Patents

Literature

109 results about "Particle classification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

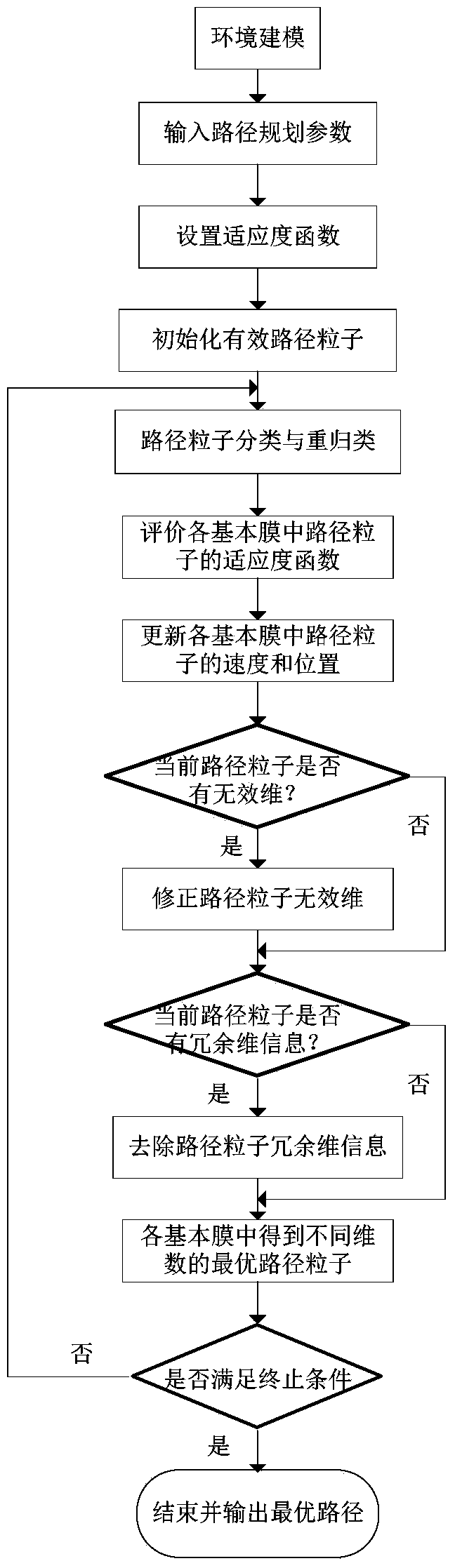

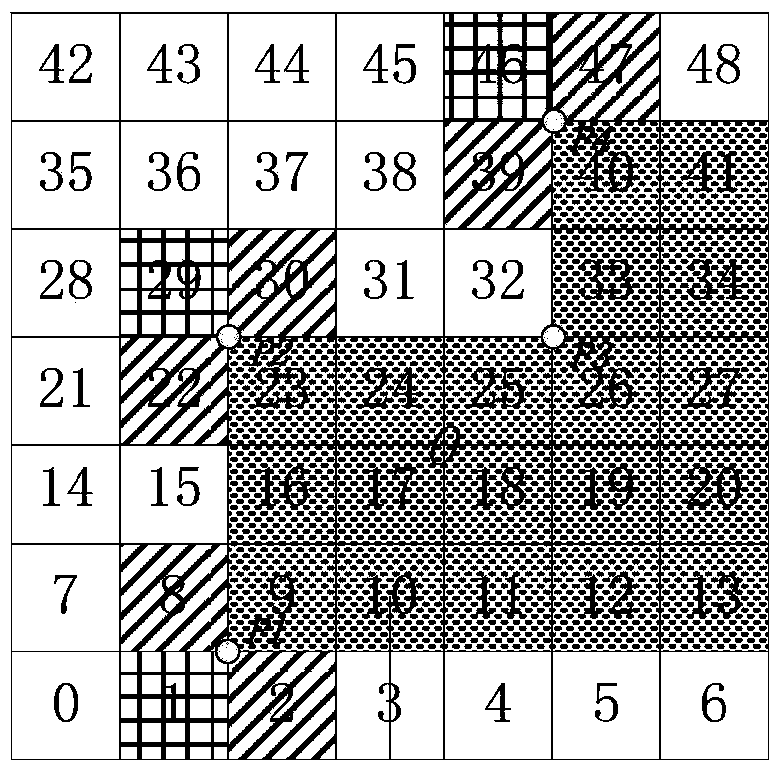

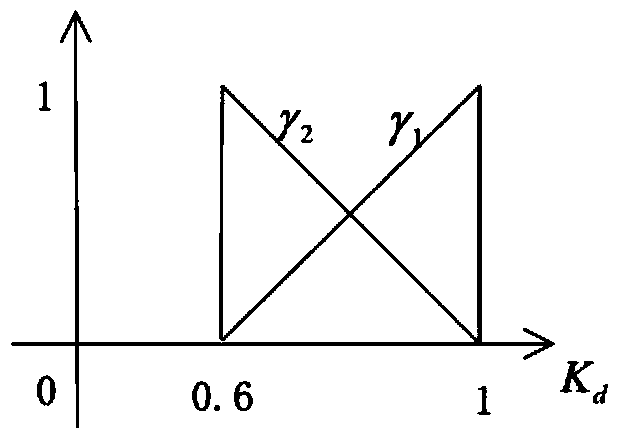

Mobile robot path planning method based on variable-dimension particle swarm membrane algorithm

InactiveCN104050390AReduce computational complexityOvercome the weakness that it is very complicated to build a topology mapSpecial data processing applicationsPosition/course control in two dimensionsAlgorithmState parameter

The invention belongs to the technical field of intelligent robots and control and particularly relates to a mobile robot path planning method based on a variable-dimension particle swarm membrane algorithm. The mobile robot path planning method based on the variable-dimension particle swarm membrane algorithm includes the main steps of performing environment modeling, inputting path parameters, setting a fitness function, initializing parent particles and child particles of an effective path, classifying and re-classifying the path particles, evaluating the fitness function, updating the positions of d-dimension particles, judging whether the current particles have invalid dimensions or not, correcting the particles with invalid dimensions, removing redundant dimension information and the like. According to the mobile robot path planning method based on the variable-dimension particle swarm membrane algorithm, the optimum path suitable for a robot to walk along can be fast planned through global known or local position information of a complex environment and state parameters of an undetermined mobile robot.

Owner:SOUTHWEST JIAOTONG UNIV

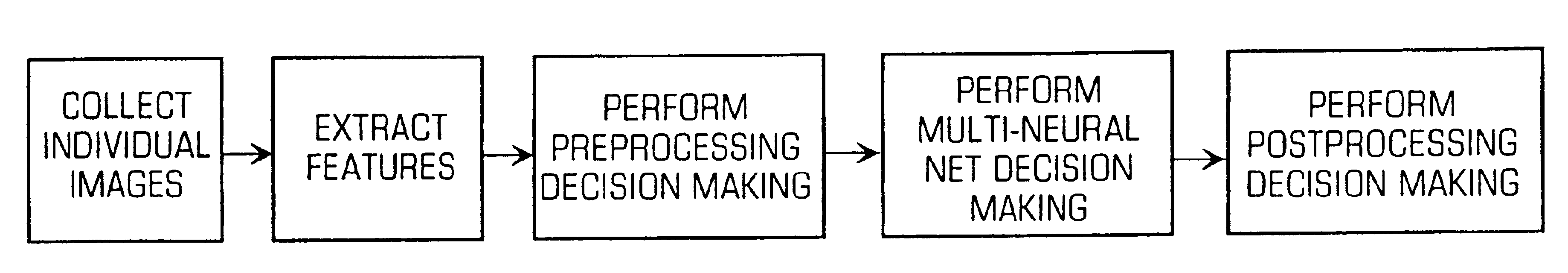

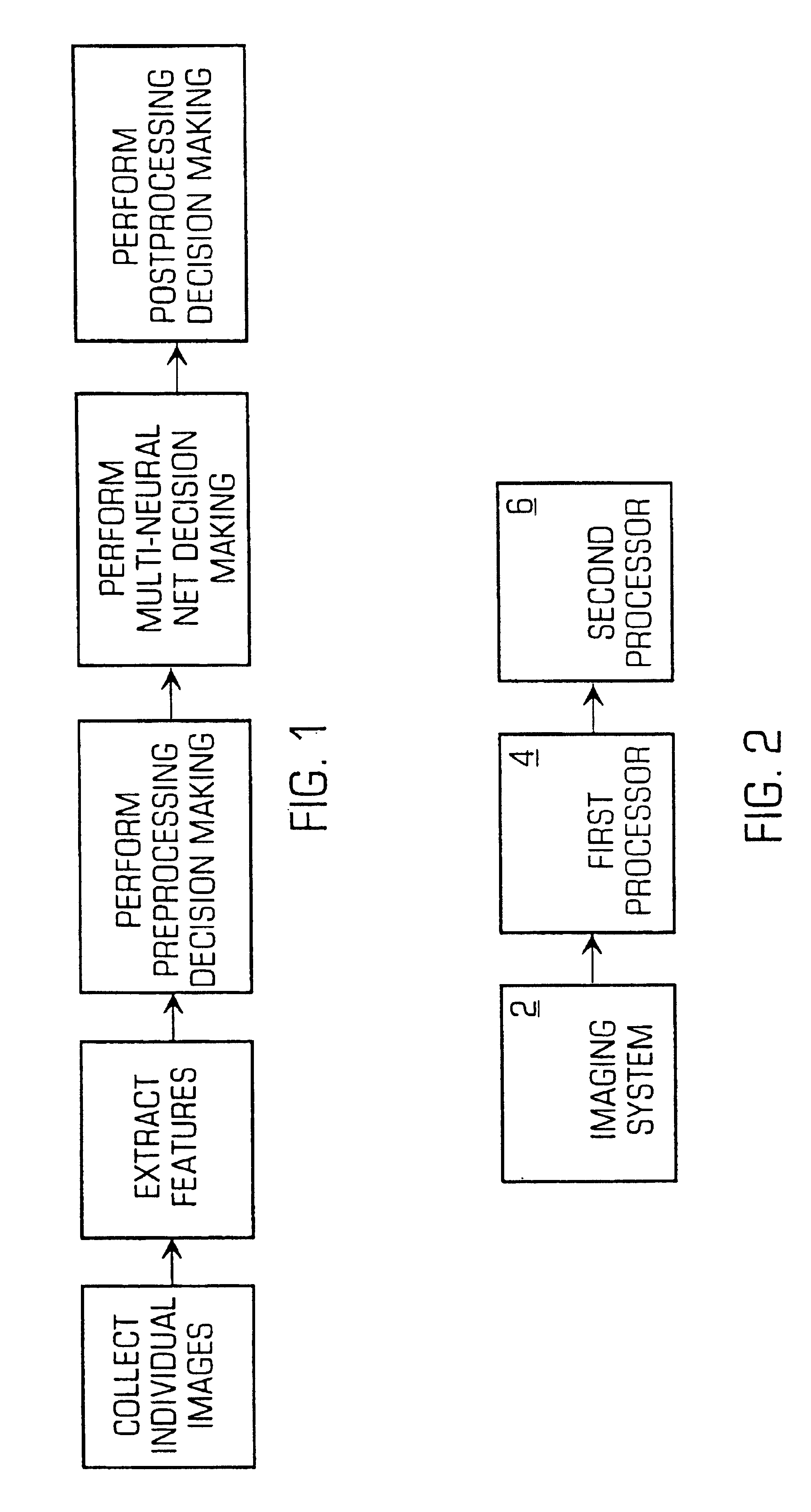

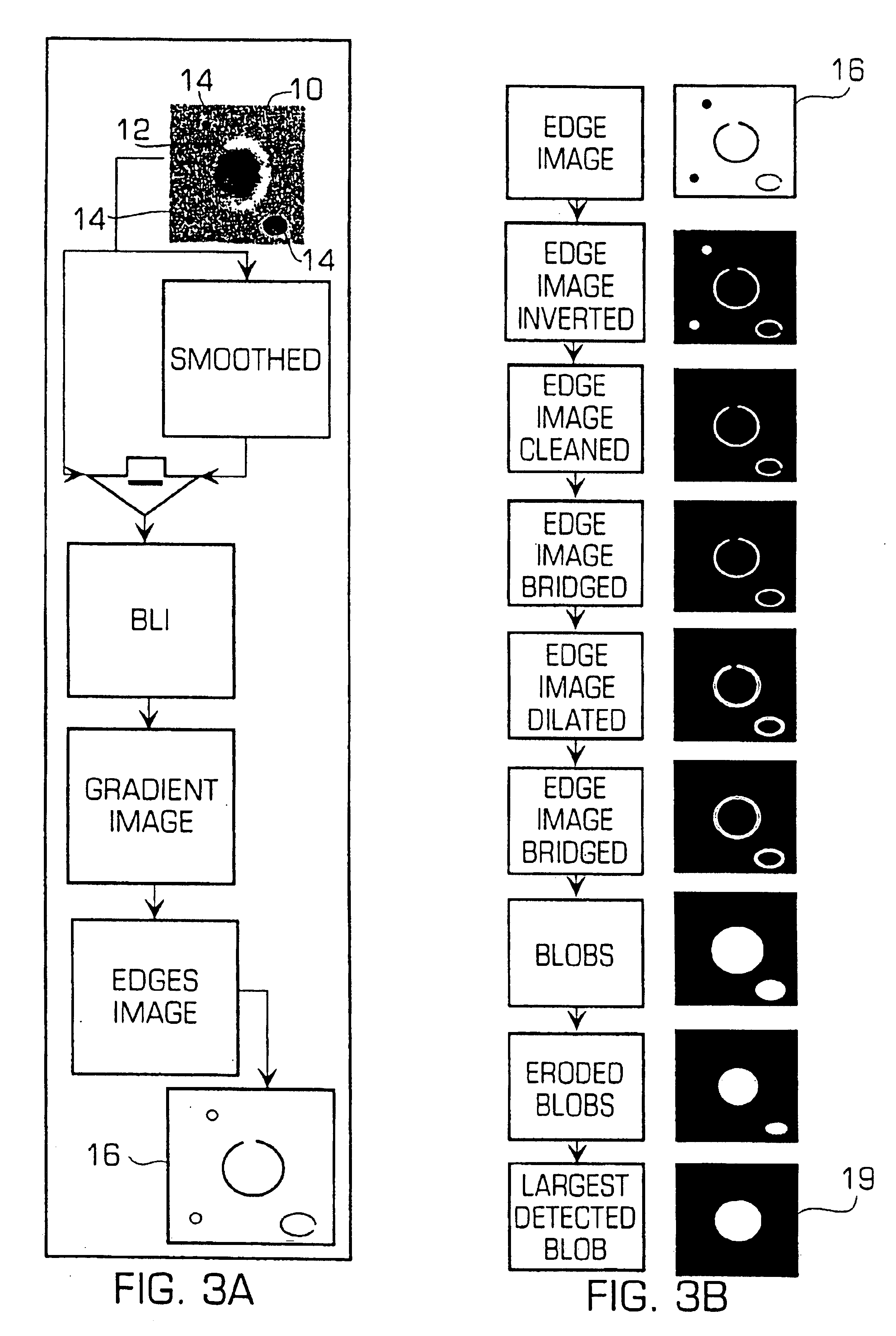

Multi-neural net imaging apparatus and method

InactiveUS6947586B2Partly effectiveEasy to useBioreactor/fermenter combinationsImage analysisPattern recognitionNetwork structure

A multi-neural net imaging apparatus and method for classification of image elements, such as biological particles. The multi-net structure utilizes subgroups of particle features to partition the decision space by an attribute or physical characteristic of the particle and / or by individual and group particle classification that includes an unknown category. Preprocessing and post processing enables heuristic information to be included as part of the decision making process. Preprocessing classifies particles as artifacts based on certain physical characteristics. Post processing enables the use of contextual information either available from other sources or gleaned from the actual decision making process to further process the probability factors and enhance the decisions.

Owner:IRIS INT

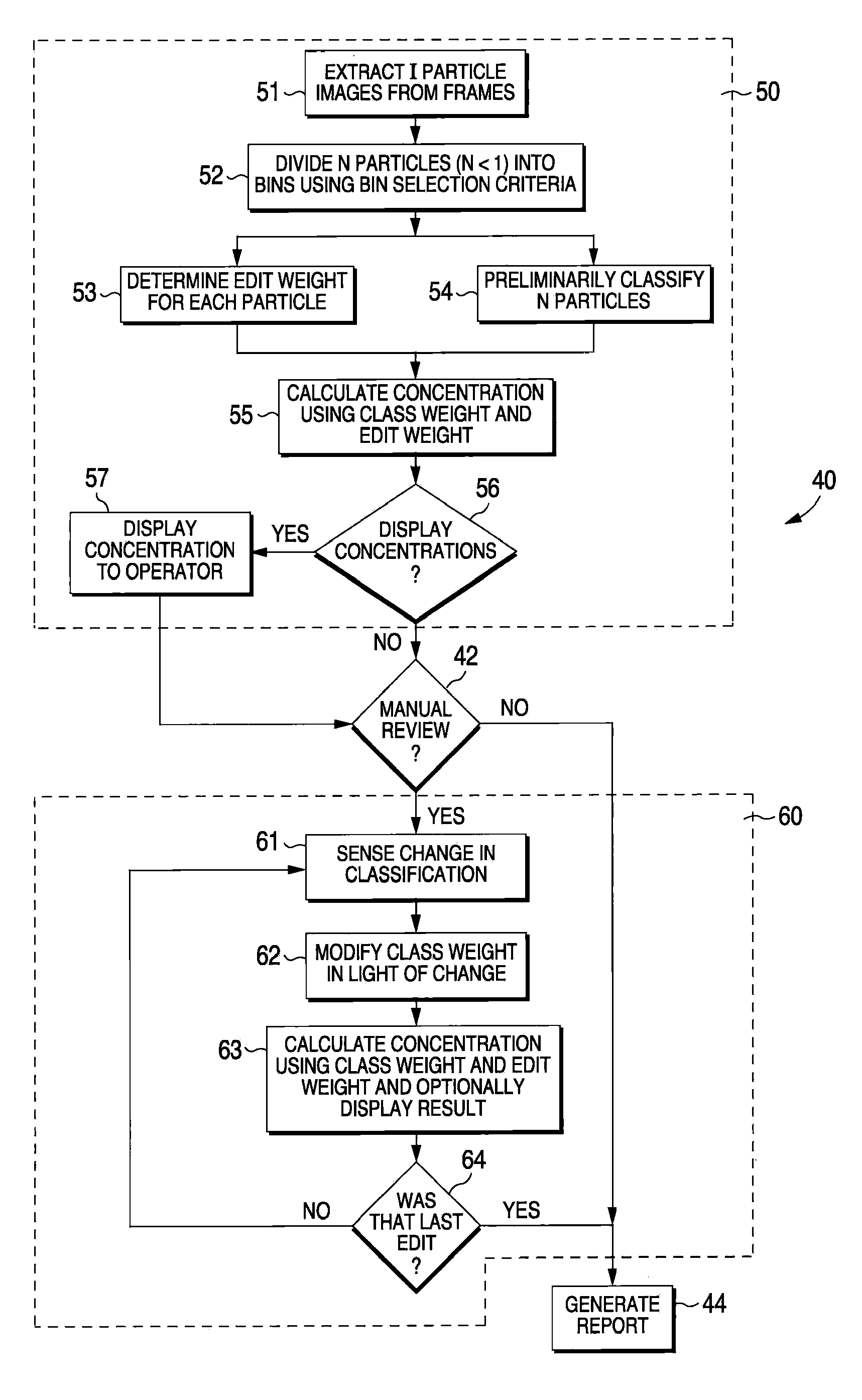

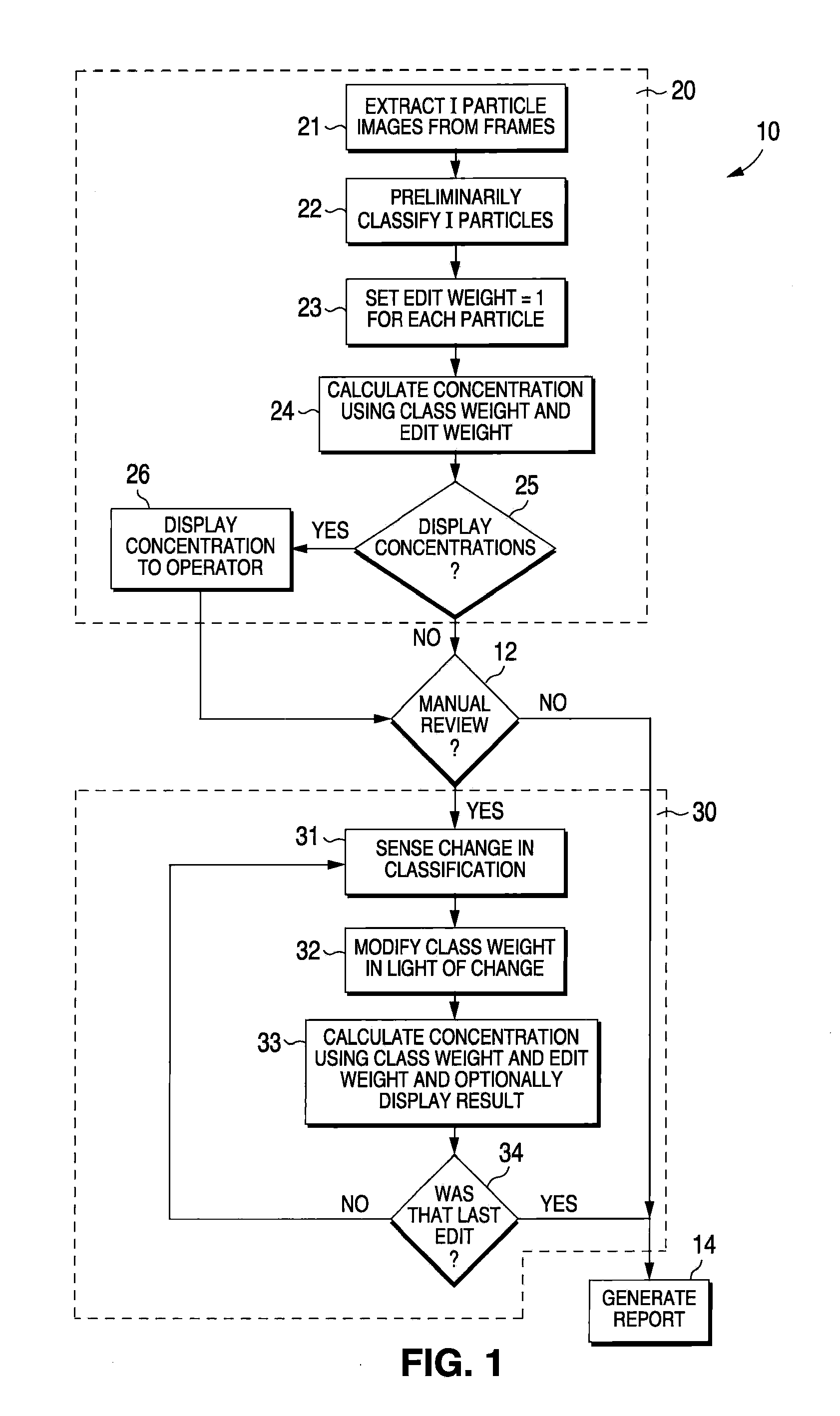

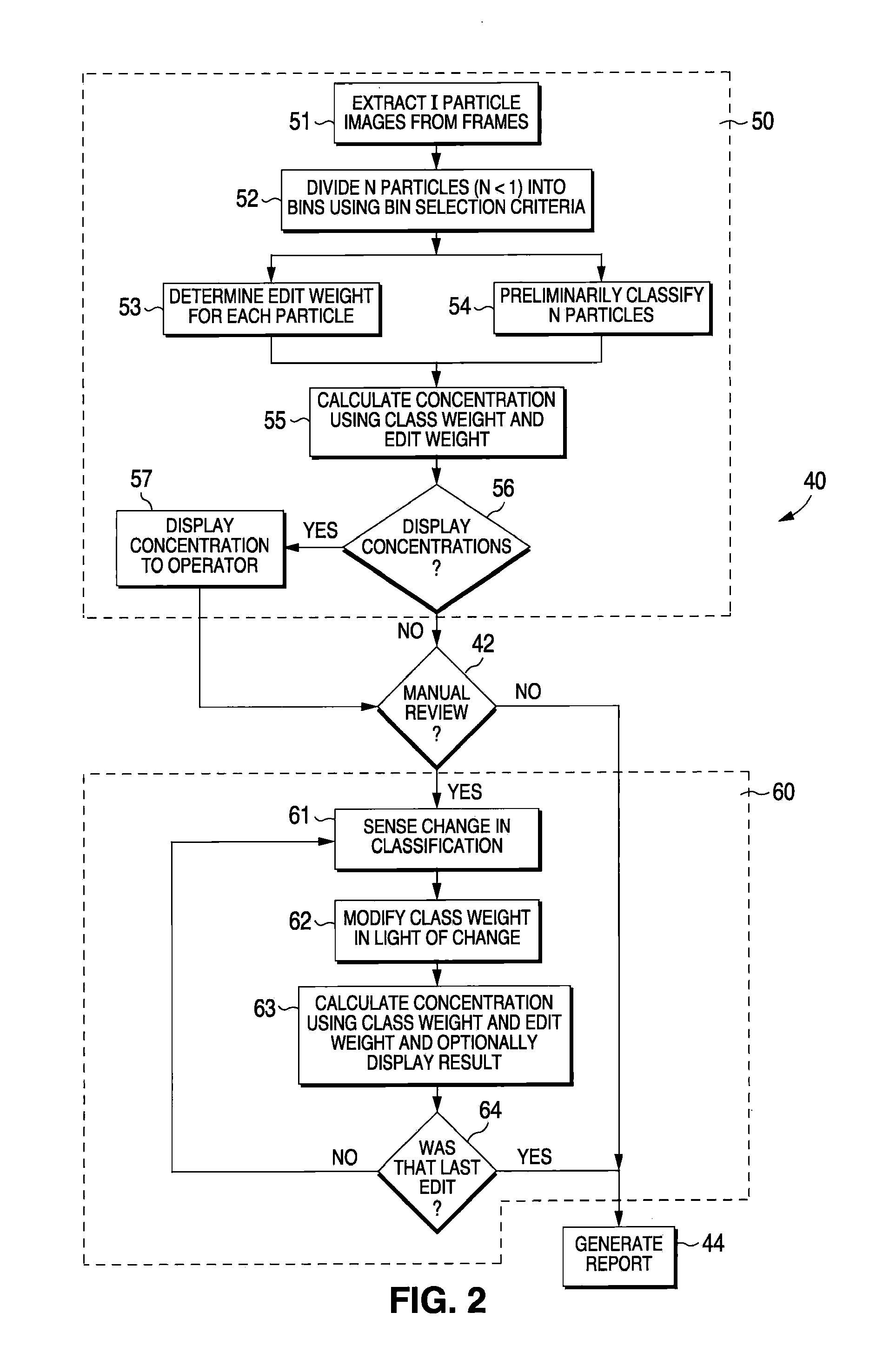

Fluid sample analysis using class weights

ActiveUS7324694B2Improve determination accuracyReduce the amount requiredAcquiring/recognising microscopic objectsIndividual particle analysisAlgorithmParticle sorting

Most automatic particle classification methods produce errors. The invention provides a method for improving the accuracy of particle classification while shortening the amount of manual review time required from the operator. The method uses class weights, which are statistically-derived correction factors that accounts for frequency of classification errors. A first class weight and a second class weight are assigned to the first class and the second class, respectively. The number of particles in each of the first and the second classes is multiplied by the first class weight and the second class weight, respectively, to generate a corrected number of particles in each of the classes. If particles are reclassified, the class weights are recalculated in response to the reclassification. The method is usable with a complete classification where all the particles in a sample are classified, or a selective classification of a subset of the particles in the sample.

Owner:IRIS INT

Airtight electrode paste and manufacturing method thereof

InactiveCN103796366ALow resistivityImprove thermal shock resistanceElectric discharge heatingMetallic materialsWaste material

The invention relates to the field of non-metallic materials for metallurgical engineering, in particular to airtight electrode paste used for a large-scale submerged arc furnace and a manufacturing method of the airtight electrode paste. The airtight electrode paste uses carbon raw materials as aggregate, uses organic compounds as binding agents, and is manufactured through the working procedures of smashing, screening, powder grinding, material mixing, melting of the binding agents, dry mixing, wet mixing, past pulling formation and the like. The airtight electrode paste and the manufacturing method of the airtight electrode paste have the advantages that when the airtight electrode paste is used on the submerged arc furnace, electrode breaking accidents do not happen easily, the manufactured airtight electrode paste is manufactured by recycling waste materials and lowers production cost, the strength of the electrode paste is improved, the specific resistance of the electrode paste is lowered, and the thermal shock resistance when the electrode paste is sintered into a self-baking electrode is improved. Through the process method of the airtight electrode paste, particle classification levels are increased, material distribution is more reasonable and more stable through detailed classification, the temperature of each working procedure point is strictly controlled, and anthracene oil is heated so that the quality of products can keep stable.

Owner:MINHE GUANGDA CARBON

Method for automatically classifying particles

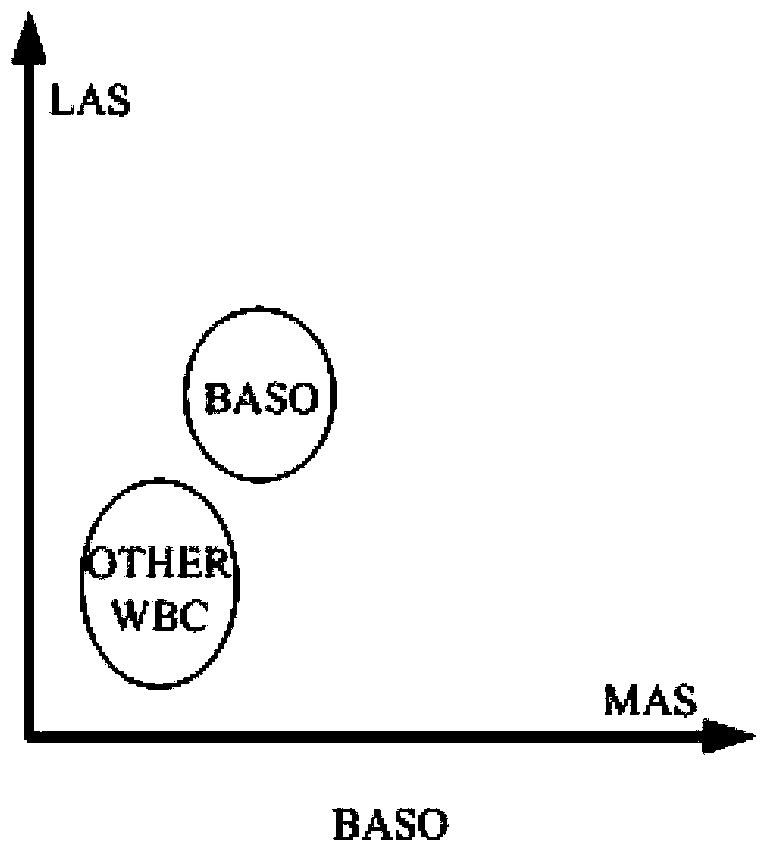

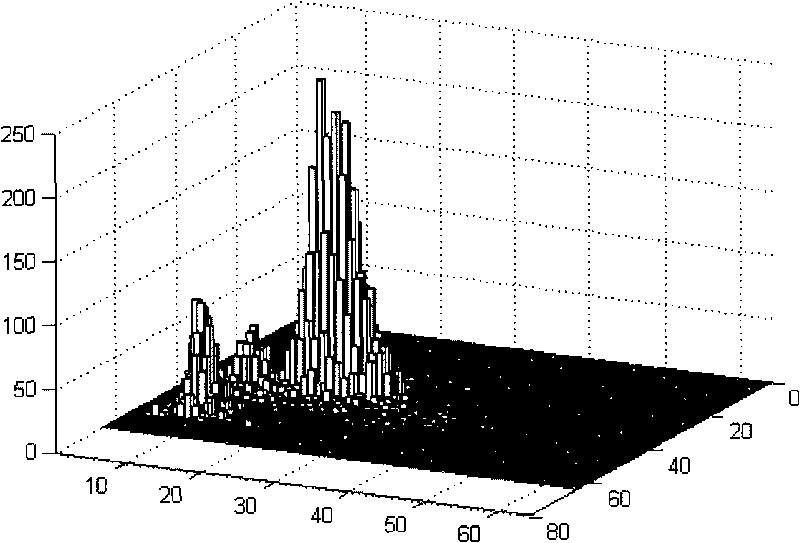

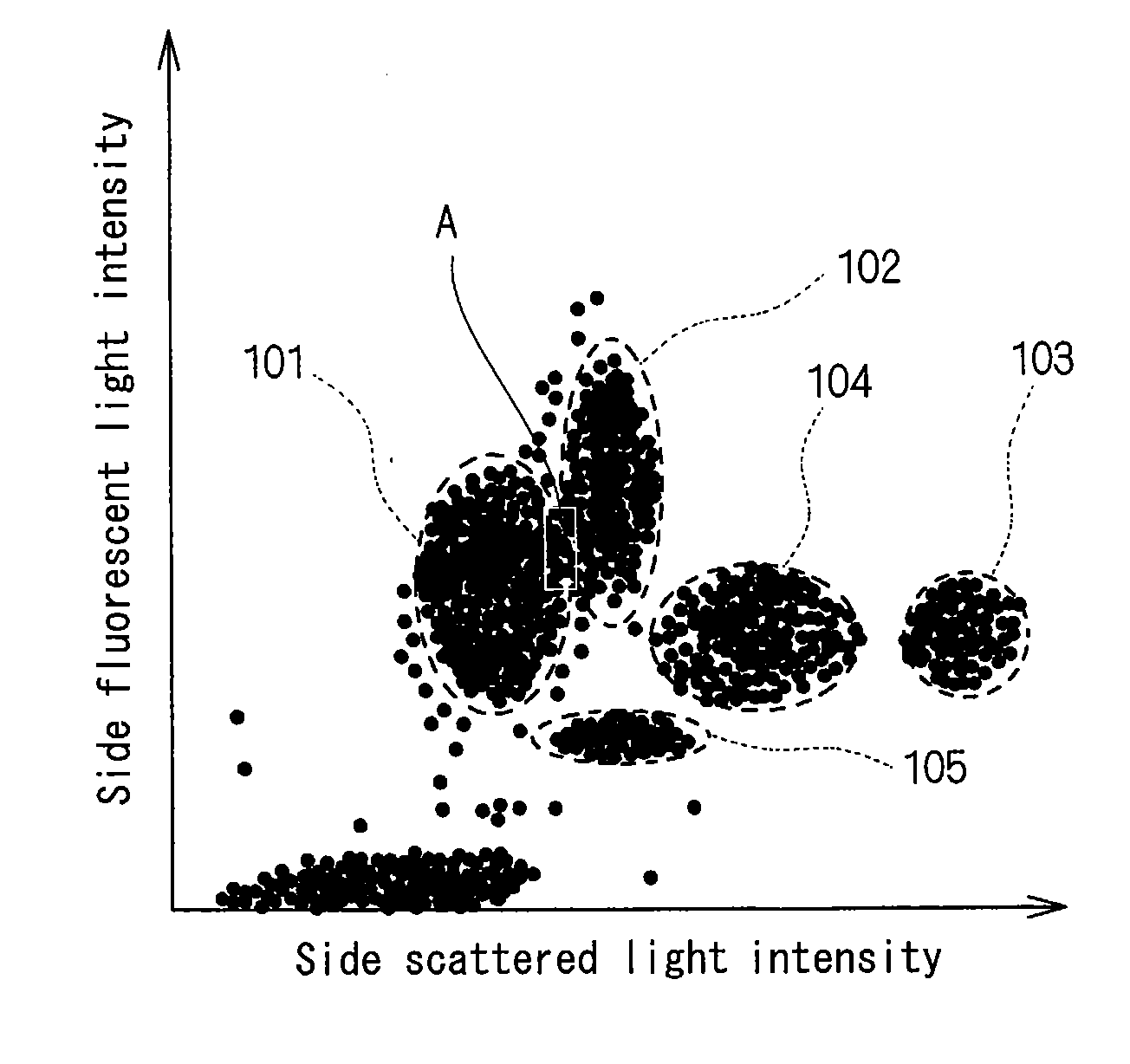

ActiveCN102507417ASmall amount of calculationShorten the timeIndividual particle analysisSpecial data processing applicationsClustered dataClassification methods

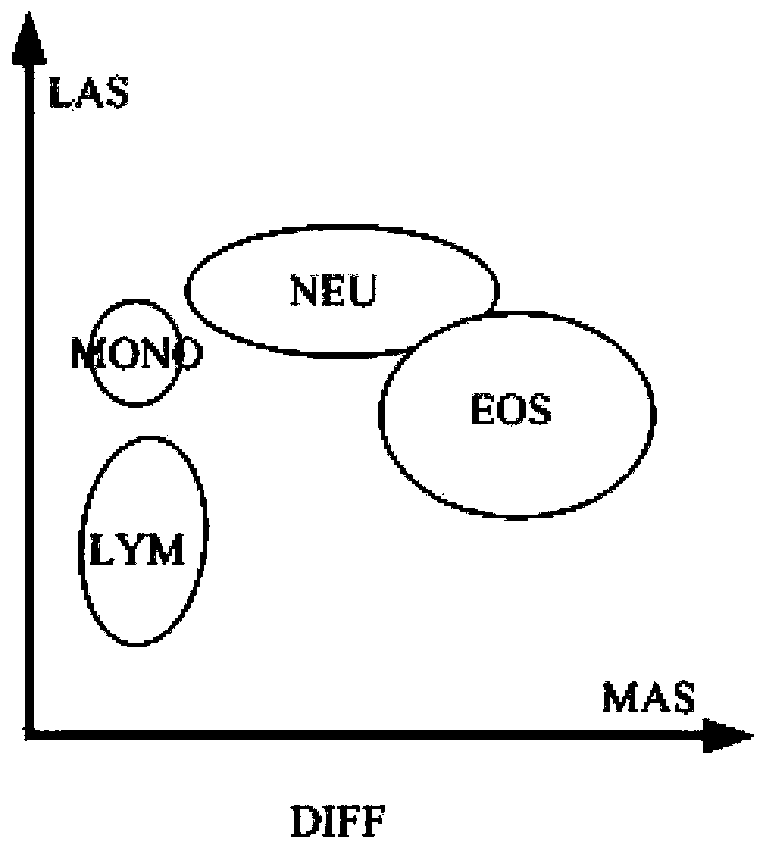

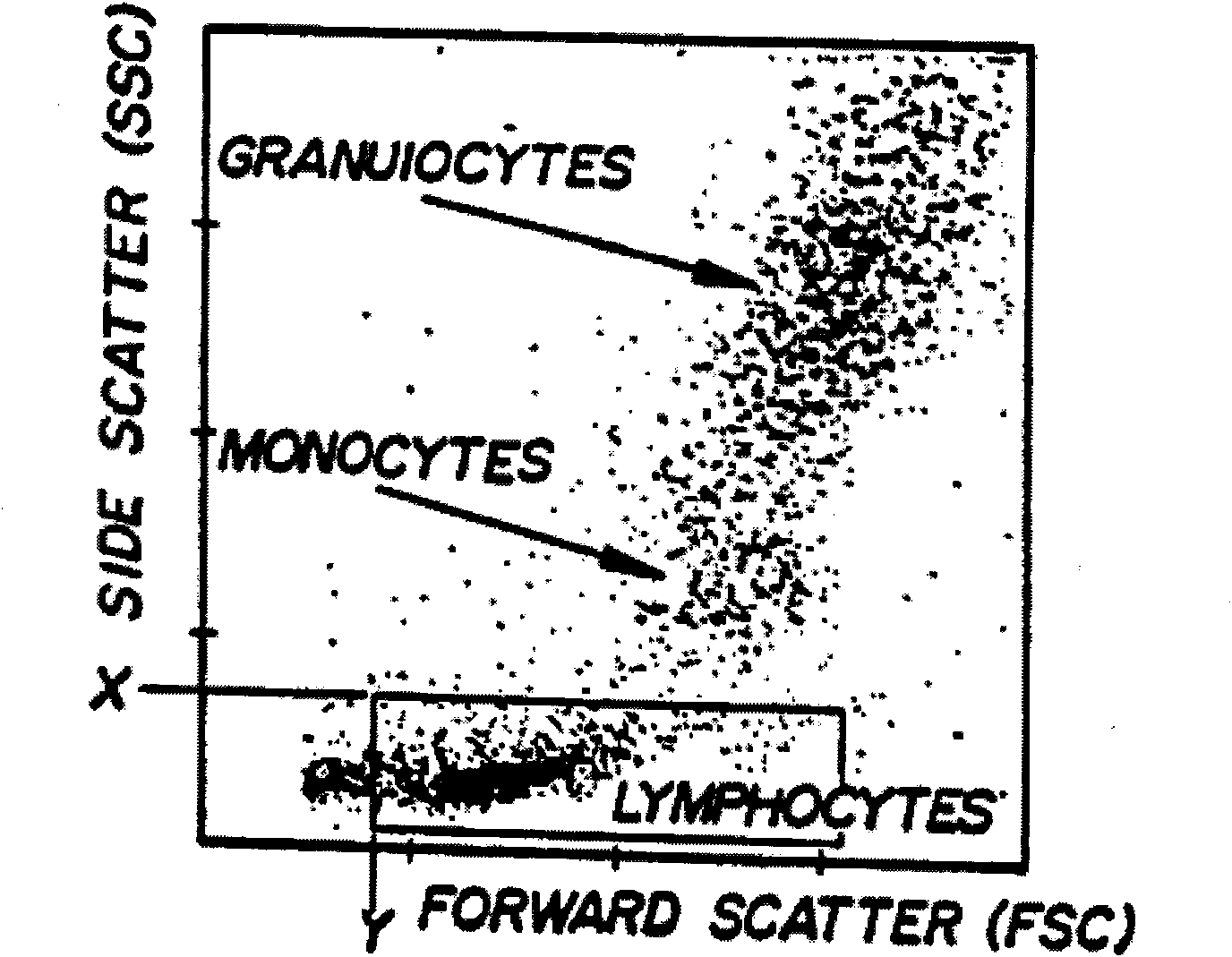

The invention relates to a method for automatically classifying particles and belongs to a particle classification method. The method comprises the following steps of: obtaining at least two types of characteristic information through collecting scattered light signals of a particle detector and respectively mapping the at least two types of the characteristic information of the particles into a two-dimensional scatter diagram; carrying out Gaussian filtering on the two-dimensional scatter diagram and selecting a peak value of the Gaussian filtering as an initial value of means clustering; clustering data of the two-dimensional scatter diagram by using the means clustering; and calculating the particle number of each area according to clustered results, so as to count percentage of the particle number of each area. According to the invention, the boundary position, shape, direction and size of each area can be adjusted; and the method provided by the invention is strong in accuracy and stability, and can be used for improving the adaptability of the scatter diagram to various samples.

Owner:DIRUI MEDICAL TECH CO LTD

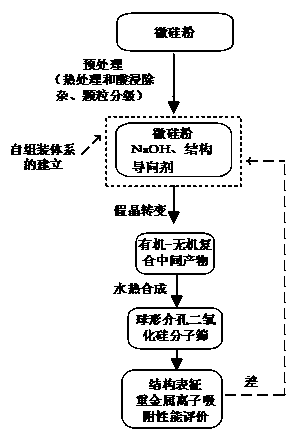

Preparation method of silicon dioxide molecular sieve

ActiveCN103539147AIncrease added valueSimple processOther chemical processesMolecular-sieve and base-exchange compoundsMaterials preparationMolecular sieve

The invention relates to a preparation method of a silicon dioxide molecular sieve, and belongs to the technical field of porous material preparation. The preparation method comprises the following steps: carrying out thermal treatment on silica fume, then carrying out particle classification and acid leaching treatment, filtering and cleaning; mixing the silica fume subjected to the acid leaching treatment, NaOH, a structure-directing agent and H2O in a molar ratio of SiO2 to NaOH to the structure-directing agent to H2O being 1: (0.2-0.4): (0.1-0.3): (150-200), reacting for 12-48 hours at the temperature of 90-120 DEG C, washing, filtering and drying, thus obtaining an organic-inorganic composite intermediate product; mixing the organic-inorganic composite intermediate product and water in a mass ratio being 1: (30-50), stirring, carrying out hydro-thermal treatment, washing, filtering and drying an obtained solid matter, then baking the obtained solid matter, and removing the structure-directing agent, thus obtaining the spherical mesoporous silicon dioxide molecular sieve. The preparation method has the advantages that the synthetic process and condition of the spherical mesoporous silicon dioxide molecular sieve are greatly simplified, the synthetic cost is reduced, and the prepared mesoporous material has excellent heavy metal adsorption property.

Owner:KUNMING UNIV OF SCI & TECH

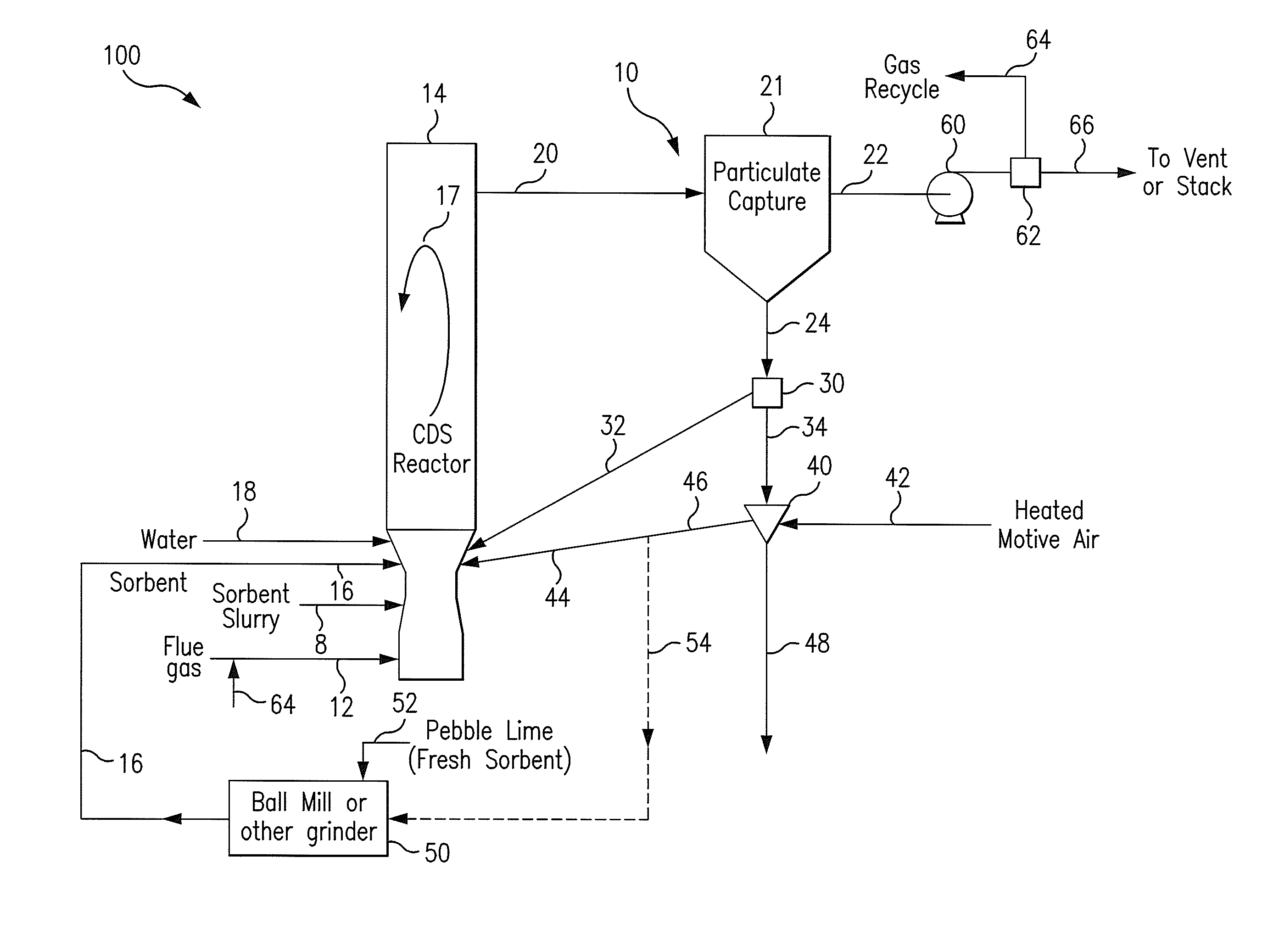

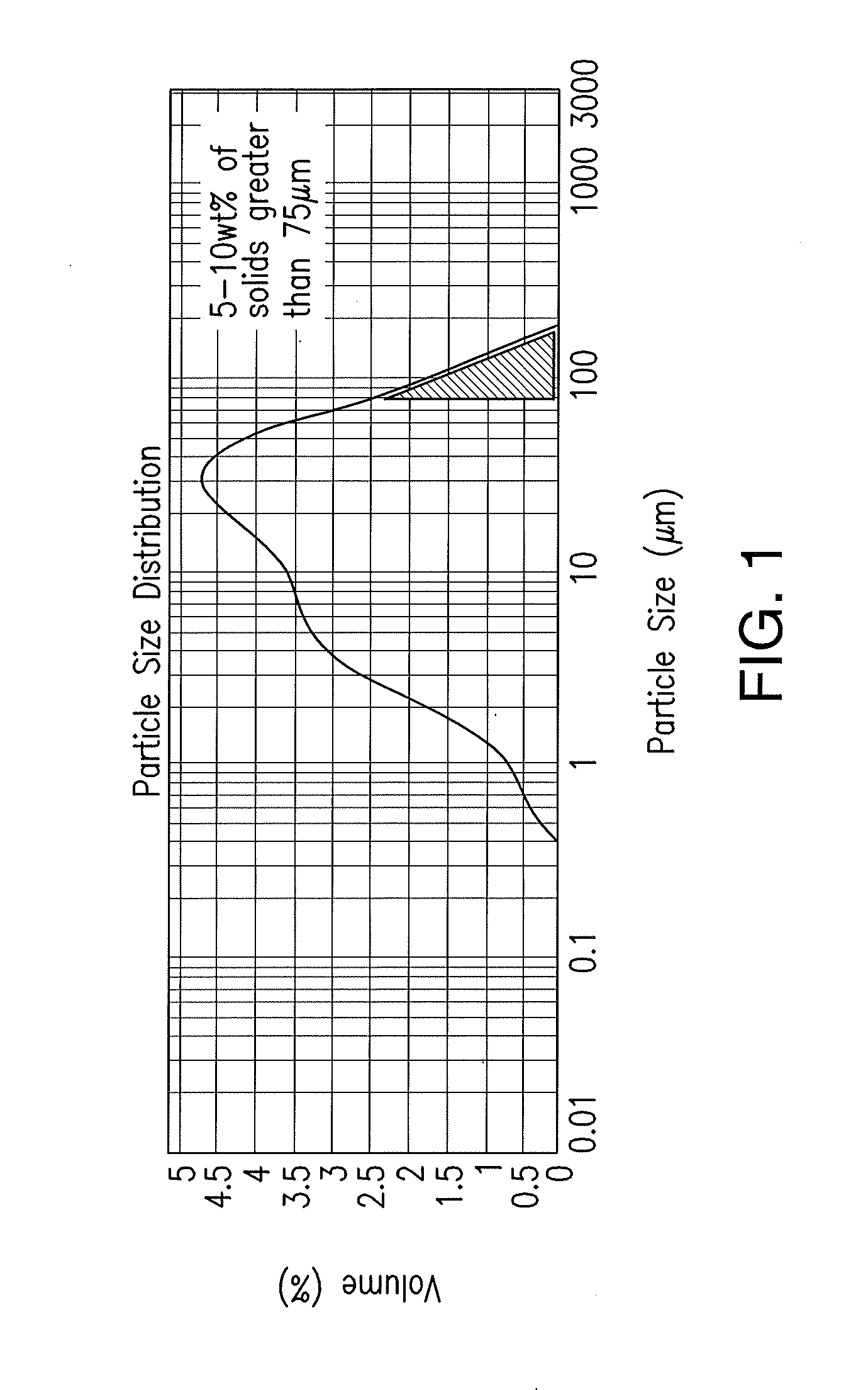

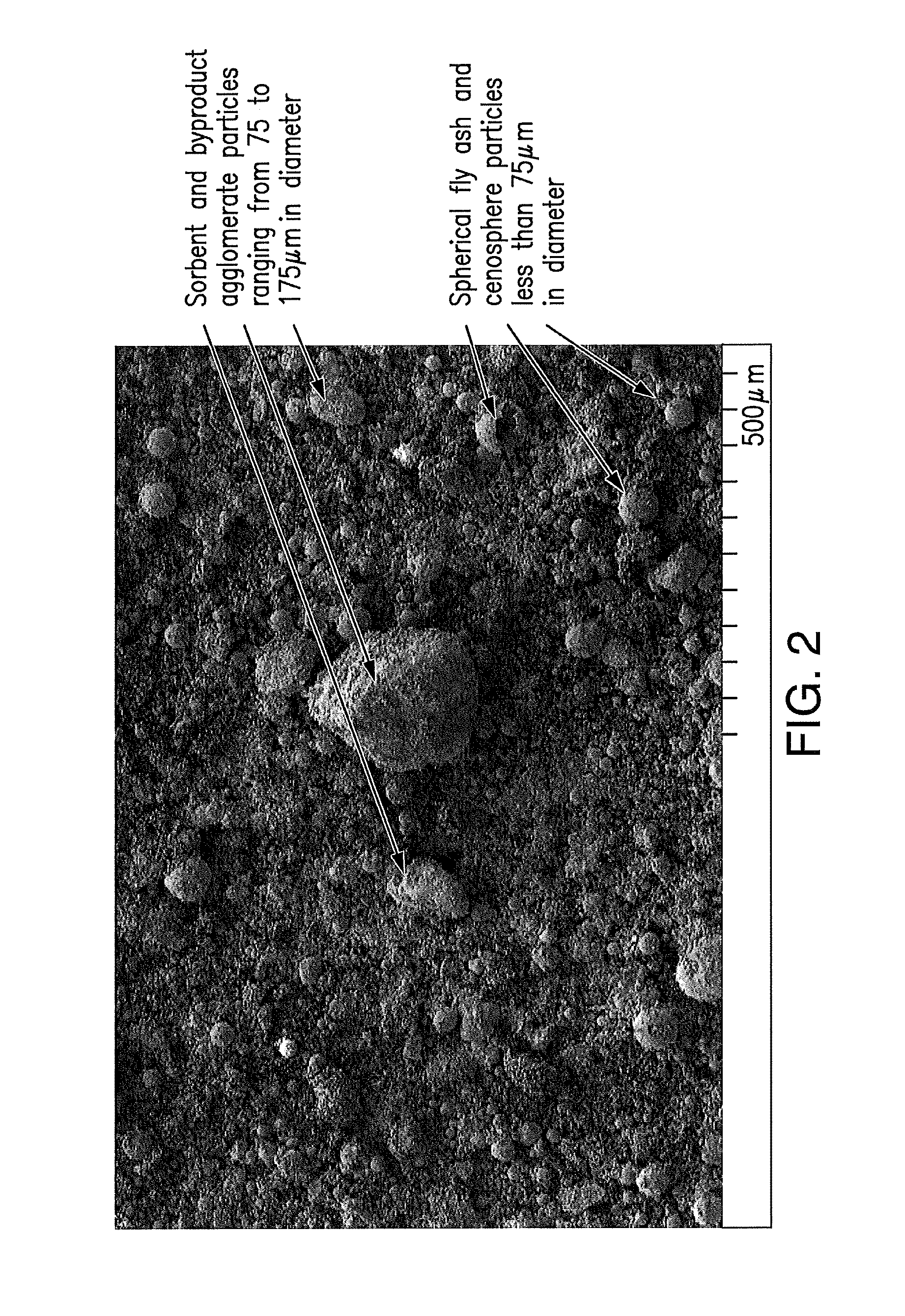

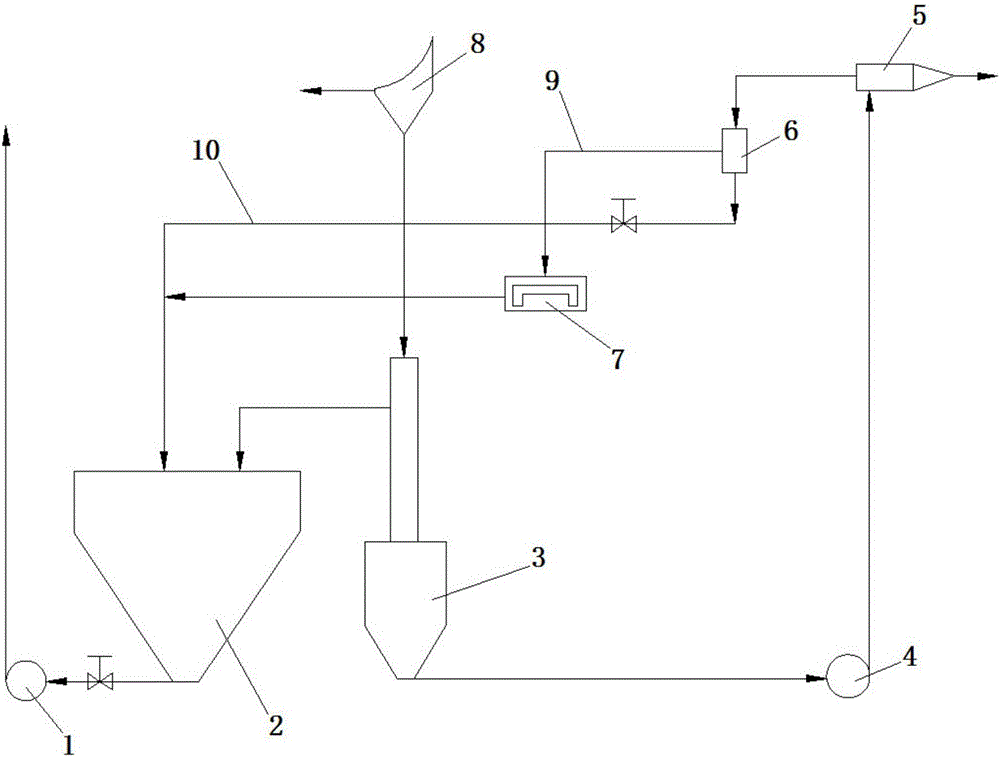

Reduced sorbent utilization for circulating dry scrubbers

Owner:BABCOCK POWER DEV

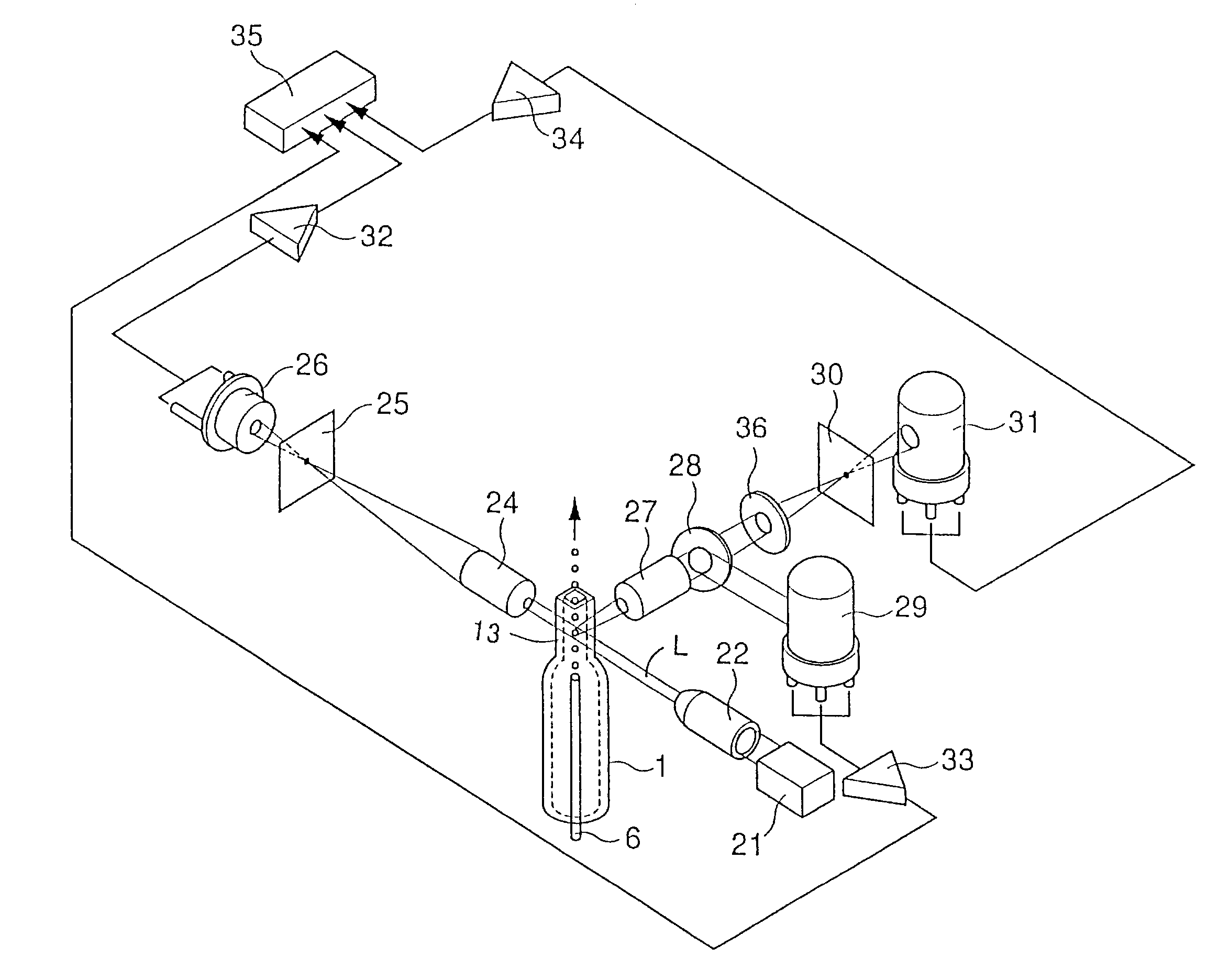

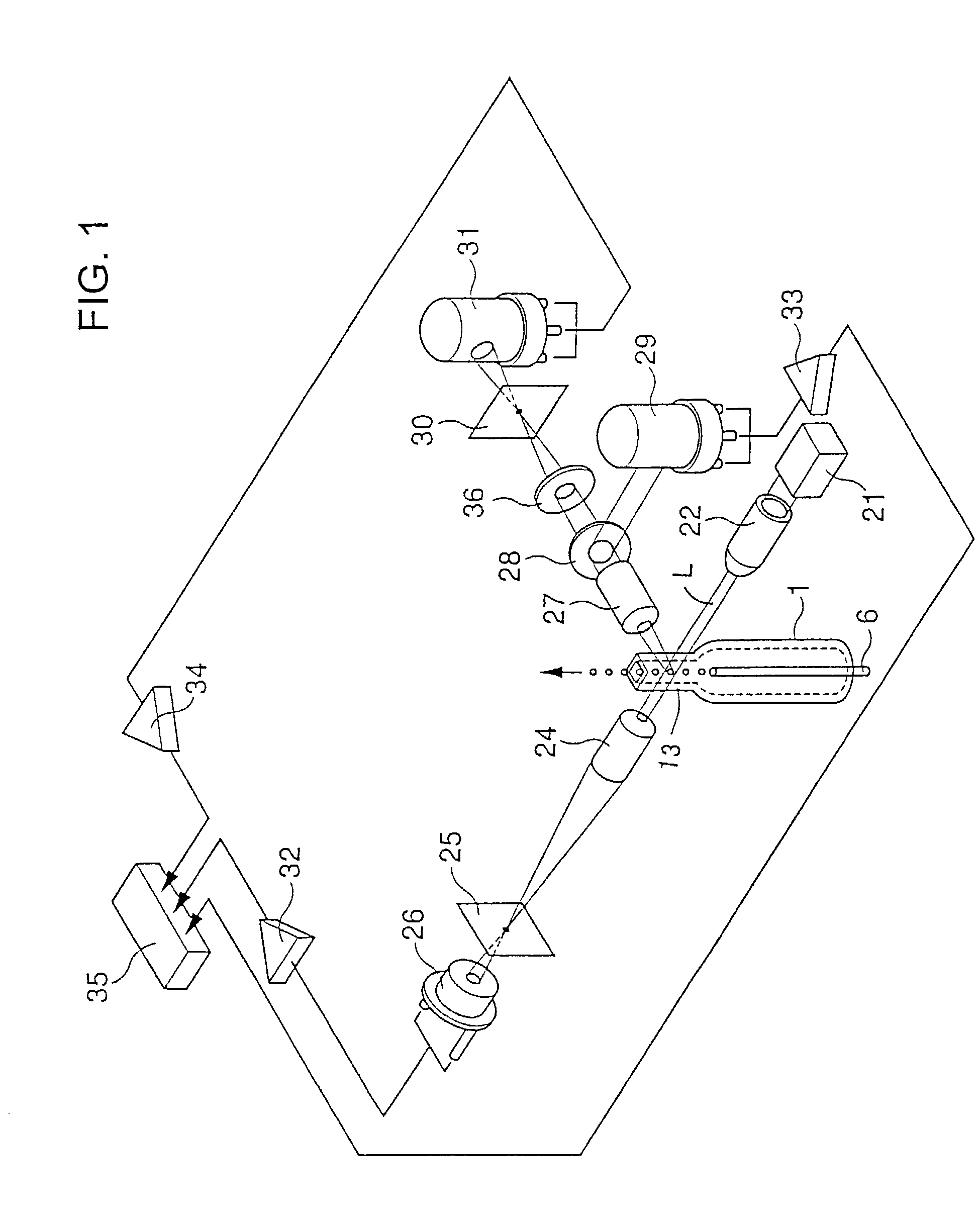

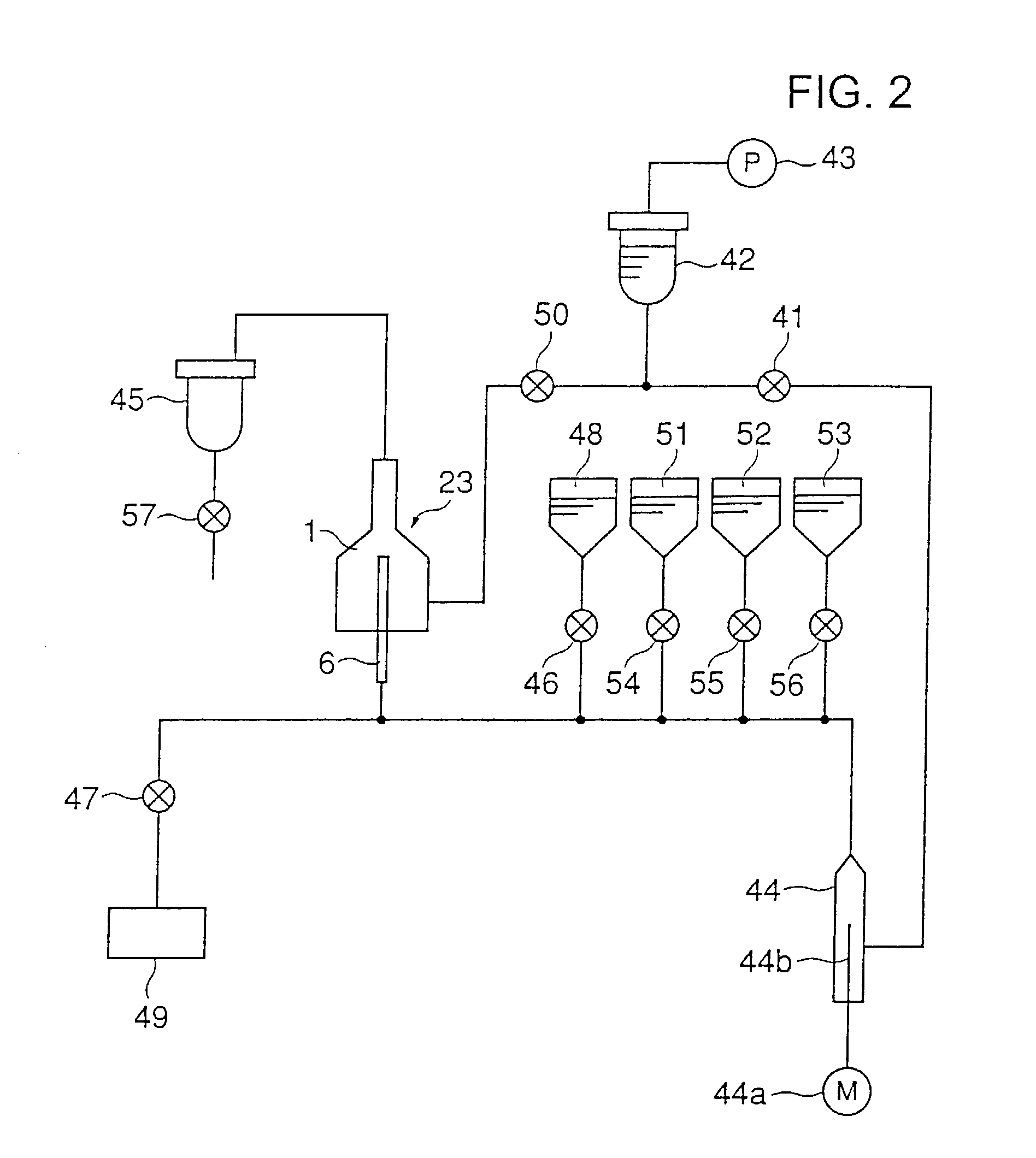

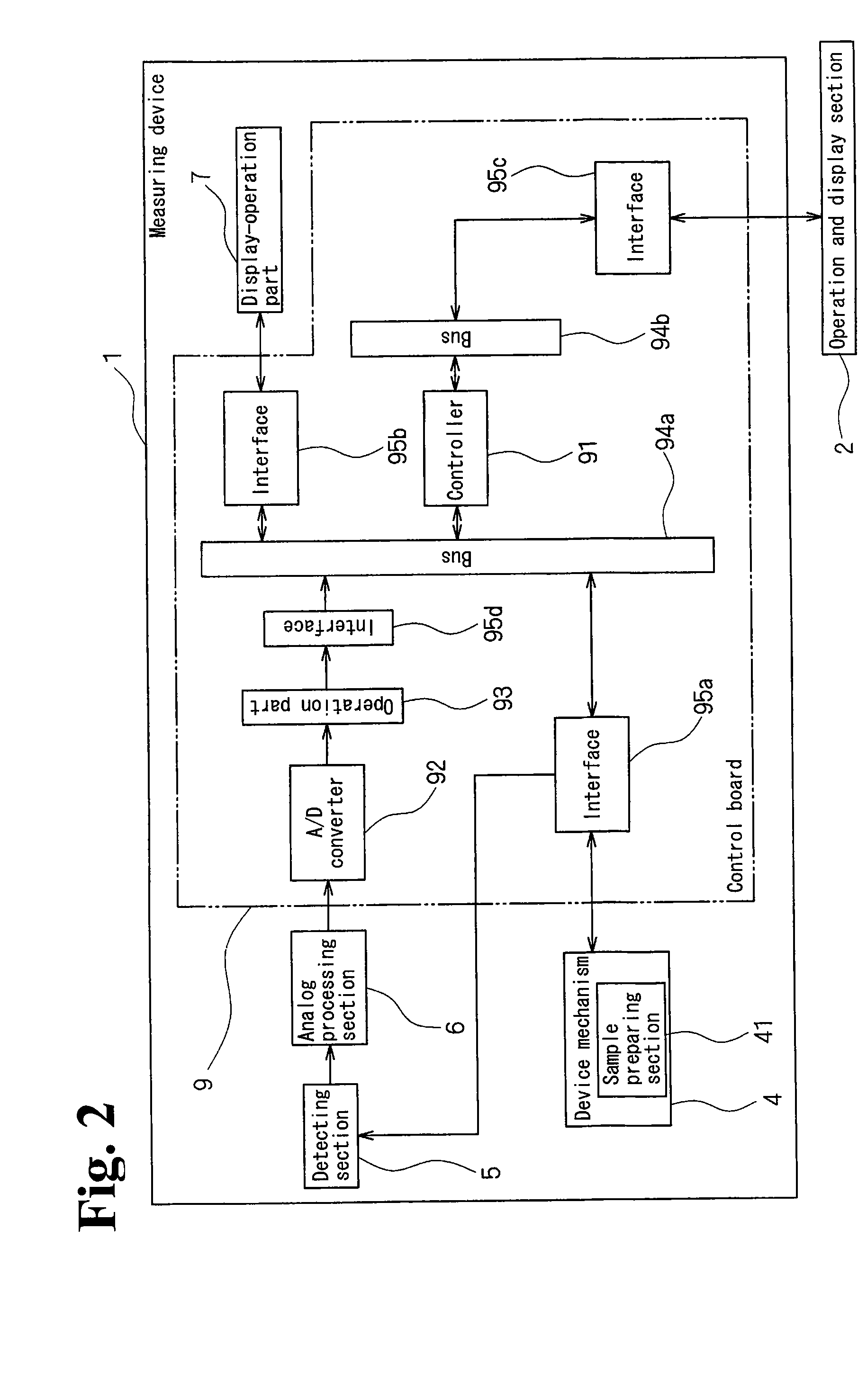

Particle analyzer and particle analyzing method

InactiveUS6979570B2Chemiluminescene/bioluminescenceAnalysis by electrical excitationFeature parameterStatistical physics

Owner:SYSMEX CORP

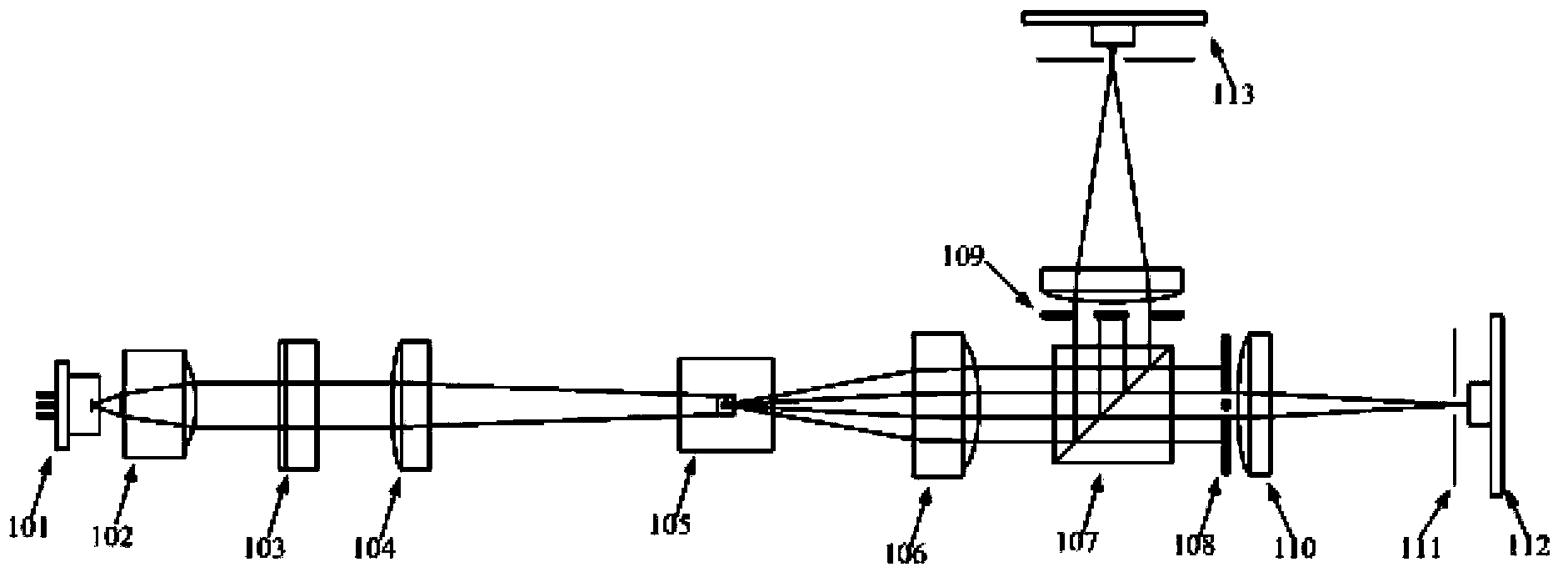

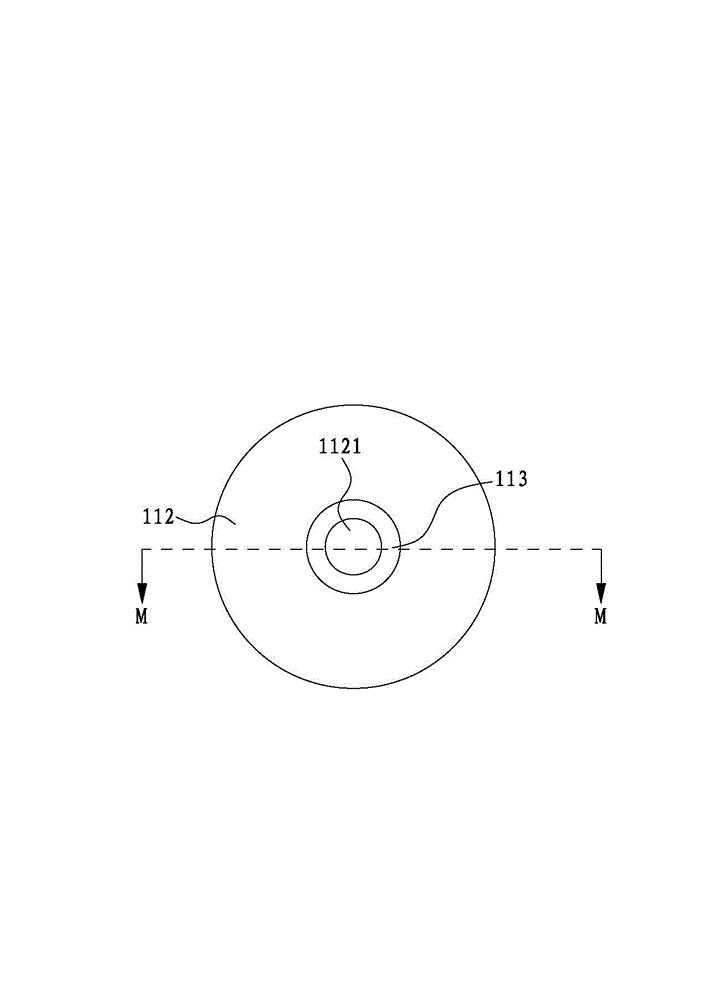

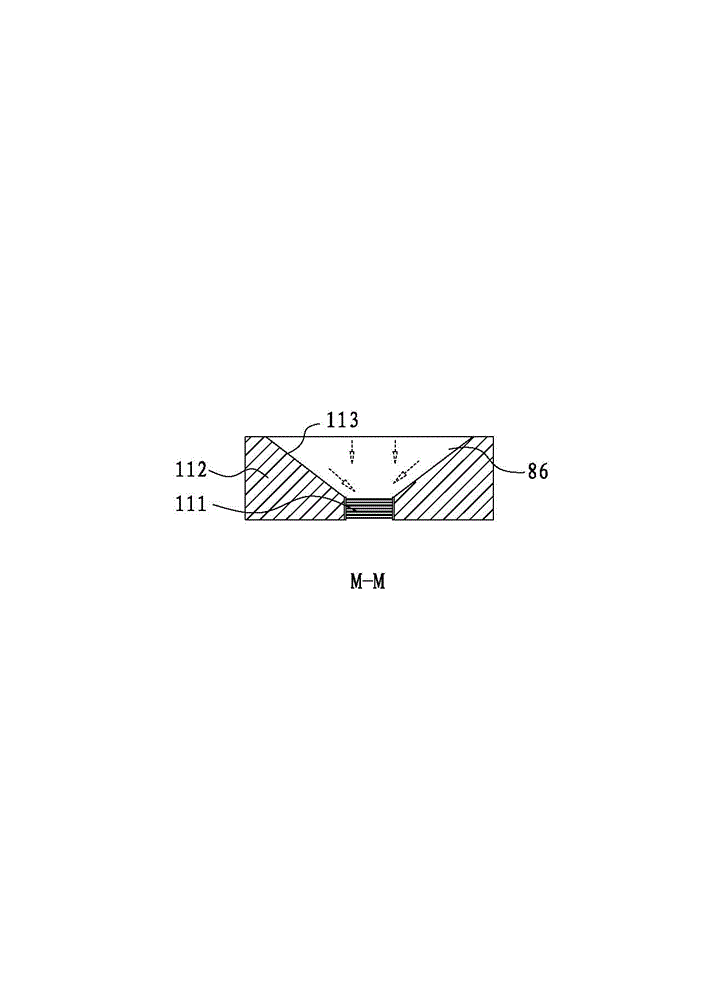

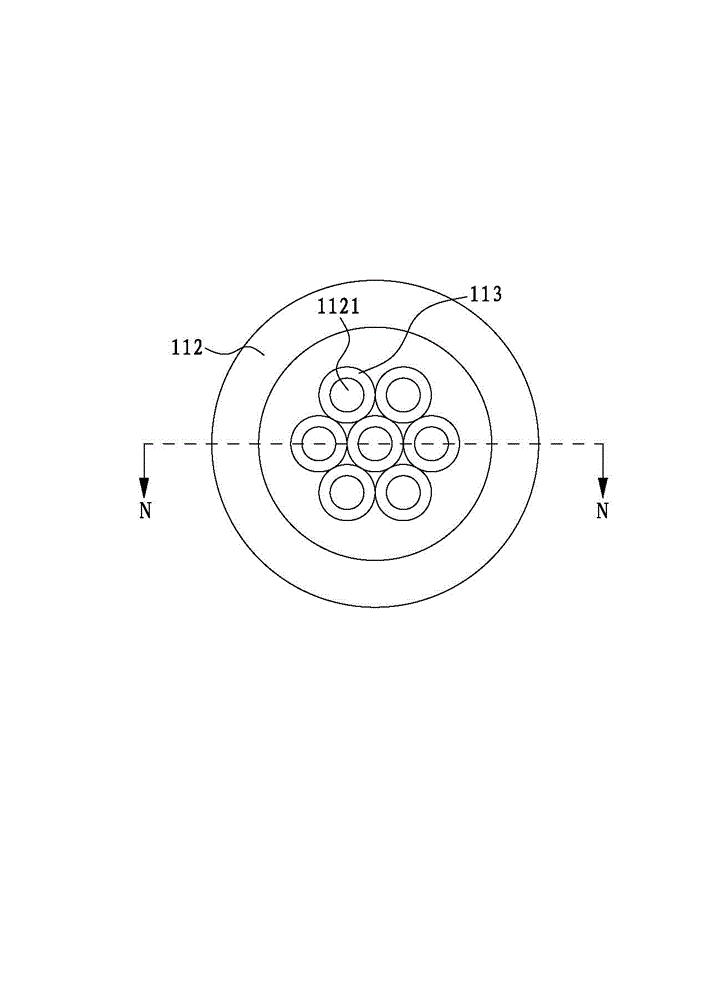

Optical system of particle analyzer

PendingCN104215562AImprove accuracyScattering properties measurementsIndividual particle analysisComputational physicsOptic system

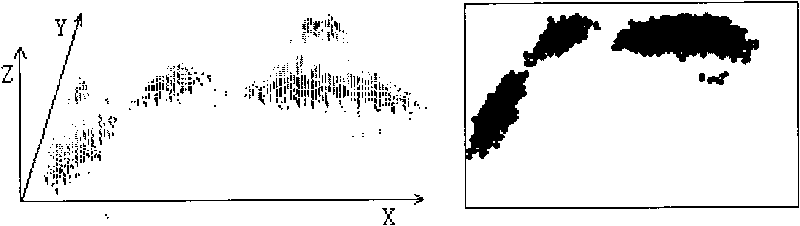

A disclosed optical system of a particle analyzer comprises a front light assembly, a flow chamber and a diffusion light collection assembly; the diffusion light collection assembly comprises a low-angle diaphragm, a low-angle photoelectric induction apparatus, a medium-angle diaphragm, a medium-angle photoelectric induction apparatus, a large-angle diaphragm and a large-angle photoelectric induction apparatus. On the detection basis of a conventional particle analyzer on low / medium-angle scope data particles, a diffusion light collection apparatus for detection of large-angle scope data particles is increased, so that detection on low / medium / large-angle scope data particles is realized, and three-dimensional data of a measured particle is obtained, and by collecting the diffusion light at a large-angle scope, more particle information can be obtained, and the particle classification accuracy is improved.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

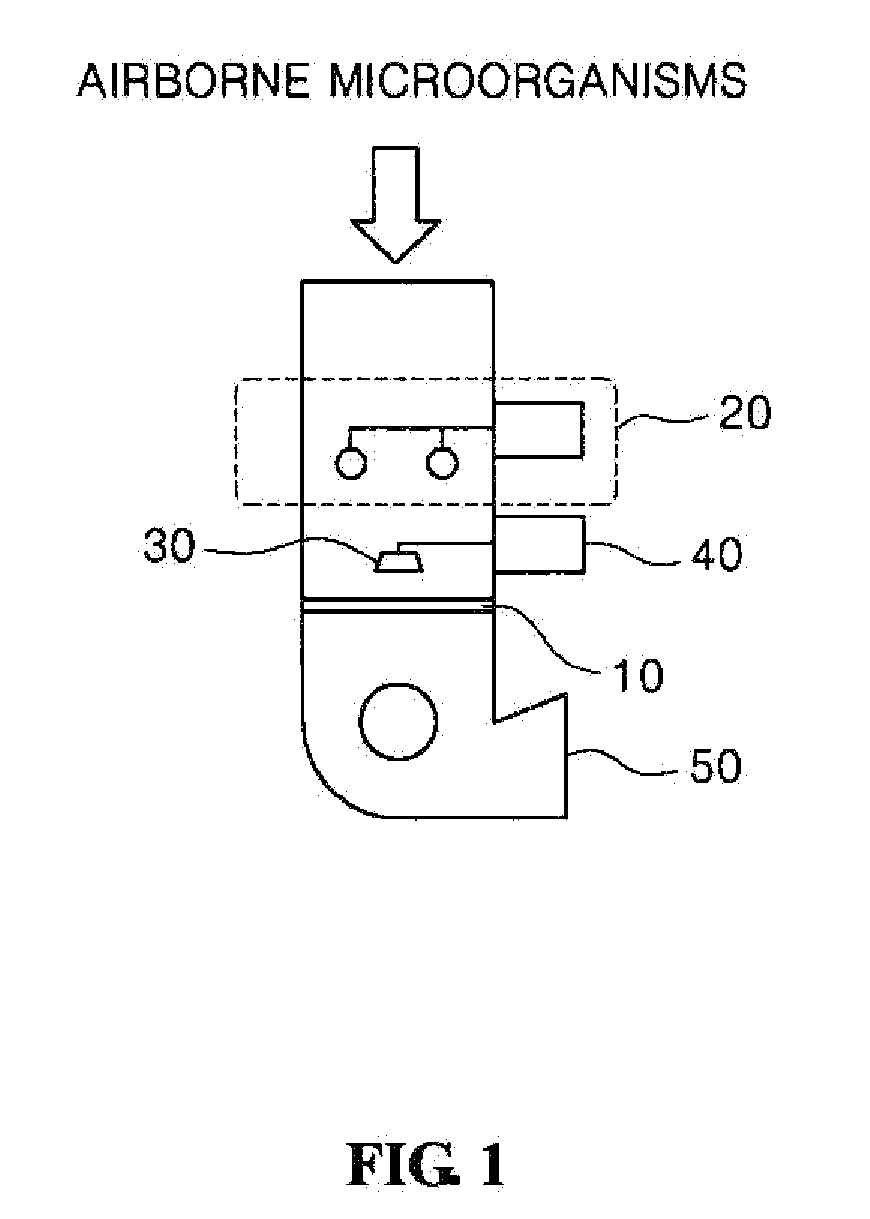

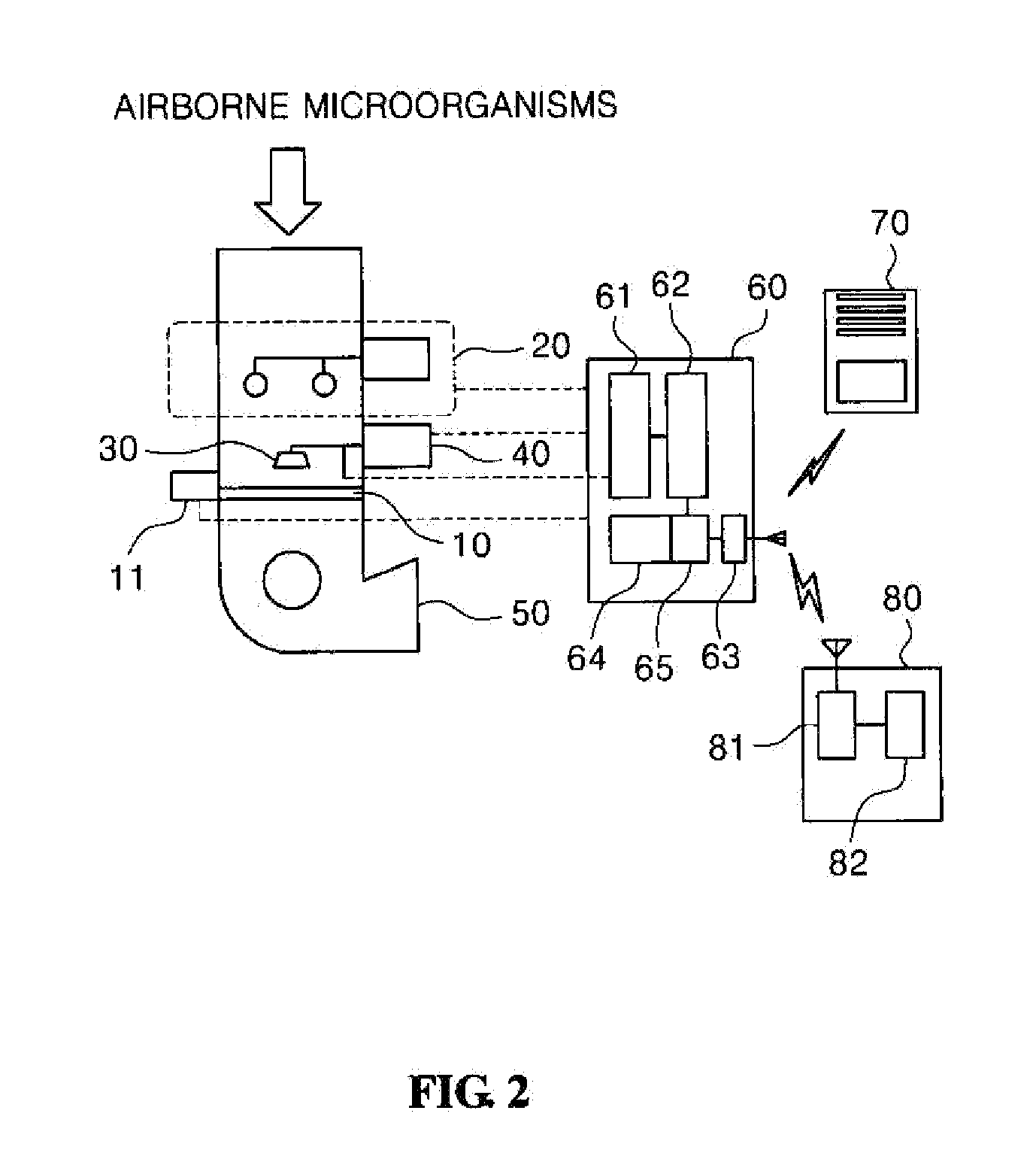

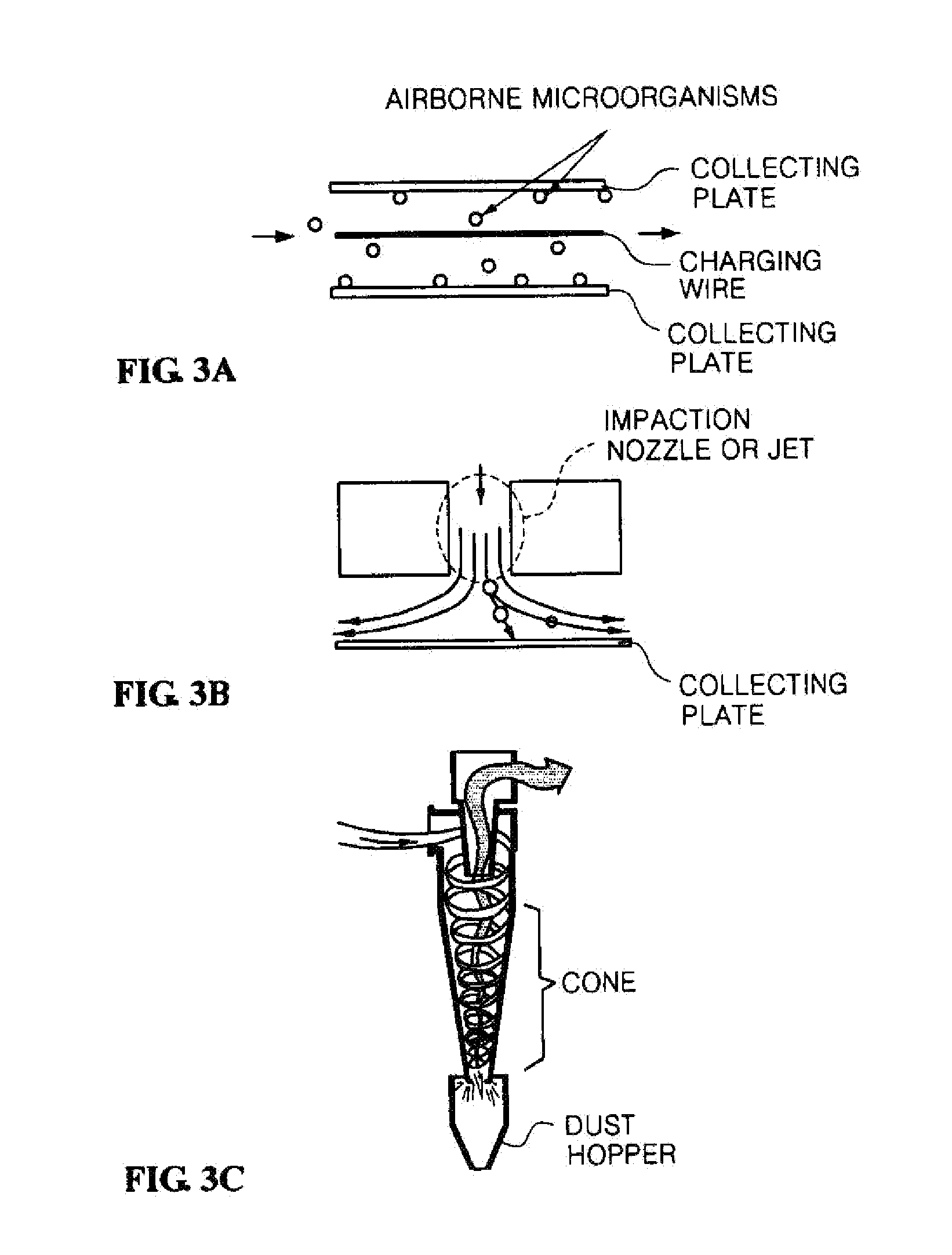

Apparatus for measuring floating microorganisms in a gas phase in real time using a system for dissolving microorganisms and ATP illumination, and method for detecting same

The present invention relates to a method for measuring airborne microorganisms in real time using a microorganism lysis system and ATP bioluminescence, the method including sampling the airborne microorganisms in a particle classification device to which an ATP-reactive luminescent agent is applied and, at the same time, lysing the microorganisms in a microorganism lysis system under continuous operation to extract adenosine triphosphate (ATP) of the microorganisms sampled in the particle classification device, thus inducing a luminescent reaction between the ATP-reactive luminescent agent and the ATP of the particle classification device in real time; and measuring the concentration of microorganisms using a light receiving device. According to the detection method using ATP organism illumination, the floating microorganisms in the gas phase can be readily detected and the detection can be automatically conducted in real time without manual labor.

Owner:IND ACADEMIC CORP FOUND YONSEI UNIV +1

Classified statistic method and device of particles

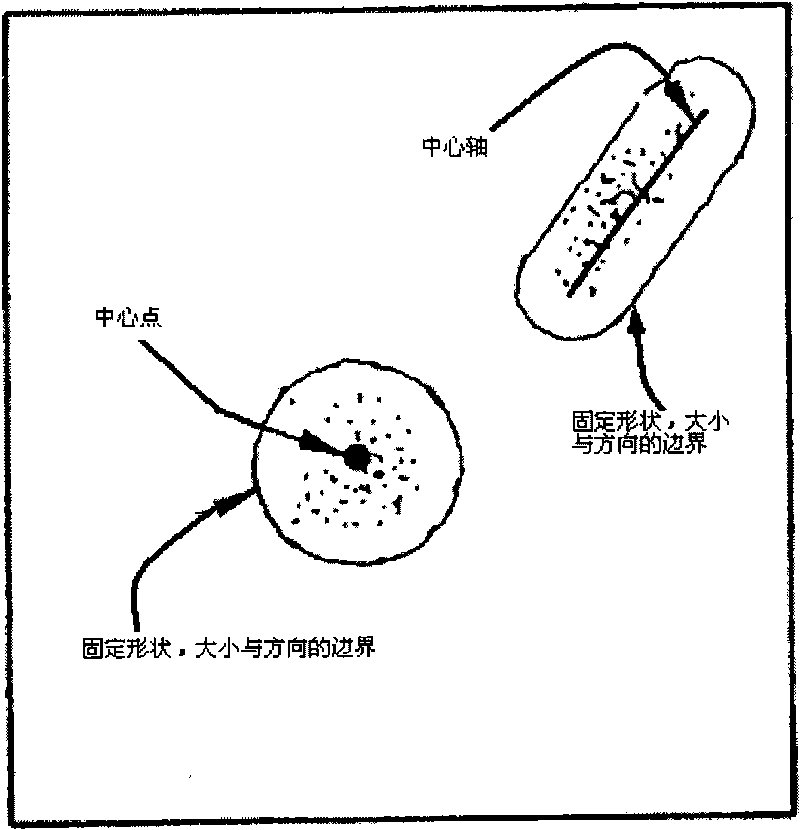

ActiveCN101672759AImprove adaptabilityImprove performanceBiological testingComputer scienceParticle classification

The invention discloses a classified statistic method of particles, which is suitable for carrying out classified statistic on particles by a particle detector. The method comprises the following steps: A1. collecting at least two features generated in the detector of each particle; B1. selecting the two features to be represented by a two-dimensional vector and mapping the two-dimensional vectoron a two-dimensional scatter diagram; C1. dividing distribution regions of various particles that need to carry out classified statistic on the scatter diagram; D1. calculating a particle distribution function in each region; and E1. carrying out classified statistic on the particles of all regions according to the particle distribution function of each region. The invention is used for automatically adjusting the size, the shape, the direction and the position of a classified boundary, has higher accuracy and stability and improves the adaptability of the scatter diagraph to an abnormal sample.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD +1

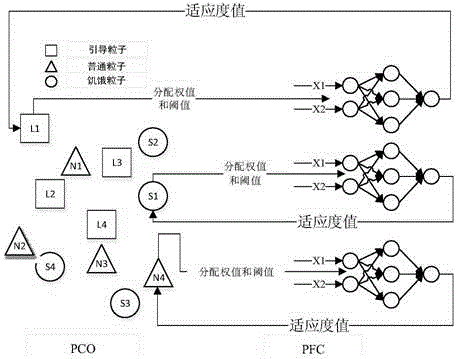

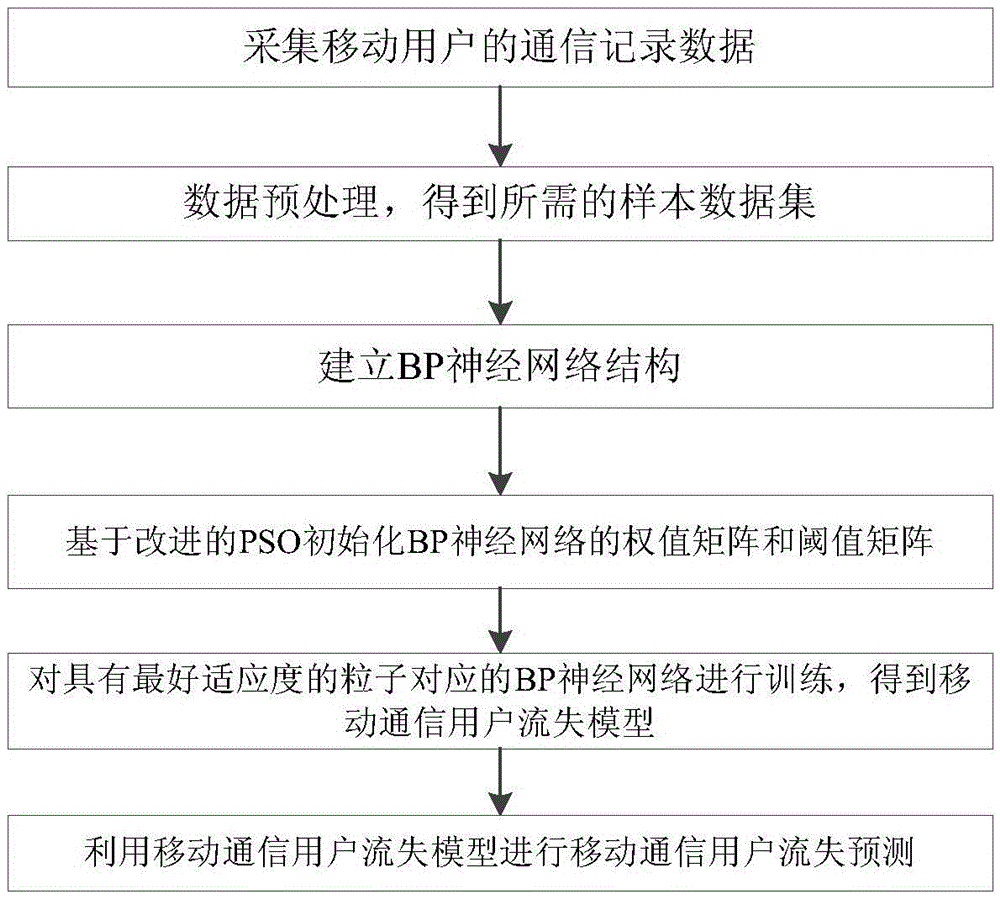

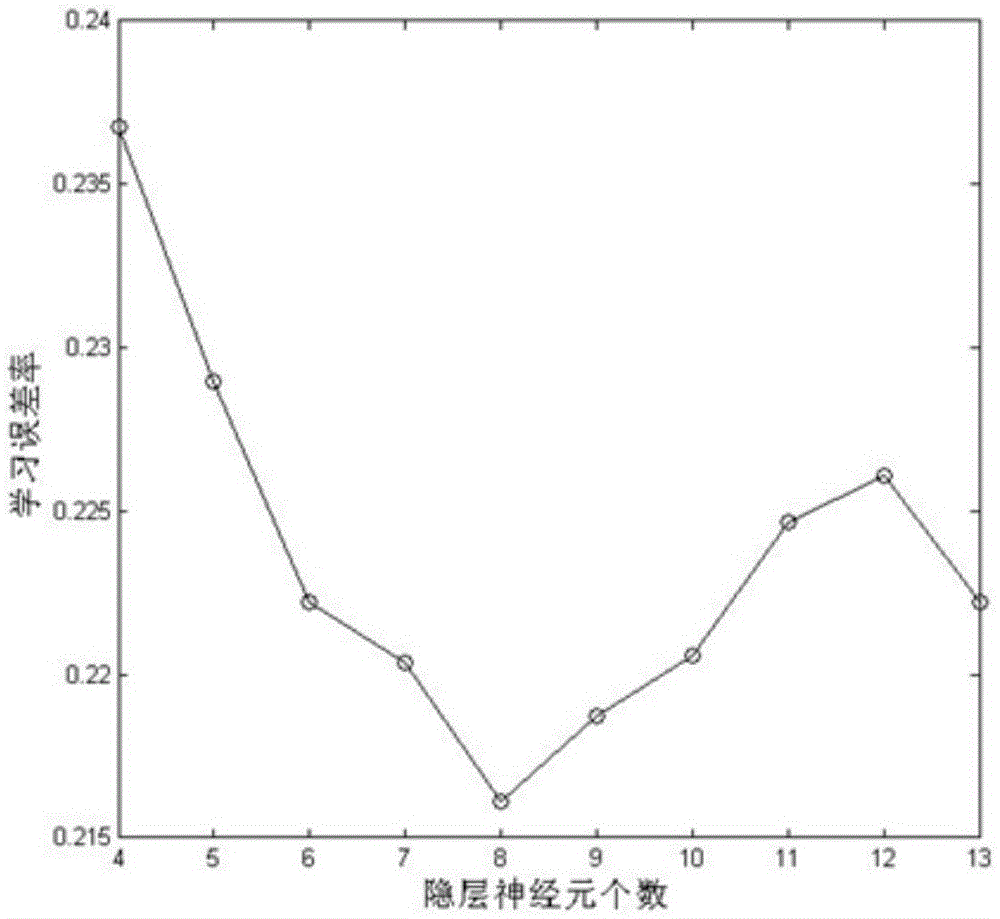

Mobile communication user loss prediction method based on particle classification and BP neural network

ActiveCN105469144AImprove accuracyData processing applicationsNeural learning methodsData setNetwork structure

The invention relates to a mobile communication user loss prediction method based on particle classification and a BP neural network. The method comprises: communication record data of a mobile user are collected; data pretreatment is carried out to obtain a needed sample data set; a BP neural network structure is established; on the basis of an improved particle swarm optimization (PSO) algorithm, a weight matrix and a threshold matrix of the BP neural network are initialized; a BP neural network corresponding to a particle having best fitness is trained to obtain a mobile communication user loss model; and mobile communication user loss prediction is carried out by using the mobile communication user loss model. According to the invention, the weight matrix and the threshold matrix of the BP neural network are initialized by combining application of a particle classification optimization (PCO) algorithm and a PFC process, so that the weight matrix and the threshold matrix of the BP neural network are close to global optimal values and thus the mobile user loss prediction accuracy of the BP neural network is improved.

Owner:NORTHEASTERN UNIV

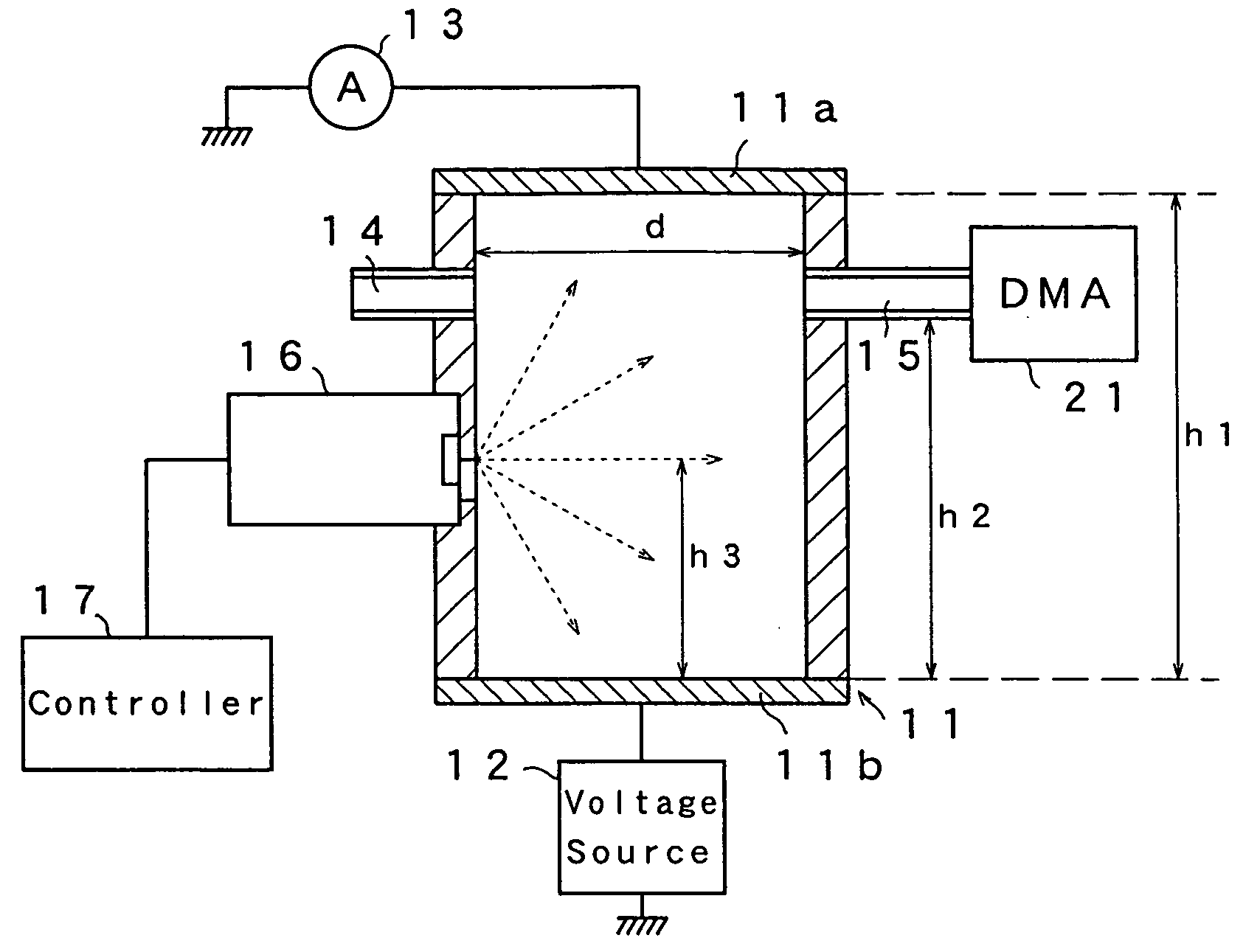

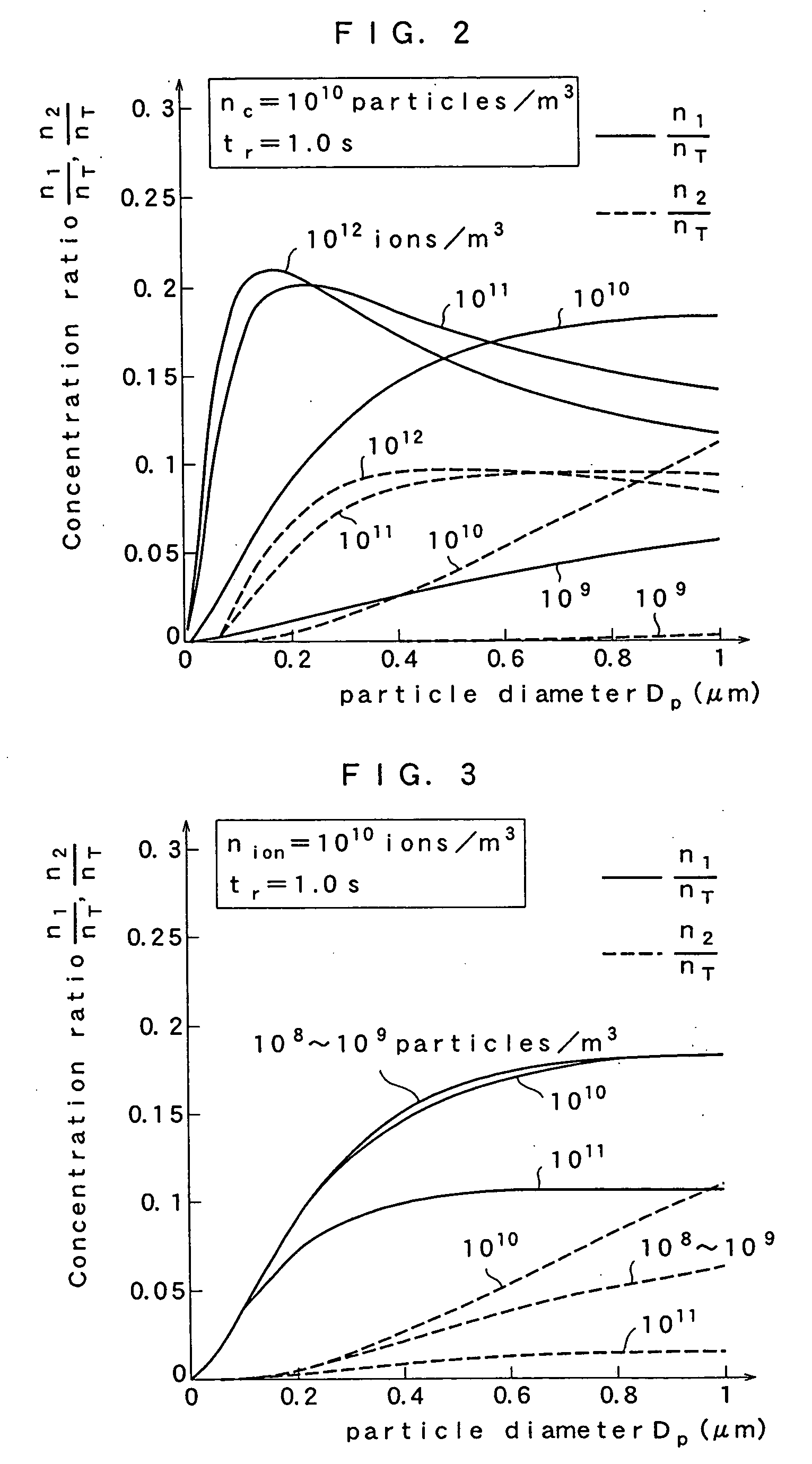

Aerosol particle classification apparatus

InactiveUS20050180543A1Material analysis using wave/particle radiationElectrostatic separationSoft x raySoft X-rays

Distributed non-charged particles having a desired particle diameter are introduced into a chamber. A photoionizer in which a soft X-ray power is adjustable is attached to the chamber, to charge the particles within the chamber. The power level of the soft X-ray is adjusted by a controller so as to produce singly charged particles. The charged particles are then introduced into a differential mobility analyzer for classification, thus producing monodisperse standard particles having particle diameter of 0.1 to 1.0 μm.

Owner:KANOMAX JAPAN +1

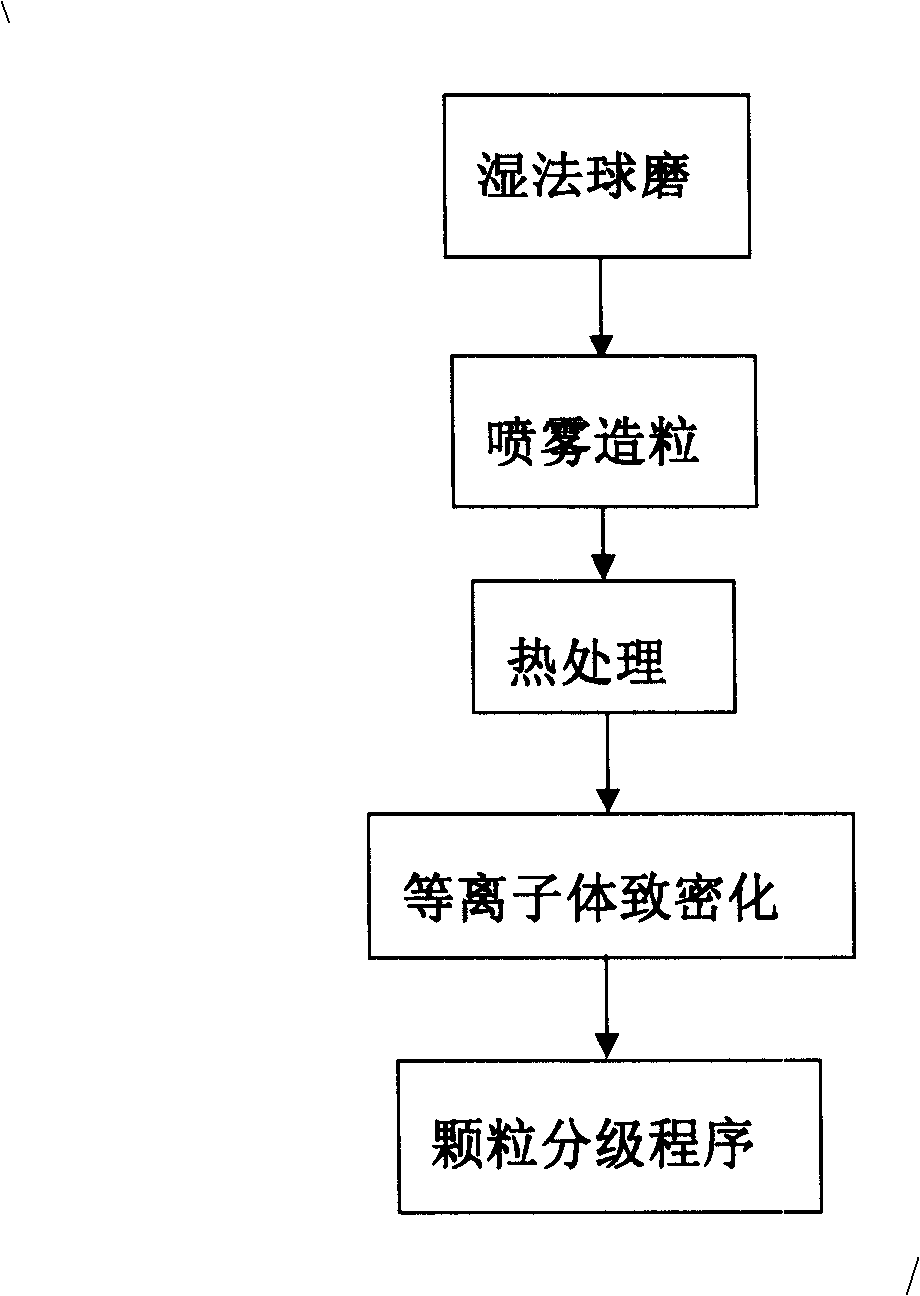

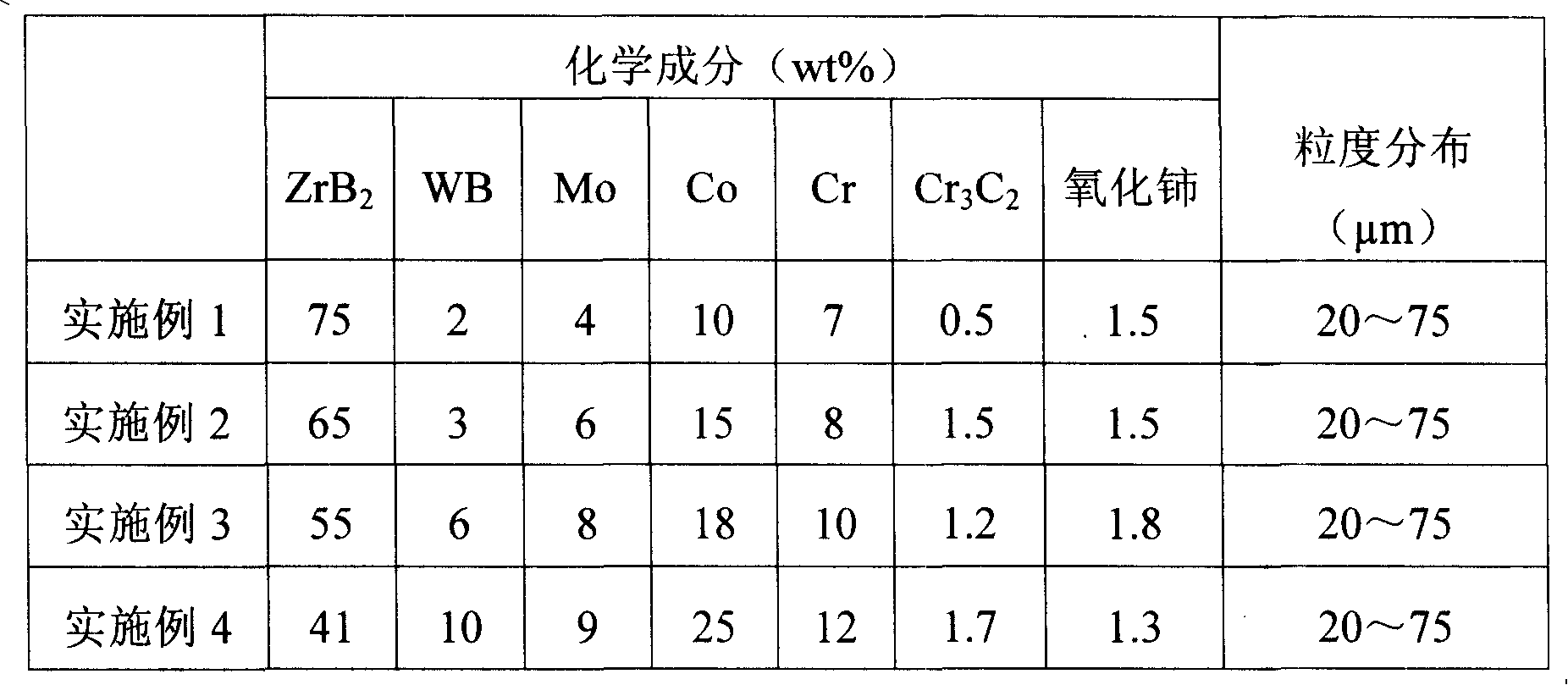

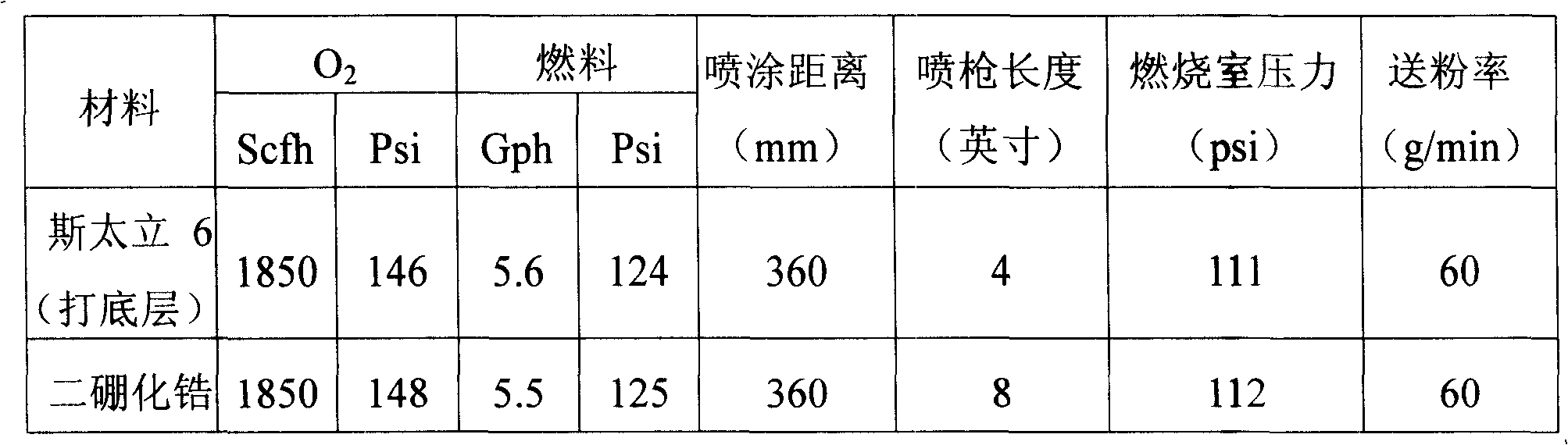

Nano-composite metal ceramic powder for molten metal resistant erosion and method for manufacturing same

InactiveCN101244937AImprove toughnessGood resistance to high temperature oxidationTemperature resistanceCobalt

The invention provides a nano complex metal ceramic powder used for the erosion of melting-resistant metals, the components and weight percentages of which are as following: 41 to 75 percent of zirconium diboride, 10 to 25 percent of cobalt, 7 to 12 percent of chromium powder, 2 to 10 percent of tungsten boride, 4 to 9 percent of molybdenum, and 0.5 to 1.7 percent of chromium carbide, the rest is cerium oxide, wherein the particle sizes of cobalt, chromium, tungsten boride, molybdenum, chromium carbide and cerium oxide are all between 0.5 Mum and 1 Mum, the particle size of zirconium diboride is less than 100nm, the powder can be produced by the processes of wet-ball grinding, spray granulation, heat treatment, plasma densification and particle classification, sink rolls and stable rolls after being sprayed by the powders has the advantages of high temperature resistance, corrosion resistance and abrasion resistance, the average time for being used on sink rolls of continuous hot-dipped al-zn group is 20 to 31 days, the times and time of changing sink rolls are reduced so as to save the cost, improve the economic benefit and improve the quality of aluminum plating zinc strip steels.

Owner:BAOSHAN IRON & STEEL CO LTD +1

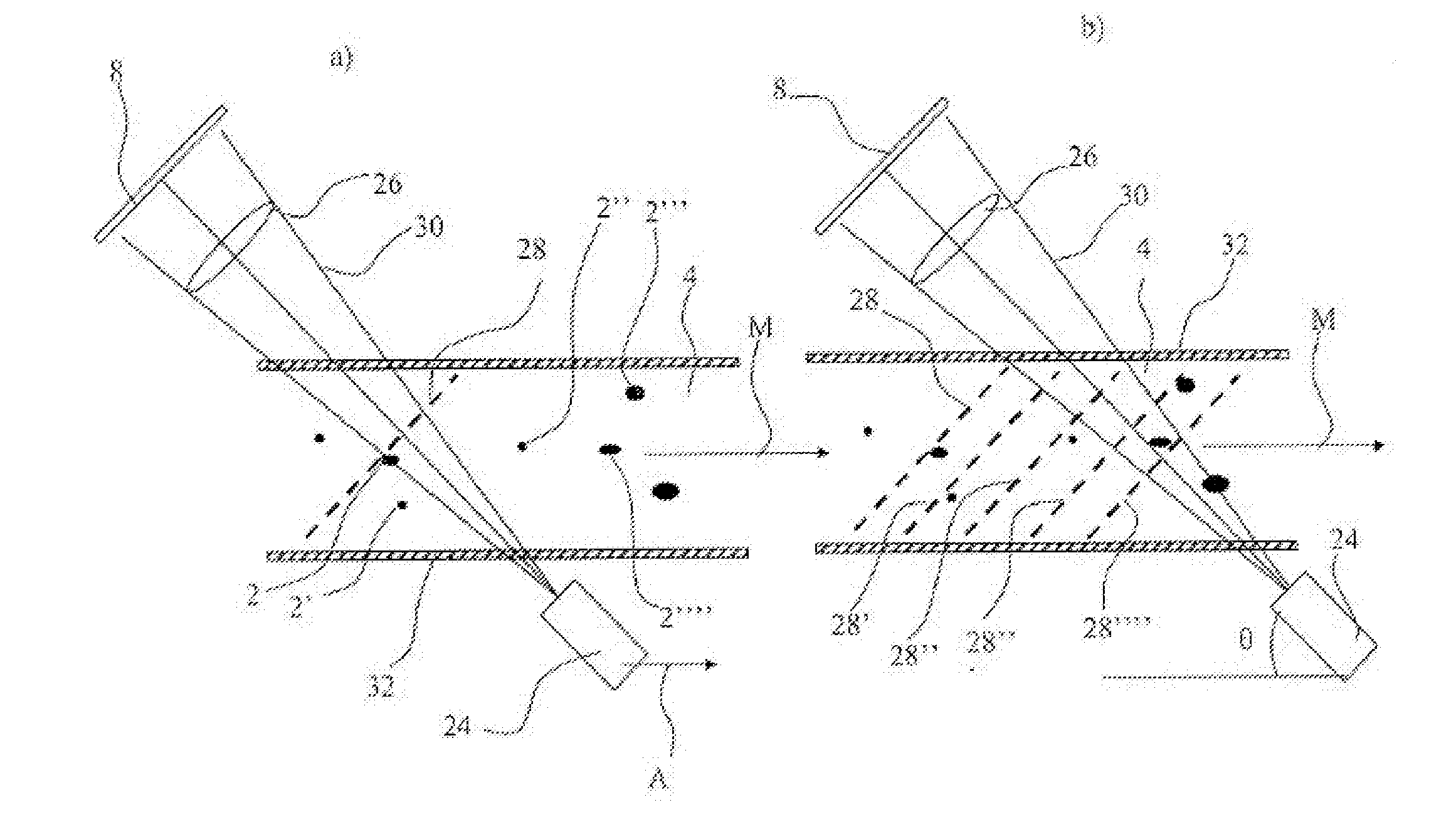

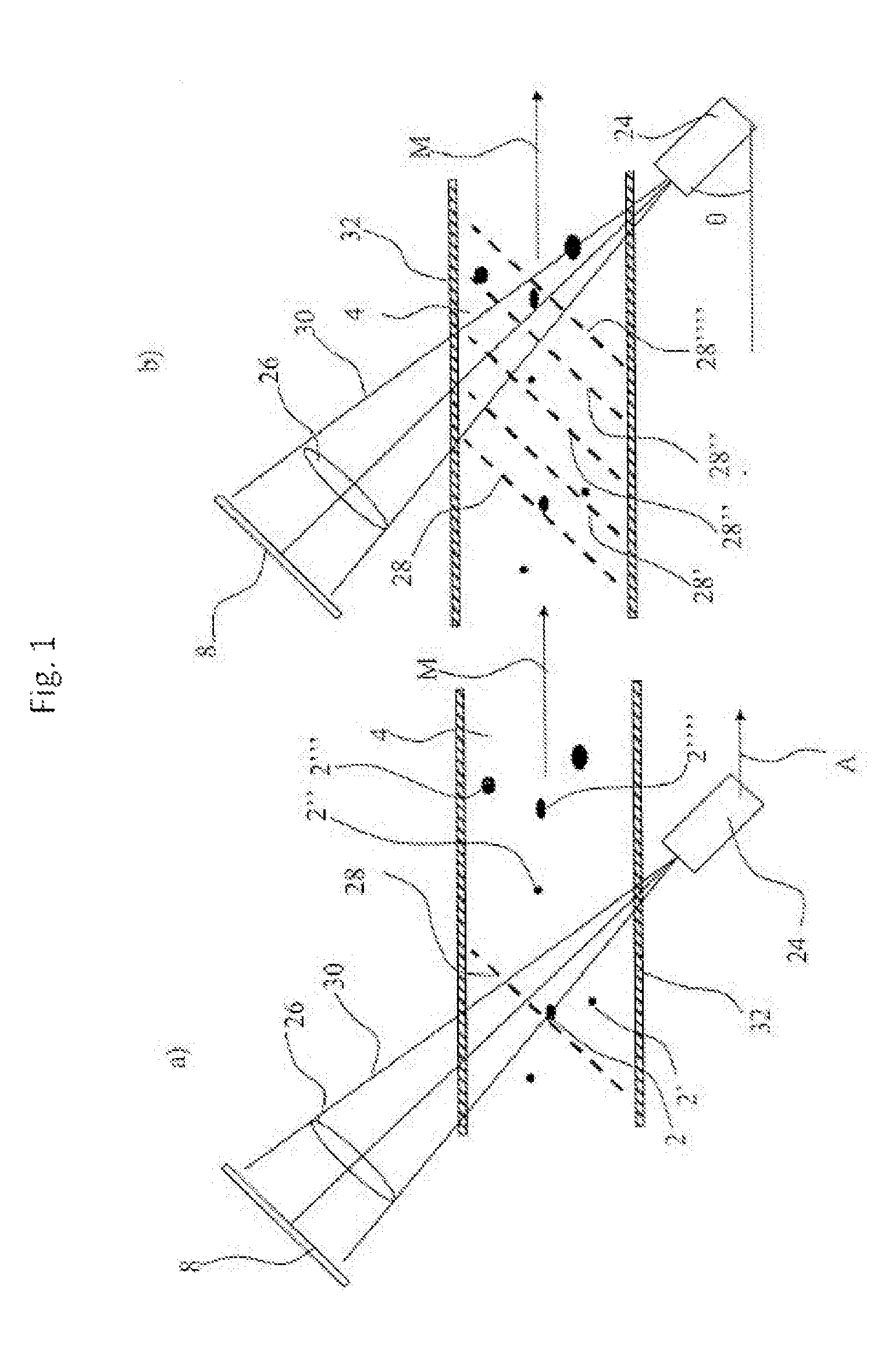

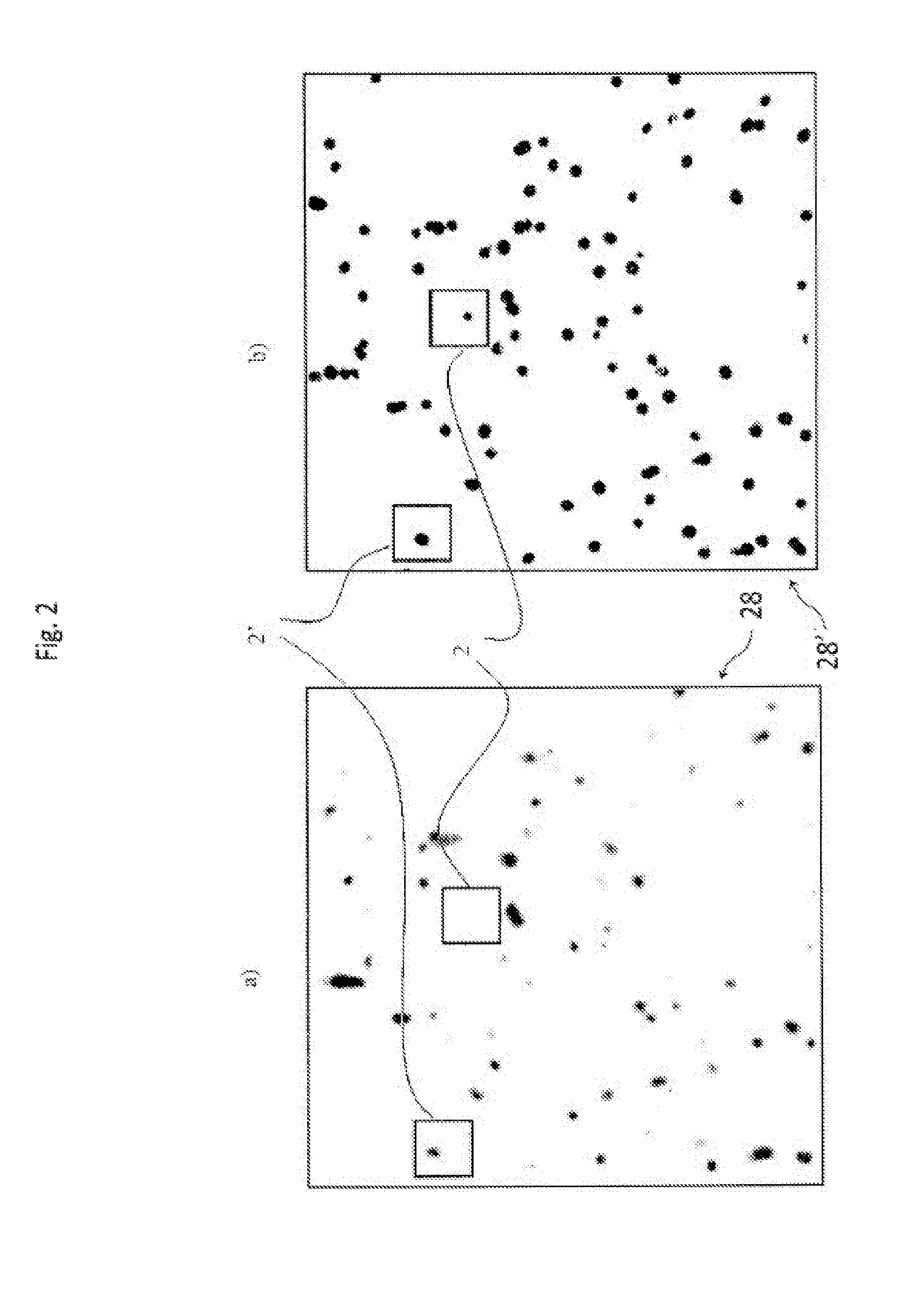

System and method for classification of particles in a fluid sample

ActiveUS20150347817A1Simple and reliable processThe process is simple and fastImage enhancementImage analysisControl systemOptical axis

A particle classifier system and a method of training the system are described. The particle classifier system is suitable for classification of particles in a liquid sample, said particle classifier system comprises—an optical detection assembly comprising at least one image acquisition device with an optical axis, the image acquisition device is configured to acquire images of an image acquisition area perpendicular to said optical axis; —a sample device comprising at least one sample container suitable for holding a sample in liquid form; —a translating arrangement configured to translate said image acquisition area through at least a part of said sample container; —a control system configured to controlling said optical detection assembly and said translating unit to acquire images of a plurality of image acquisition areas; —an image analyzing processing system programmed to analyze said acquired images by a method comprising creating objects (sub-images) of individual particles captured by said acquired images, creating stacks of objects of each individual particle, identifying complete stacks of objects comprising at least one object wherein said particle is in-focus, and two objects wherein said particle is out-of-focus, and determining, for each of said complete stacks of objects, a set of values for a set of features of at least N features, wherein N is larger than or equal to 1, and wherein the determination of said values of said set of features involve data obtained from said at least one object wherein said particle is in-focus, and / or said at least two objects wherein said particle is out-of-focus; and —an artificial intelligent processing system programmed to associate said set of values for said determined set of features for each individual particle to a particle classification.

Owner:KONINKLJIJKE PHILIPS NV

Inertial filter film and particle classification sampling device thereof

InactiveCN102743924AImplement samplingAccurate detectionCombination devicesDispersed particle filtrationParticulatesCoarse particle

The invention discloses an inertial filter film and a particle classification sampling device thereof. The particle grading sampling device comprises a coarse particle classificator and the inertial filter film; the coarse particle classificator comprises a housing and a sampling channel arranged in the housing, two ends of the sampling channel are provided with a gas inlet and a gas outlet respectively, and multi-stage coarse particle collision acquisition groups are sequentially arranged along the gas flow direction of the sampling channel; and the inertial filter film is arranged under the gas outlet of the coarse particle classificator and comprises barrier plates, each of the barrier plates is provided with flow guide apertures, several metal nets which are up-down superposed together are filled in the flow guide apertures on the barrier plates, meshes on each two adjacent metal nets are staggeredly arranged, and there is a gap between each two adjacent metal nets. Sampling of fine particles in the gas is well realized through the particle classification sampling device to accurately detect and analyze the particles in the gas, so the detection precision and the sampling quality are effectively improved.

Owner:DONGGUAN UNIV OF TECH +1

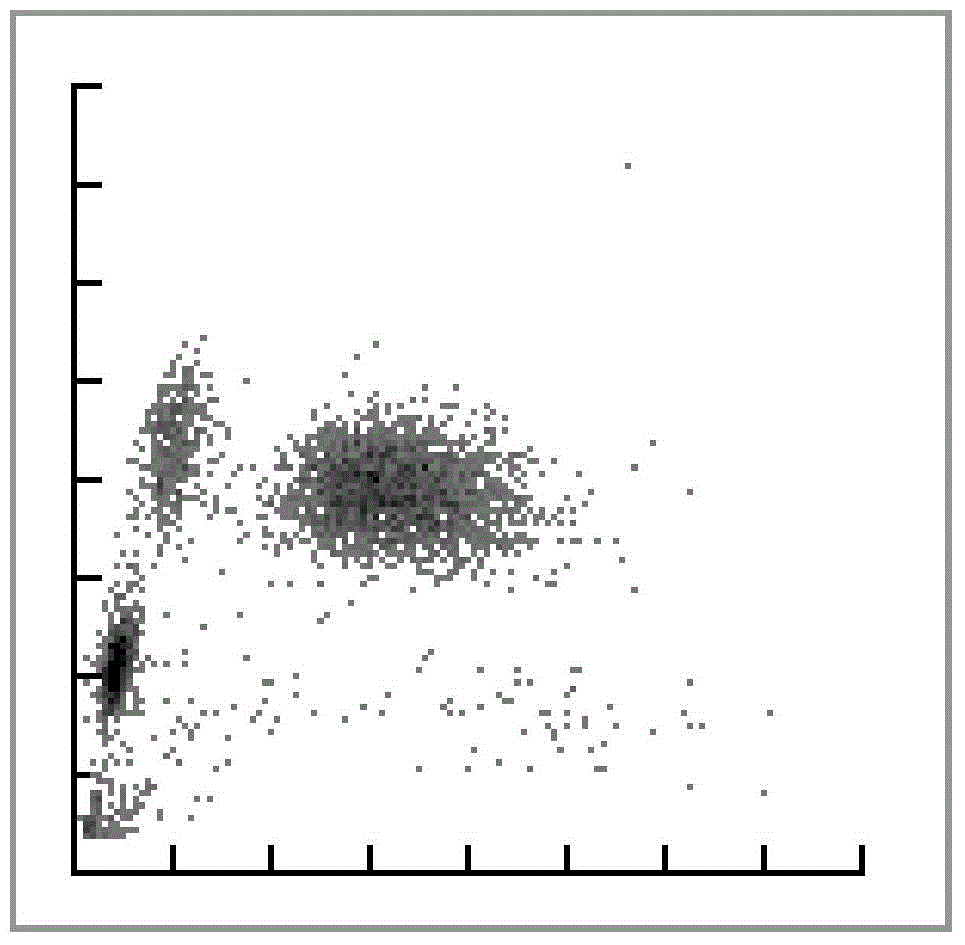

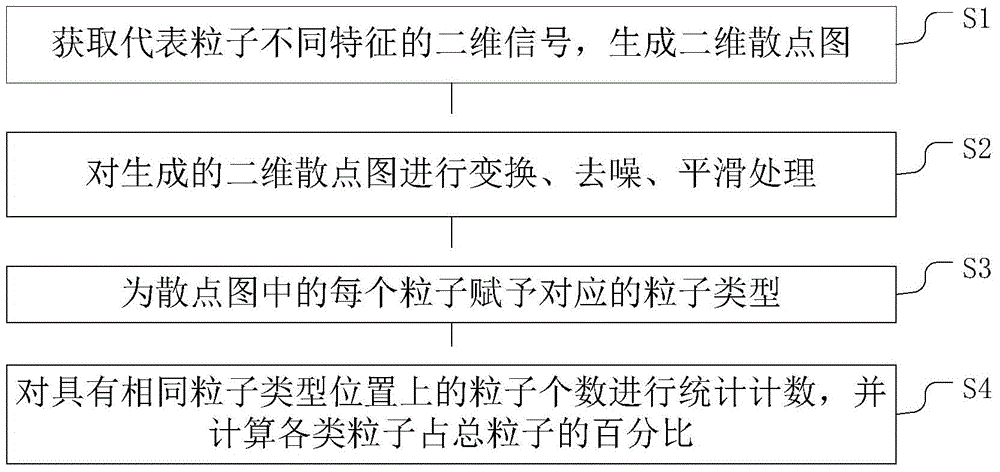

Particle classification statistic method and system for scatter diagram and blood cell analyzer

InactiveCN104359821AAccurate classificationOvercome the defect of not being able to classify and adjust according to sample characteristicsImage analysisIndividual particle analysisErrors and residualsComputer science

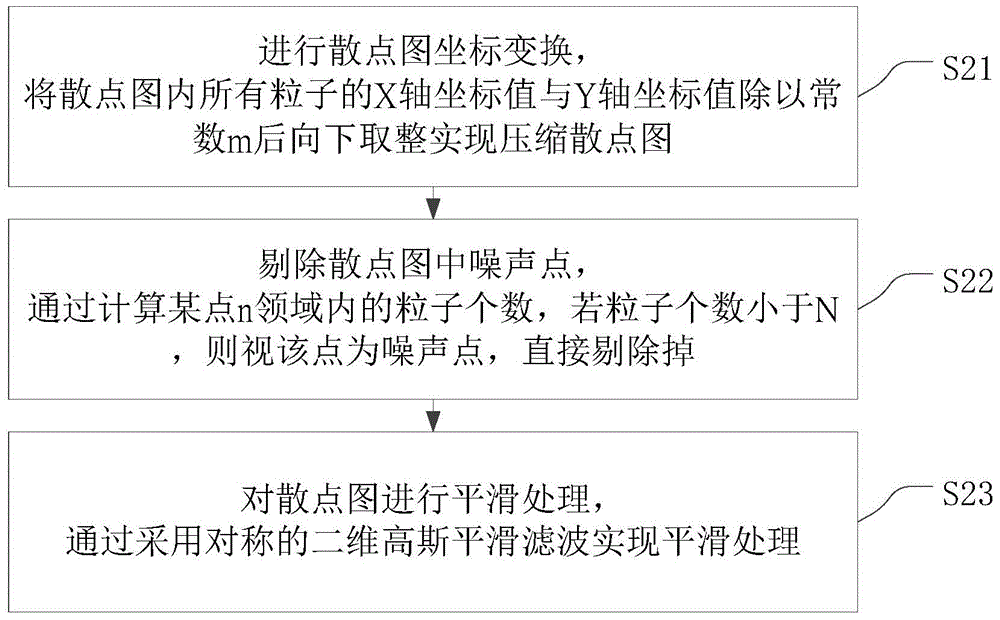

The invention discloses a particle classification statistic method for a scatter diagram, a particle classification statistic system for scatter diagram and a blood cell analyzer. The particle classification statistic method for the scatter diagram comprises the following steps of acquiring two-dimensional signals representing different features of particles, and generating a two-dimensional scatter diagram; pre-classifying the scatter diagram, and performing transformation, noise elimination and smoothing on the generated two-dimensional scatter diagram; classifying scatter diagram particles, and endowing each particle in the scatter diagram with a corresponding particle type; performing scatter diagram particle parameter counting, counting the number of the particles with the same particle type, calculating the percentage of each type of the particles in all the particles, and culling the particles with the interference type to realize classification statistics. According to the particle classification statistic method, features of normal samples can be met, and features of special samples can also be met; therefore, the identification error on the special samples is reduced.

Owner:SHENZHEN DYMIND BIOTECH

Three-dimensional particle category detection method and system based on convolutional neural network

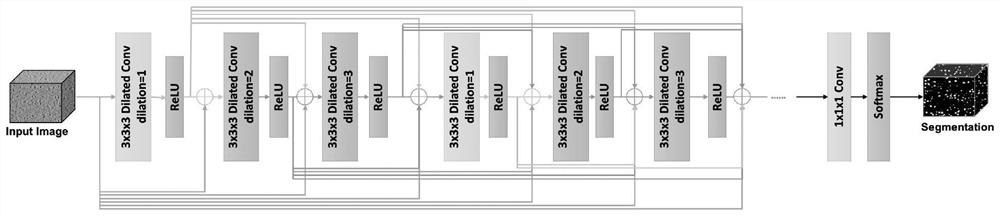

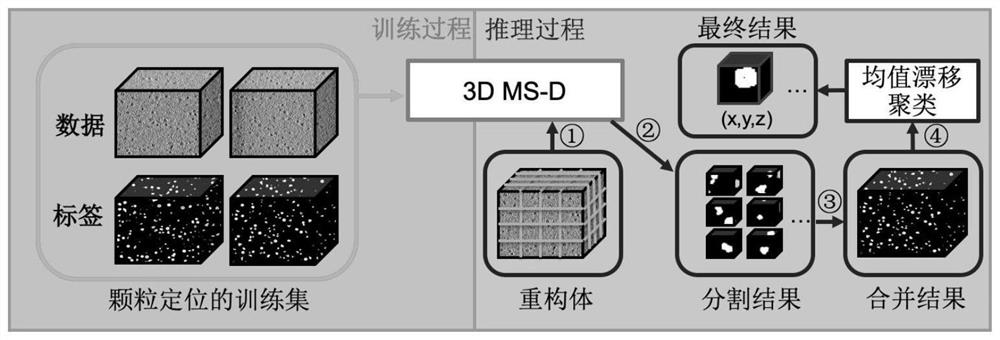

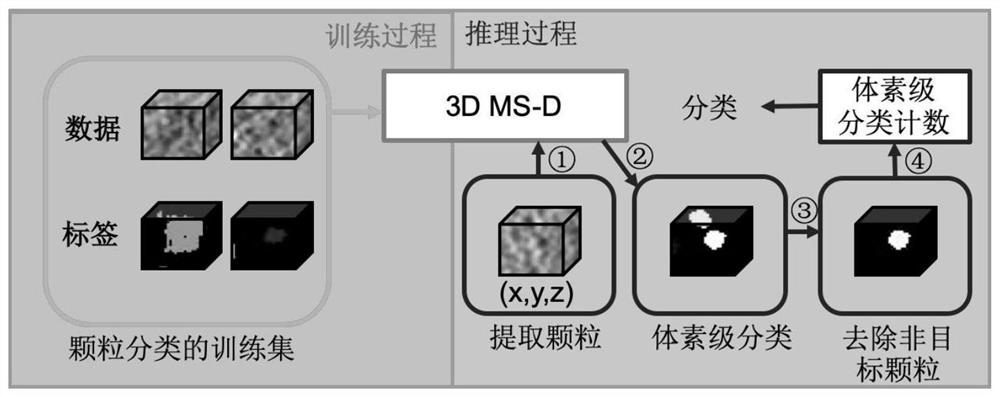

ActiveCN112001218AFew parametersImprove parametersNeural architecturesICT adaptationAlgorithm3d image

The invention provides a three-dimensional particle category detection method and system based on a convolutional neural network. The method comprises the following steps: constructing a three-dimensional mixed-scale dense convolutional neural network comprising a mixed-scale three-dimensional extended convolutional layer, dense connection and a loss function, training the convolutional neural network by using a three-dimensional frozen electron tomography image marked with the particle coordinates to obtain a particle selection model, and training the convolutional neural network by using thethree-dimensional frozen electron tomography image marked with the particle category to obtain a particle classification model; acquiring the three-dimensional frozen electron tomography image through a sliding window to obtain to-be-detected three-dimensional reconstructed subareas, predicting each subarea through the particle selection model, and combining prediction results of the subareas toobtain coordinates of each particle in the three-dimensional frozen electron tomography image; and extracting a three-dimensional image of each particle according to the coordinate of each particle, and inputting the three-dimensional image of each particle into the particle classification model to obtain the category of each particle.

Owner:INST OF COMPUTING TECH CHINESE ACAD OF SCI

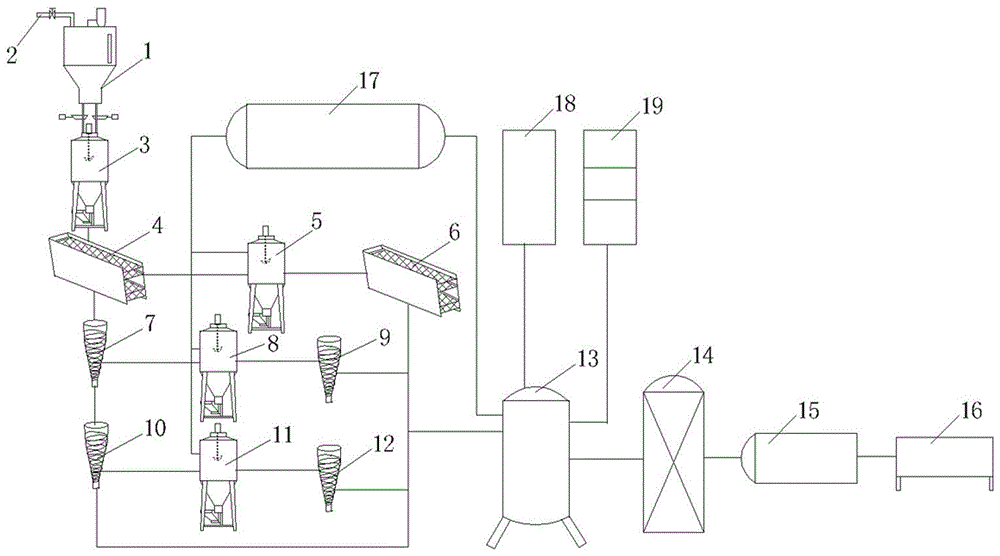

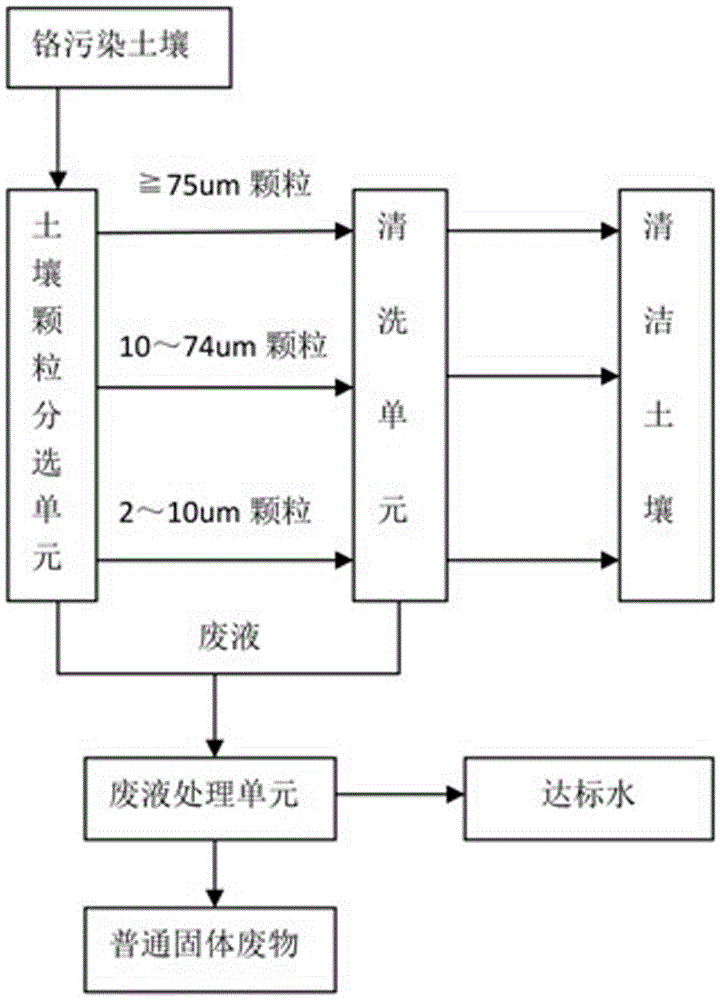

Ex-situ sorting, cleaning and repairing device for chromium-polluted soil and cleaning and repairing technology using ex-situ sorting, cleaning and repairing device

InactiveCN106391685AReduce residual concentrationEliminate the effects ofContaminated soil reclamationParticulatesLiquid waste

The invention relates to an ex-situ sorting, cleaning and repairing device for chromium-polluted soil and a cleaning and repairing technology using the ex-situ sorting, cleaning and repairing device. The ex-situ sorting, cleaning and repairing device comprises a raw material treatment unit, a first-level oversize particle treatment unit, a first-level undersize liquid treatment unit, a second-level undersize liquid treatment unit, a waste liquid collecting unit, a waste liquid treatment unit, a cleaning liquid adding unit and a chemical adding unit. The cleaning and repairing technology for conducting ex-situ sorting and cleaning on the chromium-polluted soil through the device comprises the steps of pulping, soil particle classification, cleaning of soil particles different in level and waste liquid treatment. The whole technology process is simple, equipment is easy to machine, the publicly known equipment can be adopted, the cost is low, the occupied space is small, continuous operation can be conducted, and energy consumption is low. The removal rate for hexavalent chromium in the soil can reach 95% or above, the residue concentration of the hexavalent chromium is lower than 50 mg / kg, and influences of the chromium on the soil, underground water and the surrounding environment are removed.

Owner:河南省水文地质工程地质勘察院有限公司

Process for producing microcapsules for electrophoretic display devices, as well as microcapsules for electrophoretic display devices, obtained by this process, and their applications

ActiveUS20100165447A1Improve accuracyHigh precision classificationSynthetic resin layered productsCellulosic plastic layered productsElectrophoresisDisplay device

There is disclosed a process for producing microcapsules for electrophoretic display devices, including classifying microcapsules for electrophoretic display devices from a dispersion containing microcapsules in an aqueous medium, using a specific particle classification apparatus of the particle settling type. The resultant microcapsules for electrophoretic display devices are used, as their applications, for sheets for electrophoretic display devices, electrophoretic display devices, and electronic equipments.

Owner:E INK CORPORATION

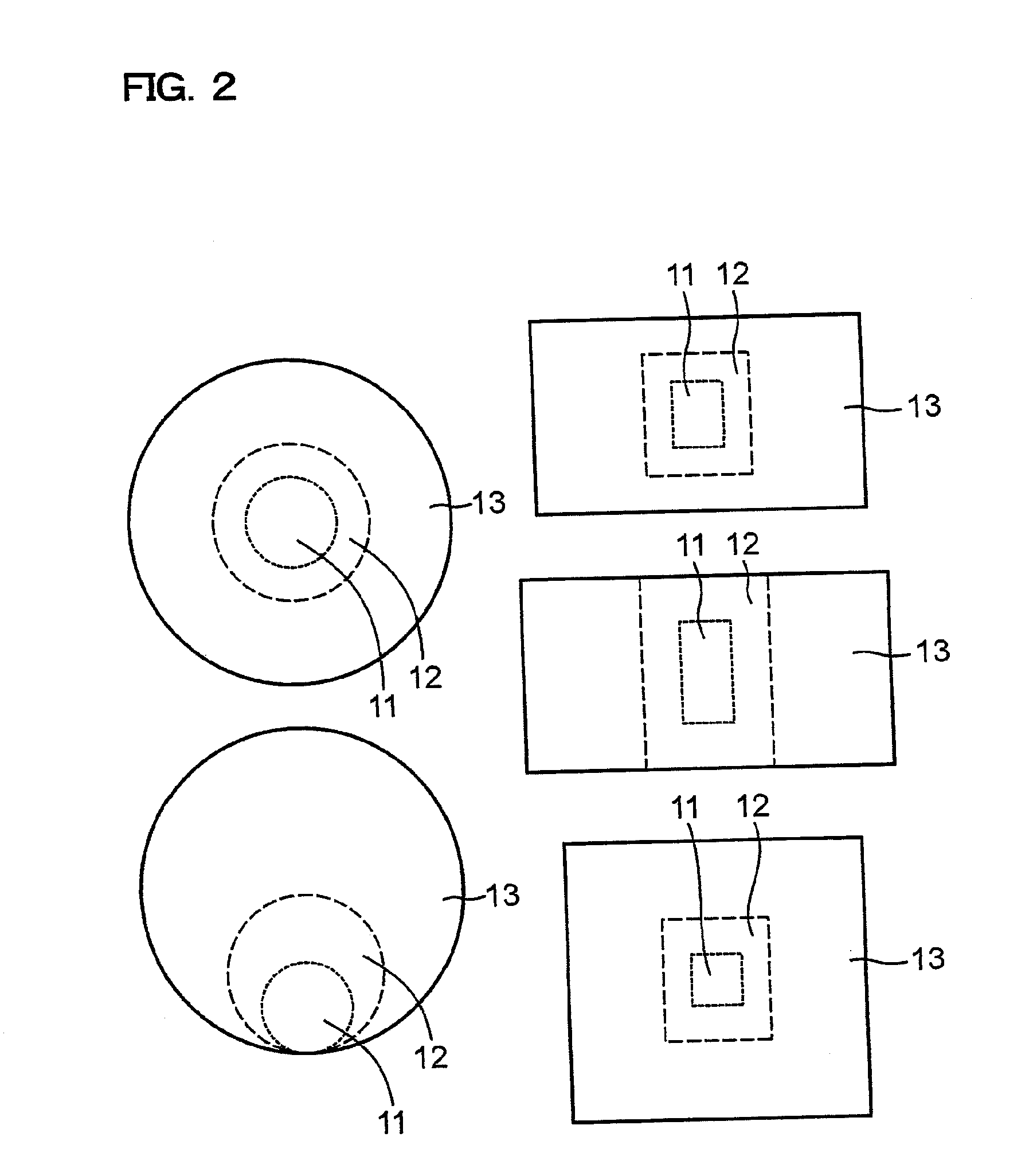

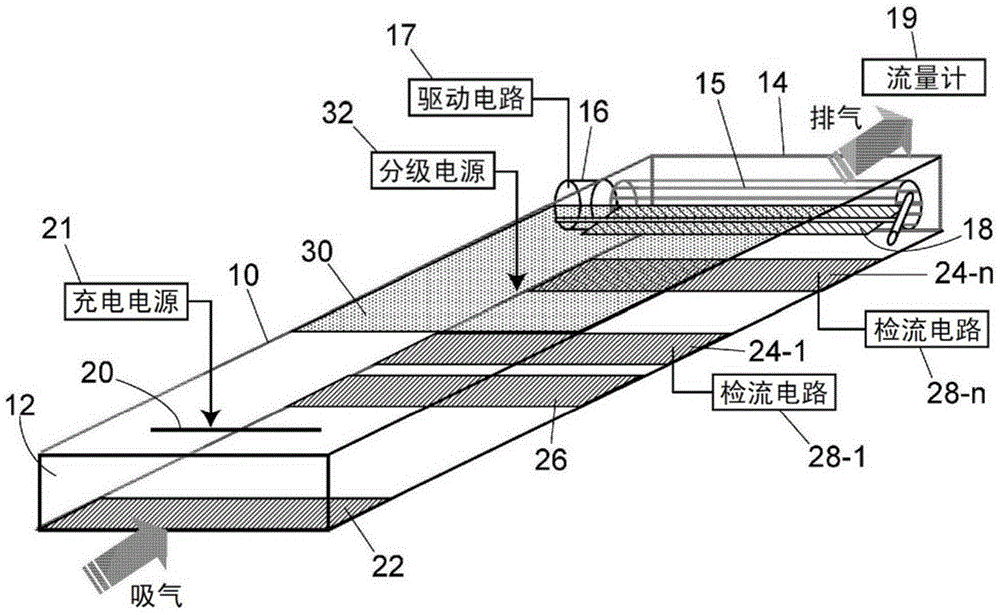

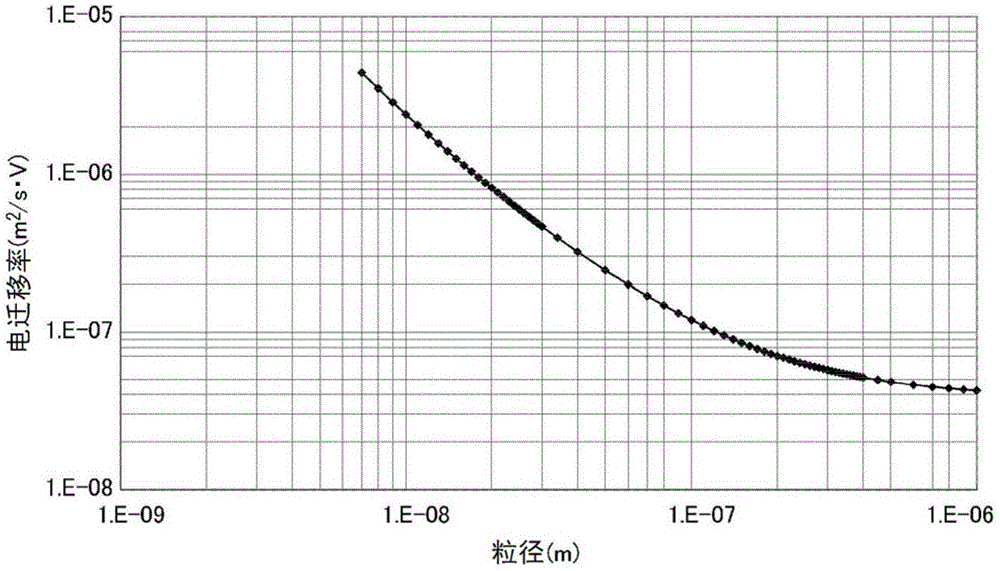

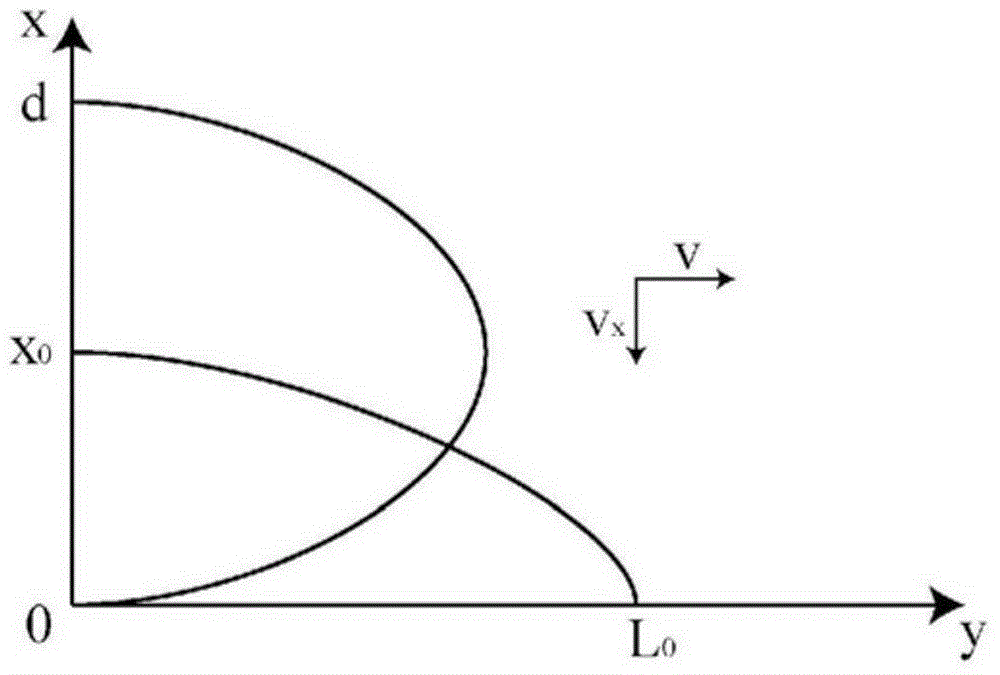

Fine particle classification measurement device, sample creation device with uniform particle concentration, and nanoparticle film forming device

InactiveCN104380078ADetermination of particle size range is clearRealize determinationNanoparticle analysisWithdrawing sample devicesMeasurement deviceNanoparticle

A charging apparatus is positioned at an intake side of a parallel flow path through which it is possible for a sample gas which flows therein to become a laminar flow. The charging apparatus comprises a discharge electrode and charges fine particles within the sample gas. On one face of a pair of opposing faces of the flow path, either one or a plurality of suction-side electrodes are positioned downstream of the charging apparatus in locations of mutually different lengths from the intake of the flow path along the flow path direction. A classification electrode is positioned upon the other face of the pair of opposing faces of the flow path. The classification electrode is positioned opposite the suction-side electrodes, and an electric field is emitted which attracts charged fine particles in the sample gas which flows between the classification electrode and the suction side electrodes toward the suction-side electrodes.

Owner:SHIMADZU SEISAKUSHO CO LTD

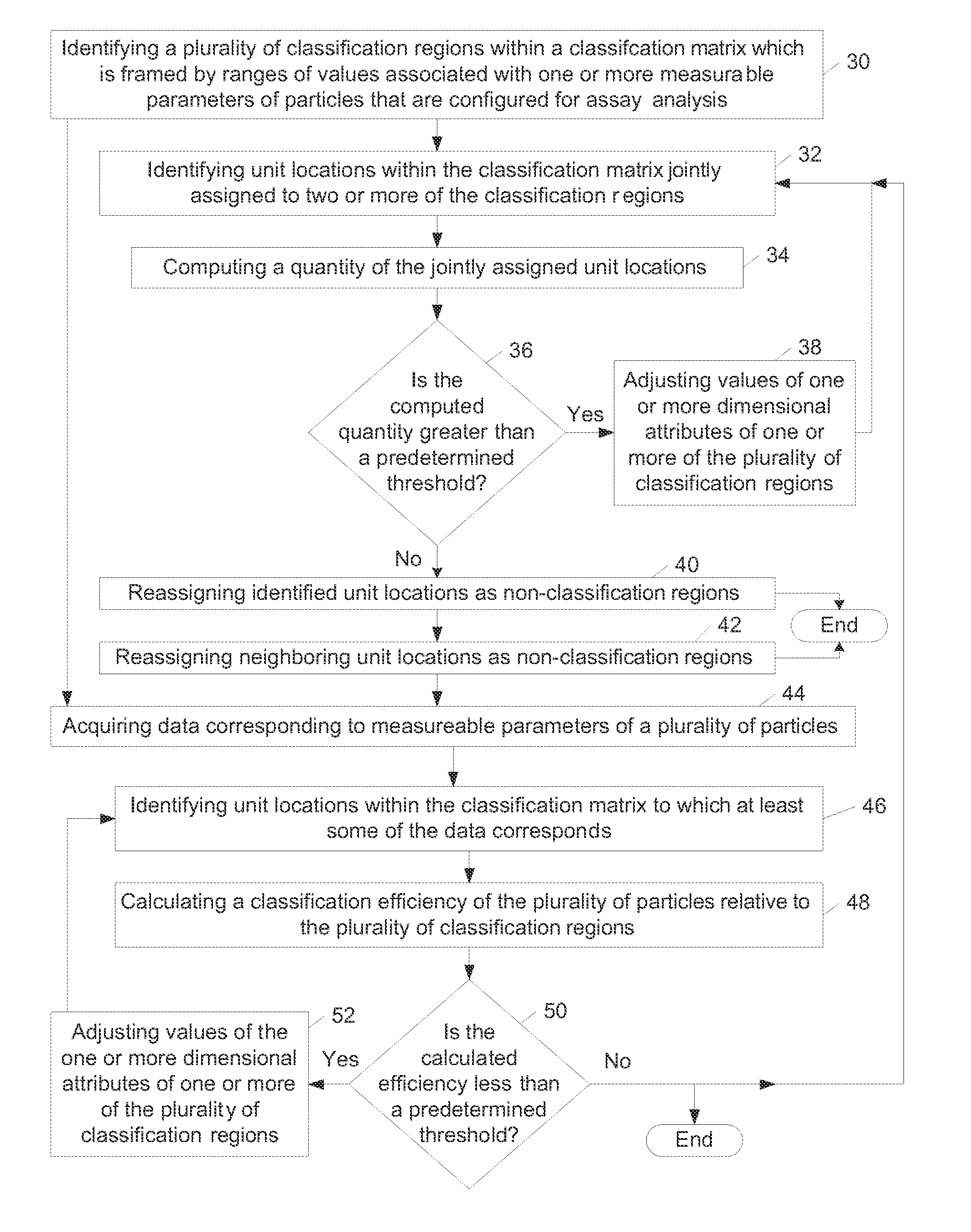

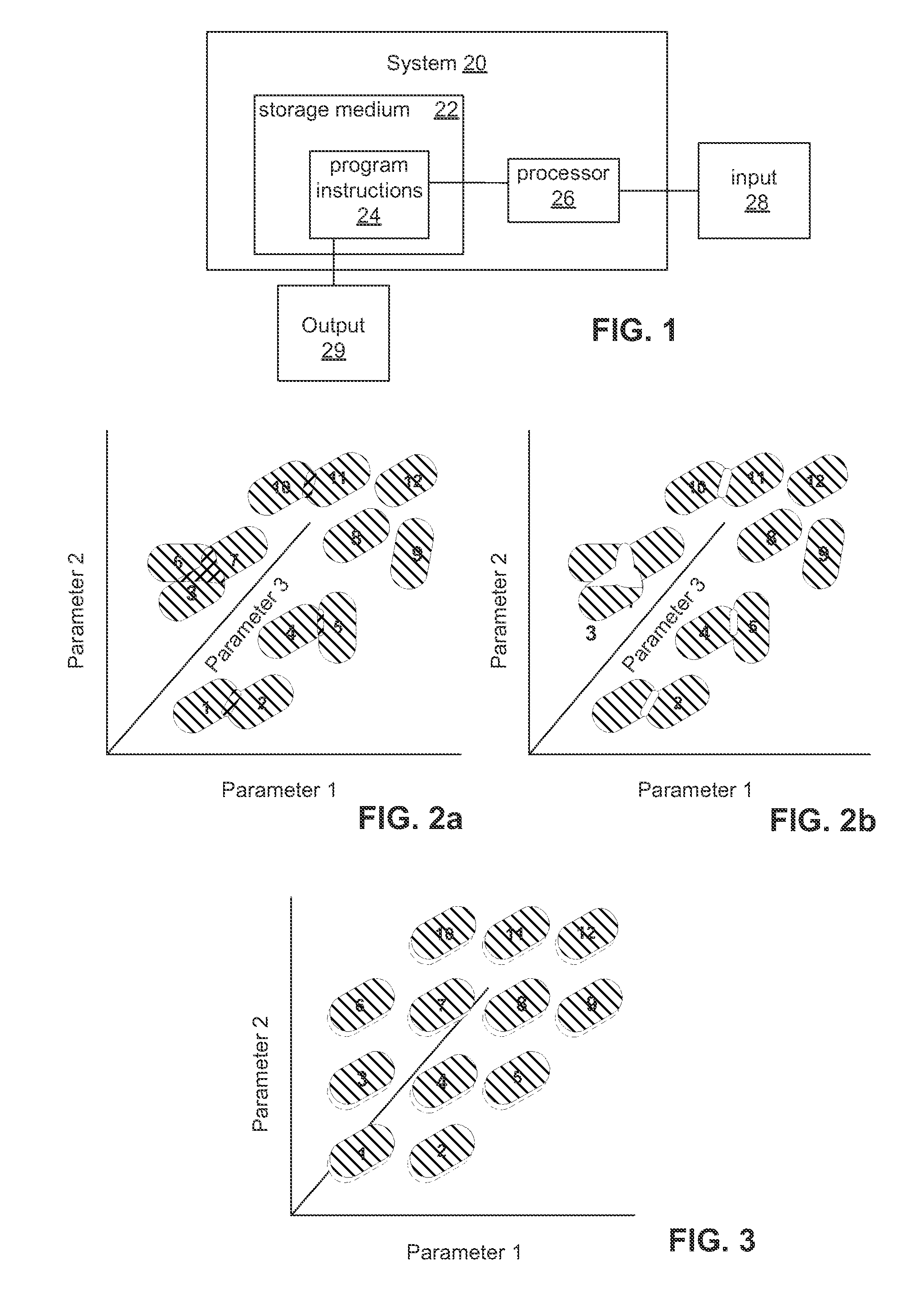

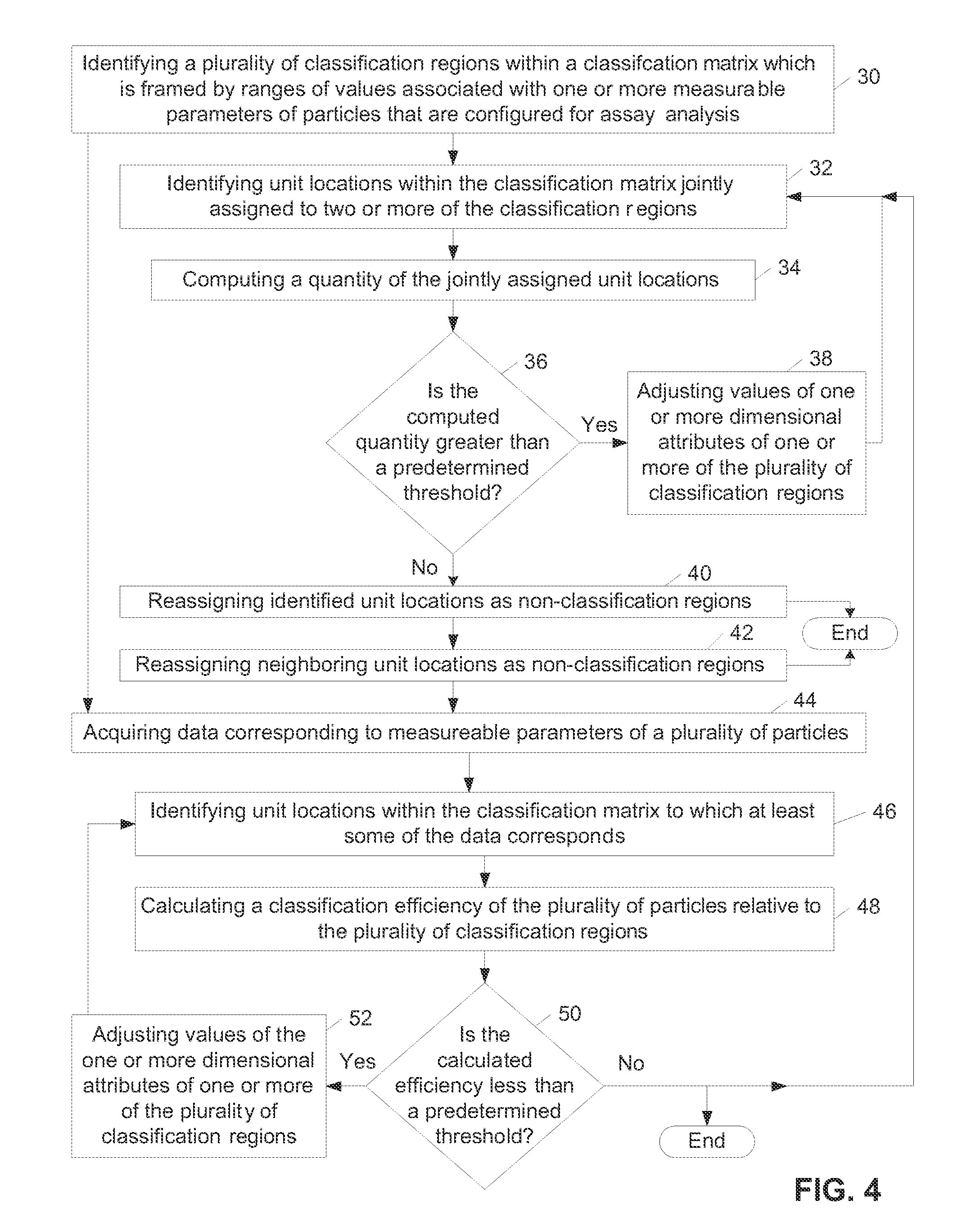

Methods, Storage Mediums, and Systems for Configuring Classification Regions Within a Classification Matrix of an Analysis System and for Classifying Particles of an Assay

ActiveUS20100017358A1Character and pattern recognitionFuzzy logic based systemsAlgorithmParticle classification

Owner:LUMINEX

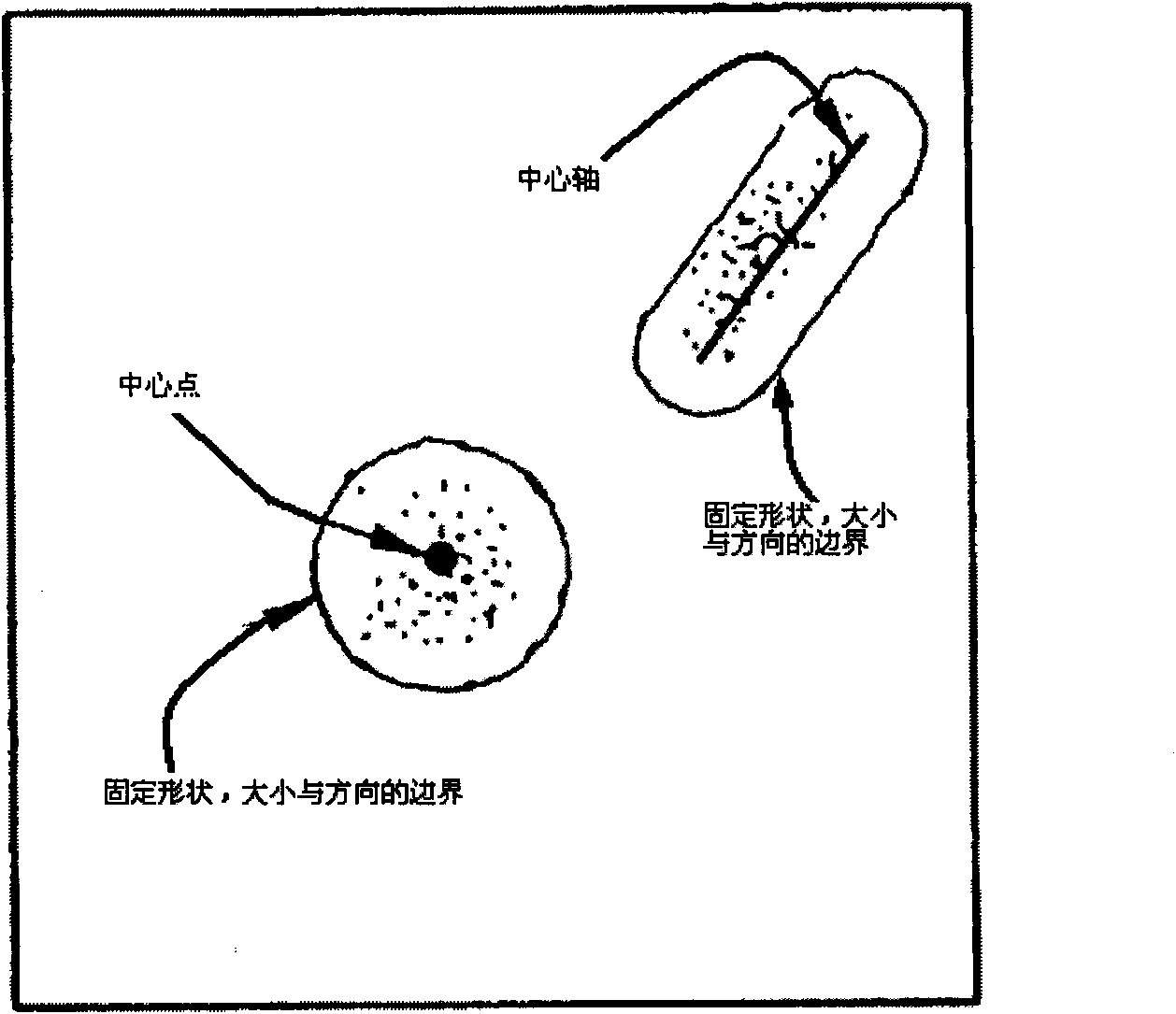

Method for classifying particles and device for detecting particles

ActiveCN101762448AAccurate classificationStatistically accurateIndividual particle analysisParticle physicsParticle classification

The invention discloses a method and a device for classifying particles. The method comprises the following steps: collecting at least two characteristics of the particles which are generated in a detector; forming a distribution scatter diagram of the particles according to the collected particle characteristics; initially dividing the scatter diagram to obtain the distribution of a particle community; determining a core area of the particle community; performing at least one expansion operation on the core area or a profile of the core area; and determining an actual boundary of the scatterdiagram of the particle community according to an expansion result. A final boundary is determined according to morphological characteristics of a scatter diagram core, the size, the shape, the direction and the position of the classification boundary can be adjusted automatically, and the statistical property of the scatter diagram core part is high, so the method and the device can reflect the form of the particle community, and have a strong accuracy and stability.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD +1

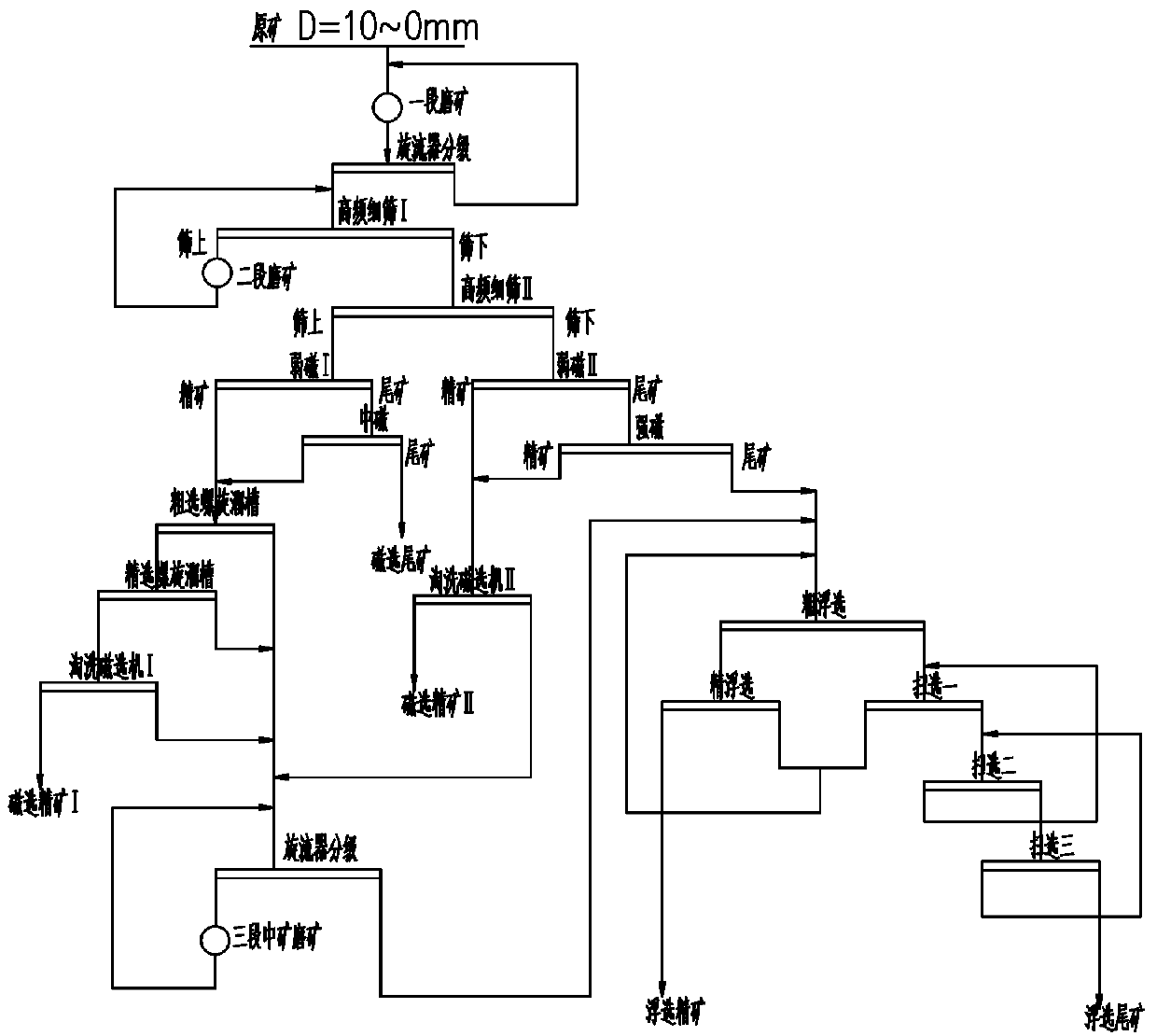

Dense-medium coal separation method

The invention relates to a dense-medium coal separation method. The method comprises the steps that firstly, the liquid level of a coal slime qualified medium barrel is kept to be higher than the liquid level of a raw coal qualified medium barrel; secondly, the undersize fractional flow of a cleaned coal medium drainage curve screen is controlled to be 1.15-1.2 times of the input amount of a coal slime dense-medium cyclone, so that the coal slime qualified medium barrel is in an overflow state all the time during production; thirdly, the overflow of the coal slime dense-medium cyclone is purposefully led into a cleaned coal magnetic separator or the raw coal qualified medium barrel; fourthly, cleaned coal magnetic separation tailings are led into a cone tank with a deep cone angle for primary fine particle classification, and low-density high-ash fine slime is removed, wherein the overflow particle size is -0.10 mm size fraction, and the underflow is 1-0.10 mm size fraction; fifthly, the underflow (1-0.10 mm) part of the cone tank with the deep cone angle is conveyed to a high-frequency electromagnetic undersize sieve through a pump and secondary fine particle classification is conducted for removing high-density high-ash fine slime. According to the dense-medium coal separation method, the problems about separation and classification of fine coal (0.1-0.075 mm) are effectively solved. The work conditions of the flotation link are improved; the ash content of flotation tailings is effectively increased by setting the processing power of a flotation machine.

Owner:内蒙古广纳煤业(集团)有限责任公司

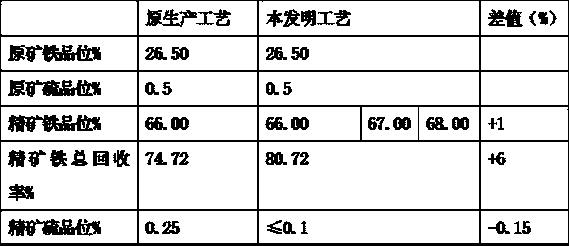

Beneficiation process for treating high-sulfur hematite-magnetic iron ore mixture

ActiveCN109675712AImprove iron gradeReduce manufacturing costWet separationGravity separationMaterials science

The invention relates to a beneficiation process for treating high-sulfur hematite-magnetic iron ore mixture. In the beneficiation process, treatment of raw ores with an iron grade being 25 -27 percent and a sulfur grade being 0.4-0.percent comprises the following step of obtaining a 58-62 percent primary overflow product with the overflow particle size being -0.074mm. The beneficiation process ischaracterized in that secondary closed circuit grinding is performed on the overflow product to obtain a product with the particle size being -0.3mm, coarse and fine particle classification is performed on the product with the particle size being -0.3mm with a high frequency fine screen II to obtain a coarse product with the particle size being 0.3-0.074mm and a fine product with the particle size being -0.074mm, beneficiation is performed on the coarse product with operation of low-intermediate intensity magnetic separation, gravity separation, low intensity magnetic separation, middling closed circuit regrinding and reverse flotation, beneficiation is performed on the fine product with operation of low-high intensity magnetic separation, middling closed circuit regrinding and reverse flotation, and iron concentrates with an iron grade being 66 percent or above and a sulfur grade being 0.1 percent or below are obtained. The beneficiation process has the advantages that technical indexes are qualified, and the economic benefit is remarkable.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

Method for producing regenerated magnesia carbon bricks by waste refractory bricks

The invention provides a method for producing regenerated magnesia carbon bricks by waste refractory bricks. The method includes steps: sorting the waste refractory bricks; preparing materials on the basis of the total mass of regenerated materials according to conditions that a mass ratio of MgO is larger than or equal to 86%, a mass ratio of SiO2 is smaller than or equal to 3.5%, a mass ratio of Al2O3 is smaller than or equal to 4.5%, and the rest is impurities; performing crushing, magnetic separation for iron removal, particle classification, heating and drying; adding materials, mixing, performing high-pressure calcination moulding, and cooling to obtain the regenerated magnesia carbon bricks. By adoption of the waste refractory bricks for production of the regenerated magnesia carbon bricks, technical simplicity and reduction of waste of the waste refractory bricks are realized, waste recycling and additional value increase are benefited, the produced regenerated magnesia carbon bricks are great in each performance, and considerable economic benefits are achieved.

Owner:浙江欣辉耐火材料股份有限公司

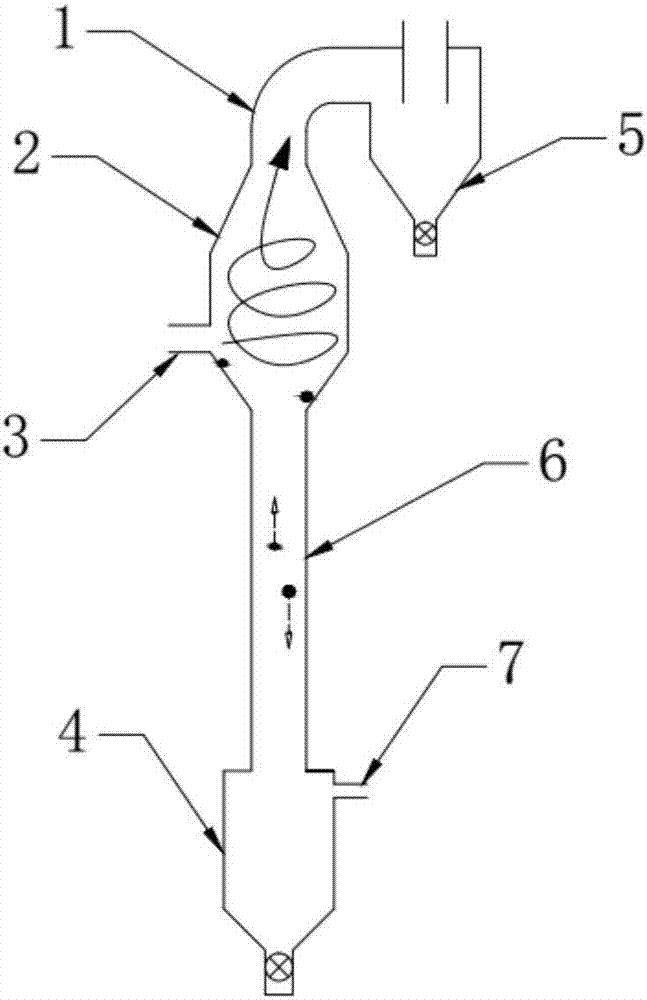

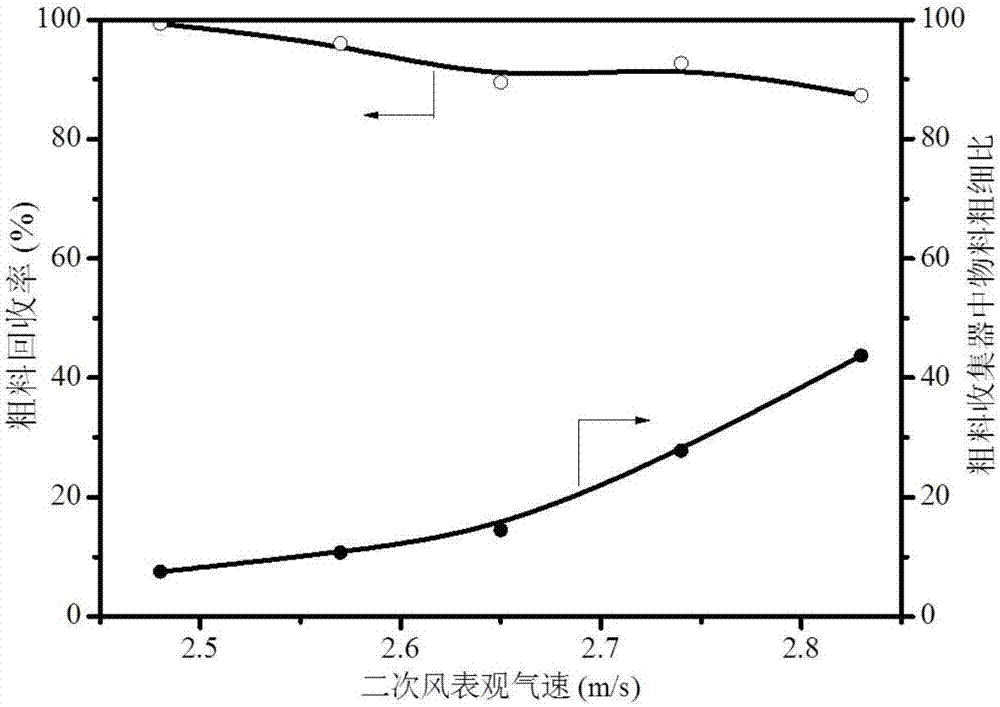

Particle classification device and method thereof

InactiveCN107185837AReinforcement brought outShort stayGas current separationHeavy particleEngineering

The invention belongs to the technical field of powder processing and utilizing and provides a particle classification device and a method thereof. The middle of the top of a barrel body of a cyclone separator is connected with the inlet end of a tail air outlet pipe, and the inlet end does not stretch into the cyclone separator; the outlet end of the tail air outlet pipe is connected with a fine / light particle set collector; the lower middle portion of the barrel body of the cyclone separator is provided with a primary air inlet pipe; the bottom of the barrel body of the cyclone separator is of a conical structure, and is connected with the top of a sedimentation classifier; the bottom of the sedimentation classifier is connected with a coarse / heavy particle set collector; and the lower portion of the sedimentation classifier or the coarse / heavy particle set collector is provided with a secondary air inlet pipe. Based on the differences of the centrifugal forces and the terminal speeds of coarse / heavy particles and fine / light particles in mixed particle size / density particle materials, the air speeds of primary air and secondary air are adjusted, it can be achieved that the cutting particle size is flexibly adjusted and changed, and the classification precision is high; and operation is easy and convenient, the structure is simple, and the particle classification device and the method thereof can be applied to the normal temperature / high temperature particle classification environment.

Owner:DALIAN UNIV OF TECH

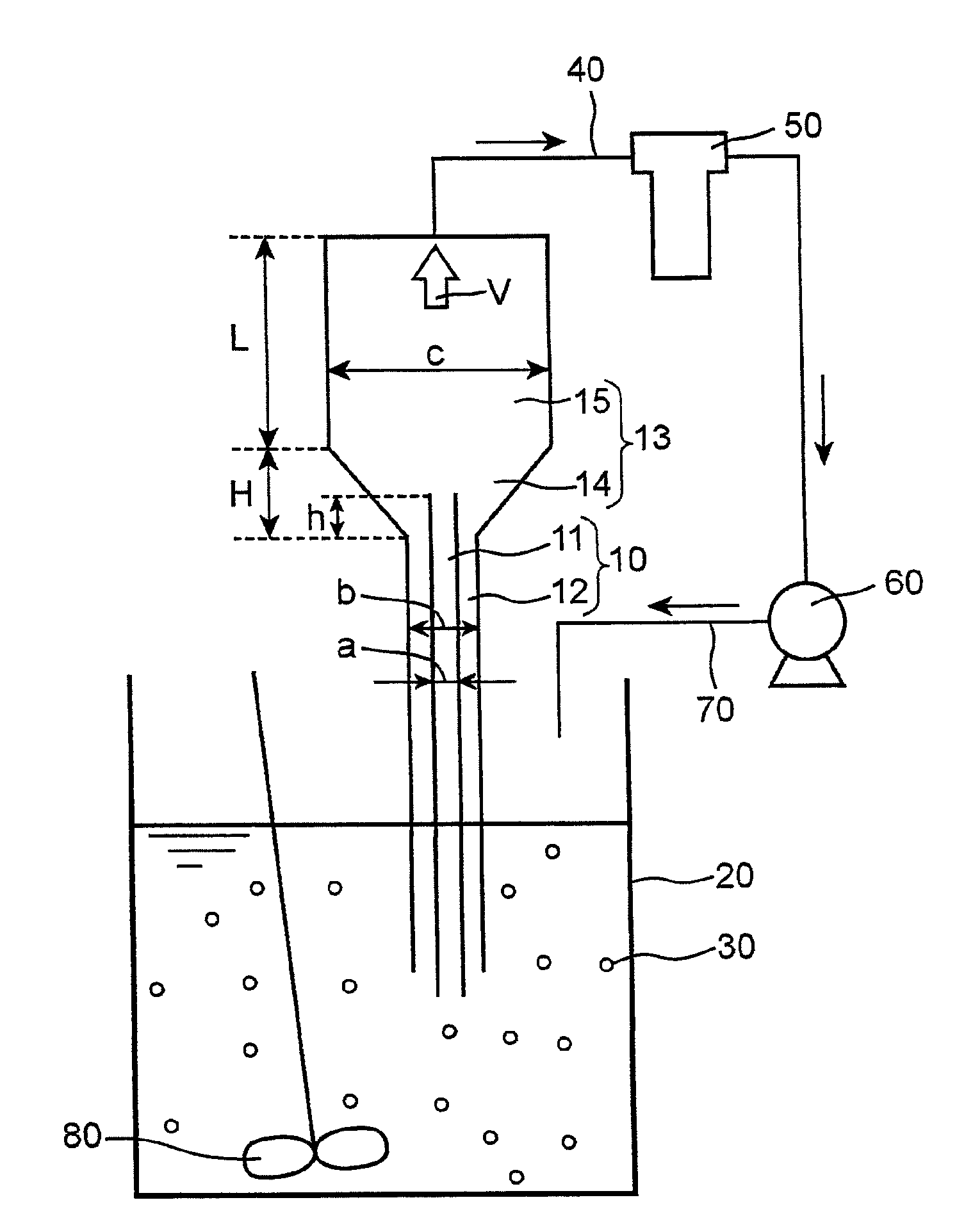

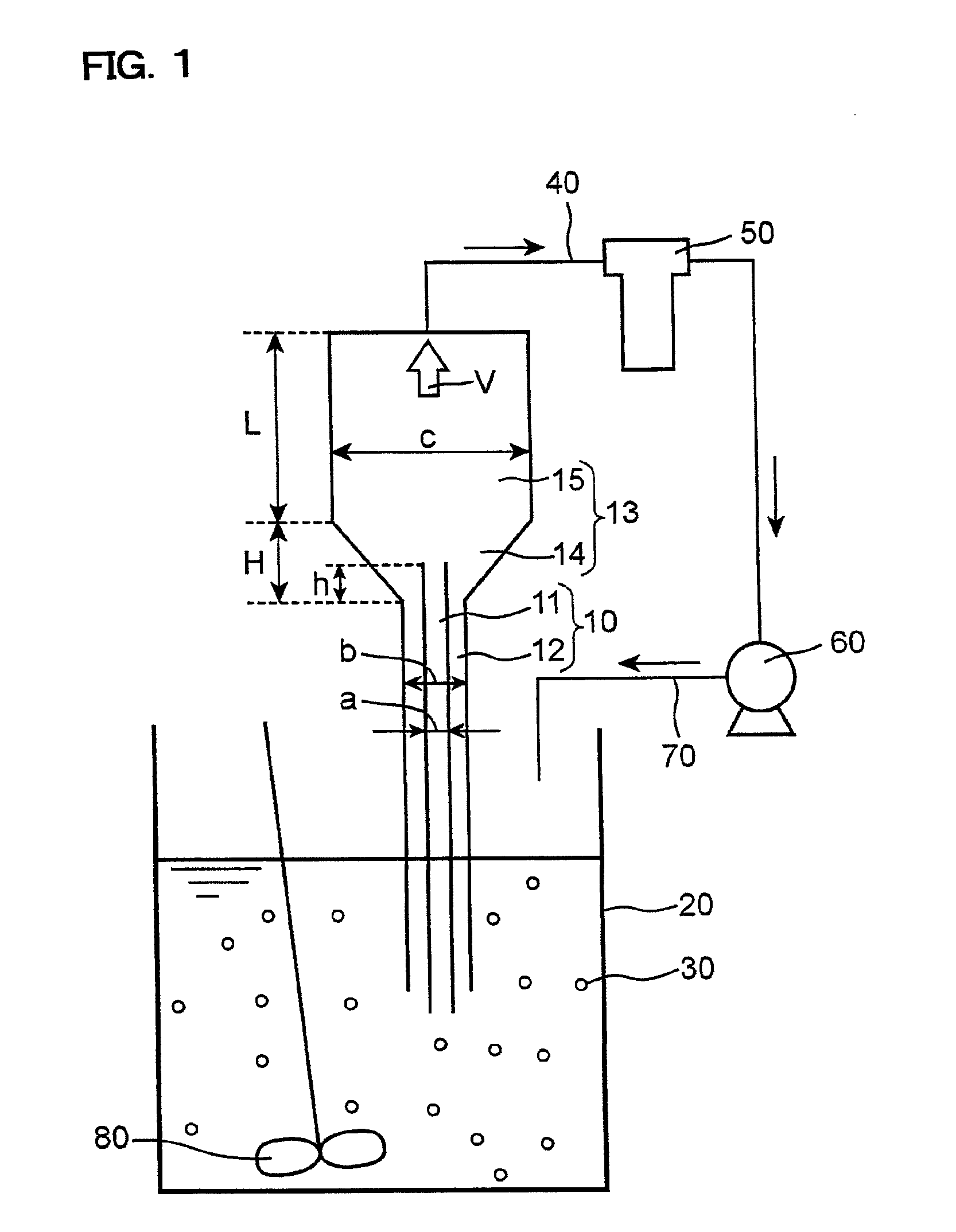

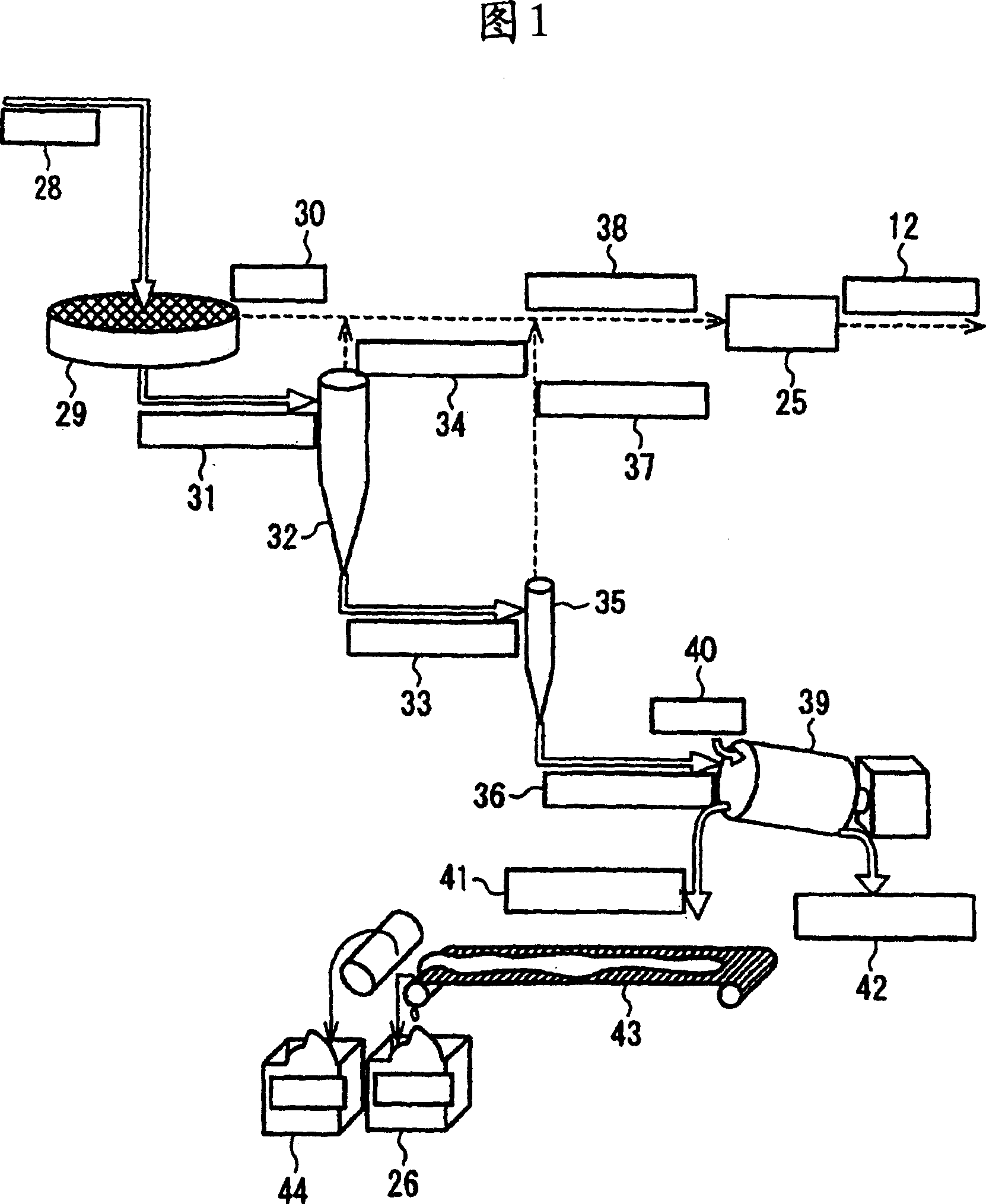

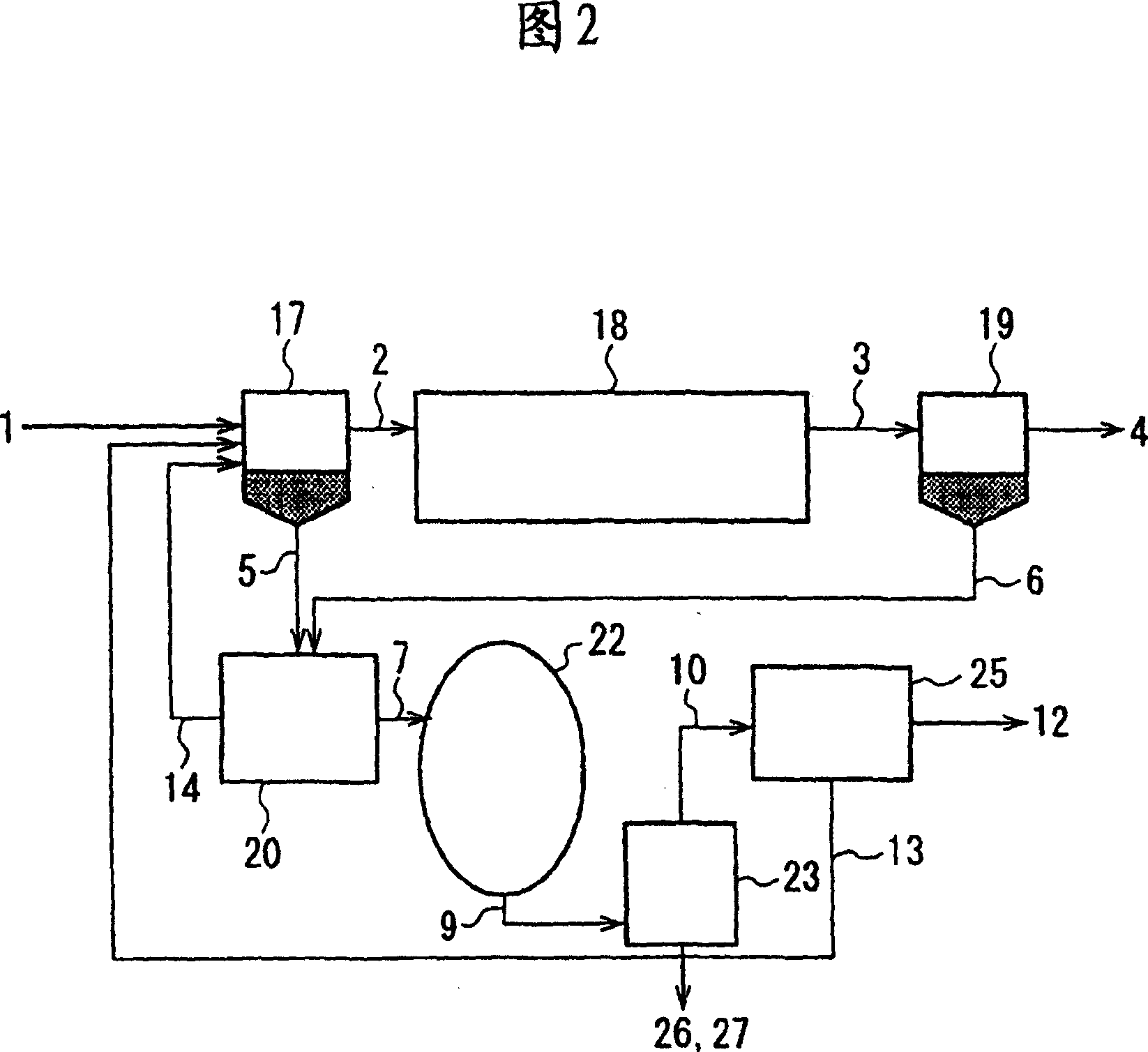

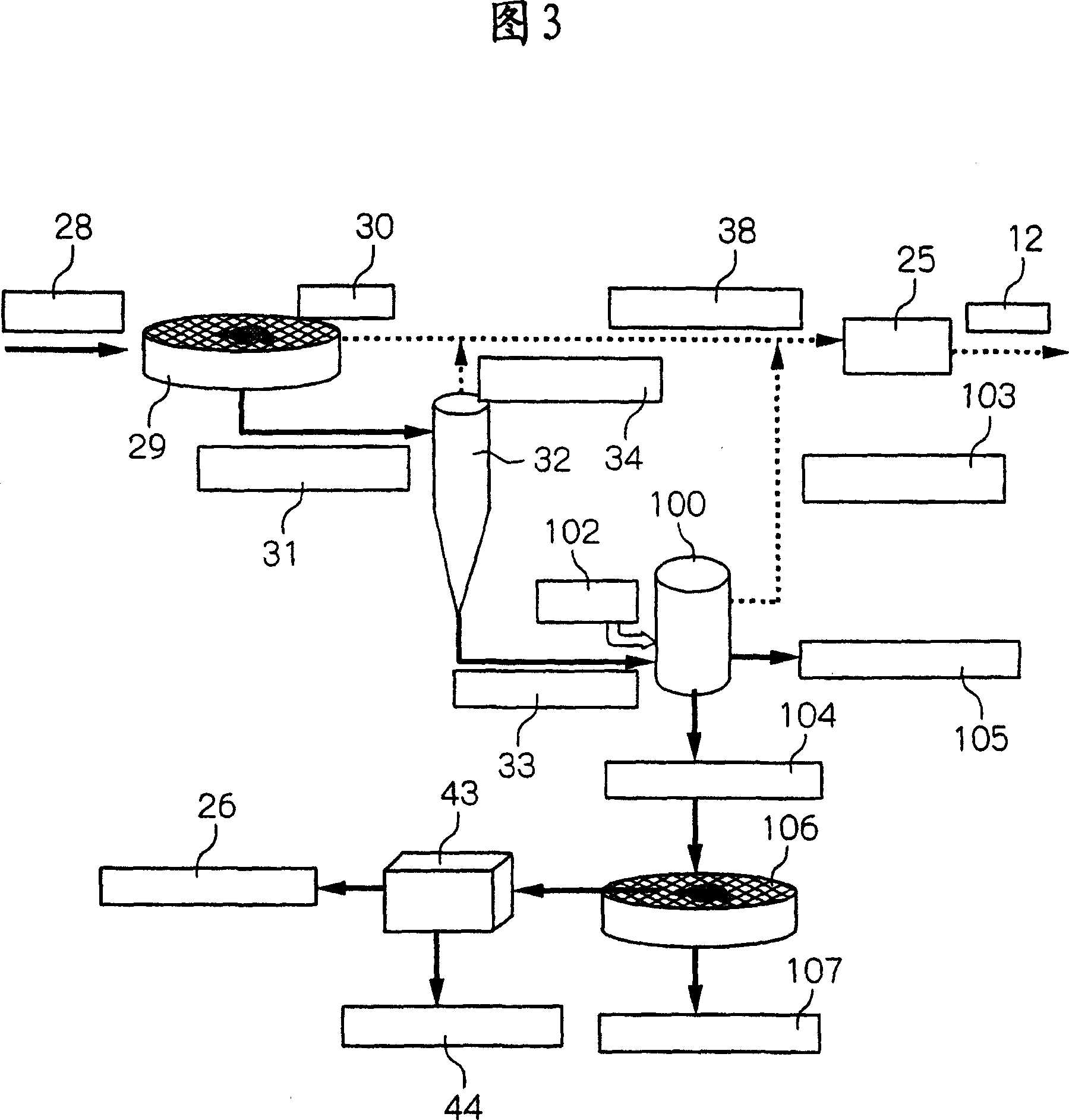

Method and apparatus for treating organic drainage and sludge

ActiveCN1968902AEfficient removalAchieve removalWater/sewage treatment by centrifugal separationWater contaminantsHigh concentrationLiquid state

The purpose of the present invention is to provide a method and apparatus for treating organic drainage or sludge which enable formation of sludge having a comparatively low content of heavy metals with ease and at a low cost and further recovery of a useful valuable substance at the same time by separating and removing heavy metal derived particles from organic drainage containing high concentration organic substances, phosphorus and nitrogen and efficiently recovering valuable particles such as MAP. One embodiment of the present invention refers to a method of treating organic drainage and sludge comprising an anaerobic digestion treatment step, which further comprises separating heavy metal derived compound particles in a particles-in-liquid state from two or more types of fine particles existing in the sludge of the anaerobic digestion treatment step utilizing a separation means comprising a fine particle classification means utilizing at least two properties of specific gravity, particle diameter, surface charge, magnetism and wettability of the particles.

Owner:EBARA ENG SERVICE

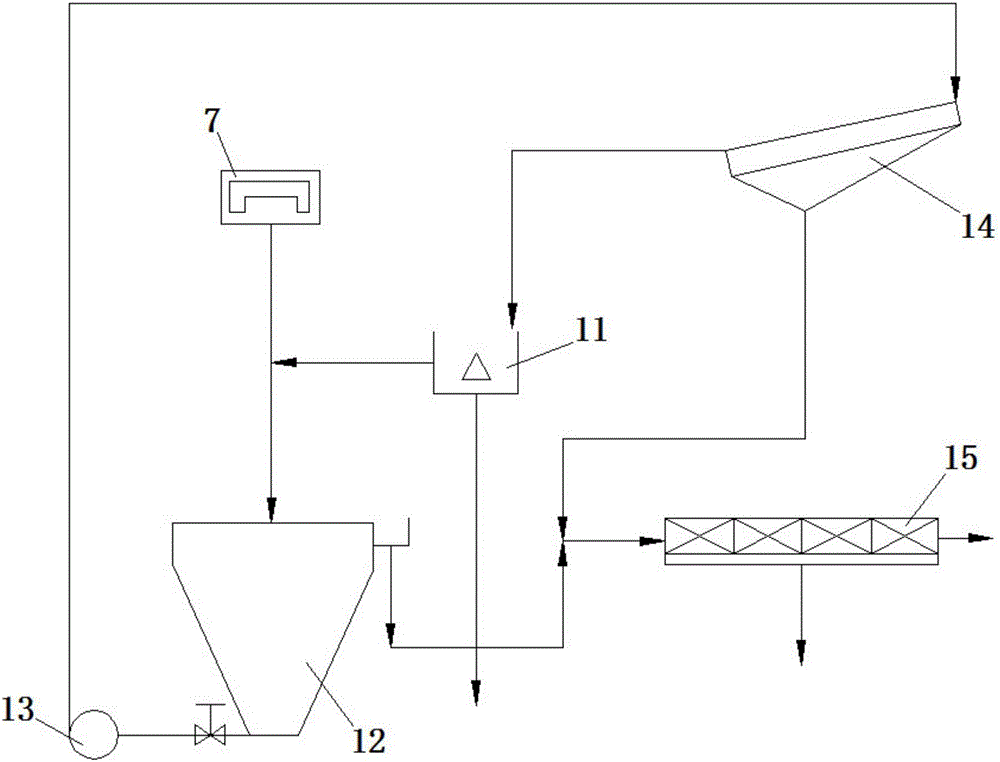

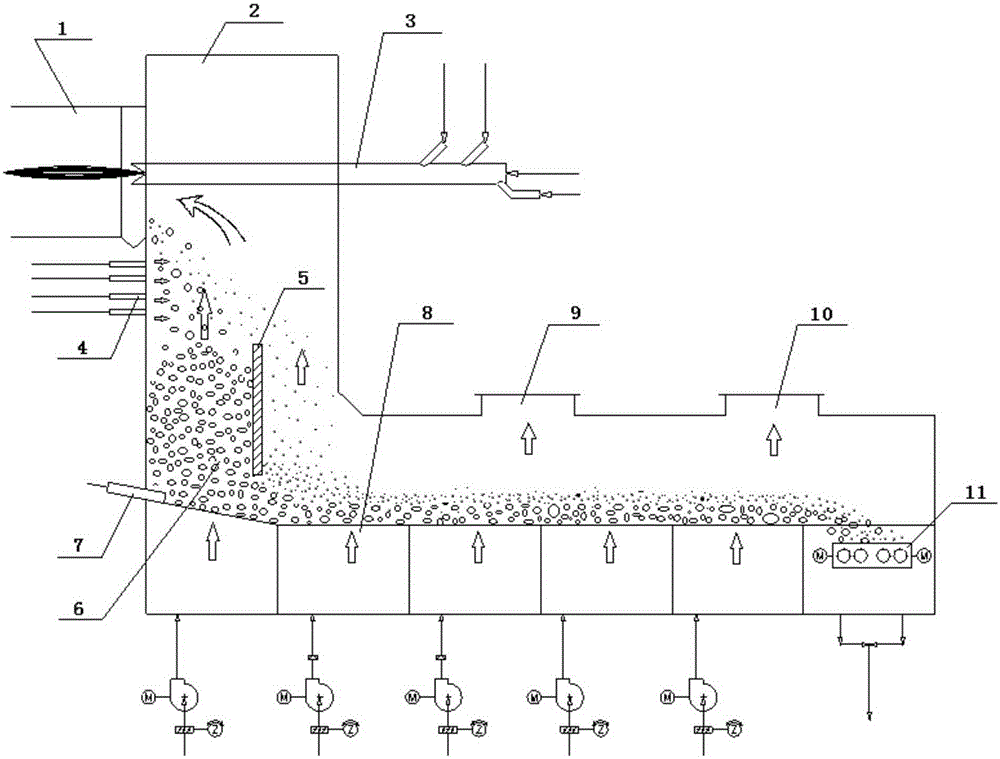

High-temperature particulate material stage cooling method and device

ActiveCN105180662AIncrease material bed thicknessReduce resistanceHandling discharged materialFine particulateQuenching

The invention discloses a high-temperature particulate material stage cooling method. According to the method, a feed inlet of a cooling material bed is transversely divided into an upper area and a lower area by a retaining wall the bottom of which is suspended, particle classification and quenching are conducted on high-temperature particulate materials discharged from a rotary kiln with airflow, coarse particulate materials obtained after classification fall into the upper area of the feed inlet of the cooling material bed to form a coarse particle material bed for thick material bed countercurrent heat exchange, fine particulate materials obtained after classification fall into the lower area of the feed inlet of the cooling material bed, and the coarse particulate materials subjected to countercurrent heat exchange enter the lower area of the feed inlet of the cooling material bed through the bottom of the retaining wall to be cooled on the cooling material bed together with the fine particulate materials in the lower area. The invention further discloses a high-temperature particulate material stage cooling device adopting the method. The high-temperature particle classification technique is adopted, the coarse particles are cooled on the thick material bed, the amount of cooling air can be reduced, the heat recovery efficiency of a system can be improved, and then energy is saved.

Owner:TIANJIN CEMENT IND DESIGN & RES INST +1

Sample analyzer and computer program product

InactiveUS20090244068A1Drawing from basic elementsBiological particle analysisComputer scienceParticle classification

Owner:SYSMEX CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com