Detecting gas in fluids

a technology of fluids and gas, applied in the direction of material analysis, optical radiation measurement, instruments, etc., can solve the problems of change in the resistance of the sensor, the physical sensor itself reacting with the gas/air mixture flowing by, and several problems, so as to achieve strong response, strong response, and the effect of not deteriorating the consistency and repeatability of the sensor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

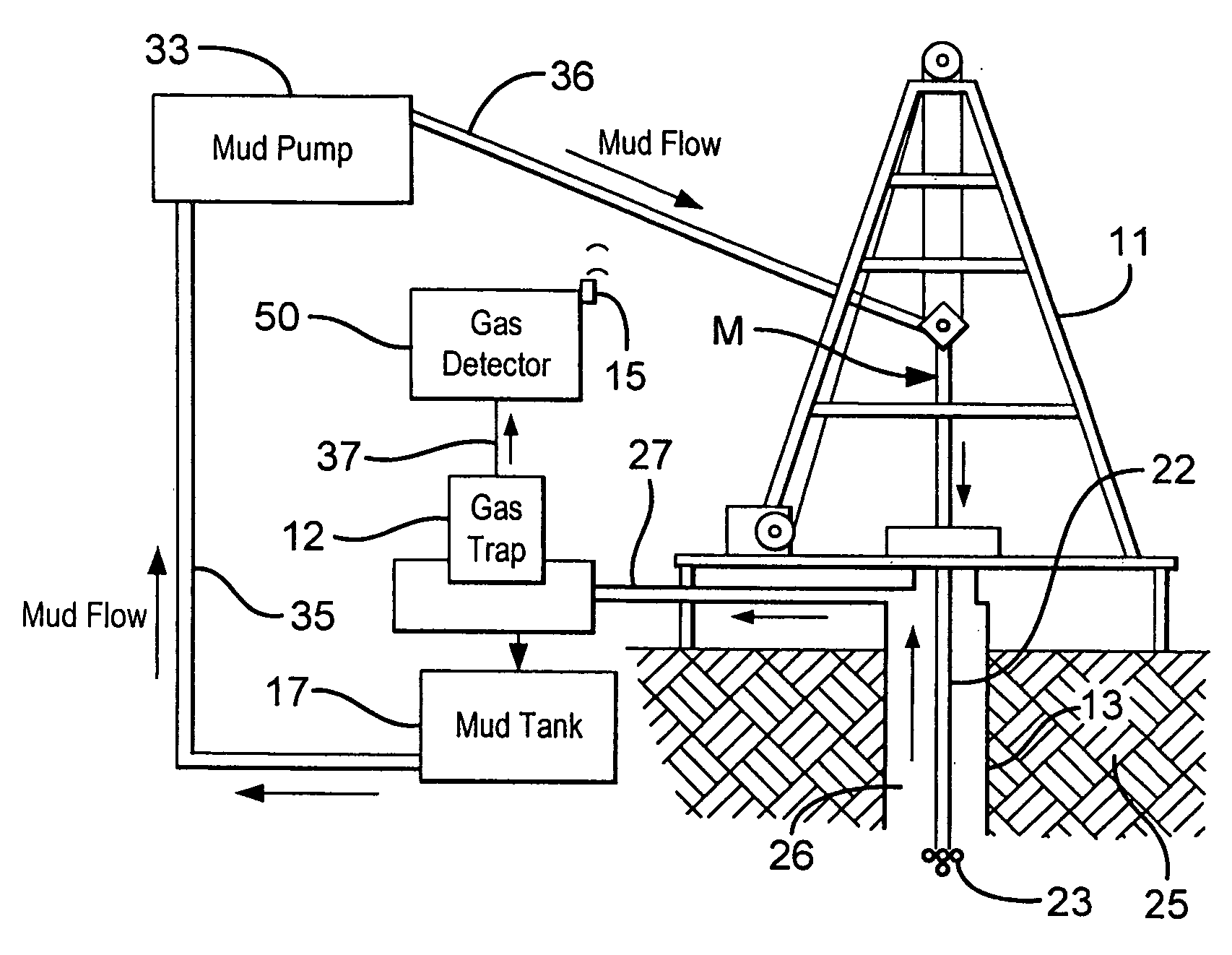

[0033] As shown in FIG. 1 a gas detector 50 according to the present invention receives gas samples in a polyflow line 37 from a gas trap 12. A drilling rig 11 drills a well 13 into a formation 25. A mud pump 33 pumps mud M in a line 36 into the well 13 down a drillstring 22, to and through a bit apparatus 23, and then up in an annulus 26 to an exit line 27 which feeds into the gas trap 12. The mud M exits the gas trap 12 and flows into a mud tank17 from which the mud pump 33 pumps the mud in a line 35 back to the line 36. A transmitter or modem 15 (e.g. wireless or hardwired) transmits signals from the gas detector 50 to apparatus or systems such as a computer, computer system, network, or a data acquisition system or apparatus.

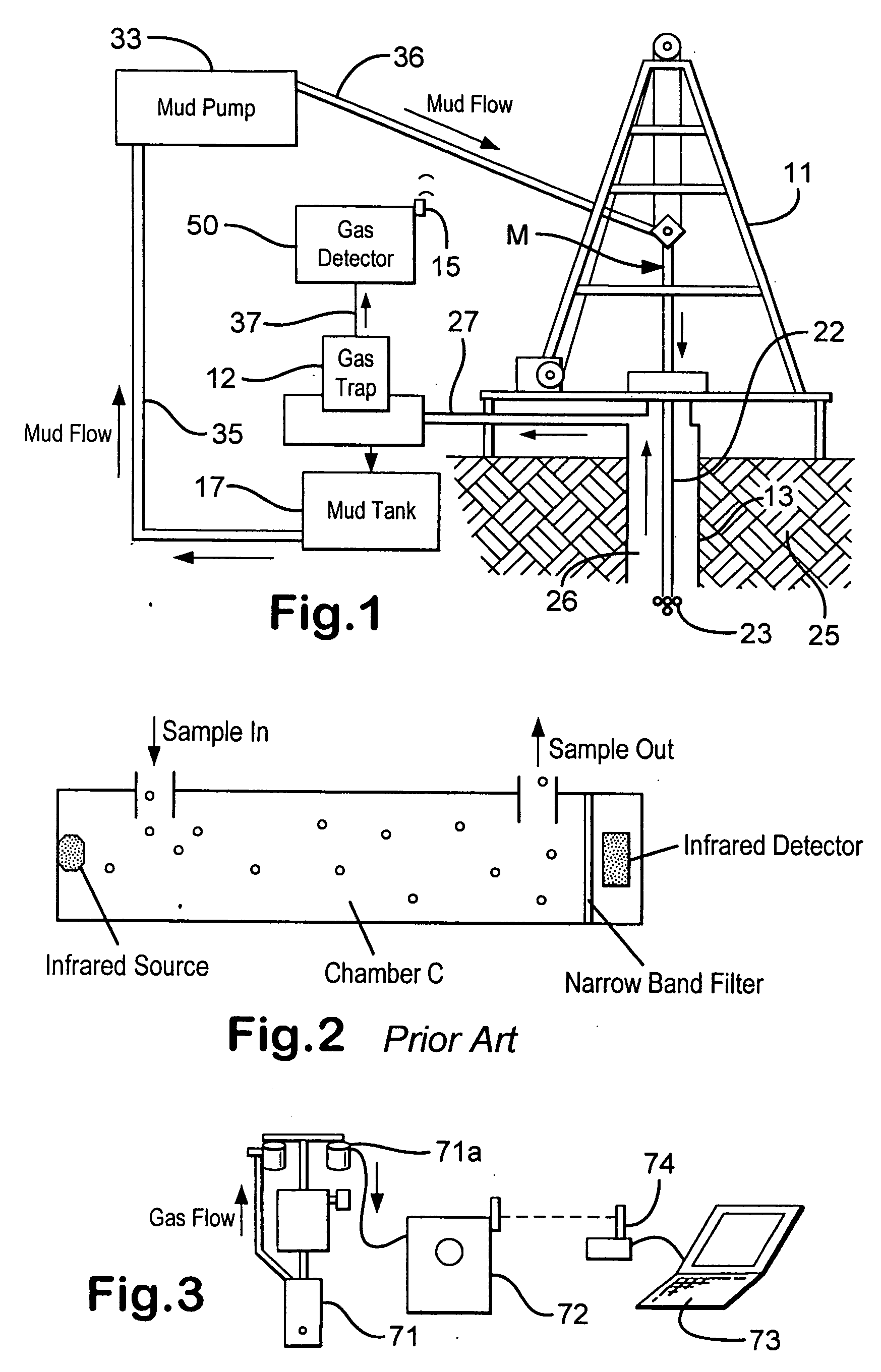

[0034]FIG. 2 shows a typical prior art infra-red sensor system in which infra-red light from an infra-red source passes through material to be analyzed in a chamber C, then through a narrow band filter, to an infra-red detector. The material flows into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com