High-strength and corrosion-resistant wet spraying material for coal mine roadway and construction process of high-strength and corrosion-resistant wet spraying material

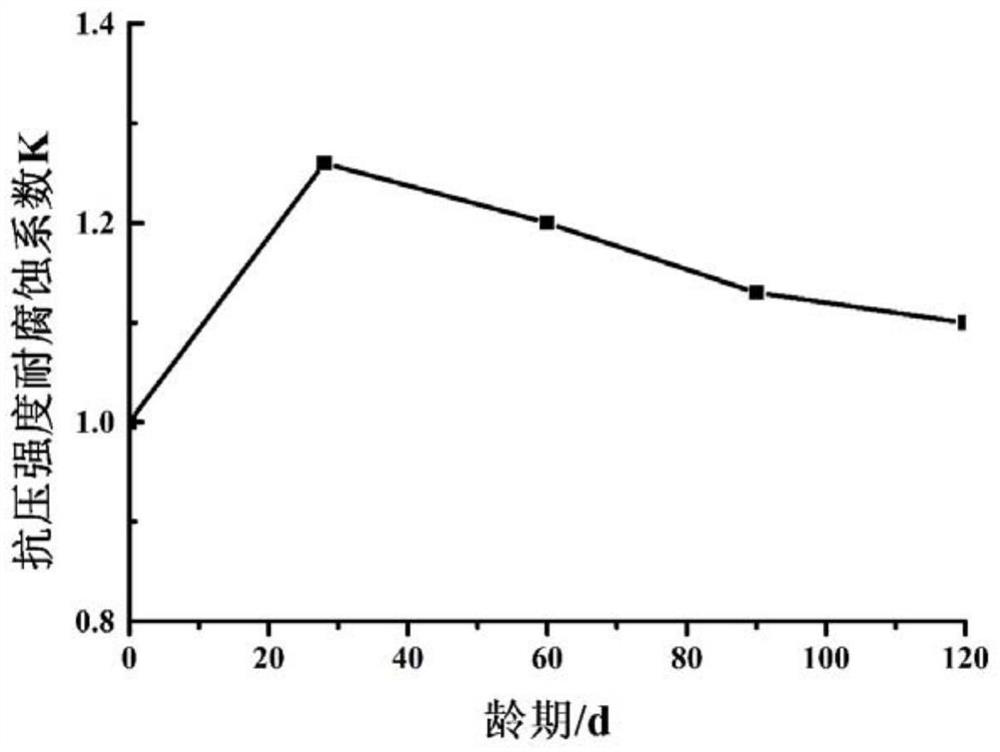

A coal mine roadway, high-strength technology, used in tunnels, tunnel linings, mining equipment, etc., can solve the problem of difficult to meet high stress, soft rock large deformation and high corrosive coal mine roadway support needs, low spray strength, corrosion resistance To achieve the effect of excellent corrosion resistance, enhanced corrosion resistance, and improved corrosion resistance

Inactive Publication Date: 2020-09-04

陕西拉发纪新材料科技有限公司 +1

View PDF2 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The invention provides a high-strength, corrosion-resistant tidal spraying material for coal mine roadways and its construction technology to solve the problem of low strength, poor corrosion resist

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Login to View More

Abstract

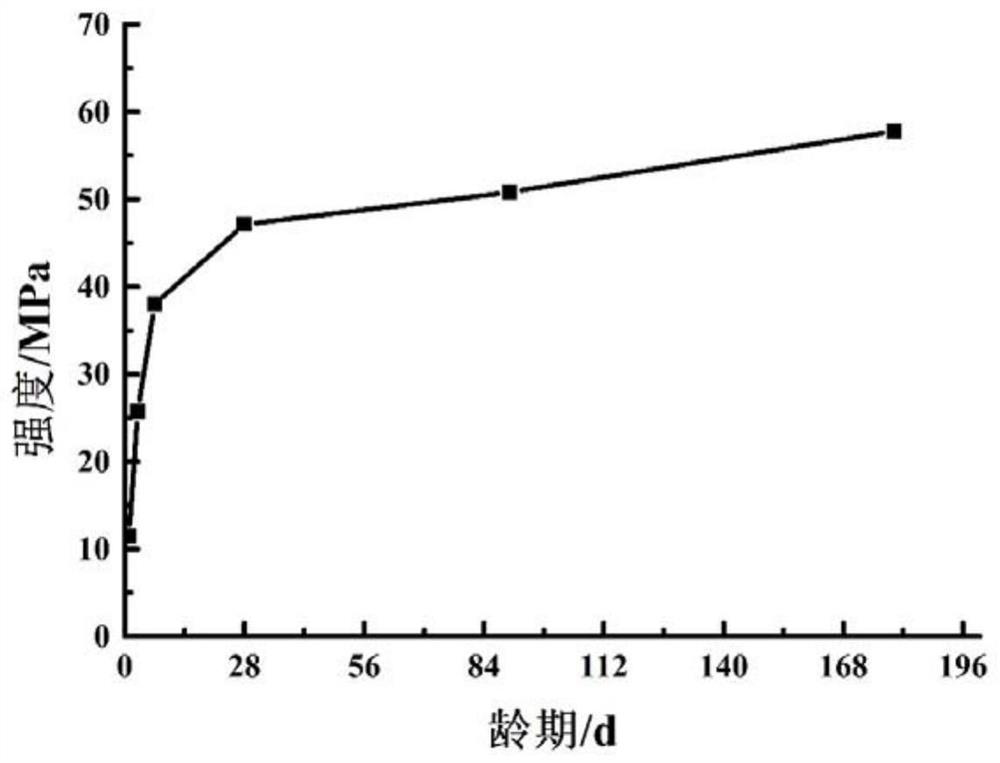

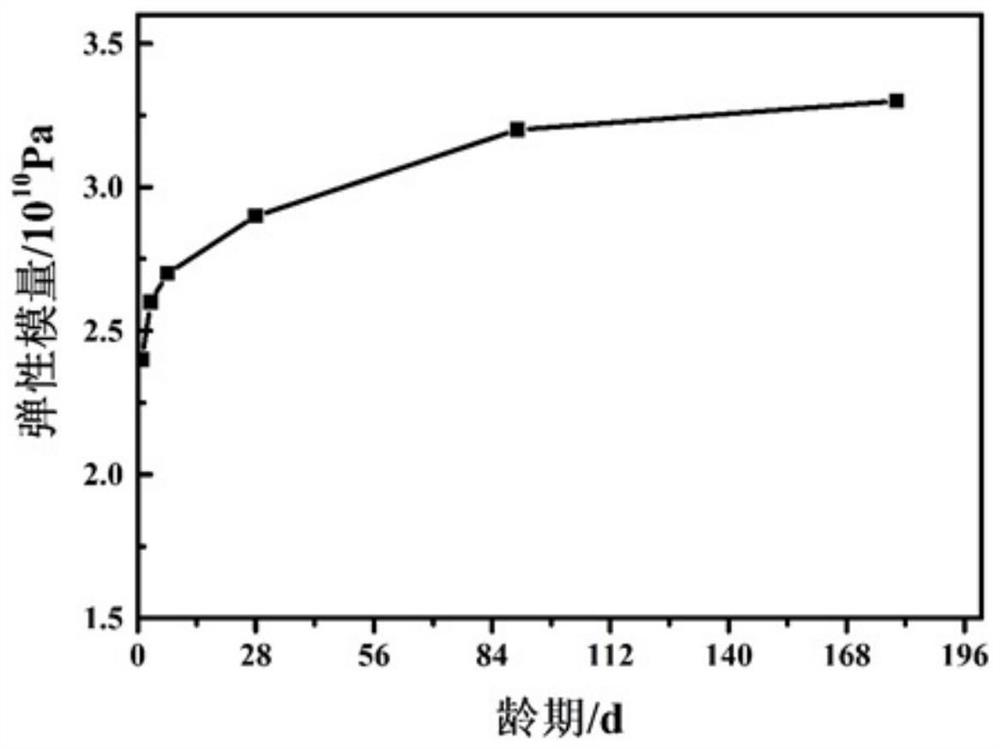

The invention relates to the technical field of coal mine roadway material spraying. The invention particularly discloses a high-strength and corrosion-resistant wet spraying material for a coal mineroadway and a construction process thereof. The wet spraying material comprises a solid raw material and water; the ratio of the water to the solid raw material is 0.09-0.11; the solid raw material comprises 15%-30% of cement, 20%-40% of sand, 20%-30% of pebbles, 5%-10% of coal ash, 10%-15% of mineral powder, 5%-10% of silica fume, 0.5-1.5 kg/m < 3 > of hybrid fibers and 2%-20% of a cement additive. The hybrid fibers are two or more of steel fibers, glass fibers, carbon fibers or polypropylene fibers, and the lengths of different fibers are different. The spraying material obtained according to the proportion in the patent can still keep better strength when being used in an acidic corrosive environment of a coal mine roadway, and can meet the requirements of high stress, large deformationof soft rock, rock burst and high-corrosivity coal mine roadway support.

Description

technical field [0001] The invention relates to the technical field of spraying materials for coal mine roadways, in particular to a high-strength, corrosion-resistant tidal spraying material for coal mine roadways and a construction process thereof. Background technique [0002] At present, my country's coal resource mining has entered the stage of deep mining. One of the problems encountered at this stage is the difficulty in roadway maintenance caused by the increase in ground stress level. The surrounding rock of the roadway shows large deformation and impact damage under the action of high stress; At the same time, in some geological structure areas such as faults and folds, the structural stress and the self-gravity stress are superimposed, which intensifies the damage to the roadway. In the past ten years, the level of coal mining equipment has been greatly improved, and high-efficiency mining technologies such as large mining height fully mechanized mining and large m...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B28/04E21D11/10E21D11/38C04B111/26

CPCC04B28/04E21D11/10E21D11/38C04B2111/26C04B2201/50C04B2111/00155C04B2111/00724C04B14/06C04B18/08C04B18/12C04B18/146C04B14/48C04B14/42C04B14/386C04B16/0633C04B2103/302C04B22/16C04B2103/0068C04B22/06C04B2103/50C04B2103/12C04B2103/601C04B2103/44C04B2103/61

Inventor 冯晶常雅吴福硕利建雨余胜

Owner 陕西拉发纪新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com