Patents

Literature

143results about How to "Avoid welding quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

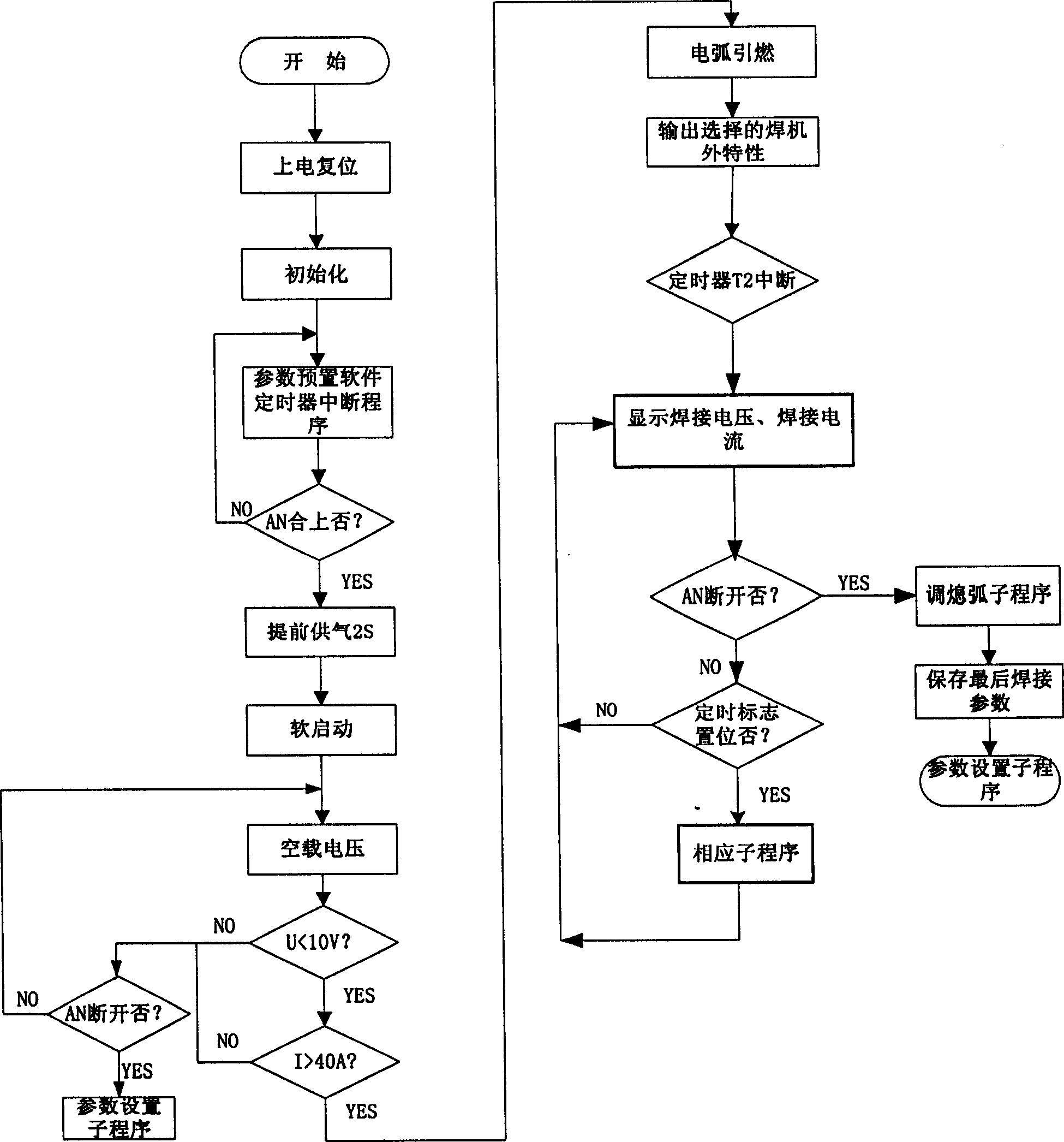

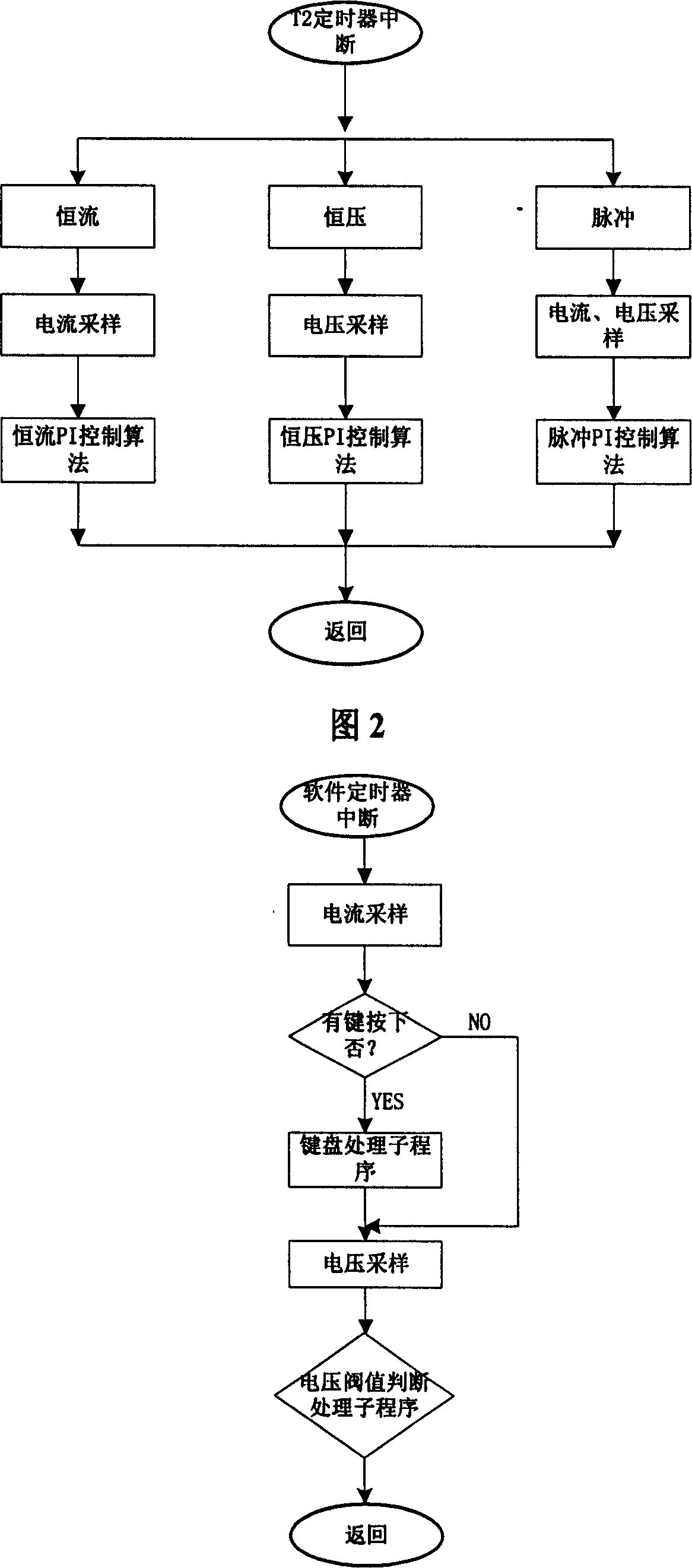

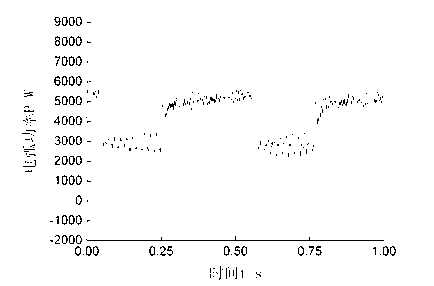

Welding machine output characteristic control method

InactiveCN1640603AAdd presetEnhance memoryArc welding apparatusNumerical controlControl theorySelf adaptive

The present invention relates to an output characteristic control method of welding machine. Said method includes the following steps: 1. preselecting correspondent welding method and presetting correspondent parameter; 2. judging that the welding operation is started or not; 3. electric arc is ignited or not; 4. judging that the welding proces is stable or not, namely, is identical to the preset parameter or not, and according to the concrete welding process adaptatively regulating welding machine output to obtain required output characteristics; and 5. judging state of welding gun with and combining welding mode, judging that the arc is blown out or not, otherwise, repeating step 4 to step 5.

Owner:SHANGHAI WTL WELDING EQUIP MFG CO LTD

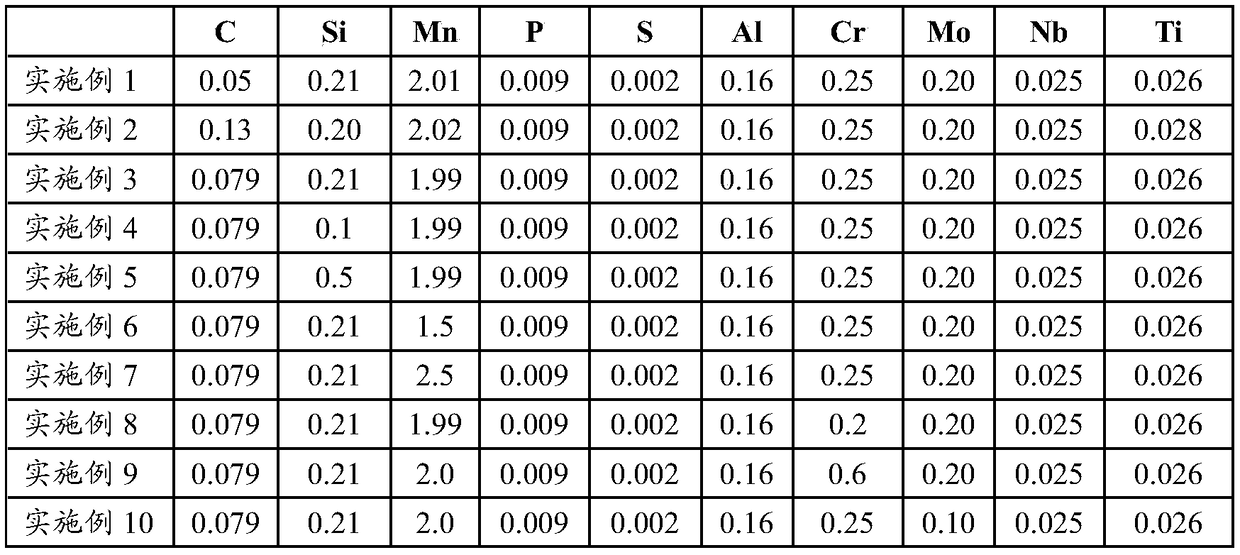

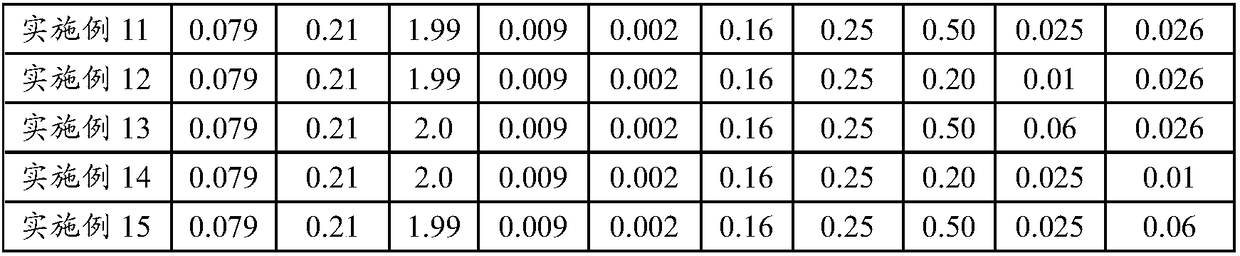

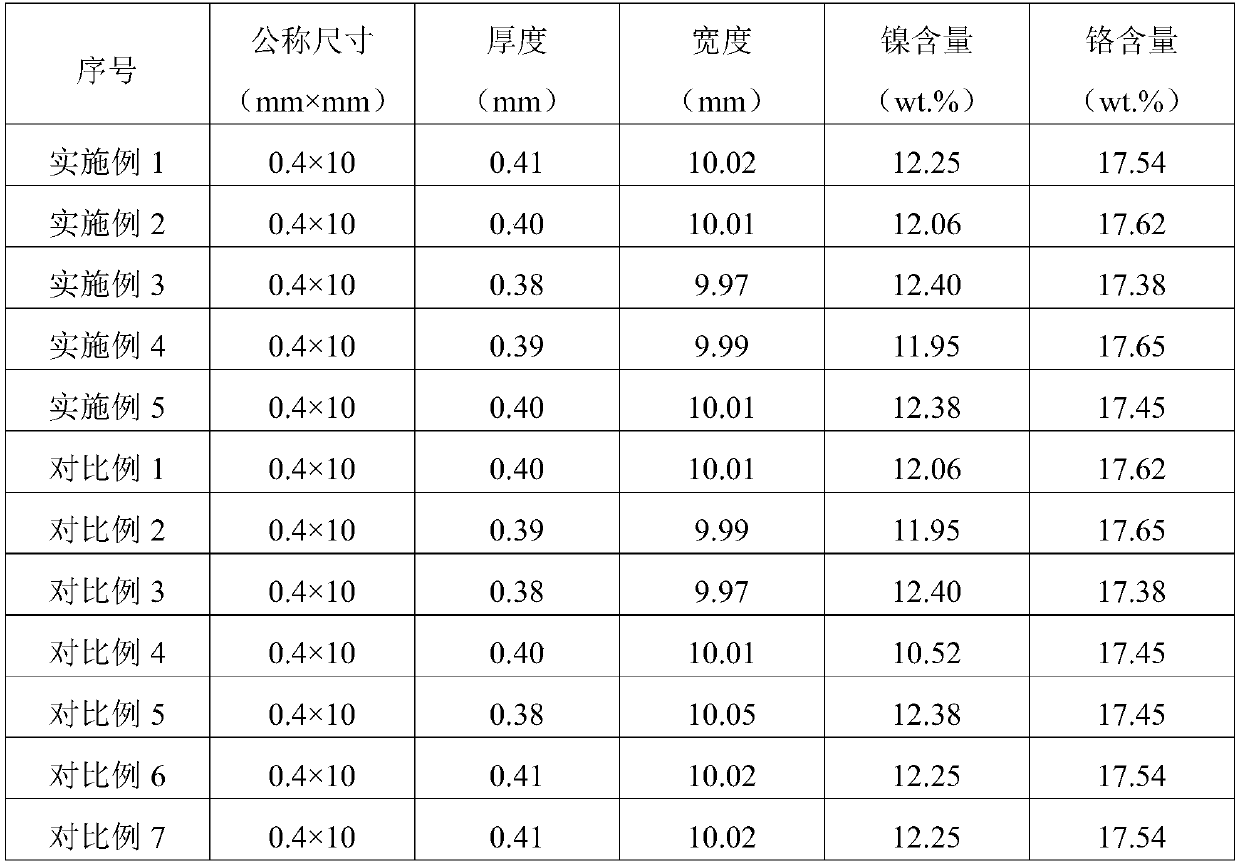

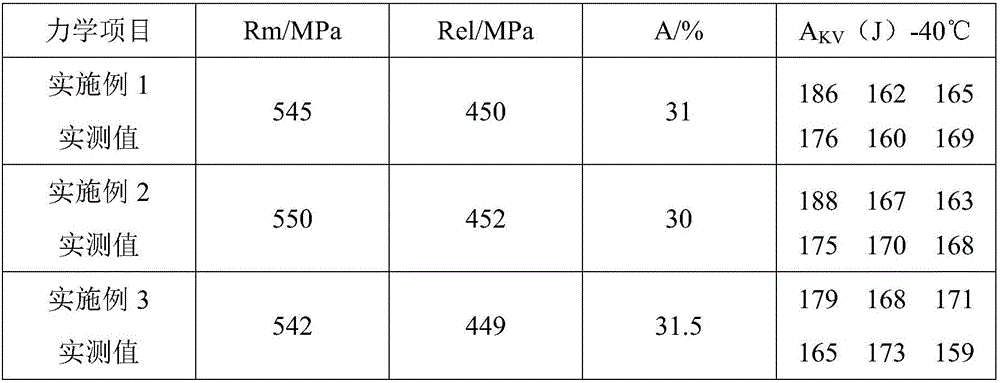

Cold-rolled hot-galvanized complex phase steel and preparation method thereof

The invention relates to a kind of cold-rolled hot-galvanized complex phase steel. Chemical components of the cold-rolled hot-galvanized complex phase steel comprise, by weight, 0.05-0.13% of C, 0.1-0.5% of Si, 1.5-2.5% of Mn, less than or equal to 0.015% of P, less than or equal to 0.015% of S, 0.1-0.6% of Al, 0.2-0.6% of Cr, 0.1-0.5% of Mo, 0.01-0.06% of Nb, 0.01-0.06% of Ti, and the balance Feand inevitable impurities. The invention further relates to a preparation method of the cold-rolled hot-galvanized complex phase steel. The preparation method comprises the following steps of castingmolten steel into a steel billet; conducting hot rolling on the steel billet to obtain a hot-rolled plate and conducting cold rolling on the hot-rolled plate to obtain a cold-hardened steel strip; conducting continuous galvanizing and annealing process treatment on the cold-hardened steel strip to obtain a finished cold-rolled hot-galvanized complex phase steel product. The bending performance ofthe cold-rolled hot-galvanized complex phase steel is improved on the basis of meeting the requirement for strength.

Owner:SHOUGANG CORPORATION

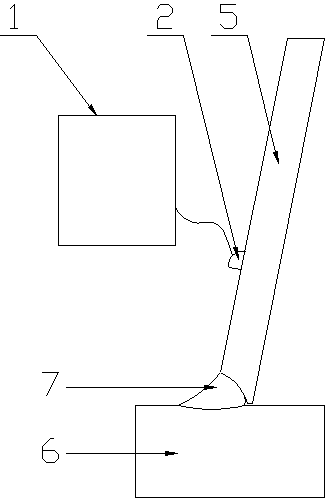

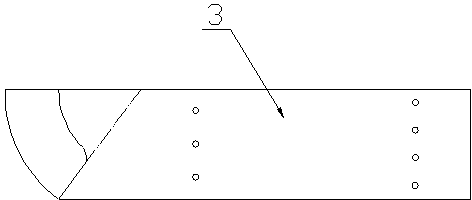

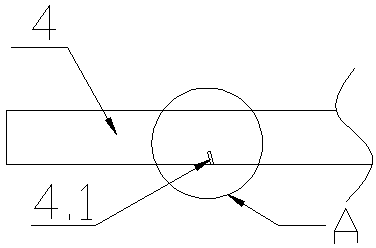

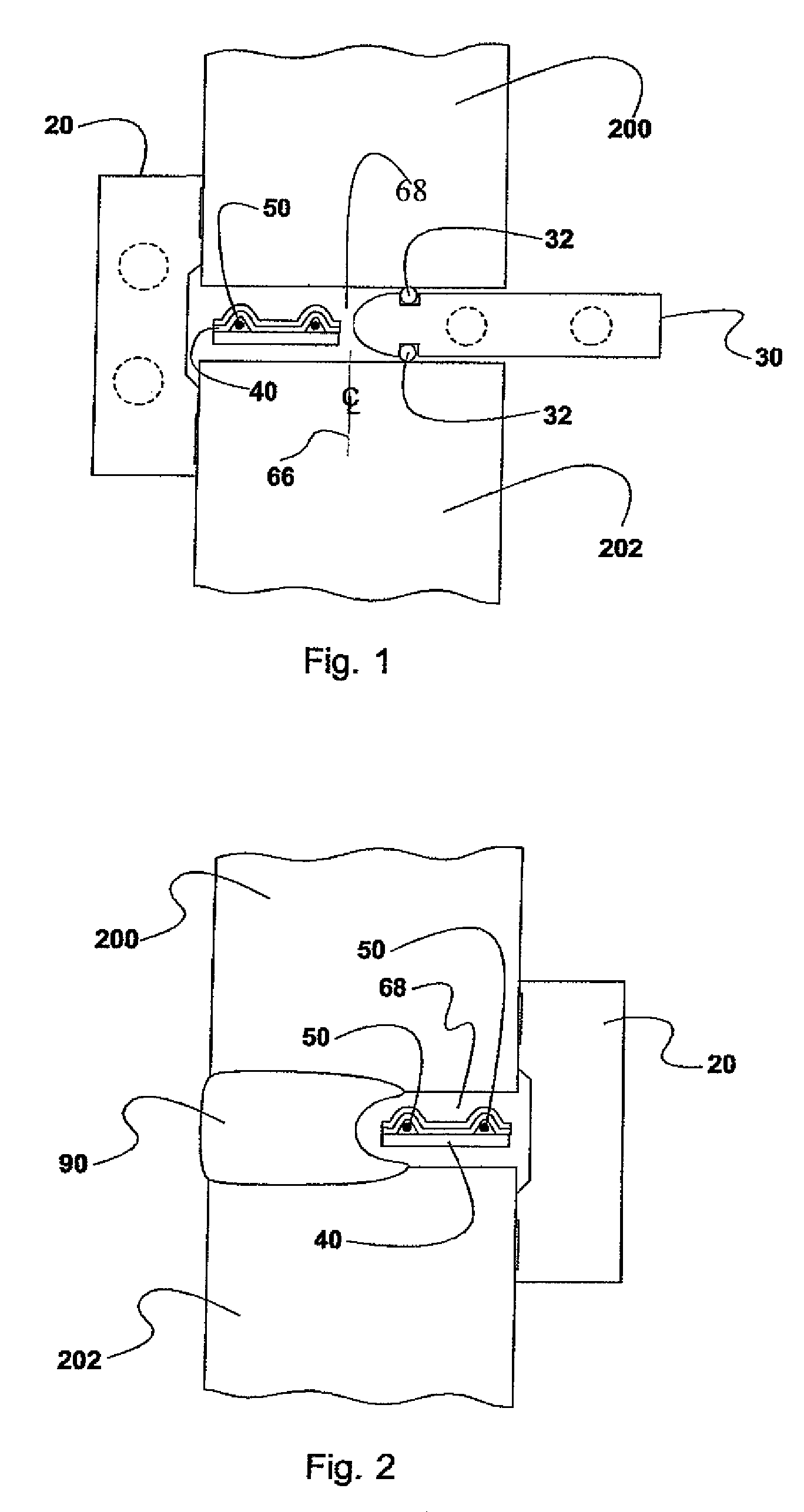

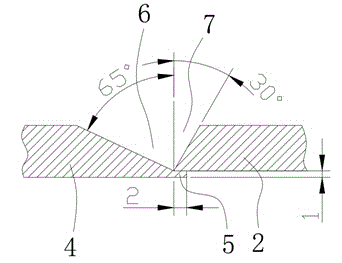

Ultrasonic phased array detection method of steel box beam U-rib angle welding seam

ActiveCN103293224ASolve penetrationResolve detectionAnalysing solids using sonic/ultrasonic/infrasonic wavesHorizonWeld seam

The invention relates to an ultrasonic phased array detection method of a steel box beam U-rib angle welding seam. A detection device of the method comprises an ultrasonic phased array detection instrument (1), a phased array probe (2), a CSK-IA test block (3), a reference block (4), a U-rib web plate (5), a panel (6) and an angle welding seam (7). The ultrasonic phased array detection method of the steel box beam U-rib angle welding seam provided by the invention comprises the following steps of: regulating the sensitivity of the equipment by utilizing the reference block, recording the horizon distance from the front end of the phased array probe to a groove, then, scratching a detection line on the U-rib web plate, and finally detecting the fusion depth and internal defect of the welding seam by adopting the phased array probe. The method provided by the invention solves the problem of detecting the fusion depth and internal defect of the steel box beam U-rib angle welding seam, and the welding quality of the steel box beam U-rib angle welding seam is effectively controlled.

Owner:JIANGSU FASTEN MATERIAL ANALYSIS & INSPECTION

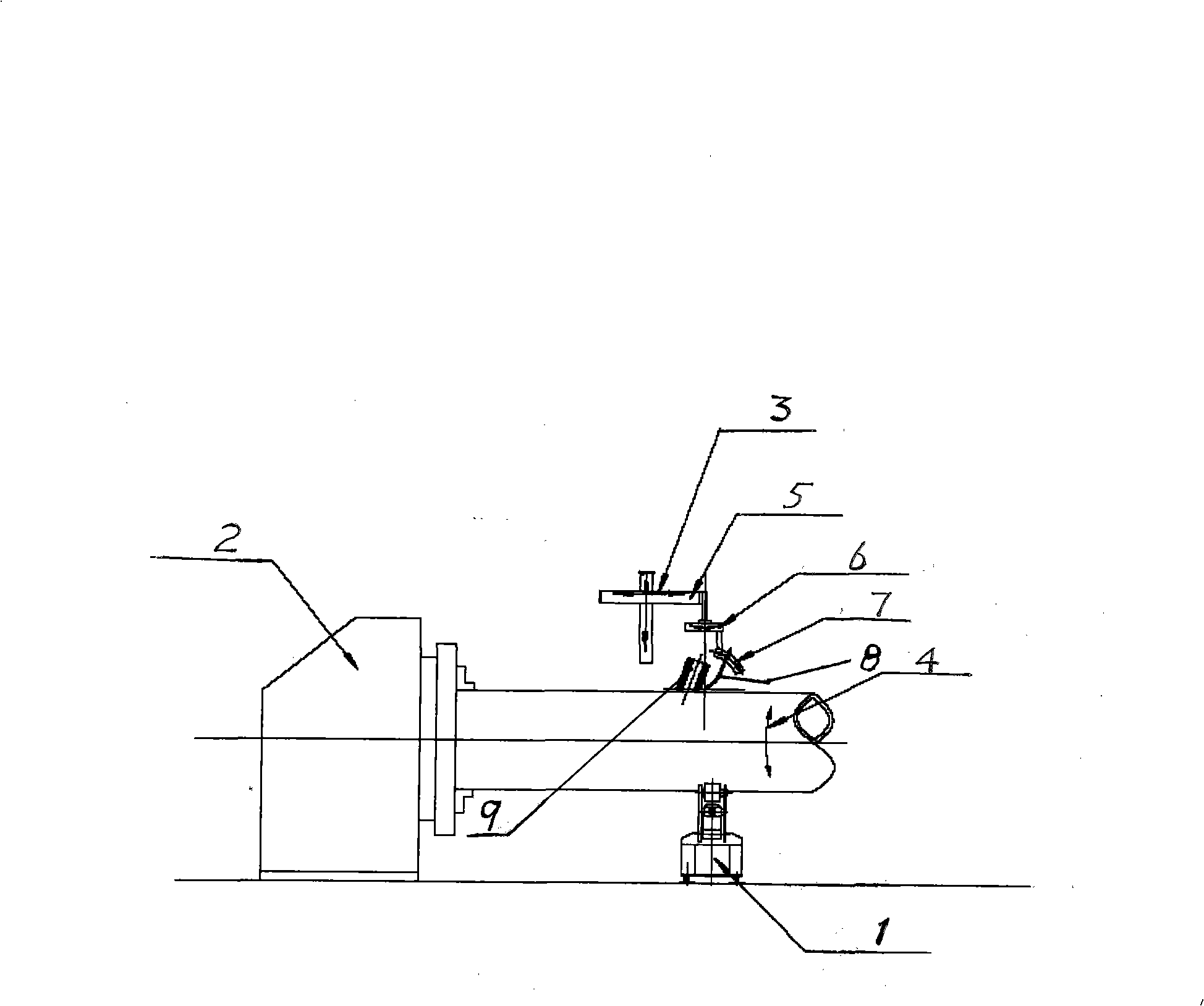

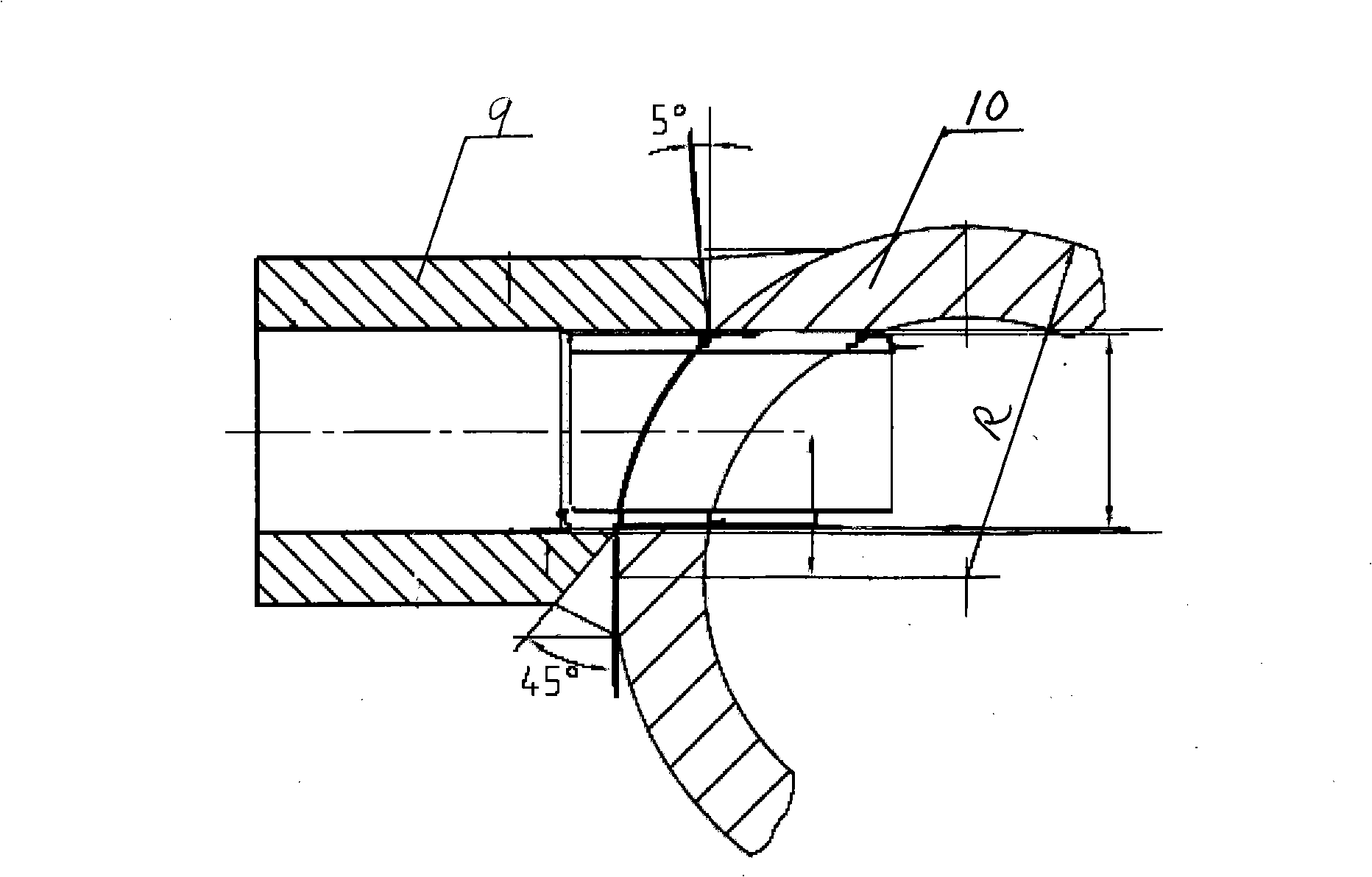

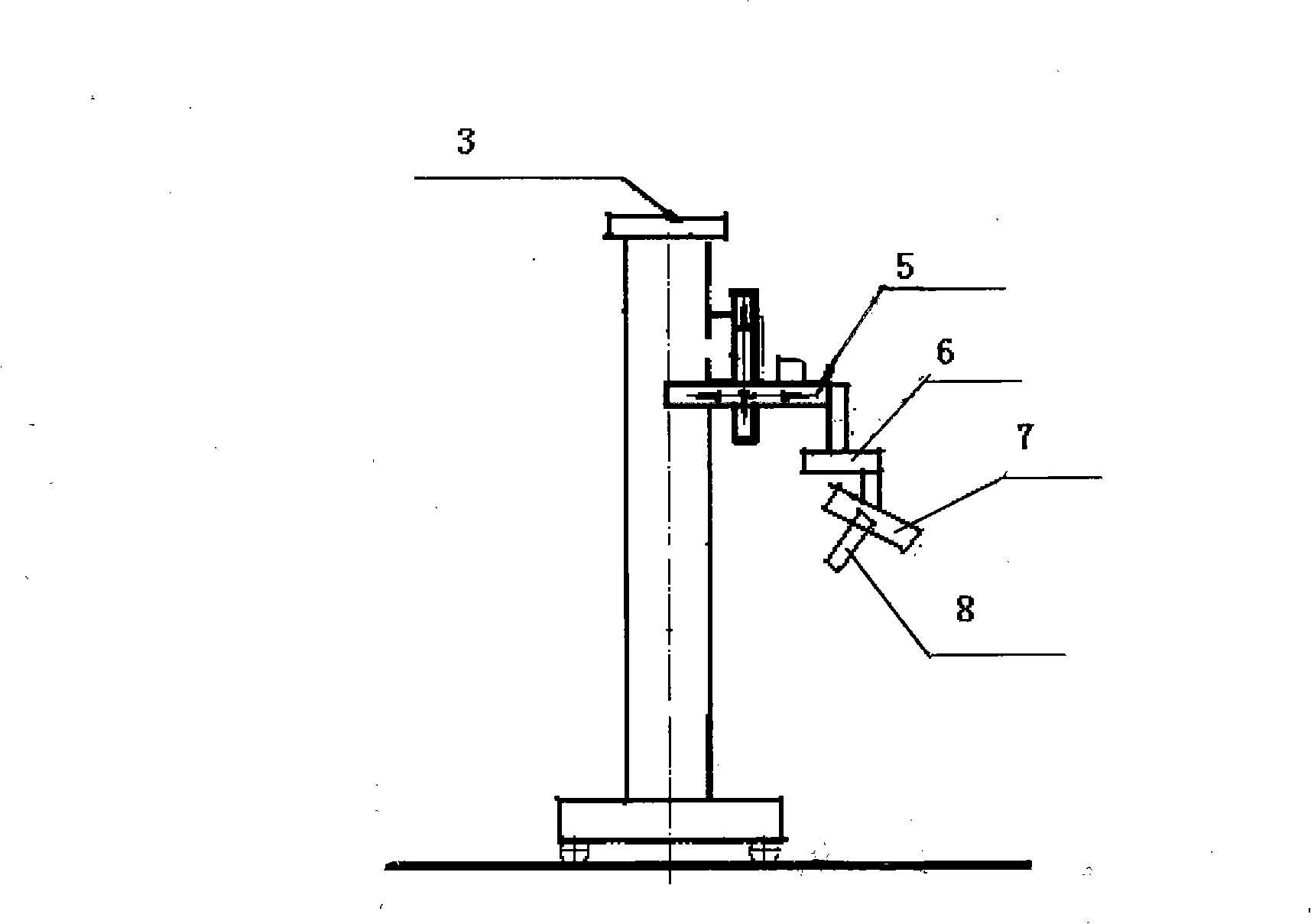

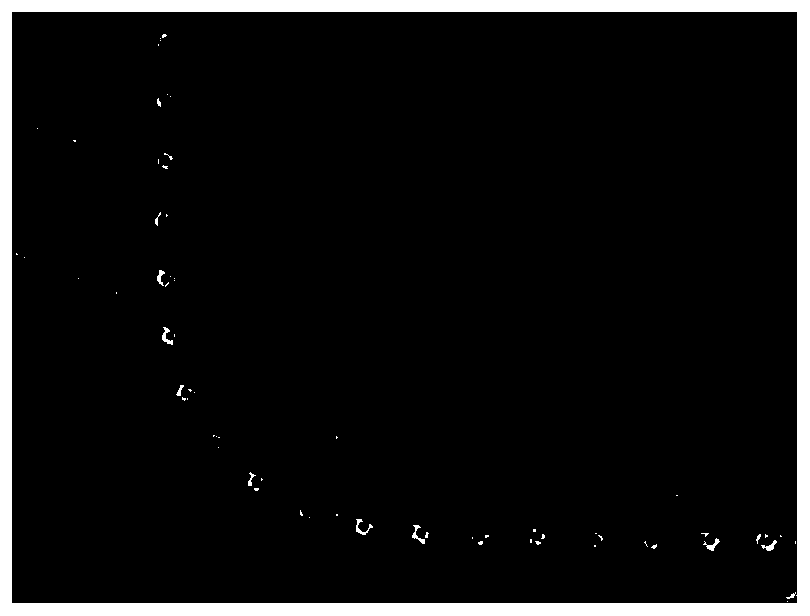

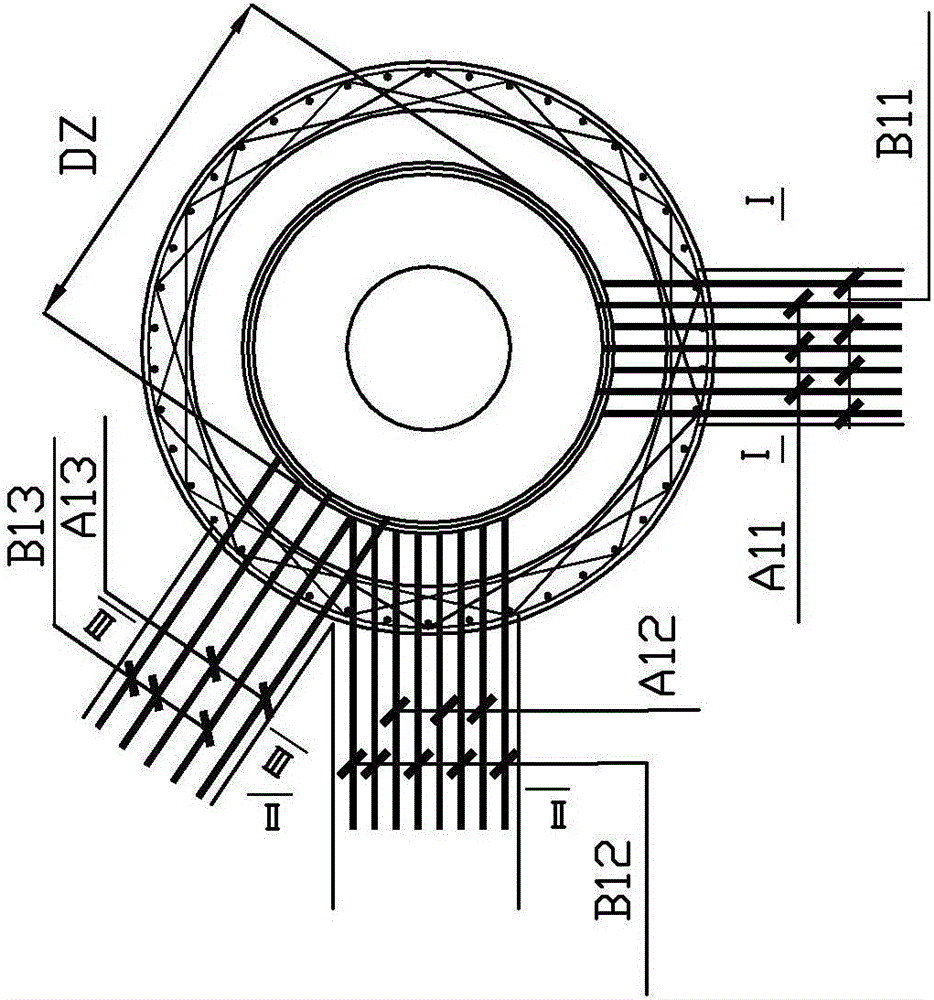

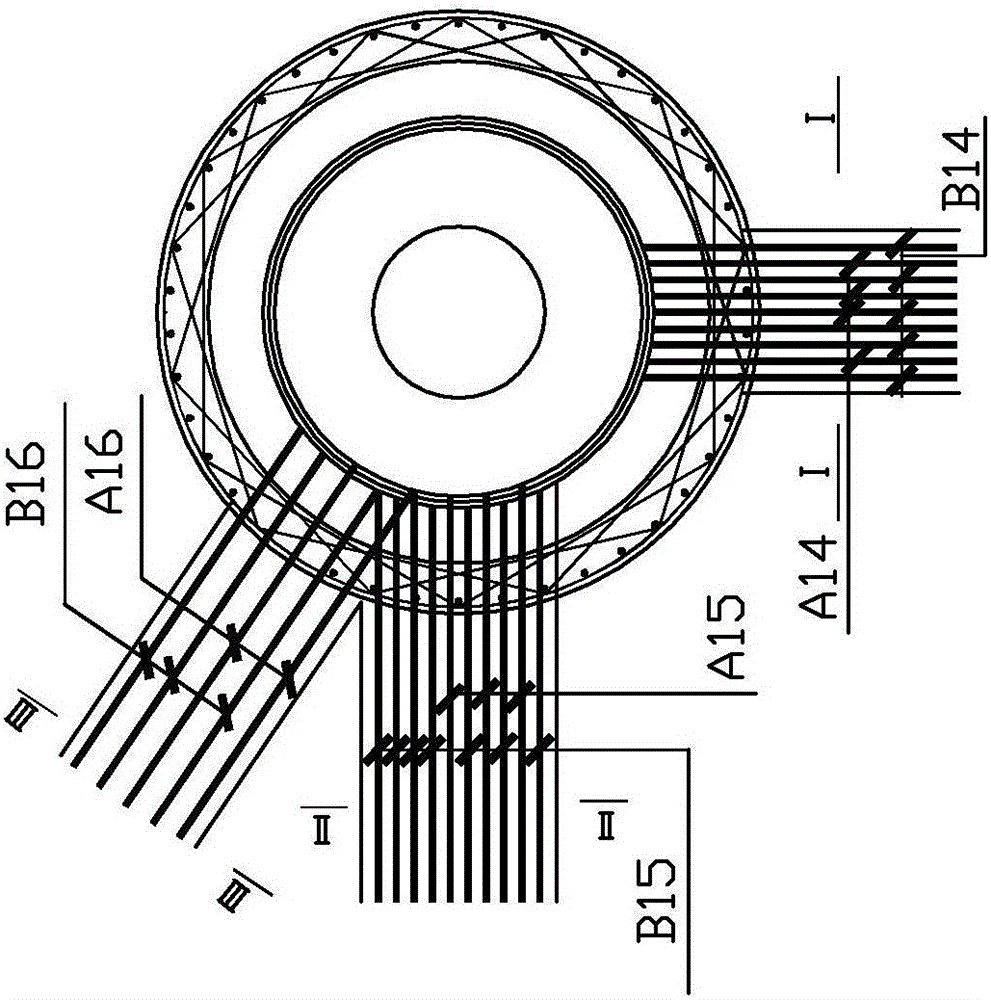

Automatic welding process of skewed tube fillet of boiler separator

ActiveCN101310909AGuaranteed matchRealize automatic submerged arc weldingArc welding apparatusNumerical controlEngineering

The invention relates to a submerged arc welding technology of an eccentric oblique crossing tube on a separator, which is characterized in that the technology of the invention includes the steps that one end of the separator is placed on a driven turning roll while the other end of the separator is clamped by a numerical control positioner; the processed eccentric oblique crossing tube and the separator are fixed at melting points; a welding device is moved to the welding part of the eccentric oblique crossing tube on the separator; a welding gun of the welding device is aligned with the position to be welded and the welding device is started so that the numerical control positioner rotates the separator; the synchronous displacement of the welding device coordinates with the synchronous interlinking of the welding gun of the welding device and the numerical control positioner, which leads to that the position to be welded of the eccentric oblique crossing tube is always at the horizontal position required by the submerged arc welding technology so as to realize the continuous automatic welding. The submerged arc welding technology of the invention has the advantages of significantly enhancing the productivity and welding quality, reducing the labor intensity and improving the working conditions.

Owner:SHANGHAI BOILER WORKS

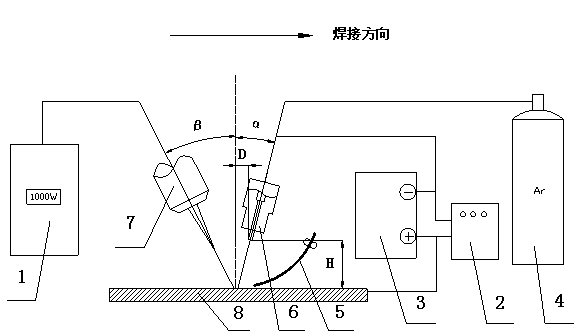

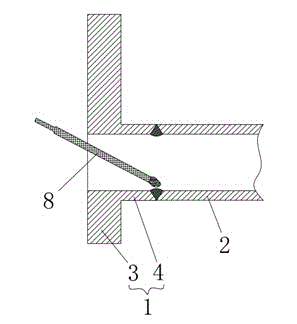

Laser high-frequency alternating-current pulse tungsten inert gas (TIG) hybrid welding process

InactiveCN103192187AGood compound effectReduce laser powerWelding/soldering/cutting articlesLaser beam welding apparatusAnti stressMolten bath

The invention discloses a laser high-frequency alternating-current pulse tungsten inert gas (TIG) hybrid welding process. The process comprises the following steps of: constructing a laser high-frequency alternating-current pulse TIG hybrid welding system, and gathering an TIG arc and a semiconductor laser beam on the same welding position of a welded workpiece 8 in the same welding direction, to form a molten bath, wherein an inclined angle alpha of 10-40 degrees is formed between the TIG arc tungsten electrode tip end and a vertical direction, the semiconductor laser beam forms an included angle beta of 10-30 degrees with the vertical direction, the TIG arc tungsten electrode tip end keeps a vertical distance H of 2-4mm with the surface of the welded workpiece 8, and the TIG arc tungsten electrode tip end and the semiconductor laser beam keep a horizontal distance D of 2-5mm with an action point of the surface of the welded workpiece 8. The process disclosed by the invention can refine weld microstructure, remarkably reduce or eliminate pores in melting area and effectively improve mechanical performance and anti-stress corrosion performance of a high-strength aluminous alloy welding joint, and the process is quite practical.

Owner:SICHUAN AEROSPACE LONG MARCH EQUIP MFG CO LTD

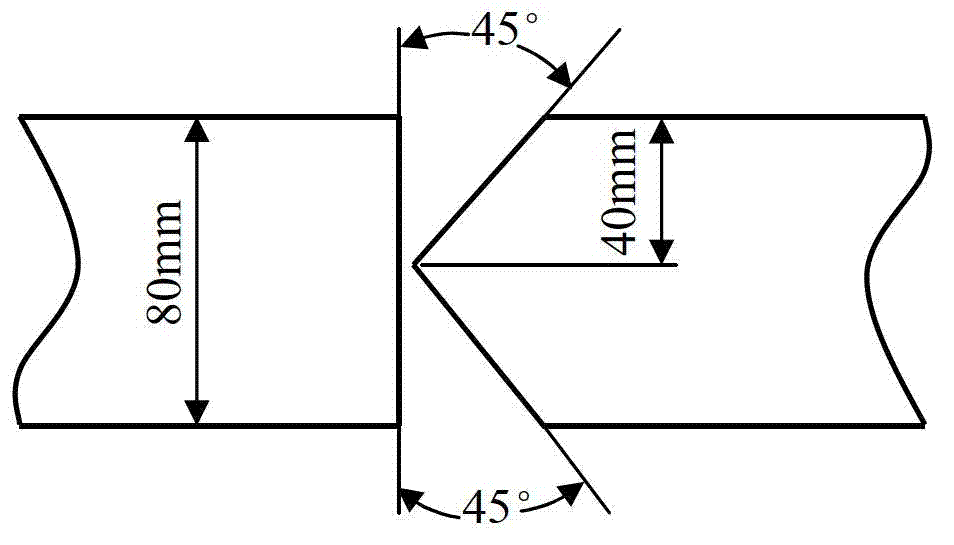

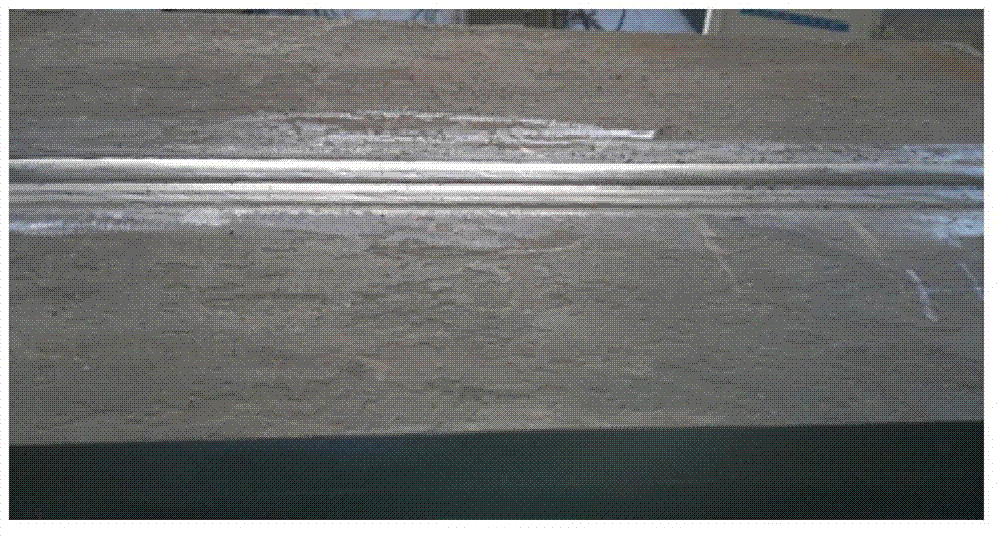

Submerged arc welding method for K-shaped groove of 80mm extra-thick steel plate with excellent plate shape after welding

InactiveCN102922103AReduce peak residual stressOffset deformationArc welding apparatusWorkpiece edge portionsResidual deformationMixed gas

Owner:NANJING IRON & STEEL CO LTD

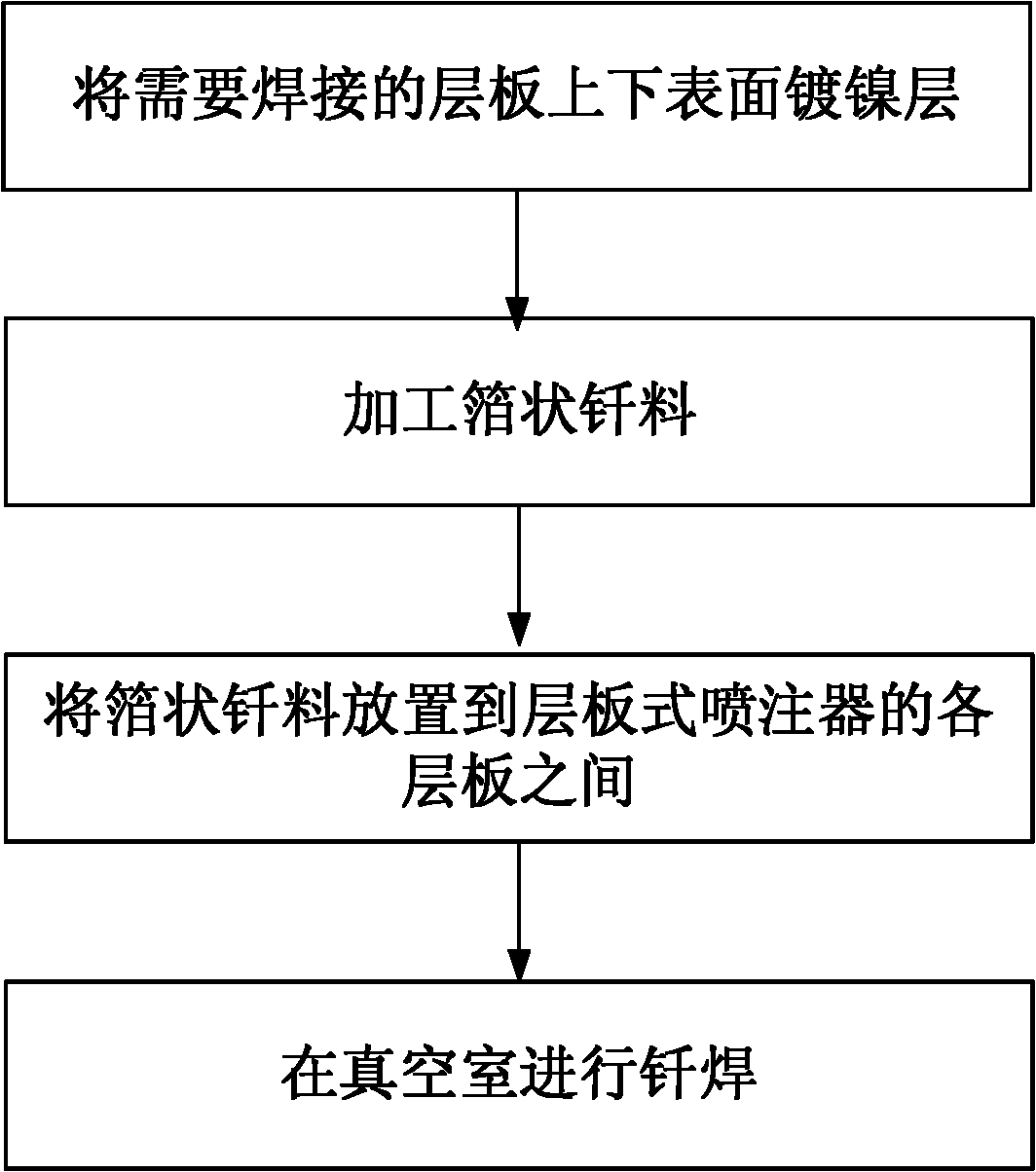

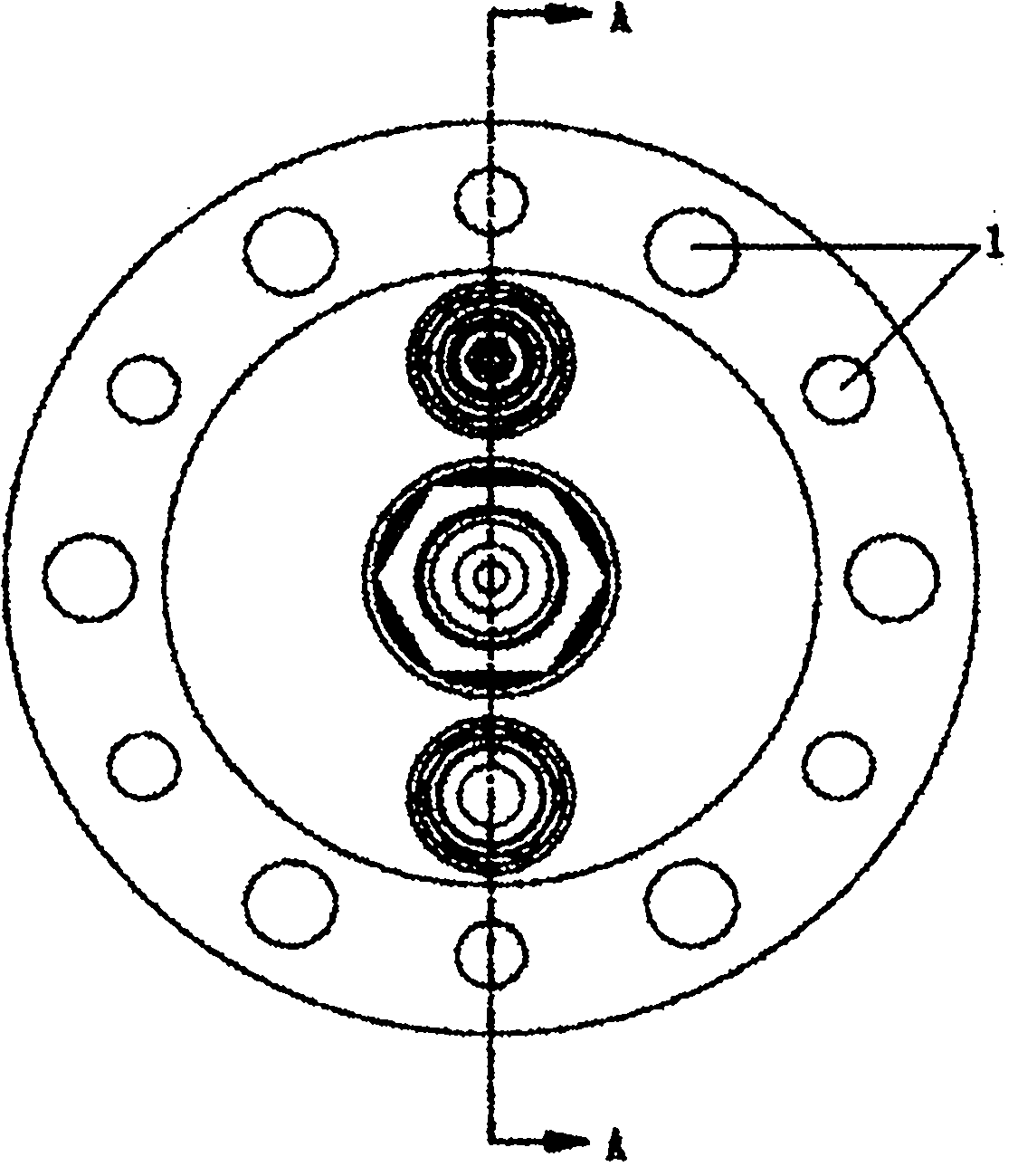

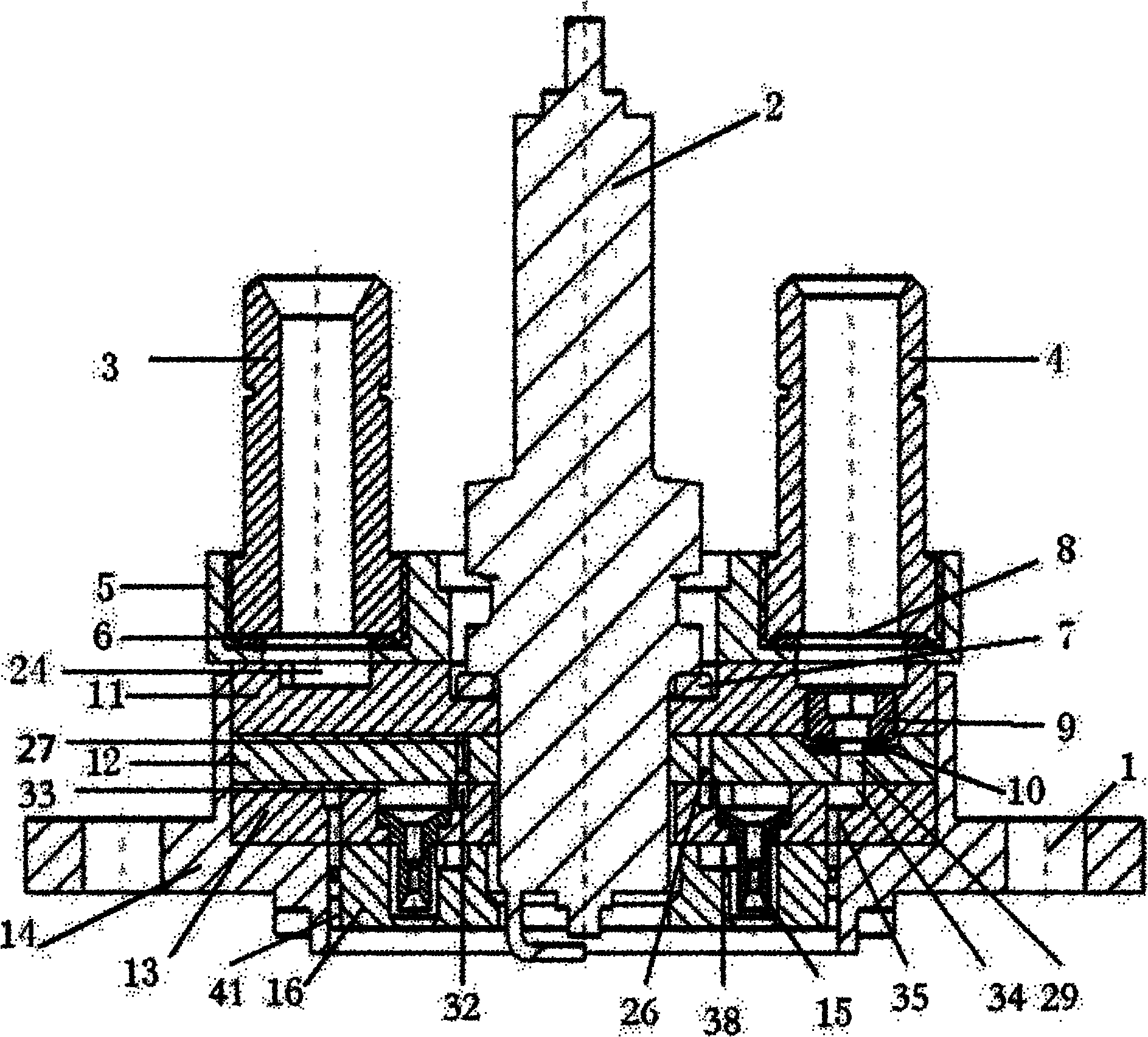

Soldering preparation method for stainless steel laminate type inspirator

InactiveCN102179586AReduce brazing temperatureRelieve pressureWelding/cutting media/materialsSoldering mediaInspiratorFiller metal

The invention provides a soldering preparation method for a stainless steel laminate type inspirator. The method comprises the following steps of: 1, plating nickel layers on the upper and lower surfaces of each laminate required to be soldered of a laminate type inspirator to be soldered; 2, machining a foil-shaped brazing filler metal according to the shapes of two adjacent layers in the laminate type inspirator; 3, placing the foil-shaped brazing filler metal between laminate parts of the laminate type inspirator; and 4, placing the laminate type inspirator into a vacuum chamber, heating and pressurizing to perform soldering. By the method, the technical problem of plastic deformation of a hole and a circulation channel between the surfaces of laminates due to overhigh temperatures andpressure in the soldering preparation process in the prior art is successfully solved by controlling the thickness and the process parameters of the brazing filler metal. In the invention, a stainless steel laminate is well dampened by the brazing filler metal, so that the probability of soldering quality problems caused by non-uniform pressure existing in the diffusion soldering process can be reduced.

Owner:BEIHANG UNIV

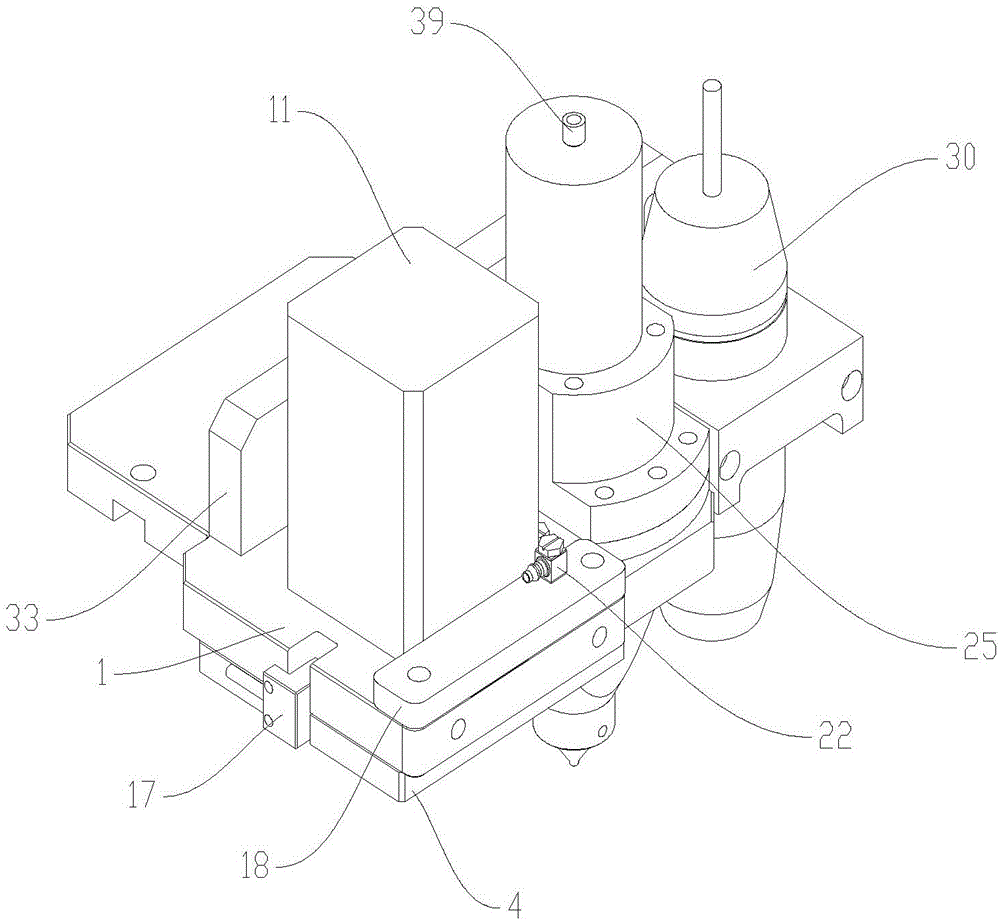

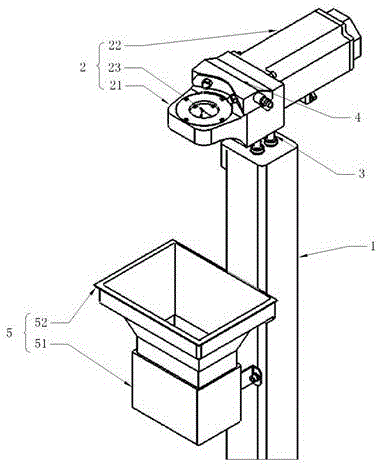

Welding device for ball type welding flux

ActiveCN104588812AAvoid Solder Quantity DeviationAvoid influenceMetal working apparatusSolder feeding devicesEngineeringLaser

The invention relates to the technical field of laser welding, in particular to a welding device for ball type welding flux. The invention discloses the welding device for the ball type welding flux. The welding device for the ball type welding flux comprises a material cabin part, a transmission part, a welding flux detection part, a welding part and a bottom plate, wherein the material cabin part is used for storing the ball type welding flux; the transmission part is connected with the material cabin part and is used for taking the ball type welding flux from the material cabin part and conveying the ball type welding flux to the welding flux detection part and the welding part; the welding flux detection part is used for detecting whether the conveying part conveys the ball type welding flux or not; the welding part is used for receiving the ball type welding flux conveyed by the conveying part and executing the welding operation; the bottom plate is used for fixing the material cabin part, the conveying part, the welding flux detection part and the welding part. The welding device has the advantages that the integration of the storage, the conveyance, the detection and the welding of the ball type welding flux is realized, and the operation of the welding device in an automatic way is realized.

Owner:GOERTEK INC

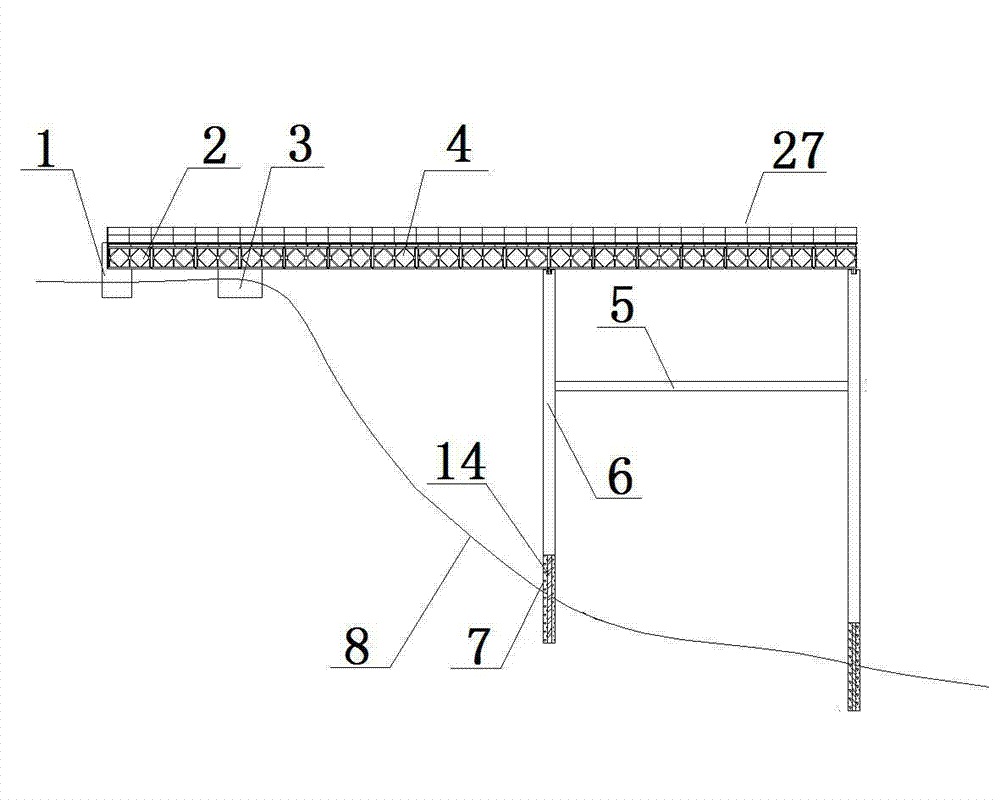

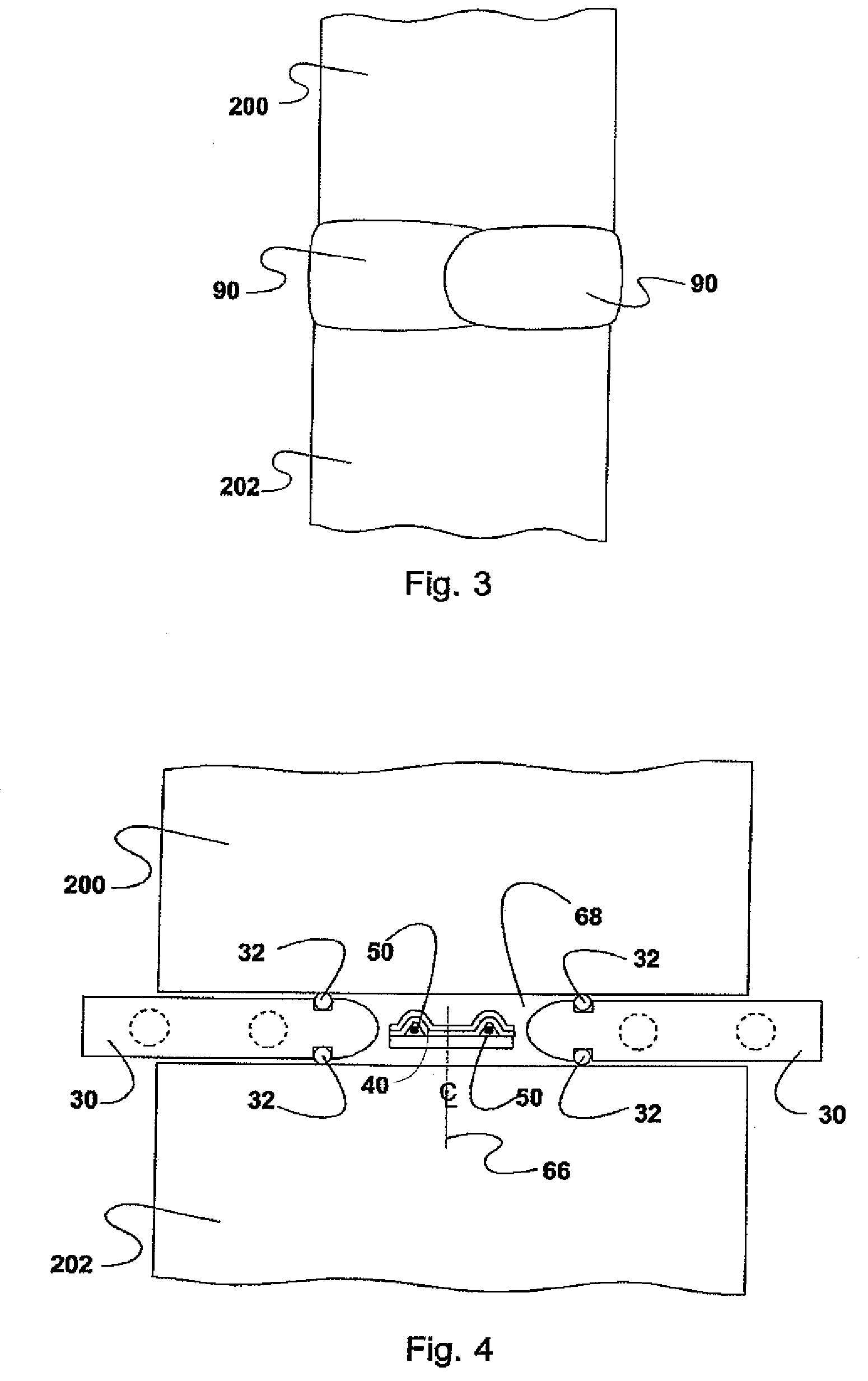

Overhead trestle structure built on non-covering steep bare rocks in deep rapids

ActiveCN102953341AControl verticalityAvoid welding qualityBridge erection/assemblyBulkheads/pilesBedrockEngineering

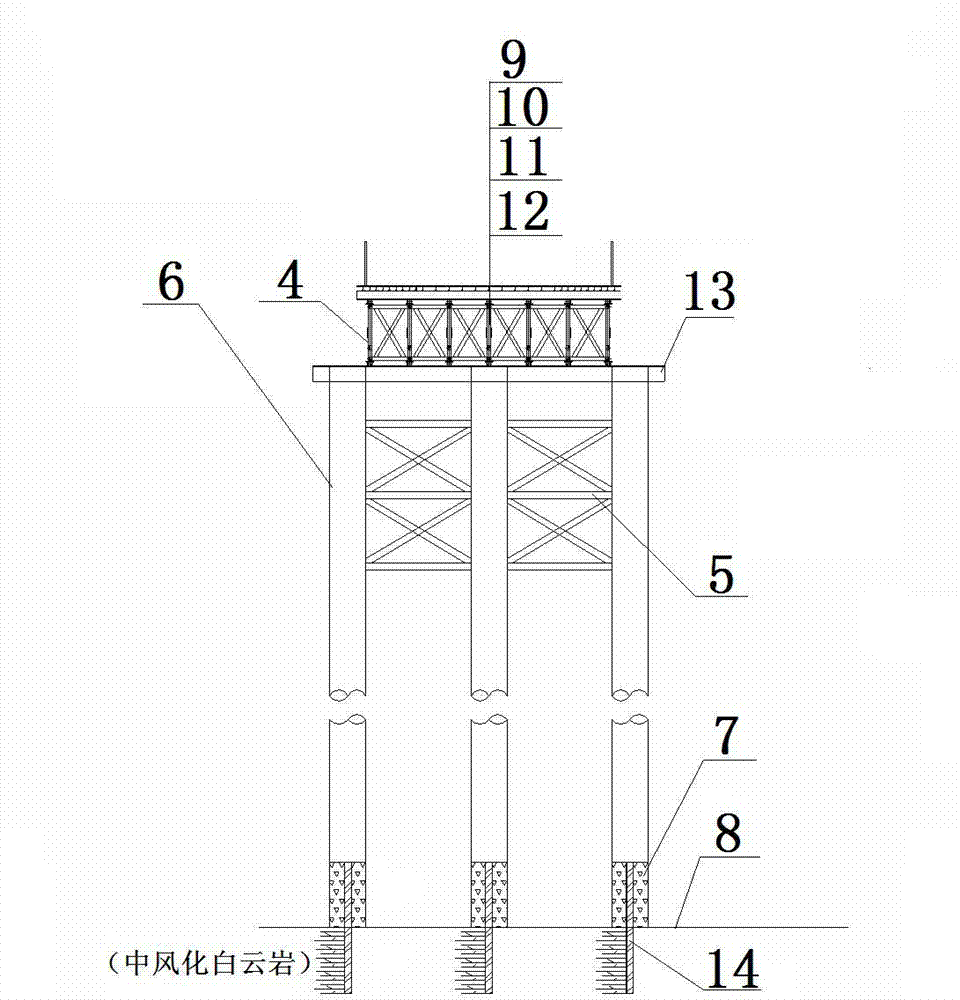

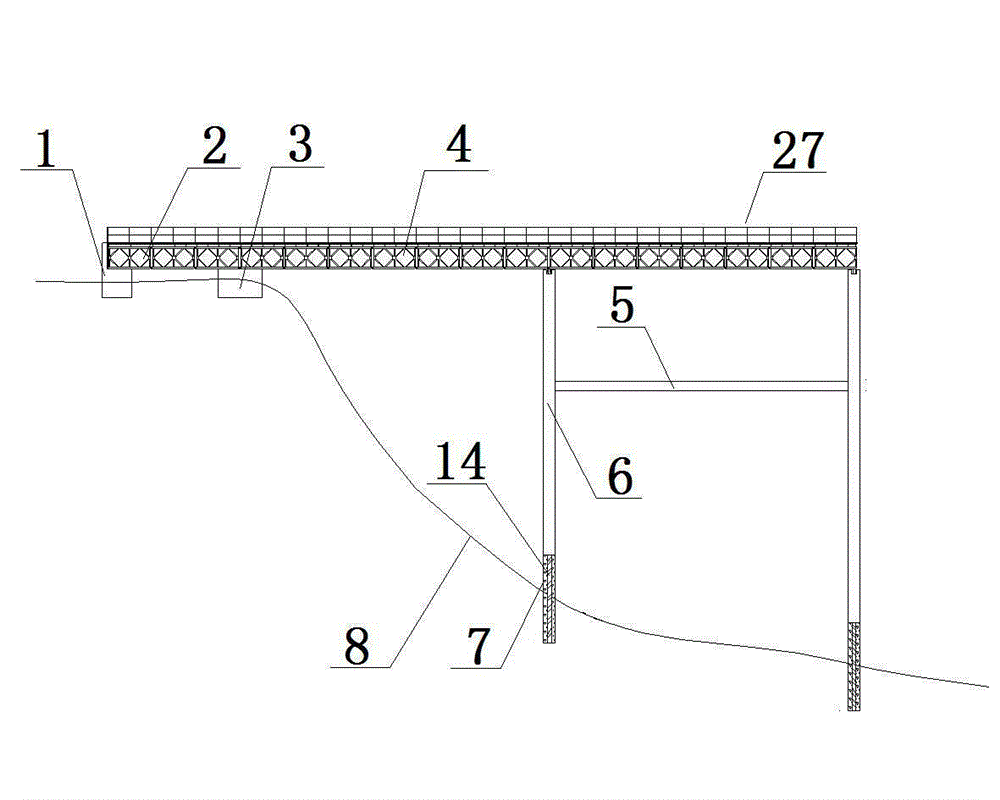

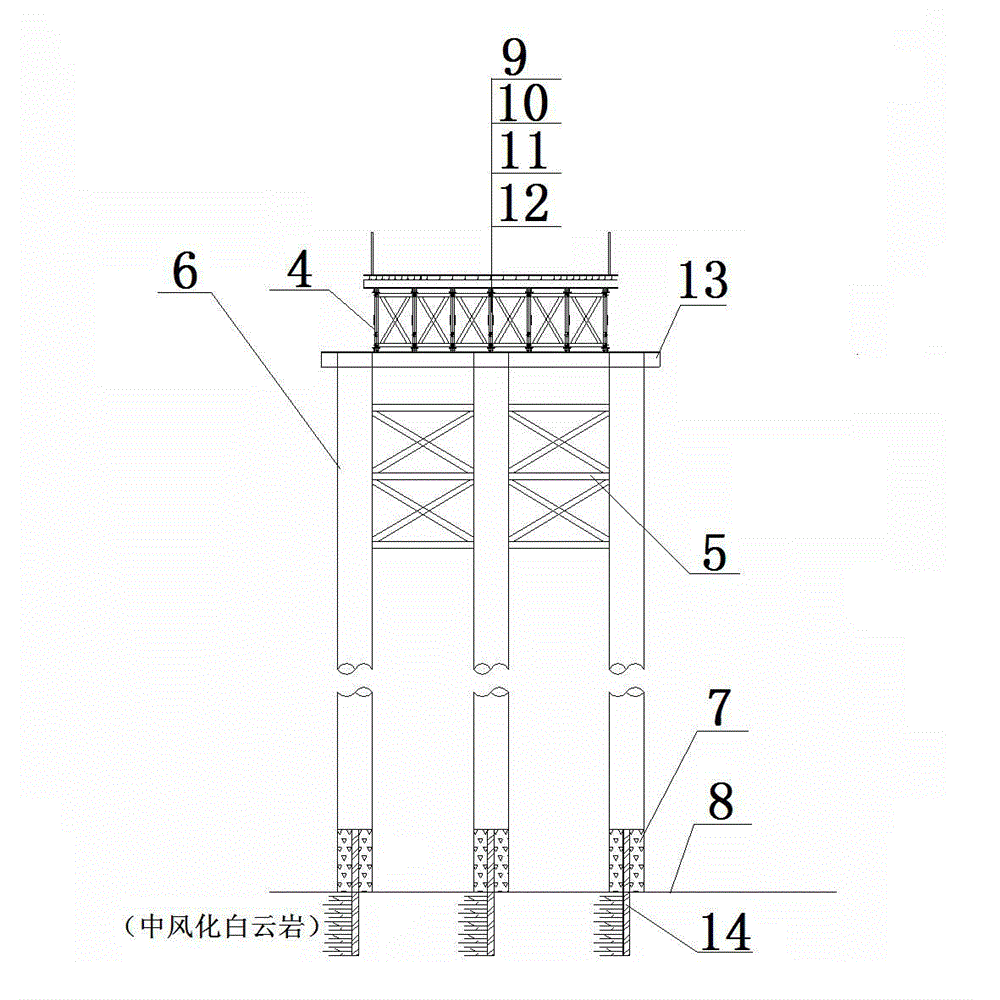

The invention belongs to the field of bridge construction and particularly relates to an overhead trestle structure built on non-covering steep bare rocks in deep rapids. The invention adopts the technical scheme that the overhead trestle specifically comprises a trestle body and steel pipe piles for supporting the trestle body, wherein the steel pipe piles are arranged on the surfaces of the steep bare rocks, bottom cavities of the steel pipe piles are connected and anchored with the steep bare rocks by anchor rods in a connected way, and the steel pipe piles, the steep bare rocks and the anchor rods are fixedly connected into an integral structure by a poured underwater concrete layer. The overhead trestle structure has the advantages that the steel pipe piles are connected with the surfaces of the steep bare rocks by a grouted and rock-socketed anchor rod structure, so that the steel pipe piles are firmly anchored to the surfaces of the steep bare rocks by the holding force of underwater concrete pulp andwith the holding force of the anchor rods, pile bottom concrete and river bed rocks; and the construction has a short period, is at a low cost and is safe and efficient.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD +1

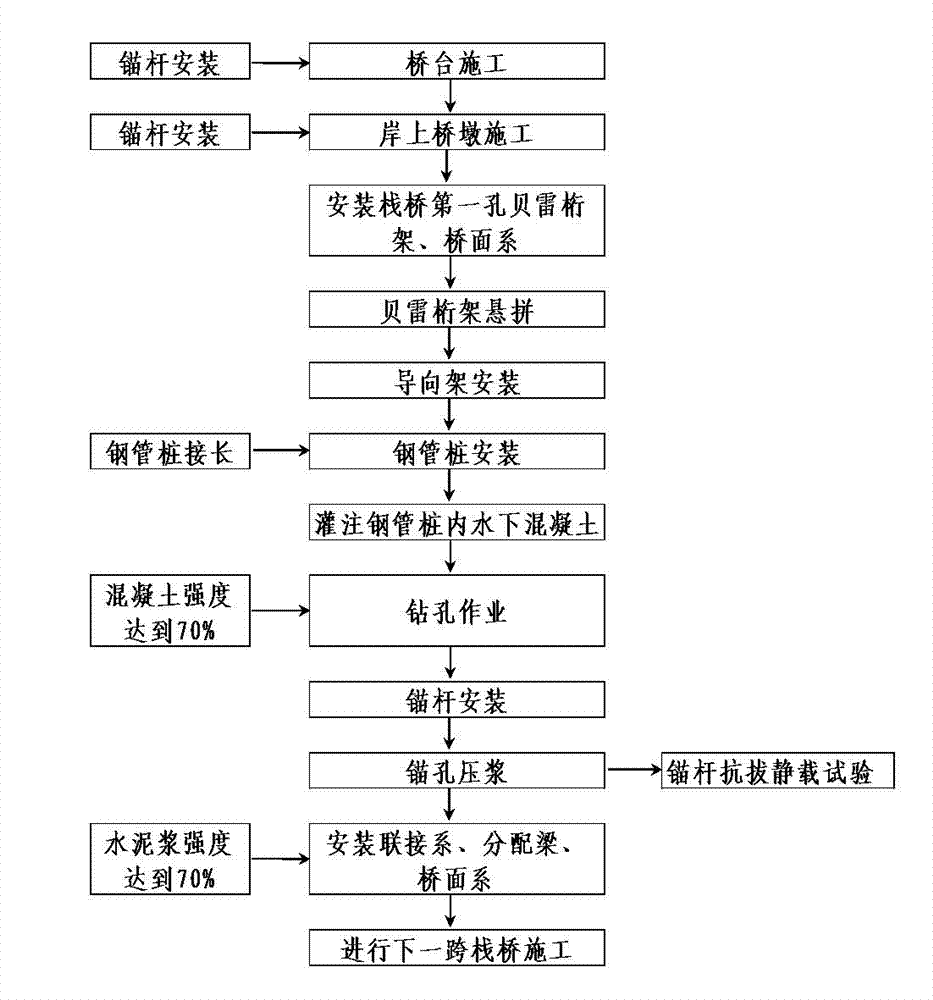

Elevated trestle bridge construction method on covering-free steep bare rock in deepwater and rapid stream

ActiveCN102979039AControl verticalityAvoid welding qualityBridge erection/assemblyBulkheads/pilesBasementBedrock

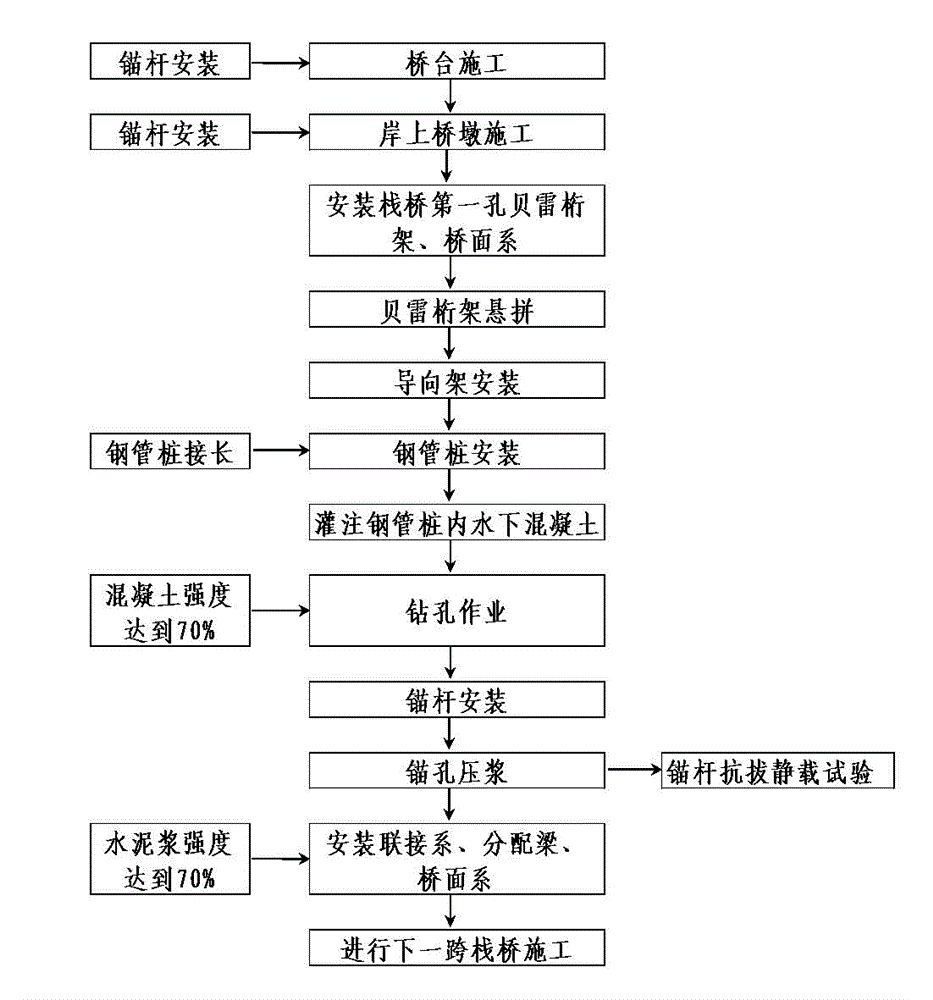

The invention specifically relates to an elevated trestle bridge construction method on covering-free steep bare rock in deepwater and rapid stream. A scheme of the invention is as follows: the elevated trestle bridge construction method comprises the following steps of: constructing a first porous trestle bridge on the bank, then constructing a second porous trestle bridge by adopting a cantilever method, and arranging guide frames on the tail end part of the second porous bridge; settling cut steel pipe piles in mounting sites, then casting an underwater concrete layer in the steel pipe piles, and drilling an anchor hole along the central axis direction of each steel pipe pile after the underwater concrete layer is cured, wherein each anchor hole penetrates through the underwater concrete layer and extends into basement rock of a river bed; and finally arranging an anchor bolt in each anchor hole, grouting and anchoring, then assembling a truss to form a third porous trestle bridge, and repeating the steps till finishing the construction of the whole trestle bridge. The elevated trestle bridge construction method disclosed by the invention has the advantages of reducing the deep diving operation load and the construction risk by adopting an underwater exploration technology in combination with precutting of a bottom opening of each steel pipe pile on the bank, enabling each steel pipe pile to be firmly anchored on the steep bare rock surface by adopting the anchor bolt grouting and rock-socketing technology between the steel pipe pile and the steep bare rock surface, shortening the construction peroiod and reducing the construction cost.

Owner:MUNICIPAL ENVIRONMENTAL PROTECTION ENG CO LTD OF CREC SHANGHAI GRP

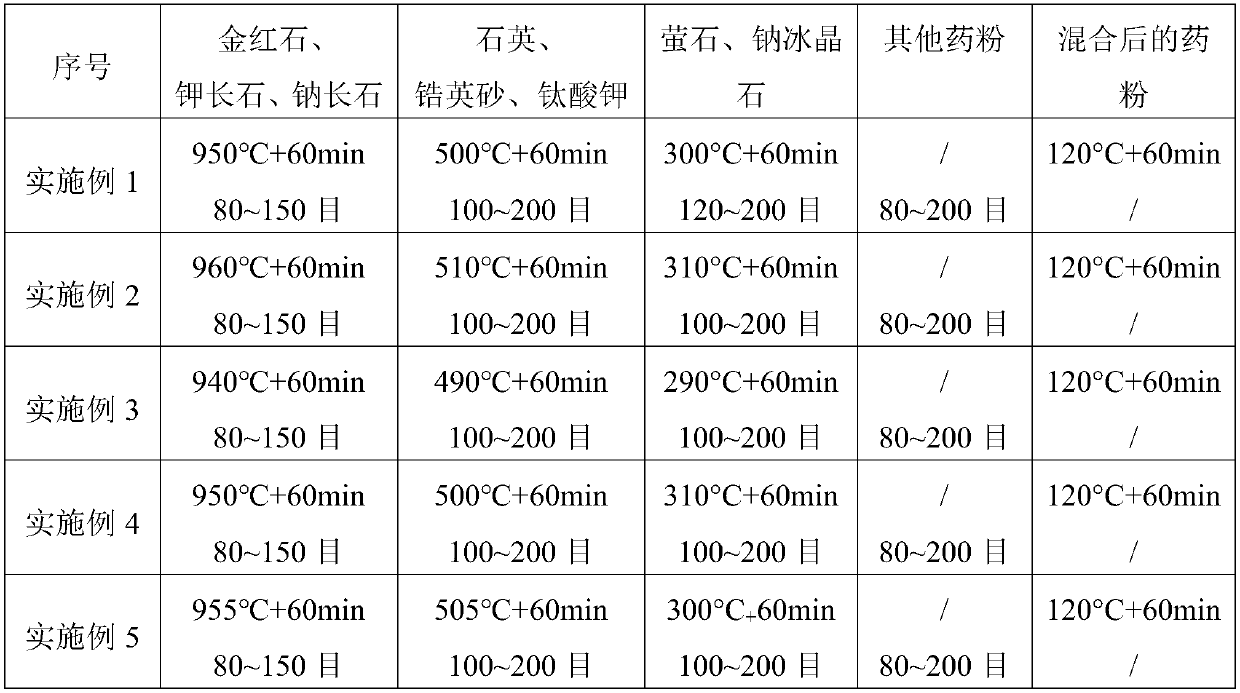

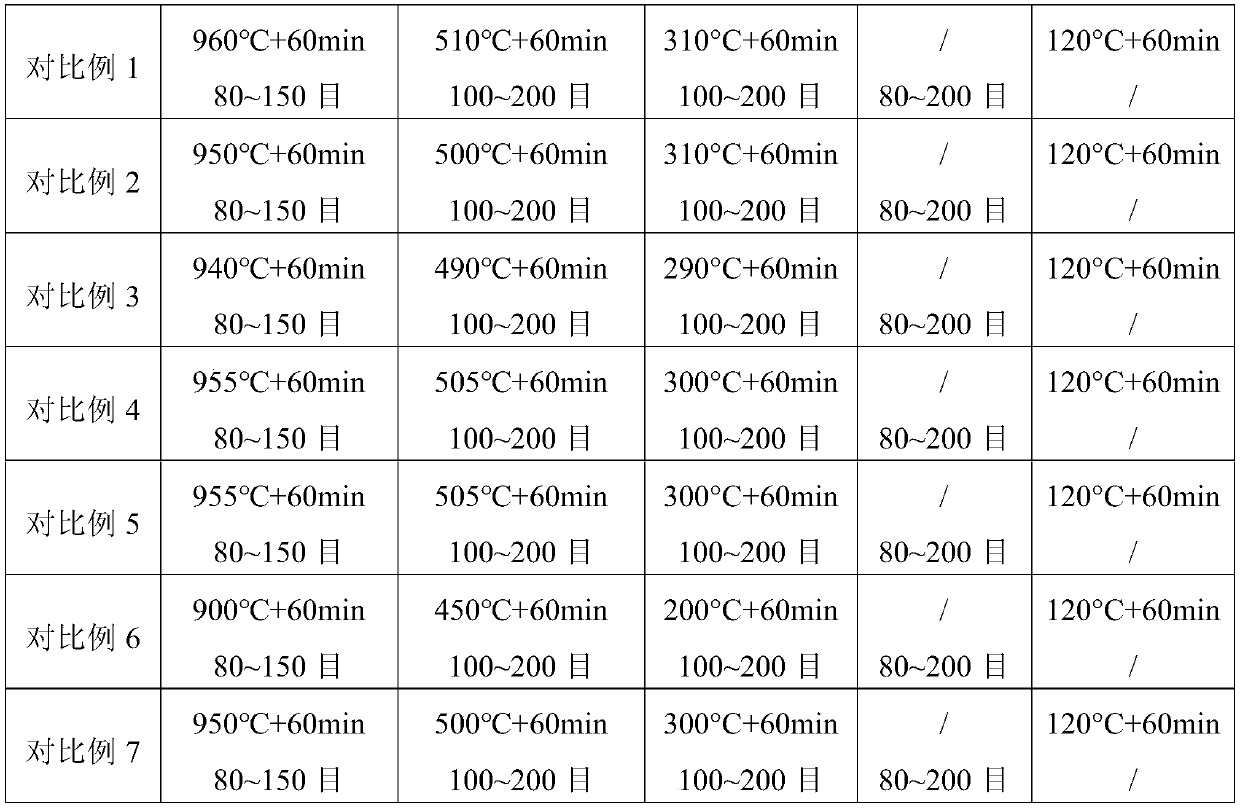

Flux-cored wire used for super duplex stainless steel gas shielded welding and preparation method thereof

ActiveCN110142529ASimple welding processReduce acidityWelding/cutting media/materialsSoldering mediaAusteniteZircon

The invention discloses a flux-cored wire used for super duplex stainless steel gas shielded welding and a preparation method thereof. The flux-cored wire is composed of an external use steel belt andflux powder, wherein the external use steel belt is made of an austenitic stainless steel belt with 17.0%-18.0% of chromium and 11.0%-12.5% of nickel; and the flux powder comprises the following components of, in percentage by weight, 36.0%-38.0% of chromium powder, 9.0%-13.0% of high-nitrogen chromium iron, 2.5%-3.0% of electrolytic manganese metal, 4.0%-5.0% of molybdenum powder, 0.5%-1.0% of ferrosilicon, 1.0%-1.5% of ferrotitanium, 0.5%-1.0% of aluminum-magnesium alloy, 18.0%-20.0% of rutile, 1.0%-2.0% of quartz, 5.0%-6.0% of zircon sand, 1.0%-1.5% of potassium feldspar, 3.0%-3.5% of albite, 1.0%-1.5% of fluorite, 0.5%-1.0% of sodium cryolite, 1.0%-1.5% of potassium titanate, 0.1%-0.3% of bismuth oxide and the balance iron powder. According to the flux-cored wire used for super duplexstainless steel gas shielded welding and the preparation method thereof, the components and the two-phase proportion of deposited metal can be balanced, thus obtaining a duplex stainless steel welding joint which is good in forming quality and excellent in corrosion resistance.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

Semiconductor lead frame surface treatment method

ActiveCN104900536AExcellent solderabilityPrevent oxidationSemiconductor/solid-state device manufacturingSuperimposed coating processBenzimidazoleSurface finishing

The invention discloses a semiconductor lead frame surface treatment method sequentially comprising ultrasonic degreasing, electrolytic degreasing, washing, sulfuric acid neutralization and activation, washing, electro-coppering, washing, acid neutralization, washing, copper protection, washing, hot washing, and drying. The step of copper protection has the following specific technical requirements: a semiconductor lead frame is guided into and immersed in protection liquid to achieve the purpose of making the semiconductor lead frame coated with a copper protective film, wherein the pH of the protection liquid is 5-7, the temperature is 20-40 DEG C, the immersion time is 10-20S, and the protection liquid contains 9-15g / L alkyl benzimidazole and 1-3g / L acetic acid. An organic protective layer is arranged on a copper surface layer to replace a diaphragm layer, and the protective layer is naturally removed during tin dipping and aluminum wire welding. Thus, protection is achieved without affecting the welding effect.

Owner:SICHUAN JINWAN ELECTRONICS

Lead-free tin-based solder for solar photovoltaic module and preparation method thereof

InactiveCN103801853AImprove wettabilityReduce performance degradationWelding/cutting media/materialsSoldering mediaIndiumSurface oxidation

The invention provides lead-free tin-based solder for a solar photovoltaic module. The lead-free tin-based solder comprises, by mass, stibium 0.05 percent-0.15 percent, silver 0.01 percent-0.05 percent, copper 0.1 percent-0.4 percent, indium 0.01 percent-0.05 percent, bismuth 0.2 percent-0.5 percent, gallium 0.06 percent-0.10 percent, phosphorus 0.02 percent-0.09 percent and the balance tin and inevitable impurities. The invention further provides a manufacturing method of the lead-free tin-based solder. The manufacturing method comprises the step that stibium, silver, copper, indium, bismuth, gallium, tin and phosphorus are placed into a smelting furnace according to the mass percentage and are smelted in an inert atmosphere or a vacuum condition, and the lead-free tin-based solder for the solar photovoltaic module is obtained. According to the lead-free tin-based solder for the solar photovoltaic module, melting temperature is low, surface gloss is good, surface oxidation resistance is high, wetting performance is good, and welding quality is superior. Besides, the lead-free tin-based solder is economical, environmentally friendly and free of threat to human health, thereby being applicable to large-scale industrial production.

Owner:THE NORTHWEST MACHINE

Welding method and clamp of Venturi tube with bend

ActiveCN102990265ASimple structural designMeet welding requirementsWelding/cutting auxillary devicesAuxillary welding devicesEdge surfaceEngineering

The invention discloses a welding method and clamp of a Venturi tube with a bend. The welding method comprises the steps of: respectively clamping and positioning an inlet section and an outlet section of a Venturi tube with a transition section for welding; sequentially spot-welding all spots on a butt seam corresponding to arcs of 0 degree->180 degrees->270 degrees->450 degrees->495 degrees->675 degrees; carrying out sealing welding along the clockwise rotation from the starting point of the butt seam, and after welding the butt seam for one circle, starting arc extinguishing in a place exceeding the starting point by 15 degrees, so as to complete the sealing welding; and selecting a point, between which and the starting point the arc angle is 180 degrees, as another starting point to perform welding, and after welding for one circle, starting the arc extinguishing in a place exceeding the starting point by 15 degrees, so as to complete the welding. The clamp comprises a center shaft with a bend, wherein an inlet inner sleeve and an outlet inner sleeve are sleeved on the center shaft, the outer edge surfaces of the inner sleeves are clung to the inner wall of the Venturi tube, and protection sleeves are respectively arranged on two ends of the inner sleeves, and clamping flanges are respectively arranged on opening ends of an inlet section and an outlet section and are fixed through nuts. According to the welding method and the clamp disclosed by the invention, the Venturi tube with a wall thickness of 1-3mm and the bend of 3-8 degrees can be welded.

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

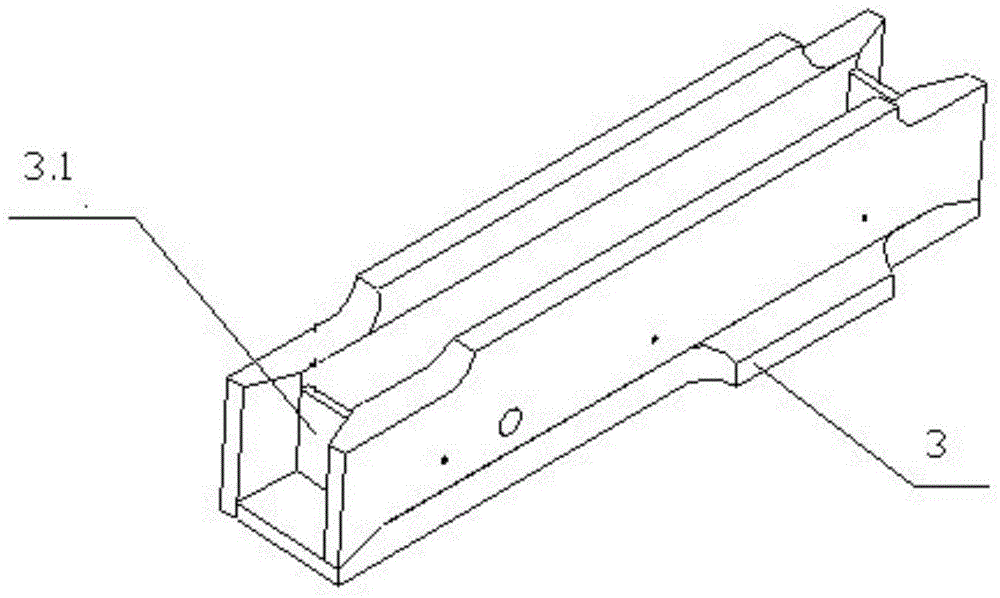

Steel column provided with thick plates, special-shaped skew bracket and truss layer and manufacturing method of steel column

ActiveCN104805961AGuaranteed assembly accuracyReduce the difficulty of productionStrutsBuilding material handlingAbnormal shapedSteel columns

The invention relates to a steel column provided with thick plates, a special-shaped skew bracket and a truss layer. The steel column is characterized by mainly comprising a steel column body formed by sequentially connecting a moderate thick plate box type column subsection, a first thick plate box type transition section, an ultra-thick plate box type column subsection and a second thick plate box type transition section, an H-shaped skew bracket is mounted on one side of the moderate thick plate box type column subsection, a bracket shaped like a Chinese character ya is arranged on one side of the ultra-thick plate box type column subsection, an H-shaped straight bracket is arranged at the bottom of the ultra-thick plate box type column subsection, the special-shaped skew bracket is arranged above the ultra-thick plate box type column subsection, and an upper wing plate and a lower wing plate of the special-shaped skew bracket are special-shaped, are bent twice in the same direction by 1 degree, and form an included angle of 135 degrees with the steel column body. According to the high-efficiency and high-quality steel column provided with the thick plates, the special-shaped skew bracket and the truss layer and a manufacturing method of the steel column, the manufacturing difficulty of the complicated steel structure is reduced, and meanwhile, the technical blank of the structure in the field is filled up.

Owner:CHINA CONSTR STEEL STRUCTURE JIANGSU CO LTD

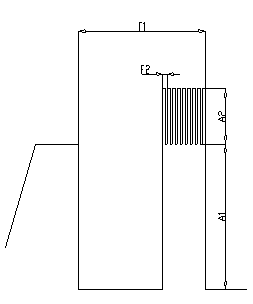

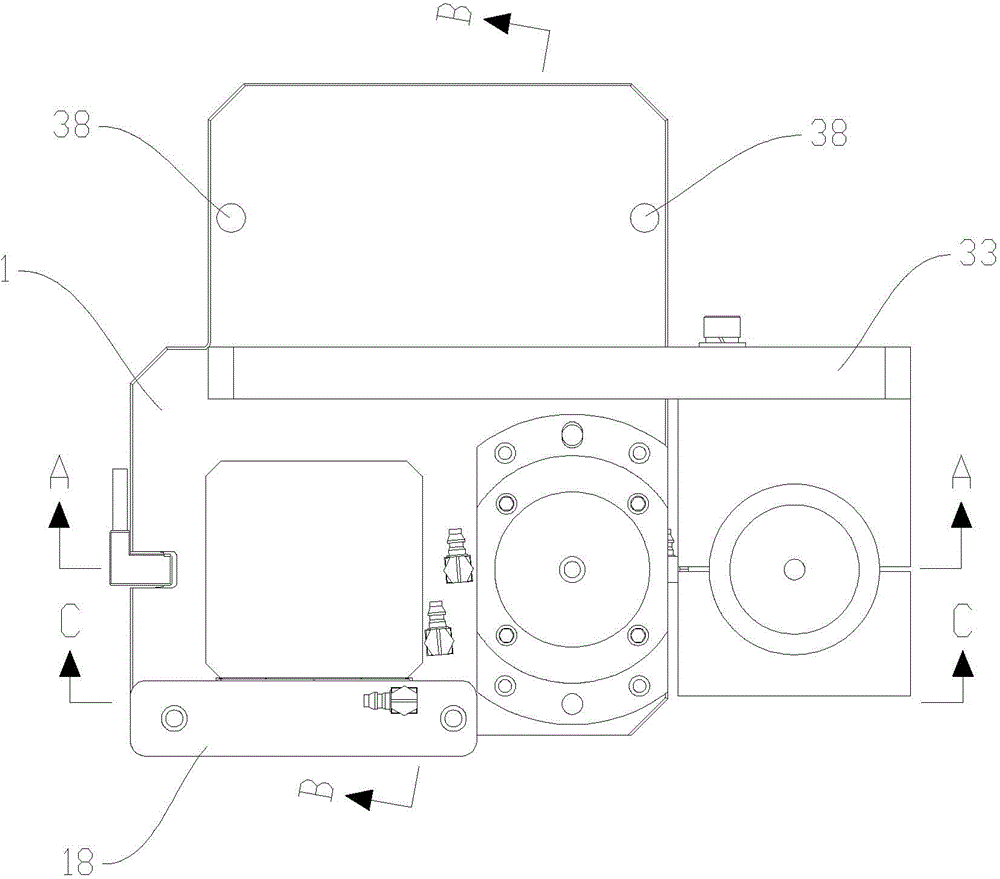

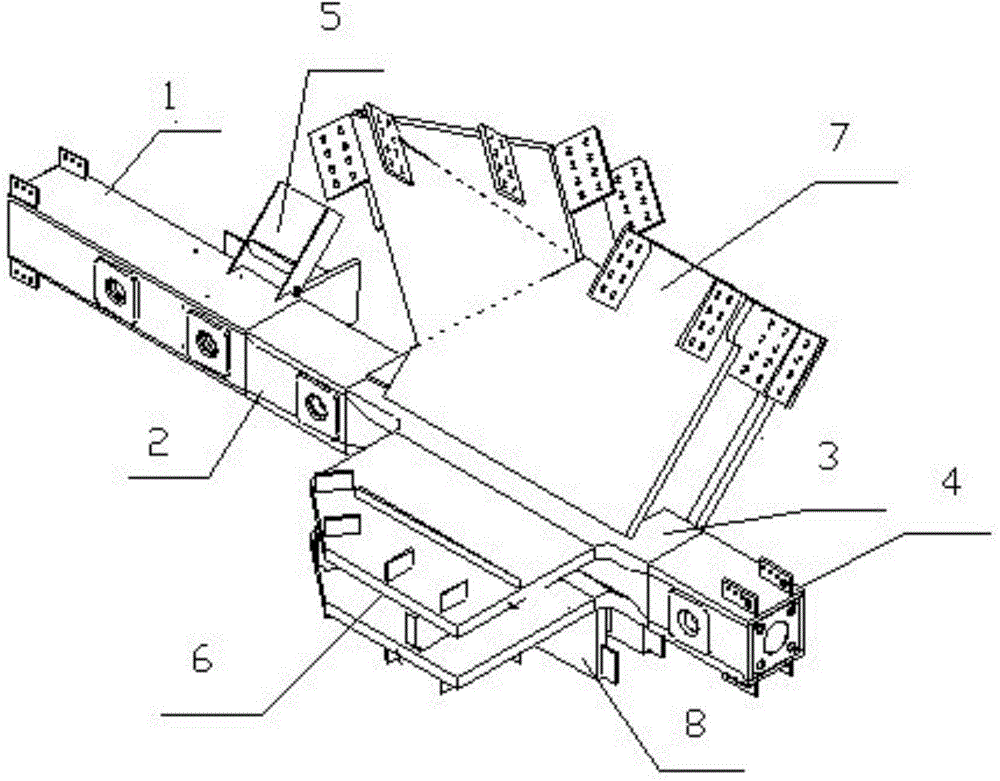

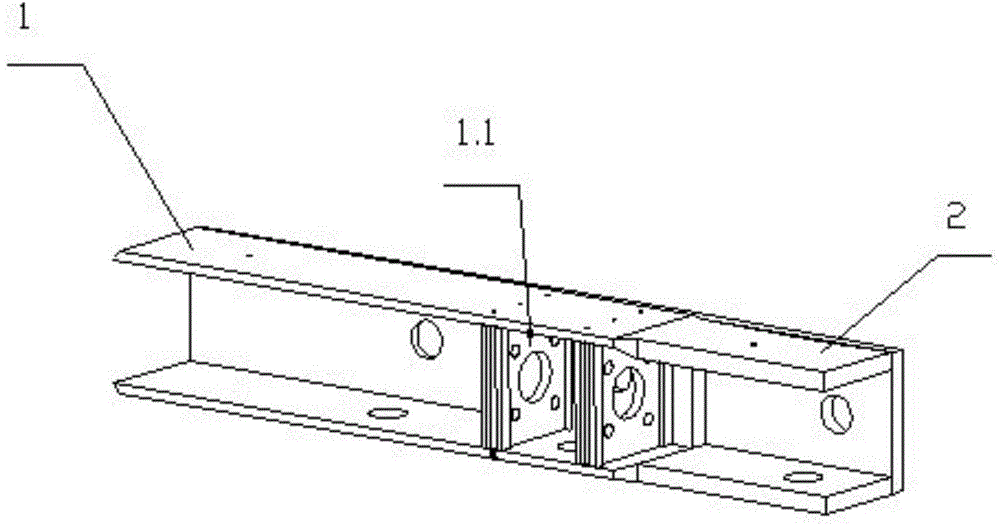

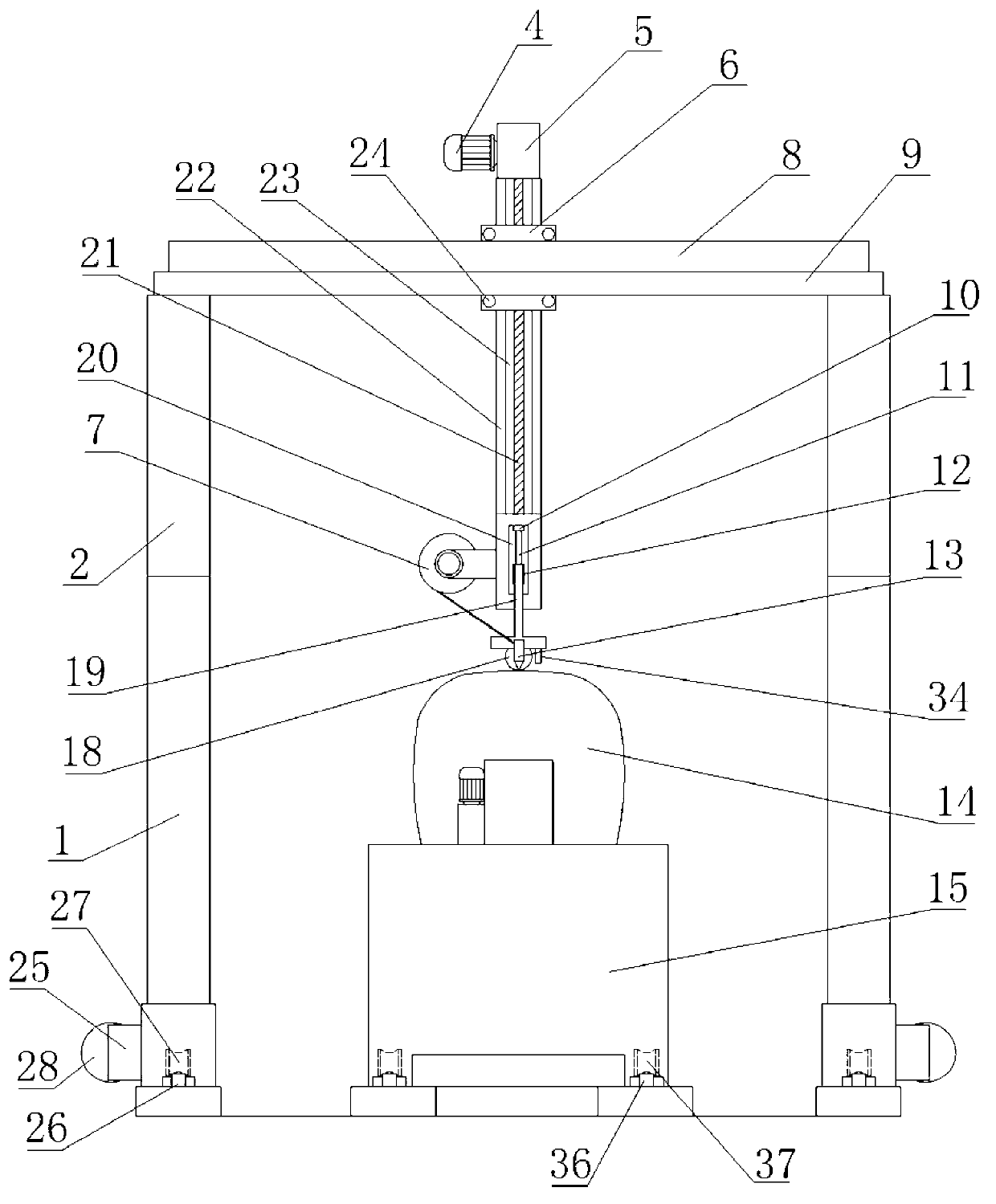

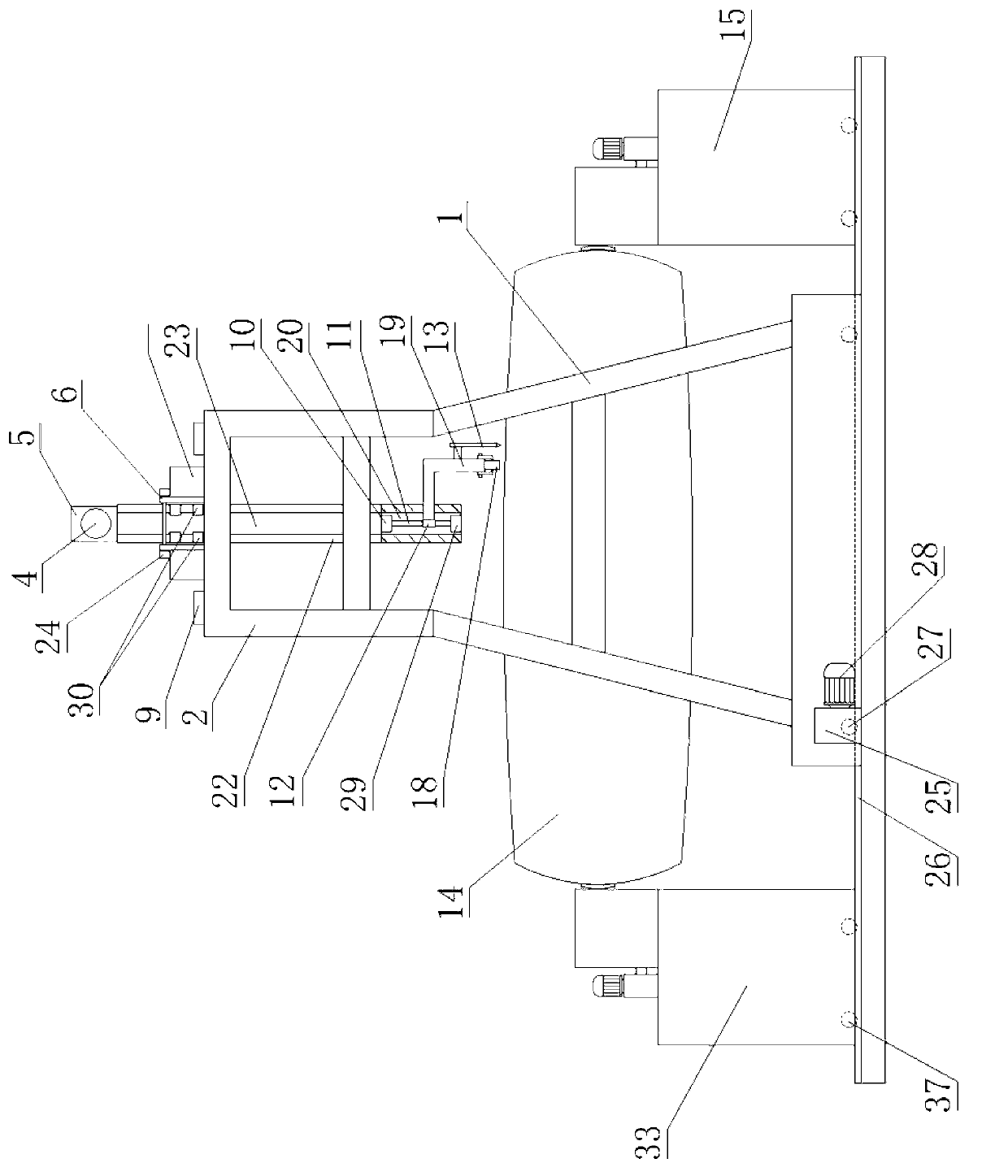

Irregular tank body circular seam automatic welding machine

InactiveCN103100809AEquipment workload is smallLow energy consumptionWelding/cutting auxillary devicesAuxillary welding devicesCarbon steelSeam welding

The invention relates to a tank body automatic welding machine, in particular to an irregular tank body circular seam automatic welding machine. The tank body automatic welding machine comprises a machine frame, a welding gun assembly arranged on the machine frame and a wire sending mechanism for sending welding wires for the welding gun assembly. The machine frame comprises a left support frame, a right support frame and two beams, wherein two ends of the beams are respectively fixed on the tops of the two support frames. The irregular tank body circular seam automatic welding machine further comprises a welding gun horizontally moving mechanism used for driving the welding gun assembly to move horizontally reciprocally and a welding gun lifting mechanism for driving the welding gun assembly to move longitudinally and reciprocally. The lower end of the welding gun lifting mechanism is provided with a welding gun automatic adjusting mechanism, horizontal rails are respectively arranged below the two lower support frames, walking mechanisms for driving the whole automatic welding machine to move reciprocally are respectively arranged at the bottoms of the two support frames. The irregular tank body circular seam automatic welding machine is small in workload, low in energy consumption, stable in welding quality, capable of saving a large amount of spaces, and suitable for circular seam welding of carbon steel tanks, stainless steel tanks, aluminum tanks and other tanks of various materials.

Owner:李宪领

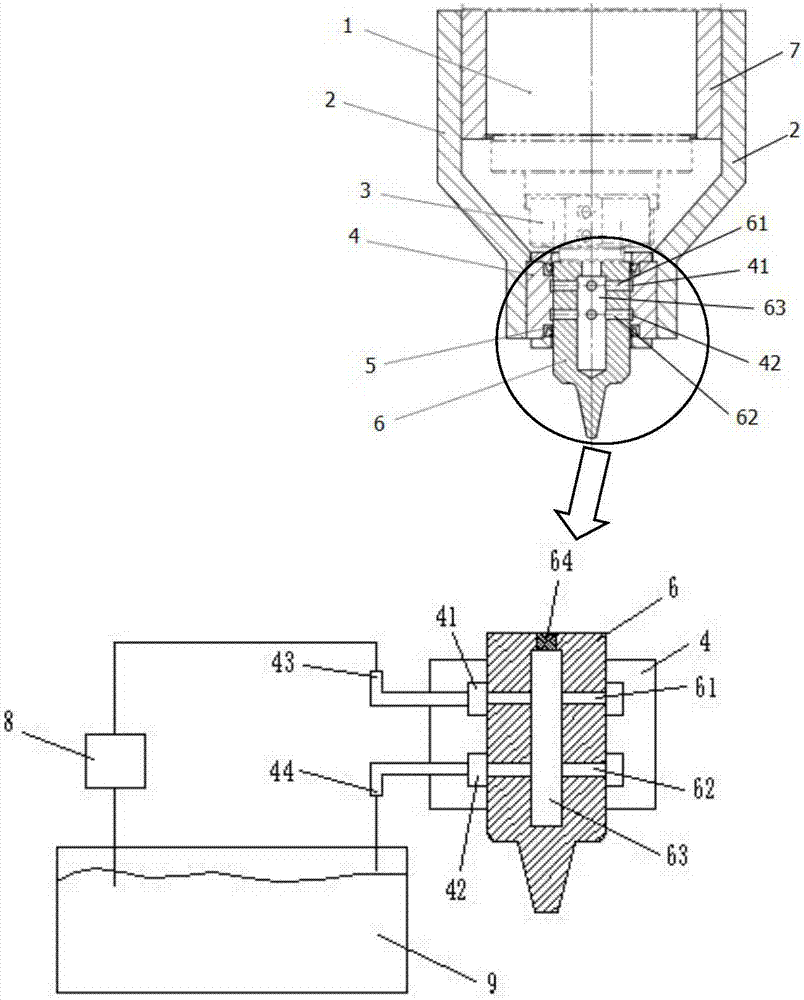

Water-cooling stirring head used for friction stir welding and water cooling circulation method

ActiveCN107470772AReasonable structural designSimple structureNon-electric welding apparatusEngineeringWater cooling

The invention discloses a water-cooling stirring head used for friction stir welding. The water-cooling stirring head mainly comprises a spindle, a fixing frame, a cutter handle, a protective jacket, a sealing ring and a stirring head body. The cutter handle is mounted at the lower end of the spindle. The stirring head body is mounted at the lower end of the cutter handle. The outer portion of the upper half part of the stirring head body is encircled with the protective jacket. The protective jacket is provided with a water inlet and a water outlet and internally provided with a water inlet tank and a water outlet tank. The position, corresponding to the water inlet tank of the protective jacket, of the stirring head body is provided with a water inlet opening. The position, corresponding to the water outlet tank of the protective jacket, of the stirring head body is provided with a water outlet opening. A cooling cavity is formed in the stirring head body. The water inlet opening and the water outlet opening communicate with the cooling cavity. The water-cooling stirring head is reasonable in structure design, simple in structure, capable of meeting the cooling liquid circulation demand, low in manufacturing cost and novel in cooling circulation mode, the stirring head is forcibly cooled, the temperature of the stirring head is lowered, abrasion of the stirring head is reduced, the service life of the stirring head is prolonged, and the welding quality and stability are improved.

Owner:BEIJING FSW TECH

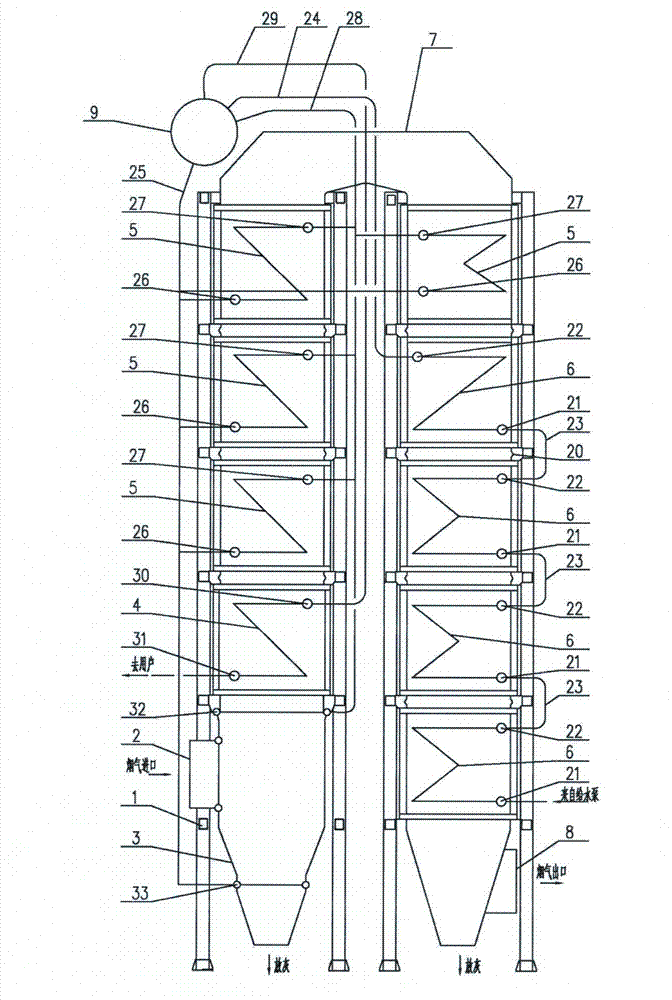

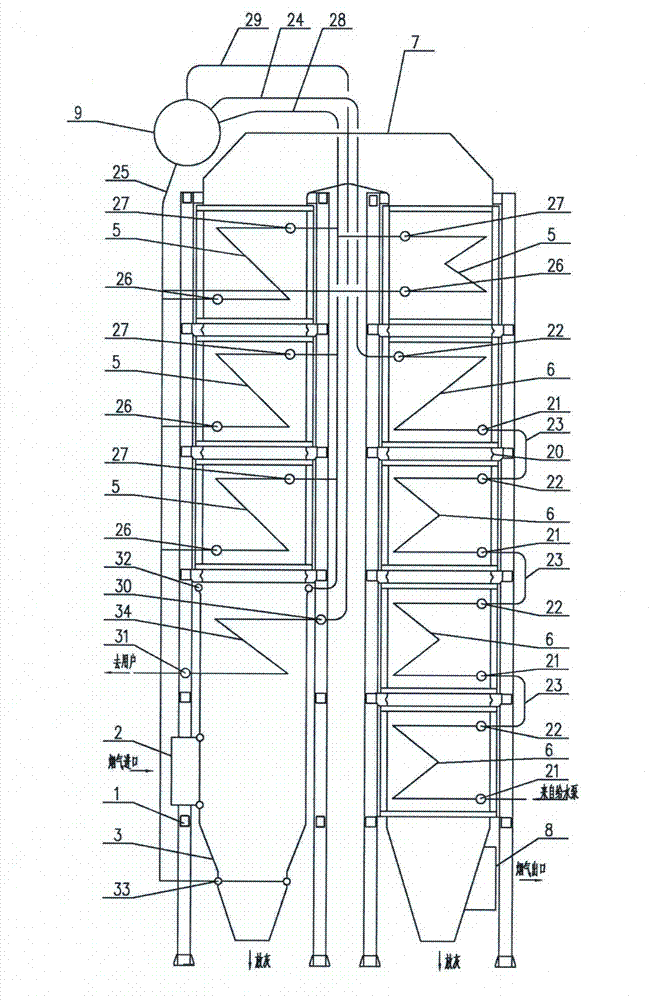

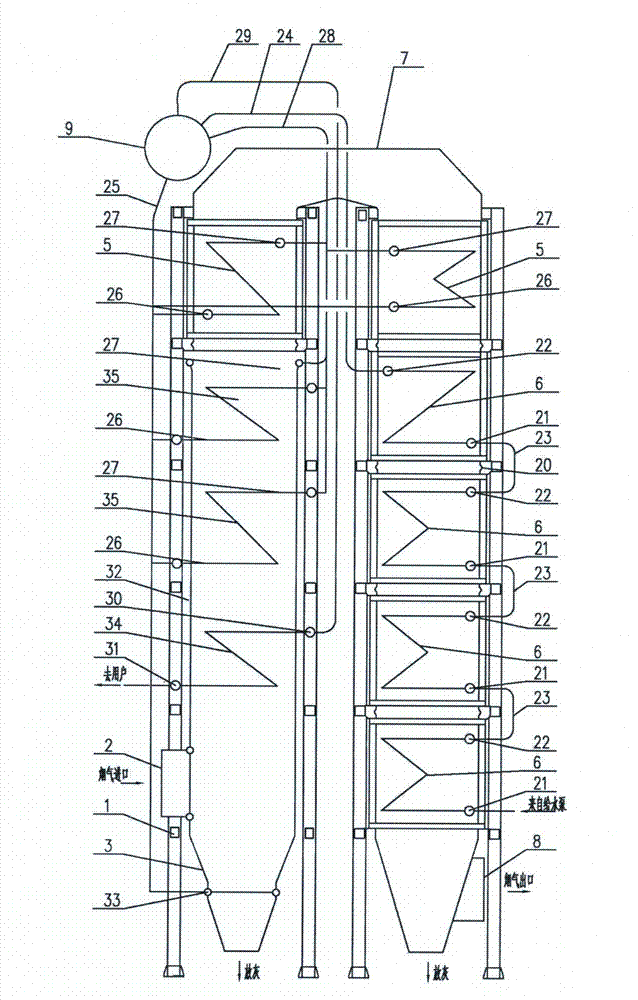

Modular bypass vent waste heat boiler at tail of cement kiln

InactiveCN102788337ASimplify on-site installation processReduce labor costsIncreasing energy efficiencySteam generation using hot heat carriersComputer moduleEngineering

A modular bypass vent waste heat boiler at the tail of a cement kiln is mainly characterized in that a part of heating surfaces adopts heating surface modules which are independent of one another, have the same structure and is provided with respective independent frames; heat insulation protection plates are arranged around the frames to form a section of cylindrical outer shell; hoisting mechanisms are arranged on the frames; the heating surfaces of the modules are arranged on the frames in the respective outer shells; one end of each of inlet / outlet headers connected with the heating surfaces of the modules is arranged outside the outer shell; upper components of the boiler are connected with lower components of the boiler; and upper and lower headers of the modules are connected with ascending and descending pipes of a boiler barrel by pipelines as required. The installation period of the waste heat boiler can be greatly shortened, the labor cost is saved, the installation cost is greatly lowered, the welding quality can be controlled better, the service life of the boiler can be prolonged, and the heating surface of the boiler can be prevented from damages in the transportation process to the full extent.

Owner:DALIAN EAST NEW ENERGY DEV

Ship-building steel small-groove submerged-arc welding agent and preparation method thereof

InactiveCN106736044ALow hygroscopicityLow costWelding/cutting media/materialsSoldering mediaSlagRutile

The invention discloses a ship-building steel small-groove submerged-arc welding agent and a preparation method thereof. The ship-building steel small-groove submerged-arc welding agent comprises the following raw materials, by weight, of 15-28% of magnesite, 15-30% of white corundum, 10-25% of grammite, 10-20% of fluorite, 10-20% of rutile, 1-10% of manganese ores and 1-7% of silicon iron. The sum of the weight percentage of the components is 100%. The ship-building steel small-groove submerged-arc welding agent has low hygroscopicity; electric arc welding is stable; the slag detachability of the welding agent after welding is good; the appearance of a welded joint is attractive after forming; slag shells can automatic cock after welding; and no defects such as undercuts exist. The production efficiency is high, the comprehensive cost is low, the welding quality is good, and the welding agent is quite suitable for submerged arc welding under the condition of small grooves of ship-building steel.

Owner:SHANGHAI HULIN HEAVY IND +2

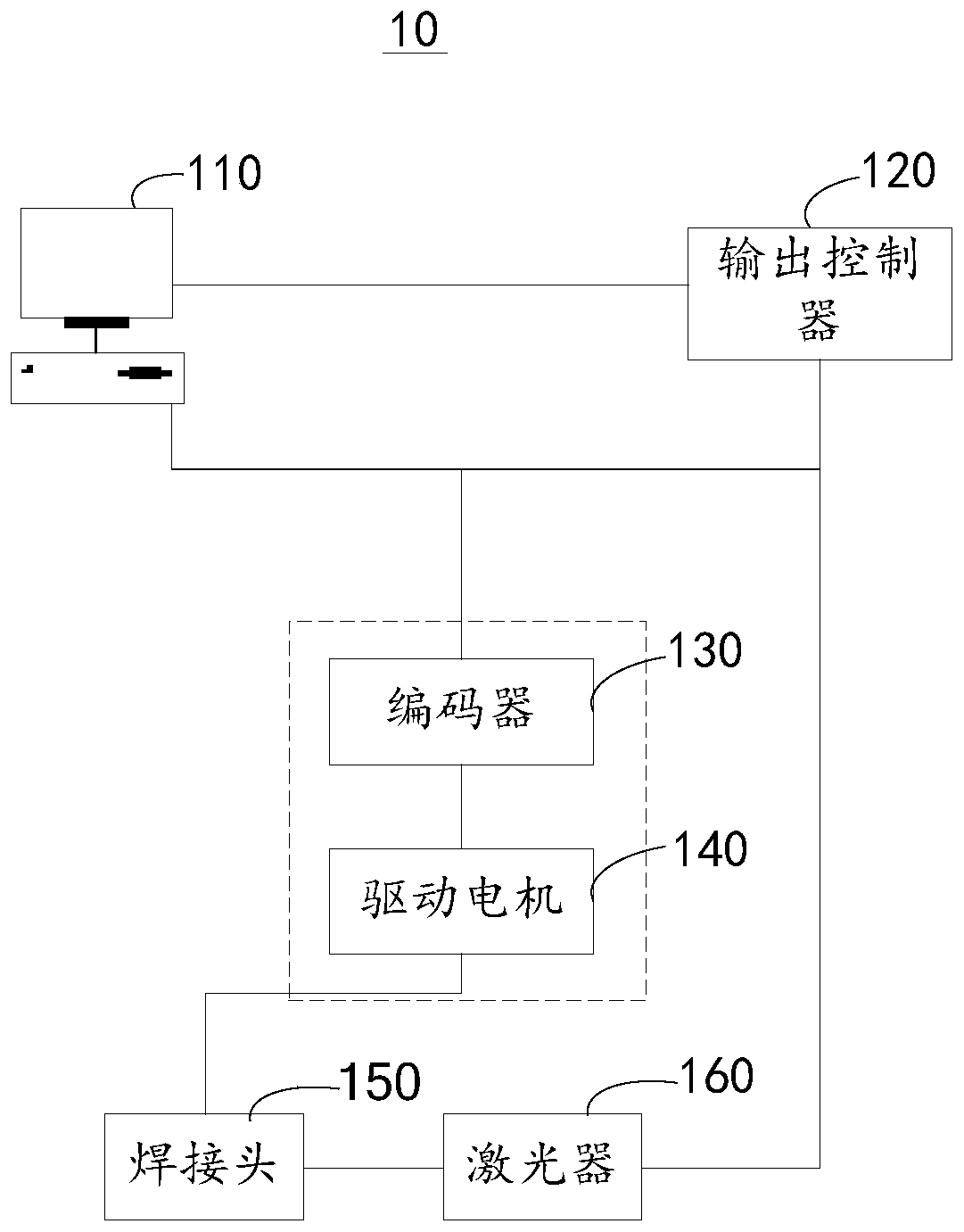

Laser welding control method, device, system and electronic device

InactiveCN110125544AUniform solder jointsUniform weldingProgramme controlWelding/cutting auxillary devicesControl signalEngineering

The invention provides a laser welding control method, a device, a system and an electronic device, wherein the laser welding control method comprises the steps of: receiving the current position of awelding head fed back by an encoder; judging whether the current position reaches a setting position; when the welding head reaches the setting position, sending a laser control signal to the laser to control the laser to output the laser at the setting position.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

Construction method of beam longitudinal bar anchorage for stiffened steel structural column-beam column joints

InactiveCN105040830AFully consider the possibility of constructionFully consider the rationalityBuilding constructionsReinforced concreteClassical mechanics

A construction method of beam longitudinal bar anchorage for stiffened steel structural column-beam column joints is characterized in that longitudinal bars of stiffened steel structural column and reinforced concrete beam joints are anchored by means of welding and hole cutting and penetrating. The method includes: performing three-dimensional modeling, performing setting-out and modeling on design drawings according to a ratio of 1:1 through detailed design by means of two-dimensional and three-dimensional software such as AutoCAD, optimally arranging the bars according to rules of the detailed design, determining an anchoring mode of the bars and hole positions, and performing editing with AutoCAD or explorer TSSD to make drawings so as to guide field actual construction. The basic rules of the detailed design include simultaneous use of welding and hole cutting, to be specific, hole cutting is optimally performed at the premise of meeting the requirement on section loss rate; beam corner bars are not holed as far as possible; beam-end crossing bars are stacked layer by layer. The method has the advantages that the bars are provided with sufficient welding space, welding quality is evidently improved, welding quantity is reduced, construction speed is increased, and engineering quality is guaranteed.

Owner:广西建工第五建筑工程集团有限公司

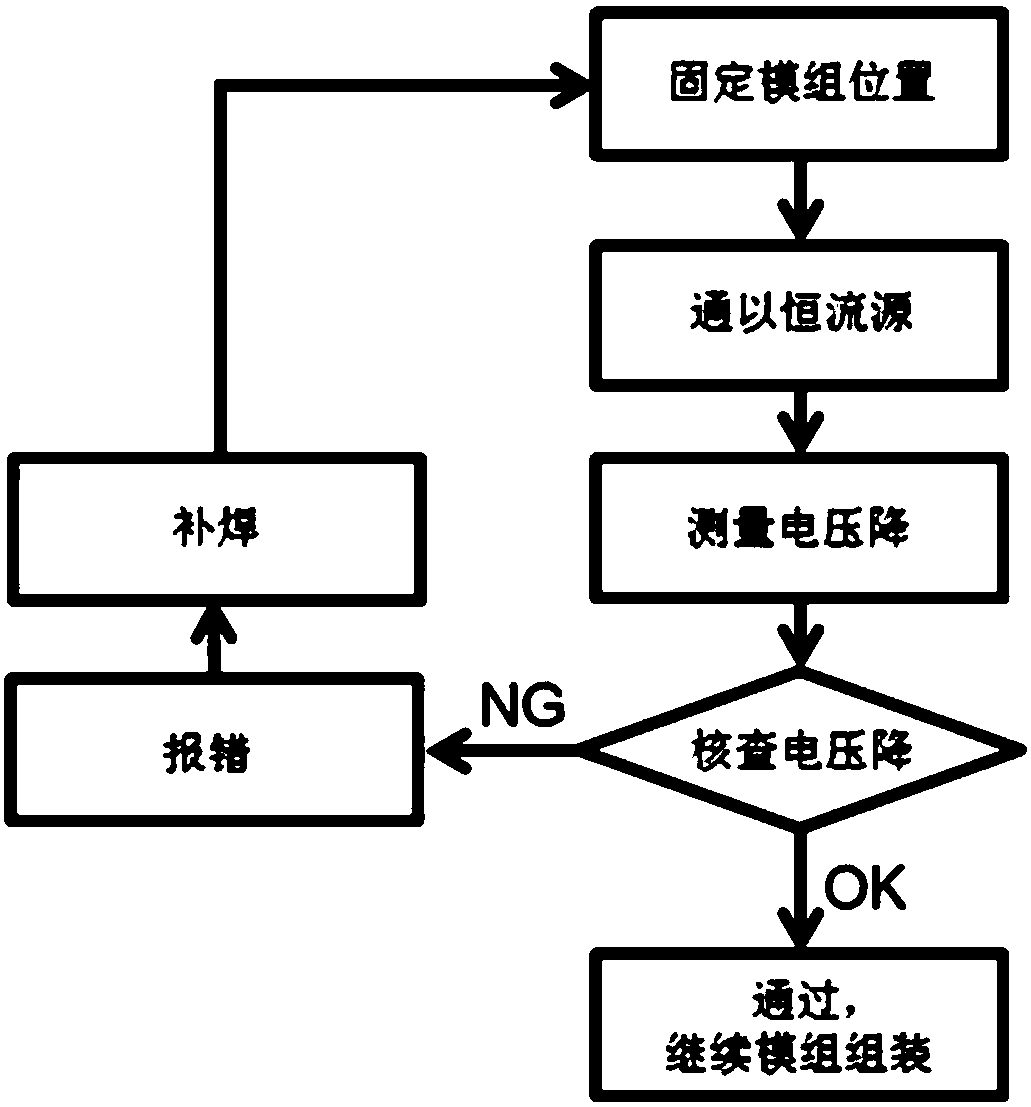

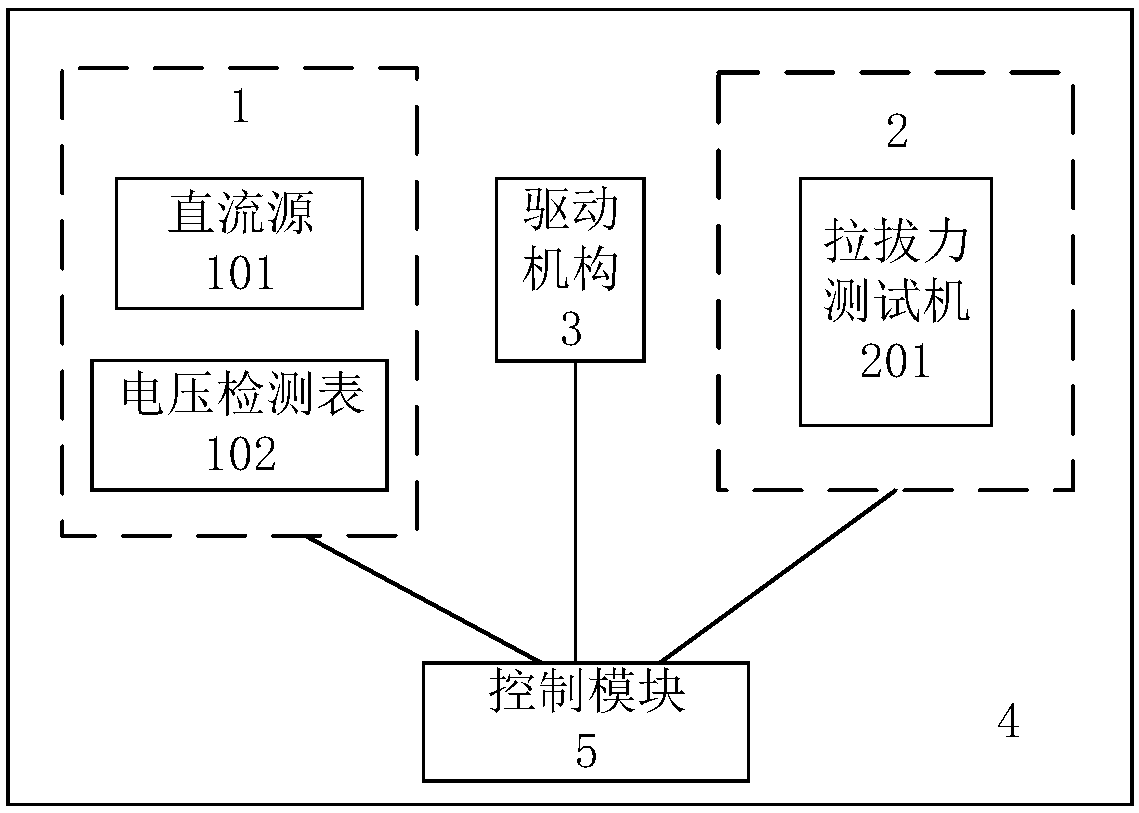

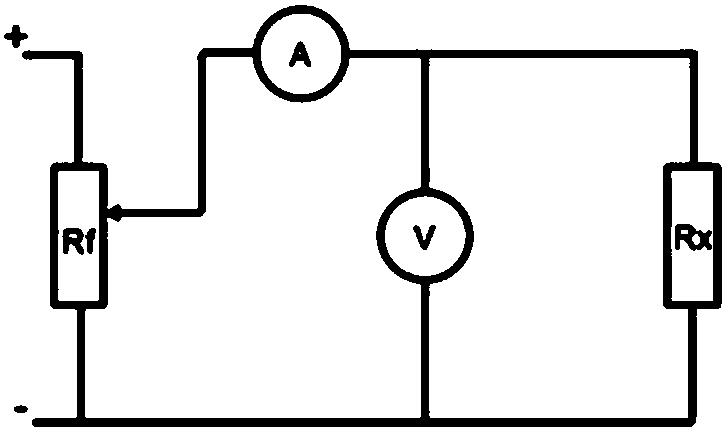

Battery cell voltage sampling piece welding quality detection method and detection device

PendingCN108037467AAvoid welding qualityReal-time measurementElectrical testingElectrical batteryVoltage drop

The invention relates to a battery cell voltage sampling piece welding quality detection method and a detection device. The detection method comprises the following steps: a voltage drop test step, namely testing whether voltage drop in a welding area of a test object meets preset conditions by adopting a voltage drop method; and a comprehensive assessment step, namely obtaining the final weldingquality according to results obtained in the voltage drop test step. The voltage drop test specifically comprises the following steps: 101) introducing a direct current source between the welding areaand battery cell tabs, and controlling stable output of the direct current source; and 102) measuring voltage drop between the welding area and the battery cell tabs, judging whether the voltage dropmeets the preset conditions, if so, exiting, otherwise generating alarm information. Compared with the prior art, the method disclosed by the invention has the advantages that the welding quality canbe effectively evaluated, thermal runaway risk of the battery module is reduced, and the like.

Owner:上海捷新动力电池系统有限公司

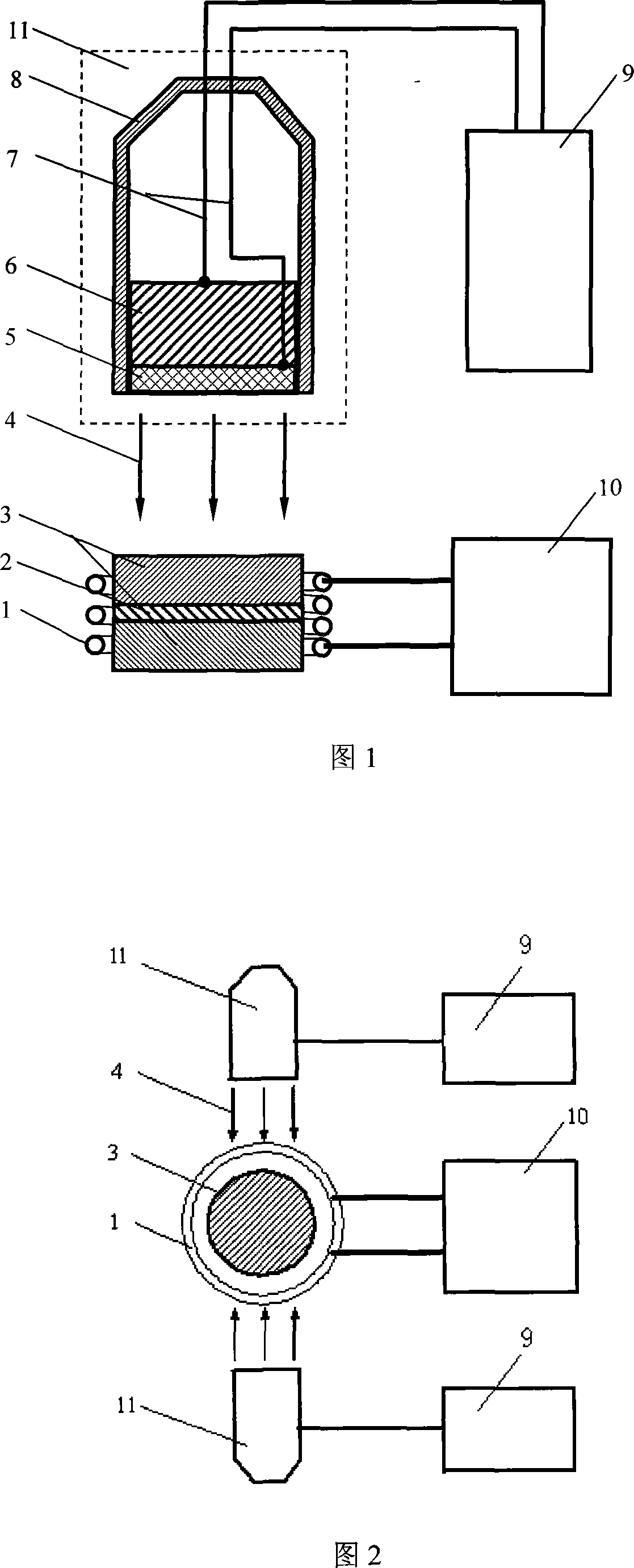

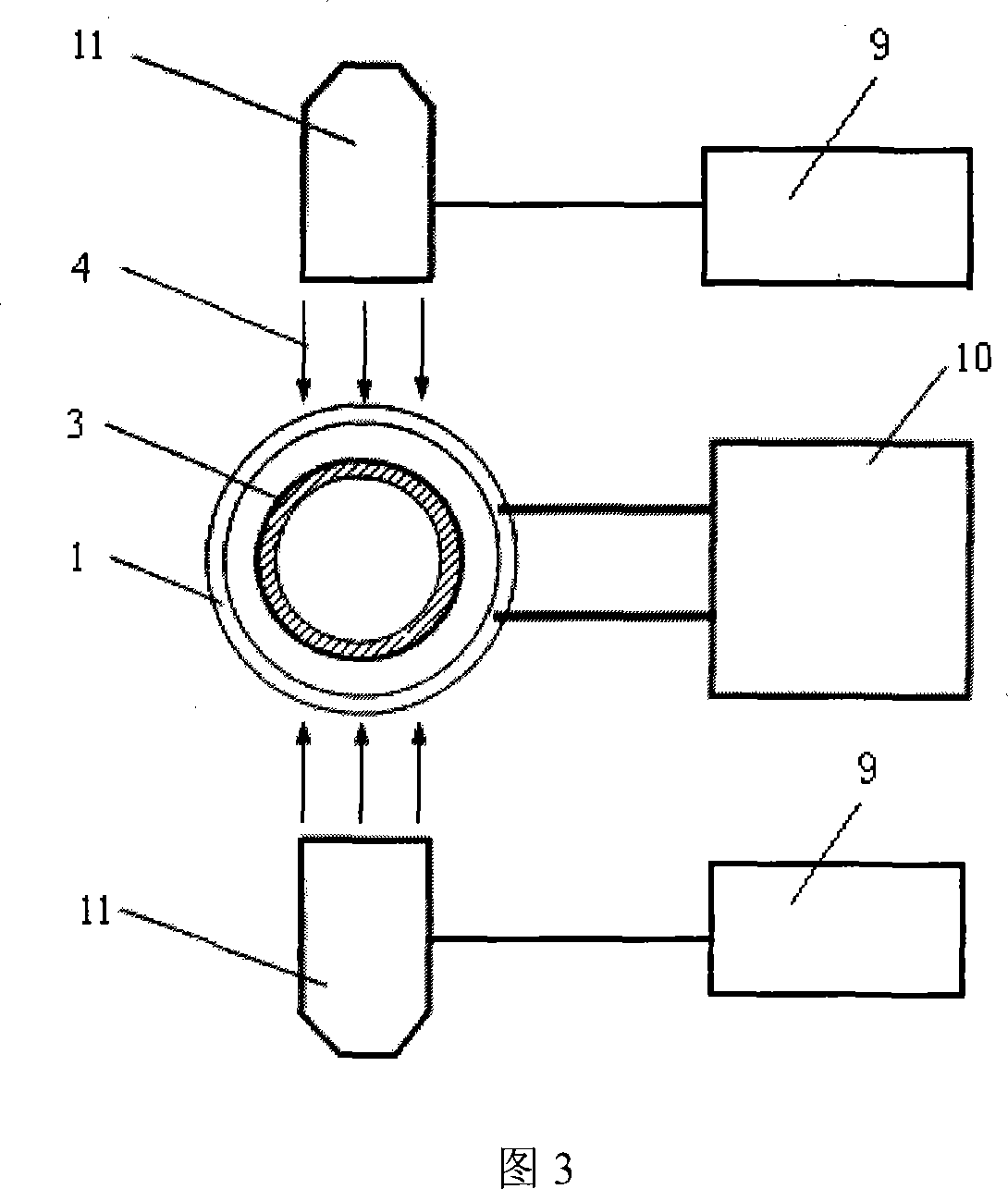

Induction brazing device and method thereof

InactiveCN101200012ASpread evenlyImprove brazing rateHeating appliancesVoltage amplitudeElectrical connection

The invention discloses an induction brazing device, comprising an induction power supply and induction coil. The invention is characterized in that an air-medium Ultrasonic probe is at least included; the air-medium ultrasonic probe is in electrical connection with a high frequency oscillator. The invention also discloses a high frequency braze welding method which uses the induction brazing device, and comprises the steps as follows: select at least one air-medium ultrasonic probe with different diameters according to the size of the connection area or complex degree; adjust the center frequency of the air-medium ultrasonic probe, the oscillating voltage amplitude of the high frequency oscillator output, and the distance between the air-medium ultrasonic probe and weld assembly connector; meanwhile connect the air-medium ultrasonic probe with the oscillator, and connect the induction coil with the induction power supply to complete the welding. Comparing with the dependant use of induction coil and induction power supply when welding the same diameter welding parts, the current output value of the induction power supply and the welding time are all reduced by 10 to 20 percent after being tested; the energy is saved and the welding efficiency is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

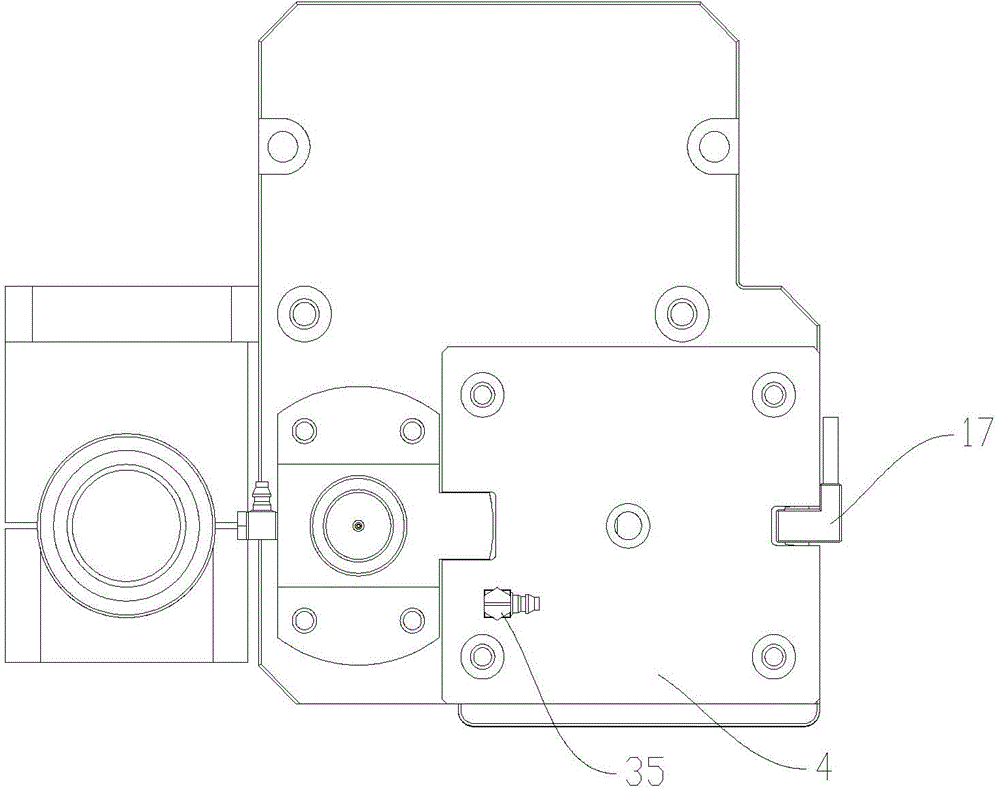

Servo grinder for electrode cap

InactiveCN106077933AReduce splashLow positioning accuracy requirementsElectrode maintenanceGrinding/polishing safety devicesEngineeringPulp and paper industry

The invention discloses a servo grinder for an electrode cap. The servo grinder is characterized by comprising a support, a grinding device, a blowing device and a garbage collecting device, wherein the grinding device is connected with the top end of the support through a floating compensation mechanism; the blowing device is arranged at the top end of the grinding device; the garbage collecting device is fixedly mounted on one side surface of the support. With the adoption of the servo grinder for the electrode cap, the problem of spattering of waste residues and chippings produced during grinding of the electrode cap can be effectively solved, besides, the requirements for the positioning accuracy of a robot because of wearing of the electrode cap are reduced, and the follow-up welding quality is further guaranteed.

Owner:SHANGHAI FANUC ROBOTICS

Welding method for plates of ladle turret

ActiveCN103658937AMake sure the welding is successful onceEnsure a successArc welding apparatusMetal working apparatusToughnessNondestructive testing

The invention discloses a welding method for plates of a ladle turret. The technical scheme includes the step 1, plate groove processing, the step 2, weldment assembling, the step 3, preheating before welding, the step 4, welding equipment and material selecting, the step 5, welding of the ladle turret, the step 6, processing after welding, and the step 7, nondestructive detection. All welded joints are subjected to complete ultrasonic detection after the welding is ended for 24 hours. By the welding method for the plates of the ladle turret, the one-step successful welding of the ladle turret can be guaranteed, cold fraction is decreased and even eliminated, certain low-temperature toughness of the ladle turret is guaranteed, welding efficiency of the ladle turret is improved, welding quality of welded joints is also guaranteed, and production cost is lowered.

Owner:ANHUI MASTEEL ENG & TECH GRP

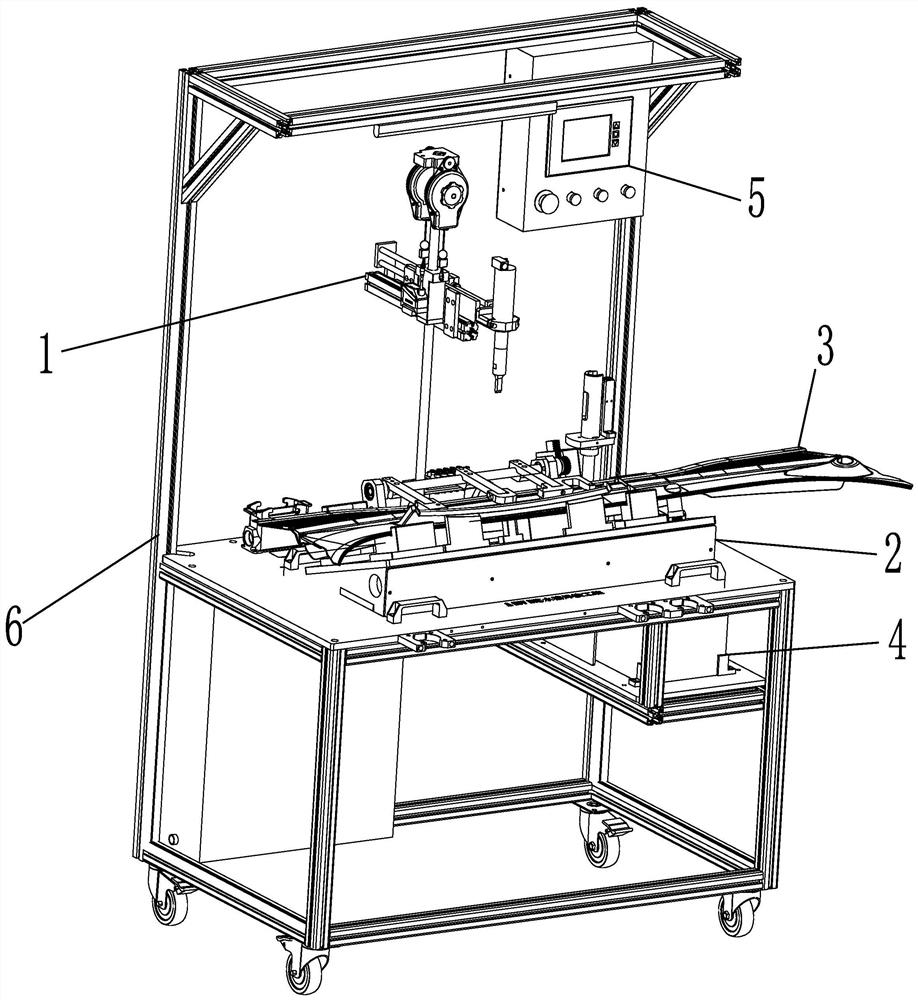

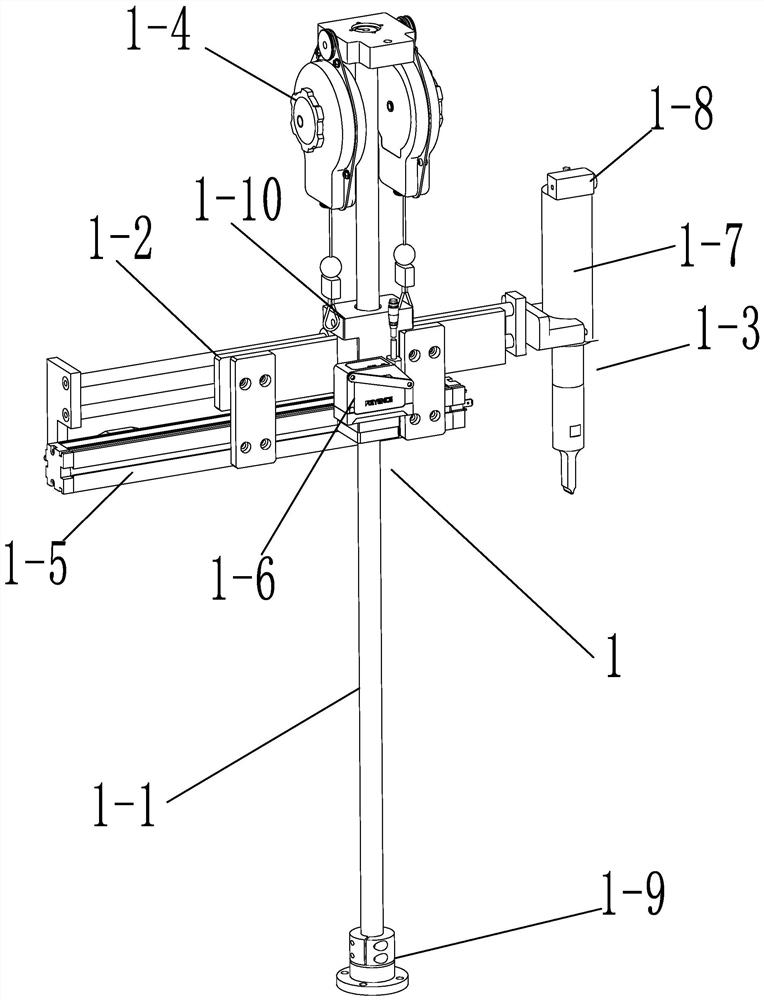

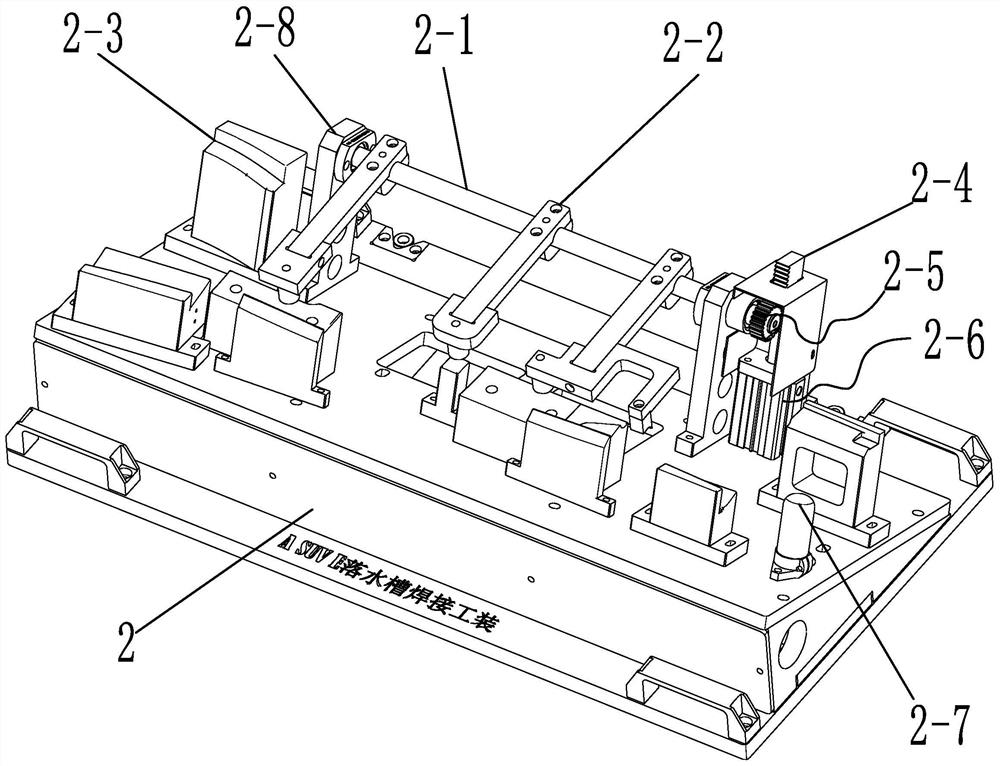

Semi-automatic welding equipment for automobile water falling groove

ActiveCN112059399AEasy to operateAvoid typosWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSoldering gun

The invention discloses semi-automatic welding equipment for an automobile water falling groove. The semi-automatic welding equipment comprises a workbench, a welding device, a welding clamp and a controller. The welding device comprises a vertical rod, a sliding block, a telescopic arm and a welding gun. The vertical rod is fixedly arranged on the workbench, the sliding block sleeves the verticalrod, the telescopic arm is perpendicular to the vertical rod, and the telescopic arm is fixedly connected with the sliding block. The welding gun is fixedly arranged at the free end of the telescopicarm, a balancer is arranged at the upper end of the vertical rod, the sliding block is connected with the balancer, and a laser displacement sensor and a displacement sensor are arranged on the telescopic arm. The position of the telescopic arm is taken as an X axis, when the telescopic arm is completely contracted, the position of a gun head of the welding gun is a zero point, the position of the vertical rod is a Z axis, the surface of the workbench is a reference surface, each welding spot is provided with a specific X value and a specific Z value, and when the X value and the Z value aremet at the same time, the welding gun works. The semi-automatic welding equipment for the automobile water falling groove can perform fixed-point welding, the welding gun only works at a specific position, wrong welding and excessive welding are avoided, and misoperation is avoided; and the welding depth can be detected, and the welding quality is controlled.

Owner:玄甲智能科技有限公司

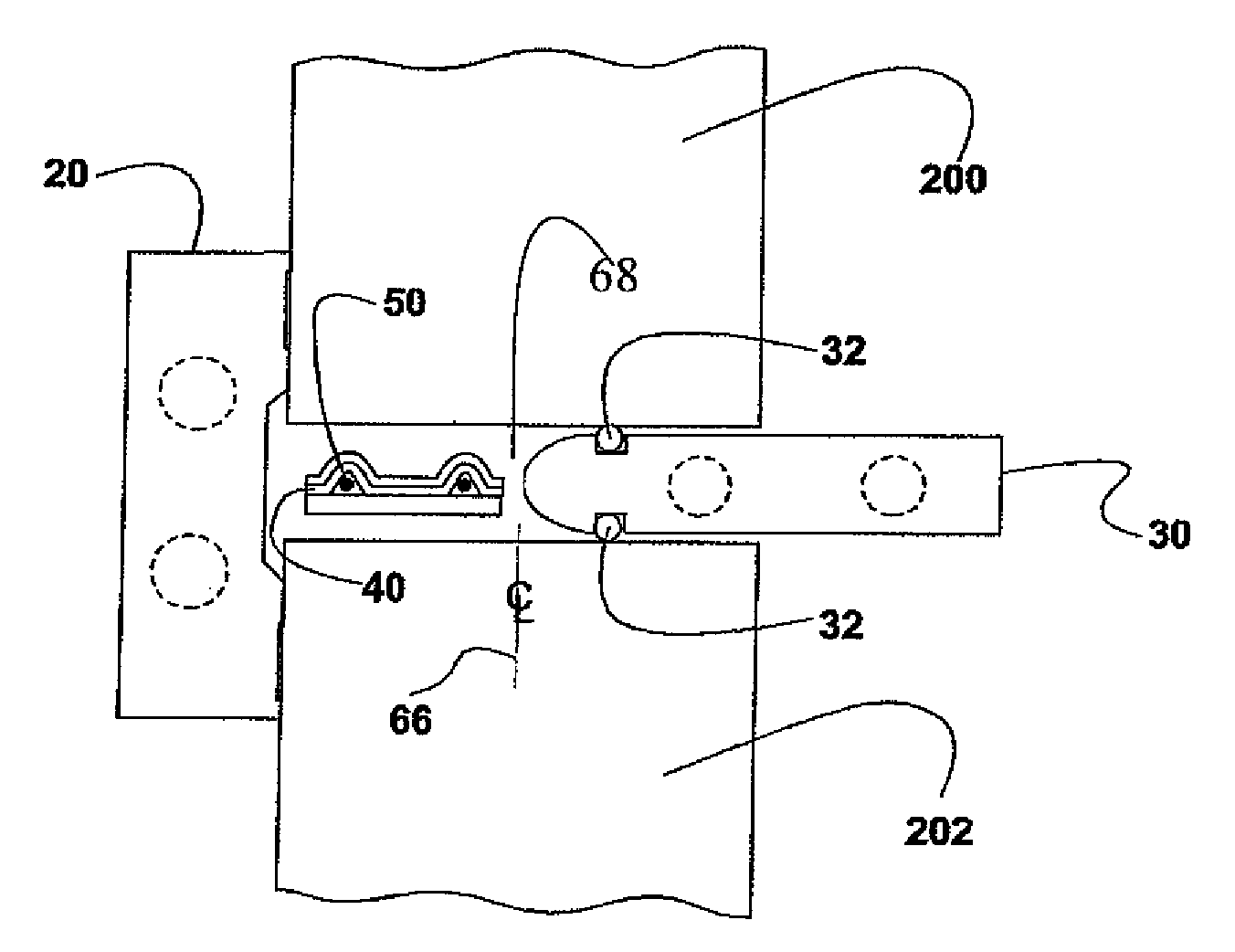

System and method for multi-pass computer controlled narrow-gap electroslag welding applications

A system and method of multi-pass computer controlled narrow-gap Electroslag welding allowing a faster vertical rate of rise at a much lower voltage, and that includes welding selected narrow-gaps within segments of a weld cavity between heavy plate steel workpieces and attendant control of the heat transfer depth penetration from the weld puddle to the workpieces according to a pre-determined profile resulting in a smaller heat affected zone and smaller grain structure in the weld metal.

Owner:ESKANDARI AMIR

A sealed cabin body of an integral wall plate type spacecraft

ActiveCN105659734BGuaranteed reliabilityReduce manual operationsFuselagesStructural reliabilityEngineering

The invention belongs to the technical field of aerospace and aviation, and relates to a spacecraft airtight cabin body, in particular to an integral wall plate type spacecraft airtight cabin cabin body. Including front frame, front cone section, front connection frame, first column section, first middle frame, second column section, second middle frame, third column section, third middle frame, fourth column section, rear connection frame and a sealed ball bottom; the invention is the first integral wall plate type spacecraft airtight cabin body applied to a long-term on-orbit spacecraft in China, which fills a gap in my country's aerospace technology. Compared with the semi-monocoque airtight cabin structure, the structural parts are reduced by more than 50%, and 90% of the welds are automatically welded, which reduces manual operations, effectively controls the welding quality, and ensures the reliability of the structure.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

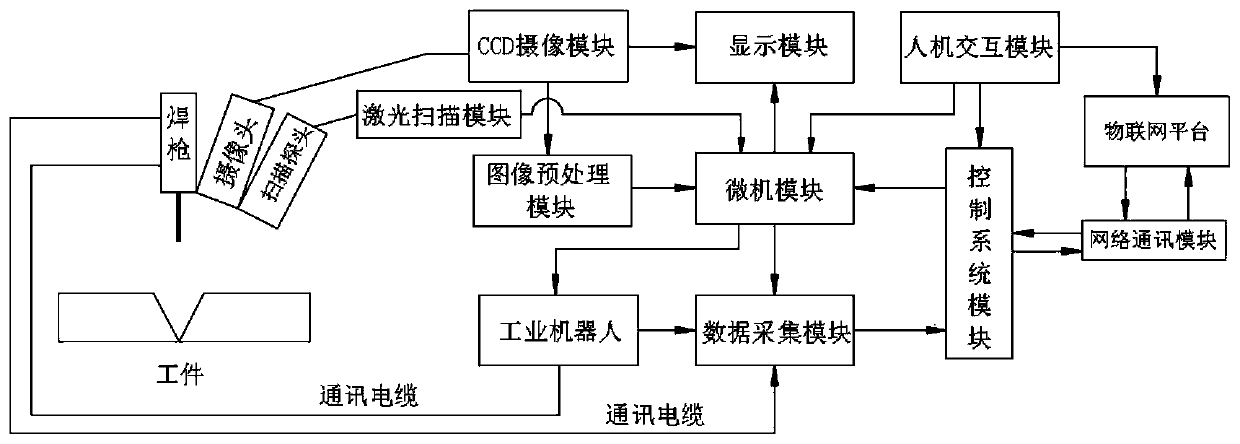

Welding system of ship assemblage plate frame structure

PendingCN109746603AReduce operating pressureLightweight and flexible for weldingWelding/cutting auxillary devicesAuxillary welding devicesMicrocomputerFillet weld

The invention provides a welding system of a ship assemblage plate frame structure. An industrial robot, a welding gun, a CCD camera shooting module, a laser scanning module, a microcomputer module, ahuman-computer interaction module, a control system module, a network communication module and an internet-of-things platform are included; the CCD camera shooting module, the laser scanning module,the industrial robot and a data acquiring module are correspondingly connected to the microcomputer module; the microcomputer module and the CCD camera shooting module are correspondingly connected toa display module; the industrial robot is connected to the data acquiring module; the welding gun is connected to the data acquiring module which is connected to the control system module; the microcomputer module is connected to the control system module; the control system module is connected to the internet-of-things platform through the network communication module; and the microcomputer module, the control system module and the internet-of-things platform are all connected to the human-computer interaction module. The welding system of the ship assemblage plate frame structure is used for automatic welding of longitudinal bone on a ship and a complicated plate frame fillet weld, and welding is portable and flexible and easy to carry out.

Owner:BEIBU GULF UNIV

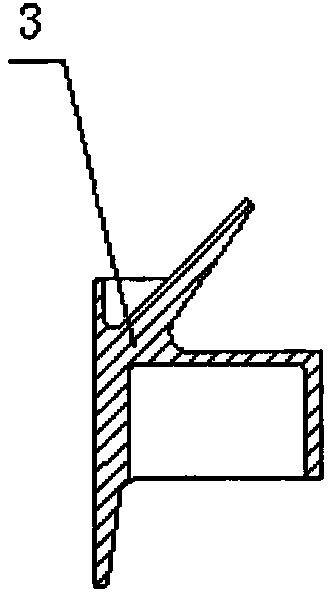

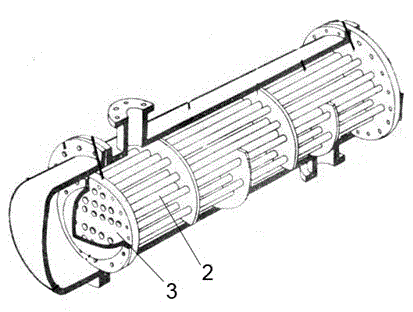

Process for machining heat exchange device of heat exchanger

ActiveCN104690524AGuaranteed quality and reliabilityImprove quality reliabilityHeat exchange apparatusMetal working apparatusPlate heat exchangerEngineering

The invention relates to the field of mechanical machining and manufacturing, in particular to a process for machining a heat exchange device of a heat exchanger. The process is characterized by comprising the following steps in sequence: (1) section manufacturing, to be specific, the section manufacturing is performed according to a design structure of a heat exchange device, wherein the components for section manufacturing comprise a tube base and several heat exchange tubes connected with the tube base, the tube base comprises a tube plate and several joints corresponding to the heat exchange tubes, and the joints are integrated with the tube plate; (2) connection of the joints and the heat exchange tubes, to be specific, the several heat exchange tubes are welded with the corresponding joints respectively, the heat exchange device of a heat exchanger is obtained after welding all the components. With adoption of the process, the machining procedure of the heat exchange device can be simplified greatly, the machining cost can be reduced, and the quality and reliability of the obtained heat exchange device are also improved greatly.

Owner:SICHUAN BLUSR MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com