Patents

Literature

1595 results about "Fire brick" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A fire brick, firebrick, or refractory brick is a block of refractory ceramic material used in lining furnaces, kilns, fireboxes, and fireplaces. A refractory brick is built primarily to withstand high temperature, but will also usually have a low thermal conductivity for greater energy efficiency. Usually dense firebricks are used in applications with extreme mechanical, chemical, or thermal stresses, such as the inside of a wood-fired kiln or a furnace, which is subject to abrasion from wood, fluxing from ash or slag, and high temperatures. In other, less harsh situations, such as in an electric or natural gas fired kiln, more porous bricks, commonly known as "kiln bricks" are a better choice. They are weaker, but they are much lighter, easier to form, and insulate far better than dense bricks. In any case, firebricks should not spall, and their strength should hold up well during rapid temperature changes.

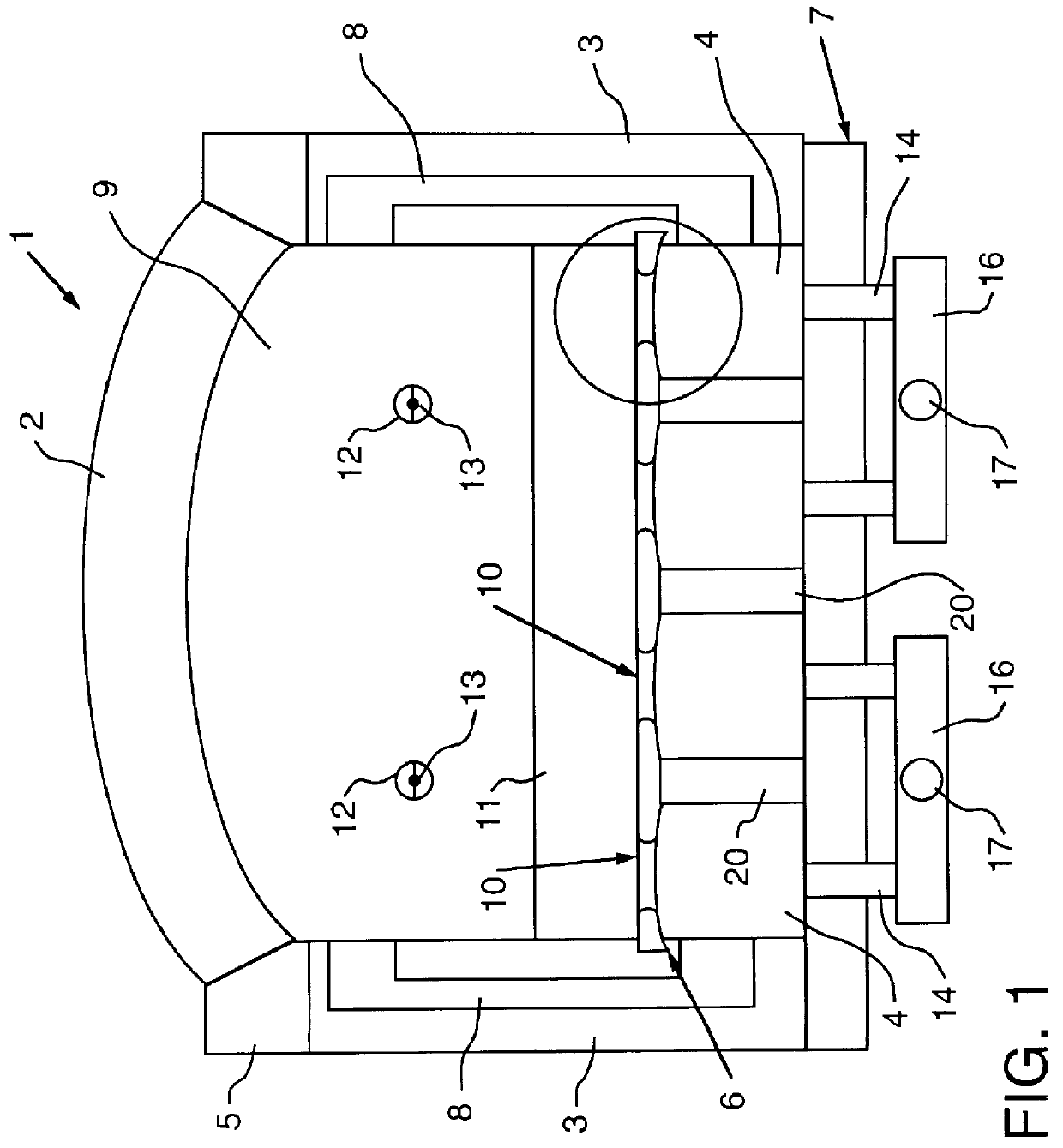

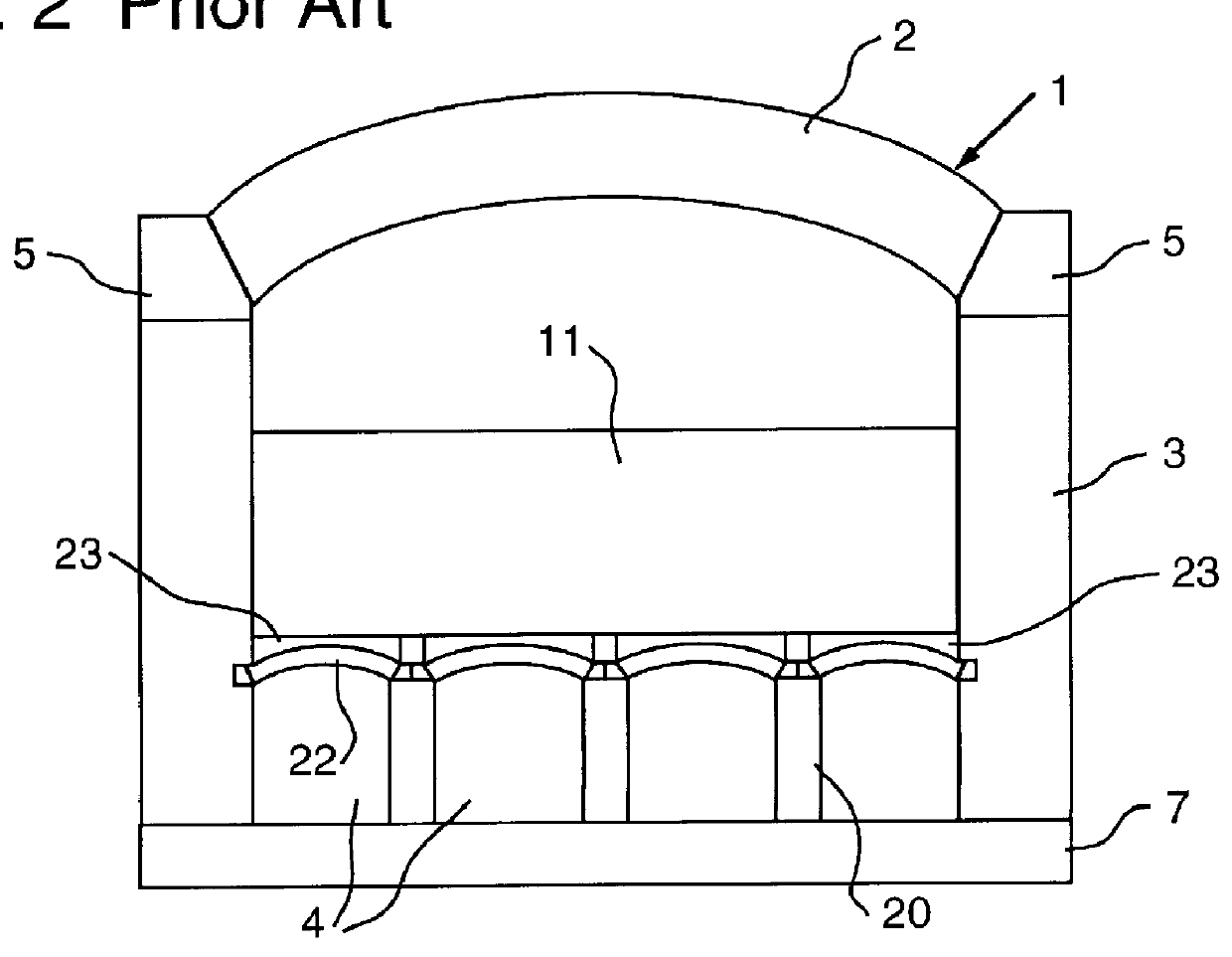

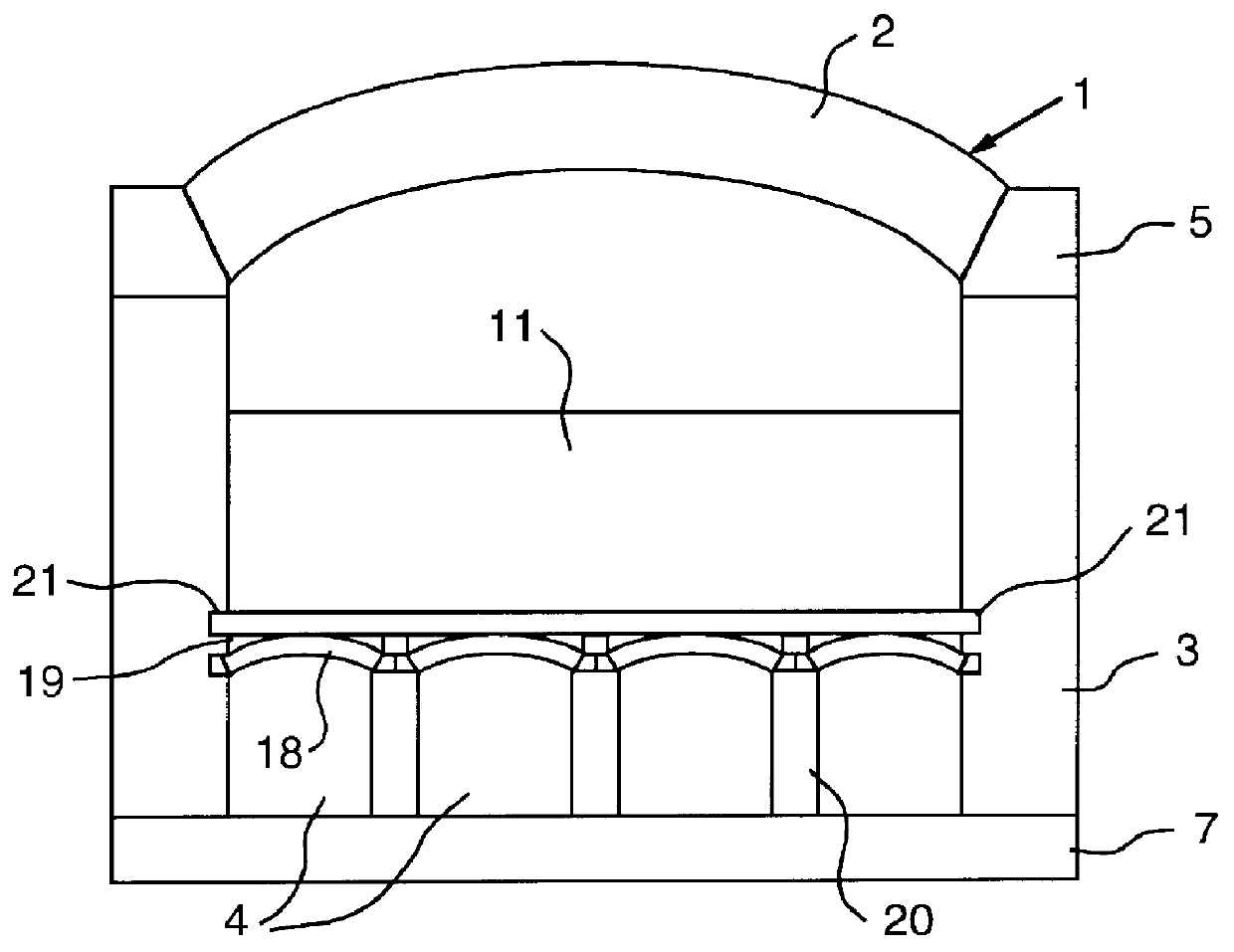

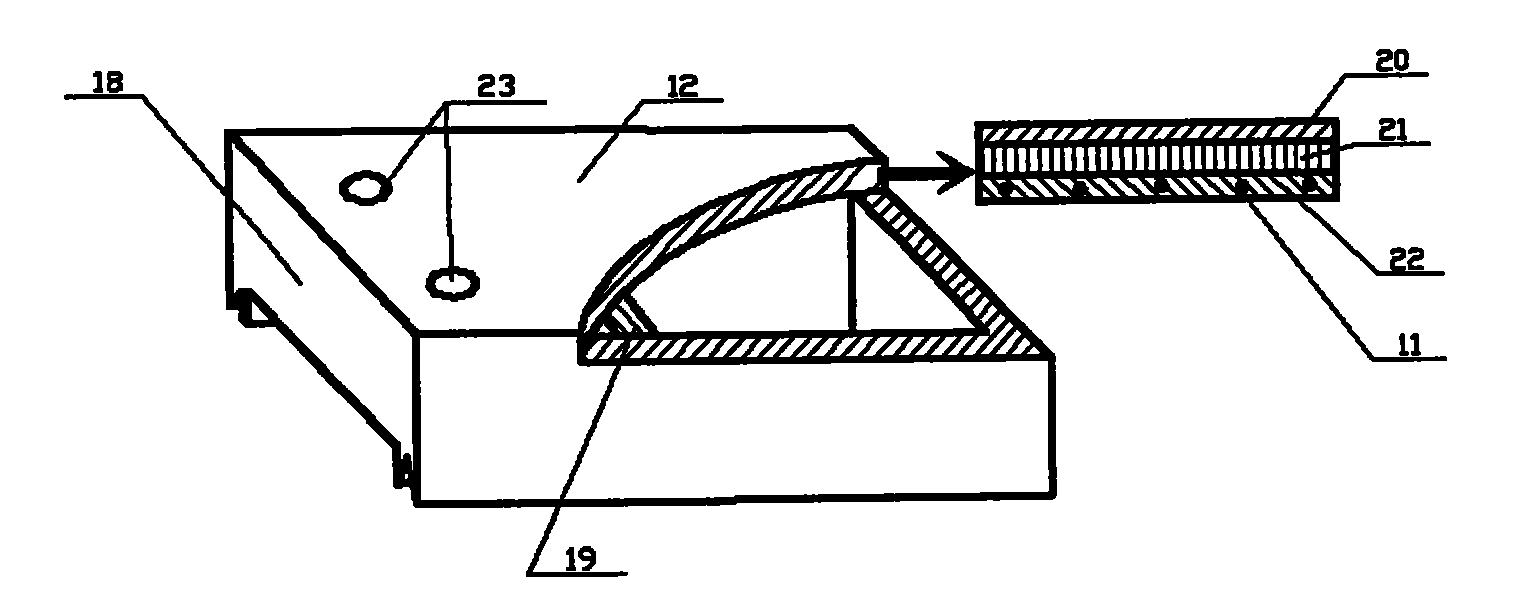

Interlocking floor brick for non-recovery coke oven

An improved non-recovery coke oven floor constructed of a single layer of refractory bricks including, for each oven sole flue, a pair of trunnion bricks and a center bridge brick spanning the width of the flue, having lower brick surfaces in the form of an arch, and joined end-to-end by a tapered tongue-and-groove joint disposed approximately perpendicular to the direction of a compression load transmitted by the center bridge brick to the trunnion bricks.

Owner:PENNSYLVANIA COKE TECH

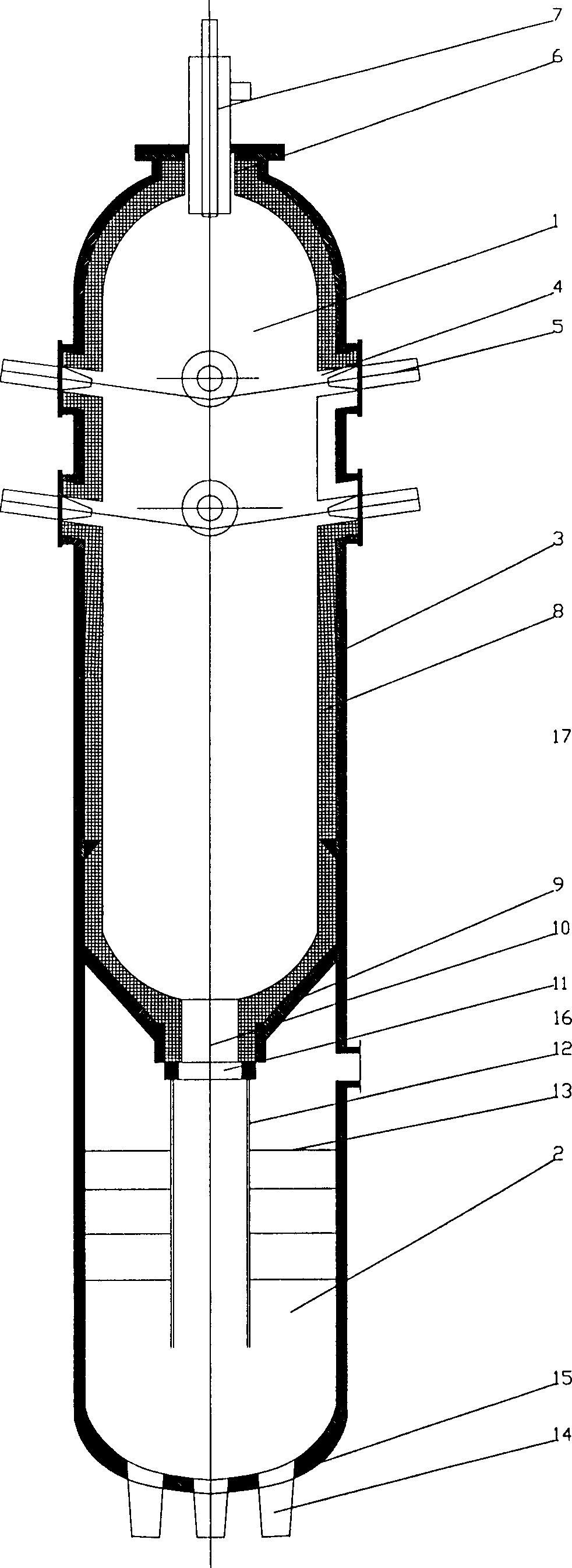

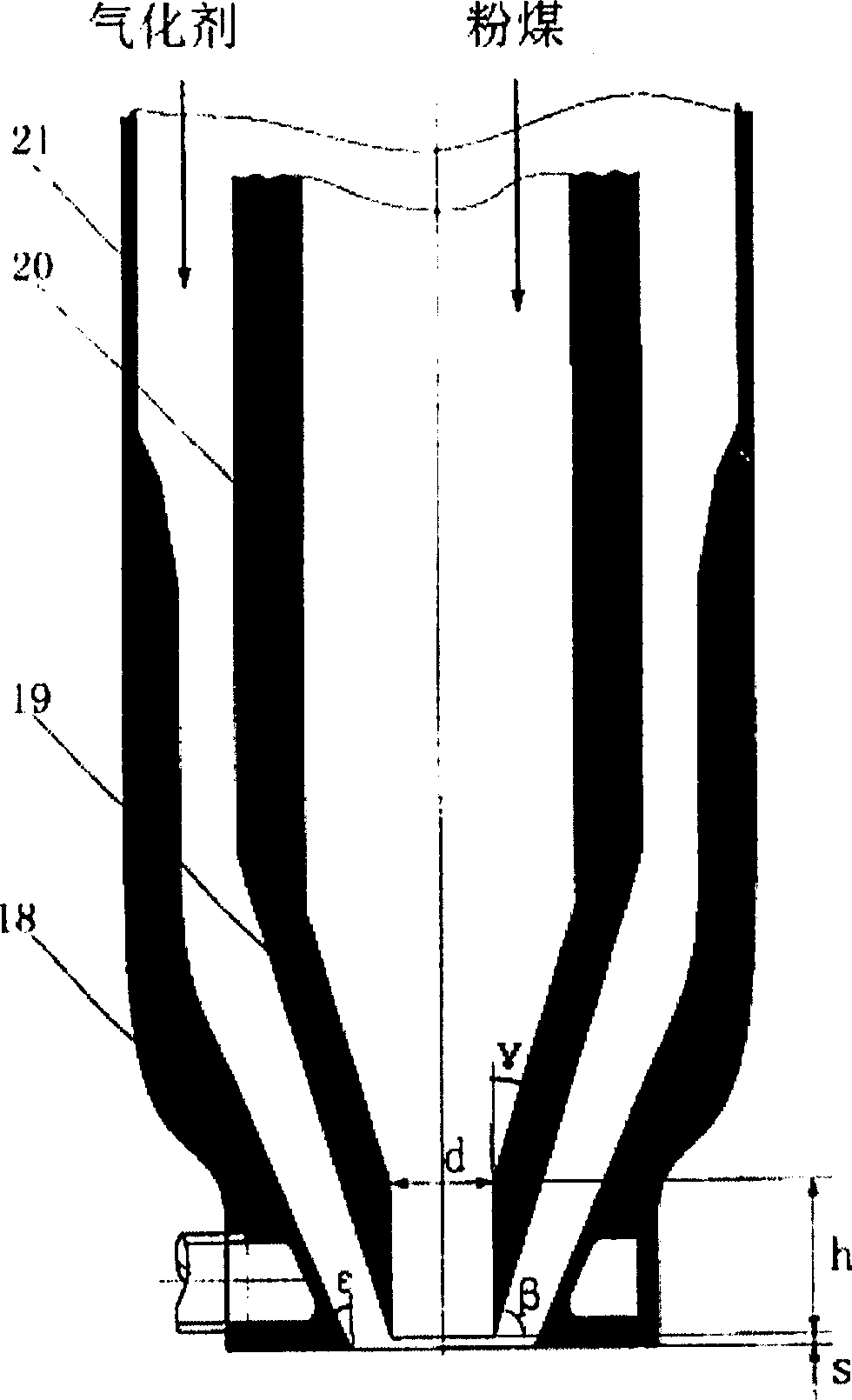

Multi-nozzle coal water mixture or fine coal gasifying furnace and its industrial application

ActiveCN1775920AUniform temperature distributionLess investmentCombined combustion mitigationGranular/pulverulent flues gasificationCoal waterSlag

The invention discloses a plural muzzles coal water slurry or fine coal gasification furnace used for gasifying coal water slurry or fine coal. The gasification room is made up of case, process muzzle room, process muzzle, preheating muzzle room, and preheating muzzle. The case has firebricks in it and washing cooling room is made up of chilling circle, down take, vesicle breaking stick and roughing slag outlet. The transforming ratio of the furnace is over 98%, and is especially suited for large scale gasification produce technology that produces 3000-5000T / day.

Owner:EAST CHINA UNIV OF SCI & TECH

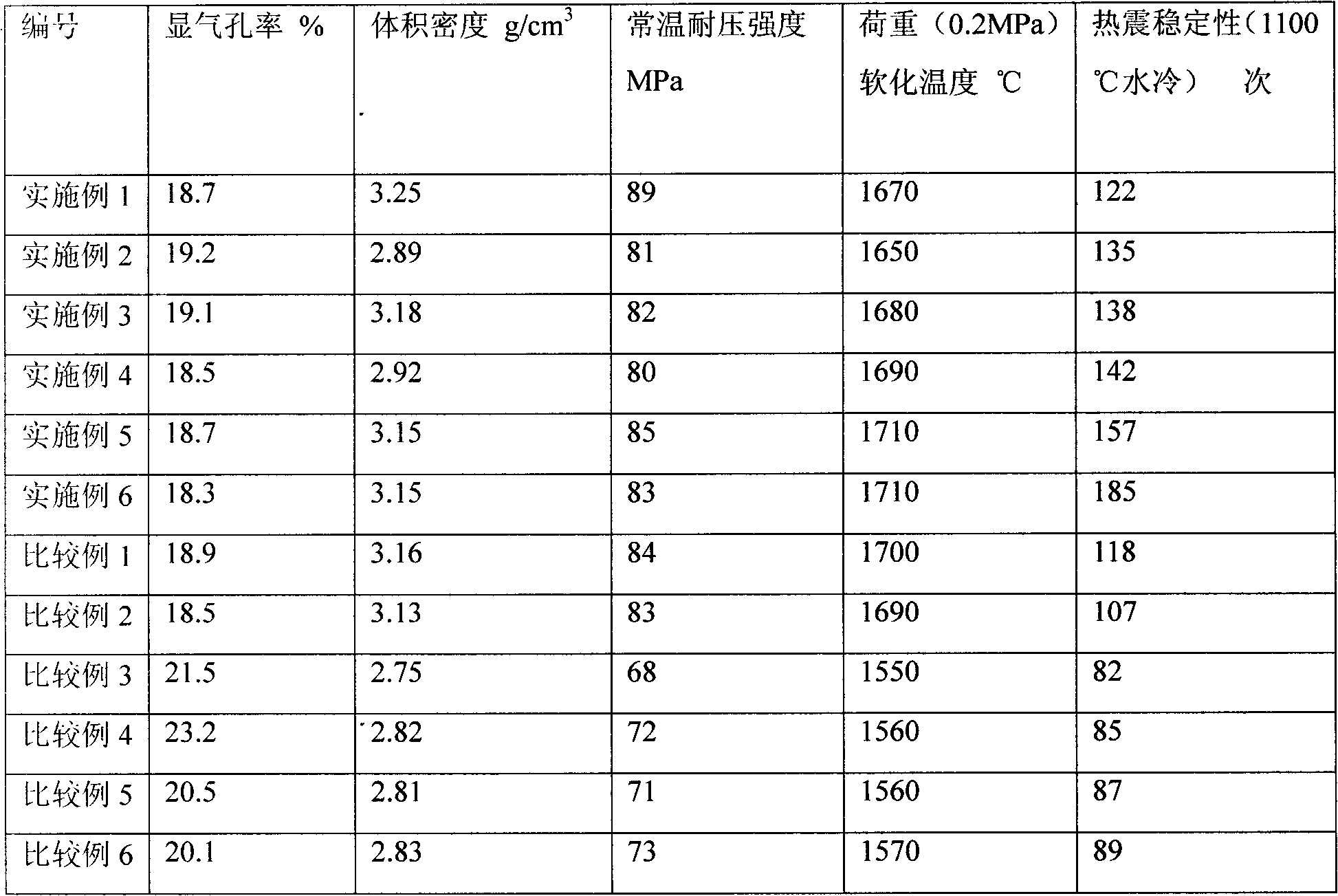

Metallic composite low carbon magnesium carbon brick for ladle slag wire and manufacture method thereof

The invention discloses a metal complex low-carbon magnesia carbon brick used for ladle slag lines, the weight percentage of the added materials is as following, 50 to 70 percent of magnesia particles, 25 to 35 percent of magnesia powder, and 3 to 6 percent of organic binder, furthermore, the following components are added which are produced by mixing, striating materials, forming and heat-treatment, 0 to 4 percent of flake graphite, 3 to 15 percent of metal powder, and 0.5 to 3 percent of antioxidant containing boron. The antioxidant properties, slag-resistance performance, high temperature strength and the thermal shock resistance of the ladle slag line used metal complex low-carbon magnesia carbon brick are greatly improved, the service life is prolonged, the consumption cost of each ton of refractories is lowered. The preparation method of ladle slag line used metal complex low-carbon magnesia carbon bricks is also disclosed, and the carbon content in the ladle slag line used metal complex low-carbon magnesia carbon bricks produced by the method is less than or equal to 6 percent, little carbon is added so as to reduce the pollution towards liquid steel, and residual strength ratio of the thermal shock resistance is kept at 70 to 80 percent.

Owner:ZHENGZHOU UNIV +1

Heat insulation non-burning refractory brick and production method thereof

ActiveCN101928152ACorrosion resistantWith thermal insulationCeramic shaping apparatusClay mixing apparatusRefractoryFire brick

The invention relates to a heat insulation non-burning refractory brick, belonging to the technical field of refractory material. The heat insulation non-burning refractory brick comprises the components by weight percent: 60-90% of compact refractory raw material with the particle size of 0-10mm, 5-30% of light refractory raw material with the particle size of 0-5mm and 2-30% of binding agent. The method takes the compact refractory raw material as main material which is added with part of light refractory raw material to be prepared into the non-burning heat insulation refractory material with the performance between the compact refractory raw material and the light refractory raw material, so that the non-burning heat insulation refractory material has the compression strength and the corrosion resistance of the compact refractory raw material as well as heat preservation and heat insulation performances of the light refractory raw material; and an industrial kiln built by the heat insulation non-burning refractory brick reduces the heat loss and the energy consumption.

Owner:鞍山钢铁冶金炉材科技有限公司

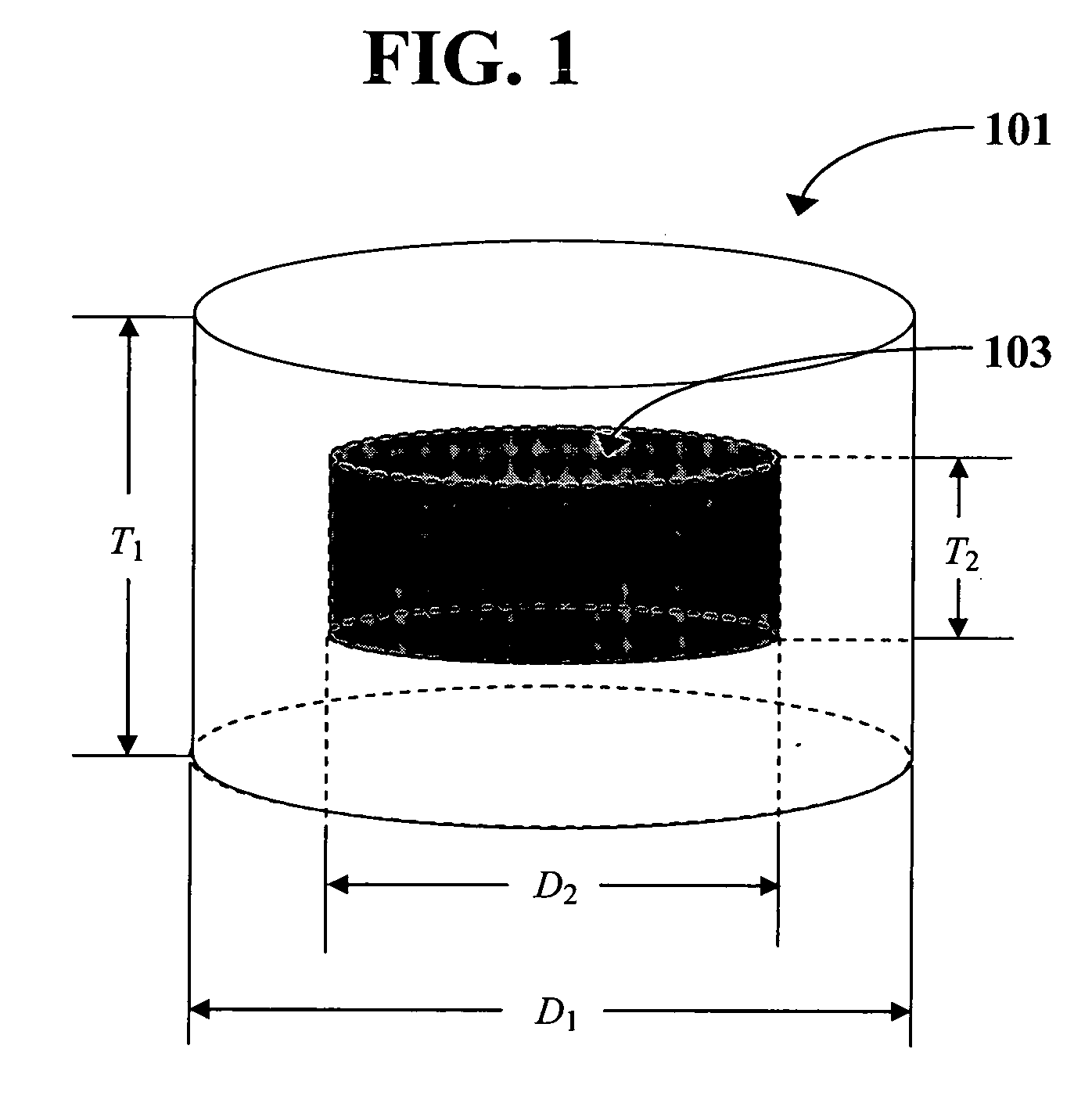

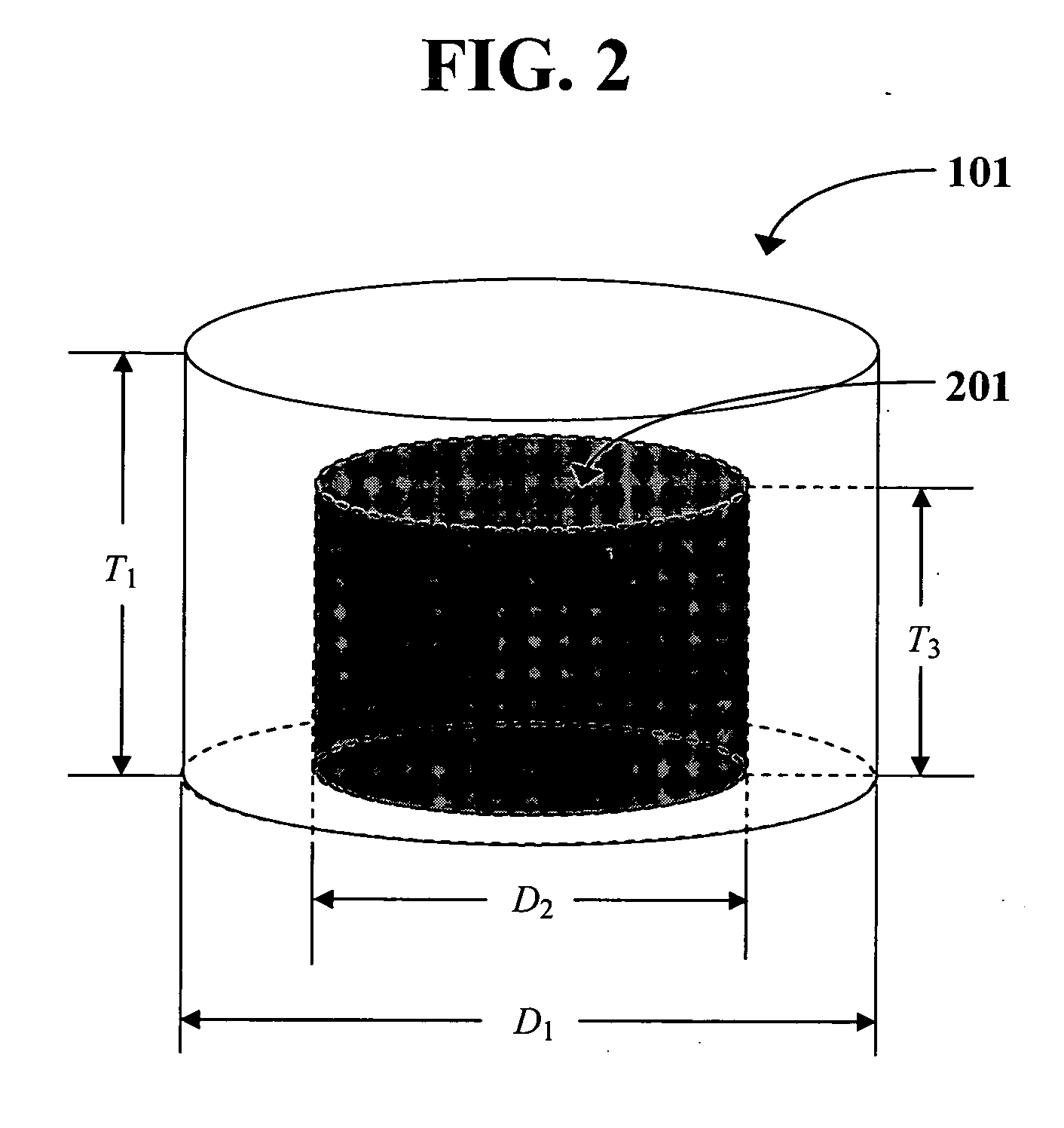

Method and apparatus for making fused silica

ActiveUS20070130995A1High purityHigh OH concentration uniformityGlass furnace apparatusMaterial analysis by optical meansBrickDeposition process

Disclosed are process and apparatus for making high purity fused silica glass materials. The process involves depositing soot particles onto an essentially planar deposition supporting surface and modulation of motion of the soot-generating device relative to the deposition supporting surface to result in a low local soot density variation. The apparatus is designed to implement the planar deposition process. The invention makes it possible to produce fused silica glass without the use of potentially contaminating refractory bricks.

Owner:CORNING INC

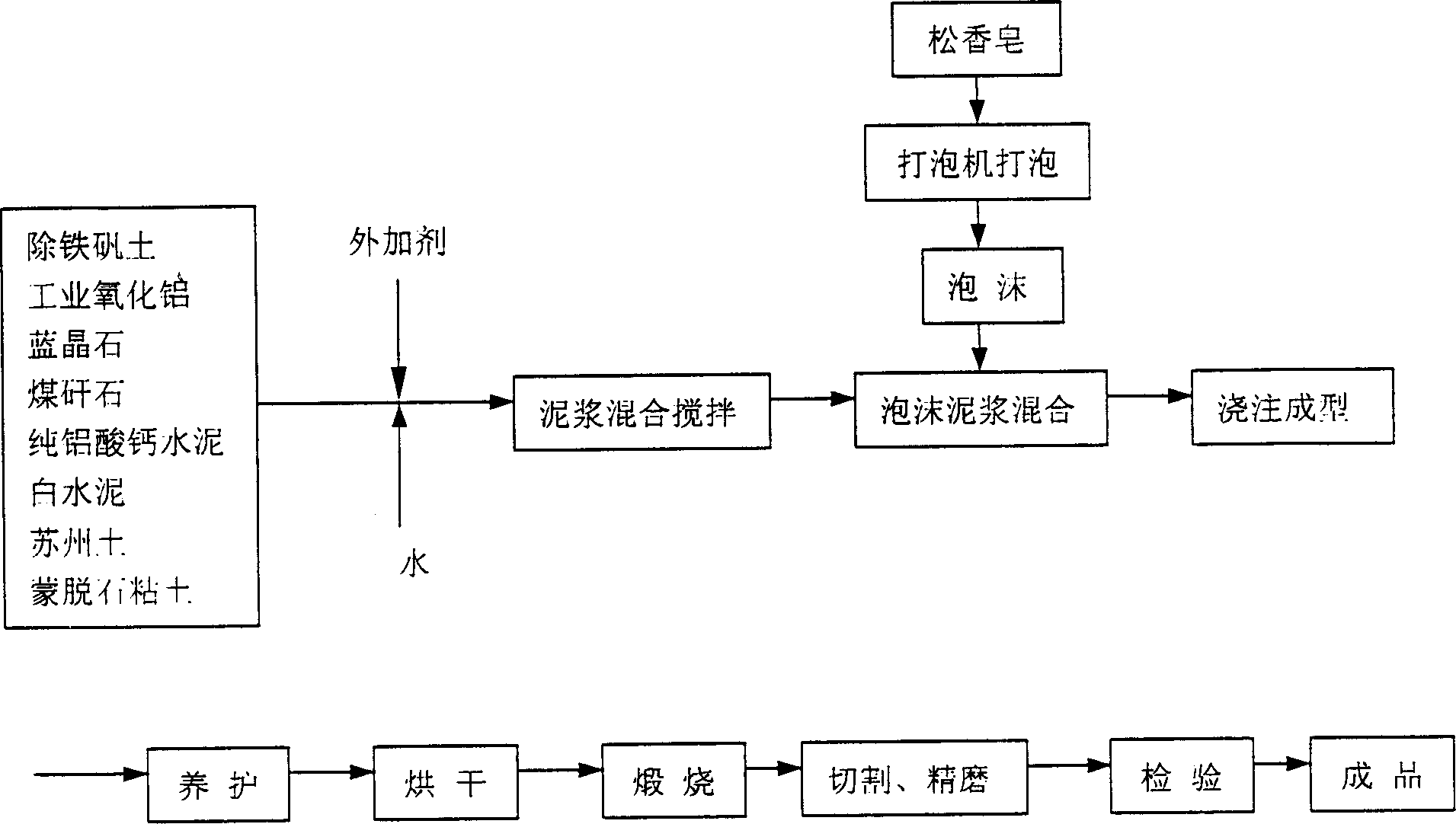

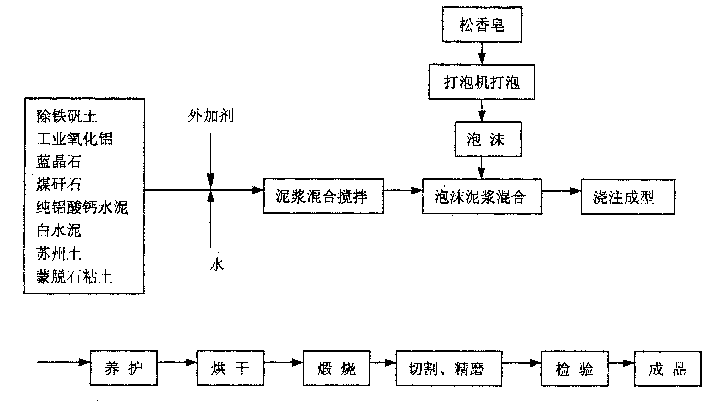

Light refractory bricks

InactiveCN1424280AIncrease optionalityReduce manufacturing costFurnace componentsCeramicwareMulliteAluminum silicate

A light-weight refractory brick used for liner of high-temp furnace is prepared from mullite as primary crystal phase, huronite as binding phase, disthene and coal gangue. Its main chemical components are Al2O3 (54-57 wt.%), SiO2 (40-43), CaO (1-2), Fe2O3 (0.1-1) and impurities (0.1-0.7). Its advantages are light weight, low heat conductivity and volume density, and high strength.

Owner:UNIV OF SCI & TECH BEIJING

Calcium hexaluminate lightweight refractory brick and preparation method thereof

The invention relates to a calcium hexaluminate lightweight refractory brick, in particular to a high-quality refractory material with low heat conduction coefficient, good stability under high-temperature reducing atmosphere, good alkali resistance and slag erosion resistance and long service life for a high-temperature kiln lining, and belongs to the technical field of refractory materials. Calcium hexaluminate is used as a main crystal phase, and the sum of the main chemical components Al2O3 and CaO of the calcium hexaluminate is more than 90 weight percent. Calcium carbonate, calcium hydroxide, calcium oxide, limestone or lime or the like is used as a calcium source; and aluminum oxide, aluminum hydroxide or the like is used as an aluminum source. The calcium hexaluminate lightweight refractory brick is prepared by a series processes of mixing the materials uniformly according to the theory of the calcium hexaluminate, grinding the mixture, adding a certain amount of pore forming agent into the mixture and stirring the mixture uniformly, then performing half dry vibration casting, wet adjusting controllable drying, high-temperature air introducing pore formation, one-step reductive reaction sintering, cutting and processing and the like. The lightweight refractory brick for the high-temperature kiln lining has low heat conduction coefficient and long service life, and can provide efficient and energy-saving guarantee for industrial furnace equipment.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

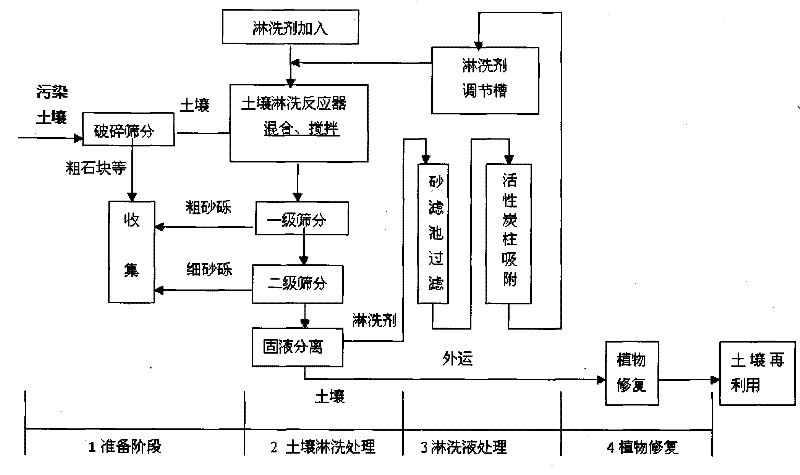

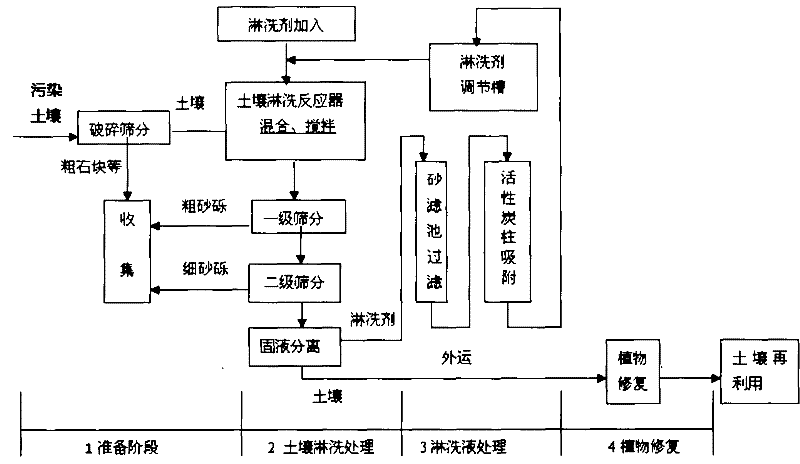

Ex-situ washing remediation method for nitrochlorobenzene-contaminated soil

InactiveCN102172614AThe process is easy to implementReduce labor inputContaminated soil reclamationEngineeringSlurry

The invention discloses an ex-situ washing remediation method for nitrochlorobenzene-contaminated soil, which comprises the following steps: crushing soil and sieving to remove stones and gravels; filling the soil into a washing reactor to fully mix the soil with a proper amount of washing solution, wherein the washing agent is ethanol; subjecting the washed mixture of slurry to two stages of sieving and filtering, wherein soil particles with large particle sizes are stopped by a screen; pumping the slurry mixture to soil-liquid separation equipment, recovering, filtering and purifying separated washing solution to regenerate the washing solution, regulating the concentration of the washing solution, and leaving the washing solution for washing at next time of washing. A sand filter column is used for filtering, active carbon is used for absorbing molecules of organic contaminants such as nitrochlorobenzene in the washing solution instead of molecules of ethanol serving as the washing agent, and thus, the washing solution is purified and can be recovered and recycling of resources is realized. The organic contaminant content of the washed soil reaches related standards. The soil particles which are sieved and filtered out can be used as building and road construction materials; and the soil particles obtained by solid-liquid separation can be used as raw materials for making concrete and fire bricks and also can be reclaimed. Thus, the whole soil remediation process is accomplished. In the invention, the process is easy to implement, small-scale industrial application can be realized, and an effective means is provided for scientific researchers for researching soil remediation.

Owner:南京市生态环境保护科学研究院

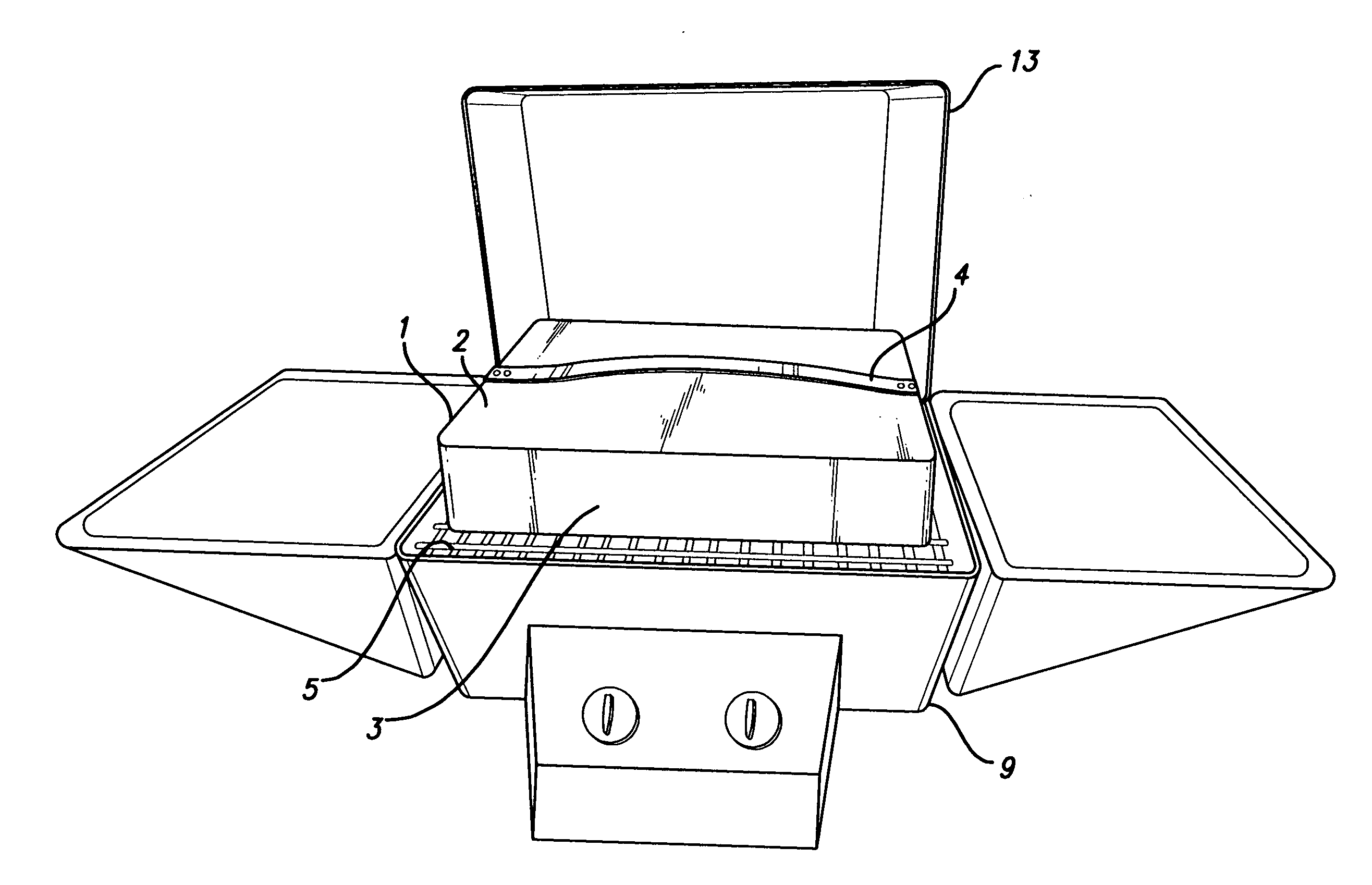

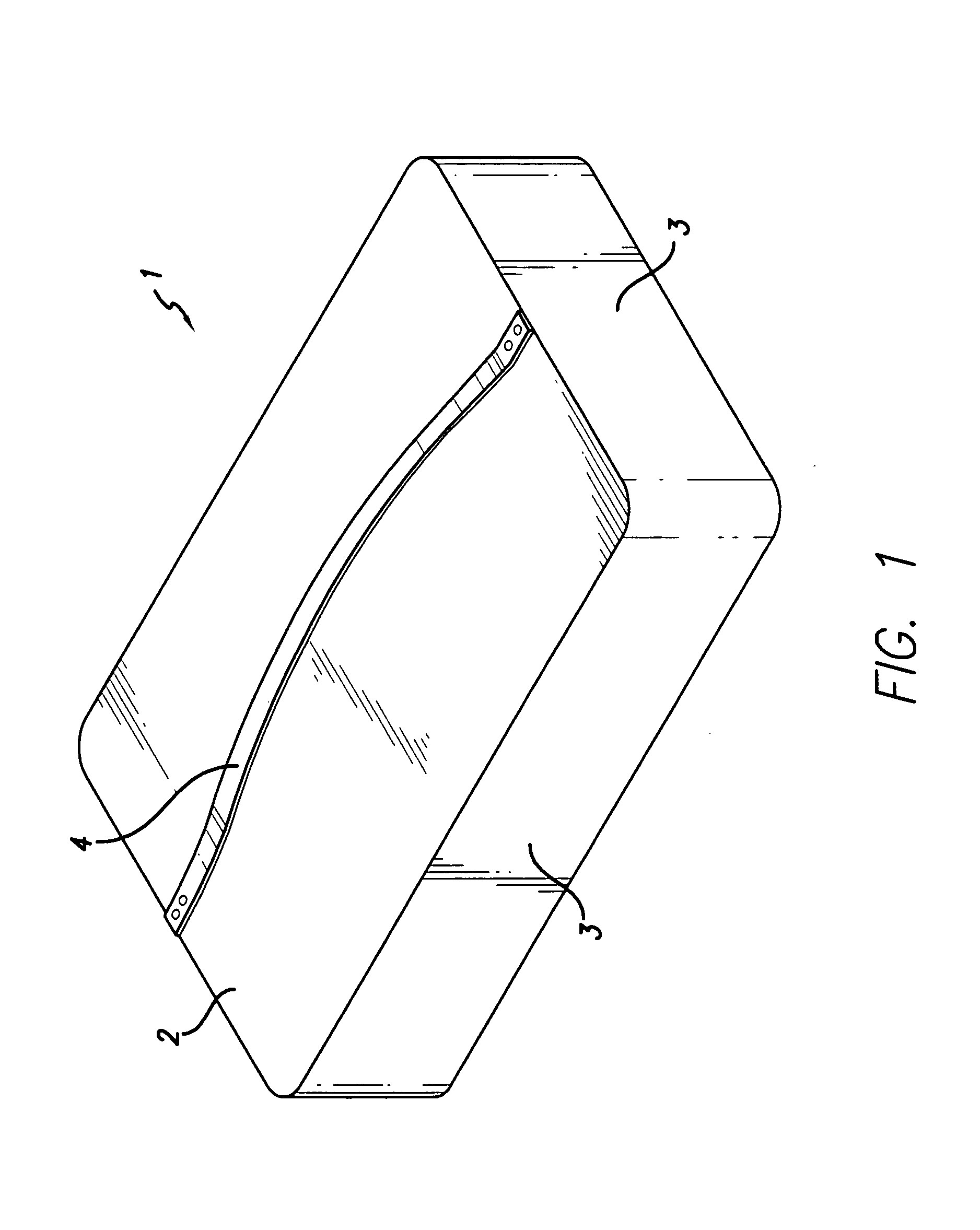

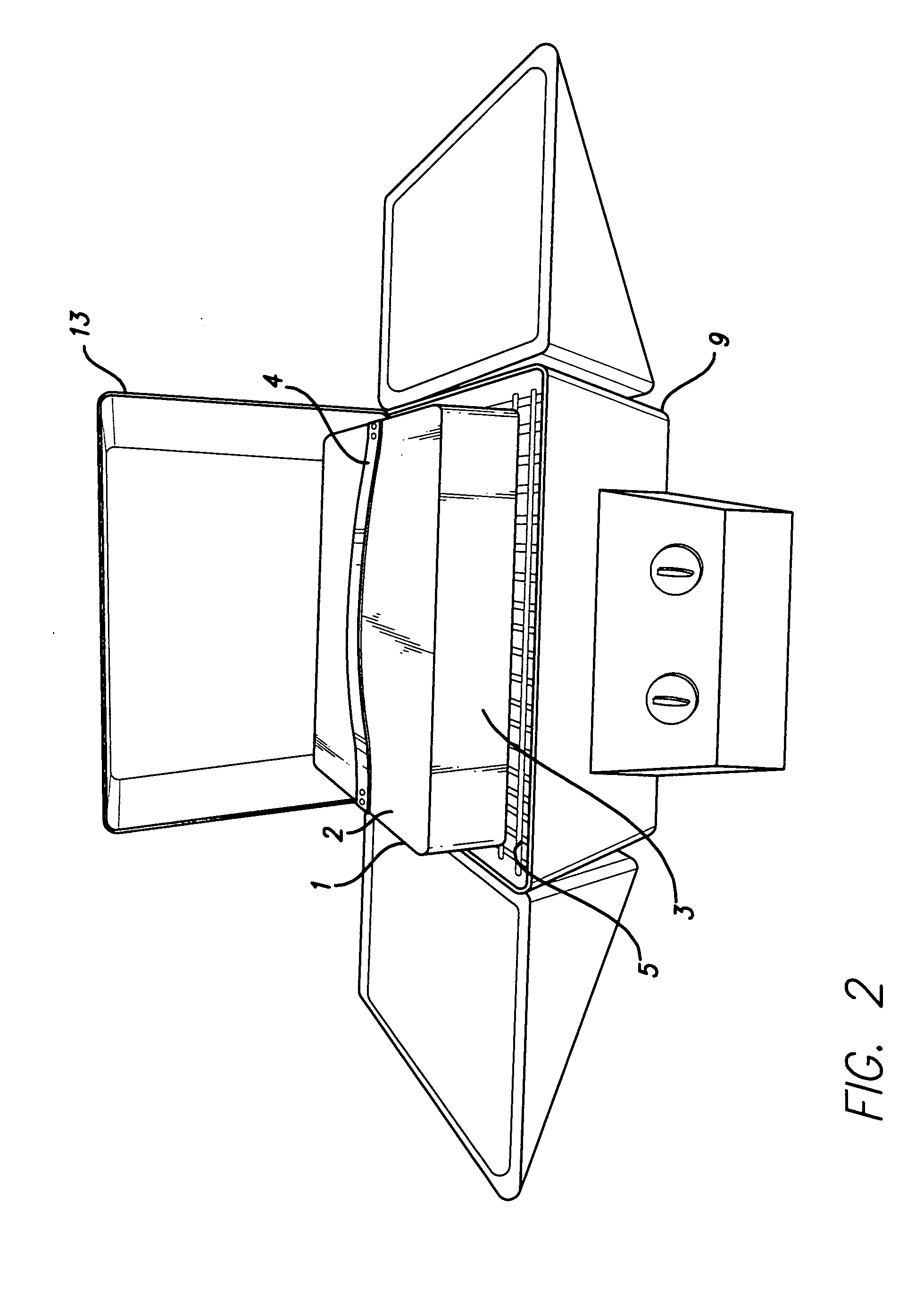

Insulated cover and method for cooking pizza and similar food items on a home gas or charcoal grill

InactiveUS20100124596A1Quickly efficiently cookQuick and efficientMilk preservationDomestic stoves or rangesThermal energyMetal foil

An insulated cover and method that makes it possible to create a thermal environment on a home gas or charcoal grill similar to that produced by a wood fired brick oven or commercial pizza oven. The cover is made from a high temperature resistant, thermal insulation material that is encapsulated (sandwiched) between thin metal sheet or metal foil skins. The insulated cover covers both a food support surface that has been placed on the grill's grate directly over the grill's heat source and the remainder of grills grate area that is suspended directly above the grills heat source that is not already covered by the food support surface. The food items are cooked from below by the thermal energy stored in the food support surface, and from above by the thermal energy contained within the low volume zone created by the insulated cover resulting in uniform, fast, even and energy efficient cooking of food items like pizza.

Owner:NELSON RANDALL WARREN

Process for preparing vapour pressure air-entrained concrete light heat-insulation fireproof bricks by gold tailings

The invention relates to a firebrick preparation method, in particular to a method of preparing an autoclaved aerated concrete light heat insulating firebrick with gold tailings. The invention takes the gold tailings as the main raw material which is made by a pre-activating treatment, then a certain amount of cement, lime, foam stabilizer of nekal bx or soap pod powder and aluminum power paste are added, and then plaster and self-made compound admixtures are added to prepare into sizing agent. The later preparing procedures are as follows: pour mold for gas-forming and stilling, dry heat pre-curing, cutting and stacking, being steamed in a caldron and being taken out of the caldron, and finally the firebrick is formed. The firebrick is put into the caldron to steam for 5 to 7 hours under constant voltage; the steam pressure is 1.1 to 1.5 MPa, the temperature is from 185 DEG C to 195 DEG C. The firebricks prepared by the method have good effect of heat insulation in stove owing to low coefficient of heat conductivity, thereby being used in the low temperature section of ceramics kiln collapses, tunnels, resistance furnace and being capable of realizing energy saving. The firebricks prepared by the method also have the advantage of being light owing to the volume and density being less than those of the majority of light heat insulating firebricks.

Owner:福建省万旗非金属材料有限公司

Silica heat-proof firebrick

ActiveCN101139210AExcellent physical and chemical indicatorsHigh temperature resistantSlurryRaw material

The present invention relates to the fireproof material technology field, in particular to a silicon heat insulation fireproof brick adaptable to be used in coke oven and carbon stove. The present invention can solve the shortcomings in the prior clay heat-insulation and fireproof brick that load distortion temperature is low; the material is easy to be shrunk in the high temperature; the heat conductivity ratio is much larger and the heat preservation effect is much worse and so on. The components and the relative weight ratio in the present invention are that: 81-85 percent of silica powder, 15-19 percent of perlite, and the following assistant materials, whose weight ratio occupied in the main raw materials is as follow: 045-0.55 percent of iron scale powder, 0.9-1.1 percent of cement, 6.5-7.5 percent of lime milk, 1.95-2.2 percent of paper slurry. The silica powder and the perlite with the stated matched ratio are added into a humid grinder and then the iron scale powder and the cement are added into to be grinded for 1-2 minutes; and then the water with the weight ratio occupied in the main raw material 1.8-2.2 percent is added, and then the lime milk is also added to be grinded and pressed for 10-15 minutes. Finally, the paper slurry is added to be grinded and pressed for 10-15 minutes. The mixture is taken out from the grinder to be molded. Each physical and chemical index of the silicon heat insulation fireproof brick in the present invention is better than the national standard; the present invention has the advantages of heat-resisting, low heat conductivity, low iron content, large compression strength and much better heat stability and so on. The present invention can be directly used as the inner bushing for the industrial stove.

Owner:山西盂县西小坪耐火材料有限公司

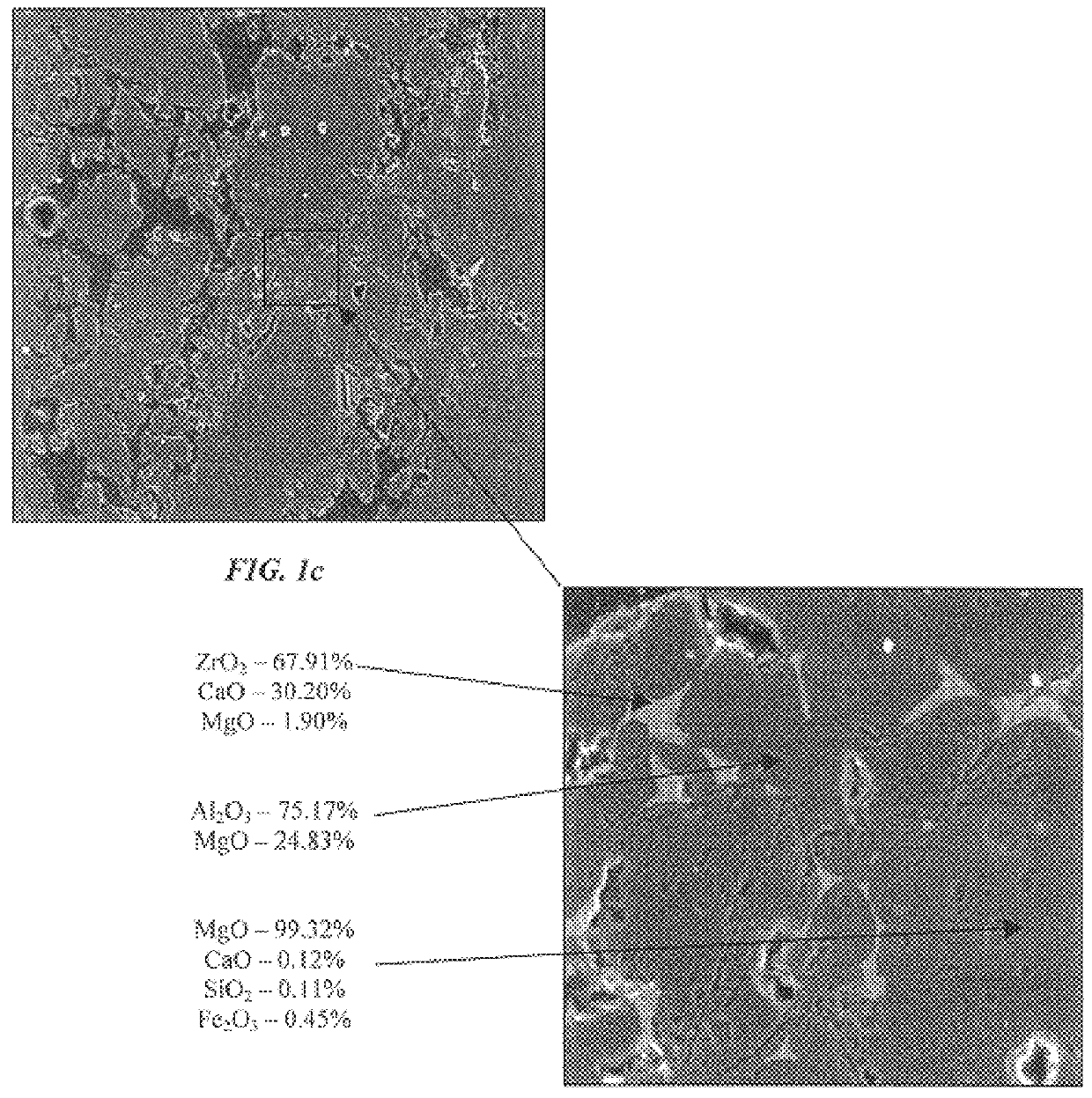

Alumina-magnesia refractory brick containing light porous aggregate and its making process

The present invention relates to one kind of alumina-magnesia refractory brick containing light porous aggregate and its production process. The technological scheme is that the alumina-silica refractory brick is produced with light porous Al2O3-MgO refractory material 30-70 wt%, compact Al2O3-MgO refractory material 0-35 wt%, fine magnesia powder 5-30 wt%, fine alpha-Al2O3 powder 3-10 wt%, fine corundum powder 0-25 wt% and fine spinel powder 0-25 wt%, and through mixture, adding waste pulp liquid in 3-7 wt% as binding agent, stirring, pressing to form adobe, drying at 100-150 deg.c for 12-48 hr, sintering at 1400-1600 deg.c for 2-5 hr and naturally cooling. The alumina-magnesia refractory brick has high macro porosity, small average pore size, low heat conductivity and high medium erosion resistance, and may be used in the permanent layer or work layer in high temperature kiln, furnace and container.

Owner:WUHAN UNIV OF SCI & TECH

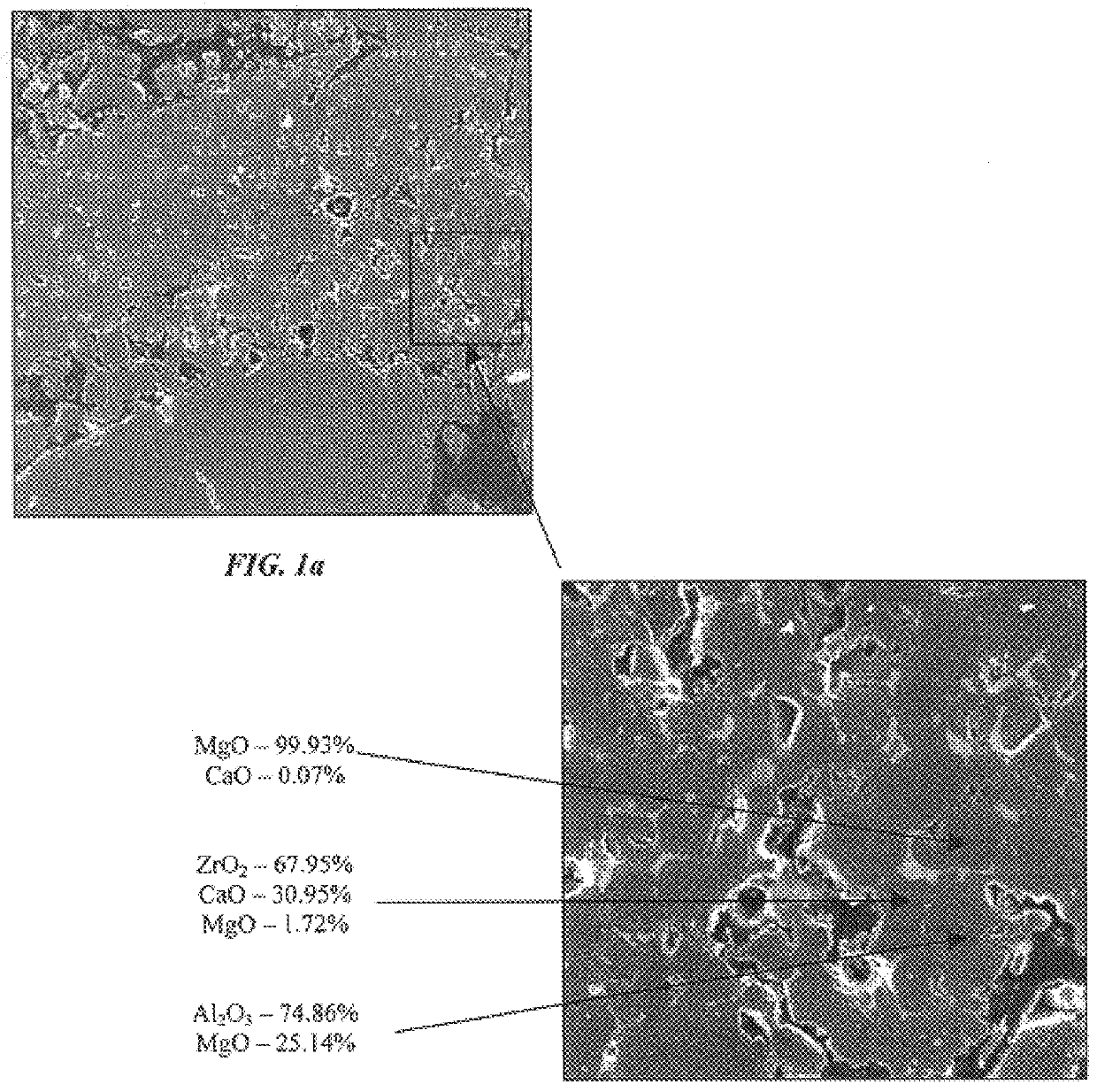

Magnesia spinel refractory brick

The present invention discloses novel magnesia-spinel refractory compositions and bricks formed thereof that exhibit longer lining life, greater hot strength and reduced tendency to spall under high thermal loading conditions. The invention is designed to slow or retard the reaction between spinel and lime through the addition of zirconia in the form of an alumina-zirconia grain to the refractory mix. Zirconia reacts more readily with the lime in the refractory composition and surrounding environment to form calcium zirconate.

Owner:BAKER REFRACTORIE

Light corundum-mullite refractory brick and preparation method thereof

The invention relates to a light corundum-mullite refractory brick and a preparation method thereof. The preparation method comprises the steps of evenly dispersing 0.5-1wt% of silicon oxide micro powder and 2-4wt% of active alpha alumina micro powder in 5-8wt% of silica sol to obtain modified silica sol, placing 40-70wt% of porous corundum-mullite ceramic particles in a vacuum mixer, carrying out vacuum pumping until the vacuum is below 2.5 kPa, keeping the constant pressure for three minutes, then pouring the modified silica sol into the vacuum mixer, mixing for ten minutes and closing the vacuum pumping system, pouring 10-25wt% of porous corundum-mullite ceramic fine powder, 10-20wt% of corundum fine powder, 1.5-4wt% of silicon oxide micro powder and 1-3wt% of active alpha alumina micro powder into the vacuum mixer for mixing and mechanical pressing, drying and finally preserving heat at 1400-1600 DEG C for 2-10 hours. The prepared product has the characteristics of controllability in apparent porosity and pore size, low thermal conductivity, good thermal shock stability and strong medium erosion resistance.

Owner:WUHAN UNIV OF SCI & TECH

Ceramic Al203SiC refractory and preparation method thereof

A refractory ceramic Al2O3-SiC brick with high strength and low porosity is prepared through proportionally mixing high-Al alumine, white corundum, brown corundum, industrial silicon carbide, andalusite, ceramic additive, adhesive and water, stirring or grinding, die pressing, drying at 60-110 deg.C for 12-24 hr or natural drying, and calcining at 1400-1470 deg.C.

Owner:WUHAN UNIV OF SCI & TECH

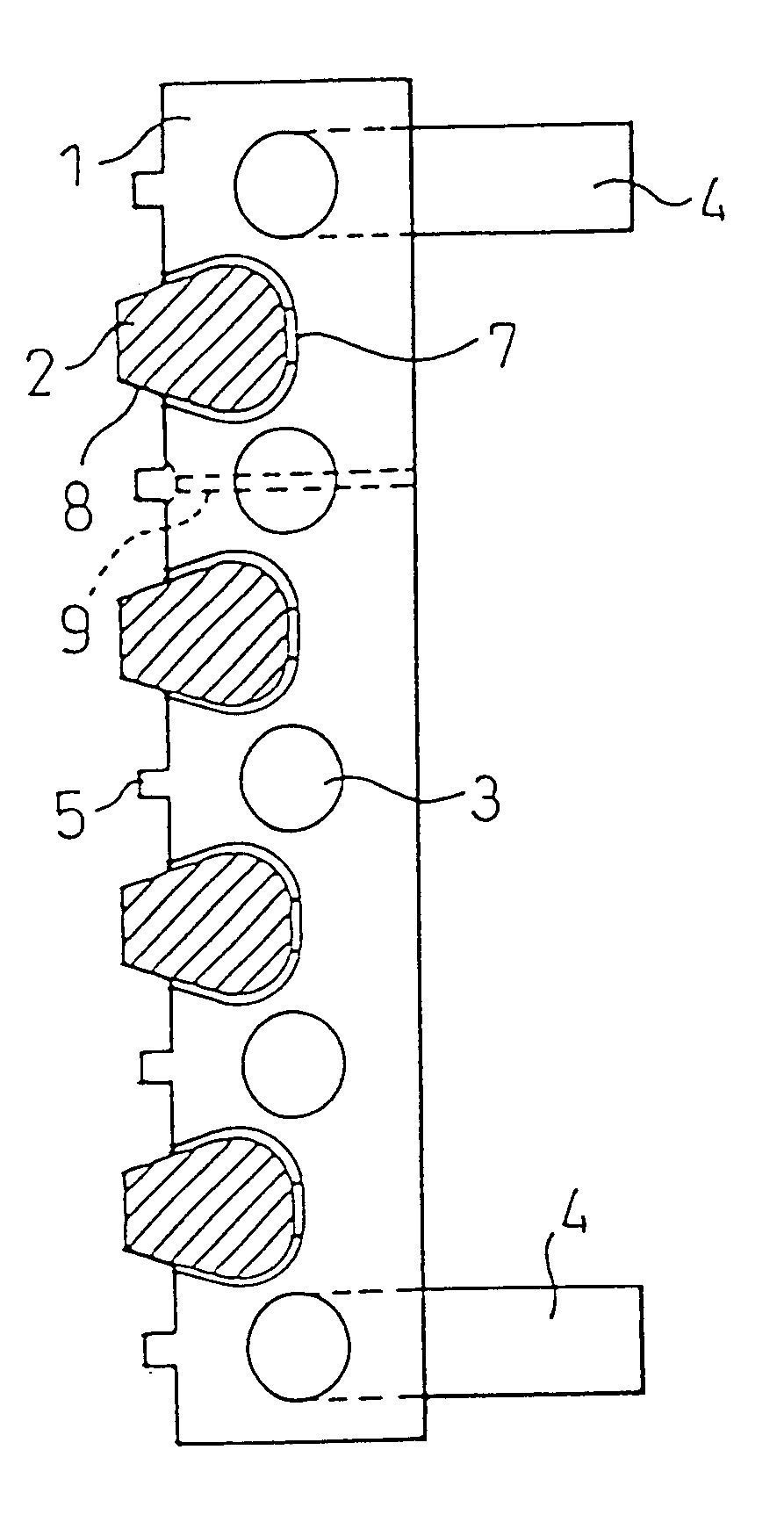

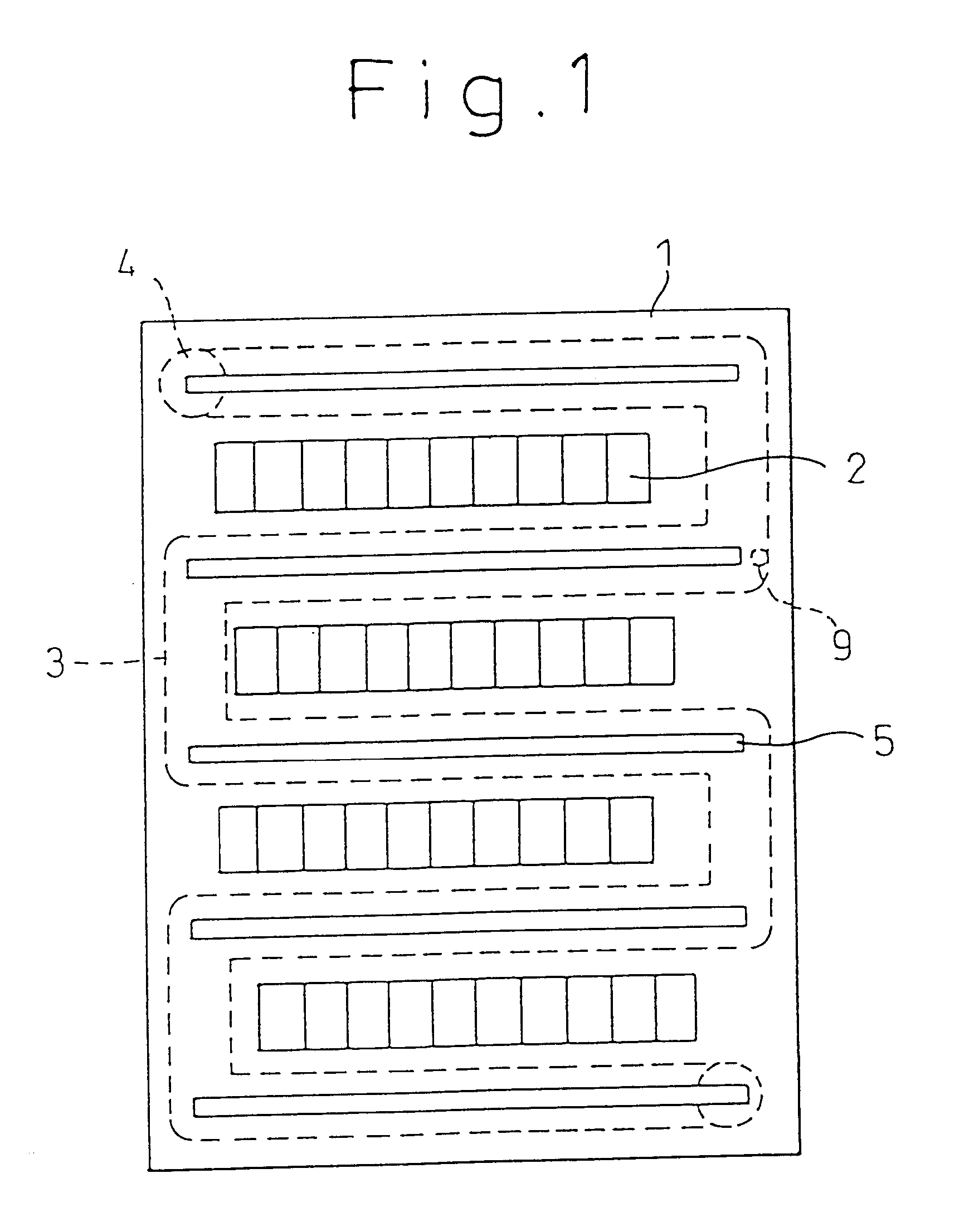

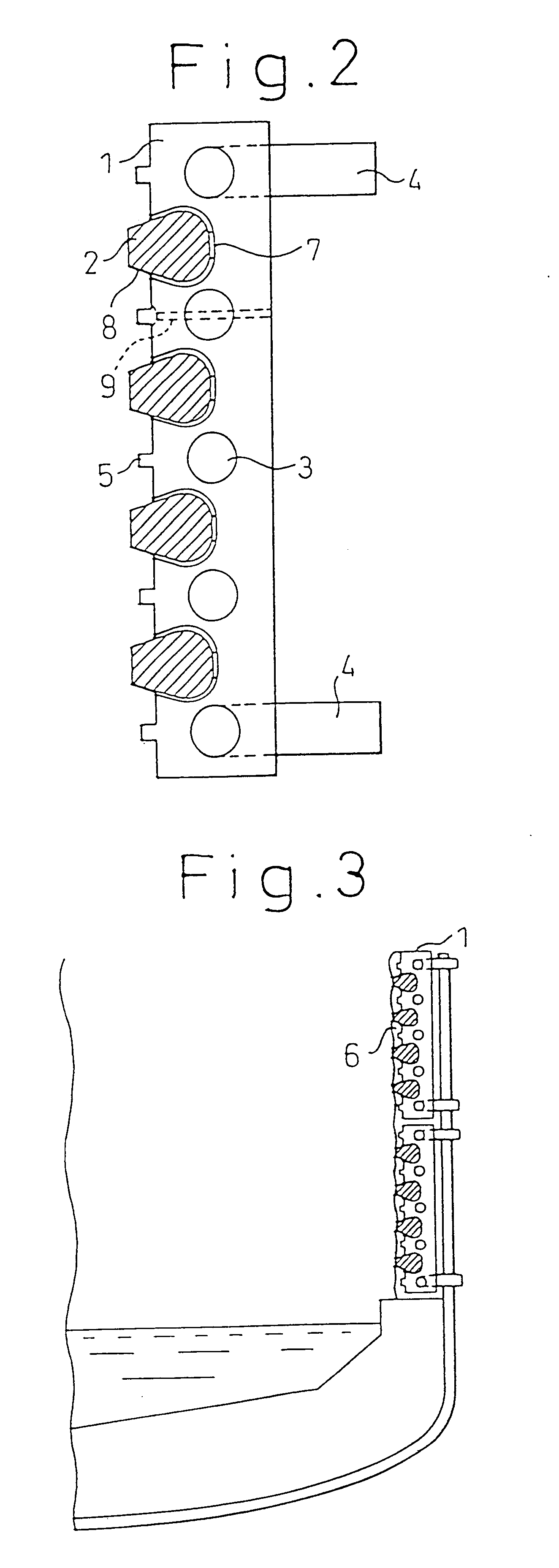

Water-cooling panel for furnace wall and furnace cover of arc furnace

A water-cooled panel for the furnace wall and furnace roof of an electric-arc furnace is integrally fabricated of refractory bricks arrayed on the furnace inner wall in multiple regularly spaced rows to be exposed at the end surfaces and cooling water pipes installed between the rows of refractory bricks (2). A furnace exterior side of the refractory bricks and a furnace interior side of a cooling water pipe are overlapped in a vertical direction of the water-cooled panel, and the cooling water pipe is provided in between an upper and lower side of refractory bricks.

Owner:NIPPON STEEL CORP

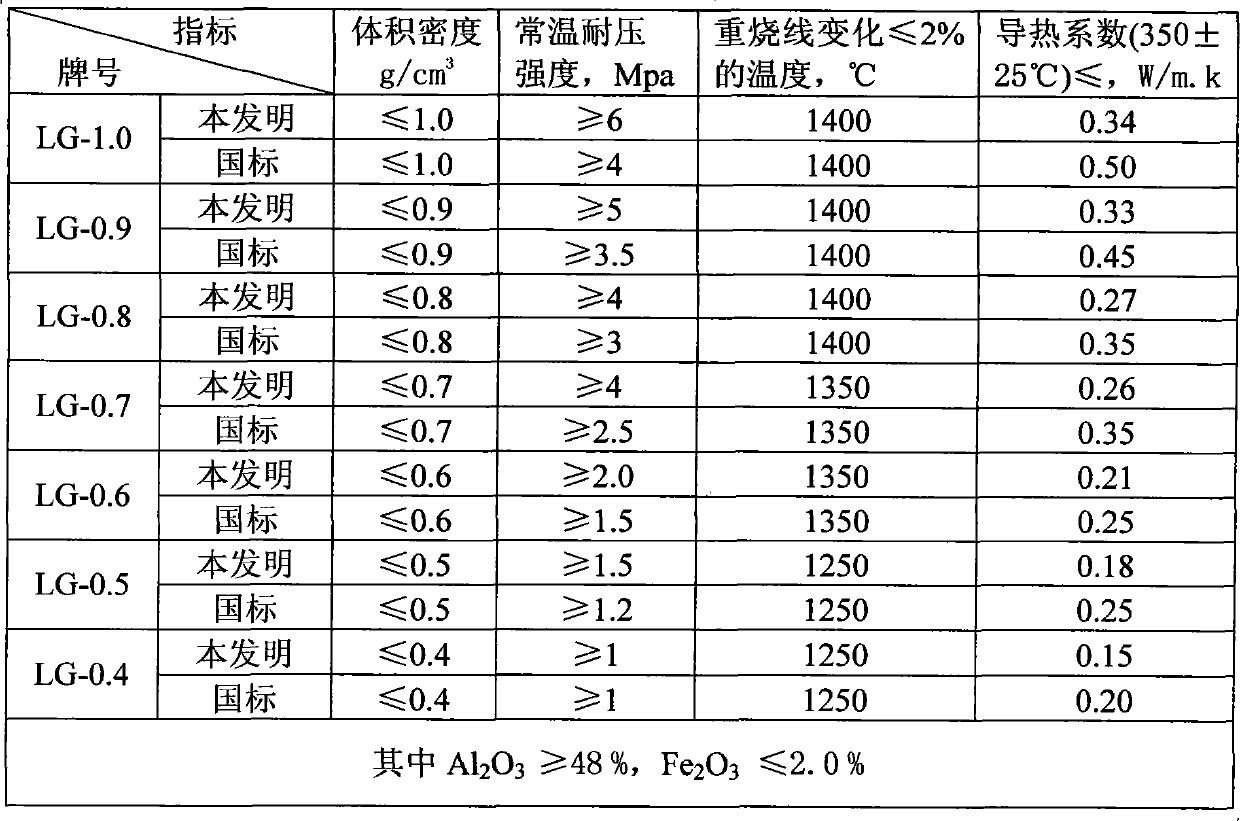

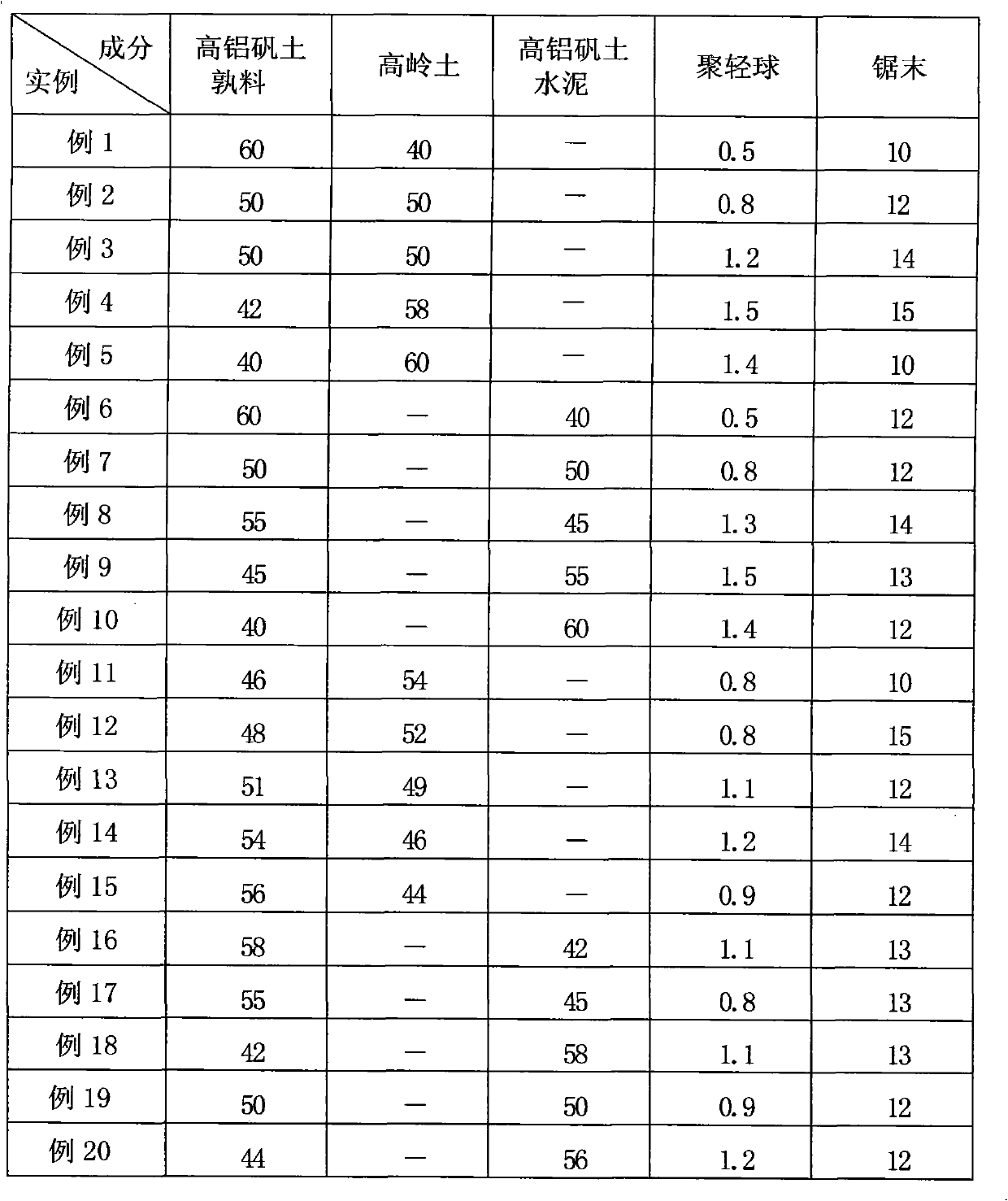

Light high-alumina insulating firebrick and preparation method thereof

The invention discloses a light high-alumina insulating firebrick and a preparation method thereof used for insulating layers of thermal equipment. The firebrick comprises the raw materials in percent by weight: 40% to 60% of high-alumina bauxite clinker and 40% to 60% of binder, polymeric light ball and sawdust respectively account 0.5% to 1.5% and10% to 15% of the total weight of the high-alumina bauxite clinker and the binder and are also added. The preparation method comprises the steps of: mixing the high-alumina bauxite clinker with the binder; then adding the polymeric light ball and the sawdust; adding water with the proportion of the dry mixed powder and the water of 1.0 to 1.75: 1; stirring into slurry-shaped materials; casting into brick blanks; drying; filling into a kiln; heating to 1270 DEG C to 1350 DEG C; and keeping the temperature for preparing the firebrick by burning. The firebrick has the advantages of simple formulation, easy acquirement of the raw materials, good compatibility, high compressive strength, low thermal conductivity, low change rate of high-temperature heavy firing line and the like, and achieves the national standards of relative products. The firebrick has simple preparation method and lower cost, can be used for the insulating layers and fireproof layers of all kinds of thermal equipment, and is beneficial to popularization and application.

Owner:郑州东方炉衬材料有限公司

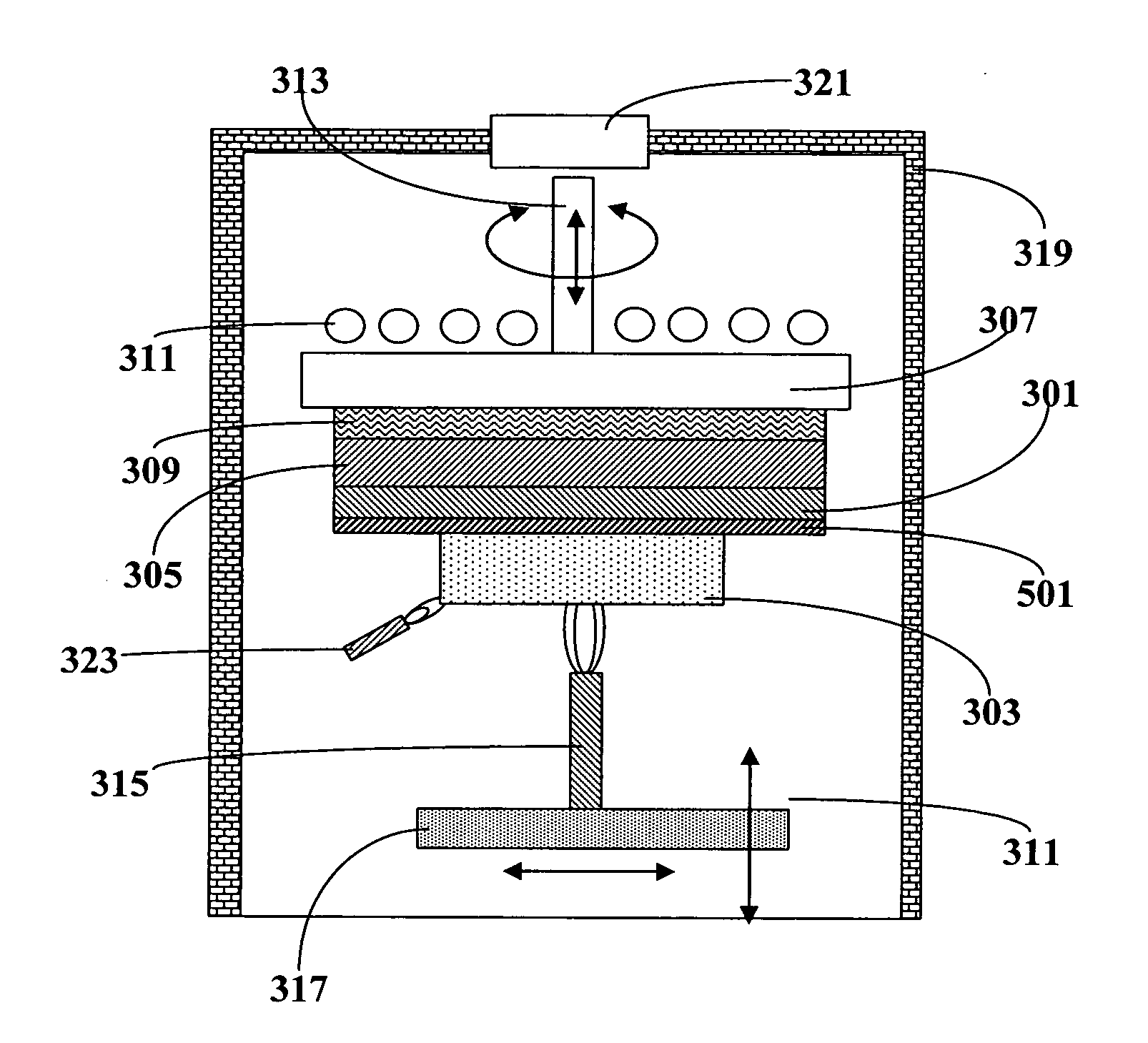

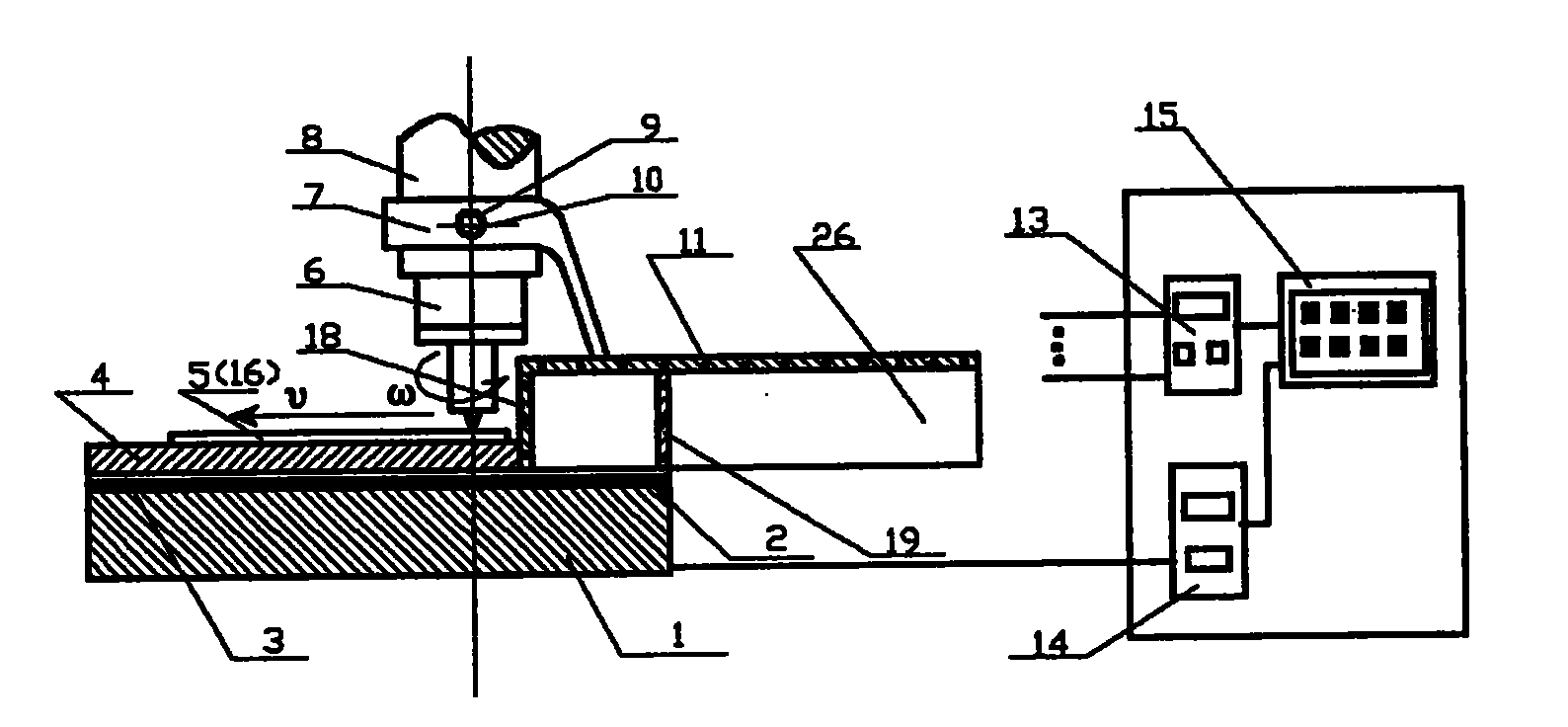

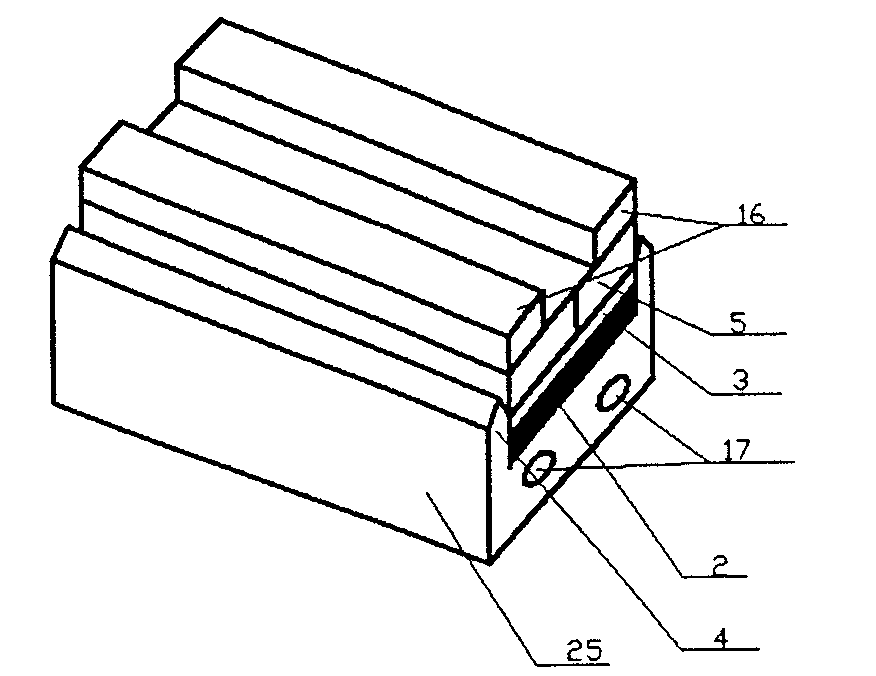

Method and device for controlling residual stress on stir friction welding surface

InactiveCN101774079AAvoid Welding Quality DeteriorationRealize full CNC controlNon-electric welding apparatusEngineeringControl equipment

The invention relates to a method and a device for controlling a residual stress on a stir friction welding surface. According to the method, an insulation box capable of moving along a stirring head is adopted to insulate the weld joint and parent metal after welding, and then furnace cooling is performed so as to reduce the residual stress on the stir friction welding surface. The device mainly comprises a sucking-disc type fixture, the insulation box and control equipment, wherein the insulation material mainly comprises fire bricks, asbestos and steel plates. During welding, the insulation box moves along the stirring head and insulates the welded workpiece continuously; and after the welding, the whole workpiece enters the insulation box to be insulated and is cooled with the furnace after being insulated for a certain time so as to control the residual stress on the welding surface and the deformation, wherein the insulating temperature is the critical temperature of the heat treatment of the materials. The device realizes full automation in the whole welding process and avoids the reduction in the welding quality due to a human factor. The method and the device have the advantages of simple device, convenient operation, high technical economic benefit, and high welding quality of the stir friction welding.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Thermal-shock resistant fireproof brick and production process thereof

The invention relates to a heat shock resistance firebrick and the manufacture method. The method is that it adopts mullite, corundum, alpha-Al2O3 powder, andalusite and clay as base material, adding 3-15wt% binding agent. The process includes the following steps: adding binding agent into the base material, grinding to equal, molding, sintering at 1450 degree centigrade. The invention has good heat shock resistance, long useful life, etc. It has great economic and social benefits.

Owner:ZHENGZHOU YUXING REFRACTORY MATERIAL

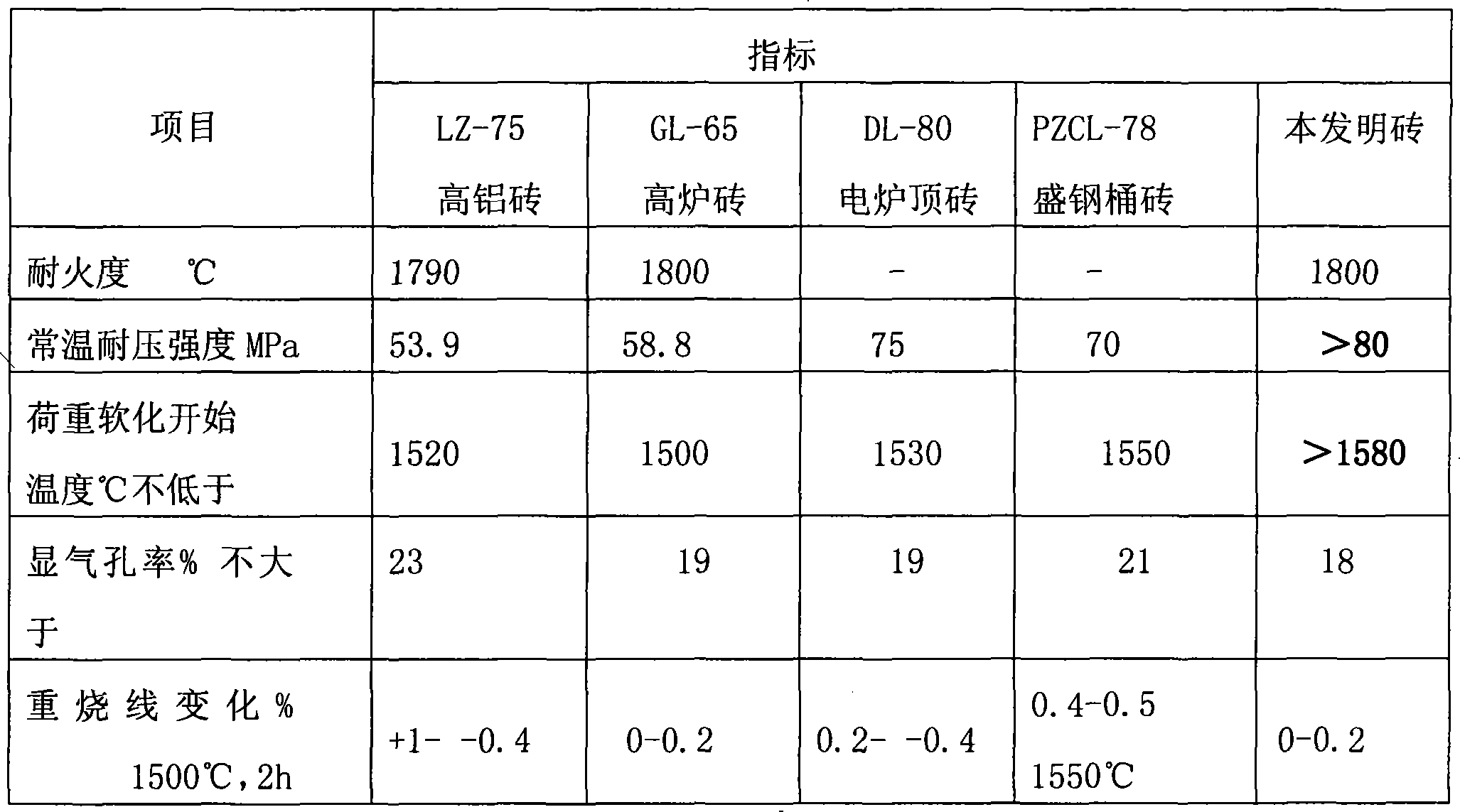

Low-temperature burning high-aluminum refractory brick and preparation method thereof

The present invention provides a low-temperature braking high-aluminum refractory brick and the preparing method thereof, and the invention is characterized in that the refractory brick is prepared by the following main raw material and bonding agent; wherein: the main material comprises the raw material with the following weight proportion: wherein the bauxite chamotte with granularity 3-0.088mm for 50-70%, bauxite chamotte with granularity less than 0.088 for 7-20%, emery with granularity less than 0.088 for 5-20%, dry powder shaped pyrophyllite for 2-10%, and dry powder shaped refractory clay for 5-20%; and the adding amount of the bonding agent is 10-20% of the weight of the raw material. The high-alumina brick is obtained using the low ore grade bauxite chamotte with low temperature 1250-1350 DEG C, and the high-quality refractory brick has the advantages of: ordinary-temperature compressive strength above 80MPa, and the load softening staring temperature above 1580 DEG C.

Owner:巩义市金岭耐火材料有限公司

Alumina-silica refractory brick containing light porous aggegate and its making process

The present invention relates to one kind of alumina-silica refractory brick containing light porous aggregate and its production process. The technological scheme is that the alumina-silica refractory brick is produced with light porous Al2O3-SiO2 refractory material 30-70 wt%, compact Al2O3-SiO2 refractory material 0-35 wt%, fine corundum powder 5-25 wt%, fine alpha-Al2O3 powder 3-10 wt%, fine mullite powder 5-15 wt% and fine clay powder 0-10 wt%, and through mixture, adding waste pulp liquid in 3-7 wt% and one or two kinds of silicasol as binding agent, stirring, pressing to form adobe, drying at 100-150 deg.c for 12-48 hr, sintering at 1400-1600 deg.c for 2-5 hr and naturally cooling. The alumina-silica refractory brick has high macro porosity, small average pore size, low heat conductivity and high medium erosion resistance, and may be used in the permanent layer or work layer in high temperature kiln, furnace and container.

Owner:WUHAN UNIV OF SCI & TECH

Light fire resisting brick of iolite-mulbite and preparation process thereby

The invention is a iolite-mullite light fireproof brick and its preparing method, and its characteristic: using coal gangue 40.0-79.8 Wt.%, magnesia 10.0-30.0Wt.%, and iron-removed bauxite 10.0-30.0 Wt.% as main raw materials, adding in sawdust 0.02-0.2 Wt.%; adding water in water-solid ratio=0.5-0.6 in a ball mill for mixing and milling, and milling up to the screening allowance of a 44 mum-pore size sieve less than 2.0Wt.%; then throwing in a mud press to form mud cake, uniformly mixing the mud cake with organic substances: sawdust, etc, and then making extrudsion forming by a mud extruder, or manually beating or making pour forming. The crude blank is dried and then burned at 1200-14400 deg.C, and then made into iolite and mullite by solid- and liquid- phase reaction. The brick blank is cut and milled to obtain the light fireproof brick with cordierite and mullite as main crystal phase. It uses solid wastes of coal gangue and can save energy sources in burning course by using combustibles in the coal gangue, and at the same time, it is easy maintain a reducing atmosphere in the brick blank, beneficial to optimizing the product properties.

Owner:UNIV OF SCI & TECH BEIJING

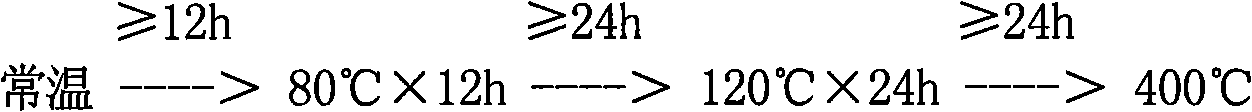

Light Al2O3-SiC-C refractory brick and preparation method thereof

The invention relates to a light Al2O3-SiC-C refractory brick and a preparation method thereof. The preparation method comprises the steps of: taking 45-65wt% of porous corundum particles, 18-25% of fine corundum powder, 4-8wt% of SiC particles, 4-8wt% of fine SiC powder, 6-12wt% of crystalline flake graphite, 1.5-2.5wt% of ganister sand and 0.2-0.6wt% of aluminite powder as materials; adding 3.5-5wt% of phenolic resin to evenly stir; and mechanically pressing and molding, carrying out heat preservation on the molded billet for 12-36 hours at 200-240 DEG C, and then carrying out heat preservation for 2-6 hours at 1400-1500 DEG C under the condition of reducing atmosphere, so as to obtain the light Al2O3-SiC-C refractory brick. The light Al2O3-SiC-C refractory brick is simple in preparation process; the prepared light Al2O3-SiC-C refractory brick not only has the characteristics of high strength, excellent thermal shock resistance, strong medium erosion resistance and low thermal conductivity, but also has the characteristics of apparent porosity and pore size controllability, and is suitable for the devices such as torpedo hot metal mixer cars, metal mixers, and ladles (tanks).

Owner:WUHAN UNIV OF SCI & TECH

Spray repair method for lining of kiln firebrick

ActiveCN101660869AExtended service lifeGood cavitation environmentLinings repairChemical industryHigh pressure

The invention mainly relates to a spray repair method for the lining of a kiln firebrick in smelting and chemical industries and the like, comprising technical processes such as scene pretreatment, spray repair, maintaining and scene heat treatment. Aiming at the damaged firebrick linings of inner walls of a roasting kiln, a sulfur kiln and a waste heat boiler in smelting and chemical industries and the like, powder-shaped high temperature fireproof material is sent to a spray pipe by directly utilizing an air compressor and an injector and then sprayed on the firebrick or a steel board needing repairing by high pressure after mixed with a certain proportion of water in a transfer piping. The method is a recovery repair technology, and is characterized in that thorough repair treatment canbe carried out on line as long as the spraying pipe can be stretched to the position needing repairing in the premise of no need for removing or bricking again; and the method has simple and effective procedure, short construction time and low repair cost, thereby effectively repairing the firebrick lining dropping from the inner part of the kiln, prolonging the service life of the kiln and guaranteeing long-term normal operation of equipment.

Owner:甘肃中顺石化工程装备有限公司

Hot-state repair method of bottom refractory brick for coke furnace carbonization chamber

InactiveCN1978590AAvoid strain cracksExtend your lifeBrickwork leakage repair/preventionCarbonizationFire brick

The invention discloses a heating repair method of the firebrick in bottom of the coke-oven charring room. The process includes: preparing the repair material, cleaning the charring room and repairing the masonry. The firebrick is selective and heated. The repairing pug is matched and kept the temperature after cleaning the charring room, last to repair the masonry above 800DEG C. The invention can avoid the firebrick crack to prolong the coke-oven life comparing to the cooling repair. The life of the repairing part can reach above 60 months by selecting the alumina brick, so it can save the cooling time and the energy.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES

Environment-friendly low-carbon magnesium carbon brick

The invention relates to an environment-friendly low-carbon magnesium carbon brick. The component ratio is counted by weight part and the processing steps are as follows: (1) crushing, grinding, magnetically separating and screening wasted carbon-containing refractory bricks being free from deteriorated layers and steel slag, thereby obtaining the waste brick grains with the grain size more than 1 mm and less than 1 mm; sending the waste brick grains being less than 1 mm to an air separating machine so as to perform air separation and obtain the light components with the average weight less than or equal to 2.4 and the heavy components with the average weight more than or equal to 2.8; (2) placing 70-90 parts of magnesium sand, 0-5 parts of carbon, 2-25 parts of heavy component, 2-5 parts of bonding agent and 0-5 parts of antioxidant into a mixing mill for mixing into a sludge material; (3) placing the sludge material into a mould, pressing and forming a magnesium carbon brick blank; and (4) roasting and curing the magnesium carbon brick blank after being formed, thereby obtaining the environment-friendly low-carbon magnesium carbon brick. In the invention, the materials with magnesium sand clinkers as main ingredients are separated from the wasted carbon-containing refractory bricks. The materials are added into the low-carbon magnesium carbon brick, so that the total porosity of the low-carbon magnesium carbon brick is reduced and the heat vibration resistance of the magnesium carbon brick is increased.

Owner:江苏苏嘉集团新材料有限公司

Iolite-mullite-andalusite thermal-shock-resistant brick and preparation method thereof

The invention relates to an iolite-mullite-andalusite thermal-shock-resistant brick, which is characterized by being basically produced by sintering the following base materials for 16 hours at a temperature of 1400 DEG C. The base materials comprise 15-42 wt% of electrofused mullite, 5-18 wt% of brown corundum, 10-32 wt% of plate corundum, 5-20 wt% of andalusite, 3-10 wt% of aluminum oxide micropowder, 5-12 wt% of iolite, and 3-6 wt% of clay; in the finished product of the thermal-shock-resistant brick, Al2O3 is not less than 60 wt%, Fe2O3 is not more than 0.4 wt%, and the sum of K2O and Na2O is not more than 0.3 wt%. According to the iolite-mullite-andalusite thermal-shock-resistant brick and the preparation method thereof, the plate corundum and the brown corundum are adopted, therefore, on basis of improvement in refractoriness under load and high temperature creep property of firebricks, the thermal-shock-resistant stability of the product is improved, and the service life of the iolite-mullite-andalusite thermal-shock-resistant brick serving as the martial of the firebricks in high-temperature-resistant ceramic burners can be obviously prolonged.

Owner:任健均

Wet process for building 3t intermediate frequency electric furnace

The invention relates to a wet process for building a 3t intermediate frequency electric furnace. By the process, 3t of materials can be melted, and the service life is prolonged. The process comprises the following steps of: (1) manufacturing a steel crucible die which has a shape of a truncated hollow cone; (2) paving an insulation layer and a thermal insulation layer by using two layers of asbestos cloth; (3) paving a furnace bottom, namely paving two layers of asbestos cloth at the furnace bottom in a staggered mode; (4) paving a furnace wall, namely paving two layers of asbestos cloth next to the inner wall of an induction coil from top to bottom, ensuring that each layer is flat and does not have any wrinkle, adhering longitudinal joints for lapping by using water glass, staggering joints of two adjacent layers, and adhering the asbestos cloth which stretches out of the upper plane to a fireproof brick plane at an upper opening of the furnace by using the water glass; (5) preparing a furnace lining material from refined quartz sand; (6) manually knotting a furnace lining, brushing a layer of water glass before filling, and tamping a filler; and (7) baking the furnace and sintering, namely baking only by using firewood after the furnace is built by the wet process, adding 50 to 60kg of firewood into a hearth for several times, and completely combusting to bake the furnace lining.

Owner:HANGZHOU ZHONGQIANG ROLLER

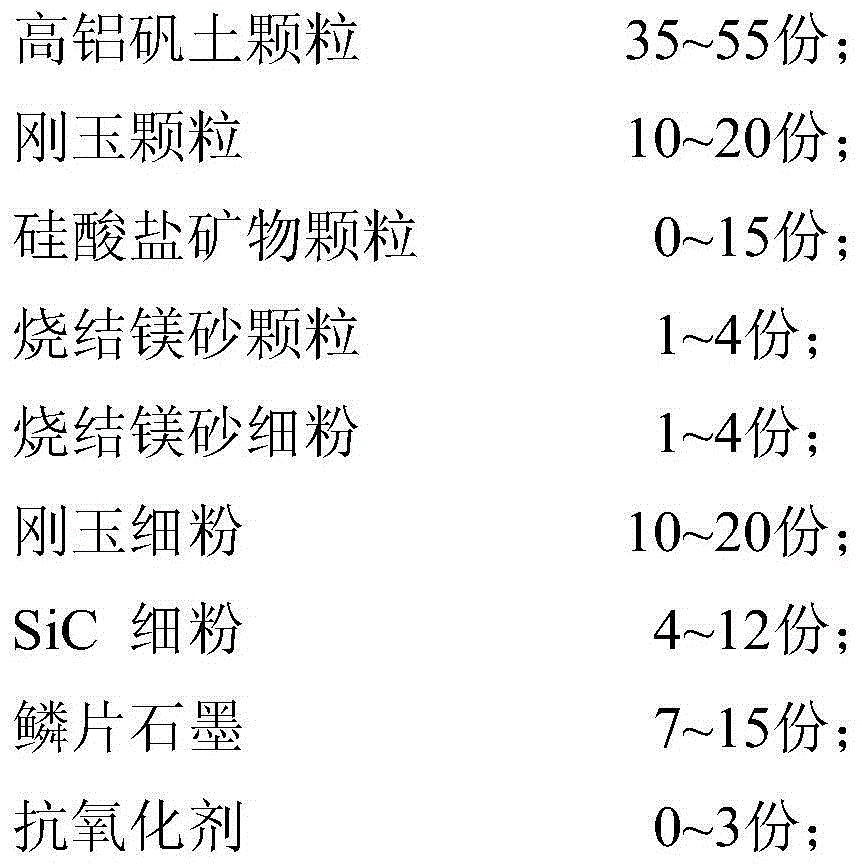

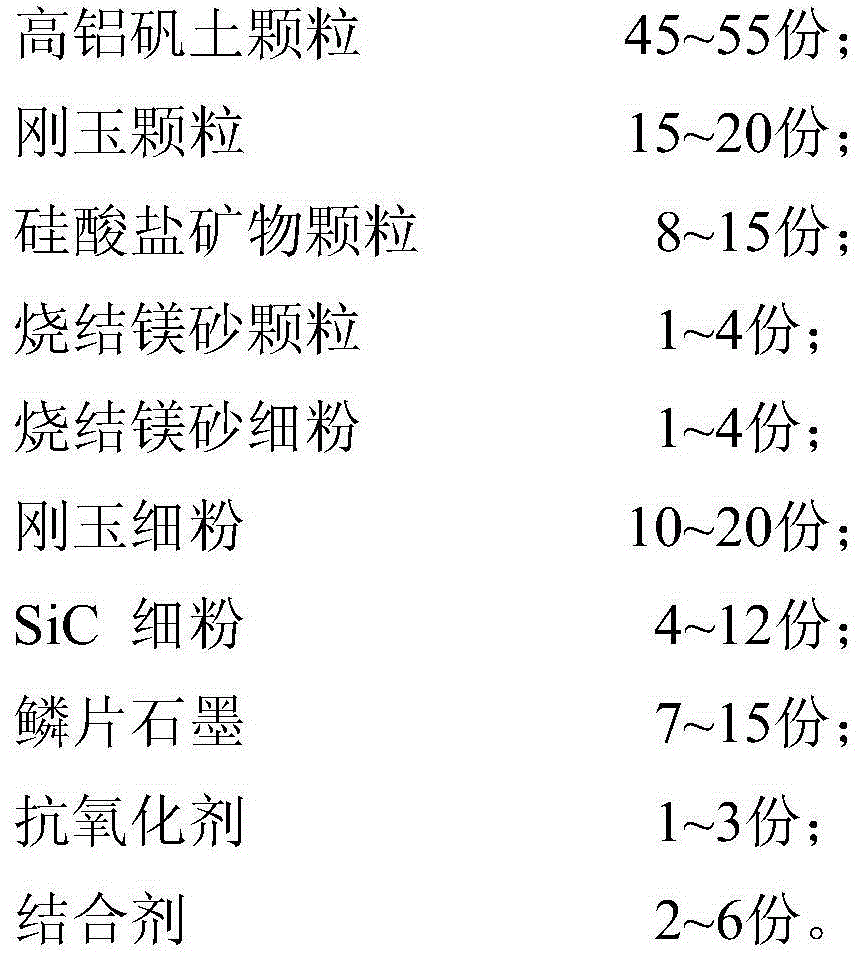

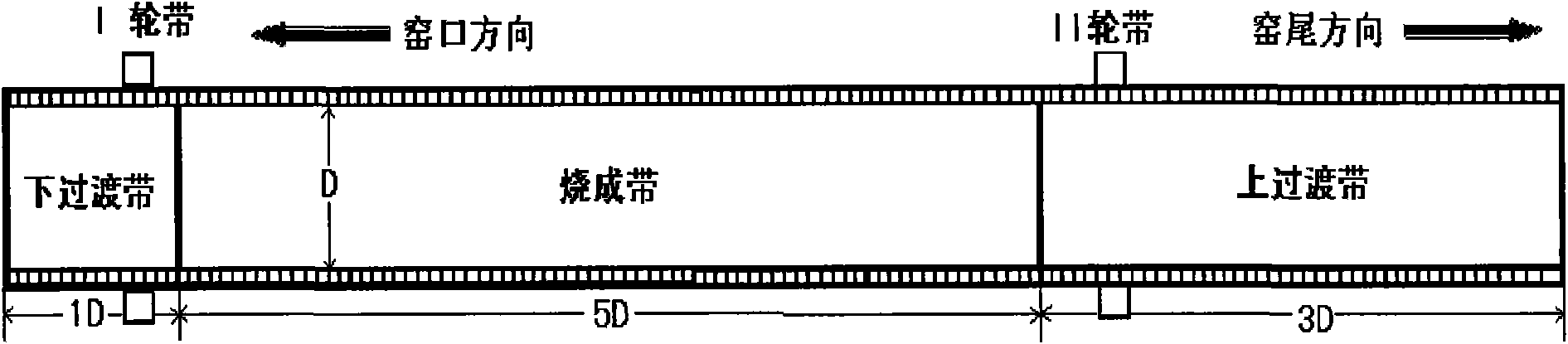

Al2O3-MgO-SiC-C brick for ladle working linings and preparation method thereof

ActiveCN104926326AReduce generationSolve the problem of melting lossOxidation resistantSilicate minerals

The invention discloses an Al2O3-MgO-SiC-C brick for ladle working linings and a preparation method thereof. The Al2O3-MgO-SiC-C brick comprises the following raw materials in parts by weight: 35-55 parts of high alumina bauxite particles, 10-20 parts of corundum particles, 0-15 parts of silicate mineral particles, 1-4 parts of magnesite clinker particles, 1-4 parts of magnesite clinker fine powder, 10-20 parts of corundum fine powder, 4-12 parts of SiC fine powder, 7-15 parts of crystalline flake graphite, 0-3 parts of an antioxidant and 2-6 parts of a binding agent. According to the preparation method, the particle size and content of magnesite clinker particles and powder in the refractory brick are set, so that on the one hand, the refractory brick is enabled to maintain a certain high temperature line expansion ratio and residual expansion ratio, and steamed bun-shaped melting loss at working lining brick joints during the using process is reduced, on the other hand, the medium-high temperature strength, properties of corrosion resistance to molten iron and molten slag and high-temperature oxidation resistance property of the refractory brick can be improved.

Owner:ZHEJIANG ZILI HIGH TEMPERATURE TECH CO LTD

Magnesia-hercynite brick used by high temperature zone of cement kiln and use method thereof

InactiveCN101613214AExtended service lifeOptimizationRotary drum furnacesAdditive ingredientPulp mill

The invention belongs to the field of refractory materials and relates to a magnesia-hercynite brick used by the high temperature zone of a cement kiln and a use method thereof. The brick is characterized in that high-quality magnesia and electric melting synthesis hercynite are taken as main raw materials which comprises the following components in percentage by weight: 40-50 percent of 3-1mm coarse magnesia, 10-15 percent of 1-0.088mm medium magnesia, 30-35 percent of fine magnesia less than 0.088mm, and 6.5-11.5 percent of 3-0mm electric melting synthesis hercynite. The raw materials after mixing are added with pulp mill waste for mixing, pressing, drying and sintering at the temperature more than 1,600 DEG C, thus obtaining the magnesia-hercynite brick. The mass percentage of the ingredients of the produced magnesia-hercynite brick is as follows: 2.5-5.5 percent of Fe2O3, 4.0-6.0 percent of Al2O3 and 93.0-89.0 percent of MgO plus other microcomponents. According to different operating situations of different cement kilns and by combining the characteristic of chrome-free brick, the invention replaces magnesite-chrome brick region by region, makes full use of the advantages and bypasses the disadvantages, improves the cost performance of the refractory brick used by the high temperature zone to the greatest extent and realizes chrome-free refractory brick used by the cement kiln.

Owner:BEIJING TONGDA REFRACTORY TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com