General purpose Portland cement based ultra-light physical foamed concrete

A Portland cement and foam concrete technology, applied in the field of concrete, can solve problems such as lack of resources, quality disputes, uneven quality, etc., and achieve the effects of reducing costs, reducing resource consumption, and reducing the use of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A general-purpose Portland cement-based ultra-light physical foamed foam concrete, the components and weight percentages are: general-purpose Portland cement 48.6%, C-type admixture 1.9%, foaming agent 0.6%, water-reducing agent 0.3%, Water 48.6%; Among them: the general-purpose Portland cement is 42.5 grade ordinary Portland cement, the C-type admixture is made of aluminum sulfate and calcium nitrate, the foaming agent is commercially available animal protein foaming agent, and the water-reducing agent is commercially available Polycarboxylate superplasticizer;

[0036] The preparation method is: first take general-purpose Portland cement, C-type admixture, foam agent, water reducer and water according to the weight percentage; dilute the foam agent and water at a ratio of 1:15 to form a foam agent solution, and place it at a speed of 3000rpm Under mechanical stirring and foaming to obtain foam; dissolve water reducer and C-type admixture into the remaining water of th...

Embodiment 2

[0039] A general-purpose Portland cement-based ultra-light physical foaming foam concrete, the components and weight percentages are: general-purpose Portland cement 44.1%, C-type admixture 1.7%, foaming agent 1.1%, water-reducing agent 0.3%, Water 52.8%; Among them: the general-purpose Portland cement is 52.5 grade ordinary Portland cement, the C-type admixture is composed of sodium aluminate, calcium formate, and triethanolamine, and the foaming agent is a commercially available animal protein foaming agent. The agent is a commercially available naphthalene-based water reducer;

[0040] The preparation method is: first take general-purpose Portland cement, C-type admixture, foam agent, water reducer and water according to the weight percentage; dilute the foam agent and water at a ratio of 1:10 to form a foam agent solution. Mechanically stir and foam to obtain foam; dissolve water reducer and C-type admixture into the remaining water of the foam preparation to obtain mixtur...

Embodiment 3

[0043] A general-purpose Portland cement-based ultra-light physical foaming foam concrete, the components and weight percentages are: general-purpose Portland cement 53.0%, C-type admixture 2.1%, foaming agent 0.4%, water reducing agent 0.3%, , Water: 44.2%; Among them: the general-purpose Portland cement is 42.5 grade slag Portland cement, the C-type admixture is composed of sodium aluminate, ferric nitrate, and potassium carbonate, and the foaming agent is a commercially available vegetable protein foaming agent. The water reducer is a commercially available naphthalene-based water reducer;

[0044] The preparation method is: first take the general-purpose Portland cement, C-type admixture, foam agent, water reducer and water according to the weight percentage; dilute the foam agent and water at a ratio of 1:15 to form a foam agent solution. Mechanically stir and foam to obtain foam; dissolve water reducer and C-type admixture into the remaining water of the foam preparation...

PUM

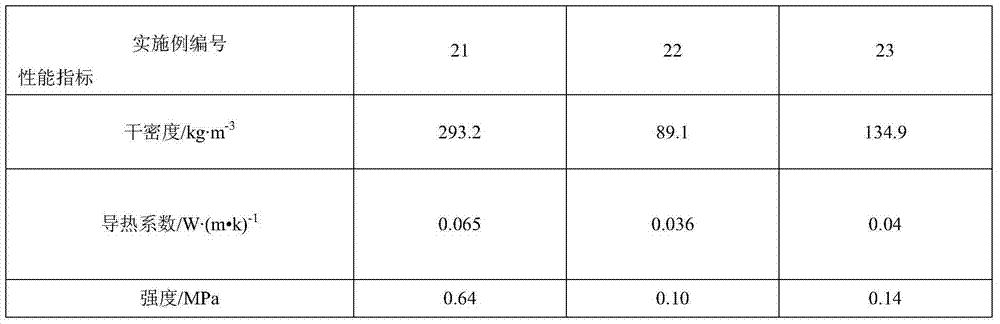

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com