Patents

Literature

1863 results about "Combined method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Combined method. The Combined method is a knitting technique developed by Annie Modesitt, author of Confessions of a Knitting Heretic. In reality, this method is a modification of existing knitting methods, and hence is used in conjuction with either the English Method or the Continental method.

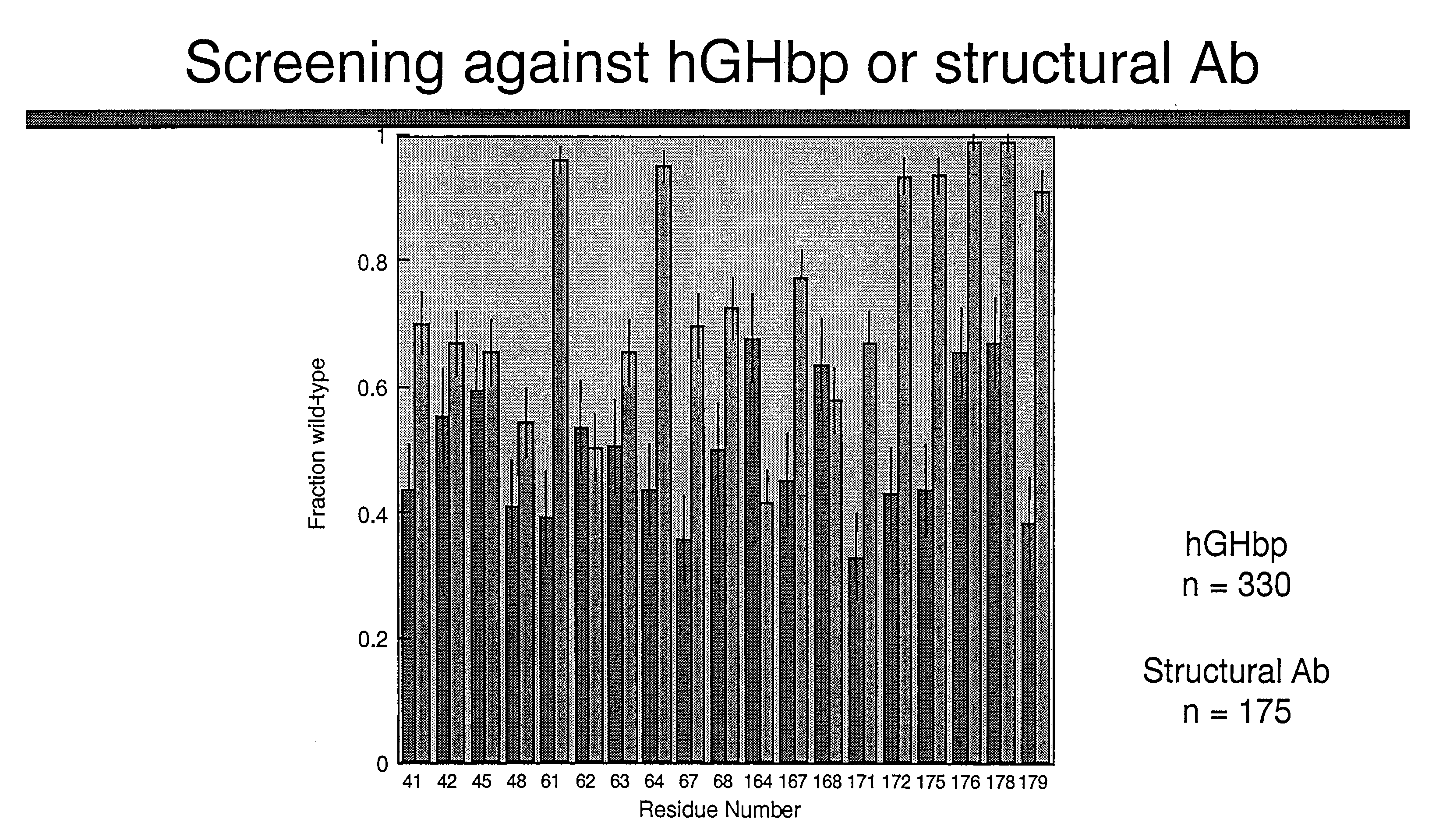

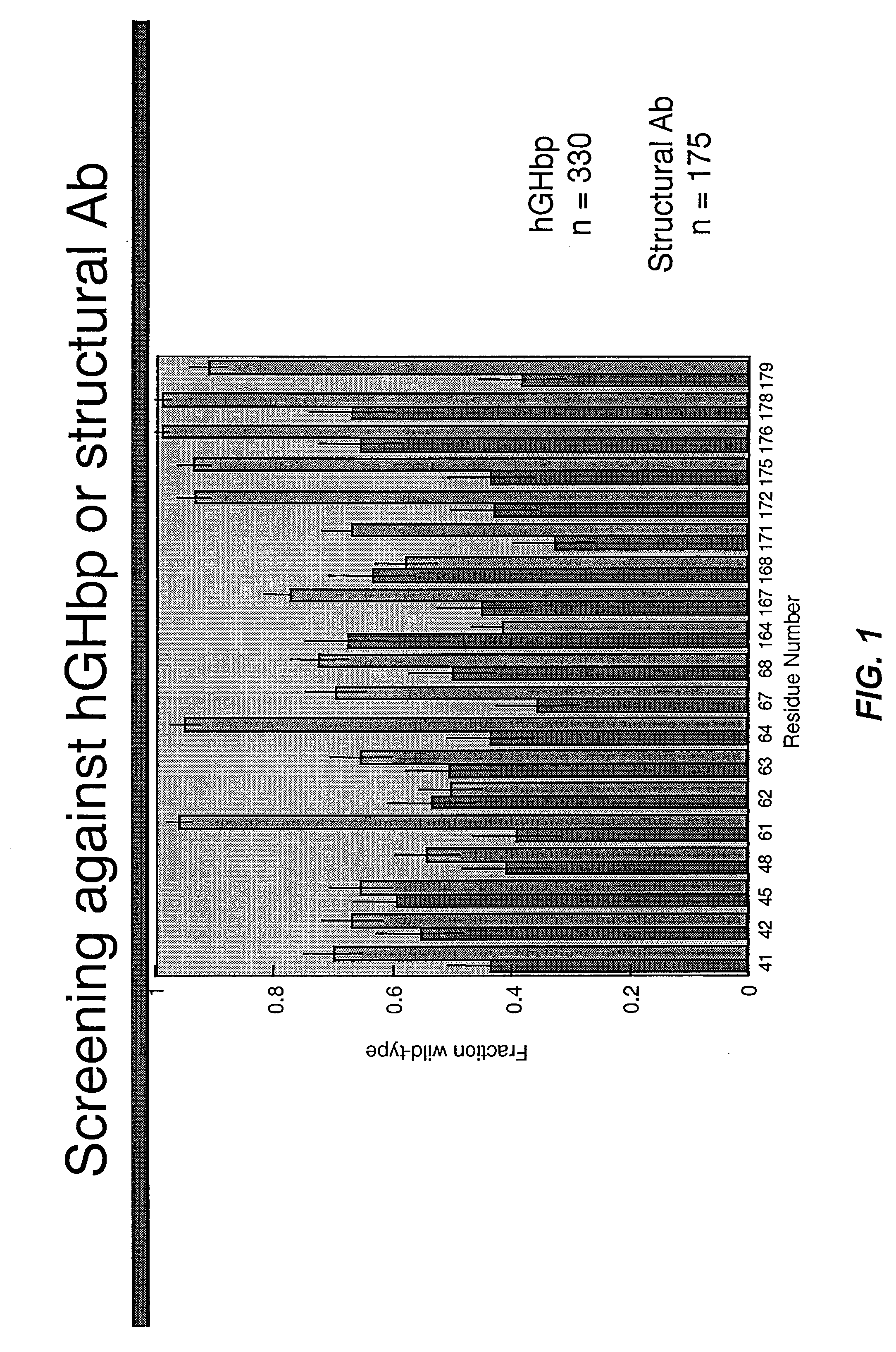

Shotgun scanning

A combinatorial method that uses statistics and DNA sequence analysis rapidly assesses the functional and structural importance of individual protein side chains to binding interactions. This general method, termed “shotgun scanning”, enables the rapid mapping of functional protein and peptide epitopes and is suitable for high throughput proteomics.

Owner:GENENTECH INC

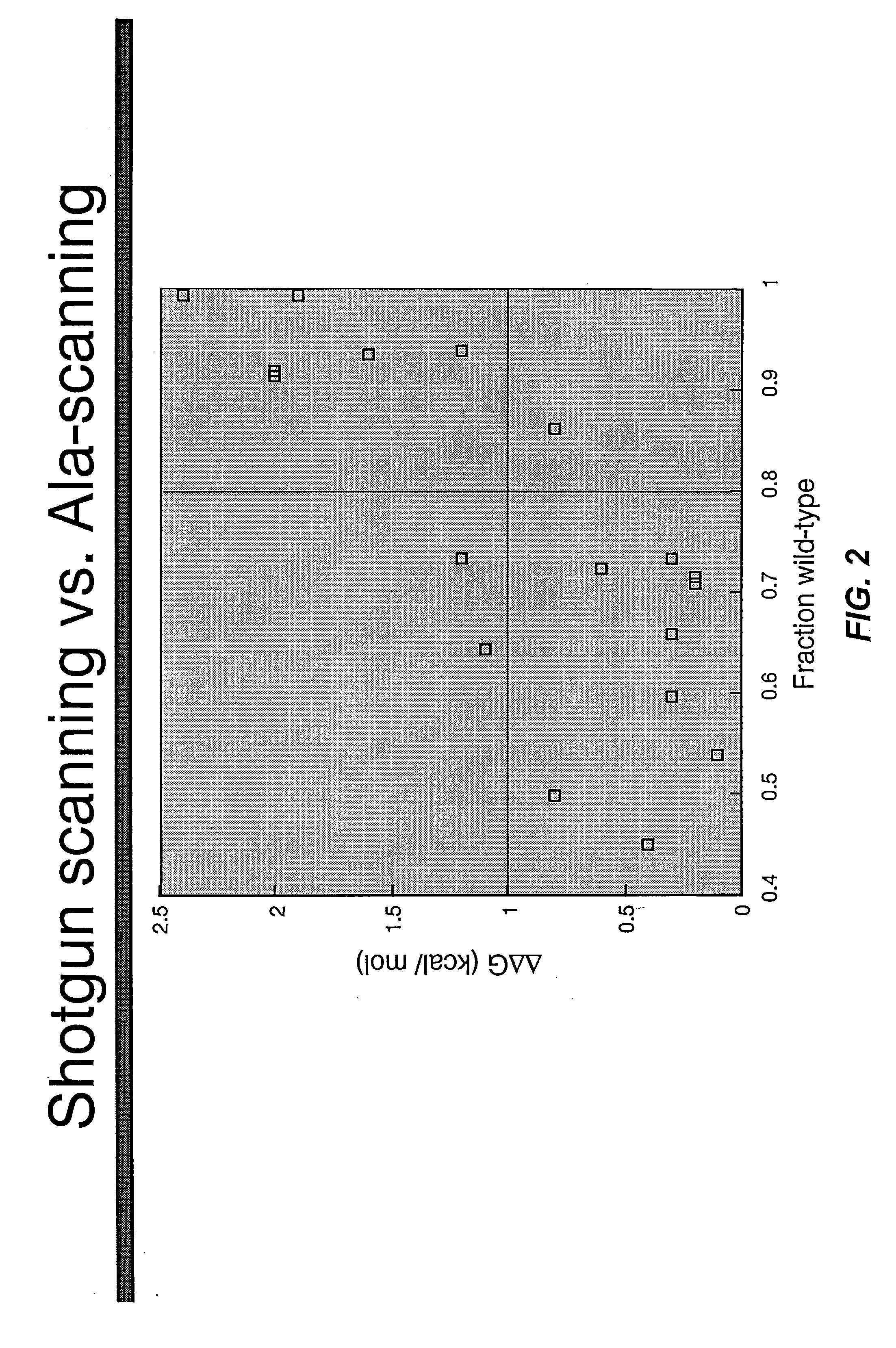

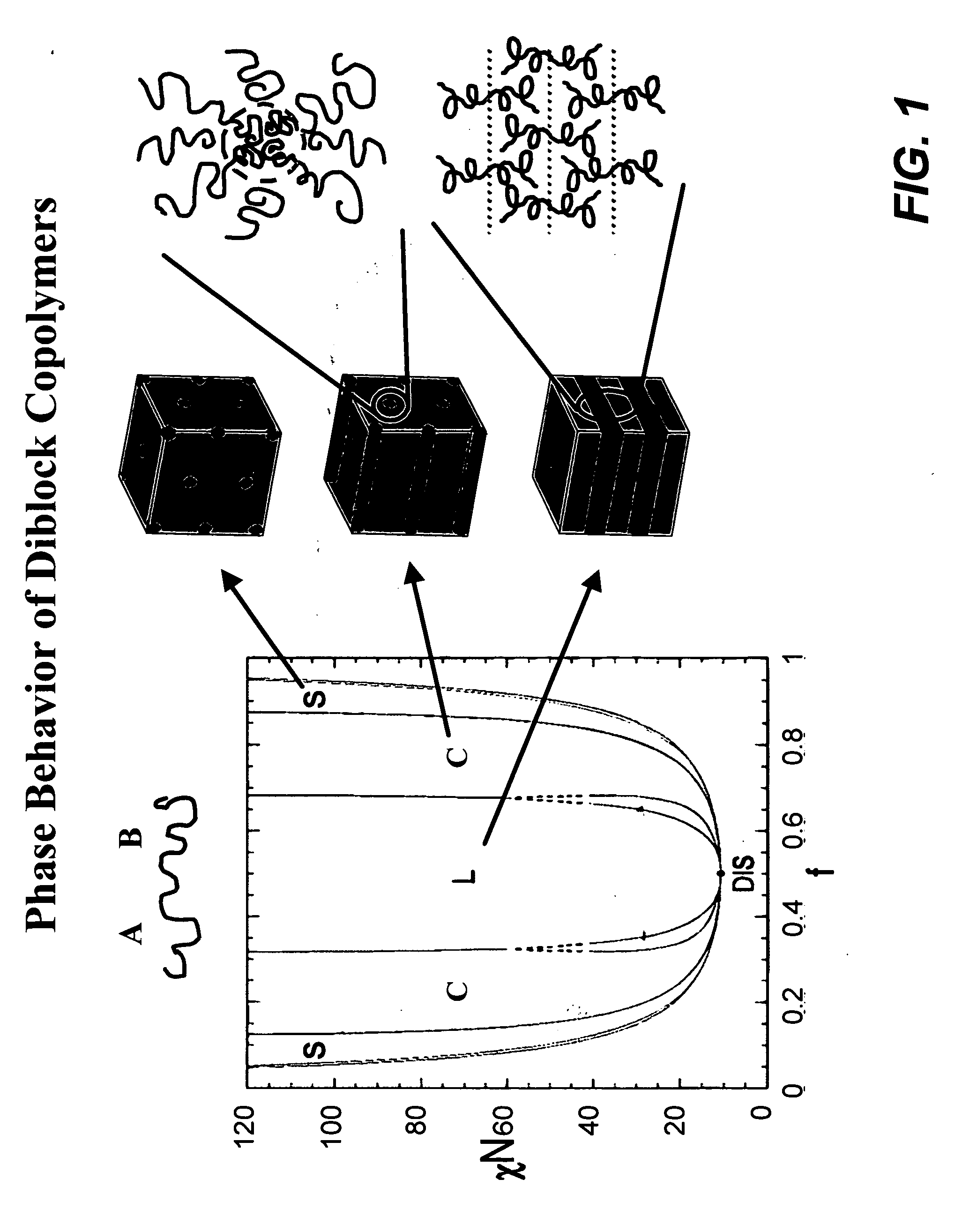

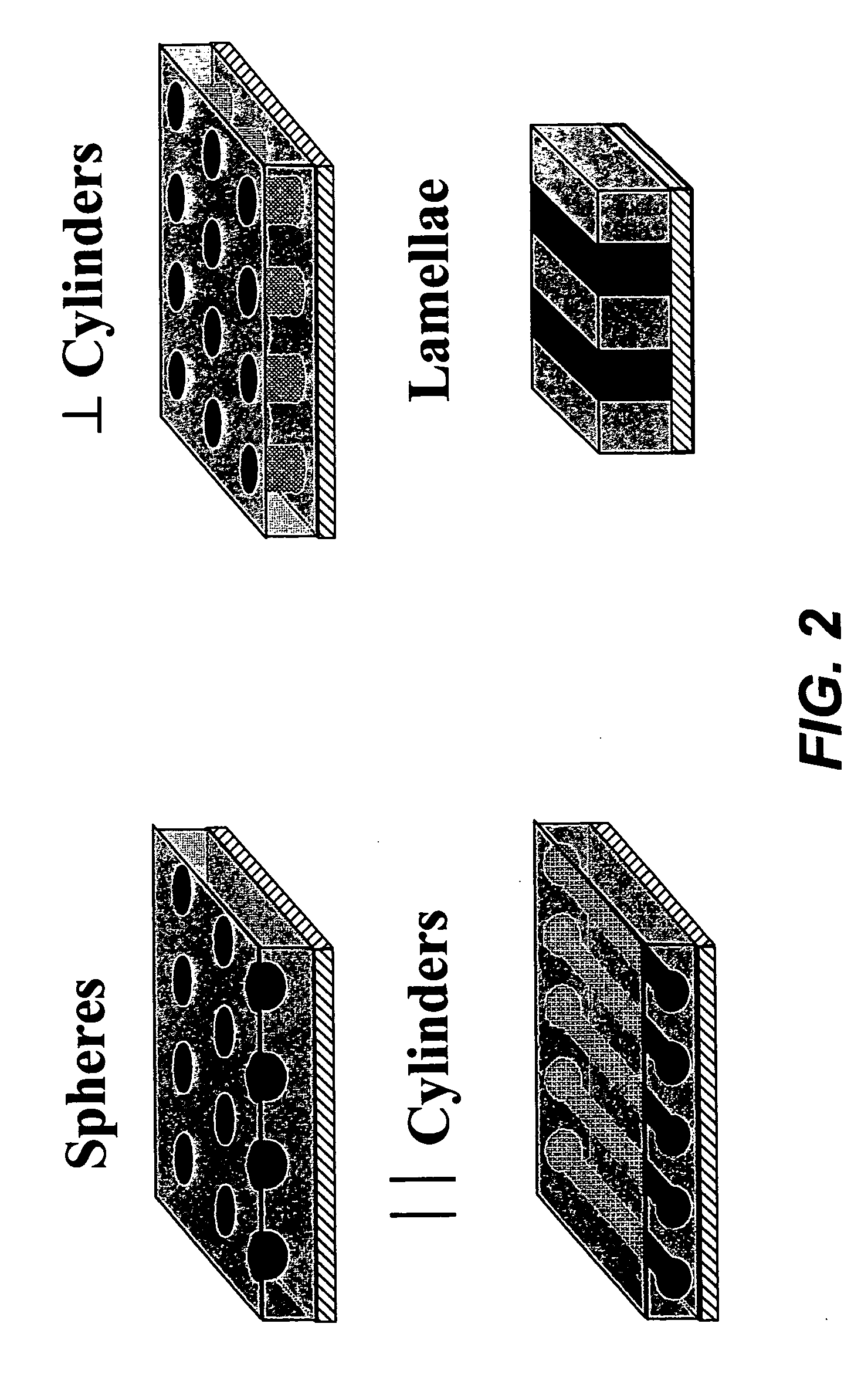

Methods and compositions for forming aperiodic patterned copolymer films

ActiveUS20060134556A1Highly mannerSimple methodMaterial nanotechnologyRadiation applicationsCombined methodOptoelectronics

The present invention provides improved and compositions methods for replicating substrate patterns including patterns containing irregular features. The methods of the invention involve depositing block copolymer materials on a patterned substrate and ordering components in the material to replicate the pattern. In some embodiments, ordering is facilitated through the use of blends of the copolymer material and / or configuring substrate patterns so that regions of the substrate pattern interact in a highly preferential manner with at least one of the components in the copolymer material. The invention also provides compositions containing a substrate pattern with irregular features replicated in a block copolymer material.

Owner:WISCONSIN ALUMNI RES FOUND

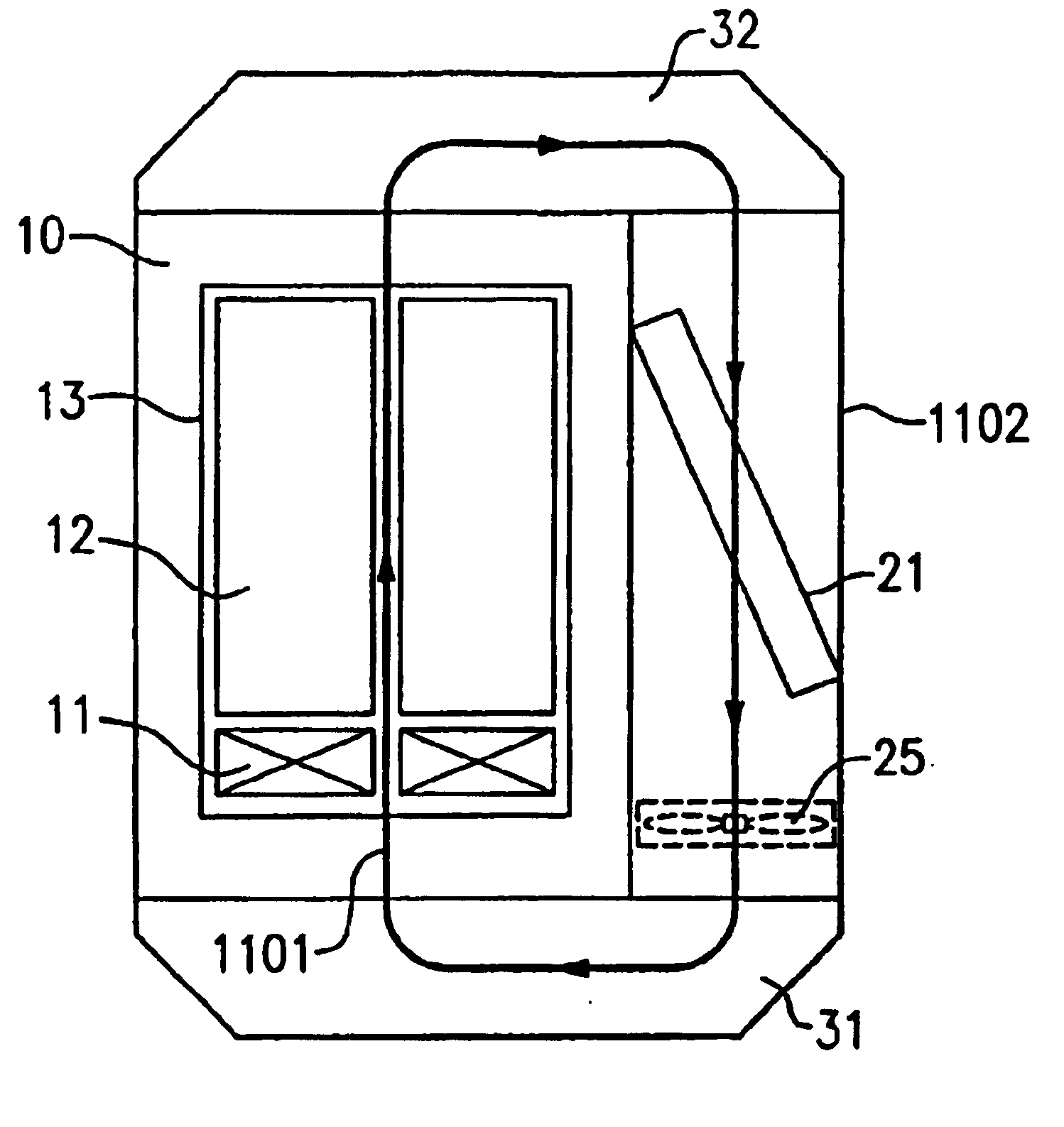

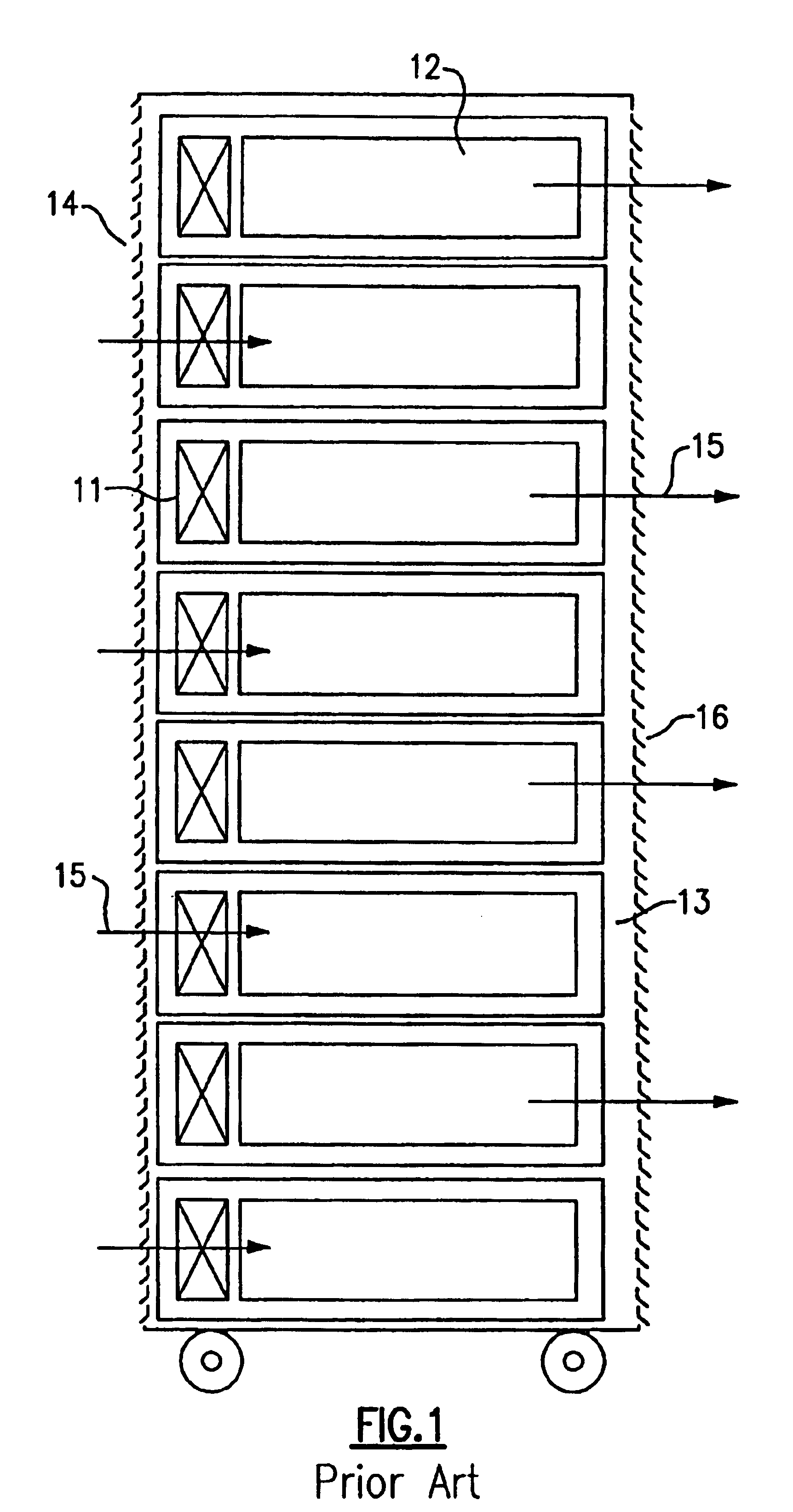

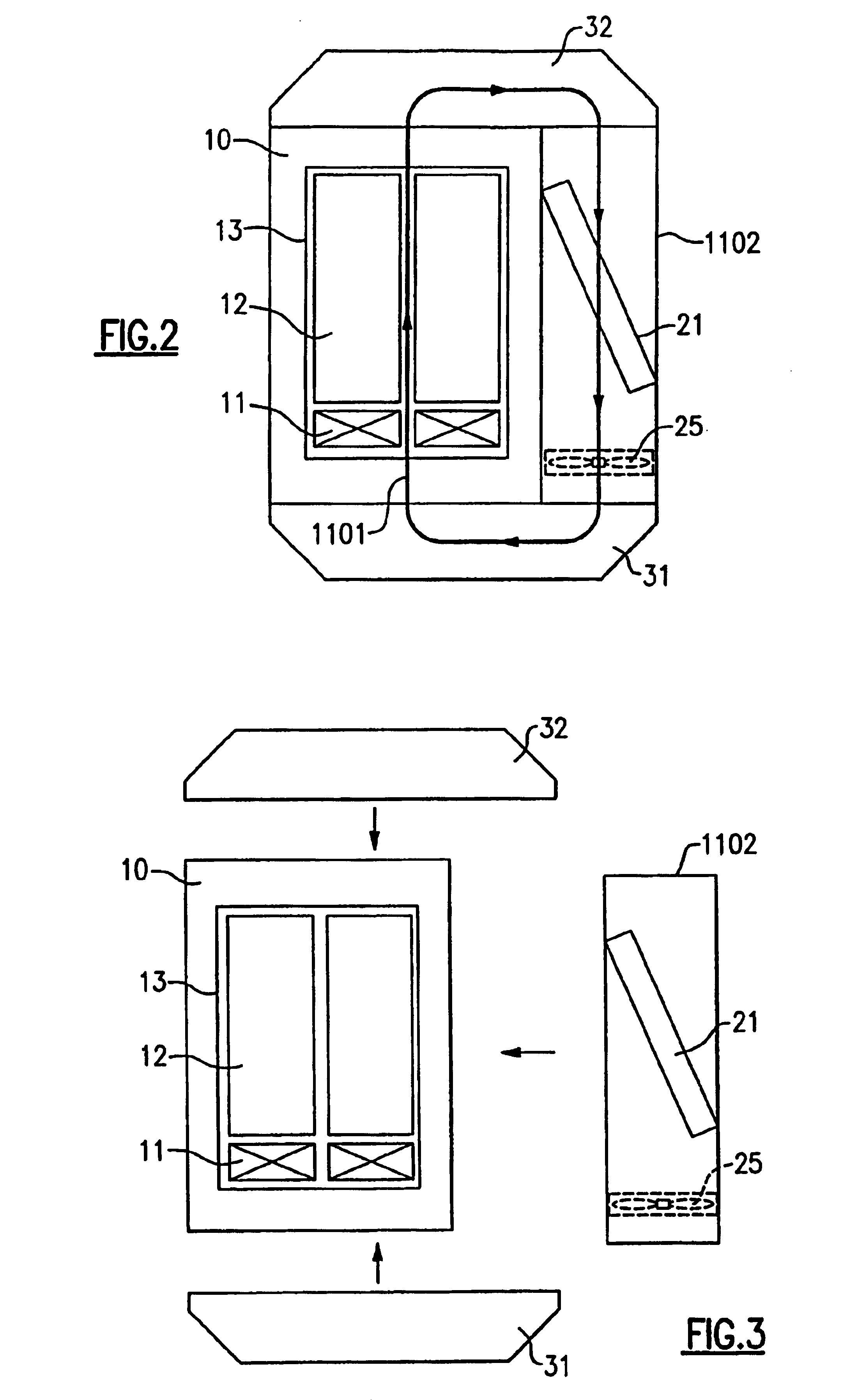

Method for combined air and liquid cooling of stacked electronics components

InactiveUS6924981B2Improve featuresReduce sensitivityDigital data processing detailsIndirect heat exchangersCombined methodElectronic component

An enclosure apparatus provides for combined air and liquid cooling of rack mounted stacked electronic components. A heat exchanger is mounted on the side of the stacked electronics and air flows side to side within the enclosure, impelled by air-moving devices mounted behind the electronics. Auxiliary air-moving devices may be mounted within the enclosure to increase the air flow. In an alternative embodiment, air-to-liquid heat exchangers are provided across the front and back of the enclosure, and a closed air flow loop is created by a converging supply plenum, electronics drawers through which air is directed by air-moving devices, diverging return plenum, and a connecting duct in the bottom. In a variant of this embodiment, connecting ducts are in both top and bottom, and supply and return ducts are doubly convergent and doubly divergent, respectively. Auxiliary blowers may be added to increase total system air flow. The enclosure also may be provided with automatically opening vent panels to allow room air to circulate and cool in the event of an over-temperature condition. The design of the enclosure permits it to be constructed apart from the rack-mounted apparatus and subsequently attached to the rack, if desired, at the facility at which the rack had been previously operating.

Owner:IBM CORP

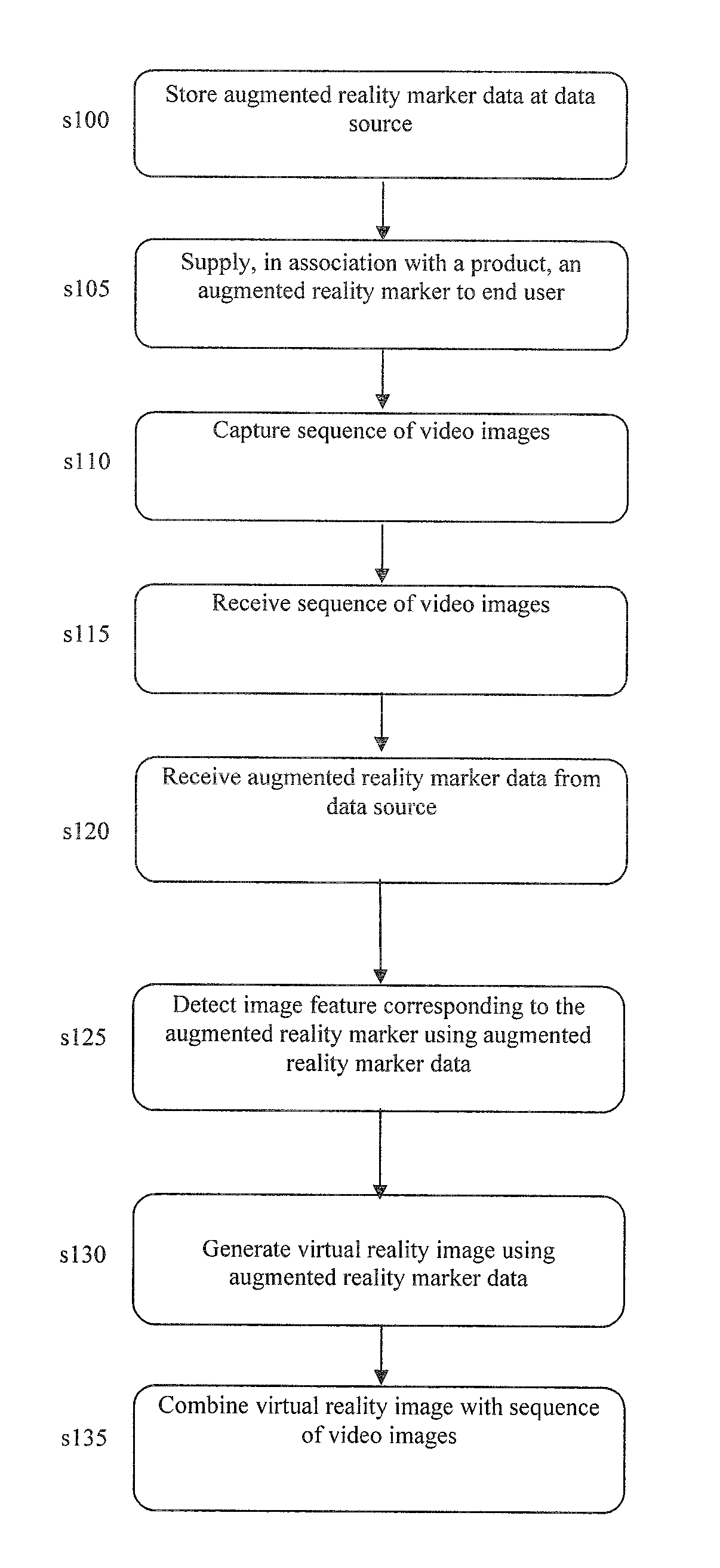

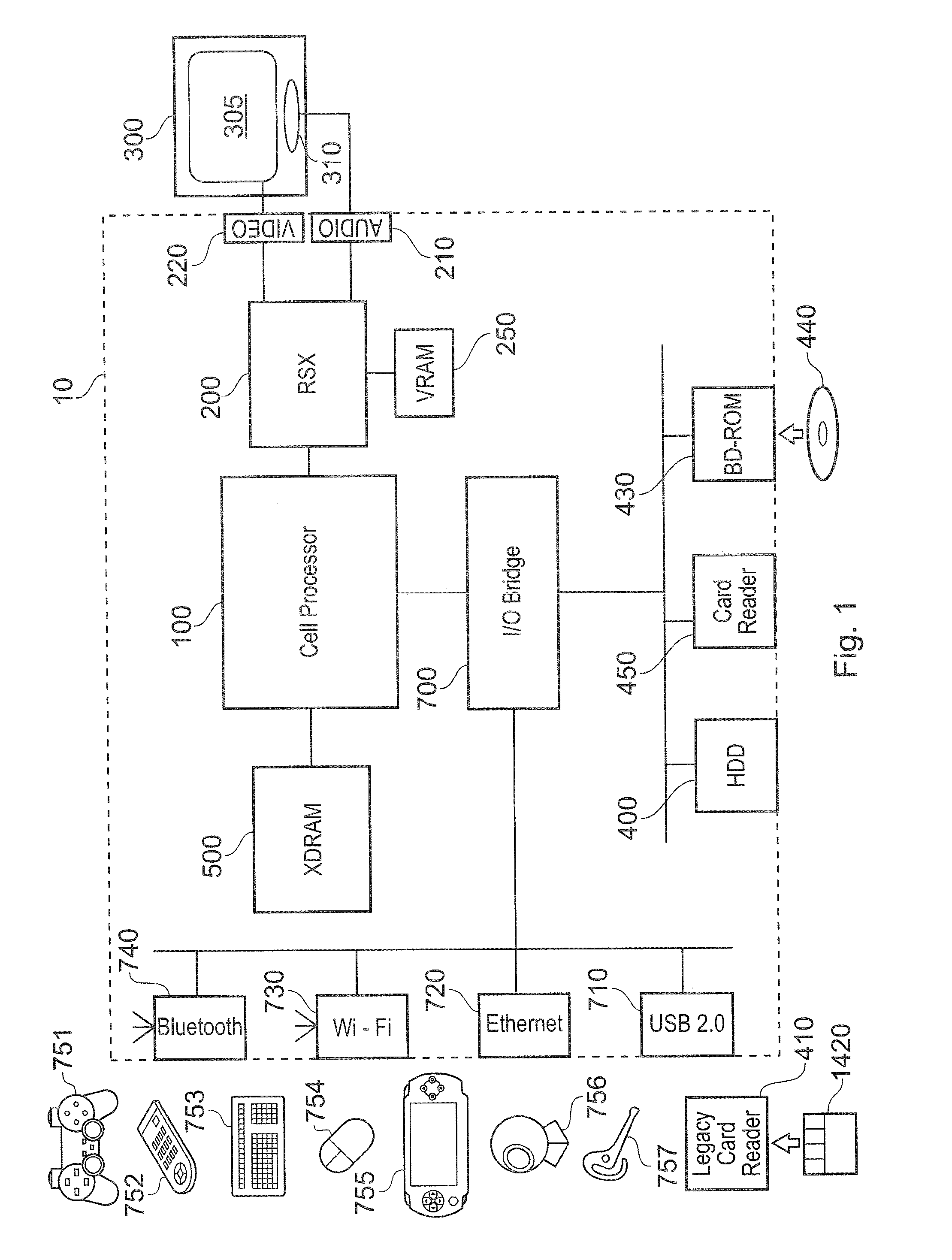

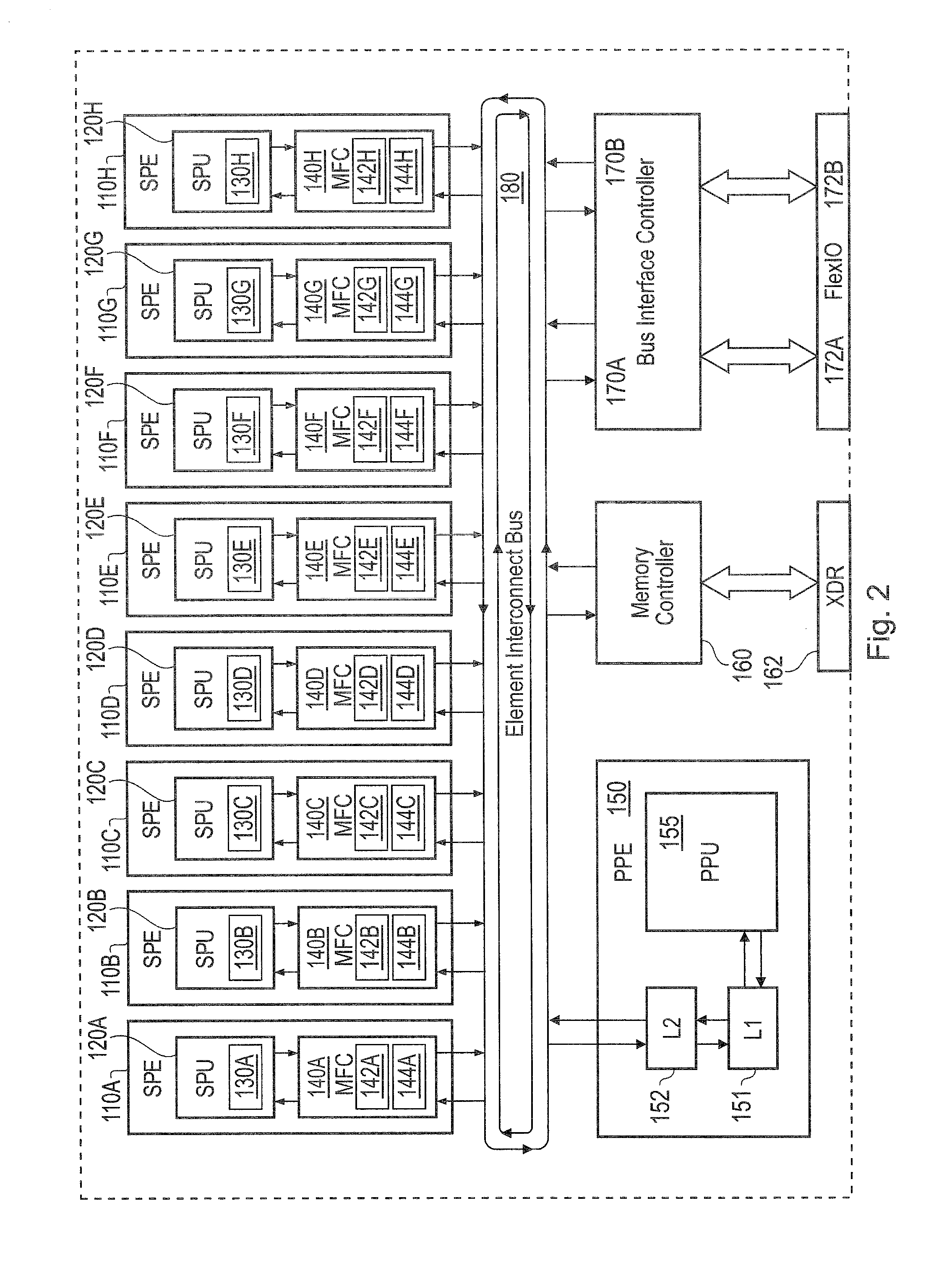

Image combining method, system and apparatus

InactiveUS20100048290A1Great functionality and interactionVideo gamesSpecial data processing applicationsCombined methodComputer science

A method of rewarding an end-user of a product. The method comprises supplying, in association with the product, an augmented reality marker for use with an augmented reality application. The augmented reality marker is provided as a free promotional supplement to the product.

Owner:SONY COMP ENTERTAINMENT EURO

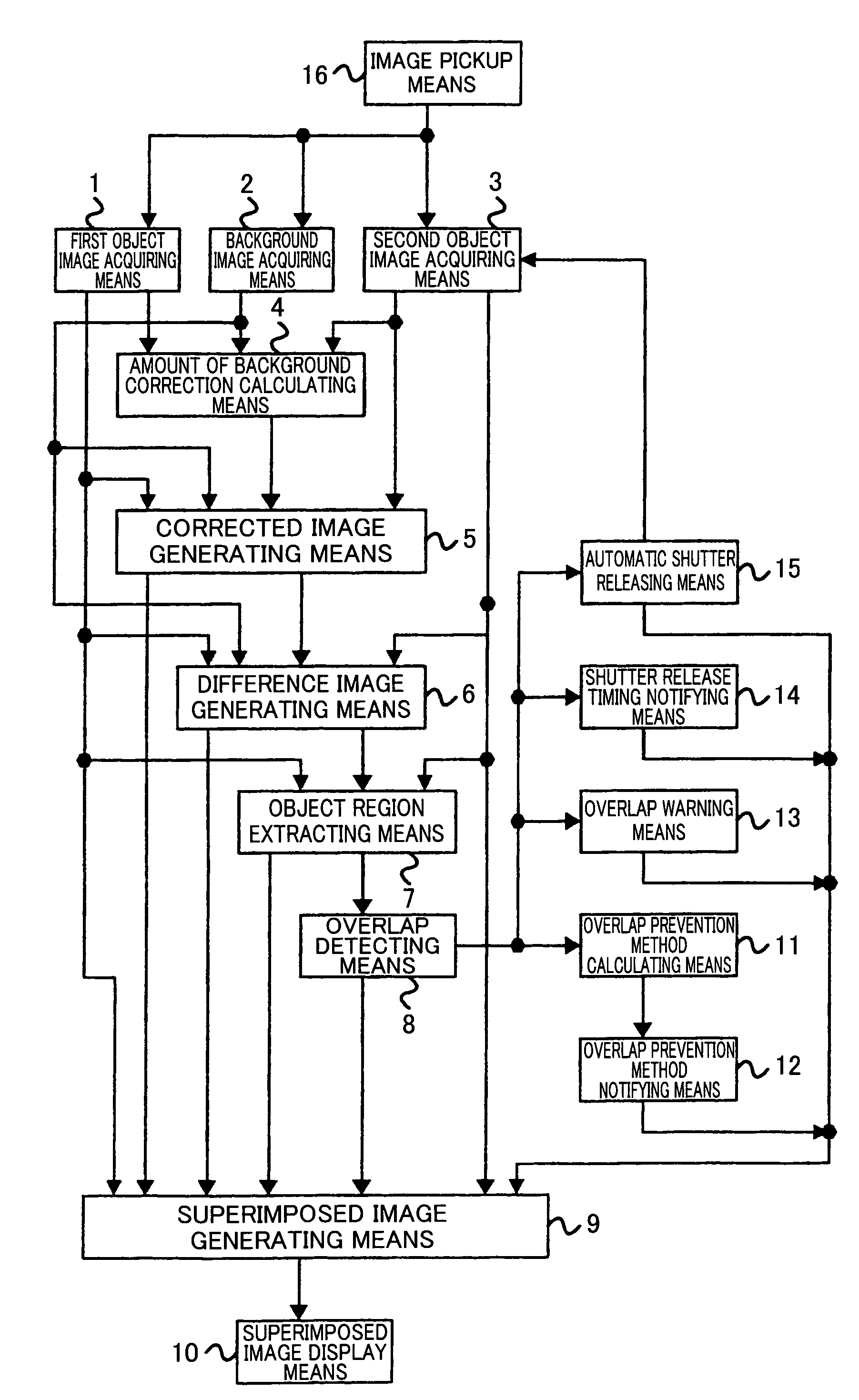

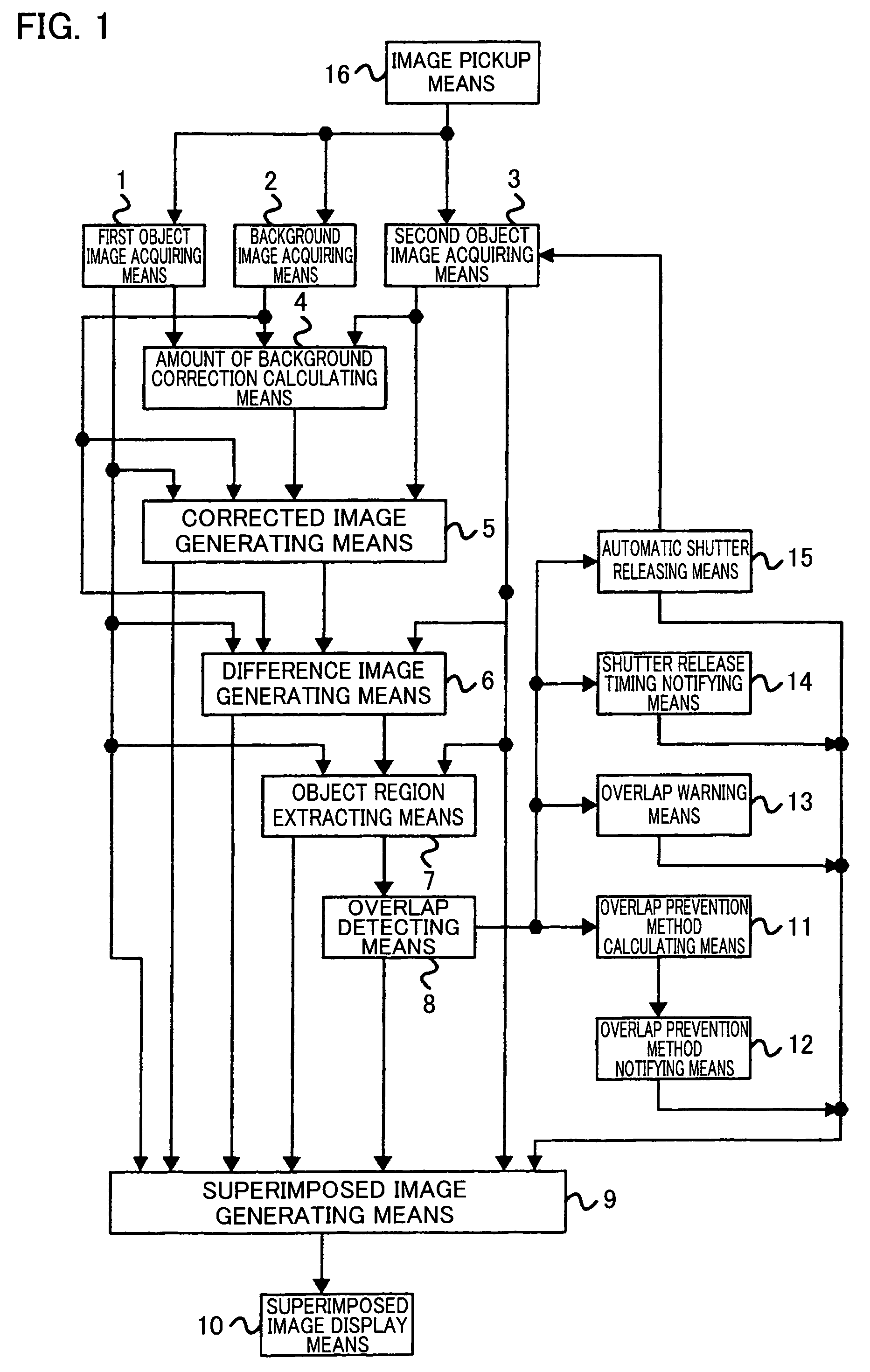

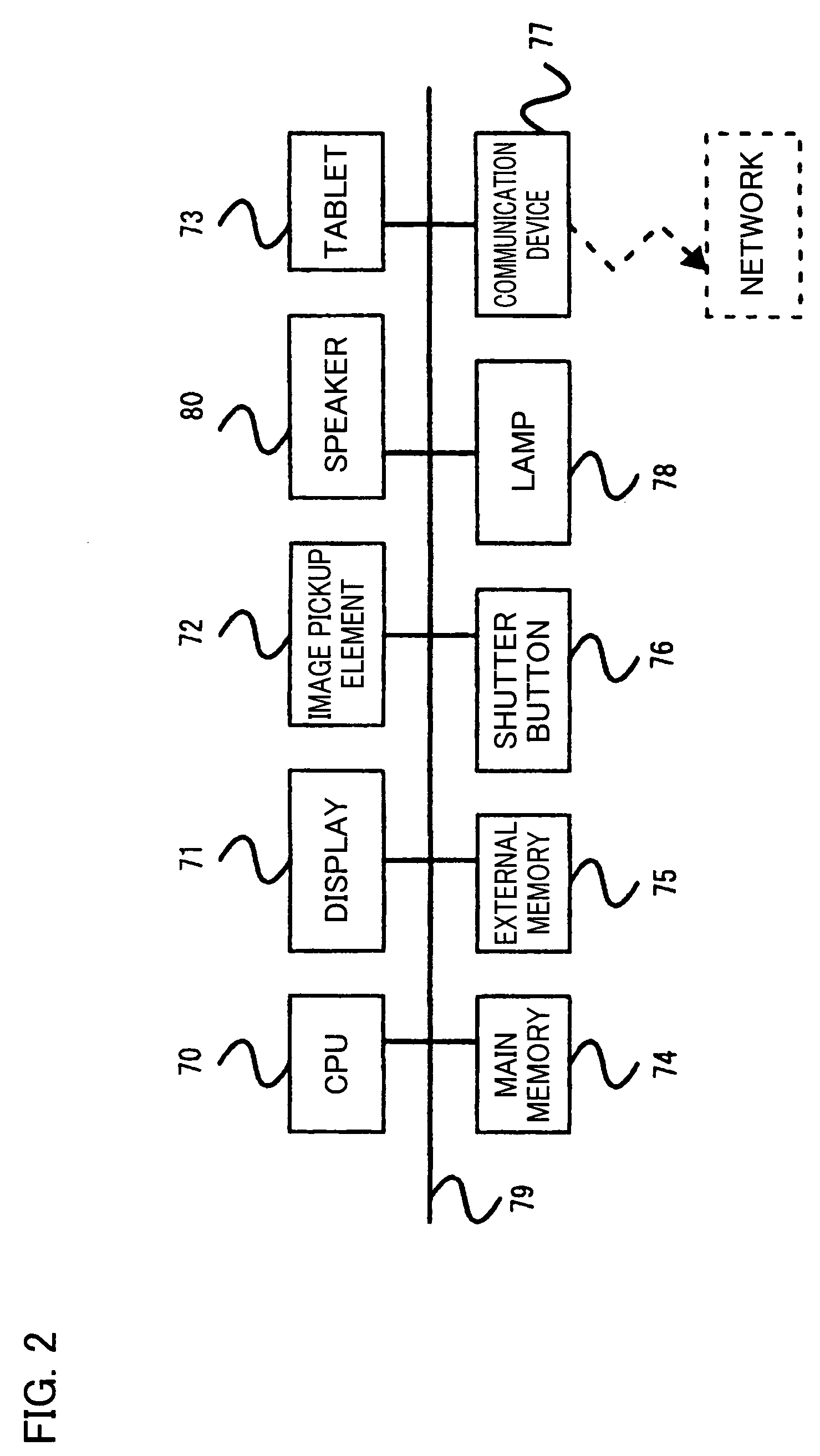

Image combination device, image combination method, image combination program, and recording medium for combining images having at least partially same background

InactiveUS7623733B2Easy for to knowTelevision system detailsCharacter and pattern recognitionCombined methodBackground image

Owner:SHARP KK

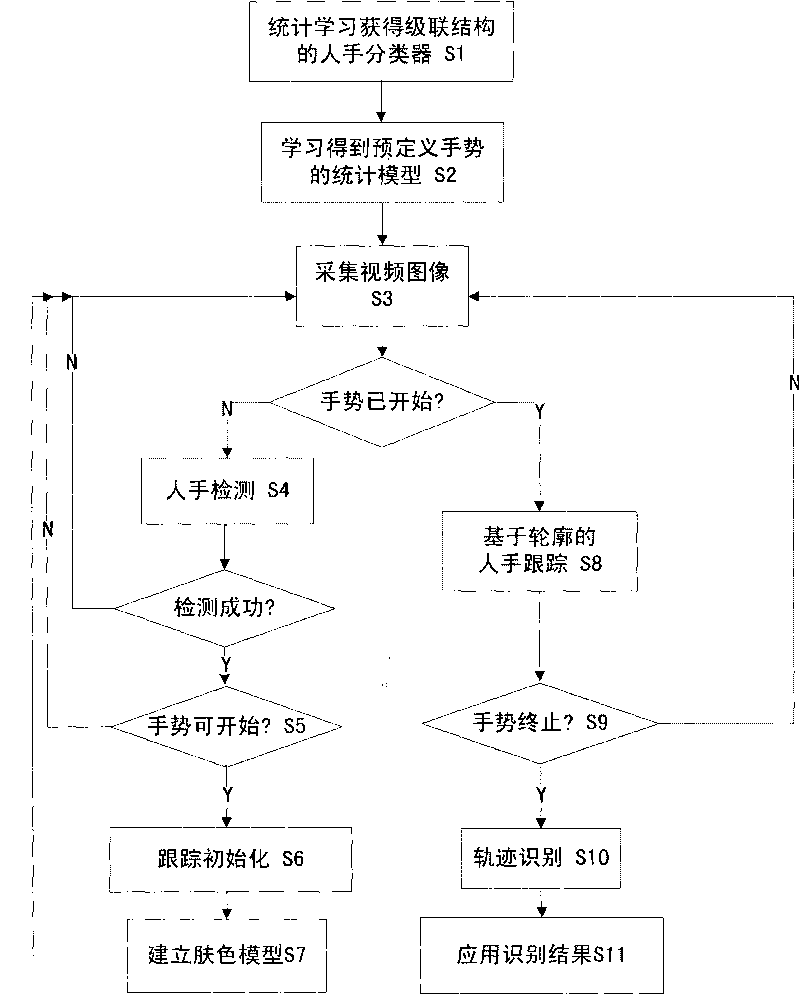

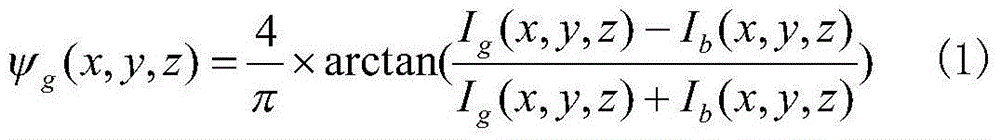

Real-time gesture interaction method based on computer vision

InactiveCN101763515AVisual technology is matureComprehensive effectCharacter and pattern recognitionComputer usersCombined method

The invention discloses a real-time gesture interaction method based on computer vision, which comprises the following steps: acquiring a digital image from an image input device; detecting hands by a statistical learning method; initializing a hand contour tracker according to the detecting result, and calculating a skin color model of a specific hand; tracking the hand contour by a combined method of a conditional probability density transmission algorithm and a heuristic search technology; analyzing the moving track of the hands by a Hidden Markov Model to obtain the gesture identifying result; and applying the gesture analyzing result to the interaction of various application programs. The real-time gesture interaction method of the invention expands the interactive mode of the traditional mouse and keyboard, realizes automatic hand detection, tracking and gesture identification by the computer vision and image processing techniques, has real-time performance, robustness and easy realization and operation, and can enable computer users to interact with the computer more naturally, visually and intelligently by hand gestures.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI +1

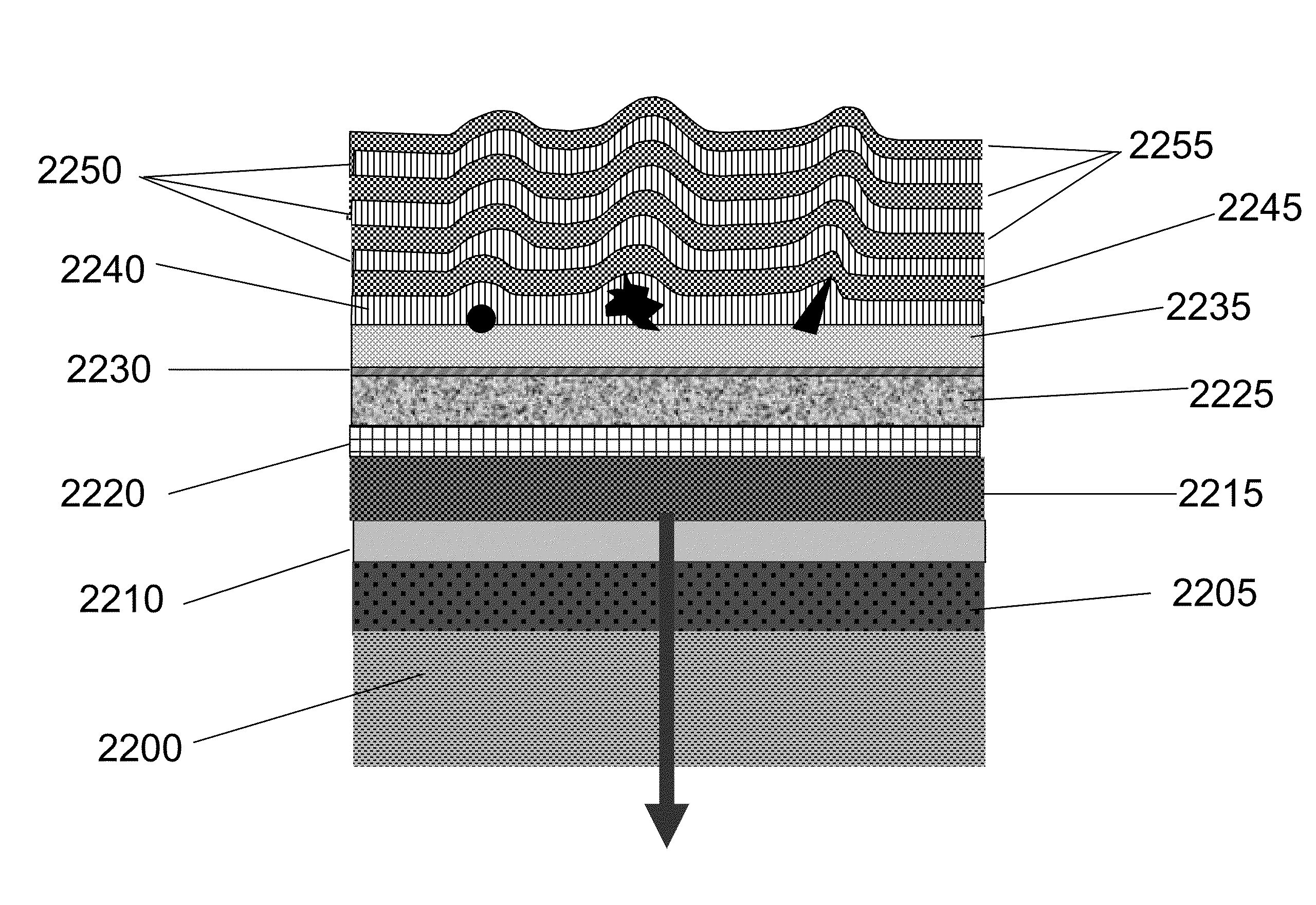

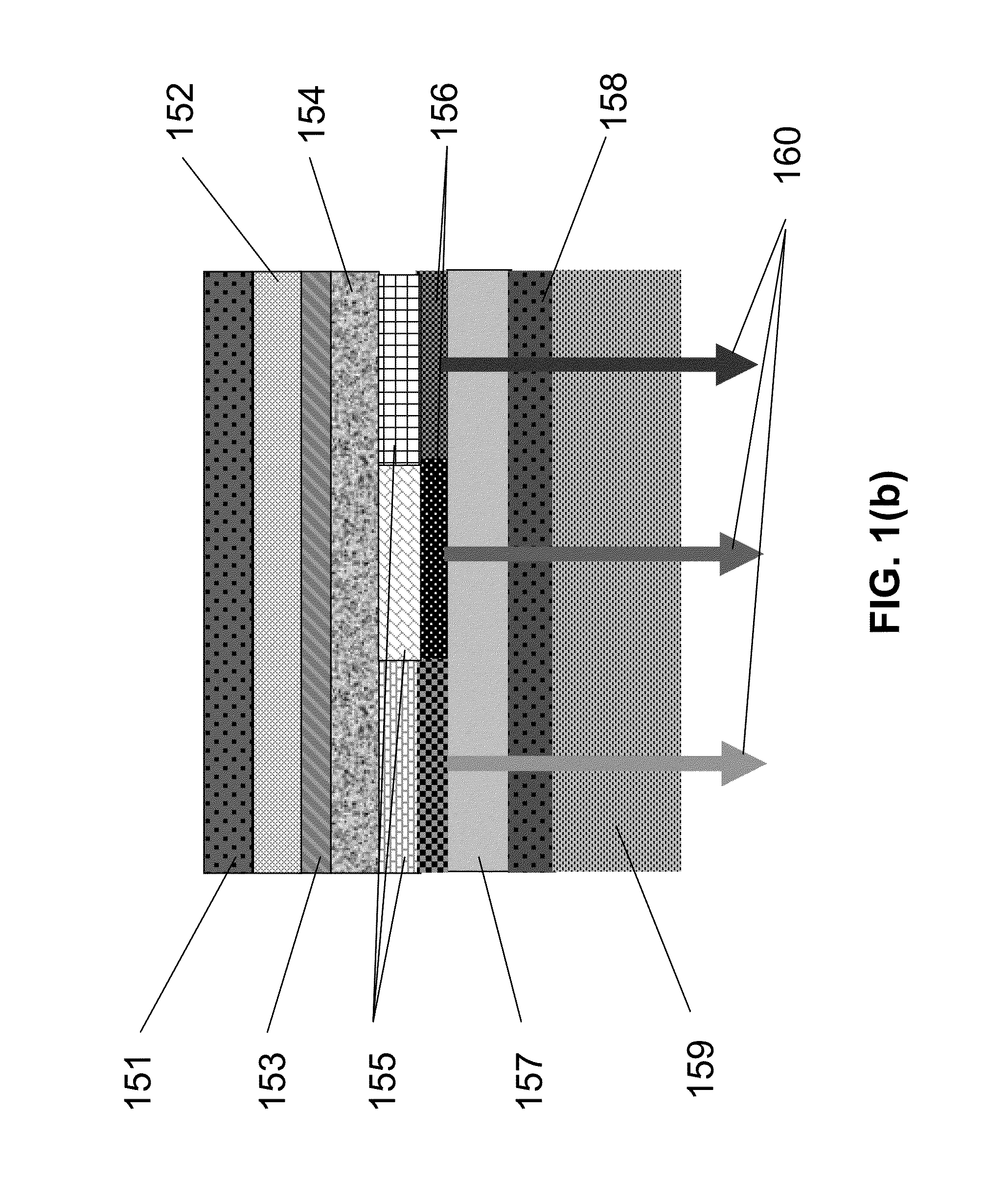

Method for deposition of high-performance coatings and encapsulated electronic devices

ActiveUS20130334511A1Without crackingWithout peelingSolid-state devicesSemiconductor/solid-state device manufacturingWater vaporEffect light

A method is disclosed for forming leak-free coatings on polymeric or other surfaces that provide optical functions or protect underlying layers from exposure to oxygen and water vapor and do not crack or peel in outdoor environments. This method may include both cleaning and surface modification steps preceding coating. The combined method greatly reduces defects in any barrier layer and provides weatherability of coatings. Specific commercial applications that benefit from this include manufacturing of photovoltaic devices or organic light emitting diode devices (OLED) including lighting and displays.

Owner:AIXTRON AG

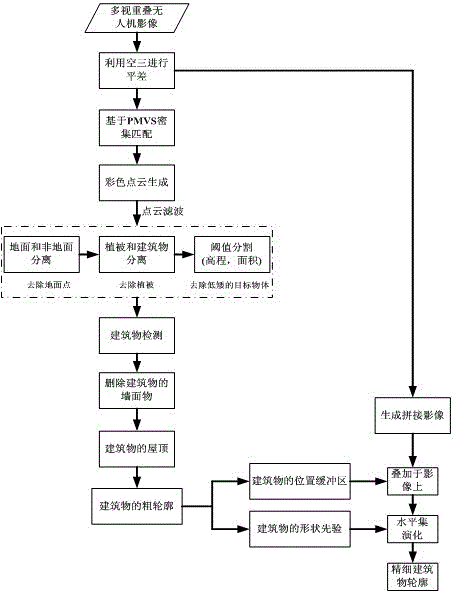

Unmanned aerial vehicle multi-overlapped-remote-sensing-image method for extracting building contour line

ActiveCN104484668AHigh precisionReduce complexityImage analysisCharacter and pattern recognitionPoint cloudPrior information

The invention discloses an unmanned aerial vehicle multi-overlapped-remote-sensing-image method for extracting a building contour line. The unmanned aerial vehicle multi-overlapped-remote-sensing-image method includes the steps that three-dimensional point cloud is generated with an aerial-triangulation and dense-matching combined method and filtered, and a building is detected from the point cloud; after the walls of the detected building are canceled, the general contour of the building is extracted from building top face information; the general contour of the building serves as a buffering area to be overlapped on spliced images and serves as shape prior information, evolution is carried out in the buffering area with a level set algorithm, and finally an accurate contour of the building is obtained. By means of the unmanned aerial vehicle multi-overlapped-remote-sensing-image method, as point cloud three-dimensional information generated by the multiple overlapped images is sufficiently used, and meanwhile the high-accuracy geometrical information of the high-resolution remote sensing images is used in a combined mode, the building contour extracting accuracy is remarkably improved, and the complexity of the method is lowered.

Owner:WUHAN UNIV

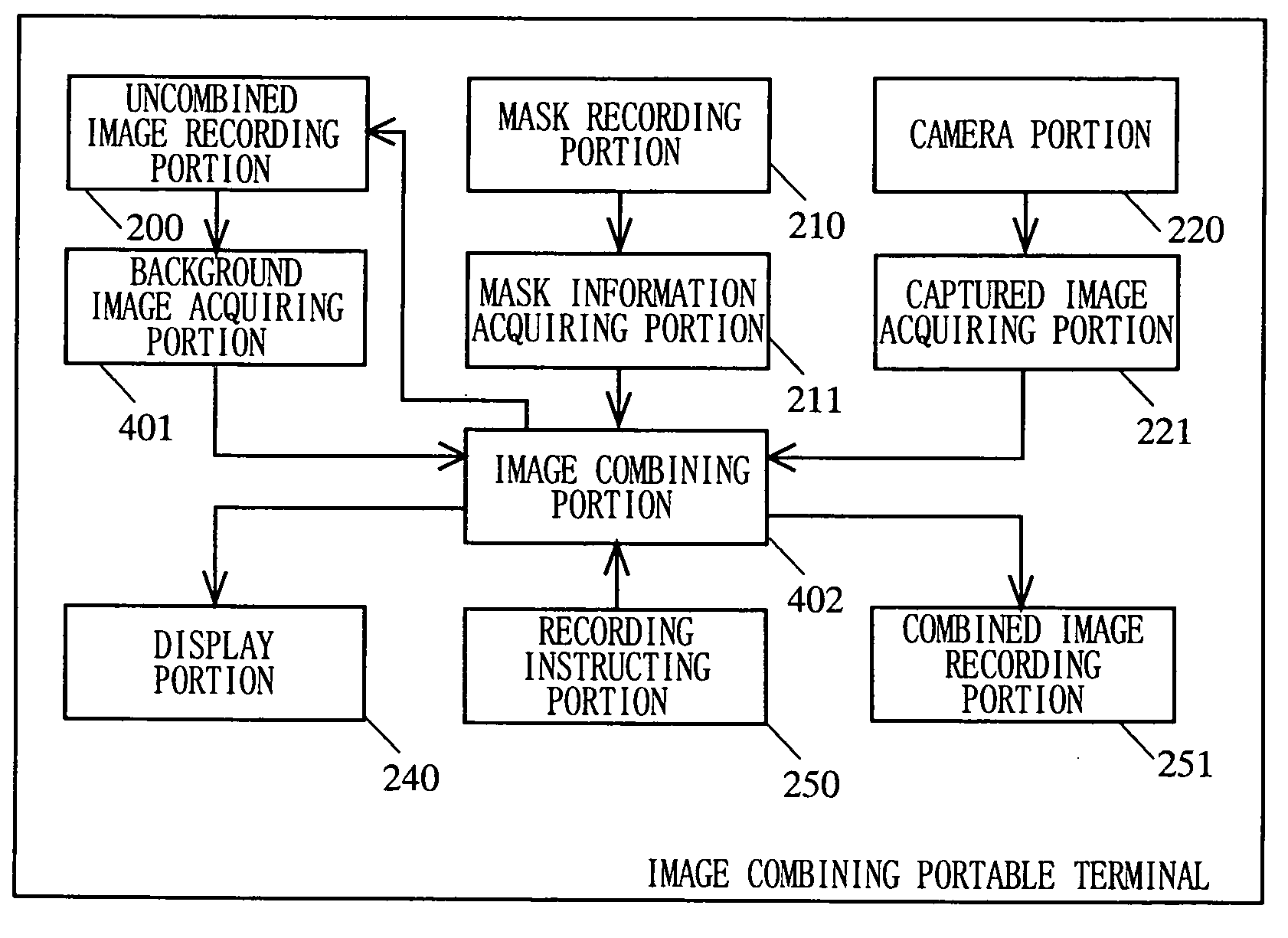

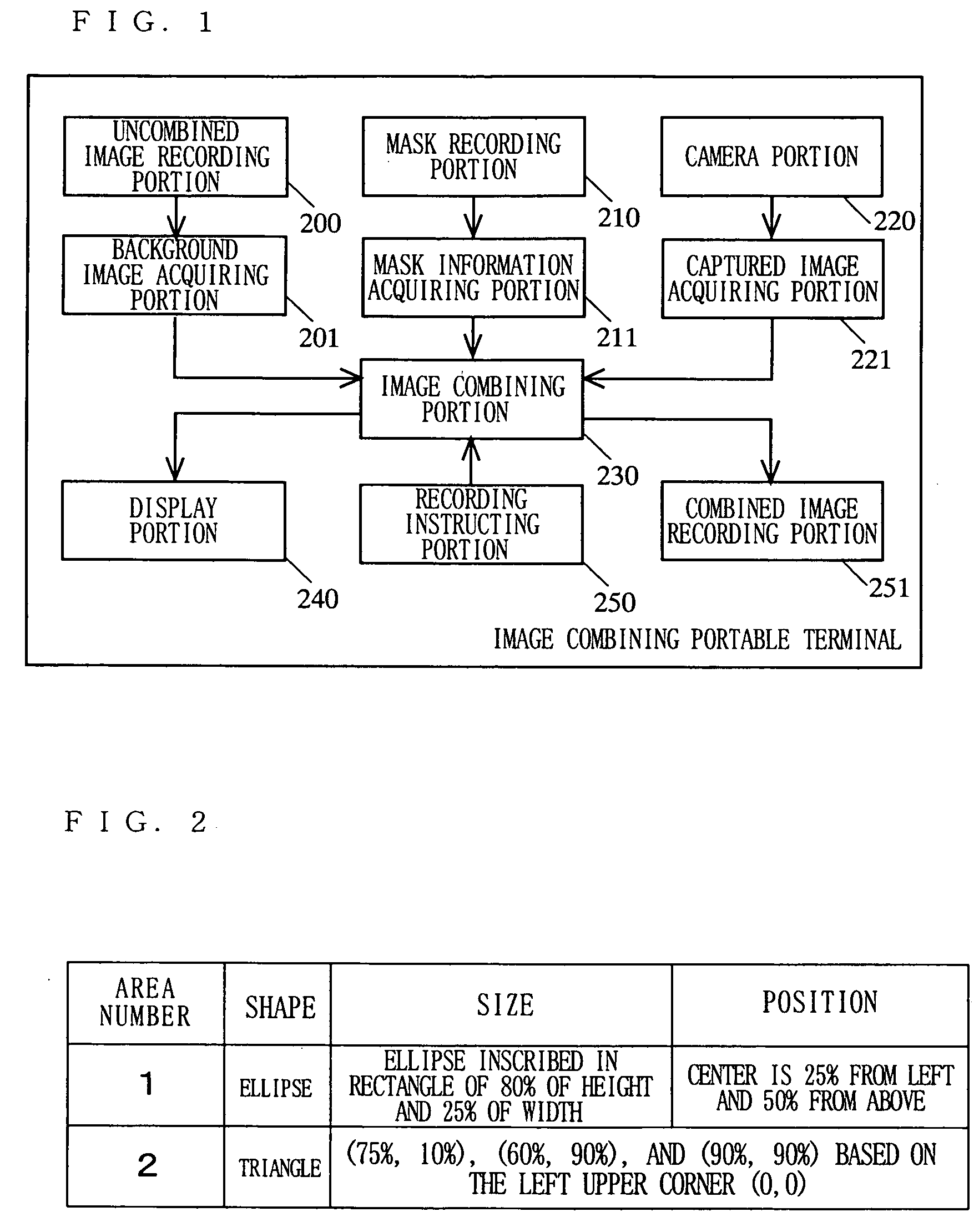

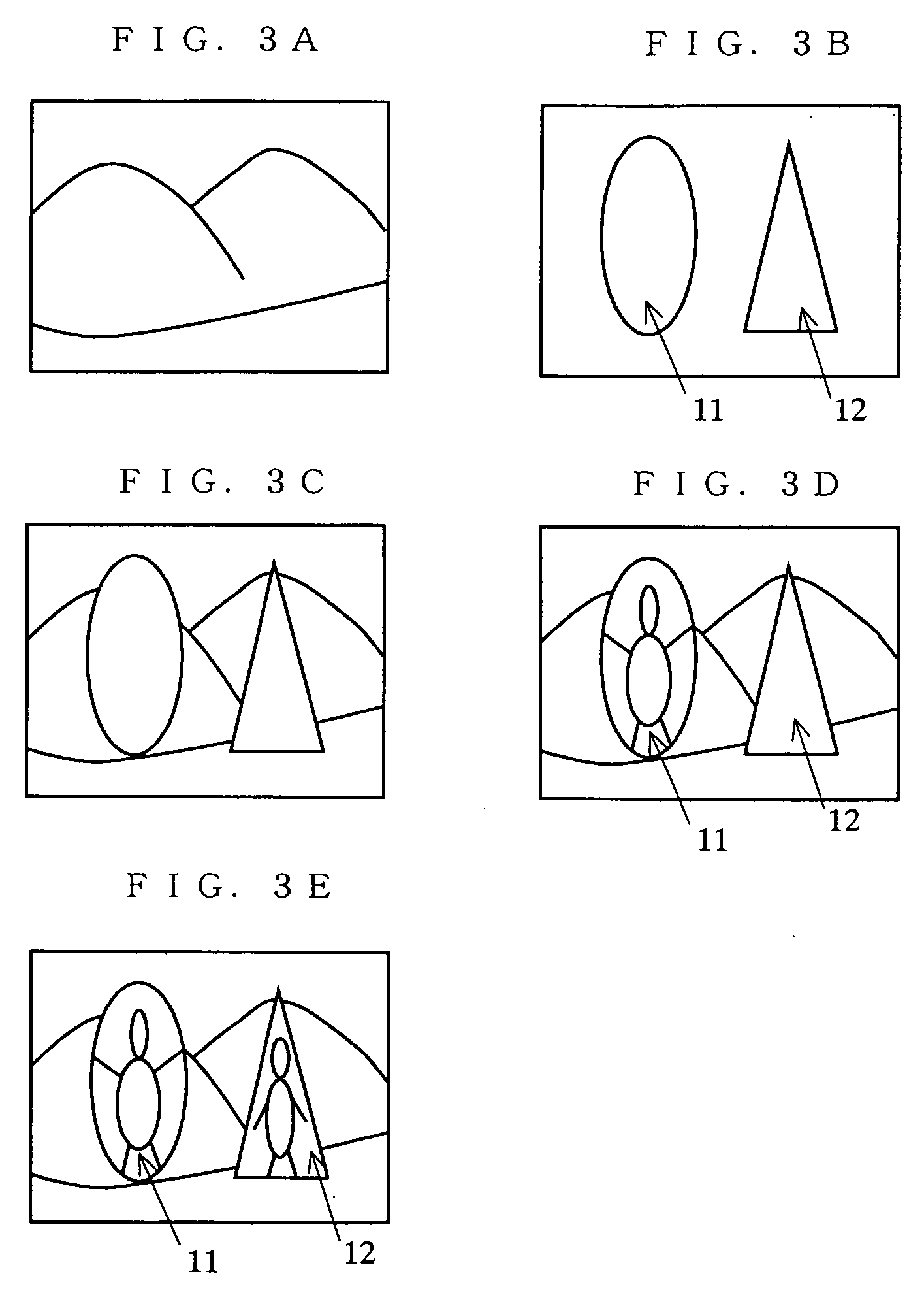

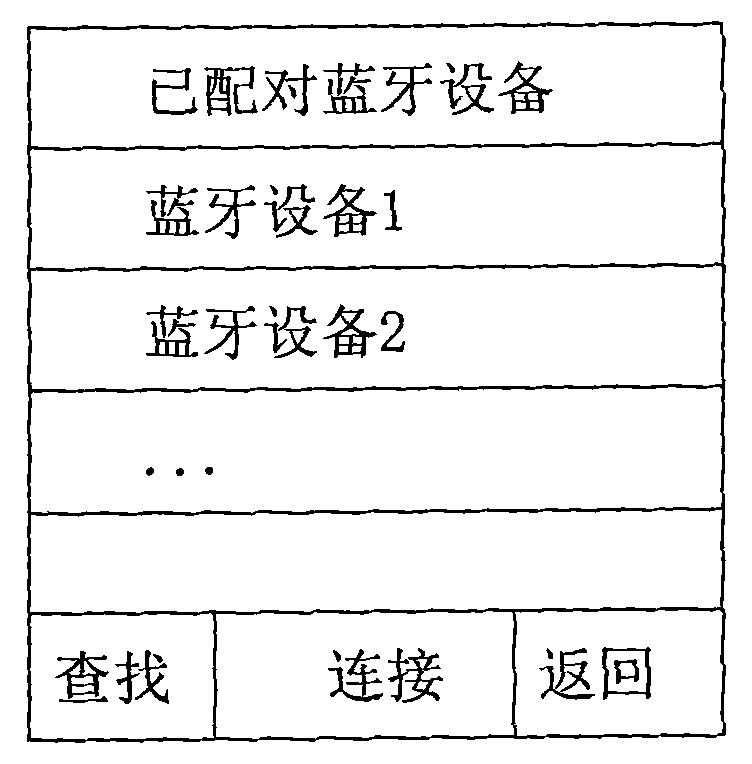

Image combining portable terminal and image combining method used therefor

InactiveUS20060140508A1Easy to operateEasy to combineTelevision system detailsCharacter and pattern recognitionComputer graphics (images)Image recording

The image combining portable terminal combines a recorded image prepared in an uncombined image recording portion (200) and a captured image captured by a camera portion (220). A plurality of sets of mask information defining at least one area in which the captured image is to be combined with the recorded image are stored in a mask recording portion (210). The mask information acquiring portion (211) selects desired mask information from the mask recording portion (210) in response to an instruction of a user. The image combining portion (230) combines the recorded image and the captured image in an area designated by the mask information selected by the mask information acquiring portion (211).

Owner:PANASONIC CORP

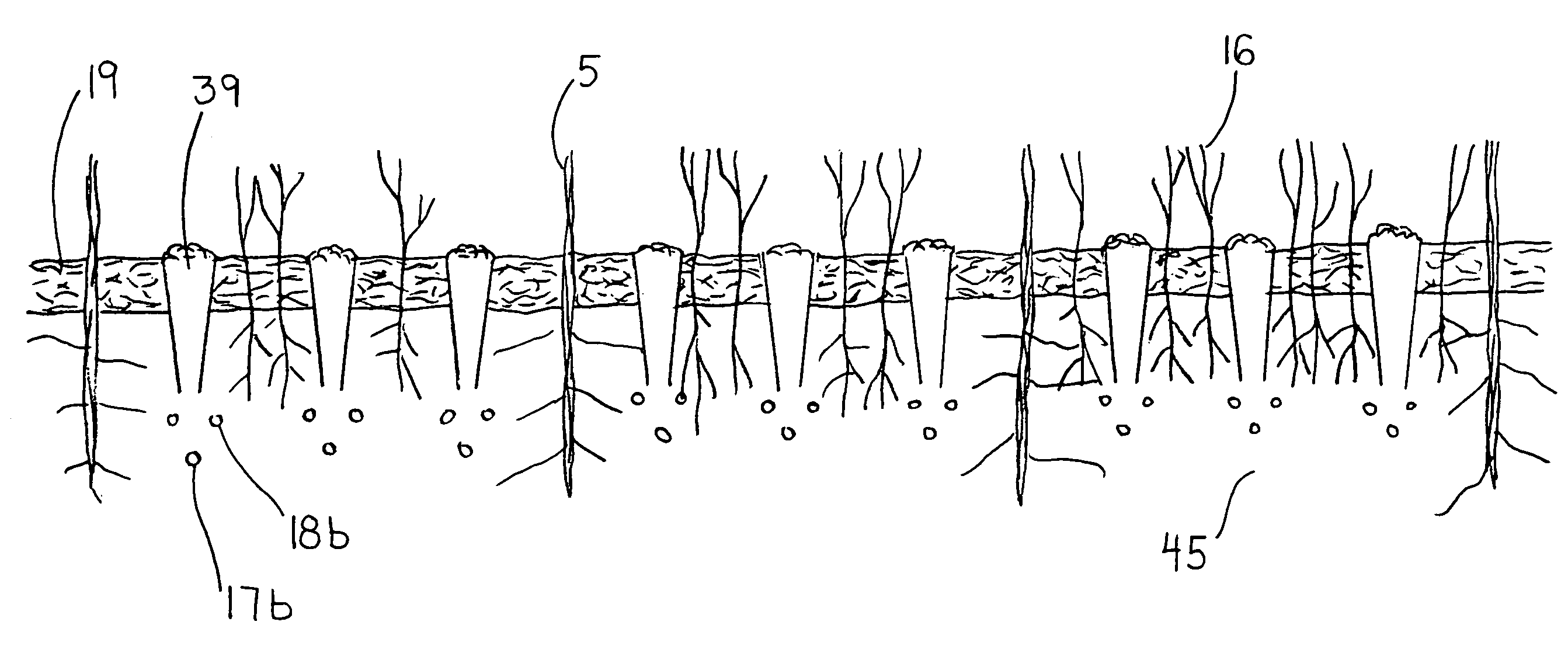

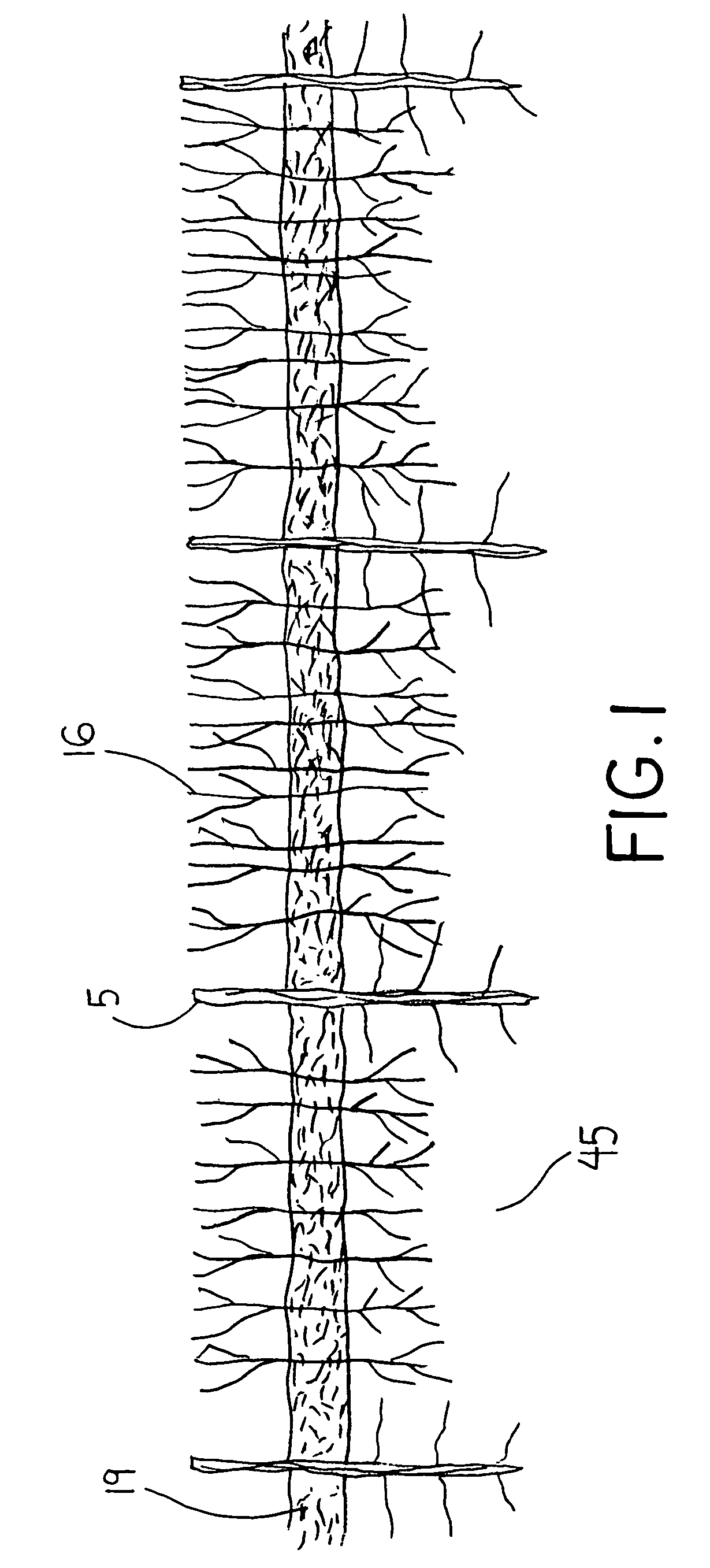

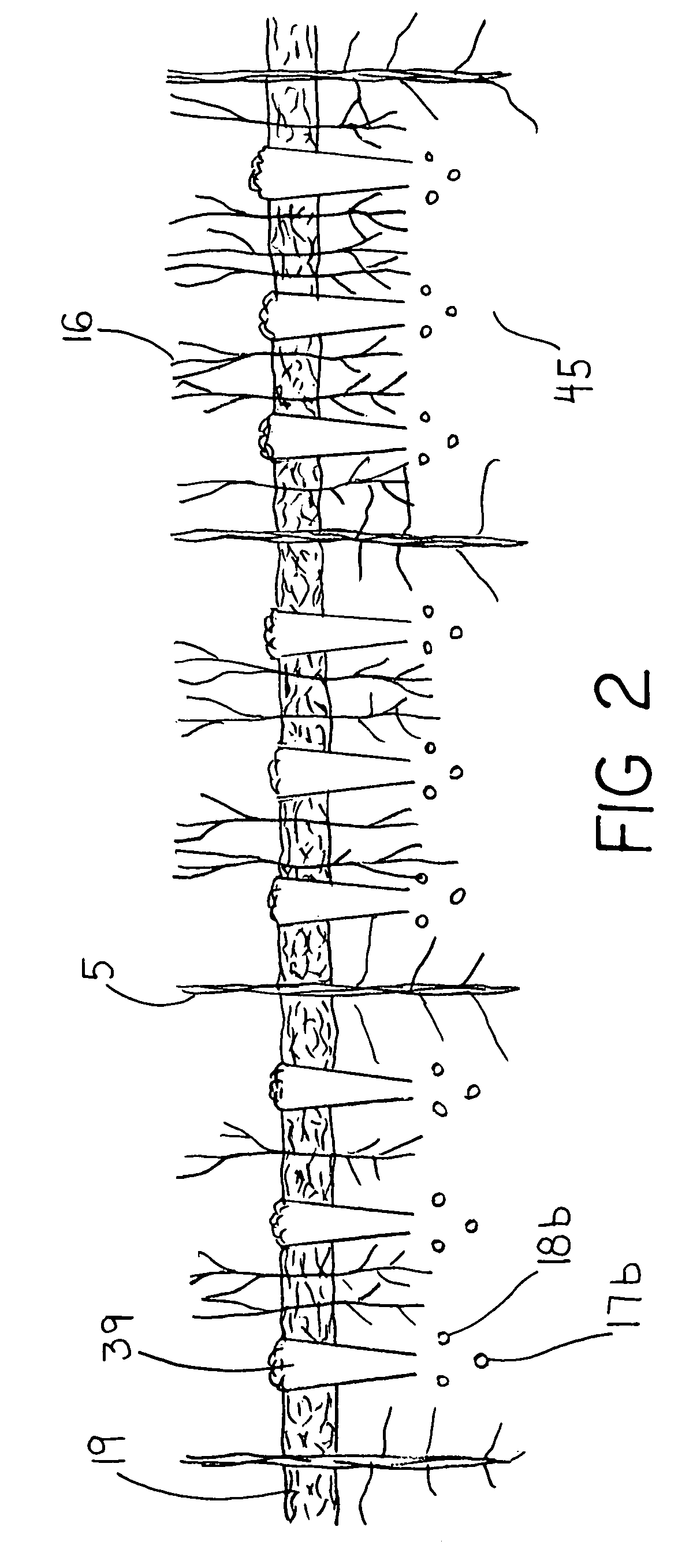

Combined intercropping and mulching method

InactiveUS7634869B1Reduce needIncrease surface moistureSeed and root treatmentFabaceae cultivationPolygonum fagopyrumMyriophyllum

A method of combined intercropping and mulching of commercial crops is described herein. Suitable annuals such as young wheat and / or buckwheat plants are planted in soil in which legumes were originally planted. A portion of the resulting upper portions of young wheat and / or buckwheat plants is mowed and blended with organic debris to provide nutrients for intercropped commercial plants such as corn and soybeans. The remaining portion is chopped blended with organic debris and sprayed onto the top layer of seeded soil as combination mulch. For larger commercial applications, conventional agricultural machines are described herein, and are modified for the most efficient intercropping. For best results, at least one intercropped commercial plant should be a legume.

Owner:WILLIAMS JR MARVIN J

Various grains nutritious vermicelli produced with dual-extrusion pressing and compound steam combined method

InactiveCN101366479AImprove qualityGreat tasteDough extruding machinesFood preparationCombined methodThermal stability

The invention relates to flour food, in particular to a minor cereal nutrient dried noodle produced by a double extrusion and secondary steaming combination method and a preparation method thereof. The invention is characterized in that the minor cereal nutrient dried noodle is prepared through the following steps: five cereals are taken as main raw materials, cucurbits, vegetables and potatoes are added or are not added, an auxiliary material capable of improving and enhancing the quality of a product and a complex quality improvement liquid are added, and processes such as raw material pretreatment, mixing and stirring, noodle-making molding by the double extrusion and secondary steaming combination method, drying, cutting, packing and so on, are performed. The reasonable formula design and the noodle-making molding process by the double extrusion and secondary steaming combination method, namely a process of steaming and cooking once again after two-stage extrusion molding, assure the balanced nutrition and the strong health care function of the product, and the minor cereal nutrient dried noodle has the advantages of long storage period, steady quality, no turbid soup during the cooking, boiling fastness, good thermal stability, smooth appearance, and chewy taste, and can be eaten as staple food like ordinary dried noodles.

Owner:奥生平 +1

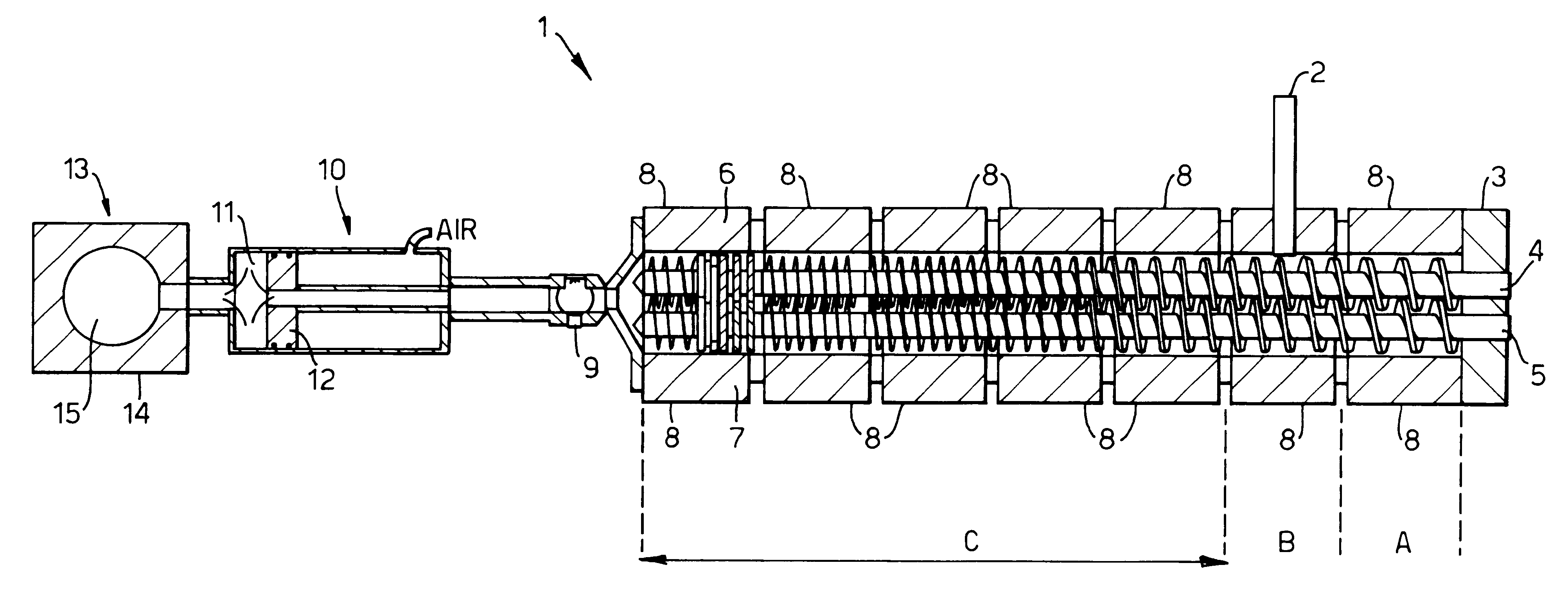

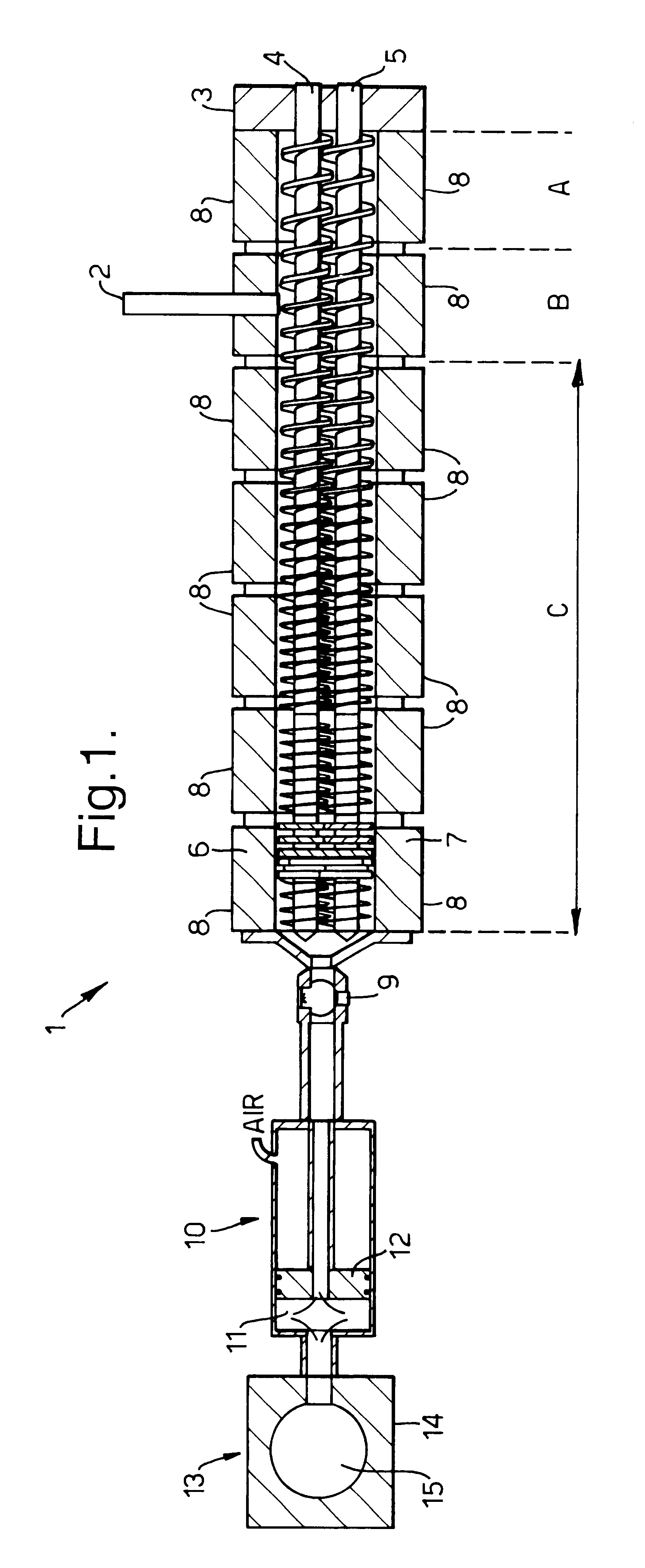

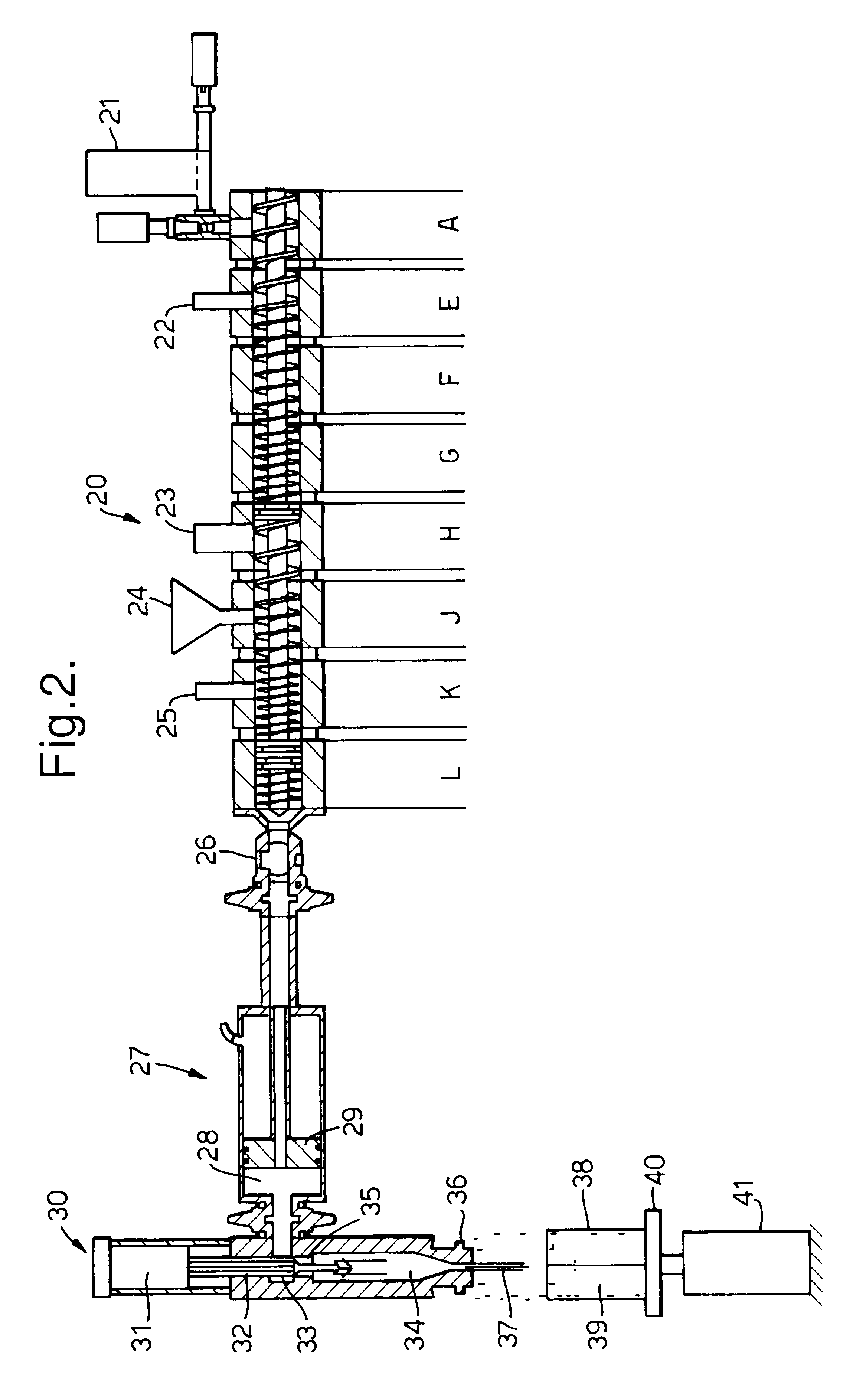

Process and apparatus for the production of a deodorant or antiperspirant composition

InactiveUS6338840B1Quicker and easy to control temperatureLess heat lossCosmetic preparationsToilet preparationsParticulatesActive agent

In a first aspect, a process for forming deodorant or antiperspirant sticks by continuously forming a mobile composition for dispensing into containers or molds at a rate matched with the rate at which it is dispensed, and in other aspects a process in which a mobile deodorant or antiperspirant composition is dispensed by injection molding, i.e. a process in which the deodorant or antiperspirant composition is dispensed under pressure. The composition at the time of injection moulding is preferably either in the vicinity of its regular set temperature, particularly in the range of about 0-3° C. below the regular set temperature and / or partially structured at the time of its delivery it into a container or mold. The deodorant or antiperspirant composition is preferably continuously produced in a screw extruder, especially a twin screw extruder, which is controlled to deliver the composition in a substantially semi-solid state, at a temperature close to its regular set temperature and is injected into the container or barrel at a pressure at the point of injection that is often greater than 15 psi. and in many instances from 200 to 400 psi in the injection head. Apparatus for forming deodorant or antiperspirant sticks by injection molding is also described. The combined process offers benefits for incorporating sensitive ingredients and ameliorating sedimentation of particulates such as particulate antiperspirant actives.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

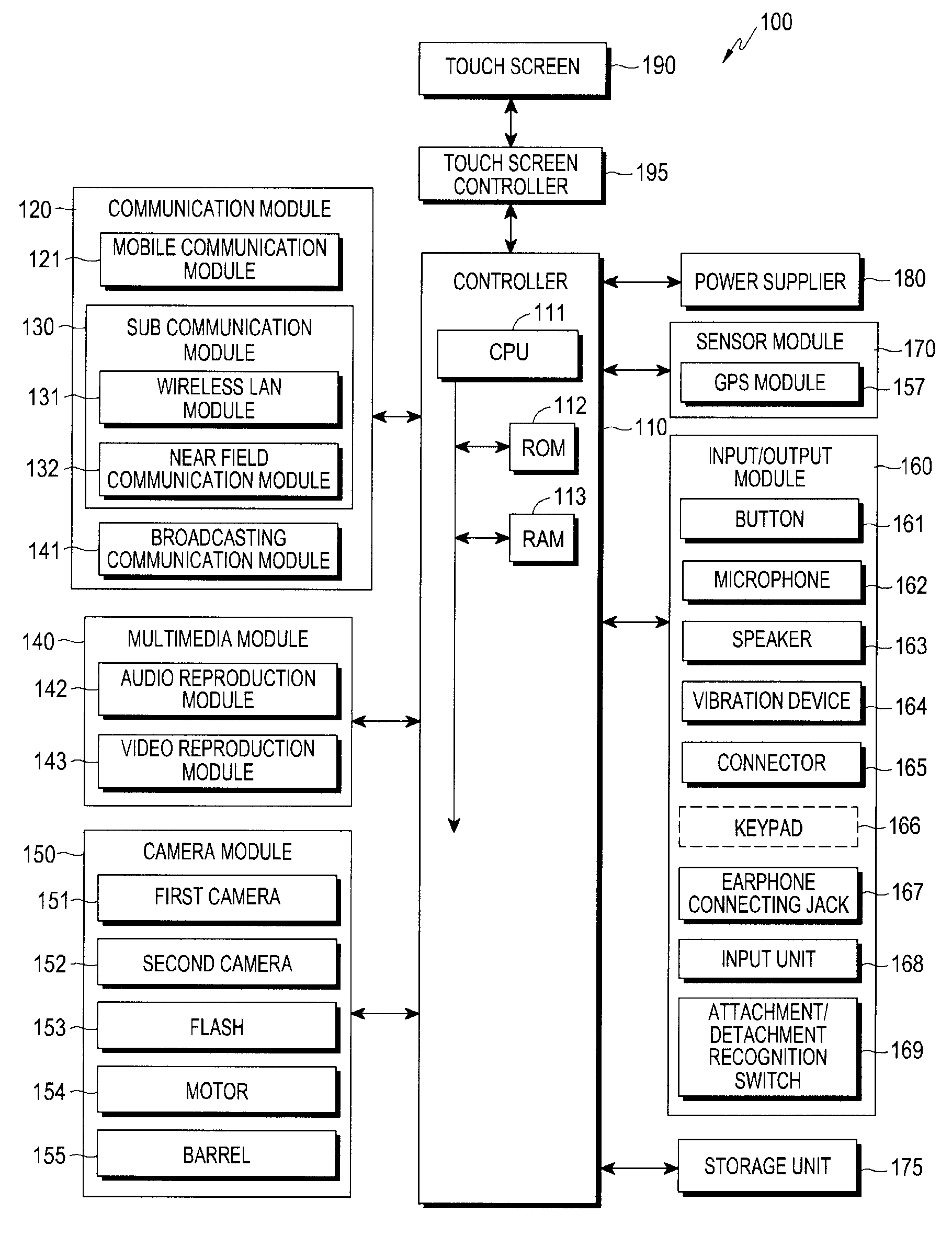

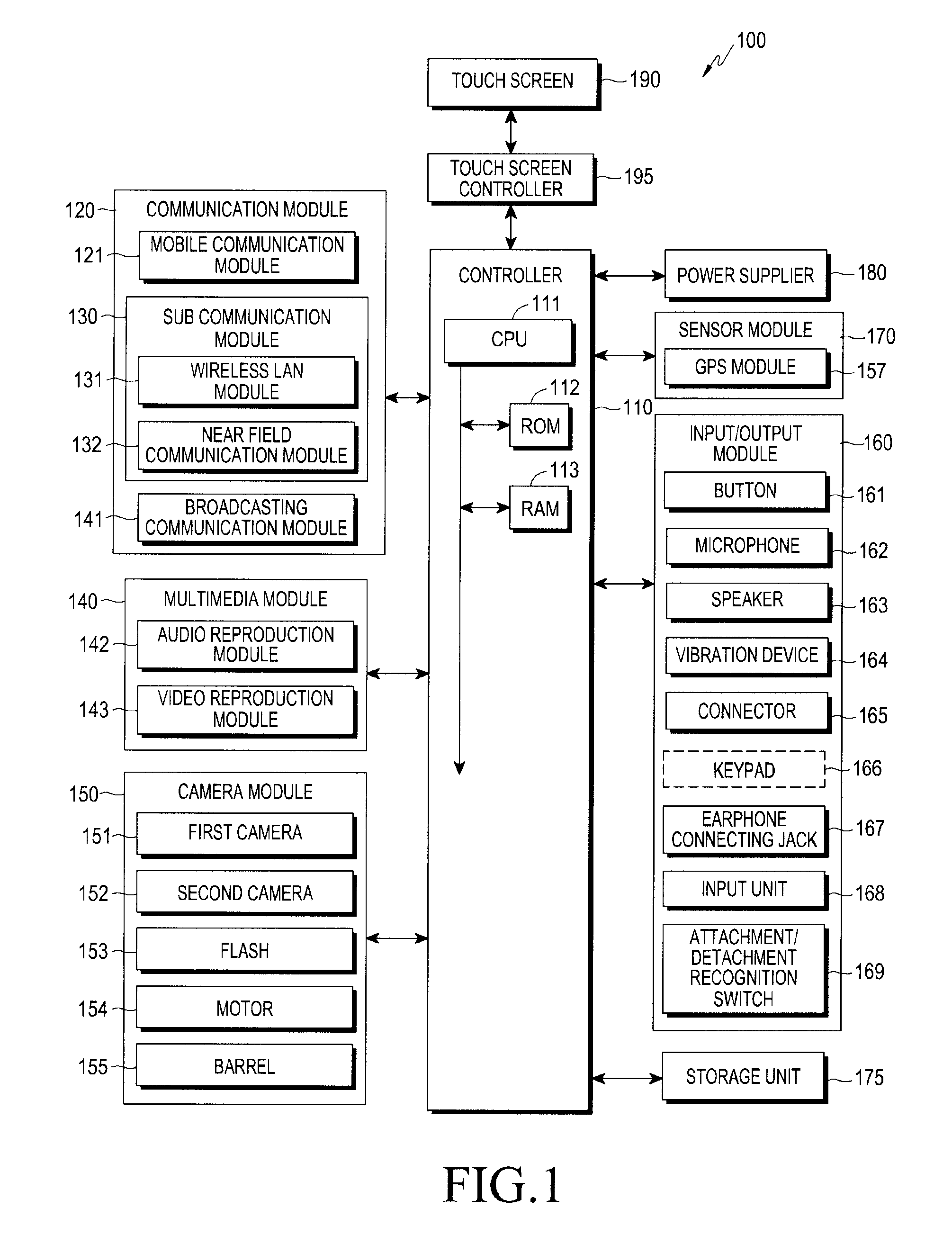

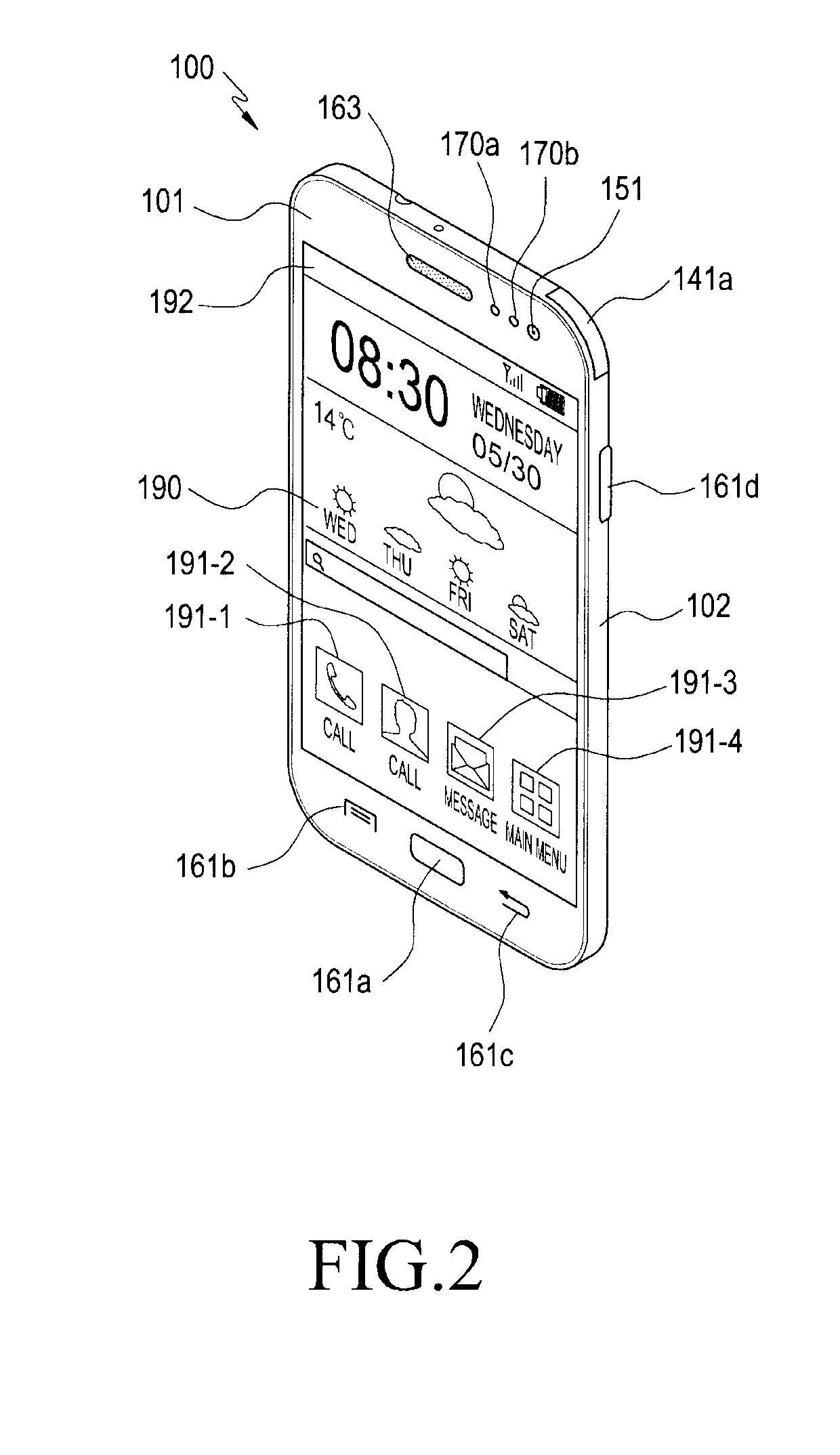

Combining effective images in electronic device having a plurality of cameras

ActiveUS20140232904A1Quality assuranceTelevision system detailsColor television detailsCombined methodFacial expression

An image combining method in an electronic device having a plurality of cameras. In response to a photographing signal, images successively photographed through at least a first camera are successively stored. A first image is selected from the successively photographed images which satisfies a predetermined classification reference, such as a degree of blurring, a facial expression, and / or a shooting composition. A second image is captured through a second camera; and the first and second images are then combined. The combined image may be a picture-in-picture (PIP) type combination image. The first and second cameras may be front and rear cameras of a portable terminal, or vice versa. The successive image capture and selection technique may also be applied to the second camera.

Owner:SAMSUNG ELECTRONICS CO LTD

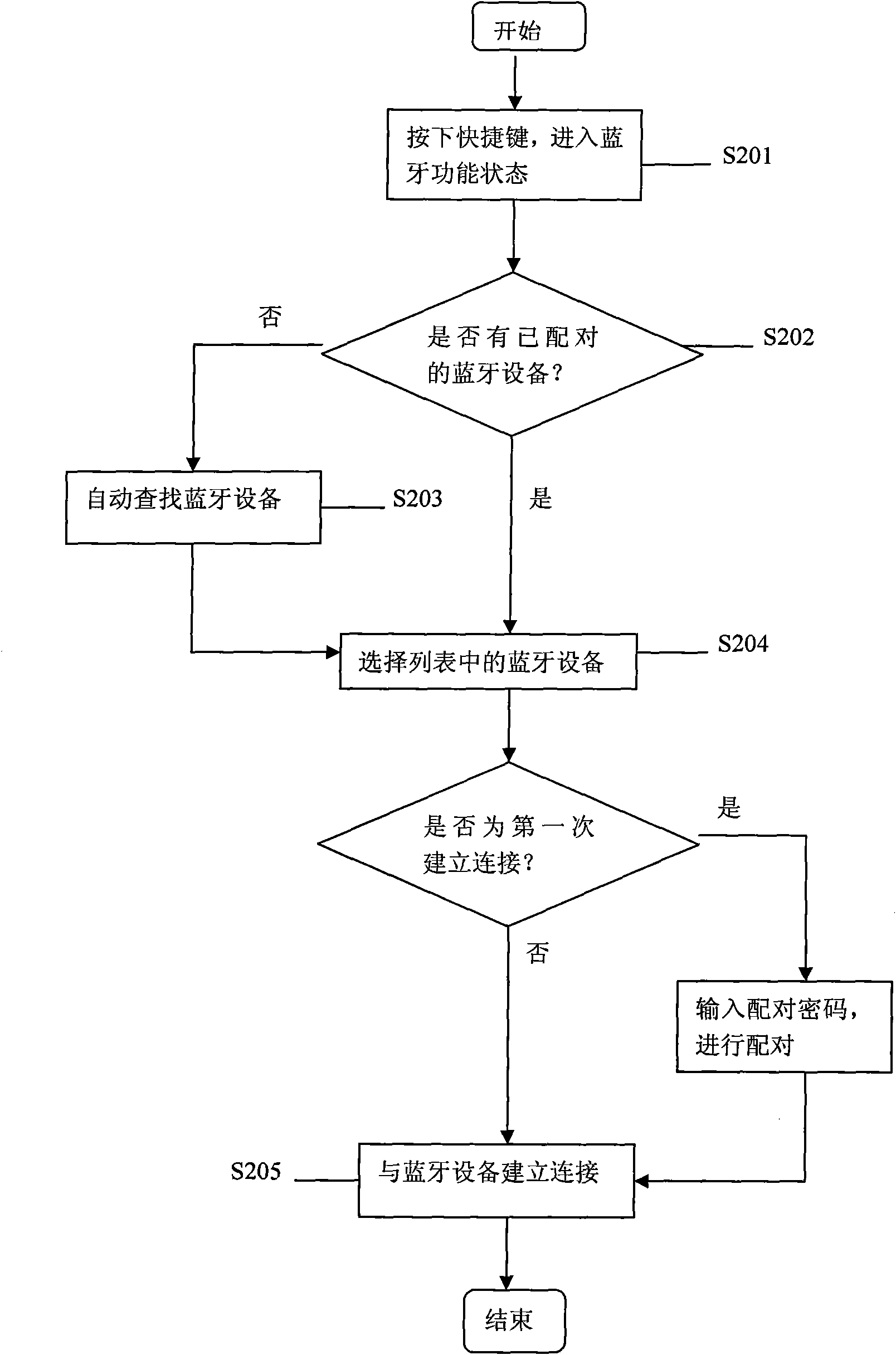

Method for simplifying mobile terminal connecting bluetooth equipment

InactiveCN101835279AReduce the number of timesEasy to operateNear-field transmissionWireless communicationCombined methodBluetooth

The invention provides a method for simplifying a mobile terminal connecting bluetooth equipment. In the method, a shortcut key for initiating the bluetooth function is set, a manual and automatic combined method is adopted in the bluetooth equipment selecting process, and the mobile terminal hidden matching type is used to replace user manual entering in the connection establishing process, thereby simplifying the process of the mobile terminal connecting the bluetooth equipment, and being convenient for the mobile terminal user to use the bluetooth equipment.

Owner:WINGTECH COMM

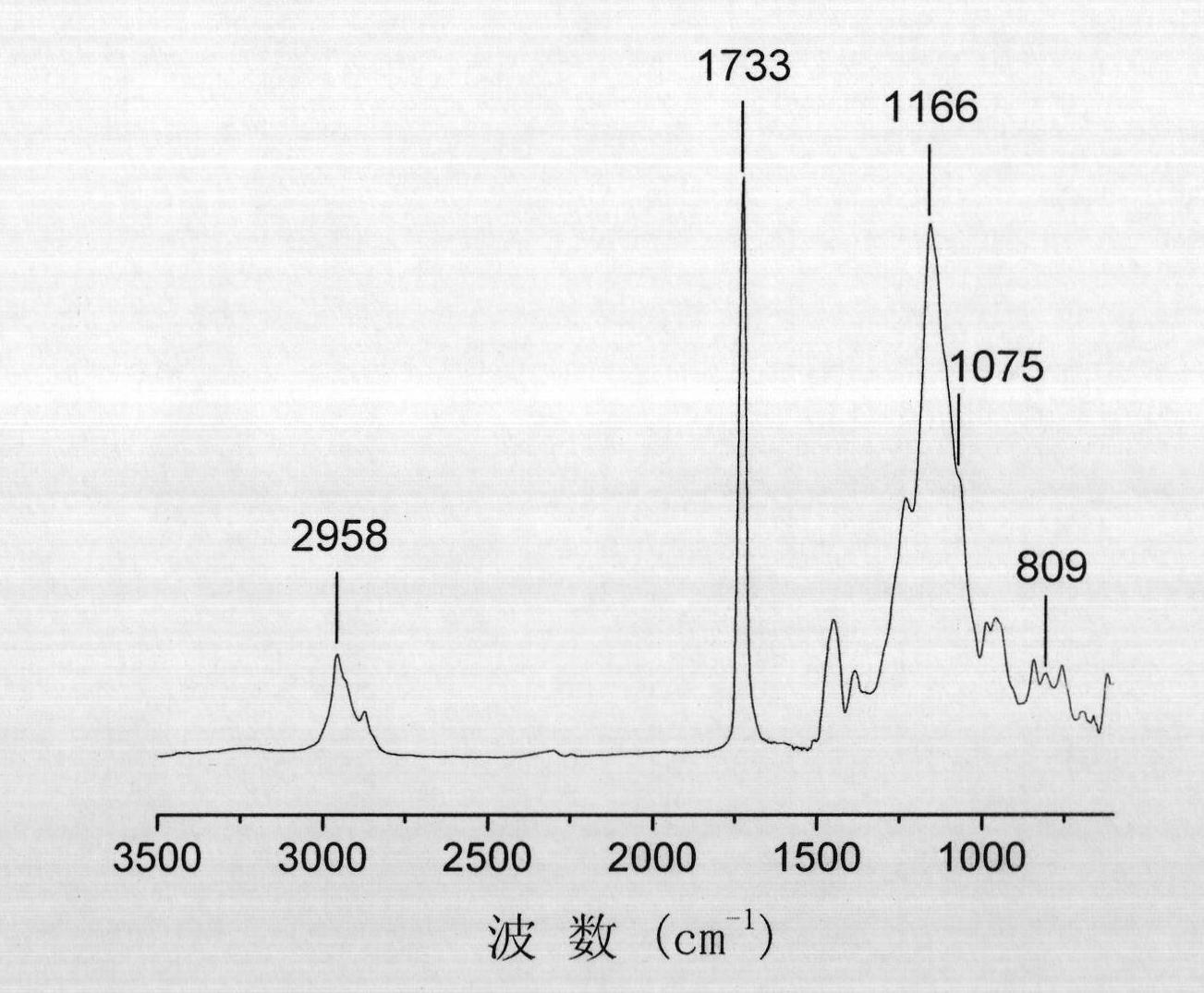

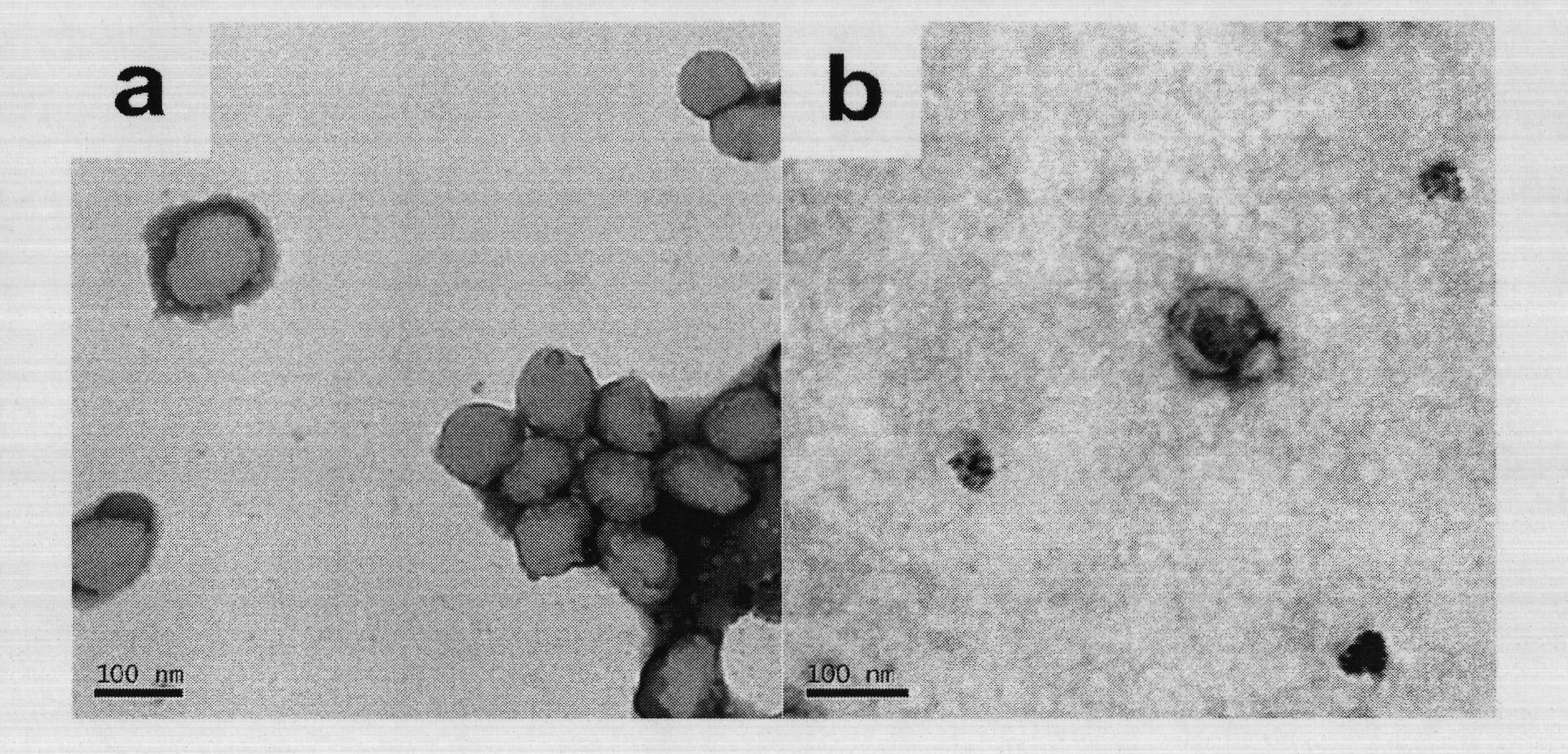

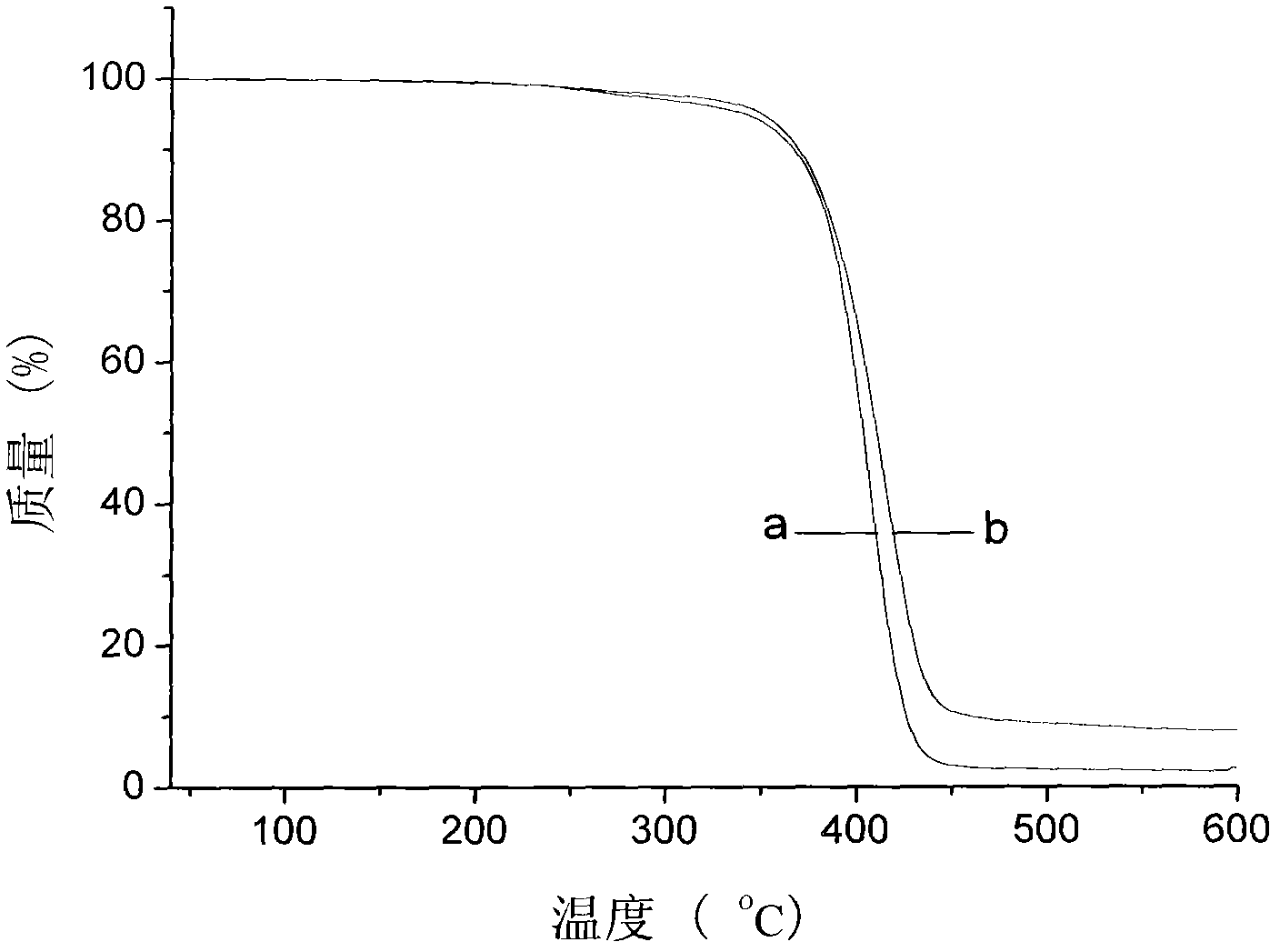

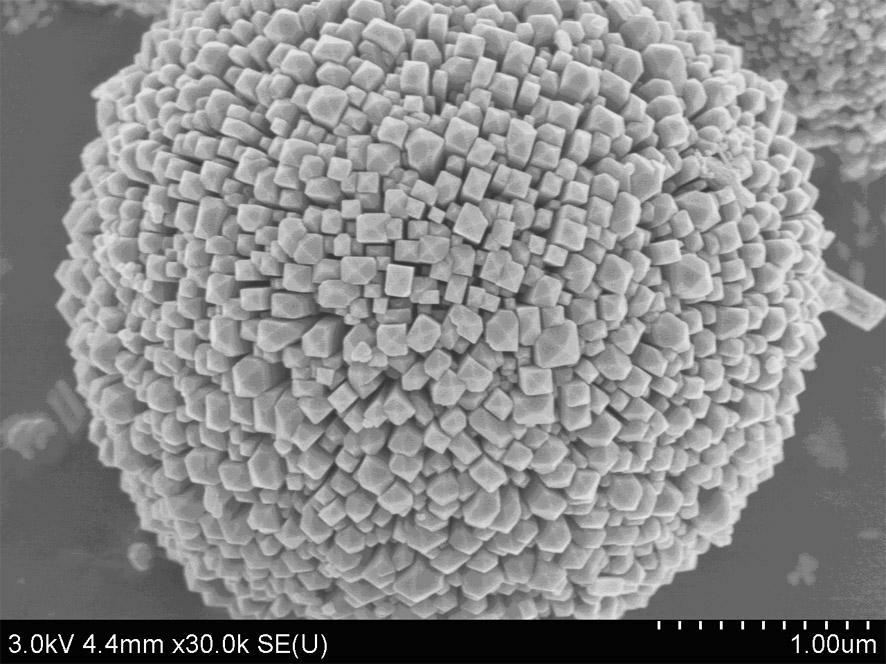

Method for preparing nano silicon/polyacrylate composite emulsion

InactiveCN102030873AAvoid the problem of "secondary reunion"Good dispersionCoatingsSilanesCombined method

The invention discloses a method for preparing nano silicon / polyacrylate composite emulsion. The method comprises the following steps of: adding the adding hydrochloric solution and an emulsifier into de-ionized water, mixing the mixed solution and tetraethoxysilane, a silane coupling agent and acrylate monomers and pre-emulsifying to obtain modified nano silicon pre-emulsion; heating, adding an initiator, and preparing the nano silicon / polyacrylate composite emulsion by adopting an in-situ emulsion polymerization and seed emulsion polymerization combined method. The method has a simple process, solves the problem of 'secondary aggregation' of the traditional nano silicon during emulsion polymerization and effectively guarantees the stable proceeding of a polymerization reaction, the prepared nano silicon / polyacrylate composite emulsion has high stability, and the film of the nano silicon / polyacrylate composite emulsion has high heat resistance.

Owner:SOUTH CHINA UNIV OF TECH

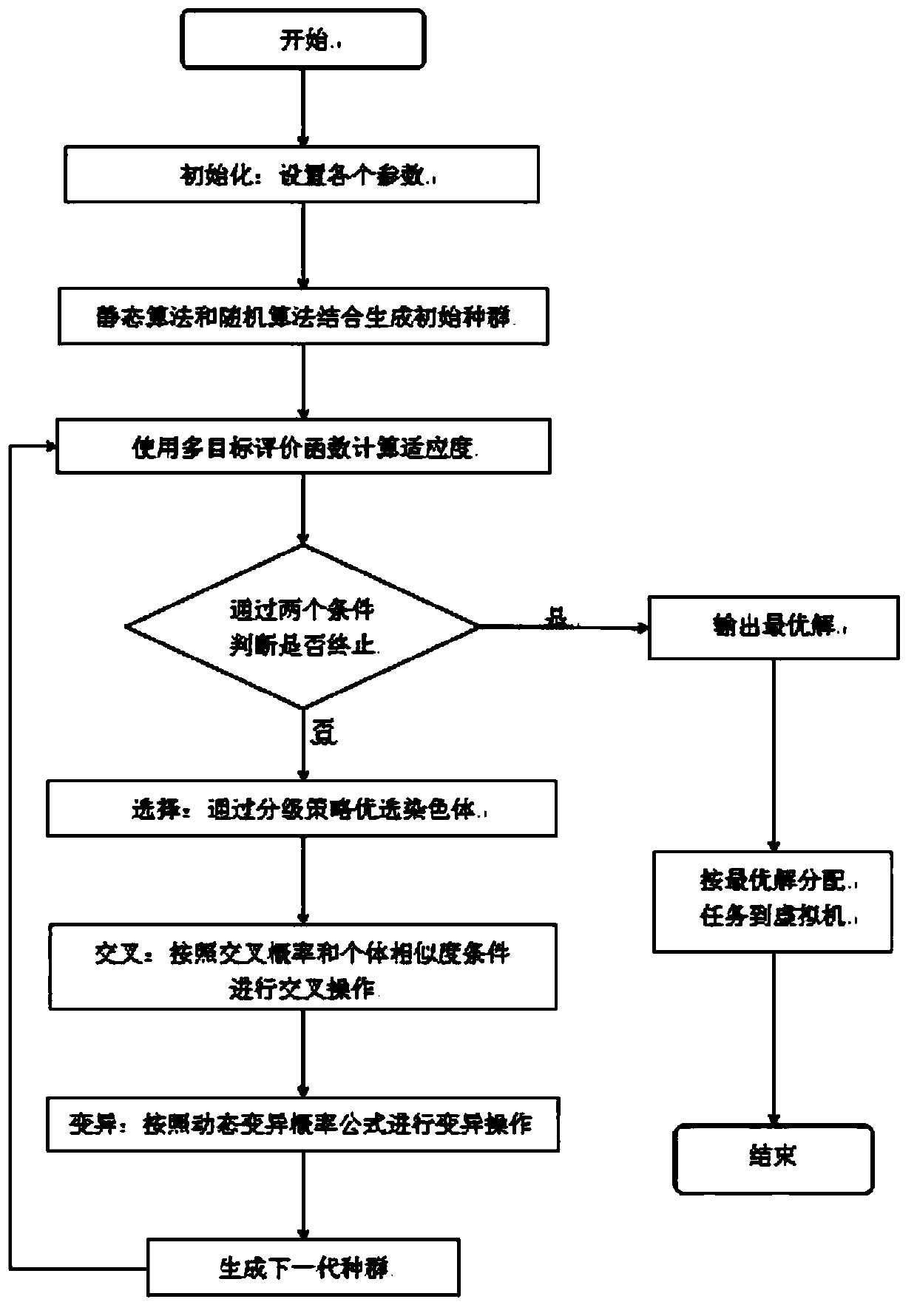

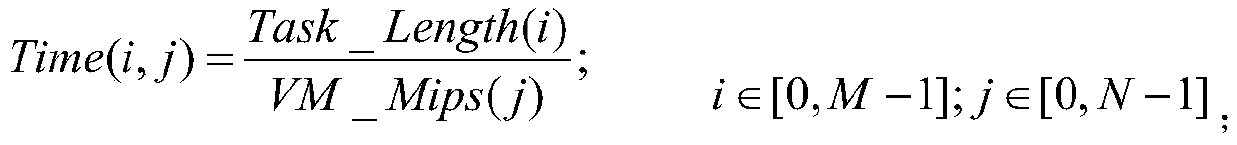

Cloud computing task scheduling method based on an improved genetic algorithm

PendingCN109800071AImprove satisfactionImprove execution efficiencyProgram initiation/switchingGenetic modelsAlgorithmCombined method

The invention discloses a cloud computing task scheduling method based on an improved genetic algorithm. A multi-objective-based weighted optimization evaluation method is adopted as a fitness function; Coding is carried out in a real number direct coding mode; Generating an initial population by adopting a static algorithm and random generation combined method; Carrying out selection operation byadopting a hierarchical selection strategy; Performing crossover operation according to the crossover probability and the chromosome difference degree; Performing mutation operation according to thedynamic mutation probability; Judging whether the program is ended or not according to the double-termination condition; And finding an optimal scheme and distributing. Multiple steps of a traditionalgenetic algorithm are optimized and improved, and the user satisfaction degree and the algorithm execution efficiency are improved.

Owner:SOUTH CHINA UNIV OF TECH

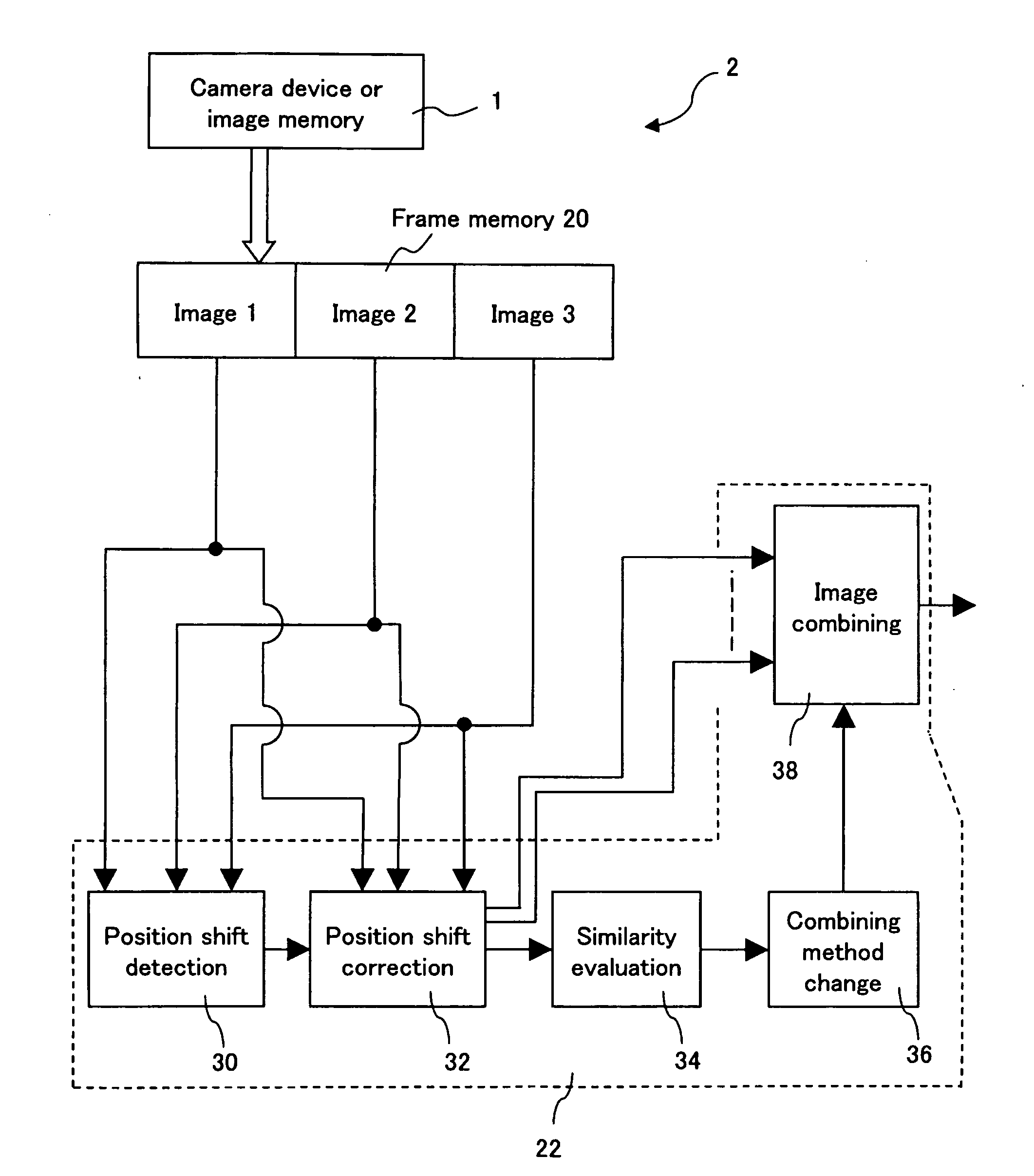

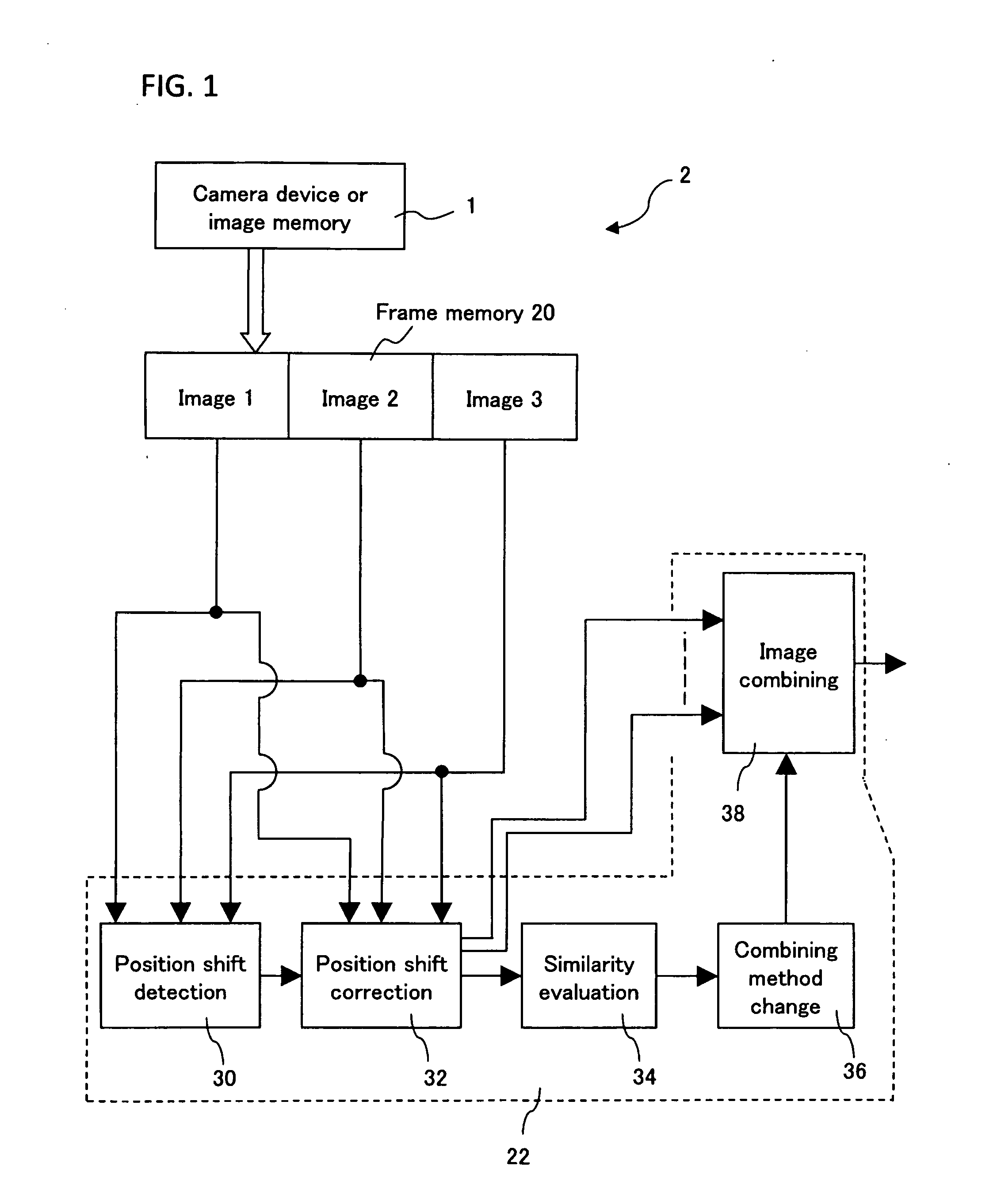

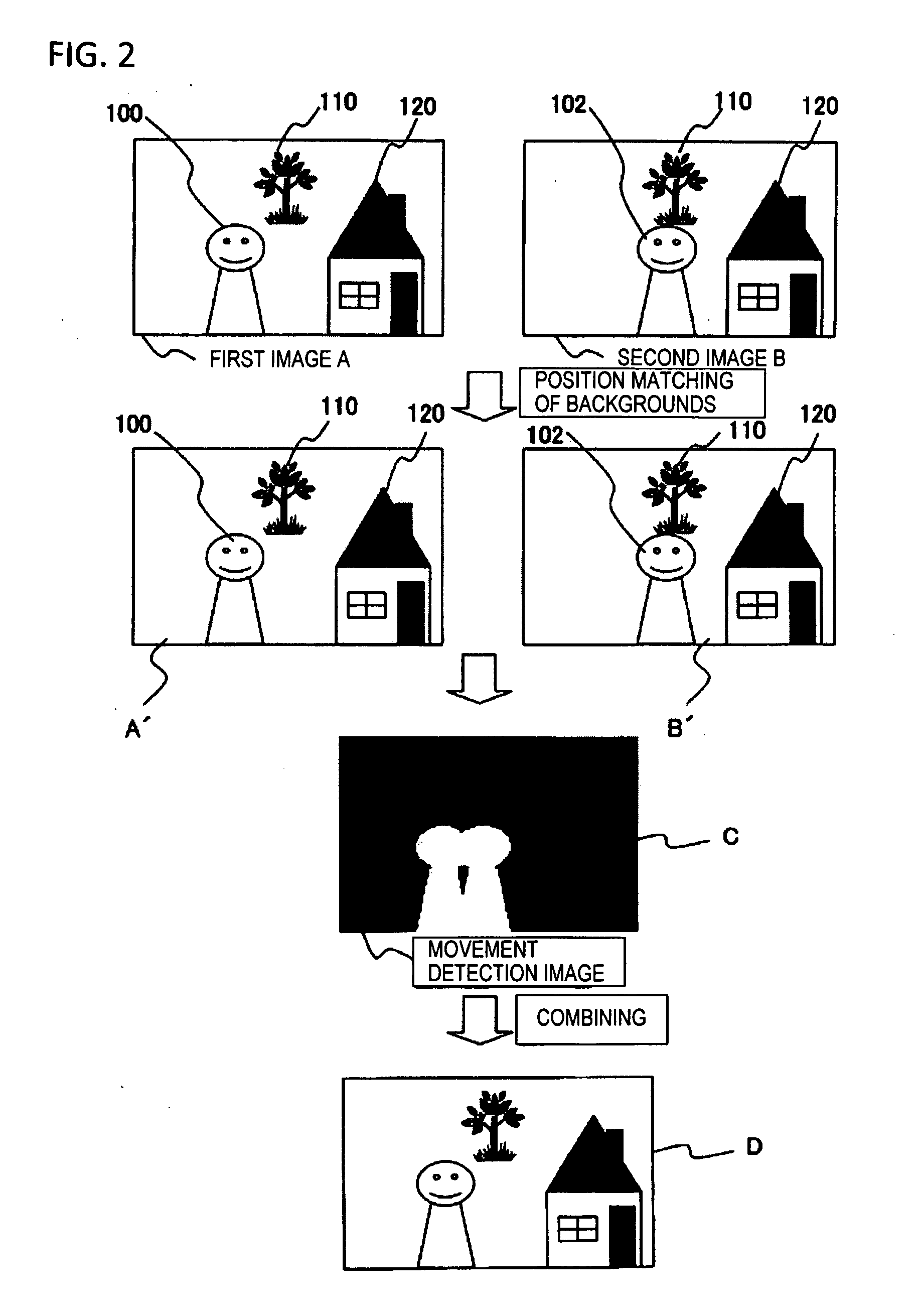

Image processing method and image processing device

InactiveUS20080187234A1Reduce processing loadObject becomes blurredImage enhancementTelevision system detailsImaging processingCombined method

In a device for combining a plurality of images having a same photograph range, a position shift between the images having the same photograph range is detected, and the position shift of the images is corrected, and after the position shift is corrected, similarity of the respective portions between the images is evaluated, and the image combining method is changed according to the similarity evaluation. Therefore it is possible to create an image having no position shift due to the shaking of a camera and object blurring due to the movement of the object. Moreover, whether the images are combined or not is determined according to the similarity, hence the processing load is reduced and an image having no object blurring can be created.

Owner:FUJITSU LTD

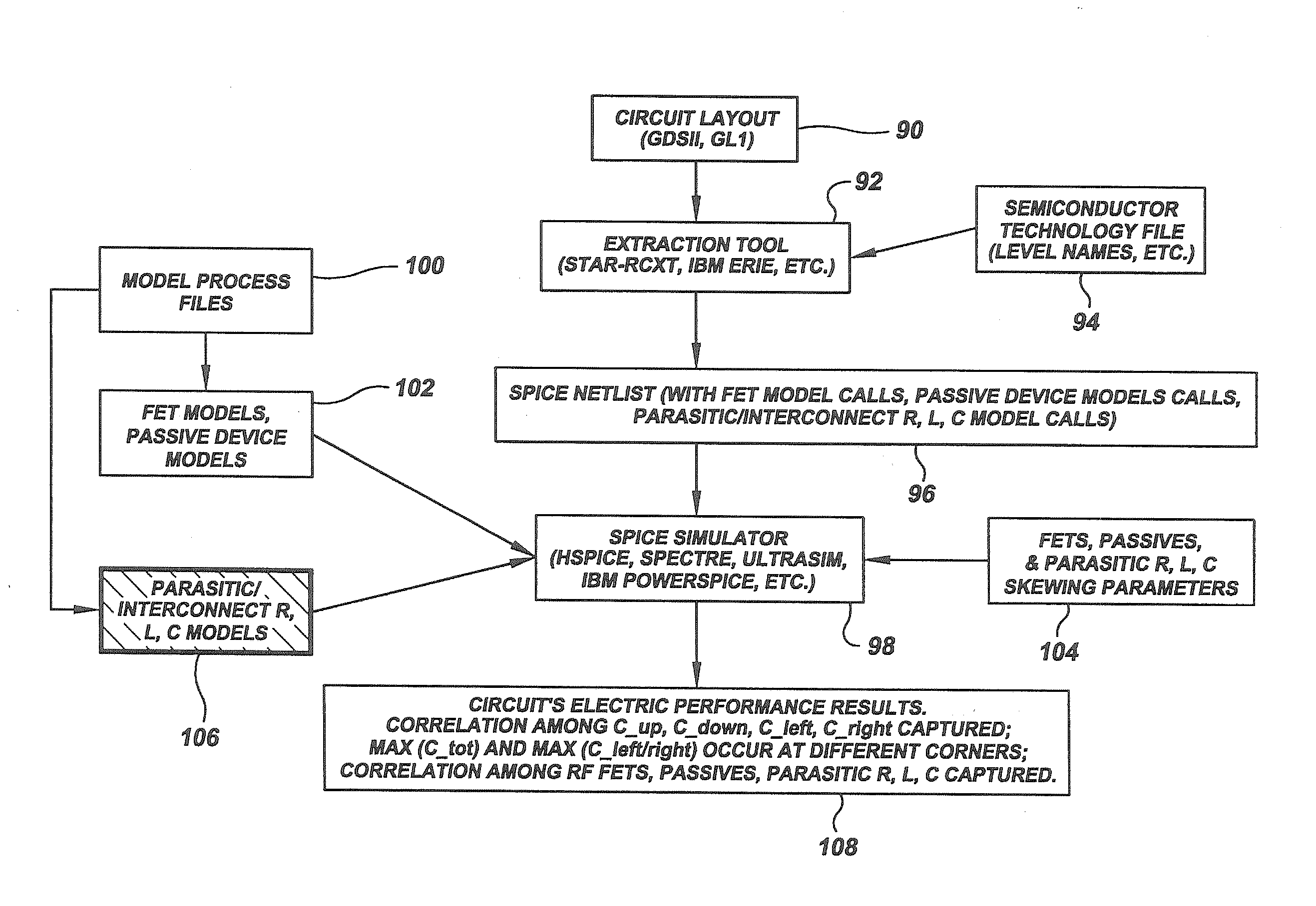

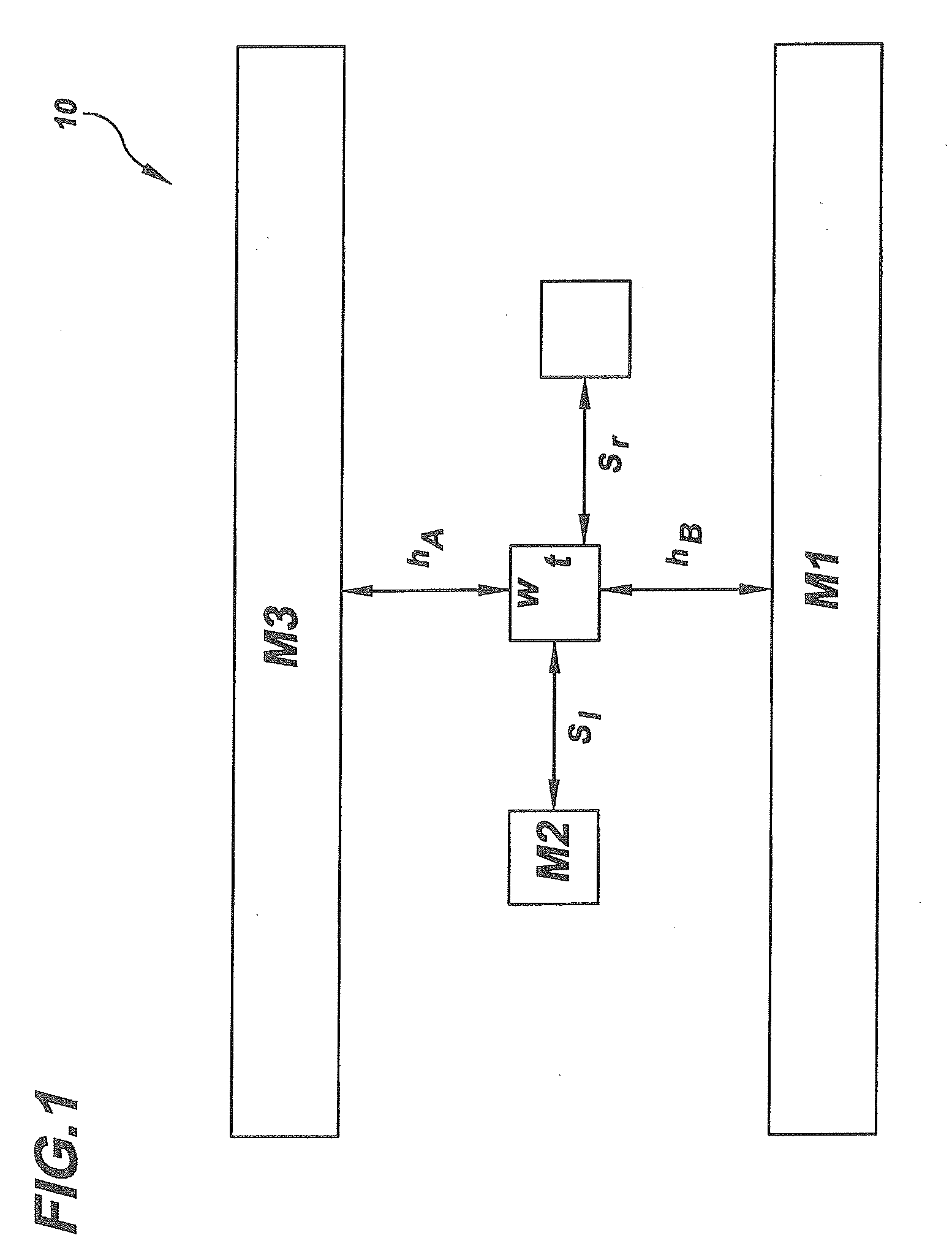

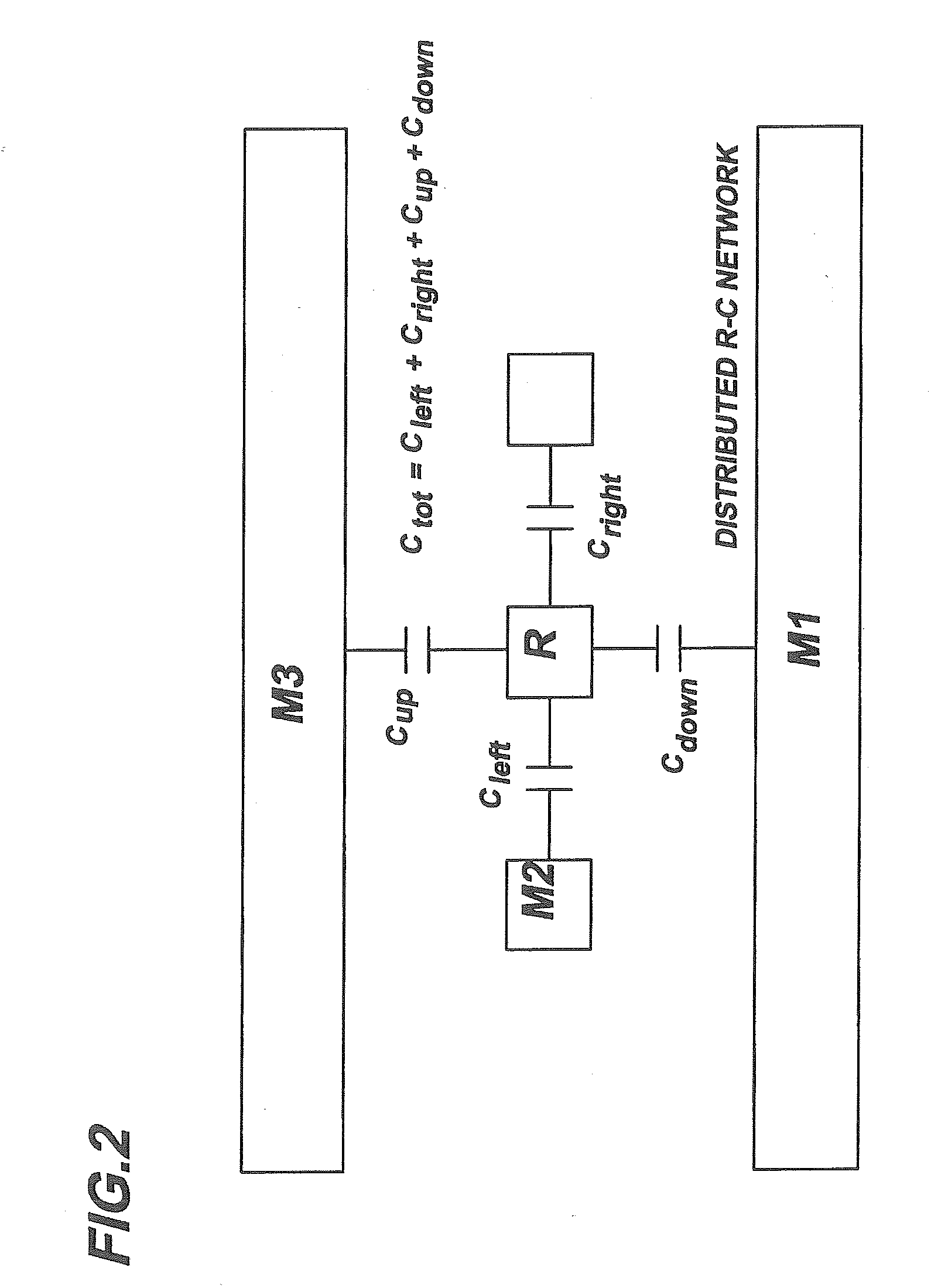

Method for treating parasitic resistance, capacitance, and inductance in the design flow of integrated circuit extraction, simulations, and analyses

InactiveUS20080028353A1Detecting faulty computer hardwareComputer aided designElectrical resistance and conductanceCapacitance

An extraction, simulation, and analysis combined method is employed to account for the parasitic couplings from interconnect wires. Variations of parasitic resistance, capacitance, and inductance are used in circuit analysis calculators, including considering the variations of the parasitics on worst case circuit performance, skewing, and statistical Monte Carlo analysis. Each parasitic element is modeled as a call-up function with associated process distributions. Circuit analysis, such as a SPICE analysis is performed on the selected models.

Owner:IBM CORP

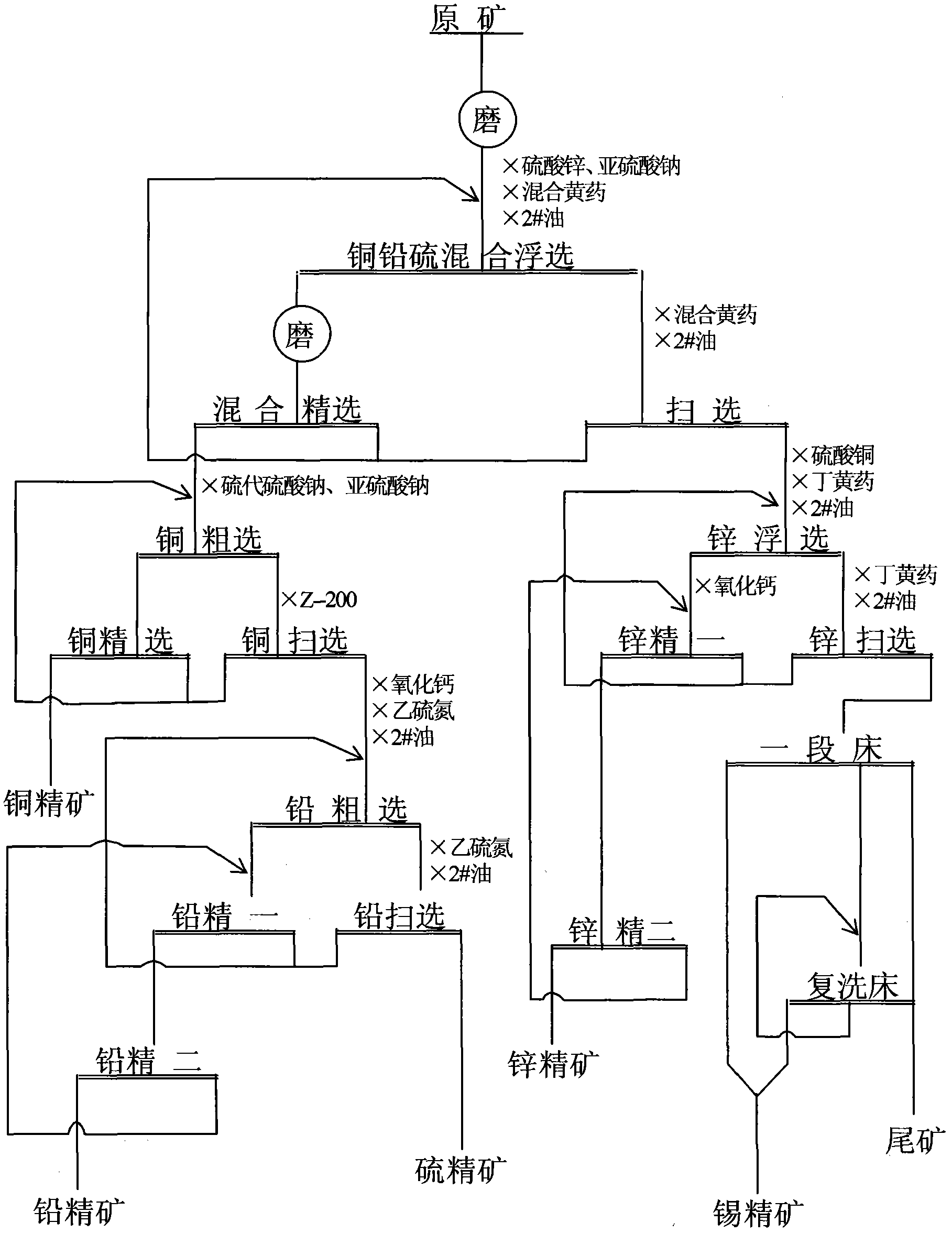

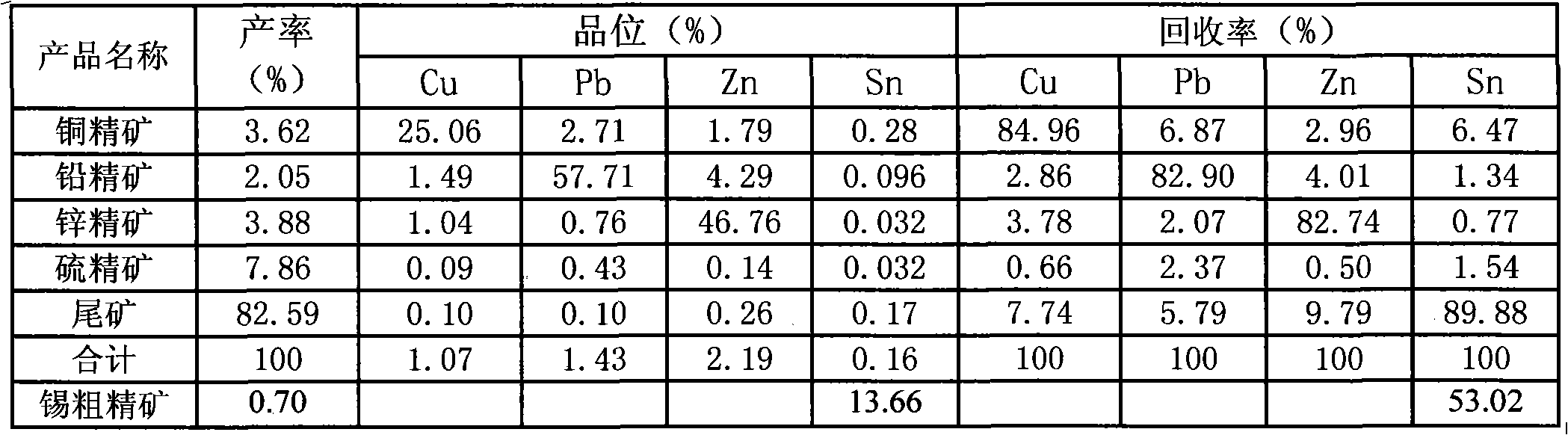

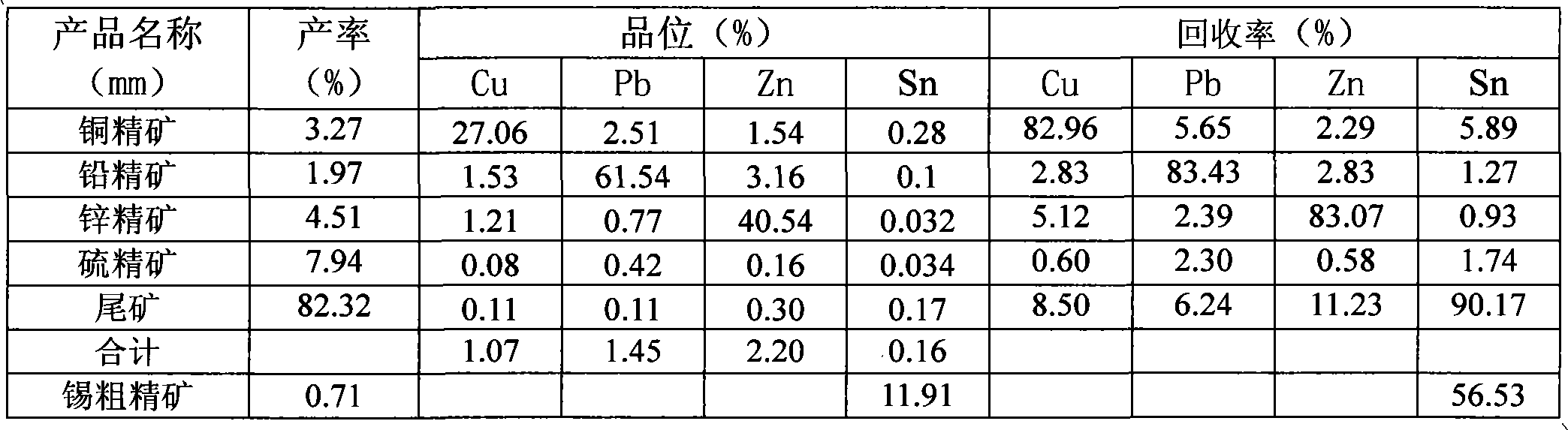

Benification combined method of polymetallic sulphide ore containing copper, lead, zinc and tin

The invention relates to a beneficiation method, in particular to a beneficiation method for separating the polymetallic sulphide ore containing copper, lead, zinc and tin. The method comprises the following steps: (1) carrying out ore grinding on the raw ore before carrying out bulk flotation on copper, lead and sulphur, using diethyl mixed with xanthate as collecting agent of copper and lead mineral, using zinc sulphate and sodium sulfite as inhibitor of zinc mineral; (2) carrying out phase-2 ore grinding and selection; (3) separating copper, lead and sulphur, using sodium sulfite and sodium thiosulfate as the inhibitor of the lead and sulphur mineral, using Z-200 as collecting agent for separation and scavenging and then carrying out lead flotation after the separation and scavenging; (4) carrying out zin flotation on the bulk flotation tailings; and (5) finally, carrying out reselection on the zinc flotation tailings to recover tin. The metalliferous mineral of the invention has the advantages of good separating effect, high metal recovery rate, more complete comprehensive recovery of useful minerals, low cost of medicament, simple method, easy operation and energy conservation.

Owner:云南锡业研究院有限公司研究设计院

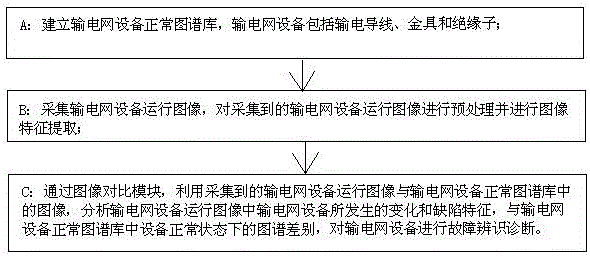

Power transmission equipment fault diagnosis method

ActiveCN106023185ATimely detection of hidden troublesReduce fault judgment errorImage enhancementImage analysisFeature extractionPattern matching

The invention discloses a power transmission equipment fault diagnosis method. The method comprises the following steps: A) establishing a normal image database of power transmission network equipment, wherein the power transmission network equipment comprises power transmission lines, fittings and insulators; B) collecting operation images of the power transmission network equipment, and carrying out pretreatment and image feature extraction on the collected operation images of the power transmission network equipment; and C) through an image comparison module, by utilizing the collected operation images of the power transmission network equipment and images in the normal image database of the power transmission network equipment, analyzing change and defect characteristics of the power transmission network equipment in the operation images of the power transmission network equipment, and image difference in the normal image database of the power transmission network equipment under normal state of the equipment, and carrying out fault identification and diagnosis on the power transmission equipment. The method can find possible fault hidden trouble of the power transmission lines in time through a structure template analysis and defect feature pattern matching combined method, thereby greatly reducing fault judgment error.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +1

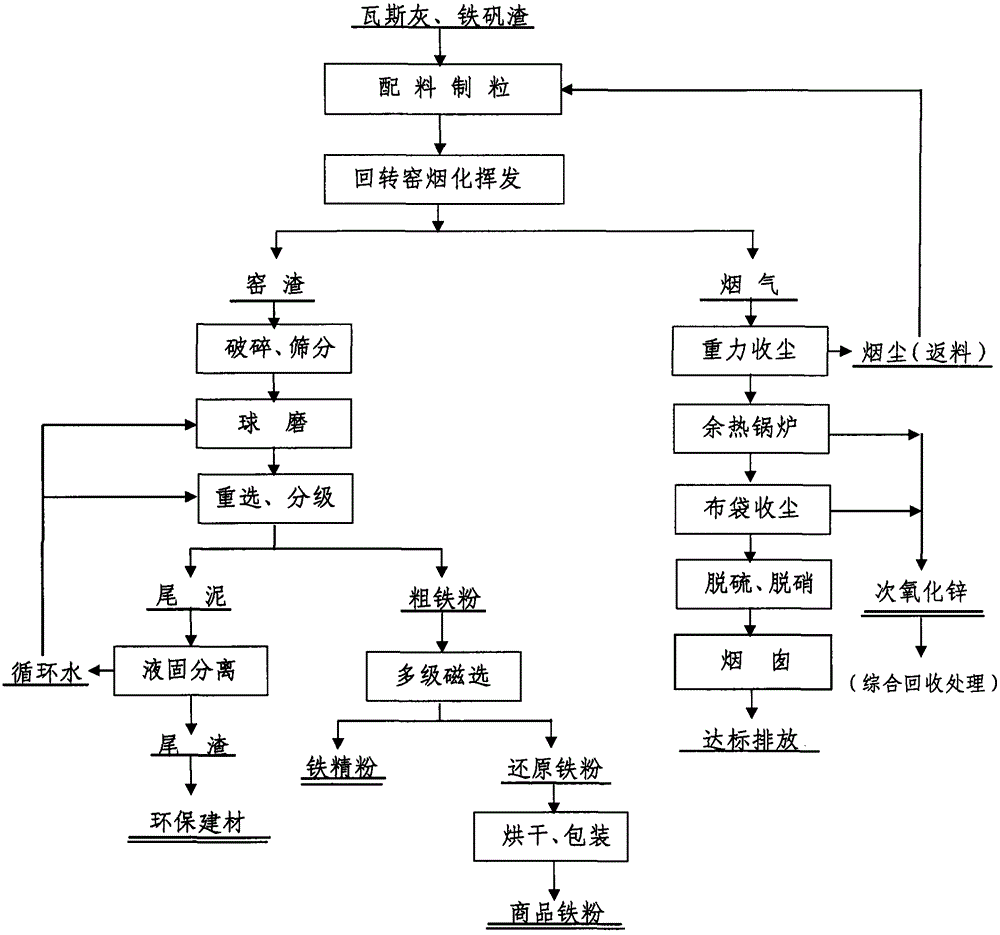

Comprehensive recovery technology of solid waste gas ash and zinc-containing ferrovanadium slag

ActiveCN104911356AImprove the level of comprehensive utilizationAchieve reductionProcess efficiency improvementSlagHigh energy

The invention provides a comprehensive recovery technology of solid waste gas ash and zinc-containing ferrovanadium slag. By combining advantages of low iron content and rich carbon of gas ash and characteristics of high iron content and rich precious metals of ferrovanadium slag, and by the adoption of a rotary-kiln fire method fuming enrichment technology, the material undergoes comprehensive recovery. Advanced equipment such as a waste heat boiler, a negative-pressure bag collector, a pneumatic emulsification desulfurization tower and the like are configured to carry out efficient recovery and harmless environmental-protection processing of flue gas so as to achieve the purpose of clean production. By a beneficiation combined method, iron-containing kiln slag undergoes high added-value exploitation. Thus, the environmental protection problem of resource disposition is solved, and the effect of comprehensive utilization with low energy consumption, high yield and high added-value is achieved. Problems of short kiln age, high energy consumption and low concentration of SO2 during the treating process of ferrovanadium slag can be solved by the technology provided by the invention, and problems of poor iron separation effect and overhigh content of fluorine and chlorine in zinc hypoxide also can be solved. The technology has good economic benefit and high popularization and practical value.

Owner:北京事竟成有色金属研究所

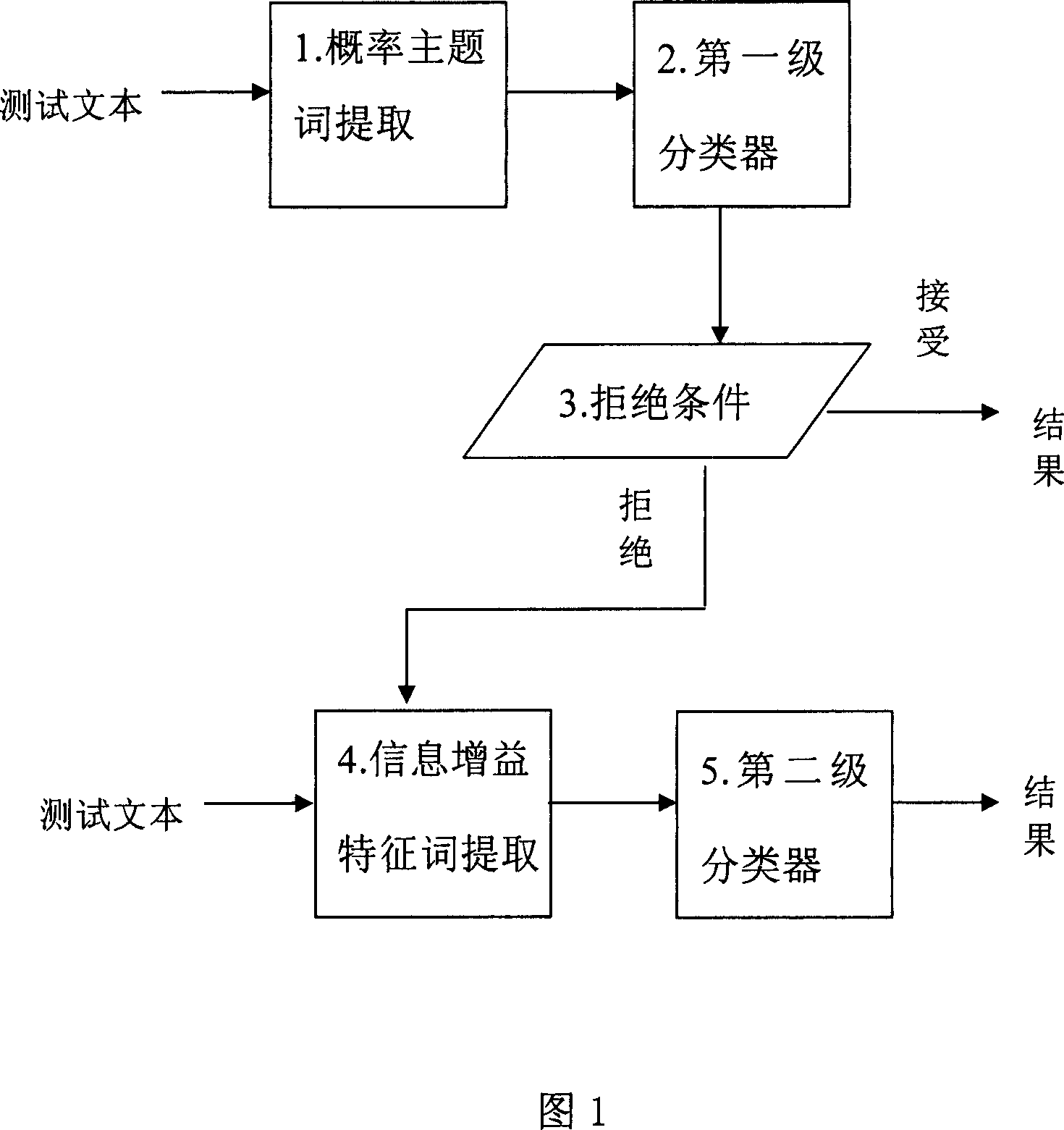

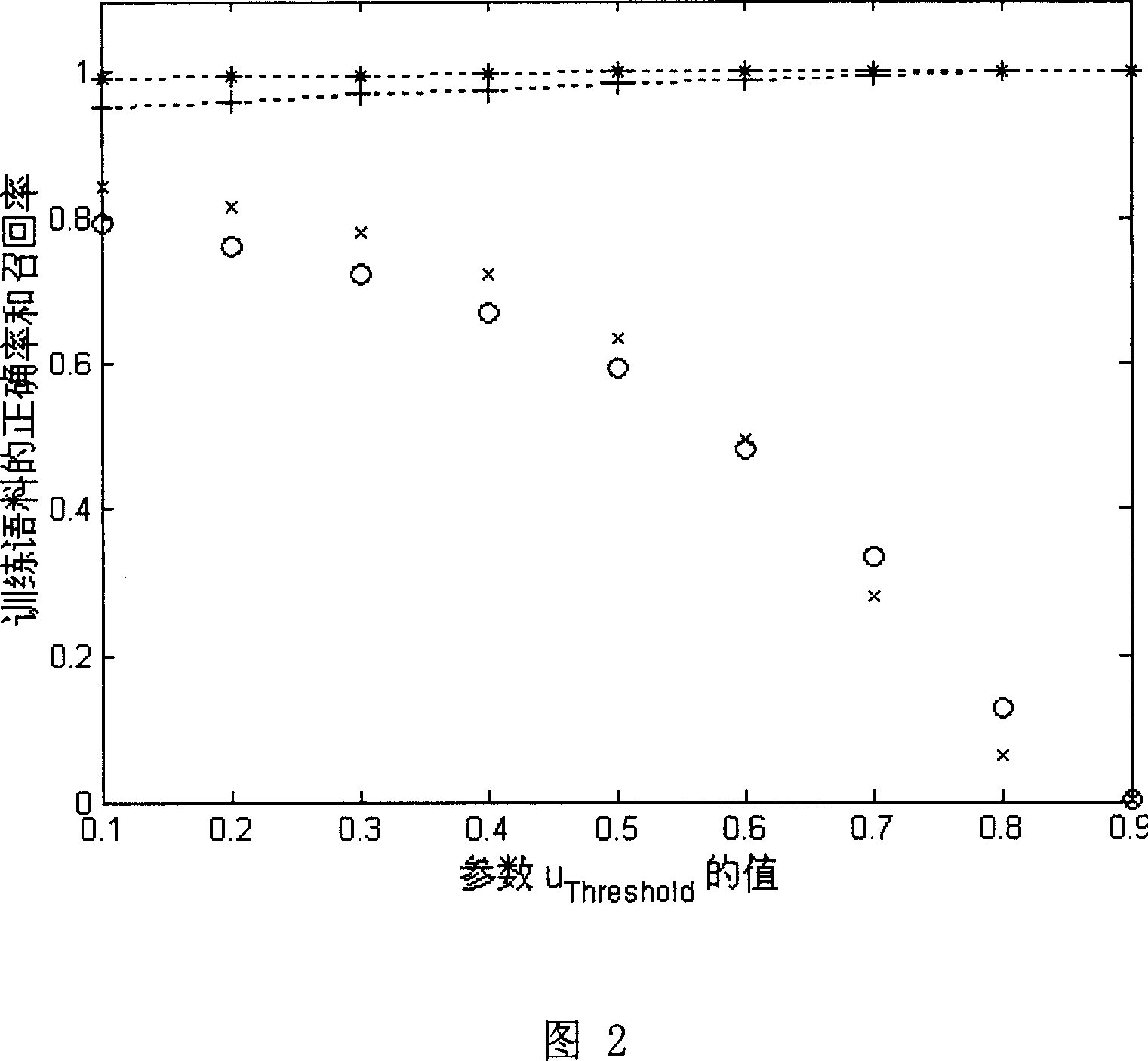

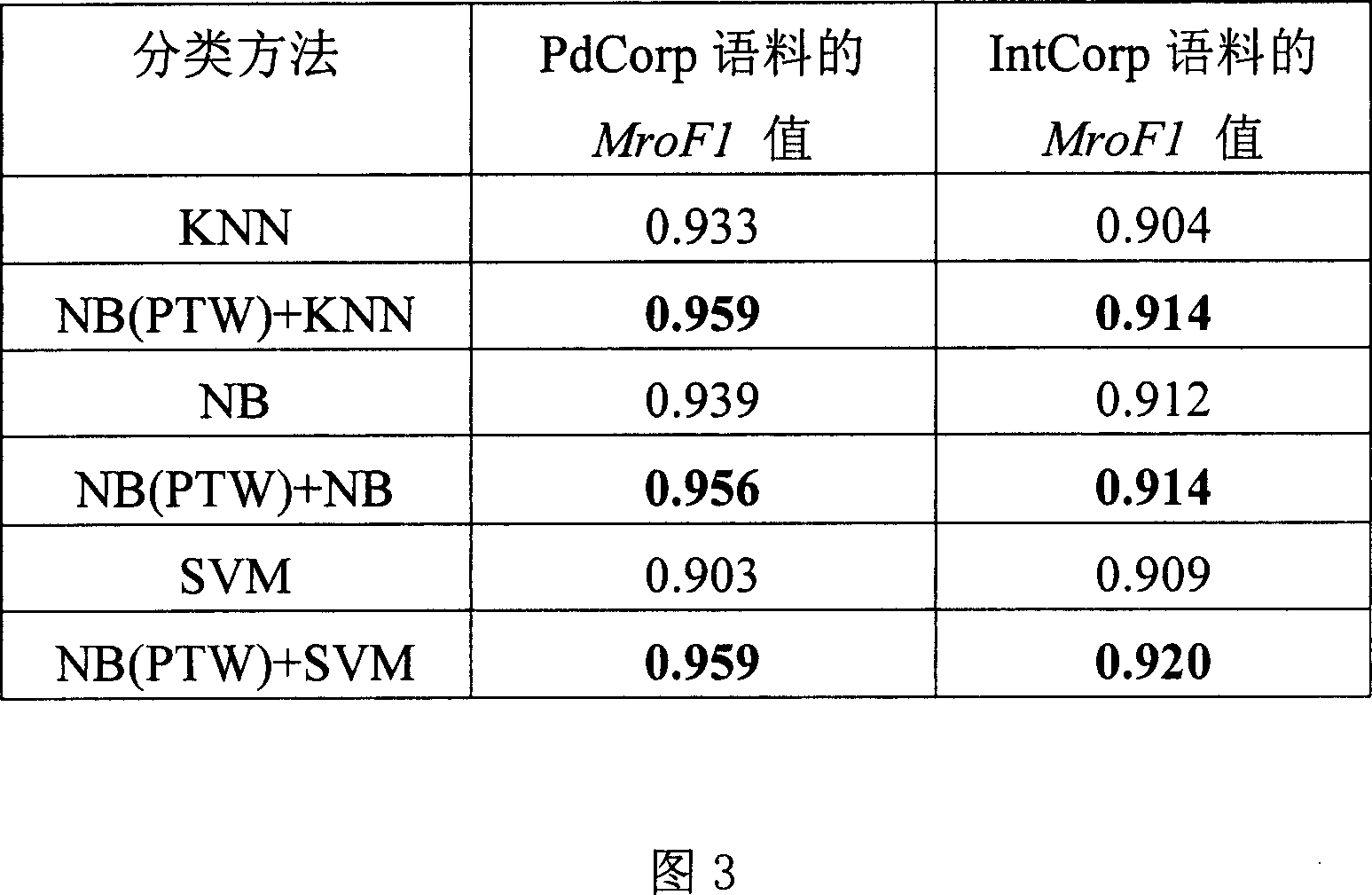

Two-stage combined file classification method based on probability subject

InactiveCN101059796AImprove classification effectImprove classificationSpecial data processing applicationsFeature extractionAlgorithm

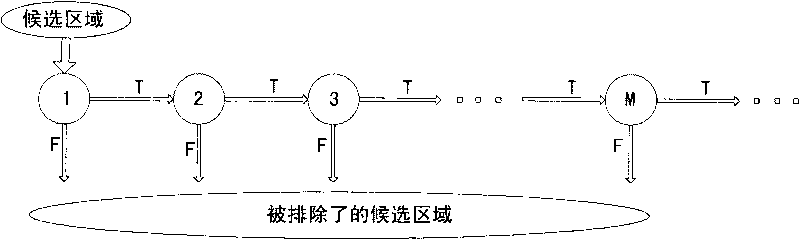

The invention relates to natural language processing and model recognizing technical field, which discloses a two-stage combine text classifying method based on probability subject word, wherein the first stage classification is based on Bayes classifying method to use probability subject word and reject condition judge couple to test the text classification, and the second stage classification is based on traditional character extraction method to extract character word to classify the test text rejected by the first stage. The inventive method classifies the text and fuses the characters of different classifiers to quickly classify various texts in the first classification, to improve classifying efficiency, to provide better treatment on the text classification system. And the invention provides probability subject word based on text character, while the probability subject word can effectively classify various texts in right reject condition. Compared with traditional single classification, the invention can reduce time consumption and improve system classification correct rate.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

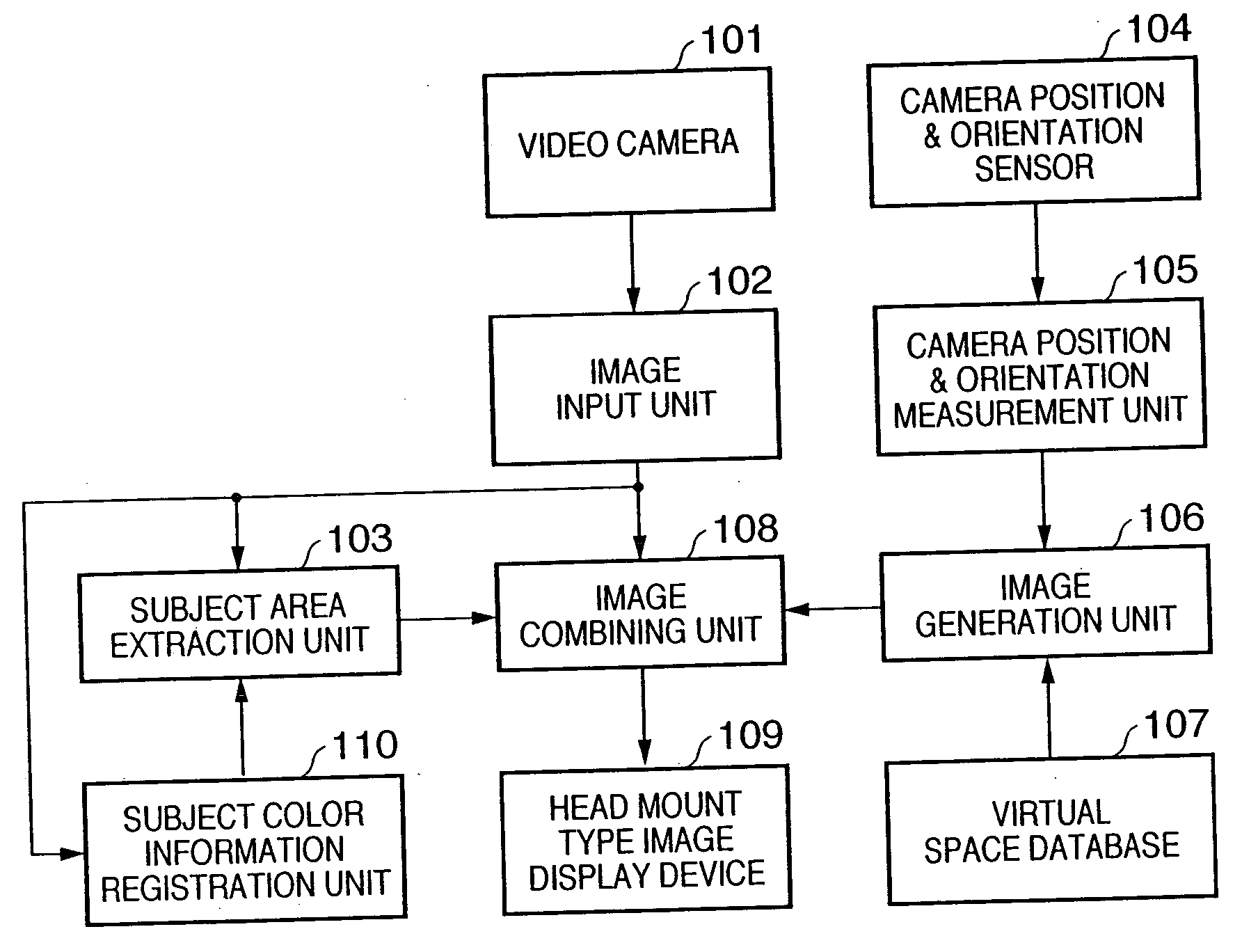

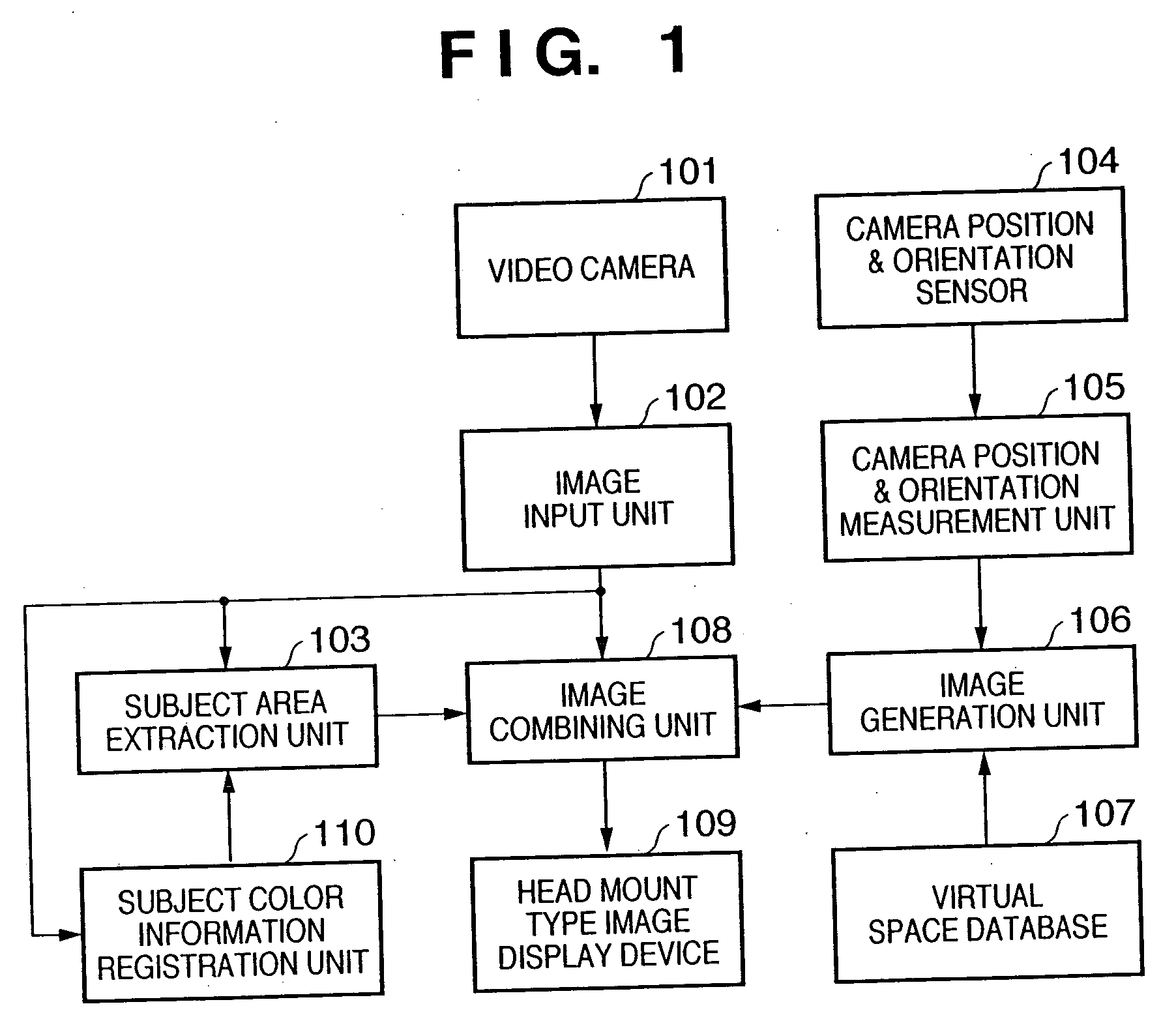

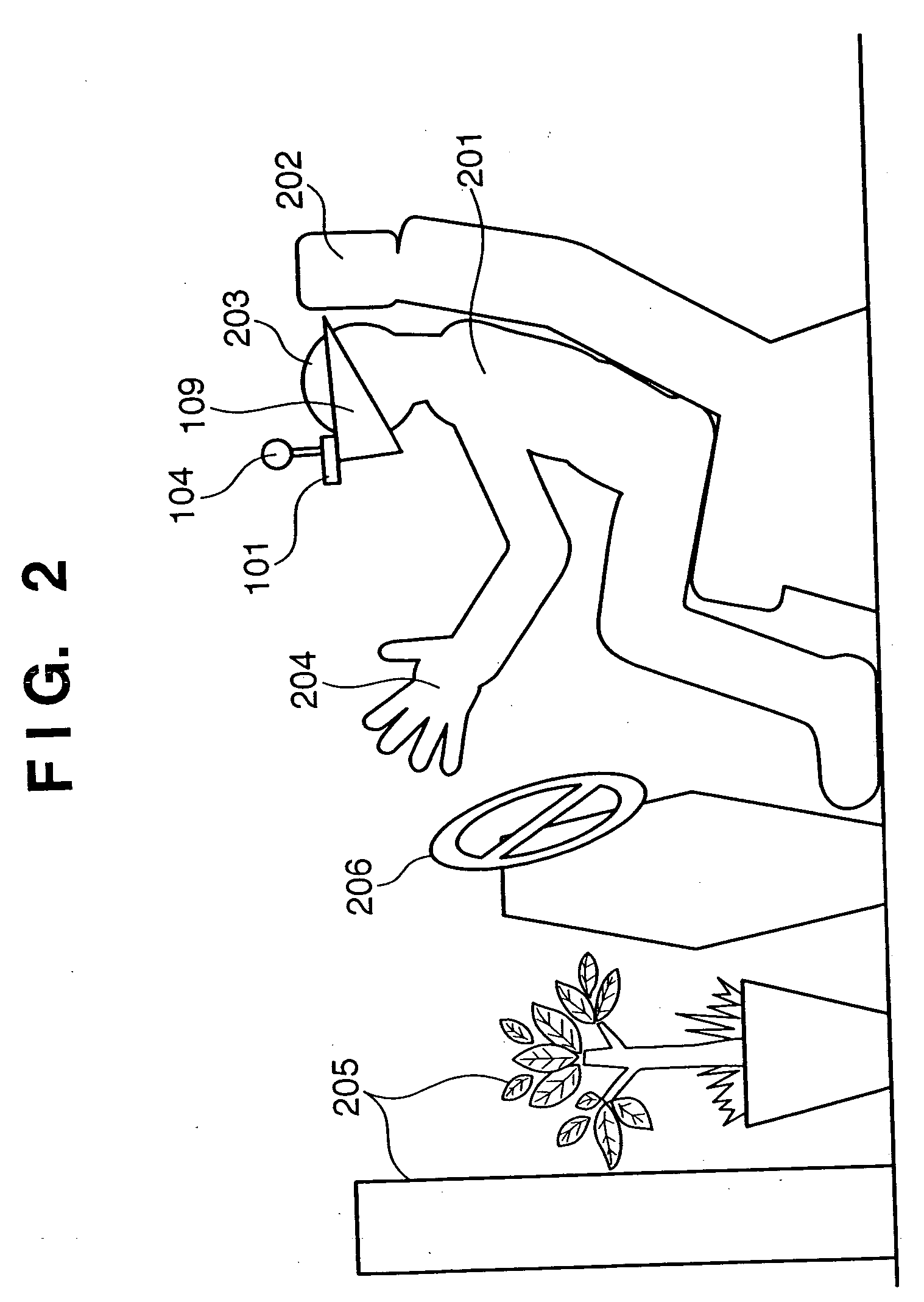

Correction of subject area detection information, and image combining apparatus and method using the correction

InactiveUS20050069223A1Cancel noiseEasy to operateImage enhancementImage analysisComputer graphics (images)Combined method

An image combining method for combining an image obtained by image sensing real space with a computer-generated image and displaying the combined image. Mask area color information is determined based on a first real image including an object as the subject of mask area and a second real image not including the object, and the color information is registered. The mask area is extracted from the real image by using the registered mask area color information, and the real image and the computer-generated image are combined by using the mask area.

Owner:CANON KK

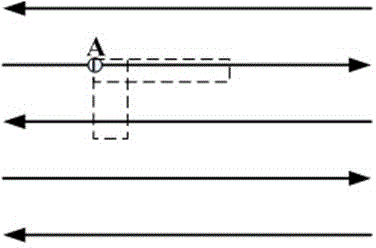

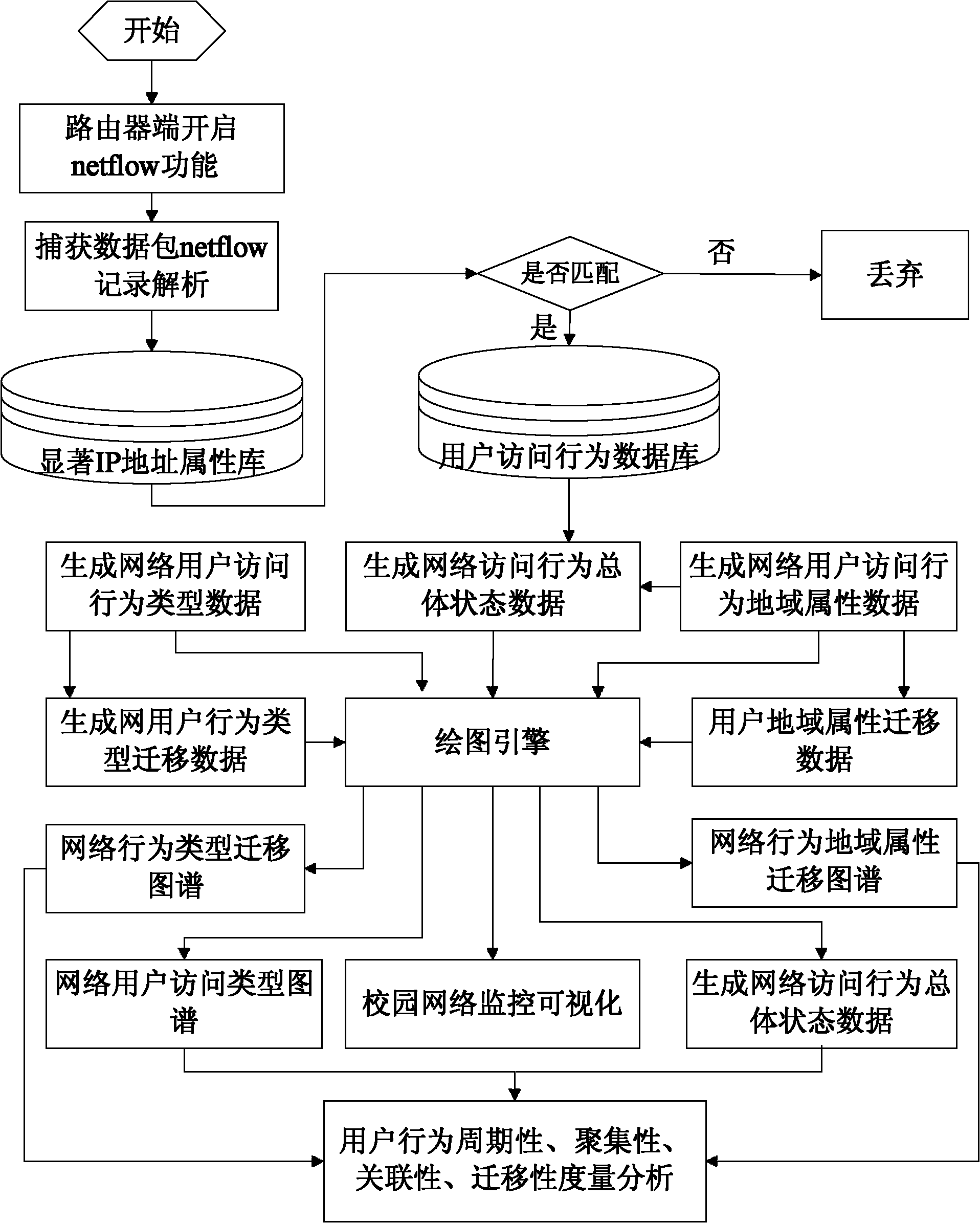

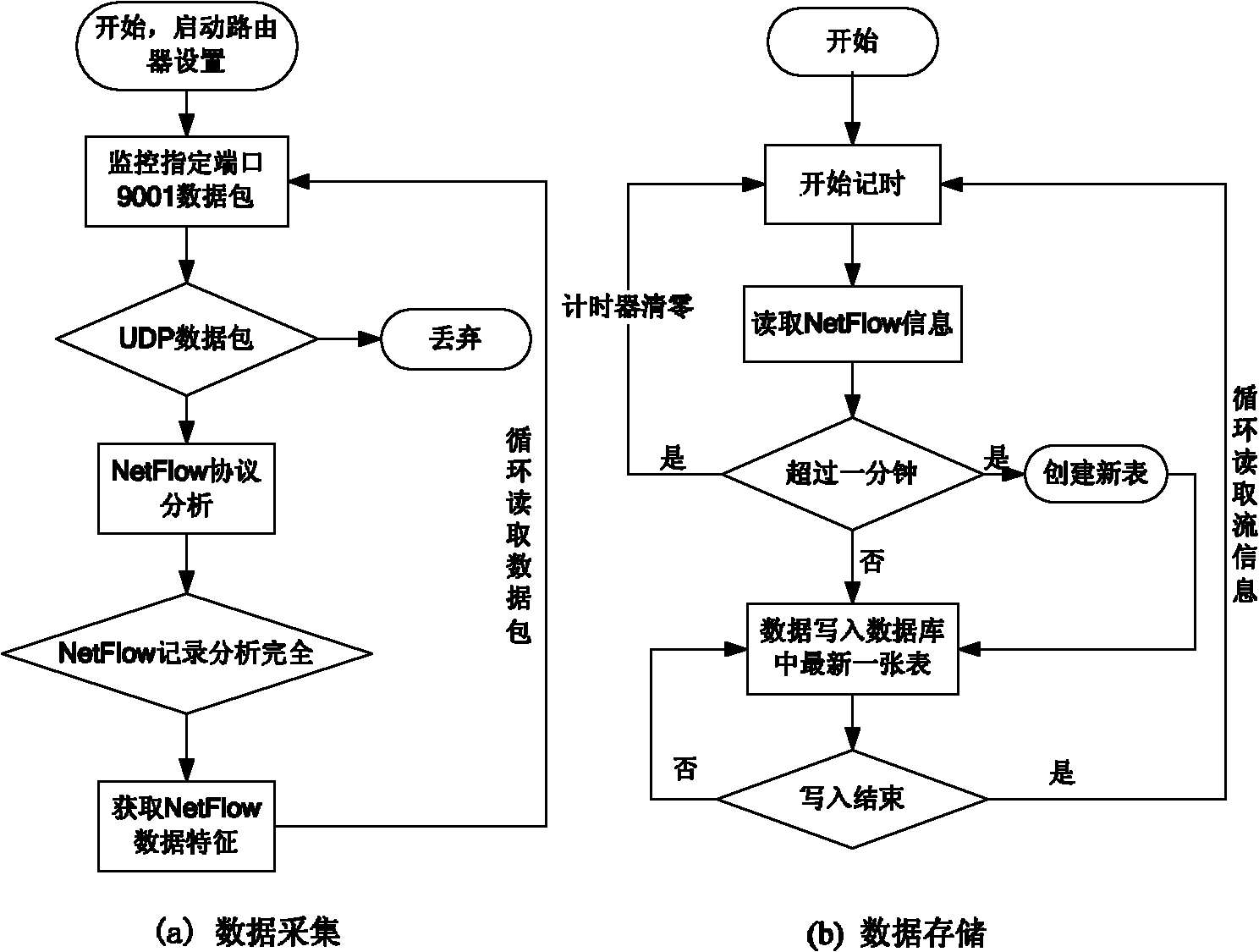

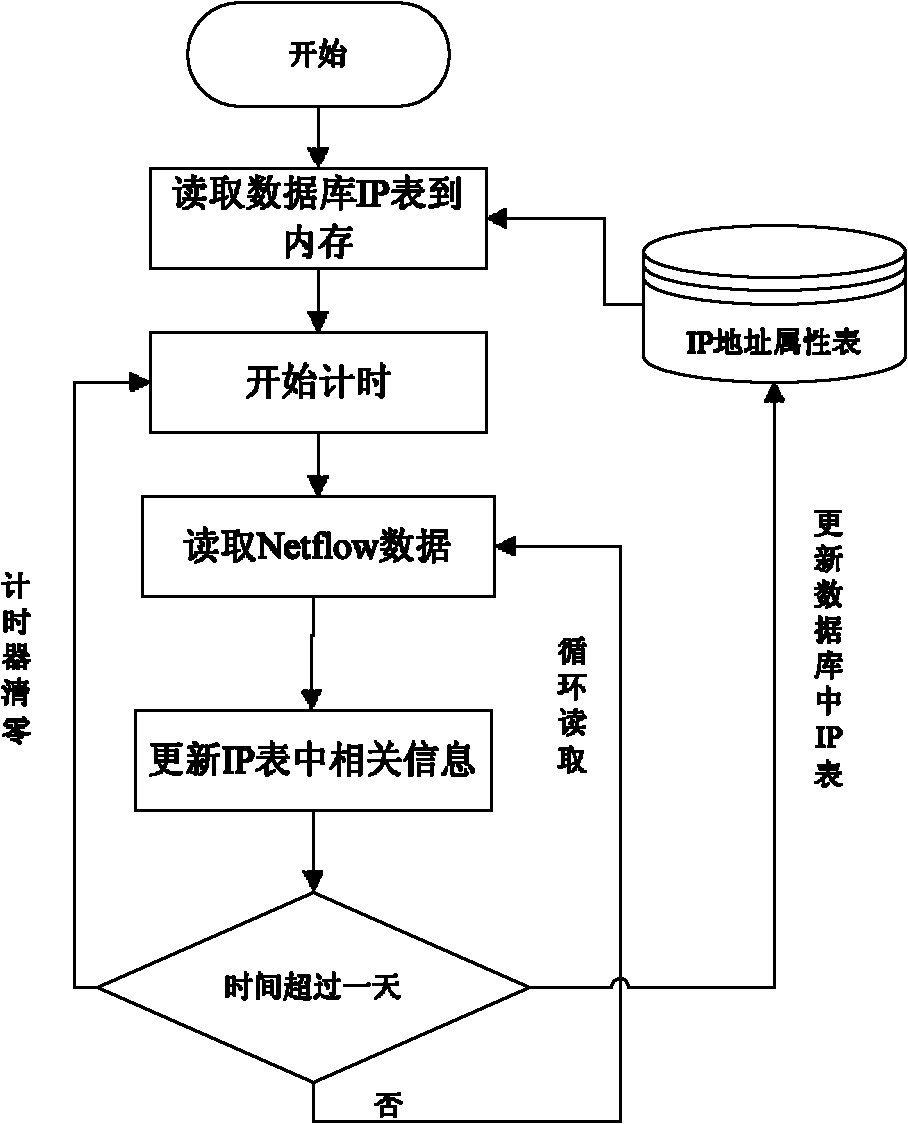

User action monitoring system and method based on IP address attribute

The invention discloses user action monitoring system and method based on an IP address attribute. The monitoring of the user action is completed by coordinating four parts of an off-line basic data acquiring data, an on-line data real-time analysis module, a data centre and an analysis module. The method comprises the following steps of: firstly proposing a concept of a significant IP address and acquiring the significant IP address by using a combined method of active and passive monitoring; and then proposing to use a service type and a geographic position as attributes of the IP address, and building an IP address attribute information library by combining the screened significant IP address. In order to comprehensively reflect the characteristic of a network user action, the characteristics of user action on the time and the space can be described by using multiple action maps, and the analysis of characteristics, such as aggregation, association, similarity, periodicity, migration, and the like, of the user action can be realized on the basis of building the action maps to further know demands and access characteristics of the network users, and the monitoring to network access is effectively enhanced.

Owner:XI AN JIAOTONG UNIV

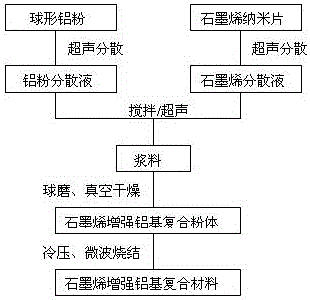

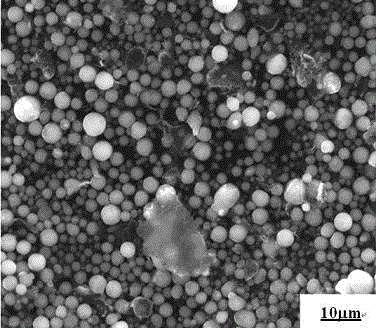

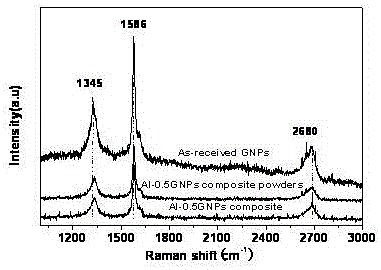

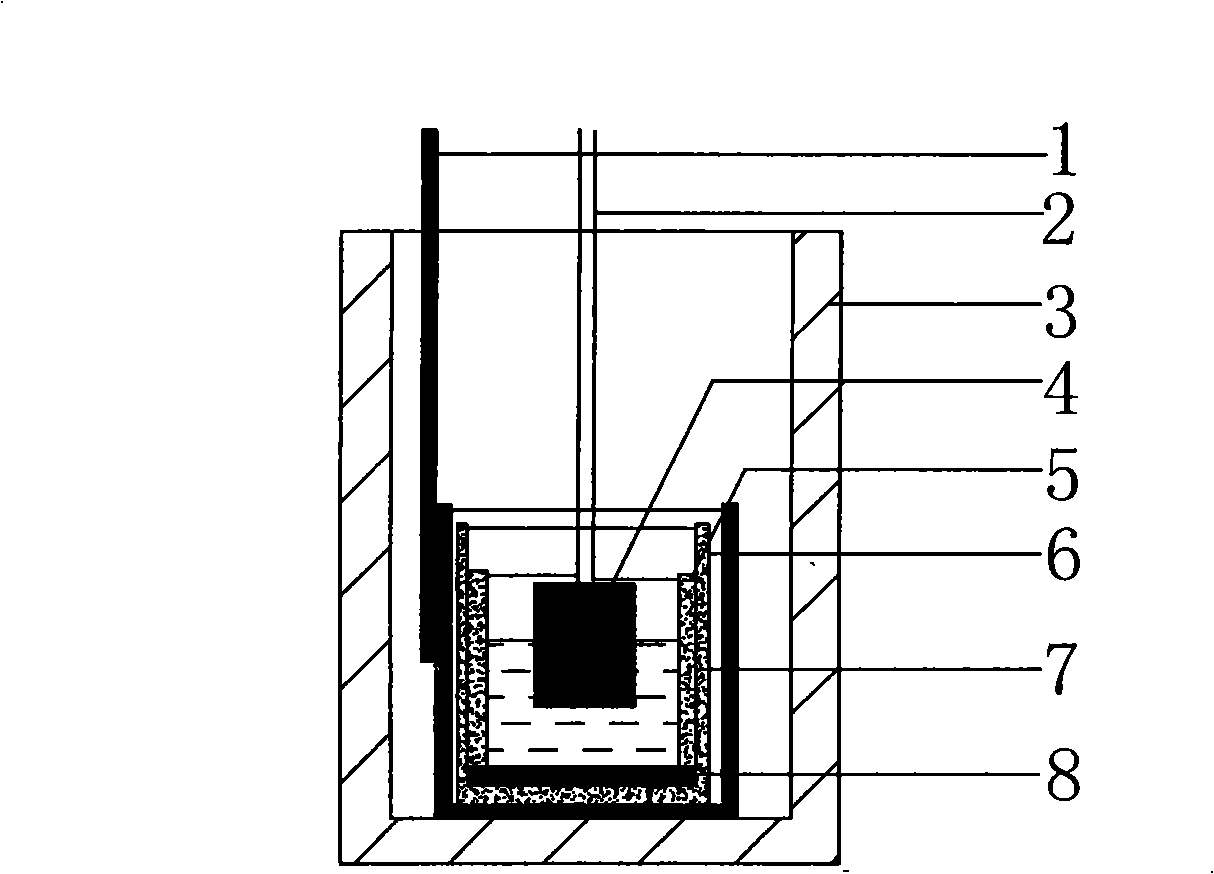

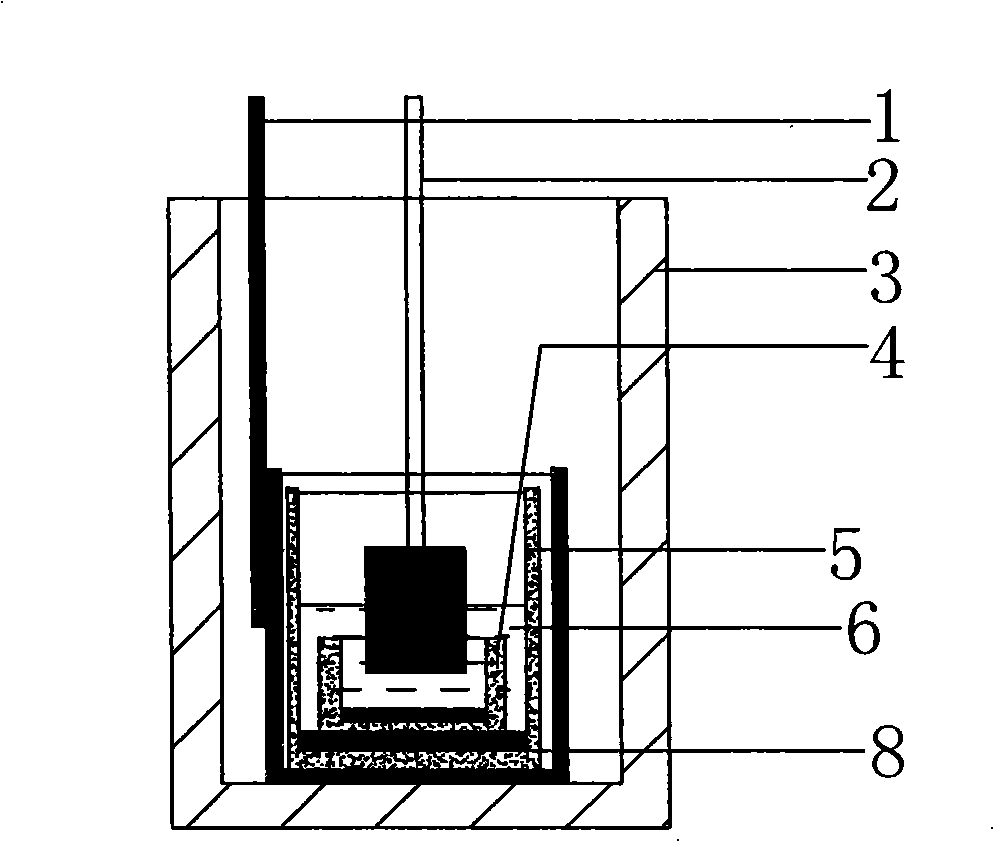

Method for preparing graphene reinforced aluminum matrix composite material by microwave sintering

The invention discloses a method for preparing a graphene reinforced aluminum matrix composite material by microwave sintering, comprising the steps of: taking graphene nano microchips and aluminum powder as raw materials, carrying out ultrasonic treatment to respectively prepare graphene dispersion liquid and aluminum powder dispersion liquid; mixing the two kinds of dispersion liquid, and carrying out low temperature ball milling, vacuum drying, press forming and microwave sintering to obtain the graphene reinforced aluminum matrix composite material with high density, high strength and high thermal conductivity. The method adopts an ethanol ultrasonic dispersion and ball milling combined method to enable the graphene to evenly disperse in the aluminum matrix, and adopts a microwave sintering technology, thus shortening the preparation time and being highly efficient and energy-saving; the production process is safe and pollution-free, and simultaneously the prepared graphene reinforced aluminum matrix composite material has high density and good heat-conducting property.

Owner:NANCHANG HANGKONG UNIVERSITY

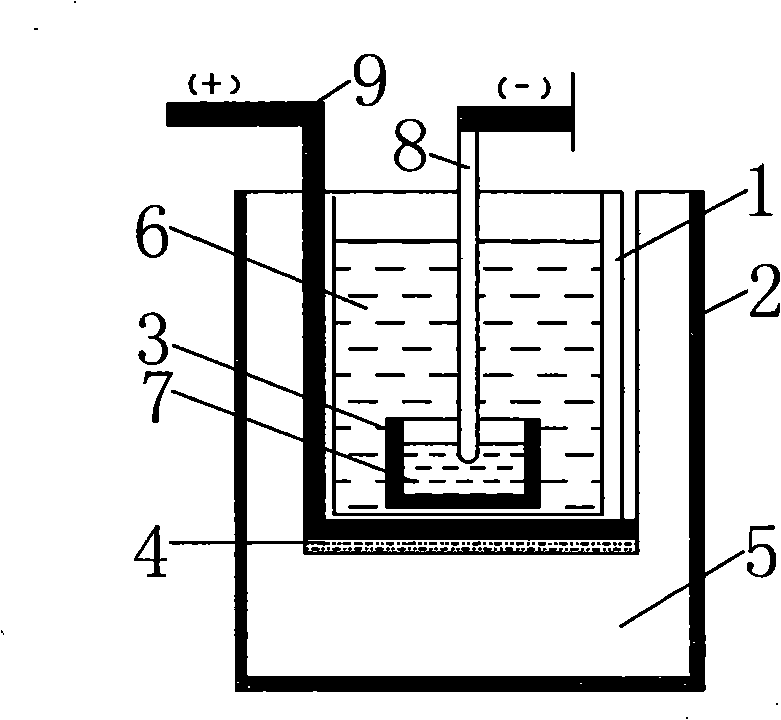

Process for preparing metallic titanium and titanium master alloy

The invention relates to the non-ferrous metal metallurgy fused salt electrolysis field, a method mainly comprises the steps of: preparing titanium dioxide, titanium tetrachloride, titanium dichloride and fluotitanate as raw materials, electrolyzing one or a plurality of combinations of TiO2, TiC14 and the fluotitanate in an electrolysis bath, preparing metallic titanium or titanium-based master alloy through an electrolysis method or a thermal reduction-electrolysis combined method, performing the TiO2 and connecting direct current to deoxidize or adopting metal (or metallic compound) for heat reducing the TiO2 beforehand, preparing the metallic titanium which contains oxygen (O) with certain concentration, and then electrolyzing aluminium, alkali metal, alkaline earth, rare earth metal, metallic copper, metallic zinc or metallic lead to deoxidize finally in the electrolysis bath. The purpose of the method is to reduce the production cost of the metallic titanium, simplify the production procedures and lower the environmental pollution in the production process, especially the titanium dioxide taken as the raw materials, the production flow is shortened, the storage and the transportation are convenient, none chlorine gas takes part in the reaction, and green metallurgy of the metallic titanium can be realized.

Owner:曹大力 +1

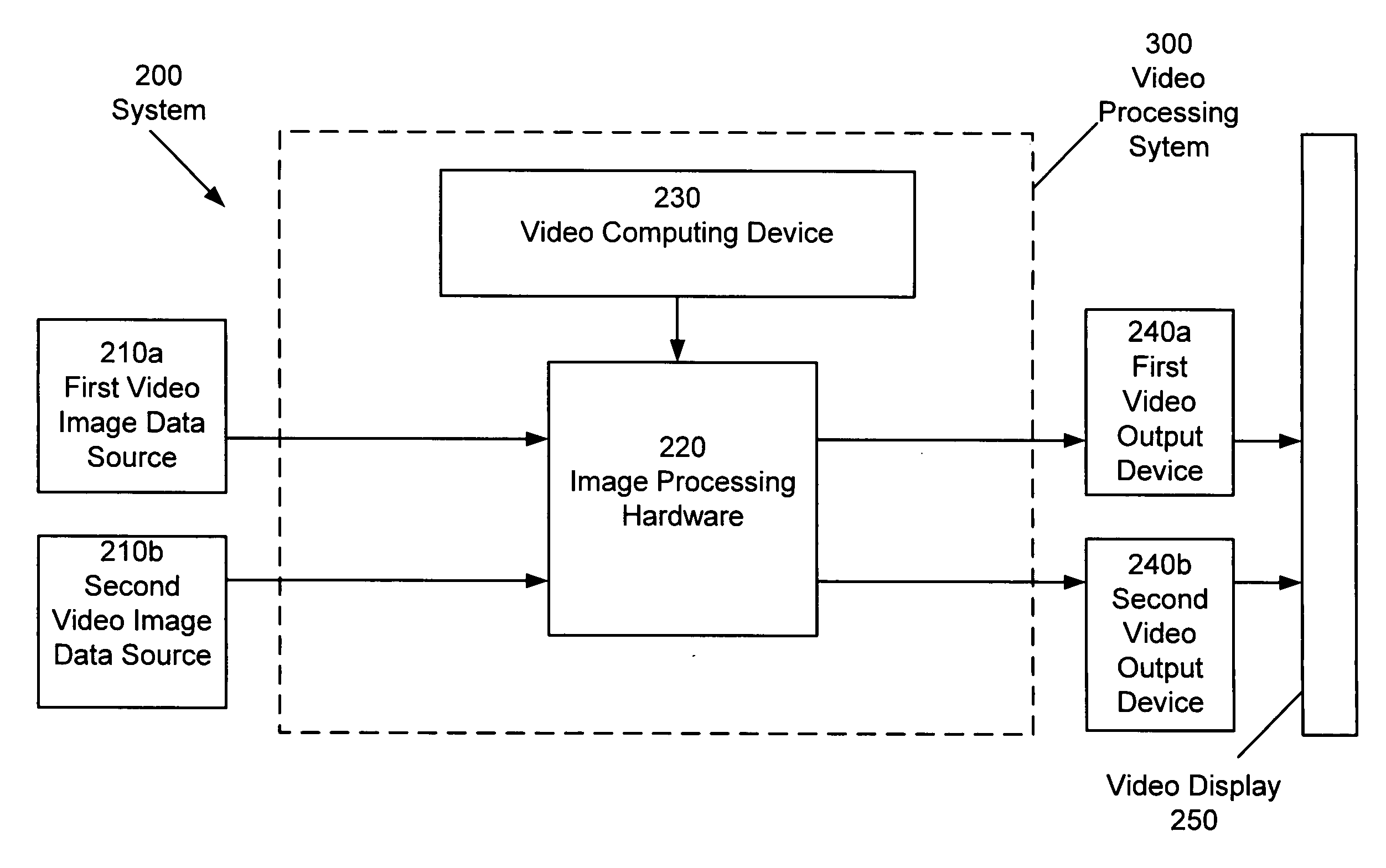

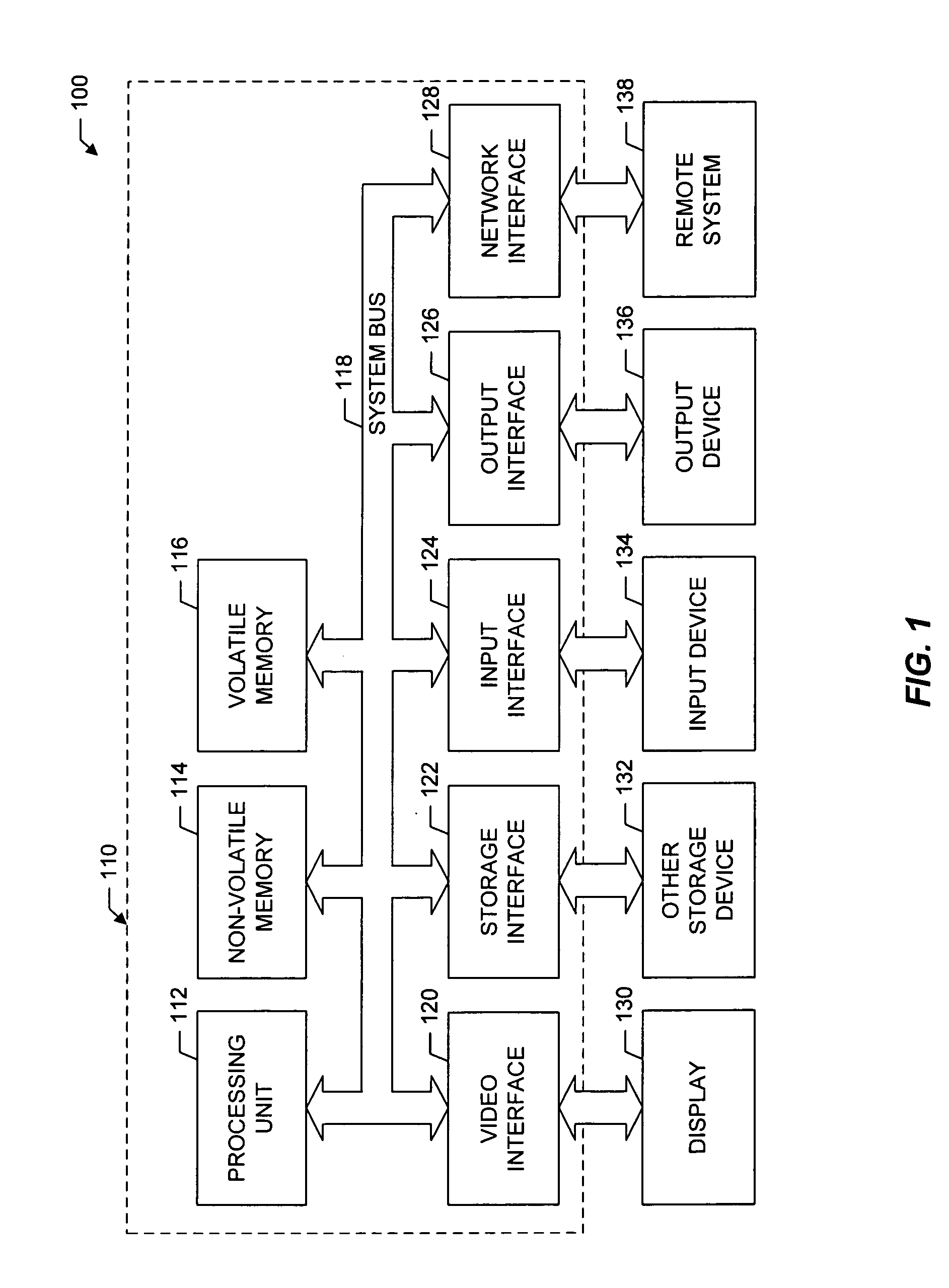

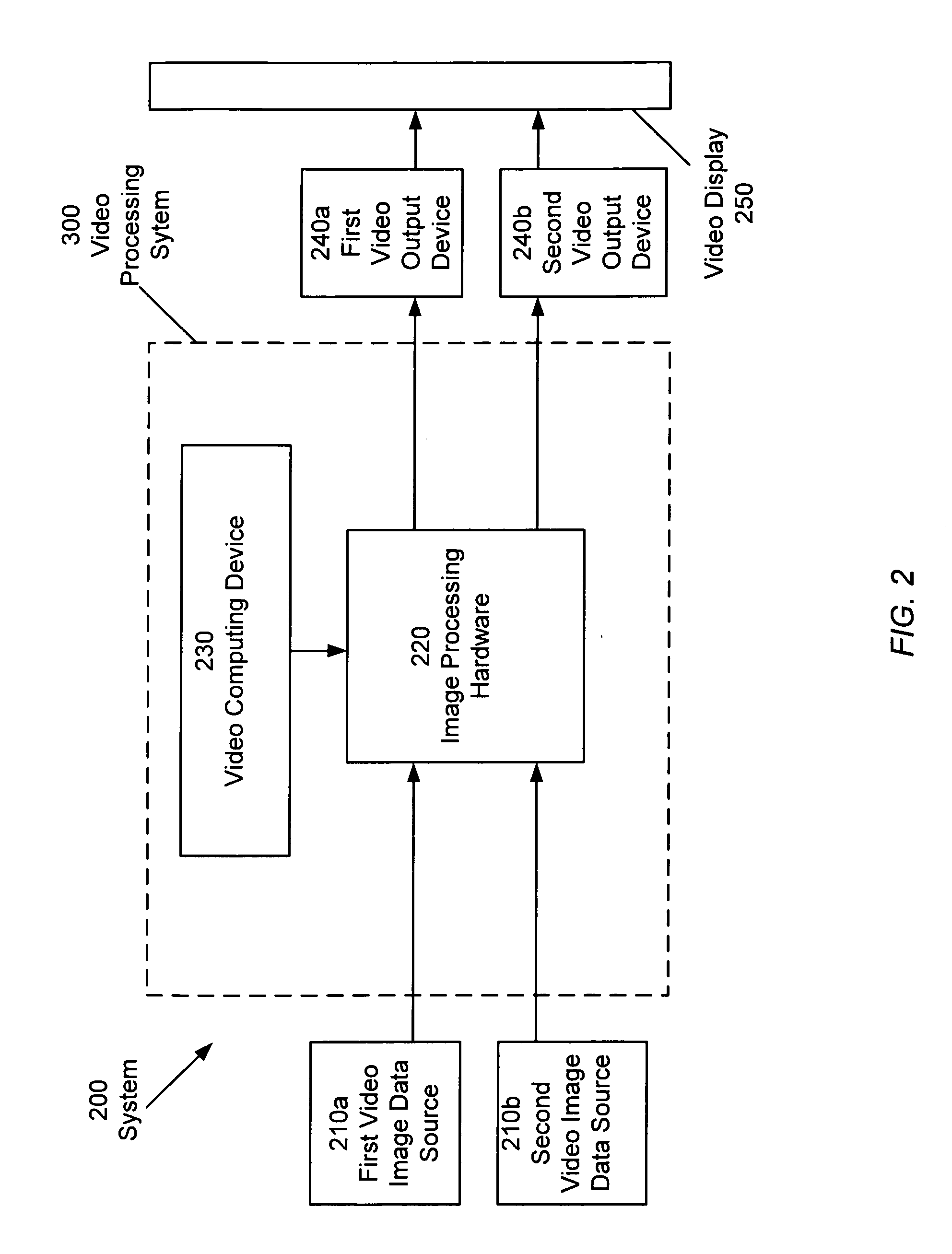

Method And System For Combining Images Generated By Separate Sources

InactiveUS20090147004A1Accurate interpolationEliminate the problemGeometric image transformationCathode-ray tube indicatorsCombined methodData source

A system and method for combining images generated by separate sources. The system comprises a plurality of video image data sources that generate separate video images. The video images are captured and scaled by image processing hardware to fit within the viewports of a target window generated by a computing device. The parameters of the viewports are associated with the parameters of the target window such that changes to the target window result in corresponding changes to the viewports. The method comprises scaling the separate images to fit within the viewports using redundant data within each video image to interpolate pixel data at the boundary regions of adjacent images to eliminate artifacts at the boundary regions.

Owner:BARCO NV

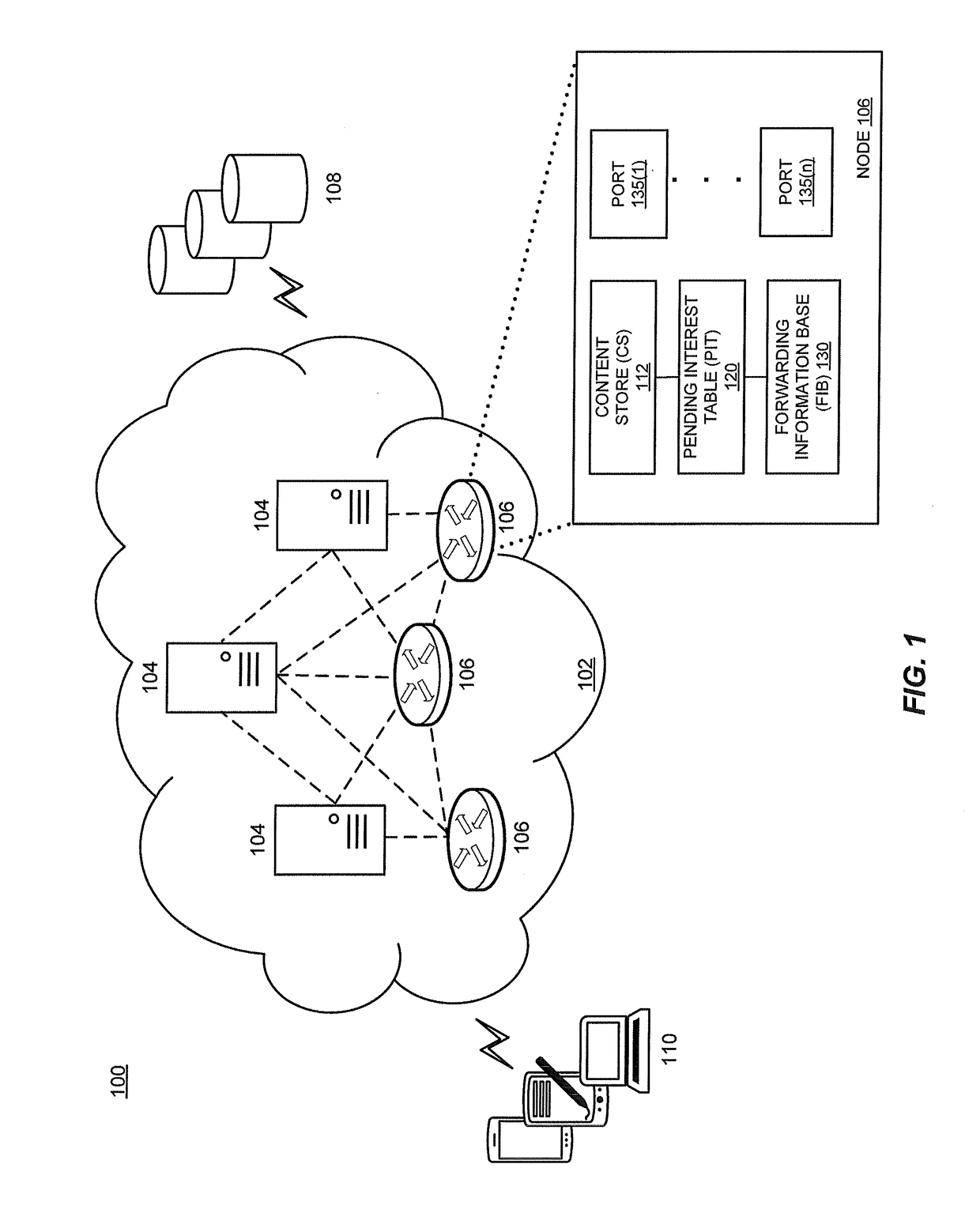

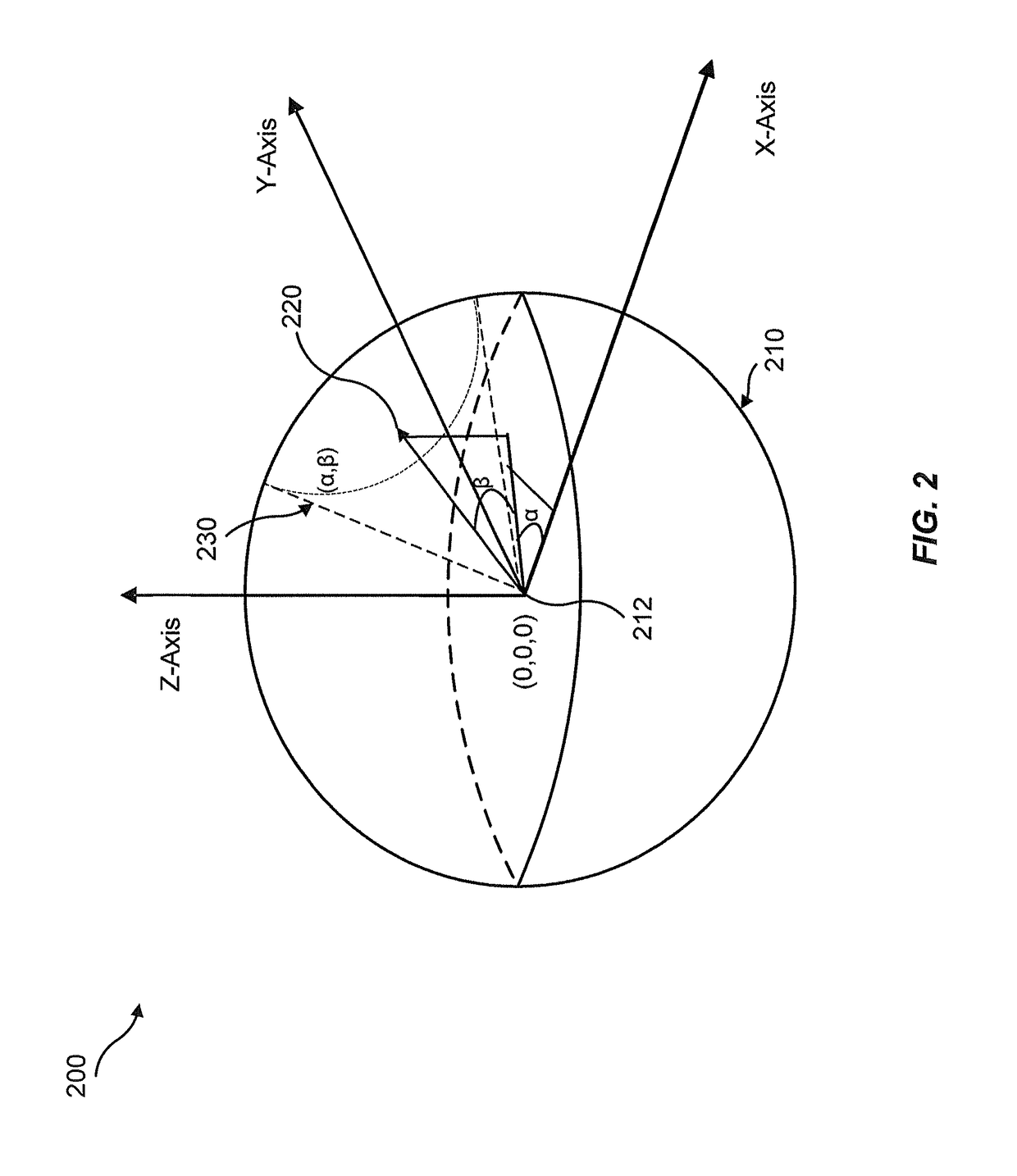

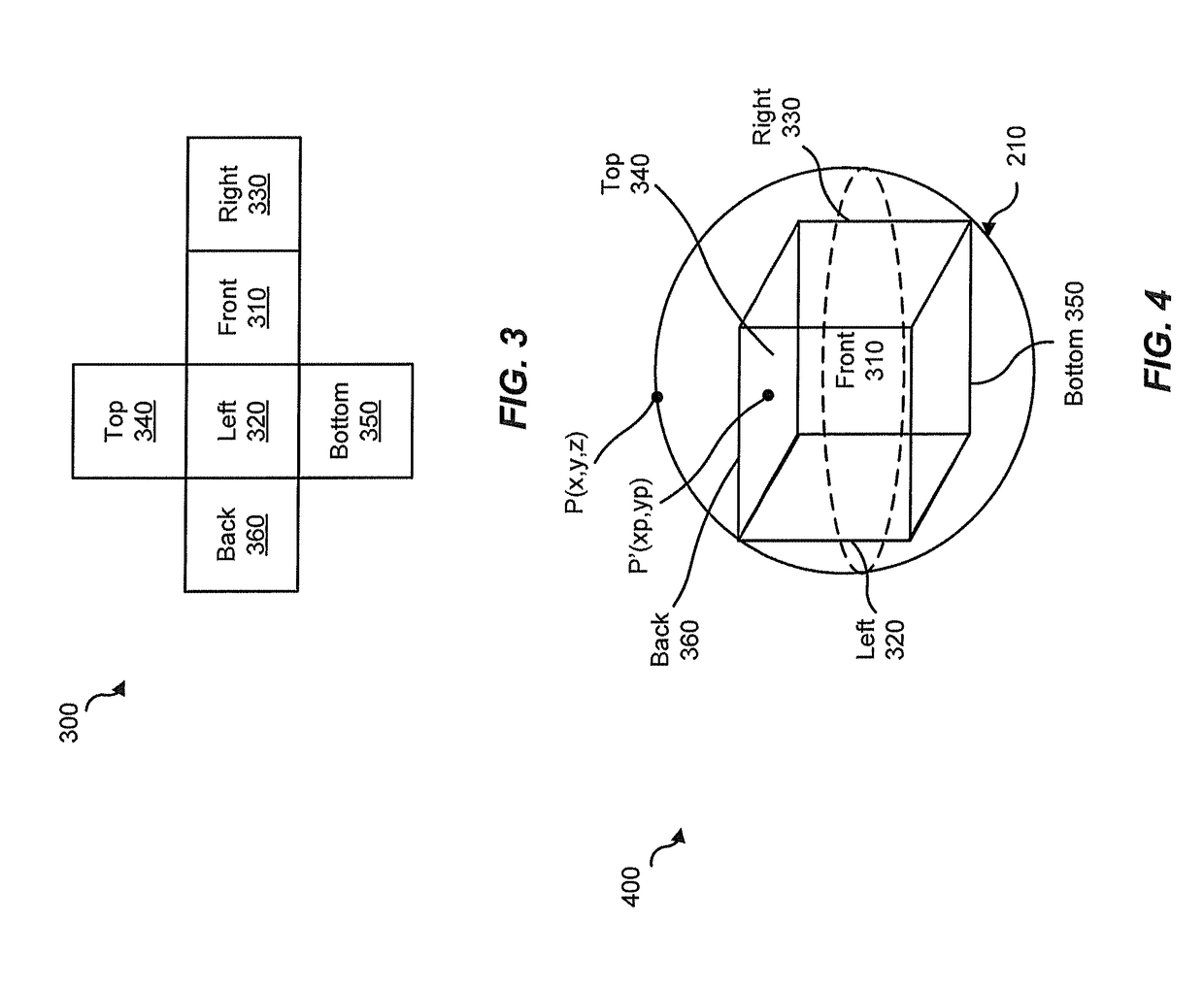

Combined method for data rate and field of view size adaptation for virtual reality and 360 degree video streaming

ActiveUS20190089643A1Well formedTelevision system detailsColor television detailsData rateCombined method

The disclosure relates to technology for a 360 degree video stream in a network. A network round trip time (RTT) is measured for a requested FoV of the 360 degree video stream, where the RTT indicates a time interval between sending a FoV interest message and receiving a response message in reply to the requested FoV. The network bandwidth is measured for the requested FoV of the 360 degree video stream, where the measured network bandwidth represents an amount of data the network transmits in the response message. A future FoV of the 360 degree video stream is then determined based on the requested FoV, the measured network bandwidth and the measured network RTT, and a video stream is prefecthced for the future FoV of the 360 degree video stream.

Owner:FUTUREWEI TECH INC

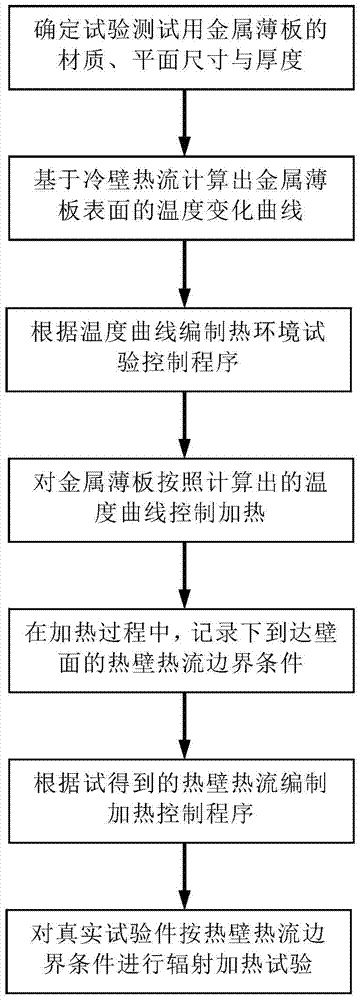

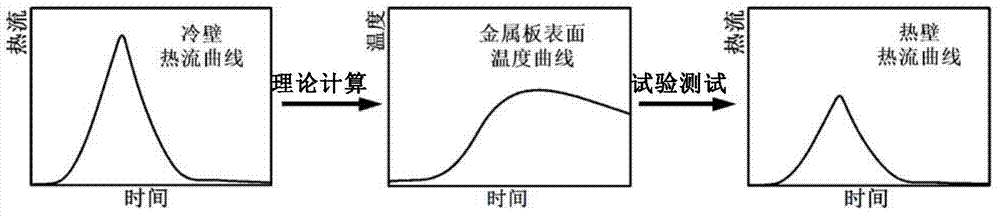

Method for converting cold wall heat flux into hot wall heat flux in aerodynamic heat simulating test

InactiveCN104267062AReliable measurementAvoid temperature measurementMaterial heat developmentThin metalHeat flow

The invention provides a method for converting cold wall heat flux into hot wall heat flux in an aerodynamic heat simulating test. The method comprises the following steps: firstly, calculating a temperature change curve for the surface of a thin metal plate according to a cold wall heat flux boundary condition; secondly, heating the thin metal plate test piece according to the calculated temperature curve, and recording a hot wall heat flux curve for the surface of a heat flux sensor in the same plane of the thin metal plate under the temperature condition, namely by a combined method of theoretical calculation and an experimental test, finally obtaining a hot wall heat flux boundary condition which corresponds to the cold wall heat flux boundary condition and is difficultly determined by a computer. The invention provides a practicable hot wall heat flux determining method for a radiant aerodynamic heat simulating test on a high-speed aircraft.

Owner:BEIHANG UNIV

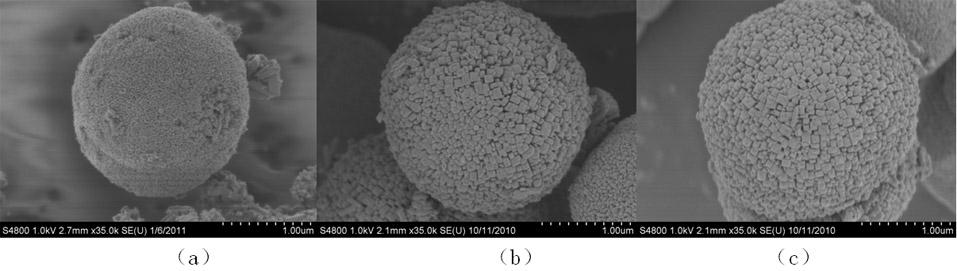

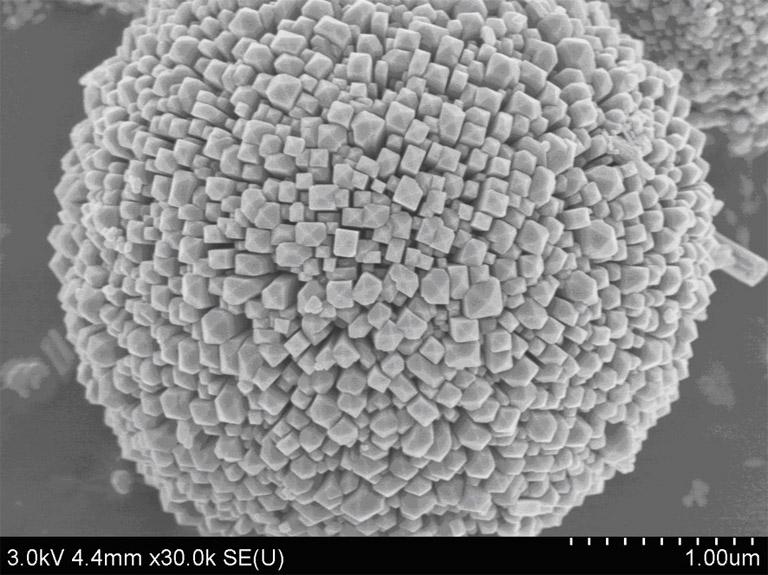

Silver-carrying titanium dioxide anti-bacterial agent and preparation method thereof

InactiveCN102205244AEnhance photocatalytic antibacterial effectReduce compoundingBiocideFungicidesMicrosphereCombined method

The invention belongs to the technical field of environmental catalytic materials and specifically relates to a preparation method of a silver-carrying titanium dioxide anti-bacterial agent. The anti-bacterial agent comprises titanium dioxide microspheres as carriers with a high length-diameter ratio and silver particles distributed on surfaces or interiors of the titanium dioxide microspheres. The preparation method comprises a titanium dioxide microsphere preparation method and a silver particle carrying method, wherein the silver particle carrying method adopts the following three methods of a complex reaction and photo-reduction combined method, a direct photo-reduction method and an excessive immersion method. The operation of the present preparation method is simple. Titanium dioxide carriers prepared by the present preparation method has a high length-diameter ratio, a high crystallinity and thus can reduce effectively recombination of electrons and holes and enhance titanium dioxide photocatalytical and anti-bacterial effects, and the silver particle carrying method can effectively control a dispersibility of silver and make silver be distributed on surfaces or interiors of titanium dioxide microspheres to realize a slow release of silver, avoid color change, and enhance anti-bacterial effects simultaneously.

Owner:FUDAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com