Patents

Literature

115results about How to "Improve casting yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sand-line iron mould casting process for grey cast iron flywheel housing of diesel engine

ActiveCN102728790AGood size consistencyPut an end to the phenomenon of sand swellingFoundry mouldsFoundry coresDieselingSurface roughness

The invention discloses a sand-line iron mould casting process for grey cast iron flywheel housings of diesel engines. In the invention, upper and lower sand-line iron mould processes are used, so that produced grey cast iron flywheel housing blanks have favorable geometric size precision which can be up to CT8 grade, favorable surface roughness which can be up to 12.5 microns and favorable mechanical properties, the blank processing has small allowance which can be controlled in 3mm, small flashing distortion which can be controlled in 0.5mm and small cleaning workload, so that the labor environment is improved, the environmental protection is improved, the yield is high and can be up to 95%, and the national policies of energy conservation, environmental protection and sustainable development are met.

Owner:JIANGSU SONGLIN AUTOMOBILE PARTS

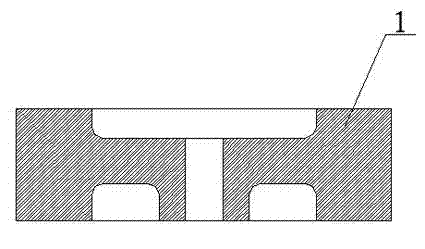

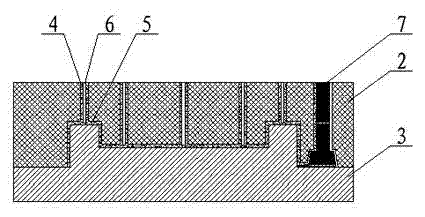

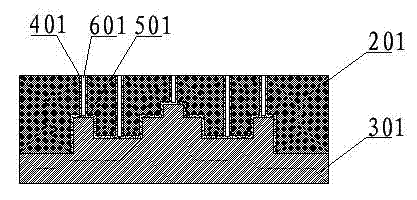

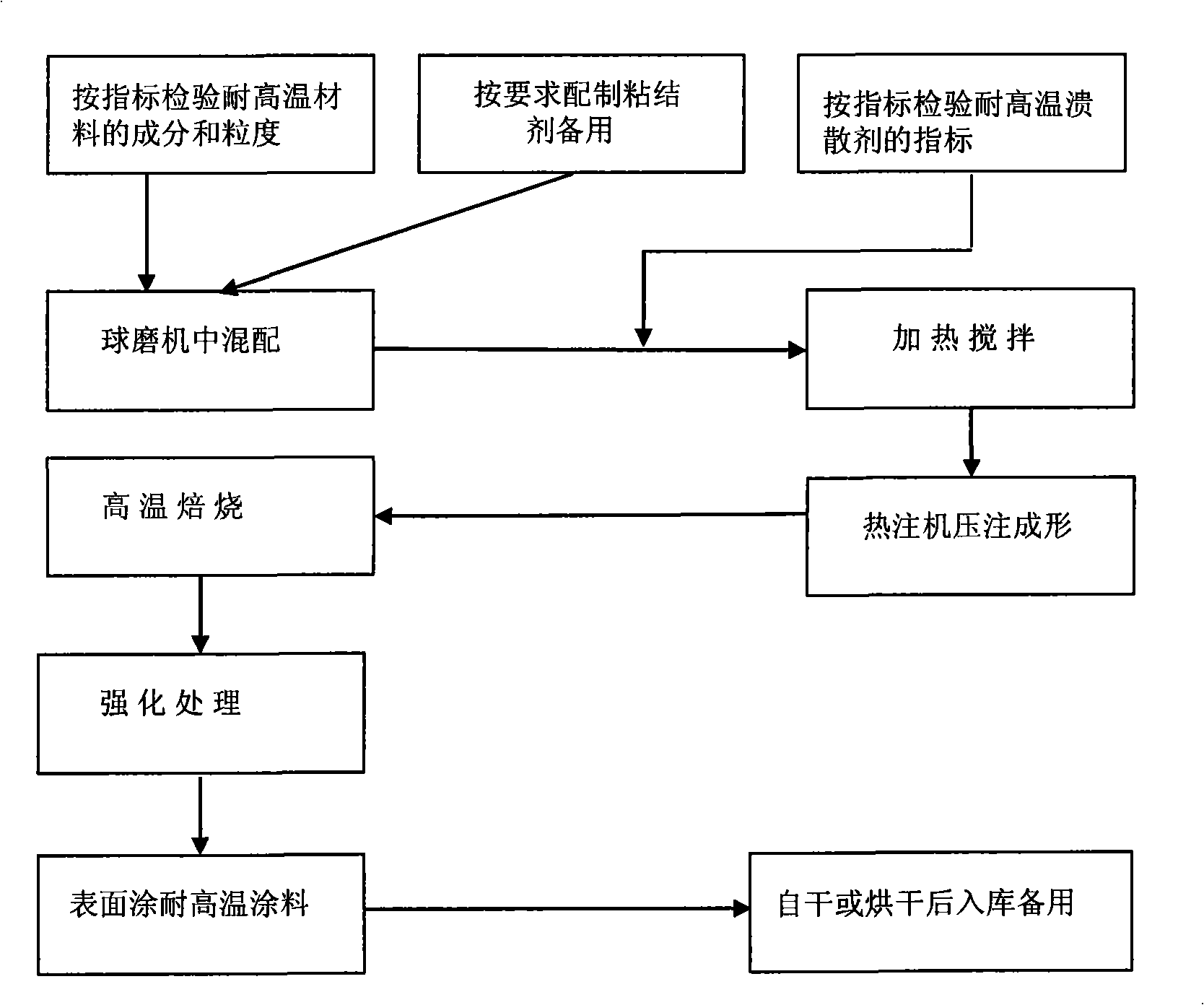

Ceramic core for silica sol precision casting and manufacturing process thereof

InactiveCN101537473AShorten roasting timeLow firing temperatureFoundry mouldsMould handling/dressing devicesTemperature resistanceChoice making

The invention discloses a ceramic core for silica sol precision casting and a manufacturing process thereof. Main body components of the ceramic core comprise refined quartz powder and a proper amount of collapsing agent, and the surface of the ceramic core is coated with high-temperature resistant paint with a thickness of 0.1 to 0.2 millimeter; and at the same reasonable manufacturing processes such as mixing, core making and roasting are adopted. In the ceramic core for casting, the unique material mixing and manufacturing processes are adopted, and the reasonable use of the refined quartz powder and the collapsing agent improves the collapsibility of the ceramic core after casting considerably, the high-quality high-temperature resistant material in ingredients enables the core to resist the erosion of high-temperature molten metals, and the high-temperature resistant paint on the surface of the ceramic core not only improves the high temperature resistance during casting, but also increases the cooling speed of the molten metal.

Owner:上海市机械制造工艺研究所有限公司

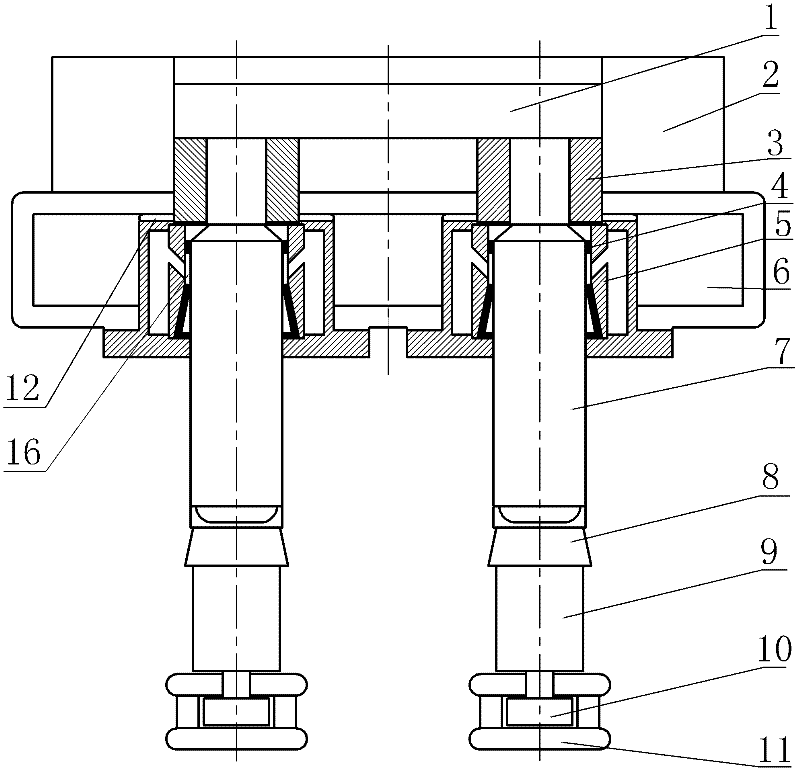

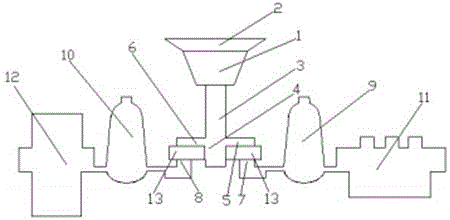

Equipment and method for casting plurality of aluminum alloy ingots with small diameters by using vertical direct chilling casting (DC)

The invention provides equipment and a method for casting a plurality of aluminum alloy ingots with small diameters by using vertical direct chilling casting (DC) and relates to the equipment and the method for casting the aluminum alloy ingots, which aim to solve the problems of low consistency of metal temperatures, low water cooling uniformity and high possibility of ingot suspension or tension fracture and flow running in each crystallizer in the process of casting the aluminum alloy ingots with the small diameters by the conventional technology for casting the plurality of aluminum alloy ingots with the small diameters by using the vertical DC. The method comprises the following steps of: communicating all branch outlets on runners with a plurality of upper end inlets of hot top caps correspondingly one by one; communicating the lower end outlet of each hot top cap with a crystallizer inlet of the crystallizer, wherein the distances between a flow storage slot and the runners of all crystallizers are same; heating a heat preserving sleeve to the temperature of between 100 and 150 DEG C; opening the outlet of a smelting furnace, feeding molten aluminum alloy into all the crystallizers through the runners, and performing water cooling; stopping for 5 to 10 seconds after the liquid level of the molten aluminum alloy in the runners reaches a preset position; and moving an ingot guiding device downwards. The surface of each ingot is smooth, does not have cracks and has small segregation tumors, and each ingot does not have air pores, is not loose and has small grains.

Owner:HARBIN ZHONGFEI NEW TECH CO LTD

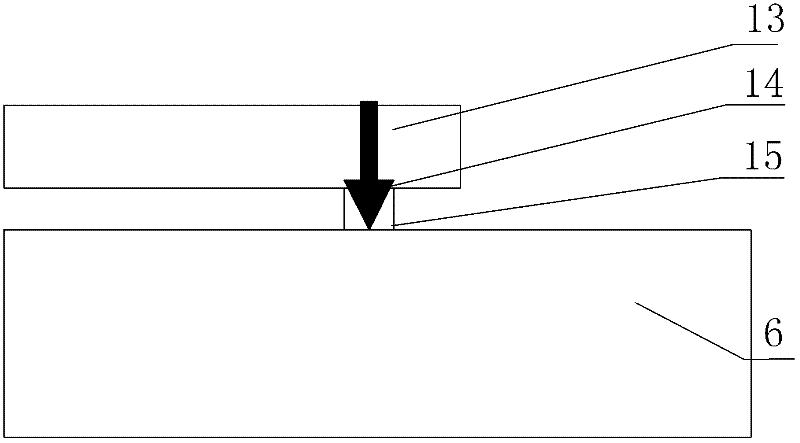

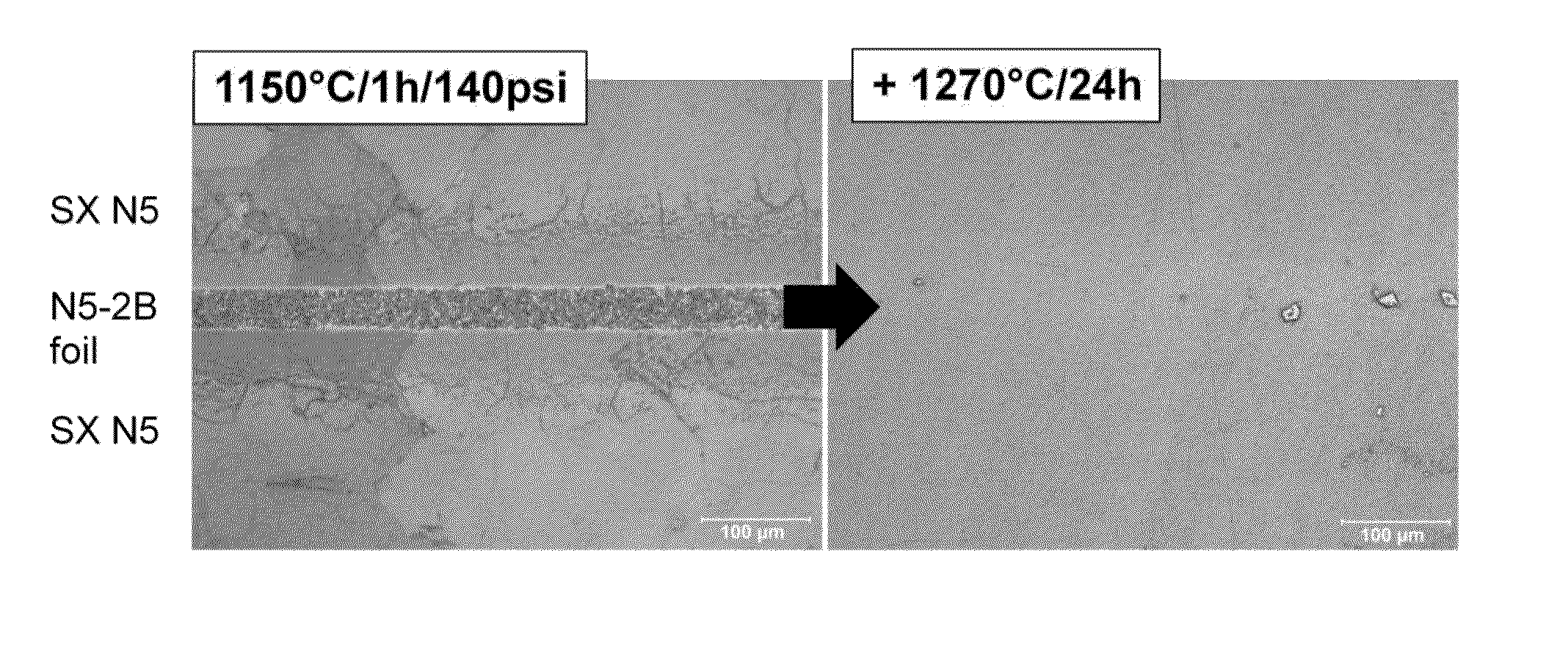

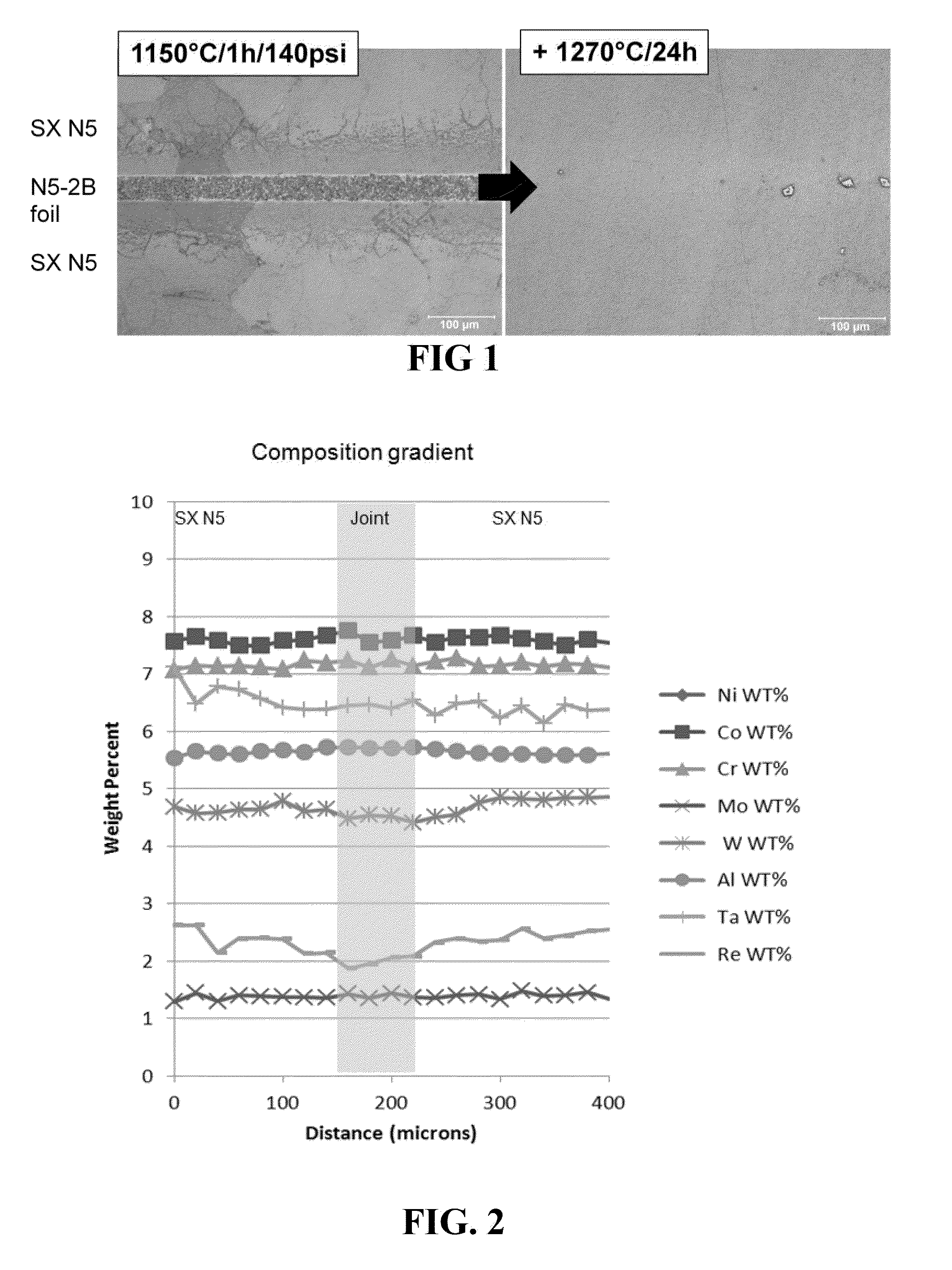

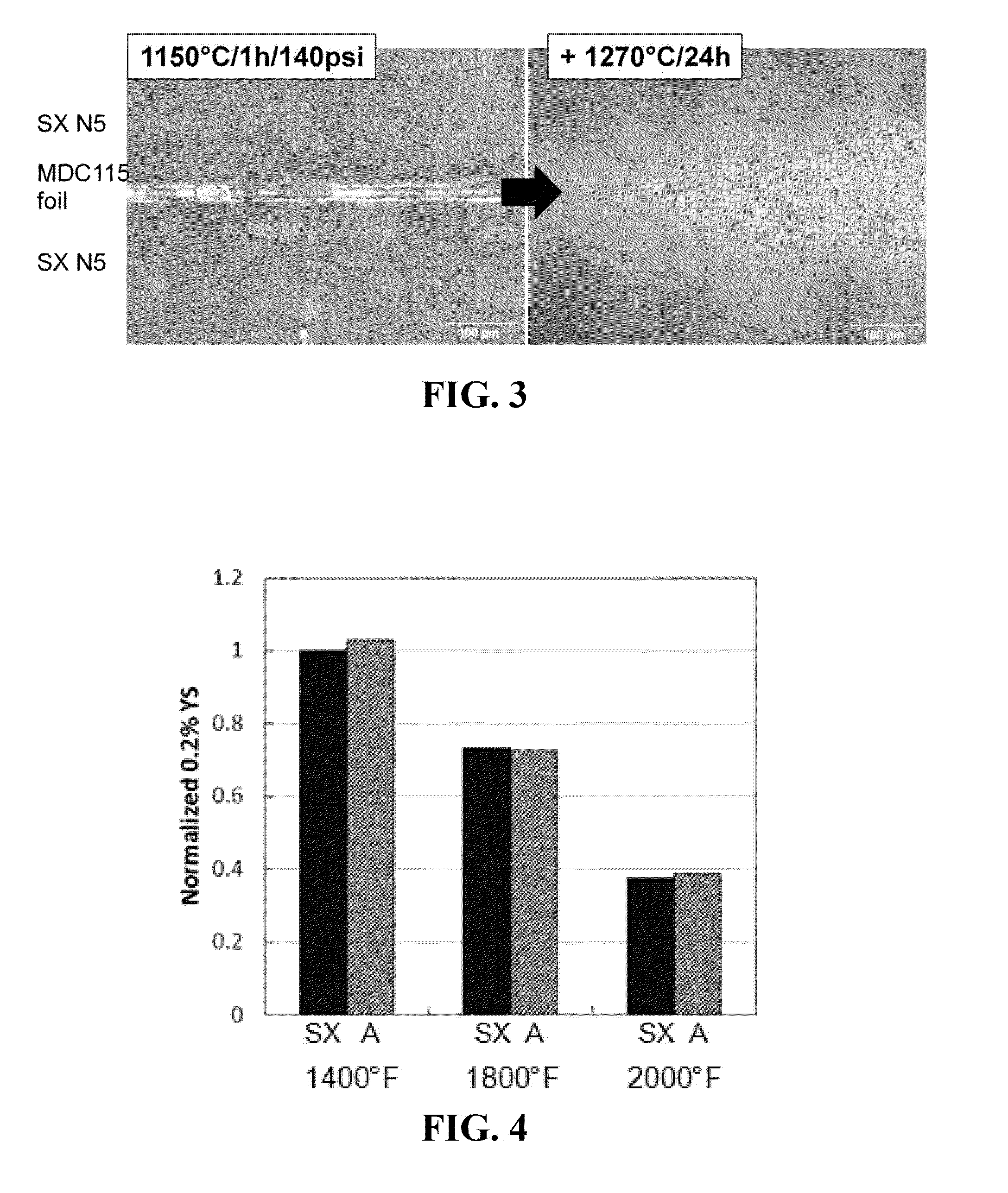

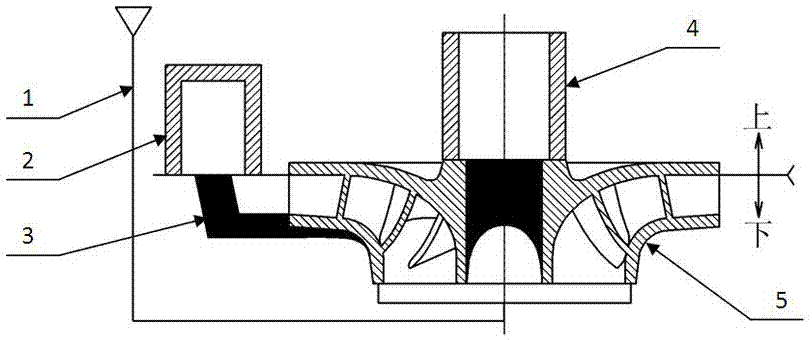

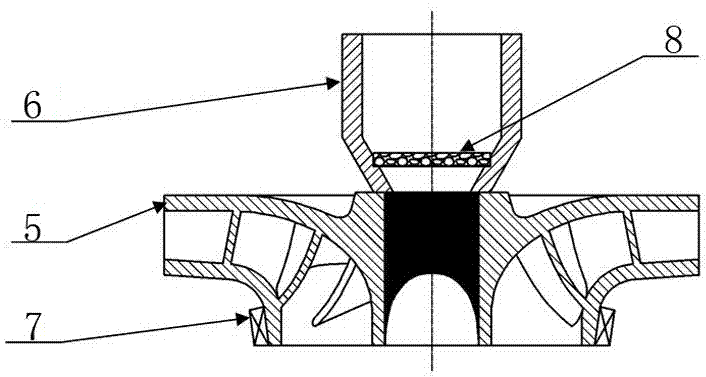

Joining process for superalloys

ActiveUS8925792B1Improve casting yieldHigh quality mechanical propertyWelding/cutting media/materialsSoldering mediaBoronHeat treated

A method of bonding superalloys is provided. The method includes: aligning a first superalloy subcomponent having a gamma-prime solvus g′1 and a second superalloy subcomponent having a gamma-prime solvus g′2, with a filler material that includes at least 1.5 wt % boron disposed between the first and second superalloy subcomponents; performing a first heat treatment at a temperature T1, where T1 is above the solidus of the filler material and below the liquidus of the filler material; and performing a second heat treatment at a temperature T2, where T2 is greater than T1, and where T2 is greater than or equal to the lower of g′1 and g′2.

Owner:GENERAL ELECTRIC CO

Casting method for impeller made of super duplex stainless steel 5A material

ActiveCN107309405AAvoid crack defectsGuaranteed denseFoundry mouldsFurnace typesImpellerVolumetric Mass Density

The invention provides a casting method for an impeller made of a super duplex stainless steel 5A material. The method comprises the steps of preparation of a casting mould and a sand core, specifically, the casting mould and the sand core are prepared in the manner that alkaline phenolic resin is added to crude sand, the casting mould is provided with an impeller cavity for storing the sand core, and a dead head is internally provided with a ceramic foam filter; casting and pouring; and sand shakeout and heat treatment of a heat-filling furnace, and an impeller finished product is obtained. The temperature ranges of precipitation of brittle phases including Eta, Chi and Sigma can be avoided, precipitation of the brittle phases by an impeller casting structure is avoided, crack defects of an impeller casting are overcome fundamentally, density of the casting structure can also be guaranteed, and the yield rate of a casting finished product can be increased to 96% or above; and meanwhile, the casting production cost is greatly lowered as the technological yield is increased, and the heat-filling furnace process is implemented.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

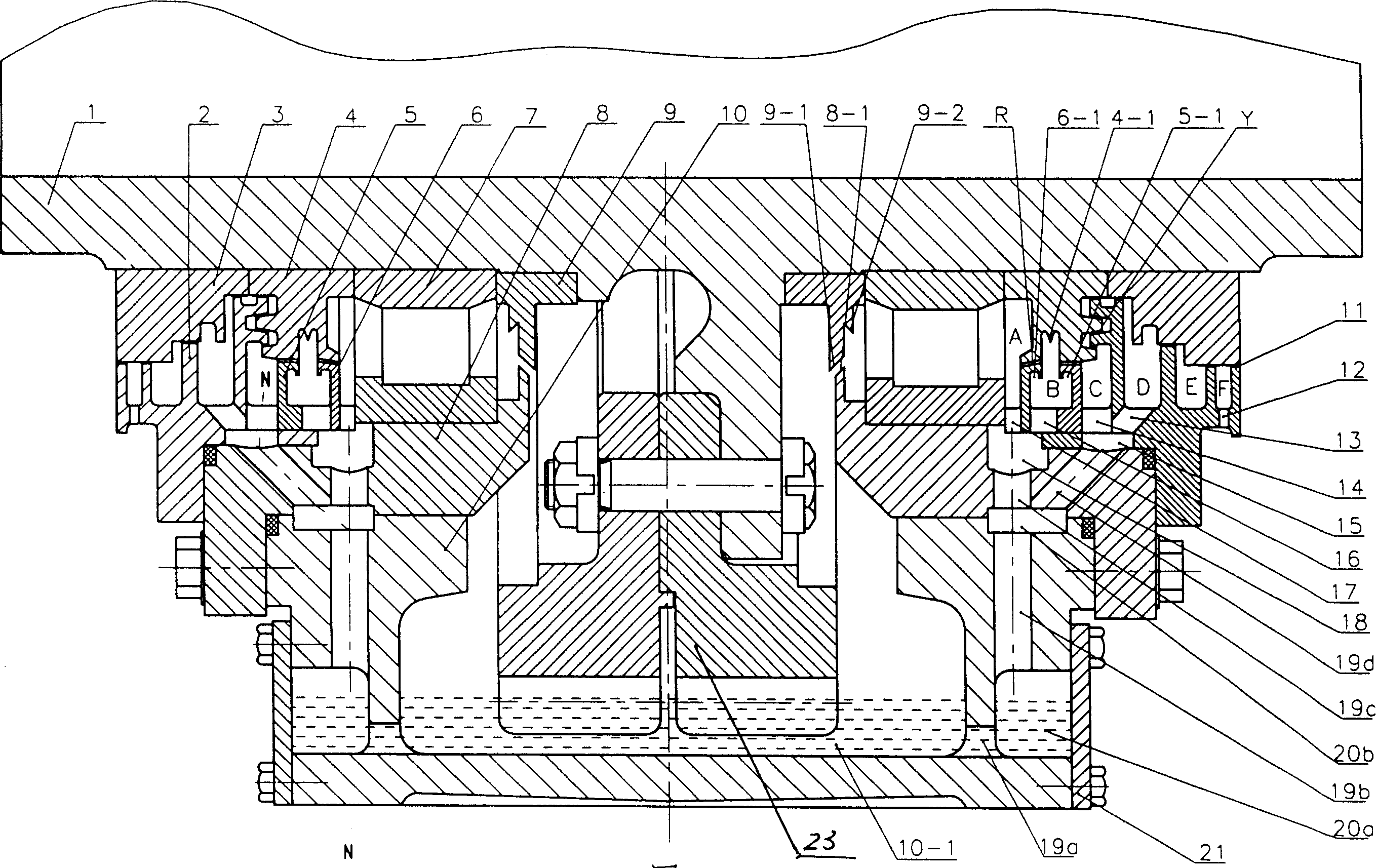

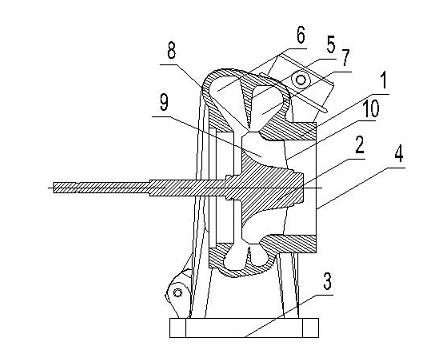

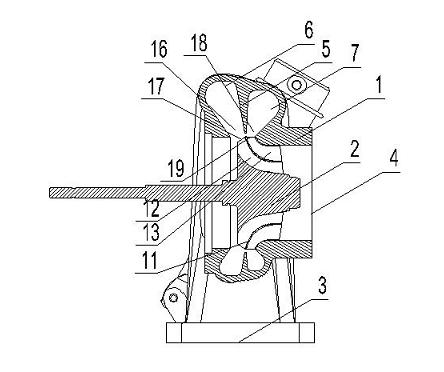

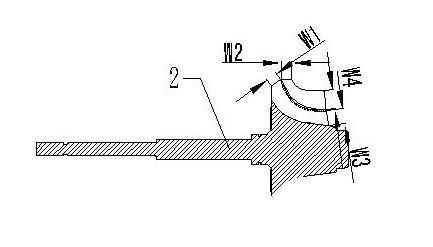

Airproof equipment for power driven gear case of high speed train

InactiveCN1467118AAvoid the problem of poor oil returnOvercoming the Limitations of InfluxRotary prime mover transmissionAxle-boxesLabyrinth sealPetroleum engineering

A sealing unit for the driven gear box of high-speed locomotive, where the lubricating oil is used, has a non-contact labyrinth seal mechanism, which features that a return oil buffering cavity is arranged in the return oil channel communicated with the internal cavity of box, the outlet of final return oil orifice is lower than the level of lubricating oil in the oil pool, and said return oil buffering cavity is communicated with said oil pool via said final return oil orifice. Its advantages are reasonable structure and high saeling effect.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

Large-sized, high-strength and high-toughness 7000 series aluminum alloy round cast ingot and preparation method thereof

The invention relates to a large-sized, high-strength and high-toughness 7000 series aluminum alloy round cast ingot and a preparation method thereof to solve the problems of low strength and low fracture toughness property of an existing large-sized 7000 series aluminum alloy round cast ingot. The aluminum alloy round cast ingot is manufactured by Si, Fe, Cu, Mn, Mg, Cr, Zn, Ti, Zr, Sb, Be, Na, Li, K and the balance Al. The preparation method comprises the following steps that step 1, that raw materials are weighed; step 2, a smelt agent is laid at the bottom of a furnace before raw materialfeeding, the raw materials are added into the smelting furnace, and then the smelt agent is laid on the surface after raw material feeding; step 3, heating is conducted until the raw materials in thefurnace smelt, and then a copper plate and zinc ingot are added; step 4, smelting is carried out, and dross on the surface is removed; step 5, refining is carried out; step 6, turning down is carriedout; step 7, casting is carried out; step 8, saw cutting is carried out, and step 9, homogenizing annealing is carried out. The aluminum cast ingot manufactured section steel has high tensile strength, compression-resisting yield strength and high fracture toughness property, and is used in the field of aluminum alloy.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Comprehensive recycling method of waste sand in green casting

ActiveCN103128228AGood effectReduce mud contentMould handling/dressing devicesFluidized bedMagnetic separator

The invention relates to a comprehensive recycling method of waste sand in green casting, and belongs to the field of novel casting processes. The comprehensive recycling method of the waste sand in green casting is characterized in that the waste sand in green casting is recycled through the following steps: a first level of magnetic separation and smashing, a second level of magnetic separation, screening, dewatering and drying, a first level of mechanical friction demoulding, a first level of winnowing and dedusting, a second level of winnowing and dedusting, a third level of mechanical friction demoulding, a third level of boiling, dedusting and screening; and finally qualified recycled sand is obtained. A permanent magnet belt magnetic separation machine is used in the first magnetic separation of the waste sand, a three-return-stroke roller dryer is adopted during dewatering and drying, a suspension-type magnetic separation machine is adopted in the second level magnetic separation, centrifugal mechanical friction demoulding is adopted in the first level of mechanical friction demoulding and the second level of mechanical friction demoulding, streaming mode winnowing and a pulse-bag-type dedusting machine are adopted in the first level of winnowing and dedusting and the second level of winnowing and dedusting, vortex kneading demoulding is adopted in the three level of mechanical friction demoulding, and a fluidized bed and the pulse-bag-type dedusting machine are adopted in the third level of boiling and dedusting.

Owner:SHANDONG YUANTONG MASCH CO LTD

Sand lined metal mould casting brake shoe tool device and production method thereof

ActiveCN103273006AImprove casting yieldUniform materialFoundry mouldsMoulding machinesBrake shoeMetal

The invention relates to a sand lined metal mould casting brake shoe tool device and a production method thereof, and belongs to the field of sand lined metal mould casting. The sand lined metal mould casting brake shoe tool device comprises a lower casting piece and a gating system, wherein the lower casting piece and the gating system are both arranged on a mould board; the sand lined metal mould casting brake shoe tool device further comprises an upper casting piece, a single casting piece, a connection board, a loam core and a flow gate; the lower casting piece and the upper casting piece are both connected with the connection board to form the single casting piece; the loam core is arranged inside an iron mould and used for forming an inner cavity of the single casting piece, a sprue base and the lower part of a cross gate; the inner flow gate is arranged in an inner pouring gate; and one end of the flow gate is connected with the cross gate, and the other end of the flow gate is connected with the single casting piece. According to the invention, the lower casting piece and the upper casting piece are connected into a circle to form the single casting piece, the inner cavity of the single casting piece is formed by the loam core, and the production method of the sand lined metal mould casting brake shoe tool device has simple operation and high efficiency, so that the yield of the casting piece is increased, the production efficiency is improved, and the produced casting piece of the brake shoe is smooth and clean in surface and accurate in size.

Owner:浙江省机电设计研究院有限公司

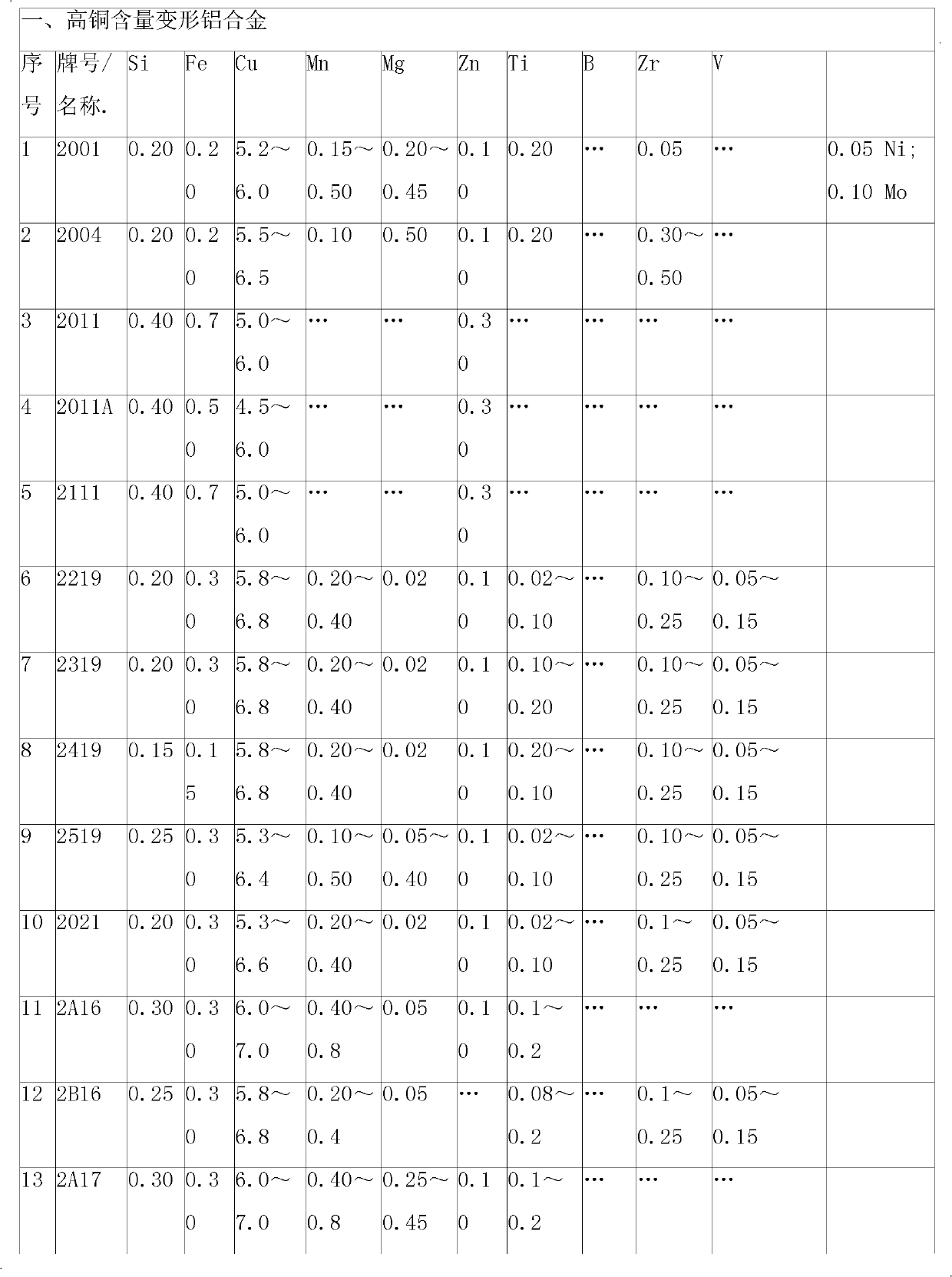

Ag-RE high-strength high-toughness aluminum alloy material and preparation method thereof

The invention discloses an Ag-RE high-strength high-toughness aluminum alloy material and a preparation method thereof. The alloy comprises the following components in percentage by weight: 1.0 to 10.0 percent of Cu, 0.05 to 1.5 percent of Mn, 0.01 to 0.5 percent of Cd, 0.01 to 0.5 percent of Ti, 0.01 to 0.2 percent of B, 0.01 to 1.0 percent of Zr, 0.01 to 1.0 percent of Ag, 0.05 to 5 percent of RE, and the balance of Al. High-quality melt, solid solution and a phase diagram theory are taken as guidance, and by using a preferable alloy main element formula of Cu, Mn and RE, the quasi solid temperature range of the alloy is reduced, and the problems of large hot tearing tendency in the casting process, low high-temperature strength of products and the like are solved; by using a preferable multielement microalloying element formula, material foundation conditions are created for the cultivation of a strengthening phase in the solid solution and grain refining effect; and the high-strength high-toughness aluminum alloy material is finally manufactured by optimizing smelting and thermal treatment process technology.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

Core-making sand composition of warm core box and sand making method

InactiveCN104439041AWide variety of sourcesLow priceFoundry mouldsMoulding machinesSilicon oxideAtmospheric pressure

The invention discloses a core-making sand composition of a warm core box and a sand making method. The composition comprises an inorganic binding agent, raw sand and non-crystallization type silicon oxide. According to the preparation method, a sand mixing machine is used for mixing, preferably a continuous sand mixing machine is adopted; the raw sand, sodium silicate and the non-crystallization type silicon oxide are automatically controlled by a pc to be fed; after the core-making sand composition is mixed, and is added into a core shooting machine sand bucket; a core-making mold is heated to 145-155 DEG C in advance to prepare the core-making sand composition; the core-making sand composition is shot into a mold cavity by a core shooting machine under the air pressure of 0.4Mpa-0.7Mpa; hot air of 120-160 DEG C is blown into a core-making cavity for 20-200 seconds; a thin core is blown for 20-40 seconds and the air blowing time is properly prolonged by a thick core; after the sand core is hardened, the box is opened and the sand core is ejected out; and the sand core can be poured on the day by assembling the box, and also can be poured by assembling the box after being stored for 3-5 days. The composition has a wide source, a high mechanical property and cheap price; and popularization and application are facilitated, the composition has no toxin and odor, and the environment protection is facilitated.

Owner:SHENYANG HYATON FOUNDRY MATERIAL

High-performance dandruff comb clay sand one-piece casting method

The invention discloses an integral forging method for a high-performance perforated strainer by clay sand, namely a method for molding and forging a high-performance perforated strainer by adopting common clay sand. The invention adopts the following specific proposal that the method comprises the following steps: using the common clay sand as a main molding material, adding 5 to 6 percent of bentonite and 3 to 5 percent of coal dust of the total weight of the clay sand into the clay sand and dry-mixing the materials, adding 3 to 4 percent of water of the total weight of the clay sand into the mixture and blending the mixture to manufacture molding sand, then molding the molding sand by an ejection molding machine with a copper molding die, and finishing the integral forging of the high-performance perforated strainer through the processes of ball-blast cleaning, painting, packing, warehousing, and the like. The method adopts the common clay sand to replace resin sand to integrally forge the high-performance perforated strainer, does not need a parting agent, does not need mechanical processing to arrange a groove and a bayonet, and has the characteristics of simple formulation and process, easy realization of industrialization, no secondary pollution during production, low production cost and high rate of forged piece finished products.

Owner:QINGDAO HEDELONG MACHINERY

PEPSET resin moulding and sand cyclic utilization clean casting technology

ActiveCN103934411AFast and uniform curingLower regenerationFoundry mouldsMould handling/dressing devicesProcess engineeringRaw material

The invention relates to a PEPSET resin moulding and sand cyclic utilization clean casting technology. The technology comprises the following steps: using raw materials to carry out PEPSET resin sand moulding: putting a sand core into a mould cavity, closing the mould cavity by using an automatic mould closer, then casting with molten iron; shaking out the sands after the moulding of product; transferring the old sands into a waste sand regeneration processing system; wherein the regenerated sands can be applied to a cold box core blower to manufacture sand cores, thus the addition amount of new sands is reduced, and the cyclic utilization of old sands is achieved.

Owner:LAIZHOU XINZHONGYAO MACHINERY

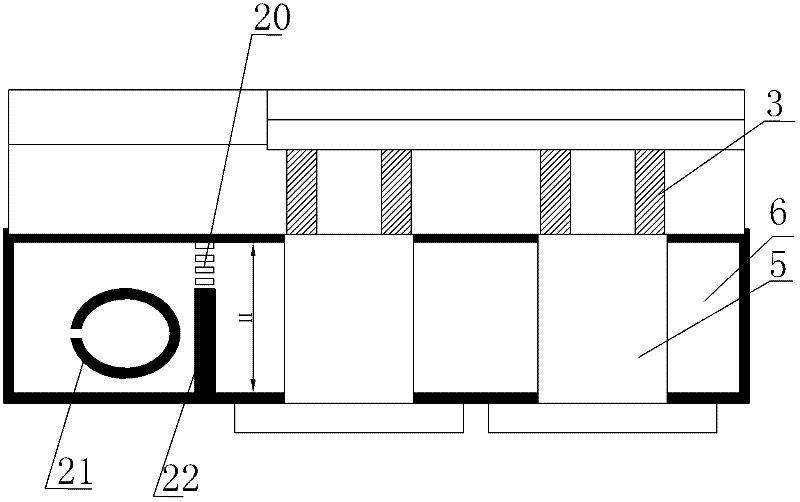

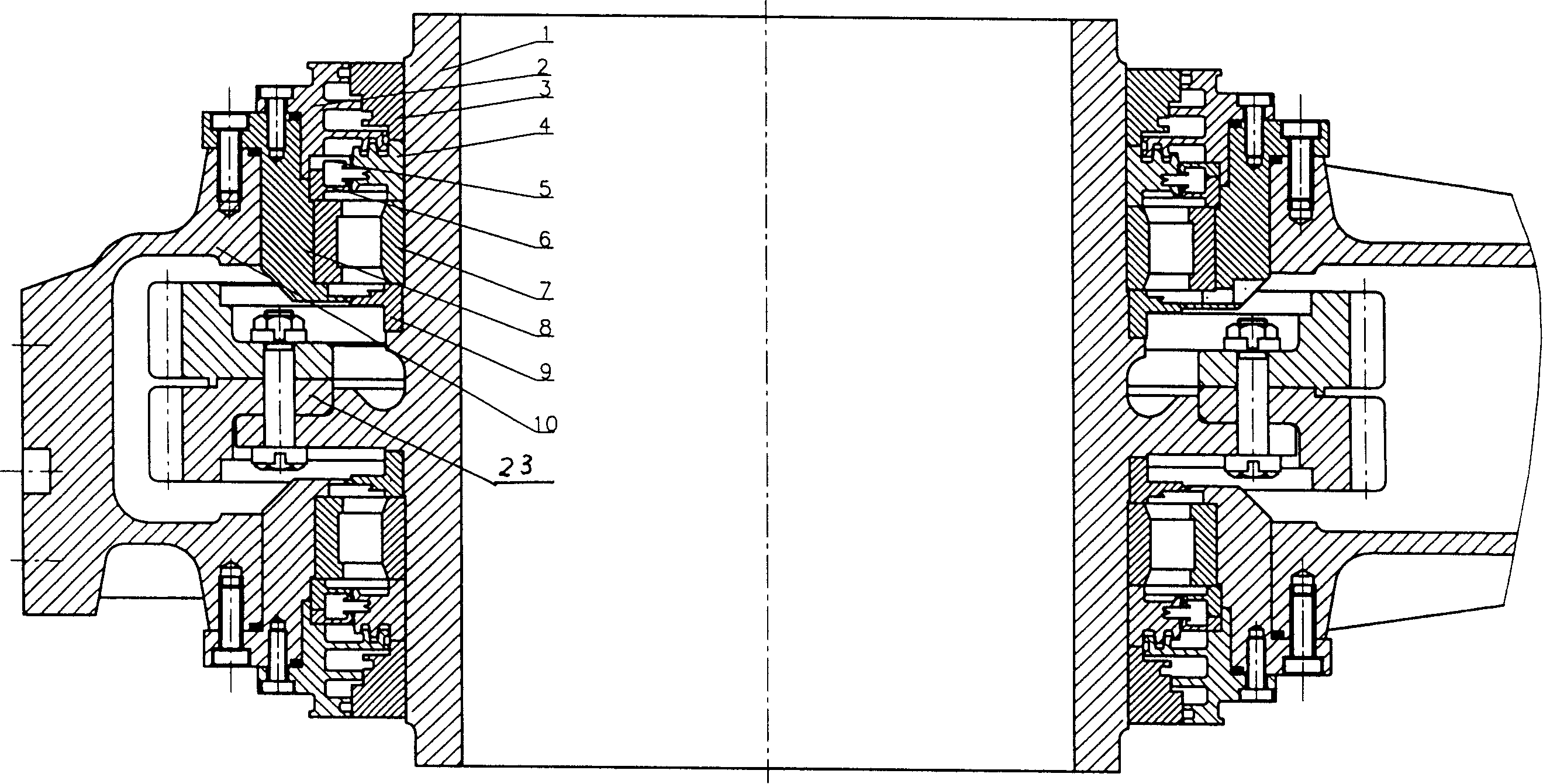

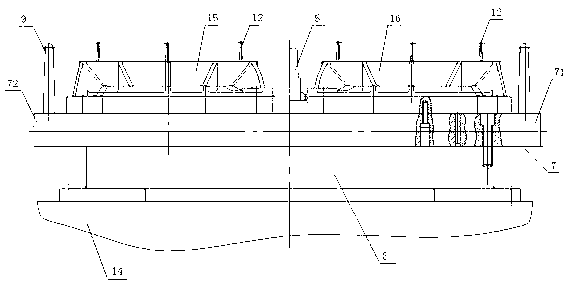

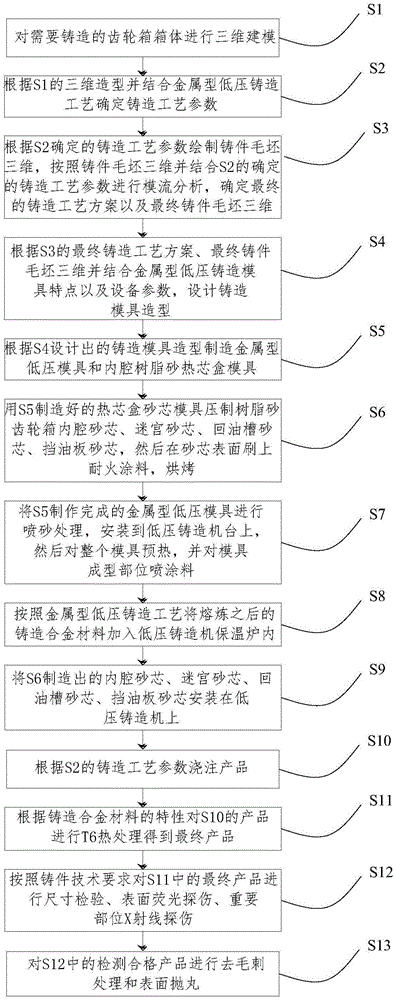

Metal mold low-pressure casting process for cast-aluminum gearbox body of high-speed train

The invention provides a metal mold low-pressure casting process for a cast-aluminum gearbox body of a high-speed train. The process comprises the following steps of S1, three-dimensional modeling; S2, determining of casting process parameters; S3, drawing of a cast blank three-dimensional drawing and determining of a final casting process scheme; S4, design of the modeling of a casting mold; S5, manufacturing of a metal mold low-pressure mold and an inner-cavity resin sand hot box mold; S6, pressing of inner-cavity sand cores, maze sand cores, oil return groove sand cores and oil baffle sand cores of a resin sand gearbox; S7, preheating of the whole molds; S8, adding of smelted casting alloy material into a low-pressure casting machine maintaining furnace; S9, mounting of the inner-cavity sand cores, the maze sand cores, the oil return groove sand cores and the oil baffle sand cores manufactured in S6 on a low-pressure casting machine; S10, product pouring according to the casting process parameters obtained through S2; and S11, obtaining of a final product after T6 thermal treatment on a product obtained in S10. The casting cast through the process is compact in structure, clear in contour, smooth in inner and outer surface, stable in mechanical property and good in size stability and uniformity.

Owner:LAIAN KELAIXING IND CO LTD

Method for casting negative pressure solid cylinder sleeve

The invention relates to a method for casting a negative pressure solid cylinder sleeve, which comprises the following steps: manufacturing a foam plastic model of a cylinder sleeve; bonding a molten iron flow passage through which molten iron flows into a cavity when casting the cylinder sleeve; forming the cavity for accommodating the foam plastic model of the cylinder sleeve by using dry sand; placing the foam plastic model of the cylinder sleeve into the cavity; filling sand into the cavity and jolting to form a solid cavity; molding the cavity by negative pressure; casting molten iron into the cavity so that the foam plastic model of the cylinder sleeve disappears due to gasification and combustion; obtaining a raw casting of the cylinder sleeve blank; taking the casting of the cylinder sleeve blank out; and shaking out the sand and cleaning to obtain a required casting of the cylinder sleeve blank. The method for casting the negative pressure solid cylinder sleeve has the following advantages of: high automation degree of production equipment, small labour intensity, high production efficiency, high utilization ratio of molten metal, high yield of castings, low production cost, high production efficiency, high casting precision, low coke consumption, low sulphur dioxide emissions, and less pollution to environment.

Owner:ANHUI PROVINCE YUEXI CYLINDER

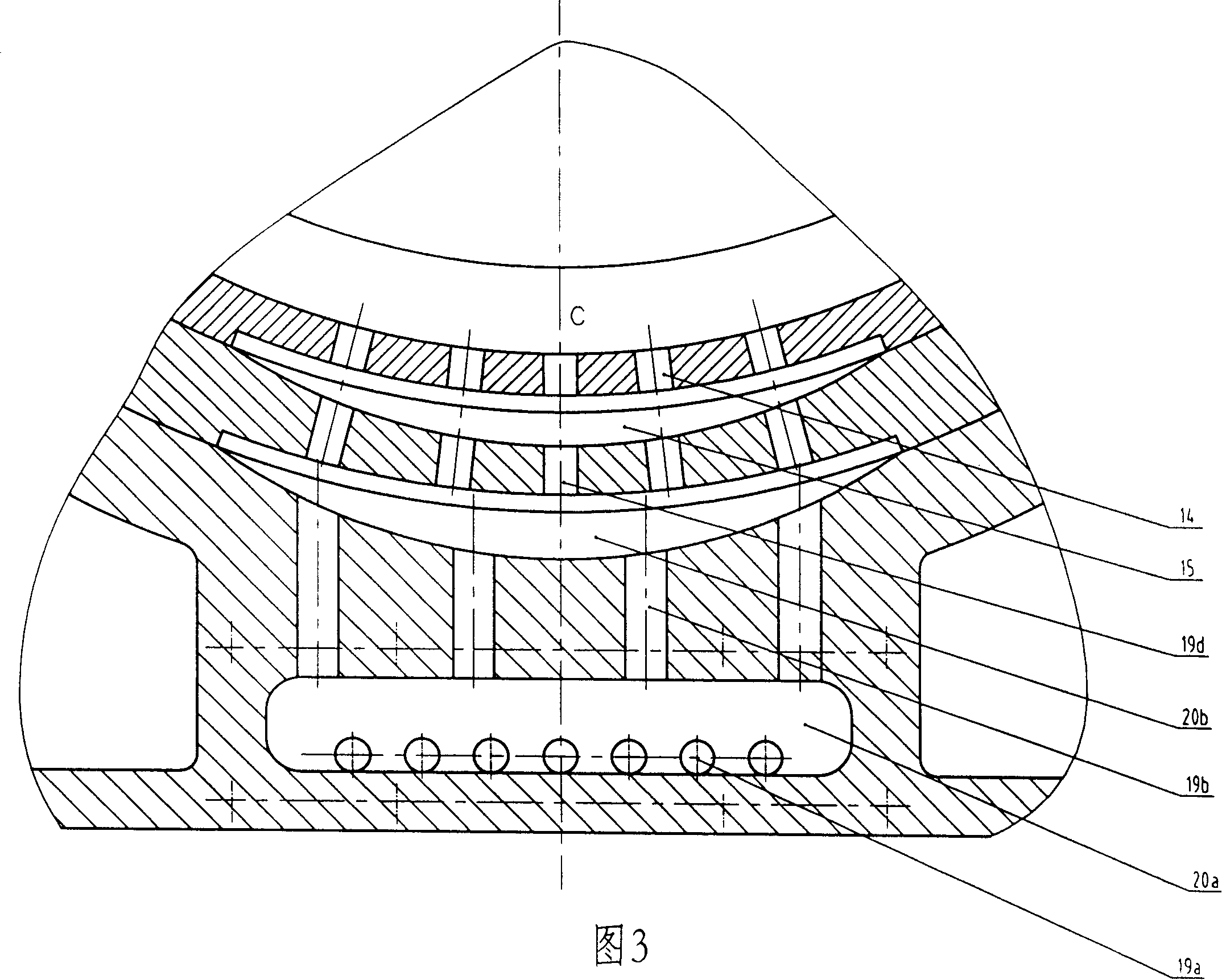

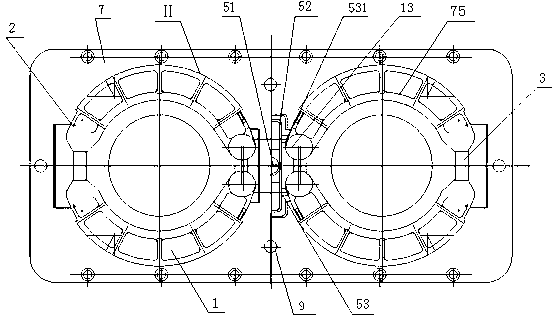

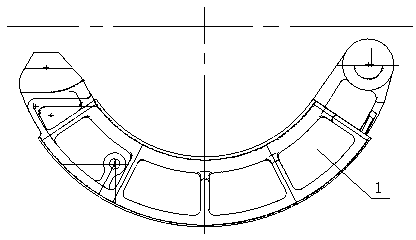

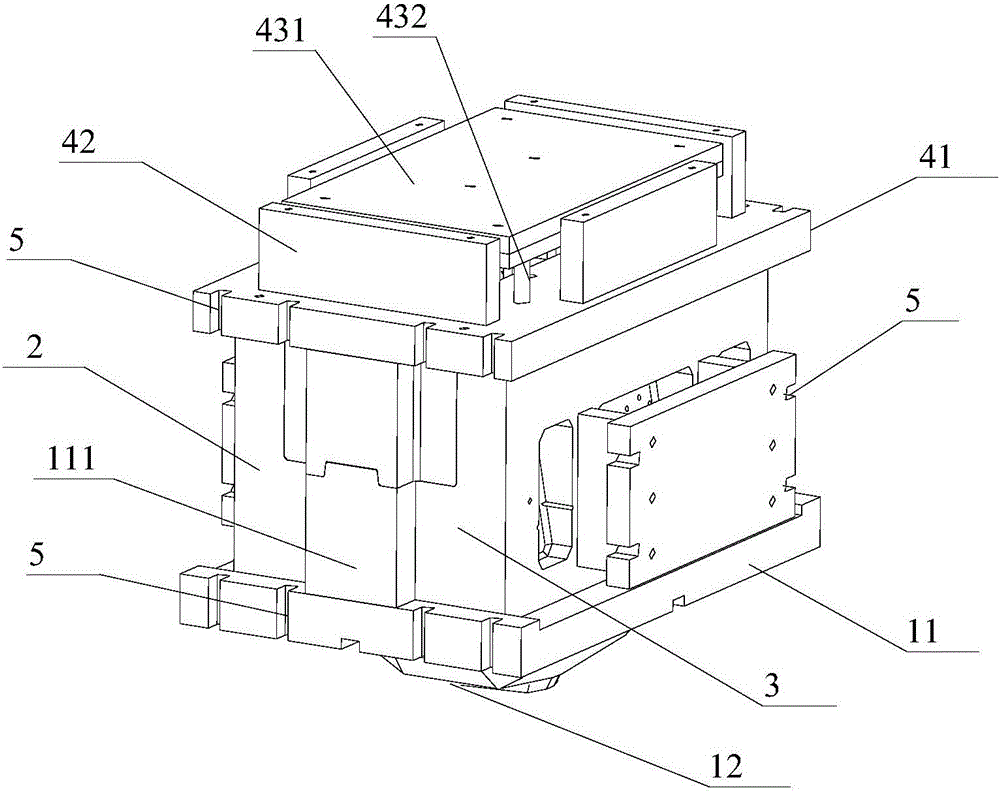

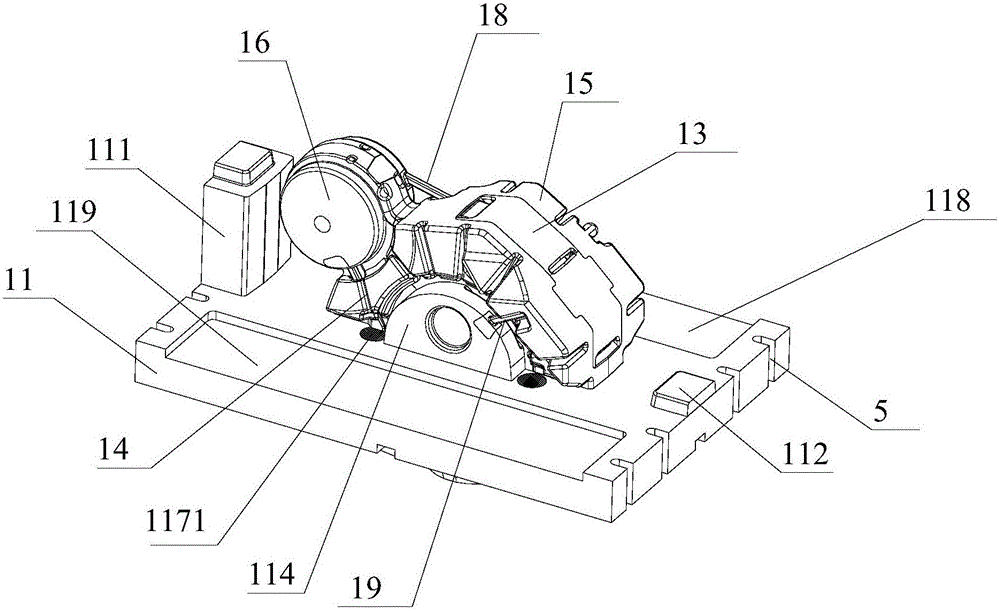

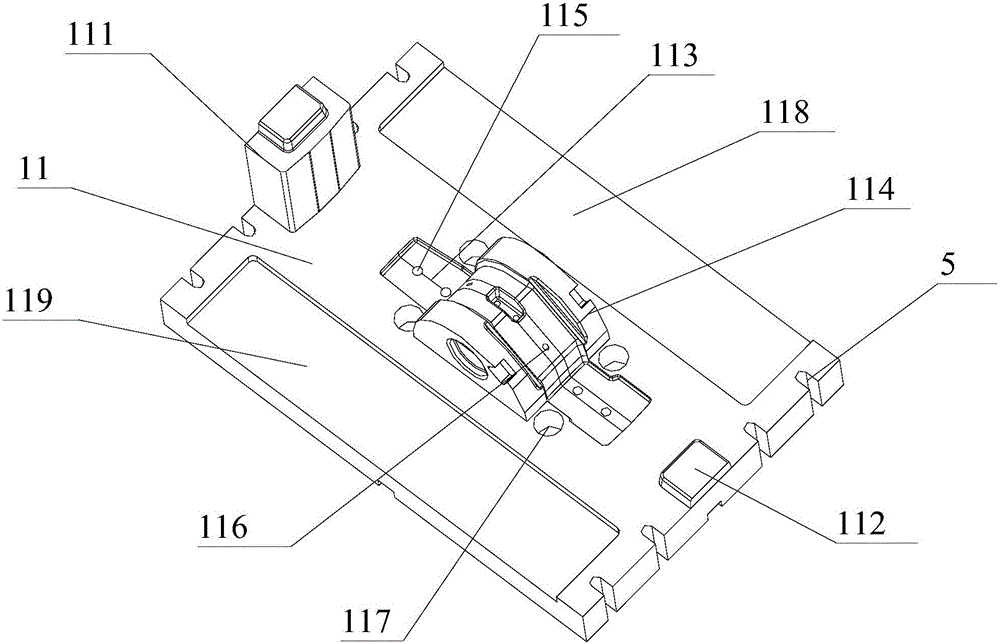

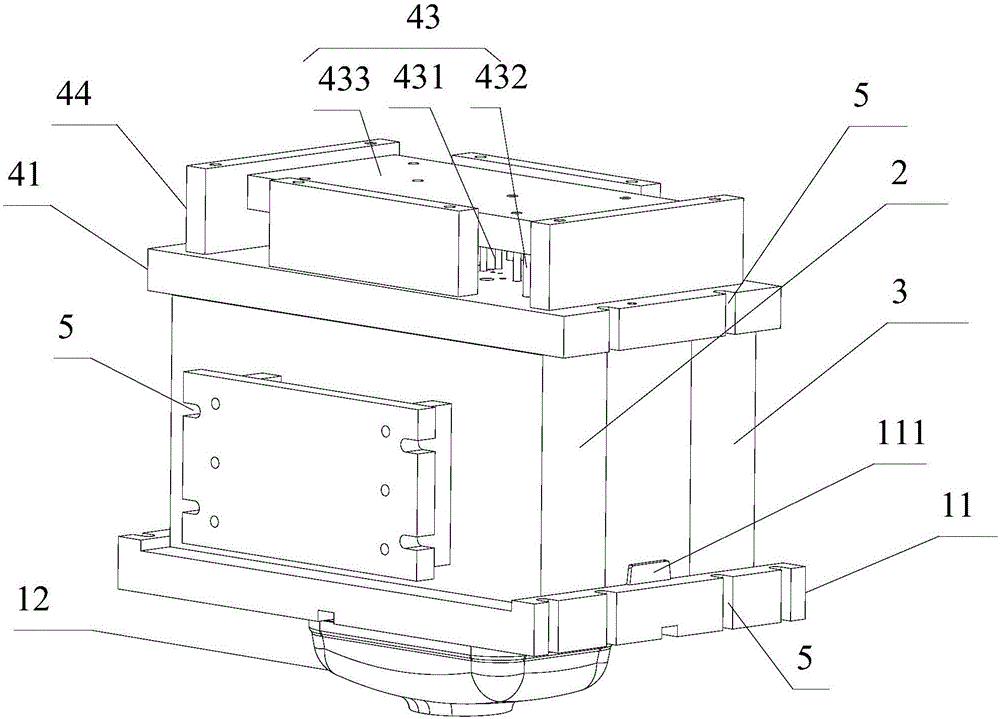

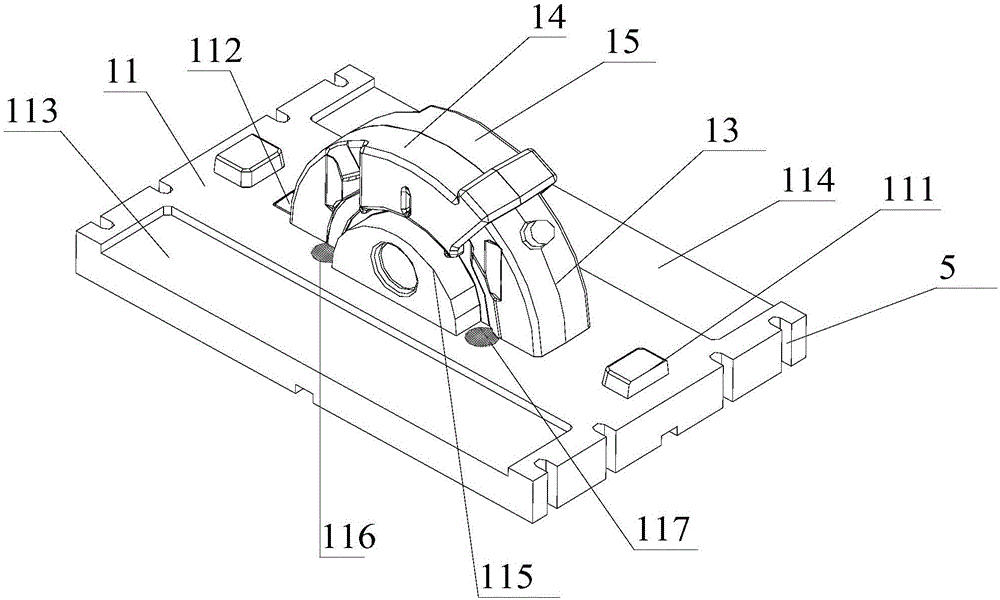

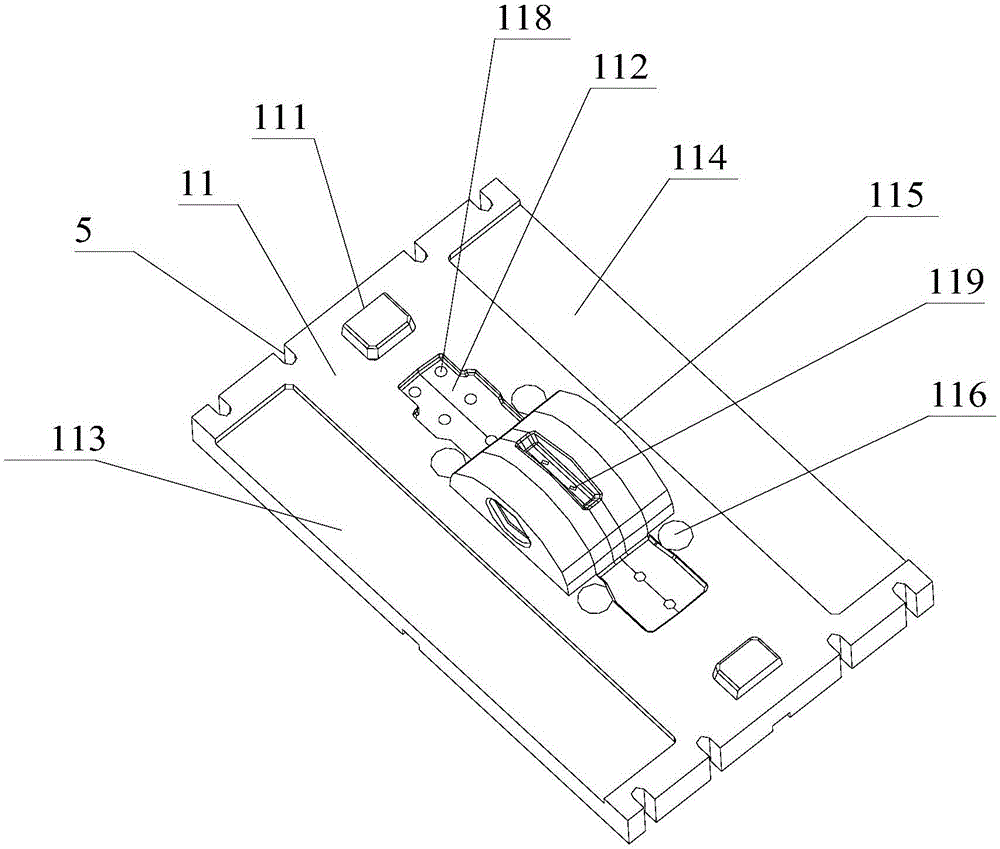

Metal mold low-pressure casting mold for lower box body of high-speed train cast aluminum gearbox

The invention provides a metal mold low-pressure casting mold for a lower box body of a high-speed train cast aluminum gearbox. The metal mold low-pressure casting mold comprises a lower mold, an upper mold, a first sliding block and a second sliding block. A casting cavity is defined by the lower mold, the upper mold, the first sliding block and the second sliding block. A sand core positioning groove is formed in the side, away from a liquid rise pouring basin, of a lower mold base. A first limiting block and a second limiting block are arranged at the two ends of the sand core positioning groove in the extension direction respectively. The first sliding block and the second sliding block are symmetrically arranged on the two sides of a sand core. A first forming convex block matched with the sand core is arranged on the side, close to the sand core, of the first sliding block. A second forming convex block matched with the sand core is arranged on the side, close to the sand core, of the second sliding block. The upper mold comprises an upper mold base. The upper mold base is provided with a forming groove matched with the sand core. The upper mold is connected with the first limiting block and the second limiting block in a clamped manner through a first limiting block clamping groove and a second limiting block clamping groove. Produced castings are compact in structure, clear in contour, stable in mechanical performance and high in casting yield, and the inner surfaces and the outer surfaces of the castings are smooth.

Owner:LAIAN KELAIXING IND CO LTD

Method for improving finished product rate of evaporated pattern casting of holes and inner cavities

InactiveCN103447463AHigh strengthNot easy to break throughFoundry mouldsFoundry coresManufacturing technologyLost-foam casting

The invention belongs to the field of evaporated pattern cast-iron manufacturing technology, in particular relates to an evaporated pattern casting process of anti-adhesive sand cast-iron and aims to provide a method for evaporated pattern casting of holes and inner cavities, which can lower the possibility of sand burning-on in the evaporated pattern casting and improve the finished product rate. According to the technical scheme, the method comprises the following steps: step I, sand core molding, namely manufacturing matched sand cores according to holes or inner cavities in foam models similar to a casting part in size and shape, wherein the holes or the inner cavities in the foam models are filled with the sand cores; step II, model cluster combination, namely placing the sand cores manufactured in the step I into the holes or the inner cavities of the foam models, and bonding the foam models to form a model cluster; step III, coating brushing; step IV, sand box pouring; and step V, cooling and then taking the casting part out. The casting process is mainly used for evaporated pattern casting of casting parts with slot holes, deep holes or inner cavities.

Owner:SHANXI HUAEN MACHINERY MFG

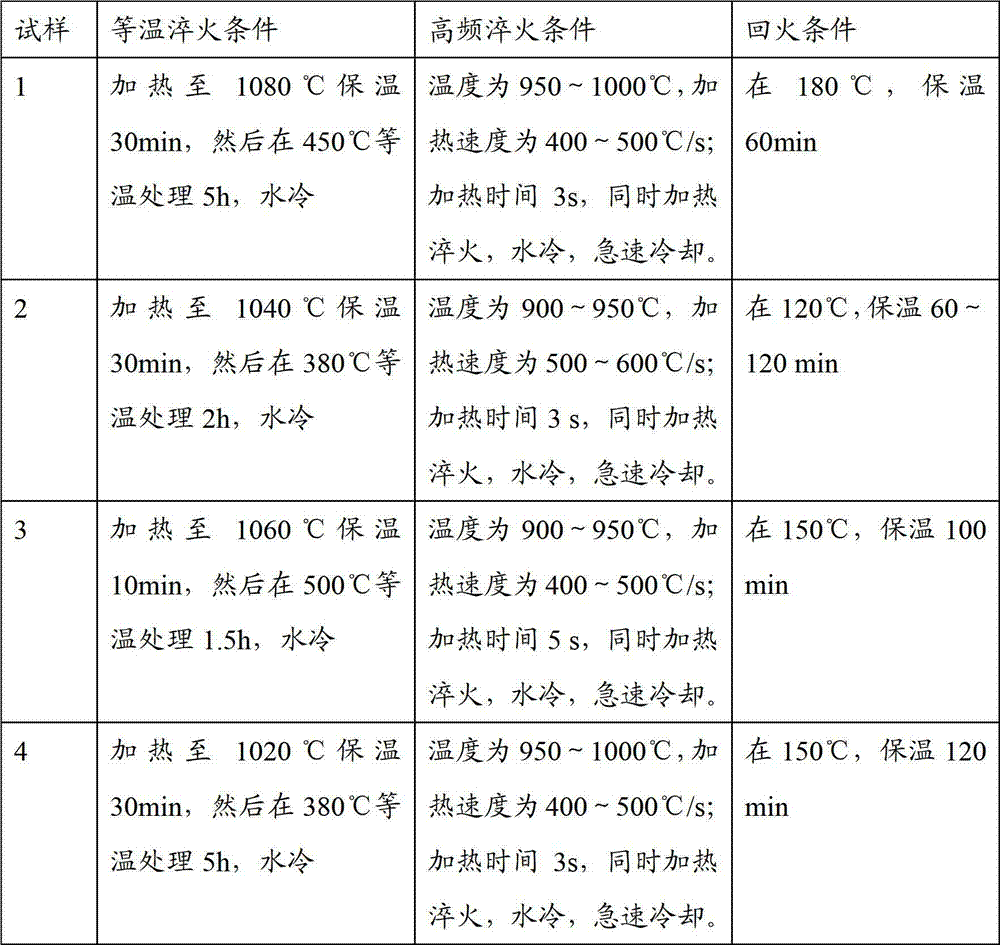

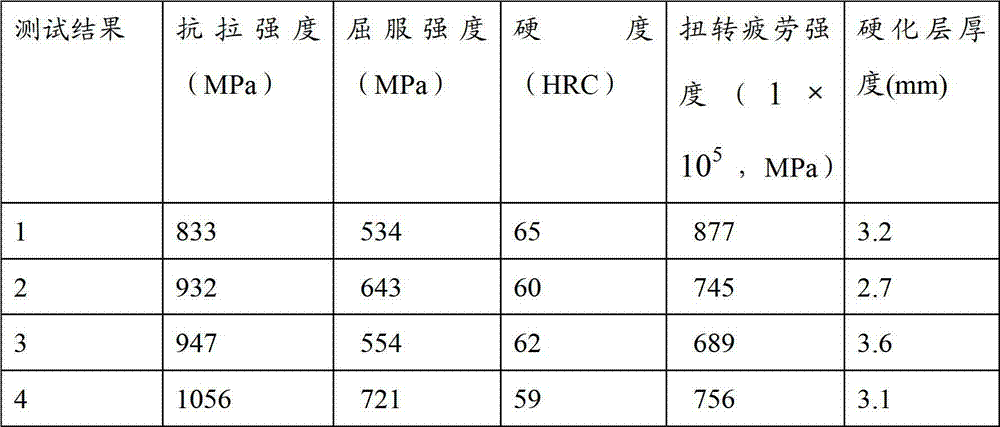

Thermal treatment method for low alloy steel

InactiveCN103388059AHigh hardnessImprove toughnessVacuum evaporation coatingSputtering coatingHigh rateCarbide

The invention relates to a thermal treatment method for low alloy steel. A material is heated to 1020-1080 DEG C and subjected to heat preservation for 10-30 min, thereby converting the material into an austenite completely and dissolving carbides into the austenite. Then, the austenite is subjected to isothermal treatment at 500-380 DEG C for 1-5 h to precipitate the carbides and convert the austenite into lower bainite. Then the lower bainite is subjected to low-temperature tempering at 160-180 DEG C for 0.8-1.5 h and is cooled in air. Compared to the prior art, the low alloy steel treated by the method has not only high hardness, but also good toughness, good wear resistance, small dynamic-load notch sensitivity, high fatigue strength, good casting performance and high rate of finished casting products.

Owner:宁波吉威熔模铸造有限公司

High fire-resistant molding sand for casting and preparation method thereof

The invention discloses high fire-resistant molding sand for casting and a preparation method thereof. The high fire-resistant molding sand for casting comprises the following raw materials in parts by weight: 60-80 parts of fused ceramsite, 20-30 parts of mullite, 10-15 parts of corundum powder, 5-10 parts of nanometer boron nitride, 3-6 parts of light magnesium oxide, 4-8 parts of kaolin, 2-4 parts of illite, 3-5 parts of modified water glass, 1.5-2.5 parts of asphalt, 1-2 parts of polytetrafluoroethylene micro powder, 2-3 parts of polyvinylpyrrolidone and 4-8 parts of water. The high fire-resistant molding sand for casting has high degree of fire resistance, good air permeability, good filling ability and good collapsibility, is difficult to break and high in repeated utilization rate, does not generate dust and cause siliceous dust damage and belongs to the green and environment-friendly molding sand for casting. Castings produced by using the molding sand are high in size precision and have few cracks and surface detects, and the rate of finished products of the castings is high.

Owner:TONGLING JINGWEI FLUID SCI & TECH

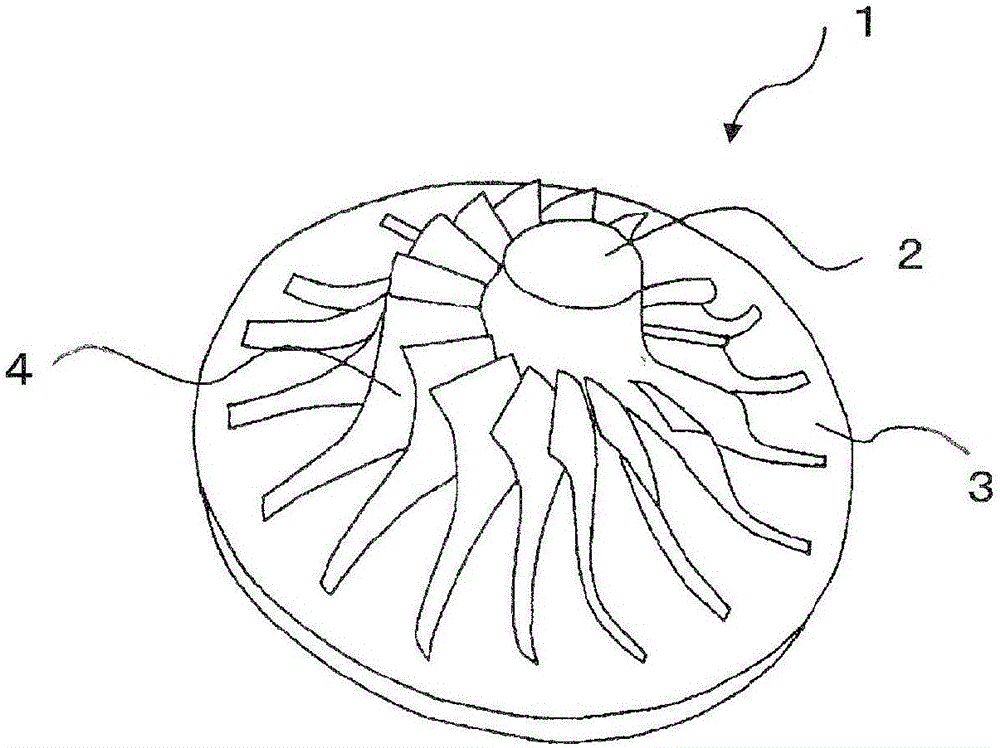

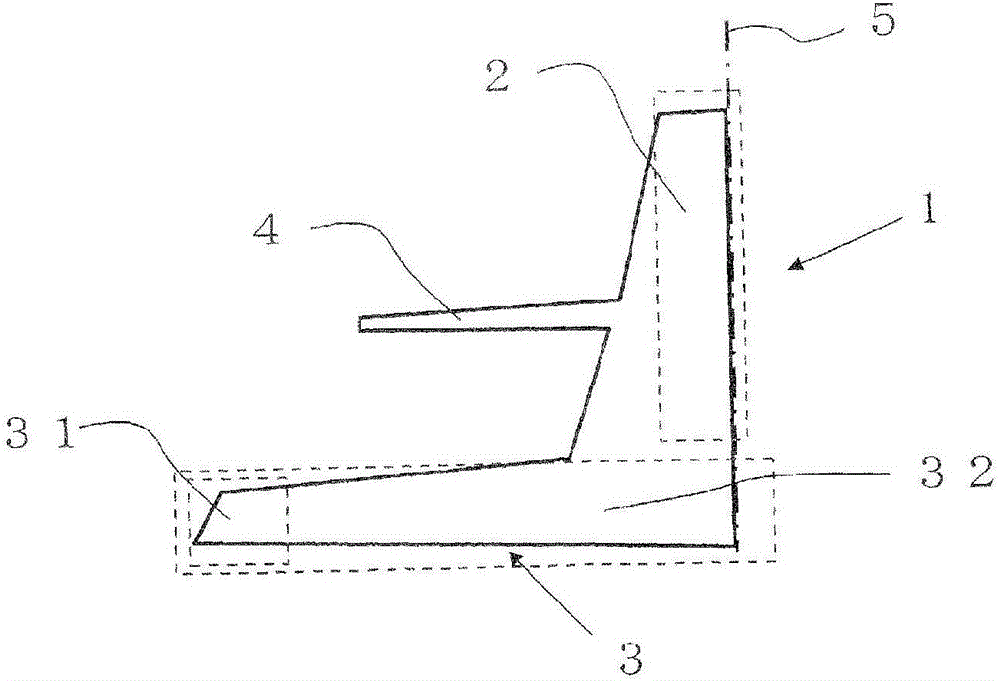

Compressor impeller cast from al alloy and method for producing same

InactiveCN106170572AImprove casting yieldImprove productivityPump componentsFoundry mouldsImpellerProduction rate

The present invention provides: a compressor impeller that is cast from an aluminum alloy, has superior production characteristics, and exhibits stable high-temperature strength when used at temperatures around 200 DEG C; and a method for producing same. The compressor impeller that is cast from an Al alloy is provided with a boss section, a plurality of vane sections, and a disc section; the boss section, the plurality of vane sections, and the disc section excluding the end section comprise an Al alloy comprising a predetermined metal composition; and at the end section of the disc section, there are at least 10,000 / mm<2> of intermetallic compounds having a circle-equivalent diameter of 1-6 [mu]m, and there are no greater than 500 / mm<2> of intermetallic compounds having a circle-equivalent diameter exceeding 6 [mu]m.

Owner:FURUKAWA SKY ALUMINUM CORP +1

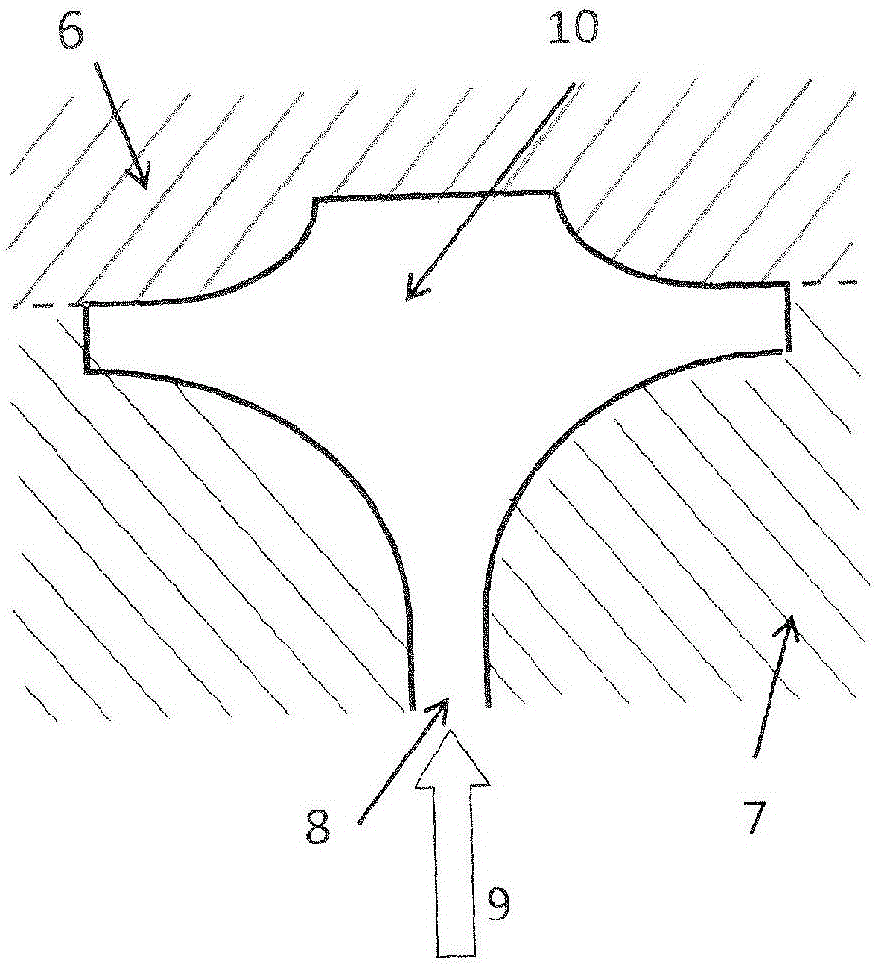

Casting gating system

InactiveCN105642833ASmall volumeDoes not affect pouring qualityFoundry mouldsFoundry coresEngineeringCasting

The invention relates to a casting gating system which comprises a pouring cup. A buffer pit is arranged in the upper portion of the pouring cup. The lower portion of the pouring cup is connected with a main pouring gate, and the bottom end of the main pouring gate is provided with a T-type tee joint. A sprue in the right end of the T-type tee joint is connected with a first transverse pouring gate. A sprue in the left end of the T-type tee joint is connected with a second transverse pouring gate. The first transverse pouring gate is connected with a first straight pouring gate. The second transverse pouring gate is connected with a second straight pouring gate. The first straight pouring gate is connected with a first riser which communicates with a cavity of a first sand mould. The second straight pouring gate is connected with a second riser which communicates with a cavity of a second sand mould finally. According to the casting gating system, on the premise of not affecting the pouring quality, the two cavities share one main pouring gate, and the volume of the buffer pit is reduced while pouring of molten iron, so that the pouring speed is increased, internal defects are reduced, the rate of finished molten iron castings is increased, and the casting cost is lowered.

Owner:四川逢顺商贸有限公司

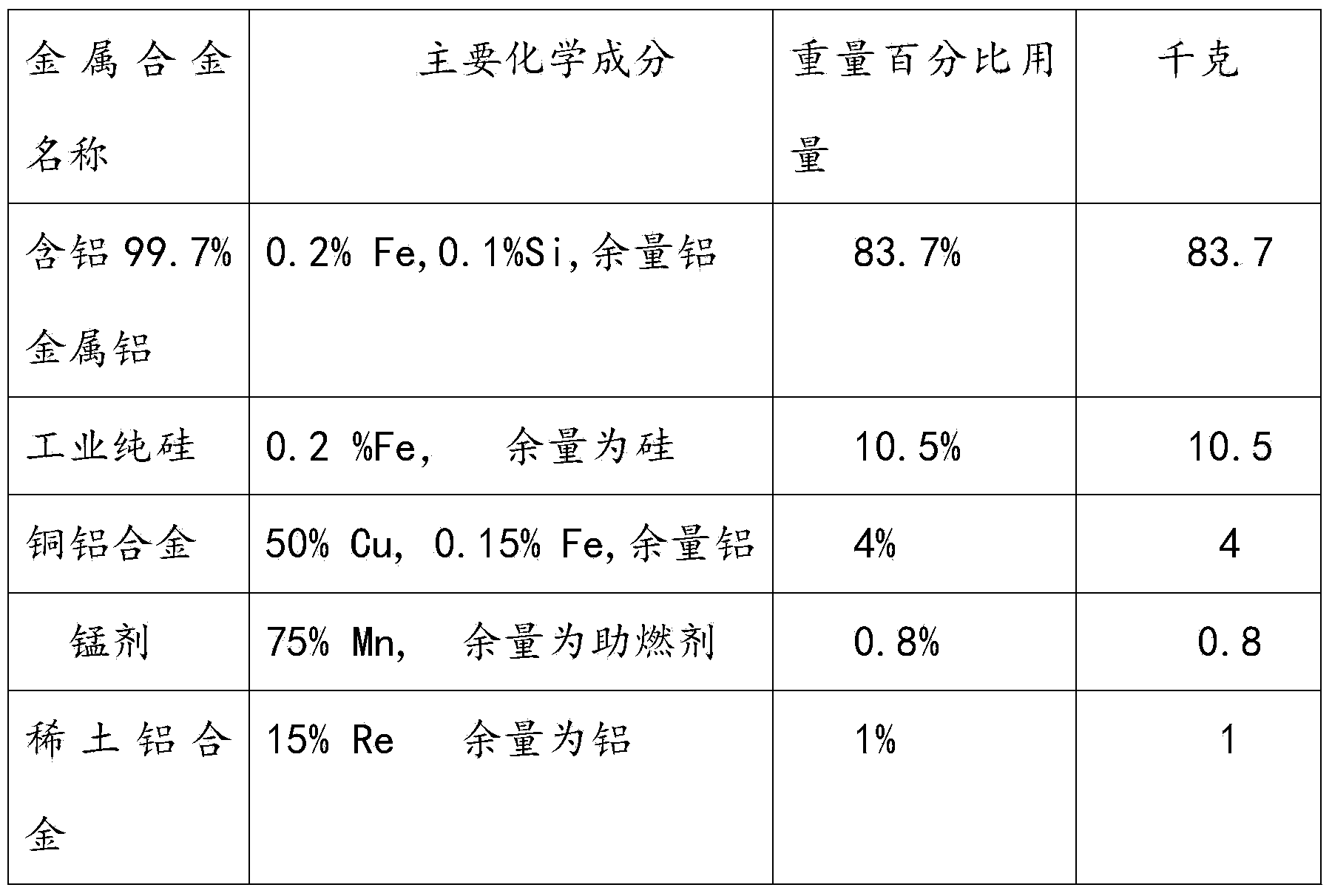

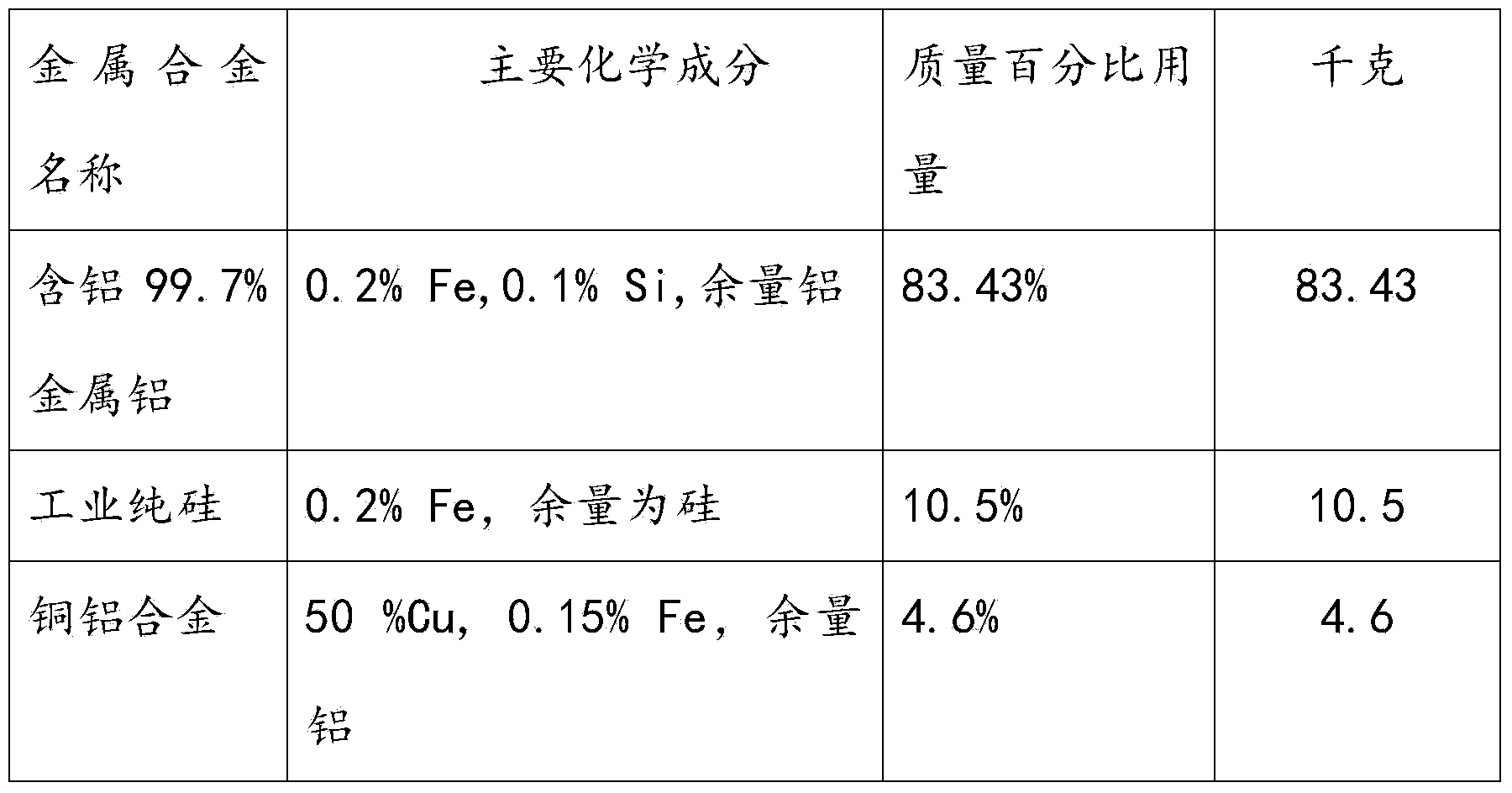

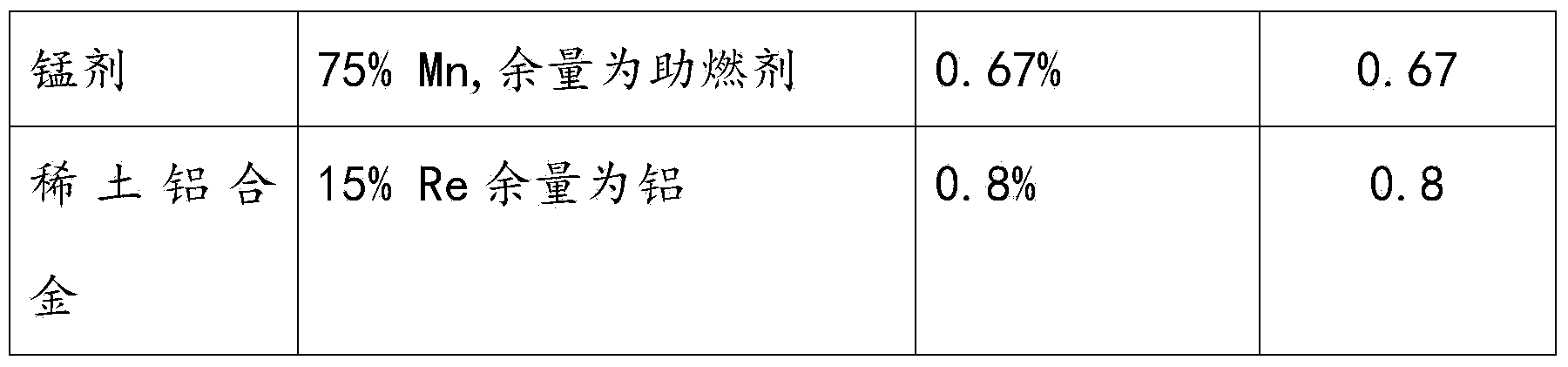

Aluminum, silicon, copper and rare earth alloy material for metal mold casting and preparation method and application thereof

The invention discloses an aluminum, silicon, copper and rare earth alloy material for casting a dual-balance shaft shell of an automobile and a preparation method of the material. The aluminum, silicon, copper and rare earth alloy material comprises the following components (in percent by weight): 10-12 percent of silicon, 1.5-2.5 percent of copper, 0.3-0.9 percent of manganese, 0.1-0.3 percent of rare earth element, 0.18-0.2 percent of impurity element iron and the balance of aluminum. The dual-balance shaft shell of an automobile is made of the aluminum, silicon, copper and rare earth material. The aluminum, silicon, copper and rare earth alloy material has the beneficial effects that the dual-balance shaft shell of the automobile, which is made of the aluminum, silicon, copper and rare earth alloy material, is capable of lightening 2 / 3 of the weight of an existing dual-balance shaft of the automobile, the corrosion resistance is good, the hardness is high, the hardness (HBM (Brinell Hardness)) of the dual-balance shaft shell of the automobile reaches 80-85, and the tensile strength (theta b) reaches 230-240MPa; the casting yield of the dual-balance shaft shell of the automobile is increased to 90 percent from 80 percent, the thermal treatment procedure is saved, and the production cost is lowered to 5000RMB / ton.

Owner:济南润祥新材料科技有限公司

Metal mold low-pressure casting die for box body on cast aluminum gearbox of high-speed train

The invention provides a metal mold low-pressure casting die for a box body on a cast aluminum gearbox of a high-speed train. The metal mold low-pressure casting die comprises a lower die body, an upper die body, a first sliding block and a second sliding block. A casting cavity is defined by the lower die body, the upper die body, the first sliding block and the second sliding block. The lower die body comprises a lower die base and a sand core. The side, away from a lifting pouring basin, of the lower die base is provided with a sand core positioning groove, a first sliding block limiting groove and a second sliding block limiting groove, wherein the first sliding block limiting groove and the second sliding block limiting groove are symmetrically formed in the two sides of the sand core positioning groove. The two ends of the sand core positioning groove are symmetrically provided with two upper die limiting blocks in the extension direction. The sand core is clamped in the sand core positioning groove. The first sliding block is clamped in the first sliding block limiting groove. The second sliding block is clamped in the second sliding block limiting groove. The upper die body comprises an upper die base. The side, away from a third molding groove, of the upper die base is provided with an ejection connecting mechanism. A produced casting is dense in structure, clear in outline, stable in mechanical performance and good in dimensional stability consistency, the inner surface and the outer surface are smooth, an inner cavity and an oil return groove are more clearly molded, and the casting yield is high.

Owner:LAIAN KELAIXING IND CO LTD

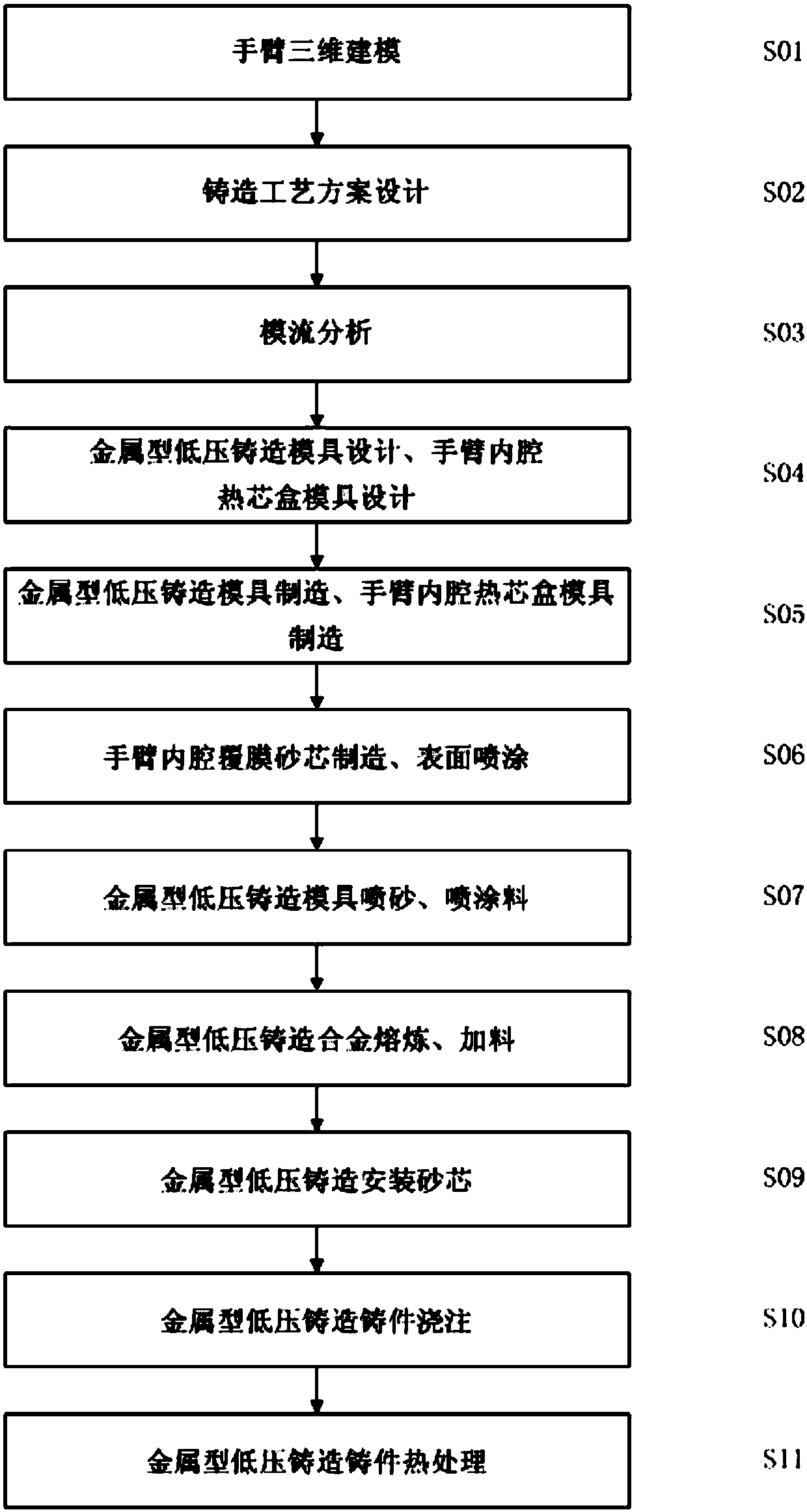

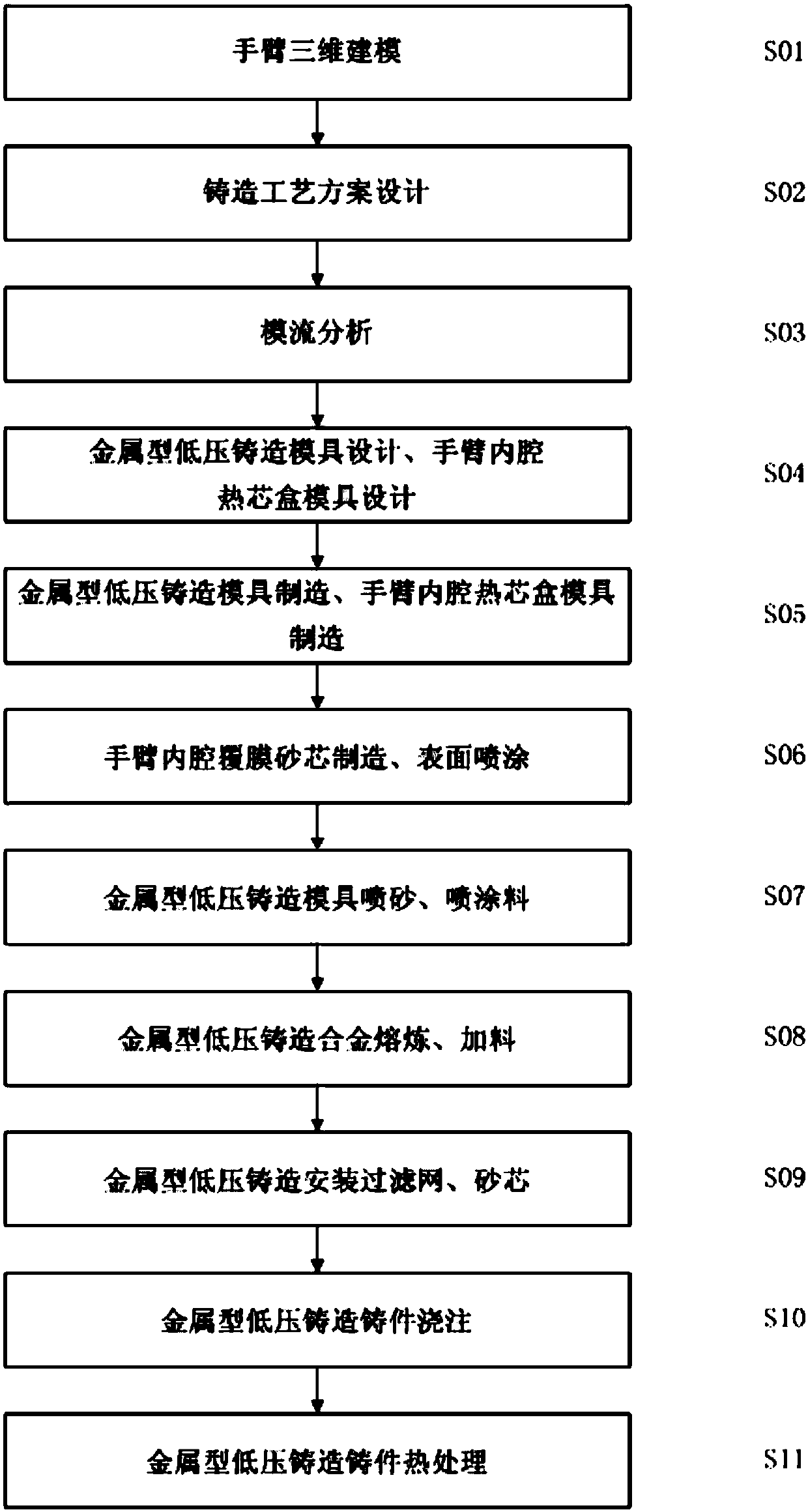

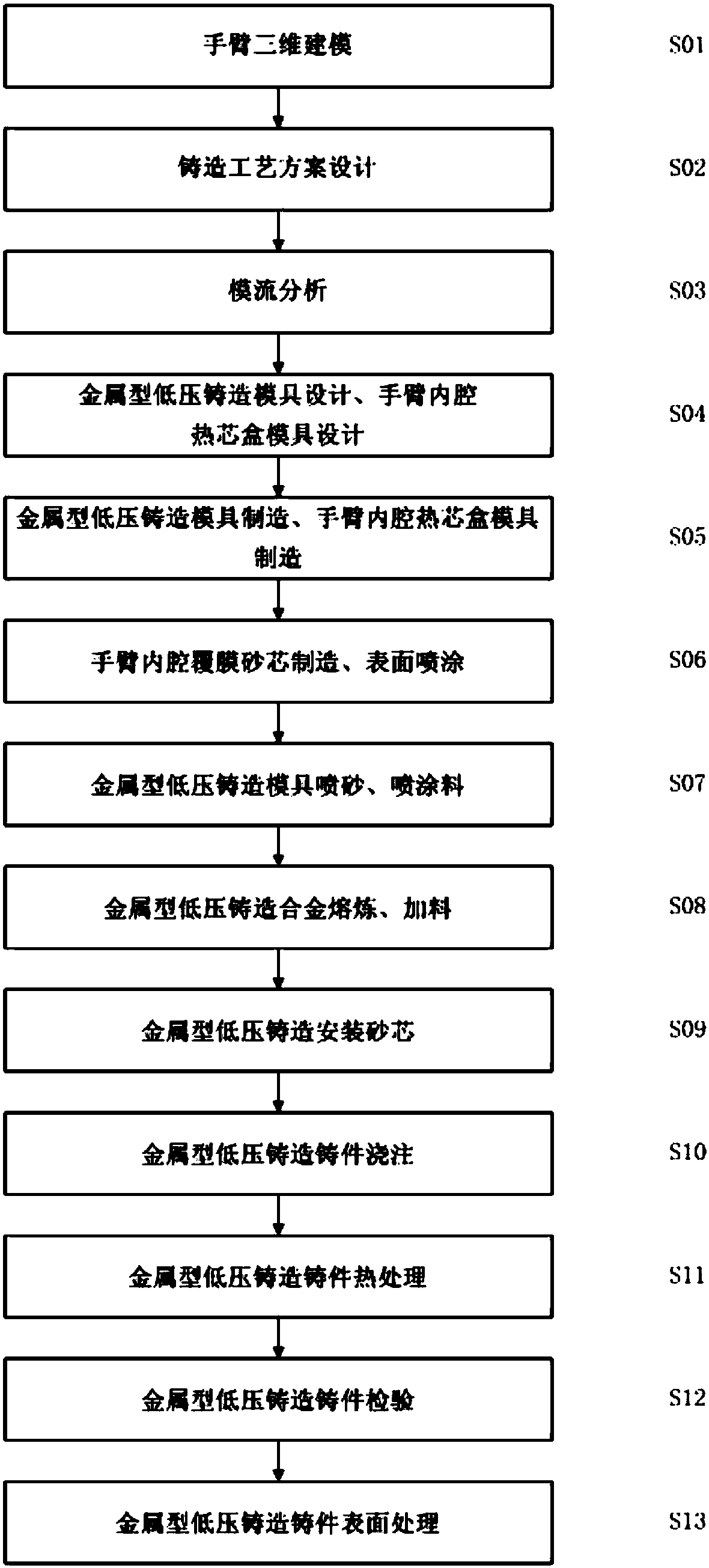

Aluminum alloy metal mold low-pressure casting technological method for collaborative robot arm

The invention discloses an aluminum alloy metal mold low-pressure casting technological method for a collaborative robot arm. The method comprises the following steps of 1, three-dimensional modelingof the arm; 2, design of a casting technological scheme; 3, mold flow analysis; 4, design of a metal mold low-pressure casting mold and an arm inner chamber hot box mold; 5, manufacturing of the metalmold low-pressure casting mold and the arm inner chamber hot box mold; 6, manufacturing of an arm inner chamber film-coated sand core, and surface coating; 7, sand blasting and paint spraying of themetal mold low-pressure casting mold; 8, smelting and feeding of a metal mold low-pressure casting alloy; 9, mounting of the sand core through metal mold low-pressure casting; 10, pouring of metal mold low-pressure casting castings; and 11, heat treatment of the metal mold low-pressure casting castings. The collaborative robot arm manufactured through the method has the beneficial effects of beingsmall in weight, high in rigidity, high in inner chamber precision and attractive and delicate in outer surface.

Owner:张希波

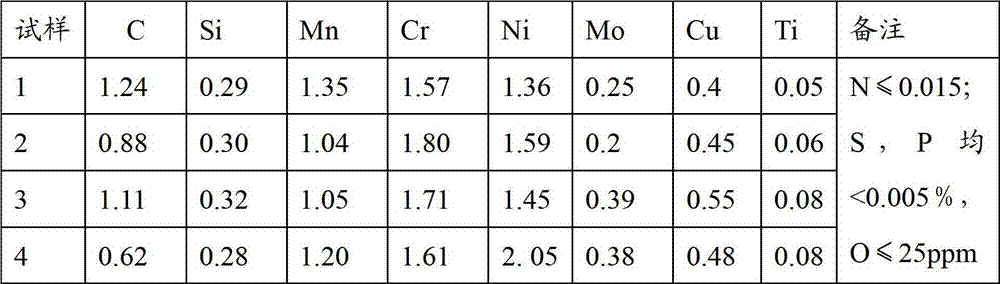

Low alloy steel

ActiveCN102864383AImprove performanceHigh hardnessFoundry mouldsFoundry coresHardnessUltimate tensile strength

The invention relates to low alloy steel. The low alloy steel comprises, by weight, C 0.55-1.24%, Si 0.2-0.35%, Mn 1.05-1.35%, Cr 1.50-1.80%, Ni 1.30-2.20%, Mo 0.20-0.45%, Cu 0.4-0.6%, Ti 0.05-0.08%, N <= 0.015%, S < 0.005%, P < 0.005%, O <= 25 ppm and the balance of Fe and inevitable impurities. Compared with the prior art, the low alloy steel is good in comprehensive performance, has high hardness, good toughness and high fatigue strength, is good in casting performance and high in finished casting product ratio, and has the advantages of having more than 900 MPa of tensile strength and more than HRC58 of Rockwell hardness and being good in ductility and toughness.

Owner:宁波吉威熔模铸造有限公司

Dual-zone turbine for turbocharging

InactiveCN102661180AImprove efficiencyIncreased torque outputInternal combustion piston enginesStatorsImpellerTurbine blade

The invention discloses a dual-zone turbine for turbocharging. The dual-zone turbine comprises a turbine volute, wherein a turbine impeller is arranged in the turbine volute; a turbine blade is arranged outside the turbine impeller; a turbine air inlet, a volute air inlet runner and a volute air outlet are arranged on the turbine volute; a turbine impeller air inlet, a turbine impeller air inlet runner, a turbine impeller air outlet and a turbine impeller blade are arranged on the turbine impeller; separation boards which are arranged according to the circumferential direction are arranged between the turbine impeller air inlet and the turbine impeller air outlet of the turbine impeller; and the turbine impeller air inlet runner is divided into an inner turbine impeller air inlet runner and an outer turbine impeller air inlet runner by the separation boards. According to the dual-zone turbine disclosed by the invention, the supercharging requirement of an engine within the all-condition range can be effectively met; the phenomenon that gas suddenly expands at a single runner air outlet of the volute at low flow can be reduced; and the efficiency of the turbine at low flow can be further increased.

Owner:KANGYUE TECH

Aluminum alloy casting moulding sand and preparing method thereof

InactiveCN107671231AEasy to prepareImprove casting yieldFoundry mouldsMould handling/dressing devicesFuranGraphite

The invention discloses aluminum alloy casting moulding sand and a preparing method thereof. The casting moulding sand comprises, by weight, 20-40 parts of quartz sand, 10-20 parts of zircon sand, 10-30 parts of emery, 5-10 parts of graphite powder, 5-15 parts of bentonite, 5-18 parts of kieselguhr, 2-6 parts of hollow micro beads, 3-6 parts of glass fiber, 4-12 parts of clay, 2-8 parts of light-roasted powder, 10-18 parts of furan resin and 2-4 parts of polypropylene fiber. The preparing method is simple, the yield of castings can be greatly increased through the prepared moulding sand, and the casting cost is reduced.

Owner:MAANSHAN SONGHAK INFORMATION TECH CO LTD

Production method of low-oxygen copper rod with diameter of 8 mm

The invention discloses a production method of a low-oxygen copper rod with the diameter of 8 mm. The production method mainly comprises the steps of compounding, smelting, casting, rolling, cleaning and cooling, blow-drying, flaw detecting, waxing, rod winding and packaging. According to the production method, energy is saved, environment friendliness is achieved, and the production cost is low. The produced finished low-oxygen copper rod with the diameter of 8 mm is stable in performance, high in quality grade and product consistency and good in economic benefit.

Owner:安徽天大铜业有限公司

Composite treatment method of regenerated deformed aluminum alloy melt

ActiveCN111411247AImprove casting yieldExpand industrial applicationsProcess efficiency improvementMechanical properties of carbon nanotubesIngot casting

The invention discloses a composite treatment method of a regenerated deformed aluminum alloy melt. The composite treatment method mainly comprises the following steps of carrying out composite treatment on a 6xxx-series regenerated aluminum alloy melt by using Mg, Sr and a C-containing refiner to change the form and distribution of a second phase of the alloy, so that a needle-like impurity phaseis converted into a Chinese character shape, and an eutectic structure is uniformly distributed; and meanwhile, grains are refined, and the alloy solidification mode is changed. After the composite treatment, the ingot casting heat crack sensitivity of the regenerated deformed aluminum alloy is obviously reduced, the reduction rate is up to 32%, the comprehensive mechanical property is also obviously improved, the tensile strength is maximally improved by 35%, and the hardness is maximally improved by 45%.

Owner:QINGYUAN ZHENGTONG METAL PROD CO LTD +1

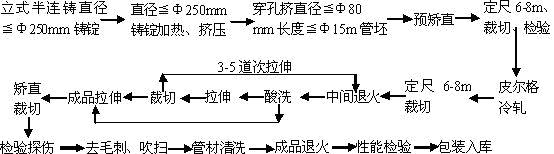

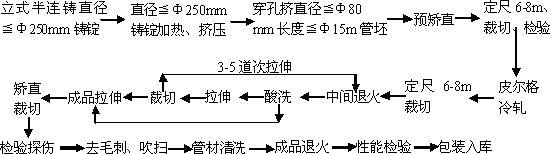

Heated mould continuous casting-continuous drawing method of cupronickel alloy condenser pipes

The invention discloses a heated mould continuous casting-continuous drawing method of cupronickel alloy condenser pipes, which is characterized by comprising the following steps: 1, obtaining cupronickel pipe blanks by the heated mould continuous casting method; 2, drawing the pipe blank; 3, carrying out 3-pass drawing; and 4, carrying out combined drawing, finishing, washing and final annealing to obtain the finished product. The pipe blanks of which the diameter is more than or equal to 1mm and less than or equal to 50mm are subject to combined drawing, and 3-pass disk drawing; the pipe blanks of which the diameter is more than 50mm and less than or equal to 108mm are subject to combined drawing, and 3-pass straight drawing; and the pipe blanks of which the diameter are more than 108mm and less than or equal to 319mm are subject to combined drawing, and 3-pass hole enlargement drawing. In the heated mold continuous casting-continuous drawing method provided by the invention, the processes are reduced, the casting yield is improved, the energy consumption of the ingot casting heating-extrusion process is lowered, and the cost is reduced greatly.

Owner:JINCHUAN GROUP LIMITED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com