Patents

Literature

10664 results about "Twin screw extruder" patented technology

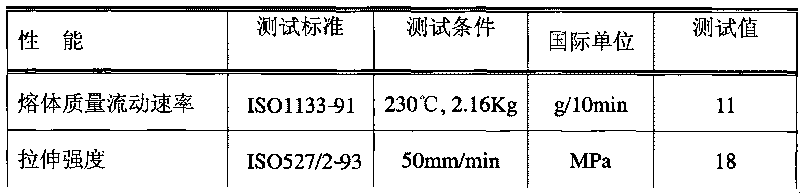

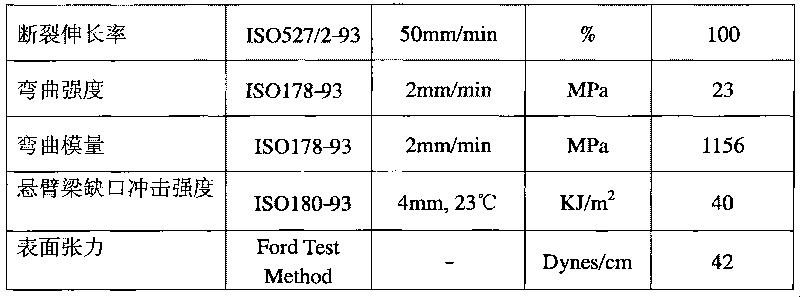

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Long glass fiber reinforced polypropylene material and preparation thereof

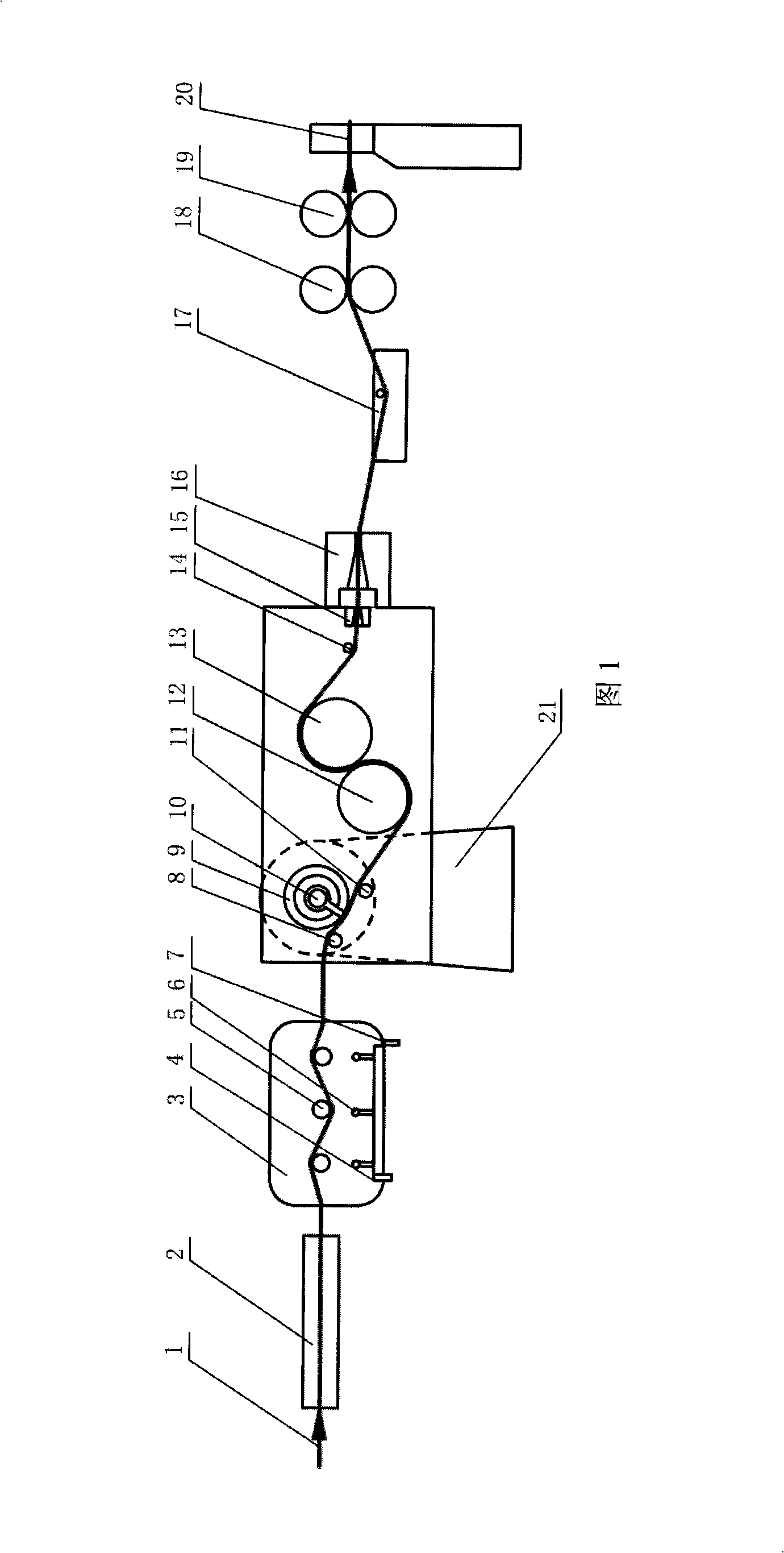

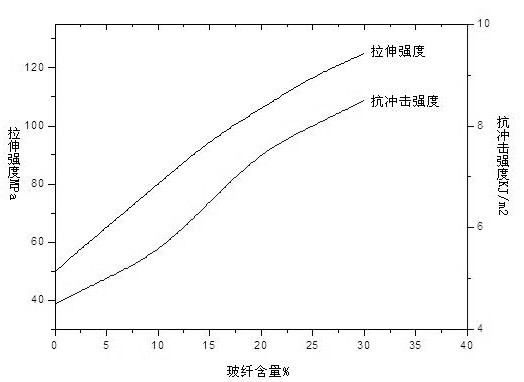

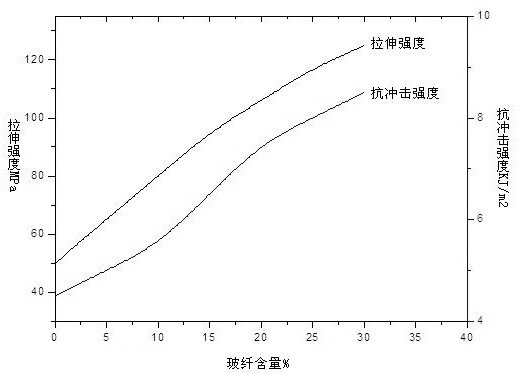

The invention provides a long glass fiber reinforced polypropylene material and a preparation method thereof. The mass ratio of the material components is: 35 percent to 55 percent of polypropylene, 35 percent to 50 percent of long glass fibers, 0.3 percent to 0.8 percent of coupling agents, 5 percent to 10 percent of compatilizers, 2 percent 4 percent of flow modifiers, 0.3 percent to 0.6 percent of antioxidants and 1 percent to 2 percent of lubricants. The invention has the process that the polypropylene, the flow modifiers, the compatilizers, the antioxidants and the lubricants are mixed firstly, then the mixture is added into a double screw extruder, and the processing temperature is 180 DEG C to 230 DEG C; a molten bath is formed by extruding melts from the extruding die of the extruder; the continuous long glass fibers are preheated for drying, and the surfaces of the long glass fibers are processed; later, a soakage device is introduced to lead a plurality of strands of the long glass fibers into the molten bath so that the long glass fibers are completely soaked and then is bundled to be packaged, and finally, the long glass fibers are discharged from a bell-mouthed die head outlet to be cooled and cut into granules to obtain the long glass fiber reinforced polypropylene granule materials. The invention has simple and practical process and favorable product performance.

Owner:SUZHOU HECHANG POLYMERIC MATERIALS

Fusion preparation method of polyvinyl alcohol film

InactiveCN101864132ALower melt processing temperatureSolving Melt Processing ProblemsFlat articlesPlasticizerPVA - Polyvinyl alcohol

The invention discloses a fusion preparation method of a polyvinyl alcohol film, which comprises the steps of mixing 100 parts by weight of polyvinyl alcohol, 10-45 parts by weight of small molecular plasticizer, 3-15 parts by weight of polymeric plasticizer, 1-5 parts by weight of processing agent, and 0.01-5 parts by weight of inorganic nanofiller, putting the components into a double-screw extruder, and fusing and plasticizing at the temperature of 140-250 DEG C and the screw rotate speed of 50-200rpm to directly extrude to form films or extrude to form films via fusing and plasticizing after pelleting. By choosing reasonable small molecular and polymeric compound plasticizers and inorganic nanofillers, the invention effectively reduces the fusing processing temperature of PVA, and solves the fusing processing problem of polyvinyl alcohol which has high molecular weight and high alcoholysis degree and is difficult to dissolve in water at normal temperature, and the obtained film has high transparency and good mechanical properties, is environmental-friendly, is non-toxic, and can be used for packaging a variety of products.

Owner:SICHUAN UNIV

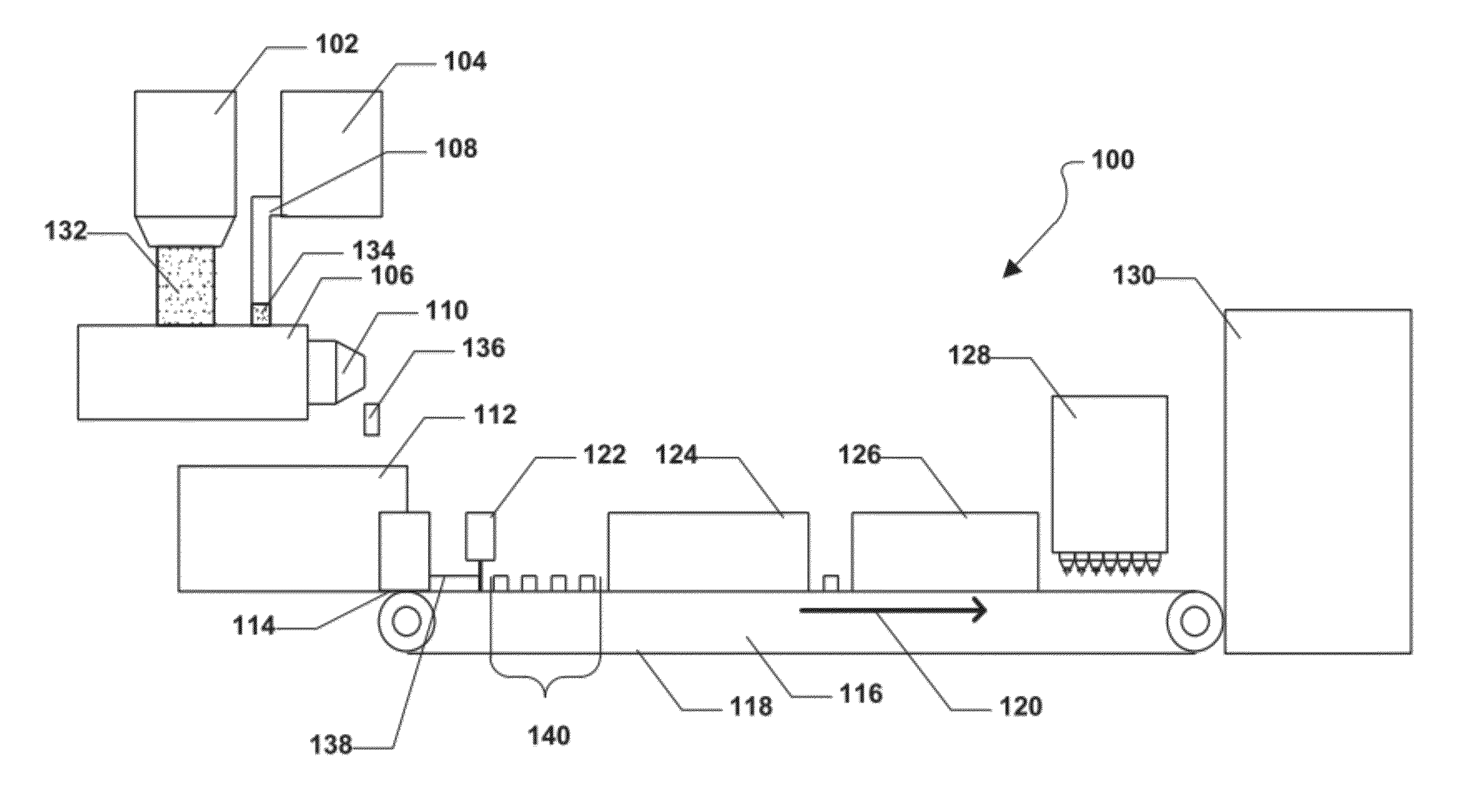

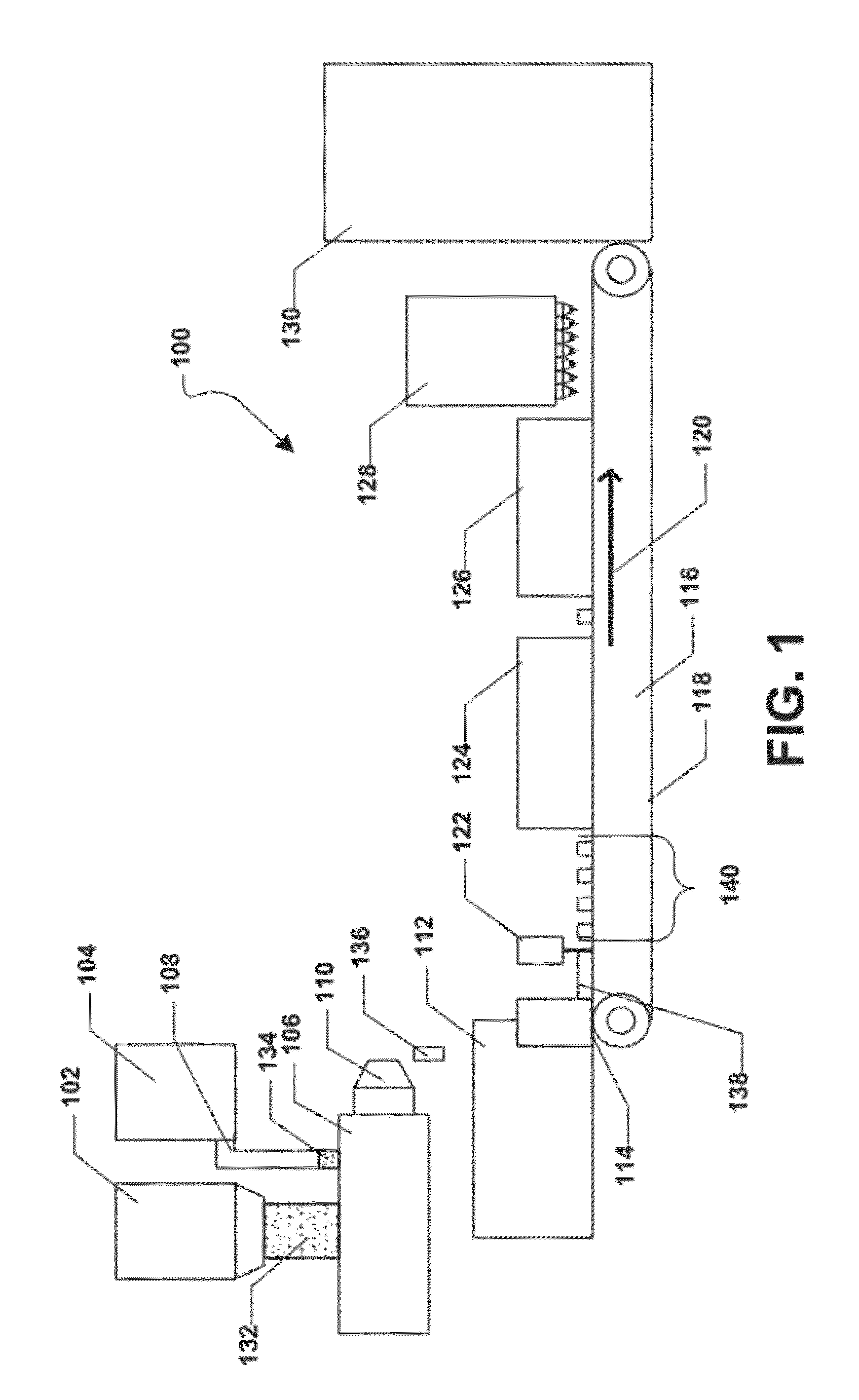

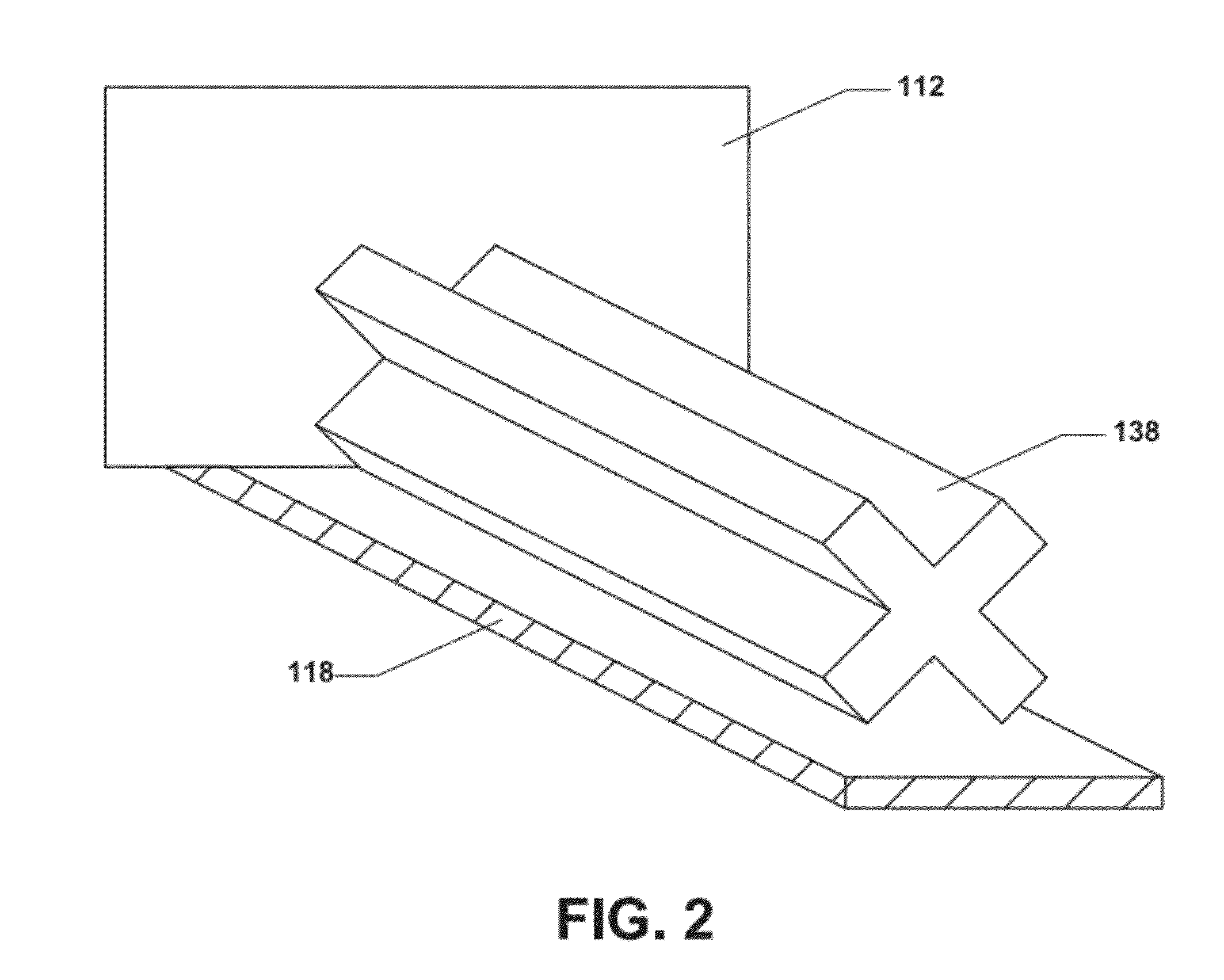

Method of forming a shaped abrasive particle

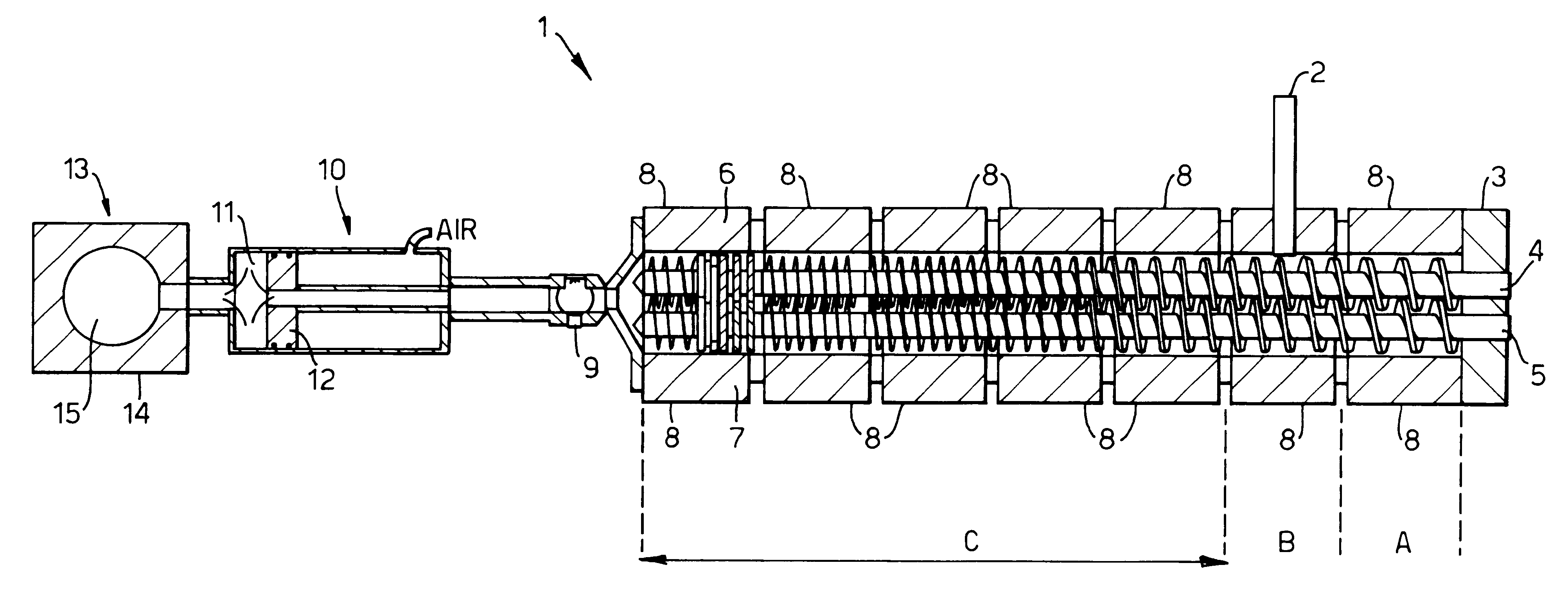

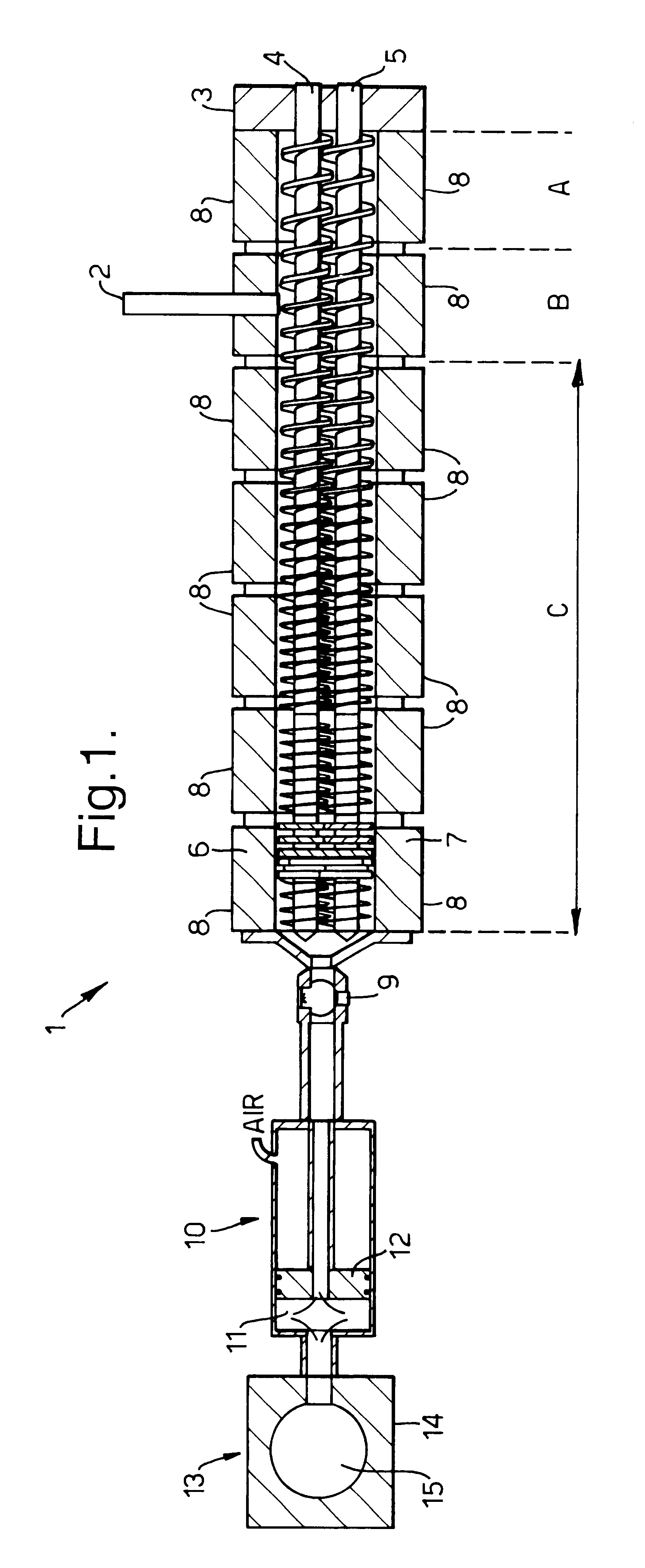

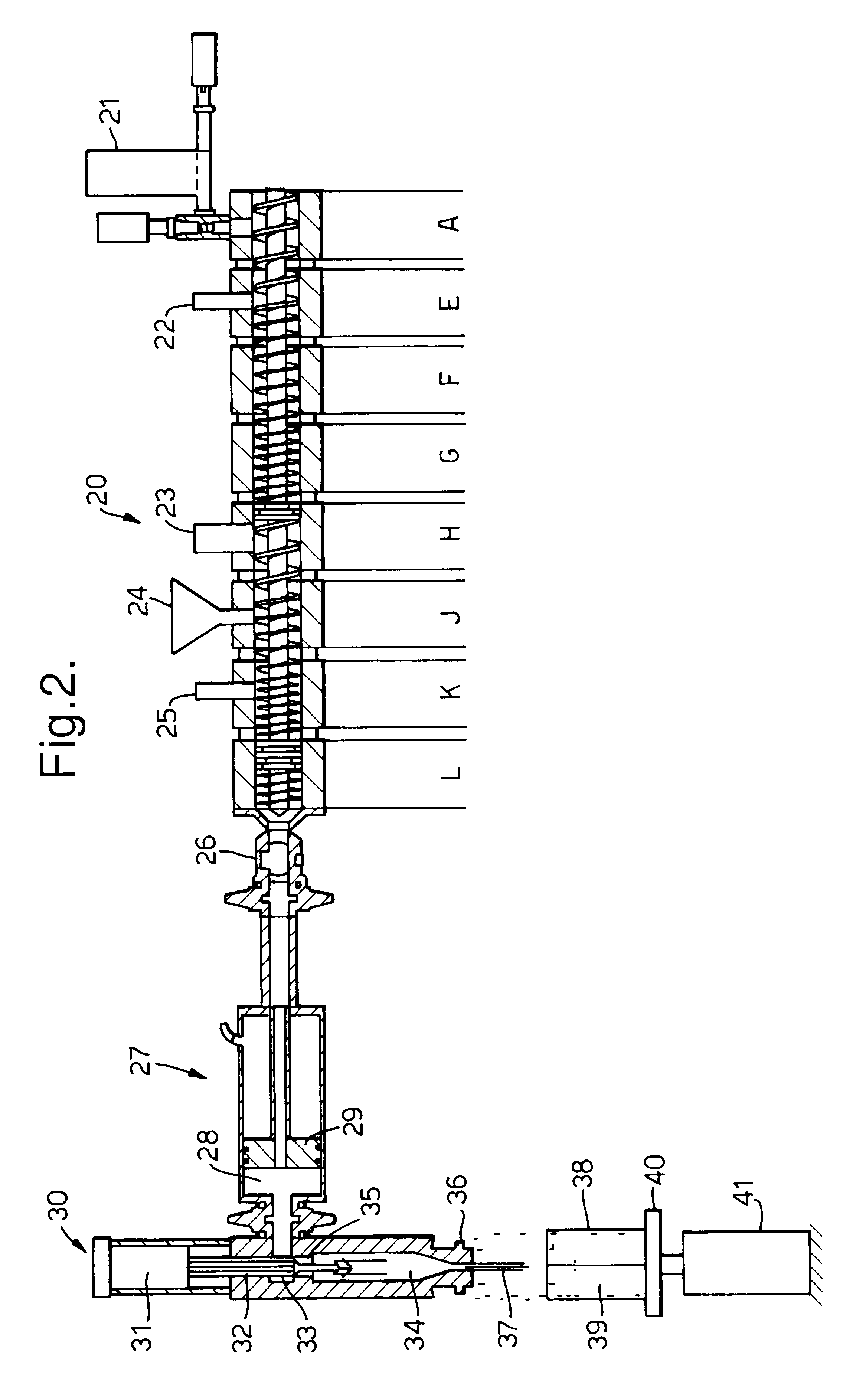

A method for making abrasive grains, the method comprising mixing one or more solids with one or more liquids in a twin screw extruder to form a mixture, transferring the mixture to a high pressure piston extruder; and extruding the mixture from the high pressure piston extruder through a die to form an extrude. The method further includes segmenting the extrudate to form extruded shaped abrasive particles.

Owner:SAINT GOBAIN CERAMICS & PLASTICS INC

Highly heat-conducting insulation engineering plastic and preparation method thereof

InactiveCN102174254AIncrease China UnicomImprove thermal conductivityPlastic/resin/waxes insulatorsHeat-exchange elementsFiberAntioxidant

The invention discloses highly heat-conducting insulation engineering plastic, which consists of the following components in part by weight: 100 parts of plastic substrate, 100 to 900 parts of heat-conducting filler, 1 to 45 parts of compatibilizer, 1 to 90 parts of toughening agent, 1 to 45 parts of reinforcing agent, 1 to 36 parts of lubricating agent and 0.3 to 5.4 parts of antioxidant. The invention also discloses a preparation method of the engineering plastic, which comprises the following steps of: drying the plastic substrate and the heat-conducting filler in a 60 to 100 DEG C air dry oven for 4 to 8 hours; putting the components into a high-speed mixer and mixing for 3 to 5 minutes; performing internal mixing on the mixture in an internal mixer for 10 to 30 minutes; and uniformly grinding the mixture in a grinder, transferring to a charging hopper of a double-screw extruder, feeding fiber fillers through a fiber inlet of the double-screw extruder, melting, mixing, extruding, cooling, drying, and pelletizing. The prepared material has high heat-conducting property and mechanical property, and is easily subjected to injection molding.

Owner:GUANGDONG JANUS SMART GRP CO LTD

Polyhydroxylkanoates as well as blending modification for copolymer thereof and polylactic acid

The invention discloses a PHBV with good performance and a copolymer of PHBV and PLA and the preparation technique method. The invention is characterized in that 1 per cent to 99 per cent of PHAs, 1 per cent to 99 per cent of PLA1 and other additives 0-40 per cent are put in a mixer for 1 to 30 minutes, and then put in an electricity hot blast drying oven a temperature ranging from 40 to 100 DEG C for 2 to 48 hours after being mixed equally. The dried compound is plastified in a double screw extruder, the highest temperature of the double screw extruder is between 90 and 180 DEG C according to the the different content of PHAs and the temperature of the mouth mold is between110 to 170 DEG C. The material extruded from a die head is cooled, stretched and grained to form the complete biodegradation aggregate. The resin consisting of PHBV and copolymer of PHBV and PLA is able to be used for producing the thin films, plates and sheet materials and injected mold to plastic materials. The compound has biological degradability and good machining performance. The target product of the compound has excellent mechanical properties and can be used for replacing the petroleum base plastic to be widely used for packing, agriculture, medical material, electron, chemical industry concerning products for daily use, etc.

Owner:深圳市奥贝尔科技有限公司

Flame-retardant polyester material with high glow wire ignition temperature and preparation method thereof

ActiveCN102250450AGWIT performance improvementsMeet performance requirementsPolyester resinUltimate tensile strength

The invention discloses a fame-retardant polyester material with a high glow wire ignition temperature and a preparation method thereof. The flame-retardant polyester material with a high glow wire ignition temperature is composed of the following components in parts by weight: 100 parts of polyester resins, 15-50 parts of bromine-series flame retardant, 5-20 parts of synergistic flame retardant, 0-20 parts of toughening agent, 0-80 parts of carbon forming agent, 5-40 parts of hot oxygen barrier agent, 0-120 parts of fibrous reinforcing agent and 0-10 parts of processing aid. The preparation method of the flame-retardant polyester material with a high glow wire ignition temperature comprises: drying the polyester resins, mixing with other components to obtain a premixed material, then feeding the premixed material into a twin-screw extruder, melting and plasticizing, kneading and mixing, extruding, drawing, cooling, pelletizing, drying and finally packaging. The flame-retardant polyester material with a high glow wire ignition temperature has the advantages of low cost, high glow wire ignition temperature, similar mechanical strength to ordinary flame-retardant polyester and wide application range.

Owner:KINGFA SCI & TECH CO LTD +1

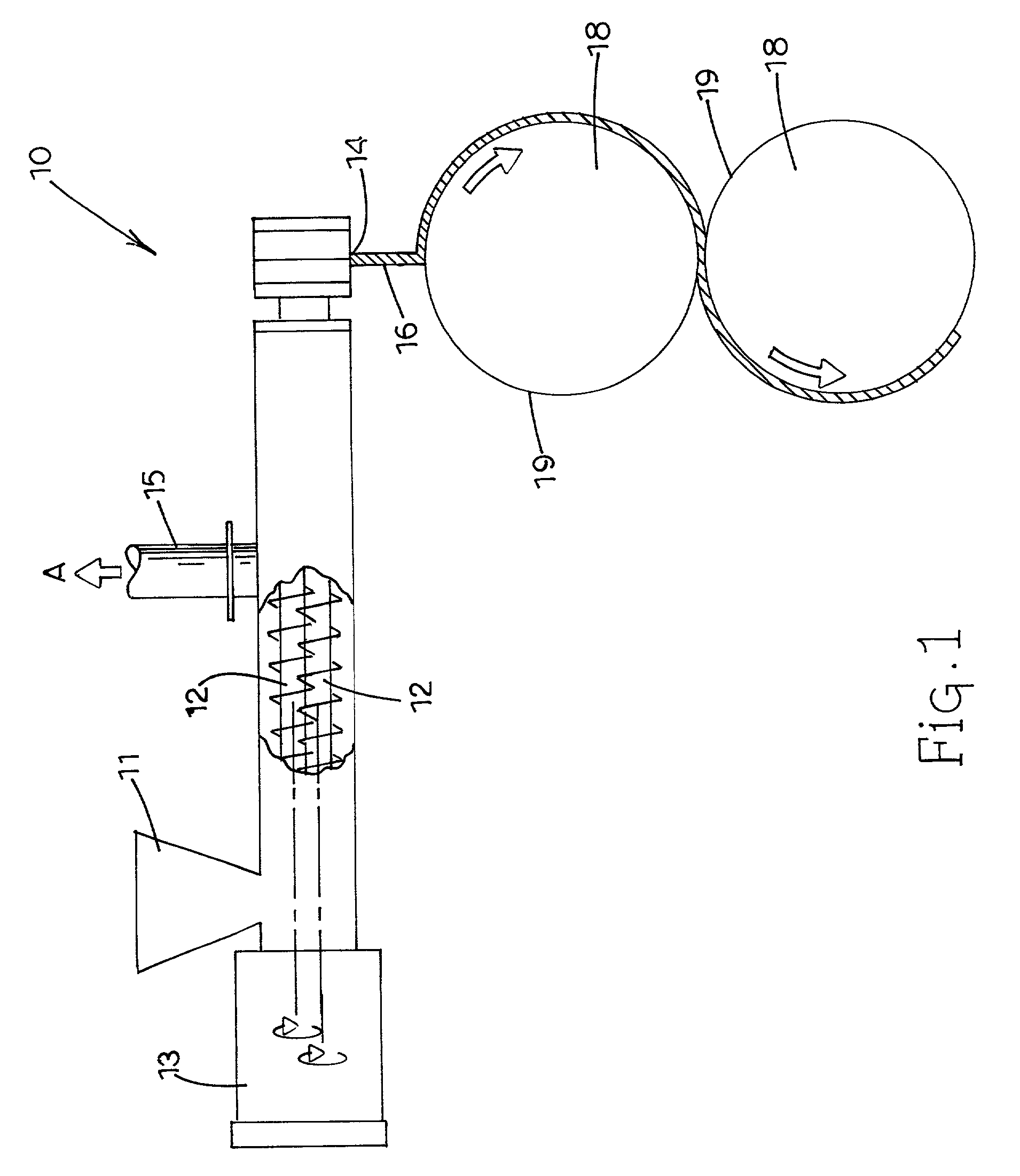

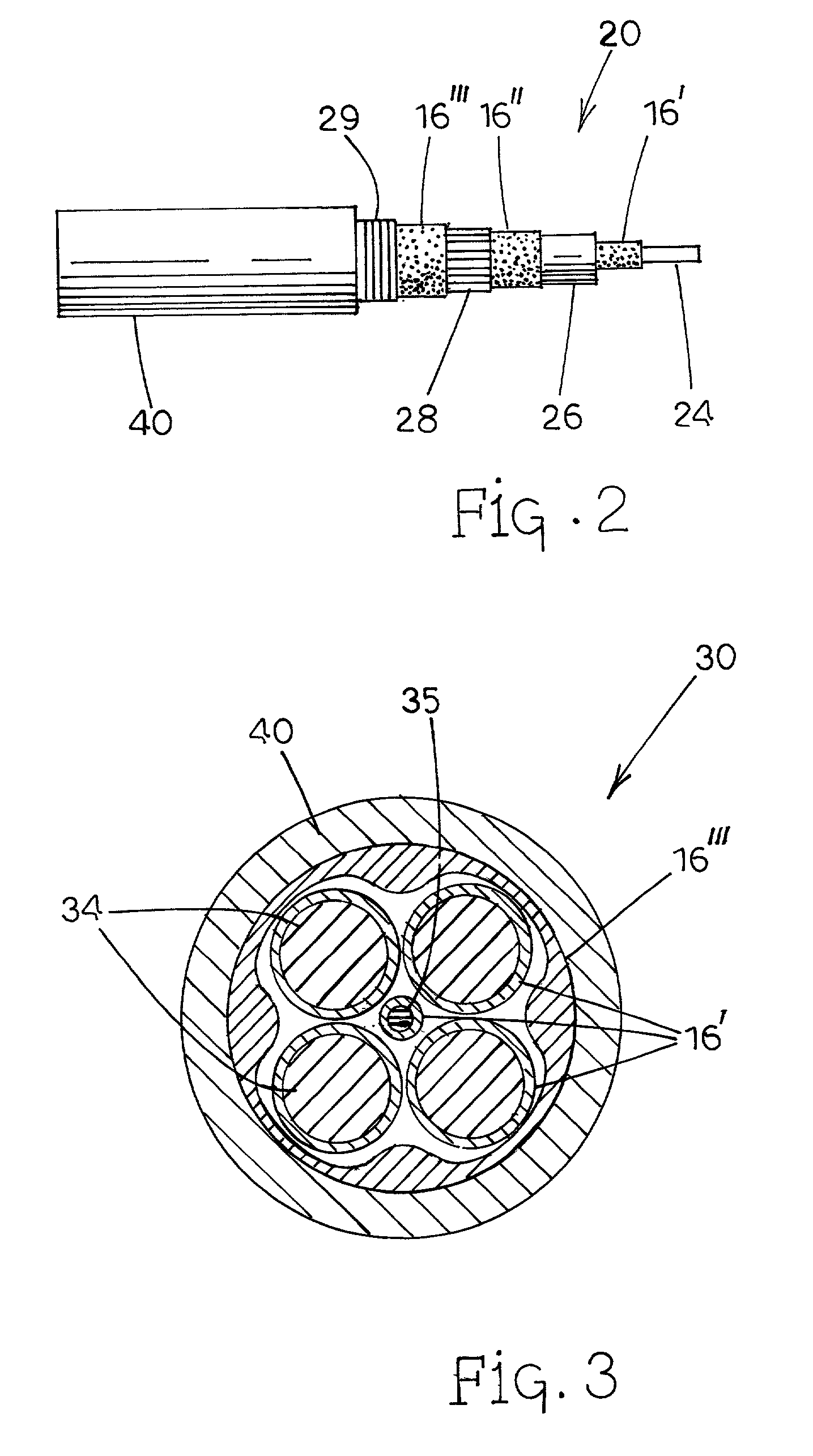

Absorbent material of water absorbent polymer, thermoplastic polymer, and water and method for making same

InactiveUS20030065296A1High tensile strengthPromote absorptionInsulated cablesBaby linensFiberPolymer science

An absorbent material is disclosed, containing at least about 30 weight percent of a superabsorbent polymer, a thermoplastic polymer binder resin, and about 0.1 to about 10 weight percent water. The absorbent material absorbs deionized water to at least about 70 percent of maximum capacity within about 20 minutes after exposure to the deionized water. The method of making the absorbent material includes combining binder resin and absorbent polymer in a twin screw extrusion mechanism, compounding and driving the composition toward exit openings, extruding the composition through the exit openings, and preferably rapidly cooling the extrudate with non-liquid quenching means. The quenched or non-quenched extrudate may be made in the form of a pellet, film, or fibrous strand.

Owner:STOCKHAUSEN GMBH & CO KG DEGUSSA-HUELS AKTIENGESE

Explosion prevention PVC sheath material for mine cable and preparation method thereof

InactiveCN101159174AImprove antistatic performanceImprove flame retardant performancePlastic/resin/waxes insulatorsOther chemical processesPlasticizerPolyvinyl chloride

The invention relates to an anti-explosion polyvinyl chloride sheath material for mining cables and a preparation method thereof. The preparation method comprises mixing evenly polyvinyl chloride resin 100 parts by weight, plasticizer 30-80 parts by weight, stuffing 0-60 parts by weight, high-conductivity carbon black 10-40 parts by weight, anti-static agent 0-10 parts by weight, and other auxiliary agent 3-20 parts by weight by a high-speed mixer, extruding at 130-170 DEG C by a single- or double-screw extruder after being melted, water-cooling drawing bar or wind-cooling die-surface hot cutting and granulating, oven-drying, and packaging to obtain the finished product. Compared with the prior art, the invention has the advantages of excellent durable anti-static property and flame retardant property.

Owner:SURREY HI TECH INC

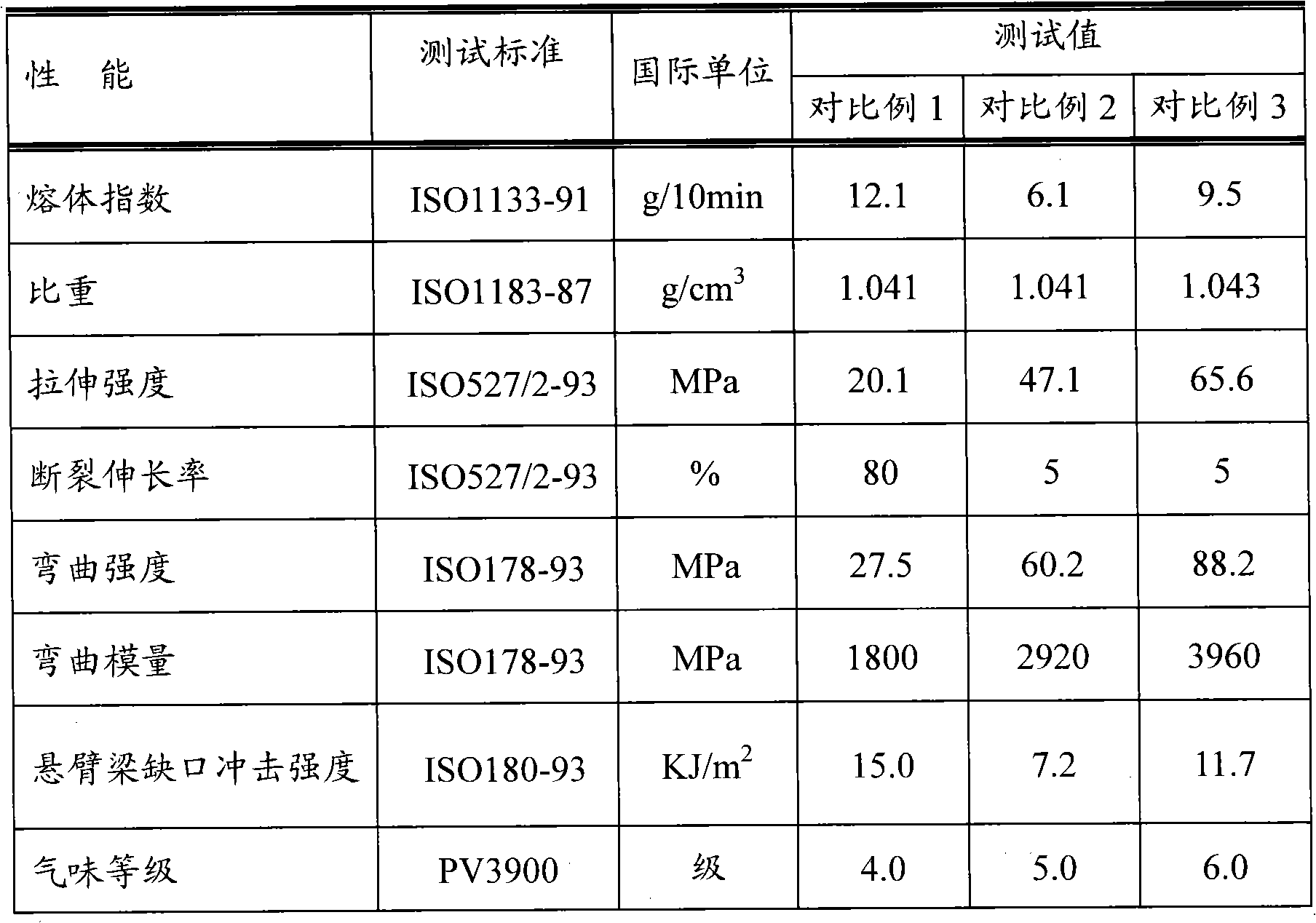

Scratch-resistance French white filled polypropylene composition and its preparing method

InactiveCN1580115AImprove scratch resistanceImproves UV resistanceProcedure AgentsSilicone Elastomers

This invention refers to a kind of component of nick resistant talcum-powder-filling polypropylene, is characterized with strengthened toughness through latex and is composed of the following materials in amounts of weight: between 50 and 80 of polypropylene, between 5 and 35 of filler, between 5 and 25 of latex, between 0.5 and 5 of high molecular silicone elastomer, between 0.05 and 0.5 of nucleater, between 0.1 and 1.0 of stabilizer, between 0.2 and 1.5 of talcum powder surface passiation agent, between 0.05 and 1.0 of processing agent and between 0.3 and 2.0 of toner. The manufacturing method is to weigh the materials in amounts of weight, to mix polypropylene, filler, latex, high molecular silicone elastomer, nucleater, stabilizer, talcum powder surface passiation agent, processing agent and toner in homo mixer, then put them into double-screwed extruder for melting and extruding. After cooling, drying and pelleting, we can get the turnoff. The invention improves the nick resistance of polypropylene, ultraviolet radiation endurance and thermal endurance and the toughness and rigidity of the material reach good balance. It can meet the requirements of the material of automobile limbs. It can demold at a relatively high temperature, improves the moulding efficiency greatly and reduces the processing cost.

Owner:SHANGHAI PRET COMPOSITES

High-temperature resistant thermoplastic polyvinyl chloride cable material and preparation method thereof

ActiveCN103524946AGood physical propertiesHigh strengthInsulated cablesInsulated conductorsProcedure AgentsPolyvinyl chloride

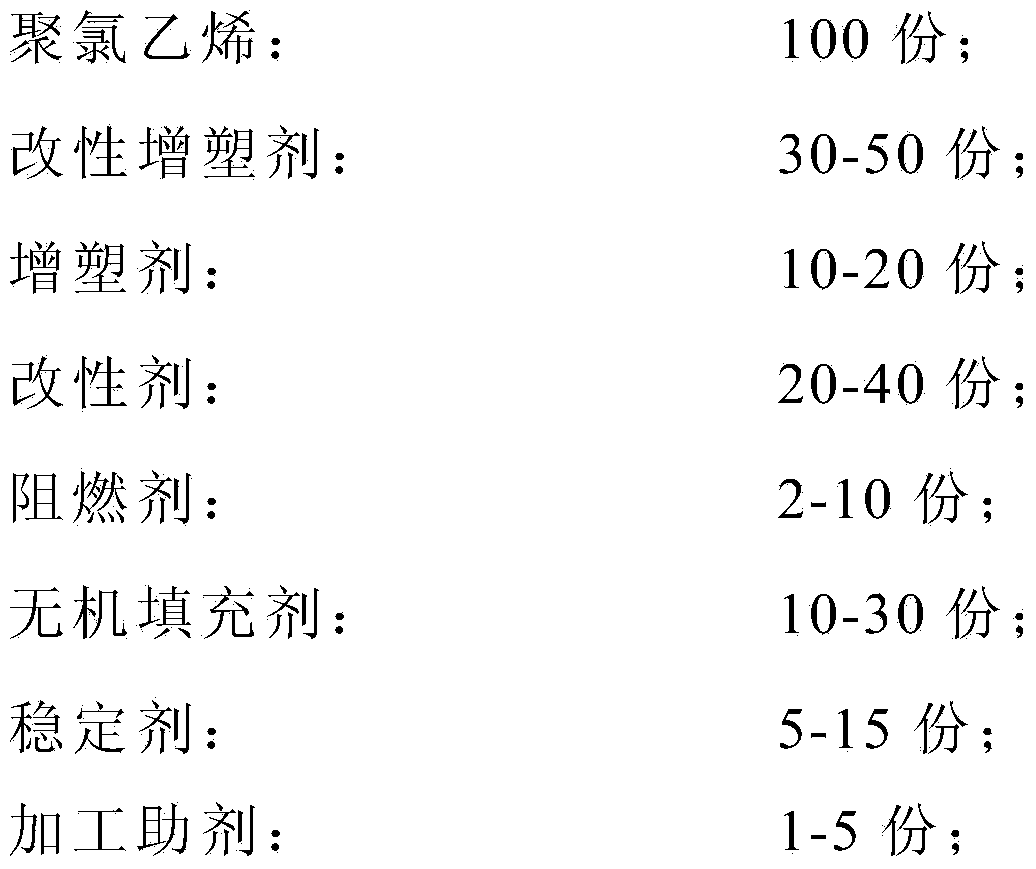

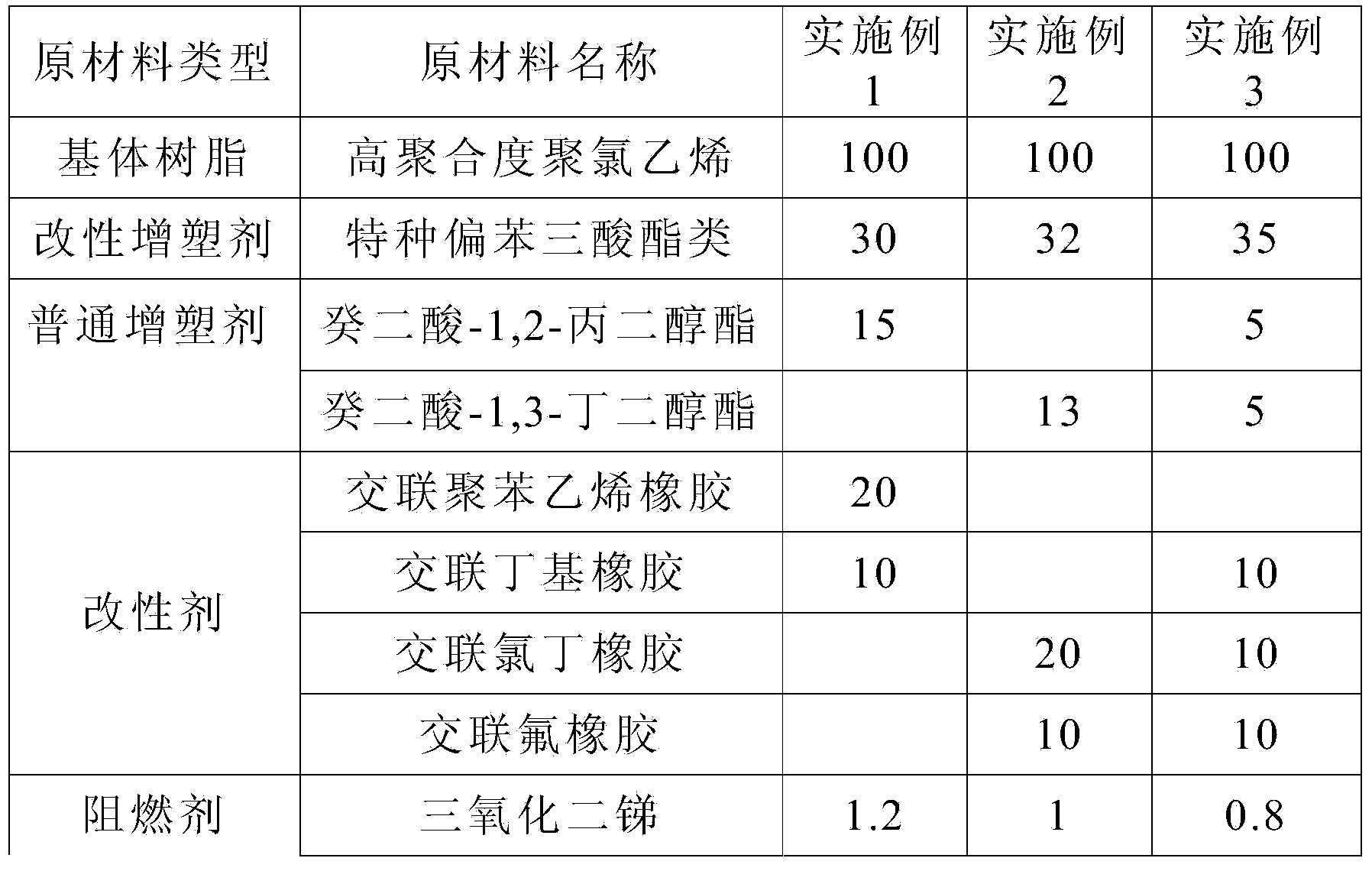

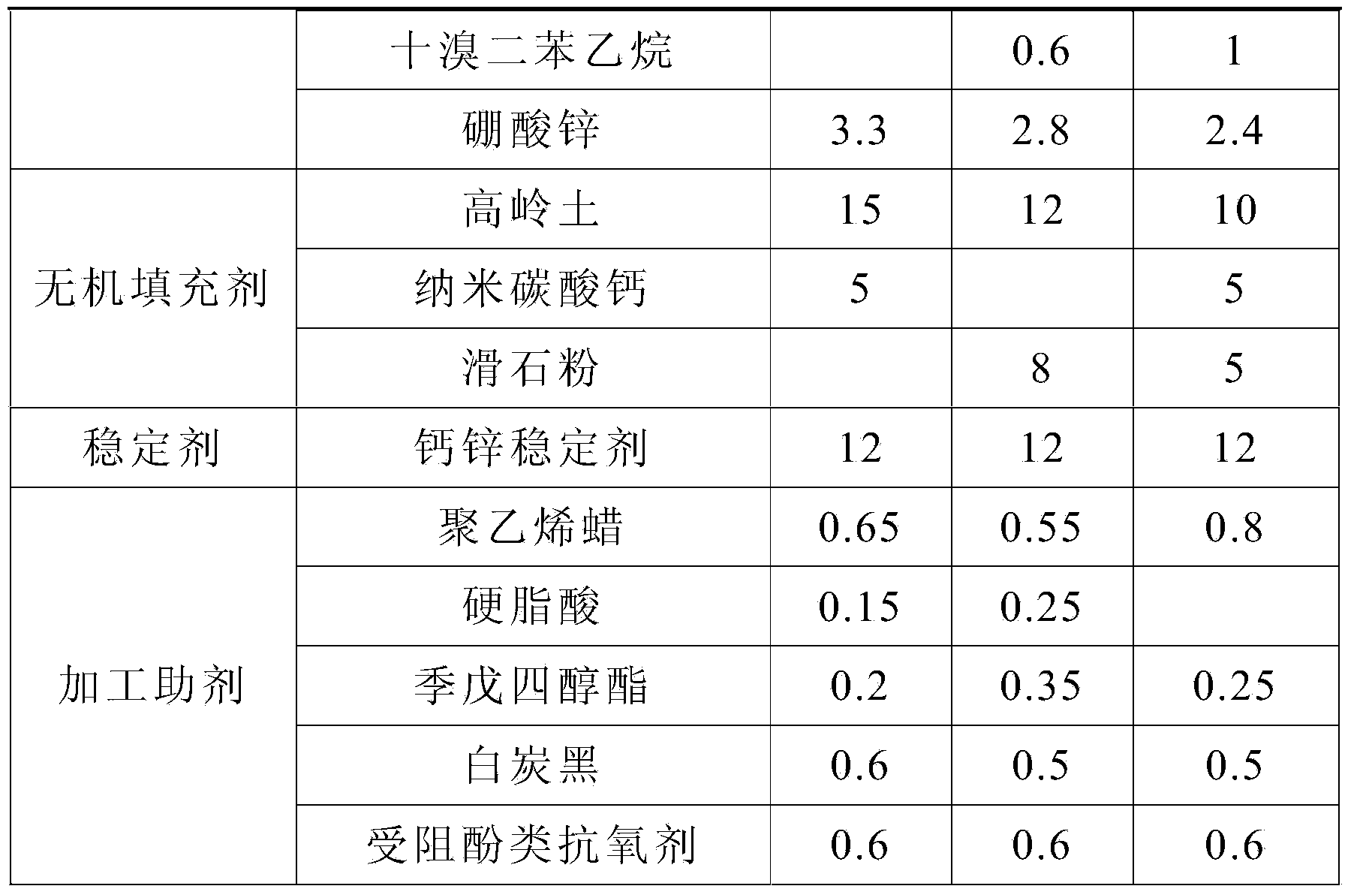

The invention relates to a high-temperature resistant thermoplastic polyvinyl chloride cable material, belonging to the technical field of new materials. The cable material consists of the following components in parts by weight: 100 parts of polyvinyl chloride, 30-50 parts of modified plasticizer, 10-20 parts of plasticizer, 20-40 parts of modifier, 2-10 parts of flame retardant, 10-30 parts of inorganic filler, 5-15 parts of stabilizer and 1-5 parts of processing aid. A preparation method of the cable material comprises the following steps: weighing the raw materials according to the components and weight parts of the cable material; uniformly mixing the polyvinyl chloride and adding the modified plasticizer and the common plasticizer; heating and stirring and adding other raw materials; discharging from a high mixing machine and feeding into a twin-screw extruder for extrusion and granulation; and performing air cooling to obtain the final product. The cable material has the advantages that the physical property is good, the applicable temperature range is wide, little pollution is caused, the flame retardance is good, the smoke output in combustion is low, the preparation method is simple, and the cost is low.

Owner:江西一舟数据技术有限公司

Prepn process of polylactic acid-base thermoplastic wood-plastic composite material

The present invention relates to preparation process of polylactic acid-base thermoplastic wood-plastic composite material, which is prepared with polylactic acid and wood powder as main materials, and through reacting and mixing with compatibilizing agent, brightening agent, plasticizer, nucleater, dispersant, stabilizer and other assistant in a high speed stirrer; extrusion pelletizing the mixture in a double screw extruder; cooling and cutting; and drying in a vacuum drier to obtain the polylactic acid-base thermoplastic wood-plastic composite material. The composite material of the present invention has excellent comprehensive performance, is degradable, and may be used as packing material, environment protecting material and decoration material.

Owner:SHANGHAI JIAO TONG UNIV

Two-step method for dehydrating plastic dispersions

InactiveUS6287470B1Avoid excessive wearQuality improvementLiquid degasificationRotary stirring mixersPolymer scienceOrganic chemistry

The invention relates to a method for dehydrating a two-phase liquid mixture consisting of a thermoplastic synthetic melt phase and an aqueous phase, comprising the following steps: a) coagulation of the two-phase liquid mixture in a first extruder; b) dehydration of the coagulate in a twin screw extruder with a de-watering zone and screws working in an opposite direction; c) separation of constituents by degasifying. The inventive method is characterized in that a single screw extruder or a twin screw extruder with screws working in the same direction is used as a first extruder in step a).

Owner:EVONIK ROEHM GMBH

Glass fiber reinforced polyethylene glycol terephthalate composite material and preparation thereof

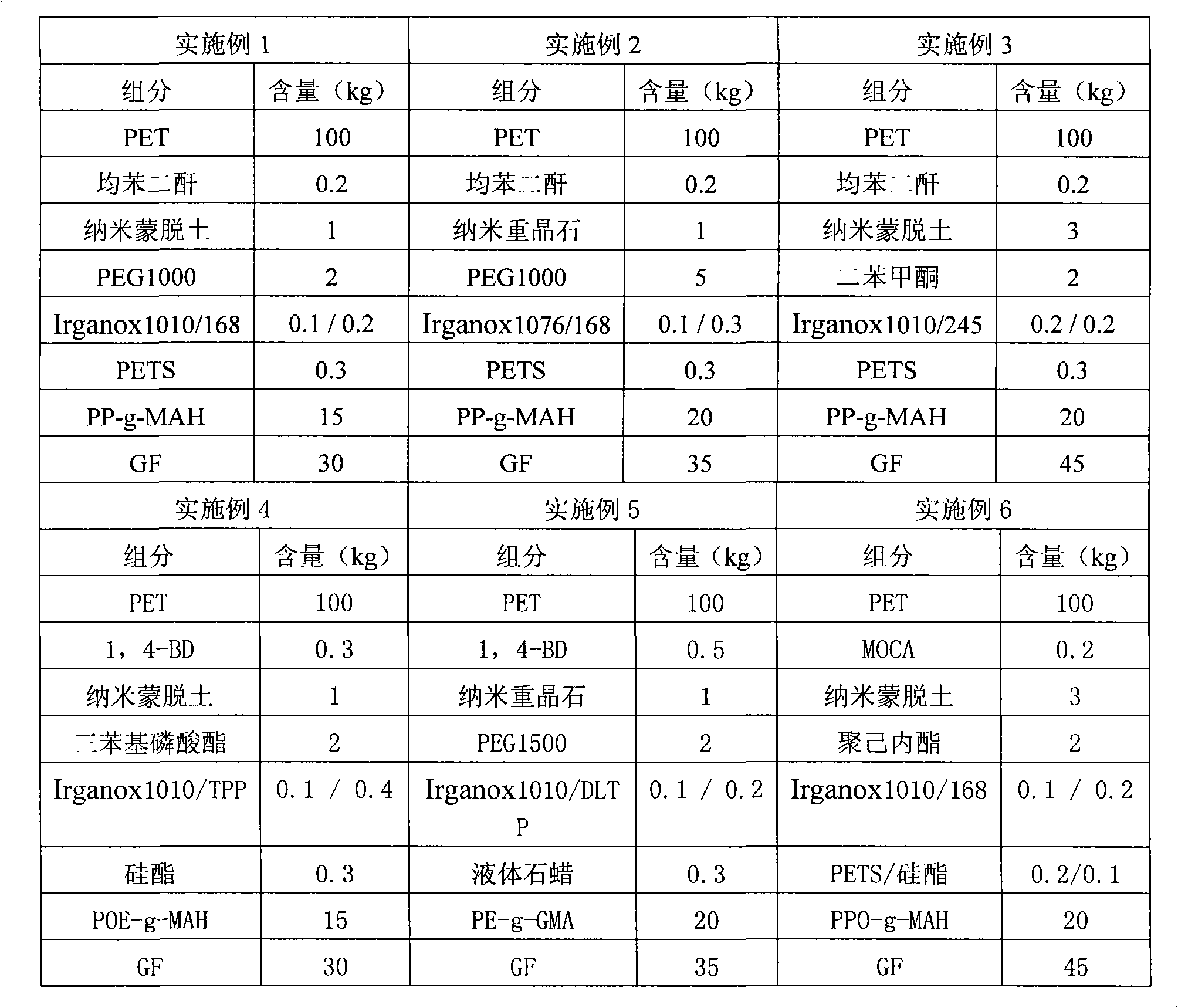

The invention relates to a PET glass fiber reinforced composite material, which has the following components based on weight proportion: 100 portions of PET, 10-45 portions of alkali-free glass fibers, 5.0-25 portions of toughener, 0.1-10 portions of crystallization promoter, 0.1-1.0 portion of chain extender, 0.5-5.0 portions of nucleating agent, 0.1-0.5 portion of antioxidant and 0.3-0.5 portion of lubricant. The preparation method is that the components are evenly mixed on a high-speed mixer and melted and blended by a twin-screw extruder to prepare the composite material. The composite material has the advantages of good mobility, high tensile strength and high impact strength, which aims to realize low-cost and high-quality PET engineering plastic scale production to effectively substitute for high-grade plastics and expensive imported special materials.

Owner:SHANGHAI UNIV +1

High-polarity polypropylene material and application thereof as inner and outer decorative parts of automobile

ActiveCN101717548AIncrease surface polarityLower surface energySuperstructure subunitsBumpersPolymer scienceDyne

The invention discloses a high-polarity polypropylene material and the application thereof as inner and outer decorative parts of an automobile. The material is prepared from the following components in percentage by weight: 50-89 polypropylene, 5-25 flexibilizer, 0-30 mineral filler, 5-15 polar additives, 0.2-3 age resister and 0-0.5 colorant, and the components are premixed and then are extruded out by a double-screw extruder to prepare particles, thereby preparing the high-polarity modified polypropylene material. The surface tension of the material is as high as 37 dyne / cm<2>, dope-binding strength is high, an automobile bumper formed by the material can be coated without being pretreated, and when being used for preparing the inner decorative part for the automobile, the material has good property of binding other materials.

Owner:WUHAN JINFA TECH CO LTD

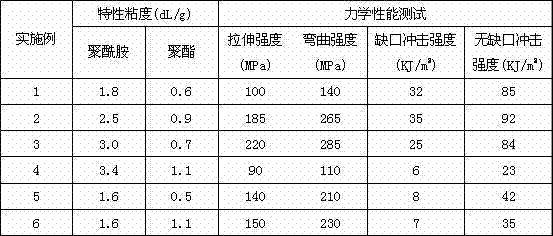

Glass fiber reinforced polyamide/polyester alloy and preparation method thereof

The invention discloses a glass fiber reinforced polyamide / polyester alloy and a preparation method thereof. The glass fiber reinforced polyamide / polyester alloy consists of the following components in percentage by weight: (A) 99-30 percent of resin component and (B) 70-1 percent of glass fiber, wherein the resin component (A) consists of the following components in percentage by weight: (1) 97-1 percent of polyamide of which the intrinsic viscosity is 1.8-3.0 dL / g, (2) 97-1 percent of polyester of which the intrinsic viscosity is 0.6-0.9 dL / g, (3) 1-20 percent of compatilizer and (4) 1 percent of other aids. The preparation method comprises the following steps of: weighing the materials with an electronic metering scale; feeding the materials into a dual-screw extruder respectively; and melting and mixing together to obtain a high-strength and high-toughness glass fiber reinforced polyamide / polyester alloy. The method is simple, and the performance of the obtained polyamide / polyester alloy is higher than that of a glass fiber reinforced nylon material.

Owner:KINGFA SCI & TECH CO LTD +1

Preparation method of fully biodegradable starch/polylactic acid base resin

InactiveCN105440606AIncrease linear contentImprove mechanical propertiesGlass transitionPolylactic acid

The invention provides a preparation method of fully biodegradable starch / polylactic acid base resin. The starch / polylactic acid base resin comprises 100 parts of polylactic acid, 30-90 parts of modified starch, 5-25 parts of biodegradable resin, 15-35 parts of a plasticizer and 1-15 parts of other assistants. The preparation method comprises the following steps: carrying out ultrasonic treatment on the modified starch, mixing the ultrasonic treated modified starch, polylactic acid powder and the other assistants in a high speed mixer at a temperature equal to or greater than the glass transition temperature of polylactic acid, and carrying out blending granulation on the above obtained blend through a double screw extruder to obtain a completely biodegradable material with excellent mechanical strength. Compared with like resins, the resin provided by the invention has the advantages of realization of reduction of the cost of the polylactic acid material while realizing high starch loading, good mechanical performances, full biodegradability and improved practicality.

Owner:JIANGSU SUPLA BIOPLASTICS CO LTD

Flame-retardant and antistatic wood-plastic composite material and preparation method thereof

ActiveCN104327530AAchieve flame retardant and antistatic effectImprove flame retardant performanceThermoplasticFiber

The invention discloses a flame-retardant and antistatic wood-plastic composite material and a preparation method thereof and relates to a wood-plastic composite material and a preparation method thereof. The invention aims at solving the problems of relatively poor flame retardance and relatively high cost of the existing antistatic wood-plastic composite material. The wood-plastic composite material is prepared from the following components in parts by weight: a lignocellulosic material, thermoplastic, a lubricant, an antistatic agent, a flame retardant, a coupling agent and an inorganic filler. The method comprises the following steps: 1) performing hot mixing on the lignocellulosic material, the thermoplastic and the lubricant to obtain a hot-mixed material; 2) putting the hot-mixed material into a cold mixing machine for cold mixing, and adding the weighed antistatic agent, the flame retardant, the coupling agent and the inorganic filler into the cold mixing machine for re-mixing when the temperature is lowered to 40-60 DEG C to obtain a premix; 3) putting the premix into a twin-screw extruder to perform melting, mixing and granulation; and 4) performing extrusion molding or thermoforming to prepare the flame-retardant and antistatic wood-plastic composite material. The flame-retardant and antistatic wood-plastic composite material is used in the fields of indoor buildings, decorations, decoration materials and the like.

Owner:NORTHEAST FORESTRY UNIVERSITY

High thermal conducting composite material and preparation method thereof

InactiveCN101775213AImprove thermal conductivityEasy to processHeat-exchange elementsGlass fiberMixed materials

This invention relates to a high thermal conducting composite material for injecting or extrusion molding, which is prepared from the following components in parts by weight: 100 parts of plastic substrate, 30 to 100 parts of thermal conducting filler with a diameter between 50 to 300 microns, 0 to 50 parts of thermal conducting filler with a small diameter between 1 to 10 microns, 10 to 50 parts of fiberglass or silicon whisker, 0 to 5 parts of coupling agent and 0 to 8 parts of additive. The preparation of the high thermal conducting composite material comprises the following steps: adding the coupling agent to the thermal conducting filler with a small diameter and the thermal conducting filler with a big diameter respectively to do surface treatment for later use; putting the plastic substrate material, the processed thermal conducting filler with a big diameter and other additives to a super mixer to mix for 1 to 5 minutes; adding the processed thermal conducting filler with a small diameter into the super mixer to mix for 2 to 3 minutes; putting the mixed material into a feeding bucket of a twin screw extruder; adding the fiberglass into a glass fiber orifice; and pelleting after melting and extruding. The composite material prepared by the invention has good thermal conducting property and processing property.

Owner:黄晓峰

Method for preparing functional chips for manufacturing antibacterial fibers and plastics

InactiveCN102336957AOvercoming Difficult Difficulties in DiffusionEvenly dispersedArtifical filament manufactureFiberPolyresin

The invention relates to a method for manufacturing functional resin chips, in particular to a method for preparing antibacterial chips used for manufacturing antibacterial fibers and plastics, which has the advantages of high dispersibility, low energy consumption and simple process. The method comprises the following steps of: 1) stirring and dispersing organic antibacterial agent powder at the concentration of 10-50,000ppm in 0.01 to 5 weight percent of dispersing agent; 2) selecting proper original resin chips, and fully stirring and mixing with blend obtained in the step 1); and 3) drying, and performing extrusion granulation by using a twin-screw extruder. The prepared chips can serve as antibacterial resin masterbatches and also can be directly used for manufacturing the antibacterial fibers and plastics.

Owner:上海亿金纳米科技有限公司

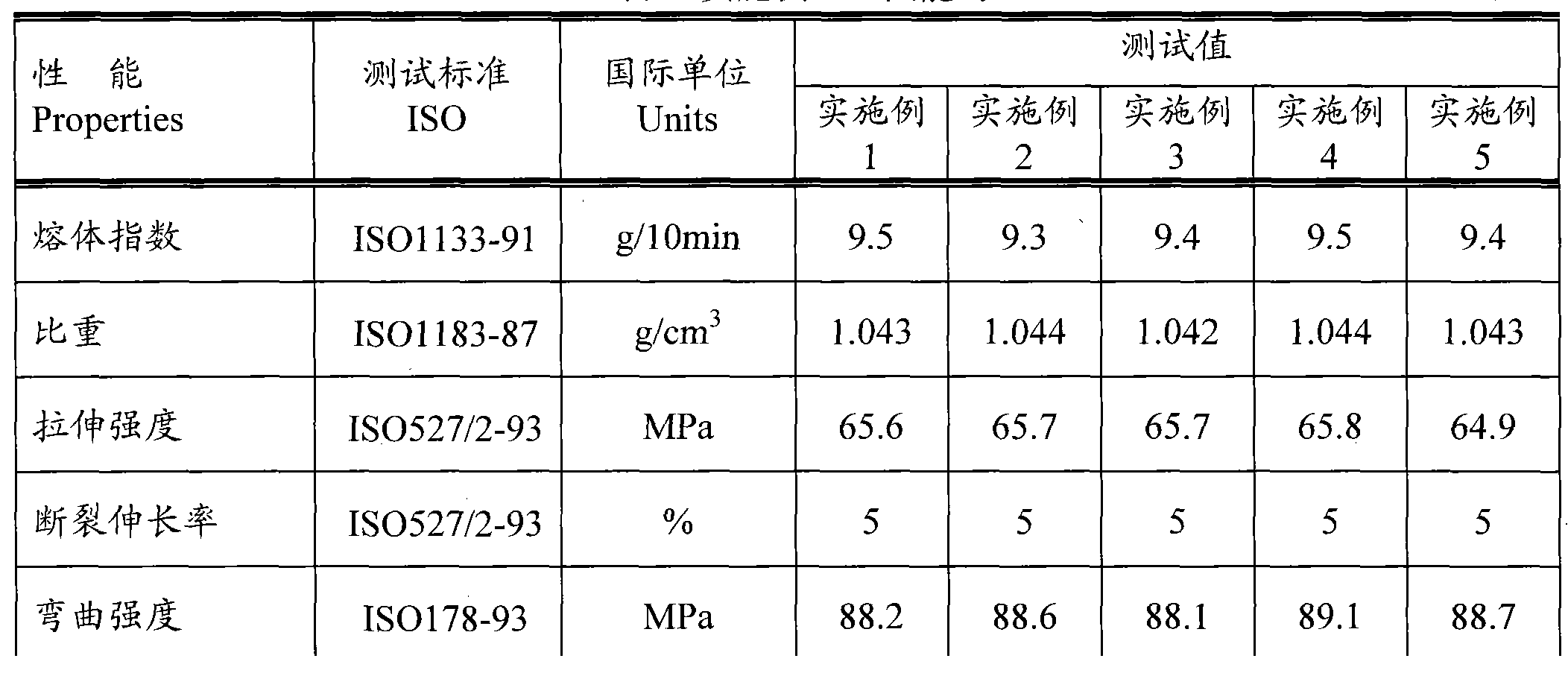

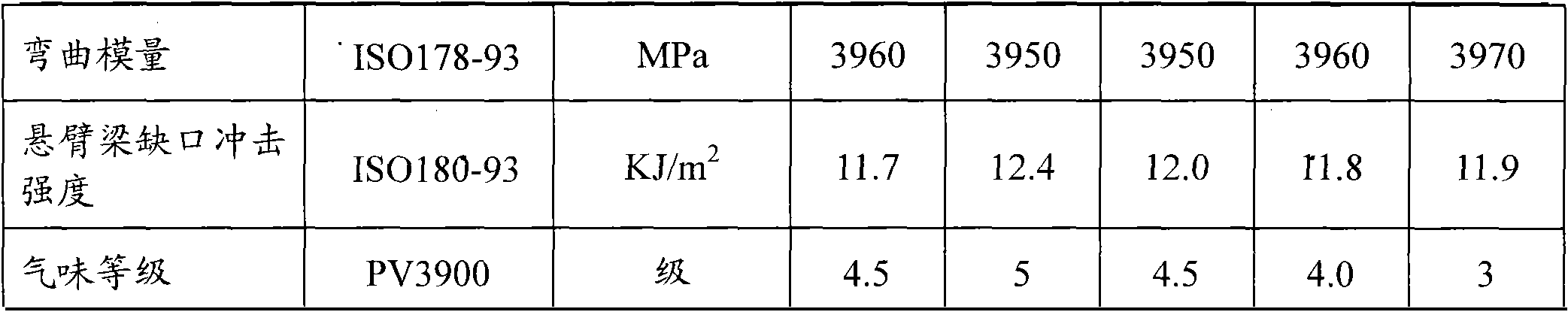

Glass fiber reinforced polypropylene composite material with low odor and preparation method thereof

The invention discloses a glass fiber reinforced polypropylene composite material with low odor and a preparation method thereof. The glass fiber reinforced polypropylene composite material comprises the following components: 32-91% of polypropylene resin, 5-50% of glass fiber, 2-8% of compatilizer, 1-6% of odor inhibitor and 1-4% of other auxiliary agent. The reinforced polypropylene material with low odor is prepared by fusing, extruding and granulating the components through a double screw extruder under the temperature control condition of 220-240 DEG C. The odor inhibitor comprises 30-50% of ricinoleic acid zinc, 20-40% of metal oxide and 10-30% of a clay mineral system. The odor of the glass fiber reinforced polypropylene composite material can be inhibited through combining a physical method and a chemical method. The glass fiber reinforced polypropylene composite material prepared by the method has excellent odor performance; the odor level can be reduced below level 3; the physical property of the glass fiber reinforced polypropylene composite material per se is not influenced after the odor inhibitor is added; and the application field of the glass fiber reinforced polypropylene material in vehicle interior trim parts and a part of home appliance parts can be widened.

Owner:CHENGDU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD +3

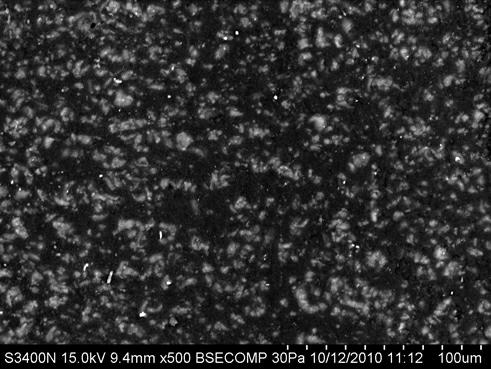

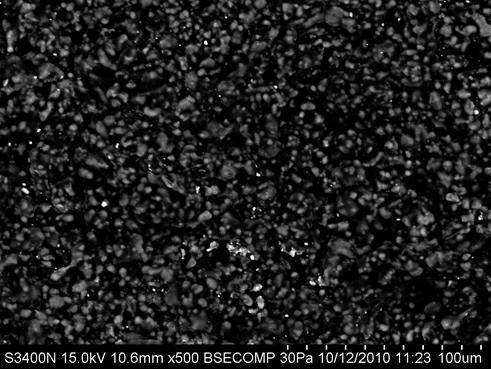

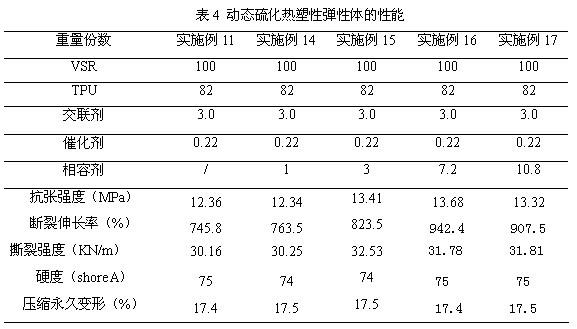

Polyurethane/silicon rubber thermoplastic elastomer and preparation method thereof

The invention discloses a polyurethane / silicon rubber thermoplastic elastomer and a preparation method thereof, and provides a polyurethane / silicon rubber thermoplastic elastomer which can be repeatedly processed and has good mechanical property and fine heat and oil resistance and a preparation method thereof. The elastomer is composed of polyurethane, silicon rubber, a cross-linking agent, a catalyst and a compatilizer. The preparation method comprises the following steps: adding the polyurethane into a blending device from an intermixing machine or a two-screw extruder at the blending temperature of 160-200 DEG C, then adding the silicon rubber and the compatilizer to blend for 3-4 minutes, then adding the cross-linking agent, and finally, adding the catalyst; and reacting and blending for 6-7 minutes so as to obtain the dynamically vulcanized polyurethane / silicon rubber thermoplastic elastomer with high performance. Compared with other types of thermoplastic elastomers, the polyurethane / silicon rubber thermoplastic elastomer has the advantages of fine heat resistance, wear resistance and mechanical property and good hand feel, and can be widely applied to the fields of automobiles, buildings, medical instruments, cables and the like.

Owner:GUANGDONG UNIV OF TECH

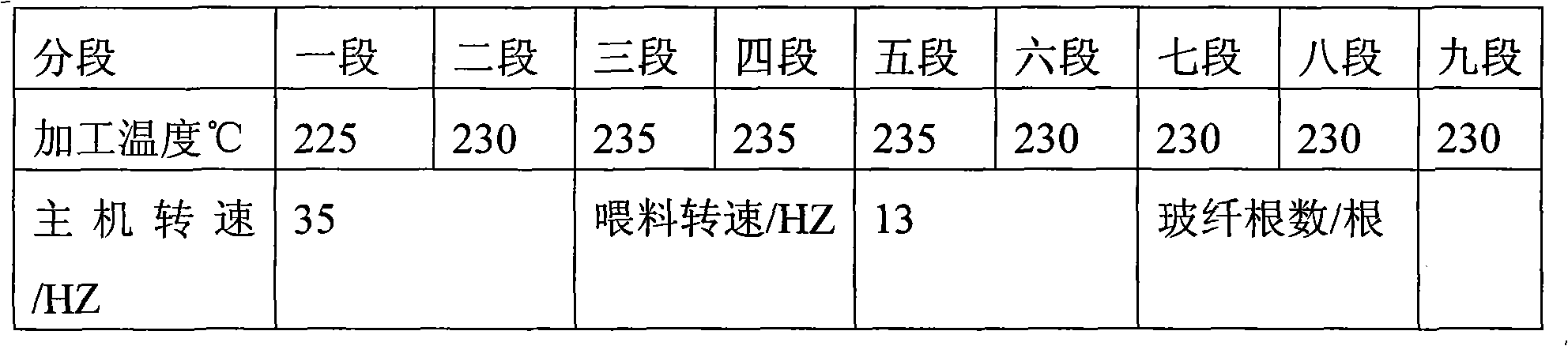

High glowing filament environmental-friendly inflaming retarding reinforced polybutylece terephthalate (PBT)/acrylonitrile butadiene styrene (ABS) alloy material and preparation method thereof

InactiveCN102108187AAvoid decompositionImprove impact performanceGlass fiberPolyethylene terephthalate

The invention relates to a high glowing filament environmental-friendly inflaming retarding reinforced polybutylece terephthalate (PBT) / acrylonitrile butadiene styrene (ABS) alloy material. The material comprises the following components in percentage by weight: 22.5-41% of PBT, 22.5-41% of ABS, 6-20% of complexing inflaming retardant, 3-15% of antimonous oxide, 20-30% of glass fiber, 2-10% of flexibilizer, 0.1-1% of antioxidant and 0.1-1% of lubrication dispersing agent. The preparation method comprises the following steps: putting raw materials weighed based on the weight proportion into a high mixer, mixing for 2-5 minutes, and then discharging; and then extruding and granulating by using an extruding machine at the processing temperature of 230-240 DEG C at the screw rotating speed of 30-40Hz. Compared with the alloy material prepared by the prior art, the high glowing filament environment-friendly inflaming retarding reinforced PBT / ABS alloy material has the advantages of high glowing filament temperature, environmental friendliness, balanced comprehensive performance and the like.

Owner:SHANGHAI SUNNY

Biodegradable resin composition for modifying toughness and heat resistance and preparation method thereof

InactiveCN101143962AImprove toughnessImprove heat resistanceHeat deflection temperatureProcedure Agents

The invention provides a biodegradable resin component with toughness and heat resistance improved and a method for preparing the same, wherein the resin component contains 100 parts by mass of biodegradable resin, 1-40 parts by mass of thermoplastic elastomer, and 0.1-30 parts by mass of inorganic additive, and preferentially contains 3-25 parts by mass of flame retardant, 0.1-10 parts by mass of performance reinforcing agent and 0.1-10 parts by mass of processing aid; the resin component is granulated by a double screw extruder after melting mixing, the forming processing cycle of the resin component is short during injection forming, and after treatment for 10 min at 110DGE C, the lzod notched impact strength is higher than 30J / m, and the heat deformation temperature is higher than 90DGE C.

Owner:CHITEC TECH

Talc powder filled polypropylene with high rigidity, high toughness and high scratch resistance and method for preparing same

The invention relates to high molecular processing field compound material, especially a high molecular organic sillicon elastomer filled with talcum powder agglomerate, with outstanding rigidity and resistance to heat and its preparing method, which can be applied in auto and toner field, such as pate of tenacity, door, plate of augxiliary tenacity, deconating stick and other polypropylene inside and outside automobile. The invention is comprised of high molecular organic sillicon elastomer and talcum powder agglomerate with high crystal and the percentages of each component are: high molecular organic sillicon elastomer 60-90, talcum powder agglomerate 10-40, scratch 3-10, dust 0.1-1.0, of talcum powder agglomerate 0.2-1.5, 0.05-1.0. The preparing method is: mix the high molecular organic sillicon elastomer, talcum powder agglomerate, dust, of talcum powder agglomerate and in, then place then into to form the particles. Its advantage is that, keeping the tenacity of polypropylene, the rigidity has also been increased, balancing its tenacity and rigidity, as well as its resistance to scratch, it can satisfy the requirements of elements in auto; besides, it also reduces dust, benefiting for protecting the work environment.

Owner:SHANGHAI PRET COMPOSITES

Process and apparatus for the production of a deodorant or antiperspirant composition

InactiveUS6338840B1Quicker and easy to control temperatureLess heat lossCosmetic preparationsToilet preparationsParticulatesActive agent

In a first aspect, a process for forming deodorant or antiperspirant sticks by continuously forming a mobile composition for dispensing into containers or molds at a rate matched with the rate at which it is dispensed, and in other aspects a process in which a mobile deodorant or antiperspirant composition is dispensed by injection molding, i.e. a process in which the deodorant or antiperspirant composition is dispensed under pressure. The composition at the time of injection moulding is preferably either in the vicinity of its regular set temperature, particularly in the range of about 0-3° C. below the regular set temperature and / or partially structured at the time of its delivery it into a container or mold. The deodorant or antiperspirant composition is preferably continuously produced in a screw extruder, especially a twin screw extruder, which is controlled to deliver the composition in a substantially semi-solid state, at a temperature close to its regular set temperature and is injected into the container or barrel at a pressure at the point of injection that is often greater than 15 psi. and in many instances from 200 to 400 psi in the injection head. Apparatus for forming deodorant or antiperspirant sticks by injection molding is also described. The combined process offers benefits for incorporating sensitive ingredients and ameliorating sedimentation of particulates such as particulate antiperspirant actives.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

Polyolefin masterbatch and preparation method thereof

The invention discloses a polyolefin masterbatch and a preparation method thereof. The polyolefin masterbatch comprises the following components by weight percent: 20-70% of carrier, 0.01-70% of toner, 0-40% of dispersant, 0.1-10% of foaming agent, 0-10% of crosslinking agent, 0-2% of heat stabilizer and 0-40% of filler. The preparation method comprises the following steps: using the components to dose in proportion, mixing, using a double-screw extruder or internal mixer to melt and blend, then granulating, and drying to obtain the masterbatch disclosed by the invention, wherein the masterbatch can be columnar, beaded, flaky or round according to different granulating ways. When the polyolefin masterbatch provided by the invention is used in polyolefin extrusion, spinning and the coloring of the injection molding product, the masterbatch has good dispersibility and color stability.

Owner:广东波斯科技股份有限公司

Electrically conductive composite fibre containing carbon nanotube and method for making same

InactiveCN1840750AGood electrical propertiesIncreased durabilityFilament/thread formingArtifical filament manufactureFiberConductive polymer

The disclosed conductive composite fiber with carbon nano tube comprises a conductive core layer with 60~99.5wt% thermoplastic polymer, 0~5% carbon nano tube, 0~15% conductive carbon black, and 0.5~20% dispersant; and a shin layer with fiber-forming polymer. Wherein, the preparation method comprises mixing, extruding for granulation, and mixed spinning. This invention improves product performance.

Owner:DONGHUA UNIV

Ultraviolet-proof environmental-friendly polyvinyl chloride (PVC) modified material and preparation method thereof

Owner:广东祺龙科技有限公司

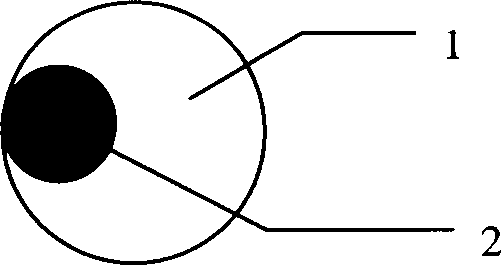

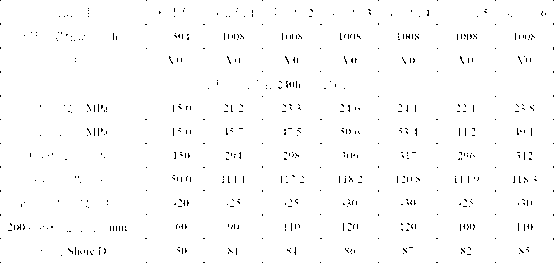

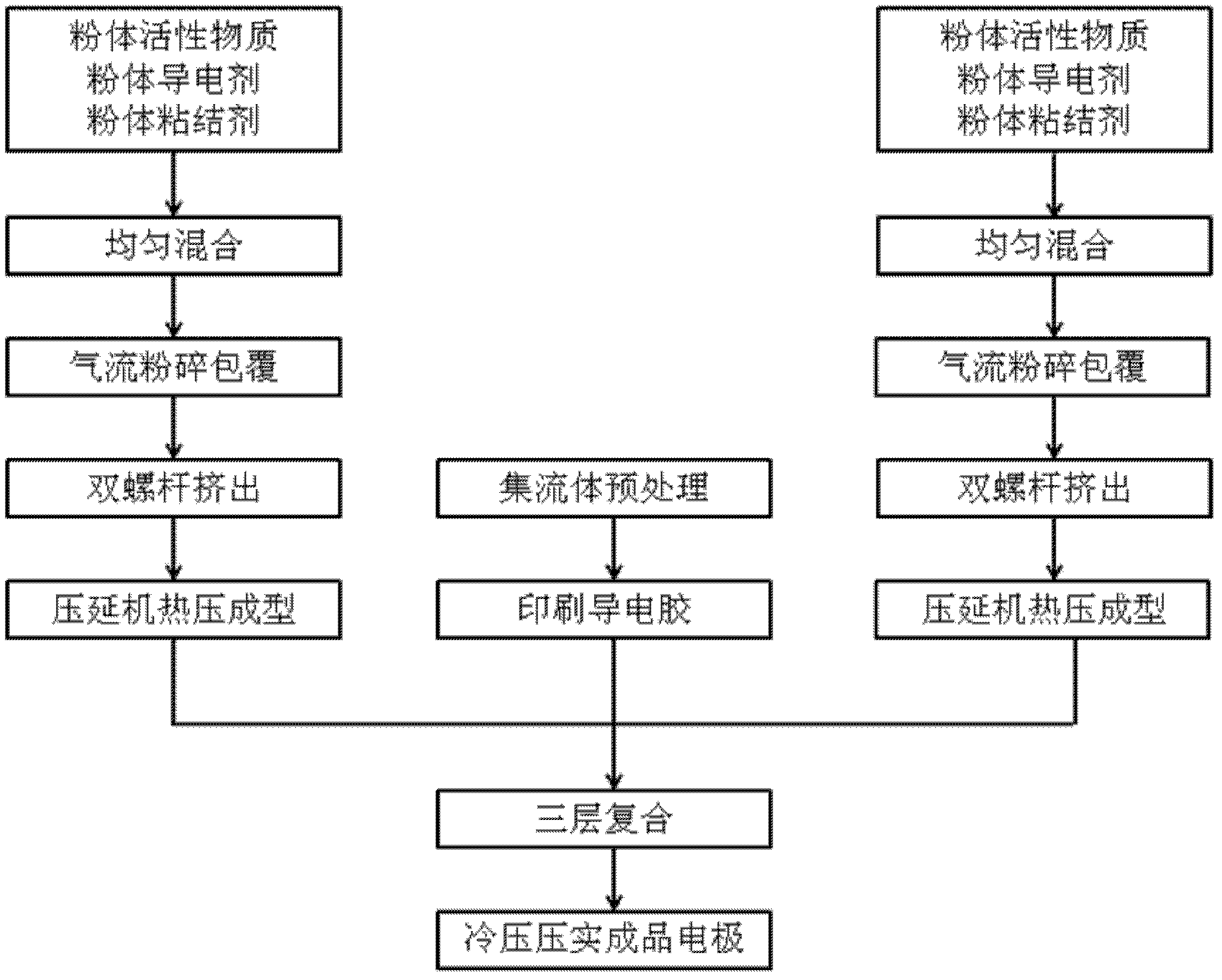

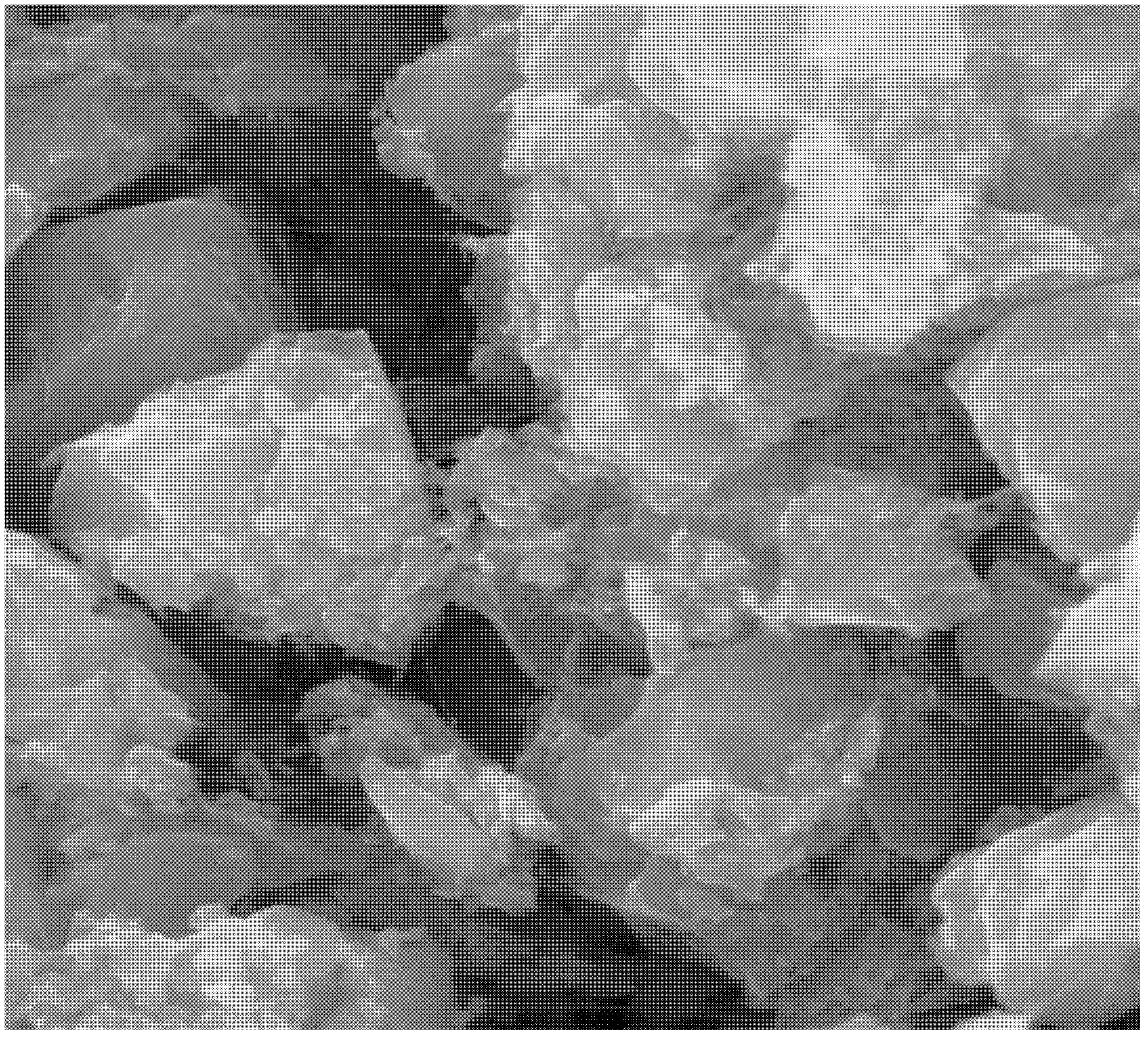

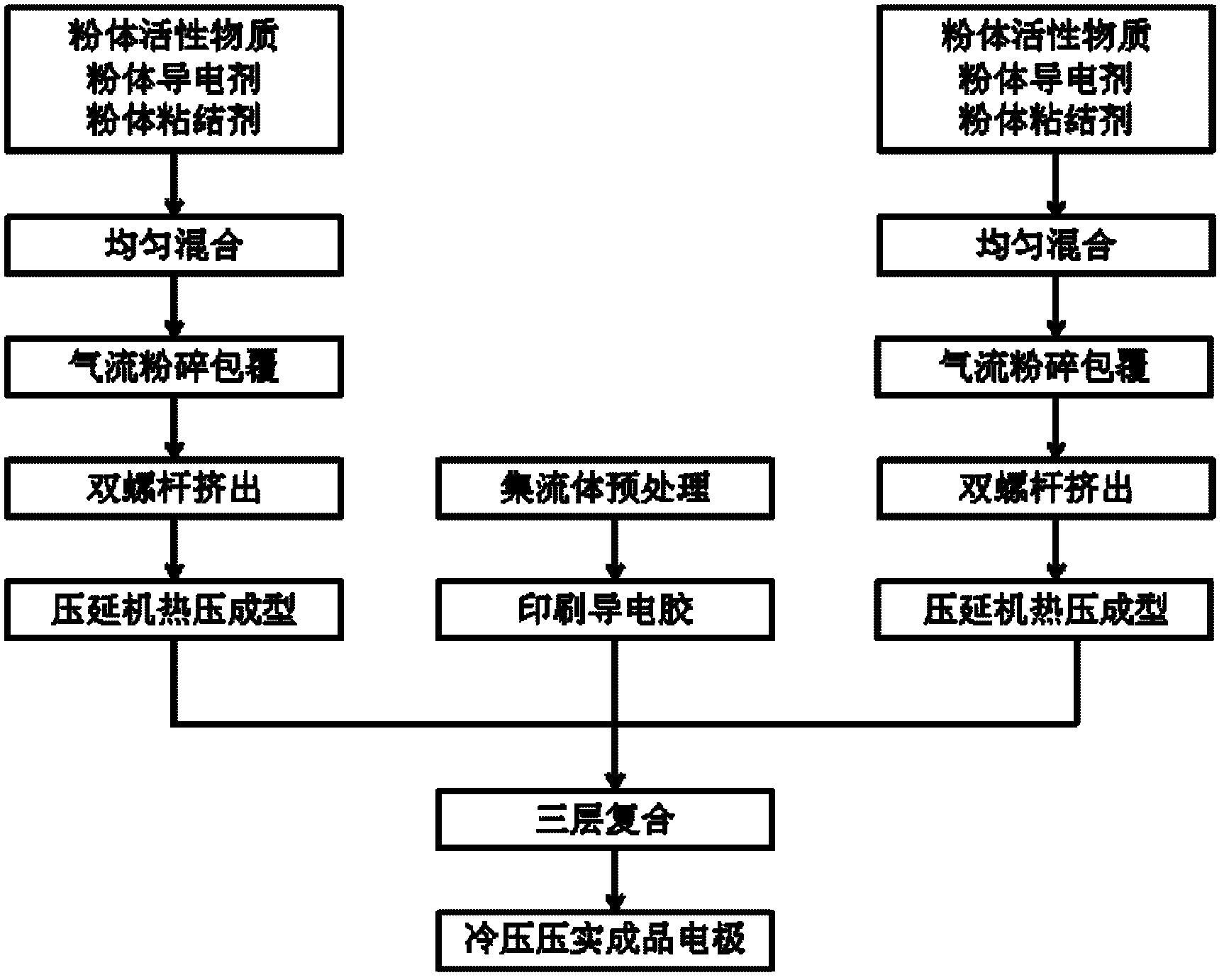

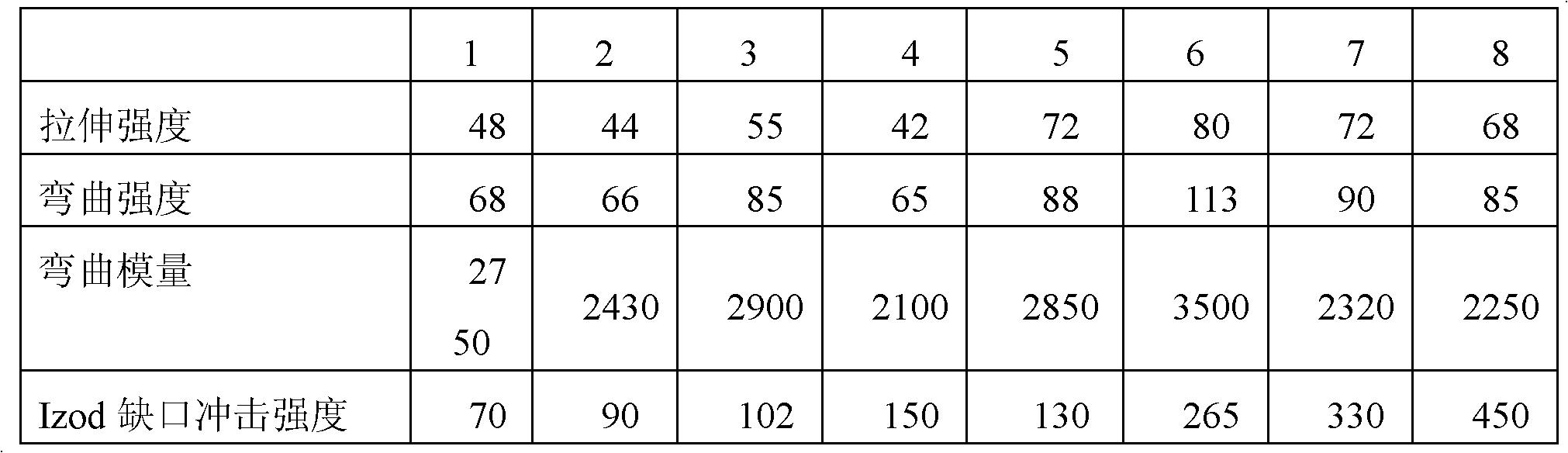

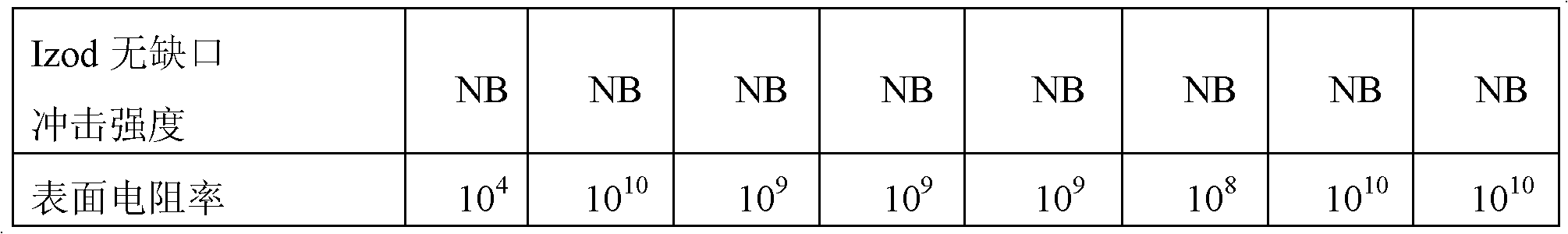

Powder-based electrode forming method

ActiveCN102629681AWell mixedImprove the mixing effectElectrode manufacturing processesHybrid capacitor electrodesAdhesiveCrusher

The invention relates to a powder-based electrode forming method, which comprises the following steps of: uniformly mixing a powder active substance, a powder conductive agent and a powder adhesive through a three-dimensional powder mixer or a zero-gravity powder mixer; crushing through a low-temperature crusher; performing fibrous extrusion forming through a double-screw extruder or an internal mixer / open mill and then achieving target thickness through hot pressing of a calender; and finally performing three-layer compounding with a current collector of a printing conductive adhesive to form an electrode and performing cold rolling to improve the compaction density. According to the powder-based electrode forming method, a method of assisting machining by using a solvent is abandoned, so that the purity of an electrode material is guaranteed to the greatest extent, no energy waste of a drying process or restriction to the time of the drying process exists in a production process, the cost is reduced, the energy loss is reduced, and the working speed is increased.

Owner:GMCC ELECTRONICS TECH WUXI CO LTD

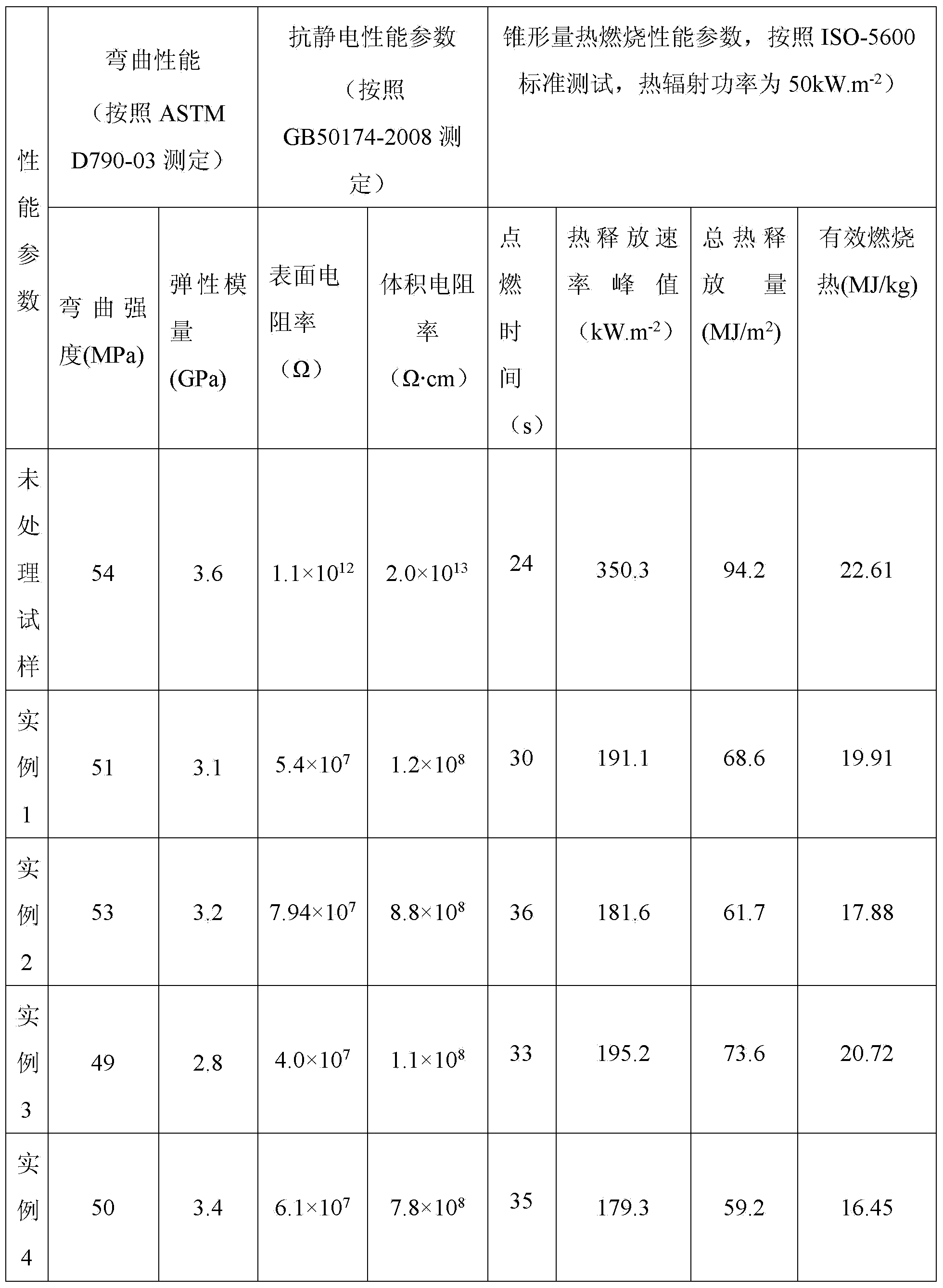

Resin material, preparation method and applications of resin material

The invention belongs to the technical field of high-polymer materials and discloses a resin material, a preparation method and applications of the resin material. The resin material disclosed by the invention comprises the following components in parts by weight: 70-95 parts of high-polymer resin, 1-15 parts of conducting material, 3-14 parts of compatilizer, 0.5-1 part of antioxidation aid and 0.5-1 part of processing aid. The preparation method for the resin material disclosed by the invention comprises the following steps of: weighing 70-95 parts of high-polymer resin, 1-15 parts of conducting material, 3-14 parts of compatilizer, 0.5-1 part of antioxidation aid and 0.5-1 part of processing aid; putting in a high-speed mixing machine and fully mixing; delivering a mixed material into a twin-screw extruder by using a metering material conveying device; fully mixing the material under the shearing actions of screws; performing extrusion, bracing, cooling and grain cutting on a molten blend; and packaging into a finished product. The resin material disclosed by the invention has an anti-static dustproof effect, is excellent in surface effect and can be used for manufacturing card readers or electrical equipment enclosures and the like.

Owner:HEFEI GENIUS NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com