Patents

Literature

2879 results about "Membrane surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

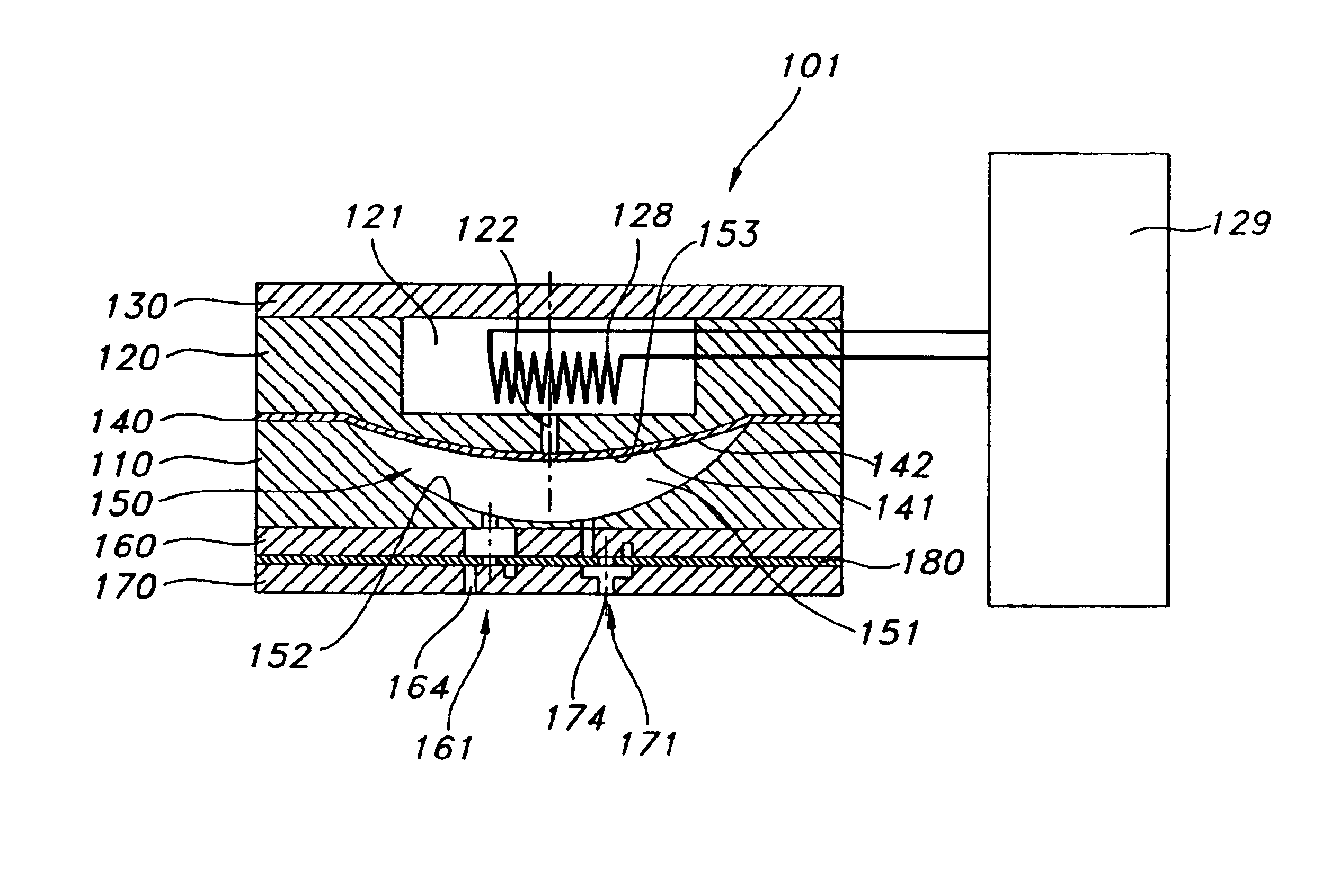

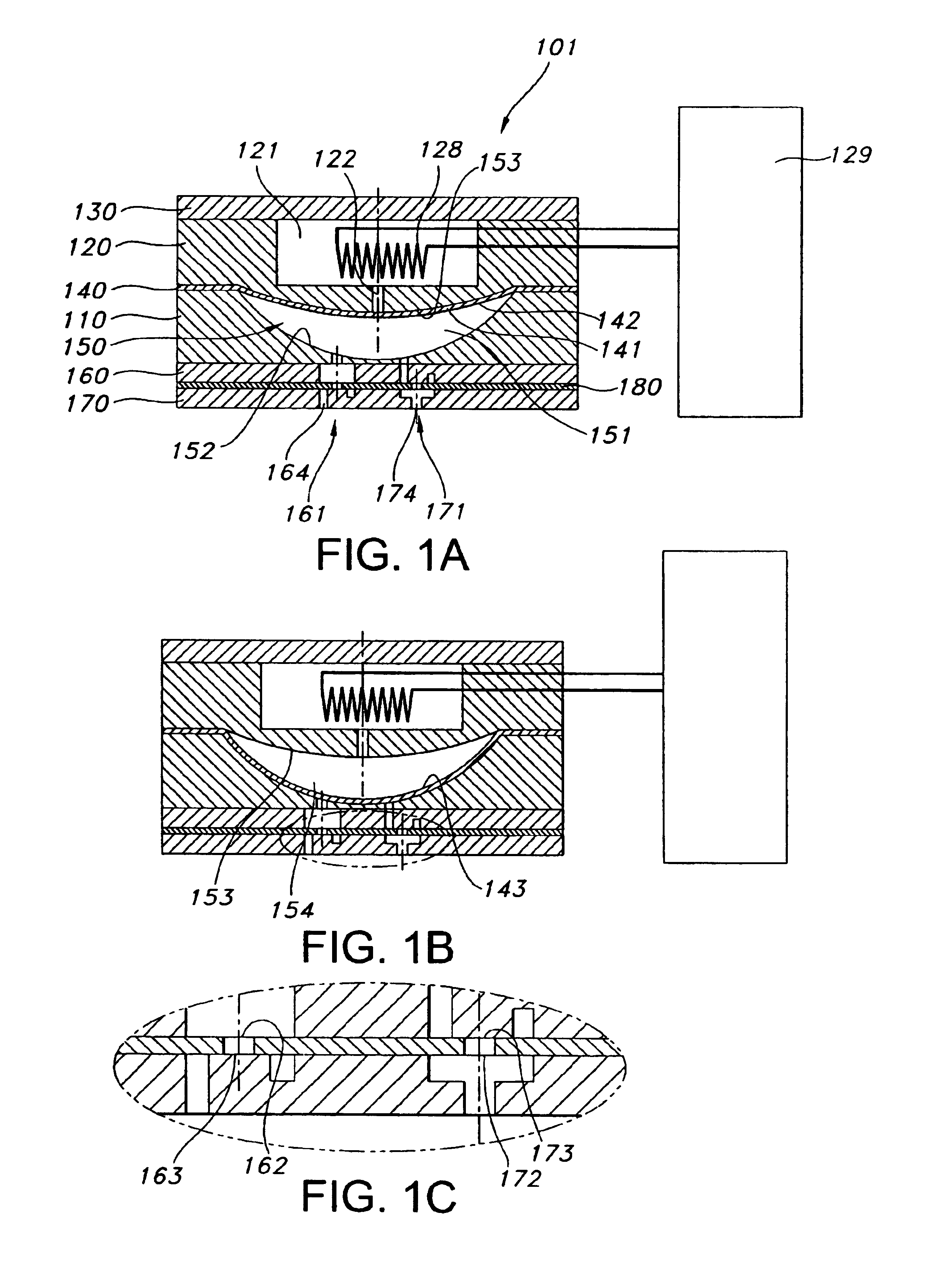

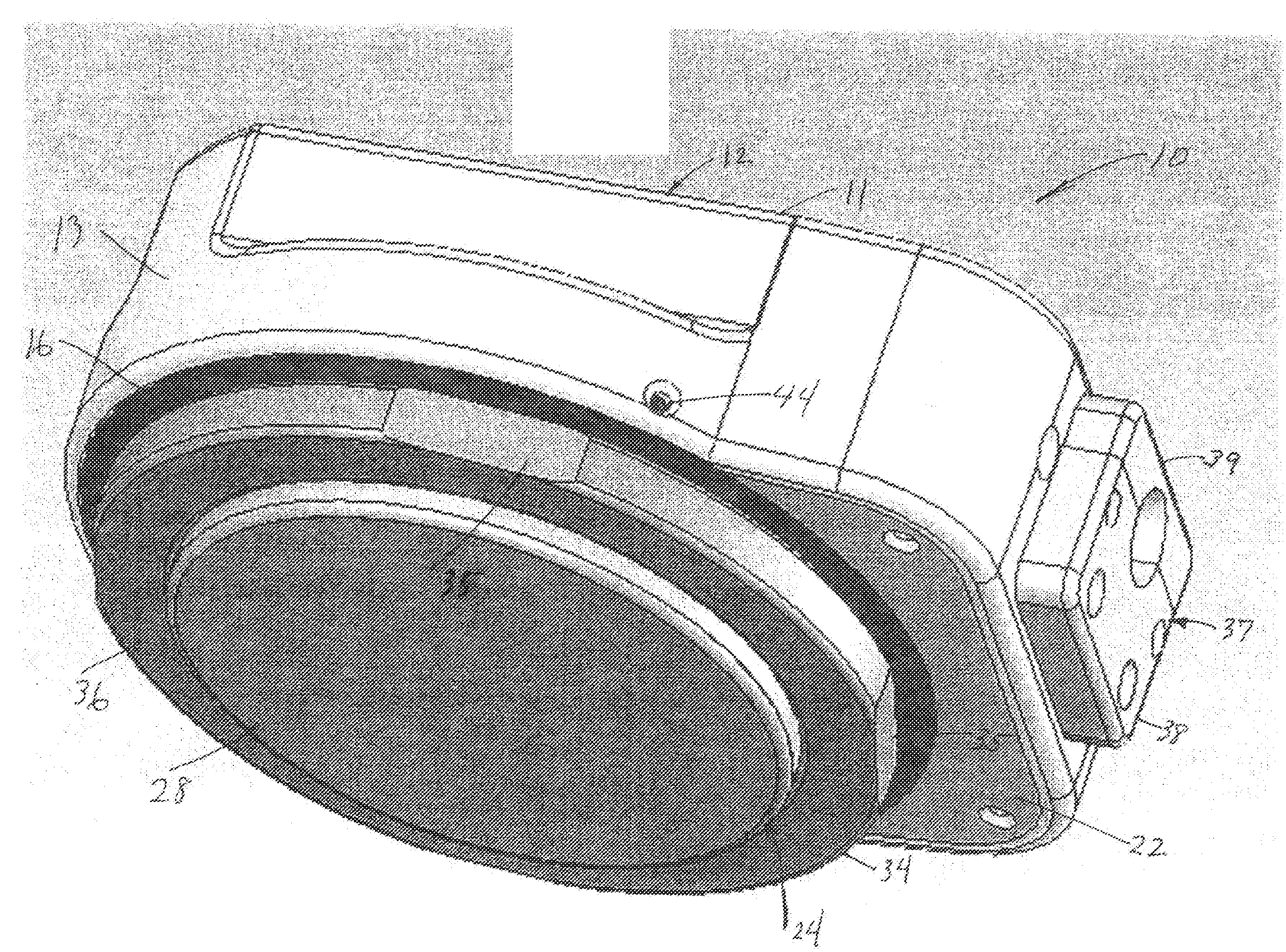

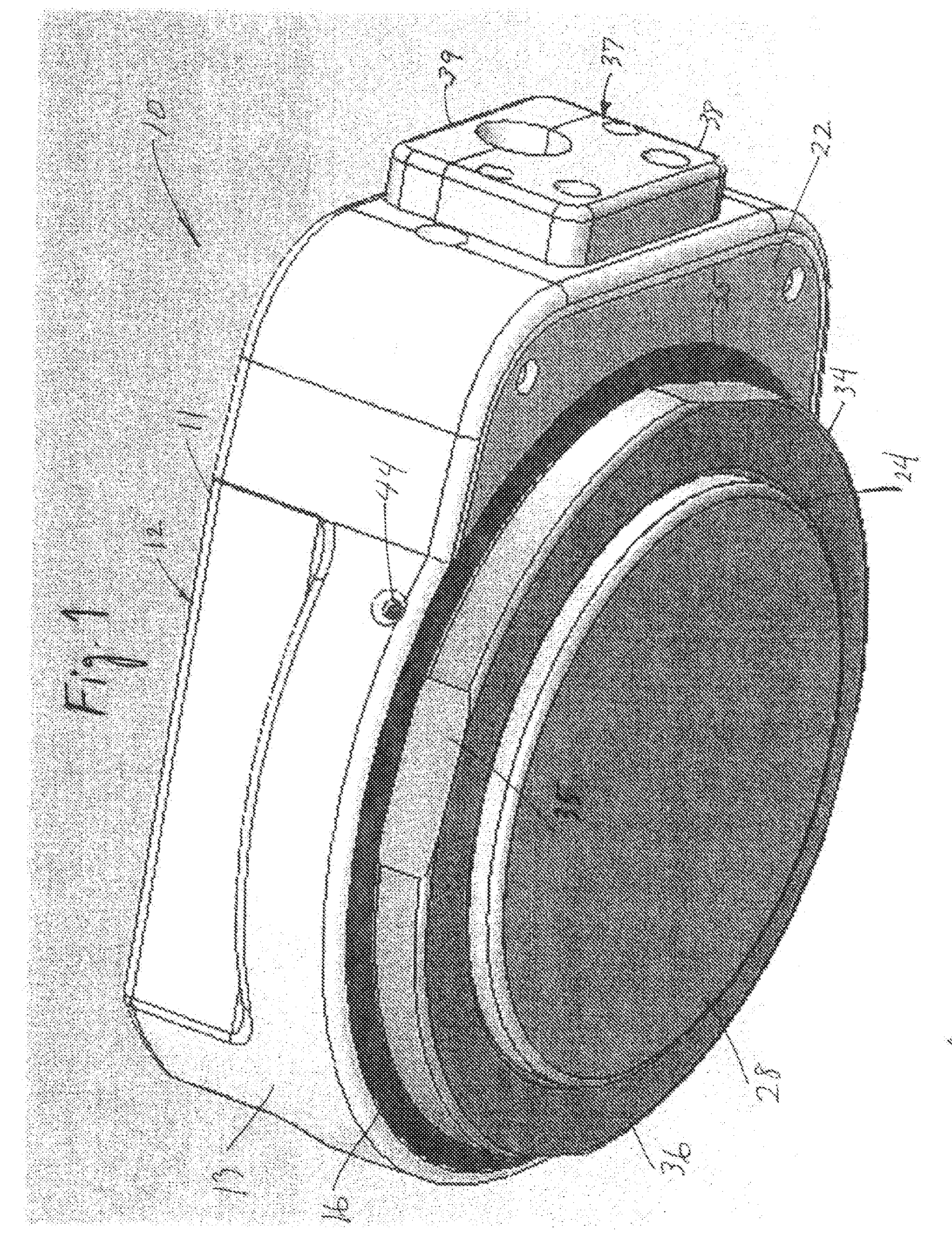

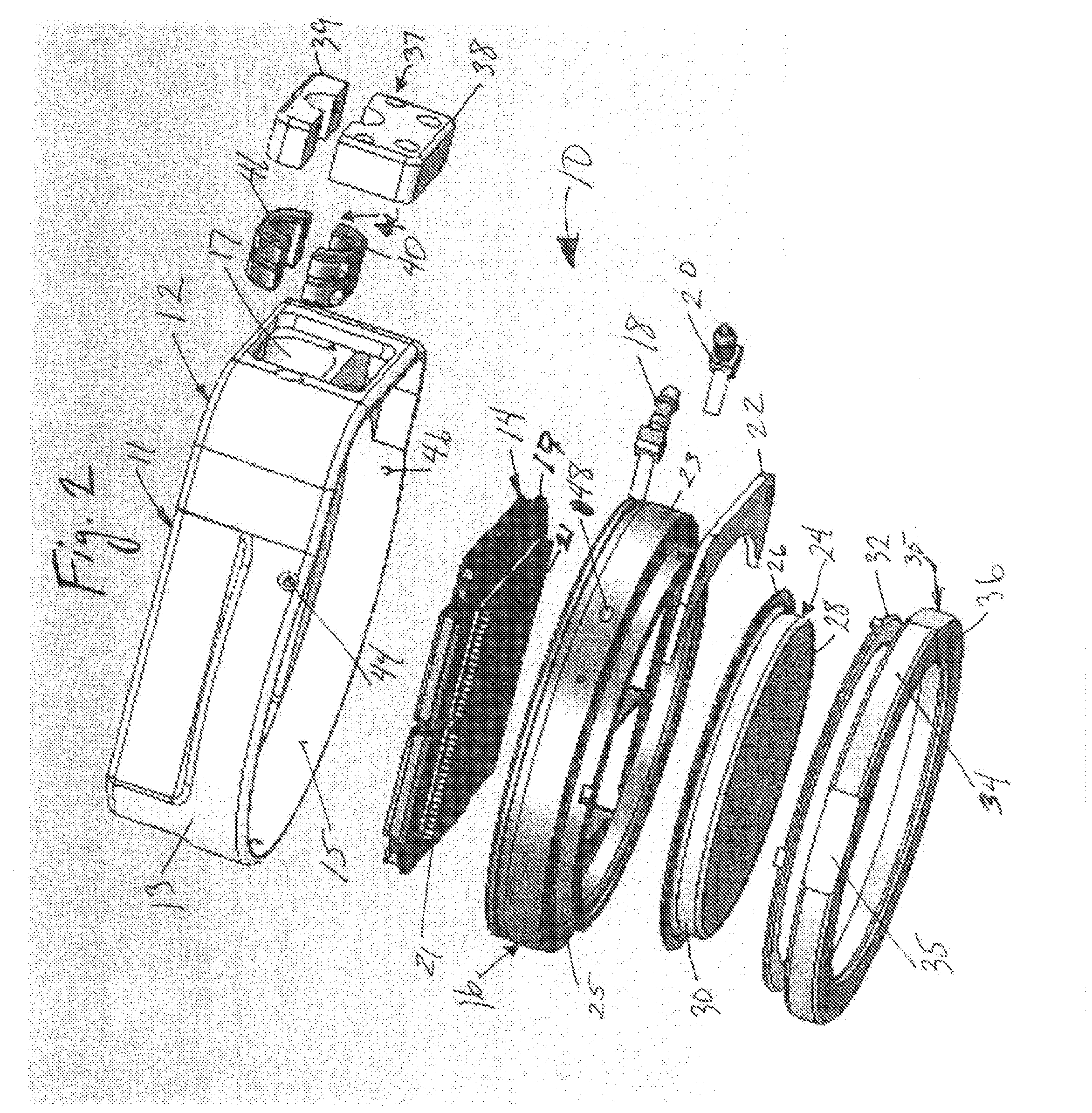

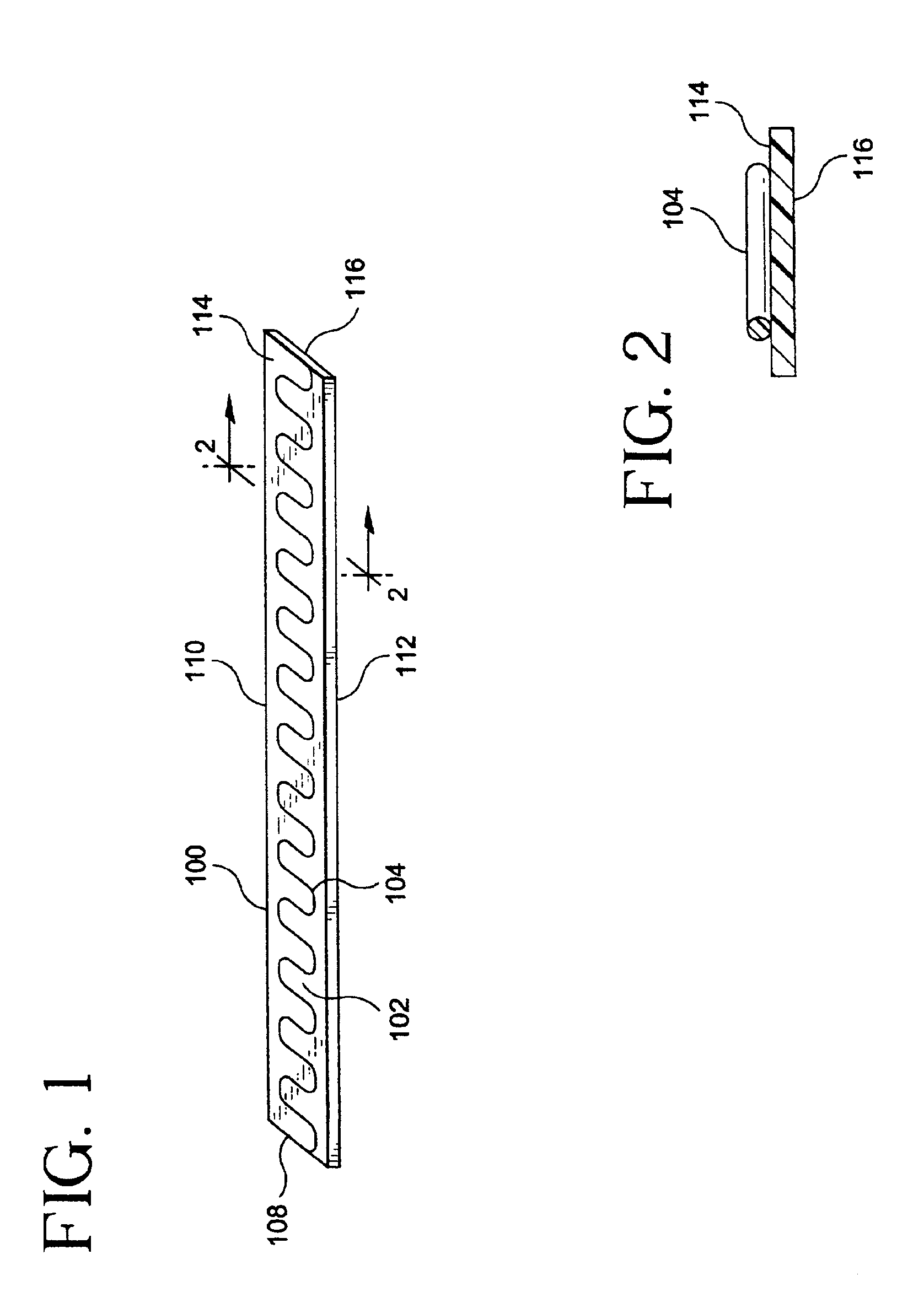

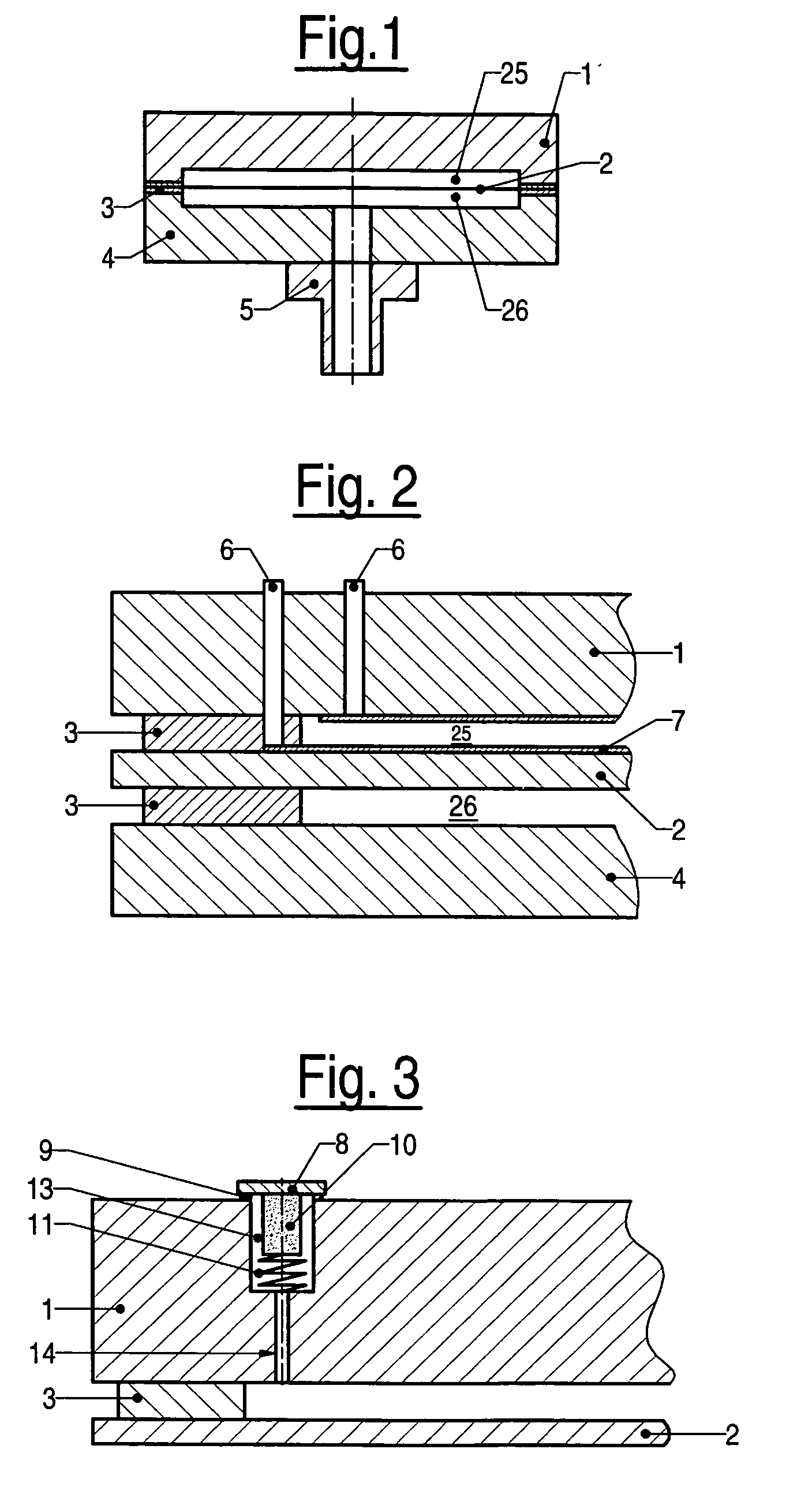

Membrane pump with stretchable pump membrane

InactiveUS6948918B2Stiff systemImprove accuracyValve arrangementsPositive displacement pump componentsPump chamberInlet valve

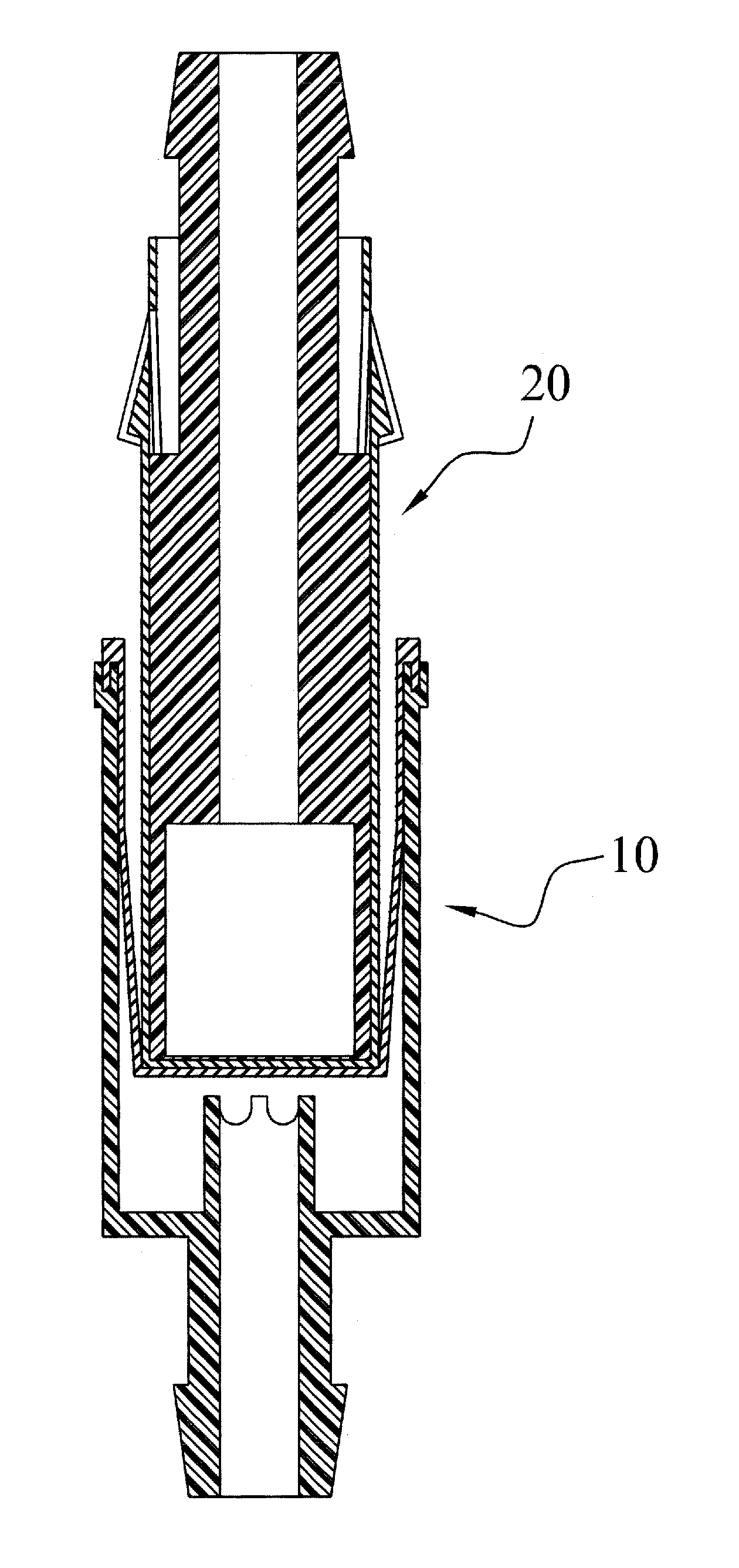

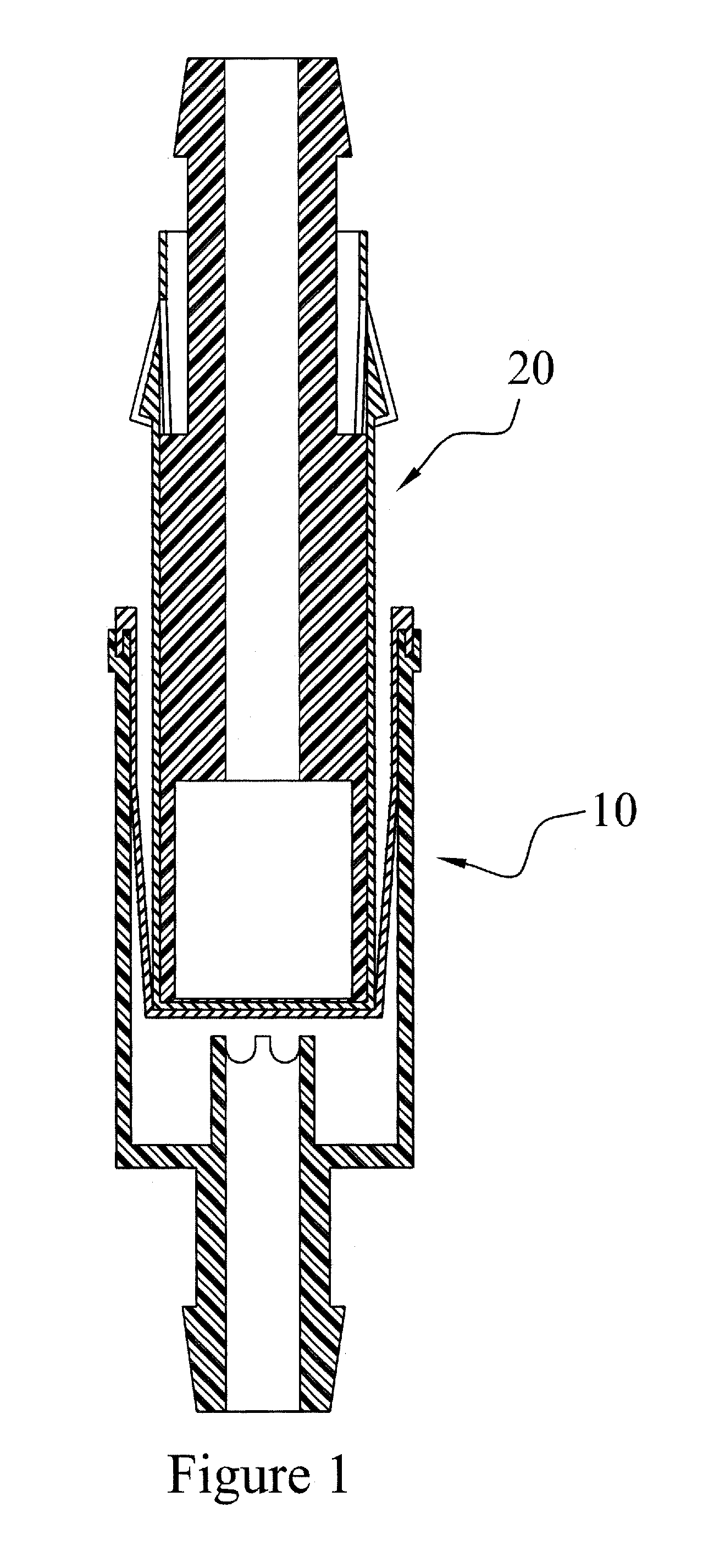

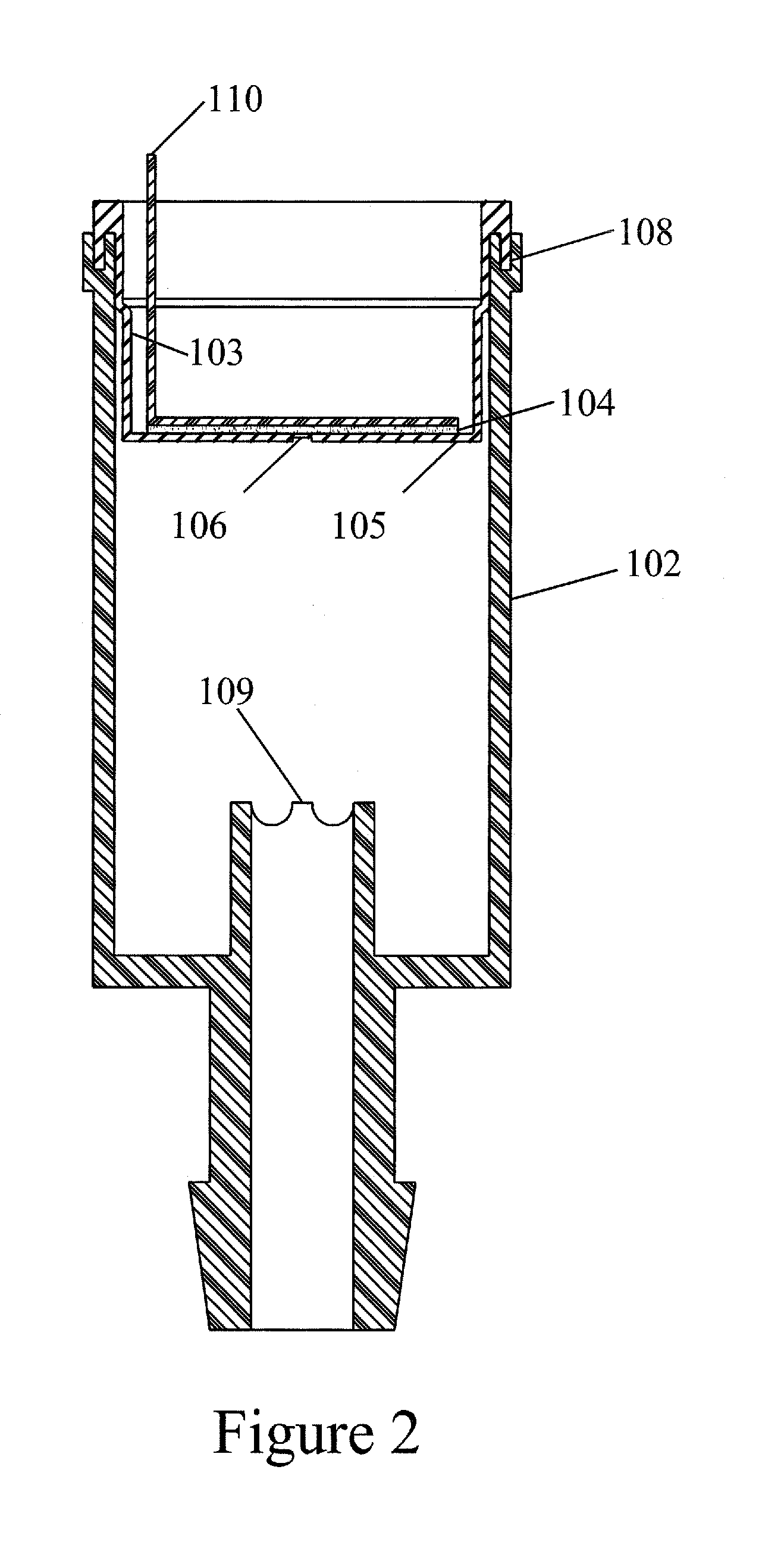

The invention relates to membrane pumps for delivering liquids. More specifically, a pump is provided having a pump housing with a pump cavity formed between first and second wall portions thereof, and an pump membrane pump membrane having first and second membrane surfaces arranged within the pump cavity, whereby a pump chamber is provided between the first wall portion and the first membrane surface, and an actuation chamber is provided between the second wall and the second membrane surface. Inlet means comprising an inlet valve in fluid communication with the pump chamber, and outlet means comprising an outlet valve in fluid communication with the pump chamber are provided. The pump membrane has a maximum volume position, and a drained volume position in which the first membrane surface in a stretched state abuts the first wall. To drive the membrane, actuating means for periodically shifting the pump membrane between the maximum volume position and the drained volume position is provided, thereby, in a situation of use, providing a flow of fluid.

Owner:NOVO NORDISK AS

Composite semipermeable membrane, processfor producing the same, and method of purifying water with the same

InactiveUS6406626B1Semi-permeable membranesWater/sewage treatment bu osmosis/dialysisPurification methodsHigh rate

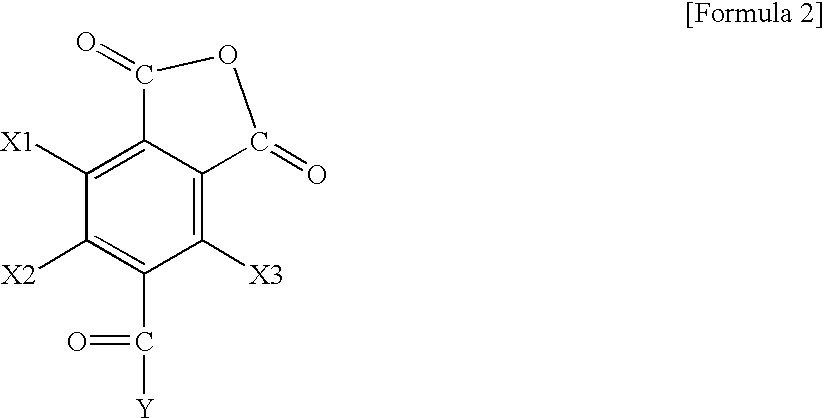

The present invention relates to a composite semipermeable membrane which is characterized in that it is a composite semipermeable membrane in which there is formed by polycondensation on top of a microporous support membrane a crosslinked polyamide ultra-thin membrane layer from polyfunctional amine, polyfunctional acid halide and polyfunctional acid anhydride halide, and the flow of water permeate at an operating pressure of 0.3 MPa, a temperature of 25° C. and a pH of 6.5 lies in the range from 0.8 to 4.0 m3 / m2.day and, furthermore, the percentage humic acid removal is at least 98%; a method for the production thereof; and a water purification method employing same. With the composite semipermeable membrane obtained by means of the present invention it is possible, in particular, to recover drinking water at a high rate by permitting passage of silica and preventing deposition thereof at the membrane surface while selectively separating / removing the pollutants and trace quantities of harmful materials and their precursors, etc, contained in the raw water in water treatment plants.

Owner:TORAY IND INC

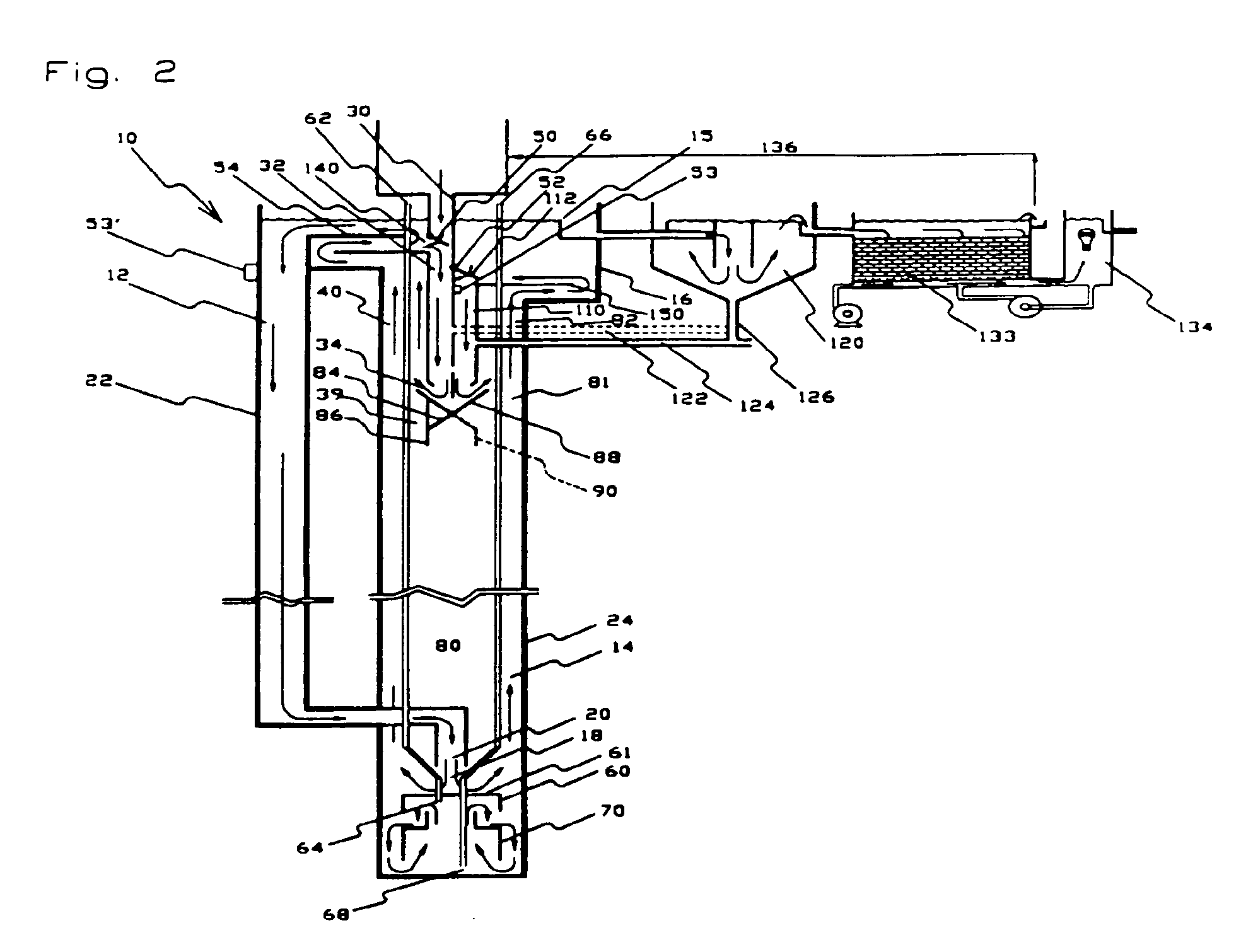

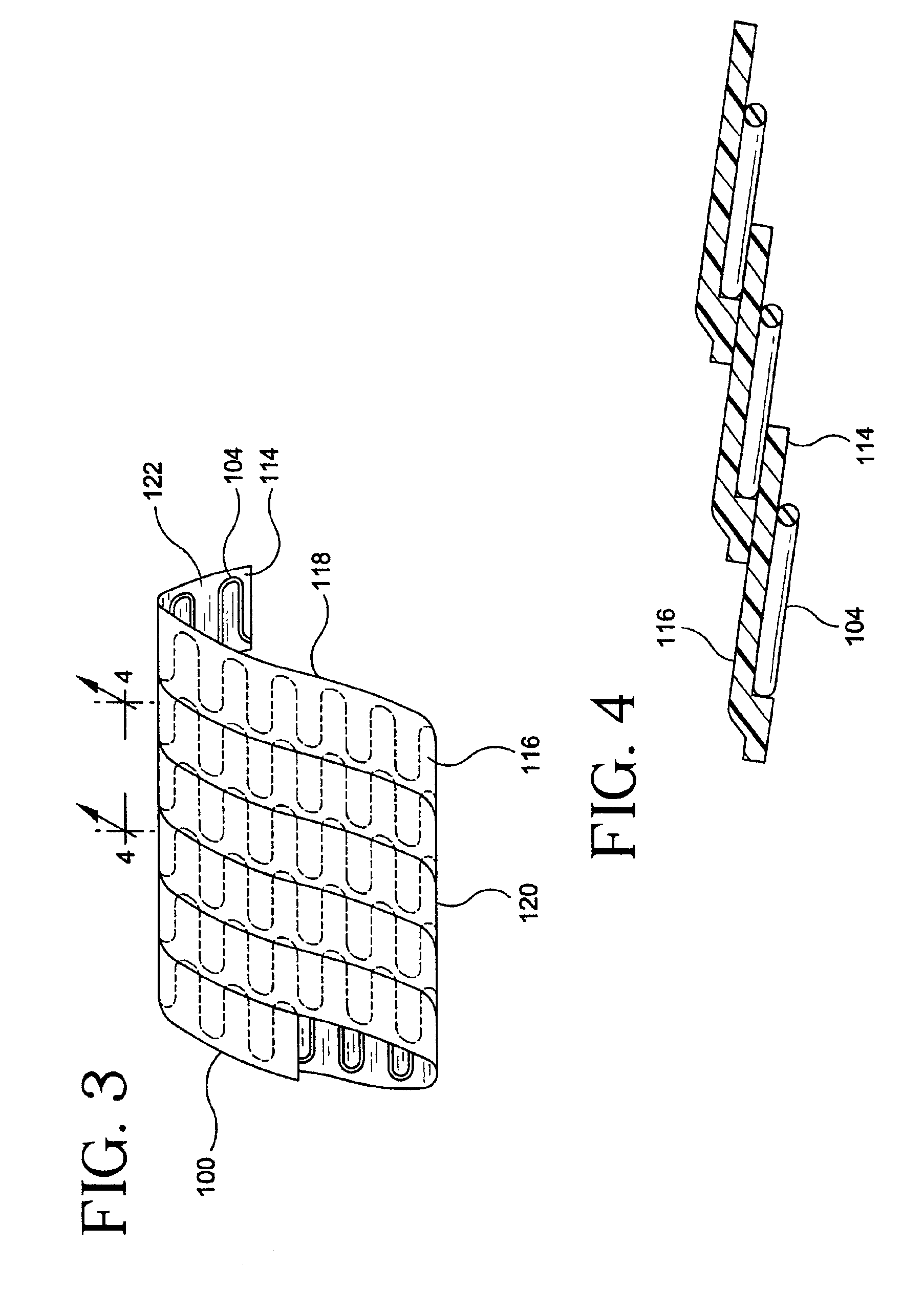

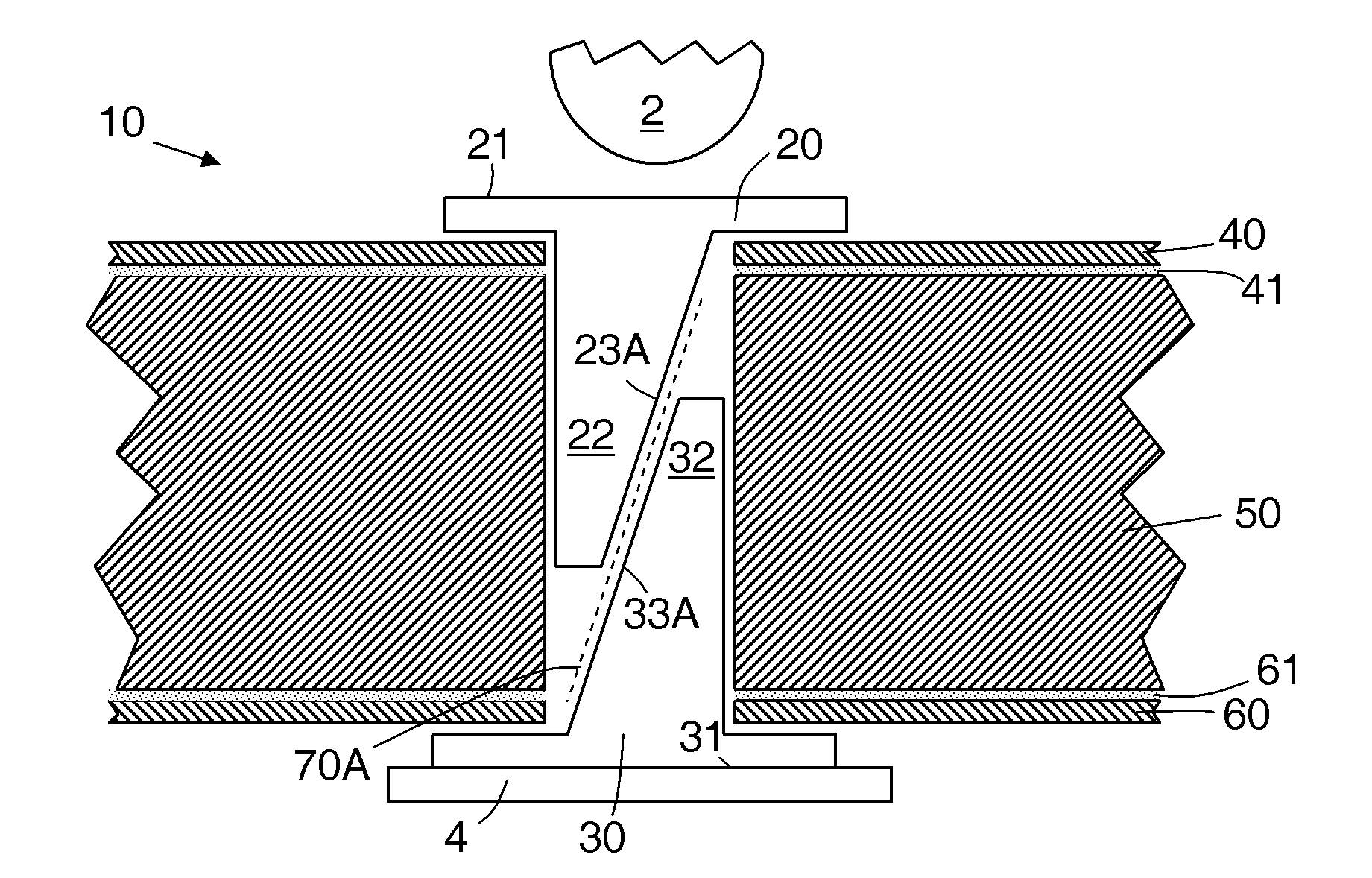

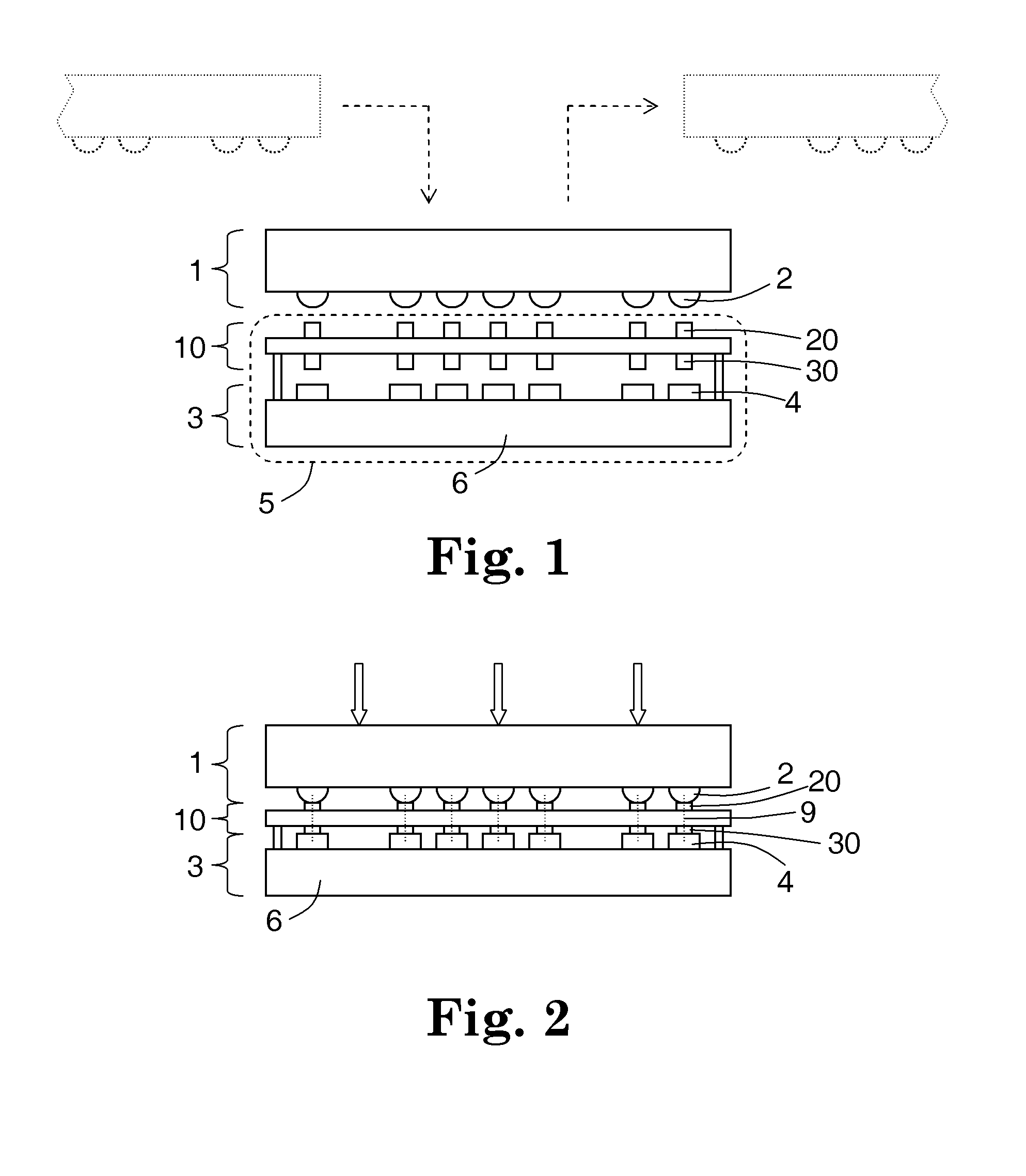

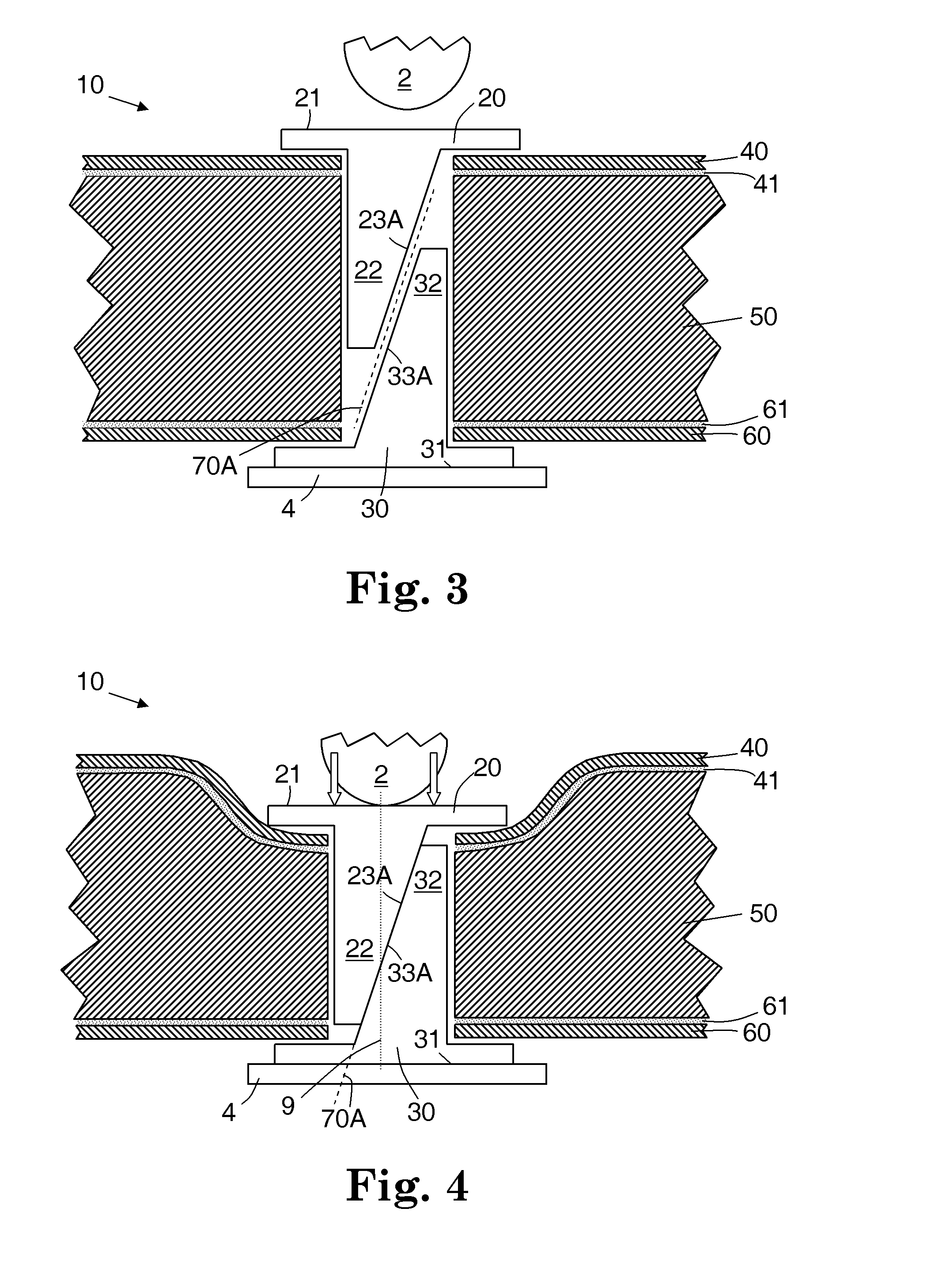

Pleated heat and humidity exchanger with flow field elements

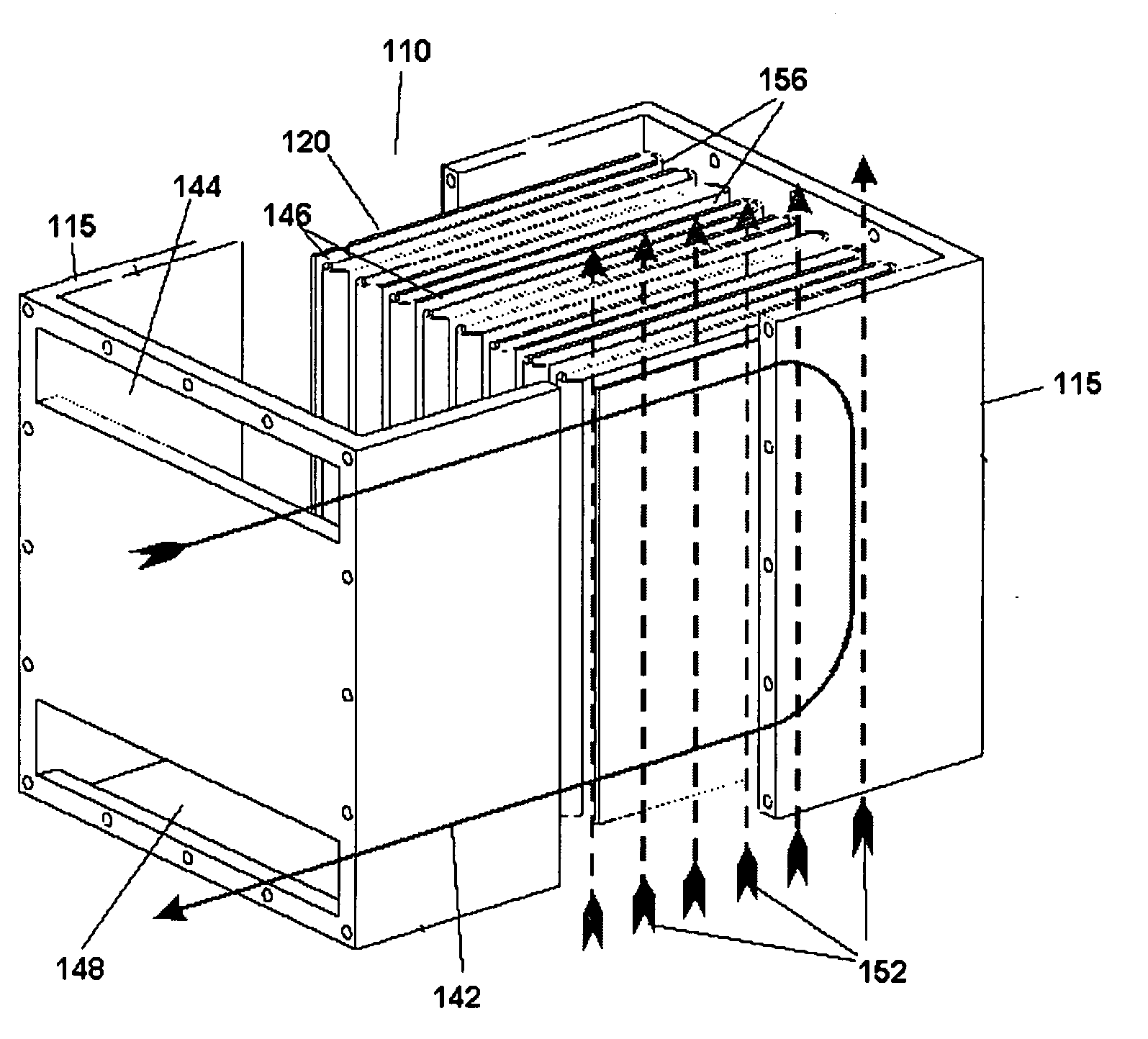

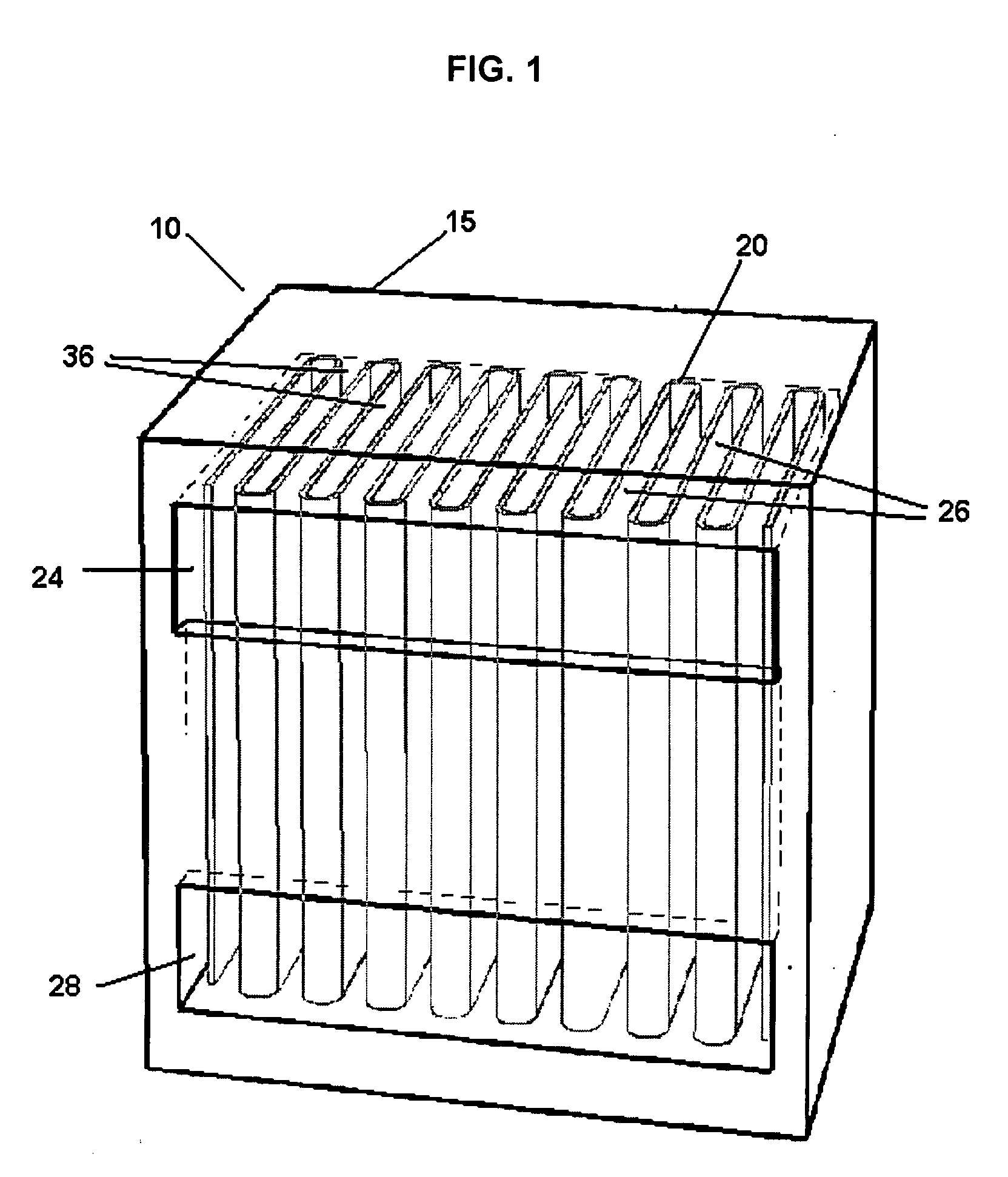

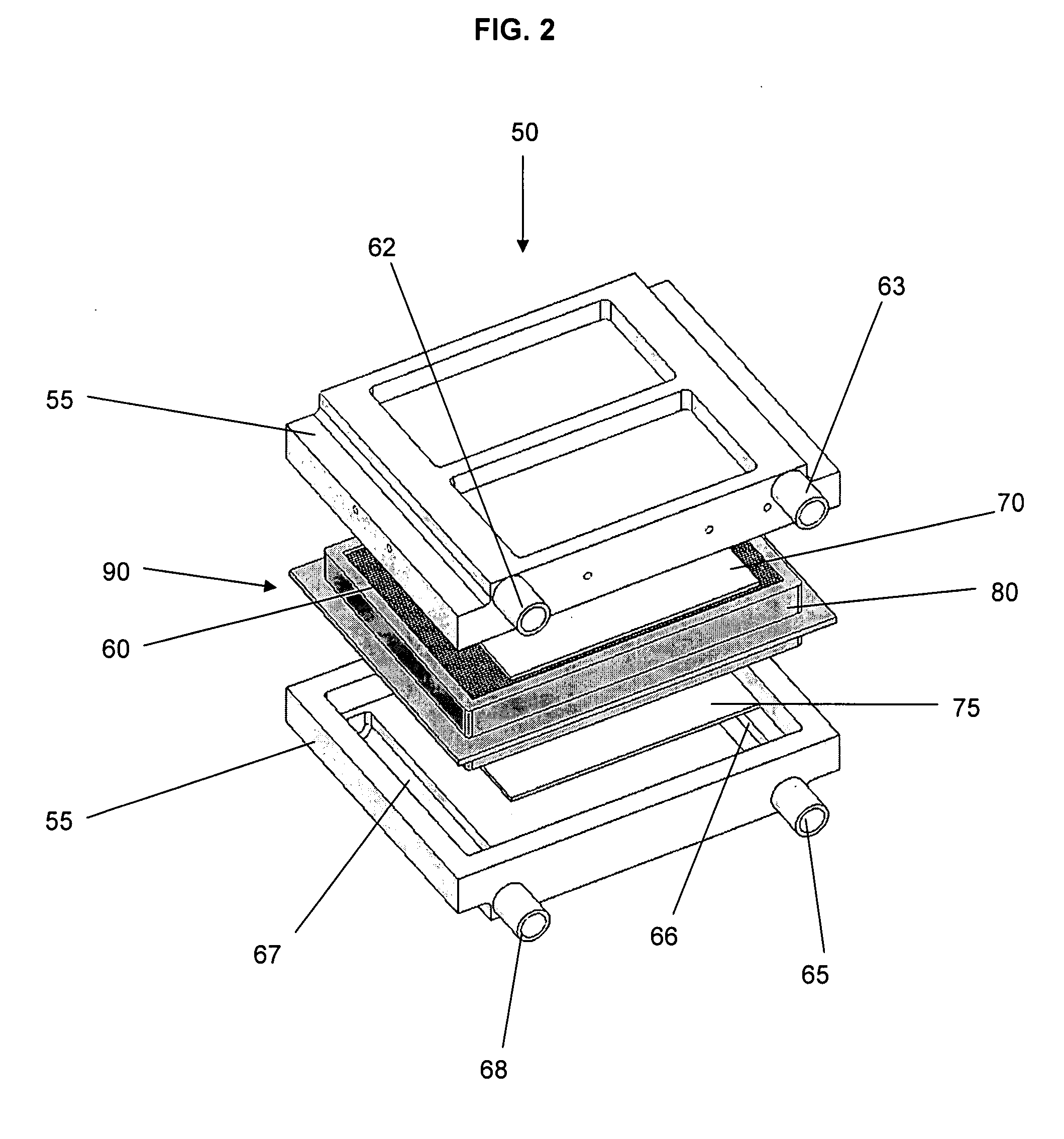

InactiveUS20080085437A1Fuel cell heat exchangeUsing liquid separation agentFuel cellsMembrane surface

A heat and humidity exchanger comprises a pleated membrane cartridge disposed in a housing. The cartridge comprises a pleated water-permeable membrane via which heat and humidity can be transferred between two fluid streams. A flow field element is disposed within some or all of the folds of the pleated membrane, for directing the stream over the inner surfaces of the folds. The flow field path defined by the flow field element enhances flow distribution across one or both membrane surfaces, controlling the relative flow paths of the two streams on opposite sides of the membrane and reducing the pressure drop across the heat and humidity exchanger. The flow field elements provide improved water transfer and allow for a more compact device. The flow field elements can also assist in supporting the pleated membrane and controlling the pleat spacing within the pleated membrane cartridge. The heat and humidity exchanger is particularly suitable for fuel cell and energy recovery ventilator (ERV) applications.

Owner:DPOINT TECH

Ultrasound patient interface device

InactiveUS20080033292A1Reduce rateImprove cooling effectInfrasonic diagnosticsSonic diagnosticsUltrasonic sensorBody contact

An ultrasound coupling device for acoustically coupling an ultrasound transducer with a patient's body comprises a fluid chamber having an ultrasound transducer interface for placing an ultrasound transducer in contact with water within said fluid chamber. The coupling device also has a patient interface comprising a water permeable membrane. The membrane has an internal membrane surface which is in contact with the water in the water tank and an external membrane surface can be placed in contact with the patient's body. The membrane is specially designed to allow water from inside the water tank to slowly permeate or “leak” to the external membrane surface while such surface is in contact or placed in very close proximity to the patient's skin. The slow permeation rate maintains the external membrane surface wet and free of air bubbles during a procedure which can take several hours. At the same time, the slow rate of permeation does not cause any water spillage around the patient.

Owner:INSIGHTEC

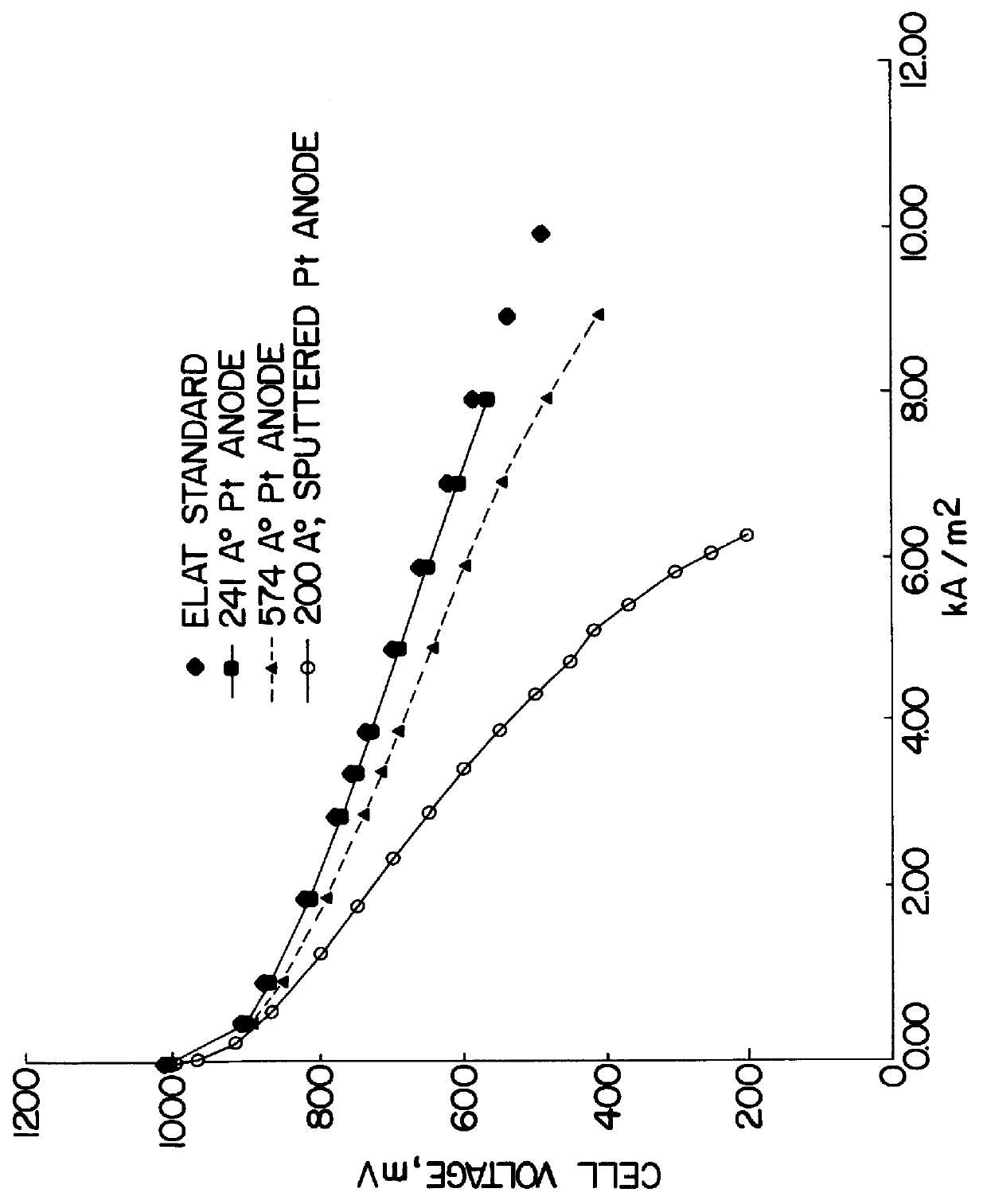

Method of forming robust metal, metal oxide, and metal alloy layers on ion-conductive polymer membranes

InactiveUS6077621AShort development timeLow costFinal product manufactureVacuum evaporation coatingConductive polymerElectron bunches

The invention is to a dual beam process for providing an ion-conducting membrane with a thin metal or metal-oxide film. The process includes the cleaning of a membrane surface with a low energy electron beam followed by the deposition of the metal or metal-oxide film by a high energy electron beam of ions.

Owner:BASF FUEL CELL

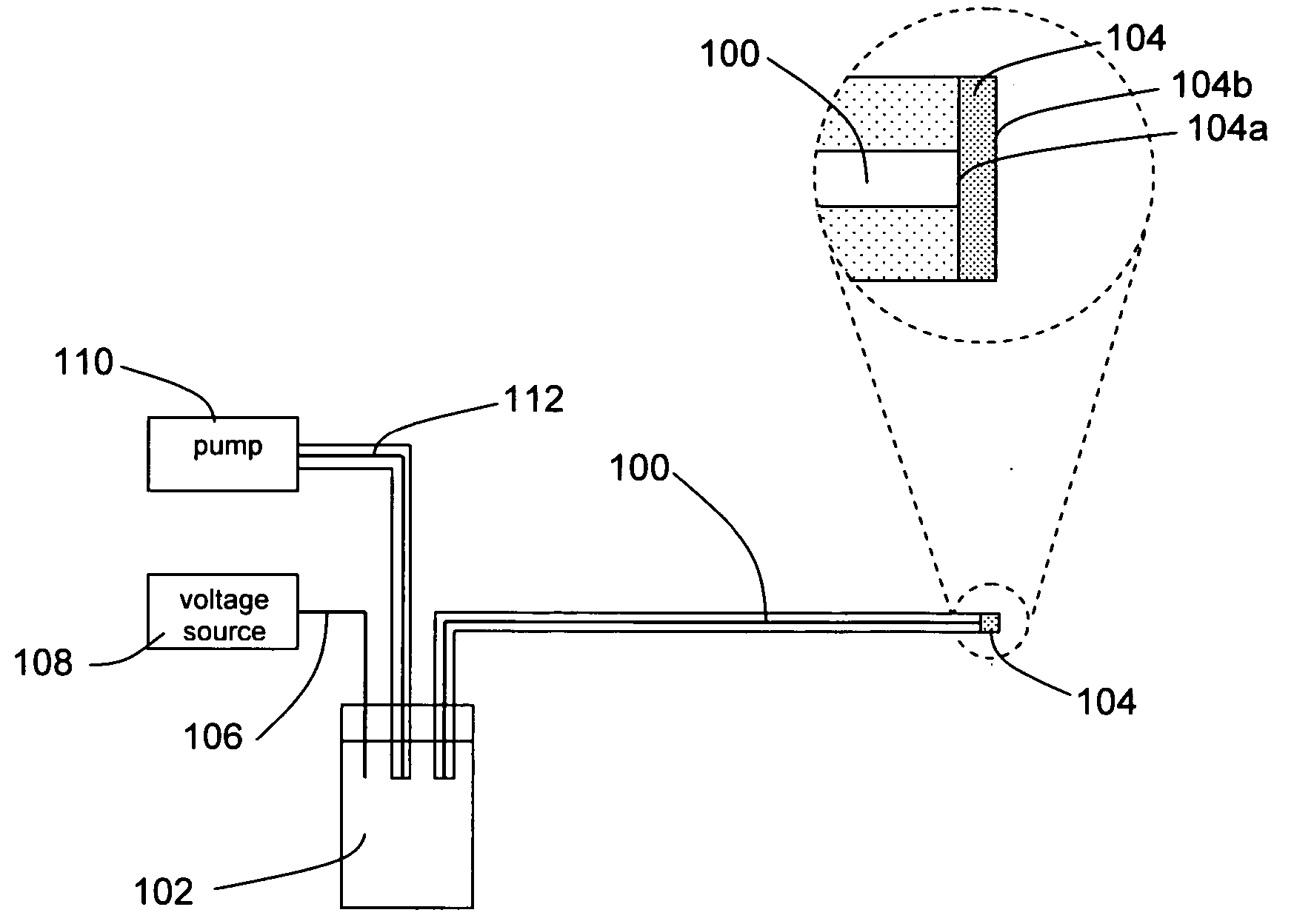

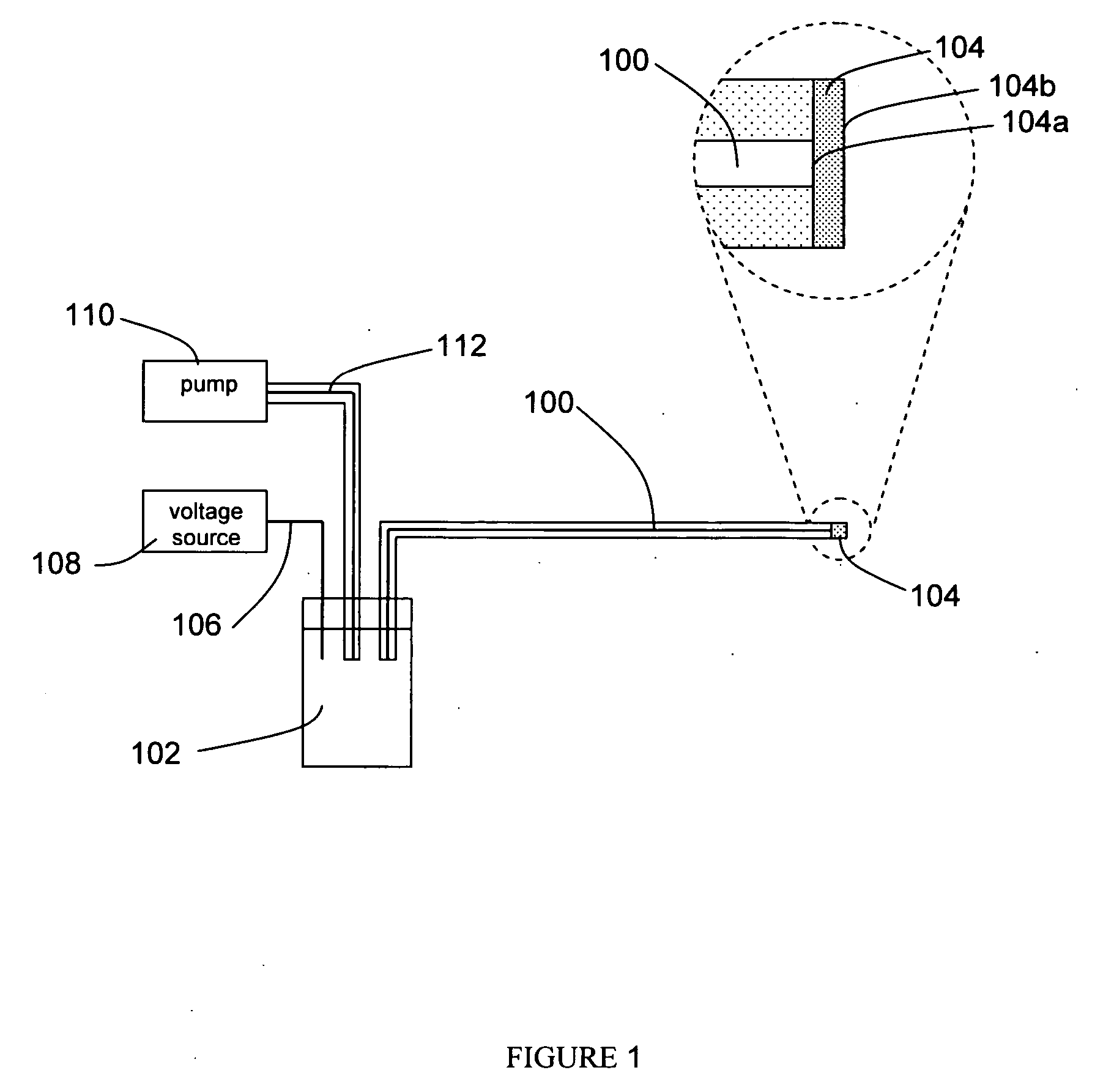

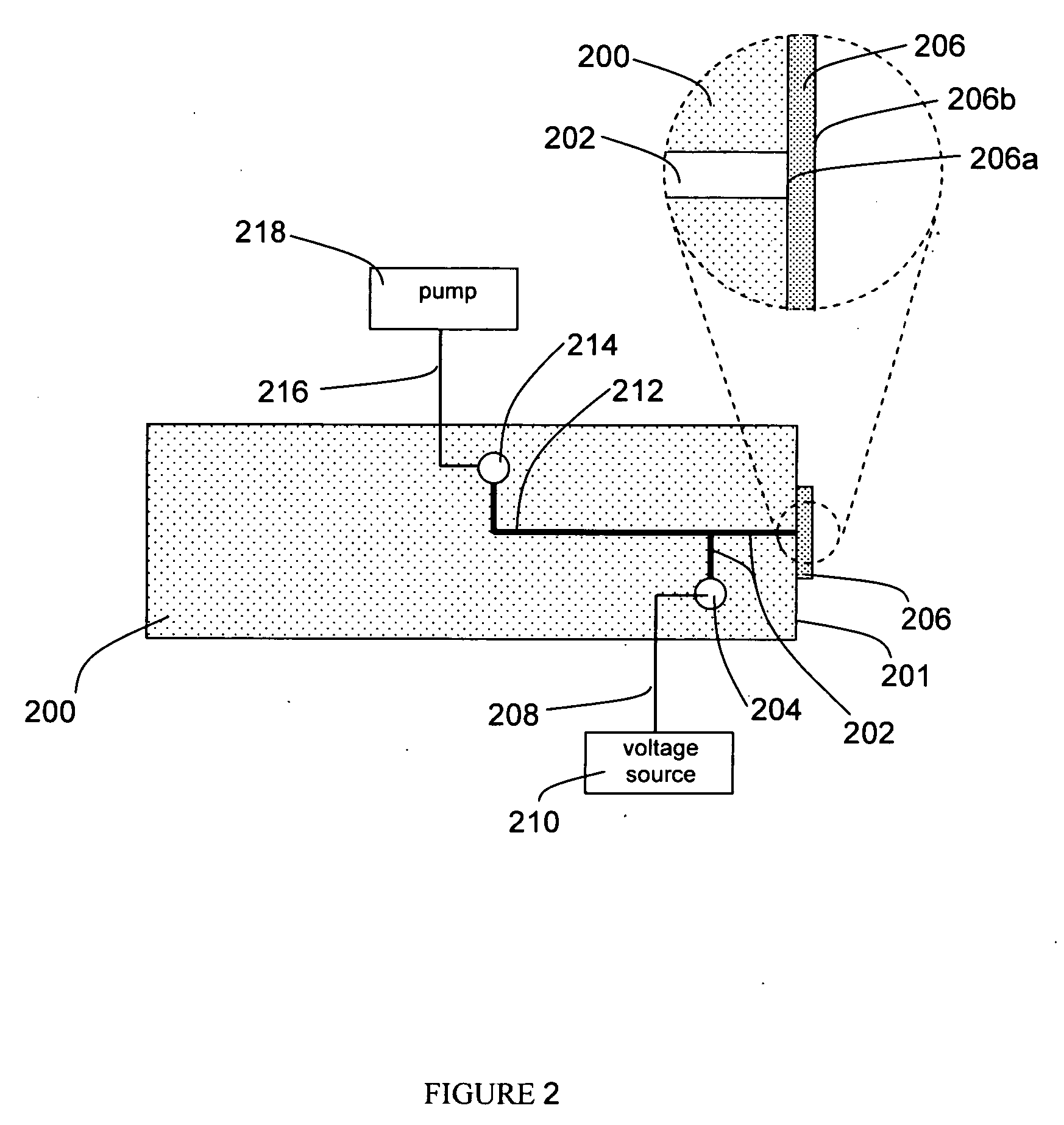

Methods and apparatus for porous membrane electrospray and multiplexed coupling of microfluidic systems with mass spectrometry

InactiveUS20060192107A1Stable electrosprayReduce pressureParticle separator tubesComponent separationTarget surfaceCoupling

Disclosed are an apparatus, system, and method for performing electrospray of biomolecules, particularly peptides, polypeptides, and proteins. The apparatus comprises at least (1) a microfluidic substrate for containing an electrospray microchannel for delivering analyte molecules to a side edge of the substrate, and (2) a porous membrane attached to the side edge for performing electrospray from the exposed membrane surface. In one preferred embodiment, the exposed membrane surface is positioned above a target surface for depositing analyte molecules onto the target surface by electrospray. In another preferred embodiment, a proteolytic enzyme is bound to the porous membrane for performing protein digestion during electrospray.

Owner:DEVOE DONALD L +3

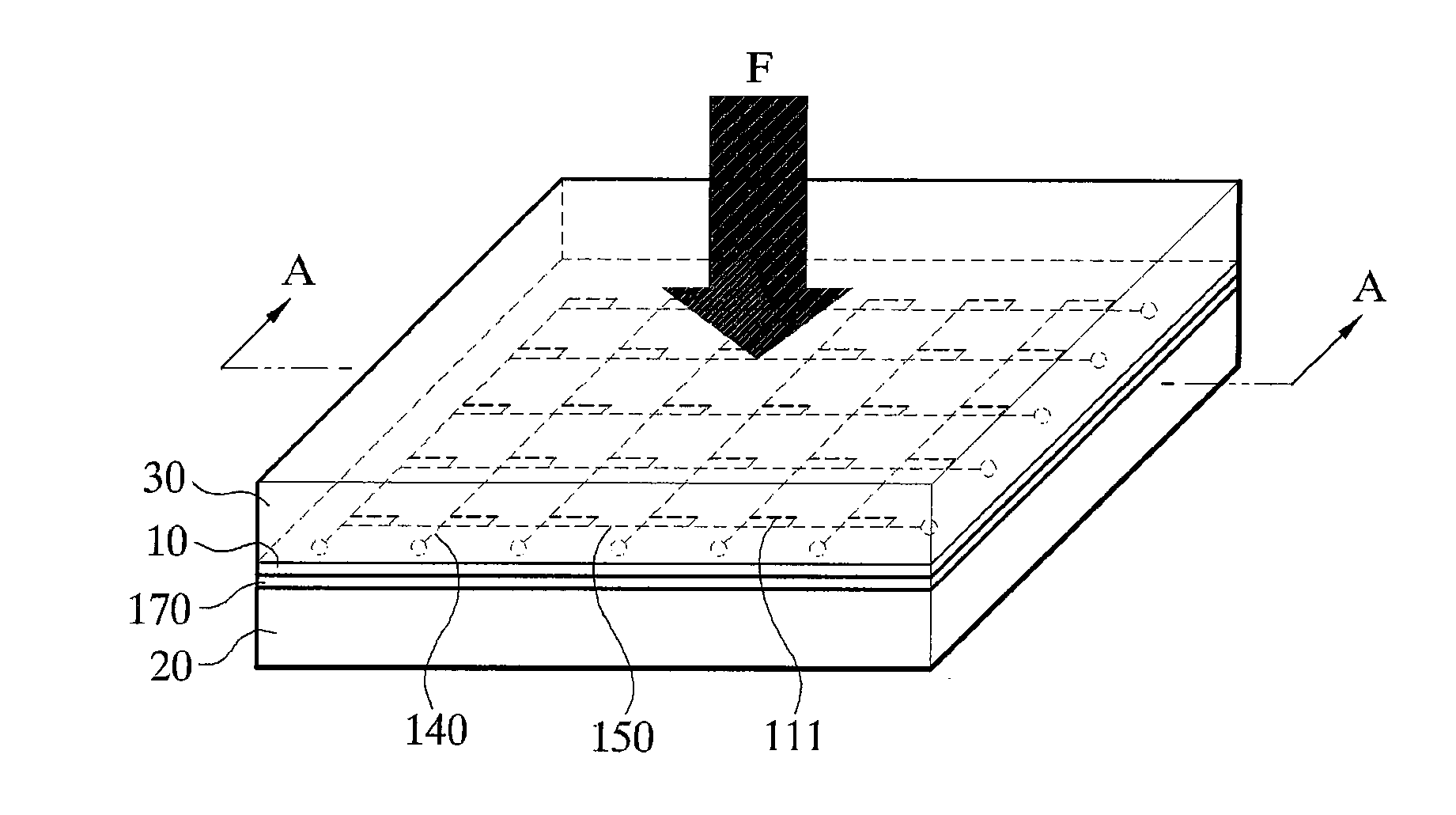

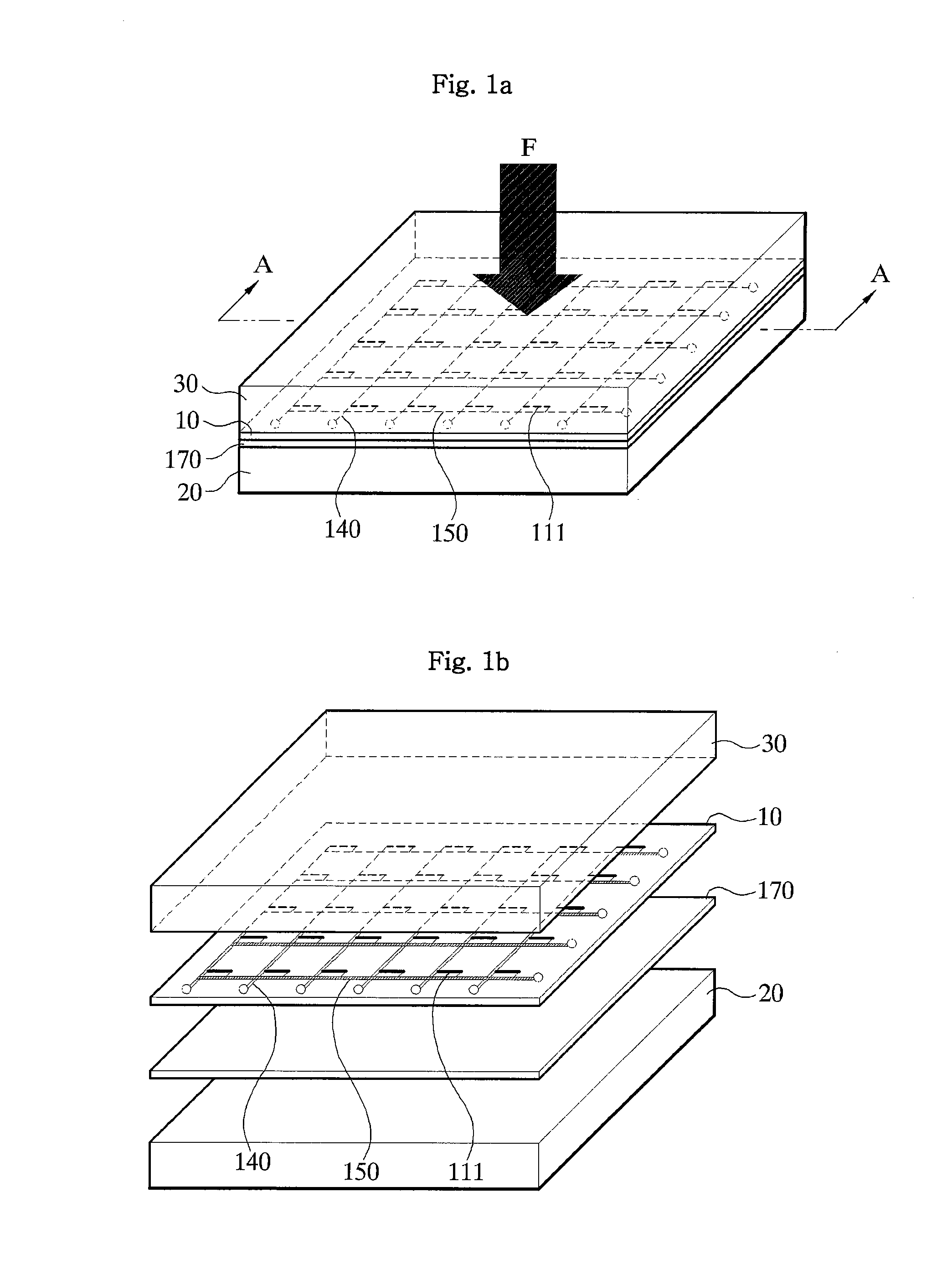

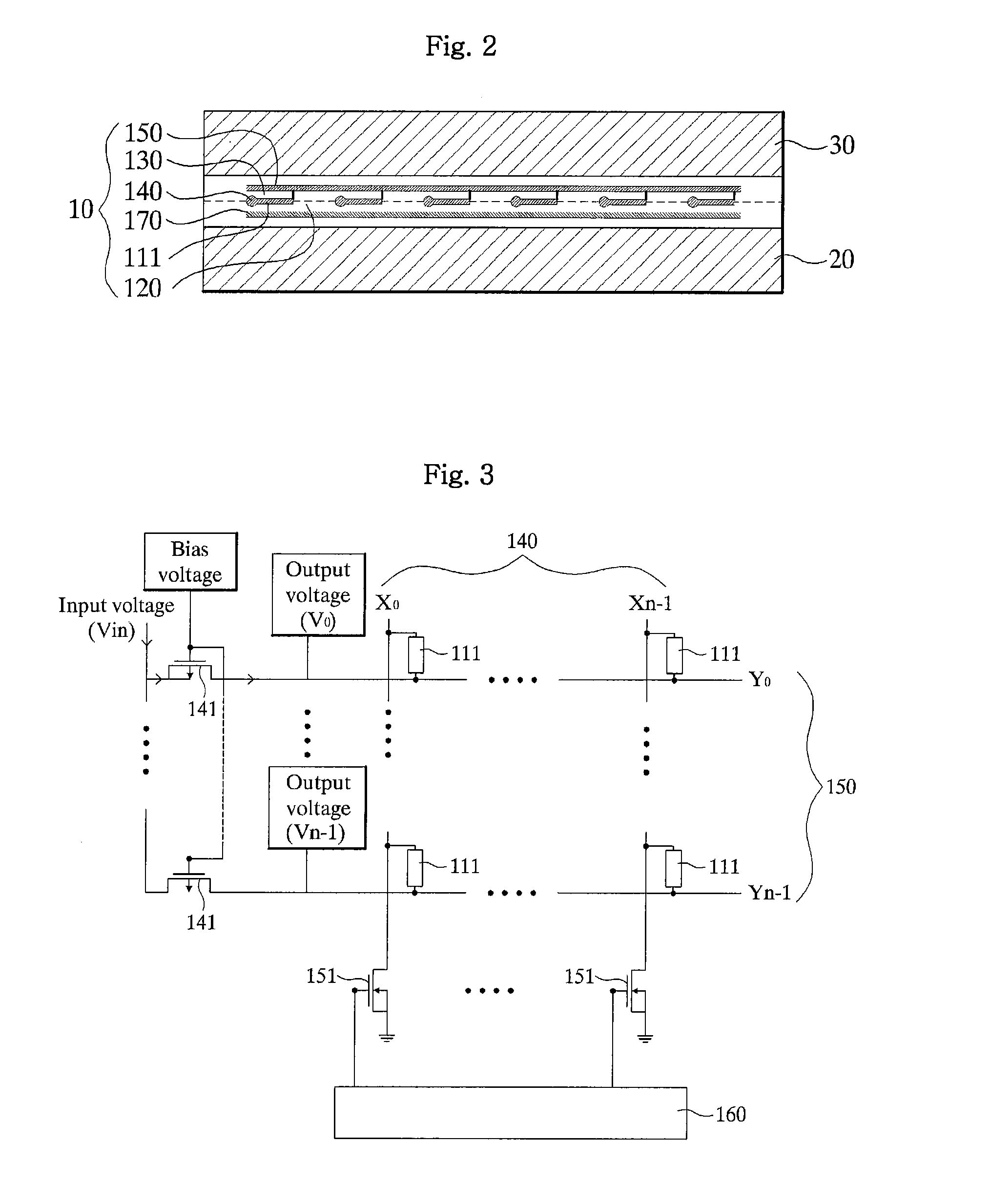

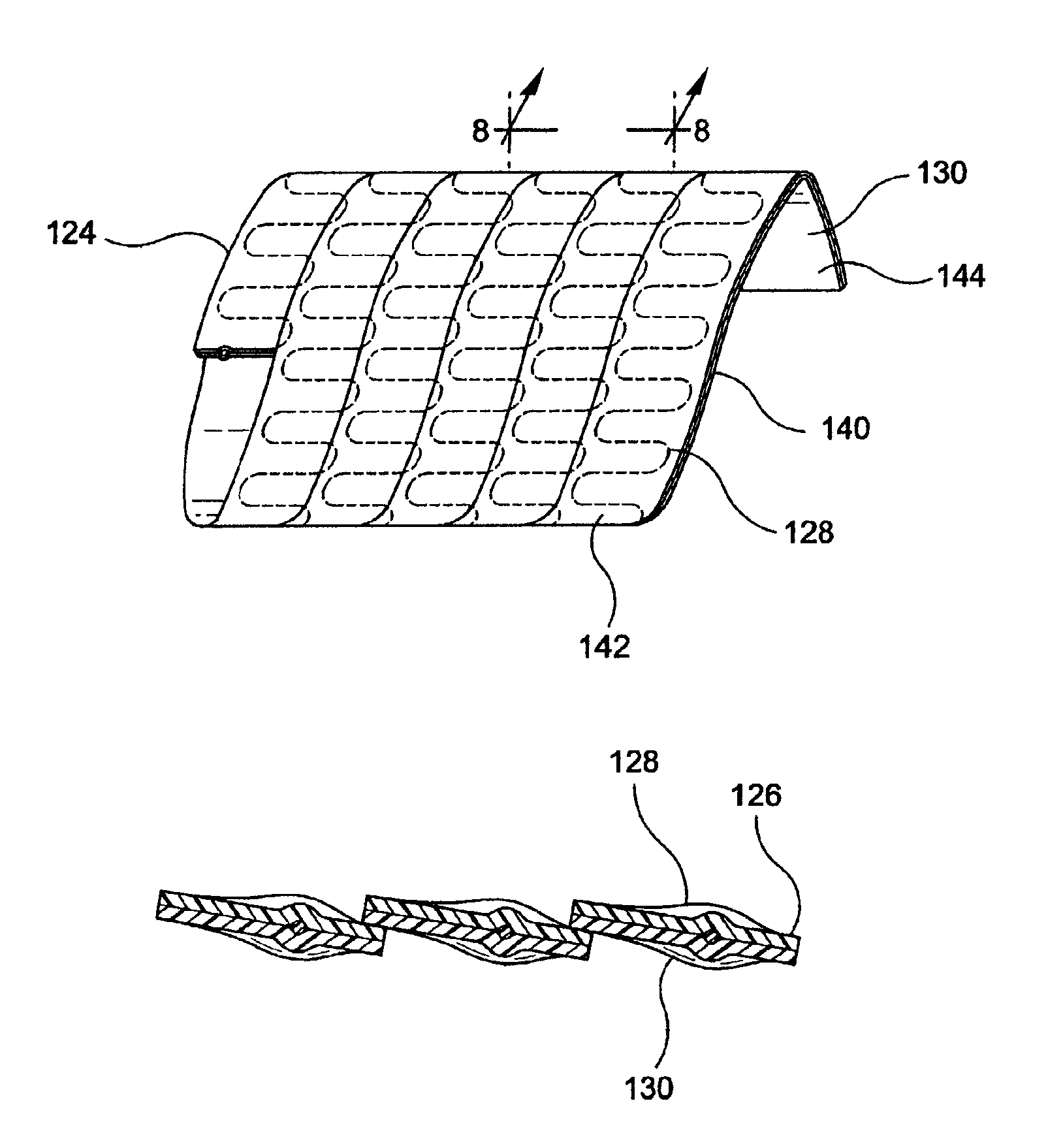

Flexible force or pressure sensor array using semiconductor strain gauge, fabrication method thereof and measurement method thereof

ActiveUS20110226069A1Simple and robust structureIncrease strainForce measurementSemiconductor/solid-state device manufacturingSensor arrayElastomer

The force or pressure sensor array of the present invention effectively has both flexibility and elasticity. Since the substrate itself is a kind of a polymer material, the substrate can be bent or expanded. Although silicon, which is a material of the semiconductor strain gauge, is easily broken and solid, mechanical flexibility can be secured if it is fabricated extremely thin. To this end, particularly, disclosed is a flexible force or pressure sensor array using semiconductor strain gauges 110, the sensor array comprising: a substrate 10 including: the semiconductor strain gauges 110 in which a plurality of elements formed in a certain array pattern is deformed by force or pressure, a pair of polymer film layers 120 and 130 having film surfaces contacted facing each other and containing the semiconductor strain gauge 110 between the film surfaces contacted with each other, and a pair of signal line layers formed on top and bottom surfaces of an insulating layer using either of the pair of polymer film layers 120 and 130 as the insulating layer and connected to the elements 111 of the array pattern to form electrodes, for fetching deformation signals outputted due to deformation of the elements 111 to outside; and a pair of elastomer layers 20 and 30 formed on both sides of the substrate 10 to contain the substrate 10 inside.

Owner:KOREA RES INST OF STANDARDS & SCI

Method of in-situ generation of nano particle on separating membrane surface

The invention relates to the technical field of separating membranes, and in particular to a method of in-situ generation of a nano particle on a separating membrane surface. The method comprises the following steps: conducting surface modification on a basic separating membrane surface for more than once, and conducting in-situ generation of the nano particle for more than once on the separating membrane surface subjected to the surface modification, wherein the special points are that the surface modification refers to the following steps: soaking the basic separating membrane in dopamine buffer salt solution with the concentration of 0.001 mg / mL-100 mg / mL and the PH value of 7-12, modifying for 1 min-7 d under the condition that oxygen or oxidant is participated to form a poly-dopamine layer on the basic separating membrane surface; the in-situ generation of the nano particle refers to the following steps: soaking the separating membrane with the poly-dopamine layer generated on the surface in metal salt solution with the concentration of 0,001-10,000 mM / L for 1 min-300 d to generate the nano particle in situ, or accelerating the in-situ generation of the nano particle under the action of reducer. Compared with the prior art, the preparation method is simple and easy to be operated, economic, efficient and environmental-friendly, and facilitates industrialisation.

Owner:山东净泽膜科技有限公司

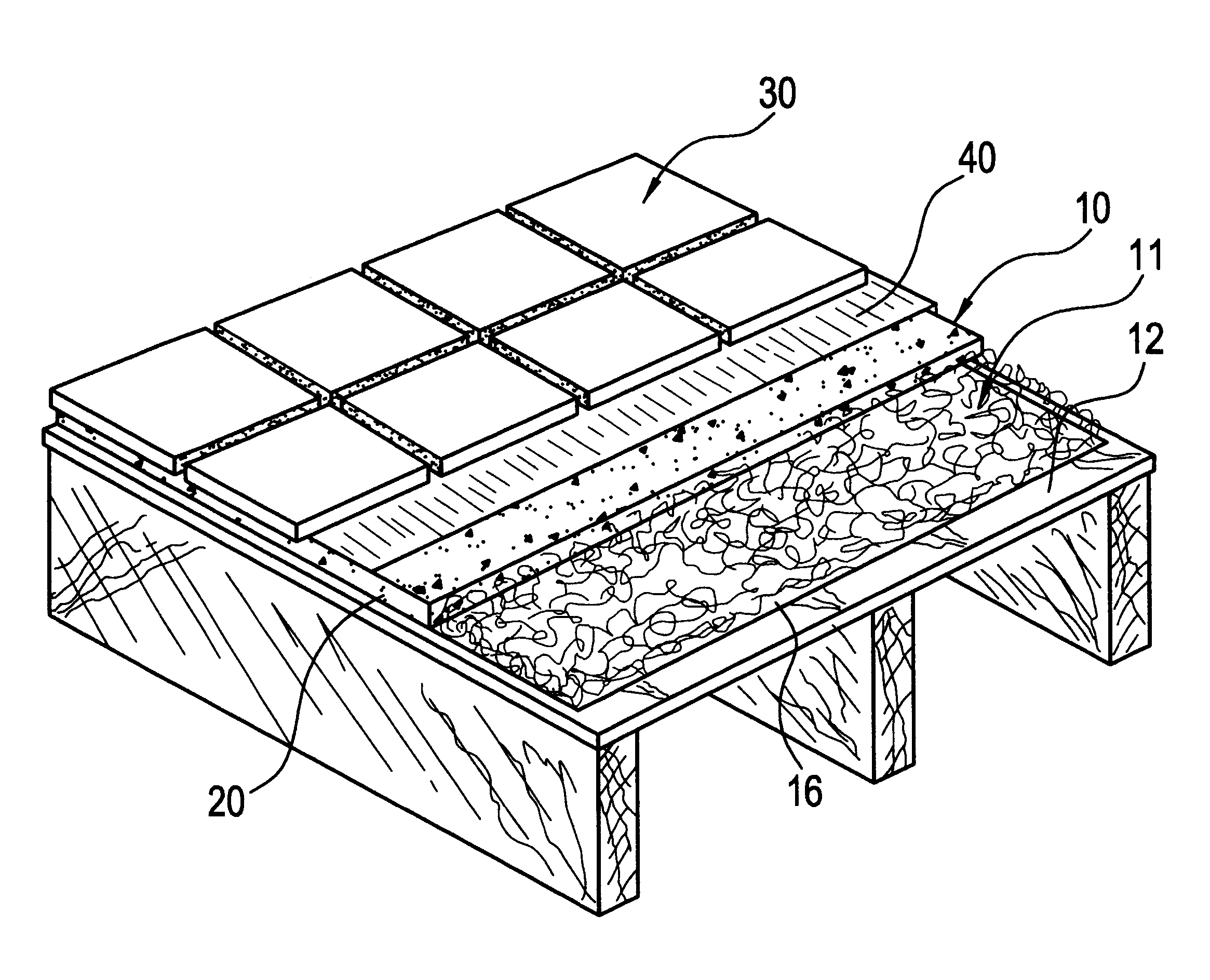

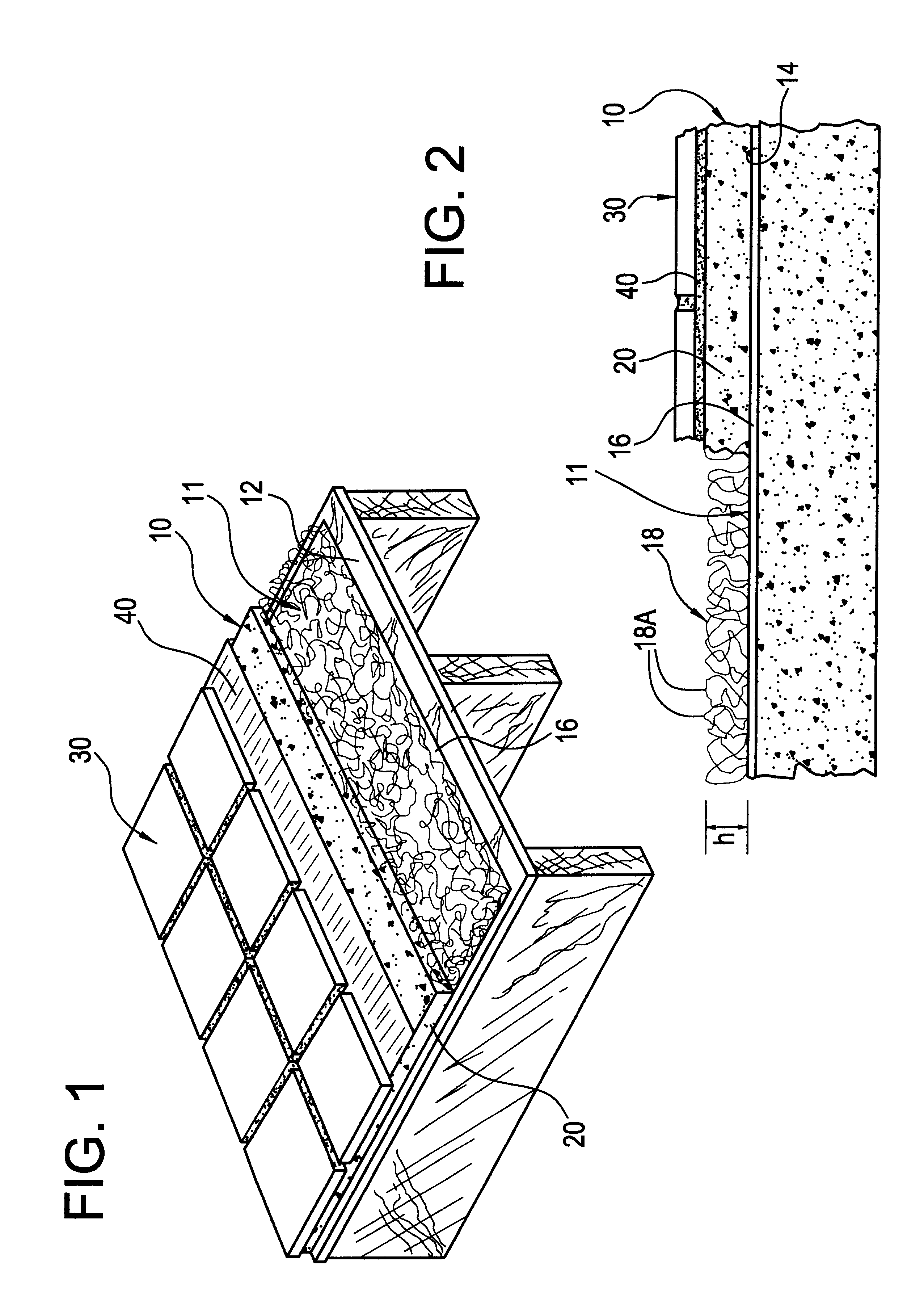

Finished flooring underlayment and method of making same

InactiveUS6167668B1Laborious and expensiveQuick installationFloorsBuilding repairsMembrane surfaceMaterials science

A finished flooring underlayment is disclosed including a flexible membrane which is resistant to water, mold and deterioration under wet or dry conditions, and which has intertwined filaments bonded to the membrane surface that act as mortar reinforcement and as gauges to provide a uniform thickness of application for cementicious mortar. The mortar is provided separately and is mixed to a suitable consistency with either water or latex additive, then poured or placed on the mat, utilizing the gauges provided by the filaments to effect a uniform thickness of application. This mortar hardens to a strong, load bearing surface or slab suitable for application of finished flooring.

Owner:CITIZENS BANK OF CONNECTICUT

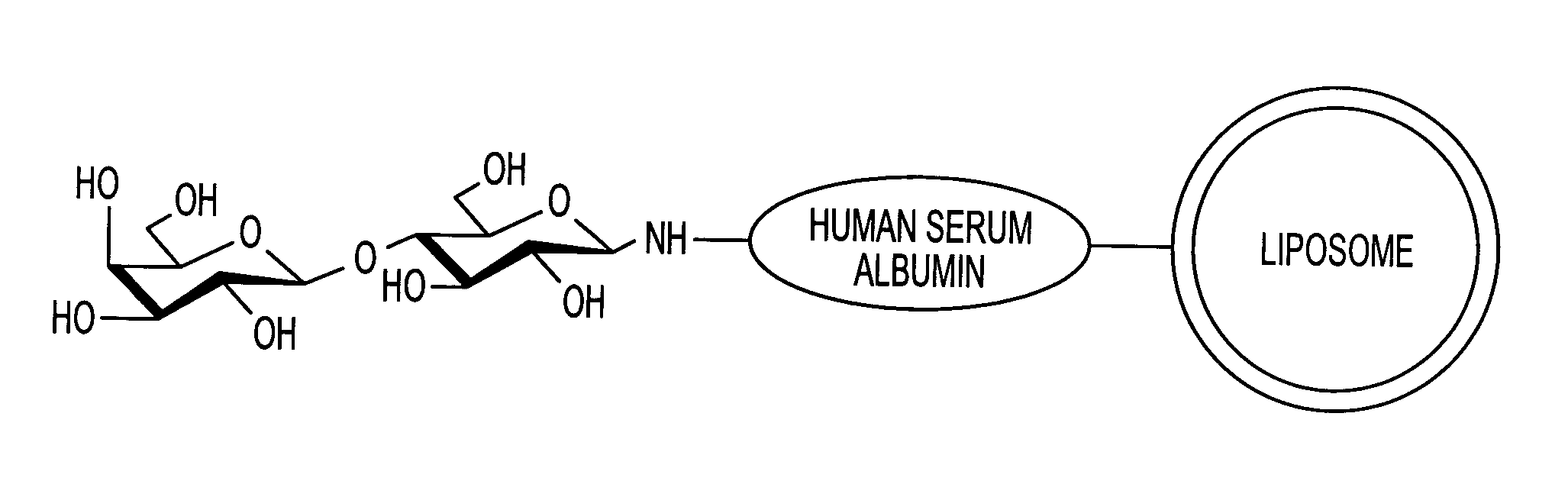

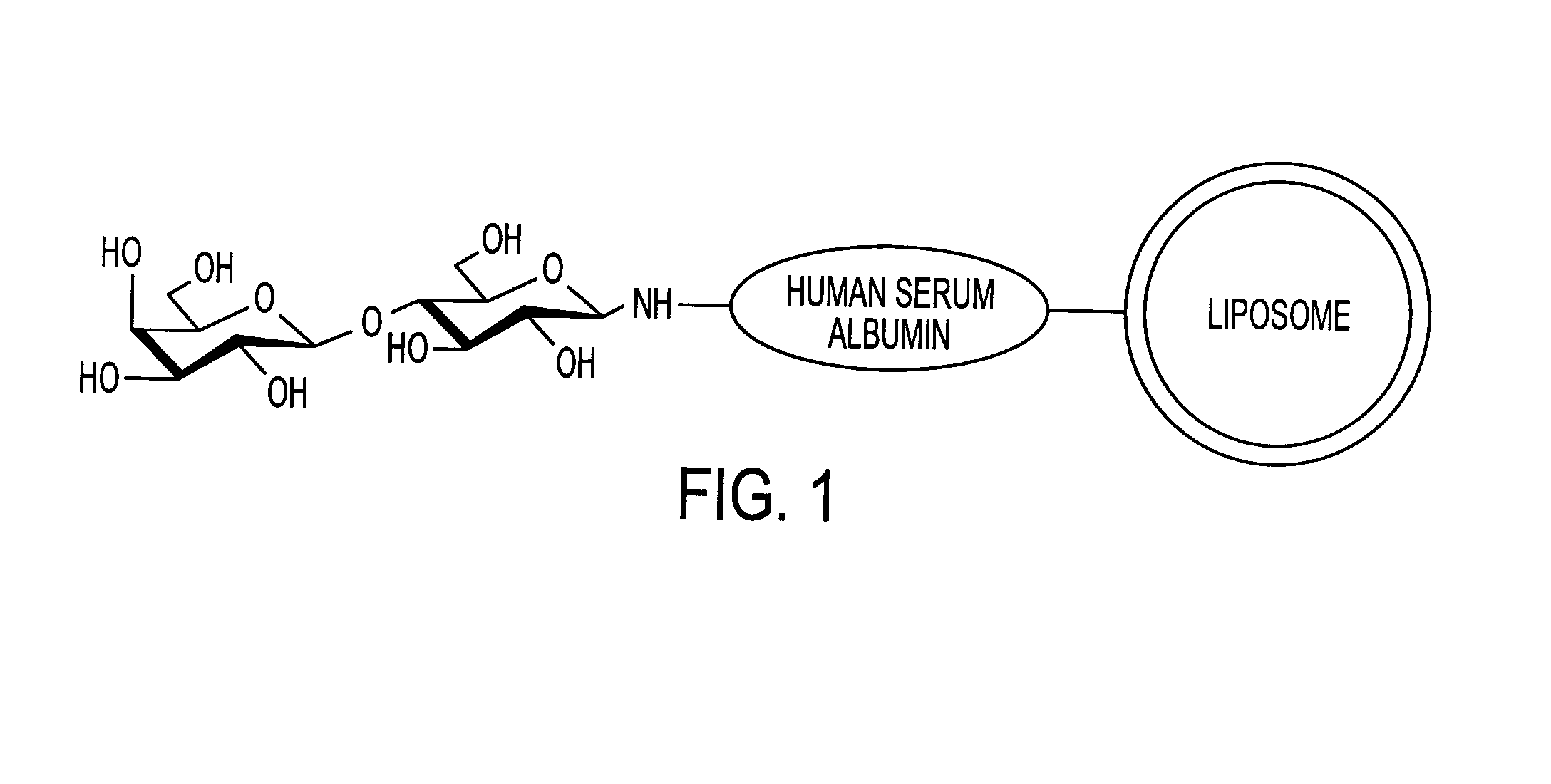

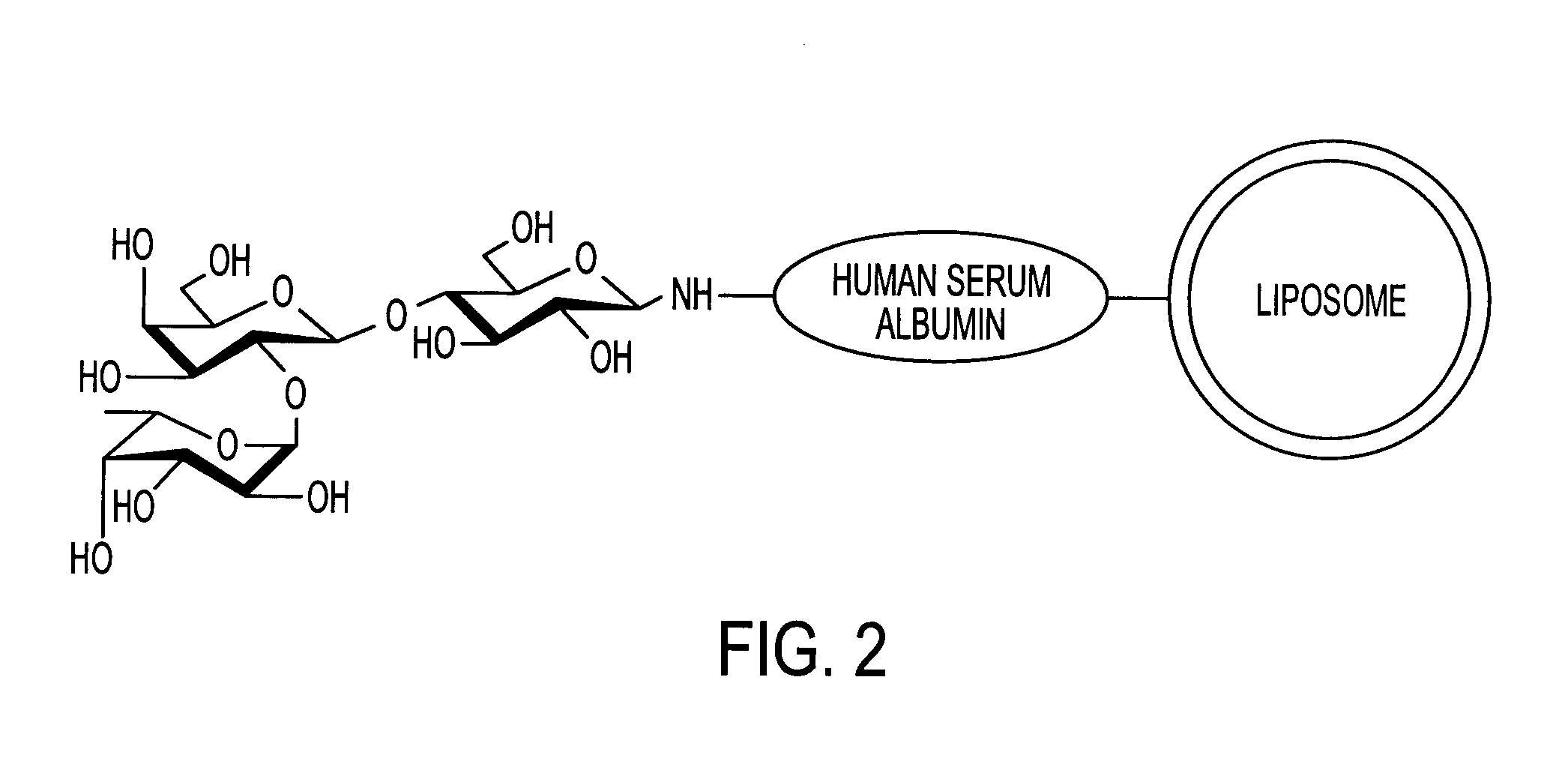

Sugar-modified liposome and products comprising the liposome

InactiveUS7070801B2Improve absorption qualityQuality improvementUltrasonic/sonic/infrasonic diagnosticsOrganic active ingredientsIntestinal structureCancer cell

The present invention provides a sugar-modified liposome having a sugar chain bonded to its membrane surface, preferably through a linker protein, and having excellent absorption qualities, particularly in the intestine. The molecular structure and quantity of the sugar chain is selectively varied to allow the liposome to be delivered in a targeted manner to selected cells and tissues. The liposome is applicable to medicinal drugs, cosmetics and other various products in the medical / pharmaceutical fields, and it is especially useful in a therapeutic drug delivery system that recognizes target cells and tissues, such as cancer cells, and in the delivery of drugs or genes locally to a selected region, or in a diagnostic cell / tissue sensing probe.

Owner:YAMAZAKI DDS

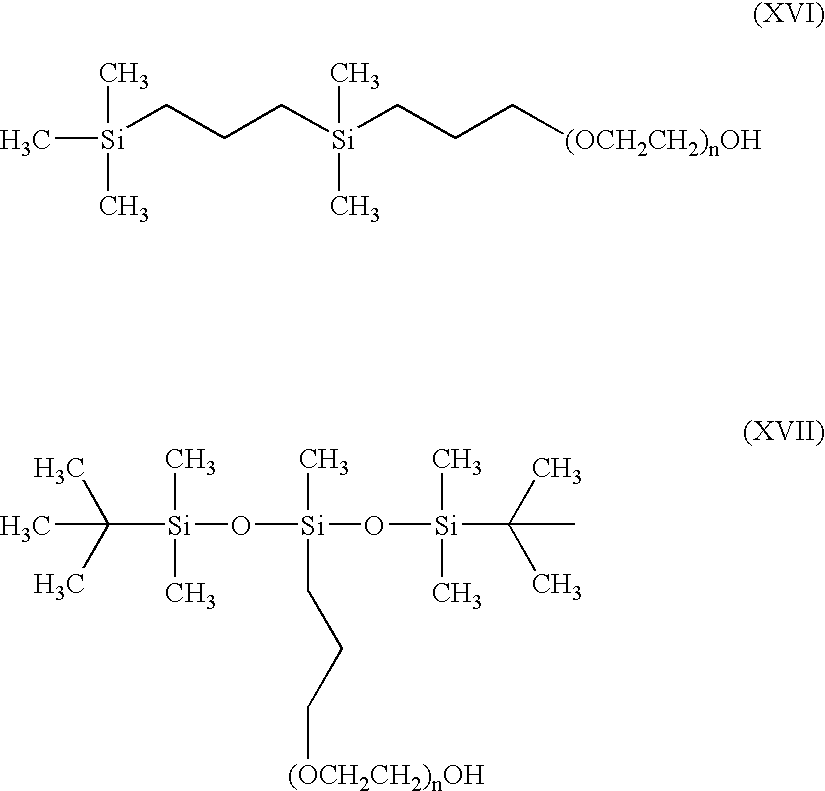

Membrane-based article and associated method

An article includes a membrane having pores extending therethrough, and a surfactant in contact with a surface of the membrane. The surfactant may function as a superspreader when in solution. The membrane surface may wet in response to contact with a fluid. An associated method is provided.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

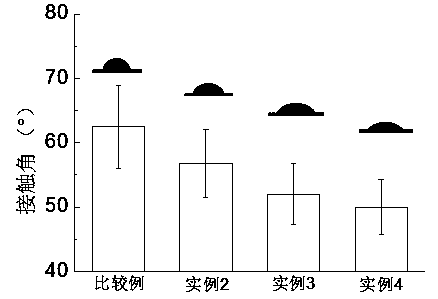

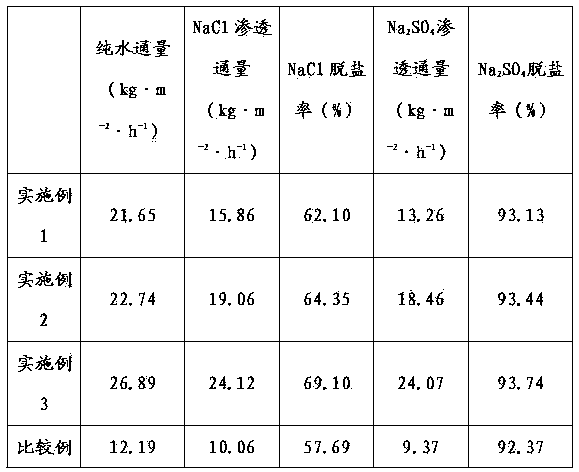

Preparation method of graphene oxide composite nano filter membrane

ActiveCN103736400AImprove throughputImprove desalination performanceSemi-permeable membranesOxide compositeMembrane surface

The invention relates to a preparation method of a graphene oxide composite nano filter membrane, and belongs to the technical field of separation membrane preparation. The preparation method of the graphene oxide composite nano filter membrane comprises the following steps: (1) preparing a graphene oxide water liquid; (2) preparing a graphene oxide cross linking liquid; and (3) preparing the graphene oxide composite nano filter membrane. The graphene oxide composite nano filter membrane provided by the invention has the characteristics that the surface of the membrane has a great deal of free carboxyl and hydroxy, the hydrophilicity is high, the flux is high, meanwhile, the charge on the surface of the membrane is negative, the salt cutting ratio is effectively improved, the flux and a desalting effect of the nano filter membrane are remarkably improved, and the graphene oxide composite nano filter membrane has the good large-scale industrialized application prospects.

Owner:OCEAN UNIV OF CHINA

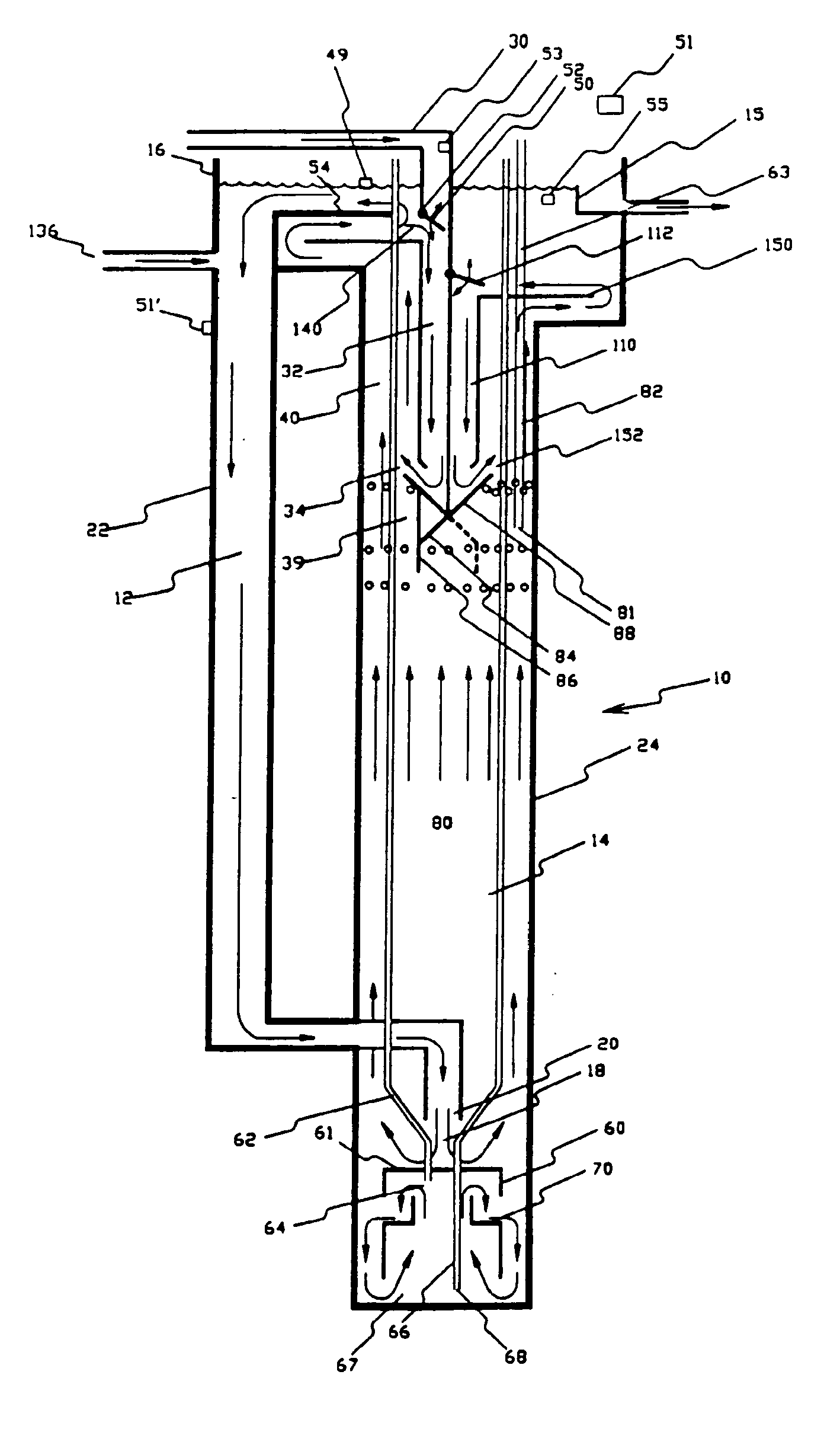

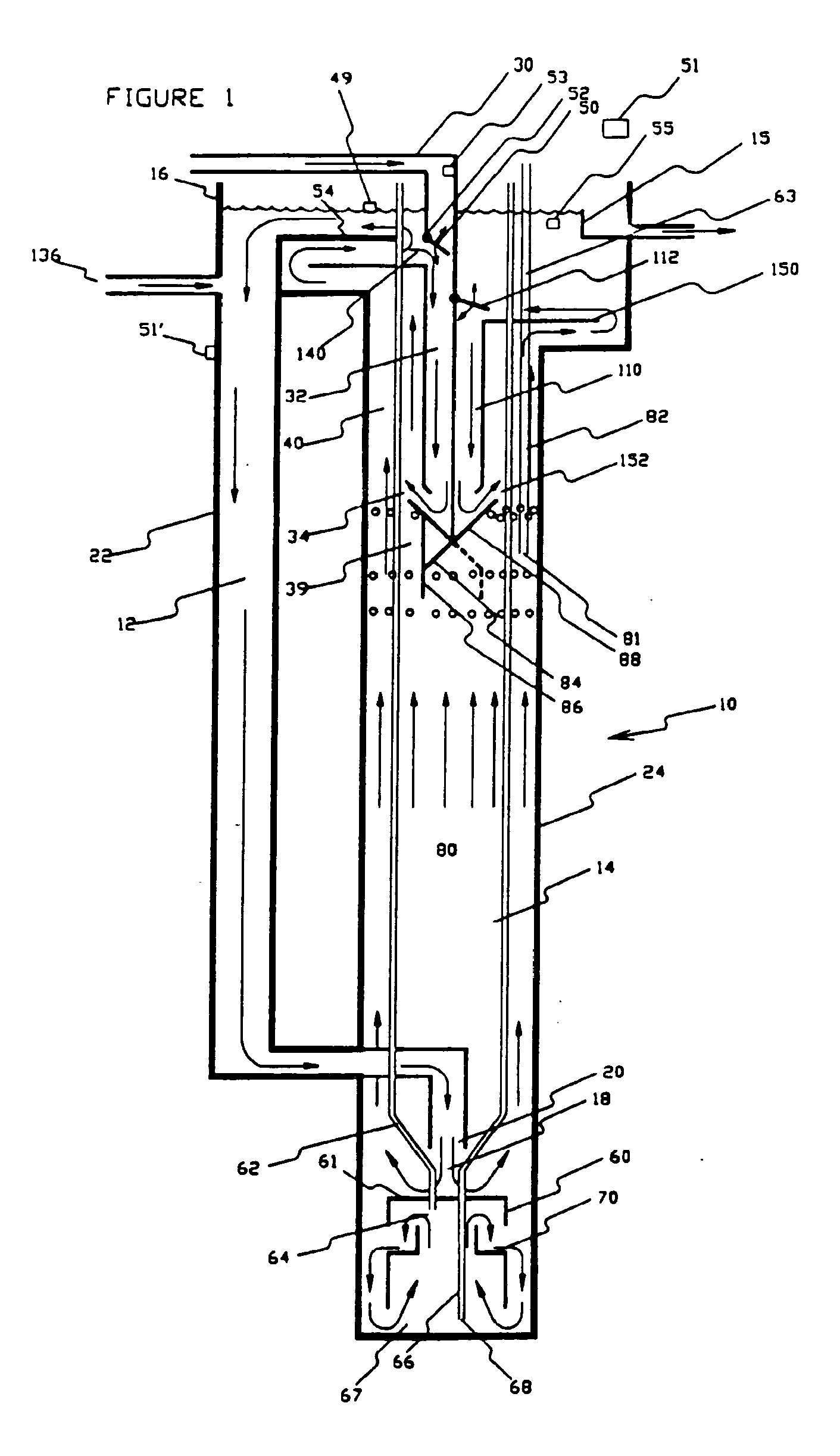

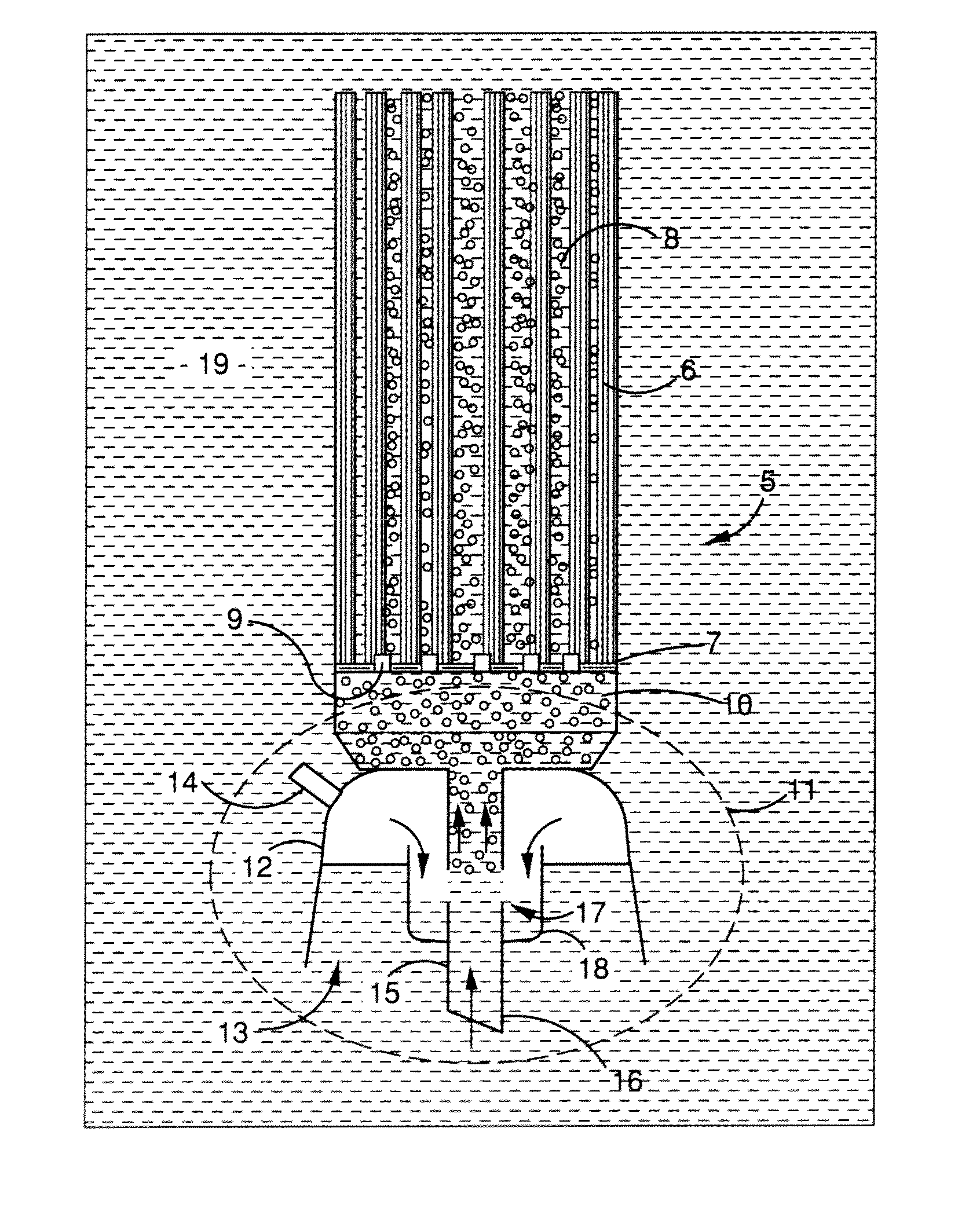

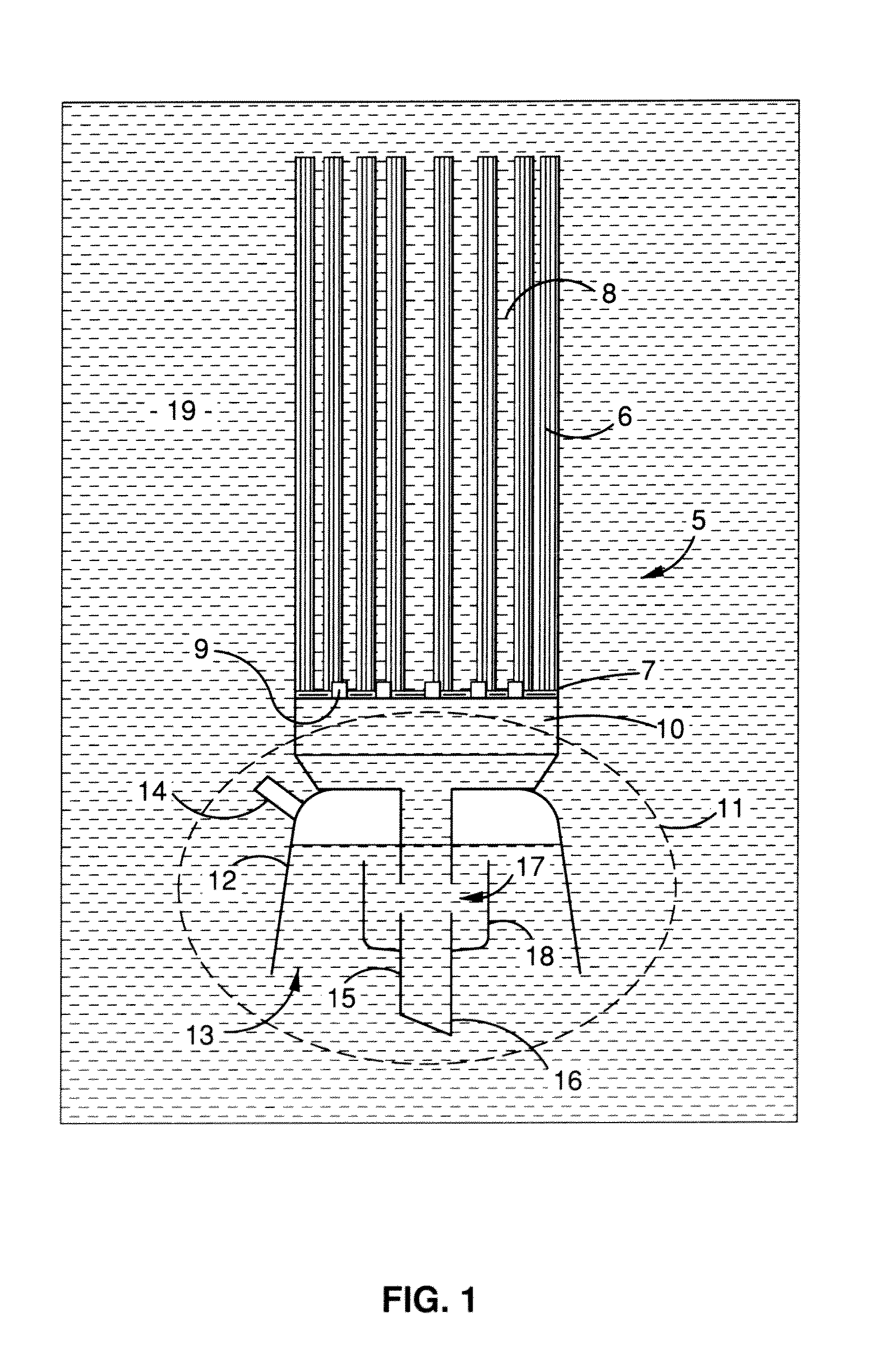

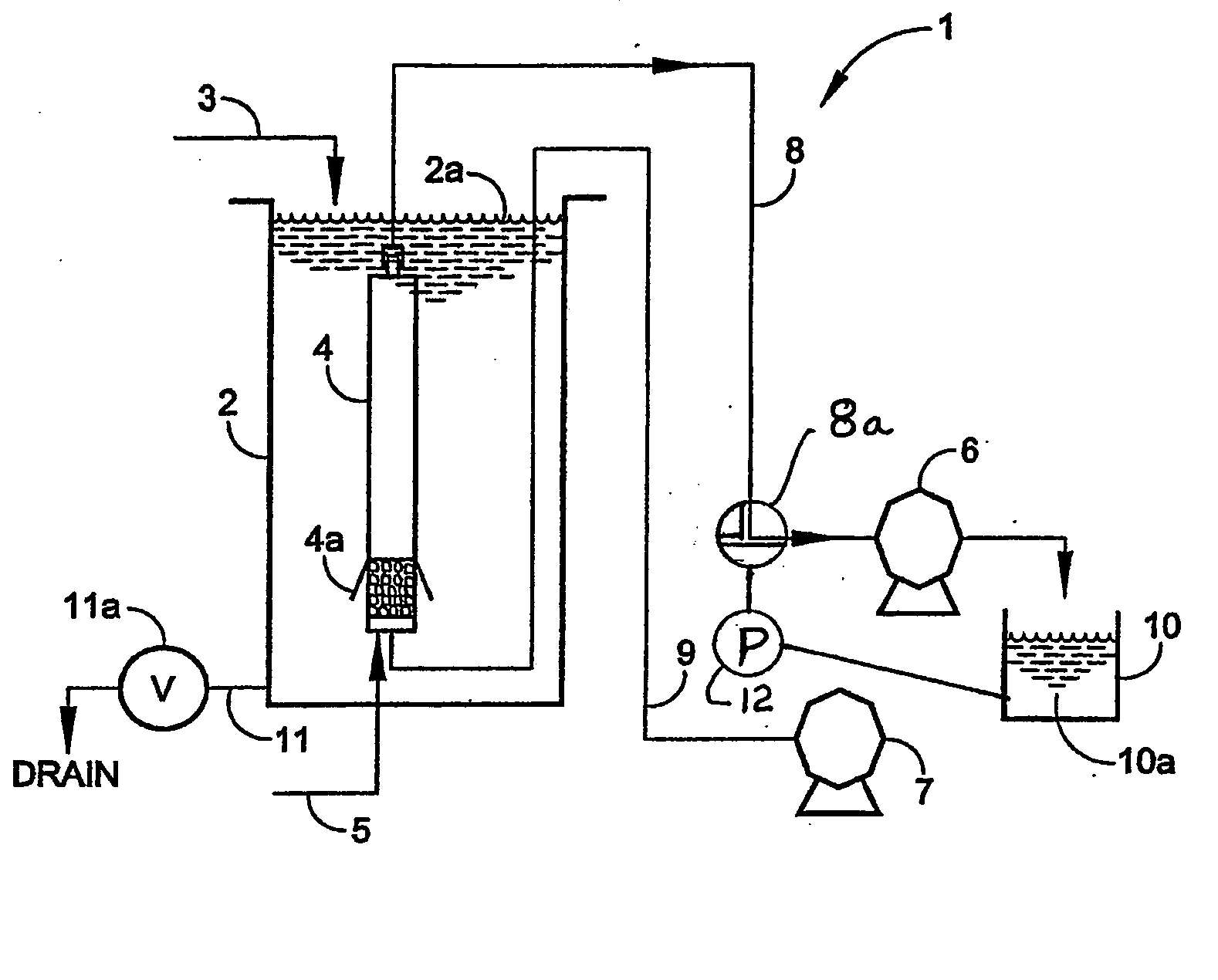

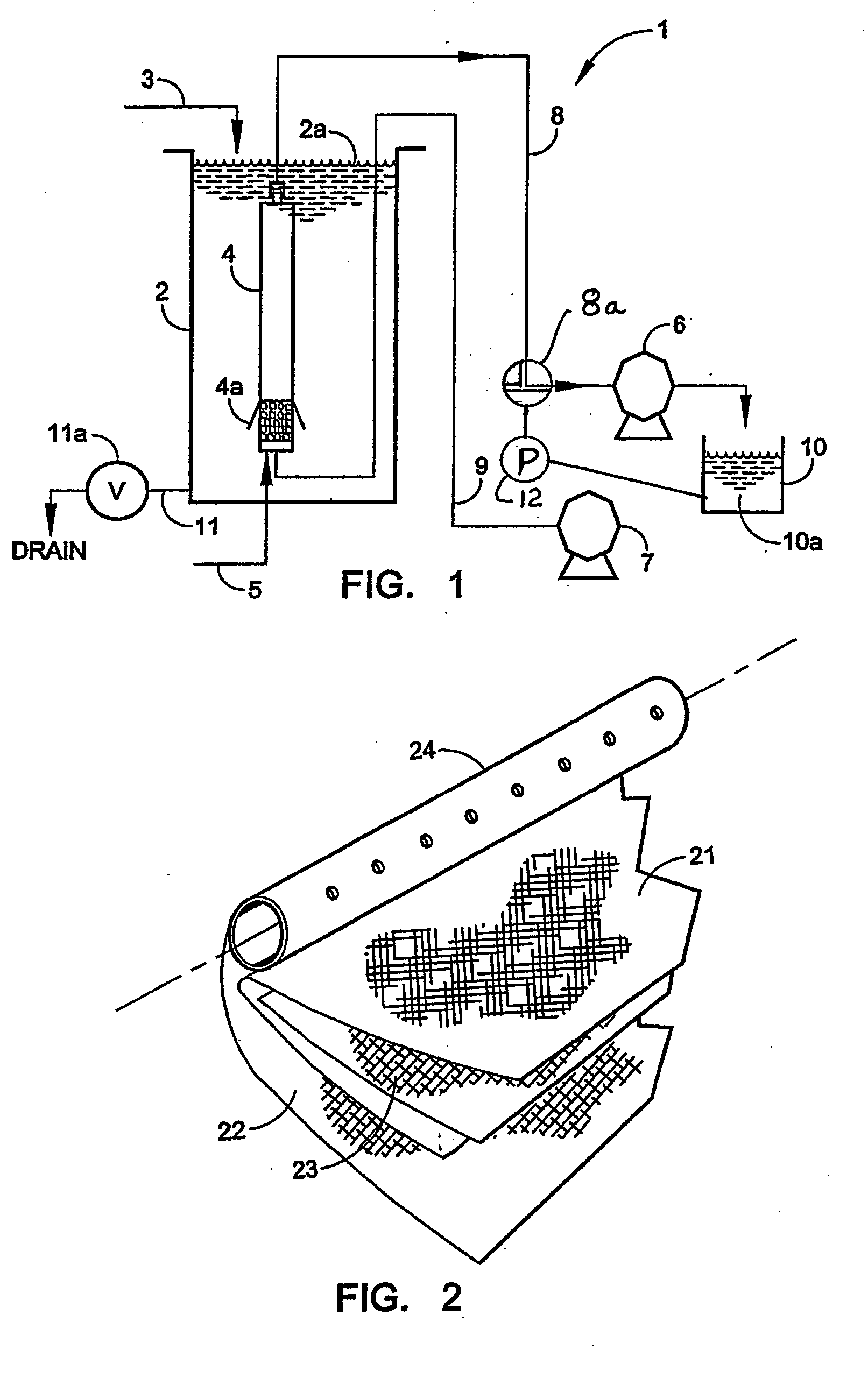

Method and apparatus providing improved throughput and operating life of submerged membranes

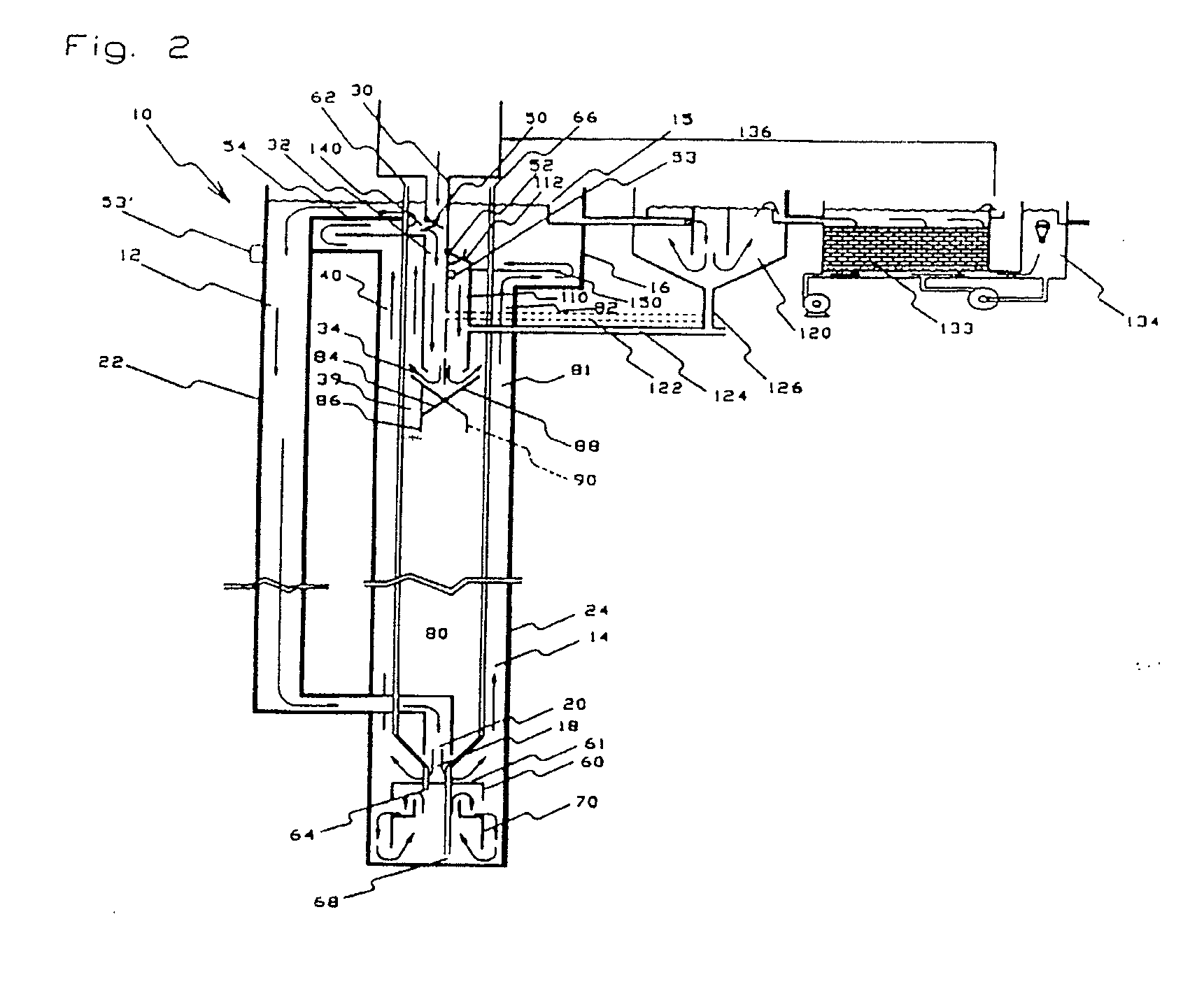

InactiveUS20050218074A1Improved through-putIncreased operating lifeWater/sewage treatment bu osmosis/dialysisSustainable biological treatmentFluid compartmentsMembrane surface

A submerged membrane assembly including a membrane having a first surface, a second surface, and a vertical axis, and which is permeable between the surfaces by molecules of less than a predetermined size. A first fluid compartment in fluid communication with the first membrane surface and that contains at a first column height a first fluid having a first specific gravity, a second fluid compartment in fluid communication with the second membrane surface and that contains at a second column height a second fluid having a second specific gravity, and means for changing the second specific gravity. The second column height being selected relative to the first column height to produce a selected pressure differential across the membrane along the vertical axis at the first specific gravity and the changed second specific gravity.

Owner:VOST ENVIRONMENTAL TECH

Helically formed stent/graft assembly

The present invention relates to a support structure / membrane composite device which includes a support structure, such as a radially expandable stent, a porous non-textile polymeric membrane adjacent to said stent and a thermoplastic anchor means attaching said stent to said porous non-textile polymeric membrane. The porous non-textile polymeric membrane is preferably made from expandable fluoropolymer materials. The anchoring means is a thermoplastic material which is dissolvable at the interface between the support structure and membrane by a suitable solvent which wets the membrane surface and deposits the thermoplastic material within the pores of the membrane. Methods of preparing the device are also disclosed.

Owner:BOSTON SCI SCIMED INC

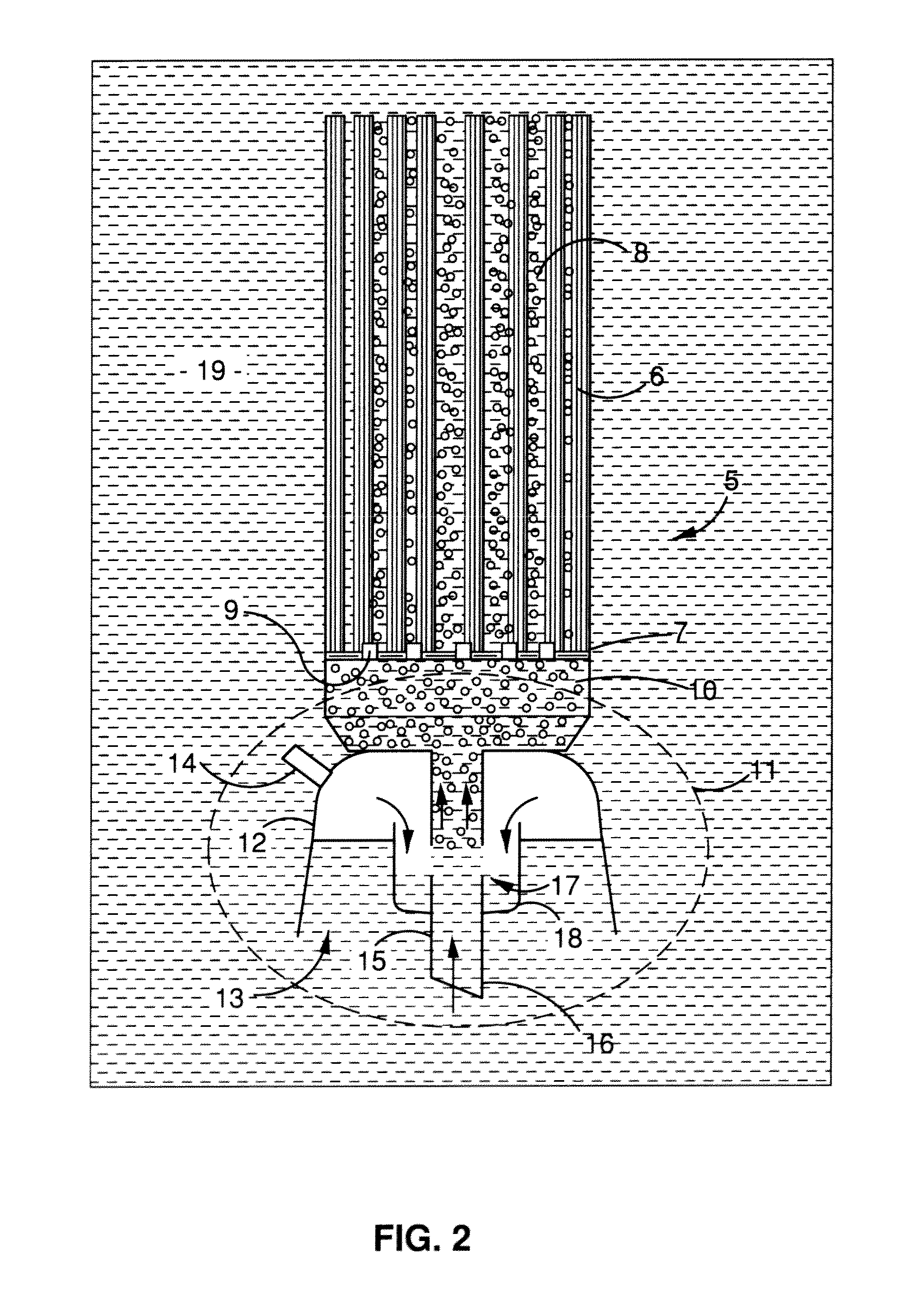

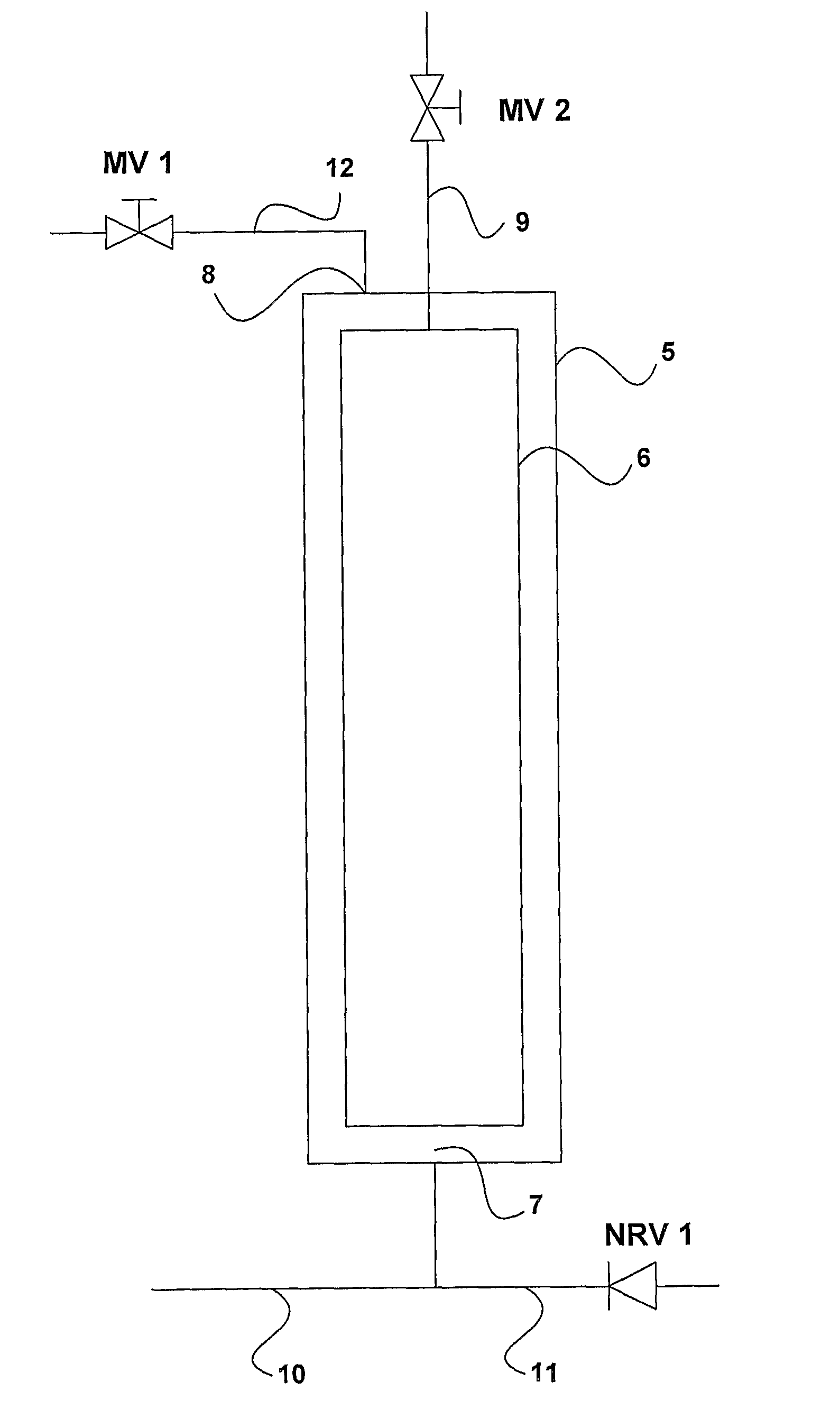

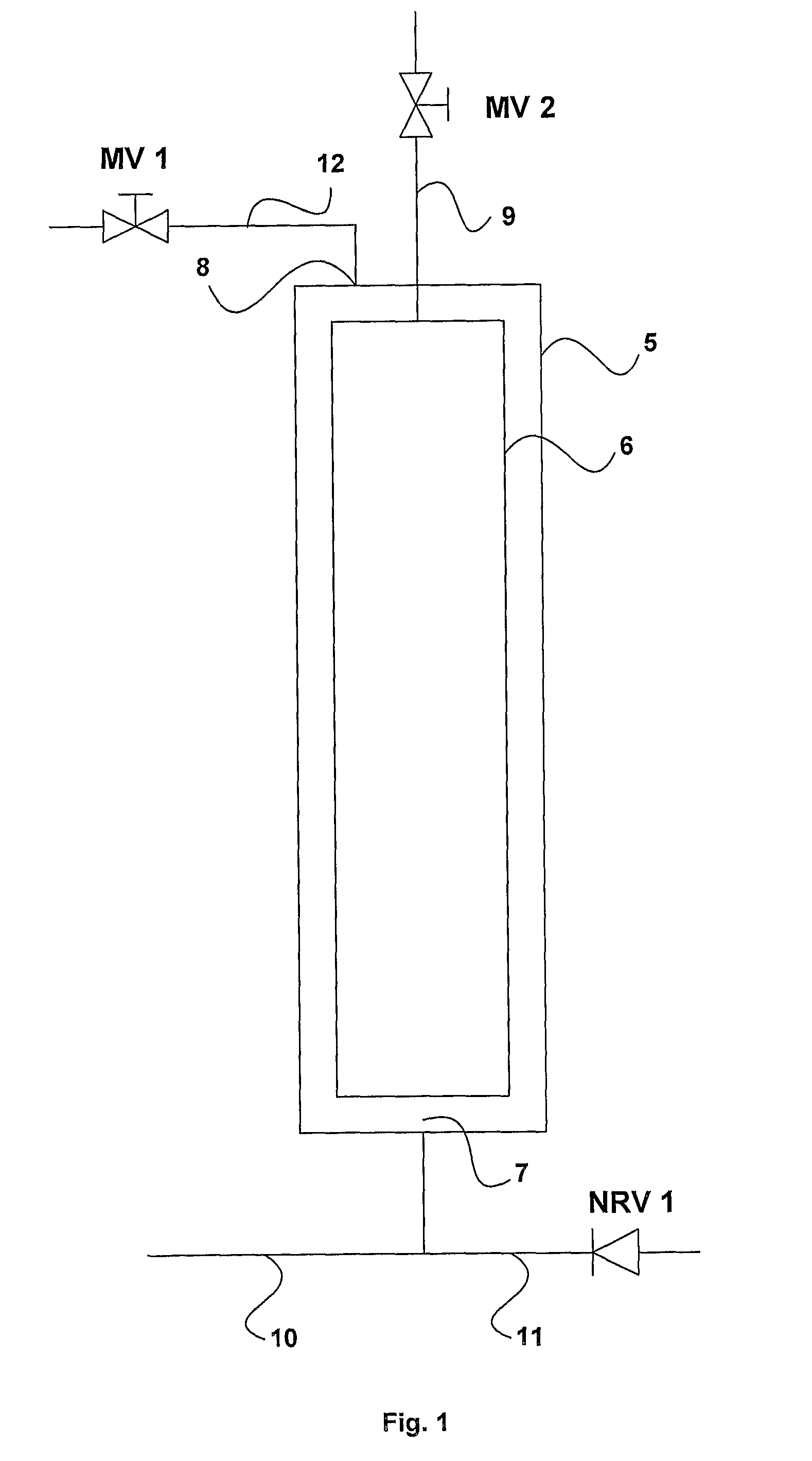

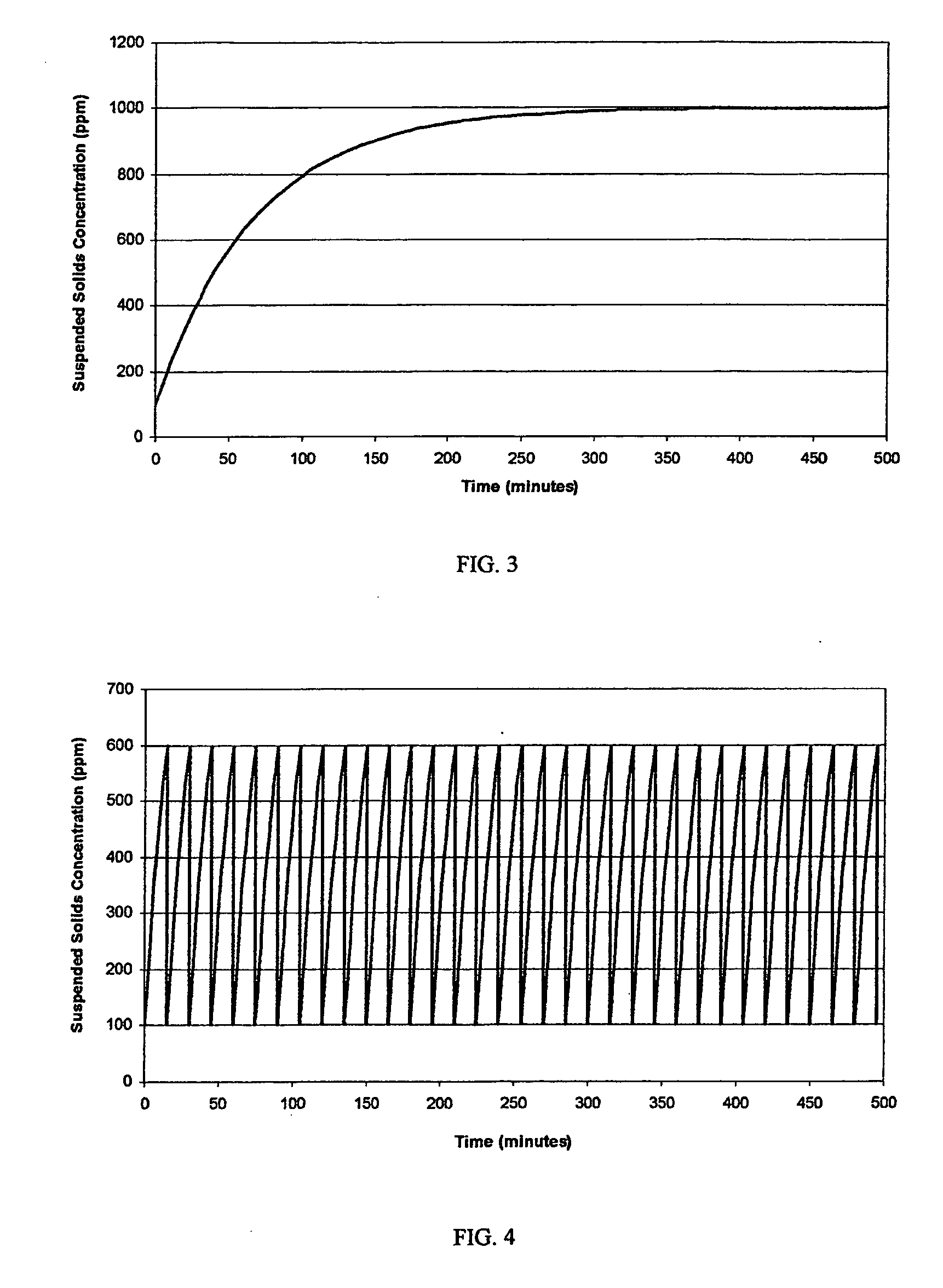

Membrane cleaning with pulsed arilift pump

ActiveUS20110100907A1Easy to cleanReduces solid concentration polarisationMembranesTreatment using aerobic processesLiquid mediumPorous membrane

A method of cleaning a membrane surface immersed in a liquid medium with a fluid flow, including the steps of providing a randomly generated intermittent or pulsed fluid flow along the membrane surface to dislodge fouling materials therefrom. A membrane module is also disclosed comprising a plurality of porous membranes (6) or set of membrane modules (5) and a device (11) for providing a generally randomly generated, pulsed fluid flow such that, in use, said fluid flow moves past the surfaces of said membranes (6) to dislodge fouling materials therefrom.

Owner:EVOQUA WATER TECH LLC

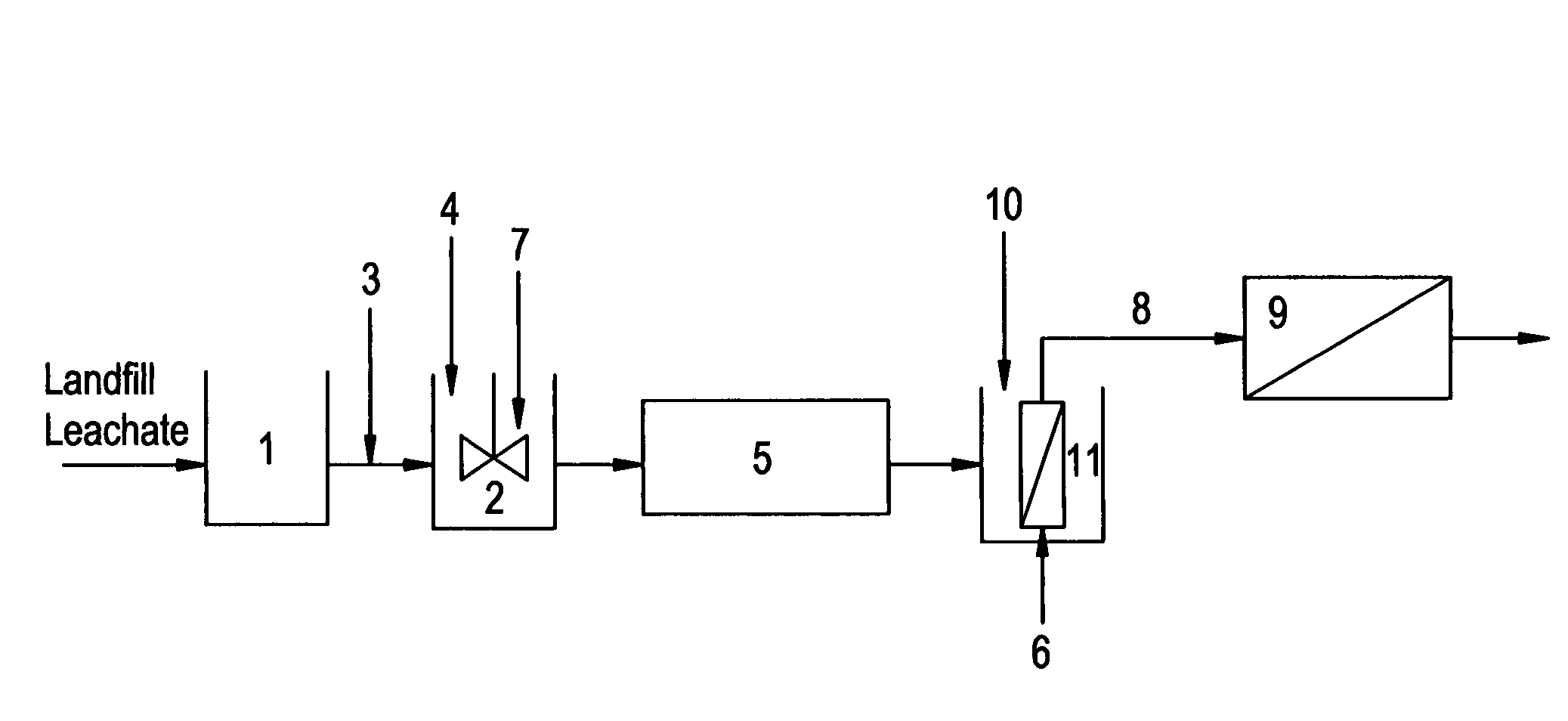

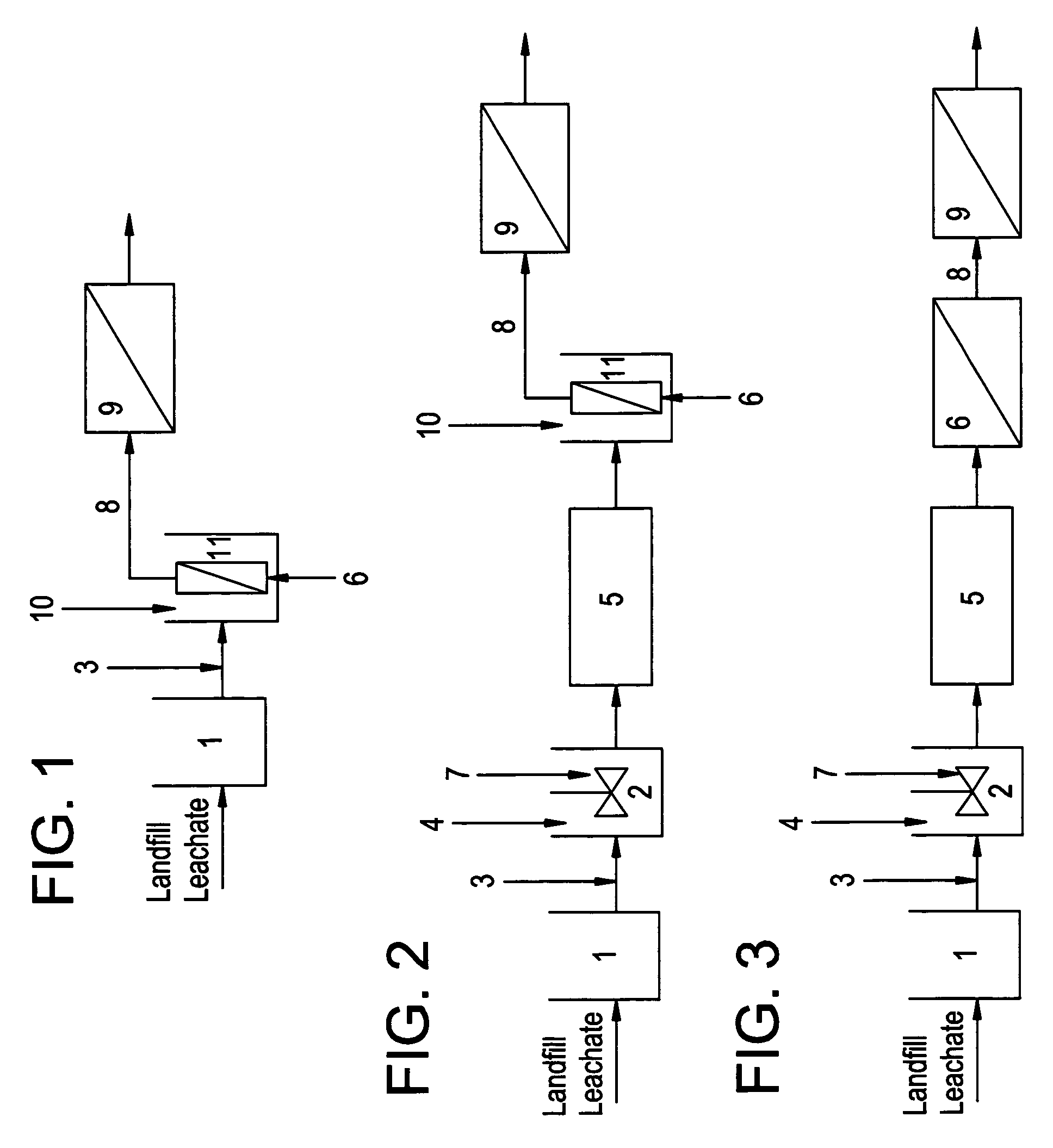

Method of improving performance of ultrafiltration or microfiltration membrane process in landfill leachate treatment

A method of processing landfill leachate by use of a membrane separation process is disclosed. Specifically, the following steps are taken to process landfill leachate: collecting landfill leachate in a receptacle suitable to hold said landfill leachate; treating said landfill leachate with one or more water soluble polymers, wherein said water soluble polymers are selected from the group consisting of: amphoteric polymers; cationic polymers; zwitterionic polymers; and a combination thereof; optionally mixing said water soluble polymers with said landfill leachate; passing said treated landfill leachate through a membrane, wherein said membrane is an ultrafiltration membrane or a microfiltration membrane; and optionally back-flushing said membrane to remove solids from the membrane surface.

Owner:ECOLAB USA INC

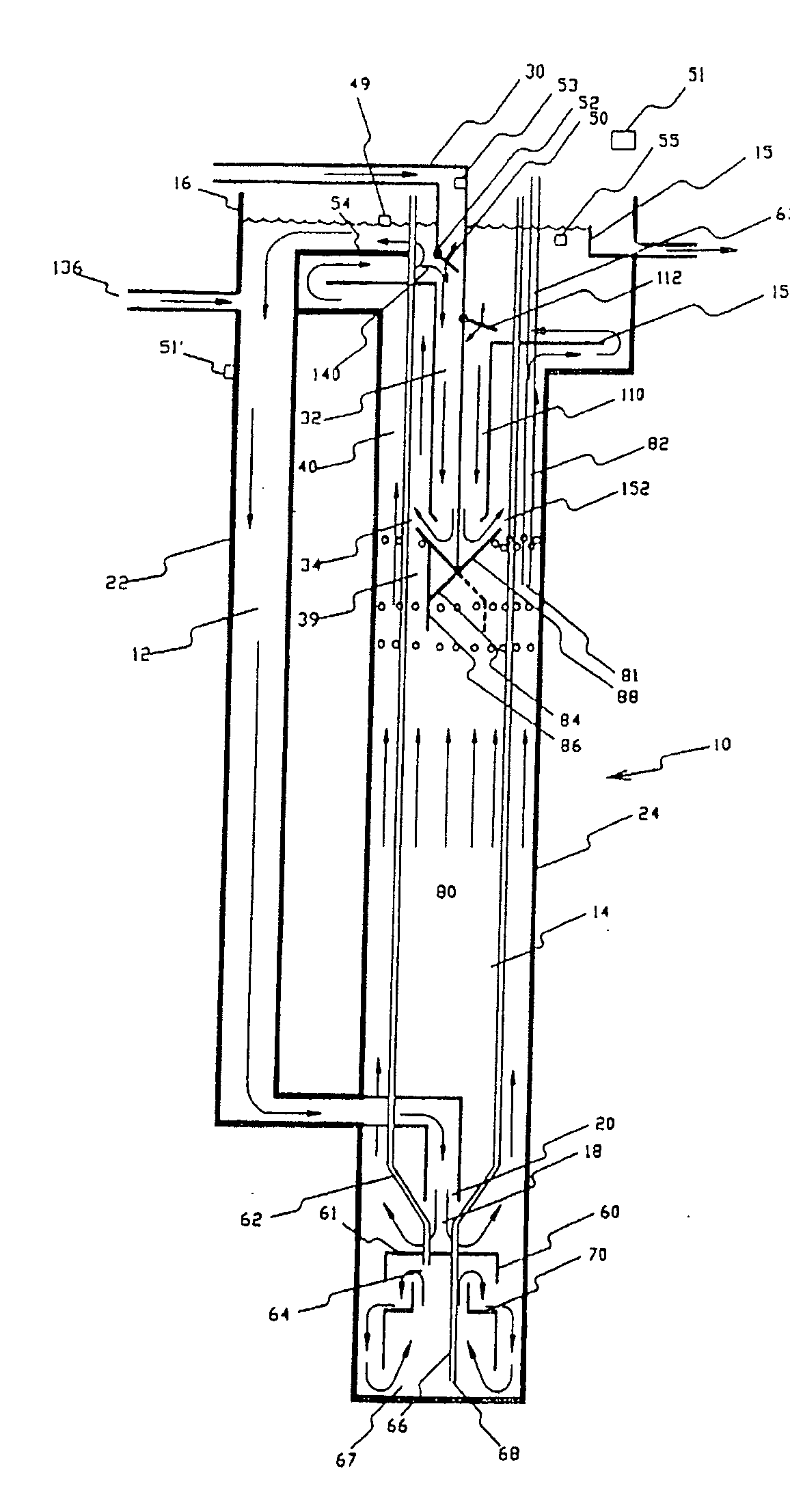

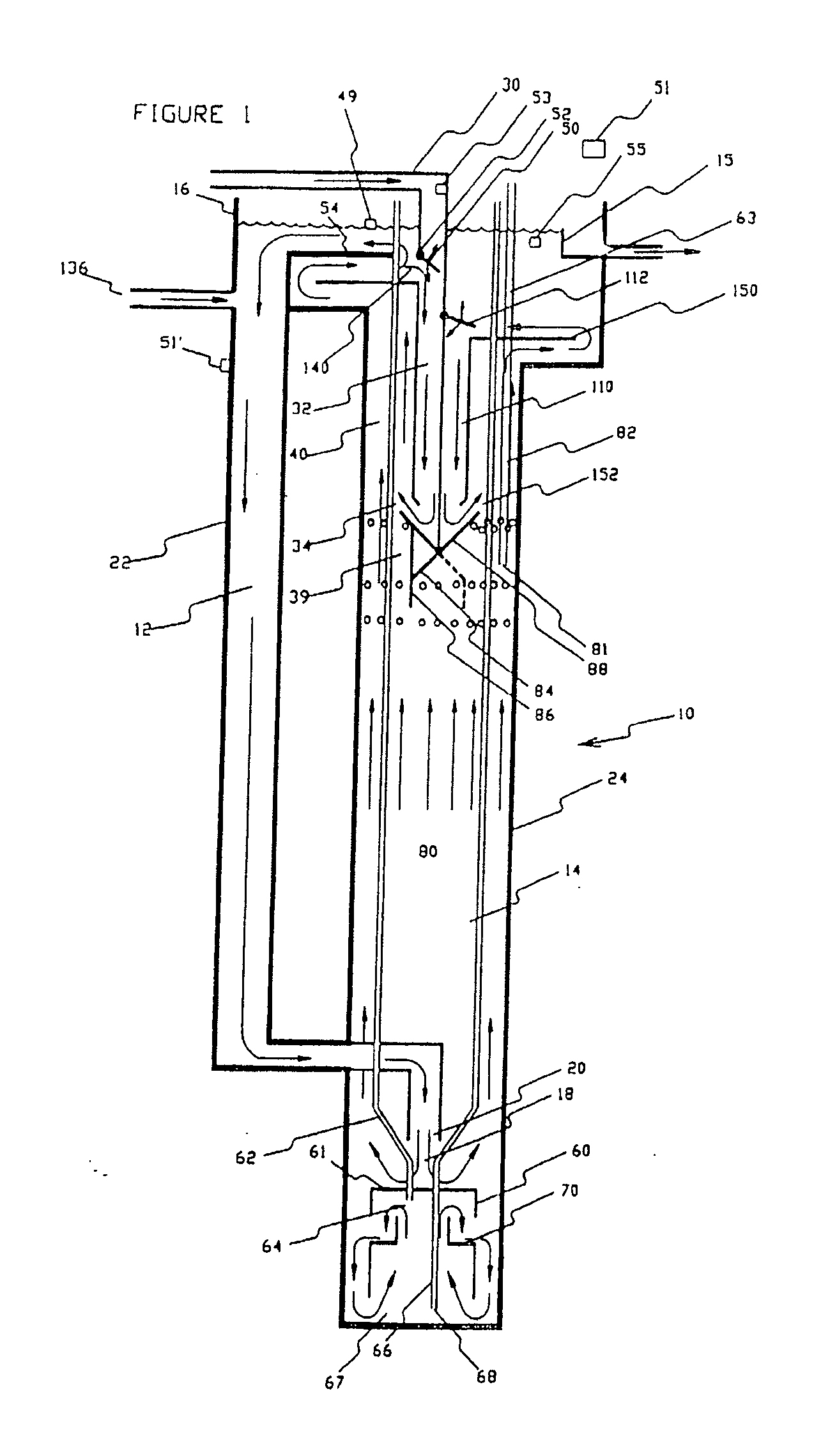

Methods And Apparatus For Biological Treatment of Waste Waters

InactiveUS20080283469A1Extension of timeFacilitated DiffusionTreatment using aerobic processesSedimentation separationFluid compartmentsMembrane surface

A submerged membrane assembly including a membrane having a first surface, a second surface, and a vertical axis, and which is permeable between the surfaces by molecules of less than a predetermined size. A first fluid compartment in fluid communication with the first membrane surface and that contains at a first column height a first fluid having a first specific gravity, a second fluid compartment in fluid communication with the second membrane surface and that contains at a second column height a second fluid having a second specific gravity, and means for changing the second specific gravity. The second column height being selected relative to the first column height to produce a selected pressure differential across the membrane along the vertical axis at the first specific gravity and the changed second specific gravity.

Owner:VAI LTD

Sterile coupling

Sterile coupling comprising a male and a female connector, each provided with a membrane device comprising a membrane surface covered with an adhesive at the exterior surface. When the connectors are brought into operation, the adhesive surface are contacted to form a bonded surface. Then, a hole is generated through the bonded surface and the sterile portions of the devices are brought into cooperations. The hole is formed by a rupture member arranged in one of the connectors. After rupturing, the membrane devices retract to a space formed between the cylindrical bodies of the connectors.

Owner:CARIDIANBCT

Method for modifying polyvinylidene fluoride ultrafiltration membrane by amphiphilic co-polymer

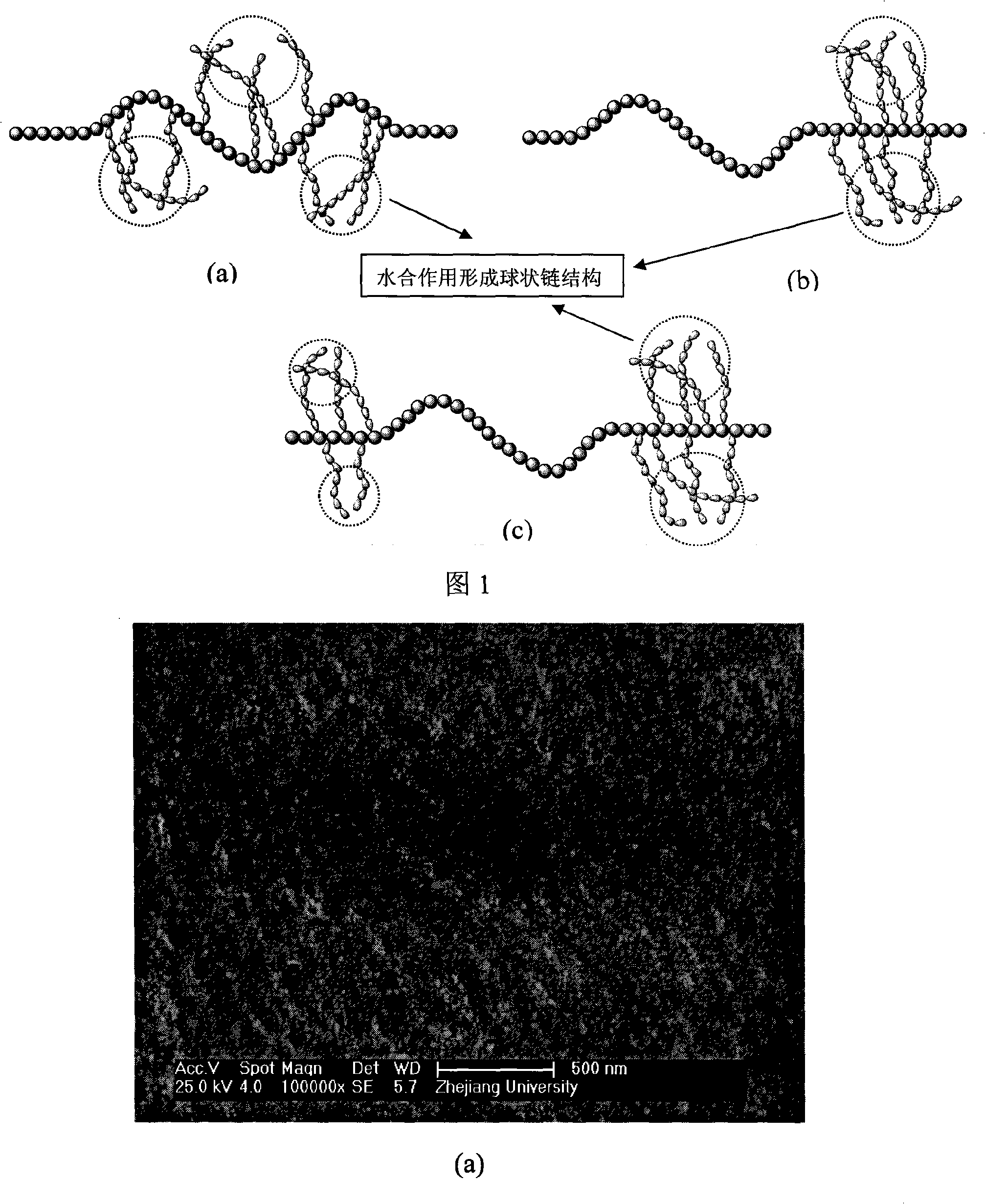

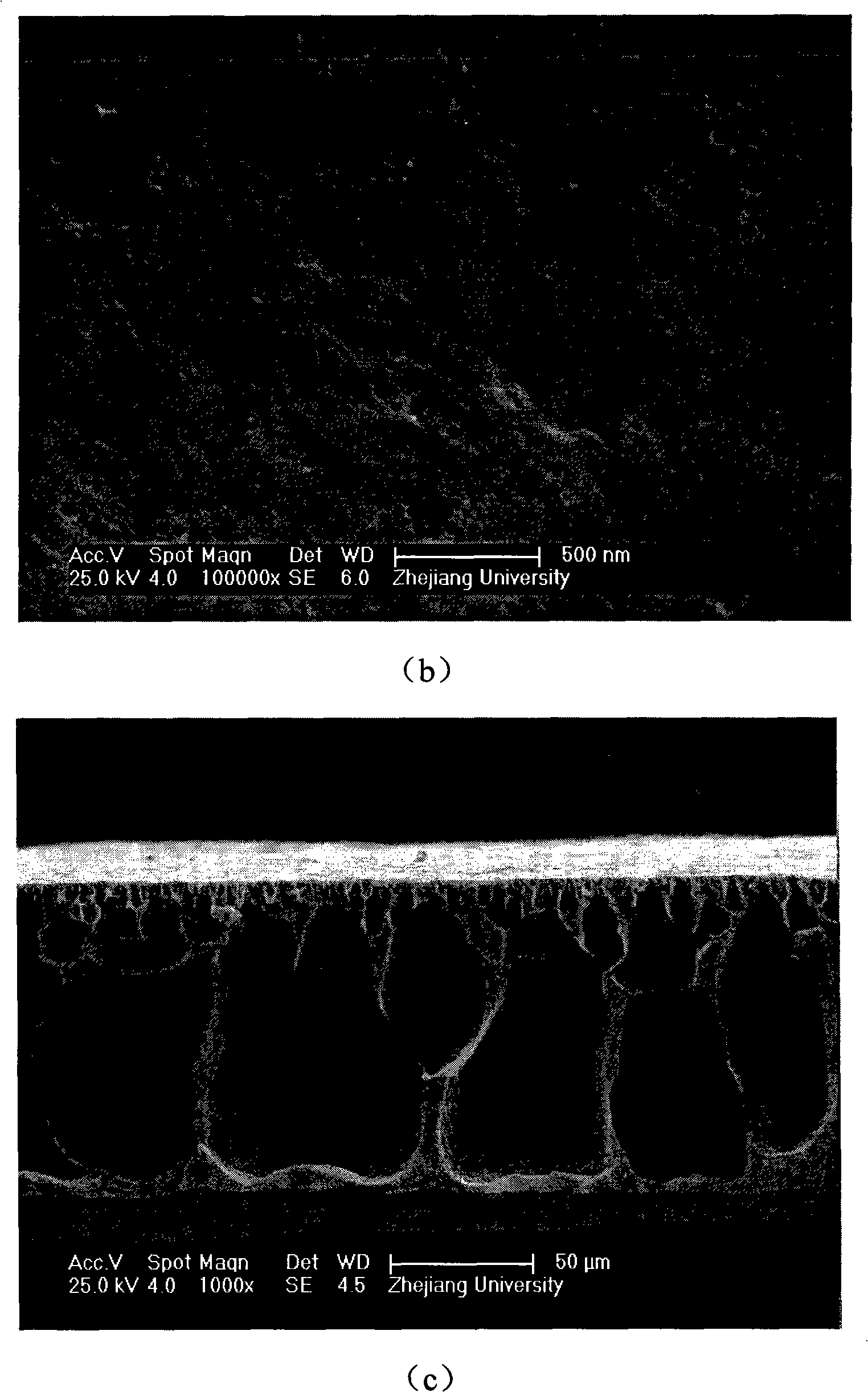

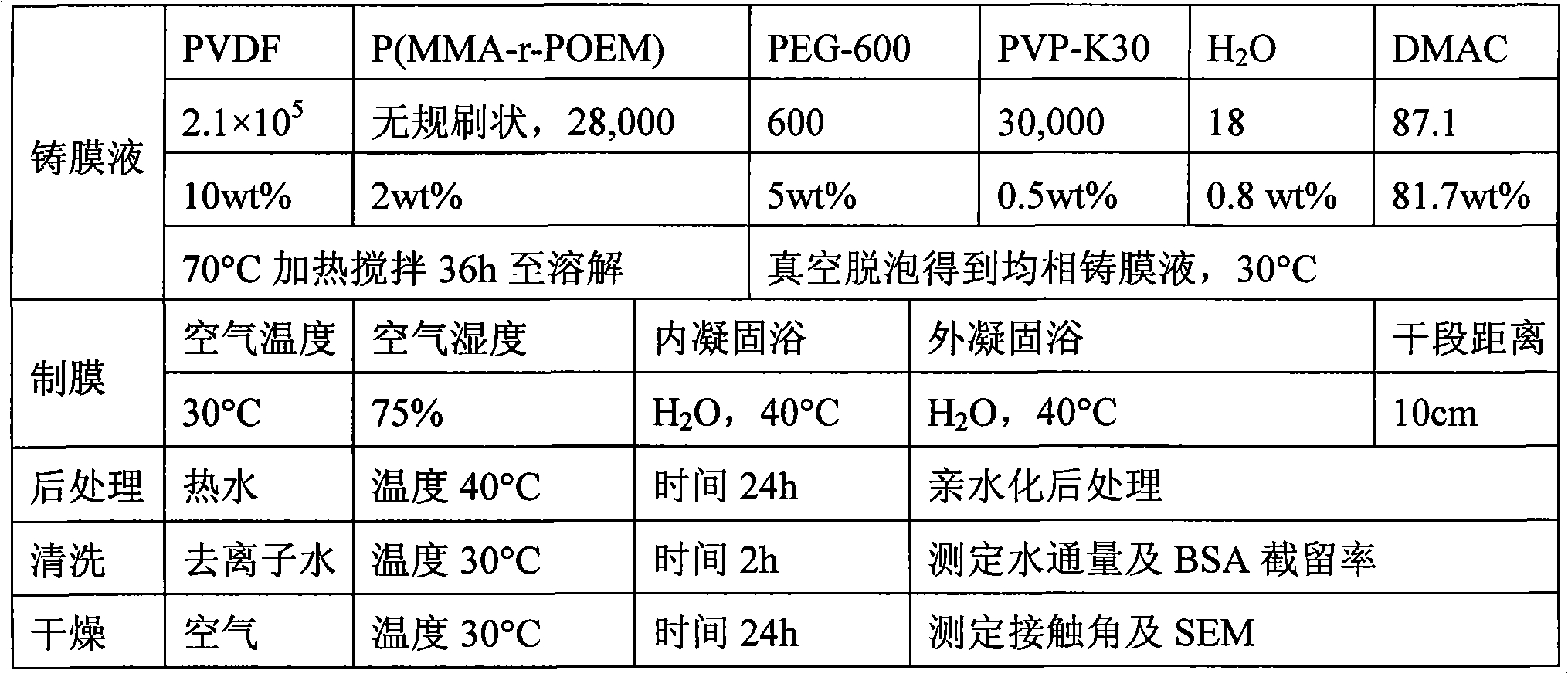

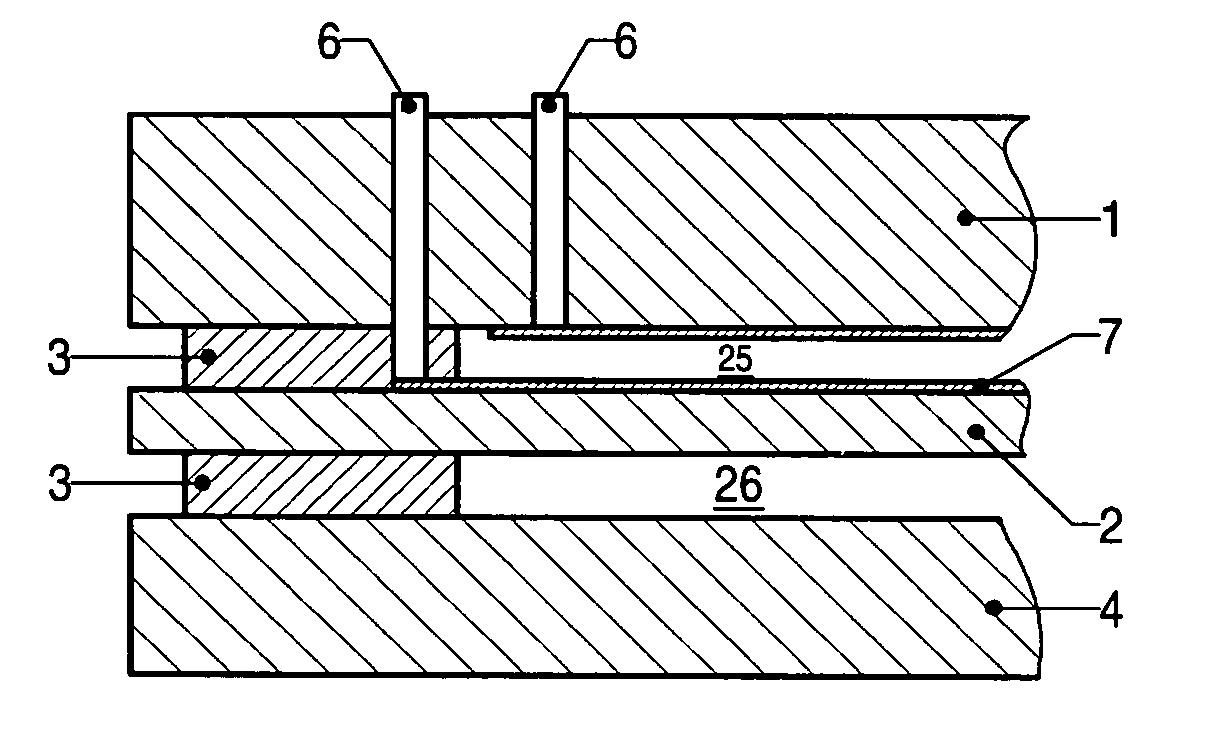

InactiveCN101264428AImprove hydrophilicityReduce energy consumptionSemi-permeable membranesUltrafiltrationDumbbell shaped

The invention discloses a method of producing the hyperfiltration membrane of amphiphilic copolymer modified polyvinylidene fluoride, comprising the following steps: 1) mixing polyvinylidene fluoride, poly (methyl methacrylate - monomethyl ether polyoxyethylene methyl methacrylate), additives, non-solvent and solvent to form the casting film solution; 2) making the casting film solution into the polyvinylidene fluoride membrane by using the film forming machine and then soaking in the coagulation bath; 3) conducting the posttreatment of hydrophilicity; 4)obtaining the hydrophilic polyvinylidene fluoride ultrafiltration membrane after cleaning and drying. The method is characterized in that the brush shape, chain ball shape or dumbbell shape amphiphilic copolymer are mixed with the polyvinylidene fluoride to produce the polyvinylidene fluoride hyperfiltration membrane with hydrophilicity, anti-pollution, large flux and high retention rate by adopting the solution phase conversion method. The method has the advantages that the obtained membrane is provided with dozens to hundreds nanometer of particular densified hydrogel surface layers, the contact angle of the membrane surface can be reduced below 60 degrees and can be lowered to 0 degree within tens of seconds, the water flux can reach 1000L / m<2> / h (0.1Mpa) or above, the retention rate of BSA can reach 90% or more and the recovery rate of water cleaning flux can reach 90% or higher.

Owner:ZHEJIANG UNIV

Optical interferometric pressure sensor

InactiveUS20070089524A1Raise the gradeFluid pressure measurement by mechanical elementsFluid pressure measurement by optical meansOptical reflectionEngineering

A capacitive vacuum measuring cell has a first housing body and a membrane, both of Al2O3 ceramic or sapphire. The membrane is planar with a peripheral edge joined by a first seal to the first housing body to form a reference vacuum chamber. A second housing body of Al2O3 ceramic or sapphire opposite the membrane, is joined to the peripheral edge of the membrane by a second seal to form a measurement vacuum chamber. A port connects the vacuum measuring cell to a medium to be measured. At least in the central area of the first housing body, an optical transparent window is formed and at least the central region of the membrane has an optically reflective surface. Outside the reference vacuum chamber, in opposition to and at a distance from the window, an optical fibre is arranged for feeding in and out light onto the surface of the membrane.

Owner:INFICON GMBH

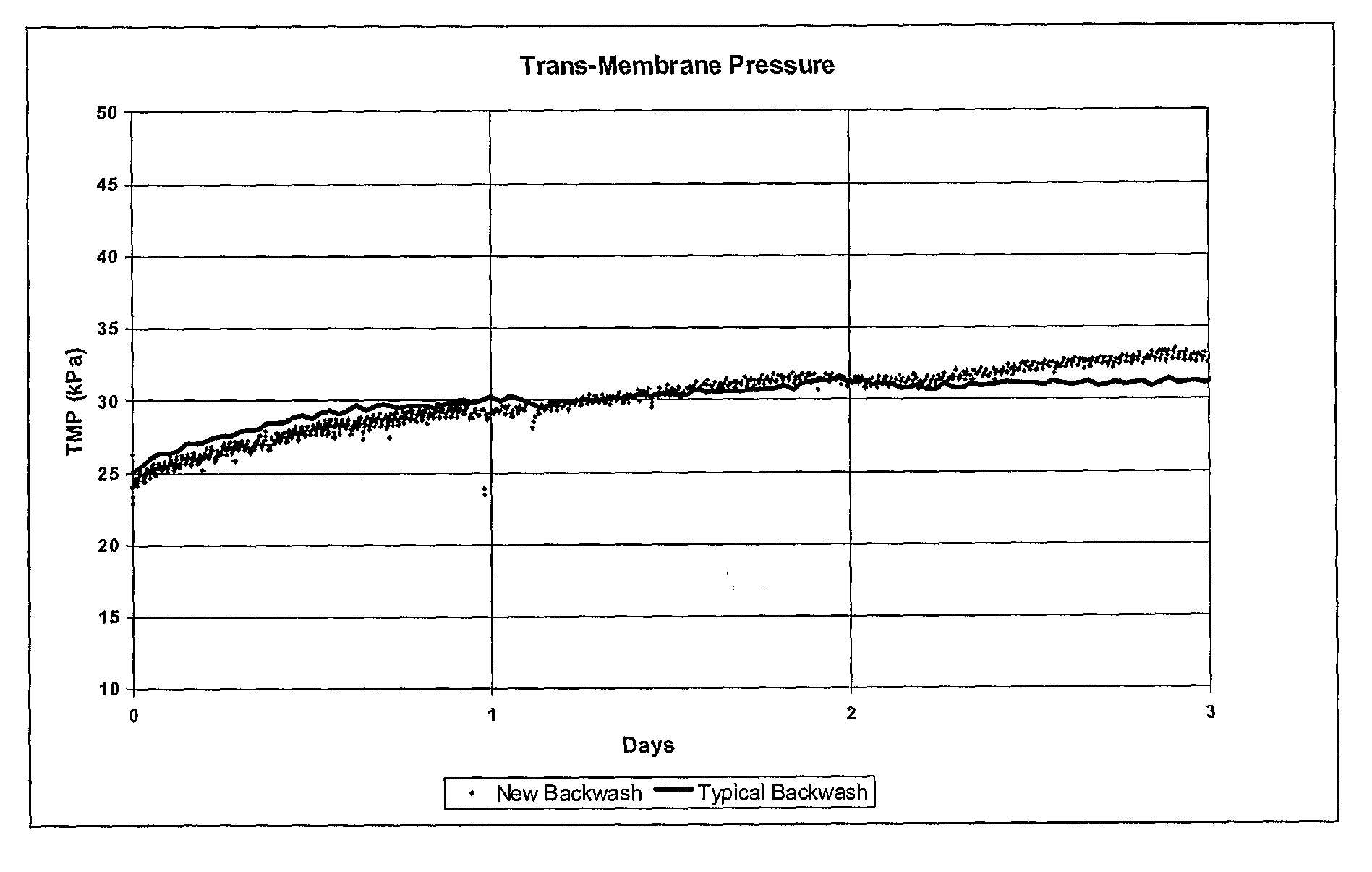

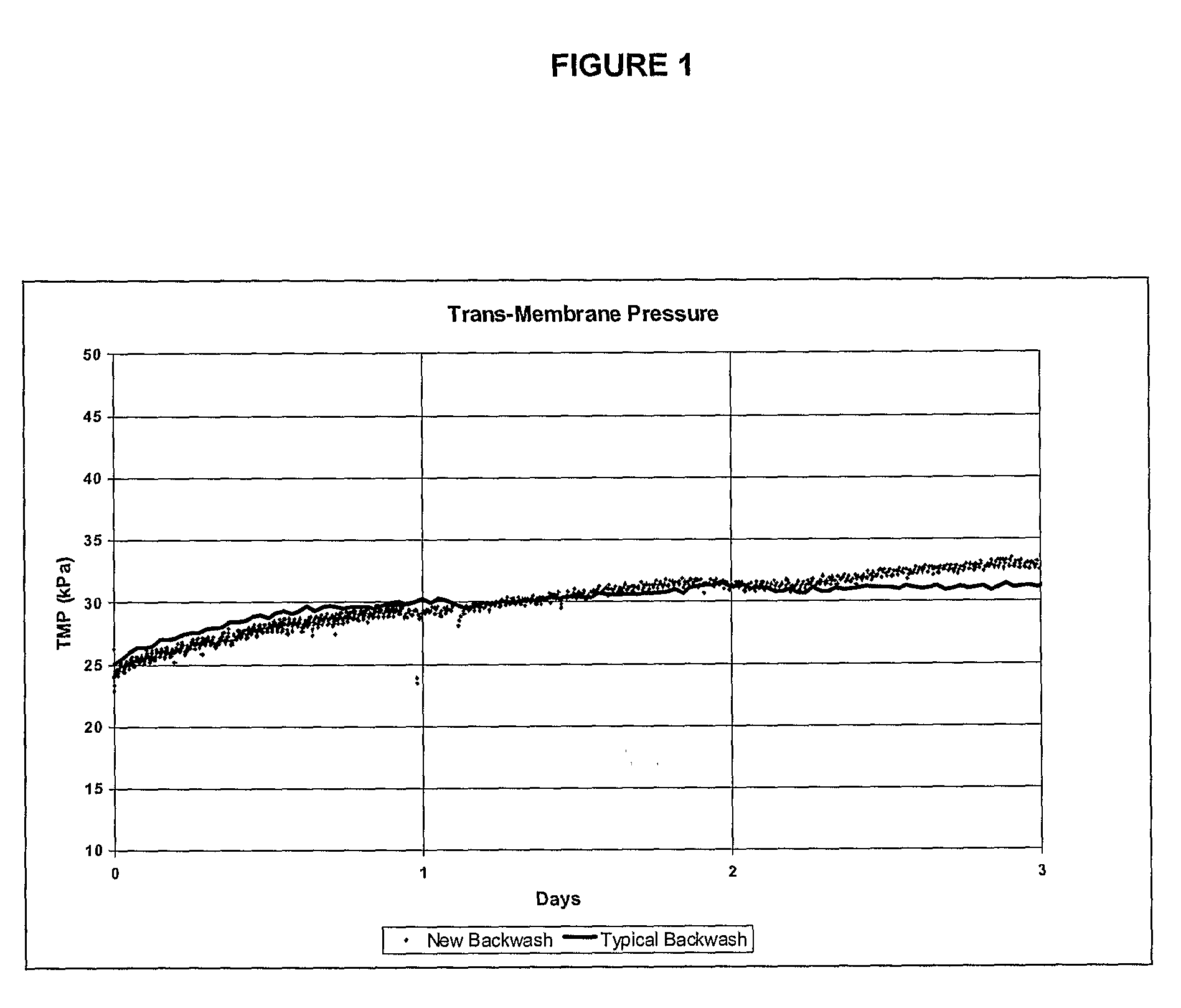

Reduced Backwash Volume Process

A method of backwashing a membrane filtration module, where the module includes one or more membranes located in a feed-containing vessel. The membranes having a permeable wall which is subjected to a filtration operation wherein feed liquid containing contaminant matter is applied to one side of the membrane wall and filtrate is withdrawn from the other side of the membrane wall. The method includes the steps of suspending the filtration operation; aerating the membrane surface with gas bubbles to dislodge fouling materials therefrom; recommencing the filtration operation while suspending the flow of feed liquid to the feed-containing vessel for a predetermined period; again suspending the filtration operation; performing a liquid backwash of the membrane wall to dislodge fouling materials therefrom; removing at least some of the liquid containing the dislodged contaminant matter from the feed-containing vessel; and then recommencing the filtration operation.

Owner:EVOQUA WATER TECH LLC

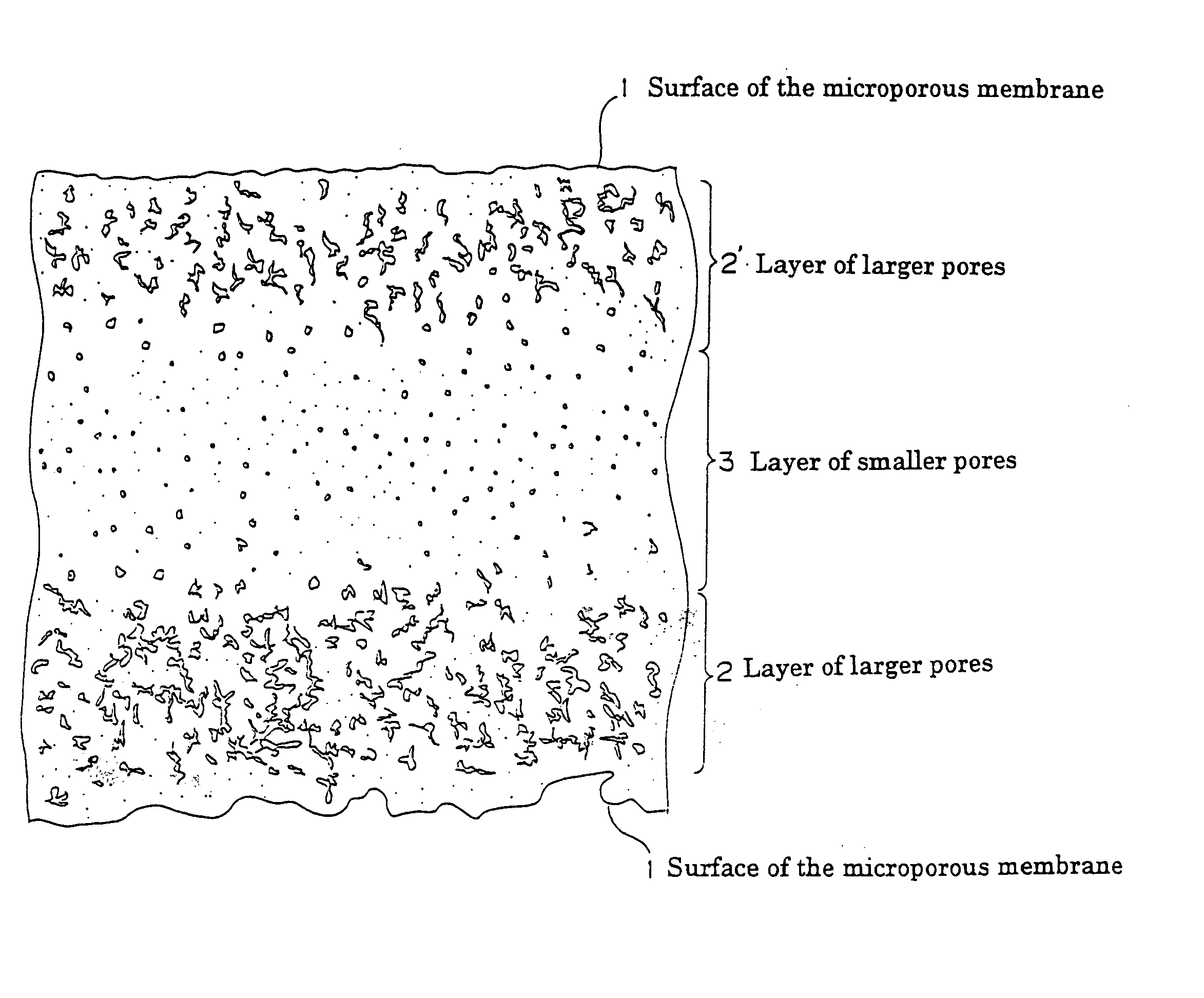

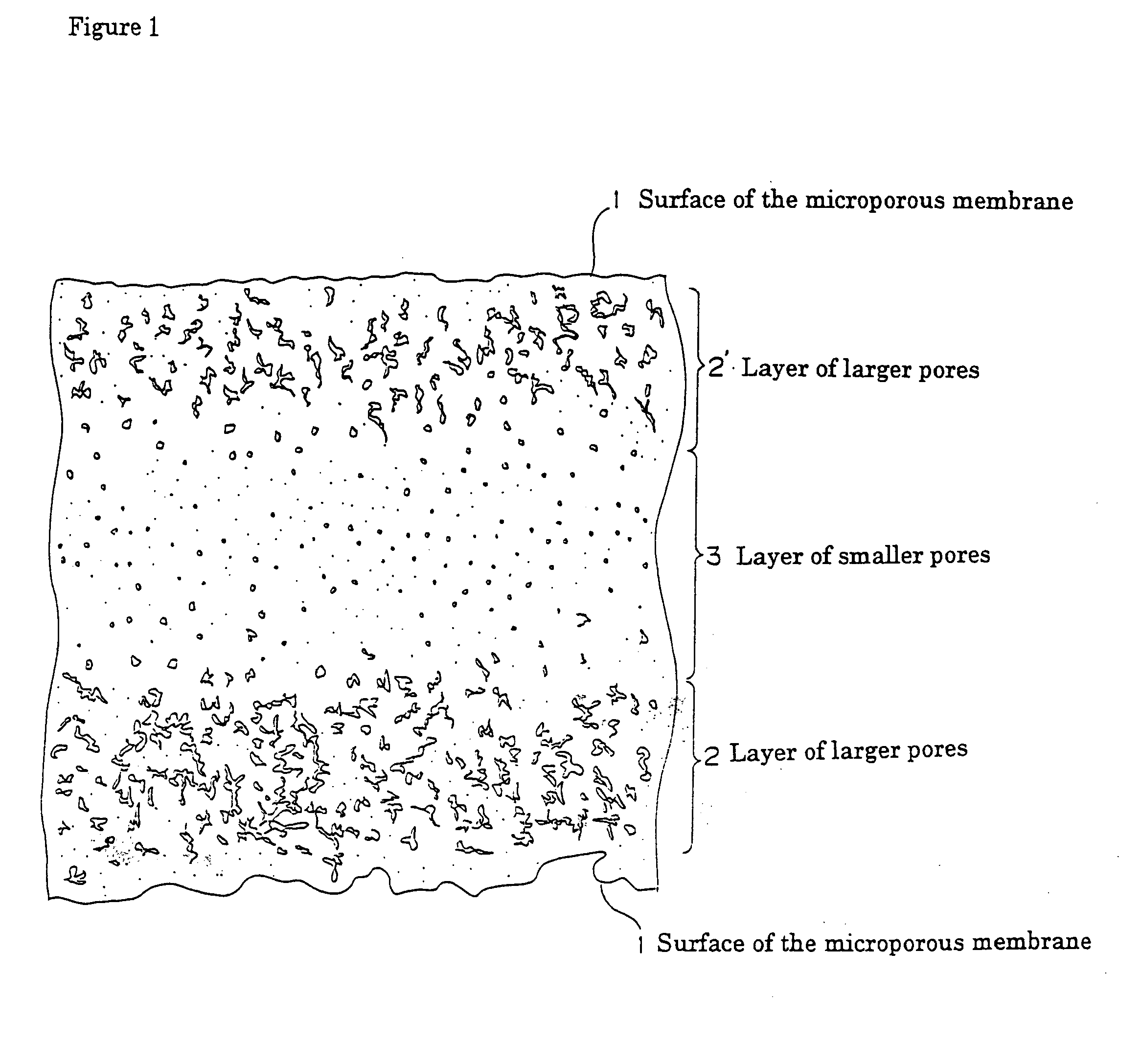

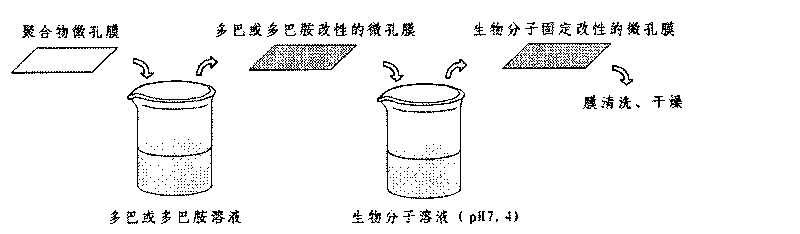

Microporous polyolefin membrane, and method of producing the same

InactiveUS20050098913A1Controllability of pore sizeControllability of porositySemi-permeable membranesMembranesPolymer sciencePolyolefin

The present invention provides a microporous polyolefin membrane of high permeability and novel structure, and also provides a method of producing the same, wherein its average pore size is gradually decreases from at least one membrane surface towards its center. The method of producing the microporous polyolefin membrane comprises the steps of extruding the solution, composed of 10 to 50 weight % of (A) a polyolefin having a weight-average molecular weight of 5×105 or more or (B) a composition containing this polyolefin and 50 to 90 weight % of a solvent, into a gel-like formed article and removing the solvent therefrom, wherein a treatment step with a hot solvent is incorporated.

Owner:TORAY IND INC

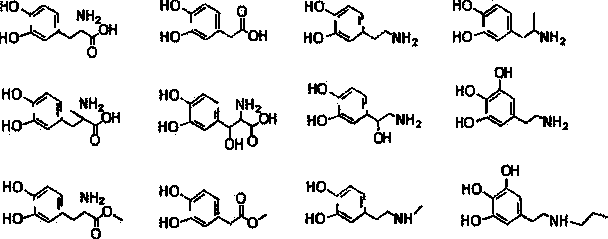

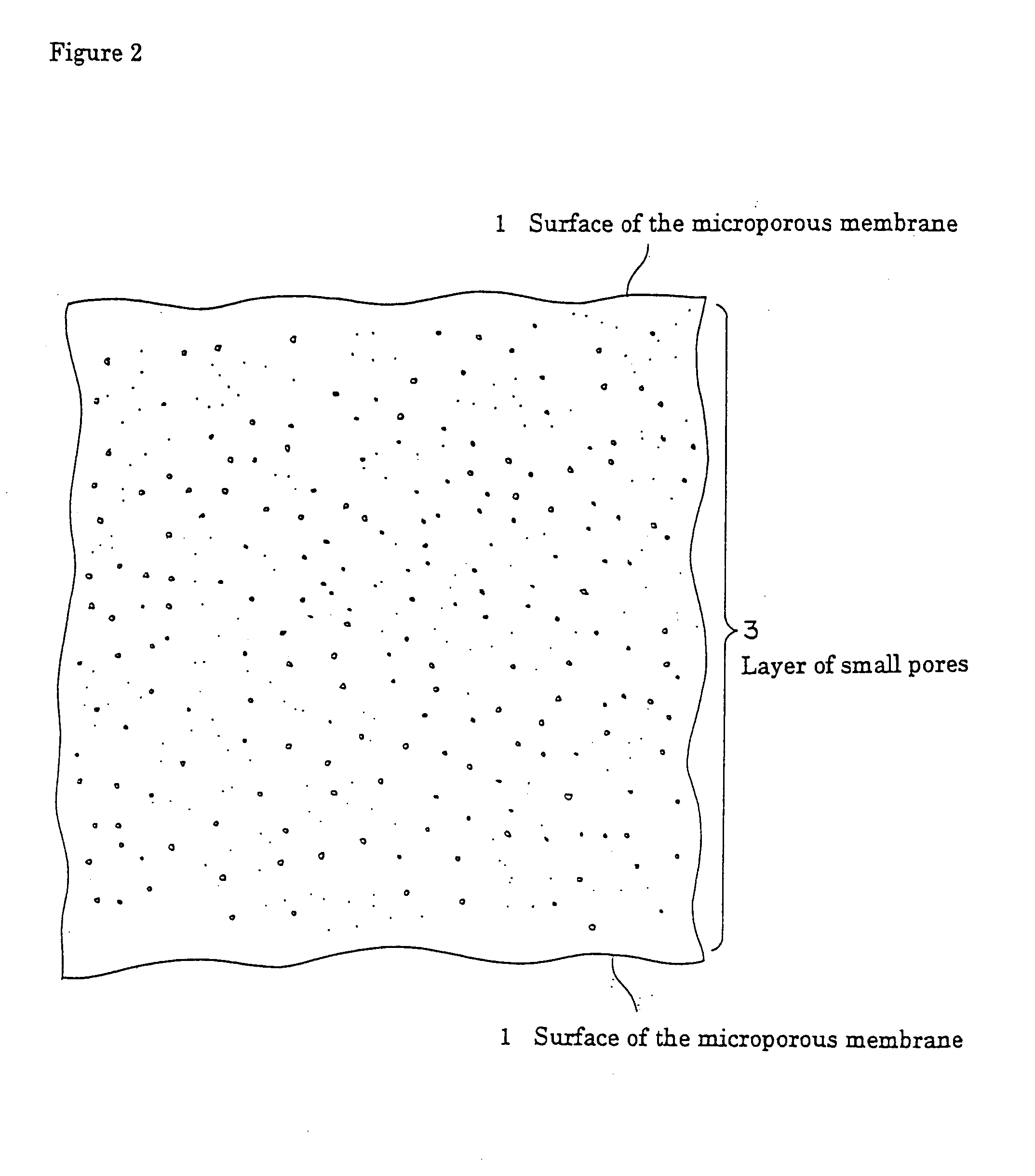

Method for fixing biological molecules on polymer microporous membrane surface

ActiveCN101745327ALow costEase of mass industrial productionSemi-permeable membranesBiocompatibility TestingPhosphoric acid

The invention discloses a method for fixing biological molecules on a polymer microporous membrane surface, comprising the following steps: (1) respectively dissolving DOPA compounds and the biological molecules in a trihydroxymethyl aminomethane - muriatic acid buffer solution and a phosphoric acid buffer solution to prepare solutions; (2) immersing a polymer microporous membrane in a DOPA compound solution and oscillating to cause the DOPA compounds to be auto-polymerized-compounded on the membrane surface and to be closely attached to the membrane surface and a membrane pore wall; (3) immersing the polymer microporous membrane modified by the DOPA compounds in a biological molecule solution, and fixing the biological molecules on the polymer microporous membrane surface by the addition reaction between catechol groups of the membrane surface and amidogen in the biological molecules. The method for fixing biological molecules on the polymer microporous membrane surface has simple process, the prepared polymer microporous membrane has good hydrophilic property and biocompatibility, and the method has important meaning for improving the permeability and the biocompatibility of the polymer microporous membrane.

Owner:ZHEJIANG UNIV

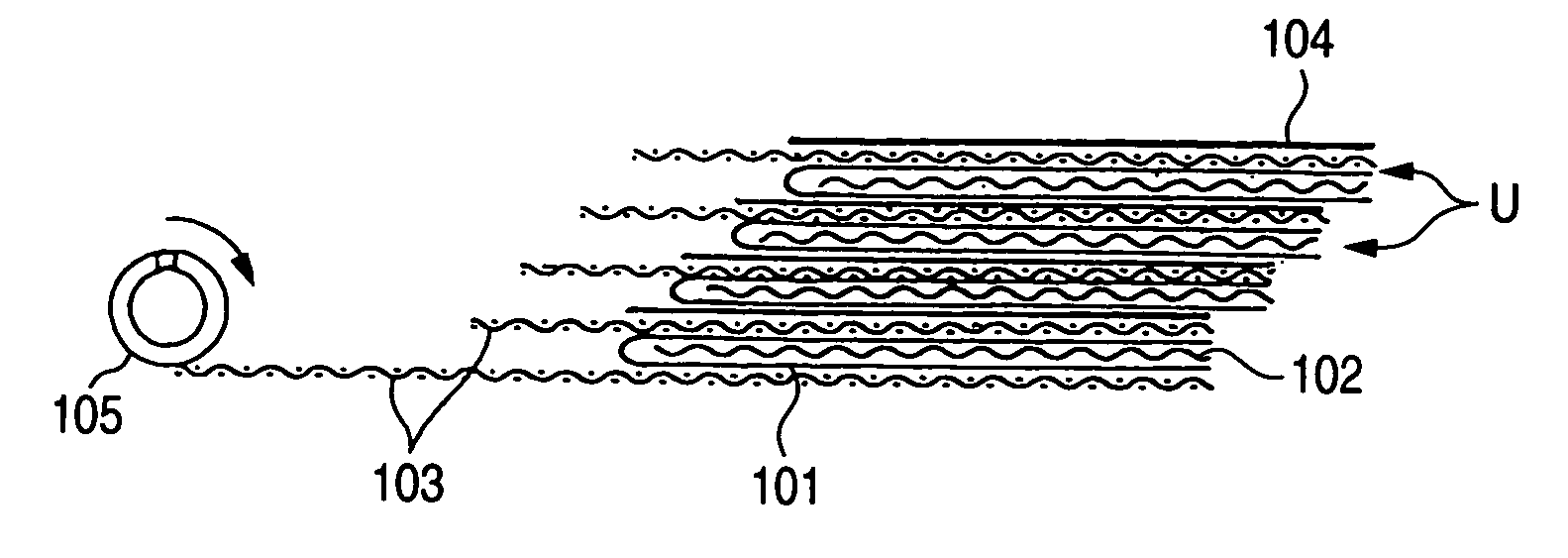

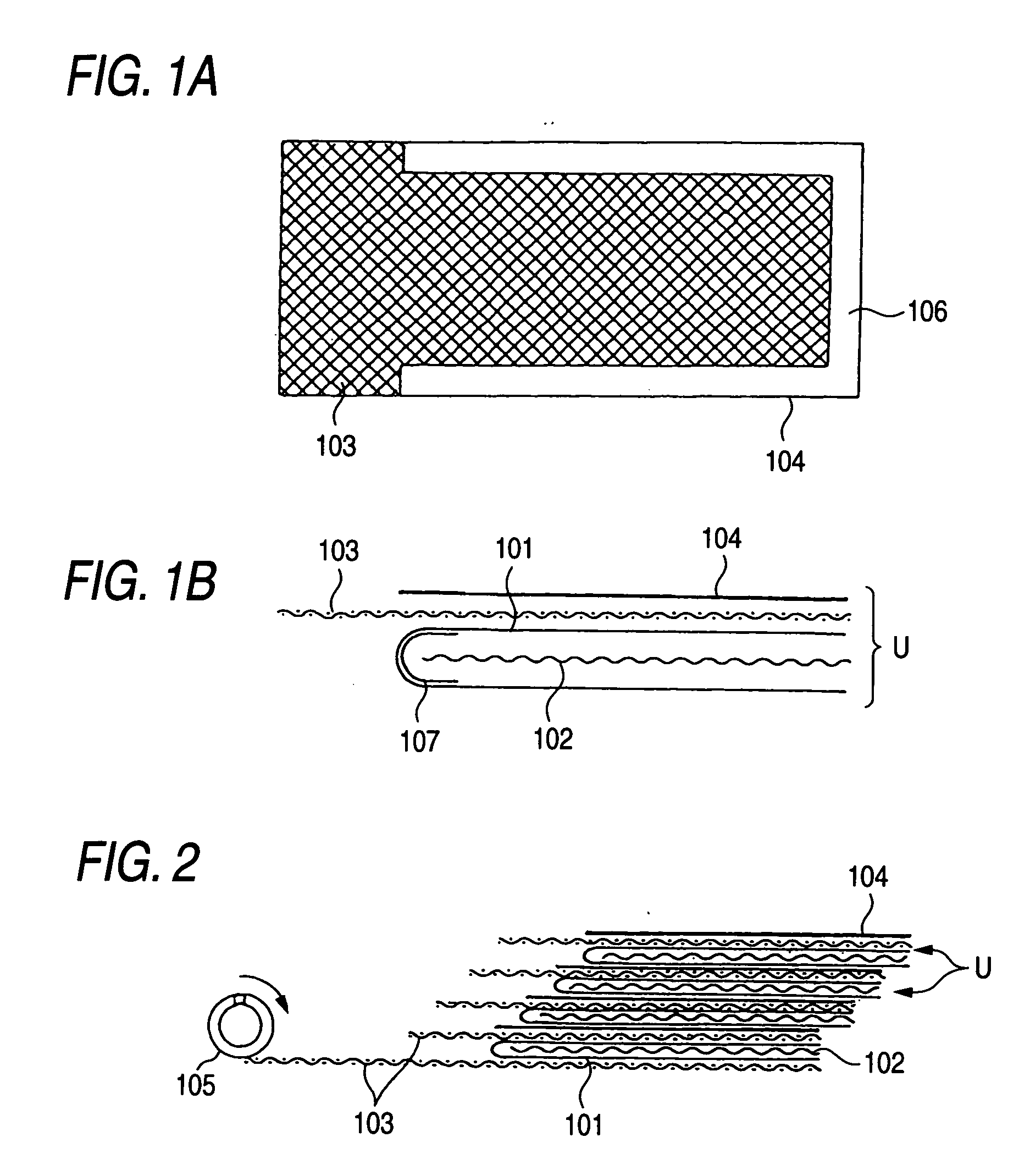

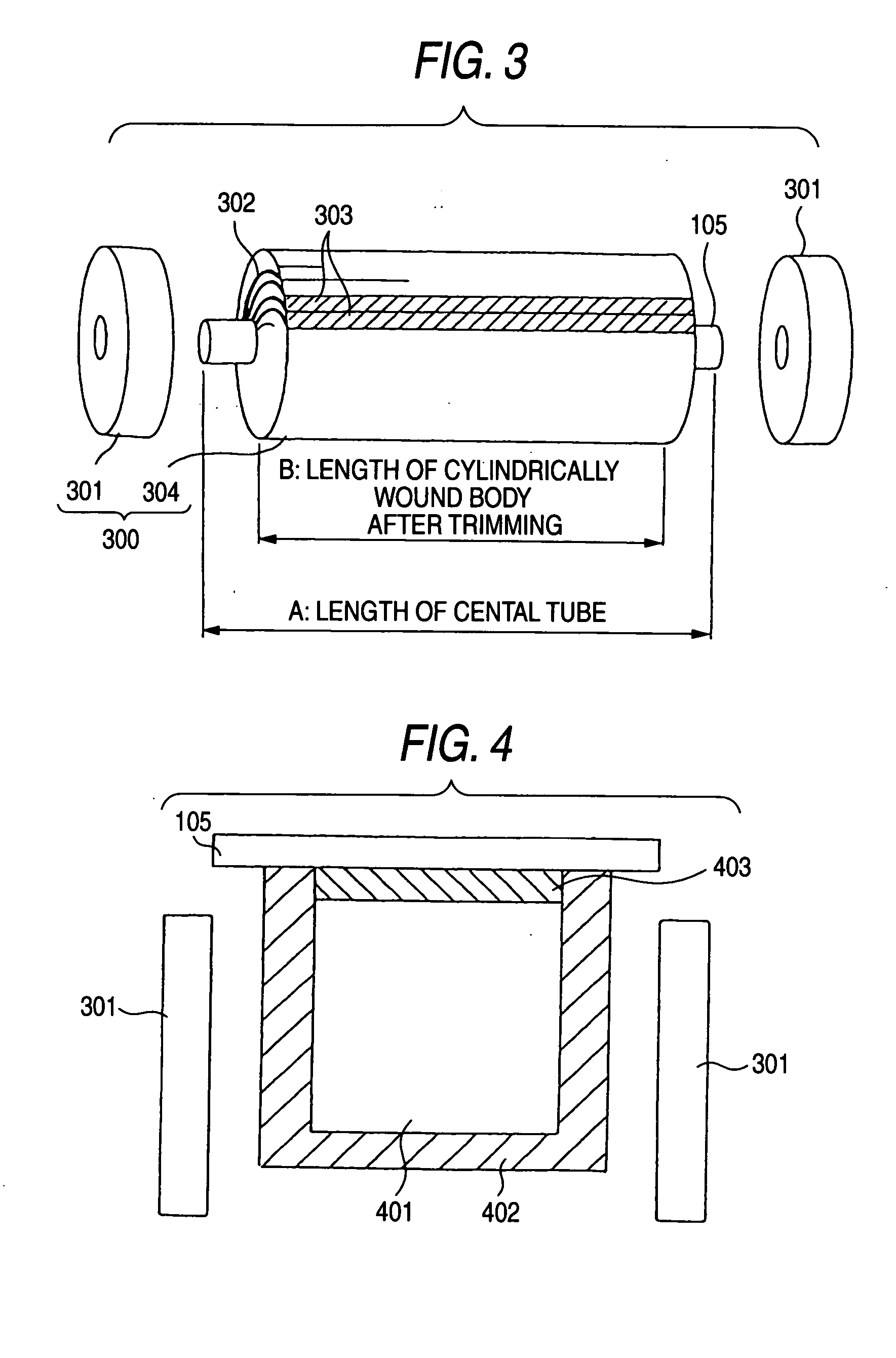

Spiral membrane element and method of manufacturing the same

InactiveUS20050077229A1Reduce total pressure lossReduce manufacturing costSemi-permeable membranesDispersed particle filtrationAdhesiveMembrane surface

A spiral membrane element having an enlarged effective membrane surface area without having its separation performance lowered, while maintaining the sealing property of any sealing portion of a cylindrically wound body, and a manufacturing method of the same are disclosed. The spiral membrane element includes a cylindrically wound body comprising a perforated central tube and, spirally wound therearound, a separation membrane, a feed-side passage material and a permeation-side passage material in a laminated state, and a sealing portion for preventing a feed-side fluid and a permeation-side fluid from being mixed together, wherein the sealing portion formed at each of both ends of the cylindrically wound body is spirally formed with a substantially constant width by an adhesive and has a trimmed section formed on its whole end surface, and the cylindrically wound body has a ratio of its length to the length of the central tube of 0.96 to 1.00, and a ratio of an ineffective membrane surface area to the entire membrane surface area of 0.02 to 0.10.

Owner:NITTO DENKO CORP

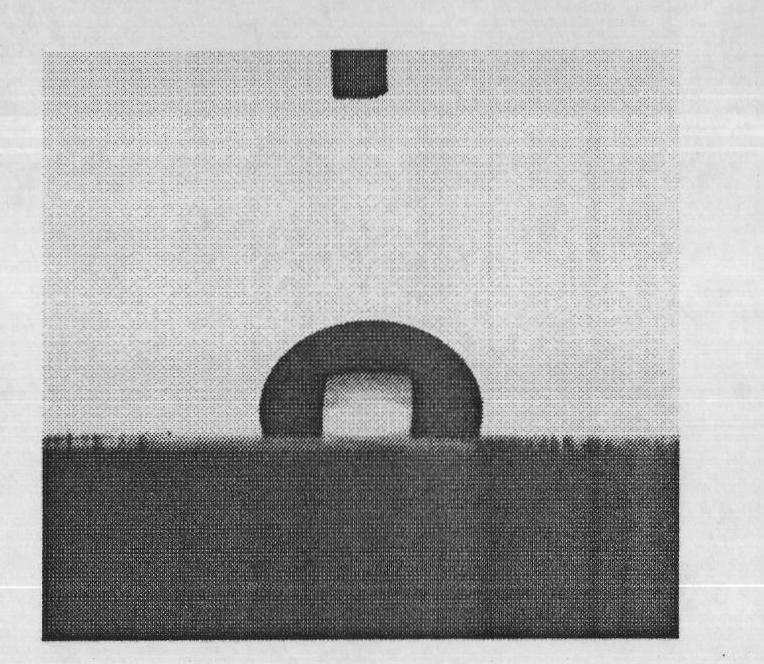

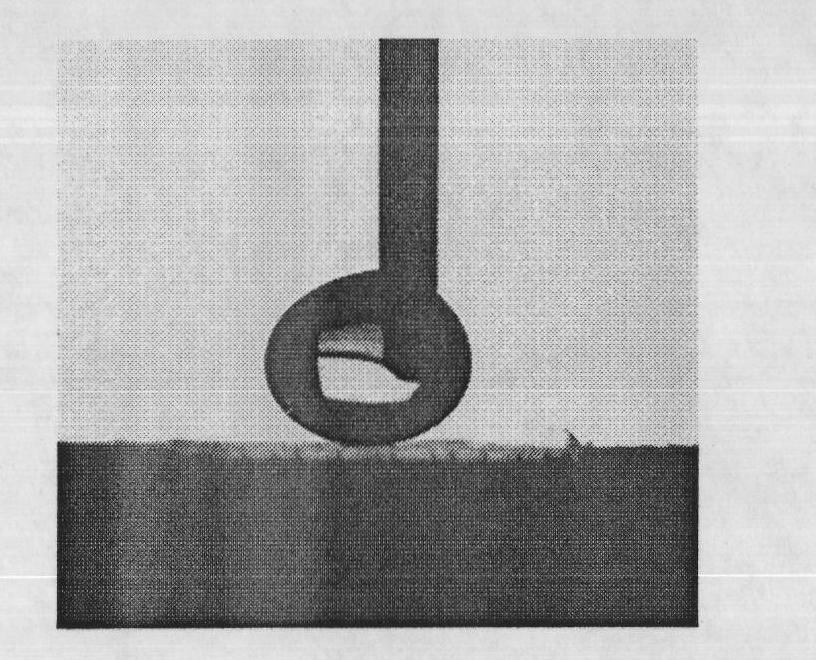

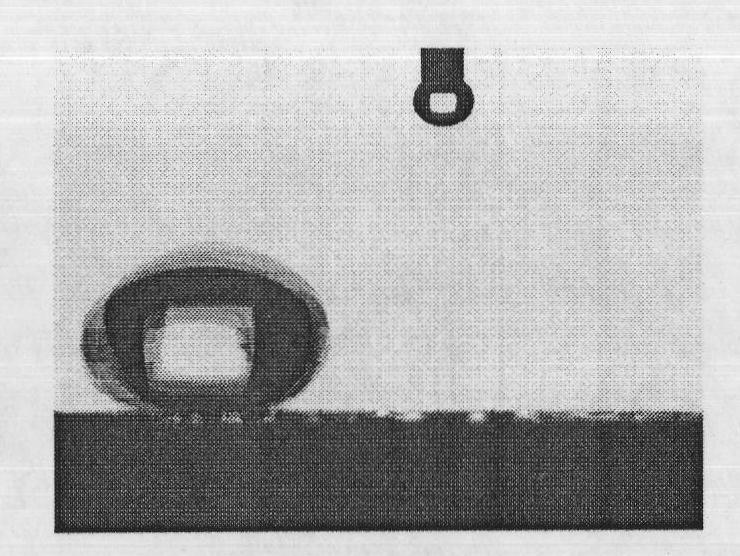

Super-hydrophobic nano-composite coating and preparation method thereof

InactiveCN101845242AExcellent superhydrophobic propertiesAchieve self-cleaning effectCoatingsProcess equipmentHydrophobic polymer

The invention discloses a super-hydrophobic nano-composite coating comprising the following components in percentage by weight: 0.5-10.5 percent of hydrophobic silicon dioxide, 0.2-5.4 percent of hydrophobic polymer material and 86.5-99.3 percent of solvent, wherein a contact angle of a water drop on a membrane surface prepared by the coating is 152-169 degrees, and a rolling angle is 1-9 degrees. When the coating is transparent, the visible light transmission of the membrane prepared from the coating is 80-94 percent. The invention also discloses a preparation method of the super-hydrophobic nano-composite coating. The nano-composite coating not only has excellent super-hydrophobicity and low cost of products, but also can obtain higher transparency by reducing the contents of the hydrophobic silicon dioxide and the hydrophobic polymer material and has simple preparation processing equipment and high production efficiency.

Owner:SICHUAN UNIV

Cleaning method for simple filtration systems

InactiveUS20100200503A1Provide usageSemi-permeable membranesSpecific water treatment objectivesFiltrationMembrane surface

A method of cleaning a permeable, hollow membrane (6) in an arrangement of the type wherein a pressure differential is applied across the wall of the permeable, hollow membrane (6) immersed in a liquid suspension provided in a vessel (5), said liquid suspension being applied to the outer surface of the permeable hollow membrane (6) to induce and sustain filtration through the membrane wall. The method of cleaning comprising the steps of: suspending the filtration process; while continuing to supply the liquid suspension to the vessel (5); aerating the membrane (6) by flowing gas into the vessel (5) to produce a flow of gas bubbles around the membrane (6) to dislodge at least some of the retained particulate material from the membrane surface; removing liquid containing dislodged particulate material from the vessel (5) during the aerating step and recommencing the filtration process.

Owner:SIEMENS IND INC

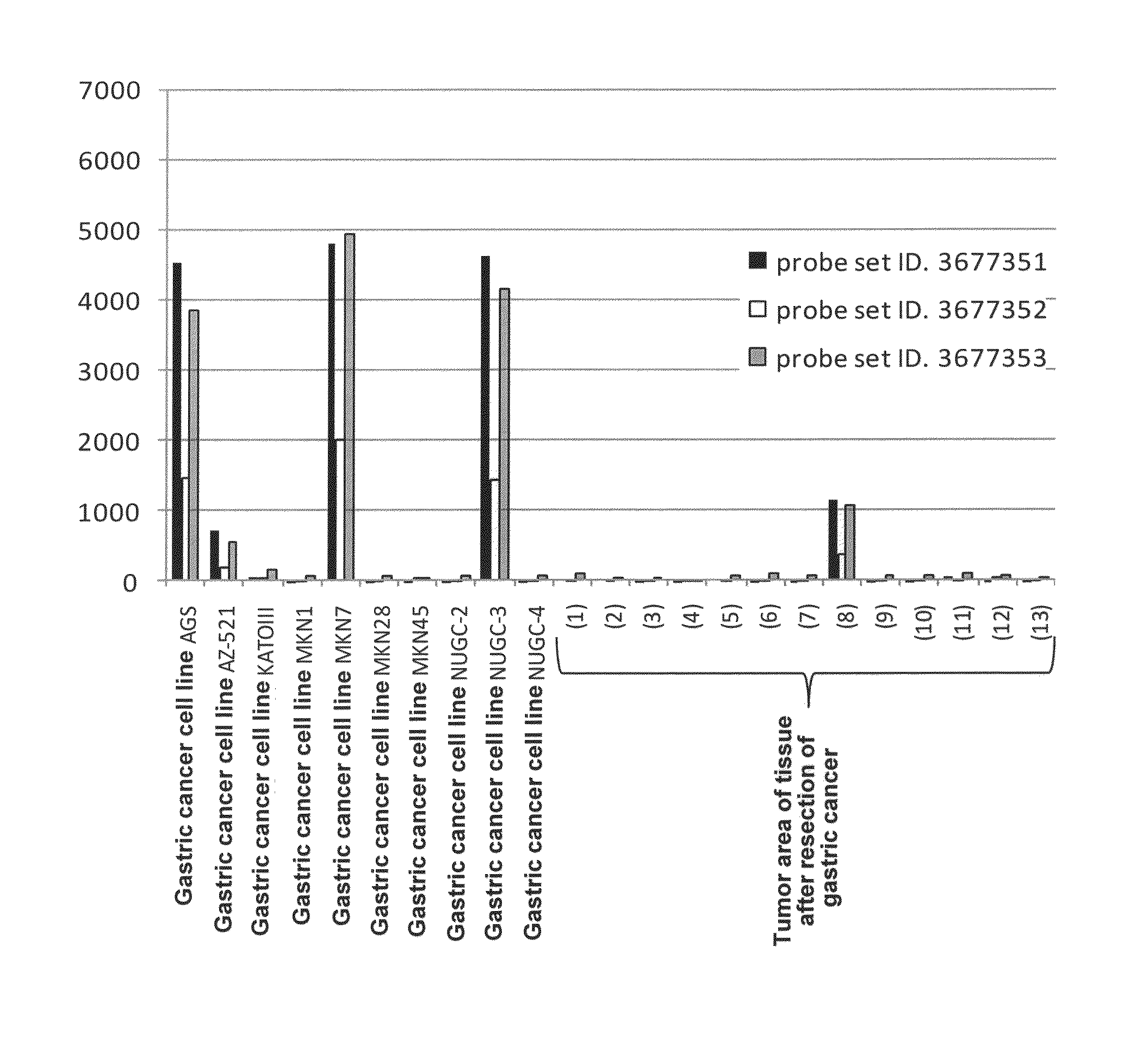

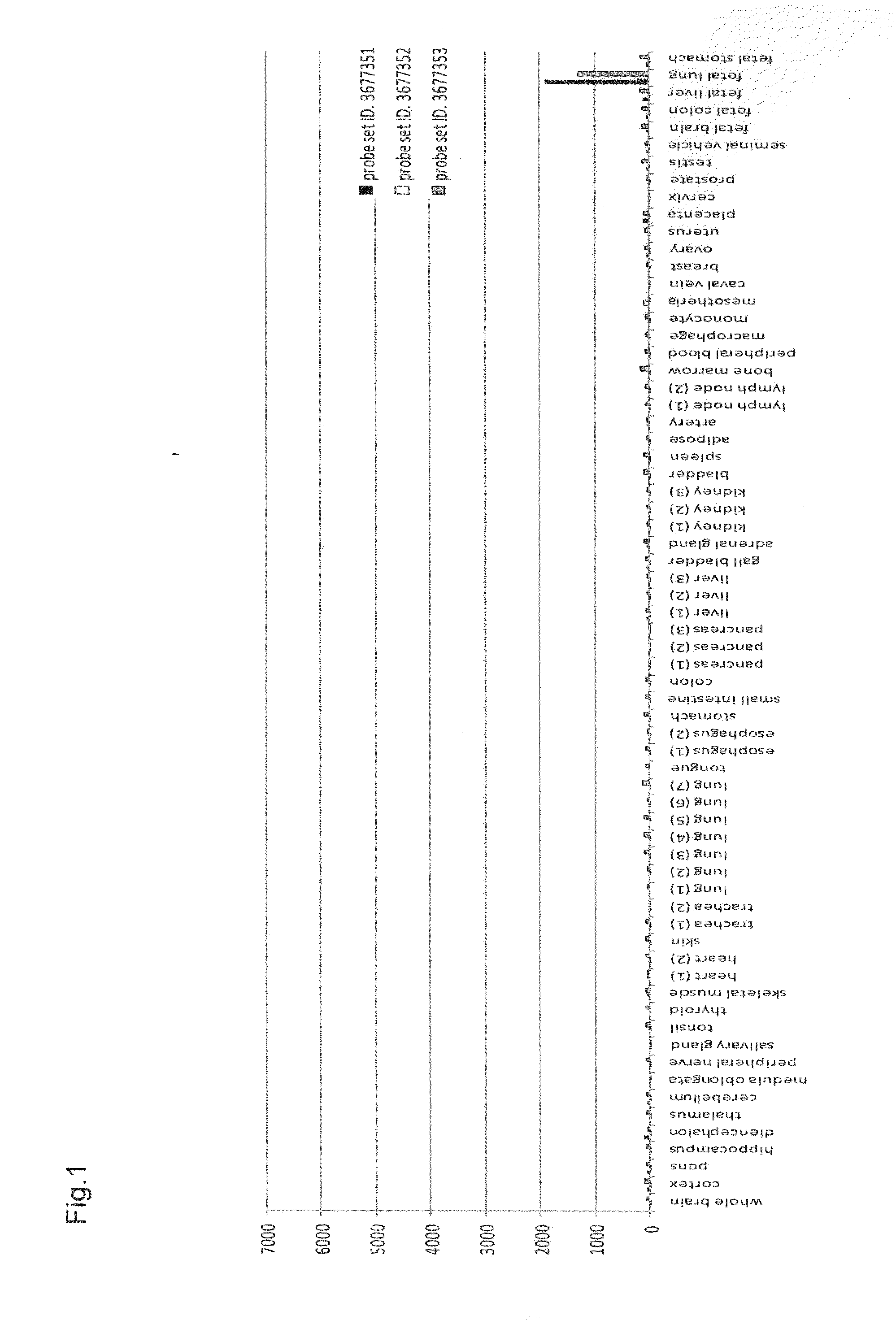

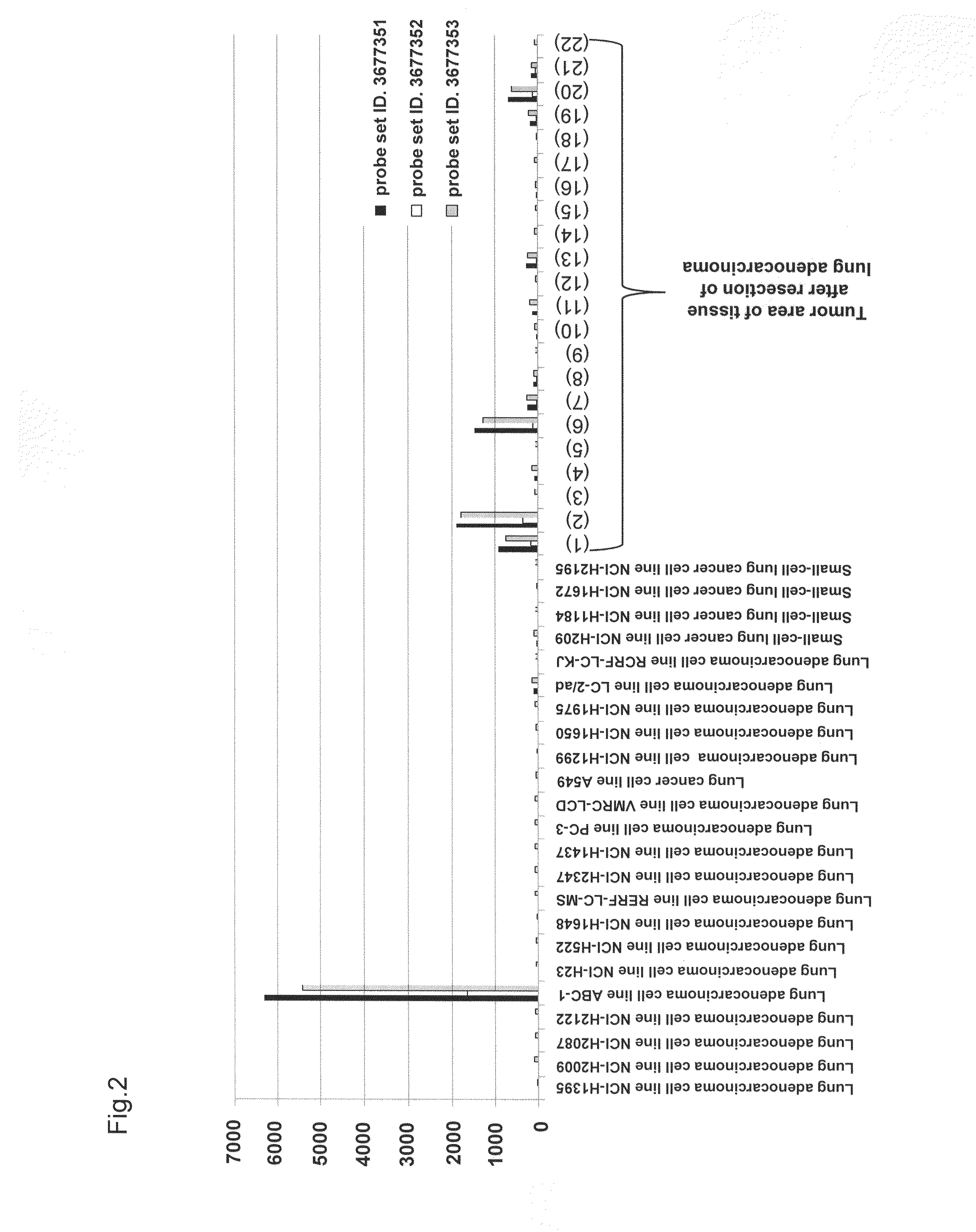

Anti-cldn6 antibody

ActiveUS20110059469A1Immunoglobulins against cell receptors/antigens/surface-determinantsAntibody ingredientsCancer cellCytotoxicity

The present invention relates to an antibody binding to Claudin6 (CLDN6) expressed on a cell membrane. The antibody of the present invention recognizes human CLDN6 present in a native form on cell membrane surface and exhibits cytotoxicity through ADCC and / or CDC activities against cancer cell lines highly expressing human CLDN6. Moreover, the antibody of the present invention has cell growth inhibitory effect through conjugation with toxin on cancer cell lines highly expressing human CLDN6. The human CLDN6 is overexpressed in tumor tissues (lung adenocarcinoma, gastric cancer, and ovarian cancer), although its expression is not observed in normal tissues. Thus, the anti-CLDN6 antibody is expected to highly accumulate in tumors highly expressing human CLDN6 and can serve as a very effective antitumor agent.

Owner:CHUGAI PHARMA CO LTD +1

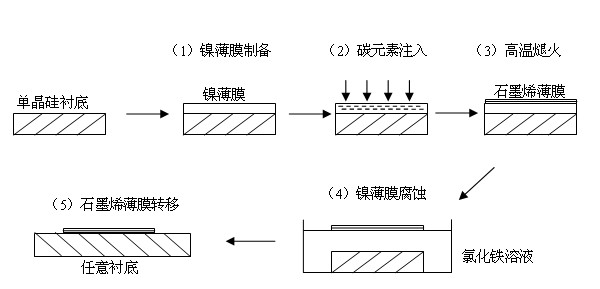

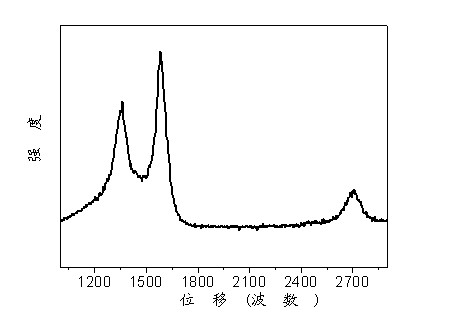

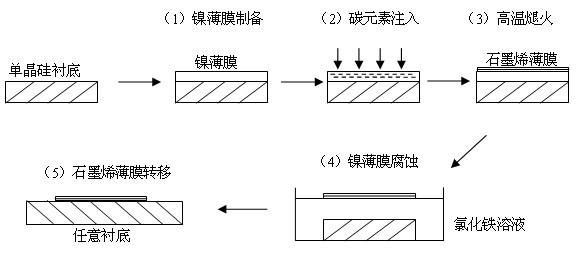

Method for preparing large-scale two-dimensional nanomaterial graphite

The invention relates to a method for preparing a large-scale two-dimensional nanomaterial graphite, comprising the following steps of: plating a nickel film with the thickness of 100-300nm on the surface of monocrystal silicon, and then injecting carbon element into the nickel film by adopting an ion implantation mode; annealing for 15min-1h at a high temperature between 600 DEG C and 1,000 DEG C and a vacuum degree of from (10-5)Pa to 1Pa, and cooling to room temperature so that carbon atoms are separated out from the nickel film and recombined. Therefore, a layer of graphite film (the film thickness depends on various experiment parameters, such as carbon injection content, and the like) can be formed on the surface of the nickel film. When a sample is put into a FeCl3 solution, the nickel film can be corroded, and the graphite film can be separated out and floats on the surface of the liquid; and at the moment, the graphite film can be transferred away from the liquid with any substrate. Therefore, the large-scale graphite film with the size of several centimeters can be prepared.

Owner:SOUTHEAST UNIV

Electrically conductive pins for microcircuit tester

ActiveUS8536889B2Improve reliabilityImprove throughputElectronic circuit testingElectrical measurement instrument detailsContact padMembrane surface

Owner:JOHNSTECH INT

Low pressure filtration

ActiveUS20070131614A1Produced economicallyReduce energy consumptionMembranesUltrafiltrationFiltrationStreamflow

High flow, low-pressure ultrafiltration or microfiltration spiral wound membrane cartridges are used in filtration of liquid feedstocks having high suspended solids. Applications may utilize either vacuum or pumping for transmembrane drive pressure (TMP), and gas may optionally be bubbled up through the cartridges with certain feedstocks. Water permeate flux rates as high as 90 gallons per square foot per day (gfd) can be obtained at TMPs below 5 pounds per square inch. By locating each spiral wound cartridge in its own casing and supplying liquid feedstock to an open lower end of the casing, as opposed to submerging such cartridges in a tank filled with feedstock, overall low pressure performance is greatly improved. High permeate flow can be maintained for long periods of time between shutdowns for intensive cleaning. TMP is gradually increased to maintain a substantially constant rate of permeate discharge until a target is reached, indicative of solids accumulation on the membrane surface to an undesirable extent; then backflushing is effected for a short time. Discarding the hold-up volume of feedstock in the cartridge, the backflushing fluid and dislodged solids, allows production to be promptly resumed with fresh feedstock at performance at near original levels.

Owner:MANNHUMMEL WATER & FLUID SOLUTIONS GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com