Magnesium oxysulfide fireproof door core board produced by rolling line

A fire door core board, magnesium oxysulfate technology, applied in the direction of pressure rollers, ceramic products, other household appliances, etc., can solve the problems of low strength and water absorption, low fire rating, poor performance, etc., to achieve high water absorption, fire prevention High Performance, Strong Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

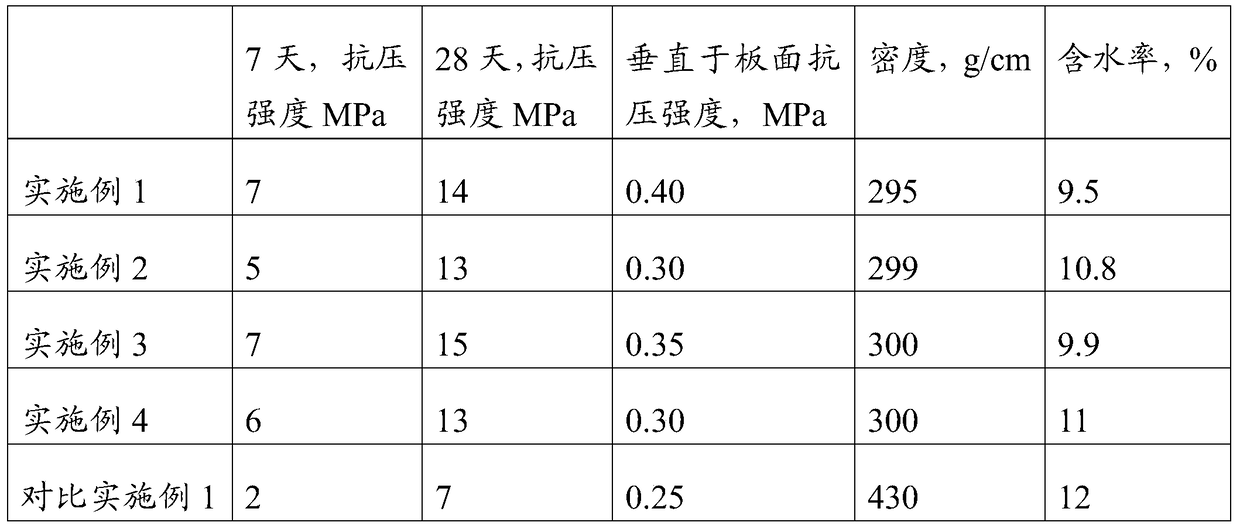

Examples

Embodiment 1

[0024] (1) Prepare each raw material in parts by weight: 30 parts of silica fume, 10 parts of magnesium sulfate, 5 parts of magnesium oxide, 30 parts of water, 2 parts of palm fiber with a length of 0.1-1mm, 3 parts of modifier and invalid 0.5 part of phosphoric acid-based polishing liquid, prepare, then load, stir and mix evenly. Among them, palm fiber is soaked in alkaline water with a mass concentration of 10% for 1 hour and rinsed with clean water before use;

[0025] (2) Paving;

[0026] (3) Keep the material paved in (2) at a temperature of 25°C and a humidity of 80% in the maintenance vehicle, curing for 7-28 days, and recording the compressive strength at 7 days and 28 days of curing;

[0027] (4) Mechanical engraving.

[0028] Among them, the modifier is a mixture of foaming agent, foam stabilizer and tackifier in parts by weight; among them, the foaming agent is 0.5 part, the foam stabilizer is 0.5 part, and the tackifier is 1 part; The foaming agent is silkworm pupa high-z...

Embodiment 2

[0030] (1) Prepare each raw material in parts by weight: 50 parts of silica fume, 15 parts of magnesium sulfate, 10 parts of magnesium oxide, 55 parts of water and 12 parts of modifier, prepare, then load, stir and mix evenly. , Palm fiber is soaked in alkaline water with a mass concentration of 15% for 2 hours and then rinsed with clean water before use;

[0031] (2) Paving;

[0032] (3) Keep the material paved in (2) at a temperature of 30°C and a humidity of 60% in the maintenance vehicle for 7-28 days of curing, and record the compressive strength at 7 days and 28 days of curing;

[0033] (4) Mechanical engraving.

[0034] Among them, the modifier is a mixture of foaming agent, foam stabilizer and tackifier in parts by weight; among them, the foaming agent is 2 parts, the foam stabilizer is 3 parts, and the tackifier is 7 parts; The foaming agent is water-soluble glutinous rice protein; the foam stabilizer is selenate polysaccharide, high-viscosity carboxymethyl cellulose (HV-CMC...

Embodiment 3

[0036] (1) Prepare the raw materials in parts by weight: 40 parts of silica fume, 12 parts of magnesium sulfate, 8 parts of magnesium oxide, 43 parts of water, 5 parts of palm fiber with a length of 0.1-1 mm and 7 parts of modifiers. OK, then load, stir and mix evenly. Among them, the palm fiber is soaked in alkaline water with a mass concentration of 20% for 3 hours and then rinsed with clean water before use;

[0037] (2) Paving;

[0038] (3) Keep the material paved in (2) at a temperature of 27°C and a humidity of 70% in the maintenance vehicle for 7-28 days of curing, and record the compressive strength at 7 days and 28 days of curing;

[0039] (4) Mechanical engraving.

[0040] Among them, the modifier is a mixture of foaming agent, foam stabilizer and tackifier in parts by weight; among them, the foaming agent is 1.2 parts, the foam stabilizer is 1.5 parts, and the tackifier is 4 parts; The foaming agent is sodium butyl naphthalene sulfonate and fish meal; the foam stabilizer i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com