Patents

Literature

48results about How to "Fast setting and hardening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

General purpose Portland cement based ultra-light physical foamed concrete

ActiveCN104774033AReduce raw material usageReduce resource consumptionCeramicwareCushionPortland cement

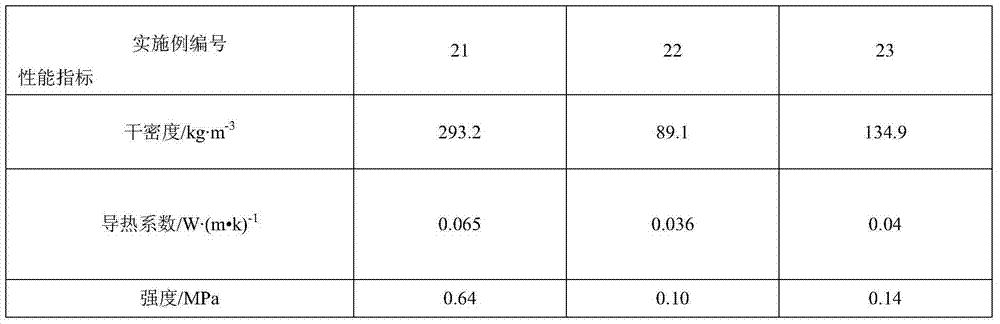

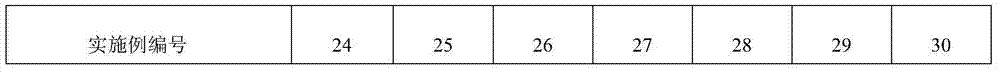

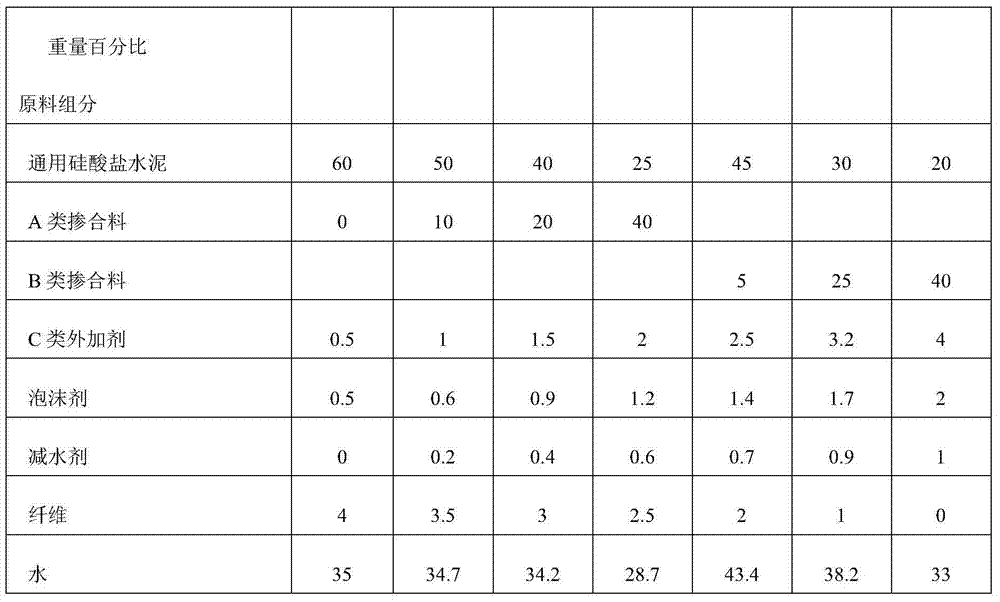

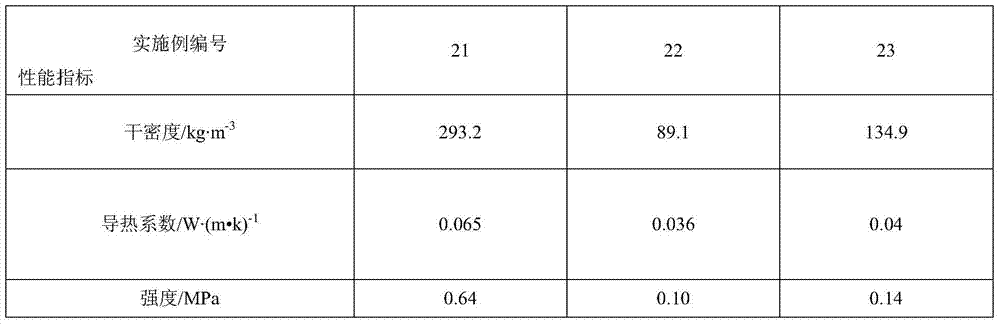

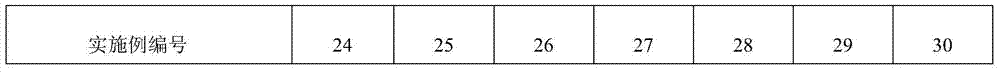

The invention discloses general purpose Portland cement based ultra-light physical foamed concrete which is characterized by being prepared by mixing, forming and maintaining the following components in percentage by weight: 20-70% of general purpose Portland cement, 0-40% of a type A admixture or / and 0-40% of a type B admixture, 0.5-4% of a type C additive, 0.3-2% of a foaming agent, 0-1% of a water reducing agent, 0-4% of fibers and 25-60% of water. The general purpose Portland cement based ultra-light physical foamed concrete disclosed by the invention has the characteristics of ultra-low dry density, low thermal conductivity, relatively high strength, wide raw material source, low cost, simple preparation process, easy maintenance process selection and the like, is suitable to serve as an earthquake-proof and energy-absorbing material, a lightweight cushion course and a catalyst carrier material in a thermal insulation project, a floor heating project and a back filling project, and is particularly suitable for a building exterior wall external thermal insulation system, a roof thermal insulation system, a composite thermal insulation wall body and a buffer energy absorbing system.

Owner:SOUTHWEAT UNIV OF SCI & TECH

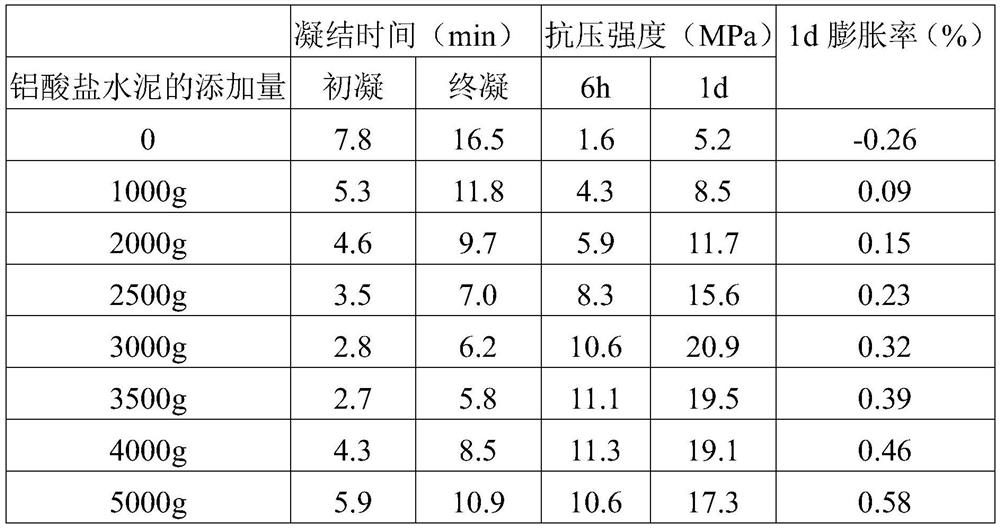

Early-strength type aluminate cement based self-leveling material

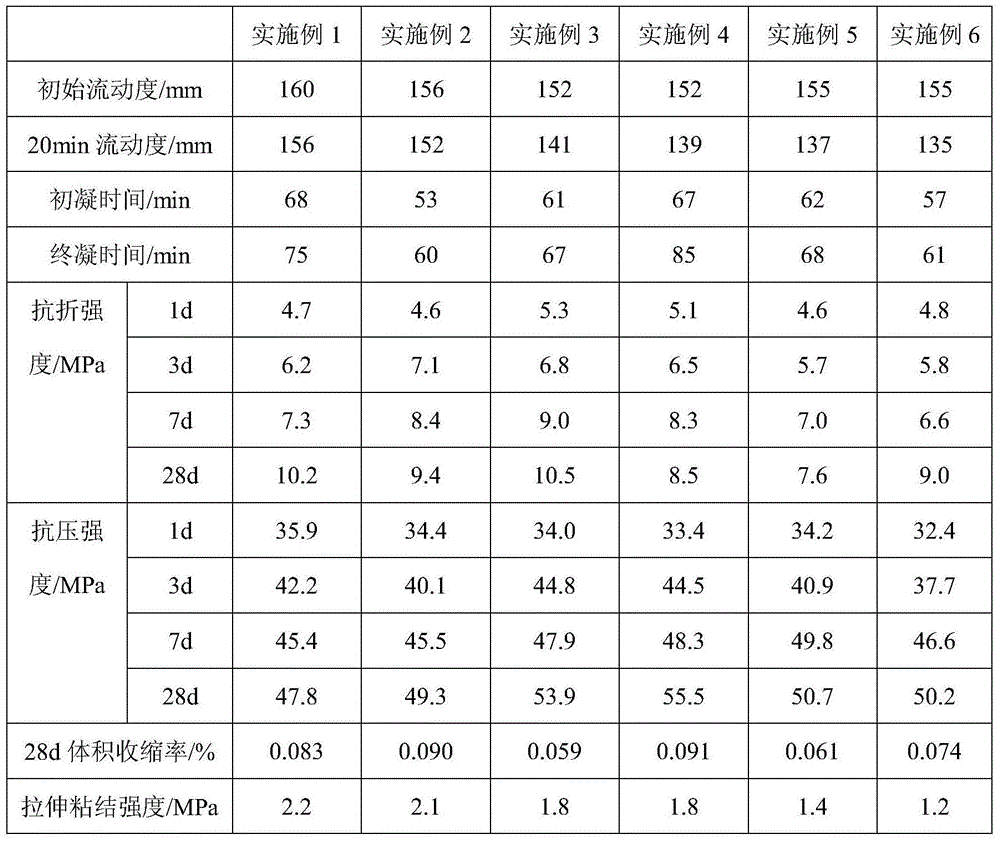

The invention relates to an early-strength type aluminate cement based self-leveling material which is characterized by comprising the following raw material components in parts by weight: 300-340 parts of aluminate cement, 40-60 parts of gypsum, 20-60 parts of portland cement, 380-420 parts of quartz sand, 180-220 parts of a heavy calcium carbonate powder, 8-20 parts of a redispersible emulsion powder, 2-2.4 parts of a water reducing agent, 0.15-0.25 part of a water-retaining agent, 1.5-2.5 parts of a defoaming agent, and 0-0.4 part of a retarder, wherein the water-material mass ratio is 0.18-0.19. The self-leveling material has the characteristics of good fluidity, high surface flatness, good stability, fast condensation hardening speed, high early strength, small volume shrinkage rate and the like, and can be used as a ground leveling material and a grouting repairing material.

Owner:NANJING UNIV OF TECH

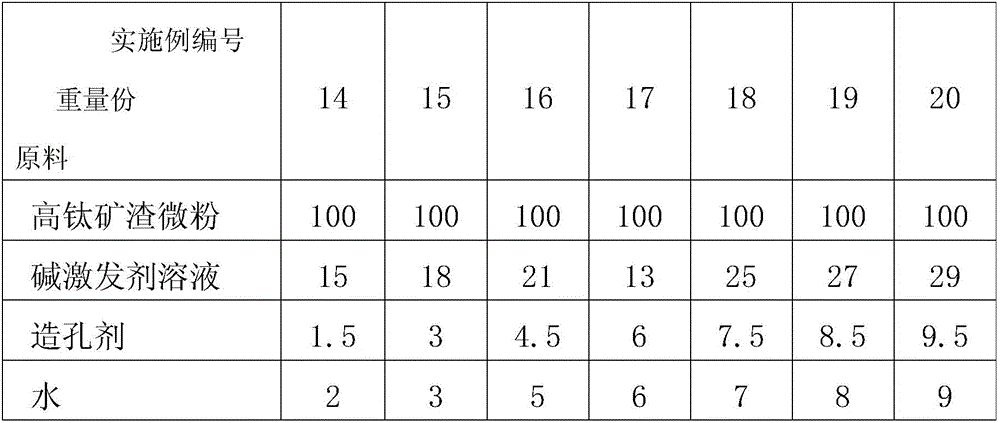

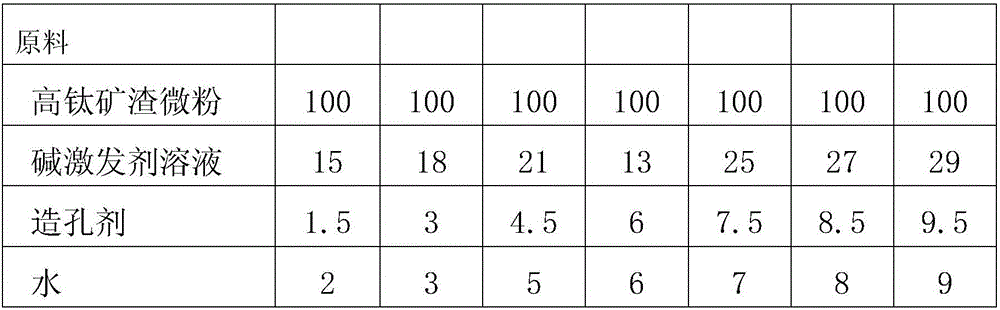

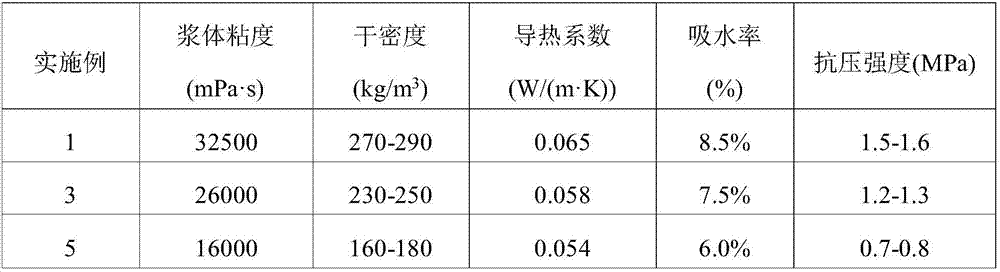

Alkali-activated high-titanium slag baking-free haycite and preparation method thereof

The invention discloses alkali-activated high-titanium slag baking-free haycite which is characterized by being prepared by mixing 100 weight parts of high-titanium slag micro powder, 12.5 to 30 weight parts of an alkali-activator, 0.5 to 10 weight parts of a pore forming substance and 0 to 10 weight parts of water. A preparation method of the alkali-activated high-titanium slag baking-free haycite comprises the following steps: putting the high-titanium slag micro powder into a disk granulator for stirring, so as to form a uniformly dispersed powder body; adding the pore forming substance, the water and the alkali-activator solution in sequence, and performing stirring, granulation and forming to obtain a blank, wherein the alkali-activator solution is water glass; maintaining the blank under a natural environment condition for 28 days, so as to obtain the alkali-activated high-titanium slag baking-free haycite. By the adoption of the preparation method for preparing the alkali-activated high-titanium slag baking-free haycite, high-temperature baking is not needed; a large mixing amount of the high-titanium slag micro powder can be used, so that a product is light in mass and high in strength; the alkali-activated high-titanium slag baking-free haycite has the characteristics of simple process, low cost, energy conservation, low carbon, environment friendliness and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Super-light foam concrete and preparation method thereof

InactiveCN107324735AImprove production qualityFast setting and hardeningCeramicwareHydroxypropylmethyl celluloseSilica fume

The invention discloses super-light foam concrete. The super-light foam concrete is characterized by comprising the following materials in parts by mass: 60-80 parts of ordinary Portland cement, 10-20 parts of rapid hardening sulphoaluminate cement, 2-5 parts of silica fume, 8-15 parts of ultra-fine fly ash, 0.5-1.0 part of a polycarboxylate superplasticizer, 1-2 parts of redispersible powder, 0.05-0.2 part of hydroxypropyl methyl cellulose ether, 0.1-0.4 part of polypropylene fibers, 0.02-0.05 part of a superfine MnO2 catalyst, 4-6 parts of hydrogen peroxide and 50-60 parts of water, wherein a sustained-release gelatin capsule is filled with the superfine MnO2 catalyst and has the collapse time limit of 5-10 min. The invention also discloses a preparation method of the super-light foam concrete. The preparation method is characterized by comprising the steps of weighing, mixing, stirring and pouring. The super-light foam concrete has the advantages of high percentage of close area, low water absorption, high compressive strength and low heat conduction coefficient. The preparation method of the super-light concrete has the advantages that the hydrogen peroxide decomposition efficiency can be improved, and the hydrogen peroxide decomposition speed can be effectively controlled.

Owner:CHONGQING UNIV +2

Fireproofing, humid conserving boards for building, and preparation method

This invention relates to a method for preparing fireproof and heat-insulating board for architectures. The fireproof and heat-insulating board comprises aggregate and gel material at a weight ratio of (100-150):(100-250). The gel material comprises: light-burned MgO 46-56 wt.%, industrial MgCl2 20-26 wt.%, H2O2 1.5-3.5 wt.%, H3PO4 0.2-0.3 wt.%, HBO3 0.2-0.3 wt.%, and water 20-26 wt.%. The method comprises: (1) screening foam glass (particle sizes are 15-35 mm, and density is 160-180 kg / m3), and placing in a mold; (2) adding industrial MgCl2 and water; (3) adding H3PO4 and HBO3, and stirring uniformly; (4) adding light-burned MgO, stirring uniformly, and adding H2O2 during stirring to obtain a gel material; (5) pouring the gel material into a mold; (6) covering the lid, and curing naturally; (7) demolding, and maintaining. The fireproof and heat-insulating board has such advantages as low weight, high strength, high impact resistance, no deformation, good heat, sound, fire and water resistance, and good processability.

Owner:上海永丽节能墙体材料有限公司

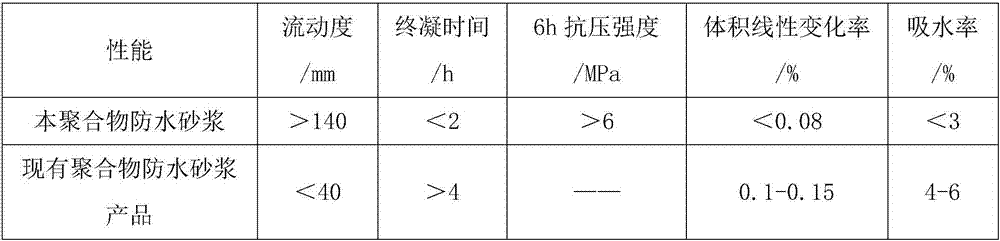

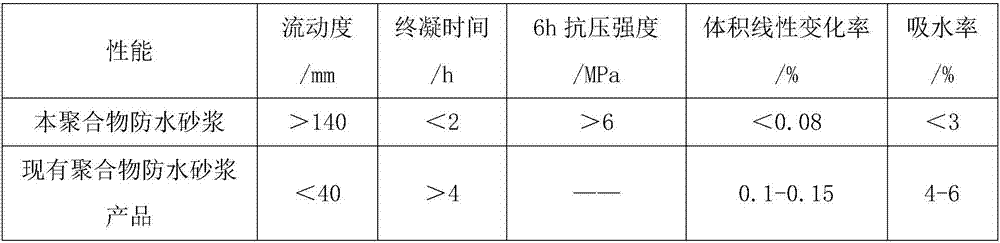

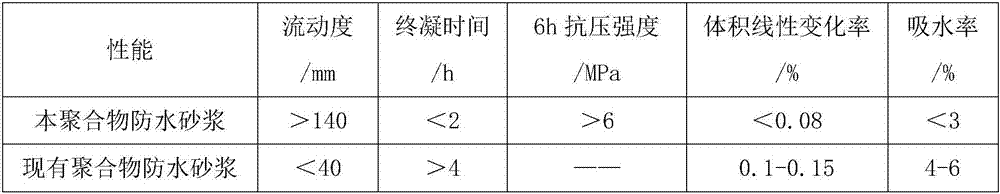

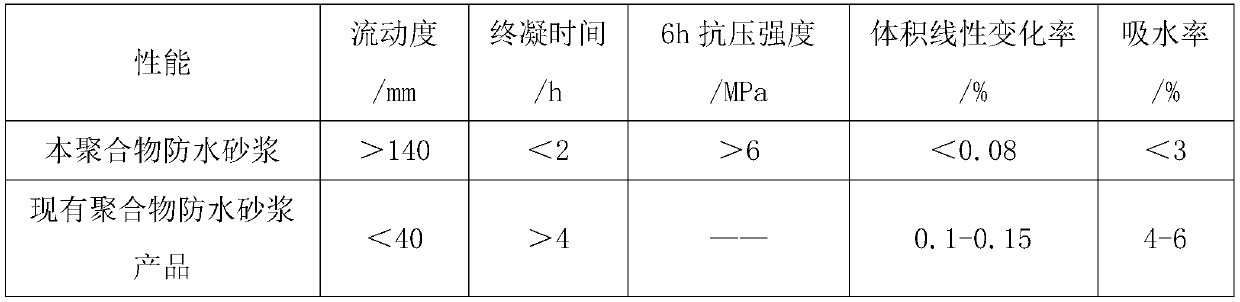

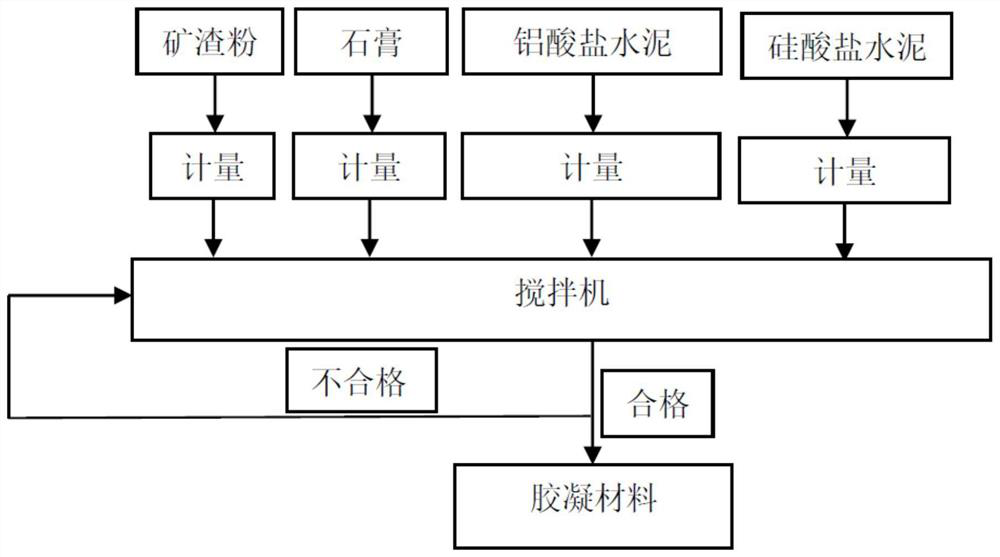

Self-leveling type II polymer cement waterproof mortar

The invention provides self-leveling type II polymer cement waterproof mortar. The mortar comprises Portland cement, a composite hardening accelerator, aggregates, water, polymer and other additives, wherein the composite hardening accelerator comprises the following raw materials in parts by weight: 3 to 6 parts of calcium lime, 2 to 5 parts of sodium sulphate, and 5 to 10 parts of aluminate cement. The mortar solves the durability problem of poor long-term waterproof anti-penetrability performance of common self-leveling motor due to high aluminum cement component content, realizes the self-leveling construction of polymer cement waterproof mortar, and can be applied to various waterproof construction projects, such as toilets, kitchens, roofs, swimming pools and subsurface structures.

Owner:SHANDONG YINGCAI UNIV

Sulphur oxide cement product and preparation method thereof

ActiveCN107140856AFast setting and hardeningIncrease productivityOxideMagnesium sulphate heptahydrate

The invention discloses a sulphur oxide cement product and a preparation method thereof. The sulphur oxide cement product is prepared from, by weight, 50-100 parts of activated magnesium oxide powder, 30-100 parts of magnesium sulfate heptahydrate, 0.05-2 parts of an additive and a basic magnesium sulfate saturated suspension. The obtained sulphur oxide cement product is high in early strength and good in early anti-cracking capability.

Owner:QINGHAI UNIVERSITY

Impervious anticorrosion pouring material

InactiveCN101475385AStrong resistance to glass chemical attackGood chemical stabilityGranularityZircon

The invention discloses a seepage and corrosion resistant casting material. The casting material comprises an A composition, a B composition and a C composition, wherein the weight percentage of various compositions is calculated by the 100 total weight percentage of the casting material; the A composition is a uniform mixture of the following compositions: 13 to 18 percent of 5-7 mm fused zircon corundum, 12 to 20 percent of 3-5 mm fused zircon corundum, 19 to 27 percent of 1-3 mm fused zircon corundum and 12 to 18 percent of 0-1 mm fused zircon corundum; the B composition is a uniform mixture of the following compositions: 3 to 5 percent of activated alumina micro powder, 2 to 4 percent of low-iron silica fume, 3 to 7 percent of desilicate zirconium, 2 to 10 percent of zircon powder and 2 to 10 percent of white alundum powder; and the C composition is a uniform mixture of the following compositions: 1 to 3 percent of alumina cement and 0.05 to 0.15 percent of sodium tripolyphosphate. The seepage and corrosion resistant casting material has the advantage of strong capacity of resisting corrosion of glass chemistry and the like.

Owner:宜兴市中韩窑业工程有限公司

Quick-setting early-strength grouting material

InactiveCN105565745AShorten the setting timeControllable clotting timeSolid waste managementSlagDefoaming Agents

The invention discloses a quick-setting early-strength grouting material, and belongs to the technical field of grouting materials. The quick-setting early-strength grouting material comprises the following raw materials in percentage by mass: 75 to 90 parts of potland clinker, 3 to 10 parts of mineral slag, 5 to 15 parts of sulphate aluminium cement, 1 to 5 parts of silica fume, 0.5 to 4 parts of bentonite, 0.05 to 0.2 part of hydroxyethyl cellulose, 0.25 to 0.5 part of water reducing agent, 0.005 to 0.1 part of lithium carbonate, and 0.05 to 0.5 part of defoaming agent. The grouting material disclosed by the invention is mainly applied to grouting leakage plugging of a rock-soil layer, and in particular to the grouting leakage plugging engineering of water burst at the positions of a dam foundation and the like, and has the advantages of short setting time, high early strength, high construction performance, and good plugging performance.

Owner:JIAHUA SPECIAL CEMENT

Freezing-thawing resistant concrete mixture and preparation method thereof

Relating to the technical field of concrete, the invention discloses a freezing-thawing resistant concrete mixture and a preparation method thereof. The key point of a technical scheme lies in that: the freezing-thawing resistant concrete mixture comprises the following raw materials by weight: 320-340 parts of cement, 700-720 parts of sand, 940-980 parts of rubble, 100-120 parts of an admixture,6-10 parts of reinforced fiber, 10-20 parts of anti-permeability agent, 10-12 parts of a water reducing agent and 120-140 parts of water. Through cooperation of the reinforced fiber and the admixture,the porosity of concrete can be reduced, the compactness of concrete can be enhanced, the anti-permeability and anti-cracking performance and freezing-thawing resistance of concrete are improved, andthe setting and hardening speed of concrete can be increased.

Owner:青岛金磐石新型建材有限公司

A seed crystal for improving early strength of concrete and its application

The invention discloses a crystal seed used for improving concrete early stage strength, and an application thereof. The crystal seed is characterized in that: the crystal seed is prepared from grinded cement stones, wherein the specific surface area of the crushed and grinded crystal seed is 8000 to 15000m<2> / kg. The cement stones are obtained through steps that: a certain amount of inorganic salt is doped into common portland cement, and the mixture is cured for a certain age, such that the cement stones are obtained. The application of the crystal seed comprises steps that: the crystal seed is added to concrete, wherein an adoption amount takes 0.8 to 3% of the mass of the concrete. The crystal seed is an additive with advantages of cheap price, good quality, and environment friendliness. When the crystal seed is added to concrete, early stage strength of concrete is improved, and later stage strength of concrete is ensured. Therefore, durability of concrete is improved.

Owner:NINGBO UNIV

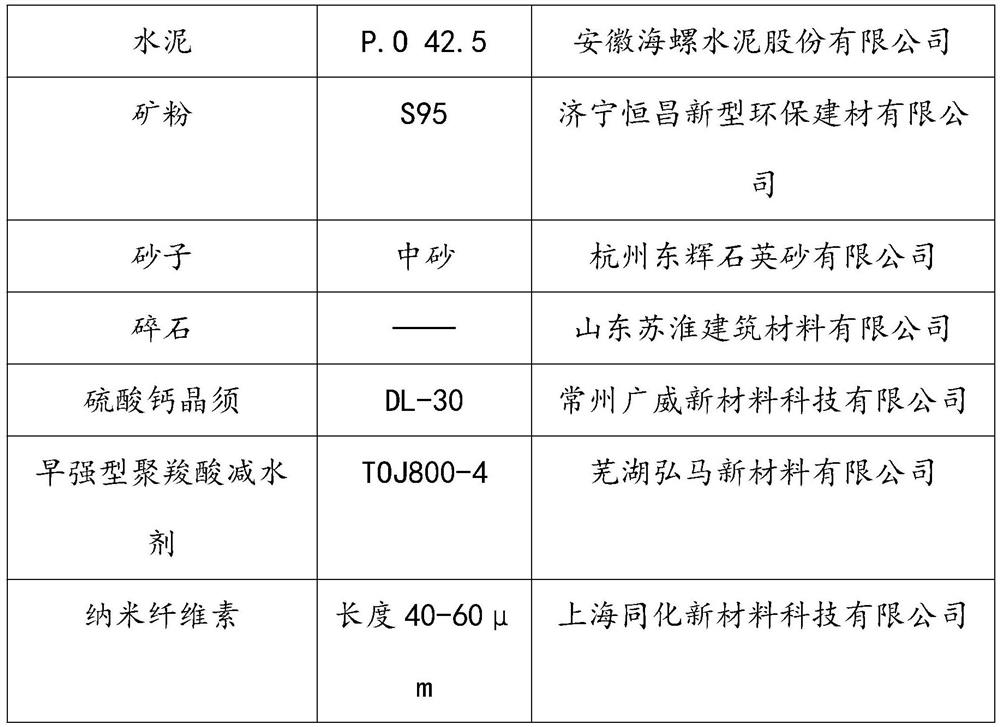

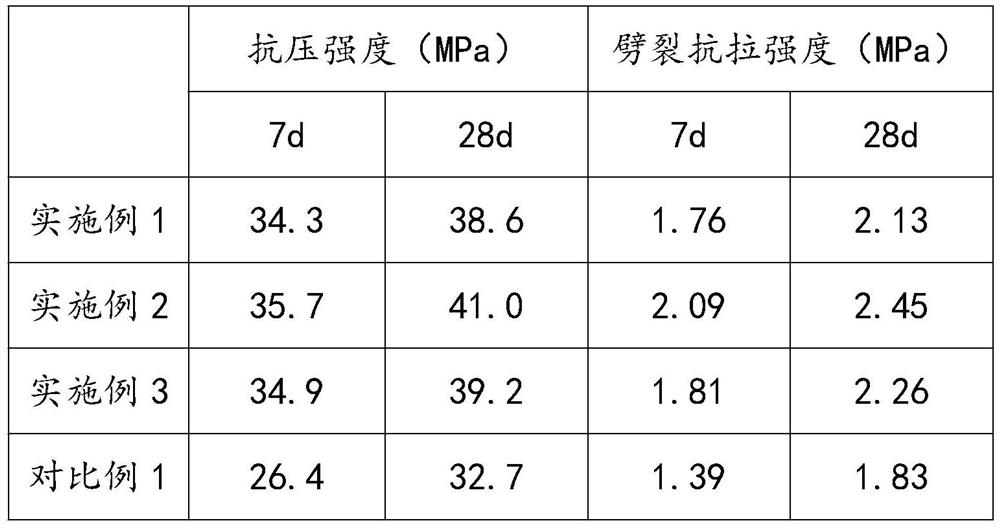

Crack-resistant early strength concrete and preparation method thereof

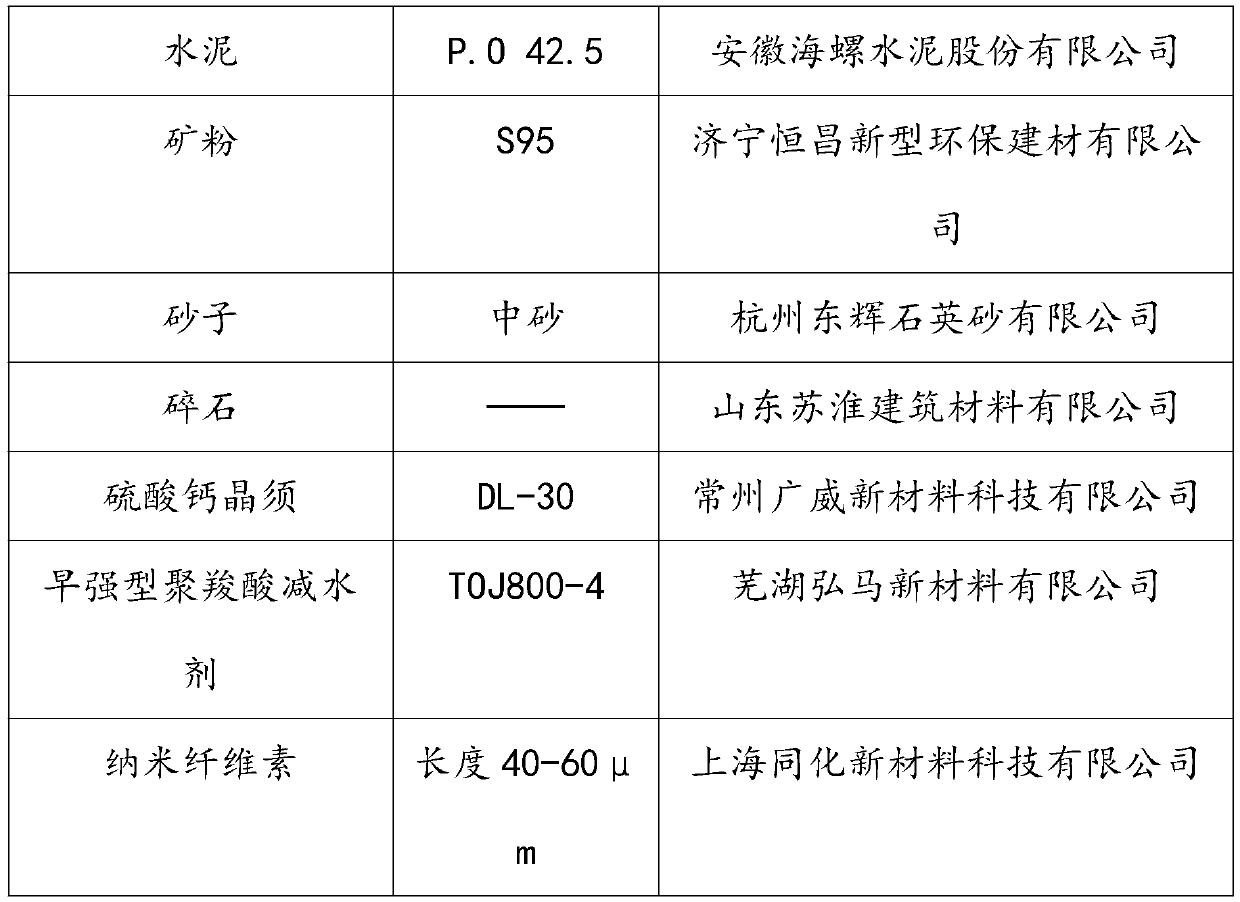

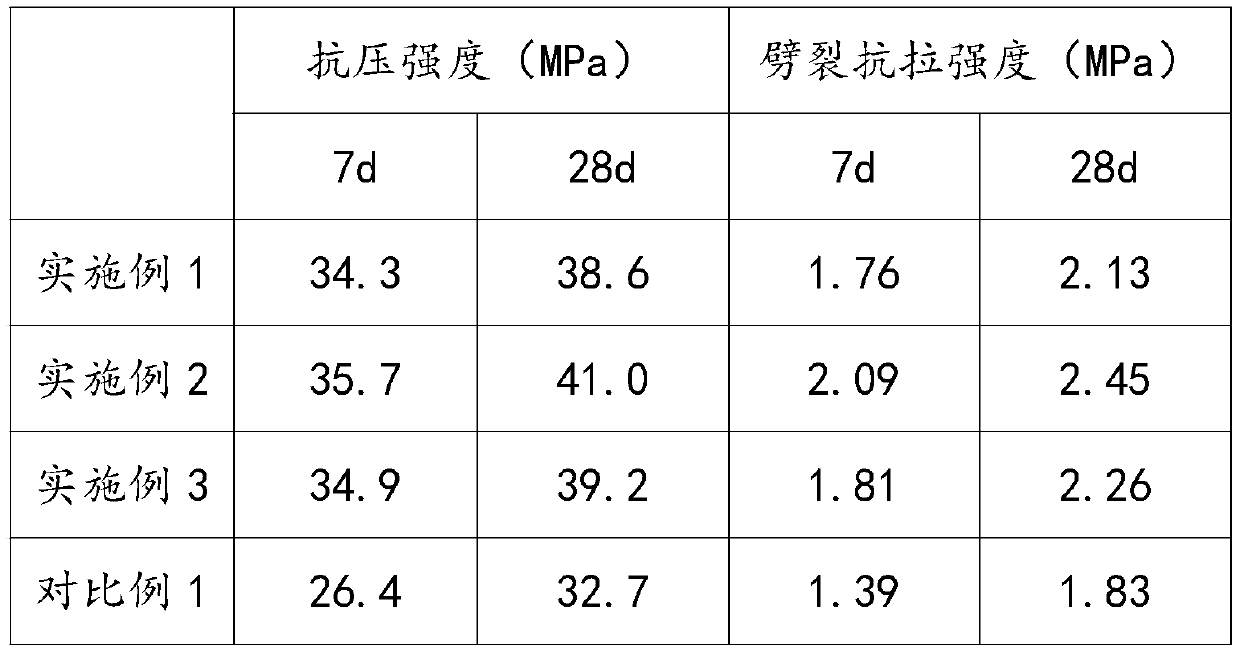

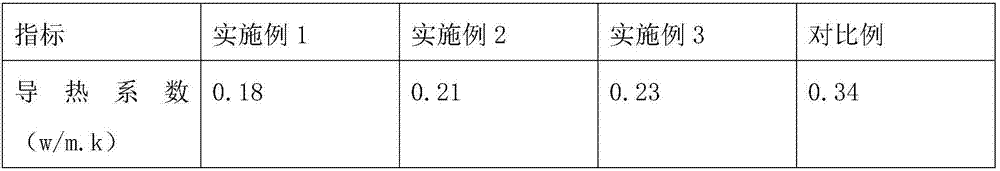

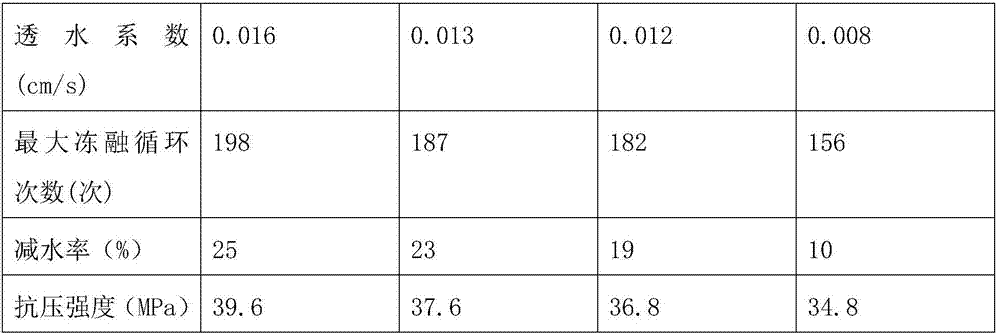

The invention discloses crack-resistant early strength concrete and a preparation method of the crack-resistant early strength concrete. The concrete is prepared from the following raw materials in parts by weight: 460 to 475 parts of cement, 60 to 65 parts of a mineral powder, 512 to 527 parts of sand, 1252 to 1288 parts of gravel, 5 to 10 parts of a cellulose-silica composite nanomaterial, 2 to5 parts of calcium sulfate whiskers, 4.1 to 4.9 parts of an early-strength polycarboxylic acid water reducer and 175 to 180 parts of water. The concrete prepared by the invention not only has fast coagulation hardening speed, high early strength and good early strength, but also has high compressive strength at the later stage, and is not easy to crack and produce cracks, and has excellent workingperformances and durability.

Owner:宁波西立混凝土有限公司

Eco-friendly pavior brick and preparation method thereof

InactiveCN107056199ASolve the problem that waste cannot be reusedSolve the insulation performanceSingle unit pavingsCeramicwareBrickSurface layer

The invention provides an eco-friendly pavior brick and a preparation method thereof, and relates to the technical field of pavior brick production. The pavior brick comprises a surface layer and a base layer, wherein the surface layer is prepared from, by weight, 15-27 parts of cement, 15-30 parts of grit, 5-7 parts of macadam, 30-40 parts of industrial waste cinder granules, 12-16 parts of waste ceramic particles, 3-6 parts of silica fume, 5-10 parts of coal ash, 3-10 parts of lime, 2-4 parts of air-entraining agents, 1.5-2.5 parts of waterproof agents, 0.3-0.5 part of antifreezing agents, 0.4-0.6 part of water reducing agent, 0.3-0.5 part of pigment powder and 1-3 parts of water; the base layer is prepared from, by weight, 16-18 parts of cement, 18-22 parts of grit, 17-25 parts of macadam and 2-3 parts of water; the preparation method includes the steps of (1) the preparation of surface layer ingredients, (2) preparation of base layer dosing, (3) molding, demoulding, stacking and maintaining; the eco-friendly pavior brick and the preparation method thereof solve the problems of unavailable recycling of wastes, poor heat insulation property, low water permeability and freezing resistance, a bad effect of reducing water and low compressive strength in the prior art.

Owner:合肥慧林建材有限公司

Concrete early strength agent, early strength concrete and preparation method of early strength concrete

The invention discloses a concrete early strength agent, an early strength type concrete and a preparation method of the early strength concrete. The concrete early strength agent is prepared from, by mass, 70-80% of a component A and 20-30% of a component B, the component A is a liquid mixture and comprises, by weight, 10-24 parts of silica sol dispersion liquid, 10-15 parts of siloxane emulsion, 2-4 parts of a surfactant, 8-15 parts of soluble calcium salt and 4-5 parts of alcamines; the silica sol dispersion liquid is a dispersion liquid of three substances, namely nanoscale silicon dioxide, a dispersing agent and a suspending agent, in water, and the dispersing agent accounts for 0.5-2% of the solvent water; the suspending agent accounts for 0.5-1% of the solvent water, and the nanoscale silicon dioxide accounts for 55-70% of the solvent water; and the component B is a solid mixture and comprises,s by weight, 30-40 parts of meta-aluminate, 20-30 parts of silicate, 20-30 parts of lithium salt, 2-10 parts of calcium tartrate and 0.5-1 part of methyl cellulose ether. The superposition effect of different early strength components can be exerted, the setting and hardening speed of cement is accelerated, the precipitation of hydration products is promoted, and the early strength of concrete can be obviously improved in a low-temperature environment.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

Medium-density high-aluminum silicon carbide castable and preparation method thereof

The invention discloses a medium-density high-aluminum silicon carbide castable which is prepared from the following components in parts by mass: 10-20 parts of light mullite aggregate with particle size of 3-8mm, 10-20 parts of light alumina aggregate with particle size of 3-5mm, 10-20 parts of iron hook waste, 10-20 parts of silicon-mullite waste aggregate, 5-10 parts of silicon carbide powder with particle size of less than 0.088mm, 5-8 parts of silica powder with particle size of less than 1mu m, 3-5 parts of Al2O3 micropowder with particle size of less than 1.2mu m, 3-8 parts of aluminate cement, 0.03-0.5 part of water reducing agent and 1.5-2.3 parts of alloy steel fiber with diameter of less than 0.3mm and length of 20-25mm. The medium-density high-aluminum silicon carbide castable disclosed by the invention has good density, thermal shock resistance, alkali resistance, wear resistance and erosion resistance, and does not crack easily; moreover, the raw materials can be saved effectively, and the cost is reduced.

Owner:长兴兴鹰新型耐火建材有限公司

High-strength cement-based self-leveling mortar prepared by desulfurization calcium plaster and preparation method thereof

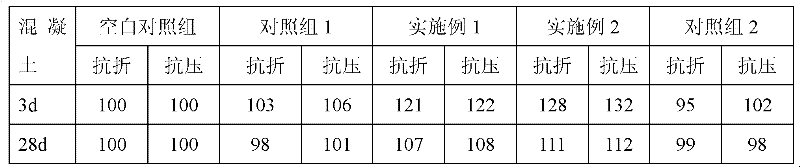

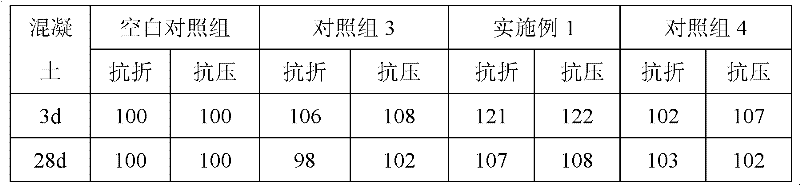

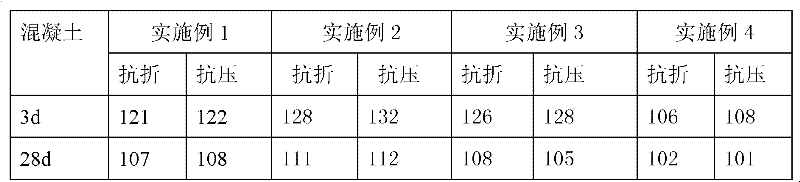

InactiveCN110342890AFast setting and hardeningHigh flexural and compressive strengthAluminiumSilicate Cement

The invention discloses a high-strength cement-based self-leveling mortar prepared by desulfurization calcium plaster, and belongs to the technical field of self-leveling mortar. The high-strength cement-based self-leveling mortar prepared by desulfurization calcium plasteris prepared from the following raw materials in parts by weight: 18 to 28 parts of desulfurized calcium plaster, 30 to 37 parts of aluminate cement, 5 to 6 parts of Portland cement, 35 to 39 parts of natural siliceous sand, 0.7 to 0.8 part of water reducing agent, and 0.01 part of thickener. The invention further discloses apreparation method of thehigh-strength cement-based self-leveling mortar prepared by the desulfurization calcium plaster. According to the high-strength cement-based self-leveling mortar prepared bythe desulfurization calcium plaster and the preparation method thereof, the performance characteristics of the desulfurized calcium plaster, high-alumina cement, and the ordinary Portland cement are fully utilized respectively, the prepared cement-based self-leveling mortar has the characteristics that the setting and hardening speeds are fast, fracture resistance and crush resistanceof early andlater periods are high, wear resistance is good,the surface is not prone to being pulverized, and impact performance is good; the plasterin the desulfurized calcium plaster is not subjected to treating processes such as pressure filtration and drying, so that the dispersion effect of the desulfurized plasterin cement slurry is better, the production cost is lowered, new approaches are provided forpreparation of cement-based self-leveling mortar and resource utilization of desulfurizedcalcium plaster,and economic and environmental benefits are good.

Owner:YANCHENG INST OF TECH

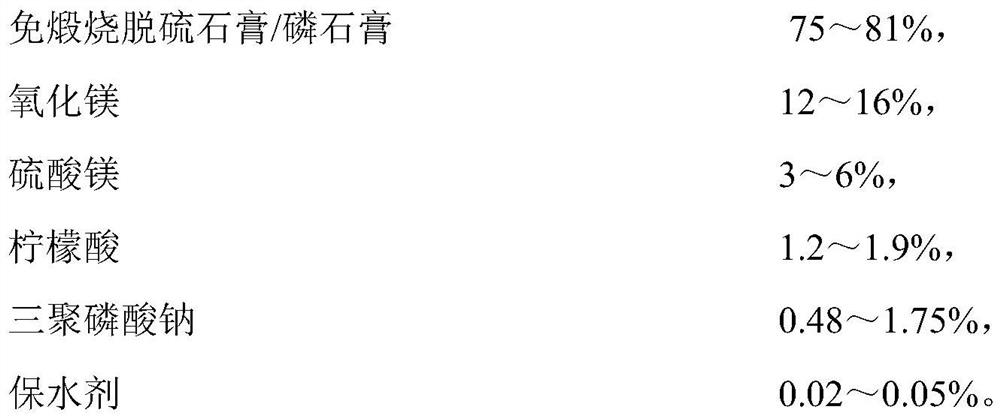

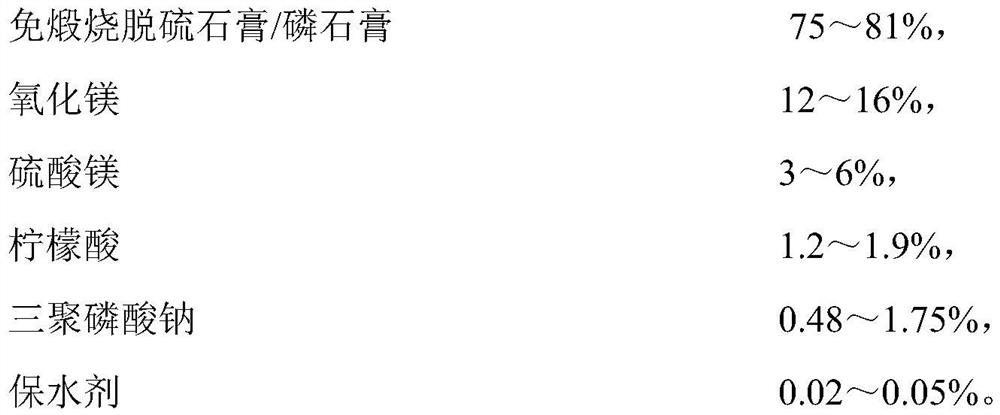

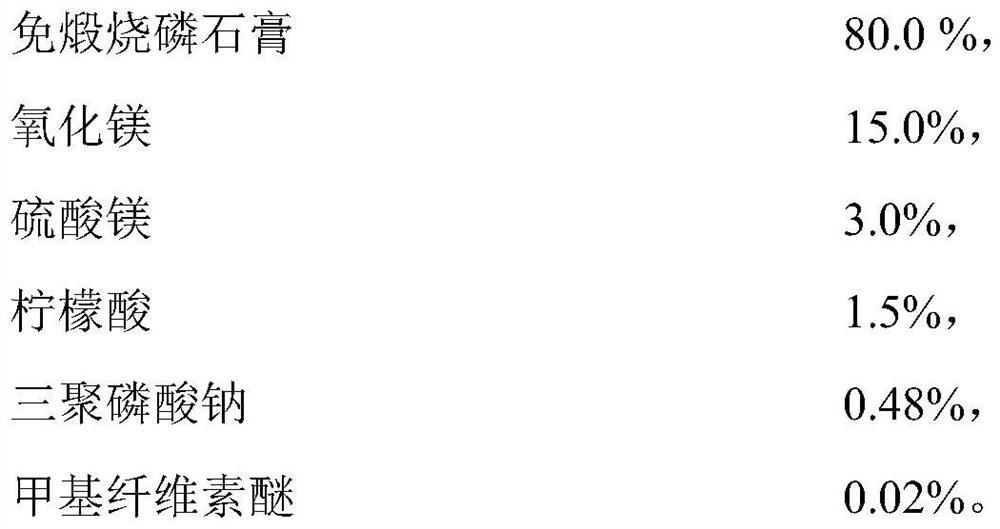

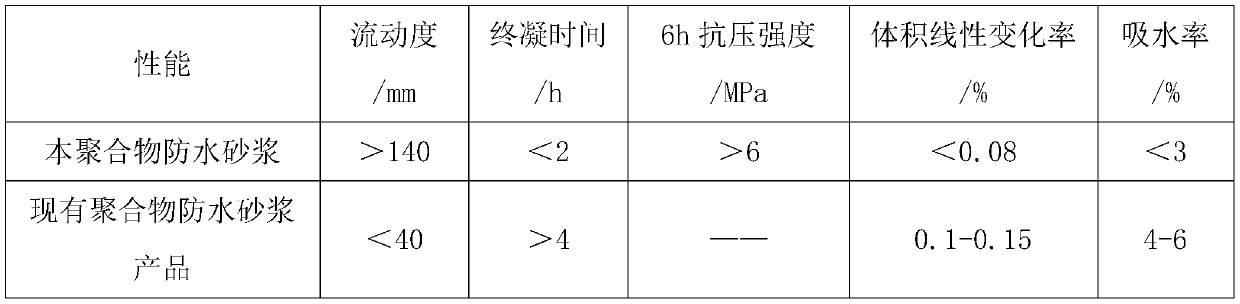

Mine filler based on calcination-free gypsum and preparation method ofmine filler

The invention discloses a mine filler based on calcination-free gypsum and a preparation method of the mine filler. The mine filler comprises the following components in percentage by weight: 75-81% of non-calcined desulfurized gypsum / ardealite, 12-16% of magnesium oxide, 3-6% of magnesium sulfate, 1.2-1.9% of citric acid, 0.48-1.75% of sodium tripolyphosphate and 0.02-0.05% of a water-retaining agent. The mine filler can be directly used for mine filling and pouring, and has the characteristics of high fluidity, good working performance, acid and erosion resistance, high later strength, high ardealite consumption and the like.

Owner:熊清平 +1

A self-leveling type II polymer cement waterproof mortar

The invention provides a self-leveling type II polymer cement waterproof mortar. The mortar includes: Portland cement, composite hardening agent, aggregate, water, polymer, and other additives, wherein the composite hardening agent is composed of the following raw materials in parts by weight: quicklime 3-6 parts, sodium sulfate 2 ‑5 parts, 5‑10 parts of aluminate cement. Solve the durability problem of ordinary self-leveling mortar due to the high content of high-alumina cement components resulting in poor long-term waterproof and impermeable performance, and realize the self-leveling construction of polymer cement waterproof mortar, which can be applied to various building waterproofing projects, such as toilets and kitchens , roofs, swimming pools, underground structures, etc.

Owner:SHANDONG YINGCAI UNIV

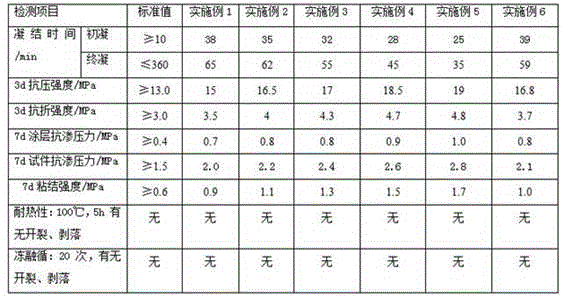

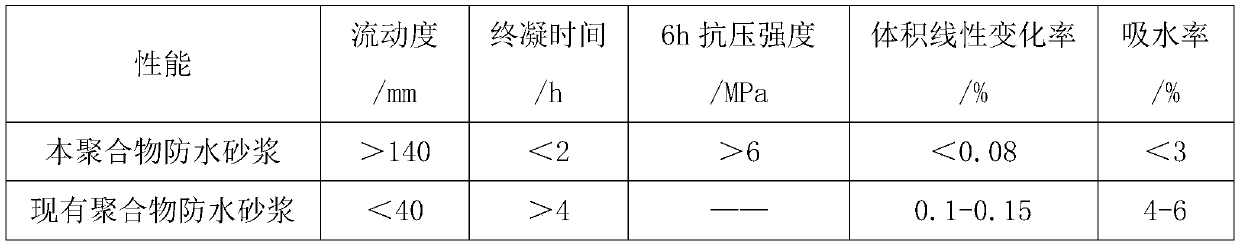

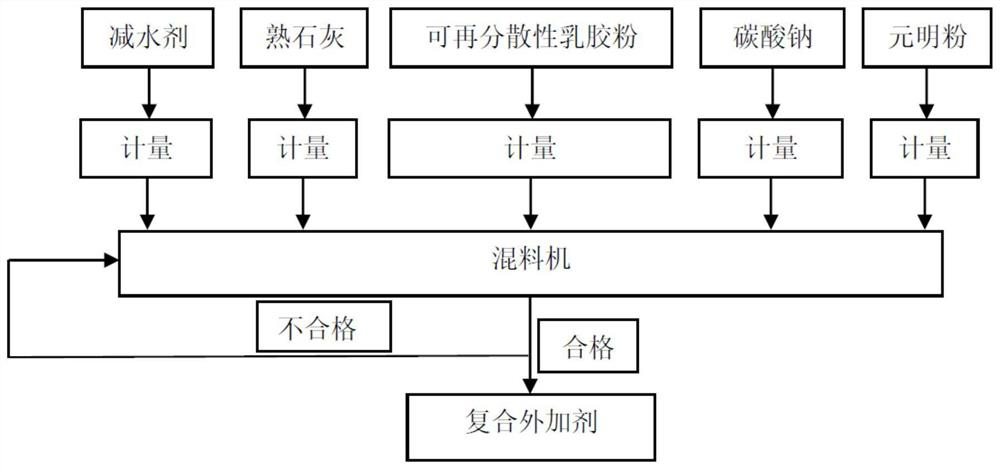

Aluminate cement-based jet mortar and preparation method thereof

ActiveCN113968714AFast setting and hardeningImprove early strengthSolid waste managementAluminatePortland cement

The invention belongs to the technical field of mining, and particularly relates to aluminate cement-based jet mortar and a preparation method thereof. The jet mortar is composed of a binding material, a composite additive, sand and water according to the weight ratio of 1: (0.03-0.06): (1.5-3.0): (0.40-0.50). The cementing material is prepared from the following raw materials in parts by weight: 20-40 parts of aluminate cement, 20-40 parts of Portland cement, 10-30 parts of slag powder and 10-30 parts of gypsum; the composite admixture is prepared from the following raw materials in parts by weight: 20-40 parts of a water reducing agent, 10-30 parts of slaked lime, 10-30 parts of sodium carbonate, 10-30 parts of anhydrous sodium sulphate and 5-10 parts of redispersible latex powder. The jet mortar has the characteristics of high setting and hardening speed, high early strength, micro-expansion and the like, and is suitable for engineering application.

Owner:安徽路源环保科技有限公司

High-strength and corrosion-resistant wet spraying material for coal mine roadway and construction process of high-strength and corrosion-resistant wet spraying material

InactiveCN111620628AStrong corrosion resistanceImprove corrosion resistanceUnderground chambersTunnel liningSilica fumeRock burst

Owner:陕西拉发纪新材料科技有限公司 +1

Exposed reinforced concrete repairing mortar and use method thereof

PendingCN112919872AFast setting and hardeningHigh compressive strengthBuilding repairsReinforced concreteMining engineering

The invention discloses exposed reinforced concrete repairing mortar and a use method thereof. The exposed reinforced concrete repairing mortar is prepared from the following raw materials: magnesium oxide, ammonium dihydrogen phosphate, fly ash, gypsum, sand, water, sodium tripolyphosphate, borax and an auxiliary agent. The concrete is prepared from the following raw materials in parts by weight: 25-30 parts of magnesium oxide, 8-13 parts of ammonium dihydrogen phosphate, 7-14 parts of fly ash, 2-3 parts of gypsum, 20-25 parts of sand, 4-7 parts of water, 2-4 parts of sodium tripolyphosphate, 1-2 parts of borax and 1-4 parts of the auxiliary agent. According to the invention, 25-30 parts of magnesium oxide, 8-13 parts of ammonium dihydrogen phosphate, 7-14 parts of fly ash, 2-3 parts of gypsum, 20-25 parts of sand, 4-7 parts of water, 2-4 parts of sodium tripolyphosphate, 1-2 parts of borax and 1-4 parts of the auxiliary agent are matched, and the raw materials of the concrete repairing mortar are selected and improved, so that the fusion degree of the raw materials reaches the best. The self characteristics and the overall reaction effect of all the raw materials are fully exerted, and the setting and hardening speed of the concrete repairing mortar is increased through flow matching of the first step, the second step, the third step, the fourth step and the fifth step.

Owner:CHONGQING ZONJO RENEWABLE RESOURCES DEV CO LTD

Cracking-resistant cement mortar

The invention relates to a cracking-resistant cement mortar for building plastering, which belongs to building materials, which is prepared from perlite, cement and 801 glue with a volume ratio of (7.5-9):(2.8-3.3):1. The cement mortar solves the cracking, bubbling and poor bonding property problems of the prior plastering material; and has the advantages of high coagulation and setting speed, and good fire resistant, acid and alkali-resistant, thermal insulation and sound absorption properties.

Owner:SHANDONG WANXIN CONSTR

A general-purpose Portland cement-based ultra-light physical foaming foam concrete

The invention discloses a general-purpose portland cement-based ultra-light physical foaming foam concrete, which is characterized in that: the components and weight percentages are 20%-70% of general-purpose Portland cement, and 0-40% of A-type admixtures % or / and B-type admixture 0-40%, C-type admixture 0.5%-4%, foaming agent 0.3%-2%, water reducing agent 0-1%, fiber 0-4%, and water 25% ~60% is made by mixing, molding and curing. The universal Portland cement-based ultra-light physical foaming foam concrete of the present invention has the characteristics of ultra-low dry density, low thermal conductivity, high strength, wide source of raw materials, low cost, simple preparation process, and easy selection of maintenance process; it is suitable for As insulation engineering, floor heating engineering, backfill engineering, anti-seismic energy-absorbing, lightweight cushion, catalyst carrier materials, it is especially suitable for external wall insulation systems, roof insulation systems, composite insulation walls, and buffer energy-absorbing systems.

Owner:SOUTHWEAT UNIV OF SCI & TECH

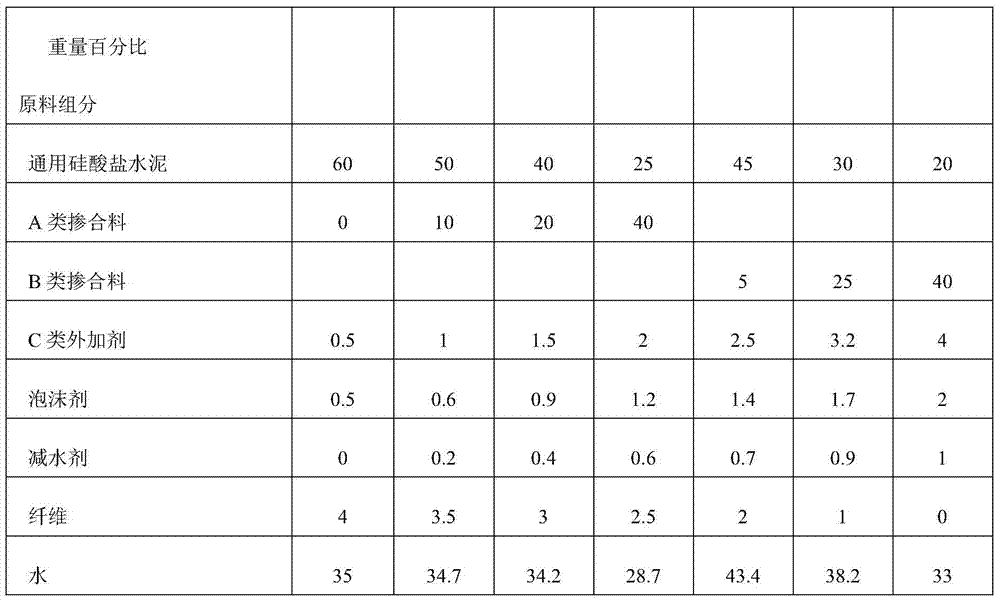

Pulse type grouting machine and double-liquid grouting construction method

PendingCN111719561AIncreased underwater dispersion resistanceImprove mobilityBallastwayFoundation engineeringRailway tunnelEngineering

The invention provides a pulse type grouting machine and a double-liquid grouting construction method. The quincuncial pile type is adopted to arrange grouting holes; grouting is carried out on one point of a central area; grouting is dense without a dead angle, the grouting effect is excellent, the grouting pressure is low, and the grouting efficiency is high; and a cabin is unlikely to be blocked on the condition that the condensation rate of mixed slurry is higher. High and low pressure peak load shifting grouting of the pulse type grouting machine is used to realize premixing; secondary mixing in a mixing pipe and third-time in-depth mixing of a vibrator are realized; the grouting speed is controllable; and on the condition that the slurry is excellent in underwater dispersity resistance and high in cohesiveness, the mixing efficiency and the uniform degree are improved. A A-component single fluid and a B-component signal fluid are designed; the single fluid components can work fora long time; when the double fluid is mixed, the underwater dispersity resistance is high, the condensation and hardening rate is high, and the underwater rapid repairing demand of a railway tunnel foundation disengaging area is met; double-liquid grouting does not affect construction due to pipe blocking caused by excessively high condensation rate. The proportion of the component A and the component B can be controlled to adjust the working time of the mixed slurry.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

Preparation method of super cementitious cement for 3D printing and super cementitious cement for 3D printing

ActiveCN113149579BImprove plasticityImprove adhesionAdditive manufacturing apparatus3d printAluminate

The invention provides a preparation method of super cementitious cement for 3D printing and super cementitious cement for 3D printing prepared by the method. The preparation method of the super cementitious cement for 3D printing provided by the present invention comprises: step 1: take 100-150 parts by weight of aluminate cement, 400-600 parts by weight of water, and 2-8 parts by weight of grinding aid into a ball mill, Wet milling obtains nano slurry A; Step 2: 380-475 parts by weight of Portland cement clinker, 20-25 parts by weight of gypsum, 120-180 parts by weight of water, 10-30 parts by weight of ultrafine ceramic fibers, 1- 5 parts by weight of water reducer are ground into slurry B by liquid phase grinding; step 3: adding the nano slurry A, 1-10 parts by weight of interface enhancer, and 15-40 parts by weight of basalt fiber to the slurry B, And mix to get super cementitious cement for 3D printing. The super cementitious cement for 3D printing provided by the present invention is easy to mass-produce, has high wet grinding efficiency, and enables 3D printing to have quick setting and easy printing, high compressive strength and excellent post-processing performance.

Owner:HUBEI UNIV OF TECH

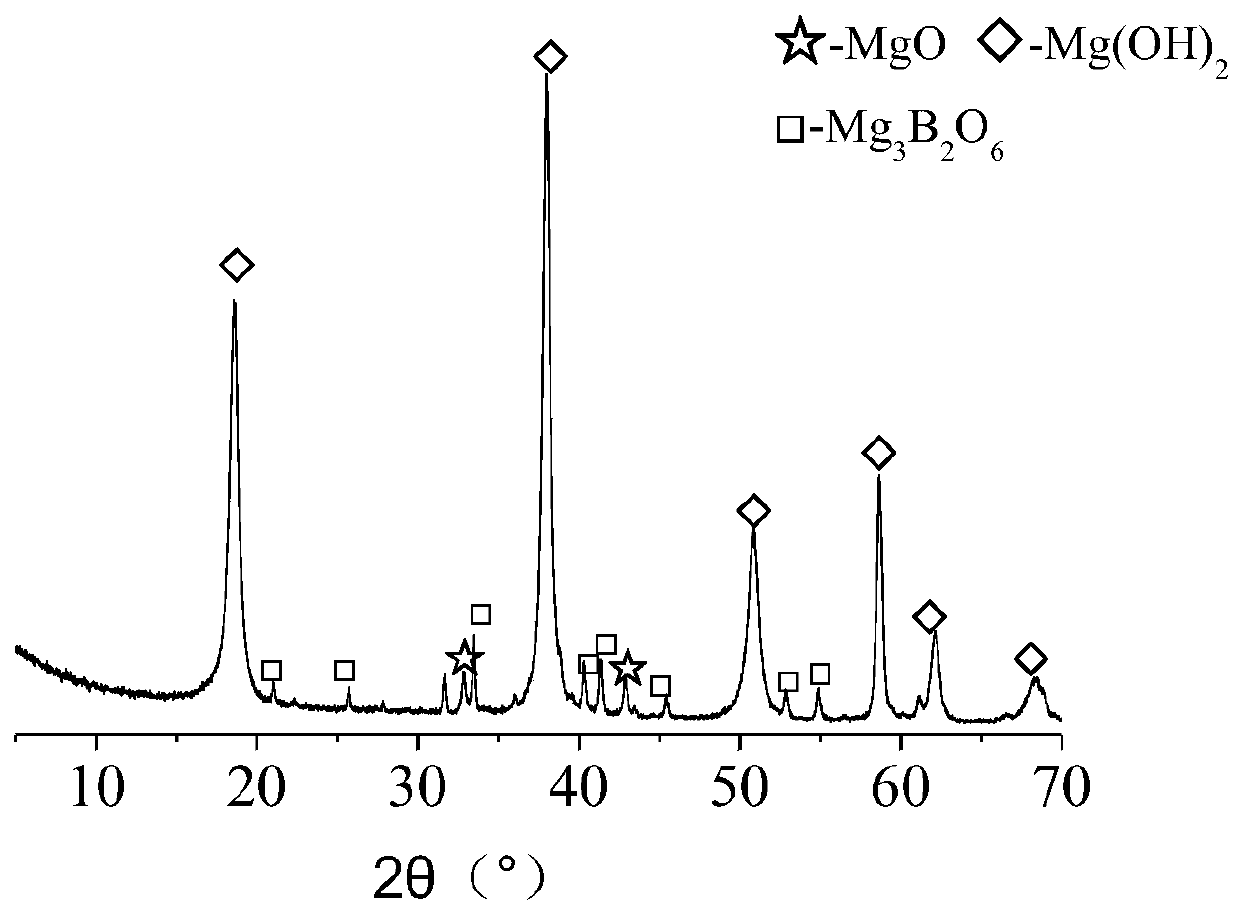

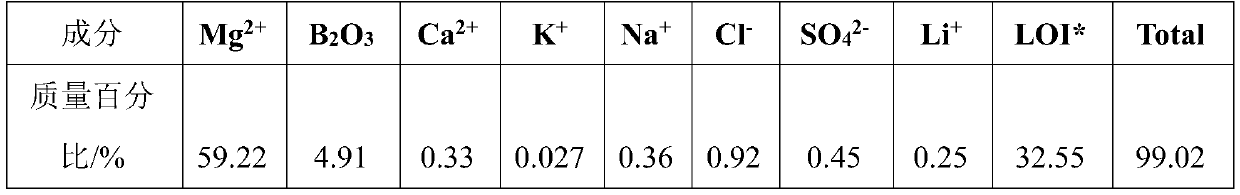

A kind of magnesium oxysulfide cement and preparation method thereof

The invention discloses magnesium oxysulfate cement and a preparation method thereof. The preparation method comprises the following steps: mixing and grinding 50 to 100 parts by mass of active magnesium oxide powder, 30 to 100 parts by mass of crystalline magnesium sulfate or anhydrous magnesium sulfate, 0.5 to 2 parts by mass of an additive and 0.5 to 10 parts by mass of a basic magnesium sulfate precursor and then carrying sieving with a 100-to-200-mesh screen so as to obtain the rapid-hardening magnesium oxysulfate cement. According to the invention, the speed of setting and hardening is substantially increased, and production efficiency of the magnesium oxysulfate cement can be improved.

Owner:QINGHAI UNIVERSITY

A kind of magnesium oxysulfide cement

The invention discloses a magnesium oxysulfate cement. The magnesium oxysulfate cement is composed of, by mass, 50 to 100 parts of active magnesium oxide powder, 30 to 100 parts of Magnesium sulfate heptahydrate, 0.05 to 2 parts of an additive, 0.5 to 10 parts of a magnesium oxysulfate precursor. According to a preparation method, the above raw materials are mixed and grinded, and are sieved using a mesh of 100 to 200 meshes so as to obtain the rapid hardening magnesium oxysulfate cement. According to the preparation method, active magnesium oxide powder is obtained low temperature calcining of salt lake extracted magnesium lithium carbonate slag, so that a novel raw material source is provided for production of the rapid hardening magnesium oxysulfate cement; adding of the magnesium oxysulfate precursor is capable of accelerating the hardening speed of the magnesium oxysulfate cement, the obtained magnesium oxysulfate cement is high in early strength, and reduction of later strength is avoided.

Owner:QINGHAI UNIVERSITY

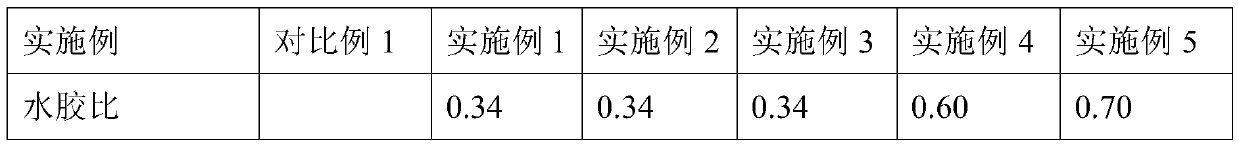

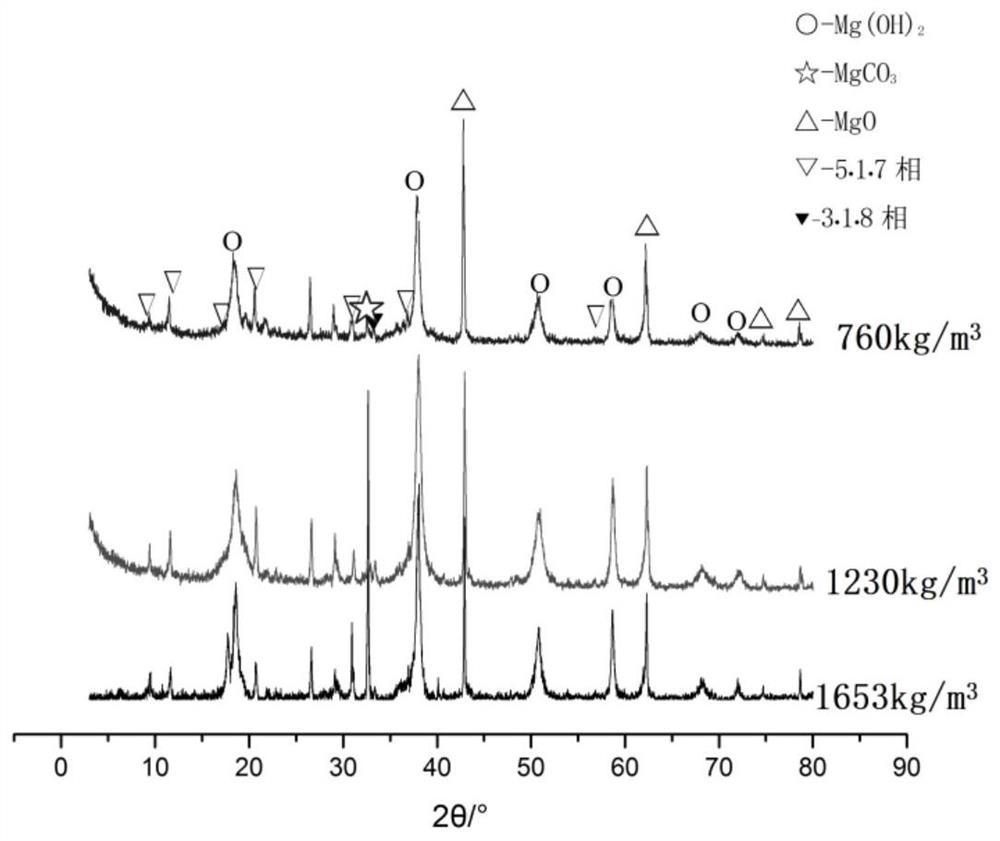

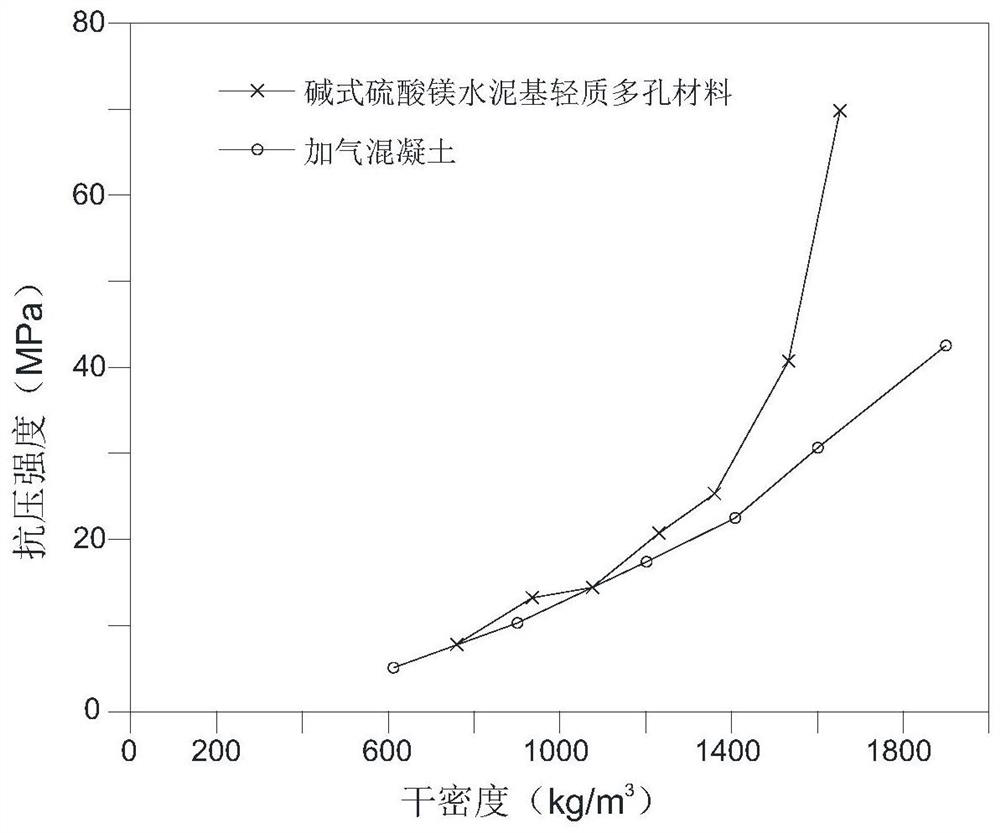

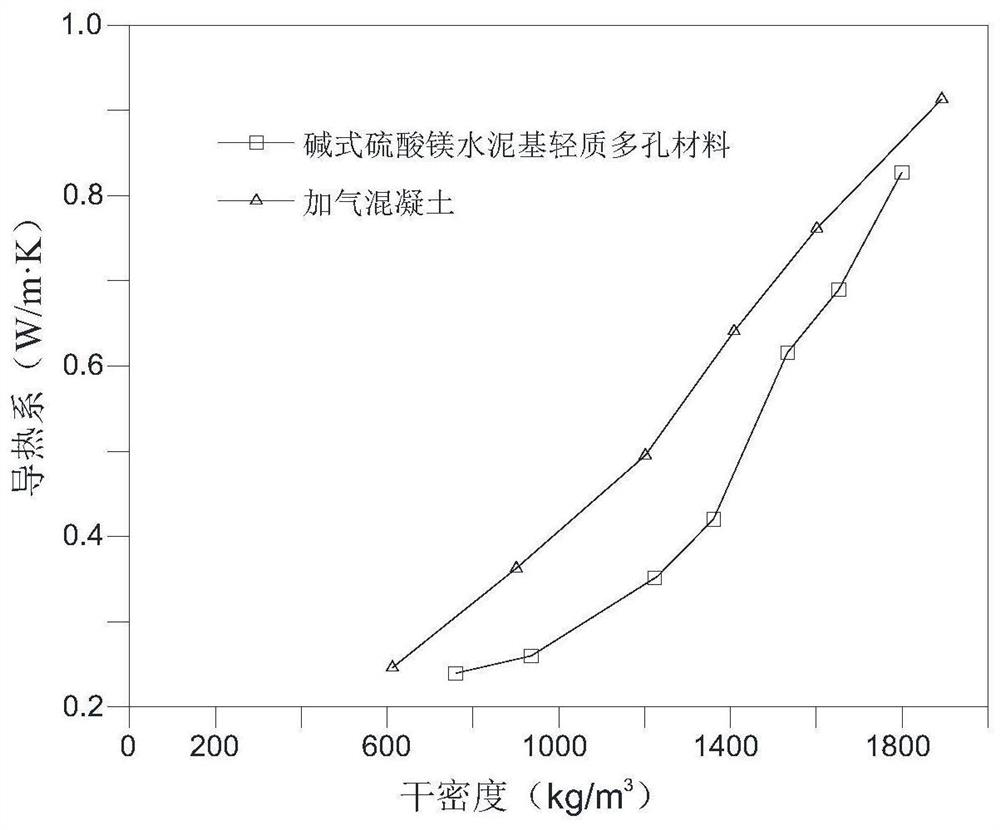

Basic magnesium sulfate cement-based lightweight porous material and preparation method thereof

ActiveCN112456955BFast setting and hardeningHigh strengthSolid waste managementCeramicwareMontmorilloniteCement slurry

The invention relates to the field of building materials, and discloses a basic magnesium sulfate cement-based lightweight porous material and a preparation method thereof. In the present invention, the magnesium oxysulfide cement slurry is modified to form basic magnesium sulfate cement slurry, and the slurry produces 5.1.7 phase, 3.1.8 phase and 5.1.3 phase crystals in the process of setting and hardening. phase, the coagulation and hardening speed of the slurry is fast, and the 5·1·7 equal hydration products overlap to form a microscopic pore structure; the main mineral montmorillonite in the mixed bentonite exists in the 5·1·7 equal hydration products. In the microscopic pore structure, cut and refine this part of the pores to produce nano- and micro-pores, realize the construction of nano-pores and micro-pores in basic magnesium sulfate cement-based lightweight porous materials, and make the originally loose pore structure dense, and obtain The basic magnesium sulfate cement-based lightweight porous material has the advantages of early strength, high strength, low thermal conductivity, and high durability.

Owner:SOUTHWEAT UNIV OF SCI & TECH

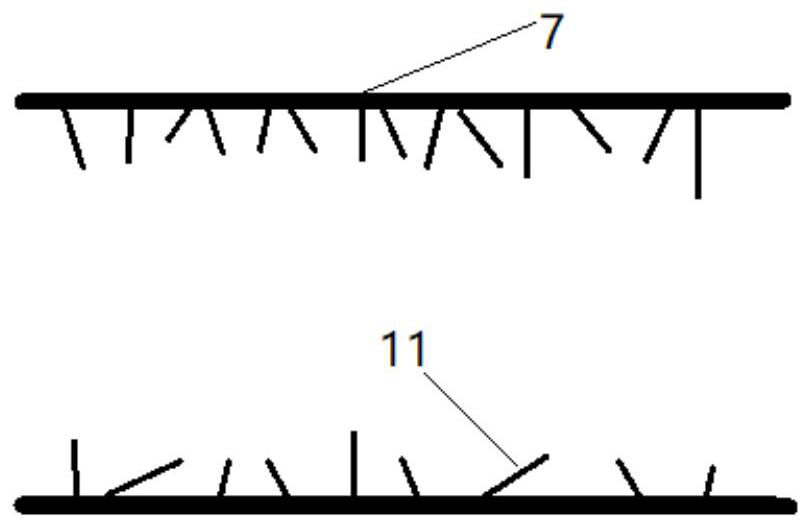

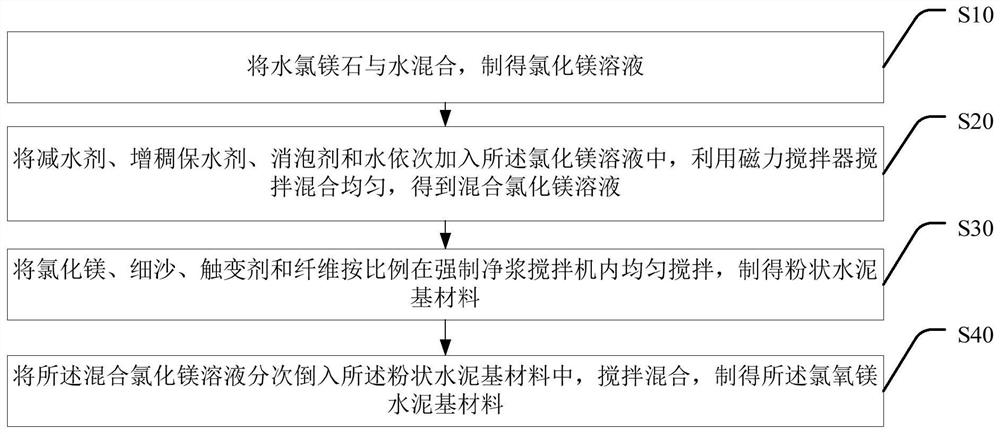

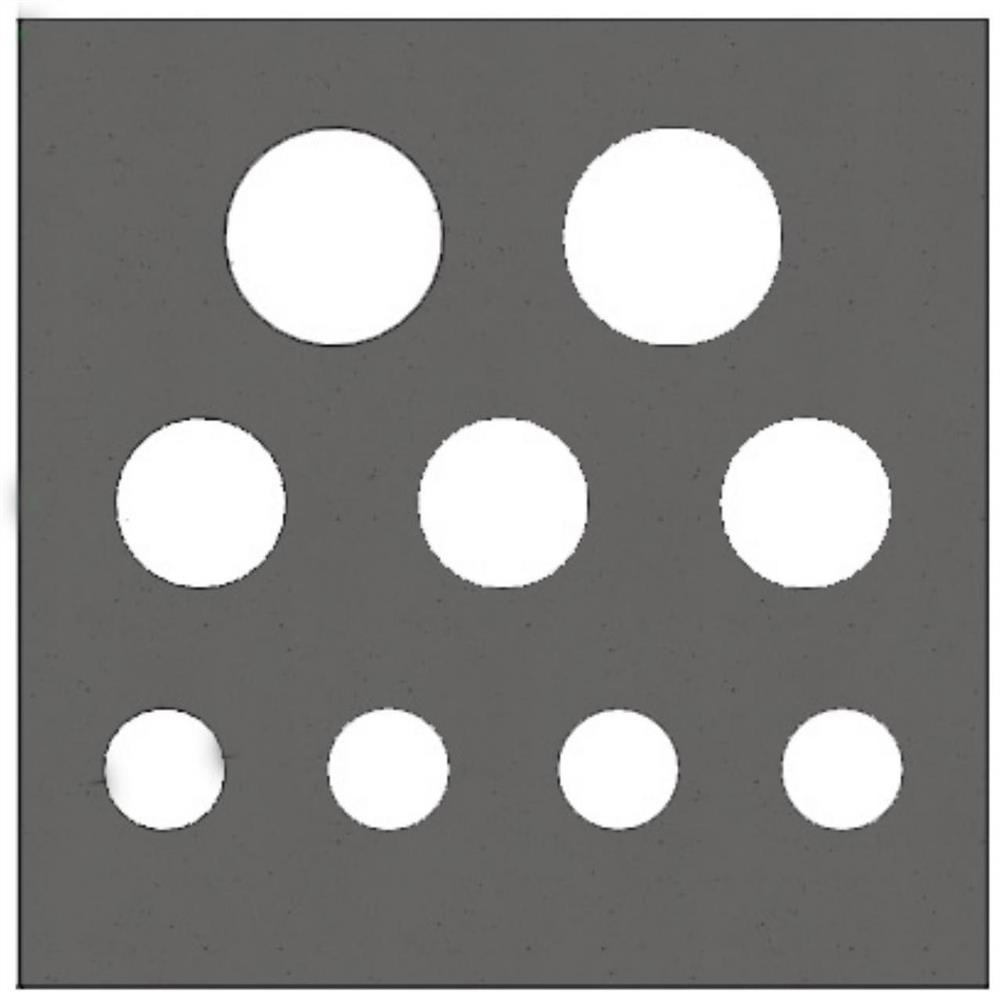

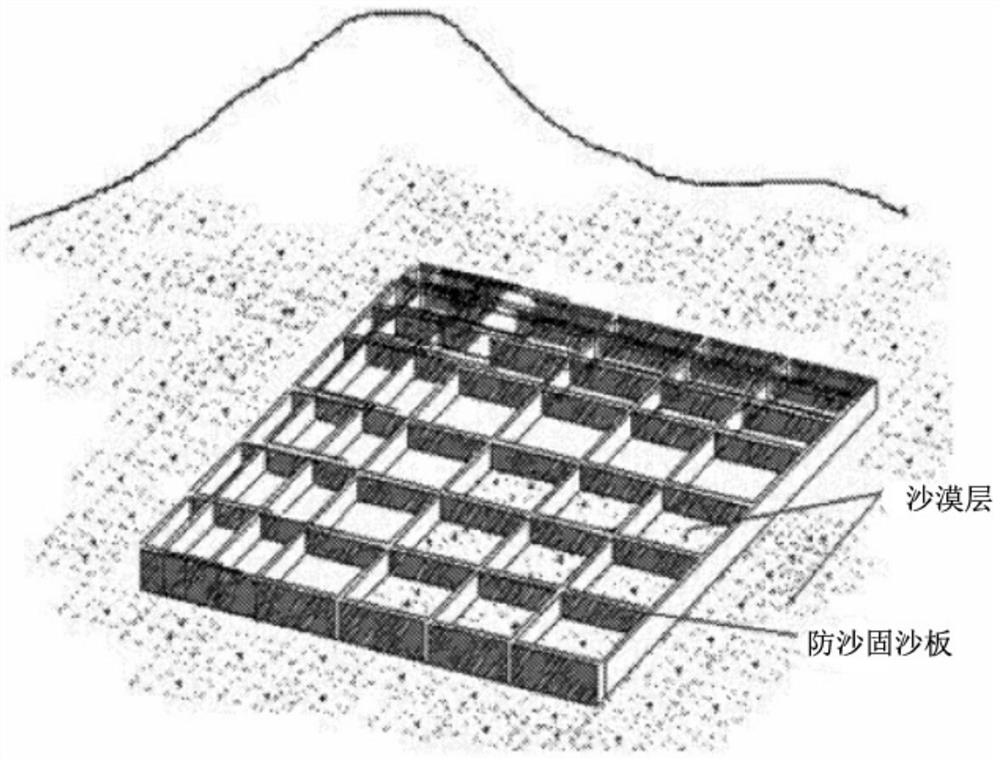

Magnesium oxychloride cement-based material, sand-preventing and sand-fixing plate and preparation methods of magnesium oxychloride cement-based material and sand-preventing and sand-fixing plate

PendingCN113277829AWide setting and hardening speedFast setting and hardeningAdditive manufacturing apparatusCeramic shaping apparatusFiberEngineering

The invention provides a magnesium oxychloride cement-based material, a sand prevention and stabilization plate and preparation methods of the magnesium oxychloride cement-based material and sand-preventing and sand-fixing plate. The magnesium oxychloride cement-based material comprises magnesium chloride, fine sand, bischofite, a water reducing agent, a thickening water-retaining agent, a thixotropic agent, a defoaming agent and fibers. The magnesium oxychloride cement-based material provided by the invention has the characteristics that the fluidity is adaptive to extrusion type printing, the early strength of the material is high in the printing process, and the bonding force between printing layers is good, can be used for 3D printing of sand prevention and stabilization plate construction operation at the room temperature of 15-45 DEG C, and can achieve the purposes of waste utilization and ecological environment improvement.

Owner:深圳市明远建筑科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com