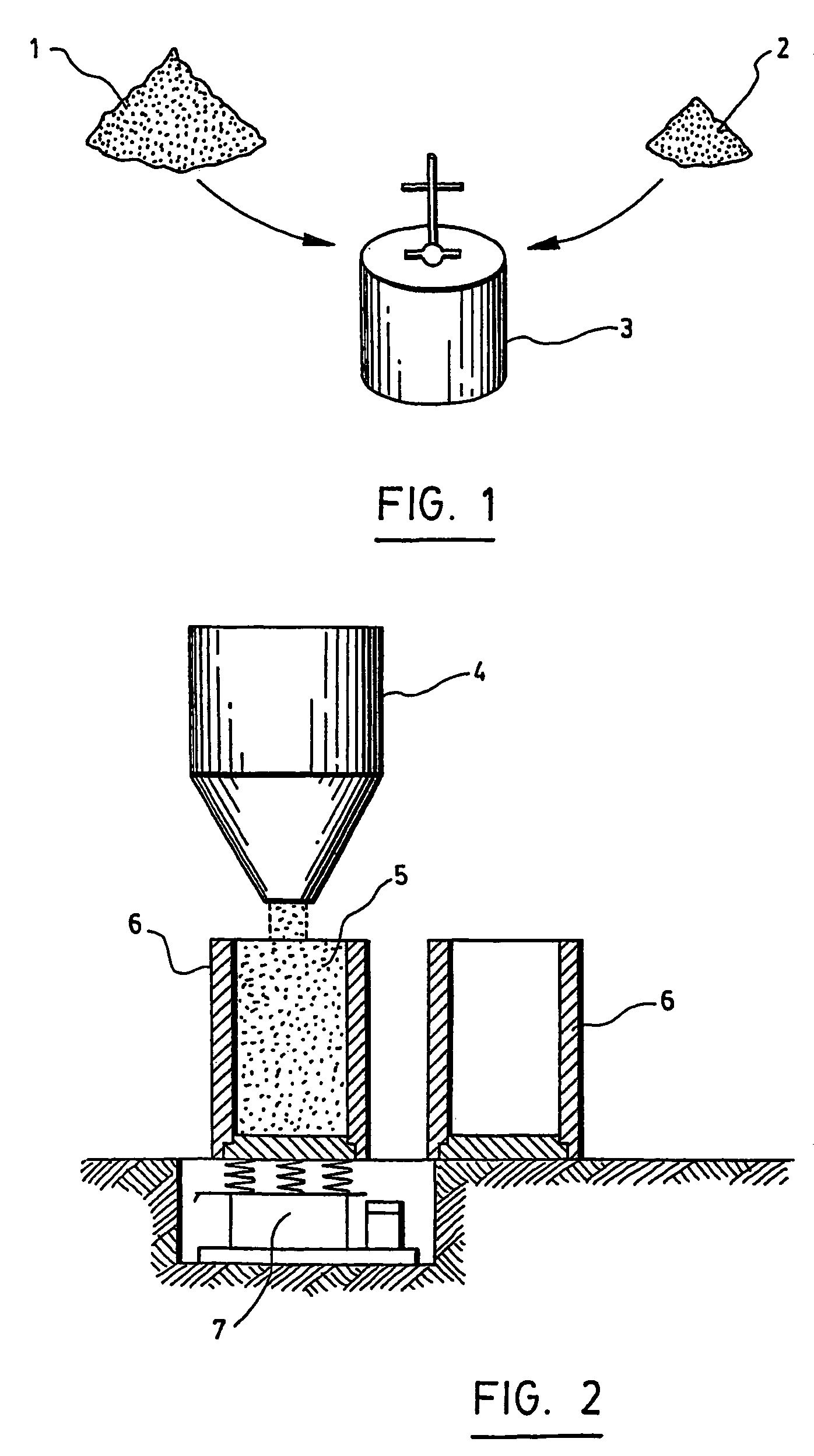

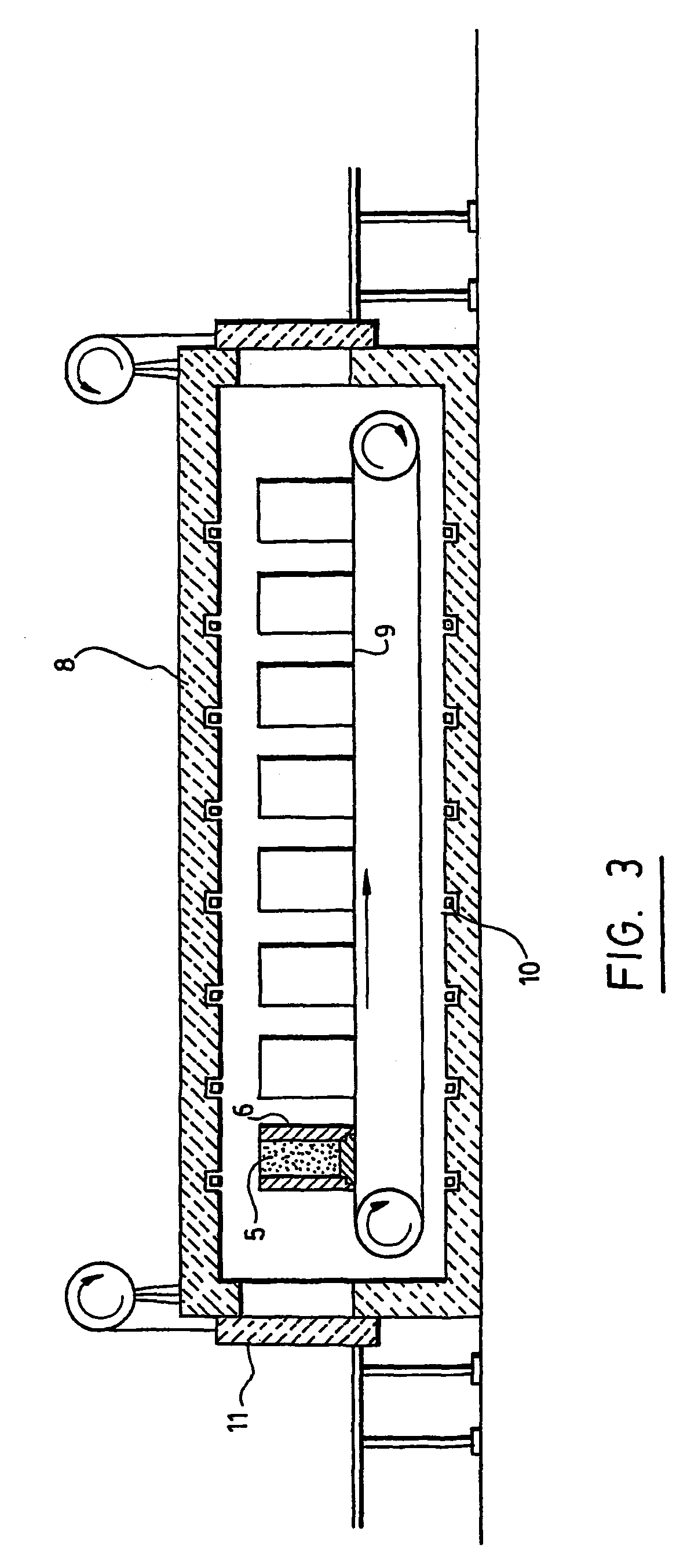

Method for production of metal foam or metal-composite bodies with improved impact, thermal and sound absorption properties

InactiveUS7105127B2Improve rigidityHigh strengthMetal-working apparatusRecycling and recovery technologiesSolidusFoaming agent

A method for the production of foamable or foamed metal pellets, parts and panels. The method comprises the steps of: i) providing a mixture of a metal alloy powder with a foaming agent powder, ii) pre-compacting the mixture of step i); iii) heating the pre-compacted mixture of step ii) to a temperature below a decomposition temperature of the foaming and at which permanent bonding of the particles occurs v) hot compacting the body for producing a compacted body made of a metal matrix embedding the foaming agent; and vi) reducing the compacted body into metal fragments and thereby obtaining dense foamable metal chips. A method for the production of a foam metal using a closed volume metal shell is also disclosed. The method comprises the steps of: a) providing metal pieces and reducing said metal pieces into smaller metal particles; b) mixing the metal particles with an additive having a decomposition temperature that is greater than a solidus temperature of said metal particles; c) pouring the mixture of step b) into a closed volume metal shell having a given thickness and providing the metal shell with at least one passage for gases to escape; d) reducing the thickness of the metal shell by applying pressure; e) heating the metal shell to a temperature above said solidus temperature of the metal particles and below said decomposition temperature of the additive, and immediately applying pressure on the metal shell sufficient to compress the metal particles and to create micro shear conditions between the metal particles so as to obtain a dense metal product.

Owner:VATCHIANTS SERGUEI MR

Laser powder bed melting additive manufacturing molten bath monitoring and pore controlling method

ActiveCN111283192ADescribe wellReduce dependenceAdditive manufacturing apparatusIncreasing energy efficiencySolidusPowder bed

The invention discloses a laser powder bed melting additive manufacturing molten bath monitoring and pore controlling method. The method includes the steps that (1) a space powder bed three-dimensional geometrical model is established; the powder model is guided into a thermal fluid model, a thermal fluid model of the powder dimension is established, the initial and boundary conditions of computational domains are set, and meshing is performed; a powder bed melting process three-dimensional model governing equation is established, and a molten bath is simulated according to the governing equation and input parameters; (2) three-dimensional profile data, including the molten bath depth, width and length, of the molten bath are extracted according to the solidus temperature and the mesh temperature of powder and a base material at each time step; and (3) a final scanning interval is obtained according to the three-dimensional profile data of the molten bath, and an ultimate molten bath is simulated according to the governing equation, the input parameters of the step (1) and the final scanning interval. In view of the difficulties of long time and high cost of the powder bed meltingexperimental research, the reliability of a solution can be evaluated, the research and development cost can be reduced, and the forming parameters are optimized.

Owner:NANJING UNIV OF SCI & TECH

High-melting point lead-free solder and production technique thereof

InactiveCN101332544APrevent leakageImprove solderabilityWelding/cutting media/materialsSoldering mediaMaterials scienceLiquidus

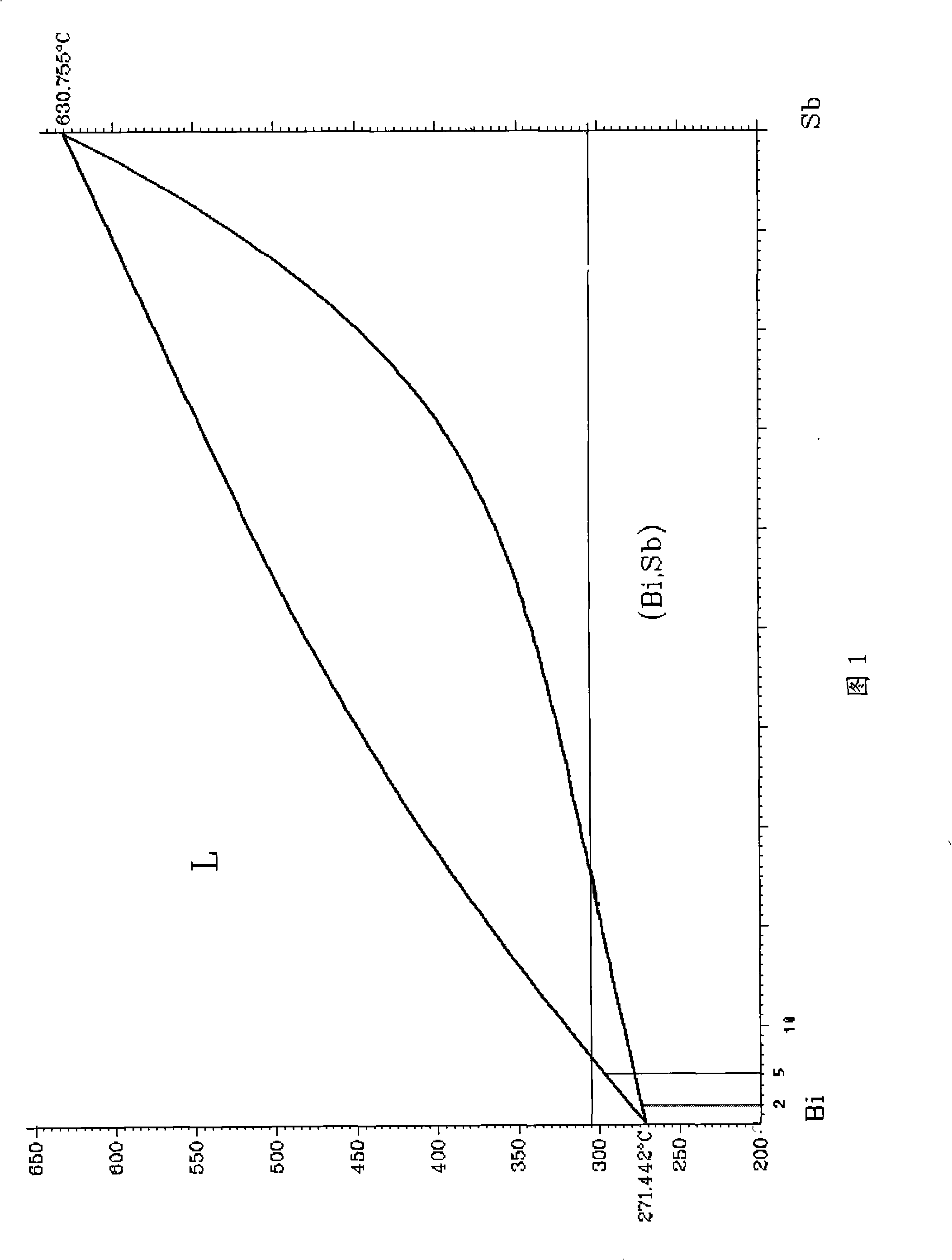

The invention provides an alloy contained in a high melting point and lead-free solder. The alloy consists of 2wt% - 5wt% of Sb and 98wt% - 95wt% of Bi, the solidus temperature of the alloy is not lower than 270 DEG C, while the liquidus temperature of the alloy is not higher than 310 DEG C. As the Bi-Sb alloy belongs to an ultimate mutual soluble alloy, the solidus point and the liquidus point of the alloy increase with the increase of Sb content. Compared with the conventional Pb-10Sn solder, the high-melting point and lead-free solder is more environmentally friendly. The alloy can be further added with a proper amount of silver when the solder is made into a welding collar in order to improve the weldability of the solder.

Owner:GUANGZHOU SOLDERWELL ADVANCED MATERIALS +1

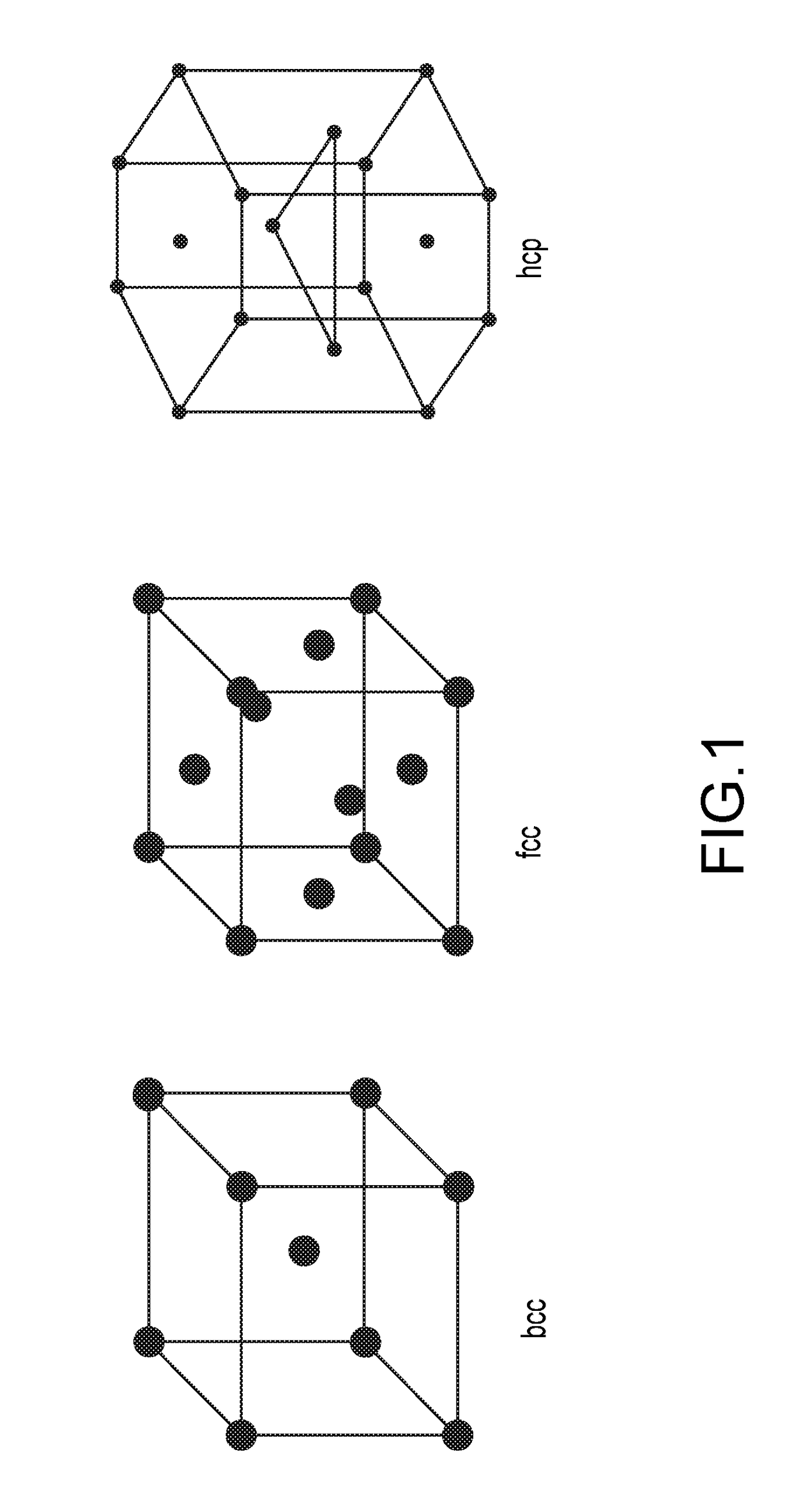

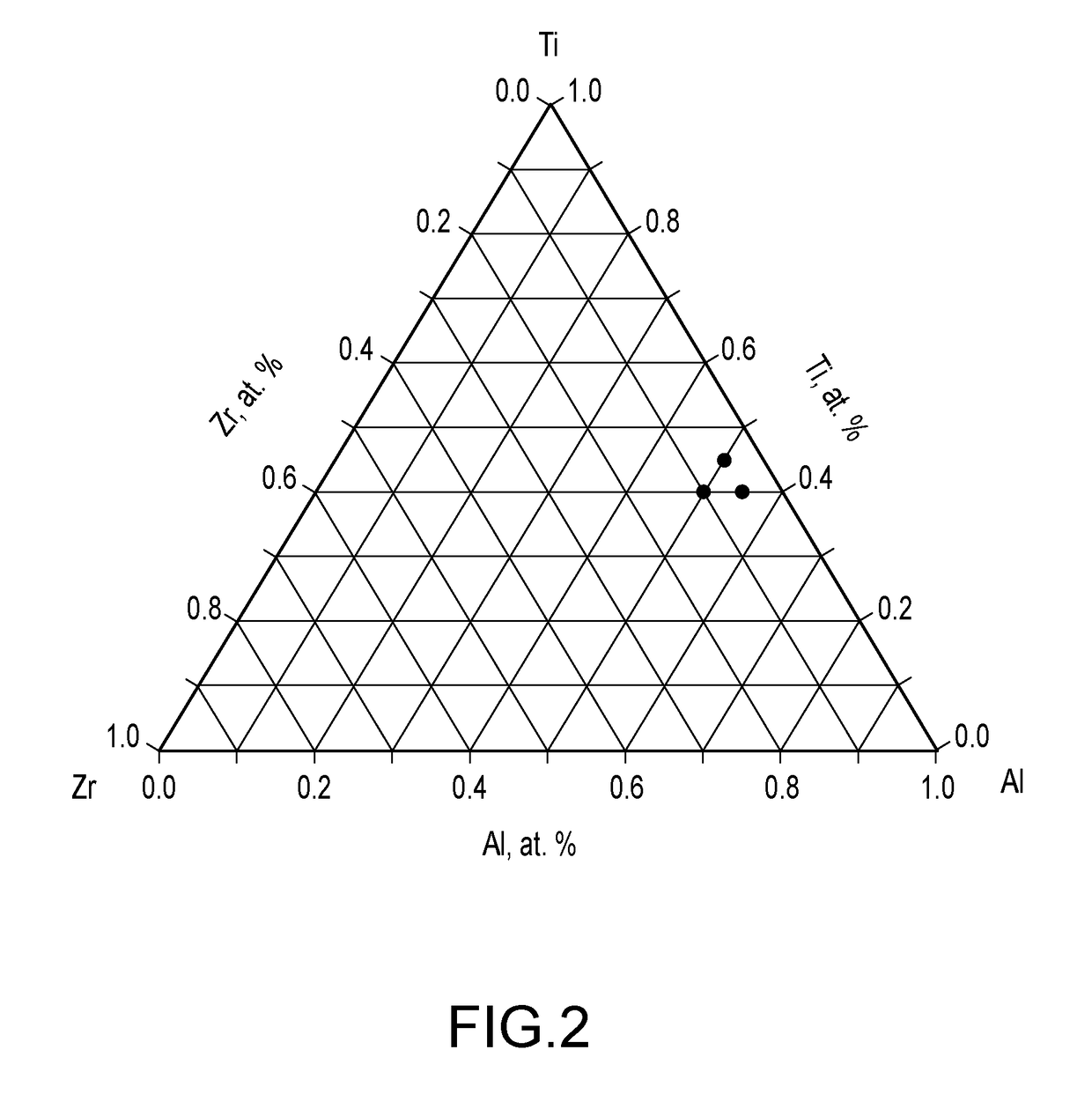

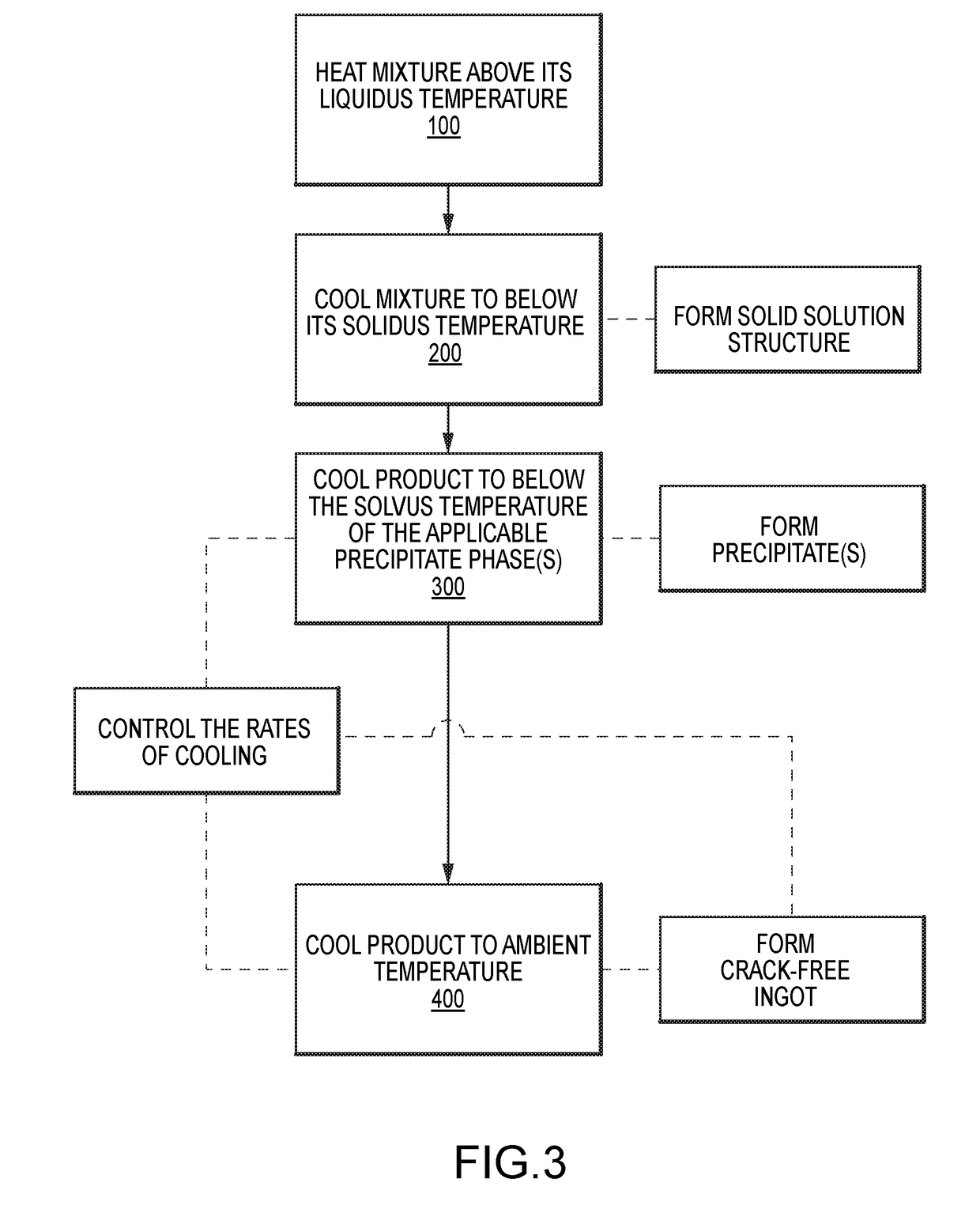

Hcp materials of aluminum, titanium, and zirconium, and products made therefrom

InactiveUS20170306447A1Improve stabilityHigh strengthTurbinesAdditive manufacturing apparatusSolidusPhysical chemistry

The present disclosure relates to new materials comprising Al, Ti, and Zr. The new materials may realize a single phase field of a hexagonal close-packed (hcp) solid solution structure immediately below the solidus temperature of the material. The new materials may include at least one precipitate phase and have a solvus temperature of at least 1240° C. The new materials may include 29.0-42.4 wt. % Al, 41.2-59.9 wt. % Ti, and 10.3-24.1 wt. % Zr. In one embodiment, the precipitate is selected from the group consisting of the L10 phase, the Al2Zr phase, and combinations thereof. The new alloys may realize improved high temperature properties.

Owner:ARCONIC INC

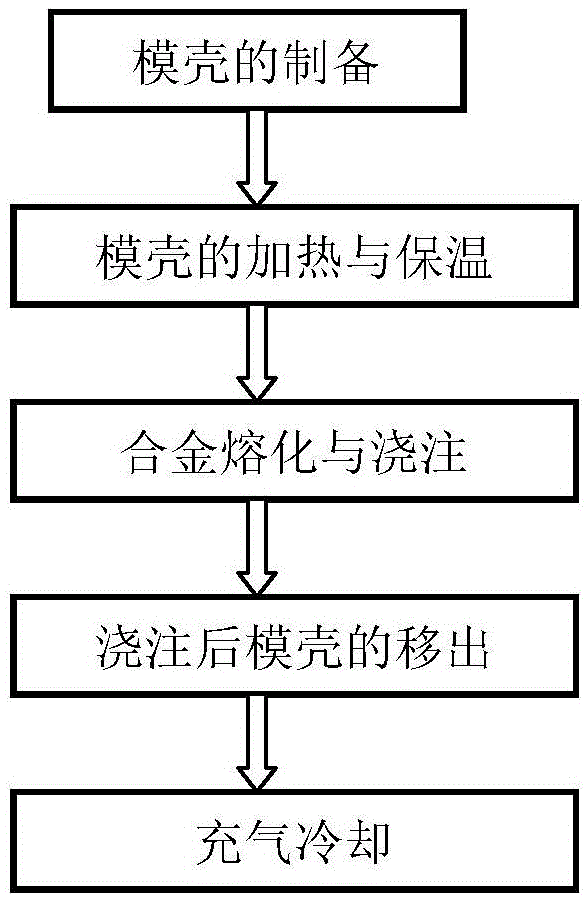

Precision casting method for thin-wall high-temperature alloy floating wall tiles

InactiveCN105583366AImprove filling abilityImprove yieldFoundry mouldsFoundry coresGrain structureNitrogen gas

Provided is a precision casting method for thin-wall high-temperature alloy floating wall tiles. The precision casting method comprises the steps that firstly, a mold shell is processed and then subjected to heating and heat preserving; secondly, after alloy is heated and melted into alloy liquid, the alloy liquid is poured into the mold shell; and finally, after the mold shell is removed out of a heat preserving furnace, nitrogen is filled to increase the cooling rate, and thus casting of the K4169 high-temperature alloy floating wall tiles is completed. According to the precision casting method for the thin-wall high-temperature alloy floating wall tiles, the heat preserving temperature of the mold shell is increased to the temperature which is 10 DEGC-40 DEG C higher than a solid phase line to improve the mold-filling capacity of alloy melt, so that forming of a casting is ensured, the pouring system size is decreased, and the yield of the casting is increased; the alloy liquid is poured into the mold shell at the temperature which is 10 DEGC-32 DEG C higher than a liquid phase line, the temperature gradient of the solidification front of the melt is decreased, isometric crystals are formed, and casting deformation is relieved; after mold filling is completed, the casting is removed out of the heat preserving furnace to be cooled, protective atmosphere is simultaneously filled to promote heat transfer, the cooling efficiency is improved, refining of grain structures is achieved, and the casting performance is improved.

Owner:XIAN JIAOTONG UNIV CITY COLLEGE +1

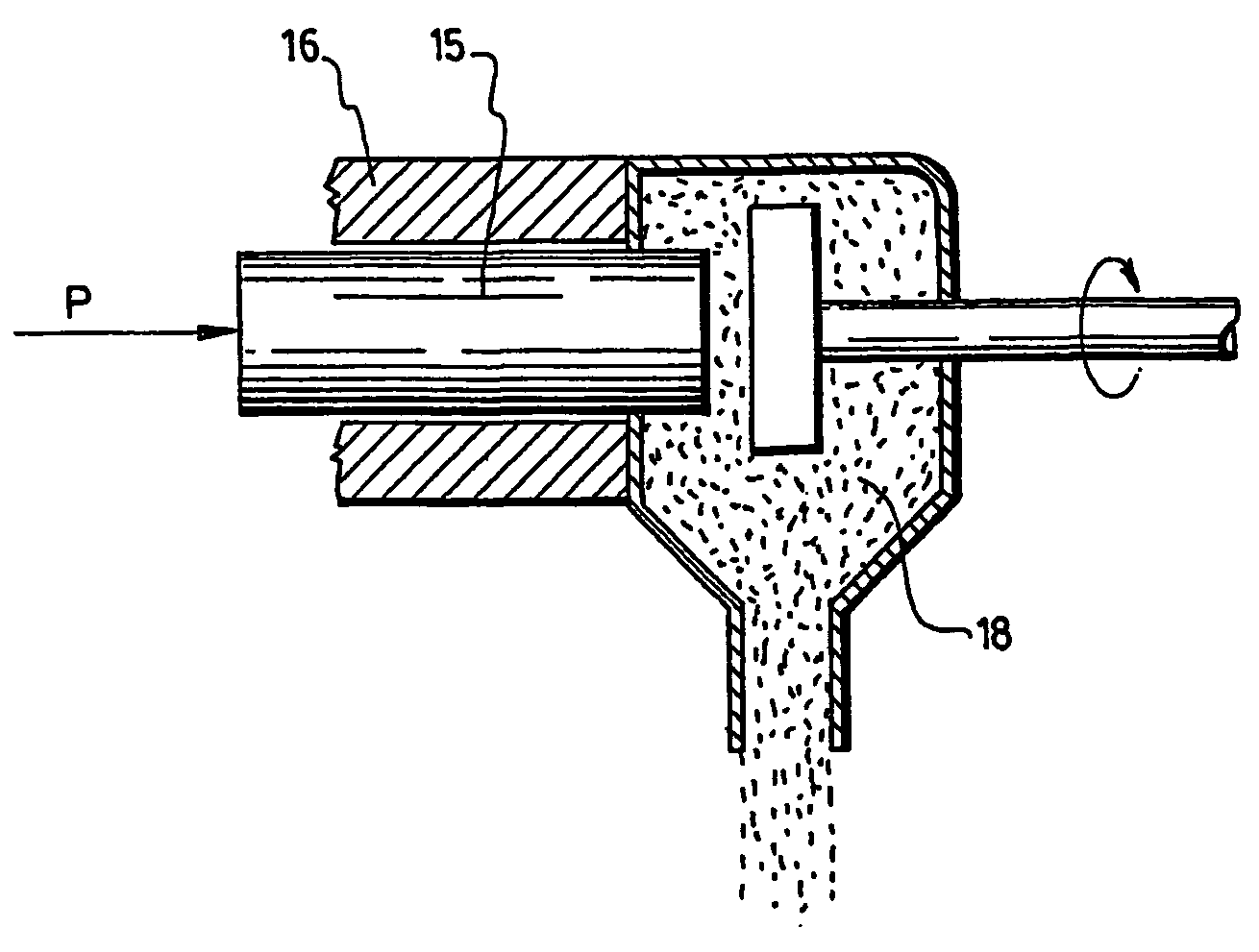

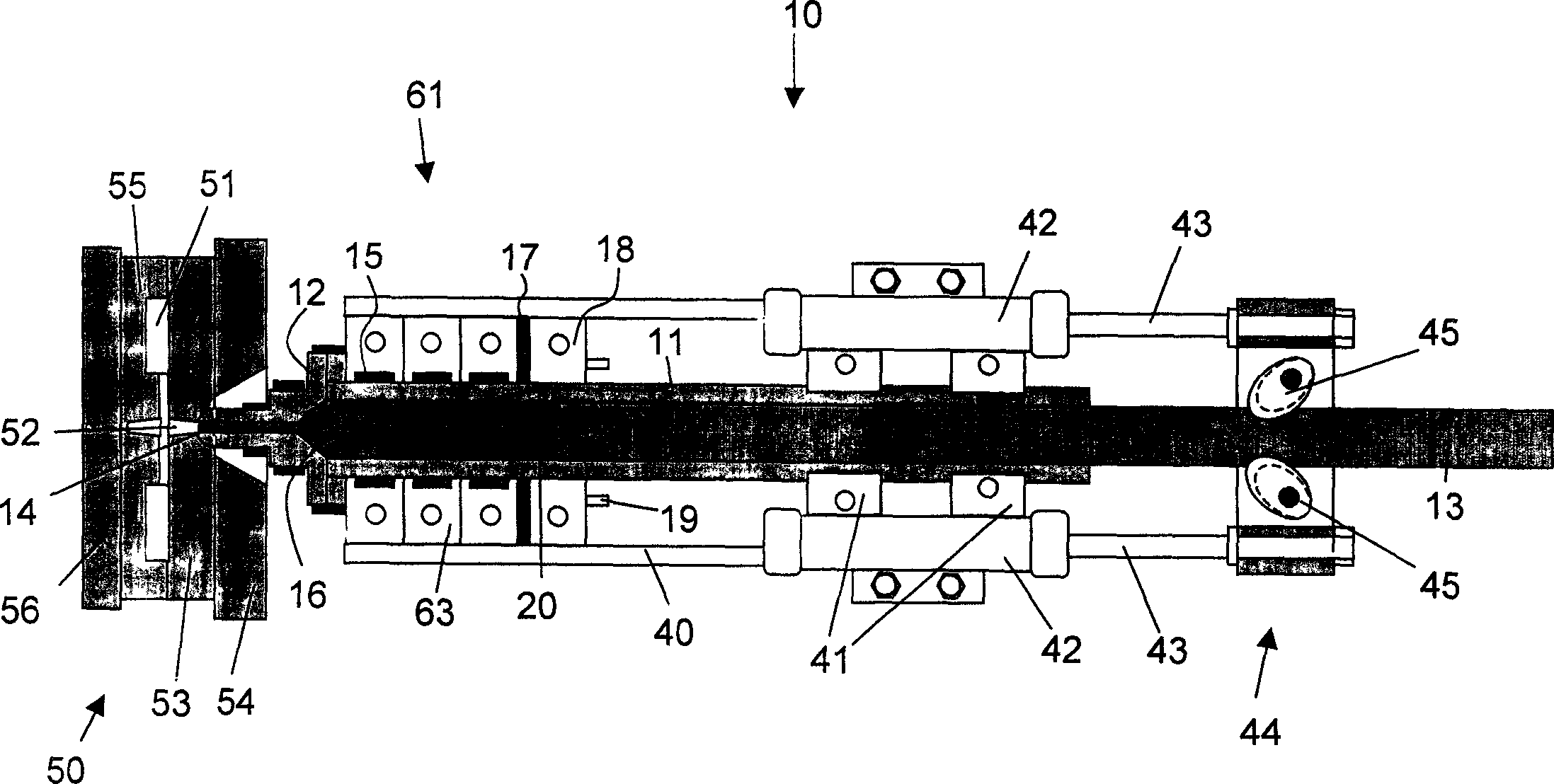

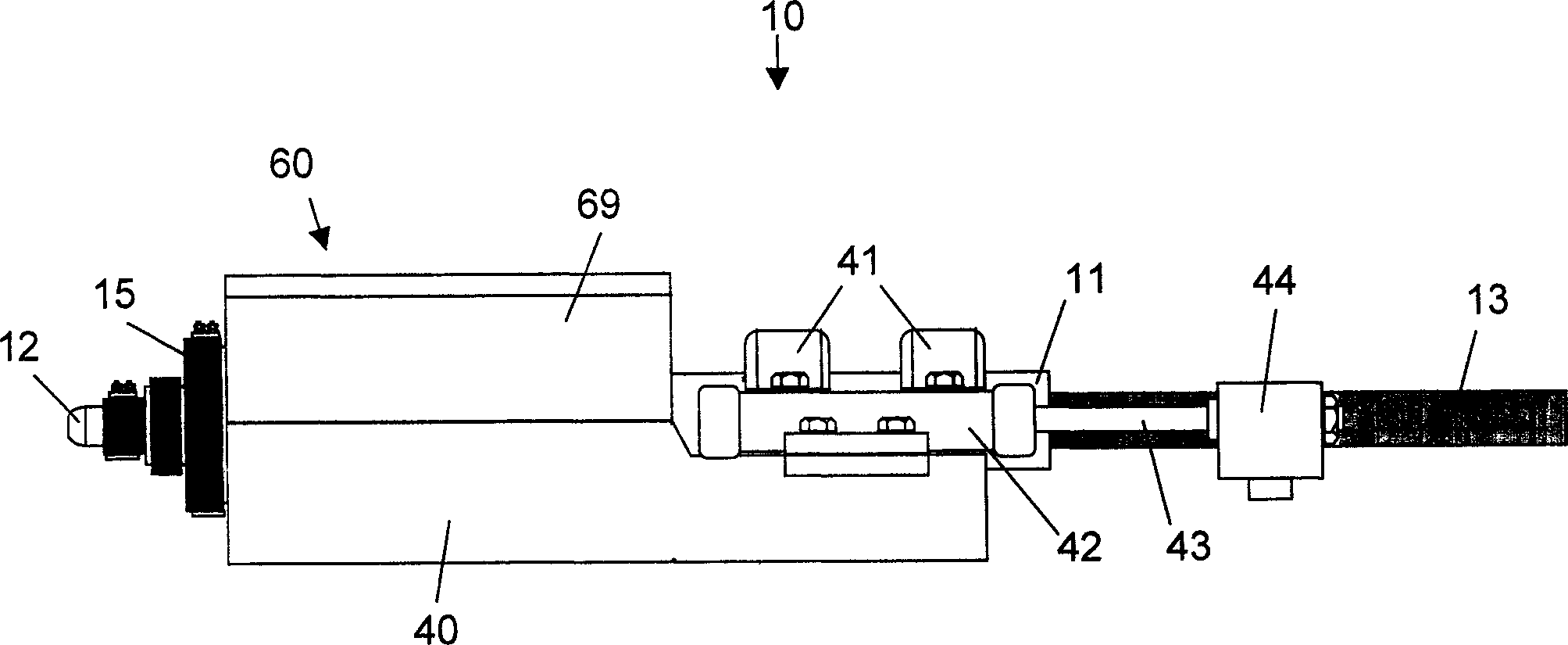

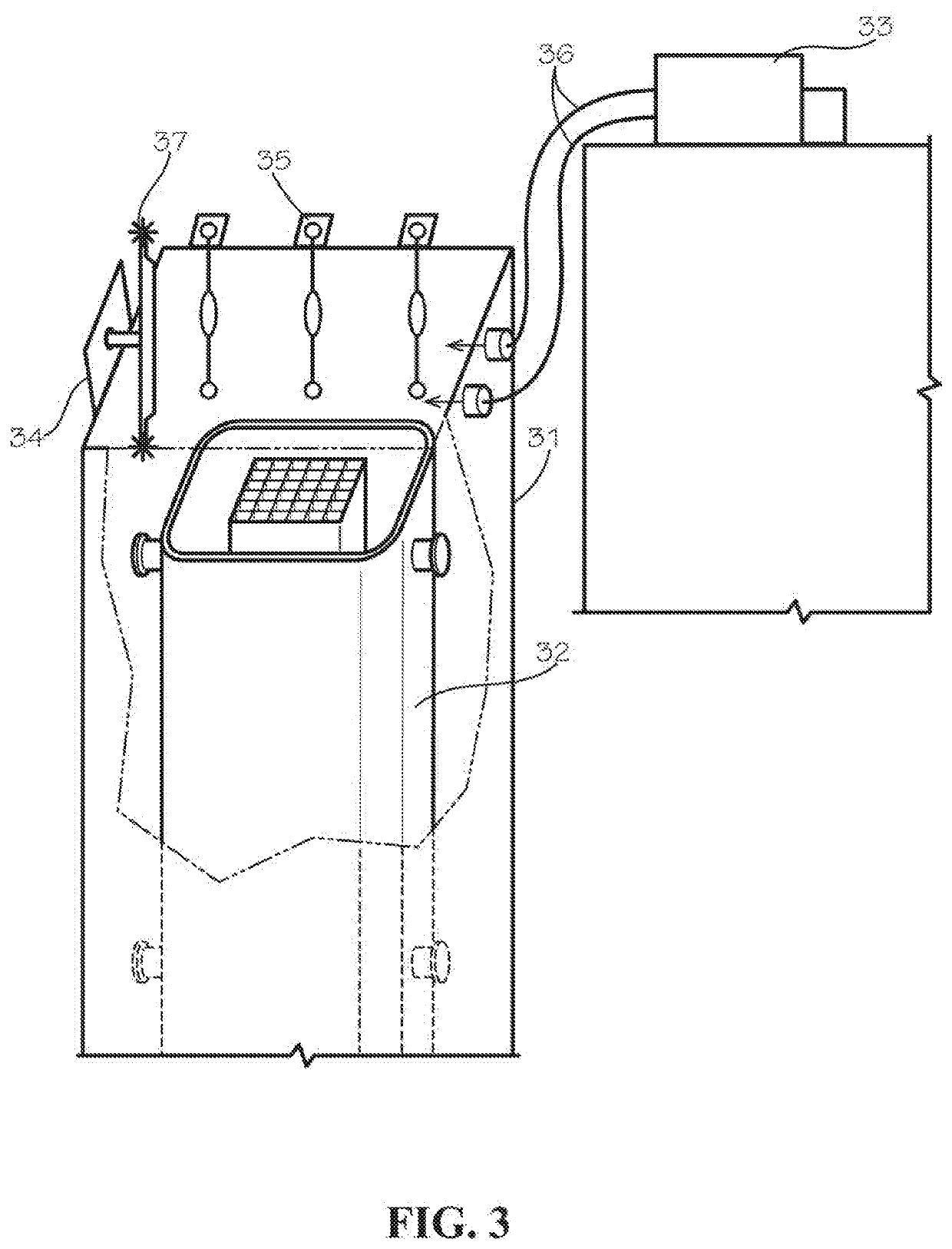

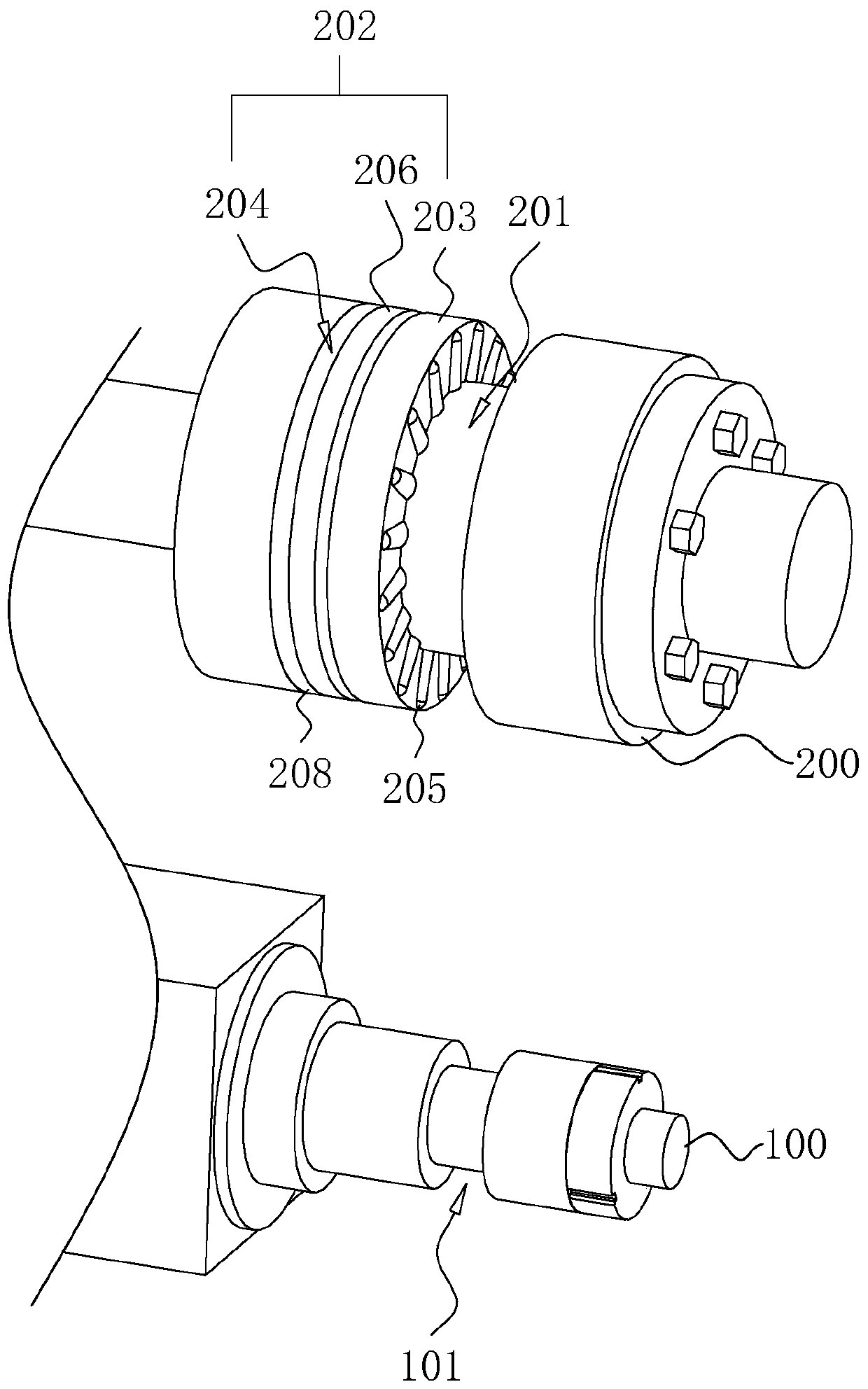

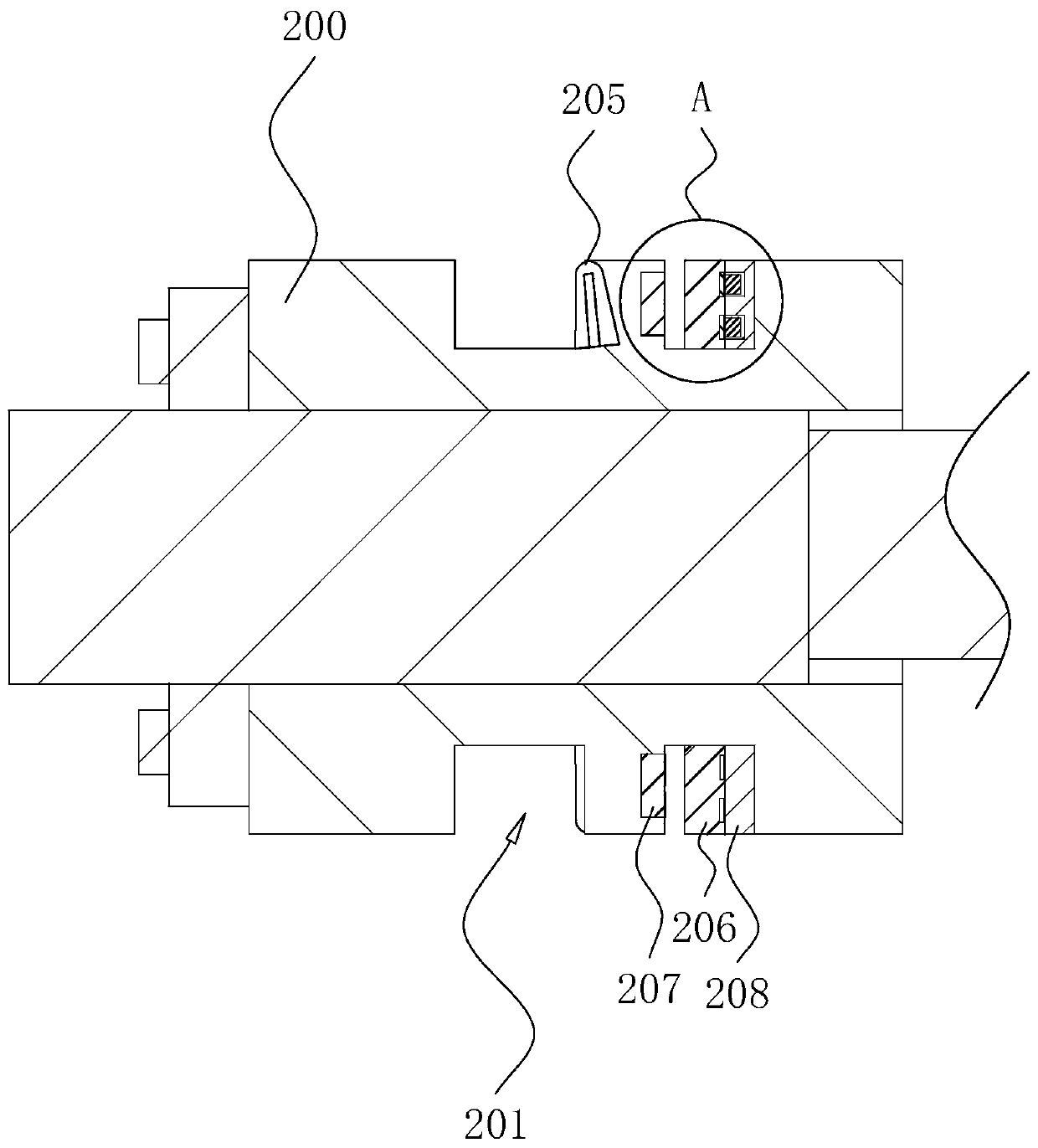

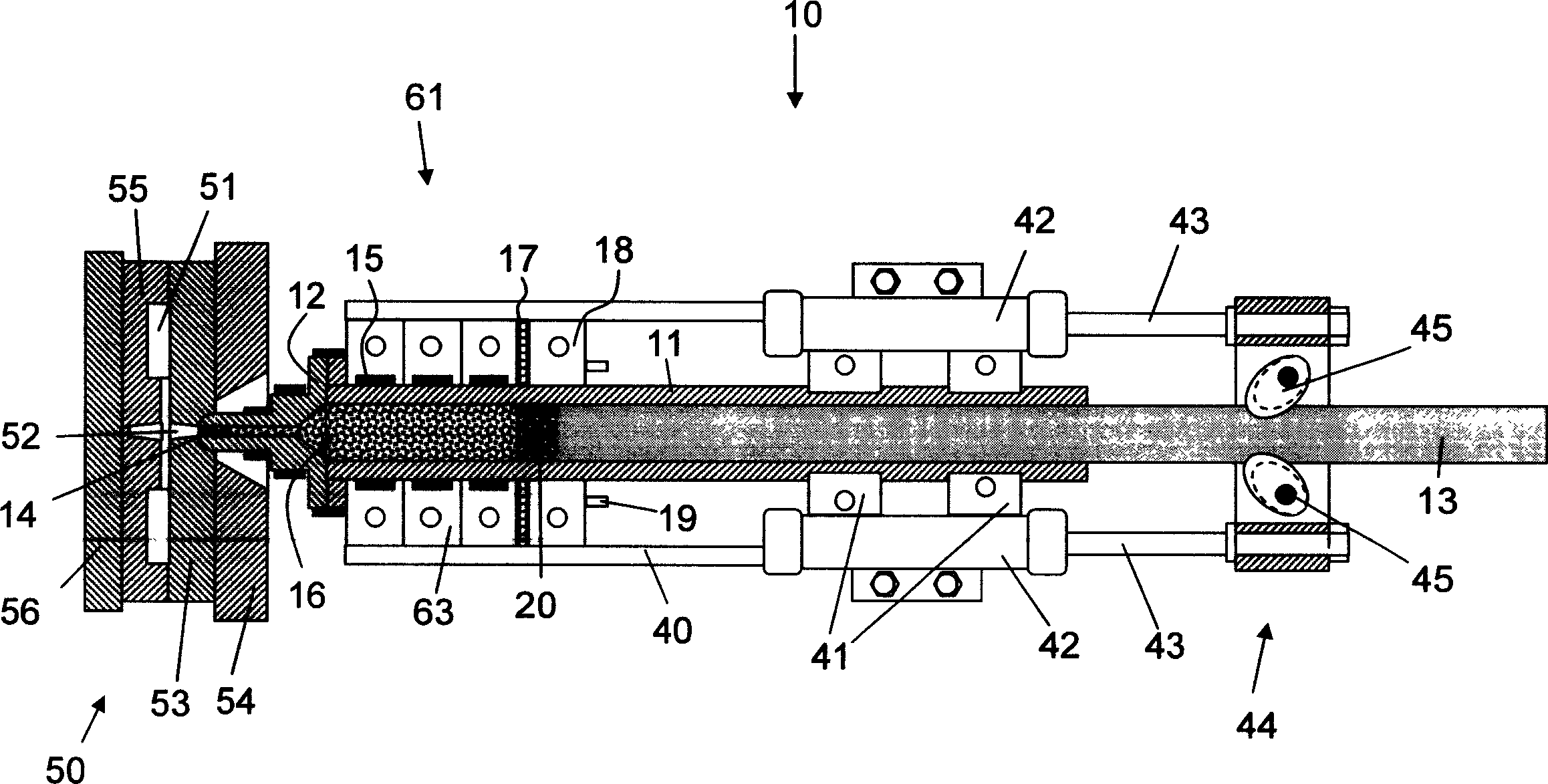

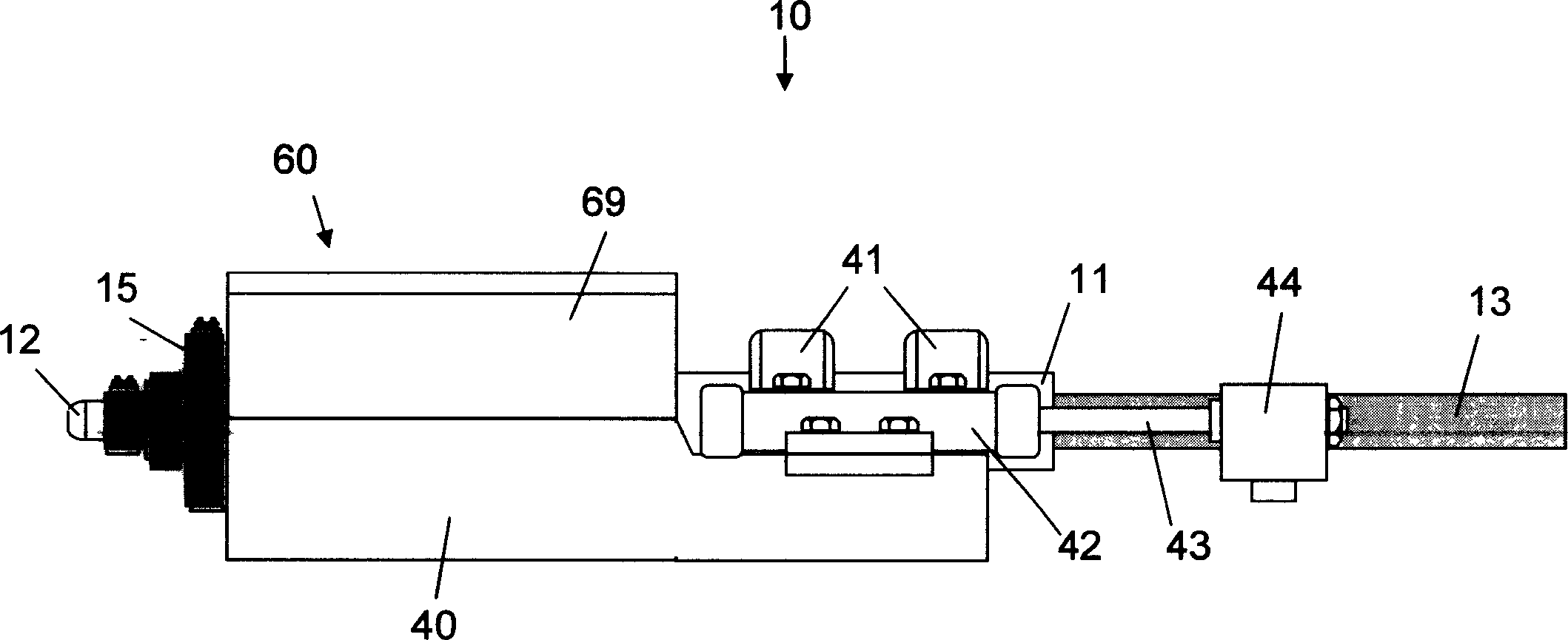

Method and apparatus for thixotropic molding of semisolid alloys

A method and apparatus for thixotropic molding of semisolid alloys are disclosed. The method comprises of feeding a dendritic-free feedstock bar into an extruder barrel, melting a terminal portion of the feedstock bar into a semisolid slurry by heating it to a temperature between its solidus and liquidus temperatures, and using the solid portion of the feedstock bar as an one-time 'plunger' to inject the semisolid slurry into a mold cavity. The apparatus based on the present method, which is equipped without a regular extruder screw or plunger, uses a feedstock bar as a one-time plunger to inject semisolid slurries formed from a terminal portion of the same feedstock bar.

Owner:刘伟杰

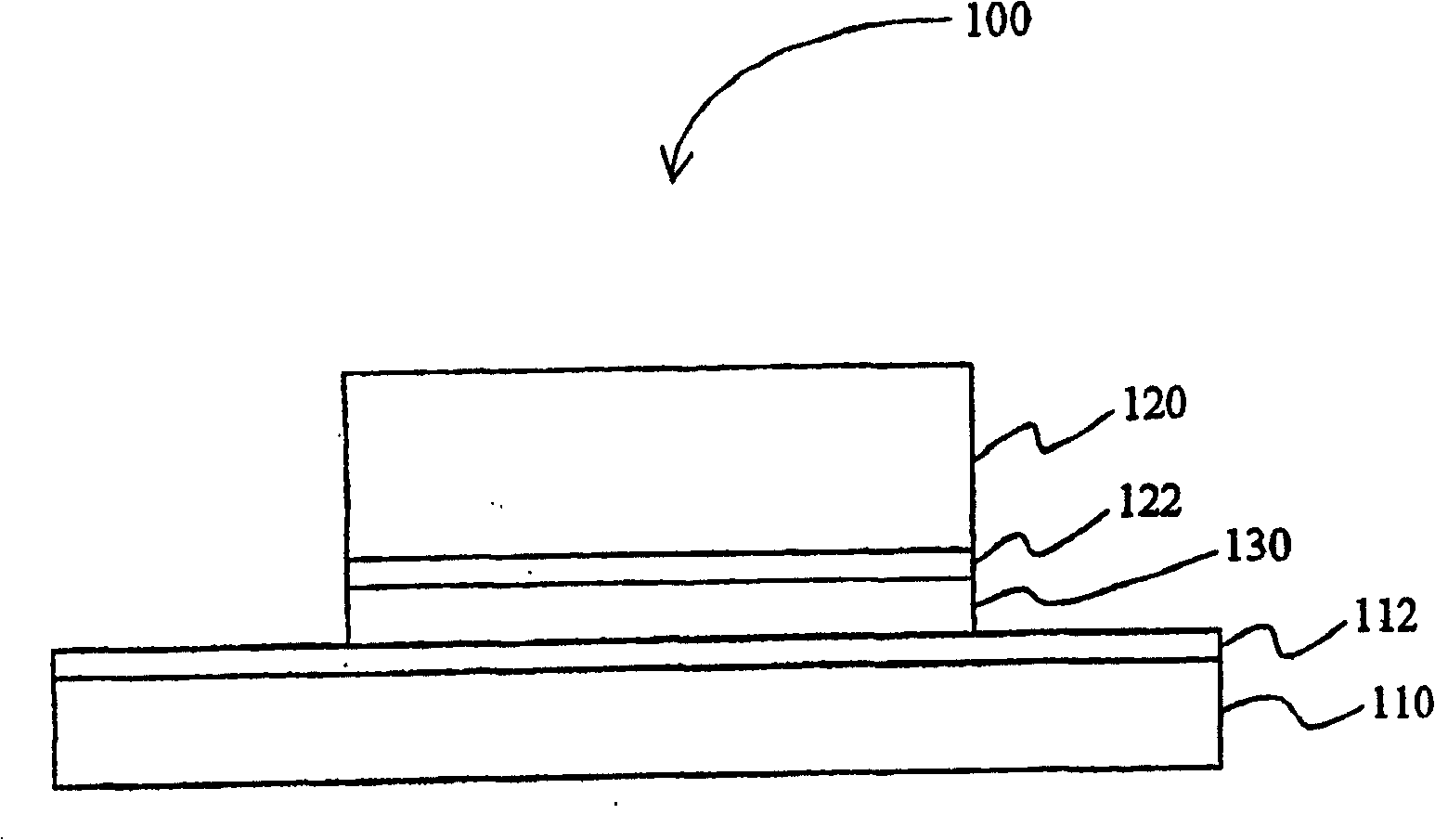

Compositions, methods and devices for high temperature lead-free solder

InactiveCN100475996CSolid-state devicesSemiconductor/solid-state device manufacturingSolidusHigh heat

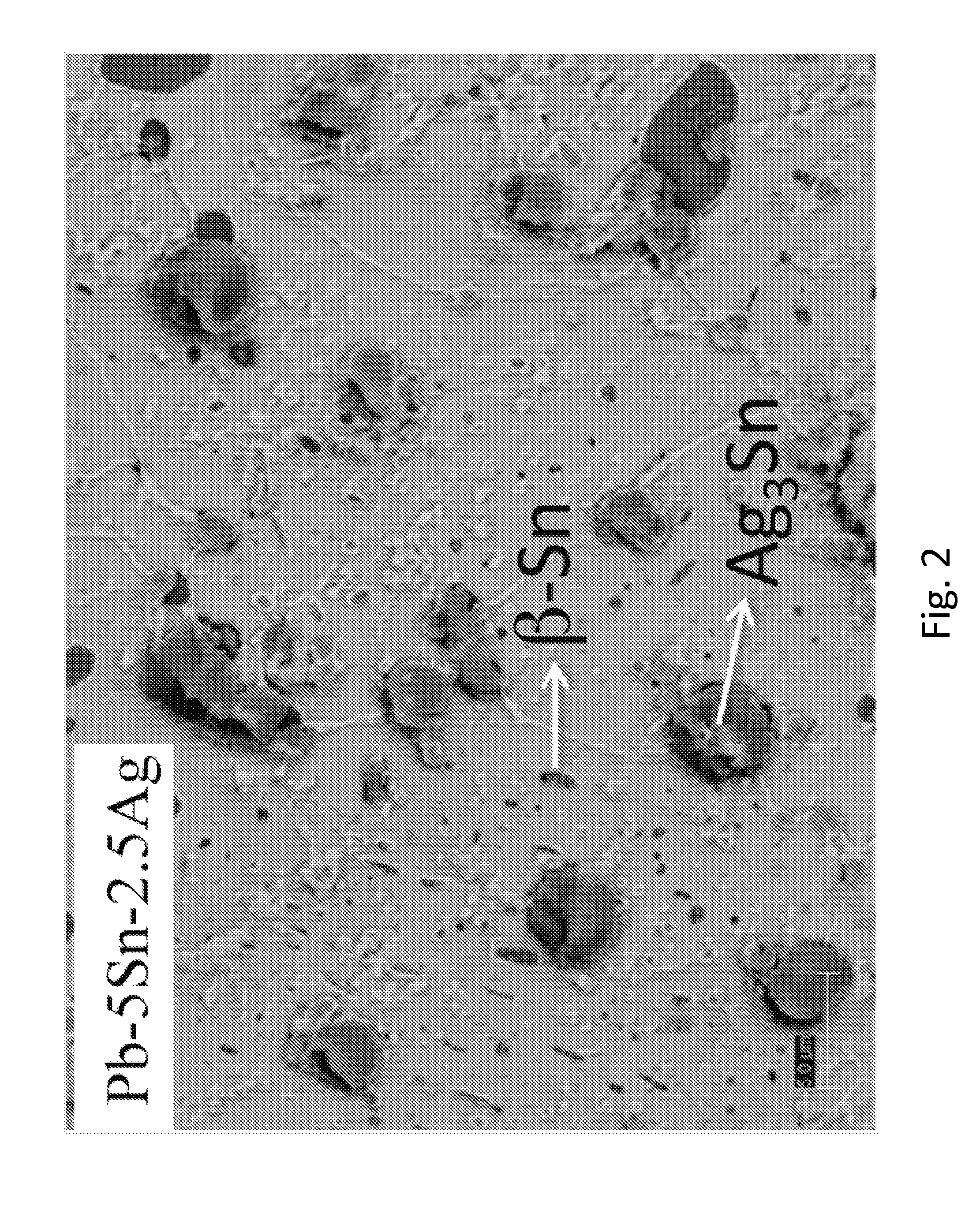

A lead-free solder (130) comprises an alloy that includes Ag in an amount of 2 wt % to 18 wt %, Bi in an amount of 98 wt % to 82 wt %, and a third element in an amount of 0.1 wt % to 5.0 wt %. The third element is selected from the group consisting of Au, Cu, Pt, Sb, Zn, In, Sn, Ni and Ge. Contemplated alloys have a solidus of no lower than 230°C and a liquidus of no higher than 400°C.

Owner:HONEYWELL INT INC

Method for making a refractory ceramic material having a high solidus temperature

ActiveUS20090315227A1Improve homogeneityImprove air tightnessCeramic shaping apparatusCeramicwarePolyvinyl alcoholPolyethylene glycol

A powder metallurgy process for the manufacture of powders of a refractory ceramic material, comprising the consecutive steps of:(i) obtaining a dry mixture of a hafnium dioxide HfO2 powder and an yttrium oxide Y2O3 powder;(ii) step of granulation by pelletization of the dry mixture under stirring in order to obtain a granulated mixture, this granulation step comprising the spraying, into the dry mixture, of an aqueous solution comprising polyvinyl alcohol (PVA) and polyethylene glycol (PEG);(iii) drying of the granulated mixture;(iv) filling of a mold with said granulated mixture;(v) isostatical or semi-isostatical pressing of the granulated mixture in order to obtain a compact mixture;(vi) sintering of the compact mixture in order to obtain a refractory ceramic material at a solidus temperature in the range between 2500° C. and 2800° C.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

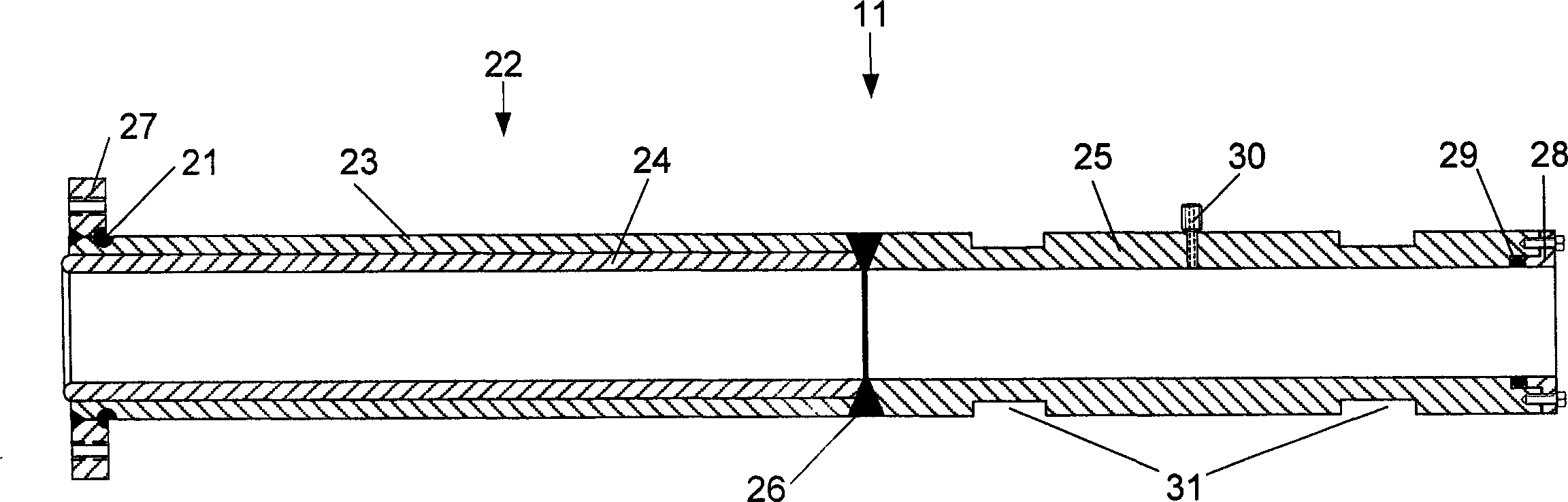

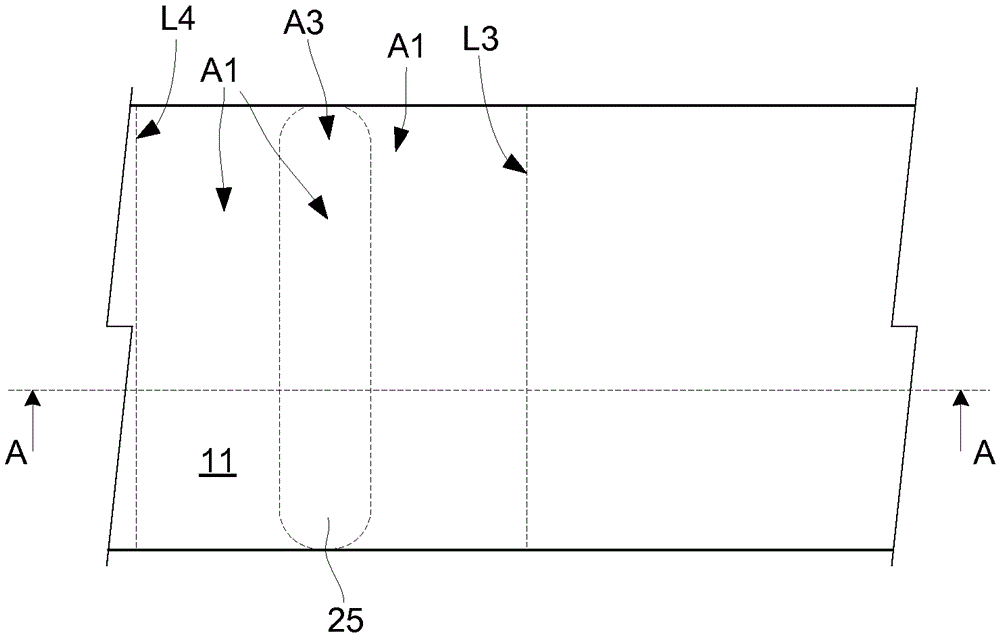

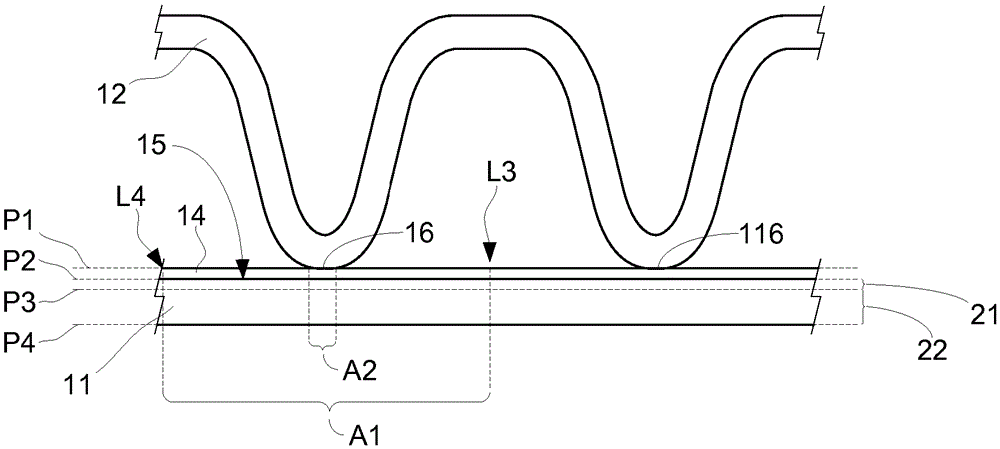

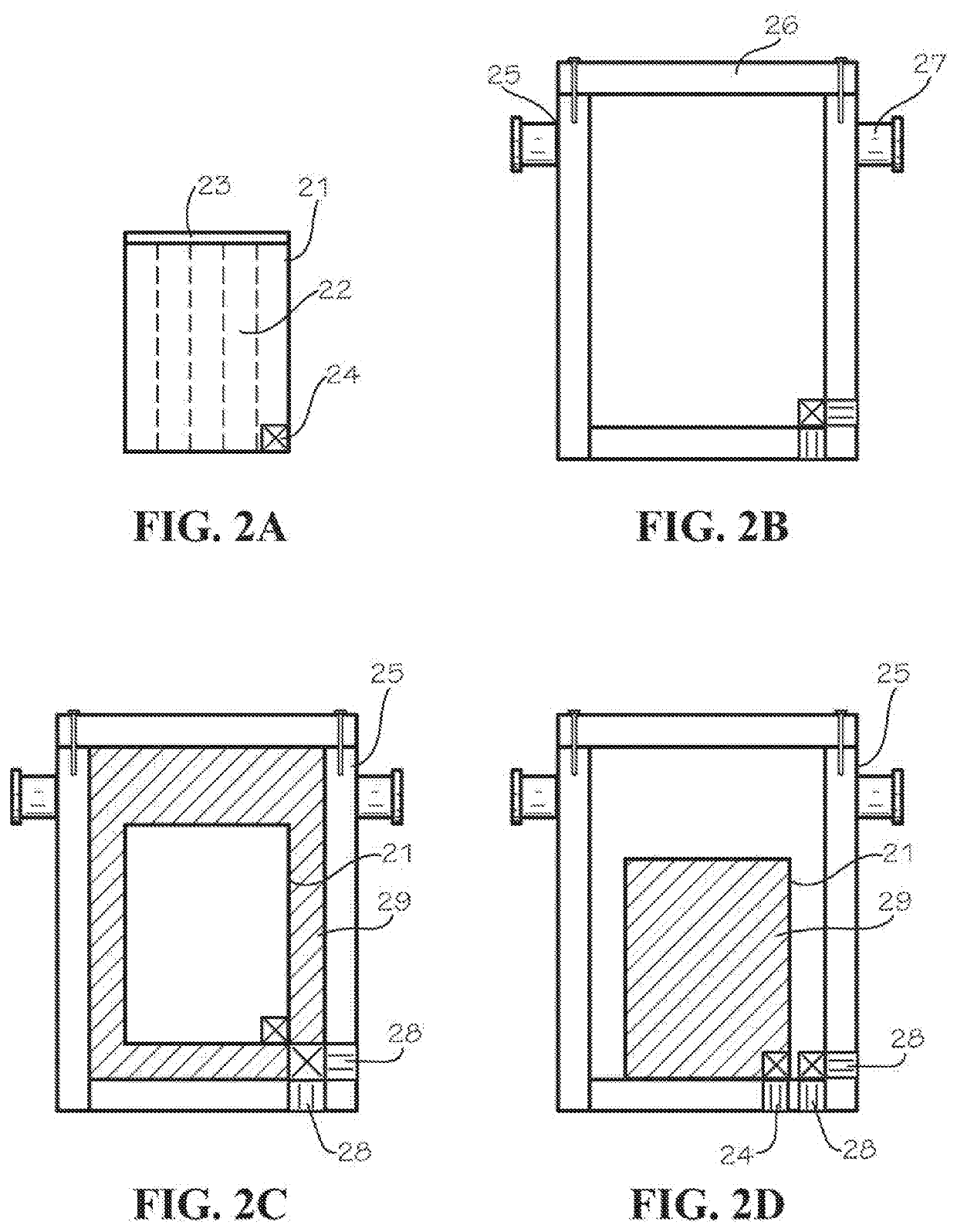

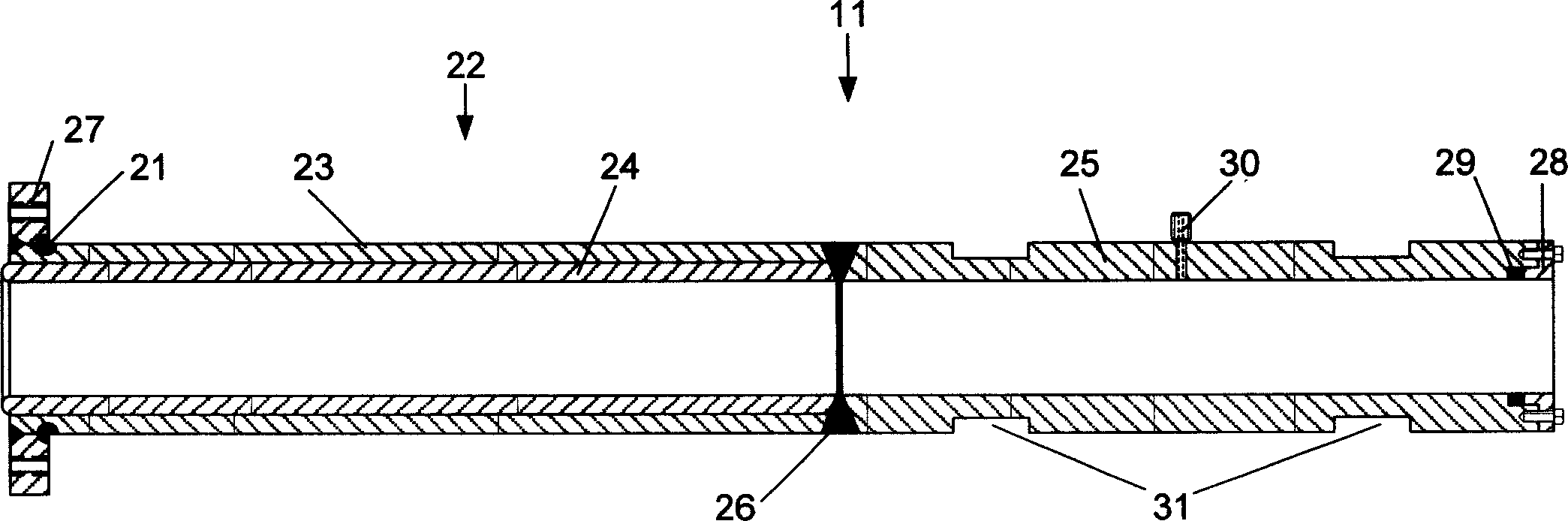

Method for joining metal parts

A method for joining a first metal part (11) with a second metal part (12), the metal parts (11, 12) having a solidus temperature above 1000 DEG C. The method comprises: applying a melting depressant composition (14) on a surface (15) of the first metal part (11), the melting depressant composition (14) comprising a melting depressant component that comprises phosphorus and silicon for decreasing a melting temperature of the first metal part (11), bringing the second metal part (12) into contact with the melting depressant composition (14) at a contact point (16) on said surface (15), heating the first and second metal parts (11, 12) to a temperature above 1000 DEG C, and allowing a melted metal layer (210) of the first metal component (11) to solidify, such that a joint (25) is obtained at the contact point (16). The melting depressant composition and related products are also described.

Owner:ALFA LAVAL CORP AB

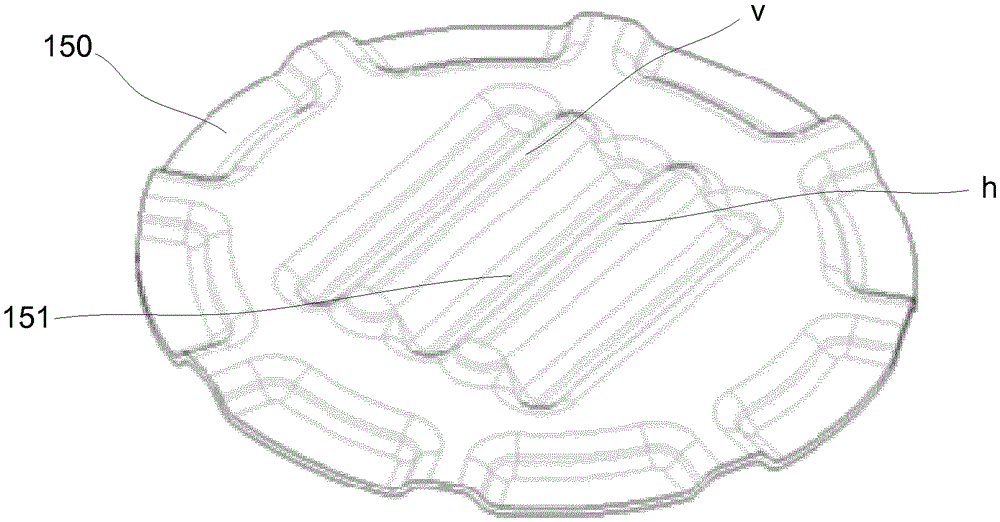

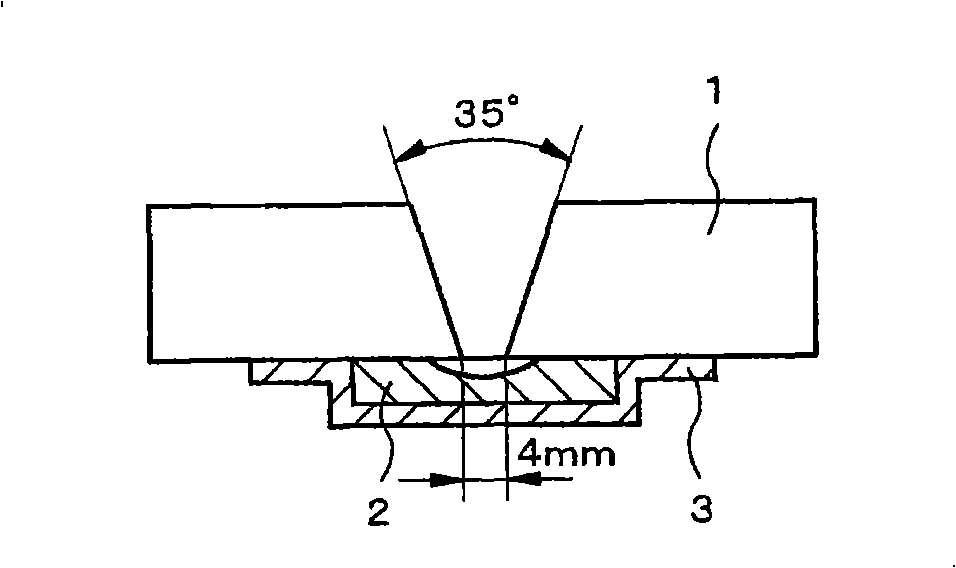

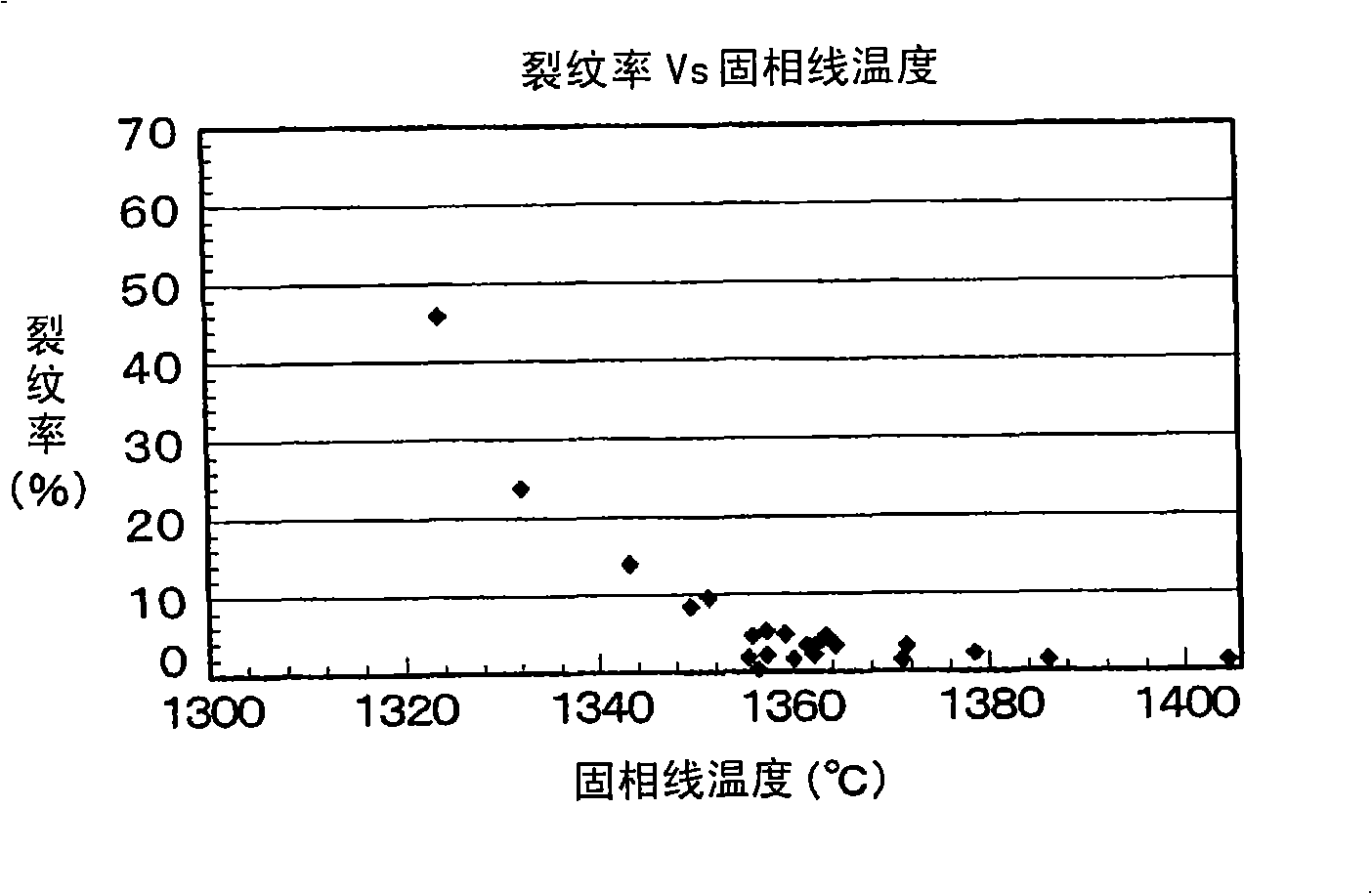

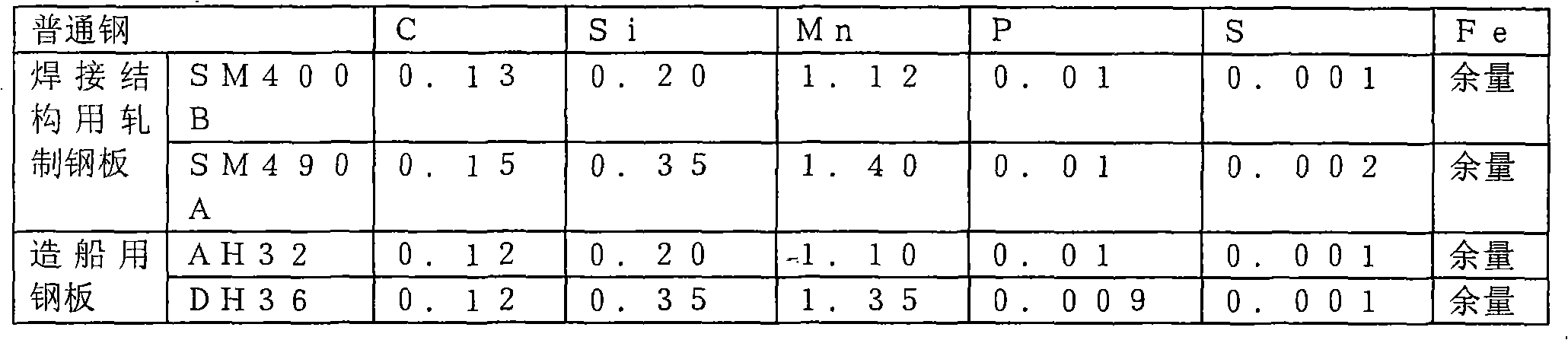

Welded metal and titanium dioxide flux-cored wire

InactiveCN101352790AExcellent high temperature crack resistanceImproved welding workabilityWelding/cutting media/materialsSoldering mediaCrack resistanceSolid core

A titanium dioxide flux-cored wire is provided that can acquire a welding metal having high-temperature crack resistance equivalent to or above that of solid core wire, and can obtain the welding metal with high welding processibility (all-attitude welding). The welding metal welded by the titanium dioxide flux-cored wire has more than 0.029% of content of C on the basis of mass percent of total mass of the welding metal, and respectively sets contents of B, C, Mn, N, P, S, Si and Ti as [B], [C], [Mn], [N], [P], [S], [Si], [Ti], temperature of solidus Ts defined by the following formula is above 1355 DEG C, so as to contain the ingredients hereinbefore. Ts = 1538-8903*[B]-982*[C]-6.64*[Mn]-511*[N]-368*[P]-3603*[S]-47.0*[Si]-205*[Ti]-17.

Owner:KOBE STEEL LTD

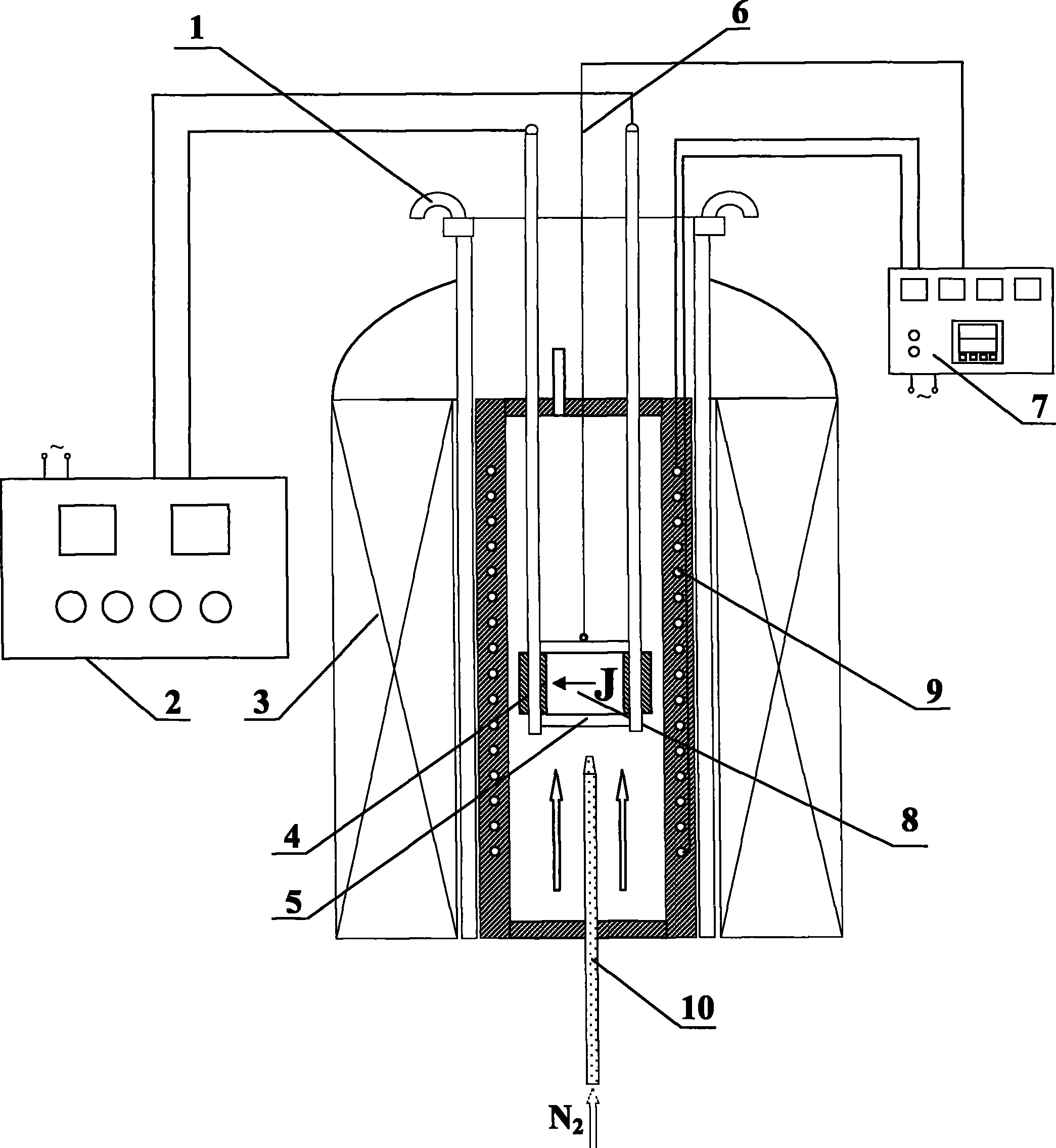

High-purity high-homogenization casting method of magnesium alloy and magnesium-lithium alloy

The invention discloses a high-purity high-homogenization casting method of magnesium alloy and magnesium-lithium alloy. The method comprises the following steps: (1) putting fully preheated magnesiumingots into a smelting crucible, and protecting the melt by adopting vacuum and inert gas; (2) performing electrifying to melt the magnesium ingots, adding alloying raw materials, keeping argon gas introduction in the feeding process, and adjusting the argon gas pressure to 1*10<5>Pa; (3) pushing the melt to carry out underflow type transfer injection by utilizing potential energy difference andgas pressure difference; and (4) carrying out homogenization solidification and waste heat homogenization on the melt. The invention realizes high-efficiency and continuous casting production of magnesium-lithium alloy ingot blanks and the casting. The reinjection process becomes simple and efficient by undercurrent reinjection. Through capturing of the valley bottom of a U-shaped solid-liquid interface in real time, the solid phase region at the lower part of the valley bottom of the solid-liquid interface starts to be homogenized at a constant temperature when the temperature of a core partis close to the solidus temperature, so that solidification shrinkage is reduced, and the cracking risk of a large ingot is greatly reduced.

Owner:GRIMAT ENG INST CO LTD

Method and equipment for producing cylindrical or tubular bimetallic parts

ActiveCN108746623AImprove organizational structureSmall spacingAdditive manufacturing apparatusMaterials processingSpray forming

The invention discloses a method for producing cylindrical or tubular bimetallic parts. A circular bar or tube is put on a loading tray, and the loading tray rotates and meanwhile moves down so as todrive the bar or the tube to rotate and move down. The surface of the bar or the tube forms an additional material layer through a jet nozzle by a precise metal jet forming process, the solidus temperature of the additional material layer is A, and the part with the temperature A being + / -8%A DEG C of the additional material layer is radially knocked by knocking equipment. Thus, the space betweenthe knocking equipment and the jet nozzle in the vertical direction can be greatly shortened. The part, approaching the solidus temperature, of the additional material layer is knocked, the resistanceto metal deformation is small, and the additional material layer is enough to be densified by less beat force and the tissue structure of the additional material layer is improved. Secondary heatingis avoided, the production efficiency is high, and energy conservation and environment protection are realized. The invention further provides equipment for implementing the production method. The method is used for additional material processing of the bar or the tube.

Owner:FOSHAN FENGHE PRECISION INJECTION MOLDING TECH CO LTD

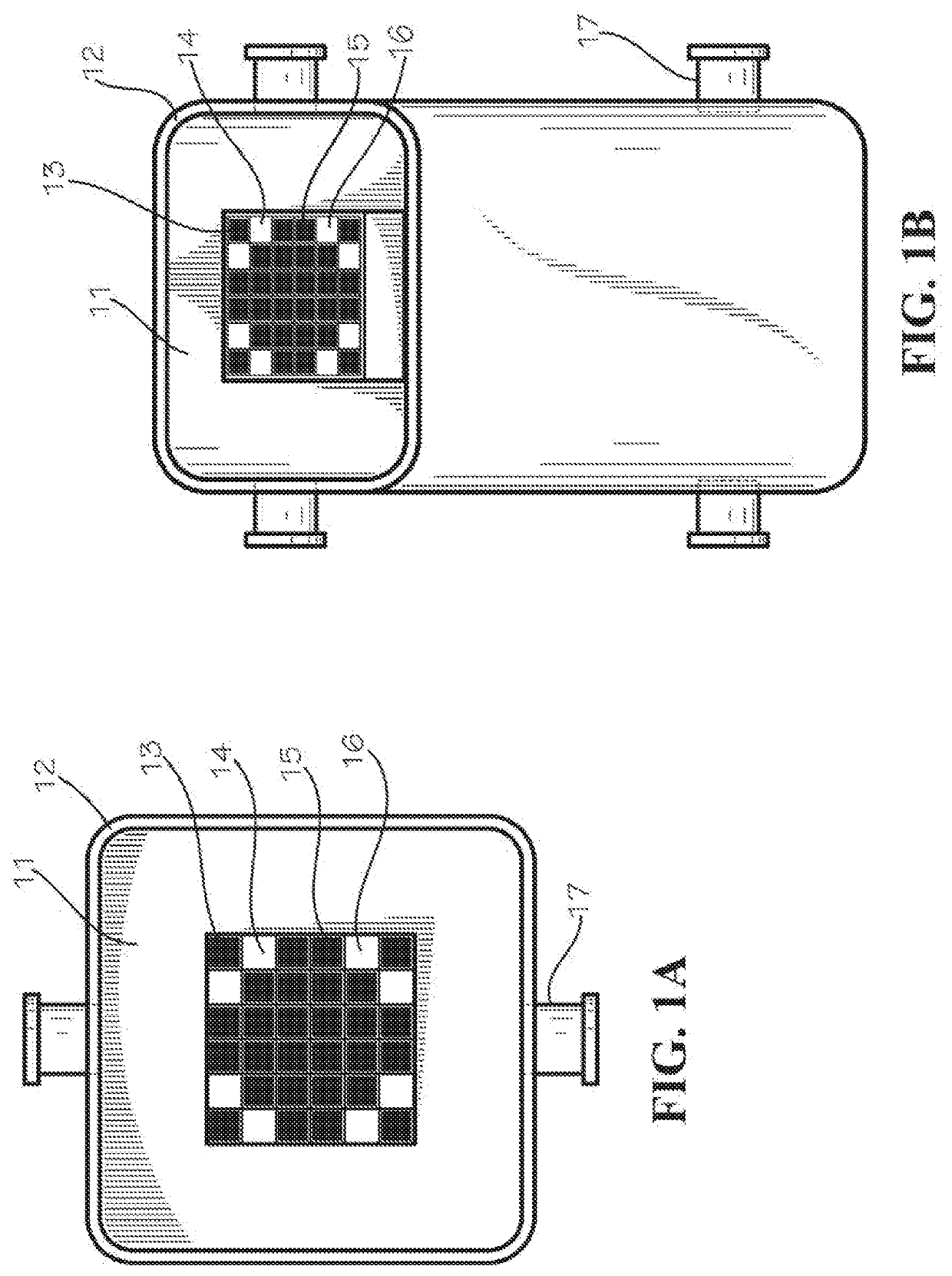

Apparatus and methods for storing hazardous waste materials by encasing same in a fusible metal alloy

ActiveUS20200005956A1Limited abilityIncrease temperatureShieldingPortable shielded containersSolidusLocal environment

An apparatus is provided for storing hazardous waste material, which includes one or more of spent nuclear fuel, radioactive material, and fissionable material. A fusible alloy material, for example, a eutectic material, resides within the apparatus and surrounds the hazardous waste material. In the preferred embodiments, it is suggested that the fusible alloy material exhibits liquidus and solidus or melting temperatures that are between about 100 and 300 degrees Fahrenheit for facilities using the apparatus and methods for liquid storage pool loading applications. For facilities using the apparatus and methods for dry loading, the fusible alloy materials may exhibit liquidus and solidus or melting temperatures that are between about 100 and 650 degrees Fahrenheit. The fusible alloy material is introduced in a liquid phase and eventually solidifies into a solid phase as the temperature of the hazardous waste material and / or the local environment decreases.

Owner:PENNINGTON CHARLES W

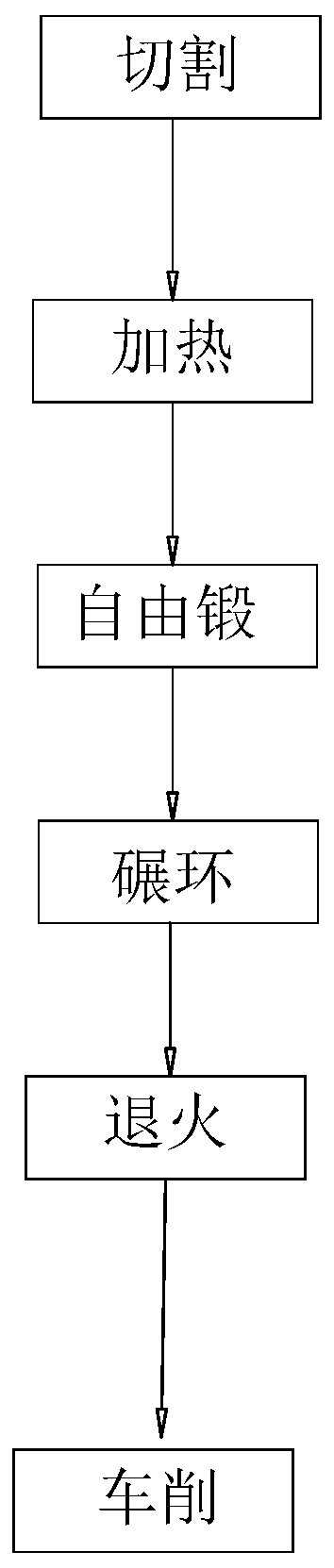

Hubbed flange production process capable of improving production efficiency

The invention discloses a hubbed flange production process capable of improving production efficiency, and belongs to the technical field of flange production. According to the technical scheme, the hubbed flange production process is characterized by comprising the following steps that S1, cutting is conducted, specifically, a blank is cut from round steel; S2, heating is conducted, specifically,the blank is heated in a heating furnace to enable the temperature of the blank to be higher than a recrystallization temperature and lower than a temperature of a solidus; S3, free forging is conducted, specifically, the heated blank is upset through a press machine, and then the blank is punched through a punch; S4, ring rolling is conducted, specifically, the blank is installed on a ring rolling machine to be subjected to ring rolling, axial pressure is applied to the edge, close to an outer circle, of the end face side wall of the blank while ring rolling is conducted, and a flange neck is formed on the end face side wall of the blank; S5, annealing is conducted, specifically, the blank is placed in a resistance furnace to be annealed; and S6, turning is conducted, specifically, the flange is turned through a lathe. The hubbed flange production process has the effect of improving the production efficiency.

Owner:章丘市普锐锻压有限公司

Method for making a refractory ceramic material having a high solidus temperature

ActiveUS8097202B2Improve air tightnessGood chemical resistanceCeramic shaping apparatusCeramicwareSolidusPolyvinyl alcohol

A powder metallurgy process for the manufacture of powders of a refractory ceramic material, comprising the consecutive steps of:(i) obtaining a dry mixture of a hafnium dioxide HfO2 powder and an yttrium oxide Y2O3 powder;(ii) step of granulation by pelletization of the dry mixture under stirring in order to obtain a granulated mixture, this granulation step comprising the spraying, into the dry mixture, of an aqueous solution comprising polyvinyl alcohol (PVA) and polyethylene glycol (PEG);(iii) drying of the granulated mixture;(iv) filling of a mold with said granulated mixture;(v) isostatical or semi-isostatical pressing of the granulated mixture in order to obtain a compact mixture;(vi) sintering of the compact mixture in order to obtain a refractory ceramic material at a solidus temperature in the range between 2500° C. and 2800° C.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

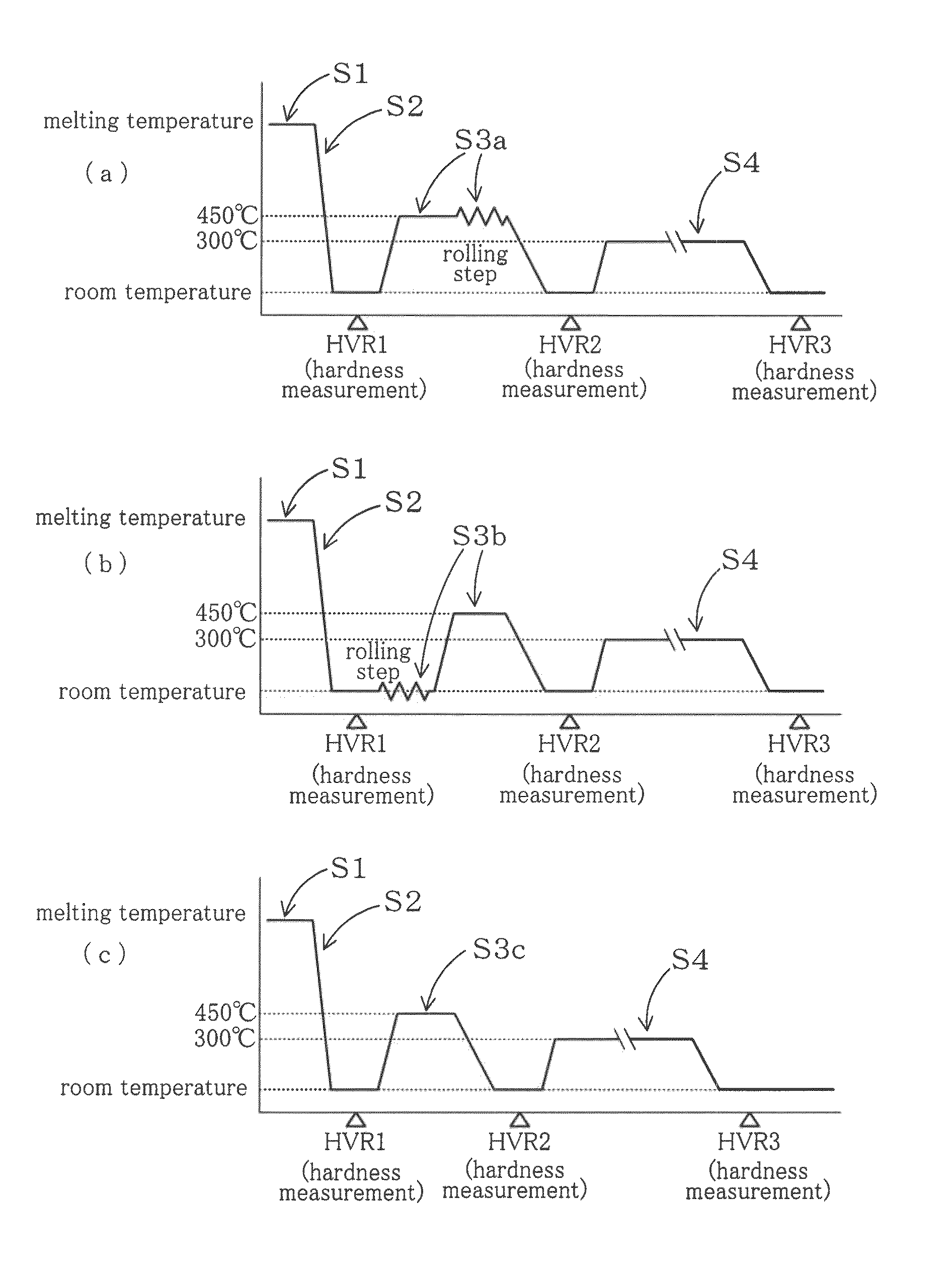

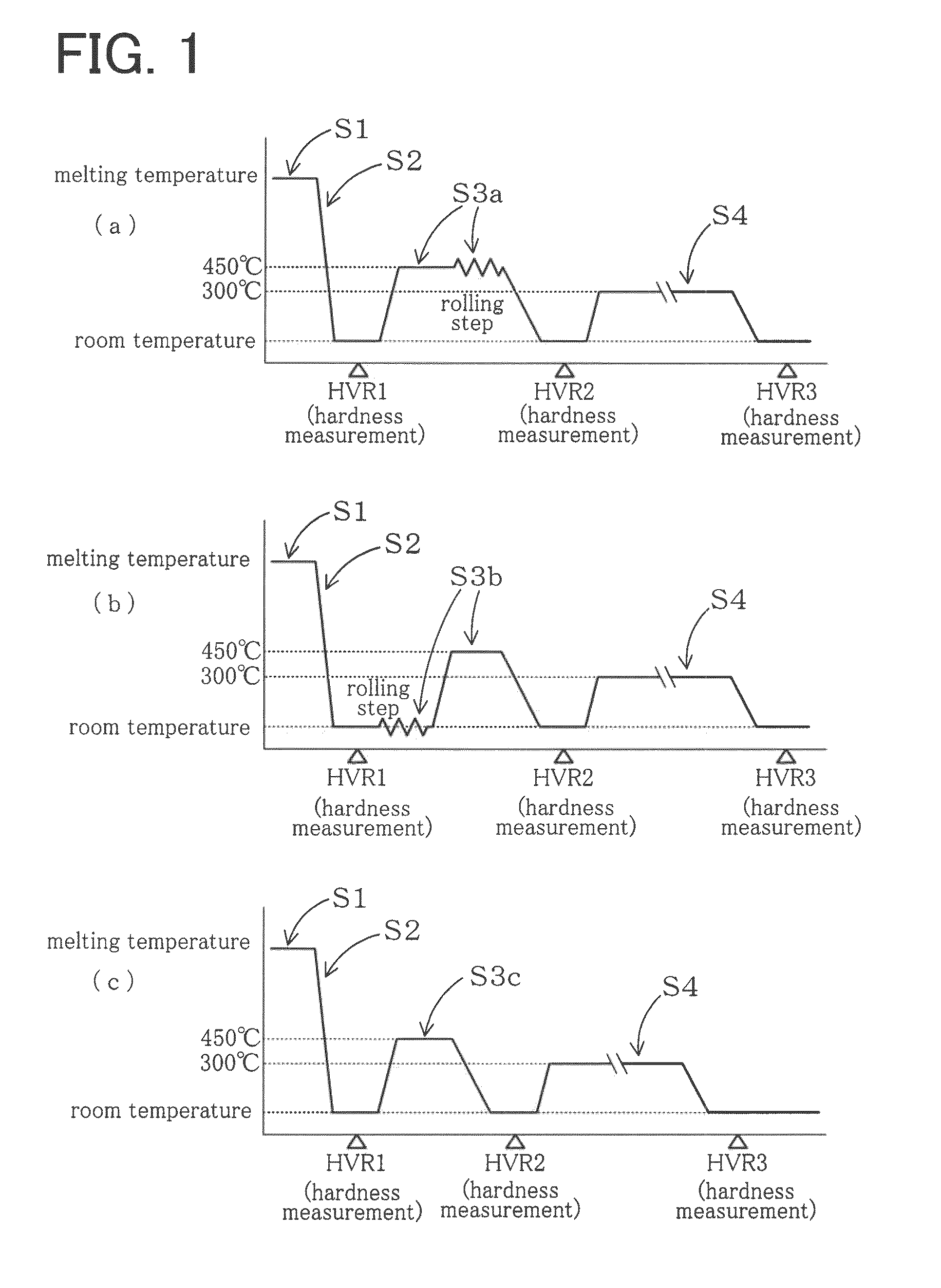

Casted aluminum alloy and method for producing the same as well as aluminum alloy material and method for producing the same

InactiveUS8303736B2Reduce the number of stepsLow costFoundry mouldsFoundry coresCasting moldImpurity

A casted aluminum alloy obtained by casting a molten metal of an aluminum alloy, an aluminum alloy material obtained by at least heating the casted aluminum alloy, and methods for producing them. In the production of the casted aluminum alloy, a molten metal is obtained by melting an aluminum alloy containing 0.8 to 5 mass % of Fe, 0.15 to 1 mass % of Ti, Zr or the like as third component elements in an specific amount, and a residual part containing Al and inevitable impurities at a certain temperature (melting step). Subsequently, the molten metal is cast into a plate-like shape by a casting mold while cooling the molten metal to a temperature that is lower by at least 10° C. than a solidus temperature of the aluminum alloy at a cooling rate of 150° C. / sec. or more and less than 10000° C. / sec. (casting step).

Owner:TOYOTA CENT RES & DEV LAB INC

Low-temperature lead-free solder paste and preparation method thereof

ActiveCN111318832AIncreased solidus temperatureHigh tensile strengthWelding/cutting media/materialsSoldering mediaSolidusCopper

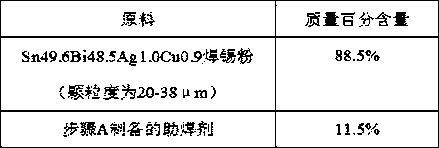

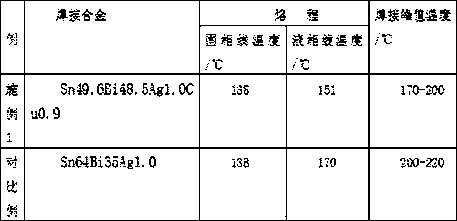

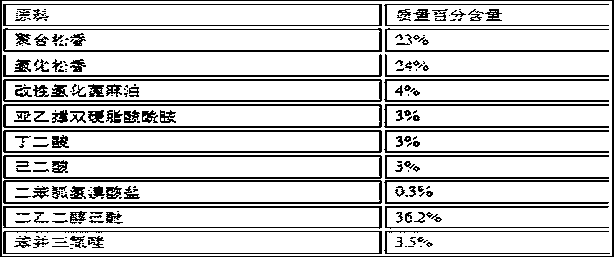

The invention discloses a low-temperature lead-free solder paste and a preparation method thereof. The low-temperature lead-free solder paste is prepared from the following raw materials according tomass percent: 86% to 91% of low-temperature tin-bismuth-silver-copper quaternary lead-free solder powder and 9% to 14% of scaling powder, wherein the low-temperature tin-bismuth-silver-copper quaternary lead-free solder powder is composed of four elements including tin, bismuth, silver and copper, the mass percent of bismuth is 46% to 52%, the mass percent of copper is 0.3% to 1.2% of copper, themass percent of silver is 0.4% to 1.2%, and the mass percent of tin is 45.6% to 53.3%. The solder paste is prepared by adopting the formula and the method, the bismuth content is in a relatively highreasonable range, so that the solidus temperature of the product is increased from 138 DEG C to 151 DEG C, the solder paste is suitable for a low-temperature packaging process, the welding peak temperature does not exceed 200 DEG C, and compared with Sn42Bi58 alloy, the tensile strength, the shear strength, the anti-dropping performance and the thermal cycle life of the product are greatly increased.

Owner:DONGGUAN YONGAN TECH

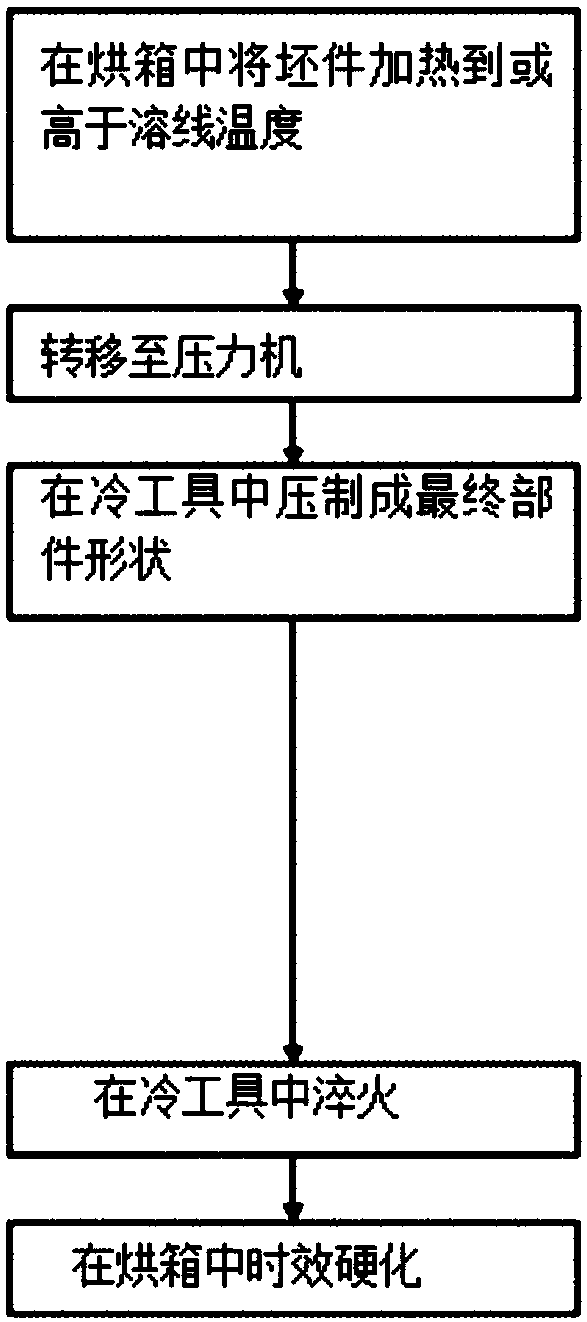

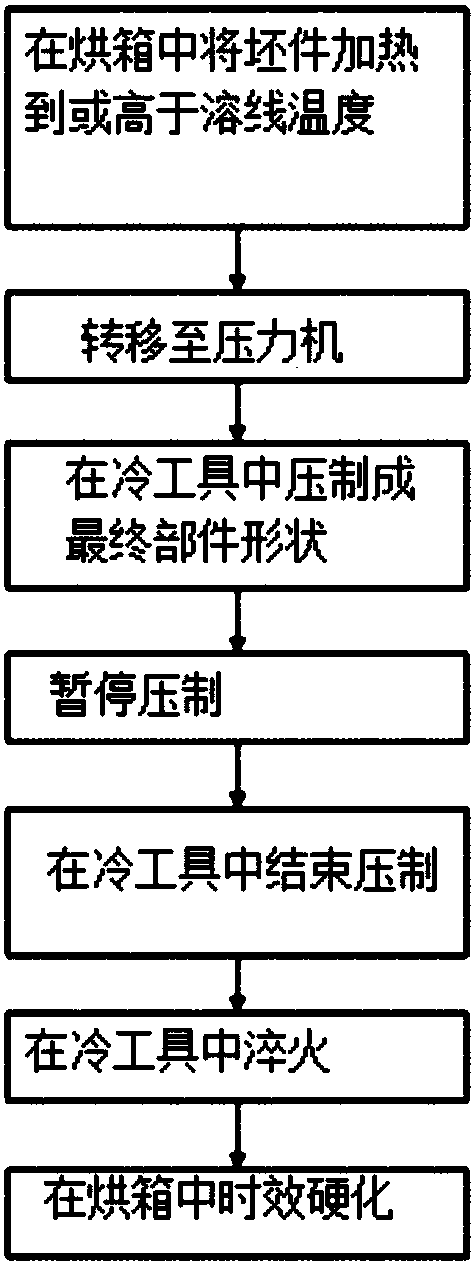

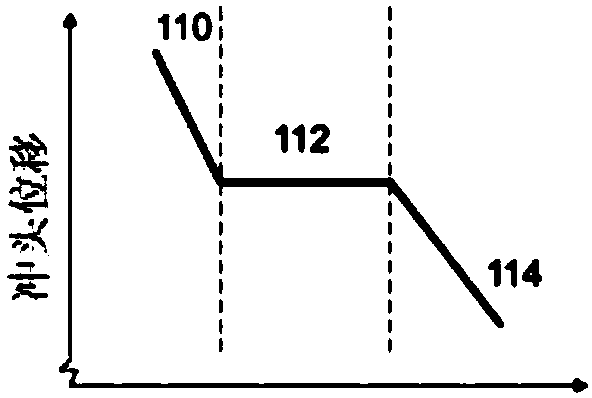

Method of forming components from sheet material

The present invention provides a method of forming a component (40) from an alloy sheet of material (30) having at least a Solvus temperature and a Solidus temperature of a precipitation hardening phase, the method comprising the steps of: heating the sheet (30) to above its Solvus temperature; initiating forming the heated sheet(30) between matched tools(32, 34) of a die press and forming by means of plastic deformation towards a final shape whilst allowing the average temperature of the sheet (30) to reduce at a first predetermined rate A; interrupting the forming of the sheet for a predetermined first interruption period P1prior to achieving said final shape; and, during the interrupt holding the sheet of material with reduced or no deformation and allowing the average temperature of the sheet to reduce at a second predetermined rate B lower than or equal to the first predetermined rate in order to allow for a reduction in dislocations and completing the forming of the heated sheetinto the final shape whilst allowing the sheet to cool at a third rate C greater than said second rate B.

Owner:IMPRESSION TECH

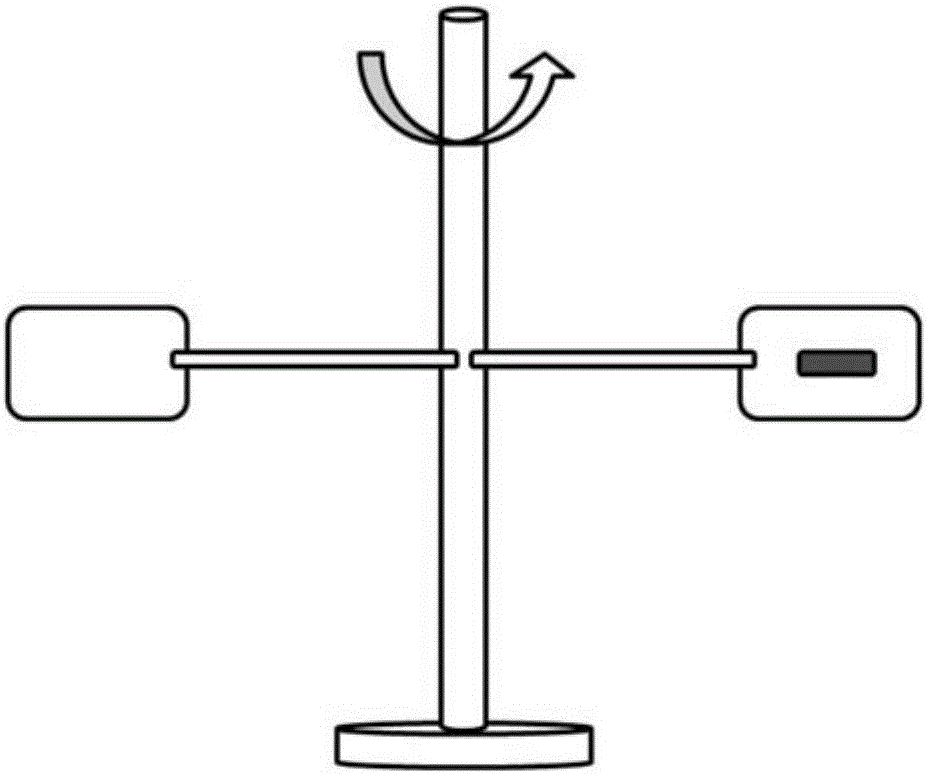

Method for supergravity refining of metal solidification structure

The invention relates to the technical field of metal grain refinement, and discloses a method for supergravity refining of a metal solidification structure. The method comprises the steps that cooling solidification is conducted on a metal melt in a supergravity field, wherein the cooling solidification speed is the constant speed or the non-constant speed, the metal cooling speed ranges from 1 DEG C / min-10 DEG C / min, the supergravity field is achieved through rotation centrifuging of equipment, the gravity coefficient of the supergravity field is 1-800, and in the other words, the supergravity acceleration is 1g-800 g; and when the temperature of the metal melt is reduced to a liquid phase line, supergravity treatment is started, and when the temperature of the metal melt is reduced to the position lower than a solid phase line by 50 DEG C, supergravity treatment is stopped. The method has the beneficial effects that the moving gathering of a primary dendritic crystal, especially the rapid moving gathering of fine crystal nucleuses in the earlier stage of solidification in the supergravity field is greatly enhanced, and the metal solidification structure is rapidly and effectively refined; other elements are not guided in, and the purity degree of metal is guaranteed; and the technology process is simple, cost is low, environment friendliness is achieved, and the application prospect is wide.

Owner:UNIV OF SCI & TECH BEIJING

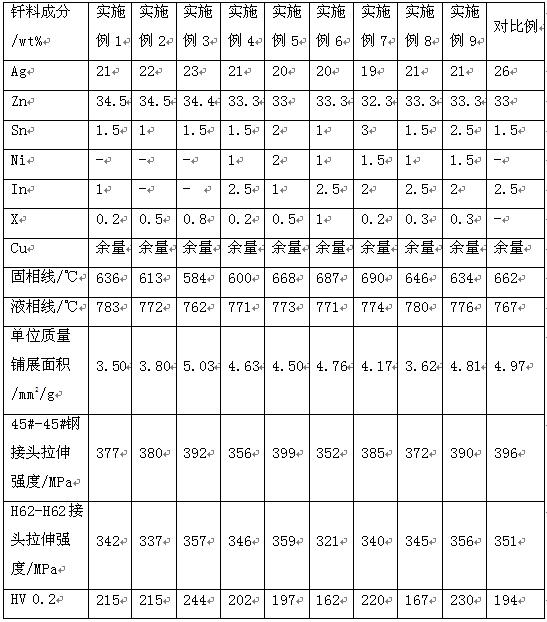

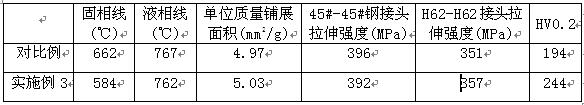

Low-melting-point and high-strength low-silver cadmium-free manganese-free multi-element silver solder and preparation method thereof

PendingCN112518169AReduce contentEasy to prepareWelding/cutting media/materialsSoldering mediaIndiumSolidus

The invention relates to a low-melting-point and high-strength low-silver cadmium-free manganese-free multi-element silver solder and a preparation method thereof. The multi-element silver solder is composed of 19%-23% of silver, 32%-35% of zinc, 1.0%-3.0% of tin, 0-2.0% of nickel, 0-3.0% of indium, 0.01%-1.0% of alloying elements and the balance of copper, wherein the alloying elements are one ormore of phosphorus, lanthanum and cerium; and the alloying elements are composed of the following components in percentage by mass: 0.2%-1% of phosphorus, 0-0.02% of lanthanum and 0-0.01% of cerium.The preparation method of the multi-element silver solder comprises the following steps: S1, heating copper in Cu-X alloy in a medium-frequency smelting furnace crucible to be completely molten, and then adding alloy metal X till the Cu-X alloy is completely molten; S2, adding silver, zinc, tin, nickel and indium with the purity being at least 99.99% and the remaining part of the Cu-X alloy from which copper is removed into the medium-frequency smelting furnace crucible containing the molten Cu-X alloy to be smelted and cast according to the component proportion of the low-silver cadmium-freemanganese-free multi-element silver solder; and S3, carrying out subsequent treatment. The silver solder is easy to prepare, the total content of cadmium, manganese, silver and indium is low, the solid phase line temperature, the liquid phase line temperature and the welding performance are proper, and the machinable performance is high.

Owner:HANGZHOU HUAGUANG ADVANCED WELDING MATERIALS CO LTD +1

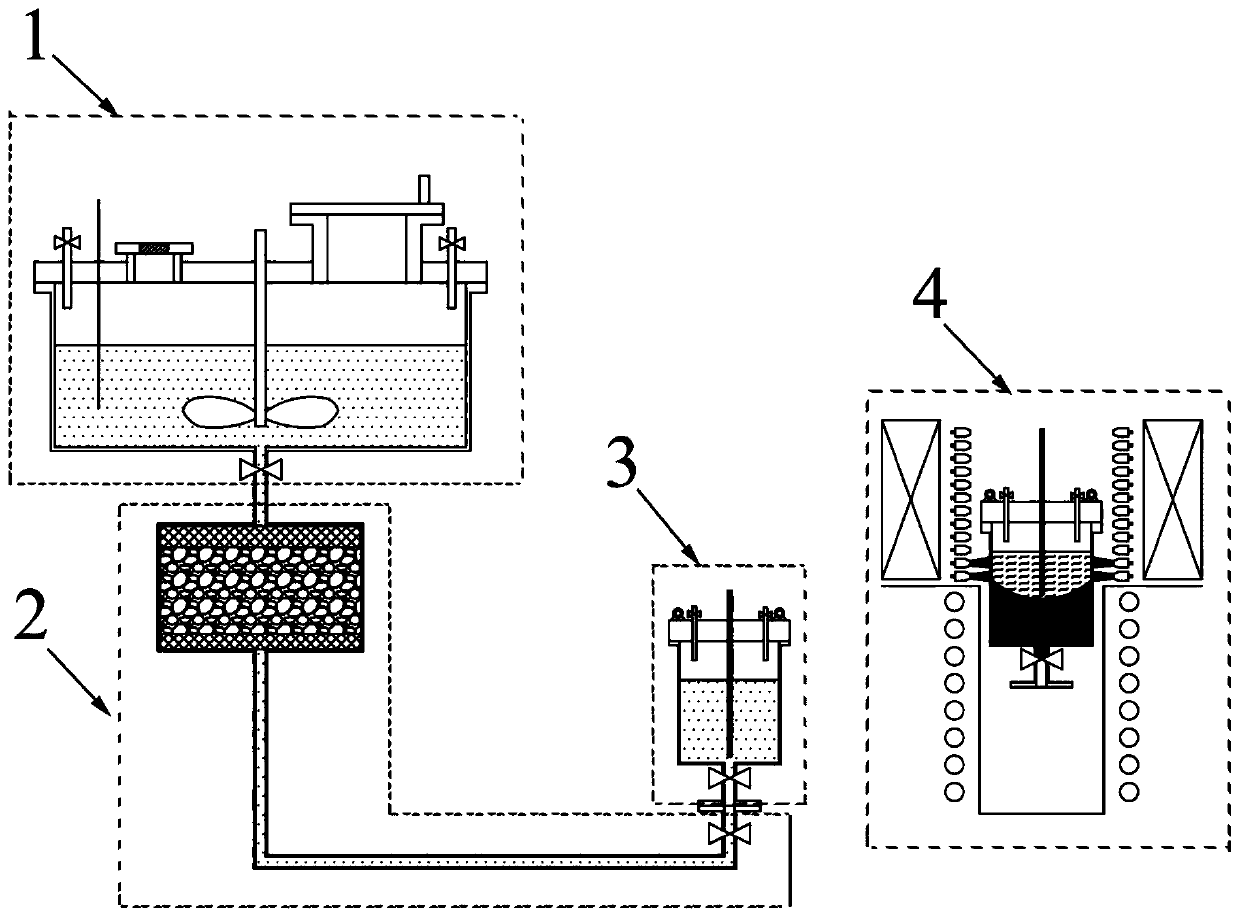

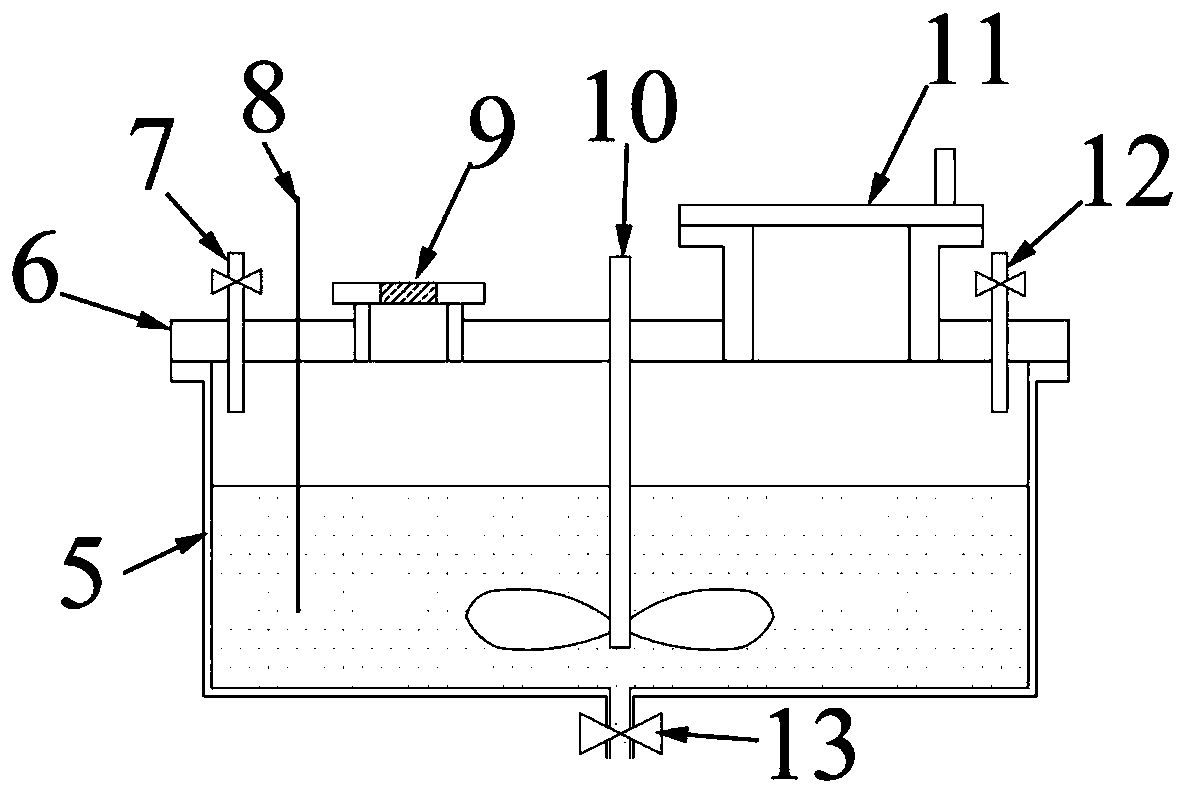

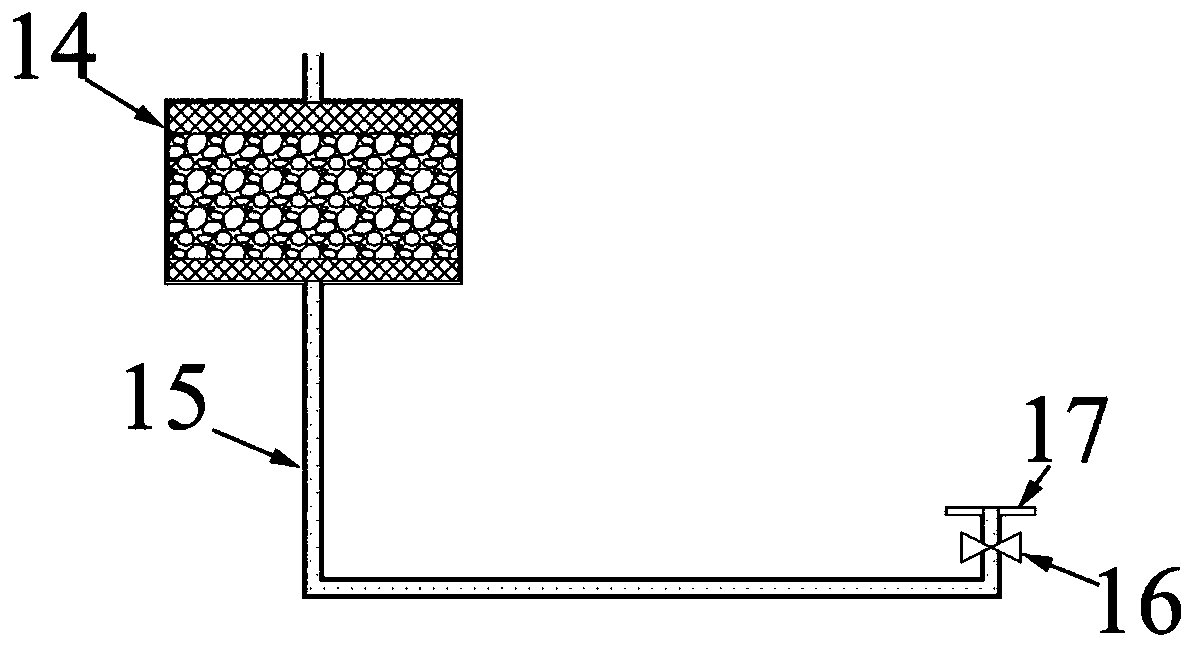

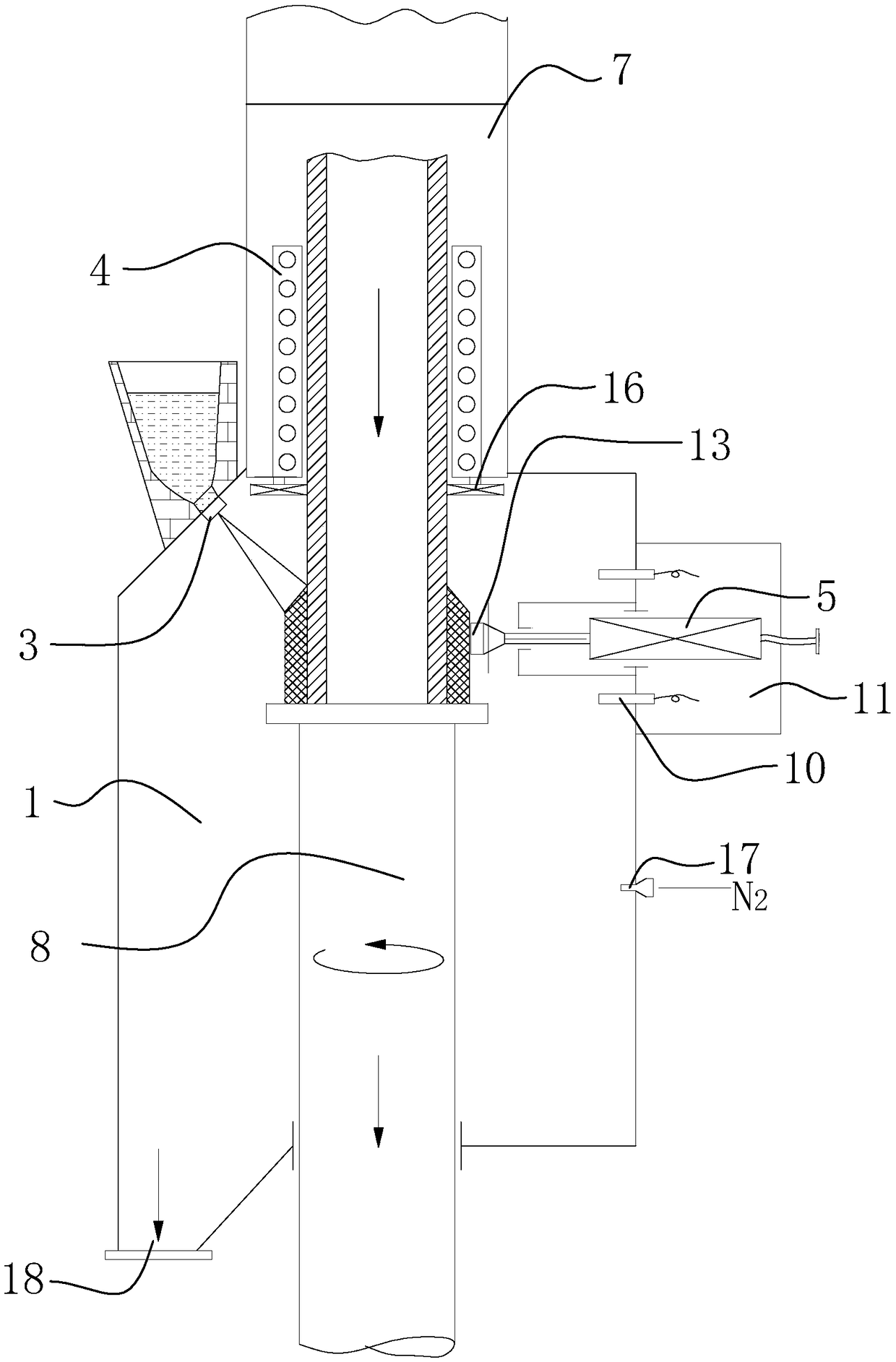

Method for preparing non-liquating monotectic alloy material and device thereof

The present invention relates to process and apparatus for preparing monotectic crystal alloy without segregation, and belongs to the field of homogeneous monotectic crystal alloy preparing technology. The present invention features that the segregation of the second phase in alloy is inhibited by means of the cooperation of steady strong magnetic field and alternate current so as to obtain monotectic crystal alloy with homogeneously distributed second phase. The process of the present invention includes the following steps: heating binary alloy with monotectic crystal component inside a crucible by means of alternate current inside a strong magnetic field a superconductive magnet generates under the protection of inert gas at temperature over the liquid temperature for several hours, andlowering the temperature in controlled speed while applying AC in proper intensity and frequency to below the solid temperature, and further cooling to room temperature to obtain the monotectic crystal alloy.

Owner:新兴发展集团有限公司

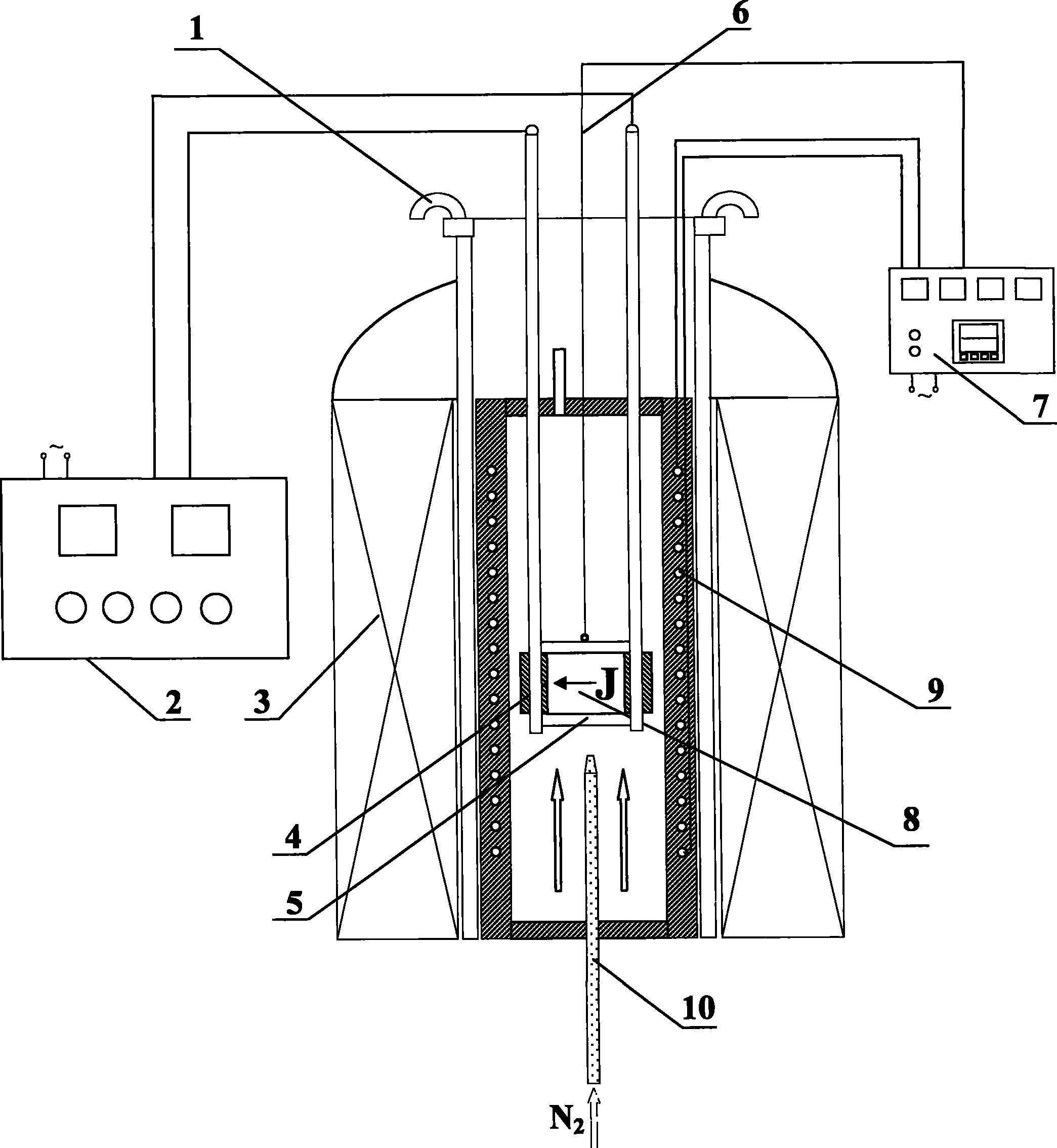

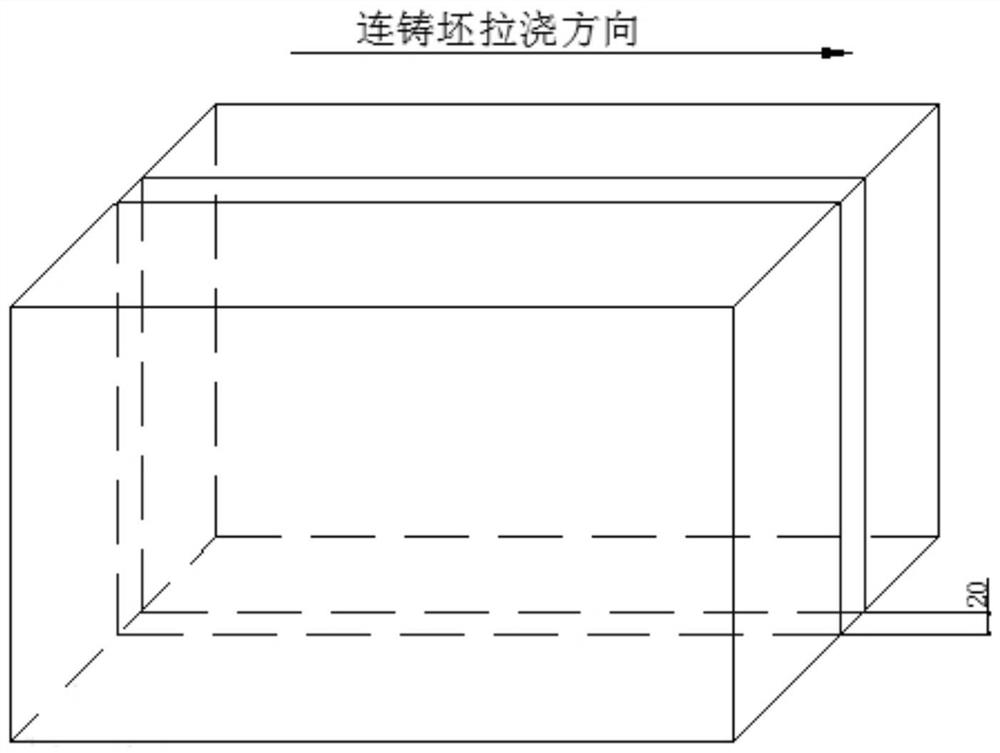

Method for calculating thickness of blank shell at position of continuous casting roller row and solidification tail end of casting machine

PendingCN112784367ANo security riskExtended preparation timeGeometric CADDesign optimisation/simulationSolidusEngineering

The invention relates to a method for calculating the thickness of a slab shell at the position of a continuous casting roller row and the solidification tail end of a casting machine. The method is characterized by comprising the following steps: according to a rule that zero plasticity temperature is approximately equal to solidus temperature, acquiring the thickness of the slab shell at the position of a pulling-straightening roller by searching point-shaped cracks on a low magnification of a continuous casting slab and measuring the distance from the cracks to the edge part of the casting slab; and according to the measured thickness of the slab shell at the position of a roller farthest from the meniscus, the position of a corresponding roller row and a pulling speed, further reckoning the comprehensive solidification coefficient and the liquid phase cavity length of the casting machine through secondary application of a solidification law square root formula, so that the effect of nail shooting or solidification model calculation is achieved. The invention discloses the method which does not need a model, does not need nail shooting and deduces the thickness of the slab shell and the solidification tail end by researching the low power of the continuous casting slab, and the method can optimize tail end electromagnetic stirring, soft reduction tool arrangement and a production process, so that the segregation problem of the continuous casting billet and a rolled material is solved.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

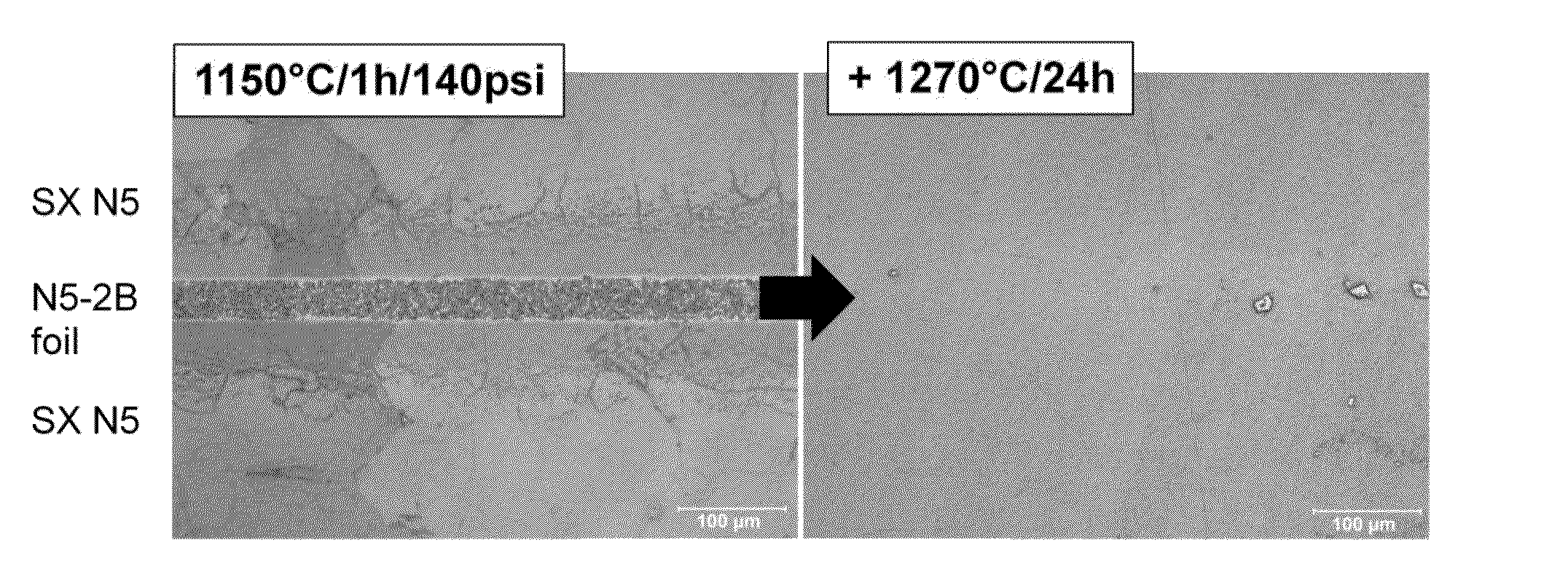

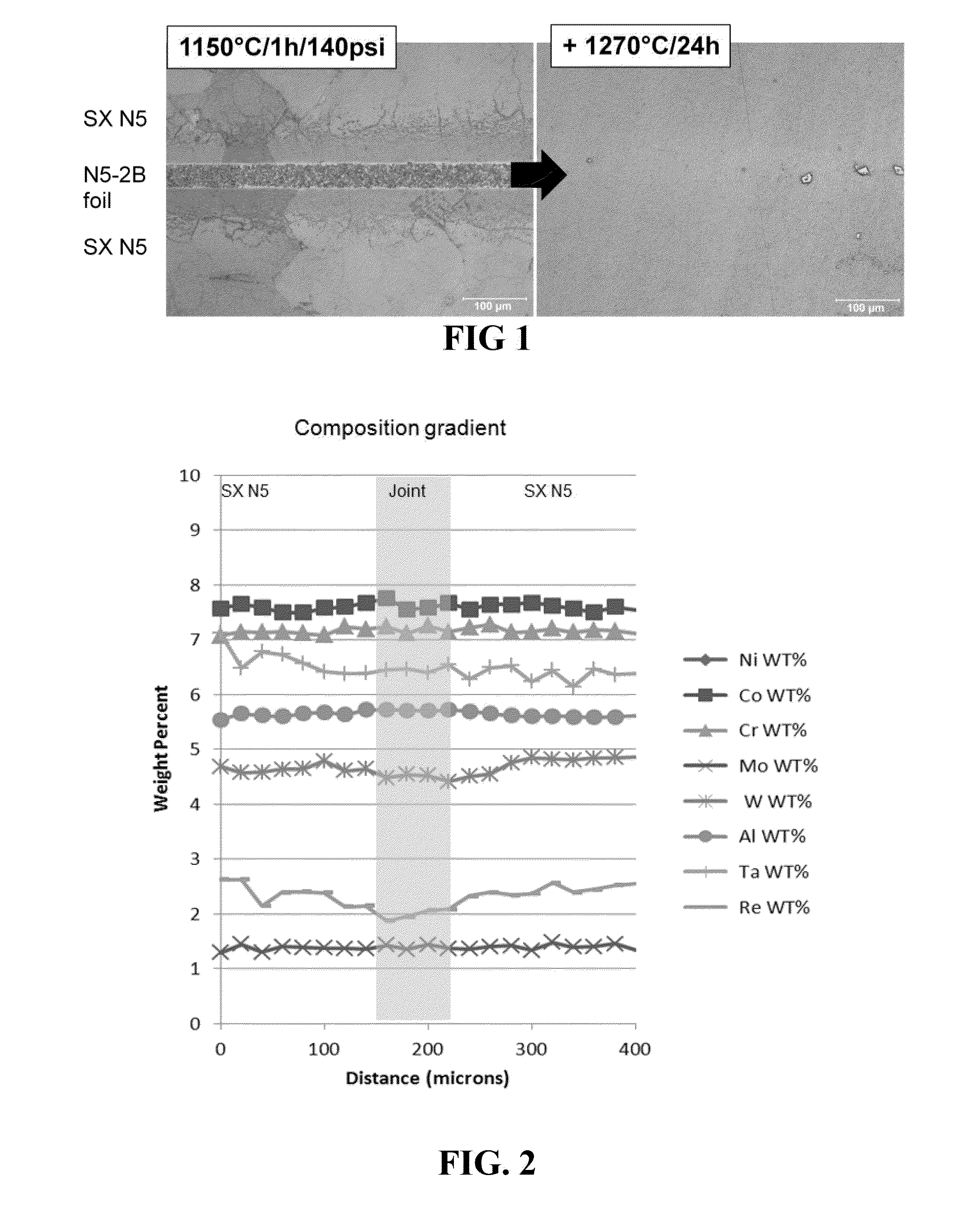

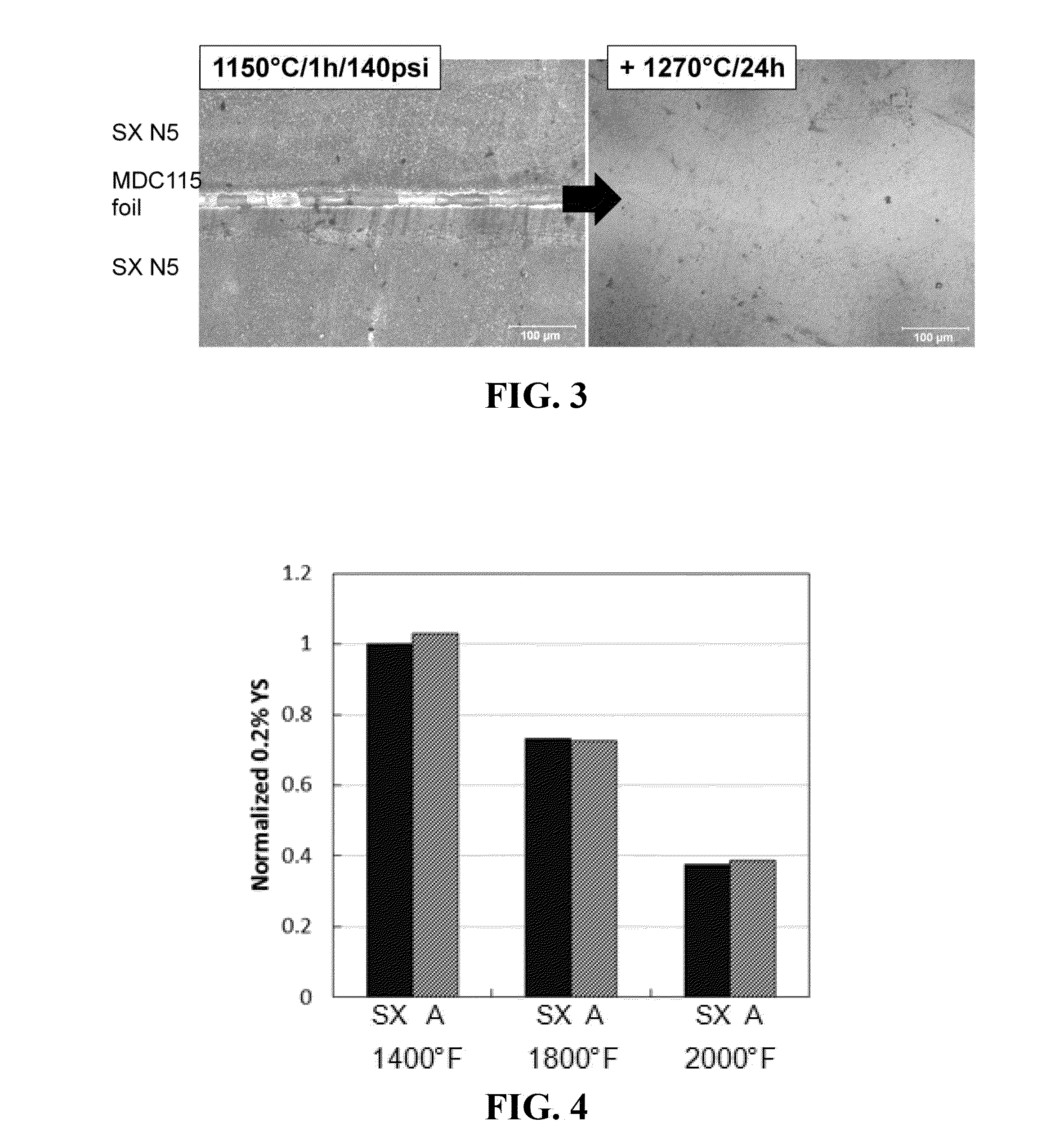

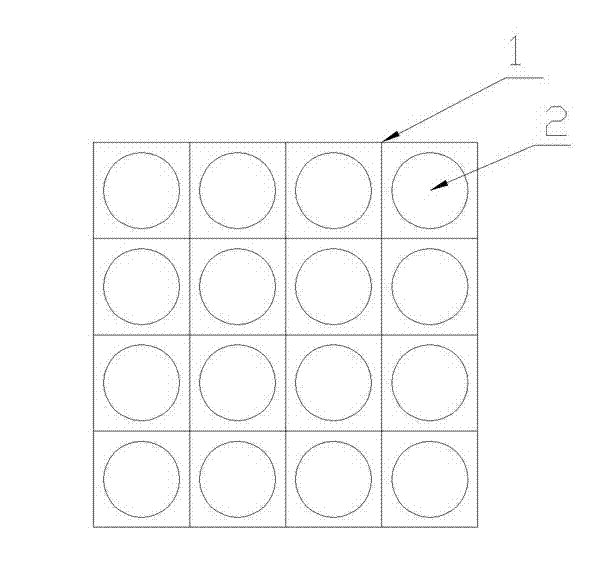

Joining process for superalloys

ActiveUS20140367455A1Problem in their useImprove casting yieldWelding/cutting media/materialsSoldering mediaSuperalloyBoron

A method of bonding superalloys is provided. The method includes: aligning a first superalloy subcomponent having a gamma-prime solvus g′1 and a second superalloy subcomponent having a gamma-prime solvus g′2, with a filler material that includes at least 1.5 wt % boron disposed between the first and second superalloy subcomponents; performing a first heat treatment at a temperature T1, where T1 is above the solidus of the filler material and below the liquidus of the filler material; and performing a second heat treatment at a temperature T2, where T2 is greater than T1, and where T2 is greater than or equal to the lower of g′1 and g′2.

Owner:GENERAL ELECTRIC CO

Heat treatment method of Hastelloy casting

InactiveCN102345081AReduce thermal deformationReduce the phenomenon of thermal crackingFurnace temperatureSolidus

The invention mainly discloses a heat treatment method of a Hastelloy casting. The method comprises the steps of: 1, setting a furnace temperature: according to the chemical components of the Hastelloy casting, heating a heat treatment casting to reach a temperature between a solid phase line and a liquid phase line of the Hastelloy casting, and carrying out heat preservation; 2, heating and preserving the temperature: placing the Hastelloy casting into a high-temperature furnace for heating, discharging automatically and obliquely by adopting a trolley, adding a body temperature-measuring thermocouple in the high-temperature furnace for detecting the temperature of a casting body, comparing with an air thermocouple, and ensuring that a temperature curve is consistent with a program set curve; and 3, water-cooling: when the casting reaches the preset heat preservation time, discharging at a temperature of 1150-1175 DEG C, and rapidly placing the casting in water of below 10 DEG C for cooling, thereby obtaining high-strength corrosion resistance. According to the invention, heat deformation and heat cracks in a heat treatment process are reduced, and the Hastelloy casting with highstrength and high flexibility is obtained.

Owner:绍兴万龙精密机械制造有限公司

Method and apparatus for injection molding of semisolid alloys

A method and apparatus for thixotropic molding of semisolid alloys are disclosed. The method comprises of feeding a dendritic-free feedstock bar into an extruder barrel, melting a terminal portion of the feedstock bar into a semisolid slurry by heating it to a temperature between its solidus and liquidus temperatures, and using the solid portion of the feedstock bar as an one-time 'plunger' to inject the semisolid slurry into a mold cavity. The apparatus based on the present method, which is equipped without a regular extruder screw or plunger, uses a feedstock bar as a one-time plunger to inject semisolid slurries formed from a terminal portion of the same feedstock bar.

Owner:刘伟杰

Copper phosphorus brazing alloy with hafnium zirconium cobalt

ActiveCN103480979AEasy to processEliminate or suppress "brittleness" problemsWelding/cutting media/materialsSoldering mediaSolidusMetallic materials

Disclosed is a copper phosphorus brazing alloy with hafnium zirconium cobalt, and belongs to the technical field of soldering material of metal materials. The chemical ingredients includes, by weight: 5.0% to 8.0% of P, 4.5% to 10.0% of Sn, 0.05% to 0.35% of Co, 0.01% to 0.2% of Hf, 0.01% to 0.2% of Zr, and the balance being Cu. The adding proportion of the Hf element and the Zr element is Hf : Zr =1:1. According to the copper phosphorus brazing alloy, obtained according to the above proportion with the hafnium zirconium cobalt, the solidus line temperature ranges from 575 to 595 DEG C, and the liquidus line temperature ranges from 635 to 655 DEG C (measuring errors are considered both). The copper phosphorus brazing alloy with the hafnium zirconium cobalt has the advantages of 'high phosphorus, high tin, high plasticity and low melting point', the copper phosphorus brazing alloy can be processed into fine wires with the diameter of 0.5 to 1.2mm, and the requirements of soldering when HPb62-3 lead brass and HPb59-3 lead brass are adopted to produce products in the household appliance industry and the hardware industry can be met.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com