Assembled joint node for column base and construction method

A connection node and assembly technology, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of insufficient deformation capacity and mechanical properties of the column foot nodes of assembly structures, achieve high-efficiency construction anti-seismic performance, reduce maximum strain, and reduce curvature Yield risk effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

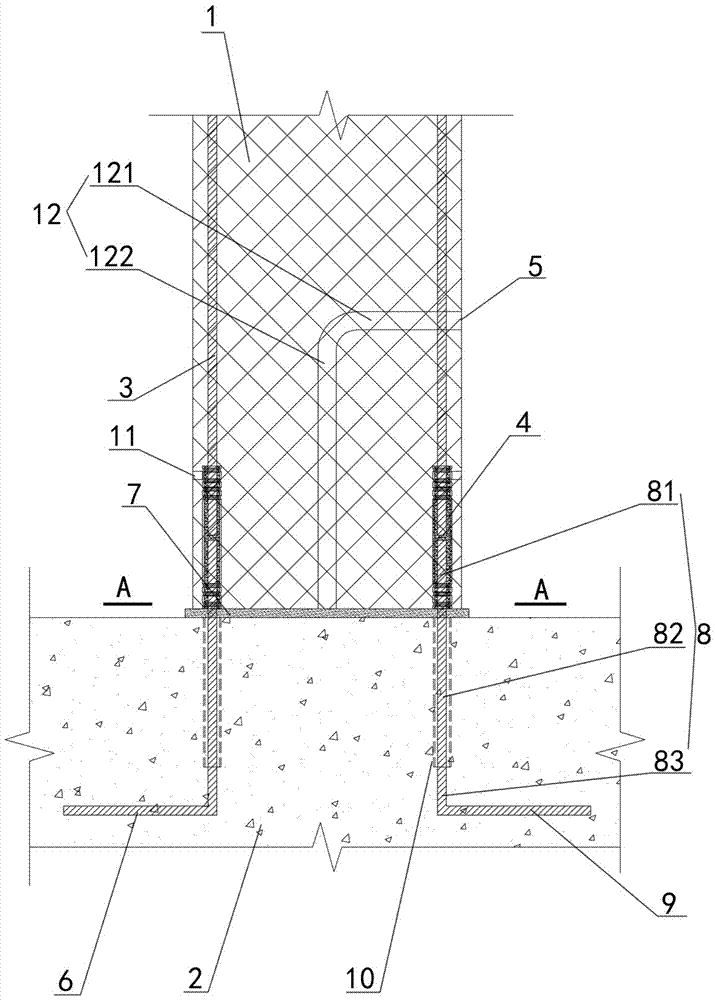

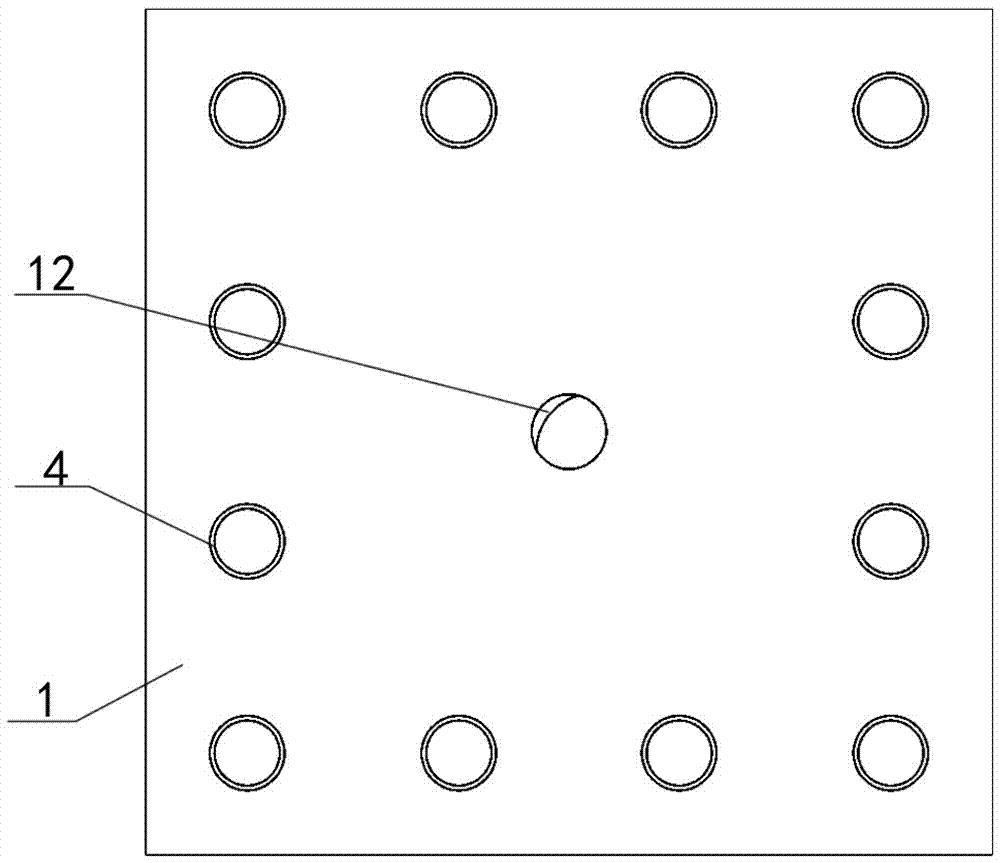

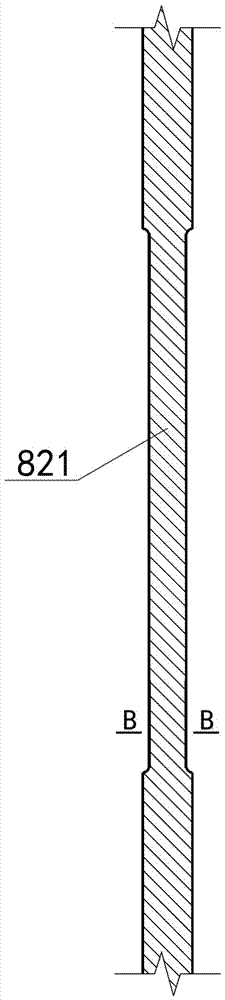

[0050] Examples see Figure 1-2 As shown, a prefabricated column-foot connection node includes an upper prefabricated reinforced concrete column 1 and a lower reinforced concrete foundation 2 that are spliced vertically, and the prefabricated reinforced concrete column 1 is pre-embedded. Column anchoring longitudinal bars 3 and grouting sleeves 4, the reinforced concrete foundation 2 is pre-embedded with foundation anchoring bars 6, and the foundation anchoring bars 6 and column anchoring longitudinal bars 3 are filled with the grouting sleeve 4 through the grouting material 7 connection, the splicing joint between the reinforced concrete foundation 2 and the prefabricated reinforced concrete column 1 is also filled with the filling material 7. Grouting sleeve 4 adopts common grouting sleeve.

[0051] The joint filling material is a high-strength rapid-hardening cement-based grout with a compressive strength of more than 45 MPa or steel fiber, carbon fiber or other fiber ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com