Surface treating agent for galvanized steel sheet

A technology of surface treatment agent and galvanized steel sheet, which is applied in the direction of coating, anti-corrosion coating, metal material coating technology, etc., can solve problems such as halo and interference color, white appearance of the film, and cracks of the film, and achieve excellent properties, Appearance and grounding are well-balanced and well-balanced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

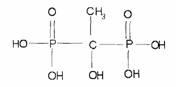

Method used

Image

Examples

preparation example Construction

[0167] The preparation method of the surface treatment agent for galvanized steel sheets of the present invention is not particularly limited. For example, it can be produced by sufficiently mixing ammonium zirconium carbonate (A), compound (B), organic phosphonic acid (C), metal compound (D), other additives, and water using a mixer such as a mixing mixer.

[0168]

[0169] The surface treatment method using the surface treatment agent for galvanized steel sheet of the present invention is not particularly limited, and the following surface treatment method is preferred: the above-mentioned surface treatment agent for galvanized steel sheet is coated on the surface of galvanized steel sheet, dried, and The amount of film formed on the surface of the steel plate is 25-1000mg / m 2 of the membrane.

[0170] Hereinafter, this surface treatment method will be described.

[0171] In order to remove oil and dirt on the surface of the galvanized steel sheet, the galvanized steel s...

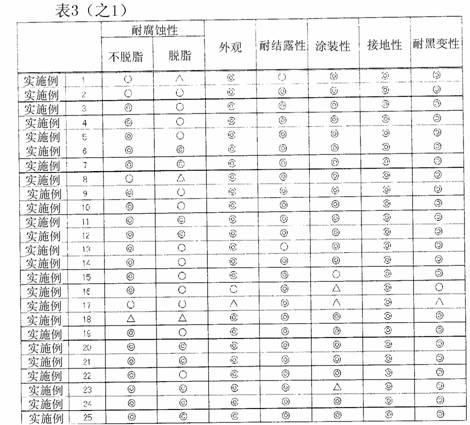

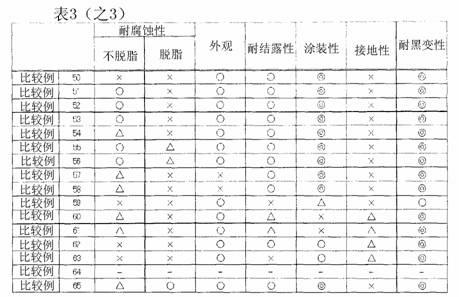

Embodiment

[0186] Hereinafter, the effects and effects of the present invention are specifically shown through examples, but the following examples are not intended to limit the present invention, and the situation of changing the plan according to the change of conditions is also included in the technical scope of the present invention.

[0187] (1) Test materials (materials)

[0188] The following commercially available materials were used as test materials.

[0189] (i) Electrogalvanized steel sheet (EG): plate thickness 0.8mm, weight per unit area = 20 / 20 (g / m 2 )

[0190] (ii) Hot-dip galvanized steel sheet (GI): plate thickness 0.8mm, unit area weight = 60 / 60 (g / m 2 )

[0191] (iii) Alloyed hot-dip galvanized steel sheet (GA): plate thickness 0.8mm, weight per unit area = 40 / 40 (g / m 2 )

[0192] In addition, weight per unit area represents the weight per unit area on the main surface of each steel plate. For example, in the case of electro-galvanized steel sheets, it is 20 / 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Plate thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com