Patents

Literature

1054results about "Filament forming substance forming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

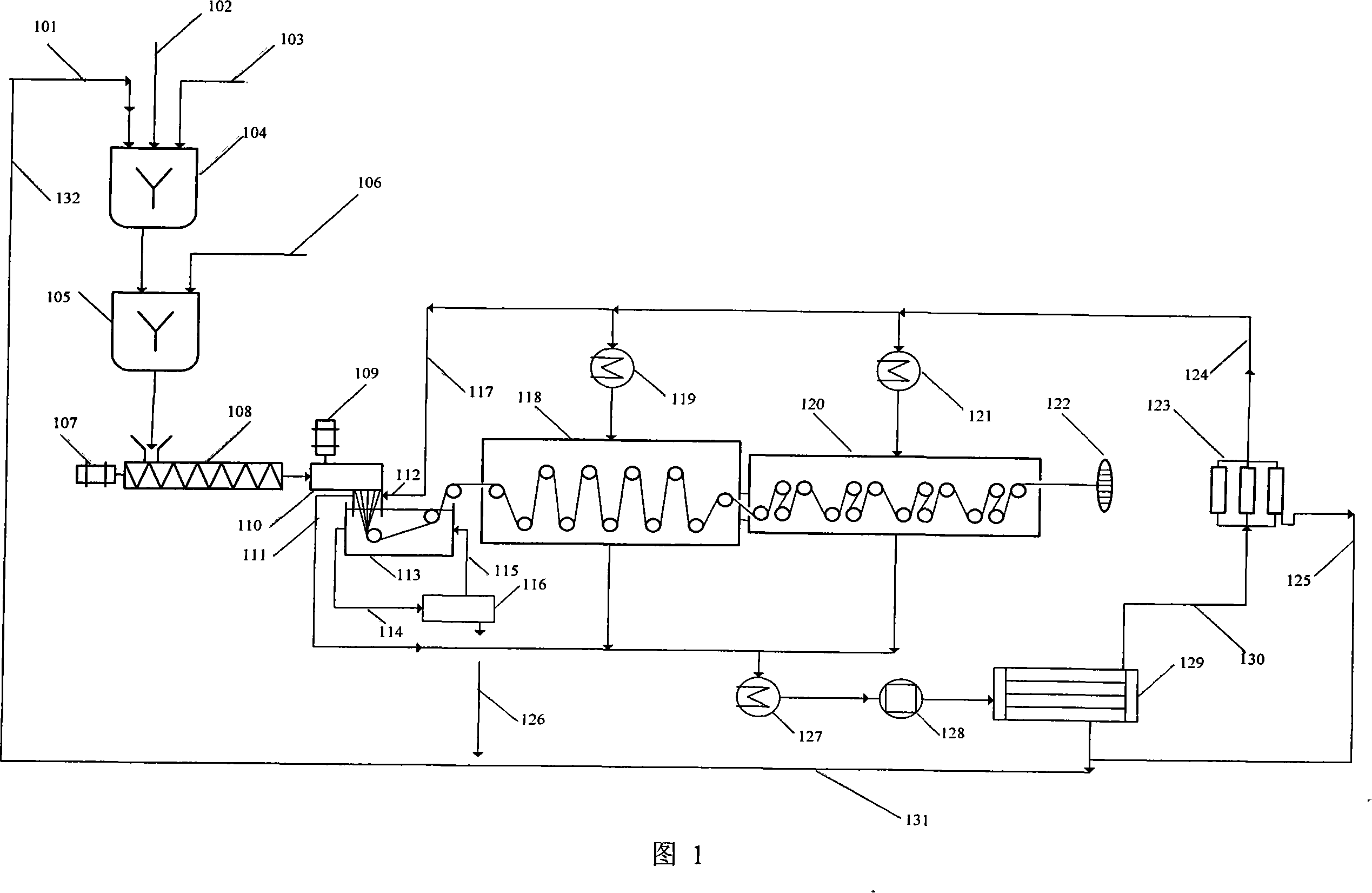

Preparation method of porous fiber non-woven fabric

ActiveCN103981635AReduce melt viscosityReduce degradationFilament forming substance formingMelt spinning methodsDiluentNonwoven fabric

The invention relates to a preparation method of a porous fiber non-woven fabric. The aim of the preparation method is to improve the product performance of the conventional non-woven fabric, so that the non-woven fabric meets the requirements on high-precision and high-performance filter. The technical scheme is that the preparation method of the porous fiber non-woven fabric comprises the following steps in sequence: (1) uniformly mixing a polymer and a diluent to obtain a blend with 10 to 60 percent of polymer; (2) melting and extruding the blend in the step (1) by adopting a screw extruder granulator, and directly cooling and granulating in air; (3) producing master batches in the step (2) by melt-down equipment to obtain a primary non-woven fabric; (4) extracting to remove the diluent from the primary non-woven fabric in the step (3), performing pore-forming on fibers in the non-woven fabric, and drying to obtain the porous fiber non-wave fabric; (5) recovering mixed waste liquid of the diluent and an extraction agent for reuse.

Owner:浙江省轻工业品质量检验研究院

Method for processing regenerated polyester staple fiber by using waste polyester textile

ActiveCN102899729AImprove qualityHigh strengthFilament forming substance formingMelt spinning methodsPolyesterPolymer science

The invention relates to a method for producing regenerated polyester staple fibers, in particular to a method for processing regenerated polyester staple fibers through a physical method by using waste polyester textiles. The method for processing regenerated polyester staple fibers by using waste polyester textiles comprises the following steps of: conducting color matching, proportioning and drying to friction materials produced by using the recovered waste polyester textiles; squeezing and fusing the dried friction materials to obtain fusant; primarily filtering the fusant, feeding the fusant into a high-vacuum tempering and viscosity-regulating reaction kettle; filtering the fusant, feeding the fusant into a spinning manifold and metering spinning; and after spun nascent fibers are bundled, conducting oiling through a dipping tank and a drawing tank, steam secondary drawing, overlapping, curling, relaxed heat setting, cutting and packing to obtain the regenerated polyester staple fibers. By adopting the method for processing regenerated polyester staple fiber by using waste polyester textiles, the technical problem of producing high-quality regenerated polyester staple fibers by using the recovered textiles is solved, the cost of raw materials for producing the regenerated polyester staple fibers is decreased and the problem of recovering the waste polyester textiles is solved.

Owner:余姚大发化纤有限公司

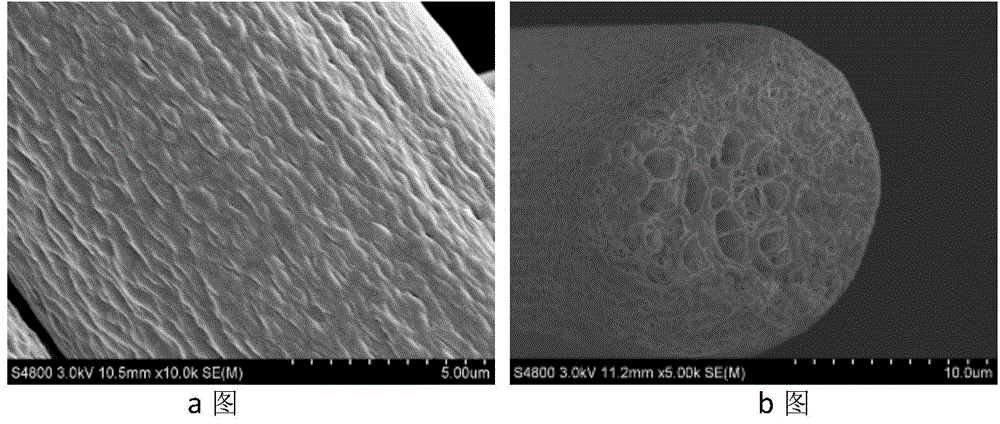

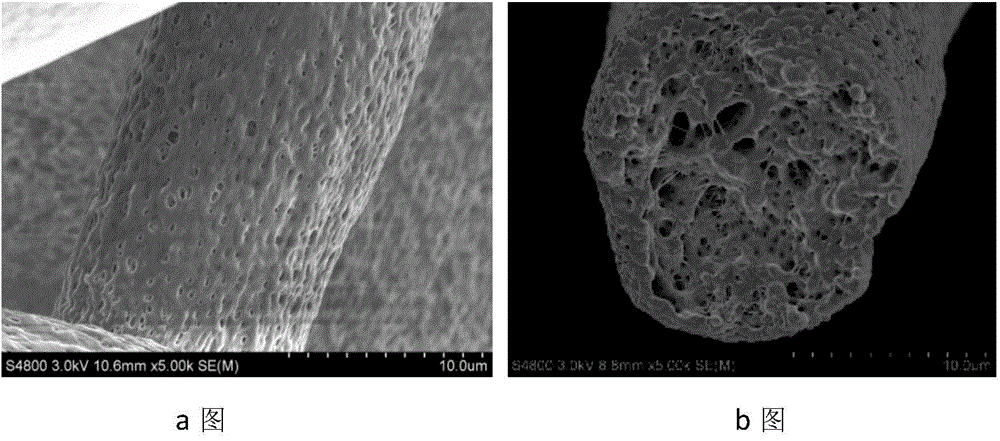

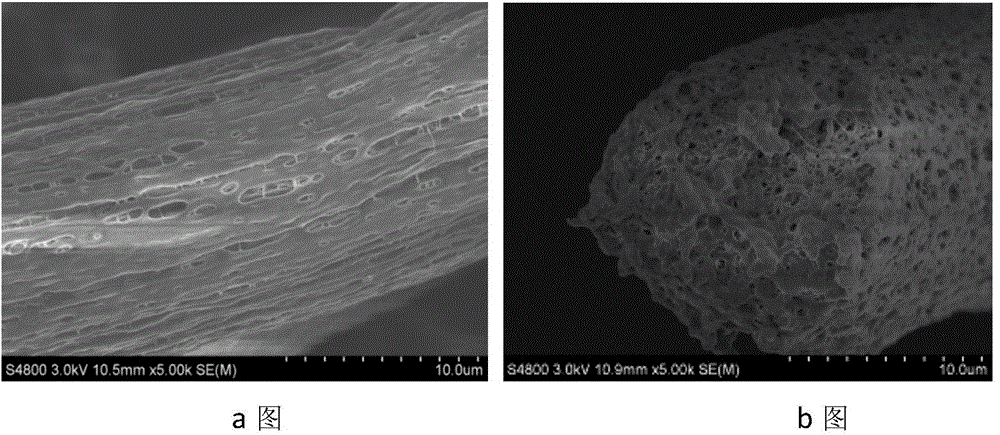

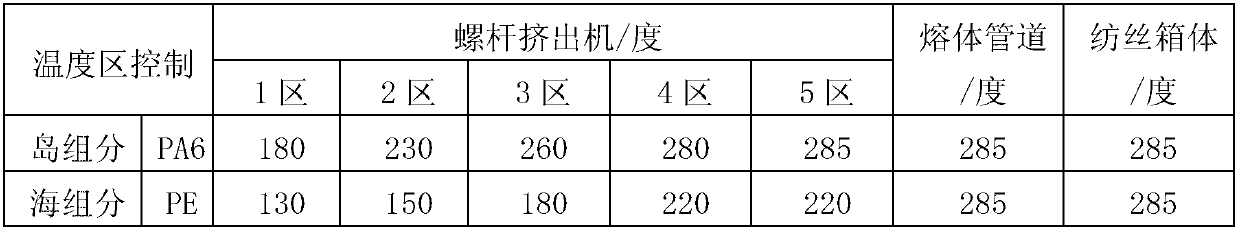

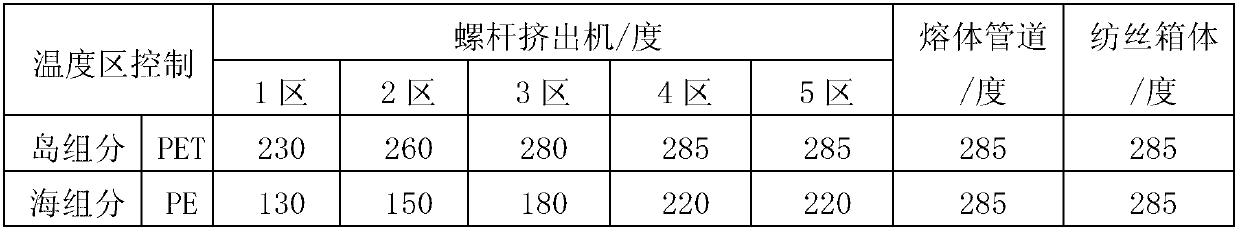

Figured island superfine fiber, figured island superfine fiber synthetic leather base cloth, suede leather for clothes, smooth synthetic leather for clothes and production method of fiber, base cloth, suede leather and smooth synthetic leather

The invention relates to figured island superfine fiber, figured island superfine fiber synthetic leather base cloth, suede leather for clothes, smooth synthetic leather for clothes and a production method of the fiber, the base cloth, the suede leather and the smooth synthetic leather and belongs to the technical field of synthetic leather and production method of the synthetic leather. The production method of the figured island superfine fiber mainly comprises the steps of 1), performing slice drying and fusion; 2), conducting composite spinning; 3), applying oil and dropping a bucket; 4), performing drafting and crimping; and 5) drying and cutting off the fiber. The figured island superfine fiber synthetic leather base cloth, the suede leather for clothes and the smooth synthetic leather for clothes can be produced through the follow-up processing of the figured island superfine fiber. A prepared synthetic leather product has excellent mechanical property, dyeing property and color fastness, is more suitable for synthetic leather of suede or synthetic leather for clothes, which is prepared by surface making, roller coating and surface printing deep processing based on the suede leather, and product application of the leather, and the product is high in durability, strong in color fastness, convenient to cut, fashionable in product design, moisture permeable, vapor permeable, fine and smooth in sensing of suede, and good in writing effect.

Owner:烟台万华超纤股份有限公司

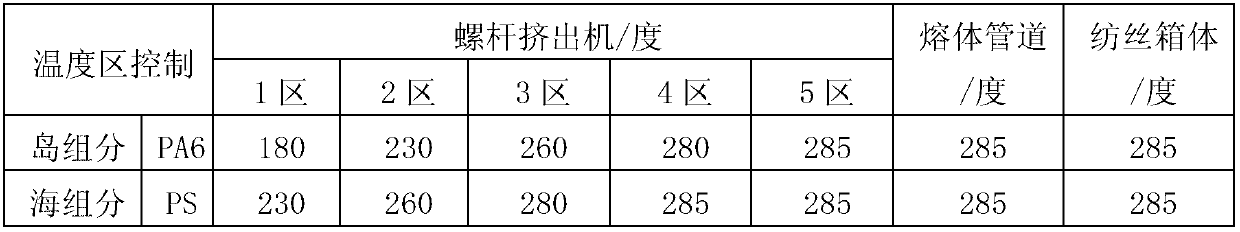

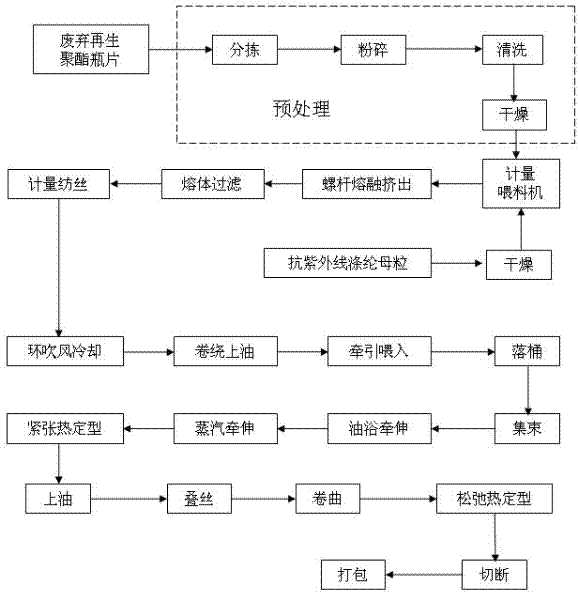

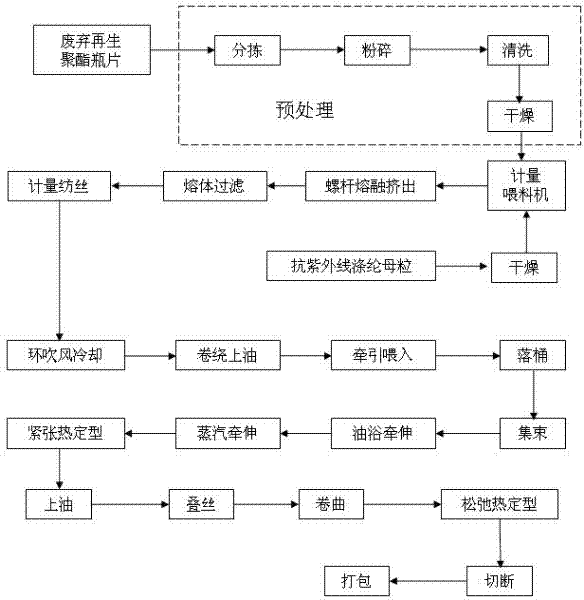

Method for producing felt polyester staple fiber by recycling polyester bottle slice

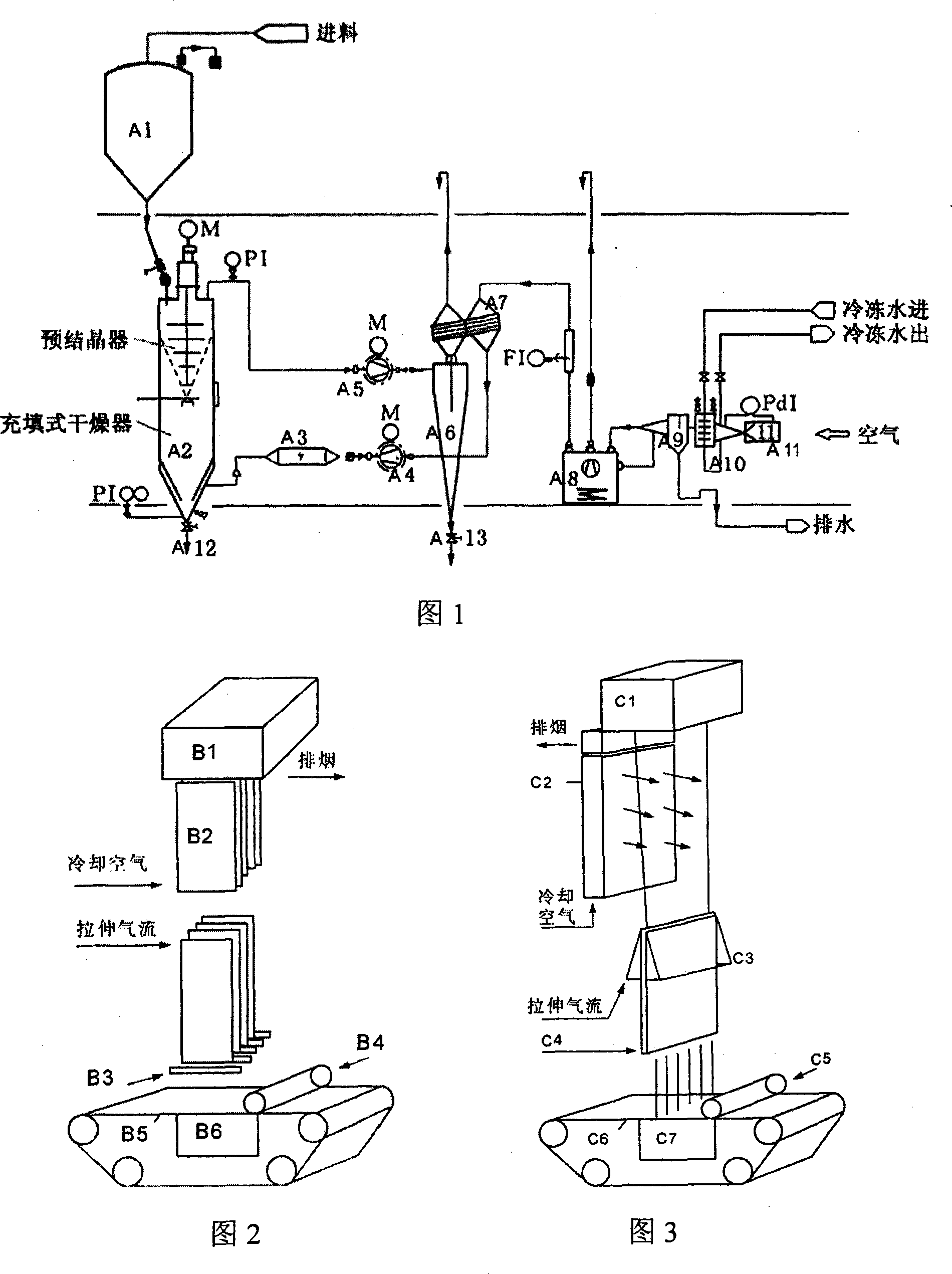

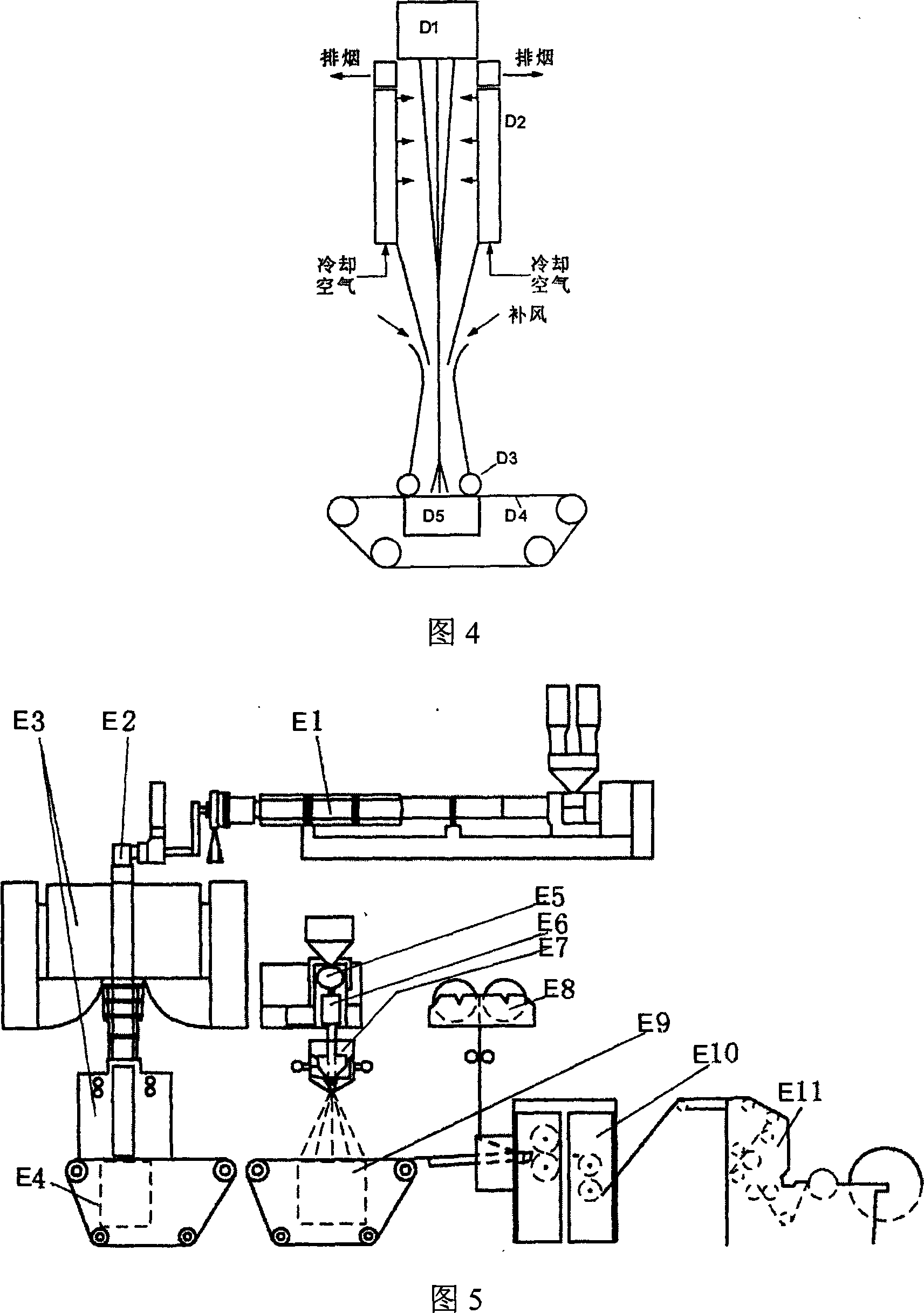

InactiveCN101487142APromote environmental protectionReduce manufacturing costFilament forming substance formingSevering to form staple fibresPolyesterBottle

The invention discloses a method for directly producing felt base cloth polyester short-fiber by recovered polyester bottle sheets, comprising the steps as follows: the recovered polyester bottle sheets are sorted, crushed, cleaned, dried, extruded in a melting state, filtrated, measured, spinned, cooled by circular wind, coiled and oiled, pulled, fed, dropped in a barrel, balanced, collected into bundles, primarily pulled by oil bath, secondarily pulled by steam, tensioned and thermally shaped, oiled, folded, curled, loosened and thermally shaped, cut off and finally packaged. Compared with the felt base cloth polyester short-fiber produced by taking the polyester new material as raw material, the felt base cloth polyester short-fiber produced by the method has almost the same performances and lower price, does not affect the production, processing and use of the next user product, still keeps all product performances of the next user product, lightens the harms of the wastes on the environment, and solves the environmental protection problem.

Owner:NANJING VOCATIONAL UNIV OF IND TECH

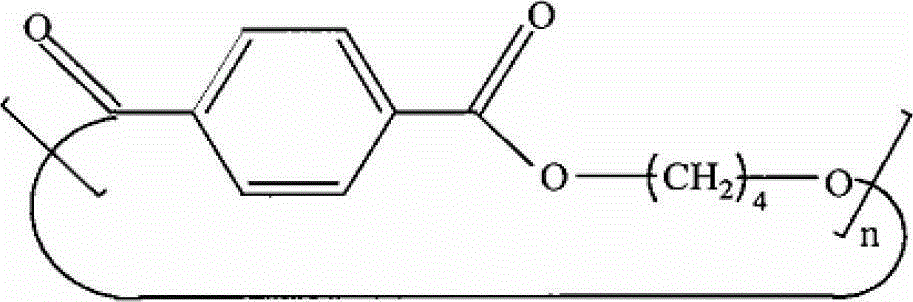

Preparation method of functional polyester fibers

ActiveCN102719932AHigh crystallinityImprove mechanical propertiesFilament forming substance formingMelt spinning methodsPolytetramethylene terephthalatePolyethylene glycol

The invention provides a preparation method of functional polyester fibers. The preparation method mainly comprises the following two steps of: firstly, mixing functional powders, polybutylene terephthalate cyclic oligomer (CBT) and a dispersing agent, performing reactive extrusion on the mixture by double screws to prepare a polybutylene terephthalate (PBT) functional master batch, wherein the functional powders are one of or several of a carbon nano tube, nano titanium dioxide, tourmaline powders, a nano-silver antibacterial agent, a nano silicon oxide and fluorescent powders; and secondly, blending and spinning the master batch, the PBT, polyethylene glycol terephthalate (PET) or polytrimethylene terephthalate (PTT) to prepare the functional polyester fibers. According to the method, the reactive extrusion process is adopted, the operation is simple and convenient, the process flow is shortened greatly, the obtained PBT functional master batch contains 30wt%-40wt% of the functional powders, and can be well dispersed in a base body, the compatibility of the obtained functional master batch and polyester polymer is good, and the fiber obtained by the method has an obvious functional effect.

Owner:ZHOUSHAN XINXIN CHEM FIBER

Production technique of three-dimensional curly hollow polyester staple fibers

InactiveCN102517675AQuality assuranceLow costFilament forming substance formingHollow filament manufacturePolyesterDrum drying

The invention discloses a production technique of three-dimensional curly hollow polyester staple fibers, wherein the production technique comprises the steps of: utilizing regenerative PET material as raw material; sequentially performing the following procedures to obtain a finished product: pre-treating, drum drying, melting spinning, cooling forming, winding, stretching, curling, oiling, cutting and heat setting, wherein the drum drying duration is 9.5-10.5 h, a spinneret plate in the melting spinning procedure is three-dimensional hollow helical, the cross section of a spinneret orifice is a sealed space formed by sealing the circular arcs of two concentric circles, the temperatures of the threaded rod of a threaded rod extruding machine and the box body of a spinning box are 265-275 DEG C; a circular air blowing asymmetrical cooling forming mode is utilized, the circular blowing blast temperature is 20-24 DEG C, and the circular blowing wind speed is 4.7-5.7 m / s; the total stretching fold is 2.5-2.7 folds, the main curling pressure of a curling wheel is 0.05-0.1 MPa, and no backpressure exists; the heat setting temperature is 175-180 DEG C, and the heat setting duration is 10-14 min. The production technique of the invention has the advantages of saving the cost and protecting the environment, and the prepared finished product not only has good three-dimensional configuration and bulkiness, but also has better thermal stability.

Owner:HANGZHOU BEST CHEM FIBER

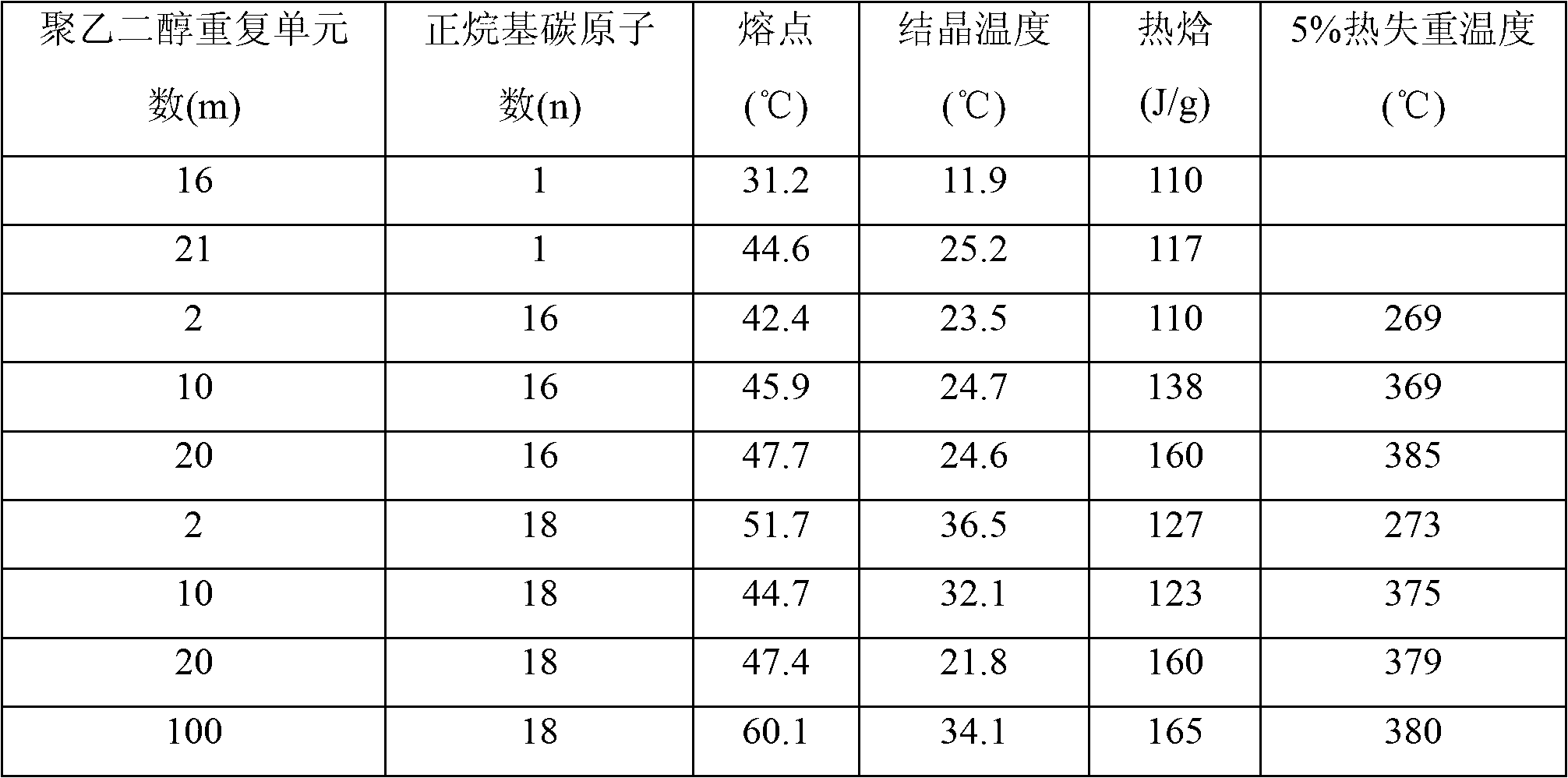

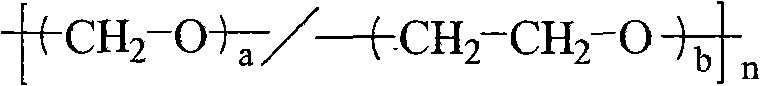

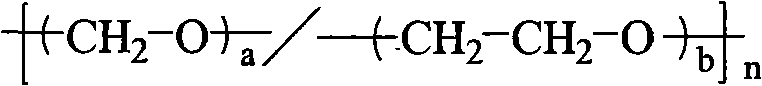

Heat accumulating temperature regulating fiber and method for preparing same

ActiveCN102704037AGive full play to the heat storage and temperature adjustment functionVarious formsFilament forming substance formingElectro-spinningFiberPolypropylene glycol

The invention discloses a heat accumulating temperature regulating fiber and a method for preparing the same. The fiber takes a polymer phase-change material as component A and a fiber-forming polymer as component B, wherein the mass fraction of the component A in the fiber counts 20-60%, while the mass fraction of the component B in the fiber counts 80-40%; the fiber is produced by using a method comprising the steps of melting composite spinning, solution composite spinning or electrostatic solution composite spinning; the fiber has a composite structure and the cross section of the fiber is shaped as an island or concentric circles, wherein the polymer phase-change material is polypropylene glycol-n-alkyl ether; the number m of glycol repetition units is 1-100; the number n of carbon atoms in alkyl is 11-30; and the heat absorption / dissipation temperature of the fiber is 11.9-53.8 DEG C, while the heat accumulation quantity is 18-55 J / g and 5% thermal gravimetric temperature is above 203 DEG C. The method for preparing the fiber employs the constitution and the structure of the heat accumulating temperature regulating fiber provided by the invention and prepares the fiber by using the method of the melting composite spinning, the solution composite spinning or the electrostatic solution composite spinning.

Owner:陕西析睿凯莱材料科技有限公司

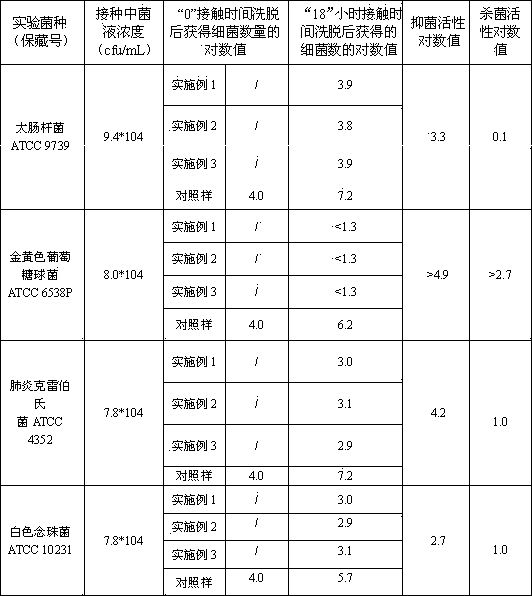

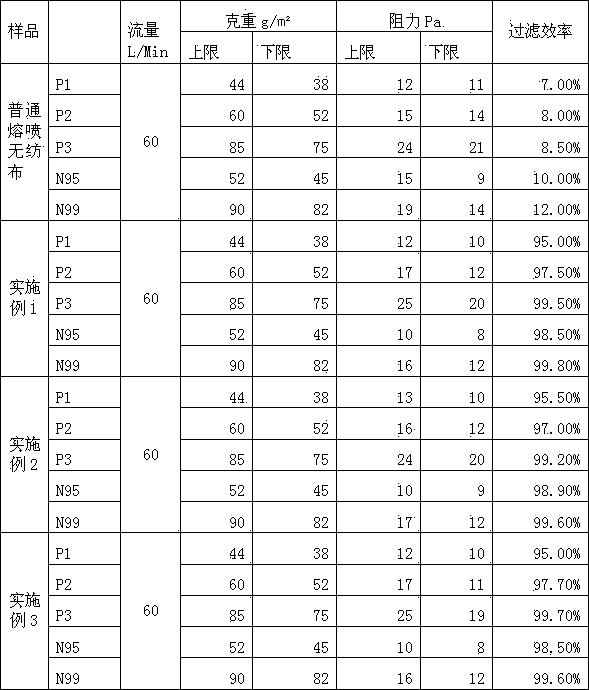

Nano-silver antibacterial melt-blown non-woven fabric and production method thereof

ActiveCN104047114AHigh strengthAvoid breakingFilament forming substance formingArtificial thread manufacturing machinesPolyesterNonwoven fabric

The invention relates to nano-silver antibacterial melt-blown non-woven fabric and a production method thereof. The nano-silver antibacterial melt-blown non-woven fabric is characterized in that the fabric contains hybrid nanoscale antibacterial powder, a non-woven fabric base stock can be polypropylene, polyester or polyphenylene sulfide, the hybrid nanoscale antibacterial powder is formed in a way that nanoscale zirconium phosphate and silver nitrate are exchanged in water to form silver phosphate, zinc oxide needs to be added in the exchange process, and the antibacterial powder has the proportion of ingredients as follows: 2-5 percent of the silver nitrate, 90-95 percent of the zirconium phosphate and 1-5 percent of the zinc oxide. The nano-silver antibacterial melt-blown non-woven fabric has excellent inhibition and stop effects on escherichia coli, staphylococcus aureus, Candida albicans and the like, and can filter various particles with the pm (particulate matter) over 2.5 in current air haze, the filter efficiency is over 95 percent, and the antibacterial ratio is over 99 percent; the fabric is tested by sgs (Societe Generale de Surveillance); the prepared nano-silver antibacterial melt-blown non-woven fabric is good in strength, not easy to break, soft and comfortable.

Owner:李文博 +1

Dry-method spinning technique for preparing super high molecular weight polyethylene fibre

InactiveCN101148783AVolatileReduce manufacturing costFilament forming substance formingArtificial filament physical treatmentSolventCarbon dioxide

The present invention is dry spinning process for preparing ultrahigh molecular weight polyethylene fiber, and belongs to the field of polymer material preparing technology. The process includes: dissolving ultrahigh molecular weight polyethylene powder and assistant in xylene solvent; filtering and debubbling the solution, extruding in a screw extruder, spraying through a metering pump, spinning manifold and spinneret and solidifying to form, hot air drying to eliminate xylene from fiber, hot drafting and final winding the product. The present invention includes also condensing and adsorbing to separate xylene from N2 or CO2, reusing the separated xylene and reusing the separated N2 or CO2.

Owner:BEIJING TEX STRONG NEW MATERIAL DEV

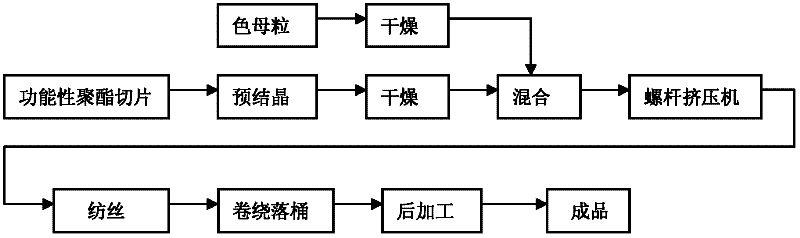

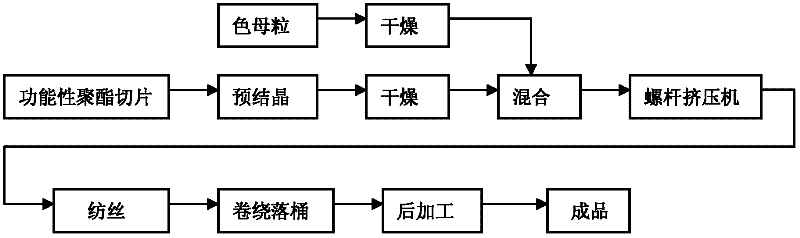

Method for producing differential terylene color yarns

InactiveCN102392317AReduce pollutionHigh fastnessFilament forming substance formingMelt spinning methodsYarnPolyester

The invention discloses a method for producing differential terylene color yarns. The method comprises the following steps of: pre-crystallizing a functional polyester chip at the temperature of between 144 and 146 DEG C for 20 to 60 minutes, and drying at the temperature of between 149 and 151 DEG C for 4 to 6 hours, so that the moisture content of the dried functional polyester chip is less than or equal to 17 ppm; and drying masterbatches for 1 to 2 hours, mixing the dried masterbatches and the dried functional polyester chip fully, adding the mixture into a screw extrusion spinning machine, spinning by using a spinneret plate of the screw extrusion spinning machine, winding and dropping into a bucket, and processing to obtain the differential terylene color yarns. In the method, the masterbatches are added into the functional polyester chip to be spun into the color yarns, the masterbatches and the functional polyester chip are mixed uniformly in a mode of dynamic mixing or static mixing in a screw extruder, and the color yarns are produced through the spinneret plate. By the method, the color fastness and stability of the products are improved, the production cost is reduced, and environmental pollution is reduced.

Owner:ZHEJIANG SANZHI TEXTILES

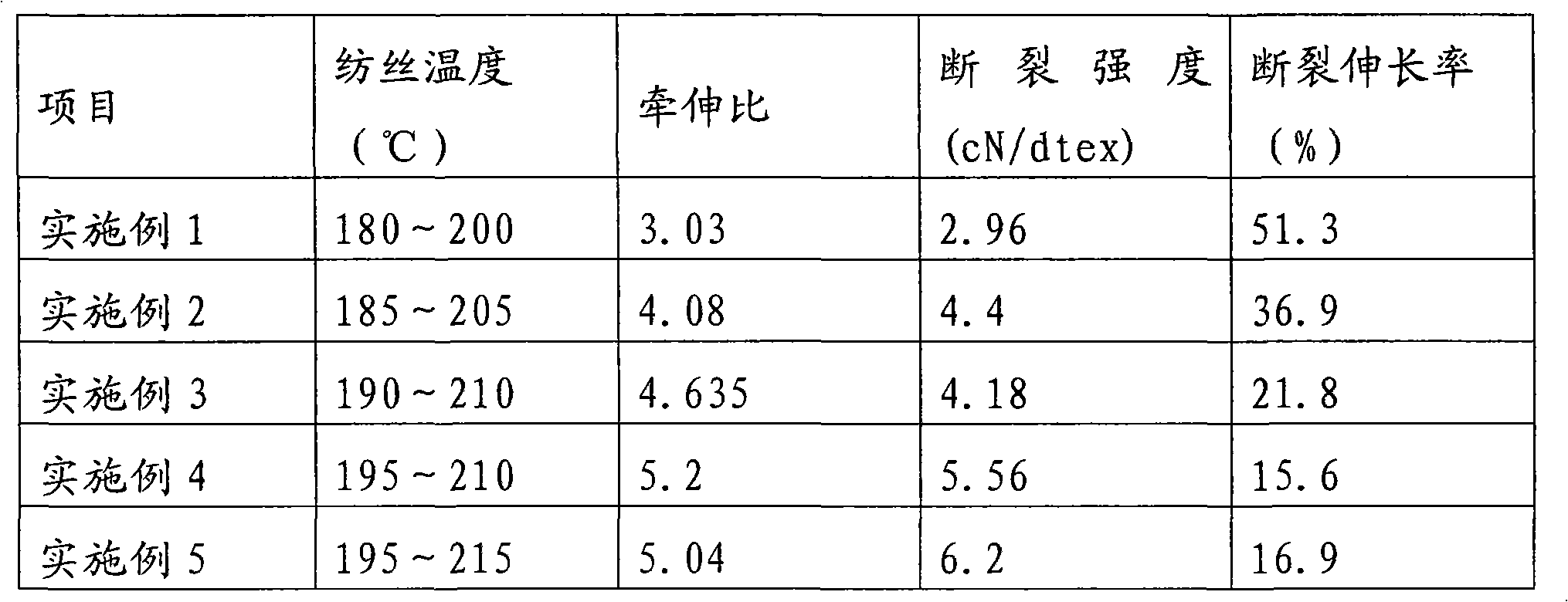

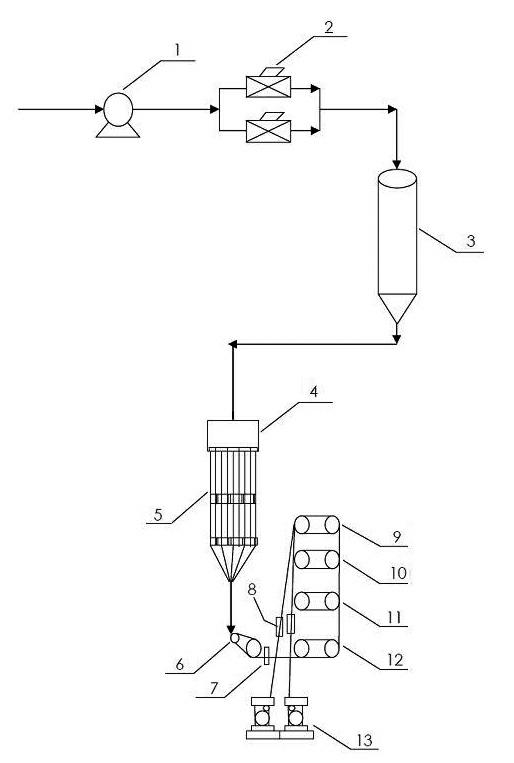

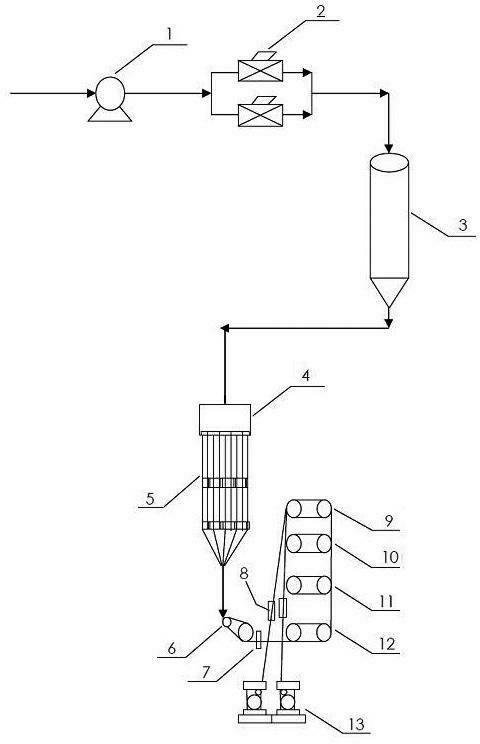

Melt-spinning method for polyformaldehyde fibers

InactiveCN102011201AFilament forming substance formingMonocomponent synthetic polymer artificial filamentBreaking strengthWater baths

The invention discloses a method for producing polyformaldehyde fibers with strong breaking strength. In the method, a melt-spinning process is adopted. Before spinning, polyformaldehyde resin is arranged in a vacuum oven, or is dried by continuous hot air or N2, and is heated from 100 DEG C to 110 DEG C within five minutes and kept at the temperature for 1 to 8 hours. Nascent fibers are slowly cooled and then quenched in hot solution or superheated vapor, so holes produced in the multi-ratio drafting process of the fibers are reduced. In the back-draft heat setting of the fibers, the difference of drafting temperature and heat crystallization setting temperature is controlled to be 20 to 45 DEG C, and multi-ratio multi-stage slow drafting is adopted, wherein hot solution water-bath pressurization drafting is adopted in primary drafting setting, and is performed for a time controlled to be 0.2 to 2 seconds.

Owner:SICHUAN TEXTILE SCI RES INST +1

Direct spinning method for single-part four-end 2200dtex high-modulus low-shrinkage polyester industrial yarns

ActiveCN102168318ADirect spinningImprove single-site production capacityFilament forming substance formingStretch-spinning methodsYarnPolyester

The invention relates to a direct spinning method for single-part four-end 2200dtex high-modulus low-shrinkage polyester industrial yarns, which comprises the following process steps of: pre-crystallizing raw materials, such as polyester slices, and obtaining polyester slices by solid phase polymerization; heating the polyester slices in a screw extruder to obtain polyester melts, distributing the polyester melts to melt branch pipes through a main melt pipe, then metering via a metering pump, feeding the melts to a spinning assembly and extruding the melts from a spinneret to form tows, and subjecting the tows to cooling shaping in a circular blowing device; oiling the surface of the tows, drawing, shaping and relaxing the tows by using six pairs of rollers, forming first-stage drawing between the first pair of rollers and the second pair of rollers, forming second-stage drawing between the second pair of rollers and the third pair of rollers, performing constant velocity shaping between the third pairs of rollers and the fourth pair of rollers as well as between the fourth pair of rollers and the fifth pair of rollers, and forming retraction shaping between the fifth pair of rollers and the sixth pair of rollers; and coiling to obtain the polyester industrial yarns. The polyester yarns produced according to the method disclosed by the invention have high breaking strength, effectively-improved the yield of single part and lowered production cost.

Owner:WUXI TAIJI IND

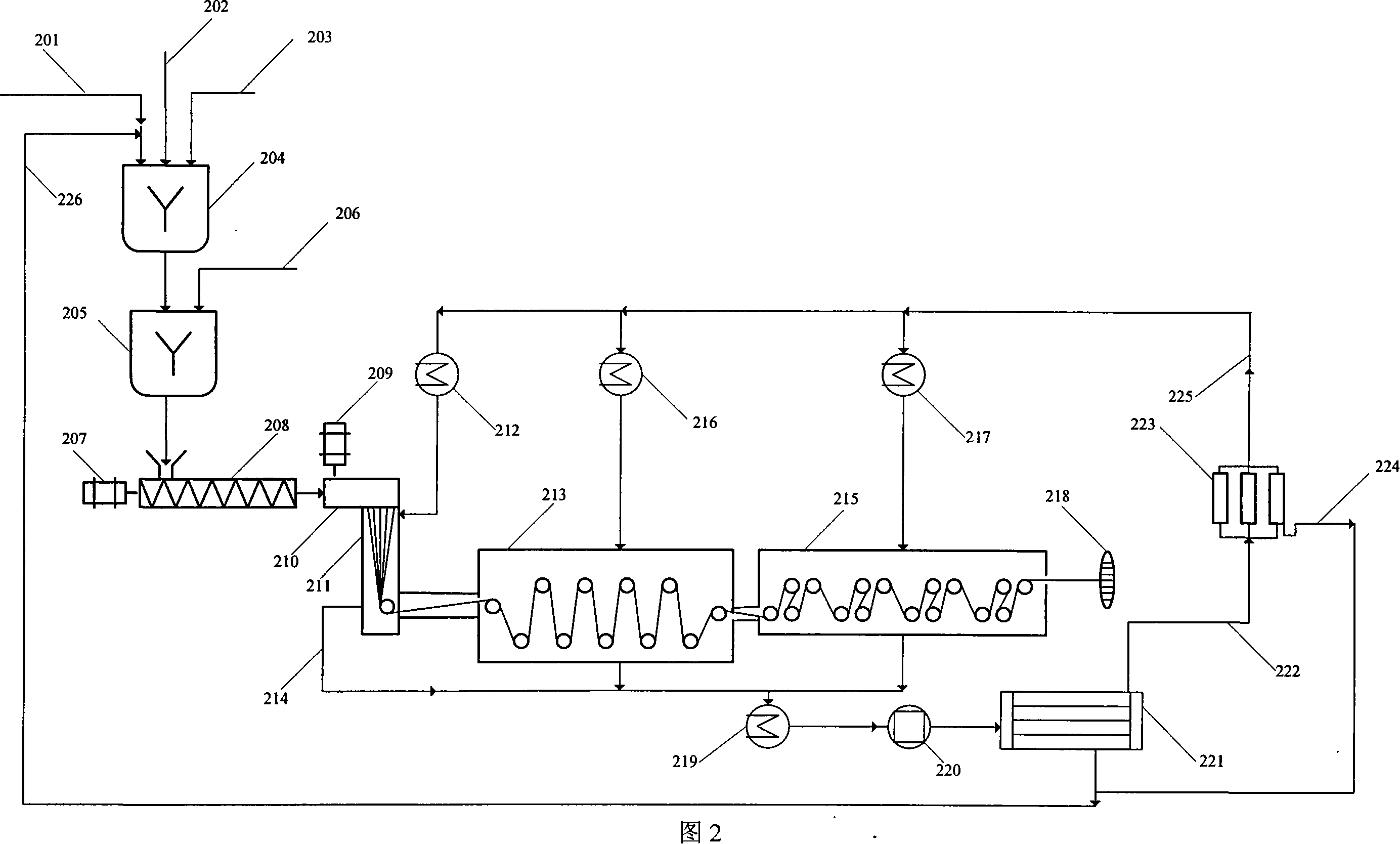

Process for producing polyester industrial yarns by liquid-phase tackified melts in multi-end direct spinning manner

ActiveCN102605444AShort turnaround timeReduce energy consumptionFilament forming substance formingNew-spun product collectionWinding machineYarn

The invention discloses a process for producing polyester industrial yarns by liquid-phase tackified melts in a multi-end direct spinning manner, which belongs to the technical field of polyester industrial yarns and includes the following steps: liquid-phase tackifying; obtaining high-viscosity polyester melts with intrinsic viscosity ranging from 0.90dl / g to 1.10dl / g by tackifying low-viscosity polyester melts in a liquid phase; double-end spinning; directly conveying the polyester melts after being subjected to liquid-phase tackifying to different spinning positions capable of spinning in 16-24 ends; drafting and thermal-forming; winding and forming; and utilization of a twin winding machine to perform high-speed winding of 16-24 spindle spinning cakes. In the process, 16-end direct spinning of high-strength or low-shrinkage polyester industrial yarns with a single end ranging from 800D to 1300D and 24-end direct spinning of low-denier polyester industrial yarns with a single end ranging from 100D to 500D can be realized on the same spinning position, and product production efficiency is high, performance is stable, production energy consumption and equipment investment cost are low.

Owner:ZHEJIANG GUXIANDAO POLYESTER DOPE DYED YARN CO LTD

Method for preparing functional ultraviolet-resistant polyester staple fiber from waste renewable polyester bottle chips

InactiveCN102505182APromote environmental protectionReduce manufacturing costFilament forming substance formingPlastic recyclingPolyesterFiber

The invention discloses a method for preparing functional ultraviolet-resistant polyester staple fiber from waste renewable polyester bottle chips. The method comprises the following steps of: pre-treating and drying recovered waste renewable polyester bottle chips; drying ultraviolet-resistant polyester master batch; conveying the dried polyester bottle chips and ultraviolet-resistant polyester master batch into a special metering feeder to quantitatively feed and mix the polyester bottle chips and the ultraviolet-resistant polyester master batch to obtain a mixture; performing screw fusion extrusion on the mixed mixture with a certain concentration to obtain melt; filtering the melt, metering and spinning, cooling through circular blowing, winding and oiling, drawing and feeding, and holding filaments and falling into a barrel; bundling the filaments in the barrel; and performing oil water bath drawing and steam drawing, tense thermal forming, oiling, filament lamination, curling, loose thermal forming, cutting and packing to obtain an ultraviolet-resistant polyester staple fiber product. The method has the advantages of rational preparation process and high operability; and the product has lower cost than a new material and has good economic benefit and social benefit.

Owner:东莞市粤盛纤维制品有限公司

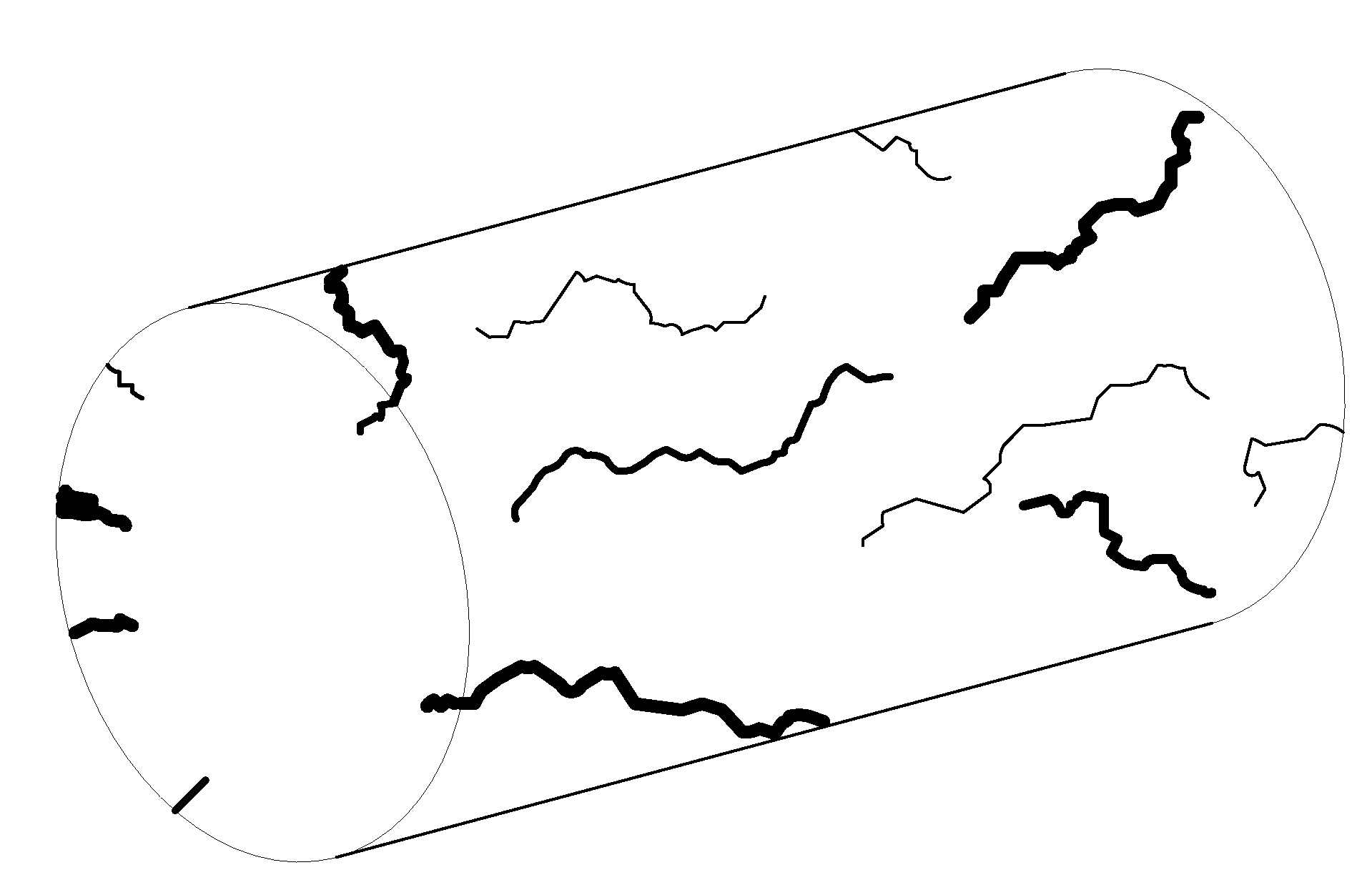

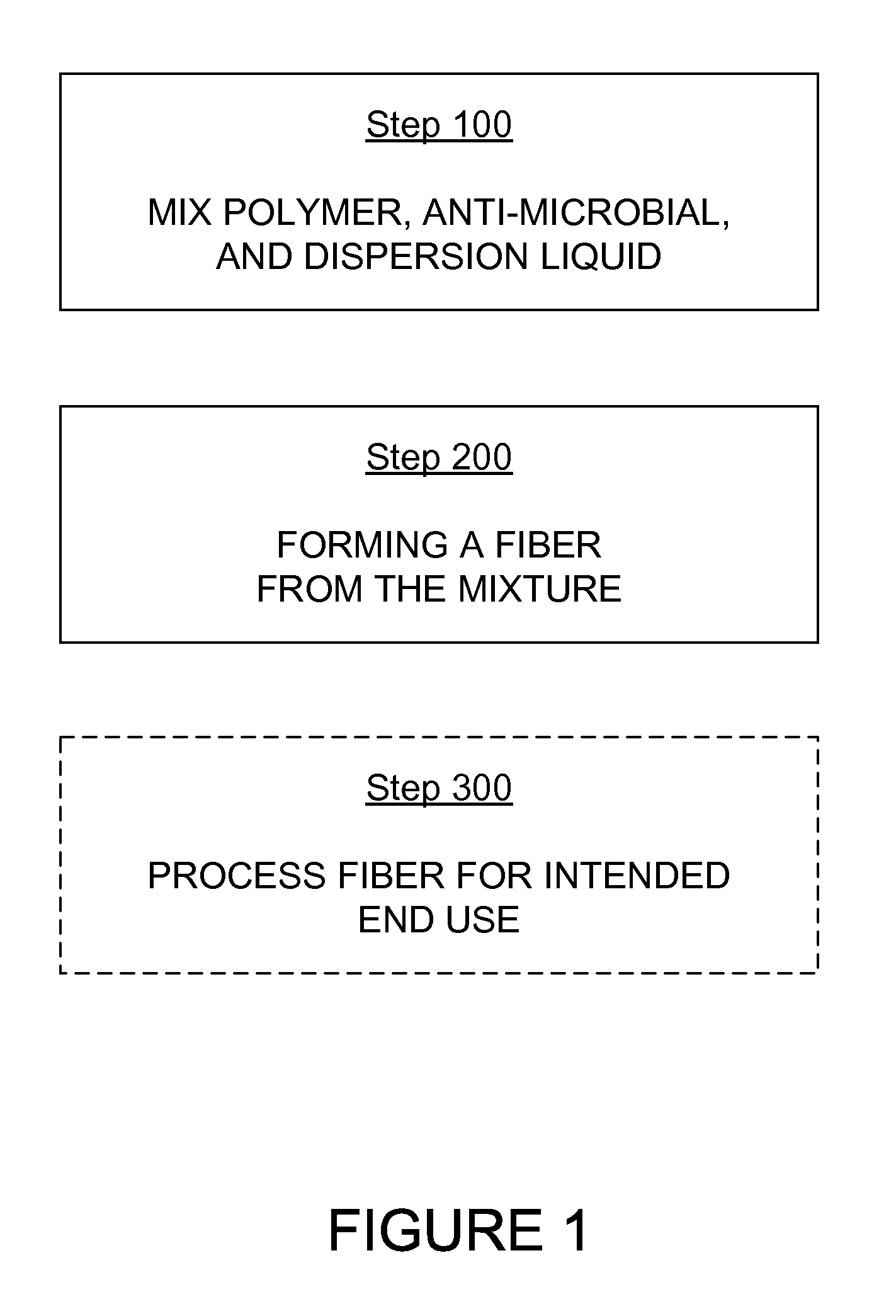

Fibers with improving Anti-microbial performance

InactiveUS20120164449A1Avoid wrinklesCurtain accessoriesFilament forming substance formingPolymer sciencePolymer

Fibers and fabrics with improved anti-microbial activity in after laundering, and a method of producing the same, are described. One embodiment includes a method for generating a synthetic fiber, the method comprising creating a mixture, the mixture comprising a polymer, an anti-microbial agent, and a dispersion liquid, and extruding the mixture to form a synthetic fiber.

Owner:PURTHREAD TECH

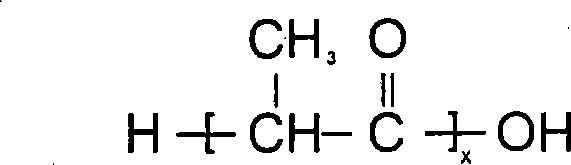

Full-degradation lactic acid polymer spun-bonded continuous yarn non-woven fabrics and preparation method thereof

InactiveCN101122065APromote degradationPromote growthFilament forming substance formingNon-woven fabricsYarnExtensibility

The invention discloses a complete degradation poly (lactic acid) spun-bond filament non-woven cloth, which is rolled and bonded by a fiber web which is paved with PLA fiber with average fiber fineness of 0.12 to 1mm. The mass per area of the cloth is 25 to 100g / m2, the thickness is 0.1 to 0.5mm, the longitudinal extensibility is 12 to 16percent and the lateral extensibility is 15 to 21percent. The invention also discloses a method of preparing the complete degradation poly (lactic acid) spun-bond filament non-woven cloth. The invention has good biological degradability and biological composing capability, and the physical mechanical performance is based on the traditional PET; the chips within the used molecular weight range are stable during the filament spinning process, have low sensitivity to the temperature changes, and the spinning continuity and stability are good; the invention is applicable in industrial operation.

Owner:豆丁乐园(南京)婴儿用品有限公司

Method for preparing polyester staple fibers from waste polyester fibers

InactiveCN105525375AProcess stabilitySave resourcesSpinnerette packsFilament forming substance formingPolyesterCrusher

The invention relates to a method for preparing polyester staple fibers from waste polyester fibers and belongs to the technical field of chemical fiber preparation. The method includes leading recycled waste polyester cloth, waste polyester fiber or waste polyester lumps into a crusher, leading the crushed materials into a compacting device for water removal and compaction to obtain dried polyester waste with the moisture content being less than 200PPm, then feeding the dried polyester waste into a screw extruder for melt extrusion, meanwhile vacuumizing to remove low molecular weight substances brought into the raw materials, filtering melt extruded via a screw extruder, leading the filtered melt into a spinning box via a metering pump for melt spinning, cooling and solidifying filaments extruded from a spinneret plate via cross air blow, oiling the filaments, gathering the filaments into tows and spooling to obtain nascent fibers; gathering the nascent fibers into tows via a creel, leading the tows into a drafting system via a godet machine for drafting, discharging from the drafting system to obtain draft filaments, and performing crimping, drying, relaxation setting, cutting off and packing to obtain finished products. The process is concise, and process stability is ensured; resources are saved; preparation efficiency is high.

Owner:CHANGSHU GOLD SPRING CHEM FIBERS & KNITTINGS

Preparation method of fishery polyamide wear-resistant monofilament

ActiveCN103147157AImprove wear resistanceImprove bending strengthFilament forming substance formingArtificial thread manufacturing machinesWinding machinePolymer science

The invention discloses a preparation method of a fishery polyamide wear-resistant monofilament. The fishery polyamide wear-resistant monofilament comprises polyamide resin, ultra-high molecular weight polyethylene powder, active nano silicon dioxide and PE (polyethylene) grafting maleic anhydride. The preparation method is characterized by comprising the following steps of: mixing polyamide resin, ultra-high molecular weight polyethylene powder, active nano silicon dioxide and PE grafting maleic anhydride; stirring by a stirrer after mixing, heating by a twin screw and granulating into particles by a granulator, mixing and melting the mixed particles through a plastic extruding machine with a mixing head, extruding through a high pressure metering pump, cooling molten and extruded monofilament to put in a drawing machine for drawing with the drawing temperature of 90-95 DEG C and the drawing time of 5-6.5 times, putting the drawn monofilament in a setting machine for setting, carrying out surface coating treatment on the monofilament through an antistatic oil, and winding the set monofilament on a winding machine, wherein the winding tension of 0.06-6mm monofilament is 50-800cN, and the winding speed is 10-200m / min.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Spinning, vacuumizing and mixing extruder of dacron waste cloth

ActiveCN105821490AReduce degradationExclude microporesFilament forming substance formingMelt spinning methodsFiberTemperature control

The invention discloses a spinning, vacuumizing and mixing extruder of dacron waste cloth. The spinning, vacuumizing and mixing extruder comprises an agglomeration machine, a reciprocating type mixing extruder and a single-screw-rod extruder in sequence along a line production direction, wherein the reciprocating type mixing extruder comprises an extruding and mixing system, a reciprocating driving system, an electric appliance control system and a temperature control system; the extruding and mixing system comprises a machine barrel which is arranged by sections, and a screw rod and a pin which are matched with each other and are arranged in the machine barrel; the machine barrel which is arranged by sections comprises an extruding section and a mixing section; the extruding section and / or the mixing section are / is provided with a vacuumizing hole; the vacuumizing hole is connected with vacuumizing equipment. By virtue of the equipment disclosed by the invention, the reciprocating type mixing extruder is innovatively used for mixing dacron materials before materials enter the single-screw-rod extruder, and steam and an oiling agent in the dacron materials, and auxiliary agents used in other spinning processes are pumped away, so that the degradation of the dacron is reduced, and the quality of regenerated dacron fiber yarns is improved.

Owner:江苏新达科技有限公司

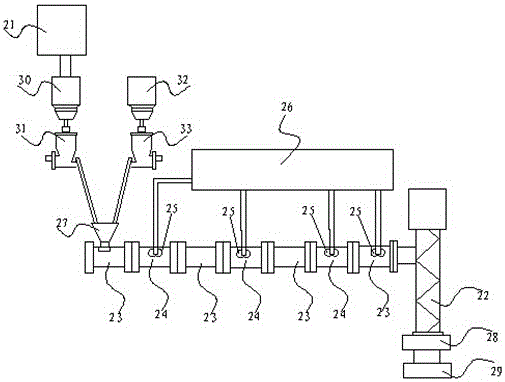

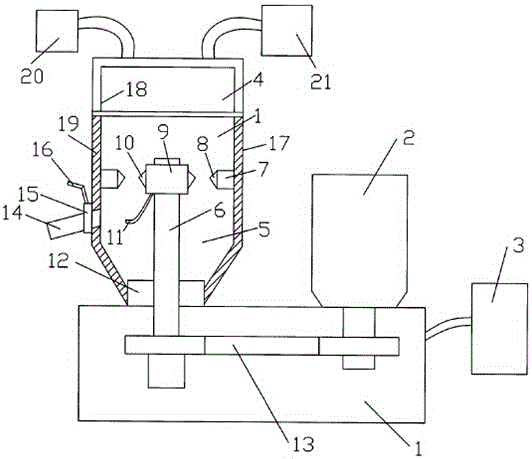

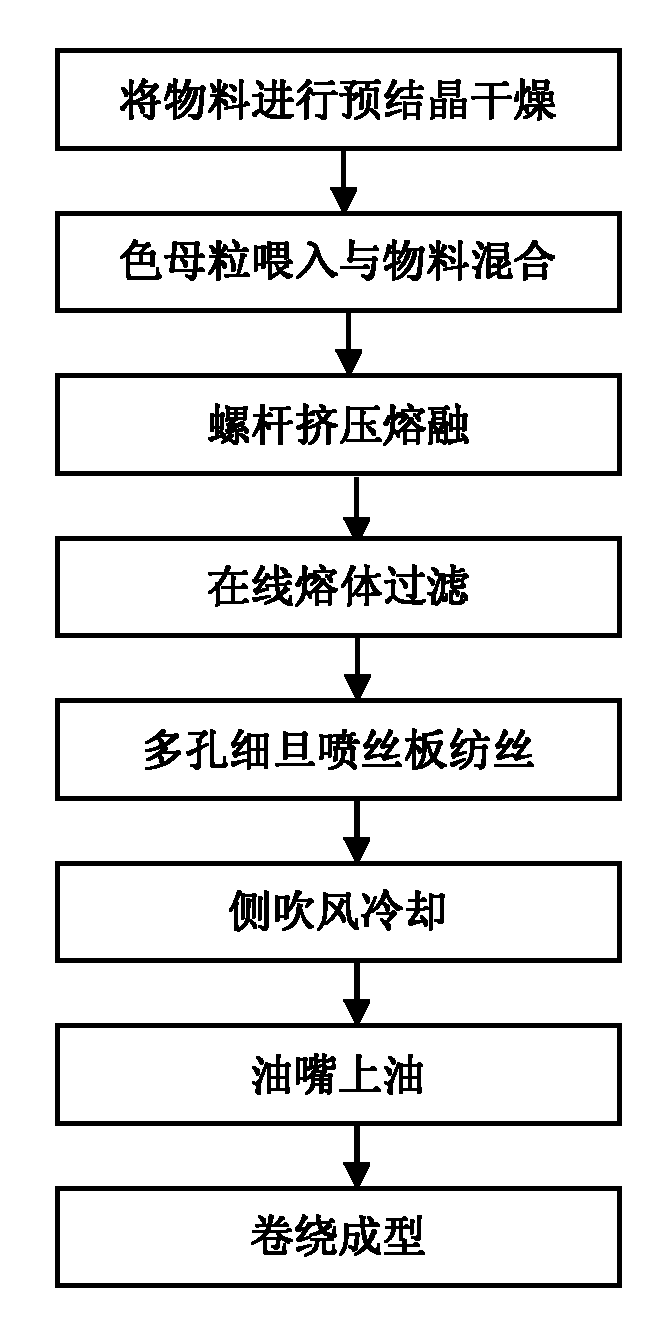

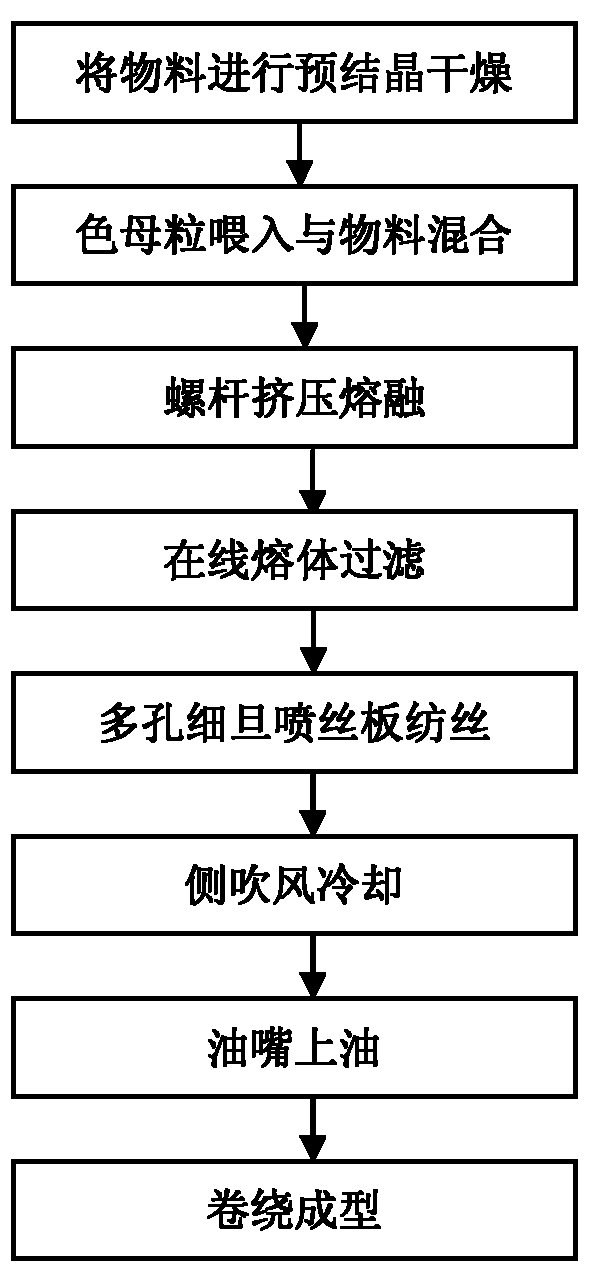

Production technology for producing porous fine denier colored terylene pre-oriented filament by utilizing recycled polyester bottle flakes

InactiveCN102168320AFeel goodFull textureFilament forming substance formingFilament/thread formingPolyesterPolymer science

The invention discloses a production technology for producing porous fine denier colored terylene pre-oriented filament by utilizing recycled polyester bottle flakes. In the invention, the porous fine denier colored terylene pre-oriented filament approximating to that produced by primary polyester chips is produced by utilizing recycled polyester bottle flakes and color master batches as main materials and through the work procedures such as melting and extrusion by a screw extruder, filtration by an on-line switchable melt filter, spinning by a porous fine denier spinneret plate, side-blowing cooling, oiling by an oiling nozzle, winding to shape, and the like. The spinneret orifice of the adopted spinneret plate is formed by the combination of multiple round holes which are arranged in a concentric circle type, the quantity of the round holes is equal to that of monofilaments, and the section of a fiber which is span from the spinneret orifice and formed after the work procedures of drafting, cooling and the like is round in shape. The product produced by the method of the invention can replace the porous fine denier colored terylene pre-oriented filament produced by the conventional method; the fineness of the monofilament is small, the handfeel is wonderful, and the production control is table; and the porous fine denier colored terylene pre-oriented filament can be broadly used in the fields of garment fabric and industrial fabric.

Owner:JIANGSU FEILIN FIBER TECH

Health-care spandex fiber and preparation method thereof

ActiveCN103194819AGuaranteed stabilityGuaranteed physical propertiesFilament forming substance formingMelt spinning methodsMoistureMelt spinning

The invention provides a health-care spandex fiber which is formed by combining a wrapper and a core part, wherein the section of the fiber is solid; the mass percentage of the core part accounts for 30-70% of that of the fiber and the mass percentage of the wrapper accounts for 30-70% of that of the fiber; and a preparation method of the health-care spandex fiber comprises the following steps of: 1, preparing a health-care spandex core part by utilizing a melt spinning technology according to a formula proportion; 2, preparing a health-care spandex fiber wrapper by utilizing a dry-method spinning technology according to the proportion; and 3, spinning by utilizing a special spinneret plate combined piece through a conventional dry-method spinning equipment process so as to obtain a health-care spandex. The health-care spandex disclosed by the invention has the effects of eliminating the peculiar smell, absorbing the moisture and proofing moulds, and inhibiting bacteria and expelling parasites; the health-care spandex can be contacted with a human body to remove the humidity and absorb the sweat so as to accelerate the blood circulation and the metabolism of the human body and relieve fatigues; and the health-care spandex also has the aroma of plant essences, and furthermore is good in utilization performance and can meet the requirements on homespun in processes of spinning, weaving, dyeing and finishing.

Owner:ZHEJIANG HUAFENG SPANDEX

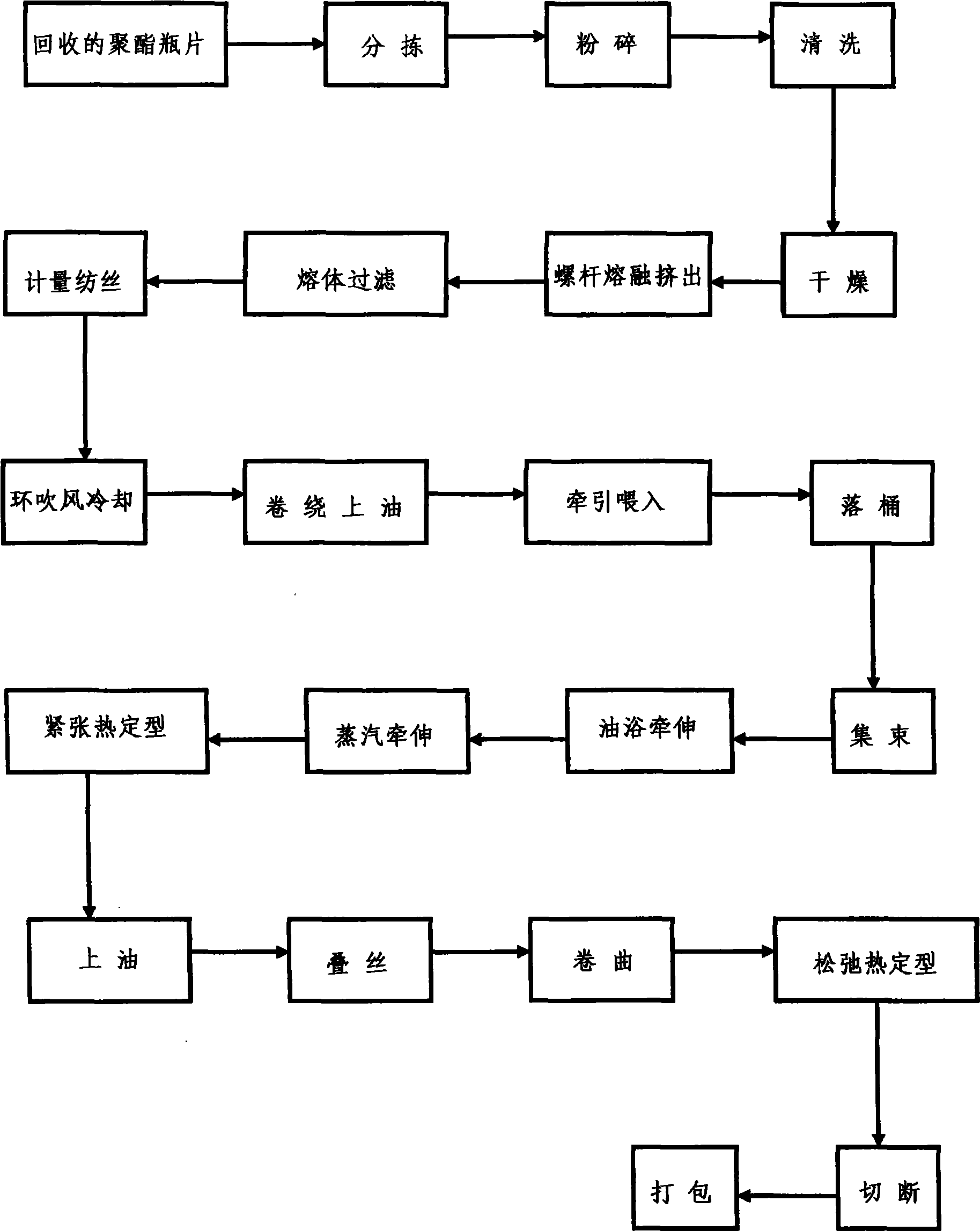

Method for producing industrial polyester filament by recycled PET (Polyethylene Terephthalate) bottle chips on scale

ActiveCN102605454ASolve the problem of water content inconsistencyGuaranteed Filtration QualityFilament forming substance formingMonocomponent polyesters artificial filamentPolyesterPolyethylene terephthalate

The invention provides a method for producing industrial polyester filament by recycled PET (Polyethylene Terephthalate) bottle chips on a scale. The method comprises the steps of crushing the recycled PET bottles into chips, washing and drying, sending into a crystallization bed body for crystallization, forming crystallization layers on the surfaces of the bottle chips, sending the crystallizedbottle chips into a drying tower which is provided with a pair of spiral agitators, leading the dried bottle chips to enter a screw extruder for melting and extrusion, sending the obtained melt into a two-stage filtration device consisting of a coarse filter, a fine filter and a pressure pump between the coarse filter and the fine filter for filtration, leading the melt which is filtrated by two stages to enter a liquid phase tackifying kettle, conducting polycondensation reaction in the liquid phase tackifying kettle, leading the melt after being subjected to liquid phase tackifying to entera spinning box, and spinning by adopting a high-speed spinning process, thus obtaining the industrial polyester filament. In the method for producing the industrial polyester filament, the liquid phase tackifying step is added in the production process, so that the problems of low viscosity and poor stability of the PET bottle chip melts are solved.

Owner:LONGFU RECYCLING ENERGY SCIENTECH

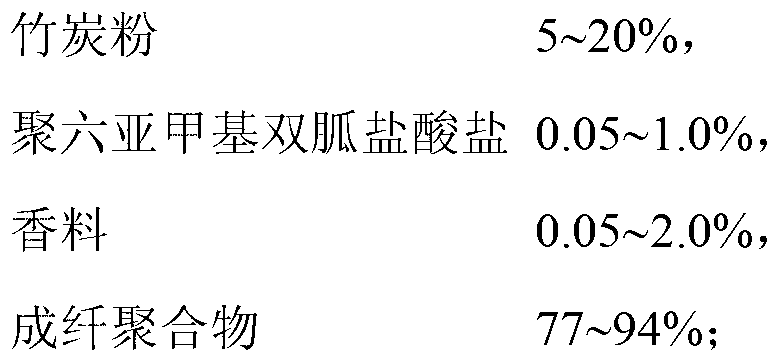

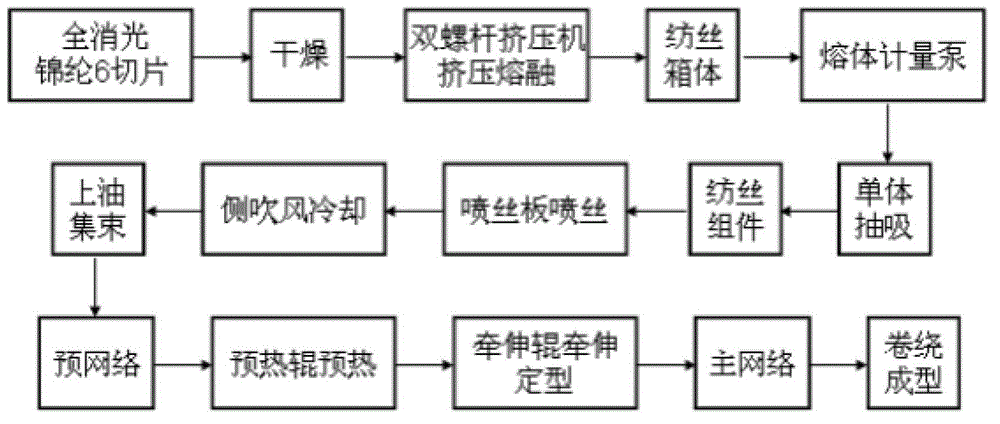

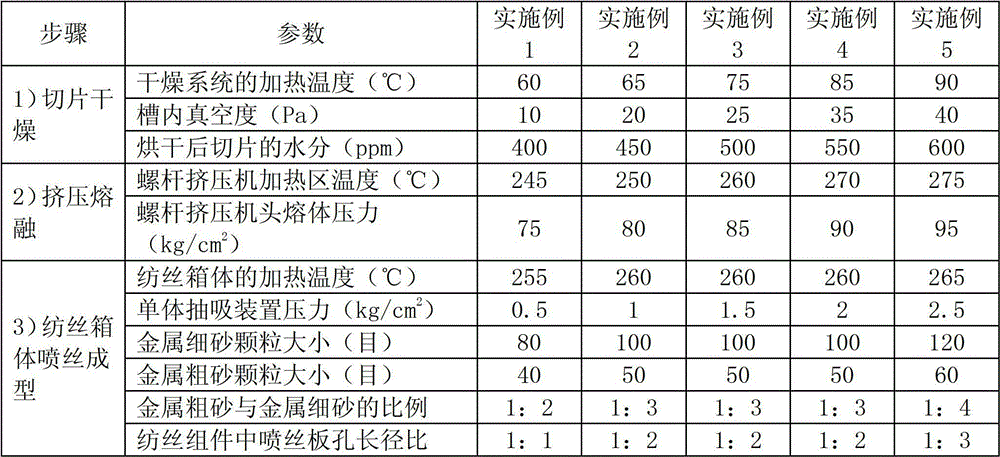

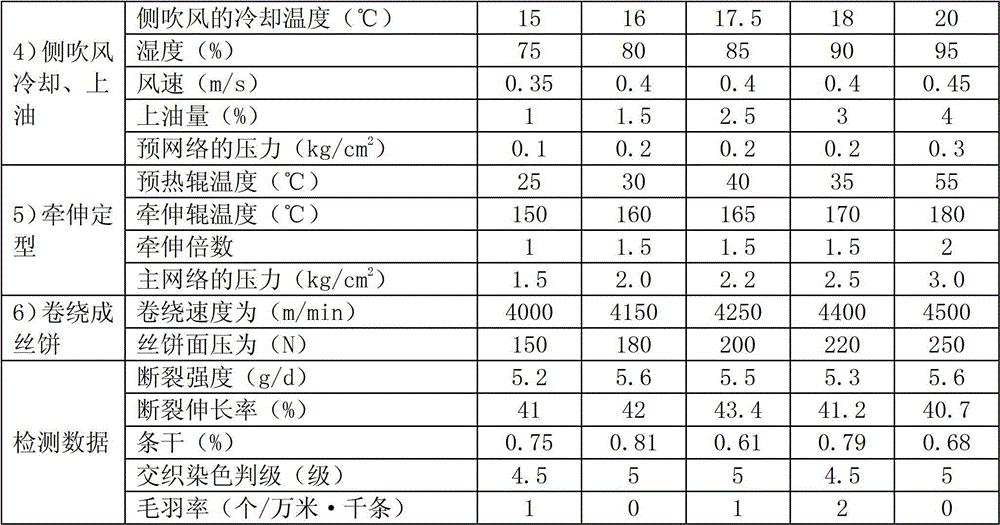

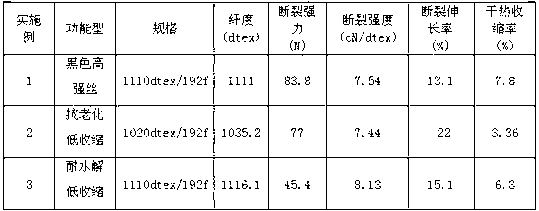

Production method for 20D/24F complete-extinction nylon 6 fully-drawn yarn

ActiveCN102747438ASimple processReduce processing costsFilament forming substance formingMelt spinning methodsYarnExtinction

The invention belongs to the field of synthetic fiber processing, relates to a preparation method for a nylon 6 fiber and discloses a production method for a 20D / 24F complete-extinction nylon 6 fully-drawn yarn. The production method comprises the following steps of: (1) slicing and drying until the water content is 400-600ppm; (2) extruding and melting by a twin-screw extruder; (3) extracting excessive monomer impurities by a single sucking device and performing spinneret and forming by a spinning manifold; (4) laterally blowing, cooling and oiling at constant temperature and humidity; (5) drafting and setting; and (6) winding to form a silk cake. The production method disclosed by the invention has the advantages of simple and feasible process and low processing cost as well as stable product quality, uniform evenness, low hairness ratio, favorable dyeing effect and excellent mechanical property by optimizing parameters.

Owner:浙江嘉华特种尼龙有限公司 +1

Process for producing melt direct-spinning multifunctional PET (Polyester) industrial yarns

ActiveCN102787376AImprove flexibilityShort turnaround timeFilament forming substance formingNew-spun product collectionYarnPolyester

The invention discloses a process for producing melt direct-spinning multifunctional PET (Polyester) industrial yarns and belongs to the technical field of preparation of PET industrial yarns. The process is characterized by comprising the following steps of: (1) melt tackification, i.e., tackifying low-viscosity PET melt obtained by condensation polymerization by a melt tackifying reactor to obtain high-viscosity PET melt; (2) mixing of functional melt, i.e., conveying the high-viscosity PET melt to a spinning manifold through a melt pipeline to carry out spinning and mixing the functional melt and the high-viscosity PET melt in the melt pipeline according to a certain ratio; and (3) spinning, i.e., directly conveying the mixed functional high-viscosity PET melt to each spinning positions to carry out spinning; (4) drafting heat setting, i.e., carrying out two-stage drafting one-stage loosening heat setting on functional high-tenacity PET industrial yarns and carrying out two-stage drafting two-stage loosening heat setting on functional low-shrink PET industrial yarns; and (5) winding formation, i.e., carrying out winding formation after carrying out network processing on fibers subjected to drafting heat setting. According to the invention, the aim of producing the multifunctional PET industrial yarns by adopting the melt to carry out direct spinning is fulfilled; and the process has the advantages of low cost, high efficiency, uniformity and stability.

Owner:ZHEJIANG GUXIANDAO POLYESTER DOPE DYED YARN CO LTD

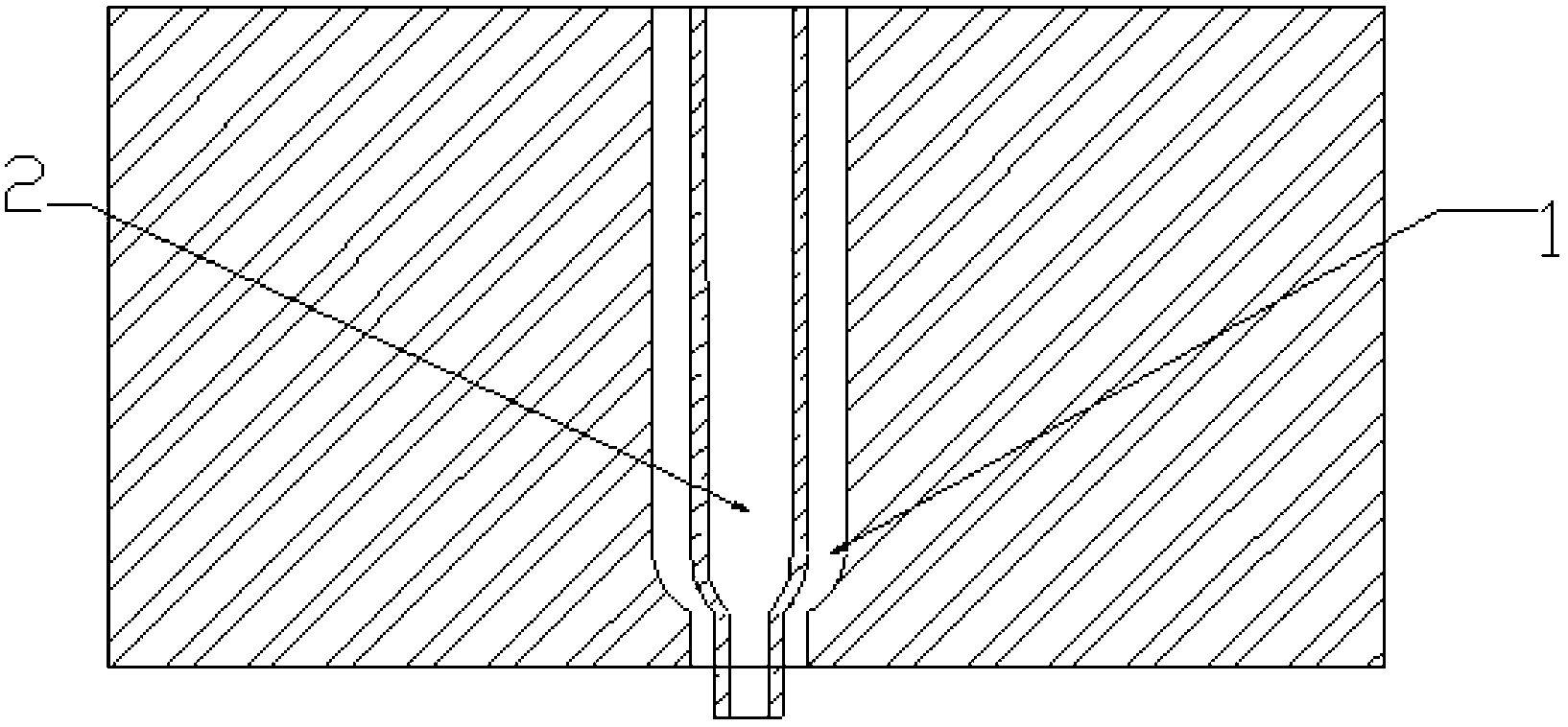

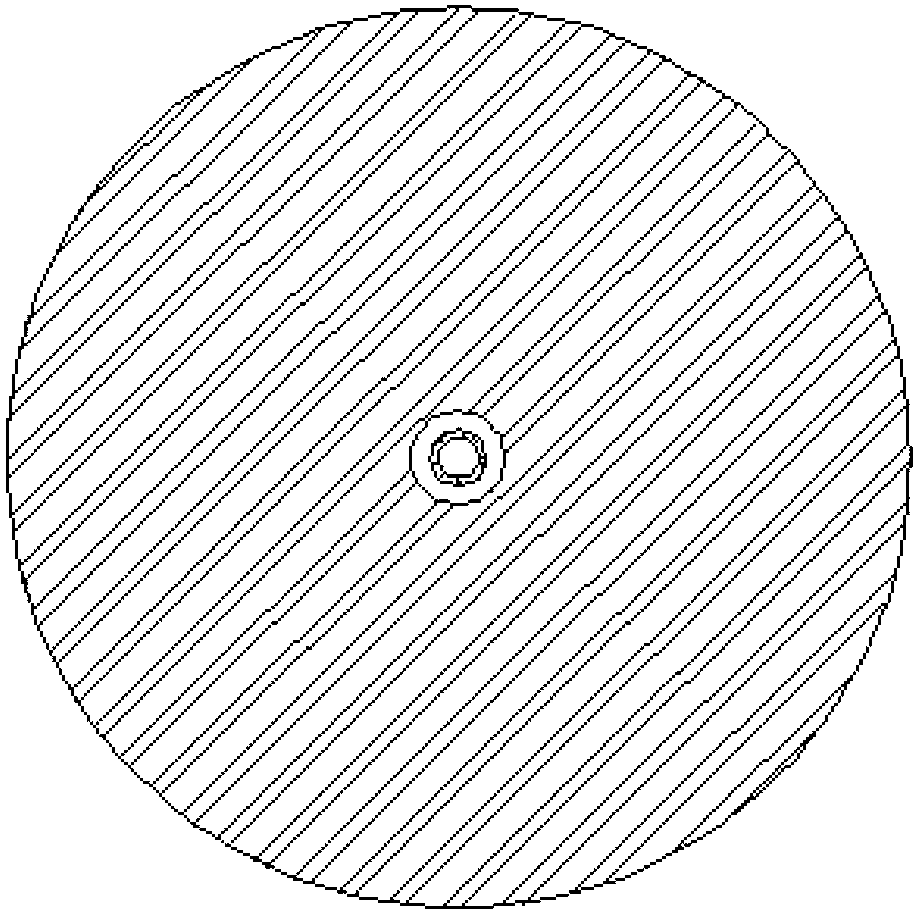

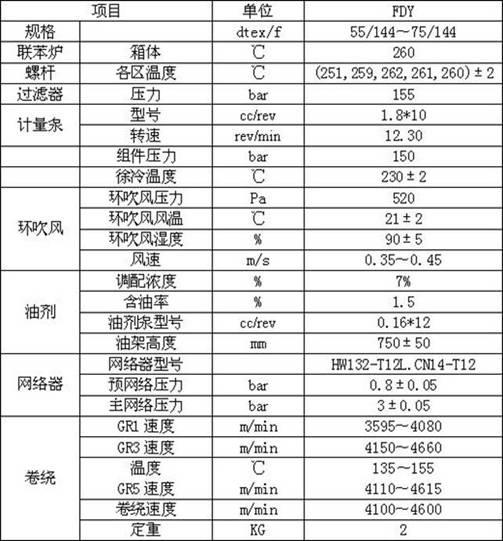

Porous superfine polyamide 6 fully-drawn yarn, preparation method thereof, and equipment thereof

InactiveCN102493016AImprove mixing uniformityImproved pressure stabilityFilament forming substance formingArtificial thread manufacturing machinesYarnAir velocity

The invention relates to a porous superfine polyamide 6 fully-drawn yarn, a preparation method thereof, and equipment thereof. According to the invention, existing FDY production equipment is adopted. A raw material polyamide 6 is sliced and dried; an additive is added on line; the material is subject to screw extrusion and melt extrusion; the material is then cured with a gradually cooling manner and a circular air blow cooling manner; with a reasonably selected spinning temperature of 259-262 DEG C, an air temperature in the circular air blowing process of 19-23 DEG C, a humidity of 85-95%, an air velocity of 0.35-0.45m / s, an oiling and clustering position of 700-800mm, and a winding speed of 4100-4600m / min, the porous superfine polyamide 6 fully-drawn yarn product with a specification of 55dtex / 144f-75dtex / 144f is prepared. Flexible operation is adopted in the preparation method. The preparation method is advantaged in simple technology and low production cost. The product is advantaged in stable performance, good yarn evenness, and good coloration property.

Owner:SUZHOU UNIV

Method for producing terylen fibers from polyester waste

ActiveCN101956240AQuality improvementImprove uniformityFilament forming substance formingPlastic recyclingPolyesterChemical reaction

Owner:BEIJING CHONGLEE MACHINERY ENG

Method for preparing ultrahigh molecular weight polyethylene (UHMWPE) colored fibre

ActiveCN102199805AUniform colorBright colorFilament forming substance formingMonocomponent polyolefin artificial filamentFiberPolymer science

The invention relates to ultrahigh molecular weight polyethylene (UHMWPE) colored fibre and a method for preparing the same. The method comprises the following steps: firstly adding nanoscale organic heterocyclic pigments to UHMWPE powder and fully stirring and mixing the pigments and the powder in a double-thread conical mixer to obtain colored polymers; then continuously adding the colored polymers and auxiliaries to an untwisting kettle which can provide at least 1000s<-1> shearing rate to form emulsion-like mixed liquor; performing the secondary shearing and grinding on the mixed liquid by a high shear dispersion and emulsification pump; and then carrying out extrusion spinning, extracting, drying and hot drawing in a screw extruder to form the UHMWPE colored fibre. The method is simple in operation and convenient in collar change, and the obtained colored fibre has bright colour and high ageing resistance; the added pigments are nontoxic and pollution-free and are harmless to thehuman bodies, and the production process is clean and environmentally-friendly; and in the production process, the solvents are never polluted by the pigments and are convenient to recycle, thus further lowering the production cost.

Owner:CHANGSHU SUPERFIBER

Profiled fire-retardant bright terylene FDY (Fully Drawn Yarn) filament and production process thereof

InactiveCN102586939AIncrease the areaImprove cooling effectFlame-proof filament manufactureFilament forming substance formingMasterbatchPolyethylene terephthalate glycol

The invention discloses a profiled fire-retardant bright terylene FDY (Fully Drawn Yarn) filament and a preparation process thereof. The raw materials of the fire-retardant bright terylene FDY filament comprises 92-94% of PET (Polyethylene Terephthalate) slice and 6-8% of fire-retardant masterbatch. The profiled fire-retardant bright terylene FDY filament produced by the invention has good fire-retardant performance and special cross section; a gap between the surfaces of single filaments can form a good capillary effect, so that the filament has a good moisture absorption function; and the filament has a bright performance so as to be particularly suitable for the production of high-grade clothes. According to the invention, through the control to the processes of crystallizing and drying the slices, melting, cooling yarn strips, bundling, applying oil, drawing and forming, and the like, the preparation process is simple, broken filaments of a prepared product are fewer, and the dyeing is uniform.

Owner:JIANG SU TIANDI CHEM FIBER

Production line and preparation method of bristles for brushes

InactiveCN102605450AMeet production needsSave energyFilament forming substance formingArtificial thread manufacturing machinesProduction lineBristle

The invention discloses a production line and a preparation method of bristles for brushes. The production line of bristles for brushes comprises an upper screw extruder, a lower screw extruder, a metering pump, die heads of the metering pump, drafting devices, a hot-forming box and a winding device, a discharge outlet of the upper screw extruder is arranged above a feed inlet of the lower screw extruder, a discharge outlet of the lower screw extruder is communicated with a filter device, a discharge outlet of the filter device is communicated with a feed inlet of the metering pump, a cold water trough is arranged blow the die heads of the metering pump, the first drafting device, a hot water trough, the second drafting device, an oil wheel, the third drafting device, the hot-forming box and the winding device are sequentially arranged behind the cold water trough. The production line of the bristles for brushes has the advantages of energy saving and low production cost.

Owner:淮安市欣佳尼龙有限公司

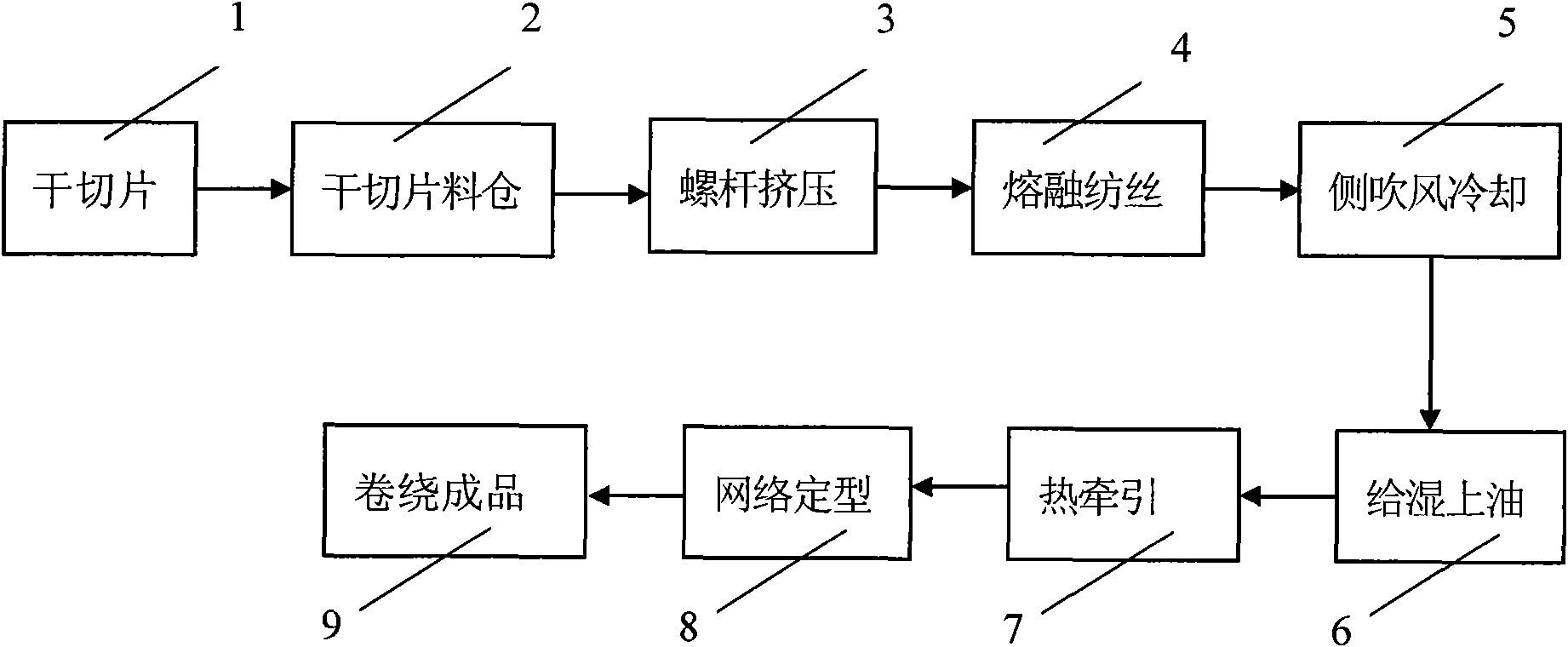

Production method of filament for capron 6 one-step full stretching superfine denier socks

InactiveCN101619505AObvious skinnyPretty styleFilament forming substance formingSpinning head liquid feederWinding machineBreaking strength

The invention discloses a production method of filament for capron 6 one-step full stretching superfine denier socks, which is characterized by comprising the following steps: firstly, melting step: guiding capron 6 semi-dulling chip raw material into a screw extruder through a dry chip bin to be melted so that the raw material is in a melting state to form a spinning molten mass; secondly, spinning step: inputting the spinning molten mass into a spinning box body, spanning on a fine denier spinning winding machine through a spinneret plate and pressing into a component after measurement, and extruding and forming asspun fiber; thirdly, cooling step: cooling the asspun fiber by a lateral blowing air duct device through lateral blowing, an oil nozzle and a corridor; and fourthly, forming step: pretangling, R1 roller and a R2 roller hot stretching and hot shaping, tangling and drawing a cooled filament bundle, winding and forming and finally forming a finished spinning cake. The filament produced by adopting the method has better fiber density CV value, breaking strength, breaking strength CV value and breaking elongation CV value than that of high-quality filament.

Owner:JIANGSU WENFENG CHEM FIBER GROUP

Popular searches

Monocomponent halogenated hydrocarbon artificial filament Conjugated synthetic polymer artificial filaments Heating/cooling textile fabrics Artifical filament manufacture Artificial filament heat treatment Monocomponent copolyesters artificial filament Synthetic polymer filament chemical after-treatment Wet spinning methods Domestic articles Thin material handling

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com