Patents

Literature

4639 results about "Thermoplastic polymer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermoplastic polymers form when repeating units called monomers link into chains or branches. Because they soften when heated, thermoplastic polymers are easy to mold into a variety of shapes and also lend themselves to recycling.

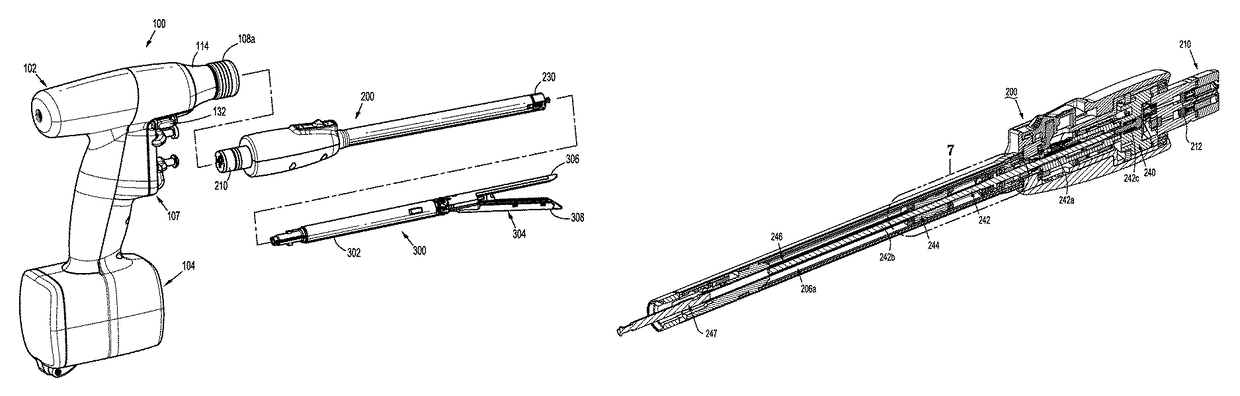

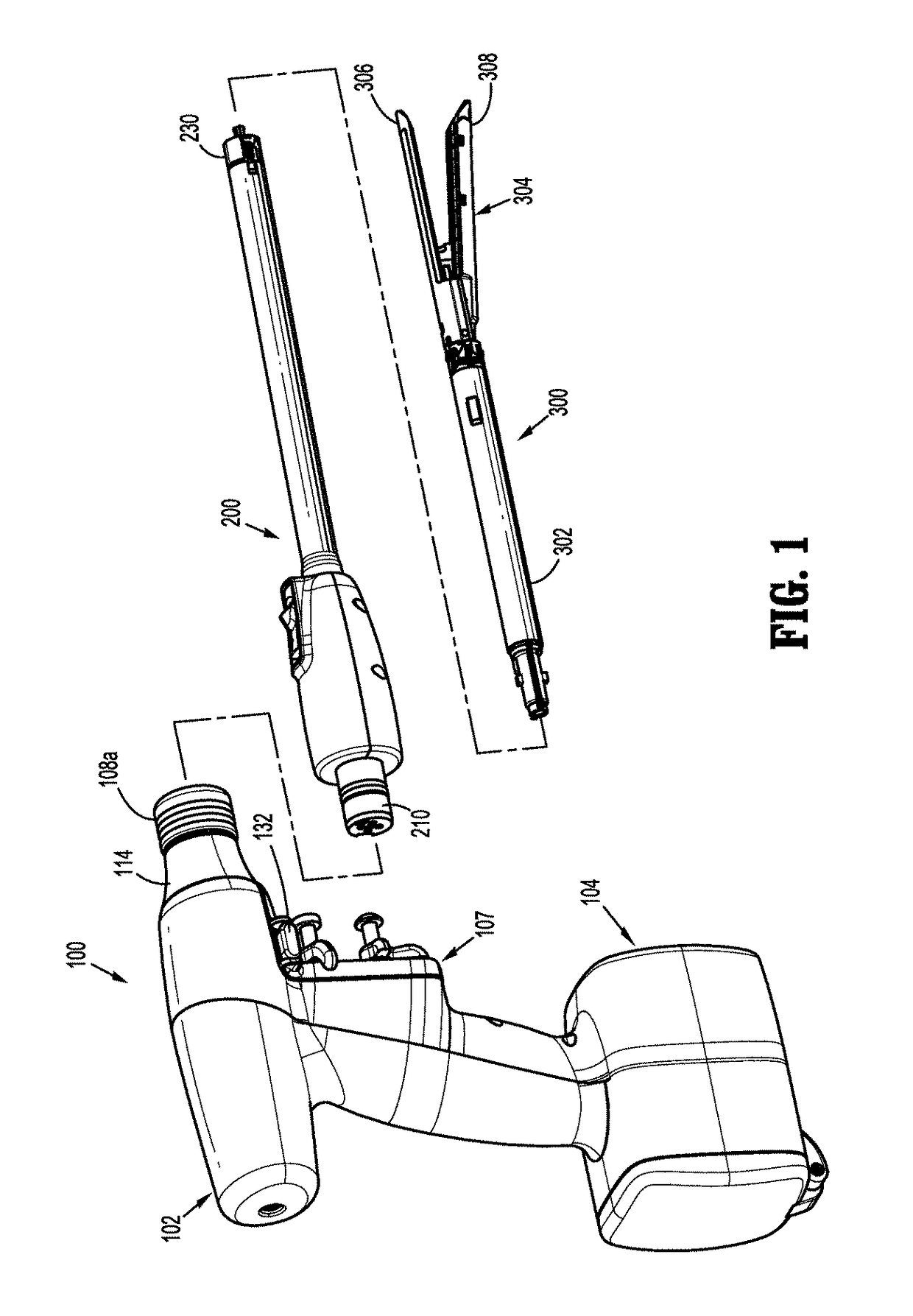

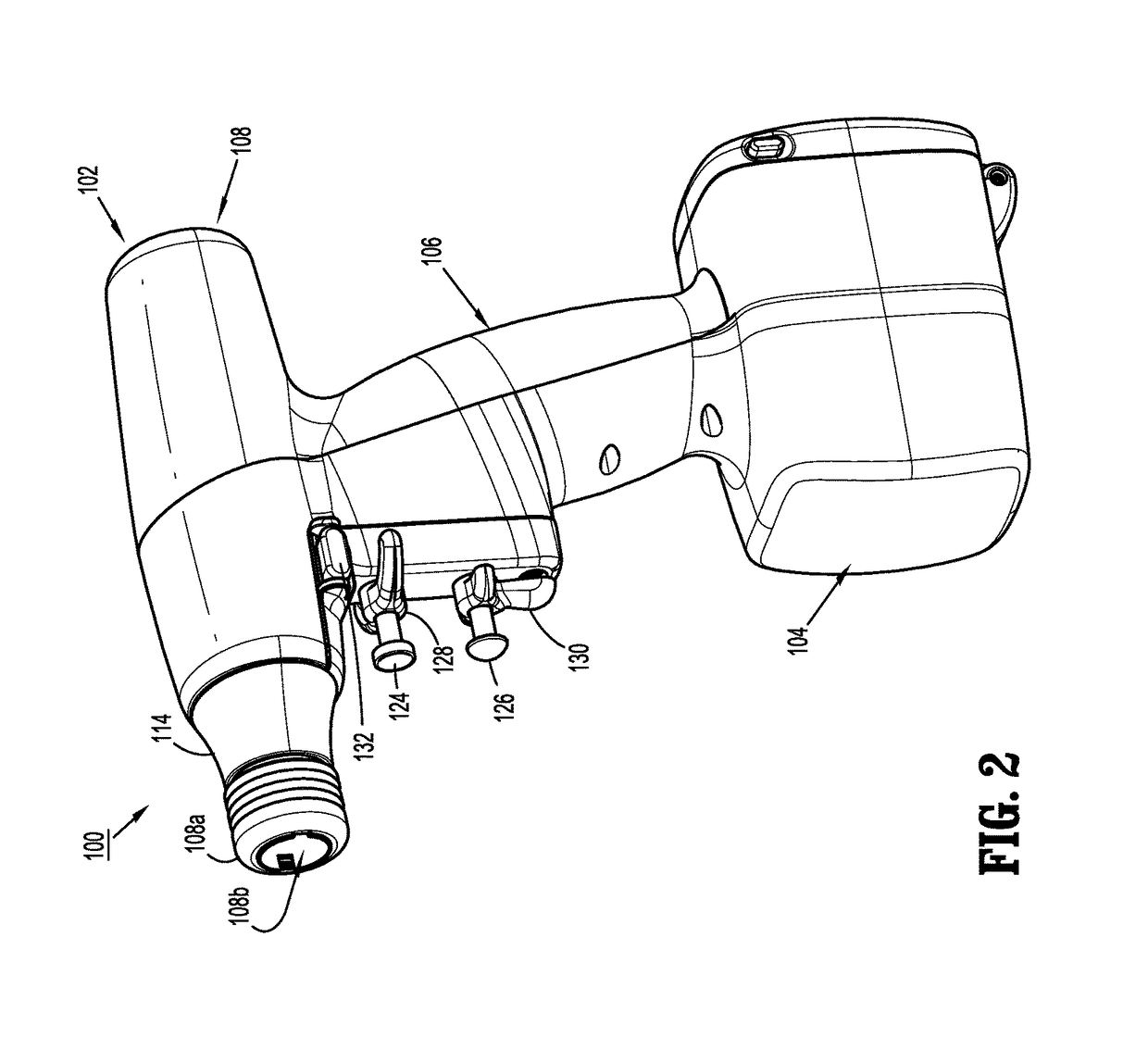

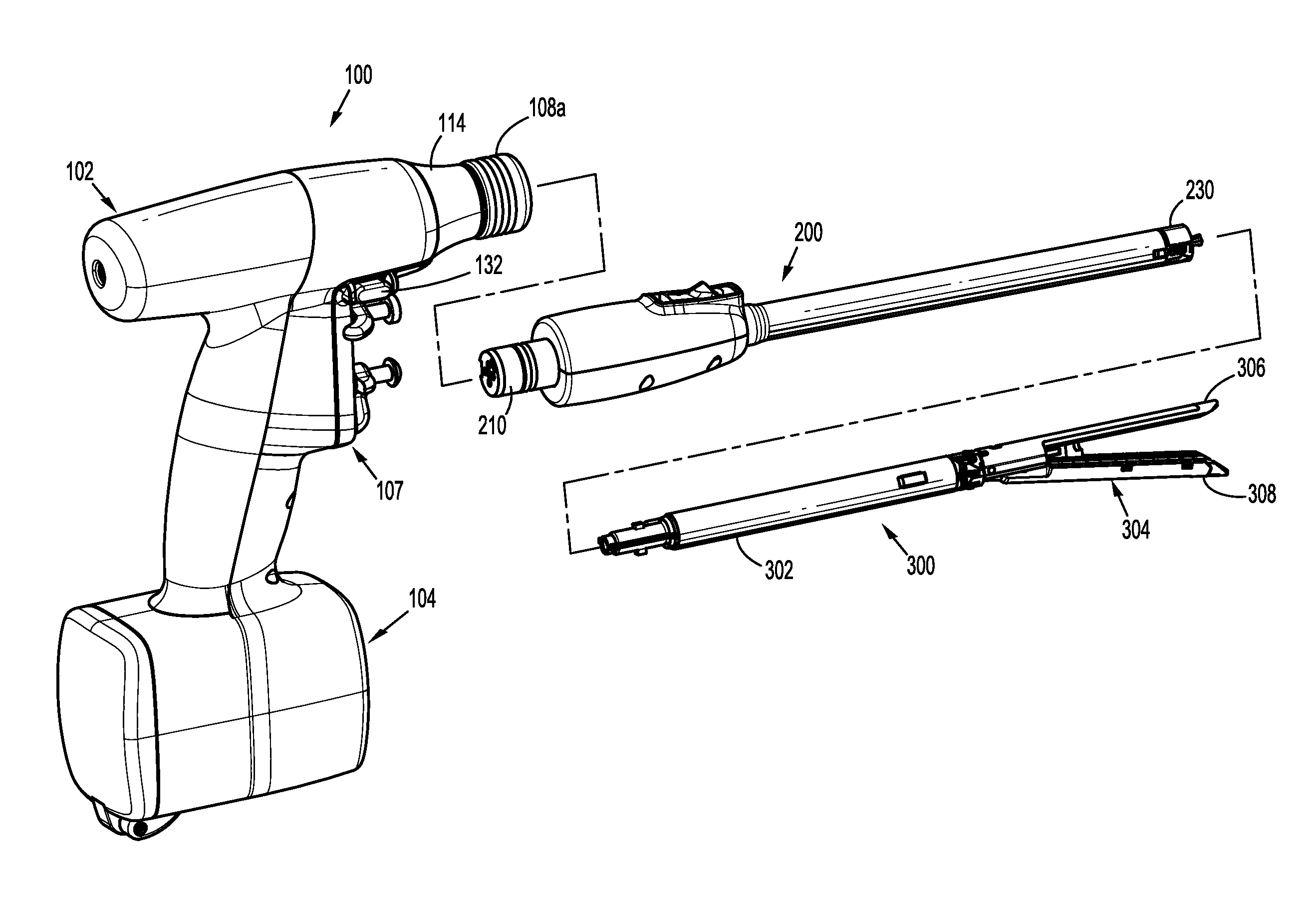

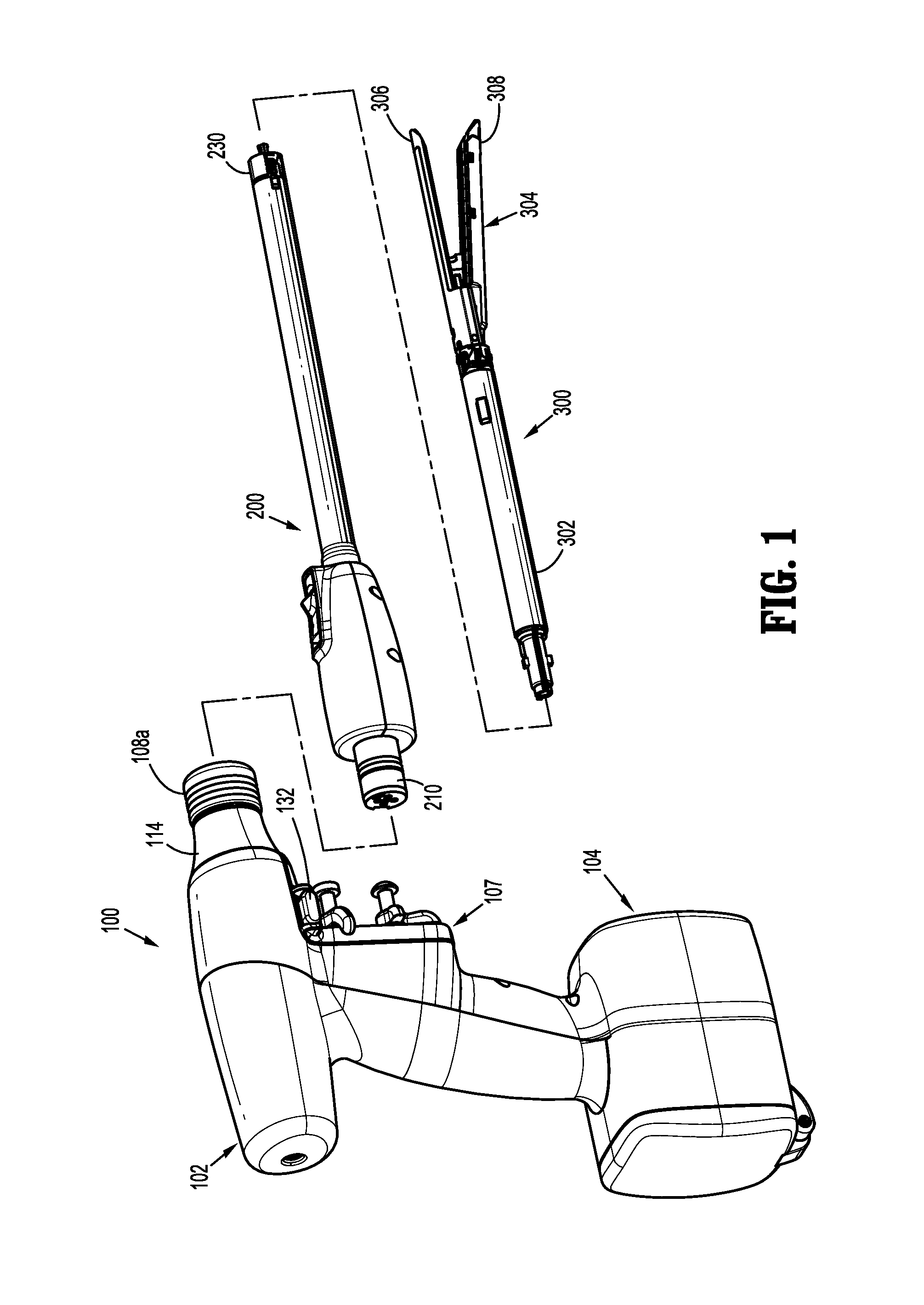

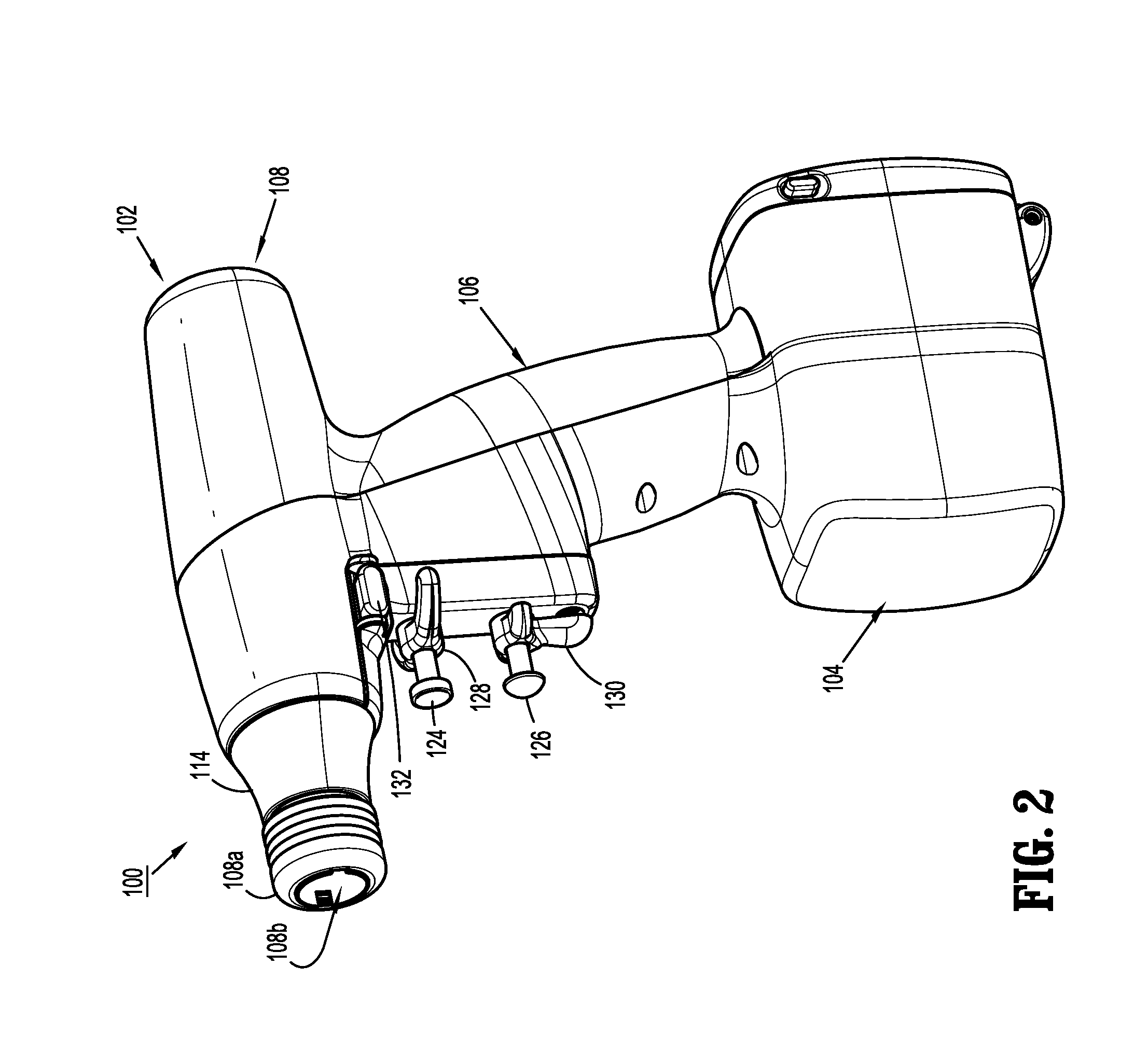

Surgical adapter assemblies for use between surgical handle assembly and surgical end effectors

Owner:TYCO HEALTHCARE GRP LP

Thermoplastic starch compositions incorporating a particulate filler component

InactiveUS6231970B1Reduce molecular weightAvoid hydrolysisProtein adhesivesPaper coatingParticulatesCross-link

Thermoplastic starch compositions that include a particulate filler, e.g. an inorganic filler component, and optional fibrous component The compositions include a thermoplastic phase comprising a thermoplastic starch melt that contains, at a minimum, starch blended with an appropriate plasticizing agent under conditions in order for the starch to form a thermoplastic melt. The thermoplastic phase may also include one or more additional thermoplastic polymers and other optional reactants, liquids or cross-linking agents to improve the water-resistance, strength, and / or other mechanical properties of the thermoplastic melt, particularly upon solidification. The inorganic filler component may affect the mechanical properties but will mainly be added to reduce the cost of the thermoplastic starch compositions by displacing a significant portion of the more expensive starch or starch / polymer melt. Fibers may optionally be included in order to improve the mechanical properties of the thermoplastic starch compositions. The thermoplastic starch compositions may be shaped into a wide variety of useful articles, such as sheets, films, containers, and packaging materials. Because the thermoplastic starch compositions will typically include a thermoplastic phase that is biodegradable, and because the other components will either constitute a naturally occurring mineral and optionally a natural fiber, the overall composition will typically be more environmentally friendly compared to conventional thermoplastic materials.

Owner:BIO TEC BIOLOGISCHE NATURVERPACKUNGEN

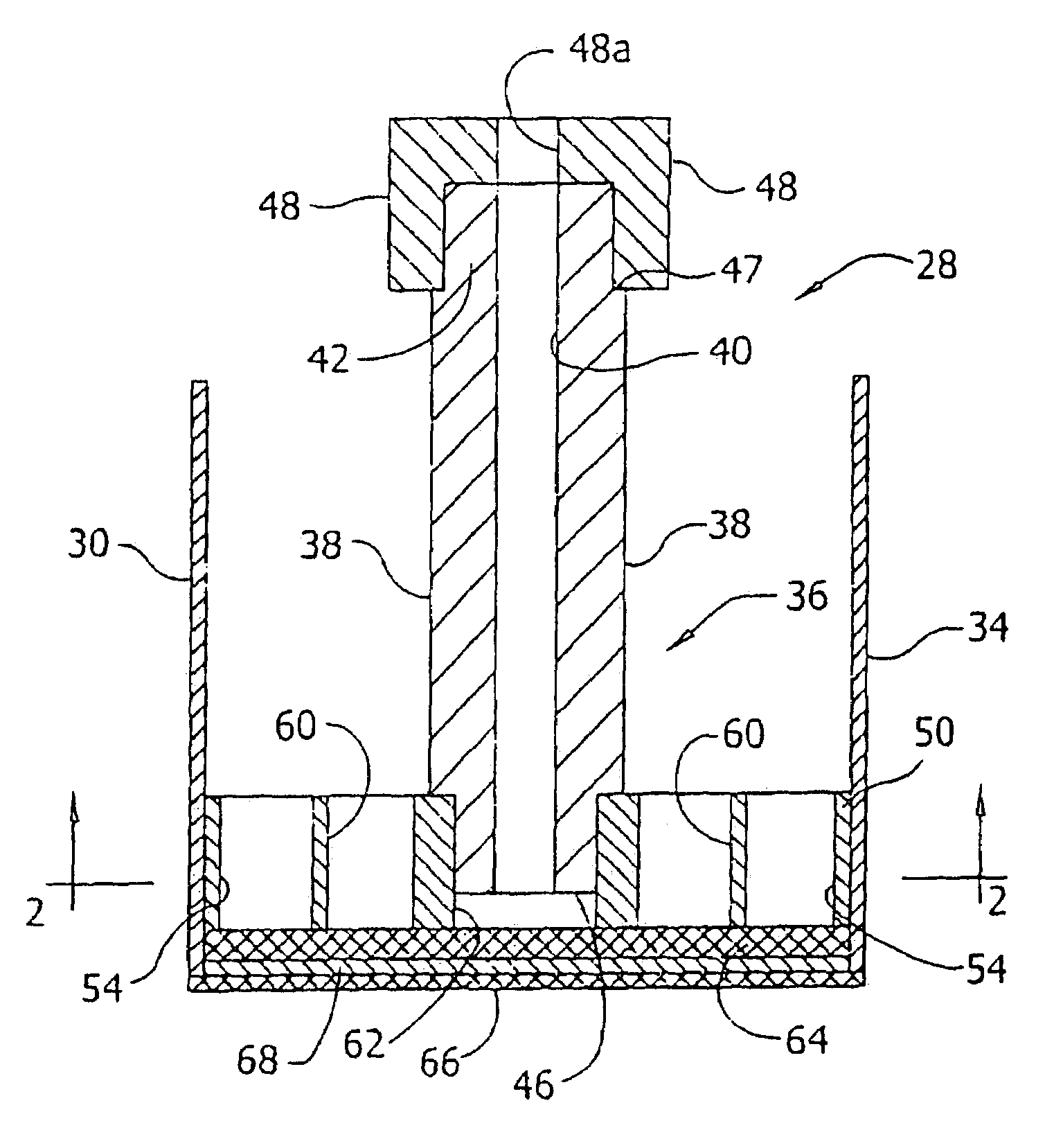

Methods for making and using composites, polymer scaffolds, and composite scaffolds

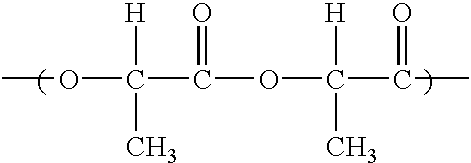

InactiveUS20070187857A1Promote safe productionTime-consumeDomestic articlesProsthesisOrganic solventTissue repair

The present invention relates to methods of making and using composites and scaffolds as implantable devices useful for tissue repair, guided tissue regeneration, and tissue engineering. In particular, the present invention relates to methods of making and using compression molded resorbable thermoplastic polymer composites which can be subsequently processed with non-organic solvents to create porous, resorbable thermoplastic polymer scaffolds or composite scaffold with interconnected porosity. Furthermore, these composites or scaffolds can be coated with an organic and / or inorganic material.

Owner:LOREM VASCULAR PTE LTD

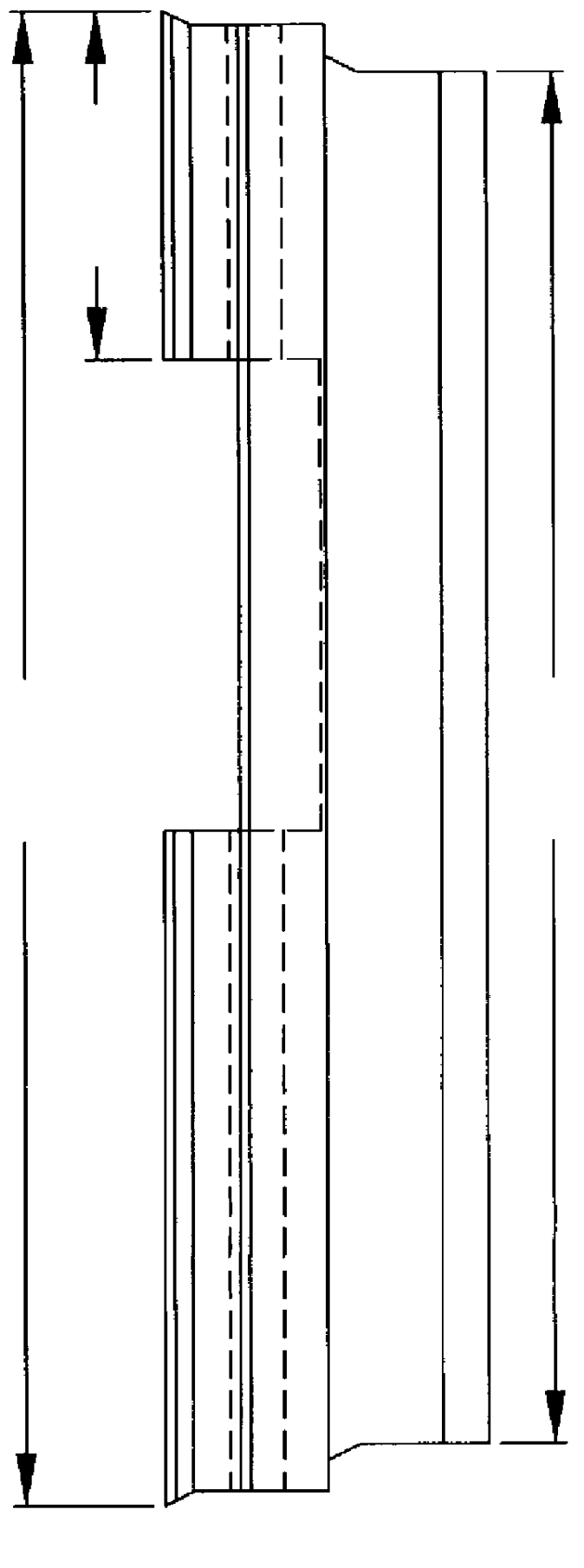

Surgical adapter assemblies for use between surgical handle assembly and surgical end effectors

An adapter assembly is provided for selectively interconnecting a surgical end effector that is configured to perform a function and a surgical device that is configured to actuate the end effector, the end effector including at least one axially translatable drive member, and the surgical device including at least one rotatable drive shaft. The adapter assembly includes at least one drive converter assembly including a drive shaft; a drive coupling nut threadably connected to a distal end portion of the drive shaft; and an axially translatable drive bar connected to the drive coupling nut, wherein rotation of the drive shaft results in axial translation of the drive bar. The drive coupling nut engages 29 teeth of the threaded distal end portion of the drive shaft. The drive coupling nut is manufactured from unreinforced PEEK thermoplastic polymer.

Owner:TYCO HEALTHCARE GRP LP

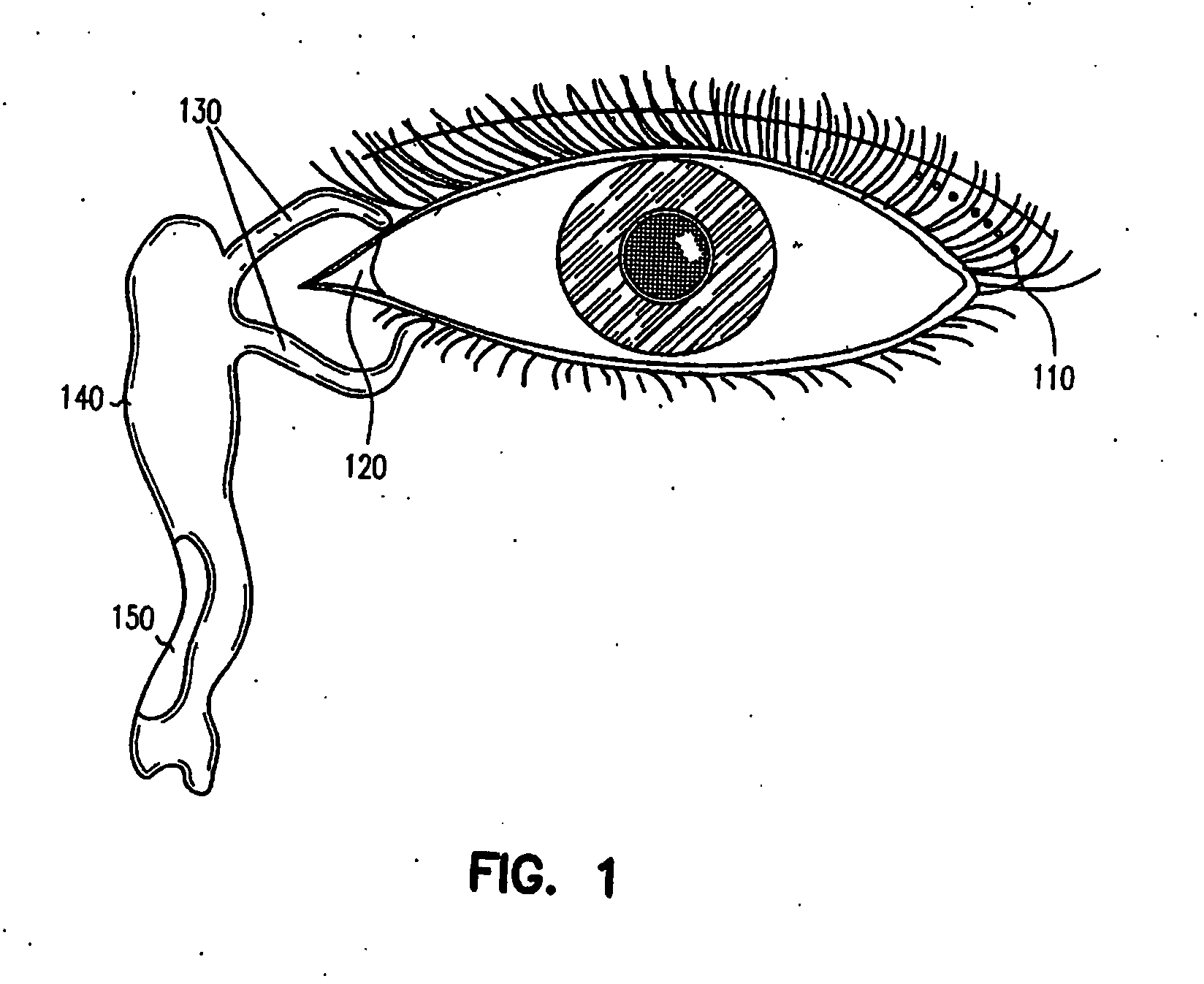

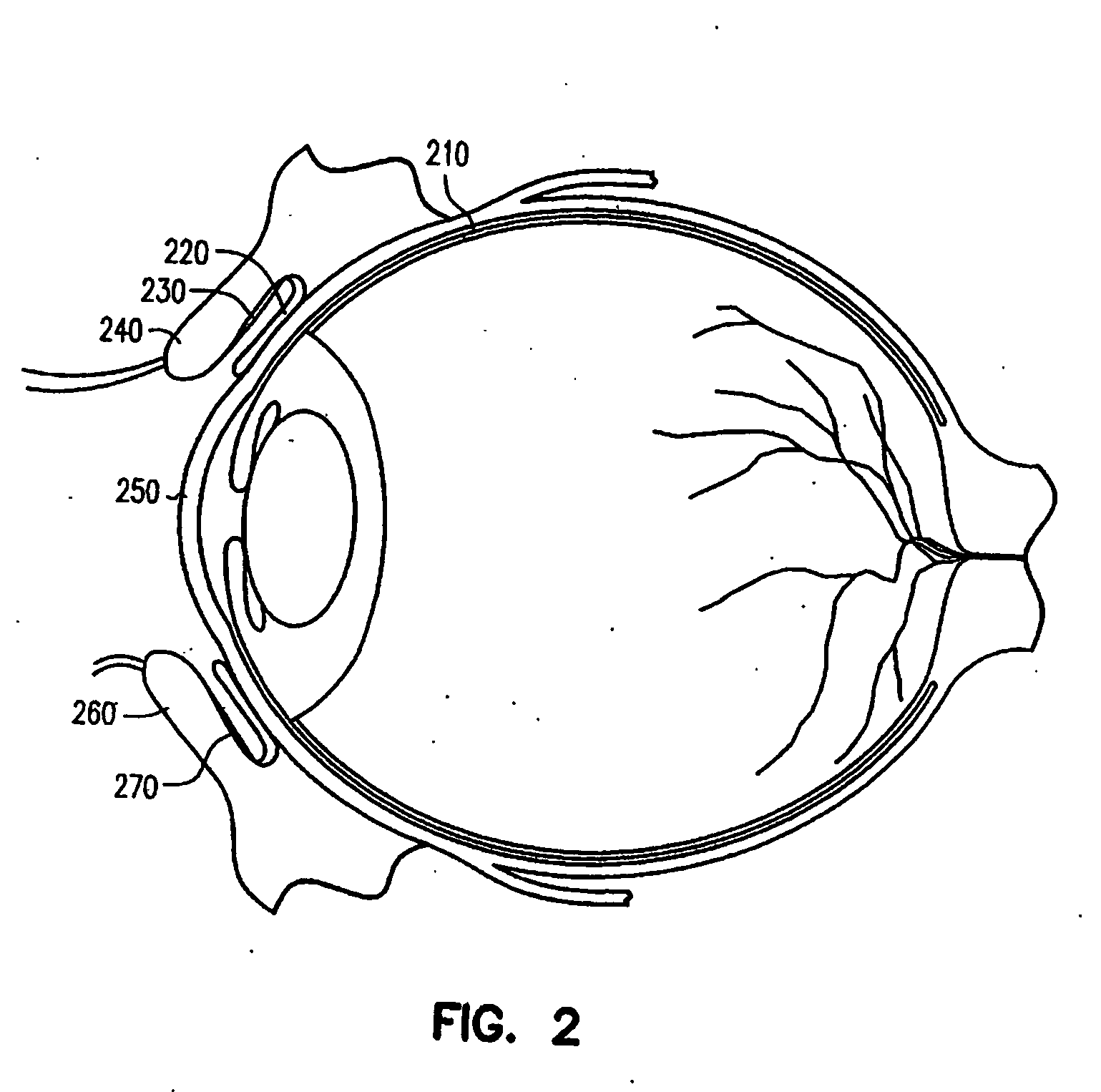

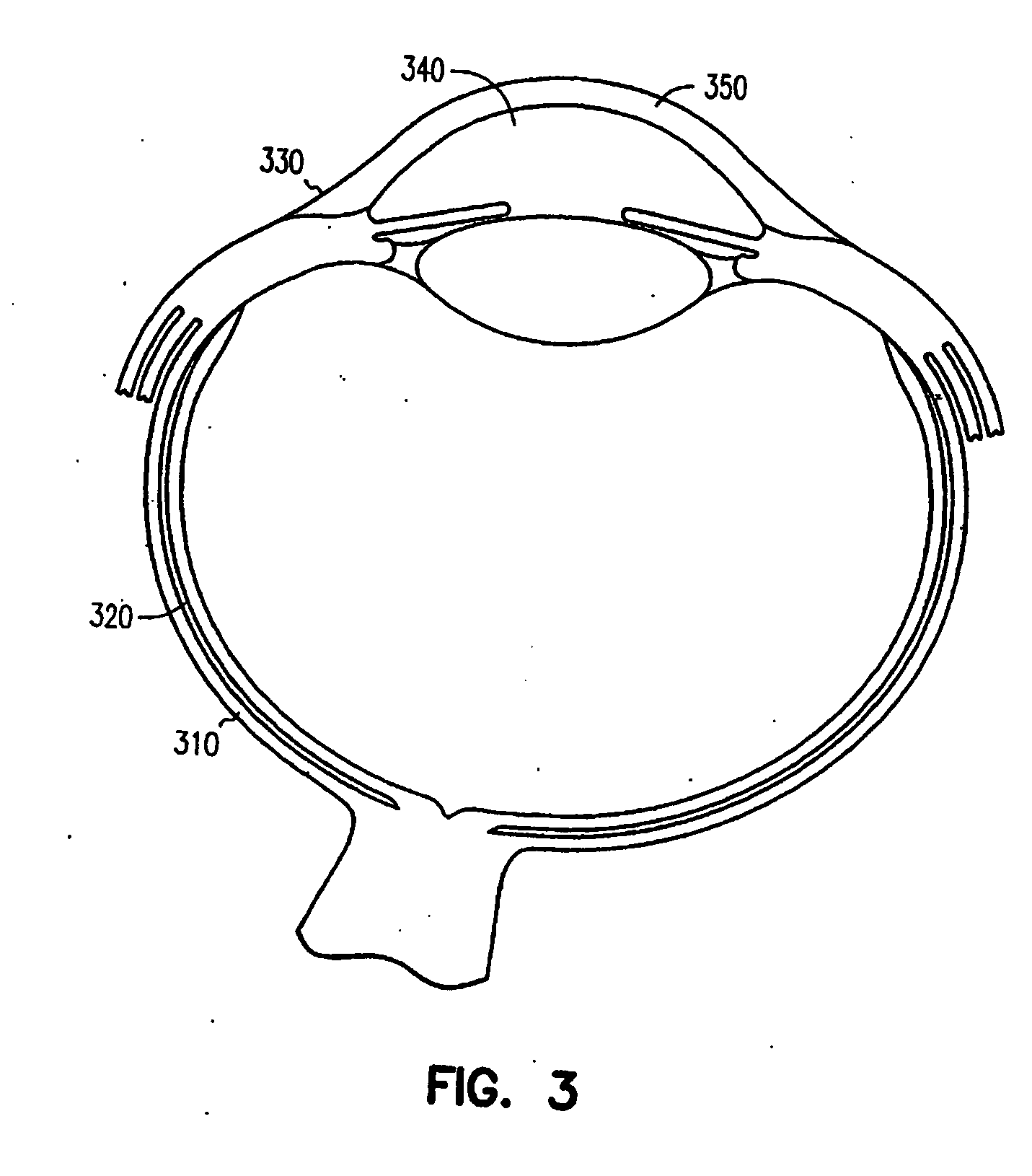

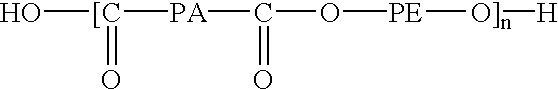

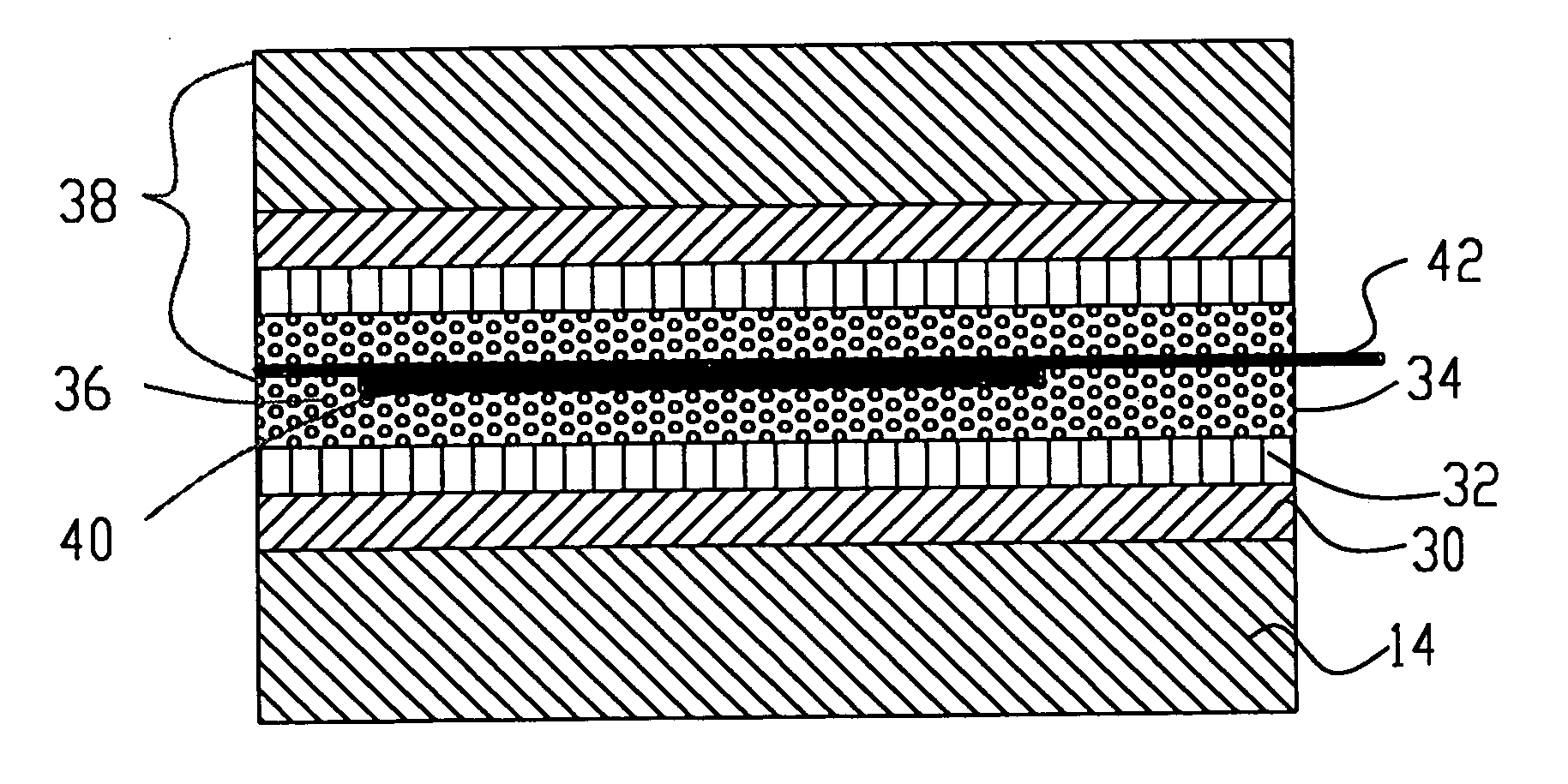

Ocular delivery of polymeric delivery formulations

InactiveUS20060210604A1Large doseEliminate lossSenses disorderPharmaceutical delivery mechanismControlled releaseMetabolite

The present invention provides a flowable composition suitable for use as a controlled release implant. The flowable composition can be administered into the ocular region of a mammal. The composition includes: (a) a biodegradable, biocompatible thermoplastic polymer that is at least substantially insoluble in aqueous medium, water or body fluid; (b) a biological agent, a metabolite thereof, a biological agently acceptable salt thereof, or a prodrug thereof; and (c) a biocompatible organic liquid, at standard temperature and pressure, in which the thermoplastic polymer is soluble. The present invention also provides methods of medical treatment that include administering the flowable composition into the ocular region of a mammal.

Owner:QLT USA INC

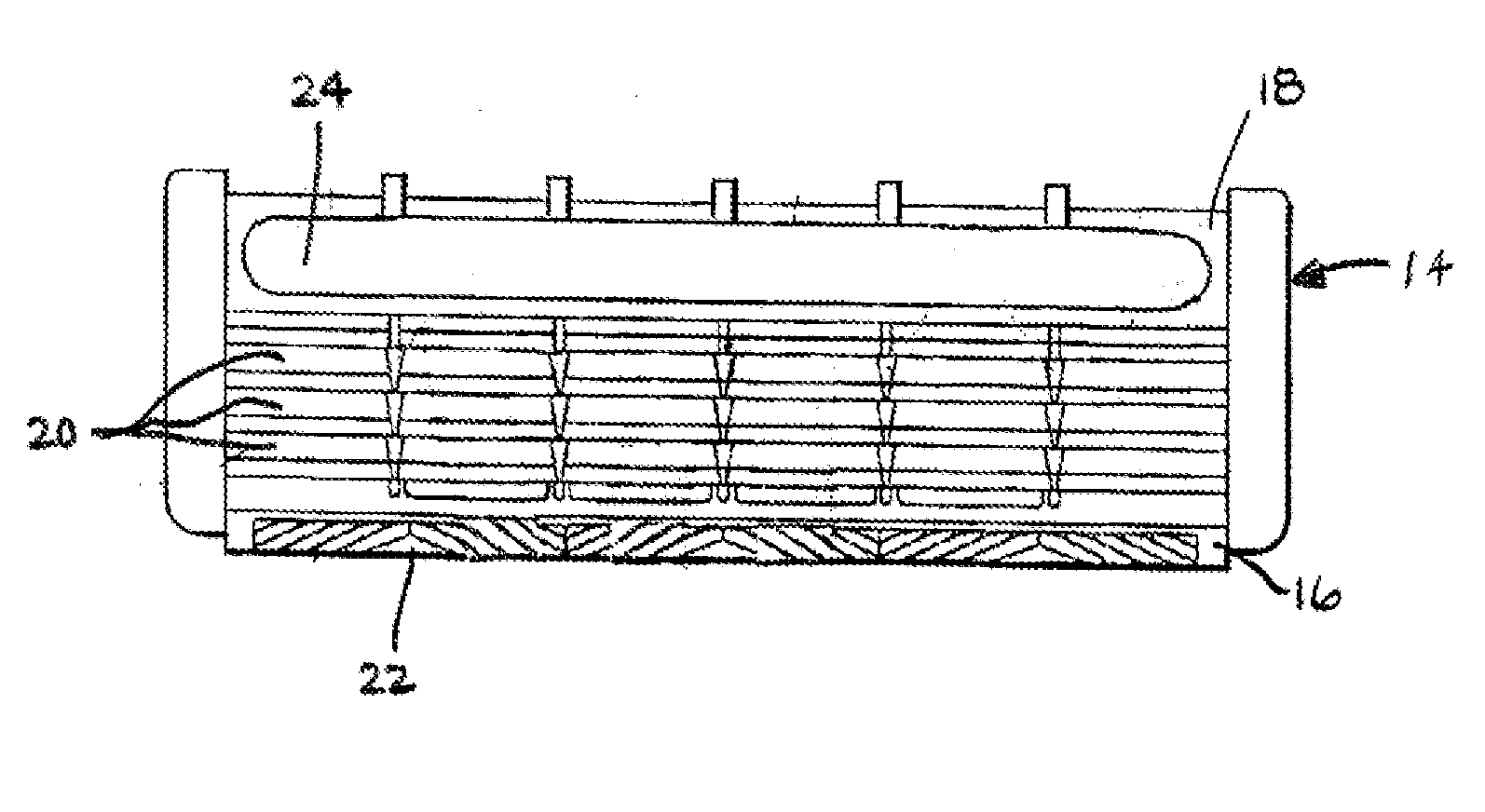

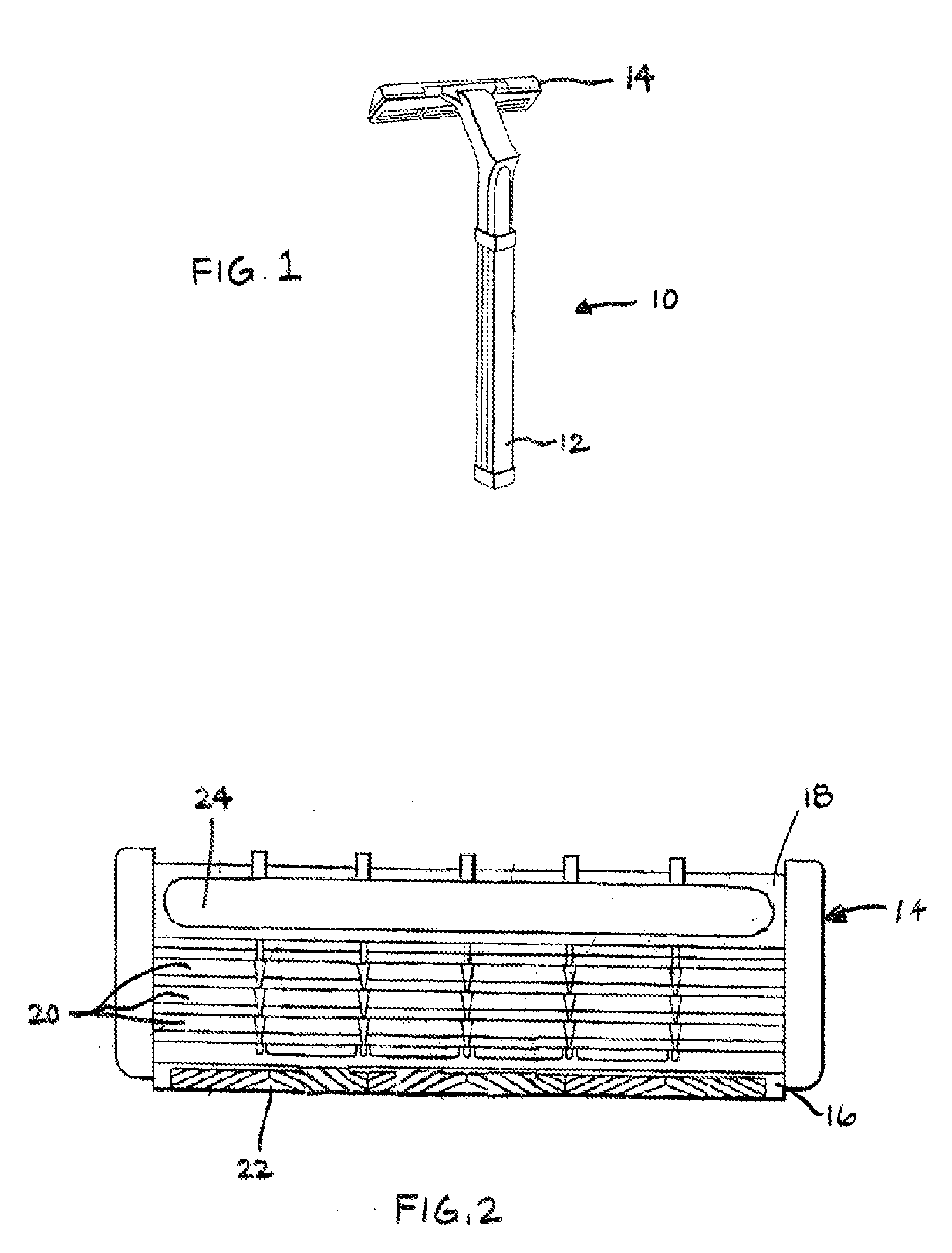

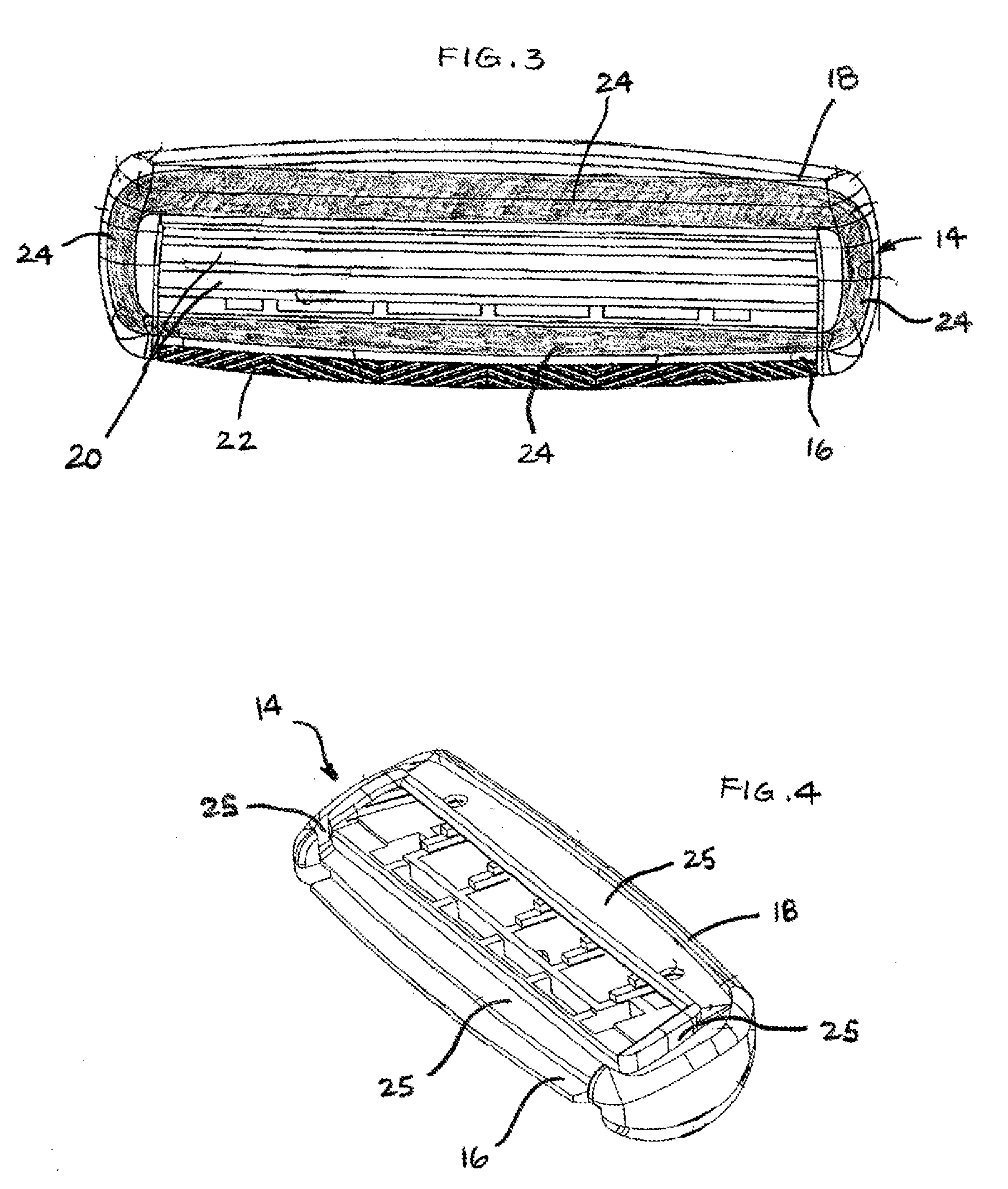

Shaving aid material

A shaving aid material is provided that includes a water-soluble lubricious shaving aid in combination with a water-insoluble erodable medium. In some embodiments, the shaving aid material further includes a water-soluble thermoplastic polymer, and may also include a plasticizer. Optional additional ingredients include emulsifiers, surfactants, skin conditioners, fragrances, depilatory agents, cleaning agents, medicinal agents, etc.

Owner:EDGEWELL PERSONAL CARE BRANDS LLC

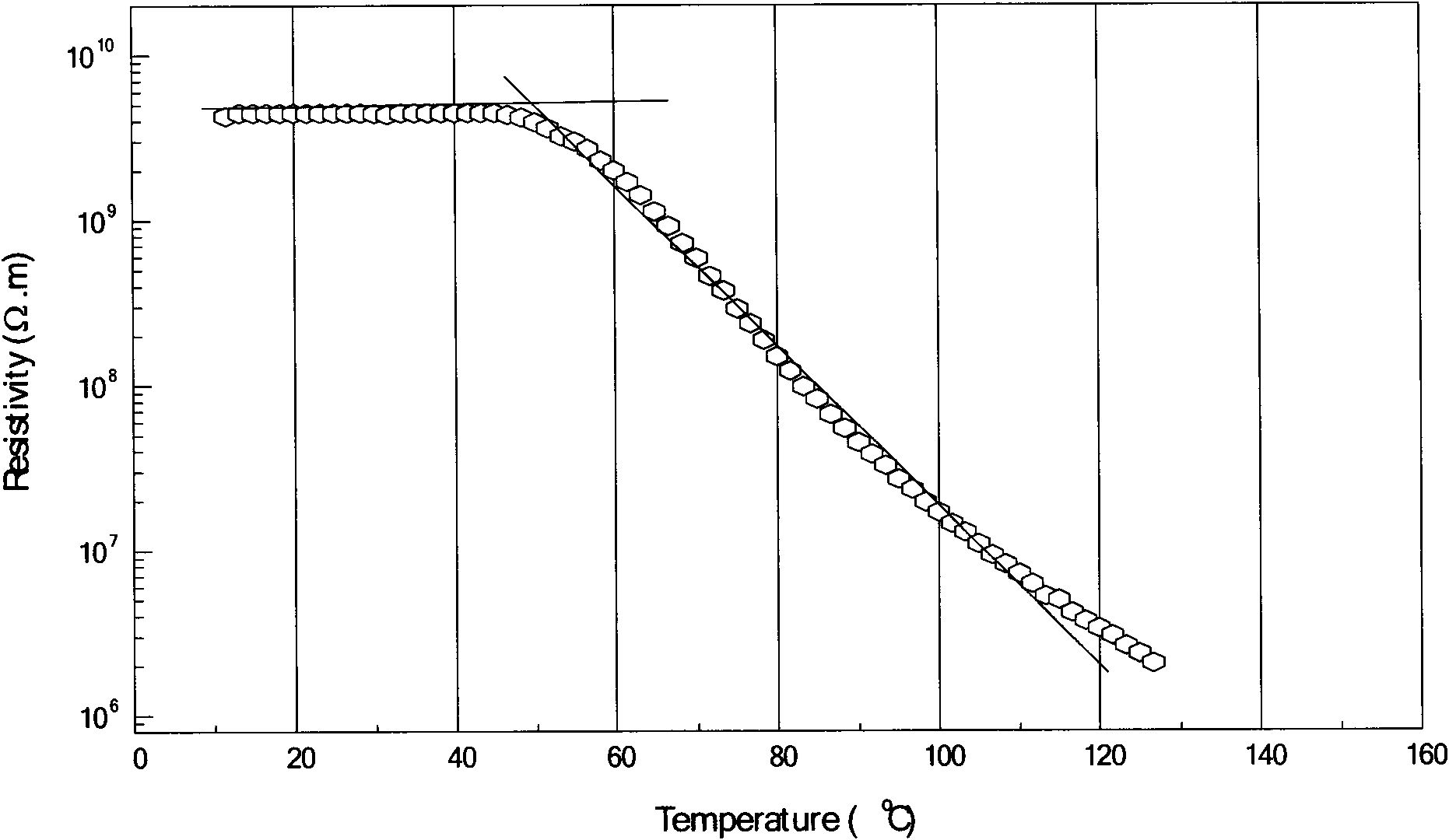

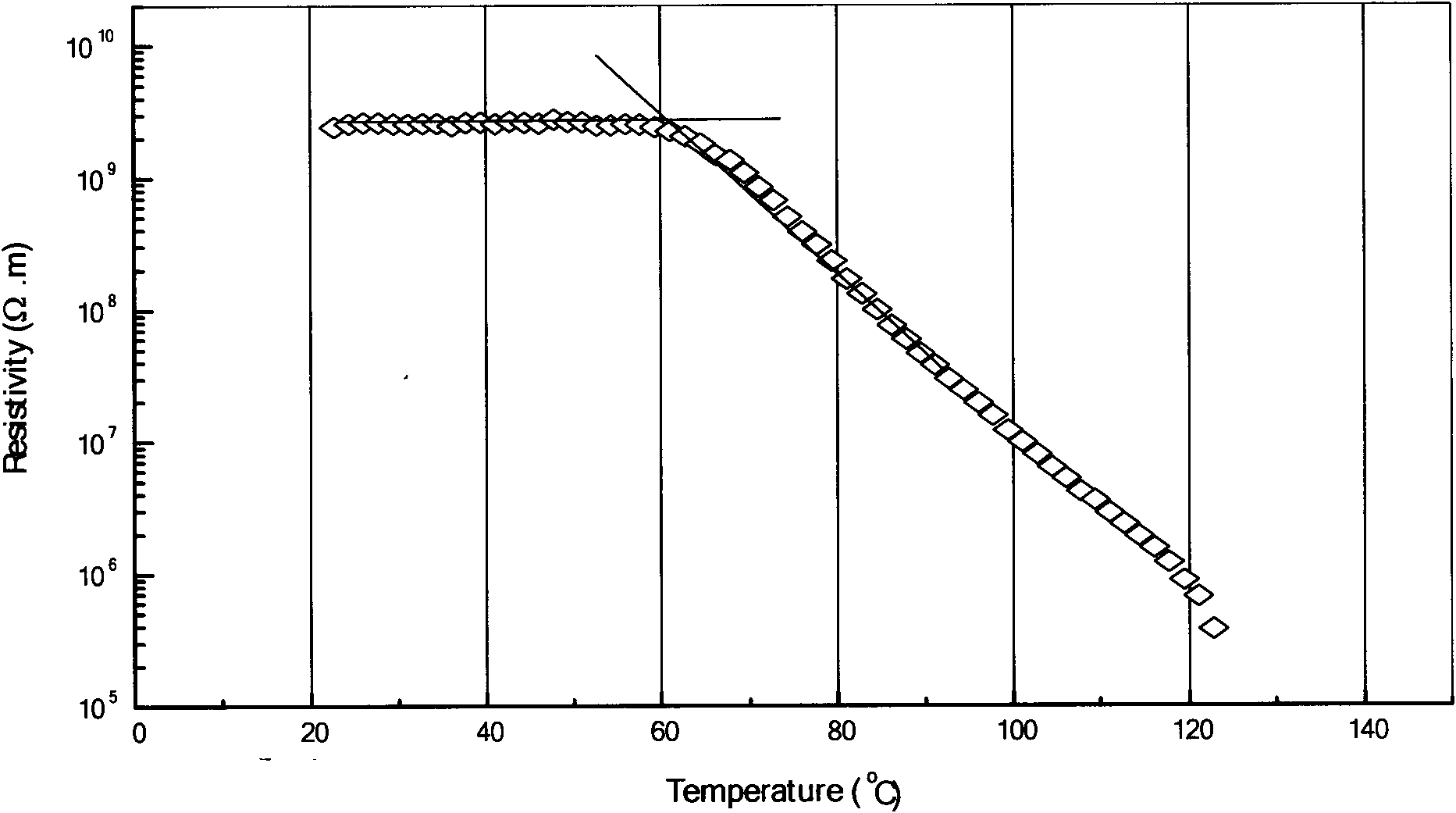

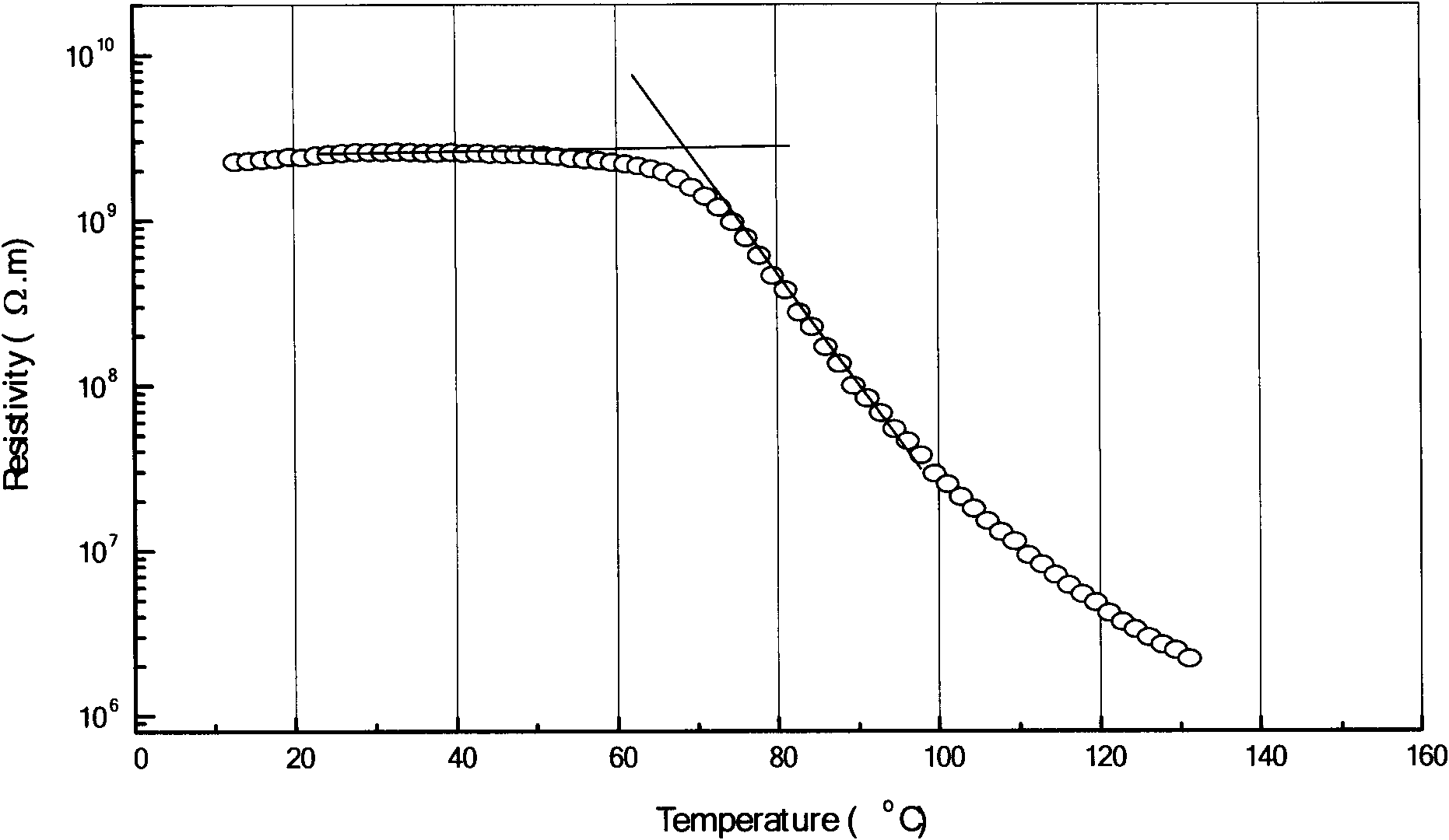

Temperature sensing cable material with CRT characteristics and preparation method thereof

ActiveCN101613504AWith CTR featureFlexibleRubber insulatorsPlastic/resin/waxes insulatorsProcedure AgentsAntioxidant

The invention relates to technical fields of materials, chemical engineering and electronics, in particular to a cable material with a polymer substrate and CTR effect and a preparation method thereof. The temperature sensing cable material with CRT characteristics consists of thermoplastic polymer, a filling agent, a plasticizer, functional additives, a stabilizing agent, a flame retardant, a lubricant, an antioxidant and a processing agent, has the use temperature range between -30 and 150 DEG C, and can be applied on occasions such as recoverable line-type temperature sensing cables, fire prewarning and alarm devices, temperature measurement, overheating alarm and protection and the like. The temperature sensing cable material with the CRT characteristics takes a polymer material as a substrate, and is added with multiple organic and inorganic compounds with special CTR characteristics taken as the functional additives, and has the characteristics of flexibility, and capacities of being continuously processed and being used like a common cable material.

Owner:QINGDAO SUNYFIRE TECHNOLOGE

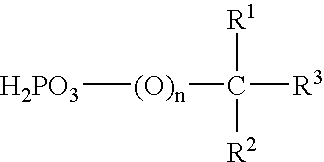

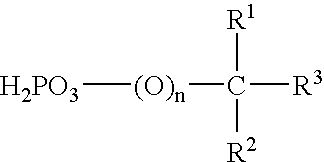

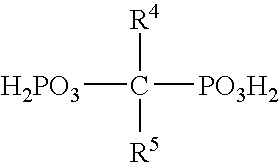

Negative Working, Heat-Sensitive, Lithographic Printing Plate Precursor

ActiveUS20080213696A1Number of defectSize of defectPhotosensitive materialsDuplicating/marking methodsSimple Organic CompoundsPhosphoric acid

A heat-sensitive negative-working lithographic printing plate precursor includes on a grained and anodized aluminum support a coating including hydrophobic thermoplastic polymer particles, a hydrophilic binder, and an organic compound, wherein the organic compound includes at least one phosphonic acid group or at least one phosphoric acid group or a salt thereof.

Owner:AGFA OFFSET BV

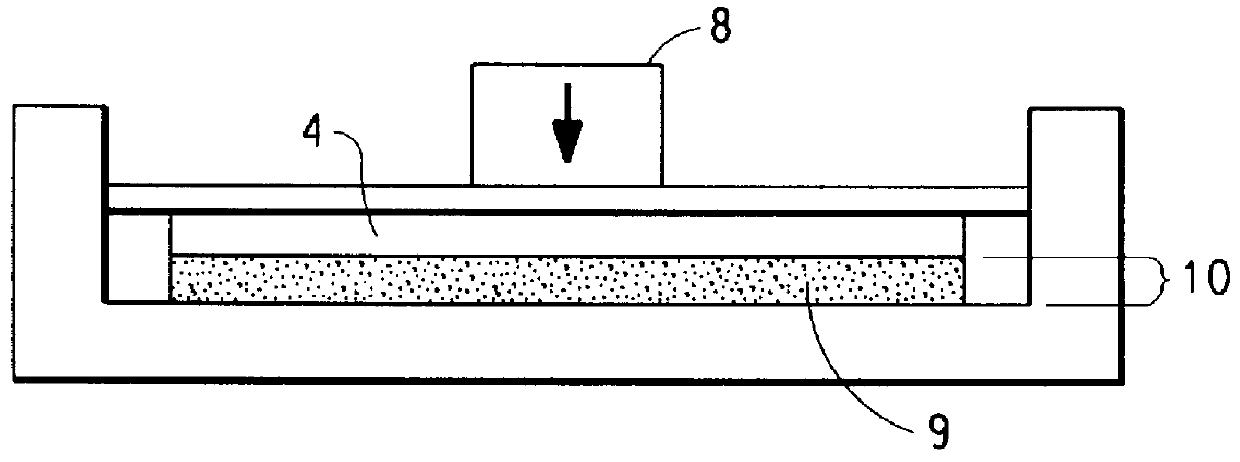

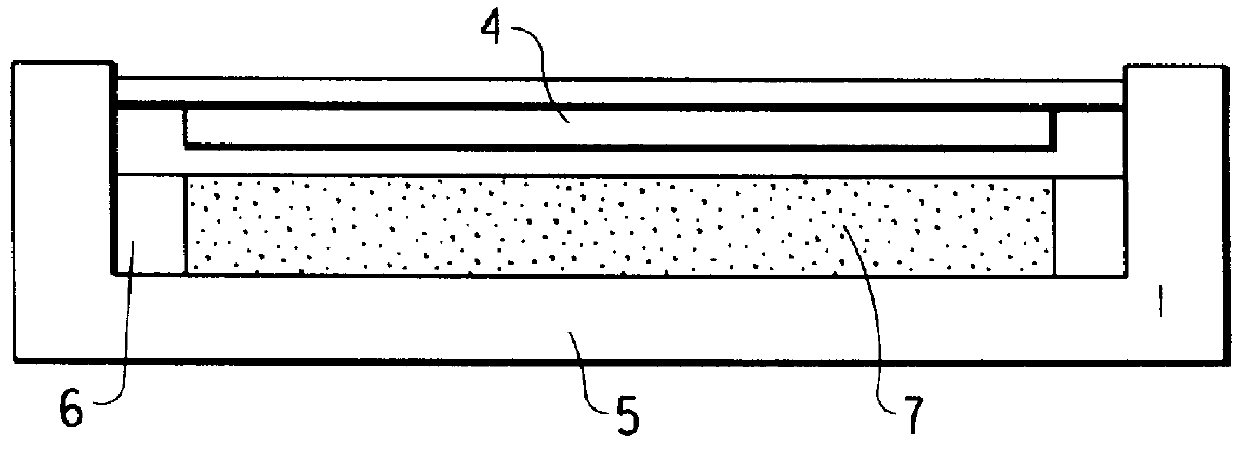

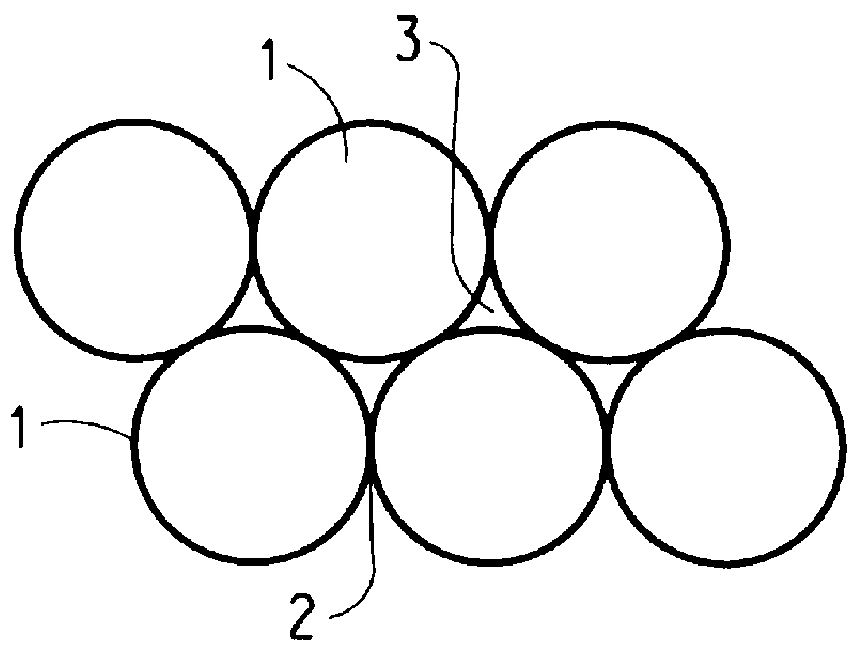

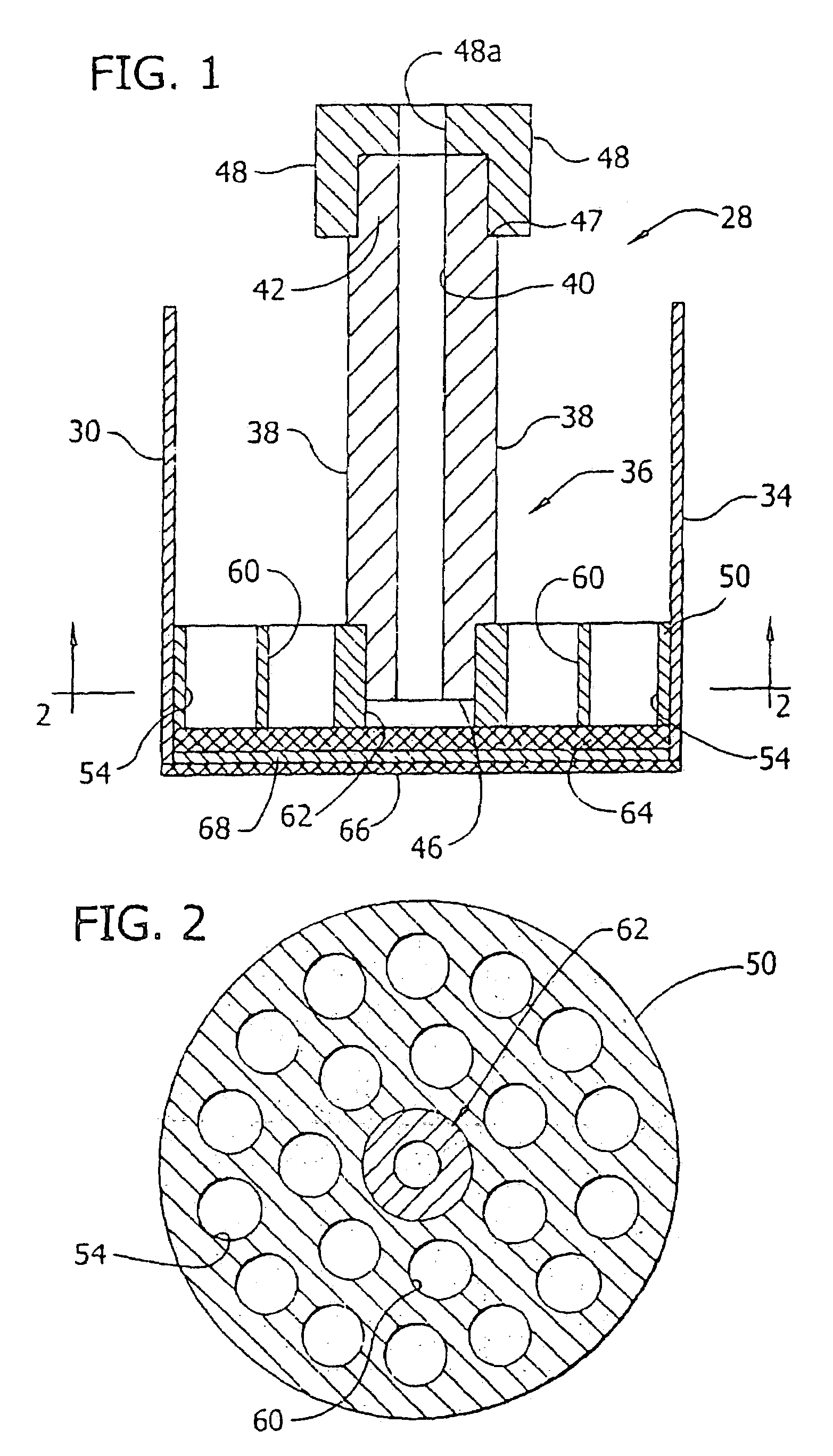

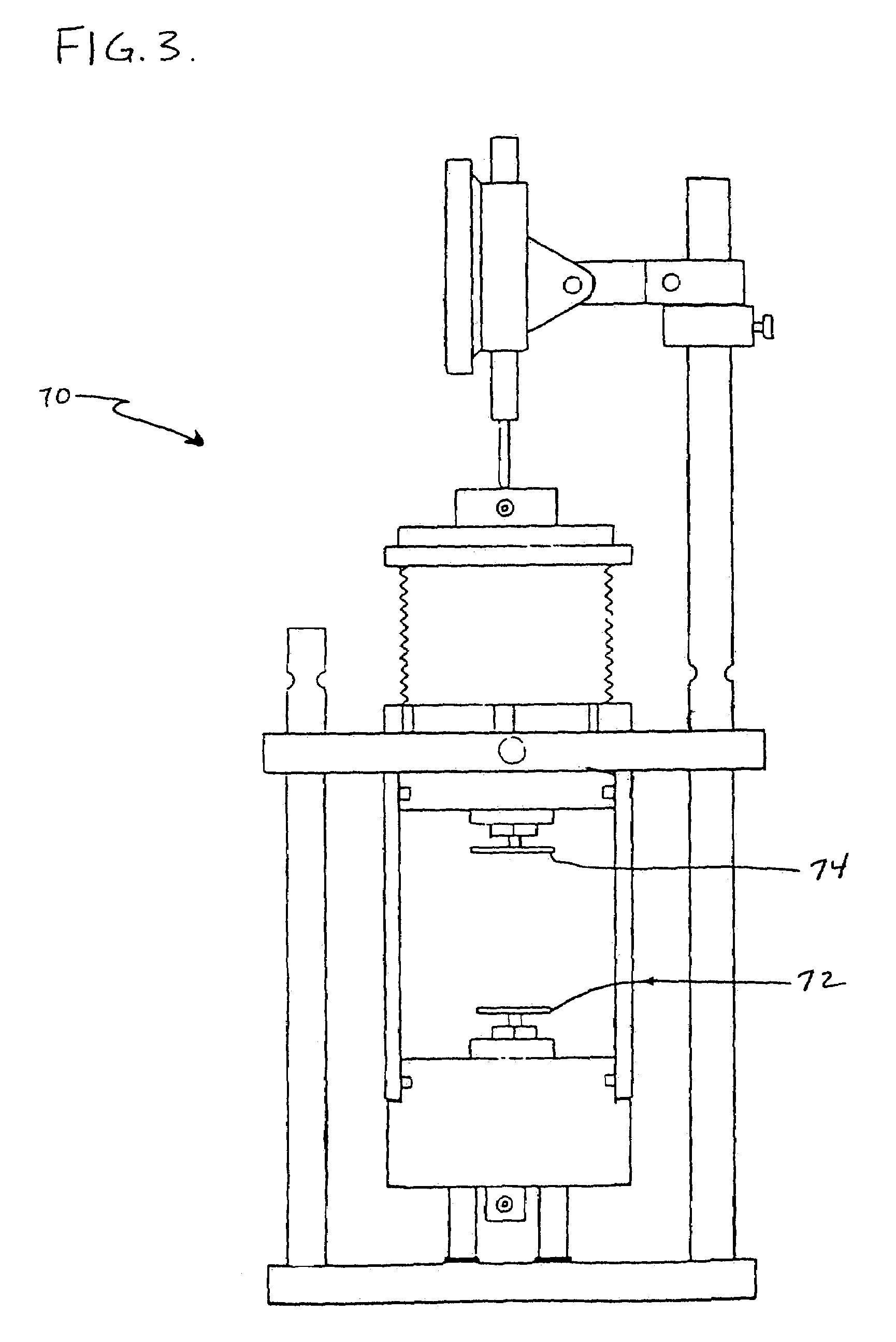

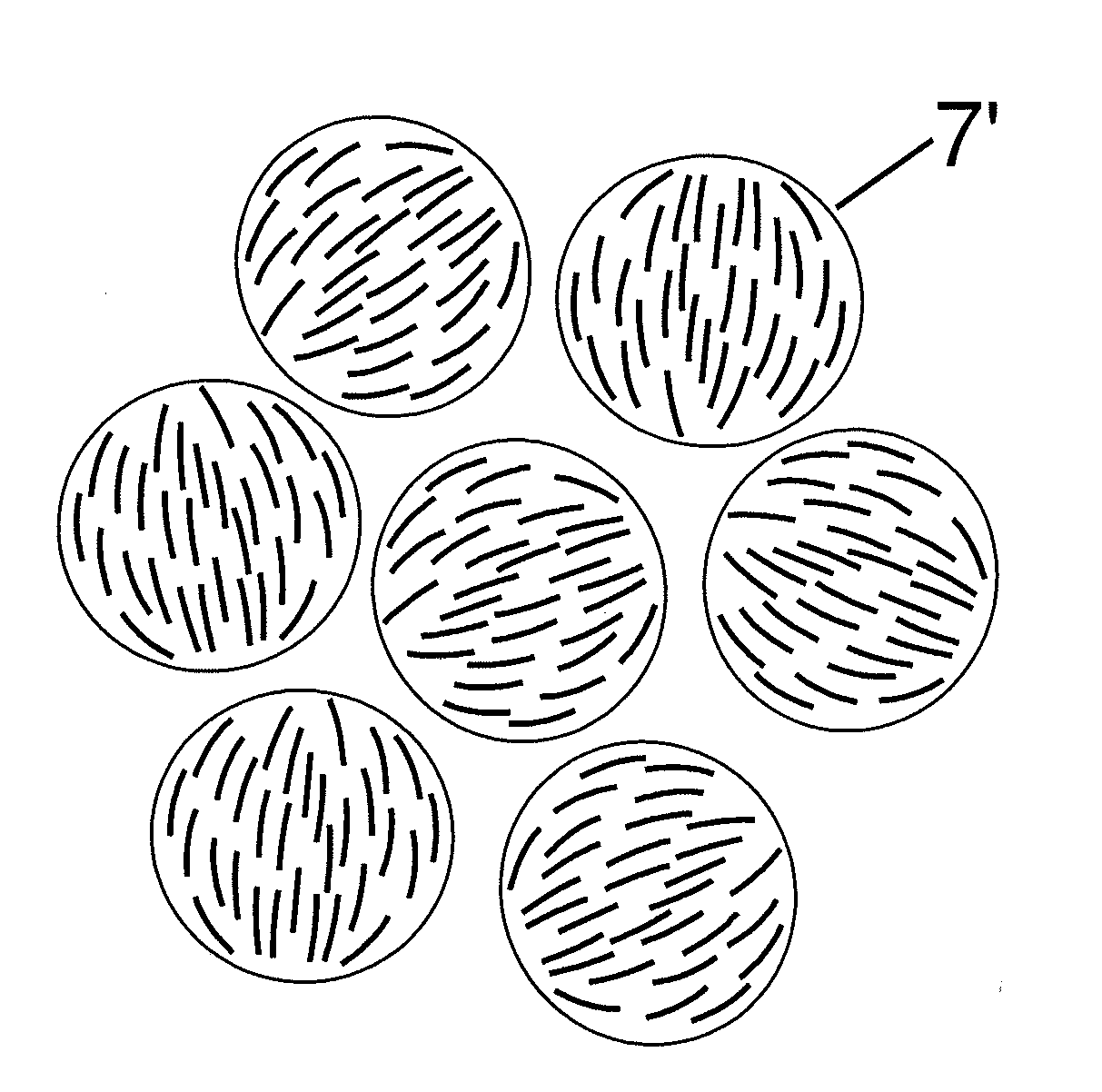

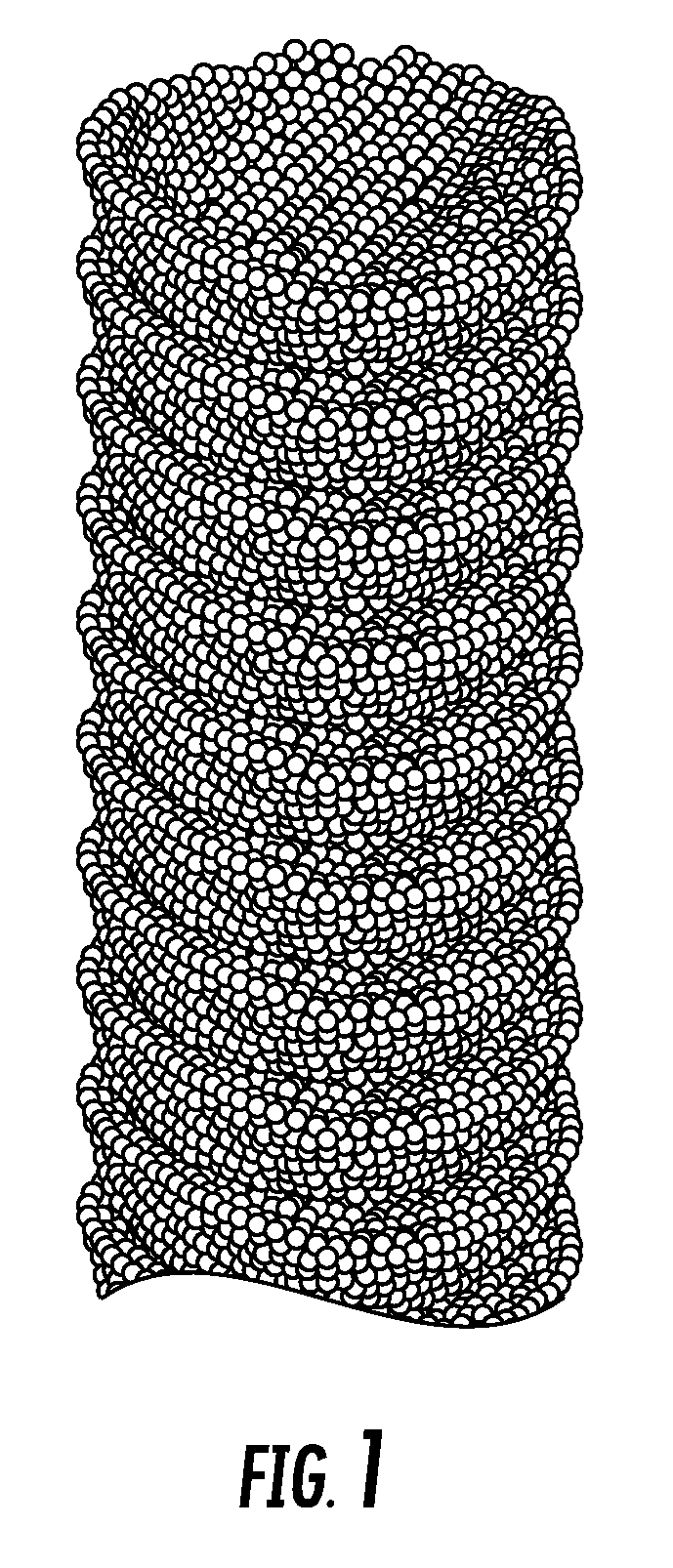

Methods for using polishing pads

Polymer-based pads useful for polishing objects, particularly integrated circuits, having interconnected porosity which is uniform in all directions, and where the solid portion of said pad consists of a uniform continuously interconnected polymer material of greater than 50% of the gross volume of the article, are produced directly to final shape and dimension by pressure sintering powder compacts of thermoplastic polymer at a temperature above the glass transition temperature but not exceeding the melting point of the polymer and at a pressure in excess of 100 psi in a mold having the desired final pad dimensions. In a preferred version, a mixture of two polymer powders is used, where one polymer has a lower melting point than the other. When pressure sintered at a temperature not to exceed the melting point of the lower melting powder, the increased stiffness afforded by incorporation of the higher melting polymer component gives improved mechanical strength to the sintered product. Conditions for producing the pads of this invention are such that the polymer powder particles from which the pads are produced essentially retain their original shape and are point bonded to form the pad.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Superabsorbent polymer with high permeability

Owner:EVONIK SUPERABSORBER LLC

Thermally conductive thermoplastic

InactiveUS6162849AImprove thermal conductivityImprove mechanical propertiesPlastic/resin/waxes insulatorsMixingThermoplasticPolymer science

This invention relates to a thermally conductive moldable polymer blend comprising a thermoplastic polymer having a tensile at yield of at least 10,000 psi; at least 60% by weight of a mixture of boron nitride powders having an average particle size of at least 50 microns; and a coupling agent. The composition displays a thermal conductivity of at least about 15 W / m DEG K and it is capable of being molded using high speed molding techniques such as injection molding.

Owner:FERRO CORP

Highly-resilient thermoplastic elastomer compositions

A thermoplastic composition of (a) an acid copolymer, (b) a salt of a high molecular weight, monomeric organic acid; (c) a thermoplastic polymer selected from copolyetheresters, elastomeric polyolefins, styrene diene block copolymers, elastomeric polyolefins thermoplastic polyurethanes and copolyetheramides; (d) cation source; and (d) optionally a filler. Also included is use of such compositions in components of one-, two- and three-piece golf balls or multi-layered golf balls made therefrom.

Owner:EI DU PONT DE NEMOURS & CO

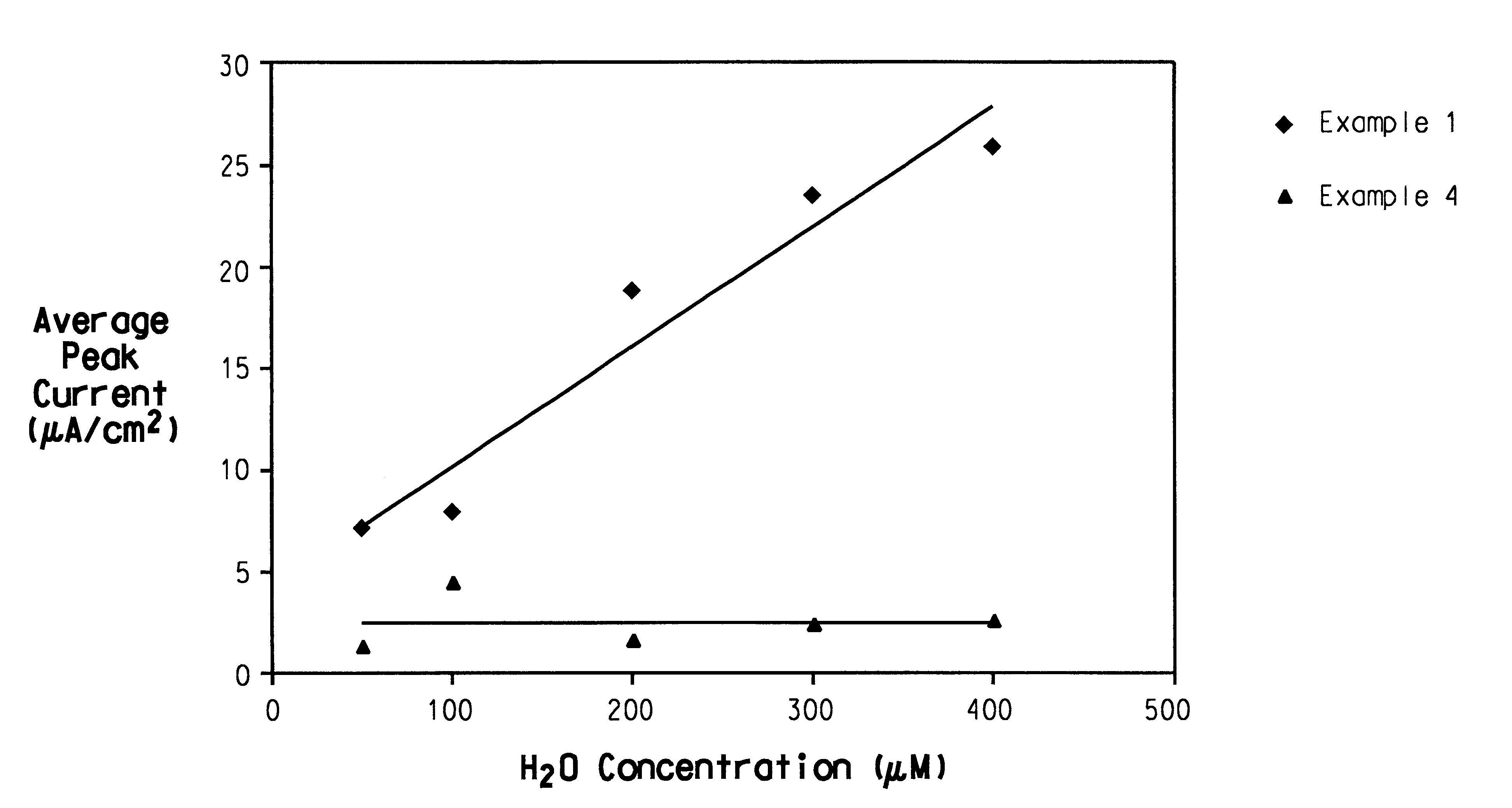

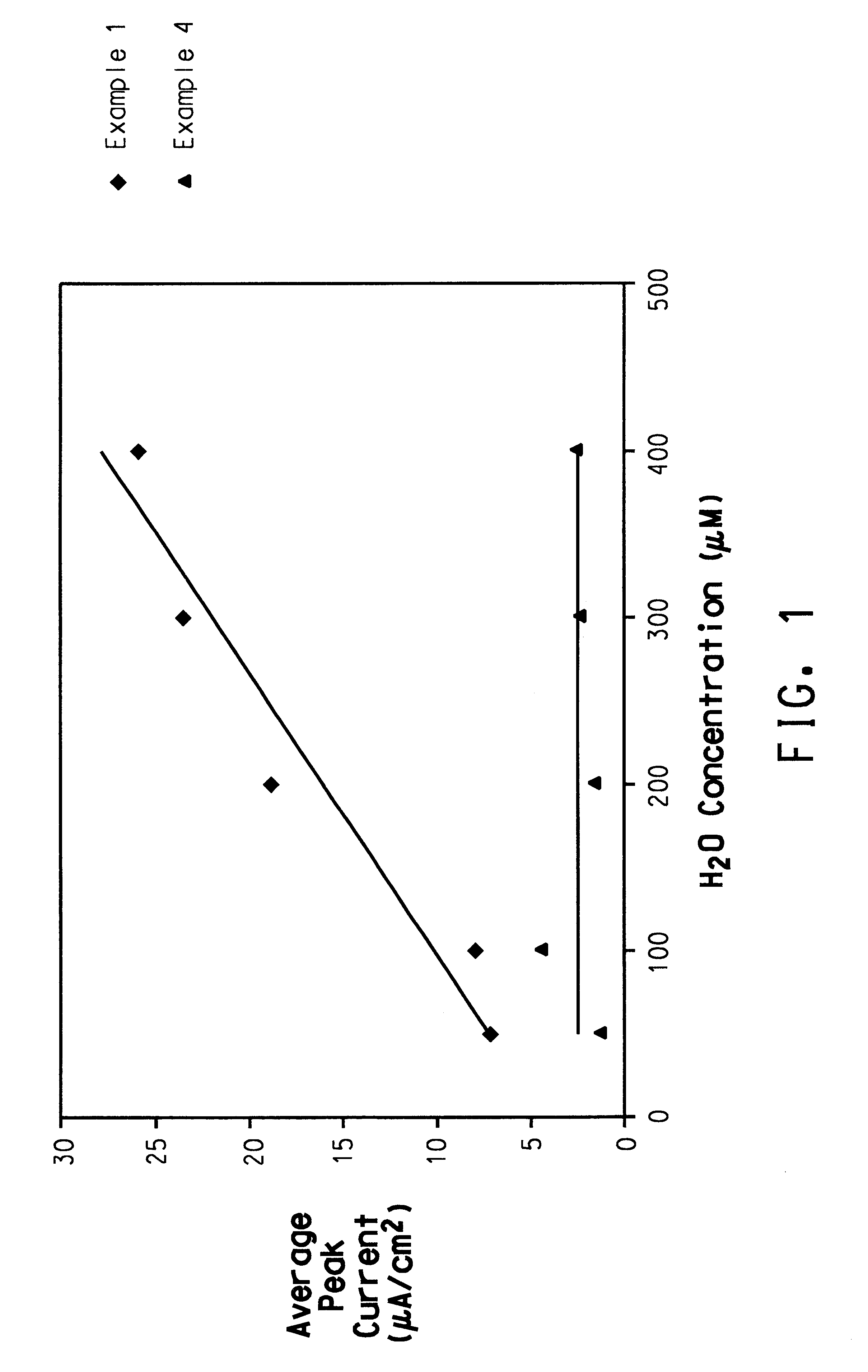

Thick film conductor composition for use in biosensors

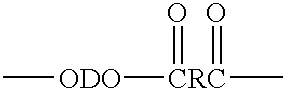

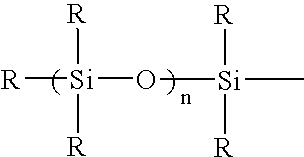

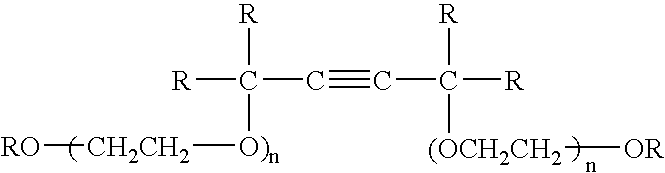

InactiveUS6627058B1Immobilised enzymesBioreactor/fermenter combinationsElectrical conductorPolyethylene glycol

This invention is directed to a composition comprising: (a) platinum group metal powder, alloys, or mixtures thereof as a powder or deposited on graphite supports; (b) poly(glycol ether), derivatives, or mixtures thereof; (c) carbon-based electrically conductive filler; and (d) thermoplastic polymer or mixtures thereof. The invention is further directed to a process for dispersing platinum group metal powder, alloys, or mixtures thereof in poly(glycol ether), derivatives, or mixtures thereof. The invention is further directed to the above composition wherein the platinum group metal powder has been dispersed according to the above process.

Owner:EI DU PONT DE NEMOURS & CO

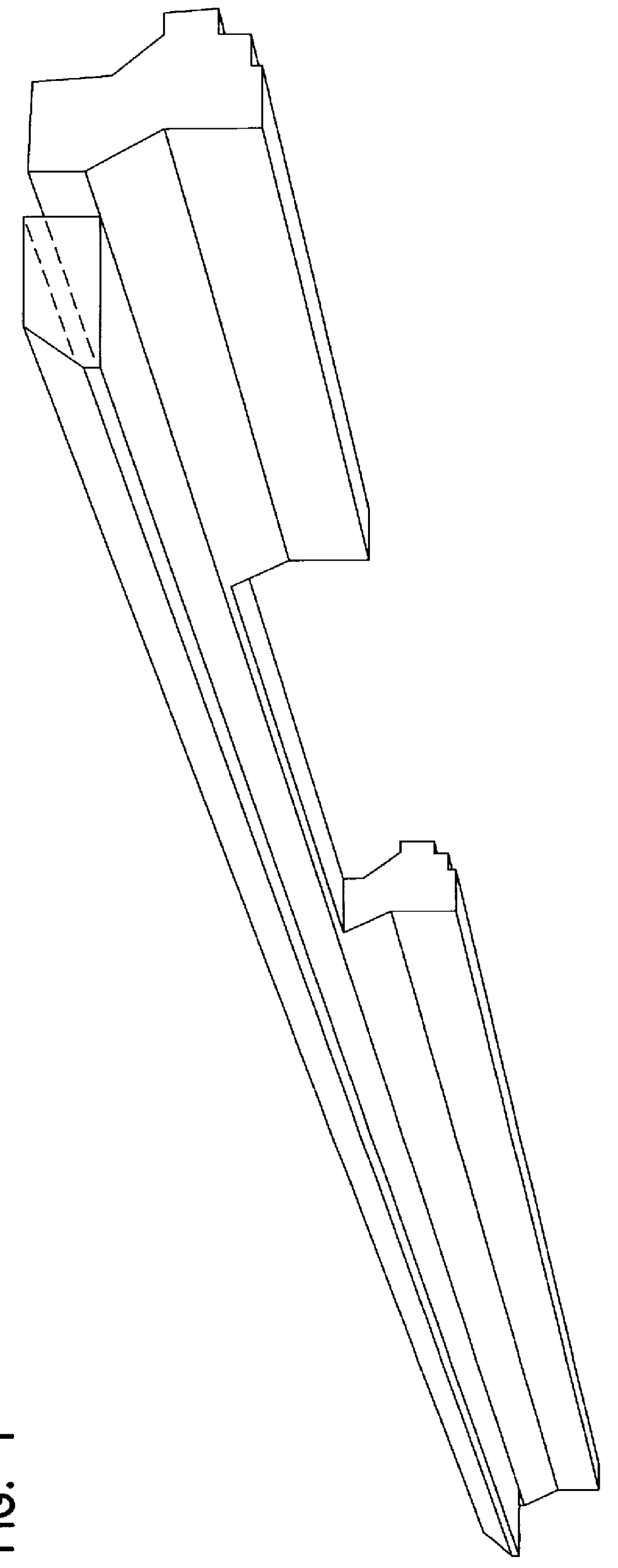

Foamed thermoplastic polymer and wood fiber profile and member

InactiveUS6054207AHigh compressive strengthImproved fastener retentionConstruction materialLoad-supporting elementsComposite constructionThermoplastic

Advanced structural components comprising a foamed thermoplastic that can be used in virtually any application where wooden components have a use. Such structural components can comprise sized lumber, shaped trim, posts, beams or shaped structural members. An advanced profile composite structural component comprising an exterior capping layer with an interior comprising a foamed thermoplastic can be used in the assembly of fenestration units adapted to residential and commercial structures. Preferably the profile structural component can be used in a window or door assembly. The profile member is adapted for ease of construction of the fenestration units, can be easily installed in a rough opening to framing members, and can be trimmed and adjusted on site. The profile is structurally strong, thermally stable, shrink resistant and will accept and retain the insertion of fasteners such as staples, nails and screws permanently with substantial retention and little or no damage to the units. The profile structural components possess strength that permits the manufacture of a structurally sound fenestration unit from two or more foamed profile members or other conventional members.

Owner:ANDERSEN CORPORATION

Antimicrobial articles

InactiveUS20050249791A1Promote migrationEliminate the problemBiocideAdhesive dressingsWound dressingSurgical tape

An antimicrobial article is disclosed comprising a layer of a thermoplastic polymer, and an adhesive layer having a antimicrobial agent dispersed therein. The antimicrobial article is useful, for example, surgical tapes, surgical drapes and wound dressings, and as disposable surfaces for food preparation and handling.

Owner:3M INNOVATIVE PROPERTIES CO

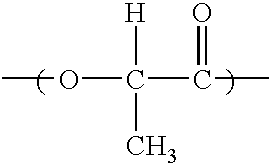

Fibers comprising starch and biodegradable polymers

Owner:PROCTER & GAMBLE CO

Elastic blends comprising crystalline polymer and crystallizable polymers of propylene

Improved thermoplastic polymer blend compositions comprising an isotactic polypropylene component and an alpha-olefin and propylene copolymer component, said copolymer comprising crystallizable alpha-olefin sequences. In a preferred embodiment, improved thermoplastic polymer blends are provided comprising from about 35% to about 85% isotactic polypropylene and from about 30% to about 70% of an ethylene and propylene copolymer, wherein said copolymer comprises isotactically crystallizable propylene sequences and is predominately propylene. The resultant blends manifest unexpected compatibility characteristics, increased tensile strength, and improved process characteristics, e.g., a single melting point.

Owner:EXXONMOBIL CHEM PAT INC

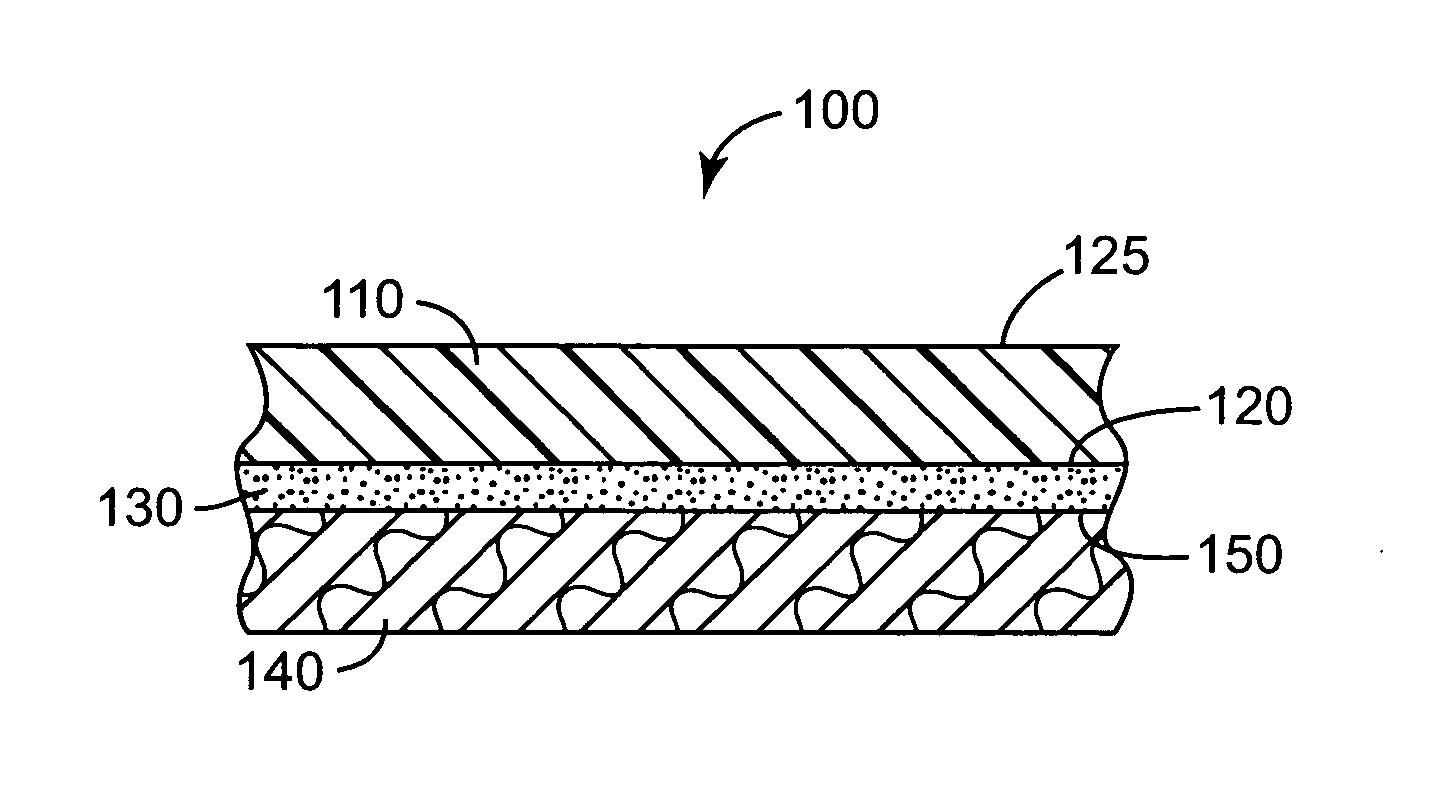

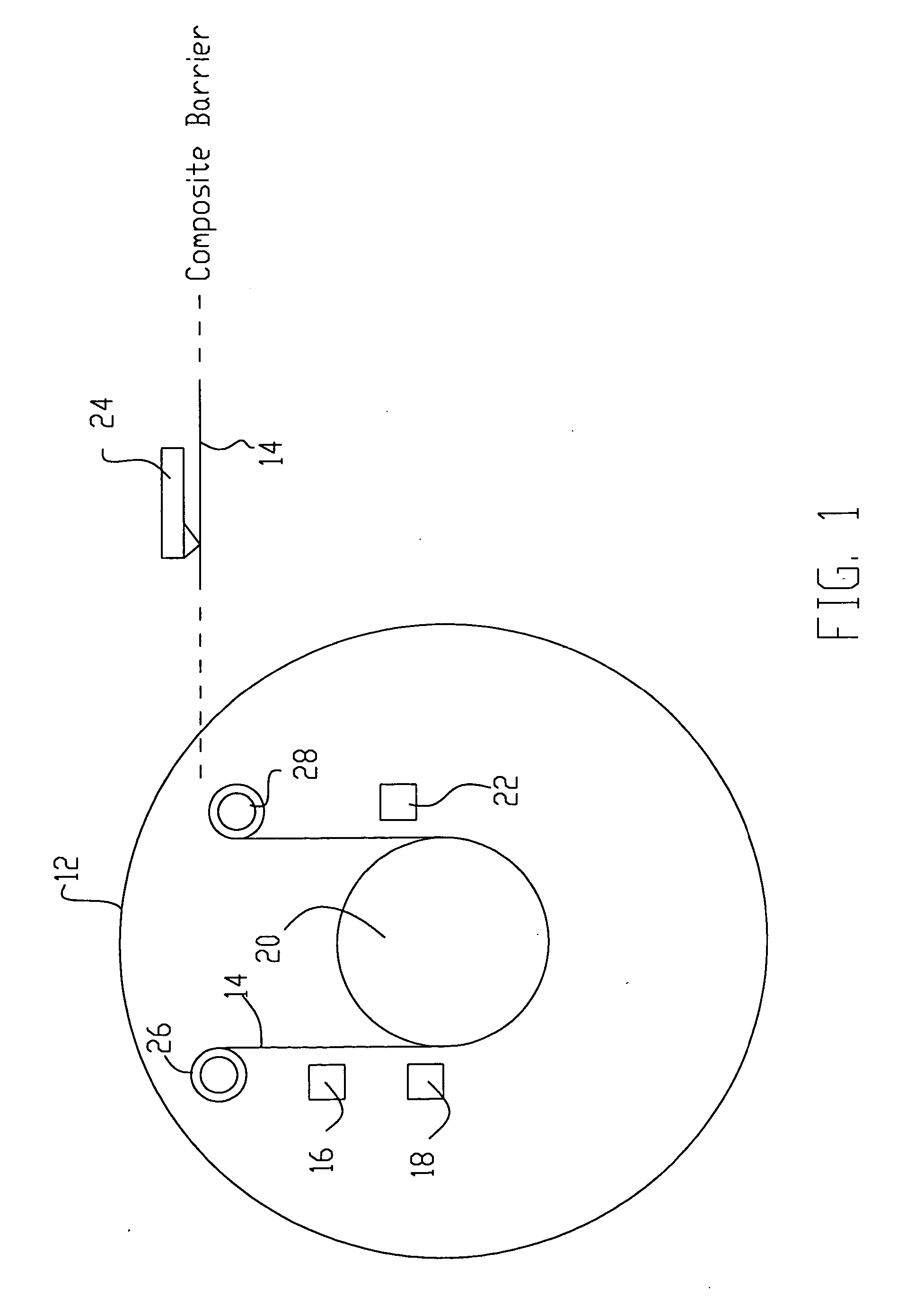

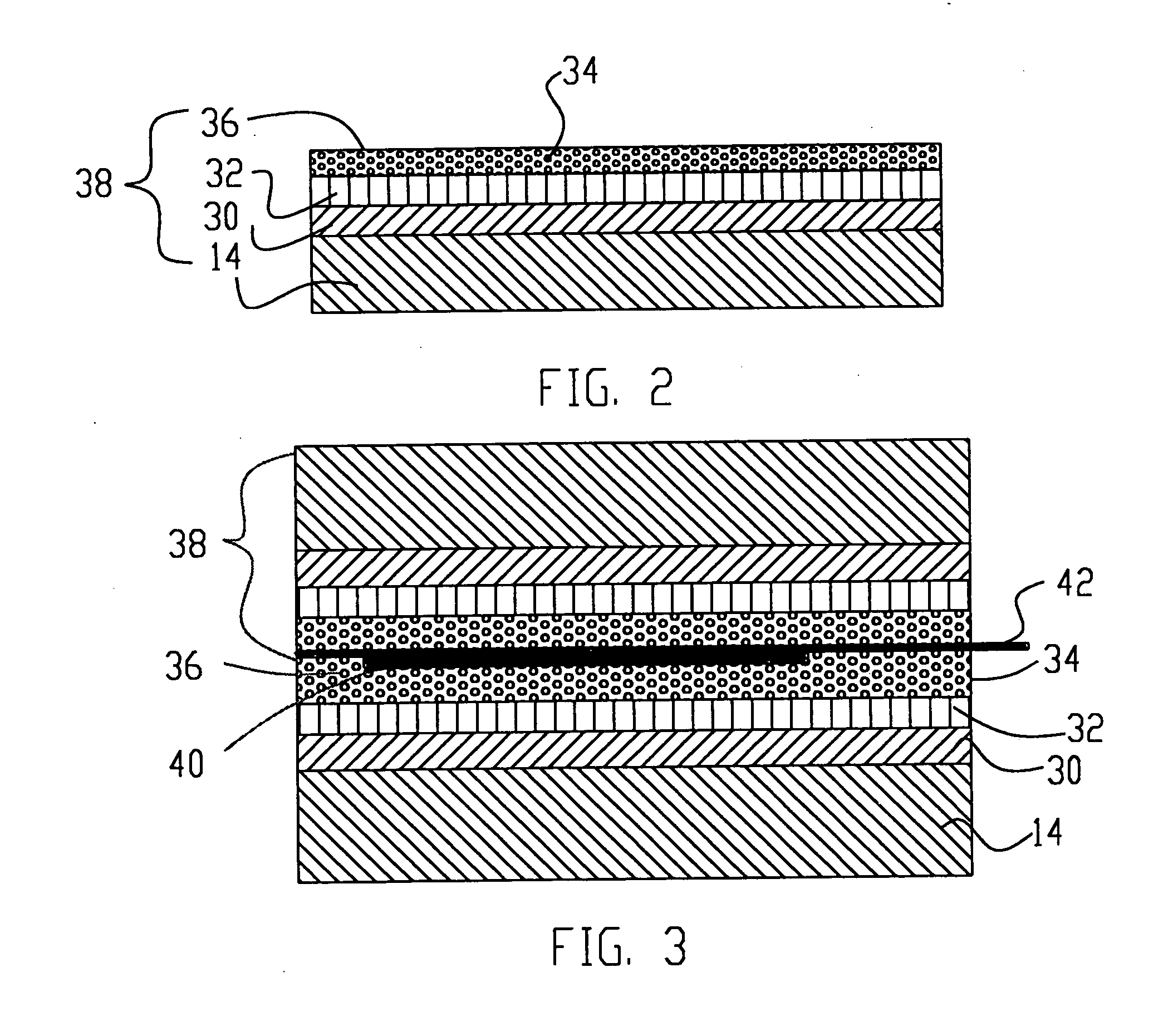

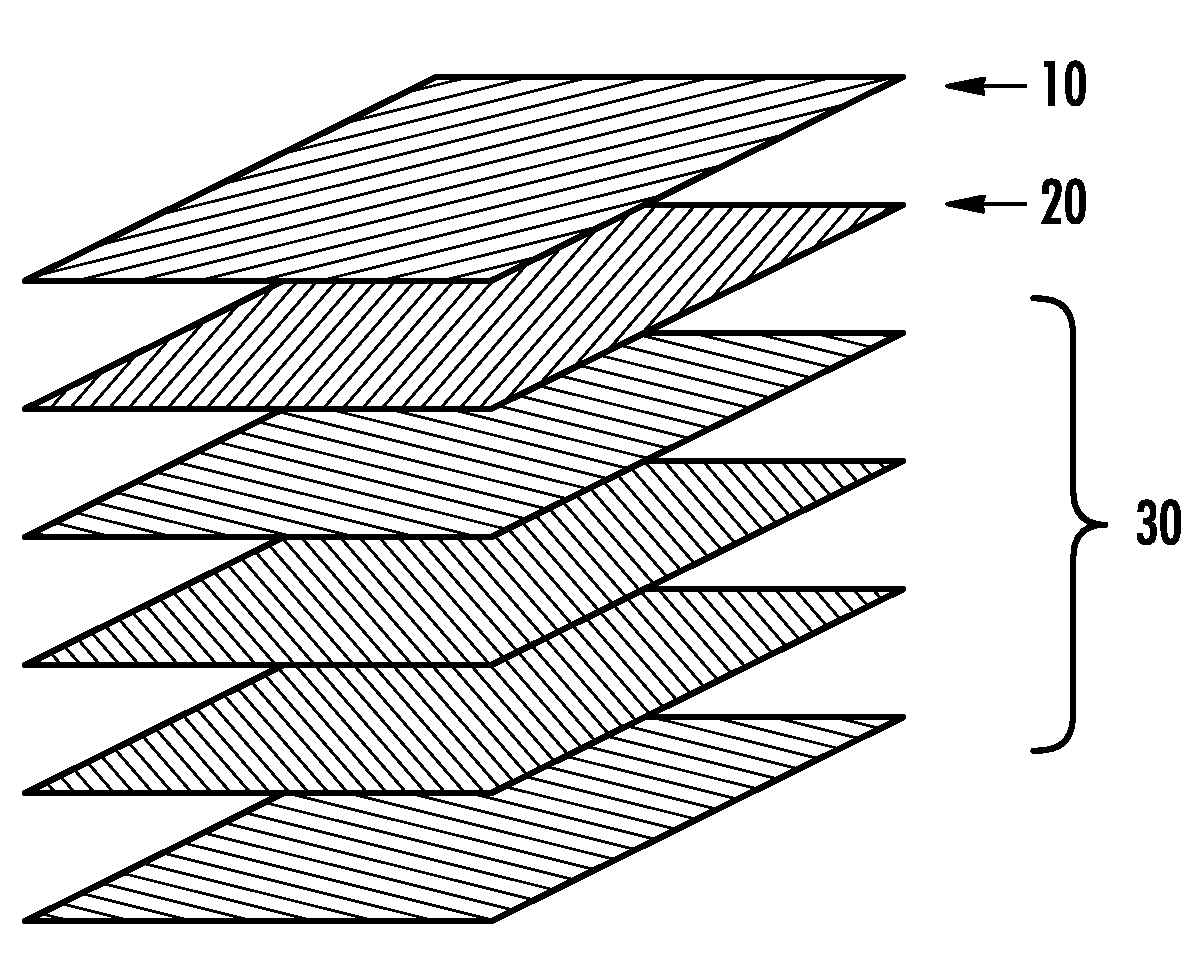

Composite modular barrier structures and packages

InactiveUS20050249901A1Improve barrier propertiesRemove moistureNanotechWrappersNanoparticleDesiccant

A composite multi-layer barrier is produced by first vapor depositing a barrier under vacuum over a substrate of interest and then depositing an additional barrier at atmospheric pressure in a preferably thermoplastic layer. The resulting multi-layer barrier is then used to coat an article of interest in a lamination process wherein the thermoplastic layer is fused onto itself and the surface of the article. The vacuum-deposited barrier may consists of a first leveling polymer layer followed by an inorganic barrier material sputtered over the leveling layer and of an additional polymeric layer flash evaporated, deposited, and cured under vacuum. The thermoplastic polymeric layer is then deposited by extrusion, drawdown or roll coating at atmospheric pressure. The resulting multi-layer barrier may be stacked using the thermoplastic layer as bonding agent. Nano-particles may be included in the thermoplastic layer to improve the barrier properties of the structure. A desiccant material may also be included or added as a separate layer.

Owner:SIGMA LAB OF ARIZONA

Thermoplastic vulcanizates and process for making the same

InactiveUS6437030B1Low hygroscopicityReduced halideSynthetic resin layered productsSolid ballsThermoplastic elastomerMetal halides

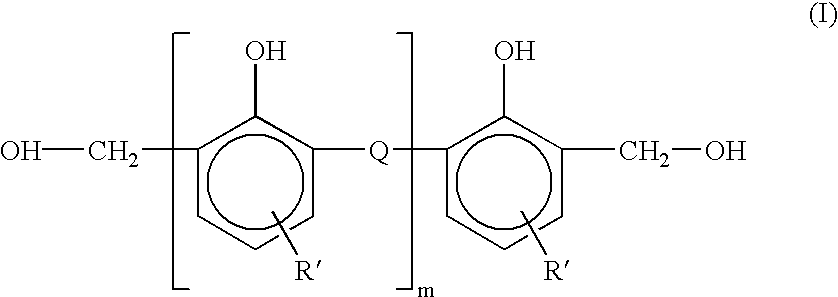

A process for forming a thermoplastic vulcanizate compromising the steps of dynamically vulcanizing a rubber within a blend that comprises the rubber and a thermoplastic polymer, where said step of vulcanizing is carried out by using a phenolic resin in the presence of a catalyst system formed by combining a metal halide and a metal carboxylate. Also, a thermoplastic vulcanizate having low moisture pick-up with a technologically useful cure.

Owner:ADVANCED ELASTOMER SYST LP

Thermoplastic polymer powder

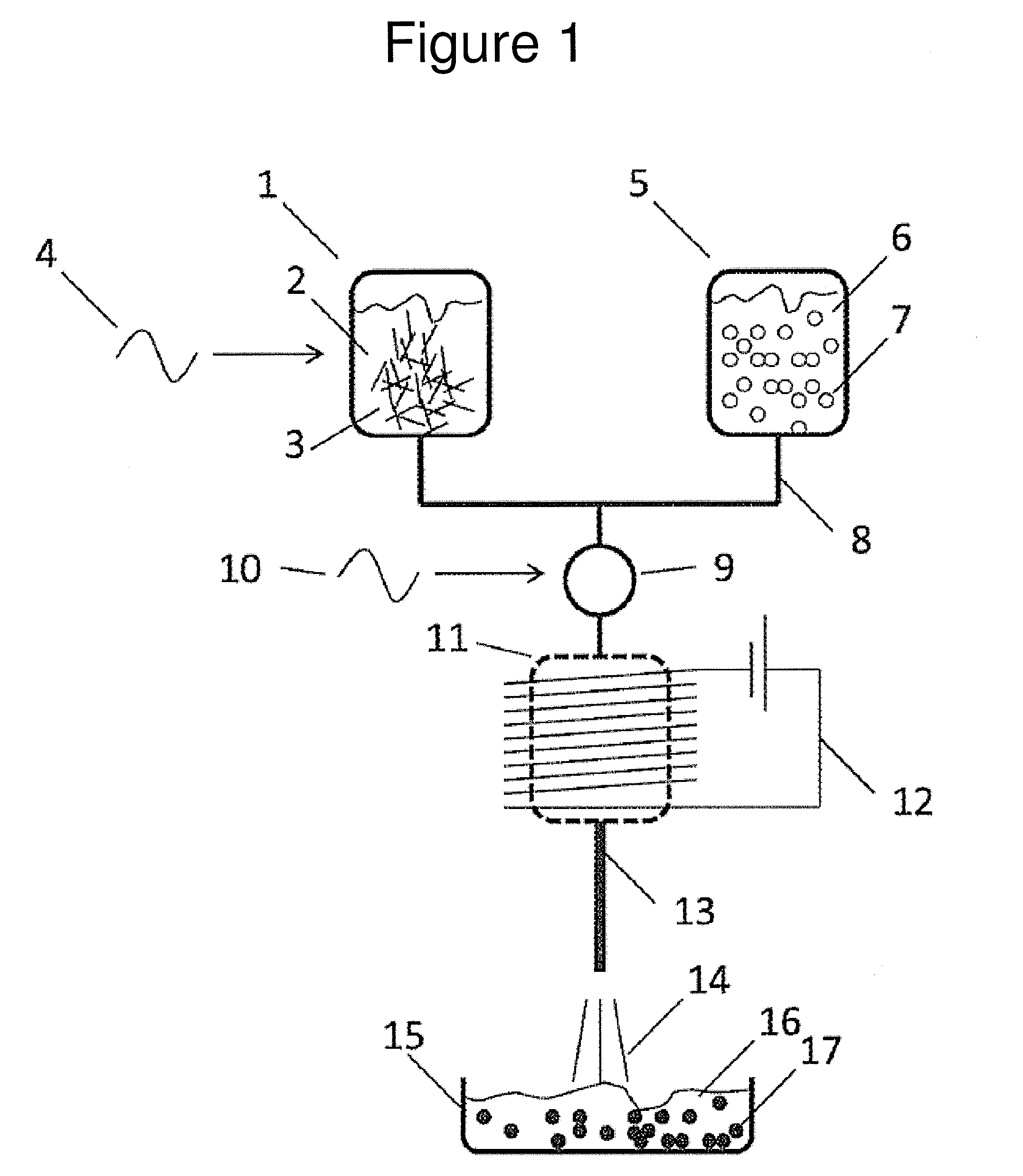

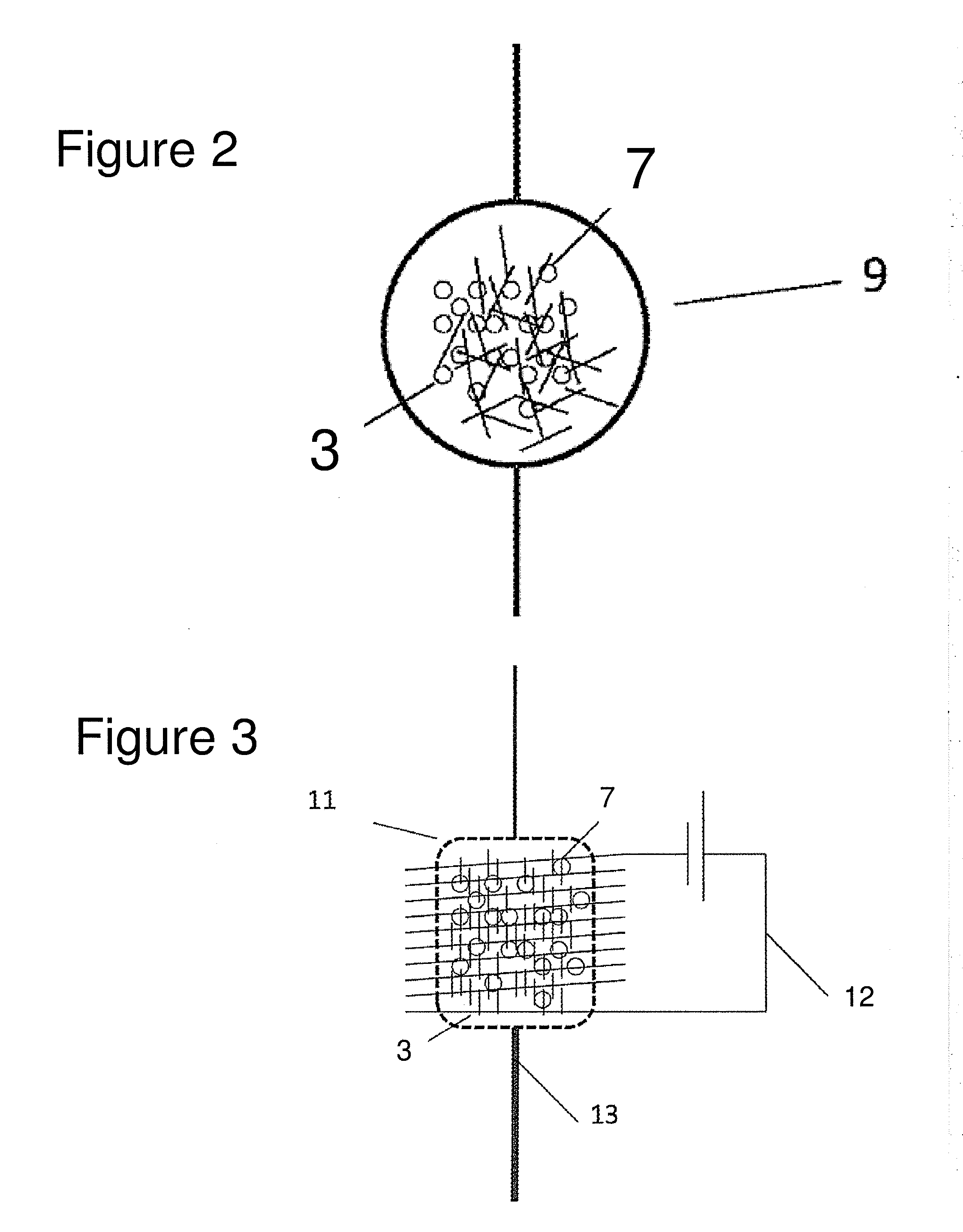

ActiveUS20130337265A1Material nanotechnologySynthetic resin layered productsElectromagnetic fieldPolymer chemistry

A method of modifying a thermoplastic polymer powder. A suspension of thermoplastic polymer powder and reinforcement elements in a liquid is heated within a reaction chamber so that the thermoplastic polymer powder becomes softened and the reinforcement elements migrate into the softened thermoplastic polymer powder to form modified thermoplastic polymer powder. The modified thermoplastic polymer powder is then separated from the liquid. The reinforcement elements have an electromagnetic moment and are subjected to an electromagnetic field as the suspension is heated. The interaction of the electromagnetic field with the electromagnetic moment of the reinforcement elements causes the reinforcement elements to become aligned with the electromagnetic field before they migrate into the powder.

Owner:EURON AERONAUTIC DEFENCE & SPACE

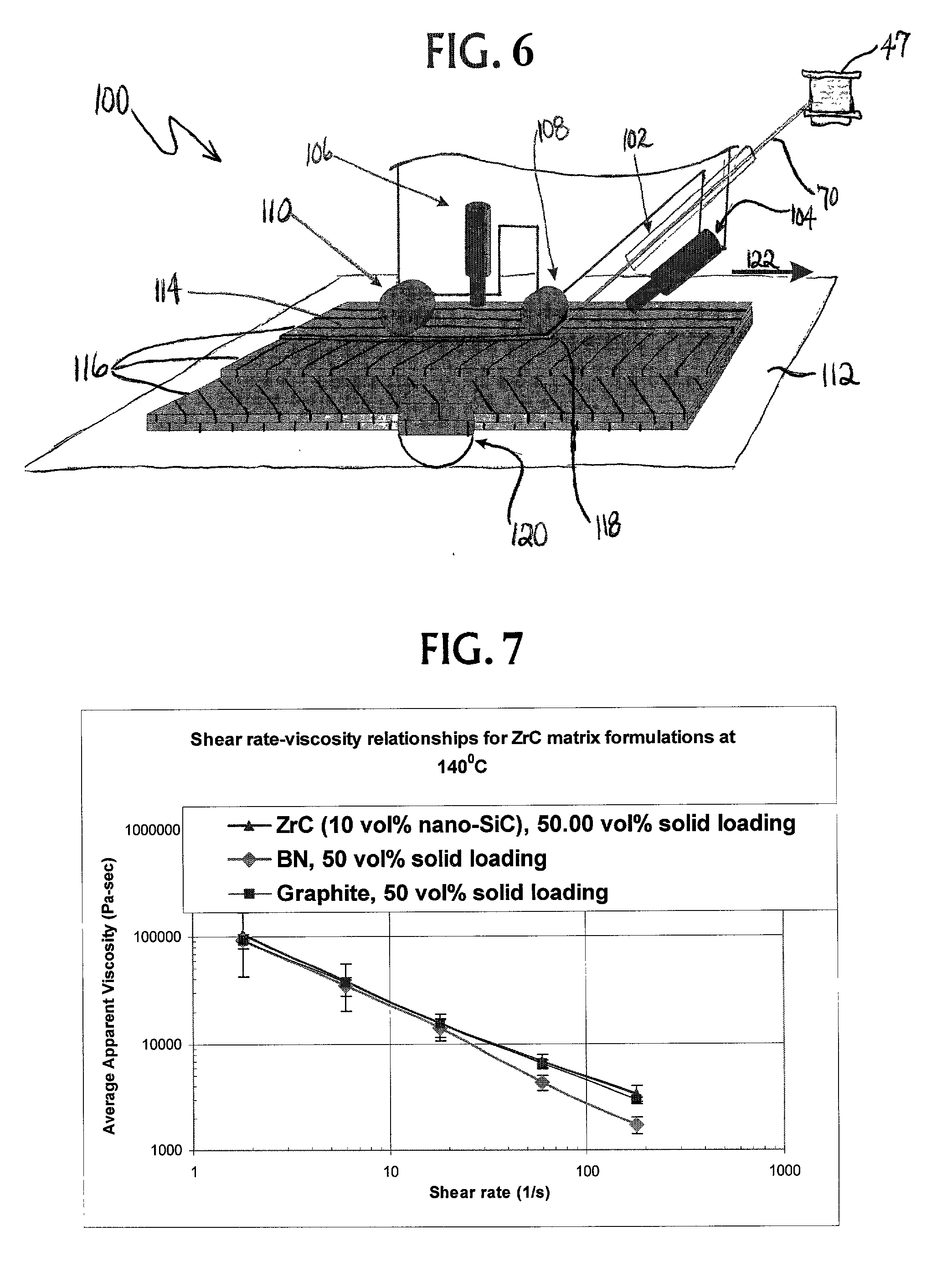

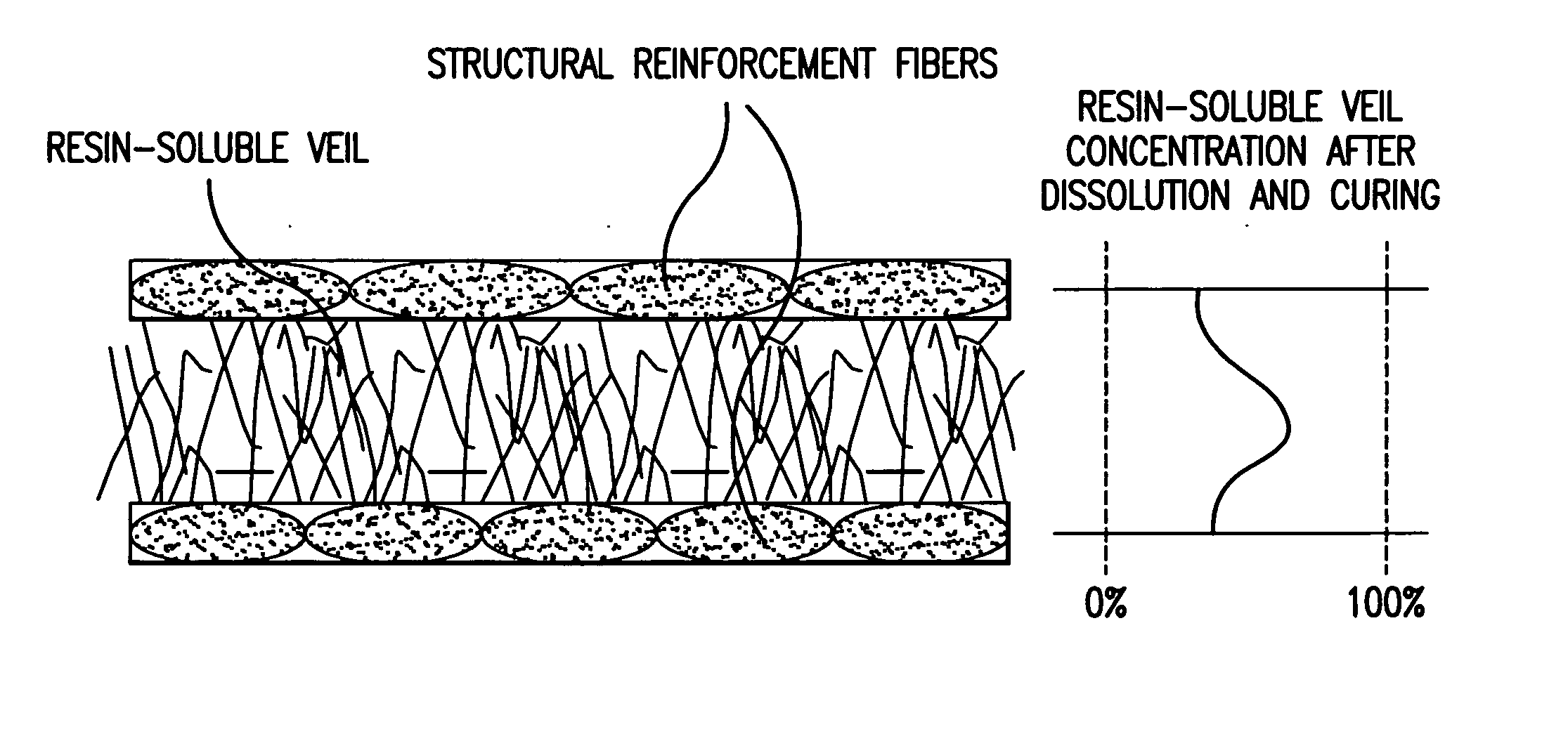

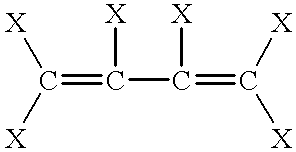

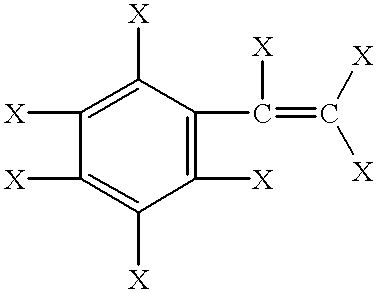

Continuous fiber reinforced composites and methods, apparatuses, and compositions for making the same

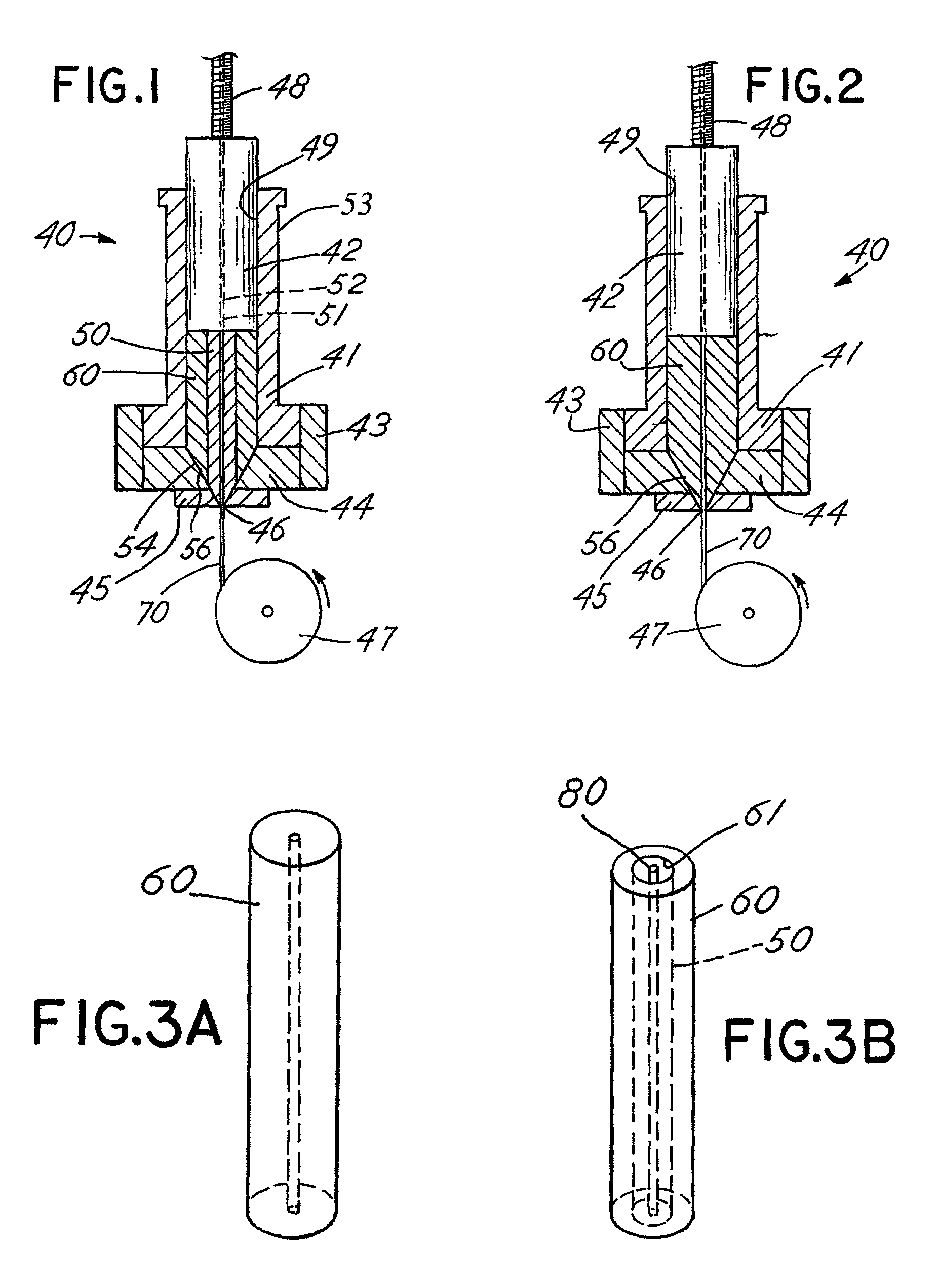

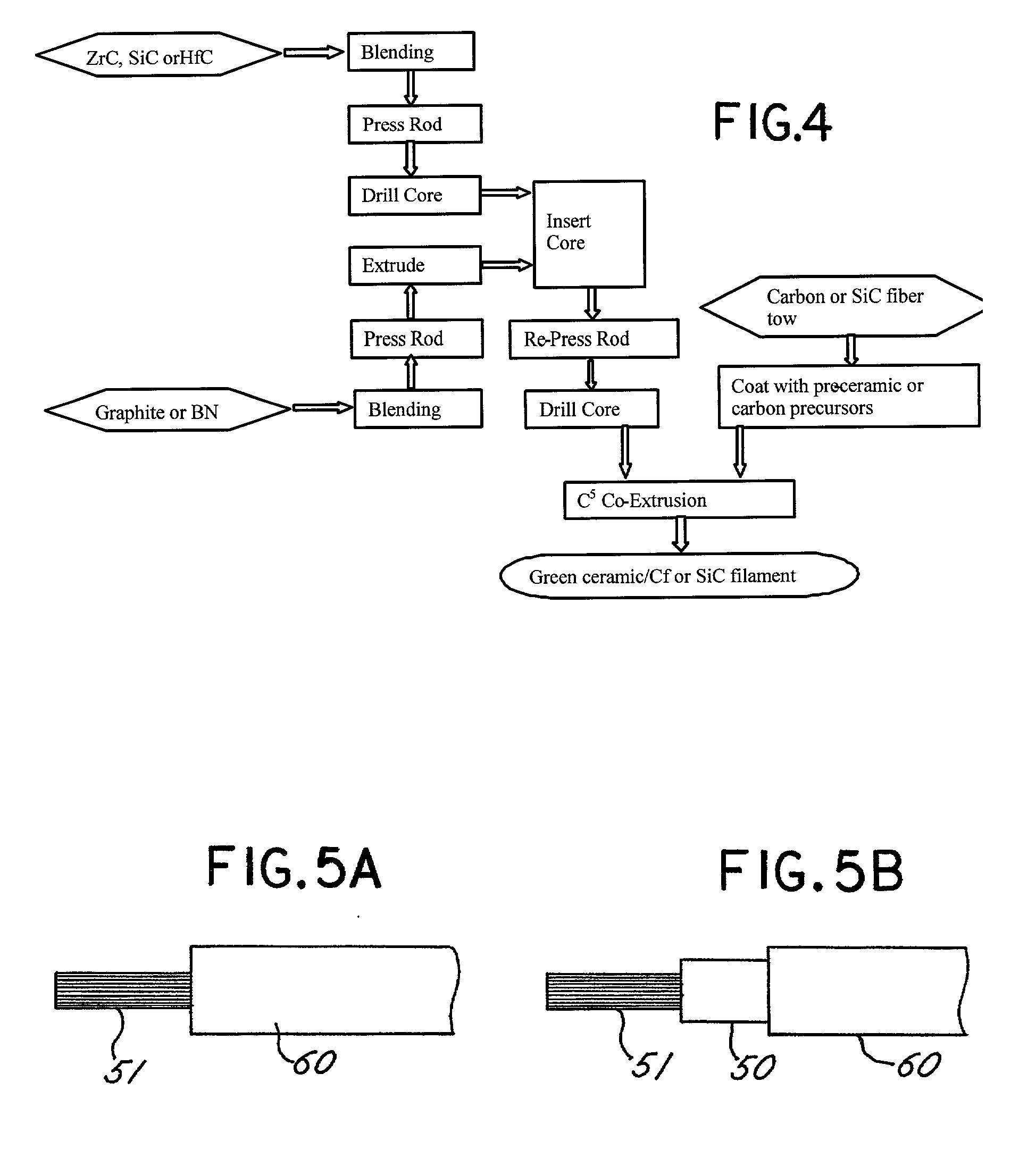

A process for continuous composite coextrusion comprising: (a) forming first a material-laden composition comprising a thermoplastic polymer and at least about 40 volume % of a ceramic or metallic particulate in a manner such that the composition has a substantially cylindrical geometry and thus can be used as a substantially cylindrical feed rod; (b) forming a hole down the symmetrical axis of the feed rod; (c) inserting the start of a continuous spool of ceramic fiber, metal fiber or carbon fiber through the hole in the feed rod; (d) extruding the feed rod and spool simultaneously to form a continuous filament consisting of a green matrix material completely surrounding a dense fiber reinforcement and said filament having an average diameter that is less than the average diameter of the feed rod; and (e) depositing the continuous filament into a desired architecture which preferably is determined from specific loading conditions of the desired object and CAD design of the object to provide a green fiber reinforced composite object.

Owner:ADVANCED CERAMICS

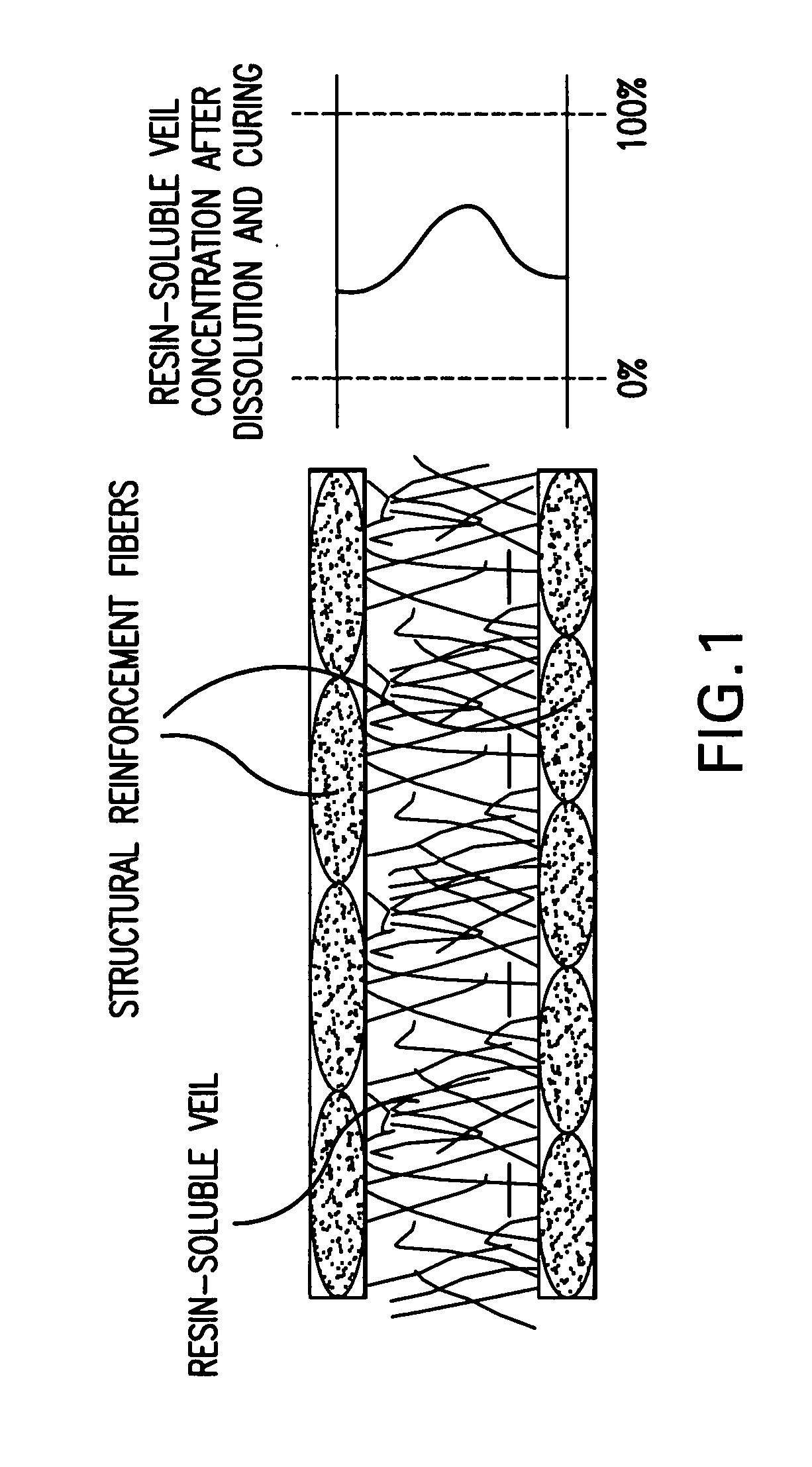

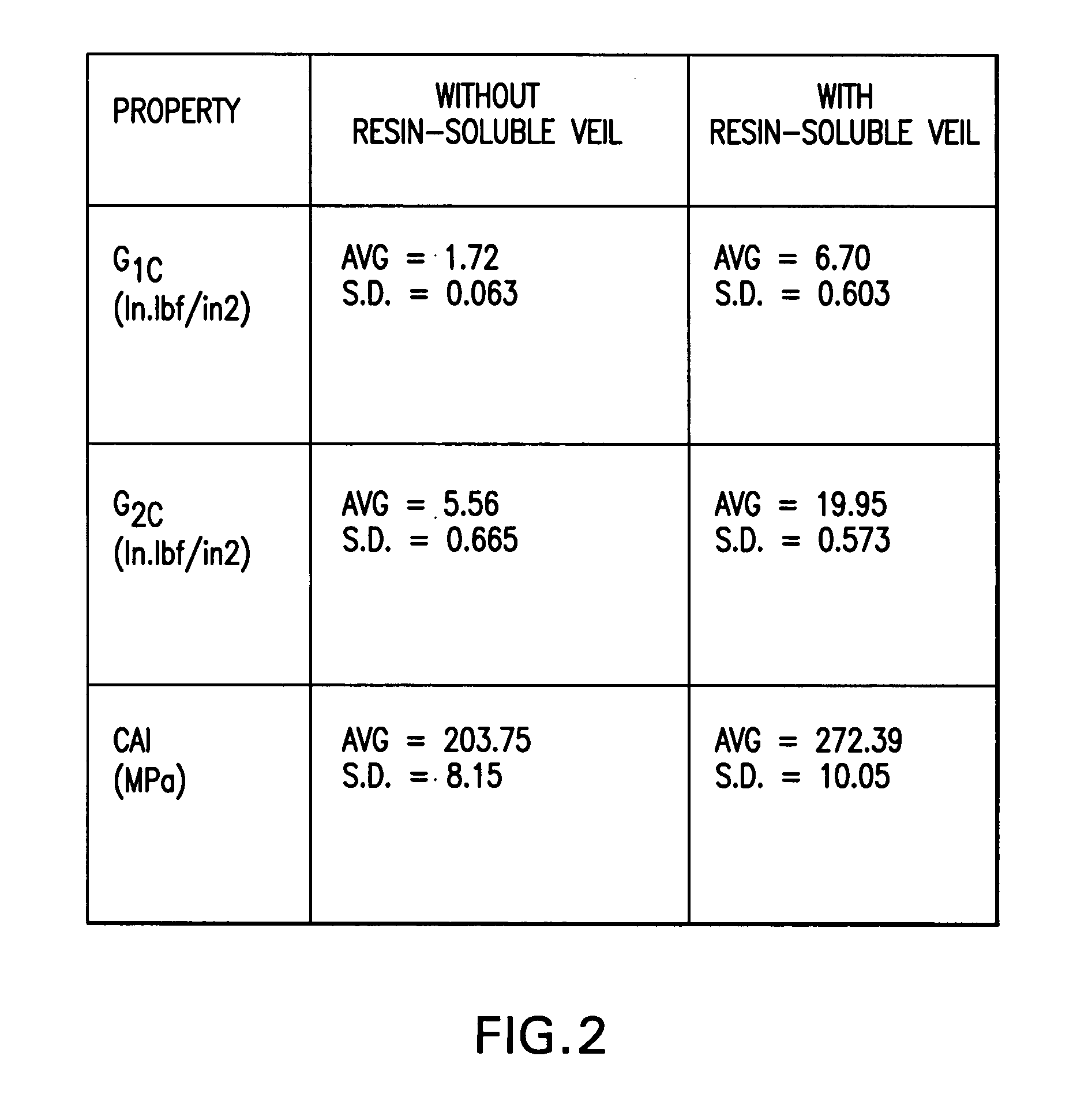

Resin-soluble thermoplastic veil for composite materials

ActiveUS20060252334A1Improve the level ofImprove toughnessWood working apparatusVehicle componentsFiberResin matrix

A resin-soluble thermoplastic polymer veil toughening element for a curable composition wherein the polymer element is a non-woven veil in solid phase adapted to undergo at least partial phase transition to fluid phase on contact with a component of the curable resin matrix composition in which it is soluble at a temperature which is less than the temperature for substantial onset of gelling and / or curing of the curable composition and which temperature is less than the polymer elements melt temperature; a method for the preparation thereof, a preform support structure for a curable composition comprising the at least one thermoplastic veil element together with structural reinforcement fibers, methods for preparation thereof, a curable composition comprising the at least one thermoplastic veil element or the support structure and a curable resin matrix composition, a method for preparation and curing thereof, and a cured composite or resin body obtained thereby, and known and novel uses thereof.

Owner:CYTEC TECH CORP

Advanced compatible polymer wood fiber composite

InactiveUS6210792B1Improve compatibilityGood material compatibilitySynthetic resin layered productsCellulosic plastic layered productsThermoplasticFiber

The invention relates to a composition comprising a thermoplastic polymer and wood fiber composite that can be used in the form of a linear extrudate or thermoplastic pellet to manufacture structural members. The polymer, the fiber or both can be modified to increase compatibility. The wood fiber composite structural members can be manufactured in an extrusion process or an injection molding process. The linear extrudate or pellet can have a cross-section of any arbitrary shape, or can be a regular geometric. The pellet can have a cross-section shape having a volume of at least about 12 mm3. Preferably the pellet is a right cylindrical pellet having a minimum radius of about 1.5 mm and a minimum length of 1 mm weighing at least 14 mg. The invention also relates to an environmentally sensitive recycle of waste streams. The polymer and wood fiber composite contains an intentional recycle of a waste stream comprising polymer flakes or particles or wood fiber. The waste stream can comprises, in addition to polymer such as polyvinyl chloride or wood fiber, adhesive, paint, preservative, or other chemical stream common in the wood-window or door manufacturing process, or mixtures thereof. The initial mixing step before extrusion of the composite material insures substantial mixing and melt contact between molten polymer and wood fiber. The extruded pellet comprises a consistent proportion of polymer, wood fiber and water. During the extrusion, water is removed intentionally to dry the material to a maximum water content of less than about 10 wt-% based on the pellet weight. To make a structural unit, the pellet is introduced into an extruder or injection molding apparatus wherein, under conditions of temperature and pressure, the composite pellet material is shaped into a useful cross-section. Alternatively, the extruded thermoplastic mass, in the form of a elongated linear extrudate without a pelletizing step, can be immediately directed after formation into an extruder or injection molding apparatus.

Owner:ANDERSEN CORPORATION

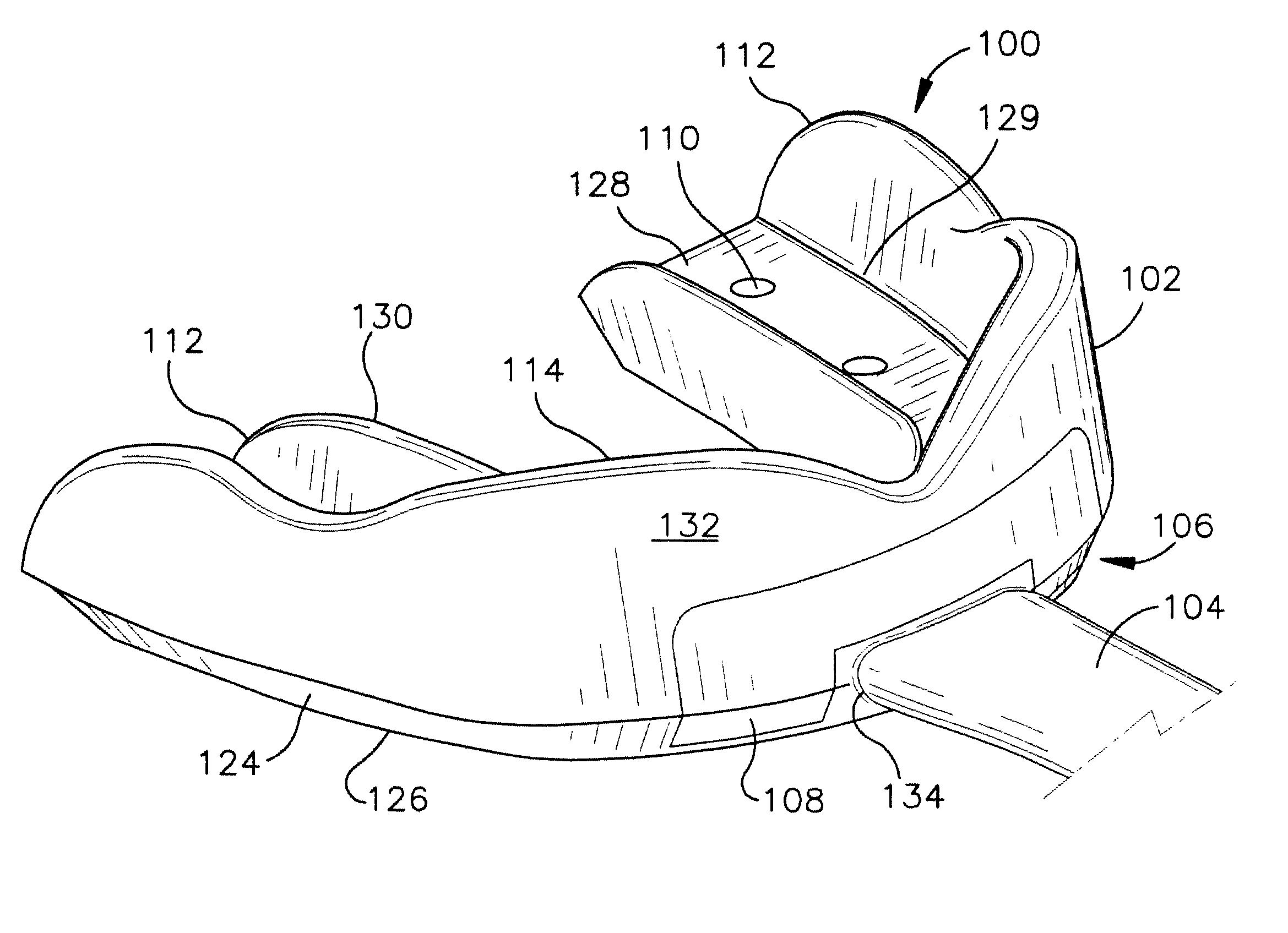

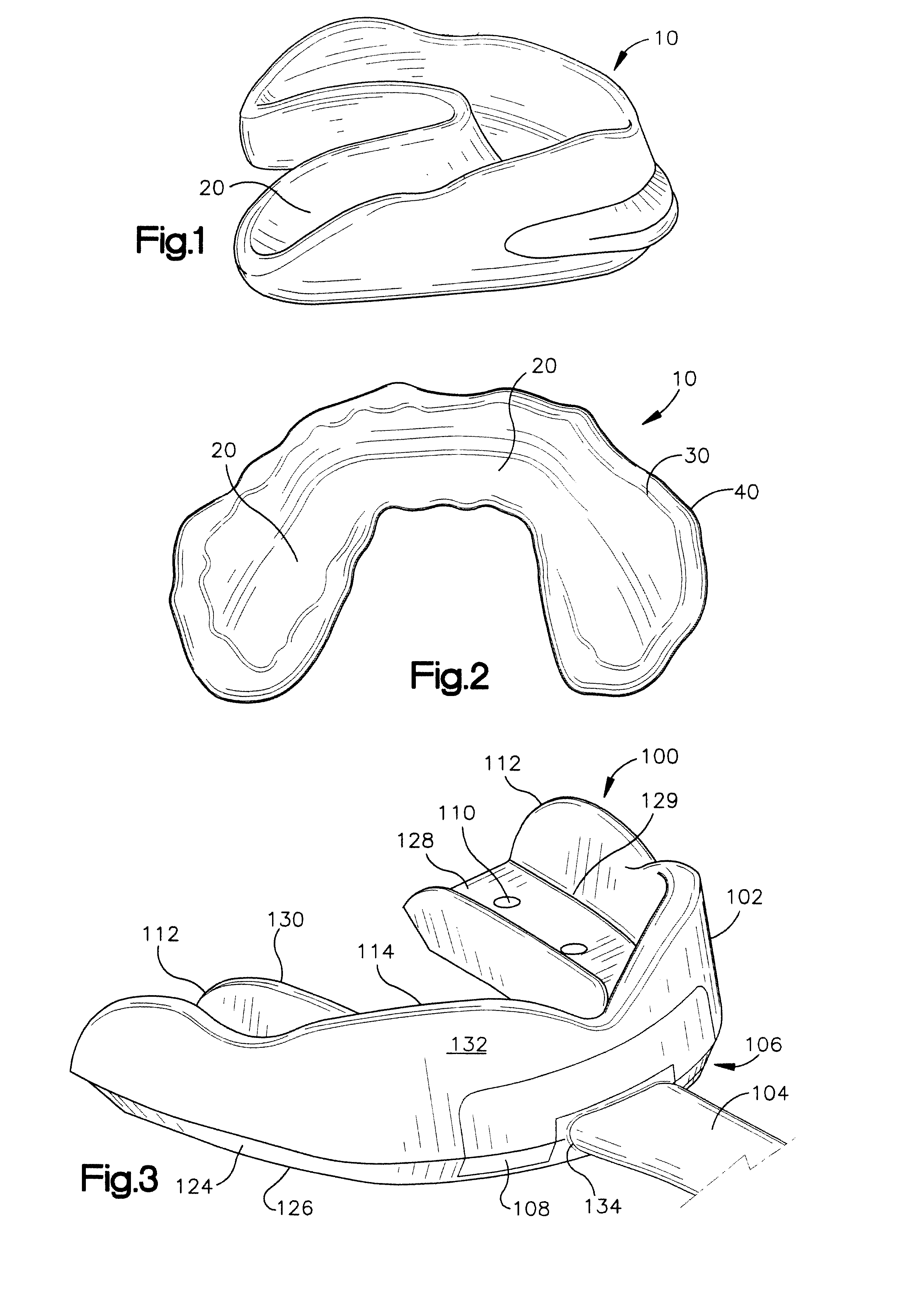

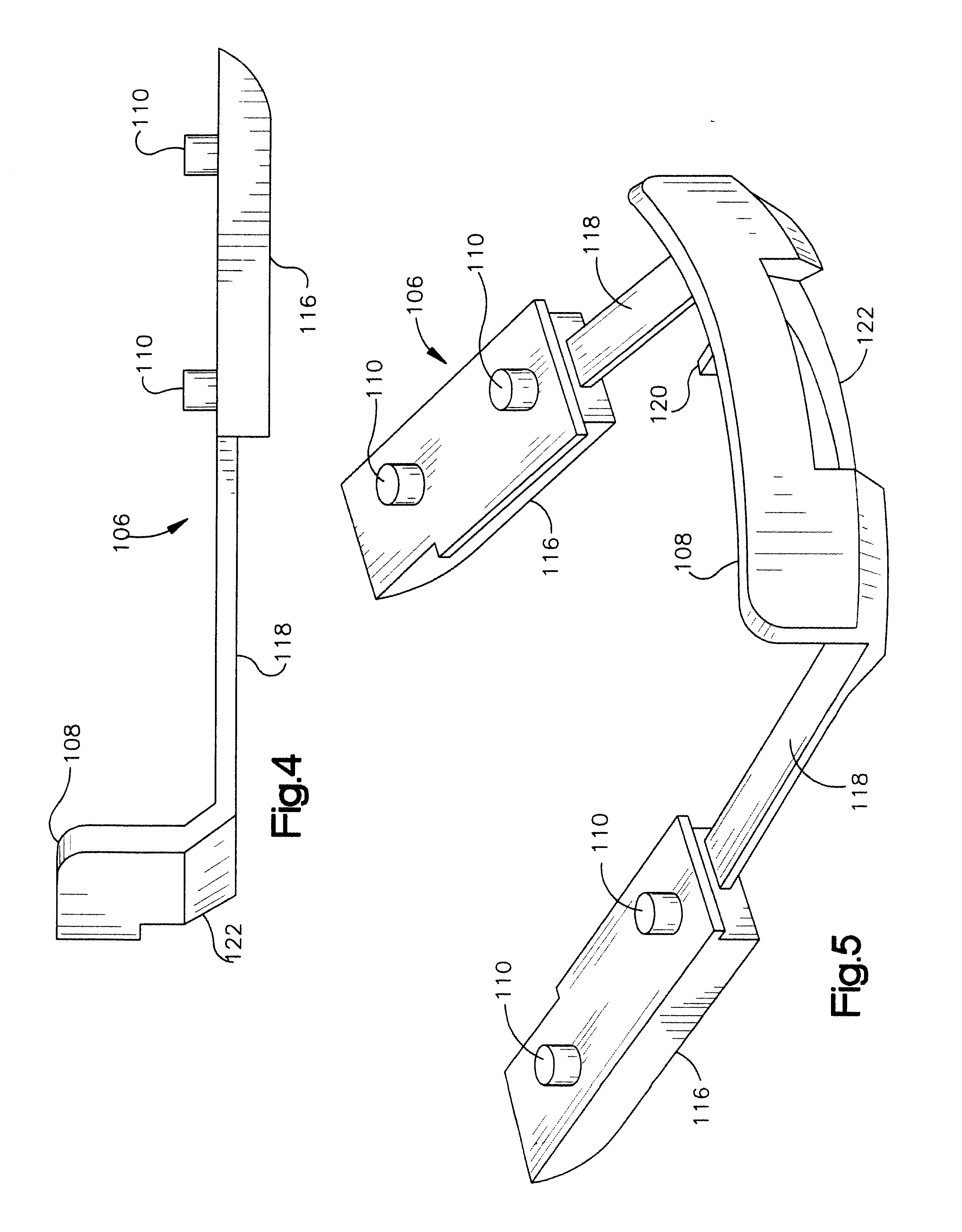

Mouthguard and method of making

The present invention relates to a bilayer mouthguard fabricated from a high impact thermoplastic polymer blend having the ability to absorb, attenuate, and dissipate shock forces and a method of fabricating a mouthguard. The present invention utilizes a polymer blend comprising ethylene vinyl acetate and a thermoplastic urethane. The bilayer mouthguard has a U-shape base and is defined by inner lingual and outer labial walls, a channel for receiving the upper jaw and teeth, cushion pads laying within the U-shape base, and in certain designs a transition support portion extending forward from the posterior cushion pads connecting with an anterior impact brace that extends into the outer labial wall.

Owner:SPORTSGUARD LAB

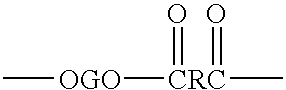

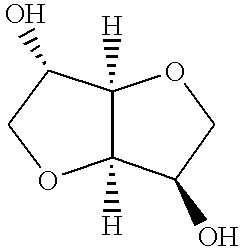

Polyesters including isosorbide as a comonomer blended with other thermoplastic polymers

A polymer blend including a polyester and another thermoplastic polymer. The polyester includes terephthaloyl moieties and, optionally, other aromatic diacid moieties; and ethylene glycol moieties; optionally diethylene glycol moieties; isosorbide moieties; and, optionally one or more other diol moieties. The polyester has an inherent viscosity of at least about 0.35 dL / g.

Owner:EI DU PONT DE NEMOURS & CO

Low density lightning strike protection for use in airplanes

ActiveUS20090227162A1Minimize micro-crackingWeight optimizationConductive materialWarp knittingFiberEpoxy

Surface films, paints, or primers can be used in preparing aircraft structural composites that may be exposed to lightning strikes. Methods for making and using these films, paints or primers are also disclosed. The surface film can include a thermoset resin or polymer, e.g., an epoxy resin and / or a thermoplastic polymer, which can be cured, bonded, or painted on the composite structure. Low-density electrically conductive materials are disclosed, such as carbon nanofiber, copper powder, metal coated microspheres, metal-coated carbon nanotubes, single wall carbon nanotubes, graphite nanoplatelets and the like, that can be uniformly dispersed throughout or on the film. Low density conductive materials can include metal screens, optionally in combination with carbon nanofibers.

Owner:ROHR INC +1

Stable breathable elastic garments

InactiveUS6909028B1Good body conformanceImprove breathabilityPersonal careSynthetic resin layered productsPolyvinyl polymerPolymer science

A thermally stable microporous breathable film is provided comprising at least 35% filler, by weight of the filled-film, and a thermoplastic polymer blend of a first polyethylene polymer and a second polyethylene polymer. The first polyethylene polymer comprises 30%-70% by weight of the polymer blend and can have a density between about 0.86 g / cm3 and 0.89 g / cm3 and the second polyethylene polymer can have a density between about 0.90 g / cm3 and 0.92 g / cm3. The filled-film can be uniaxially or biaxially oriented to form a microporous film and / or film laminate having good body conformance and which retains a high WVTR at 37° C. and above.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Method for making a lithographic printing plate involving on press development

InactiveUS6030750AImprove printing effectSemiconductor/solid-state device manufacturingPlate printingEngineeringPrinting press

The present invention provides a method for making a lithographic printing plate comprising the steps of: (1) image-wise exposing to light an imaging element comprising (i) on a hydrophilic surface of a lithographic base an image forming layer comprising hydrophobic thermoplastic polymer particles capable of coalescing under the influence of heat and dispersed in a hydrophilic binder and (ii) a compound capable of converting light to heat, said compound being comprised in said image forming layer or a layer adjacent thereto; (2) and developing a thus obtained image-wise exposed imaging element by mounting it on a print cylinder of a printing press and supplying an aqueous dampening liquid and / or ink to said image forming layer while rotating said print cylinder.

Owner:EASTMAN KODAK CO

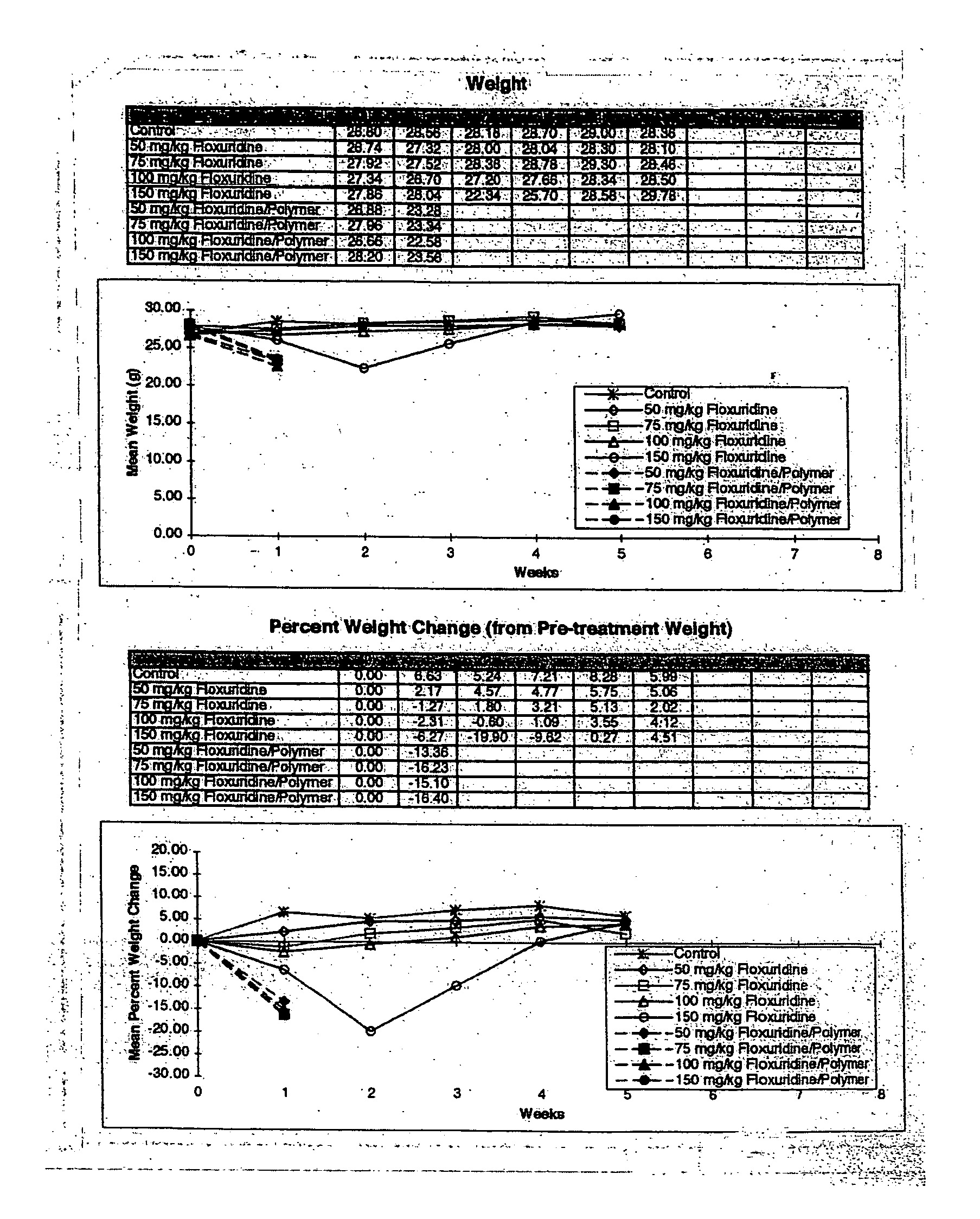

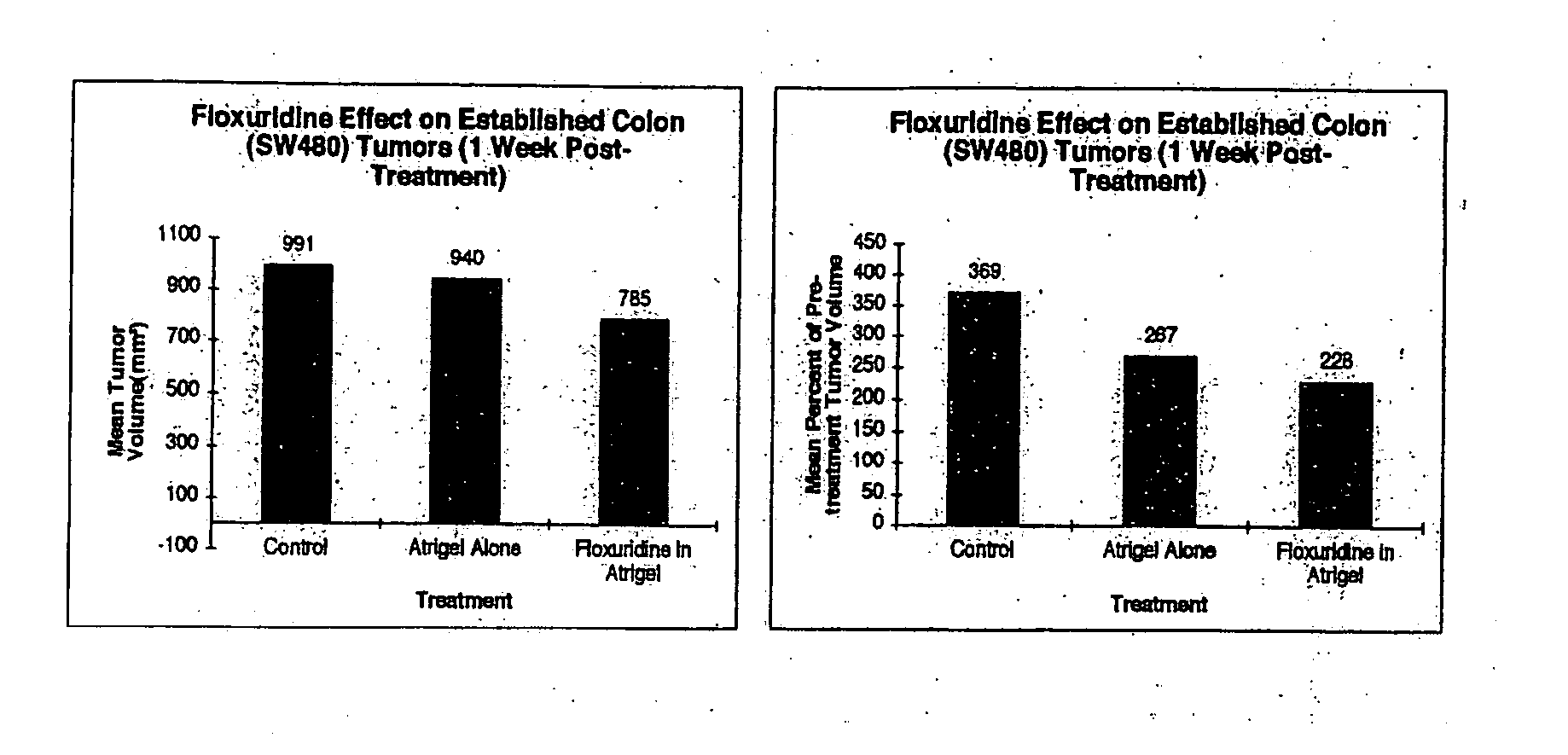

Formulations for cell-schedule dependent anticancer agents

InactiveUS20060121085A1Strong specificityEliminate side effectsPowder deliveryBiocideMetaboliteAnticarcinogen

The present invention provides a flowable composition suitable for use as a controlled release implant. The composition includes: (a) a biodegradable, biocompatible thermoplastic polymer that is at least substantially insoluble in aqueous medium, water or body fluid; (b) a cell-cycle dependent biological agent, a schedule-dependent biological agent, a metabolite thereof, a pharmaceutically acceptable salt thereof, or a prodrug thereof; and (c) a biocompatible organic liquid, at standard temperature and pressure, in which the thermoplastic polymer is soluble. The present invention also provides a method of treating cancer in a mammal. The present invention also provides a method of blocking, impeding, or otherwise interfering with cell cycle progression at the G1-phase, G1 / S interphase, S-phase, G2 / M interface or M-phase of the cell cycle in a mammal. The methods includes administering to a mammal an effective amount of a flowable composition of the present invention.

Owner:QLT USA INC

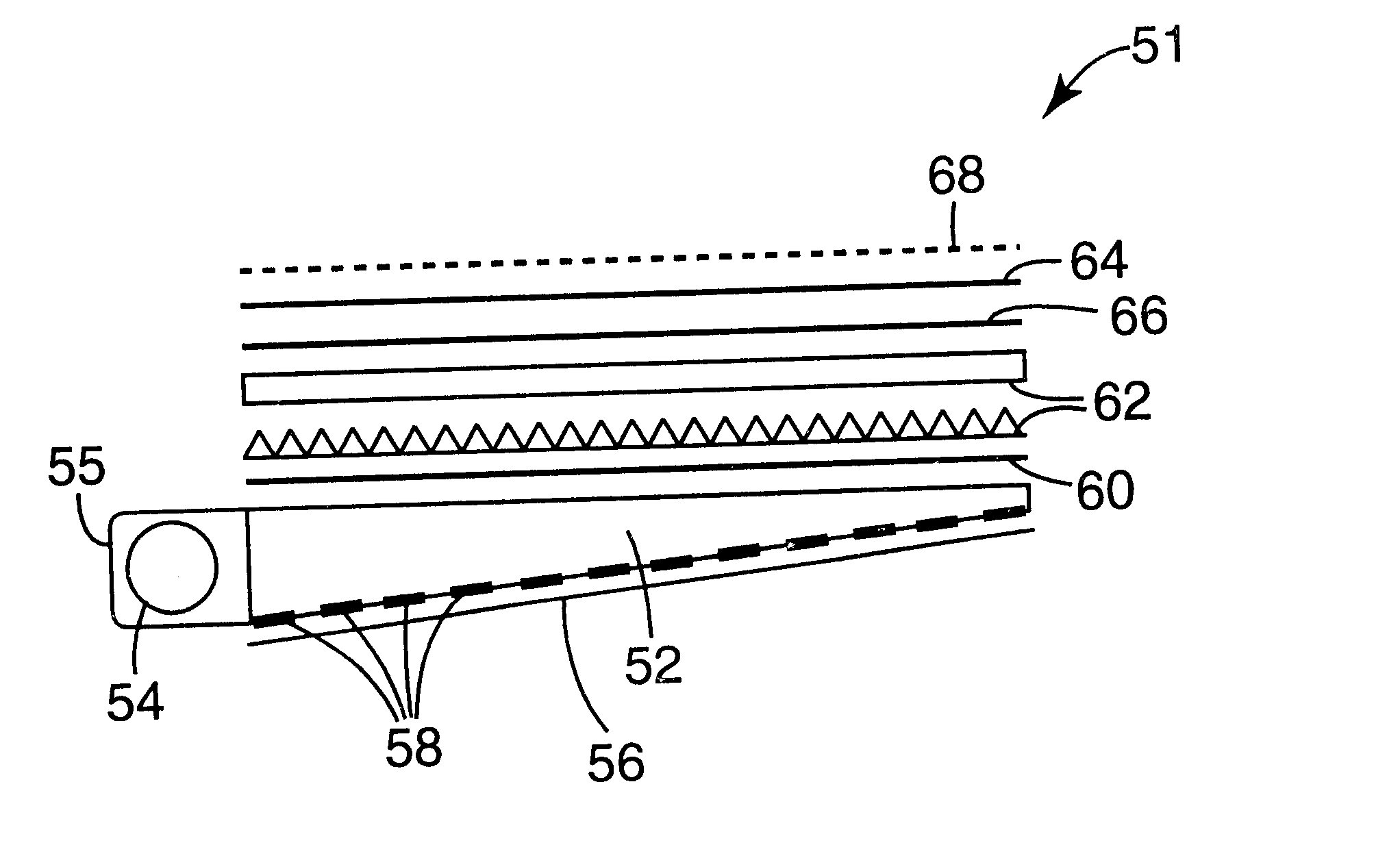

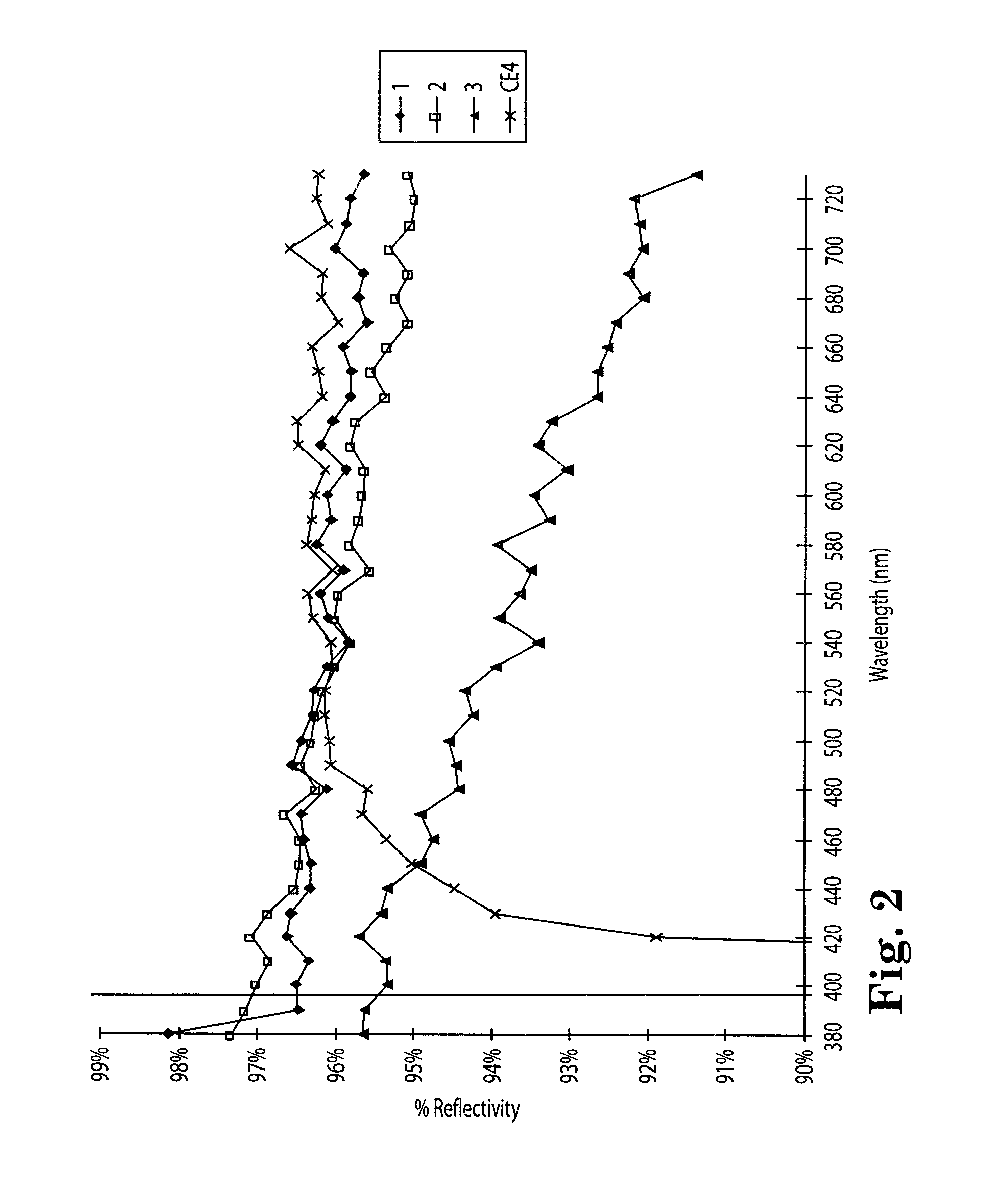

Diffuse reflective articles

InactiveUS6497946B1Improve reflectivityInexpensive and readily availableMechanical apparatusMirrorsLiquid-crystal displayDiluent

Diffuse reflective materials proximate to a structure formed by thermally induced phase separation of a thermoplastic polymer and a diluent providing enhanced flexibility and reflectivity especially in the visible wavelengths of 380-730 nanometers are described. Such materials find a wide variety of application among combinations with other reflective layers. The diffuse reflective articles are useful in backlight units of liquid crystal displays, lights, copy machines, projection system displays, facsimile apparatus, electronic blackboards, diffuse white standards, photographic lights and the like.

Owner:3M CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com