Modular bypass vent waste heat boiler at tail of cement kiln

A bypass exhaust, waste heat boiler technology, applied in furnaces, waste heat treatment, furnace components, etc., can solve the problems of heat exchange efficiency affecting the power generation efficiency of waste heat power plants, difficult welding quality control, and large welding workload, etc., to simplify the site. The effect of installation process, labor cost saving, and installation cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

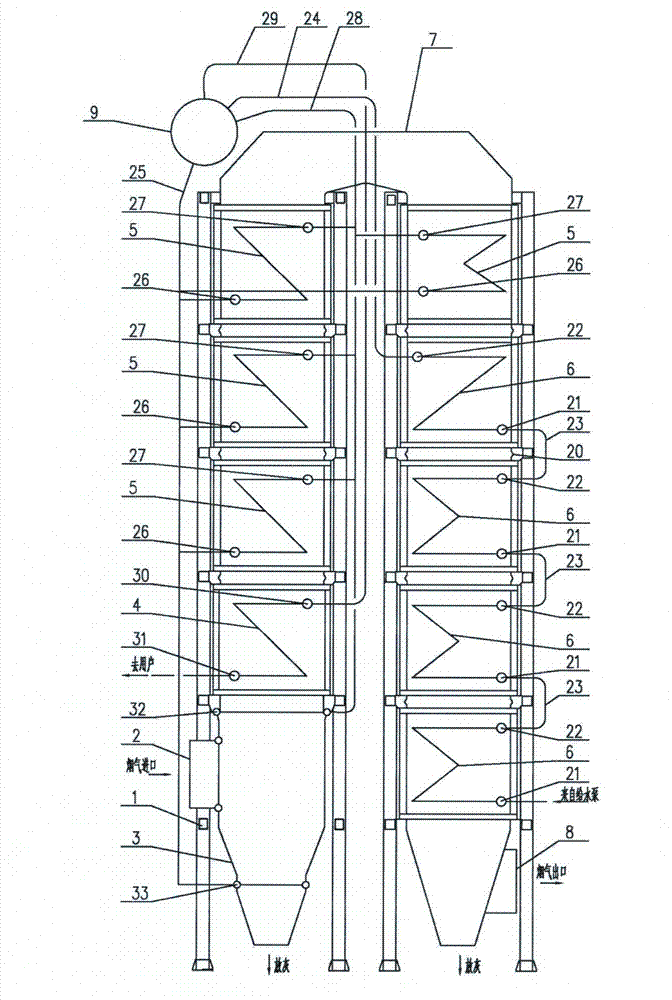

[0016] exist figure 1 In the schematic diagram of the front view of the cement kiln kiln tail modular bypass venting waste heat boiler shown in Example 1, the bypass venting boiler in an inverted "U" shape includes the following components: steel frame platform 1, flue gas inlet 2 , water wall 3, superheater module 4, evaporator module 5, economizer module 6, steering flue 7, flue gas outlet 8 and drum 9. Among them, the superheater module, evaporator module and economizer module have the same structure, such as Figure 4 As shown, they each have an independent frame 10, and the frame is surrounded by a heat-insulating guard plate 11 to form a section of a cylindrical outer shell. The guard plate is double-layered, and insulating materials are filled between the guard plates. ; The frame is provided with a ventilation mechanism 13; the frame is also provided with 2 pairs of hoisting mechanisms 14; the heating surfaces 15 of the superheater module, the evaporator module and th...

Embodiment 2

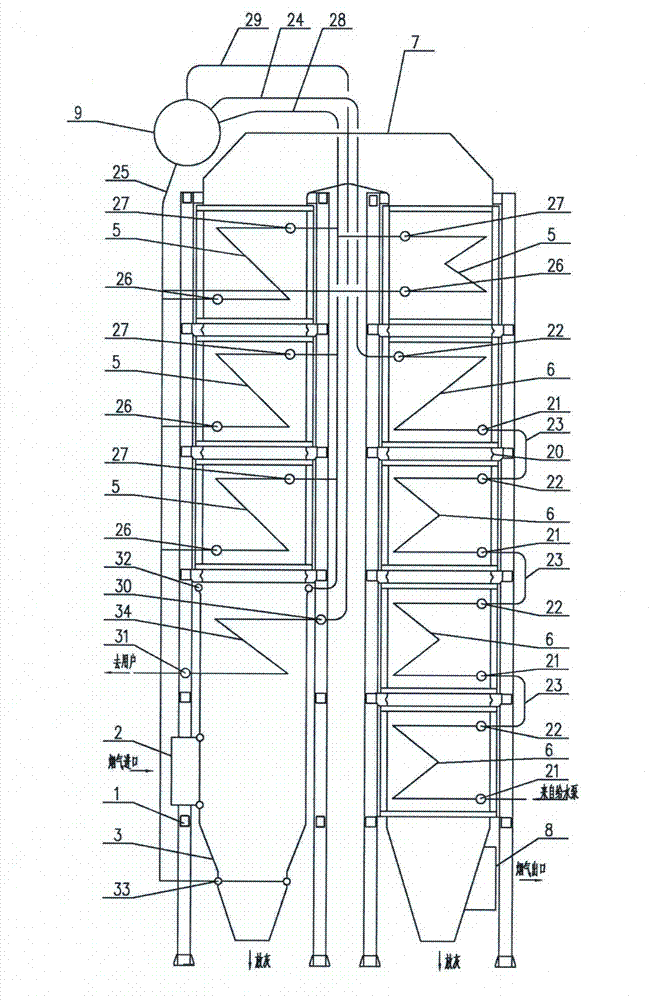

[0019] exist figure 2 In the schematic diagram of the front view of the cement kiln tail modular bypass venting waste heat boiler shown in Example 2, the bypass venting boiler in an inverted "U" shape includes the following components: steel frame platform, flue gas inlet, water cooling Wall, superheater parts 34, evaporator module, economizer module, steering flue, flue gas outlet and drum. Among them, the evaporator module and the economizer module have the same structure, such as Figure 4 As shown, they each have an independent frame, and the frame is surrounded by a heat-insulating guard plate to form a cylindrical shell. The guard plate is double-layered, and the insulating material is filled between the guard plates. There is a ventilation mechanism; there are also two pairs of hoisting mechanisms on the frame; the heating surfaces of the evaporator module and the economizer module are set on the frames in their respective shells; they are connected to the heating sur...

Embodiment 3

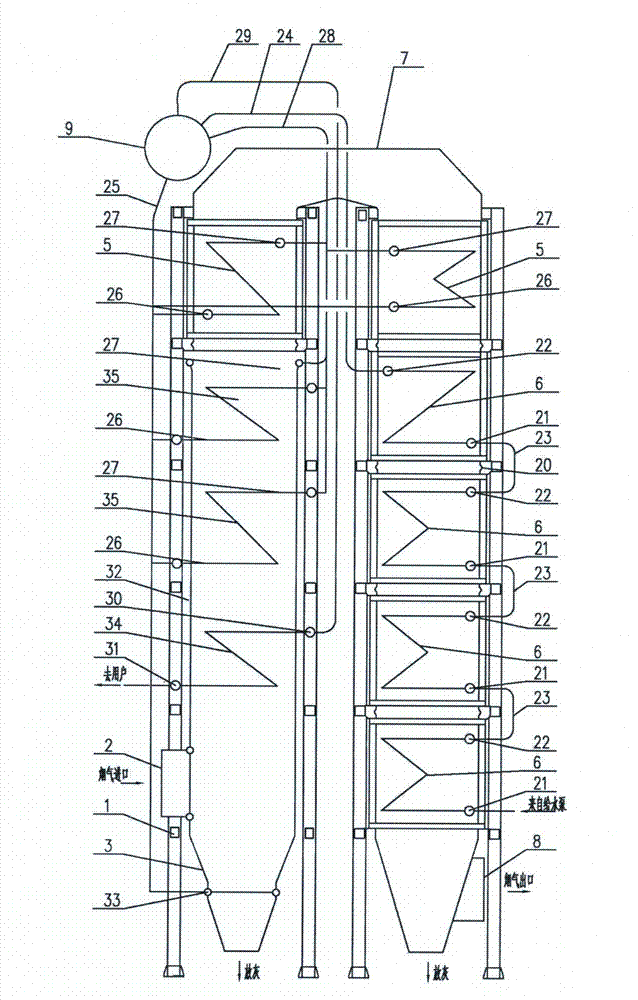

[0022] exist image 3 In the schematic diagram of the front view of the cement kiln tail modular bypass venting waste heat boiler shown in Example 3, the bypass venting boiler in an inverted "U" shape includes the following components: steel frame platform, flue gas inlet, water cooling Wall, superheater parts, evaporator parts 35, evaporator module, economizer module, steering flue, flue gas outlet and drum. Among them, the evaporator module and the economizer module have the same structure, such as Figure 4 As shown, they each have an independent frame, and the frame is surrounded by a heat-insulating guard plate to form a cylindrical outer shell. The guard plate is double-layered, and the insulating material is filled between the guard plates. There is a ventilation mechanism; 2 pairs of hoisting mechanisms are provided on the frame; the heating surfaces of the evaporator module and the economizer module are all set on the frames in the respective shells; they are connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com