Whitebait sauce and preparation method thereof

A technology of whitebait sauce and whitebait, which is applied in the field of condiments, can solve the problems of unstable spices, toxic and side effects of human body, high water content, etc., and achieve the effect of removing the fishy smell of whitebait, simple production process and reasonable formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

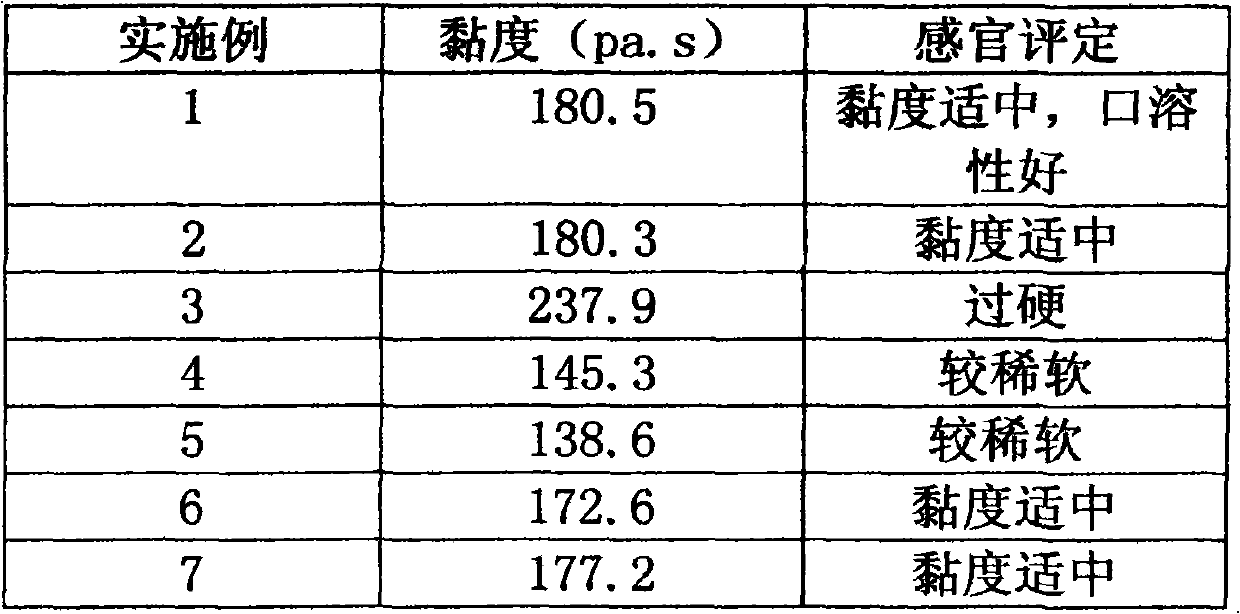

Examples

Embodiment 1

[0028] Embodiment 1, whitebait sauce, made from the raw and auxiliary materials of following weight ratio: 40 parts of whitebait, 55 parts of water, 5 parts of chili powder, 3 parts of black sesame, 2 parts of small sesame oil, 6 parts of vegetable oil, 0.2 parts of monosodium glutamate 4 parts of garlic, 0.5 parts of sugar, 10 parts of table salt, 1.5 parts of white pepper, 0.3 parts of guar gum, 0.10 parts of carboxymethyl cellulose, 7.02 parts of deodorant;

[0029] Wherein, guar gum and carboxymethyl cellulose are thickeners;

[0030] Among them, the deodorizing agent is: 4.5 parts of inclusion compound of β-cyclodextrin and perilla extract, 0.5 part of white vinegar, 1 part of cooking wine, 1 part of tea polyphenol, and 0.02 part of ethyl maltol;

[0031] The preparation method of the clathrate between β-cyclodextrin and perilla extract is as follows: weigh dried perilla, add drinking water 10 times the amount of dried perilla, decoct for 1.5 hours, and filter to obtain p...

Embodiment 2

[0039] Embodiment 2, whitebait sauce, made from the raw and auxiliary materials of following weight ratio: 40 parts of whitebait, 55 parts of water, 5 parts of chili powder, 3 parts of black sesame, 2 parts of small sesame oil, 6 parts of vegetable oil, 0.2 parts of monosodium glutamate 4 parts of garlic, 0.5 parts of sugar, 10 parts of table salt, 1.5 parts of white pepper, 0.3 parts of guar gum, 0.10 parts of carboxymethyl cellulose, 7.02 parts of deodorant;

[0040] Wherein, guar gum and carboxymethyl cellulose are thickeners;

[0041] Among them, the deodorizing agent is: 4.5 parts of inclusion compound of β-cyclodextrin and perilla extract, 0.5 part of white vinegar, 1 part of cooking wine, 1 part of tea polyphenol, and 0.02 part of ethyl maltol;

[0042] The preparation method of the clathrate between β-cyclodextrin and perilla extract is as follows: weigh dried perilla, add drinking water 10 times the amount of dried perilla, decoct for 1.5 hours, and filter to obtain p...

Embodiment 3

[0050] Embodiment 3, whitebait sauce, made from the raw and auxiliary materials of following weight ratio: 40 parts of whitebait, 55 parts of water, 5 parts of chili powder, 3 parts of black sesame, 2 parts of small sesame oil, 6 parts of vegetable oil, 0.2 parts of monosodium glutamate 4 parts of garlic, 0.5 parts of sugar, 10 parts of table salt, 1.5 parts of white pepper, 0.4 parts of guar gum, 7.02 parts of deodorant;

[0051] Wherein, guar gum is a thickener;

[0052]Among them, the deodorizing agent is: 4.5 parts of perilla extract, 0.5 part of white vinegar, 1 part of cooking wine, 1 part of tea polyphenol, and 0.02 part of ethyl maltol;

[0053] The preparation method of the perilla extract is as follows: take dried perilla, add 15 times the amount of drinking water to dry perilla, decoct for 1.5 hours, and filter to obtain the filtrate for later use;

[0054] How to prepare whitebait sauce:

[0055] 1. Raw material pretreatment: select high-quality whitebait, remove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com