Polyurethane/silicon rubber thermoplastic elastomer and preparation method thereof

A thermoplastic elastomer and silicone rubber technology, which is applied in the field of polyurethane/silicone rubber thermoplastic elastomer and its preparation, can solve problems such as insufficient heat resistance, and achieve high production efficiency, excellent heat resistance, and good hand feel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

[0038] Examples 1~4: Heat the torque rheometer (Shanghai Kechuang Co., Ltd.) to 190°C, add polyurethane TPU and silicone rubber VSR in the formula listed in Table 1 to the torque rheometer, and wait for the materials to melt After mixing evenly, add a cross-linking agent. The cross-linking agent is dimethylhydrogen polysiloxane (the same below) with a silicon hydrogen content (weight fraction) of 0.3~2% organosilicon compound methaneoxy end-capped. After the torque was balanced, the catalyst was added, the rotor speed was 70 r / min, the mixture was kneaded for 10 minutes, the samples were taken out, and the tableting performance was tested. The catalyst used in this experiment is a platinum complex complexed with chloroplatinic acid and tetramethyldivinyldisiloxane (the same below).

Embodiment 5~8

[0041] Examples 5-8: Heat the torque rheometer to 190°C, add the TPU and VSR in the formula listed in Table 2 into the rheometer, and after the materials are melted and kneaded evenly, add a crosslinking agent, and wait for conversion After the moment is balanced, the catalyst is added, the rotor speed is 70 r / min, the kneading is carried out for 10 minutes, the sample is taken from the press plate, and the performance is tested.

[0042]

[0043] It can be seen from Table 2 that the mechanical properties of thermoplastic elastomers increase with the increase of catalyst content. When the catalyst content reaches a certain ratio, the performance of thermoplastic elastomers is almost unchanged.

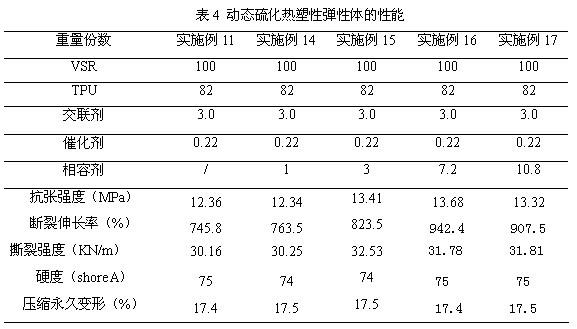

[0044] Examples 9~10 and 12~13: Heat the torque rheometer to 190°C, put the TPU and VSR in the formula listed in Table 3 into the rheometer, and after the materials are melted and kneaded evenly, add crosslinking After the torque is balanced, add the catalyst, the rotor speed is 70 ...

Embodiment 11

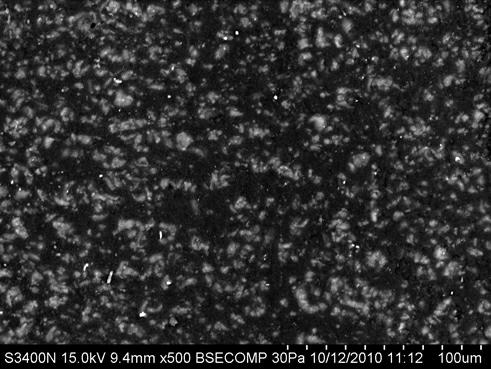

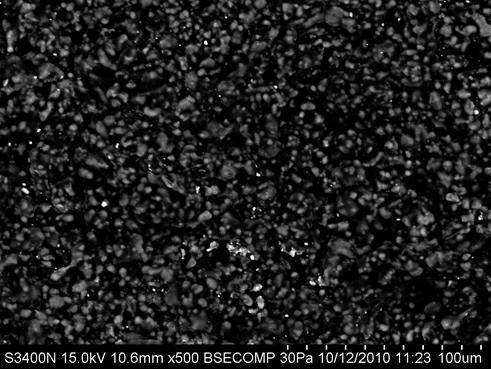

[0045]Example 11: Heat the torque rheometer to 190°C, add the TPU and VSR in the formula listed in Table 3 to the torque rheometer, and after the materials are melted and kneaded evenly, add a crosslinking agent, and wait for conversion After moment balance, the catalyst was added, the rotor speed was 70 r / min, and kneading was carried out for 10 minutes. The sample was cooled in liquid nitrogen, ultra-thin sectioned, and the morphology of the sample was observed by SEM. Sampling and tableting, performance testing.

[0046]

[0047] It can be seen from Table 3 that when the content of crosslinker is less, the mechanical properties of the elastomer are poor. When the content of crosslinking agent is 3 parts, the performance of the elastomer is the best.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com