Flying body with curved-surface micro groove structures and manufacturing method of flying body

A manufacturing method and micro-groove technology, applied in the direction of aircraft control, manufacturing tools, and affecting the air flow flowing through the aircraft surface, etc., can solve the problems of difficult precision machining of curved surfaces, failure to process microstructured curved surfaces, etc., and achieve enhanced Radar scattering capability, improved flight stability, and smooth bottom contour effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036]A CNC precision grinder (SMRART B818) was used to process ceramic rods, and the cylindrical ceramic rod was fixed on a Michelin three-jaw grinder (MCL-550) and rotated accordingly. The rotation speed of the flying body was n=500 rpm, and the diamond grinding wheel was fixed on on the wheel shaft. The coarse-grained diamond grinding wheel 2 for processing flying objects 1 has a diameter of 160 millimeters and a thickness of 10 millimeters, and is composed of diamond abrasives and bronze bonding agents. The diamond abrasive grain size is 120 meshes; the fine-grained diamond grinding wheel 7 for processing smooth curved surface flying objects Its diameter is 150 millimeters, thickness is 4 millimeters, is made up of diamond abrasive grain and resin bond, and diamond abrasive grain size is 3000 meshes; The diameter of the diamond grinding wheel 9 of processing the V tip of the smooth curved surface flying body with micro-groove structure is 160 millimeters , the thickness is...

Embodiment 2

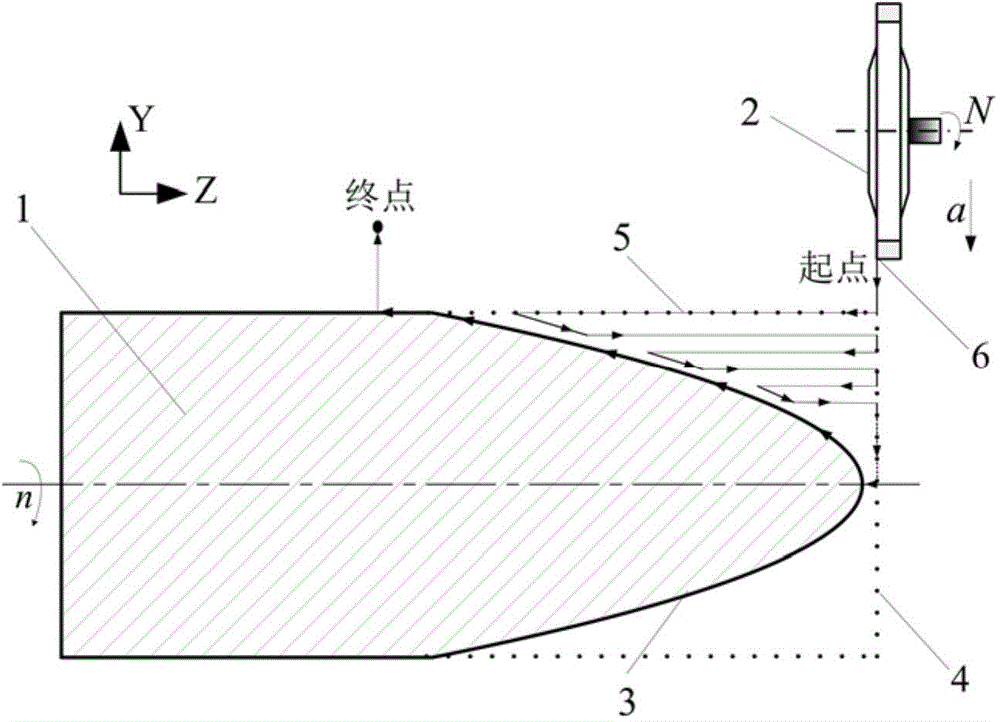

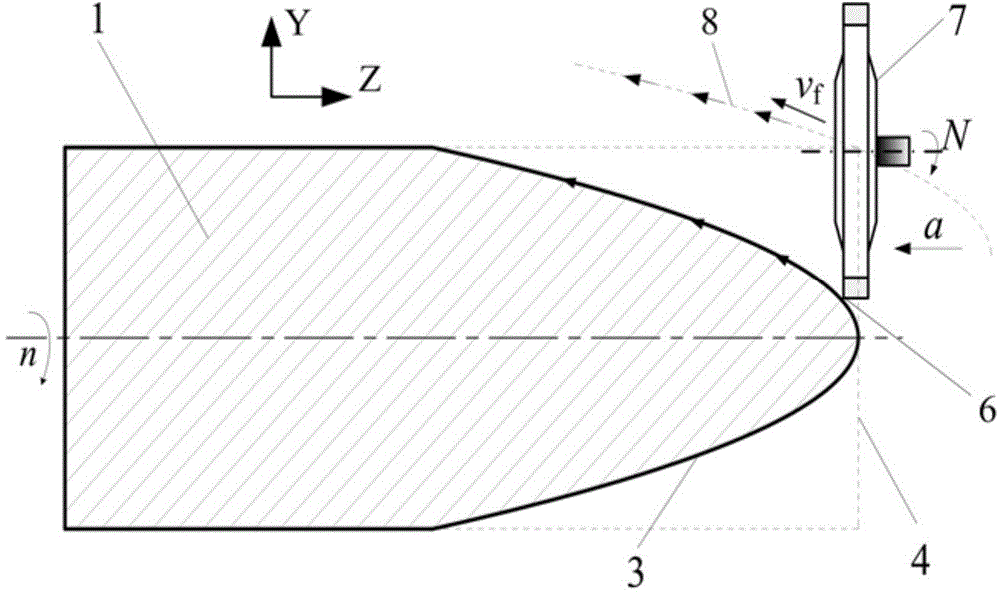

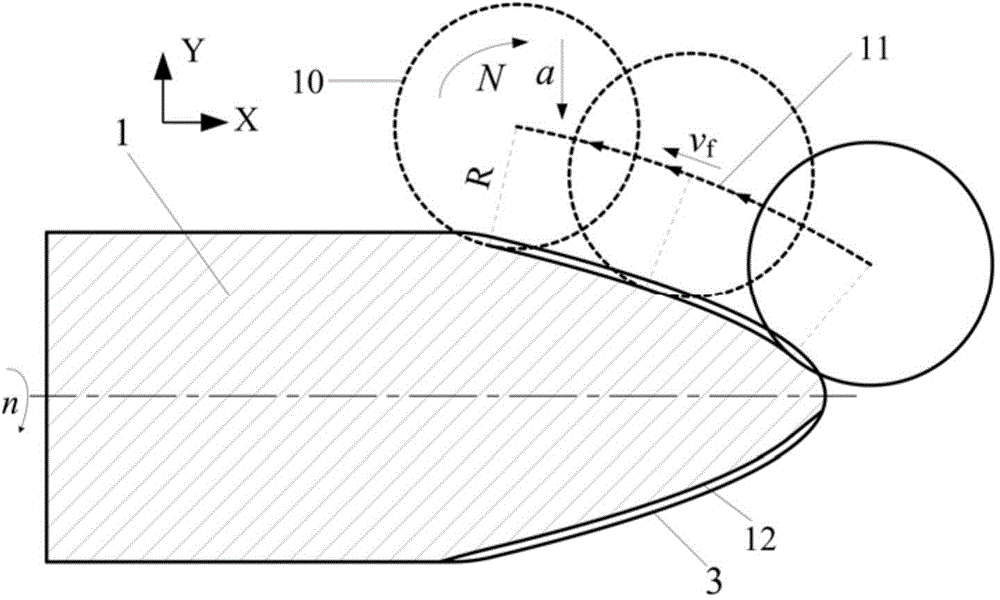

[0040] First, the axial direction of the ceramic rod is consistent with the axial direction of the grinding wheel. On the vertical section of the workpiece axial direction, the grinding path 5 of the ring end face corner 6 of the diamond grinding wheel 2 is used to adopt the layered feed (the grinding path 5 is Along the axial direction of the ceramic rod, according to the set CNC linear reciprocating path layered feeding (reciprocating broken line) for rough grinding of ceramics, the flying body is processed from the rough contour 4 to the curved surface contour 3, and the rough curved surface is processed. Body 1 (eg figure 1 shown), grinding wheel speed N=2500 rpm, feed speed v f =10 mm / min, depth of feed a=30 microns; Then, in the same orientation, utilize diamond emery wheel 7 to grind path 8 (parabolic track, its equation is z=y 2 / 7, z is the abscissa value (along the axial direction of the flying body) of the curved surface profile of the flying body head, and y is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com