Patents

Literature

515 results about "Fluid bearing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluid bearings are bearings in which the load is supported by a thin layer of rapidly moving pressurized liquid or gas between the bearing surfaces. Since there is no contact between the moving parts, there is no sliding friction, allowing fluid bearings to have lower friction, wear and vibration than many other types of bearings.

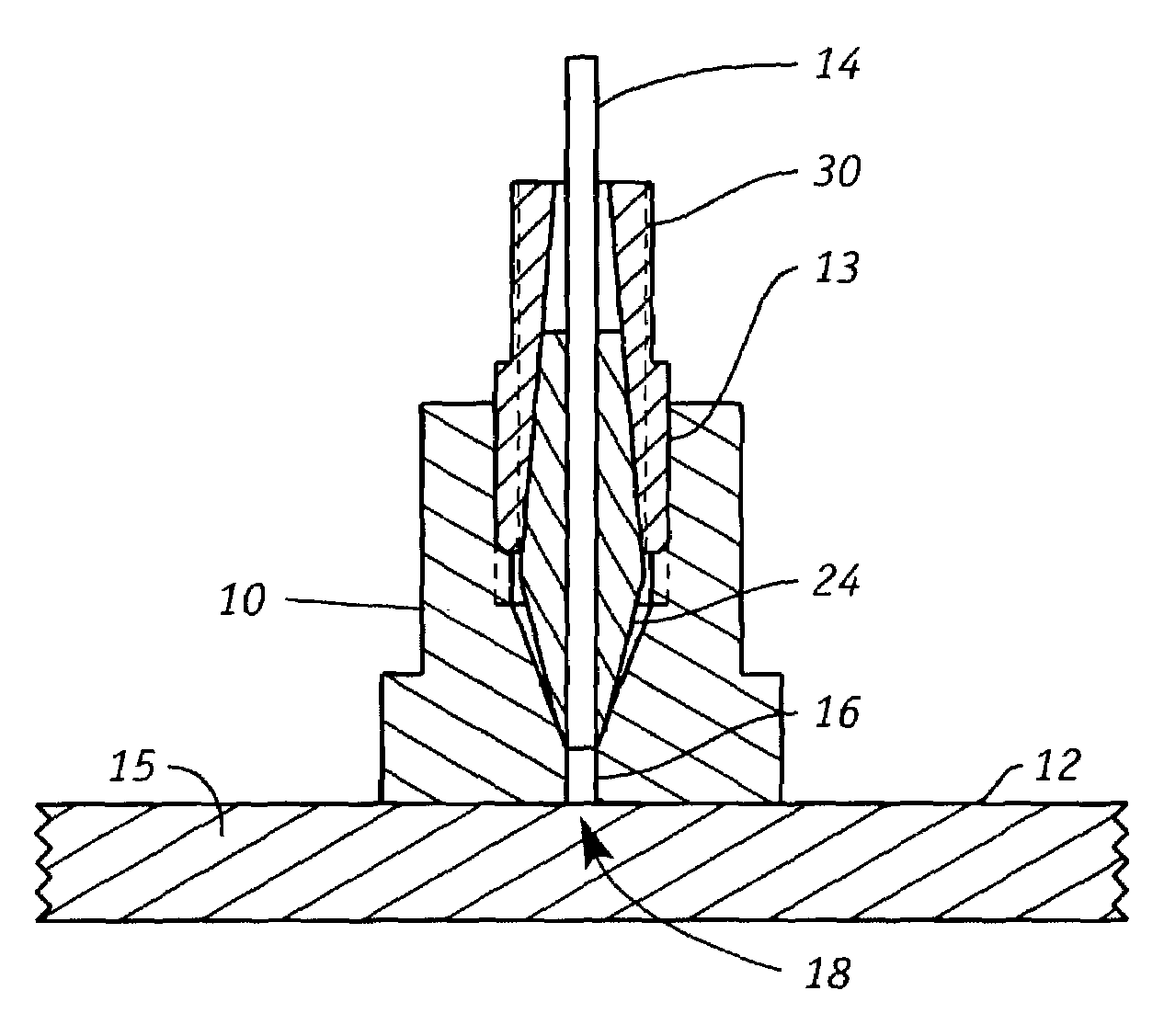

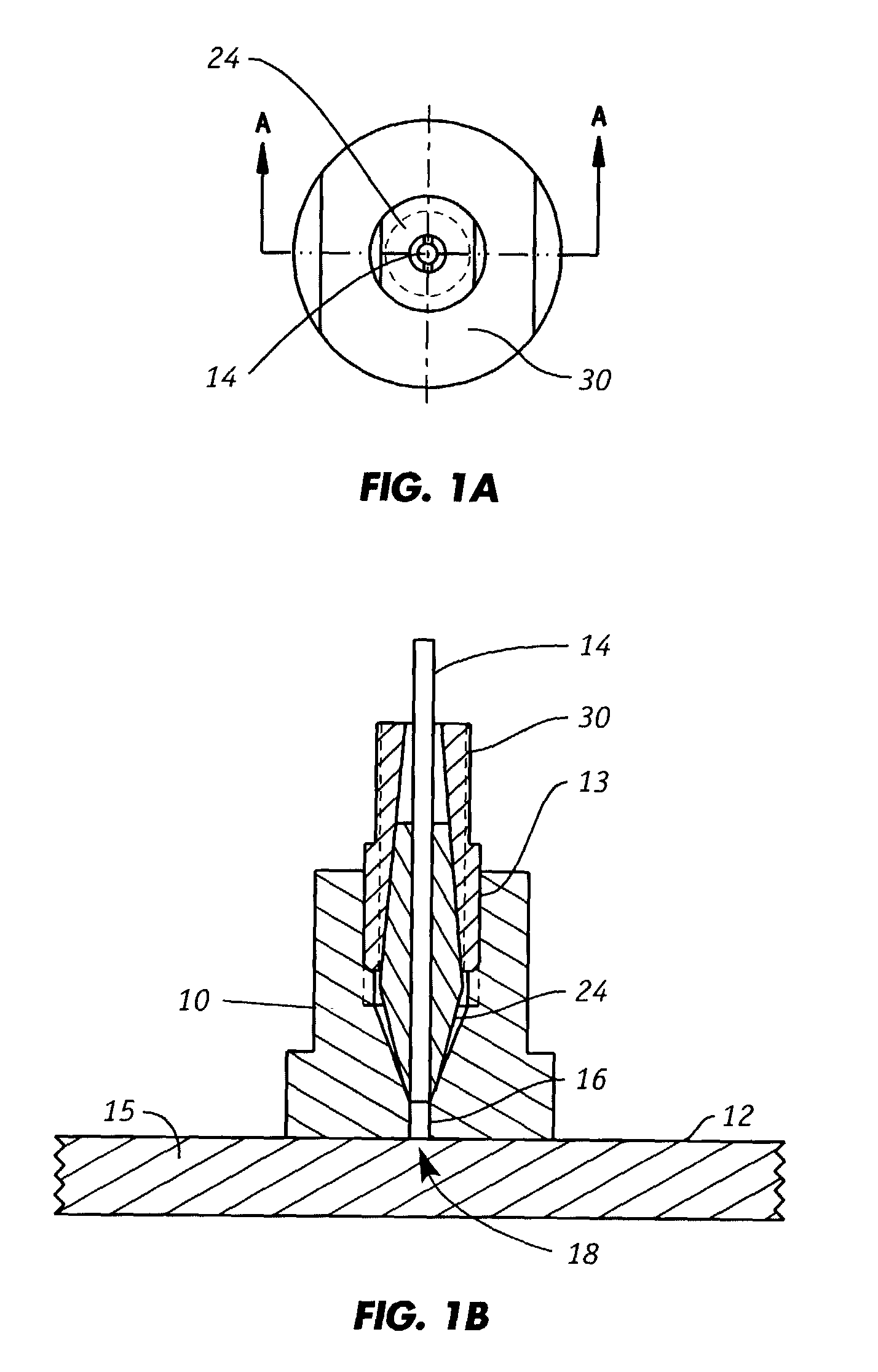

High pressure capillary connector

InactiveUS6926313B1Small sizeHigh strengthSleeve/socket jointsPositive displacement pump componentsCatheterHigh pressure

A high pressure connector capable of operating at pressures of 40,000 psi or higher is provided. This connector can be employed to position a first fluid-bearing conduit that has a proximal end and a distal end to a second fluid-bearing conduit thereby providing fluid communication between the first and second fluid-bearing conduits. The connector includes (a) an internal fitting assembly having a body cavity with (i) a lower segment that defines a lower segment aperture and (ii) an interiorly threaded upper segment, (b) a first member having a first member aperture that traverses its length wherein the first member aperture is configured to accommodate the first fluid-bearing conduit and wherein the first member is positioned in the lower segment of the internal fitting assembly, and (c) a second member having a second member aperture that traverses its length wherein the second member is positioned in the upper segment of the fitting assembly and wherein a lower surface of the second member is in contact with an upper surface of the first member to assert a compressive force onto the first member and wherein the first member aperture and the second member aperture are coaxial.

Owner:SANDIA NAT LAB

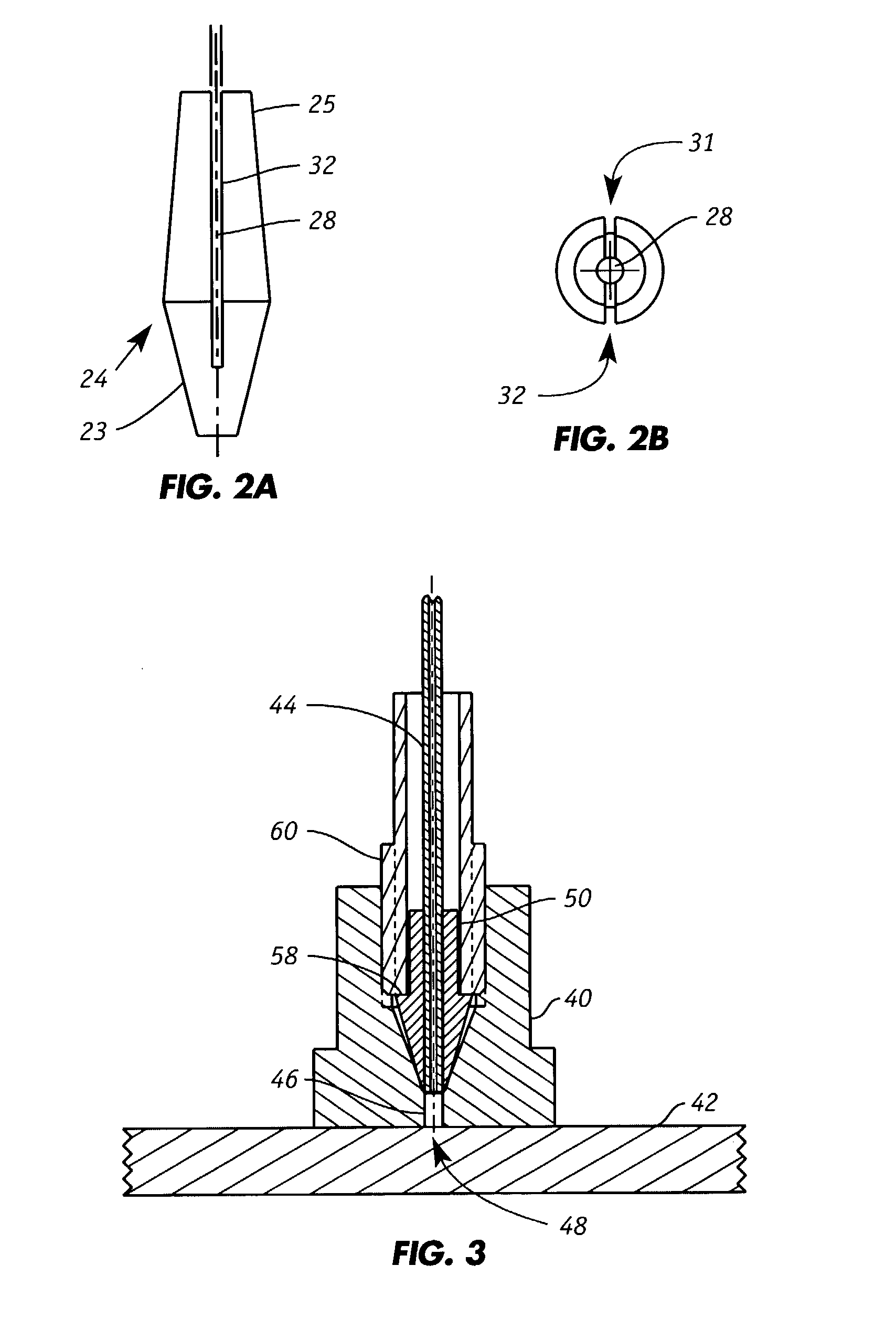

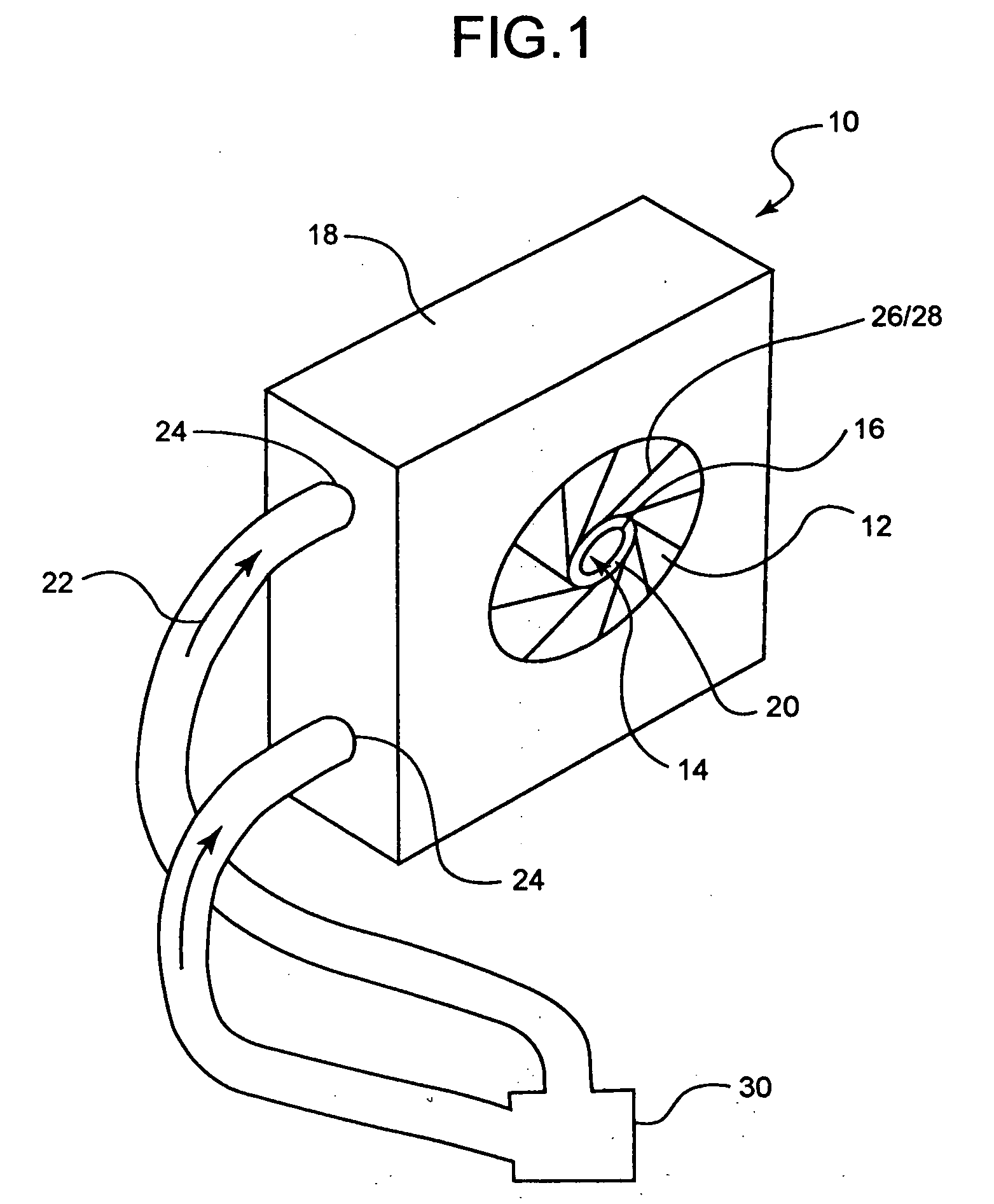

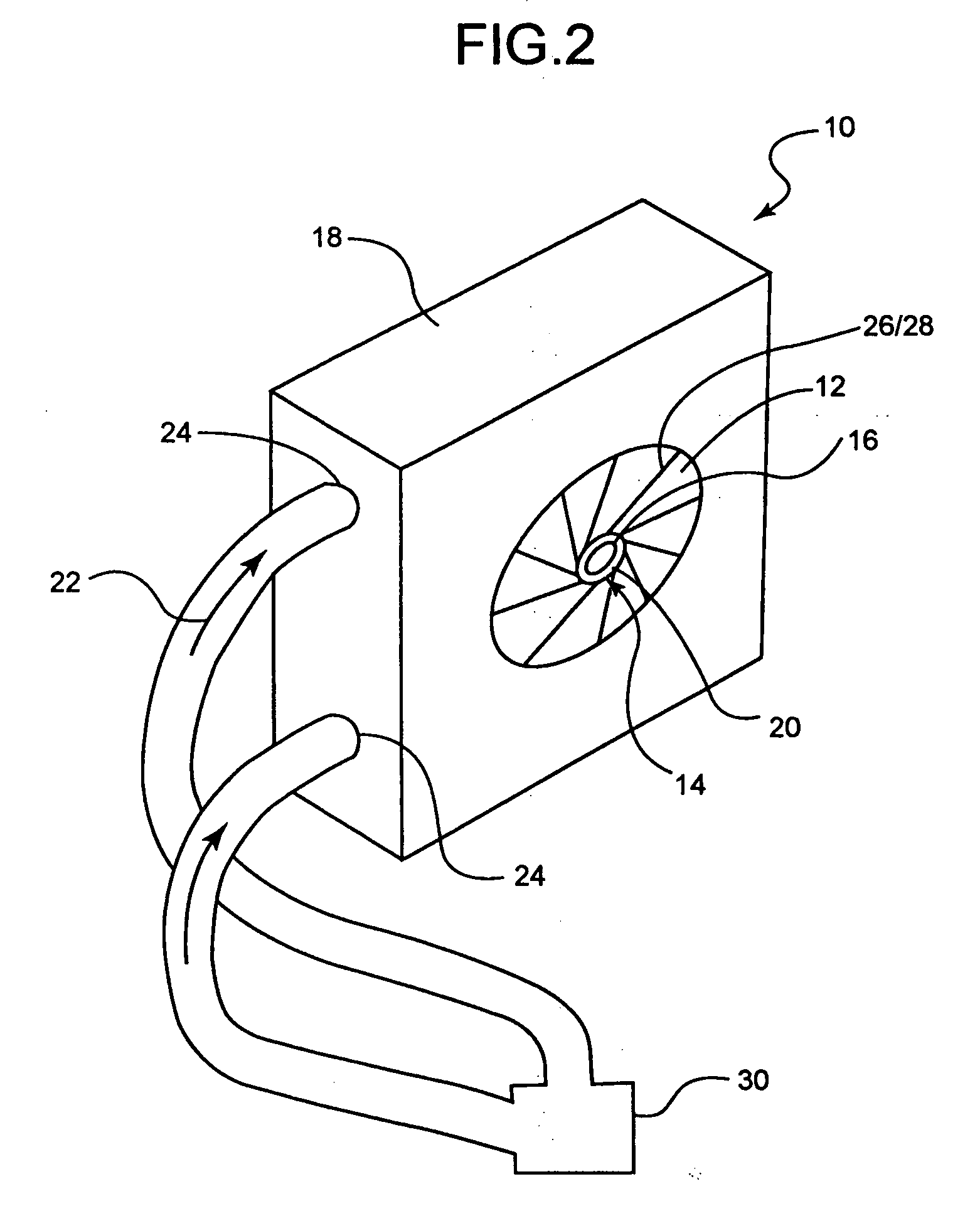

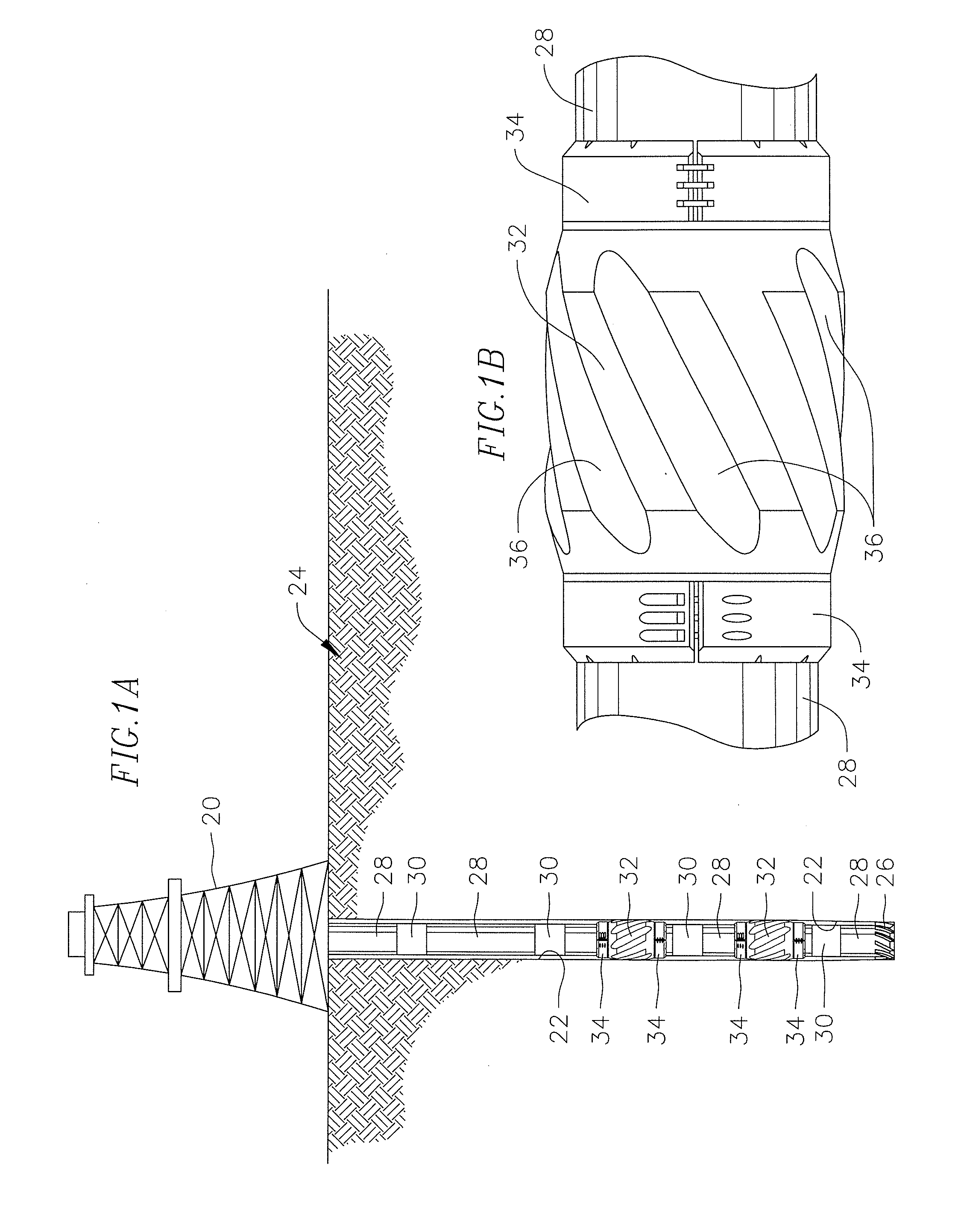

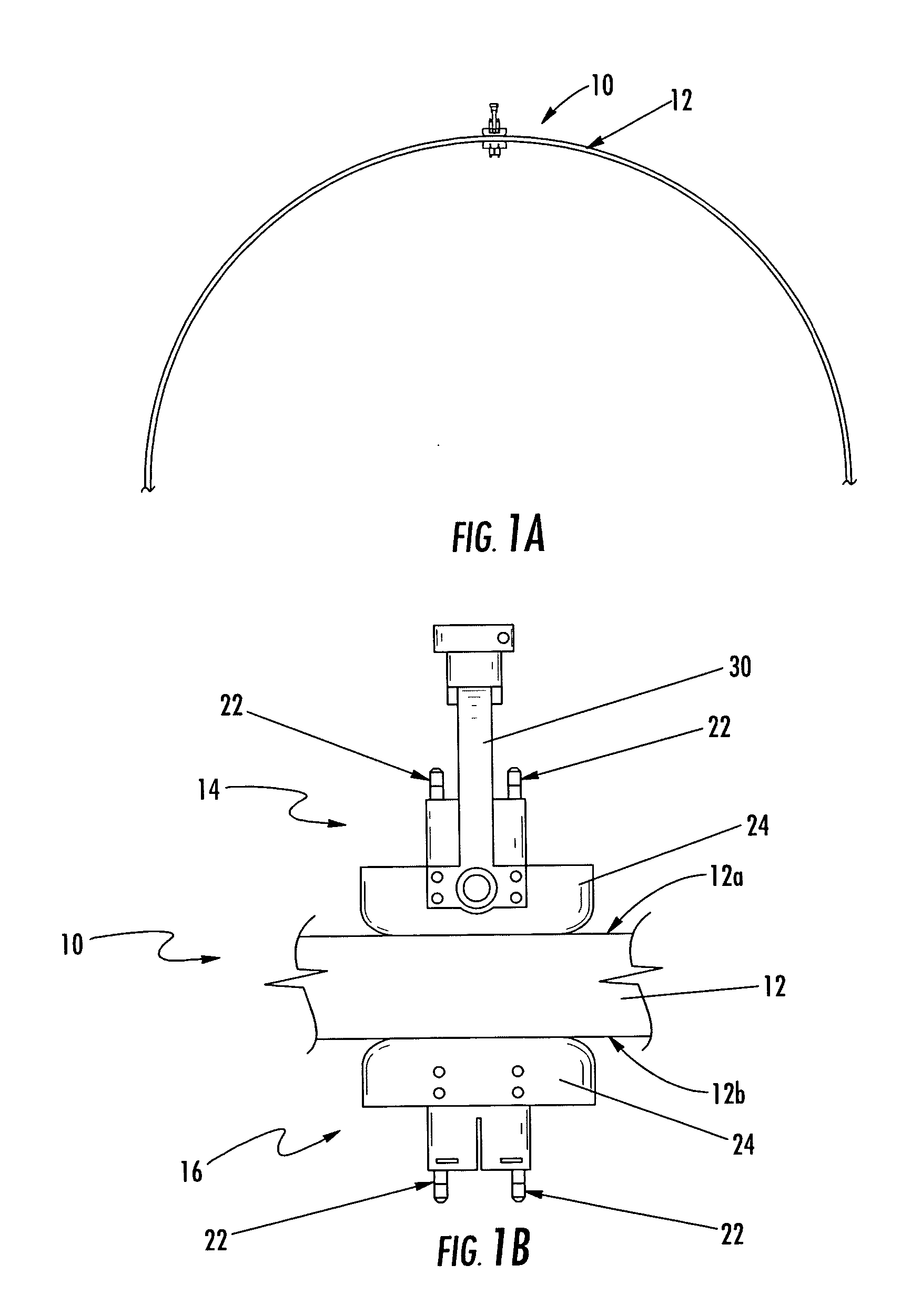

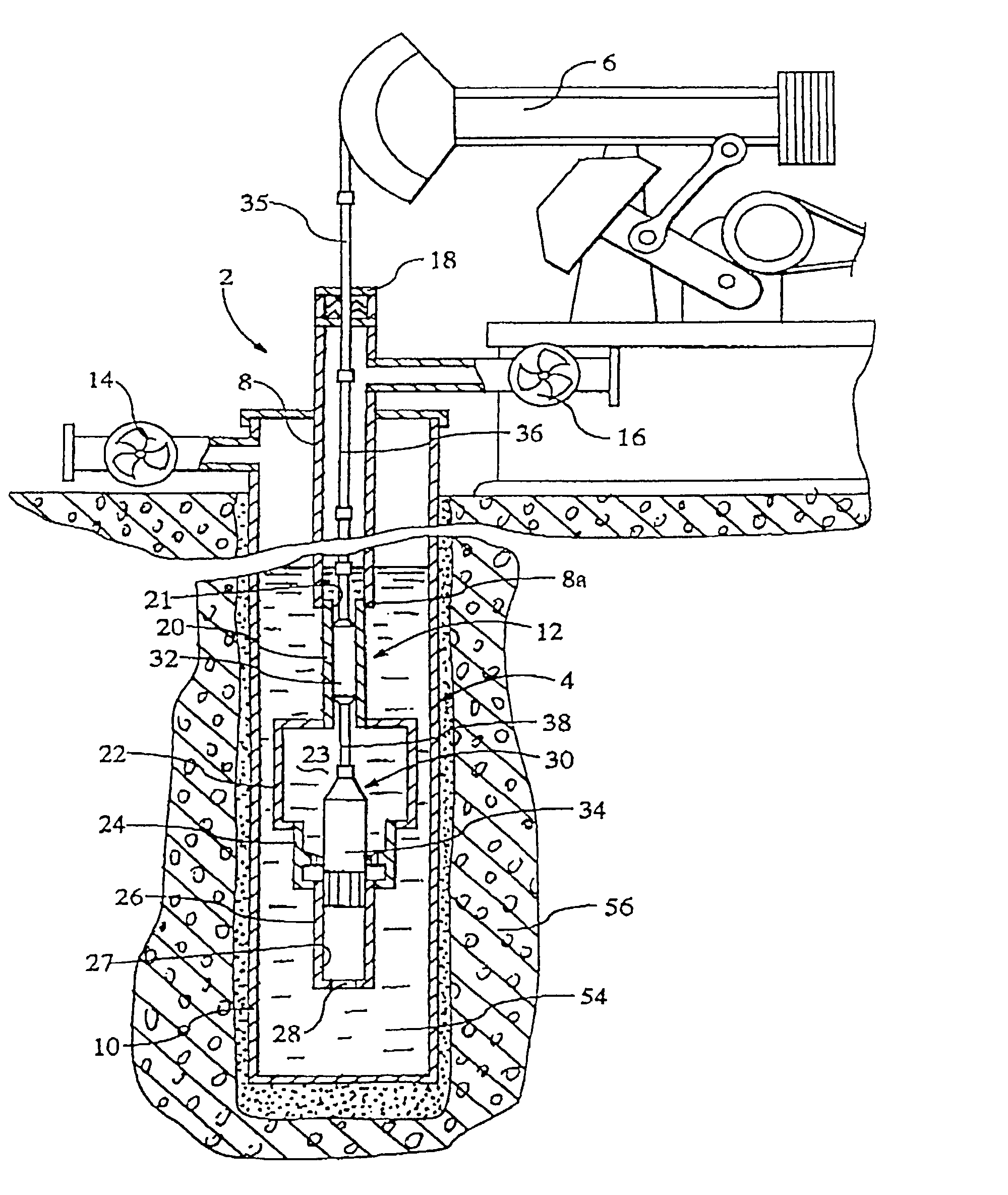

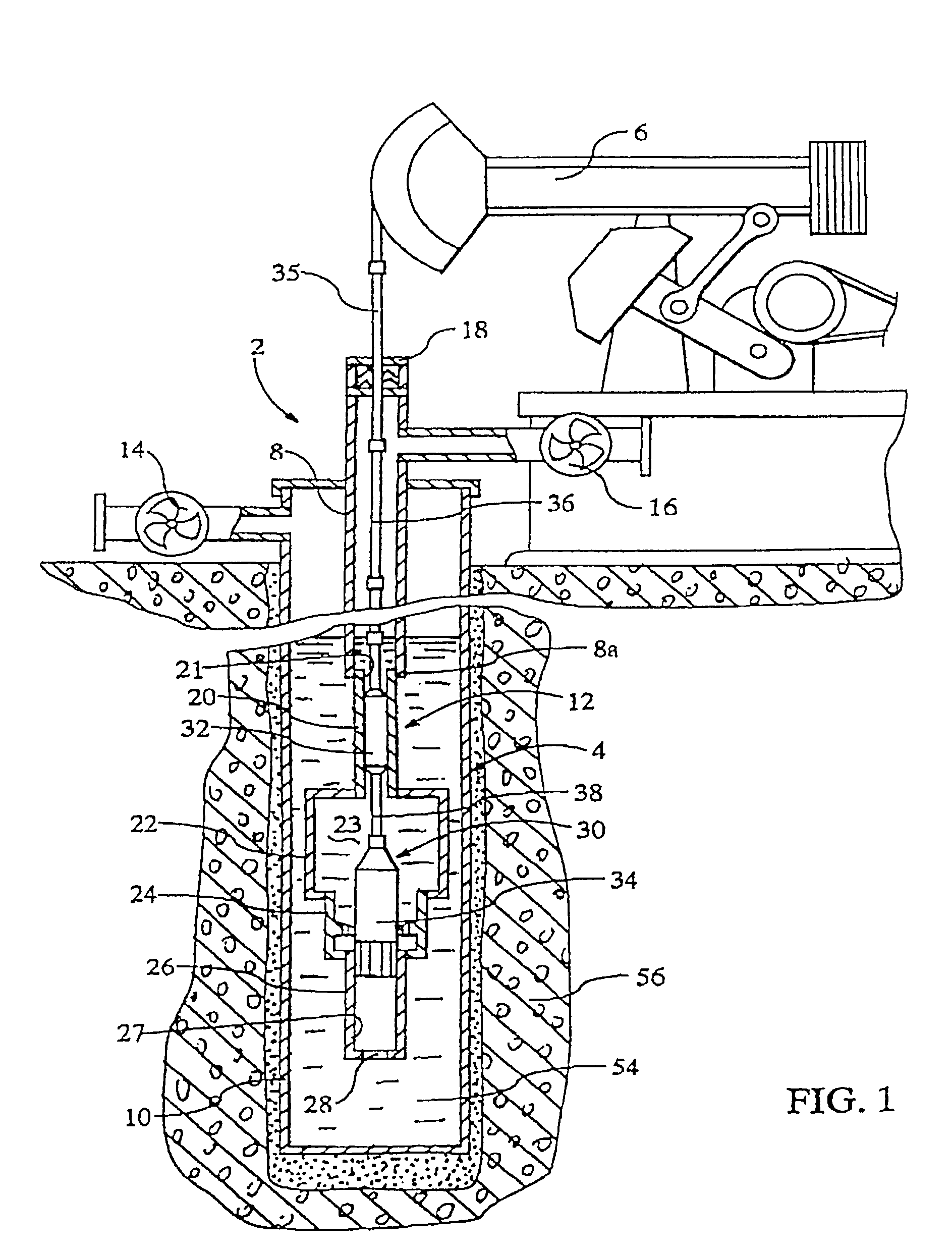

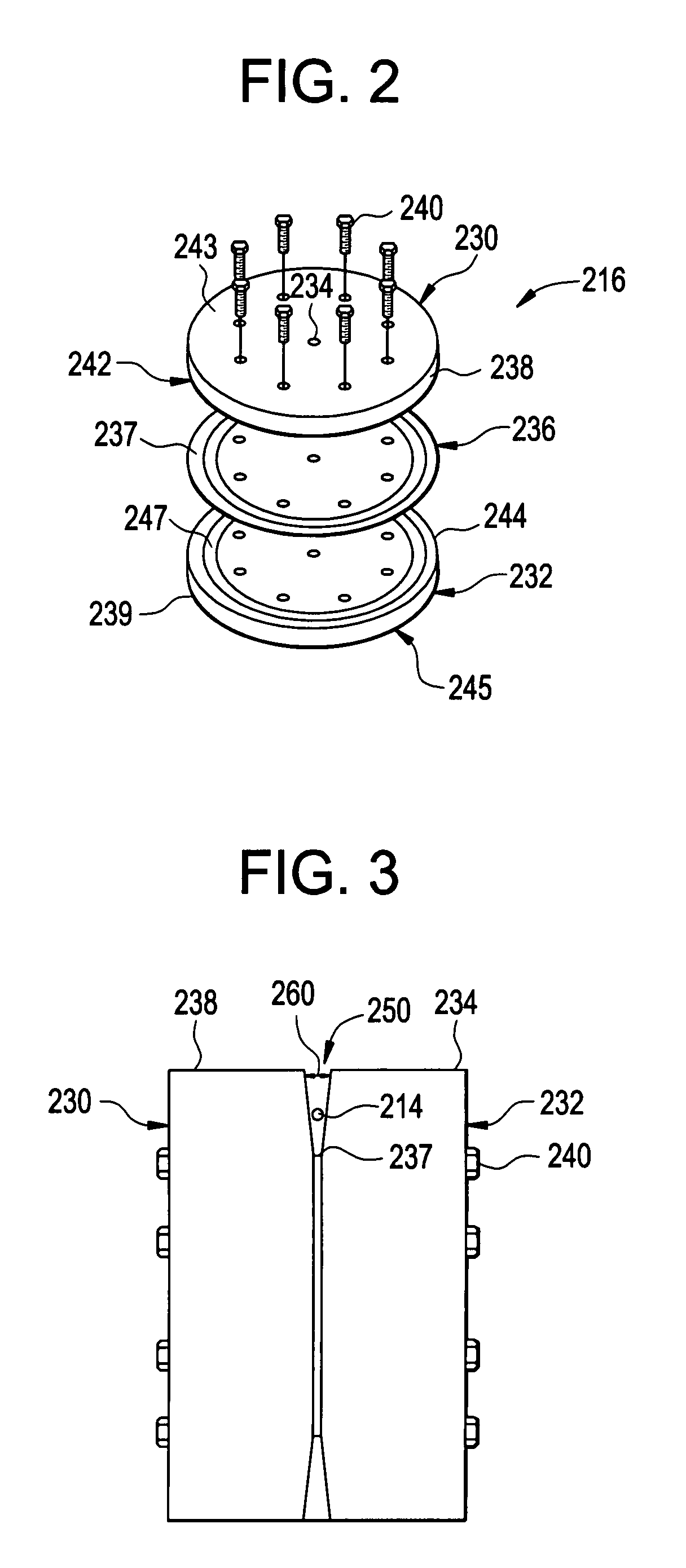

Stent reducing system and device

ActiveUS20050154450A1Reduce frictionMinimize adhesionStentsForging hammersInsertion stent% diameter reduction

A system for reducing the diameter of a stent comprises a stent contracting assembly and a fluid source. The assembly comprises a plurality of contracting members that define a diameter reduction chamber for receiving a stent. When the chamber is in a pre-reduction configuration the stent has a first diameter and when the chamber is in a reduced configuration the stent has a second diameter. The second diameter is less than the first diameter. The fluid source is in fluid communication with the chamber and is constructed and arranged to inject a fluid therein. The fluid forms a fluid bearing between the contracting members and the stent which prevents the contracting members from contacting the stent in the reduced diameter configuration.

Owner:BOSTON SCI SCIMED INC

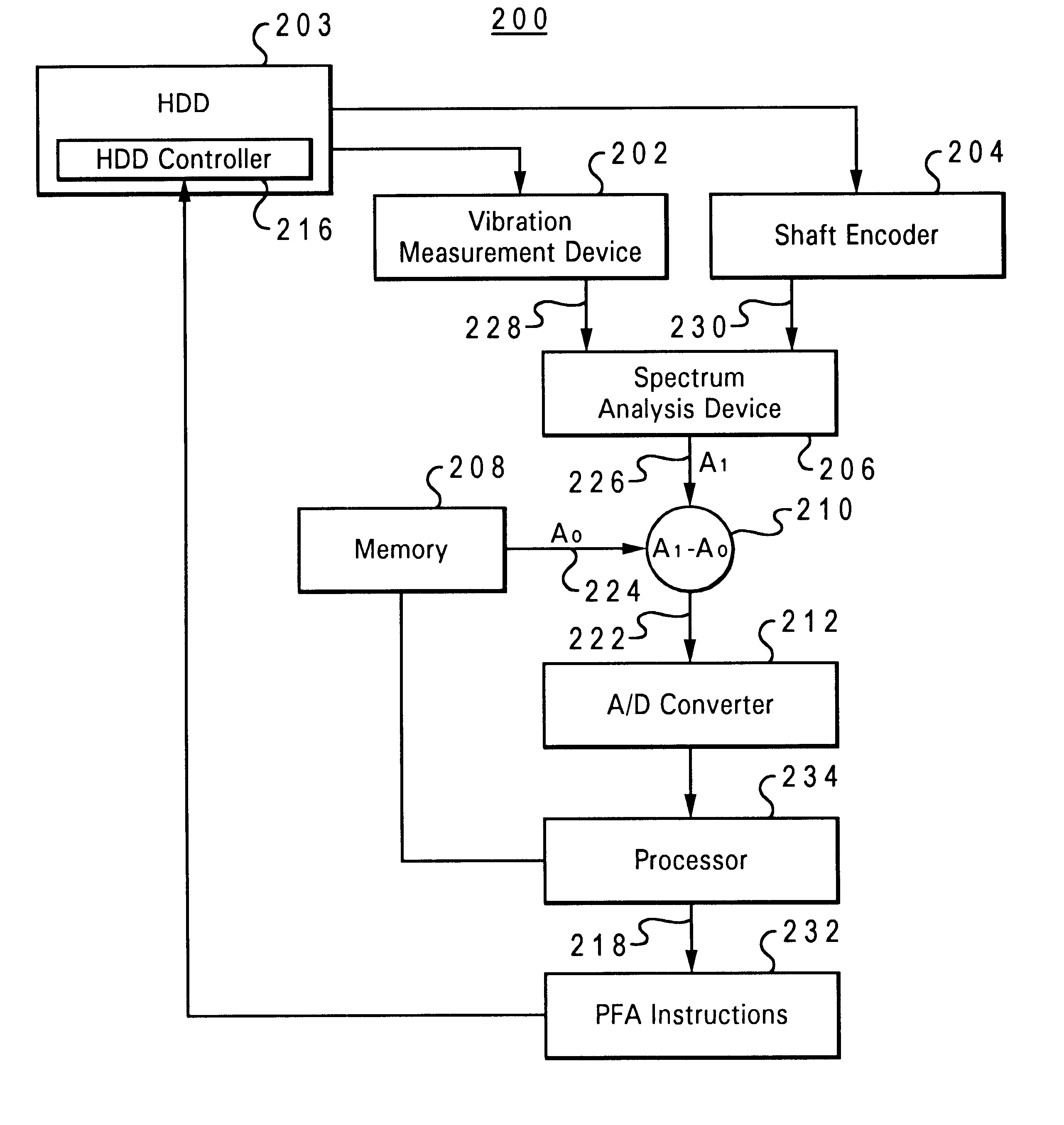

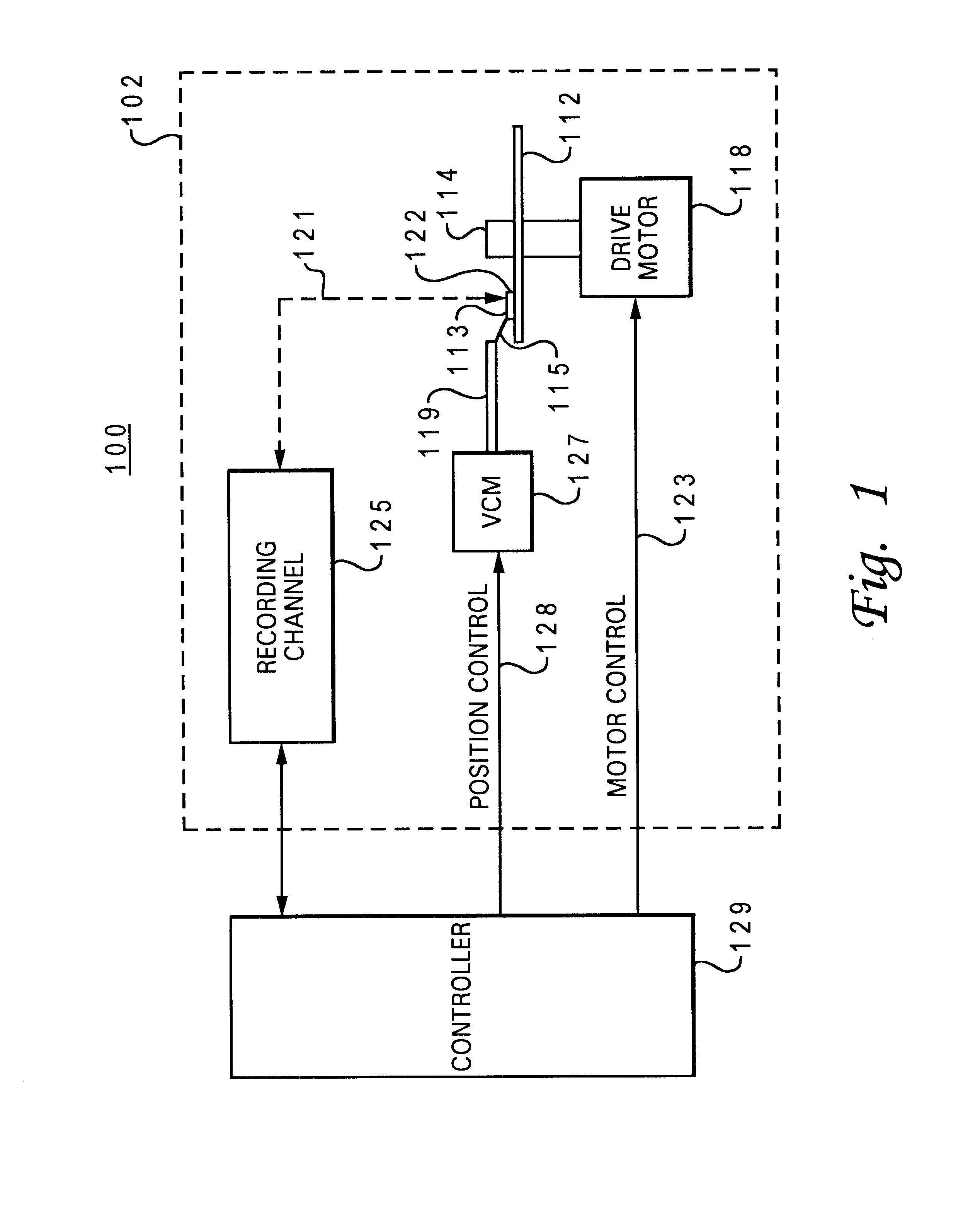

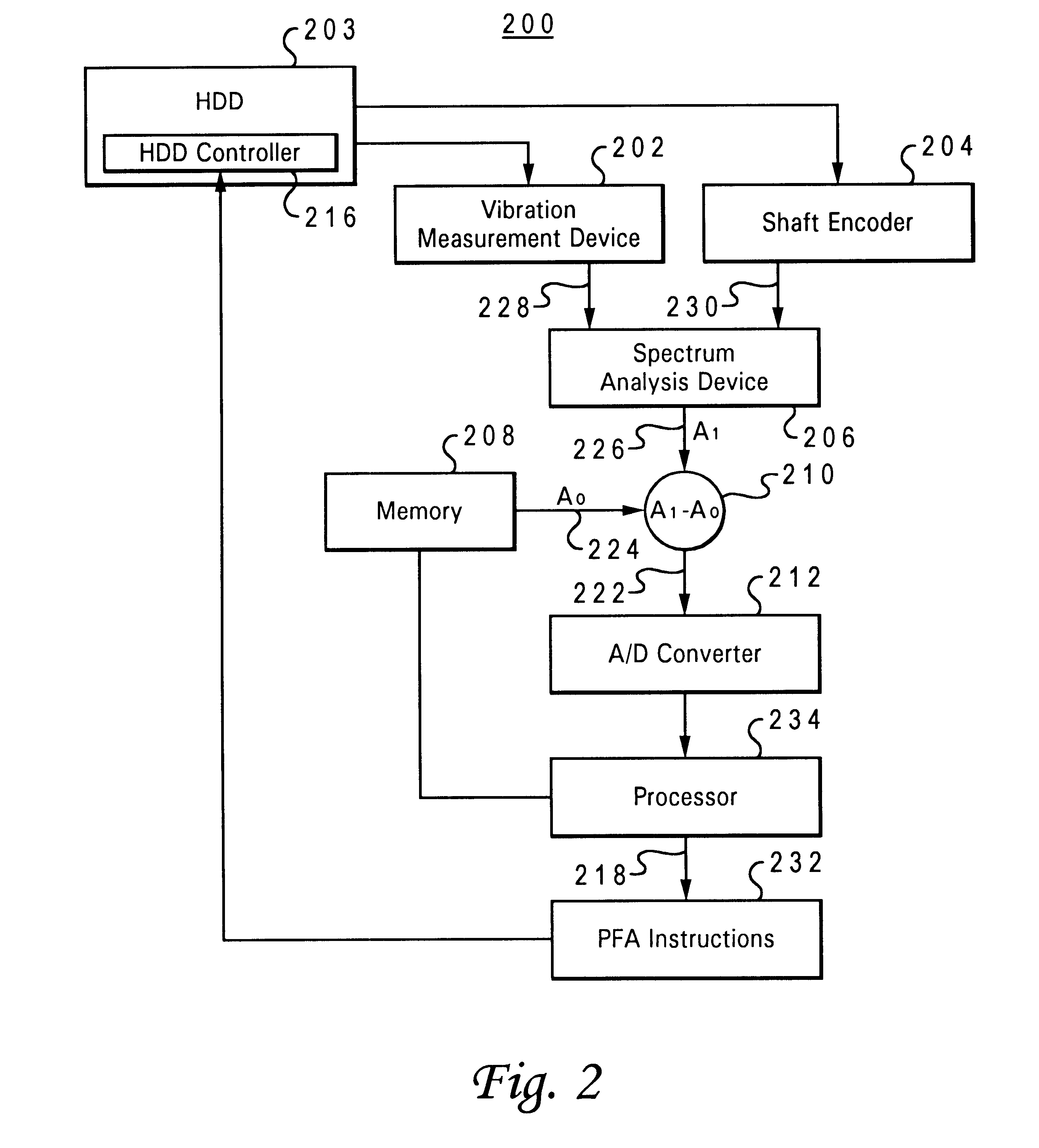

Method and system for predicting disk drive failures

InactiveUS6415189B1Not easy to failAvoid data lossVibration measurement in solidsMaterial analysis using sonic/ultrasonic/infrasonic wavesData processing systemHard disc drive

A method and system within a data processing system for predicting failure of a hard disk drive having a fluid bearing during runtime operation of said hard disk drive, wherein said fluid bearing has an established signature dynamic fluid response. First, a runtime vibration level of the fluid bearing is measured. This runtime vibration level is then translated into a runtime dynamic fluid response which provides an indication of the operating condition of the fluid bearing. The runtime dynamic fluid response is compared with the baseline dynamic fluid response in real-time during operation of the hard disk drive. Finally, in response to a predetermined departure of the runtime dynamic fluid response from the baseline dynamic fluid response, a protective response is initiated, such that data loss within the data storage system due to fluid bearing failure is prevented.

Owner:WESTERN DIGITAL TECH INC

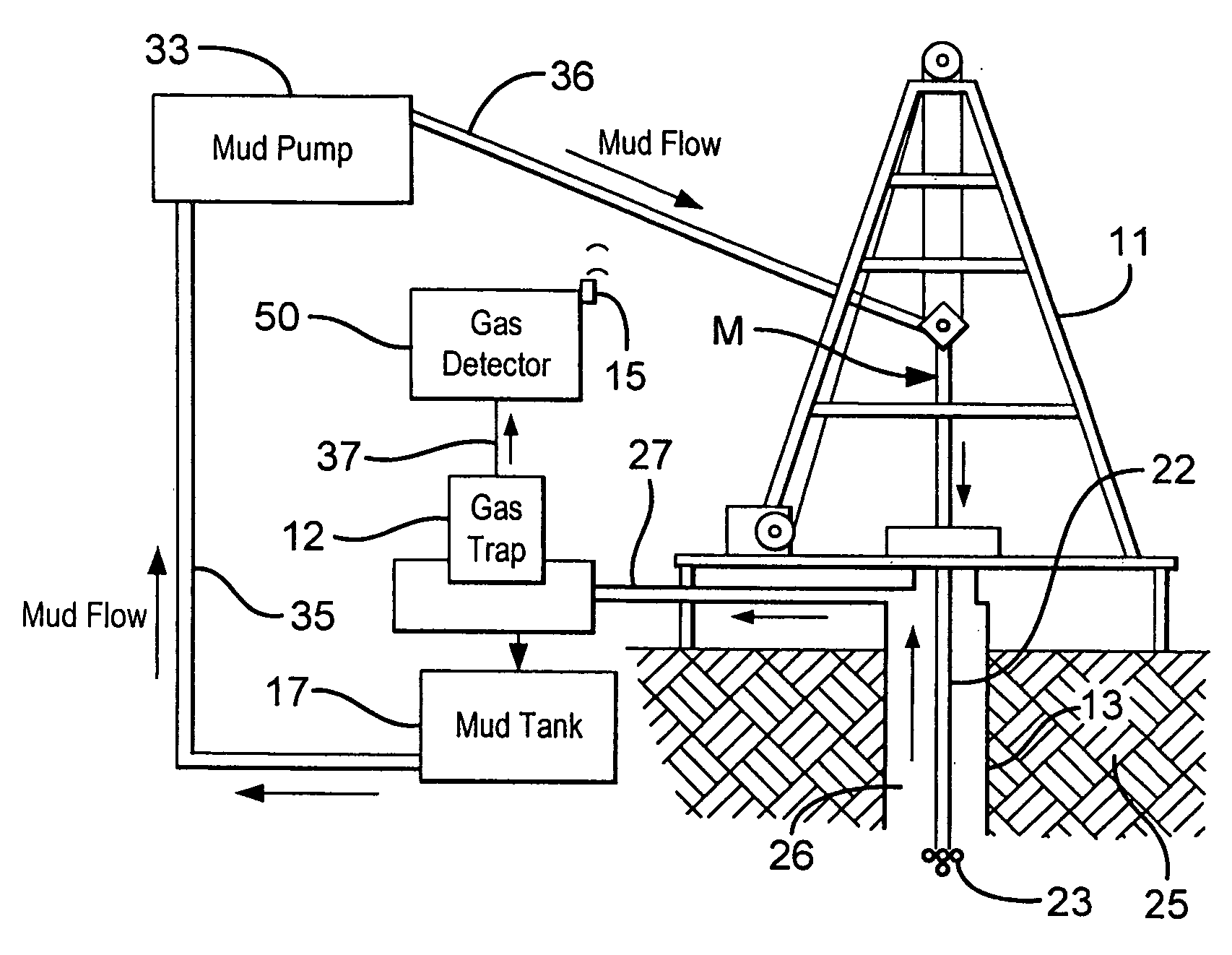

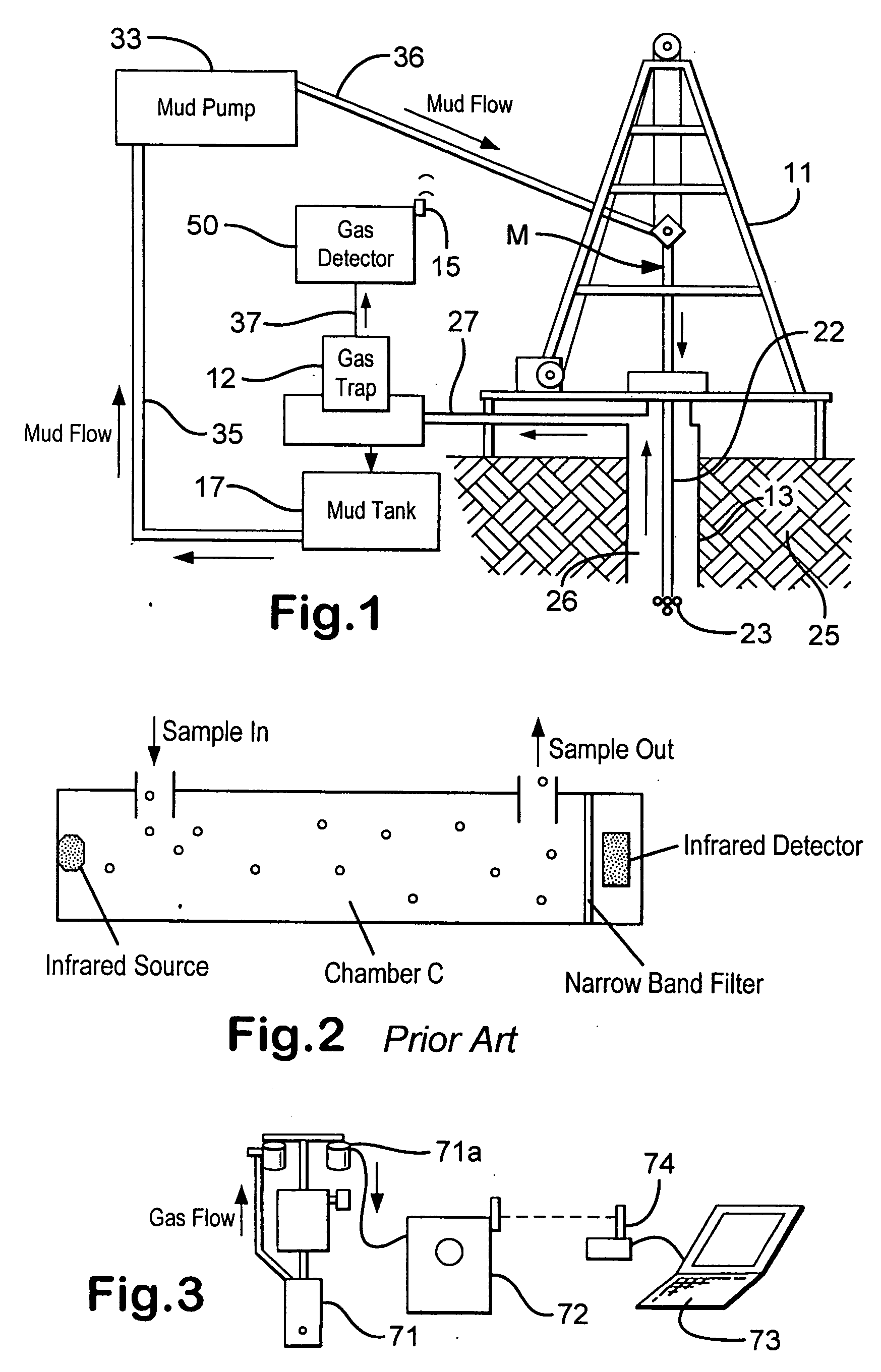

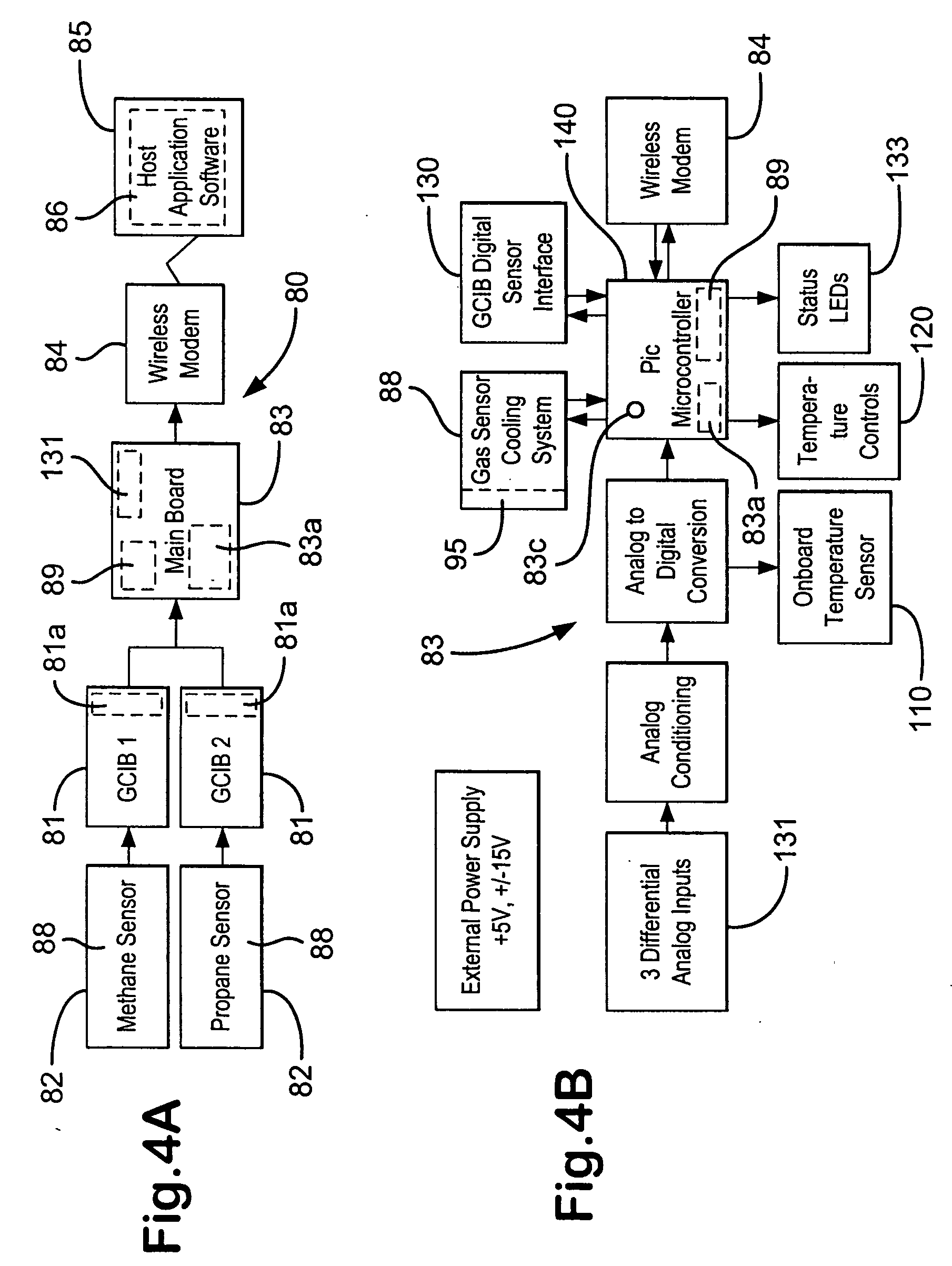

Detecting gas in fluids

InactiveUS20060202122A1Reduce sensitivityStrong responseRadiation pyrometryConstructionsEngineeringAnalog signal

A method for detecting gas in a fluid, the system including flowing fluid bearing gas through a gas trap apparatus, flowing gas trapped by the gas trap apparatus to and through an infra-red gas detection system for detecting the gas, the infrared gas detection system having apparatus for isolating absorption spectra of the gas, producing with the infra-red gas detection system analog signals indicative of levels of the gas, transmitting the analog signals to a first processor for converting the analog signals to digital signals, transmitting the digital signals from the first processor to a second processor, producing with the second processor digital signals indicative of the level of the gas.

Owner:VARCO I P INC

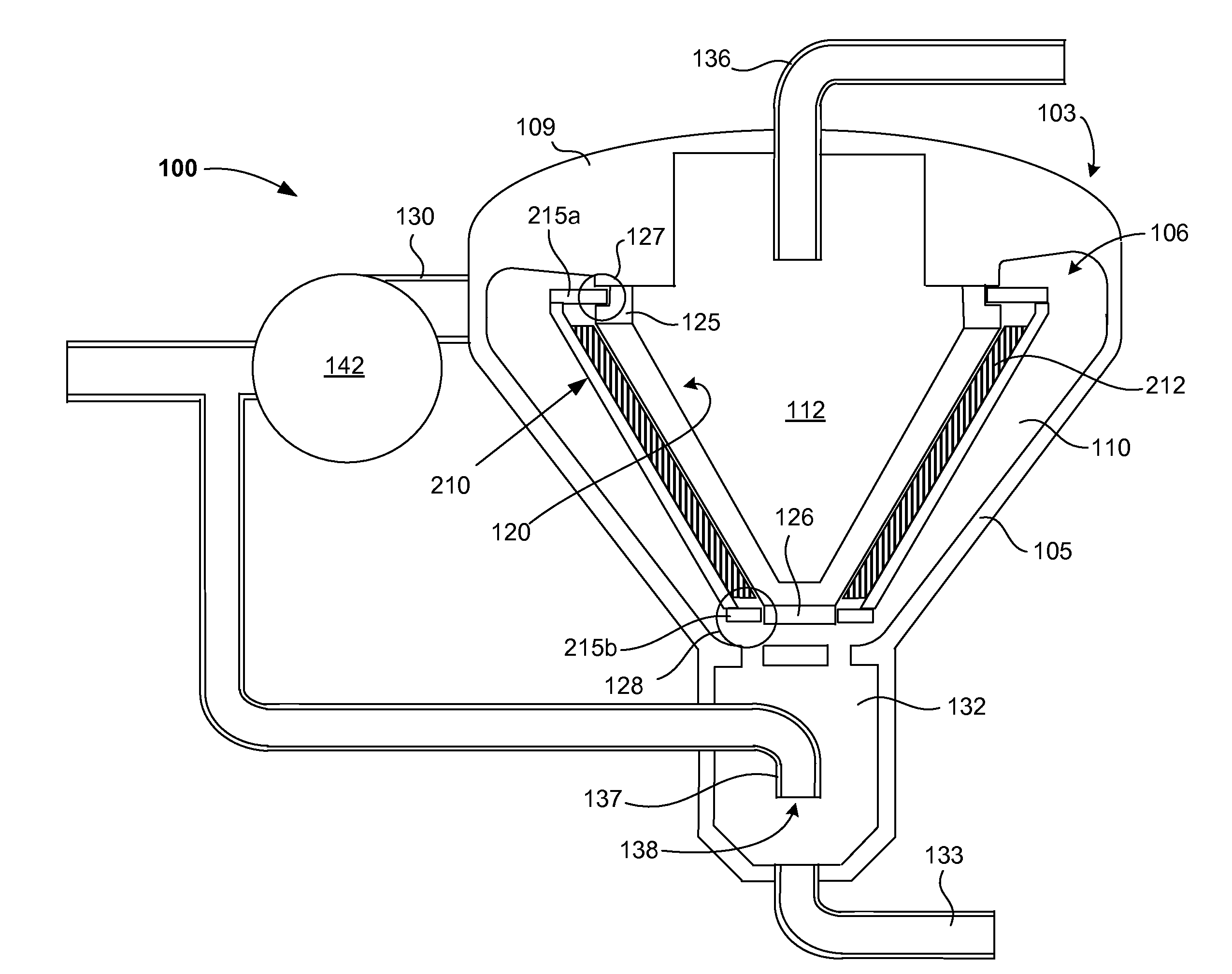

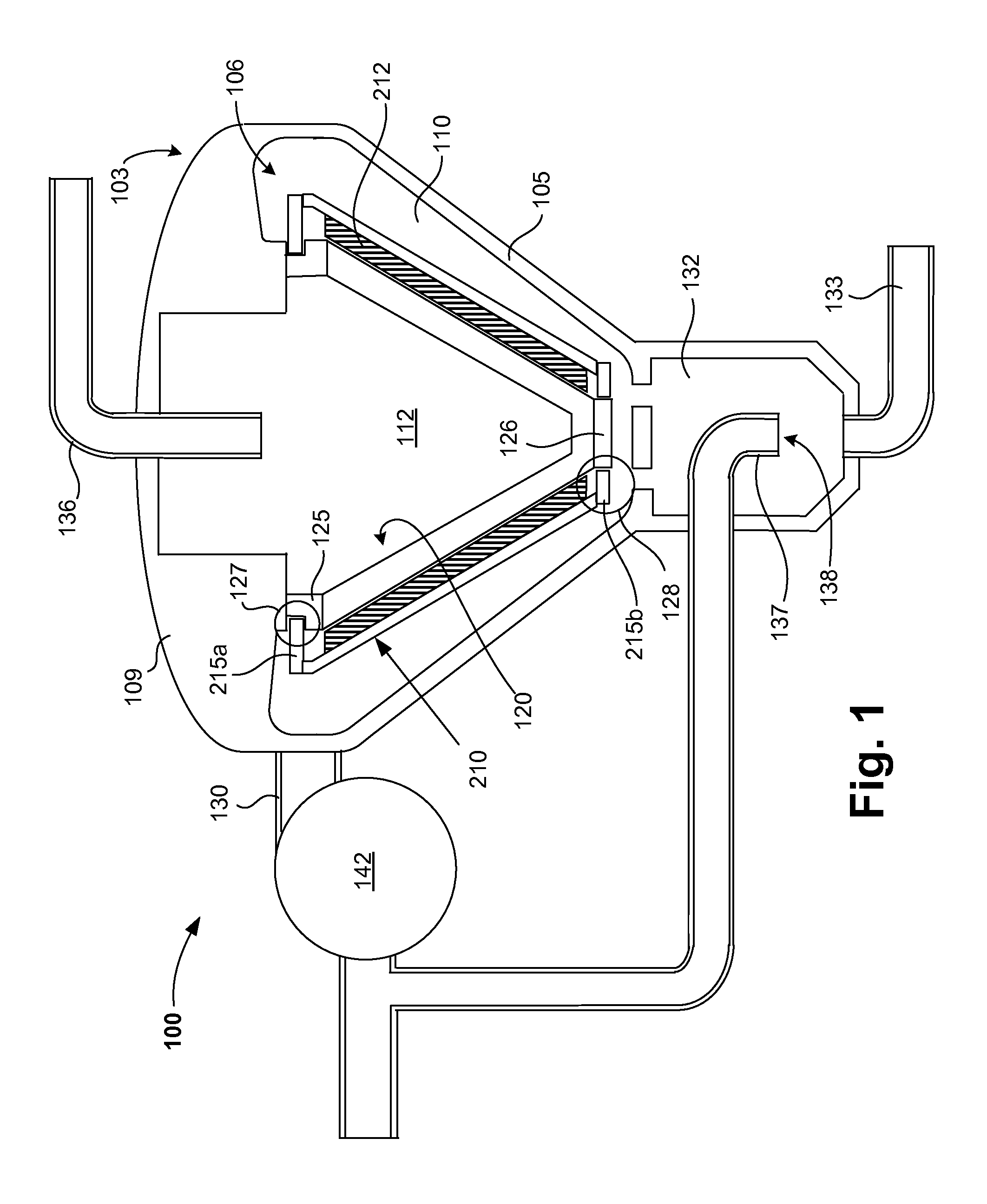

Cleaning assembly for use in fluid filtration systems

ActiveUS20120010063A1Easy to useEasy to disassembleWater/sewage treatment by centrifugal separationSemi-permeable membranesFluid filtrationFluid bearing

Cleaning assemblies and particulate tolerant fluid bearings that are particularly well suited for use in centrifugal separation enhanced filtration devices are described. In one aspect of the invention, at least one bearing is arranged to carry a circulating cleaning assembly such that the cleaning assembly can rotate around a filter membrane during filtering operation of the filtration device. The bearing is preferably arranged to maintain the circulating cleaning assembly in a substantially coaxial alignment with the filter membrane and in a substantially stable longitudinal position relative to the filter membrane as the circulating cleaning assembly is rotated around the filter membrane. In another aspect of the invention a variety of particulate tolerant bearings are described.

Owner:ACCELERATED FILTRATION INC

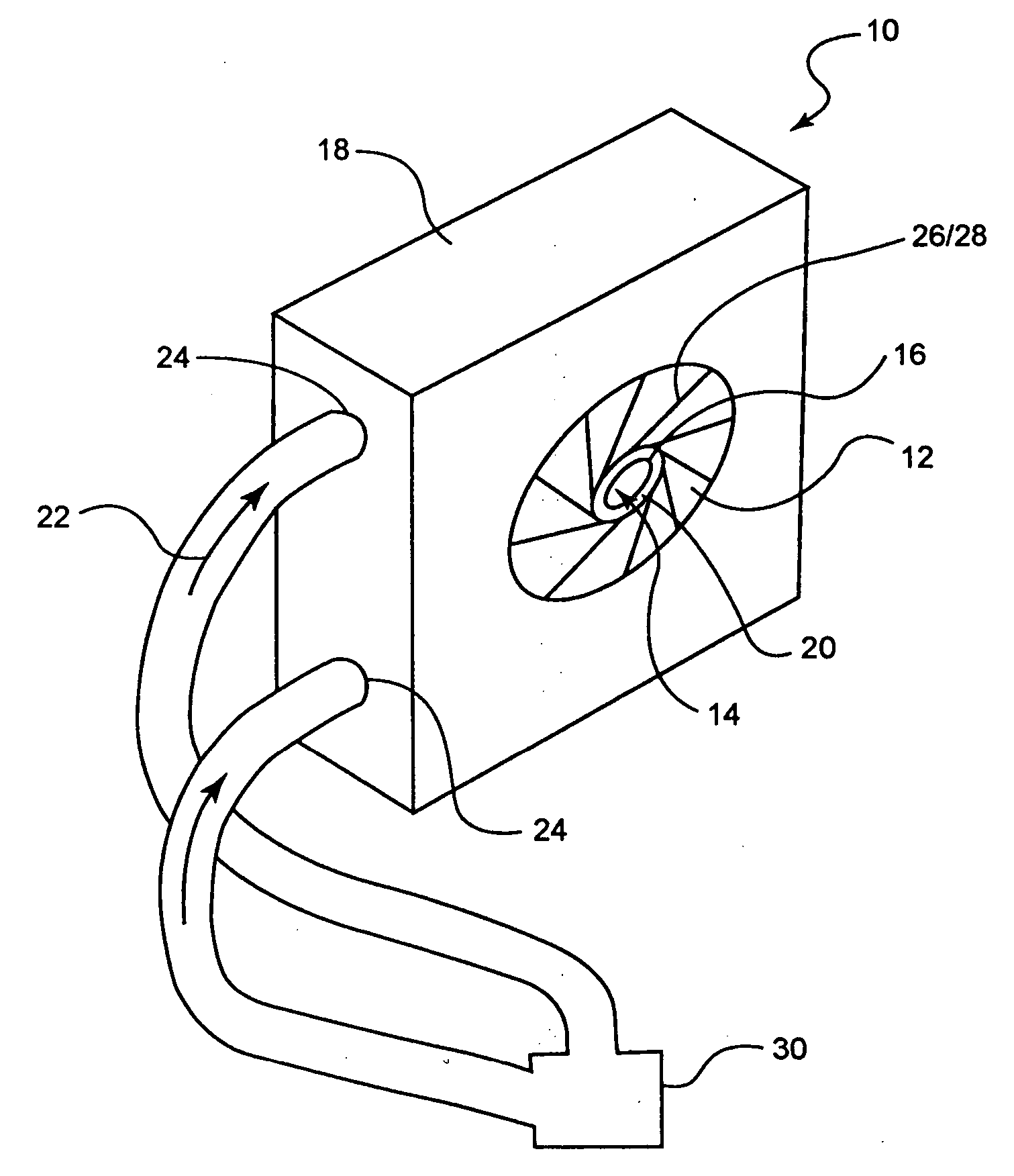

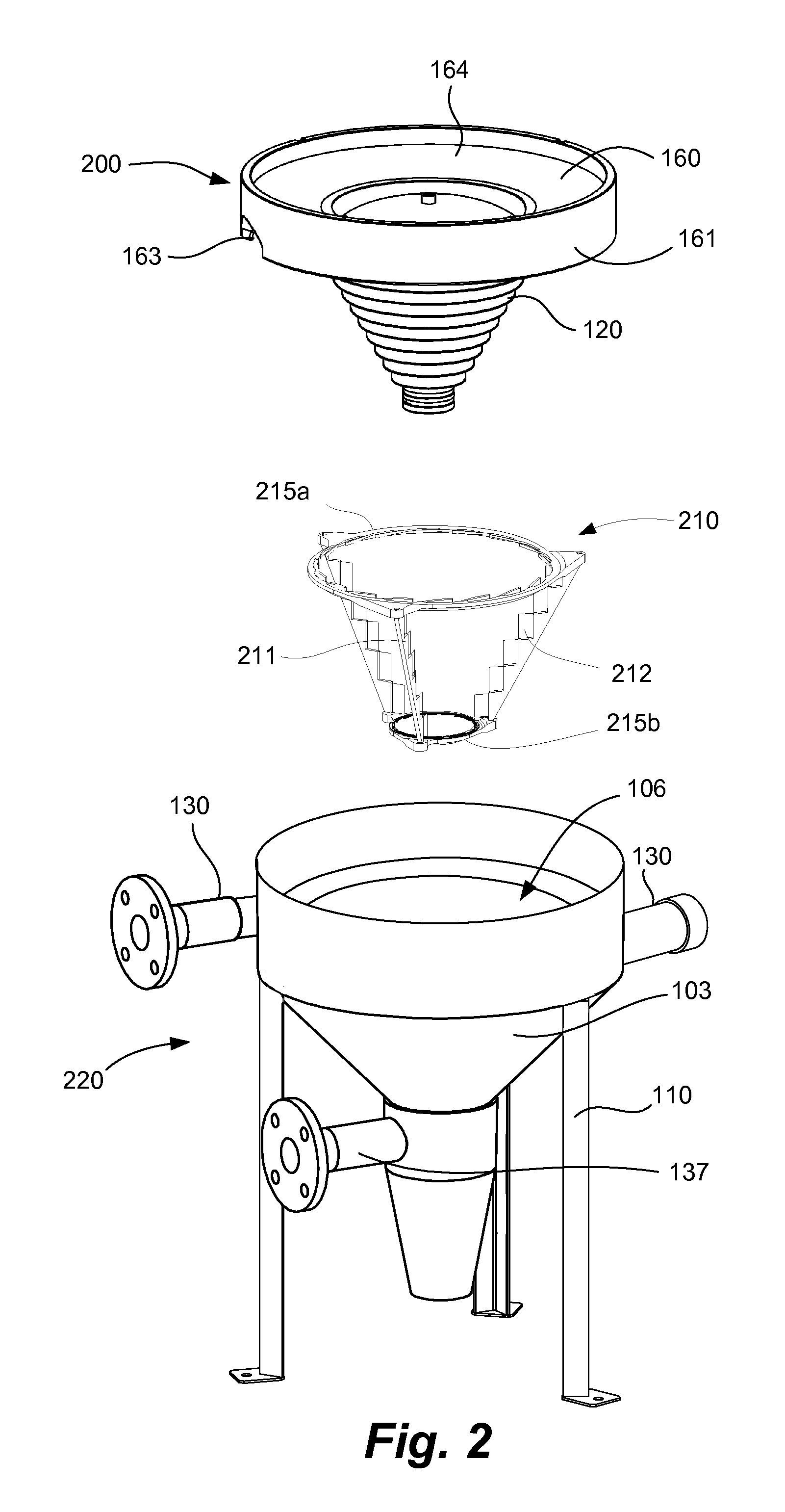

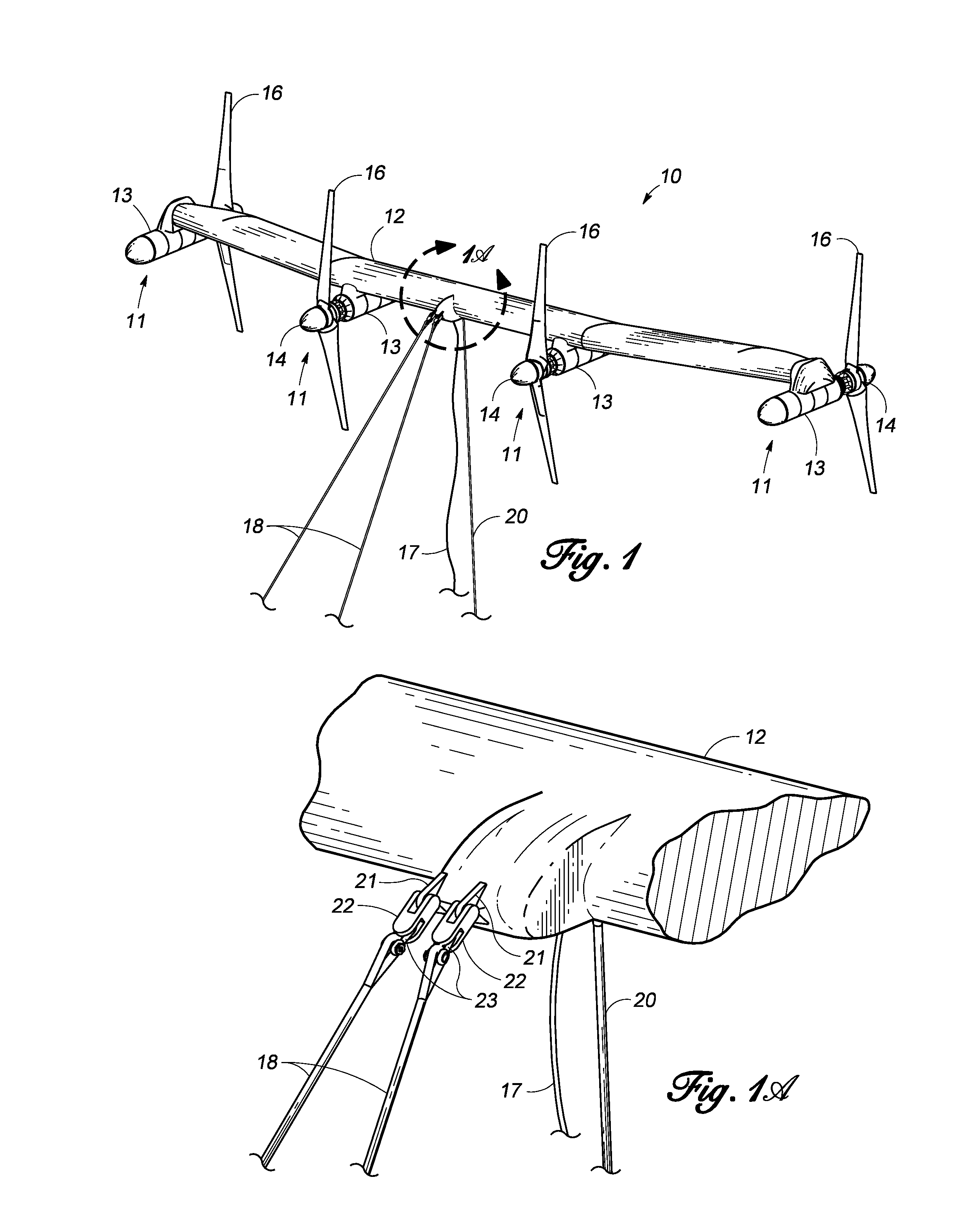

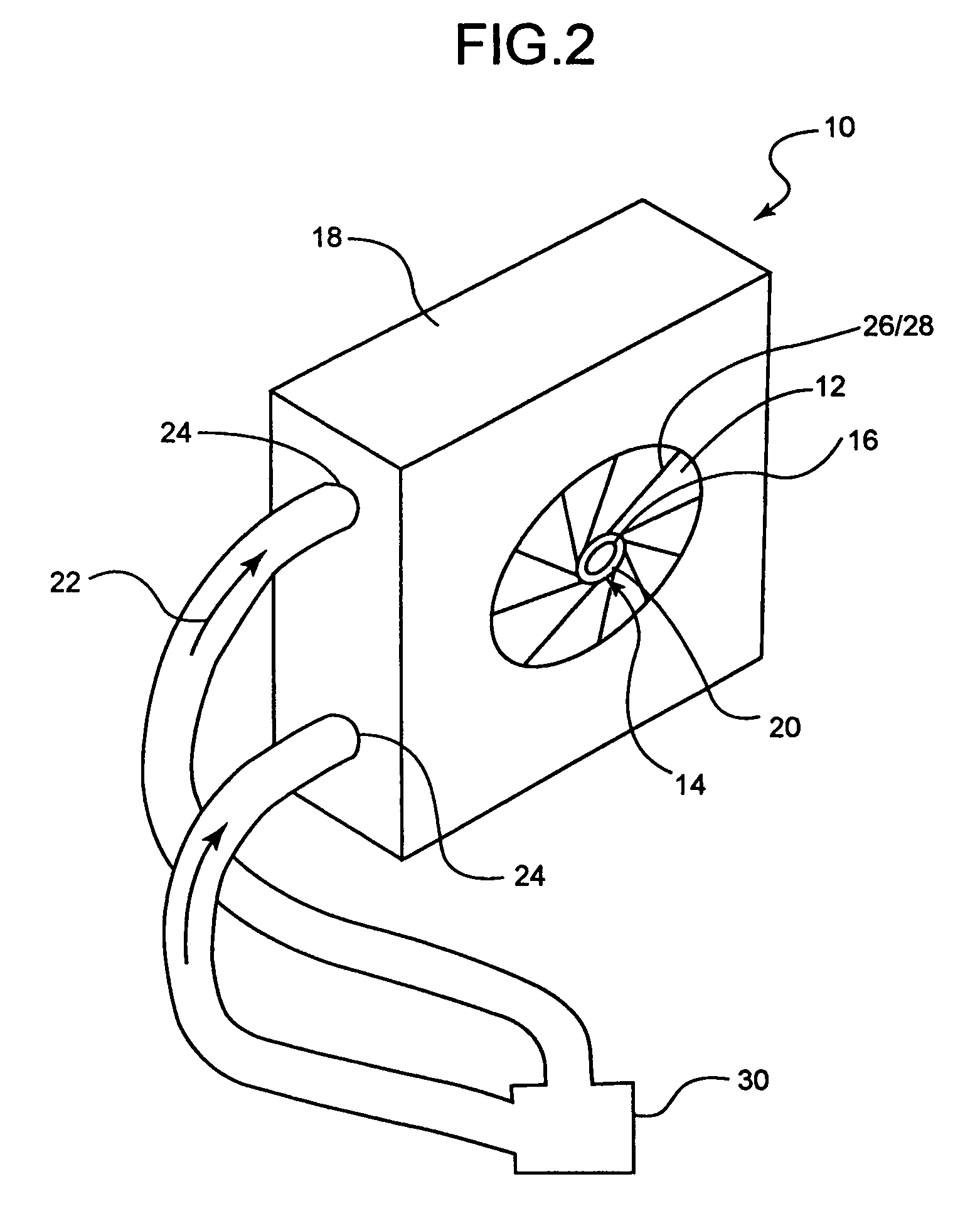

Multi-Megawatt Ocean Current Energy Extraction Device

InactiveUS20130106105A1Counteract buoyancyReduce the average velocityEngine fuctionsBuoyancy controlOcean bottomDrivetrain

An underwater apparatus for generating electric power from ocean currents and deep water tides. A submersible platform including two or more power pods, each having a rotor with fixed-pitch blades, with drivetrains housed in pressure vessels that are connected by a transverse structure providing buoyancy, which can be a wing depressor, hydrofoil, truss, or faired tube. The platform is connected to anchors on the seafloor by forward mooring lines and a vertical mooring line that restricts the depth of the device in the water column. The platform operates using passive, rather than active, depth control. The wing depressor, along with rotor drag loads, ensures the platform seeks the desired operational current velocity. The rotors are directly coupled to a hydraulic pump that drives at least one constant-speed hydraulic-motor generator set and enables hydraulic braking. A fluidic bearing decouples non-torque rotor loads to the main shaft driving the hydraulic pumps.

Owner:AQUANTIS

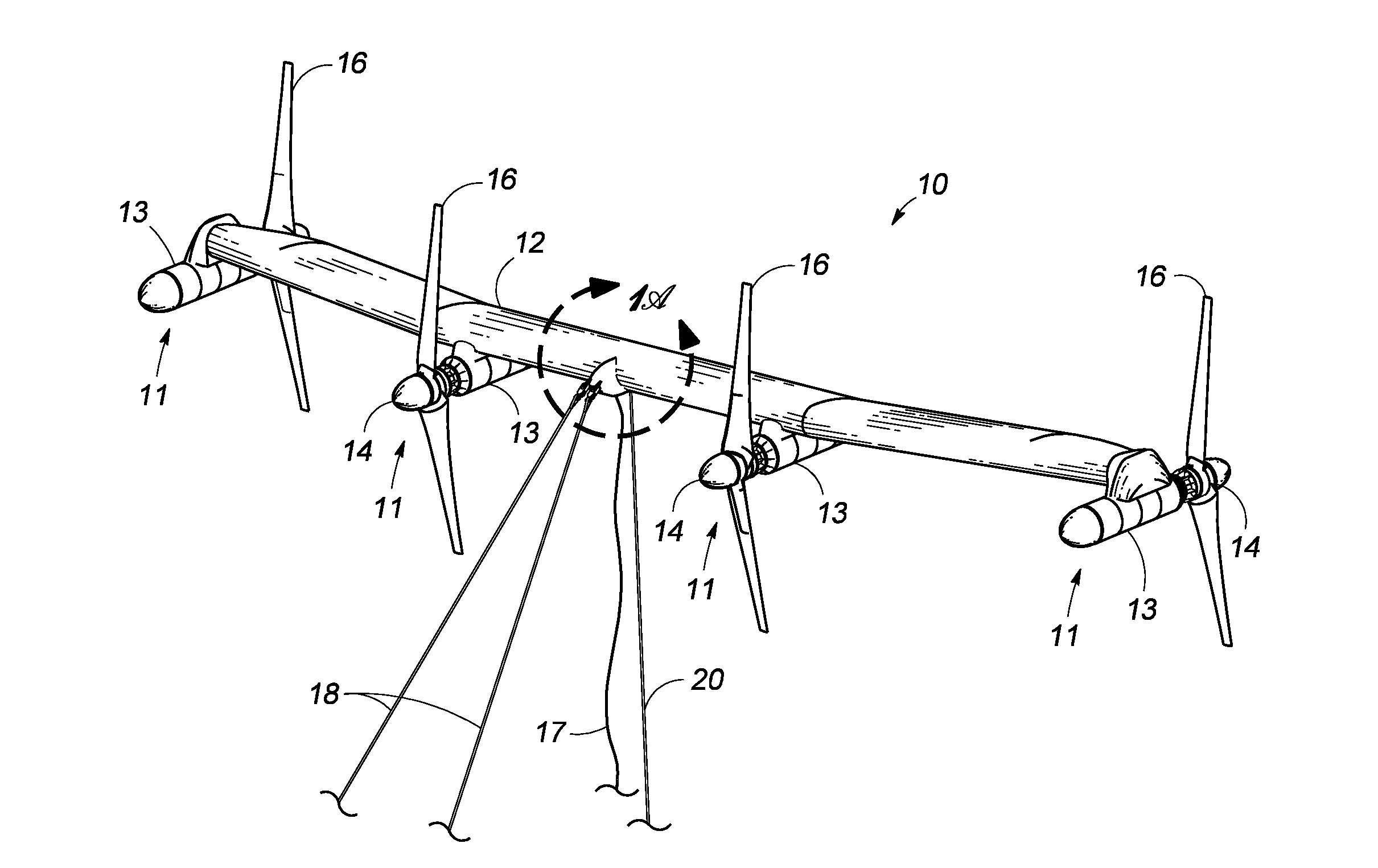

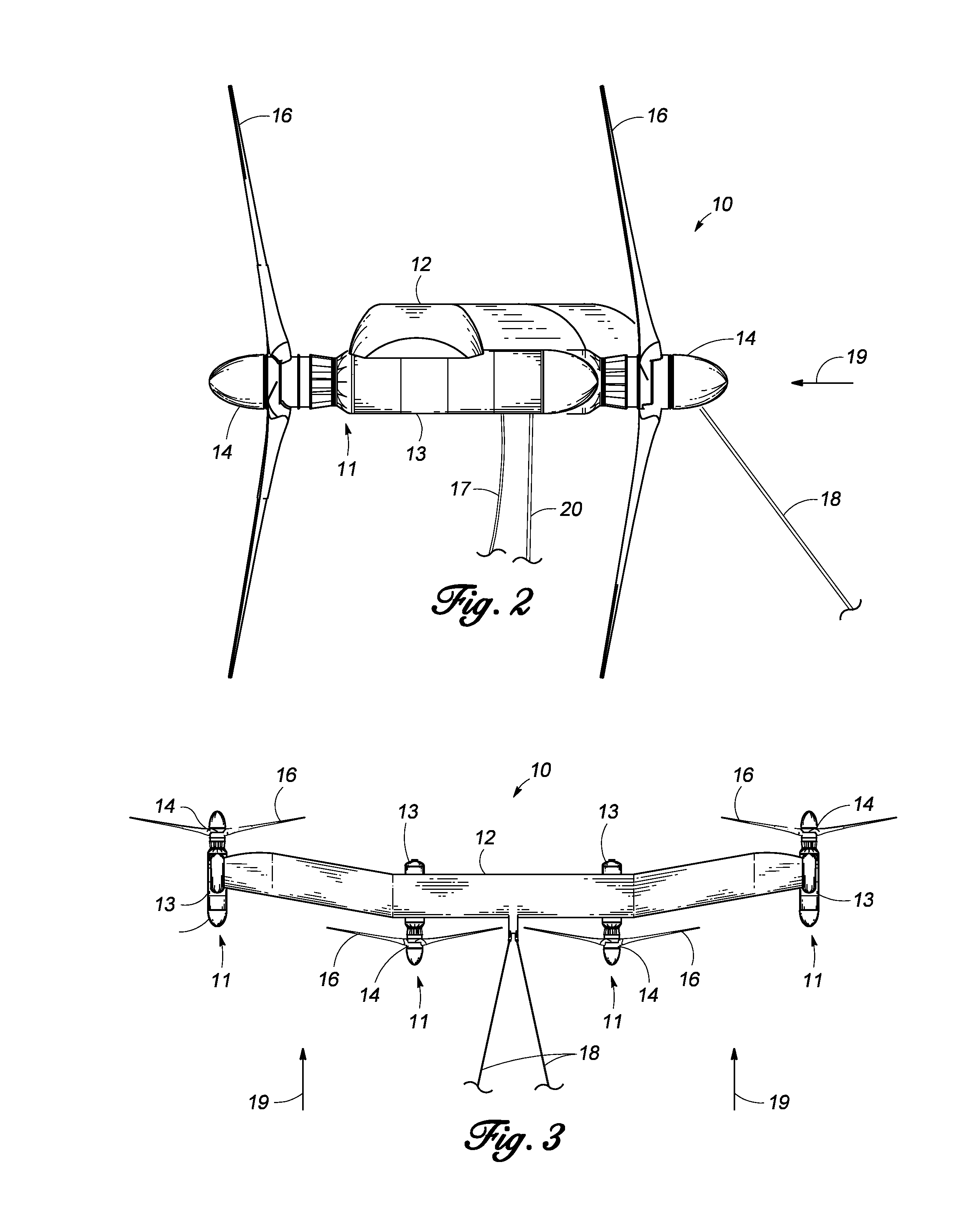

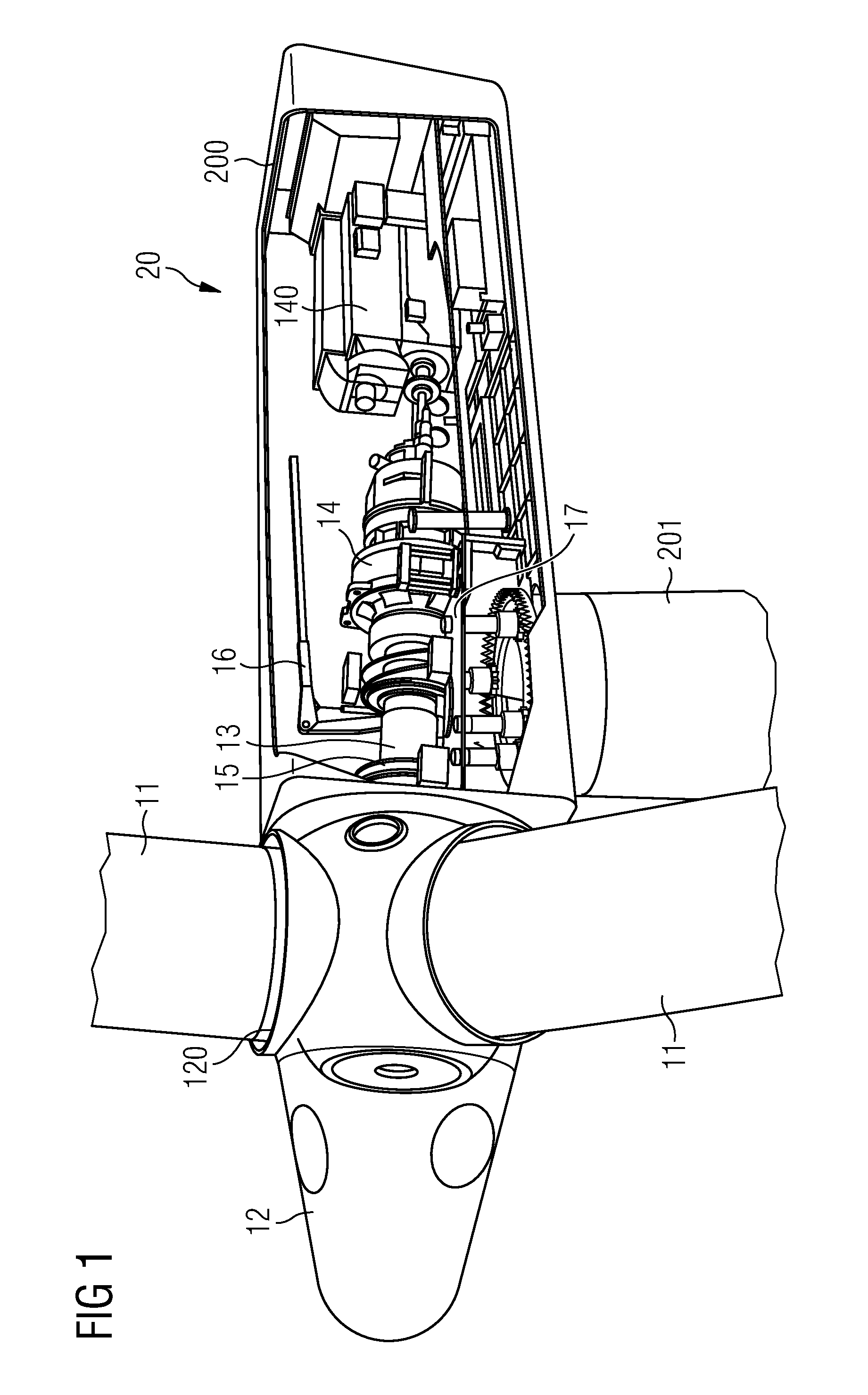

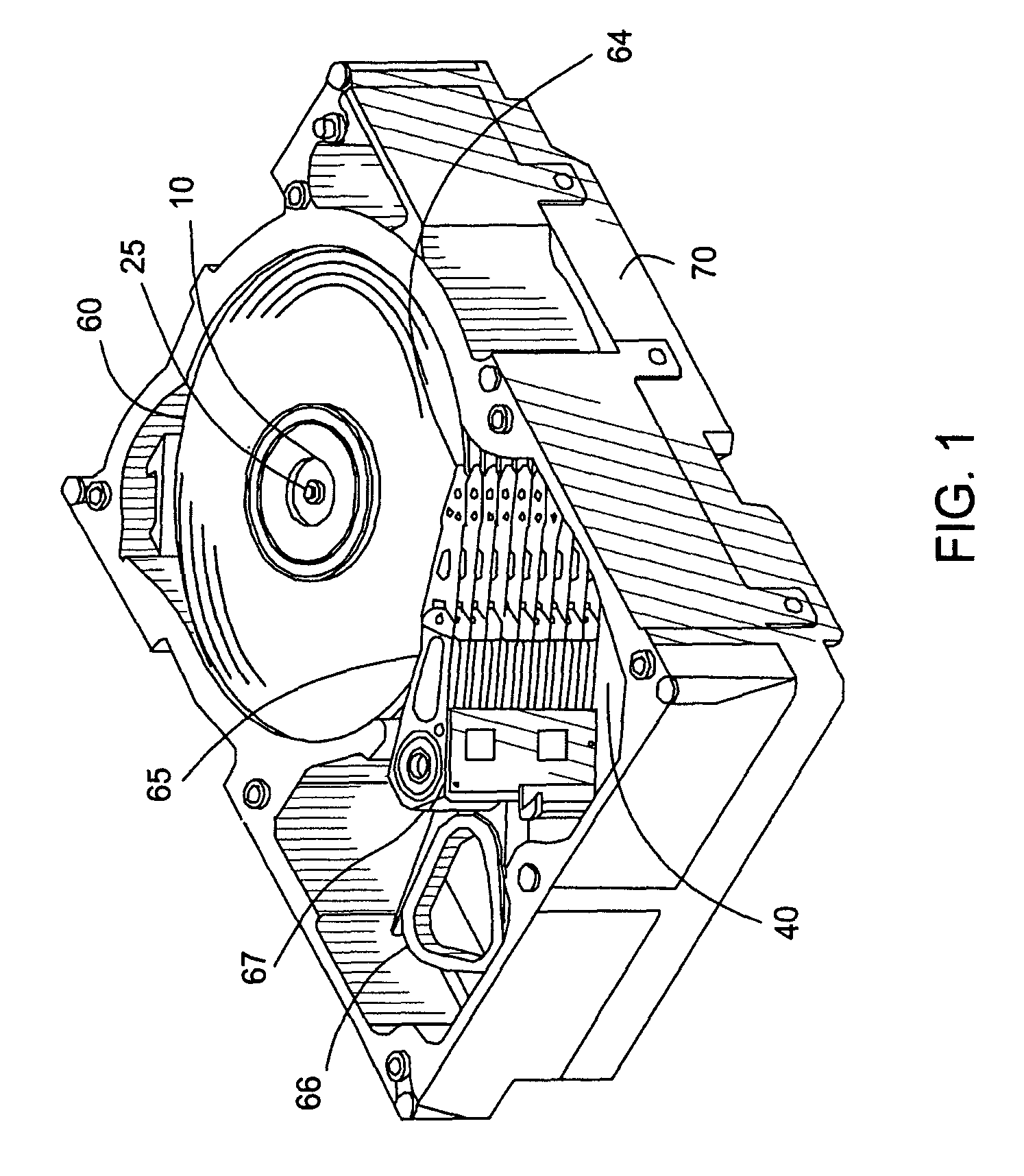

Wind turbine main bearing

ActiveUS20120099993A1Reduce loadEasy to removeBearing repair/replacementPropellersTurbineFluid bearing

A wind turbine main bearing realized to bear a shaft of a wind turbine, which shaft is caused to rotate by a number of blades connected to the shaft is disclosed. The wind turbine main bearing includes a fluid bearing with a plurality of bearing pads arranged about the shaft. Also disclosed is a wind turbine with a number of blades connected to a shaft and realized to rotate the shaft, which wind turbine includes as main bearing a wind turbine main bearing. Further described is a method of performing maintenance on a wind turbine, including the steps of halting a rotation of the shaft, operating a lifting arrangement to raise the shaft, and removing a bearing pad of the wind turbine main bearing from the bearing housing of the wind turbine main bearing.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

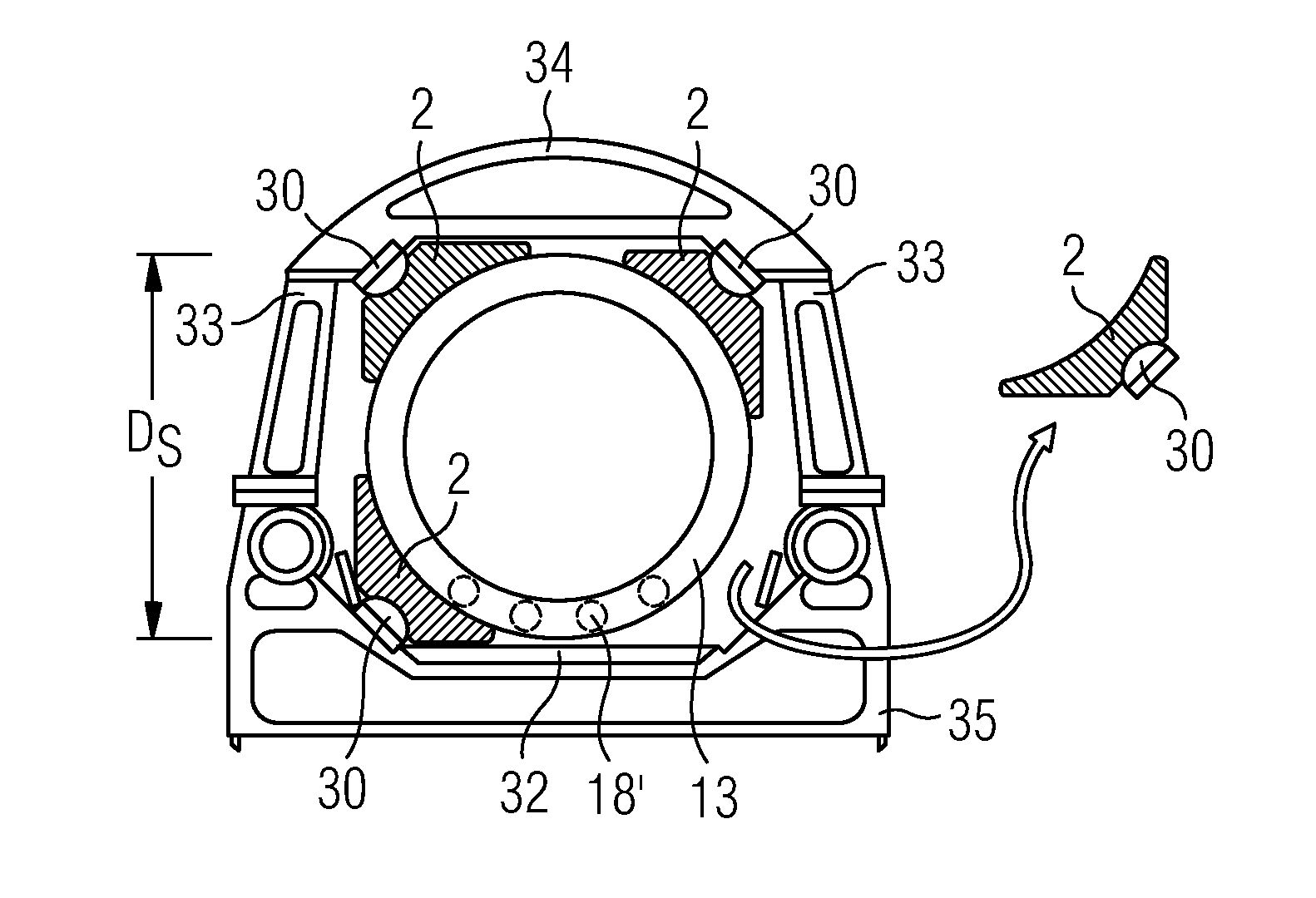

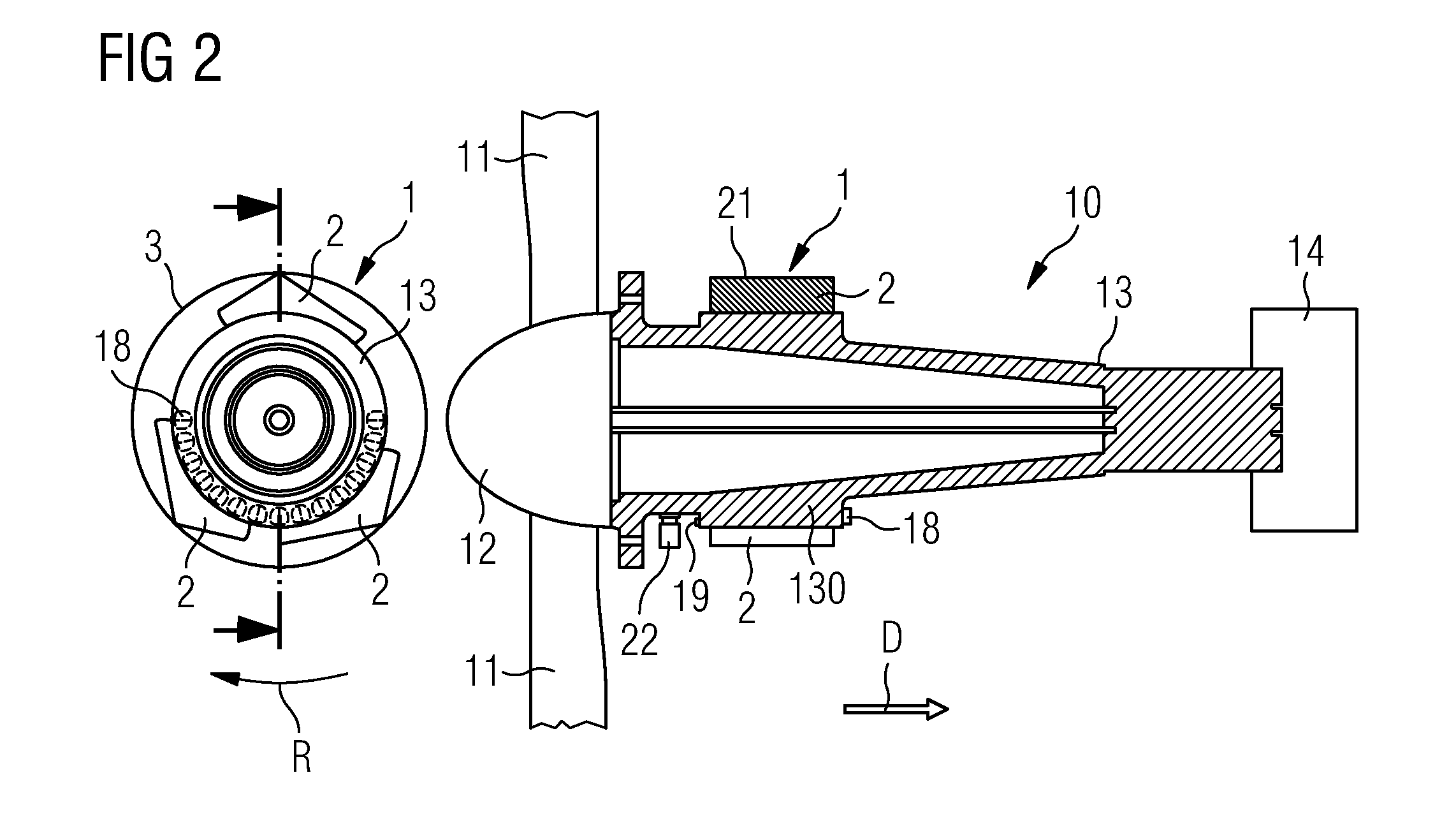

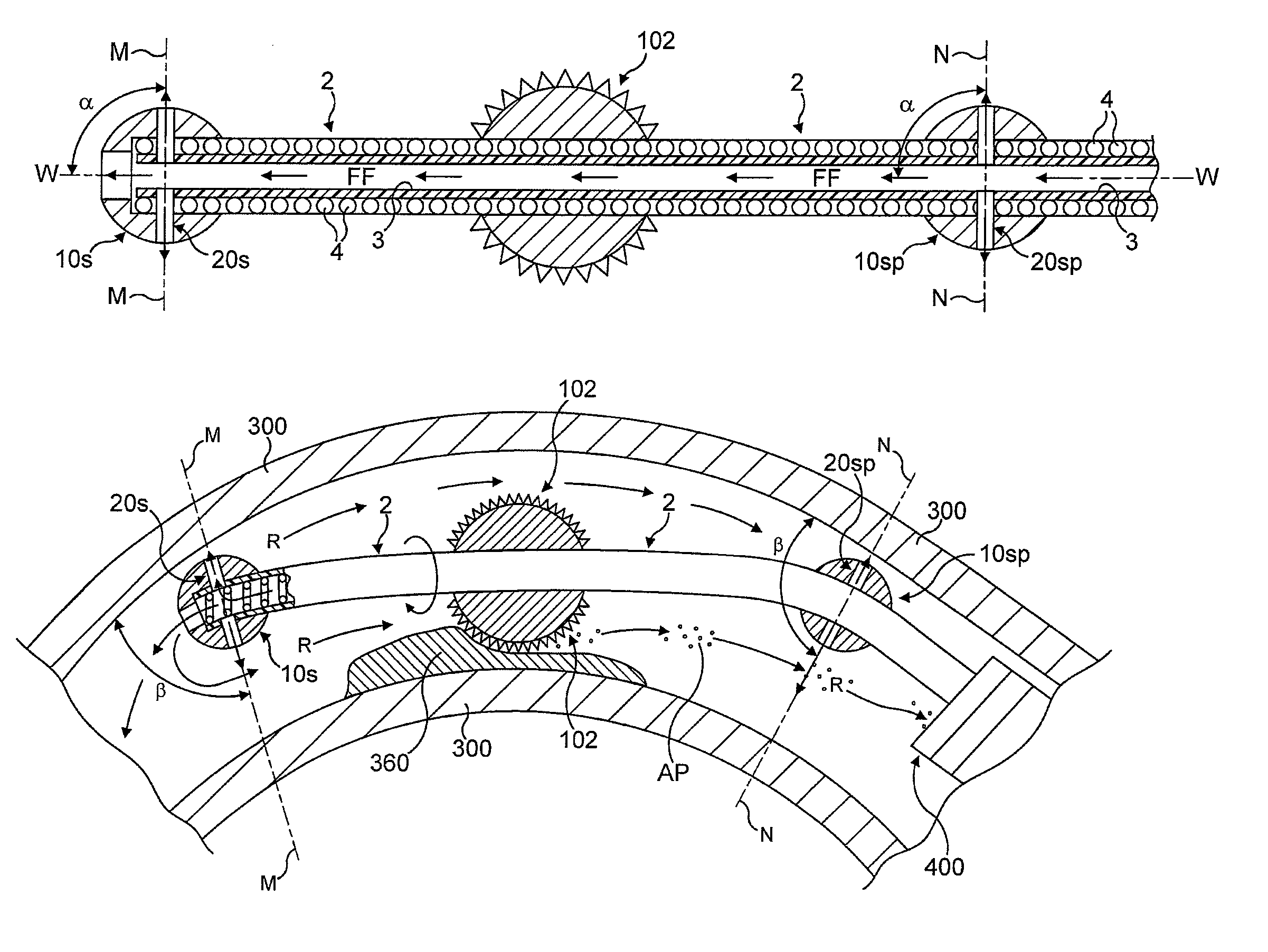

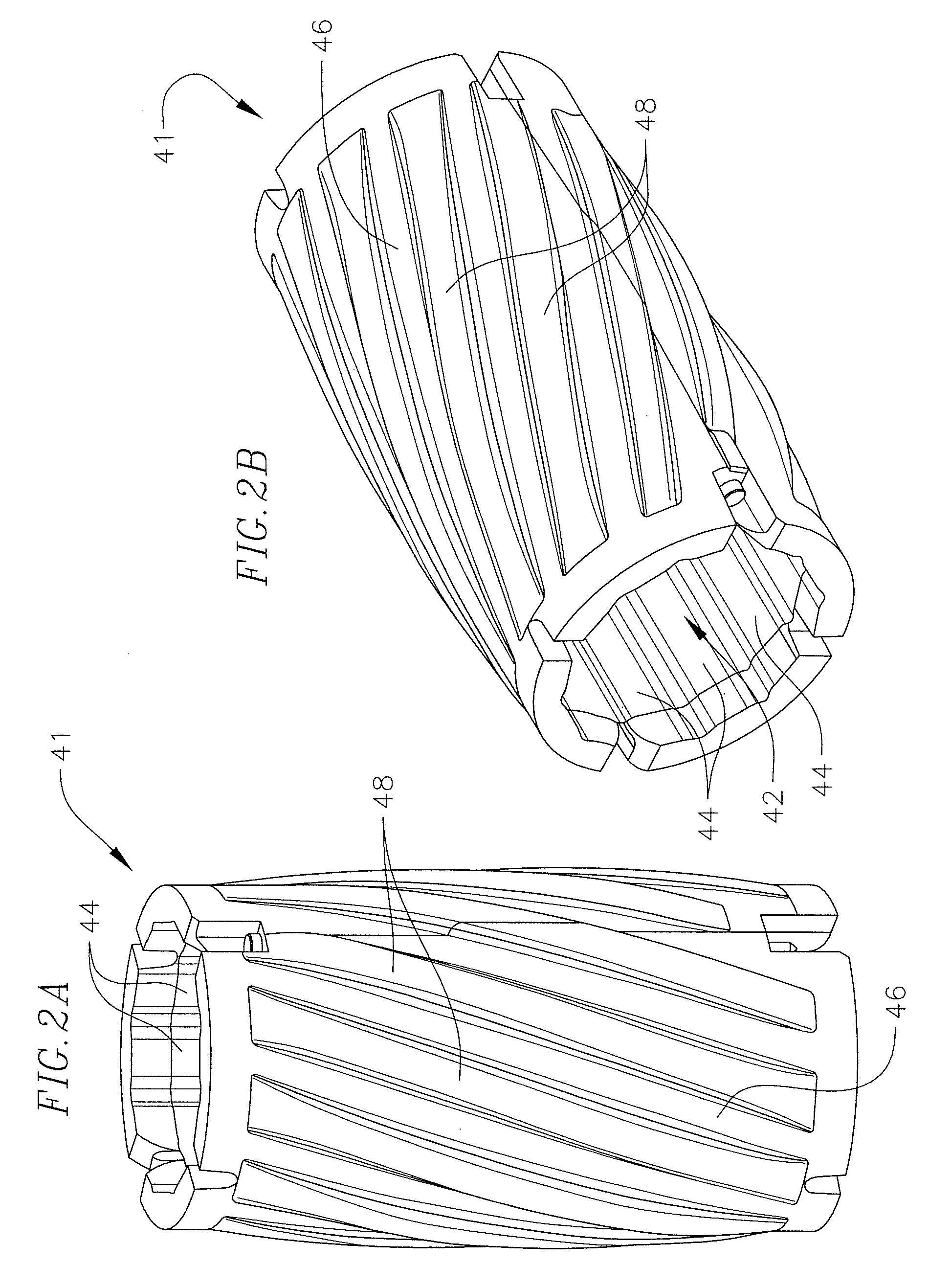

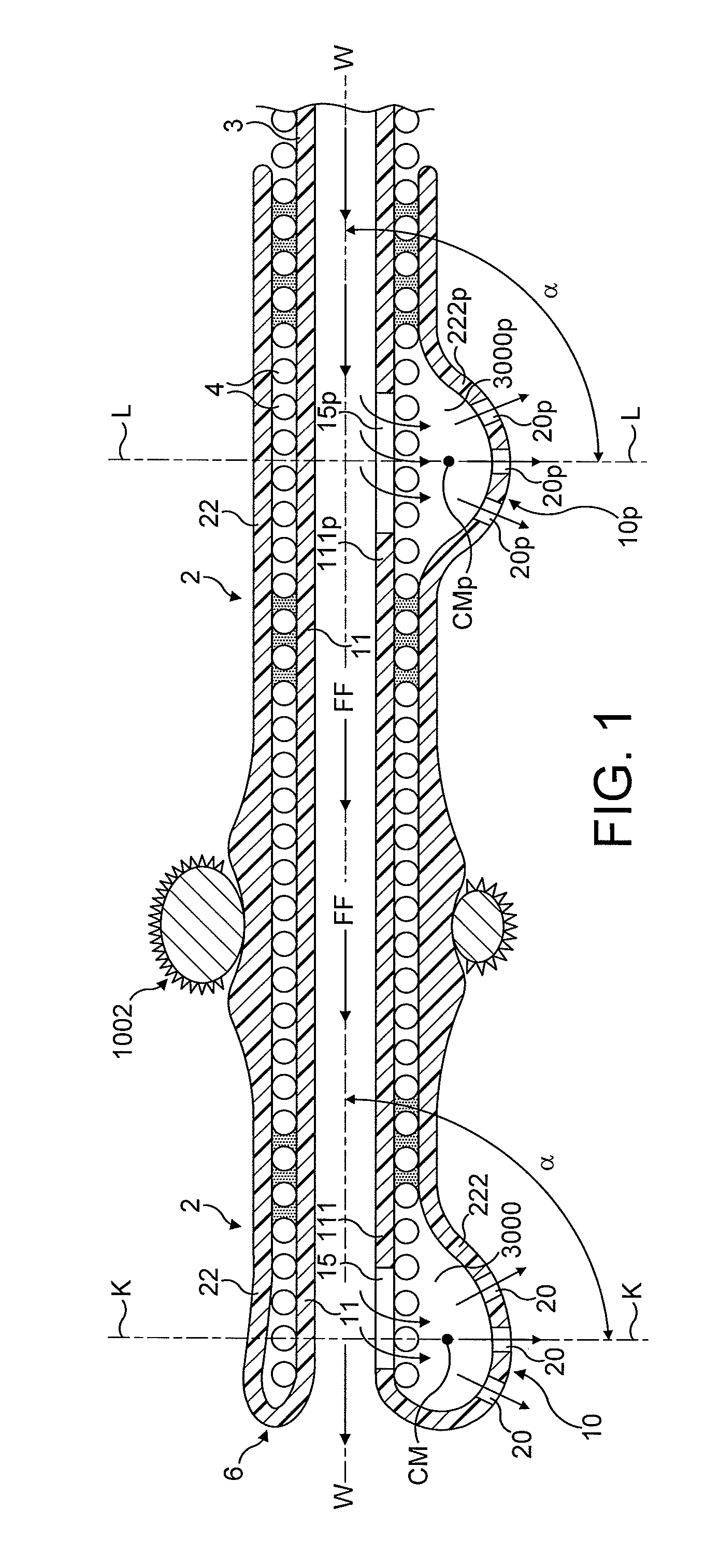

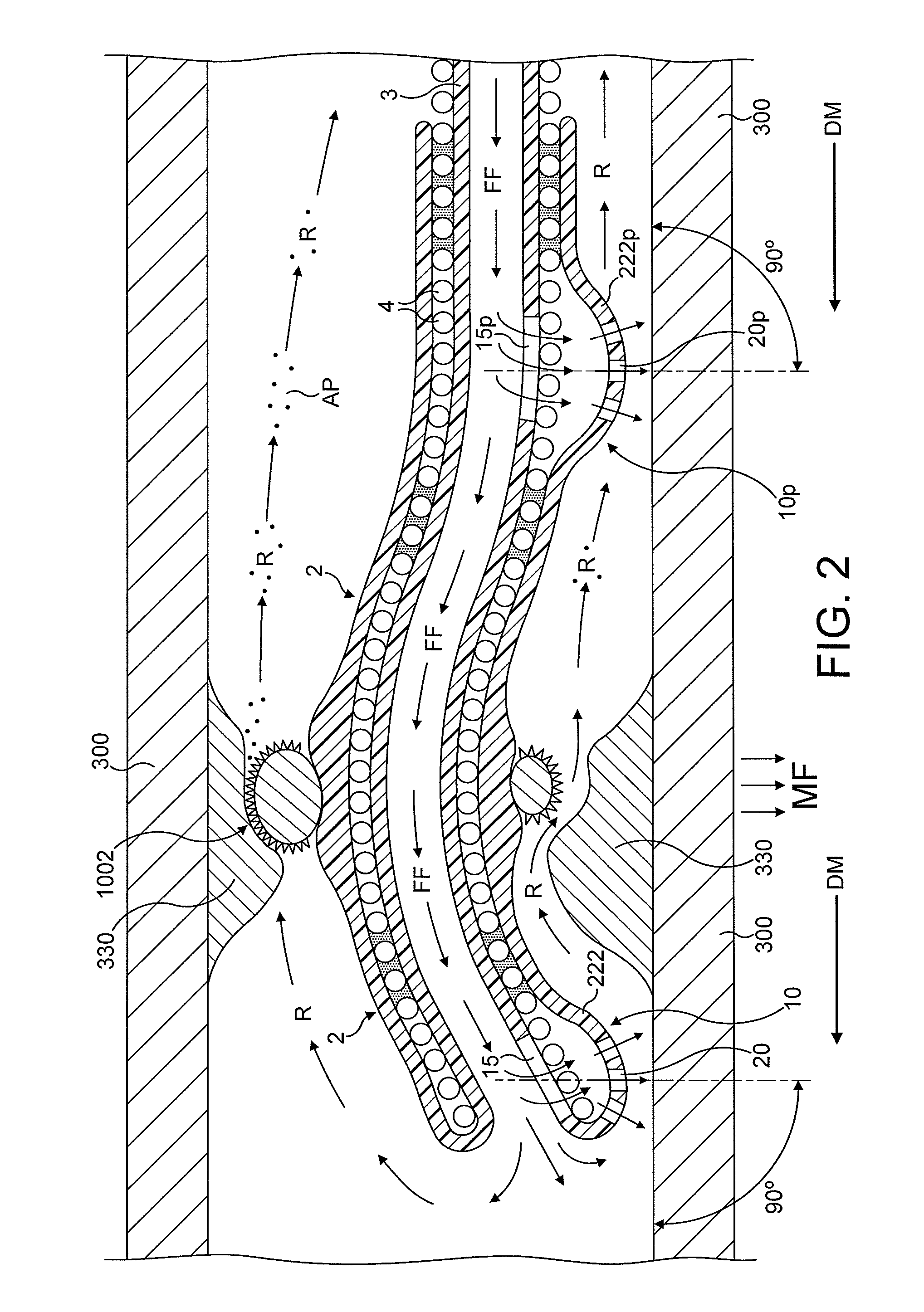

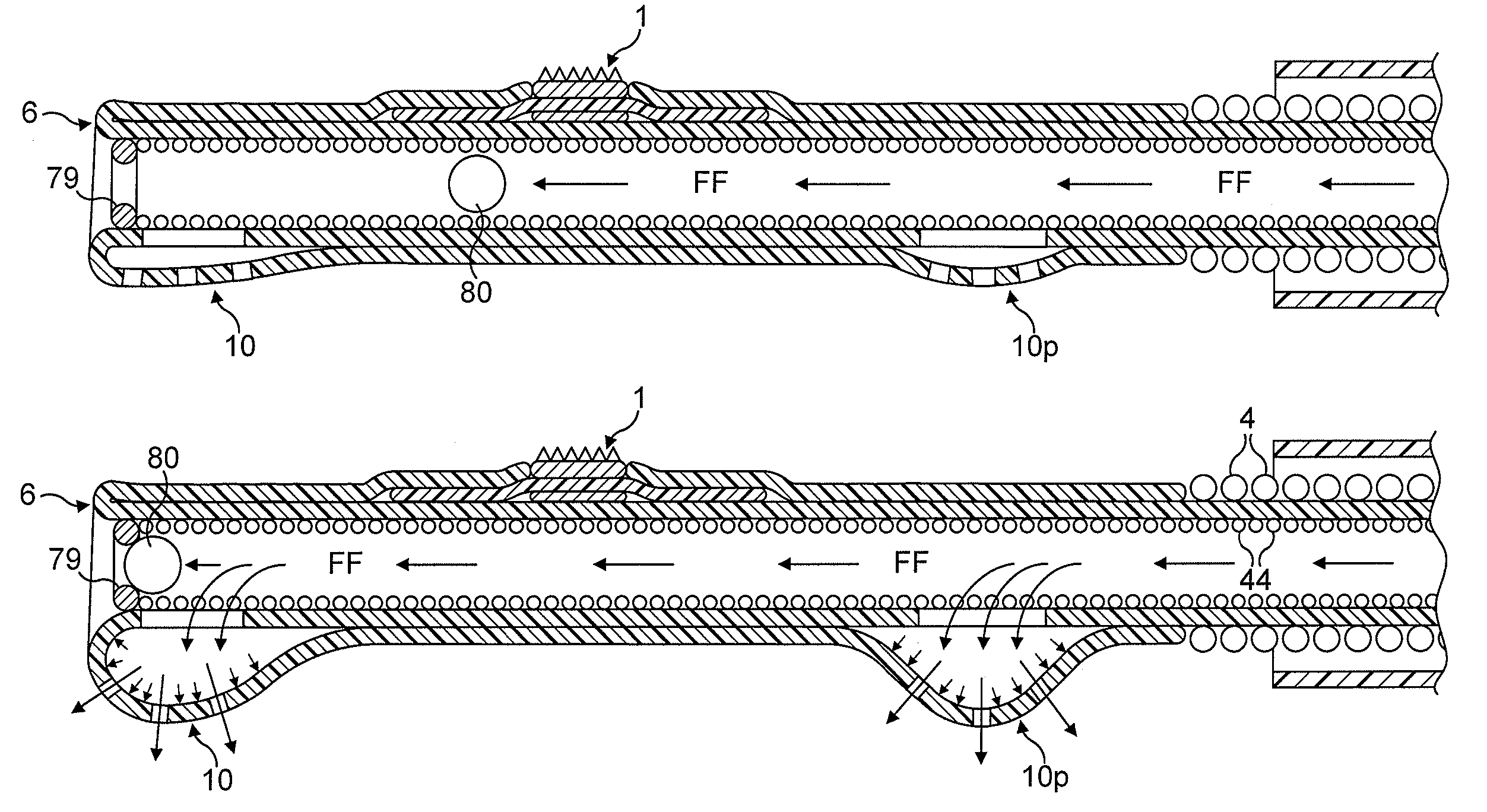

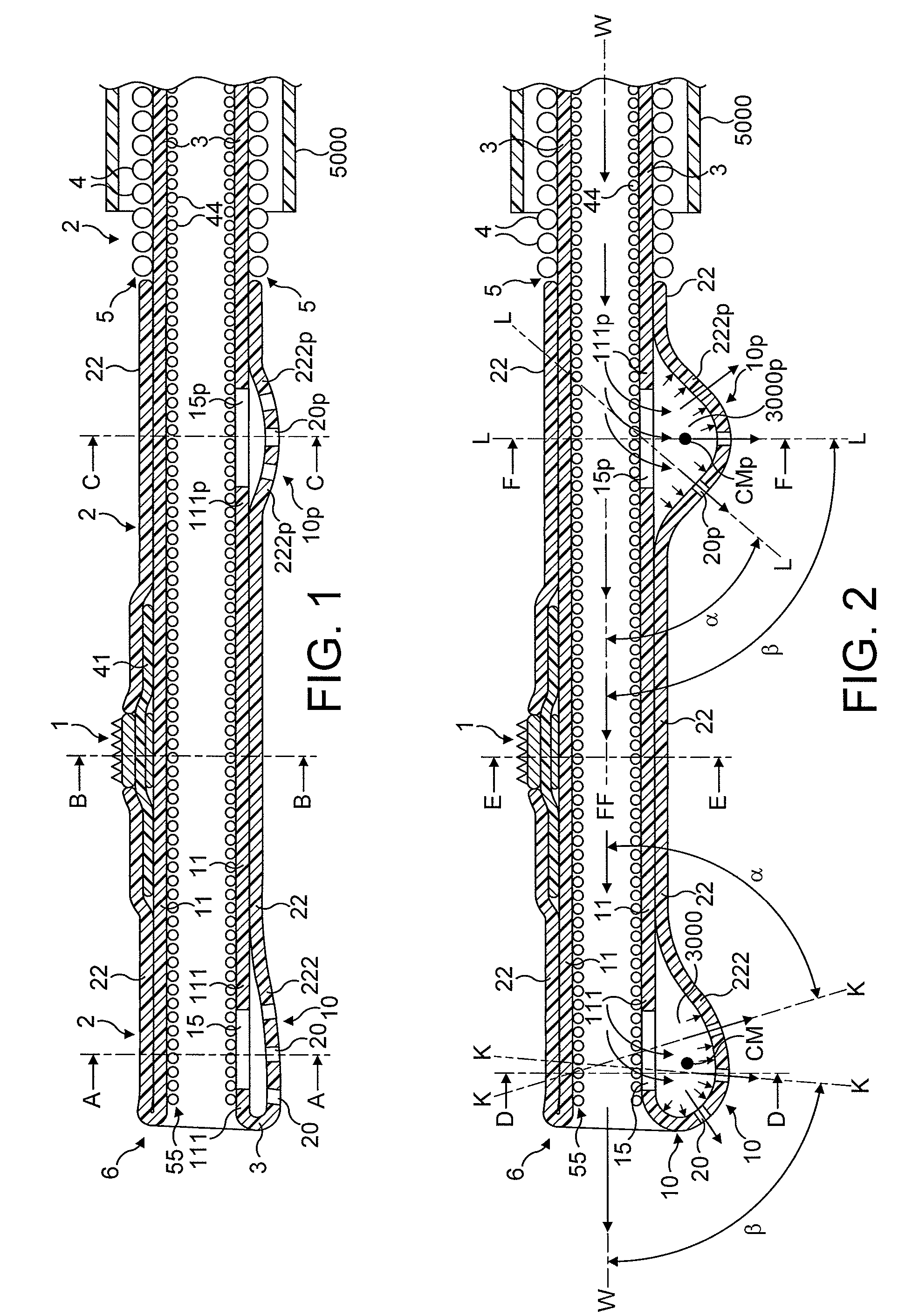

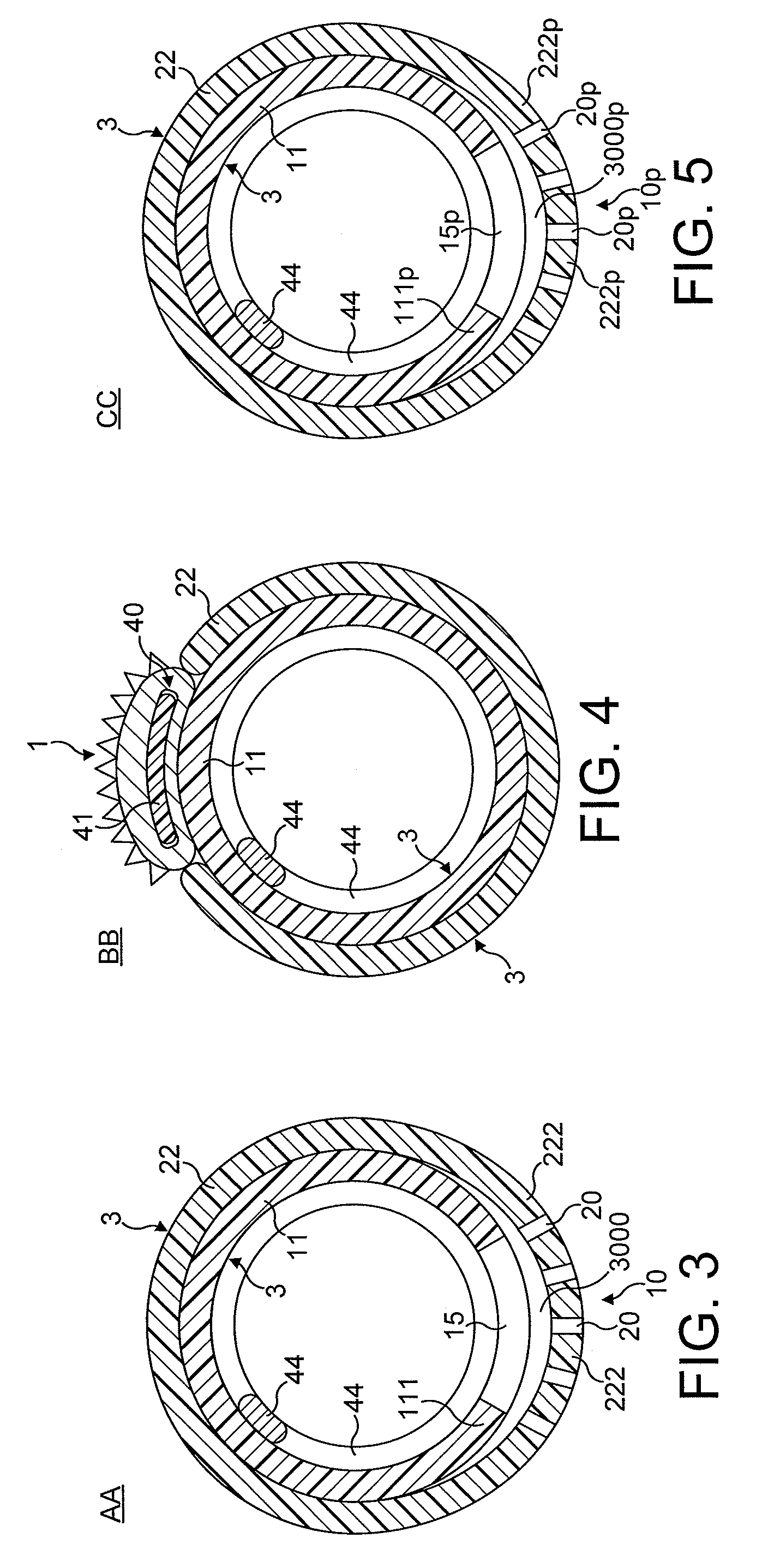

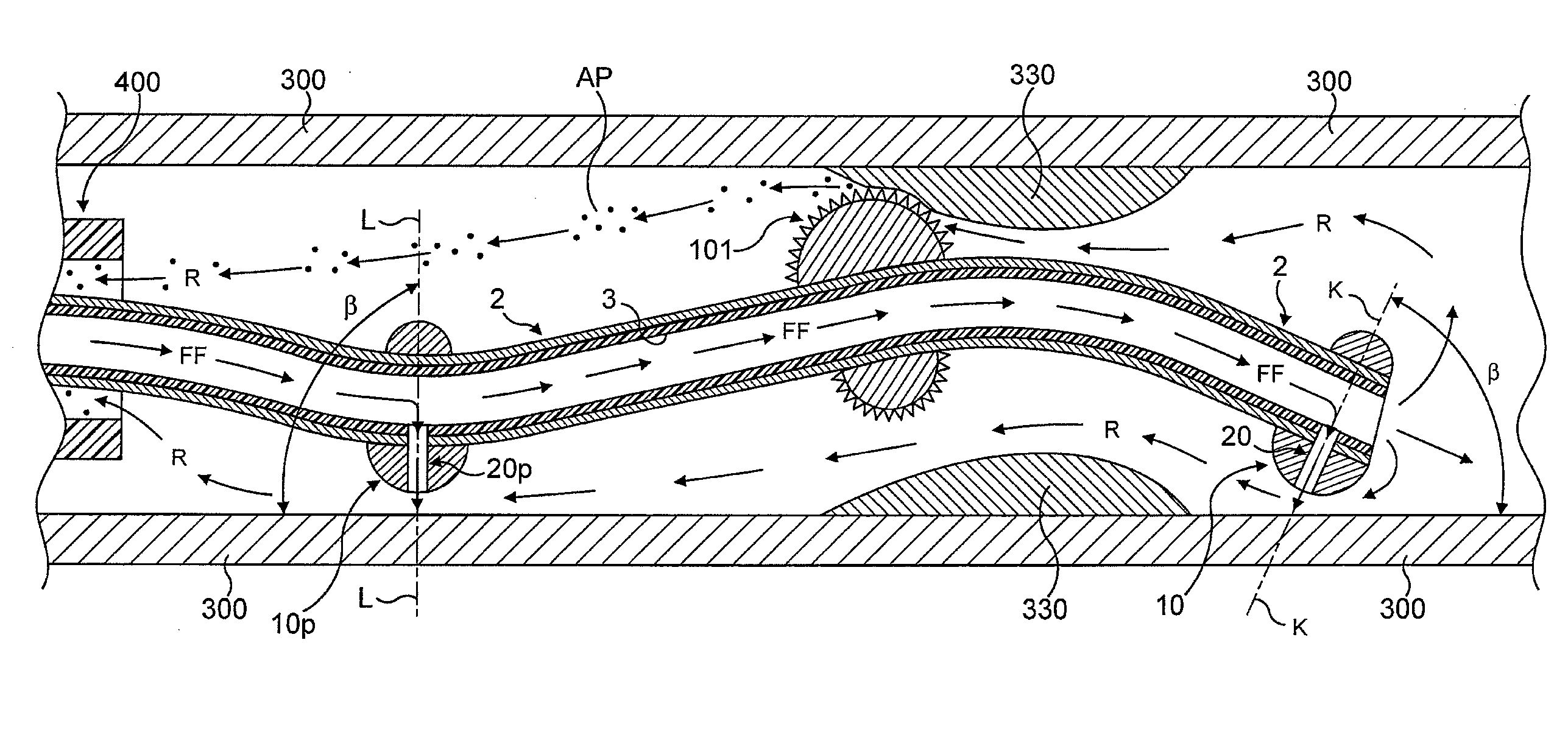

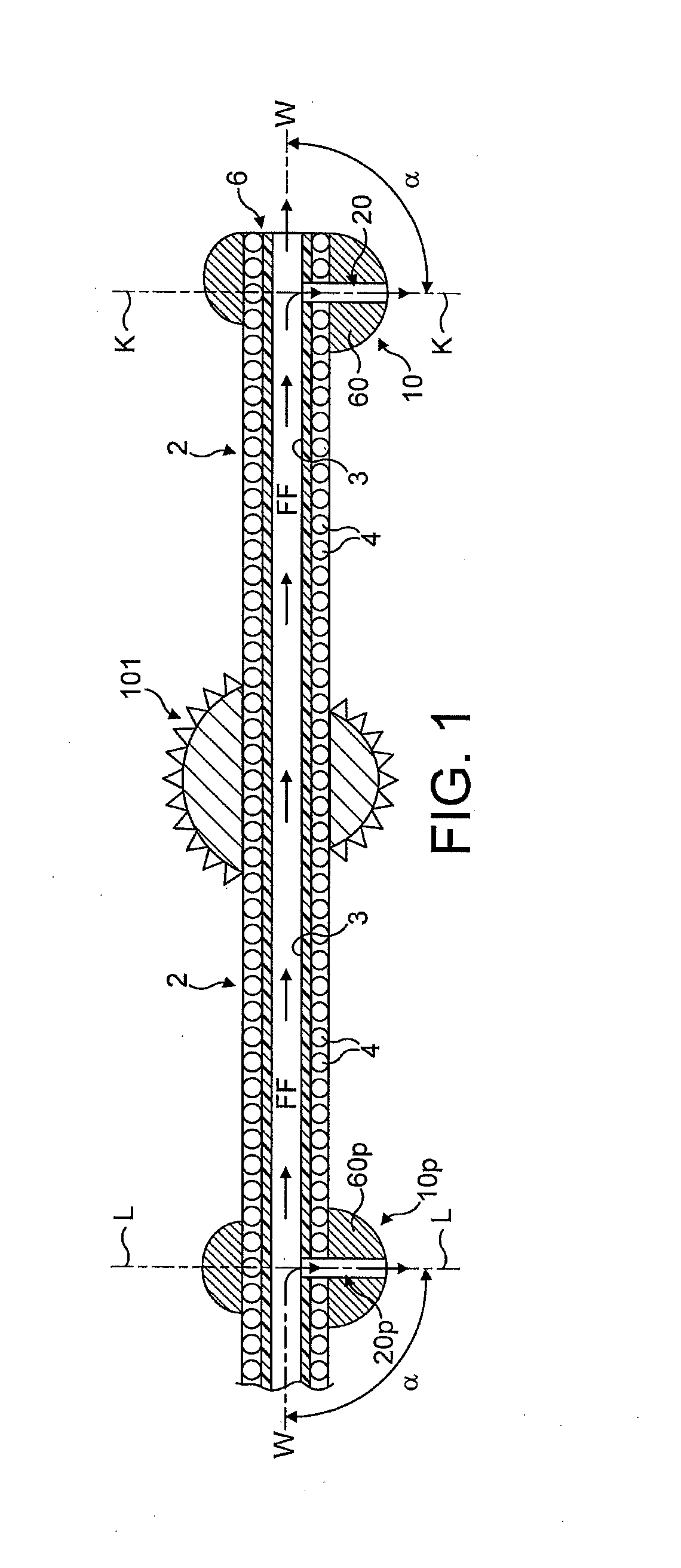

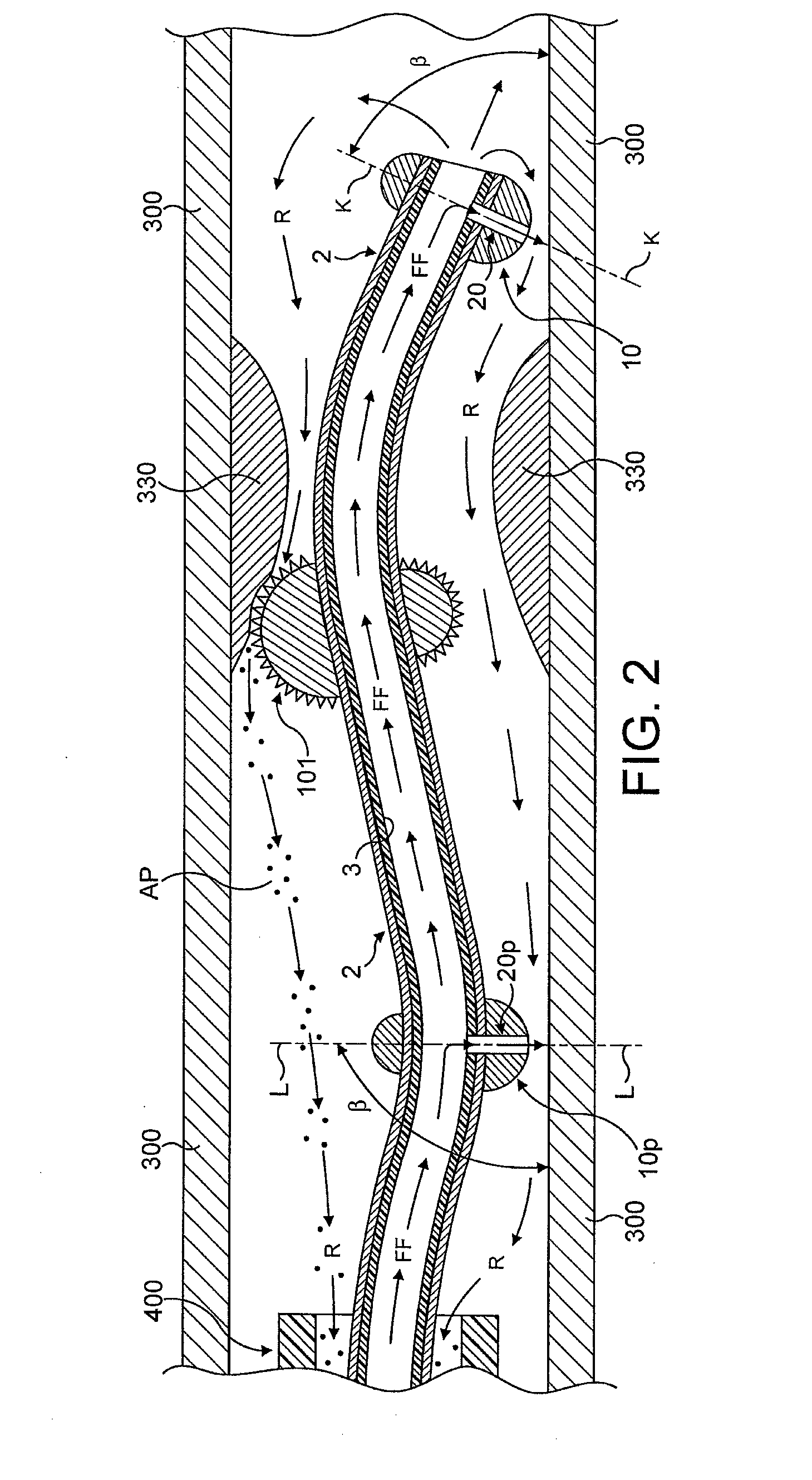

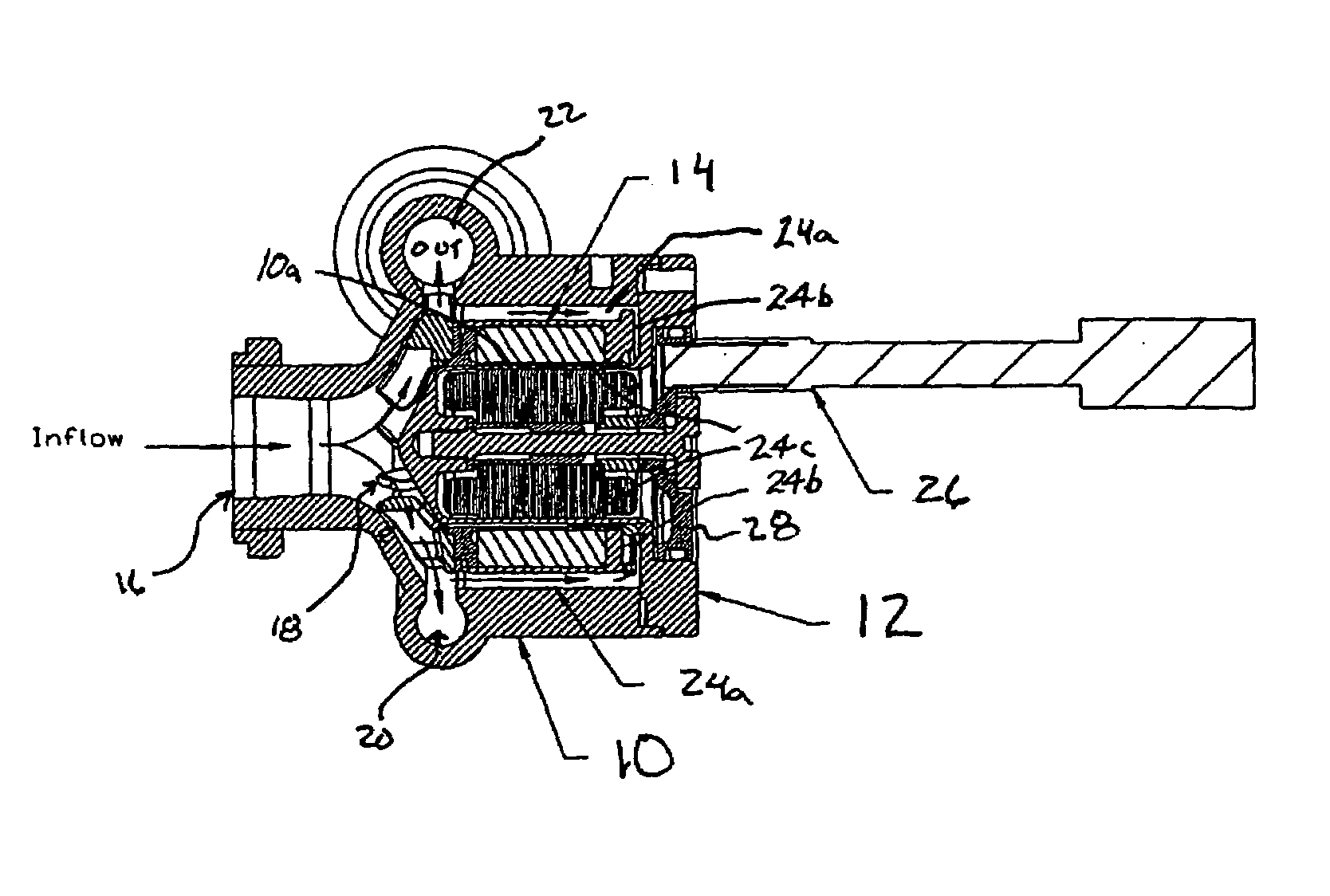

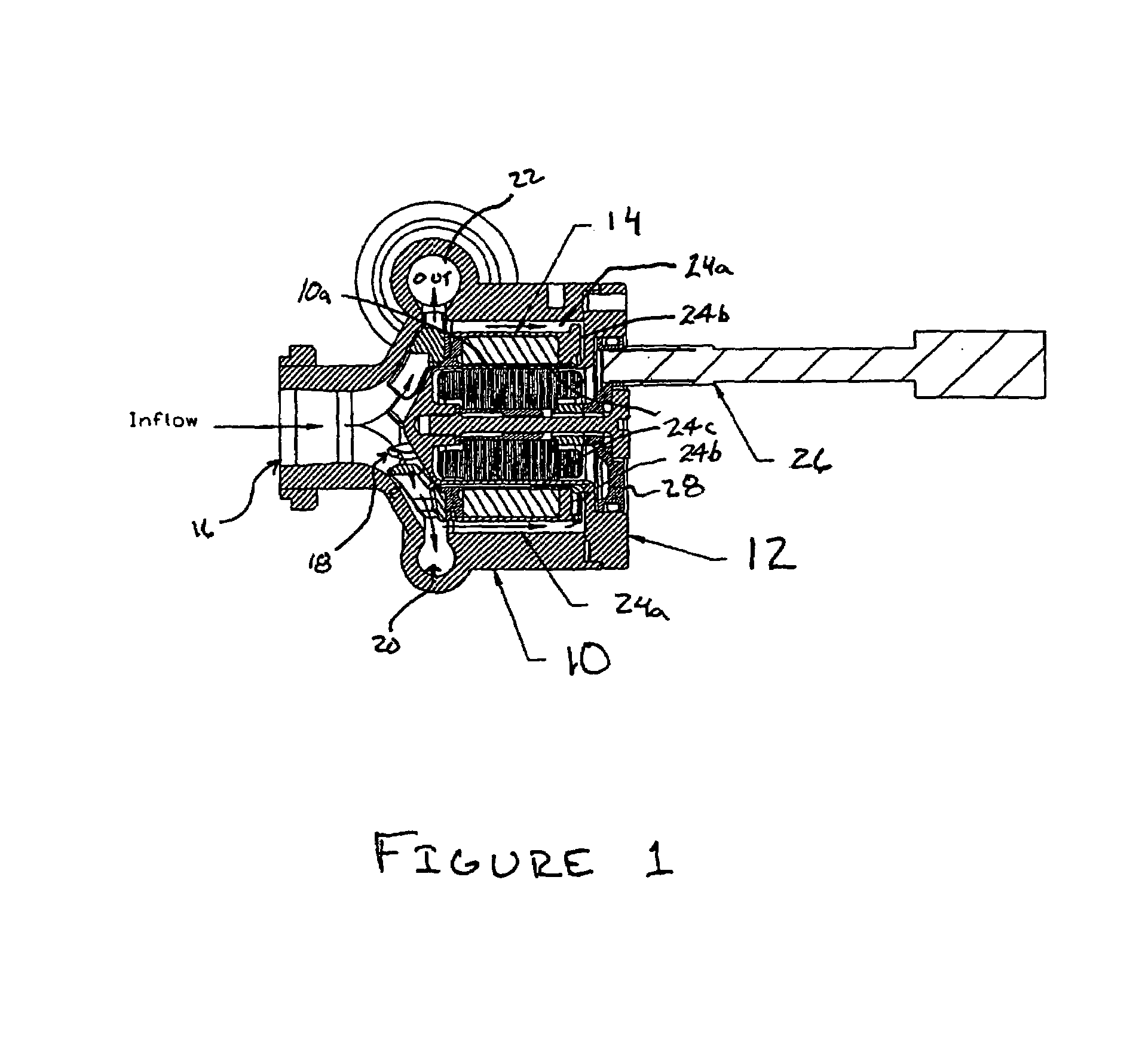

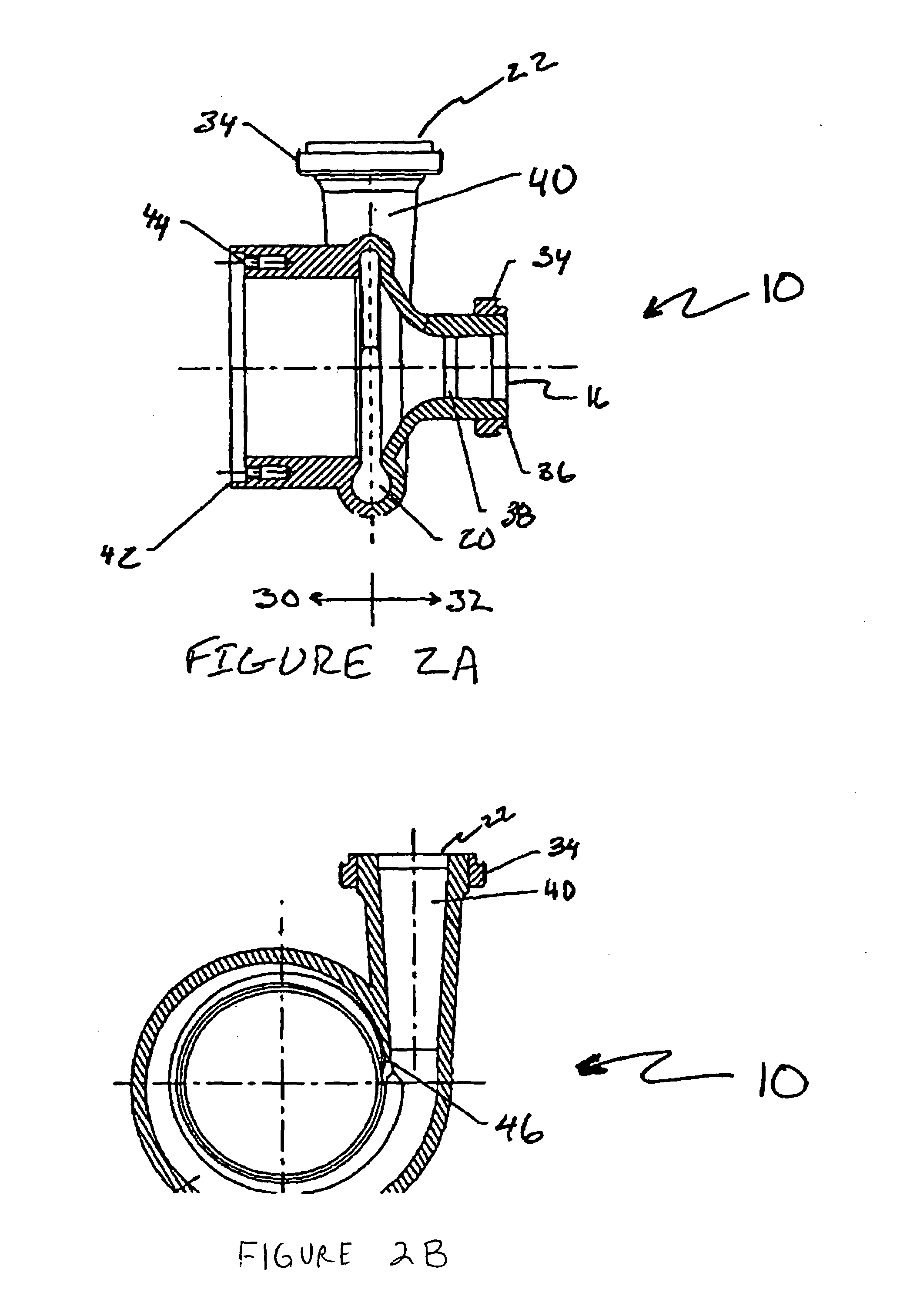

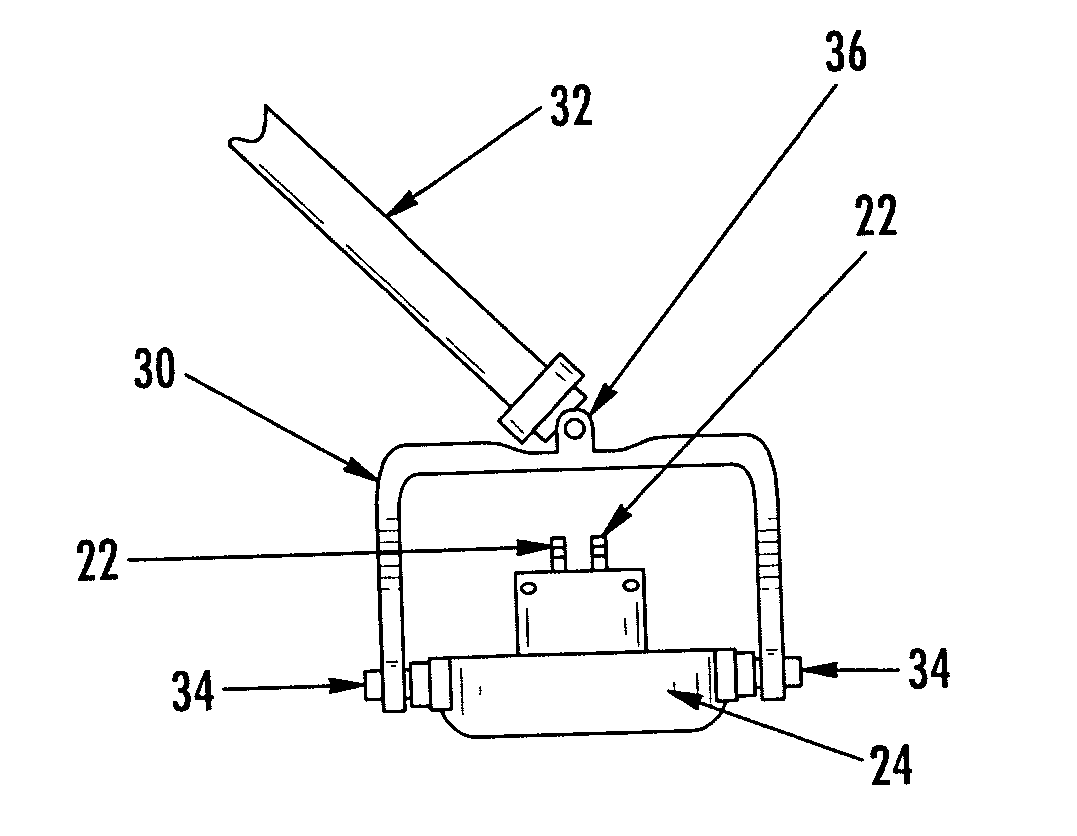

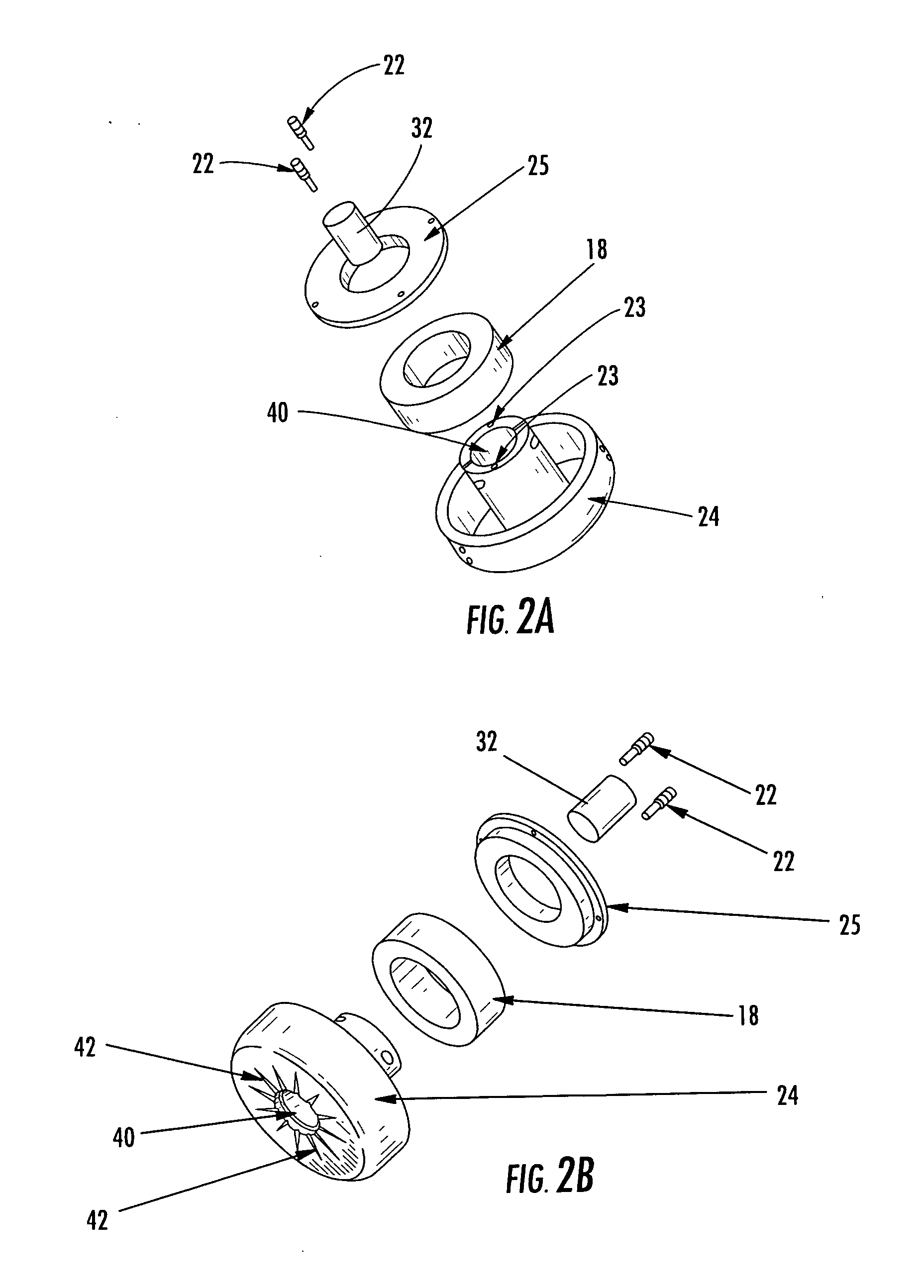

Atherectomy device supported by fluid bearings

A rotational atherectomy device for removing a stenotic tissue (330, 360) from a vessel (300) of a patient comprises a flexible hollow drive shaft (2) and an abrasive element (101, 102) mounted to the drive shaft proximal to and spaced from a solid support element (10, 10s) mounted at the distal end (6) of the drive shaft, the solid support element having a rounded outer surface and an outflow channel (20, 20s) with an outflow opening in said rounded outer surface. The drive shaft comprises a torque transmitting coil (4) and at least one fluid impermeable membrane (3) forming a fluid impermeable lumen for the antegrade flow (FF) of fluid into the outflow channel such that, during rotation of the drive shaft, a flow of fluid out of said outflow opening forms a fluid bearing between the rotating solid support element and the wall of the treated vessel.

Owner:CARDIOFLOW

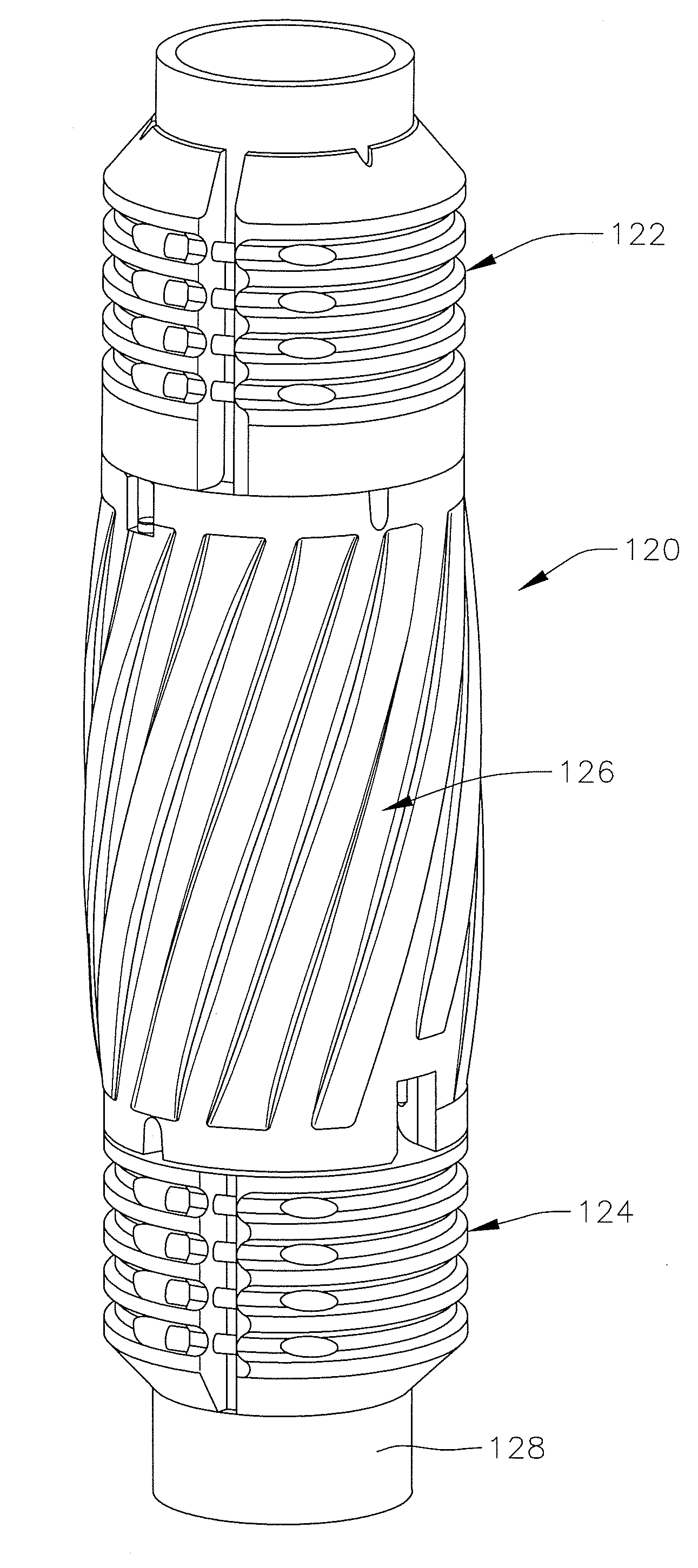

Non-rotating casing centralizer

ActiveUS20110114338A1Reduce slidingReduces rotating torqueDrilling rodsFluid removalHelical bladeFluid bearing

A non-rotating downhole sleeve adapted for casing centralization in a borehole. The sleeve includes a tubular body made of hard plastic with integrally formed helical blades positioned around its outer surface and an inner surface which allows drilling fluid to circulate to form a non-rotating fluid bearing between the sleeve and the casing. The tubular sleeve comprises a continuous non-hinged wall structure for surrounding the casing. The non-rotating centralizer sleeve reduces sliding and rotating torque at the surface while drilling the casing, for example, with minimal obstruction to drilling fluid passing between the casing and the surrounding borehole.

Owner:WWT NORTH AMERICA HLDG

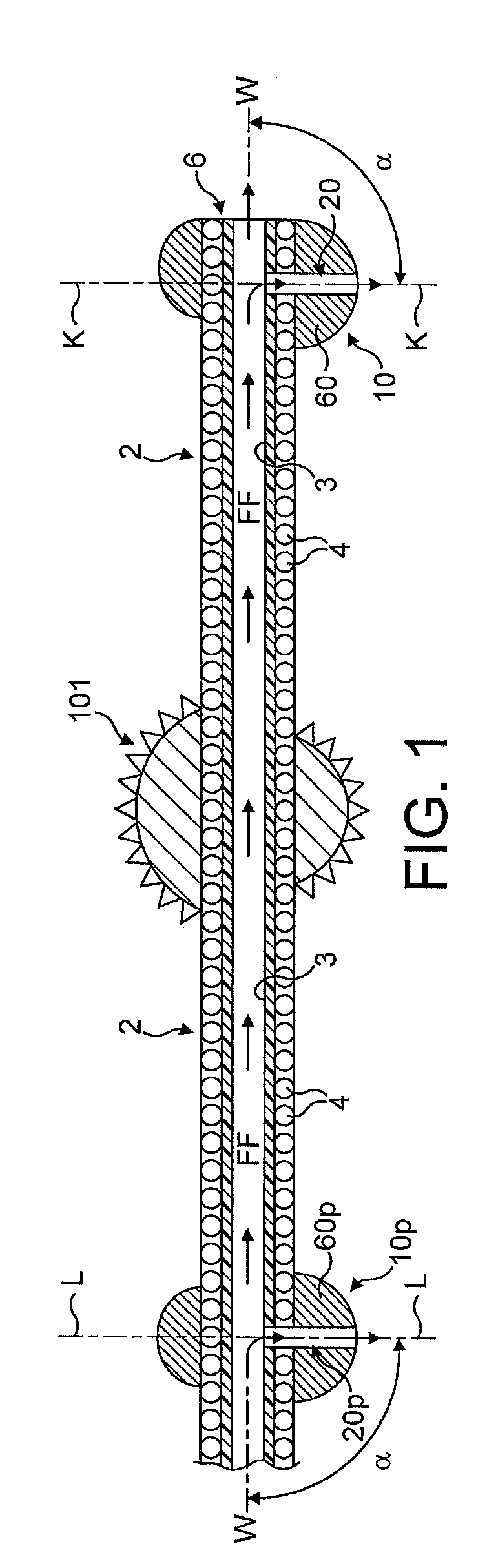

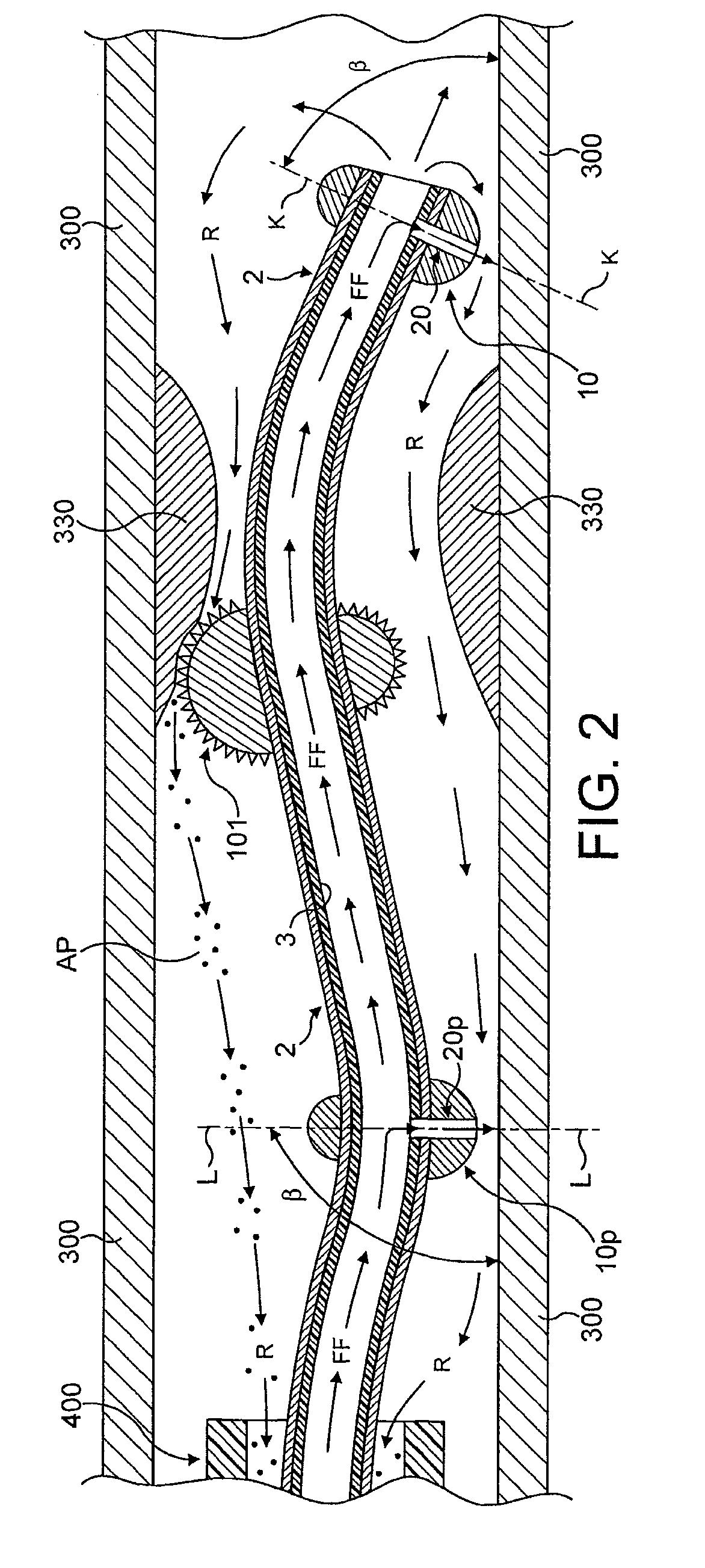

Rotational atherectomy device with fluid inflatable support elements supported by fluid bearings

A rotational atherectomy device for removing a stenotic tissue from a vessel of a patient is disclosed. The device comprises a rotatable, flexible, hollow drive shaft having an open distal end. The drive shaft comprising a fluid impermeable wall, an abrasive element mounted to the drive shaft proximal to and spaced away from its distal end, the fluid impermeable wall being formed from a torque transmitting coil and at least one fluid impermeable membrane which define a lumen for the antegrade flow of pressurized fluid through the drive shaft and into a distal fluid inflatable support element to inflate said fluid inflatable support element. The distal fluid inflatable support element is located at the distal end of the drive shaft and has an outer wall comprising an outflow opening located such that said outflow opening faces an inner surface of a treated vessel during rotation of the drive shaft so that a flow of fluid out of said opening forms a layer of fluid between the outer wall of the fluid inflatable distal support element and a wall of the treated vessel. The layer of fluid forming a fluid bearing between the outer wall of the rotating fluid inflated distal support element and the wall of the treated vessel.

Owner:CARDIOFLOW

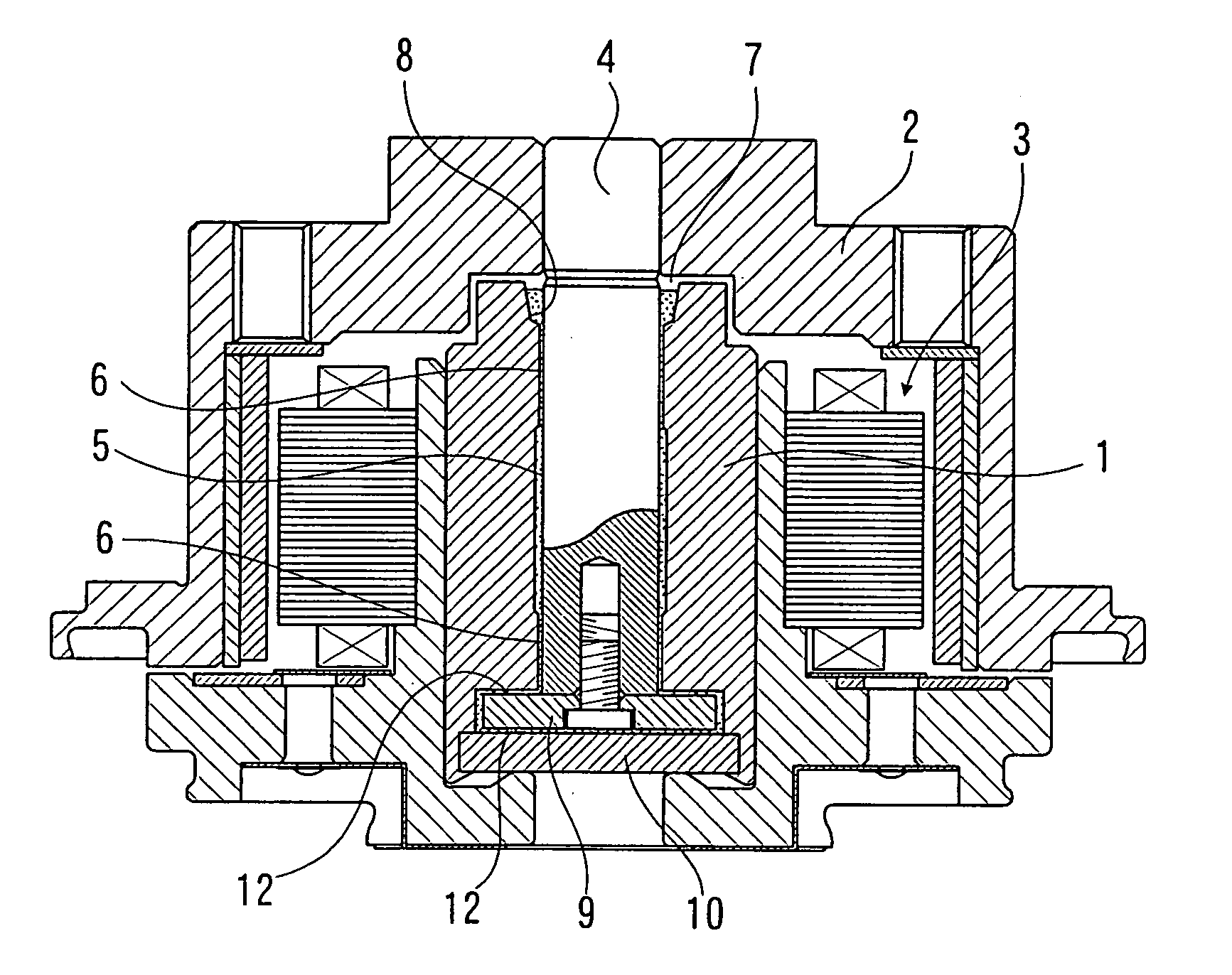

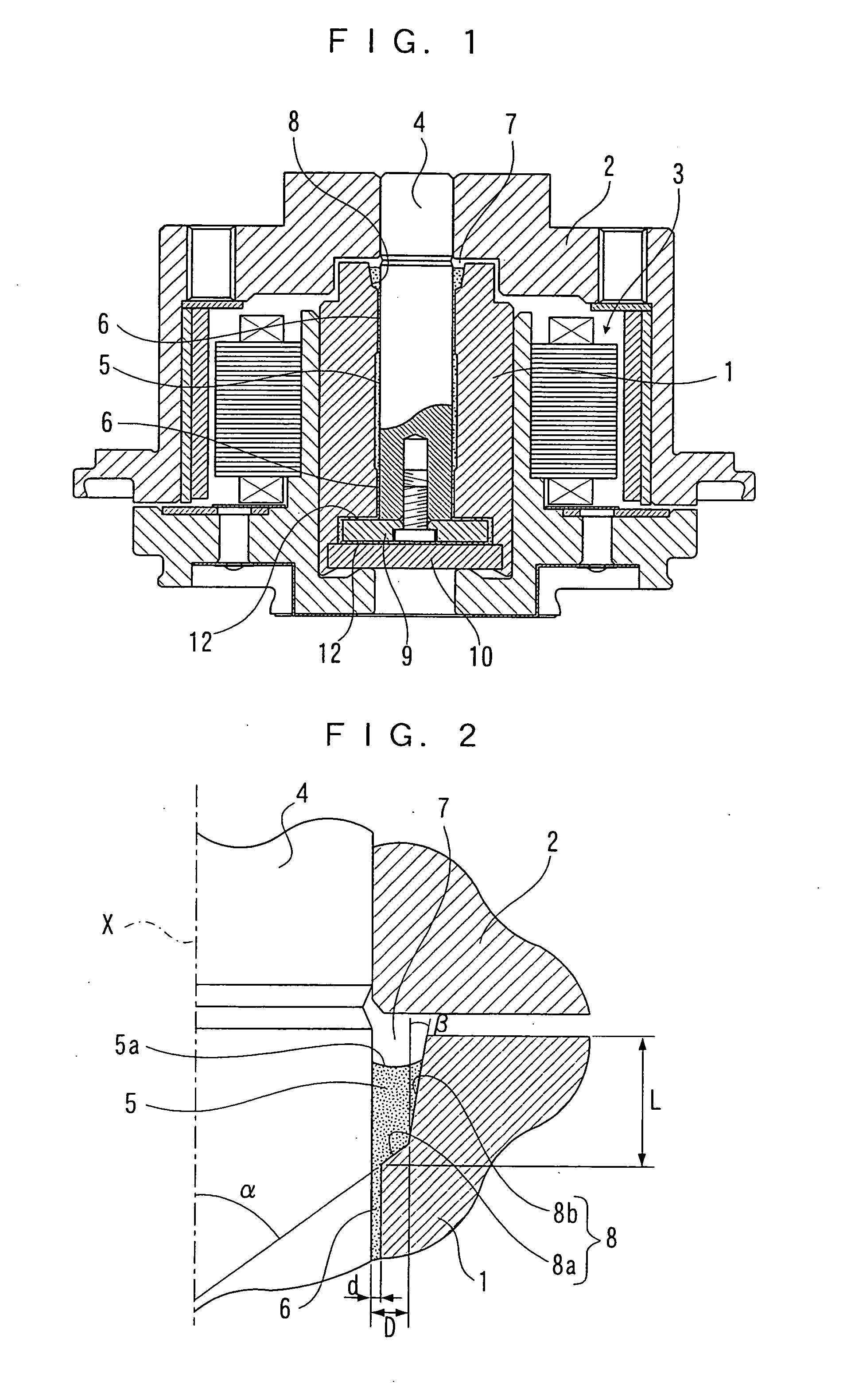

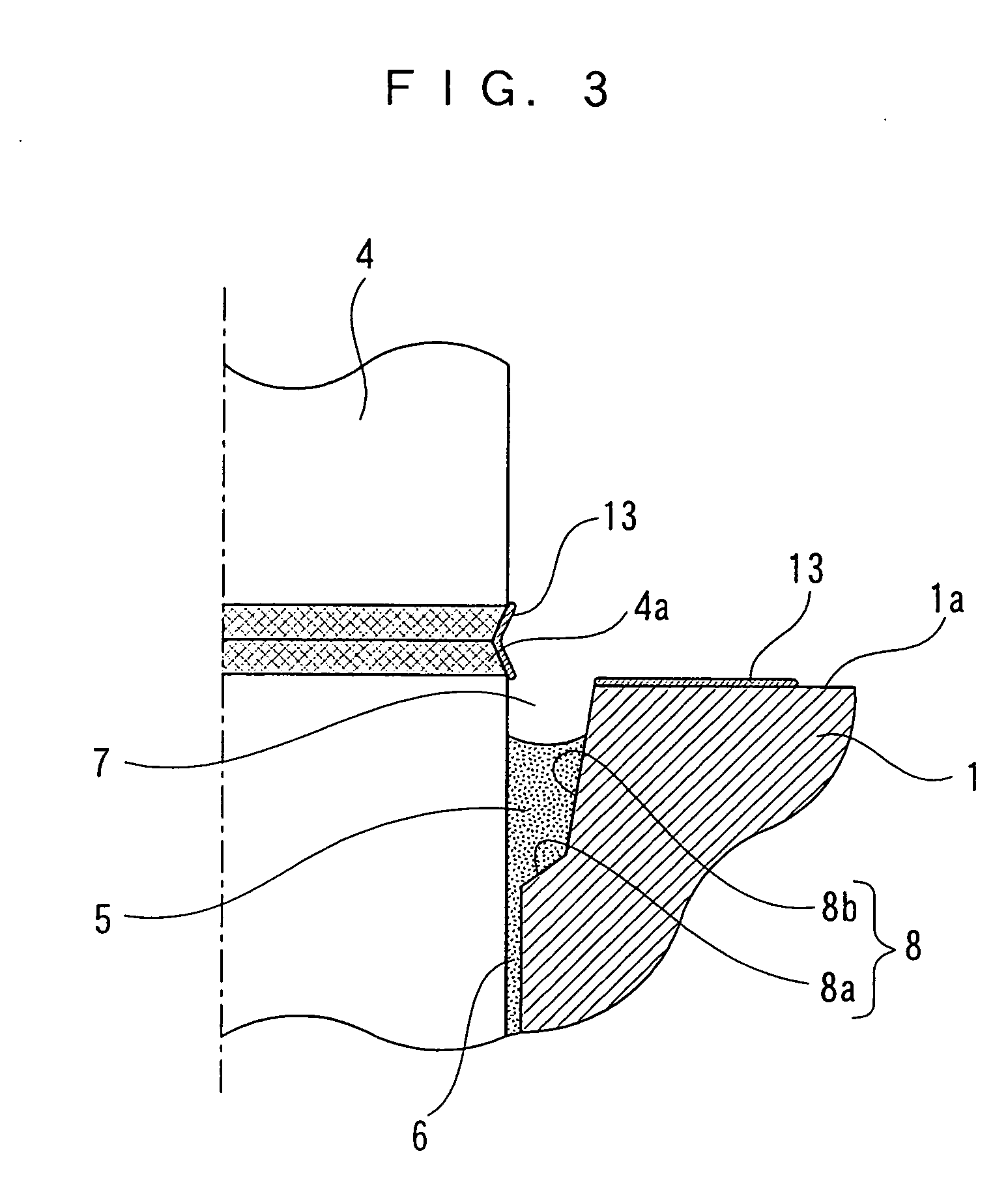

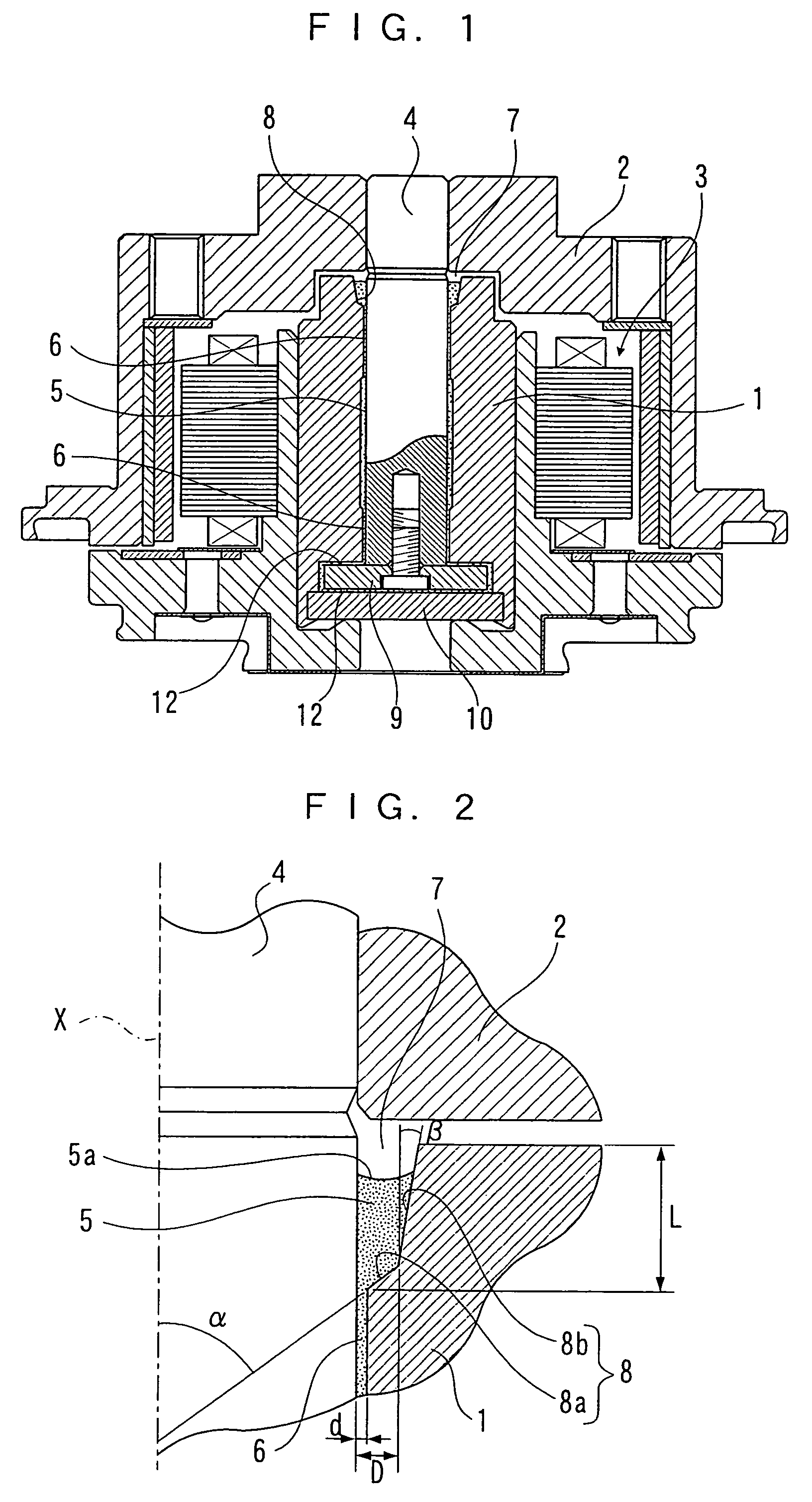

Fluid bearing device

ActiveUS20050111769A1Sufficient length dimensionSmall depthCrankshaftsRecord information storageEngineeringFluid bearing

A fluid bearing device capable of preventing a lubricant from scattering outward even during rotation thereof, while holding a relatively large amount of lubricant at a seal surface portion. A lubricant is filled between a sleeve and a shaft, a seal surface portion is formed on the sleeve in a location facing an open end thereof, the seal surface portion has a sectional shape defined by a plurality of inclined surfaces, and an inclination angle α of the inclined surface of the seal surface portion adjacent a radial bearing portion with respect to a shaft axis is formed to be larger than an inclination angle β of the inclined surface of the seal surface portion distant away from the radial bearing portion with respect to the shaft axis.

Owner:PHC HLDG CORP

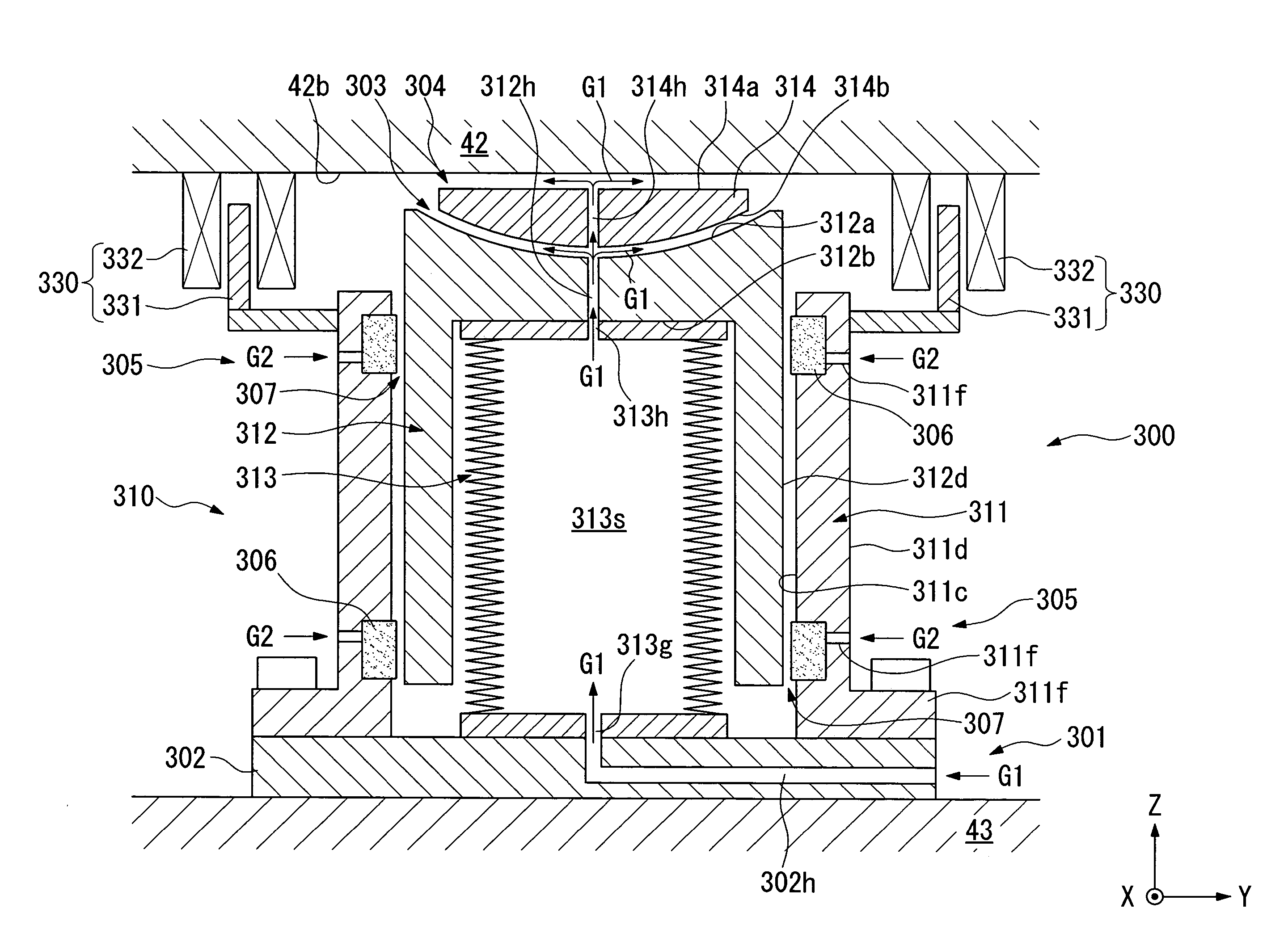

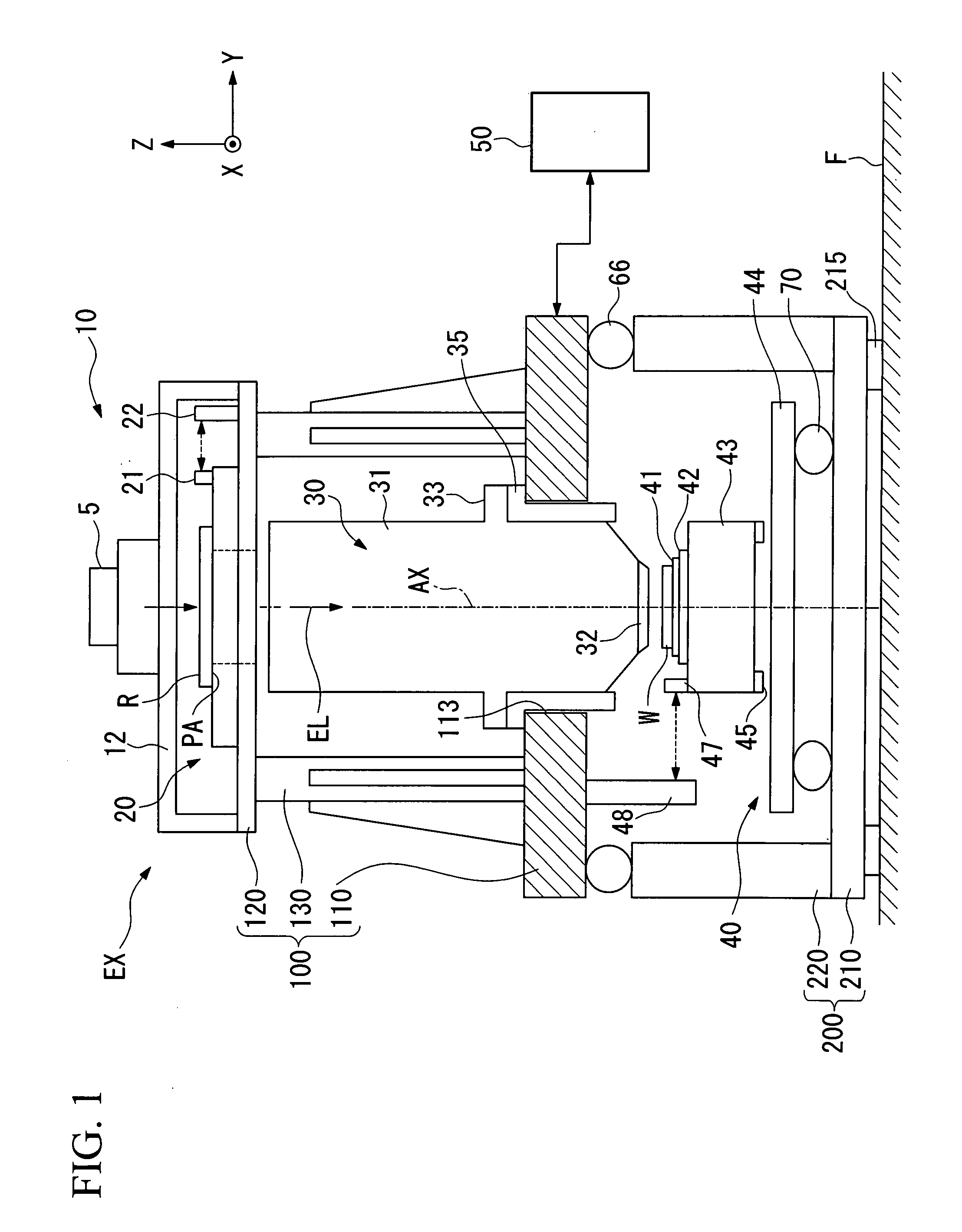

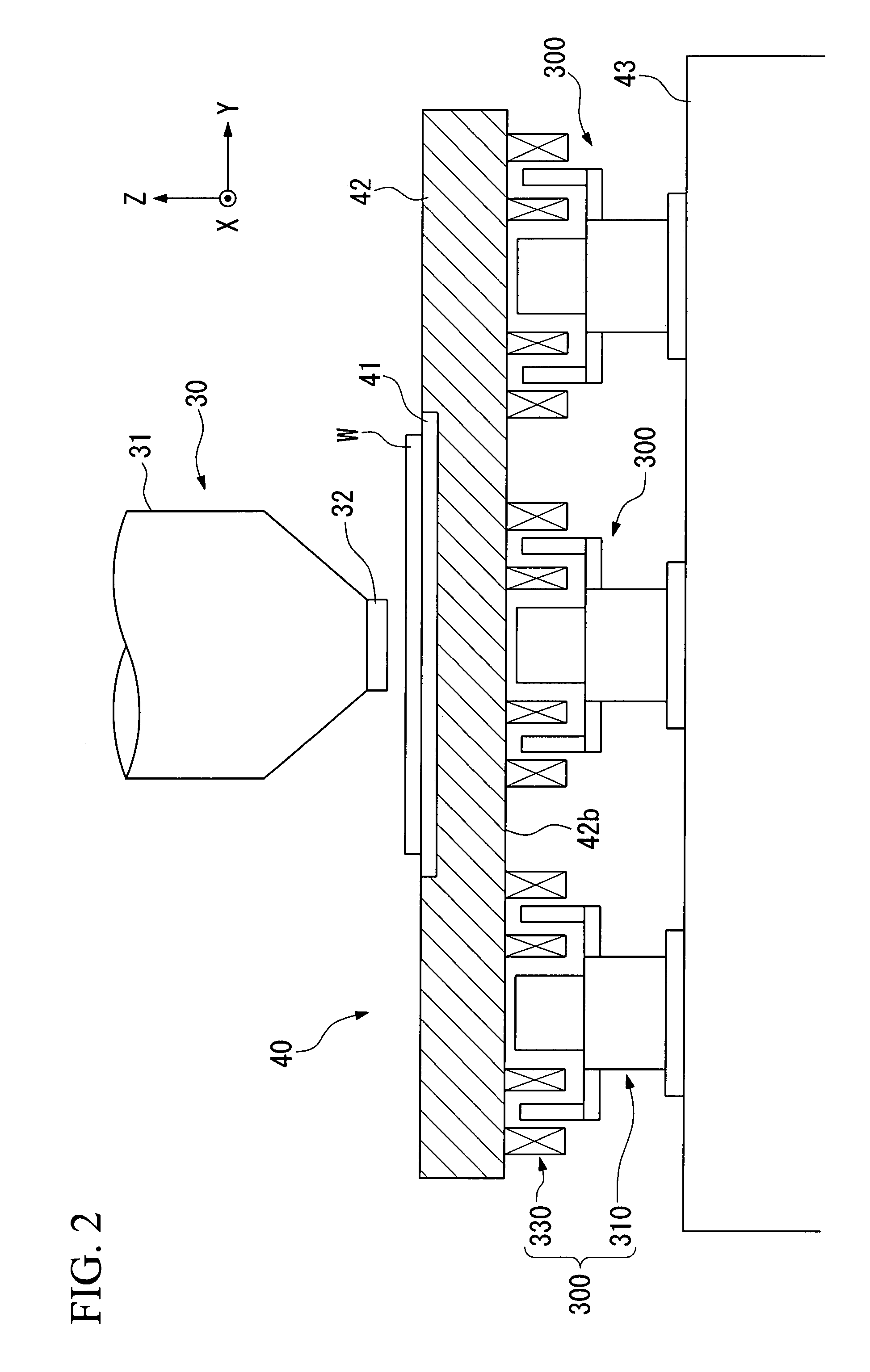

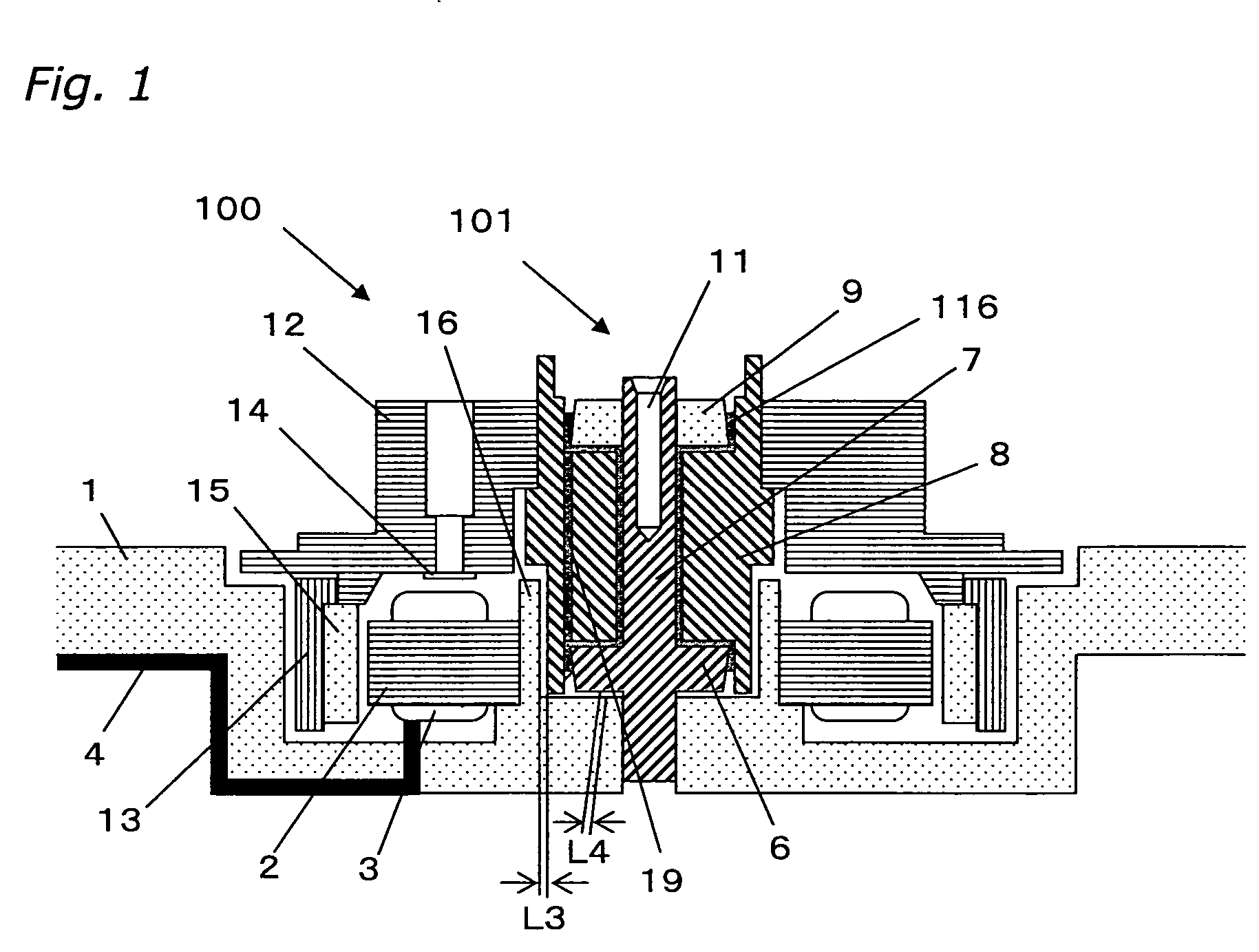

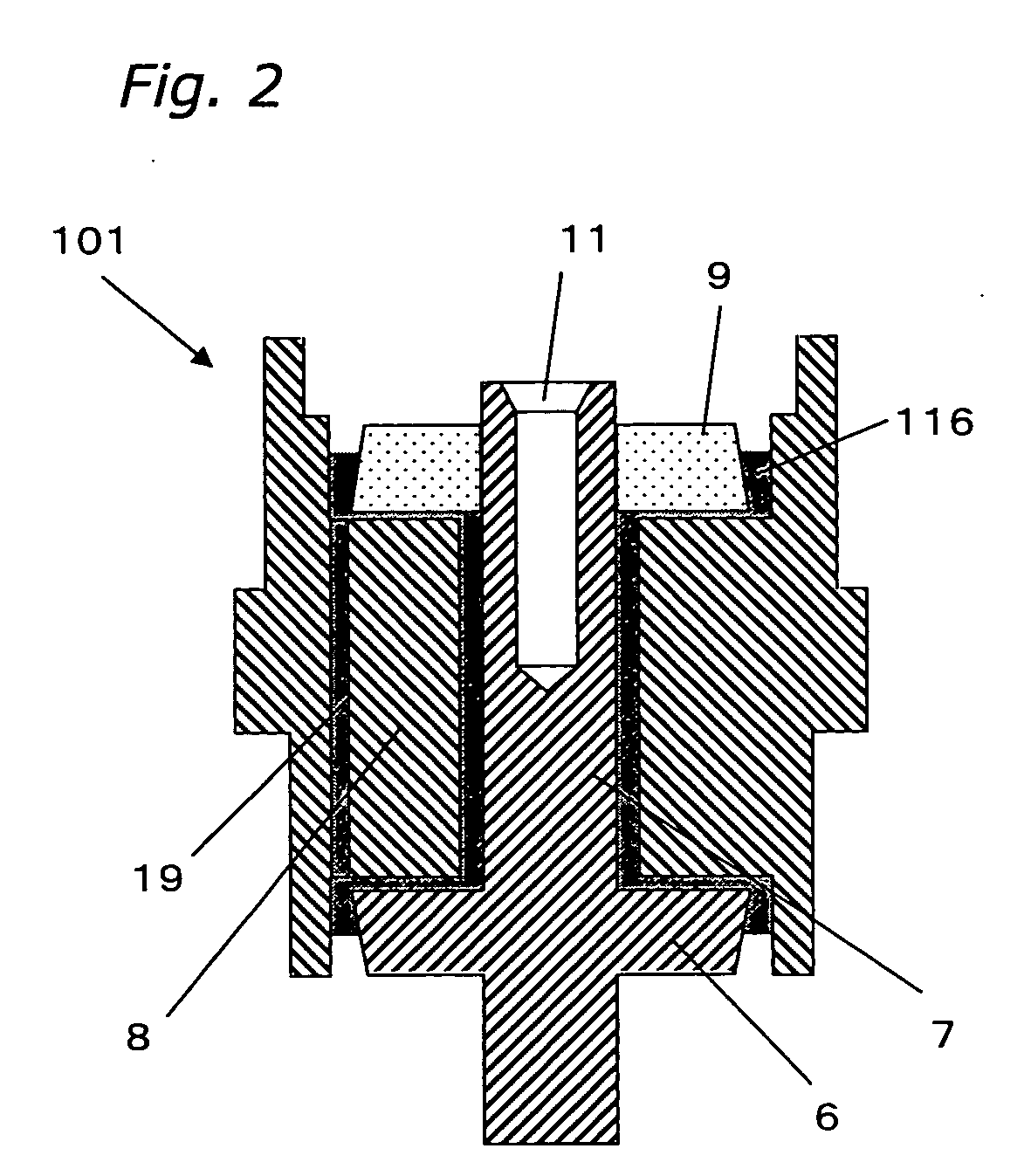

Support Apparatus, Stage Apparatus, Exposure Apparatus, And Device Manufacturing Method

InactiveUS20080013060A1Supported can be changedImprove responseLinear bearingsGas cushion bearingsEngineeringCylinder block

A support apparatus, a stage apparatus, an exposure apparatus, etc. are proposed that can increase response of a relative movement between a piston and a cylinder, etc. are proposed. There is provided a support apparatus including: a cylinder portion; a piston portion that is provided inside the cylinder portion and is movable in a Z direction; a fluid bearing formed in at least a portion between an inner wall of the cylinder portion and an outer wall of the piston portion, the support apparatus supporting a supported member in the Z direction with respect to a support member by means of a biasing force generated by the cylinder portion and the piston portion, in which fluids are supplied independently inside the fluid bearing and the cylinder.

Owner:NIKON CORP

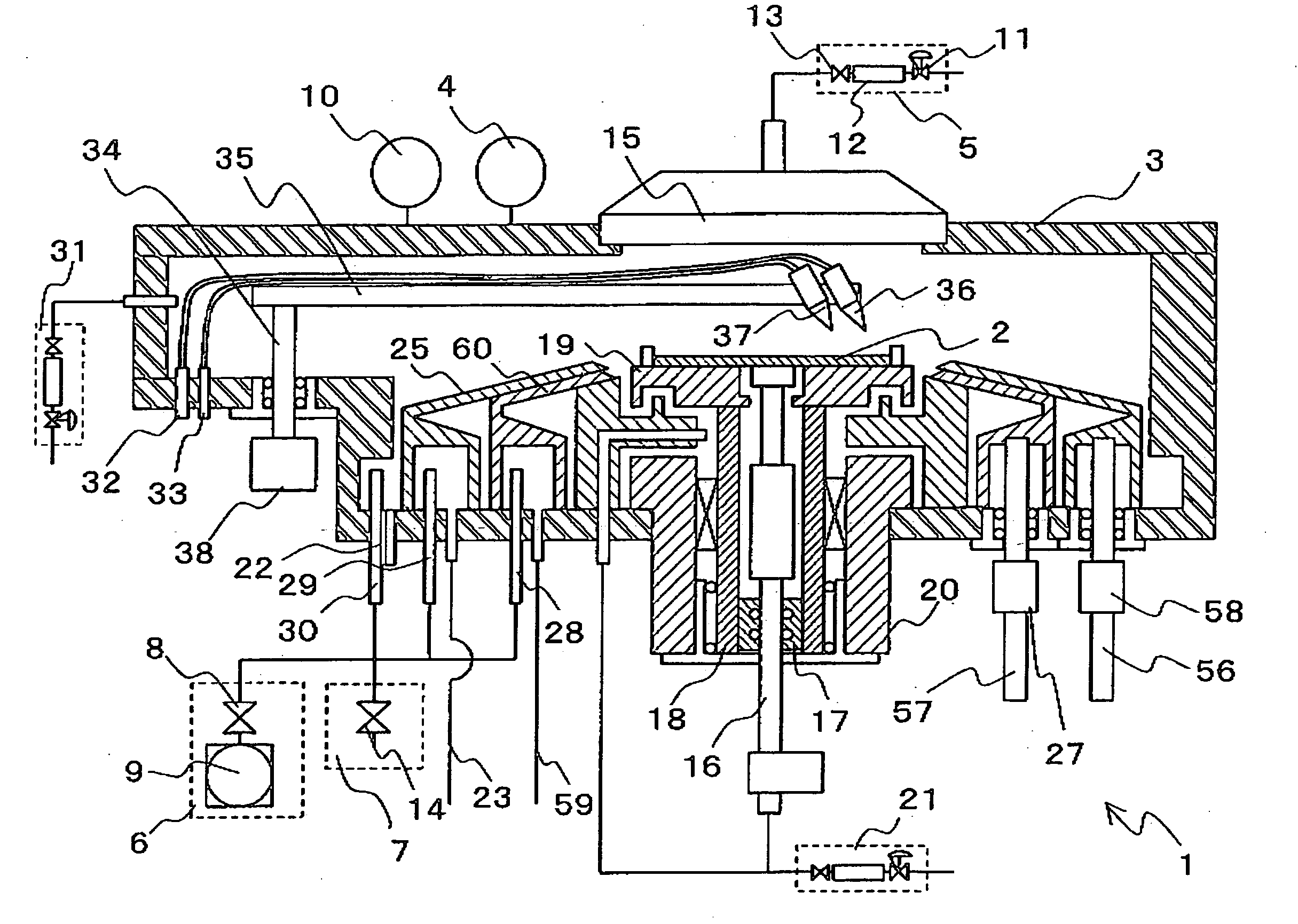

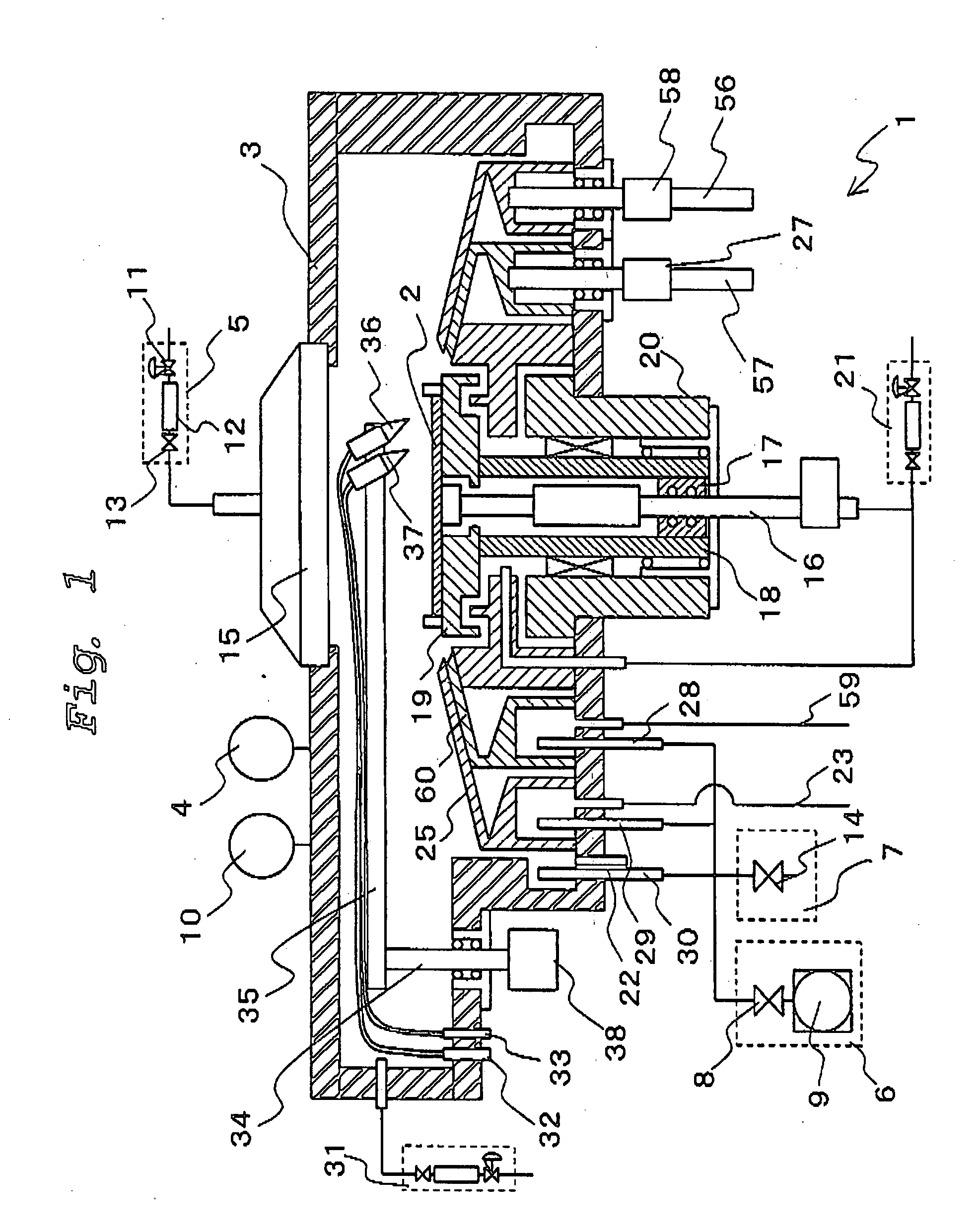

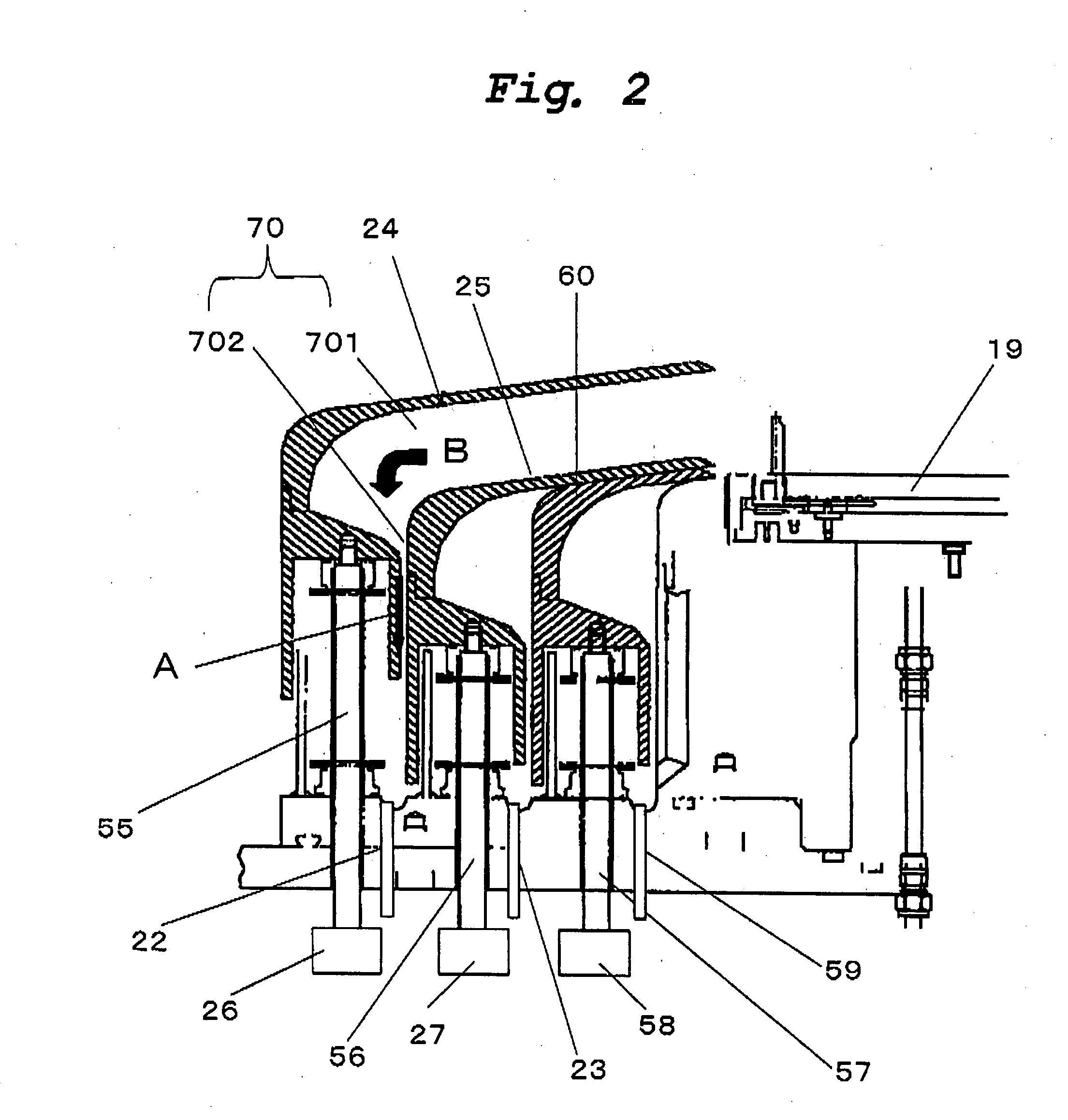

Cleaning apparatus, cleaning system using cleaning apparatus, cleaning method of substrate-to-be-cleaned

InactiveUS20090084409A1Quality improvementMaintaining degreeSemiconductor/solid-state device manufacturingDirt cleaningProduct gasCleaning methods

[Object] It is an object of the invention to provide a cleaning apparatus for cleaning a precision substrate capable of preventing a contamination factor from adhering again, to prevent a natural oxide film from being formed, and to prevent a water mark.[Solving Means] In a cleaning apparatus 1, a substrate-to-be-cleaned 2 is disposed in a container 3, and an atmosphere component measuring device 4 which measures an atmosphere in the container 3, gas supply means 5 for controlling an atmosphere, and gas discharge means 6 and 7 are disposed in the cleaning apparatus 1, the cleaning apparatus 1 includes at least one the gas supply means 5 which equally supplies gas from a portion opposed to a surface-to-be-cleaned, gas supply means 21 for supplying gas to a rotating / holding mechanism comprising a cylindrical stationary shaft 16, a fluid bearing 17 and a rotation support member 18, gas discharge means 7 for discharging gas into a drainage mechanism, and gas supply means 31 for supplying gas for controlling an atmosphere when cleaning liquid is injected. The atmosphere component measuring device 4 which measures the atmosphere in the cleaning apparatus 1 can measure at any timing, and can detect one or more of a flammable component, a combustible component and a oxdizer component.

Owner:REALIZE ADVANCED TECH

Rotational atherectomy device with fluid inflatable support elements and two torque transmitting coils

A rotational atherectomy device for removing a stenotic tissue from a vessel of a patient is disclosed. The device comprises a rotatable, flexible, hollow drive shaft having a fluid impermeable wall defining a fluid impermeable lumen of the drive shaft and, an abrasive element mounted to a distal end portion of the drive shaft proximal to and spaced away from a distal support element formed at a distal end of the drive shaft, the distal support element being inflatable by pressurized fluid which flows in an antegrade direction through said lumen of the drive shaft and is at least partially re-directed into the distal fluid inflatable support element. The distal fluid inflatable support element has an outer wall comprising an outflow opening located such that said outflow opening faces an inner surface of a treated vessel during rotation of the drive shaft so that a flow of fluid through said outflow opening forms a layer of fluid between the outer wall of the rotating fluid inflated distal support element and a wall of the treated vessel to form a fluid bearing between the outer wall of the rotating fluid inflated distal support element and the wall of the treated vessel, the drive shaft being comprised of at least one fluid impermeable membrane and at least two torque transmitting coils, one of said coils extending distally beyond the distal end of the other coil and conveying torque to the abrasive element mounted to the drive shaft distal to and spaced away from a portion of the drive shaft formed from the fluid impermeable membrane and said torque transmitting coils.

Owner:CARDIOFLOW

Stent reducing system and device

ActiveUS7284401B2Reduce frictionMinimize adhesionShaping toolsStentsFluid bearing% diameter reduction

Owner:BOSTON SCI SCIMED INC

Atherectomy device supported by fluid bearings

A rotational atherectomy device for removing a stenotic tissue (330, 360) from a vessel (300) of a patient comprises a flexible hollow drive shaft (2) and an abrasive element (101, 102) mounted to the drive shaft proximal to and spaced from a solid support element (10, 10s) mounted at the distal end (6) of the drive shaft, the solid support element having a rounded outer surface and an outflow channel (20, 20s) with an outflow opening in said rounded outer surface. The drive shaft comprises a torque transmitting coil (4) and at least one fluid impermeable membrane (3) forming a fluid impermeable lumen for the antegrade flow (FF) of fluid into the outflow channel such that, during rotation of the drive shaft, a flow of fluid out of said outflow opening forms a fluid bearing between the rotating solid support element and the wall of the treated vessel.

Owner:CARDIOFLOW

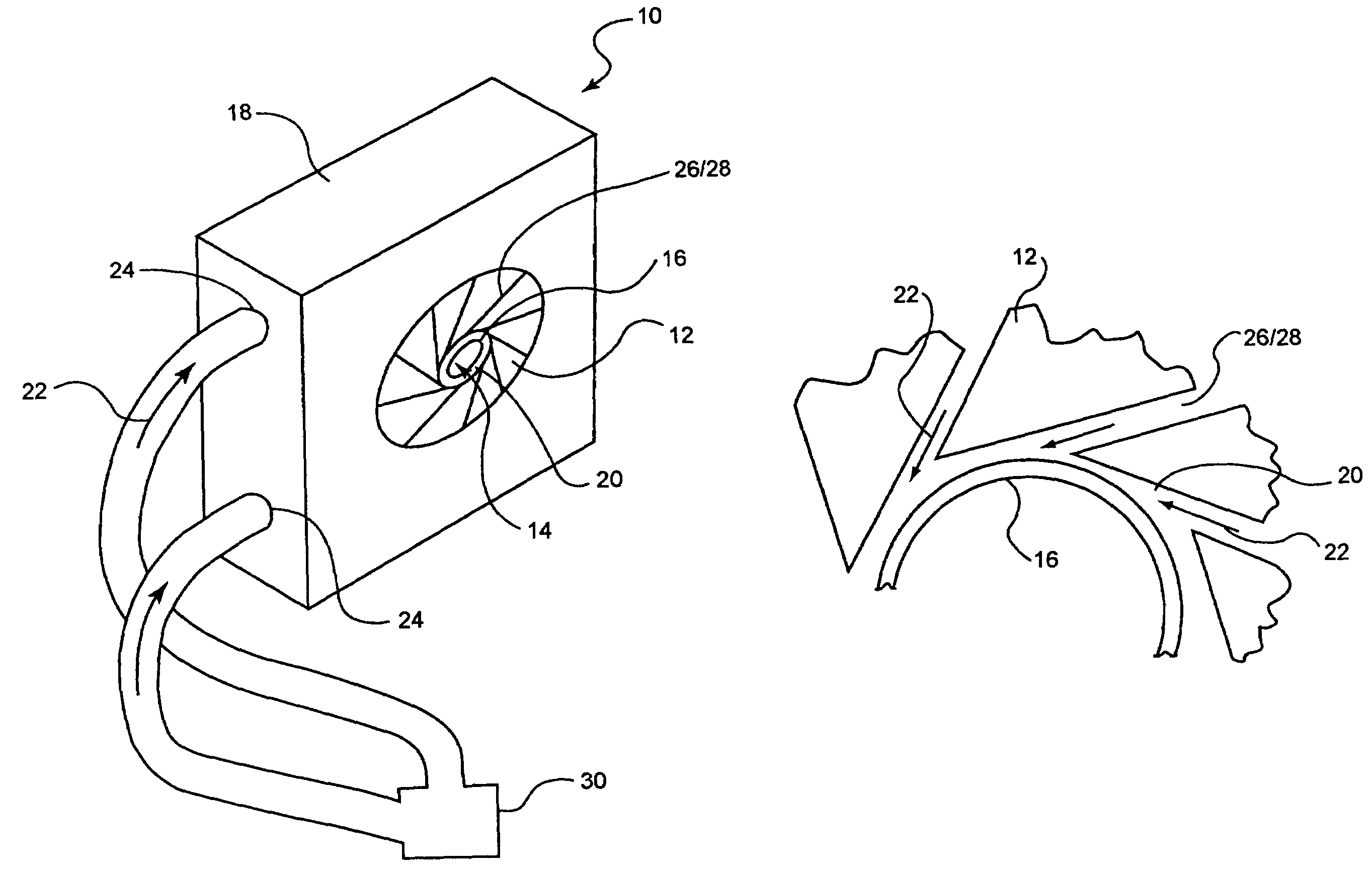

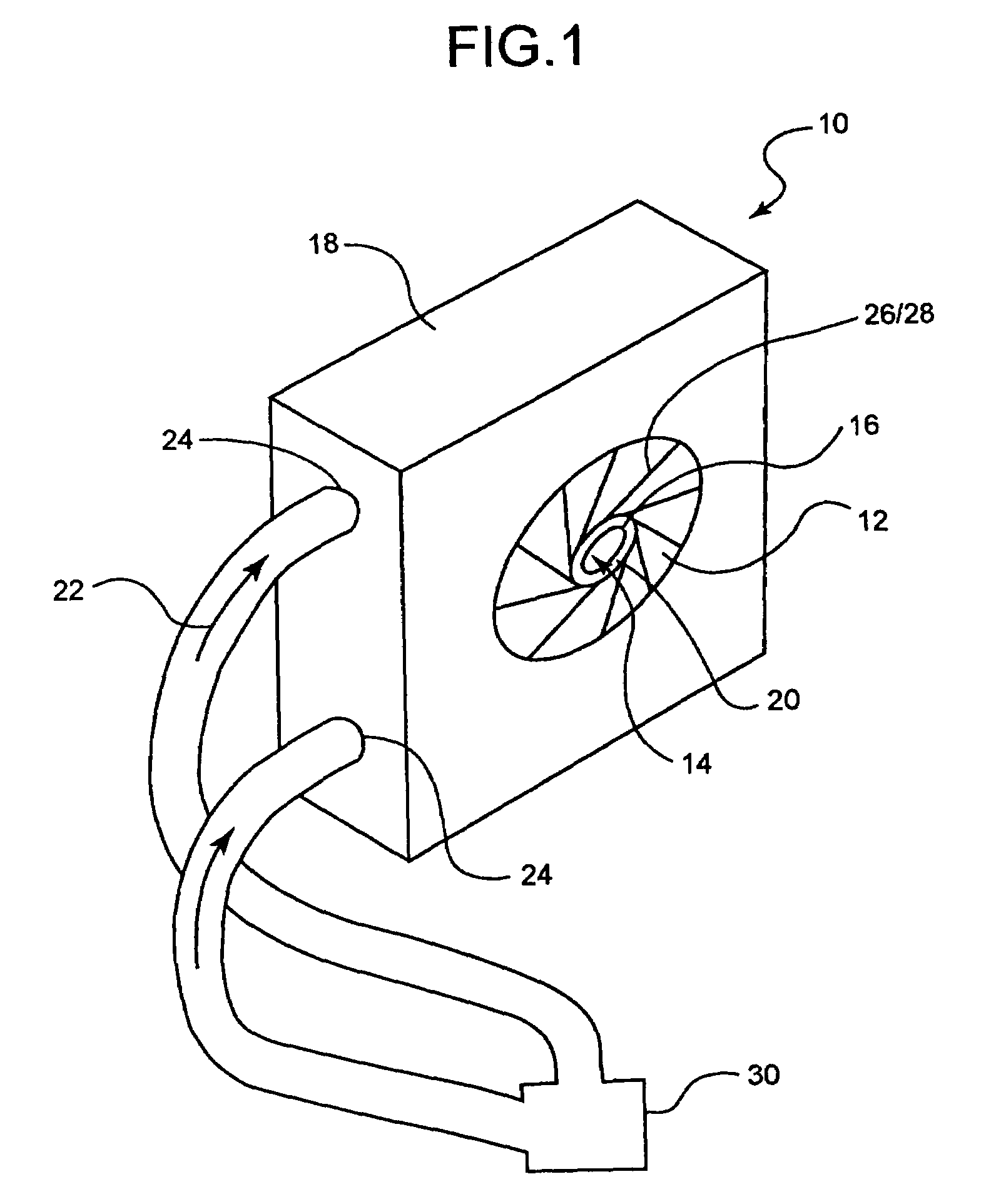

Ventricular assist system secondary impeller

InactiveUS7189260B2Avoid problemsInhibition formationSpecific fluid pumpsPump componentsImpellerLeft ventricular size

In a centrifugal flow blood pump, usable in left ventricular assist applications, blood is pumped from an inlet (16) to an outlet (22) by a primary impeller (18). A portion of the blood that enters the pump follows a secondary channel (24) where a secondary impeller (70) routes the blood to lubricate a bearing between an impeller assembly (14) and a post formed by a component of the pump housing. The unique shape of the secondary impeller (70) prevents blood stagnation and provides for a well-washed fluid bearing.

Owner:HORVATH DAVID +2

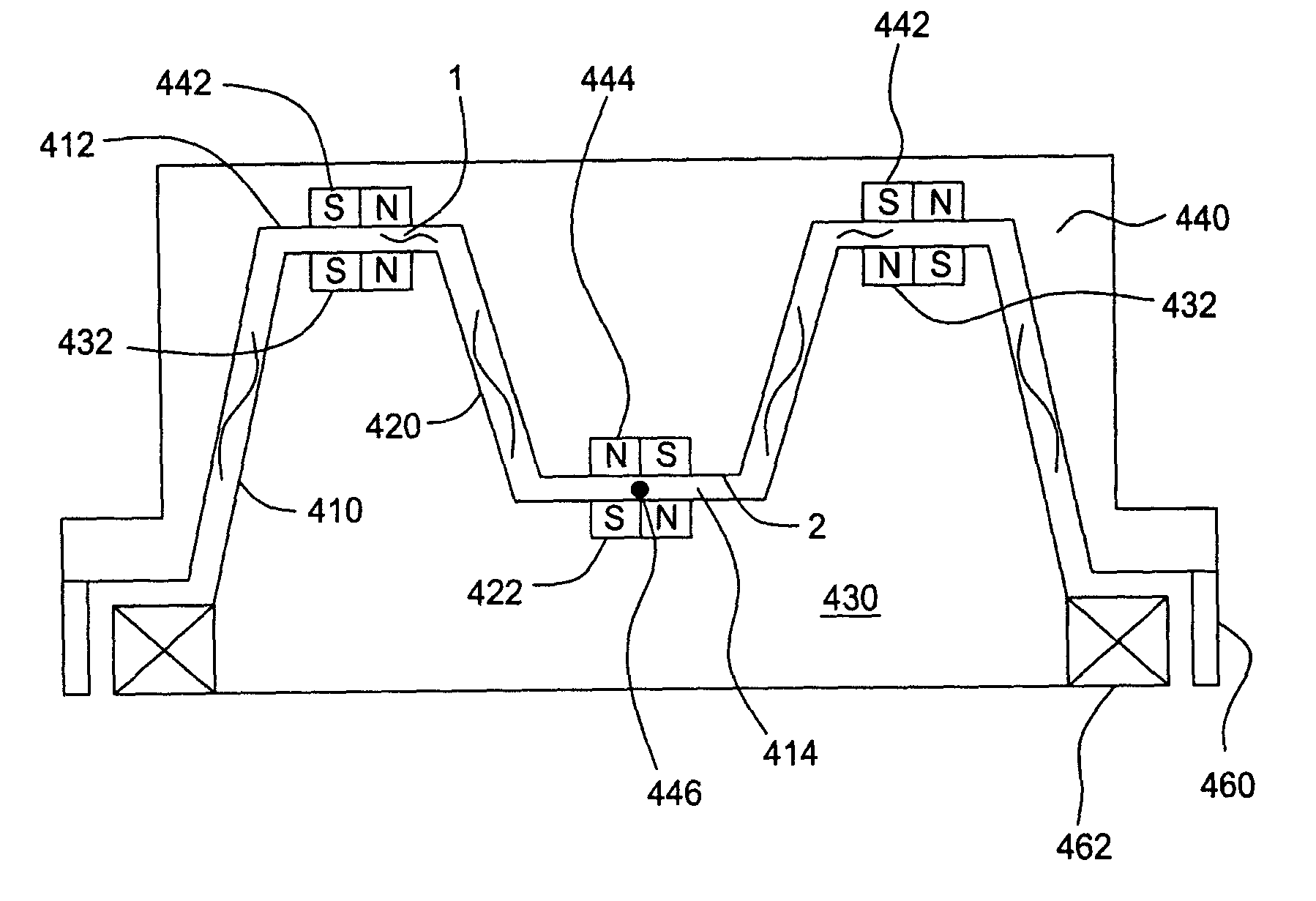

Magnetically attracted inspecting apparatus and method using a fluid bearing

InactiveUS20060053892A1Expand accessContinuous inspectionAnalysing solids using sonic/ultrasonic/infrasonic wavesMagnetic property measurementsAir bearingUltrasonic sensor

An apparatus and method for inspecting a structure are provided which include probes with sensing elements and are disposed proximate opposite surfaces of a structure, where only one of the probes need be driven. A tracking probe may be magnetically coupled to a driven probe and move in coordination therewith. Ring magnets may be used in the driven and tracking probes to provide the magnetic coupling and align sensing elements disposed in the centers of the ring magnets. The probes may include a fluid bearing, such as a water bearing or an air bearing, for supporting the structure and maintaining the desired orientation and spacing of the probes relative to the structure. The fluid of a fluid bearing may be used as a couplant between an ultrasonic transducer and a structure. A flow moderating skirt may be used to with a probe employing a fluid bearing for support.

Owner:THE BOEING CO

Multiple radial/axial surfaces to enhance fluid bearing performance

InactiveUS6933643B1Low powerIncrease the lengthBearing assemblySliding contact bearingsEngineeringFluid bearing

In one embodiment, a plurality of axially oriented bearings defined along gaps between rotor and stator are provided to provide radial stiffness to the system; and these bearings are coupled together by radially oriented gaps. Grooves and / or magnets may be defined in order to maintain the stability and relative spacing of the gaps, while allowing free relative rotation of parts of the system with minimum power loss. A central conical bearing may be provided, having a fluid dynamic bearing around its conical surface, and being connected to an axially parallel but radially displaced axially oriented journal style bearing. The combined effects of these bearings is sufficient to maintain or even enhance the overall stability of the system.

Owner:SEAGATE TECH LLC

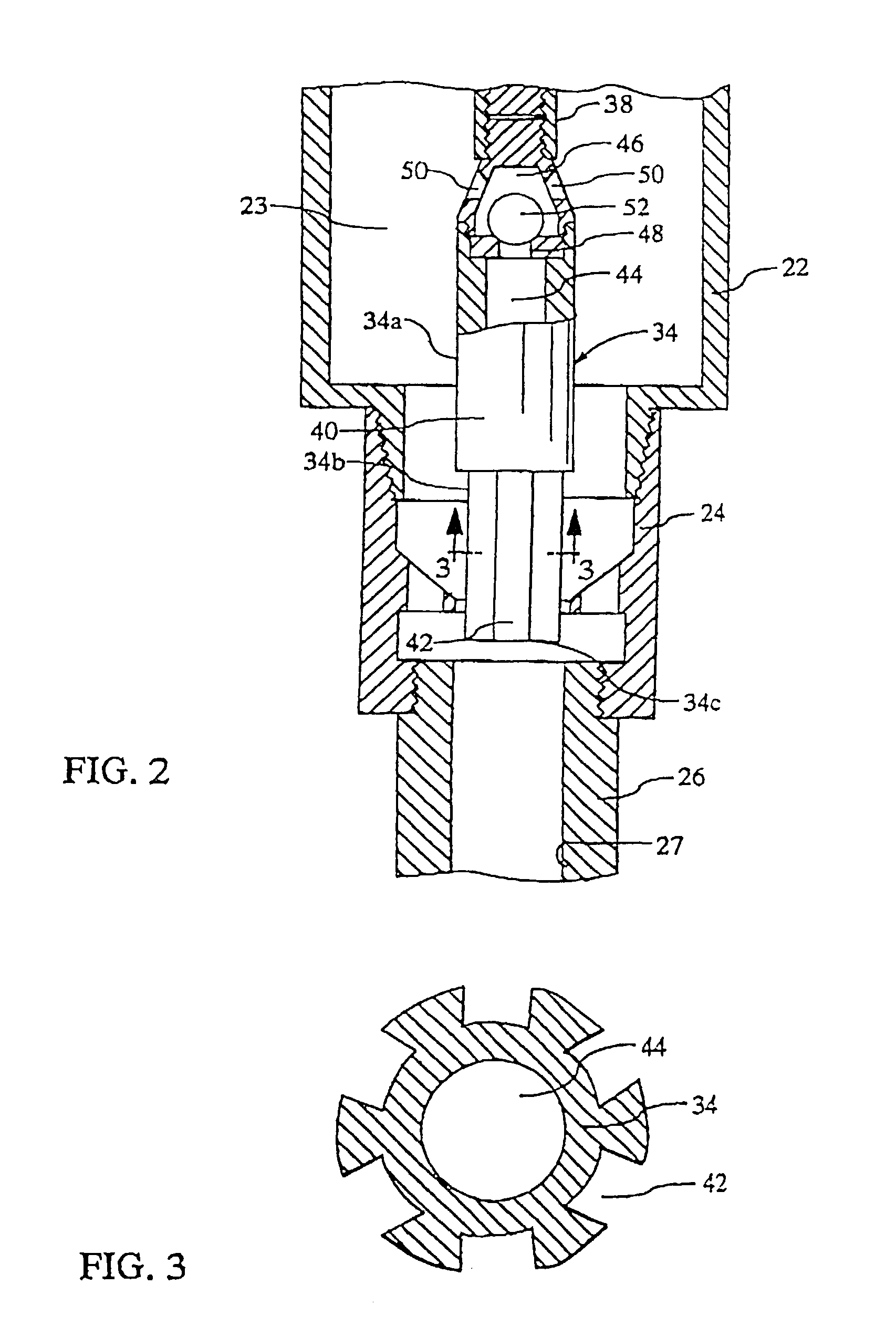

Method and apparatus for seismic stimulation of fluid-bearing formations

InactiveUS20030201101A1Volume of compression is reducedLarge caliberConstructionsFluid removalShock waveEngineering

An apparatus and seismic method for producing an shock wave in an oil well borehole, with a pumping unit arranged at the wellhead, a tubing string extending downward into the production casing of the well, a hollow cylinder assembly connected with the bottom of the tube string, and pair of plungers arranged within the cylinder assembly and connected with the pumping unit with sucker rods and a polish rod for compressing liquid contained within the cylinder assembly and discharging the compressed liquid into the production casing, thereby generating a shock wave. The cylinder assembly includes an upper cylinder, a lower cylinder below the upper cylinder, a crossover cylinder below the upper and lower cylinders, and a compression chamber cylinder containing a compression chamber arranged between the crossover cylinder and the upper cylinder. The lower cylinder is adapted to receive the lower plunger, and the upper cylinder is adapted to receive the upper plunger. The lower plunger has a larger diameter than the upper plunger, and the plunger movement effects the volume of the compression chamber by reduction, the liquid contained therein becomes compressed and is discharged on the down stroke into the well. In addition, remote seismic data is collected and processed from remote well locations.

Owner:APPLIED SEISMIC RES CORP

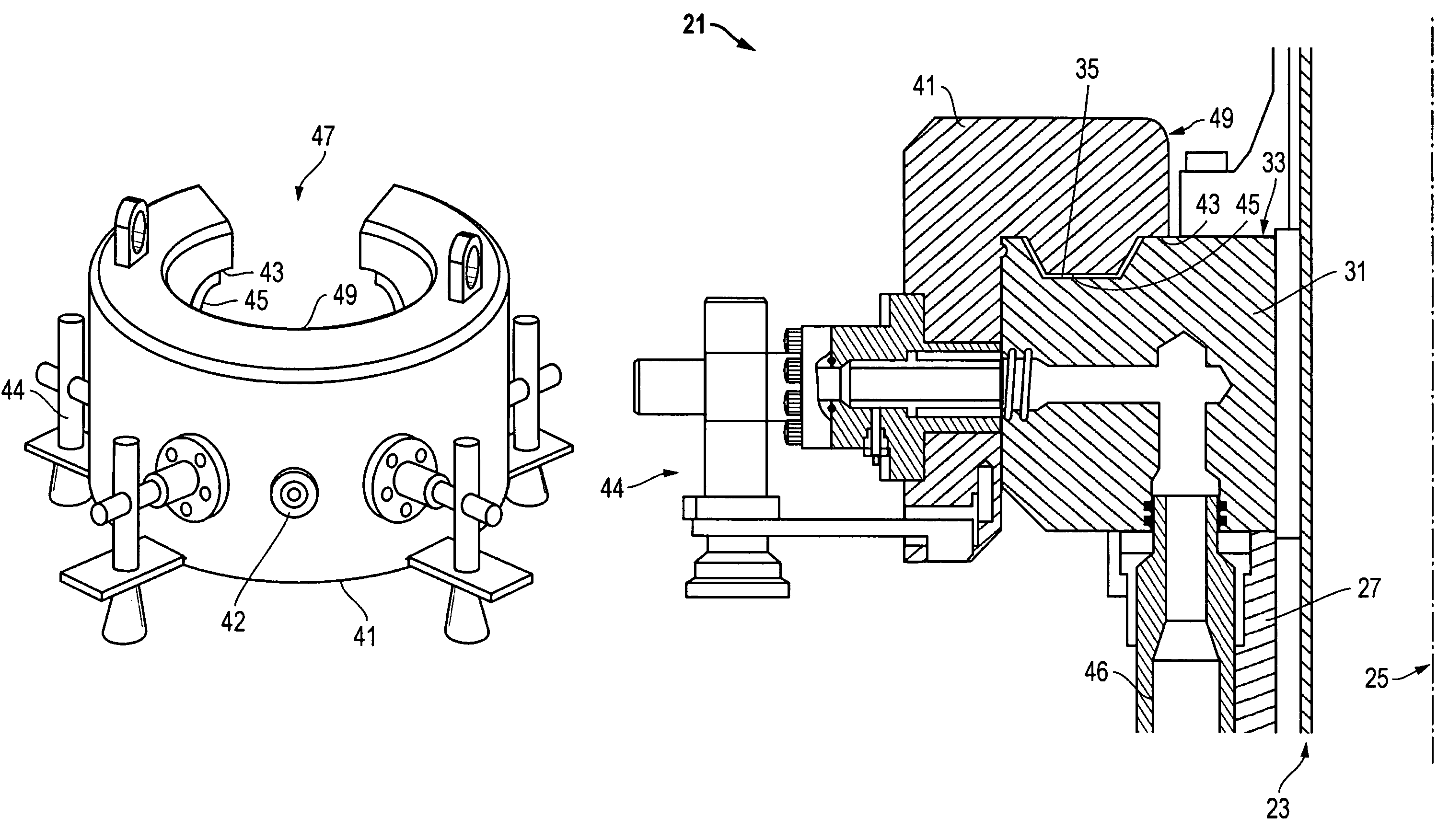

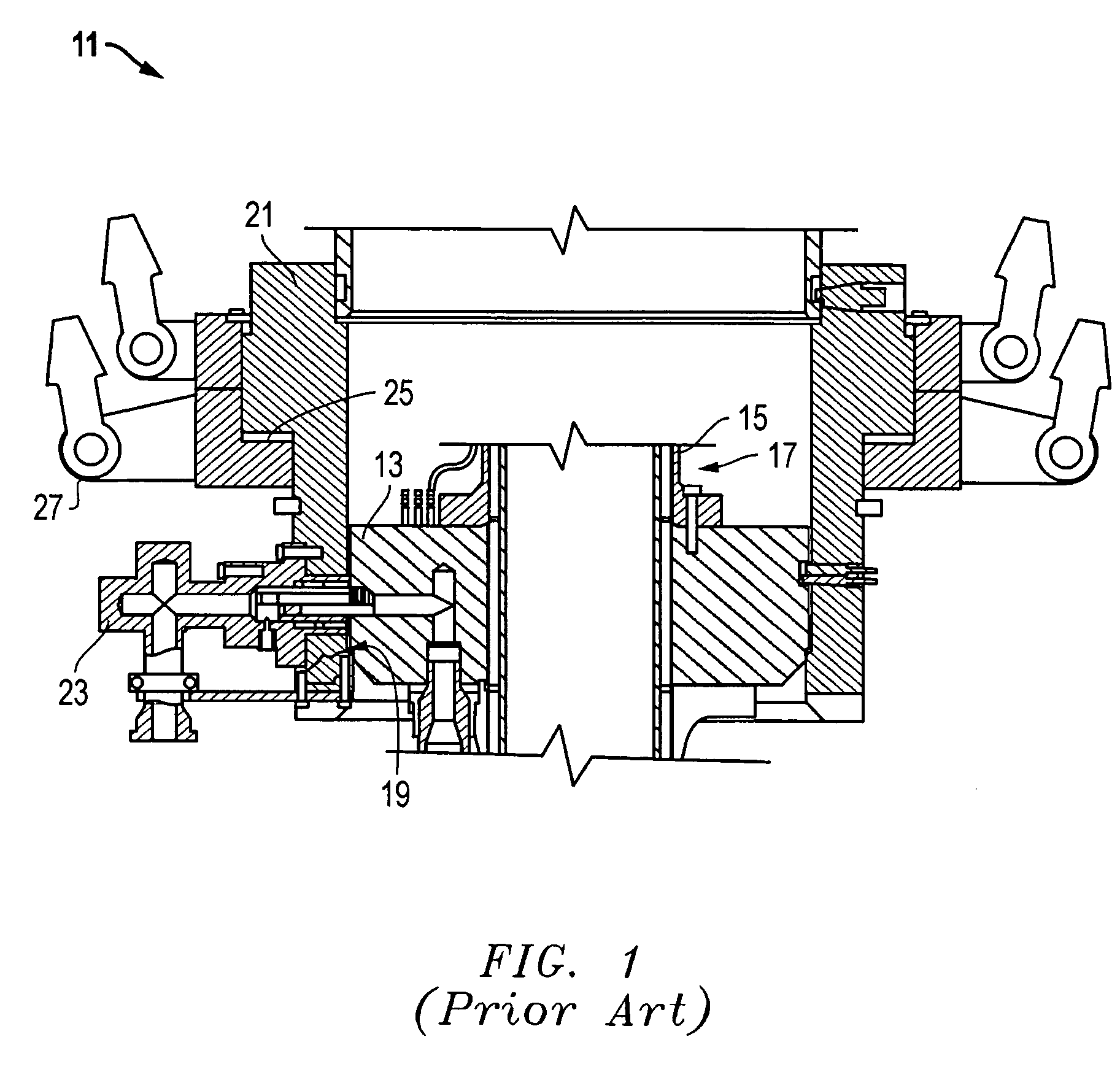

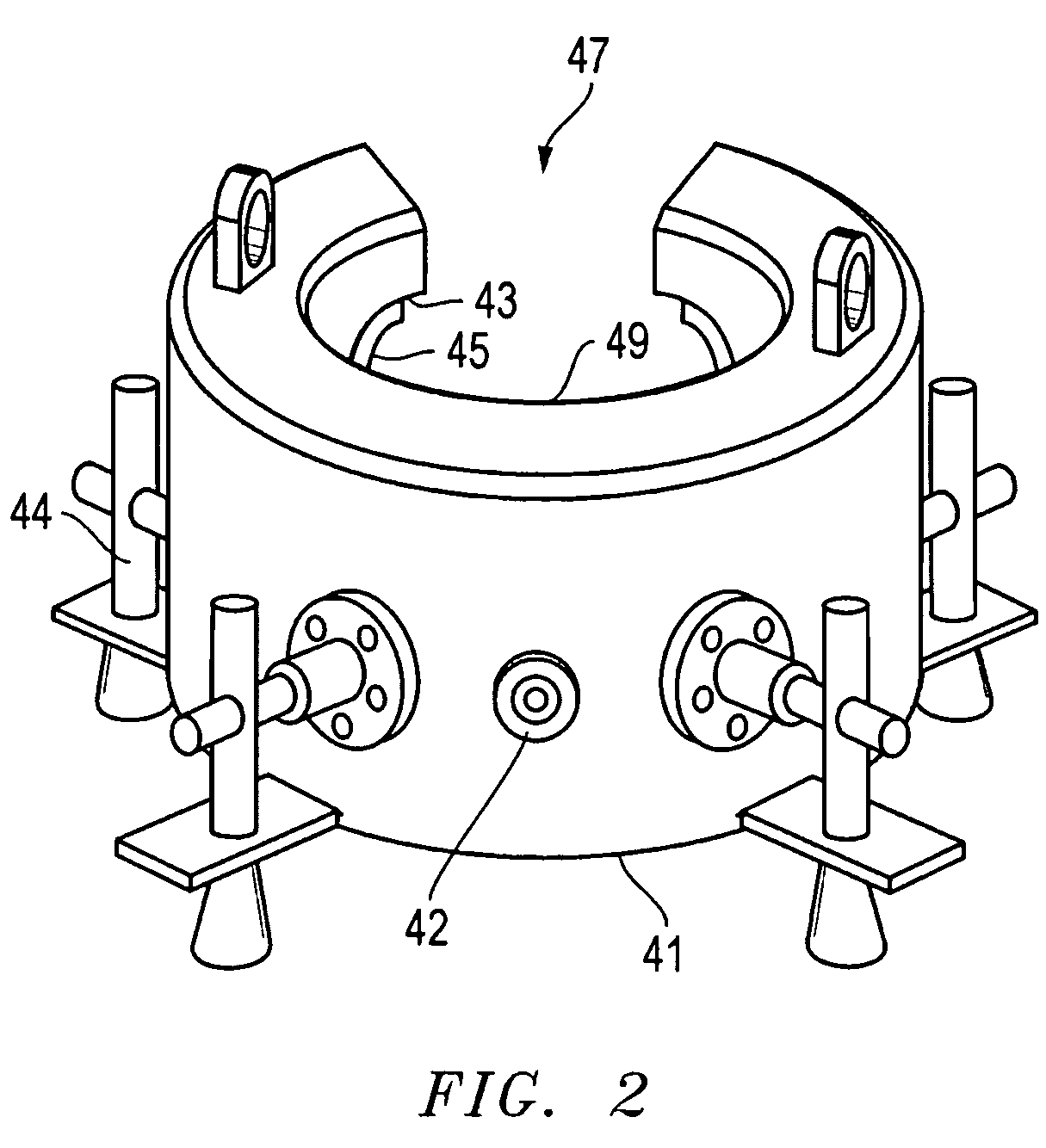

System, method, and apparatus for a radially-movable line termination system for a riser string on a drilling rig

A line termination assembly for a riser string has a ring adapter mounted to a slip joint and a ring body mounted on top of the ring adapter. The ring adapter radially aligns with the ring body, which forms an inner diameter for receiving the slip joint. The ring body also has a discontinuity for radial access to the inner diameter, such that the ring body is circumferentially discontinuous. The discontinuity defines a chord dimension that exceeds the outer diameter of the slip joint, such that the slip joint may move radially through the discontinuity and into the inner diameter during assembly and disassembly of the system. Fluid bearings and tension rings are mounted to the slip joint and are axially spaced apart from the ring adapter and the ring body.

Owner:VETCO GRAY

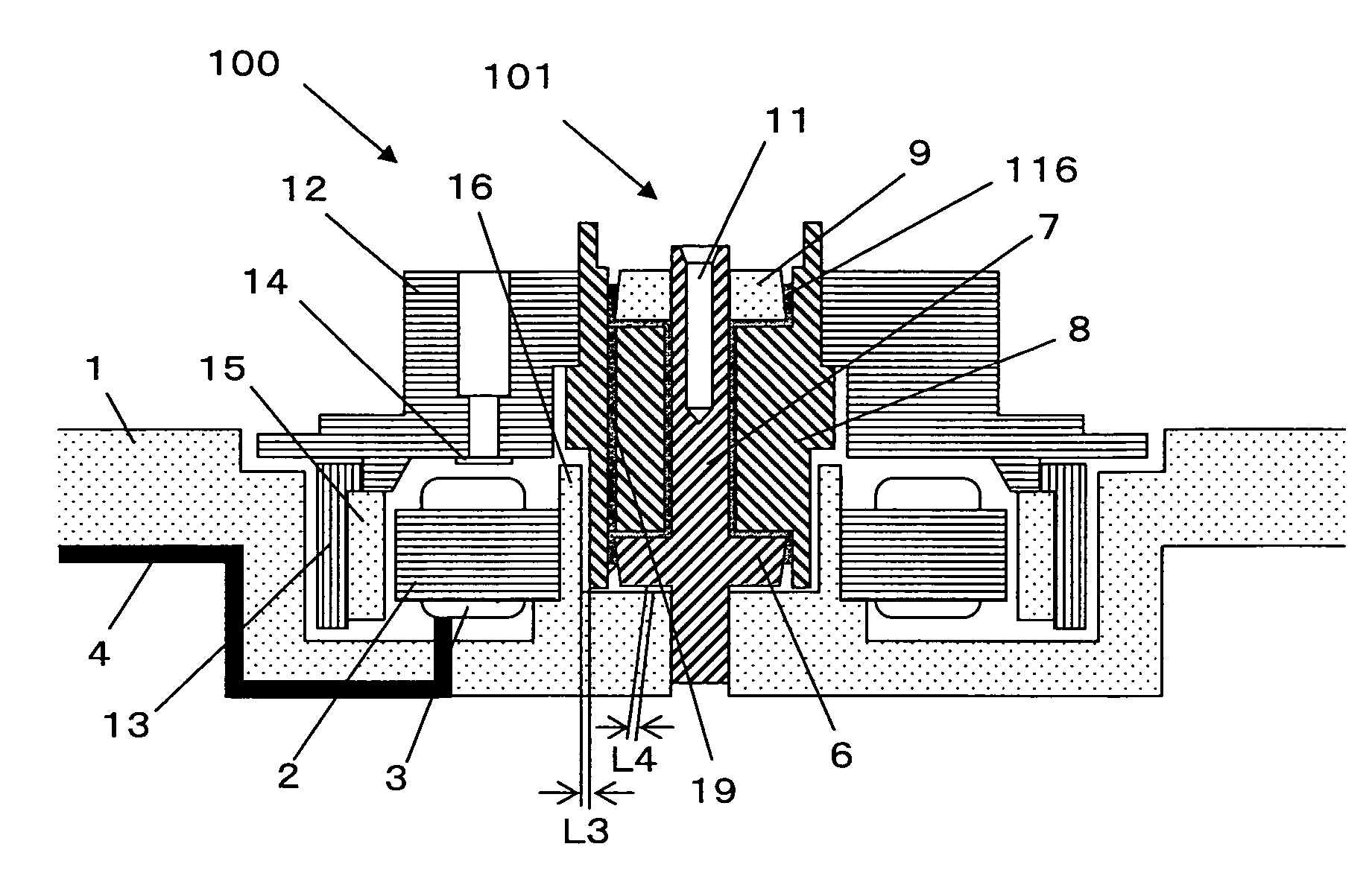

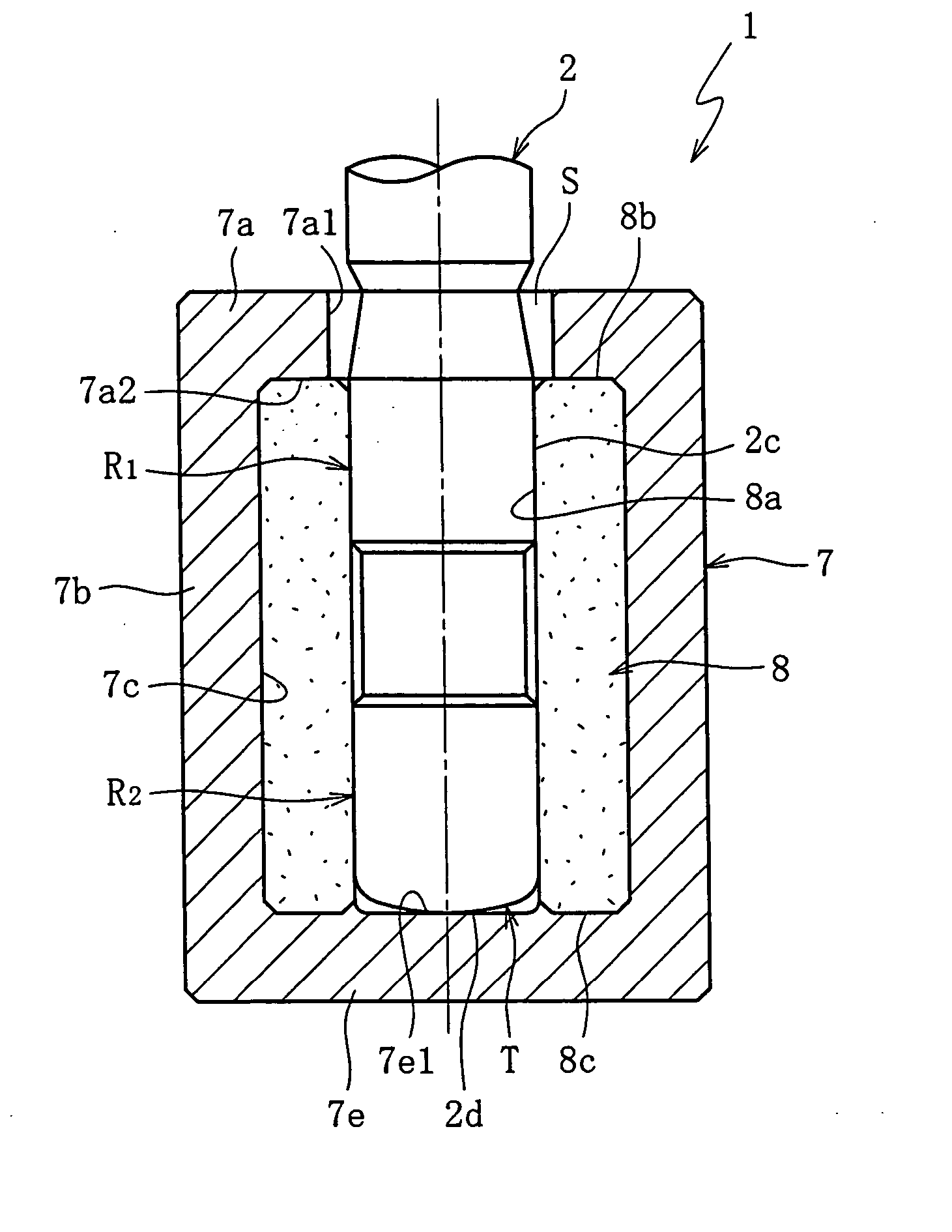

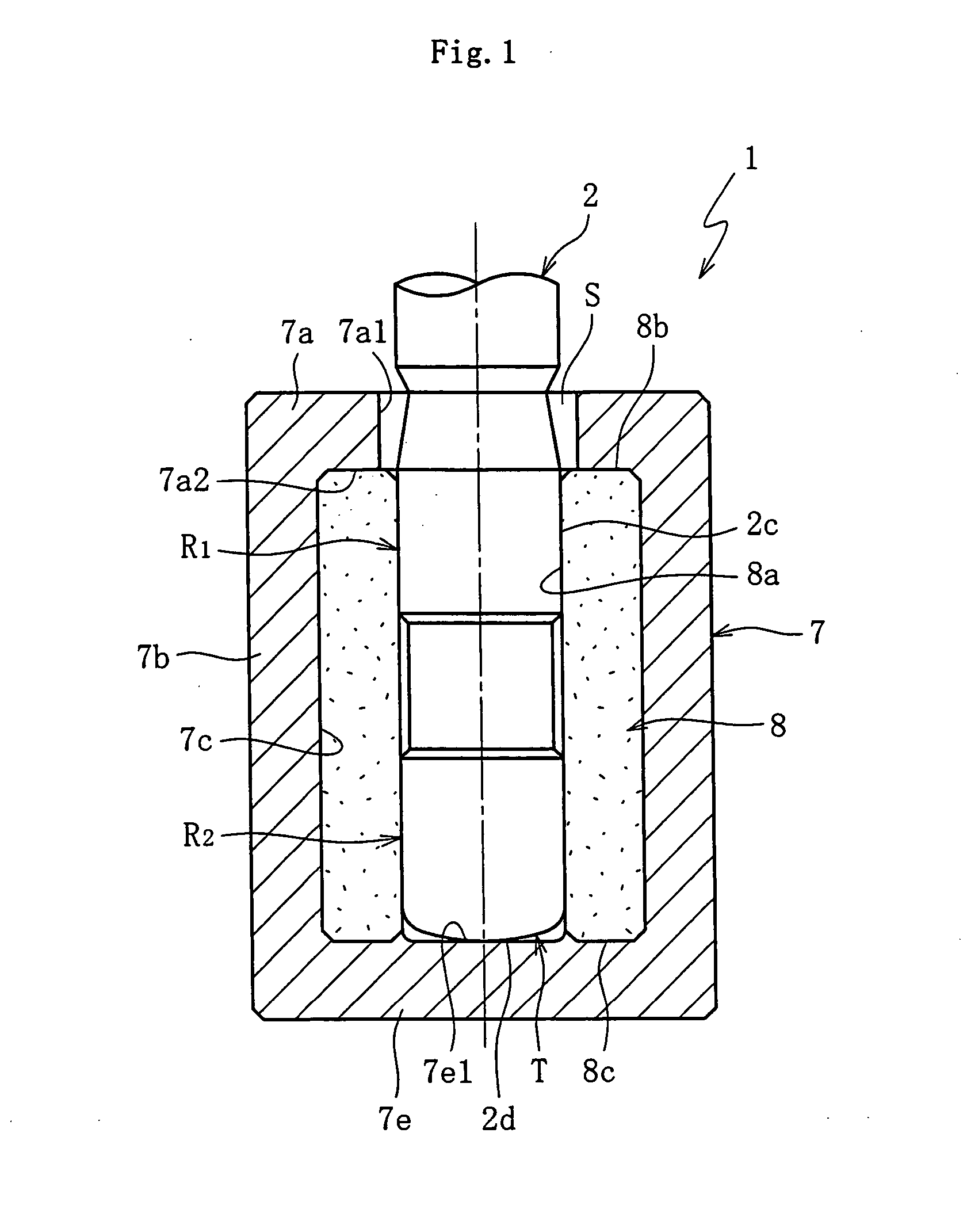

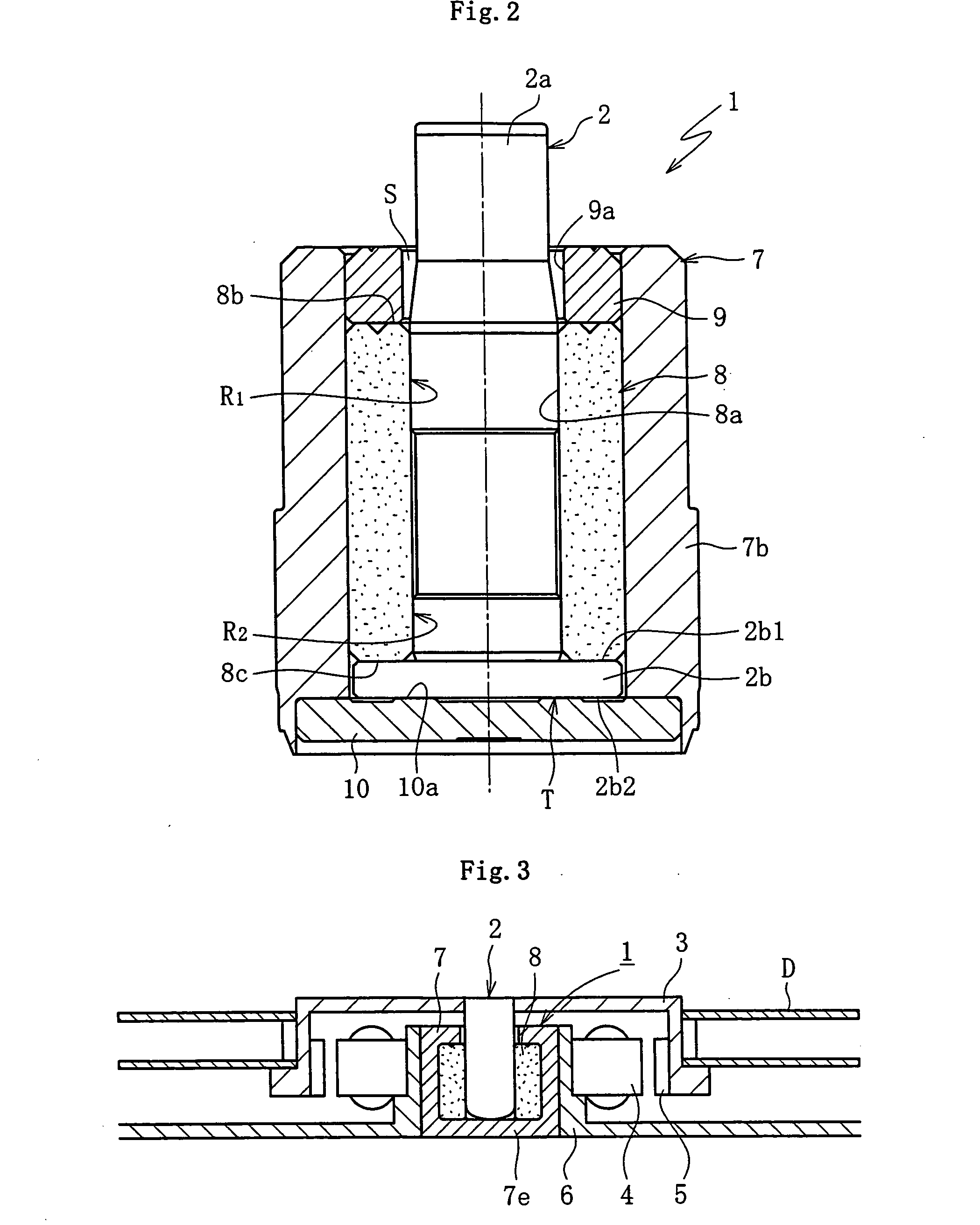

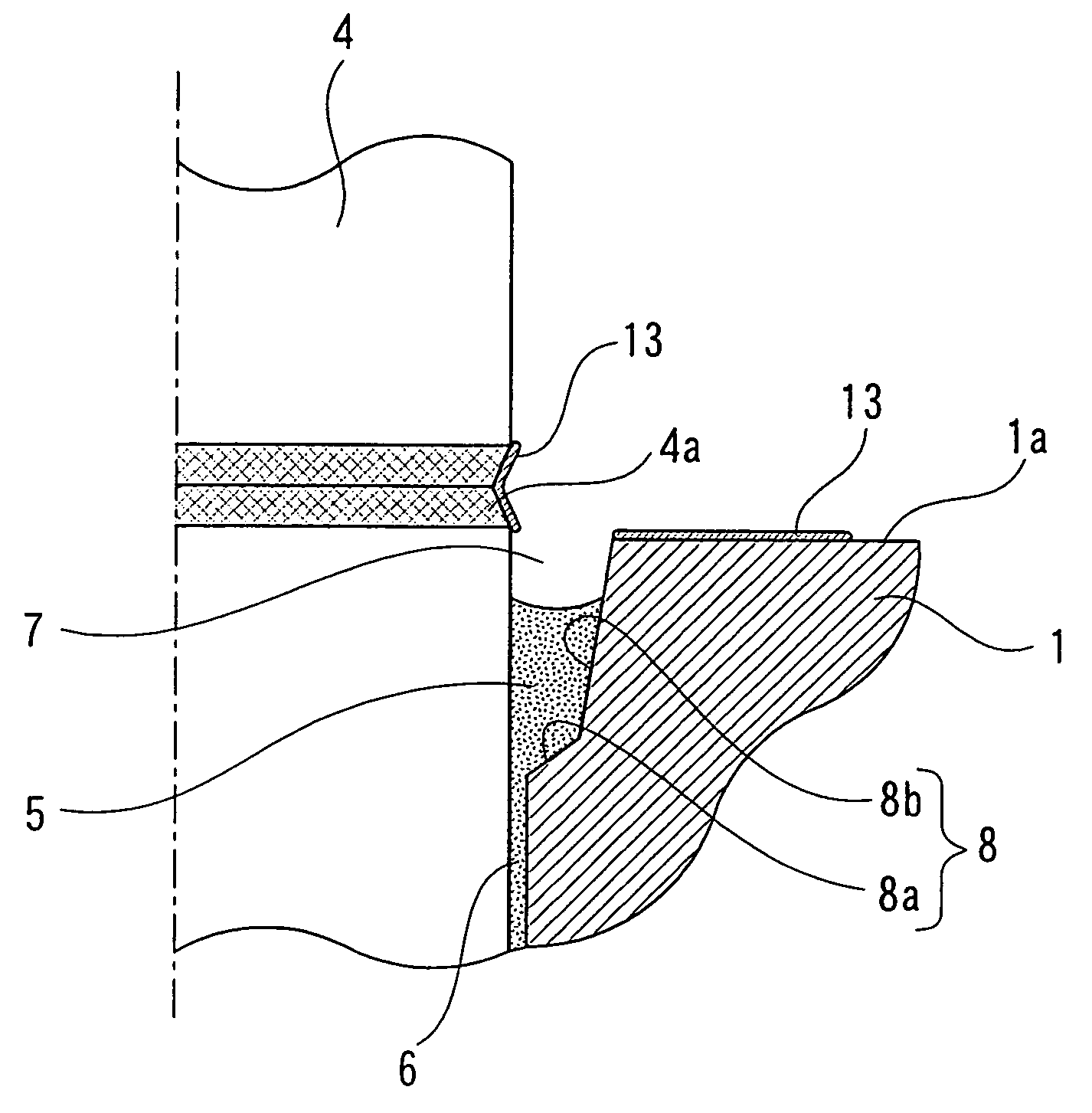

Hydrodynamic bearing and method for manufacturing the same, and spindle motor and method for manufacturing the same

ActiveUS20060202577A1Reduce performanceGood precisionMetal-working apparatusBearing componentsEngineeringFluid bearing

The object of the present invention is to provide a hydrodynamic bearing, a method for manufacturing the same, and a spindle motor, with which the gap in the axial direction required for the smooth operation of a bearing can be sufficiently ensured. A method for manufacturing a hydrodynamic bearing comprising a shaft 7, a sleeve 8 attached so as to be capable of relative rotation with respect to the shaft 7, a first flange unit 6 fixed to or integrated with the shaft 7, and a second flange unit 9 fixed to the shaft 7, the method comprising at least inserting the shaft 7 into the sleeve 8, and inserting the shaft 7 into the second flange unit 9, pressing the top face of the second flange unit 9 in the axial direction, and fixing the second flange unit 9 to the shaft 7 by welding the shaft 7 and the second flange unit 9 while maintaining the pressing state.

Owner:PHC HLDG CORP

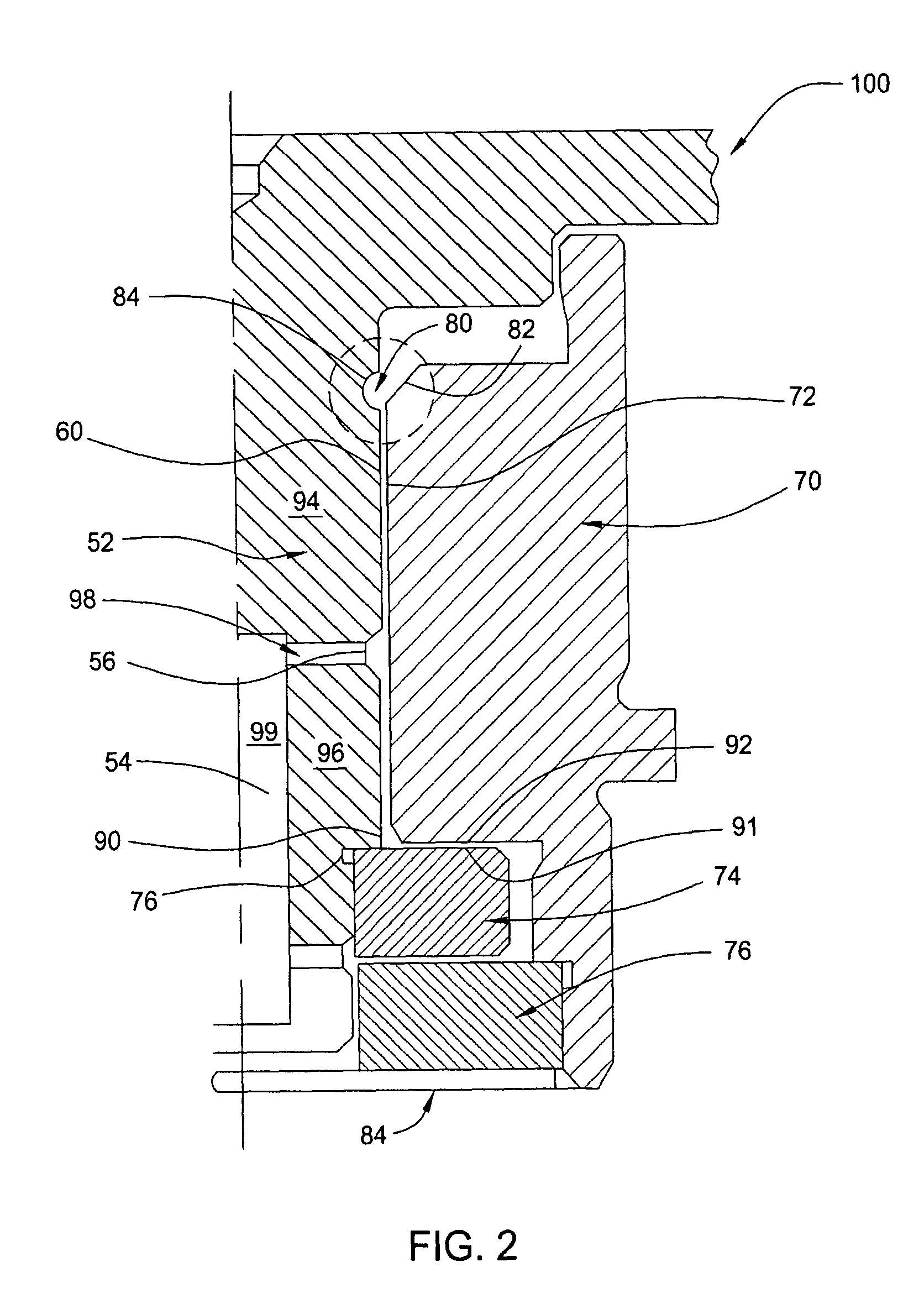

Fluid bearing device

InactiveUS20070025652A1Improve accuracyLower assembly costsAssociation with grounding devicesShaftsEngineeringCarbon nanofiber

A fluid bearing device which enables cost reductions and prevents static electricity charging. A bearing sleeve is secured inside a housing, and a shaft member is inserted inside an inner peripheral surface of the bearing sleeve. A lubricating oil dynamic pressure effect is used to generate pressure within a bearing gap between the inner peripheral surface of the bearing sleeve and an outer peripheral surface of the shaft member, thereby supporting the shaft member in a non-contact manner in the radial direction. An axial end portion of the shaft member contacts a housing bottom portion, enabling conductivity between the two members, and the housing is made of a conductive resin composition containing added carbon nanofiber with a volume resistivity of 106 Ω·cm or less.

Owner:NTN CORP

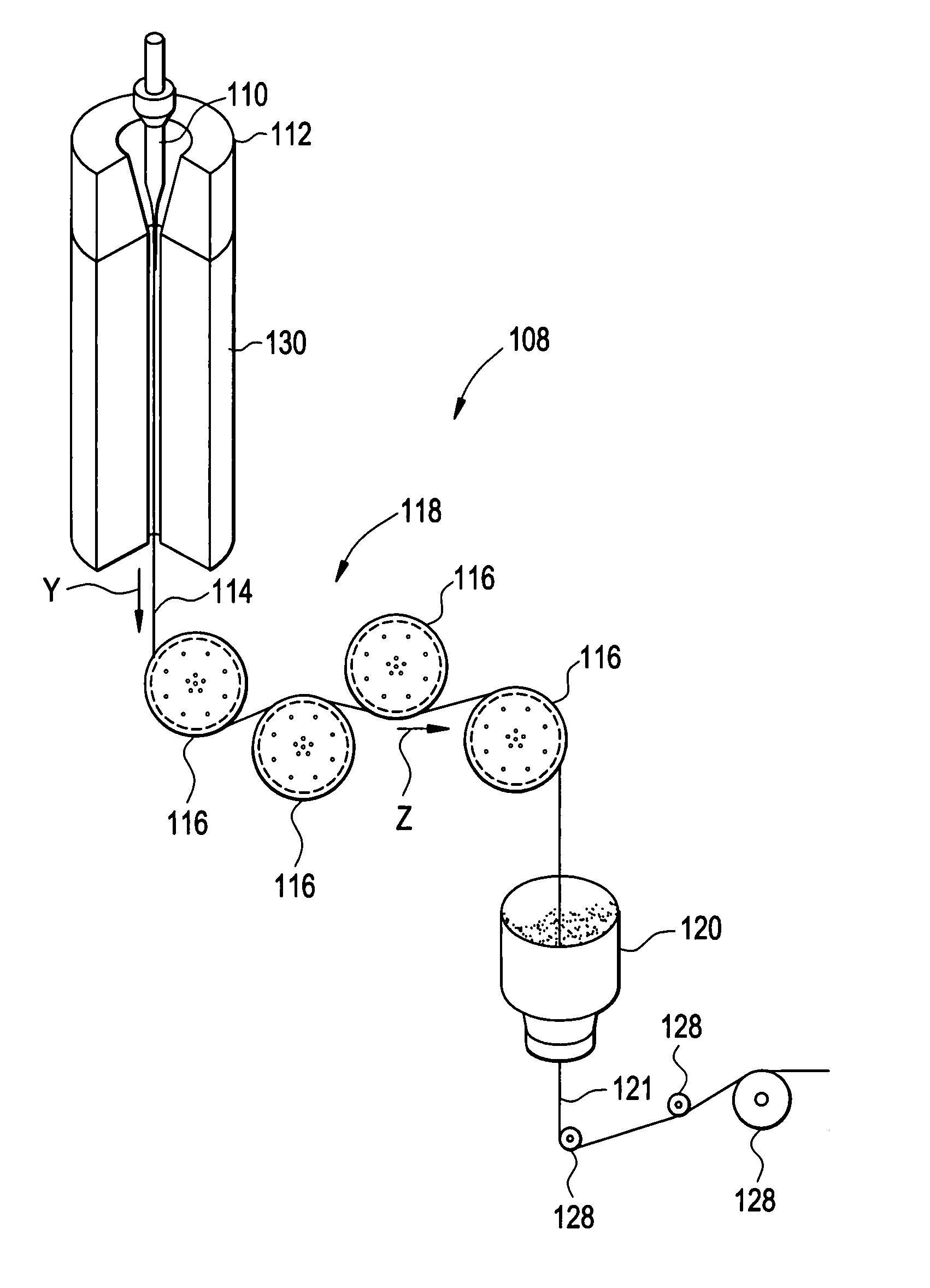

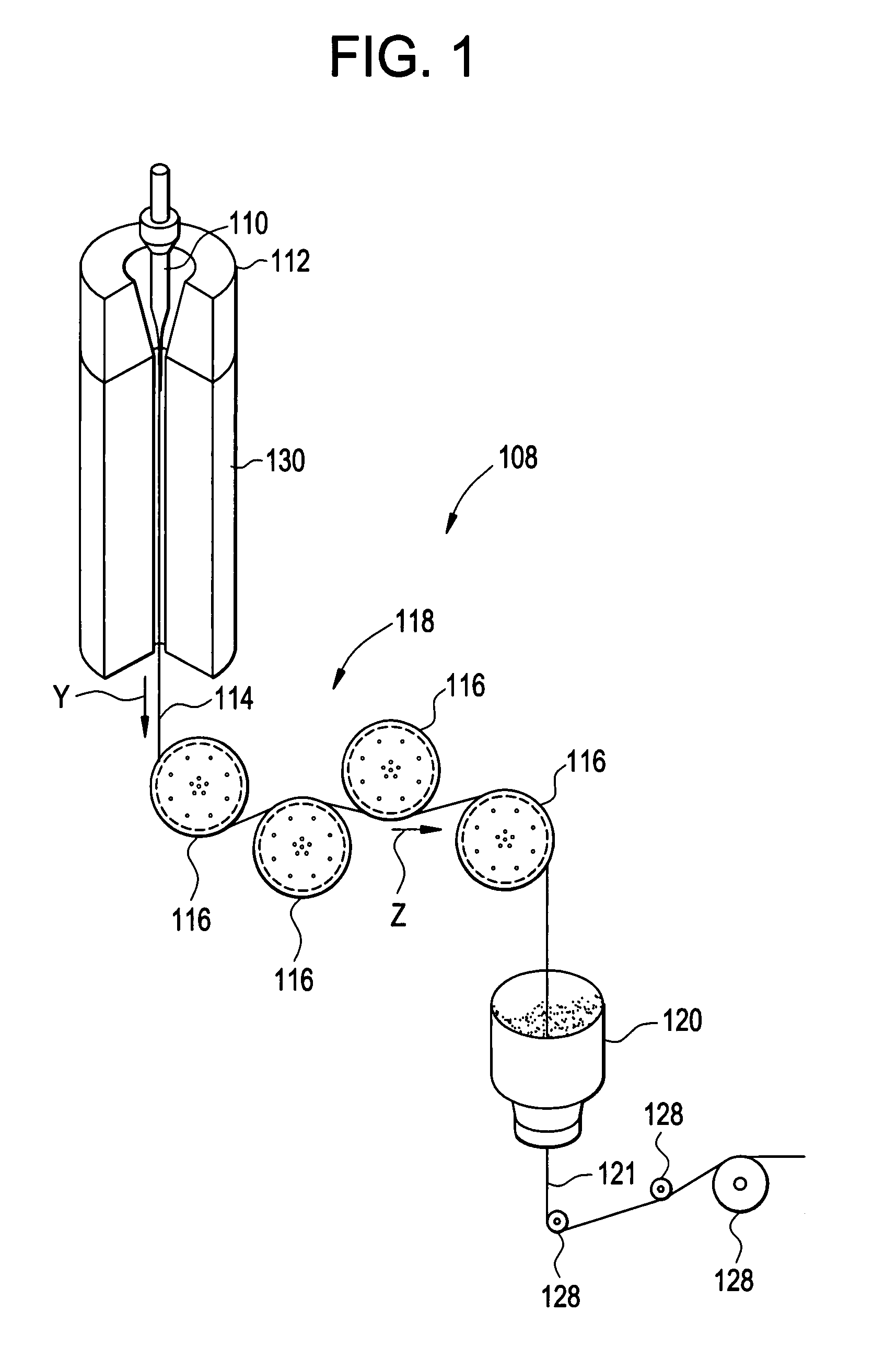

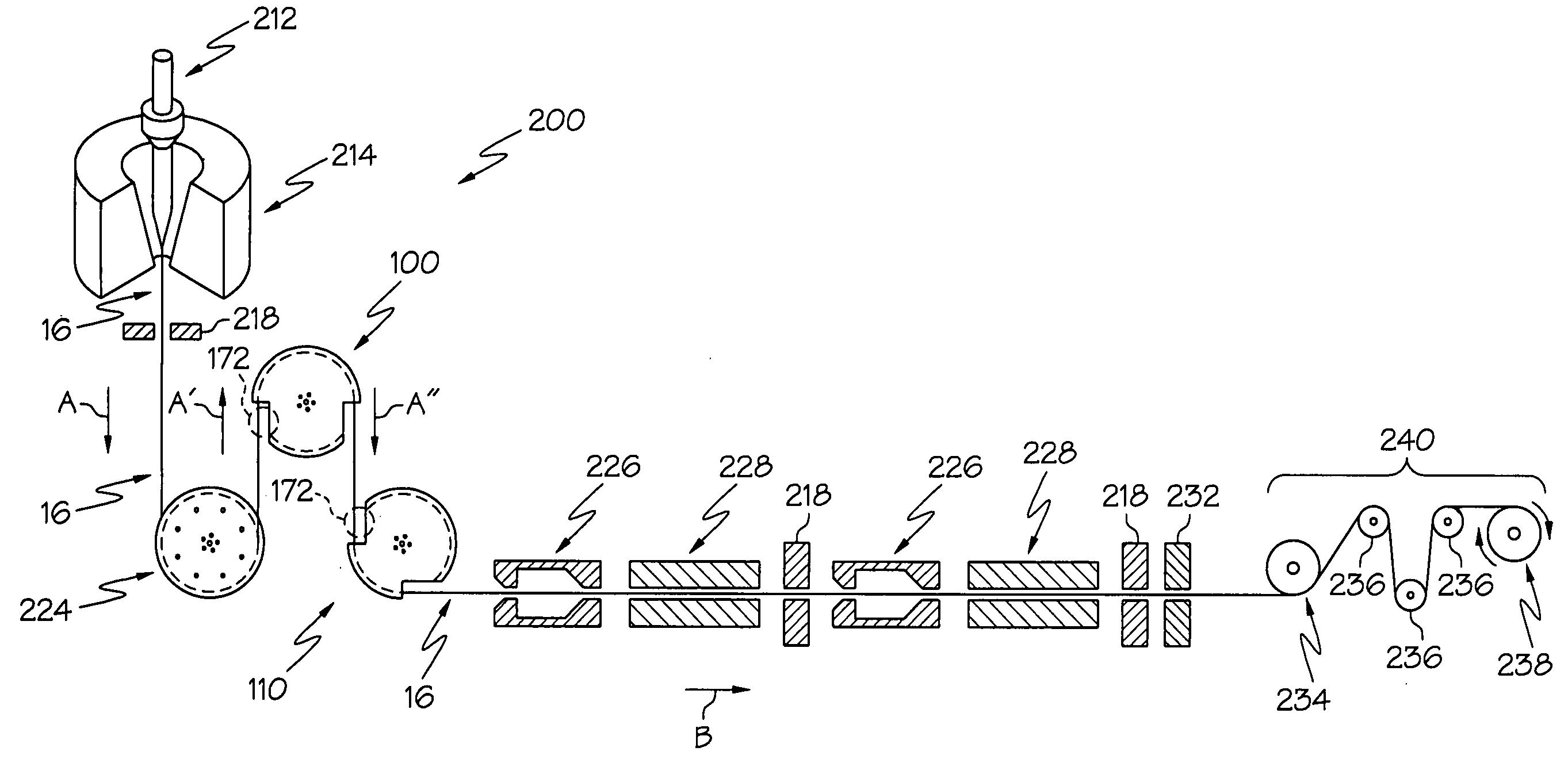

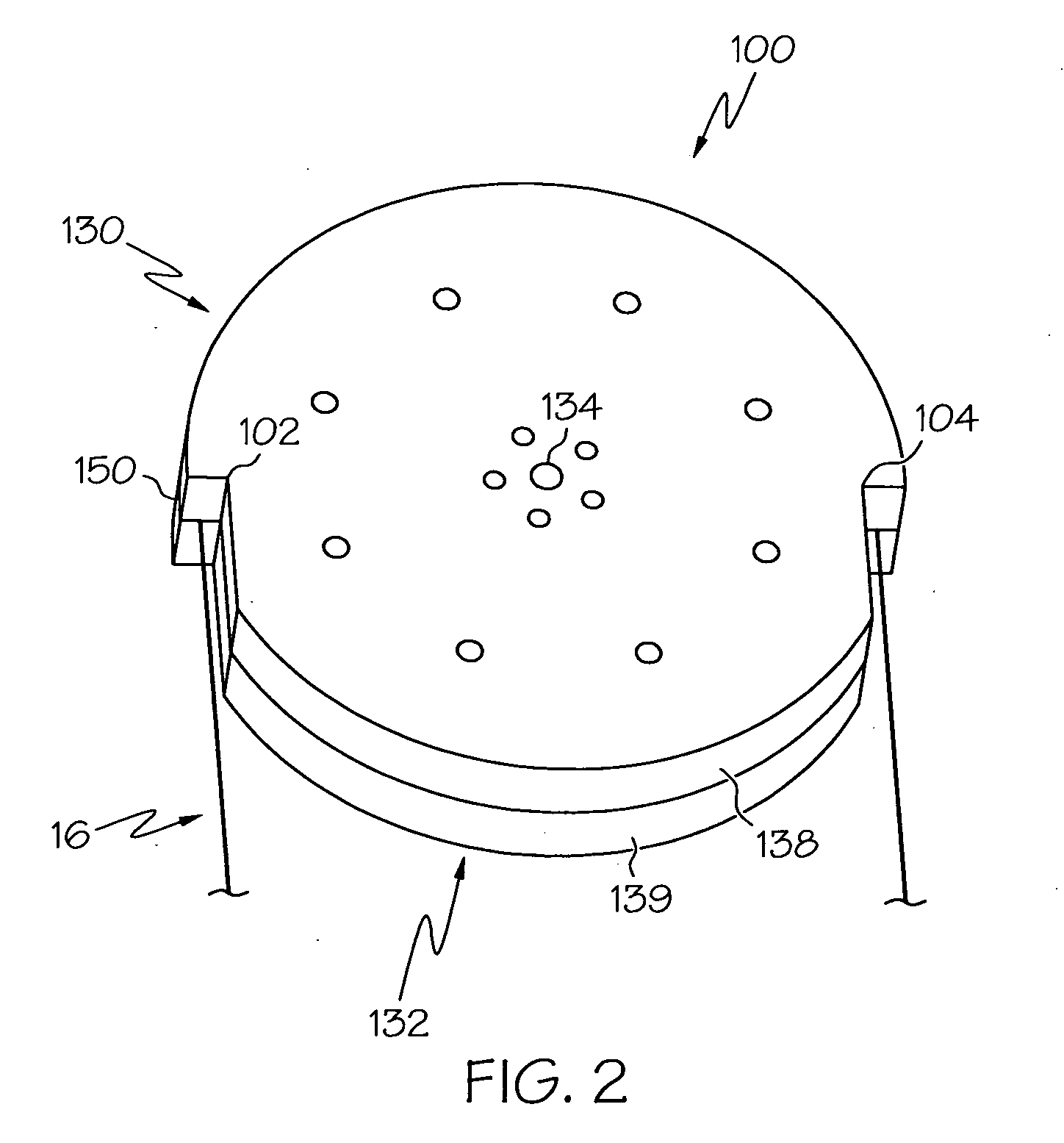

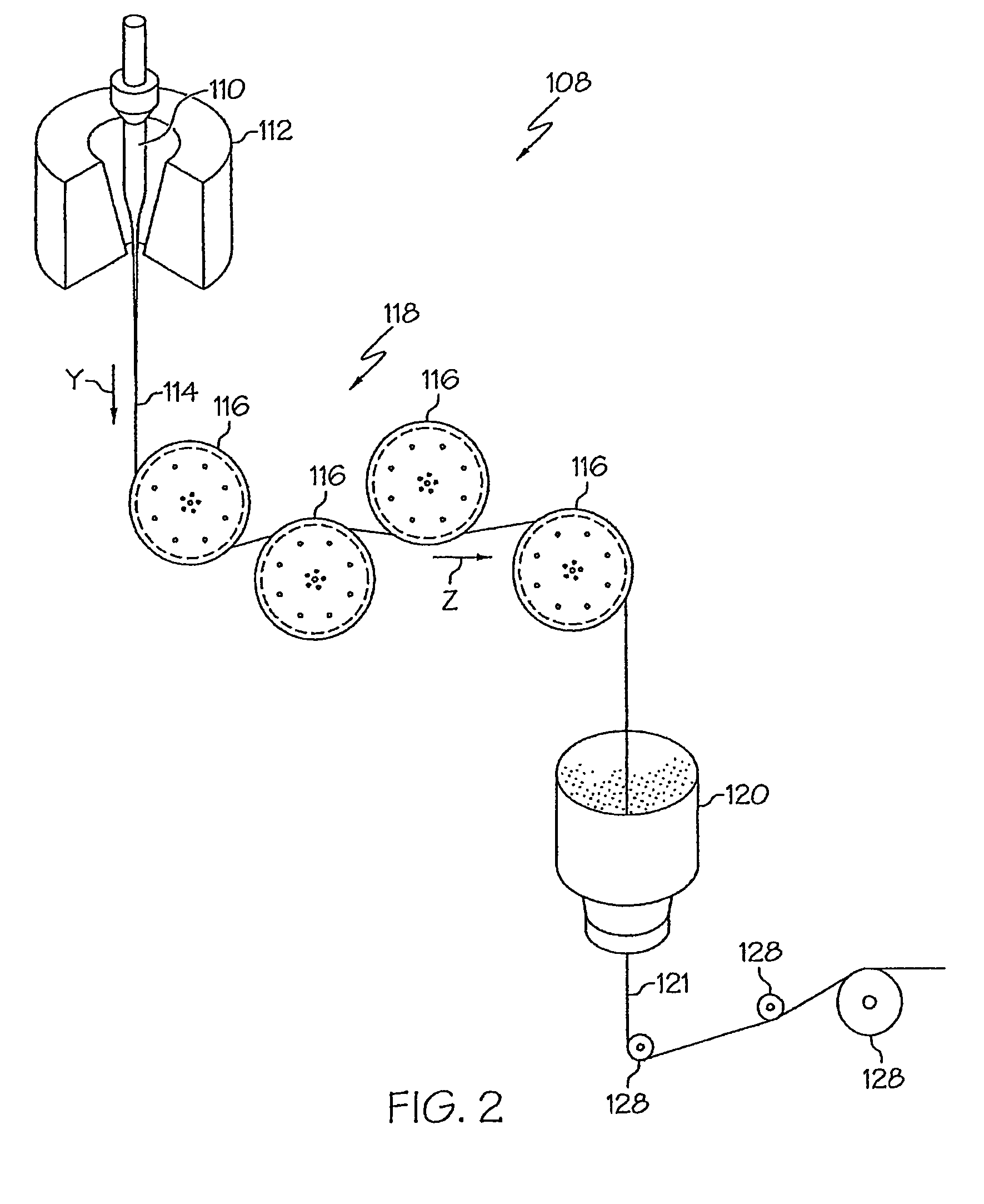

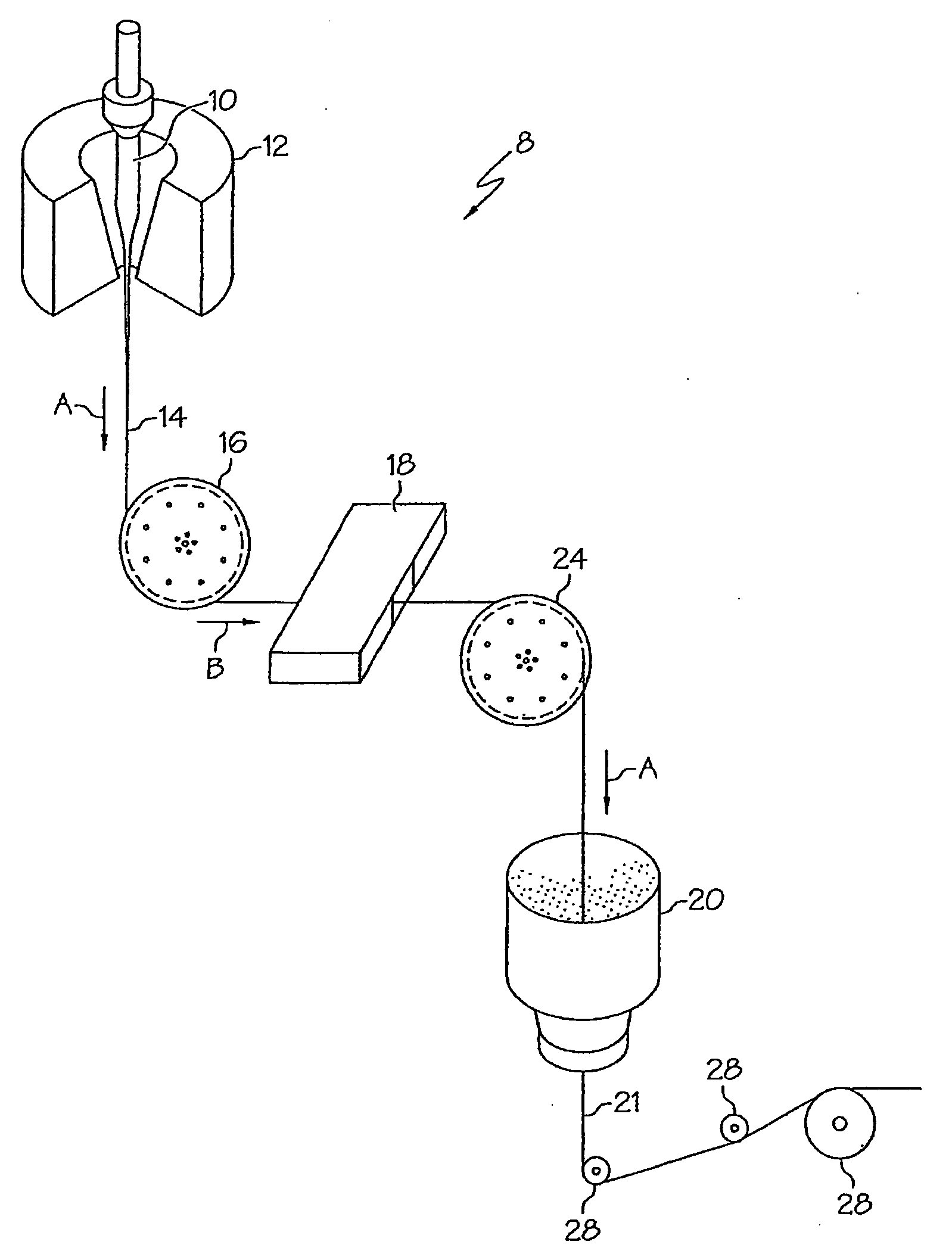

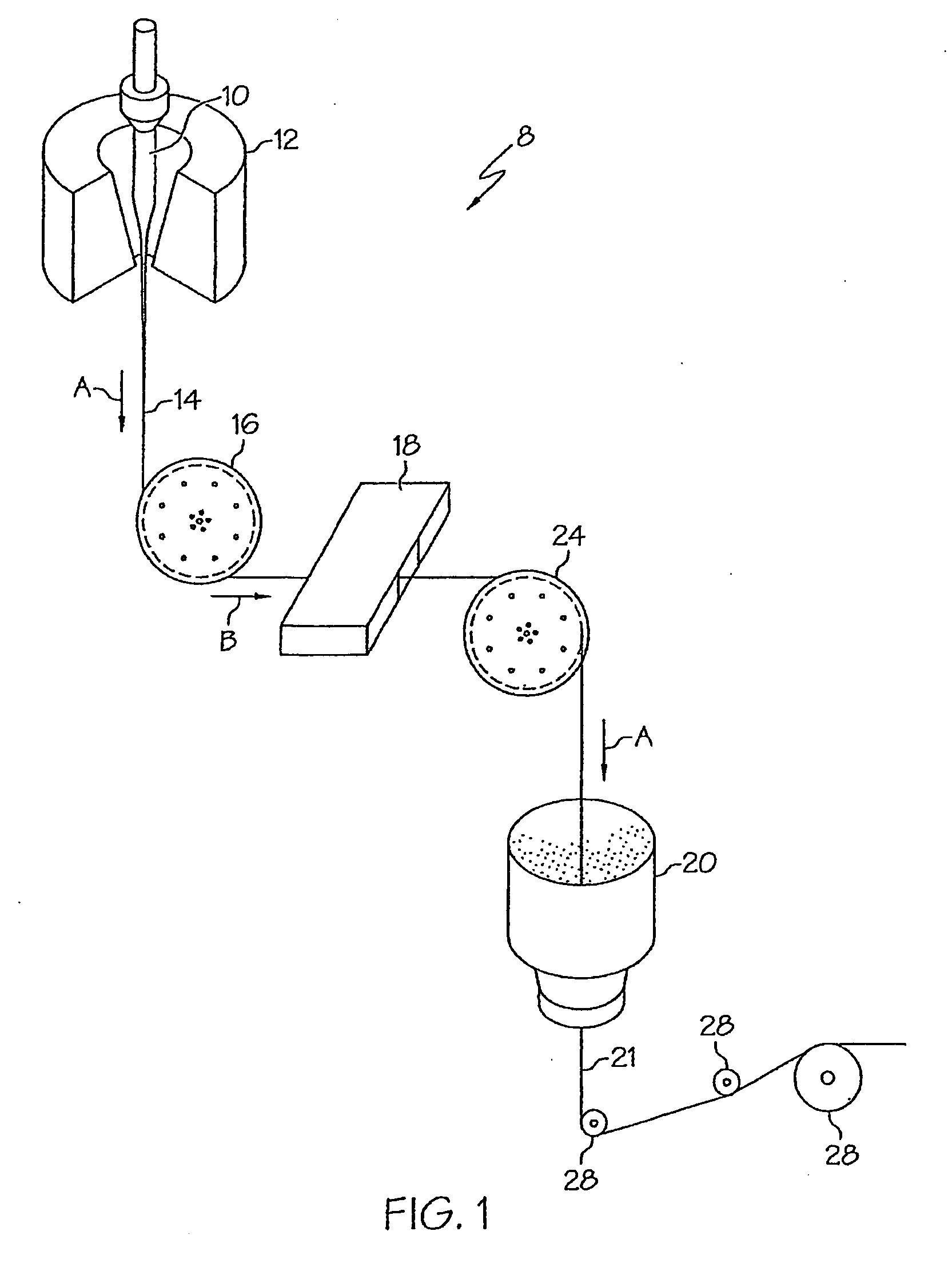

Fiber air turn for low attenuation fiber

ActiveUS8074474B2Glass furnace apparatusGlass fibre drawing apparatusRayleigh scatteringUltrasound attenuation

A method for forming an optical fiber includes drawing the optical fiber from a glass supply and treating the fiber by maintaining the optical fiber in a treatment zone wherein the fiber is cooled at a specified cooling rate. The optical fiber treatment reduces the tendency of the optical fiber to increase in attenuation due to Rayleigh scattering, and / or over time following formation of the optical fiber due to heat aging. Methods for producing optical fibers along nonlinear paths incorporating fluid bearings are also provided thereby allowing for increased vertical space for the fiber treatment zone.

Owner:CORNING INC

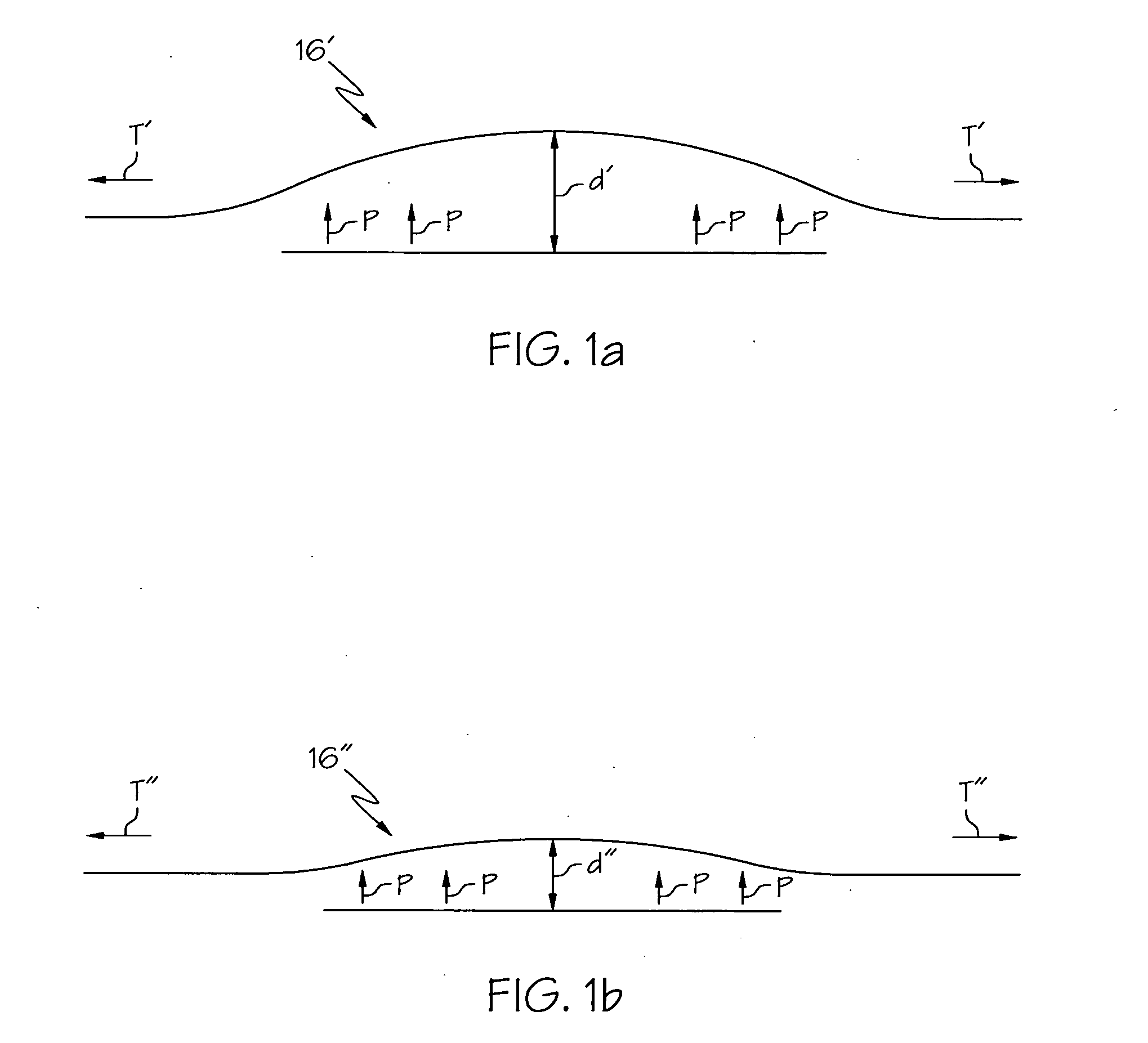

Methods for measuring the tension of optical fibers during manufacture

A non-contact method for measuring the tension applied to a drawn optical fiber includes drawing an optical fiber and displacing the optical fiber by applying a pressurized fluid to the optical fiber. The pressurized fluid may be applied to the optical fiber using a fluid bearing. The fluid bearing may include a fiber support channel. The optical fiber may be directed through the fiber support channel and is displaced relative to the fluid bearing by supplying the pressurized fluid to the fiber support channel. The displacement of the optical fiber caused by the application of the pressurized fluid to the optical fiber may then be measured. The tension applied to the optical fiber may then be determined based on the determined displacement.

Owner:CORNING INC

Fluid bearing device

ActiveUS7201516B2Small depthSufficient length dimensionShaftsRecord information storageEngineeringFluid bearing

A fluid bearing device capable of preventing a lubricant from scattering outward even during rotation thereof, while holding a relatively large amount of lubricant at a seal surface portion. A lubricant is filled between a sleeve and a shaft, a seal surface portion is formed on the sleeve in a location facing an open end thereof, the seal surface portion has a sectional shape defined by a plurality of inclined surfaces, and an inclination angle α of the inclined surface of the seal surface portion adjacent a radial bearing portion with respect to a shaft axis is formed to be larger than an inclination angle β of the inclined surface of the seal surface portion distant away from the radial bearing portion with respect to the shaft axis.

Owner:PHC HLDG CORP

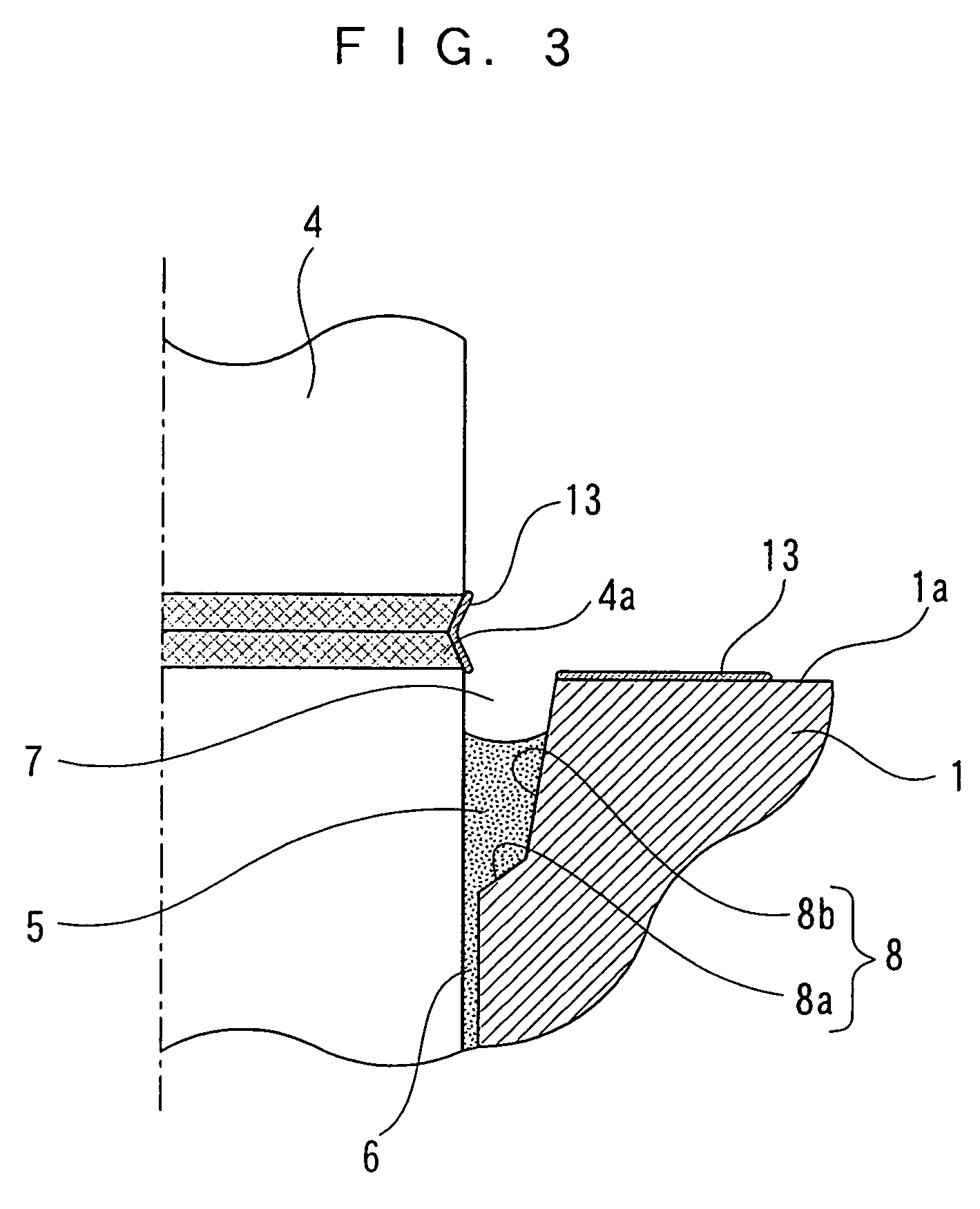

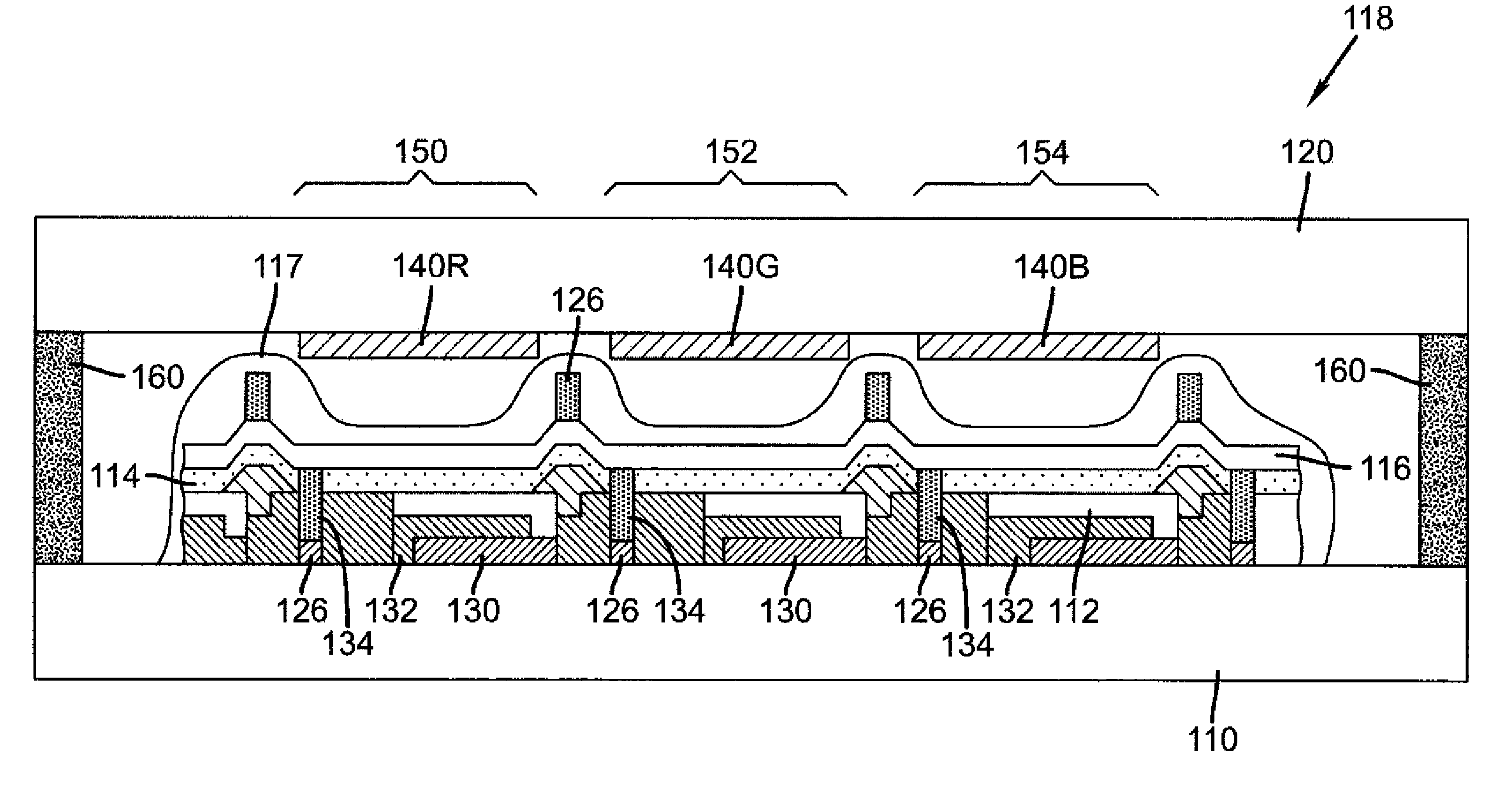

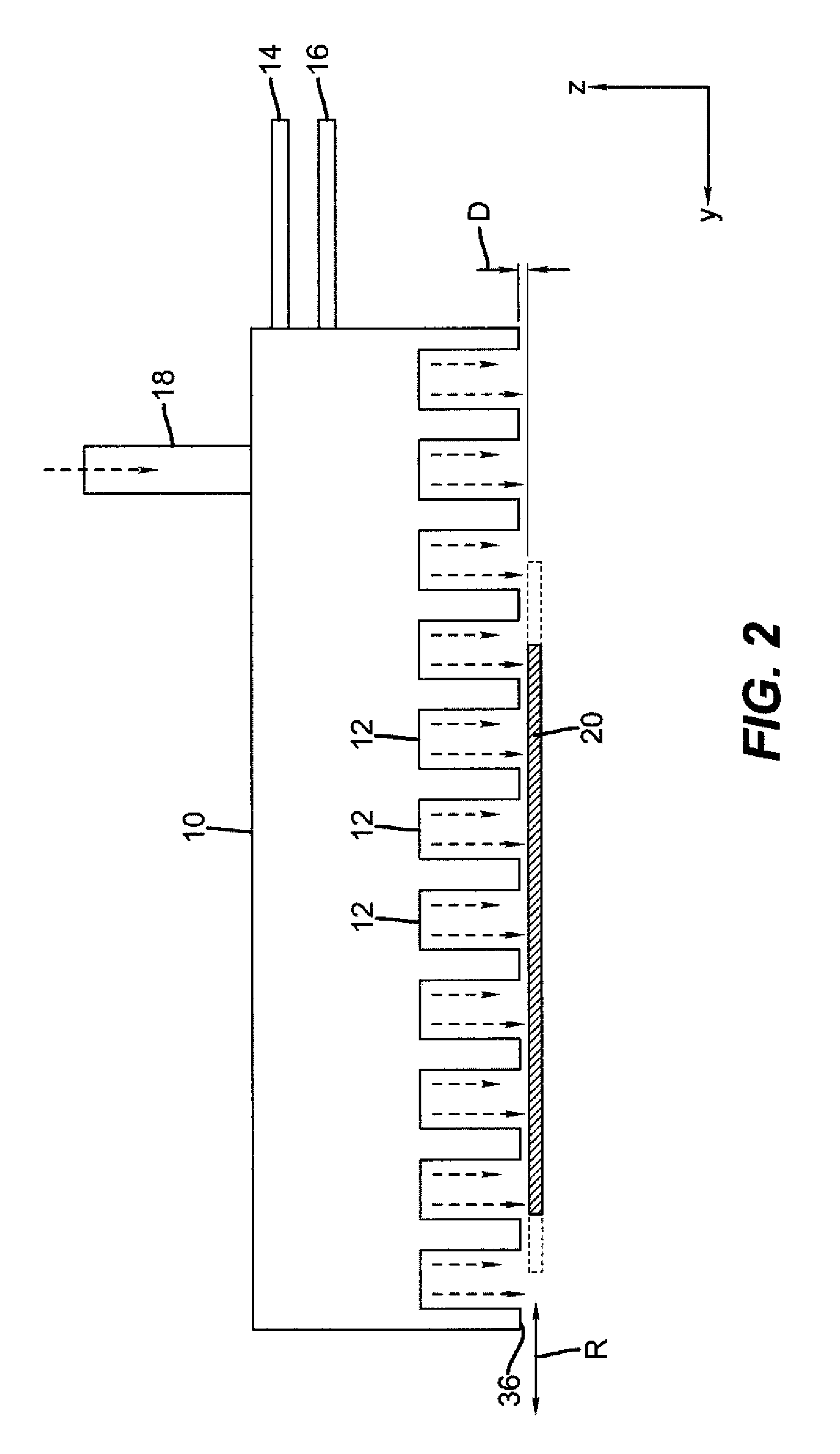

Process for forming thin film encapsulation layers

ActiveUS20120070942A1Suitable for processingSolid-state devicesSemiconductor/solid-state device manufacturingRelative motionFluid bearing

A thin film environmental barrier encapsulation process includes providing an electronic device on a substrate, a first reactant gaseous material, a second reactant gaseous material, an inert gaseous material; and a delivery head through which the reactant gaseous materials and the inert gaseous material are simultaneously directed toward the electronic device and the substrate. One or more of the reactant gaseous materials and the inert gaseous material flows through the delivery head. The flow of the one or more of the reactant gaseous materials and the inert gaseous material generates a pressure to create a gas fluid bearing that maintains a substantially uniform distance between the delivery head and the substrate. Relative motion between the delivery head and the substrate causes the second reactant gaseous material to react with at least a portion of the electronic device and the substrate that has been treated with the first reactant gaseous material.

Owner:EASTMAN KODAK CO

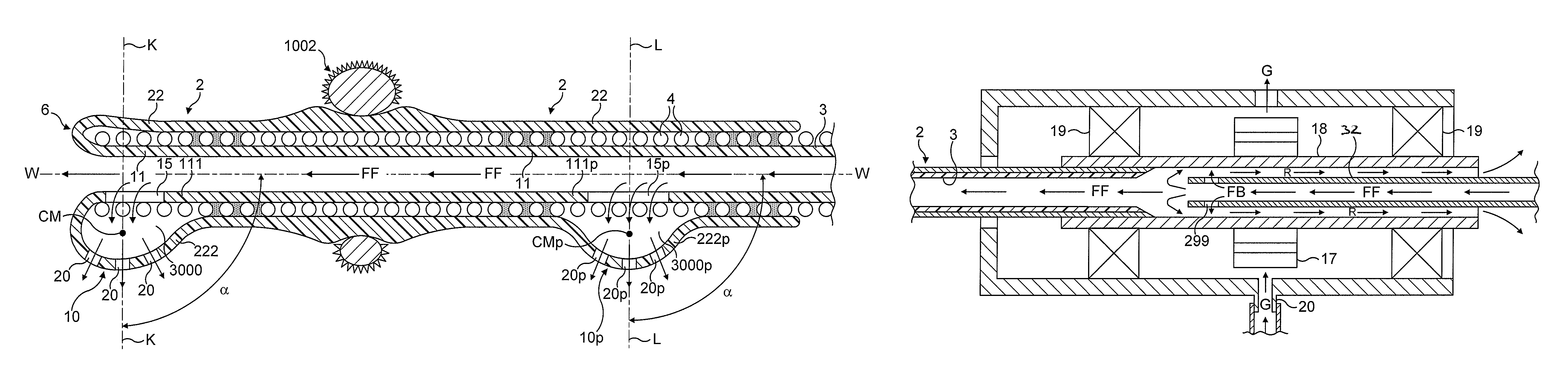

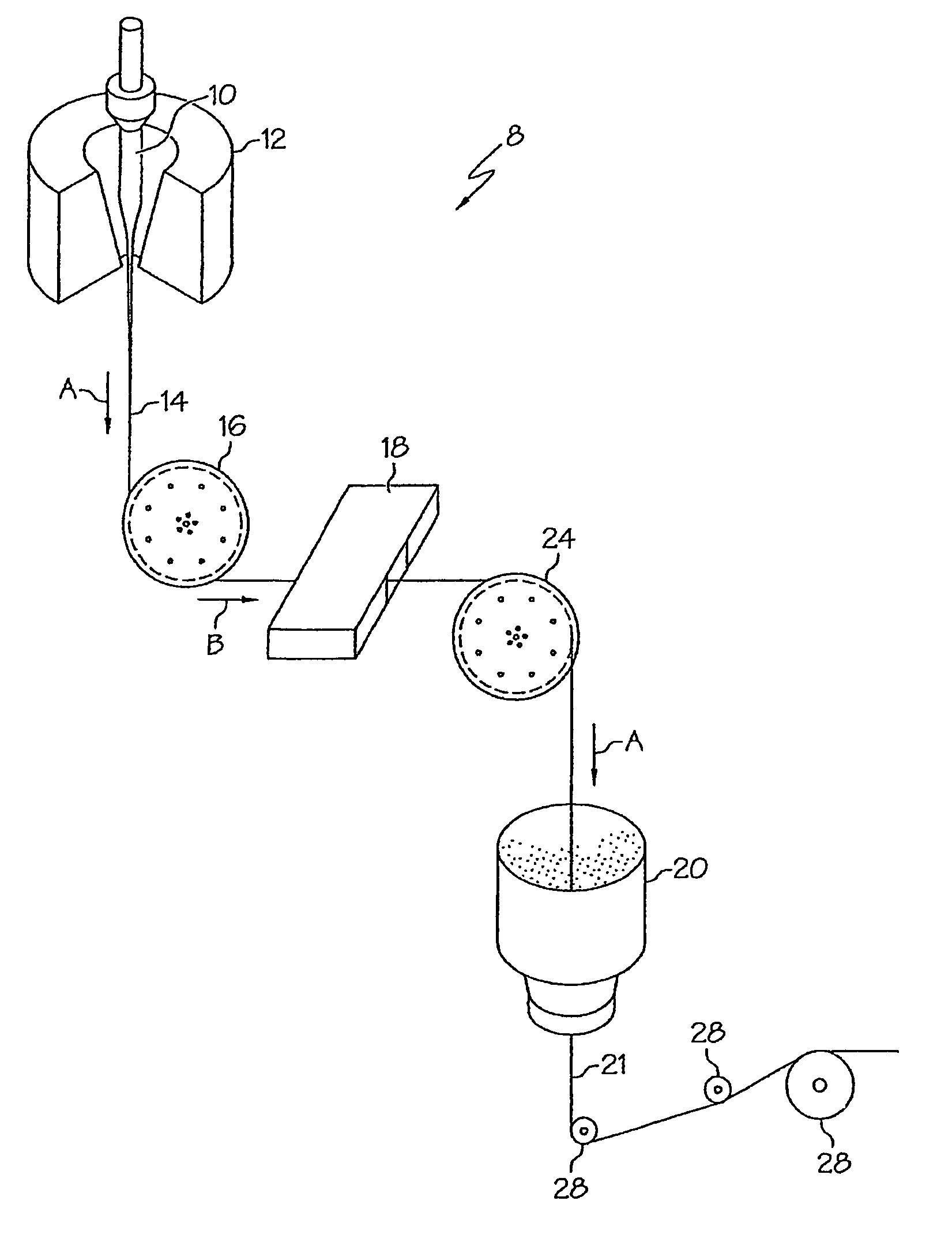

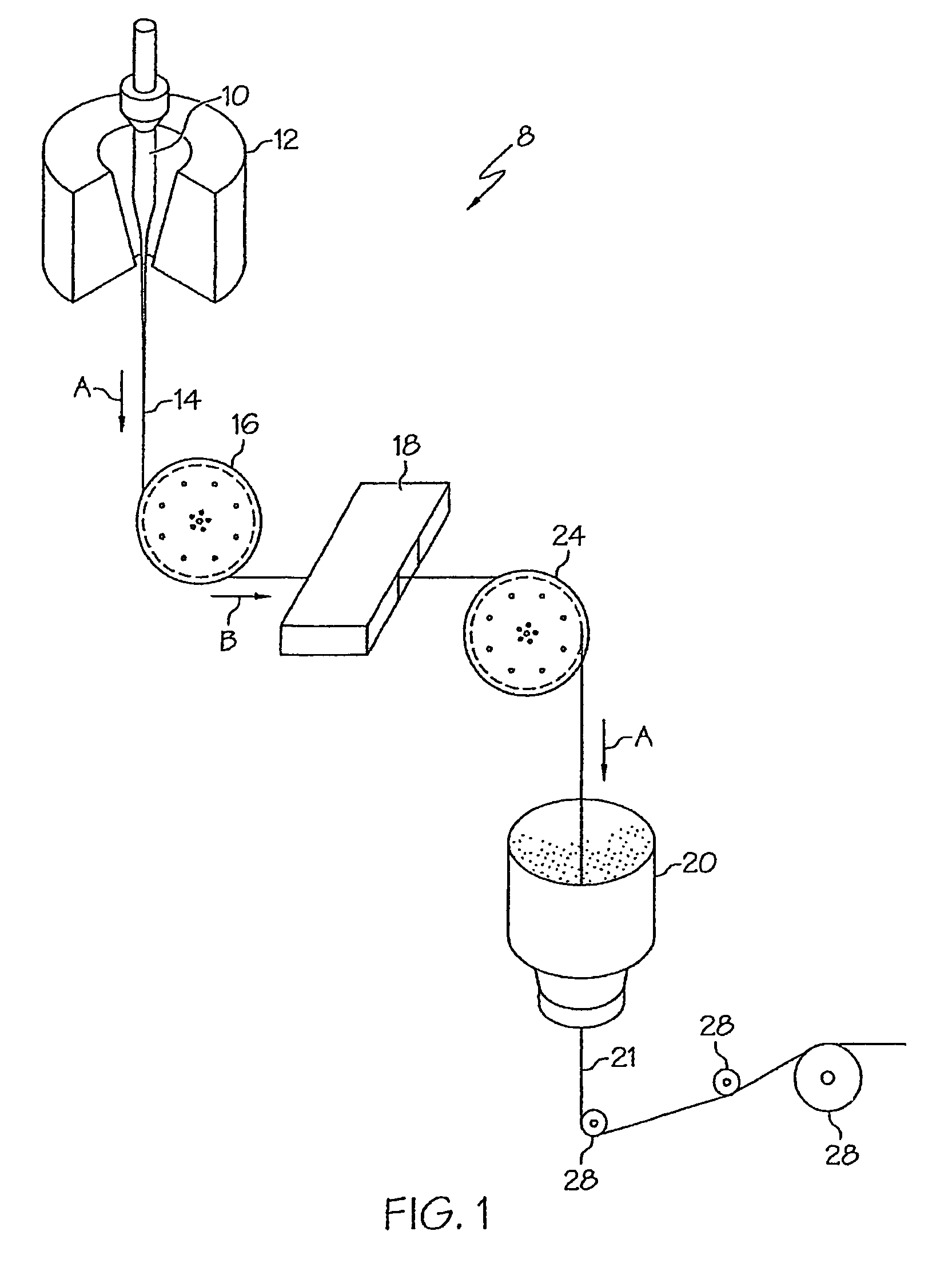

Methods for drawing optical fibers using a fluid bearing

ActiveUS7937971B2Improve system flexibilityAdditional componentsGlass fibre drawing apparatusRotary drum furnacesFiberFirst pathway

Methods for producing optical fibers along nonlinear paths include incorporating fluid bearings. An optical fiber is drawn from a preform along a first pathway, contacted with a region of fluid cushion of a fluid bearing, and redirected along a second pathway as the fiber is drawn across said region of fluid cushion.

Owner:CORNING INC

Methods for producing optical fibers

ActiveUS20100281922A1Strengthen the systemImprove methodGlass fibre drawing apparatusRotary drum furnacesFiberFirst pathway

Methods for producing optical fibers along nonlinear paths include incorporating fluid bearings. An optical fiber is drawn from a preform along a first pathway, contacted with a region of fluid cushion of a fluid bearing, and redirected along a second pathway as the fiber is drawn across said region of fluid cushion.

Owner:CORNING INC

Optical platelet counter method

ActiveUS20140205176A1Poor spherical aberrationLow costBiological particle analysisMicroscopesOptical depthFluid bearing

Platelets or blood cells are detected in a fluid sample by adjusting a focal depth of a microscope through a range of values, the microscope having a mounted sample and an objective lens adapted with one or both of (a) a spherical aberration correction unmatched to a utilized cover plate for the sample, or (2) a numerical aperture unmatched to a utilized illumination source for the sample. Images are recorded at different specific focal depths and in multiple z planes of a fluid bearing the platelets, where the position of platelets may overlap on different of the multiple z planes that are recorded, the images recorded through the cover plate, thus causing the generation of a specific light-dark pattern indicative of platelets at particular positions and at multiple depths in the fluid media. The images are analyzed for the specific light-dark pattern.

Owner:FOCE TECH INT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com