Joining process for superalloys

a superalloy and bonding technology, applied in the field of superalloy bonding methods, can solve the problems of low casting yield of large superalloy components, failure of mechanically sound joints of superalloys, and prior art focusing on joining processes, including welding and brazing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example a

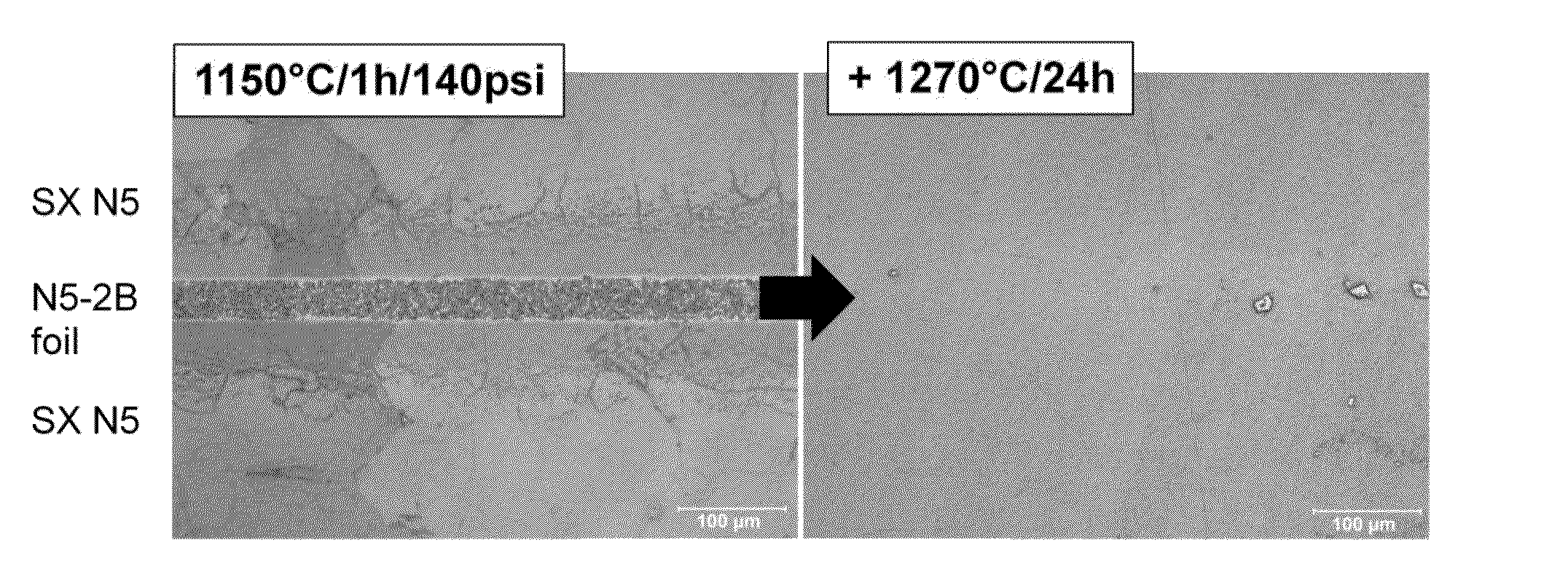

[0071]Two Rene N5 nickel-based single crystal superalloy subcomponents (composition shown in Table I) were prepared by finishing with low stress grinding, such that the subcomponents had less than 10° crystal orientation deviation from each other, had substantially flat mating surfaces, and were smooth and clean. The Rene N5 subcomponents were aligned with a ˜2 mil thick N5-2B foil (see Table I), which comprised 2 wt % boron, as filler material in a fixture, and pressure was applied at about 1 MPa. In vacuum environment, the aligned subcomponents were subjected to a first heat treatment while in the fixture at 1150° C. for one hour, then the subcomponents were allowed to cool to room temperature. During the first heat treatment, the filler partially melted, and the subcomponents were metallurgically joined. Following heating, the joint area was made up of fine grains.

[0072]The cooled joined components were removed from the fixture, and, in the absence of pressure, were subjected to ...

example b

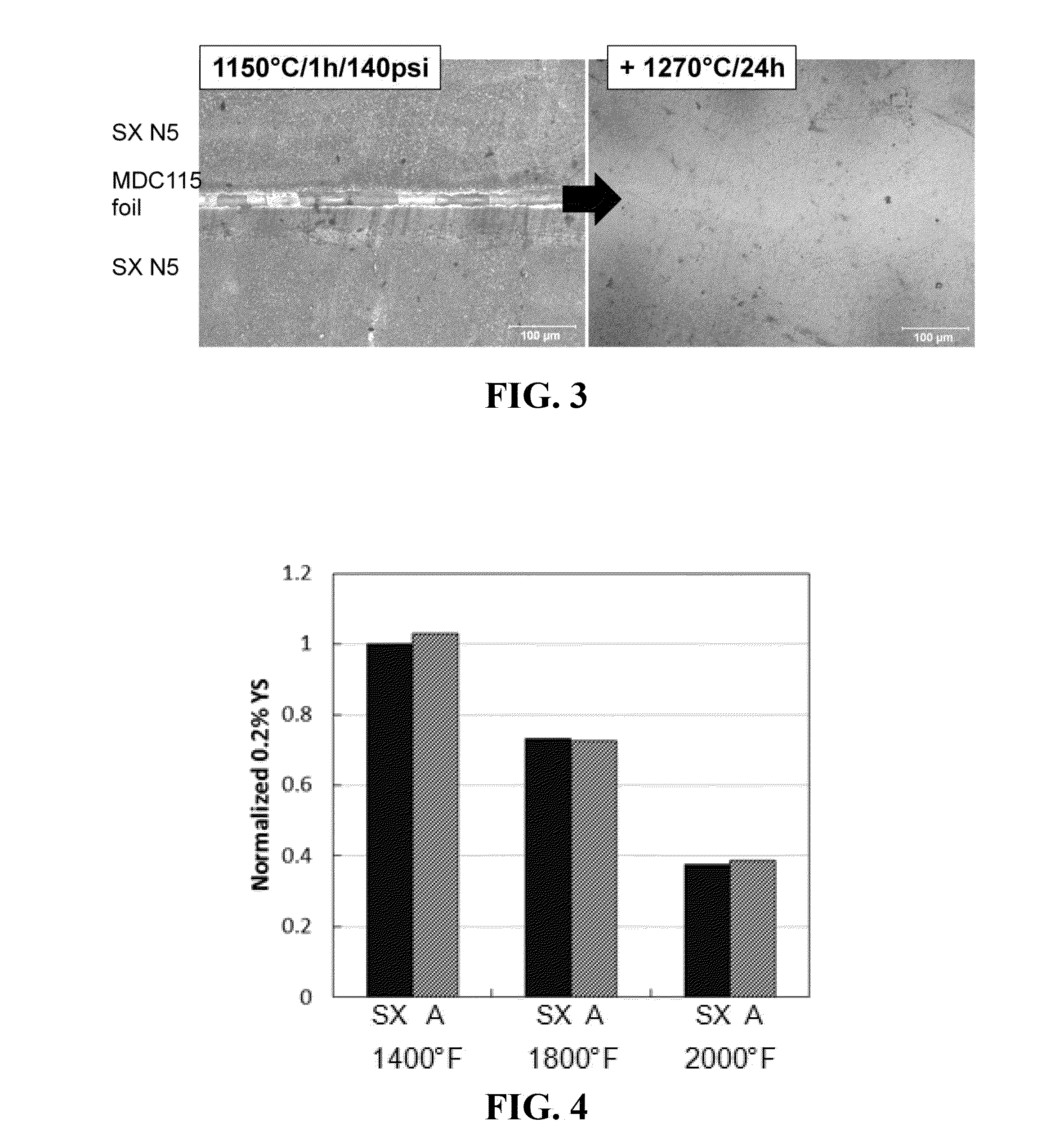

[0073]Example B was prepared following the protocol set forth above for Example A, except that for Example B, instead of using the N5-2B foil, the Rene N5 subcomponents were aligned in a fixture with a ˜2 mil thick MDC 115 foil (see Table I) comprising 3 wt % boron, obtained from Materials Development Corporation, as filler material. FIG. 3 is a photo micrograph showing the microstructure change at the joint following the first and second heat treatments.

Analysis of Inventive Example A

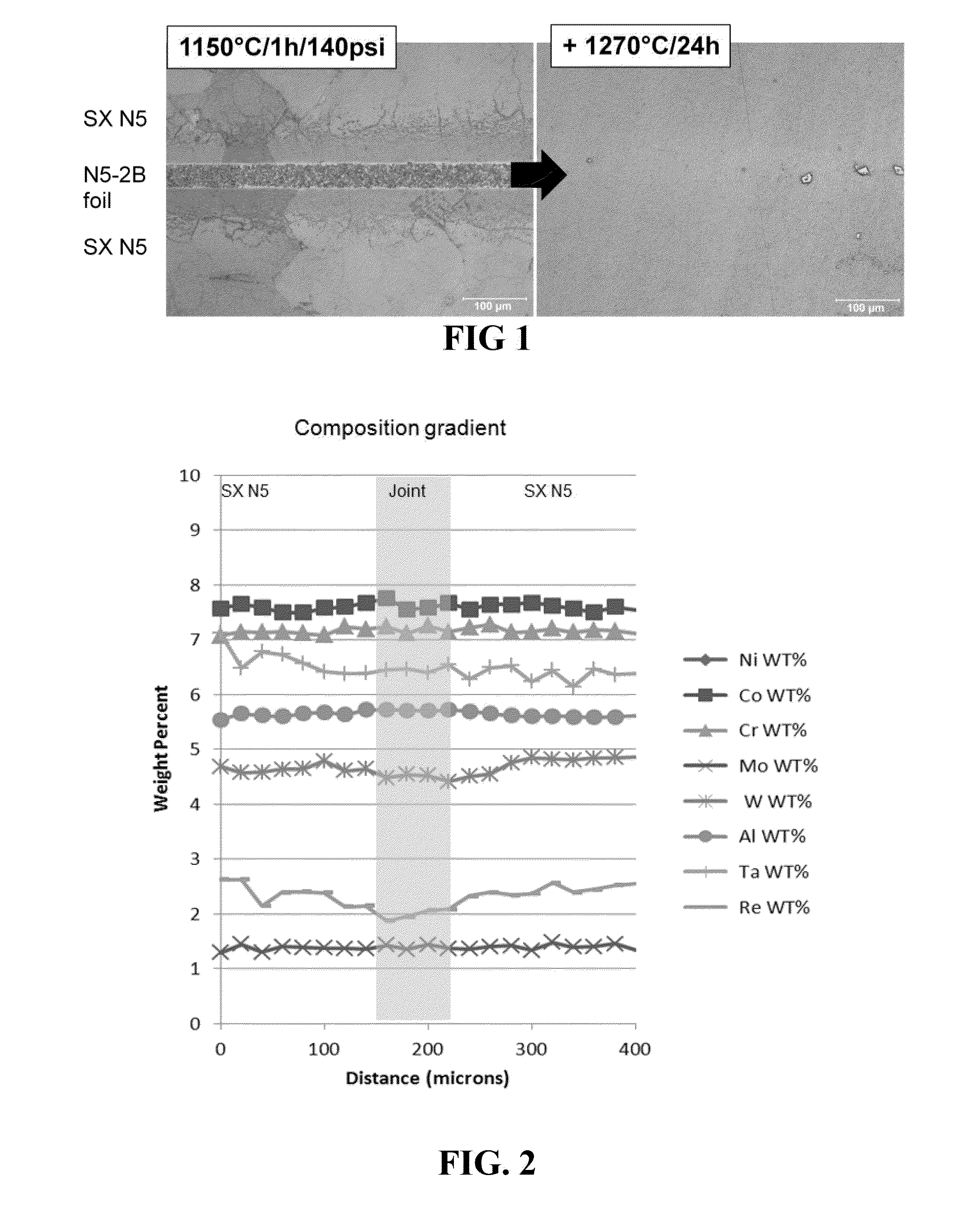

[0074]High temperature tensile and creep properties of the single-crystal Rene N5 subcomponents joined with the N5-2B foil comprising 2 wt % boron (Example A) were measured and compared with a single crystal Rene N5 superalloy without a joint (Counter Example SX). The joined N5 was solution treated at 1300° C. for 2 h, followed by aging treatments at 1120° C. / 4 h, 1080° C. / 4 h and 900° C. / 4 h. FIG. 4 depicts a chart showing the results of the normalized yield strength testing. FIG. 5 depicts a chart sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com