Patents

Literature

889 results about "Reinforced concrete column" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A reinforced concrete column is a structural member designed to carry compressive loads, composed of concrete with an embedded steel frame to provide reinforcement. For design purposes, the columns are separated into two categories: short columns and slender columns.

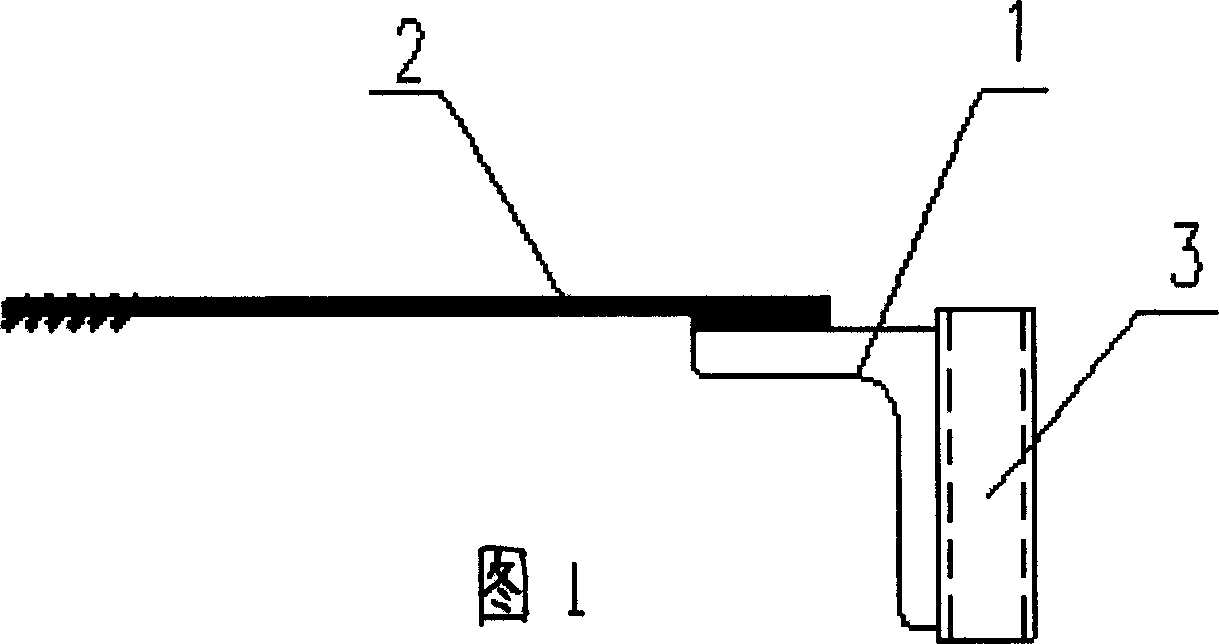

Novel method for quickly assembling low-cost energy-saving house with prefabricated pole, beam, plate

InactiveCN101294419ANo wasteReduce the amount of manual laborBuilding constructionsReinforced concrete columnHigh density

A novel method for rapidly assembling a low-cost energy-saving house with precast columns, beams and slabs comprises the steps of preparing house columns, beam molds and built-in reinforcing steel bars or profiled steel bars, pouring concrete grout into the molds, high-speed rotating in a centrifuge, curing, and demolding to obtain precast reinforced concrete columns and beam components; and inserting the precast columns on a cup foundation element, passing the precast beams through the preformed pores on the precast column, lapping precast floor slabs on the precast beams, and embedding wall slabs inside the embedding grooves of the precast beams, so as to form the major structure of the rapidly assembled low-cost energy-saving house. The inventive method has the advantages of application to industrial production, no air holes in components, high density, high strength, long service life, standardized production, low production cost, low time and raw materials consumption, rapid house construction speed, and high quality; and is a novel energy-saving house construction method in the construction field.

Owner:丁公权 +1

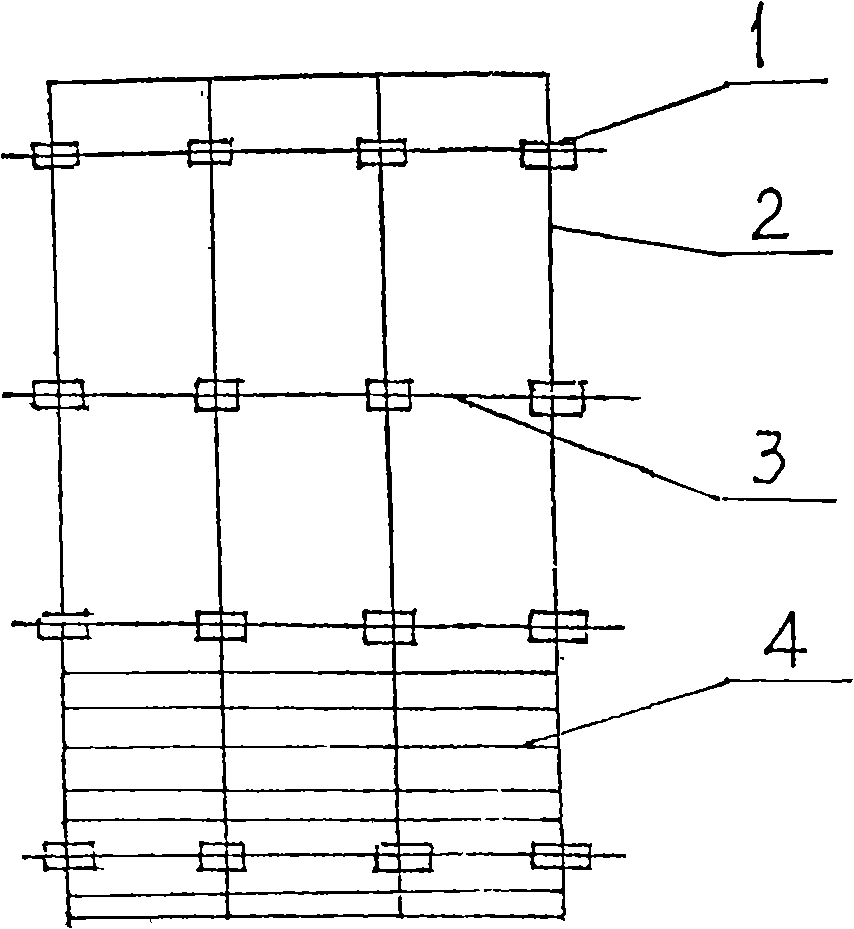

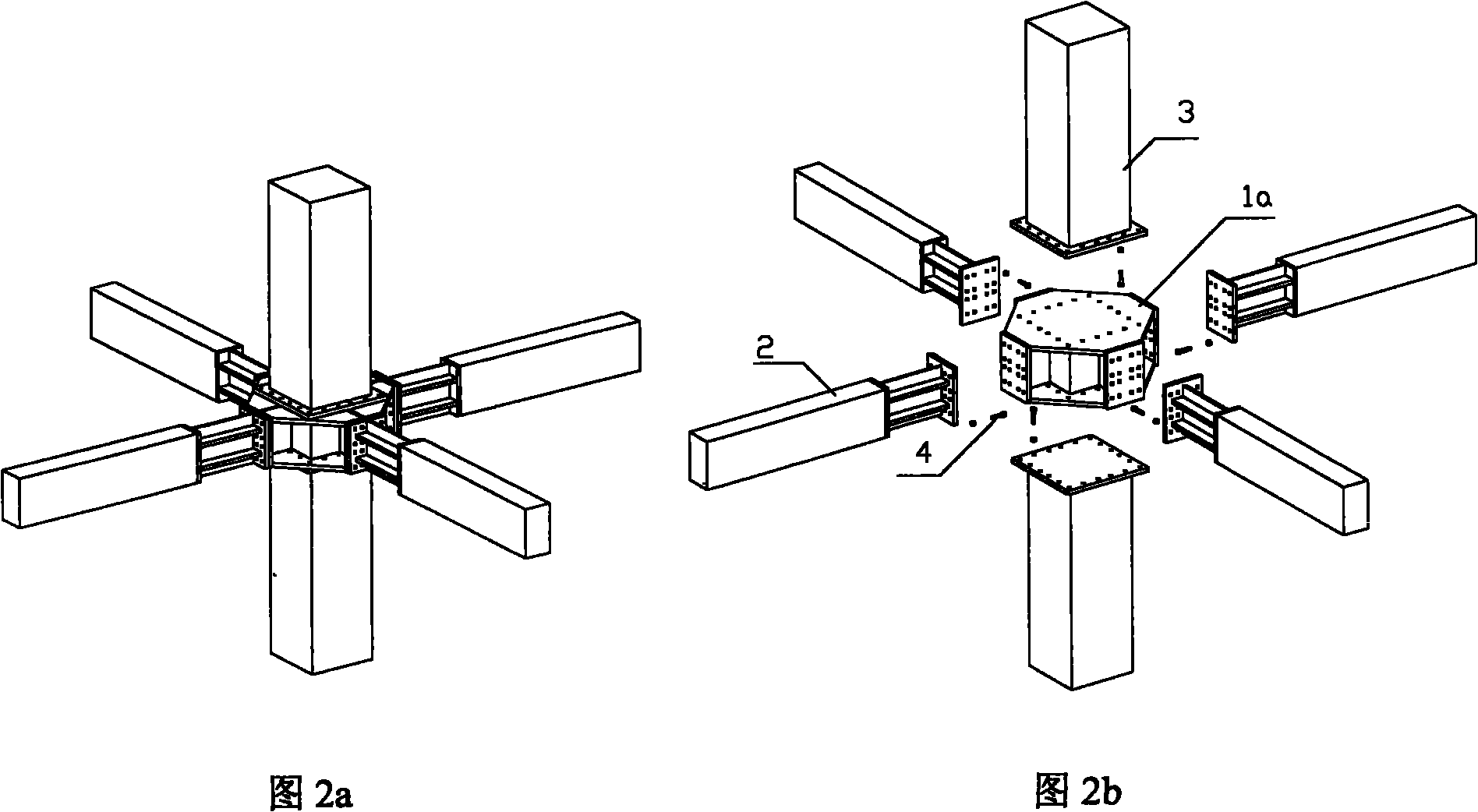

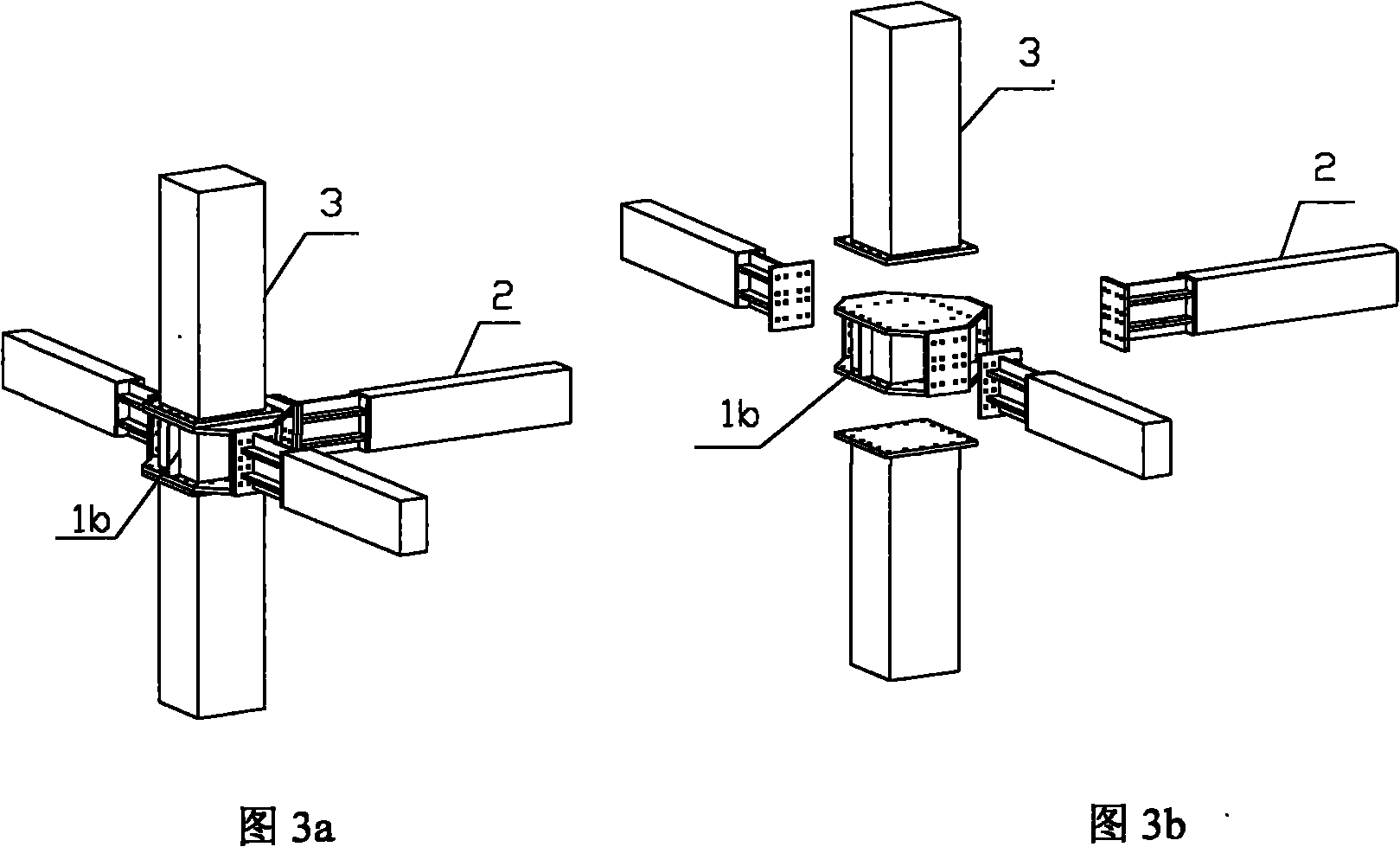

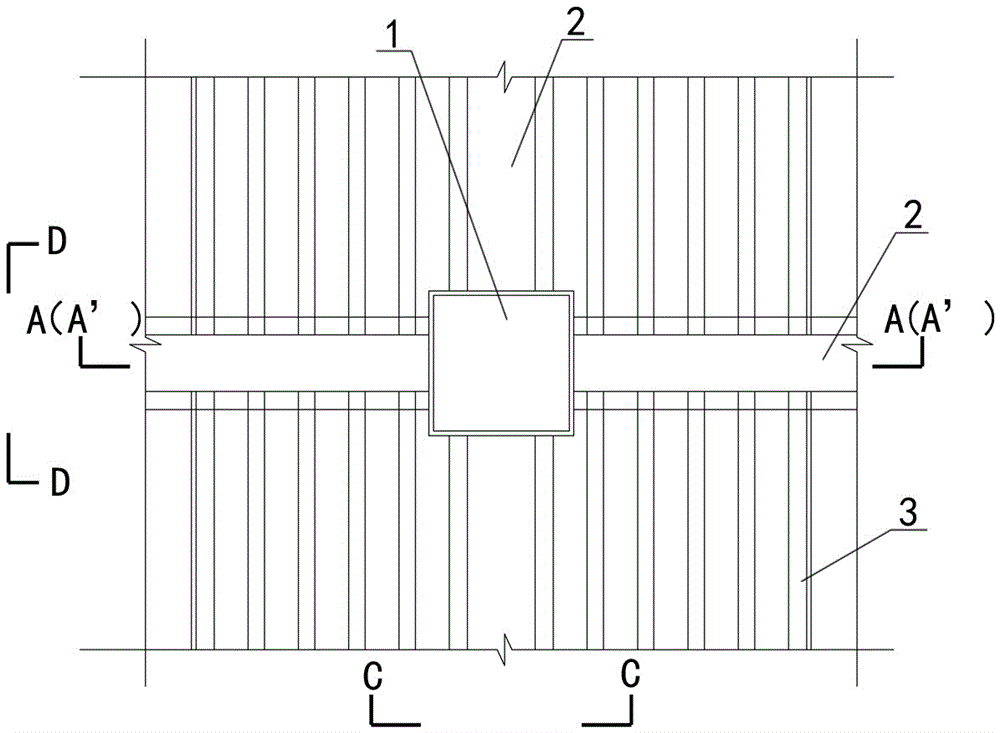

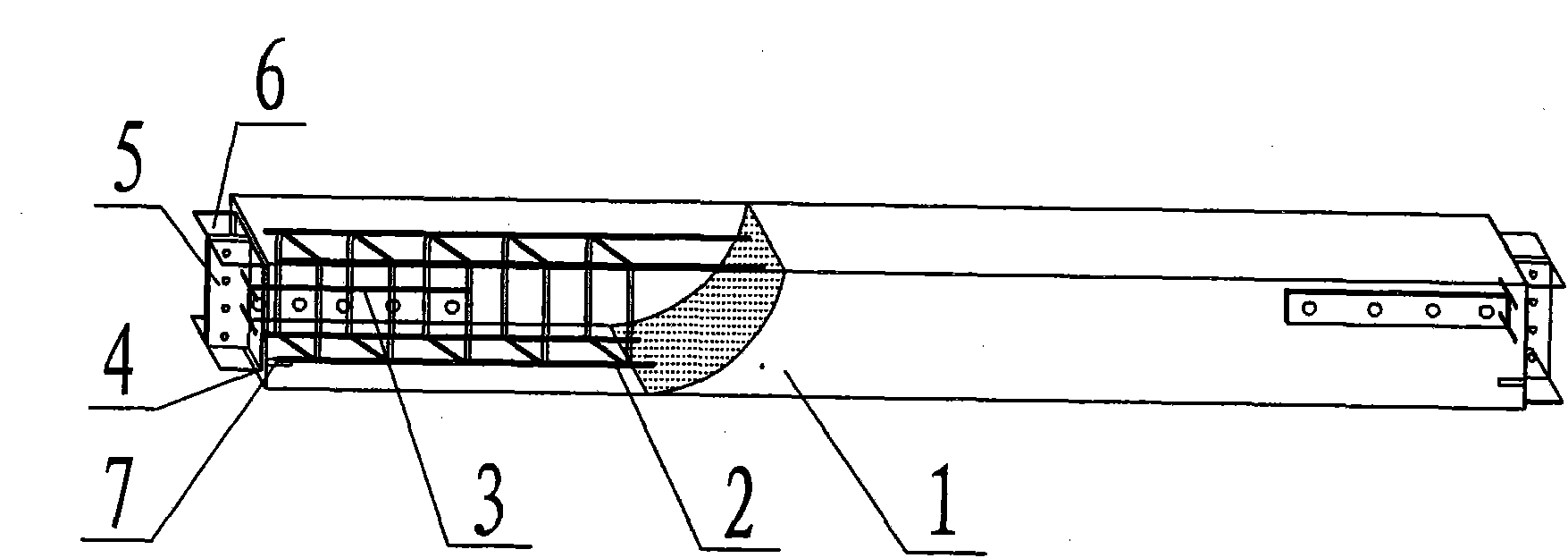

Steel joint precast and assembled reinforced concrete frame structure

InactiveCN101818521AEasy to replace and maintainEasy to replaceBuilding constructionsReinforced concrete columnRebar

The invention discloses a steel joint precast and assembled reinforced concrete frame structure, which comprises precast beam members, precast column members and joints, wherein each of the nodes comprises a steel plate box in which annular horizontal reinforced rib plates and vertical reinforced rib plates are arranged; the upper and lower surfaces of the steel plate box are respectively provided with an upper force bearing plate and a lower force bearing plate; the outer surface of the steel plate box is provided with rib plates which are respectively connected with the upper and lower force bearing plates; the rib plates are connected with vertical force bearing plates which are respectively connected with the upper and lower force bearing plates; each precast beam member comprises a precast reinforced concrete beam; a beam-end precast steel plate is precast on the end part of the precast reinforced concrete beam, and is connected with a shaped steel beam which is connected with a beam-end force bearing plate; each precast column member comprises a precast reinforced concrete column; a steel plate enclosure box is arranged on the lateral surface of the end part of the precast reinforced concrete column; studs are arranged on the inner lateral surface of the closure box; the end part of the steel plate closure box is provided with a column-end steel force bearing plate; the upper and lower force bearing plates of each joint are respectively with the adjacent columns; and the vertical force bearing plates are connected with adjacent beams.

Owner:SOUTHEAST UNIV

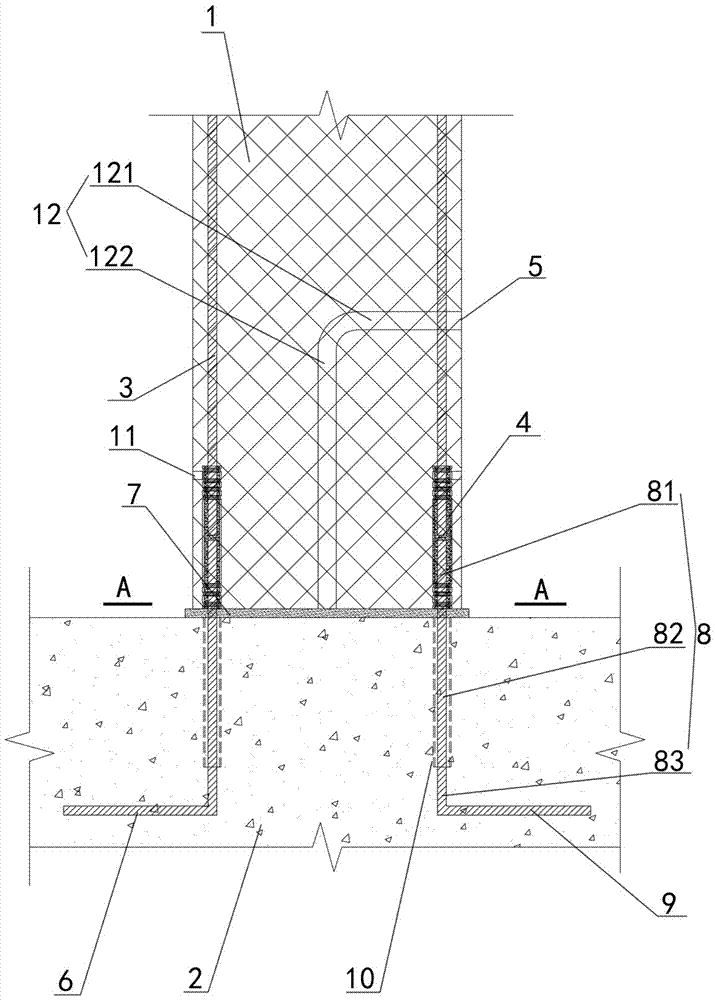

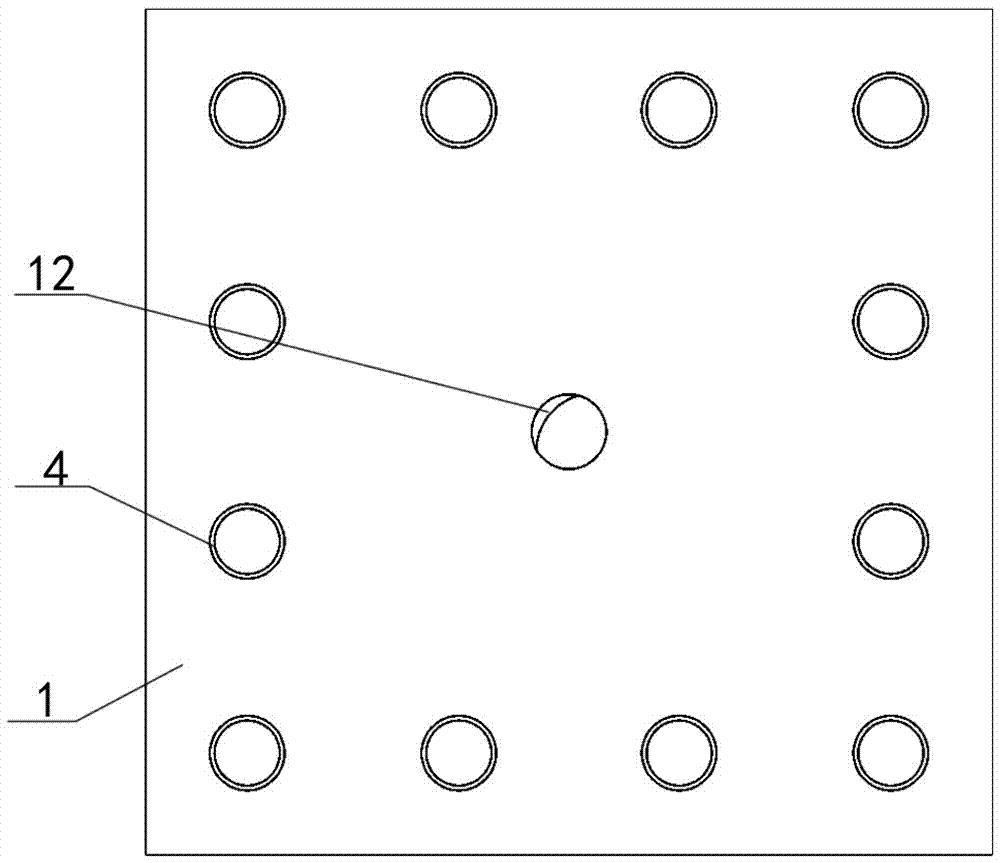

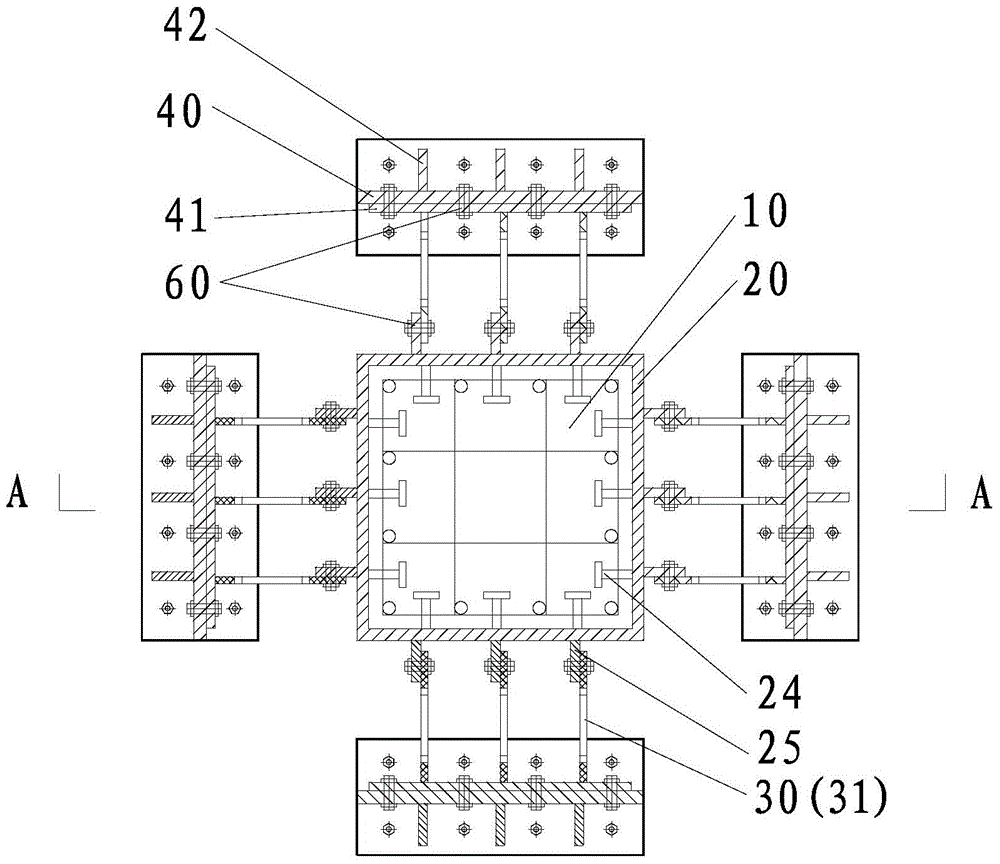

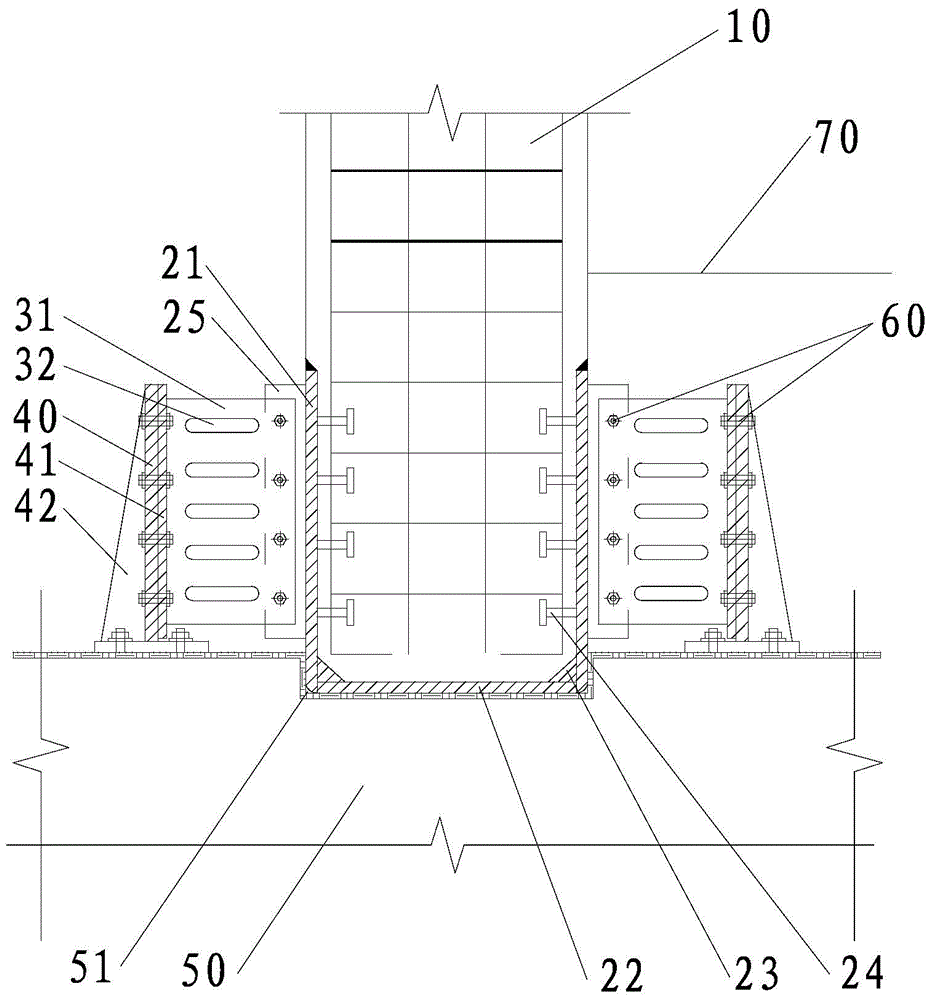

Assembled joint node for column base and construction method

PendingCN107299641AImprove seismic performanceImprove abilitiesStrutsWallsReinforced concrete columnRebar

Provided is an assembled joint node for a column base and a construction method thereof. The assembled joint node for the column base can be used in a prefabricated reinforced concrete column, a reinforced concrete foundation, a column anchorage longitudinal rib, a grouting sleeve and a foundation anchor steel bar, wherein the foundation anchor steel bar is connected with the column anchorage longitudinal rib through a crack pouring material, and the grouting sleeve is filled full with the crack pouring material; a spliced seam of the reinforced concrete foundation and the prefabricated reinforced concrete column is also filled with the crack pouring material, and the foundation anchor steel bar comprises a vertical part and a horizontal part; the vertical part comprises an upper anchorage section, which extends beyond the upper surface of the reinforced concrete foundation, a middle no-bonding section, which is embedded in the reinforced concrete foundation, and a lower anchorage section; the outside of the middle no-bonding section is provided with an isolation suite which is used for isolating the the middle no-bonding section and preventing the middle no-bonding section from being bonded with concrete; the top surface of the isolation suite is aligned with the upper surface of the reinforced concrete foundation. According to the assembled joint node for the column base and the construction method of the assembled joint node, the deformation capability and the mechanical property of the node at the column base in an assembled structure, the construction is efficient, and the seismic performance is good.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

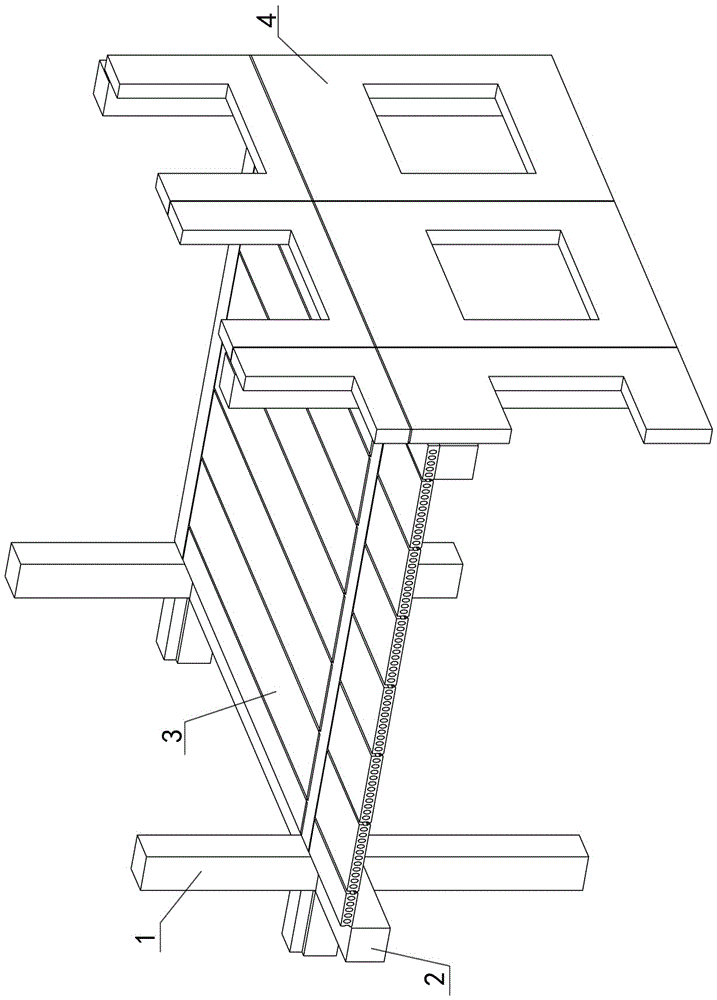

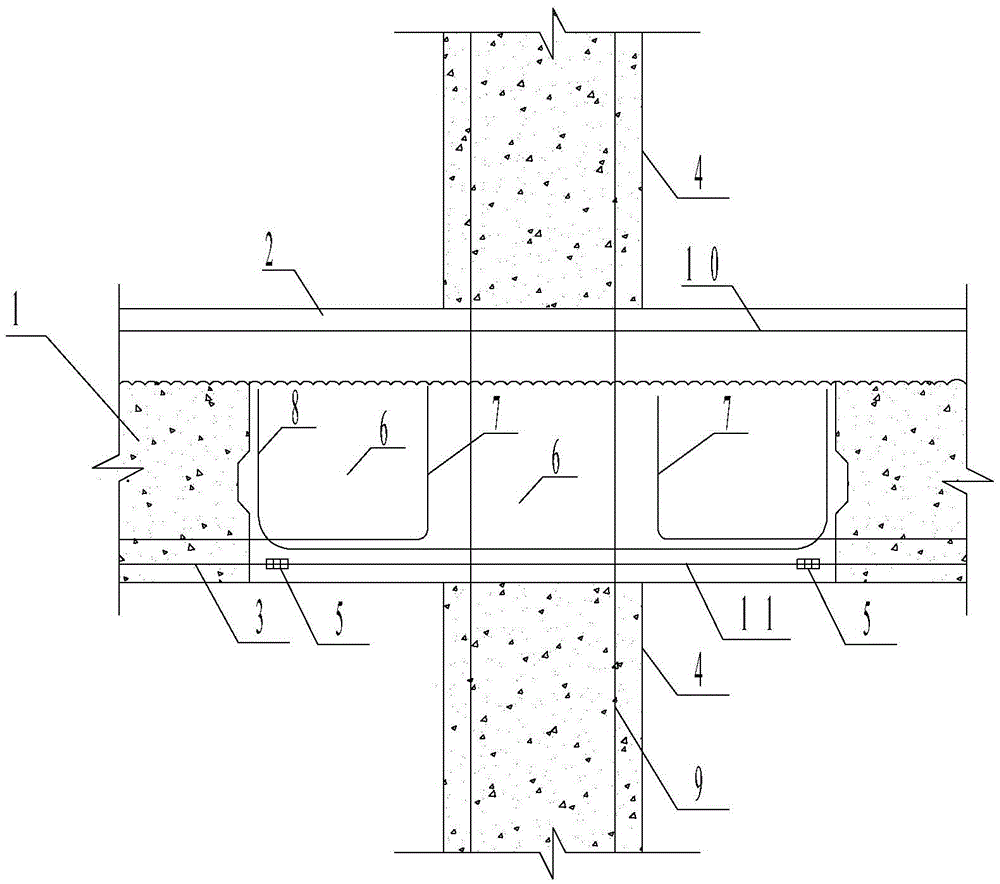

Column-through assembled prestressed concrete frame system and construction method thereof

ActiveCN106499051AEfficient constructionImprove seismic performanceBuilding constructionsReinforced concrete columnFloor slab

The invention discloses a column-through assembled prestressed concrete frame system and a construction method thereof. The system comprises a foundation, a prefabricated reinforced concrete column, a prefabricated reinforced concrete beam, a superimposed floor slab and an external hung prefabricated wallboard, wherein a column prestressed duct is formed in the prefabricated reinforced concrete column; a beam prestressed duct is formed in the prefabricated reinforced concrete beam; post-tensioned unbonded prestressed tendons are penetrated into the beam prestressed duct and the column prestressed duct; energy-dissipation steel bars are anchored between the prefabricated reinforced concrete column and the superimposed floor slab. The structure provided by the invention has a good seismic performance; the lower part of a beam-column joint is subjected to unreinforced connection so that the structure is simple; the post-tensioned unbonded prestressed tendons and a replaceable column base energy dissipater are used so that the structure is less damaged and easy to be repaired in the earthquake; a construction manner of using the prefabricated superimposed floor slab and prestressed assembly makes site construction convenient and rapid and saves a lot of supports compared with a traditional prefabricated assembly structure; the column-through assembled prestressed concrete frame system provided by the invention is used in combination with lateral supports, shear walls and other lateral force resisting members, and is applicable to most high-rise public buildings.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

Prefabricated reinforced concrete beam and connection joint of reinforced concrete column and beam

InactiveCN102086677ASmall sectionOvercome CorrosionLoad-supporting elementsReinforced concrete columnPre stress

The invention relates to the improvement of reinforced concrete beams for buildings and the connection joints of beams and columns, and is characterized in that transverse T-shaped structural section steel joints are disposed at the two ends of the reinforced concrete beam, wherein the T-shaped transverse end surface is at least equal to the cross section formed by the steel reinforcement cage in the beam, and at least in the reinforced concrete prefabricated beam, through holes are disposed at the corresponding positions of the main and auxiliary steel reinforcement; perforating plug welding or connection is formed by each main and auxiliary steel reinforcement perforating through the through holes; the reinforced concrete column connects the joints; an axial steel pipe is disposed at least in the cross section of the connecting part section of the column and the prefabricated beam; and a section steel joint extending outside the side surface of the column is disposed at the connecting surface of the steel pipe and the beam. Therefore, a strong joint structure is formed which is shear resistant, bending resistant, and has strong bearing capability; and also an elastic structure with a steel structural beam is formed which is anti-seismic and has good security. Prestress tension is built-in, so the invention is applicable to the production of large-span prefabricated reinforced concrete beams with a length more than 8 meters. The advantages of quick installation, high strength, elastic structure, and good security of steel structural beams are combined, and the cost is only 1 / 3 of steel structures, so the comprehensive benefit cost remains lower than that of reinforced concrete.

Owner:张吉华 +1

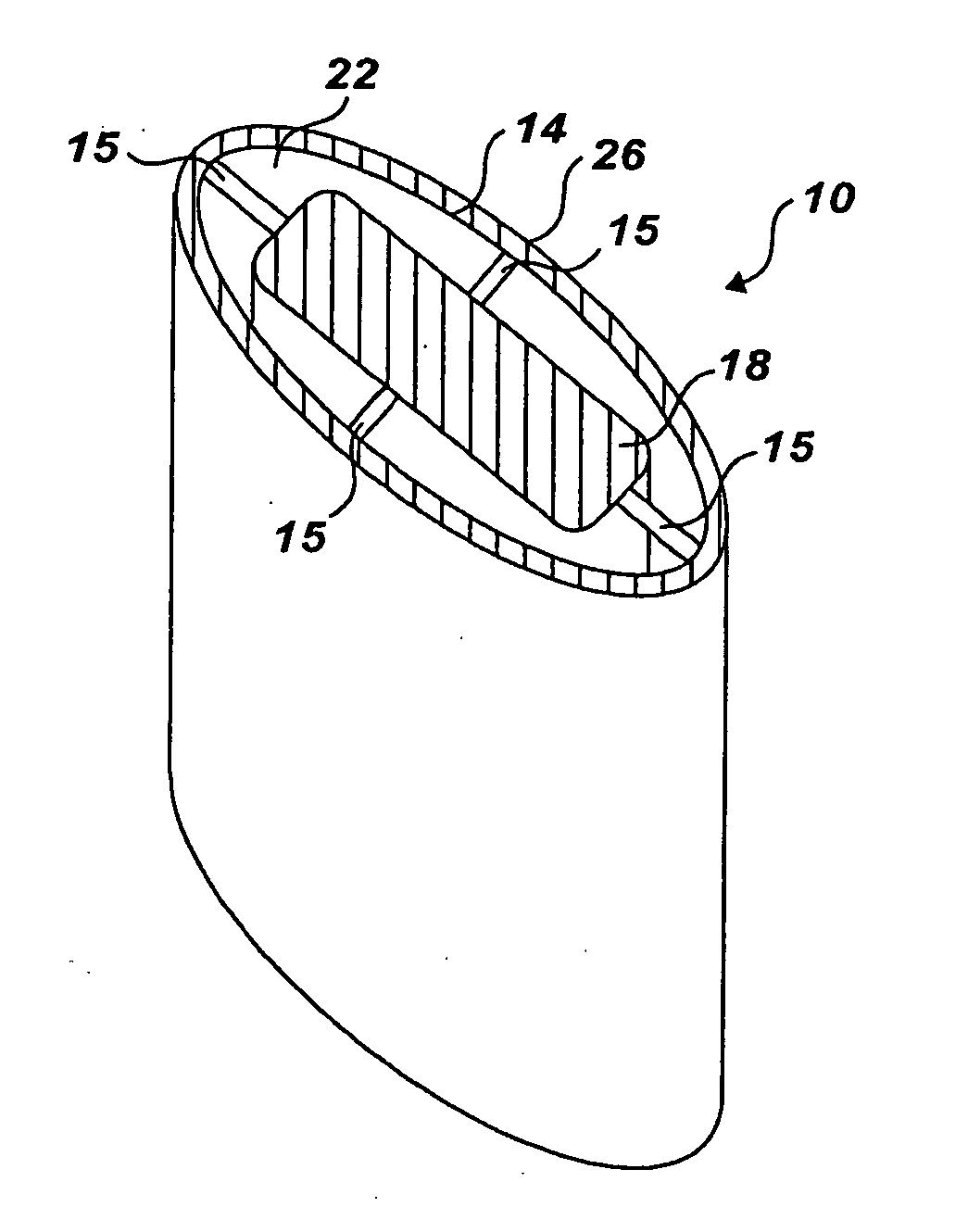

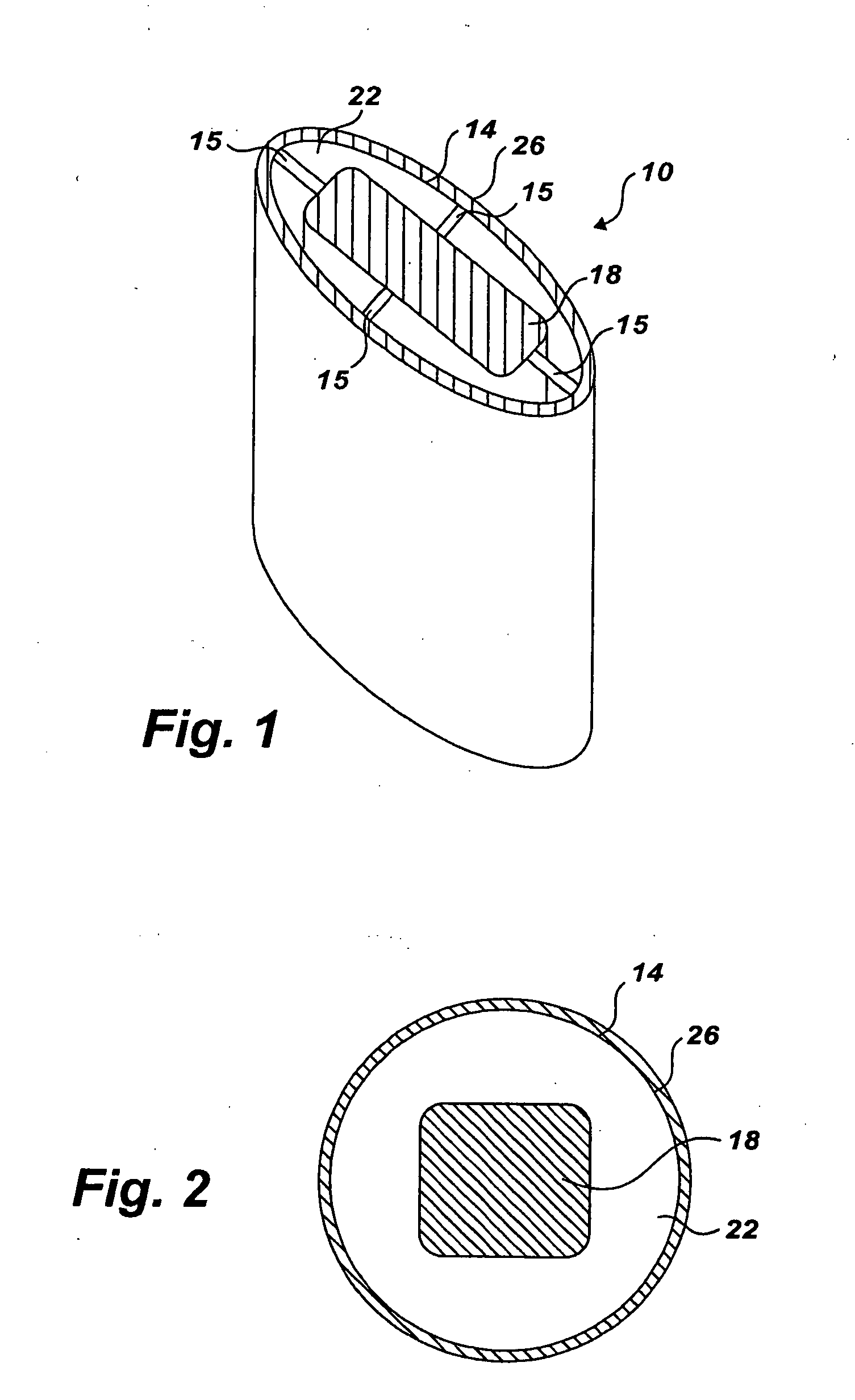

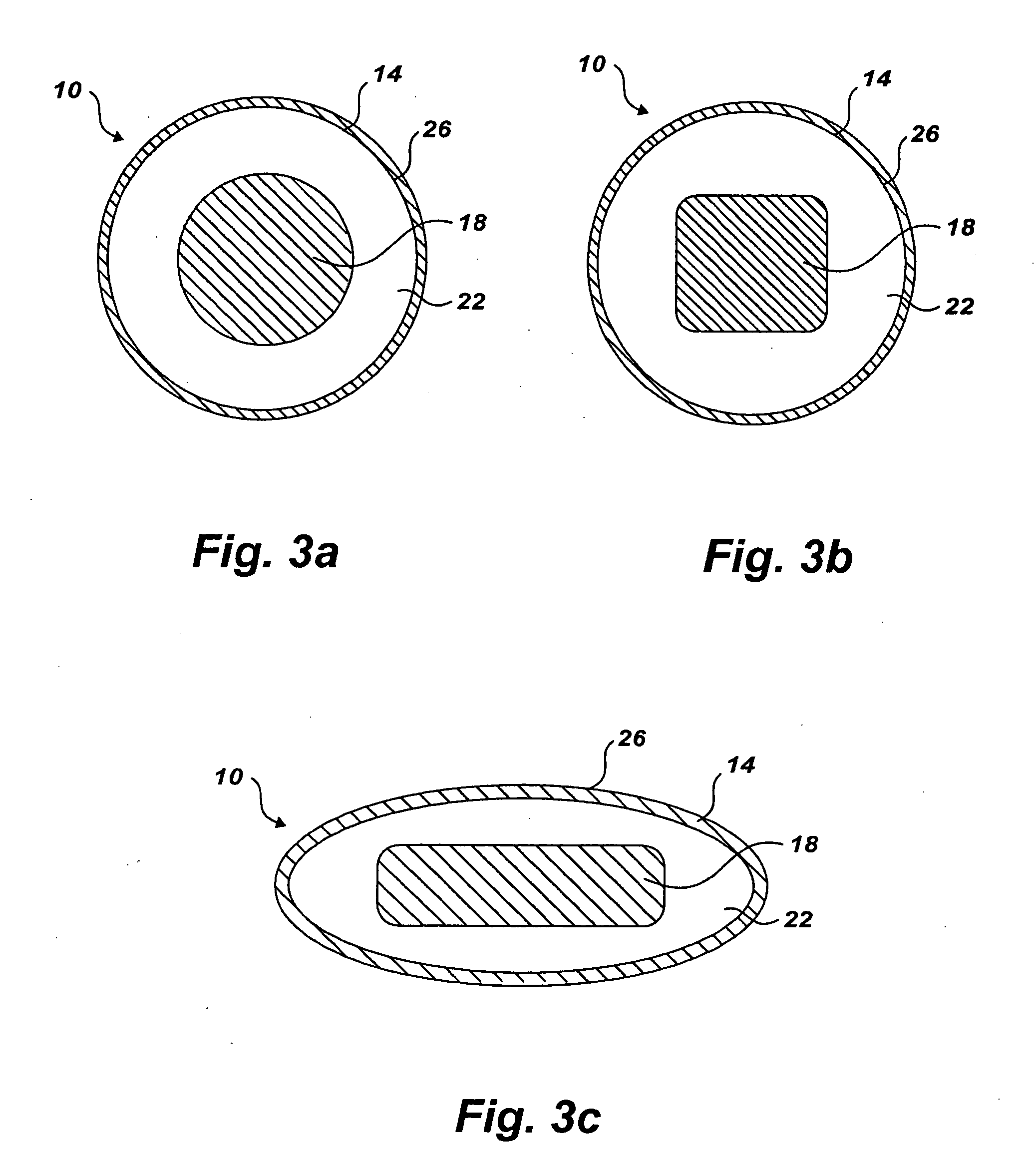

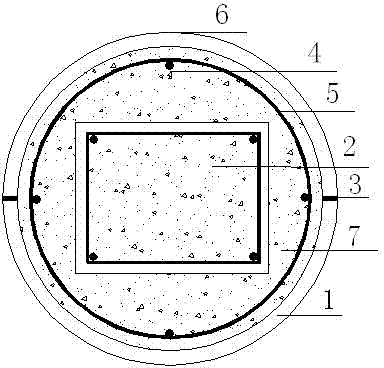

Shape modification and reinforcement of columns confined with FRP composites

InactiveUS20060070338A1Reduce concentrationReduce failureStrutsPillarsReinforced concrete columnHigh intensity

Strengthening reinforced concrete columns by using Fiber Reinforced Polymer (FRP) composites can be an effective method of retrofitting existing columns. FRP composites have a number of advantages over steel, including their high strength-to-weight ratio and excellent durability. The confinement effectiveness of FRP materials for rectangular sections can be improved by performing shape modification such that a rectangular column section is modified into a shape that does not have 90 degree comers such as an elliptical, oval or circular column. An expansive concrete can be advantageously used between the FRP material and the existing concrete in order to post-tension the FRP material circumferentially and improve confinement of the concrete. A finite element analytical model is also disclosed which model describes the stress-strain relationship for the FRP-confined columns after shape modification.

Owner:PANTELIDES CHRIS P +1

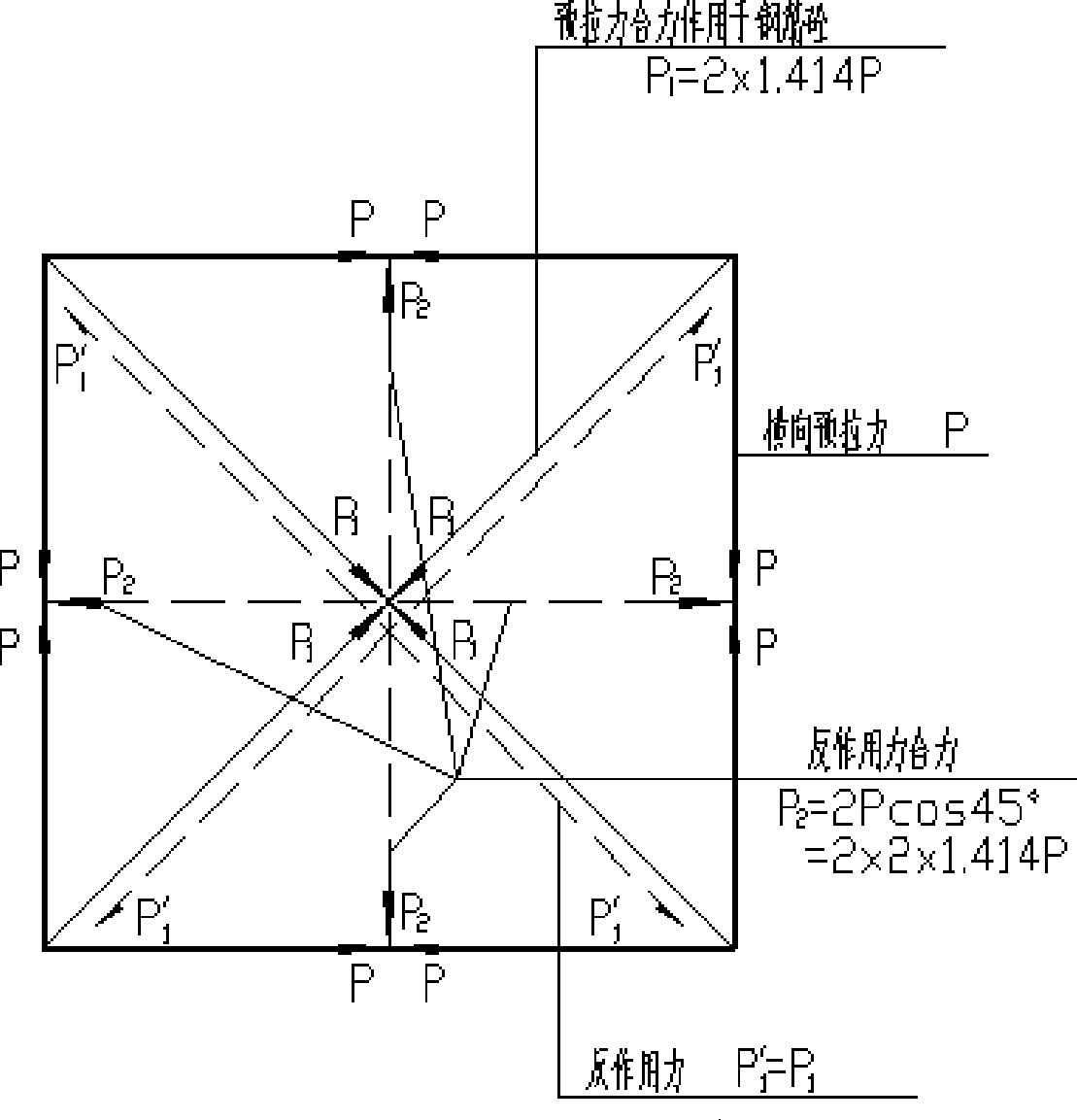

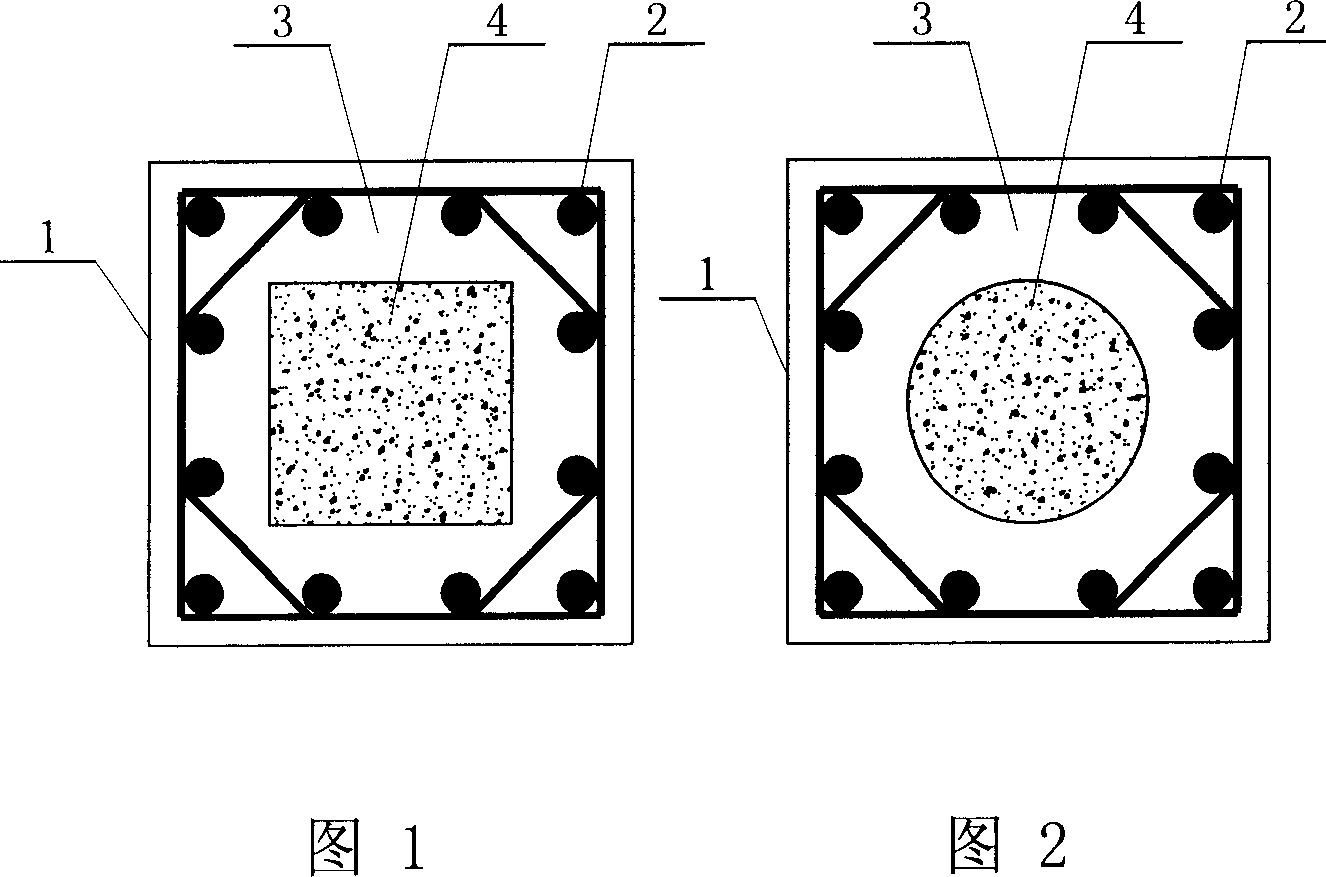

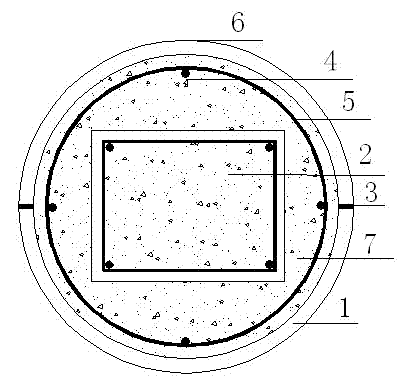

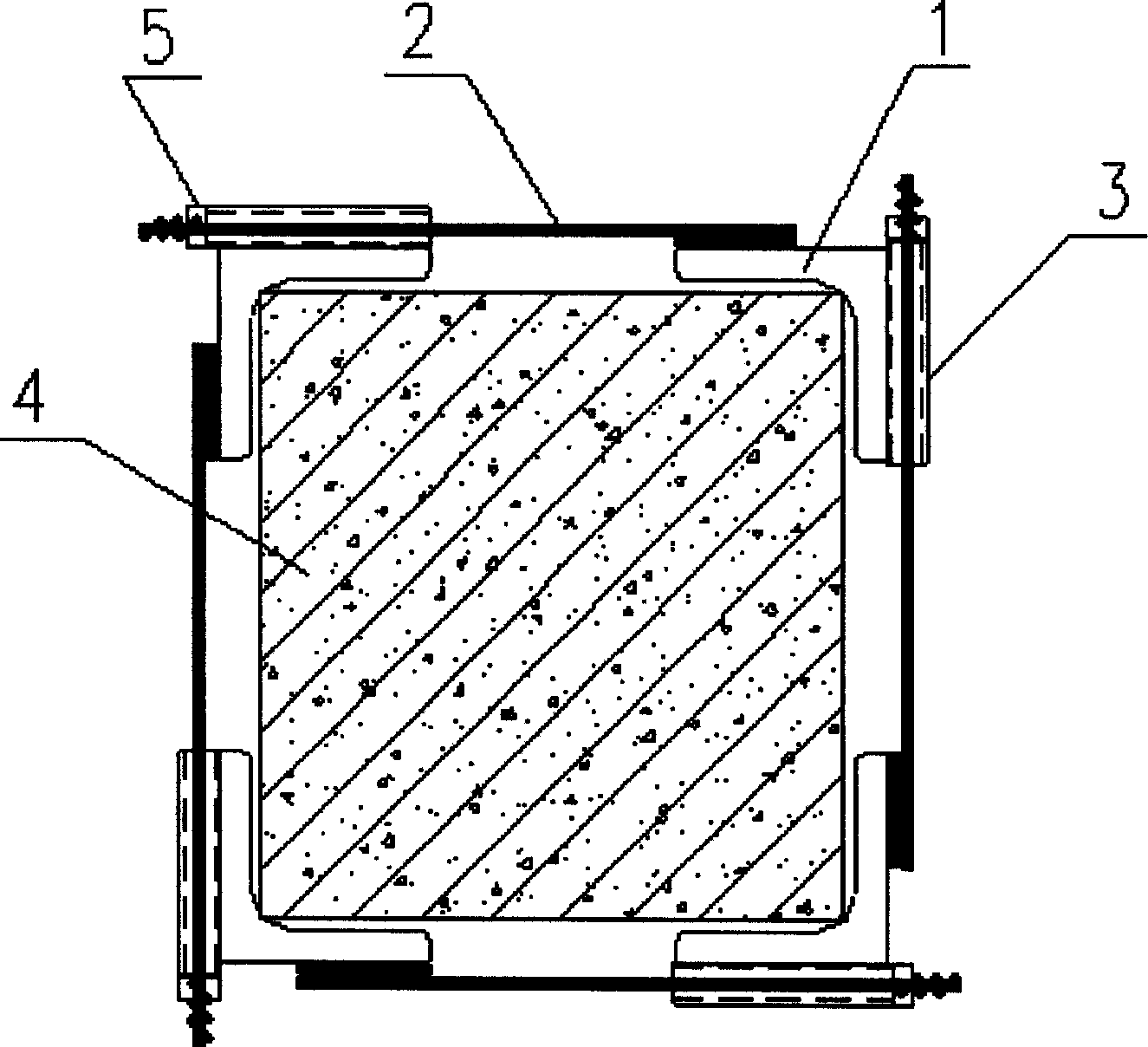

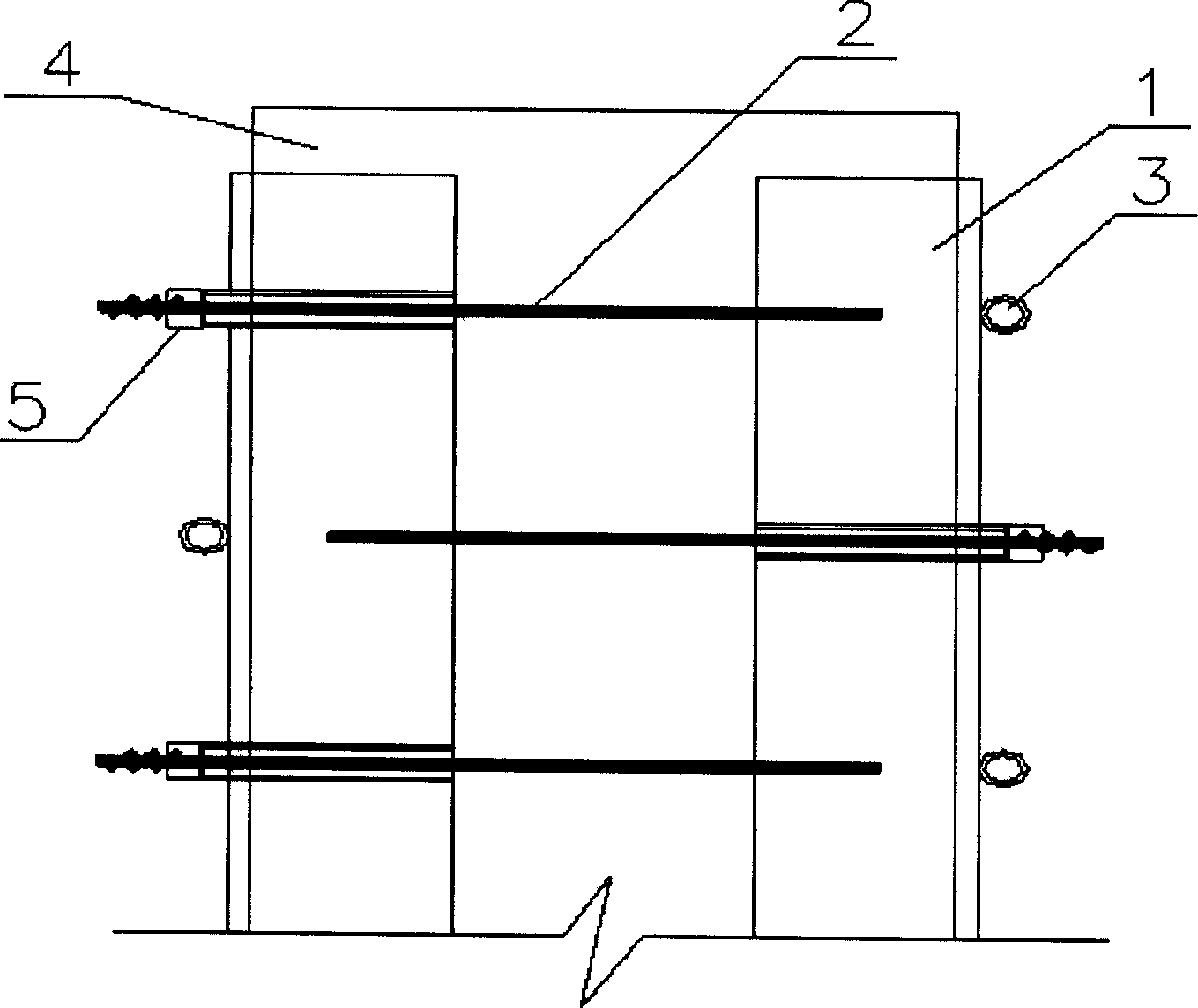

Enveloping prestressing force fastening type steel tube concrete column and reinforcement method

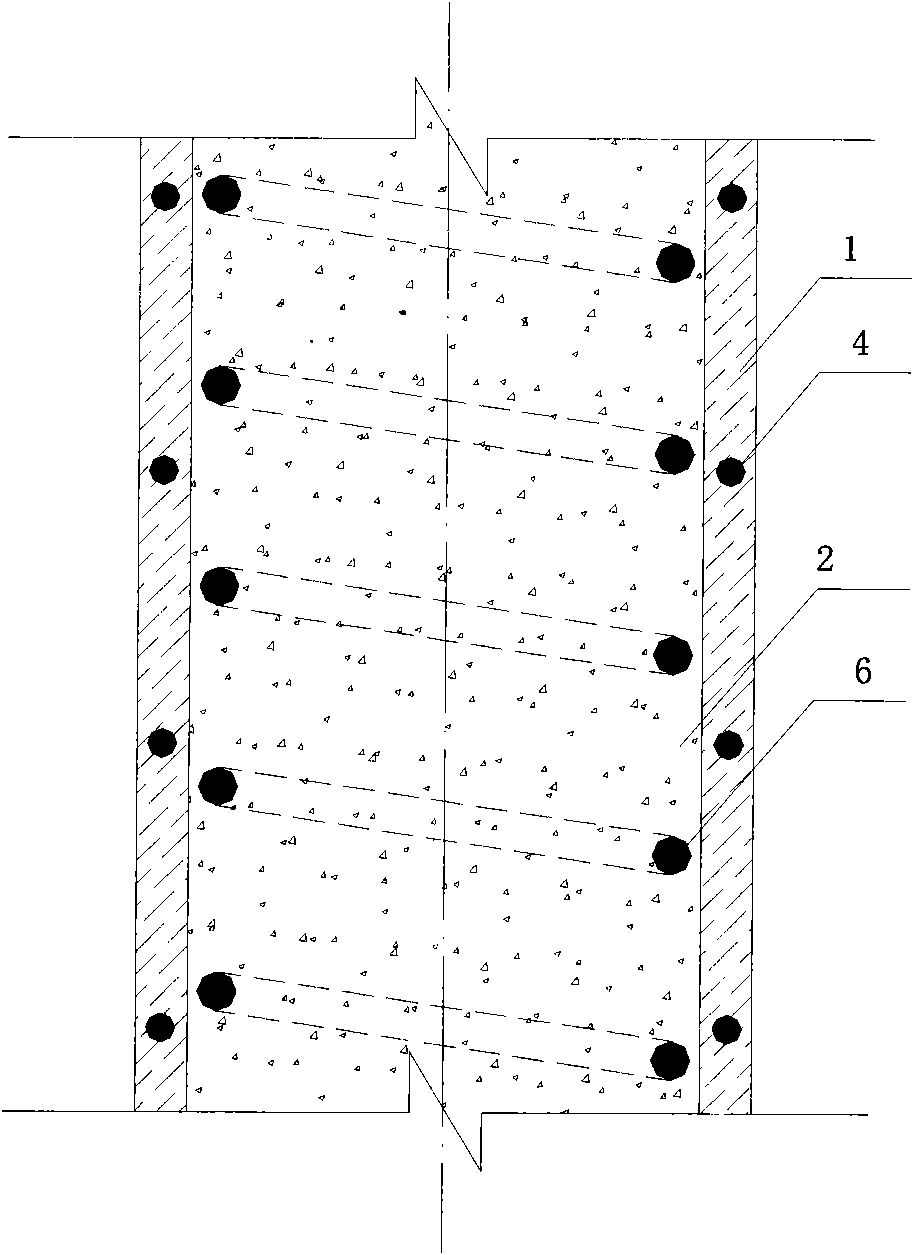

InactiveCN101397854ASimple prestressingAccurate prestressingStrutsBuilding repairsReinforced concrete columnPositive pressure

The invention discloses a fastened steel pipe concrete column confined by pre-stress and a reinforcement method thereof. The column is mainly applied to the reinforcement of a monolayer, multilayer or high-rise frame column which exceeds the limit value of the strength, rigidity or axial compression ratio. The basic principle of the invention is as follows: transverse pre-tensioning of a steel plate which is added to the surface of a rectangular or round reinforced concrete column is built up by screwing down a shear high strength bolt and the resultant force thereof acts on the surface of the reinforced concrete column; in accordance with the principle that acting force equals to counter acting force, the surface of the reinforced concrete column generates a counter acting force (positive pressure) towards the inner wall of the steel plate; in such way, friction force, which is corresponding to the positive pressure and is the so-called shear resistant bearing capacity in a project, is generated between the concrete surface and the inner wall of the steel plate, thereby achieving the loaded effect of the current steel pipe concrete column that is manufactured by casting concrete on the prepared steel pipe. Due to the existence of the transverse pre-stress, the mechanical effect of the steel pipe concrete column in the invention is better than the current one.

Owner:GUIZHOU UNIV +2

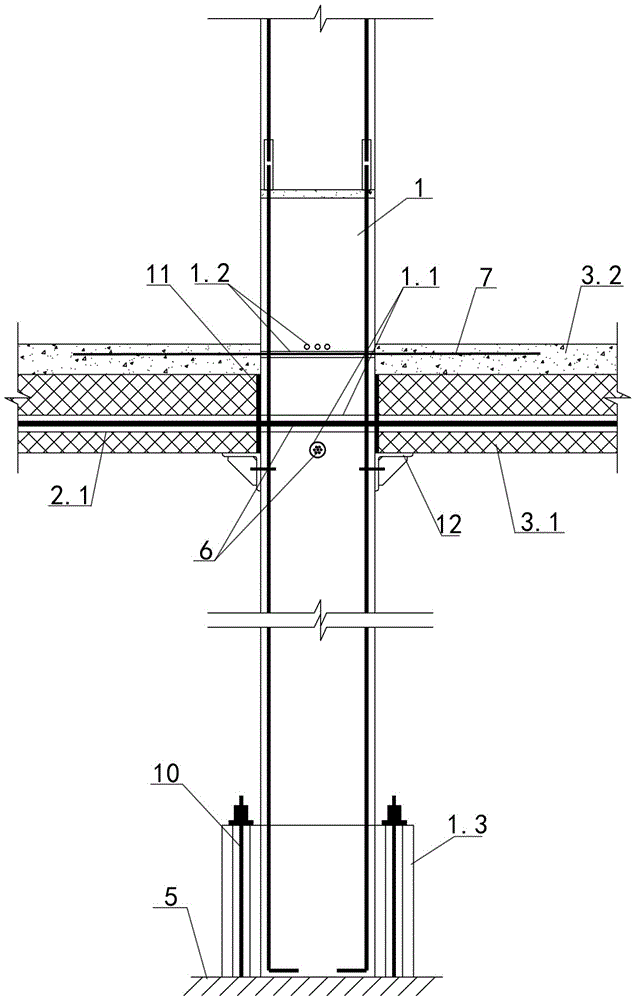

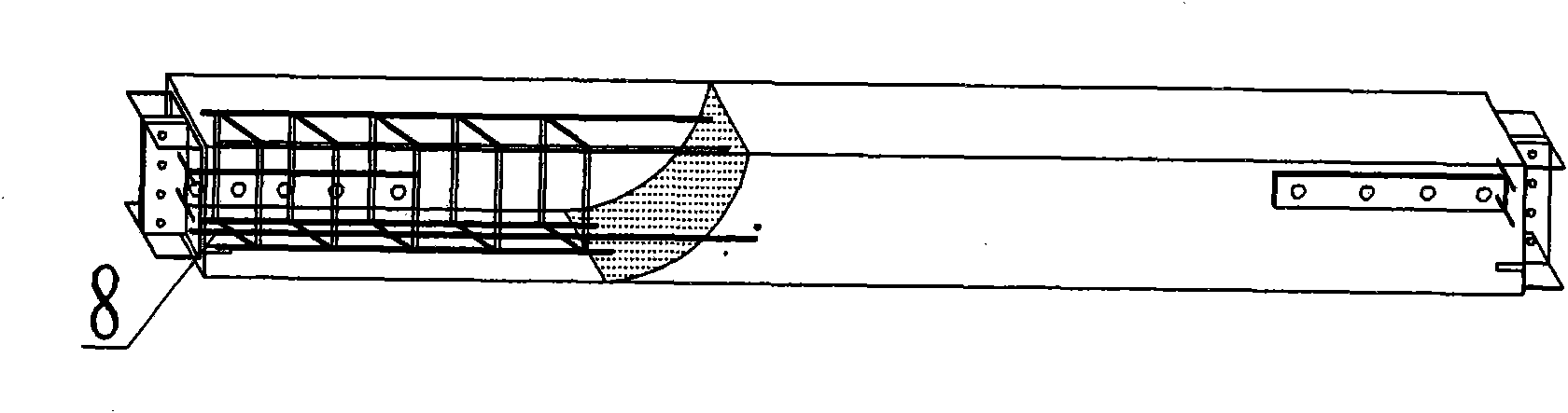

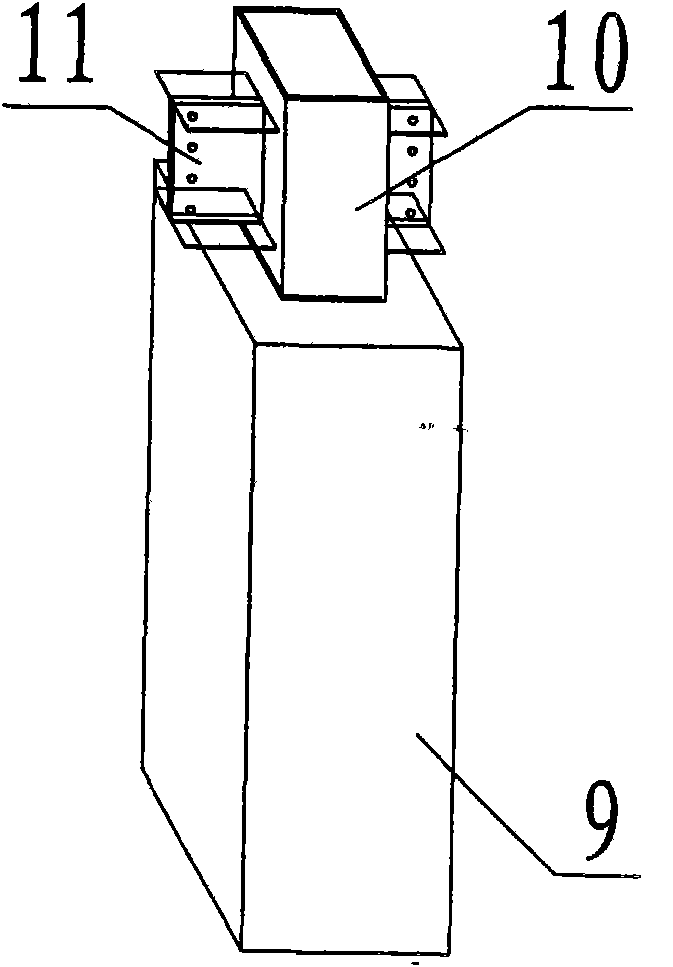

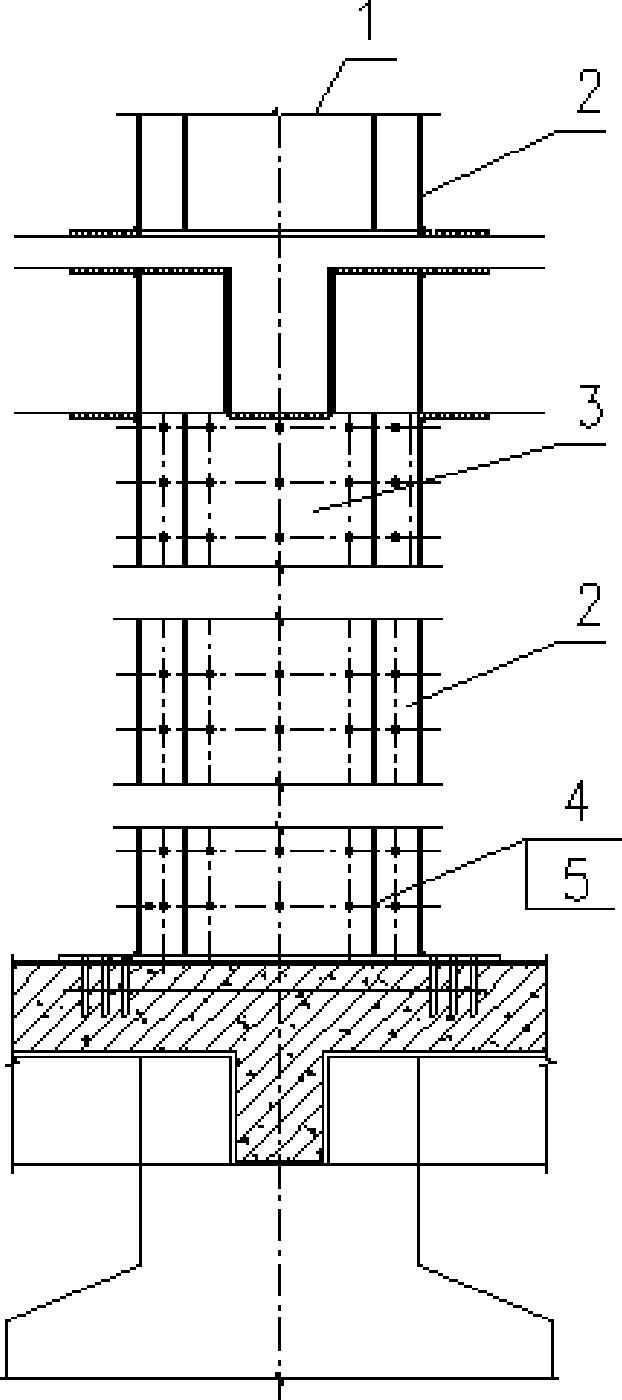

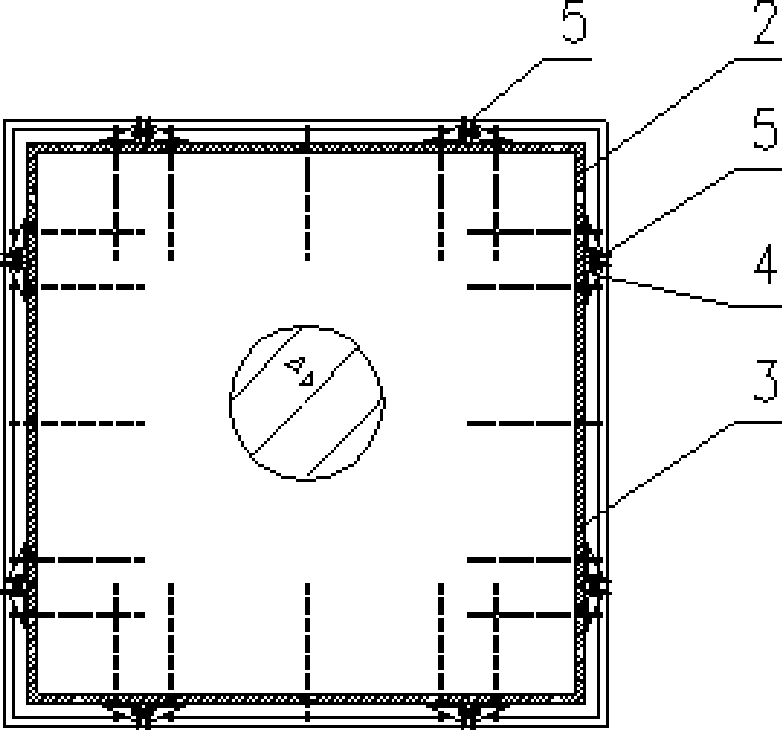

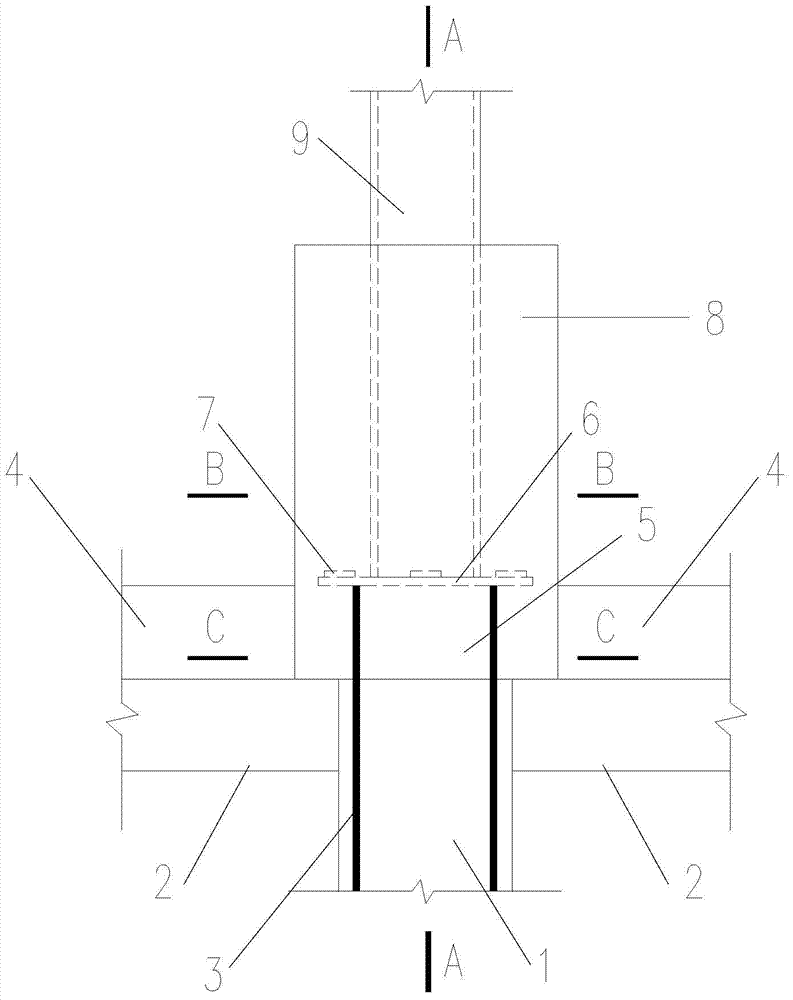

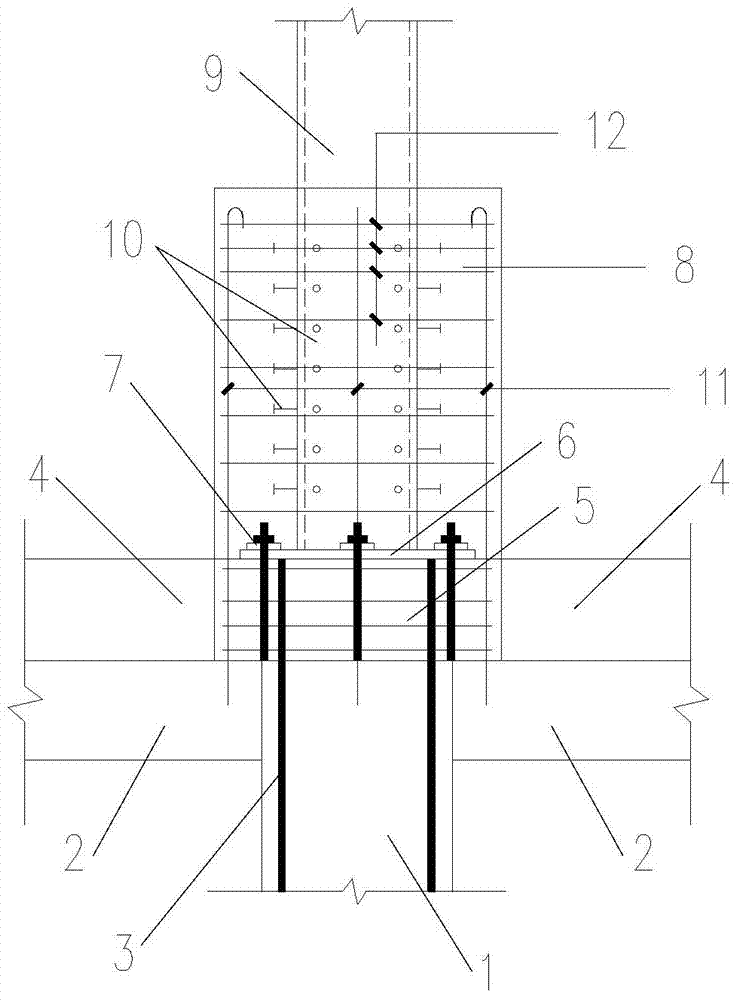

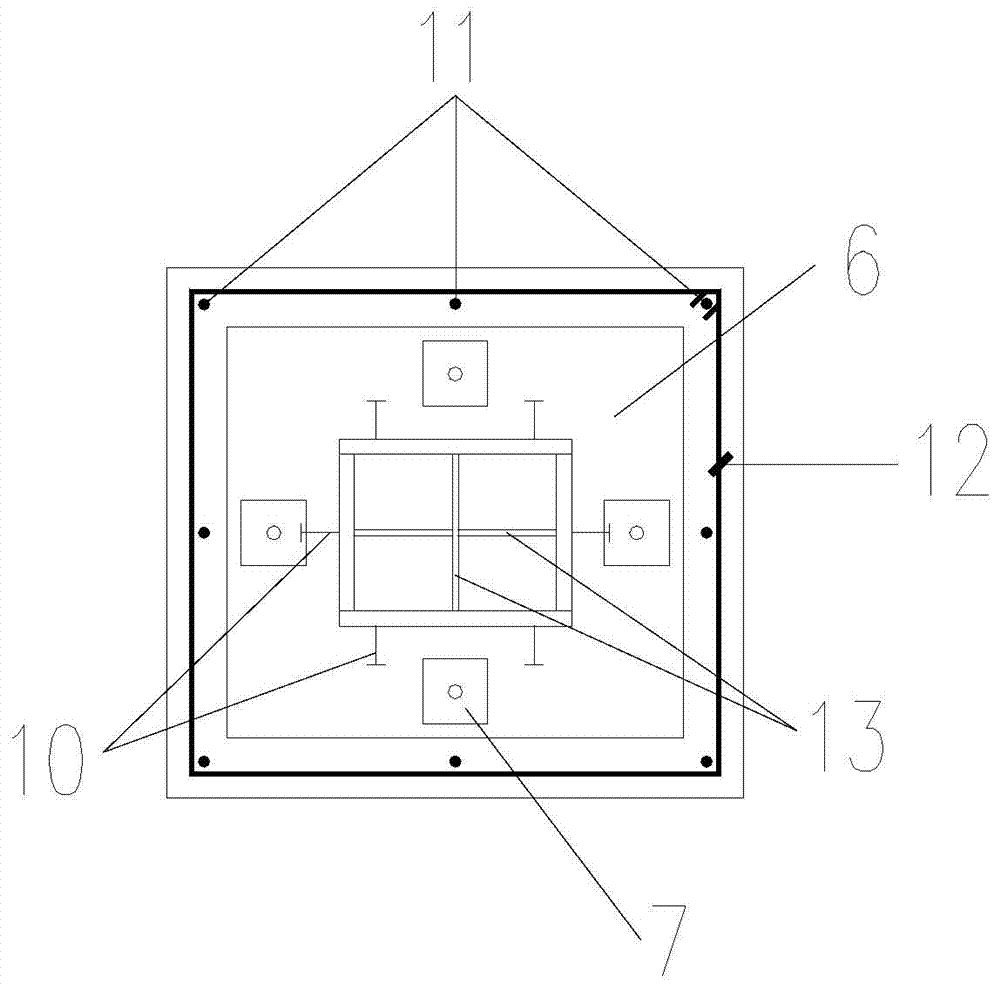

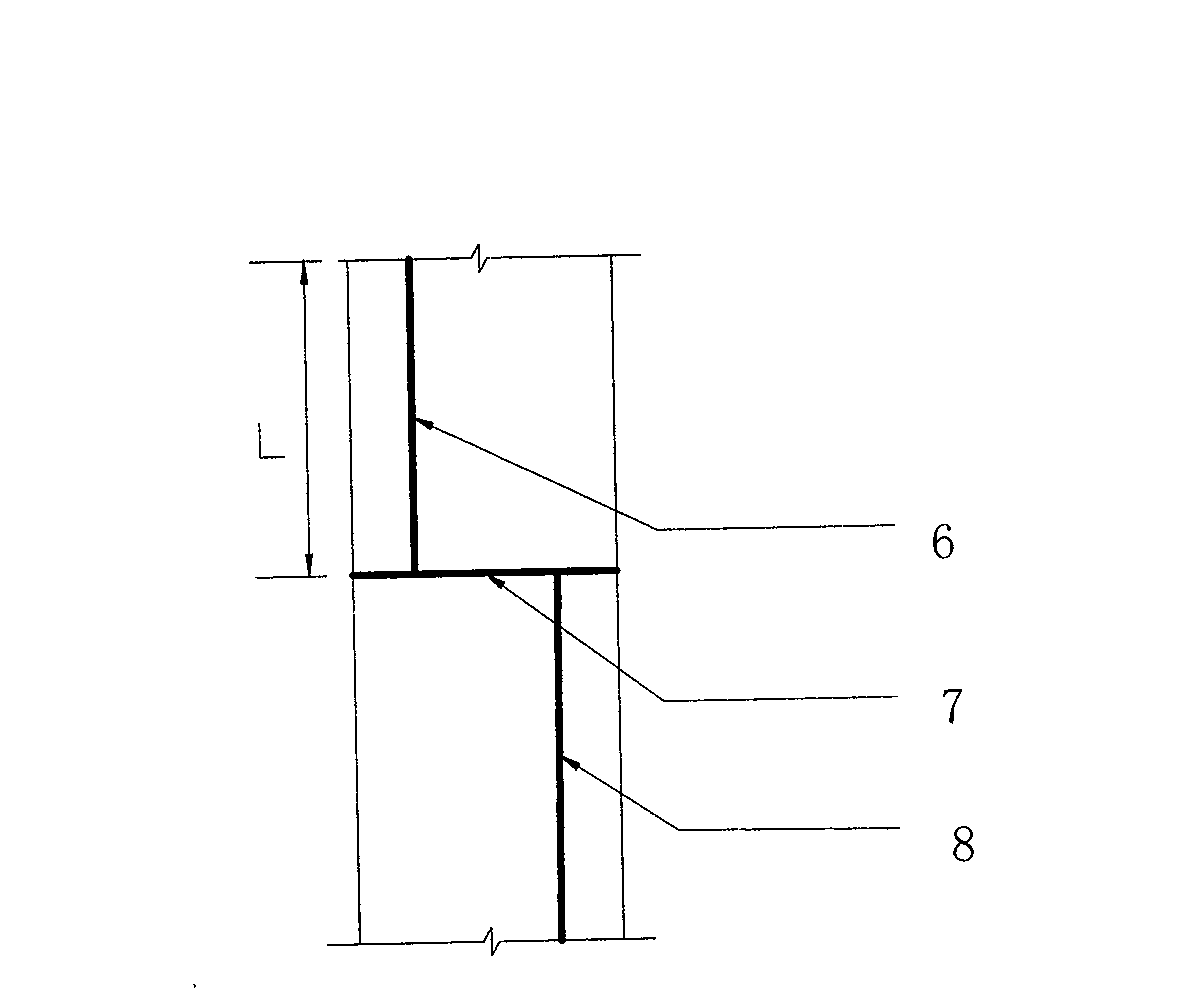

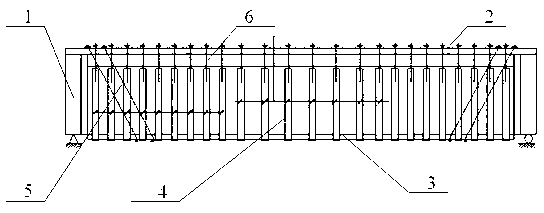

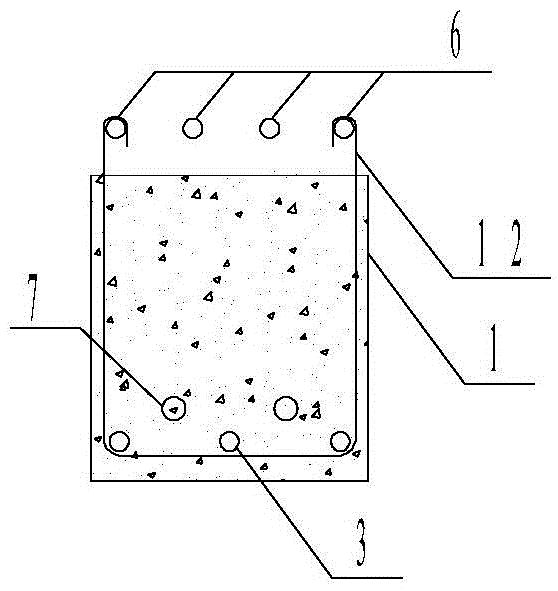

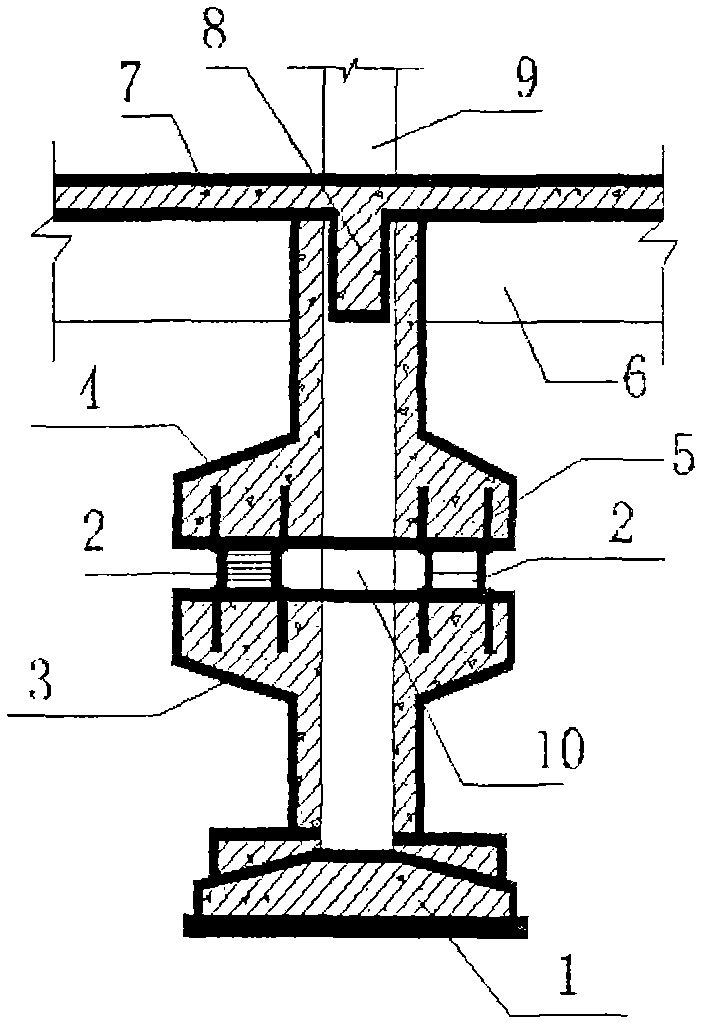

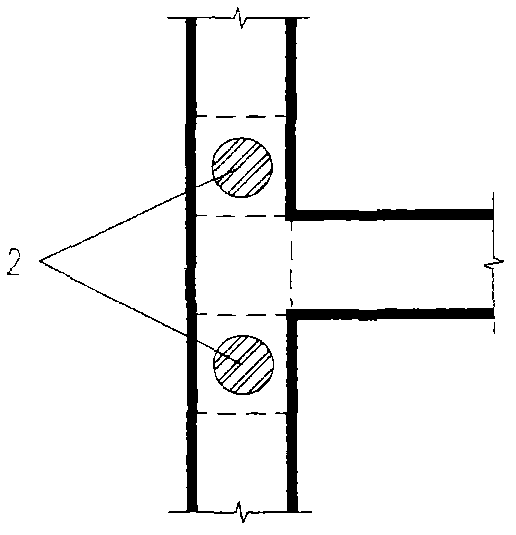

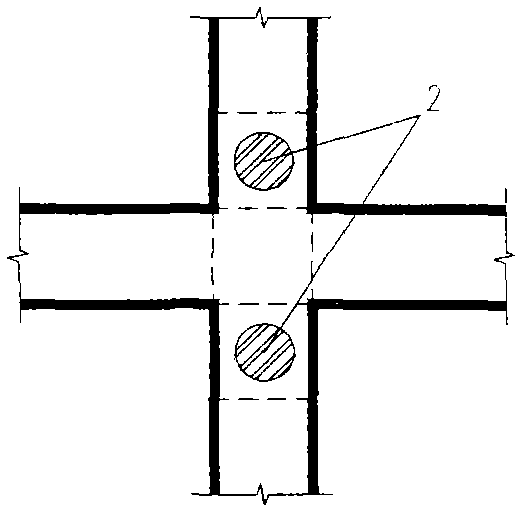

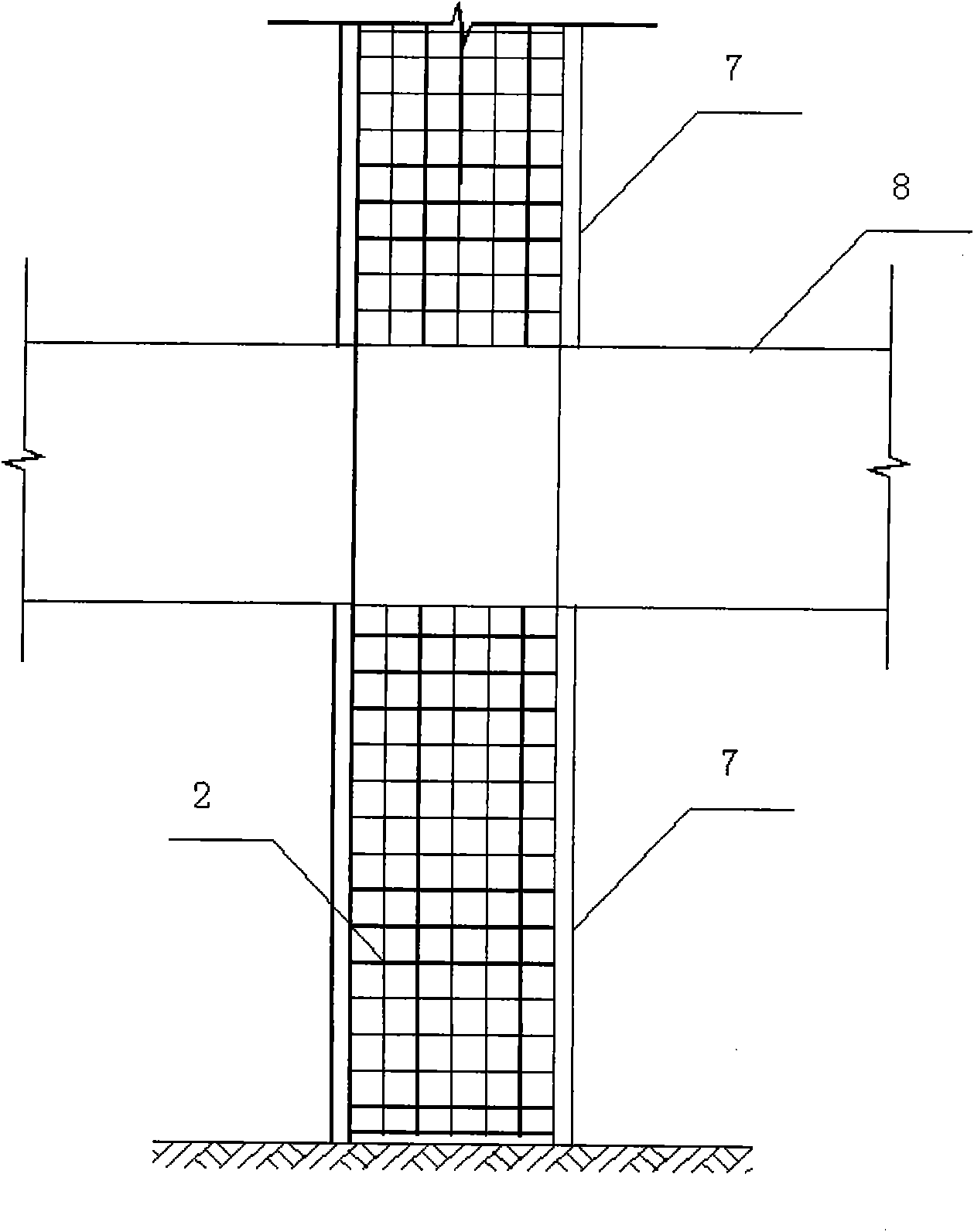

Layer added steel framework column base node on top of multi-layer concrete framework structure and construction method thereof

InactiveCN103669598AFacilitate adjustment and determinationSolve installation problemsBuilding constructionsReinforced concrete columnRebar

The invention provides a layer added steel framework column base node on the top of a multi-layer concrete framework structure and a construction method thereof; the column base node comprises a section of concrete column head (5) which is cast on an original reinforced concrete column (1) and the top of a beam (2) which is connected with the original reinforced concrete column, has an enlarged cross section and is connected with a steel column (9), and a ring beam (4) which is cast together with the concrete column head (5); an anchor bolt (7) and a longitudinal bar (3) are buried in the concrete column head (5); the root of the longitudinal bar (3) is implanted into the reinforced concrete column (1); a bottom plate (6) at the bottom of the steel column (9) is fixed with the concrete column head (5) through the anchor bolt (7); an outsourced reinforced concrete column (8) at the bottom of an outsourced steel column is cast on the top of the concrete column head (5). According to the layer added steel framework column base node on top of the multi-layer concrete framework structure and the construction method thereof, the connection rigidity of a column base is improved, so that the internal force which is produced by the added layer of an upper steel structure is effectively transmitted to an original structure, meanwhile the connection integrity on an interface between new and old structures is improved, and the anti-seismic performance of the structure is improved.

Owner:ANHUI TIANZHU CONSTR GRP +1

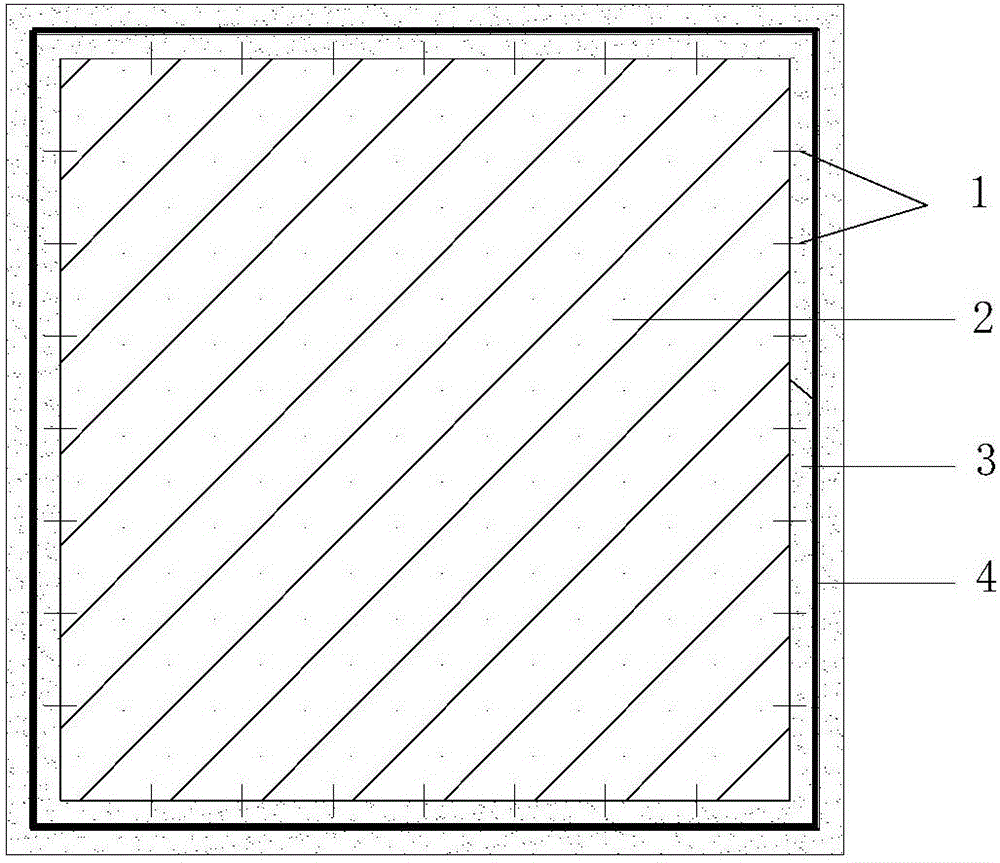

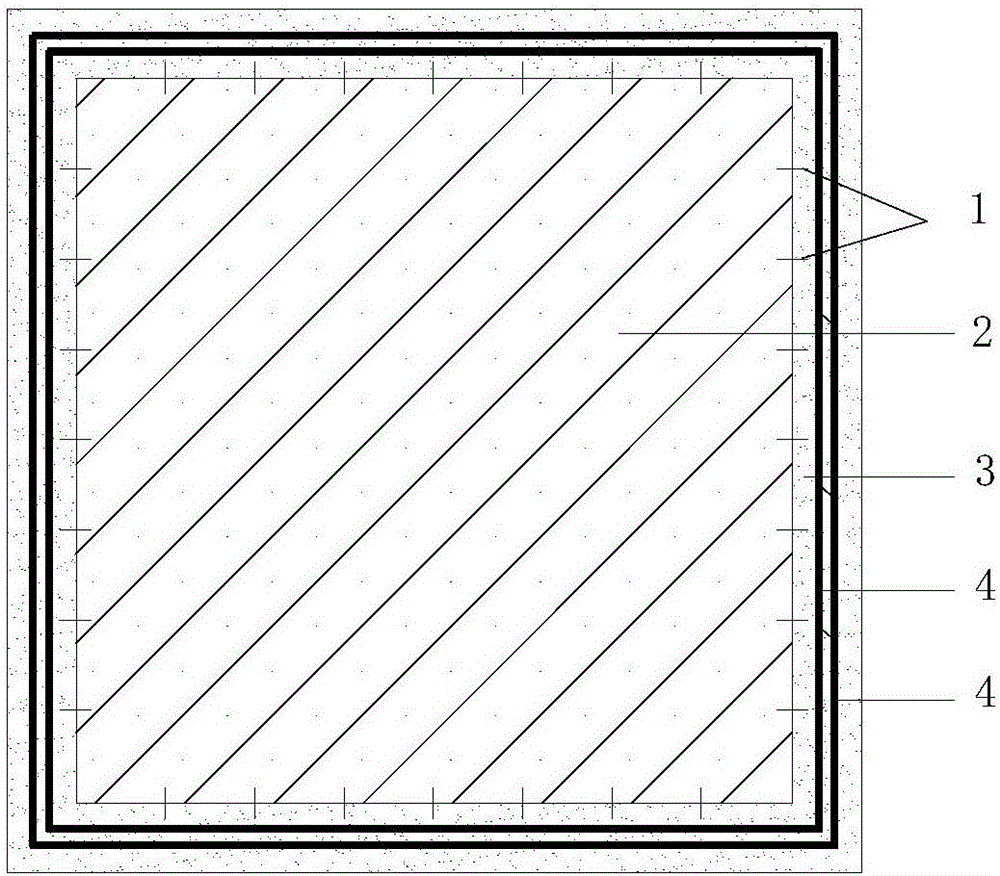

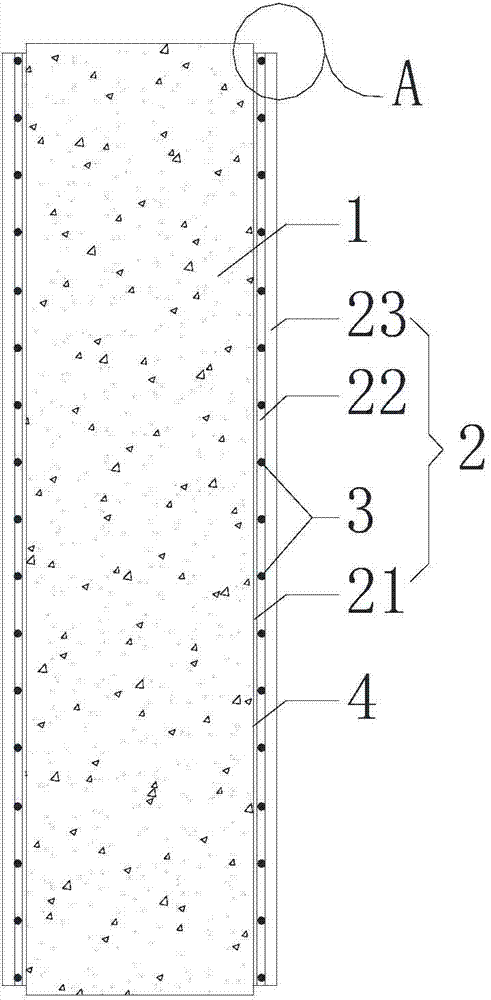

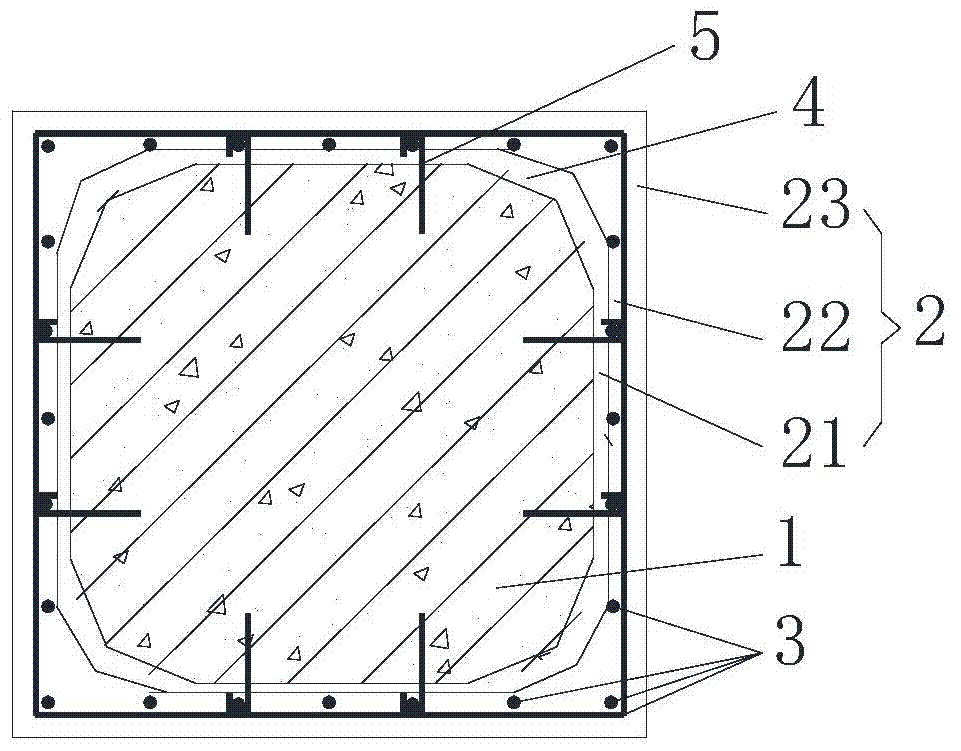

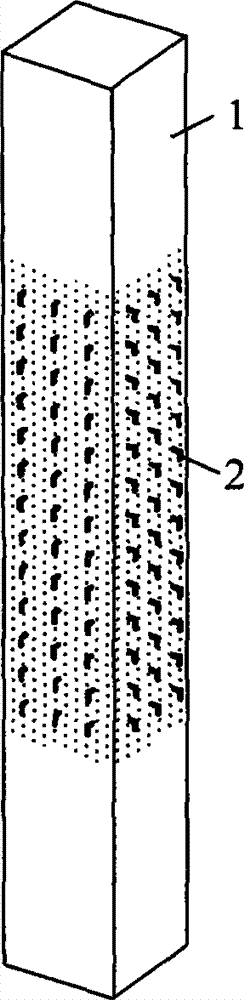

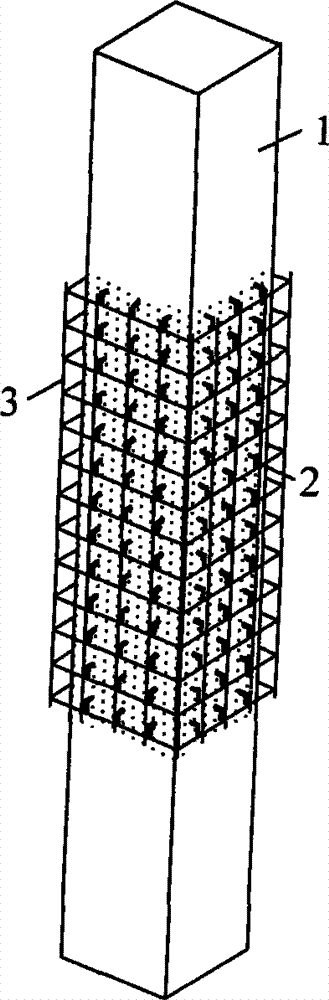

Preparation method for TRC formwork reinforced concrete column

ActiveCN106760207AAvoid erosionEven by forceStrutsForms/shuttering/falseworksReinforced concrete columnResist

A preparation method for a TRC formwork reinforced concrete column comprises the following steps that a fiber woven mesh with high tensile resist strength and good decay resistance is adopted, and the fiber woven mesh is dipped into glue or strengthened through a steel wire mesh liner; an inner mould is mounted, shear resistant hooks are mounted in drill holes of the inner mould in an inserting mode, and the fiber woven mesh is fixed to the outer side of the inner mould; an outer mould is built on the outer side of the fiber woven mesh, prepared high-performance concrete is slowly poured into space formed by the inner mould, the fiber woven mesh and the outer mould, and manufacturing of a TRC formwork is finished; and after a TRC formwork layer reaches the set strength, formwork disassembling is carried out, the concrete is poured into the TRC formwork, and preparing of the TRC formwork reinforced concrete column is finished. Compared with the prior art, time and labor are saved, the cost is reduced, and the construction efficiency is improved; the bearing capacity and ductility of the reinforced concrete column are improved, and the durability of components in severe environments such as a cold environment and an alkalinity environment is improved; and strengthening of a building is more efficient, simpler, cheaper and more environmentally friendly.

Owner:CHINA UNIV OF MINING & TECH

Reactive powder fiber concrete reinforced concrete column and reinforcement method

InactiveCN103590616ALight weightSelf-respect and high strengthBuilding repairsReinforced concrete columnFiber

The invention discloses a method for reinforcing a reactive powder fiber concrete reinforced concrete column. The method includes the steps that firstly, cleaning treatment is carried out on the surface of an original concrete column so that a concrete structure layer of the original concrete column can be exposed, and then impurity removal and dabbing are carried out till a new surface is exposed and an aggregate surface of the concrete structure layer is reached; secondly, positioning, lining and drilling are carried out on the surface of the column, shear pins are embedded into drilled holes through rib embedding glue, and a reinforcing mesh is bound at the lining position; thirdly, interface agents are applied, specifically, reactive powder fiber concrete is applied with the interface agents in a layered mode, joints between the layers are made staggered, and reinforcement of the concrete column is completed after the processes of flattening, burnishing and maintenance. The reinforced concrete column obtained through the method mainly comprises the original concrete column structure layer and a reactive powder fiber concrete reinforced layer, and the reactive powder fiber concrete reinforced layer is formed by mutually overlaying multiple unit reinforced layers with the reactive powder fiber concrete as a base material and the reinforcing mesh as a reinforcing material. The reactive powder fiber concrete reinforced concrete column has the advantages of being small in sectional dimension change, good in durability, long in service life, easy and convenient to construct, high in construction efficiency and the like.

Owner:湖南大兴加固改造工程有限公司

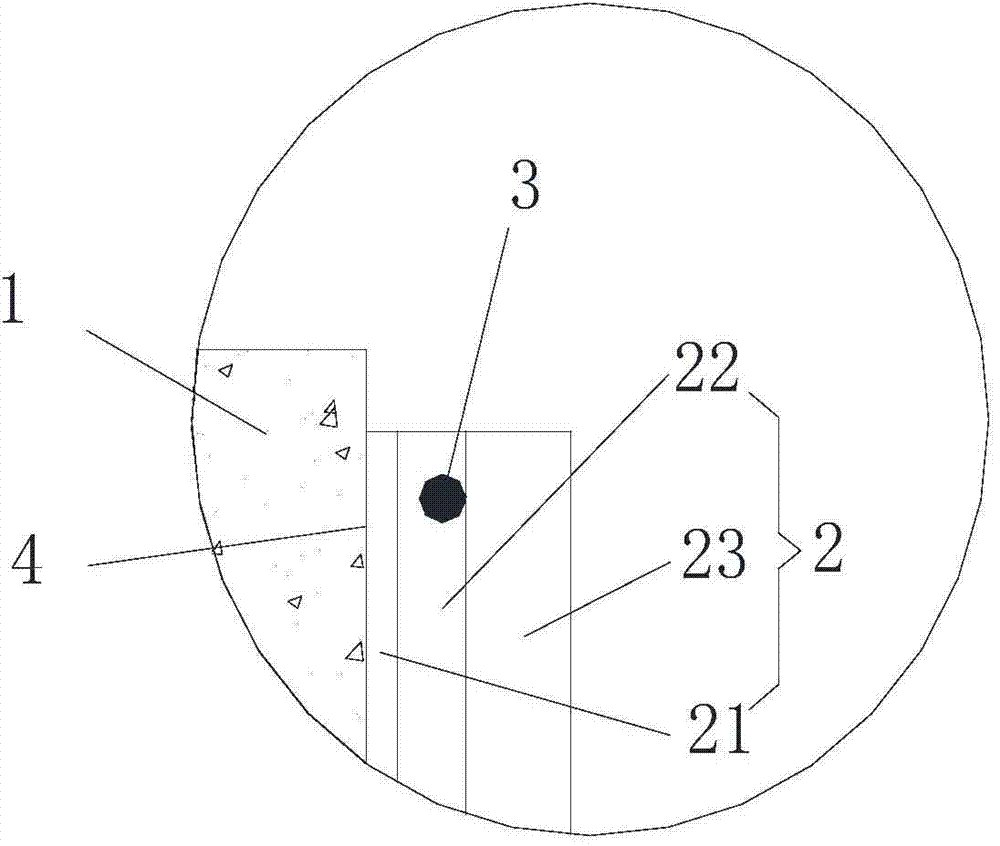

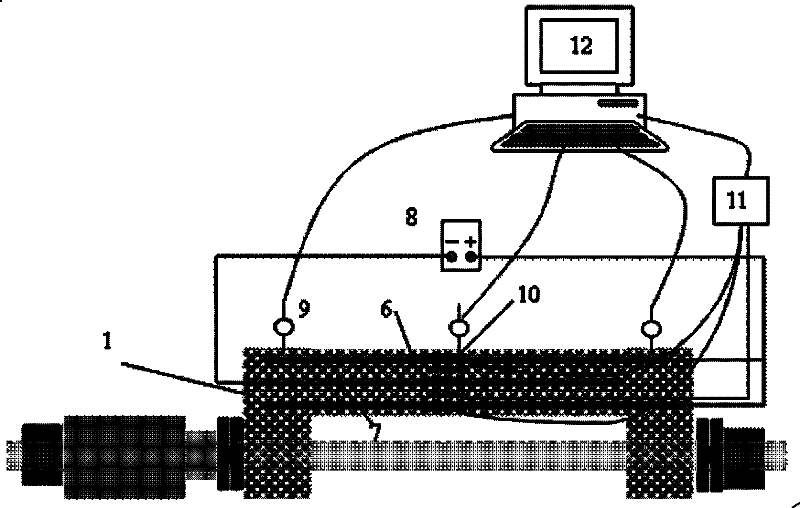

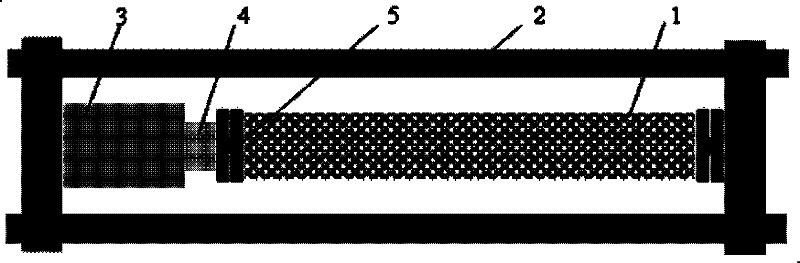

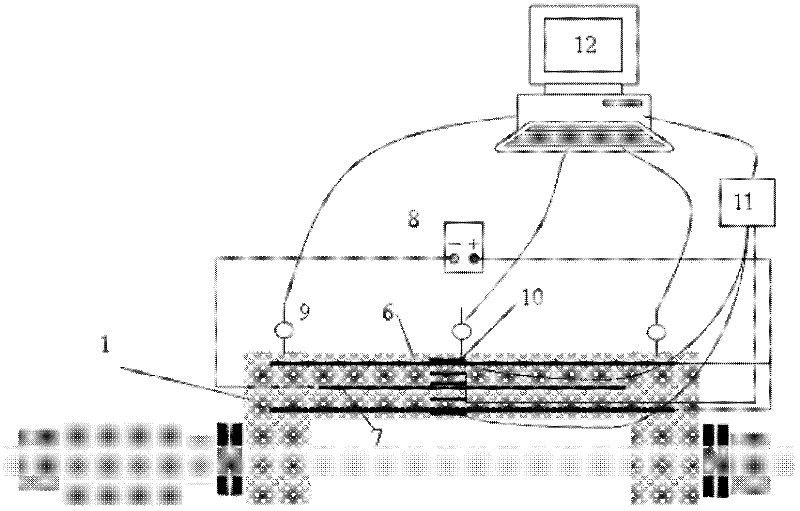

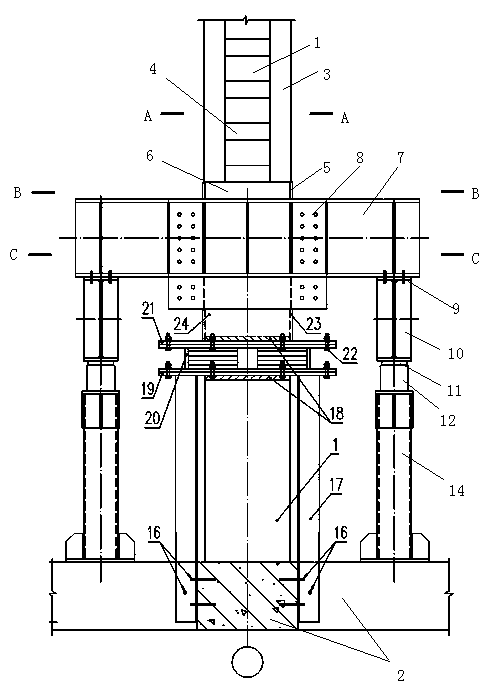

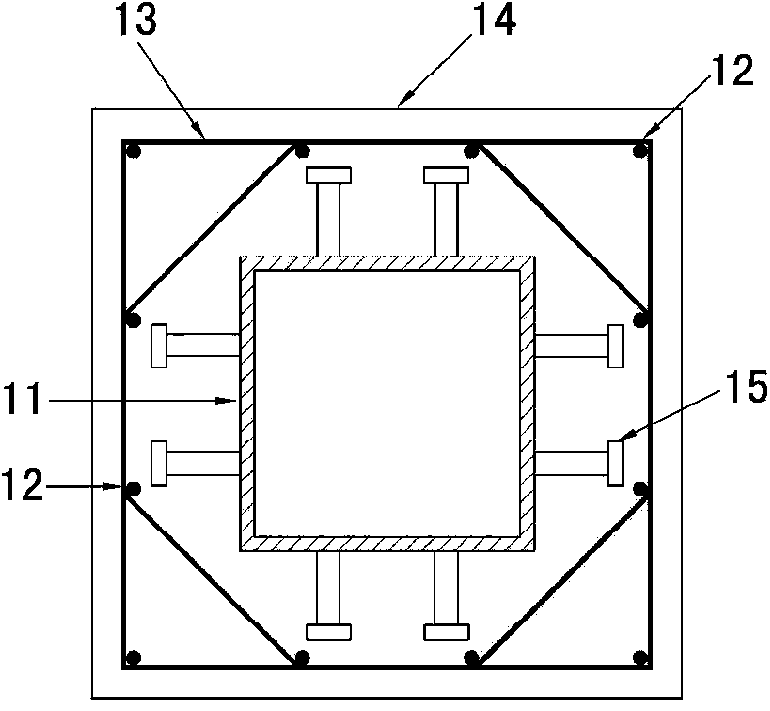

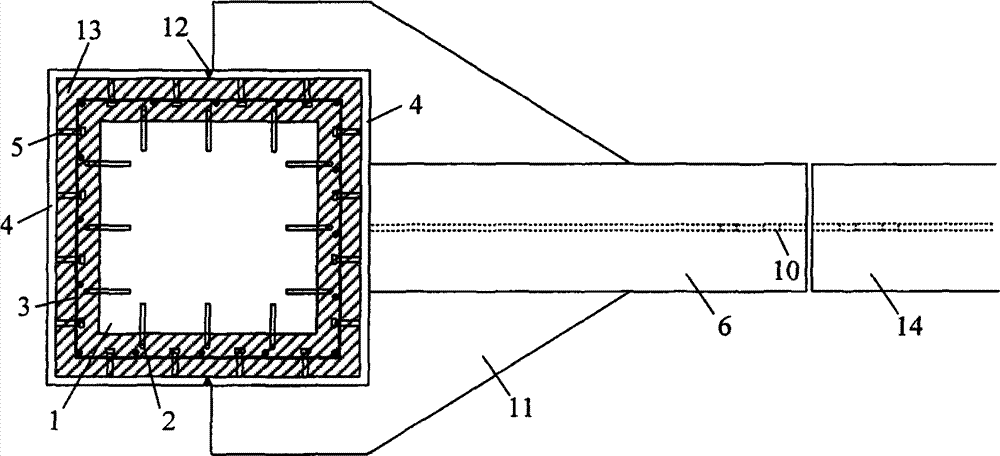

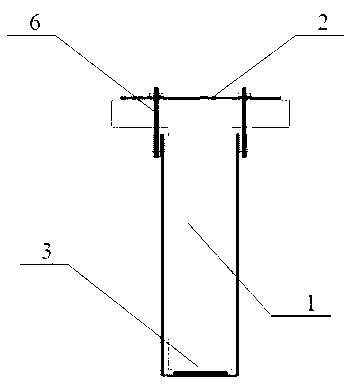

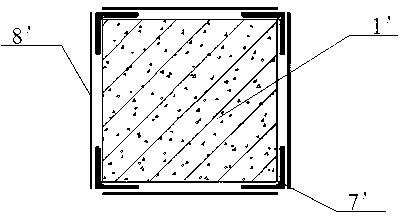

Test device for time varying mechanical properties of column under load-environment coupling effect

InactiveCN102393329ASolve the problem of stiffness degradation stress relaxationUnrestricted arrangementWeather/light/corrosion resistanceStrength propertiesReinforced concrete columnEngineering

Relating to the field of civil engineering, the invention provides a test device for time varying mechanical properties of a column under a load-environment coupling effect. The device comprises a column, a loading system, an environment corrosion accelerating system, and a measuring system. Specifically, the column is installed on the loading system which imposes a load on the column; the column is also in connection with the environment corrosion accelerating system so as to accelerate environment corrosion of the column; and the column is connected to the measuring system for real-time monitoring of time varying mechanical properties of the column. In the corrosion acceleration process of a member, the device of the invention not only can realize real-time observation of a member deflection change and the stress strain changes of steel bars and concrete, but also can observe the whole cracking and development process of a crack on the column during degradation, thus simulating the actual working state of the column completely, and successfully providing a solution to monitoring of time varying degraded mechanical properties of a reinforced concrete column under a load-environment coupling effect.

Owner:ZHEJIANG COLLEGE OF CONSTR

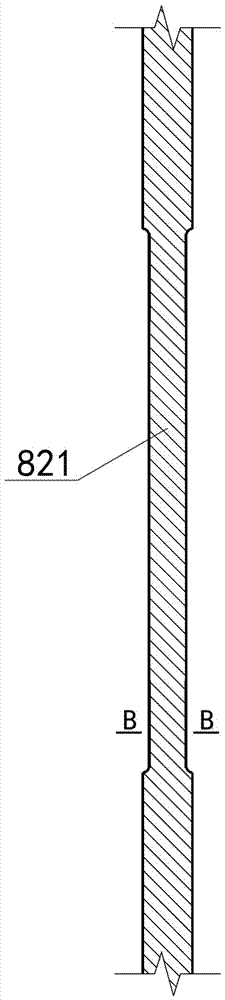

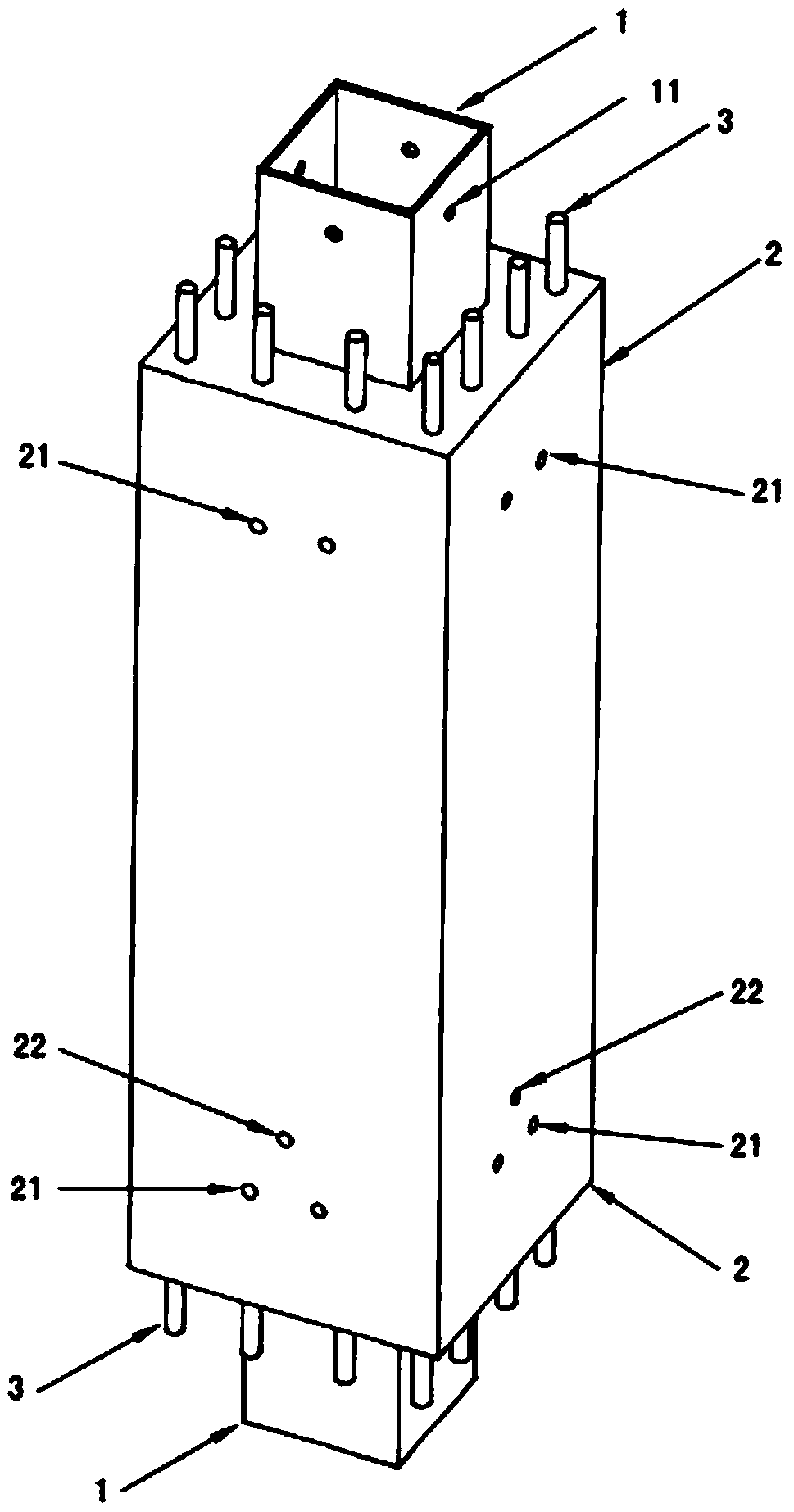

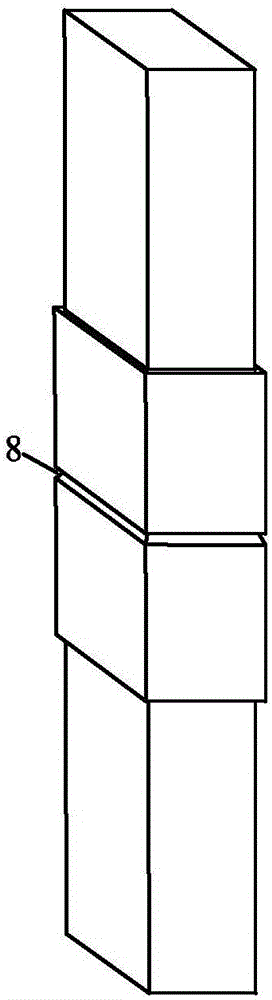

Prefabricated hollow steel-reinforced concrete column and splicing structure and splicing method thereof

InactiveCN103422620ALight weightExtend your lifeStrutsBuilding material handlingReinforced concrete columnRebar

The invention discloses a prefabricated hollow steel-reinforced concrete column. The prefabricated hollow steel-reinforced concrete column comprises a central steel pipe, concrete, a plurality of longitudinal reinforcing steel bars and stirrups strapped on the longitudinal reinforcing steel bars; the concrete wraps the central steel pipe, the longitudinal reinforcing steel bars and the stirrups, the two ends of the central steel pipe and the two ends of each longitudinal reinforcing steel bar stretch outside the upper end face and the lower end face of the concrete, and the parts, stretching outside the end faces of the concrete, of the central steel pipe are longer than the parts, stretching outside the end faces of the concrete, of each longitudinal reinforcing steel bar; a plurality of lifting holes are formed in the side face of the upper end of the central steel pipe, and erection bolt holes penetrating through the central steel pipe and the concrete are formed in the upper end and the lower end of the side face of the concrete. The invention further provides a splicing structure and a splicing method of the prefabricated hollow steel-reinforced concrete column. The prefabricated hollow steel-reinforced concrete column can effectively increase construction speed and the use ratio of resources.

Owner:SHAANXI JIANKE XINGYE STEEL STRUCTURE

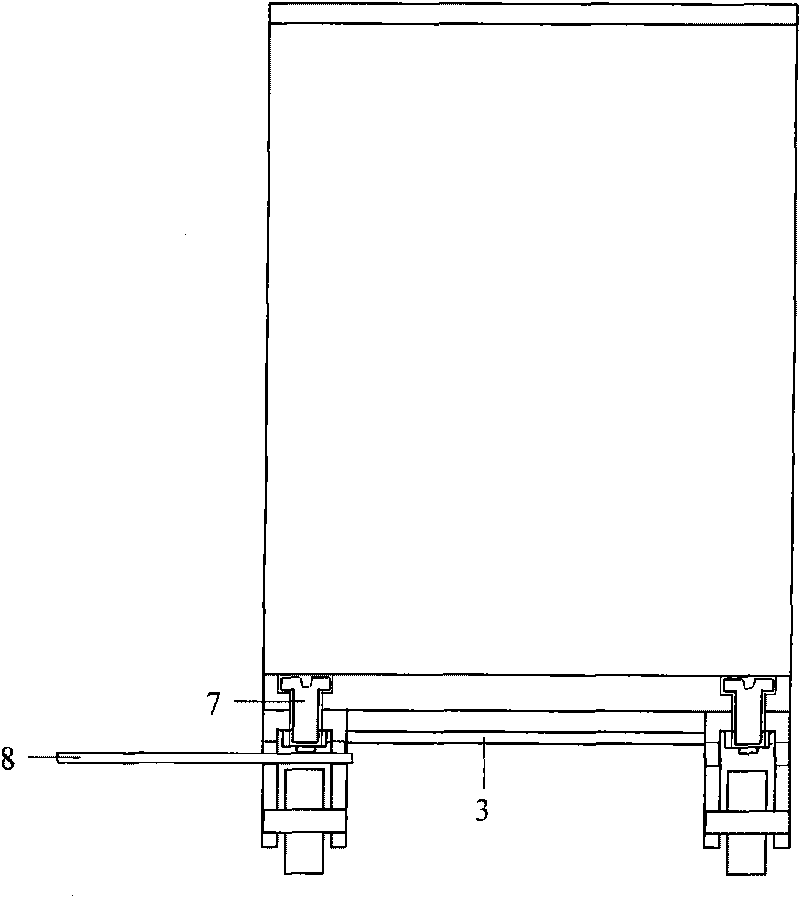

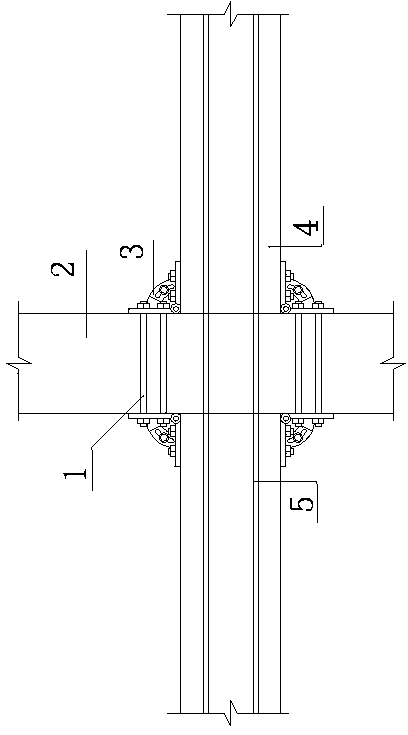

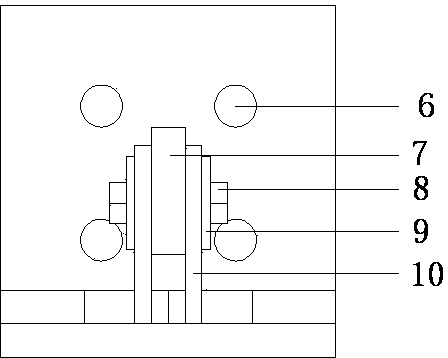

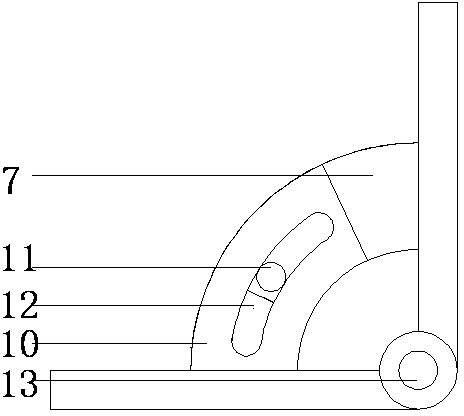

Building column-truncating, replacing and seismic-isolating support construction method and supporting device

InactiveCN103741832AImproving and enhancing resilience to earthquakesLow costBuilding material handlingShoresEarthquake resistanceReinforced concrete column

The invention relates to a building column-truncating, replacing and seismic-isolating support construction method and a supporting device. The construction method includes 1), mounting the supporting device, namely mounting the supporting device around an original-structure reinforced concrete column where a seismic-isolating support is needed to be mounted; 2), after the supporting device is mounted, truncating the column at a position where the seismic-isolating support is mounted; 3), disposing the seismic-isolating support in the position to complete mounting of the rubber seismic-isolating support. Seismic isolating technology is applied onto an existing building by utilizing a supporting system, so that cost for reinforcement and reconstruction is greatly lowered, earthquake resistance of the building is effectively improved and enhanced, a mode which is safer, more economical and more environment friendly is brought to proprietors, and a novel reinforcement method solution and a more scientific anti-seismic mode are provided for old buildings positioned in seismic areas.

Owner:KUNMING TIANJIAOLI REINFORCING TECH ENG +1

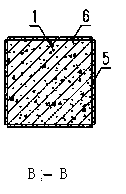

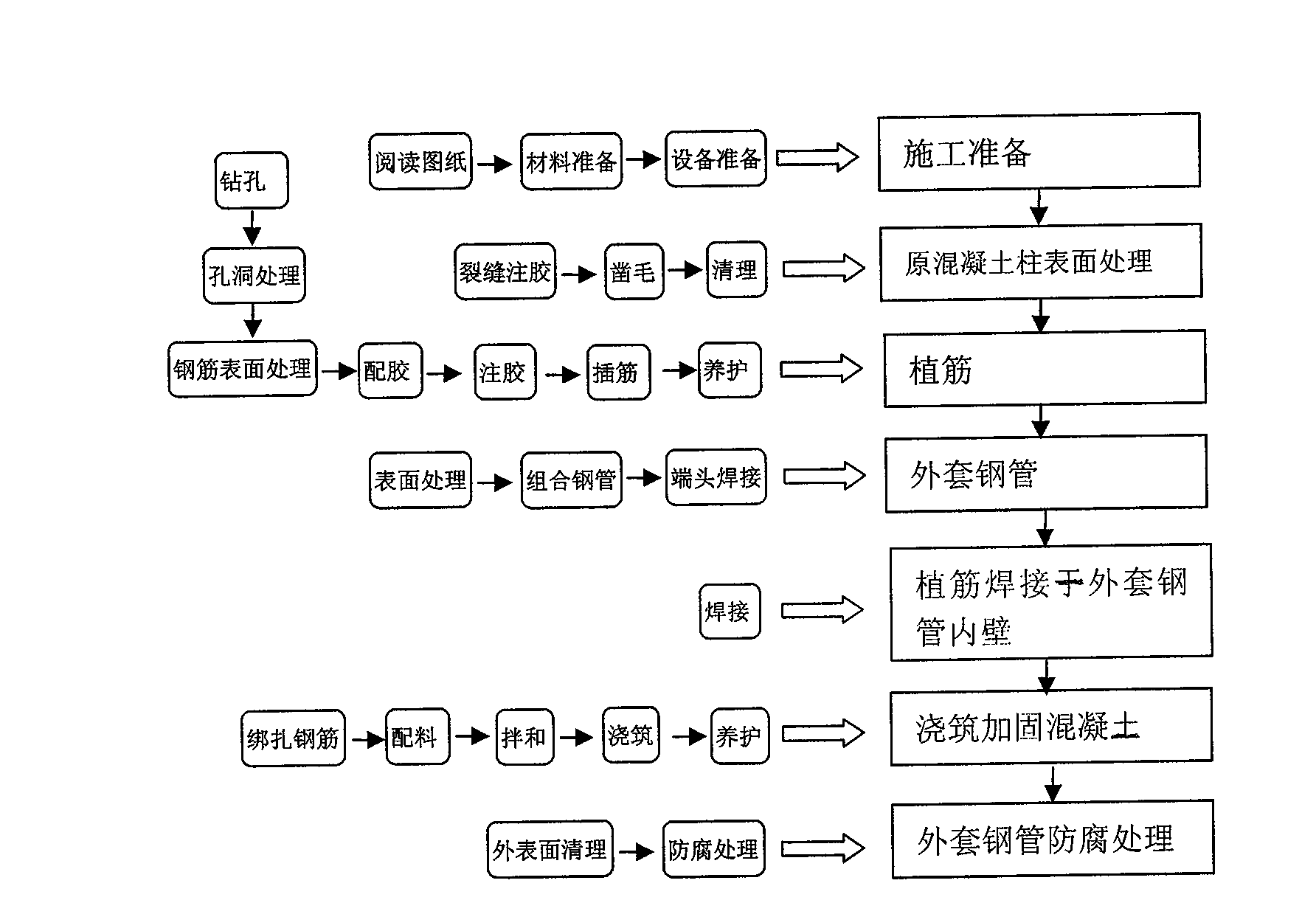

Method for reinforcing concrete column by expanding section of coated concrete-filled steel tube (CFST)

InactiveCN101581152AImprove integrityImprove adhesionBuilding repairsReinforced concrete columnRebar

The invention discloses a method for reinforcing a concrete column by expanding section with coated concrete-filled steel tube (CFST), comprising the following steps: (1) preparing for construction; (2) treating the surface of the concrete column; (3) planting steel bars around the concrete column; (4) coating steel tubes outside the concrete column and welding the steel tubes and the concrete column together; (5) welding the planted steel bars and the inner wall of the coated steel tubes together; (6) casting high performance micro-expansion concrete in the gap between the planted steel bars and the coated steel tubes; (7) protecting the outside surface of the steel tubes from corrosion and performing the exterior decoration. The method has a wide application range, thus being applicable to the structural damage caused by the physical ageing of the concrete column and the like, the destroyed structure caused by striking, fire, earthquake, and other disasters, or bad bearing capacity and rigidity of the concrete column caused by story-adding and the like.

Owner:WUHAN UNIV

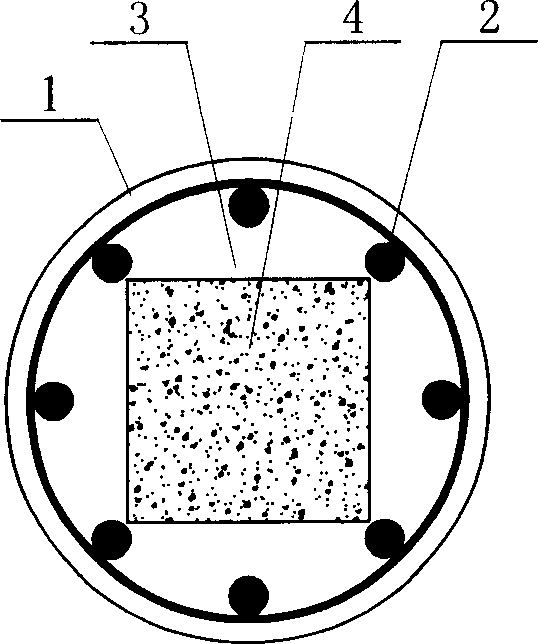

Ribbed concrete column with built-in high-strength or super-strength concrete core column

InactiveCN1818276AReduce section sizeThe problem of difficult node construction is overcomeStrutsPillarsReinforced concrete columnRebar

A reinforced concrete pile with super strength load concrete core includes a normal reinforced concrete shell and a super strength load concrete core of the same length with the shell. This could reduce the sectional area of the traditional pile and the consumption of reinforcing materials.

Owner:HARBIN INST OF TECH

Connecting joint of prefabricated hollow steel-reinforced concrete column and steel beam and construction method

InactiveCN103437425AReliable power transmissionImprove working conditionsBuilding material handlingReinforced concrete columnEngineering

The invention discloses a connecting joint of a prefabricated hollow steel-reinforced concrete column and a steel beam and a construction method. The connecting joint comprises the prefabricated hollow steel-reinforced concrete column, the H-type steel beam, a horizontal connecting disc and a connecting piece. In the construction process, the horizontal connecting disc and the connecting piece are attached to a central steel tube to be manufactured with the hollow steel-reinforced concrete column in a factory, and prefabricated hollow steel-reinforced concrete column splicing and steel beam installation are carried out at the construction site. The connecting joint is simple in structure and reliable in force transmission. The steel beam and the hollow steel-reinforced concrete column are manufactured in the factory, therefore, the operation condition can be improved, and the quality is easily guaranteed. The construction method for connecting the steel beam with the prefabricated hollow steel-reinforced concrete column is easy and convenient to achieve, and influences of installation errors on stress in a joint area are fewer. After concrete is poured, two materials including steel and the concrete are mutually limited and jointly stressed, and the improvements of the bearing capacity, the rigidity and the ductility of the joint are facilitated.

Owner:SHAANXI JIANKE XINGYE STEEL STRUCTURE

Connecting method of steel beam and existing reinforced concrete column

InactiveCN102966245AEasy to get materialsReduce wet work loadBuilding repairsReinforced concrete columnEngineering

The invention relates to a connecting method of a steel beam and an existing reinforced concrete column, which can be used for reinforced modification of an existing reinforced concrete structure, and belongs to the technical field of structural engineering. The method comprises the steps of: scabbling, planting bars and binding reinforced mesh pieces on the surface around with a node connection domain of the original reinforced concrete column; processing two pieces of channel steel and welding a stud connection piece inside; extending an extending bracket and external reinforcing plate on the channel steel connected to the steel beam; buckling the two pieces of channel steel and wrapping the original reinforced concrete column; welding in an abut manner; pouring node area concrete; and finally connecting the steel beam. The method overcomes the deficiencies of the conventional connection method, is simple in structure, quick and convenient to construct, good in stress performance of the connecting node, reliable in force transfer, and can efficiently prevent a node core area from cracking and being exposed. The core area concrete is wrapped by a steel plate so that the concrete is strongly constrained, and the quake-proof ductility of the node is good. The method has high practicality and wide application prospect.

Owner:TSINGHUA UNIV

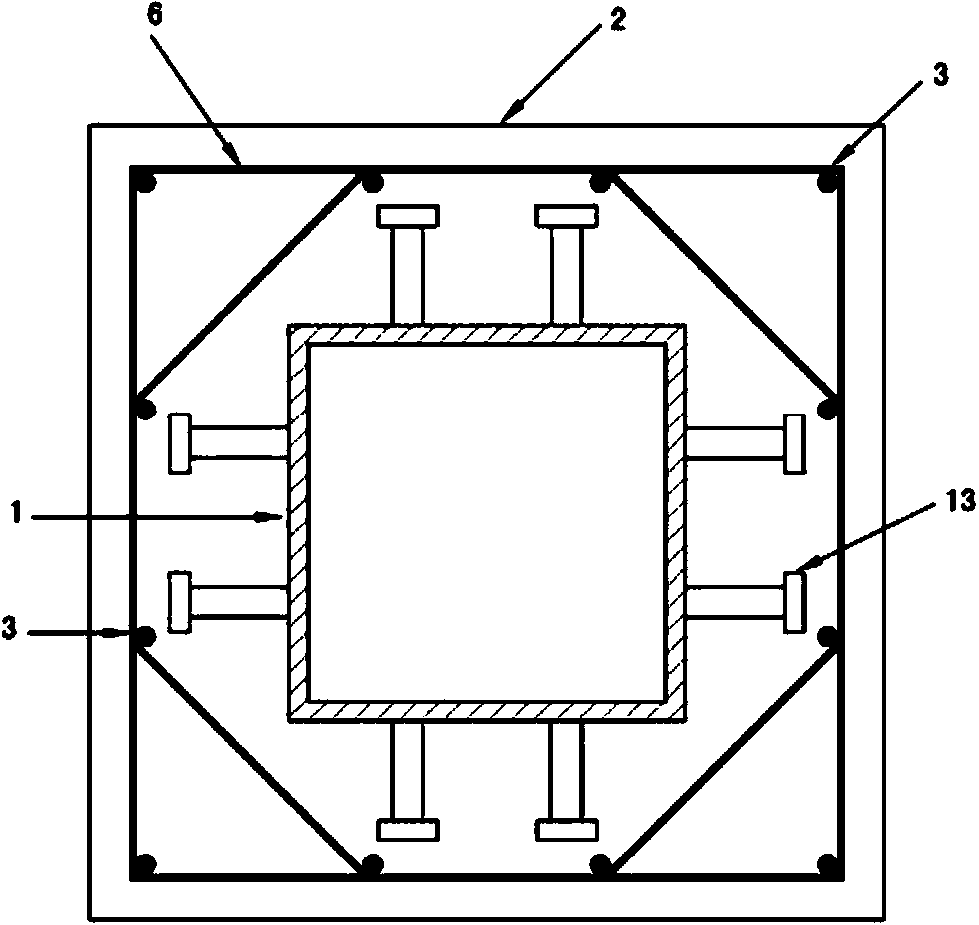

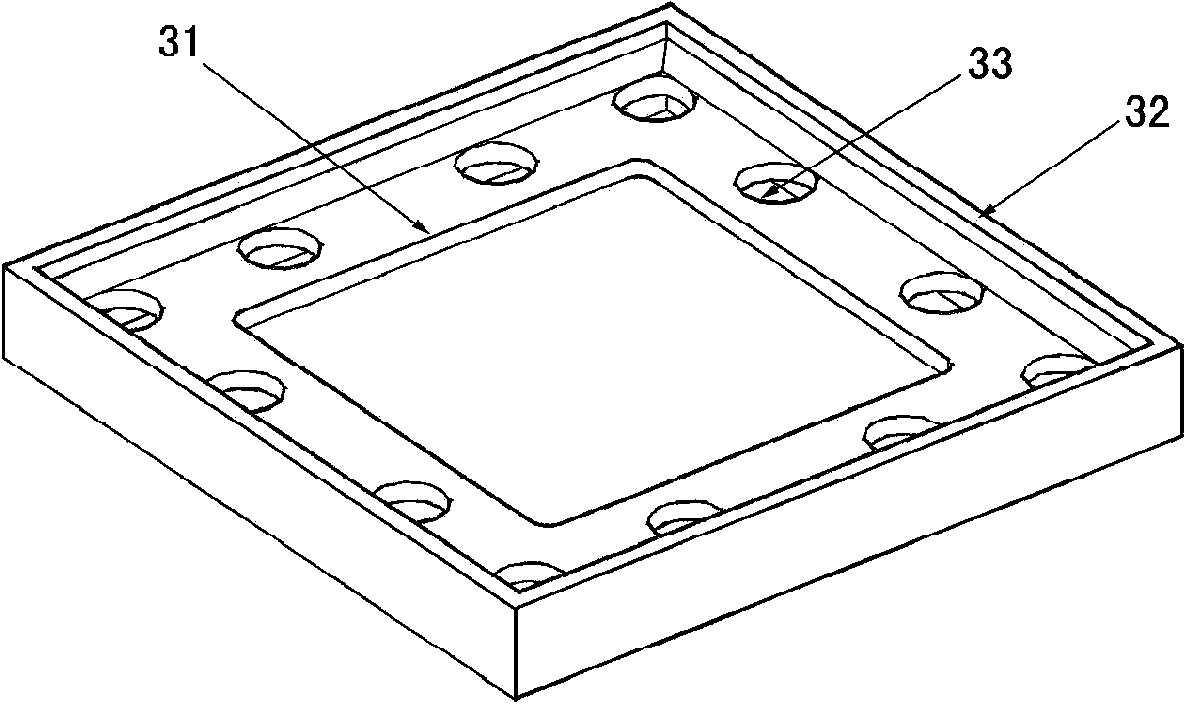

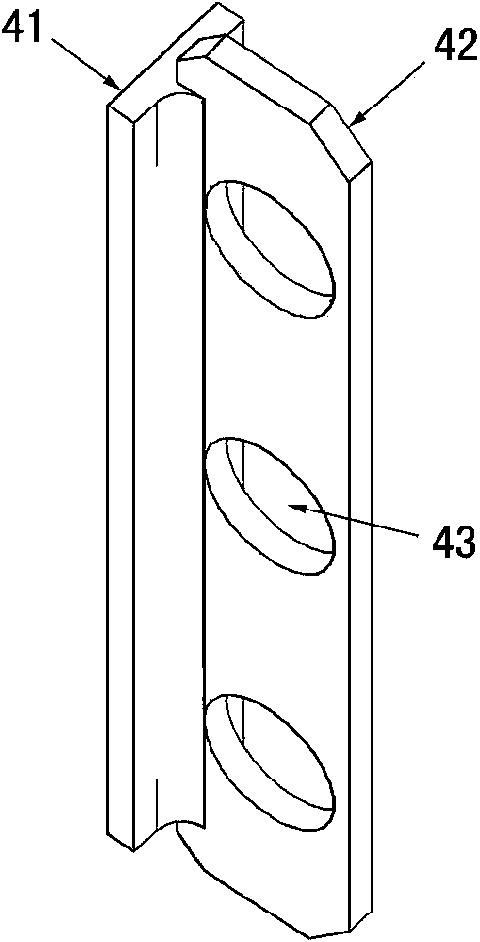

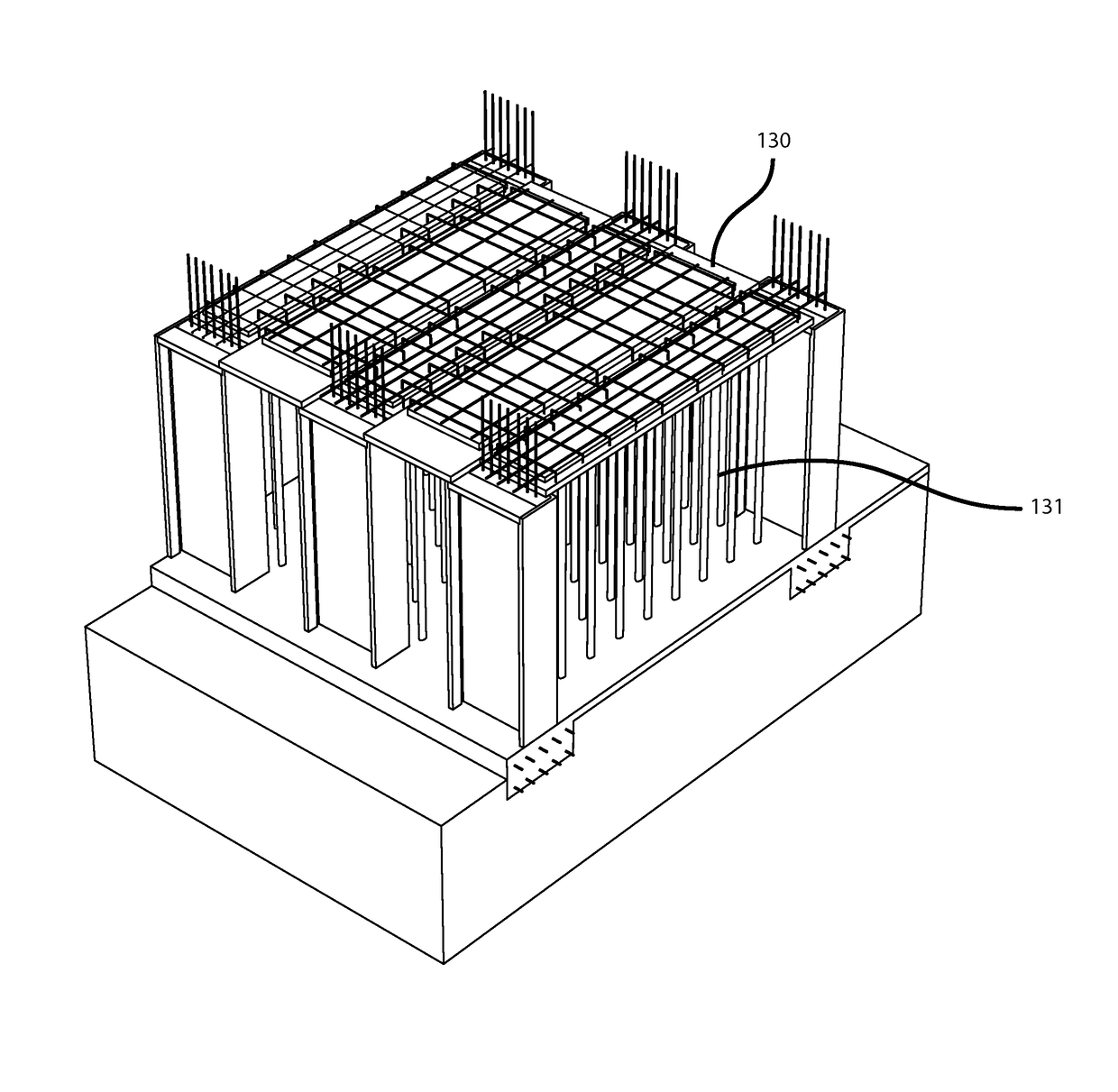

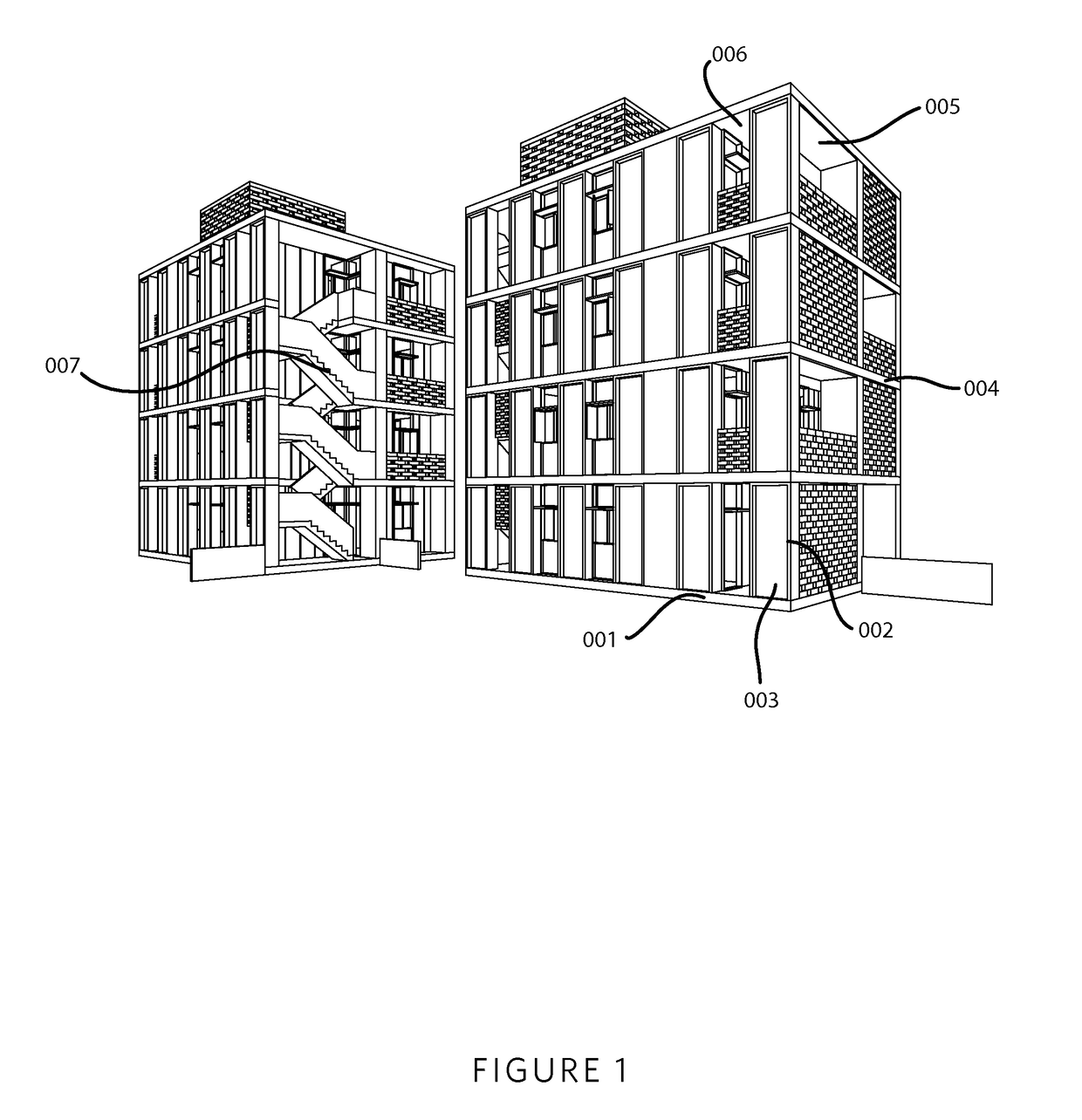

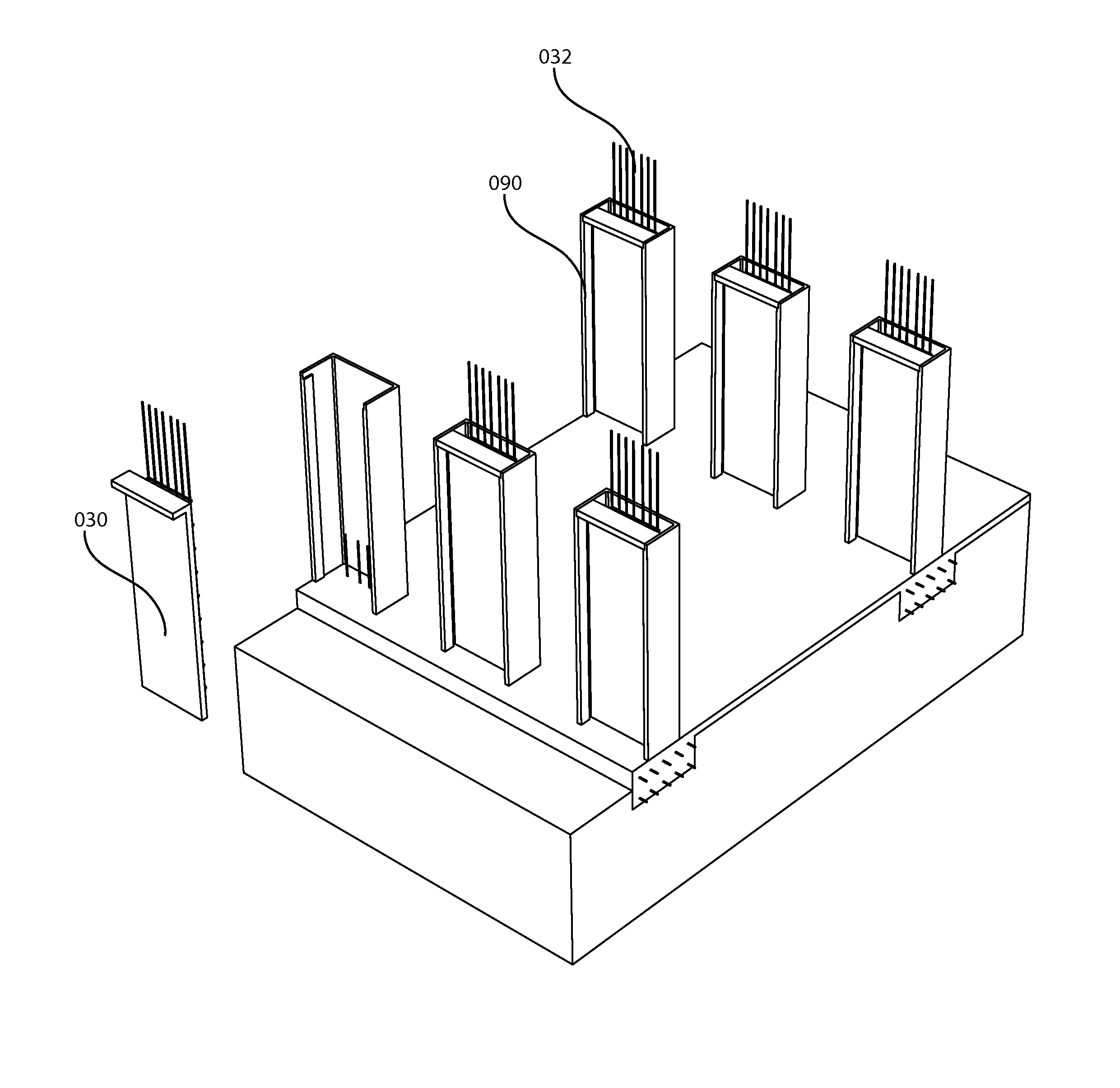

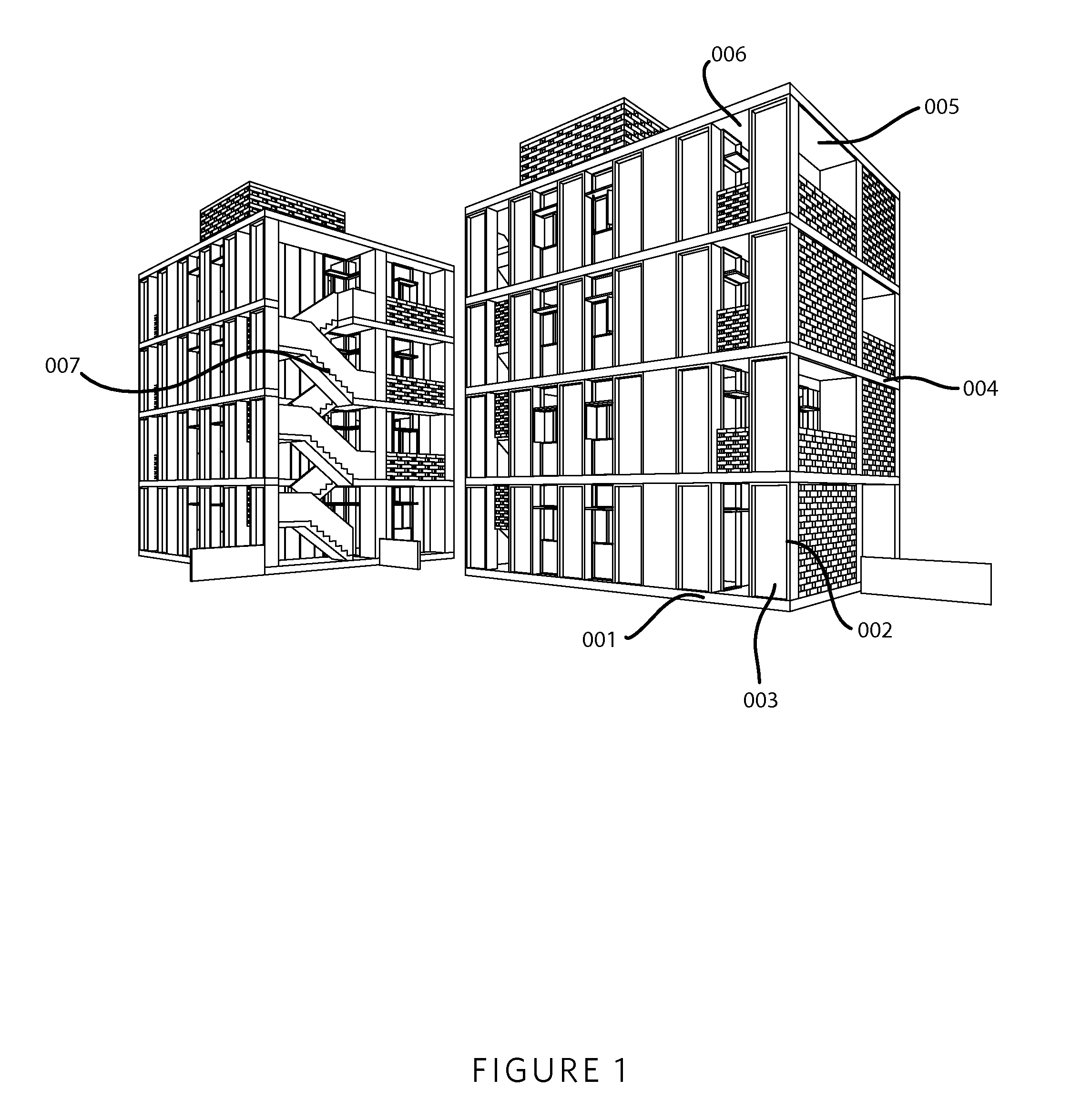

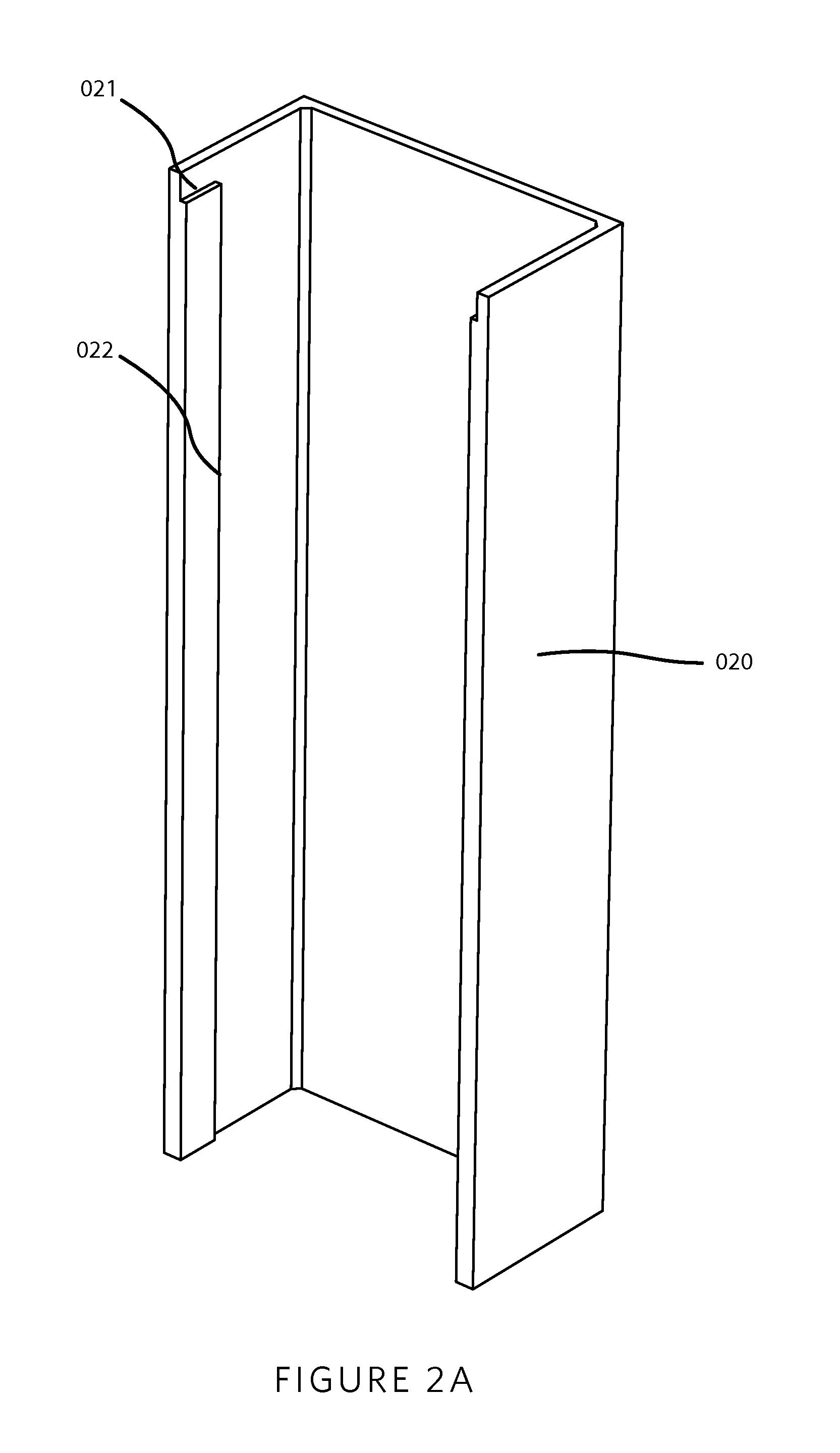

Method and system for rapid construction of structurally reinforced concrete structures using prefabricated assemblies and method of making the same

The present invention includes prefabricated assemblies which are assembled on a construction site to provide a permanent concrete mold with integrated structural reinforcement and structural splices for cast-in-place concrete structures. The invention enhances the quality of the cast concrete structure while lowering the cost of construction and construction time. Described herein is a column form assembly, a column closure panel assembly, a beam form assembly, and a slab form assembly which are used to construct cast in place structurally reinforced concrete columns, beams, and floor slabs with minimal form work and construction site logistics. Also described herein are a method of assembly of said structures and a method of fabricating said assemblies.

Owner:KT INDIA

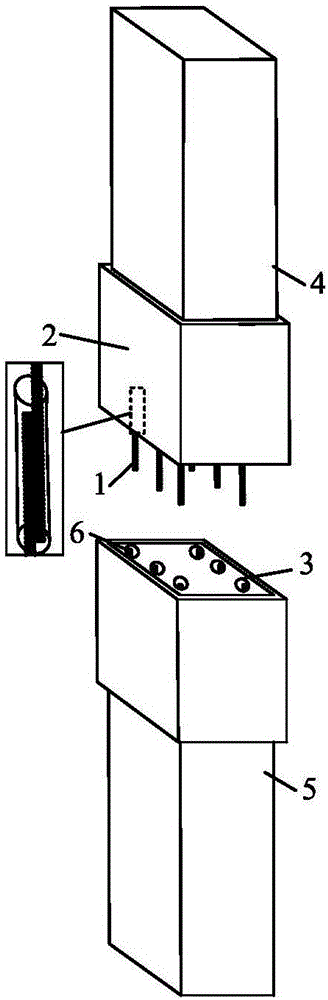

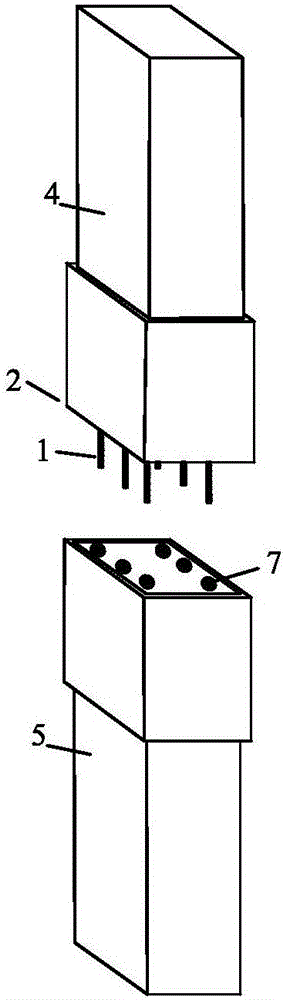

Combined column foot capable of being repaired in situ

The invention provides a combined column foot capable of being repaired in situ, which is good in anti-earthquake performance and capable of being rapidly repaired after an earthquake. The combined column foot comprises a steel plate bucket, a damper with one end connected to the outer side surface of the steel plate bucket, and a connection plate connected with the other end of the damper, wherein the connection plate is fixedly installed on a ground beam corresponding to a reinforced concrete column, the damper is provided with a detachable flexible steel plate, and the flexible steel plate is vertically placed. By arranging the damper (the flexible steel plate), in case of a small earthquake, the flexible steel plate used as an energy-consuming plate of the damper is capable of generating a concentrated deformation to absorb most of earthquake energy due to a relatively good plasticity; in case of a strong earthquake, the flexible steel plate generates a shear yield to consume the earthquake energy, thus greatly protecting the reinforced concrete column from being damaged or collapsing and further achieving good anti-earthquake performance; meanwhile, because the flexible steel plate is detachable, the damaged flexible steel plate can be taken off and replaced by a complete flexible steel plate after the strong earthquake, thus realizing post-earthquake rapid repair.

Owner:HUAQIAO UNIVERSITY +1

Fully prestressed and compositely integrally reinforced concrete structure

InactiveCN102704698AGood secondary stress performanceImprove playbackBuilding repairsReinforced concrete columnCable stayed

The invention provides a fully prestressed and compositely integrally reinforced concrete structure of adopting a compositely integral dual-measure reinforcing technology of prestress and binding to reinforce a concrete beam, a plate, a column and a joint. The reinforced concrete structure comprises a beam to be reinforced, a stressed area steel plate, a tensile region steel plate, a steel plate hoop, a cable-stayed rebar and a screw, wherein a column structure of the reinforced concrete structure comprises a column to be reinforced, a jack, a welding temporary bracket and at least two groups of reinforcing assemblies; the reinforced concrete column structure comprises the column to be reinforced, a fixing component, a connection steel plate and at least two groups of reinforcing assemblies, and the reinforced concrete cantilever plate structure comprises a cantilever plate extension end to be reinforced, a steel plate strip, an chemical anchor bolt and a fastener, so as to solve essential issues that old and new structures of the known reinforced concrete structure reinforcing technology cannot cooperatively work.

Owner:NANJING SHENGYUAN CIVIL ENG HIGH TECH +1

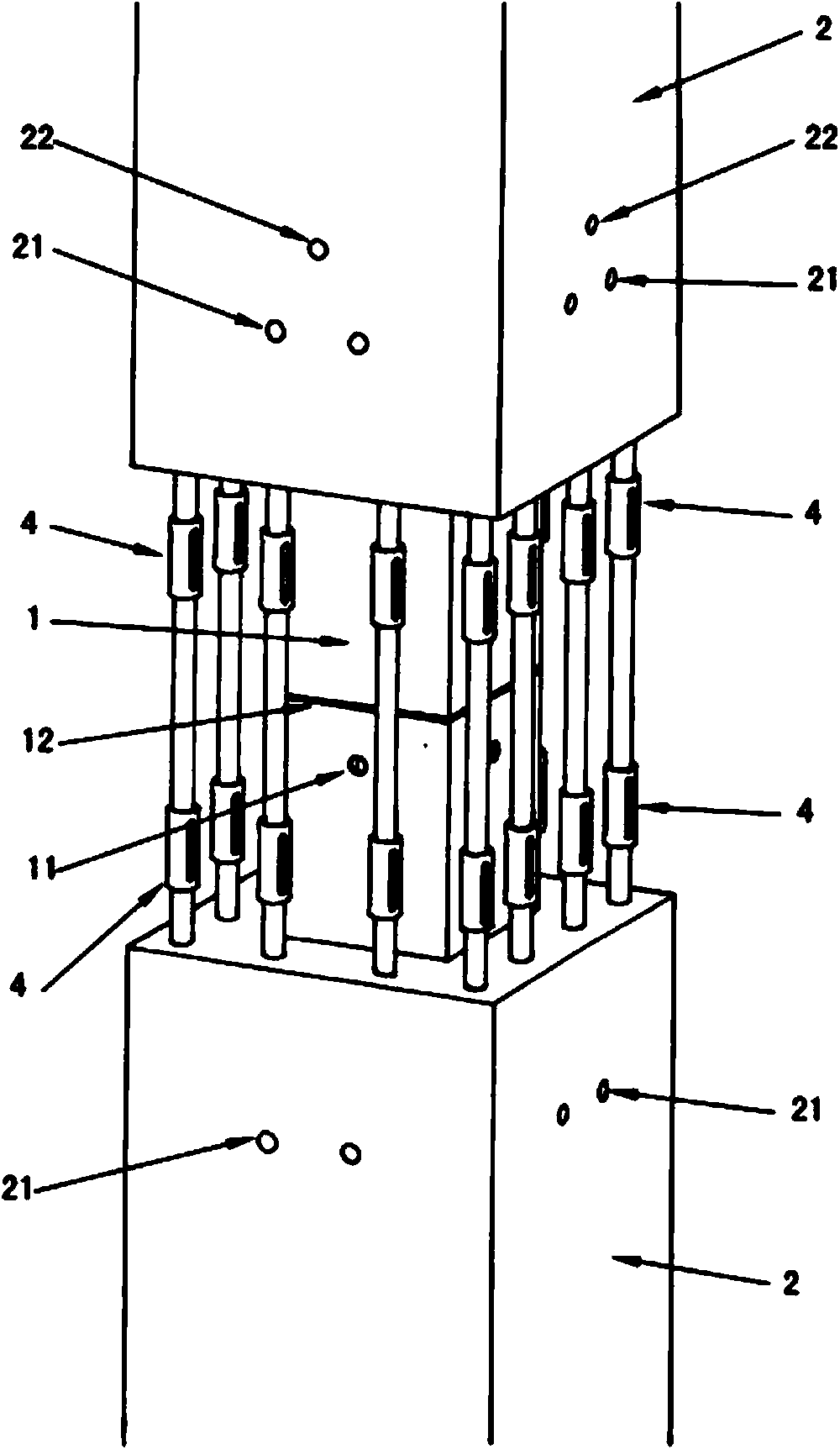

Prefabricated reinforced concrete column and column splice joint with sleeves

InactiveCN106381925AImprove bending abilityAchieve connectionBuilding reinforcementsHigh strength concreteReinforced concrete column

The invention discloses a prefabricated reinforced concrete column and column splice joint adopting connection of embedded corrugated sleeves and high-strength reinforcement. The splice joint mainly comprises a prefabricated reinforced concrete upper column, a prefabricated reinforced concrete lower column, steel sleeves, the embedded corrugated sleeves and the high-strength reinforcement. An installation method of the splice joint comprises the following steps: in a factory, realizing the embedded high-strength reinforcement by a method of firstly pouring non-shrinkage self-compacting high-strength concrete into the embedded corrugated sleeves of the prefabricated reinforced concrete upper column and then inserting the high-strength reinforcement; and at the construction site, grouting the corrugated sleeves of the reinforced concrete lower column, inserting the embedded high-strength reinforcement of the upper column in the corrugated sleeves of the lower column and simultaneously welding the steel sleeve joint parts on the outer surfaces of the columns, thus realizing prefabricated reinforced concrete column and column splicing. The splice joint has the beneficial effects that all the used components are assembled and connected on the site, thus reducing reinforcement assembling and formwork supporting on the site, improving the building industrial assembly efficiency and reflecting the novel building concepts of environment friendliness and energy saving of building components.

Owner:HUNAN UNIV

Method for reinforcing concrete column by utilizing PVC-FRP (Poly Vinyl Chloride-Fiberglass Reinforced Plastic) pipe

ActiveCN102392541AIncrease profitImprove bearing capacityStrutsBuilding repairsReinforced concrete columnInternal pressure

The invention provides a method for reinforcing a concrete column by utilizing a PVC-FRP (Poly Vinyl Chloride-Fiberglass Reinforced Plastic) pipe and belongs to the technical field of civil engineering. The method is suitable for maintaining and reinforcing the concrete columns in civil buildings, industrial plants and bridge structures. By mainly aiming at the reinforced concrete column, a PVC pipe is sheathed outside the concrete column, a reinforcing steel bar is configured in the PVC pipe, FRP cloth is wound outside the PVC pipe to form restraint action on the concrete column with the PVCpipe, and the internal pressure of the PVC pipe sheathed outside should reach above 1Mpa. The FRP cloth can adopt a carbon fiber composite material, a glass fiber composite material or an aramid fiber composite material. Compared with the traditional reinforcing method, the method for reinforcing the concrete column by utilizing the PVC-FRP pipe has the advantages that the reinforced concrete column is high in bearing capacity, small in cross section size and good in ductility and durability; and the method is convenient to construct, low in construction price and the like.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Prefabricated prestressed concrete frame beam-column joint making disparate use of high performance materials

ActiveCN105625572AReduce Beam SectionReduce steel consumptionShock proofingReinforced concrete columnConcrete beams

The invention discloses a prefabricated prestressed concrete frame beam-column joint making disparate use of high performance materials, comprising prefabricated concrete beams, prefabricated concrete columns, prefabricated beam-bottom prestressed tendons, common rebars, beam-top common rebars, in-column vertical rebars, sleeves, connecting rebars, and U-shaped rebars. Post-cast sections are reserved at two ends of the pre-fabricated beams, and the prestressed tendons fitted to the bottom of the prefabricated beams extend out of beam ends and are anchored to the beam-end post-cast sections, forming the prefabricated concrete beam-column joint with the prefabricated concrete beams and columns through post-cast concrete. In order to ensure the integrity of the beam-column joint, the beam-bottom common stressed rebars are connected with aseismic rebars through the sleeves and the U-shaped rebars are disposed in a joint post-cast area. In order to improve the energy dissipating capacity of the beam-column joint, the two ends of the prefabricated beams are made by casting high ultimate strain concrete. The invention reduces the production and construction difficulty, decreases the section height or steel usage of the prefabricated concrete beams and ensures the integrity and aseismic performance of the beam-column joint.

Owner:SOUTHEAST UNIV

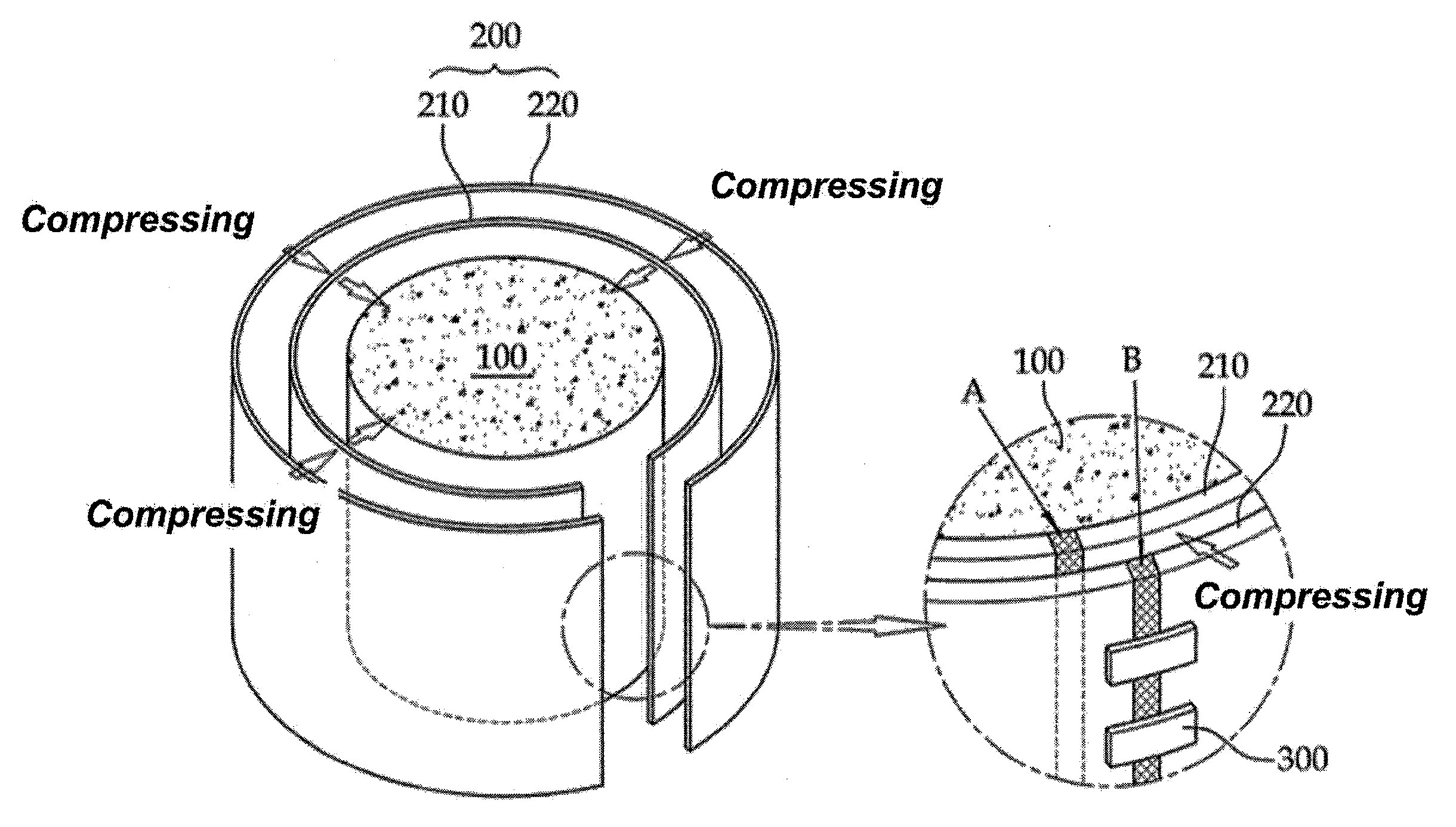

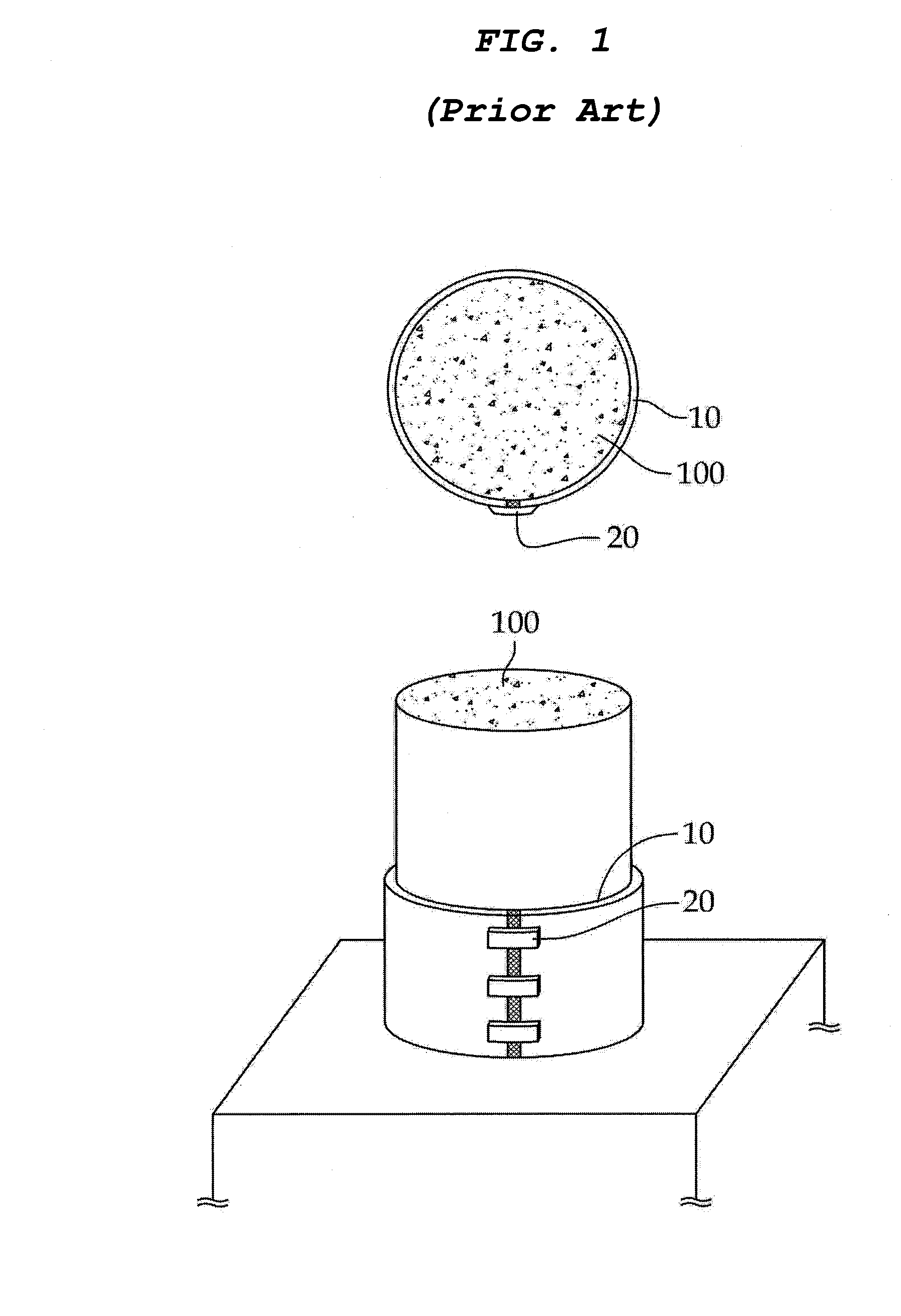

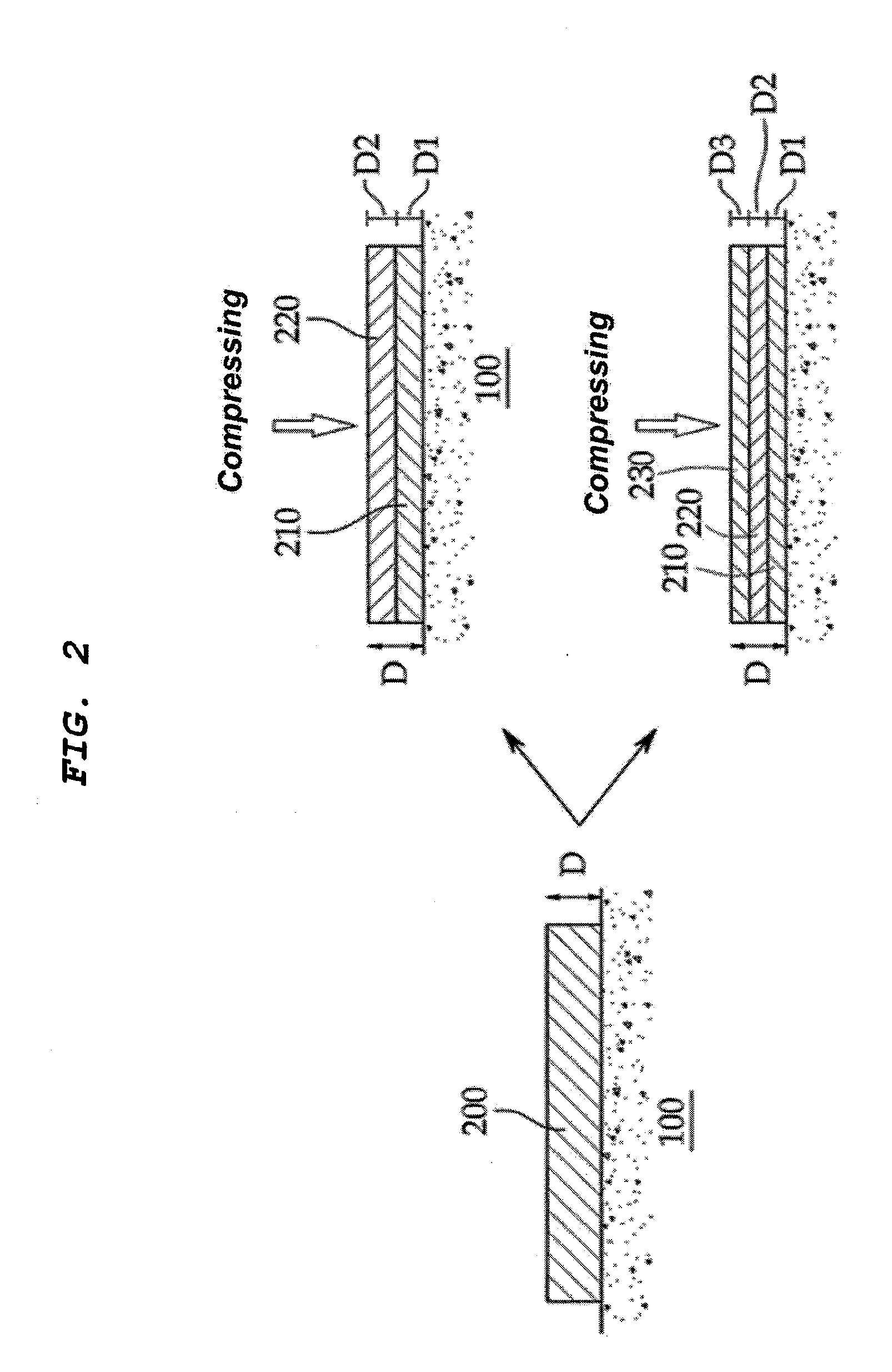

Method for retrofitting reinforced concrete column using multi-layered steel plates, and retrofitting structure of reinforced concrete column using the same

InactiveUS20090165404A1Improve work performanceImprove constructabilityStrutsBuilding repairsReinforced concrete columnEnergy absorption

A method for retrofitting a reinforced concrete column by compressing a reinforcing plate including a steel plate using an external pressure is provided. The reinforcing plate is compressed to double-layer or more, that is, multi-layer in due order, on the reinforced concrete column. Accordingly, since a workability of the retrofit is excellent and since the reinforcing plate is easily compressed on the surface of the reinforced concrete column by a small lateral pressure, sufficiently the reinforced concrete column could be reinforced. Besides, a compressive strength of the reinforced concrete column could be increased. In addition, the flexibility of the reinforcing plate and the energy absorption force of the reinforcing plate could be increased.

Owner:KANG WON IND +1

Installation underpinning method for existing framed building reinforced by parallel seismic isolation supports

ActiveCN102587684AImprove shortcomingsImprove seismic performanceBuilding repairsShock proofingReinforced concrete columnRebar

Owner:HENGSHUI JIJUN ENG RUBBER FOR GATE OR BRIDGE

Method and structure for reinforcing concrete post using angle steel

InactiveCN1702271ASolve the problem of not sticking tightlyHigh strengthStrutsBuilding repairsReinforced concrete columnArchitectural engineering

This invention discloses a method for bracing concrete column by angle steer in the architectural engineering, in addition to its structure. The method comprises the following steps: a) making the angle steer assembly, that is, welding steer bar bolt in outboard of one limb of the angle steer, welding steer pipe in the other limb; b) setting up the assembly around the concrete column to be braced, each assembly are connected with each other through the steer bar bolt crossing the steer pipe; c) installing cap nut in the steer bar bolt and screwing up, which makes the nearside of each angle steer sticking to the surface of the concrete column. The structure comprises the angle steer, steer bar bolt and the steer pipe, and along the angle steer, the steer bar bolt and steer pipe are set alternatively, which forms interlace arrangement of the adjacent steer hoop.

Owner:GUIYANG AL-MG DESIGN & RES INST

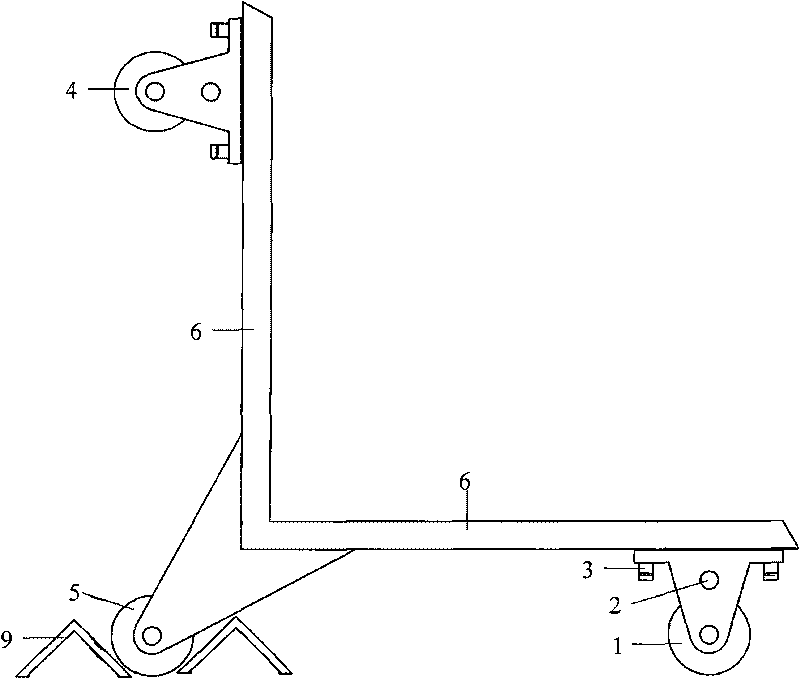

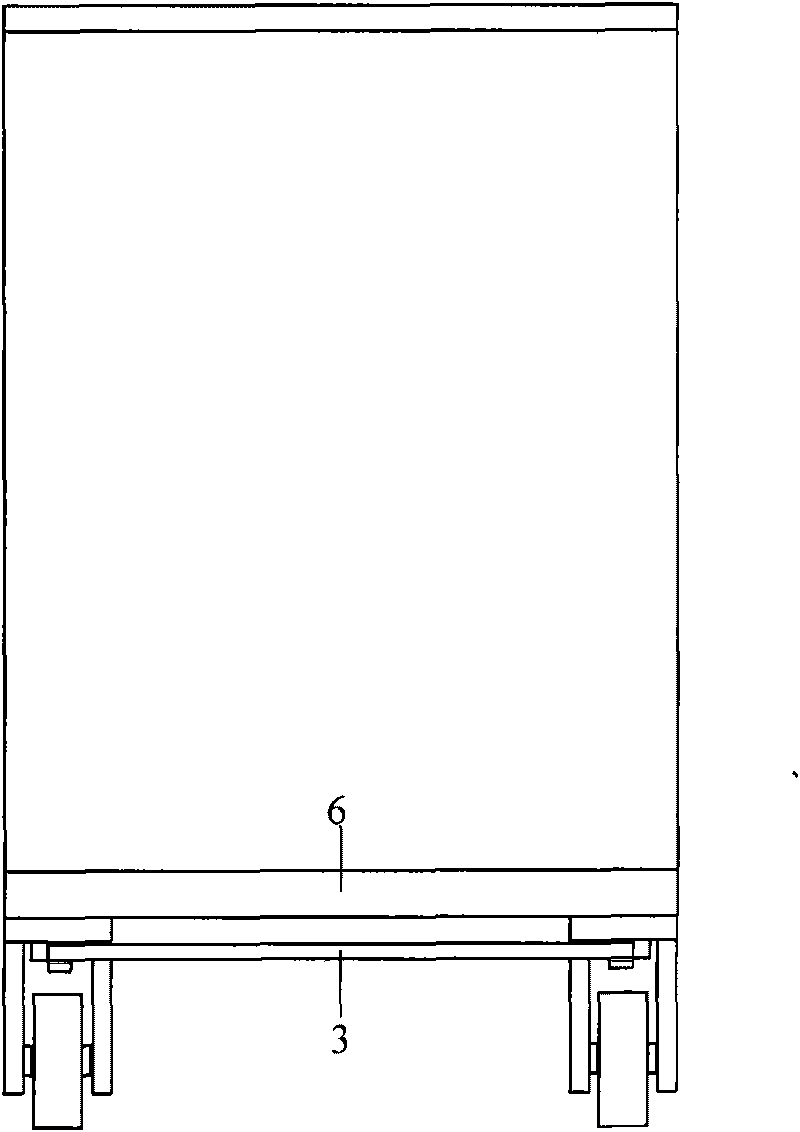

Device for hoisting prefabricated reinforced concrete column on site and walking technology thereof

InactiveCN101713254AShorten the timeUprighting vertical process is stableBuilding material handlingLoad-engaging elementsReinforced concrete columnEconomic benefits

The invention relates to the field of building operations, in particular to a device for hoisting prefabricated reinforced concrete column on site and a walking technology thereof. The purpose of the invention lies in providing a simple yet effect walking technology for hoisting prefabricated reinforced concrete column on site and the device for realizing the technology; the design is simple and the operation is effective. To achieve the purpose, the invention provides the following technical proposal: the device of the invention is composed of a wheeled supporting plate, steel sheets and braking angle iron and has the following characteristics: the supporting plate is a right-angle structure, the top of the right angle is provided with deflectable rolling-over wheels, the two ends of the supporting plate far away from the top of the right angle are respectively provided with deflectable wheels, rotary connecting rods are arranged on a deflectable wheel seat. With the device of the invention adopted, mechanical efficiency can be effectively improved, construction productivity can also be enhanced, thus accelerating construction progress and enjoying extremely noticeable economic benefits and comprehensive benefits.

Owner:DALIAN ZHUCHENG CONSTR GRP

Connecting structure of frictional type damper assembling type frame joint and constructing method thereof

InactiveCN104032839AImprove energy consumptionActive connectionShock proofingReinforced concrete columnPre stress

Disclosed is a connecting structure of a frictional type damper assembling type frame joint. Prestress steel strands are arranged in steel strand embedded pipes of the structure, precast reinforced concrete beams are connected with precast reinforced concrete columns through the prestress steel strands, the seams between the beams and the columns are filled of high-strength grouting materials, and beam and column connecting joints are formed. Frictional type dampers are arranged at the positions of the beam and column connecting joints, and the connecting structure of the whole frictional type damper assembling type frame joint attached with prestress is formed. The constructing method comprises the steps that the precast reinforced concrete beams are aligned to the damper embedded pipes on the precast reinforced concrete columns; the steel strands are arranged in the steel strand embedded pipes of the precast reinforced concrete beams in a penetrating mode; the seams are filled with the high-strength grouting materials, and the whole beam and column joints are formed; frictional damper fixing screw rods are arranged in the damper embedded pipes in a penetrating mode to mount the frictional type dampers. According to the structure, the energy-dissipating capacity of the assembling type frame structure under the earthquake action can be effectively improved, effective connection of the columns and the beams is ensured, the earthquake energy can be effectively consumed, and the building structure is protected.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

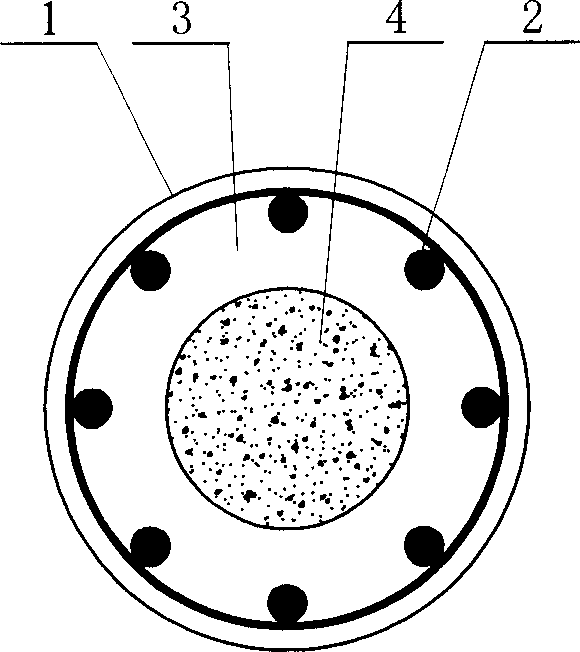

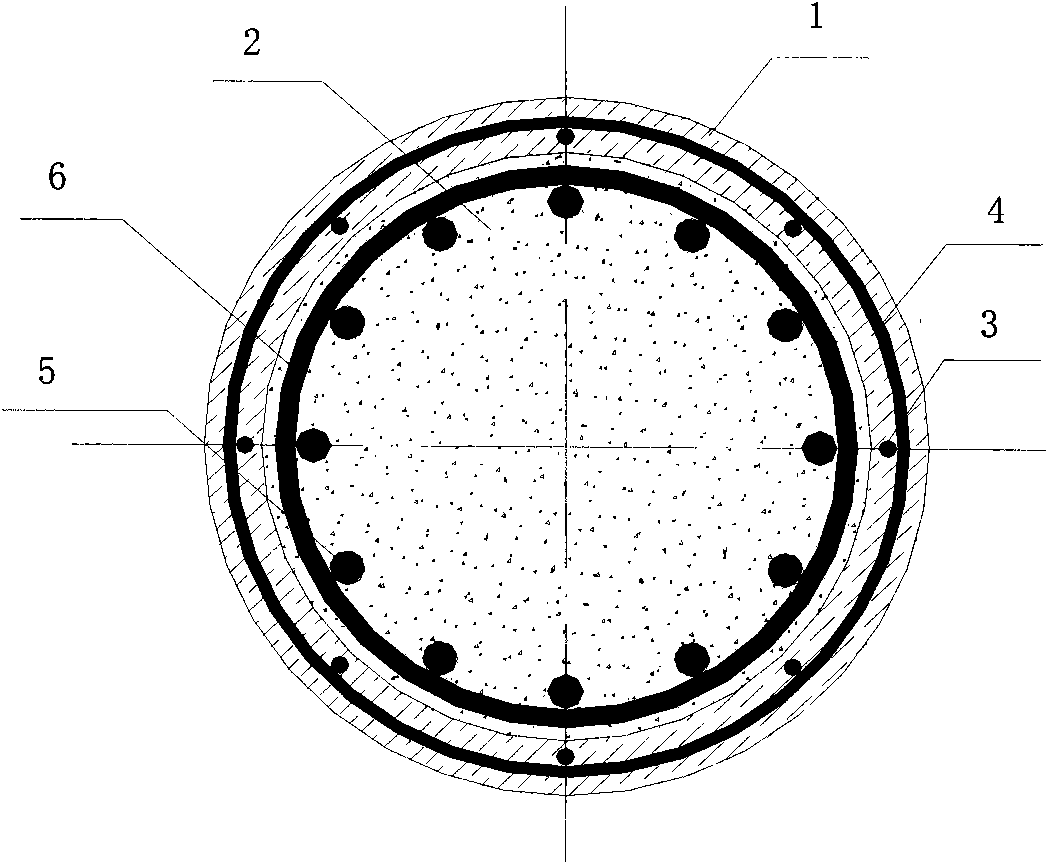

Sleeve reinforced concrete column

InactiveCN102102423AGive full play to the material performanceEasy constructionStrutsPillarsReinforced concrete columnShock resistance

The invention discloses a sleeve reinforced concrete column. The sleeve reinforced concrete column is characterized in that: a sleeve (1) of a reinforced concrete column (2) is a prefabricated active powder concrete sleeve. The sleeve reinforced concrete column has the advantages of convenience for construction, low cost, high axial bearing capacity, good shock resistance, predominant fireproof performance, excellent durability and the like, meanwhile, saves more resources and energy, and accords with the requirements of sustainable development.

Owner:HUNAN UNIV

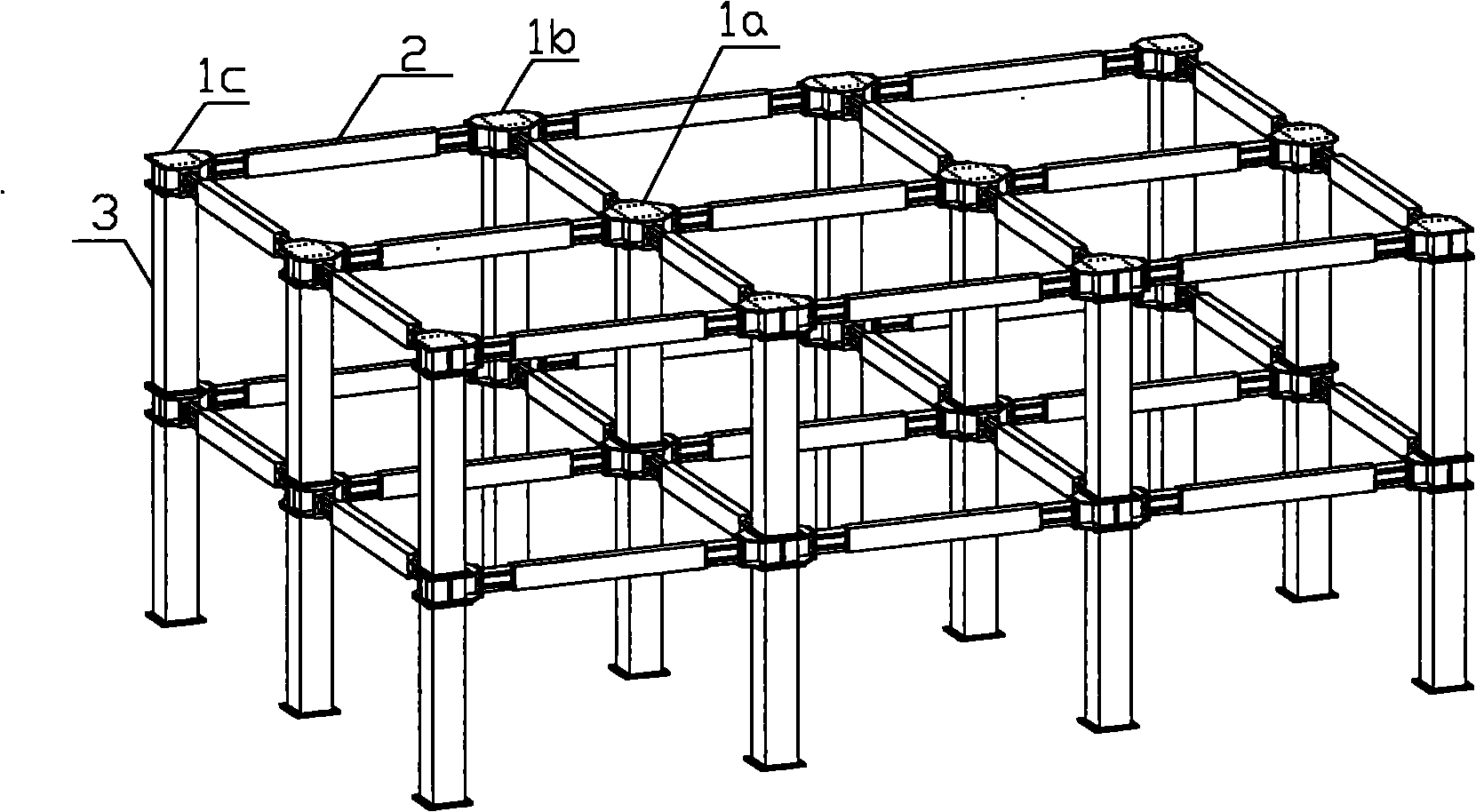

Method and system for rapid construction of structurally reinforced concrete structures using prefabricated assemblies and method of making the same

ActiveUS20160122996A1High quality constructionLow costConstruction materialFloorsReinforced concrete columnFloor slab

The present invention includes prefabricated assemblies which are assembled on a construction site to provide a permanent concrete mold with integrated structural reinforcement and structural splices for cast-in-place concrete structures. The invention enhances the quality of the cast concrete structure while lowering the cost of construction and construction time. Described herein is a column form assembly, a column closure panel assembly, a beam form assembly, and a slab form assembly which are used to construct cast in place structurally reinforced concrete columns, beams, and floor slabs with minimal form work and construction site logistics. Also described herein are a method of assembly of said structures and a method of fabricating said assemblies.

Owner:KT INDIA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com