V-belt corner cutting machine for front wheel with convex edge and corner cutting method

A corner cutting machine and corner cutting technology, applied in the direction of metal processing, etc., can solve the problems of reducing production costs, time-consuming and labor-intensive, high cost, etc., and achieve the effects of reducing production costs, reducing power consumption, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

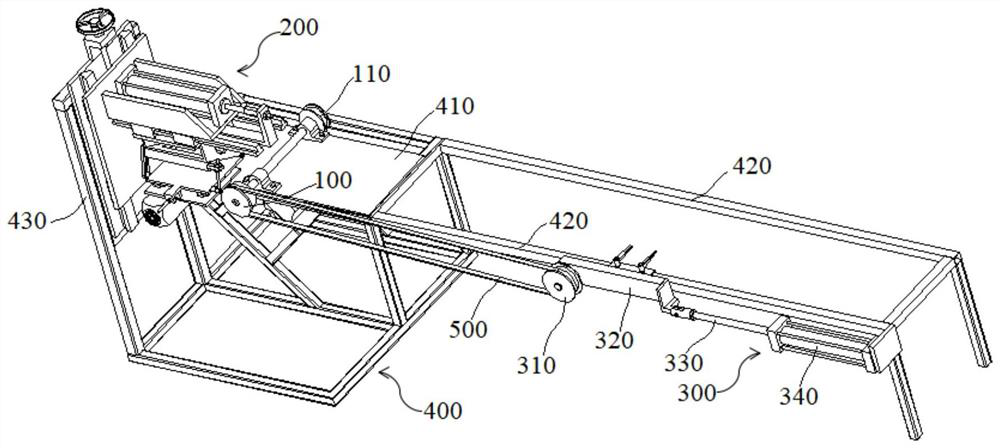

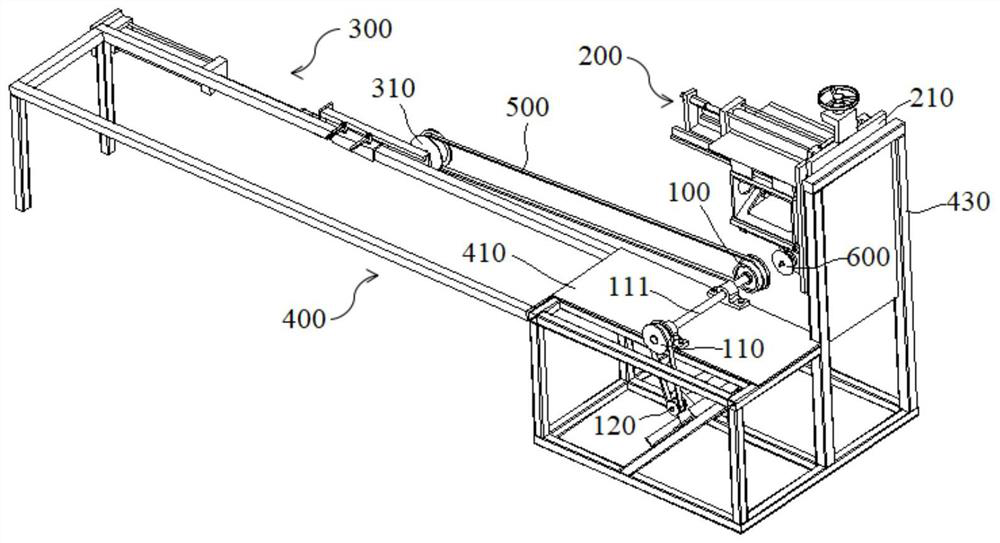

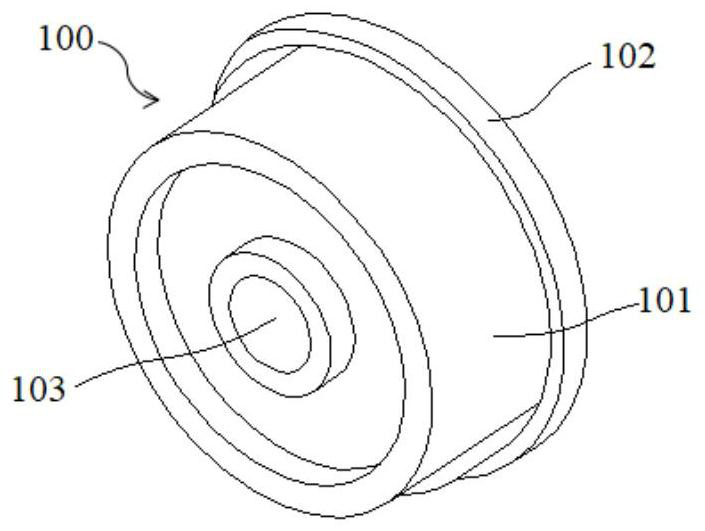

Embodiment 1

[0041] In the prior art, the toothed rubber sleeve 500 used to manufacture V-belts is usually ground and repaired by using the grinding wheel of the belt grinding machine, which not only has low efficiency, but also has serious wear of the grinding wheel, excessive power consumption, and high manufacturing costs. And adopt a kind of V-belt chamfering machine with flanged front wheel of this embodiment, then can directly carry out the shearing repair of certain angle to the side of tooth-shaped rubber sleeve 500, compared with the previous edging treatment, not only The production efficiency is greatly improved, and the produced tooth-shaped rubber sleeve 500 has neat corners, good performance, long service life, and greatly reduces power consumption, thereby reducing production costs. Such as figure 1 and figure 2 As shown, this embodiment includes a positioning cam 100 and a tensioning wheel 310. The tensioning wheel 310 and the positioning cam 100 are placed vertically and...

Embodiment 2

[0056] The corner cutting method of a V-belt chamfering machine with a flanged front wheel in this embodiment of the present embodiment, the basic structure is the same as that of Embodiment 1, the difference is that in this embodiment, the corner cutting knife 600 is connected with the vertical The angle range between the straight faces is 40°.

[0057] In this embodiment, a blade cooling unit is also provided above the corner cutter 600, wherein the blade cooling unit includes cooling nozzles sprayed towards the direction of the corner cutter 600, the cooling nozzles are connected to the cooling pipes, and the cooling pipes are connected to the cooling water pipes or lubricating cooling. The oil pipelines are connected.

Embodiment 3

[0059] The corner cutting method of a V-belt chamfering machine with a flanged front wheel in this embodiment of the present embodiment, the basic structure is the same as that of Embodiment 1, the difference is that in this embodiment, the corner cutting knife 600 is connected with the vertical The angle range between the straight faces is 30°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com