Patents

Literature

2889 results about "Filtration membrane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

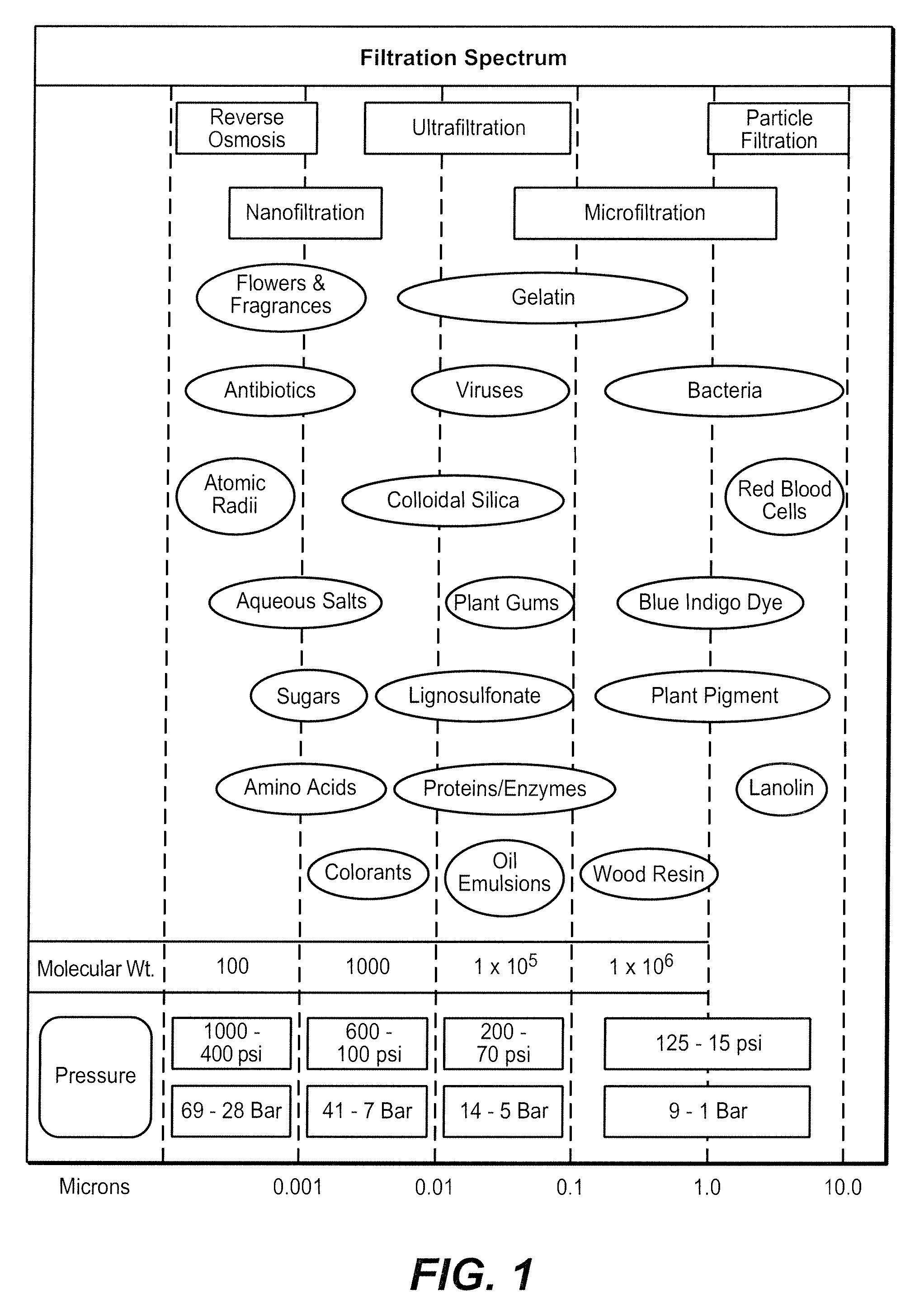

Filtration Membrane. Glomerular Filtration. The first step in renal processing involves the filtration of plasma in the glomerulus. Glomerular filtration is a process of bulk flow: water and low molecular weight substances move from the lumen of the capillary, across the filtration membrane, and into Bowman’s space.

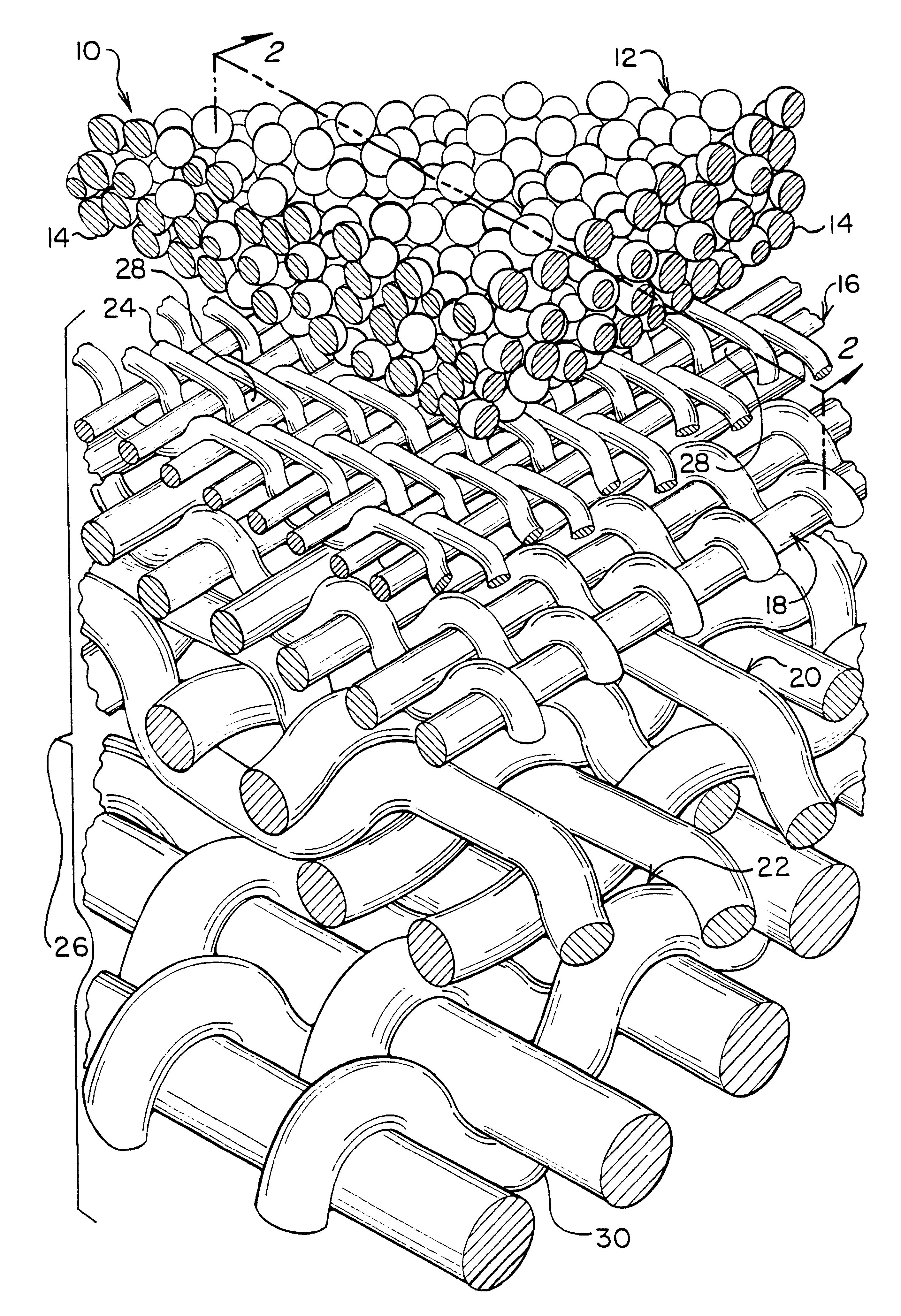

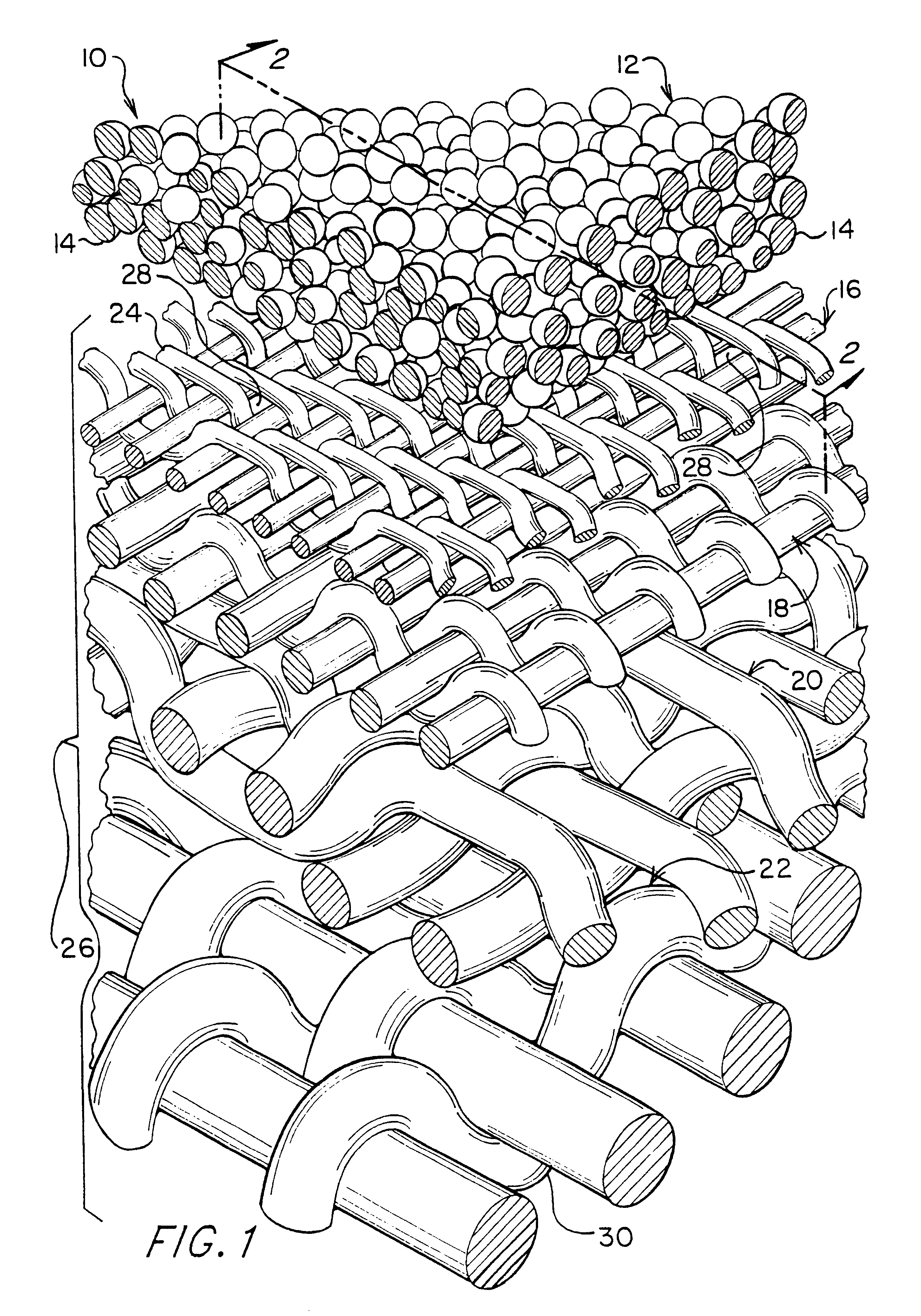

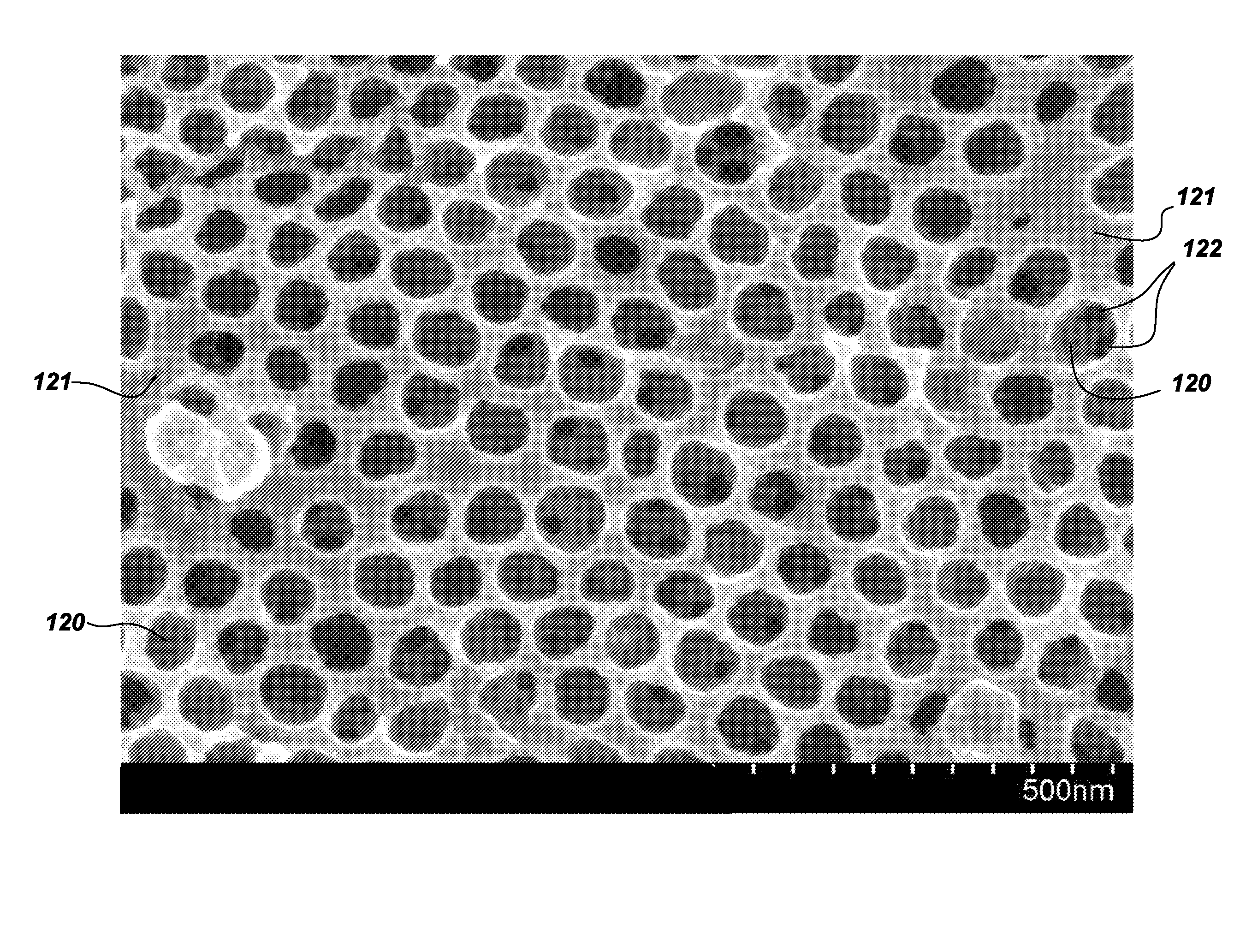

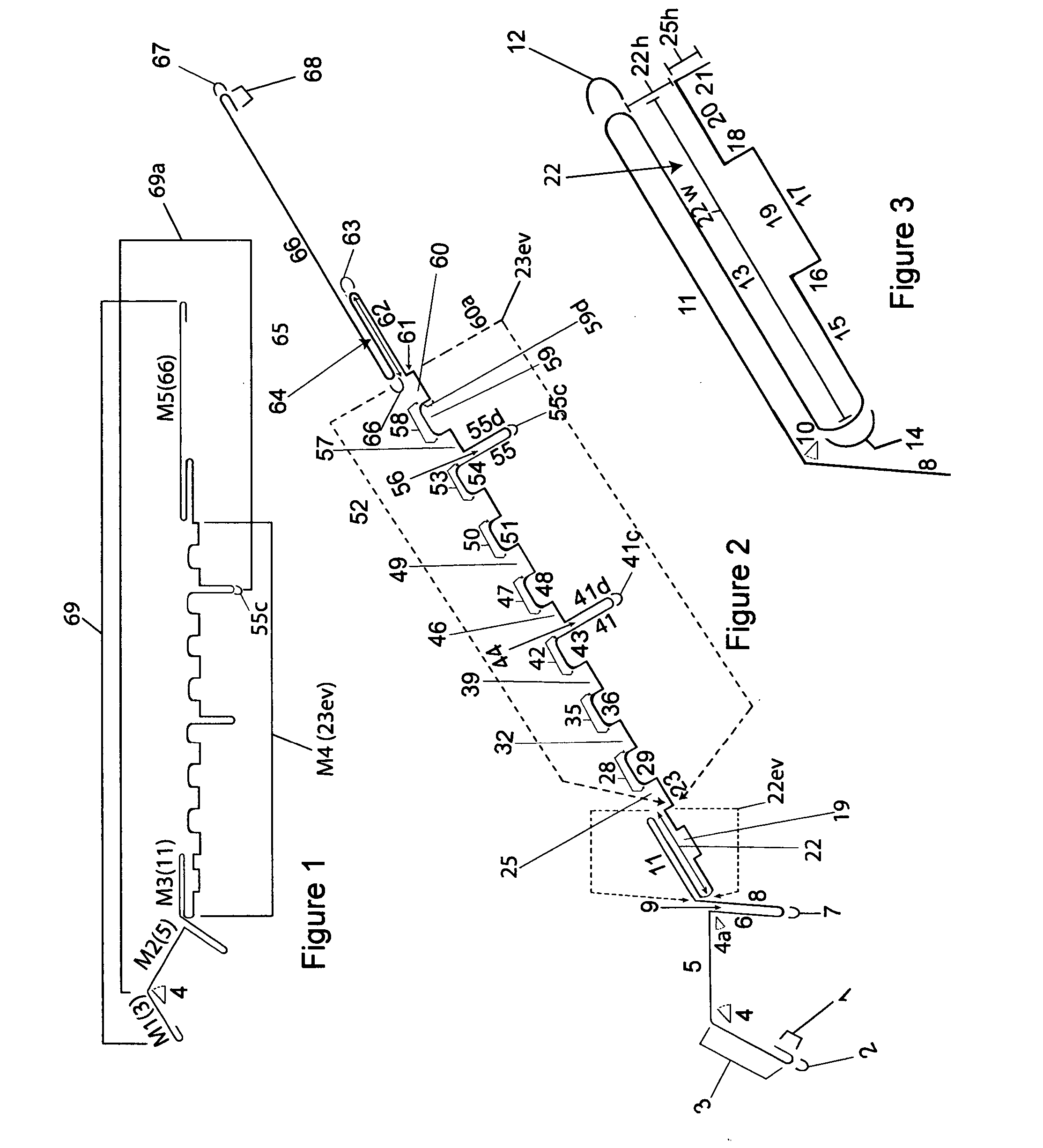

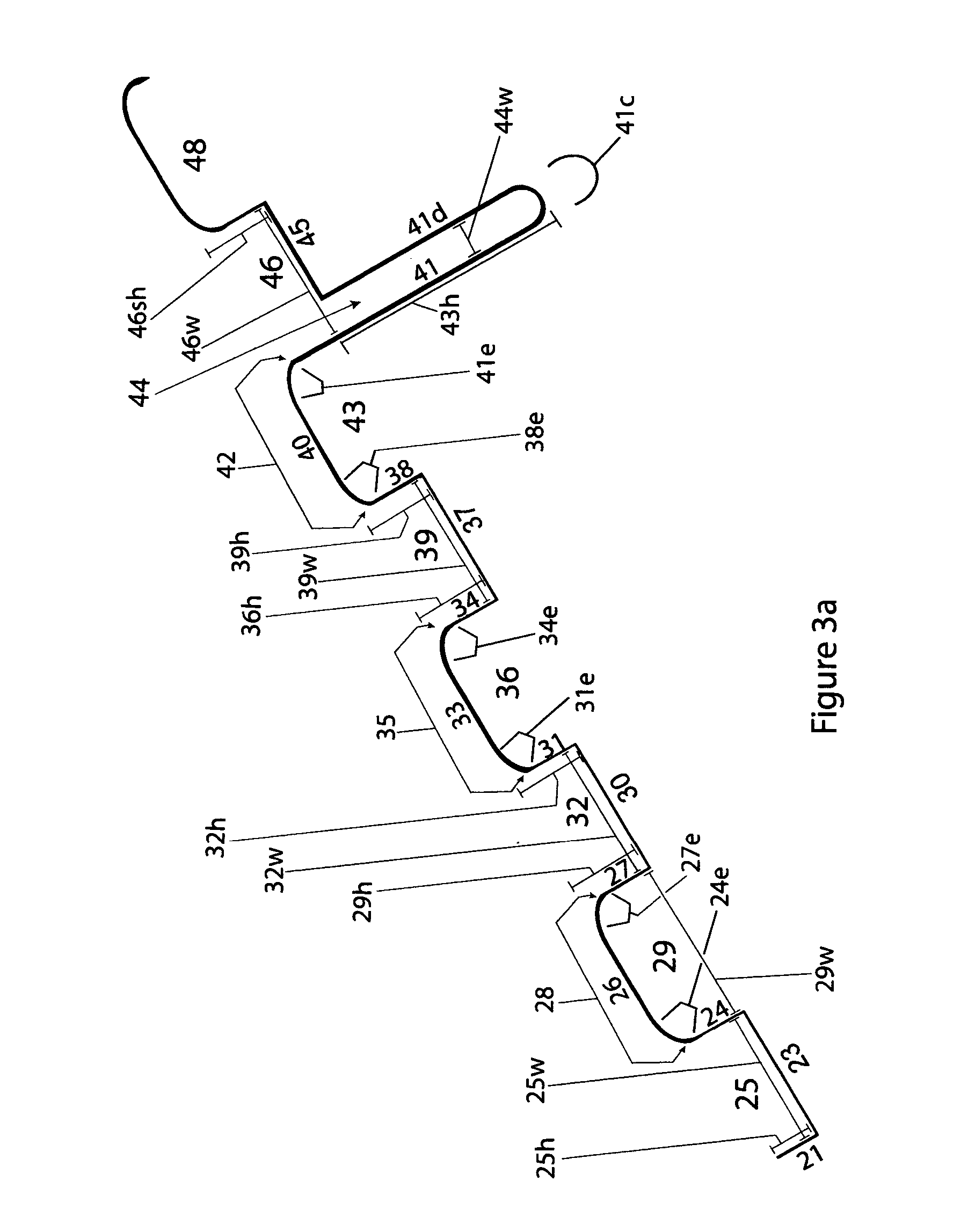

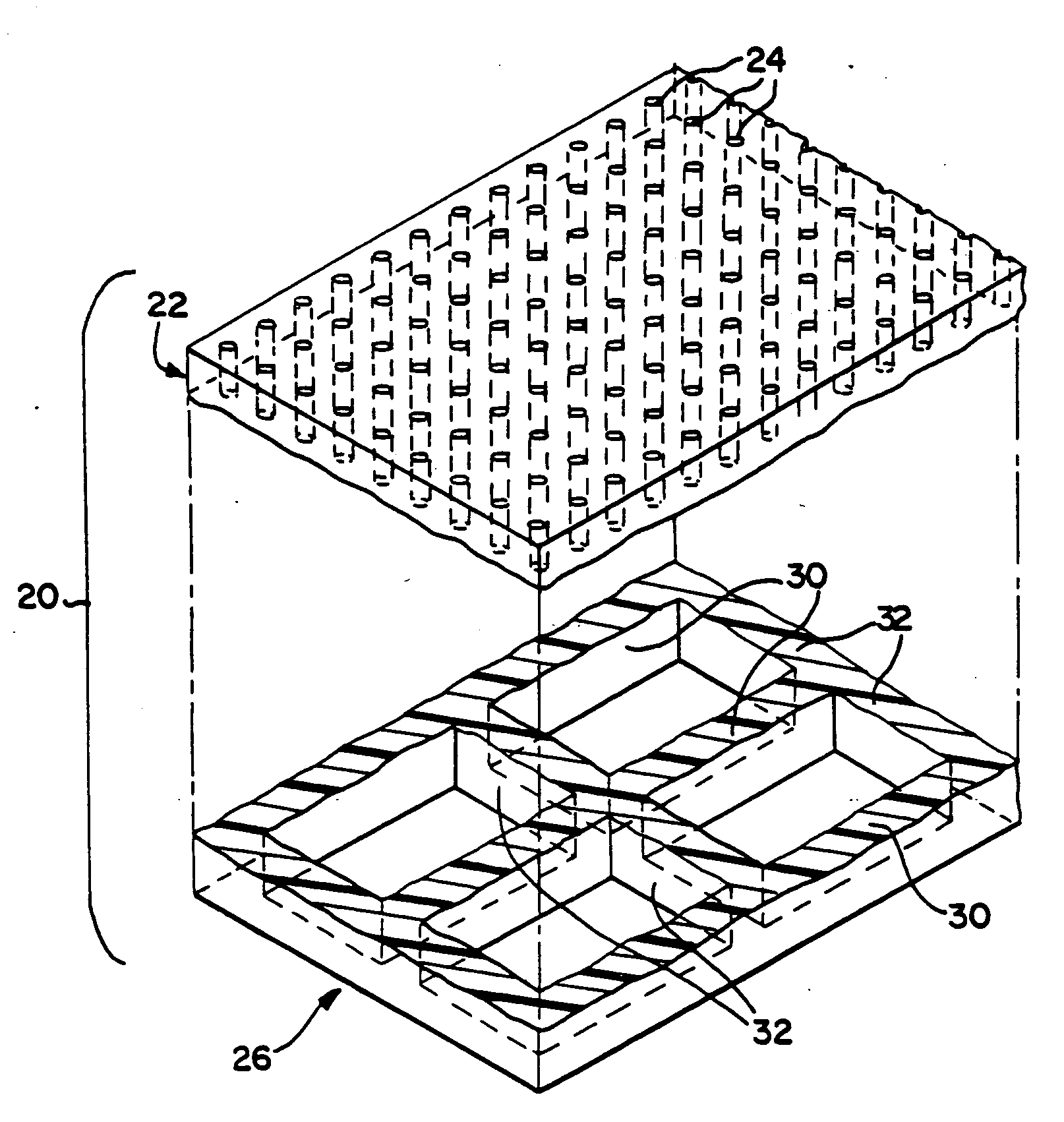

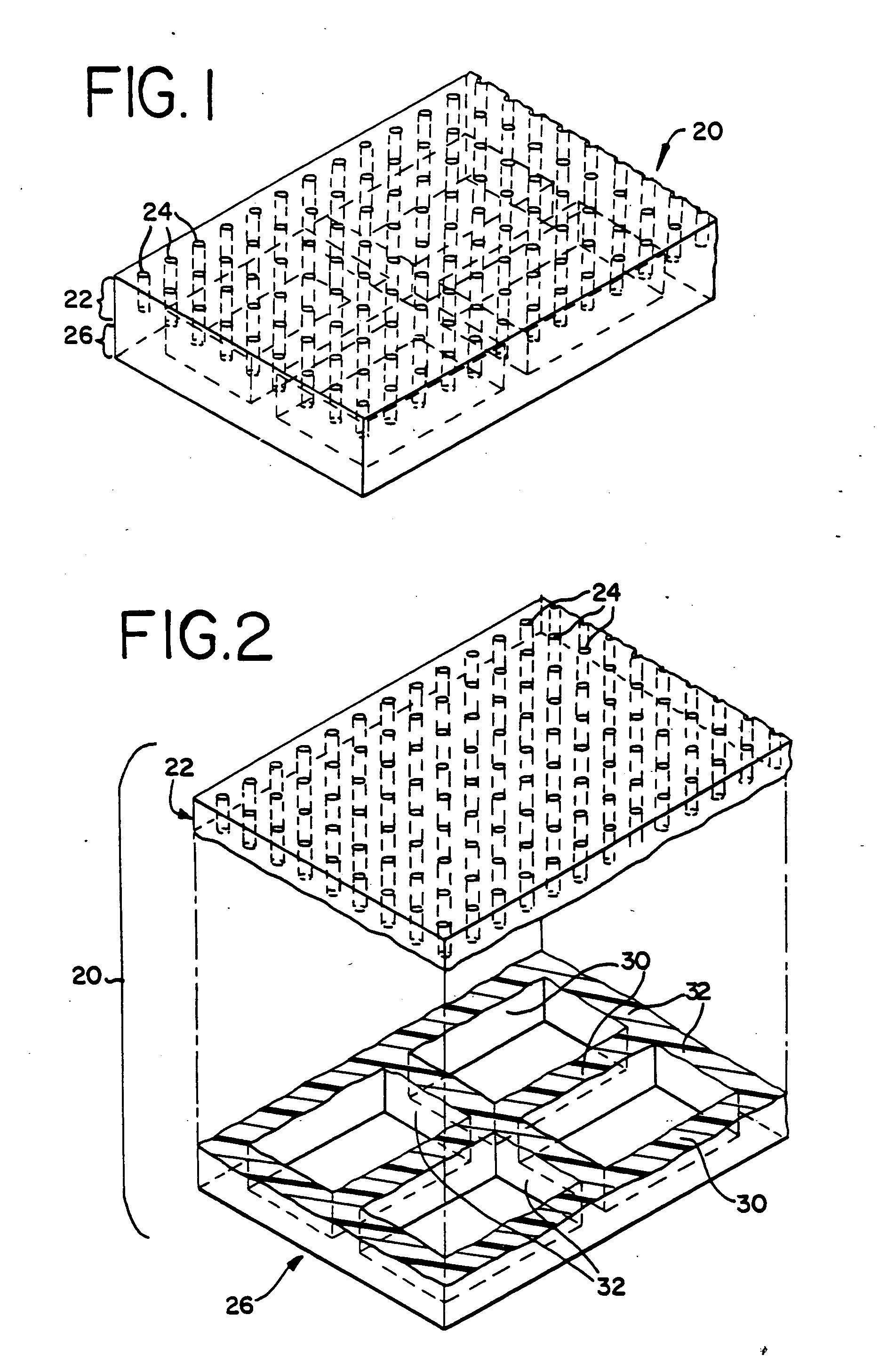

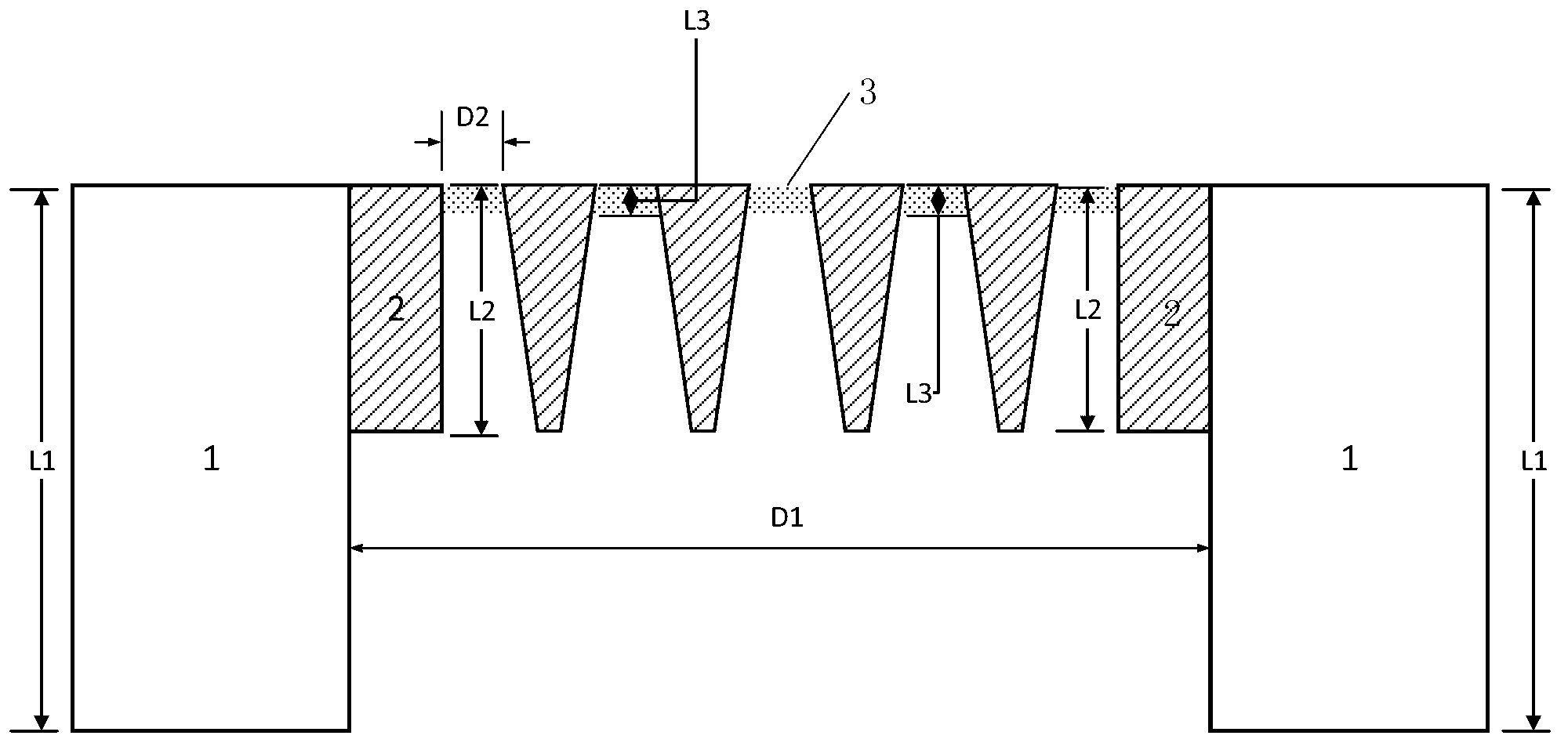

Micro and ultrafilters with controlled pore sizes and pore size distribution and methods for making

InactiveUS6309546B1High permeabilityMinimal pressure dropSemi-permeable membranesMembranesMicrometerPore diameter

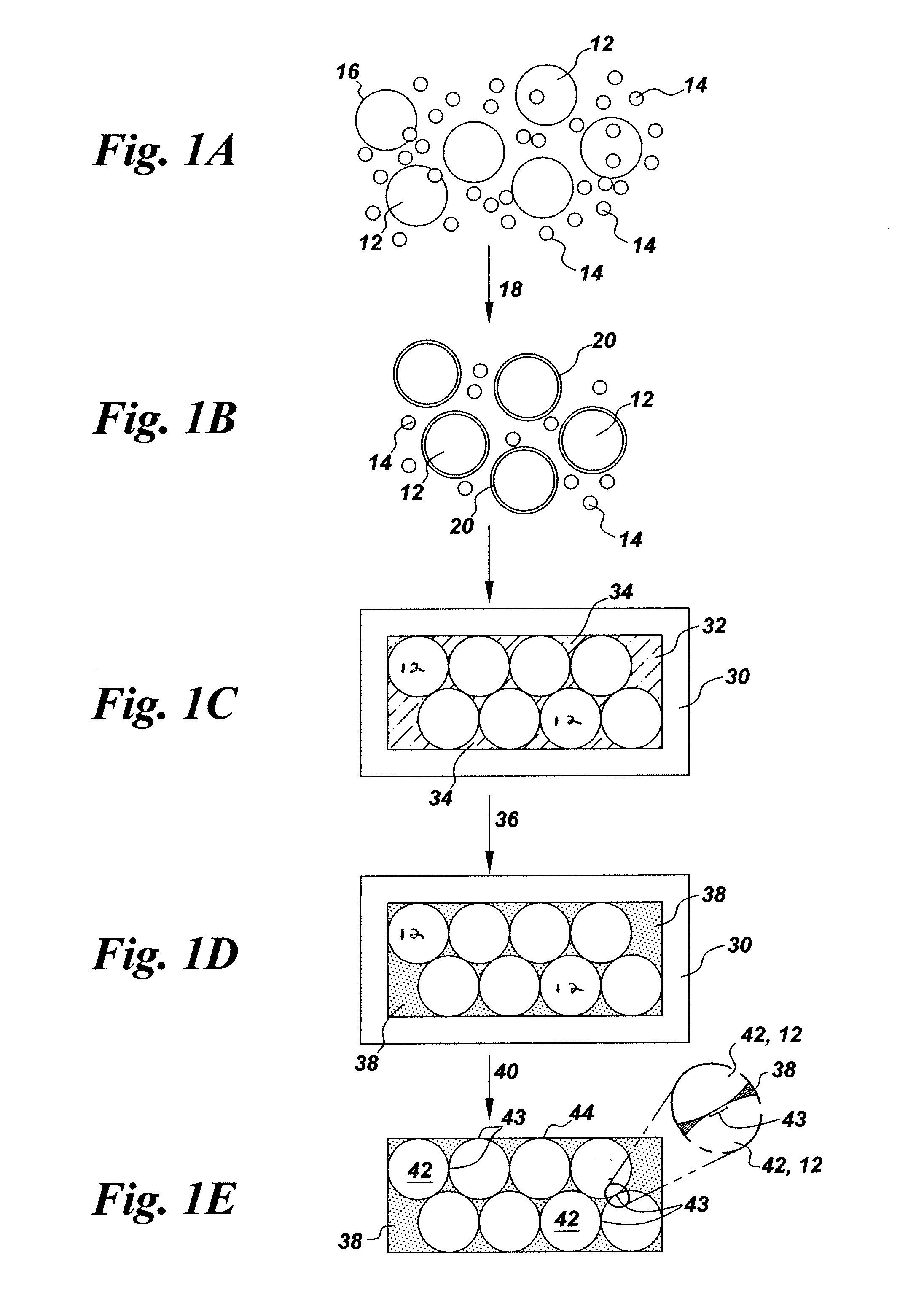

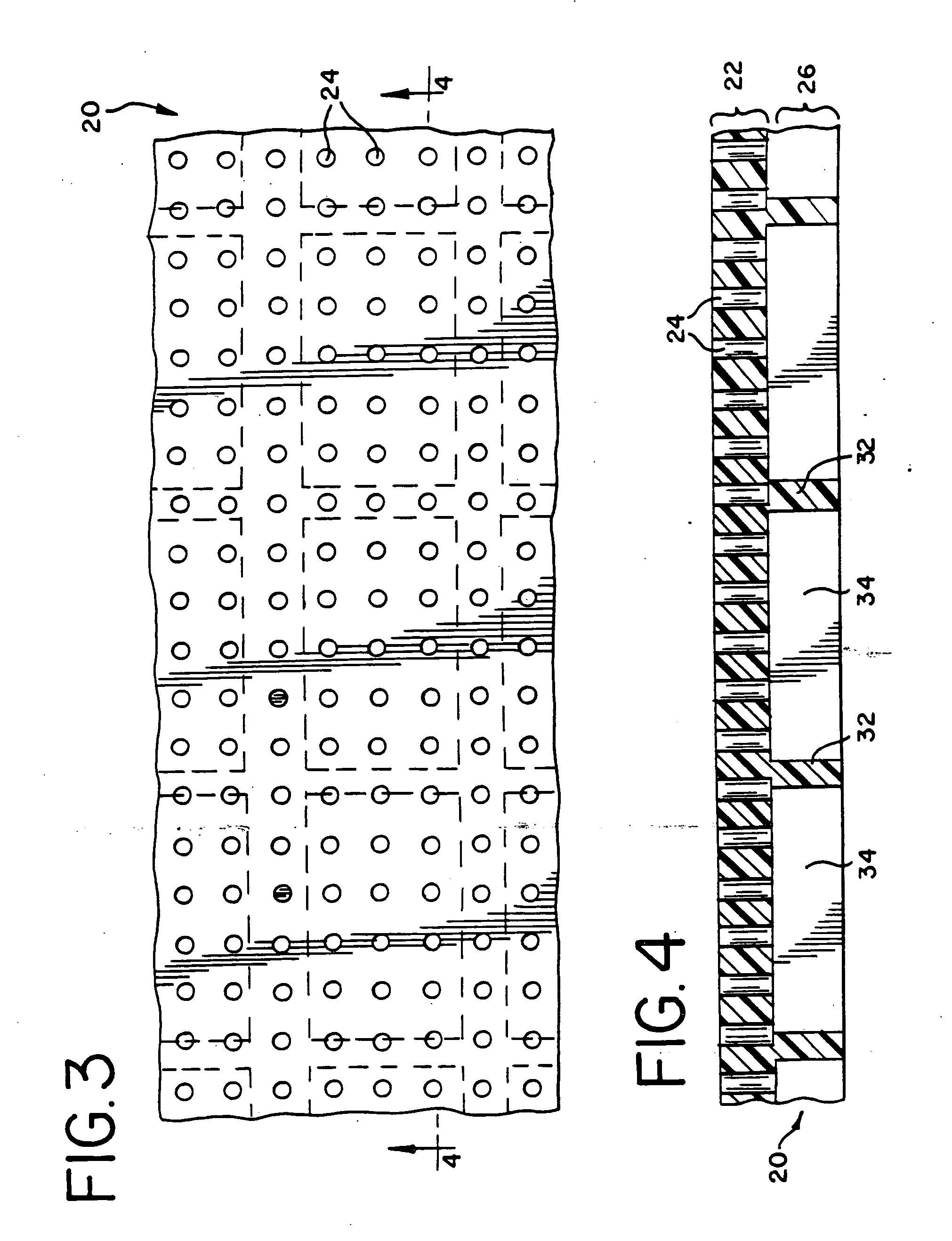

A micro / ultrafiltering element (10) and method for making a filter element are provided. The filtering element comprises a multi-level support (26) having a filtering membrane layer (12) formed thereon comprising sintered particles (14) of uniform diameter. The filtering membrane preferably has an average pore size of from about 0.005-10 micrometers. The filter element is capable of being formed in a variety of geometrical shapes based on the shape of the porous support,

Owner:ELLIPSIS CORP

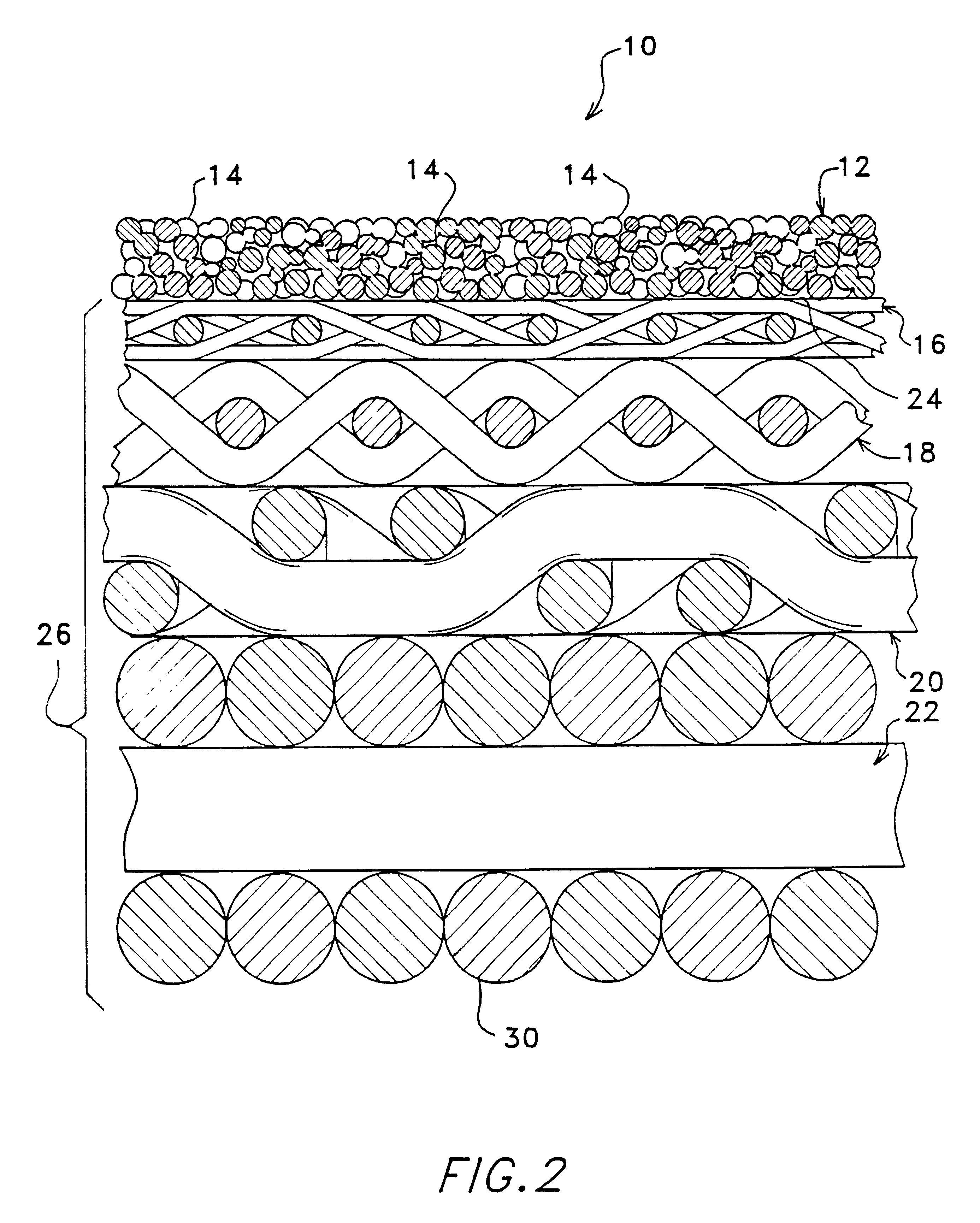

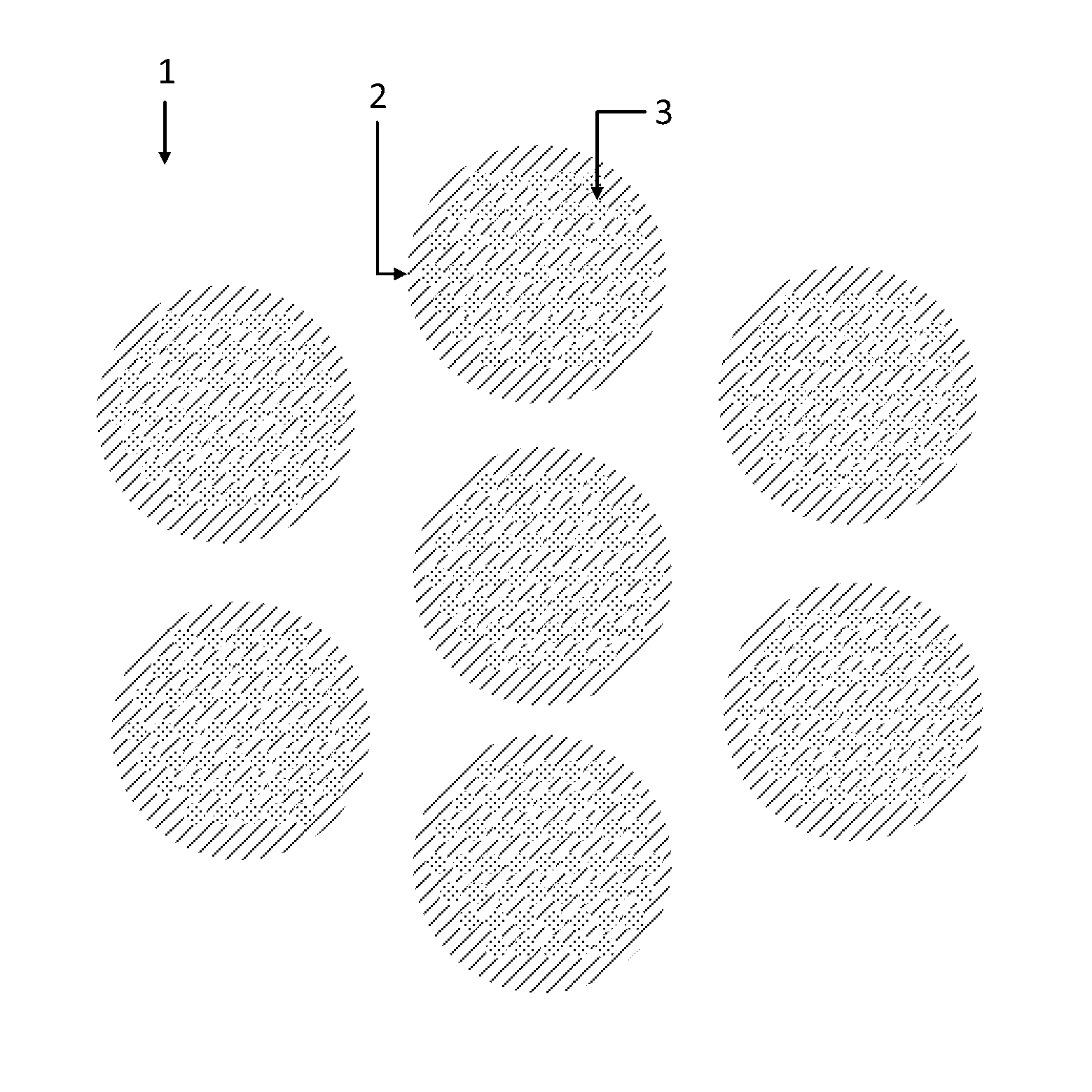

Particle-templated membranes, and related processes for their preparation

InactiveUS20100155325A1Small sizeSemi-permeable membranesMembranesInterfacial reactionFiltration membrane

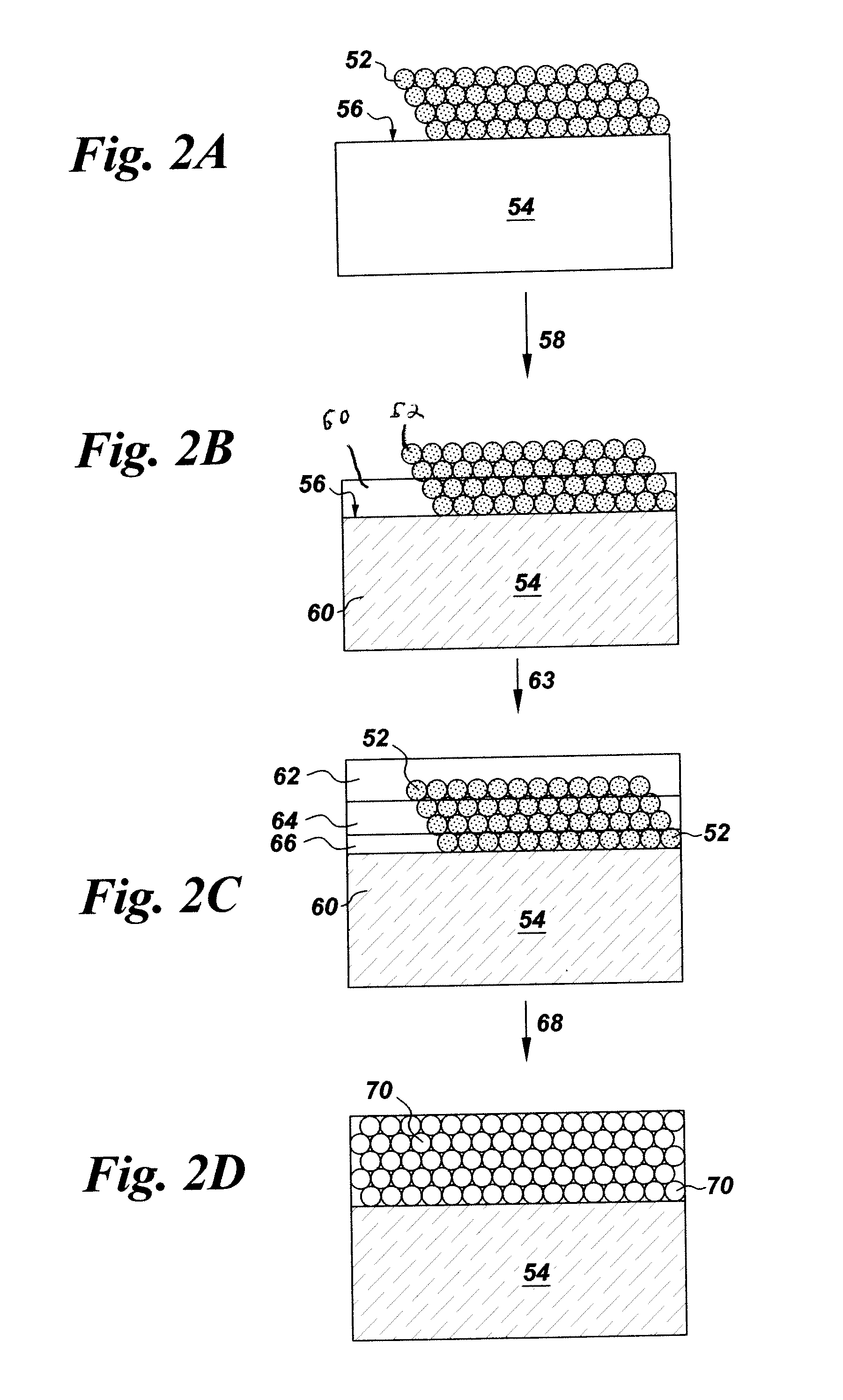

A method for the formation of a membrane is described. A collection of substantially spherical particles formed from a selected material is contacted with at least one reactive material. The reactive material is cured or otherwise polymerized by various techniques, so that it forms a matrix that substantially surrounds and contains the particles. A portion of the particle material is then removed, so that the matrix contains a pattern of pores that are permeable to selected substances in solution. In some instances, the matrix is formed by an interfacial reaction between at least two reactive materials. Related filtration membranes are also described.

Owner:GENERAL ELECTRIC CO

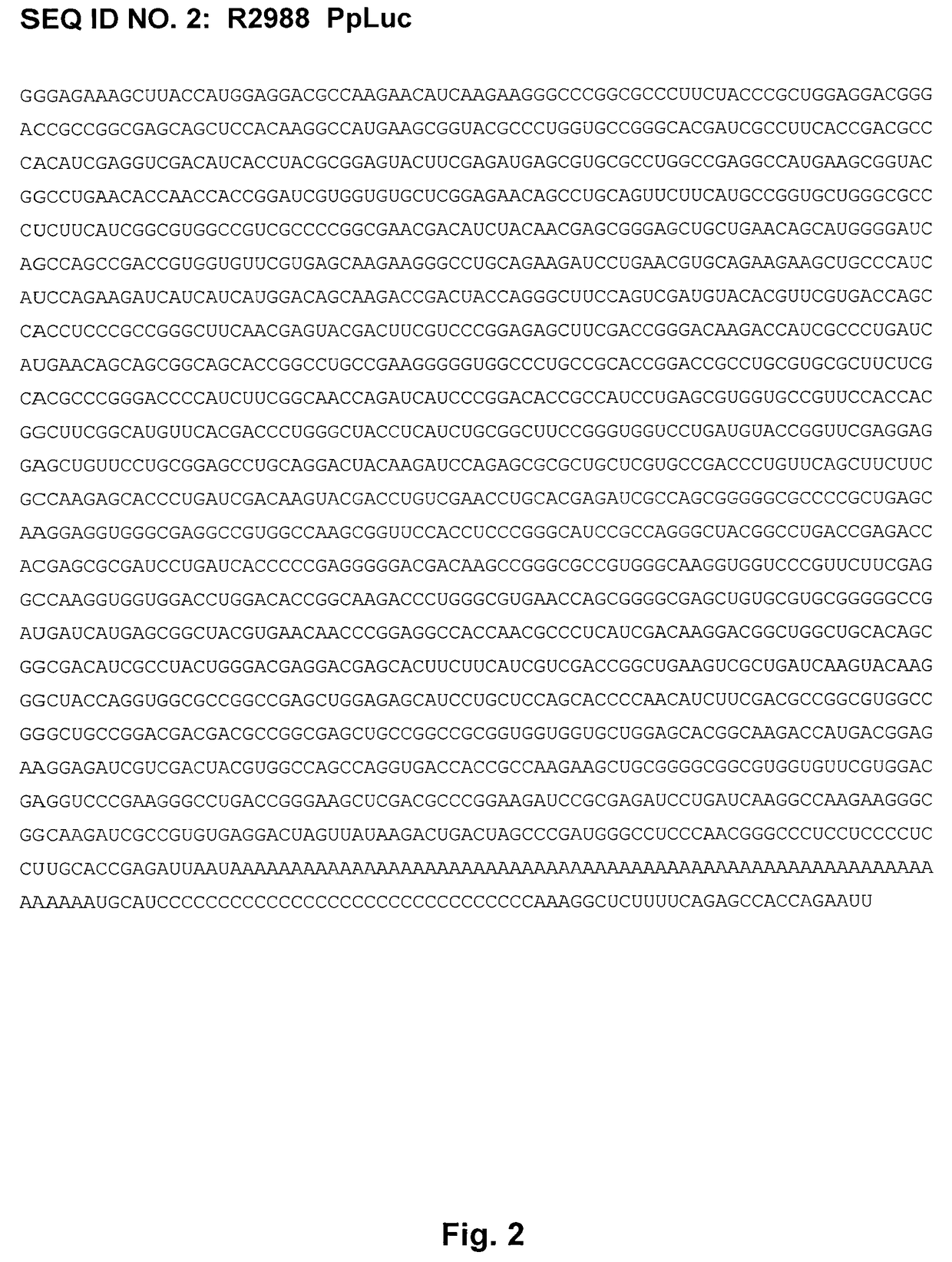

Methods and means for enhancing RNA production

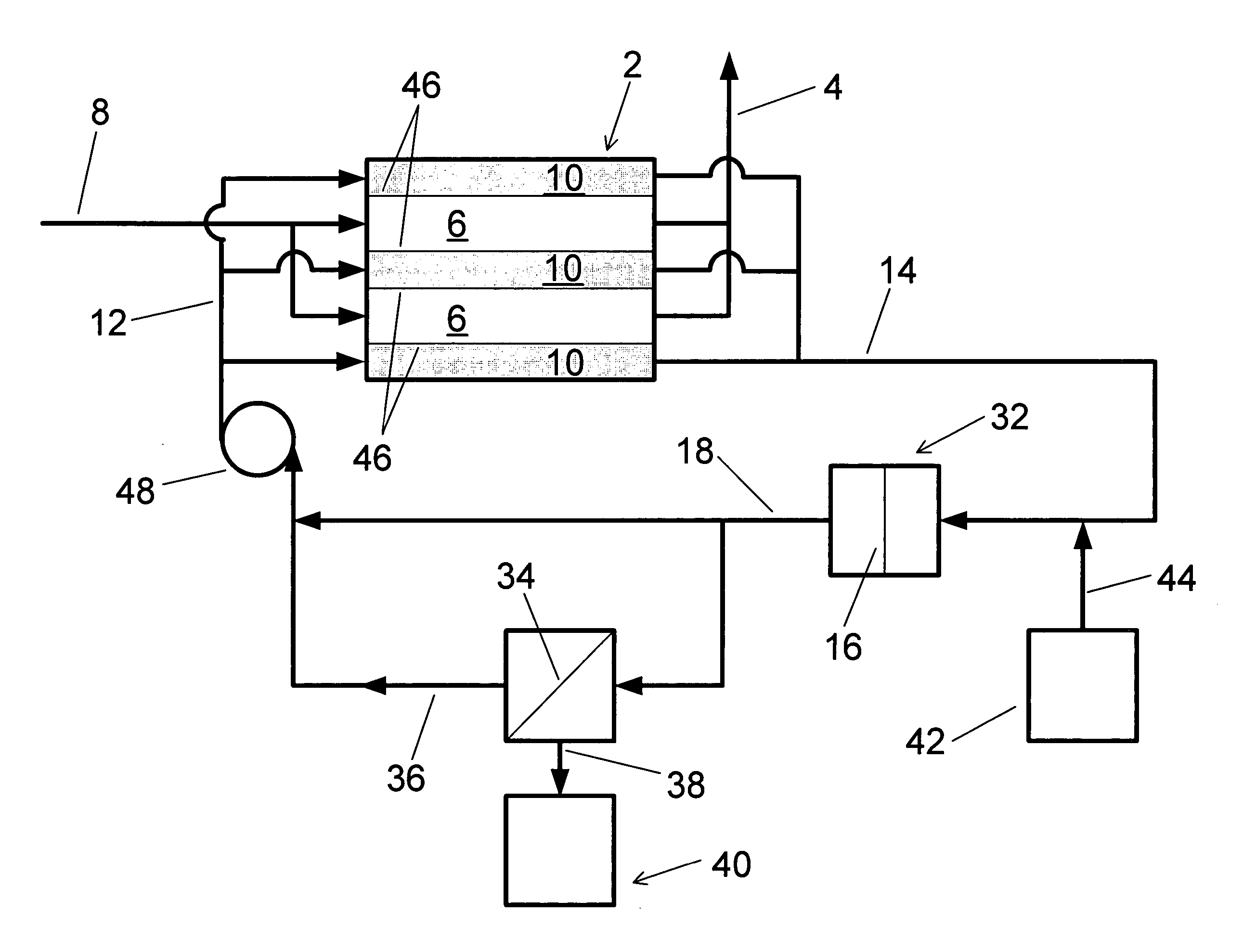

ActiveUS20170114378A1Improved and economical meanImproved and economical and methodBioreactor/fermenter combinationsBiological substance pretreatmentsRibonucleosideFiltration membrane

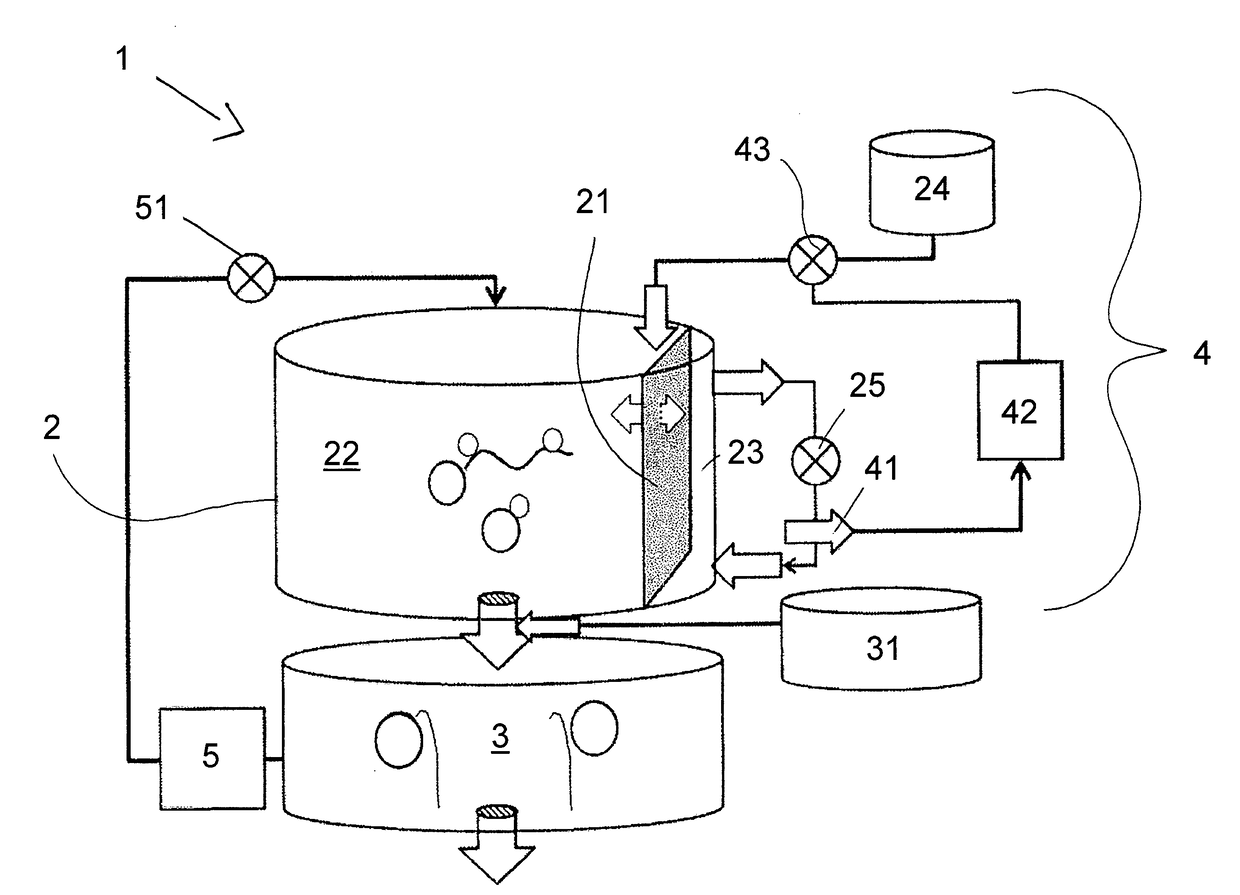

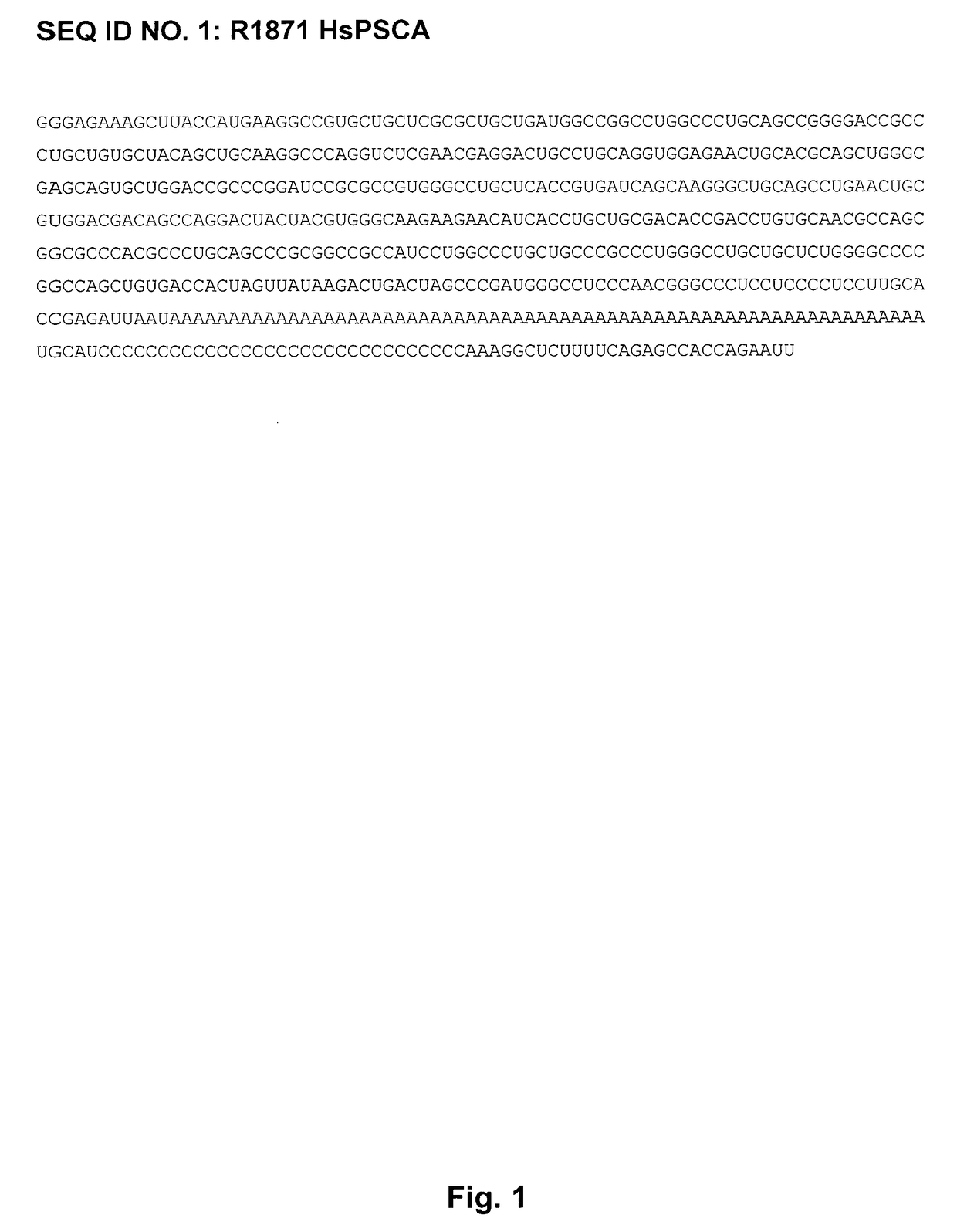

The present invention relates to a method for synthesizing an RNA molecule of a given sequence, comprising the step of determining the fraction (1) for each of the four nucleotides G, A, C and U in said RNA molecule, and the step of synthesizing said RNA molecule by in vitro transcription in a sequence-optimized reaction mix, wherein said sequence-optimized reaction mix comprises the four ribonucleoside triphosphates GTP, ATP, CTP and UTP, wherein the fraction (2) of each of the four ribonucleoside triphosphates in the sequence-optimized reaction mix corresponds to the fraction (1) of the respective nucleotide in said RNA molecule, a buffer, a DNA template, and an RNA polymerase. Further, the present invention relates to a bioreactor (1) for synthesizing RNA molecules of a given sequence, the bioreactor (1) having a reaction module (2) for carrying out in vitro RNA transcription reactions in a sequence-optimized reaction mix, a capture module (3) for temporarily capturing the transcribed RNA molecules, and a control module (4) for controlling the infeed of components of the sequence-optimized reaction mix into the reaction module (2), wherein the reaction module (2) comprises a filtration membrane (21) for separating nucleotides from the reaction mix, and the control of the infeed of components of the sequence-optimized reaction mix by the control module (4) is based on a measured concentration of separated nucleotides.

Owner:CUREVAC REAL ESTATE GMBH

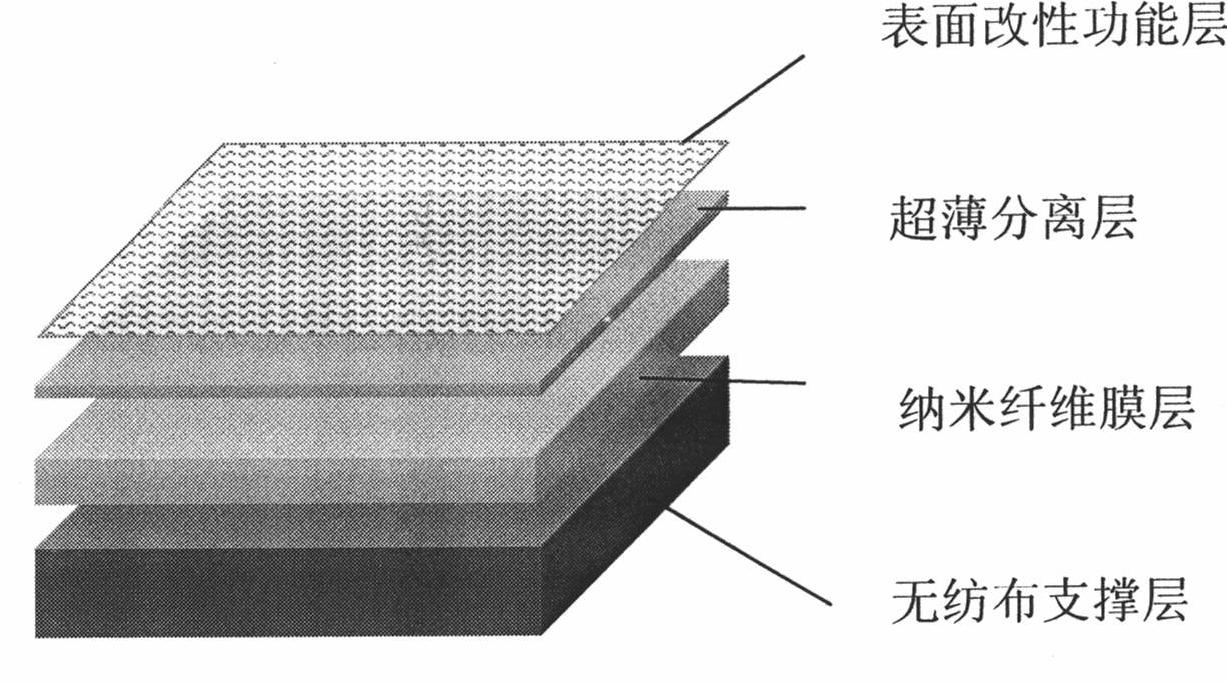

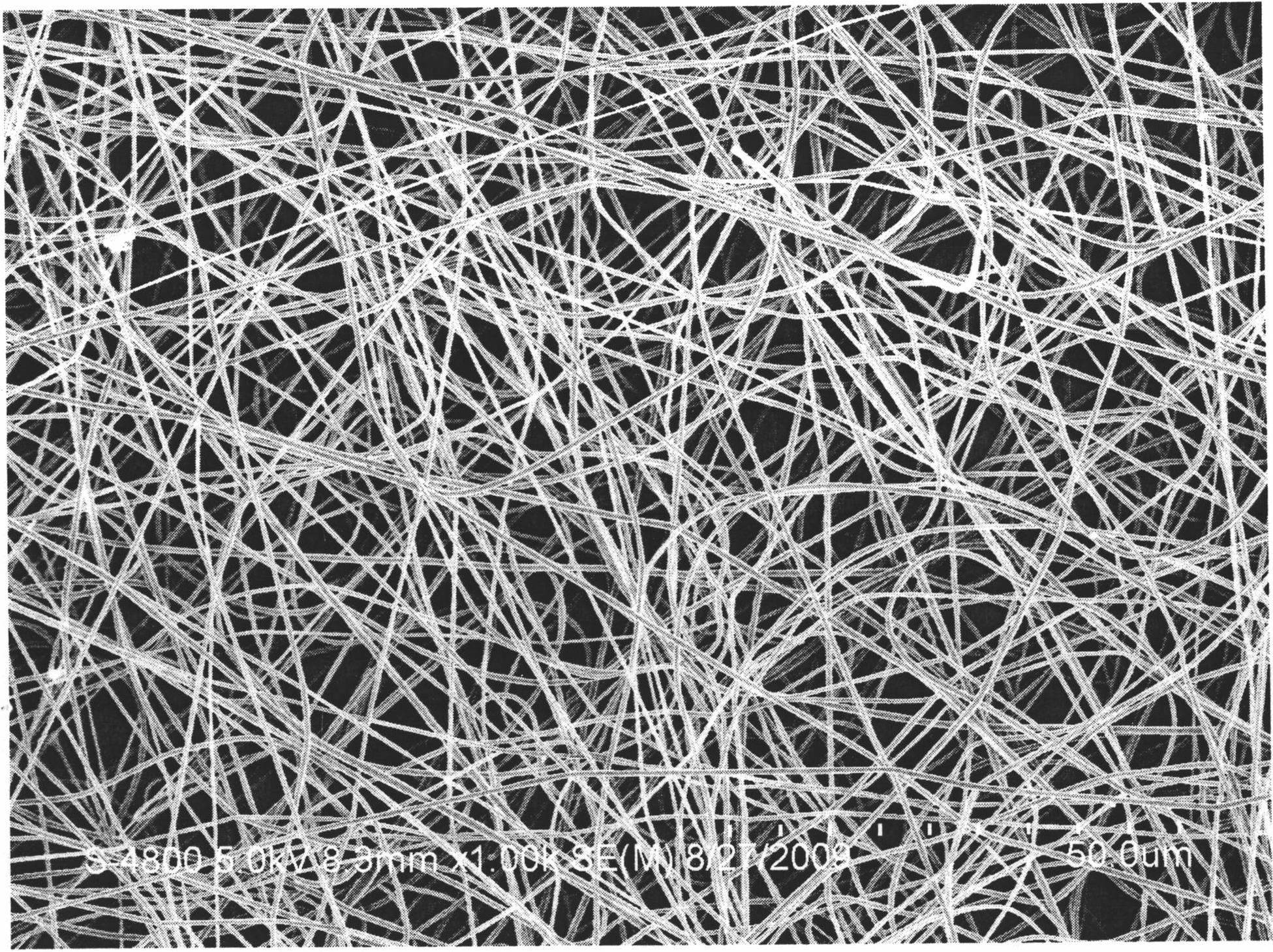

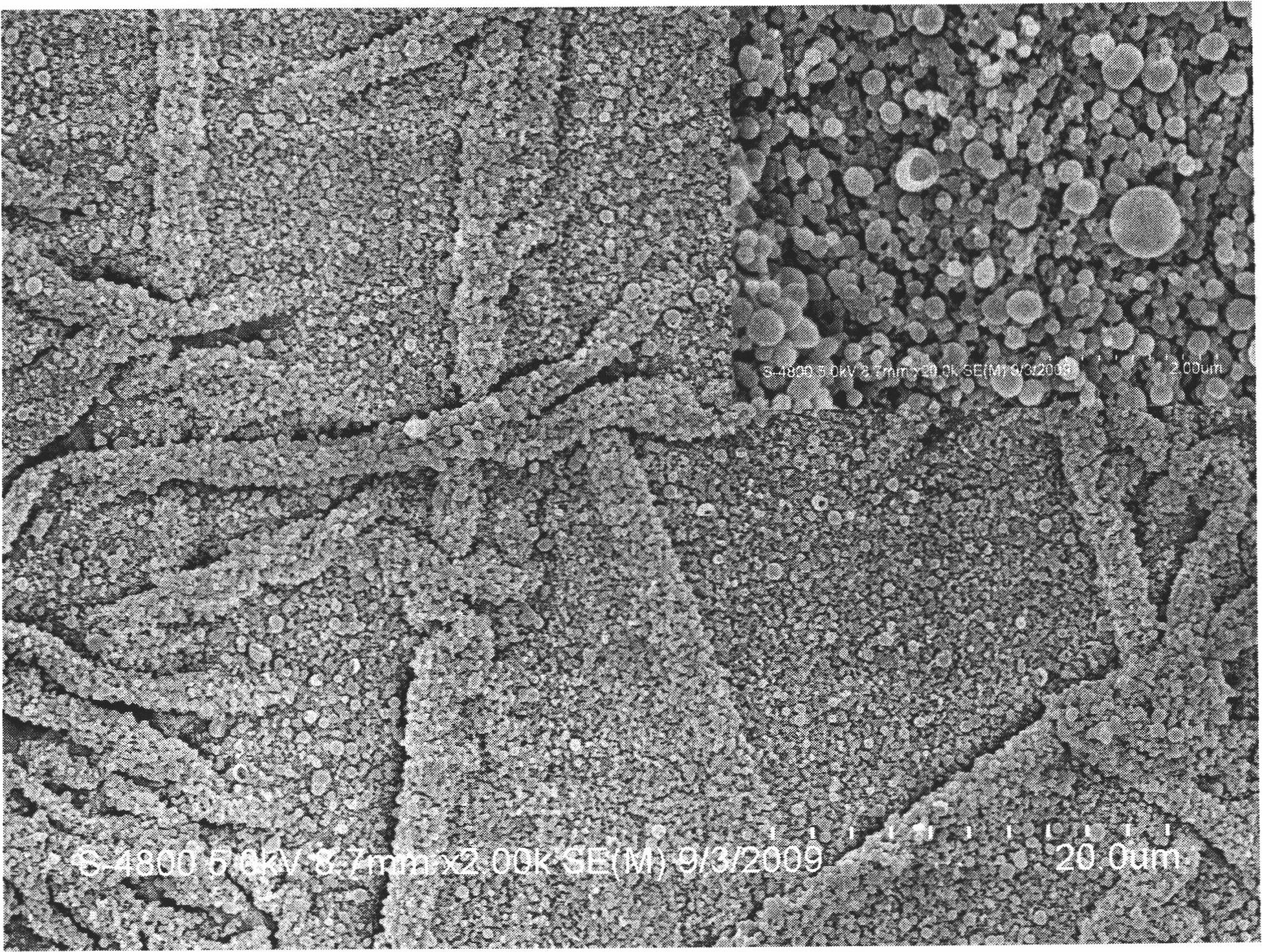

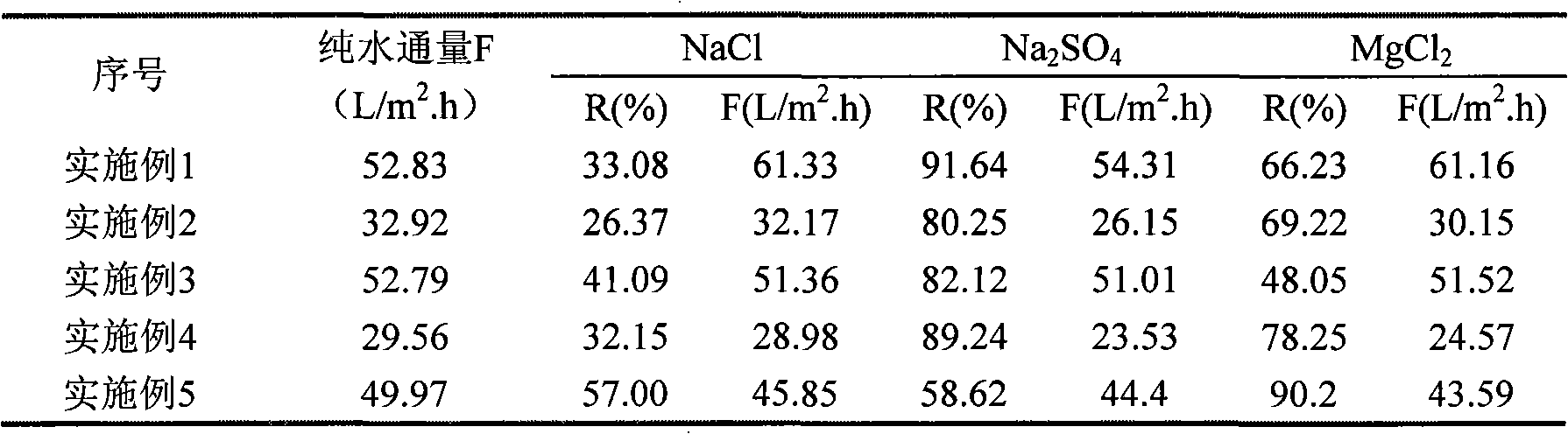

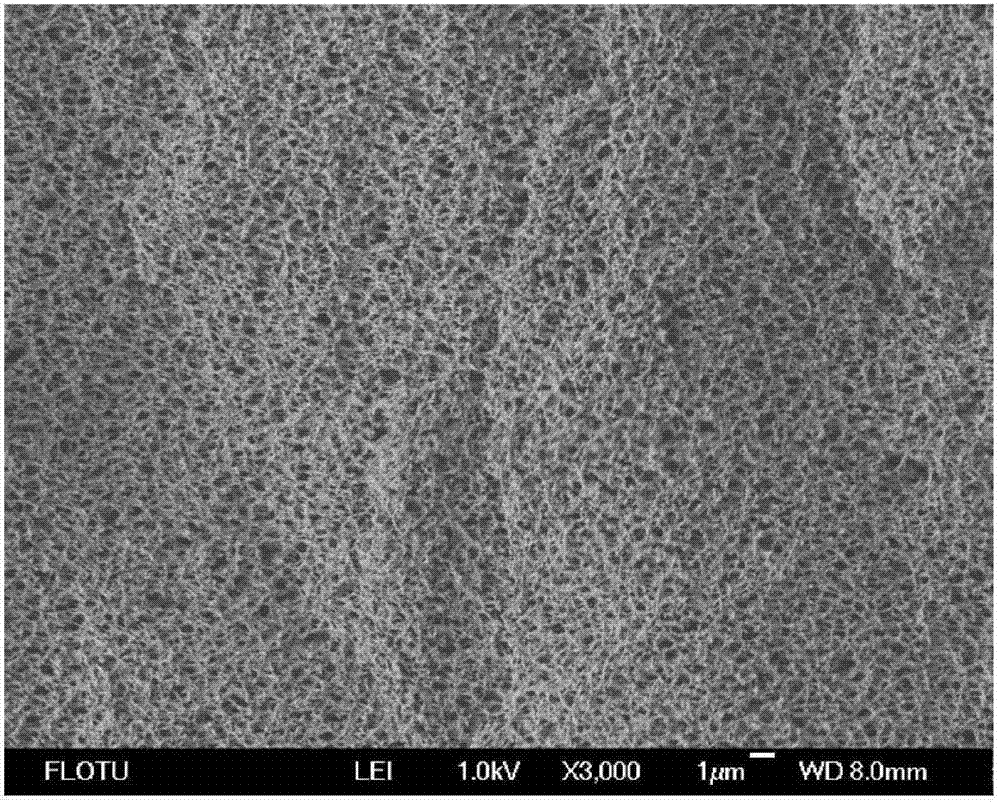

Hyperfiltration membrane or nanofiltration membrane with multi-layered composite structure and preparation method thereof

InactiveCN102139187AIncrease water fluxHigh retention rateSemi-permeable membranesEnvironmental resistanceHydrophilic polymers

The invention relates to a hyperfiltration membrane or nanofiltration membrane with a multi-layered composite structure and a preparation method thereof. The hyperfiltration membrane or nanofiltration membrane is a polymer electrostatic spinning nanofiber membrane layer characterized in strong chemical resistance prepared through an electrostatic spinning method, a hydrophilic polymer ultra-thin separation layer obtained through interfacial polymerization, and a functional group surface modification functional layer formed through the grafting reaction of reactant gases on the surfaces of hydrophilic polymers, or a long-chain polymer surface modification functional layer formed through the grafting reaction of the reaction gases on the surfaces of the hydrophilic polymers, or a functionalgroup-containing long-chain polymer surface modification functional layer through the grafting reaction of the reaction gases with the functional groups on the surfaces of the hydrophilic polymers. The hyperfiltration membrane or nanofiltration membrane with the multi-layered composite structure has the advantages of high water flux, high cutting rate and stable chemical performances. The filtration membrane can be used for the production of domestic water, drinking water or water in special conditions, and is suitable for the medical field, food field, environmental protection field and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

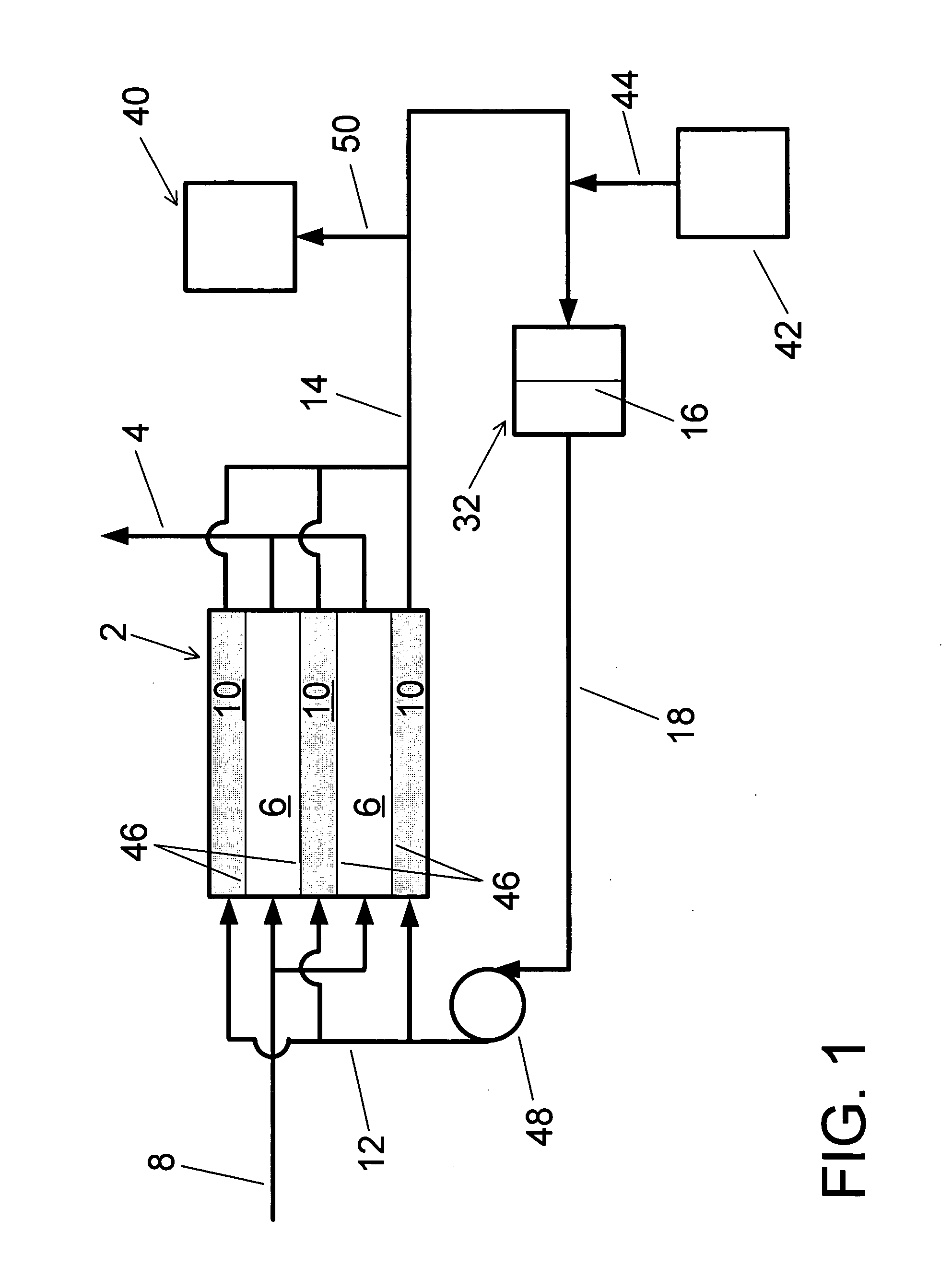

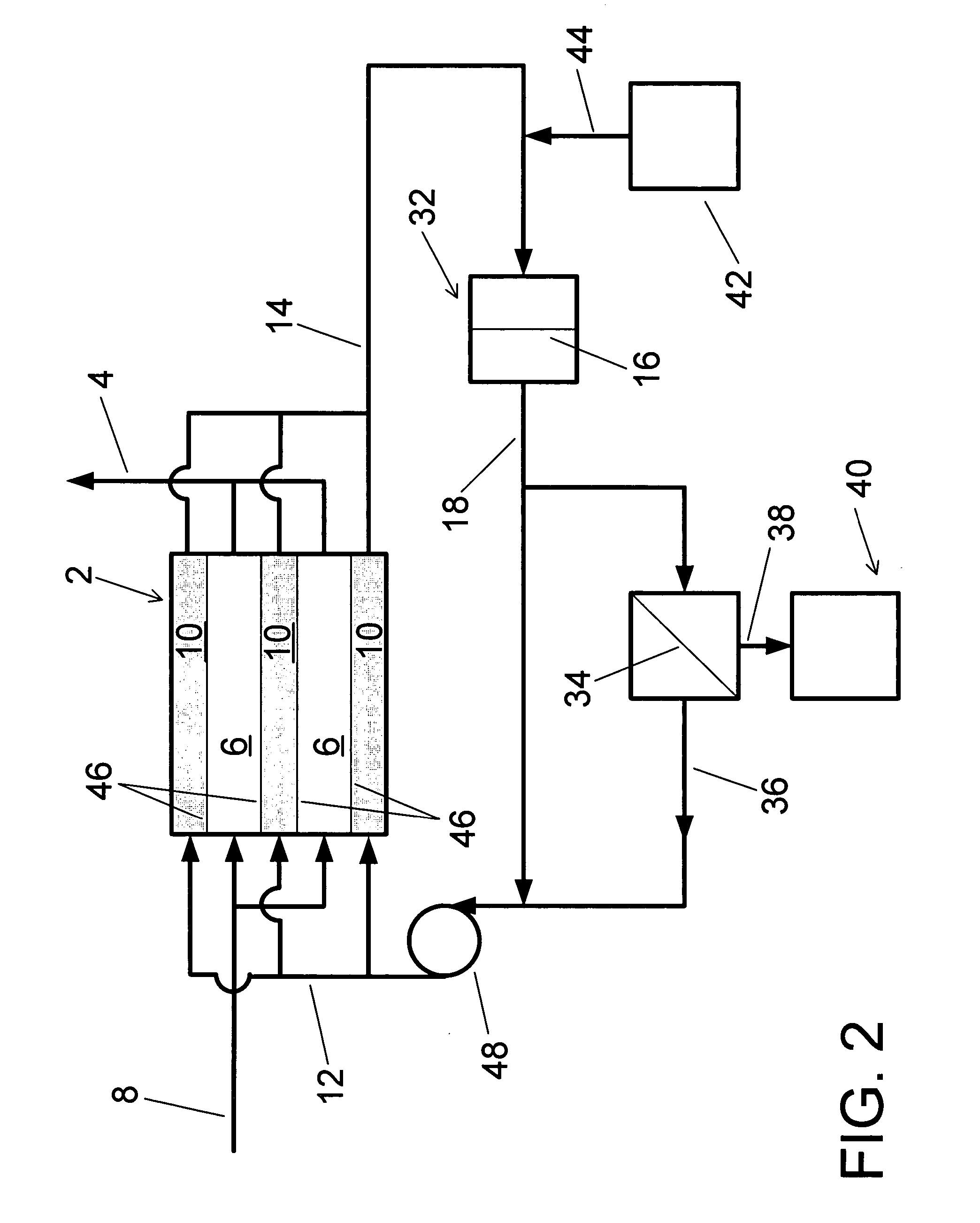

Apparatus of produced water treatment, system and method of using the apparatus, and method of water reuse by using the same

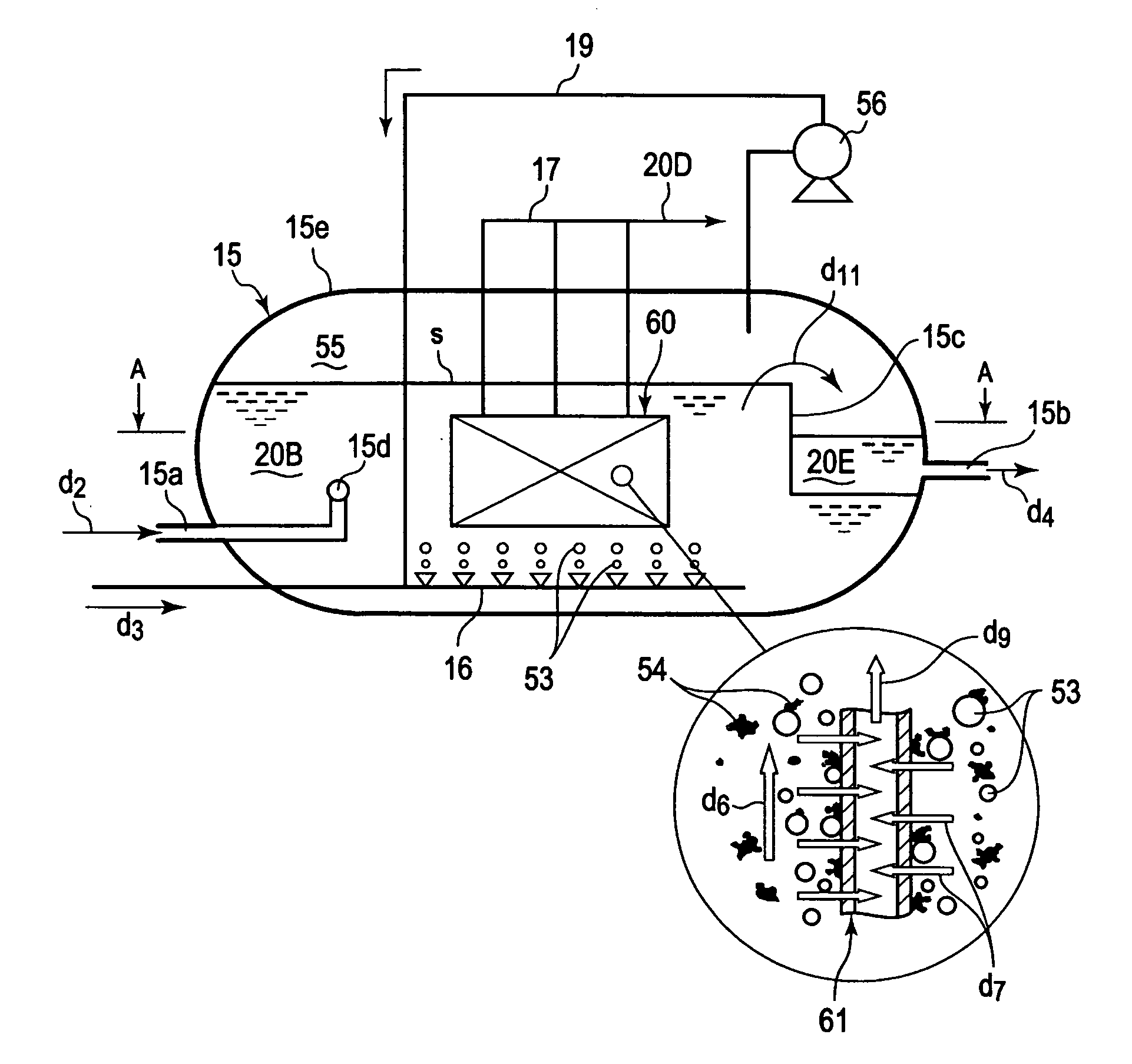

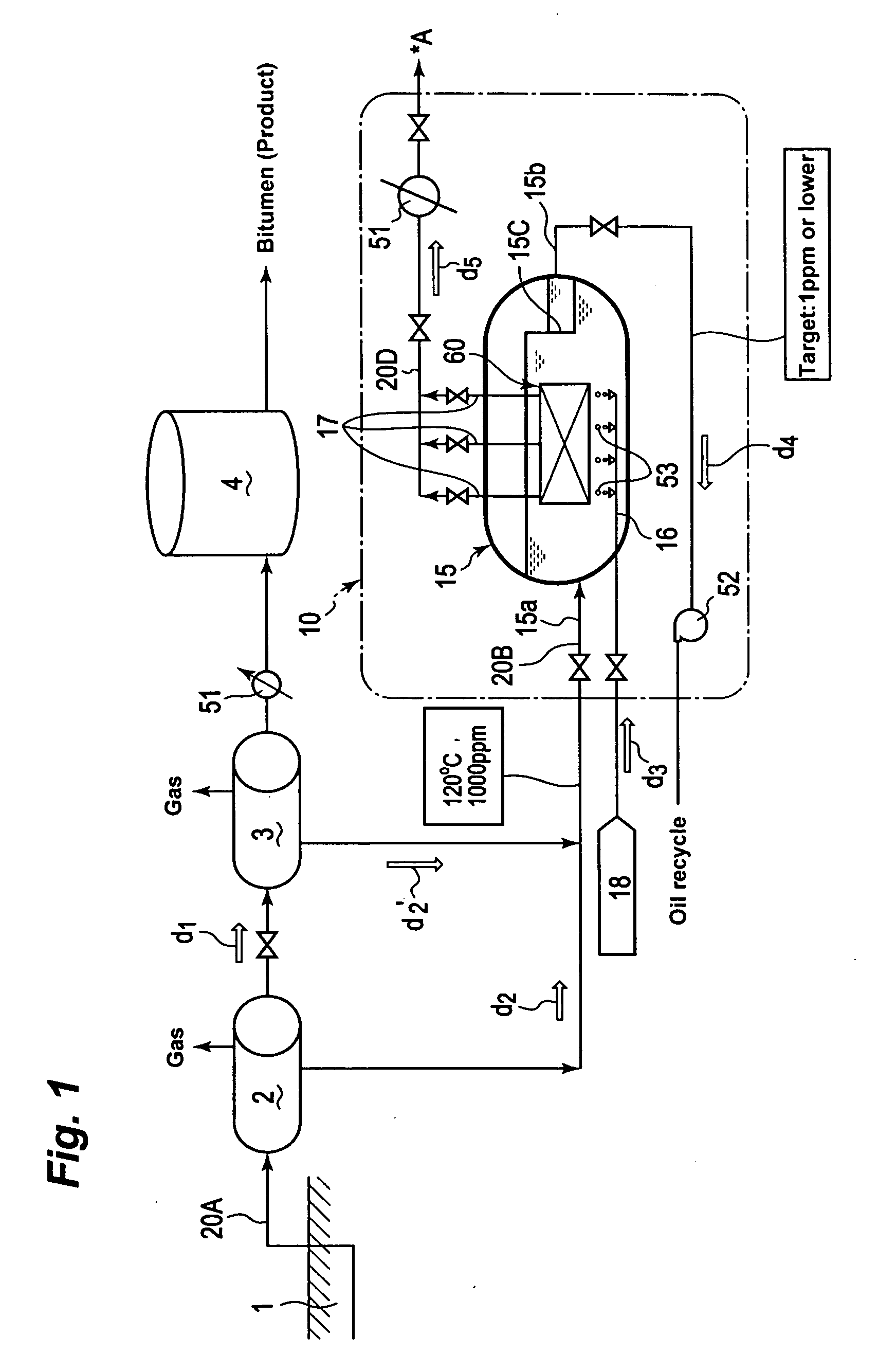

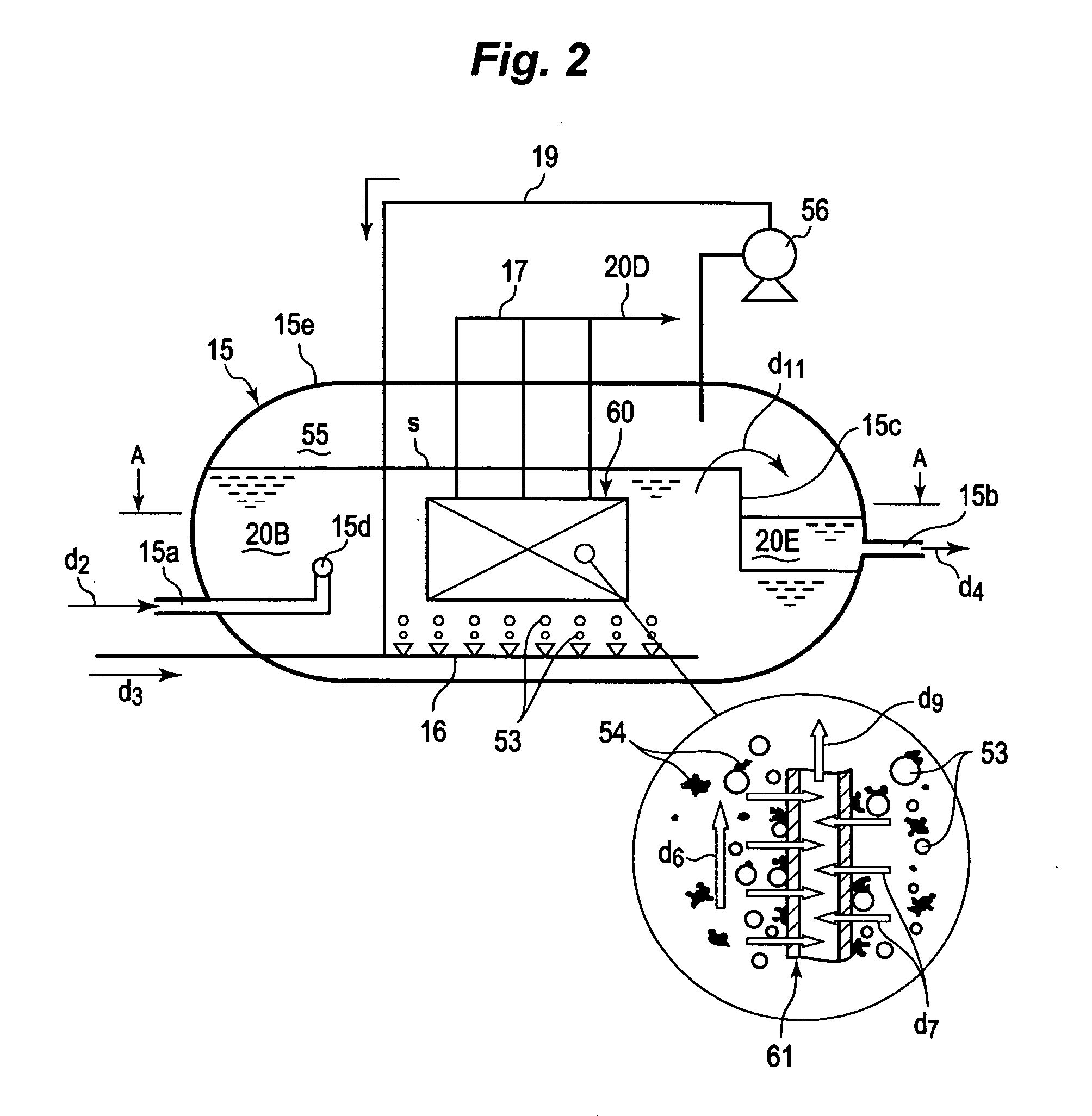

An apparatus of produced water treatment, to be adopted in an in-situ recovery method of producing bitumen from oil sand, the apparatus capable of removing the oil from produced water, the produced water of being left by separating the bitumen from bitumen-mixed fluid having been recovered from the oil sand, the apparatus having: a vessel for receiving the produced water; a submerge type filtration membrane module, installed in the vessel, for filtering the produced water in the condition of the membrane being submerged in the produced water; and a bubble generator for generating bubbles to be forwarded toward the submerged filtration membrane in the produced water.

Owner:TOYO ENG CORP +1

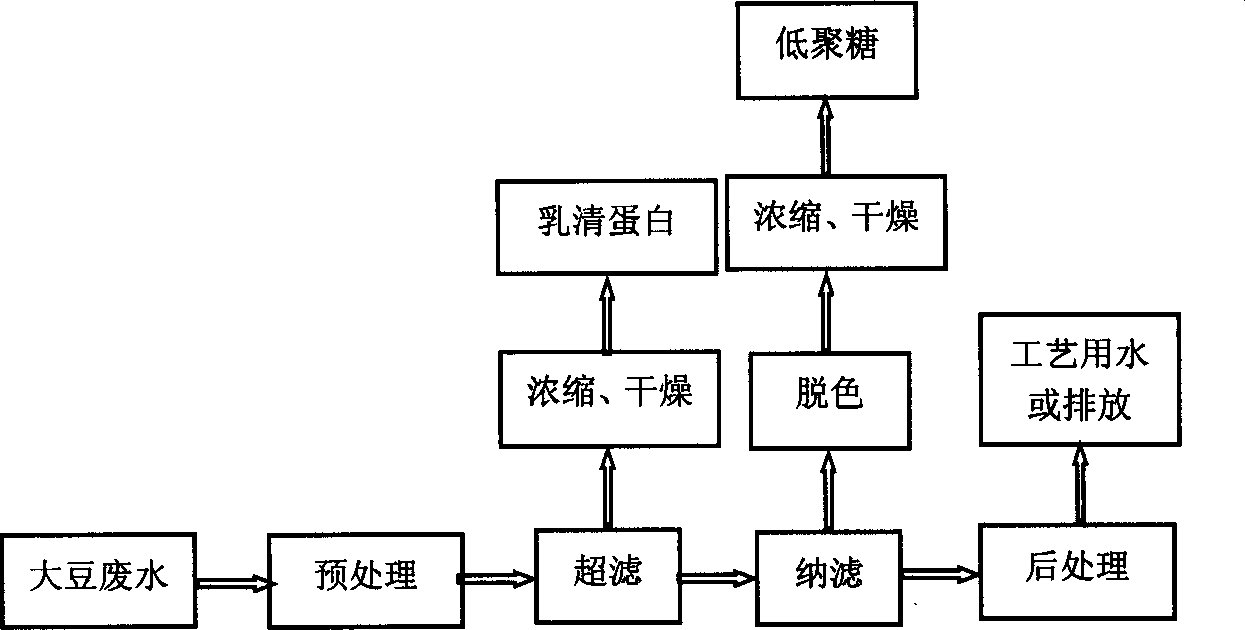

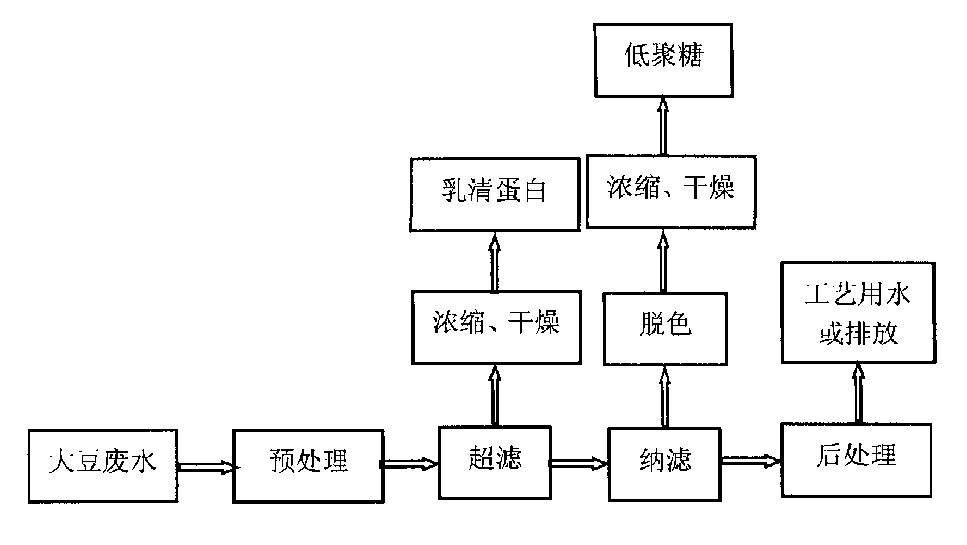

Membrane separation process of treating soybean processing waste water

InactiveCN1336333AAchieve separationAchieve enrichmentUltrafiltrationWater/sewage treatment bu osmosis/dialysisFiltration membraneWastewater

The present invention relates to method of treating soybean processing waste water by using membrane filtration technique, the soybean processing waste water is pretreated through pH value regulation, centrifuge, prefiltration, microfiltration, and temp regulation etc; then the pretreated soybean processing waste water is passed through ultrafiltration membrane system under pressure to extract soybean lactoalbumin; then the filtrate from ultrafiltration membrane is passed through nm filtration membrane system under pressure to extract soybean oligosaccharide which is further decolorized; the filtrate from nm filtration membrane system is post treated to obtain water suitable for use in production or water conformed with state discharge standard. Advantages: low cost, high purity of soybean lactoalbumin and oligosaccharide.

Owner:TSINGHUA TONGFANG CO LTD

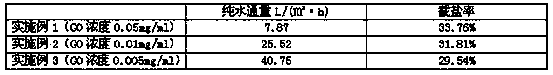

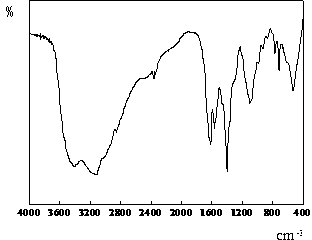

Layer-by-layer self-assembling oxidized graphene nano-filtration membrane and preparation method thereof

ActiveCN103706264AImprove permeabilityImprove interception effectSemi-permeable membranesFiltration membraneGraphene nanoribbons

The invention relates to a layer-by-layer self-assembling oxidized graphene nano-filtration membrane and a preparation method of the layer-by-layer self-assembling oxidized graphene nano-filtration membrane, which belongs to the technical field of the preparation of a nano-filtration membrane. The layer-by-layer self-assembling oxidized graphene nano-filtration membrane comprises a supporting layer and a functional layer, wherein the functional layer is in a layered structure which is different from the compact structure of the traditional nano-filtration membrane functional layer. The preparation method comprises the following steps of (I) preparing an oxidized graphene solution through a hummers method; and (II) preparing an oxidized graphne nano-filtration membrane through a layer-by-layer self-assembling method. The oxidized graphene nano-filtration membrane is prepared through the layer-by-layer self-assembling method, a water passage is formed between the oxidized graphene lamellas, the distance of the oxidized graphene layer has a good interception effect for ions, the hydrophilia can be improved through the oxygen-containing functional groups on the surface of the oxidized graphene layer, so that the membrane is good in permeability and interception property. By utilizing the layer-by-layer self-assembling method, the high requirement of the traditional nano-filtration membrane preparation process on the condition can be avoided, the process is simple, the condition is easily controlled, and the application prospect is wide.

Owner:OCEAN UNIV OF CHINA

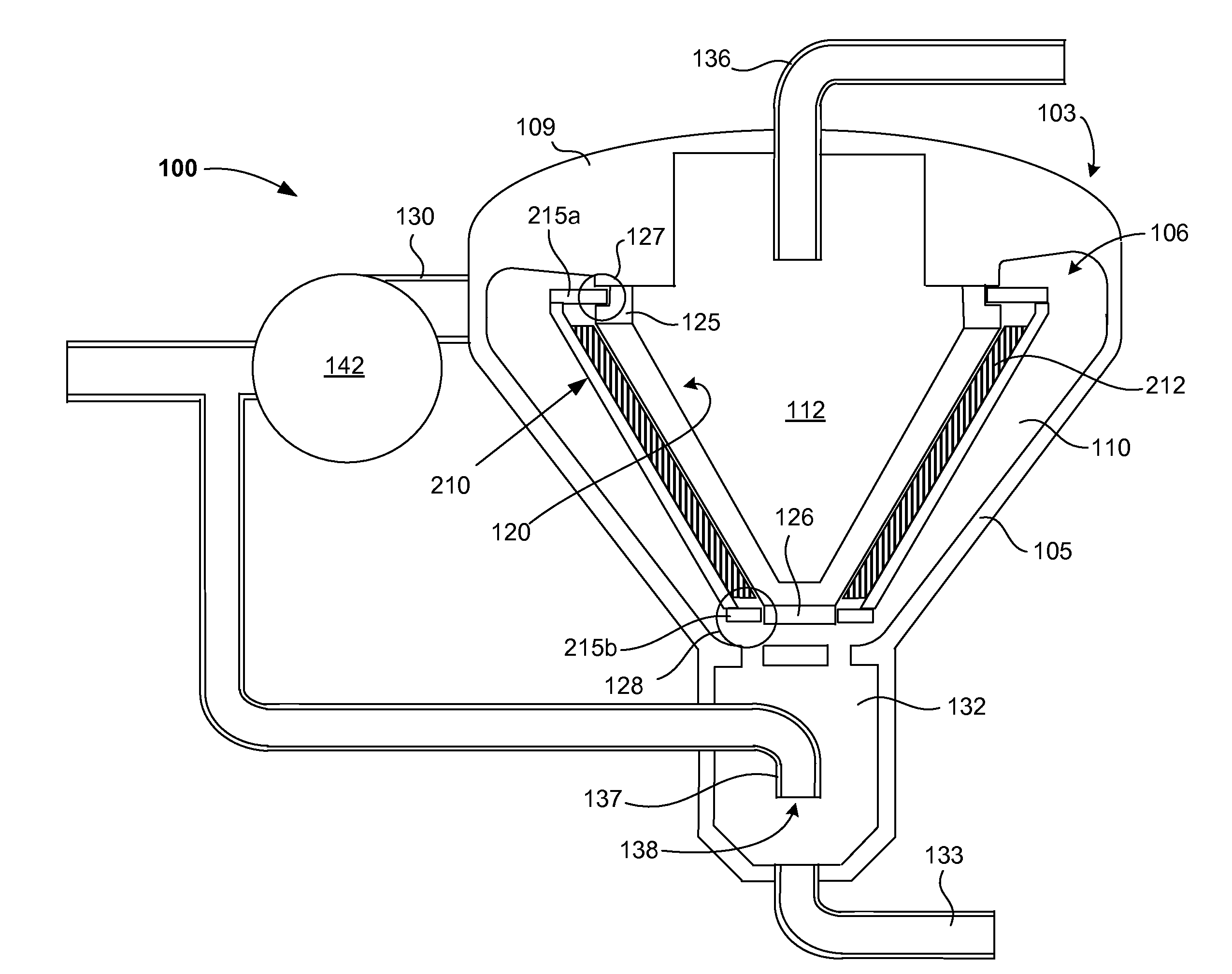

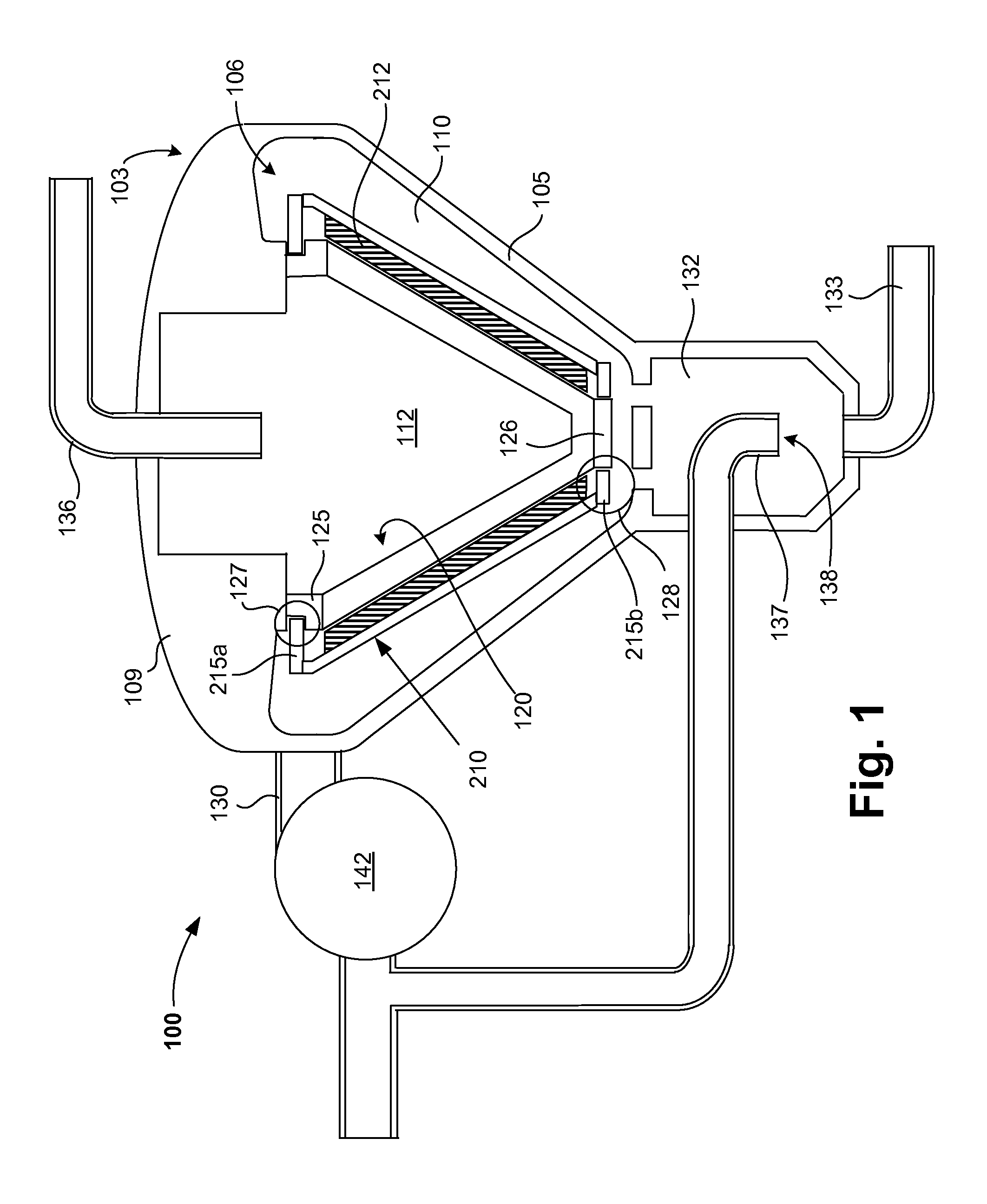

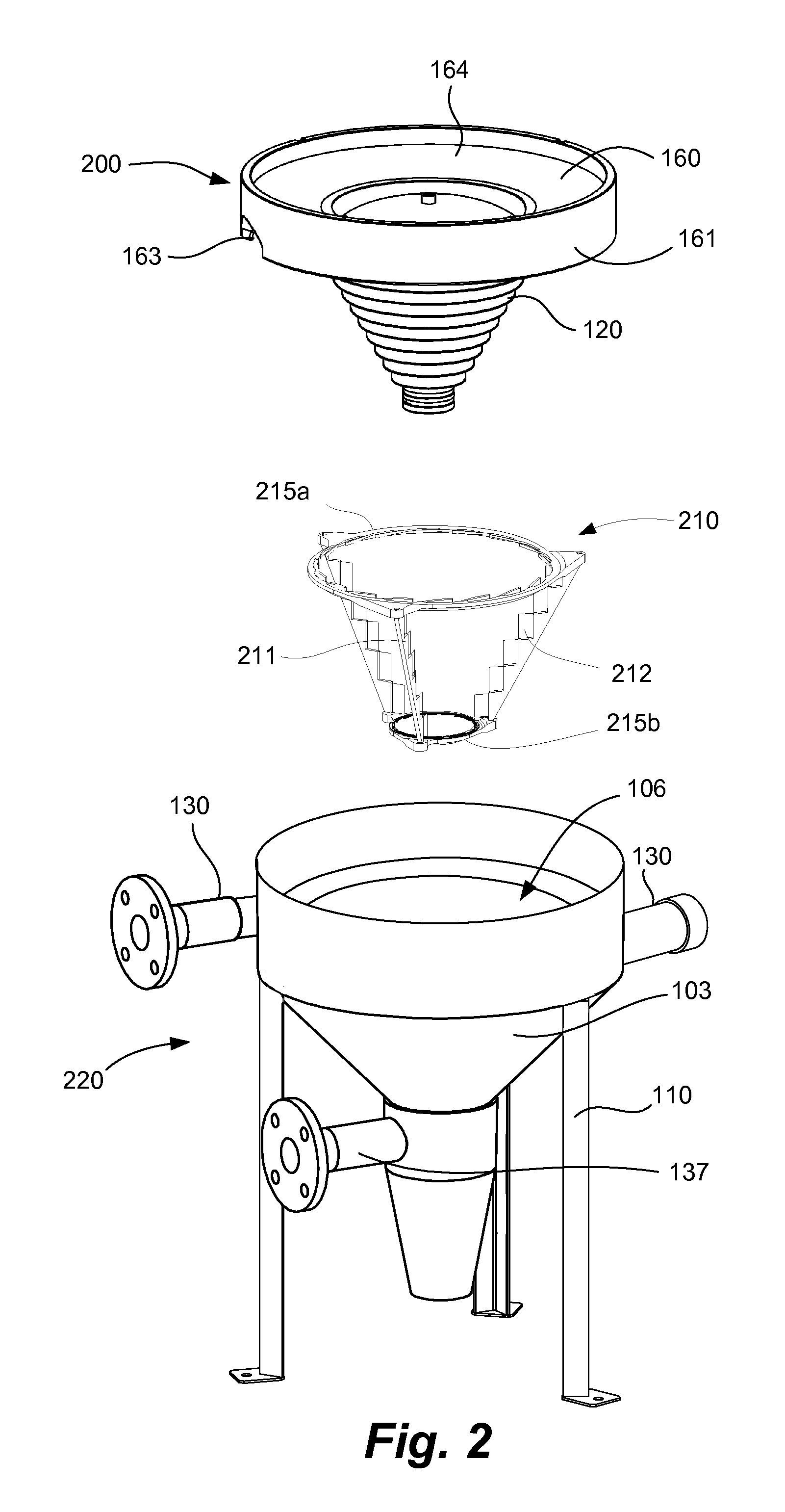

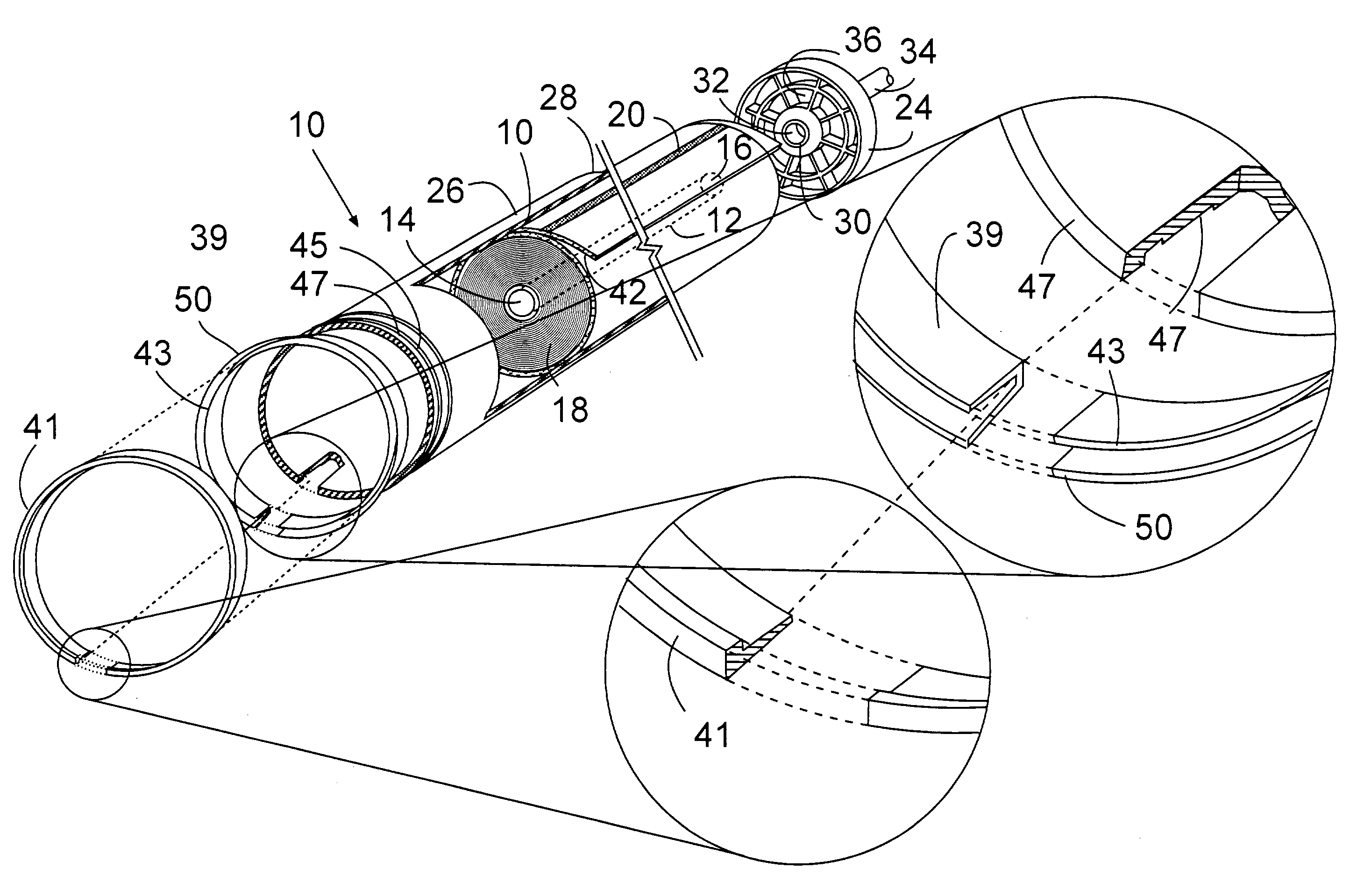

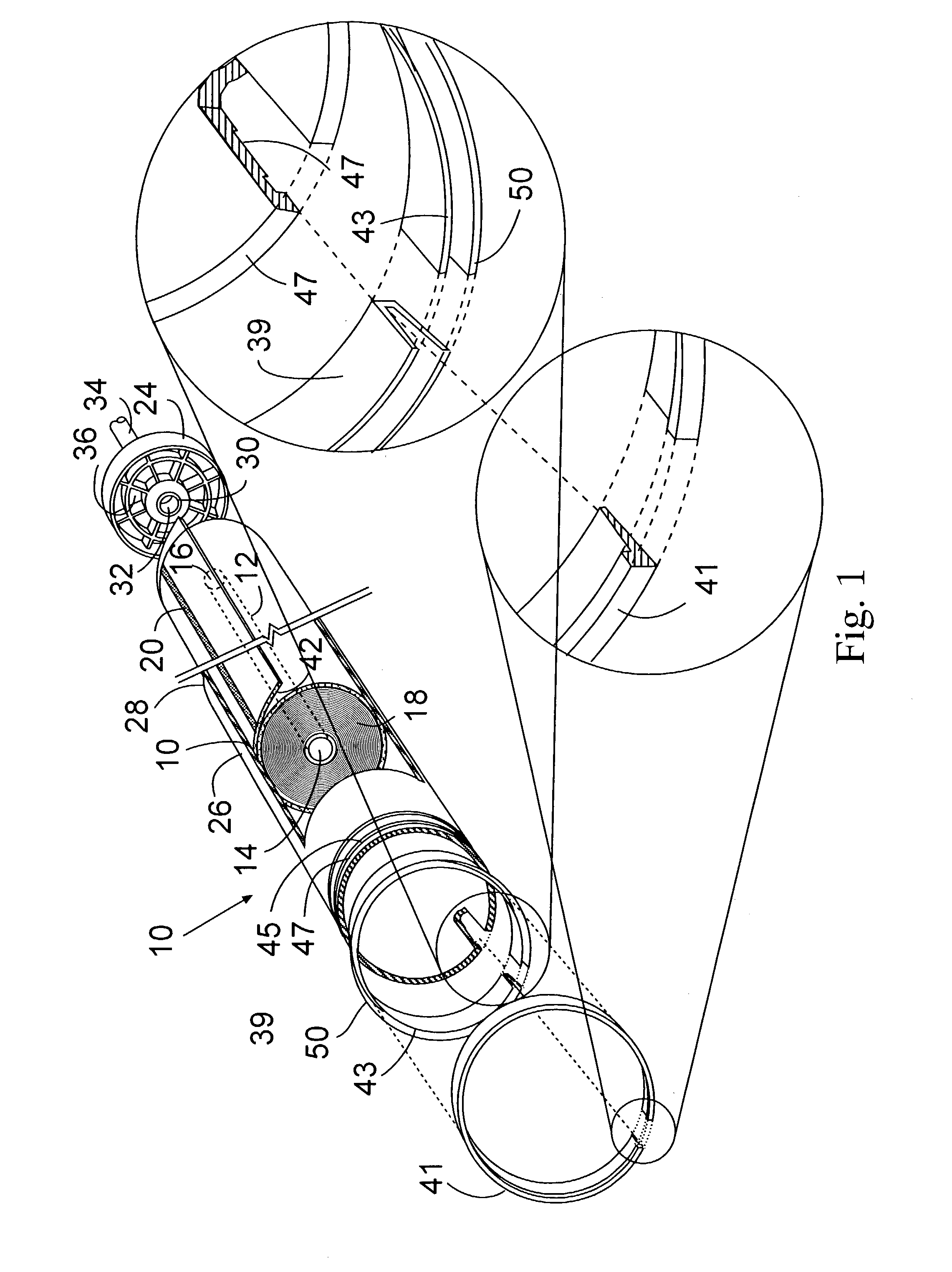

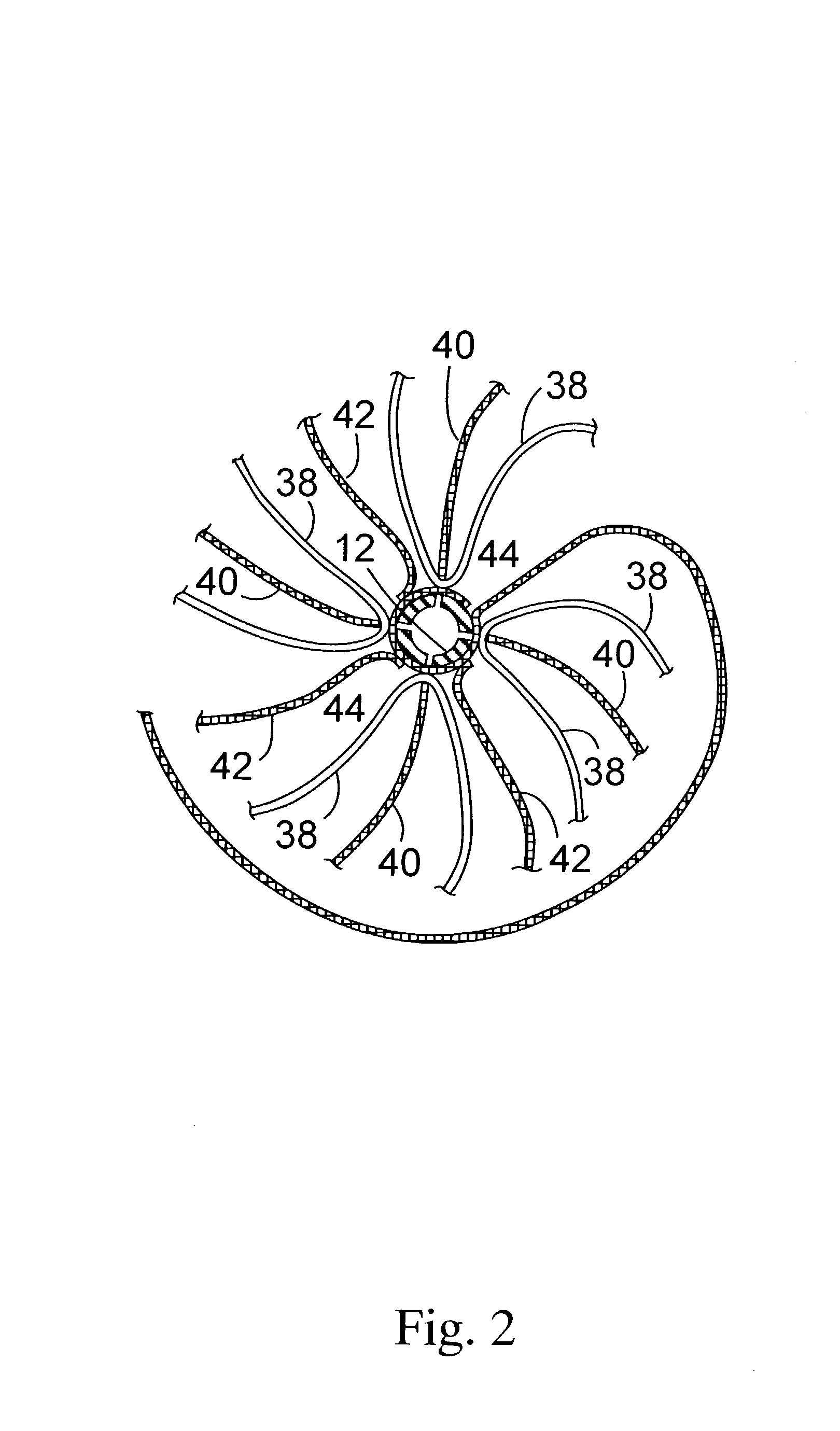

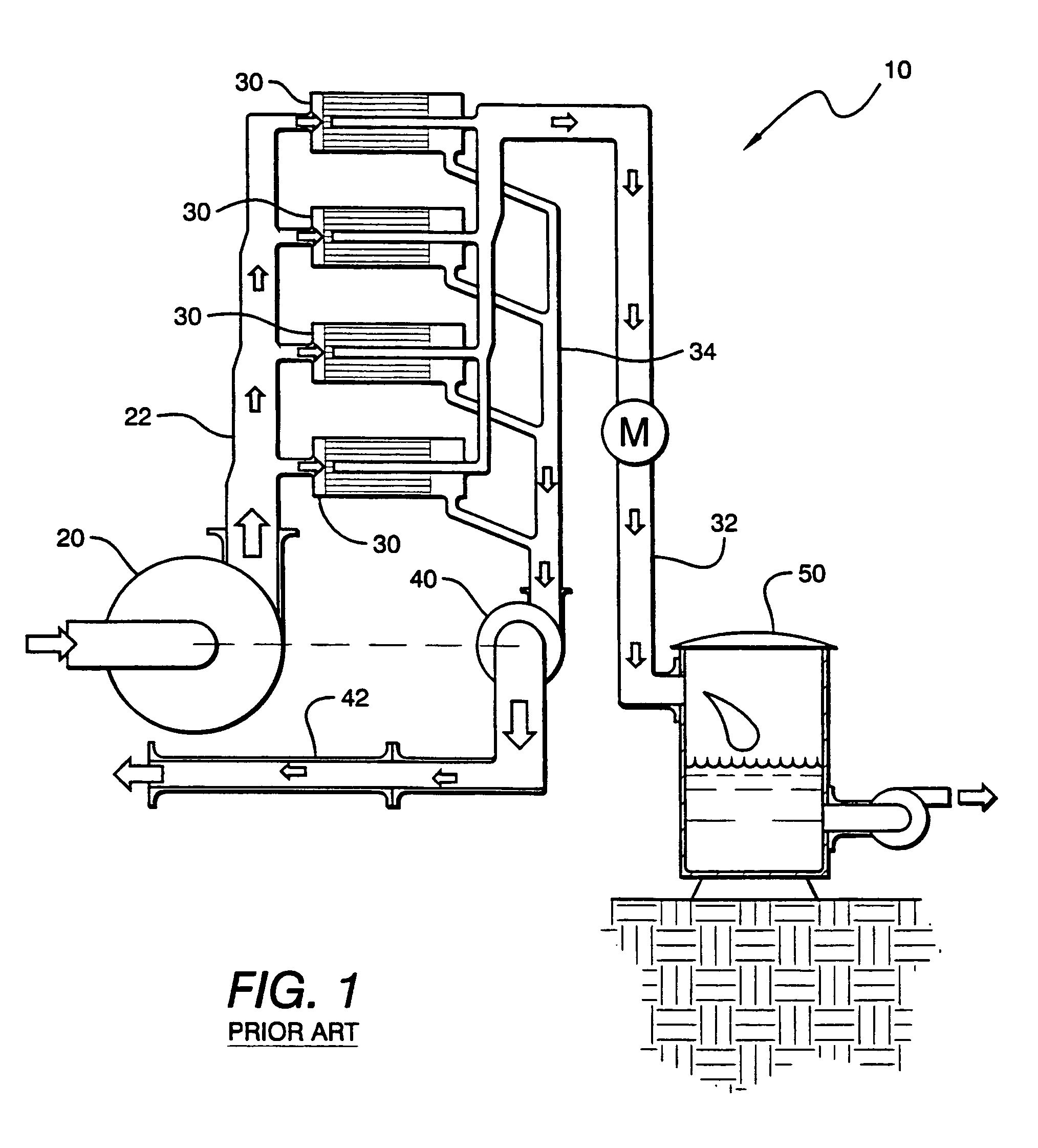

Cleaning assembly for use in fluid filtration systems

ActiveUS20120010063A1Easy to useEasy to disassembleWater/sewage treatment by centrifugal separationSemi-permeable membranesFluid filtrationFluid bearing

Cleaning assemblies and particulate tolerant fluid bearings that are particularly well suited for use in centrifugal separation enhanced filtration devices are described. In one aspect of the invention, at least one bearing is arranged to carry a circulating cleaning assembly such that the cleaning assembly can rotate around a filter membrane during filtering operation of the filtration device. The bearing is preferably arranged to maintain the circulating cleaning assembly in a substantially coaxial alignment with the filter membrane and in a substantially stable longitudinal position relative to the filter membrane as the circulating cleaning assembly is rotated around the filter membrane. In another aspect of the invention a variety of particulate tolerant bearings are described.

Owner:ACCELERATED FILTRATION INC

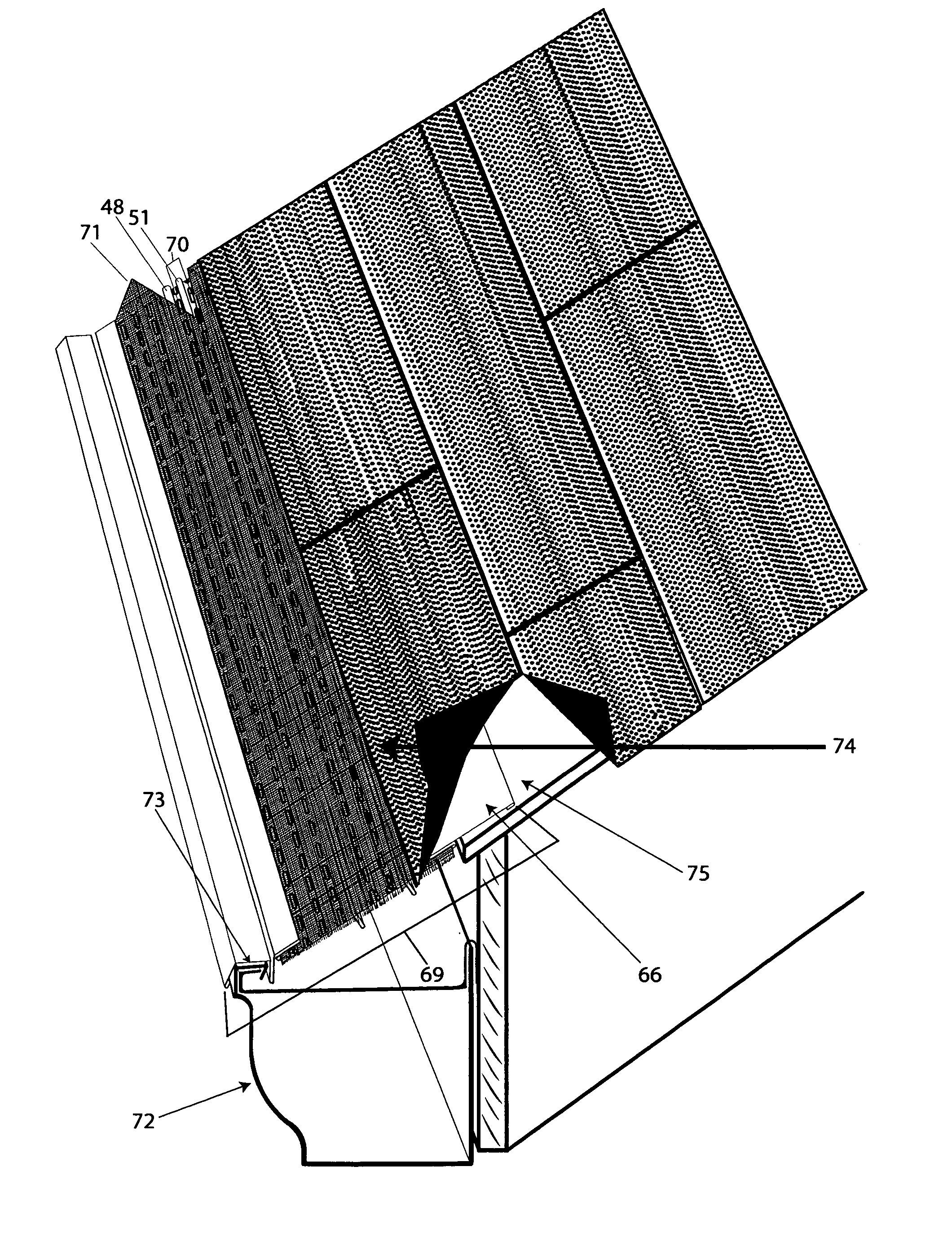

Self cleaning shield

Owner:MGP MFG

Passiflora coerulea and honey peach complex juice and preparation method thereof

The present invention relates to a passiflora coerulea and honey peach complex juice and a preparation method thereof. The complex juice consists of 20-30% passiflora coerulea juice, 10-15% honey peach juice, 3-5% honey and water and the preparation method of the complex juice is made of the following steps: washing, cleaning and cutting the passiflora coerulea, removing the fruit pulp with seeds to squeeze juice, washing and cleaning honey peaches, peeling honey peaches to squeeze juice, mixing the two juices evenly and heating to a temperature of 20-60 DEG C, adding pectinase and amylase to conduct enzymolysis, filtering the juice and adding water and honey to flavor, removing parts of bacteria with sterilizing filtration membranes; then homogenizing and degassing the sterilized juice, and vacuum packaging and treating the packaged juice with super-high pressure sterilization and enzyme inactivation treatment, thereby obtaining the complex juice. The preparation method of the complex juice can maintain the unique flavor of passiflora coerulea and delicate fragrance of honey peaches, thus the prepared complex juice has authentic taste of the raw juice, natural and lingering flavor, and improved the quality of fruit juice, and meet the pursuit of natural fruit juice of the majority of consumers.

Owner:黄志娟

Microporous filter membrane, method of making microporous filter membrane and separator employing microporous filter membranes

InactiveUS20050263452A1High porosityLittle precisionPaper/cardboard articlesDispersed particle filtrationMicron scaleFiltration membrane

A filter membrane, methods of making such filter membrane and apparatus employing such filter membrane are disclosed, in which the filter membrane is a monolithic polymeric membrane that includes a polymeric filter layer including a micron-scale precision-shaped pores and a polymeric support layer that has a precision-shaped porous support structure for the filter layer. Several methods are disclosed for making such a membrane using micromachining techniques, including lithographic, laser ablation and x-ray treatment techniques. Several filter apparatus employing such a membrane are also disclosed.

Owner:BAXTER INT INC

Asymmetric forward osmosis membranes

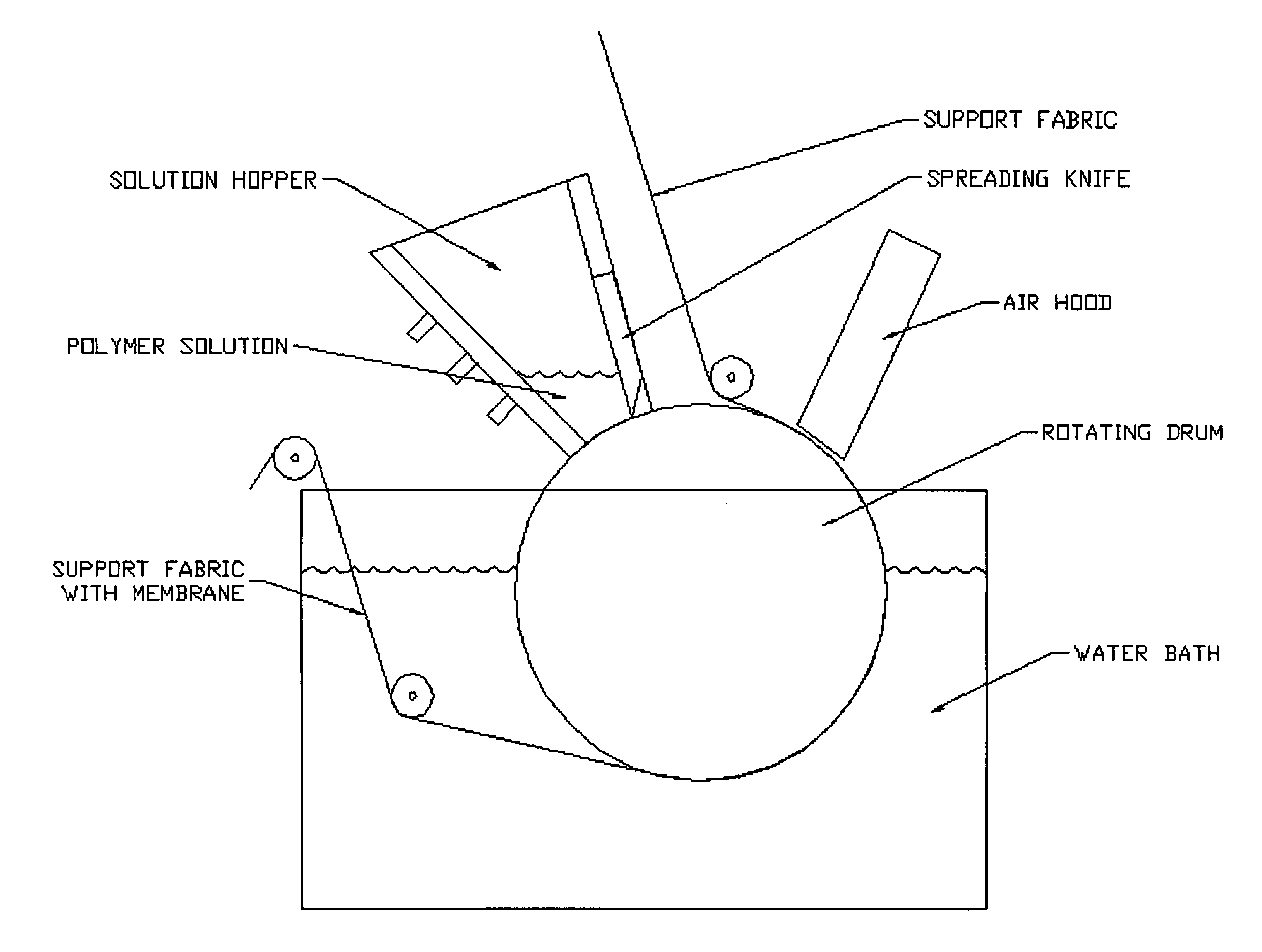

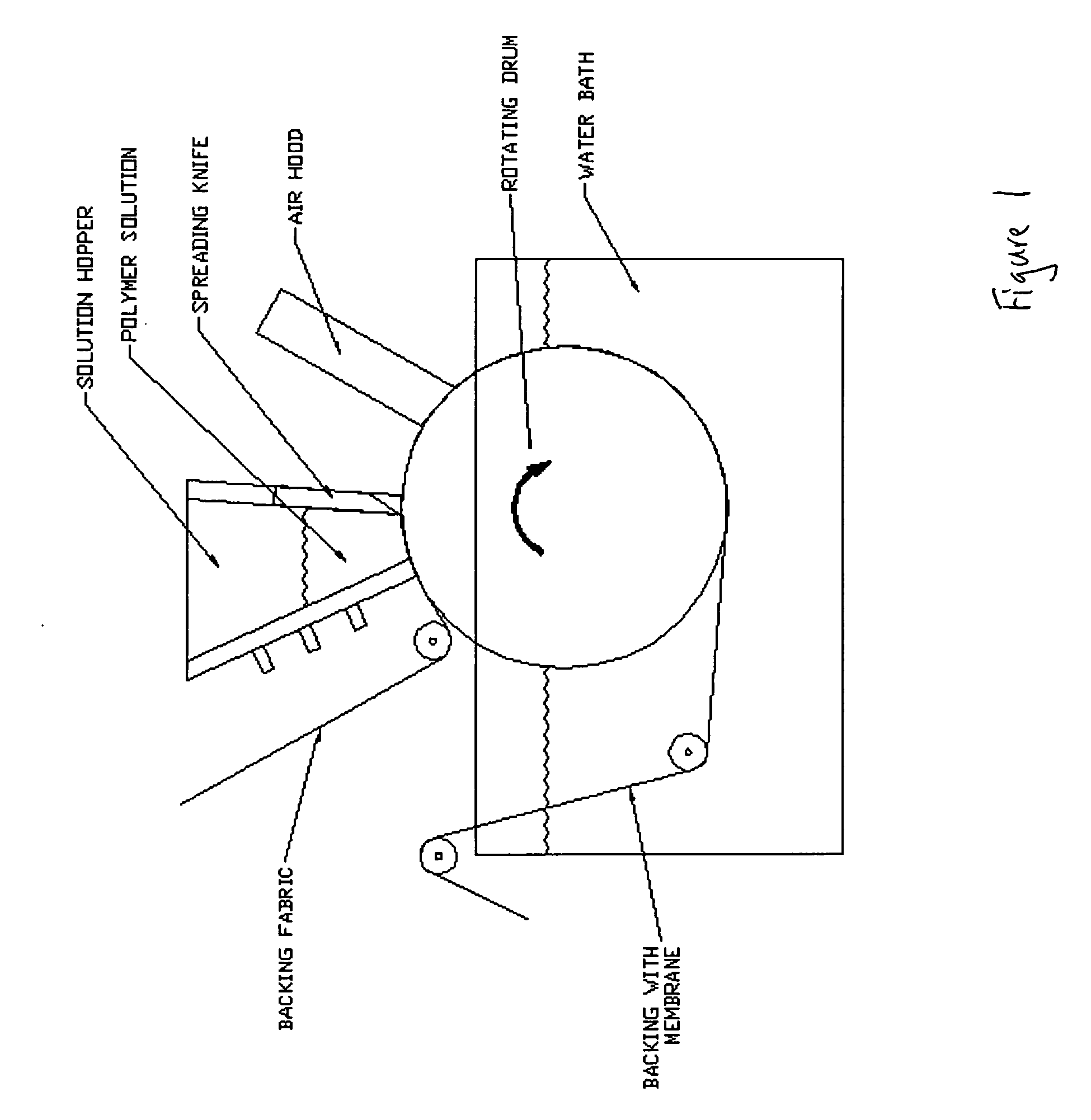

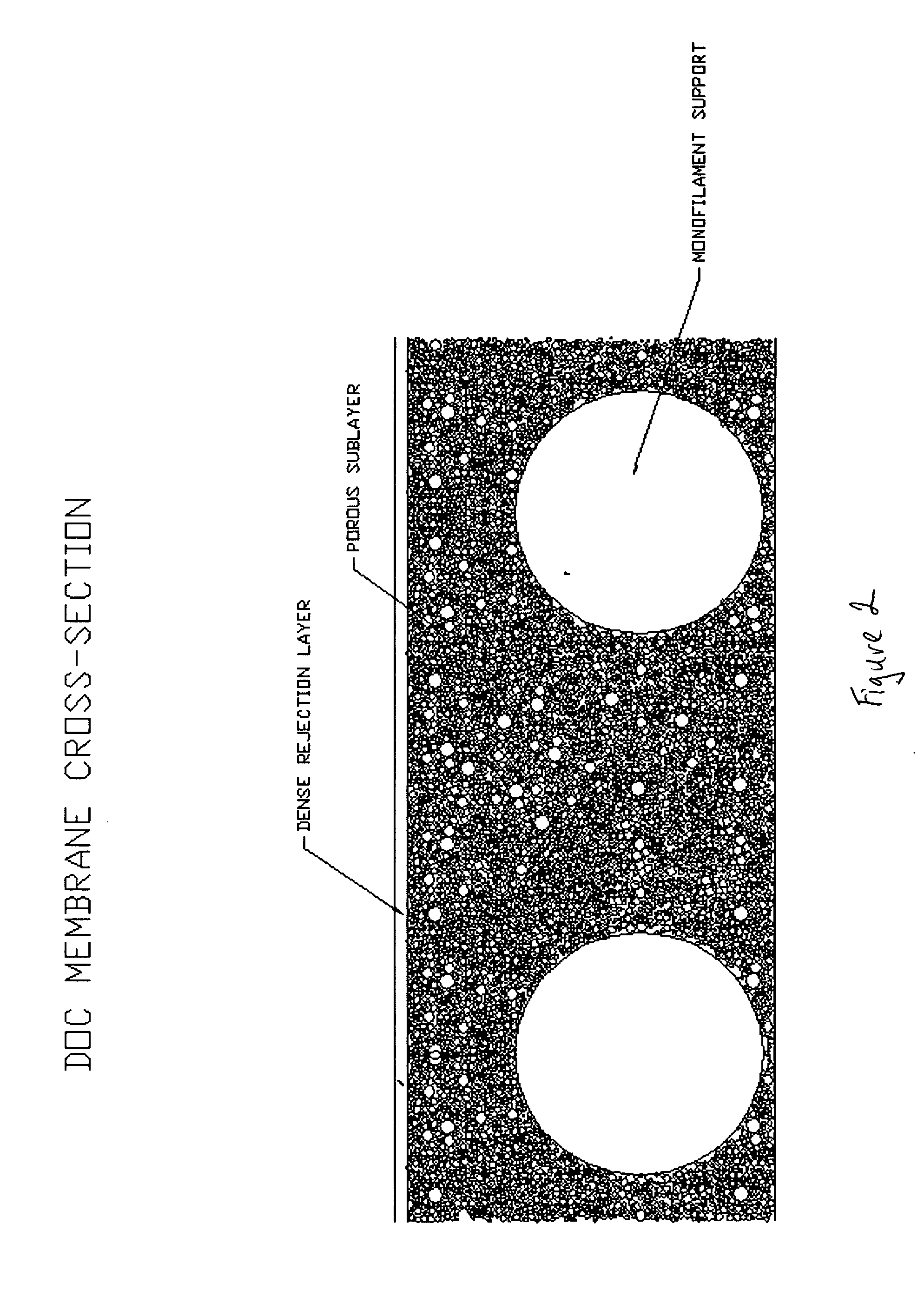

InactiveUS20060226067A1Lower resistanceHigh titer reductionSemi-permeable membranesMembranesFiltration membraneWaste stream

There is disclosed a membrane formulation having high flux for forward osmosis applications. There is disclosed a forward osmosis filtration membrane having a salt rejection 99+% or greater, and comprising an asymmetric hydrophobic porous backing and cellulosic fibers. The membranes of the present invention find use in a variety of applications including osmotic-driven water purification and filtration, desalination of sea water, purification of contaminated aqueous waste streams, and the like. Specifically, there is disclosed a forward osmosis filtration membrane having a skin layer for salt rejection and a porous scaffold layer having a woven or non-woven mesh embedded within it.

Owner:HYDRATION SYST

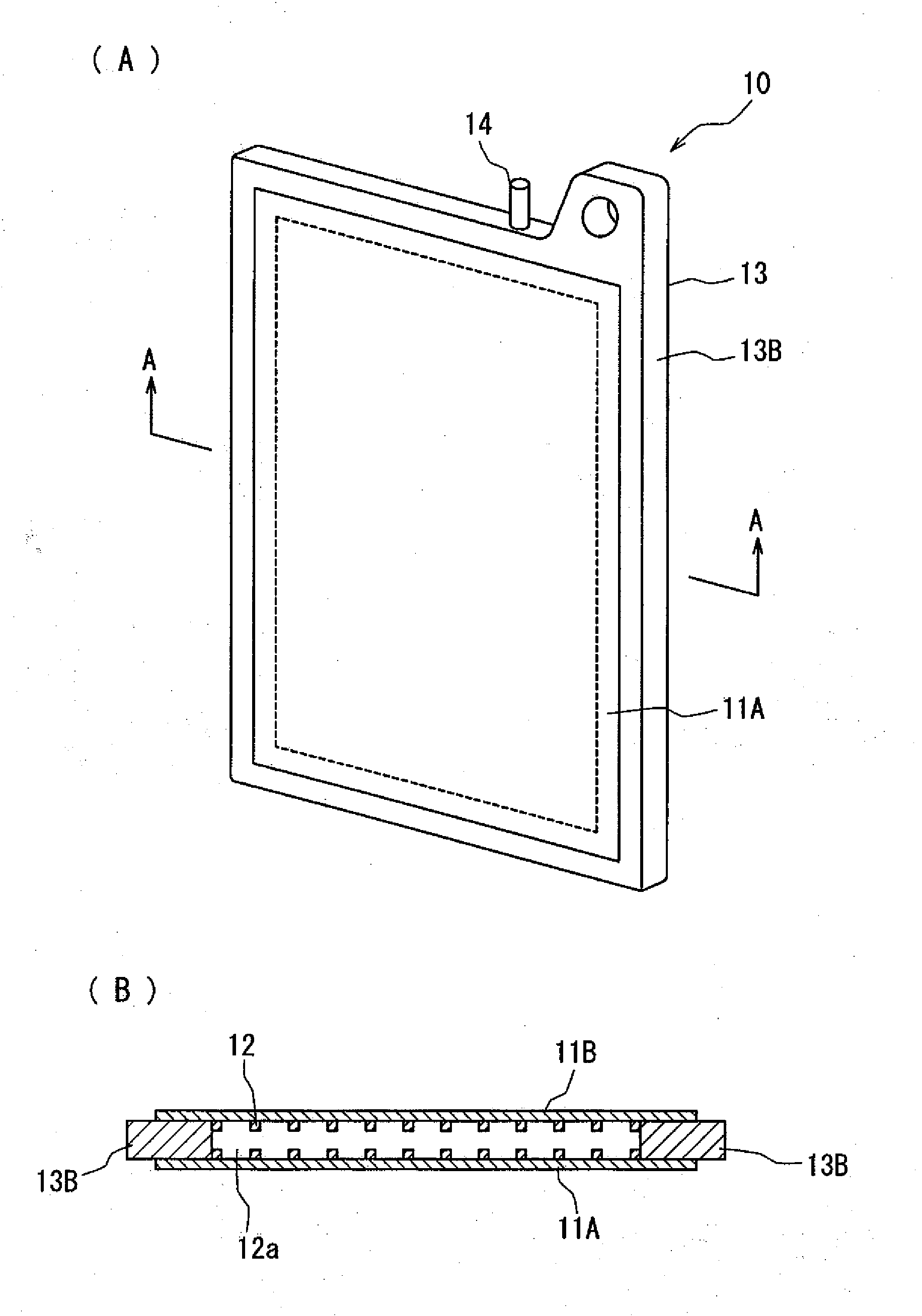

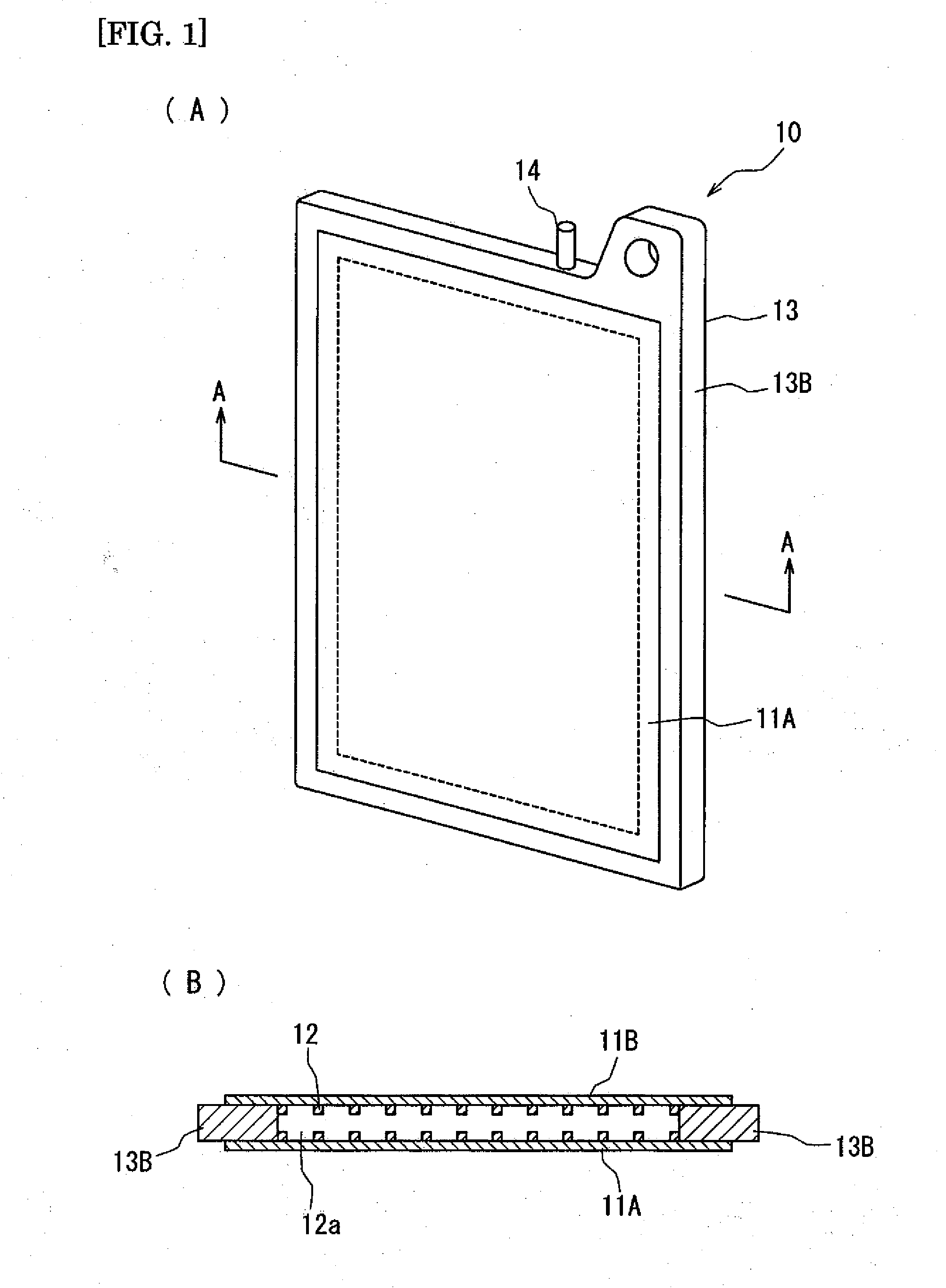

Flat sheet membrane element for filtration and flat sheet membrane filtration module

InactiveUS20100096317A1Improve performanceStable permeation flow rateMembranesUltrafiltrationFiltration membranePorous membrane

A flat sheet membrane element for performing solid-liquid separation by immersion in a liquid to be treated which contains a suspended component includes sheet-shaped filtration membranes disposed opposite to each other with a space for a treated liquid flow path, a support portion for securing the space for the treated liquid flow path, and a peripheral sealing portion for sealing the peripheral edges of the filtration membranes arranged opposite to each other so as to form at least one treated liquid outlet, the filtration membranes including at least expanded PTFE (polytetrafluoroethylene) porous membranes.

Owner:SUMITOMO ELECTRIC IND LTD

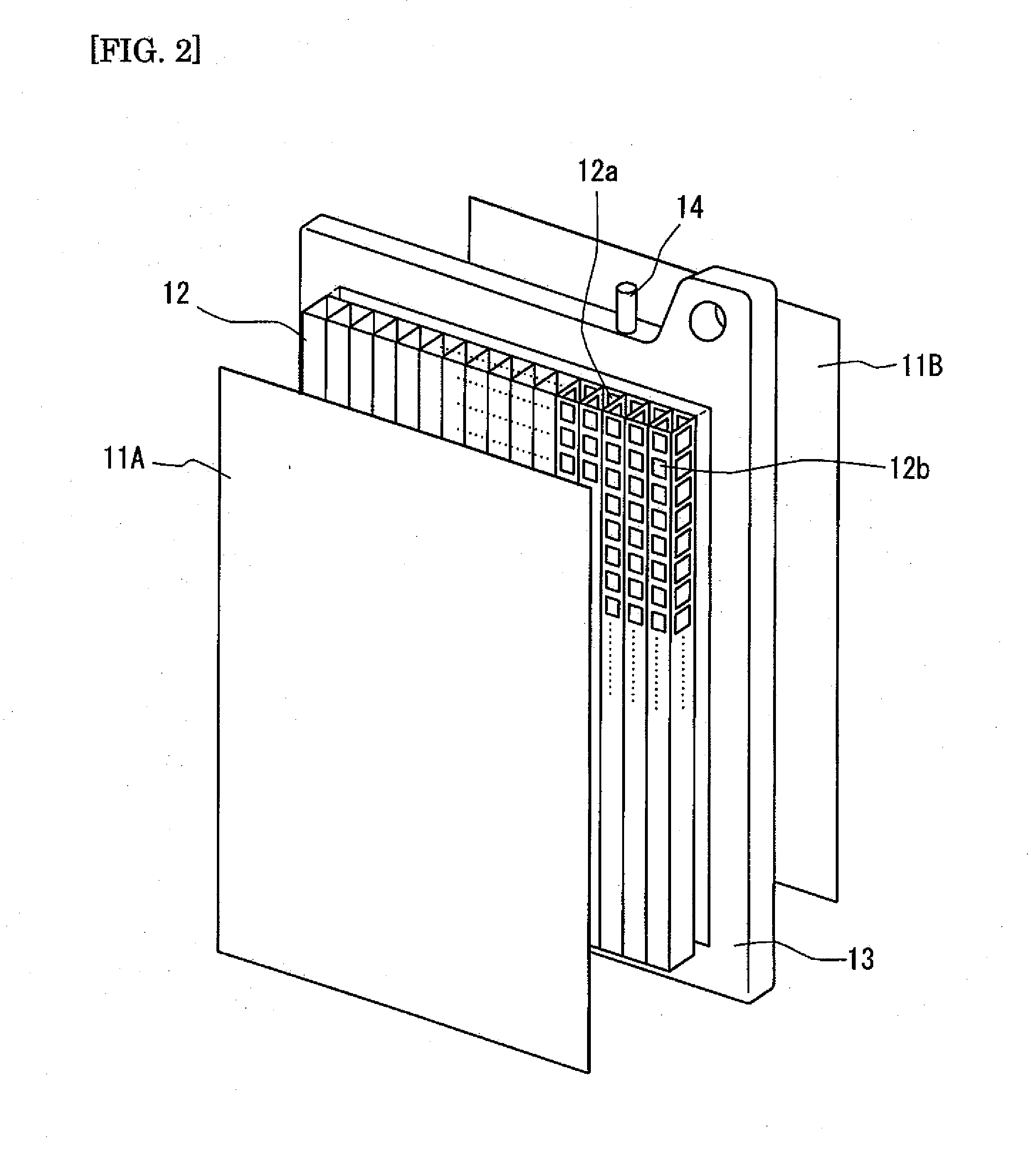

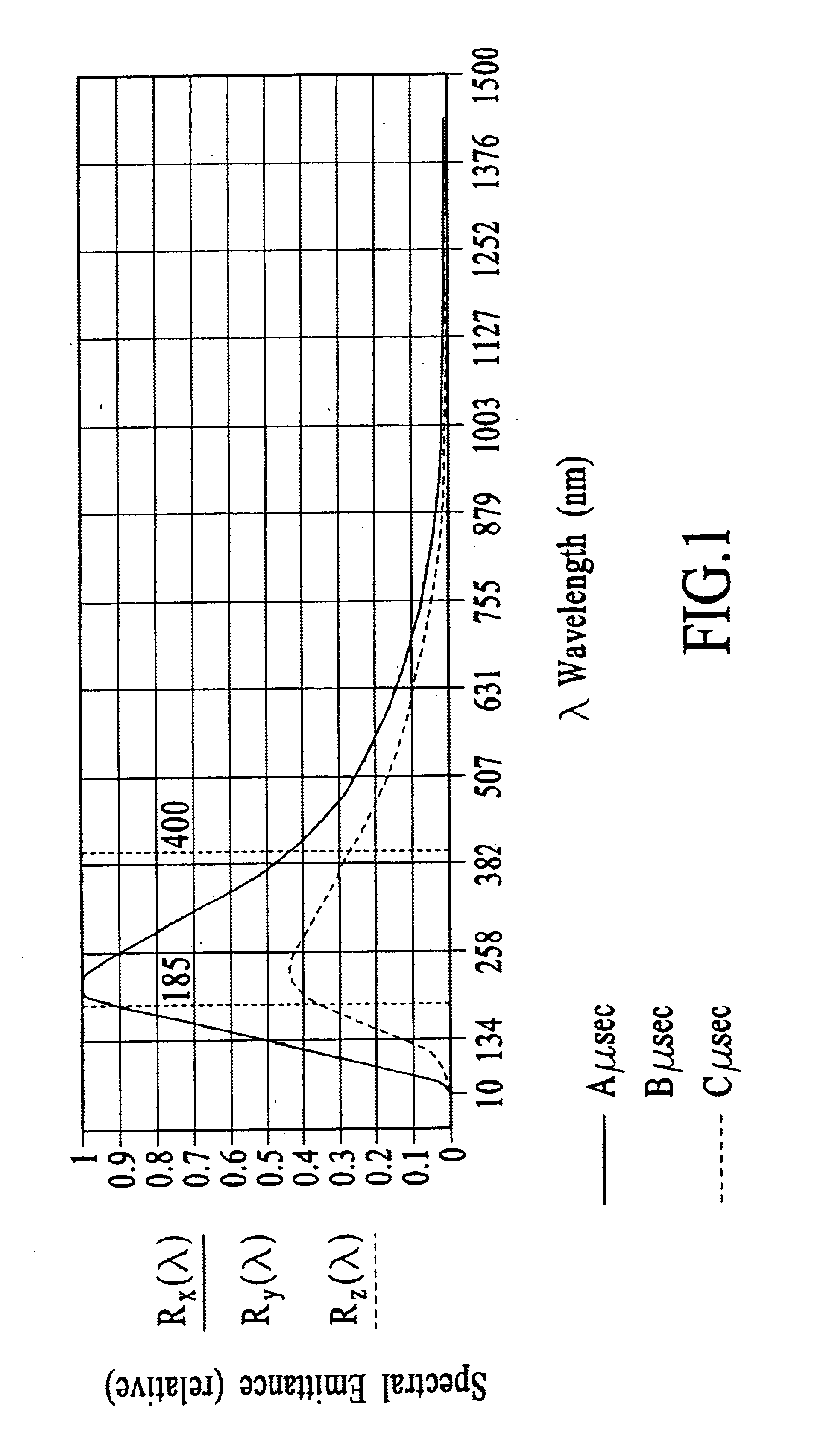

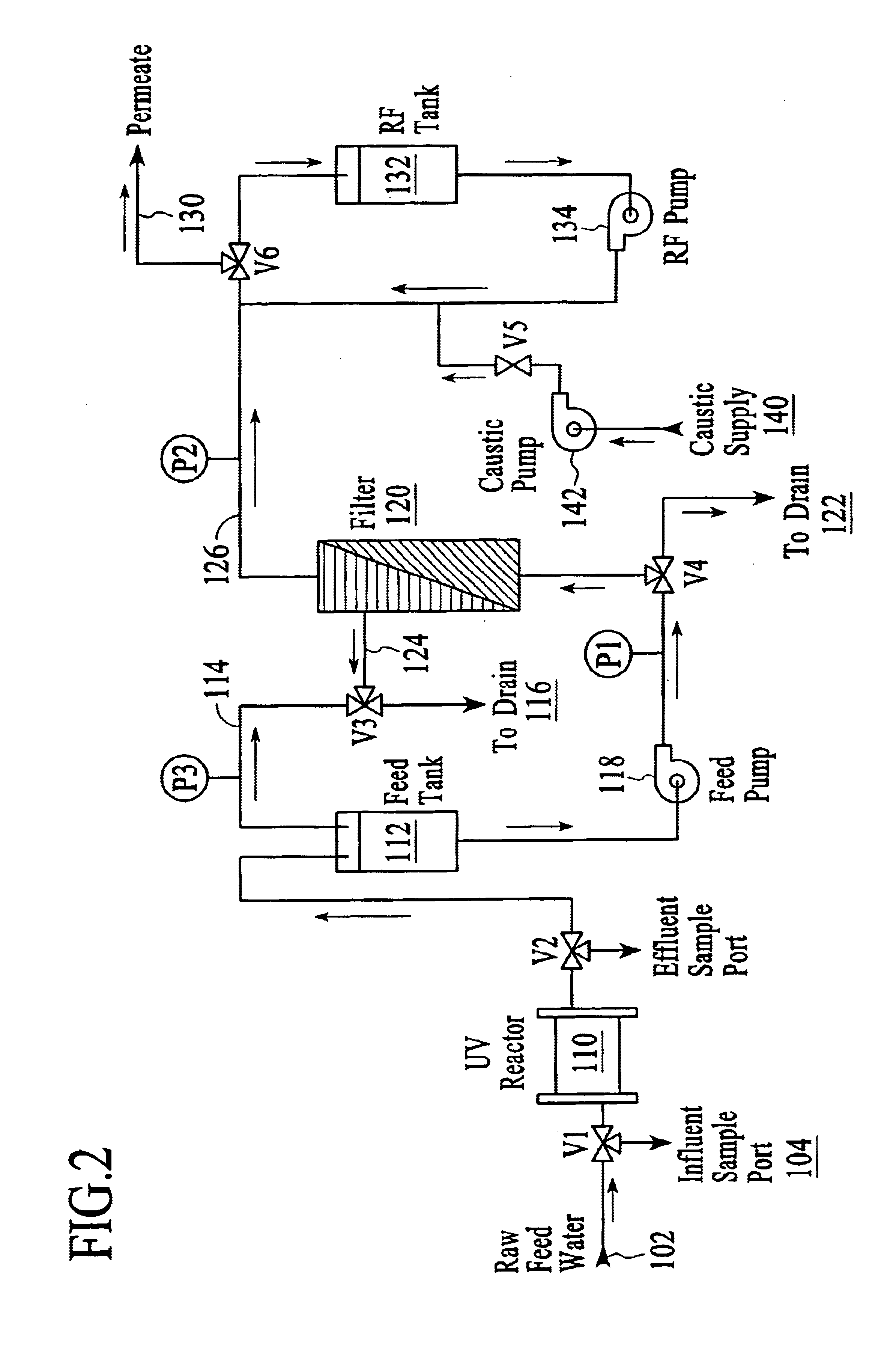

Pulsed blackbody radiation flux enhancement

A system and method for enhancing the flux and separation properties of water filtration membranes by oxidizing raw or processed water constituents with direct photolysis of the water matrix by pulsed blackbody UV, yielding ozone and hydrogen peroxide, hydroxyl radicals and other short lived oxidizing species. The result thereof, causing precipitation of inorganic molecules or organically complexed minerals, partial or complete mineralization of organic molecules and the deactivation or destruction of microbes including: virus, bacteria and protozoa. The system and method comprises a pulsed blackbody, deep-UV reactor having at least one treatment chamber, the reactor having a conveying assembly to convey the water to be treated into the chamber; a filter assembly to screen the UV treated water; a caustic supply means for the post-treatment of water; a recovering assembly recovering the permeate at an outlet of the filtration means. The effect of such UV water treatment is multifaceted. One aspect is the reduction of the transmembrane pressure (TMP), another is the reduction of duration of backwash and caustic cleaning cycles. Also, the oxidation of iron and manganese to insoluble compounds, without the addition of oxidizing agents, does not harm the membranes. Iron and manganese turn into hydroxide crystals trapped by the filtration membrane and separated from the permeate. These effects integrate to enhance the water flux through the filter membrane.

Owner:NEW STAR LASERS

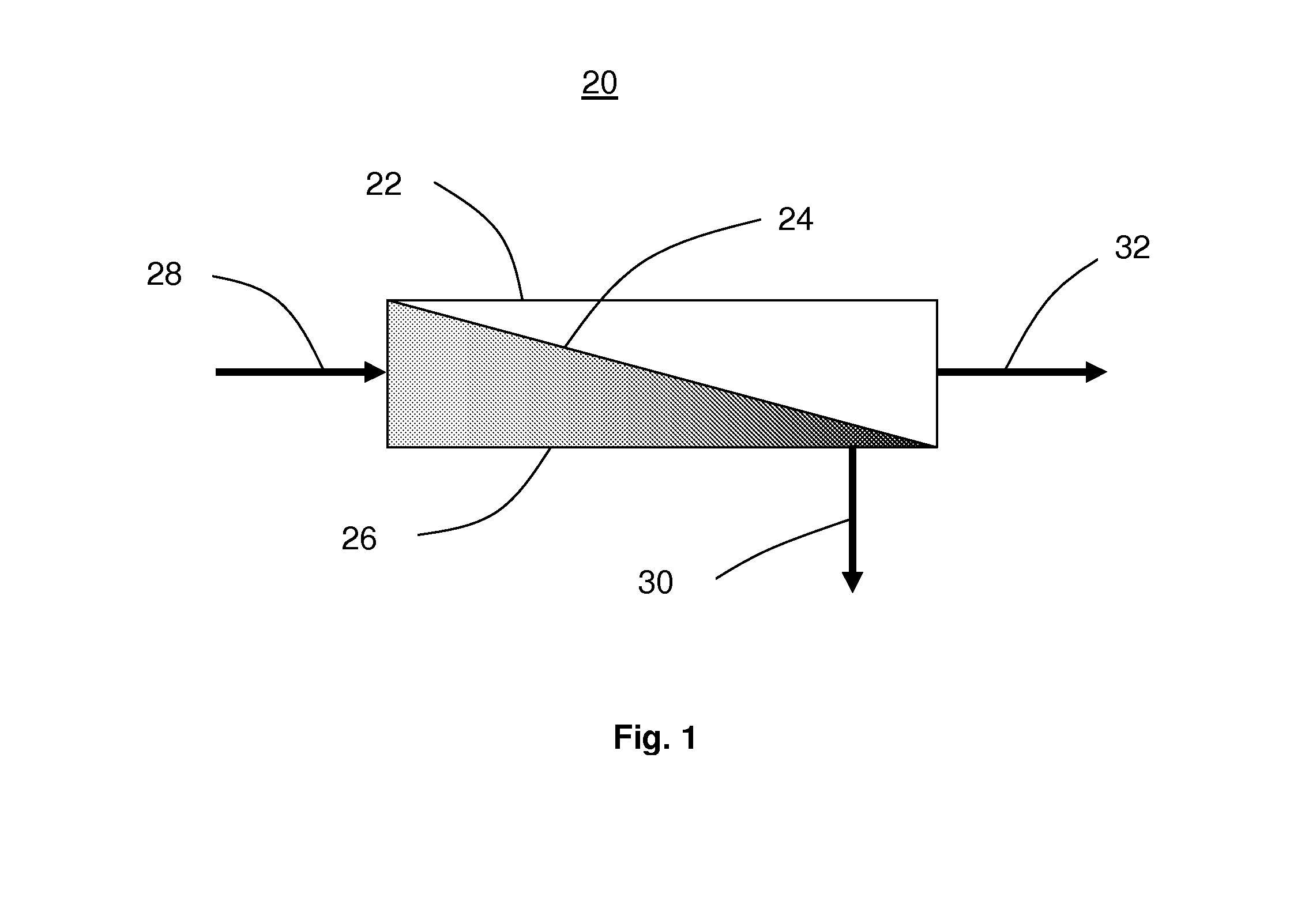

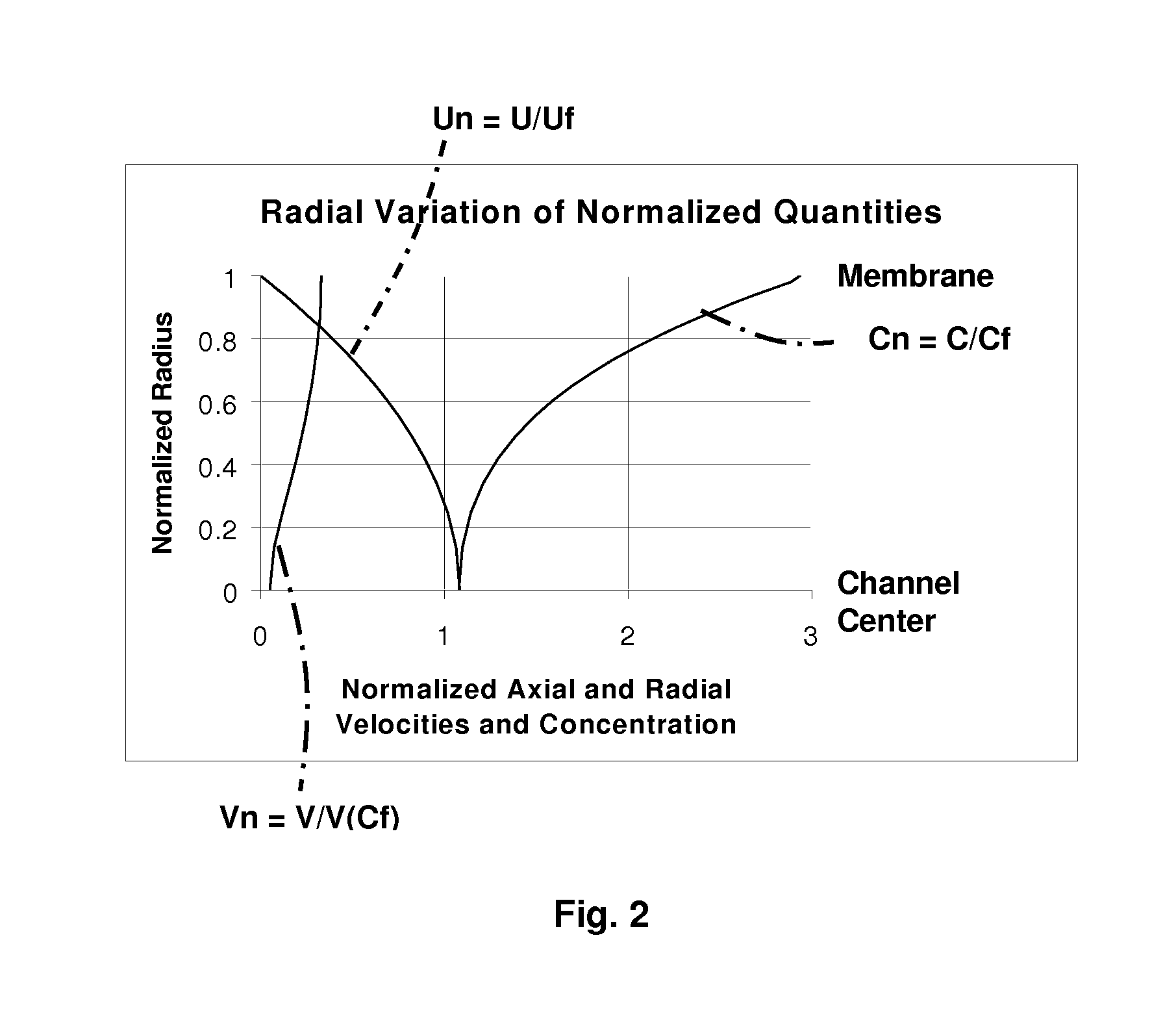

Filtration with internal fouling control

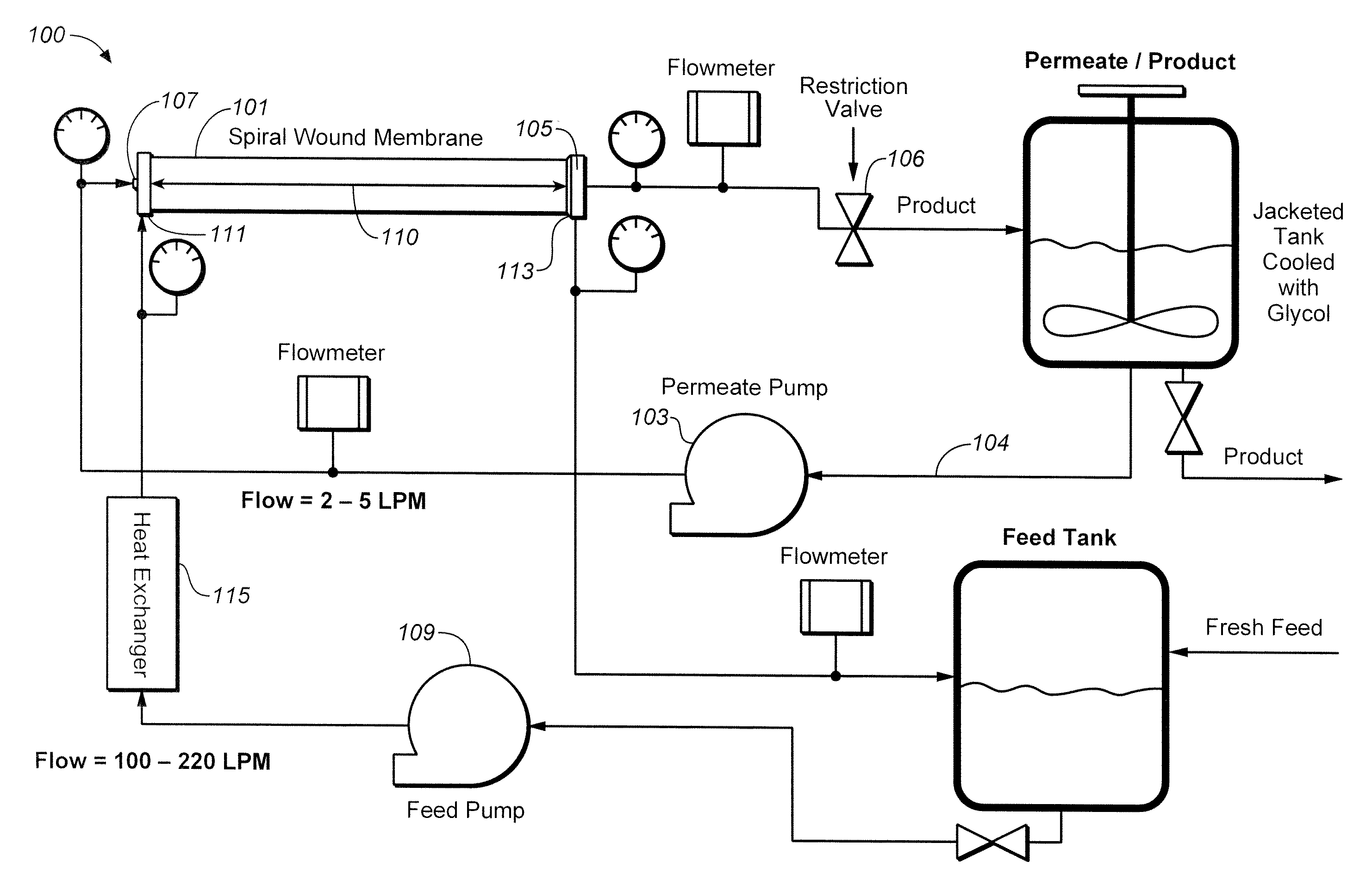

Filtration processes and systems are provided for the separation of a filterable fluid stream by a filtration membrane module with uniform transmembrane pressure and flux along the membrane and internal control of membrane fouling via intermittent periodic reduction of the pressure differential between the permeate and retentate sides of the membrane and / or backwashing cycles during separation, recovery, and / or purification of proteins, peptides, nucleic acids, biologically produced polymers and other compounds or materials from aqueous fluids.

Owner:DANISCO US INC

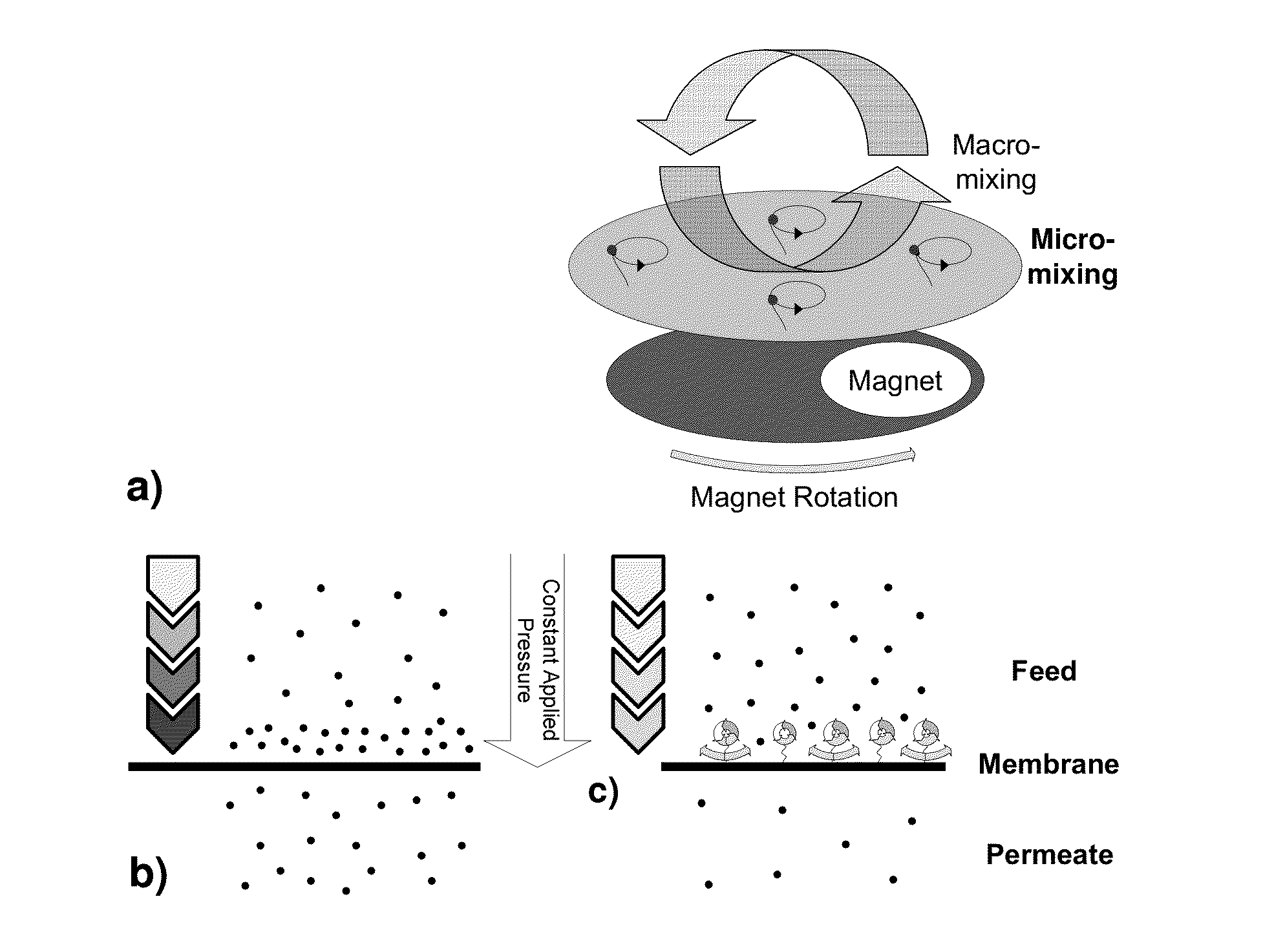

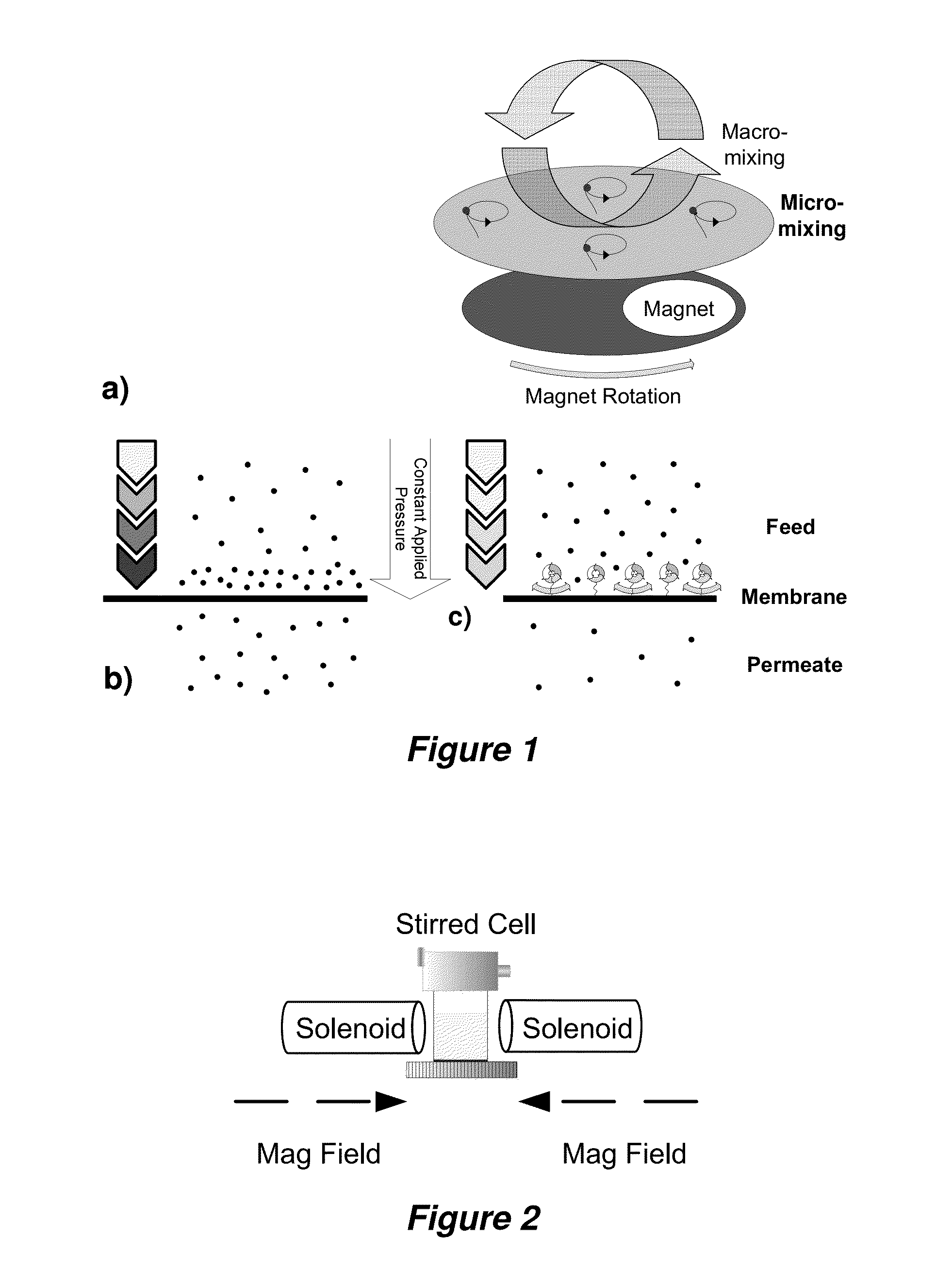

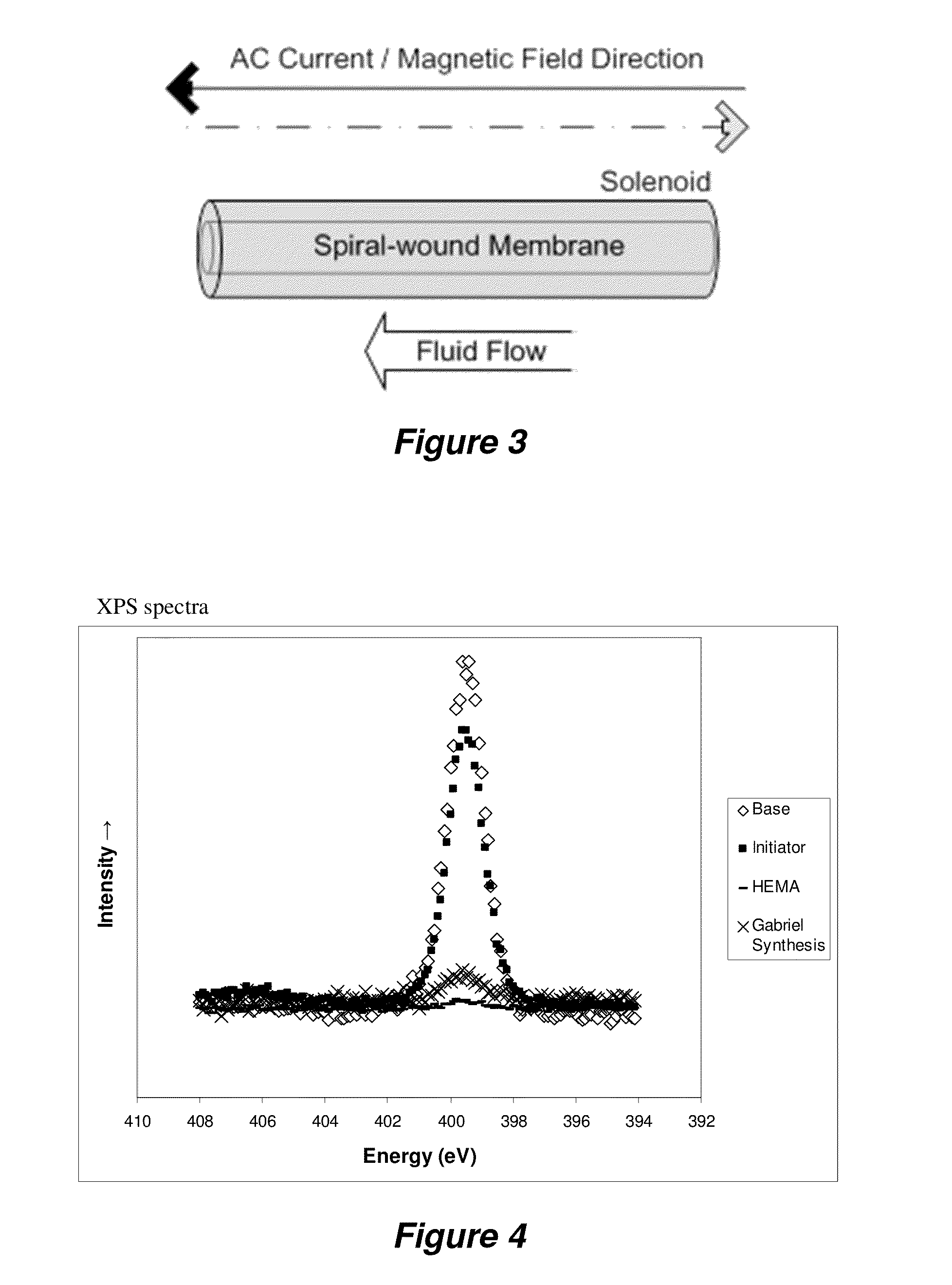

Magnetically responsive membranes

ActiveUS20140231351A1Low purityReduced effectivenessMembranesWater/sewage treatment bu osmosis/dialysisPolymer scienceHydrophilic polymers

The invention provides permeable magnetically responsive filtration membranes that include a filtration membrane polymer base suitable for fluid filtration; hydrophilic polymers conjugated to the surface of the filtration membrane polymer; and magnetic nanoparticles affixed to the ends of a plurality of the hydrophilic polymers, wherein the hydrophilic polymers are movable with respect to the surface of the filtration membrane polymer surface in the presence of an oscillating magnetic field.

Owner:LEHRSTUHL FUR TECHN CHEM II UNIV DUISBURG ESSEN +2

Dynamic self-assembled process for preparing low-pressure high-throughput charged nanofiltration membrane

InactiveCN101274222AImprove efficiencySimple methodSemi-permeable membranesFiltration membraneLow voltage

The invention discloses a method for preparing low-voltage high-flux charged nano-filtration membrane by dynamic self-assembly, which is characterized in that polymer ultra-filtration membrane is taken as a basic film; polycation electrolyte and polyanion electrolyte are alternatively and dynamically self-assembled on the surface of the basic film to gain a selective separation layer and to prepare the nano-filtration membrane of charged surface; wherein, the used ultra-filtration membrane molecular weight cutoff is less than 0.1 million; the ultra-filtration membrane material is surface-charged or modified-charged polymer. Nano-filtration membrane preparation by polyelectrolyte dynamic self-assembly has high efficiency, simple and convenient method and controllable assembly process and film structure; pure water solution is used in the whole preparation process, which is green and environmental protective; the applicable polyelectrolyte has a plurality of types; the separation films with different performances can be obtained by adjusting the types of the polyelectrolyte and the assembly conditions. Furthermore, the prepared nano-filtration membrane has low operation pressure, high removal rate on high valence inorganic salts and far greater flux than the current commercial nano-filtration membrane and the nano-filtration membrane preparation method has good application prospect.

Owner:ZHEJIANG UNIV

Water flux polymer membranes

The invention relates to a polymer membrane composition having improved water flux and stable pore size. The water flux is improved by increasing the hydrophilicity of the membrane using a matrix polymer blended with controlled architecture amphiphilic block copolymers. Preferred membranes are those having a fluoropolymer matrix and acrylic amphiphilic block copolymers. The addition of the amphiphilic block copolymers are especially useful in microfiltration and ultra filtration membranes when used in water filtration.

Owner:ARKEMA INC

Preparation method of positively charged composite nanofiltration membrane

The invention discloses a preparation method of a positively charged composite nanofiltration membrane, belonging to the technical field of the membrane. The key technology comprises the processes of utilizing polyethyleneimine (PEI), chitosan quaternary ammonium salt, and nano TiO2 as water-phase film-forming materials; taking trimesoyl chloride (TMC) as an organic-phase film-forming material; taking ultrafiltration membranes such as polysulfone, polyether sulfone and sulfonated polyethersulfone as supported base membranes, and preparing the PEI / chitosan quaternary ammonium salt / TiO2 / TMC composite nano-filtration membranes by an interfacial polymerization method. The membrane has the advantages of high flux, high dye intercept rate, and low intercept rate of inorganic salt such as sodium sulfate and sodium chloride, can generate negative intercept phenomenon of salt when dye / salt system is separated, is high in dye and inorganic salt separating efficiency, and is suitable for desalination and purification of coarse liquid dye, especially the preparation of high-purity liquid dye for digital ink-jet printing.

Owner:ZHENGZHOU UNIV

Spiral wound filtration membrane cartridge with chevron seal

InactiveUS7208088B2Reduced tightnessEasy to replaceUltrafiltrationReverse osmosisFiltration membraneSpiral wound

A spiral wound filtration cartridge construction is provided which includes a cartridge positioned within a solid outer cylinder which, in turn is positioned within a solid outer cylinder which, in turn is positioned within a solid housing. Fluid flows within the space between the outer cylinder and housing is controlled by a ring and flexible chevron construction. The chevron construction includes outer peripheral holes, the sizes and number of which are set to determine by-pass flow.

Owner:MILLIPORE CORP

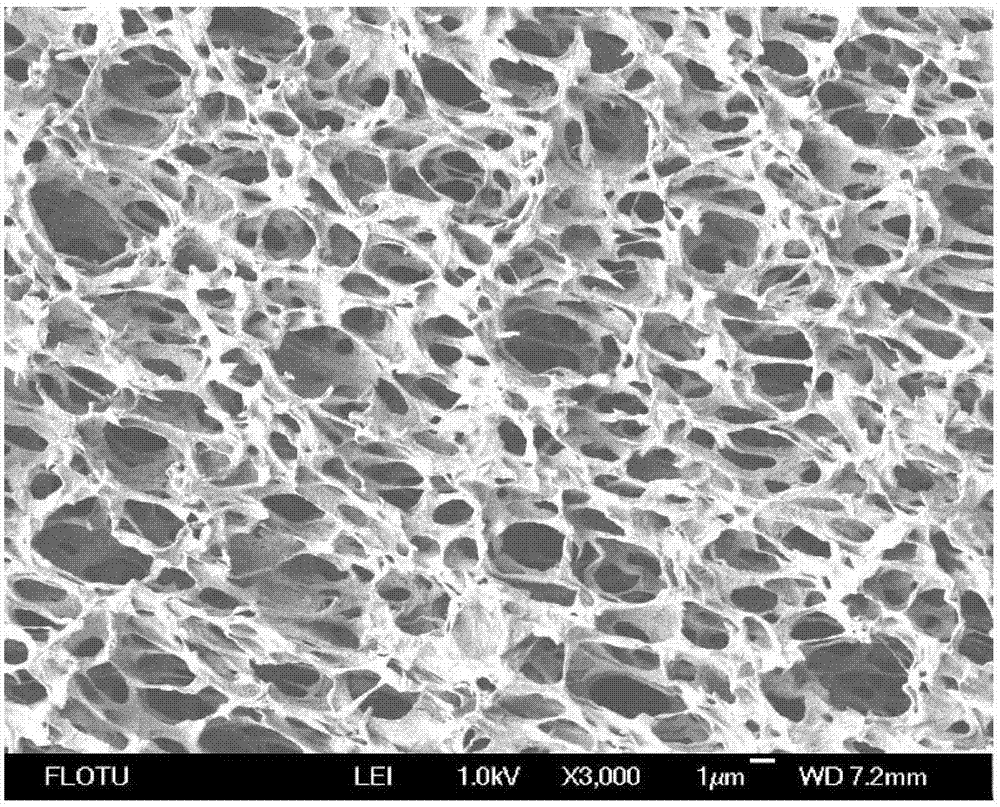

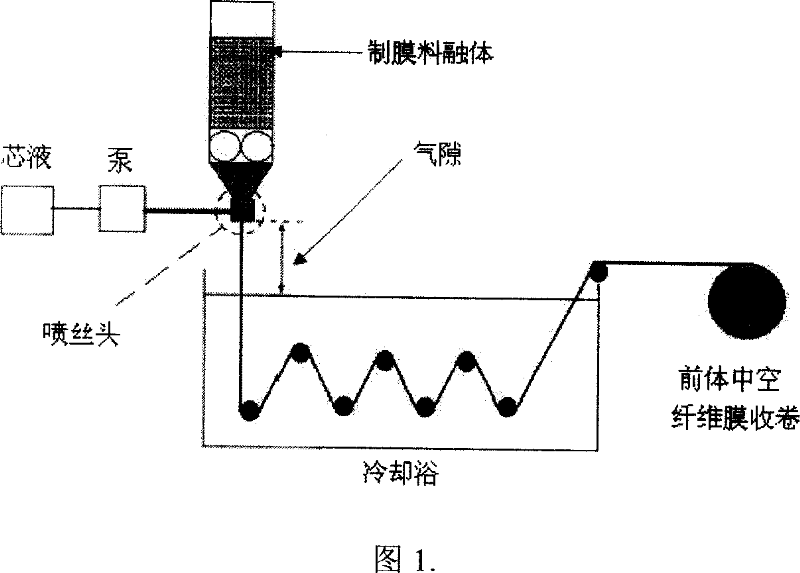

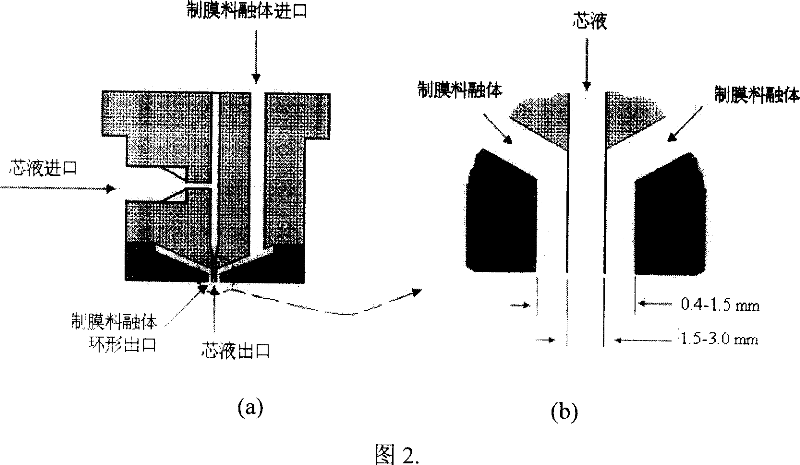

Method for preparing polyvinylidene fluoride ultra-filtration membranes

The invention discloses a method for preparing polyvinylidene fluoride ultra-filtration membranes. The method includes the steps of mixing the polyvinylidene fluoride with diluents, and heating the mixture to form a homogeneous phase solution, wherein the diluents are a mixture of a solvent and a non-solvent of the polyvinylidene fluoride, and at least one of the solvent and the non-solvent of the polyvinylidene fluoride can be dissolved in water; subjecting the homogeneous phase solution to knife coating on a supporting screen to form a plate-shaped membrane casting solution or to be spinned into a membrane casting solution in a hollow fiber shape by a spinneret, submerging the membrane casting solution into a cooling liquid to be cooled, subjecting the membrane casting solution to phase separation and solidifying into membranes; extracting the diluents in the membranes through an extracting agent to obtain the polyvinylidene fluoride membranes. Sections of the polyvinylidene fluoride membranes are in a homogeneous spongeous structure with bore diameters in a range of 0.02 to 4 microns, and the membranes have surface layers with surface bore diameters ranging from 2 nanometers to 100 nanometers. Simultaneously, the polyvinylidene fluoride ultra-filtration membranes have the advantages of high strength, porosity, flux and separation accuracy.

Owner:TSINGHUA UNIV

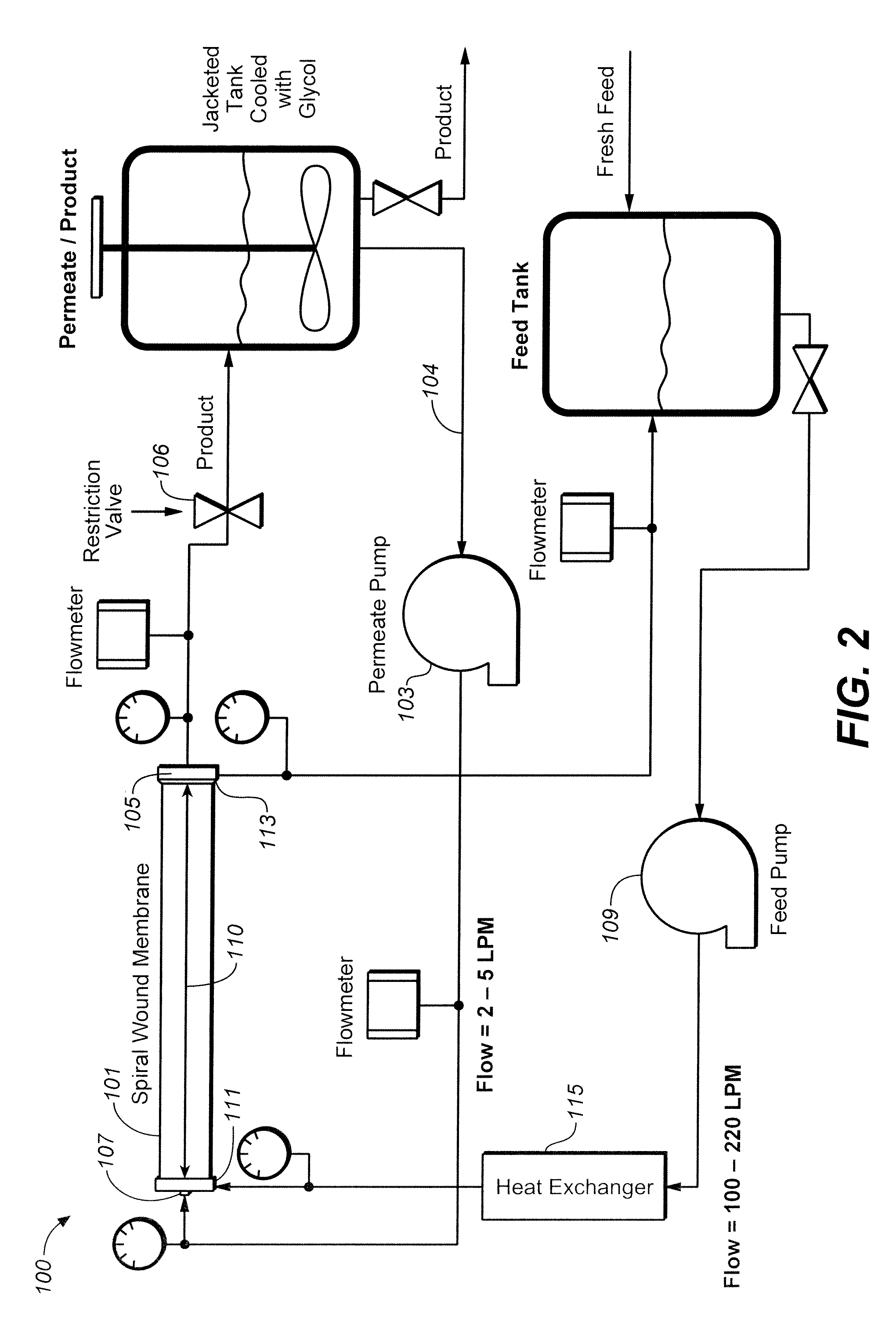

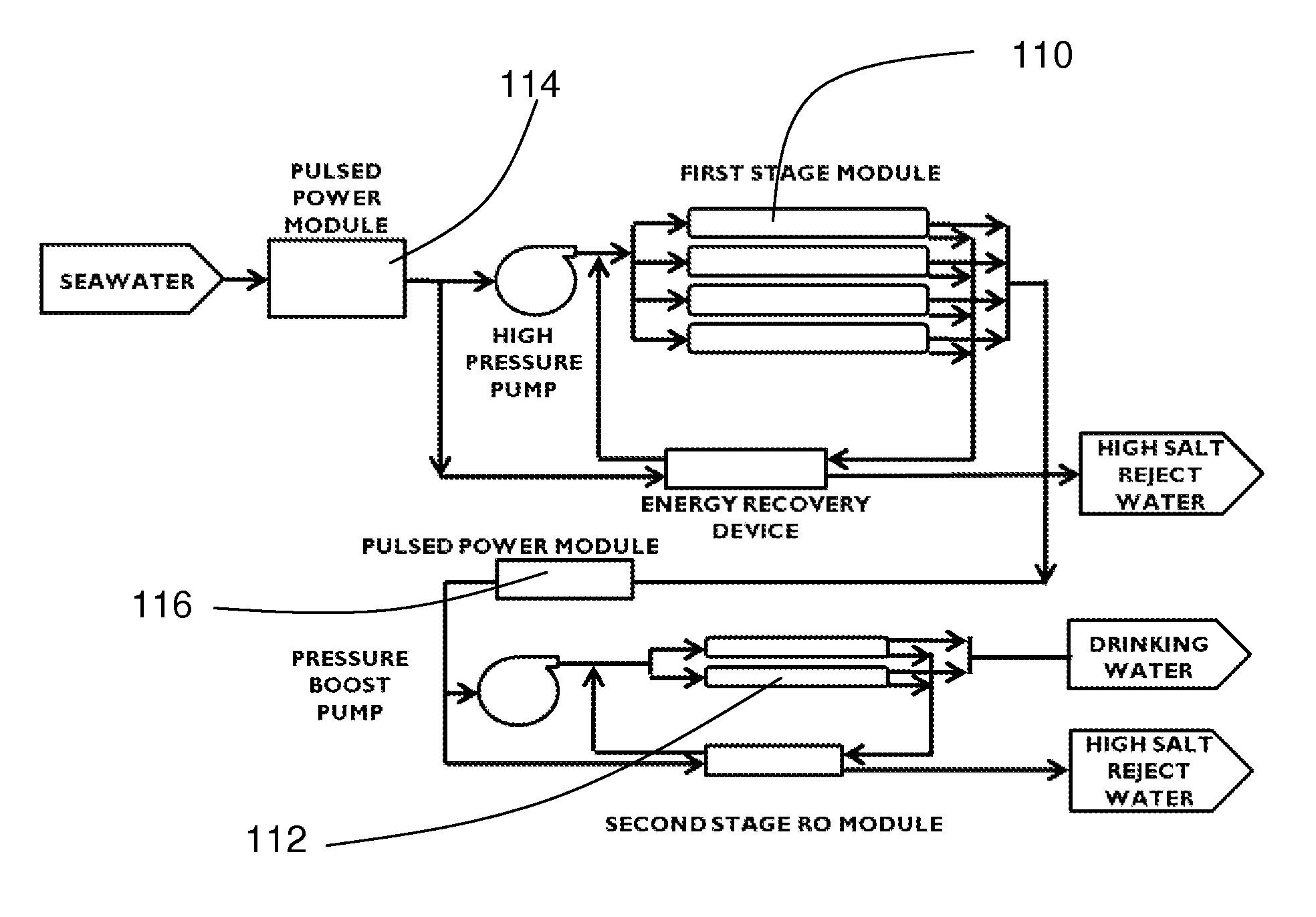

Systems and methods for filtration

InactiveUS20120298578A1Reduce foulingImprove water qualityMaterial nanotechnologyGeneral water supply conservationMicroorganismFiltration membrane

Filtration systems (40) utilize a pre-treatment method to cause scale formation to occur on particles (94) in the fluid stream (96) rather than on the filter surface and may also destroy microorganisms in the fluid stream. More specifically, but not limited to, a filtration device can be a filtration membrane, such as spiral wound filtration membrane (60), that utilizes an open feed spacer (80), such for example an embossed or printed pattern on the membrane, to create a thin feed spacer channel which replaces a conventional feed spacer mesh material. System (40) further utilizes a treatment device (54) to enable a pulsed power, magnetic, electro-magnetic, electro-static, or hydrodynamic fluid treatment scheme to condition particles in the fluid stream (96) such that scale forming elements precipitate (94) on to the particles in the fluid stream rather than on the filtration surfaces.

Owner:AQUA MEMBRANES +1

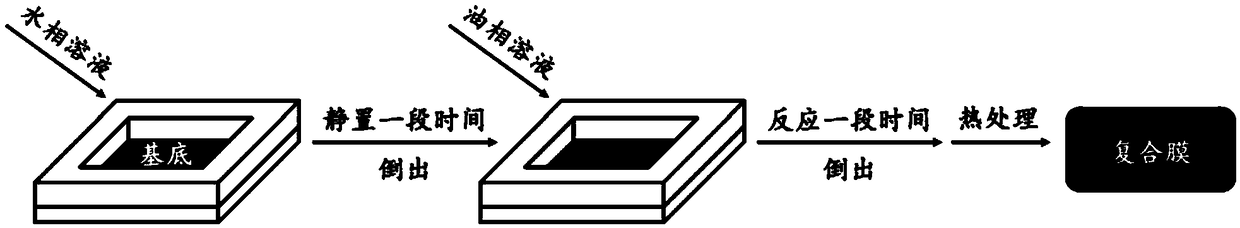

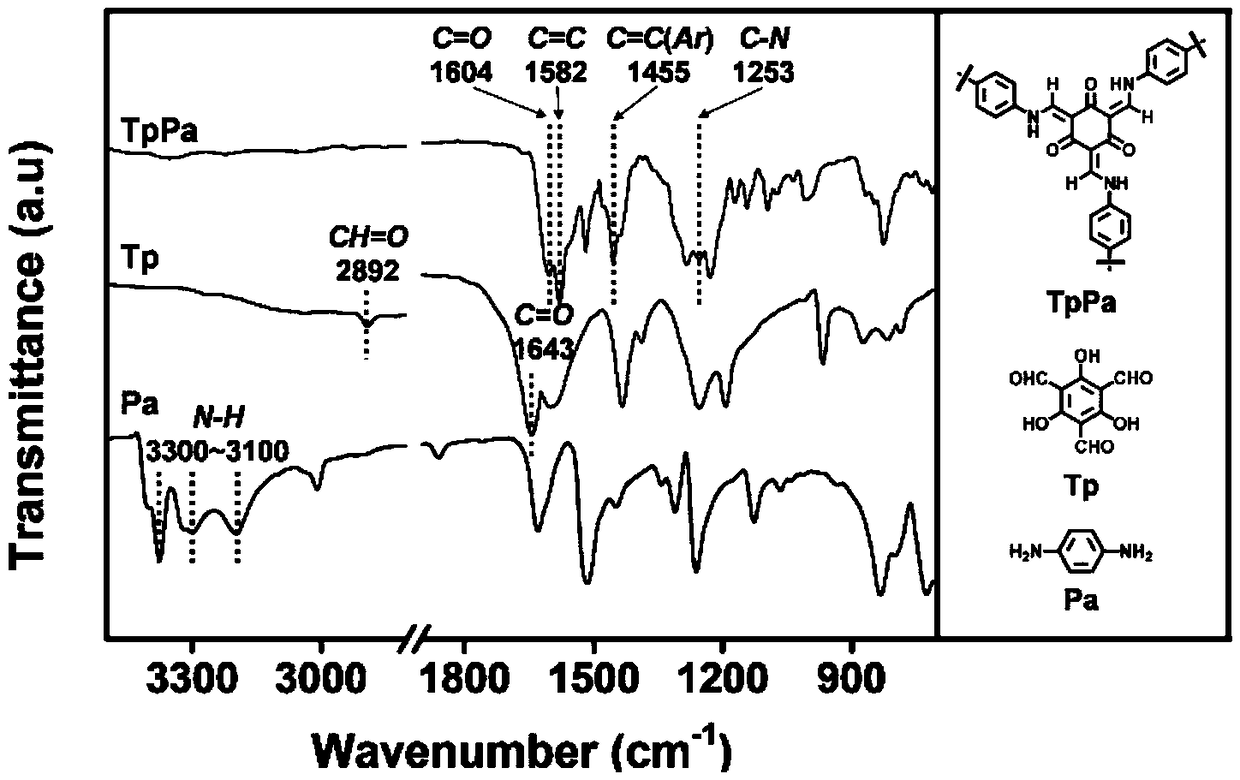

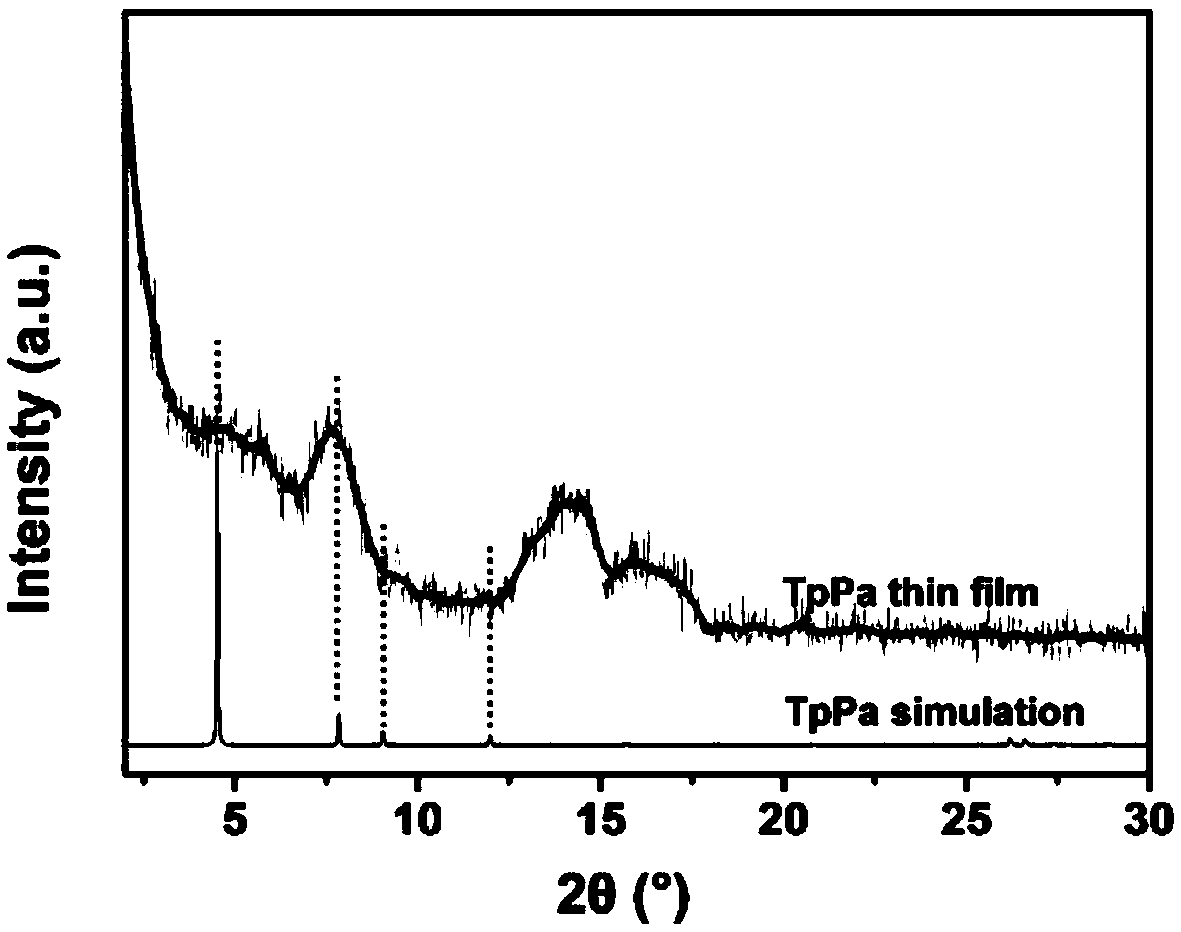

Method for preparing high-throughput covalent organic framework nano-filtration membrane on basis of interfacial polymerization

ActiveCN108889139AGood chemical stabilityHigh permeation fluxSemi-permeable membranesFiltration membraneBinding force

The invention provides a method for effectively preparing a high-throughput covalent organic framework (COFs) nano-filtration membrane on the basis of interfacial polymerization. The method comprisesthe following steps: sequentially applying an aqueous phase solution dissolved with polyamine monomers and an organic phase solution dissolved with polyaldehyde / polyketones monomers to the surface ofa porous carrier to carry out interfacial polymerization; diffusing the polyamine monomers in the aqueous phase solution saturated porous carrier to a water / oil interface to carry out schiff base reaction with polyaldehyde / polyketones in an organic phase, and gradually forming a covalent organic framework separating layer on the surface of the porous carrier by a conformal growth manner; and thencarrying out heat treatment on a composite membrane consisting of the separating layer and the porous carrier to enhance the binding force of the covalent organic framework separating layer and the porous carrier, and promoting crystallization and conversion of the covalent organic framework. The method not only is simple and convenient to operate and short in technological process, but also is well compatible with an existing process, thus, continuous product becomes possible, and the prepared composite membrane has high flux.

Owner:NANJING UNIV OF TECH

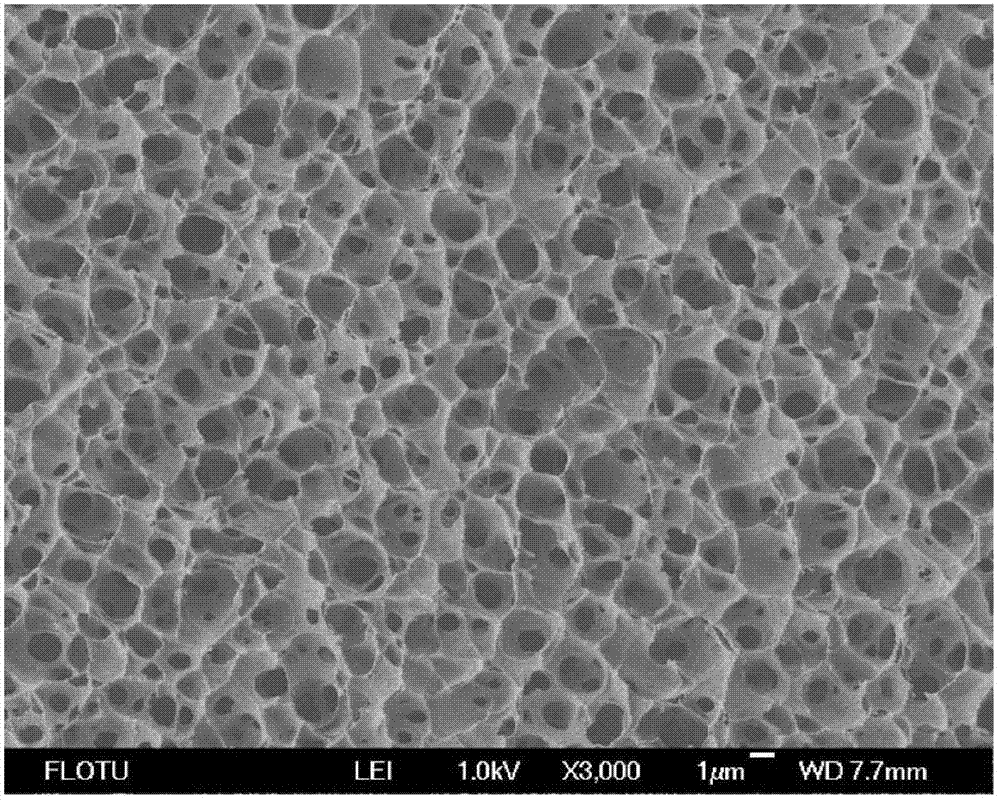

Hydrophilicity polyethylene hollow fiber micro-hole film and the preparation method

InactiveCN101036861AExtended cleaning cycleHydrophilic realizationSemi-permeable membranesFiberMolten state

The invention discloses hydrophilic polyethylene hollow fiber microporous membrane and preparation process thereof. Said membrane is characterized in that it mainly comprises polyethylene, amphoteric copolymer containing polyethylene oxide, and inorganic nano particles. The membrane preparing process is carried out based on thermally induced phpase separation and surface segregation principles, comprising the steps of (1) preparing membrane blank by fusion and blending of amphoteric copolymer containing polyethylene oxide, diluent, and inorganic nano particles; (2) preparing hollow fiber membrane precursor by hollow process spinning of membrane blank in molten state; (3) extracting diluent in hollow fiber membrane precursor by using organic solvent to obtain said hydrophilic polyethylene hollow fiber microporous membrane, wherein the porosity of said membrane is between 40% and 80%, and average pore diameter is between 0.1mum and 5.0mum. The microporous membrane in the invention has the characteristics of high hydrophilicity, narrow pore size distribution, high strength, and good chemical stability, and serves as micro-filtration and ultra-filtration membrane material with high performance, low cost, pollution resistance, and long serve life for water treatment.

Owner:ZHEJIANG UNIV

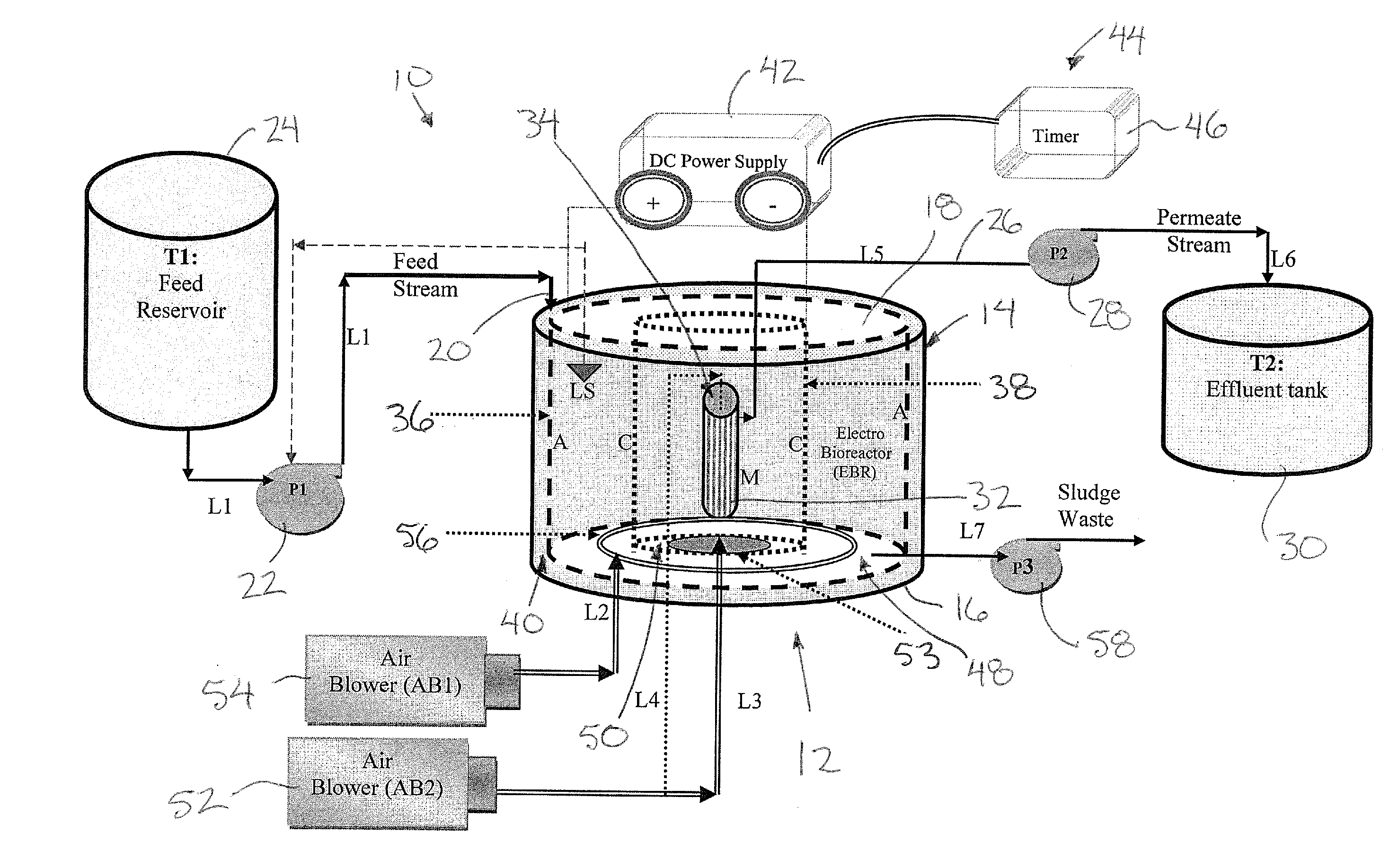

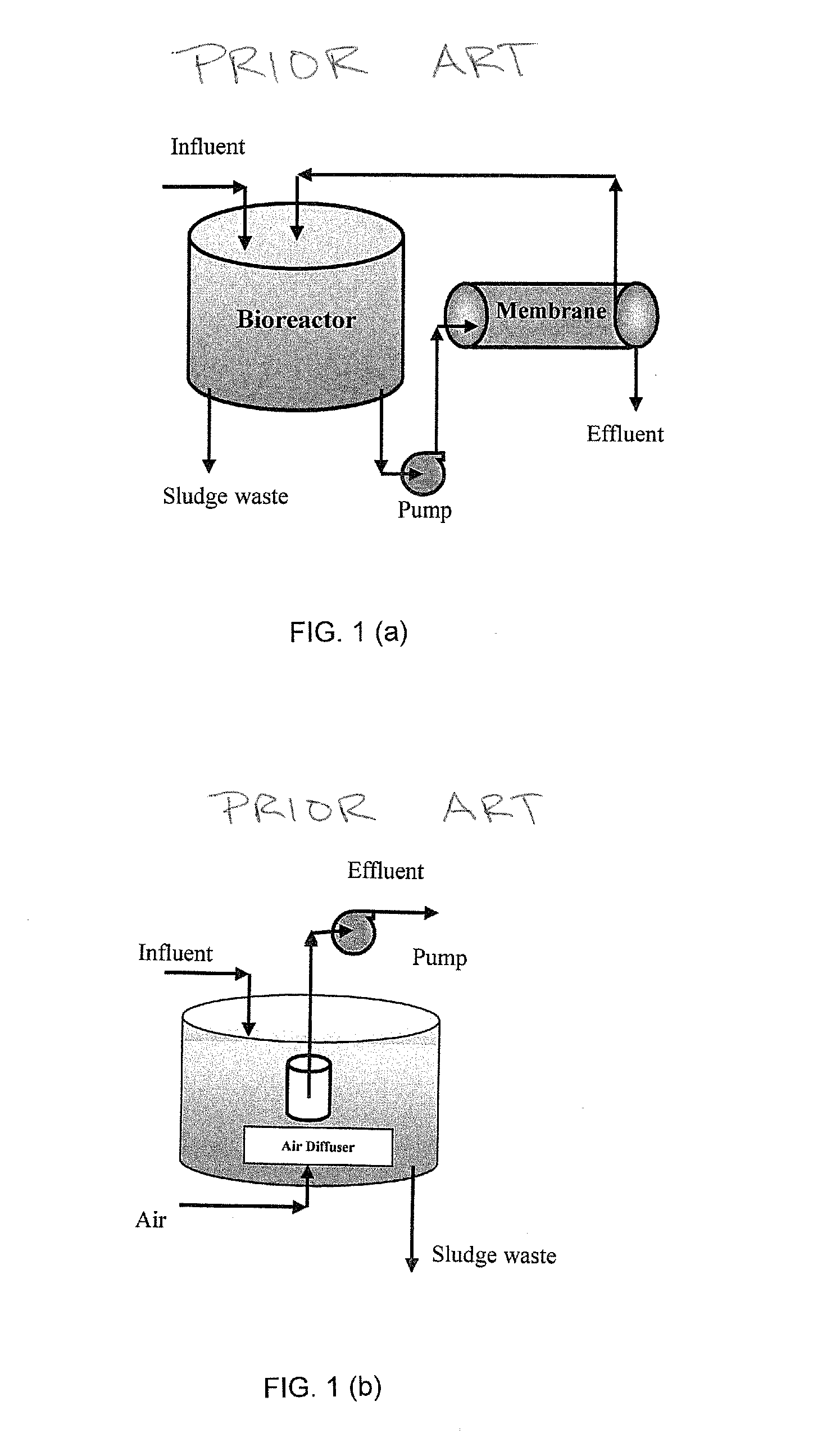

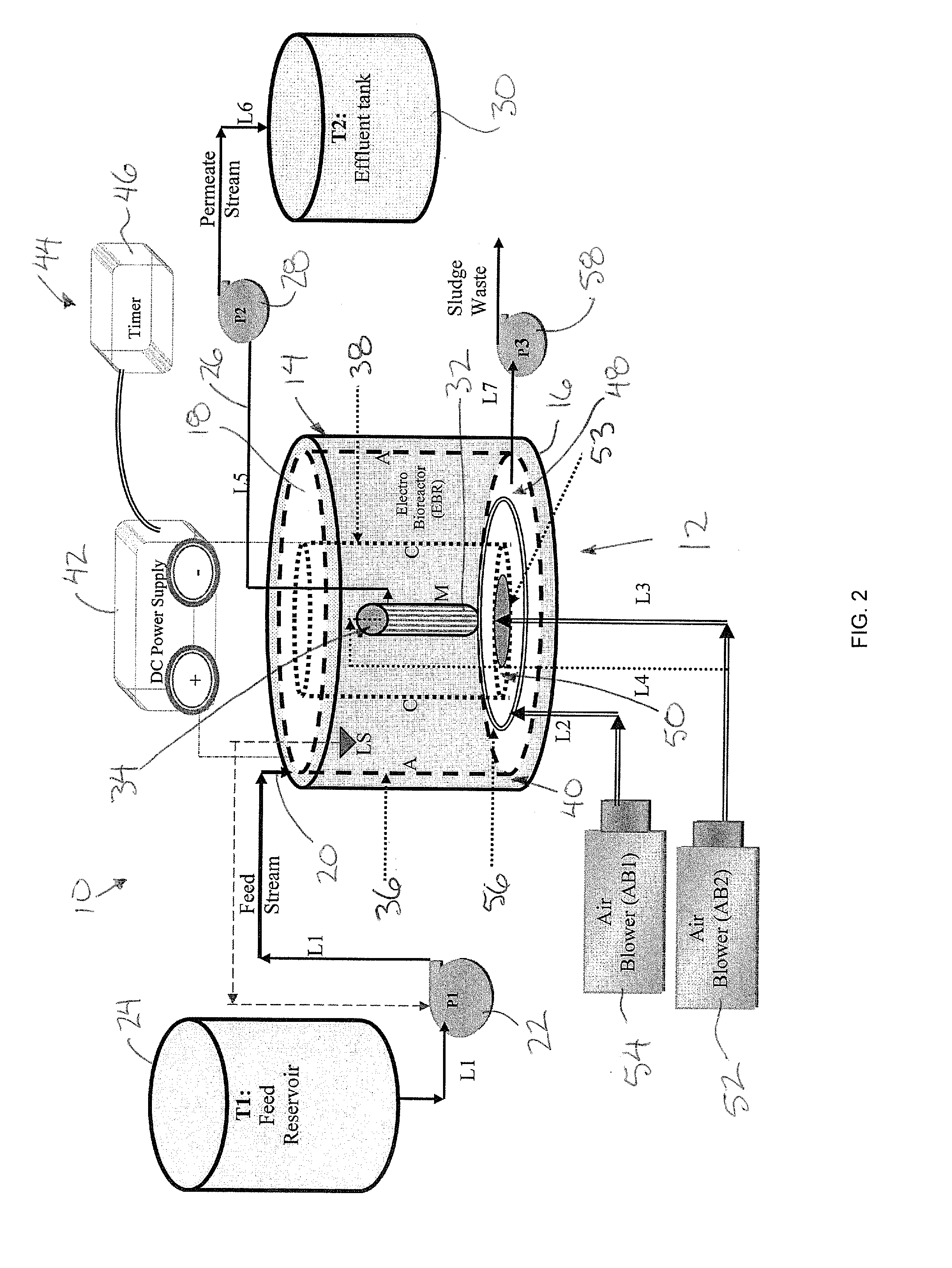

Wastewater Treatment System and Method

ActiveUS20100051542A1Reduce operating costsQuality improvementTreatment using aerobic processesTreatment by combined electrochemical biological processesFiltration membraneMedicine

A wastewater treatment system and method comprises a treatment chamber having a filtration membrane spanning an effluent outlet of the chamber and a pair of electrodes in the treatment chamber so as to be in communication with the wastewater. An electrical potential difference is applied between the electrodes such that one of the electrodes functions as an anode and one of the electrodes functions as a cathode. A flow of fluid is induced out of the treatment chamber through the filtration membrane to the effluent outlet. Accordingly the treatment chamber is arranged to biologically treat the wastewater, electrochemically treat the wastewater and mechanically filter the wastewater through the filtration membrane commonly therein.

Owner:ELEKTOROWICZ MARIA +2

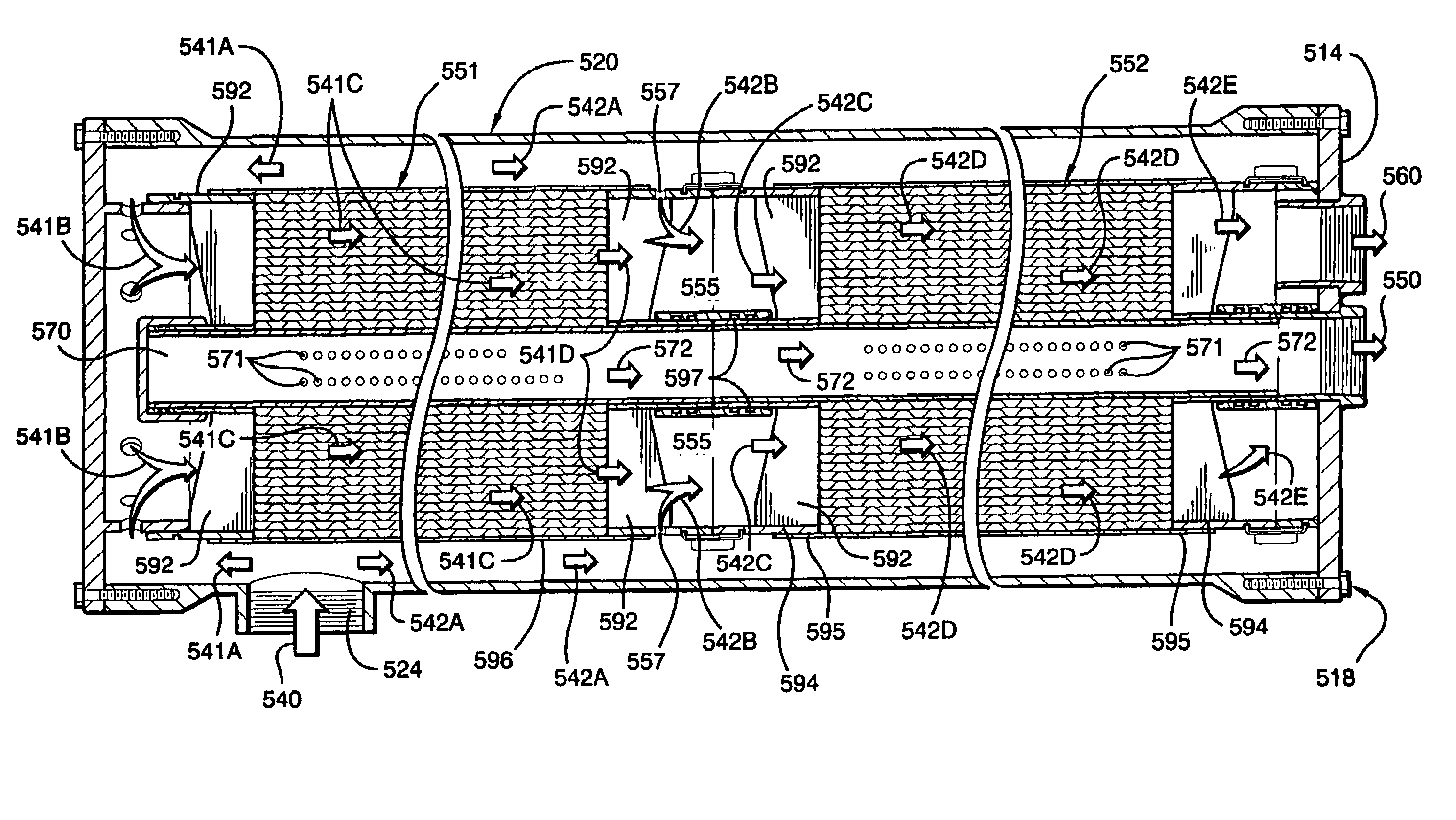

Filtration using pressure vessel with multiple filtration channels

InactiveUS6942797B1Reduce the ratioMembranesWater/sewage treatment bu osmosis/dialysisFiltration membraneCoupling

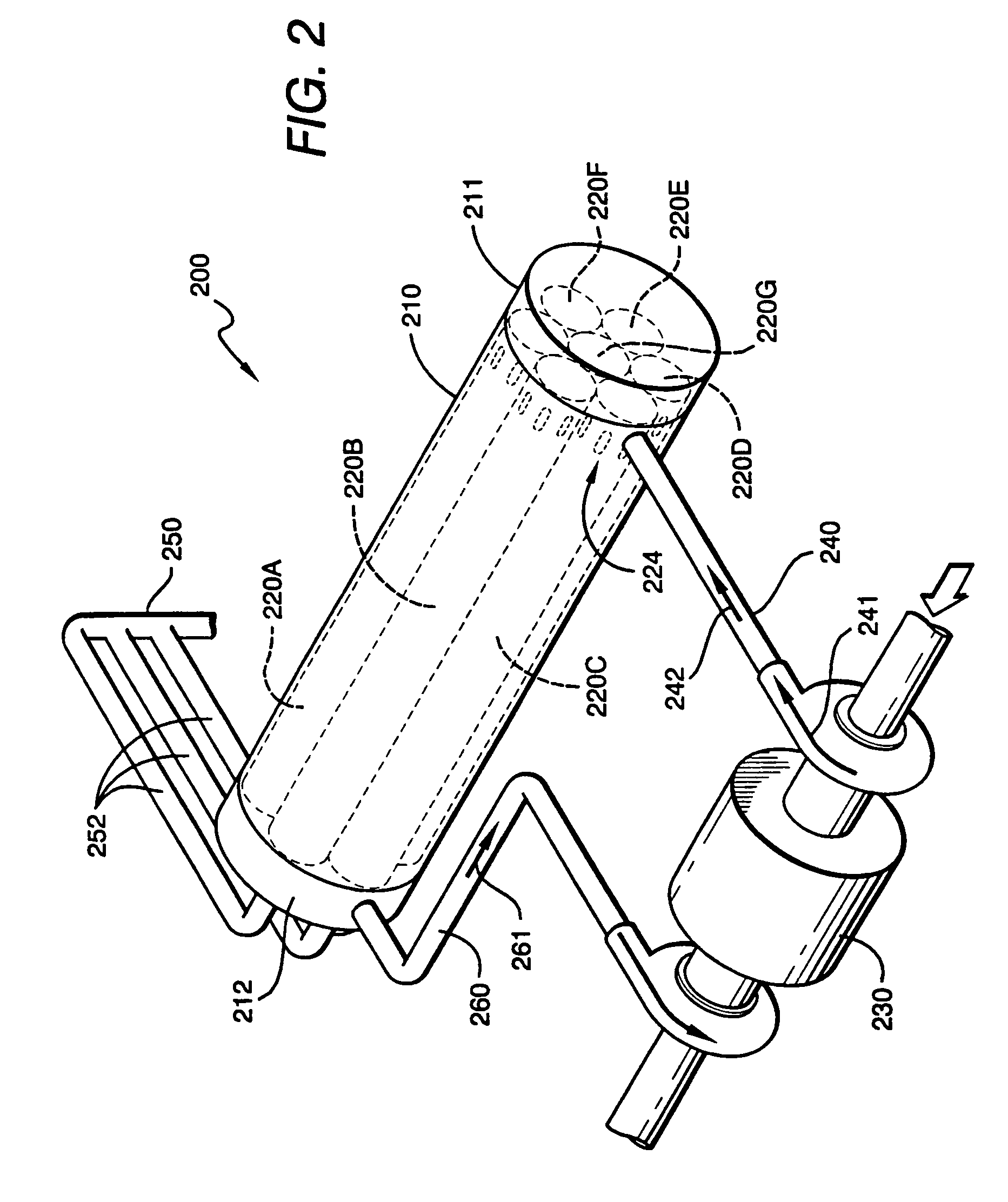

A filtration system includes an outer casing (210) that houses a plurality of elongated inner casings (220A–220F), which in turn house a plurality of filtration membranes. The outer casing, inner casing, and filtration membranes are disposed relative to one another to provide a three-flow channel system that provides additional feed fluid at one or more membrane couplings between membranes of the same inner casing. Ths arrangement defines a feed fluid flow path in which a feed fluid exiting from an upstream filter into a downstream filter is diluted by additional feed fluid.

Owner:DESALNATE INC

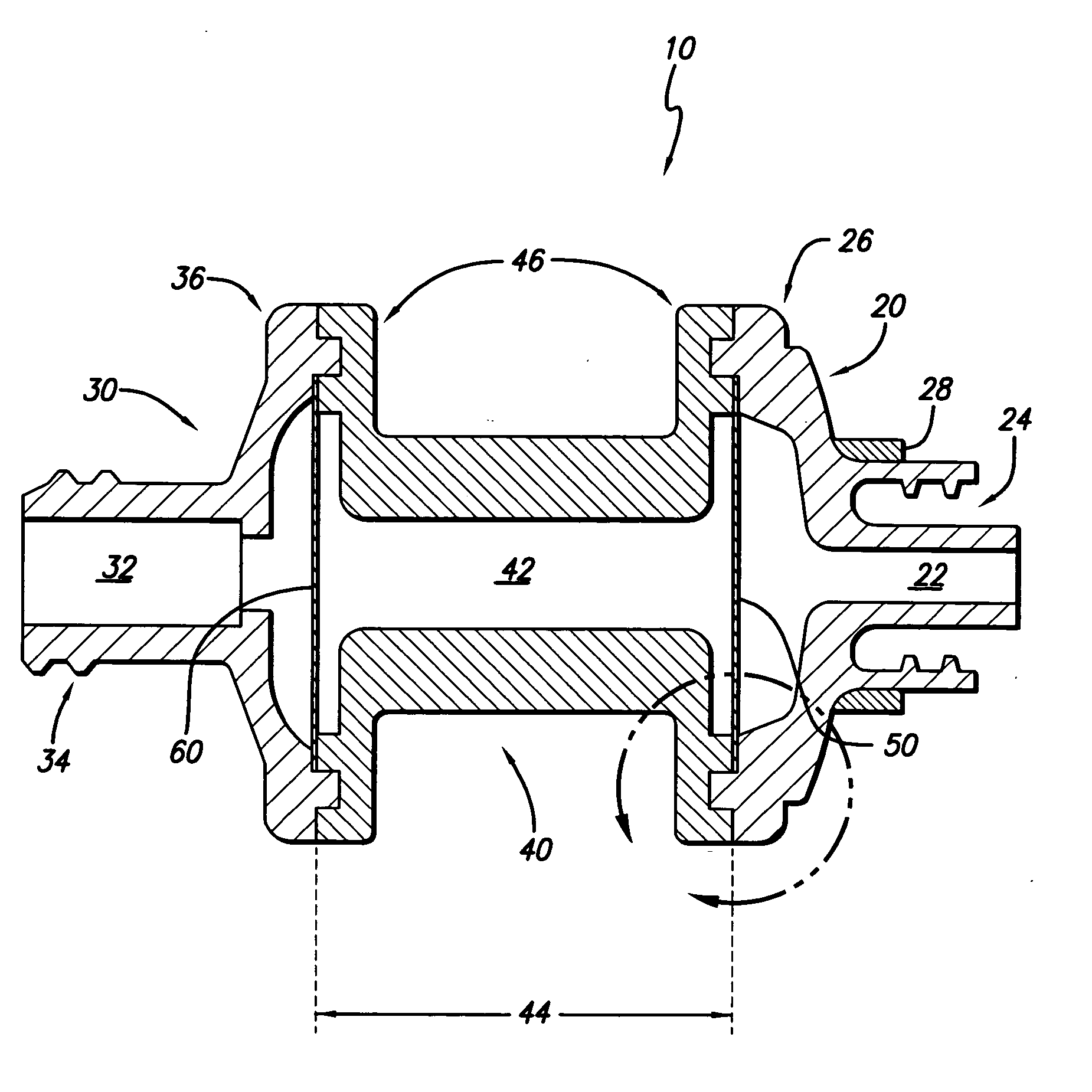

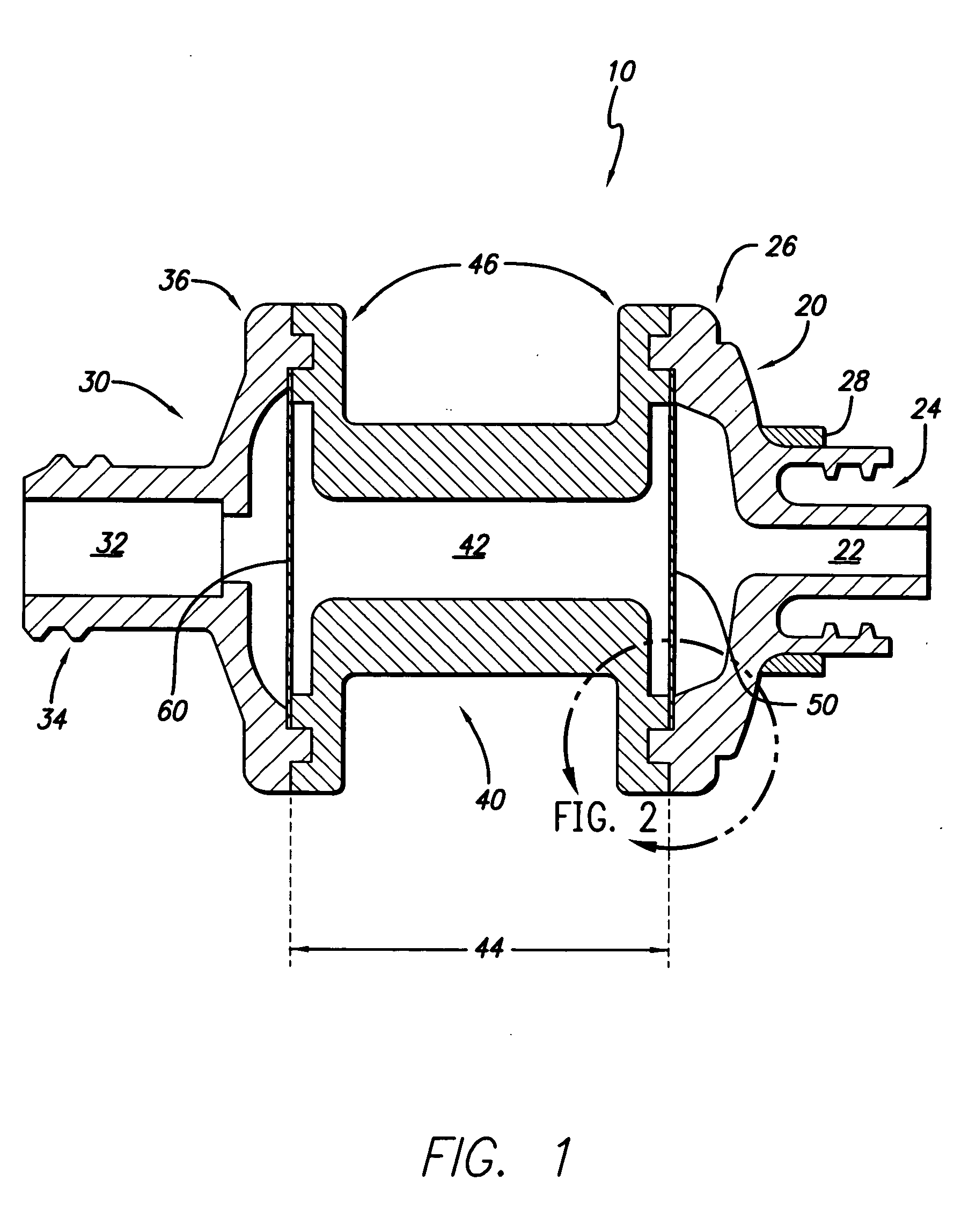

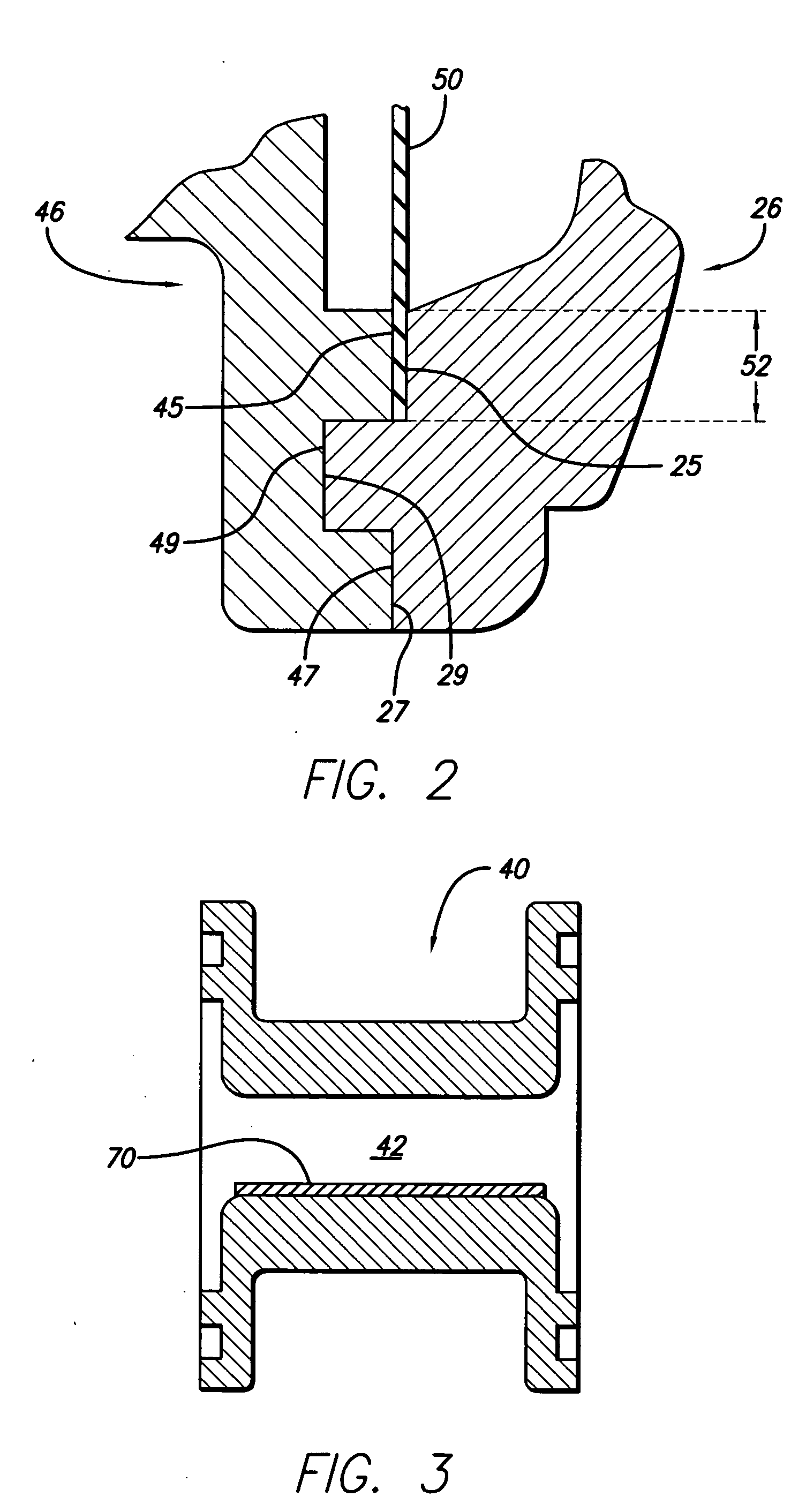

Double membrane transducer protector

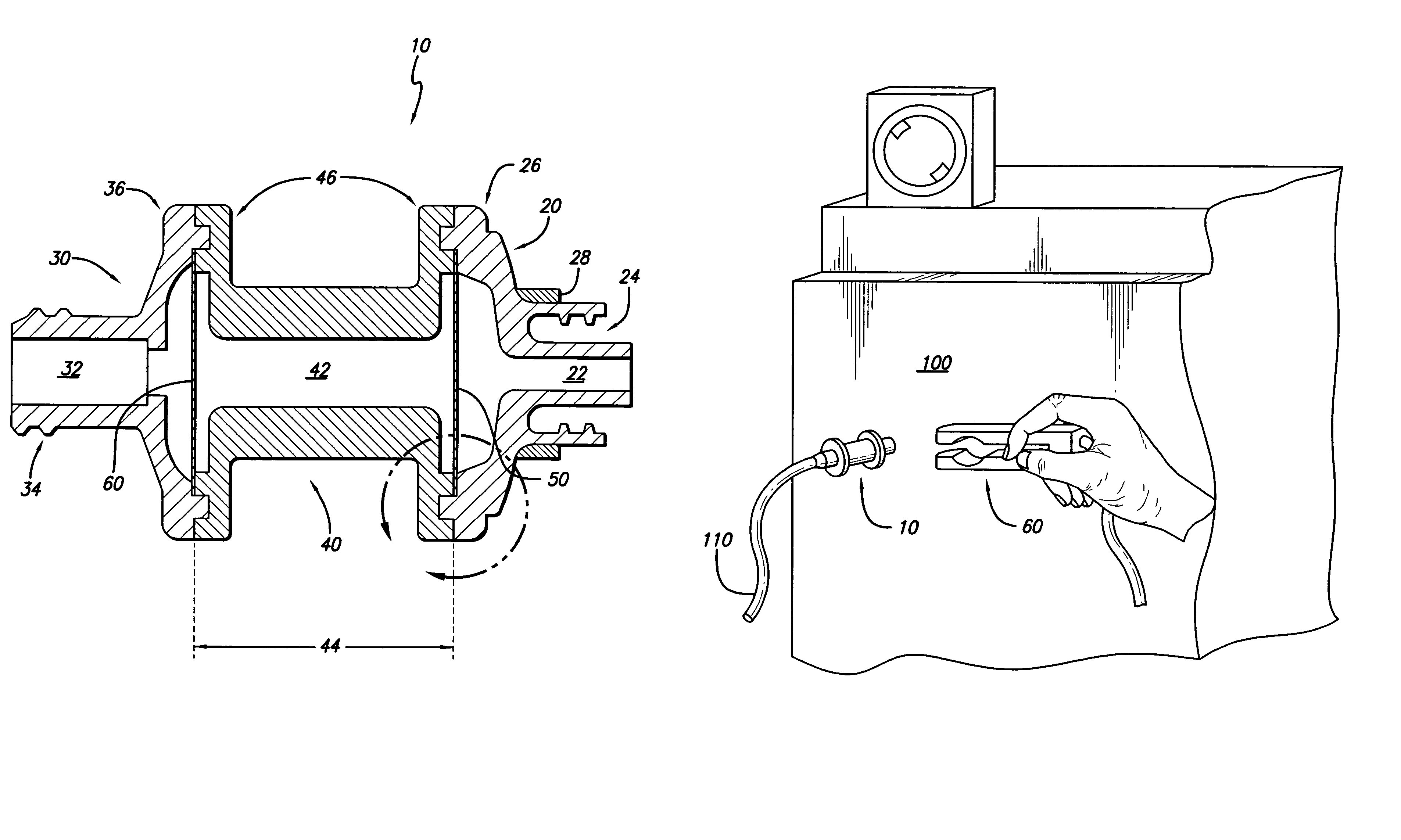

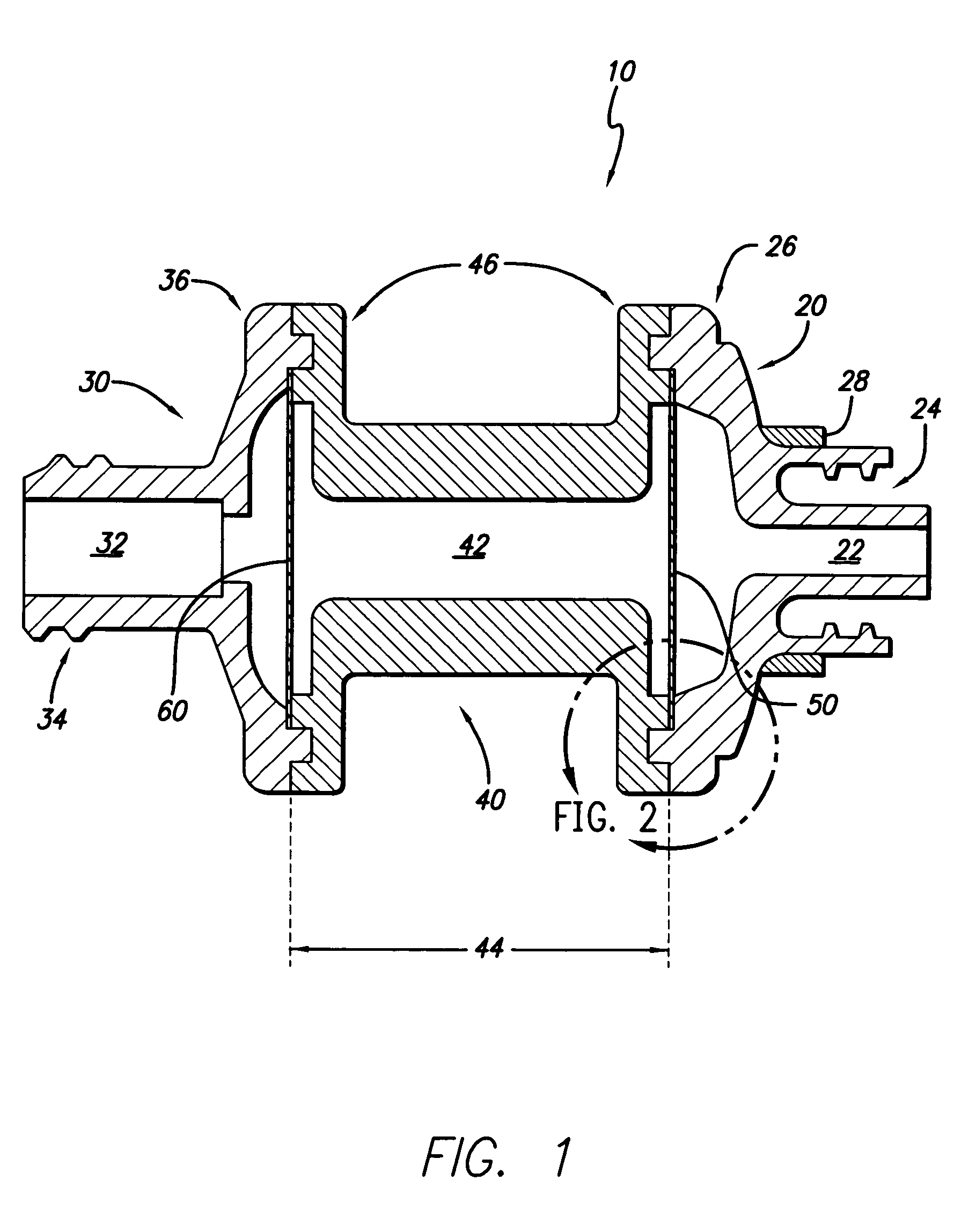

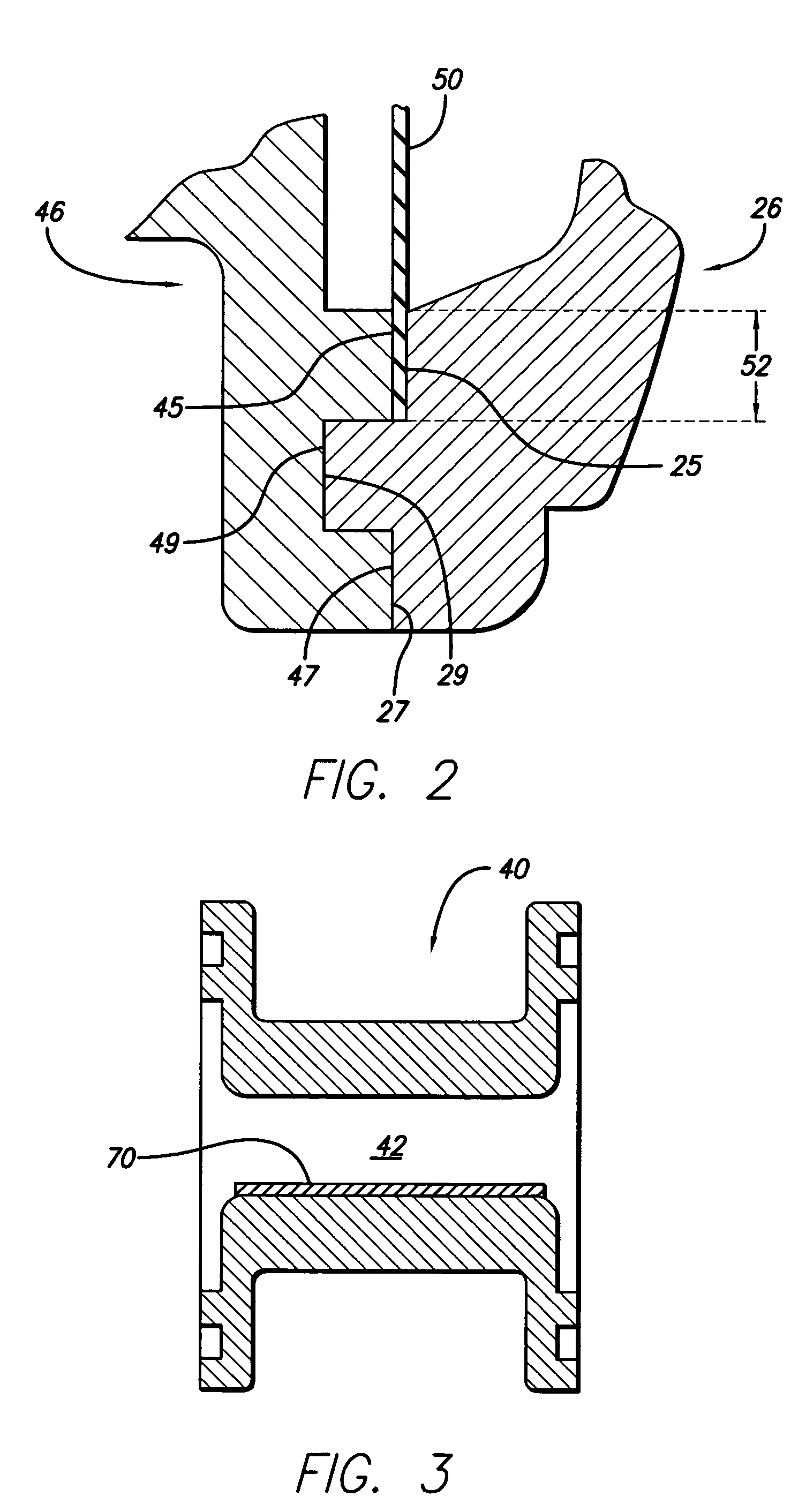

A transducer protector having at least two filter membranes. In one embodiment, the transducer protector includes a body between two tubular connectors, each of which has a lumen that may be axially aligned. The body lumen is separated from the lumen of each of the tubular connectors by a filter membrane. In one embodiment, the body is transparent and the body lumen has an indicator to alert a user that the filter membrane has been breached by a contaminant so that the user can take immediate steps to prevent further contamination of the system. The configuration of the transducer protector also facilitates the use of separate indicator devices, such as sensor clips.

Owner:JMS NORTH AMERICA

Double membrane transducer protector

InactiveUS20050132826A1Detection of fluid at leakage pointSemi-permeable membranesFiltration membraneTransducer

A transducer protector having at least two filter membranes. In one embodiment, the transducer protector includes a body between two tubular connectors, each of which has a lumen that may be axially aligned. The body lumen is separated from the lumen of each of the tubular connectors by a filter membrane. In one embodiment, the body is transparent and the body lumen has an indicator to alert a user that the filter membrane has been breached by a contaminant so that the user can take immediate steps to prevent further contamination of the system. The configuration of the transducer protector also facilitates the use of separate indicator devices, such as sensor clips.

Owner:JMS NORTH AMERICA

Concentrate recycle loop with filtration module

InactiveUS20060091077A1Increase flow rateVolume/mass flow measurementFluid pressure measurement by electric/magnetic elementsFiltration membraneMineralogy

Water purification systems include a concentrate filtration membrane and an electrodeionization unit. A concentrate effluent stream from the electrodeionization unit is filtered in the concentrate filtration membrane; the filtered concentrate effluent stream is provided to concentrating compartments of the electrodeionization unit.

Owner:ECOLOCHEM

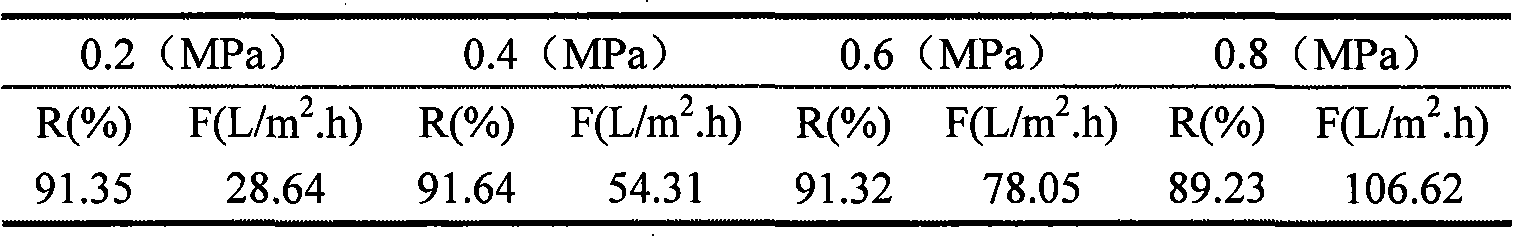

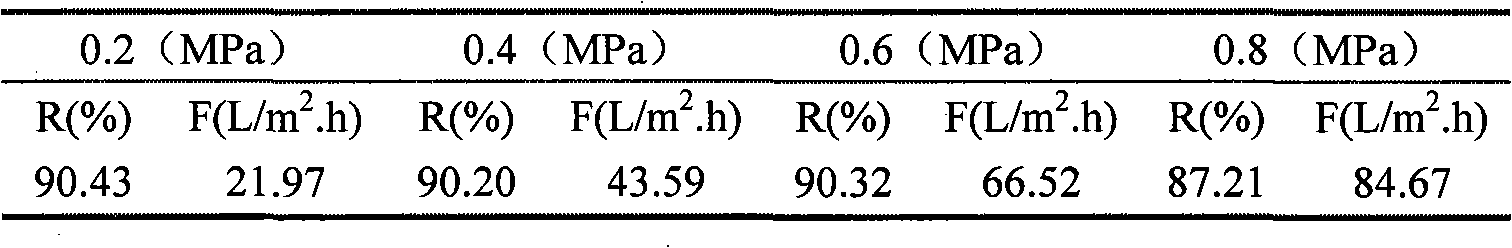

Hollow fiber type composite nano-filtration membrane and preparation method thereof

ActiveCN103223300AHigh strengthImprove anti-scourSemi-permeable membranesHollow fibreFiltration membrane

The invention relates to a hollow fiber type composite nano-filtration membrane and a preparation method thereof. The hollow fiber type composite nano-filtration membrane comprises a hollow fiber microporous base membrane adopted as a supporting layer, a polysulfone transition layer, and a polyamide composite layer, wherein the polysulfone transition layer is positioned inside membrane holes of the hollow fiber microporous base membrane, and the polyamide composite layer is positioned inside membrane holes of the polysulfone transition layer. The preparation method comprises: adopting a thermally induced phase separation method to obtain an asymmetric microporous base membrane, adopting an impregnation phase transformation method to obtain the polysulfone transition layer in the micro holes, and adopting pressure control and an interface condensation polymerization reaction to obtain the polyamide composite layer. The hollow fiber type composite nano-filtration membrane provides a sodium chloride salt solution entrapment rate of more than 90%, a divalent salt ion entrapment rate of more than 95%, and a pollutant entrapment rate of more than 99% under 0.2-0.8 MPa, such that the hollow fiber type composite nano-filtration membrane has characteristics of high strength, washing resistance, large flux and the like, wherein the pollutants have a molecular weight of 300-200,000 Daltons.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com