Patents

Literature

1187 results about "Polymeric membrane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Poly(ethylene chlorotrifluoroethylene) membranes

InactiveUS7247238B2Improve permeabilityImprove integrityMembranesSemi-permeable membranesFiberGlycerol

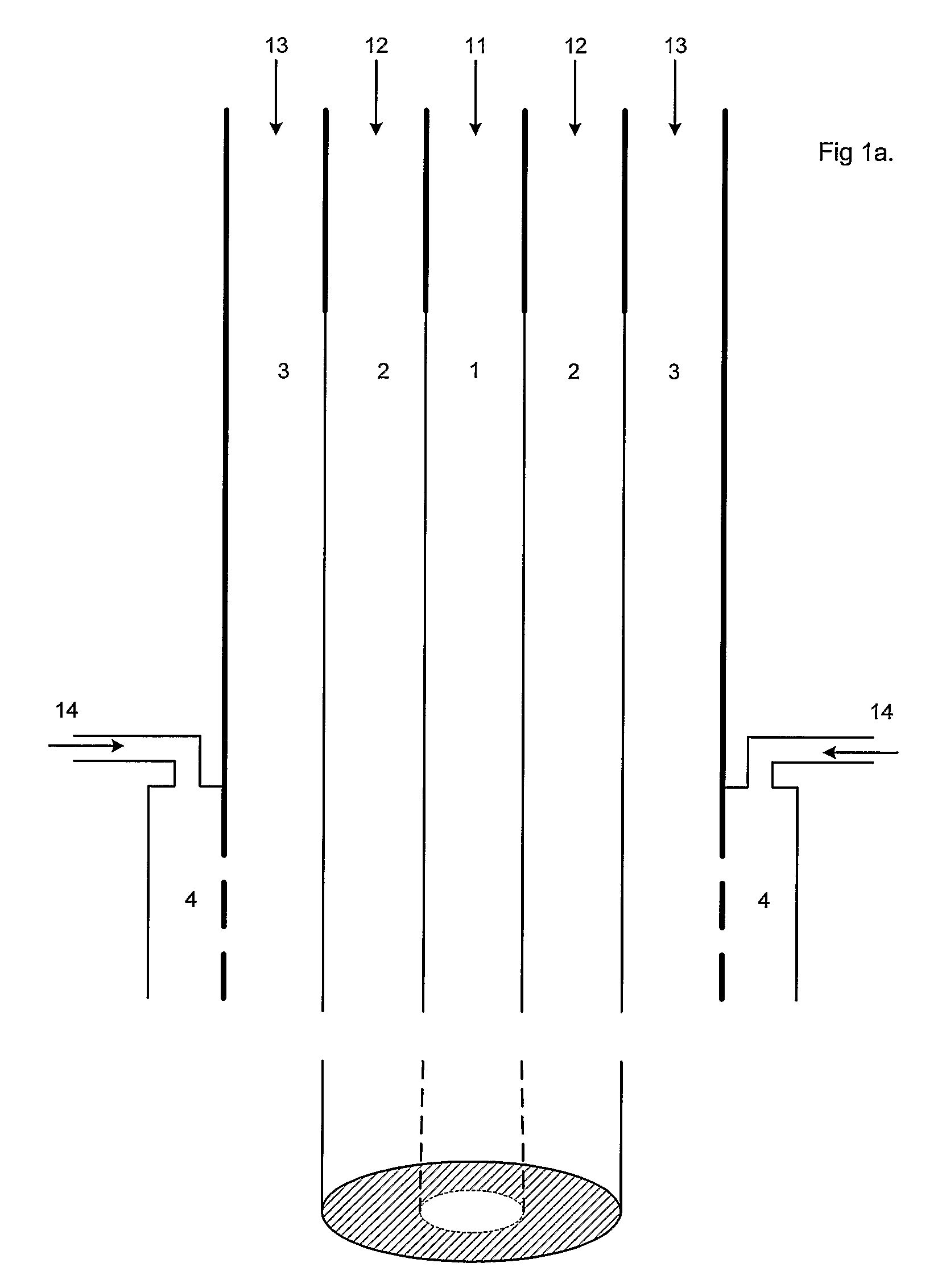

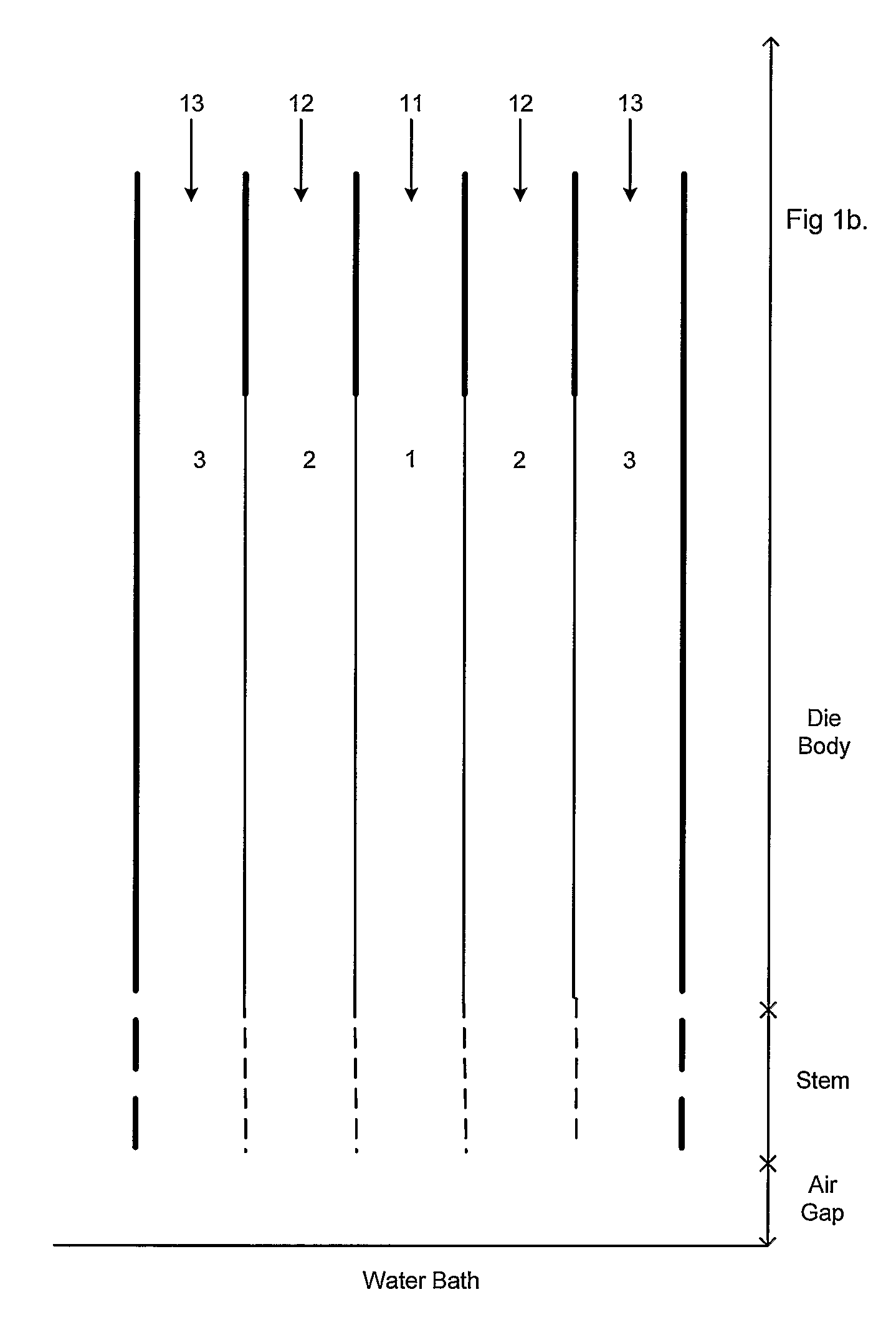

Porous polymeric membranes including Halar (poly (ethylene chlorotrifluoroethylene)) and related compounds and the methods of production thereof which avoid the use of toxic solvents. Preferred solvents, coating agents and pore forming agents are citric acid ethyl ester or glycerol triacetate. The membranes may be in the form of a hollow fiber or flat sheet, and may include other agents to modify the properties of the membrane, such as the hydrophilic / hydrophobic balance. Leachable agents may also be incorporated into the membranes.

Owner:EVOQUA WATER TECH LLC

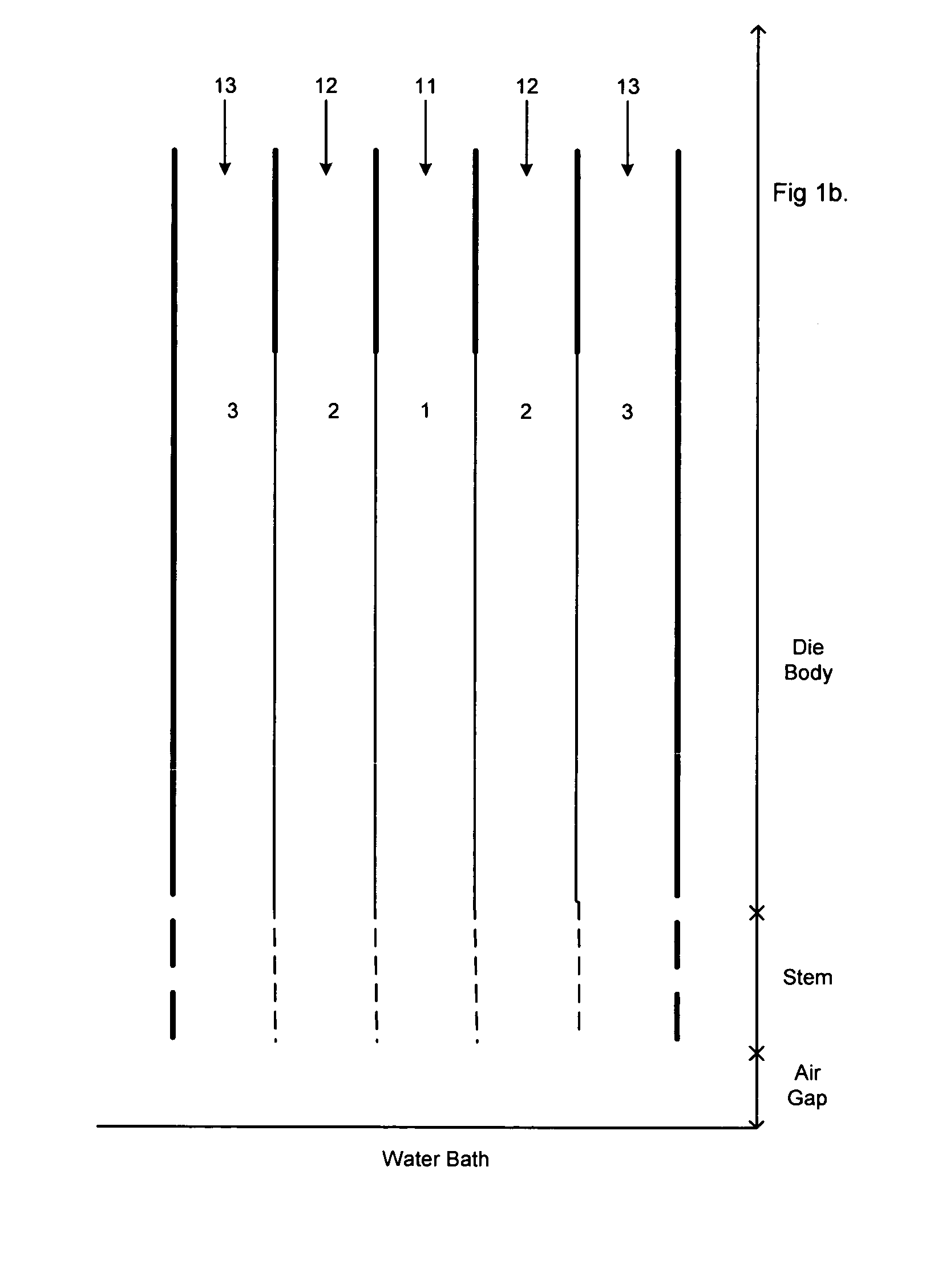

Method for isolating and culturing unculturable microorganisms

The invention provides a method for isolating and culturing a previously unculturable microorganism, which comprises: (i) collecting a sample from an environmental source; (ii) counting / estimating the number of microorganisms in the sample; (iii) diluting the sample in an appropriate medium; (iv) adding a gelating agent such as to entrap one or more microorganisms within a sphere of the gelating agent; (v) coating the spheres containing the entrapped microorganism(s) with a natural or synthetic polymer to form a polymeric membrane; (vi) incubating the coated spheres in the original environment for an appropriate time; (vii) cutting the spheres and scanning for microorganisms colonies; and (viii) isolating the microorganisms, and repeating steps (iii) to (vii) until a pure clone of said previously unculturable microorganism is obtained.

Owner:BEN GURION UNIVERSITY OF THE NEGEV

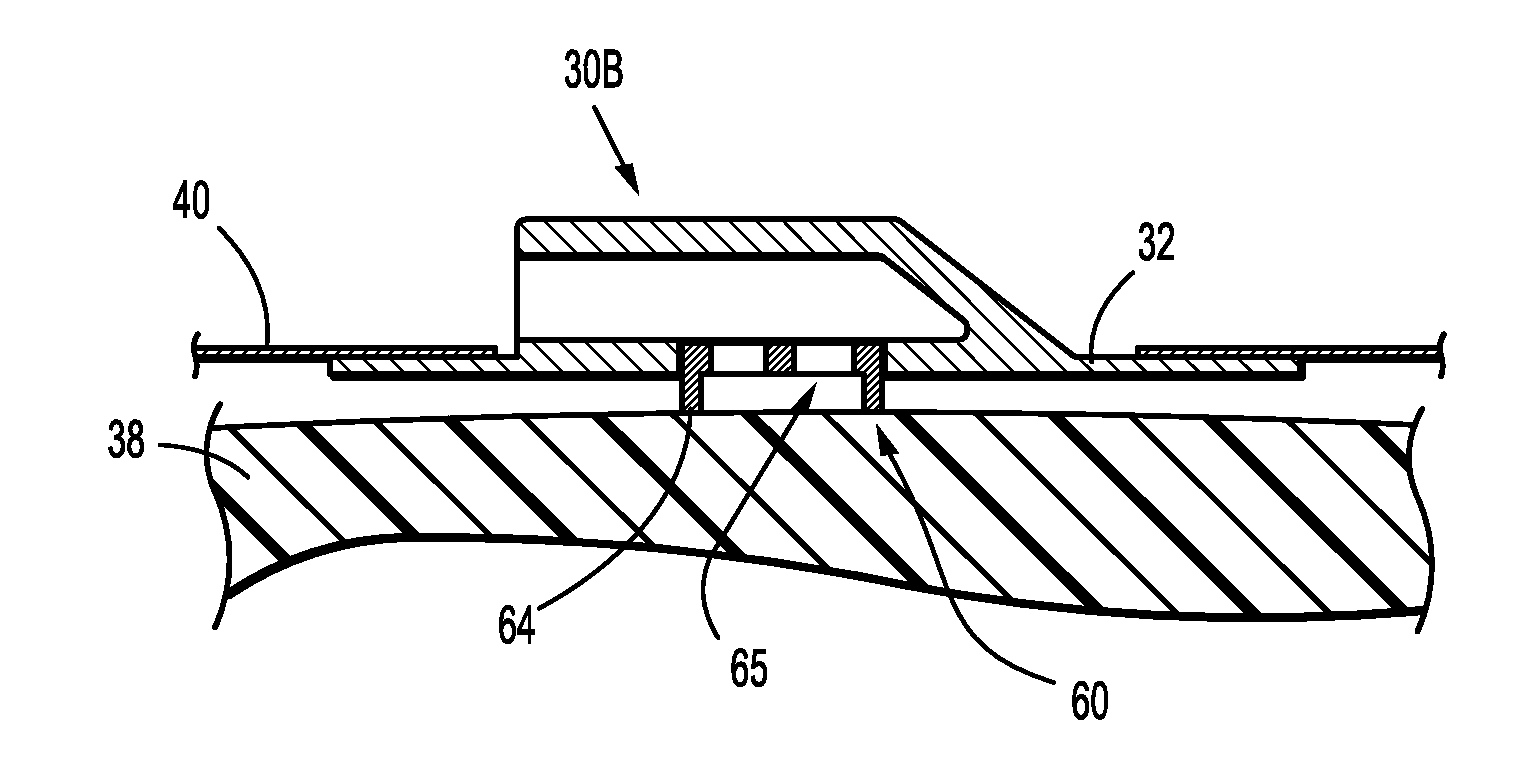

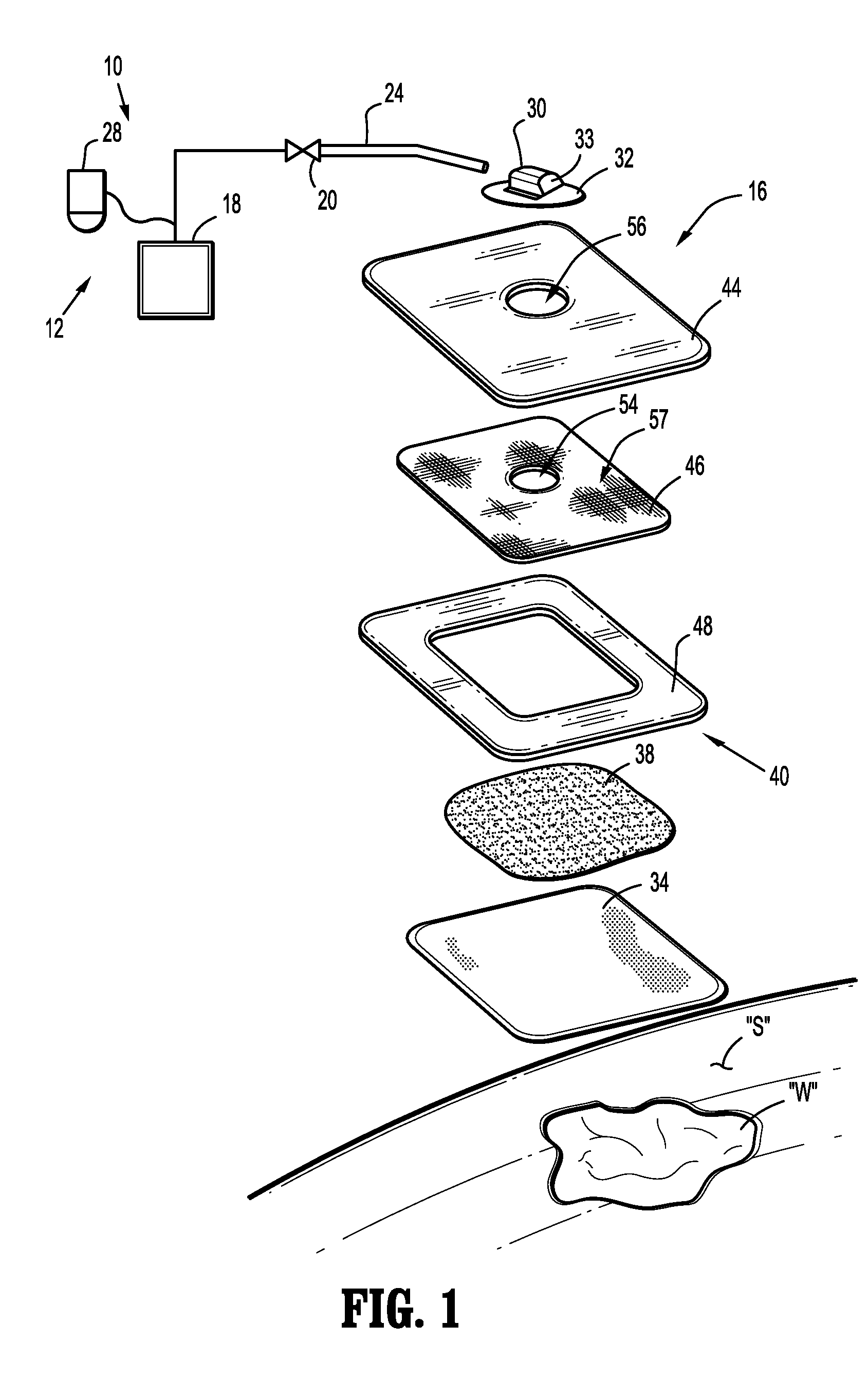

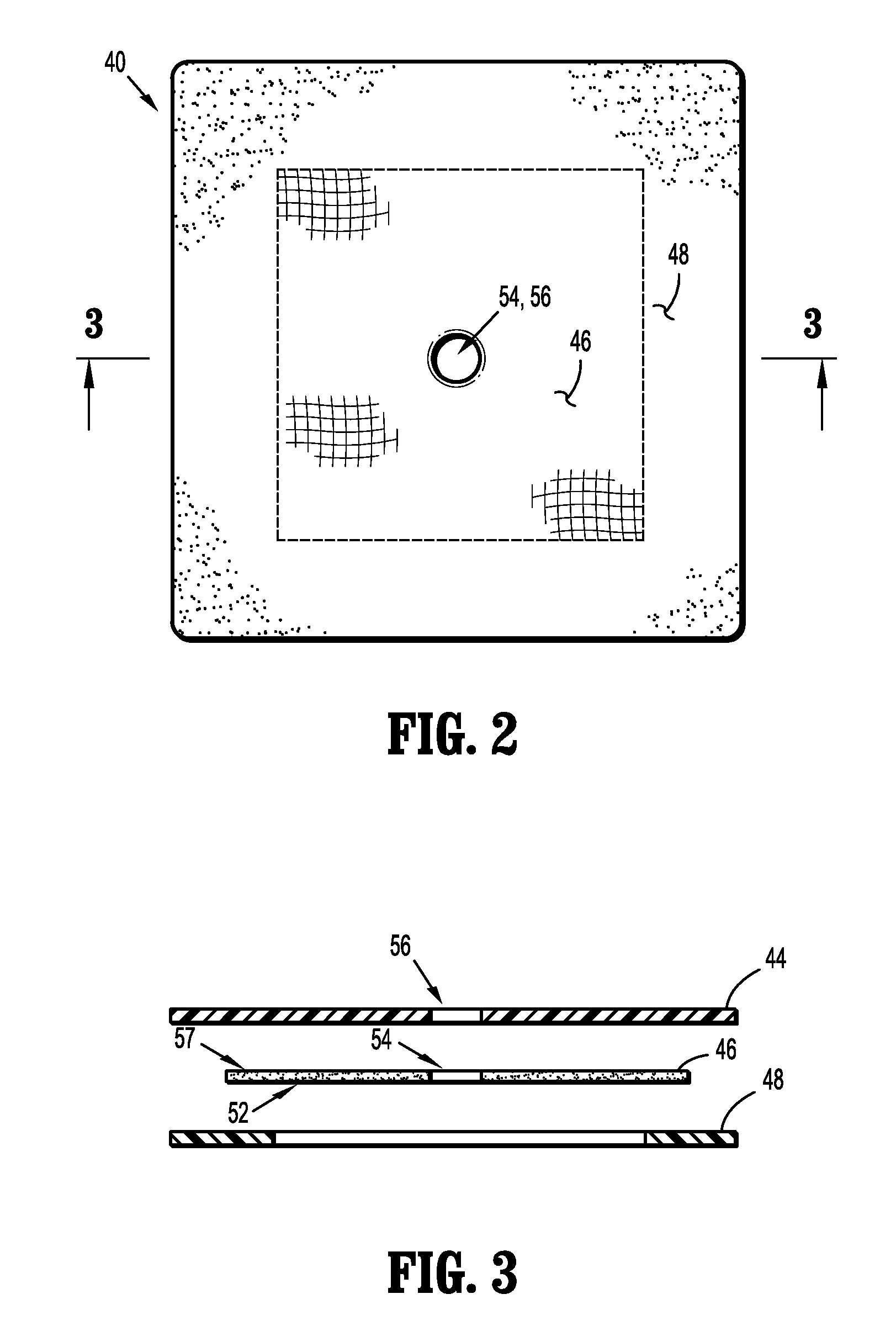

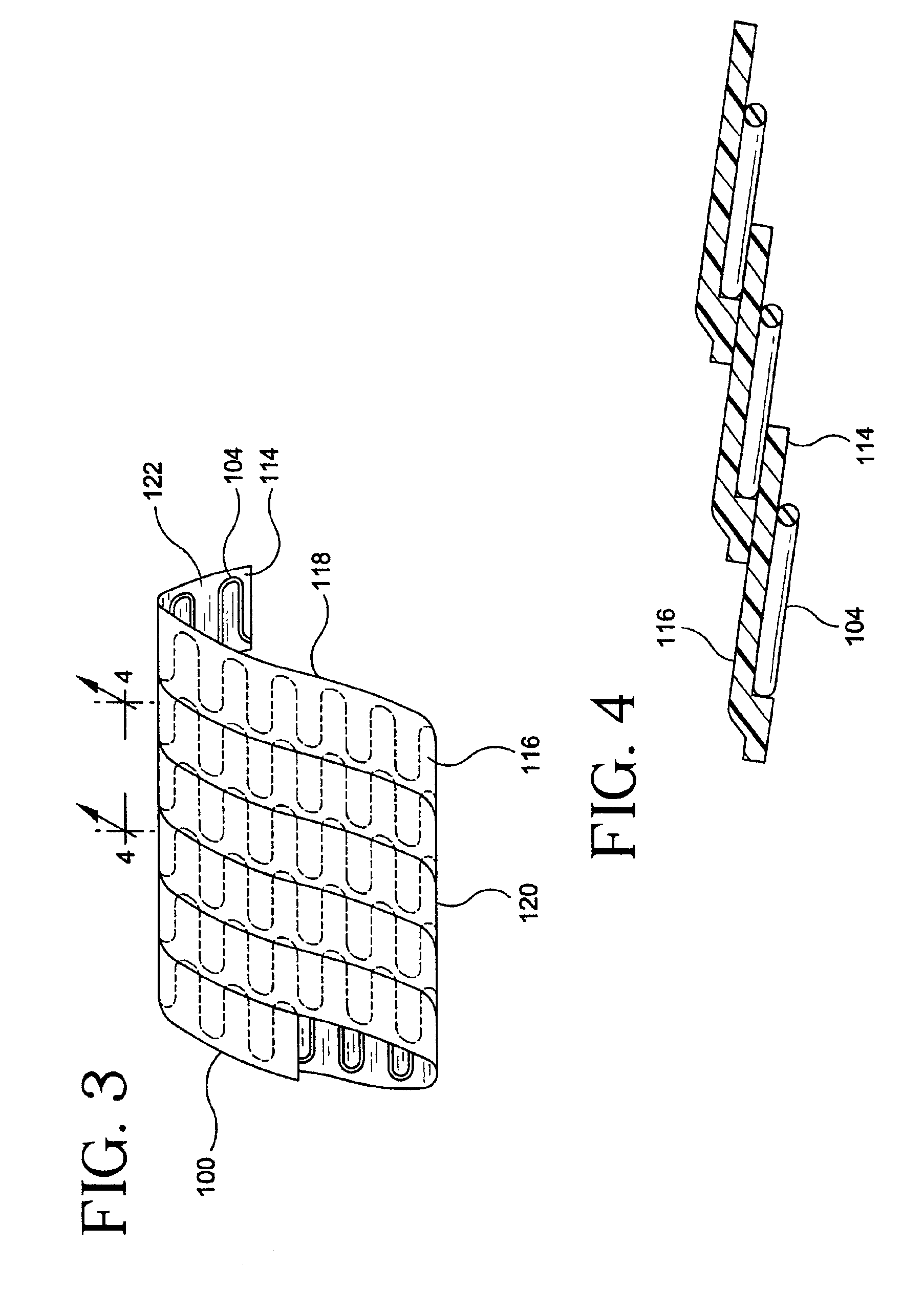

Shear Resistant Wound Dressing for Use in Vacuum Wound Therapy

ActiveUS20090234309A1Promote wound healingDegree of reductionNon-adhesive dressingsPlastersWound dressingWound therapy

A cover layer for a vacuum wound therapy dressing includes a backing layer formed from a flexible polymeric membrane and an adhesive layer for affixing the backing layer over a wound bed to provide a substantially fluid-tight seal around a perimeter of the wound bed. The cover layer is reinforced with a reinforcement layer extending to a peripheral region of the backing layer to distribute forces associated with evacuating a reservoir, as defined by or within the cover, to stimulate healing of the wound bed.

Owner:SMITH & NEPHEW INC

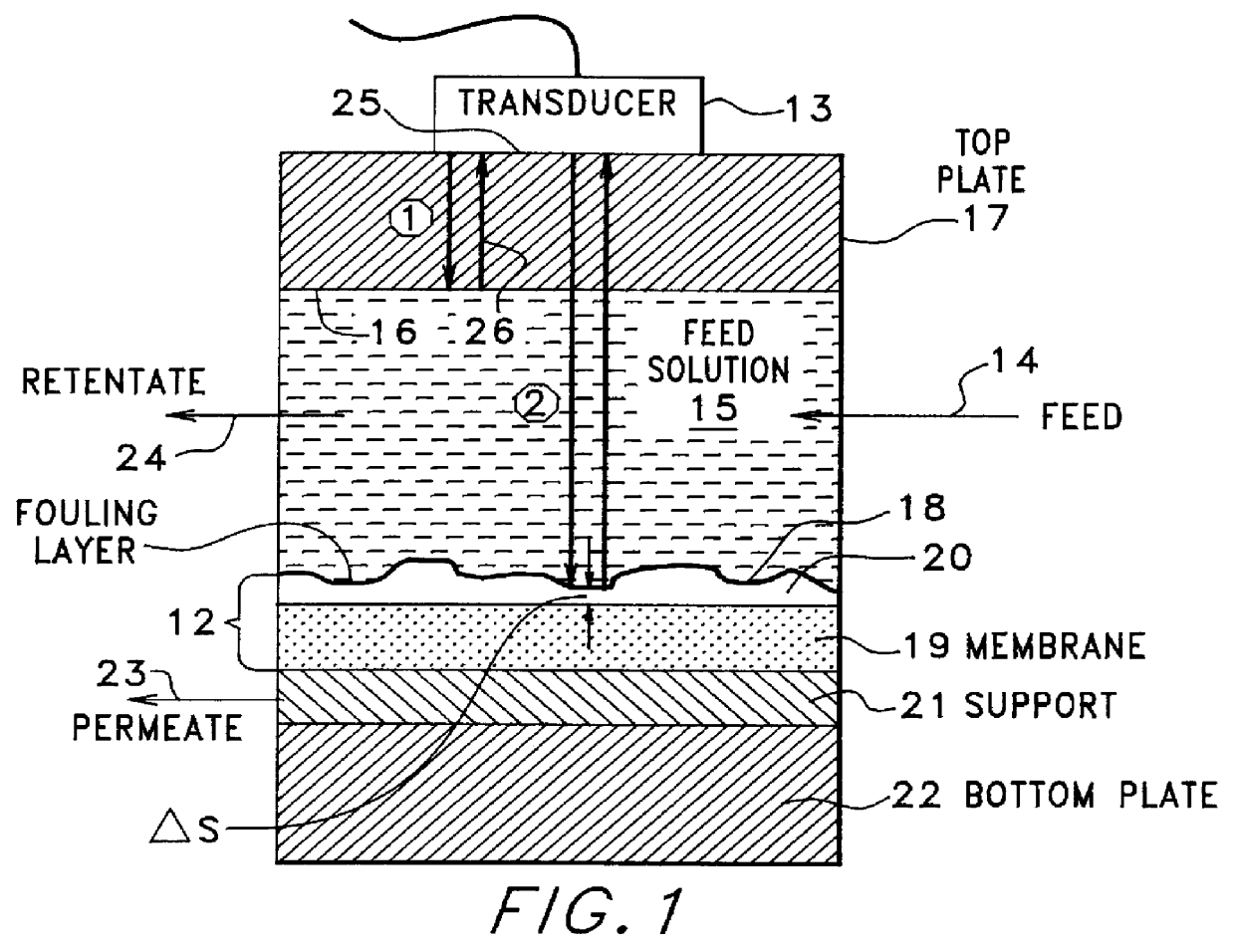

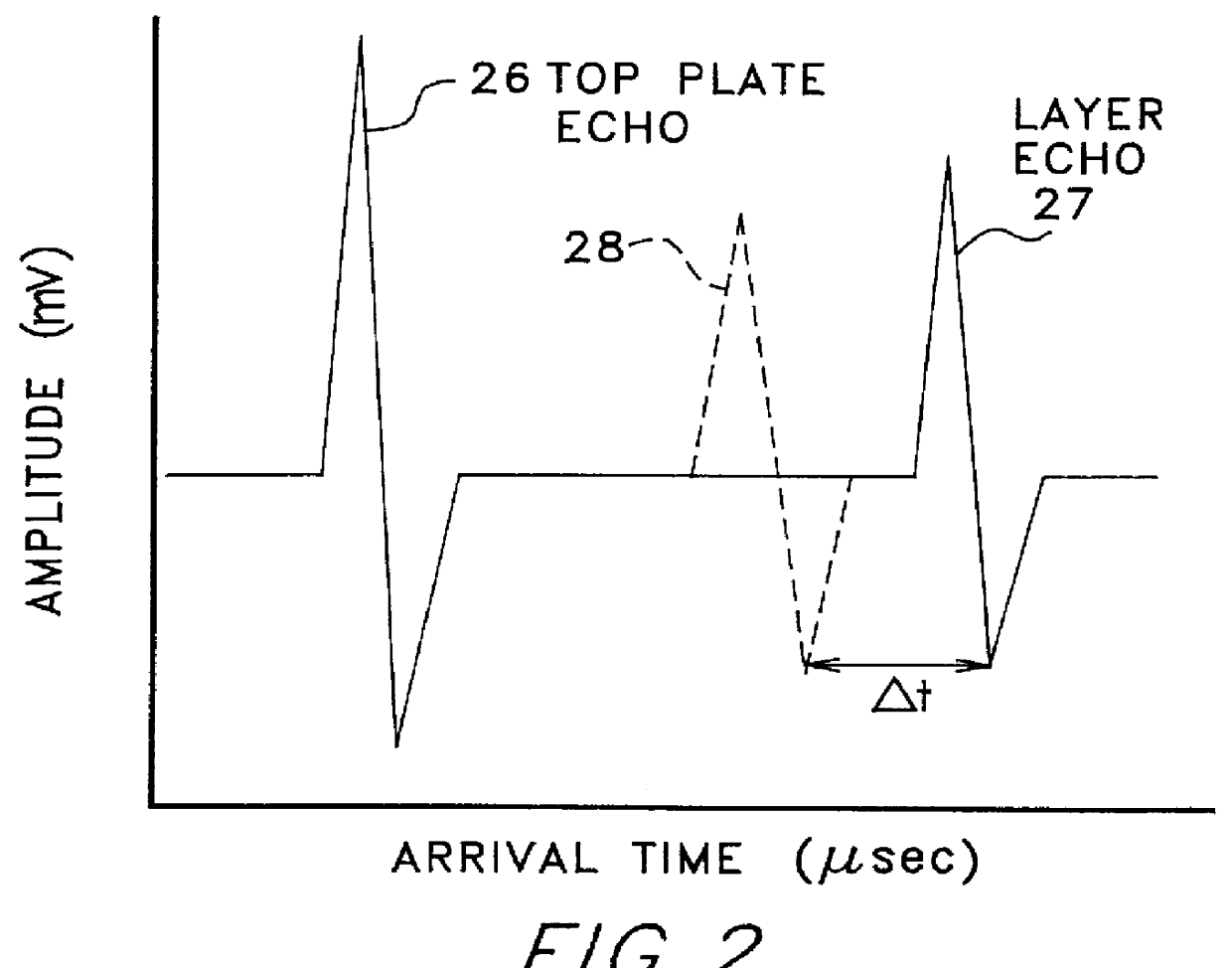

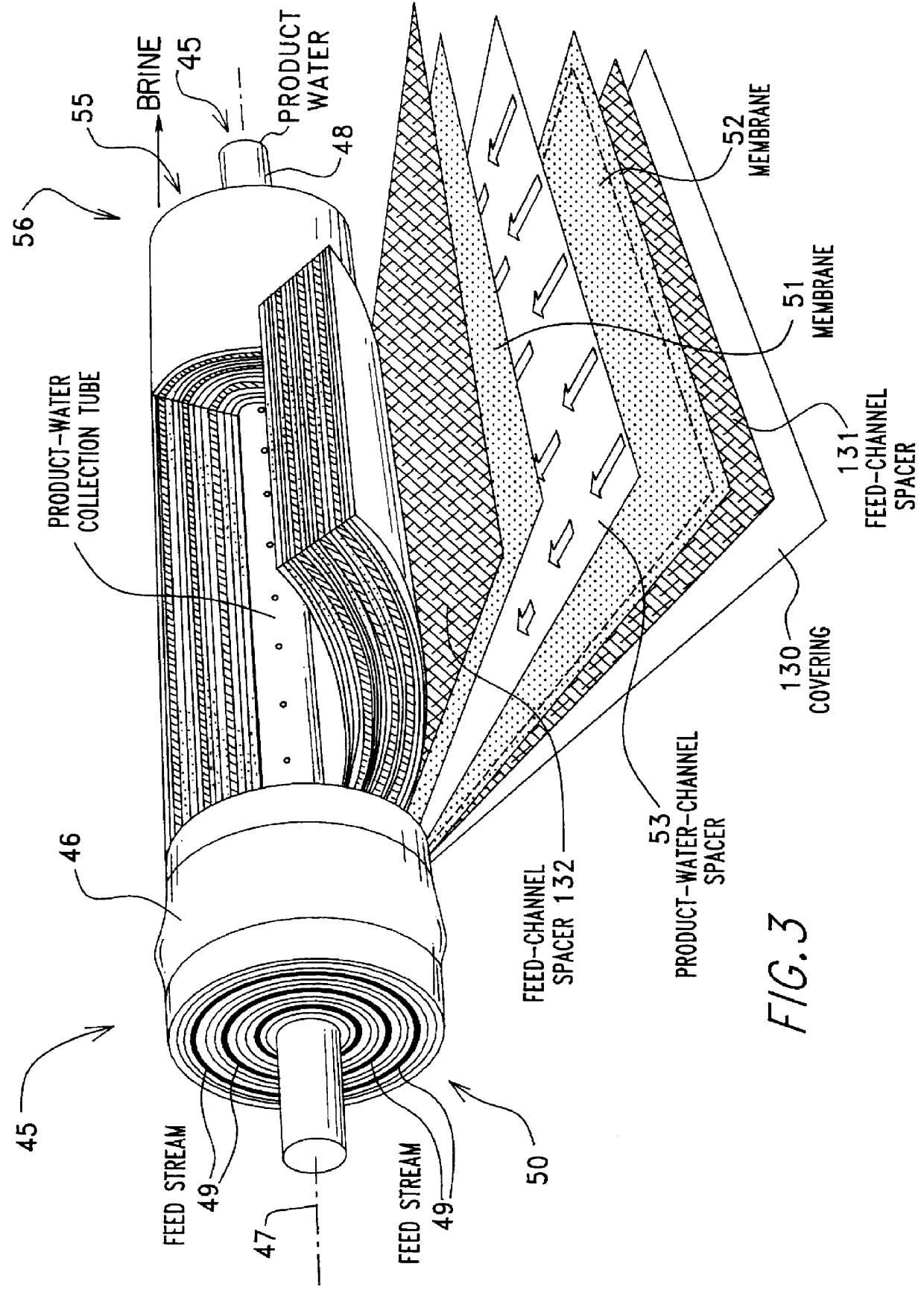

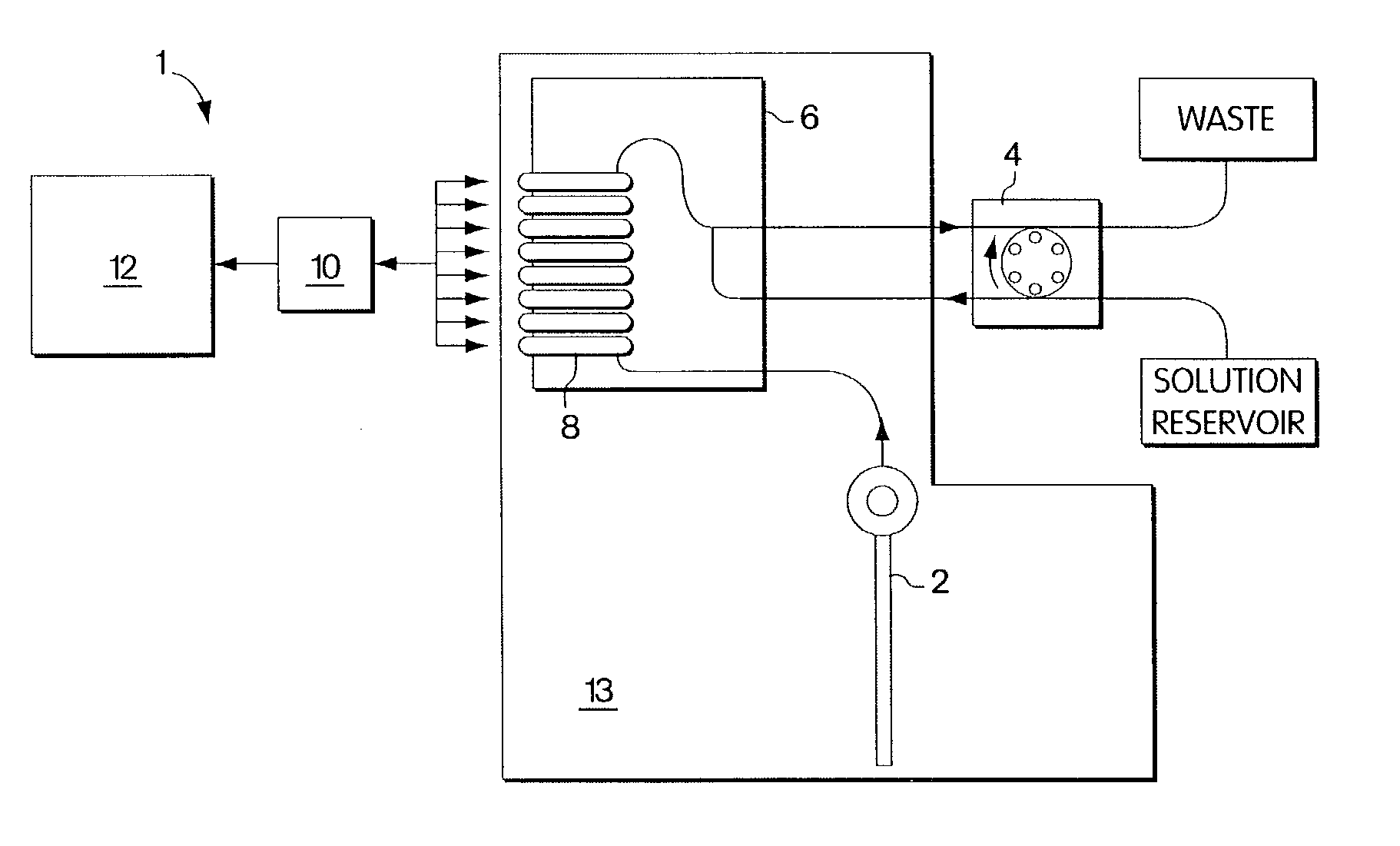

Method and apparatus for determining the state of fouling/cleaning of membrane modules

InactiveUS6161435AVibration measurement in solidsAnalysing fluids using sonic/ultrasonic/infrasonic wavesTime domainSpiral wound

The fouling state of a polymeric membrane within the high pressure housing of a spiral wound or a hollow fiber membrane module is determined. An ultra sonic transducer positioned with its emitting face in physical engagement with the outer surface of the housing is pulse energized by a pulser / receiver device. A membrane echo signal is detected by a receiver of the pulser / receiver device. A reference echo signal indicative of a fouled or an unfouled state of the membrane is compared to the echo signal to determine the membrane fouling state. The echo to reference comparing step can be based upon comparing amplitude domain signals, comparing time-domain signals, comparing combinations of amplitude domain and time-domain signals, and comparing transformations of amplitude domain and time-domain signals. A clean or a fouled reference echo can be provided from a clean or a fouled membrane and then stored for use during a liquid separation process, or a clean reference echo signal can be obtained on-line from a second transducer whose echo signal is derived from an area of the membrane known to remain relatively unfouled during the liquid separation process, or a clean or fouled reference echo signal can be provided for later use during a cleaning process or during a liquid separation process. Multiple transducers and a switching network can sample the fouling state at different positions within the membrane module.

Owner:UNIV TECH

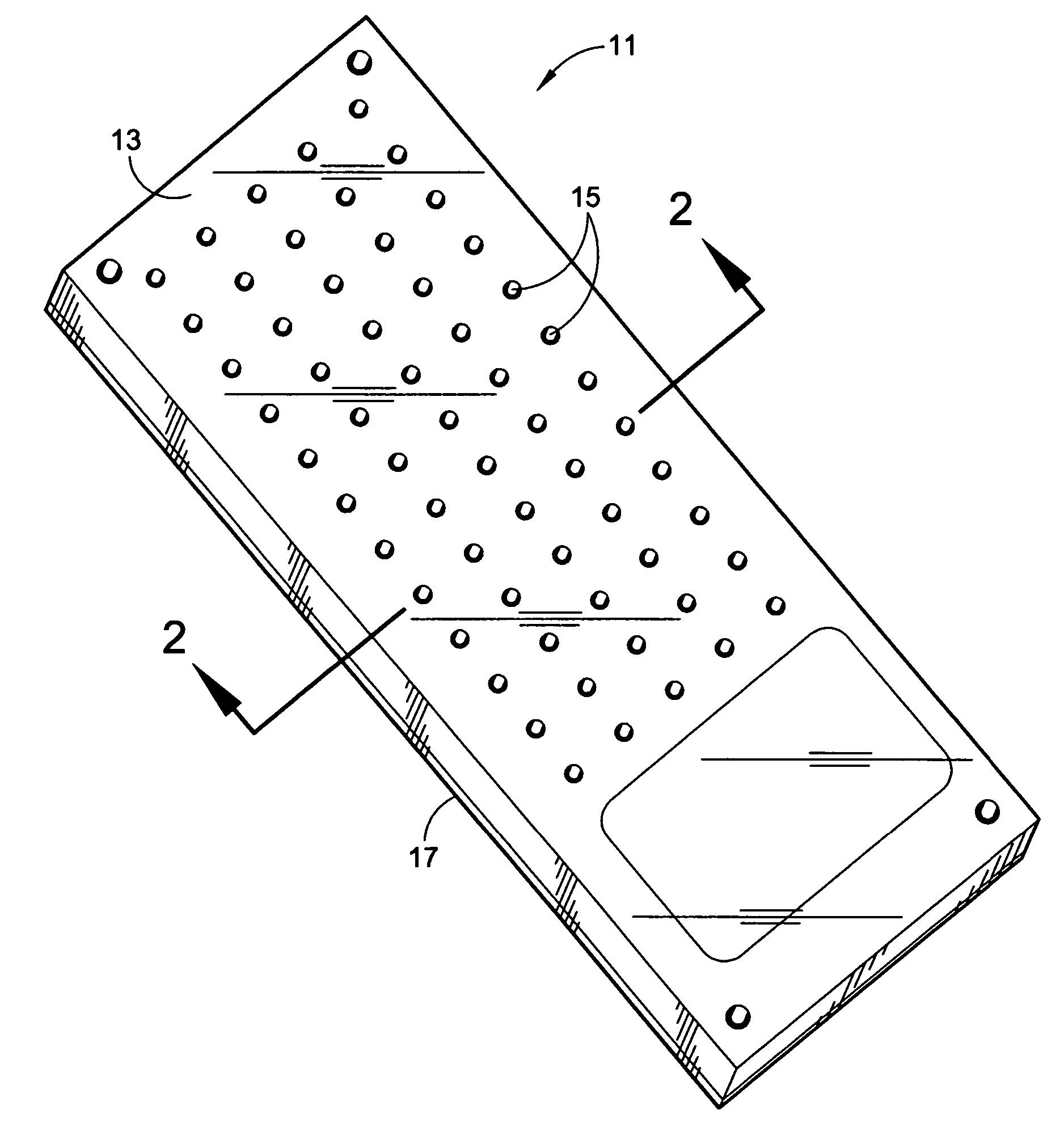

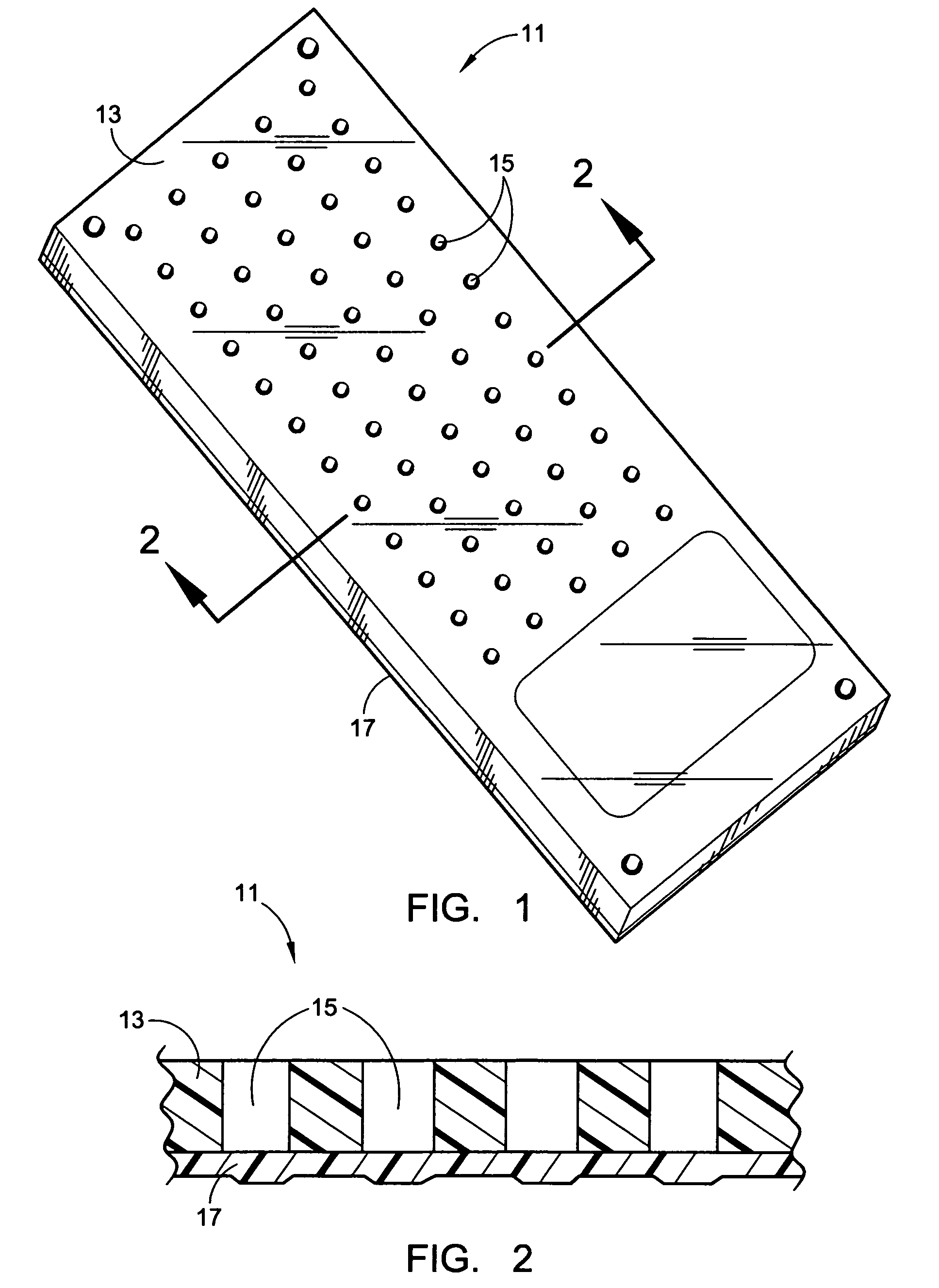

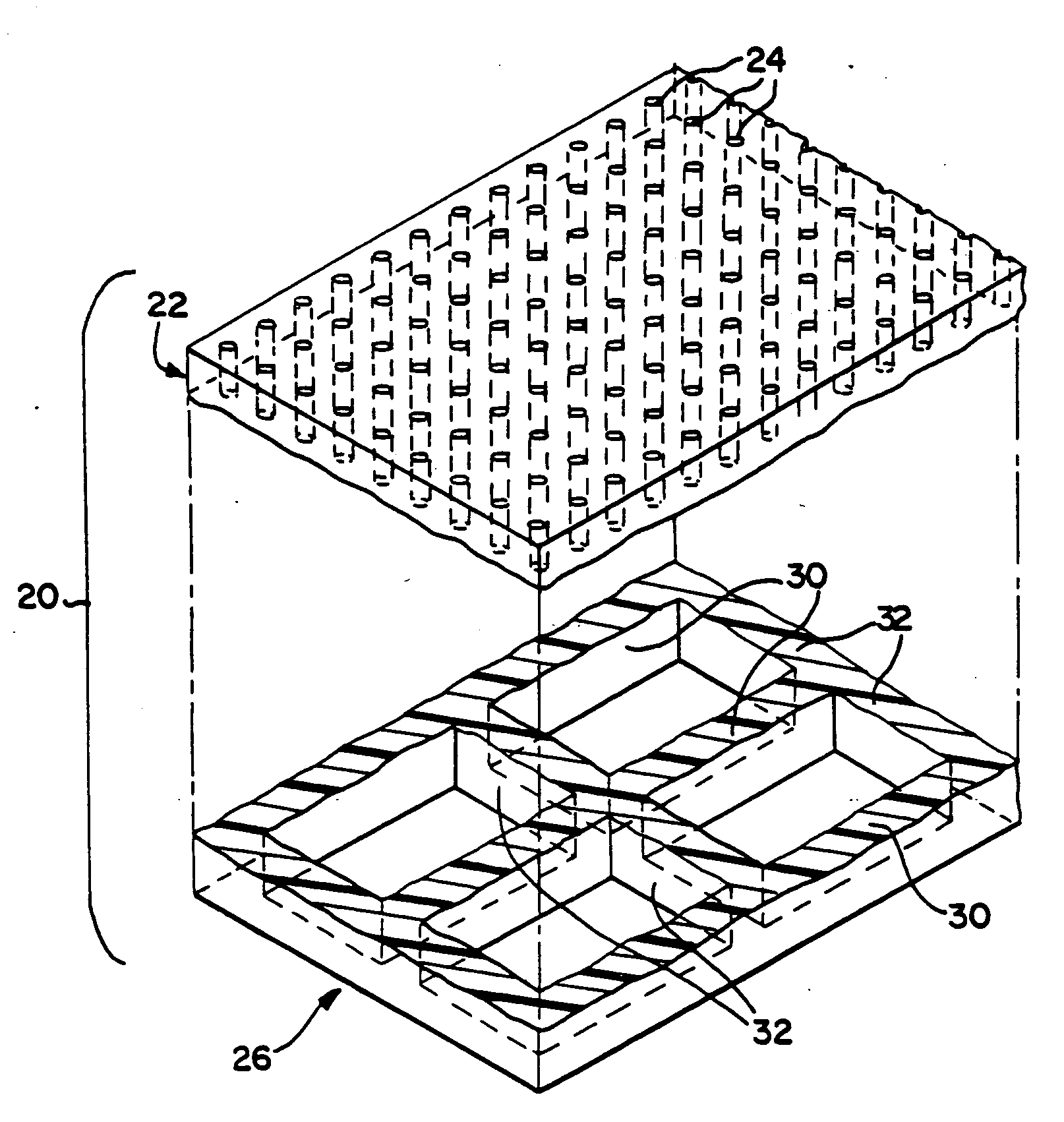

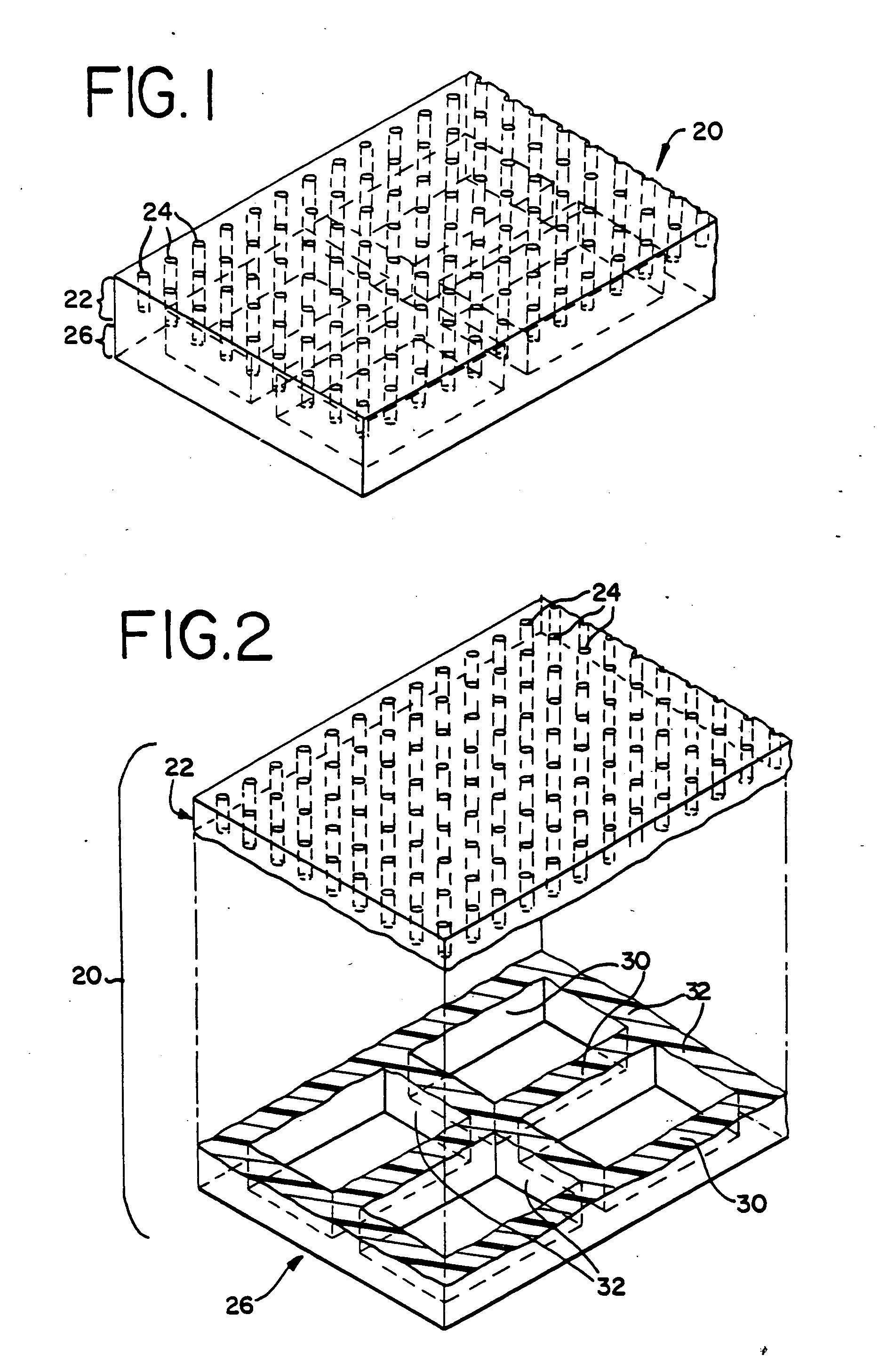

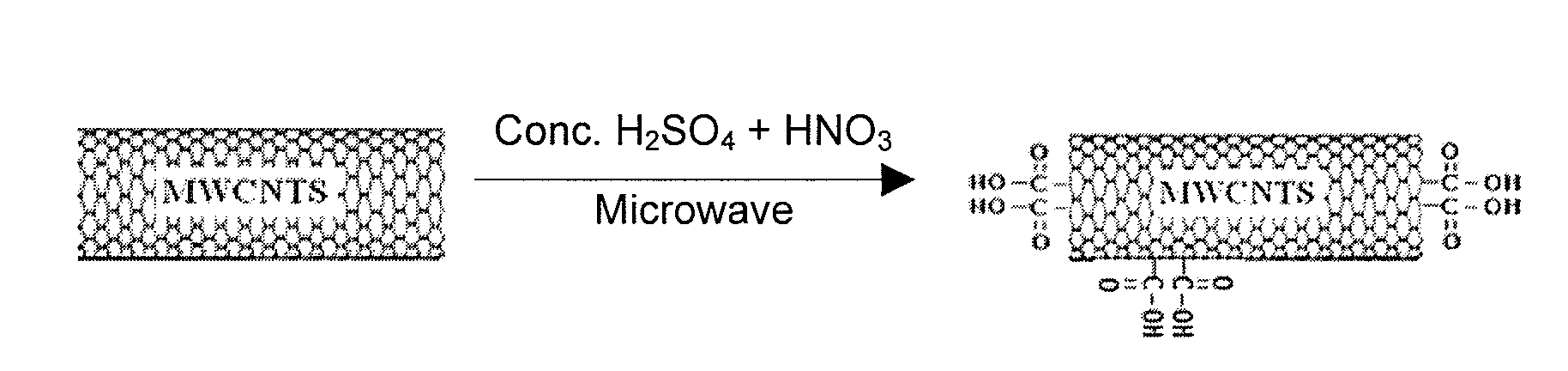

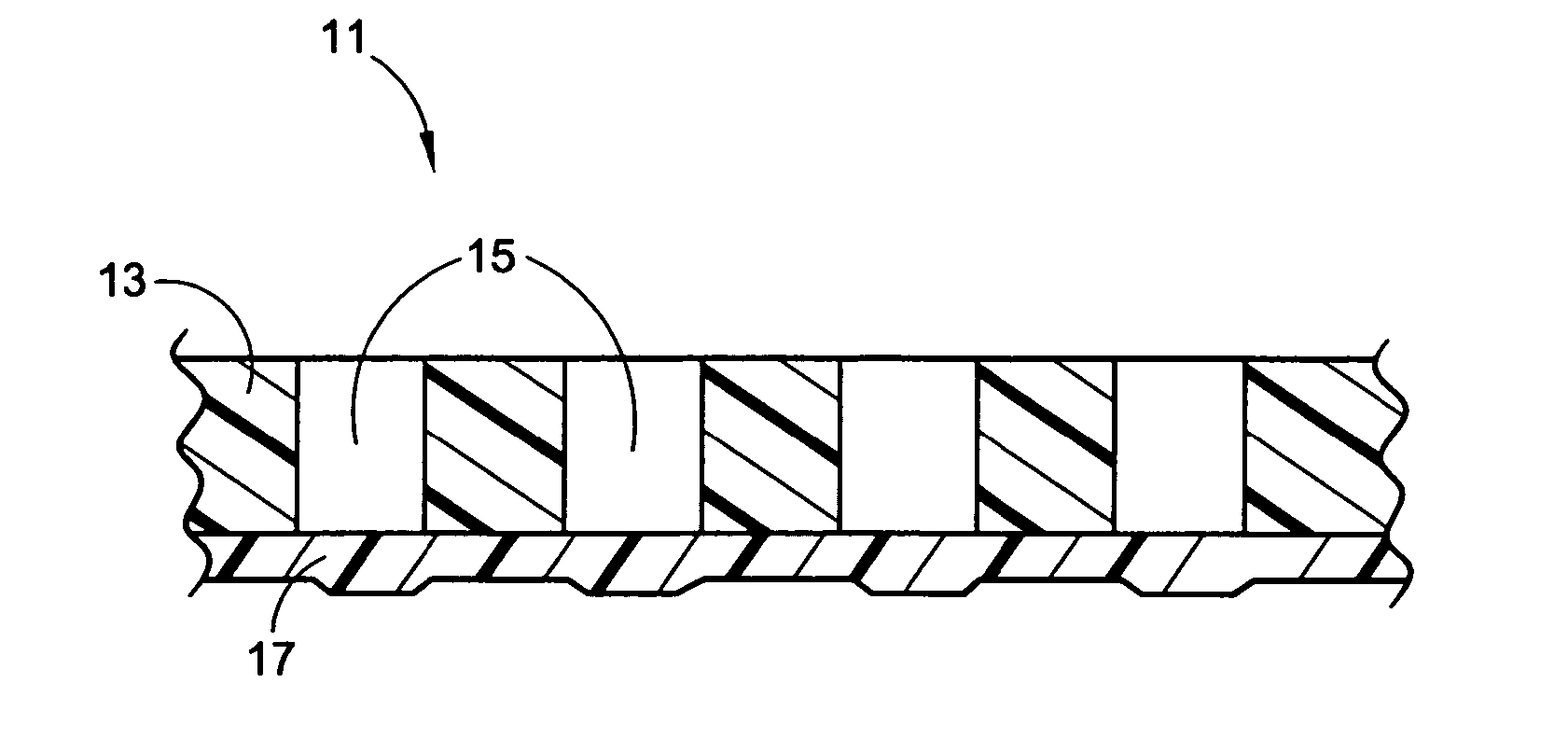

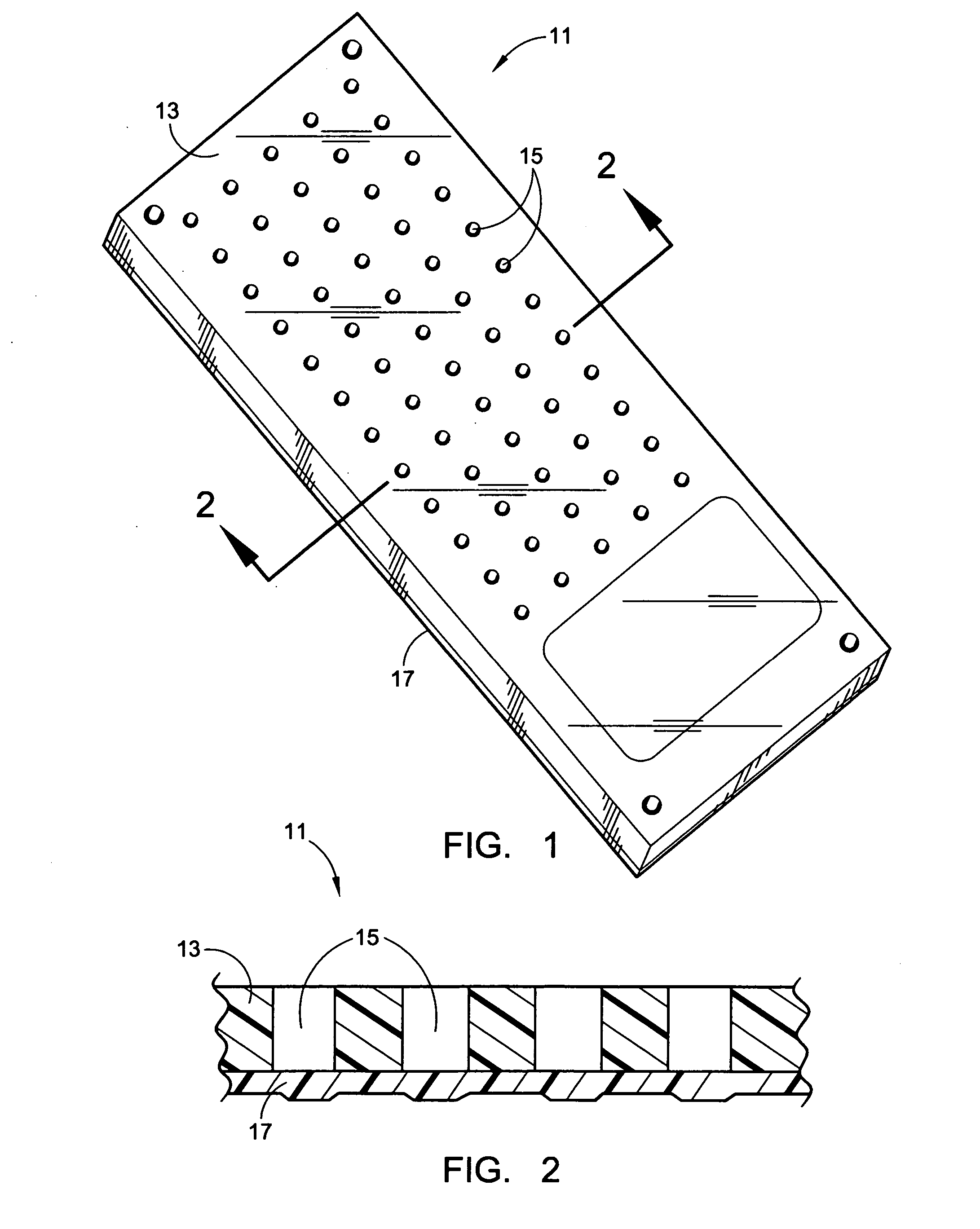

Microwell biochip

InactiveUS7217520B2Improve abilitiesSimple and versatile formatImmobilised enzymesBioreactor/fermenter combinationsPorous membraneEngineering

Microwell biochips (11) are formed from a thin flat plate (13) of polymeric material having a plurality of regularly spaced holes (15) that extend completely therethrough and create microwells. The lower end of each hole is closed by a microporous, hydrophobic, polymeric membrane (17) laminated to the undersurface of the plate which retains an aqueous test solution in the wells until a vacuum is applied to the undersurface thereof to effect draining of the solution and of any wash solution that might be subsequently added. A spot of polymerizing isocyanate-functional hydrogel is applied generally centrally to the porous membrane surface at the bottom of each well in a manner so as to cover only a minor portion of the surface and out of contact with the well sidewalls, thus leaving substantial surface area through which drainage can be readily effected. Biological capture agents are associated with the polymerizing hydrogel so as to become immobilized as a part thereof.

Owner:BIOCEPT INC

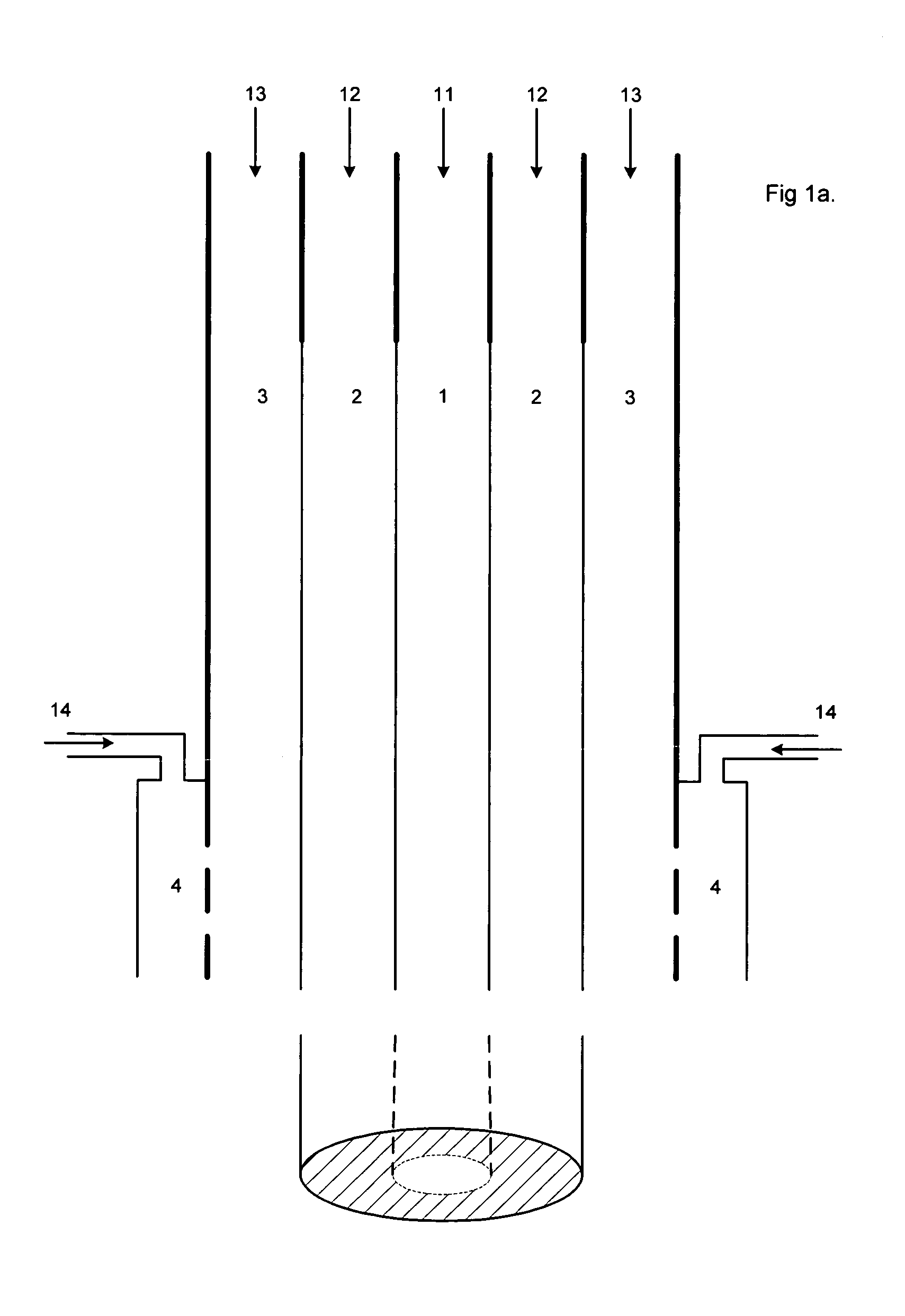

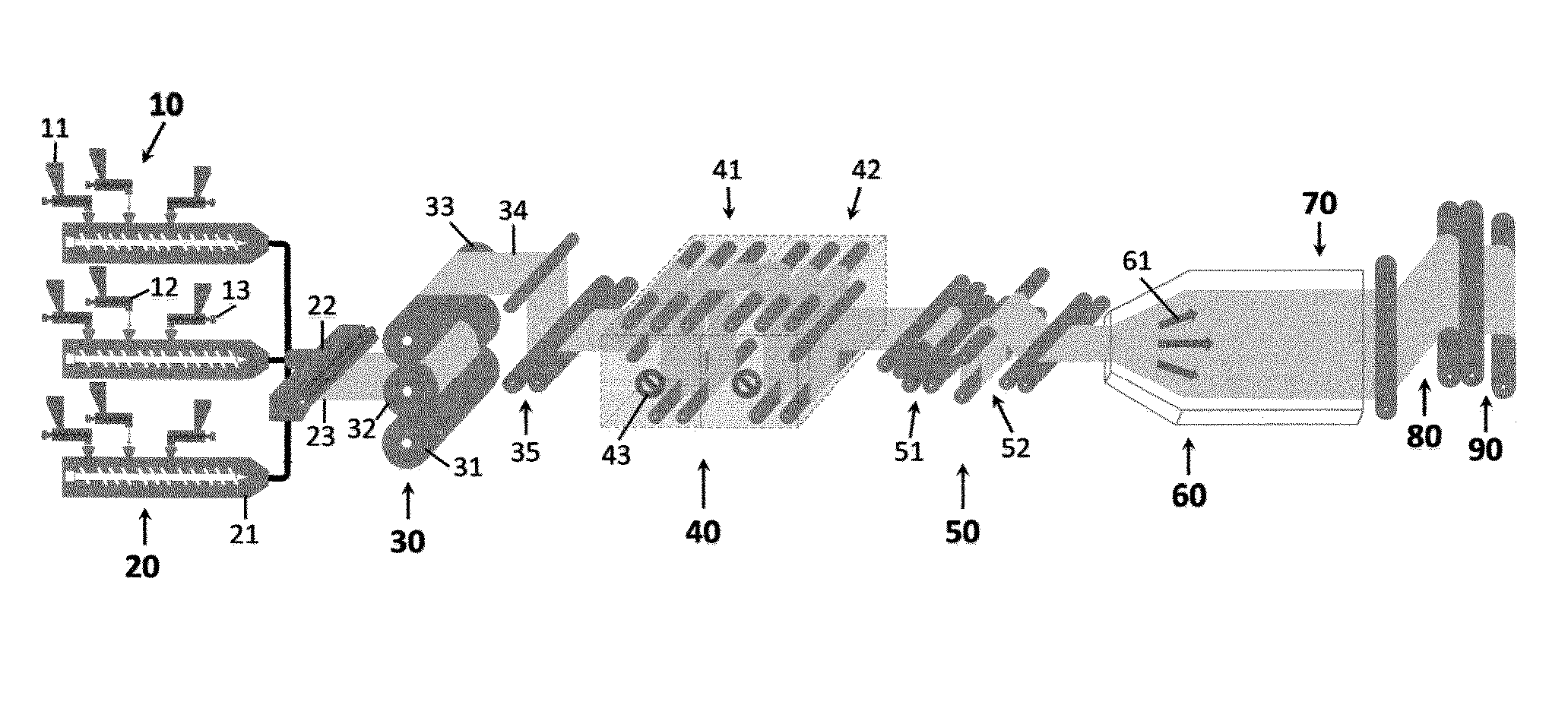

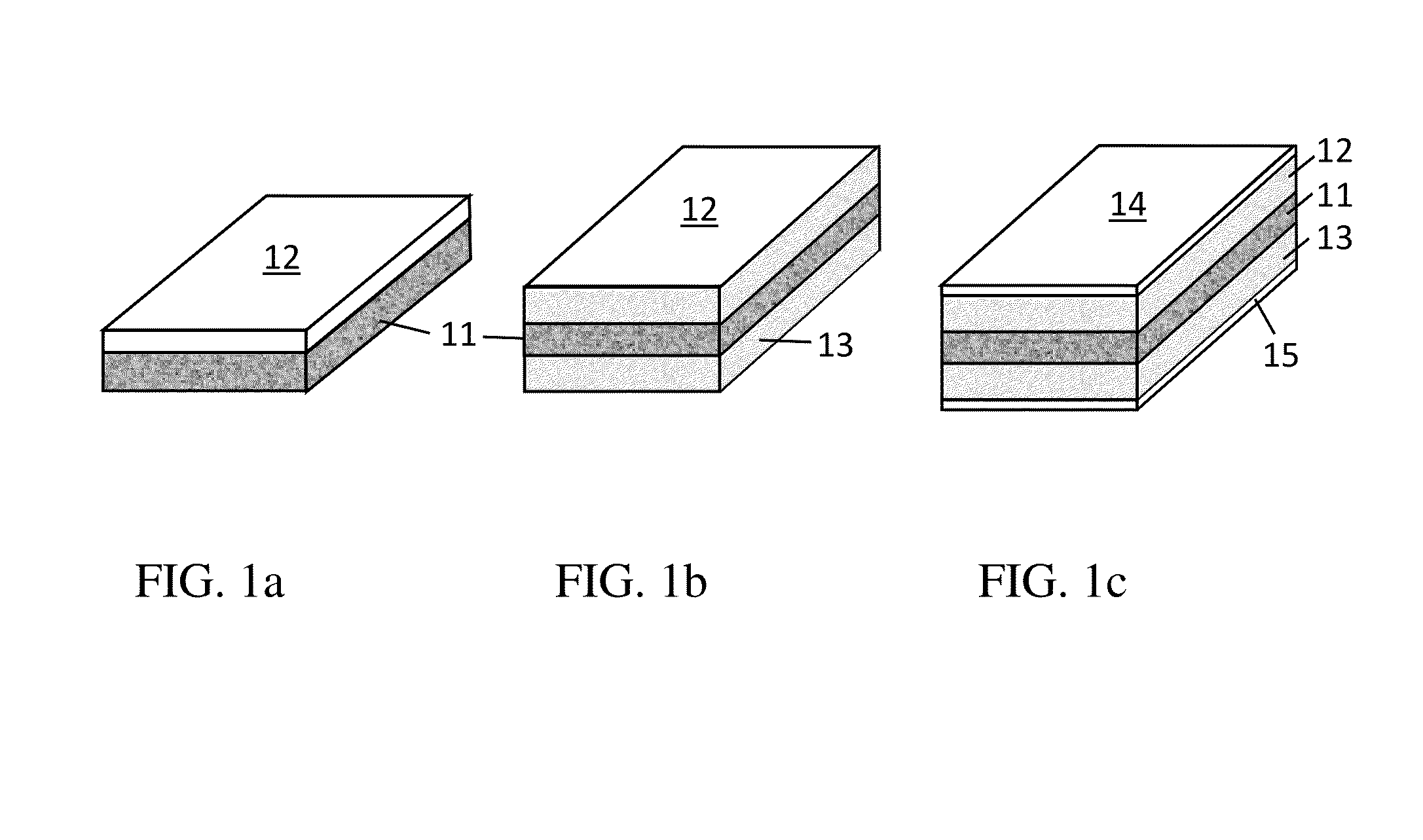

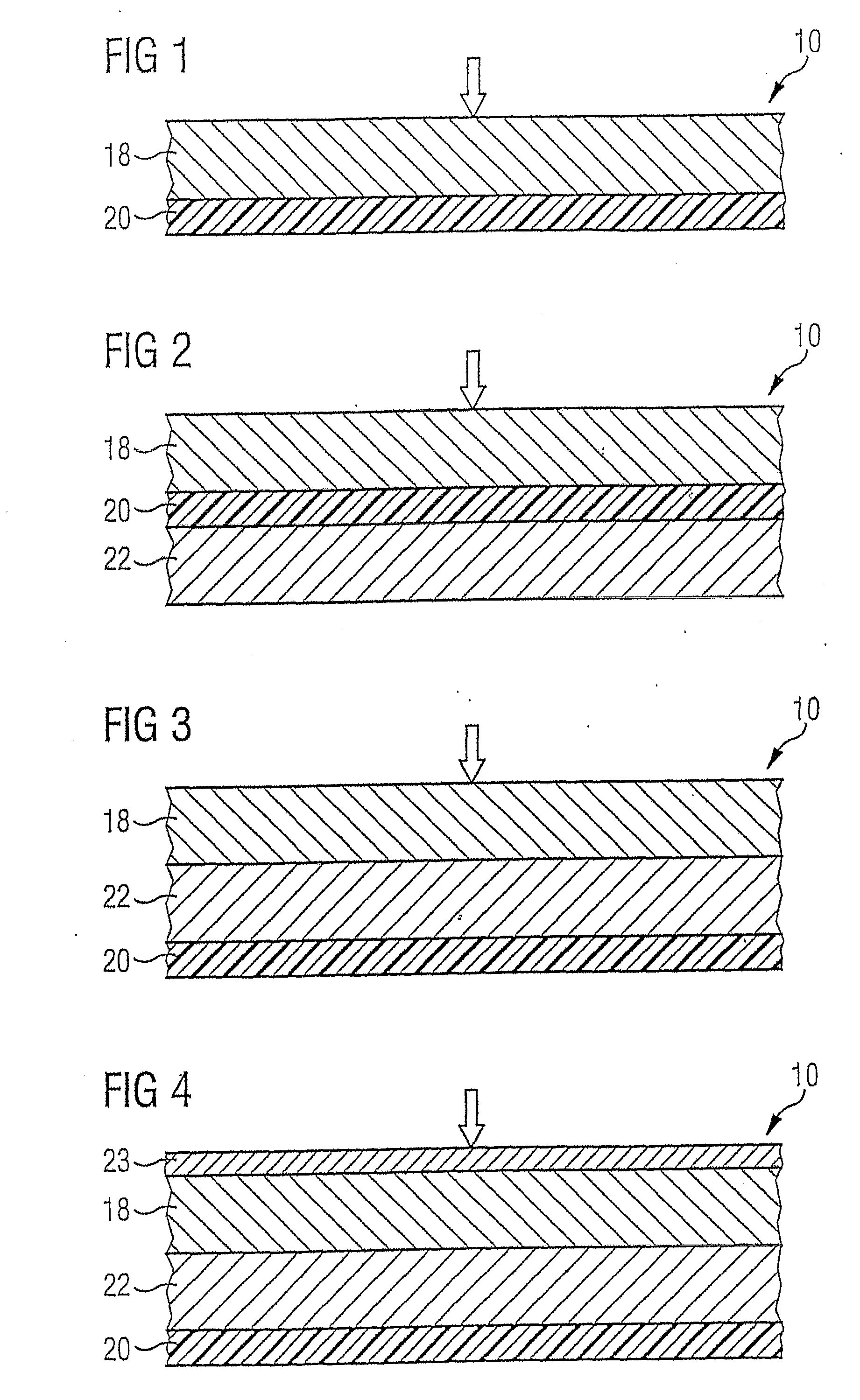

Multilayer Polymeric Membrane and Process

ActiveUS20160243525A1Improve adhesionImprove wettabilityOther chemical processesAlkali metal oxides/hydroxidesProduction rateSorbent

Provided is a novel continuous single-step method of manufacturing a multilayer sorbent polymeric membrane having superior productivity, properties and performance. At least one layer of the polymeric membrane comprises sorbent materials and a plurality of interconnecting pores. The method includes: (a) coextruding layer-forming compositions to form a multilayer coextrudate; (b) casting the coextrudate into a film; (c) extracting the film with an extractant; and (d) removing the extractant from the extracted film to form the multilayer sorbent polymeric membrane. The sorbent membrane of this disclosure can find a wide range of applications for use in filtration, separation and purification of gases and fluids, CO2 and volatile capture, structural support, vehicle emission control, energy harvesting and storage, device, protection, permeation, packaging, printing, and etc.

Owner:LISO PLASTICS L L C

Multilayer polymeric membrane and process

ActiveUS20180065105A1Improve adhesionImprove wettabilitySemi-permeable membranesMembranesProduction rateFiltration

Provided is a novel continuous single-step method of manufacturing a multilayer sorbent polymeric membrane having superior productivity, properties and performance. At least one layer of the polymeric membrane comprises sorbent materials and a plurality of interconnecting pores. The method includes: (a) coextruding layer-forming compositions to form a multilayer coextrudate; (b) casting the coextrudate into a film; (c) extracting the film with an extractant; and (d) removing the extractant from the extracted film to form the multilayer sorbent polymeric membrane. The sorbent membrane of this disclosure can find a wide range of applications for use in filtration, separation and purification of gases and fluids, CO2 and volatile capture, structural support, vehicle emission control, energy harvesting and storage, electrolyte batteries. device, protection, permeation, packaging, printing, and etc.

Owner:LISO PLASTICS L L C

Timed pulsatile drug delivery systems

A pharmaceutical dosage form such as a capsule capable of delivering therapeutic agents into the body in a time-controlled or position-controlled pulsatile release fashion, is composed of a multitude of multicoated particulates (beads, pellets, granules, etc.) made of one or more populations of beads. Each of these beads except an immediate release bead has at least two coated membrane barriers. One of the membrane barriers is composed of an enteric polymer while the second membrane barrier is composed of a mixture of water insoluble polymer and an enteric polymer. The composition and the thickness of the polymeric membrane barriers determine the lag time and duration of drug release from each of the bead populations. Optionally, an organic acid containing intermediate membrane may be applied for further modifying the lag time and / or the duration of drug release. The pulsatile delivery may comprise one or more pulses to provide a plasma concentration-time profile for a therapeutic agent, predicted based on both its pharmaco-kinetic and pharmaco-dynamic considerations and in vitro / in vivo correlations.

Owner:ADARE PHARM INC

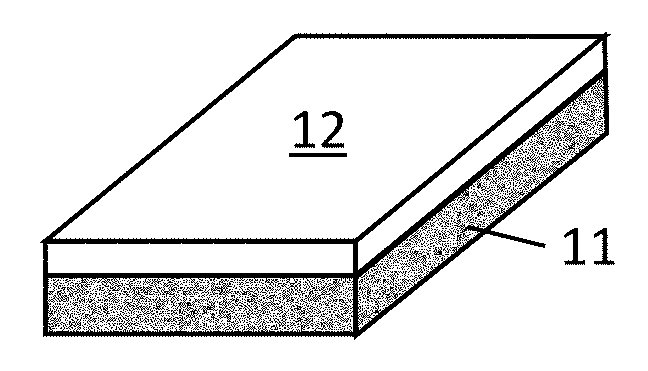

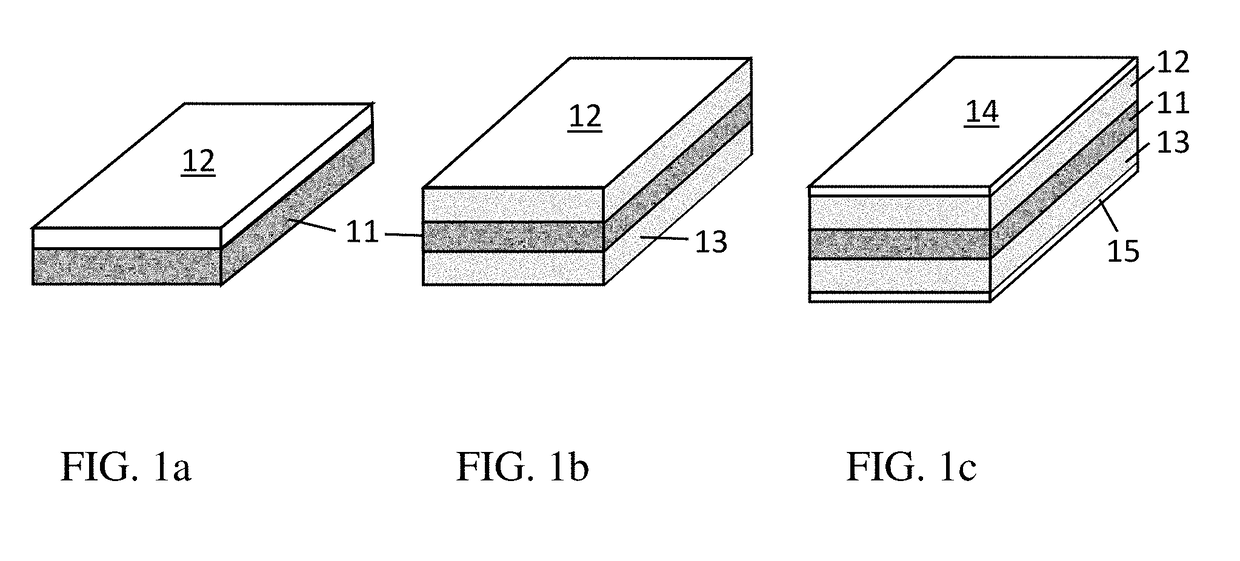

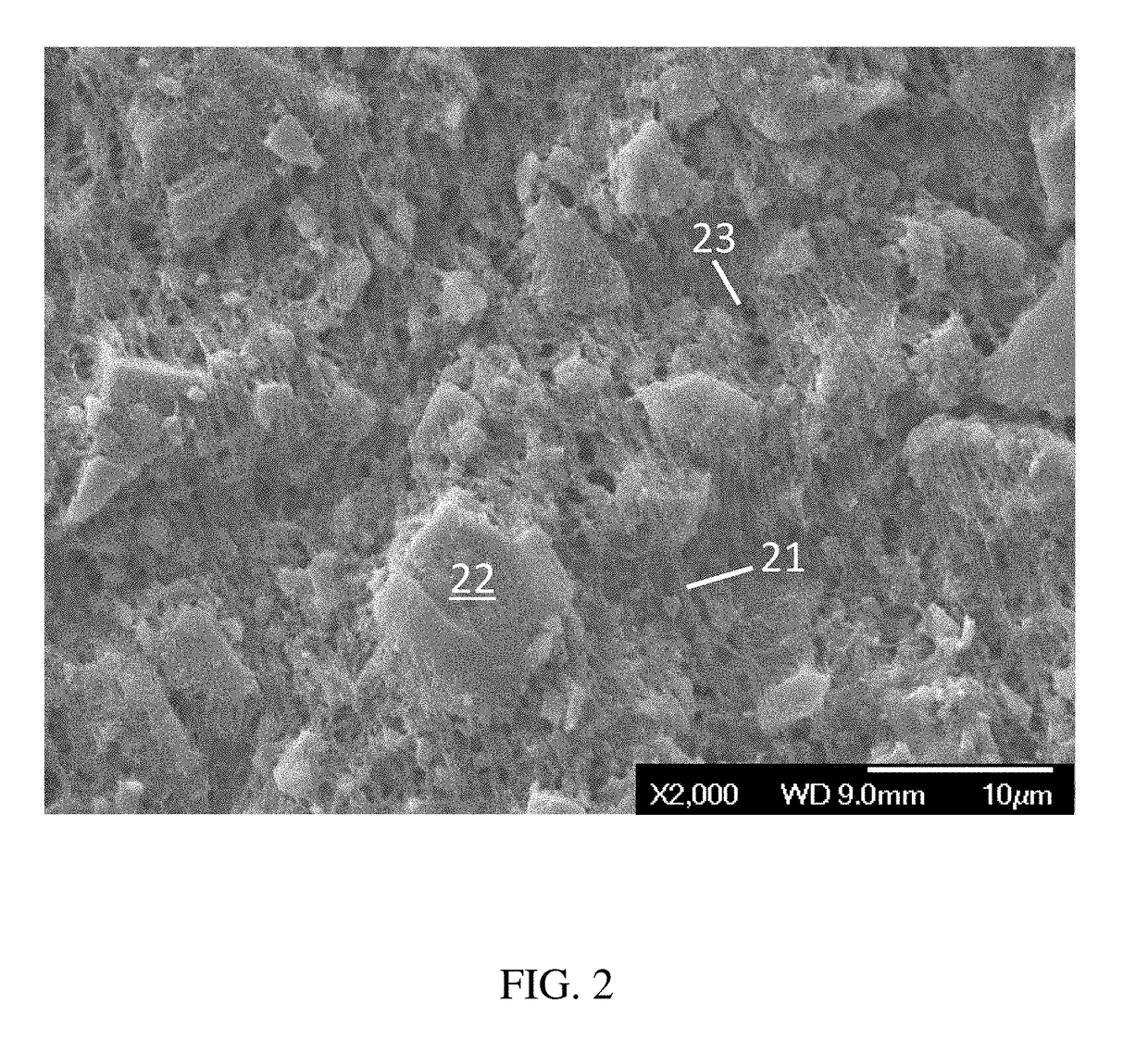

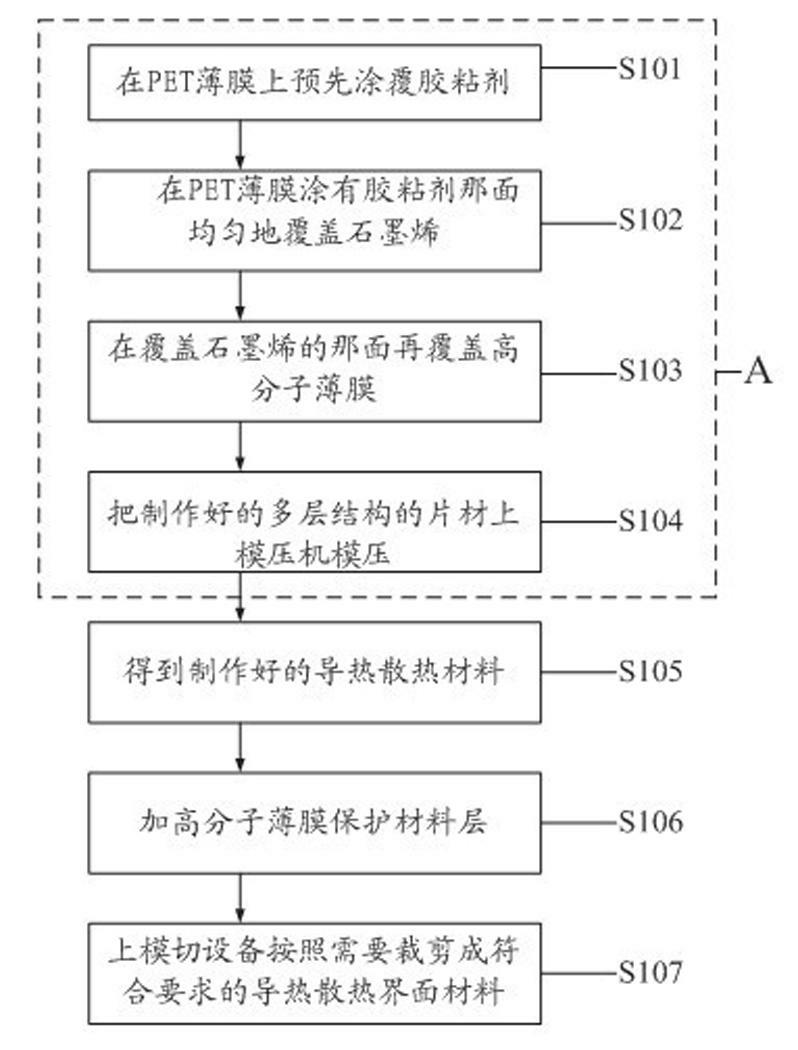

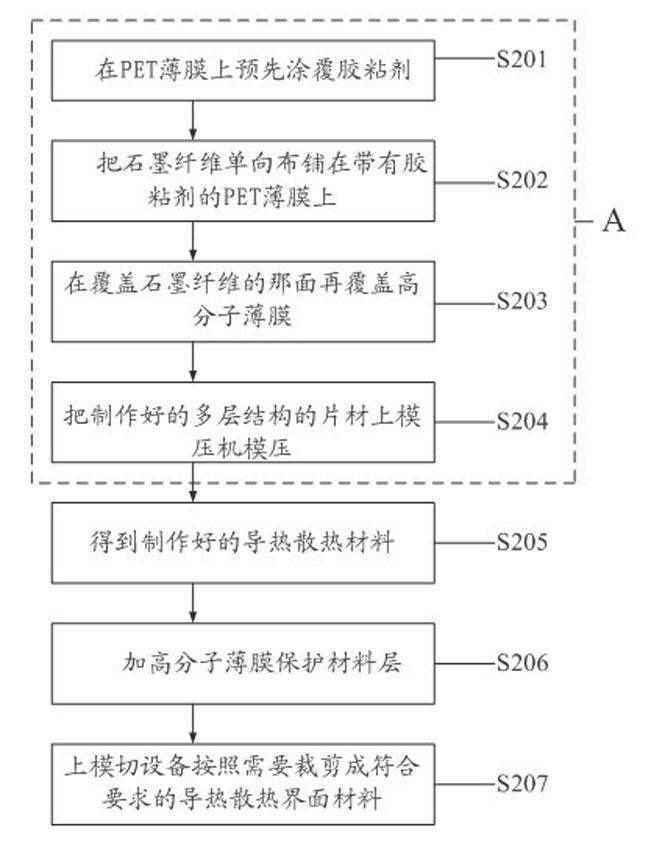

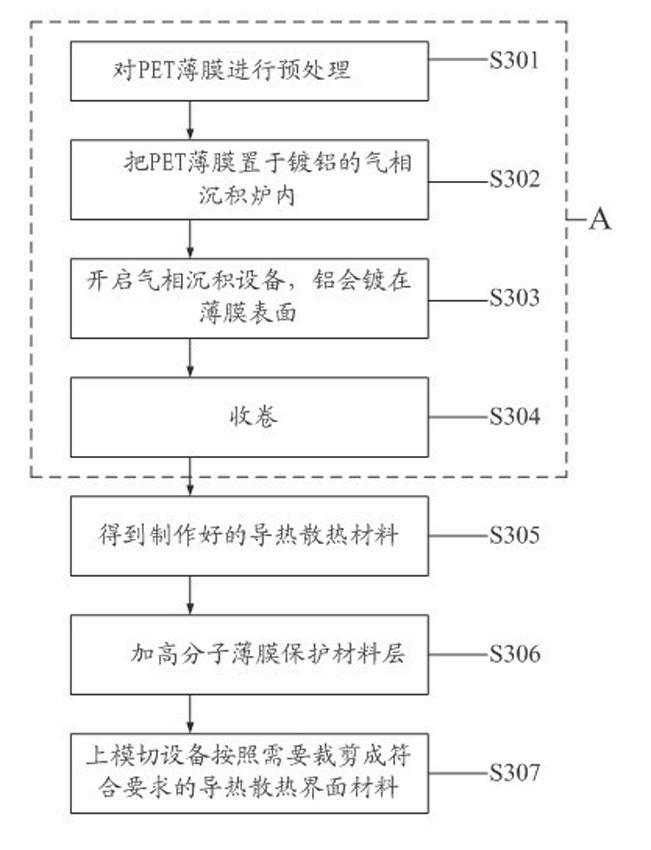

Heat-conduction heat-dissipation interface material and manufacturing method thereof

ActiveCN102651961AReduce volumeThe overall thickness is thinLayered productsCooling/ventilation/heating modificationsMetal fiberCalcium silicate

The invention provides a heat-conduction heat-dissipation interface material and a manufacturing method thereof, wherein the heat-conduction heat-dissipation interface material is applied to the field of heat dissipation of electronic products. The heat-conduction heat-dissipation interface material comprises a heat-conduction heat-dissipation layer and a surface protective material layer, wherein the heat-conduction heat-dissipation layer consists of one or more of graphite, nano graphite, crystalline flake graphite, graphene, pyrolytic carbon, pyrolytic graphite, graphite powder, carbon nano tubes, carbon fibers, graphite fibers, resin, ceramic fibers, quartz fibers, metal fibers, zirconia, boron nitride, silicon nitride, boron carbide, silicon carbide, magnesia powder, metasillicio acid fibers, calcium silicate aluminum fibers, aluminium oxide fibres, copper power, aluminium power, silver power, tungsten power and molybdenum power; and the surface protective material layer is a polymeric membrane. The heat-conduction heat-dissipation interface material manufactured according to the materials and the method provided by the invention has the advantages of effectively improved heat-dissipation performance, small volume, light weight and small thickness, can be used for prolonging the service life of an electronic component, and simultaneously is easy to produce and process.

Owner:SHANGHAI QI JIE CARBON MATERIALS

Timed pulsatile drug delivery systems

A pharmaceutical dosage form such as a capsule capable of delivering therapeutic agents into the body in a time-controlled or position-controlled pulsatile release fashion, is composed of a multitude of multicoated particulates (beads, pellets, granules, etc.) made of one or more populations of beads. Each of these beads except an immediate release bead has at least two coated membrane barriers. One of the membrane barriers is composed of an enteric polymer while the second membrane barrier is composed of a mixture of water insoluble polymer and an enteric polymer. The composition and the thickness of the polymeric membrane barriers determine the lag time and duration of drug release from each of the bead populations. Optionally, an organic acid containing intermediate membrane may be applied for further modifying the lag time and / or the duration of drug release. The pulsatile delivery may comprise one or more pulses to provide a plasma concentration-time profile for a therapeutic agent, predicted based on both its pharmaco-kinetic and pharmaco-dynamic considerations and in vitro / in vivo correlations.

Owner:ADARE PHARM INC

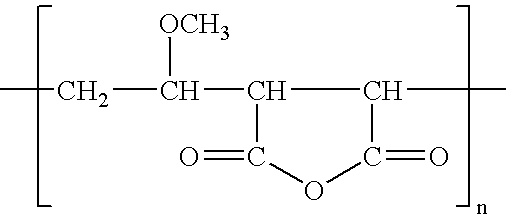

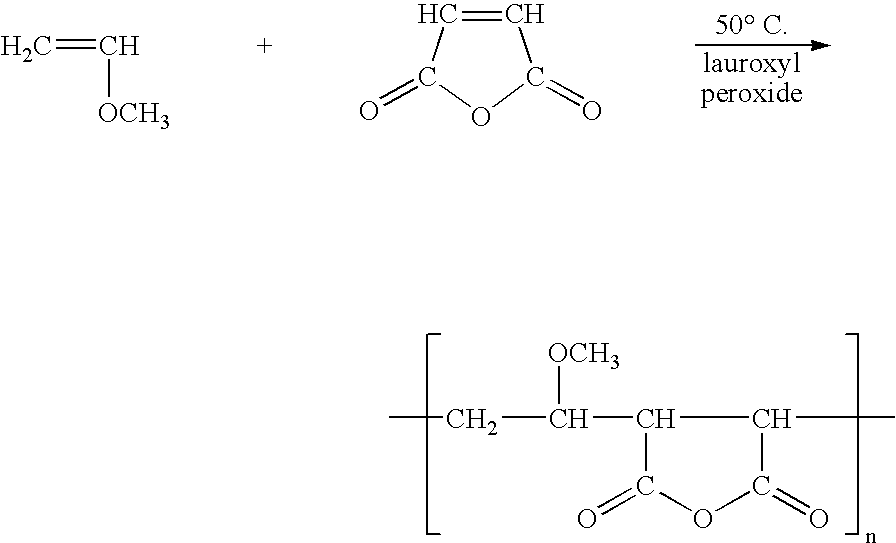

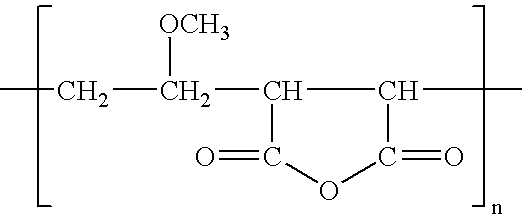

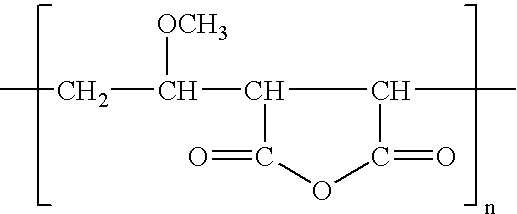

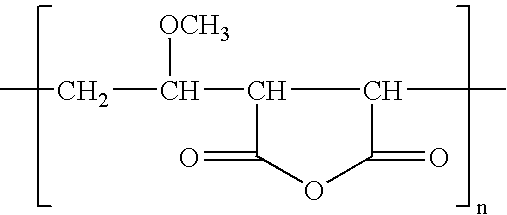

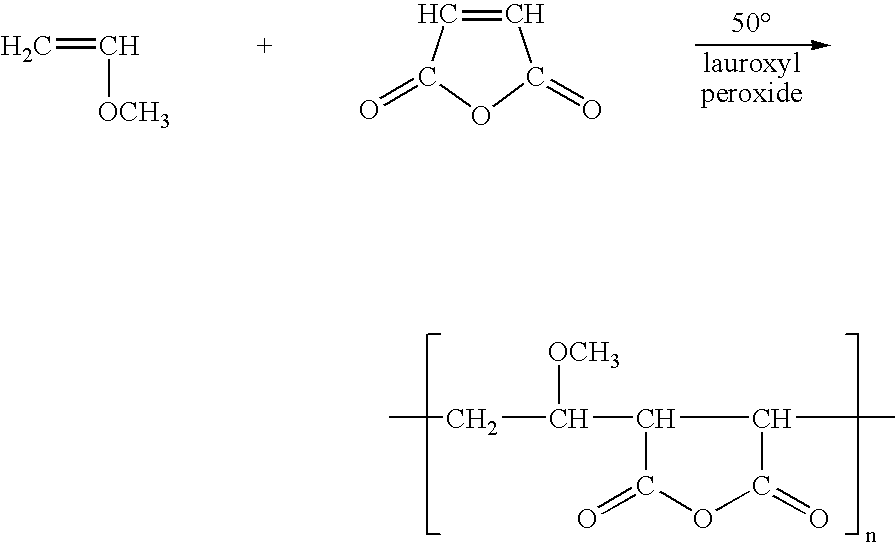

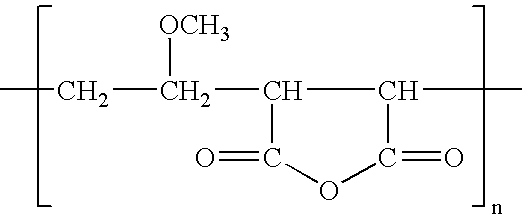

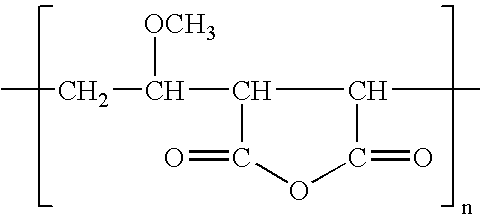

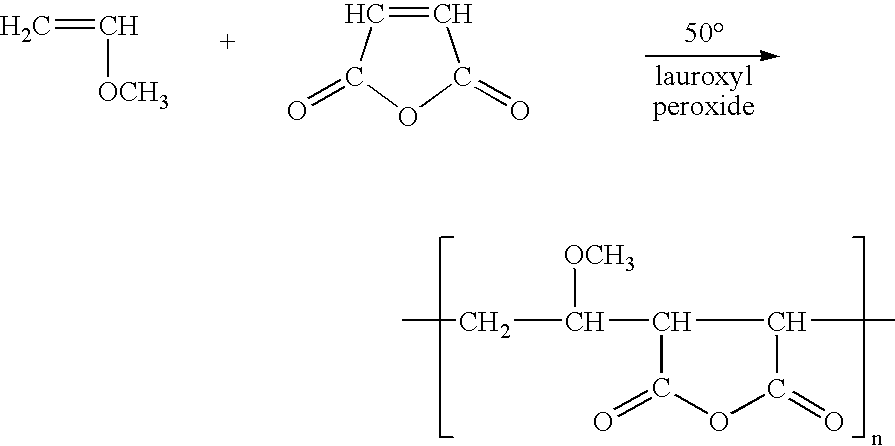

Modified membranes

InactiveUS20050029186A1Reduce dirtEssential mechanical properties of the membranesSemi-permeable membranesMembranesVinyl etherReverse osmosis

A porous polymeric membrane formed from a blend of a polymeric membrane forming material, such as polyvinylidene fluoride or polysulfone and a polymeric reactivity modifying agent adapted to modify the surface active properties of the porous polymeric membrane. The reactivity modifying agent is preferably a linear polymeric anhydride, such as poly(alkyl vinyl ether / maleic anhydride). The surface activity modifications include modification of the hydrophilicity / hydrophobicity balance of the membrane, or hydrolysis followed by reaction with a polyamine to form a crosslinked polyamide layer. Such modified membranes have use as reverse osmosis membranes.

Owner:EVOQUA WATER TECH LLC

Modified membranes

InactiveUS6884350B2Reduce dirtEssential mechanical properties of the membranesMembranesSemi-permeable membranesVinyl etherPolyamide

A porous polymeric membrane formed from a blend of a polymeric membrane forming material, such as polyvinylidene fluoride or polysulfone and a polymeric reactivity modifying agent adapted to modify the surface active properties of the porous polymeric membrane. The reactivity modifying agent is preferably a linear polymeric anhydride, such as poly(alkyl vinyl ether / maleic anhydride). The surface activity modifications include modification of the hydrophilicity / hydrophobicity balance of the membrane, or hydrolysis followed by reaction with a polyamine to form a crosslinked polyamide layer. Such modified membranes have use as reverse osmosis membranes.

Owner:EVOQUA WATER TECH LLC

Modified membranes

InactiveUS20050032982A1Reduce dirtEssential mechanical properties of the membranesSemi-permeable membranesMembranesVinyl etherReverse osmosis

A porous polymeric membrane formed from a blend of a polymeric membrane forming material, such as polyvinylidene fluoride or polysulfone and a polymeric reactivity modifying agent adapted to modify the surface active properties of the porous polymeric membrane. The reactivity modifying agent is preferably a linear polymeric anhydride, such as poly(alkyl vinyl ether / maleic anhydride). The surface activity modifications include modification of the hydrophilicity / hydrophobicity balance of the membrane, or hydrolysis followed by reaction with a polyamine to form a crosslinked polyamide layer. Such modified membranes have use as reverse osmosis membranes.

Owner:MULLER HEINZ JOACHIM

Modified membranes

InactiveUS20050029185A1Reduce dirtEssential mechanical properties of the membranesSemi-permeable membranesMembranesVinyl etherReverse osmosis

A porous polymeric membrane formed from a blend of a polymeric membrane forming material, such as polyvinylidene fluoride or polysulfone and a polymeric reactivity modifying agent adapted to modify the surface active properties of the porous polymeric membrane. The reactivity modifying agent is preferably a linear polymeric anhydride, such as poly(alkyl vinyl ether / maleic anhydride). The surface activity modifications include modification of the hydrophilicity / hydrophobicity balance of the membrane, or hydrolysis followed by reaction with a polyamine to form a crosslinked polyamide layer. Such modified membranes have use as reverse osmosis membranes.

Owner:EVOQUA WATER TECH LLC

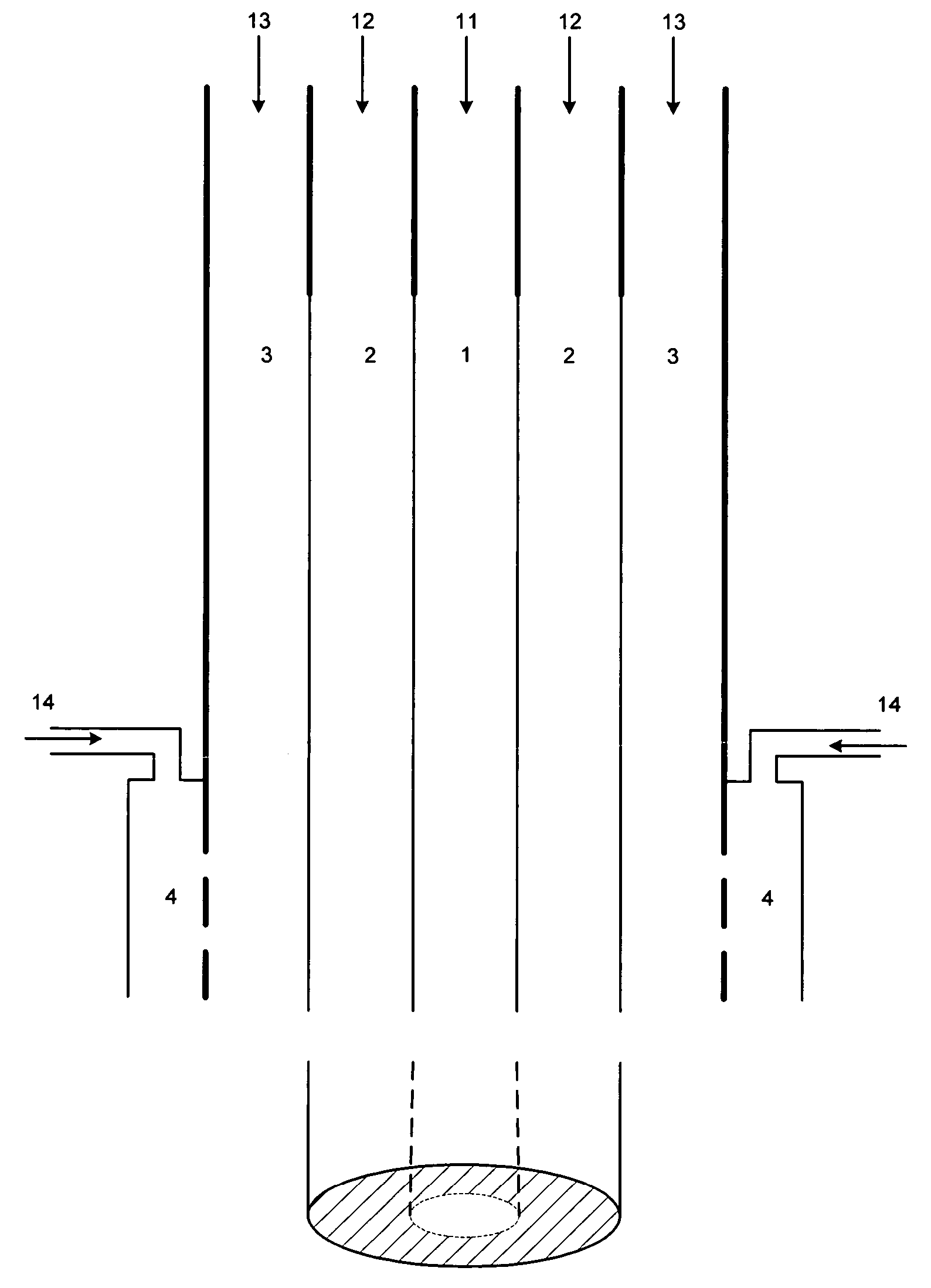

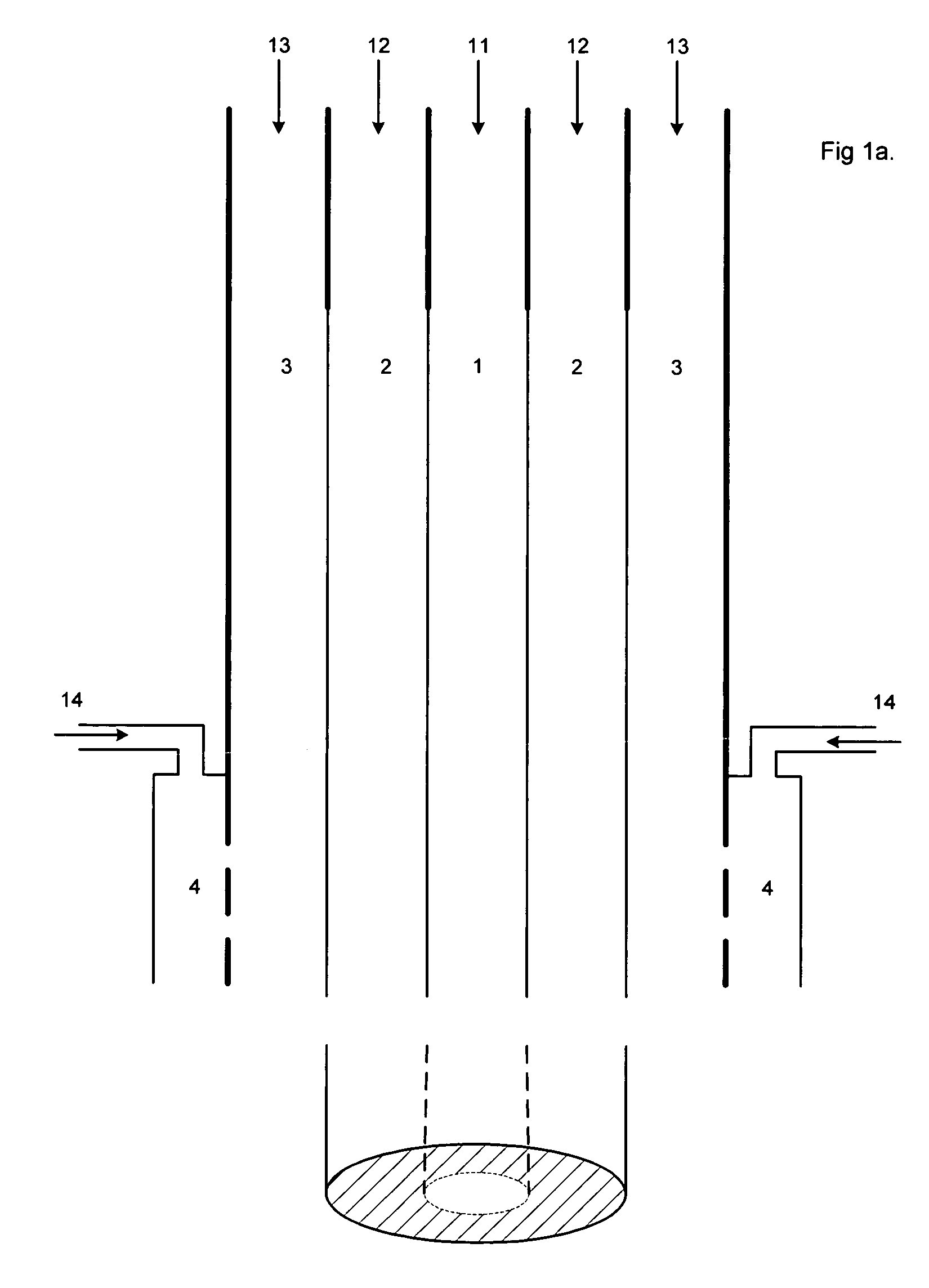

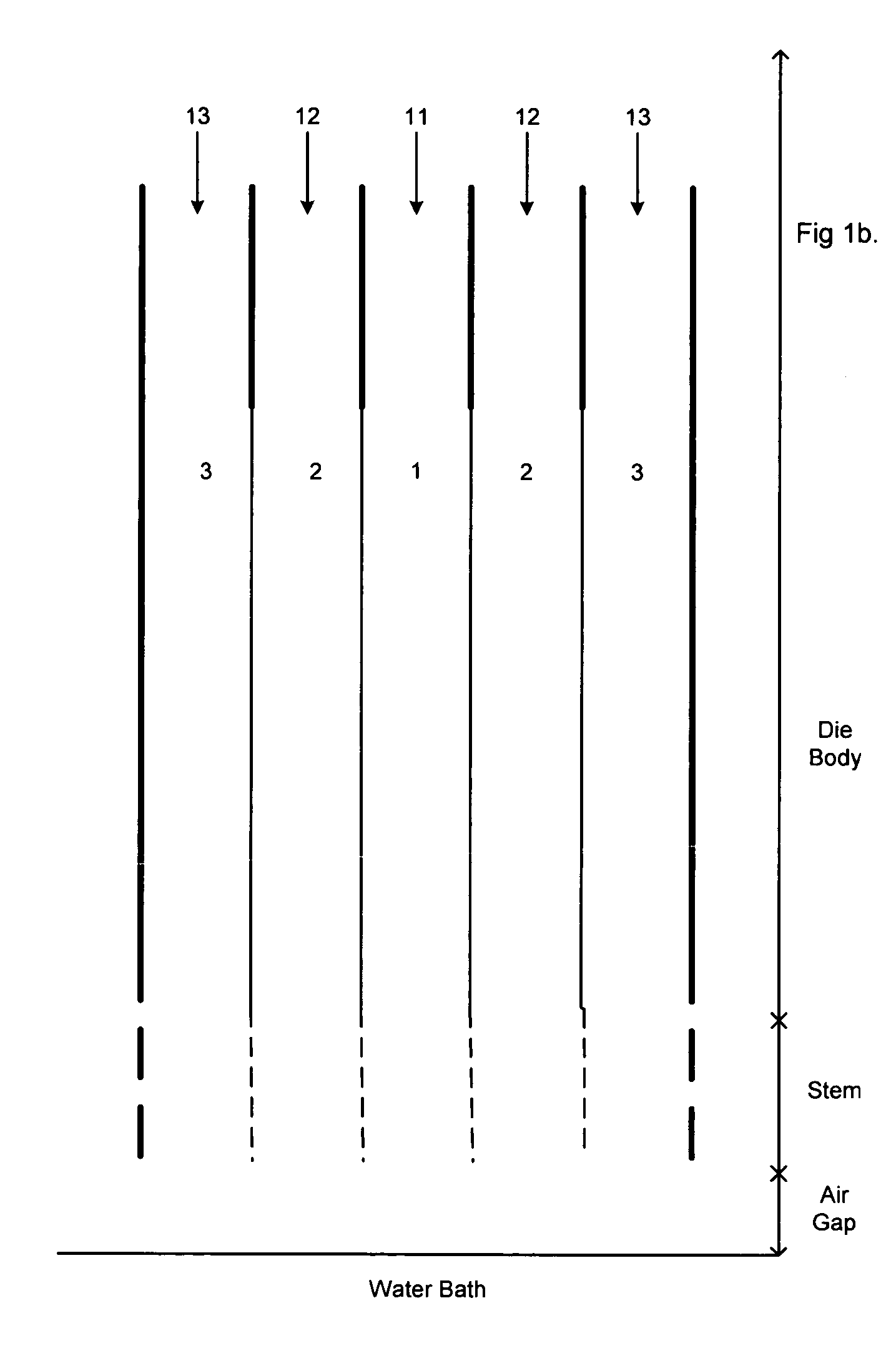

Halar membranes

InactiveUS20050098494A1Low toxicityImprove permeabilityMembranesSemi-permeable membranesFiberGlycerol

Porous polymeric membranes including Halar (poly (ethylene chlorotrifluoroethylene)) and related compounds and the methods of production thereof which avoid the use of toxic solvents. Preferred solvents, coating agents and pore forming agents are citric acid ethyl ester or glycerol triacetate. The membranes may be in the form of a hollow fibre or flat sheet, and may include other agents to modify the properties of the membrane, such as the hydrophilic / hydrophobic balance. Leachable agents may also be incorporated into the membranes.

Owner:EVOQUA WATER TECH LLC

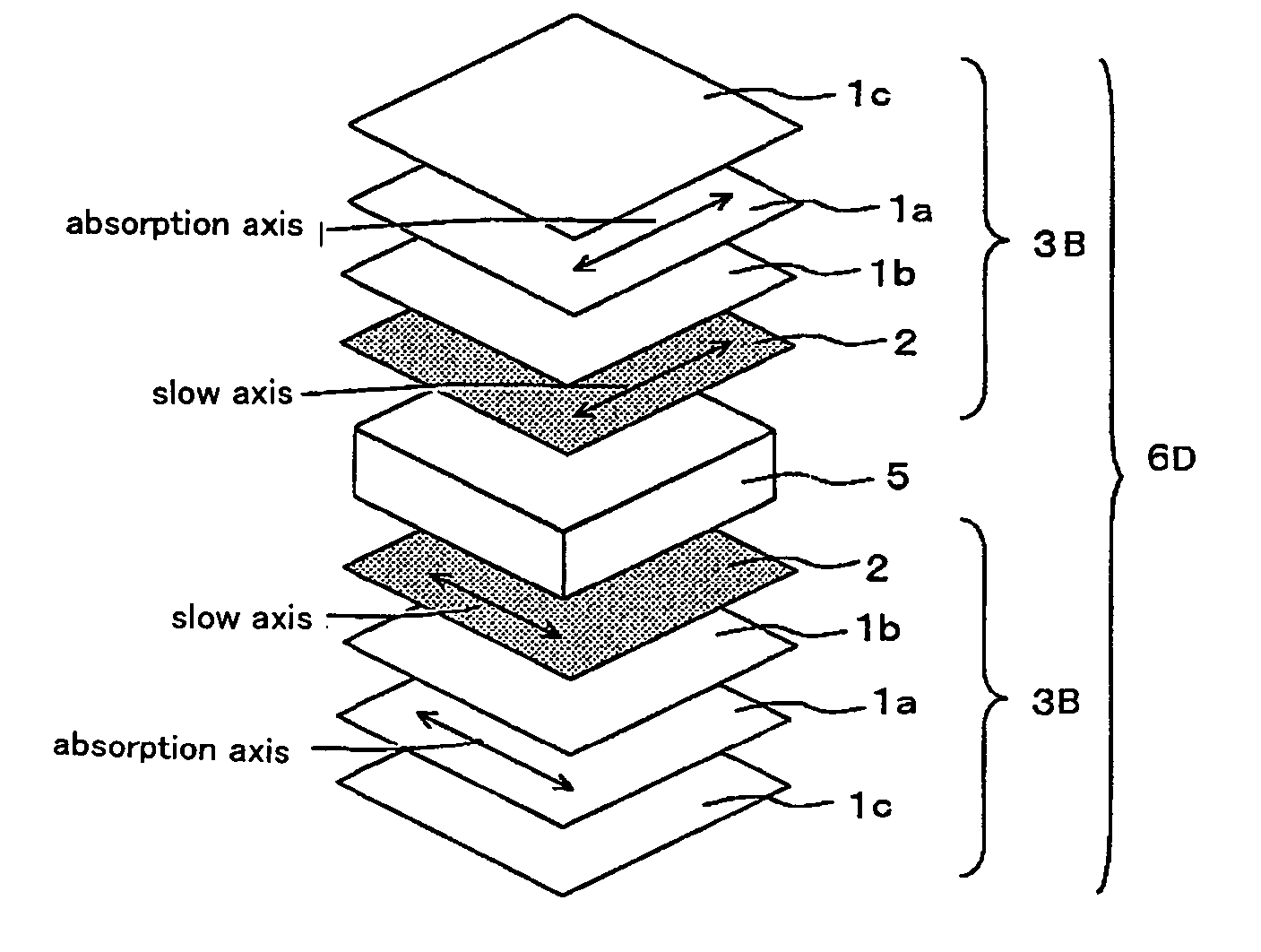

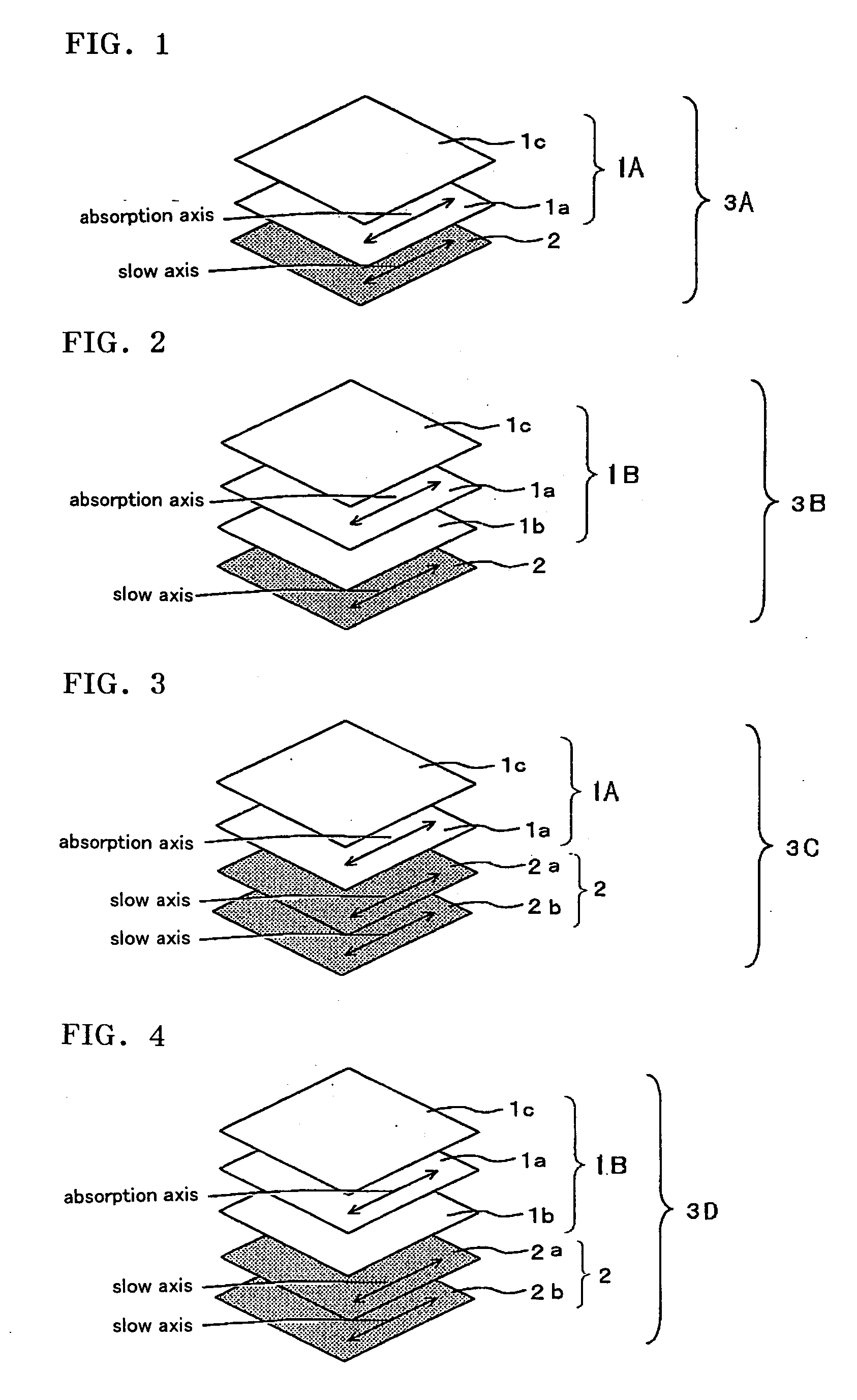

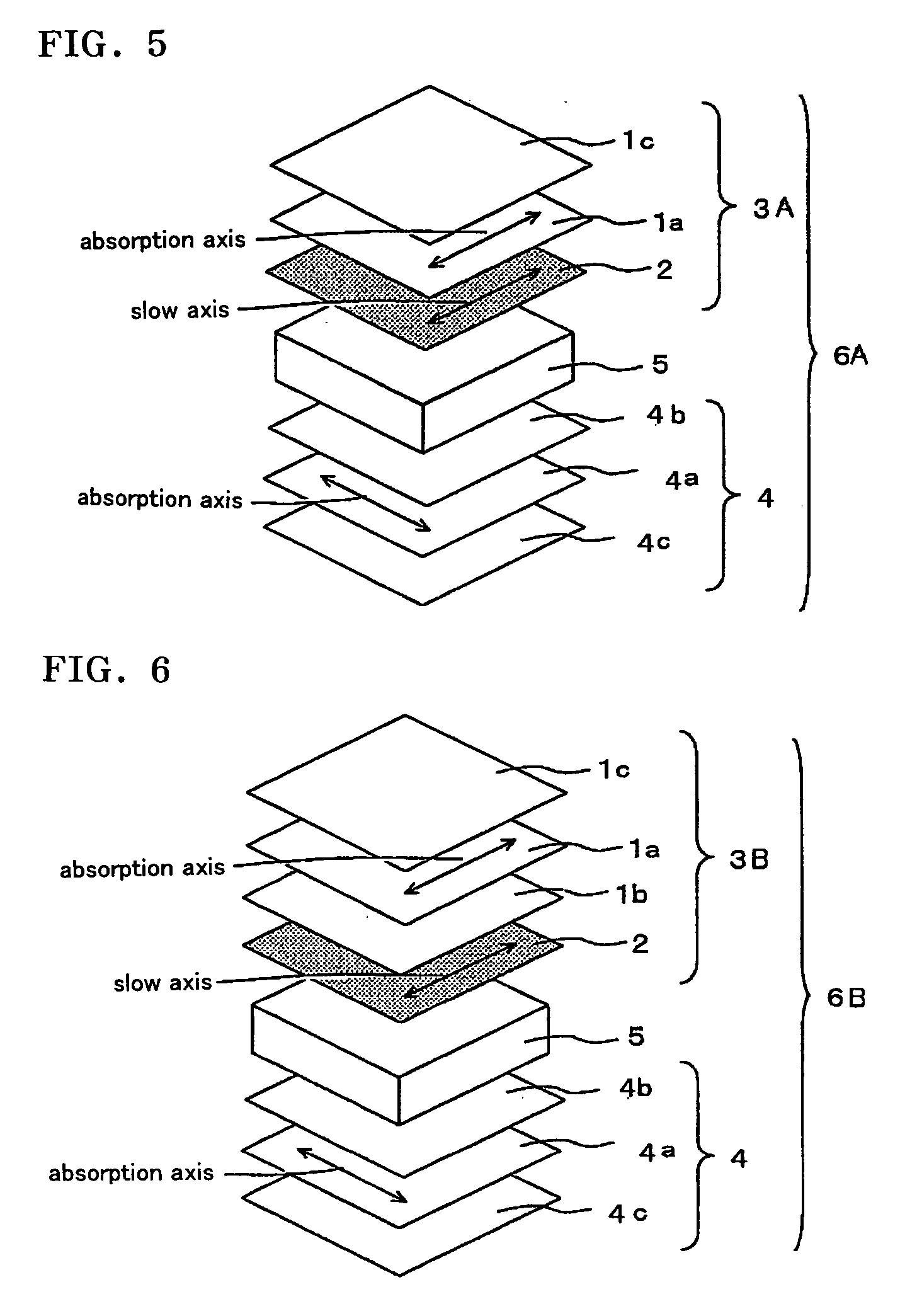

Retardation film, process for producing the same, optical film, image display, liquid crystal panel and liquid crystal display

ActiveUS20060028601A1Retardation valueHard to cause a shift or an unevenness of a retardation valueOptical light guidesNon-linear opticsRefractive indexDisplay device

A retardation film of the present invention comprises a stretched film of a polymer film containing a norbornene-based resin, wherein the stretched film satisfies the following equation (1) and the equation (2); 100 nm≦(nx−ny)·d≦350 nm . . . (1),0.1≦(nx−nz) / (nx−ny)≦0.9 . . . (2), where the refractive indices in the slow axis direction, the fast axis direction and the thickness direction of the film are nx, ny and nz, respectively, d(nm) is thickness of the film, and the slow axis direction is a direction that the refractive index in film plane is maximum. The retardation film is hard to cause a shift or an unevenness of a retardation value due to a stress.

Owner:NITTO DENKO CORP

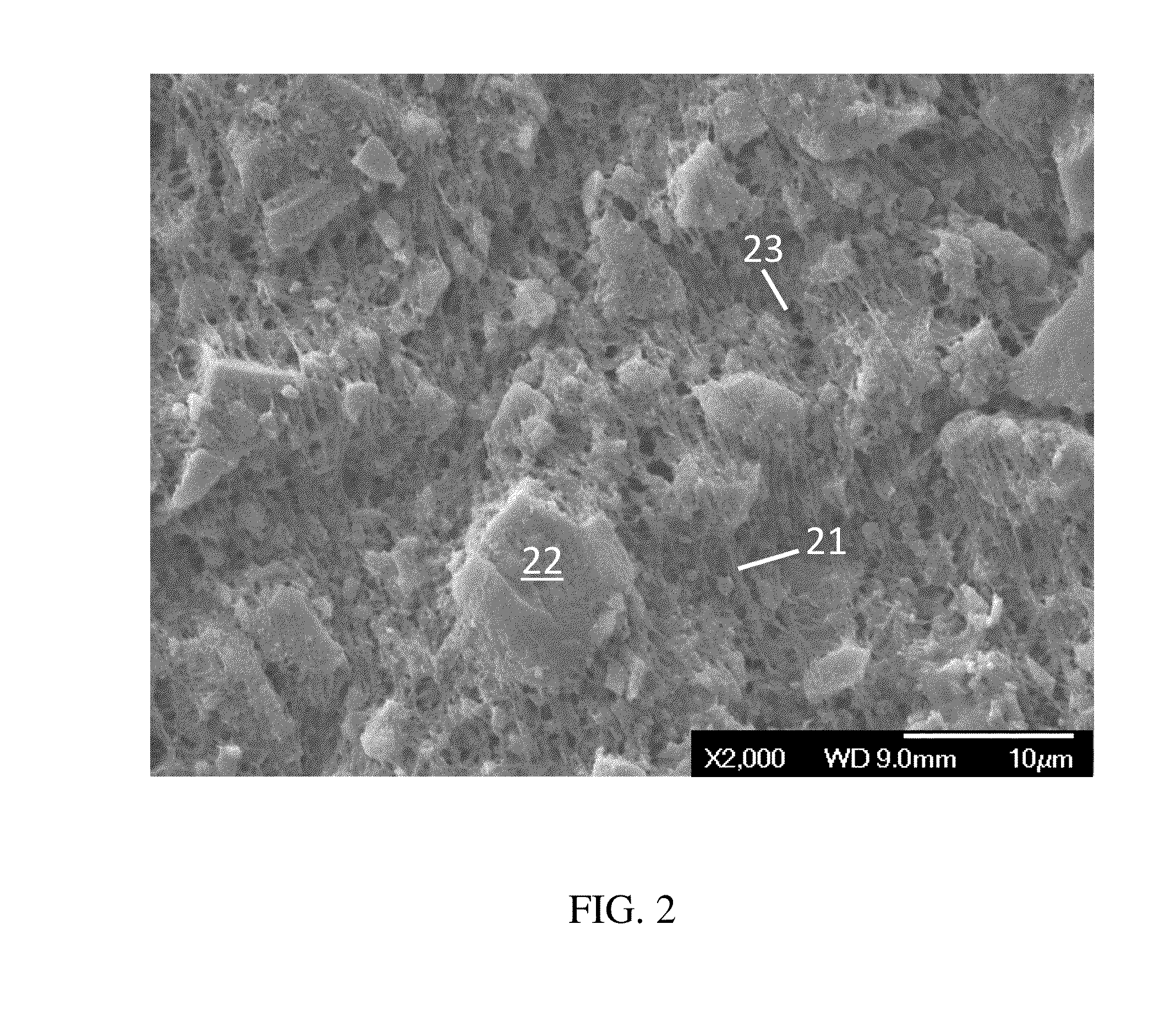

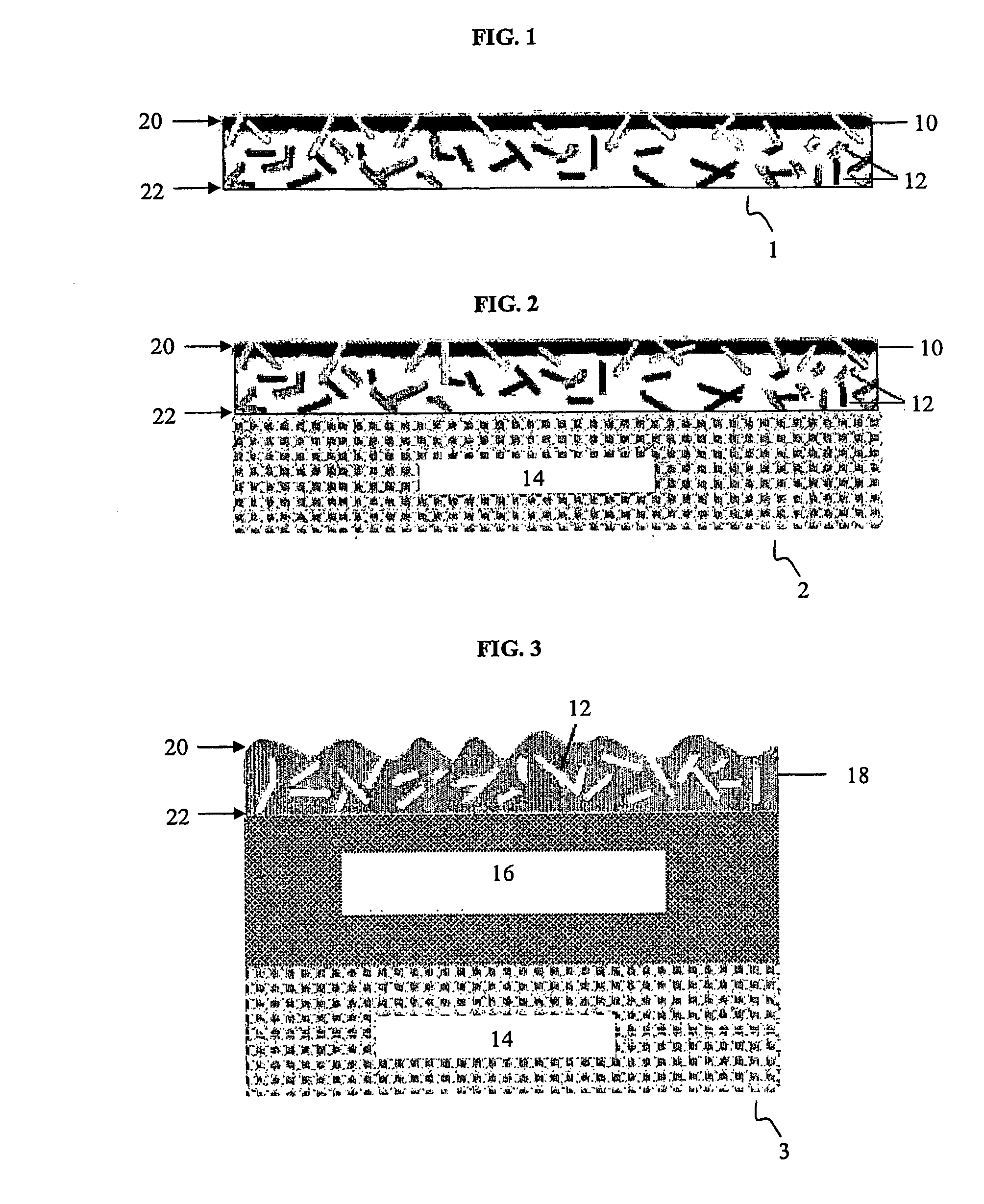

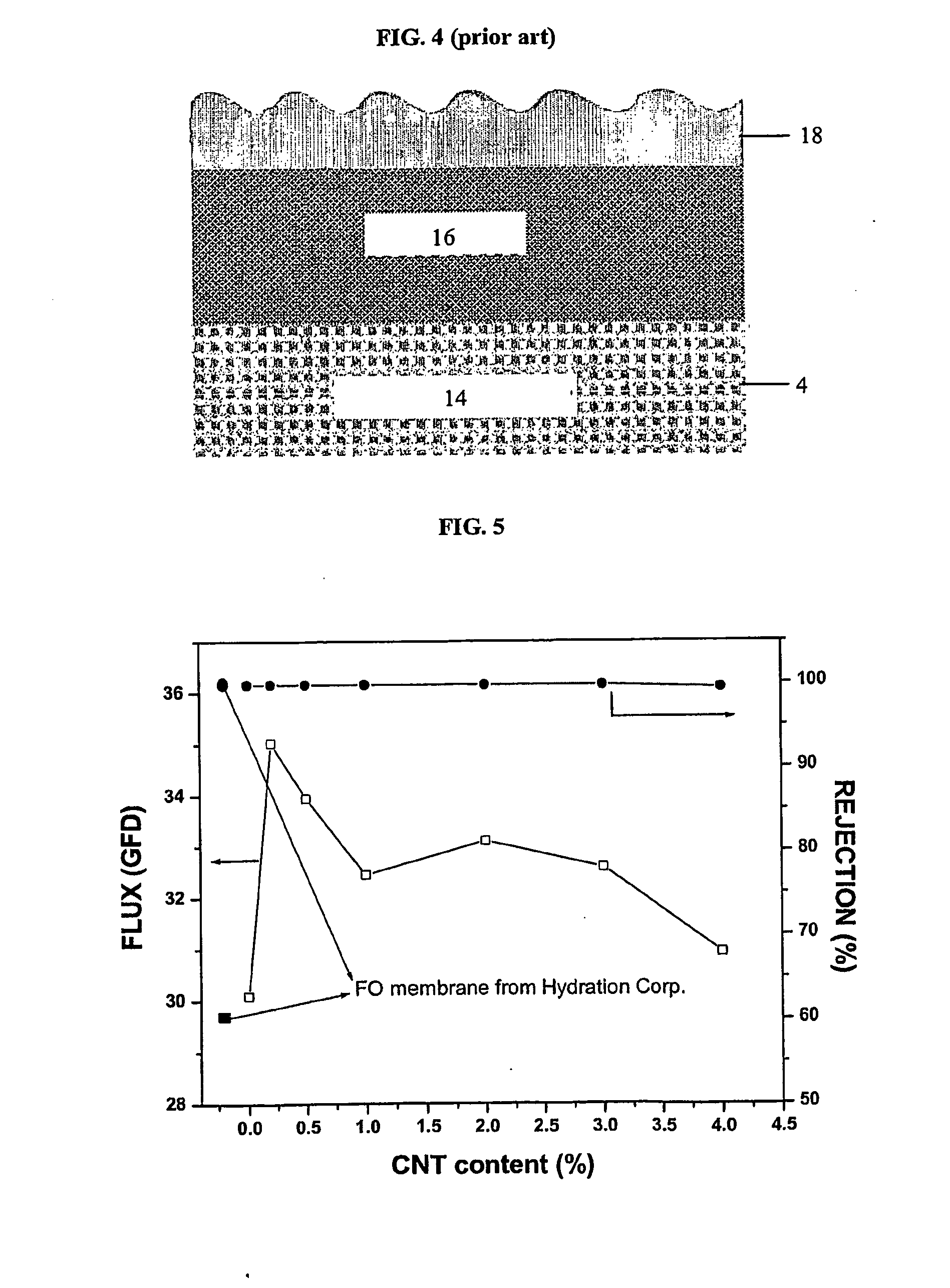

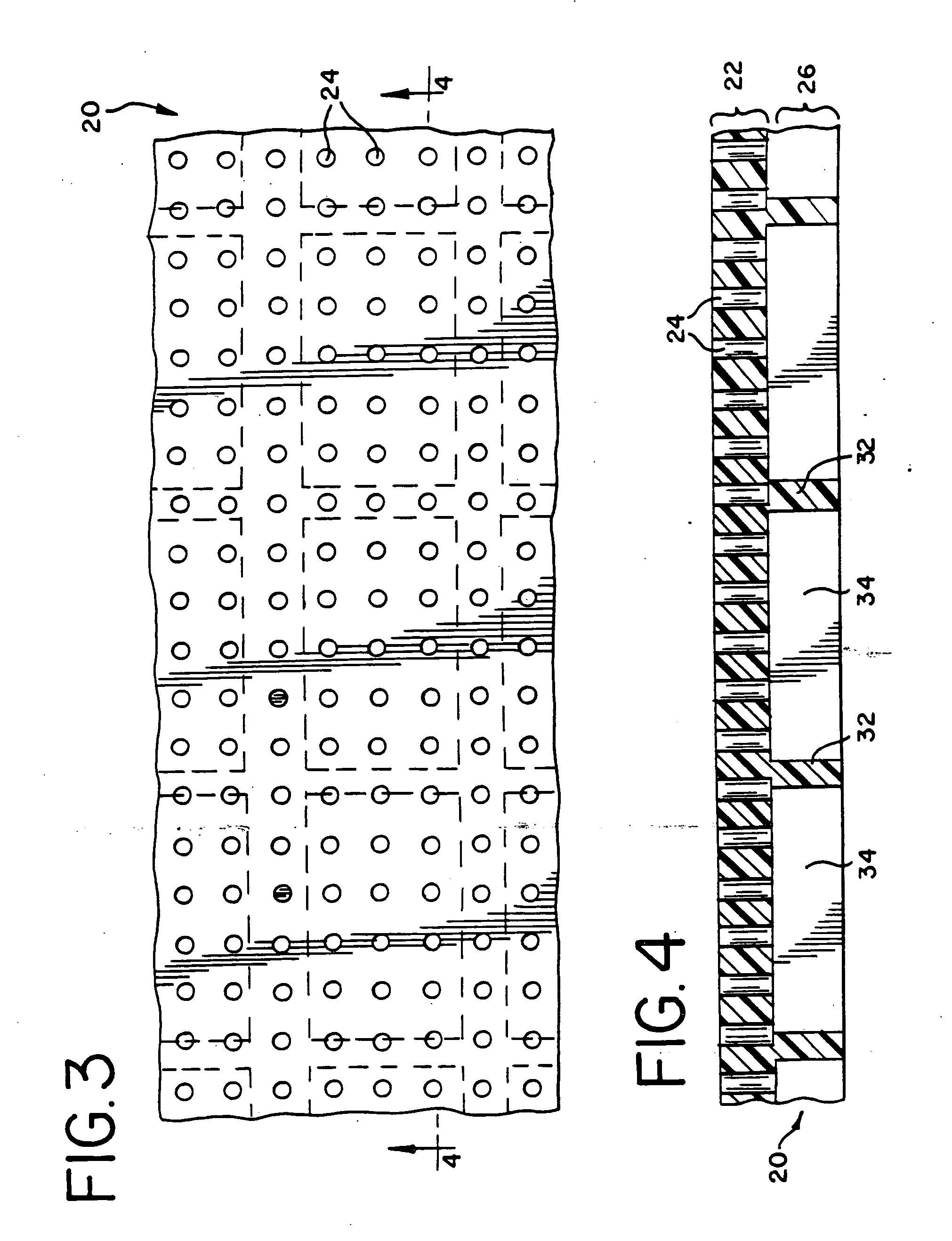

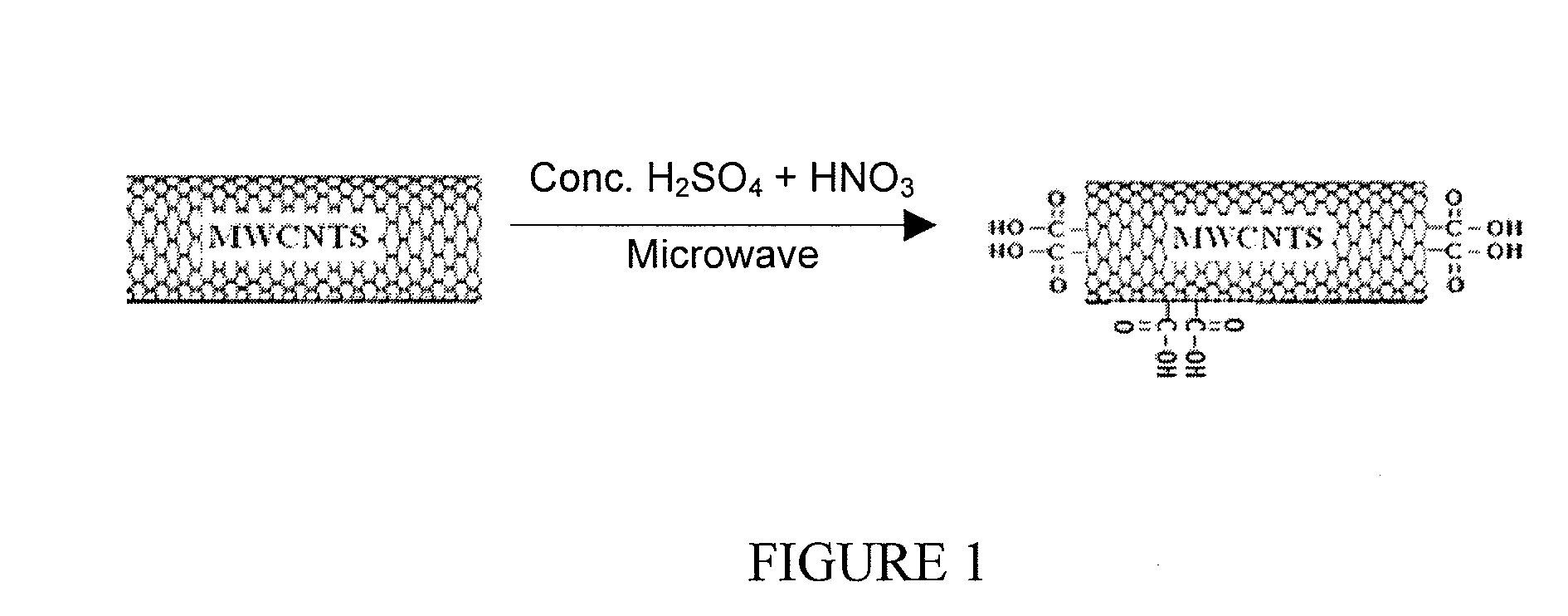

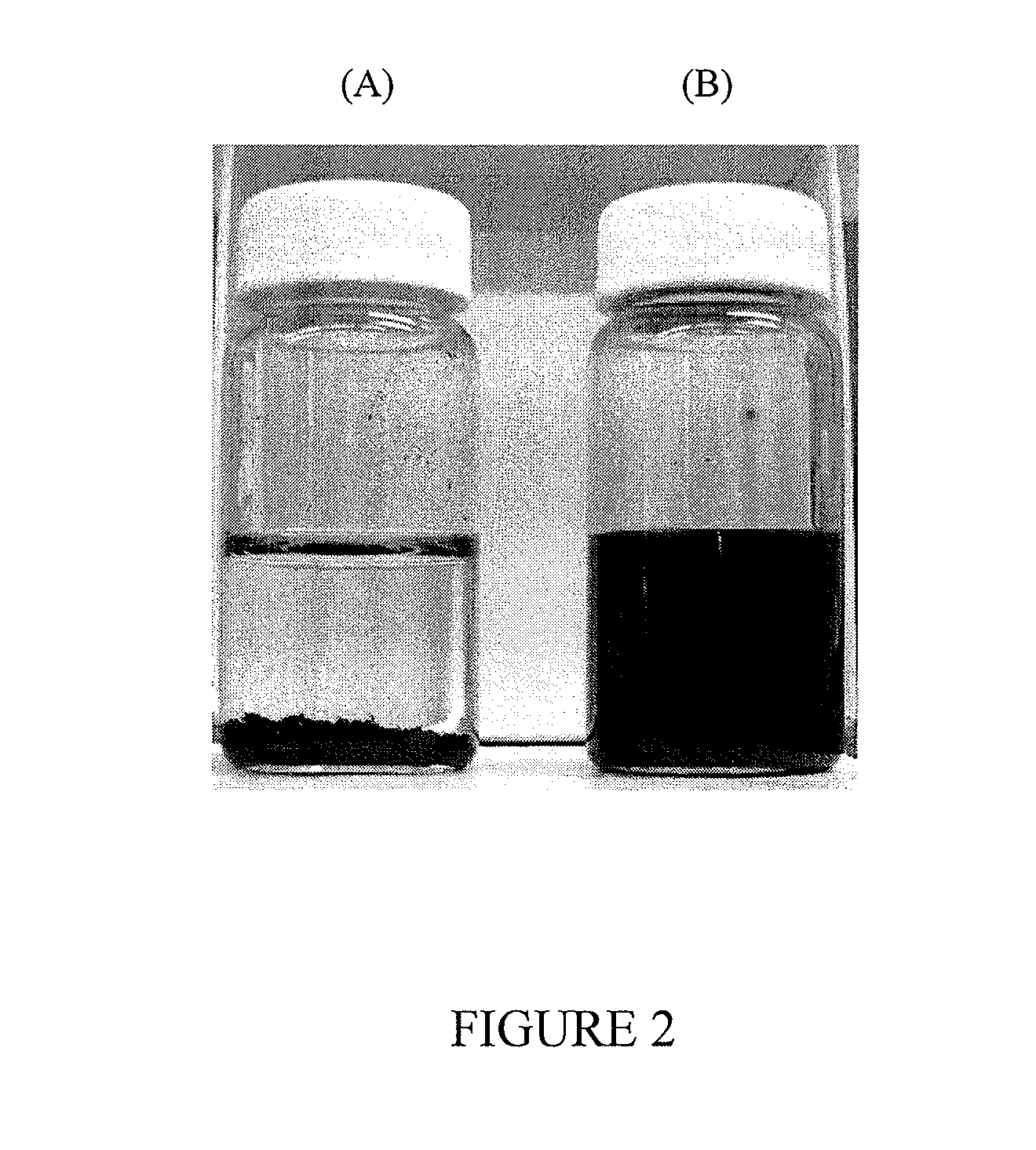

Polymeric membranes incorporating nanotubes

InactiveUS20100206811A1Inhibition formationMaterial nanotechnologyMembranesSemipermeable membraneNanotube

The present invention relates to semipermeable membranes with nanotubes dispersed therein, and the methods of preparing the same.

Owner:NAT UNIV OF SINGAPORE

Helically formed stent/graft assembly

The present invention relates to a support structure / membrane composite device which includes a support structure, such as a radially expandable stent, a porous non-textile polymeric membrane adjacent to said stent and a thermoplastic anchor means attaching said stent to said porous non-textile polymeric membrane. The porous non-textile polymeric membrane is preferably made from expandable fluoropolymer materials. The anchoring means is a thermoplastic material which is dissolvable at the interface between the support structure and membrane by a suitable solvent which wets the membrane surface and deposits the thermoplastic material within the pores of the membrane. Methods of preparing the device are also disclosed.

Owner:BOSTON SCI SCIMED INC

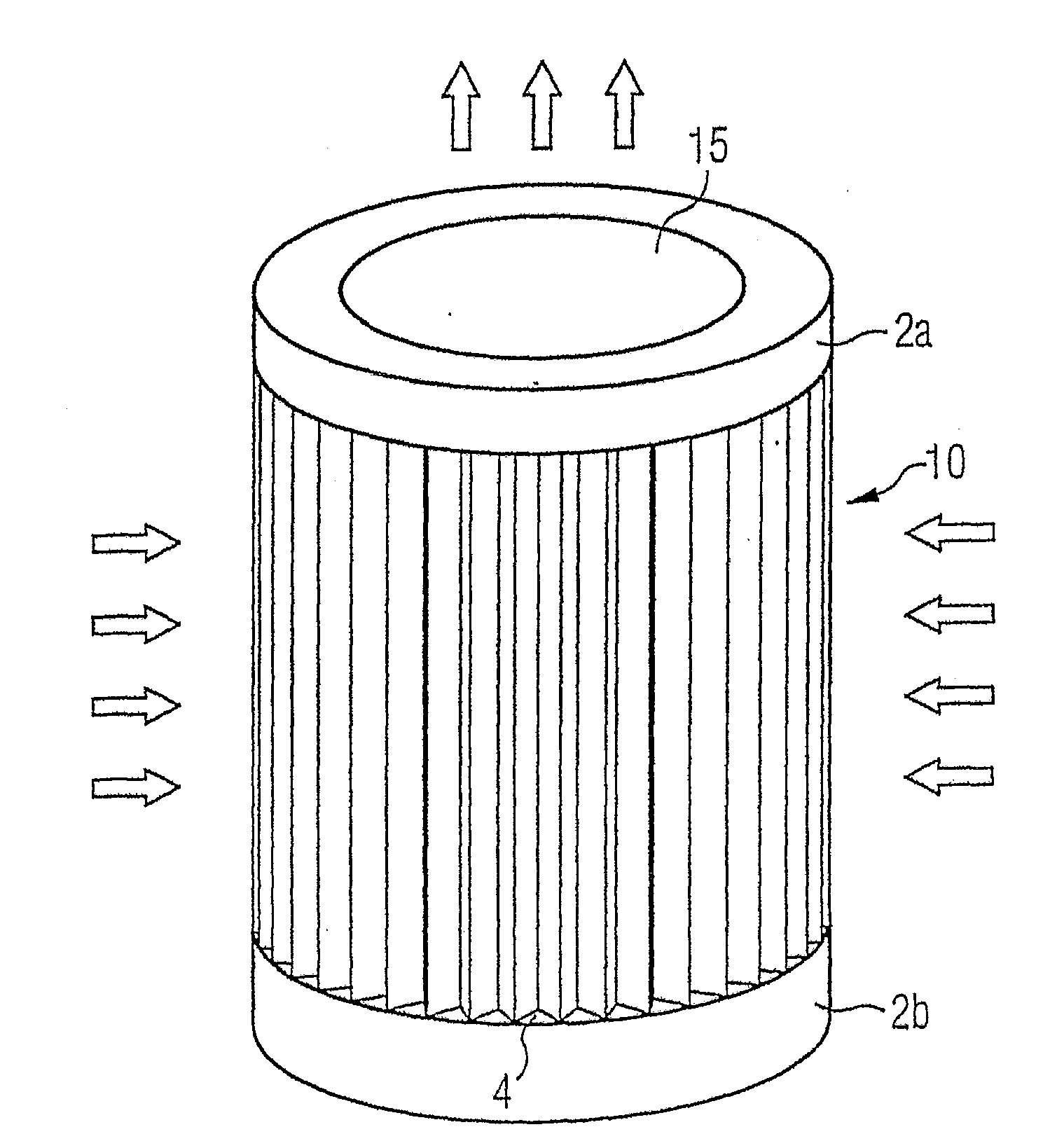

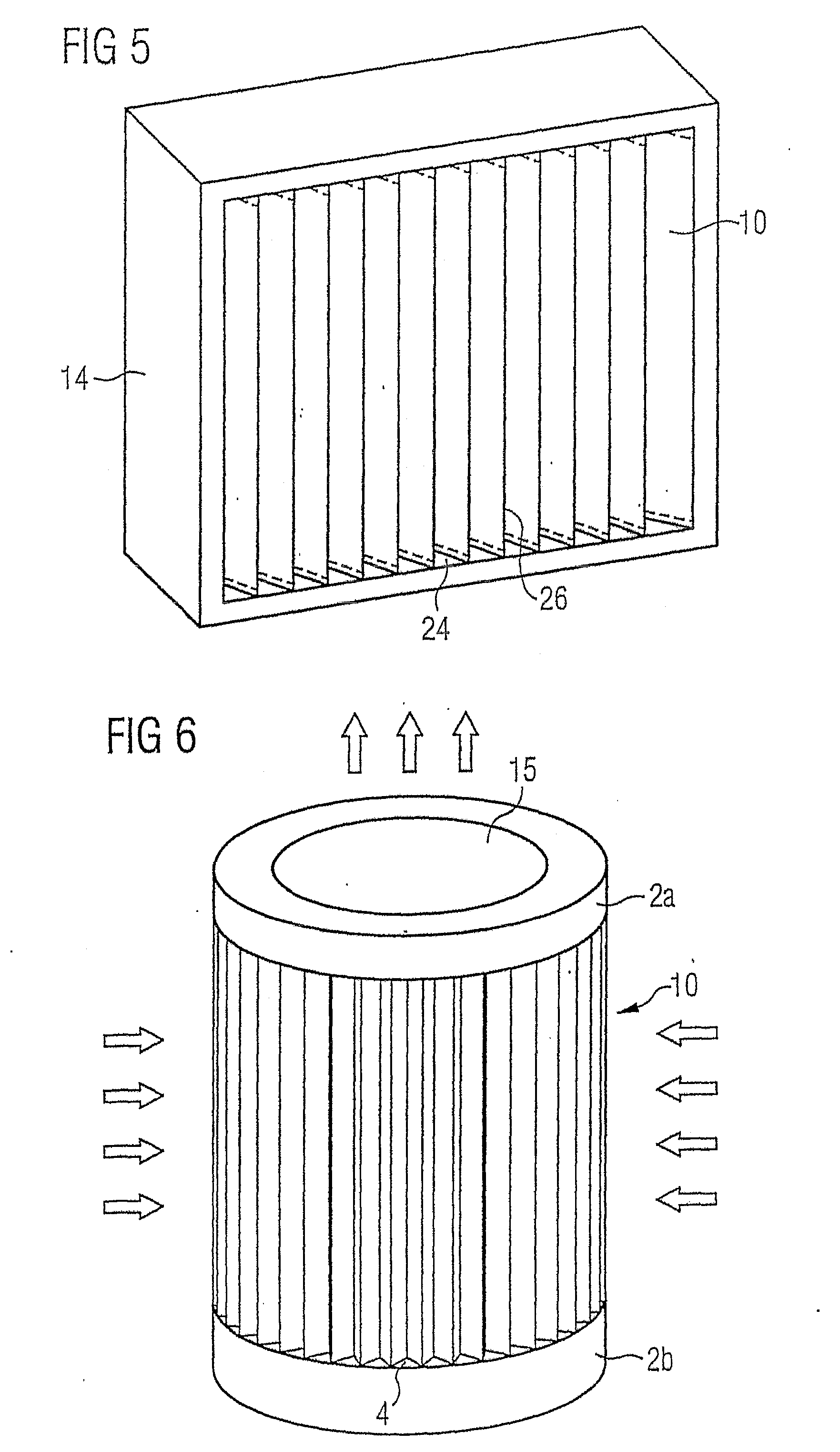

Turbine Air-Intake Filter

InactiveUS20090266048A1Improve filtering effectSimple wayGas treatmentDispersed particle filtrationFiberFiltration

A turbine air-intake filter for removal of particles from an air stream entering a gas turbine comprises a composite filter media (10) being made from a membrane filtration layer (20) comprising a porous polymeric membrane, such as porous polytetrafluoroethylene (ePTFE), and at least one depth filtration media layer (18) comprising fibers, such as a melt blown web, and being disposed on an upstream side of the membrane filtration layer (20) relative to a direction of gas flow through the filter. The fibers of the depth filtration media layer (18) have an electrostatic charge. The ePTFE membrane is preferably made from a blend of a PTFE homopolymer and a modified PTFE polymer.

Owner:SCHWARZ ROBERT

Microporous filter membrane, method of making microporous filter membrane and separator employing microporous filter membranes

InactiveUS20050263452A1High porosityLittle precisionPaper/cardboard articlesDispersed particle filtrationMicron scaleFiltration membrane

A filter membrane, methods of making such filter membrane and apparatus employing such filter membrane are disclosed, in which the filter membrane is a monolithic polymeric membrane that includes a polymeric filter layer including a micron-scale precision-shaped pores and a polymeric support layer that has a precision-shaped porous support structure for the filter layer. Several methods are disclosed for making such a membrane using micromachining techniques, including lithographic, laser ablation and x-ray treatment techniques. Several filter apparatus employing such a membrane are also disclosed.

Owner:BAXTER INT INC

Carbon Nanotube Mediated Membrane Extraction

ActiveUS20090283475A1Improve performanceSimple systemMaterial nanotechnologySolvent extractionImproved methodNanotube

The present disclosure provides an improved membrane or substrate having carbon nanotubes introduced and / or immobilized therein, and an improved method for introducing and / or immobilizing carbon nanotubes in membranes or substrates. More particularly, the present disclosure provides for improved systems and methods for fabricating membranes or substrates having carbon nanotubes immobilized therein. In one embodiment, the present disclosure provides for systems and methods for introducing and / or immobilizing functionalized carbon nanotubes into the pore structure of a polymeric membrane or substrate, thereby dramatically improving the performance of the polymeric membrane or substrate. In exemplary embodiments, the present disclosure provides for systems and methods for the fabrication of nanotube immobilized membranes by incorporating CNTs in a membrane or substrate.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

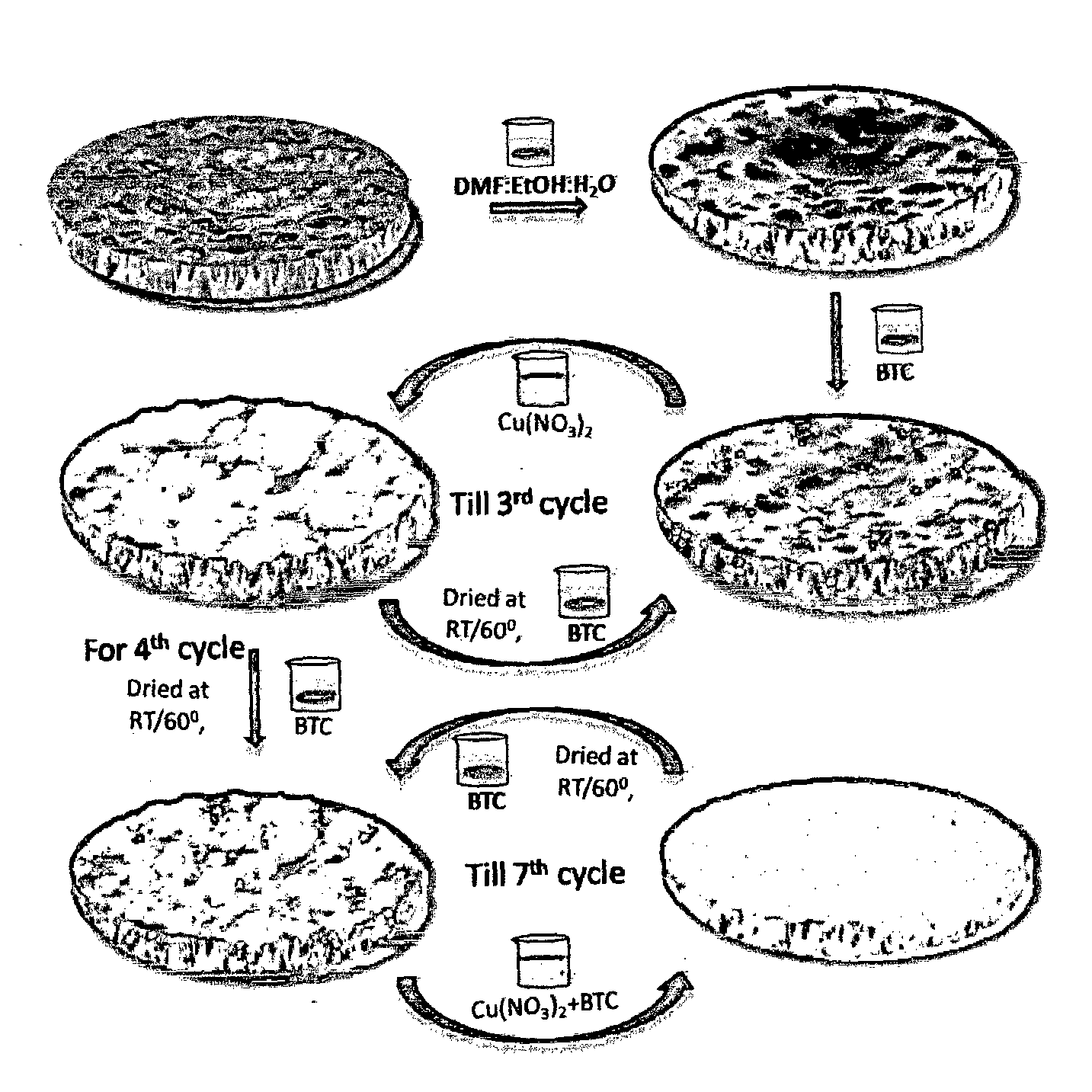

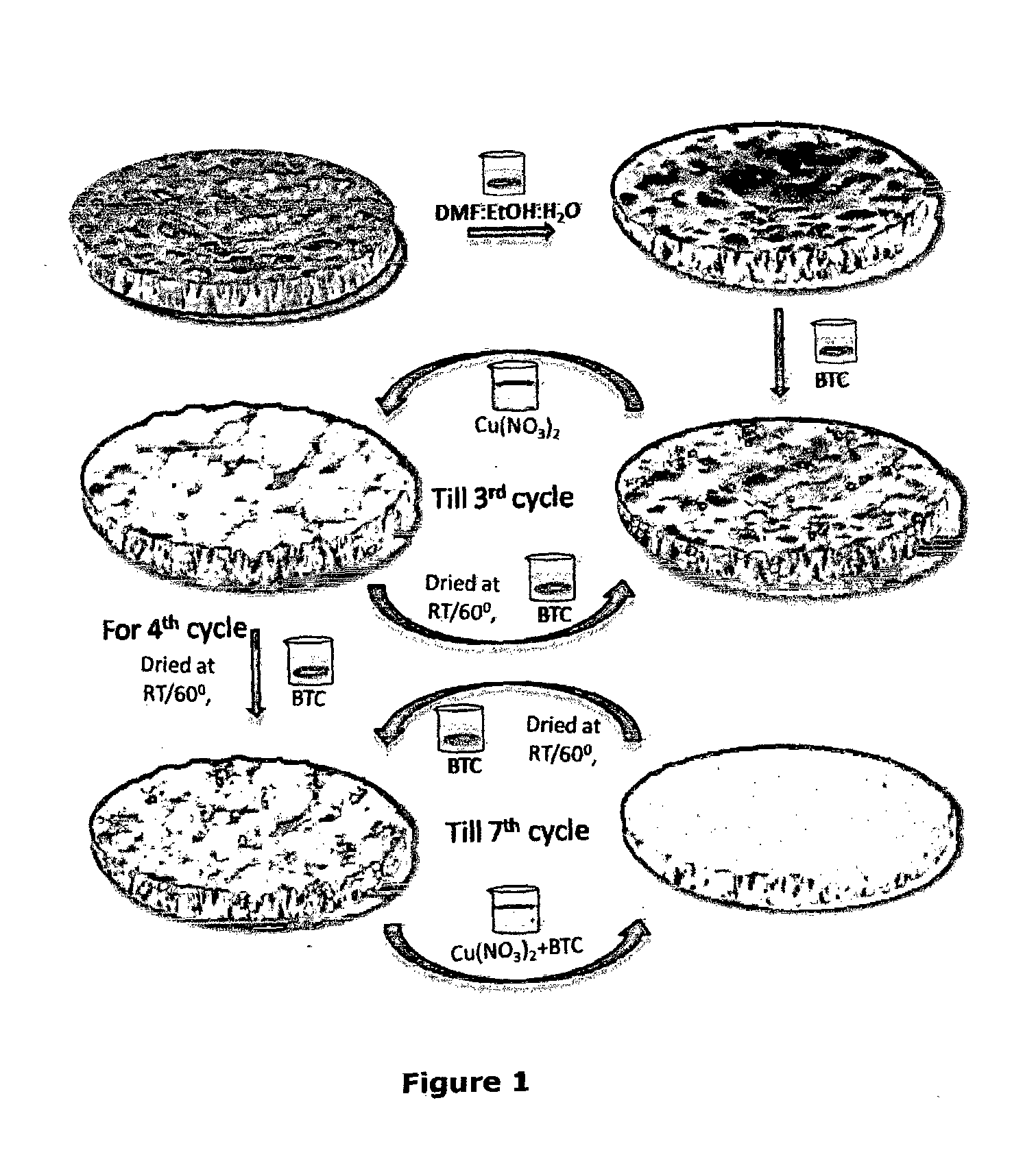

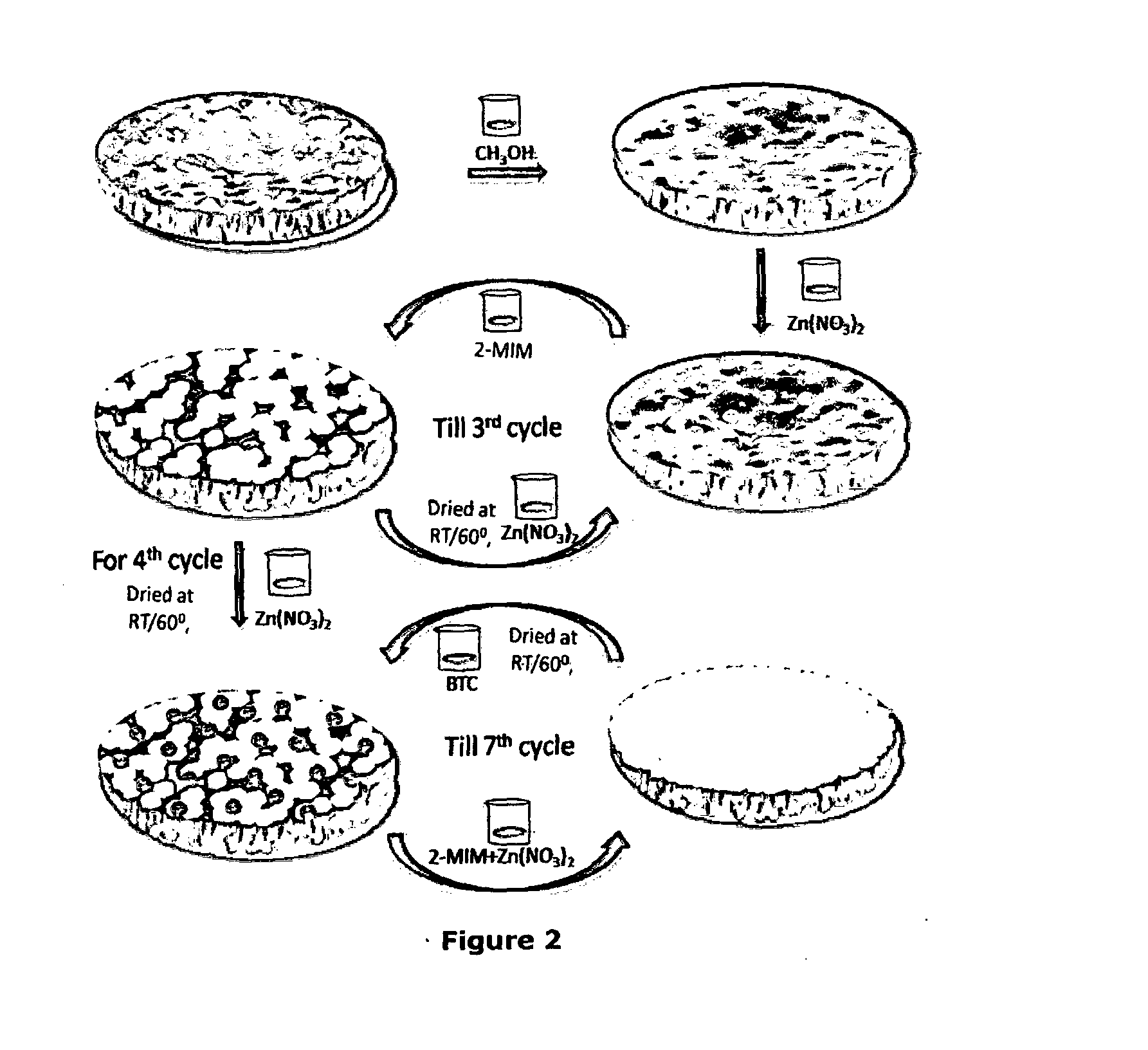

Process for the preparation of mofs-porous polymeric membrane composites

ActiveUS20150367294A1Separation efficiency can be improvedMembranesSemi-permeable membranesPolymer sciencePolymer composites

Disclosed herein is an in-situ process for the preparation of Metallic Organic Framework's (MOF's)—polymer composites at room temperature, without requirement of pre-seeding o MOF's or substrate modification. Further, the invention provides MOF-polymer composites membranes, wherein MOF forms a layer substantially covering the porosity of the membrane.

Owner:COUNCIL OF SCI & IND RES

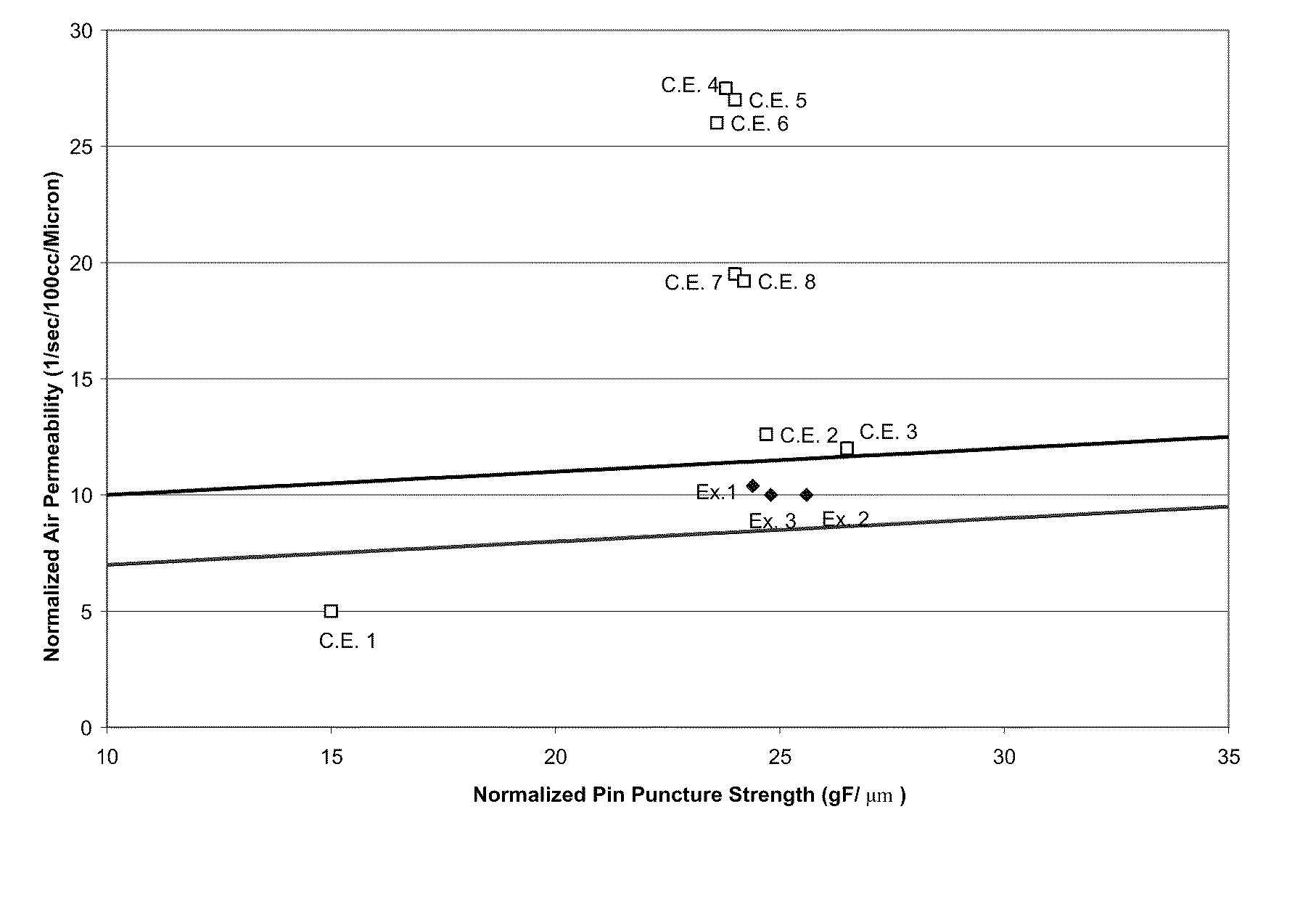

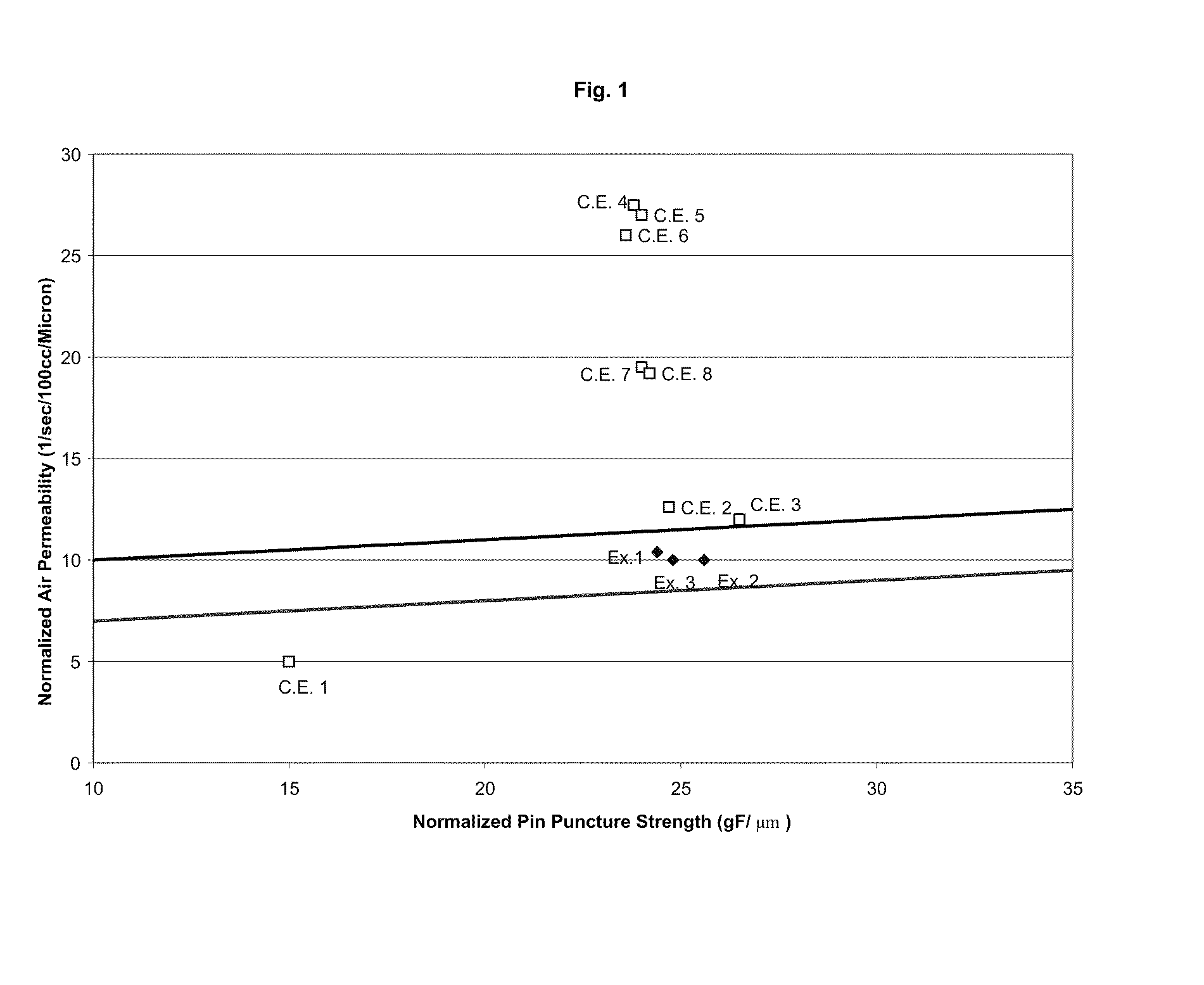

Microporous membranes and methods for producing and using such membranes

Owner:TORAY BATTERY SEPARATOR FILM

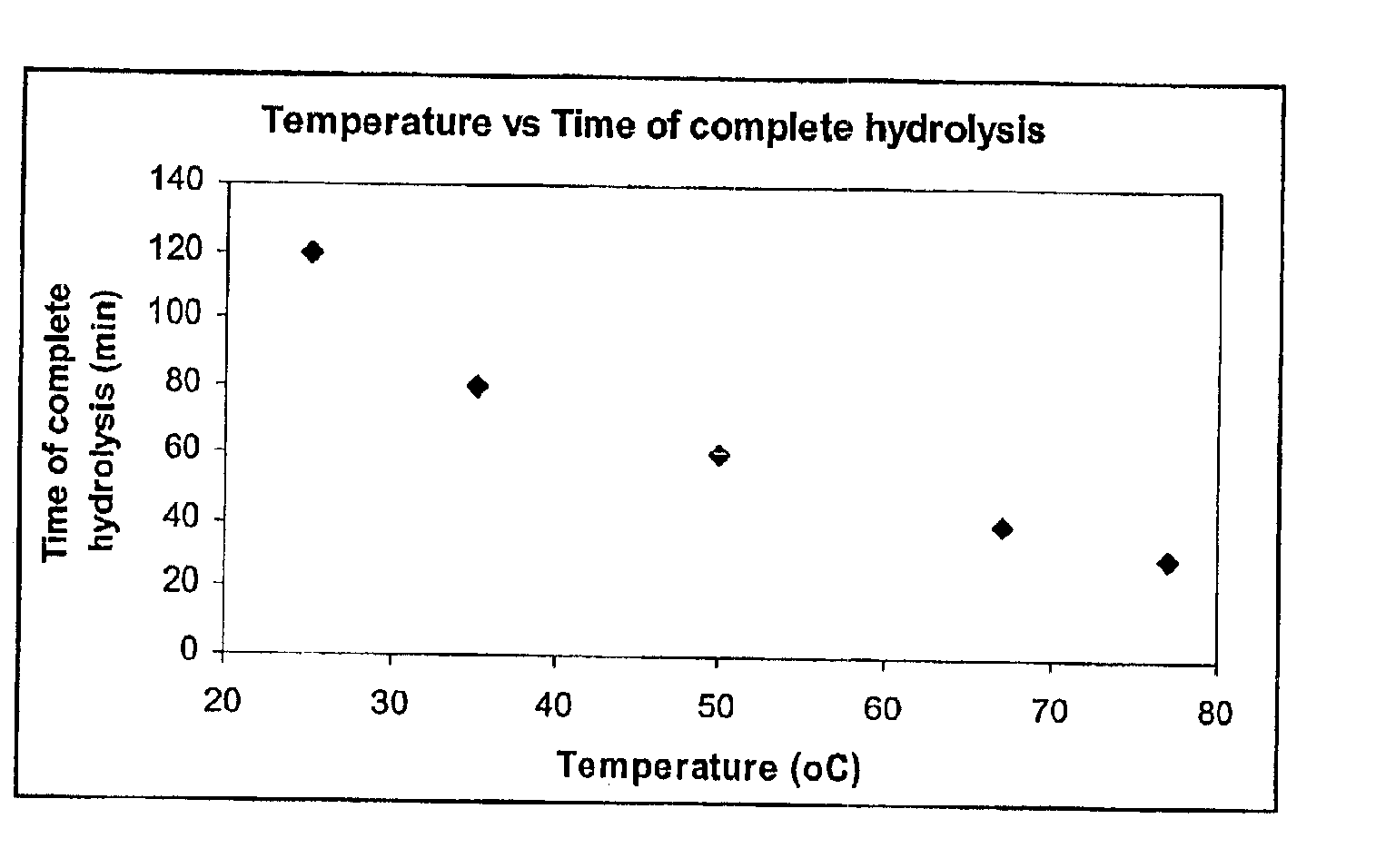

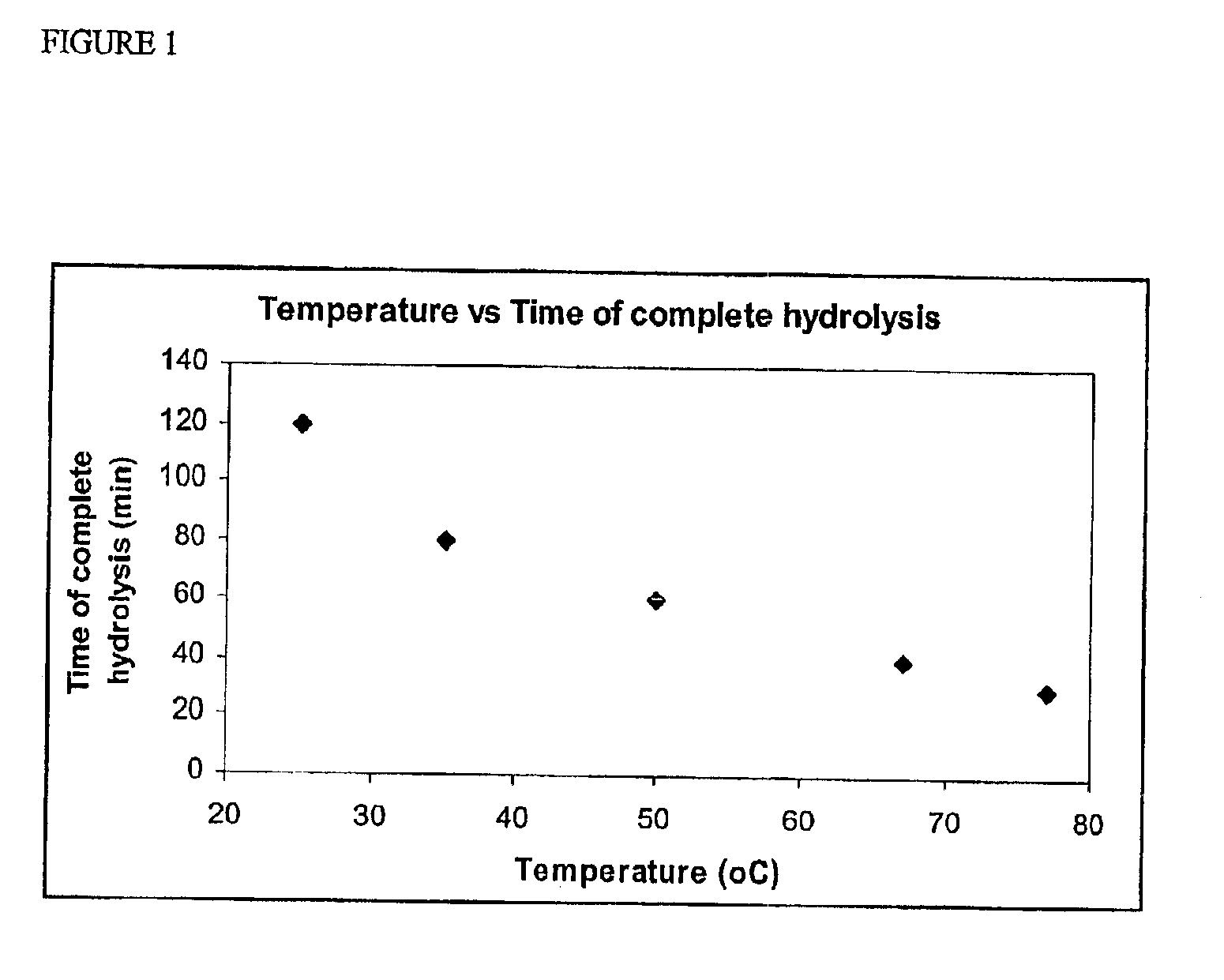

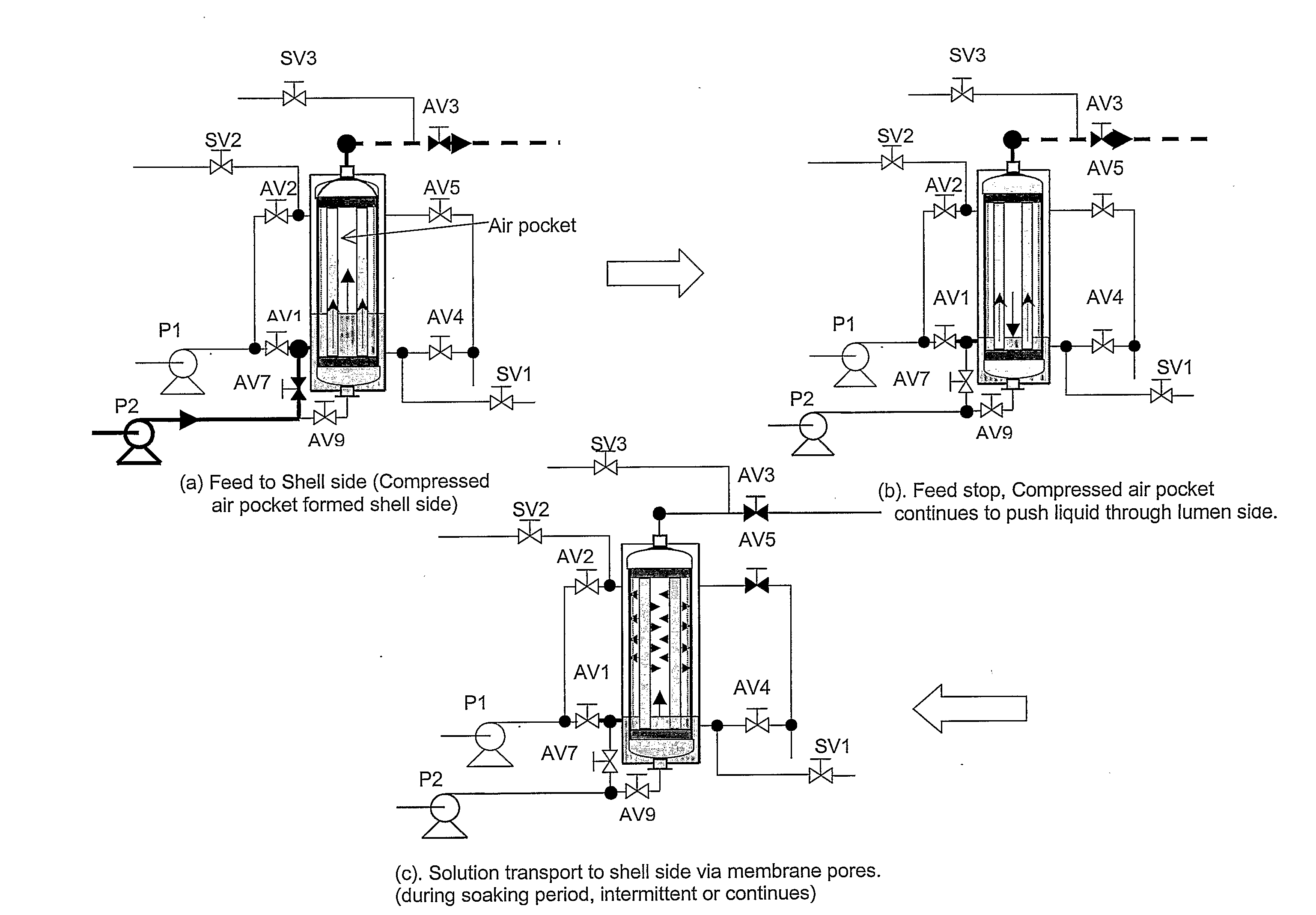

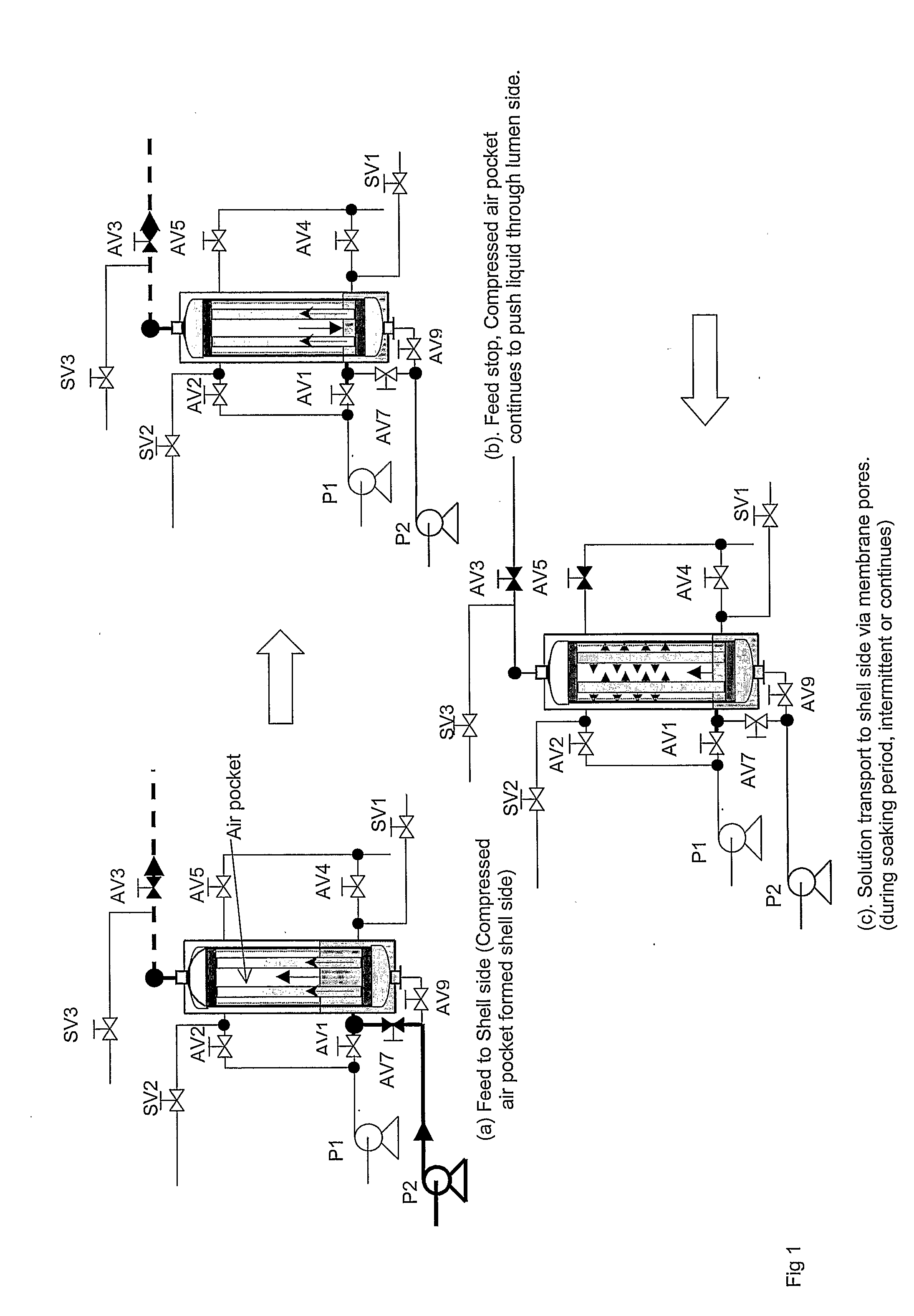

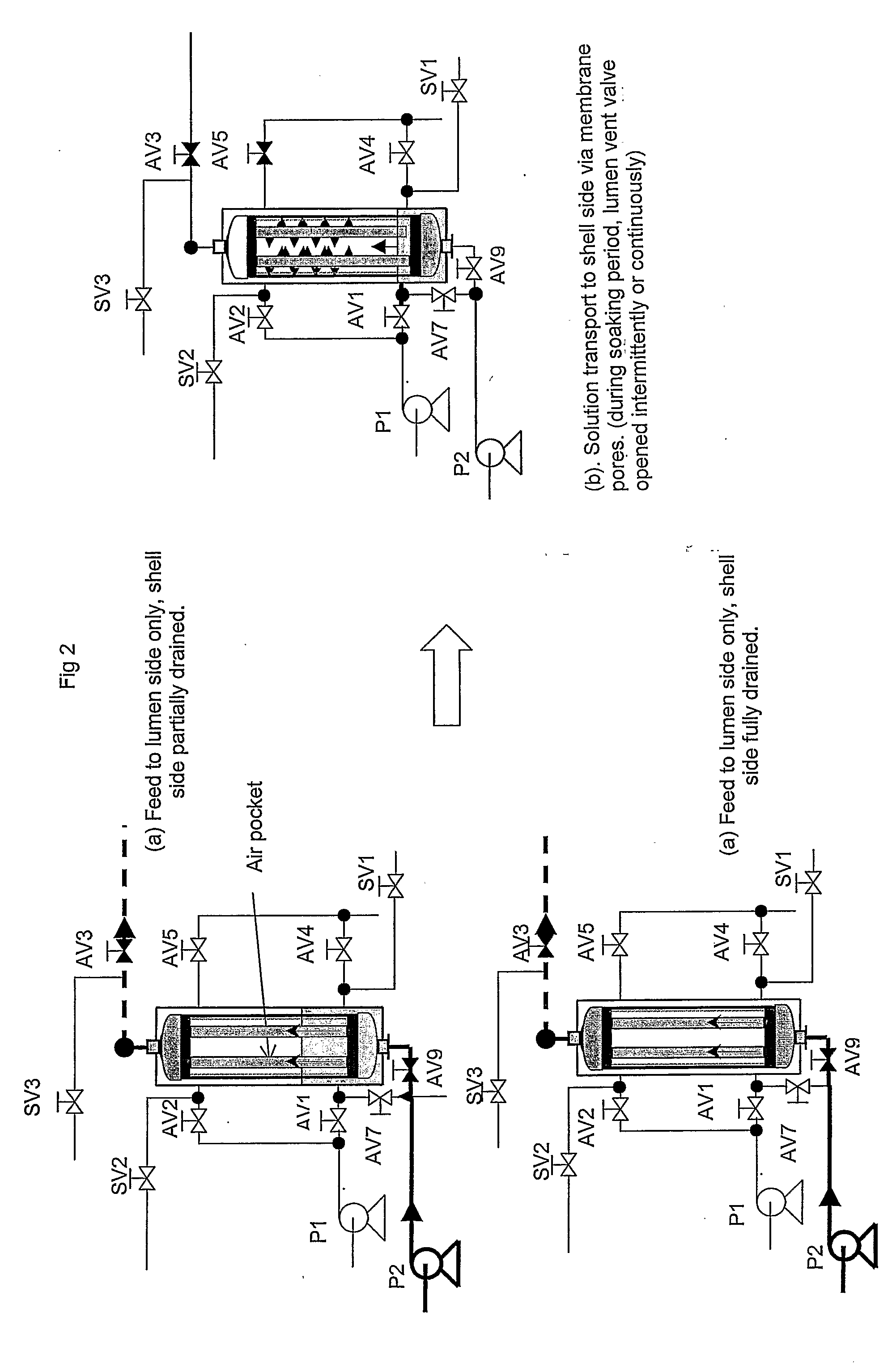

Chemical Clean For Membrane Filter

ActiveUS20080203017A1Facilitate wetting out and dissolvingLower the volumeSpecific water treatment objectivesUltrafiltrationConcentration gradientCleansing Agents

A method of cleaning a porous polymeric membrane having a feed side and a permeate side including the steps of introducing a fluid containing a cleaning agent to the permeate side of a membrane allowing the cleaning agent to contact the permeate side of the membrane for a predetermined time, and contact the pores of the membrane, or introducing a fluid containing a cleaning agent to the feed side of a membrane; applying a transmembrane pressure to force the fluid containing the cleaning agent from the feed side to the permeate side of the membrane; allowing the cleaning agent to contact the permeate side of the membrane for a predetermined time, and contact the pores of the membrane. Preferably a concentration gradient between the feed side fluid and the lumen side fluid containing the cleaning agent causes cleaning agent to diffuse into the feed side fluid. Pressure may be applied to the fluid containing a cleaning agent to dislodge, where present, dissolved and undissolved solid from the membrane pores. The pressure may be applied in a pulsed fashion, and can be by way of compressed air at a pressure not more than the membrane's bubble point. The methods of the present invention may be preceded by, or followed with a backwash.

Owner:EVOQUA WATER TECH LLC

Microwell biochip

InactiveUS20040191891A1Immobilised enzymesBioreactor/fermenter combinationsPorous membraneAqueous solution

Microwell biochips (11) are formed from a thin flat plate (13) of polymeric material having a plurality of regularly spaced holes (15) that extend completely therethrough and create microwells. The lower end of each hole is closed by a microporous, hydrophobic, polymeric membrane (17) laminated to the undersurface of the plate which retains an aqueous test solution in the wells until a vacuum is applied to the undersurface thereof to effect draining of the solution and of any wash solution that might be subsequently added. A spot of polymerizing isocyanate-functional hydrogel is applied generally centrally to the porous membrane surface at the bottom of each well in a manner so as to cover only a minor portion of the surface and out of contact with the well sidewalls, thus leaving substantial surface area through which drainage can be readily effected. Biological capture agents are associated with the polymerizing hydrogel so as to become immobilized as a part thereof.

Owner:BIOCEPT INC

Hydrophilic membrane and process for making the same

InactiveUS7067058B2Practical and convenientEconomical and simpleMembranesSemi-permeable membranesDiacrylate esterEthylene oxide

A process for imparting hydrophilic properties to a polymeric membrane by exposing the membrane to an acrylate monomer containing hydrophilic segments, such as ethylene oxide, and a hydrophilic functional group, a diacrylate monomer containing hydrophilic functional groups, and an initiator for facilitating crosslinking and polymerization reactions.

Owner:3M INNOVATIVE PROPERTIES CO

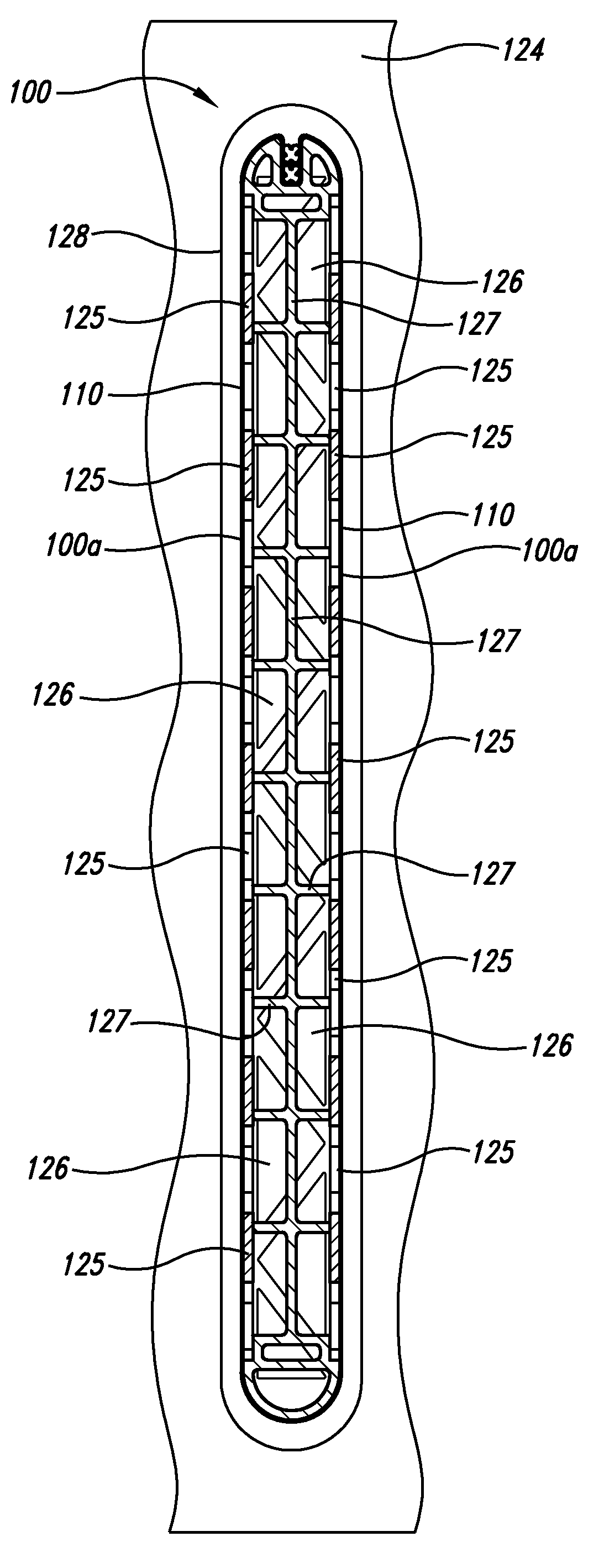

Gas transfer membrane

Porous polymeric membranes formed from a hydrophobic polymer, such as halar having membrane pores of a size sufficient to permit gas and / or vapor permeation 0.05 μm to 5 μm without permitting the flow of a hydrophilic fluid across the membrane. Pore distribution is uniform and porosity is high, in some cases up to 80%. Membranes may be in the form of a flay sheet or hollow fibre for example and can be used in a variety of applications such as stripping HF gas, degassing of caustic solution, chlorine gas / alkaline filtration, degassing tap water to remove dissolved chlorine. Processes used to make such membranes can be carried out using relatively non toxic solvents such as citric acid ethyl ester or glycerol triacetate.

Owner:EVOQUA WATER TECH LLC

Nano-composite proton exchange membrane as well as preparation method and application thereof

ActiveCN103715438AImprove battery performanceCell component detailsSolid electrolyte fuel cellsEtherProton

The invention belongs to the technical field of a proton exchange membrane fuel cell, and particularly relates to a nano-composite proton exchange membrane for the proton exchange membrane fuel cell under a high-temperature anhydrous condition as well as a preparation method and an application thereof. The nano-composite proton exchange membrane is a graphene oxide nano-composite proton exchange membrane which is modified by sulfonated poly(ether ether ketone) and polydopamine. Compared with a pure polymeric membrane, the nano-composite proton exchange membrane provided by the invention has more excellent battery performance and is particularly suitable to be applied under the high-temperature anhydrous condition.

Owner:ZHENGZHOU UNIV

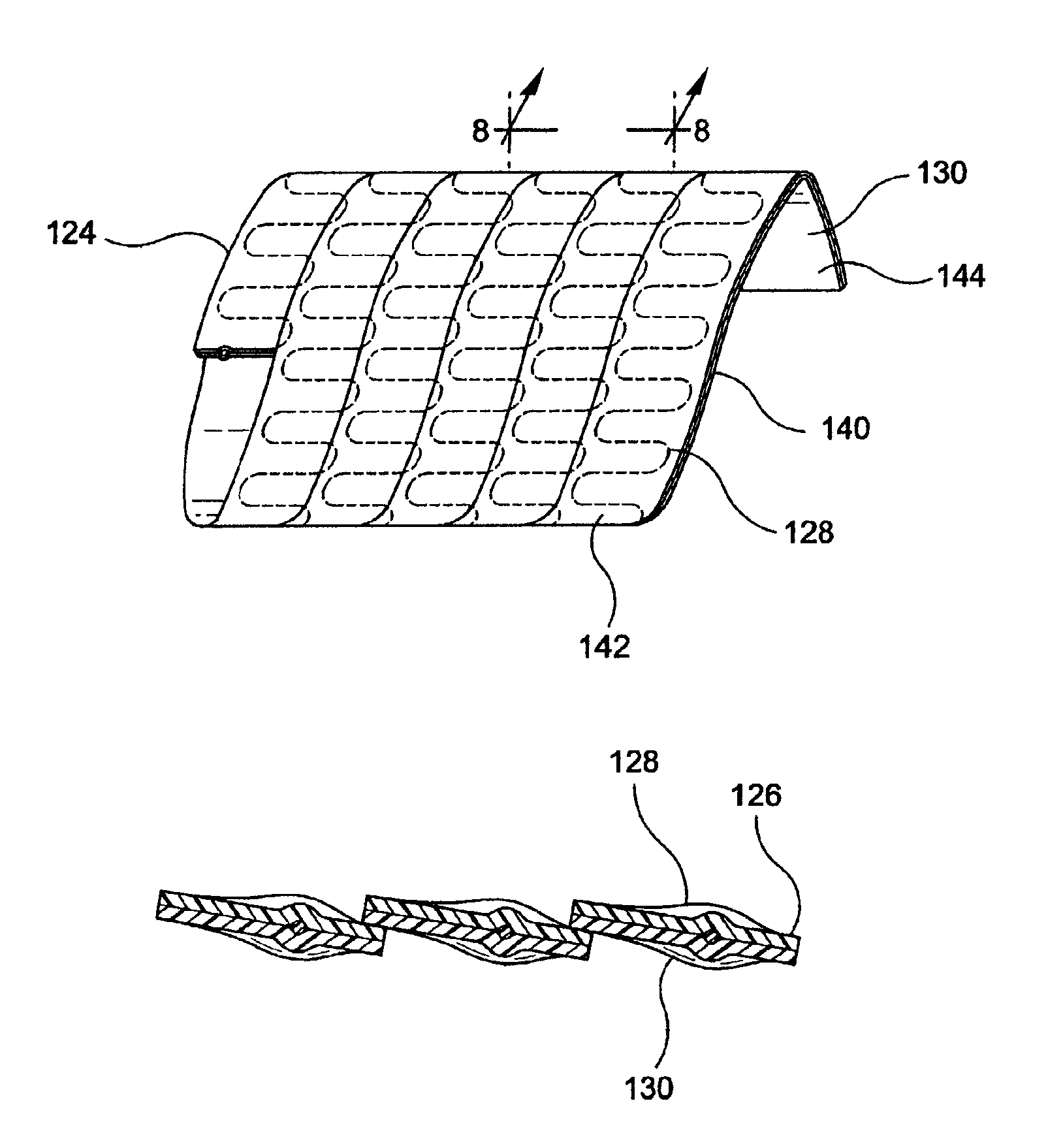

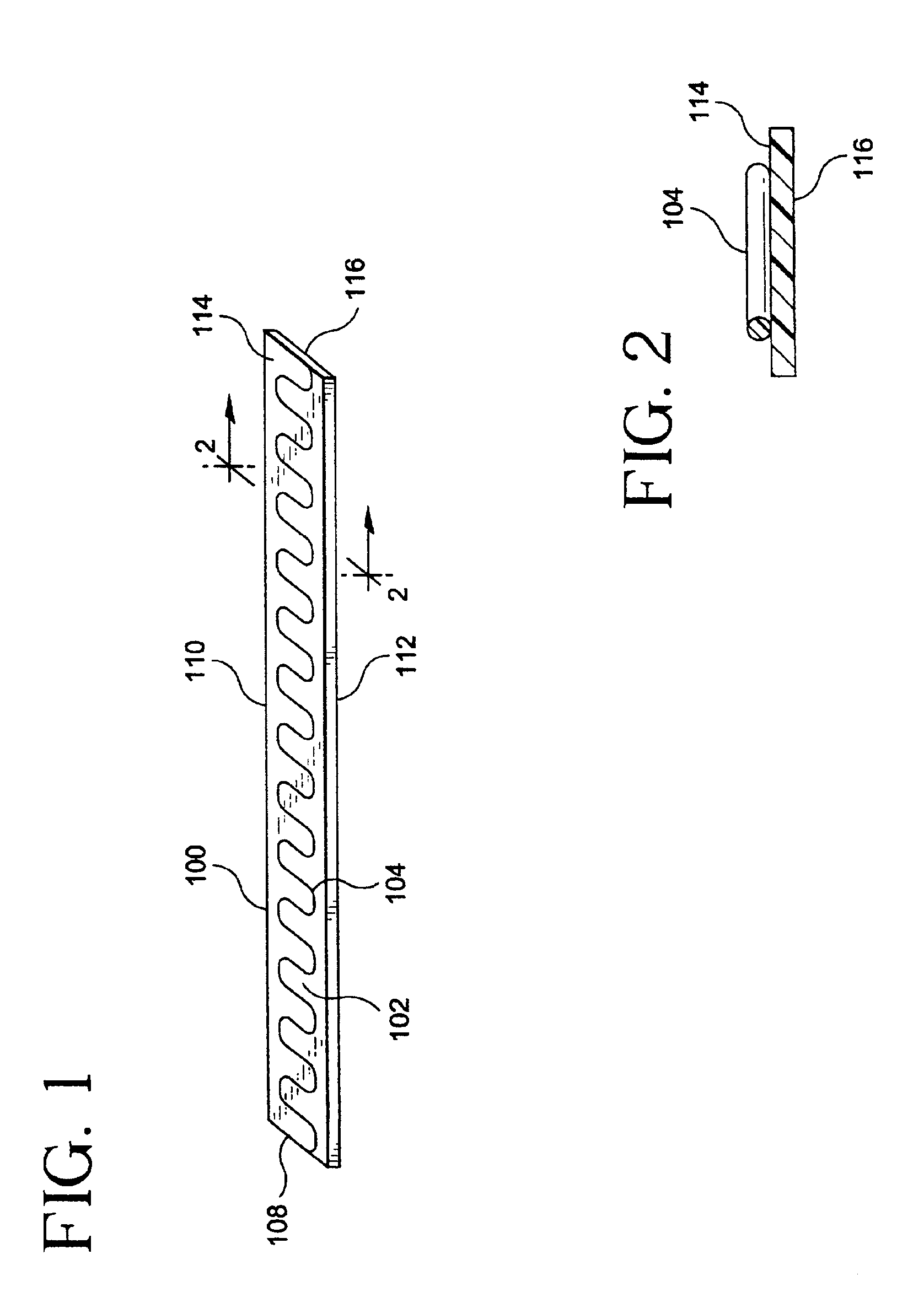

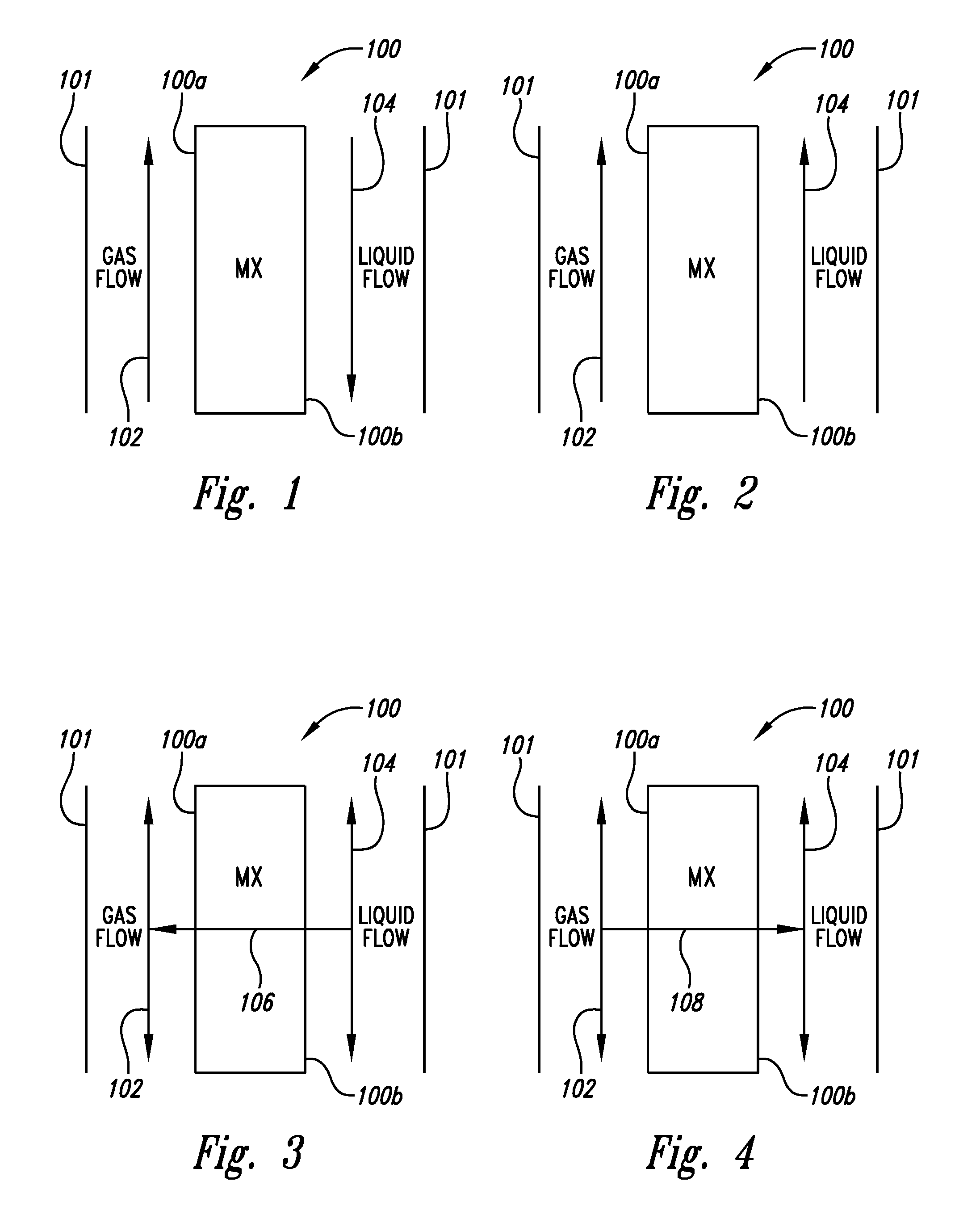

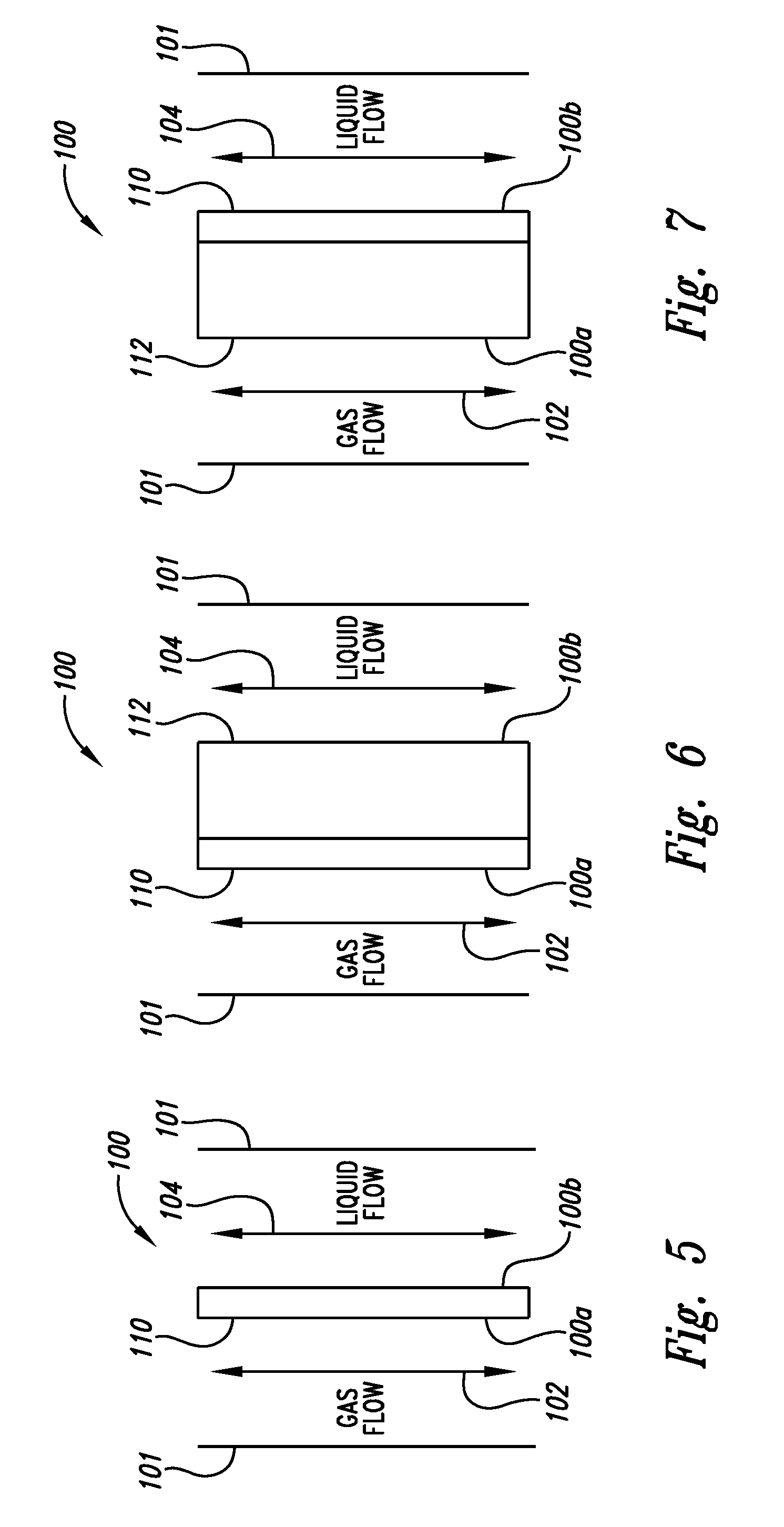

Enhanced HVAC system and method

Particular embodiments disclosed herein relate to methods, compositions, and systems relating generally to heating, ventilation, and air conditioning (HVAC) systems, and more specifically, to HVAC systems that transfer sensible and / or latent energy between air streams, humidify and / or dehumidify air streams. In certain embodiments, a polymeric membrane is utilized for fluid exchange, with or without an additional support. Certain embodiments allow for individual regulation of air temperature and humidity.

Owner:TANGREDI PATRICIA

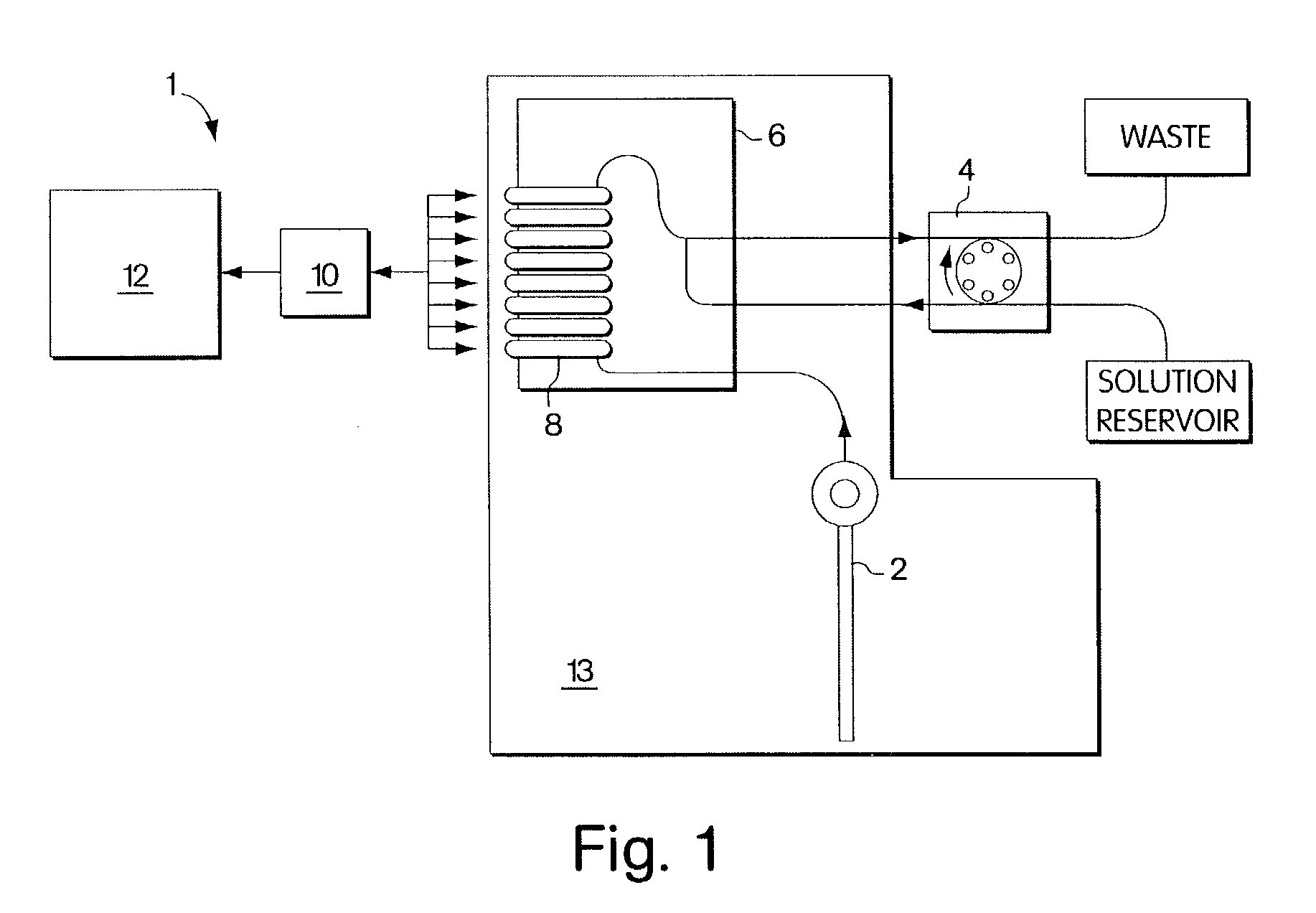

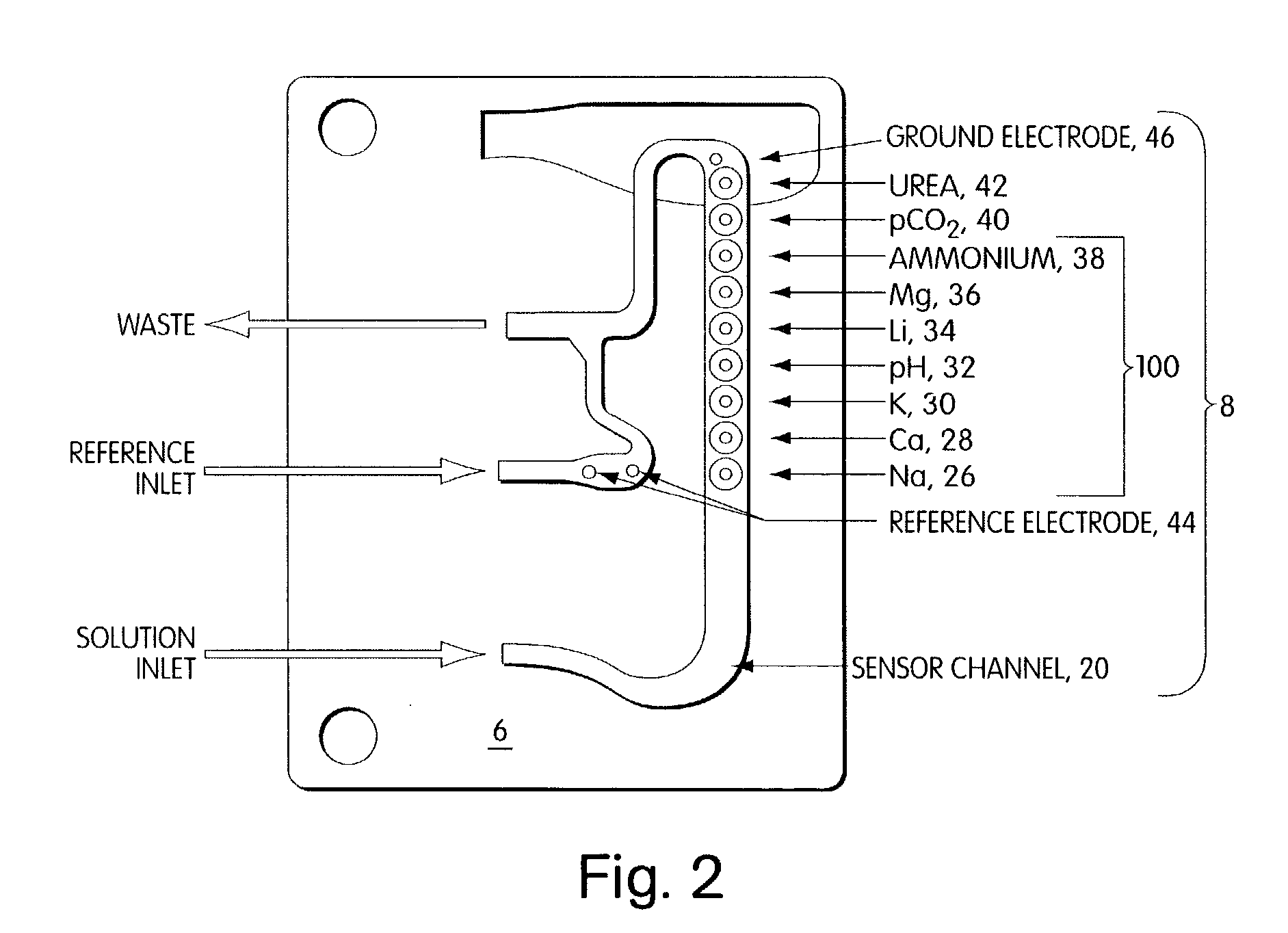

Polymeric membranes for use in electrochemical sensors

InactiveUS20040154933A1Reduce distractionsWeather/light/corrosion resistanceVolume/mass flow measurementTarget analysisAnalyte

A method for reducing interference caused by contaminants on the detection and / or measurement of an analyte in a biological sample includes providing a chemical sensor that contains carboxylated polyvinyl chloride (PVC-COOH) as a polymer component of the sensor's polymeric membrane. A biological sample containing the analyte of interest and a contaminant is placed in contact with the chemical sensor that includes PVC-COOH as a polymer component of the sensor's polymeric membrane. The analyte of interest in the biological sample is then measured and / or detected by the chemical sensor without interference by the contaminant.

Owner:INSTR LAB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com