Method and device for controlling residual stress on stir friction welding surface

A technology of residual stress and friction stirring, applied in welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve the problems of inability to obtain weld quality, achieve the effect of avoiding the decline of welding quality, simple device, and ensuring welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

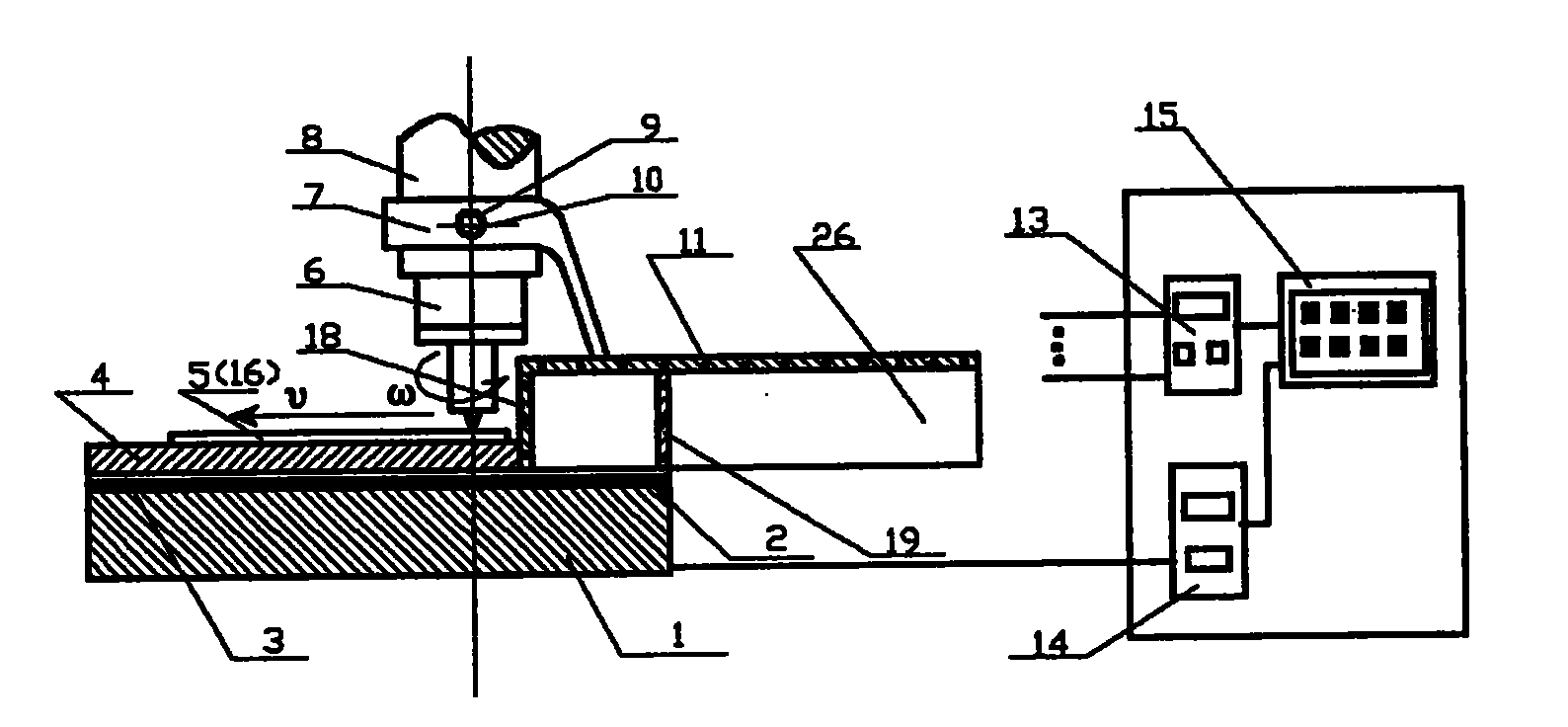

[0026] Such as figure 1 shown.

[0027] A method for controlling the surface residual stress of friction stir welding. First, an incubator that can move synchronously with the stirring head is installed on the workpiece to be welded, and an insulation layer is installed at the bottom of the fixture that fixes the workpiece to be welded as the bottom plate of the incubator. The weld cover after friction stir welding is installed in an incubator, and the temperature in the incubator is adjusted according to the length of the weld in the cover to keep it constant within the required range of heat preservation temperature. The performance of the welding material, after about 0.5-2 hours of heat preservation, it is cooled with the furnace to eliminate the surface residual stress at the weld. The specific heat preservation time can be determined by consulting the relevant material heat treatment manual. The heat preservation temperature is the heat treatment critical temperature of ...

Embodiment 2

[0029] Such as figure 1 , 2 , 3, 4 shown.

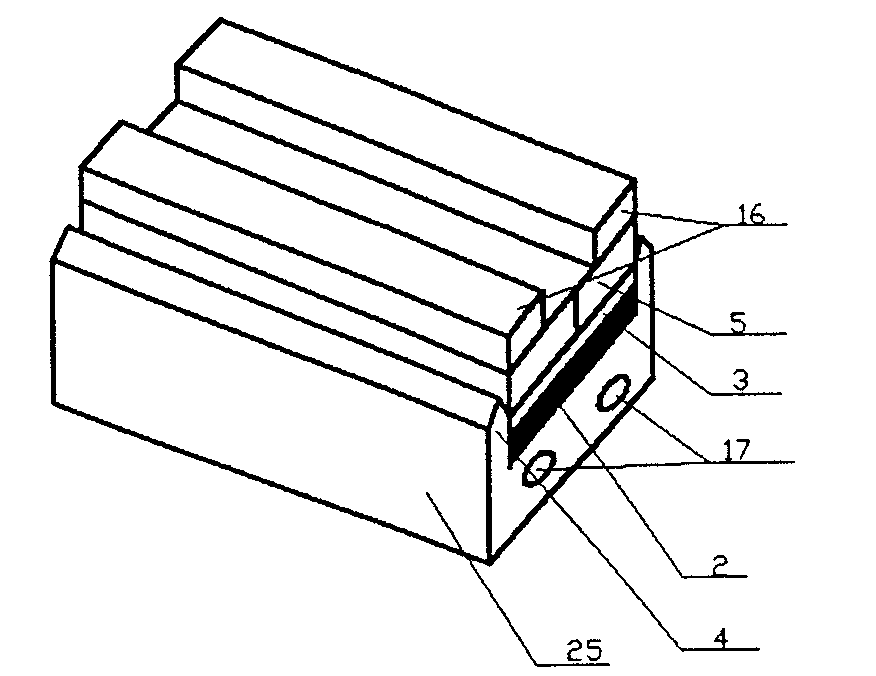

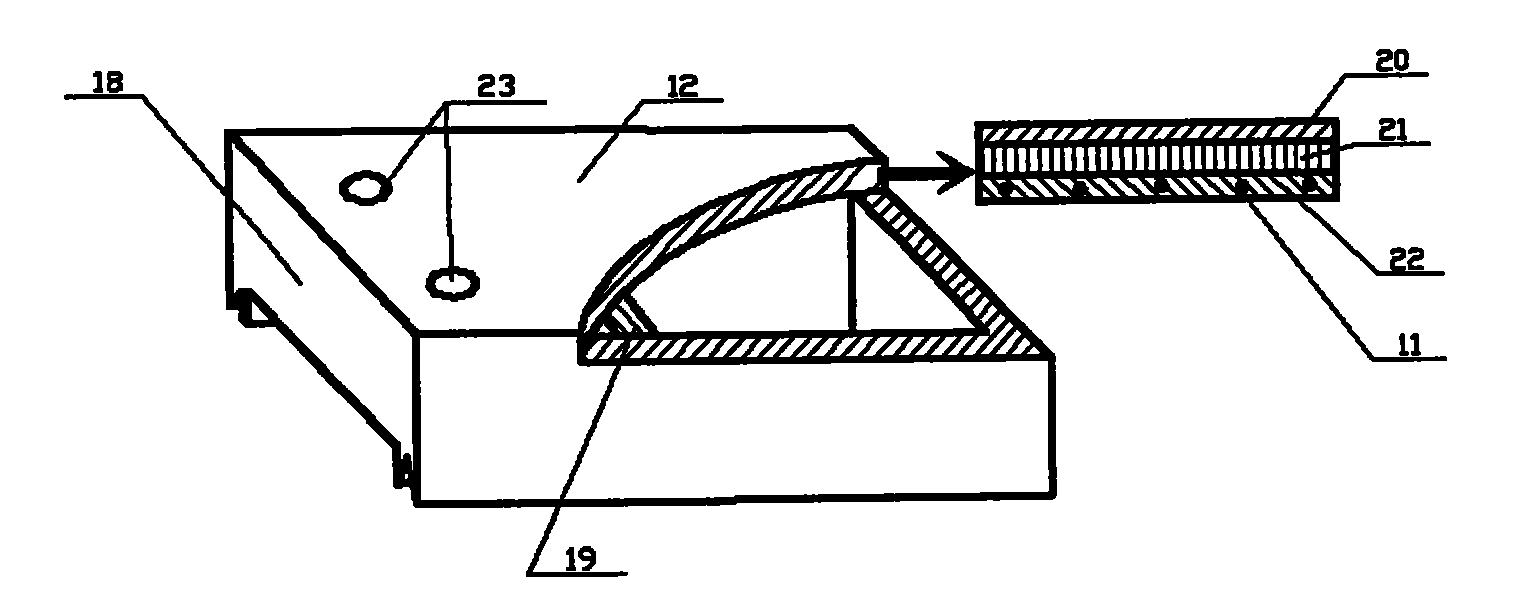

[0030] A friction stir welding surface residual stress control device, which is mainly composed of a suction cup type clamping fixture 25, an incubator 26, a fixing frame 7 and a control system, such as figure 1 As shown, the suction cup type clamping fixture 25 is mainly composed of a base 1, an asbestos heat insulation layer 2, a flat steel plate 3 and an electromagnetic pressure plate 16, as figure 2 As shown, the two sides of the base 1 extend upwards to form an incubator guide rail 4, and the asbestos heat insulation layer 2 is installed on the upper surface of the base 1 between the incubator guide rails 4 on both sides, and the flat steel plate 3 is located on the asbestos heat insulation layer 2, The welded part 5 is placed on the flat steel plate 3, the electromagnetic pressure plate 16 is respectively placed on the two welded parts 5, the base 1 is equipped with an electromagnetic block, and the electromagnetic block pas...

Embodiment 1

[0041] Choose the aluminum alloy sheet material that thickness is 10mm, carry out friction stir welding with conventional friction stir welding and adopt the device of the friction stir welding surface residual stress control method designed by the present invention respectively, the specification of two kinds of methods is the same, both are stirring The rotational speed of the head spindle is 400rpm, and the welding speed is 100mm / min. When applying the device of the present invention, the temperature of heat preservation is 450 DEG C, and the heat preservation time is 1 hour (during specific implementation, according to the difference of welding materials, the heat preservation time generally varies from 0.5-2 hours, which can be determined by consulting the heat treatment manual of relevant materials, as follows same), and then cooled with the furnace. After welding, the distribution of residual stress and residual plastic strain on the inner surface of the plate was analy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com