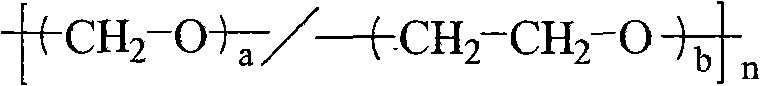

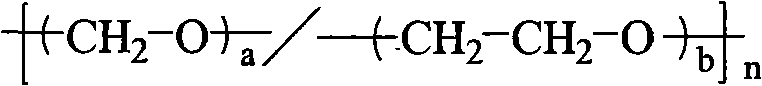

Melt-spinning method for polyformaldehyde fibers

A polyoxymethylene fiber and melt spinning technology, which is applied in the melting of filament raw materials, drawing spinning, fiber processing, etc., can solve the problems such as not being popularized and applied, the industrialized production of polyoxymethylene fibers, and resin bubbles being solved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

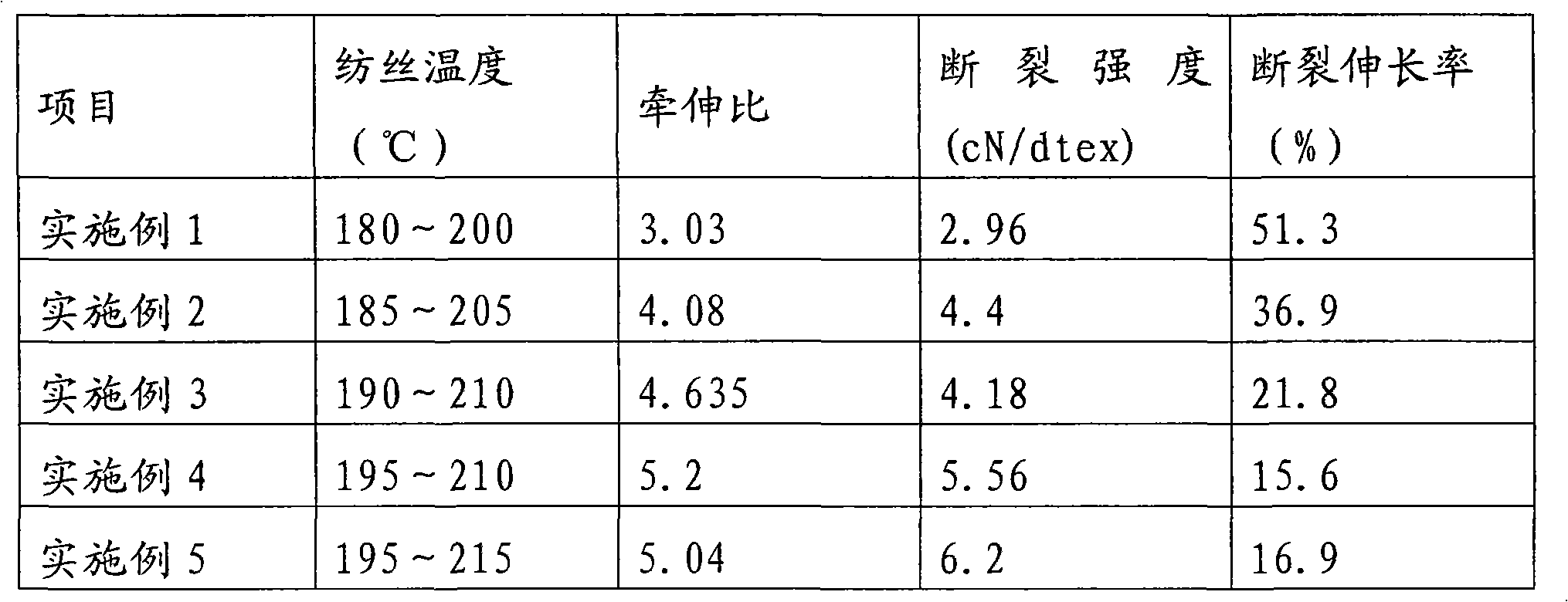

Embodiment 1

[0017] The molecular weight M of the polyoxymethylene resin ranges from 20000 to 40000, and the melt index is 10 to 12g / 10min. The temperature of the polyoxymethylene resin is raised from 100°C to 110°C within 5 minutes, and vacuum dry distillation is carried out for 2 hours. The pre-crystallization time was 4 hours, and the pre-crystallization temperature was 90°C. Produced by melt spinning at a draw speed of 800 m / min. 100°C ethylene glycol aqueous solution is slowly cooled, and 2°C water bath is strongly cooled. During the post-stretching finishing process, the stretching ratio in the pre-stretching area is controlled at 1.01, and the stretching ratio in the hot-stretching area is 3.0. The stretching temperature and thermal crystallization The setting temperature differs by 50°C, and the drawing environment is propane.

Embodiment 2

[0019] The molecular weight M range of the polyoxymethylene resin is 40000-50000, and the melt index is 7-9g / 10min. The temperature of the polyoxymethylene resin is raised to 110°C within 3 minutes at 110°C, and the hot air is continuously dried for 4h. The pre-crystallization time was 5 hours, and the pre-crystallization temperature was 100°C. Produced by melt spinning at a draw speed of 1500 m / min. Slow cooling of acetamide aqueous solution at 100°C, strong cooling in a water bath at 2°C, during the post-stretching finishing process, the stretching ratio in the pre-stretching area is controlled at 1.02, and the stretching ratio in the hot-stretching area is 4.0. Stretching temperature and thermal crystallization The temperature difference is 30°C, the hot water bath is pressurized and stretched, the time is controlled within 1s, and the pressure is 100 atmospheres.

Embodiment 3

[0021] The molecular weight M range of the polyoxymethylene resin is 60000-80000, and the melt index is 7-9g / 10min. The temperature of the polyoxymethylene resin is raised to 110°C within 2 minutes at 110°C, and vacuum dry distillation is carried out for 5 hours. The pre-crystallization time was 4 hours, and the pre-crystallization temperature was 110°C. Produced by melt spinning at a draw speed of 1800 m / min. Slow cooling with water vapor at 110°C and strong cooling in a water bath at 3°C. During the post-stretching finishing process, the stretching ratio in the pre-stretching area is controlled at 1.03, and the stretching ratio in the hot-stretching area is 4.5. The stretching temperature and thermal crystallization setting temperature With a difference of 20°C, fluoroethane is stretched under pressure, the time is controlled within 0.5s, and the pressure is 150 atmospheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com