Polyvinylidene fluoride microporous film and preparation method

A polyvinylidene fluoride, microporous membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as insufficient hydrophobicity of membrane surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

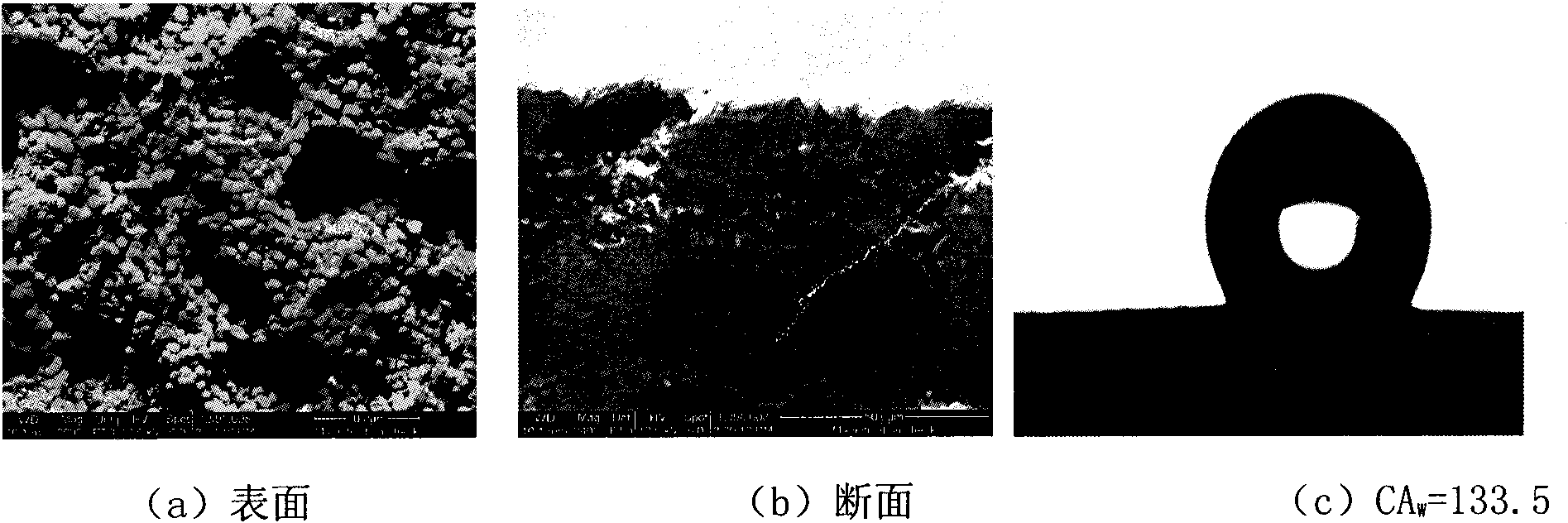

Embodiment 1

[0029] 1) Prepare a total of 100g of casting solution, first mix PVDF (13wt%), octanol (6wt%) and DMAc (81wt%), place it in a jar, and then put it in an electric oven at 70°C for 48 hours , to completely dissolve the polymer. Shake well and filter, let stand to defoam and mature fully for 24 hours.

[0030] 2) Stick clean water-resistant sandpaper (1000 mesh) on the glass plate with double-sided tape;

[0031] 3) Evenly scrape the casting solution with a temperature of 35°C on the water-resistant sandpaper of the glass plate, and place it in the air with a relative humidity of 40% for 1 min.

[0032] 4) The glass plate is immersed in a coagulation bath (water) at 35° C. for 2 to 3 hours, and the gel is solidified to form a film.

[0033] 5) Heat-treat the formed membrane in deionized water at 50°C for 15 minutes, then soak it in deionized water for 9 days, change the water frequently (twice a day), and then soak it in absolute ethanol for 24 hours to obtain highly hydrophobi...

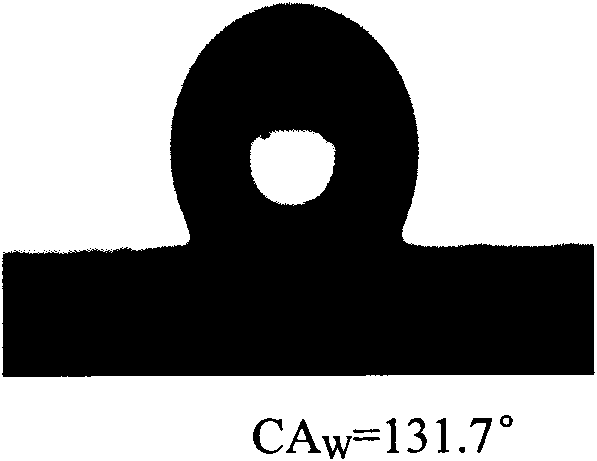

Embodiment 2

[0035] 1) The total amount of casting liquid is 100g. First, PVDF (10wt%), octanol (10wt%) and DMAc (80wt%) are mixed, placed in a jar, and then placed in a 70°C electric oven for 48 hours. Allow the polymer to dissolve completely. Shake well and filter, let stand to defoam and mature fully for 24 hours.

[0036] 2) Stick clean water-resistant sandpaper (1200 mesh) on the glass plate with double-sided tape;

[0037] 3) Evenly scrape the casting solution at a temperature of 35°C on the water-resistant sandpaper of the glass plate, and place it in the air with a relative humidity of 50% for 1 min.

[0038]4) The glass plate is immersed in a coagulation bath (water) at 35° C. for 2 to 3 hours, and the gel is solidified to form a film.

[0039] 5) Heat-treat the formed membrane in deionized water at 50°C for 15 minutes, then soak it in deionized water for 8 days, change the water frequently (twice a day), and then soak it in absolute ethanol for 24 hours to obtain highly hydroph...

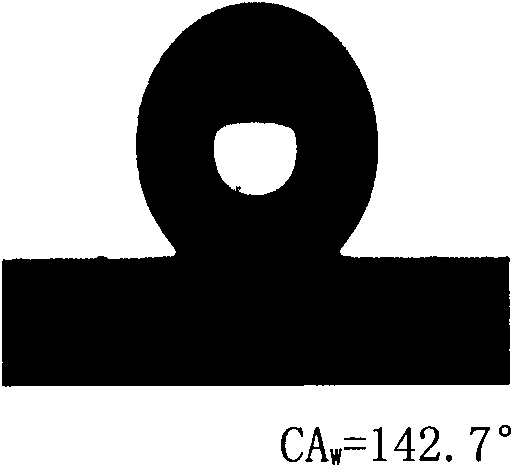

Embodiment 3

[0042] 1) The total amount of casting solution is 100g. First, PVDF (15wt%), octanol (10wt%) and DMAc (75wt%) are mixed, placed in a jar, and then placed in a 70°C electric oven for 48 hours. Allow the polymer to dissolve completely. Shake well and filter, let stand to defoam and mature fully for 24 hours.

[0043] 2) Stick clean water-resistant sandpaper (1500 mesh) on the glass plate with double-sided tape;

[0044] 3) Evenly scrape the casting solution at a temperature of 35°C on the water-resistant sandpaper of the glass plate, and place it in the air with a relative humidity of 70% for 1 min.

[0045] 4) The glass plate is immersed in a coagulation bath (water) at 35° C. for 2 to 3 hours, and the gel is solidified to form a film.

[0046] 5) Heat-treat the formed film in deionized water at 60°C for 15 minutes, then soak it in deionized water for 6 days, change the water frequently, and then soak it in absolute ethanol for 24 hours to obtain highly hydrophobic polyvinyli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Maximum aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com