Patents

Literature

134results about How to "Clear shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Embossed crepe paper and its manufacturing method

ActiveUS20060278357A1Property is spoiled littleDestruction of hydrogen bondingNon-fibrous pulp additionNatural cellulose pulp/paperCrêpe paperPulp and paper industry

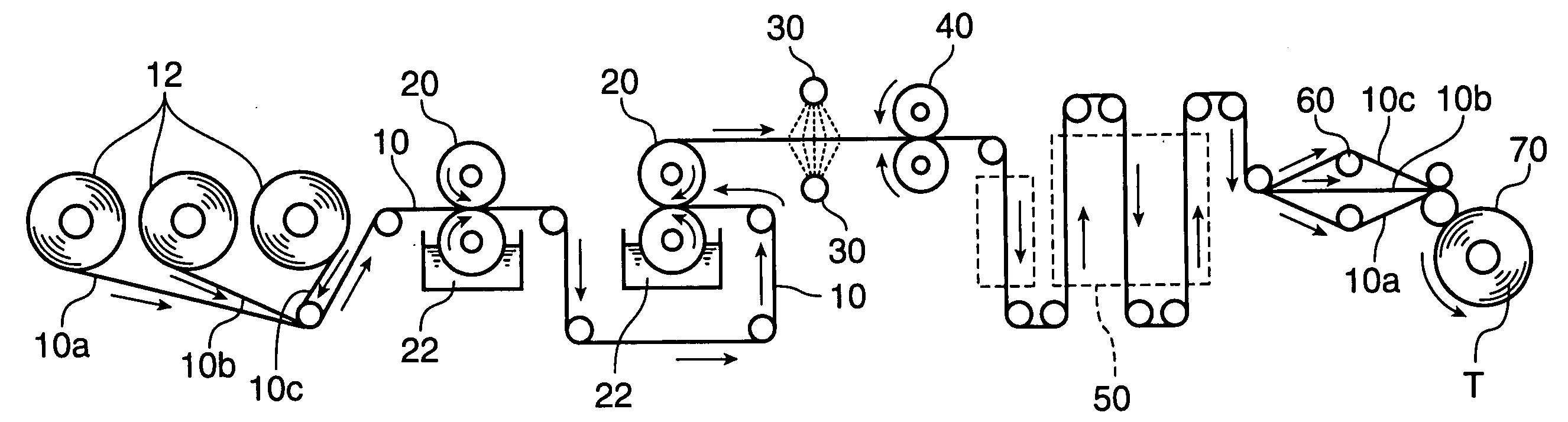

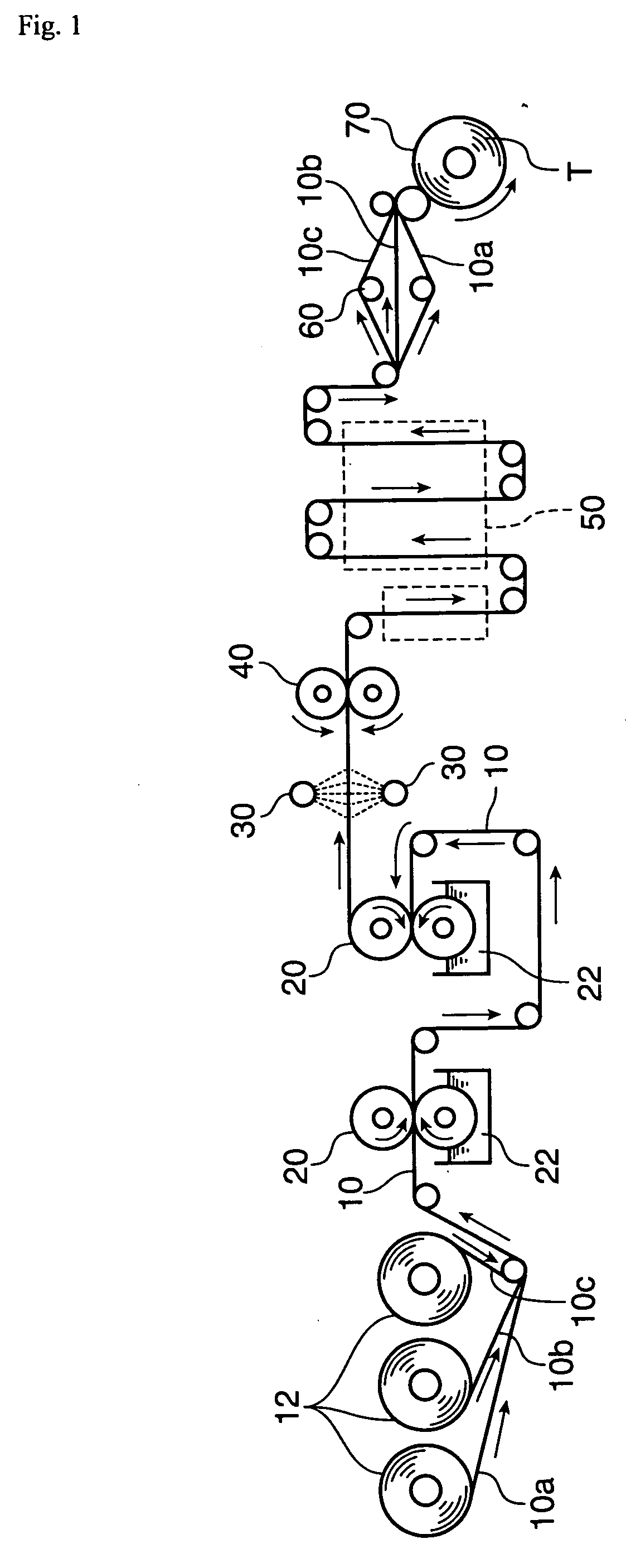

An object of the present invention is to provide an embossed crepe paper which can clearly be formed into fine embossed shapes, and is excellent in the fluffy feel and therefore excellent in such as absorbency for fats. As a means of achieving this object, the method for manufacturing an embossed crepe paper, according to the present invention, is a method for manufacturing an embossed crepe paper comprising a step of embossing a raw crepe paper, wherein: a raw paper having a basis weight of 6 to 28 g / m2 is used as the raw crepe paper; and the embossing step includes the steps of: (a) supplying the raw crepe paper with water in an amount of 0.1 to 100 weight % based on the basis weight to thereby put the raw crepe paper in a wet condition; (b) embossing the wet-conditioned raw crepe paper; and (c) drying the embossed wet-conditioned raw crepe paper.

Owner:KAWANO PAPER

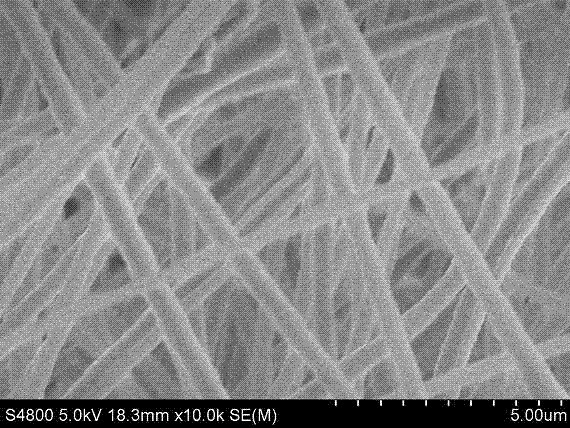

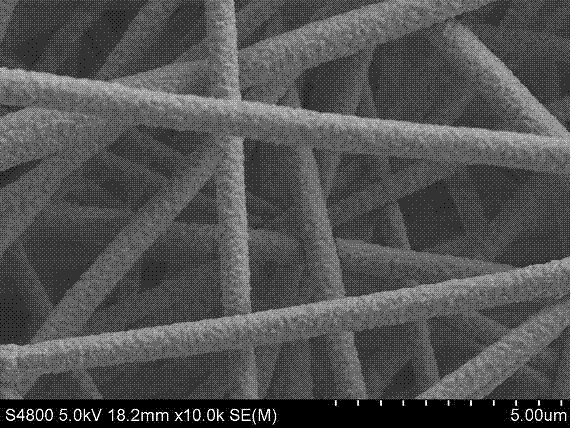

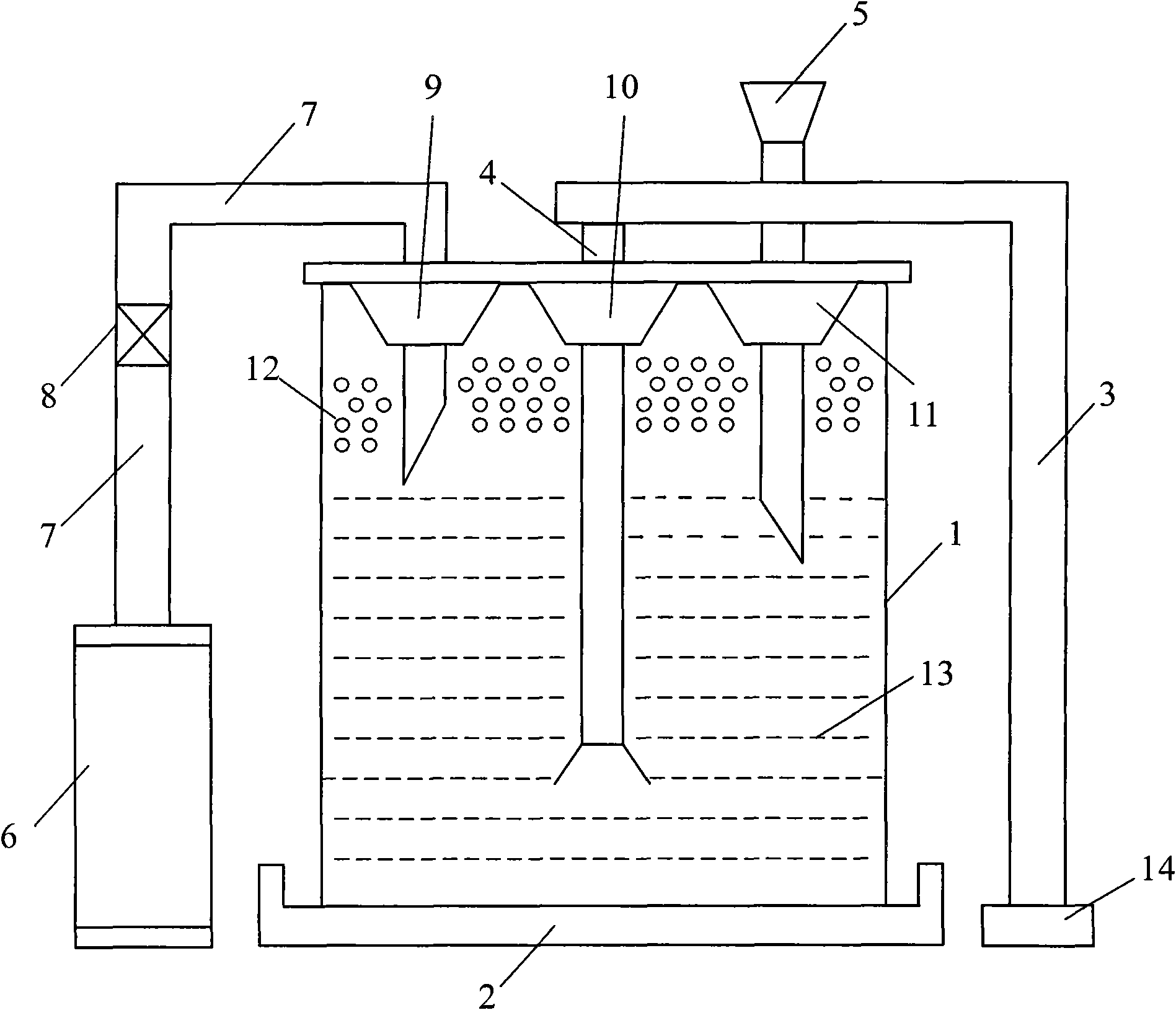

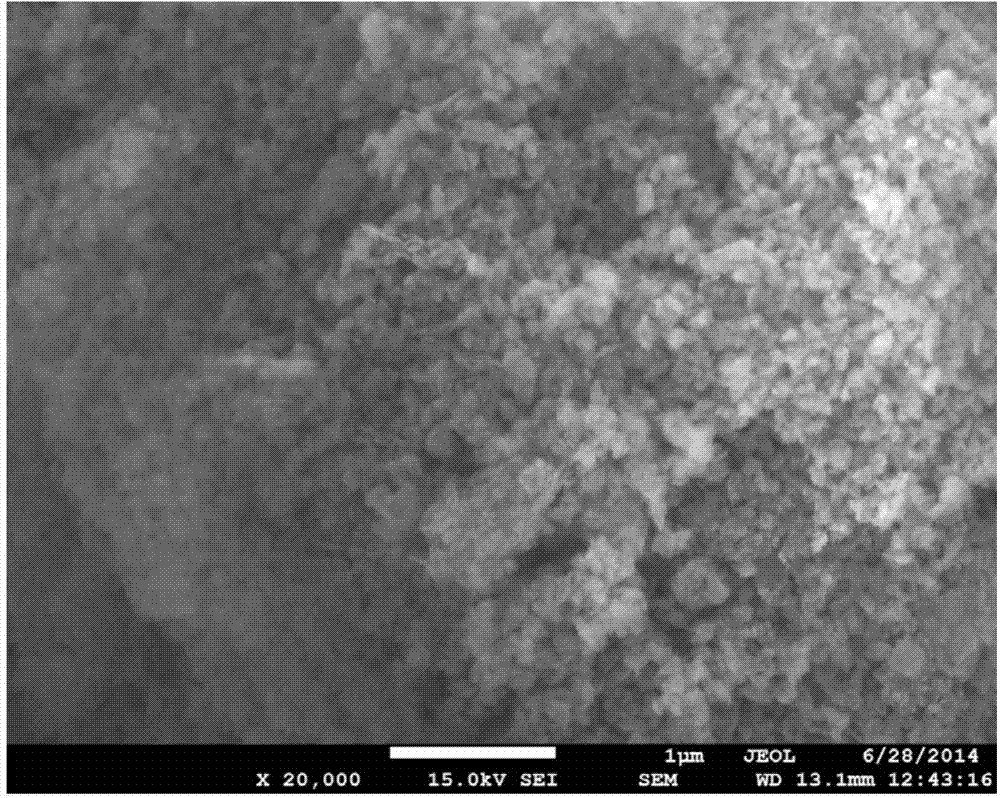

Low-concentration copper-doped titanium dioxide nanotube photocatalyst and preparation method thereof

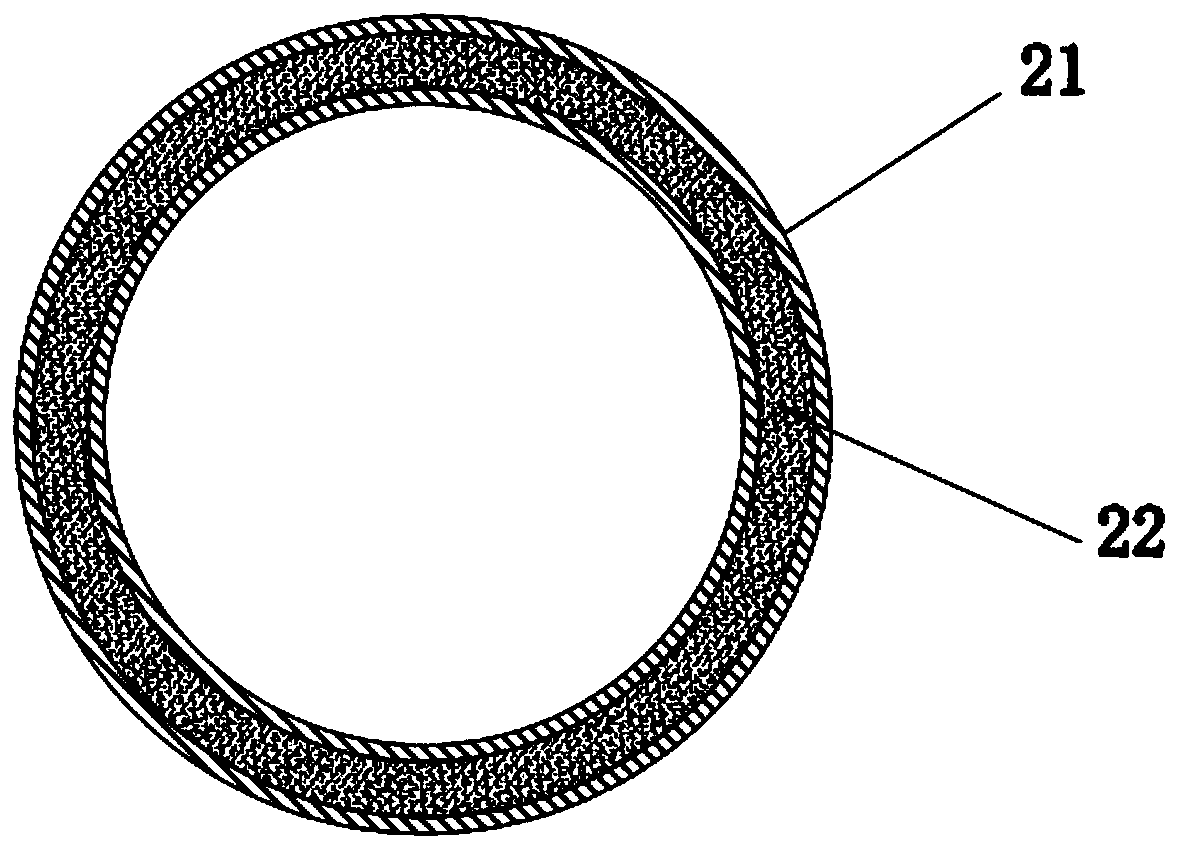

InactiveCN102240550AClear shapeImprove photocatalytic activityWater/sewage treatment by irradiationCatalyst activation/preparationElectrolytic agentTio2 nanotube

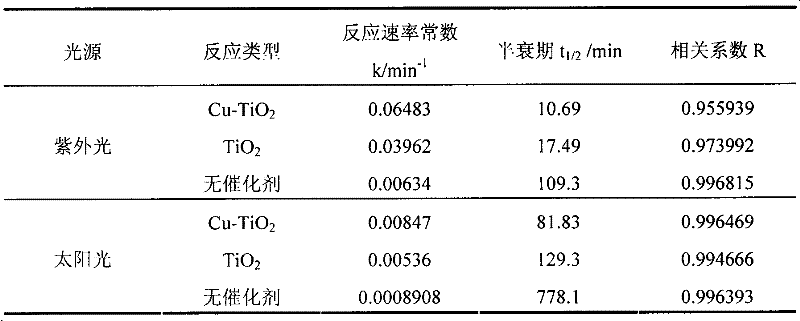

The invention relates to the field of titanium dioxide photocatalysis, in particular to researches in application of a titanium dioxide nanotube modified through metal doping to the field of photocatalysis. The invention provides a simple and feasible preparation method of a copper-doped TiO2 nanotube catalyst. According to the preparation method provided by the invention, low-concentration copper is effectively doped into a titanium dioxide nanotube array through adoption of a constant-voltage electrodeposition method; and the copper inside the titanium dioxide nanotube exists in the form of copper oxide; the copper-doped TiO2 nanotube catalyst has a good photocatalytic activity under ultraviolet light and sunlight; and the composition of electron hole pairs contained in titanium dioxide is effectively inhibited through copper doping, and therefore the photocatalytic property of the titanium dioxide nanotube is enhanced. The preparation method of the photocatalyst is a constant-voltage electrochemical deposition method, in which copper sulfate is taken as electrolyte, and a preparation process is simple; and in addition, the prepared copperdoped TiO2 nanotube catalyst has a stable property and can be used repeatedly.

Owner:NANKAI UNIV

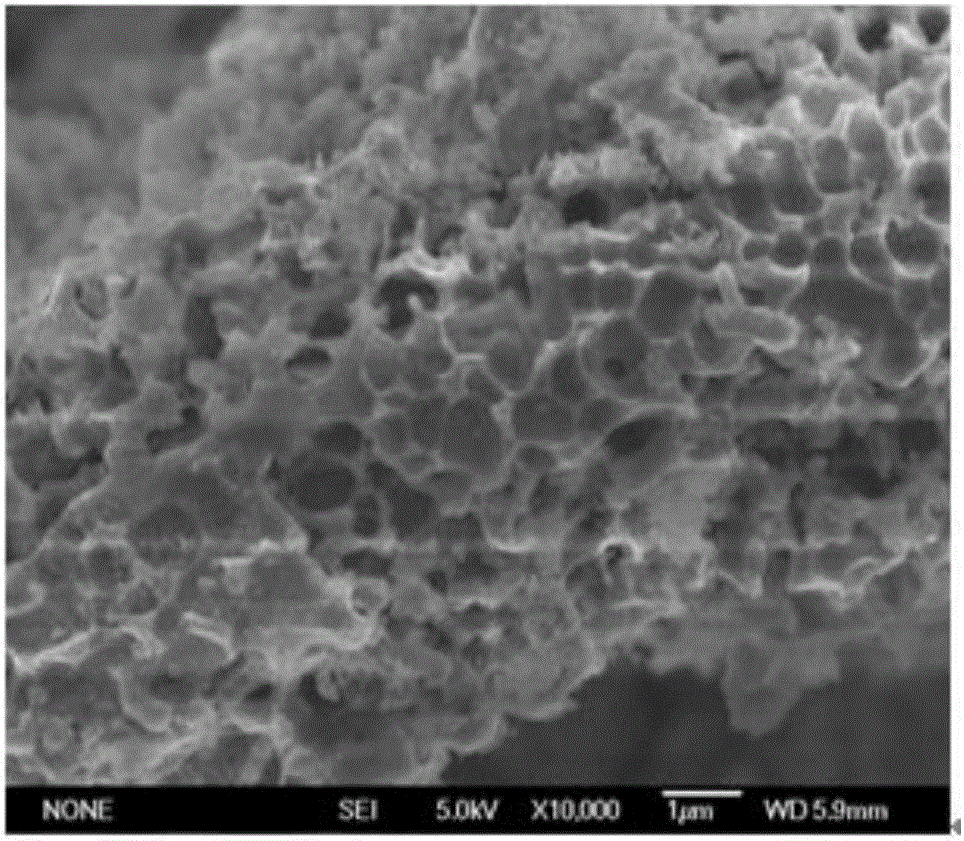

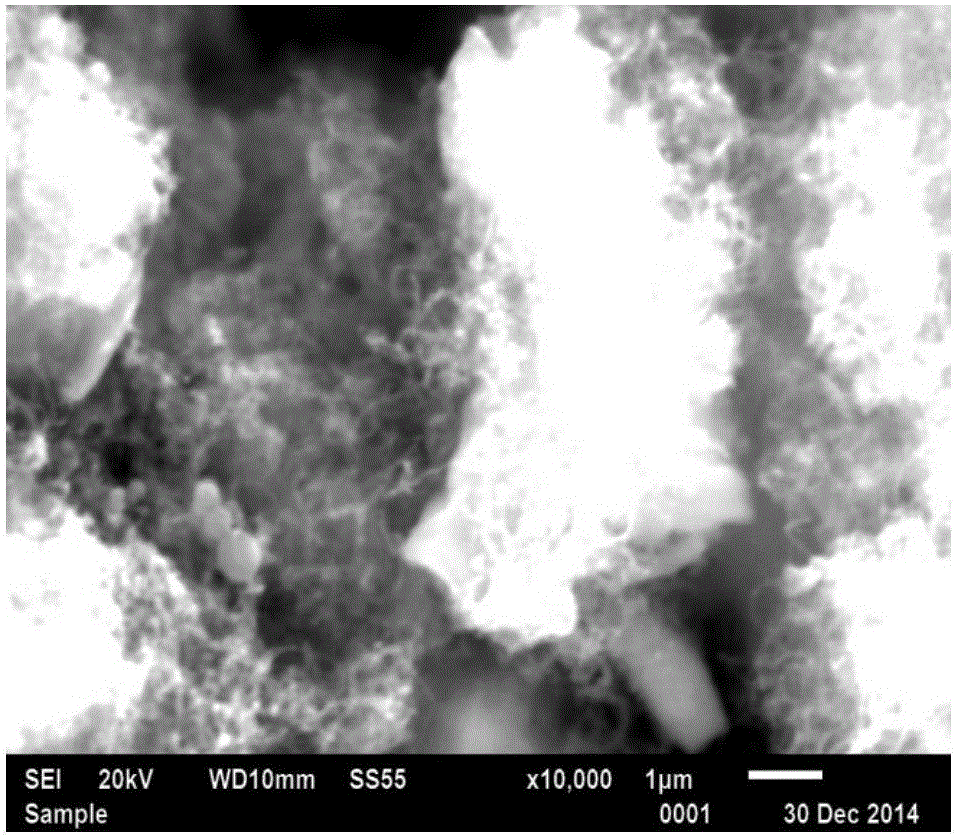

Method for preparing porous silicon carbon nanotube composite negative electrode material of lithium ion battery by diatomite

InactiveCN105845911AUnique pore structurePore structure retentionCell electrodesSecondary cellsCarbon compositesPtru catalyst

The invention relates to a method for preparing a porous silicon carbon nanotube composite negative electrode material of a lithium ion battery by diatomite. The method is characterized in that the diatomite is a silicon source, comprises the steps of preparing porous silicon, preparing a porous silicon matrix surface supported catalyst precursor and preparing a porous silicon carbon nanotube composite material, has the advantages of availability in raw material, low cost, clearness in morphology of the prepared porous silicon, high capacity of the silicon carbon composite material, cycle stability, high production efficiency, low cost and the like, and is suitable for industrial production. Under the test in which current density is 100mA / g, the initial reversible specific capacity of a negative electrode, prepared from the material, of the lithium ion battery reaches 1,529.1mAh / g, the reversible specific capacity reaches 885.4mAh / g after circulation of 40 times, and the subsequent cycle capacity is almost unchanged; and through the rate performance test, the reversible specific capacity is restored to about 800mAh / g when the current density is restored to 100mA / g, and the test shows that the material is high in connection tightness performance.

Owner:NORTHEAST DIANLI UNIVERSITY

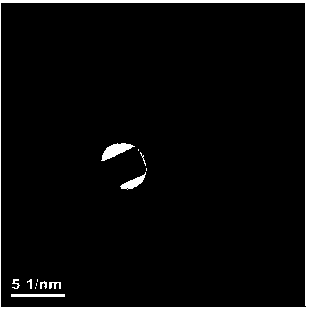

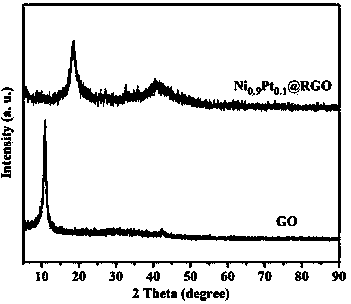

NiPt@RGO composite nano catalyst for producing hydrogen by using hydrazine borane and preparation method thereof

ActiveCN103949272AImprove catalytic performanceEasy to useHydrogen productionMetal/metal-oxides/metal-hydroxide catalystsNano catalystHydrogen

The invention provides a NiPt@RGO composite nano catalyst for producing hydrogen by using hydrazine borane and a preparation method thereof. The catalyst is prepared by using sodium borohydride (NaBH4) as a reducing agent to reduce precursors of metallic Ni and Pt and a graphene oxide (GO) carrier together. The catalyst shows very excellent catalytic performance and can catalyze the hydrazine borane at 50 DEG C, so that the hydrazine borane can be completely hydrolyzed, and hydrazine can be cracked to produce hydrogen, and the hydrogen turnover frequency (TOF) of the catalyst reaches 240 (molH2.mol<-1>metal.h<-1>). The method for preparing the catalyst is simple and convenient to operate, particularly the noble metal Pt content of the obtained optimal alloy catalyst is low (the molar ratio Ni / Pt is 9 / 1), and the catalyst is cheap and efficient.

Owner:JIANGXI NORMAL UNIV

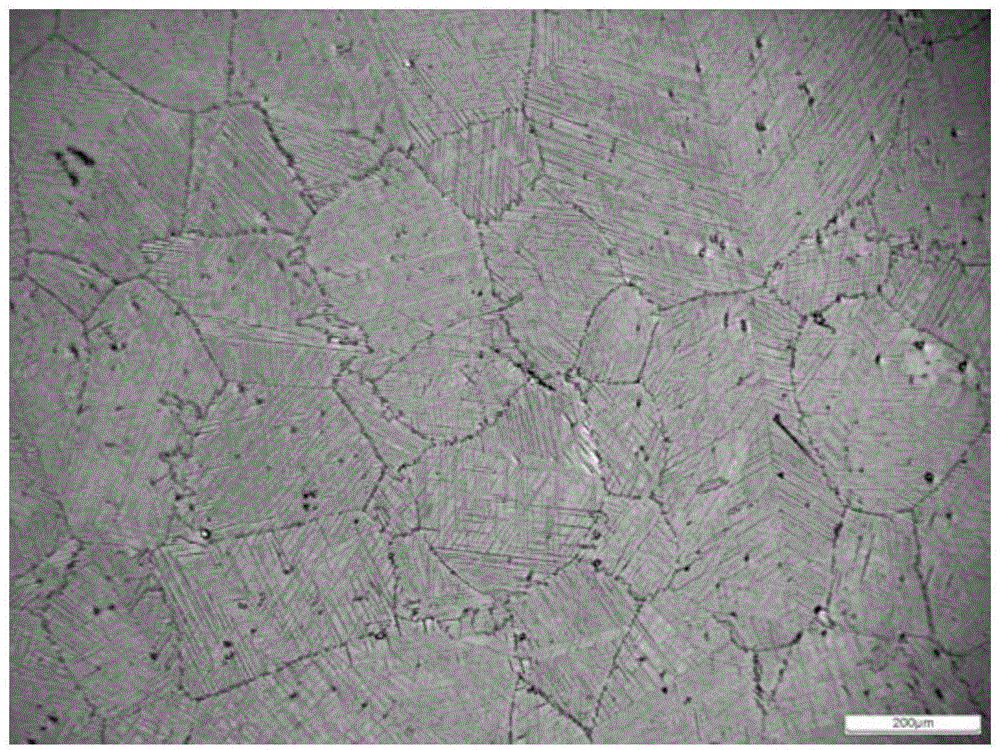

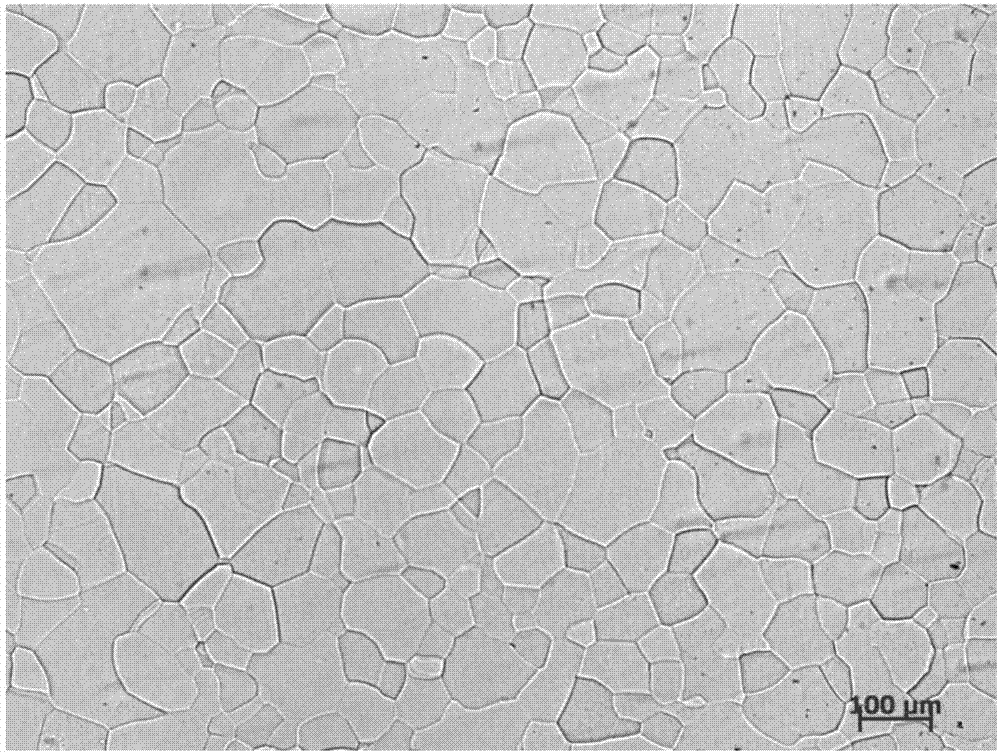

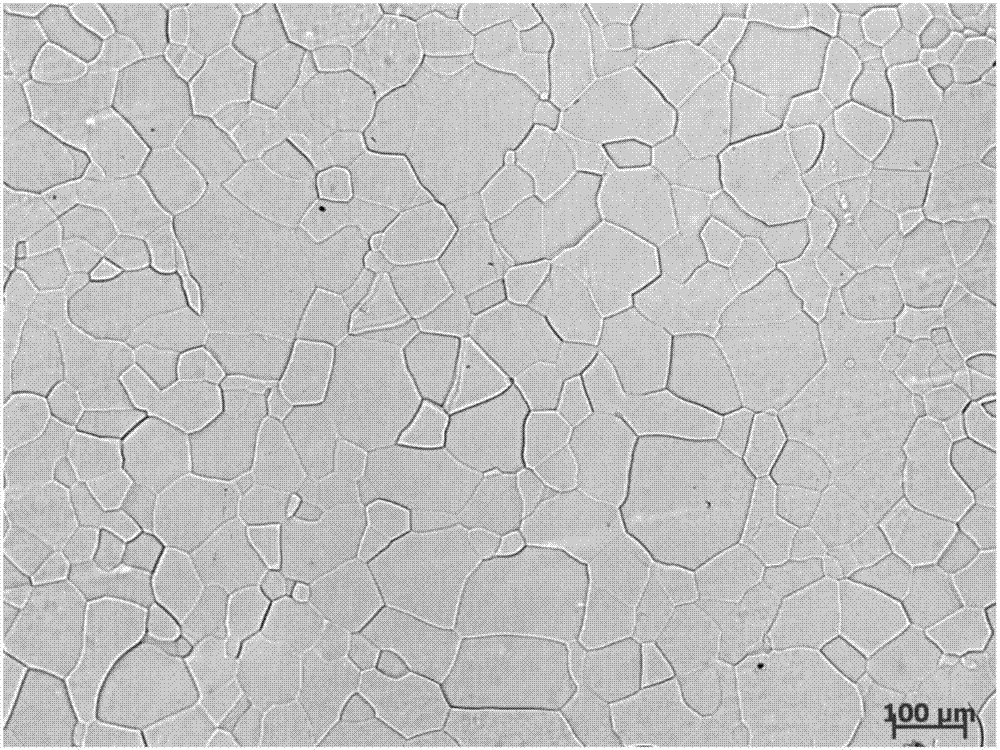

Metallographic etchant capable of clearly displaying delta phase in GH4169 alloy and application method

InactiveCN110455605AΔ phase appearance is clearSuitable for analysis and researchPreparing sample for investigationMaterial analysis by optical meansCopper chlorideMicroscopic observation

The invention belongs to the technical field of advanced deformed superalloy materials and metallographic analysis and relates to a metallographic etchant capable of clearly displaying a delta phase in a GH4169 alloy and an application method. The etchant is prepared from the following main components of 50-55g of copper chloride, 100-120ml of concentrated hydrochloric acid, 1-3ml of concentratedsulfuric acid and 90-110ml of methanol. The method is characterized by comprising the following steps of grinding and polishing a deformed superalloy sample; preparing an etchant; mixing the etchant;adjusting and controlling the temperature; carrying out etching; cleaning the sample by using flowing clear water; drying the etched surface of the sample with hot air; and observing a delta phase through a metallographic microscope. The etchant provided by the invention is simple and convenient to prepare, the delta phase in the GH4169 alloy can be quickly displayed, the etching effect is good, display of the delta phase is clear, the phenomenon of overetching or uneven etching is avoided, and the metallographic etchant is very suitable for evaluation of the metallurgical quality of GH4169 alloy bars and forging and analysis of the metallurgical defects.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

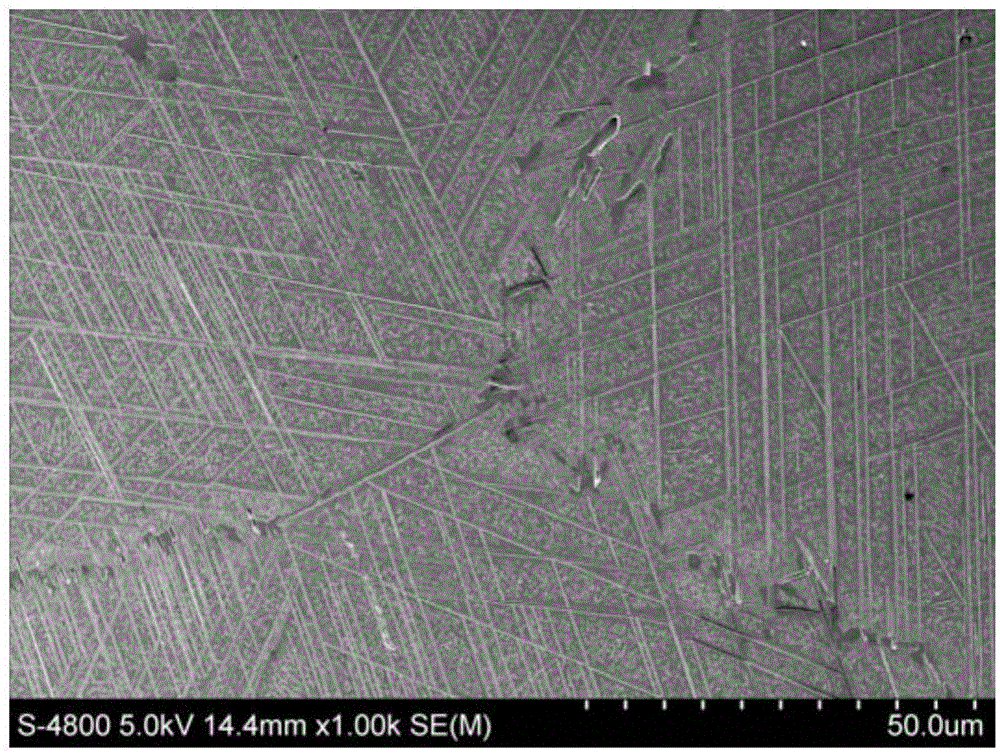

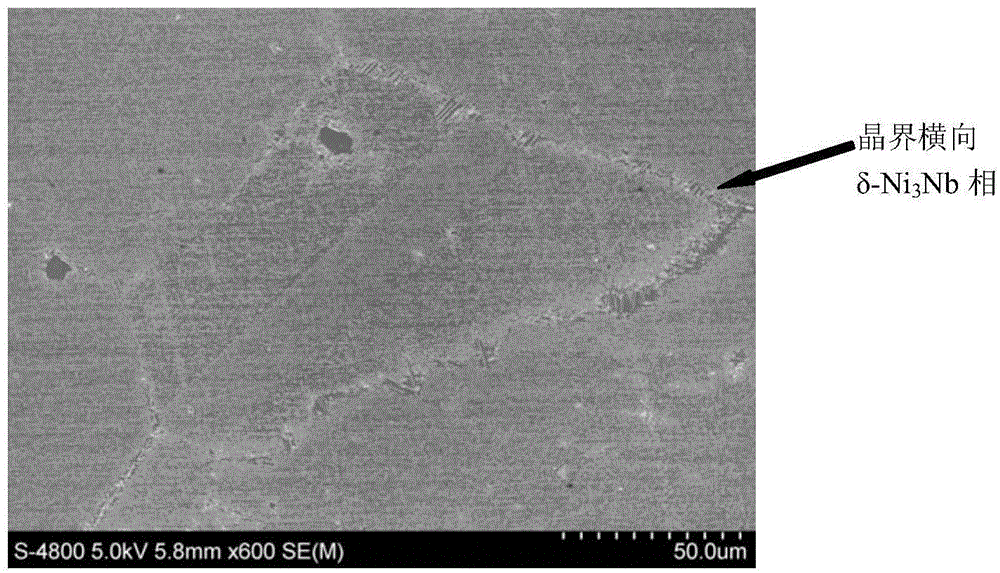

Metallographical corrosive for observing delta-Ni3Nb phase in ferronickel-based superalloy structure and using method of metallographical corrosive

ActiveCN104593775AGood chemical stabilityControl Corrosion RatePreparing sample for investigationSuperalloyCopper sulfate

The invention discloses a metallographical corrosive for observing delta-Ni3Nb phase in a ferronickel-based superalloy structure and a using method of the metallographical corrosive. The metallographical corrosive comprises the following components by volume fraction: 26-33% of hydrochloric acid, 30-37% of nitric acid, 13-18% of hydrofluoric acid and 12-31% of ethyl alcohol; every 100 mL of the metallographical corrosive contains 2g of oxalic acid and 1g of copper sulfate; the mass percentage concentration of the hydrochloric acid is 36%; the mass percentage concentration of the nitric acid is 68%; the mass percentage concentration of the hydrofluoric acid is 40%; the copper sulfate is anhydrous copper sulfate; the ethyl alcohol is anhydrous ethyl alcohol; and the selected chemical reagents are analytical reagents. The using method comprises the following steps: coating the prepared metallographical corrosive on the metallographical surface of a ferronickel-based superalloy sample; chemically corroding for 5-8 seconds; washing and drying the metallographical corrosive on the metallographical surface by clear water and alcohol; and observing the delta-Ni3Nb phase in the microscopic structure through an optical microscope and a scanning electron microscope.

Owner:CHINA HUANENG GRP CO LTD +1

Biological tissue fixing agent and preparation method thereof

InactiveCN102246742AEasy to carryConvenient remote mailingDead animal preservationBiological tissueGlycerol

The invention discloses a biological tissue fixing agent and a preparation method thereof. The biological tissue fixing agent comprises the following components in percentage by weight: 1-10% of formaldehyde, 1-10% of agar, 0.5-5% of glycerol, 0.2-1% of NaH2PO4, 0.5-2% of Na2HPO4 and the balance of water. The biological tissue fixing agent disclosed by the invention is gelatinous, overcomes the defects of a liquid fixing agent, is convenient in carrying and long-distance mailing, can not leak in a non-tight container, can not cause insufficient fixation resulting from tissue floatation or adherence or the like when tissues are put in the biological tissue fixing agent, is used for fixing needle biopsy tissues, can keep perfect tissue structures and clear cellular morphology, and has a good fixing effect. In the invention, the preparation method is simple, the cost is low, and the period of validity lasts more than one year.

Owner:THE THIRD AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIV OF PLA

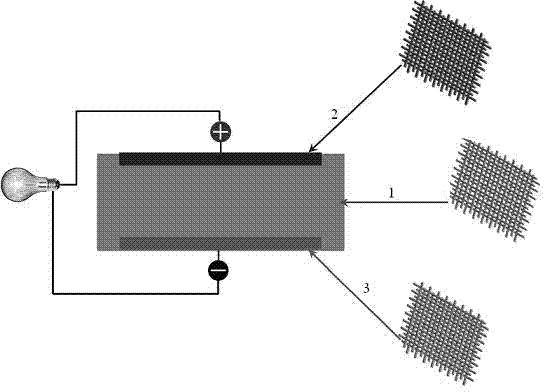

Low-cost high-integrated flexible ultrathin ultralight supercapacitor

InactiveCN103545119ALight in massHigh mechanical strengthHybrid capacitor separatorsHybrid/EDL manufactureFlight vehicleSupercapacitor

The invention relates to a low-cost high-integrated flexible ultrathin ultralight supercapacitor comprising a polymer nanofiber diaphragm, an anode and a cathode. The polymer nanofiber diaphragm is 40-150 micrometers in thickness, and the anode and the cathode are directly made on front and back of the polymer nanofiber diaphragm. Meanwhile, the invention further discloses a production method of the supercapacitor. The supercapacitor is small in size, light in weight and high in energy storing capacity; the production method is simple; the supercapacitor is low in cost, convenient to industrialize and widely applicable to the fields such as lightweight aircrafts, portable energy storage systems, and wearable power systems.

Owner:LANZHOU UNIVERSITY

Method for separating cotton chromosomes

The invention belongs to the technical field of molecular cytogenetics and particularly relates to a method for separating cotton chromosomes, which comprises the following steps: preparing material, preprocessing the material, performing primary hypotonic treatment, performing enzymolysis, performing secondary hypotonic treatment, drying and covering a plate, removing the cover plate, performing chromosome microisolation and collecting the chromosomes. In the method of the invention, the primary hypotonic treatment, emzymolysis, secondary hypotonic treatment and plate covering method are combined to prepare for making a chromosome membrane sheet; cell walls are completely removed; the chromosomes well disperse after being compressed slightly; and the shapes of the chromosomes are so clear as to facilitate the recognition of target chromosomes.

Owner:INST OF COTTON RES CHINESE ACAD OF AGRI SCI

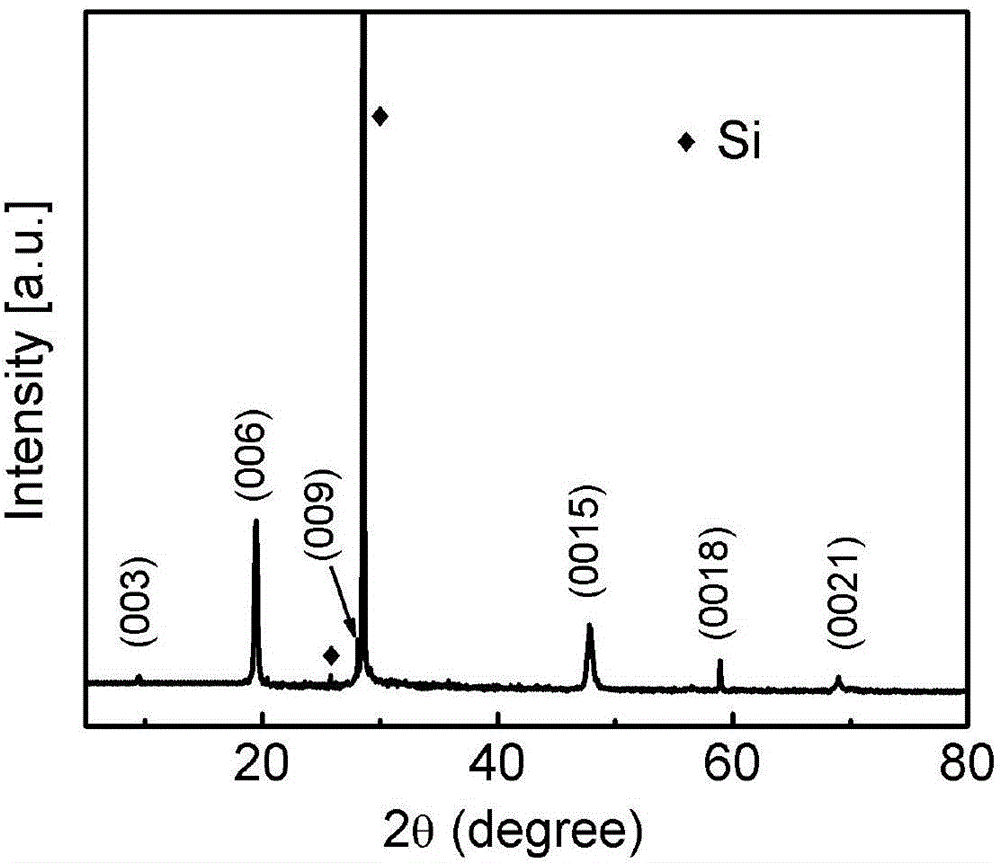

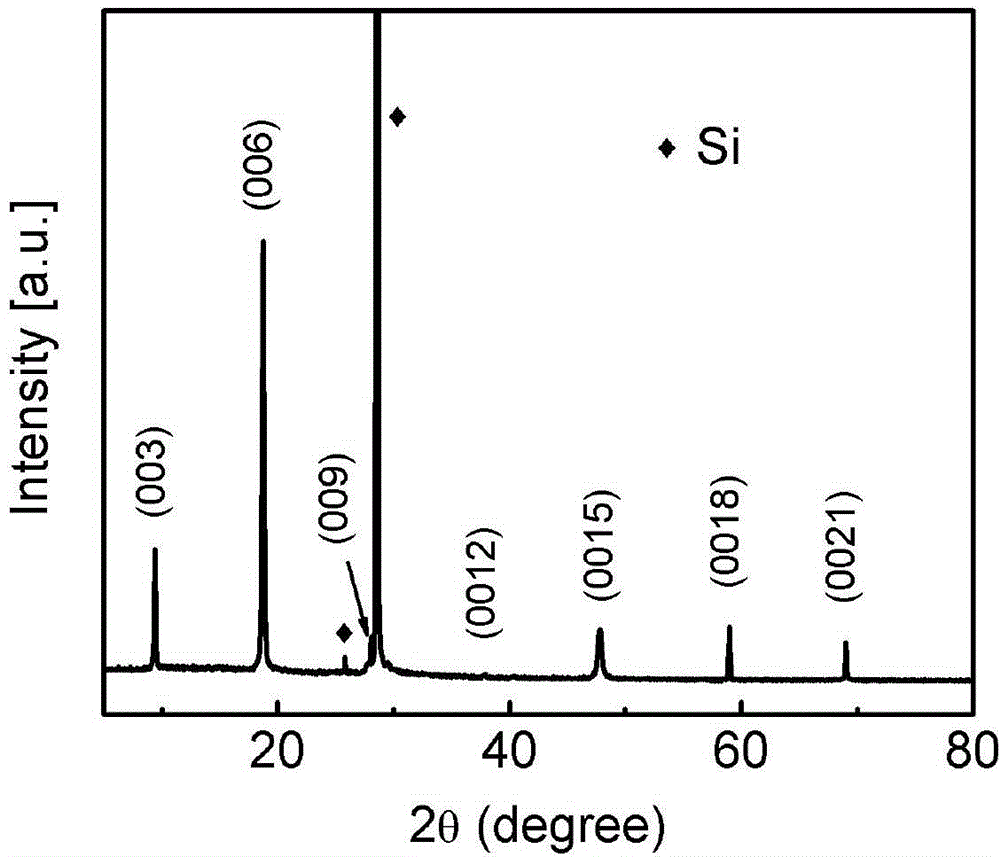

Method for preparing Bi2Se3 thin film by virtue of magnetron sputtering process

ActiveCN104152856AReduced Se vacancy densityClear shapeVacuum evaporation coatingSputtering coatingSputter depositionTube furnace

The invention discloses a method for preparing a Bi2Se3 thin film by virtue of a magnetron sputtering process. The method mainly comprises the following steps: a, substrate cleaning; b, sputtering preparation: drying silicon substrates, putting the silicon substrates on an underlayer, and assembling a Bi2Se3 target material of which the purity is 99.99% on a sputtering target; c, Bi2Se3 thin film sputtering: performing vacuum pumping on a sputtering chamber until the air pressure is less than 2*10<-4>Pa, then introducing 99.995% of argon to ensure that the air pressure of the sputtering chamber is 0.4-0.6Pa and the temperature of the underlayer is 360 DEG C, and performing sputtering deposition for 60-600 seconds at a power of 4-6W / cm<2>; d, post-annealing treatment: sealing deposited silicon substrates and selenium particles into a vacuum quartz tube of which the air pressure is less than 1*10<-2>Pa, putting into a tubular furnace, and performing post-annealing treatment for 2-3 hours at 250-300 DEG C under an argon protective atmosphere to obtain the Bi2Se3 thin film. The method disclosed by the invention is low in vacuum condition requirement, short in preparation time and low in cost.

Owner:中天苏武(苏州)新材料科技有限公司

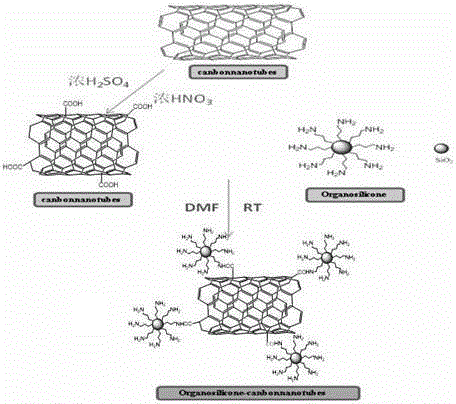

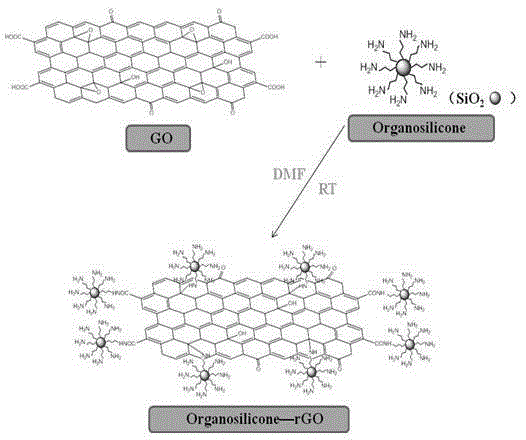

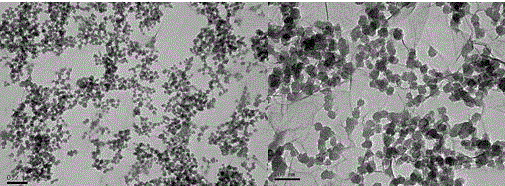

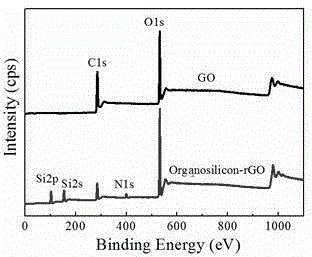

Carbon nanotube rodlike nanocomposite material modified by organic spherical silica and preparation method thereof

ActiveCN105175781ASimple structureShort structural unityInorganic pigment treatmentSilica nanoparticlesCarbon nanotube

The invention discloses a carbon nanotube rodlike nanocomposite material modified by organic spherical silica and a preparation method thereof. The carbon nanotube rodlike nanocomposite material modified by the organic spherical silica is characterized in that organic spherical silica nanoparticles with amidogen react with a carboxyl functional group on the surface of an oxidized carbon nanotube through the amidogen to form amido bond, and therefore covalently-bound carbon nanotube rodlike nanocomposite material modified by the organic spherical silica is obtained, wherein the mass ratio of the oxidized carbon nanotube to the organic spherical silica nanoparticles with the amidogen is 1:2-15, and the organic spherical silica nanoparticles with the amidogen are of a core-shell structure that the surface of the core of silica is coated with the amidogen. The technology is easy and convenient to implement, the reaction period is short, the obtained material is regular in structure, clear in appearance, high in productivity and purity and good in stability, has the certain organic compatibility and can be used for polymer modification prepared high-performance nanocomposite materials such as thermosetting resin, thermosetting resin and rubber. The method is compact in technology, low in cost and short in reaction time, and the product is good in structure oneness and suitable for large-scale industrial production.

Owner:SHANGHAI UNIV

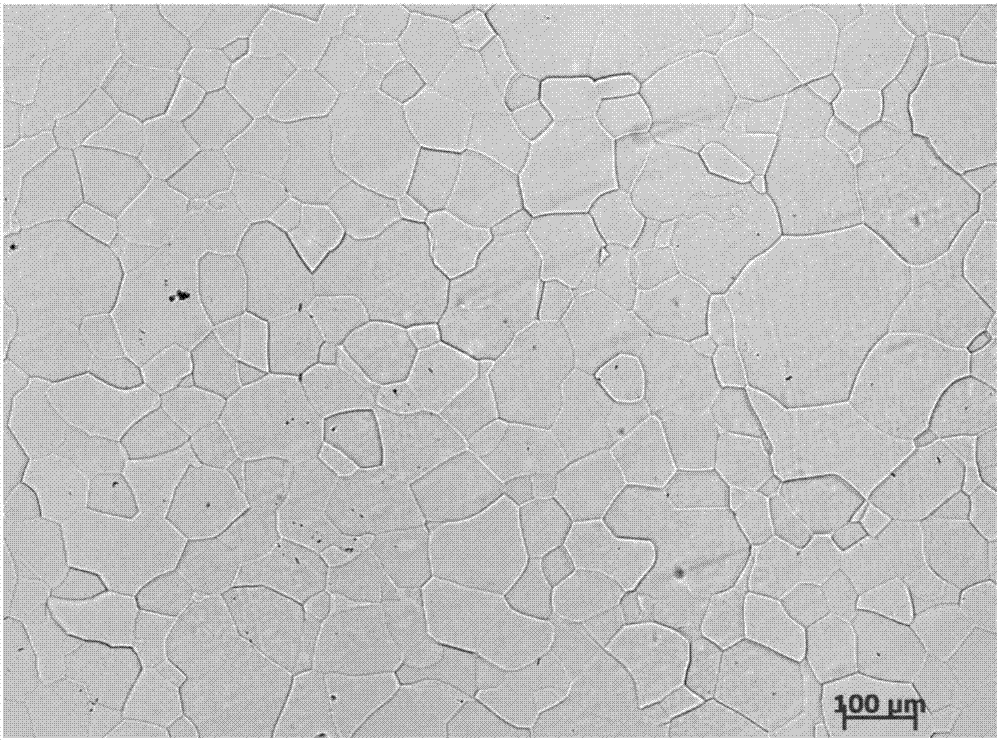

Electrolytic corrosive agent and corrosion method for displaying metallographic structure of high-purity aluminum

InactiveCN106987893ASimple compositionLow pricePreparing sample for investigationHydrogen fluorideElectrolysis

The invention discloses an electrolytic corrosive agent and corrosion method for displaying the metallographic structure of high-purity aluminum. The electrolytic corrosive agent is a mixture of the 40% hydrogen fluoride solution, boric acid and distilled water, wherein the ratio of the 40% hydrogen fluoride solution (ml) to the boric acid (g) to the distilled water (ml) is 18-23 to 2.5-3 to 200. The corrosion method comprises the following steps: (1) cleaning the surface of a sample before electrolytic corrosion; (2) preparing the electrolytic corrosive agent; (3) using the corrosive agent prepared in the step (2) for carrying out electrolytic corrosion according to specific electrolysis parameters; and (4) after electrolytic corrosion, cleaning the sample. According to the electrolytic corrosive agent and corrosion method, the corrosion effect is obvious, the operation is simple, the corrosion efficiency is high, the metallographic structure after corrosion can be clearly seen under a common optical microscope, a professional polarization device does not need to be additionally arranged, the experiment cost is reduced, and convenience is provided for better observing the structure texture of the high-purity aluminum.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

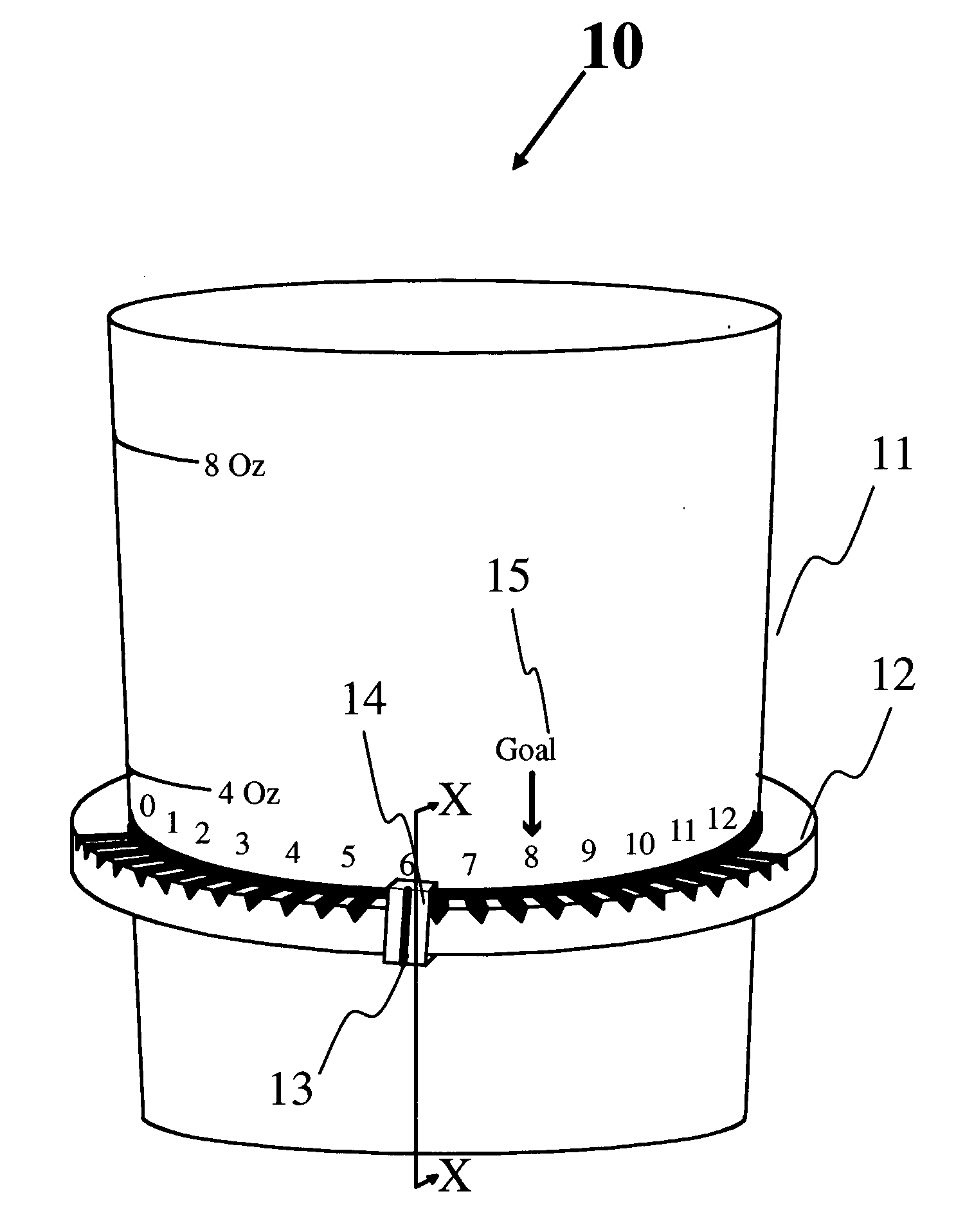

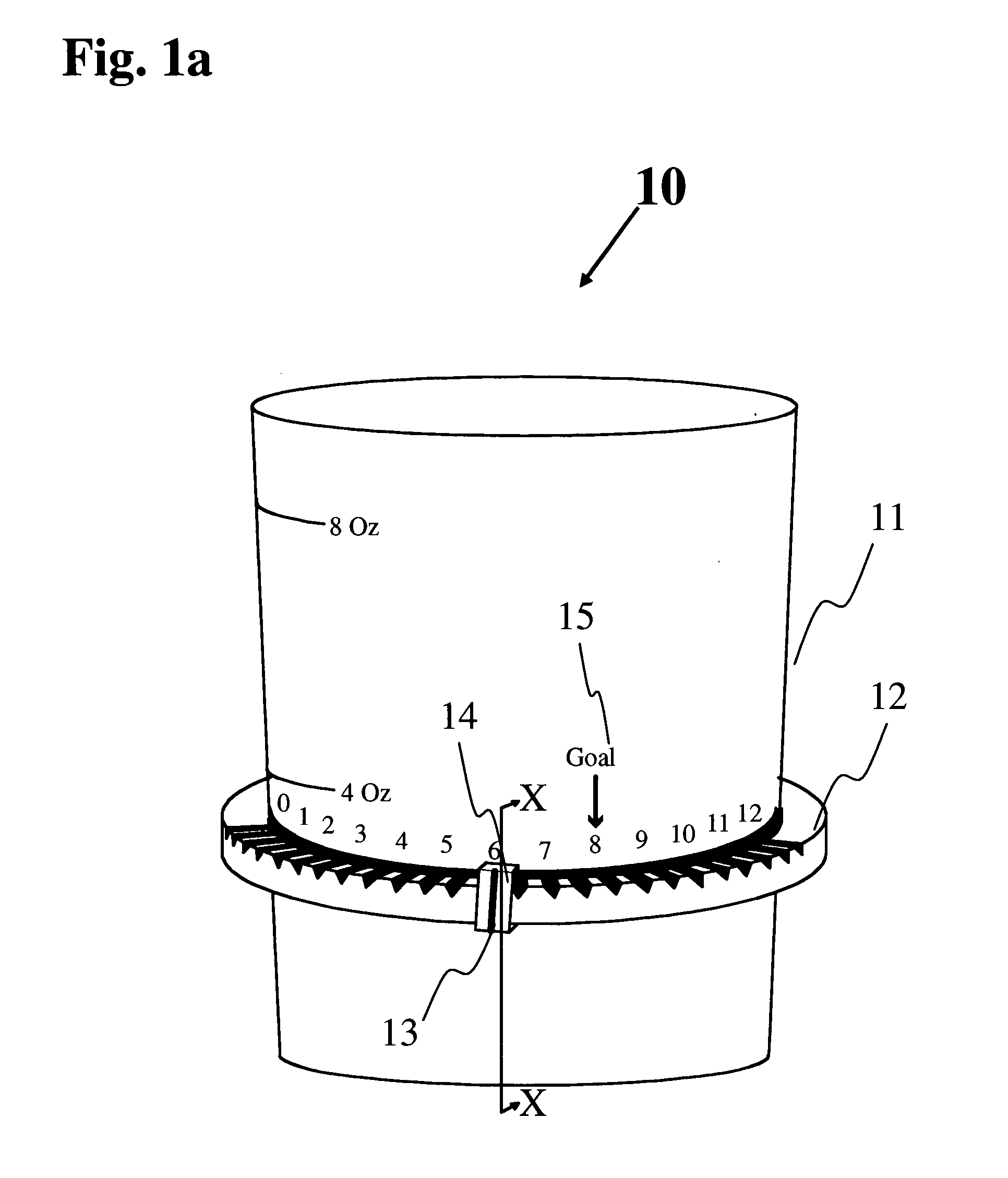

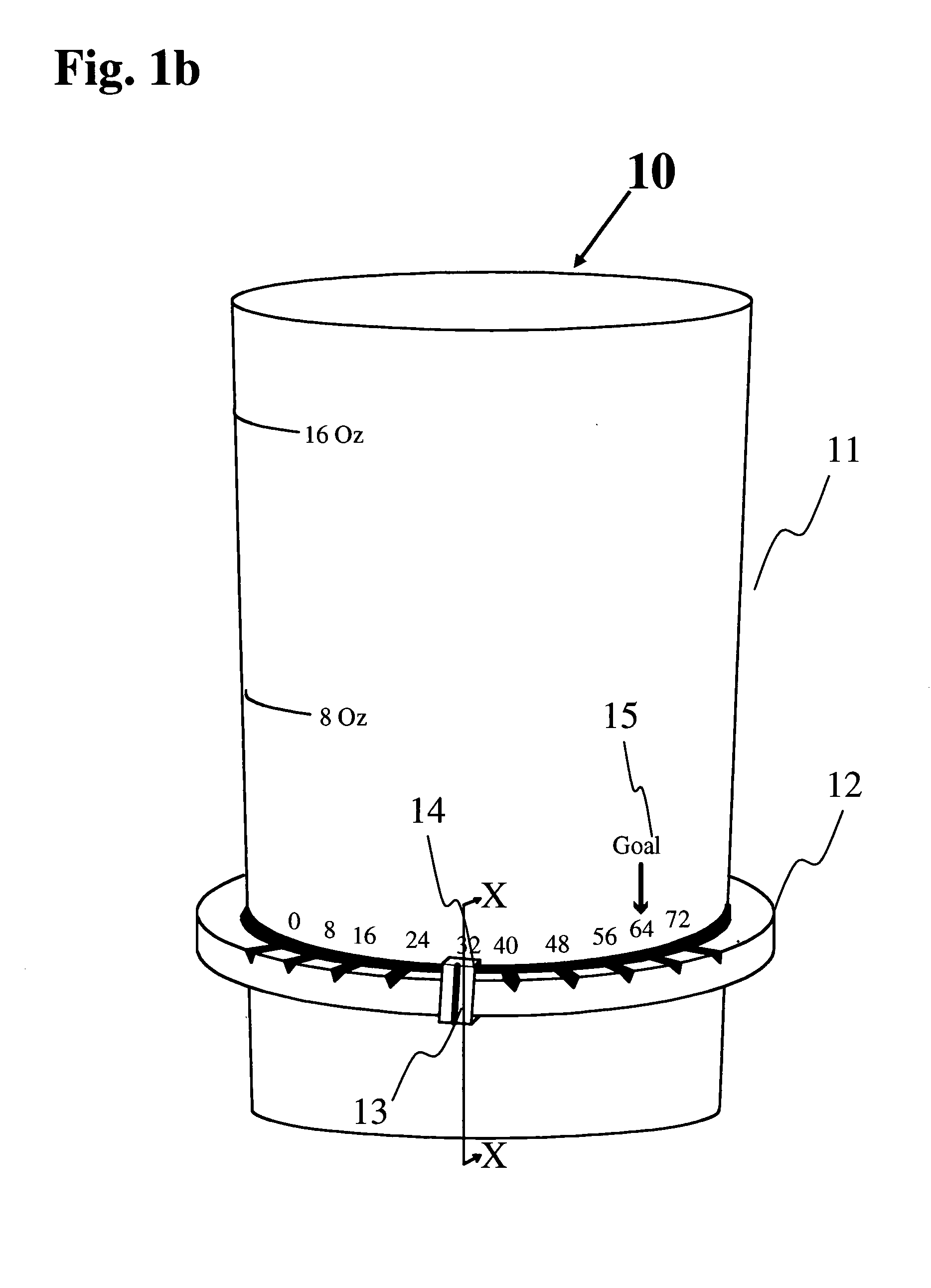

Dieter's water intake quantity tracking vessel

InactiveUS20080257898A1Avoid accidental removalNot accidentally displacedDrinking vesselsIdentification meansMarine engineeringWater intake

A drinking vessel for dieters keeps track of water consumed during a 24-hour period using liquid level markers for 4, 8, 16 or 24 ounce water consumption. The vessel is preferably a glass having an integrally attached T cross section ring over which is moved a rider carrying a marker that points to an indicia on the glass outer surface The rider has a V shaped projection that engages with one of a plurality of notches present on the upper surface of the T cross section ring. Engagement between the rider and the V shaped projection is secured by a spring within the rider, preventing accidental displacement thereof. The user drinks water, pushes the rider upwards to clear the projection of the rider from the notch of the ring, and advances the rider according to volume of water consumed. The position of rider tracks the volume of water consumed during a 24-hour period. The rider may be removed and replaced after cleaning the drinking glass. Tracking of water consumption remains accurate and reliable over a prolonged period of time despite repeated cleaning of the vessel in domestic or commercial dishwashers.

Owner:POLLIO MICHAEL J

Surface-modified silica/oxidized graphene nanocomposite and preparation method thereof

The invention discloses a surface-modified silica / oxidized graphene nanocomposite and a preparation method thereof. The nanocomposite is prepared as follows: amide bonds are formed between silica nanometer particles with amino groups and a two-dimension oxidized graphene sheet by reaction between amino groups as well as carboxyl groups and epoxy functional groups which are at double sides of the two-dimension oxidized graphene sheet, in order to obtain the silica / oxidized graphene nanocomposite with covalent binding. The preparation method has the advantages of simple and easy technology and short reaction time; the nanocomposite has the advantages of regular structure, clear morphology, high yield, high purity, good stability and good organic dissolvability; the nanocomposite can be applied to high-molecular modification preparation of thermosetting resin, thermoplastic resin, rubber and other high-performance nanocomposites; the preparation method has the advantages of compact process, low cost, short reaction time and good identity of product structure, and the method can be applied to large scale industrial production.

Owner:SHANGHAI UNIV

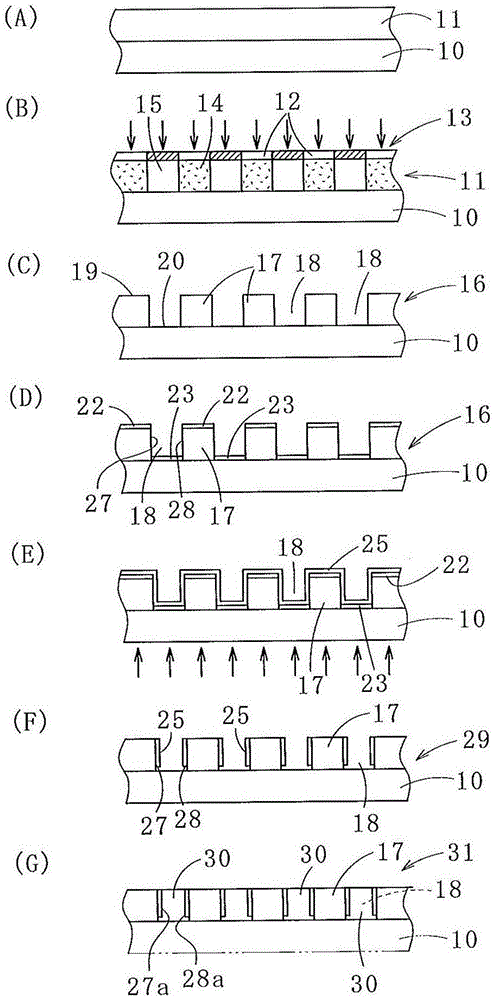

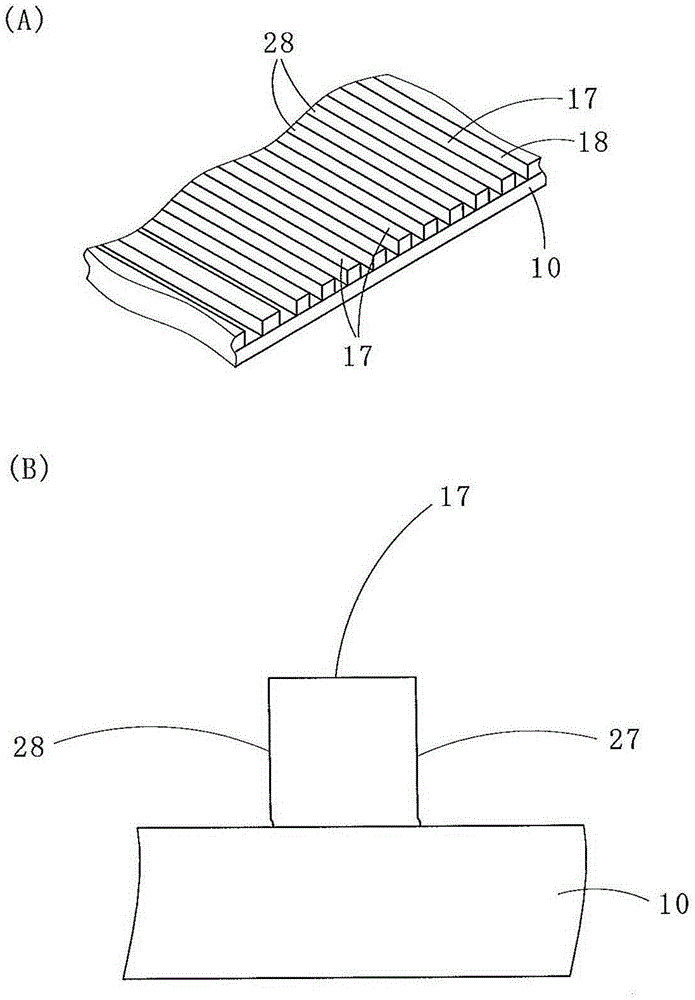

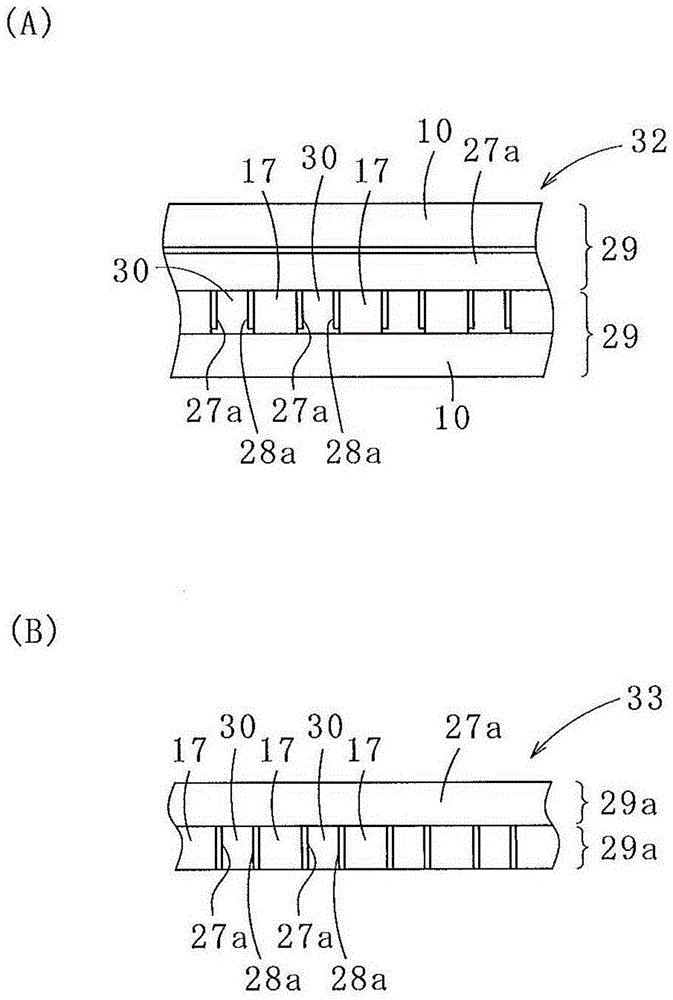

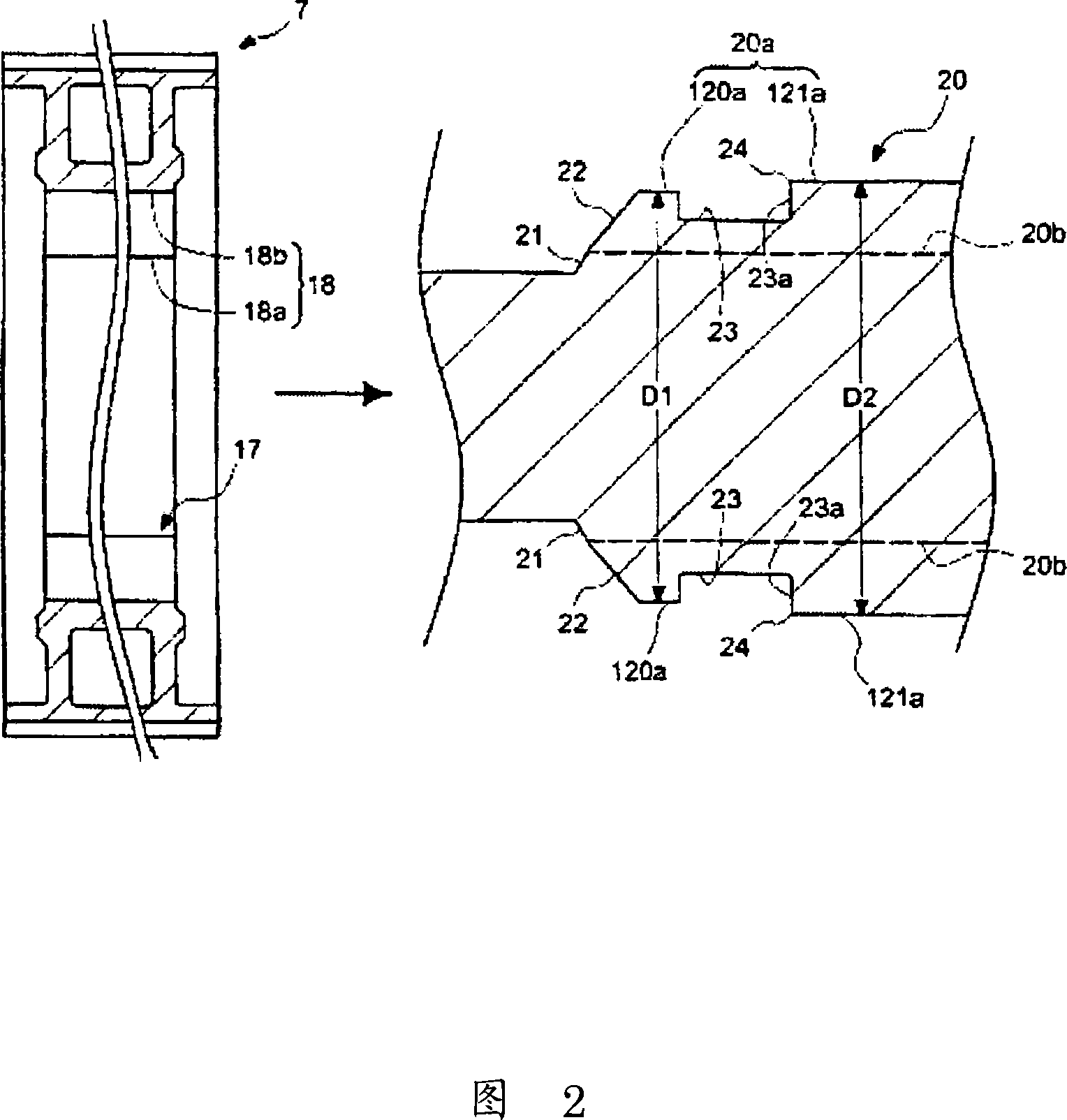

Method for fabrication of photo-control panel comprising photo-reflector parts which are positioned in parallel

InactiveCN104937448AEasy to manufactureCheap manufacturingMirrorsOptical articlesUltravioletEngineering

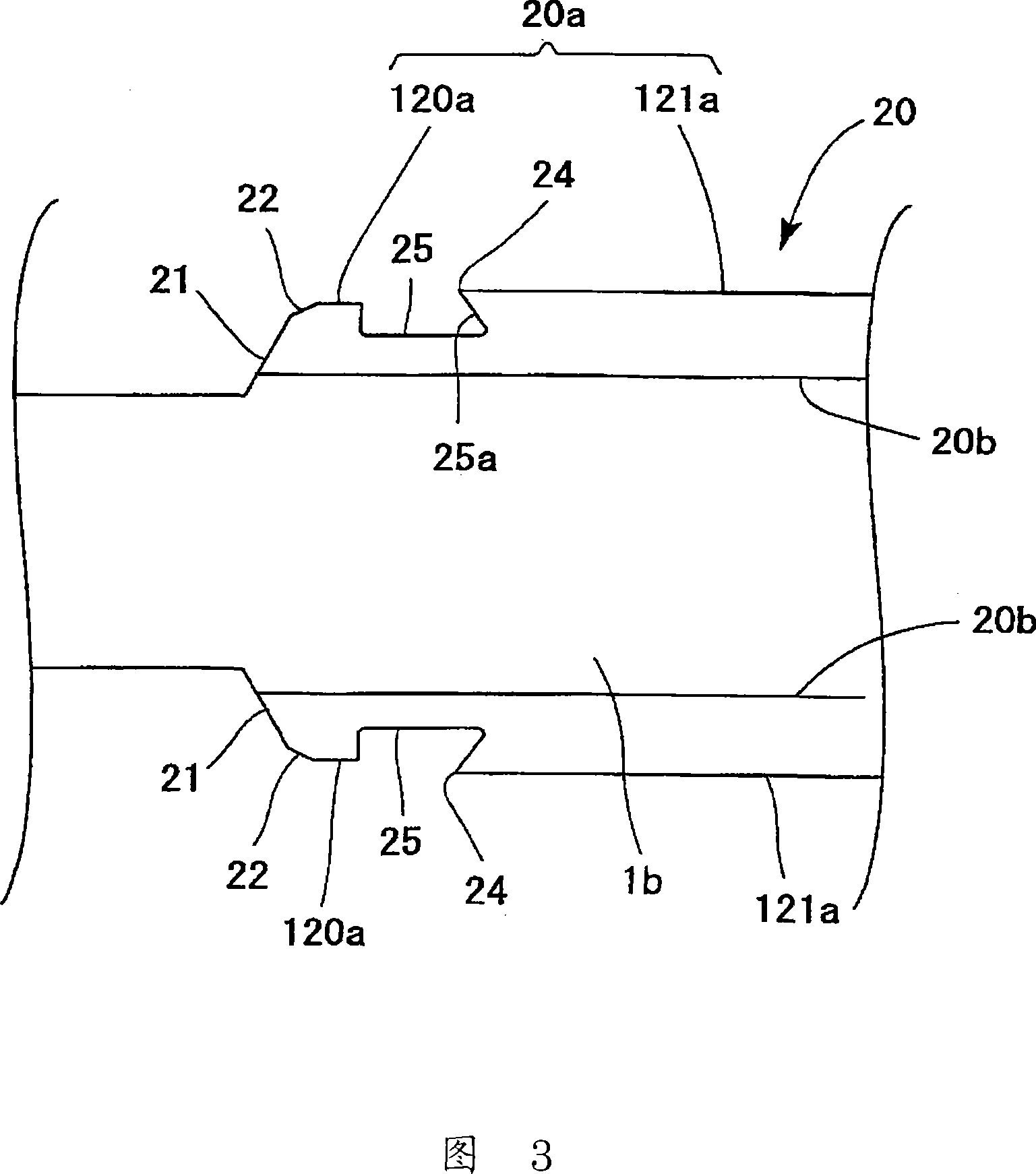

Provided is a method for fabrication of a photo-control panel, comprising: a first step of preparing a transparent uneven board (16) with quadrilateral cross-section depressions (18) which are formed by parallel banks (17) thereof; a second step of covering obverse faces (19) of the banks (17) and bottom faces (20) of the depressions (18) with ultraviolet projection peeling resins (22, 23); a third step of forming metal vapor deposition upon the obverse face of the uneven board (16) whereupon the obverse faces (19) of the banks (17) and the bottom faces of the depressions (18) are covered with the ultraviolet projection peeling resins (22, 23); and a fourth step of projecting ultraviolet from the rear face of the uneven board (16), and removing the ultraviolet projection peeling resins (22, 23), the obverse faces whereof have had the metal vapor deposition carried out thereupon. Photo-reflector parts are formed upon parallel opposing lateral faces (27, 28) of the depressions (18).

Owner:ASUKANET

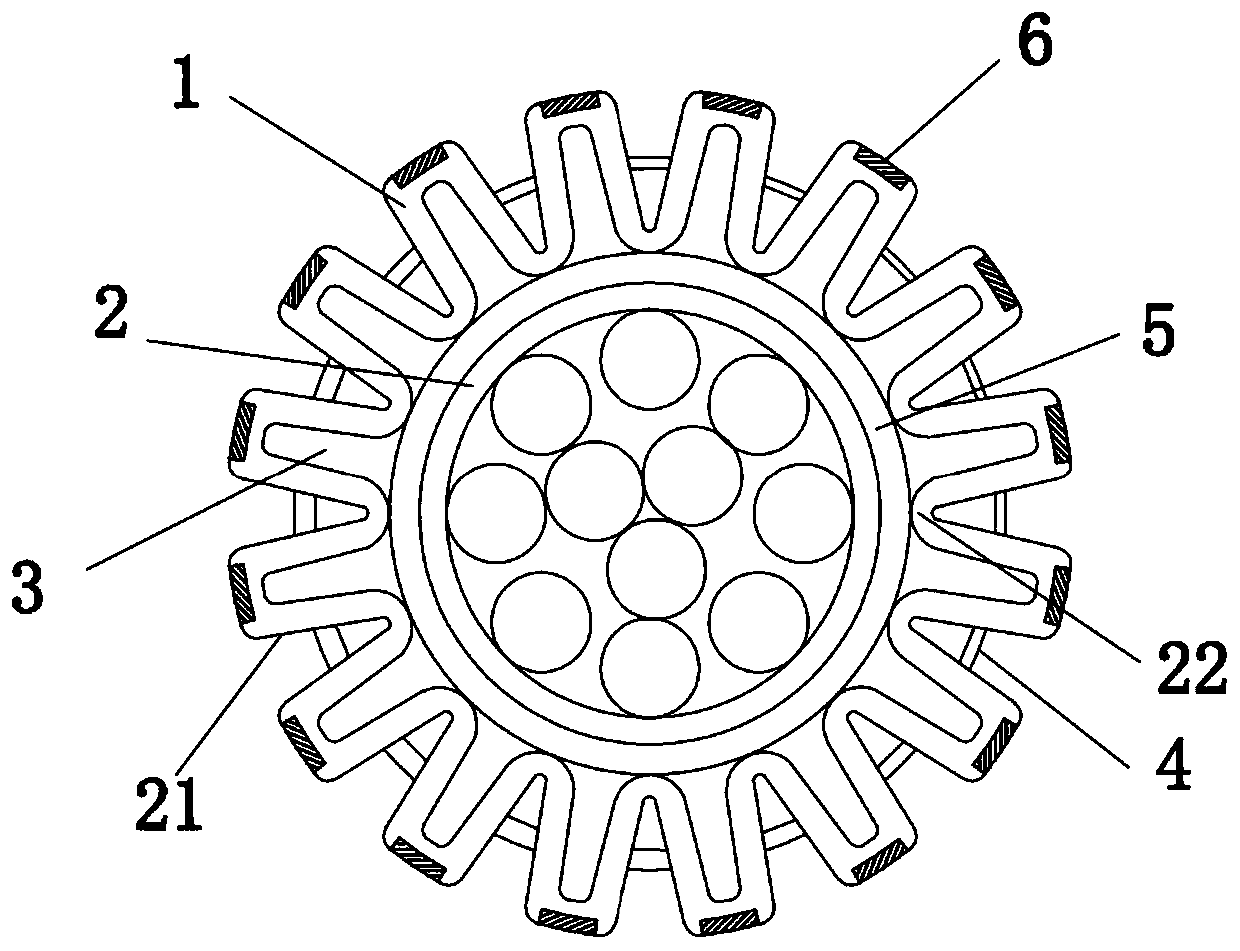

Directly-buried semi-armored cable

ActiveCN109994269AGood flexibilityHigh strengthInsulated cablesInsulated conductorsMetallic materialsEngineering

The invention discloses a directly-buried semi-armored cable, which comprises a cable outer cover layer and an inner core wire arranged in the cable outer cover layer. The cable outer cover layer hasan installation chamber in which the inner core wire is installed. The outside of the inner core wire is coated with an expansion layer. The cable outer cover layer is bent to form more than one support section extending inward. The support sections are arranged in a circle around the cable outer cover layer, and the inner ends of the support sections are in contact with and support the outer wallof the expansion layer. Clamp openings are formed between the support sections. More than one positioning through hole is opened equidistantly on both sides of the inner walls of the clamp openings along the lengthwise direction of the cable outer cover layer. The cable of the invention adopts a semi-armored design, which can save a lot of metal materials and achieve very good protection performance. The whole cable can be expanded after resisting enough pressure, and the inner core wire can be protected by the expansion layer. The directly-buried semi-armored cable is especially suitable forthe field of directly-buried installation.

Owner:浙江亘古电缆股份有限公司

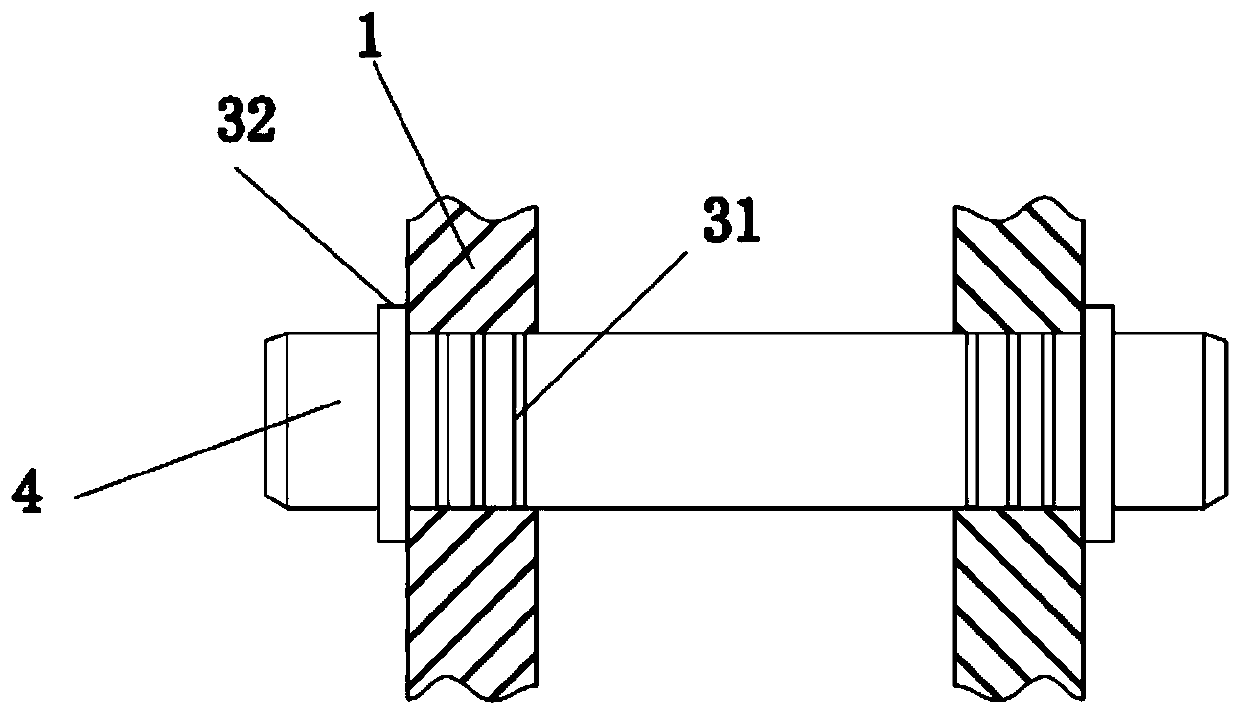

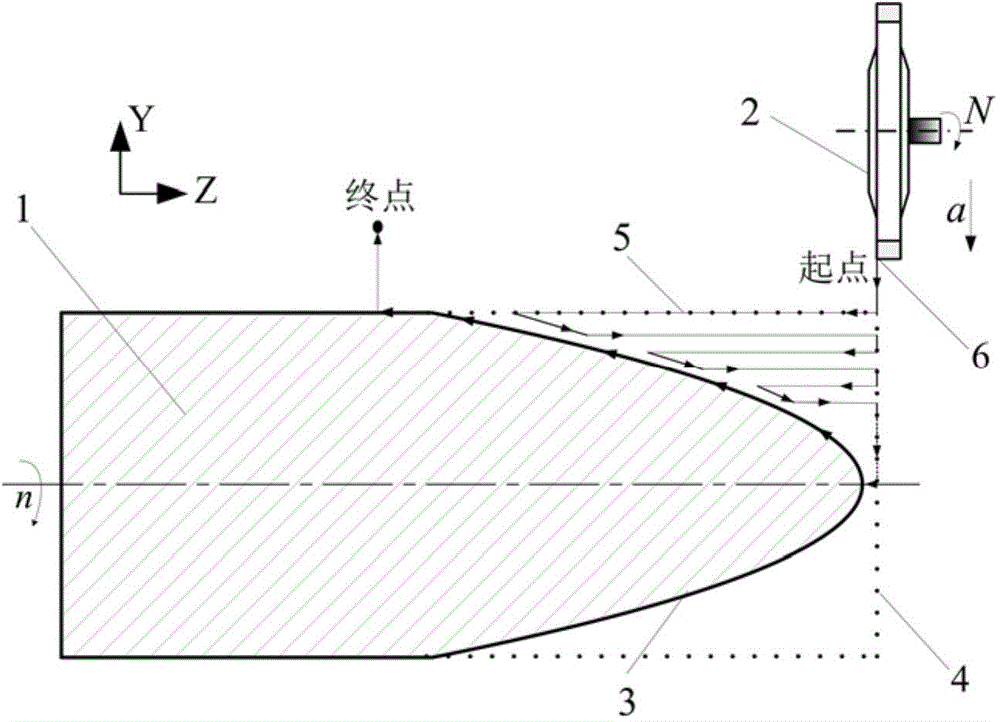

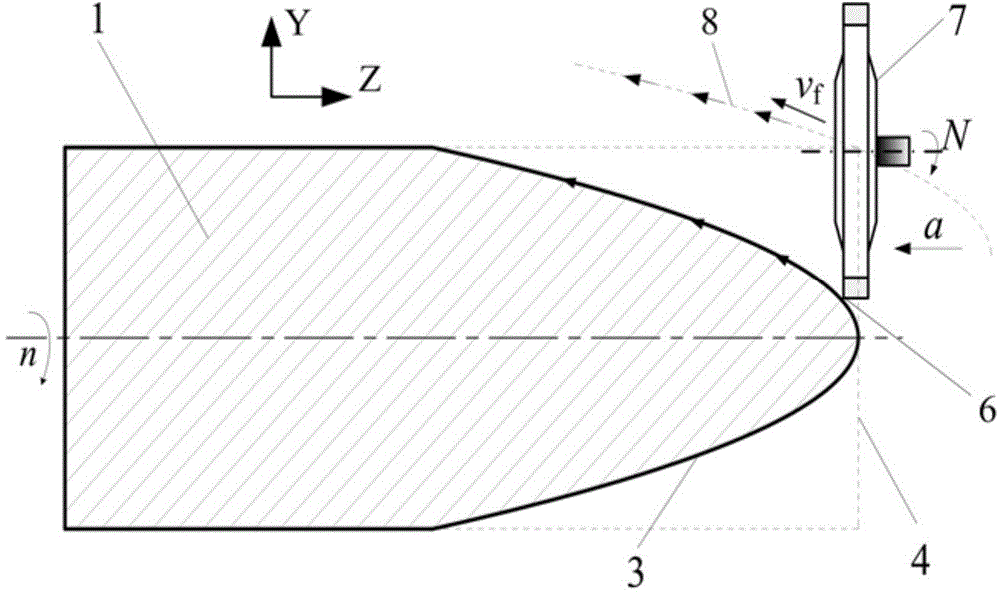

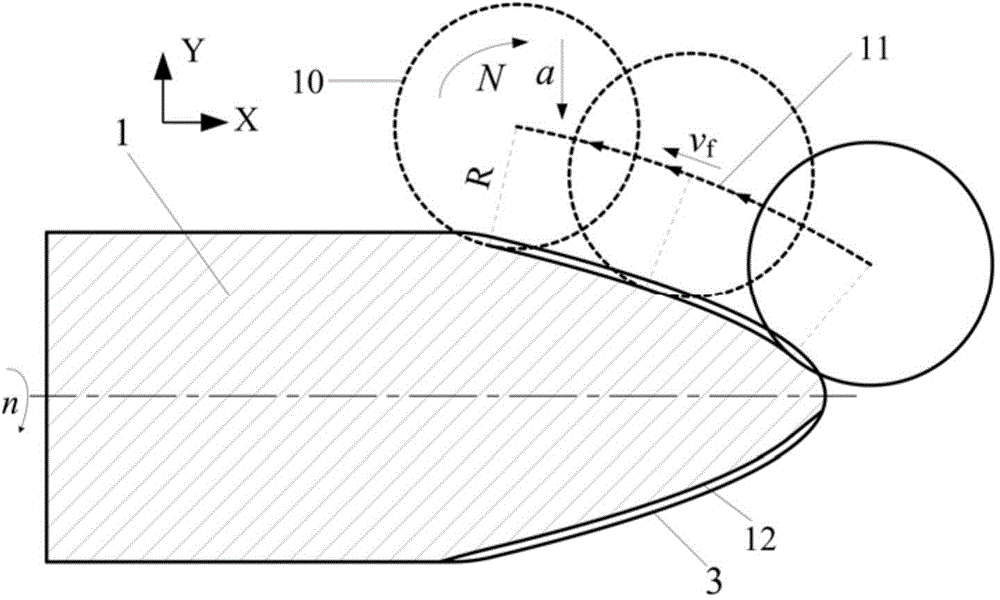

Flying body with curved-surface micro groove structures and manufacturing method of flying body

InactiveCN104647168AClear cornersNeat cornersGrinding machinesAir-flow influencersAerodynamic dragRadar

The invention discloses a flying body with curved-surface micro groove structures and a manufacturing method of the flying body. The flying body comprises a cylinder and a conical head, wherein multiple micro grooves are uniformly distributed at intervals along the axial section of the curved surface of the conical head, and the curved surface is a two-dimensional rotating surface in a parabolic surface or an elliptical surface. During machining, the manufacturing method comprises the steps of firstly machining a cylindrical material into the flying body which is provided with the conical head and has a rough curved surface with a curved surface profile; then machining the rough curved surface into a smooth curved surface along the curved surface profile by utilizing a corner of the annular end surface of a fine-grained diamond grinding wheel; finally axially steering the grinding wheel, enabling the grinding wheel to be vertical to a workpiece rotating shaft or to be in a certain inclination angle relative to the workpiece rotating shaft, enabling a workpiece to be fixed, and carrying out radial feeding along the radial direction of the smooth curved surface profile by utilizing a V-shaped pointed end of the diamond grinding wheel in high-speed rotation so as to machine the micro grooves in the curved surface. According to the manufacturing method disclosed by the invention, the smooth curved surface with the regular and controllable micro groove structures is machined on the flying body, the air resistance of the flying body can be reduced, the laser scattering can be enhanced, and resistance reduction and invisibility of flying can be finally realized.

Owner:SOUTH CHINA UNIV OF TECH

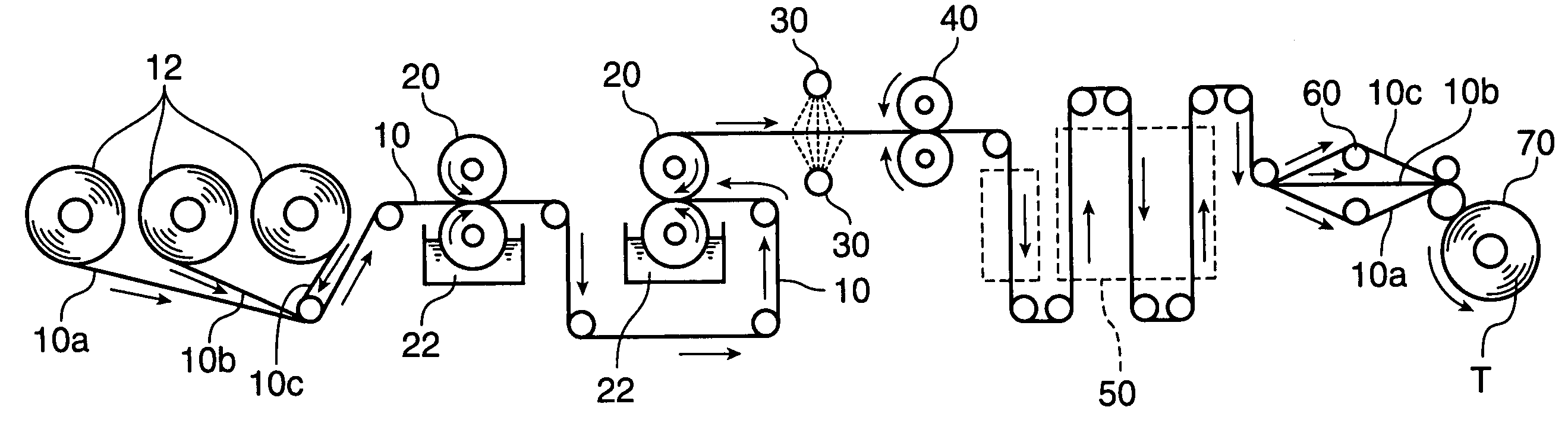

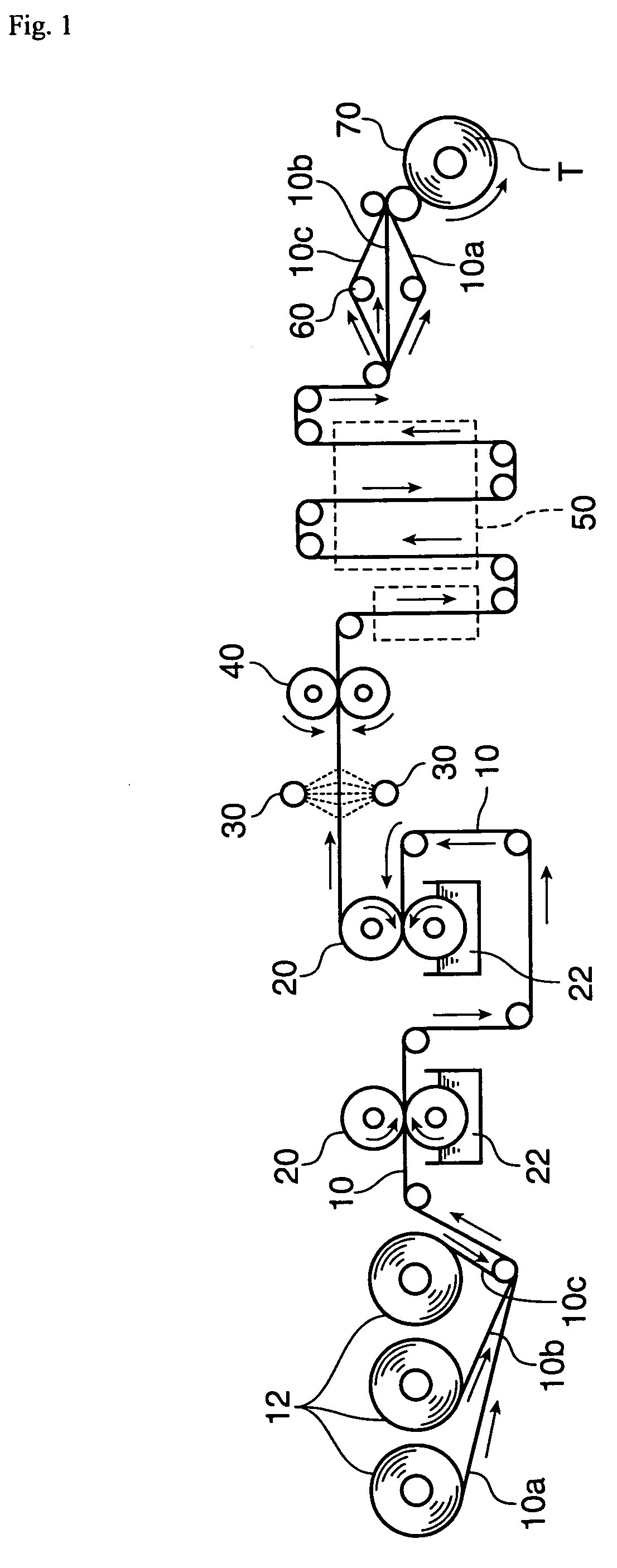

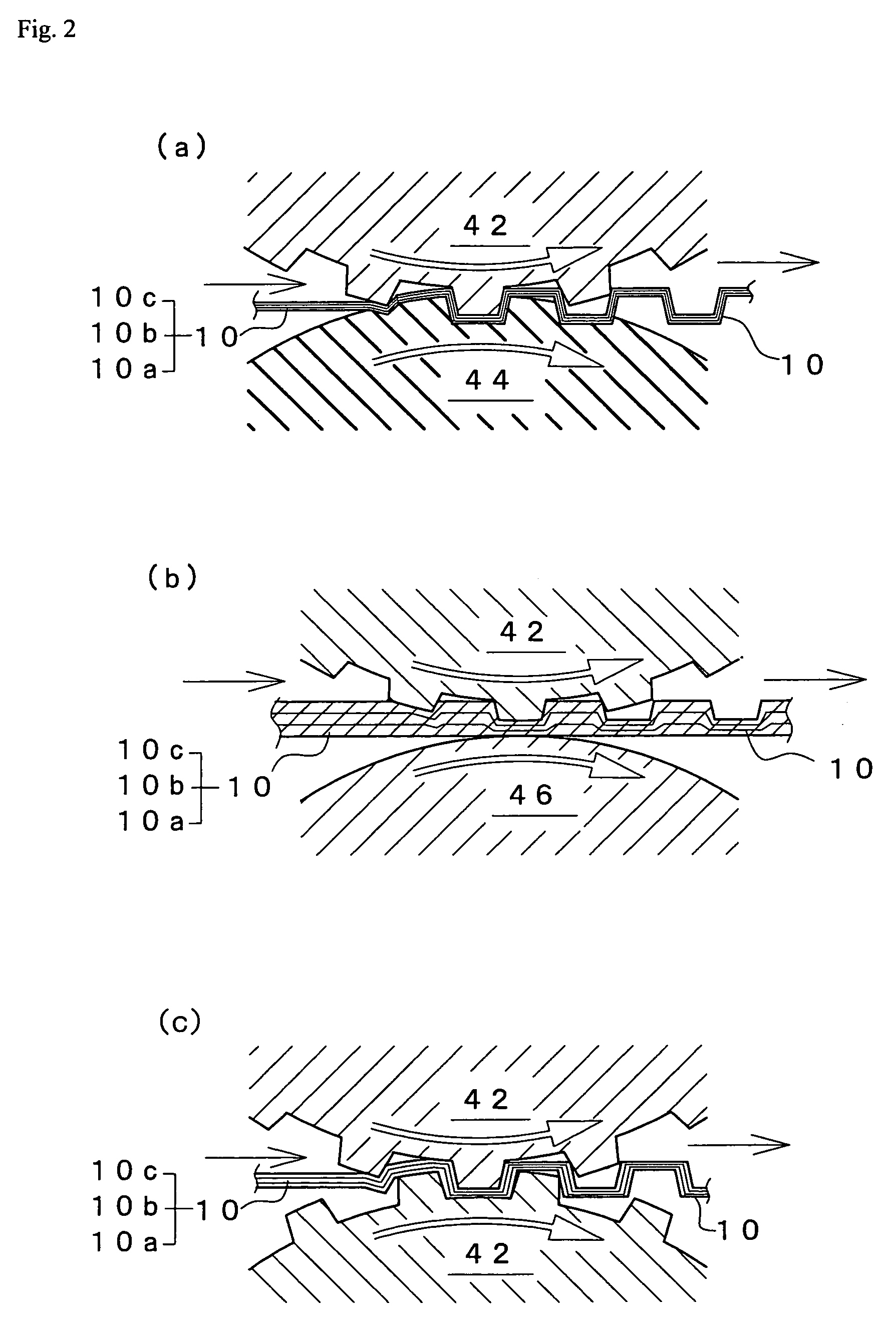

Embossed crepe paper and its manufacturing method

ActiveUS7799167B2Property is spoiled littleDestruction of hydrogen bondingNon-fibrous pulp additionNatural cellulose pulp/paperCrêpe paperPulp and paper industry

An object of the present invention is to provide an embossed crepe paper which can clearly be formed into fine embossed shapes, and is excellent in the fluffy feel and therefore excellent in such as absorbency for fats. As a means of achieving this object, the method for manufacturing an embossed crepe paper, according to the present invention, is a method for manufacturing an embossed crepe paper comprising a step of embossing a raw crepe paper, wherein: a raw paper having a basis weight of 6 to 28 g / m2 is used as the raw crepe paper; and the embossing step includes the steps of: (a) supplying the raw crepe paper with water in an amount of 0.1 to 100 weight % based on the basis weight to thereby put the raw crepe paper in a wet condition; (b) embossing the wet-conditioned raw crepe paper; and (c) drying the embossed wet-conditioned raw crepe paper.

Owner:KAWANO PAPER

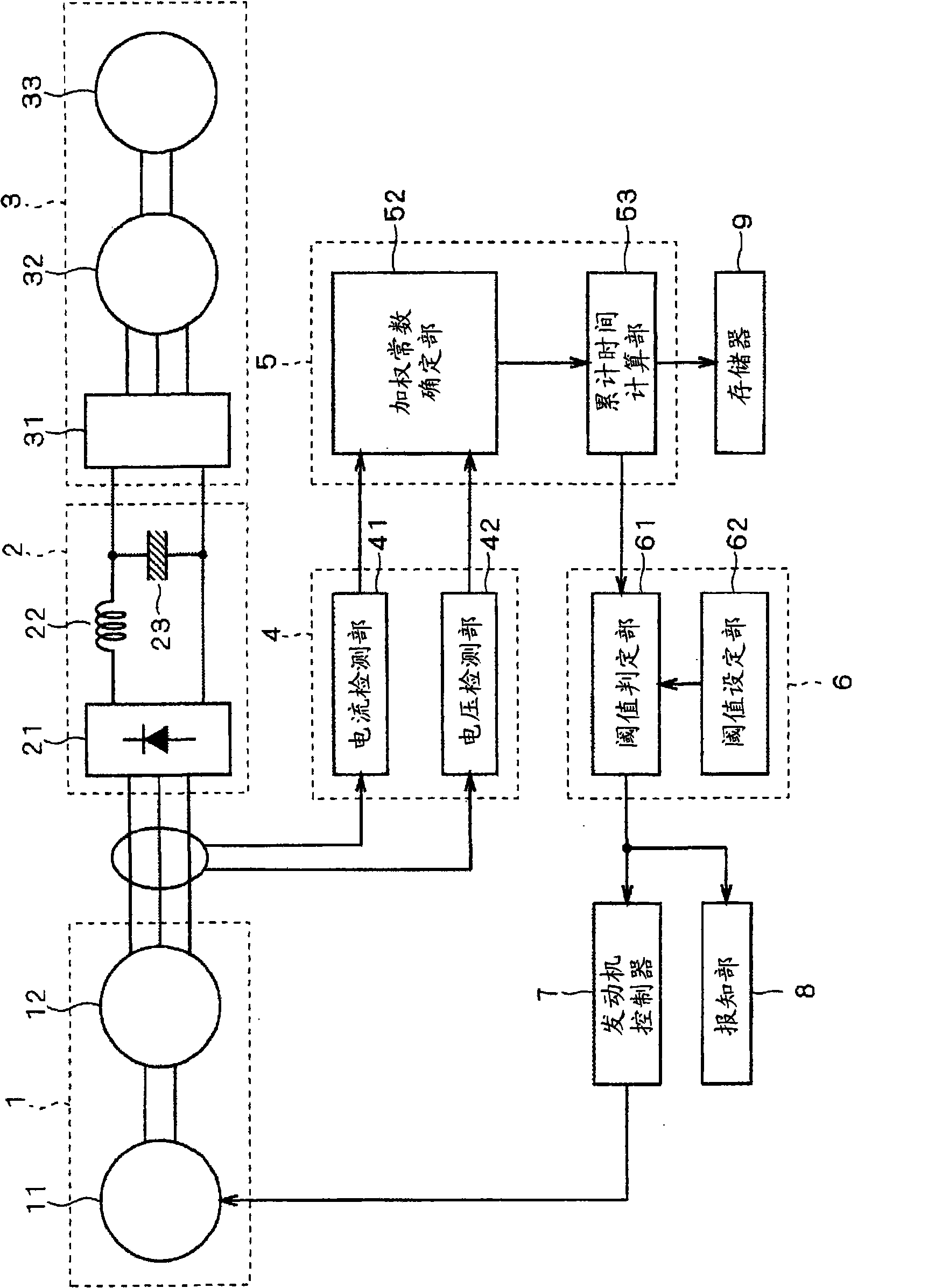

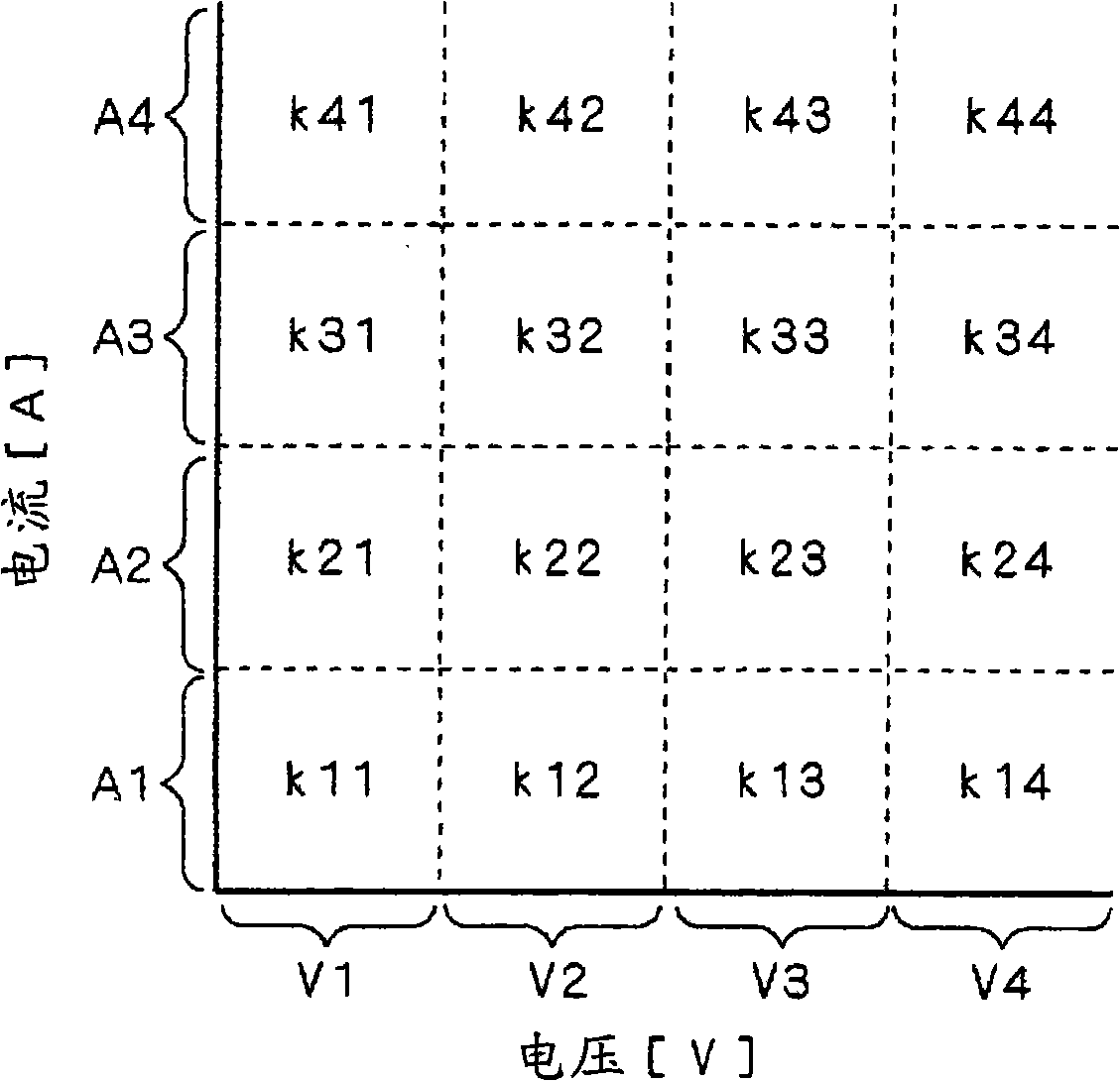

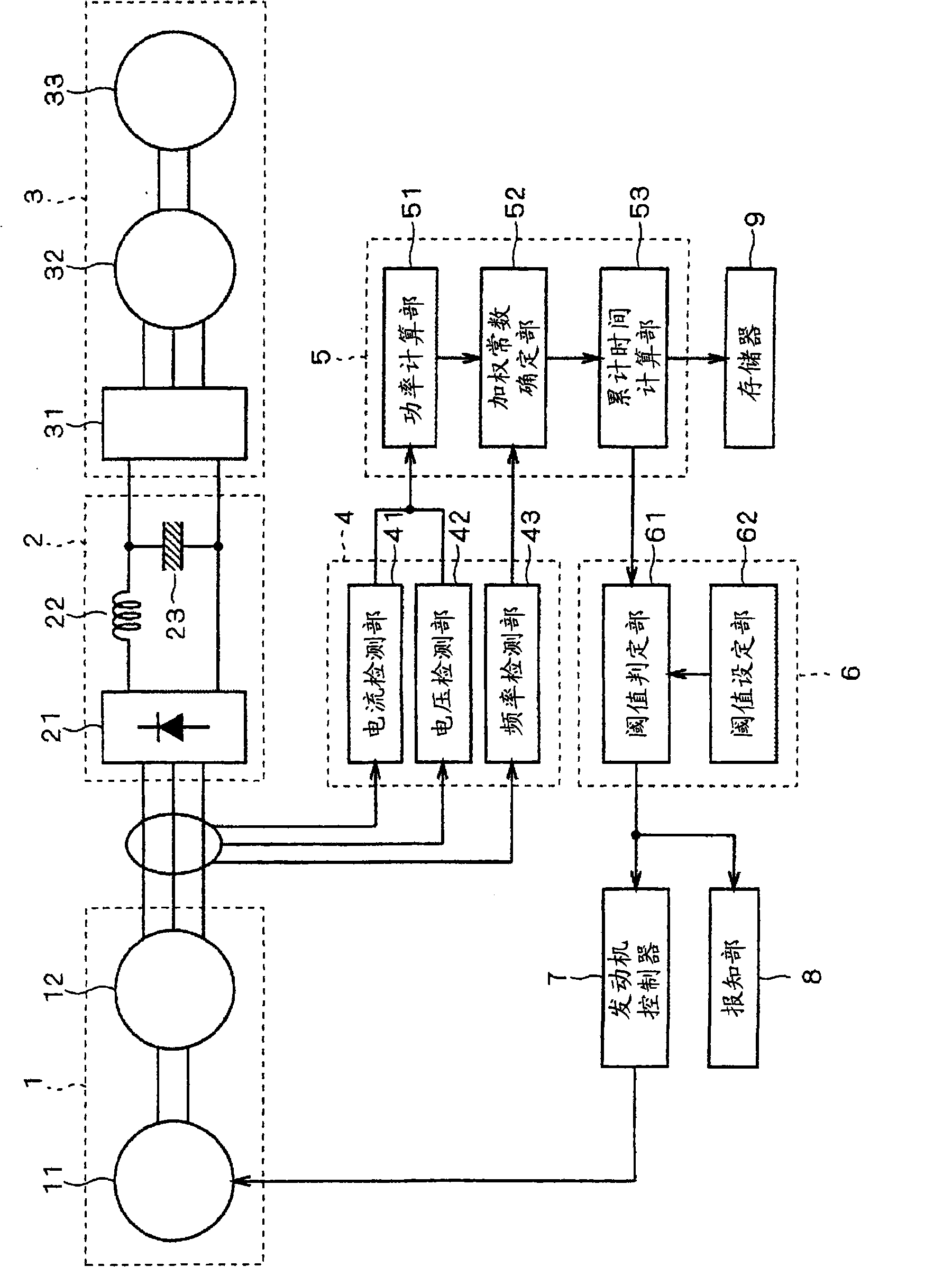

Engine life predication apparatus and refrigerator

InactiveCN101542261ALow costImprove reliabilityEngine testingDomestic refrigeratorsEngineeringRefrigerated temperature

An engine life prediction apparatus produced at a low cost and having a high reliability is provided. A current detecting section (41) and a voltage detecting section (42) detect the value of a current and the value of a voltage which are outputted by an engine generator (1), respectively. An arithmetic section (5) determines a weight constant from the current value and the voltage value, assigns the weight to the operating time of an engine (11) by using the weight constant, and integrates the weighted operating time to calculate the integrated time. A judgment section (6) compares the integrated time with a reference time and, when judging that the integrated time exceeds the reference time, notifies it to a report section (8). The report section (8) having received the notification reports it to the outside. The current detecting section (41) and the voltage detecting section (42) can be configured by an electrical circuit. Thus, the engine life can be predicted at the low cost and with the high reliability.

Owner:DAIKIN IND LTD

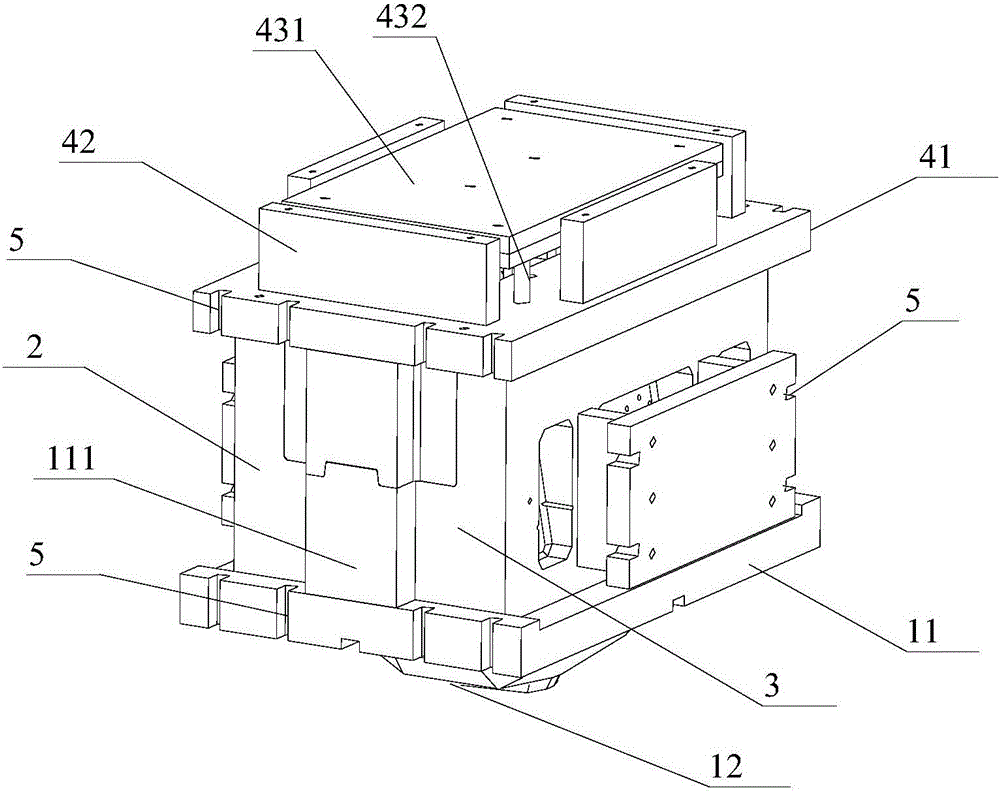

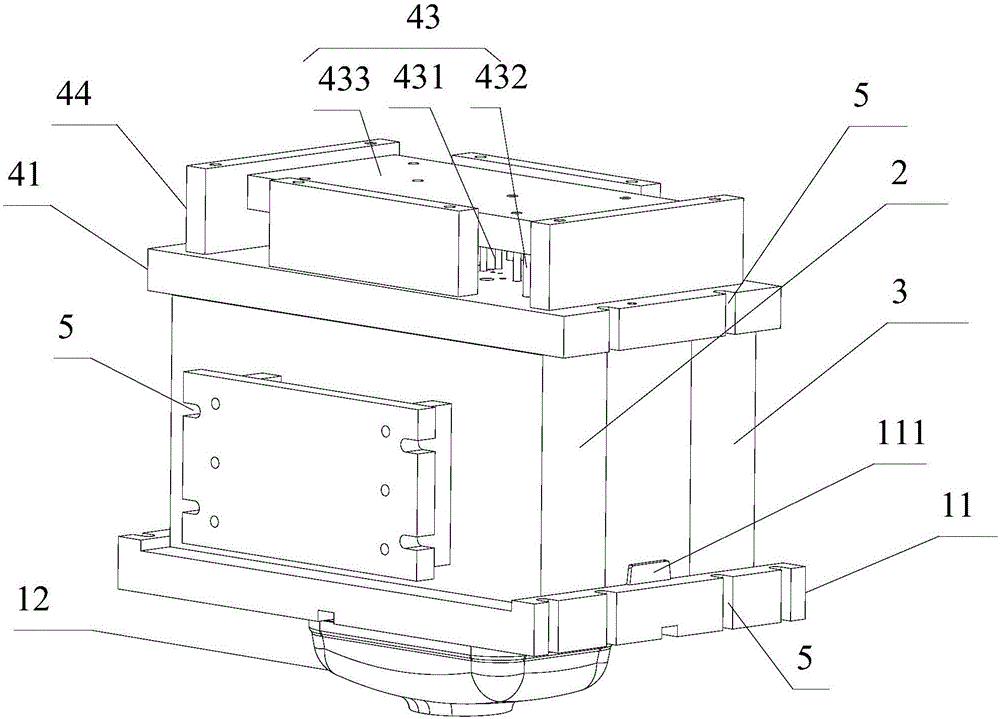

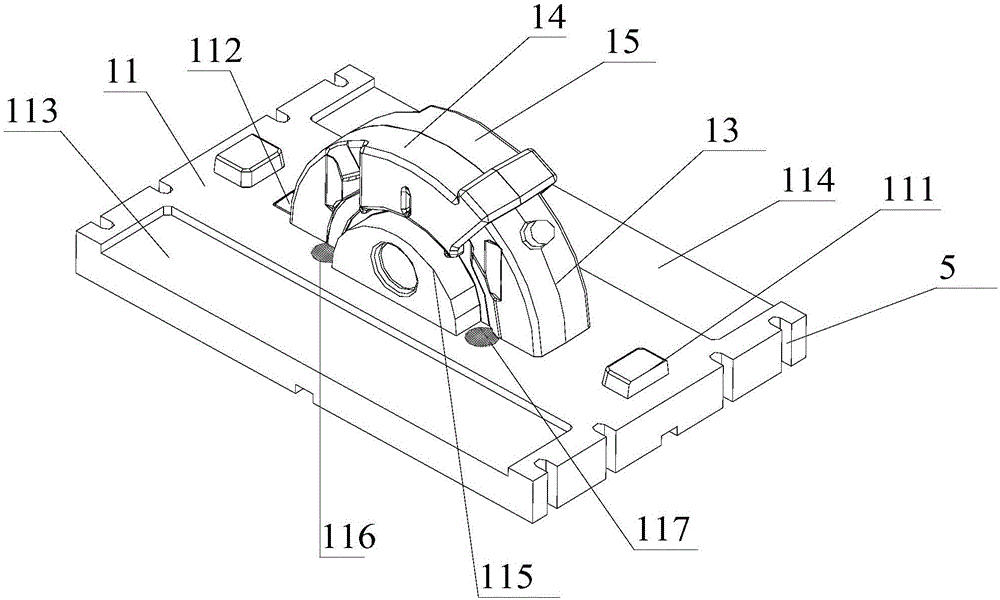

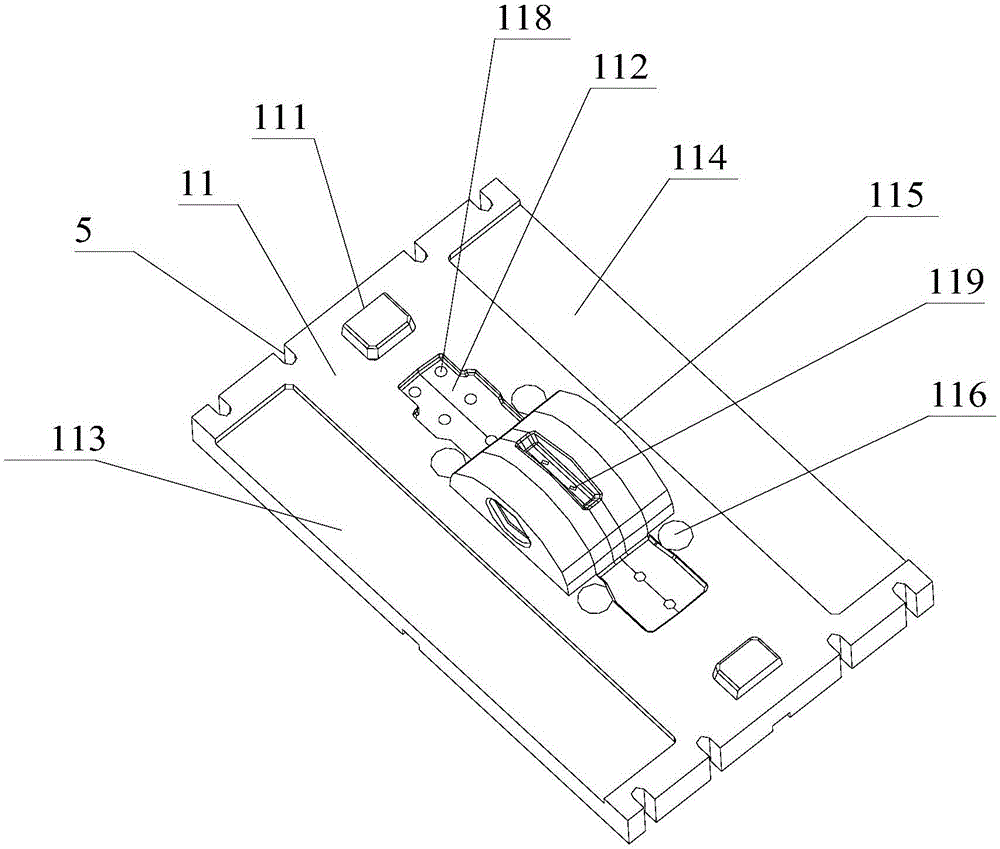

Metal mold low-pressure casting mold for lower box body of high-speed train cast aluminum gearbox

The invention provides a metal mold low-pressure casting mold for a lower box body of a high-speed train cast aluminum gearbox. The metal mold low-pressure casting mold comprises a lower mold, an upper mold, a first sliding block and a second sliding block. A casting cavity is defined by the lower mold, the upper mold, the first sliding block and the second sliding block. A sand core positioning groove is formed in the side, away from a liquid rise pouring basin, of a lower mold base. A first limiting block and a second limiting block are arranged at the two ends of the sand core positioning groove in the extension direction respectively. The first sliding block and the second sliding block are symmetrically arranged on the two sides of a sand core. A first forming convex block matched with the sand core is arranged on the side, close to the sand core, of the first sliding block. A second forming convex block matched with the sand core is arranged on the side, close to the sand core, of the second sliding block. The upper mold comprises an upper mold base. The upper mold base is provided with a forming groove matched with the sand core. The upper mold is connected with the first limiting block and the second limiting block in a clamped manner through a first limiting block clamping groove and a second limiting block clamping groove. Produced castings are compact in structure, clear in contour, stable in mechanical performance and high in casting yield, and the inner surfaces and the outer surfaces of the castings are smooth.

Owner:LAIAN KELAIXING IND CO LTD

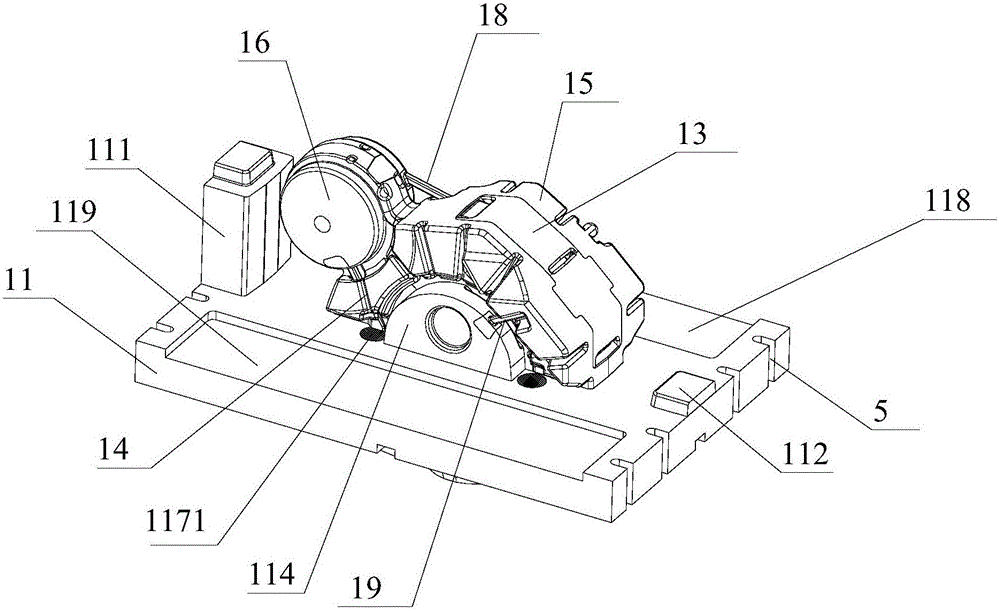

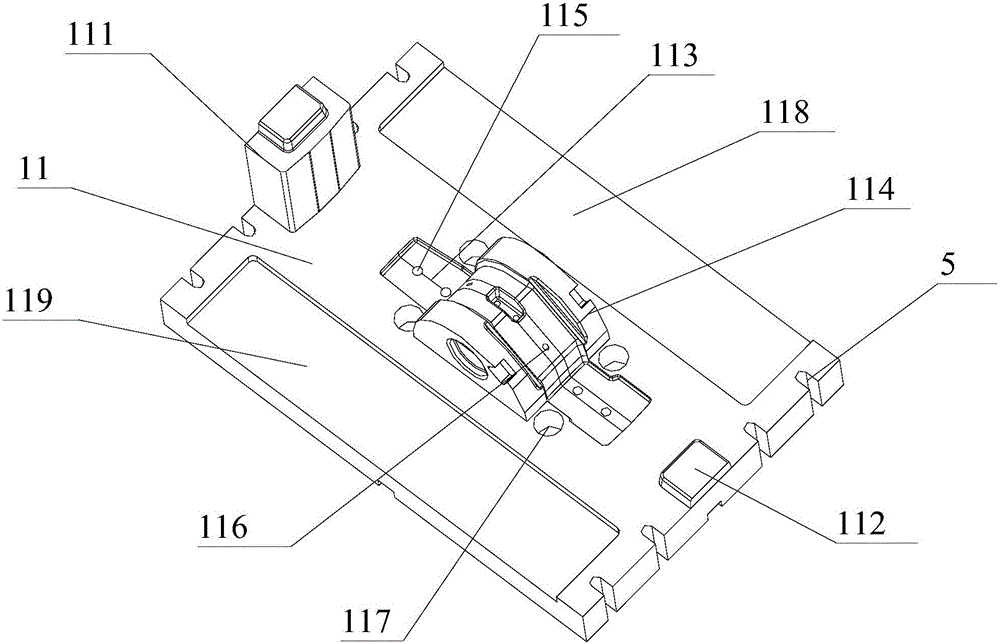

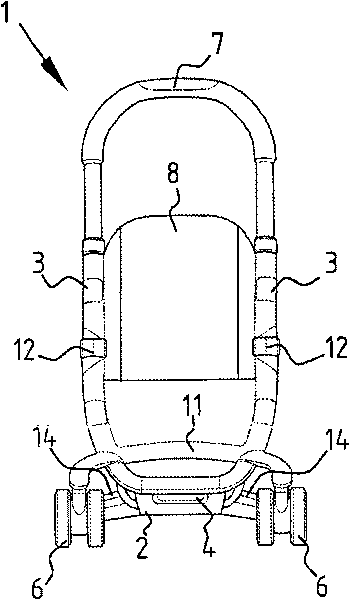

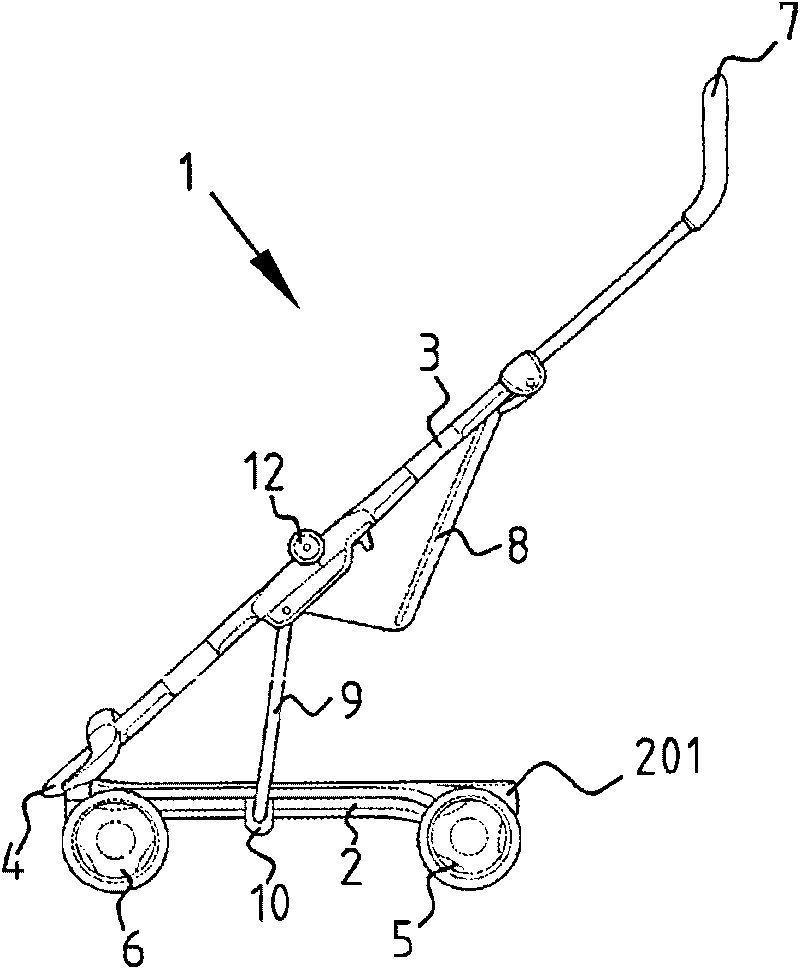

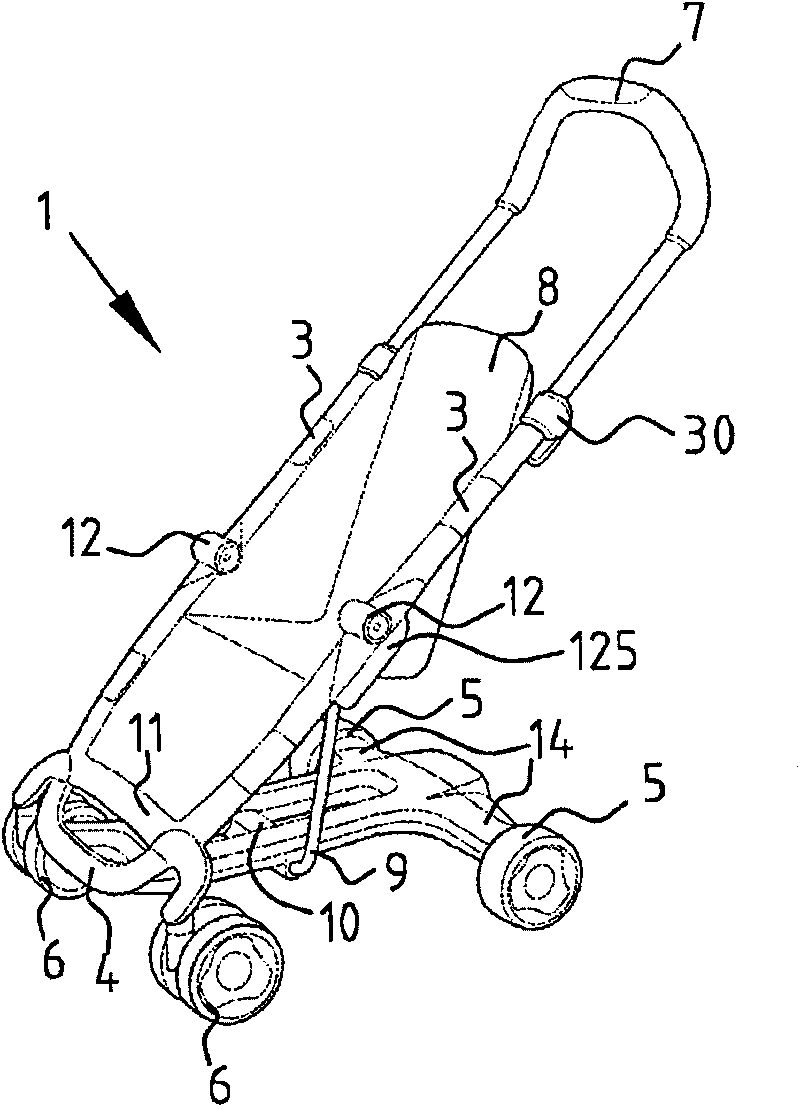

Foldable stroller

ActiveCN101715404AClear shapeCarriage/perambulator accessoriesCarriage/perambulator with multiple axesEngineeringMechanical engineering

Owner:WONDERLAND NURSERYGOODS CO LTD

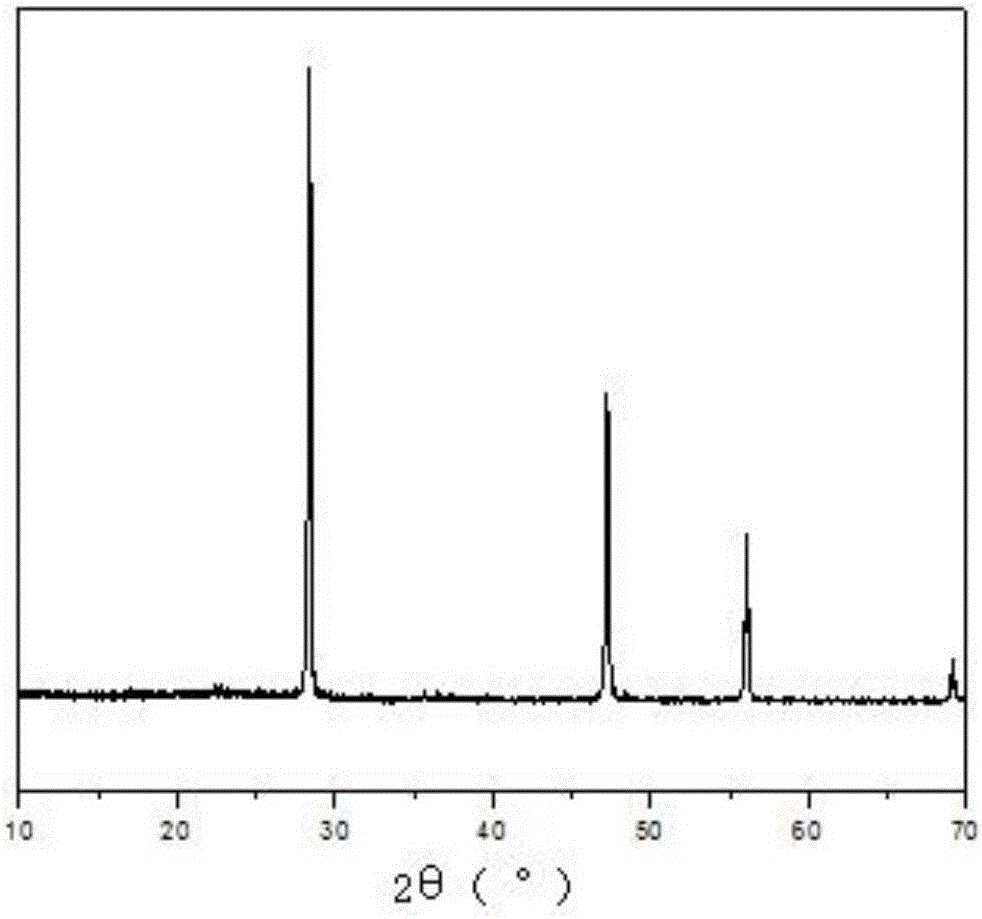

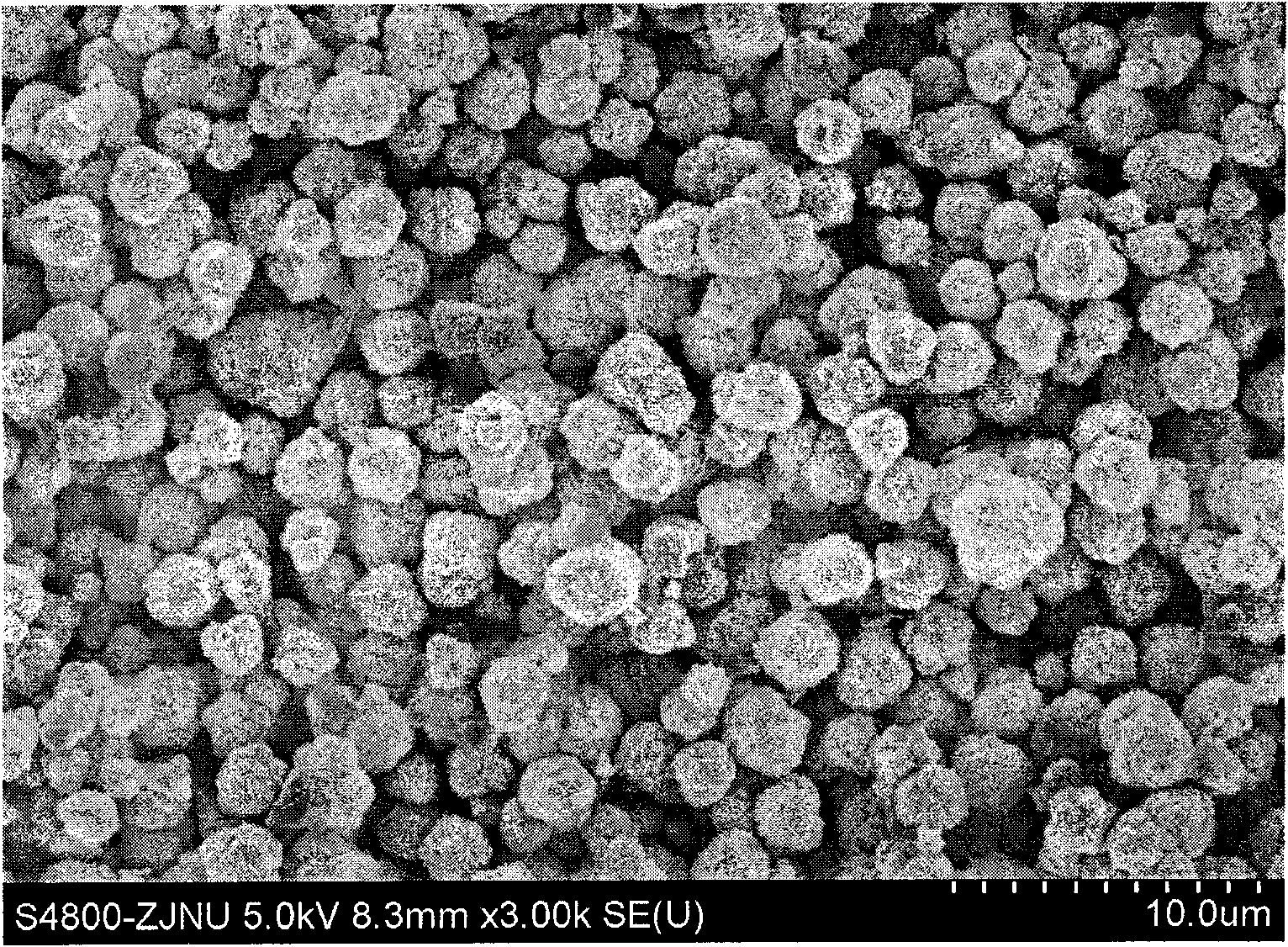

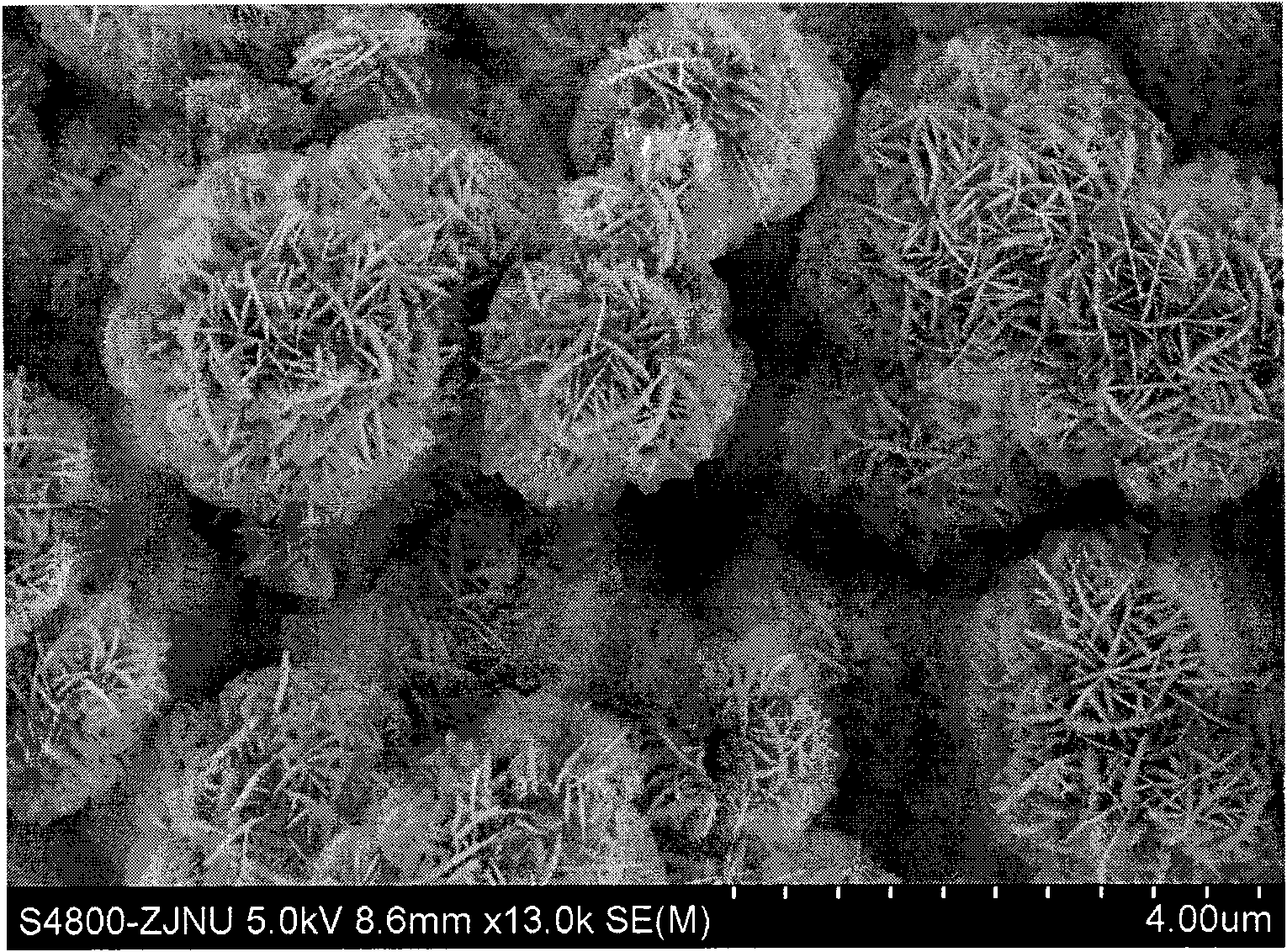

Rapid and simple preparation method of nano-zinc oxide

InactiveCN101643235AFast preparationFast preparation methodNanostructure manufactureZinc oxides/hydroxidesChemical reactionShielding gas

The invention relates to a rapid and simple preparation method of nano-zinc oxide, which takes zinc chloride and sodium hydroxide as raw materials, takes the sodium hydroxide as a strong alkaline regulator, takes oleic acid as a precipitant, takes anhydrous ethanol as a solvent and a centrifugal separating agent, takes deionized water as the solvent and a cleaning agent and takes argon as protective gas. The rapid and simple preparation method comprises the steps of firstly preparing zinc chloride and sodium hydroxide water solution, then mixing with the oleic acid and the anhydrous ethanol for forming solution, carrying out chemical reaction and grain growth under the state of 20 DEG C, carrying out high-speed centrifugal separation, washing and vacuum drying, and finally preparing the white, granular, petal-shaped and single crystal nano-zinc oxide. The preparation method is rapid and simple and can be completed within 4-5 hours without the need of heating, the product has regular and clear appearance, the diameter of single crystal is 2-4mu m, the thickness of single flake is 4-5nm, the chemical and physical performances are stable, the prepration cost is low, the yield can be as high as 92.5%, the product has high purity which can achieve 99.7%, so that the preparation method is the ideal rapid and simple preparation method of the nano-zinc oxide.

Owner:TAIYUAN UNIV OF TECH

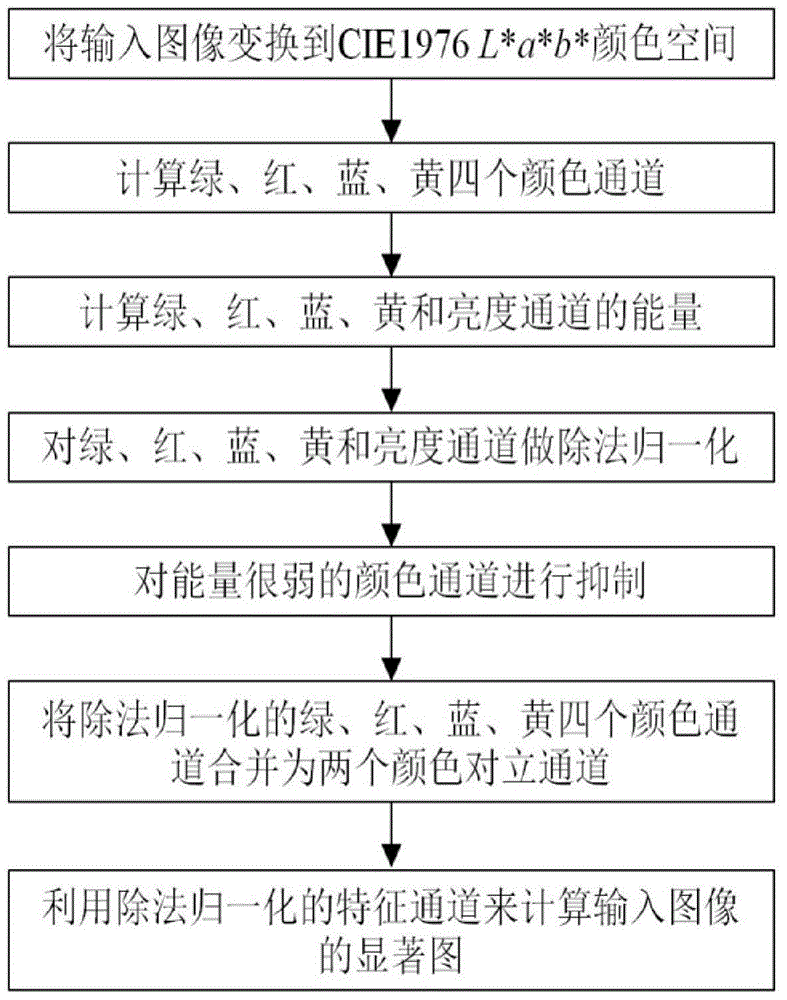

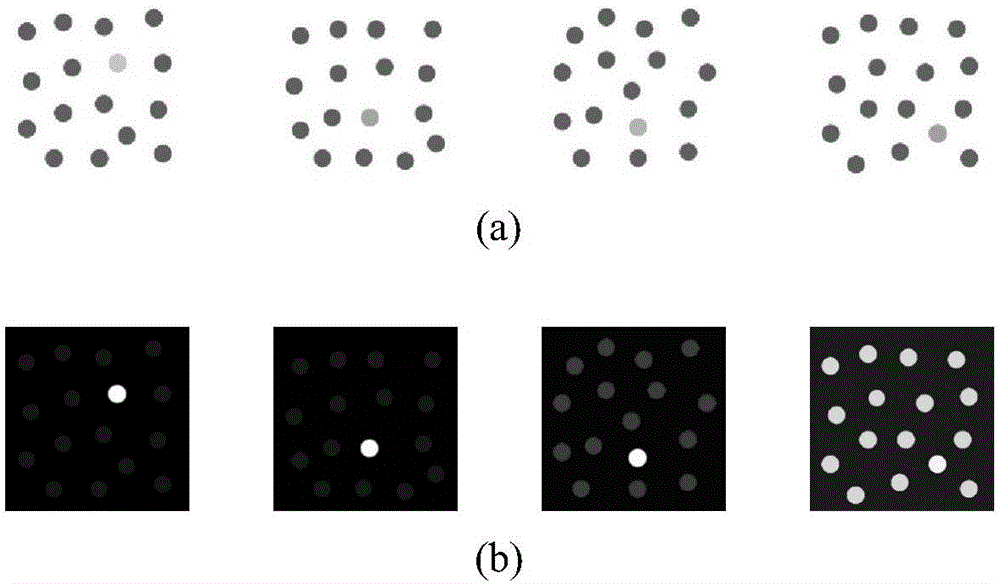

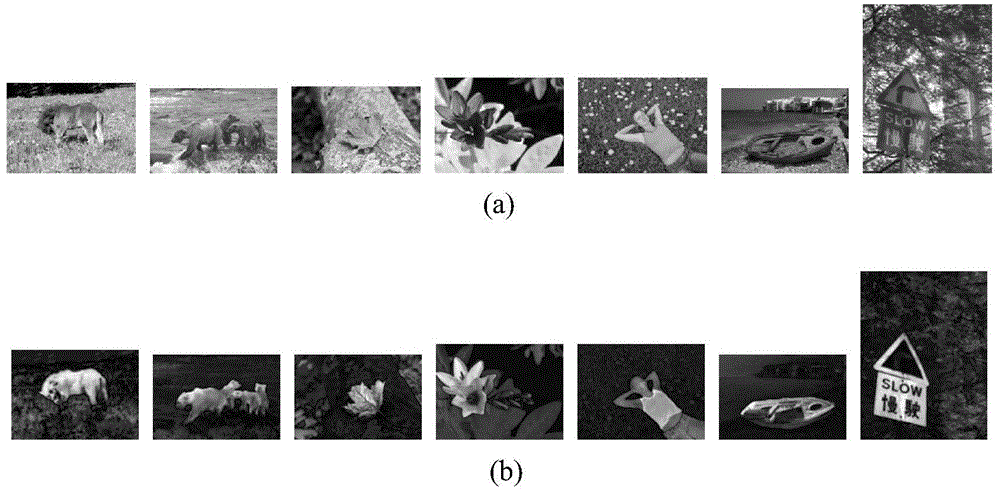

Image visual saliency detection method based on division method normalization

ActiveCN104463917ABiologically plausibleSimple calculationImage enhancementImage analysisVisual cortexPattern recognition

The invention discloses an image visual saliency detection method based on division method normalization, and belongs to the field of automatically calculating the visual saliency from bottom to top. According to the image visual saliency detection method, the color and brightness features of each pixel are utilized for calculating the visual saliency, division method normalization is adopted for calculating and stimulating the mutual inhibiting effect of nerve cells of similar detection features in the primary visual cortex, and the method has biological fitness. Compared with a traditional saliency calculating method, calculation is easy and efficient, the visual saliency caused by color differences can be accurately detected, the salient value of the salient region is integrally enhanced, and an obtained image visual saliency map has the clear shape.

Owner:YUNNAN UNIV

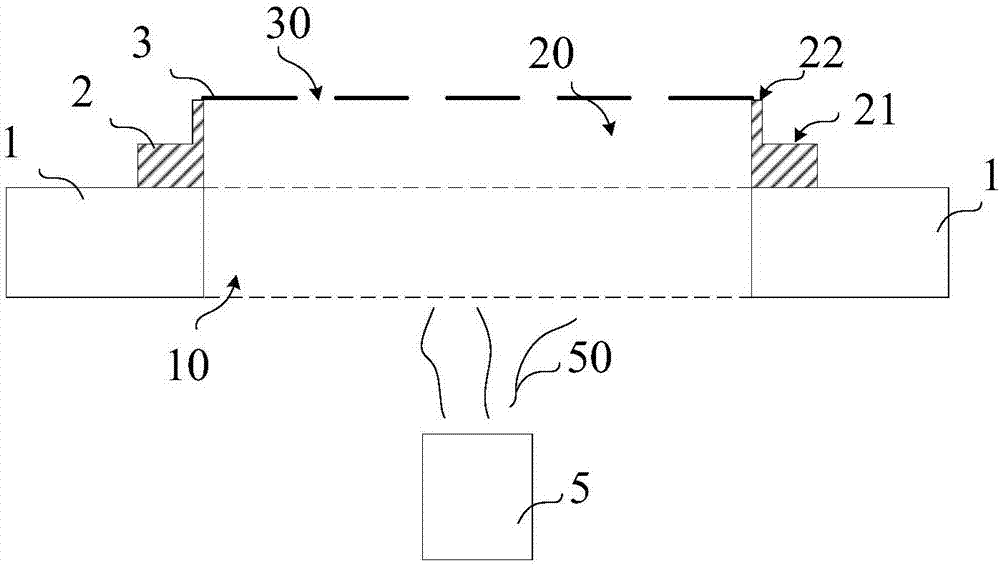

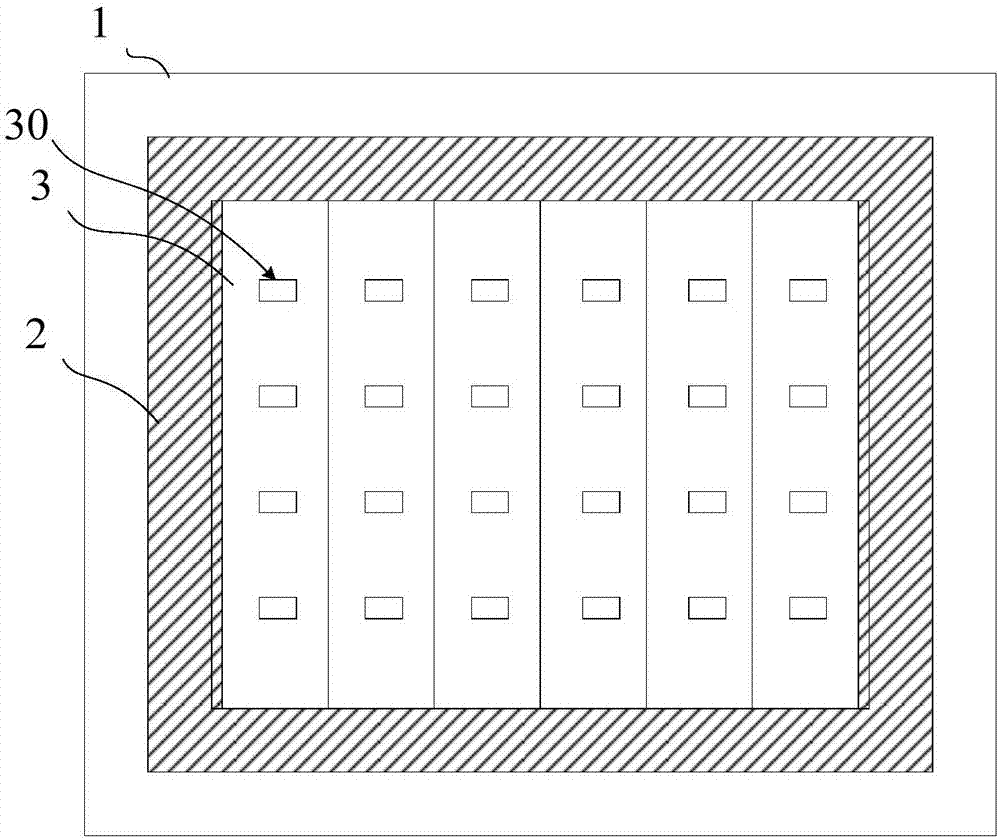

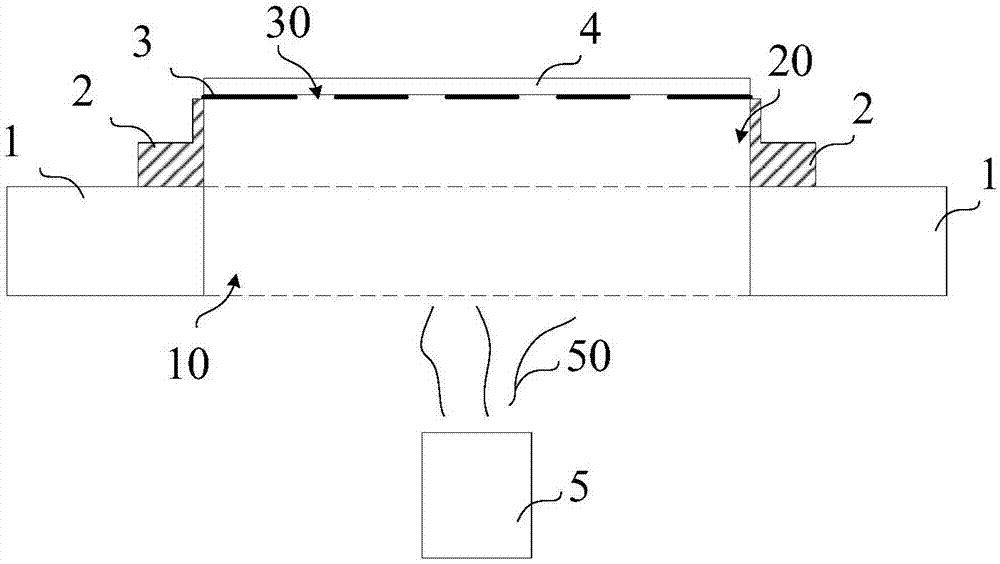

Mask plate carrying table and evaporation system

ActiveCN107354427AAvoid deformationGap reduction or even eliminationVacuum evaporation coatingSputtering coatingColor effectEvaporation

The invention discloses a mask plate carrying table and an evaporation system, belonging to the field of evaporation processes. The mask plate carrying table comprises a base and at least two correcting clamps arranged on the base at intervals, wherein the two correcting clamps are configured for tightly clamping a framework of a metal mask plate for evaporation on the base, and a first opening for allowing organic materials to pass is formed in the base. According to the embodiment of the invention, the mask plate carrying table comprises the base and the correcting clamps arranged on the base at intervals, and the first opening for allowing organic materials to pass is formed in the base; in an organic evaporation film coating process, the framework of the metal mask plate is clamped by the correcting clamps on the mask plate carrying table, so that the deformation of the framework is avoided, the gap between a base plate and the metal mask plate is reduced or even eliminated after the base plate is overlapped with the surface of the metal mask plate, the shapes and outlines of evaporated patterns are clear, the sizes of the evaporated patterns are normal, the poor mixed color effect is improved, and the product yield is increased.

Owner:BOE TECH GRP CO LTD +1

Leadless copper alloy for amiable cutting smithing

The invention relates to a lead-free copper alloy which is easy to cut and forge, which relates to a low-lead brass alloy pipe and steel bar which are used in various hot-water heating, sanitary spare parts and equipment which is forged or is directly processed and produced in hot-water heating industry and sanitary industry. The invention is characterized in that the percentage by weight composition of alloy comprises Cu 57.5%-59.0%, Fe 0.05%-0.2%, Si 0.3%-0.4%, Bi 0.7%-1.2% and the allowance is zinc and unavoidable impurity, wherein Pb<=0.05, Sn<=0.2%, Ni<=0.2%. The alloy component of lead-free copper alloy which is easy to cut and forge of the invention is on the basis of copper and adds main elements such as proper zinc, antimony, bismuth, aluminium, iron and the like, which strictly controls impurity component, easy-cutting brass alloy material for casting which is produced is particularly suitable for various hot-water heating, sanitary components and equipment, and the products have the advantages of aesthetic appearance, compact structure, clean shape and bright color, copper alloy pipe and steel bar which are produced by the lead-free recasting copper alloy are particularly applicable for processing vehicles, milling, grinding, polishing, welding, electroplating and the like besides the above advantages, and has the advantages of corrosion prevention, long service span and the like.

Owner:ZHUHAI EDISON ECOTECH CORP CO LTD

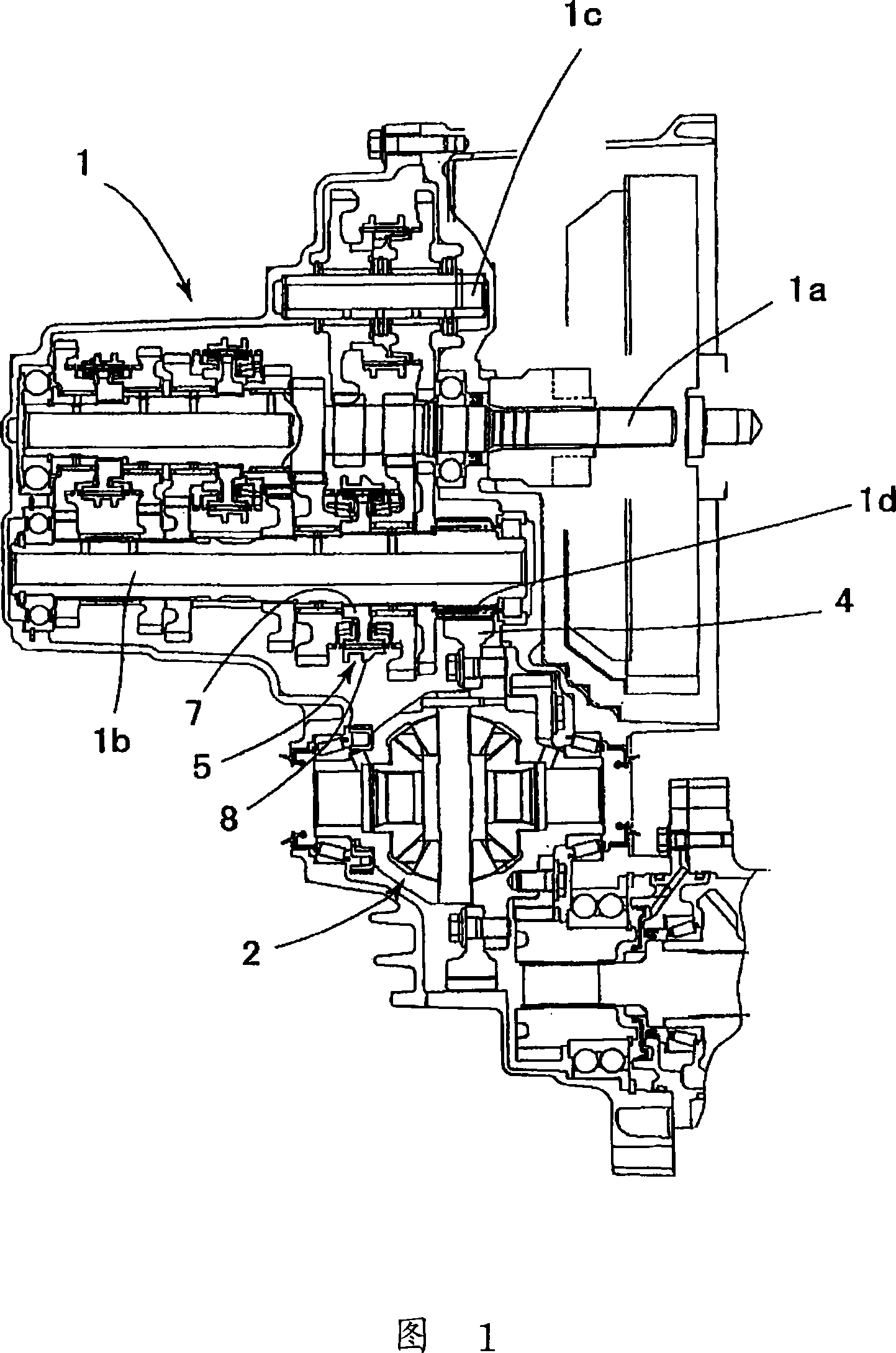

Rotating member fixing structure

ActiveCN101144507ASuppression of local stress concentrationEasy to adjustGearboxesShrinkage connectionsEngineeringMechanical engineering

Owner:NISSAN MOTOR CO LTD

Metal mold low-pressure casting die for box body on cast aluminum gearbox of high-speed train

The invention provides a metal mold low-pressure casting die for a box body on a cast aluminum gearbox of a high-speed train. The metal mold low-pressure casting die comprises a lower die body, an upper die body, a first sliding block and a second sliding block. A casting cavity is defined by the lower die body, the upper die body, the first sliding block and the second sliding block. The lower die body comprises a lower die base and a sand core. The side, away from a lifting pouring basin, of the lower die base is provided with a sand core positioning groove, a first sliding block limiting groove and a second sliding block limiting groove, wherein the first sliding block limiting groove and the second sliding block limiting groove are symmetrically formed in the two sides of the sand core positioning groove. The two ends of the sand core positioning groove are symmetrically provided with two upper die limiting blocks in the extension direction. The sand core is clamped in the sand core positioning groove. The first sliding block is clamped in the first sliding block limiting groove. The second sliding block is clamped in the second sliding block limiting groove. The upper die body comprises an upper die base. The side, away from a third molding groove, of the upper die base is provided with an ejection connecting mechanism. A produced casting is dense in structure, clear in outline, stable in mechanical performance and good in dimensional stability consistency, the inner surface and the outer surface are smooth, an inner cavity and an oil return groove are more clearly molded, and the casting yield is high.

Owner:LAIAN KELAIXING IND CO LTD

Transistor forming method

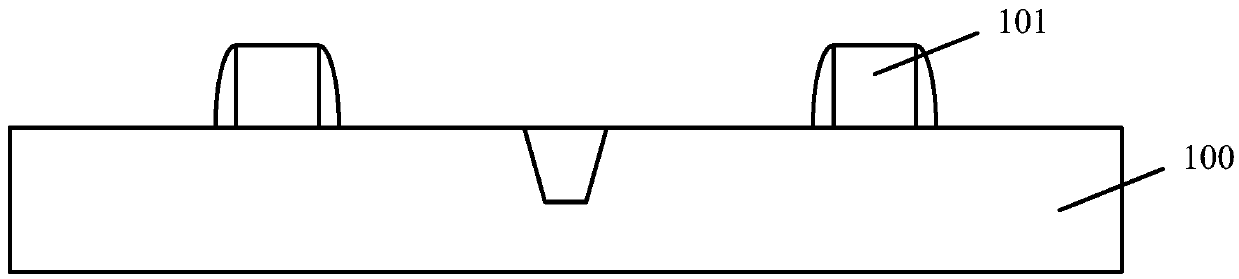

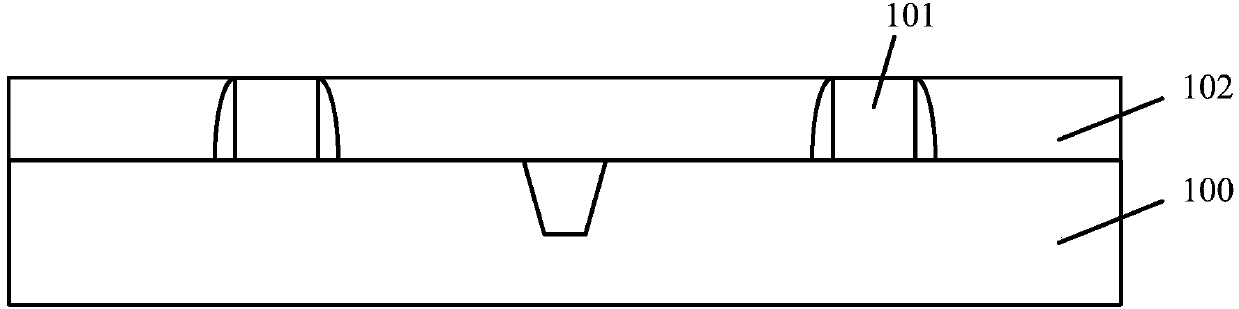

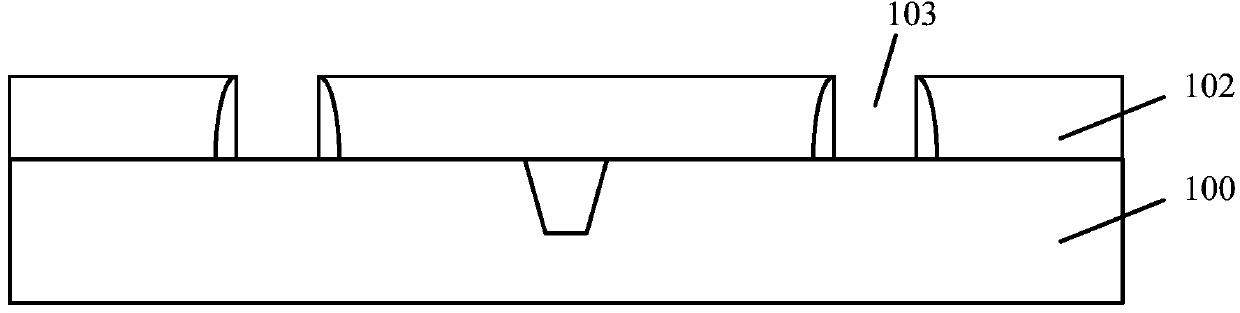

ActiveCN105513969ALarge thinning rateSmall thinning rateSemiconductor/solid-state device manufacturingNon dopedThinning

The invention discloses a transistor forming method. The transistor forming method is characterized in that a dummy grid film is disposed on a surface of a substrate; the dummy grid film is provided with ions in a doped manner, and a doped area and a non-doped area are formed in the dummy grid film, and in addition, the surface of the doped area is aligned with the surface of the dummy grid film, and the non-doped area is disposed on the bottom part of the doped area; after the dummy grid film is provided with the ions in a doped manner, parts of the dummy grid film can be etched until parts of the surface of the substrate is exposed, and the surface of the substrate is provided with dummy grid layers; the side walls of the dummy grid layers can be thinned, and the side walls of the non-doped area is recessed with respect to the side walls of the doped area; after the thinning of the side walls of the dummy grid layers, source-drain areas can be formed in the substrate on two sides of the dummy grid layers; after the forming of the source-drain areas, and dielectric layers can be formed on the surface of the substrate, and in addition, the dielectric layers are disposed on the side walls of the dummy grid layers in a covered manner, and the surfaces of the dielectric layers are aligned with the surfaces of the dummy grid layers; the dummy grid layers are removed, and first openings are formed in the dielectric layers; and grids can be formed in the first openings. The performance of the formed transistor can be improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

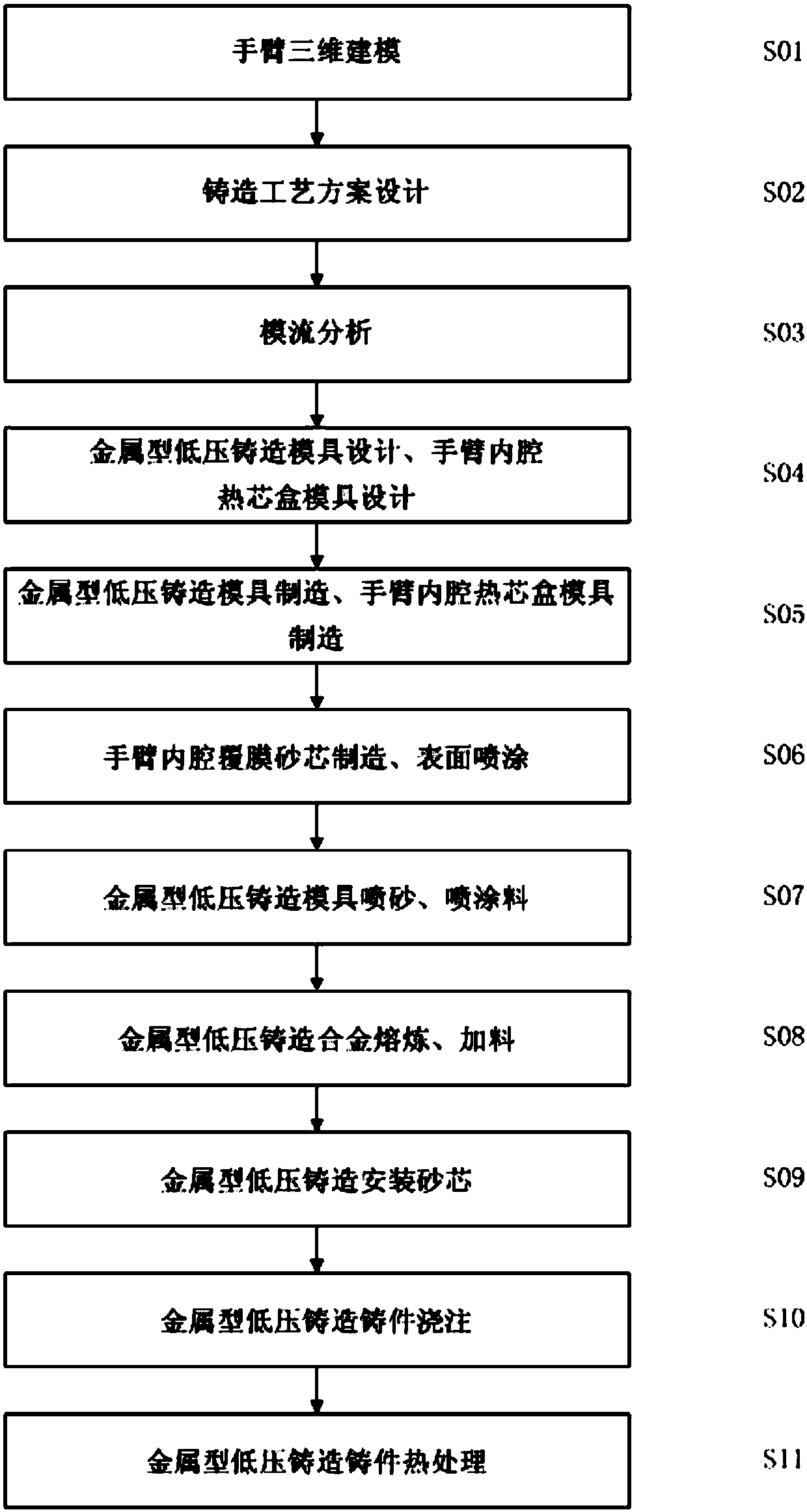

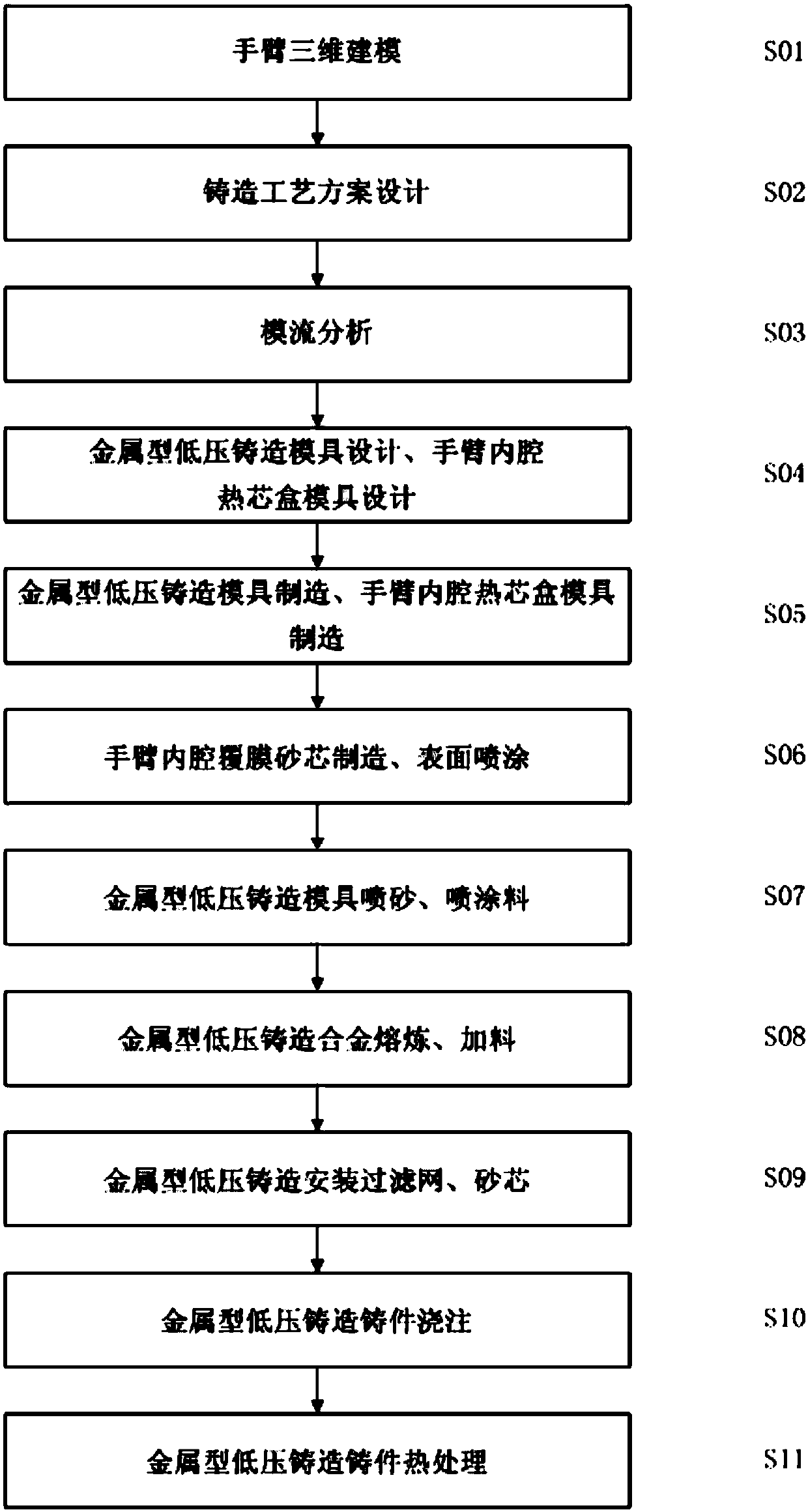

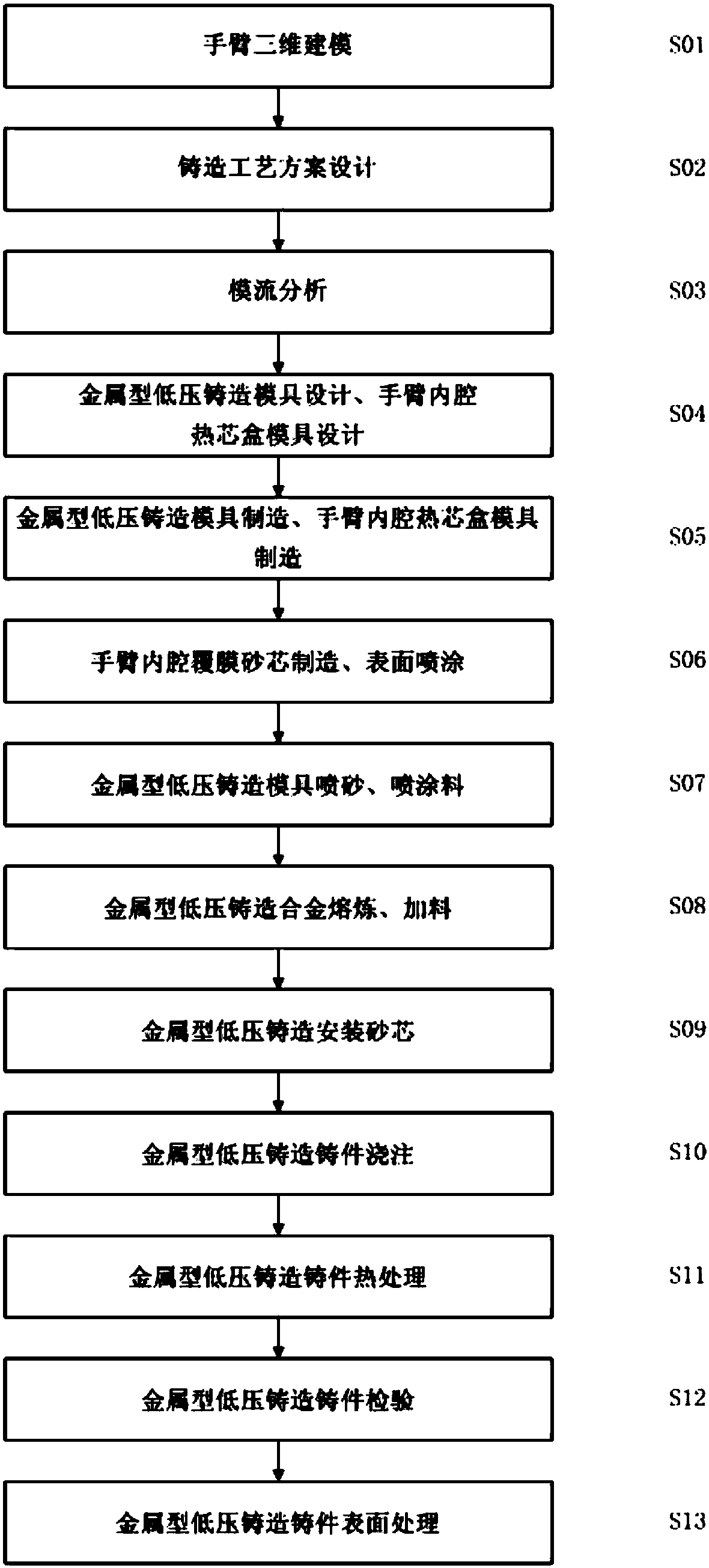

Aluminum alloy metal mold low-pressure casting technological method for collaborative robot arm

The invention discloses an aluminum alloy metal mold low-pressure casting technological method for a collaborative robot arm. The method comprises the following steps of 1, three-dimensional modelingof the arm; 2, design of a casting technological scheme; 3, mold flow analysis; 4, design of a metal mold low-pressure casting mold and an arm inner chamber hot box mold; 5, manufacturing of the metalmold low-pressure casting mold and the arm inner chamber hot box mold; 6, manufacturing of an arm inner chamber film-coated sand core, and surface coating; 7, sand blasting and paint spraying of themetal mold low-pressure casting mold; 8, smelting and feeding of a metal mold low-pressure casting alloy; 9, mounting of the sand core through metal mold low-pressure casting; 10, pouring of metal mold low-pressure casting castings; and 11, heat treatment of the metal mold low-pressure casting castings. The collaborative robot arm manufactured through the method has the beneficial effects of beingsmall in weight, high in rigidity, high in inner chamber precision and attractive and delicate in outer surface.

Owner:张希波

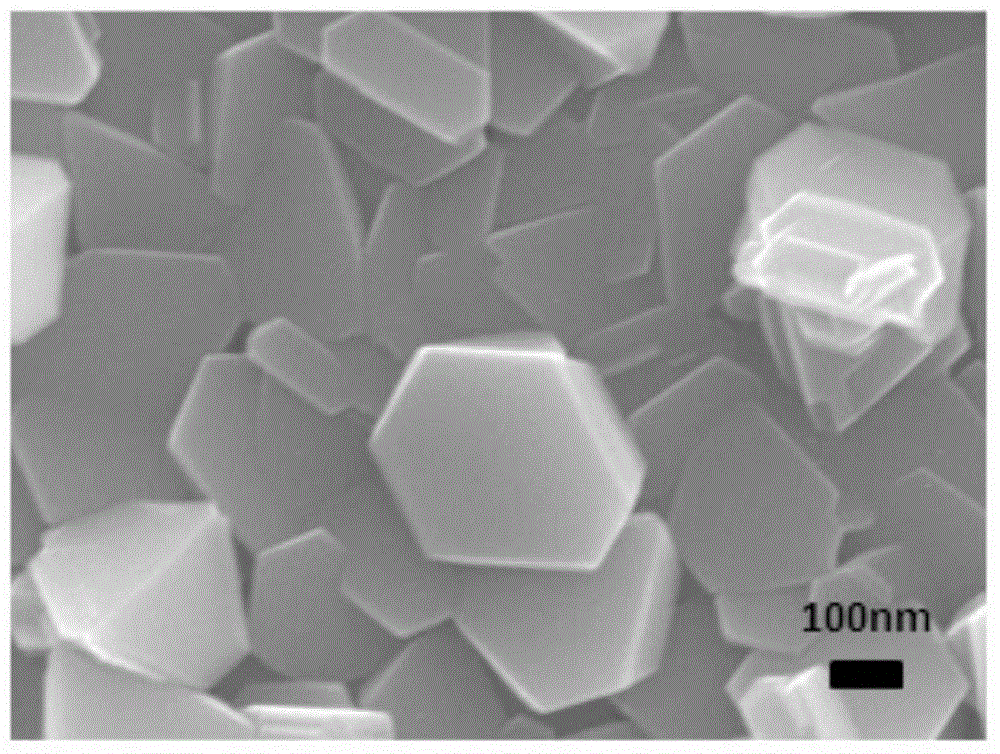

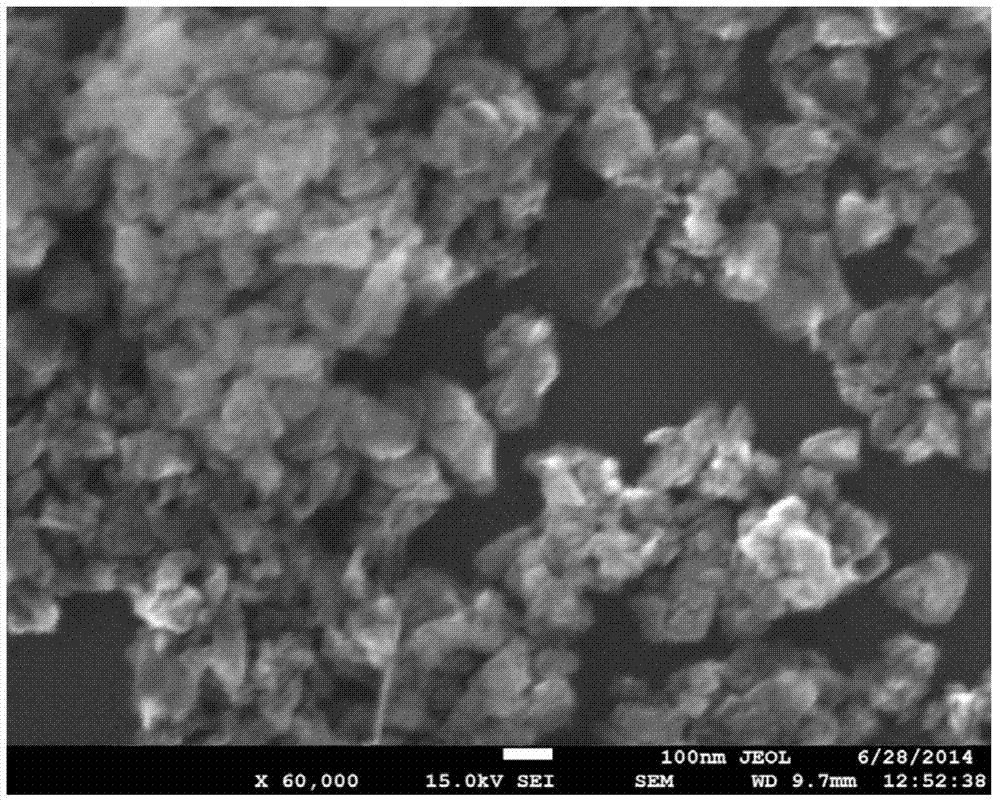

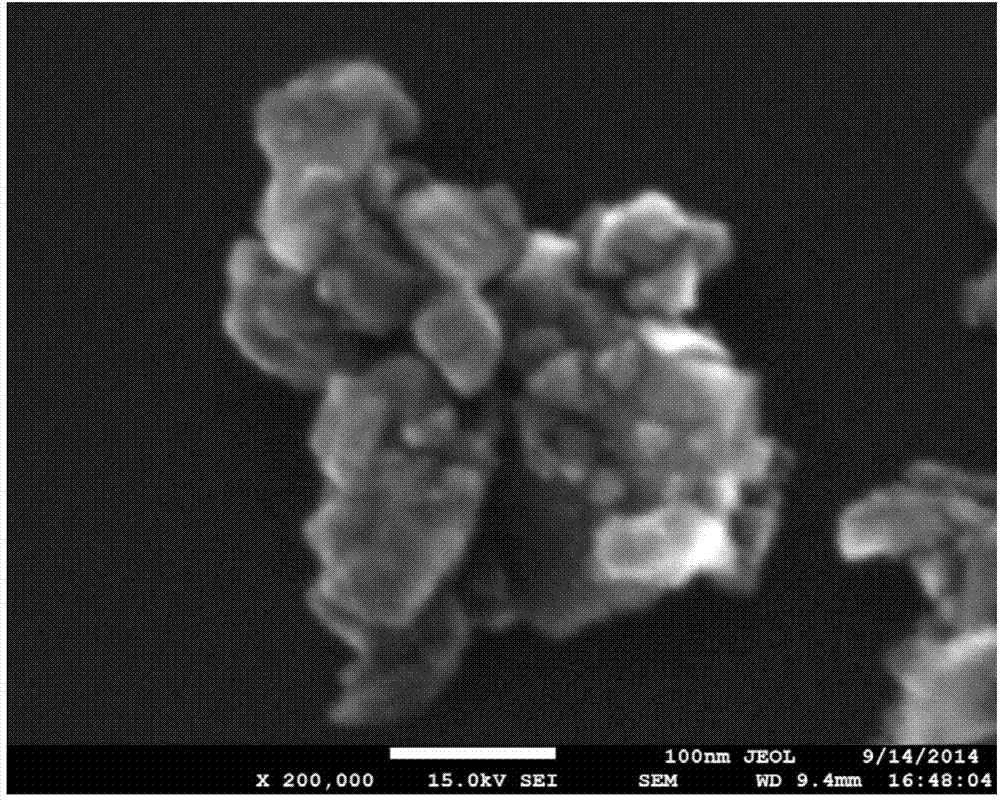

Preparation method of cubic boron nitride micro-powder scanning electron microscopy sample

InactiveCN104777019AReduce reunionAvoid damagePreparing sample for investigationBoron nitrideElectron microscope

The invention discloses a preparation method of a cubic boron nitride micro-powder scanning electron microscopy sample. The method comprises the following steps: 1, taking cubic boron nitride micro-powder, adding the micro-powder into a dispersant, and carrying out ultrasonic dispersion to obtain a suspension; and 2, adding the suspension obtained in step 1 to conducting resin in a dropwise manner or adhering the suspension to the silicon chip of the conducting resin, and drying to obtain the sample. The cubic boron nitride micro-powder in the sample prepared through the preparation method of the cubic boron nitride micro-powder scanning electron microscopy sample has less agglomeration and is uniformly dispersed, and the microscopic morphology of the micro-powder can be easily observed; the process is simple and fast when the sample is used in scanning electron microscopy detection, and a high-amplification clear electron microscope photograph is obtained, so the dimension of the cubic boron nitride micro-powder is convenient to observe and position, and the sample is suitable for sample production detection of ultrafine micro-powder with the particle size of 300nm or less; in the preparation process, the sample is difficult to pollute, and damages of the micro-powder to an electron microscope sample chamber are reduced; and the preparation method has the advantages of simple process, convenient operation, simple and easily available dispersant, and suitableness for popularization and application.

Owner:FUNIK ULTRAHARD MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com