Patents

Literature

1073 results about "Dry mixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

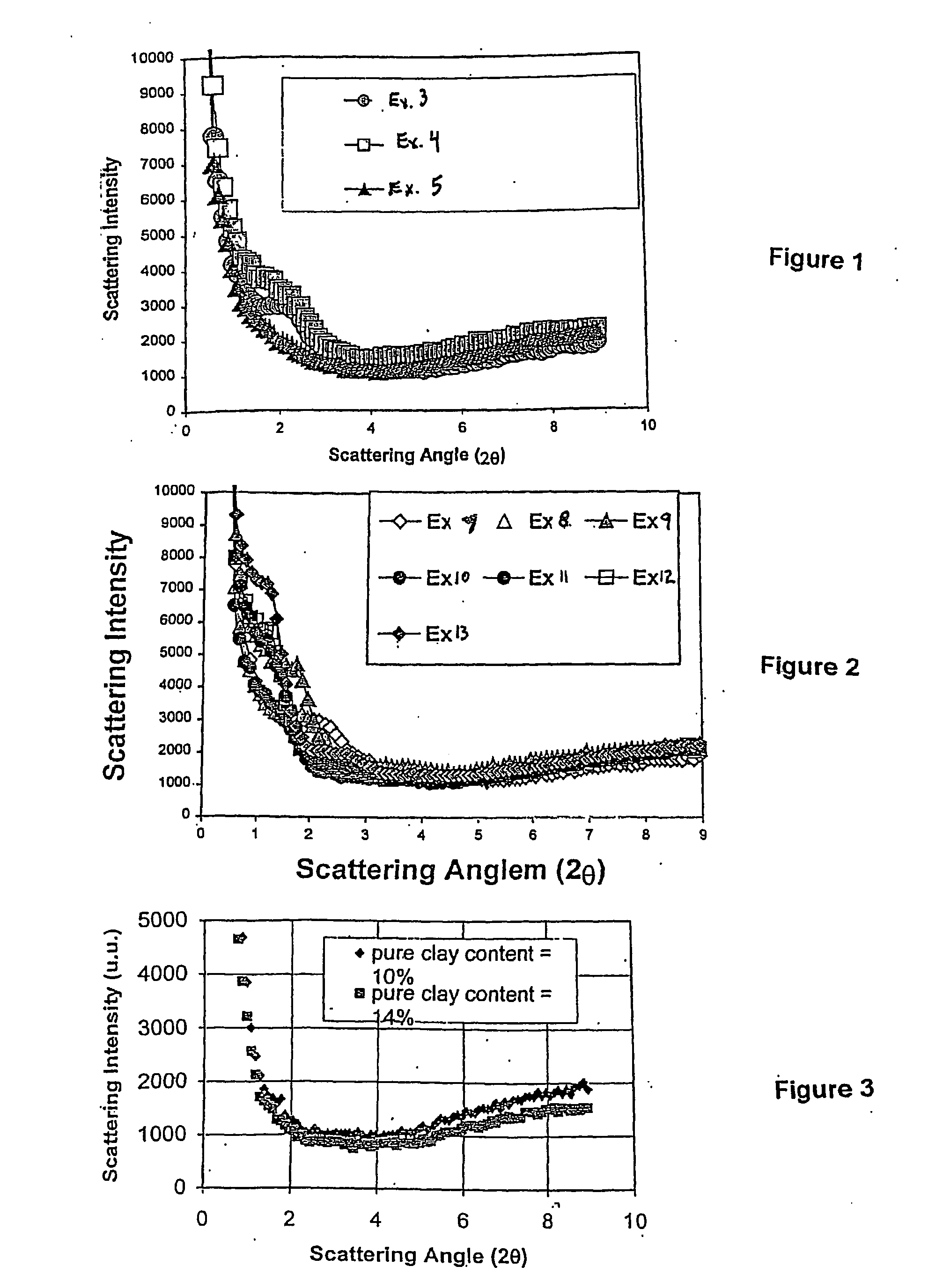

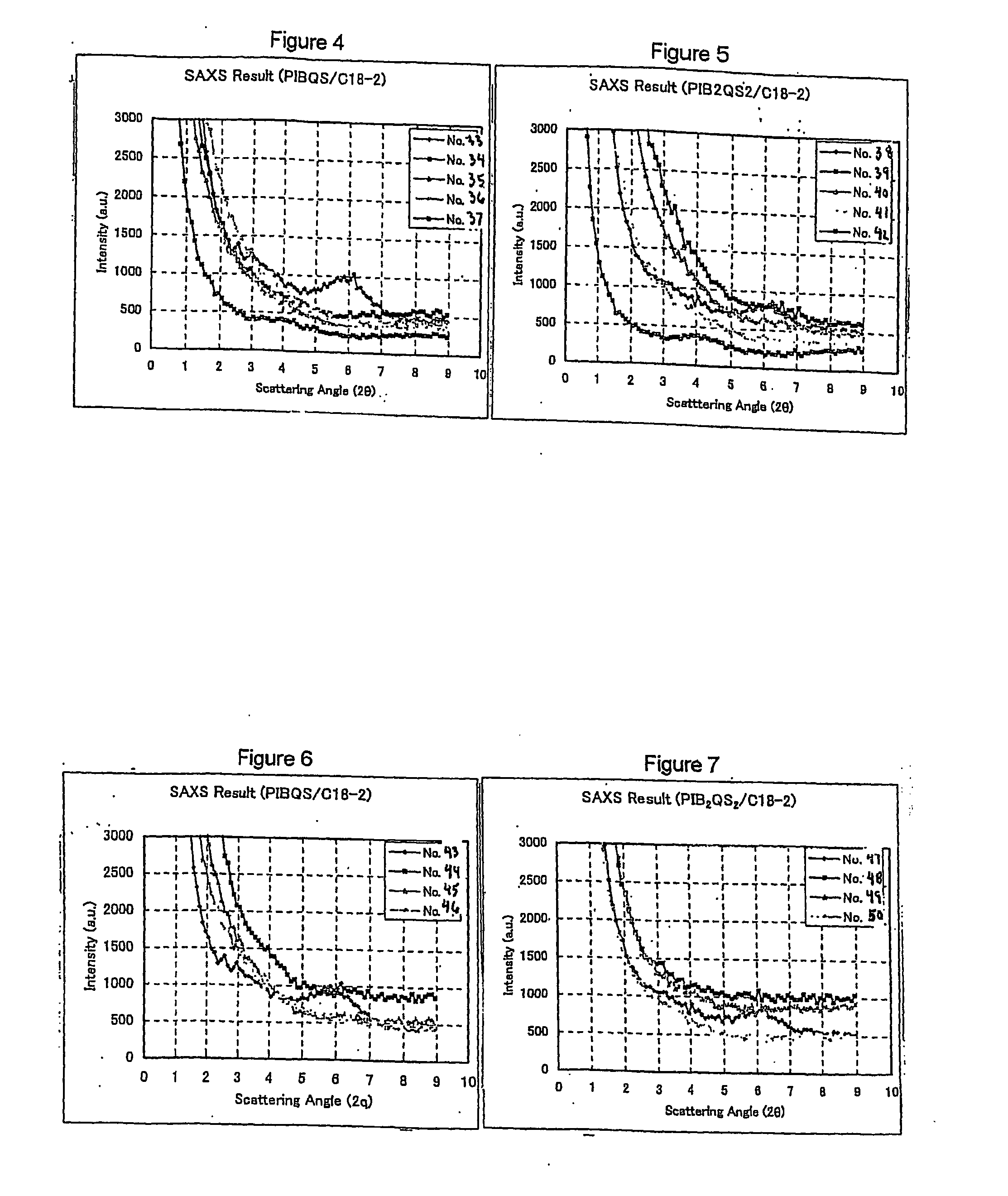

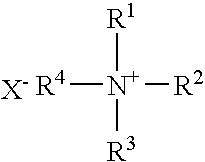

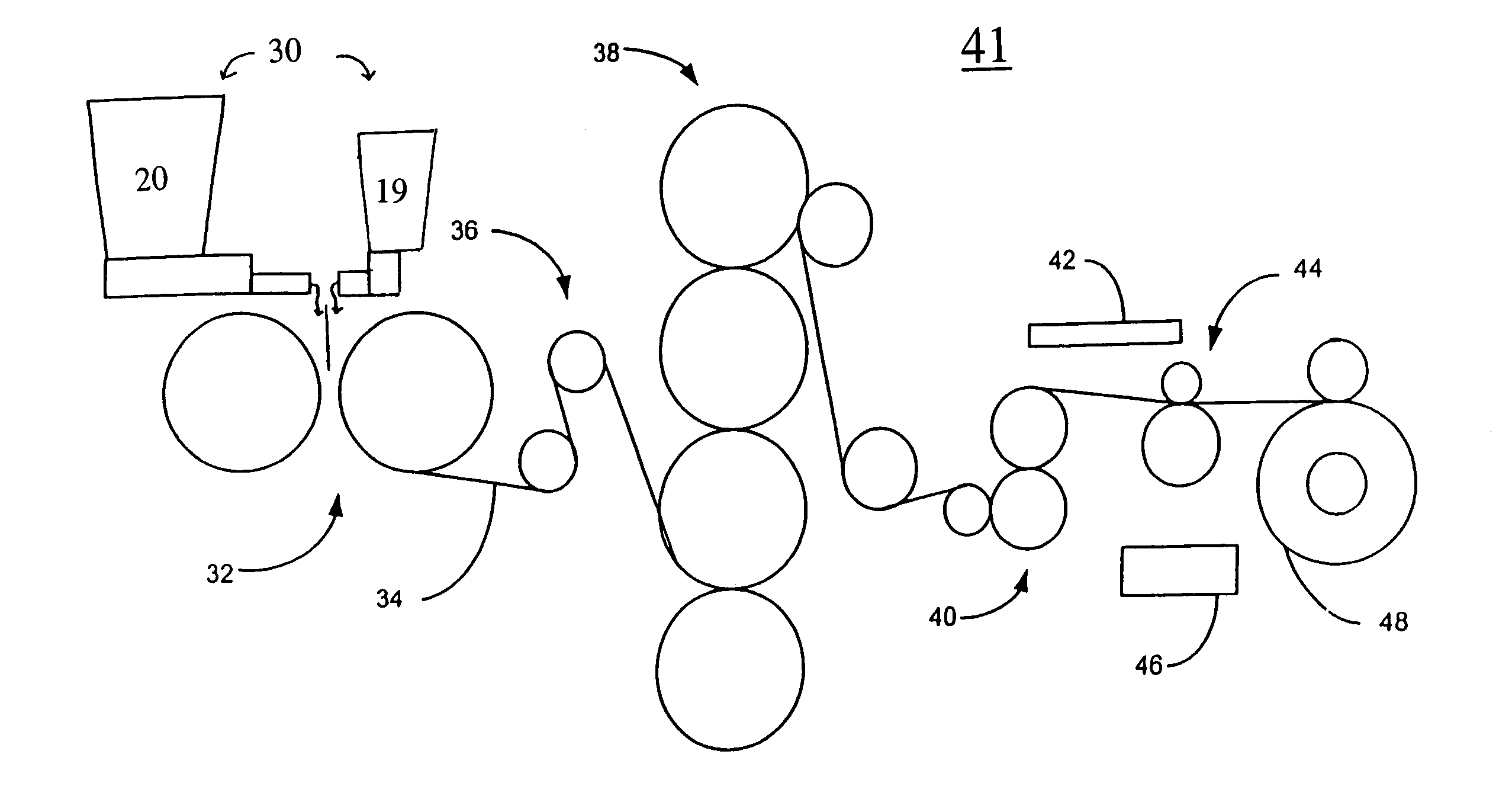

Method for clay exfoliation, compositions therefore, and modified rubber containing same

InactiveUS20060235128A1Reduce air permeabilityLow gas permeabilityPigmenting treatmentLayered productsPolymer scienceButyl rubber

A polymer composition of low gas permeability. The composition includes an exfoliated organically-modified clay, butyl rubber, and a polymeric exfoliant. A method for producing the butyl composition by dry mixing the butyl rubber with the exfoliated clay is also provided.

Owner:BRIDGESTONE CORP

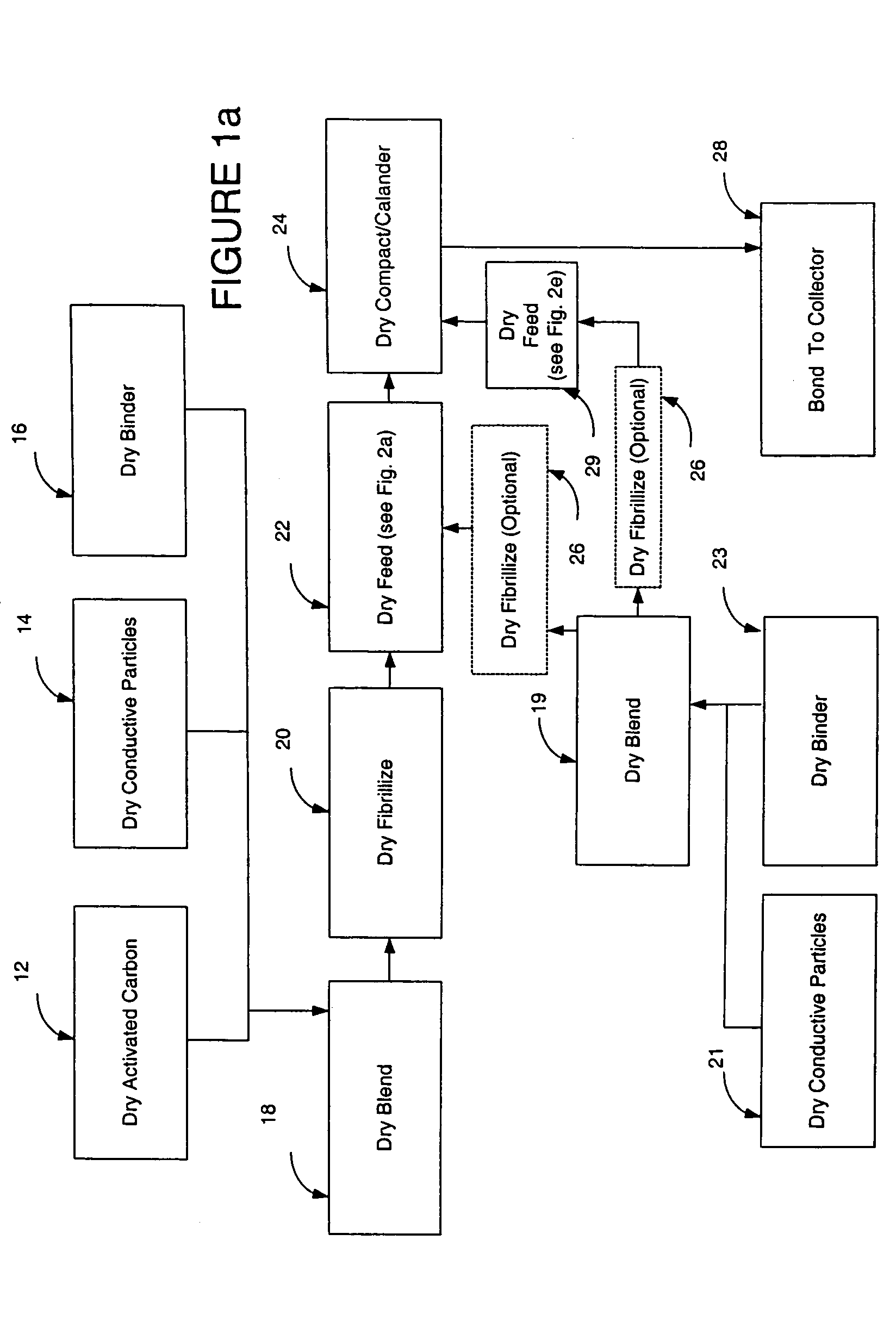

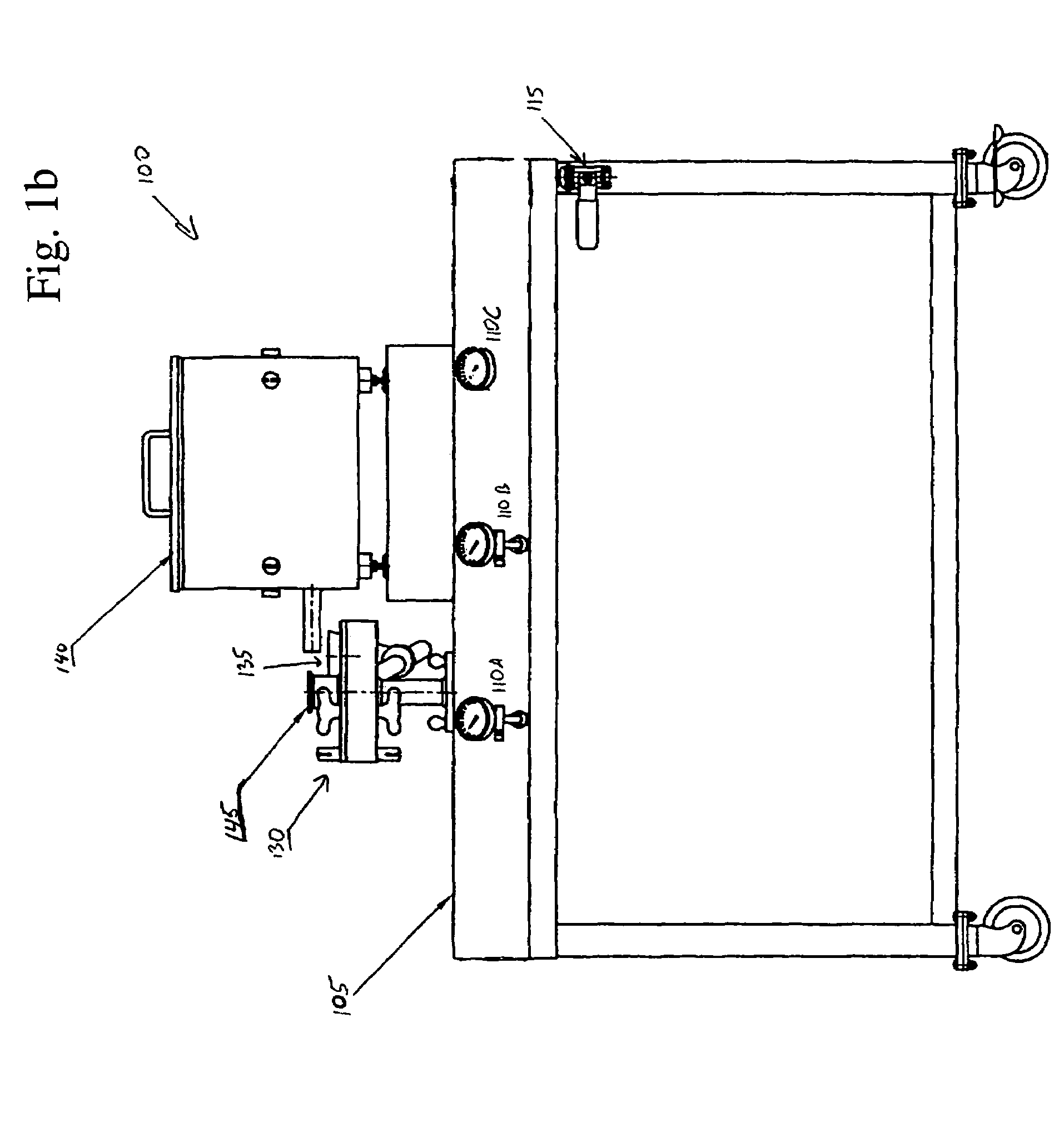

Dry particle based capacitor and methods of making same

ActiveUS7352558B2High yieldInexpensive and durable and highly reliableHybrid capacitor electrodesWound capacitorsFiberDry mixing

An inexpensive and reliable dry process based capacitor and method for making a self-supporting dry electrode film for use therein is disclosed. Also disclosed is an exemplary process for manufacturing an electrode for use in an energy storage device product, the process comprising: supplying dry carbon particles; supplying dry binder; dry mixing the dry carbon particles and dry binder; and dry fibrillizing the dry binder to create a matrix within which to support the dry carbon particles as dry material.

Owner:TESLA INC

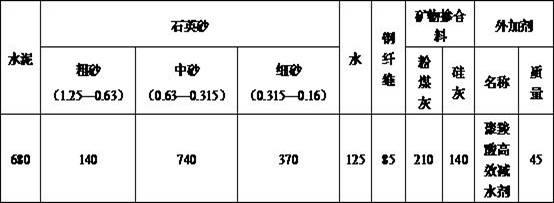

High-strength active powder concrete and preparation method

InactiveCN102320789AImprove performanceImprove uniformityCeramic shaping apparatusDry mixingWater reducer

The invention discloses a cement-based composite material - high-strength active powder concrete which comprises the following raw materials by weight: 40-55 parts of quartz sand, 25-30 parts of cement, 0-10 parts of fly ash, 0-7 parts of silica fume, 1-4 parts of steel fibers, 1-2 parts of water reducers, and 2-7 parts of water; in the components, the particle size of quartz sand is less than 1.25 mm, wherein the weight content of SiO2 is 97%. The mixing preparation comprises the following steps: weighing quartz sand and steel fibers according to the mixing ratios, adding into a stirring pot, performing dry mixing for 2 min; weighing cement and a special composite admixture according to the mixing ratios, adding into the stirring pot, performing dry mixing with quartz sand and steel fibers for 2 min; finally adding the high-efficient water reducer and water together, stirring for 6 min; after the stirring of the concrete, blanking and molding. The concrete of the invention has ultrahigh strength, low brittleness, high durability, and high compactness, brings into better play of the excellent performance of the active powder concrete, and reaches the purposes of less maintenance or free of maintenance, and prolongation of structure service life.

Owner:SICHUAN SOUTHWEST JIAOTONG UNIV RAILWAY DEV

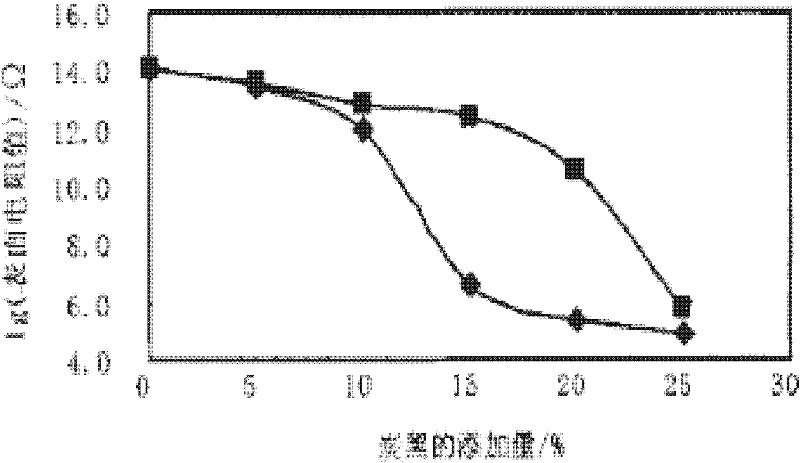

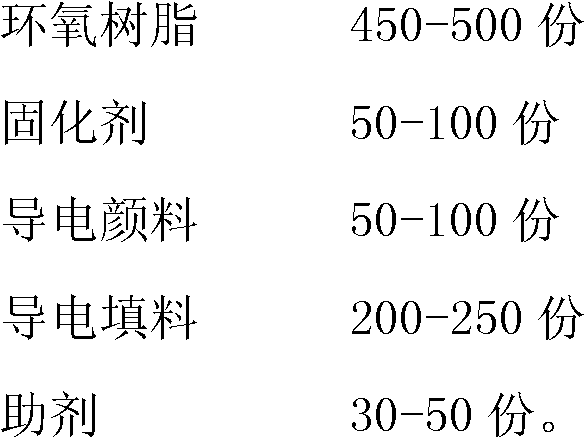

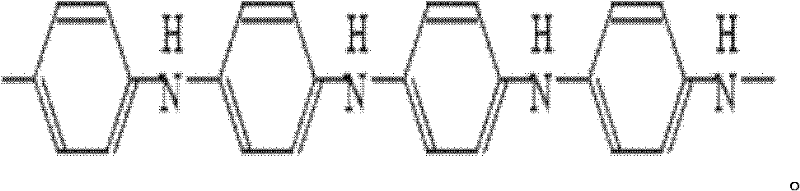

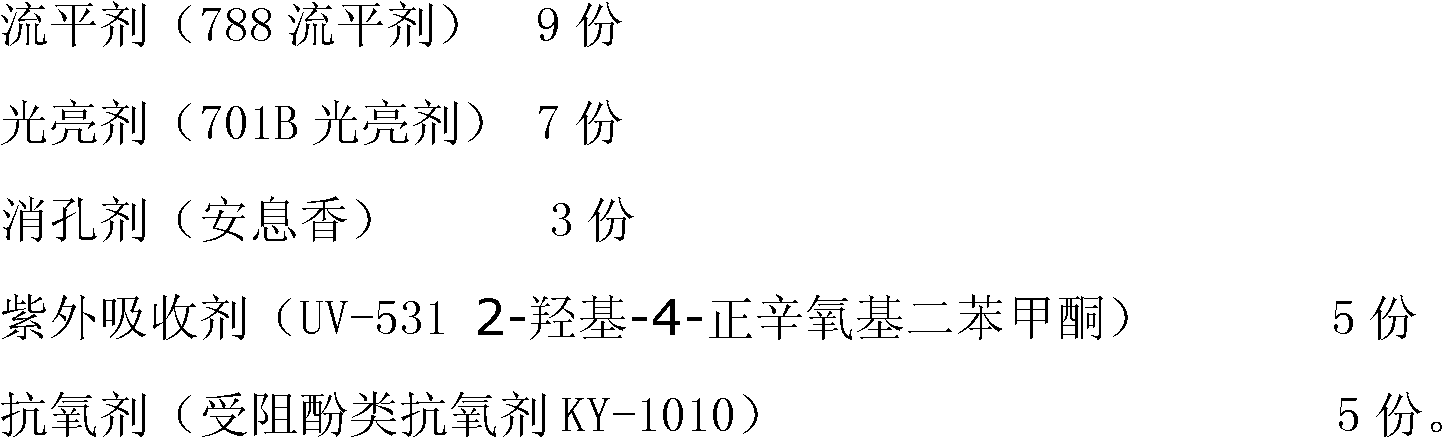

High-electric-conductivity heavy-anticorrosion wave-absorbing powder paint

ActiveCN102408813AImprove corrosion resistanceImprove bending resistanceAnti-corrosive paintsPowdery paintsEpoxyElectrical conductor

The invention relates to a high-electric-conductivity heavy-anticorrosion wave-absorbing powder paint which is prepared from the following raw materials in parts by weight: 450-500 parts of epoxy resin, 50-100 parts of curing agent, 50-100 parts of conductive pigment, 200-250 parts of conductive filler and 30-50 parts of assistant. The preparation method of the high-electric-conductivity heavy-anticorrosion wave-absorbing powder paint comprises the following steps: adding the materials into a high-speed mixer; after carrying out dry mixing, adding the mixture into an extruder, and melting, mixing, cooling and pelleting at the extrusion temperature of 80-90 DEG C; and pulverizing with a pulverizer, grading, screening and packaging to obtain the finished powder paint product. The invention has the characteristic of high electric conductivity, has an absorption action on certain electromagnetic waves, can be used as a preferred coating for electromagnetic shielding, and is applied to thefields of frequency converter shells, micro-current and light-current component shells and the like. In addition, the invention has excellent anticorrosion property and favorable electric conductivity (105 ohm), and the conducting power is almost approximate to that of a metallic conductor; and thus, the high-electric-conductivity heavy-anticorrosion wave-absorbing powder paint is an ideal antistatic coating, and can ensure safety in the aspects of fire resistance and explosion resistance.

Owner:国润恒科(天津)防腐工程技术有限公司

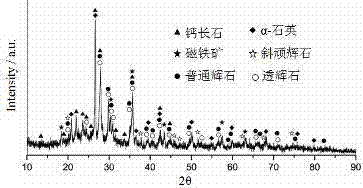

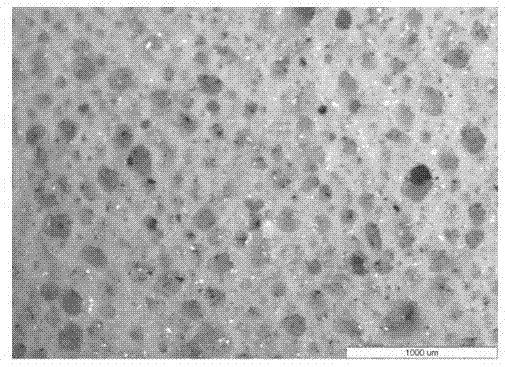

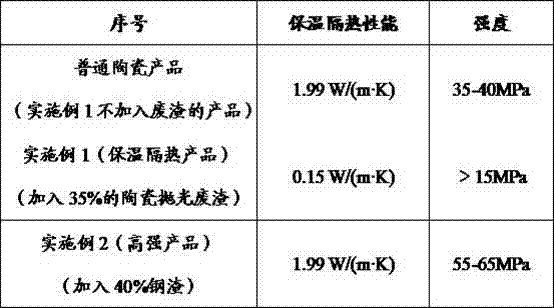

Architectural ceramic prepared from industrial solid waste through dry method and process for preparing architectural ceramic

ActiveCN103570340AReduce the cost of degummingSave the drying processCeramic materials productionClaywaresFluidized bed dryingThermal insulation

The invention discloses architectural ceramic prepared from industrial solid waste through a dry method and a process for preparing the architectural ceramic. The architectural ceramic comprises the following components in percentage by mass: 30-60% of solid waste, 40-70% of ceramic raw material and 1-3% of ceramic additive, wherein the ceramic raw material is selected from one or a composition of multiple of clay raw material, feldspar raw material or talc, and the ceramic additive is one or a combination of multiple of sodium tripolyphosphate, sodium silicate, ammonium chloride, ammonium citrate, sodium humate, sodium lignin sulfonate sodium, ethylenediamine tetraacetic acid disodium and edetic acid. After being pretreated, the granules of the solid waste are fine and are mixed evenly in a dry mixing manner and a spray drying manner and are directly used for pressing of green bricks or stored in a bin for standby, so that the ball milling energy consumption and the peptization cost are reduced, the humidification pelleting and fluidized bed drying procedures are omitted, the formula can be quickly adjusted according to the functional characteristics of the architectural ceramic, the process is simple and convenient to control, and the architectural ceramic has such good properties as heat preservation, thermal insulation and high strength.

Owner:FOSHAN OCEANO CERAMICS +1

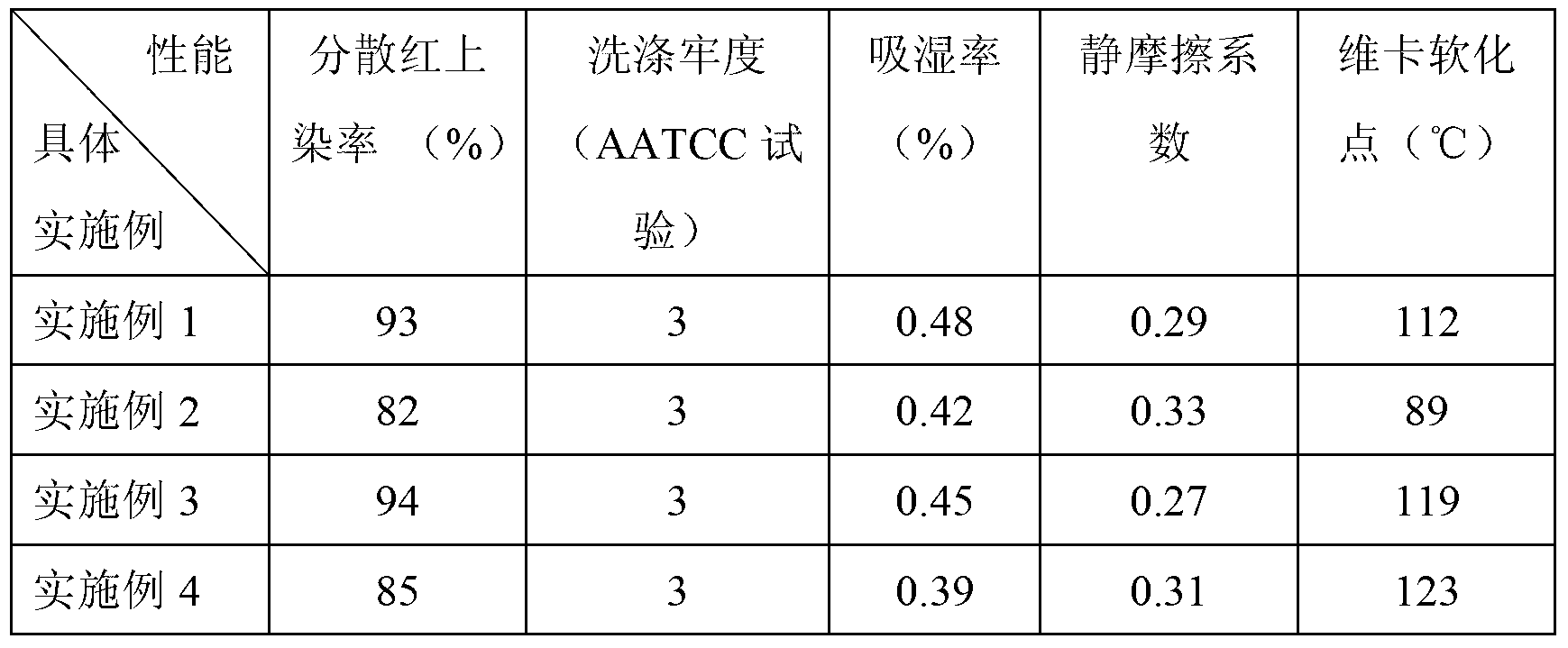

Modified polylactic acid fiber and preparation method thereof

ActiveCN103225125ASave raw materialsRich sourcesMelt spinning methodsMonocomponent polyesters artificial filamentEnvironmental resistanceCellulose diacetate

The invention discloses a modified polylactic acid fiber and a preparation method thereof. The modified polylactic acid fiber is prepared through blending polylactic acid, a cellulose derivative, a cellulose diacetate grafted polylactic acid copolymer, a lubricant, inorganic nanoparticles, a nucleating agent and an antioxidant. The preparation method comprises the following steps: adding partial polylactic acid slices and all other raw materials to a high speed mixer according to a mass component ratio, carrying out high speed dispersion, and carrying out melt blending and extrusion through a double screw extruder to obtain modified polylactic acid master batch slices; and carrying out dry mixing of the modified polylactic acid master batch slices and residual polylactic acid slices in the high speed mixer, carrying out melt spinning through a melt spinning machine, and stretching to obtain the modified polylactic acid fiber. The prepared polylactic acid fiber has the advantages of low cost, complete biodegradation, environmental protection, good spinning performance, stable filament bundle quality, excellent flexibility, excellent antifriction, excellent dyeing property and excellent comfortableness, and is a very good high-performance environmentally-friendly fiber material. The preparation method has the advantages of simplicity, low equipment requirement, and environmental protection in the production process, and is in favor of the industrialized production.

Owner:长沙乐远化工科技有限公司

Krill oil microcapsual powder and its preparation method

The invention discloses a krill oil microcapsual powder and its preparation method. The preparation method comprises steps of: preparation of an oil phase solution and an aqueous phase solution, mixing and emulsification of the two solutions, homogenizing, drying and the like. The krill oil microcapsual powder is prepared from the following raw materials of: by weight, 0.001-90% of krill oil, 0.5-90% of sodium caseinate and 0-99% of a filler. In addition, 0.001-10 wt% of an oil phase antioxidant, 0.001-5 wt% of an aqueous phase antioxidant, 0.001-5 wt% of an aqueous stabilizer and 0.001-5 wt% of an anti-caking agent can also be added. The krill oil microcapsual powder has high content of the encapsuled krill oil and has good stability and fluidity. After rehydration, krill oil can be dispersed into water completely in the form of particles (nm); and krill oil is stable if stored for a long time, and has no phenomenon such as floating oil, precipitation, adhesion to bottles and the like. therefore, the application range of krill oil is broadened, and krill oil is applied to fields such as dry mixing, drinks, dairy products, bakery, tablets and the like.

Owner:辽渔集团有限公司

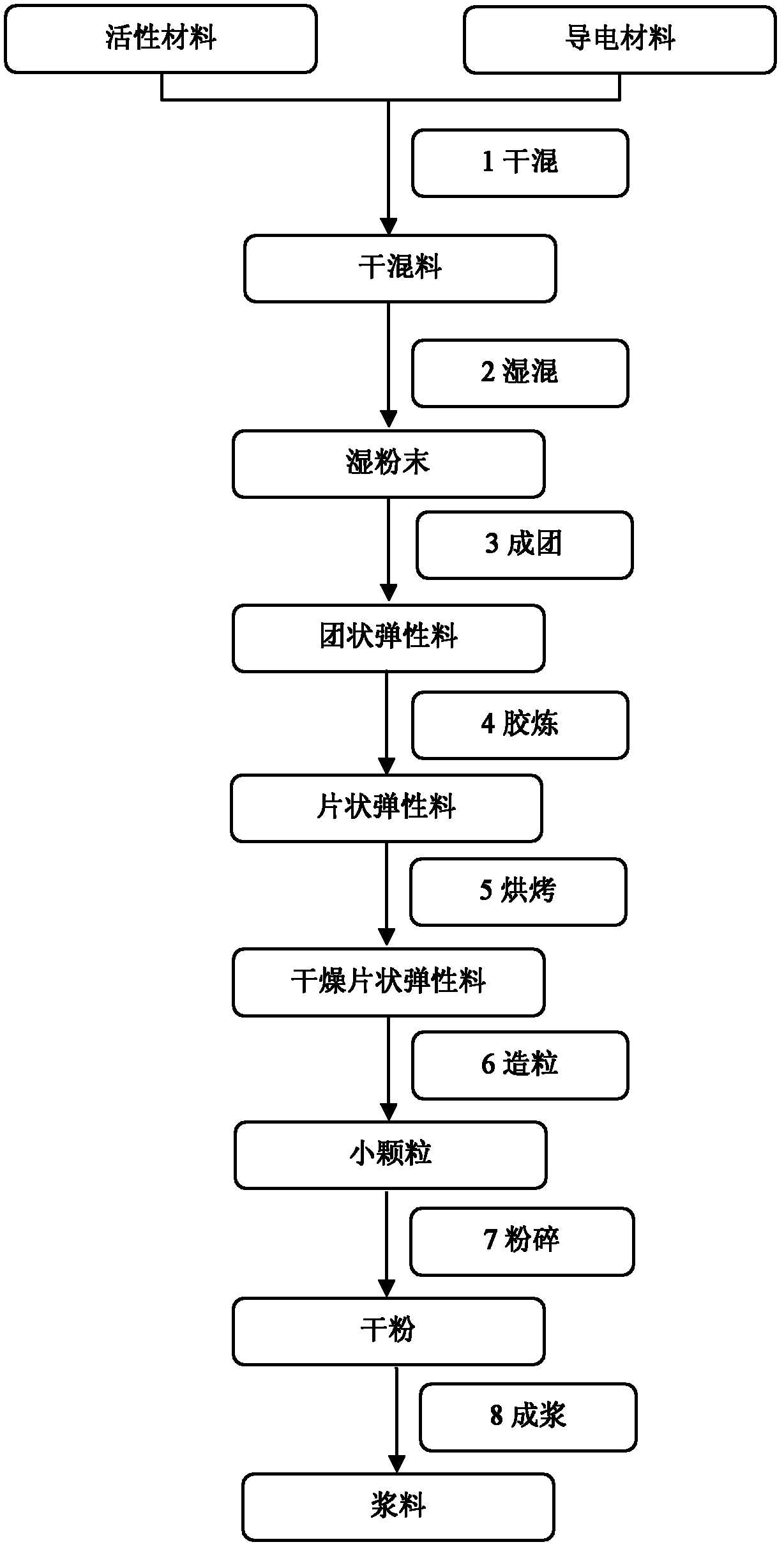

Electrode of supercapacitor, preparation method of electrode and preparation method of slurry of electrode

ActiveCN102637531AHigh solid contentGood dispersionProtecting/adjusting hybrid/EDL capacitorElectrolytic capacitorsInternal resistanceAdhesive

The invention provides a preparation method of slurry for an electrode of a supercapacitor, the electrode of the supercapacitor and a preparation method of the electrode of the supercapacitor. A eight-stage slurry preparation process is adopted in the preparation method of the slurry, and the preparation method of the slurry comprises the following steps of: I, dry mixing; II, wet mixing; III, lumping; IV, rubber mixing; V, roasting; VI, pelleting; VII, smashing; and VIII, slurry forming. The preparation method of the slurry can be used for increasing the solid content of the slurry, reducing the using amount of an adhesive, improving the dispersing effect of the slurry, realizing the quantitative control for the slurry preparation process and achieving better process stability and consistency. The electrode prepared by using the slurry has the advantages that the strength of the electrode is enhanced, the internal resistance of the electrode is reduced, the electrochemical stability and the structural stability of the electrode are improved, the reliability of the supercapacitor with the electrode is improved, and the service life of the supercapacitor is prolonged.

Owner:TIG TECH CO LTD

Mixed casting molding sand and preparation method thereof

The invention discloses a mixed casting molding sand and a preparation method thereof. The preparation method mainly comprises: performing dry mixing of component raw materials including quartz sand, attapulgite, wax, asbestos, a furan resin, a phenolic resin, bentonite and potassium dichromate by certain weight parts; and adding water, mixing, placing sand, molding, casting, cooling and separating to obtain finished product. The preparation method of the invention is simple, the formula is reasonable, the cost is low, the production efficiency is high, the surface of an aluminum sand piece is made smooth by strictly controlling the particle size of quartz sand, and the breathability is high.

Owner:邹平县永通金属材料有限公司

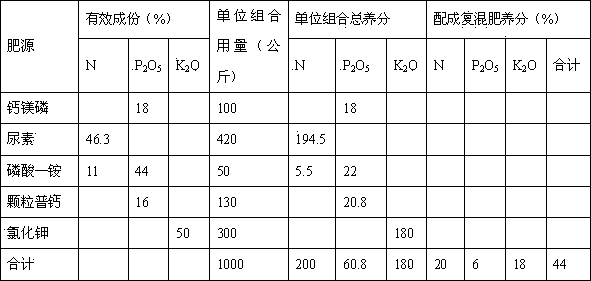

Formula for producing special blending fertilizer for paddy rice by combining calcium magnesium phosphate powder with fertilizer source of granular superphosphate

The invention discloses a formula for producing a special blending fertilizer for paddy rice by combining a calcium magnesium phosphate powder with a fertilizer source of urea. The invention is characterized in that: the calcium magnesium phosphate powder is combined with fertilizer sources of granular superphosphate and urea to form a layer of calcium magnesium phosphate film on the granular surface; the special blending fertilizer not only prevents the deliquescing phenomenon caused by direct contact of superphosphate with urea, but also can reduce phosphorus fixation and utilization of slow release nitrogen when applied into soil; furthermore, the calcium magnesium phosphate fertilizer contains medium trace elements essential to crop growth, and is truly a multi-element compound fertilizer. 0.9-1.1 parts of high quality calcium magnesium phosphate powder, 4.1-4.3 parts of combination urea, 0.4-0.6 part of monoammonium phosphate, 1.2-1.4 parts of granular superphosphate and 2.9-3.1 parts of potassium chloride are subjected to dry mixing and blending and packaging by bags; and the blending fertilizer contains 44% of total nutrients of nitrogen, phosphorus and potassium, wherein the three are in the ratio of 20:6:18.

Owner:刘吴阳

Gabapentin tablets and method for their preparation

InactiveUS20060039968A1Treat painOrganic active ingredientsPeptide/protein ingredientsGabapentinDry mixing

The present invention is generally directed to methods for preparing stable gabapentin tablets by wet granulation. A wet granulation method for preparing gabapentin tablets includes forming a mixture by dry mixing of a first portion of a binder with the gabapentin, one or more excipients, or a combination of the gabapentin and the one or more excipients; and adding a second portion of the binder to the mixture, wherein the second portion of the binder is in the form of a solution or dispersion.

Owner:RANBAXY LAB LTD

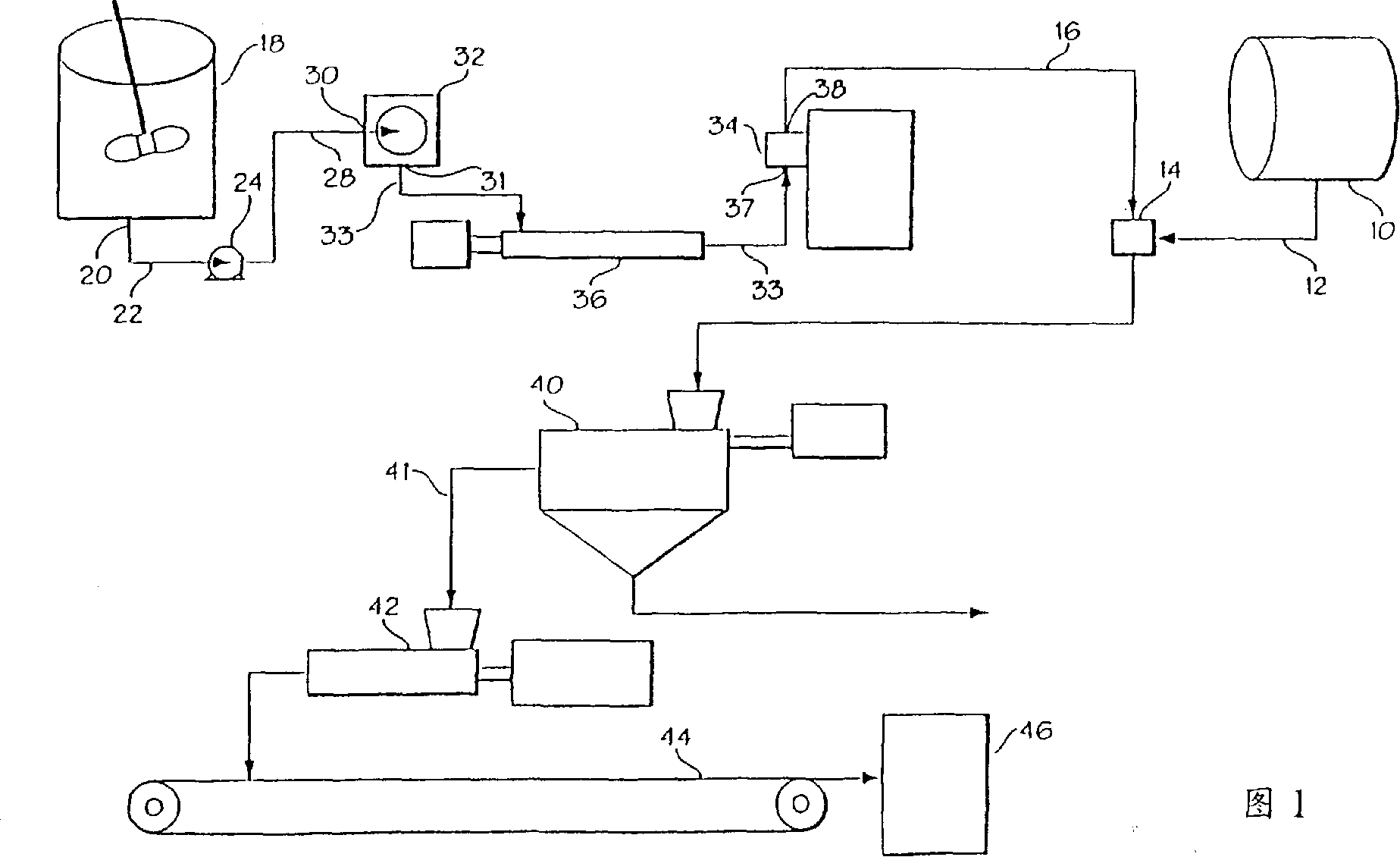

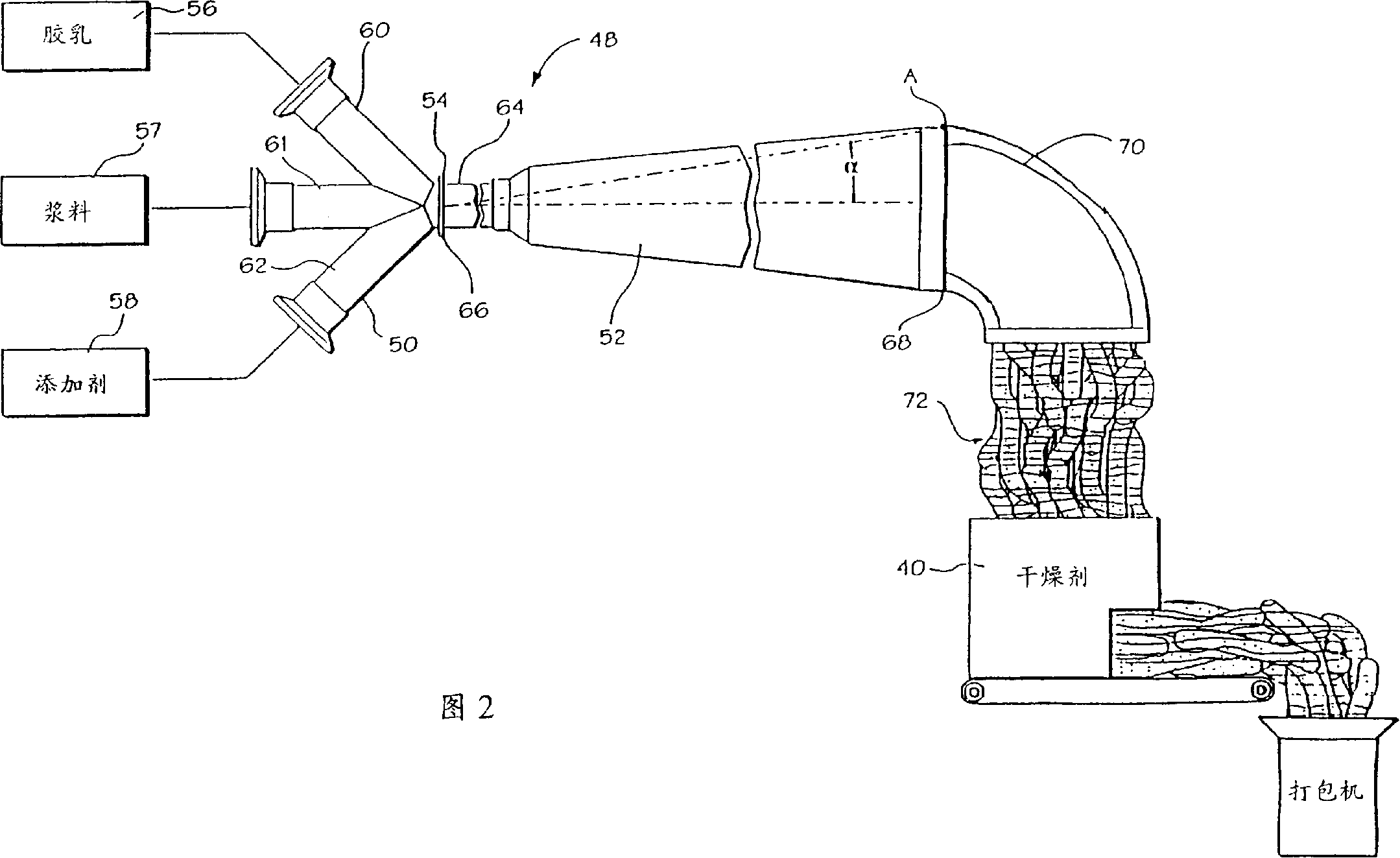

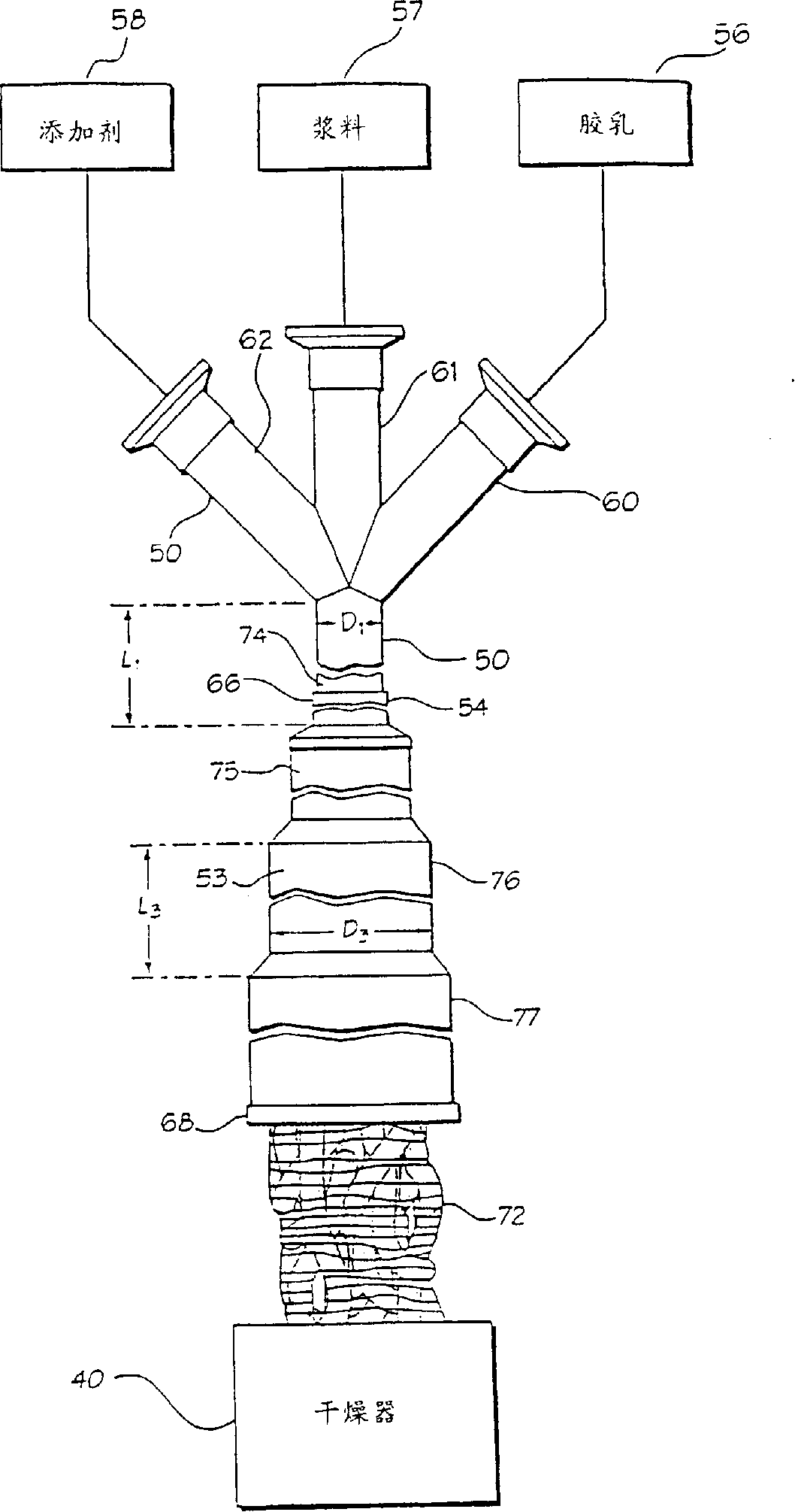

Elastomer composite blends and method for producing them

Elastomer composite blends are produced by novel wet / dry mixing methods and apparatus. In the wet mixing step or stage, fluid streams of particulate filler and elastomer latex are fed to the mixing zone of a coagulum reactor to form a mixture in semi-confined flow continuously from the mixing zone through a coagulum zone to a discharge end of the reactor. The particulate filler fluid is fed under high pressure to the mixing zone, such as to form a jet stream to entrain elastomer latex fluid sufficiently energetically to substantially completely coagulate the elastomer with the particulate filler prior to the discharge end. Highly efficient and effective elastomer coagulation is achieved without the need for a coagulation step involving exposure to acid or salt solution or the like. Elastomer composites are produced. Such elastomer composites may be cured or uncured, and combine material properties, such as choice of filler, elastomer, level of filler loading, and macro-dispersion, nor previously achieved. The coagulum produced by such wet mixing step, with or without intermediate processing steps, is then mixed with additional elastomer in a dry mixing step or stage to form elastomer composite blends. The additional elastomer to the coagulum may be the same as or different from the elastomer(s) used in the wet mixing step.

Owner:CABOT CORP

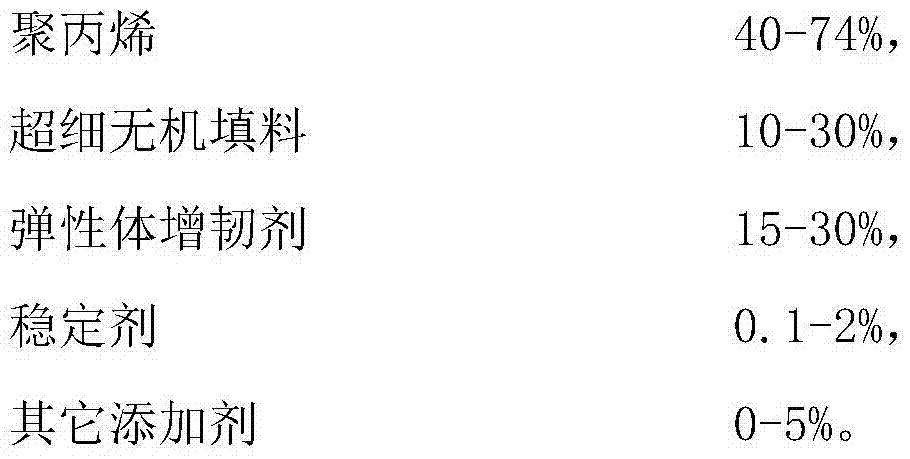

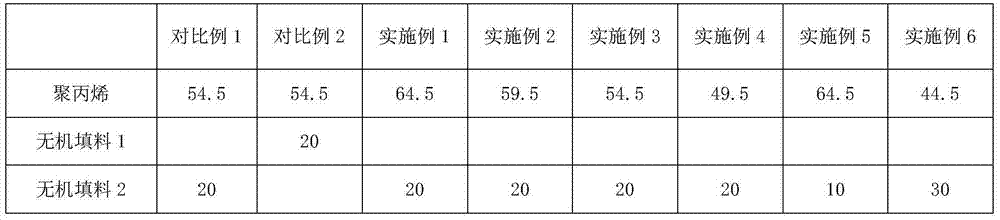

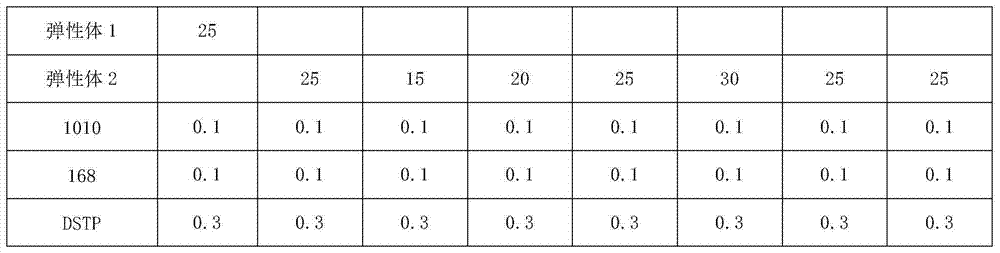

High-modulus and ultrahigh-impact polypropylene composite material and its preparation method

ActiveCN103923381AImprove low temperature toughnessImprove rigidityElastomerPolypropylene composites

The invention discloses a high-modulus and ultrahigh-impact polypropylene composite material and its preparation method. The composite material comprises 40-74wt% of polypropylene, 10-30wt% of an ultrafine inorganic filler, 15-30wt% of an elastomer flexibilizer, 0.1-2wt% of a stabilizer, and 0-5wt% of other additives. The preparation method comprises the following steps: carrying out dry mixing on raw materials in a high speed mixer for 3-15min, adding the mixed raw materials into a double screw extruder, carrying out melt extrusion, and carrying out cooling granulation. The preparation method has the following advantages:1, a ethylene-butylene copolymer is used as the elastomer flexibilizer, so the polypropylene composite material has better low temperature toughness than traditional toughening modified polypropylene; 2, ultrafine talcum powder is used as the inorganic filler, so the toughness loss can be reduced as much as possible, and the rigidness of the material is greatly improved; and 3, the synergistic effect of the ultrafine talcum powder and the elastomer flexibilizer is utilized, so the polypropylene composite material has more ideal rigidness-toughness balance than the traditional toughening modified polypropylene.

Owner:SHANGHAI PRET COMPOSITES +2

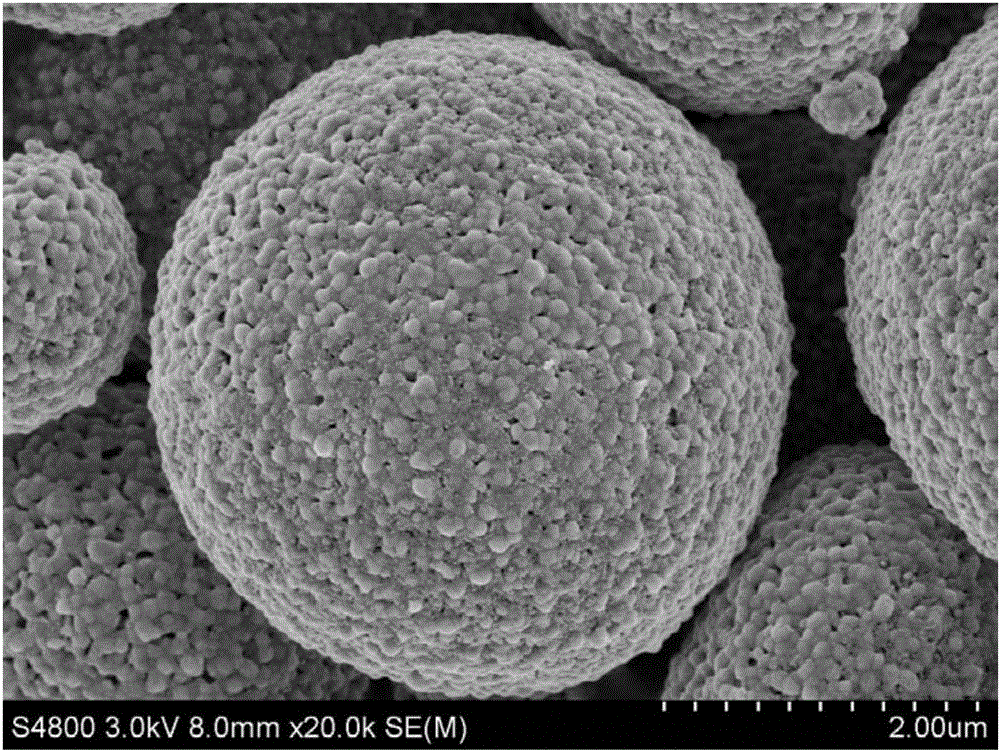

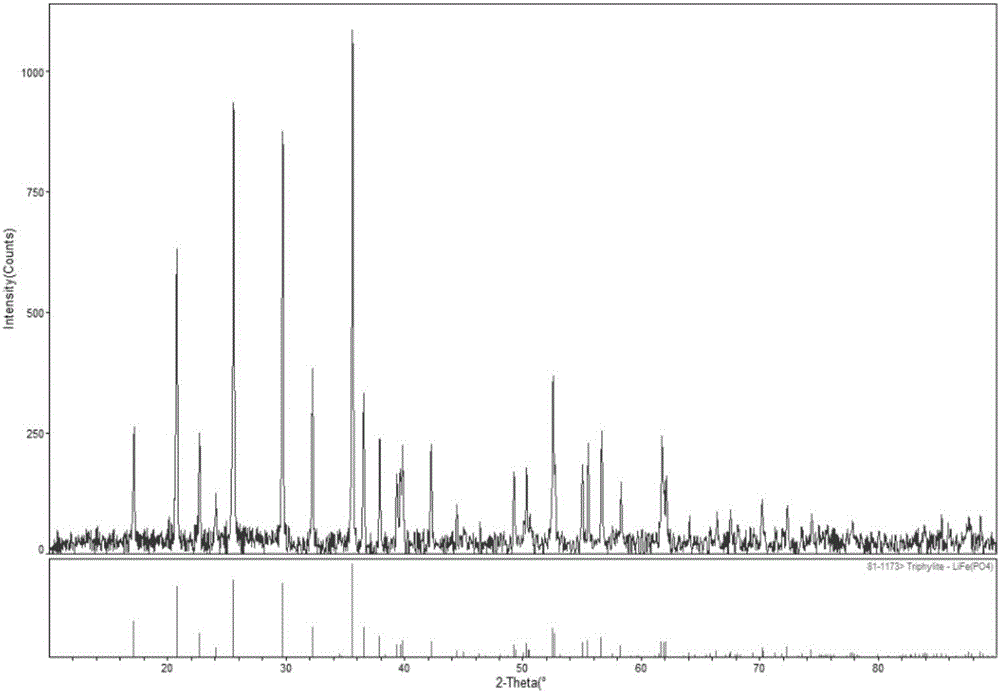

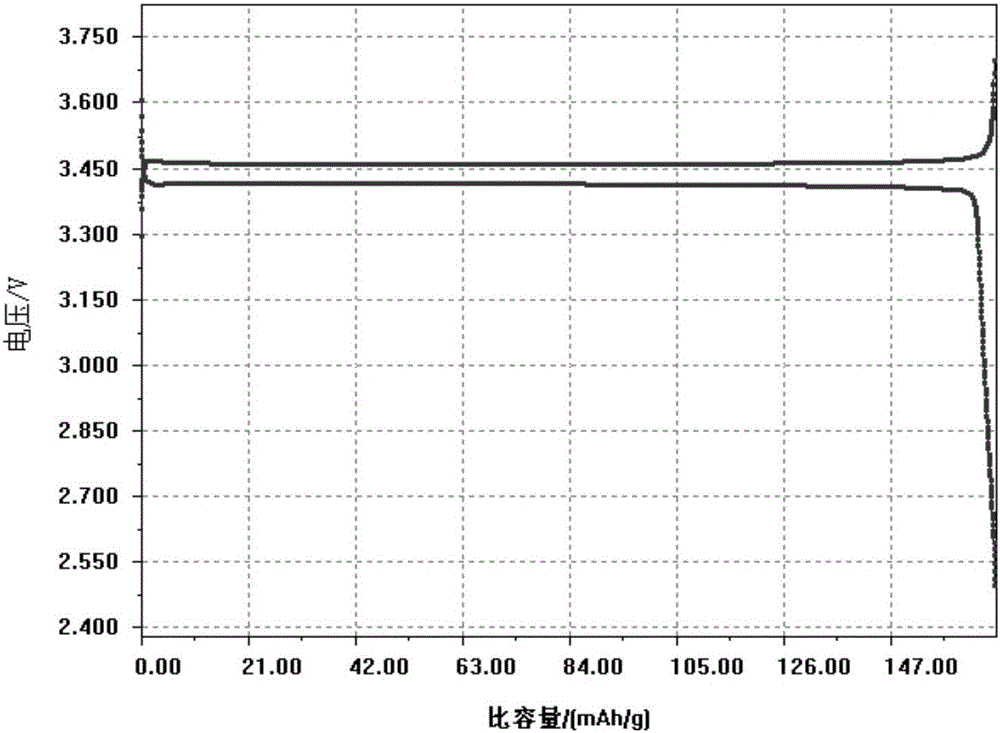

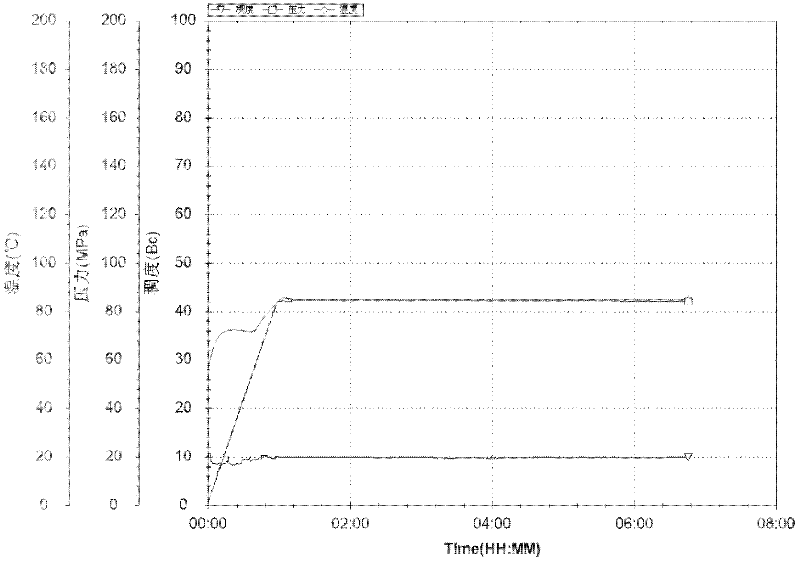

High density spherical nano lithium iron phosphate material, a preparation method thereof, and lithium ion battery containing same

ActiveCN106229505ATightly boundImprove liquidityCell electrodesSecondary cellsSodium-ion batteryLithium-ion battery

A high density spherical nano lithium iron phosphate material, a preparation method thereof, and a lithium ion battery containing the same are provided. The preparation method comprises the following steps: (1) pre-sintering a lithium resource, iron phosphides, adulterant, and a carbon source with protective gas after dry mixing; (2) mixing a pre-sintering material, dispersant, and deionized water, and performing ultra fine grinding; (3) performing spray drying on a sizing agent obtained by ultra fine grinding, to obtain a spherical nano lithium iron phosphate precursor; and (4) performing chemical vapor deposition coating on the spherical nano lithium iron phosphate precursor obtained in step (3), to prepare the high density spherical nano lithium iron phosphate material. A primary particle size of the lithium iron phosphate material prepared in the present invention is not large, and a powder conductivity may reach 10.1 S / cm, so that a material capacity, low temperature, rate performance, and fabrication and cycling performance may be well balanced.

Owner:江苏贝特瑞纳米科技有限公司

Efficient anti-pollution isolation liquid for well cementation and preparation method thereof

ActiveCN102337108AWide temperature rangeFlexible control of rheologyDrilling compositionDry mixingEngineering

The invention relates to an efficient anti-pollution isolation liquid for well cementation and a preparation method thereof, belonging to the technical field of well cementation. The isolation liquid comprises the following components in parts by weight: 100 parts of clear water, 4-29 parts of suspending stabilizer, 0.5-5 parts of fluid loss additive, 0.3-2 parts of tackifier, 0.1-5 parts of diluting agent, 0-5 parts of viscosity and shearing force increasing agent, 30-350 parts of weighting agent, 1-25 parts of pH value regulating agent and 0.1-0.5 part of defoamer. The isolation liquid provided by the invention has wide density regulation range, large temperature resisting range, strong anti-pollution capacity, wide applicability and strong maneuverability, can be conveniently subjected to in-situ preparation, can be prepared by using a mud tank equipment base fluid method or cement vehicle equipment dry-mixing method, and can apply effective abrasion, scraping and carrying effects to attachments on an interface of a well wall; and by using the isolation liquid, the problems that in the well cementation operation, pollution is generated by fluid displacement, the adhering quality of a well cementation interface is poor and the like are effectively solved.

Owner:SOUTHWEST PETROLEUM UNIV

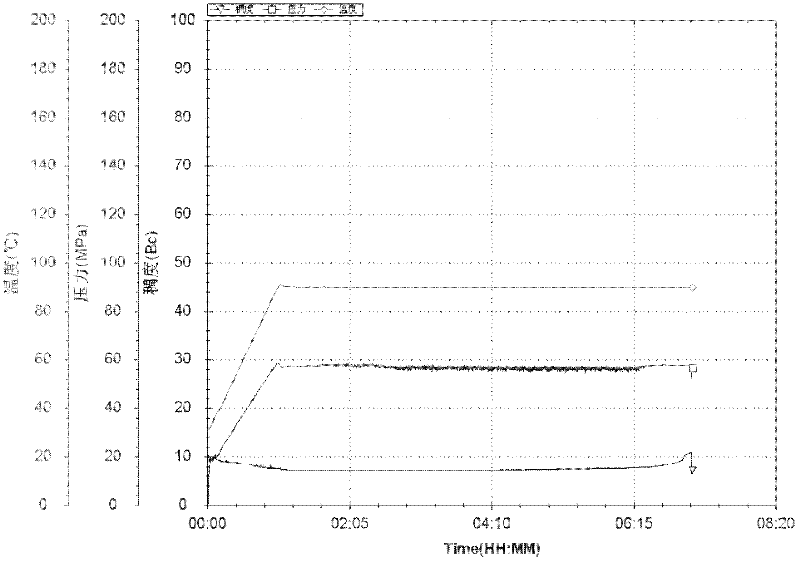

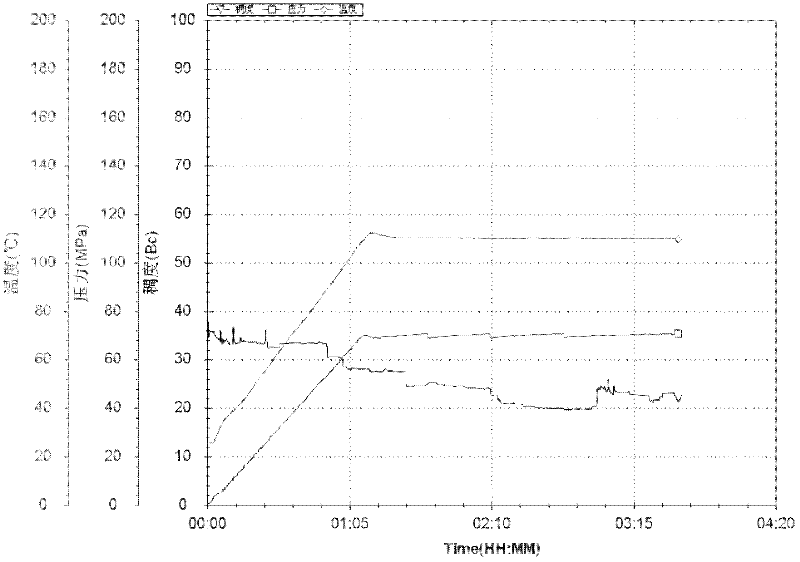

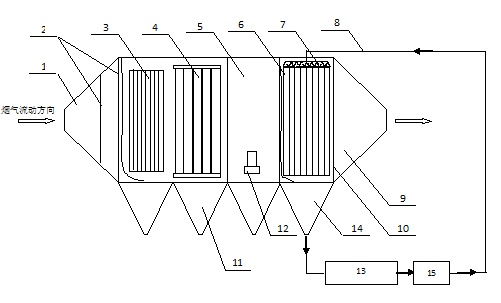

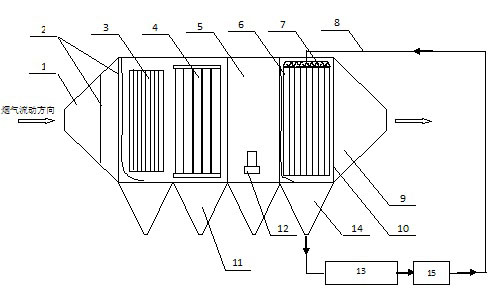

Wet-dry mixing electric dust remover

InactiveCN101816975AEfficient dust removalImprove dust removal efficiencyExternal electric electrostatic seperatorElectrodes cleaningEmission standardEngineering

The invention relates to a wet-dry mixing electric dust remover. The electric dust remover mainly consists of an inlet smoke box, an air flow uniformly-distributing plate, a shell, a cathode line, an anode plate, an outlet smoke box, an outlet trough-shape plate, a rapping device, an ash bucket, a water distribution device and a water tank. The electric dust remover is characterized in that the upstream in the inflow direction of the smoke gas or the exhaust gas is provided with a dry-type ash removal electric field which adopts mechanical rapping, electromagnetic rapping or acoustic wave to remove the ash, the last electric field is a wet-type ash removal electric field which adopts a water film to remove the ash, the dry-type ash removal electric field and the wet-type ash removal electric field are arranged in the same shell, and the wet-type ash removal electric field is connected with an ash removal water treatment recycling system. The invention integrates the advantages of the dry-type electric dust removal and the wet-type electric dust removal, efficiently removes dust, ensures emission standards and minimizes the corrosion protection investment caused by the wet-type ash removal, the water treatment equipment investment and the running cost.

Owner:SHANDONG ELECTRIC POWER RES INST

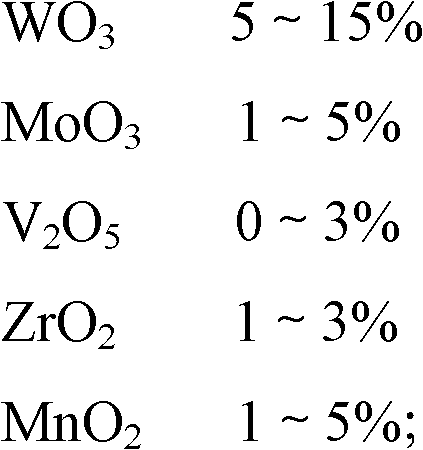

Monolithic cellular catalyst for SCR smoke denitration and preparation technology thereof

ActiveCN102380370AReduce dry molding conditionsHigh mechanical strengthDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsGlass fiberDry mixing

The invention discloses a monolithic cellular catalyst for SCR smoke denitration, which adopts TiO2 powder as a substrate. The catalyst is added with active ingredients and additive at the same time. The active ingredients comprise TiO2, WO3, MoO3, V2O5, ZrO2 and MnO2. The additive comprises water reducer, binder, pore-forming agent, extrusion assistant and glass fiber. The invention further discloses a preparation technology for the monolithic cellular catalyst for SCR smoke denitration, comprising the following steps: dry mixing, kneading and pugging to obtain a mud section with good plasticity and a compact structure; extruding to obtain the blank of the monolithic cellular catalyst; drying and baking to obtain the monolithic cellular catalyst for SCR smoke denitration. The invention has simple preparation technology, greatly reduces the water quantity during the kneading process through adding the water reducer which is adopted as one active ingredient, reduces the maintaining conditions of the catalyst after being formed, and improves the strength, abrasion resistance and yield for forming the catalyst.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

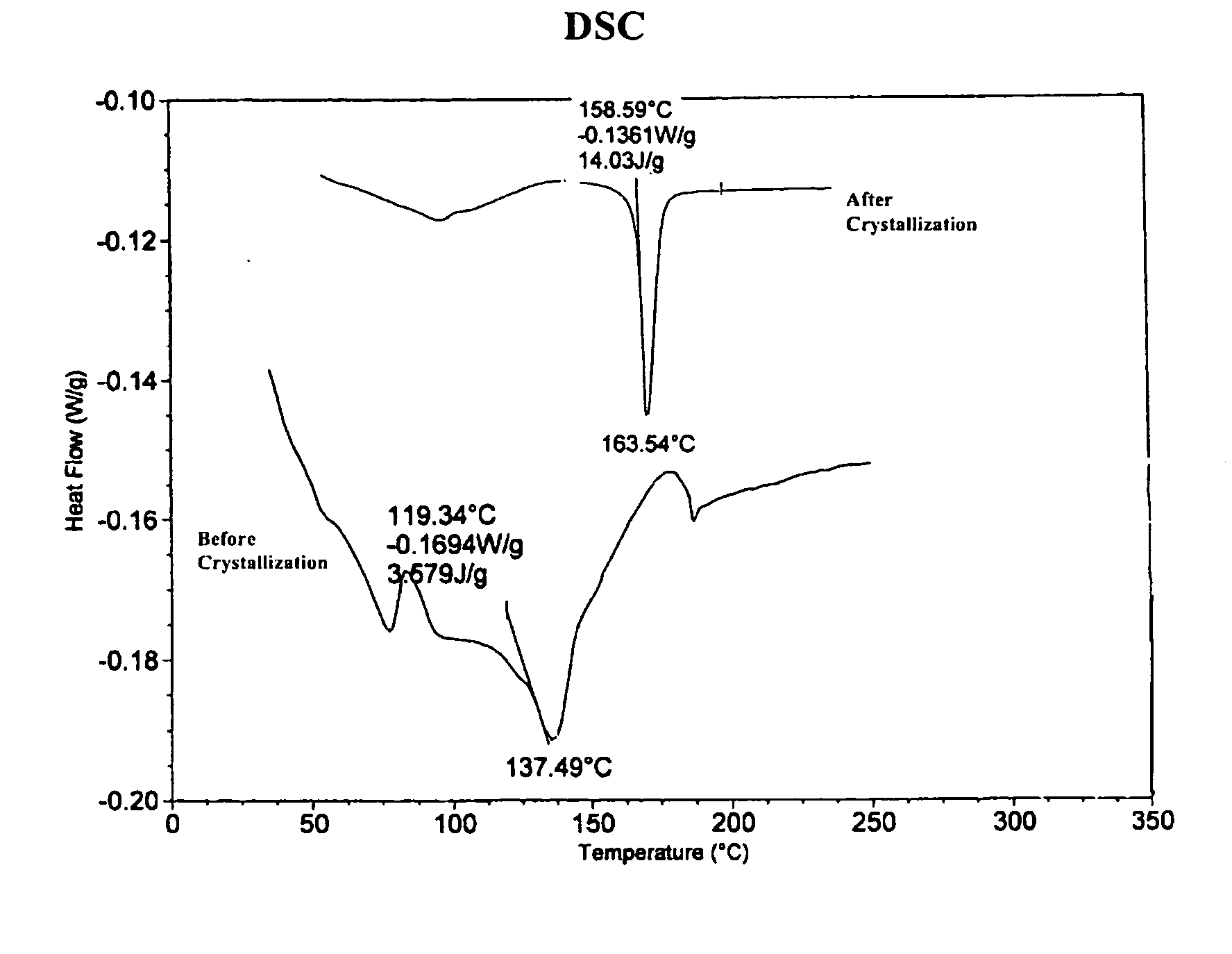

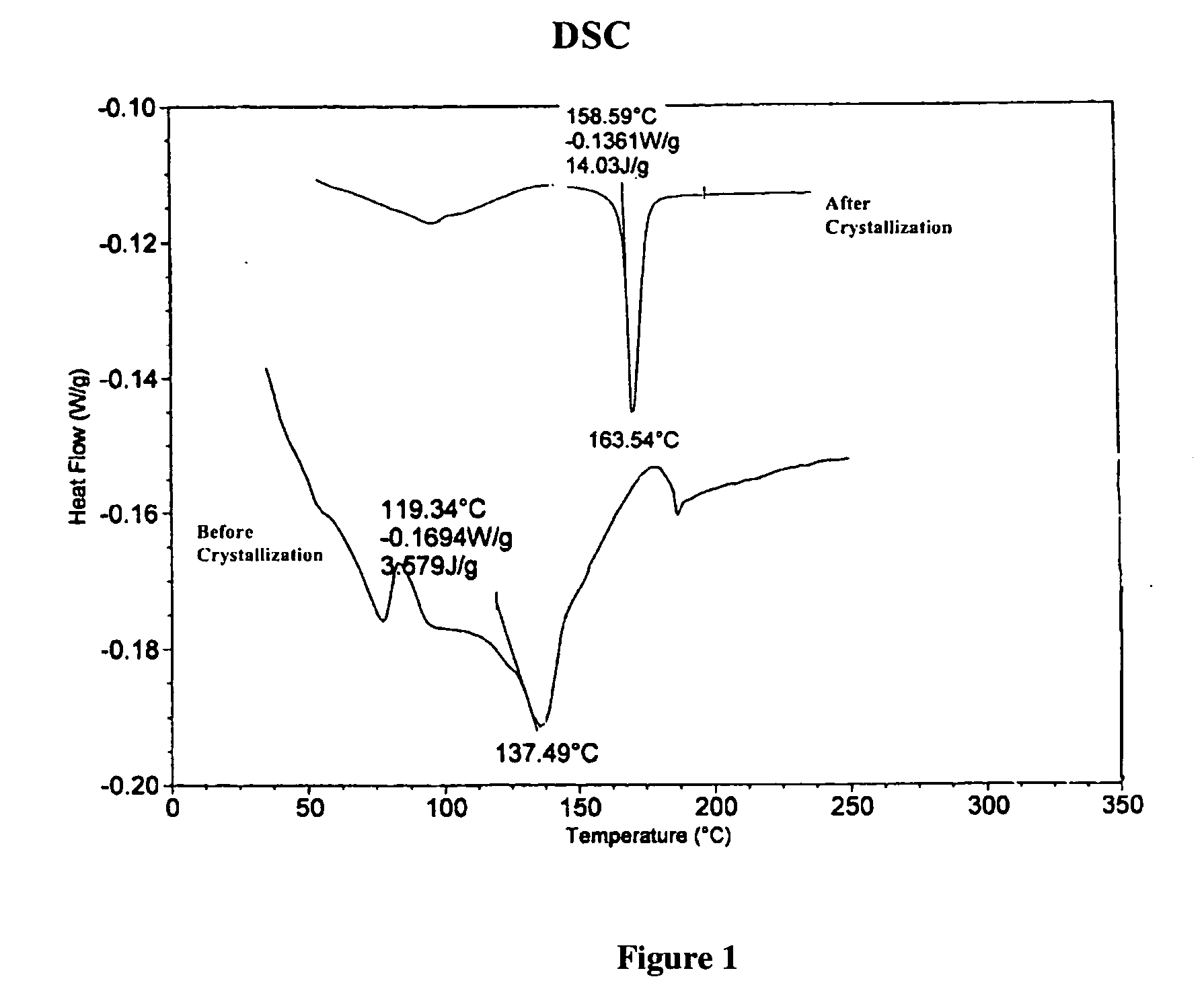

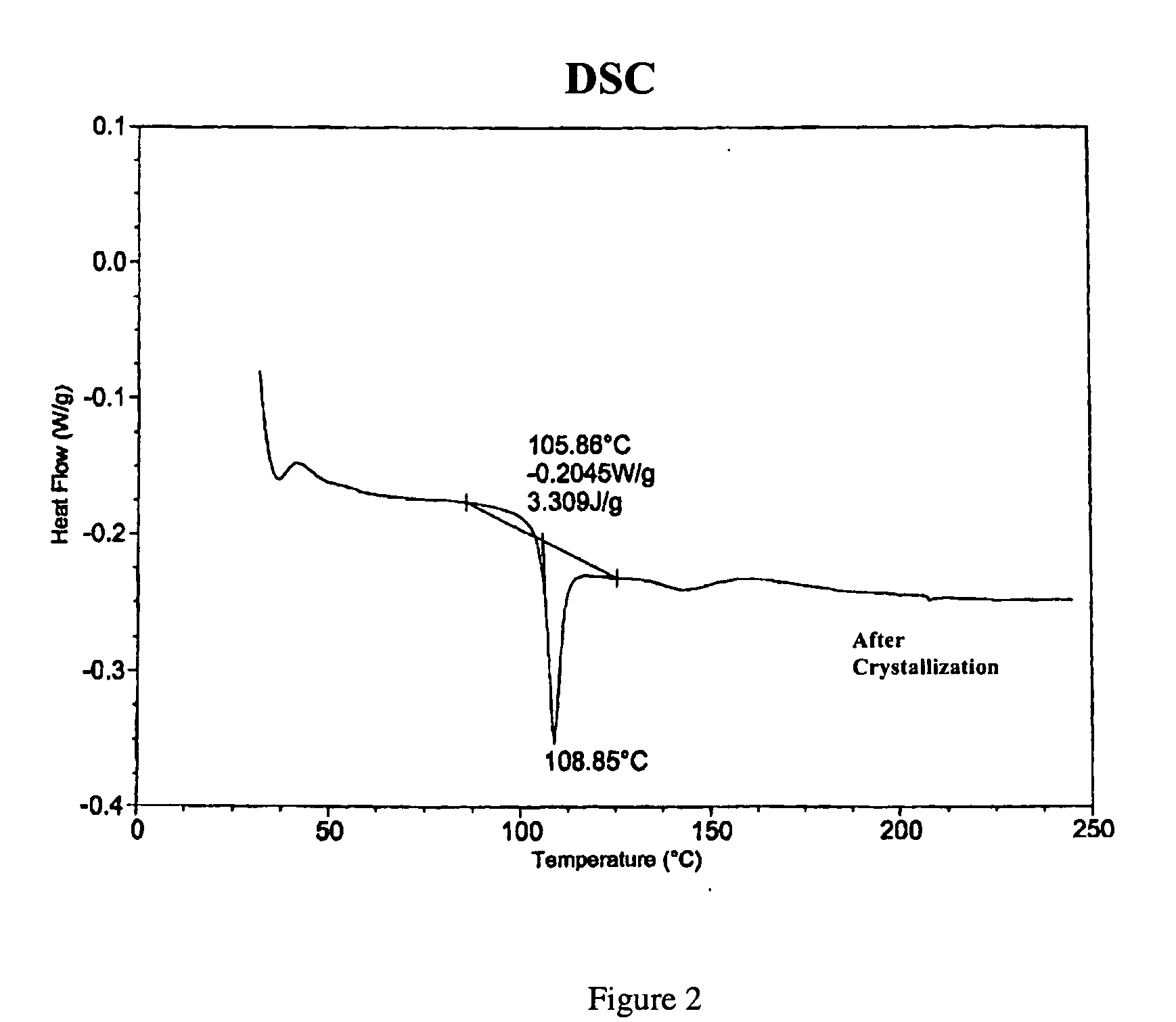

Crystalline polyphosphonates and methods related thereto

InactiveUS20050222370A1High molecular weightExcellent combination of fire resistanceFiberPolymer science

Disclosed are crystalline polyphosphonates and a method to induce crystallization. These crystalline polyphosphonates exhibit a unique and advantageous combination of properties, allowing for solid state post polymerization reactions and solid state dry mixing with other polymers. Also disclosed are polymer compositions that comprise these polyphosphonates and at least one other polymer, wherein the resulting polymer compositions exhibit flame retardant properties. Further disclosed are articles of manufacture produced from these crystalline polyphosphonates and polymer compositions, such as fibers, films, coated substrates, moldings, foams, fiber-reinforced articles, or any combination thereof.

Owner:FRX POLYMERS LLC

Graphite-paraffin composite phase-changing and energy-storing concrete and preparation method thereof

The invention relates to a graphite-paraffin composite phase-changing and energy-storing concrete and a preparation method thereof. In the phase-changing and energy-storing concrete, cement, water, sand, gravels and a water reducer are used as substrates, and paraffin phase-changing materials, graphite with enhanced heat conducting function, and fiber reinforced materials with enhanced mechanical strength are also comprised. The preparation method comprise the steps of: firstly, mixing the paraffin and the graphite, heating until the paraffin totally melts, and continuously stirring to uniformly mix the paraffin and the graphite into a viscous form; putting the sand and the gravels into a stirrer, then putting fibers and the cement, carrying out dry mixing, adding the water and the water reducer subsequently, and rapidly stirring to reach a uniform state; and then putting the molten paraffin-graphite viscose mixture into the obtained concrete mixture, and uniformly mixing. Because the graphite is added into the paraffin to be used as an additive, the coefficient of heat conductivity of the phase-changing and energy-storing concrete is greatly enhanced, so that the heat storing and releasing efficiency of an energy-storing material is enhanced.

Owner:SOUTHEAST UNIV

Resin casting molding sand and preparation method thereof

ActiveCN102380575AEasy to prepareReasonable formulaFoundry mouldsFoundry coresDry mixingPotassium dichromate

The invention discloses resin casting molding sand and a preparation method thereof. The method mainly comprises: performing dry mixing of component raw materials including quartz sand, straw ash, tung oil, asbestos, a furan resin, a phenolic resin, kaoline and potassium dichromate by certain weight parts; and adding water, mixing, placing sand after mixing, molding, casting, cooling and separating to obtain a finished product. The preparation method is simple, the formula is reasonable, the cost is low, the production efficiency is high, the surface of the aluminum sand is made smooth by strictly controlling the particle size of the quartz sand, and the breathability is high.

Owner:托普工业(江苏)有限公司

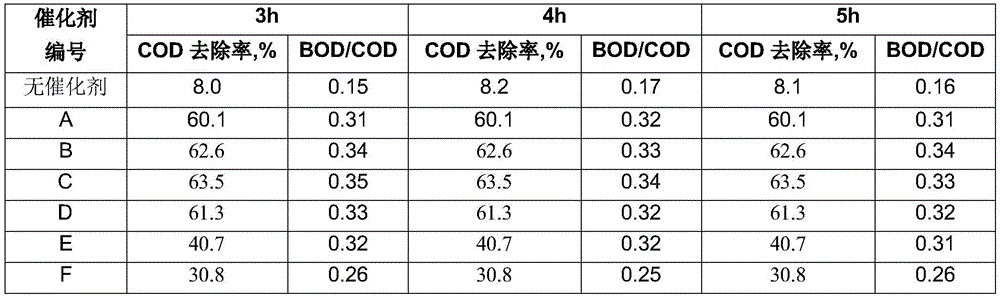

Catalytic ozonation catalyst for wastewater treatment and preparation method thereof

InactiveCN105536813AHigh removal rateExtended service lifeHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsAlkali metal oxideLanthanide

The invention belongs to the technical field of water treatment, and in particular relates to a catalytic ozonation catalyst for the wastewater treatment and a preparation method thereof. The catalyst is prepared from an active component, an auxiliary and a carrier, wherein the active component is a transition metal oxide, the auxiliary is an alkali metal oxide, an alkaline earth metal oxide or a lanthanide metal oxide, and the carrier is an aluminum oxide, active carbon or ceramsite. The invention further provides a preparation method of the catalyst. The preparation method comprises the steps: loading the active component, the auxiliary and a dispersing agent on the carrier by utilizing an impregnation method or a dry mixing method, curing, drying and roasting, thereby obtaining the catalyst. According to the catalytic ozonation catalyst for the wastewater treatment and the preparation method thereof, the COD removal rate is higher, and the service life is longer; the preparation process is simple, the costs are low, no secondary pollution exists, and the catalytic ozonation catalyst for the wastewater treatment and the preparation method thereof are very suitable for industrial production.

Owner:KMD BEIJING ENERGY & ENVIRONMENT TECH CO LTD

Airtight electrode paste and manufacturing method thereof

InactiveCN103796366ALow resistivityImprove thermal shock resistanceElectric discharge heatingMetallic materialsWaste material

The invention relates to the field of non-metallic materials for metallurgical engineering, in particular to airtight electrode paste used for a large-scale submerged arc furnace and a manufacturing method of the airtight electrode paste. The airtight electrode paste uses carbon raw materials as aggregate, uses organic compounds as binding agents, and is manufactured through the working procedures of smashing, screening, powder grinding, material mixing, melting of the binding agents, dry mixing, wet mixing, past pulling formation and the like. The airtight electrode paste and the manufacturing method of the airtight electrode paste have the advantages that when the airtight electrode paste is used on the submerged arc furnace, electrode breaking accidents do not happen easily, the manufactured airtight electrode paste is manufactured by recycling waste materials and lowers production cost, the strength of the electrode paste is improved, the specific resistance of the electrode paste is lowered, and the thermal shock resistance when the electrode paste is sintered into a self-baking electrode is improved. Through the process method of the airtight electrode paste, particle classification levels are increased, material distribution is more reasonable and more stable through detailed classification, the temperature of each working procedure point is strictly controlled, and anthracene oil is heated so that the quality of products can keep stable.

Owner:MINHE GUANGDA CARBON

Method for preparing haydite from sludge incineration ash in chemical industry

ActiveCN102249730AAchieve reductionRealize resourcesSludge treatmentCeramicwareChemical industryDry mixing

The invention relates to recycling of industrial solid waste, and discloses a method for preparing haydite from sludge incineration ash in chemical industry. The method comprises the following steps: drying sludge subjected to mechanical dewatering, incinerating at high temperature, proportioning, carrying out dry mixing, adding water, evenly mixing, granulating to obtain fresh pellets, drying the fresh pellets, and roasting at 1050-1150 DEG C to form sludge haydite. The leaching concentration of heavy metals is far below GB 5085.3-2007 (Identification Standards for Hazardous Wastes-Identification for Extraction Toxicity). The method has the advantages of low energy consumption and low production cost, develops a new way for recycling sludge in the fields of waste treatment with waste andcyclic utilization of waste, and has obvious environmental benefit and economic benefit.

Owner:江苏江淮环保科技有限公司

Molding sand containing wood fiber and production method thereof

The invention discloses a molding sand containing wood fiber and a production method thereof. The method comprises steps of: carrying out dry mixing on raw materials of 80-90 parts of mixed wood, 10-20 parts of recycling sand, 5-10 parts of quartz sand, 3-5 parts of glass fiber, 1-3 parts of cement, 3-5 parts of water glass, 1-3 parts of wood fiber, 5-10 parts of flour and a proper amount of water; then adding and mixing with water; and carrying out sand release, molding, casting aluminum water, and cooling and separation to obtain a finished product. The invention has advantages of simple production method, reasonable formula, low cost, high production efficiency; adoption of quartz sand and glass fiber as variant sand raw materials can change waste into treasure; and addition of wood fiber can increase the strength of the molding sand.

Owner:繁昌县琦祥铸造厂普通合伙

Cement-based no-shrinkage grouting material

The invention discloses a cement-based no-shrinkage grouting material which is prepared by carrying out dry mixing on the following raw materials in parts by weight: 350-400 parts of cement, 550-600 parts of sand, 4-6 parts of water reducing agent, 20-40 parts of rigid expanding agent, 0.1-0.25 part of plastic expanding agent, 0.3-0.8 part of defoaming agent, 0.8-1.6 parts of retarder and 0-8 parts of property regulator. The grouting material disclosed by the invention has the advantages of low consumption of expanded components, high plastic expansion ratio, high rigid expansion ratio, short stabilization time, low dependence on wet curing, excellent flowability and excellent strength property, and can be used for large-scale equipment installation, bolt anchorage and structure reinforcement.

Owner:SUZHOU UNIV OF SCI & TECH +1

Hard surfacing sintered flux and manufacturing method thereof

InactiveCN101564804AMeet different requirements of hardnessImprove performanceWelding/cutting media/materialsSoldering mediaMaterials preparationThermal fatigue

The invention relates to a hard surfacing sintered flux and a manufacturing method thereof. The sintered flux comprises MgO of 30 percent to 50 precent, CaO of 2 percent to 10 percent, Al2O3 of 10 percent to 20 percent, CaF2 of 18 percent to 28 percent, SiO2 of 10 percent to 20 percent, SiC of 0 percent to 1.5 percent and other components of 0 percent to 5 percent such as ferroalloy mainly playing a role of desoxidation and the like. Material preparation, dry mixing and wet mixing by adding soluble glass into a blender are conducted until granules which have the required sizes are formed, then the granules are dried in a rotary drying way at the low temperature of 200 DEG C to 250 DEG C, and then finished products are obtained by high-temperature sintering in a rotary drying oven at the high temperature of 700 DEG C to 750 DEG C, sieving and packaging. The invention has low flux cost so as to meet the requirements of different hardness, excellent technique and good high-temperature slag detachability; the deposited metal has no gas hole, no crackle but adjustable hardness; and the high-temperature wear-resistance, oxide etch resistance and cold and thermal fatigue resistance of a hot roll are greatly improved.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

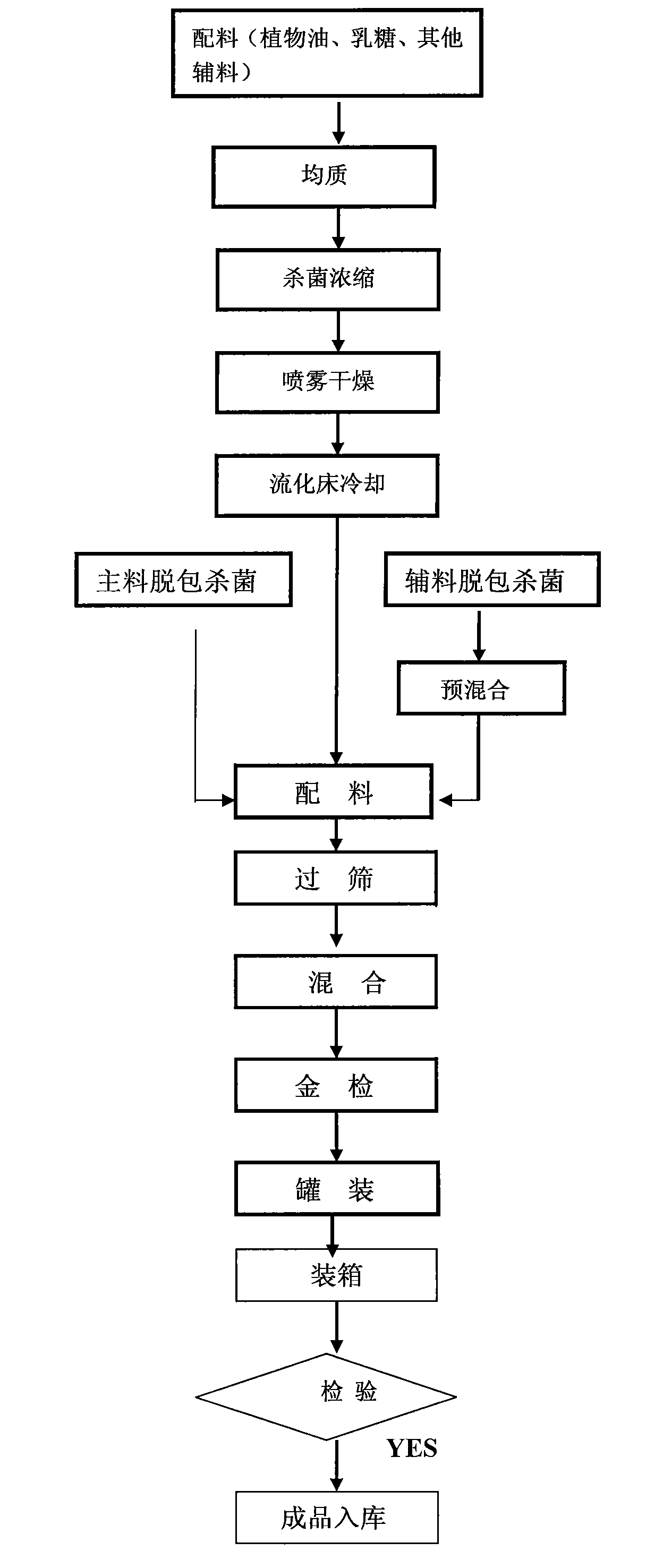

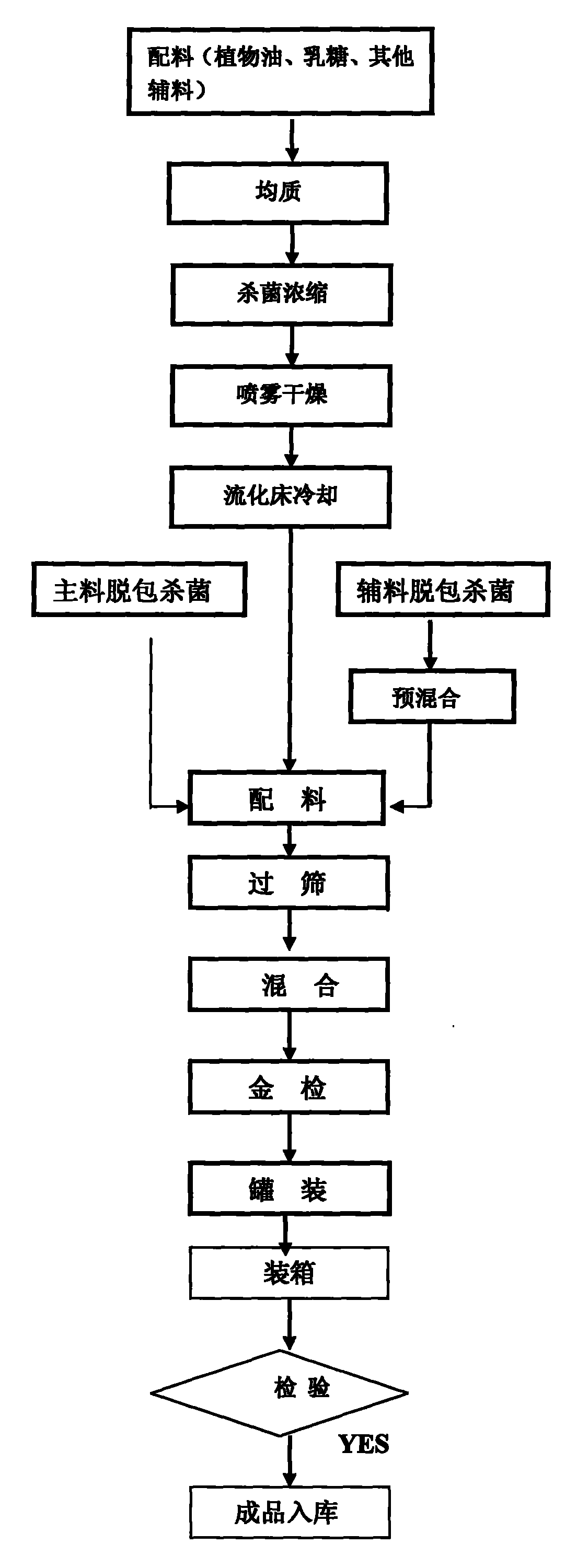

Method for producing novel infant formula milk powder

ActiveCN101984836ALess investmentReduce site constructionMilk preparationAdditive ingredientDry mixing

The invention discloses a method for producing novel infant formula milk powder, which comprises: producing vegetable fat powder by a wet-method process; and dry-mixing the vegetable fat powder with other main ingredients, auxiliary ingredients and bioactive materials by using a dry-method process to prepared the infant formula milk powder for infant of different ages. The method has the advantages that: the dry-method process and the wet-method process are combined, the vegetable fat powder is produced by the wet-method process and then the vegetable fat powder is dry-mixed with other main ingredients, auxiliary ingredients and bioactive materials to prepare the infant formula milk powder for infant of different ages, so the investments in milk source construction, equipment, site construction and the like are reduced; high-quality whole milk powder can be directly purchased in China or from foreign countries; and energy conservation, emission reduction, production enlargement and production plan optimization can be realized, and the method has a great instructive significance for improving product nutritional value and the like.

Owner:贝因美股份有限公司 +2

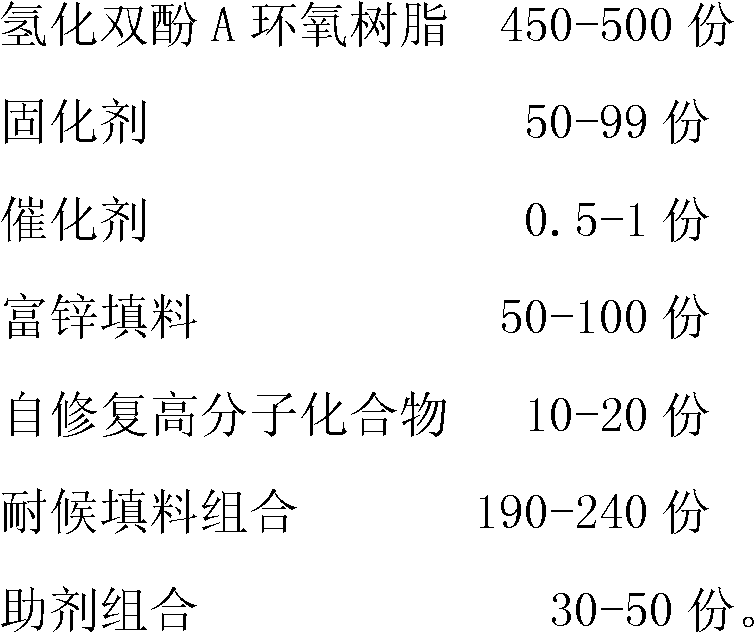

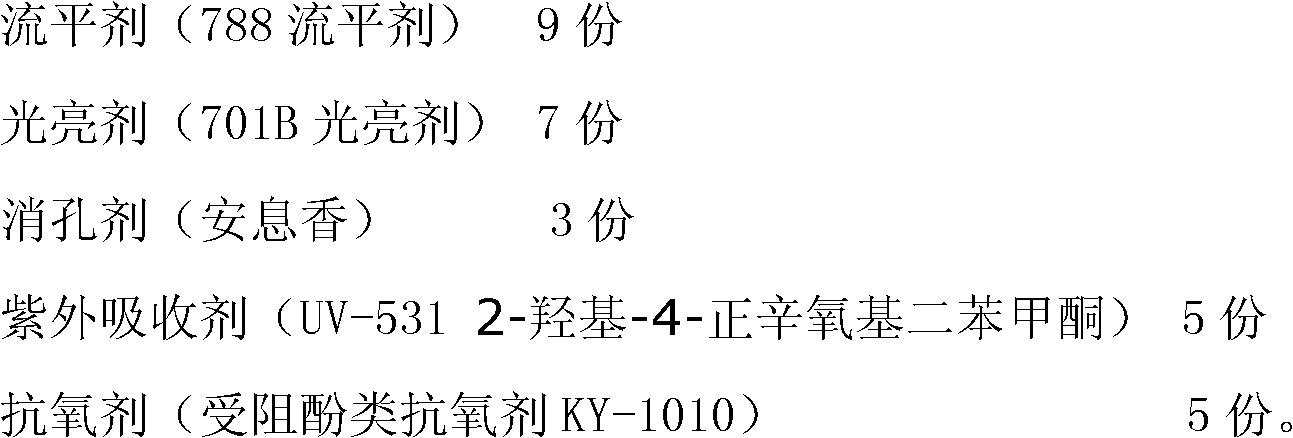

Weather-resistant heavy-duty anticorrosive powder coating

InactiveCN102634266AGood weather resistanceImprove corrosion resistanceAnti-corrosive paintsPowdery paintsDry mixingHeavy duty

The invention relates to a weather-resistant heavy-duty anticorrosive powder coating comprising the raw materials in parts by weight: 450-500 parts of hydrogenated bisphenol A epoxy resins, 50-99 parts of curing agents, 0.5-1 part of catalysts, 50-100 parts of zinc-rich fillers, 10-20 parts of self-repairing conductive macromolecule compounds, 190-240 parts of weather-resistant pigments and fillers and 30-50 parts of additives. A preparation method of the coating comprises the steps of putting the raw materials into a high-speed mixer, putting in an extruder after subjecting to dry mixing, carrying out fusion, mixing, cooling and preforming at an extrusion temperature of 80-90 DEG C, grinding by utilizing a grinder, grading, sieving and packaging to obtain finished products of the powder coating. The powder coating disclosed by the invention is mainly applied in the coating of outdoor heavy-duty anticorrosive environments, has excellent anticorrosive performance and weather-resistant performance and is an ideal heavy-duty anticorrosive coating capable of being used for outdoors. Proved by customer use and detection of relevant authoritative departments, the anticorrosive performance and the weather-resistant performance of the coating are excellent and can be completely up to indexes of imported similar products and certain indexes even exceed those of foreign products; the price of the coating is superior than that of the imported products; and therefore, the coating is well received by customers.

Owner:国润恒科(天津)防腐工程技术有限公司

Al2O3-SiC-C iron runner casting material and preparation method thereof

InactiveCN103011868AImprove high temperature performanceGood toughening effectPtru catalystAnti oxidant

The invention particularly relates to an Al2O3-SiC-C iron runner casting material and a preparation method thereof. The technical scheme is as follows: the preparation method comprises the following steps: carrying out uniform dry mixing on raw materials 50-60 wt% of electrofused brown corundum granules, 8-12 wt% of electrofused brown corundum fine powder, 3-10 wt% of silicon carbide granules, 6-11 wt% of silicon carbide fine powder, 3-7 wt% of alpha-Al2O3 micropowder, 2-4 wt% of pelleted pitch, 2-4 wt% of silicon dioxide micropowder, 2-4 wt% of calcium aluminate cement, 2-4 wt% of metal antioxidant and 0.1-0.3 wt% of dispersant together with catalyst accounting for 0.1-3 wt% of the raw materials to obtain the Al2O3-SiC-C iron runner casting material. The invention has the advantage of low preparation cost; and the prepared Al2O3-SiC-C iron runner casting material has the advantages of low water addition amount, high flow value, favorable high-temperature service performance and high thermal shock stability, and so that the blast furnace iron runner has high iron flux and low refractory material consumption.

Owner:WUHAN UNIV OF SCI & TECH

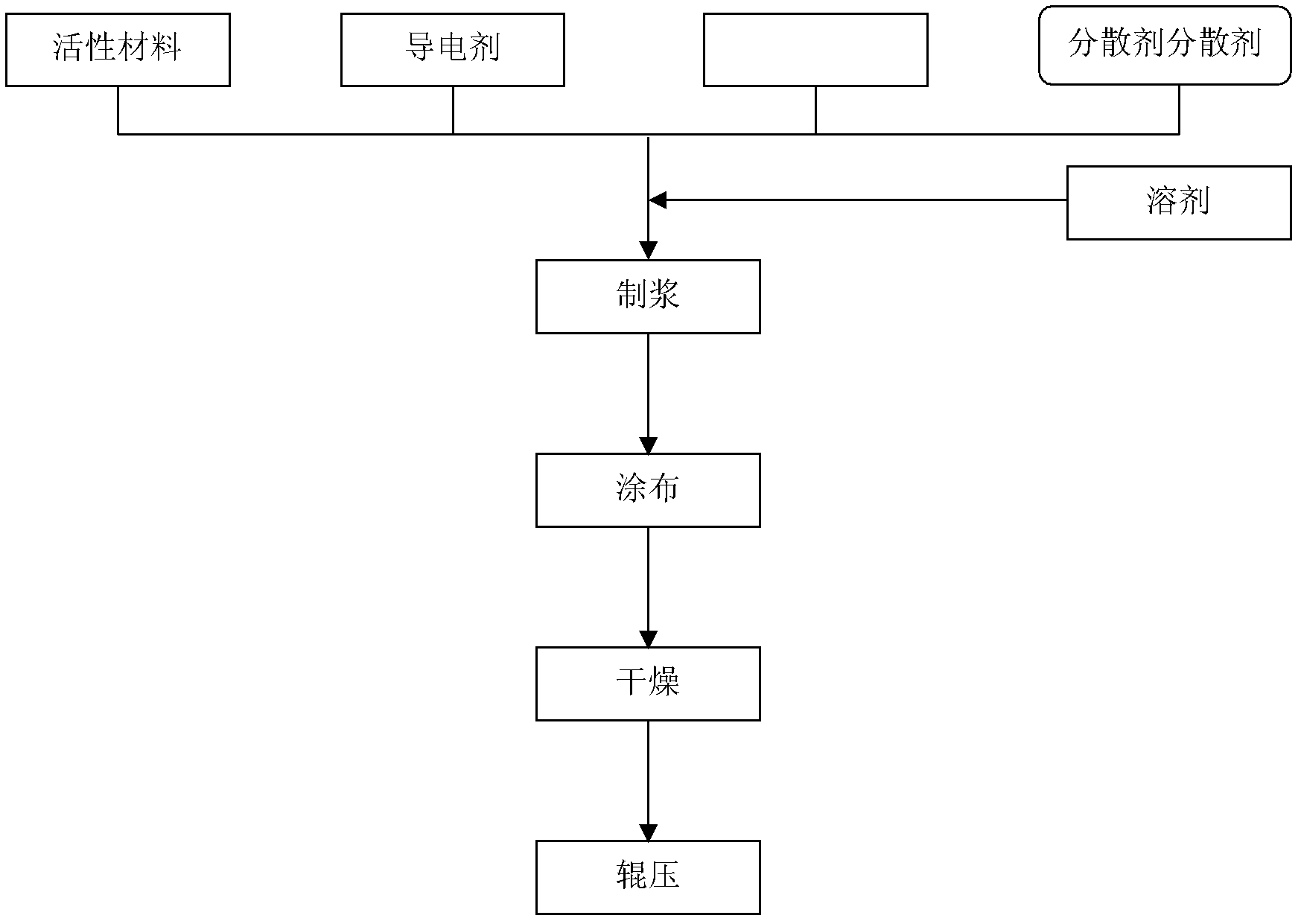

Preparation method of stable slurry of lithium ion battery

The invention discloses a preparation method of stable slurry of a lithium ion battery. The preparation method comprises the steps of: preparing mixed material and glue from an active substance, a conductive agent, a bonding agent, a dispersing agent, a solvent and other additives by a few steps of dry mixing, wet mixing and glue preparation, and then subjecting the mixed material and the glue to wet mixing by a stirrer to obtain mixed slurry, and further comprises the steps of: (1) dispersing the mixed slurry for 10 to 20 minutes by a high speed dispersing machine of 15 to 50m / s, and storing the slurry in a storage tank upon the completion of the dispersion; (2) returning the slurry in the storage tank to the stirrer and then dispersing the slurry for 10 to 20 minutes by the high speed dispersing machine according to the step (1); (3) circularly repeating the step (1) and the step (2) 2 to 5 times; and (4) after the dispersion is completed, performing defoaming, filtration and iron impurity removal on the slurry based on the prior art to obtain the finished product. The slurry in the invention is homogeneous in dispersion and can be stable for a long time; and compared with the traditional way that the stirrer is used to stir for a quite long time, the method can shorten the time for slurry preparation greatly and is favorable for automatic continuous production.

Owner:HUNAN FENGYUAN YESHINE KINGCO NEW ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com